Page 1

OPERATING INSTRUCTIONS FOR

4/09/12

MAX 5

Portable Combustion Efficiency Monitor

D ANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS V OL TAGES EXIST ON CER T AIN COMPONENTS INTERNALLY WHICH MAY PERSIST FOR

A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONL Y A UTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SER VICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

P/N M39218

08/06/99

ECO # 99-032

Page 2

INSTRUCTION MANUAL

MAX 5

PORTABLE COMBUSTION EFFICIENCY MONITOR

SALES ORDER:

SERIAL NUMBER:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91748

Phone: (626) 9341500

Fax: (626) 9612538

Web: www.teledyneai.com

Page 3

TABLE OF CONTENTS

MAX 5 PORTABLE COMBUSTIBLE EFFICIENCY MONITOR

GENERAL DESCRIPTION

Introduction 1

Main Features 1

OPERATION OF CONTROLS, DISPLAYS, & INDICATIONS

Front Panel Controls 3

Back Panel Controls 4

PRINCIPLE OF OPERATION

Sensor Description 4

Temperature & Calculated Values 5

Sampling System Description 6

INSTALLATION AND START UP PROCEDURES

Precautions 9

Electronic Zeroing of Oxygen Section 10

Sensor Installation and Replacement 11

INSTRUMENT OPERATING PROCEDURE

Installation of Thermocouple 12

Initiating & Adjusting Air & Sample Flow 13

Temperature, Efficiency, & Carbon Dioxide Sections 13

Initial Calibration/Automatic Calibration 13

Manual Span (CO

& CO) 14

2

Manual Calibration (Optional) 15

Special Functions 16

Temperature Simulation 16

Cost Savings 16

To Store Readings 17

To Display Readings 17

To Print Readings (Optional) 18

To Test Keyboard 18

Automatic Data Output 18

To Print Instruction Manual 18

To Check the Version of Software 19

Electronic Zeroing of Oxygen

19

Page 4

TABLE OF CONTENTS (continued)

ROUTINE MAINTENANCE

Scrubber 19

Battery Recharging 20

Battery Replacement 20

Sensor Replacement 21

OPERATOR’S CHECKS & ADJUSTMENTS

Messages 22

Failure Warning Signs

APPENDIX

To Print Stored Readings 24a

Material Safety Data Sheets (MSDS) 24b-g

LIST OF SPARE PARTS

DRAWINGS

LIST OF FIGURES

Figure

1 Display Panel 2

2 Membrane Keyboard 2

3 Back Panel 3

4 Location of Sensors (Top View) 11

5 Sample Probe With Built-In Thermocouple 12

LIST OF TABLES

Tables

1 Detector Response To Gases 8

23

Page 5

MAX5 PORTABLE COMBUSTION EFFICIENCY MONITOR

GENERAL DESCRIPTION

INTRODUCTION

The MAX 5 Portable Combustion Efficiency Analyzer provides several special features and

applications. It directly measures oxygen, carbon monoxide, combustibles, and temperature

levels in a subject sample stream. The MAX 5 also includes microprocessor-based special

functions enabling the computer to calculate levels of carbon dioxide and combustion efficiency.

As an added bonus, the computer can calculate and display actual fuel cost savings (CompuCentsTM), by using the efficiency level prior to an adjustment, the level after an adjustment, and

an average fuel cost as reference points.

The MAX 5 incorporates an internal microcomputer. The computer program resides in ROM

(read only memory) and is not affected by shutdown periods, loss of power, or battery failure.

However, the calibration parameters and stored measurement readings are retained in RAM

(random access memory) which requires operating power to protect it; thus, the information

stored in RAM will be lost if battery power is interrupted (during battery replacement, for

example).

The computer controls the display and reads the keyboard. A 12-bit analog-to-digital (A-D)

converter converts the output signals from the various measurement sensors and the

thermocouple into digital data that goes to the computer. The computer interprets this and

compares the data to calibration data you have entered. The computer displays the corrected

values on the LCD.

Also, the computer performs error checking and reporting, as well as the other special functions

available for selection via the special function keys.

The actual program that runs the computer is compiled into machine language for faster

execution and more efficient use of memory. It is not accessible by high-level interpreters, such

as Basic, and it is not available to the user for modification in any way.

Page 6

MAIN FEATURES

1. Auto Zero. MAX 5 offers automatic zero calibration for carbon monoxide and

combustibles and automatic span calibration for oxygen. Also, you can adjust

them manually. You have to adjust the span calibration manually for carbon

monoxide and combustibles.

2. Stored Readings. The computer stores up to 20 sets of readings and reports them

to the LCD (Liquid Crystal Display) or to an optional serial printer.

3. Computer Memory. A 16-bit microprocessor and 40 kilobytes of memory are

standard.

4. ROM Instruction Manual. The MAX 5 stores an abbreviated but complete

instruction manual in ROM and prints the manual upon request.

5. Rechargeable Batteries. Nickel-cadmium batteries provide power to the unit for up

to 8 hours of continuous operation. You recharge the batteries by plugging a standard

power cord into a 115V receptacle. TBE/AI also offers 220V and 100V versions.

6. Proven Sensors. The MAX 5 uses Teledyne’s standard line of sensors, already proven

to be among the best in the instrumentation industry.

7. CO Analysis. Four ranges of CO analysis are available for the MAX 5; one standard

0-1000 ppm CO and three optional ranges - 0-500 ppm CO, 0-1% CO and 0-25% CO.

OPERATION OF CONTROLS, DISPLAYS & INDICATORS

Initial Display. Shortly after it is first switched on, the computer will test all its internal

functions and then automatically enter its normal operating mode. During this time, it will

display random segments on the LCD.

Temperature Display. Readings below 1000 degrees (Fahrenheit or centigrade) are read

directly (for example, 100 means 100 degrees). If a reading is over 1000 degrees, it will be

displayed as a number with two decimal places, and you must multiply by 1000 to get the actual

temperature. For example, 1.50 means 1.50 x 1000, or 1500 degrees.

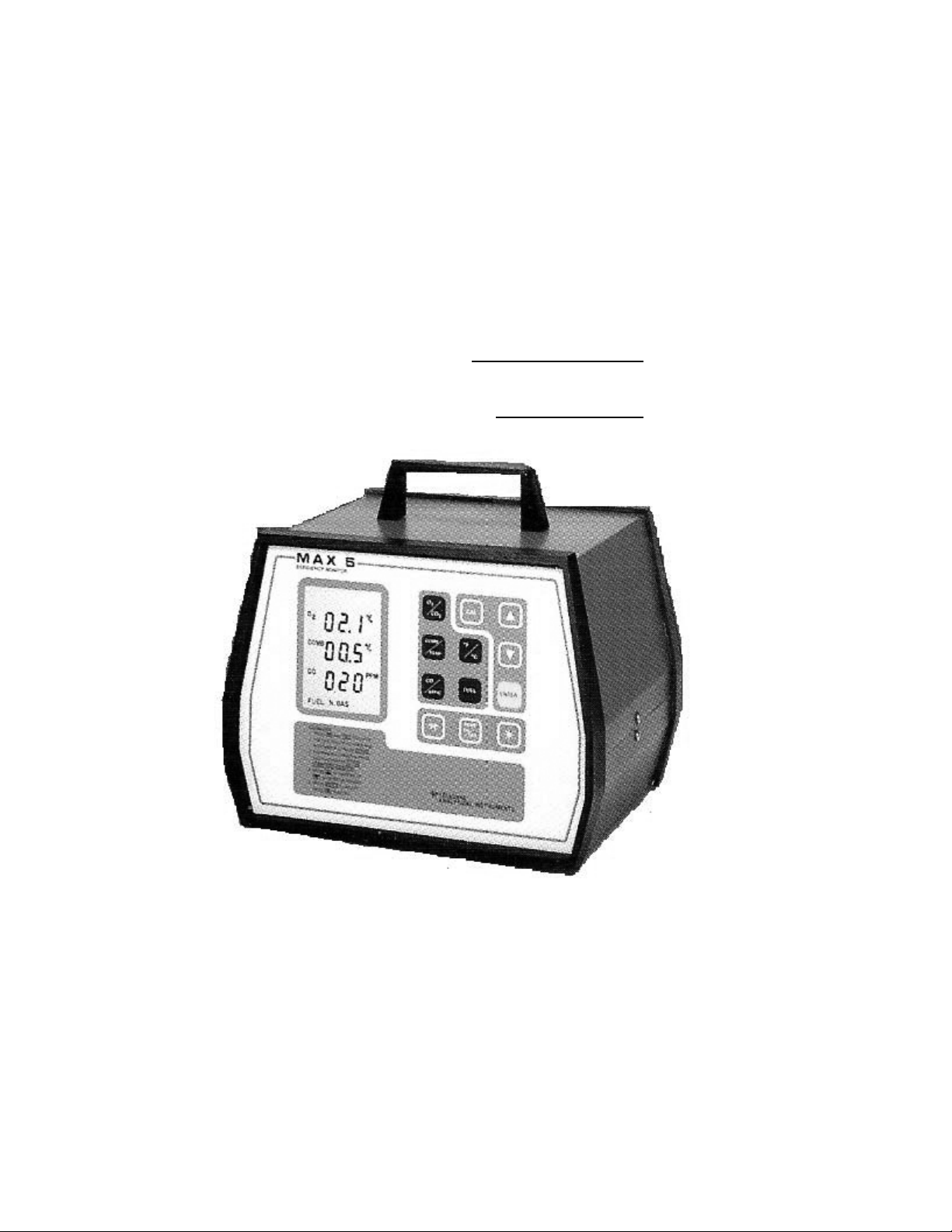

Display Panel. A continuous updated LCD monitors O

, CO, CO2, Combustibles, Temperature,

2

& Net Combustion Efficiency. The membrane keyboard includes all needed controls to select

functions; display three parameters at once, control the sampling pump, and choose degrees

Centigrade or Fahrenheit as shown in Figures 1 & 2.

(INSERT FIGURES 1 & 2)

FRONT PANEL CONTROLS

Page 7

Temp Key (°F or °C). This key, when pressed, determines which of the two available

temperature scales (toggles between degrees Fahrenheit or degrees Centigrade) will be used to

display temperature readings. See “Initial Calibration/Automatic Calibration” - “Temperature”.

O2 / CO2. Because both the oxygen and carbon dioxide readings occupy the top row of the

LCD, you press this key to display one or the other. To get a valid CO2 reading, you must select

the proper fuel (see “FUEL” below).

COMB/TEMP. You select either the combustibles or the temperature readings for display by

pressing this key. The readings appear in the center row of the display.

CO/EFFIC. You press this key to toggle between the carbon monoxide and calculated

efficiency readings. The readings appear in the bottom row of the display.

FUEL. This key is primarily used for CO2 calculation and efficiency readings. You must

choose one of the four pre-selected fuels (#2 fuel oil, #6 fuel oil, natural gas, or solid fuels such

as coal) so that the computer calculations will be valid. Pressing the FUEL key causes the fuel

selection (across the bottom of the display) to toggle through the four selections. When you see

the fuel that you are using, simply leave it that way, and the calculations will be valid for that

fuel.

CAL. Calibration is automatic for O2. MAX 5 also includes auto-zeroing for Carbon Monoxide

(CO) and combustibles, so the user need only set the spans. Calibration settings remain in

memory even when the power is off.

TELEDYNE LOGO. Used to exit from calibration procedures and used in conjunction with

calibration functions.

(INSERT FIGURE 3)

BACK PANEL CONTROLS

A. Thermocouple Connections for type “K” thermocouple supplied in probe (type “J”

optional).

B. Vent.

C. AC Power connection for recharging NiCad batteries, which provide up to eight hours

of operation.

D. Battery Power ON-OFF switch.

E. RS-232-C Serial output to provide:

* short-form Operations Manual

* up to 20 sets of stored data

Page 8

* continuous flow of all six readings

F. Air Flowmeter with flow set valve to regulate air flow.

G. Sample Flowmeter with flow set valve to regulate sample flow.

H. Chemical Scrubber for removal of corrosive compounds, such as SO2,, H2S, and NOx.

I. Sample-in Port.

J. Coalescing Filter (to remove particulates and water) and filter-drop out pot.

PRINCIPLE OF OPERATION

SENSOR DESCRIPTION

Oxygen. The oxygen section uses Teledyne’s Micro-Fuel Cell, Class B-3 oxygen sensor (U.S.

Patent No. 3,429,796). The B-3 Micro-Fuel Cell measures the concentration of oxygen in a gas

stream. The analysis is specific for oxygen; i.e., the measuring cell will not generate an output

current unless oxygen is present in the sample gas. Therefore, the oxygen channel has absolute

zero, and no zero gas is required to standardize the analyzer. The standard range is 0-25%

oxygen, and you perform span calibration with atmospheric air as the span gas, where feasible.

Carbon Monoxide. The class F-1R* solid-state electrochemical sensor measures CO. The

solid- state design eliminates leakage. You zero the CO section against air and span with a span

gas that contains the measured component in a concentration equivalent to 80-90% of the

instrument’s maximum fullscale value. TBE/AI sets the standard measurement range at 0-1000

PPM.

Combustibles. The combustibles sensor is a low-temperature, catalytic bead type transducer in

a constant current-excited Wheatstone Bridge circuit. Two legs of the bridge are exposed to the

sample gas. The other two legs are passive elements.

Gas diffuses into the sensing element and oxidizes at the catalytic surface of the active or

measuring bead, causing its temperature to rise. The reference head is not catalytically coated,

so it is not heated by the combustibles. The difference in temperature and therefore resistance of

the otherwise matched pair of catalytic beads creates a signal in the bridge circuit.

Use of the uncoated reference bead compensates for the effects of temperature variations,

humidity changes, ambient pressure changes, and variations in line resistance. The beads are

installed in a housing that has a flashback arrestor screen at the sensing aperture to prevent flame

propagation into the process.

The combustibles readout is expressed in percentage LEL (methane equivalents). Air is the zero

gas, and the span gas follows the 80-90% fullscale rule. By far the most common range is 0-5%

methane equivalence (0-100% LEL), and the span gas for that range would be 3% to 4%

Page 9

methane in nitrogen. In other cases, a hydrogen and carbon monoxide mixture might be used. In

the presence of catalyst poisons, the combustibles sensor will hold its sensitivity to a

hydrogen/CO mixture far longer than to methane; therefore, it is important to calibrate it with the

right mixture.

TEMPERATURE AND CALCULATED VALUES

Temperature. The MAX 5 uses a type “K” thermocouple. The temperature section includes

circuitry and software to linearize the thermocouple signal and provide a zero-point reference.

The temperature display reads in degrees Centigrade or degrees Fahrenheit depending on which

temperature you select.

Carbon Dioxide. Because carbon dioxide is a combustion product, and its concentration level at

any given time depends on how completely a given fuel is burned and its by-product of carbon

monoxide is oxidized, the computer is able to calculate the carbon dioxide level. The oxygen

and combustibles section readings and the fuel type you selected at the front panel are factors in

the calculation resulting in the carbon dioxide concentration on a dry basis.

*U.S. Patent No. 4,477,403; U.K. Patent No. GB21405S6B; France Patent No. 2546626.

Efficiency. The computer calculates the efficiency level. The reading, calculated from the

temperature and oxygen readings and the type of fuel selected, is not absolute; rather, it is a

relative indication of the degree of improvement achieved by adjusting the burner. The

efficiency is based on British Standards recommendations and is calculated from this formula:

Efficiency = 100--K3 -- _____K1 x T_____

K2 x (1 - O2)

21

Where: T = net temperature °C

O

= oxygen concentration %

2

K1 = fuel factor on hydrocarbon composition

K2 = theoretical maximum CO

concentration of flue gas

2

K3 = correction factor for latent heat (“wet” losses)

The values of K1, 2 and K3 for the four fuels covered by the MAX 5 are:

K1

K2 K3

Natural Gas 0.38 11.8 11.0

#2 oil 0.56 15.6 6.0

#6 oil 0.6 15.9 5.0

Coal 0.63 18.6 3.0

SAMPLING SYSTEM DESCRIPTION

Page 10

The analyzer should be inspected and calibrated each time it is used. This includes inspecting

the filter/water trap and scrubber, checking the condition of the batteries, and calibrating the

instrument.

The sample gas and the ambient temperature must be between 32° and 122°F (0° to 50°C) for the

temperature compensation to operate properly. For maximum accuracy, the analyzer should be

calibrated at the same pressure, flow rate, and temperature anticipated in the sample gas. To

minimize water condensation in the instrument, the sample gas temperature should be

approximately the same as the ambient temperature of the analyzer. The sample gas temperature

should never be more than 10°F (5°C) above the analyzer temperature.

Measurement accuracy can be affected by abrupt changes in the ambient temperature. If

possible, place the analyzer in the environment where it will be used for at least one hour before

operation. This permits temperature stabilization of the thermistor and oxygen cell. Or, if

desired, recalibrate the oxygen analyzer section in the environment where it will be used.

All sample line tubing and fittings must be leak-free. Air entering the sample line under pump

suction can dilute the sample gas to a point where errors in readings will result. The sample line

can be connected to the analyzer with a short section of tubing.

Note: Certain types of plastic tubing (e.g. silicone tubing) contain plasticizers which can leach

from the tubing and cause readings on the combustibles section of the analyzer, and in extreme

cases damage the combustible sensor.

If too short a sample line is used, the sample gas may not have sufficient time to cool, resulting

in water being condensed into the analyzer sampling system. The introduction of liquid water

into the system can damage the pumps and/or temporarily affect performance of the oxygen

sensor (cause erroneous readings, etc.) and certain other components.

If the flue gas sample contains more water than the condensate trap can reasonably handle, it

may be necessary to install a larger trap upstream of the sample intake into the analyzer.

If span gas is connected to the analyzer sample intake without the pumps operating, “coking” (or

carbonizing) of the combustible sensor will occur. In most cases, the concentration of any

particular compound you expose the combustibles sensor should not exceed the LEL (Lower

Explosive Limits) of that compound.

Response factors have been determined to relate the sensor output of a specific compound to the

output obtained using methane. Table 1 shows a list of some typical compounds and their LEL

(Lower Explosive Limits) values. To determine the output of the sensor to any of the gases

listed, compared to the same concentration of methane, multiply the MAX 5 reading obtained by

the factor listed. For example, if the output is calibrated with methane at 2%, the output for

ethylene at 2% would be 2.0% X 1.26 = 2.52% methane equivalent.

If you want to establish a reading for a particular gas, you can calibrate with that gas.

Alternately, you can calculate what the Methane equivalency is for that particular gas and

Page 11

calibrate the instrument with Methane, but make it read as if it were exposed to the gas of

interest. For example, if you calibrate with Methane and the MAX 5 reads 3%, but Propane

would read 4%, you calibrate with Methane and adjust the MAX 5 to read 4%.

TABLE 1

DETECTOR RESPONSE TO GASES

COMPOUND LEL* RESPONSE FACTOR

Methane 5.0 1.00

Hydrogen 4.0 0.86

Carbon Monoxide 12.5 0.32

Ethane 3.0 1.20

Ethylene 2.7 1.26

Acetylene 2.5 1.39

Propane 2.2 1.42

Propylene 2.0 1.33

Butane 1.9 1.54

Hexane 1.1 1.50

Cyclohexane 1.3 1.44

Heptane 1.05 1.59

Benzene 1.3 1.50

Pentane 1.5 1.45

Toluene 1.2 1.48

Ethylene Oxide 3.8 0.76

Methyl Ethyl Ketone 1.8 0.96

Methyl Acrylate 2.8 0.59

*Taken from Fire Hazard Properties of Flammable Liquids, Gases and Volatile Solids, National

Fire Protection Agency.

To determine the concentration of a compound present at the sensor from the MAX 5 reading,

when calibrated with Methane, divide the MAX 5 reading (in percent Methane) by the factor.

For example, if Ethylene is flowing by the sensor, and a MAX 5 reading of 2.0% is obtained, the

concentration of Ethylene would be:

MAX 5 Reading = 2.0% = 1.59%

Factor 1.26

For Hydrogen:

2.0

.86

For Carbon Monoxide:

2.0

= 2.32%

= 6.25%

Page 12

.32

For a mixture of 70% Hydrogen and 30% Carbon Monoxide:

0.7(2.0) + 0.3(2.0) = 3.5%

.86 .32

CAUTION

In most cases, the concentration of any particular compound that the sensor is exposed to should

not exceed the LEL of that compound or sensor damage could occur.

The concentration of combustibles should never exceed that which will react completely with the

available oxygen present in the sample (stoichiometric burning), otherwise “coking” (the

deposition of carbon from incomplete combustion) will occur at the sensor, and drift and a loss

of sensitivity will result.

Note: For compounds not listed in Table 1, consult Teledyne Brown Engineering/Analytical

Instruments.

Because of the electrochemical properties of the B-3 oxygen cell, the MAX 5 is designed for

spot checking, not continuous on-line application. The maximum continuous sampling period

should not exceed 30 minutes, followed by a 30-minute purge with atmospheric air.

INSTALLATION AND START-UP PROCEDURES

Upon receipt, of the MAX 5, inspect the entire unit for damage. If damage is found, notify the

shipper. Check unit, and included accessories, for broken or loose parts. DO NOT CONNECT

THE INSTRUMENT UNTIL ALL INSTRUCTIONS HAVE BEEN READ! If damage is

not found, check for the following parts:

* Probe

* Power Cord

* Sensor - F-1R - blue label, B-3 - orange label. (The Combustible sensor is factory installed).

* Instruction Manual

* Calibration Kit - Optional, however, required for calibration purposes.

* Printer (optional)

* Printer interface (with printer option)

* RS-232 Module (with printer option)

PRECAUTIONS

1. Do not press on the sensing surface (membrane) of the Micro-Fuel Cell sensor.

Puncturing or other damage will require replacement of the sensor.

2. The F-1R and Micro-Fuel cell sensors contain a caustic mixture, which is harmful if

touched, inhaled, or swallowed. In case of eye contact, immediately flush eyes with

Page 13

water for at least 15 minutes. Call a physician. See Material Safety Data Sheets

(MSDS).

3. The PURAFIL Media Scrubber contains Potassium Permanganate. PURAFIL Media

is non-toxic upon oral, dermal, and inhalation exposure. Breathing of the dust may cause

sneezing. Skin may feel dry after contact. PURAFIL Media is an eye irritant. In case

of eye contact, immediately flush eyes with cold water for at least 15 minutes. Call a

physician immediately. See Material Safety Data Sheet (MSDS).

4. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause interference

to radio communications. It has been tested and found to comply with the limits for

a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference when operated in

a commercial environment. Operation of this equipment in a residential area is likely

to cause interference, in which case, the user, at his own expense, will be required to

take whatever measures may be required to correct the interference.

5. DO NOT RUN UNIT OFF AC POWER. UNIT IS MADE FOR PORTABLE

APPLICATION - NOT CONTINUOUS LINE APPLICATION.

ELECTRONIC ZEROING OF OXYGEN SECTION

1. Turn power switch on. If a negative O2 reading is displayed proceed to step 2. If a

negative reading is not displayed, turn off unit and proceed to “Sensor Installation/

Replacement” section.

2. Press the CAL and LOGO keys simultaneously. CAL will display on the screen.

4. Press the CAL, UP and DOWN keys simultaneously. A double beep will occur

followed by a short internal and a second double beep. Electronic zeroing is now

completed.

SENSOR INSTALLATION AND REPLACEMENT

To install (or replace) the sensors in the MAX 5, proceed as follows:

1. Unplug the charging cord from the analyzer and turn power switch off. Then loosen

the two screws (no more than 3/4”) indicated on the back panel of the MAX 5.

2. Remove the upper screws on each of the MAX 5 case and lift the cover off the unit.

3. Remove the finger nuts and bracket holding the sensors in place.

NOTE: As you face the unit (keyboard toward you) the combustibles sensor is on the

far left, the CO sensor is in the center and the oxygen sensor is on the right as

Page 14

shown in Figure 4.

Figure 4. Location of Sensors (Top View)

CO SENSOR: (Refer to Interconnection Diagram)

a. Installation:

To install the F-1R sensor, remove the sensor from its protective bag

and plug it into the center receptacle in the bottom of the MAX 5. Next, take the

the connector from J6 on the analog board and plug it into the top of the F-1R

sensor.

b. Replacement

: To replace the F-1R sensor, unplug the connector from J6 at the

top of the sensor, remove the sensor by pulling up on it, and throw away the old

sensor. Take a new F-1R sensor from its protective bag, insert it into the recep tacle (center bottom of the MAX 5), and attach the connector from J6 to the top

of the sensor.

OXYGEN SENSOR: (See Interconnection Diagram)

CAUTION:

Do not scratch, puncture, or otherwise damage the Micro-Fuel Cell membrane (screen

surface). Damage to the membrane will require sensor replacement. NEVER PRESS ON

THE SENSING SURFACE (screen); you might damage the sensor.

Page 15

a. Remove the sensor from its protective bag. Carefully remove the shorting clip.

b. Pull up on the oxygen sensor holder (on the right), place the Micro-Fuel Cell

(membrane side down) onto the surface under the sensor holder, and place the

sensor holder over the cell. Be sure that the sensor is connected to J5 on the

analog board.

COMBUSTIBLES SENSOR: (Replacement Only): (See Interconnection Diagram)

a. The combustibles sensor is connected to J4 on the analog board. If the sensor

is not connected to J4 or is not present, connect it to J4 to find it in the shipping

carton. Then, remove the protective bag, connect it to J4, and plug it into the

receptacle in the bottom left side of the MAX 5.

b. To replace the combustibles sensor, remove the existing sensor from the recep tacle, detach the connector from the sensor, and throw away the old sensor.

Remove the protective bag from a new sensor, connect the sensor to J4, and

then plug the sensor into the receptacle.

6. Replace the bracket over the sensors, insert the finger nuts, and tighten them to secure

the bracket.

7. Replace the cover, insert and tighten the side screws, and tighten the screws on the back

panel.

8. Allow the unit to charge overnight to stabilize the sensors and to obtain a full charge.

CAUTION: POWER SWITCH MUST BE IN THE OFF POSITION.

INSTRUMENT OPERATING PROCEDURE

1. Plug the thermocouple connector into the back panel jack (for initial calibration) as

shown in Figures 3 & 5.

2. Turn the power switch on and allow the readings to stabilize for approximately 30

seconds.

(INSERT FIGURE 5)

INITIATING AND ADJUSTING AIR AND SAMPLE FLOW

CAUTION;

The analyzer is intended to operate at atmospheric (14.7 psi) or near-atmospheric pressure.

Page 16

If the analyzer is subject to high positive pressures, damage may occur to the pumps or

other flow systems. A regulator may be necessary upstream to maintain sample pressure

at or below atmospheric level, if you want to use this analyzer to measure a high pressure

sample.

1. Connect the probe sample line to the inlet port of the analyzer, being sure that the exhaust

port is vented to a safe area.

2. Press the PUMP ON/OFF key.

3. Adjust both flowmeters (on back panel) at 2 scfh for standard range (0-1000 ppm CO).

NOTE: For 0-2.5% CO range: Adjust the sample flowmeter to .75 scfh; set air flowmeter

2 scfh.

4. After measuring a sample gas (not more than 30 minutes), expose the inlet port to clean

dry air (be sure the pumps are still on).

5. Purge with atmospheric air for an amount of time equal to the operating time. If water

appears at the vent, purge until water no longer appears.

CAUTION:

To avoid sucking in water, turn off the pump before opening the filter drain.

6. Empty the water condensate trap, as required. If necessary, replace the filter element.

TEMPERATURE, EFFICIENCY AND CARBON DIOXIDE SECTIONS

Carbon dioxide and efficiency levels are calculated; no calibration or adjustments are necessary

here. The thermocouple section may be calibrated if desired.

INITIAL CALIBRATION and AUTOMATIC CALIBRATION (carbon monoxide and

combustibles zero, oxygen span)

1. Press the LOGO and CAL keys simultaneously. “CAL” will appear on the LCD.

2. Press ENTER for autocal; “AUTO CAL” will appear on the LCD. When all readings

are stable, a beep will sound. Press the LOGO key to exit autocal, if desired.

NOTE: If any negative readings appear, press the LOGO key to exit autocal. Proceed to the

“Manual Calibration” section.

MANUAL SPAN (carbon monoxide and combustibles span calibration)

Page 17

CAUTION: ADJUST SPAN GAS PRESSURE REGULATOR TO MINIMUM FLOW

RATE (2-3 scfh) BEFORE CONNECTING TO ANALYZER.

NOTE: To perform manual spanning of the MAX 5, the Calibration Kit is required. The

calibration kit consists of 3 gases; 2 calibration (CO & Combustible) and a background

(nitrogen).

1. For Carbon Monoxide (CO) Span:

a. Run span gas through the analyzer; adjust the span gas pressure regulator until the

analyzer’s flowmeter indicates 2.0 SCFH. NOTE: This is for standard range only

(0-1000 ppm). Set as required for optional ranges (0-1% and 0-2.5%).

b. Press the LOGO and CAL keys simultaneously, followed by CO/EFFIC, and ENTER.

A number will appear in the CO section of the LCD.

c. When the number stabilizes, use the arrow keys to change the reading, as necessary,

to agree with the span gas concentration marked on the tank. When the reading is

correct, press ENTER to store the value.

d. If the reading is very unstable, the LCD will display “bAd”.

2. For Combustibles Span: (Standard) (0-5% Comb. - % CH4).

a. Run span gas through the analyzer; adjust the span gas pressure regulator until the

analyzer’s flowmeter indicates 2.0 SCFH. Make sure the air flowmeter also reads

2.0 SCFH.

b. Press the LOGO and CAL keys simultaneously, followed by COMB/TEMP and

ENTER. A number will appear in the COMB section of the LCD.

c. When the number stabilizes, use the arrow keys to change reading as necessary, to

agree with the span gas concentration (marked on tank % CH

). When the reading

4

is correct, press the ENTER key once again to store the value.

d. If the reading is very unstable, refer to “Operator’s Checks and Adjustment” section.

3. Temperature: (Optional). If calibration of the temperature probe is desired then press

CAL and LOGO keys simultaneously, followed by the F/C key. The current temperature

reading is displayed with the word ZERO in the upper left corner. The reading may now

be changed using the arrow keys to a known temperature. Calibration is now completed!

NOTE: In the ZERO mode upward adjustment of reading may be limited to a few degrees.

Page 18

To store reading press ENTER. The word SPAN will light up on top of the LCD. For span

calibration a known higher temperature input would be required or changes to the low

temperature. So if span calibration is not desired, press ENTER to return to normal operation.

NOTE: Centigrade readings are automatically stored in memory. To store Fahrenheit readings,

press COMB/TEMP key, then press °F/°C key.

MANUAL CALIBRATION (OPTIONAL) (For Oxygen Span, CO and Combustibles Zero)

NOTE: If automatic calibration is not desired, the following manual calibration procedure

applies.

NOTE: All references to zero gas during calibration means clean ambient air.

1. Oxygen Span:

Press LOGO and CAL at the same time, then the “O2 key. A number will appear in the

“O2” section of the LCD; use the arrow keys to increase or decrease the reading as

necessary to agree with the span gas concentration (usually air at 20.9% oxygen). Press

ENTER to store the value and return to normal operation.

2. Combustibles:

Press LOGO and CAL simultaneously, then COMB. The LCD will display the current

combustibles reading and the word “ZERO” at the top. Expose the combustibles sensor

to its zero gas and use the arrow keys, as needed, to adjust the reading to the zero gas

concentration (usually zero). To accept the value press ENTER. SPAN is displayed at

the top of the LCD display. Run combustibles span gas through the instrument; use the

up or down arrow to adjust the number displayed on the LCD to match the concentration

marked on the tank (% CH4), if required. Press ENTER to store the value and return it to

the operating mode.

3. Carbon Monoxide:

Press LOGO and CAL at the same time, then CO/EFFIC. The LCD will display the

current carbon monoxide reading and the word “ZERO”. Run zero gas through the

analyzer, use the arrow keys, as needed, to adjust the reading to the zero gas con centration (usually zero). To store and proceed to manual span calibration, press

ENTER,

SPAN & WAIT is displayed at the top of the LCD. Run carbon monoxide span gas

through the instrument; use the up or down arrow keys to adjust the number displayed

on the LCD to match the concentration marked on the tank (PPM CO), if required.

Press ENTER (after WAIT message disappears) to store the value and return to the

normal operating mode.

Page 19

To restore the built in temp. calibration constants press the CAL and LOGO keys

simultaneously, then press °F/°C key. Press the CAL and COMB/TEMP keys

simultaneously. This restores the proper values and exits the calibration mode.

SPECIAL FUNCTIONS

To activate the other special functions press both the arrow keys simultaneously. The LCD will

show:

1 2 3

4 5 6

7 8 9

The numbers 1 through 9 represent the nine keys on the keypad. The “1” above represents the

“O2/CO2” key, the “9” represents the “ENTER” key, etc. The keys 1 through 9 correspond to the

special functions below.

TEMPERATURE SIMULATION

If the thermocouple probe is disconnected or bad, the display will show “OPt”, and “CELL

FAIL” at the bottom, when temperature mode is selected. If a temperature simulation is desired

press the F/C key. The “OPt” is replaced by a simulated temperature reading. To change the

temperature press LOGO and CAL keys simultaneously, followed by F/C (this key toggles

between °F & °C). The simulated temperature is displayed. Use the arrow keys to change

reading, as desired. To store reading and return to normal mode press ENTER.

COST SAVINGS

(Keys 1 and 2)

1. Press CO/EFFIC key to display efficiency on the LCD.

2. Activate Special Functions.

3. Press O2/CO2 (number 1 above); instrument will store measurement and return to the

operating mode for burner adjustments.

4. Adjust the burner for optimum conditions.

5. Press arrow keys again to resume Special Functions; then press key 2.

6. The display will read “5 0 0”; adjust with arrow keys to represent three significant

figures of an average fuel expense over some period of time. Press ENTER; the top

line of the display will show the fuel savings. The second line will show the efficiency

before adjustment, and the third (bottom) line will show the current efficiency. Press

any key to return to normal operation (previous operation will resume).

Page 20

To STORE current readings

(Key 3)

1. Activate Special Functions.

2. Press key number 3; the display will read “5 0 0”.

CAUTION: If you press ENTER while the display reads “0 0 0”, you will ERASE all

previous readings. To abort the erasing feature, simply press the LOGO key instead of

ENTER.

3. Set the display to an ID number (1 to 999 set-table) using the arrow keys.

4. Press ENTER to store the reading and the I.D. number (or Teledyne key to exit). Normal

operation will resume.

5. The readings of up to twenty burners can be stored by the above method of selecting an

I.D. number for each. Multiple readings under one I.D. number are OK (up to 20

readings

total). All 20 readings and I.D. numbers can be printed under function 5.

To DISPLAY readings that have been stored

(Key 4)

1. Activate Special Functions.

2. Press key #4. The instrument will display the first I.D. number. Press the LOGO key to

escape; and other key to proceed. The instrument will display the first set of readings.

Press any key except the LOGO key to display the second set of readings and repeat for

all readings. Press the LOGO, PUMP ON/OFF, and *keys to return to normal operation.

To PRINT stored readings

(Key 5) (Optional - See Appendix)

1. Plug the printer cable into the MAX 5 serial port and the printer. Turn on the printer.

2. Activate Special Functions and press key #5. The printer will print the I.D. number and

the six numerical values of each of the stored readings in chronological order.

To TEST the keyboard/LCD/RESET

(Key 6)

1. Activate Special Functions.

2. Press key 6 to call for a keyboard test.

Page 21

3. To test, press any key other than the LOGO or ENTER keys; to resume normal operation

press the LOGO key.

4. To perform a total memory reset press the ENTER key twice in succession.

AUTOMATIC DATA OUTPUT

(Function 7)

1. Activate Special Functions.

2. Press key 7 to activate the Data Output function.

3. Press the up or down arrow as needed to cause the display to read the desired time

interval (002 to 999 seconds) between reports. Press ENTER. A report is a continuous

transmission, through the serial port, of all six data factors (measurements and

calculations).

4. To stop data output, repeat steps 1 & 2 and set the time interval in step 3 to “000”

followed by the ENTER key.

To PRINT an instruction manual

(Key 8)

1. Connect a serial printer to the instrument’s serial port. Turn on the printer and switch

it “on-line”.

2. Activate Special Functions, then press key 8.

3. This abridged version of the instrument’s instruction manual will be printed.

-18-

To check the VERSION of your instrument’s software

(Key 9)

1. Activate Special Functions.

2. Press key number 9.

3. The display will show the model number and the month on the first line, the hour and

the date on the second line, and the year on the third line. The model, month, day, and

year correspond to the date of software release.

4. Press any key to resume normal operation.

ELECTRONIC ZEROING OF OXYGEN SECTION

Page 22

1. Turn power switch on (without O2 sensor installed). If a negative O2 reading is

displayed,

proceed to step 2. If a negative reading is not displayed, electronic zeroing is not

required.

2. Press the CAL and LOGO keys simultaneously. CAL will display on the screen.

3. Press the CAL key.

4. Press the CAL, UP and DOWN keys simultaneously. A double beep will occur followed

by a short interval and a second double beep. Electronic zeroing is now completed.

ROUTINE MAINTENANCE

WARNING: THE ELECTRONIC COMPONENTS IN THE MAX 5 CAN PRESENT AN

ELECTRICAL SHOCK HAZARD. BEFORE REMOVING THE ANALYZER COVER

FOR ANY REASON, DISCONNECT THE CHARGING CORD FROM THE POWER

SOURCE AND THE ANALYZER.

SCRUBBER

The analyzer needs the scrubber to remove interfering gases, such as sulfur and nitrogen oxides,

or hydrogen sulfide. These gases can cause false readings if they are not removed from the flue

gas sample. The scrubber is disposable and must be periodically replaced.

Replace the scrubber when its granules have changed color from purple to gray. When all traces

of purple are gone, the scrubber is not operating effectively.

To replace the scrubber, proceed as follows:

1. Obtain a new scrubber.

2. Carefully pull the old scrubber out of its bracket holder on the back of the unit.

3. The scrubber is attached to tubes on both sides; remove each end of the scrubber from

the end of each tube and throw away the old scrubber.

4. Take the new scrubber out of its plastic bag and carefully

tube.

5. Feed the tubes into the analyzer very slowly as you insert the new scrubber into its

bracket holder.

NOTE: You must be careful not to crimp the tubes when you replace the scrubber. You may

want to open the MAX 5 to check the tubing the first time you replace the scrubber.

To open the MAX 5, loosen the screws on the back, remove the top screws on the

attach the scrubber to each

Page 23

case, and lift the hood off the unit.

BATTERY RECHARGING

The rechargeable Nickel-Cadmium batteries need to be recharged after about 8 hours of use.

To Recharge the Batteries:

1. Turn the back panel power switch off.

2. Plug the power cord (connector end) into the back panel AC power receptacle and

plug the other end into the correct voltage outlet.

3. Allow the batteries to recharge for the required line power:

100VAC, 50/60 Hz - 24-30 hrs.

115VAC, 50/60 Hz - 14-16 hrs.

230VAC, 50/60 Hz - 14-16 hrs.

BATTERY REPLACEMENT

Rechargeable Nickel-Cadmium batteries last for many years; however, you may need to replace

them after a period of time. Before you replace the batteries, perform the following tests (make

sure the MAX 5 is unplugged from the wall):

To Test the Power Supply (charging circuit):

1. Open the MAX 5 as instructed in Steps 1 and 2 under the “To Replace Batteries” section

below.

2. Locate R39 resistor.

3. Put test meter leads across R39 resistor. The reading should be 40 mVDC +2 mVDC

when you plug the AC power cord into the wall.

4. If you get the correct reading in step 3, this indicates that the charging circuit is okay.

To Test the Batteries:

1. Unplug the MAX 5 from the wall.

2. Put the red lead from the test meter to J2 pin 1 (red) and the black lead to J2 pin 2

(green). The reading should be approximately 7.5 VDC. Move red lead to J2 pin 3

(black). The reading should be approximately -5 VDC. If your readings do not equal

these, replace the batteries (see “To Replace Batteries” section below).

Page 24

To Replace Batteries:

1. Loosen the screws indicated on the back panel of the MAX 5.

2. Remove the upper and lower screws on the outside of the MAX 5 housing and remove

both panels of the MAX 5. Disconnect J2 from the analog PCB (smaller PCB assy.).

3. Remove the screw holding the battery pack in place. Carefully lift out the battery pack.

4. Remove the tape and plate holding the existing batteries in place. Replace the batteries

with new Nickel-Cadmium rechargeable batteries.

5. Tape the new batteries in place and replace the plate. Insert the battery pack in the

MAX 5 and screw it in place. Reconnect J2 to analog PCB. Put on the bottom of the

case, insert and tighten the screws on the sides and tighten the screws in the back of

the MAX 5.

SENSOR REPLACEMENT

When the sensor’s (CO, Comb., and O2) near the end their useful life, sensitivity will decline

rapidly and the readings will be very unstable. Refer to “Operator’s Checks & Adjustment” -

Messages and Failure Warning Signs for further details. For sensor replacement, refer to

“Installation Procedures.”

AFTER REPLACING ANY SENSOR, PROCEED TO THE “INSTRUMENT OPERATING

PROCEDURE” SECTION FOR CALIBRATION.

Important: To avoid the possibility of not having a replacement cell available when it is

needed, Teledyne recommends that a spare cell be ordered shortly after the instrument is placed

in service, and each time the cell is replaced thereafter.

Caution:

instrument should be in reserve.

OPERATOR’S CHECKS & ADJUSTMENTS

MESSAGES

This section describes messages that may appear on the MAX 5 LCD so that you can correct the

problem.

DO NOT OVER ORDER (OR STOCKPILE) SPARE CELLS. Only one cell per

-0.0 Indicates a negative reading. A bad sensor, a downward shift in zero calibration since the

last adjustment, or an improper calibration might produce this error message.

REMEDY:

Recalibrate the instrument.

Page 25

-0.00/-0.0 The negative sign in a reading of -0.00 or -0.0 in the CO or COMB section after

auto zero is not significant.

bAd Indicates a bad reading from the cell. If the cell is outside its specifications or is noisy

and unstable, the computer cannot get a good reading, and the calibration adjustment required to

compensate may be greater than the maximum allowable adjustment, resulting in this error

message. REMEDY: Recalibrate the instrument or replace the cell.

CELL FAIL Means that a cell has failed or that a problem has occurred in a sensor circuit.

REMEDY: Isolate the faulty sensor circuit, replace the bad sensor, or rectify the circuit

problem, as necessary. Example: Thermocouple is not connected.

- - - Means that the value cannot be calculated. If the thermocouple is disconnected, for

example, then the computer cannot perform the efficiency calculation (which depends on

temperature data), and this error may occur; the efficiency reading will be - - -, and the

temperature reading will be OPt.

OFF Means off-scale for CO reading.

LO BATT Indicates the batteries are depleted or near depletion after about 8 hours use.

REMEDY: Recharge the batteries.

FAILURE WARNING SIGNS

The MAX 5 indicates failure warning signs with a CELL FAIL message on the LCD and a bAd

reading.

O2 The cell output is low which results in too high a span requirement.

CO The inability to span or excessive noise indicate cell failure.

COMB. Excessive drift and the inability to span or zero indicate cell failure.

TEMP. A failure message on the temperature section indicates an open or short

thermocouple circuit.

CO

Conditions that contribute to failure or erroneous reporting of the carbon dioxide section

2

include failure of any of the other sensors or incorrect fuel selection.

OPt Open thermocouple or optional temperature simulation (Refer to “Temperature

Simulation” section).

Page 26

APPENDIX

TO PRINT STORED READINGS (KEY 5) - OPTIONAL

1. On the back of the instrument is a “serial output” receptacle for connection to a serial

(RS-232C) printer (see Note). The RS-232C data output format is as follows: 1 start

bit, 8 data bits, and 1 stop bit, at a rate of 300 baud (bits/sec.). A connecting cable is

available from TBE/AI when using a standard serial printer with the analyzer. To use

the printer, proceed as follows:

Plug the cable into the MAX 5 “serial output” receptacle and the printer

(see Figure 3).

Align the paper.

Turn the power on.

Press the “FF (Form Feed)/Auto Sheet Load” button to advance the paper one

sheet.

Press the “ONLINE” button.

NOTE: If the printer is purchased from TBE/AI, refer to the printer “instruction manual” for set

up. If the printer is not purchased from TBE/AI, any serial printer may be used if it complies

with the following minimum specifications:

a. It can accept RS-232C serial data in the speed and format shown.

b. It has a standard 25 pin RS-232C connector, so it can be used with the

optional factory-supplied cord).

c. It has a minimum print speed of 50 characters per second (cps).

d. It has an input buffer of at least 1024 bytes (1Kb).

Page 27

MATERIAL SAFETY DATA SHEET

Section I - Product Identification

Product Name: Micro-Fuel Cells, all classes except A-2, A-3, A-5, B-2F and B-2VF.

Electrochemical Oxygen Sensors, all classes except R-19.

Mini Micro-Fuel Cells, all classes.

Manufacturer: Teledyne Brown Engineering/Analytical Instruments

Address: 16830 Chestnut Street, City of Industry, CA 91749

Phone Number: (818) 961-9221

MSDS Prepared By: Chuck Molloy

Date Prepared or Last Revised: 3-31-88

Emergency Phone Number: (818) 961-9221

Section II - Physical and Chemical Data

Chemical and Common Names: Potassium Hydroxide (KOH) 15%

Granular Lead (Pb) pure

CAS Number: KOH 1310-58-3

Pb 7439-92-1

Melting Point/Range: -10 to 0 deg. C.

Boiling Point/Range: 100 to 115 deg. C

Specific Gravity: 1.09 @ 20 deg. C

pH: >14

Solubility in Water: Completely soluble

Percent Volatiles by Volume: None

Appearance and Odor: Colorless, odorless solution

Page 28

Section III - Physical Hazards

Potential for Fire and Explosion: The electrolyte in micro-fuel cells is not flammable. There are

no fire to explosion hazards associated with micro-fuel cells.

Potential for Reactivity: The sensors are stable under normal conditions of use. Avoid contact

between the sensor electrolyte and strong acids.

Section IV - Health Hazard Data

Primary Route(s) of Entry: Ingestion, Eye/Skin Contact

Exposure Limits: OSHA PEL .05 mg/cu.m. (Pb)

ACGIH TLV 2 mg/cu.m. (KOH)

Effects of Overexposure:

Ingestion: The electrolyte could be harmful or fatal if swallowed.

Oral LD50 (RAT) = 2433 mg/kg

Eye: The electrolyte is corrosive and eye contact could result in permanent

loss of vision.

Dermal: Liquid inhalation is unlikely.

Signs/Symptoms of Exposure: Contact with skin or eyes will cause a burning sensation and/or a

soapy feeling for skin contact.

Medical Conditions Aggravated by Exposure: None

Carcinogenicity:

NTP Annual Report on Carcinogens: Not listed.

LARC Monographs: Not listed.

OSHA: Not listed

Other Health Hazards: Lead is listed as a chemical known to the State of California to cause

birth defects or other reproductive harm.

Page 29

Section V - Emergency and First Aid Procedures

Eye Contact: Flush eyes with water for at least 15 minutes and get immediate medical attention.

Skin Contact: Wash affected area with plenty of water and remove contaminated clothing. If

burning persists, seek medical attention.

Ingestion: Give plenty of cold water. Do not induce vomiting. Get medical attention.

Inhalation: Liquid inhalation is unlikely.

SECTION VI - HANDLING INFORMATION

Handling Precautions: Note: The oxygen sensors are sealed and under normal circumstances,

the contents of the sensors do not present a health hazard. The following information is given as

a guide in the event that a cell leaks.

Protective Clothing: Rubber gloves, chemical splash goggles.

Clean-up Procedures: Wipe down the area several times with a wet paper towel. Use a fresh

towel each time.

Protective Measures during Cell Replacement: Before opening the bag containing the cell,

check the cell for leakage. If the cell leaks, do not open the bag. If there is liquid around the cell

while in the instrument, put on gloves and eye protection before removing the cell.

Disposal: Should be in accordance with all applicable state, local and federal regulations.

Page 30

MATERIAL SAFETY DATA SHEET

Section I - Product Identification

Product Name: Carbon Monoxide Sensor, Class F-1R, F-1RH and F-2

Manufacturer: Teledyne Brown Engineering/Analytical Instruments

Address: 16830 Chestnut Street, City of Industry, CA 91749

Phone Number: (818) 961-9221

MSDS Prepared By: Chuck Molloy

Date Prepared or Last Revised: 3-31-88

Emergency Phone Number: (818) 961-9221

Section II - Physical and Chemical Data

Chemical and Common Names: Sulfuric Acid (H2SO4) 17%

Silica (SiO

) 50%

2

CAS Number: H2SO4 7664-93-9

SiO

7631-86-9

2

Melting Point/Range: 1700 deg. C

Boiling Point/Range: N/A

Specific Gravity: 2.2 @ 20 deg. C

pH: Less than 1

Solubility in Water: Insoluble

Percent Volatiles by Volume: None

Appearance and Odor: White powder with an irritating odor.

Page 31

Section III - Physical Hazards

Potential for Fire and Explosion: The electrolyte in carbon monoxide sensors is not flammable.

There are no fire or explosion hazards associated with carbon monoxide sensors.

Potential for Reactivity: The sensors are stable under normal conditions of use. Avoid contact

between sensor electrolyte and strong acids, strong bases, strong oxidizers and reducers.

Primary Route(s) of Entry: Ingestion, Eye/Skin Contact

Exposure Limits: OSHA PEL N/A

ACGIH TLV 1 mg/cu.m. (H2SO4)

10 mg/cu.m. (Total Dust)

5 mg/cu.m. Respirable Dust (SiO2)

Effects of Overexposure:

Ingestion: The electrolyte could be harmful or fatal if swallowed.

Oral LD50 (RAT) = 2433 mg/kg

Eye: The electrolyte is corrosive and eye contact could result in permanent

loss of vision.

Dermal: The electrolyte is corrosive and skin contact could result in a chemical

burn.

Inhalation: Solid inhalation is unlikely.

Signs/Symptoms of Exposure: Contact with skin or eyes will cause a burning sensation.

Medical Conditions Aggravated by Exposure: None

Carcinogenicity:

NTP Annual Report on Carcinogens: Not listed

LARC Monographs: Not listed

OSHA: Not listed.

Other Health Hazards: None

Page 32

Section V - Emergency and First Aid Procedures

Eye Contact: Flush eyes with water for at least 15 minutes and get immediate medical attention.

Skin Contact: Wash affected area with plenty of water and remove contaminated clothing. If

burning persists, seek medical attention.

Ingestion: Give plenty of cold water. Do not induce vomiting. Get medical attention.

Inhalation: Solid inhalation is unlikely.

Section VI - Handling Information

Handling Precautions: Note: The carbon monoxide sensors are sealed and under normal

circumstances, the contents of the sensors do not present a health hazard. The following

information is given as a guide in the event that a cell leaks.

Protective Clothing: Rubber gloves, chemical splash goggles.

Clean-up Procedures: Wipe down the area several times with a wet paper towel. Use a fresh

towel each time.

Protective Measures during Cell Replacement: Before opening the bag containing the cell,

check the cell for leakage. If the cell leaks, do not open the bag. If there is liquid around the cell

while in the instrument, put on gloves and eye protection before removing the cell.

Disposal: Should be in accordance with all applicable state, local and federal regulations.

Page 33

RECOMMENDED SPARE PARTS LIST

MAX 5 MONITOR

P/N DESCRIPTION

QTY.

1 C-6689-B3 MICRO-FUEL CELL - OXYGEN SENSOR

1

* C-40371-F1R ELECTROCHEMICAL SENSOR - CO (01000 PPM STD.)

1 A-39202A COMBUSTIBLE PROBE/CABLE

1 B-39764A PROBE GUN ASSEMBLY (TYPE “K” HI TEMP.

THERMOCOUPLE)

1 B-39764B PROBE GUN ASSEMBLY (TYPE “J” LO TEMP.

THERMOCOUPLE)

1* D-38370A PC BOARD ASSEMBLY - ANALOG (TYPE “K”

THERMOCOUPLE)

1* D-38370B PC BOARD ASSEMBLY - ANALOG (TYPE “J”

THERMOCOUPLE)

1* D-38584A PC BOARD ASSEMBLY - MICROPROCESSOR

1 L-182 LCD DISPLAY

10 F-6 FUSES, 3AG, 1/4A

5 B-71 NiCAD BATTERIES

1 C-964 POWER CORD

1 B-64942 PUMP ASSY

1 F-273 SAMPLE FLOWMETER

1 F-274 AIR FLOWMETER

1 B-25900 SCRUBBER

1 A-13455 FILTER ELEMENT

1 F-513 FILTER ASSY

1 A-40688 CAL KIT FOR 0-1000 PPM CO; Replacement CAL Gas G-222

1 A-48231 CAL KIT FOR 0-1% CO; Replacement CAL Gas G-41 & G-259

(CO)

1 A-48232 CAL KIT FOR 0-2% CO; Replacement CAL Gas G-41 & G-162

(CO)

1 C-967 CARRYING CASE (MAX)

1 P-528 PRINTER

1 I-106 INTERFACE for printer

1 A-40342 PRINTER CABLE ASSEMBLY (for printer)

1 T-823 TRANSFORMER (used w/printer for 220V application only)

*Specify CO range when ordering.

A MINIMUM CHARGE IS APPLICABLE TO SPARE PARTS ORDERS.

IMPORTANT: Orders for replacement parts should include the part number (if available) and

the model and serial number of the system for which the parts are intended.

Page 34

SEND ORDERS TO:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91748

Telephone: (626) 9341500

Fax: (626) 9612538

Web: www.teledyneai.com

or your local representative.

Page 35

REFERENCE DRAWINGS

MAX 5 MONITOR

INSTALLATION DRAWINGS

B-39437 OUTLINE DIAGRAM

B-39430 PIPING DIAGRAM (STANDARD)

B-43108RF PIPING DIAGRAM (%CO) (OPTIONAL)

C-39776 CONNECTION DIAGRAM

ASSEMBLY DRAWING

A-40342 ASSEMBLY - PRINTER CABLE

Page 36

(INSERT DRAWINGS)

Loading...

Loading...