Page 1

Model LXT-230 Transmitter

Installation and Operating Manual

for

pH and ORP

Teledyne Analytical Instruments

16830 Chestnut Street • City of Industry, CA 91748

888-789-8168 • ask_tai@teledyne.com • www.teledyne-ai.com

Page 2

Model LXT-230 Instruction Manual / 2

TABLE OF CONTENTS

UNPACKING THE INSTRUMENT.................................................................................... 4

1.0 GENERAL DESCRIPTION........................................................................................ 4

1.1 Membrane Switches .......................................................................................... 4

1.2 Digital Display .................................................................................................. 4

1.3 Automatic Buffer Calibration ............................................................................... 4

1.4 Back To Factory Calibration ................................................................................ 4

1.5 Current Output ................................................................................................. 4

1.6 Temperature Conversion .................................................................................... 4

1.7 PID Output (Optional)........................................................................................ 5

1.8 Dual Input (Optional) ........................................................................................ 5

1.9 Dual Output (Optional) ...................................................................................... 5

1.10 Three Outputs (Optional).................................................................................. 5

1.11 Optional Software............................................................................................ 5

1.11.1 Security Access ......................................................................................... 5

1.11.2 Differential Output..................................................................................... 5

1.11.3 Ratio Output ............................................................................................. 5

1.11.4 Averaged Outputs...................................................................................... 5

1.12 Identification .................................................................................................. 5

2.0 INSTALLATION..................................................................................................... 6

2.1 Mounting.......................................................................................................... 6

2.2 Power Wiring .................................................................................................... 6

2.3 Sensor Wiring ................................................................................................... 6

3.0 FAMILIARIZATION................................................................................................ 7

3.1 Key Functions ................................................................................................... 7

3.1.1 Menu Selection Keys.................................................................................... 7

3.1.2 Calibrate Keys............................................................................................. 7

3.2 Display Menus and Screens ................................................................................ 7

3.2.1 Contrast Menu ............................................................................................ 7

3.2.2 Main Menu.................................................................................................. 8

3.2.3 Electrode Diagnostic Screen.......................................................................... 8

3.2.4 Electrode Standardization Menu .................................................................... 8

3.2.5 Electrode Span Menu ................................................................................... 8

3.2.6 Output Calibration Menu............................................................................... 9

3.2.7 Temperature Calibration Menu ...................................................................... 9

4.0 SENTINEL DIAGNOSTICS .................................................................................... 10

4.1 Diagnostic set up and configuration menus......................................................... 10

4.1.1 Main Menu................................................................................................ 10

4.1.2 SENTINEL DIAGNOSTIC SCREEN ................................................................. 10

5.0 MAINTENANCE................................................................................................... 12

5.1 Cleaning ........................................................................................................ 12

5.2 Replacement of the Microprocessor ................................................................... 12

6.0 CALIBRATION .................................................................................................... 13

6.1 Manual Output Mode........................................................................................ 13

6.2 Contrast Adjustment........................................................................................ 13

6.3 One-Point Buffer Calibration (Standardize) ......................................................... 13

6.4 Two-Point Buffer Calibration (Span)................................................................... 14

6.5 Calibration Using a Grab Sample as a Standard................................................... 15

Page 3

Model LXT-230 Instruction Manual / 3

6.6 Calibration Error Detection & Electrode Operational Guidelines.............................. 15

6.7 Back-to-Factory Calibration .............................................................................. 15

6.8 Output Calibration........................................................................................... 15

6.9 Temperature Calibration - Trim Adjustment........................................................ 16

6.10 Temperature Units Calibration - Celsius/Fahrenheit Conversion ........................... 16

7.0 LXT-230 MODEL NUMBER DESIGNATORS .............................................................. 18

8.0 TROUBLESHOOTING GUIDE................................................................................. 19

APPENDIX A - SPECIFICATIONS................................................................................. 21

Page 4

Model LXT-230 Instruction Manual / 4

UNPACKING THE INSTRUMENT

Your Teledyne instrument has been carefully packaged to protect it from damage during

shipment and dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper

handling by the carrier. If damage is noted, save the shipping container as proof of

mishandling for the carrier.

2. Check the contents of the shipping container with the items and quantities shown on the

packing list. Immediately report any discrepancies to TAI.

3. Save the original packing material until you are satisfied with the contents. In the event

the transmitter must be returned to TAI, the packing material will allow you to properly ship

it to TAI.

4. Familiarize yourself with the instrument before installation, and follow proper installation

and wiring procedures.

1.0 GENERAL DESCRIPTION

Teledyne's Model LXT-230 is a microprocessor-based two-wire transmitter for process

control of pH, ORP and Specific Ion. Incorporating microprocessor technology, the LXT-230

provides the following features:

1.1 Membrane Switches

Calibrations can be performed via membrane switches located on the front cover, removing

the need to open the NEMA 4X enclosure and exposing components to the environment. No

potentiometric adjustments are required.

1.2 Digital Display

A 32-character Supertwist alphanumeric liquid crystal display (LCD) is used to display data

menus. The two rows of 16 characters can be adjusted to different contrast intensities for

easy viewing.

1.3 Automatic Buffer Calibration

Allows buffer points to be defined upon initialization of the transmitter so that no

adjustments are required for future buffer calibrations.

1.4 Back To Factory Calibration

Allows the transmitter to be returned to a predetermined factory calibration. The default

parameters are zero electrode offset at 7.00pH or 0.00mV ORP and the ideal Nernstian

slope for the appropriate measurement.

1.5 Current Output

A standard LXT-230 transmitter is provided with a 4-20 mA current output transmitted on

the same 24-vdc power wiring. The current output may be expanded to any range within

the transmitter's full operating range (see specifications). For customer controllers that are

not capable of reverse acting control, the LXT-230 allows the current output to be reversed;

for example, a 4-20 mA output for a range of 0-14 pH can be reversed to 14-0 pH.

1.6 Temperature Conversion

This standard feature allows the temperature displays to be presented in Celsius or

Page 5

Model LXT-230 Instruction Manual / 5

Fahrenheit. A toggle function in the Temperature Calibration Menu allows this selection to

be performed in the field.

1.7 PID Output (Optional)

An optional PID output is available and provides a 4-20 mA, three-mode control signal to a

transducer or a final control element. Proportional band is adjustable from 0.1 to 1,000%.

Reset and Rate are adjustable from 0.00 to 100 repeats per minute and 0.00 to 1,000

minutes, respectively.

1.8 Dual Input (Optional)

An optional second input can be provided for pH, ORP, Dissolved Oxygen or Specific Ion.

This input can be used as a second analysis or as specific compensation for the primary

input. Temperature compensation for the secondary input (channel 2) is provided through

the primary input (channel 1).

1.9 Dual Output (Optional)

The standard LXT-230 is provided with a single output; however, the dual output option

provides a second output in either a 4-20 mA regenerated or a 4-20 mA PID format.

Outputs can be defined in pH, ORP, Specific Ion, Dissolved Oxygen or Temperature. The

second output is fully isolated from the inputs and the primary output and is "floating" so it

can have either a positive or negative common.

1.10 Three Outputs (Optional)

Because temperature is an input on the primary channel, TAI has made it available as a

third 4-20 mA output. The third output for the LXT-230 can only be a temperature output.

1.11 Optional Software

To enhance the capability of the LXT-230, other software options are available.

Among the options are:

1.11.1 Security Access

Allows only authorized personnel entry to calibration modes.

1.11.2 Differential Output

Provides an output expressed as the difference between two inputs.

1.11.3 Ratio Output

Provides an output expressed as the ratio of two inputs. This is applicable to percent

rejection in some applications.

1.11.4 Averaged Outputs

1. Provides an output expressed as the average of two inputs.

2. Provides a field selectable time average (2 to 32 seconds).

1.12 Identification

The full model number, as found on the packing slip, is a list of alphanumeric characters

used to designate certain features of the transmitter. See section 10.0 (Table 1) for the list

of designators used for the LXT-230.

Page 6

Model LXT-230 Instruction Manual / 6

2.0 INSTALLATION

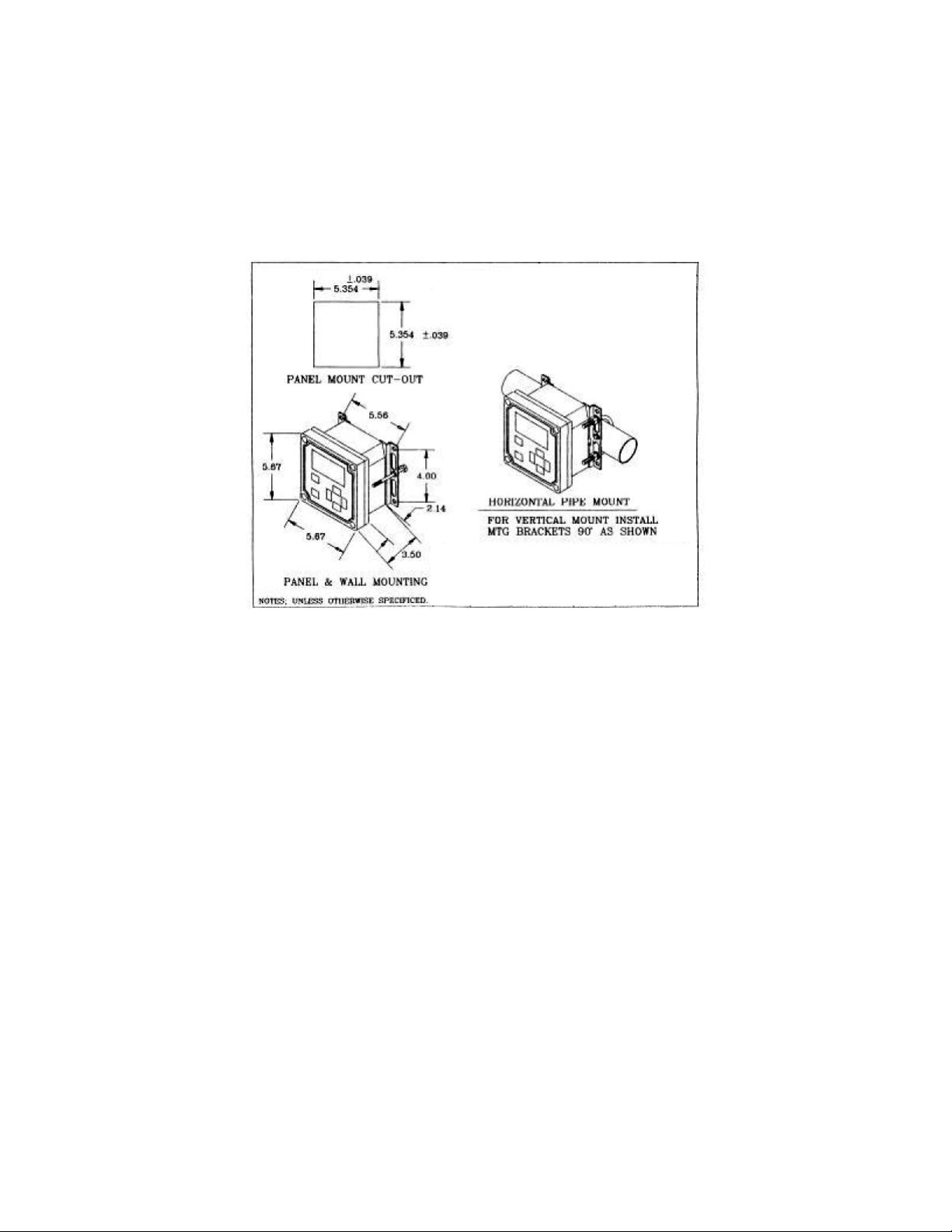

2.1 Mounting

Three typical installation configurations are available for the LXT-230 transmitter: universal

mounting, handrail mounting, and panel mounting configurations. The universal mounting

configuration allows the LXT-230 to be mounted on a wall or a 2” pipe stand. U-bolts may

be ordered separately for pipe stand mounting.

2.2 Power Wiring

The LXT-230 transmitter requires a nominal 24-vdc voltage source. With zero loop

impedance, the minimum voltage requirement is 13.5 vdc. The maximum voltage limit is 50

vdc. Maximum loop impedance at 24 vdc is 525 ohms for the 4-20 mA compliance.

Impedance levels higher than 525 ohms will require additional dc voltage.

When connecting the power wires, it is important to observe the polarity. Although no

damage to the LXT-230 will result from polarity reversal, the LXT-230 will not function.

CAUTION

Do NOT apply 110 vac to the 24-vdc wiring terminals. Damage to the instrument

will result!

Multiple channel transmitters can have each channel powered by separate power supplies,

or they can be powered by one power supply.

2.3 Sensor Wiring

A conditioned input is required from the sensor or electrode to the LXT-230 transmitter for

proper operation. In cases where S10 and S17 sensors are not used, a signal conditioning

module is available and can be mounted inside the LXT-230 enclosure.

If preferred, the signal conditioner can be mounted remotely within a separate NEMA 4X

enclosure. When used without an S10 or S17 sensor, signal conditioners for the LXT-230 do

not provide temperature compensation. In these cases, a separate temperature sensing

element is required for input to the temperature compensation circuitry.

Page 7

Model LXT-230 Instruction Manual / 7

3.0 FAMILIARIZATION

This section will provide an overview of the front panel key functions and the display menus

for a single channel pH and ORP transmitter. Multiple channel transmitters will have the

same menus.

3.1 Key Functions

Cursor positions or numeric adjustments are performed by pressing the appropriate keypad.

The LXT-230 uses an "underline" cursor in each of the menus. Holding down the keypad will

automatically scroll the cursor or numeric values. Please note that simultaneous pressure on

both vertical keys or any combination of keys other than the two horizontal CALIBRATE keys

is not recommended.

3.1.1 Menu Selection Keys

The MENU SELECTION keys are used to change the display menu and move the cursor

vertically. Any menu can be accessed by the use of the appropriate up or down MENU

SELECTION key, advancing the screen to the desired menu. These keys are also used to

exit the calibration mode and save calibration data.

3.1.2 Calibrate Keys

The horizontal CALIBRATE keys are used to enter the calibrate mode and move the cursor

horizontally. To enter the calibrate mode, both horizontal CALIBRATE keys must be pressed

simultaneously. Once in the calibrate mode, the cursor can be positioned by pressing the

individual right-hand or left-hand CALIBRATE keys.

The vertical CALIBRATE keys are used to perform numeric adjustments to displayed values.

To use these keys, the LXT-230 must be in the calibrate mode. Pressing the upper

CALIBRATE key will increase the value; pressing the lower CALIBRATE key will decrease the

value.

To exit the calibrate mode, press either of the MENU SELECTION keys.

3.2 Display Menus and Screens

When the LXT-230 is first powered, the Copyright Display will appear for a few seconds,

then the LXT-230 will display the Main Menu.

The Copyright Display provides the software "version" number and the software serial

number. TAI will require this information if software updates are to be performed. To access

any of the menus listed below, press the desired MENU SELECTION key.

3.2.1 Contrast Menu

Display contrast can be adjusted to allow for variations of ambient lighting. The Contrast

Menu is the same for all LXT-230 transmitters and is the uppermost screen. To access this

menu from the Main Menu, press the upper MENU SELECTION key.

S/N 1234 V 2.01

(C) ECD 2002

Contrast 20

Page 8

Model LXT-230 Instruction Manual / 8

3.2.2 Main Menu

This menu appears after the Copyright Display when power is first applied to the LXT-230.

The Main Menu displays the measured process variable, temperature, and the current

output in percent of full-scale. While in this menu, the current output can be adjusted and

locked in a manual mode to provide an undisturbed output during buffer calibrations.

3.2.3 Electrode Diagnostic Screen

As an informational screen only, this display provides diagnostic data pertaining to the

electrode. The top line displays the real-time (active) absolute millivolt value (mVa) the

electrode is generating, not compensated for temperature variations. The bottom line

displays the electrode isopotential from the last calibration. The isopotential (electrode

offset) is the value at which the electrode output is zero millivolts. A perfect pH electrode

will indicate an isopotential of 7.00 pH. Replace the electrode if the isopotential is less than

6.00 pH or greater than 8.00 pH.

A perfect ORP electrode will indicate an isopotential of 86 mV @ 25°C. Replace the electrode

if the isopotential is less than 36 mV or greater than 136 mV @ 25°C.

This information is extremely helpful in determining the diagnostic status of a pH or ORP

electrode. In conjunction with regular calibrations, the Electrode Diagnostic Screen provides

valuable information to track electrode performance.

3.2.4 Electrode Standardization Menu

Provides the means with which to perform a one-point calibration (standardization) or the

first point of a two-point calibration. For pH this point is typically 7.00 pH and ORP this point

is typically 0.00 mV.

Before entering the calibrate mode, the menu provides historical data from the last

calibration. The top line displays the buffer, or calibration point, at which the last calibration

was performed. The bottom line displays the temperature compensated mV value the

electrode generated at the buffer point. Please note that temperature compensation is not

performed for ORP. When in the calibrate mode, the bottom line displays the real-time, or

active, millivolt value.

3.2.5 Electrode Span Menu

Provides the means to perform the span calibration, or the second point of a two-point

calibration. Before entering the calibrate mode, the menu provides historical data from the

last calibration.

pH 7.00

_50.0% 25.0°C

ORP -500.0 mV

_25.0% 25.0°C

Input .0 mVa

0 mVa 7.00

Input -500.0 mVa

0 mVa .0 mVa

1 pH 7.00

Cal .0 mV/pH

1 ORP .0 mV

Cal .0 mVa

2 pH .00

Cal -59.1 mV/pH

2 ORP .0 mV

Cal 1.000 mV / ORP

Page 9

Model LXT-230 Instruction Manual / 9

The top line displays the buffer, or calibration point, at which the last calibration was

performed. For pH transmitters, the bottom line displays the electrode slope, or efficiency,

in millivolts per pH (mV/pH). ORP transmitters express efficiency in absolute millivolts per

millivolt (mVa/mV). When in the calibrate mode, the bottom line displays the real-time, or

active, millivolt slope value.

3.2.6 Output Calibration Menu

Current output ranges are adjusted in this menu. The top line defines the 4 mA point, while

the bottom line defines the 20 mA point. Between these points, the output current is linear

with respect to the sensor input. By reversing the signs, the European convention or the

Thermodynamic (American) convention can be defined.

3.2.7 Temperature Calibration Menu

This Menu has two calibrate functions. It is used to adjust or trim the temperature

compensation for variations in the sensing element. This menu can also provide a manual

temperature input for the process. The top line displays the temperature offset value. The

bottom line displays the adjusted temperature value.

Second, the menu is used to change the units of display to either Celsius or Fahrenheit. The

change is performed as a toggle function and changes the displayed units on all screens or

menus where temperature is displayed to the desired unit of measurement.

_4 mA .00

20 mA 14.00

_4 mA -1000.0 mV

20 mA 1000.0 mV

Trim °C .0

Unit 24.3°C

Page 10

Model LXT-230 Instruction Manual / 10

4.0 SENTINEL DIAGNOSTICS

The basic menu structure of the LXT-230 transmitter is architecturally the same as the LXT230 pH, ORP and PION, with the only variable being the diagnostic information on the main

and special diagnostic menus. The critical path to your process measurement is via the TAI

sensor/electrode.

Under perfect conditions, the electro-chemical interface between the electrode’s internal

reference cell (the measurement standard) and the liquid junction (bridge between the

internal electrolyte and the wet process) should be in balance (stable potential values).

However, a dominant failure mechanism of an Electro-Chemical (pH, ORP, PION)

Reference Half Cell is insidious process contamination impacting that balance (electrode

internal chemistry).

Contamination from the wet process will eventually migrate through the electrode’s inner

structure eventually changing Electro-Chemical balances via oxidation/reduction of the

metal/metal salts and gels.

4.1 Diagnostic set up and configuration menus

4.1.1 Main Menu

The degree to which the intrusive process chemicals degrades the “insitu” electrode is

graphically depicted on the right side of the LXT-230 main process screen as a vertically

expanding diagnostic bar, culminating in a flashing pre-pHault alert. This pre pHault Alert

warns the user of a pending chemical alteration of the Electro-Chemical Reference

Measurement Cell prior to the actual measurement error, hence the designation, “PrepHault.”

4.1.2 SENTINEL DIAGNOSTIC SCREEN

The lower section of this (split screen – over under) menu will indicate default mV values as

set by the factory; the default value will be 60mV in all cases. This value is Nurnstian in that

it signifies one decade change in 4 molar reference gel. The transmitter has been designed

so that the customer can input other mV values based on individual experience that may

differ from the default mV number.

To change the “LIMIT” values, enter the CALIBRATE MODE by simultaneously pressing the

two horizontal CALIBRATE keys; observe the cursor move to the right allowing LIMIT value

change. Once in CAL MODE, the cursor can be moved to different digit placements, then,

using the vertical key, the LIMIT value can be decreased or increased based on process

demands.

NOTE:

This value responds to contamination of the secondary electrolyte chamber with a Nurnstian

response (log 10 System)

pH 7.00

_50.0% 25.0°C

Ref 25.2 mV

Limit 30.0 mV

ORP 100.0 mV

25.0% 25.0°C

Page 11

Model LXT-230 Instruction Manual / 11

To file the input, with the microprocessor, exit the calibrate mode by pressing either menu

selection key. The upper half of the split screen menu displays absolute reference potential

(±2 millivolts) directly from the electrode via the diagnostic signal co conditioner located in

the sensor. This half of the menu is “read only” and cannot be accessed.

It is this half of the menu where you will observe the state of the electrode’s performance in

terms of process relates aging.

The mV LIMIT value, as set in by the user or TAI at time of shipment, may require

adjustment from process to process due to major chemical changes that would introduce

new electrolyte contaminants thereby impacting the rate of reference contamination in the

electrode.

After the desired mV values are set into the DIAGNOSTIC CALIBRATION SCREEN, further

electrode “INSITU” diagnostic information can be obtained by scrolling to the main process

menu where VISUAL electrode diagnostic information is displayed as a cursor/growing black

vertical bar. As process intrusion threatens the electrode’s internal balance, the bar

correspondingly grows in height (it will

eventually flash as a final pre-pHault alert).

The user can toggle between the main process screen and the dedicated diagnostic screen

where specific, real time DIAGNOSTIC engineering data can be obtained. There is also an

option (at time of purchase) to add a 4-20mA output card for the transmission of this

“INSITU” diagnostic engineering data.

Page 12

Model LXT-230 Instruction Manual / 12

5.0 MAINTENANCE

If service of the internal components is required, always turn off the power to the

instrument.

5.1 Cleaning

Cleaning the front panel can be performed with a detergent and water. DO NOT USE

ACETONE, ACID OR CAUSTIC SOLUTIONS ON THE ENCLOSURE SURFACE. If the enclosure

cover must be removed, it is wise to clean and inspect the gasket seal. If the seal is

damaged, replace the gasket. Always keep the gasket lightly lubricated with a silicone

grease.

5.2 Replacement of the Microprocessor

Contact factory.

Page 13

Model LXT-230 Instruction Manual / 13

6.0 CALIBRATION

6.1 Manual Output Mode

To perform calibrations without interfering with control or recorder functions, the LXT-230

incorporates a manual output mode. The current output is set to the desired level and saved

until changed or released from the manual mode.

NOTE: Prior to any calibration the LXT-230 transmitter should be placed into the

manual mode.

Procedure:

1. If not at the Main Menu, press the appropriate MENU SELECTION key to reach the

Main Menu.

2. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode

and observe the "M" appear in front of the % current output value; The current

output is now locked in the manual mode.

3. Using the horizontal CALIBRATE keys, position the cursor under the digit to be

adjusted.

4. Increase or decrease the value by pressing the appropriate vertical CALIBRATE key.

5. When the desired value is reached, exit the calibrate mode by pressing either MENU

SELECTION key. The current output will be held at the filed value.

To release manual output:

1. Return to the Main Menu by pressing the appropriate MENU SELECTION key.

2. Observe that the "M" appears in front of the % current output value. The "M"

signifies that the output is being held at the displayed value.

3. Press the left-hand CALIBRATE key and observe the "M" disappear, releasing the

LXT-230 from the manual output mode. The % output value will return to the realtime current output.

6.2 Contrast Adjustment

Procedure:

1. Press the upper MENU SELECTION key to reach the Contrast Menu (upper most

menu).

2. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode.

Observe the cursor move to the last digit.

3. Using the horizontal CALIBRATE keys, position the cursor under the digit to be

adjusted.

4. Increase or decrease the value by pressing the appropriate vertical CALIBRATE key.

5. To file the contrast value and exit the calibrate mode, press either MENU SELECTION

key.

6.3 One-Point Buffer Calibration (Standardize)

Because all pH and ORP electrodes experience minor variations, buffer calibrations are

necessary before installing the electrodes in service. Also, occasional calibrations are

necessary to compensate for electrode degradation while in service. For measurement

specifics, refer to the pH/ORP sensor manual.

pH 7.00

M24.3% 25.0°C

ORP -500.0 mV

M 55.0% 25.0°C

Page 14

Model LXT-230 Instruction Manual / 14

2 pH 4.00

-58.2 mV/pH

2 ORP 180.0 mV

.980 mV/ORP

Procedure:

1. Press the appropriate MENU SELECTION key to reach the Electrode Standardization

Menu and locate the cursor under the "1" as illustrated in section 3.2.4.

2. For diagnostic reasons note the pH and mV values from the prior calibration.

3. Clean the electrode and insert the sensor into the desired buffer.

4. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode.

Observe the diagnostic value on the bottom line change from historical data to a

real-time value and that the term "CAL" has disappeared.

5. To change the buffer point, position the cursor under the desired digit using the lefthand CALIBRATE key.

6. Increase or decrease the value by pressing the appropriate vertical CALIBRATE key.

7. Wait for the real-time mV value to stabilize.

8. To file the calibration and exit the calibrate mode, press either MENU SELECTION

key.

6.4 Two-Point Buffer Calibration (Span)

When first installing an electrode, a two-point buffer calibration should be used to

compensate for electrode slope variations or efficiency.

Procedure:

1. Perform a one-point calibration as outlined in section 5.3.

2. Press the appropriate MENU SELECTION key to reach the Electrode Span Menu and

locate the cursor under the "2" as illustrated in section 3.2.5.

3. For diagnostic reasons note the pH and mV values from the prior calibration.

4. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode.

Observe the diagnostic value on the bottom line becomes a real-time value and that

the term "CAL" has disappeared.

5. To change the buffer point, position the cursor under the desired digit using the lefthand CALIBRATE key.

6. Increase or decrease the value by pressing the appropriate vertical CALIBRATE key.

7. Wait for the real-time mV value to stabilize.

8. To file the calibration and exit the calibrate mode, press either MENU SELECTION

key.

A perfect electrode slope (efficiency) is -59.1 mV/pH and ORP is 1mV/mV. If the value falls

below -50.0 mV/pH or ORP .9 mV/mV, the electrode should be serviced or replaced.

IMPORTANT

If a flashing asterisk appears during or after calibration, the electrode may require service,

or the buffer solution may be contaminated. Refer to section 5.6 for details.

NOTE:

Comparing the millivolt values before and after the calibration provides a valuable

1 pH 7.00

-3.2 mV@25

1 ORP .0 mV

85.9 mVa

Page 15

Model LXT-230 Instruction Manual / 15

diagnostic tool in determining the degradation of the electrode. Large differences between

calibrations may indicate coating or damage to the measurement half-cell.

6.5 Calibration Using a Grab Sample as a Standard

The LXT-230 allows easy standardization to a grab sample value by placing the process

value into the first calibration point.

Procedure:

1. Record the pH value of the process when the sample is extracted.

2. Record the pH value of the grab sample.

3. Calculate the difference between the two values as follows:

4. Immediately before making the calibration adjustment, note the current pH value on

the display and add the pH differential to the current value. This "total adjusted"

value is entered as the buffer value.

6.6 Calibration Error Detection & Electrode Operational Guidelines

If the slope calibration performed in section 5.4 is not within the predetermined limits of the

instrument, a flashing asterisk (*) will appear. The presence of the asterisk indicates a

potential calibration problem. In general, if the asterisk appears, the integrity of the

electrode, the buffer solutions or the handling procedure should be questioned. See the

pH/ORP sensor manual for specifics on the electrode.

6.7 Back-to-Factory Calibration

This feature allows the LXT-230 to be reset to "ideal electrode" (Nernst equation) for

electrode potentials. According to the Nernst equation, an ideal pH electrode has a zero

isopotential at 7.00 pH and a slope of -59.16 mV per pH unit, an ORP electrode has an ideal

slope of 1 mV per ORP. This feature is useful in providing a reliable starting point if the LXT230 has been mis-calibrated.

IMPORTANT: Ideal instrumentation calibration does not imply ideal system

calibration.

The following procedure for returning the LXT-230 to factory calibration can be used for

both standardize and span calibrations.

Procedure at the Standardization Menu:

1. Position the cursor under the "C" in "Cal."

2. Press both horizontal CALIBRATE keys simultaneously and observe the cursor briefly

move to the right. The default setting is complete.

3. This procedure is required at BOTH of the calibration points.

6.8 Output Calibration

The Output Calibration Menu is used to define the 4-20 mA range for the measurement. To

change or expand the 4-20 mA range, use the following procedure.

2 pH .00

Cal -59.1 mV/ph

2 ORP .0 mV

Cal 1.000 mV/ORP

1 pH 7.00

Cal 0 mV@25

1 ORP .0 mV

Cal .0 mVa

Page 16

Model LXT-230 Instruction Manual / 16

Procedure:

1. Press the appropriate MENU SELECTION key to reach the Output Calibration Menu.

2. Position the cursor on the top line to change the 4 mA point or the bottom line to

change the 20 mA point.

3. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode.

4. To change the value, position the cursor under the desired digit using the left-hand

CALIBRATE key.

5. Increase or decrease the value by pressing the appropriate vertical CALIBRATE key.

6. When the desired value is reached, file the calibration and exit the calibrate mode by

pressing either MENU SELECTION key.

6.9 Temperature Calibration - Trim Adjustment

When the process demands a tighter tolerance than ±3ºC the LXT-230 allows adjustment,

or trim, of the temperature compensation element. This adjustment only compensates for

deviations in the RTD input (as a sensor input standardize or zero adjustment).

Procedure for trim adjust:

1. Begin with the temperature sensing element (located in the sensor) in a solution of

known temperature. If the temperature is not known, insert a precision thermometer

in the same solution and allow it time to stabilize.

2. Press the appropriate MENU SELECTION key to reach the Temperature Calibration

Menu.

3. Position the cursor on the top line.

4. Press both horizontal CALIBRATE keys simultaneously to enter the calibrate mode.

Observe the cursor move under the last digit.

5. Position the cursor under the desired digit using the left-hand CALIBRATE key.

6. Dial in the difference between the displayed temperature and the actual

temperature.

NOTE

Make temperature adjustments slowly to allow time for the bottom line of the

display to update. This can take 5 to 7 seconds.

7. When the desired temperature value is reached, file the calibration and exit the

calibrate mode by pressing either MENU SELECTION key. The value on the top line

expresses the temperature error or deviation between the RTD and the precision

thermometer. The value on the bottom line expresses the real-time process

temperature.

6.10 Temperature Units Calibration - Celsius/Fahrenheit Conversion

The Temperature Calibration Menu is also used to change the units of display to either

Celsius or Fahrenheit. The change is performed as a toggle function and changes the

displayed units to the desired unit of measurement on all screens or menus where

temperature is displayed.

The following procedure describes how to use this feature.

Procedure:

1. Press the appropriate MENU SELECTION key to reach the Temperature Calibration

Menu.

2. Position the cursor on the bottom line under the "U" in Unit.

3. Press both horizontal CALIBRATE keys simultaneously. Observe the unit of

measurement change.

Page 17

Model LXT-230 Instruction Manual / 17

4. To toggle back to the first unit of measurement, press the CALIBRATE keys again.

Trim °C .0

Unit 25.0°C

Trim °F .0

Unit 77.0°F

Page 18

Model LXT-230 Instruction Manual / 18

7.0 LXT-230 MODEL NUMBER DESIGNATORS

Channel 1 Input & Output

LXT-230-PH/MA pH

LXT-230-OR/MA ORP

LXT-230-PION/MA Specific Ion

(see note 1)

Note 1: For PION, the model number will

reflect the ion being measured; for

example, Ca for calcium, Fl for

fluoride, etc.

Channel 2 Input

PH pH

OR ORP

PION Specific Ion (see note 1)

DO Dissolved Oxygen

Channel 2 Output

MA 4-20 mA, standard

PID 4-20 mA, 3-mode PID control

TMP1 4-20 mA, Temperature (adjustable

-100° to +200°C)

Channel 3 Output

TMP1 Only output available on this

channel.

Mounting Hardware

UM Universal mounting plate

PM Panel mounting hardware

HM Handrail mounting plate

(including 2” hardware)

Other Options

KSx Keyboard Security Code (x

= level of security. See

Security Code Option)

F2 Output is the function of

two inputs: ratio,

differential, average.

SPH Specific pH (TC for NH3 in

condensate)

PA Signal conditioner is

mounted inside the

transmitter enclosure

SC Signal conditioner is

mounted through the side

of the enclosure

ZPR Hazardous area Z-purge

AV Field selectable time

average (2 to 32 seconds)

Typical Example

LXT-230-OR/MA-PM - LXT-230 transmitter

for use with an ORP sensor.

Page 19

Model LXT-230 Instruction Manual / 19

8.0 TROUBLESHOOTING GUIDE

Symptom

Possible Causes

Suggested Actions

No power to the instrument.

Check power supply to be

sure the correct voltage is

being supplied to the

transmitter. (13.5 to 50

VDC)

Check polarity of transmitter

wiring.

Contrast level is set too low.

Set contrast level to a higher

value. Because the contrast

menu is always the top

menu, it can be reached by

pressing the upper MENU

SELECTION key at least 12

times. Enter the calibrate

mode and increase the

value.

The LCD does not display.

Sensor or signal conditioner

has a short that draws too

much power from the

transmitter.

Check the sensor for proper

operation. To verify,

disconnect all sensor wires

and cycle power off, then on.

The slope calibration is miscalibrated. Typically the

transmitter is calibrated with

no slope (0 mV/pH).

Check buffers to make sure

they are the correct values.

Use the Back-to-Factory

calibration feature on the

Electrode Span Menu, then

perform a buffer calibration.

Check the electrode and

sensor for proper operation.

The pH fluctuates from

minimum scale to full-scale,

or the pH is locked at high or

low scale.

Wrong temperature

correction has been

calibrated in the temperature

trim.

Examine the temperature

and the Temperature

Calibration Menu. Adjust trim

as required.

The pH or ORP reading short

spans.

The transmitter may have

been mis-calibrated.

Check buffers to make sure

they are the correct values.

Use the Back-to-Factory

calibration feature on the

Page 20

Model LXT-230 Instruction Manual / 20

Electrode Span Menu, then

perform a buffer calibration.

Check the sensor and

electrode for proper

operation.

Wrong temperature

correction has been

calibrated in the temperature

trim.

Examine the temperature

and the Temperature

Calibration Menu. Adjust trim

as required.

LCD turns black.

Power to the transmitter

dropped below the minimum

required voltage for a

fraction of a second (grayout). Typically caused by a

voltage transient.

Cycle power off for

approximately 10 seconds,

and then on again.

Page 21

Model LXT-230 Instruction Manual / 21

APPENDIX A - SPECIFICATIONS

MEASUREMENT RANGE

pH: 0.00 to 14.00, fully expandable

and reversible, standard. -2.00 to

14.00 pH, optional.

ORP: +1000 to -1000 mV, fully

expandable and reversible,

standard.

OUTPUT 4-20 mA or 20-4 mA, linear

and expandable. Up to a maximum

of 3 outputs.

POWER REQUIREMENTS

(with zero loop impedance)

Recommended 24 vdc

Maximum 50 vdc

Minimum 13.5 vdc

MAXIMUM LOOP IMPEDANCE

(@ 24 vdc)

525 ohms for 4-20 mA compliance on

primary (channel 1) output;

approximately 800 ohms on secondary

outputs

OPERATING TEMPERATURE

-4°F to +158°F (-20°C to +70°C)

DISPLAY

Menu driven, 32 character alpha-numeric,

Supertwist LCD. The main menu

simultaneously displays (1) process

identity (2) process value (and

engineering units), (3) percent output, (4)

temperature in °C or °F.

ENCLOSURE

NEMA 4X, weatherproof

SHIPPING WEIGHT

Standard LXT-230: 2 lbs (0.91 kgs)

ACCURACY

± 0.10% of full scale

LINEARITY

± 0.05% of full scale

SENSITIVITY

± 1.0 mV

STABILITY

± 0.2% per year @ 0°C to 70°C

RESPONSE TIME

1 second to reach 90% of the change.

REPEATABILITY

± 1.0 mV

TEMPERATURE COMPENSATION

pH: Automatic, -30°C to +140°C, RTD.

Accuracy within ±0.1°C over a 0°C

- 100°C span.

Specific pH compensation temperature

correction) is available. Consult the

factory.

ORP: Not used for compensation;

however, temperature is displayed.

Accuracy within ±0.1°C over a

0°C-100°C span.

50/60 Hz NOISE REJECTION

Greater than 70 db

INPUT/OUTPUT ISOLATION

Maximum 300 volts between process input

and any 4-20 mA output (single

and multiple channel outputs). No

isolation between inputs on

multiple channel units.

CALIBRATION

Auto Buffer Calibration

Allows the definition of two buffer points,

saved in memory, during the initial

start-up. This will allow subsequent

standardize and span buffer

calibrations with only 2 keystrokes.

Back-to-Factory Calibration (Factory

Restart)

With 2 keystrokes, allows the technician

to return the transmitter to a zero

electrode offset (asymmetry

potential) and to an ideal Nernstian

slope (1.000 mV per ORP unit).

Page 22

Model LXT-230 Instruction Manual / 22

Temperature Trim

Allows for compensation for any

differences in RTDs by

programming the offset into the

transmitter.

Temperature Display

Temperature can be field configured to

display in OC or OF.

Display Contrast

Fully adjustable for ambient lighting

conditions

Loading...

Loading...