Page 1

Teledyne Analytical Instruments

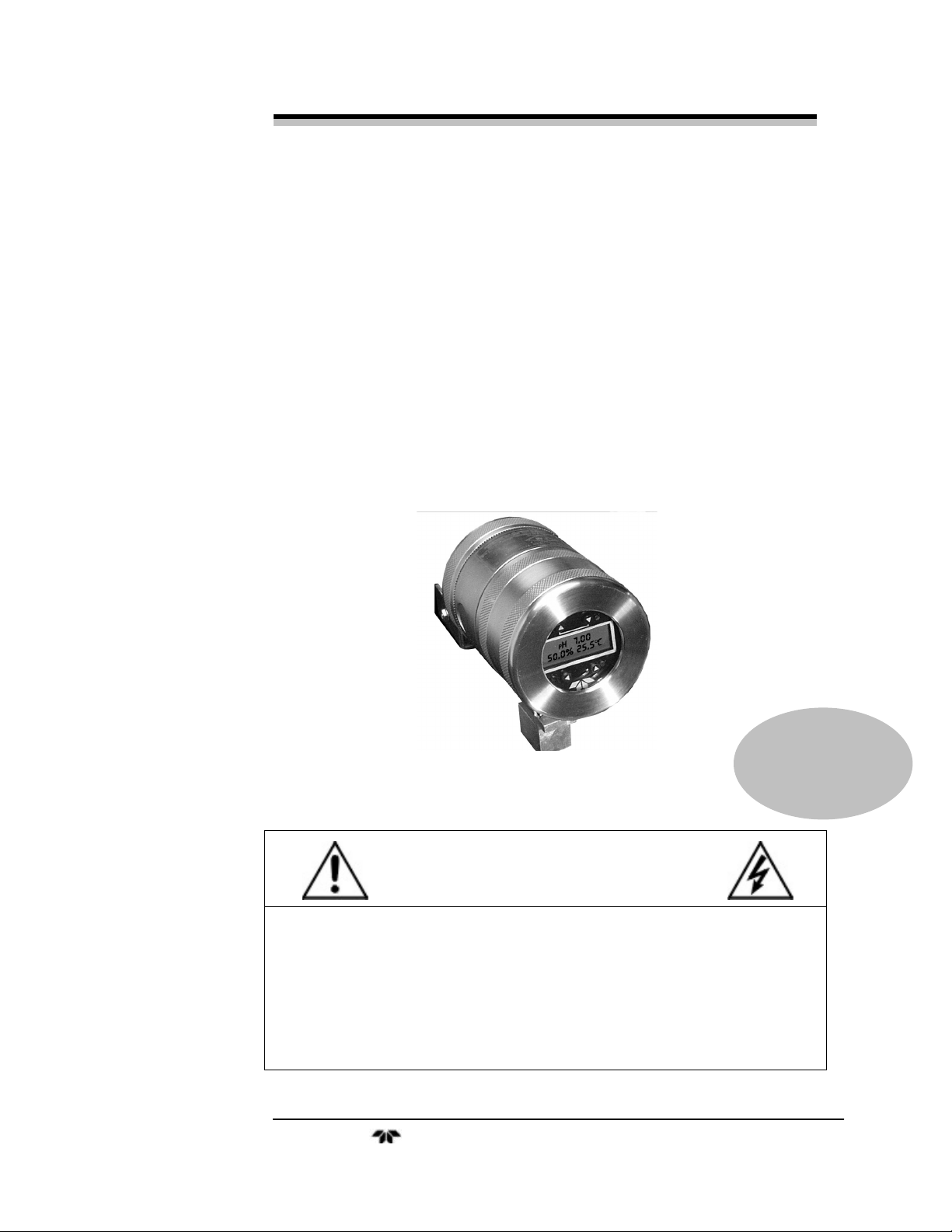

OPERATING INSTRUCTIONS FOR

LXT-280

Dissolved Oxygen

Transmitter

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

P/N M

ECO:

Page 2

LXT-280

Teledyne Analytical Instruments ii

Copyright © 2006 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/ Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/ Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Page 3

Dissolved Oxygen Transmitter

Teledyne Analytical Instruments iii

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Page 4

LXT-280

Teledyne Analytical Instruments iv

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the

instructions for details on the specific danger. These cautions

warn of specific procedures which if not followed could cause

bodily Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

No

Symbol

Page 5

Dissolved Oxygen Transmitter

Teledyne Analytical Instruments v

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

process controller. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

TI/AI at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Page 6

LXT-280

Teledyne Analytical Instruments vi

Table of Contents

List of Figures............................................................................ viii

List of Tables ............................................................................... ix

Introduction .................................................................................. 1

1.1 Overview 1

1.2 Main Features of the Transmitter 2

1.3 Optional Features 2

1.4 Front Panel 2

1.5 Model Identification 4

Installation .................................................................................... 5

2.1 Unpacking the Instrument 5

2.2 Mounting 5

2.3 Wiring 7

2.3.1 Site Wiring 7

2.3.2 Power Wiring 7

2.3.3 Sensor Wiring 8

2.3.4 DC Power 8

2.4 Configuring the LXT-280 9

2.5 Calibration 9

Operation .................................................................................... 11

3.1 Using the Front Panel Keys 11

3.2 Menus 12

3.2.1 Contrast 13

3.2.2 Main Menu 14

3.2.3 Electrode Data Screen 14

3.2.4 Electrode Zero Menu 15

3.2.5 Electrode Span Menu 16

Page 7

Dissolved Oxygen Transmitter

Teledyne Analytical Instruments vii

3.2.6 Output Calibration Menu 16

3.2.7 DO Locus 16

3.2.8 Temperature Calibration Menu 17

Calibration ...................................................................................19

4.1 Calibration 19

4.2 Manual Output Mode 19

4.3 Contrast Adjustment 20

4.4 Zero Calibration 21

4.5 Span Calibration 22

4.6 Automatic Buffer Calibration 24

4.7 Calibration Error Detection 24

4.8 Back-to-Factory Calibration 25

4.9 Output Calibration 26

4.10 Locus Calibration 27

4.11 Temperature Calibration 27

4.11.1 Temperature Adjustment 27

4.11.2 Temperature Calibration—Manual TC Adjustment 28

4.11.3 Temperature Units Calibration – °C/°F Conversion 29

Calibration Correction Factors...................................................31

5.1 Calibration Correction Factors 31

5.2 Salinity Correction 34

5.3 Calibration Example 35

5.4 Grab Sample Calibration 35

5.5 Dissolved Oxygen Units of Measurement 36

Maintenance ................................................................................37

6.1 Routine Maintenance 37

6.1.1 Cleaning 37

6.1.2 Replacement of the Microprocessor: 37

Appendix .....................................................................................41

A.1 Specifications 41

A.2 Spare Parts Listing 43

Index ............................................................................................45

Page 8

LXT-280

Teledyne Analytical Instruments viii

List of Figures

Figure 1-1: LXT-280 User Interface ................................................ 3

Figure 2-1: Typical Installation for the LXT-280 Transmitter............ 6

Figure 2-2: Intrinsically Safe Wiring Diagram .................................. 7

Figure 2-3: LXT-280 Wiring ............................................................ 8

Figure 3-1: LXT-280 Operator Interface........................................ 11

Figure 3-2: Available Menus ......................................................... 13

Page 9

Dissolved Oxygen Transmitter

Teledyne Analytical Instruments ix

List of Tables

Table 5-1: Oxygen Saturation vs. Temperature.............................32

Table 5-2: Relative Humidity Correction Factors ...........................33

Table 5-3: Elevation Correction Factor..........................................33

Table 5-4: Salinity Correction Factor .............................................34

Table 6-1: Troubleshooting ...........................................................38

Page 10

LXT-280

Teledyne Analytical Instruments x

DANGER

COMBUSTIBLE GAS USAGE

WARNING

This is instrument is Factory Mutual Approved as an

intrinsically safe and explosion proof gas analyzer for use in

Class I, II, and III Divisions 1 Groups A through G hazardous

areas. This approval applies only to the equipment specified

and installed in accordance with the information contained

within this manual. It is the customer's responsibility to

ensure safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment is well understood by the user and that the

instrument as well as any approved support equipment is

properly installed. Misuse of this product in any manner,

tampering with its components, or unauthorized substitution

of any component may adversely affect the certification and

the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Page 11

Dissolved Oxygen Transmitter Introduction

Teledyne Analytical Instruments 1

Introduction

1.1 Overview

Teledyne’s Model LXT-280 Transmitter is a robust and versatile

instrument for measurement and process control of dissolved oxygen.

This instrument is Factory Mutual Approved as intrinsically safe and

explosion proof for use in Class I, II, and III Divisions 1 Groups A

through G hazardous areas. The Model LXT-280 transmitters provide

solutions to a variety of liquid analytic applications involving hazardous

areas. The LXT-280 accepts input from a variety of sensors for specific

process measurements such as:

• Dissolved Oxygen (DO)

• pH

• Resistivity ( or conductivity)

• Oxidation-Reduction Potential (ORP)

• Specific Ion

The standard instrument is powered from an external 24 VDC

source and is equipped with a 4-20mA current output transmitted on the

same 24 VDC wiring. The power supply and electronics are remote from

each other and for FM approval, should be connected through an

intrinsic safety barrier. Separate compartments in the stainless steel

explosion proof housing keep the wiring and the electronics separate and

sealed from each other. This prevents the sensitive electronics from

being exposed to hostile environments.

The LXT-280 is housed in a Factory Mutual Approved explosion

proof stainless steel NEMA-7C housing. The operator interacts with the

instrument via magnetic switches located on the front panel behind a

removable cover. The magnetic switches can be activated without

having to open the cover.

This transmitter is capable of measuring dissolved oxygen in ppm

or in the percent oxygen range.

Page 12

Introduction LXT-280

Teledyne Analytical Instruments 2

1.2 Main Features of the Transmitter

The LXT-280 Transmitter for dissolved oxygen applications

incorporates the following standard features:

• Magnetic switches located behind a glass window can be

activated without having to open the instrument.

• Menu driven backlit display with contrast adjustment

• Automatic Calibration. This allows calibration points to be

defined upon initialization of the transmitter.

• An easy back to factory calibration menu allows the instrument

to return to a predetermined factory calibration. The default

parameters are: zero electrode offset at 0 ppm or 0% oxygen and

-400 mV at full scale.

• 4-20mA current output transmitted on the same 24 VDC power

wiring. The current output is fully expandable to any range

within the transmitter’s full operating range. The current output

can be configured to be reverse acting.

• Temperature Conversion. Temperature can be displayed in either

Fahrenheit or Celsius. The units can be toggled from one to the

other in the field with the conversion calculation performed

automatically.

1.3 Optional Features

The Model LXT-280 Transmitter is a versatile instrument designed

to meet the needs for liquid analytics and process control across a wide

range of applications. Options available for this transmitter includes:

Optional Software

Security Access—keyboard security option: Allows only

authorized personnel entry to calibration modes.

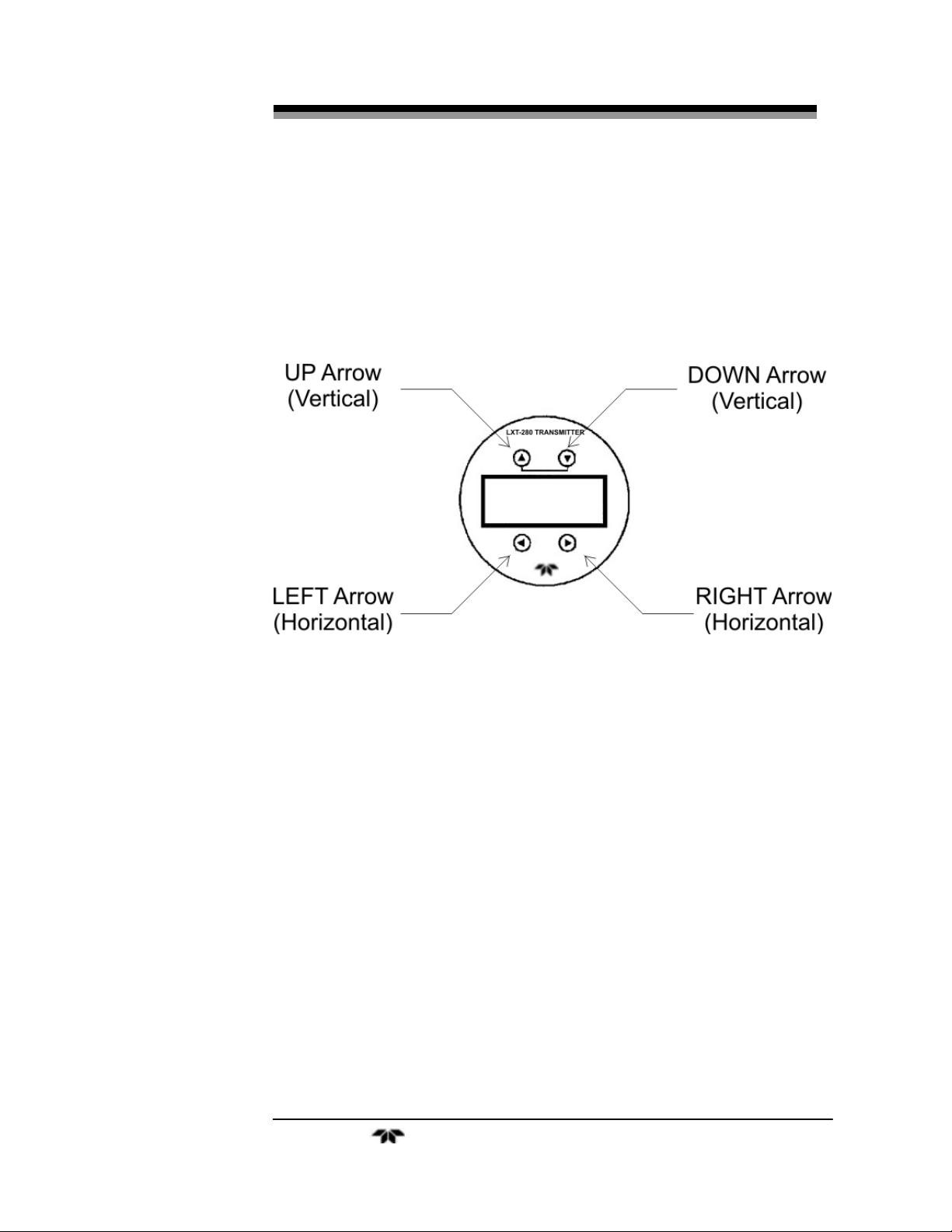

1.4 Front Panel

The operator interfaces with the instrument through a sight glass

window using magnetically activated arrow keys. This is accomplished

by touching an instrument magnet to the glass window directly over the

Page 13

Dissolved Oxygen Transmitter Introduction

Teledyne Analytical Instruments 3

appropriate magnetic switch. The LXT-280 uses an "underline" cursor in

each of the menus.

Figure 1-1 shows the user interface for the LXT-280 instrument.

The interface includes the LCD display capable of outputting

alphanumeric information in 2 rows of 16 characters per row and 4

magnetic switch arrow keys that control the operation of the unit.

Figure 1-1: LXT-280 User Interface

The keys are in two groups:

VERTICAL UP/DOWN (▲/▼) Arrow Keys

• These keys are used to change the display menu.

• They also move the cursor vertically. Any menu can be

accessed by magnetically activating the appropriate UP or

DOWN key

• These keys also perform numeric adjustments to display

values while in the calibrate mode. Magnetically activating

the up vertical arrow key will increase the value or

magnetically activating the down vertical arrow key will

decrease the value.

Page 14

Introduction LXT-280

Teledyne Analytical Instruments 4

HORIZONTAL LEFT/RIGHT (◄/►) Arrow Keys

• The right and left arrows are used to enter the calibrate mode.

To enter the calibrate mode, magnetically activate the right

horizontal arrow key. Once in the calibrate mode, the cursor

can be positioned by magnetically activating the right or the

left horizontal arrow key. To exit the calibrate mode,

magnetically activate left horizontal arrow key until the

cursor is all the way to the left.

• These keys also move the cursor horizontally.

1.5 Model Identification

The LXT-280 Transmitter is a 24VDC unit. The instrument is

configured at the factory for the customer’s application and so there are

many different model designators.

The following codes will help in identifying a specific instrument

configuration.

Base Model:

LXT-280 LXT-280 Transmitter

Channel 1 Input with 4-20mA Output:

-DO/MA Dissolved Oxygen (specify ppm or %)

-PH/MA pH

-ORP/MA Oxidation Reduction Potential (REDOX)

-PION/MA Specific ion

-CD/MA Conductivity, 0-20 mS

-CDT/MA Conductivity Toroidal (form 50mA to 1S)

-RS/MA Resistivity (0 to 50 megohms)

Mounting Hardware:

-UM Universal mounting plate

Other Options:

KSx Keyboard Security Code (x = level of security,

see Security Code Option)

Page 15

Dissolved Oxygen Transmitter Installation

Teledyne Analytical Instruments 5

Installation

Installation of the LXT-280 Transmitter involves:

• Unpacking the instrument

• Mounting

• Making Electrical Connections

• Configuring the Instrument

• Calibration

2.1 Unpacking the Instrument

The LXT-280 Transmitter has been carefully packaged to protect it

from damage during shipment and dry storage. Upon receipt please

follow the procedure outlined below:

1. Before unpacking, inspect the condition of the shipping container

to verify proper handling by the carrier. If damage is noted, save

the shipping container as proof of mishandling for the carrier.

2. Check the contents of the shipping container with the items and

quantities shown on the packing list. Immediately report any

discrepancies to TI/TAI.

3. Save the original packing material until you are satisfied with the

contents. In the event the transmitter must be returned to the

factory, the packing material will allow you to properly ship it to

TI/TAI.

4. Familiarize yourself with the instrument before installation, and

follow proper installation and wiring procedures.

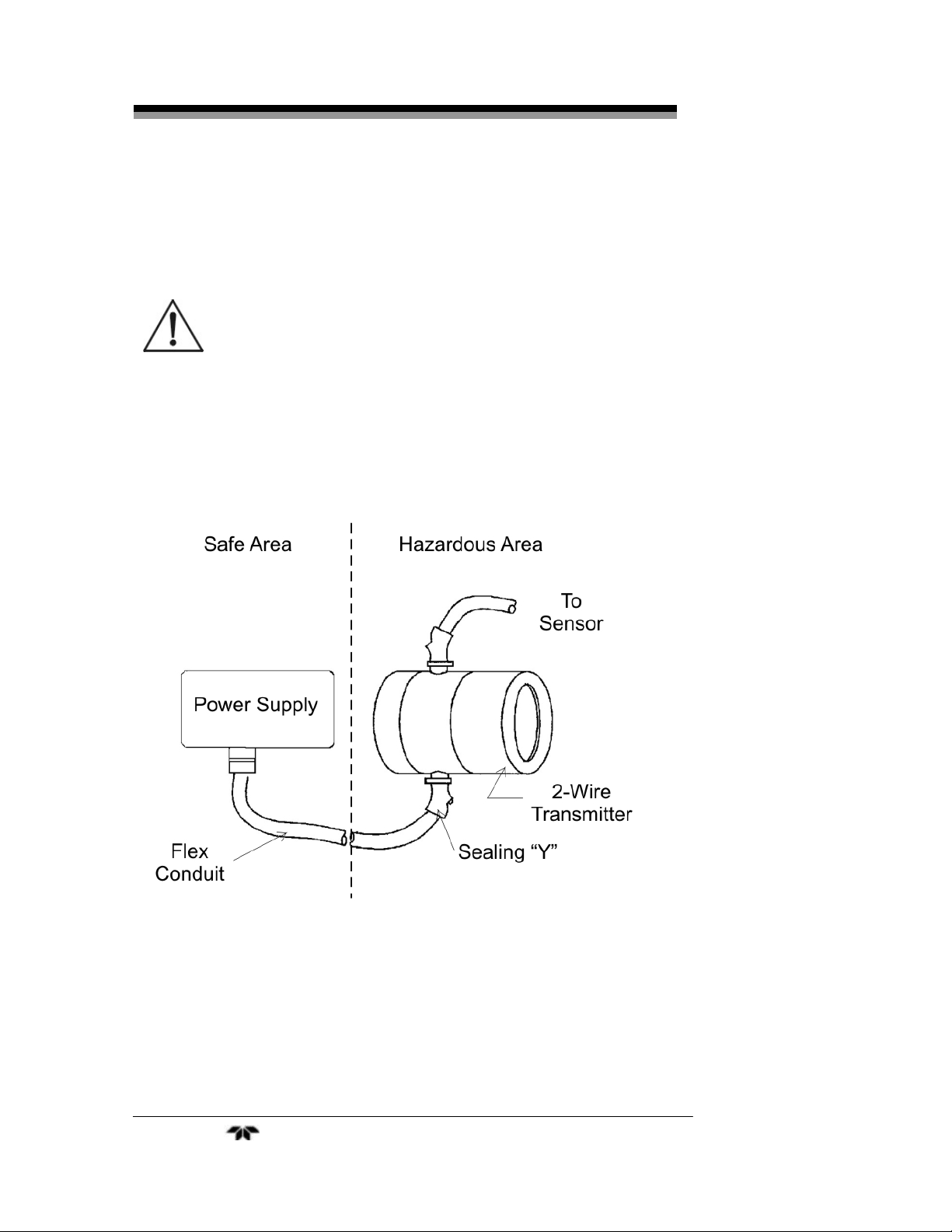

2.2 Mounting

The LXT-280 transmitter can be wall mounted or pipe mounted.

Installation drawings with dimensions are included at the back of this

manual. The power supply must be located in a non-hazardous area

while the transmitter and sensor can be installed in a hazardous

Page 16

Installation LXT-280

Teledyne Analytical Instruments 6

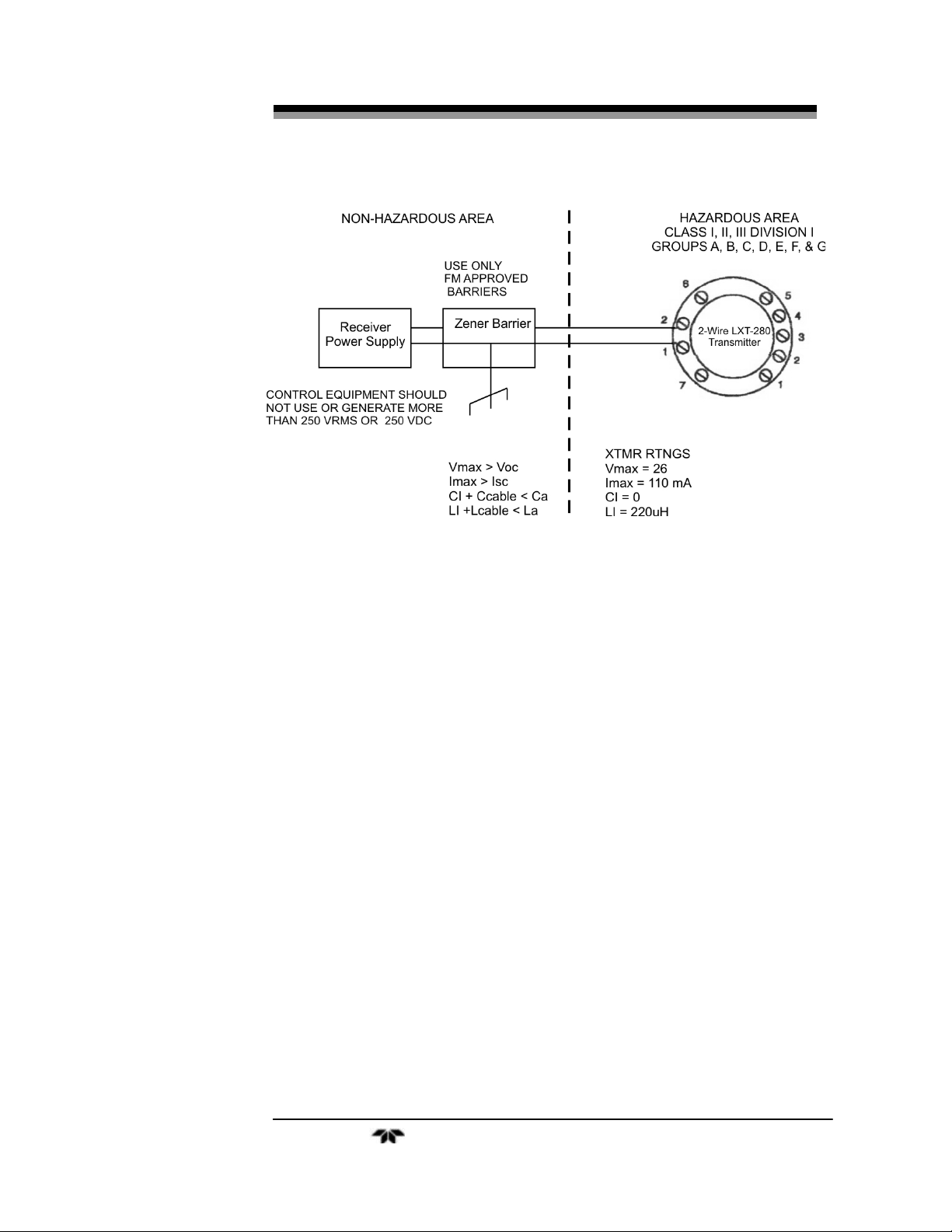

environment as shown in Figure 2-1. For intrinsically safe installation,

an FM approved safety barrier must be installed between the power

supply/receiver and the transmitter as shown in Figure 2-2.

CAUTION: USE ONLY FM APPROVED SAFETY BARRIERS.

CONTACT TELEDYNE FOR A LIST OF FM

APPROVED INTRINSIC SAFETY BARRIERS FOR

YOUR APPLICATION.

If mounting hardware is ordered with the instrument, it has been

factory assembled and the LXT-280 is ready for mounting. A sunshade

should be considered during the selection of the mounting location

this prevents direct sunlight from creating an oven effect inside of the

enclosure.

Figure 2-1: Typical Installation for the LXT-280 Transmitter

Page 17

Dissolved Oxygen Transmitter Installation

Teledyne Analytical Instruments 7

Figure 2-2: Intrinsically Safe Wiring Diagram

2.3 Wiring

2.3.1 Site Wiring

Two conduits should be run to the transmitter locat i o n , one for

the sensor and the other for the 24 VDC-power source. Proper methods

of terminating the conduit for hazardous locations should be reviewed

by your local plant safety engineer based on State and Federal

requirements.

2.3.2 Power Wiring

For power wiring, the LXT-280 transmitter requires a nominal 24VDC voltage source. With zero loop impedance, the minimum voltage

requirement is 14 VDC. The maximum voltage limit is 50 VDC.

Maximum loop impedance at 24 VDC is 450 ohms for the 4-20 mA

compliance. Impedance levels higher than 450 ohms will require

additional DC voltage.

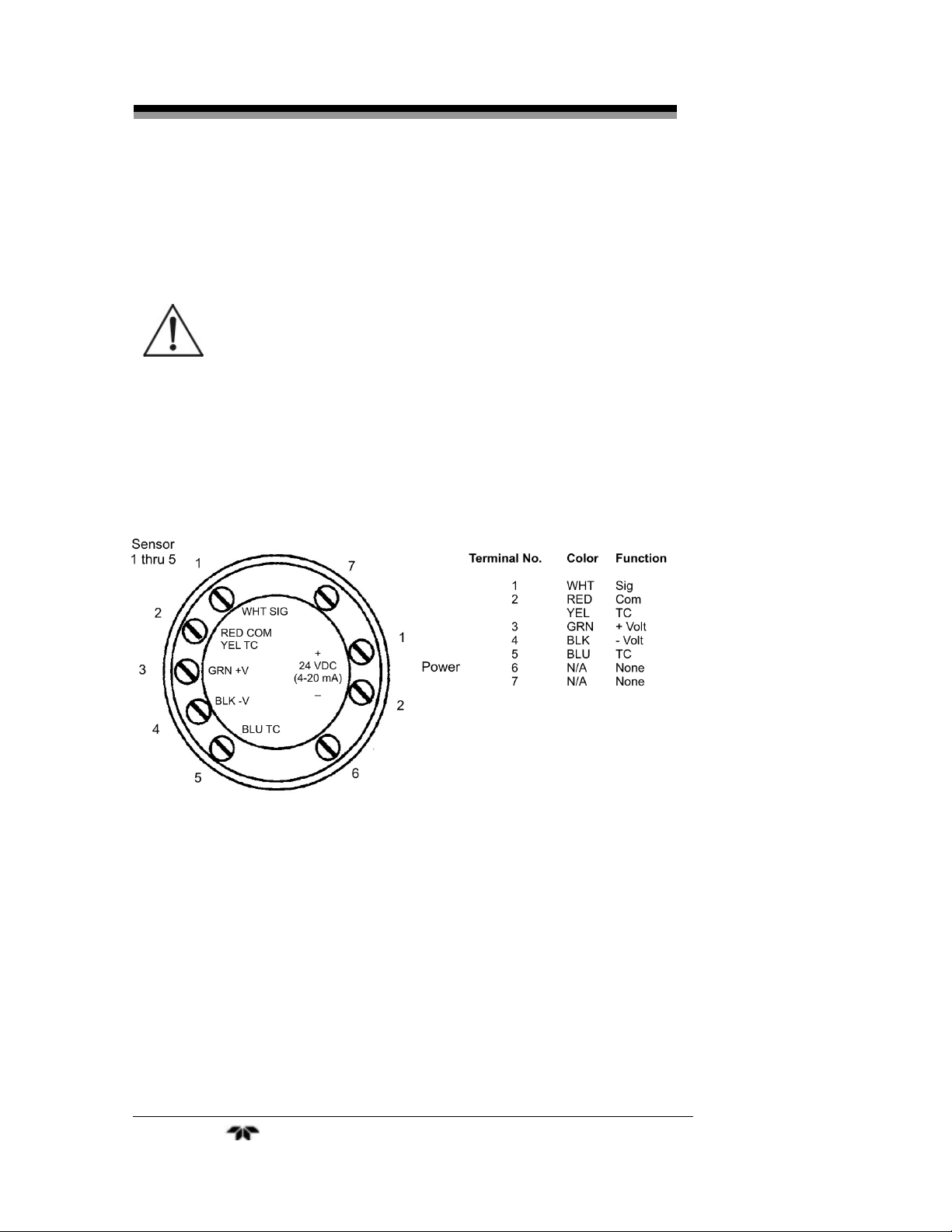

Figure 2-3 illustrates the proper 24 VDC power wiring for the LXT280 transmitter. When connecting the power wires, it is important to

Page 18

Installation LXT-280

Teledyne Analytical Instruments 8

observe the polarity. Although no damage to the LXT-280 will result

from polarity reversal, the instrument will not function.

For intrinsically safe wiring see Figure 2-2.

CAUTION: DO NOT APPLY 110 VAC TO THE 24 VDC WIRING

TERMINALS. DAMAGE TO THE INSTRUMENT WILL

RESULT!

2.3.3 Sensor Wiring

A conditioned input is required from the sensor or electrode to the

LXT-280 transmitter for proper operation. Teledyne models SP-1 and SP2 sensors will provide the required conditioning. Figure 2-3 illustrates the

proper wiring of the sensor to the LXT-280 transmitter.

Figure 2-3: LXT-280 Wiring

2.3.4 DC Power

The LXT-280 requires an external 24 VDC power source to

operate. With zero loop impedance, the minimum voltage requirement is

13.5 VDC. The maximum voltage limit is 50 VDC. Maximum loop

impedance at 24 VDC is 525 ohms for the 4-20 mA compliance.

Impedance levels higher than 525 ohms will require additional DC

voltage.

Page 19

Dissolved Oxygen Transmitter Installation

Teledyne Analytical Instruments 9

2.4 Configuring the LXT-280

The LXT-280 Transmitter is used for measurement and control in

hazardous environments for a wide range of liquid analytical

applications. This manual describes the configuration for use in

dissolved oxygen measurement and control applications. The unit is

Factory Mutual approved as intrinsically safe for use in Class I, II, and

III Divisions 1 Groups A through G hazardous areas.

Configuring the instrument is described in Section 3 of this manual.

2.5 Calibration

Prior to using the instrument for the first time, the LXT-280 must

be calibrated. The specific calibration procedure used depends on the

application. Among other things, the calibration routine establishes the

correspondence between the 4-20 mA output signal and the application

dependant measurable parameter.

Calibration can be performed without disturbing control or recorder

functions using a manual output mode (see Section 4.2). Typically, the

calibration is done using either a one-point buffer calibration

(standardization) or two-point (span) calibration. There is also a Back to

Factory calibration feature which resets the LXT-280 to “nominal

electrode” situation. This reverts to an electrode with zero millivolts

offset at zero percent or ppm oxygen and a full scale output of –400 mV.

This is useful as a starting point if the instrument has been miscalibrated.

The calibration routines require a familiarity with the instrument

operation and is described after fundamental operational parameters are

discussed in Section 3.

Page 20

Installation LXT-280

Teledyne Analytical Instruments 10

Page 21

Dissolved Oxygen Transmitter Operation

Teledyne Analytical Instruments 11

Operation

This section will provide an overview of the front panel key

functions and the display menus for the LXT-280 Dissolved Oxygen

transmitters.

3.1 Using the Front Panel Keys

The operator keys on the explosion proof model are located behind

a sight glass window sealed from the environment. They are magnetic

and are operated by touching the glass in front of the appropriate key

using the supplied magnetic screwdriver. This allows instrument

operation without having to open the cover and expose the internal parts

to the environment. Figure 3-1 shows the layout of the LXT-280

faceplate.

Figure 3-1: LXT-280 Operator Interface

The operator keys are arranged in two groups:

1. VERTICAL UP/DOWN (▲/▼) Arrow Keys

These keys are used to change the display menu and to move the

cursor vertically. Any menu can be accessed by magnetically

activating the appropriate UP or DOWN key.

Page 22

Operation LXT-280

Teledyne Analytical Instruments 12

These keys also perform numeric adjustments to display values

while in the calibrate mode. Magnetically activating the UP

▲vertical arrow key will increase the value; magnetically

activating the DOWN ▼ vertical arrow key will decrease the

value.

2. HORIZONTAL LEFT/RIGHT (◄/►) Arrow Keys

The RIGHT and LEFT arrows are used to enter the calibrate

mode. To enter the calibrate mode, magnetically activate the

RIGHT ► horizontal arrow key. Once in the calibrate mode, the

cursor can be positioned by magnetically activating the RIGHT

or the LEFT horizontal arrow key. To exit the calibrate mode,

magnetically activate LEFT ◄ horizontal arrow key until the

cursor is all the way to the left.

These keys are also used to move the cursor horizontally.

3.2 Menus

The LXT-280 contains a series of menus from which different

functions can be accessed. You can scroll through all available menus

by activating the VERTICAL ▲ and ▼ keys.

The menus available in the LXT-280 instrument configured for

dissolved oxygen transmitters are shown in Figure 3-2.

When the instrument is first powered up, a copyright display will

appear for a few seconds. This screen displays the serial number and

software version for your instrument. After a few seconds the display

changes to the main menu . The Copyright Display provides the

software "version" number (2.20) and the software serial number (67).

Teledyne will require this information if software updates are to be

performed.

To access any of the menus listed below, magnetically activate the

desired vertical arrow key with an instrument magnet.

S/N 18 V 2.23

(C)TI/TAI 2006

Page 23

Dissolved Oxygen Transmitter Operation

Teledyne Analytical Instruments 13

From the main menu, you can scroll up (▲) to the Contrast menu

or down (▼) through the available menus for your transmitter.

.

Figure 3-2: Available Menus

In this manual, gray screens apply to dissolved oxygen in percent

instruments while white screens apply to dissolved oxygen in ppm

instruments. When only one screen is illustrated, the screen is applicable

to both instruments.

3.2.1 Contrast

Display contrast can be adjusted to allow for variations of ambient

lighting and viewing angle by using this menu. The Contrast Menu is

always located as the uppermost menu. To access the contrast menu

from the Main Menu, magnetically activate the UP vertical arrow key

once.

Contrast 50

Page 24

Operation LXT-280

Teledyne Analytical Instruments 14

3.2.2 Main Menu

This menu appears after the copyright display when power is first

applied to the LXT-280. The MAIN MENU displays the measured

process variable, temperature, and the current output in percent of fullscale. While in this menu, the current output can be adjusted and locked

in a manual mode to provide an undisturbed output during sensor

calibrations.

3.2.3 Electrode Data Screen

As an informational screen only, this display provides diagnostic

data pertaining to the electrode. The top line displays the real-time

(active) absolute millivolt value (mVa) the electrode is generating; it is

not compensated for temperature variations.

This value can be used to determine the saturation limit of the

sensor and the maximum effective range of the instrument with that

sensor and electrode. For example, if the maximum desired instrument

range is 20 ppm, and the real-time mVa is 275 mV at an oxygen level of

10 ppm, the maximum effective range of the sensor and electrode is

18.18 ppm. This is calculated by using the equation below. Please note

that the 500 mV value used in the equation is the maximum input to

which the LXT-280 Dissolved Oxygen transmitter will respond.

Effective range = (500 mVa/Input mVa) x (DO value @ the Input mVa)

In the example above, the effective range was calculated as:

DO 90.0 %

50.0% 25.0OC

DO 10.0 ppm

50.0% 25.0OC

Input 480.0

0 mV .1

Electrode Diagnostic Screen,DO %

Input 275.0

0 mV .4

Electrode Diagnostic Screen, DO ppm

Page 25

Dissolved Oxygen Transmitter Operation

Teledyne Analytical Instruments 15

Effective Range = (500 mVa/275 mVa) x (10 ppm)

Effective range = (1.818) x (10 ppm)

Effective range = 18.18 ppm

A reading higher than 18.18 ppm is not meaningful under the

circumstances given in the above example. At 18.18 ppm, the millivolt

input from the sensor is greater than 500 mV and saturates the

transmitter input circuitry.

The bottom line of the Electrode Data Screen displays the electrode

zero offset from the last zero calibration. This value is the dissolved

oxygen value at which the electrode output is zero millivolts. Because

the Electrode Data Screen indicates the deviation from zero, the

information is helpful in determining the quality of the dissolved

oxygen electrode. In conjunction with regular calibrations, the

Electrode Data Screen can provide valuable information to track

electrode service.

3.2.4 Electrode Zero Menu

This menu provides the means with which to perform the zero

calibration for the Dissolved Oxygen electrode. The screen shown below

shows the Electrode Zero Menu for Dissolved Oxygen in percent

oxygen or ppm oxygen.

Before entering the calibrate mode, the menu provides historical

data from the last calibration. The top line displays the buffer, or

calibration point, at which the last calibration was performed. The

bottom line displays the temperature compensated mV value the

electrode generated at the calibration point.

Calibration procedures are described in Section 4.

2 DO 100.0

Cal -400.0

ElectrodeSpsn Menu, %

2 DO .0

Cal -400.0

Electrode Span Menu, ppm

Page 26

Operation LXT-280

Teledyne Analytical Instruments 16

3.2.5 Electrode Span Menu

From this menu, you can perform the span calibration for the

dissolved oxygen electrode. Before entering the calibrate mode, the

menu provides historical data from the last calibration.

The top line displays the calibration point at which the last

calibration was performed. For DO transmitters, the bottom line displays

the electrode slope, or efficiency, in millivolts at full scale. When in the

calibrate mode, the bottom line displays the real-time, or active,

millivolt value.

3.2.6 Output Calibration Menu

On the next menu, the current output ranges are displayed and can

be adjusted in this menu.

The 4 mA and 20 mA points may be defined in percent dissolved

oxygen or parts per million dissolved oxygen, depending on the software

installed in the transmitter. The maximum allowable ranges are 0 to

200% and 0 to 20 ppm.

3.2.7 DO Locus

The DO Locus Menu defines the point at which a family of

dissolved oxygen concentration curves intersect for a specific sensor or

electrode. The locus is derived by plotting the sensor output versus

temperature at different dissolved oxygen concentrations. Empirical

data for Teledyne sensors defines the locus to be approximately -17°C.

Because dissolved oxygen sensors have different temperature slopes at

2 DO 100.0

Cal -400.0

Output Calibration Menu, %

2 DO .0

Cal -400.0

Output Calibration Menu, ppm

4 mA .0

20 mA 200.0

Output Calibration Menu, %

4 mA .0

20 mA 20.0

Output Calibration Menu, ppm

Page 27

Dissolved Oxygen Transmitter Operation

Teledyne Analytical Instruments 17

different concentrations, the locus must be determined and used to

normalize the temperature to 25°C. This value should not be changed

unless a sensor different than the Teledyne sensor is used. Each sensor

manufacturer should define the locus for their sensor.

3.2.8 Temperature Calibration Menu

This screen has two calibrate functions and a conversion function.

It is used to adjust or trim the temperature compensation for variations in

the sensing element. It is also used to provide a manual temperature

input for the process. The top line displays the temperature offset value.

The bottom line displays the adjusted temperature value. You can also

convert and toggle between °C and °F temperature units from this

screen. See Section 4.11.3.

__Trim °C .0

Unit 24.3°C

Locus -17.0

Output Calibration Menu, %

Page 28

Operation LXT-280

Teledyne Analytical Instruments 18

Page 29

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 19

Calibration

4.1 Calibration

A complete calibration of the LXT-280 Dissolved Oxygen

transmitter involves:

1. Zero calibration

2. Span calibration

3. Output calibration

4. DO Locus calibration

5. Temperature calibration (trim)

In general, once the instrument has been setup, only step 2 will be

required for calibration although it is recommended that the output and

temperature calibration be occasional rechecked and adjusted as

necessary. It is also highly recommended that you perform a zero

calibration (step 1) periodically to check for drift and whenever a new

sensor is installed.

It may be useful to set the contrast of the display prior to calibration

to compensate for current lighting conditions.

Note: Before calibrating the LXT-280, place the instrument in

Manual Mode. See the following section.

4.2 Manual Output Mode

In order to perform calibrations without interfering with control or

recorder functions, the LXT-280 incorporates a manual output mode. In

the manual output mode, the current output is set to the desired level and

saved until changed or released from the manual mode. The following

procedure demonstrates the use of the manual output.

Procedure:

1. If not at the Main Menu, magnetically activate the appropriate

VERTICAL ▲/▼ arrow key.

Page 30

Calibration LXT-280

Teledyne Analytical Instruments 20

2. With the cursor on the second line of the main menu,

magnetically activate the RIGHT HORIZONTAL key ► to enter

the calibrate mode and observe the "M" appearing in front of the

% current output value. The "M" signifies that the manual

output is locked in the manual mode.

3. Using the HORIZONTAL arrow keys, position the cursor under

the digit to be adjusted.

4. Increase or decrease the value by magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

5. When the desired value is reached, exit while leaving the

transmitter in the manual output mode, by magnetically

activating the LEFT ◄ arrow key until the cursor is under the

“M”. As long as the “M” is in front of the output % the current

output of the transmitter will be held at that filed value.

To release manual output:

1. Return to the Main Menu by magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

2. Observe that the "M" appears in front of the % current output

value. This "M" signifies that the transmitter output is in manual

mode.

3. Magnetically activate the LEFT HORIZONTAL◄ arrow key

and observe the "M" disappear, releasing the LXT-280 from the

manual output mode. The % output value will return to the realtime current output.

4.3 Contrast Adjustment

Display contrast can be adjusted to allow for variations of ambient

lighting and viewing angle. The Contrast Menu is the uppermost menu

and is accessed with the UP VERTICAL ▲ arrow key.

Procedure:

DO 17.00 ppm

M24.3% 25.0°C

Page 31

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 21

1. With an instrument magnet, activate the UP VERTICAL ▲

arrow key to reach the Contrast Menu.

2. Magnetically activate the RIGHT HORIZONTAL ► arrow key

to enter the calibrate mode. Observe the cursor move to the last

digit.

3. Using the HORIZONTAL ◄► arrow keys, position the cursor

under the digit to be adjusted. Increase or decrease the value by

magnetically activating the appropriate VERTICAL ▲/▼ arrow

key.

4. To save the contrast value and exit the calibrate mode,

magnetically activate the LEFT HORIZONTAL◄ arrow key

until the cursor is all the way to the left.

4.4 Zero Calibration

Because dissolved oxygen sensors experience minor variations in

membrane thickness, permeability, surface area and in the signal

conditioning amplifier from one sensor to the next, the zero point may

differ. In some cases, especially in low ppm measurements, a zero

calibration may be desirable.

Two zero calibrations are possible with a dissolved oxygen sensor:

1. Simulation of a zero oxygen environment

2. Using a true zero oxygen environment

The simulation of a zero oxygen environment is the easiest and can

be performed with good results; however, for extreme accuracy at the

low-end (near zero), the true oxygen environment is preferred. These

two calibration procedures are discussed in detail in the SP-1/SP-2

Sensor Manual. The following procedure describes the steps used to

calibrate a DO sensor to the LXT-280 instrument.

Procedure:

1. With an instrument magnet, activate the appropriate VERTICAL

▲/▼ arrow key to reach the Electrode Standardization Menu and

locate the cursor under the "1".

2. For diagnostic reasons note the pH and mV values from the prior

calibration.

3. Clean the electrode and insert the sensor into the desired buffer.

Page 32

Calibration LXT-280

Teledyne Analytical Instruments 22

4. Magnetically activate the RIGHT HORIZONTAL ► arrow

key to enter the calibrate mode. Observe the diagnostic value

on the bottom line change from historical data to a real-time

value and that the term "Cal" has disappeared.

5. To change the buffer point, position the cursor under the desired

digit using the LEFT HORIZONTAL◄ arrow key.

6. Increase or decrease the value by magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

7. Wait for the real-time mV value to stabilize.

8. To save the calibration and exit the calibrate mode, magnetically

activate the LEFT HORIZONTAL◄ arrow key until the cursor

is all the way to the left and the term “Cal” on the second line

reappears.

Perform a span calibration after the zero calibration.

4.5 Span Calibration

The span calibration is typically the only calibration that needs to

be performed on a routine basis. This calibration compensates for

changes in the membrane or deterioration of the electrolyte. Teledyne

recommends the span calibration be performed in air or in an oxygen

standard that is near the range in which the process normally operates.

These two span calibrations are described in the SP-1/SP-2 Sensor

Installation and Maintenance Manual.

The following procedure describes the steps used to calibrate the

LXT-280 to the sensor. If performing an air span calibration where the

unit of measurement is ppm, review Section 5.0, Calibration Correction

Factors. This instrument calibration procedure can also be used to

calibrate to a sample that has been analyzed through a wet chemical

process, such as a Winkler analysis.

Procedure:

1. Perform a zero calibration as outlined in Section 4.4.

1 DO 0

0.2 mV

Page 33

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 23

2. Magnetically activate the DOWN VERTICAL ▼ arrow key to

reach the Electrode Span Menu and locate the cursor under the

"2".

3. For diagnostic reasons note the slope values from the prior

calibration.

4. Magnetically activate the RIGHT HORIZONTAL ►arrow key

to enter the calibrate mode. Observe the diagnostic value on the

bottom line change from historical data to a real-time value and

that the term "Cal" has disappeared.

5. To change the buffer point, position the cursor under the desired

digit using the LEFT HORIZONTAL◄ arrow key.

6. Increase or decrease the value by magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

7. Wait for the real-time mV value to stabilize.

8. To file the calibration and exit the calibrate mode, magnetically

activate the LEFT HORIZONTAL◄ arrow key until the cursor

is all the way to the left and the term “Cal” on the second line

reappears.

A typical DO electrode will indicate a full scale value of –400 mV.

See the equation in Section 3.2.3 for information on determining the

effective range of the electrode.

CAUTION: IF A FLASHING ASTERISK APPEARS DURING OR

AFTER CALIBRATION, THE ELECTRODE MAY

REQUIRE SERVICE, OR THE BUFFER SOLUTION

MAY BE CONTAMINATED. SEE SECTION 4.7.

Comparing the millivolt values before and after the calibration

provides a valuable diagnostic tool in determining the degradation of the

electrode. Minor differences in the full scale value is normal; however,

2 DO 100.0

mv/dec

Page 34

Calibration LXT-280

Teledyne Analytical Instruments 24

large differences between calibrations may indicate coating or damage to

the membrane.

4.6 Automatic Buffer Calibration

Once the calibration points have been defined in the LXT-280 by

performing the zero and span calibration, the Automatic Buffer

Calibration feature can be utilized. This feature allows calibrations to be

performed without making any adjustments. The procedure is the same

for the zero and span calibrations.

Procedure:

1. Go to the appropriate calibration menu and locate the cursor on

the top line

2. Insert the sensor in the known solution as defined by the

calibration point on the top line.

3. Magnetically activate the RIGHT HORIZONTAL ►arrow key

to enter the calibrate mode.

4. Wait for the real-time mV to reach its minimum value (zero

calibration) or wait for the real-time mV value to stabilize (span

calibration).

5. Magnetically activate the LEFT HORIZONTAL ◄ arrow key

until the cursor is all the way to the left and the term “Cal”

appears on the second line. This will store the calibration data.

4.7 Calibration Error Detection

If the calibration performed in section 4.5 is not within the

predetermined limits of the instrument, a flashing asterisk (*) will

appear behind the full scale millivolt value.

The presence of the asterisk indicates a potential calibration

problem and can be ignored if there are special considerations allowing

this condition to be valid. In general, if the asterisk appears, the integrity

of the electrode, the calibration procedure or the handling procedure

should be questioned.

Page 35

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 25

4.8 Back-to-Factory Calibration

This feature allows the LXT-280 to be reset to "nominal electrode"

situation. This condition is an electrode with zero millivolts offset at

zero percent or ppm oxygen, and a full scale output of –400 mV. This

factory calibration feature is very useful in providing a reliable starting

point if the instrument has been mis-calibrated.

CAUTION: IDEAL INSTRUMENTATION CALIBRATION DOES

NOT IMPLY IDEAL SYSTEM CALIBRATION.

Before using the factory calibration feature, it must be understood

that it provides a nominal instrument calibration and does not allow for

electrode variations or shortened span of the electrode in service. In

order to obtain ideal system calibration, a span calibration is required.

The following procedure for returning the LXT-280 back-to-factory

calibration can be used for both zero and span calibrations.

This procedure is required at BOTH of the calibration points.

Procedure at the Zero Menu:

6. Magnetically activate the appropriate VERTICAL ▲/▼ arrow

key to reach the Electrode Zero Menu.

7. Position the cursor under the “C” in “Cal.”

8. Magnetically activate the RIGHT HORIZONTAL ►arrow key

and observe the cursor briefly move to the right and the mV

value change to 0.00. The default setting is complete.

9. Verify the calibration by observing a .0 calibration point at .0

mV.

Procedure at the Span Menu:

1. Magnetically activate the appropriate VERTICAL ▲/▼ arrow

key to reach the Electrode Span Menu.

2. Position the cursor under the “C” in “Cal.”

2 DO .0

Cal -400.0 mV

Page 36

Calibration LXT-280

Teledyne Analytical Instruments 26

3. Magnetically activate the RIGHT HORIZONTAL ►arrow key

and observe the cursor briefly move to the right and the full scale

millivolt value changes to –400.0. The default setting is

complete.

4. Verify the calibration by observing a .0 calibration point at –400

mV/FS.

4.9 Output Calibration

The Output Calibration screen is used to define the 4-20 mA range

for the measurement. The values in the menu are in the units being

measured. Maximum ranges are 0-200 % and 0-20 ppm.

To change or expand the 4-20 mA range, use the following

procedure.

Procedure:

1. Magnetically activate the appropriate VERTICAL▲/▼ arrow

key to reach the Output Calibration Menu.

2. Position the cursor on the top line to change the 4 mA point or

the bottom line to change the 20 mA point.

3. Magnetically activate the RIGHT HORIZONTAL ► arrow key

to enter the calibrate mode.

4. To change the value, position the cursor under the desired digit

using the left LEFT HORIZONTAL◄ arrow key.

5. Increase or decrease the value by magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

6. When the desired value is reached, save the calibration and exit

the calibrate mode by magnetically activating the LEFT

HORIZONTAL ◄ arrow key until the cursor is all the way to

the left.

2 DO .0

Cal -400.0

Page 37

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 27

4.10 Locus Calibration

As stated in section 3.2.7, the locus value for Teledyne SP-1 and

SP-2 sensors is approximately -17.0°C and should not be changed

unless a different manufacturer's sensor is used. If the locus is not -17°C,

use the following procedure to define the correct locus.

Procedure:

1. Magnetically activate the appropriate VERTICAL ▲/▼ arrow

key to reach the Locus Menu.

2. Magnetically activate RIGHT HORIZONTAL ► arrow key to

enter the calibrate mode. Observe the cursor move to the last

digit on the right.

3. Using the HORIZONTAL ◄► arrow keys, position the cursor

under the digit to be adjusted.

4. Increase or decrease the value by Magnetically activating the

appropriate VERTICAL ▲/▼ arrow key.

5. To file the locus value and exit the calibrate mode, Magnetically

activate the LEFT HORIZONTAL ◄ arrow key until the cursor

is all the way to the left.

4.11 Temperature Calibration

The Temperature Calibration screen is used to:

1. Adjust the temperature to coincide with measuring device

2. Toggle temperature units between °C and °F

4.11.1 Temperature Adjustment

When the process demands a tighter tolerance than ±3°C of the

temperature input, the LXT-280 allows adjustment, or trim, for

variations in the temperature compensation element. This adjustment

only compensates for deviations in the RTD input (as a sensor input

Locus -17°C

Page 38

Calibration LXT-280

Teledyne Analytical Instruments 28

standardize or zero adjustment). It is independent of the zero and span

adjustments for the temperature output on LXT-280 models with the

temperature output option.

Note: The tolerance of standard Teledyne TC elements is ±3°C If

greater precision is desired, contact the factory.

Procedure for trim adjust:

1. Begin with the temperature sensing element (located in the

sensor) immersed in a solution of known temperature. If the

temperature is not known, insert a precision thermometer in the

same solution and allow time for it to stabilize.

2. Magnetically activate the appropriate VERTICAL▲/▼ arrow

key to reach the Temperature Calibration Menu.

3. Position the cursor on the top line under the “T” in Trim.

4. Magnetically activate the RIGHT HORIZONTAL ► arrow key

to enter the calibrate mode. Observe the cursor move under the

last digit.

5. Position the cursor under the desired digit using the left

HORIZONTAL◄ arrow key.

6. Increase or decrease this value to make the value on the bottom

line read the same as the temperature indicated by the precision

thermometer.

Note: Make temperature adjustments slowly to allow time for the

bottom line on the display to update. This can take 5 to 7

seconds.

7. When the desired temperature value is reached, save the

calibration and exit the calibrate mode by magnetically

activating the LEFT HORIZONTAL ◄ arrow key until the

cursor is all the way to the left. The value on the top line

expresses the temperature error. The value on the bottom line

expresses the real-time process temperature.

4.11.2 Temperature Calibration—Manual TC Adjustment

The manual TC feature allows the LXT-280 to operate without a

temperature sensor only if the process temperature is known and

Page 39

Dissolved Oxygen Transmitter Calibration

Teledyne Analytical Instruments 29

constant. This adjustment also applies should the TC element in the

sensor fail to either an open or shorted condition.

Procedure to adjust manual TC:

1. Place a 3,000 ohm, 1% resistor across terminals TB1-2 and TB1-

5 in place of the sensor wires on the LXT-280 transmitter.

2. Magnetically activate the appropriate VERTICAL ▲/▼ arrow

key to reach the Temperature Calibration Menu.

3. Position the cursor on the top line.

4. Magnetically activate the RIGHT HORIZONTAL ► arrow key

to enter the calibrate mode. Observe the cursor move under the

last digit.

5. Position the cursor under the desired digit using the LEFT

HORIZONTAL◄ arrow key.

6. Increase or decrease this value with the VERTICAL ▲/▼ arrow

keys to make the value on the bottom line read the process

temperature.

Note: Make temperature adjustments slowly to allow time for the

bottom line on the display to update. This can take 5 to 7

seconds.

4.11.3 Temperature Units Calibration – °C/°F Conversion

The Temperature Calibration screen is also used to change the units

of display to either Celsius or Fahrenheit. The displayed temperature is

converted as the units are toggled from one unit to the other. Changes in

the displayed units are automatically made on all screens or menus

where temperature is displayed. The following procedure describes how

to use this feature.

Procedure:

1. Magnetically activate the appropriate VERTICAL▲/▼ arrow

key to reach the Temperature Calibration Menu.

2. Position the cursor on the bottom line under the “U” in Unit.

3. Magnetically activate the RIGHT HORIZONTAL ► arrow key.

Observe the unit of measurement change.

4. To toggle back to the first unit of measurement, magnetically

activate the RIGHT HORIZONTAL ► arrow key again.

Page 40

Calibration LXT-280

Teledyne Analytical Instruments 30

Trim° .0

Un it 25.0°C

Trim° .0

Un it 77.0°F

Page 41

Dissolved Oxygen Transmitter Calibration Correction

Teledyne Analytical Instruments 31

Calibration Correction Factors

5.1 Calibration Correction Factors

Temperature, relative humidity, elevation and salinity factors affect

the solubility of oxygen in a liquid and thus affect the accuracy of the

dissolved oxygen calibration using the air calibration method. The affect

on solubility is caused by barometric pressure changes due to changes in

the atmospheric environment. Because the dissolved oxygen sensor

responds to pressure changes, the output of the sensor will be affected

by these pressure variations. To correct for these factors, refer to the

tables below.

Please note that the tables only apply to absolute dissolved oxygen

measurements (those in ppm or mg/l and not to relative dissolved

oxygen measurements (typically expressed as percent oxygen). The data

is used when performing an air span calibration or an air saturated

sample calibration.

To compensate for these effects, use the following procedure:

1. Determine the temperature of the air (if the electrode is being

calibrated in air only) or the temperature of the air saturated

sample (if the electrode is being calibrated in solution).

2. Refer to Table 5-1, Oxygen Saturation vs. Temperature and find

the solubility value of oxygen in ppm for that temperature.

Interpolation may be necessary if the temperature is between the

listed values. Record this value.

Page 42

Calibration Correction LXT-280

Teledyne Analytical Instruments 32

Table 5-1: Oxygen Saturation vs. Temperature

Oxygen Saturation in ppm (mg/l) at an Overall Pressure of a Water Vapor

Saturated Atmosphere at 29.9” Hg (760 mm Hg)

Temp.

°C

Solubility in ppm

Temp.

°C

Solubility in ppm

0

14.62

22

8.83

2

13.84

24

8.53

4

13.13

25

8.37

6

12.48

26

8.22

8

11.87

28

7.92

10

11.33

30

7.63

12

10.83

32

7.40

14

10.37

34

7.20

16

9.95

36

7.00

18

9.54

38

6.80

20

9.17

40

6.60

3. Determine the relative humidity if performing the calibration in

air only. If calibrating in an air saturated sample, assume a

relative humidity of 100%.

4. Referring to Table 5-2, Relative Humidity Correction Factors,

find the intersection of the relative humidity and the temperature

axis. Use the temperature closest to the values listed.

Interpolation is not necessary. Record the correction value.

5. Determine the elevation from sea level.

6. Referring to Table 5-3, Elevation Correction Factors, find the

intersection of the nearest thousand feet and hundred feet to the

elevation at which the calibration is being performed. Record the

correction value.

Page 43

Dissolved Oxygen Transmitter Calibration Correction

Teledyne Analytical Instruments 33

Table 5-2: Relative Humidity Correction Factors

Temperature in °C

Relative

Humidity

0 5 10

15

20

25

30

35

0%

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

10%

.999

.999

.999

.998

.998

.997

.996

.994

20%

.999

.998

.998

.997

.995

.994

.992

.989

30%

.998

.997

.996

.995

.993

.991

.987

.983

40%

.998

.997

.995

.993

.991

.987

.983

.978

50%

.997

.996

.994

.992

.988

.984

.979

.972

60%

.996

.995

.993

.990

.986

.981

.975

.967

70%

.996

.994

.992

.988

.984

.978

.971

.961

80%

.995

.993

.990

.987

.982

.975

.967

.956

90%

.995

.992

.989

.985

.979

.972

.962

.950

100%

.994

.991

.988

.983

.977

.969

.958

.945

Table 5-3: Elevation Correction Factor

Elevation Correction Factor

Feet

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

0

1.000

.964

.930

.897

.865

.834

.804

.775

100

.996

.961

.926

.893

.861

.831

.801

.772

200

.993

.957

.923

.890

.858

.828

.798

.770

300

.989

.954

.920

.887

.855

.825

.795

.767

400

.986

.950

.916

.884

.852

.822

.792

.764

500

.982

.947

.913

. 880

.849

.819

.788

.761

600

.978

.943

.910

.877

.846

.816

.787

.758

700

.975

.940

.906

.874

.843

.813

.784

.756

800

.971

.937

.903

.871

.840

.810

.781

.753

900

.968

.933

.900

.868

.837

.807

.778

.750

Page 44

Calibration Correction LXT-280

Teledyne Analytical Instruments 34

7. To calculate the compensated dissolved oxygen value, multiply

the ppm oxygen value (recorded from Table 5-1) by the two

correction factors (recorded from Tables 5-2 and 5-3). This value

is the dissolved oxygen value of air or an air-saturated sample

corrected for temperature, relative humidity and elevation.

8. After the corrected value has been calculated, but before the

value has been entered in the instrument, the temperature

element in the sensor must have time to stabilize. The

temperature of the sensor must be the same as the temperature

used in selecting the ppm value in Table 5-1. If the temperature

of the sensor and value used from Table 5-1 are not the same, an

error will be introduced into the calibration.

5.2 Salinity Correction

When seawater, brine or brackish samples or processes are being

measured, a special salinity correction table is required. The correction

factor is multiplied by the corrected dissolved oxygen value as

determined in Section 5.1. Table 5-4 summarizes the salinity correction

factors at a barometric pressure of 29.92" Hg (760 mm Hg).

Table 5-4: Salinity Correction Factor

Dissolved Oxygen Salinity Correction Factors

at a Barometric Pressure of 29.92" Hg (760 mm Hg)

Salinity in

ppt

Correction

Factor

Salinity in

ppt

Correction

Factor

0

1.00

20

0.81

2

0.98

22

0.80

4

0.96

24

0.78

6

0.94

26

0.76

8

0.92

28

0.75

10

0.90

30

0.73

12

0.88

35

0.70

14

0.86

40

0.66

16

0.85

45

0.63

18

0.83

50

0.60

Page 45

Dissolved Oxygen Transmitter Calibration Correction

Teledyne Analytical Instruments 35

5.3 Calibration Example

As an example of a ppm calibration, assume a dissolved oxygen

application where the sample temperature is 30°C at an elevation of

1,500 feet. The calibration is being performed in the sample which is a

brine having a salinity value of 6 ppt.

1. Determine the oxygen saturation in ppm at 30°C from Table 5-1.

This value is 7.63 ppm.

2. Determine the relative humidity correction factor (CFRH) from

Table 5-2. Because the calibration is being performed in the

sample, a relative humidity of 100% is assumed. At a relative

humidity of 100% and a temperature of 30°C, the relative

humidity correction factor is 0.958.

3. Determine the elevation correction factor (CFE) from Table 5-3.

At 1,500 feet, the elevation correction factor is 0.947.

4. Determine the salinity correction factor (CFS) from Table 5-4. At

6 ppt, the salinity correction factor is 0.94.

5. Calculate the corrected ppm value as follows:

Corrected ppm = oxygen saturation x CFRH x CFE x CF

s

Using the data from the tables,

Corrected ppm = 7.63 ppm x 0.958 x 0.947 x 0.94

Corrected ppm = 6.51

5.4 Grab Sample Calibration

In some cases, calibration to a grab sample is desired. If so, the

sensor can be compared to a sample that has been analyzed through a

wet chemical process (Winkler analysis) or by using a laboratory

electrode. After determining the dissolved oxygen concentration by one

of these methods, the SP-1 or SP-2 can be standardized to that value.

Page 46

Calibration Correction LXT-280

Teledyne Analytical Instruments 36

5.5 Dissolved Oxygen Units of Measurement

One popular dissolved oxygen unit of measurement is an absolute

value and is expressed as milligrams per liter (mg/l) or parts per million

(ppm). Milligrams per liter and parts per million are two ways of

expressing the same measurement (i.e. 1 mg/l = 0.000001 part of oxygen

per weight). These units of measurement are typically found in

applications where saturated oxygen must be controlled for a chemical

reaction or where the presence of saturated oxygen is detrimental to the

process.

Another unit of measurement is a relative value and is expressed as

percent oxygen saturation or percent solubility. With percent oxygen,

the instrument is calibrated to 100% in air or an oxygen rich

environment. Subsequent measurements are an indication of oxygen

consumption. This unit of measurement is typically used in

environments that must be oxygen-rich, such as bioreactors, fermenters

and waste-water aeration basins.

Page 47

Dissolved Oxygen Transmitter Maintenance

Teledyne Analytical Instruments 37

Maintenance

6.1 Routine Maintenance

Aside from normal cleaning routine maintenance is limited to

recalibration. For recalibration, see Section 4 Calibration. However, if

service of the internal components is required always turn off the power

to the instrument.

6.1.1 Cleaning

Before cleaning, the integrity of the enclosure seals should be

inspected. Also check the conduit fittings and seals to make sure

moisture does not enter the enclosure while cleaning.

If the enclosure cover must be removed, it is wise to clean and

inspect the o-ring seal. If the seal is damaged, replace the o-ring. Always

keep the gasket lightly lubricated with a silicone grease.

6.1.2 Replacement of the Microprocessor:

For replacement of the microprocessor, contact the factory .

CAUTION: NEVER INTERCHANGE EPROMS FROM ONE

TRANSMITTER TO ANOTHER. DOING SO WILL

AFFECT TRANSMITTER PERFORMANCE.

Page 48

Maintenance LXT-280

Teledyne Analytical Instruments 38

Table 6-1: Troubleshooting

SYMPTOM

POSSIBLE CAUSES

SUGGESTED

ACTION

No power to the

instrument.

Check power supply to be

sure the correct voltage is

being supplied to the

transmitter.

Check polarity of

transmitter wiring.

Contrast level is set too

low.

Set contrast level to a

higher value. Because the

contrast menu is always

the top menu, it can be

reached by pressing the

upper MENU SELECTION

key at least 12 times.

Enter the calibrate mode

and increase the value.

The LCD does not display.

Sensor or signal

conditioner has a short that

draws too much power

from the transmitter.

Check the sensor for

proper operation. To

verify, disconnect all

sensor wires and cycle

power off, then on.

Sensor not wired properly

Using the proper wiring

diagram, verify that the

sensor is properly wired to

the transmitter.

Sensor and the electrode

are not properly

submerged in the process

Verify that the sensor

housing and the electrode

are in contact with the

process.

Electrode cartridge is not

fully engaged in the sensor

body

Check electrode cartridge

to see that it is fully

engaged in sensor body

Erratic dissolved oxygen

readings or the sensor is

not responsive to oxygen

changes

Air bubble is trapped in

front of the electrode.

Remove the electrode

from the sensor body and

shake air bubble away

from the membrane.

Check the sensor position

with respect to horizontal.

Make sure air is not

trapped in the guard.

Page 49

Dissolved Oxygen Transmitter Maintenance

Teledyne Analytical Instruments 39

Broken membrane

Replace the electrode

cartridge.

Process flow is not

adequate across the

electrode membrane

Locate the sensor within an

adequate flow or create

agitation within the

process.

Sensor is located too close

to the oxygen injection

point.

Locate the sensor further

from the oxygen injection

point.

Signal conditioner not

properly engaged in the

rear of the sensor body.

Verify that the signal

generator is properly

engaged in the rear of the

sensor body.

Instrument has been

improperly calibrated. May

have been calibrated with

no slope (infinite gain)

Verify instrument

calibration electronically,

then recalibrate per

Section 4.

Membrane is coated

Clean the membrane. See

Sensor manual.

Slow Response

Protective Boot was left on

the front of the sensor.

Carefully remove the

protective boot.

Broken membrane

Replace electrode

cartridge.

No Span

Temperature compensator

(TC) is open.

Verify that the sensor is

properly connected

including the TC

connections. Check for a

damaged TC in the sensor

body. Replace if damaged.

Reading drifts upscale or

zero calibration reads

upscale

Broken membrane

Replace the electrode

cartridge.

Broken membrane

Replace the electrode

cartridge.

Coated membrane

Clean the membrane. See

Sensor manual. Verify

instrument calibration.

Short span or the electrode

does not respond to a

second calibration point.

Electrode cartridge is not

fully engaged in the sensor

body

Check electrode cartridge

to see that it is fully

engaged in sensor body

Page 50

Maintenance LXT-280

Teledyne Analytical Instruments 40

Sensor not wired properly

Using the proper wiring

diagram, verify that the

sensor is properly wired to

the transmitter.

Sensor is not wired

properly.

Verify that the sensor is

wired properly to the

transmitter using the

applicable wiring diagram.

Sensor and the electrode

are not properly submersed

in the process.

Verify that the sensor body

and the electrode are

submersed in the process.

Electrode cartridge is not

fully engaged in the sensor

body

Check cartridge to see that

it is fully engaged in the

sensor body.

TC Module in sensor is not

functioning properly

Observe temperature

reading on display. If it

shows a major discrepancy

to the actual temperature,

measure across TC wires

on sensor — it should be

3000 ohms at 25°C.

Signal conditioner not

properly engaged in the

rear of the sensor body.

Verify that the signal

generator is properly

engaged in the rear of the

sensor body.

Temperature trim not

properly adjusted

Verify temperature display

and temperature trim

adjustment.

Sensor output is off-scale

Transmitter or analyzer

failure

Verify that the sensor is not

the cause of the problem.

Troubleshoot the

instrument and correct the

problem

The DO reading is oversensitive or under-sensitive

with temperature changes.

The locus point is not

correct

Verify the correct locus. If

using Teledyne sensors,

the locus must be -17°C.

A troubleshooting procedural recommendation:

In troubleshooting an analytical measurement loop, it should be

kept in mind that the majority of the problems encountered with the

measurement are due to failures of the sensing element. Therefore, it is

recommended that the troubleshooting procedure start with the sensing

end of the measurement and work backwards to the instrument.

Page 51

Dissolved Oxygen Transmitter Appendix

Teledyne Analytical Instruments 41

Appendix

A.1 Specifications

Packaging: FM approved SS NEMA-7C explosion-

proof enclosure suitable for use in Class I,

Div. I, Groups C through G.

Electronics: FM approved for use in Class

I, Div. I, Groups A through G

Power Requirements: 24 VDC, Maximum 50 VDC, Minimum

13.5 VDC

Output: 4-20 mA or 20-4 mA, linear and

expandable. Maximum 3 outputs.

Max. Loop Impedance: 525 ohms for 4-20 mA compliance.

Power Supply— Relay Module (Optional):

115/230 VAC, 50/60 Hz, 0.5 A

2 ea. Form C, SPDT dry contacts, 5.0 A.

Display: Menu driven 32 alphanumeric character

display, Supertwist LCD. Simultaneously

displays process ID, Process value and

units, % output and temp in °C or °F.

Sensor: Application specific

Ranges: 0-200 % fully expandable and reversible.

0-20 ppm.

Response Time: 90% of step change in 1 second

Accuracy: ±0.10% of full scale

Linearity: ±0.05% of full scale

Sensitivity: ±0.01 ppm

±0.1 percent saturation

Stability: ±0.2% per year @ 0 to 70°C

Page 52

Appendix LXT-280

Teledyne Analytical Instruments 42

Input/Output Isolation: Max 300V between process input and 4-

20mA output (single and multiple channel

outputs). No isolation between inputs on

multiple channel units.

Operating Temperature: -4 to 158°F (-20 to 70°C)

Temp. Compensation: Automatic, -30 to 140°C, RTD. Accuracy

within ±0.1% over a 0-100°C span.

Dimensions: 8.7 cm x 12.5 cm

Calibration: Auto Buffer Calibration

Allows definition of two buffer points,

saved in memory, during the initial

startup. This allows subsequent zero and

span calibrations with only 2 keystrokes.

Back-to-Factory Calibration

With 2 keystrokes, allows user to to return

to a zero electrode offset and to the typical

full scale millivolt offset.

Temperature Trim

Allows for compensation for any

differences in RTDs by programming the

offset to the transmitter.

Temperature Display

Temperature can be field-configured to

display in °C or °F.

Page 53

Dissolved Oxygen Transmitter Appendix

Teledyne Analytical Instruments 43

A.2 Spare Parts Listing

Qty

P/N

Description

1

ECD-2000261

Universal Mounting Bracket Assembly

(not including U-bolt)

1

ECD-2000300

O-ring kit, Viton, for LXT-280 Enclosure

(2 O-rings & lubricant)

1

ECD-2000394

Front Cover, Housing, LXT-280, Stainless

Steel

1

ECD-3300071

Rear Cover Housing, LXT-280, Stainless

Steel

1

ECD-

2000403.3001

Electronic Module, including PROM

calibrated for DO %

1

ECD-

2000403.3013

Electronic Module, including PROM

calibrated for DO ppm

1

ECD-2000404

LXT-280 Enclosure, complete, without

Universal Mounting Bracket

1

ECD-9680066

“U” bolt 2” x 3 1/2”, 304 SS (includes nuts

and washers)

1

ECD-9680069

Terminal Screw and Clamp Assembly, set

of 9

1

ECD-9680044.1

Instrument Screwdriver with Magnetic Top

Note: In order to provide replacement proms for the LXT-280, the

transmitter serial number and the software serial number

are needed. The transmitter serial number is located on

the serial number tag located inside the instrument. The

software serial number can be found by briefly turning off

the power to the instrument, then applying the power

again. The serial number is a four-digit number located on

the Copyright Display.

A minimum charge is applicable to spare parts orders.

Note: Orders for replacement parts should include the part

number (if available) and the model and serial number of

Page 54

Appendix LXT-280

Teledyne Analytical Instruments 44

the instrument for which the parts are intended.

Orders should be sent to:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

Web: www.teledyne-ai.com

or your local representative.

Page 55

Dissolved Oxygen Transmitter Index

Teledyne Analytical Instruments 45

Index

absolute dissolved oxygen, 31

absolute millivolt value, 14

accuracy, 31, 41

active millivolt value, 16

address, 44

arrow keys, 2

automatic buffer calibration, 24

automatic calibration, 2

back to factory calibration, 2, 9, 25, 42

barometric pressure, 31

buffer point, 15

calibrate mode, 4, 12

calibration, 9, 19, 42

calibration correction factor, 31

calibration error, 24

calibration example, 35

caution sign, iv

change menu, 11

combustible gas warning, x

compensated dissolved oxygen, 34

conditioned input, 8

conductivity, 1

conduit, 7

contrast, 13

contrast adjustment, 2, 20

contrast menu, 13, 20

copyright, ii

copyright display, 12

current output, 14. See output

cursor, 3

cursor positioning, 4, 11

dc power, 8

default parameters, 2

dimensions, 42

display, 2, 3, 41

display contrast. See contrast

dissolved oxygen, 1

dissolved oxygen unit, 36

DO locus menu, 16

effective range, 14, 15

electrode, 8, 14