Page 1

MANUAL ADDENDUM

MODEL M201E

AMMONIA ANALYZER

(For use with the M200E Operators Manual, P/N 04410)

TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

(TELEDYNE-API)

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

TOLL-FREE: 800-324-5190

FAX: 858-657-9816

TEL: 858-657-9800

E-MAIL: api-sales@teledyne.com

WEB SITE: www.teledyne-api.com

Copyright 2006-2012 05206H DCN5910

Teledyne Advanced Pollution Instrumentation

07 May 2012

Page 2

Page 3

ABOUT THIS MANUAL

This manual is an addendum that supplements the M200E NOx Analyzer manual, p/n 04410; it

includes document(s) as listed below.

Part No. Name/Description

M201E Spare Parts List (in Section 6.0)

06185H

Note: Please refer to our Website or Sales for more

recent updates.

NOTE

We recommend that this manual and the M200E manual be read in their

entirety before any attempt is made to operate the instrument.

REVISION HISTORY

M201E, MANUAL ADDENDUM, PN 05206

Date

07 May 2012 H 5910 Updated specs and valve port labels

14 May 2010 G 5731 Administrative additions

17 Nov 2009 F 5588

To Rev DCN Change Summary

Added thermoco uple replacement

instructions

Updated catalytic cartridge illustration

Updated pneumatic diagrams

Updated Spare Parts List Rev E to F

05206H DCN5910 i

Page 4

This page intentionally left blank.

ii 05206H DCN5910

Page 5

Teledyne API Model M201E NH3 Analyzer Operator Manual M201E Ammonia Analyzer

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many safety messages

throughout this manual; please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Safety messages

are associated with a safety alert symbol. These symbols are found in both the M200E and

M201E manuals and are also located inside the instrument. The definition of these symbols is

described below:

GENERAL WARNING/CAUTION: Refer to the instructions for details on the

specific danger.

CAUTION: Hot Surface Warning

WARNING: Electrical Shock Hazard

Technician Symbol: All operations marked with this symbol are to be performed

by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central safety

grounding point for the instrument.

CAUTION The analyzer should only be used for the purpose

and in the manner described in this manual.

If you use the analyzer in a manner other than that for which

it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

05206H DCN5910 iii

Page 6

This page intentionally left blank.

iv 05206H DCN5910

Page 7

TABLE OF CONTENTS

1.0 M201E AMMONIA ANALYZER .............................................................7

1.1 Theory of Operation...................................................................................................... 10

1.1.1 Minim

1.1.2 Purging the Reaction Cell..................................................................................... 12

1.2

1.3 Sa

1.4 M201E Analyzer Specifications................................................................................... 14

Special Considerations For Ammonia Measurement ................................................... 12

mple Filtration........................................................................................................... 13

2.0 CALIBRATION PROCEDURE .............................................................15

2.1 Zeroing The Analyzer................................................................................................... 16

2.2 Spanning The Analyzer With Nitric Oxide Gas........................................................... 17

2.3 Spanning The Analyzer With Ammonia Gas ............................................................... 20

3.0 CONFIGURABLE ANALOG OUTPUT OVERVIEW ...........................25

3.1 Analog Output - Electronic Configuration ................................................................... 27

3.2 Analog Output Signal Type and Range Selection ........................................................ 28

3.3 Selecting Auto Or Manual Analog Output Calibration ................................................29

3.4 Manually Calibrating Analog Output Signal Levels .................................................... 32

3.5 Analog Output Recorder Offset Adjustment ................................................................34

4.0 MAINTENANCE SCHEDULE...............................................................35

4.1 M501 NH3, Maintenance ............................................................................................. 35

4.2 Replacing the Catalytic Cartridge................................................................................. 36

4.3 Replacing the Thermocouple........................................................................................ 37

4.4 AutoZero Flow Check................................................................................................... 39

5.0 ALARMS AND CAUTIONS ..................................................................41

5.1 Alarm ............................................................................................................................ 41

5.2 Caution.......................................................................................................................... 41

6.0 M201E SPARE PARTS LIST ...............................................................43

7.0 CALCULATING MOLY CONVERTER EFFICIENCIES ......................47

7.1 Purpose:......................................................................................................................... 47

7.2 TOOLS:......................................................................................................................... 47

7.3 PARTS:......................................................................................................................... 47

7.4 PROCEDURE............................................................................................................... 47

izing PMT Drift.......................................................................................... 11

LIST OF FIGURES

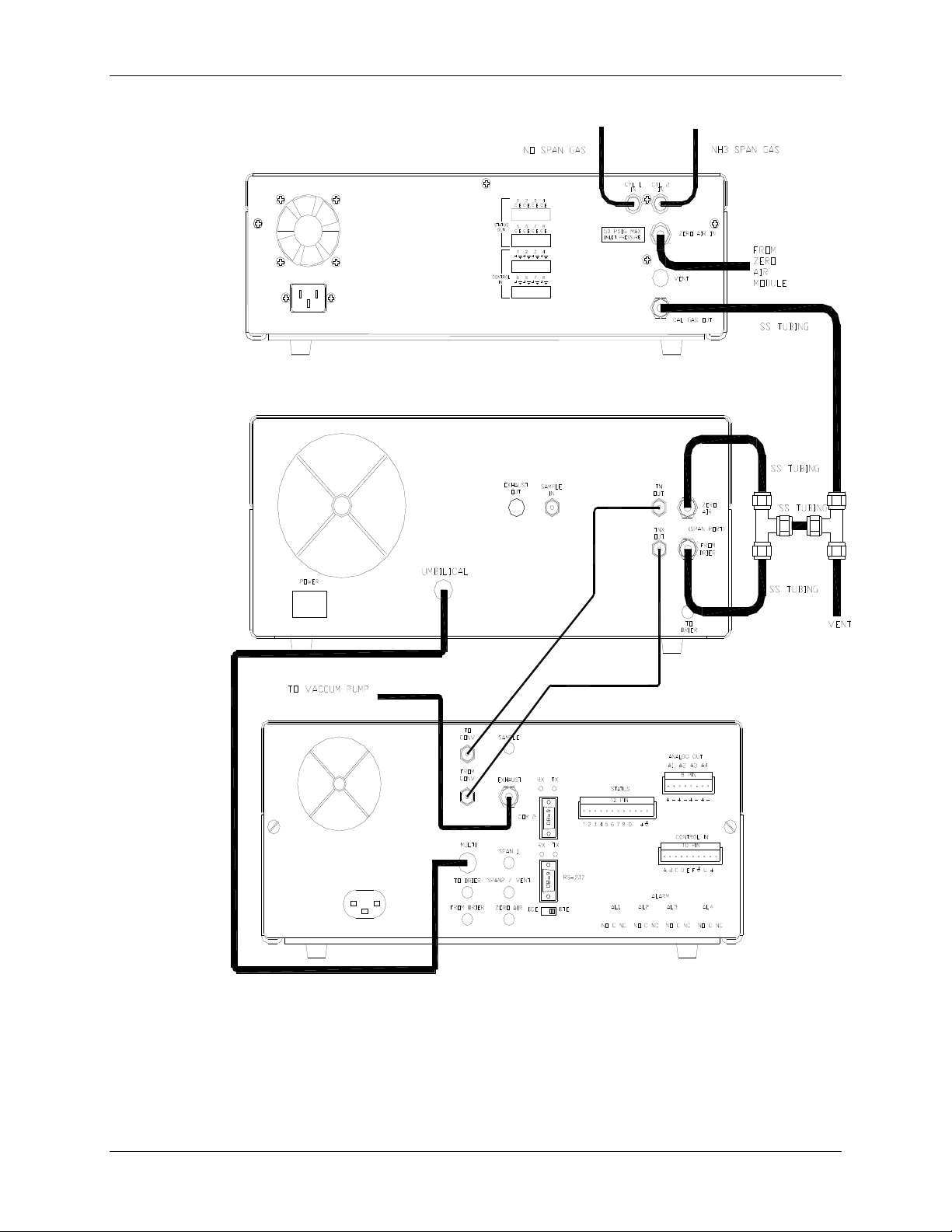

Figure 1-1. M201E Pneumatic Connection Diagram with External Calibrator Option (ECO)...... 8

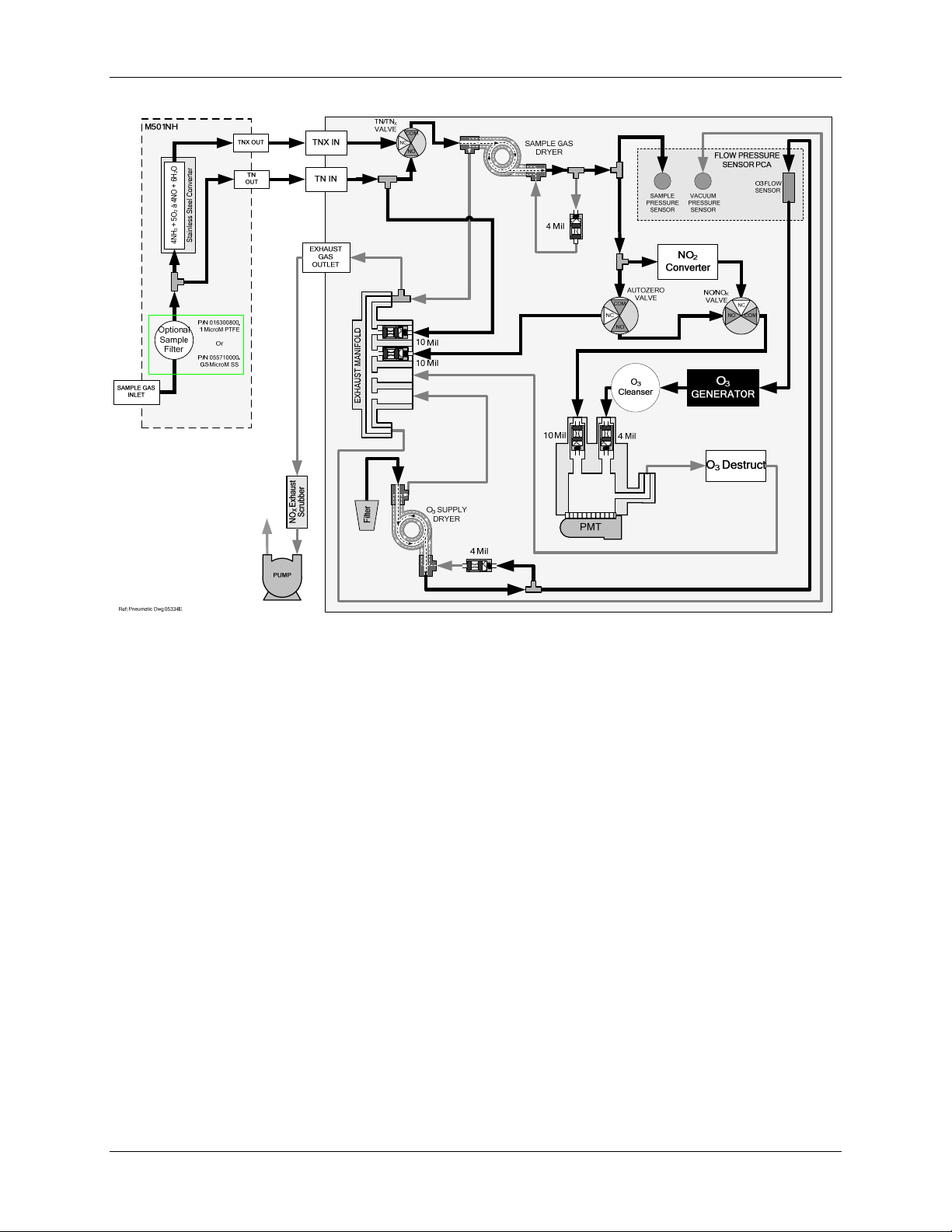

Figure 1-2. M201E and M501 NH

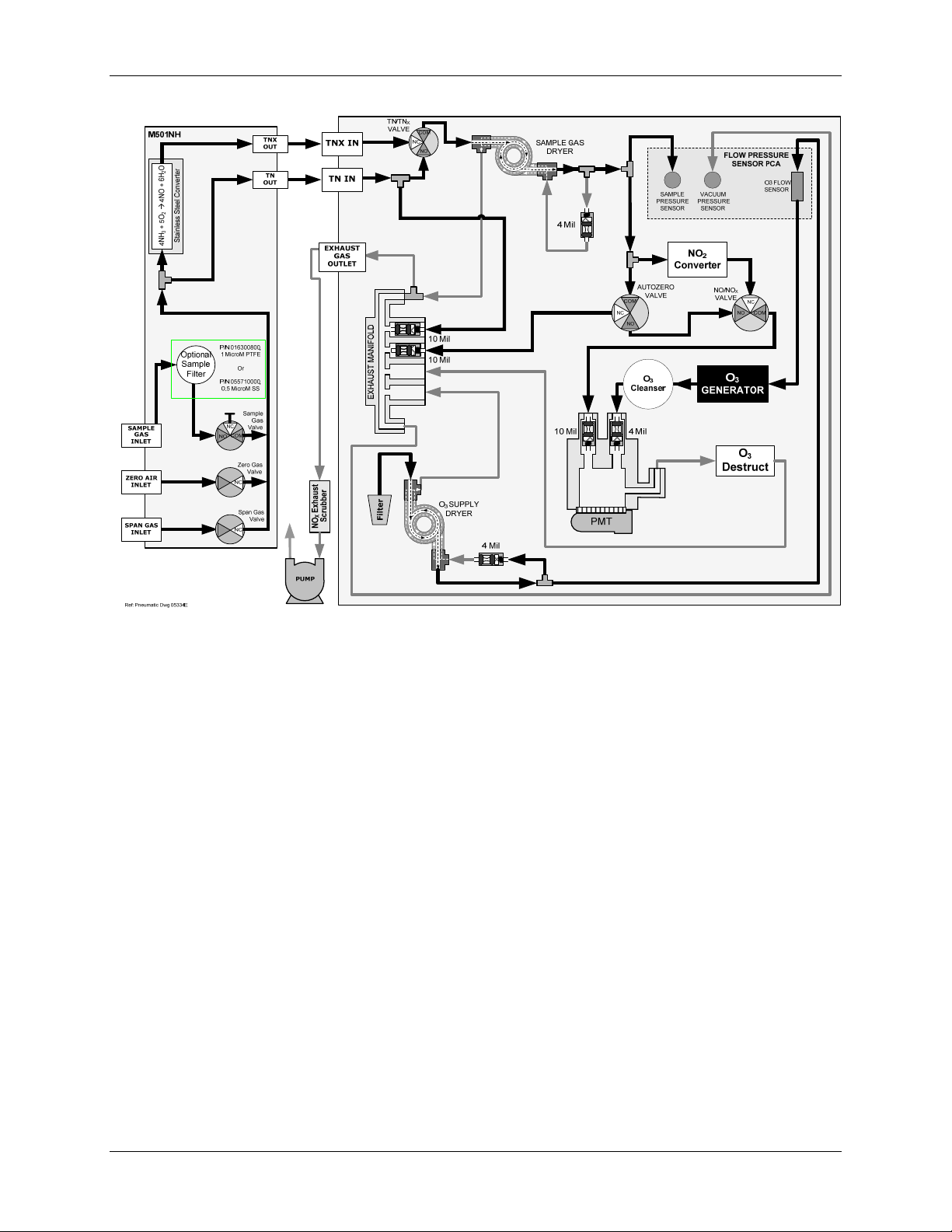

Figure 1-3. M201E and M501 NH3, with Zero and Span Valve Options Pneumatic Flow.......... 10

Figure 3-1. Analog Output Connector.......................................................................................... 25

Figure 3-2. Analog Output Signal T

Figure 3-3. Auto Or Manual Analog Output Calibration ............................................................. 30

Figure 3-4. Analog Output Group Calibration

Figure 3-5. Setup For Calibrating Analog Output Signal Levels

05206H DCN5910 v

, Pneumatic Flow.................................................................... 9

3

ype ....................................................................................... 28

.............................................................................. 31

................................................. 32

Page 8

Figure 3-6. Analog Output Manual Calibration............................................................................ 33

Figure 3-7. Analog Output Recorder Offset Calibration.............................................................. 34

Figure 4-1. Catalytic Cartridge..................................................................................................... 36

Figure 4-2. Thermocouple Location............................................................................................. 37

Figure 5-1. M201E Functional Block Diagram

............................................................................ 42

LIST OF TABLES

Table 1-1. M201E Operating Specifications ................................................................................ 14

Table 2-1. Zero Calibration Procedure – Zero Gas Through the SAMPLE Port ......................... 16

Table 2-2. Zero Calibration Procedure - Zero Gas Through ZERO Port .....................................17

Table 2-3. NO Calibration Procedure – NO Gas Through the SAMPLE Port............................. 18

Table 2-4. NO Calibration Procedure - NO Gas through the SPAN Port.................................... 19

Table 2-5. Confirming Ammonia Converter Efficiency............................................................... 21

Table 2-6. NH3 Calibration Procedure – NH3 Gas Through The SAMPLE Port........................ 22

Table 2-7. NH3 Calibration Procedure – NH3 Gas through the SPAN Port................................ 23

Table 3-1. Analog Output Data Default Settings.......................................................................... 25

Table 3-2. Analog Output Pin-Outs.............................................................................................. 26

Table 3-3. Analog Output Voltage Range Min/Max.................................................................... 27

Table 3-4. Analog Output Current Loop Min/Max ...................................................................... 27

Table 3-5. ZERO/SPAN Analog Output Signal Calibration Tolerances...................................... 32

Table 4-1. Preventative Maintenance Schedule............................................................................ 35

Table 4-2. M501 NH3, Converter Rebuild Parts List.................................................................... 36

Table 4-3. Analyzer Flow Check.................................................................................................. 39

vi 05206H DCN5910

Page 9

1.0 M201E AMMONIA ANALYZER

This manual is to be used in conjunction with the M200E NOx Analyzer

manual, p/n 04410 supplied with this instrument. It is important that you

familiarize yourself with the workings of the NOx analyzer before proceeding

with NH3 measurements.

The M201E ammonia analyzer consists of a modified M200E nitrogen oxide

analyzer and an M501 NH3, ammonia converter. The analyzer measures the

following individual gas concentrations: TNx (NH

and NO in the sample gas.

and NOx), NOx (NO and NO2)

3

The

ammonia concentration is calculated by subtracting the NOX

reading from the TNx measurement.

The

nitrogen dioxide concentration is calculated by subtracting the NO

reading from the NOx measurement.

The instrument is available in three pneumatic configurations:

The M201E with External Calibrator Option (ECO) is shown in Figure

1-1.

The basic system is shown in Figure 1-2.

The M201E with Zero/Span valves is shown in Figure 1-3.

Note: For an M201E analyzer with Zero/Span option you must connect the

umbilical cord P/N 02255 between the analyzer and the external M501 NH3,

converter assembly.

If the analyzer is purchased without the Zero/Span option t hen the zero and span

calibration gases must be individually applied to the sample port. Remember, the

gases must be clean/dry and supplied at ambient pressure.

CAUTION

Do not pressurize the Sample/Span/Zero port above ambient

05206H DCN5910 7

Page 10

M201E Ammonia Analyzer Teledyne API Model M201E NH3 Analyzer Operator Manual

Figure 1-1. M201E Pneumatic Connection Diagram with External Calibrator Option (ECO)

8 05206H DCN5910

Page 11

Teledyne API Model M201E NH3 Analyzer Operator Manual M201E Ammonia Analyzer

Figure 1-2. M201E and M501 NH3, Pneumatic Flow

05206H DCN5910 9

Page 12

M201E Ammonia Analyzer Teledyne API Model M201E NH3 Analyzer Operator Manual

Figure 1-3. M201E and M501 NH3, with Zero and Span Valve Options Pneumatic Flow

1.1 THEORY OF OPERATION

The Teledyne-API Model M201E analyzer measures ammonia by oxidizing it to

nitric oxide by the following reaction:

+ 5O2 4NO + 6H2O

4NH

3

The resulting nitric oxide is then measured by the chemiluminescent reaction with

ozone. Consult Section 10.1 in the M200E manual (provided with this

instrument) for more details on the nitric oxide measurement.

The analyzer uses two converters to oxidize the different sample gases. A high

temperature catalytic converter, the M501 NH3,, converts NH3 and NOx into NO

creating the TN

analyzer and consisting of heated molybdenum, converts all of the NOx in the

sample to NO producing the NOx channel. The nitric oxide channel is measured

while bypassing both the M501 NH

operated in reflux mode, is installed prior to the molybdenum converter and the

AutoZero valve. The drier removes ammonia and water from the switched

stream. The ammonia would have otherwise been converted by the molybdenum

channel. A second converter, housed inside the M201E

x

, and molybdenum converter. A Nafion® drier

3

10 05206H DCN5910

Page 13

Teledyne API Model M201E NH3 Analyzer Operator Manual M201E Ammonia Analyzer

and registered as NOx. This location provides the drier with continuous flow,

thereby allowing it to stabilize faster.

Note: Due to the Nafion® drier, the analyzer has a maximum am monia range of

2.0 PPM.

The calculated gas concentrations, ammonia and nitrogen dioxide, are computed

from the differences between the measured channels, as outlined in the following

equations:

NO (Nitric Oxide) Concentration = Measured

TNx (Total Nitrogen) Concentration = Measured (NH3 + N02 + NO)

NOx (Total Nitrogen – Ammonia) Concentration = Measured (NO2 + NO)

NH3 (Ammonia) Concentration = Calculated as follows:

[(TNx - NOx) / (NH3_CE_FACTOR1)]

NO2 (Nitrogen Dioxide) Concentration = Calculated as follows:

[(NOx – NO) / (NO2_CE_FACTOR1)]

Note: The nitrogen dioxide efficiency factor (NO2_CE_FACTOR1) must be

calculated by conducting a GPT (gas phase titration) as described in Section

8.3.3 of the M200E manual and Section 7.0 of this manual. This value gives a

good indication of how well the molybdenum is converting nitrogen dioxide into

nitric oxide. In a properly functioning analyzer the value should be close to 1.0. It

is recommended that the molybdenum efficiency be checked every three months.

The ammonia converter efficiency factor (NH3_CE_FACTOR1) is discussed in

more detail in Section 2.3 of this manual. The conversion efficiency of the M501

NH3, should be checked prior to starting long term tests. Both efficiency factors

can be accessed through the analyzer VARS MENU.

The actual formula for computation of the gas concentrations is more

complicated than the above equations, as it includes sample, reaction cell

pressure changes and averaging the PMT signal. Then the zero offset and

slopes are applied to the separate channels (TNx, NOx, NO) to determine the

concentrations. Concentration compensation occurs while the variable

TP_FACTOR under the VARS MENU is switched ON. Otherwise the displayed

concentration is uncompensated. It is recommended that the variable

TP_FACTOR remain on at all times.

1.1.1 Minimizing PMT Drift

In order to account for PMT drift in the analyzer, the AutoZero valve switches

once a minute allowing the analyzer to read zero background. The AutoZero

valve directs the sample gas stream to completely bypass the reaction cell, while

simultaneously filling the reaction cell with Ozone for dark noise measurement.

This is then subtracted as a measurement offset from the raw PMT concentration

05206H DCN5910 11

Page 14

M201E Ammonia Analyzer Teledyne API Model M201E NH3 Analyzer Operator Manual

signal. This process improves zero baseline stability by minimizing the effect of

PMT sensor drift.

1.1.2 Purging the Reaction Cell

As with many chemical reactions the conversion of ammonia in the presence of

other oxides of nitrogen is complicated. It is important to note that the valve

DWELL time for an AZERO measurement has a default setting of 8 seconds.

Shortening this value may not allow enough time to properly purge the reaction cell

of excess nitric oxide from the previous measurements.

In the molybdenum converter operating at 315oC the following significant reactions

are taking place:

Mo + NO2 MoO3 + NO ~100% Efficiency

The M501 NH3, ammonia converter operates at 825oC. At this high temperature,

several reactions occur:

NO NO Loss = ~ 3%

NO2 NO Efficiency = ~97%

NH3 NO Efficiency = ~97%

NH3 NO2 Efficiency = ~5%

As can be seen from the above reactions, the calculation of the ammonia

concentration and overall calibration of the instrument must be done carefully, if

accurate ammonia concentrations are to be measured.

1.2 SPECIAL CONSIDERATIONS FOR AMMONIA MEASUREMENT

Ammonia is a difficult gas to measure due to its chemical characteristics. The

gas tends to adsorb onto surfaces and diffuse into many materials. The following

precautions should be observed when designing ammonia sampling systems and

connecting them to the M201E analyzer:

Do NOT use copper tubing or fittings designed for household plumbing.

Use ONLY Chromatography grade (cleaned, passivated) stainless steel

tubing.

Use ONLY Glass tubing for sample inlet manifold.

ALWAYS keep the tubing from the M702SS calibrator to the analyzer as

short as possible. USE stainless steel tubing throughout, especially from the

ammonia calibration bottle to the calibrator.

If possible HEAT the sample line and DRY the sample gas.

Sample filters Will cause response delays on both the rise and fall of the

sample signal.

12 05206H DCN5910

Page 15

Teledyne API Model M201E NH3 Analyzer Operator Manual M201E Ammonia Analyzer

These rules apply also to your calibrator’s internal plumbing. It is highly

recommended that you use a M702SS calibrator in conjunction with the M 201E.

The calibrator has stainless steel plumbing throughout. The M700 calibrator

contains Teflon tubing and internal MFC’s that can be affected by the ammonia

gas, therefore, the M700 calibrator is not recommend for use with the M201E

analyzer. It is important to keep the sampling system well maintained.

1.3 SAMPLE FILTRATION

The instrument can be provided with an optional stainless steel sample filter P/N

05571. For minimum response time operation, the instrument should be supplied

with clean sample gas at ambient pressure.

An additional filter resides in the M201E pneumatic pathway. The filter is a

¼” diameter stainless steel sintered filter used to protect the reaction cell flow

control orifice from plugging. This filter will plug rapidly if contaminated sample

gas is not filtered before entering the analyzer.

NOTE: In situations where the sample gas is known to be contaminated with

particulate material it is advisably to add extra filtration. However, it must be

noted that the response time is directly extended through filter additions.

05206H DCN5910 13

Page 16

M201E Ammonia Analyzer Teledyne API Model M201E NH3 Analyzer Operator Manual

1.4 M201E ANALYZER SPECIFICATIONS

Table 1-1. M201E Operating Specifications

Ranges

Measurement Units

Noise at Zero1

Noise at Span1

Lower Detectable

2

Limit

Zero Drift

3, 6

Span Drift6

Lag Time

Rise Time

4

Fall Time4

Sample Flow Rate

Linearity

Temp Range

Dimensions HxWxD

Weight, Analyzer

Weight, Converter

Weight, Pump

Power, Analyzer

Power, Analyzer5

Power, Pump

Power, Pump CEMark5

Environmental

Analog Output

Analog Output

Resolution

Serial I/O

Status Option

1

As defined by USEPA

2

Defined as twice the zero noise level

3

At constant temperature and voltage

4

When pneumatics are conditioned with NH3 overnight and the gases (zero air to NH3) are manually

switched at the sample inlet at the rear of the M501.

5

Electrical rating for CE Mark Compliance

6

Applies when sampling NH3; better results expected for NO/NOx gas measurements.

0-50 to 0-2000 ppb in 1 ppb increments (selectable, independent

, NO, NO2, NOx ranges supported)

NH

3

PPB, PPM, microgram/m

<

0.5 ppb RMS

<

1.0% of reading above 50 ppb

3

, milligram/m3 (user selectable)

1 ppb RMS

2 ppb / 24 hours

<

1.0% FS Range / 24 hours

40 seconds

90% 300 seconds

90% 300 seconds

3

1000 cm

500 cm

/min + 10% (500 cm3/min bypass to vacuum manifold,

3

/min to reaction cell)

NO calibration 1% of full scale

NH

calibration 2% of full scale

3

o

15-40

C

7” x 17” x 23.6” (18cm x 43cm x 61cm)

43 lbs (20 kg)

24 lbs (11 kg)

16 lbs (7 kg)

100V ~50/60 Hz, 120V ~60 Hz, 220V ~50Hz, 240V ~50 Hz, 125

watts

230V ~50 Hz, 125 watts

110V ~60 Hz, 220V ~50 Hz, 240V ~50 Hz, 295 watts

230 V ~50 Hz, 2.5 A peak

Installation Category Pollution Degree 2, Over-voltage Category II

4 user configurable outputs, each can be configured as

0.1, 1V, 5V or 10V. Three outputs convertible to 4-20mA isolated

current loop.

1 part in 4096 of selected full-scale voltage (12 bit)

1x RS-232, 1 x RS-485 or RS-232 or Ethernet(optional).

Communication speed: 300 – 115200 baud (user selectable)

8 status outputs from opto-isolators, 7 defined, 1 spare

14 05206H DCN5910

Page 17

2.0 CALIBRATION PROCEDURE

This section begins with a high-level overview of the calibration procedure for the

M201E analyzer. Details are provided starting in Section 2.1:

First, take the time to read the M200E manual to familiarize yourself with

the Chemiluminescence process. It is important to remember that the

analyzer is merely measuring different levels of nitric oxide sample gas on

three separate channels (TN

dioxide concentrations are then calculated using this information.

Assemble the M201E analyzer according to the pneumatic configurations

outlined in Figure 1-1. Remember: DO NOT pressurize the sample, span or

zero ports (Zero/SPAN valves are optional) during calibration. Allow the

analyzer to pull the gas through the system using the vacuum pump.

, NOx, NO). The ammonia and nitrogen

x

CAUTION!

If the presence of ozone is detected at any time, call Teledyne API Customer Service as

soon as possible:

800-324-5190 or email: api-customerservice@teledyne.com

Next, zero the analyzer using an approved zero air source, such as, bottled

zero air, nitrogen or zero air generated by a Teledyne-API M701 zero air

source. This sets the zero offset for the three individual channels

(TNx_OFFS, NOx_OFFS, NO_OFFS). Confirm that all displayed

concentrations read zero.

Span the analyzer using bottled nitric oxide gas diluted to a level set to 80%

of the expected sample range, preferably using a M702 Calibrator. This

sets the slope for the three individual channels (TN

_SLOPE, NOx_SLOPE,

x

NO_SLOPE). Confirm that displayed concentrations TNx , NOx and NO

display the correct span concentration.

If you haven’t done so recently, conduct a GPT (gas phase titration) and

confirm the molybdenum is functioning accordingly. Section 8.3.3 of the

M200E manual outlines the GPT procedure. Section 7.0 of this manual

consists of a service note for checking the molybdenum converter. There

should be no reason to adjust the molybdenum efficiency factor on a new

analyzer. If a diluted bottled of

nitrogen dioxide gas is used to determine

the molybdenum efficiency, allow enough time for the span value to

stabilize. Nitrogen dioxide exhibits similar hold up issues as ammonia gas.

Therefore, it may take a number of hours before the NO

reading

x

stabilizes.

Span the analyzer using bottled

ammonia gas diluted to a level set to 80%

of the expected sample range, preferably using a M702 Calibrator. Note:

05206H DCN5910 15

Page 18

Calibration Procedure Teledyne API Model M201E NH3 Analyzer Operator Manual

The first time bottled ammonia is connected to the gas dilution system,

regulator/calibrator, the TNx reading may take a number of hours to

stabilize.

2.1 ZEROING THE ANALYZER

The analyzer can be zeroed by either applying zero air straight to the sample port

or through the optional Zero/Span valves, if installed. It is important to remember

that if the analyzer was previously sampling ammonia gas, prior to conducting a

Zero calibration, it will take some period of time before the zero baseline is

reached. The process of zeroing the analyzer consists of delivering dry zero air

to the analyzer. The operator then manually zeros the TNx and NOx channels

individually through the user interface. The following Tables outline the steps

necessary to zero the analyzer.

Table 2-1. Zero Calibration Procedure – Zero Gas Through the SAMPLE Port

Important: Each channel (TNx and NOx) must be zeroed individually

Step No. Action Comment

1. Press CAL The M201E enters the calibrate mode from sample

mode. Confirm zero gas is flowing past the sample

port.

2. Channel Selection Press TNX or NOx then Press ENTR.

3. Range Selection Press LOW or HIGH range then Press ENTR.

Always calibrate the LOW range, section 3.0 below.

4. NH3 STB Reading Wait for the displayed stability reading to fall below

1.0 PPB. The lower the stability reading the better the

zero value.

5. Press ZERO If you change your mind after pressing ZERO, you

can still press EXIT without zeroing the instrument.

You don’t have to enter concentration values. The

analyzer knows to apply 0 PPB.

6. Press ENTR Pressing ENTR actually adjusts the Offset value for

the selected channel.

7. Press EXIT The M201E returns to sampling mode.

8. Check

Concentrations

/Offsets

16 05206H DCN5910

All displayed concentrations should read zero. The

offset values should be close to zero (-20 to 150 mv)

Page 19

Teledyne API Model M201E NH3 Analyzer Operator Manual Calibration Procedure

Table 2-2. Zero Calibration Procedure - Zero Gas Through ZERO Port

Step No.

Action Comment

1. Press CALZ The M201E enters the calibrate mode from sample

mode. The zero gas is supplied through the ZERO

inlet port on the rear panel of the M501 NH3,.

2 Table 2.1 Follow Steps 2 to 8 in Table 2-1.

Notes:

Since the zero gas concentration is defined as 0 ppb, it is not necessary to

enter the expected concentration values.

Both the TNx and NOx channels must be zeroed individually. When you

zero the NOx channel both the offsets for NOx and NO are configured. All

readings should display zero following this action.

It is recommended that the calibration of both the TNx and NOx channels

be done at one time.

Always confirm that excess zero air is flowing past the sample or zero

port, if the Zero/Span option is present, on the rear of the M501 NH3,

converter. There should always be some excess flow. If insufficient flow is

supplied to the analyzer ambient gas will be entrained and the zero offset

values will be incorrect. However, it is important not to over pressurize the

analyzer.

It is a good idea to allow the analyzer to sample zero gas for extended

periods following zero calibration. Large drifts can signify leaks or indicate

an issue with the zero air source.

2.2 SPANNING THE ANALYZER WITH NITRIC OXIDE GAS

The analyzer can be spanned by either applying nitric oxide gas straight to the

Sample port or through the Zero/Span valve option, if installed. It is important to

remember that if the analyzer was previously sampling ammonia gas, prior to

conducting a nitric oxide span calibration, it will take some period of time before

the TNx channel stabilizes. The process of spanning the analyzer consists of

diluting bottled gas, using a calibrator and delivering to the analyzer. The

05206H DCN5910 17

Page 20

Calibration Procedure Teledyne API Model M201E NH3 Analyzer Operator Manual

_

operator then manually spans the TNx and NOx channels individually through the

user interface. The following Tables outline the manual steps necessary to span

the analyzer.

Table 2-3. NO Calibration Procedure – NO Gas Through the SAMPLE Port

Important: Each channel (TNx and NOx) must be Spanned individually

Step No. Action Comment

1. Press CAL The M201E enters the calibrate mode from sample

mode. Confirm that excess NO gas is flowing past the

sample port.

2. Channel Selection Press TNX or NOx then Press ENTR.

3. Range Selection Press LOW or HIGH range then Press ENTR.

Always calibrate the LOW range, Section 3.0below.

4. Press CONC If NOx was chosen previously then the following will

be displayed:

NOx NO CONV Exit

Press NOx, If you are delivering 450 PPB of NO then

Enter 450 PPB, Press ENTR.

Repeat the same steps for NO.

Press EXIT

Once stability has been achieved,

Press SPAN, ENTR, EXIT

NOTE: Both NO

and NO should read 450 PPB.

x

___________________________________________

If TNx was chosen previously then the following will

be displayed:

TNx CONV Exit

Press TNx enter 450 PPB, Press ENTR

Press EXIT

Once stability has been achieved,

Press SPAN, ENTR, EXIT

should read 450 PPB.

TN

x

5. Check Slopes The slopes should be close to 1.0 +/- 0.300

18 05206H DCN5910

Page 21

Teledyne API Model M201E NH3 Analyzer Operator Manual Calibration Procedure

Table 2-4. NO Calibration Procedure - NO Gas through the SPAN Port

Step No.

Action Comment

1. Press CALS The M201E enters the calibrate mode from sample

mode. The NO gas is supplied through the SPAN inlet

port on the rear panel of the M501 NH3,.

2 Table 2.3 Follow Steps 2 to 5 in Table 2-3.

Notes:

Both the TNx and NOx channels must be spanned individually with nitric

oxide gas. When you span the NOx channel both the NO and NOx

concentrations must be manually inputted.

It is recommended that the calibration of both the TNx and NOx channels

be done at the same time.

Always conf irm that SPAN gas is flowing past the sample or span port on

the rear of the M501 NH3, converter. There should always be some

excess flow. If insufficient flow is supplied to the analyzer ambient gas will

be entrained and the span values will be incorrect. However, it is important

not to over pressurize the analyzer.

It is a good idea to allow the analyzer to sample span gas for extended

periods following span calibration. Large drifts can signify leaks or indicate

an issue with the span gas source.

If after spanning with nitric oxide, the analyzer slopes are out of range

conduct the following:

Confirm the gas sources are good. Usually the bottle is certified to

a known level of nitric oxide. The bottle should be balanced with

nitrogen. Try not to use the same regulator for nitric oxide as was

used on ammonia. This also holds for the tubing between the

different bottles and the mixing source (calibrator).

Confirm the zero reading is good by delivering Zero gas.

Confirm that the concentration delivered to the analyz er is equal to

what you entered under the CONC menu NOx and TNx.

Leak check both the M501 NH3, and analyzer together.

Using section 11.6.5 of the M200E manual confirm that the PMT

sensor hardware calibration is set correctly.

05206H DCN5910 19

Page 22

Calibration Procedure Teledyne API Model M201E NH3 Analyzer Operator Manual

2.3 SPANNING THE ANALYZER WITH AMMONIA GAS

The most important criterion an individual can avail themselves of when spanning

an analyzer with ammonia gas is “patience”. Ammonia is a very sticky gas and

the response of the analyzer/calibration system depends on a number of factors.

The following lists some important points the user should be aware of when

calibrating:

Is this the first time the analyzer/calibration system has seen ammonia gas

in the last couple of days? If so, spanning to a fixed value will take

considerably longer than normal: possibly 12 hours to completely stabilize.

Is the tubing that is delivering span gas from the calibration bottles , made

of stainless steel? Is the tubing from the rear of the calibrator to the

analyzer, made of stainless steel? Where possible use stainless steel

tubing.

Note: The operator is responsible for delivering a set amount of ammonia

to the analyzer, calculating the converter efficiency of the M501 NH3, and

entering the efficiency value through the user interface, if required.

Is the environment where the analyzer resides undergoing large

temperature swings (+/- 5 C about the norm Temperature)? If so the

sample line can absorb and desorb ammonia at concentration rates that

are distinguishable to the analyzer. If possible, heat the sample line to a

constant maximum ambient temperature. Otherwise the FILT_SIZE = 42

Samples variable located under the VARS MENU can be lengthened.

However, lengthening the filter size slows the rise/fall response time of the

analyzer.

Does the sampling environment contain large amounts of particulates? If

so, it may be necessary to add the sampling filter option. As outlined

previously, this will affect the analyzer response.

One method to increase the response of both the sampling system and

the analyzer is to flow a larger concentration of ammonia gas through the

pneumatics for a couple of hours. For example, if the expected range is

500 PPB of ammonia, then flowing 1.0 PPM speeds up the absorption

which occurs throughout the pneumatics. The long delays in

ammonia

response occur when the analyzer hasn’t sampled the gas for some time.

Ammonia desorbs from the pneumatics, these surfaces need to be

rewetted before span stability is achieved.

Prior to conducting the ammonia calibration, confirm that the ammonia

converter efficiency is initially set to 1.000 using the following menu key

selections:

20 05206H DCN5910

Page 23

Teledyne API Model M201E NH3 Analyzer Operator Manual Calibration Procedure

Table 2-5. Confirming Ammonia Converter Efficiency

Step No. Action Comment

1. Press CAL The M201E enters the calibrate mode from Sample

mode.

2. Channel Selection Press TNX then Press ENTR.

3. Range Selection Press LOW range then Press ENTR.

4. Press CONC The following will be displayed:

TNx CONV Exit

Press CONV enter 1.0000, Press ENTR

Press EXIT, EXIT

05206H DCN5910 21

Page 24

Calibration Procedure Teledyne API Model M201E NH3 Analyzer Operator Manual

Table 2-6. NH3 Calibration Procedure – NH3 Gas Through The SAMPLE Port

Step No. Action Comment

1. Generate a known

level of NH3 gas

using a calibration

gas source

Monitor the TNx concentration until it has stabilized;

this signifies that both the NOx and NH3 gases have

stabilized. This could range from 20 minutes to

several hours depending on whether the analyzer /

calibration system has recently been subjected to

ammonia gas.

2. NH3 Conversion

efficiency

calculation

When the TNx channel is stable, note the

concentration of NH3 displayed. The calculation for

the NH3 Conversion efficiency is:

(Displayed NH3 concentration) divided by

(Delivered NH3 concentration)

Example: The operator is delivering 450 PPB of NH3.

The displayed concentration for NH3 is 440 PPB then

the efficiency factor = 440/450 = 0.9777

3. Press CAL The M201E enters the calibrate mode from Sample

mode.

4. Channel Selection Press TNX then Press ENTR.

5. Range Selection Press LOW range then Press ENTR.

6. Press CONC Since TNx was chosen previously, then the following

will be displayed:

TNx CONV Exit

Press CONV enter 0.9777, Press ENTR

Press EXIT, EXIT

Note: In the example outlined above, the displayed

ammonia

concentration is being increased by 2.27%. Newer M501 NH3, converters

should have efficiency values very close to 1.00. Depending on the

operator’s acceptable level of error, it may not be necessary to change the

efficiency factor from 1.00. Therefore, calibration with nitric oxide gas is all

that is required.

The efficiency factor may also be changed by entering the VARS MENU

and editing NH3_CE_FACTOR1 = 1.0000.

22 05206H DCN5910

Page 25

Teledyne API Model M201E NH3 Analyzer Operator Manual Calibration Procedure

Table 2-7. NH3 Calibration Procedure – NH3 Gas through the SPAN Port

Step No.

Action Comment

1. Press CALS The M201E enters the calibrate mode from Sample

mode. The ammonia gas is supplied through the

SPAN inlet port on the rear panel of the M501 NH3,.

Calculate the Efficiency factor as outlined in Steps 2

in table 2.5.

2 Table 2.5 Follow Steps 4 to 6 in table 2.5.

Note: The response time of the analyzer increases when using the Zero/Span

valve option.

05206H DCN5910 23

Page 26

Calibration Procedure Teledyne API Model M201E NH3 Analyzer Operator Manual

This page intentionally left blank.

24 05206H DCN5910

Page 27

3.0 CONFIGURABLE ANALOG OUTPUT OVERVIEW

There are three different methods to extract concentration data from the E-Series

analyzers. By one method, the operator can set up an iDas (internal data

acquisition) configuration either through the user display or using TAPI’s window s

based software called APICOM. The analyzer stores data internally, which is

available later for download through the RS-232 or Ethernet port. The second

method involves the use of hyperlink where the user sends text based commands,

to retrieve data, through the RS-232 port. With the third method, the operator can

interface a strip chart recorder and/or data-logger to the ana lyzer analog outputs.

The following sections outline the steps necessary to calibrate and configure the

analog outputs.

There are four analog outputs on the rear of the analyzer. The default

configurations of the M201E analog outputs are as follows:

Table 3-1. Analog Output Data Default Settings

ANALYZER

M201E

A1 A2 A3 A4

TNxCNC1

5 Volts 5 Volts 5 Volts 5 Volts

500 PPB 500 PPB 500 PPB 500 PPB

CHANNEL DEFAULT SETTING

NH3CNC1 NOCNC1

NO2CNC1

To access these signals attach a strip chart recorder and/or data-logger to the

appropriate contacts of the analog output connecter on the rear panel of the

analyzer.

ANAL OG O UT

A1 A2 A3 A4

+ - + - + - + -

Figure 3-1. Analog Output Connector

05206H DCN5910 25

Page 28

Configurable Analog Output Overview Teledyne API Model M201E NH3 Analyzer Operator Manual

Table 3-2. Analog Output Pin-Outs

PIN ANALOG OUTPUT VOLTAGE SIGNAL CURRENT SIGNAL

1 V Out I Out +

2

3 V Out I Out +

4

5 V Out I Out +

6

7 V Out N/A

8

A1

A2

A3

A4

Ground I Out -

Ground I Out -

Ground I Out -

Ground N/A

Additionally A1, A2 and A3 may be equipped with optional 0-20 mA current loop

drivers. The 4-20 mA option is not available on A4.

Note: In actuality the analog output configuration of the analyzer may be different

than stated above. The outputs can be configured differently at the factory

depending on whether they were assigned during the procurement of the product.

It is possible to check the configuration of the analyzer by accessing the ANALOG

I/O CONFIGURATION through the DIAG menu.

The analyzer operates in Dual Mode during gas detection. This means each of the

measured concentrations can have two separate slopes and offsets, one for the

low range and one for the high range. Though uncommon, a user may dec ide to

calibrate the analyzer with nitric oxide at, for example, 100 PPB using the LOW

range and then perform another calibration at 450 PPB using the HIGH range.

Through the analog outputs the user can then assign analog output A1 to

TNxCNC1 and output A2 to TNxCNC2. Gases with the “1” designation use the

slope and offset for the LOW range, while gases with the “2” designation will use

the slope and offset for the HIGH range. It is recommended that both the LOW and

HIGH ranges be calibrated at the same time. Independent of whether the HIGH

range is actually being outputted to the analog outputs.

26 05206H DCN5910

Page 29

Teledyne API Model M201E NH3 Analyzer Operator Manual Configurable Analog Output Overview

3.1 ANALOG OUTPUT - ELECTRONIC CONFIGURATION

The final step in configuring the analyzer’s four analog output channels is to set the

electronic signal type and range of each channel. This consists of:

Selecting an output type for A1 – A4 (voltage or current if an optional

current output driver has been installed) and the signal level that matches

the input requirements of the recording device attached to the channel.

Calibrating the electr onic circuitry of the output channel. For each channel

this can be done either automatically or manually.

Adding a bipolar recorder offset to the signal if required.

In its standard configuration the analyzer’s Analog Outputs can be set for the

following DC voltage signal levels. Each range is usable from -5% to + 5% of the

rated range.

Table 3-3. Analog Output Voltage Range Min/Max

RANGE SPAN

0-0.1 VDC -0.005 VDC 0.105 VDC

0-1 VDC -0.05 VDC 1.05 VDC

0-5 VDC -0.25 VDC 5.25 VDC

0-10 VDC -0.5 VDC 10.5 VDC

MINIMUM OUTPUT MAXIMUM OUTPUT

The default offset for all ranges is 0 VDC.

The following DC Current output options are also available from the factory:

Table 3-4. Analog Output Current Loop Min/Max

RANGE SPAN MINIMU M OUTPUT MAXIMUM OUTPUT

2-20 mADC 1 mADC 21 mADC

4-20 mADC 3 mADC 21 mADC

The default offset for all ranges is 0 mADC.

05206H DCN5910 27

Page 30

Configurable Analog Output Overview Teledyne API Model M201E NH3 Analyzer Operator Manual

A

A

3.2 ANALOG OUTPUT SIGNAL TYPE AND RANGE SELECTION

To select an analog output signal type (DC voltage or current) for one of the

analyzer analog output channels press SETUP - MORE -DIAG - 818…ENTERNEXT…NEXT:

FROM ANALOG I/O CONFI GURA TION ME NU

Press SET> to sel ect the channel

DATA_ OUT_2 RANGE: 5V

DATA_ OUT_2 OVERRANG E: ON

DATA_ OUT_2 REC OFS : 0 mv

DATA_ OUT_2 AUTO CAL: ON

DATA_ OUT_2 CALIBRATED: YES

DATA_ OUT_2 OUTPUT: ON

DATA_ OUT_2 DATA: NO

DATA_OUT_2 SCALE: 500 PPB

DATA_ OUT_2 PRECISI ON: 1

DATA_ OUT_2 UPDATE: 5 S EC

Then Press EDIT t o conti nue

parameter:

CNC1

2

DIAG

PREV NEXT ENTR EXIT

DIAG AIO

< SET SET> CAL EXIT

DIAG AIO DATA_OUT_2: 5V, NH3CNC1, CAL

< SET SET> EDIT EXIT

DIAG AIO DATA_OUT _2 RANGE: 5V

SET> EDIT EXIT

DIAG AIO DATA_OUT_2 RANGE: 5V

0.1V 1V 5V 10 V CURR ENTR EXIT

These Keys set

the Si g nal Level

of the selected

channel

NALOG I / O CONFI GURATION

OUTS CALIBRATED: NO

Press SET> to select the Analog

Output channel to be configur ed:

DISPLAYED AS = CHANNEL

DATA_OUT_1 = A1

DATA_OUT_2 = A2

DATA_OUT_3 = A3

DATA_OUT_4 = A4

Then Press EDIT to co ntin ue

Pressing ENTR re c or ds

an d r eturns to the previous me n u

Pressing EXI T ignores the new setting

an d r eturns to the previous me n u

t he new sett i ng

Figure 3-2. Analog Output Signal Type

28 05206H DCN5910

Page 31

Teledyne API Model M201E NH3 Analyzer Operator Manual Configurable Analog Output Overview

3.3 SELECTING AUTO OR MANUAL ANALOG OUTPUT CALIBRATION

The analog outputs configured for voltage mode can be calibrated either

automatically or manually. In its default mode the instrument is configured for

automatic calibration. Note: manual calibration should only be used for the 0.1V

range or in cases where the outputs must be closely matched to the

characteristics of the recording device. Outputs configured for automatic

calibration can be calibrated as a group or individually.

To select auto-calibration for a particular channel press the following:

05206H DCN5910 29

Page 32

Configurable Analog Output Overview Teledyne API Model M201E NH3 Analyzer Operator Manual

O

O

O

FROM ANALOG I/O CONFIGURATIO N MENU

DIAG ANALOG I / O CONFIGURATION

PREV NEXT ENTR EXIT

DIAG AI

< SET SET> CAL EXIT

DIAG AIO DATA_OUT_2: 5V, NH3CNC1, CAL

< SET SET> EDIT EXIT

DIAG AIO DATA_OUT_2 RANGE: 5V

SET> E DIT EXIT

AOUTS CALIBRATED: NO

Exit to Return

to the main

Sample Dis play

Press SET> to s elect the Analog Output

channel to be conf igured:

DISPLAYED AS = CHANNEL

DATA_OUT_1 = A1

DATA_OUT_2 = A2

DATA_OUT_3 = A3

DATA_OUT_4 = A4

Then Press EDIT to con tinue

Toggles the Aut o

Cal Mode

ON/ OFF for this

Analog Output

channel only .

DIAG AI

< SET SET> EDIT EXIT

DIAG AI

< SET SET> EDIT EXIT

DIAG AIO DATA_OUT_2 AUTO CAL: ON

DIAG AIO DATA_OUT_2 AUTO CAL: ON

ON ENTR EXIT

DATA_OUT_2 OVERRANGE: ON

DATA_OUT_2 REC OFS: 0 mv

< SET SET> E DIT EXIT

Pressing ENTR records

and r eturns to the previous menu

Pressing EXI T ignores the n ew set ting and

re turns to the pr evious menu

the new setting

Figure 3-3. Auto Or Manual Analog Output Calibration

30 05206H DCN5910

Page 33

Teledyne API Model M201E NH3 Analyzer Operator Manual Configurable Analog Output Overview

_

A

A

To calibrate the output channels as a group press the following, (Note: this is the

recommended calibration approach):

Exit at Any

Time to Return

to the main

DIAG Menu

FROM ANALOG I/O CONFIGURATION ME NU

DIAG

PREV NEXT ENTR EXIT

NALOG I / O CONFIGURATION

DIAG AIO

< SET SET> CAL EXIT

DIAG AIO AUTO CALIBRATING DATA_OUT _1

AUTO CALIB RAT ING DATA_OU T _2

AUTO CALIB RAT I N G DATA

DIAG AIO AOUTS CALI BRATED: YES

< SET SET> CAL EXIT

OUTS CALI BRATED: NO

…

OUT_4

Figure 3-4. Analog Output Group Calibration

If AutoCal h as been manually

t ur ne d of f for any channe l th e

message f or that channel will be

NOT AUT O CAL DAT A_OUT _1

similar to:

Exit t o Return

to the I/O

Configuration

Menu

05206H DCN5910 31

Page 34

Configurable Analog Output Overview Teledyne API Model M201E NH3 Analyzer Operator Manual

R

3.4 MANUALLY CALIBRATING ANALOG OUTPUT SIGNAL LEVELS

The analog outputs in voltage mode can be manually calibrated to closely match

the characteristics of the data recorder. Outputs configured for 0.1V full scale

should always be calibrated manually.

Calibration is done through the instrument software in conjunction with a v oltmeter

connected across the output terminals. Adjustments are made using the front

panel keys. First the zero-point is set then the span-point.

The software allows this adjustment to be made in 100, 10 or 1 count increments.

Table 3-5. ZERO/SPAN Analog Output Signal Calibration Tolerances

Full Scale Adjust Zero Within Span Voltage Adjust Span Within

0.1 VDC ±0.0005V 90 mV ±0.001V

1 VDC ±0.001V 900 mV ±0.001V

5 VDC ±0.002V 4500 mV ±0.003V

10 VDC ±0.004V 4500 mV ±0.006V

See Table 6-8 for pin

assignments on the

for ANALOG

connector located on

the instruments rear

panel

VDC

+DC Grnd

V OUT +

V OUT -

ANALYZE

V IN +

V IN -

Recording

Device

Figure 3-5. Setup For Calibrating Analog Output Signal Levels

32 05206H DCN5910

Page 35

Teledyne API Model M201E NH3 Analyzer Operator Manual Configurable Analog Output Overview

G

A

A

O

–

g

To make these adjustments the auto calibration feature “DATA_OUT_1 AUTO

CAL: OFF” must be turned off for each output channel then press the following:

FROM ANALOG I/O CONFIGURATION MENU

Press SET> to select the Analog Output

channel to be confi gured:

DISPLAYED AS = CHANNEL

DATA_OUT_1 = A1

DATA_OUT_2 = A2

DATA_OUT_3 = A3

DATA_OUT_4 = A4

Then Press EDIT to continue

Press SET Until

These keys

increment/decrement the

ZERO/SPAN D-to-A converter

output by

100, 10 or 1 counts

respectively.

Continue adjustments until the

voltage measured at the

output of the analyzer and/or

the input of the recording

device matches the value in

the upper right hand corner of

the display to the tolerance

listed previously.

The analyzer display WILL

NOT CHANGE. Only the

voltage reading of your volt

meter will chan

e.

DIA

PREV NEXT ENTR EXIT

DIAG AIO

< SET SET> CAL EXIT

DIAG AIO DATA_OUT_1 :5V, TNXCNC1, NO CAL

< SET SET> EDIT EXIT

DIAG AIO DATA_OUT_1 RANGE: 5V

SET> EDIT EXIT

DIAG AIO DATA_OUT _1 CALIBRATED: N

< SET CAL EXIT

NALOG I / O CONFIGURATION

OUTS CA LIBRATED: NO

DIAG AIO DATA_OUT_1 VOLT

U100 UP10 UP DOWN DN10 D100 ENTR EXI T

DIAG AIO DATA_OUT_1 VOLT–S : 4500 mV

U100 UP10 UP DOWN DN10 D100 ENTR EXIT

DIAG AIO DATA_OUT_1 CA LIBRATED: YES

< SET CAL EXIT

Z : 0 mV

EXIT ignores the

new setting.

ENTR accepts

new setting.

the

Figure 3-6. Analog Output Manual Calibration

05206H DCN5910 33

Page 36

Configurable Analog Output Overview Teledyne API Model M201E NH3 Analyzer Operator Manual

A

A

3.5 ANALOG OUTPUT RECORDER OFFSET ADJUSTMENT

An offset can be added to individual output channels by pressing the following:

Press SET Until

FROM ANALOG I/O CONFIGURATION MENU

DIAG

PREV NE XT ENTR EXIT

DI AG AIO

SET> CAL EXIT

DI AG AIO DATA_OUT_2 : 5V, NH3CNC1, CAL

< SET SET> EDIT EXIT

DI AG AIO DATA_OUT_2 RANGE: 5V

SET> EDIT EXIT

NALOG I / O CONFIGU RATIO N

OUTS CALIB RATED:NO

Press SET> to select the A nalog O utput

ch annel to be con fi gu re d:

DISPLAYE D AS = CHANNEL

DATA_OUT_1 = A1

DATA_OUT_2 = A2

DATA_OUT_3 = A3

DATA_OUT_4 = A4

Then Press EDIT to continue

These Keys set

the Recorder

of the s elected

Offset

channel

DIAG AIO DATA_O UT_2 REC OFS: 0 m V

< SET SET> EDIT EXIT

DIAG AIO RE CO RD OFFSET: 0 MV

+ 0 0 0 0 ENTR EXIT

Pressing ENTR re cords the new setting

and returns to the previous menu

Pressing EXIT ignores

returns to the previous menu

Figure 3-7. Analog Output Recorder Offset Calibration

t he new setti ng and

34 05206H DCN5910

Page 37

4.0 MAINTENANCE SCHEDULE

The maintenance requirements of the M201E are the same as a standard M200E

NO

analyzer but with additional maintenance items (Table 4-1). Please refer to

x

Section 13 in the M200E Operator Manual for the M200E maintenance schedule

and for maintenance and repair procedures.

The M201E requires the following additional maintenance items.

Table 4-1. Preventative Maintenance Schedule

Item Maintenance Interval Reference Section

NO

molybdenum converter

2

M501 NH

Reaction Cell Clean annually or as necessary Section 9.3.9 M200E Manual

AutoZero flow check Quarterly as needed Section 4.4 of this manual.

Converter

3

Test Every Three Months

Section 8.2.3 M200E Manual

Section 4.1of this manual.

4.1 M501 NH

The M501 NH3 external converter is operated at 825 ºCelsius. Because of this the

stainless steel ¼” tube internal to the converter slowly oxidizes and may require

replacement. Over time the converter’s efficiency will degrade, due to aging of

the internal catalyst. This is characterized by a CONV value on the TNx channel

of < 0.8 or > 1.2, despite the converter being at temperature. The efficiency of the

converter should be checked quarterly. The converter should be cleaned out on a

yearly basis by removing the outer tube and shaking the fine dust particles from

both the outer and inner tubes. This is also a good time to replace the catalyst

screen, if necessary.

The following procedure describes how to disassemble and replace converter

parts. The various parts in the converter become delicate and brittle after

prolonged exposure to high temperatures. It is therefore a good idea to have a

complete set of replacement parts on hand before starting, as listed in Table 4-2.

MAINTENANCE

3

05206H DCN5910 35

Page 38

Maintenance Schedule Teledyne API Model M201E NH3 Analyzer Operator Manual

Table 4-2. M501 NH3 Converter Rebuild Parts List

Part No. Description

KIT000193 RETROFIT, M501NH INNER TUBE w/SCREEN

KIT000139 REBUILD, CERAMIC BUSHINGS, M501NH

HE0000007 CERAMIC HEATER, 220W@60V M501XX

4.2 REPLACING THE CATALYTIC CARTRIDGE

1. Turn off power to the converter and allow to cool. IT IS VERY IMPORTANT

THAT THE CONVERTER BE COOL BEFORE ATTEMPTING ANY

DISASSEMBLY OR REPAIRS.

CAUTION VERY HOT

Will cause severe burns – disassembly while hot will

2. Remove the chassis cover of the M501 NH3, remove the aluminum cover over

the oven, remove the two U-shaped hold down clamps.

damage other converter components. Allow sufficient

time to cool.

3. Disconnect the 1) stainless steel and 2) PTFE tubes from the converter

cartridge.

4. Loosen the nut holding the cartridge assembly in the U-shaped angle bracket

mounted on the chassis floor.

5. Gently lift and tilt the converter assembly out of the U-shaped bracket and

slide the assembly out of the oven.

6. Loosen the ¼” SS tube fitting nearest the hold-down bracket; this fitting holds

the central tube in the converter. Replace the tube that is part of KIT000193.

7. Re-assemble the converter by doing the above steps in reverse order.

Figure 4-1. Catalytic Cartridge

36 05206H DCN5910

Page 39

Teledyne API Model M201E NH3 Analyzer Operator Manual Maintena nce Schedule

4.3 REPLACING THE THERMOCOUPLE

The following instructions provide the necessary information to replace the

existing thermocouple. Figure 4-2 is provided for reference.

You must obtain the following replacement parts kit from T-API:

010820000 , Type K thermocouple

You will need the following tools:

Nutdriver, 5/16

Nutdriver, 11/32

Diagonal Cutter

Philips head Screwdriver #2

CAUTION

Avoid damage to the unit: use only Type K thermocouple in

the M501 NH3, converter. It can be distinguished by its wire

colors: red and yellow. If you have any other thermocouple,

do NOT install it; call T-API to obtain the correct part.

Figure 4-2. Thermocouple Location

Once you have the right tools and parts, replace the thermocouple as follows:

1. Ensure power is removed from the

been operational you will need to wait for at least 2 hours for the Converter oven to

cool before continuing with the replacement of the thermocouple.

05206H DCN5910 37

M501 NH3, Converter. If the Converter has

Page 40

Maintenance Schedule Teledyne API Model M201E NH3 Analyzer Operator Manual

2. Remove the cover from the Converter chassis.

3. Unscrew the (4) nuts that secure the front panel to the chassis. They are located just

behind the Front Panel along the top.

4. Lower the Front Panel to gain easier access to the end of the quartz tube.

5. Unscrew the (3) nuts that secure the inner cover protecting the Heater Block and

quartz tube. Remove this cover.

6. Cut the tie-wrap that secures the thermocouple to the fitting at the end of the quartz

tube.

7. Loosen the Teflon fitting at the end of the quartz tube taking care not to put any

stress on the tube, and slide the fitting off the tube.

8. Remove the thermocouple.

9. Disconnect the thermocouple wires from the Temperature Controller noting that the

‘Yellow’ wire goes to pin 1 and the ‘Red’ wire goes to pin 2.

10. The thermocouple should slide into the Heater Block.

11. Replace the Tie-Wrap Hold-Down.

12. Form the thermocouple wire so that it rests in the cavity with little movement.

13. Connect the (2) wires of the thermocouple to the Temperature Controller. The

“yellow” wire should be connected to pin 1 and the “red” wire should be connected to

pin 2.

14. At this point, all connections have been made, both electrically and pneumatically. A

leak check should be performed on the Converter to verify that all connections are

leak free. If a leak is detected, the leak should be resolved before continuing.

15. Install the inner cover of the Heater Block and secure with the (3) nuts. Close the

Front Panel and secure with the (4) nuts. Install the top cover on the Converter

chassis.

16. The Converter is now ready for the application of power. You will be looking for an

indication from the Temperature Controller that it is functioning correctly and driving

the heater to the desired “set” temperature. Apply power now.

17. After the Converter comes to the regulated temperature, perform the Auto Tune

function to tune the Temperature Controller to the new thermocouple.

18. After the Auto-Tune process is completed, verify that the “process” temperature is

indicating that the desired temperature is stable and being regulated.

The converter is now ready for operation.

38 05206H DCN5910

Page 41

Teledyne API Model M201E NH3 Analyzer Operator Manual Maintena nce Schedule

4.4 AUTOZERO FLOW CHECK

Since the M201E is an ammonia analyzer, the flow through t he AutoZero orifice is

especially important. Check the AutoZero flow as follows:

1. This procedure should be performed with the sample pump running.

2. Remove the top cover of the analyzer. Locate the vacuum manifold at the

center rear of the chassis. Locate the 1/8” tube fitti ng located on the very left

side, as viewed from the rear of the analyzer. It will have a label of “0.010”

indicating the flow orifice installed.

3. Remove the fitting and attach a calibrated flowmeter to the block fitting capable

of measuring in the range of 500 cc/min. The flowmeter should indicate a flow

of 500 cc/min 10%.

4. If the flow is outside this range (most likely lower, due to plugging):

1. Turn off the sample pump and instrument.

2. Remove the 1/8” pipe-to-tube fitting and remove the ¼” sintered filter (p/ n

FL0000001). This filter is meant to protect the orifice; it will usually

become plugged and need replacement rather than the orifice. Rep lace

the filter, and then re-assemble the manifold. Restart the sample pump

and recheck the flow.

Table 4-3. Analyzer Flow Check

M501 NH3, Converter sample flow check

Note: Connect both the Teflon tubes between analyzer and converter

GAS PORT Expected Flow (cc/min)

“Sample In” 1000 +/- 10 %

Analyzer sample flow check

Note: Disconnect both the Teflon

tubes between analyzer and converter

GAS PORT Expected Flow (cc/min)

“To Conv”

1000 or 500, +/- 10 % When the analyzer is sampling

TNx only, the bypass flow is

0

measured. Therefore, the flow

alternates between 500 and

1000 cc/min. This is the NOx

channel.

“From Conv” 500 +/- 10% This is the TNx channel.

05206H DCN5910 39

Page 42

Maintenance Schedule Teledyne API Model M201E NH3 Analyzer Operator Manual

This page intentionally left blank.

40 05206H DCN5910

Page 43

5.0 ALARMS AND CAUTIONS

A functional block diagram of the analyzer is shown in Figure 5-1.

5.1 ALARM

During initial warm up the internal Zero/Span factor y option may exhibit a “Block

Temperature” warning. This can be cleared once the block temper ature stabilizes

at 50 degrees Celsius. The block temperature is the actual temper ature of the IZS

block manifold inside the M501 NH3, converter. If the block temperature warning

exhibits a negative number such as (-37), then the umbilical cord is probably not

attached or the Thermistor has become disconnected.

5.2 CAUTION

Be aware that the ammonia converter operates at 825 degrees Celsius. Do not

flow highly flammable gases through the M201E analyzer. When the analyzer is

not in use, it is advisable to turn off the M5 01 NH3,. If the converter hasn’t been

powered for an extended period of time it is recommend that the analyzer be

operated overnight prior to use.

Before spanning the analyzer it is good practice to observe the NORM PMT

signal. Its value should be equal to twice the concentration of the delivered span

gas. A common error made during calibration is to span the analyzer with either

too low a gas concentration or an incorrect value entered into the CONC menu

for TNx and NOx. Commonly this will cause a slope value much greater than

one.

Note: Always zero then span as a basic rule of thumb.

05206H DCN5910 41

Page 44

Alarms and Cautions Teledyne API Model M201E NH3 Analyzer Operator Manual

KEYBOARD/DISPLAY

DIGITAL

ANALOG

THERMOCOUPLE

I/O

I/O

ANALOG

OUTPUTS

OZONE

CLEANSER

OZONE

GENERATOR

MOTHERBOARD

PREAMP

PHOTONS

REACTION

CELL

NO/NOx

VALVE

MOLYBDENUM

CONVERTER

STD

BUS

RCELL

PRESSURE

AUTOZERO

VALVE

SAMPLE

PRESSURE

CPU

VACCUM BLOCK

RS-232

OZONE

DESTRUCT

VACUUM

PUMP

NAFION DRIER

DFU FILTER

NAFION DRIER

SCRUBBER

NH3

TNx / NOx

VALVE

M501NH

NH3 CONVERTER

SAMPLE MANIFOLD

Figure 5-1. M201E Functional Block Diagram

42 05206H DCN5910

Page 45

6.0 M201E SPARE PARTS LIST

While this section lists the spare parts for the M201E, it is recommended that you refer to

our Website or Sales for updates.

M201E Spare Parts List, Source: PN 06185H (DCN5494)

Part Number Description

000940100 CD, ORIFICE, .003 GREEN

000940400 CD, ORIFICE, .004 BLUE

000940500 CD, ORIFICE, .007 ORANGE

000940600 CD, ORIFICE, .010 BROWN

002730000 CD, FILTER, 665NM (KB)

005960000 AKIT, EXP, 6LBS ACT CHARCOAL (2 BT=1)

005970000 AKIT, EXP, 6LB PURAFIL (2BT=1)

009690200 AKIT, TFE FLTR (FL19) ELEM, 47MM, (100)

010820000 ASSY, THERMOCOUPLE, HICON, M501

011630000 HVPS INSULATOR GASKET (KB)

013140000 ASSY, COOLER FAN (NOX/SOX)

014080100 ASSY, HVPS, SOX/NOX

016680600 PCA, O3 GEN DRIVER, NOX, E SERIES

018080000 AKIT, DESSICANT BAGGIES, (12)

025070000 ASSY, IZS VALVE HEATER, M501NH

025250000 ASSY, VALVE/THERM, M501NH

037860000 ORING, TEFLON, RETAINING RING, 47MM (KB)

039700100 HEATER, BAND, TYPE K, DUAL VOLTAGE(KB)

040010000 ASSY, FAN REAR PANEL, E SERIES

040030800 PCA, PRESS SENSORS (2X), FLOW, E (NOX)

040400000 ASSY, HEATERS/THERMAL SWITCH, RX CELL

041710000 ASSY, CPU, CONFIGURATION, "E" SERIES * (USE WITH DOC 053150100)

041800500 PCA, PMT PREAMP, VR, M200E/EM/EH

041920000 ASSY, THERMISTOR, M200E (KB)

042580000 PCA, KEYBOARD, E-SERIES, W/V-DETECT

042680100 ASSY, VALVE (SS), M200E

043220000 TUBING, CERAMIC, .25OD X .156 ID

043220100 THERMOCOUPLE INSULATING SLEEVE, M501NH *

043940000 PCA, INTERFACE, ETHERNET, E-SERIES

044100000 MANUAL, OPERATORS, M200E

045230100 PCA, RELAY CARD, E SERIES

04550010A ASSY, ORIFICE HOLDER, 4 MIL

04550030A ASSY, ORIFICE HOLDER, 10 MIL, (NOX) (KB)

05206H DCN5910 43

Page 46

M201E Spare Parts List Teledyne API Model M201E NH3 Analyzer Operator Manual

M201E Spare Parts List, Source: PN 06185H (DCN5494)

Part Number Description

046030000 AKIT, CH-43, 3 REFILLS

048620200

049310100 PCA, TEC DRIVER, PMT, M100/200, E SERIES

051211000 ASSY, O3 DESTRUCT W/FTGS (MNFLD - EXH) *

052060000 MANUAL, 201E STDL ADDENDUM

052930200 ASSY, BAND HEATER TYPE K, M200EX

053150100 DOC, w/SOFTWARE, M201E* (USE WITH ACROSSER CPU 041710000)

053950000 MANUAL, OPERATORS, M200E w/M201E ADDEND

055710000 ASSY, FLT, INLINE SS, 3/8” CONN, 0.5 MIC

058021100

062390000 ASSY, MOLY GUTS w/WOOL, M101E/M200EX

062420200

062870000 CPU, PC-104, VSX-6150E, ICOP *(KB) (MUST USE WITH 058021100 MB)

063570100 DOM, w/SOFTWARE, M201E * (USE WITH ICOP CPU 062870000)

CH0000037 PURACARB AMMONIA

CP0000014 CONTROLLER, TEMP, W/PG-08 (CN262)

DS0000025 DISPLAY, E SERIES (KB)

FA0000006 FAN, 115VAC (KB)

FL0000001 FILTER, SS

FL0000003 FILTER, DFU (KB)

FL0000034 FILTER, DISPOSABLE, PENTEK (IC-101L)(KB)

FT0000010 CONNECTOR-ORING, SS, 1/8" (HK)

HE0000007 CERAMIC HEATER, 220W@60V M501XX

HW0000005 FOOT

HW0000020 SPRING

HW0000030 ISOLATOR, M100/M200 A/E/H/U

HW0000031 FERRULE, SHOCKMOUNT

HW0000036 TFE TAPE, 1/4" (48 FT/ROLL)

HW0000101 ISOLATOR

HW0000416 COVER, CRYDOM RELAYS, RL9, 19 and 20

HW0000453 SUPPORT, CIRCUIT BD, 3/16" ICOP

KIT000095 AKIT, REPLACEMENT COOLER, A/E SERIES

KIT000219 KIT, 4-20MA CURRENT OUTPUT (E SERIES)

KIT000253 ASSY and TEST, SPARE PS37, E SERIES

KIT000254 ASSY and TEST, SPARE PS38, E SERIES

OR0000001 ORING, 2-006VT *

OR0000002 ORING, 2-023V

OR0000025 ORING, 2-133V

OR0000027 ORING, 2-042V

OR0000034 ORING, 2-011V FT10

PCA, SERIAL INTERFACE, w/ MD, E SERIES (USE WITH ACROSSER CPU

041710000)

PCA, E-SERIES MOTHERBD, GEN 5-ICOP (ACCEPTS ACROSSER OR ICOP

CPU)

PCA, SER INTRFACE, ICOP CPU, E- (OPTION) (USE WITH ICOP CPU

062870000)

44 05206H DCN5910

Page 47

Teledyne API Model M201E NH3 Analyzer Operator Manual M201E Spare Parts List

M201E Spare Parts List, Source: PN 06185H (DCN5494)

Part Number Description

OR0000039 ORING, 2-012V

OR0000044 ORING, 2-125V

OR0000083 ORING, 105M, 1MM W X 5 MM ID, VITON

OR0000086 ORING, 2-006, CV-75 COMPOUND(KB)

OR0000094 ORING, 2-228V, 50 DURO VITON(KB)

RL0000015 RELAY, DPDT, (KB)

RL0000019 SSRT RELAY, TA2410, CE MARK

RL0000020 SSRT RELAY, TD2410, CE MARK

SW0000040 PWR SWITCH/CIR BRK, VDE CE (KB)

SW0000051 SWITCH, POWER CIRC BREAK VDE/CE, w/RG(KB

SW0000058 SWITCH, THERMAL/450 DEG F

WR0000008 POWER CORD, 10A

05206H DCN5910 45

Page 48

M201E Spare Parts List Teledyne API Model M201E NH3 Analyzer Operator Manual

This page intentionally left blank.

46 05206H DCN5910

Page 49

7.0 CALCULATING MOLY CONVERTER EFFICIENCIES

7.1 PURPOSE

To provide instructions on how to calculate the efficiency of a Moly converter

when using a GPT method of testing converters, by using the US EPA method,

where the actual concentration of ozone is not a factor in the accuracy of the

calculation of the converter efficiency. This procedure is based on the Code of

Federal Regulations, Title 40, Chapter I, subchapter C, Part 50, Appendix F.

7.2 TOOLS

API M700 calibrator with O3 Gen option (or equivalent)

7.3 PARTS

NONE

7.4 PROCEDURE

1. For the sake of numbers to input into this note, we have chosen 450 PPB NO

gas as our reference point, you don’t have to pick these values, they are just an

example. There is also an assumption that the analyzer has a good calibration

done @ 450 PPB NO span gas. If this is not the case, then once you are done

with the leak check on the analyzer input your 450 PPB NO span gas and

calibrate the analyzer.

NOTE: for the GPT to be performed correctly, there must be a minimum of 10%

MORE NO than O3 produced. For example, if the Ozone produced is 400 PPB

then the NO used must be 440 or more. Typically 450 PPB NO is made and 400

PPB of Ozone is produced.

2. Leak check machine to ensure that there are no leaks in the analyzer.

3. If you have input a CE factor into the instrument firmware (this would be in the

CAL-CONC-CONV-SET menu) other than 100%, change this back to 100% for

the duration of this test.

4. The first gas check is to test to see how much the converter is eating NO gas or

out gassing NO gas. Bypass the converter in the machine, by placing a short

piece of tubing in place of the converter. Perform a straight dilution with NO gas

and air as a diluent gas. Input this 450 PPB NO gas into the analyzer, allow the

machine to stabilize, and write down the NOx value on your data sheet on line 3.

05206H DCN5910 47

Page 50

Calculating Moly Converter Efficiencies Teledyne API Model M201E NH3 Analyzer Operator Manual

5. Remove the converter bypass and install the converter back into the NOx sample

stream, such that the NO sample goes through the converter again and allow the

machine to stabilize. Write down your NOx value on your data sheet on line 4

AND line 6 of the data sheet.

6. Note the NO value and input that on line 9 of the data sheet.

7. Subtract line 3 from line 4 and write that number down on line 5. The spec on the

data sheet is the value that we use here in house, and your spec might be a bit

higher. We have found that on NEW Moly converters this spec is a good one

that predicts a good performing Moly converter, but in an older converter might

eat a bit more NO, and this would be acceptable. If it is a constant value, or

changes little over time, this is not a problem the machine will calibrate this out.

8. The next step is to perform your GPT. Generate the same 450 PPB NO gas and

input 400 PPB of O3 (or generate 450 PPB NO and 400 PPB NO2, if that’s what

your calibrator says). Allow the machine to stabilize for 10 minutes and then

write down the NOx value on line 7 and the NO value on line 10.

9. Subtract line 7 from line 6 and put that onto line 8

10. Subtract line 10 from line 9 and put that onto line 11

11. Put the number from line 8 into the letter A on line 12 and put the number from

line 11 into the letter B on line 12.

12. Divide A by B and multiply it by 100 and put it into letter C on line 12.

13. Put the number in letter C onto the C on line 13 and subtract that value from 100

and put it into letter D on line 13. this is the converter efficiency.

14. This value should be >96%. For CEMS applications, a CE of <96% might be

acceptable, depending on application and the guideline set up by the regulatory

agency. In any application, check with your regulatory agency to see what the

minimum CE factor is before replacing the converter.

48 05206H DCN5910

Page 51

MOLY TEST DATA SHEET

Line # TEST RESULT

2 LEAK-CHECK (WHEN HOT) YES / NO

3 NO

RESPONSE (MOLY BYPASSED) __________

X

4 NO

RESPONSE (MOLY IN-LINE) __________

X

5 OUT-GASSING / EATING (NO – NOX) __________ (>-5 PPB, <5

PPB)

6 (NOx

) (NOX mode, O3 off) __________ PPB

ORIG

7 (NOx

) (NOX mode, O3 on) __________ PPB

REM

8 NO

NOx

ORIG;

LOSS (9A - 10B) __________ (A) (<4% of

X

ex: for

450PPB

4% is 18PPB)

9 (NO

) (NO mode, O3 off) __________ PPB

ORIG

10 (NO

) (NO mode, O3 on) __________ PPB

REM

11 NO

(9B - 10A) __________ (B)

2

(>300PPB)

12 Efficiency LOSS [ (

A / B ) x 100 ] = [ ( ____A____ / ____B____ ) x 100 ] =

____C____%

13 Total Conv Eff [ 100% – C ] = 100% - ____C_____ = _____D_____ % ( > 96%)

05206H DCN5910 49

Loading...

Loading...