Linea

™

CL

Camera User’s Manual

sensors |

cameras

| frame grabbers | processors | software | vision solutions

2k, 4k, 8k and 16k Monochrome CMOS Line Scan

P/N: 03-032-20206-02

www.teledynedalsa.com

Notice

Revision

Description

Date

00

Initial release.

April 6, 2014.

01

8K and 16K models descriptions and features added .

December 4, 2 014

-Updated manual format and corrected errors.

© 2015 Teledyne DALSA

All information provided in this manual is believed to be accurate and reliable. No

responsibility is assumed by Teledyne DALSA for its use. Teledyne DALSA reserves the right

to make changes to this information without notice. Reproduction of t his m anual in whole or

in part, by any means, is prohibited without prior permission having been obtained from

Teledyne DALSA .

Microsoft and Windows are registered trademarks of M icro soft Corporation in the United

States and other countries. Windows, Windows 7, Windows 8 are trademarks of Microsoft

Corporation.

All other trademarks or intellectual property mentioned herein belong to their respective

owners.

Document Number: 03-032-20206-02

02 -Maximum line rate for the 16K model revised from 50 kHz to 48 kHz.

-16K responsi vity revised to 66 DN from 80 DN.

-8K and 16K mass revised to < 36 0 g from < 250 g.

-16K power dissipation revised to < 11 W from < 14 W.

July 16, 2015

About Teledyne DALSA

Teledyne DALSA is an international high performance semiconductor and electronics

company that designs, develops, manufactures, and markets digital imaging products and

solutions, in addition to providing wafer foundry services.

Teled y n e DALSA Digital Imaging offers the widest range of machine vision components in

the world. From industry-leading image sensors through powerful and sophisticated

cameras, frame grabbers, vision processors and software to easy-to-use vision appliances

and custom vision modules.

Contents

LINEA™ CL SERIES OVERVIEW ...................................................................... 4

DESCRIPTION ................................................................................................ 4

CAMERA HIGHLIGHTS ....................................................................................... 5

Key Features ......................................................................................... 5

Programmability ..................................................................................... 5

Applications ........................................................................................... 5

PART NUMBERS AND SOFTWARE REQUIREMENTS ....................................................... 6

CAMERA SPECIFICATIONS OVERVIEW ..................................................................... 7

Compliance, EMI Certifications ................................................................. 8

SUPPORTED INDUSTRY STANDARDS ....................................................................... 9

GenICam™ ............................................................................................ 9

ASCII COMMANDS .......................................................................................... 9

RESPONSIVITY ............................................................................................. 10

Effective Quantum Efficiency: ................................................................ 11

LINEA CL CAMERA SETUP ............................................................................ 12

SYSTEM PRECAUTIONS AND CLEANING ................................................................. 12

Precautions ......................................................................................... 12

Cleaning the Device .............................................................................. 12

Electrostatic Discharge and the CMOS Sensor .......................................... 12

RECOMMENDED SYSTEM REQUIREMENTS ............................................................... 12

SETUP STEPS: OVERVIEW ................................................................................ 13

Step 1: Install and Configure Frame Grabber and Softw are ....................... 13

Step 2: Connect Camera Link and Power Cables ....................................... 13

Step 3: Establish Communication with the Camera ................................... 16

USING CAMEXPERT WITH LINEA CL CAMERAS ............................................ 18

CamExpert Panes ................................................................................. 18

Creating a Camera Configuration File in the Host...................................... 20

CAMERA OPERATION ................................................................................... 21

FACTORY SETTINGS ....................................................................................... 21

TYPICAL SETUP AND EVALUATION ....................................................................... 22

Optical Configuration ............................................................................ 22

Camera Timing & Control ...................................................................... 22

Acquiring an Image .............................................................................. 22

CHECK CAMERA AND SENSOR INFORMATION .......................................................... 23

Verify Temperature and Voltage ............................................................. 23

Camera Configuration Selection Dialog .................................................... 24

SET BAUD RATE ........................................................................................... 26

CAMERA LINK CONFIGURATION .......................................................................... 27

Pixel Format ........................................................................................ 28

INTERNAL TEST IMAGE GENERATOR ..................................................................... 28

CALIBRATING THE CAMERA ............................................................................... 29

Flat Field Parameters ............................................................................ 30

TRIGGER MODES .......................................................................................... 32

EXPOSURE CONTROLS .................................................................................... 33

Linea CL Series Camera Contents • 1

GAIN AND BLACK LEVEL (OFFSET) ...................................................................... 37

BINNING .................................................................................................... 38

PIXEL READOUT DIRECTION (MIRRORING MODE) .................................................... 39

AREA OF INTEREST (AOI) SETUP ....................................................................... 40

SAVING AND RESTORING CAMERA SETTINGS .......................................................... 43

Camera Configuration Selection Dialog .................................................... 43

CAMERA FIRMWARE UPDATES ............................................................................ 45

DOWNLOAD A LI ST OF CAMERA PARAMETERS .......................................................... 45

FILE ACCESS VIA T H E CAMEXPERT TOOL ............................................................... 46

RESETTING THE CAMERA ................................................................................. 47

TECHNICAL SPECIFICATIONS ...................................................................... 48

MECHANICAL SPECIFICATIONS ........................................................................... 48

2K and 4K Cameras .............................................................................. 48

8K and 16K Cameras ............................................................................ 49

ADDITIONAL NOTES ON LINEA CL IDE NTIFICATION AND MECHANICAL ............................. 50

EMC DECLARATIONS OF CONFORMITY ................................................................. 50

ADDITIONAL REFERENCE INFORMATION .................................................... 53

OPTICAL CONSIDERATIONS .............................................................................. 53

Illumination ......................................................................................... 53

Light Sources ....................................................................................... 53

Lens Modeling ...................................................................................... 54

Magnification and Resolution ................................................................. 54

SENSOR HANDLING INSTRUCTIONS ..................................................................... 55

Electrostatic Discharge and the Sensor ................................................... 55

Protecting Against Dust, Oil and Scratches .............................................. 55

Cleaning the Sensor Window ................................................................. 56

APPENDIX A: GENICAM COMMANDS ............................................................ 57

CAMERA INFORMATION CATEGORY ...................................................................... 57

Camera Information Feature Descriptions ................................................ 57

CAMERA CONTROL CATEGORY ........................................................................... 60

Camera Control Feature Descriptions ...................................................... 60

I/O CONTROLS CATEGORY ............................................................................... 61

I/O Control Feature Descriptions ............................................................ 61

FLAT FIELD CATEGORY .................................................................................... 62

Flat Field Feature Descriptions ............................................................... 62

IMAGE FORMAT CONTROL CATEGORY ................................................................... 63

Image Format Control Feature Description .............................................. 63

TRANSPORT LAYER CATEGORY ........................................................................... 65

Transport Layer Descriptions ................................................................. 65

DEVICE STREAMING REGISTERS ......................................................................... 66

Start – End Command Requirements ...................................................... 66

FILE ACCESS CONTROL CATEGORY ...................................................................... 66

File Access Control Feature Descriptions .................................................. 66

APPENDIX B: AS CII COMMANDS ................................................................. 68

ACCESSING THE THREE LETTER COMMANDS (TLC) .................................................. 68

Port Configuration ................................................................................ 68

Notes on Using Alternatives to HyperTerminal .......................................... 69

ASCII TO GENCP ......................................................................................... 69

Disabling the Esc Key for Direct Access to ASCII Commands ...................... 69

2 • Contents Linea CL Series Camera

Commands .......................................................................................... 70

APPENDIX C: ERROR AND WARNING MESSAGES ......................................... 82

OPERATIONAL ERROR CODES ............................................................................ 83

APPENDIX D: CAMER A, F RAME GRABBER COMMUNICATION ....................... 84

Setting Up Communication between the Camera and the Frame

Grabber ......................................................................................... 84

APPENDIX E: CAMERA LINK CONNECTOR INFORMATION ............................ 86

DATA CONNECTOR: CAMERA LINK ...................................................................... 86

Full Configuration ................................................................................. 87

Camera Link Bit Definitions.................................................................... 89

Camera Control Configuration ................................................................ 90

CAMERA LINK DRIVE CAPABILITY ....................................................................... 90

Input Signals, Camera Link.................................................................... 90

Output Signals, Camera Link Clocking Signals .......................................... 91

CONTACT INFORMATION ............................................................................. 92

SALES INFORMATION ...................................................................................... 92

TECHNICAL SUPPORT ...................................................................................... 92

Linea CL Series Camera Contents • 3

Linea™ CL Series Overview

Description

Teledyne DALSA introduces a new CMOS camera family with the 2K, 4K, 8K, and 16K resolution

Linea monochrome cameras. These new camera models use Teledyne DALSA's single line, 7.04

µm x 7.04 µm (2k, 4k, 8k) or 3.52 µm x 3.52 µm (16k) pixel array, delivering both speed and

responsivity at a competitive price.

The Linea CL linescan is a new affordable single line, camera delivering both speed and

responsivity at a competitive price. Th is small, low power camera is designed for application s such

as materials grading and inspection, transportation s a fety, automated optical inspection and

general purpose machine vision.

The Linea CL camera, is one of a new series of affordable easy to use digital cameras specifically

engineered for industrial imaging applications requiring embedded image processing and improved

network integration. Linea CL provides features to cycle a user defined sequence of imaging

setups, features providing line & frame triggers, image transfer-on-demand, all part of a

comprehensive camera package.

Linea uses industry standard CameraLink protocol to dependably capture and transfer images from

the camera to the host PC.

4 • Linea™ CL Series Overview Linea CL Series Camera

Camera Highlights

Teledyne DALSA introduces a new CMOS camera family with the 2K, 4K, 8K, and 16K resolution

Linea monochrome cameras. These new camera models use Teledyne DALSA's single line, 7.04

µm x 7.04 µm (2k, 4k, 8k) or 3.52 µm x 3.52 µm (16k) pixel array, delivering both speed and

responsivity at a competitive price.

These small, affordable, low power cameras are designed for applications such as materials grading

and inspection, transportation safety, automated optical inspection and general purpose machine

vision.

Key Features

• High speed: up to 80 kHz (2k, 4k, 8k) and 48 kHz (16k)

• 2048, 4096, 8192, and 16,384 pixel resolutions

• Compact camera body

Programmability

• Multiple regions of interest for calibration and data reduction

• 8 bit or 12 bit output

• Small flat field and lens shading correction

• 8 programmable coefficient sets

• GenICam or ASCII compliant interfacing

Applications

• Automated optical inspection

• Security systems

• High performance sorting systems

• Materials grading and inspection syste ms

• Web inspection

• General purpose machine vision

Linea CL Series Camera Linea™ CL Series Overview • 5

Part Numbers and Software Requirements

This manual covers the Linea CL models summarized below. New models area added to this

manual as they are released by Teledyne DALSA.

Camera Resolution Pixel size

Linea 2K CL 2048 x 1 7.04 x 7.04 µm

Linea 4k CL 4096 x 1 7.04 x 7.04 µm

Linea 8k CL 8192 x 1 7.04 x 7.04 µm

Linea 16K CL 16384 x 1 3.52 µm x 3.52 µm

Max. Line Rate Lens Mount

(threaded)

80 kHz M42 x 1 LA-CM-02K08A-xx-R

80 kHz M42 x 1 LA-CM-04K08A- xx -R

80 kHz M72 x 1 LA-CM-08K08A- xx -R

48 kHz M72 x 1 LA-CM-16K05A- xx -R

Camera Accessories Order Number

2K and 4k M42 x 1 to F-mount adapter for 12mm BFD lens, he avy d uty with clip AC-LA-00115-xx-R

2K and 4k M42 x 1 to C-mount adapter for 12 mm BFD lens AC-LC-00001-xx-R

8k and 16k M72 x 0.75 F, F-mount adapter 12 mm BFD lens, heavy duty AC-LN-0001-xx-R

8k and 16k Linea Heatsink AC-MS-00108-xx-R

For a list of accessories go to http://www.teledynedalsa.com/imaging/products/cameras/accessories/

Optical filters are available from http://www.midwestopticalsystems.com/

Teledyne DALSA Software Platform

Sapera LT version 7.50 or higher

includes CamExpert GUI application

Sapera provides everything needed to develo p imag ing applicatio ns .

Camera Firmware Embedded within camera

GenICam™ support (XML camera descrip tio n file ) Embedded within camera

Sapera Processing Imaging Developm e nt Libr ary

(available for Windows or Linux - sold separ a te ly):

Available for free download:

http://www.teledynedalsa.com/imaging/pr

oducts/software/sapera/lt/

Contact Teledyne DALSA Sales

Product Number

Third Party GenICam GenCP Software Requirements

Support of GenICam GenApi version 2.3 General acquisition and control. File access: firmware,

Support of GenICam XML schema version 1.1

GenICam™ support — XML camera description file Embedded within Linea CL

FFC, configuration data, upload & download.

6 • Linea™ CL Series Overview Linea CL Series Camera

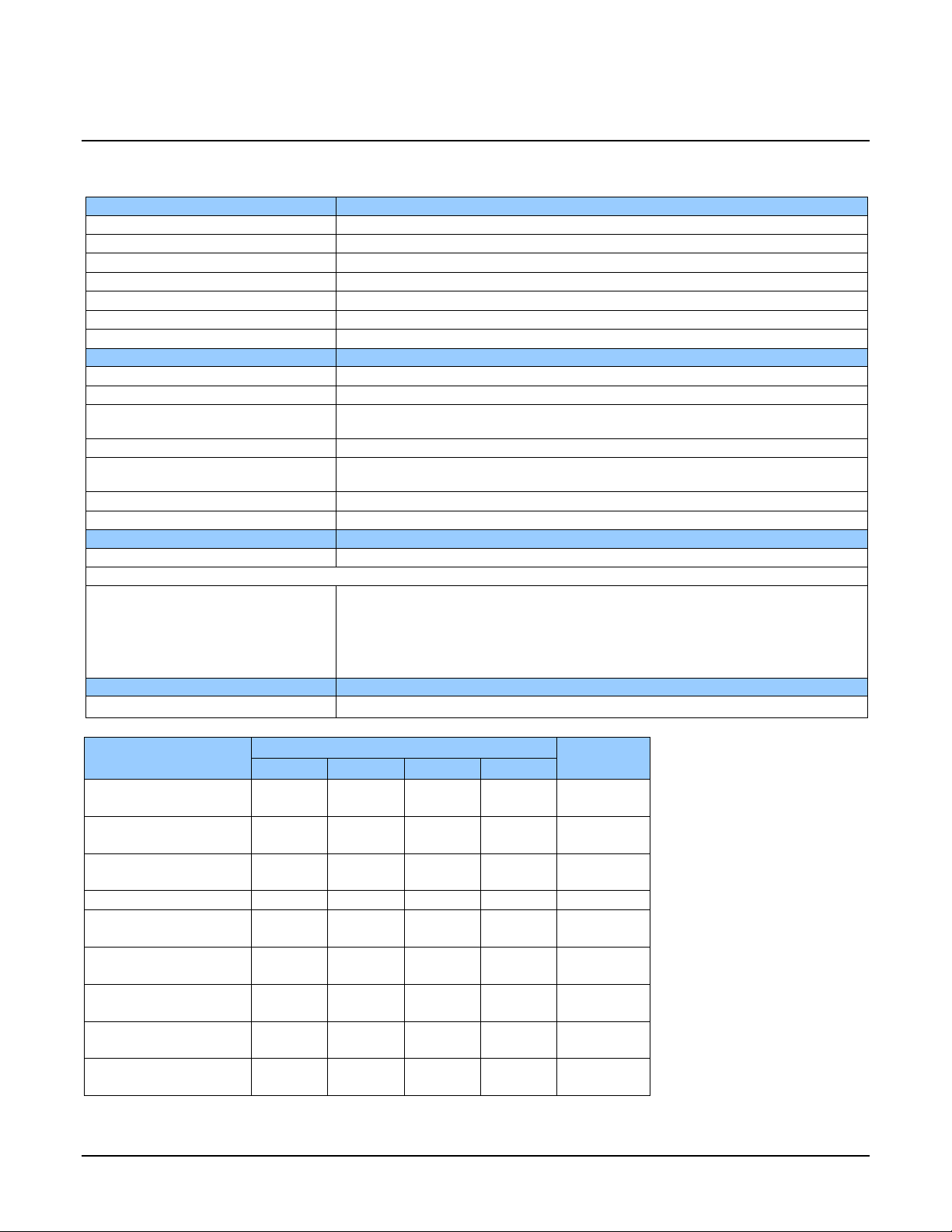

Specifications

Performance

Imager Format

High speed CMOS line scan

Resolution

2048, 4096, 8192, and 16,384 pixels

Pixel Size

7.04 µm x 7.04 µm (2k, 4k, 8k) and 3.52 µm x 3.52 µm (16k)

Pixel Fill Factor

100 %

Line Rate

Up to 80 kHz (2k, 4k, 8k) and up to 48 kHz (16k)

Exposure Time

4 µs to 3 ms

Bit Depth

8 bit or 12 bit, selectable

Connectors and Mechanicals

Control & Data Interface

Base, Medium, Full, and Deca Camera Link configur ati o ns (2 x SDR-26)

Power Connector

Hirose 6-pin male circular

+12 V to + 24 V DC (+11.4 V to +25.2 V maximum limits), 8k and 16k

Power Dissipation

< 4.5 W (2k and 4k), < 8 W (8k), < 11 W (16k)

76.0 mm (W) x 76.0 mm (H) x 36.7 mm (D) (8k and 16k)

Mass

< 190 g (2k and 4k), < 360 g (8k and 16k)

Operating Temp

0 °C to 65 °C, front plate temperature

Optical Interface

Sensor to Camera Front Distance

12 mm

Sensor Alignment (aligned to sides of camera)

Θ z

± 0.3°

Compliance

Regulatory Compliance

CE, FCC, and RoHS; GenICam

Operating Ranges

Performance

Notes

dB

DN* rms

DN / (nJ / cm2)

Gain Nominal range

1x to 10x

1x to 10x

1x to 10x

1x to 10x

DN

@ 50% Sat

DN

nJ / cm2

pJ / cm2

Camera Specifications Overview

Power Supply + 5 V to + 24 V DC (+4.8 V to +25.2 V maximum limits), 2k and 4k

Size 62.0 mm (W) x 62.0 mm (H) x 30.9 mm (D) (2k and 4k)

Θ y (parallelism)

x

y

z

Dynamic Range

Random Noise

Broadband Responsivity

DC Offset

PRNU

FPN

SEE

0.08° or 100 µm

± 300 µm

± 300 µm

± 300 µm

2K 4K 8K 16K

> 60 > 60 > 60 > 60

< 3.75 < 3.75 < 3.75 < 3.75 FFC enabled

320

7 7 7 7 FFC enabled

< 1.5% < 1.5% < 1.5% < 1.5%

< 7 < 7 < 7 < 7

12.5 12.5 12.5 46.9

320 320 80

NEE

11.7 11.7 11.7 51

Linea CL Series Camera Linea™ CL Series Overview • 7

Operating Ranges

Performance

Notes

Antiblooming

(x Saturation)

DN

2K 4K 8K 16K

> 100 > 100 > 100 > 100

Integral non-linearity

*DN = digital number

Test Conditions:

• Values measured using 12-bit @ 1x gain.

• 10 kHz line rate.

• Light source: broadband, quartz halogen, 3250 K with 700 nm IR cut-off filter.

• Front plate temperature: 45º C.

1.5 % 1.5 % 1.5 % 1 .5 %

Compliance, EMI Certifications

Compliance Directives Standards ID Overview

EN55032 (2012) Electromagnetic compatibil ity of multime dia

EN55011 (2009) with A1(2010) Industrial, scientific and medic al e quipment —

EN 61326-1 (2013) Electrical equipment for measurement, co ntrol and

CE

FCC

RoHS

For im ages of the Linea CL certificates see the EMC Declarations of Conformity section.

EN 55024 (2010) Information technology equipment —

CISPR 11 Industrial, scientific and medic al e quipment —

CISPR 32 Electromagnetic compatibil ity of multime dia

Part 15, class A

Compliancy as per European directive 2004 /105 /EC

equipment — Emission requirements

Radio-frequency disturbance characteristics —

Limits and methods of measurement

laboratory use — EMC requirements —

Part 1: General requirements

Immunity characteristics —

Limits and methods of measurement

Radio-frequency disturbance characteristics —

Limits and methods of measurement

equipment - Emission requirements

8 • Linea™ CL Series Overview Linea CL Series Camera

Supported Industry Standards

GenICam™

Linea cameras are GenICam™ compliant. They implement a superset of the GenICam™ Standard

Features Naming Convention specification V1.5.

This description takes the form of an XML device description file respecting the syntax defined by

the GenApi module of the GenICam™ specification. The camera uses the GenICam™ Generic

Control Protocol (GenCP V1.0) to communicate over the Camera Link serial port.

For more information see www.genicam.org

Teledyne DALSA recommends using Sapera CamExpert as your Camera Link compliant camera

interface application. CamExpert is the camera interfacing tool supported by the Sapera library and

comes bundled with SaperaLT. Using CamExpert is the simplest and quickest way to send

commands to and receive information from the camera.

Sapera uses the GenICam™ Generic Control Protocol (GenCP V1.0 ) to communicate with the

camera over the Camera Link serial port. When communications ar e first estab lished , Sapera

downloads the GenICam™ XML Description file. This file details how to access and control the

camera.

.

ASCII Commands

As an alternative to the CamExpert (or equivalent) GUI, you can communicate with this camera

using ASCII-based commands. Using a terminal emulating program, establish a serial port

connection with the c amera.

In the ASCII interface press the ESC key; the communication mode w ill be switched into the ASCII

command mode other than the GenICam mode.

A complete list of the commands and a description of how to access them can be found in Appendix

B: ASCII Commands.

Linea CL Series Camera Linea™ CL Series Overview • 9

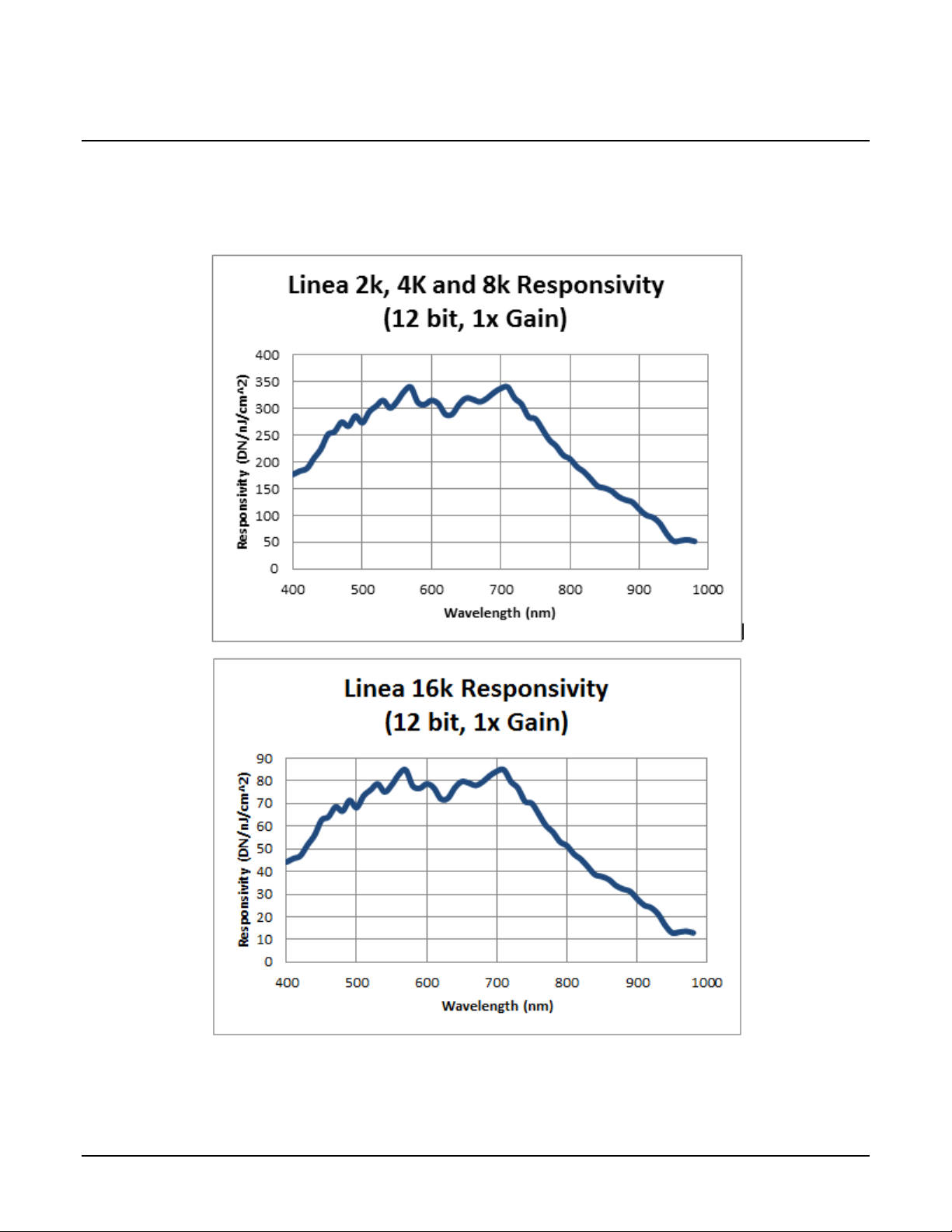

Responsivity

The responsivity graph describes the sensor response to different wavelengths of light (excluding

lens and light source characteristics).

10 • Linea™ CL Series Overview Linea CL Series Camera

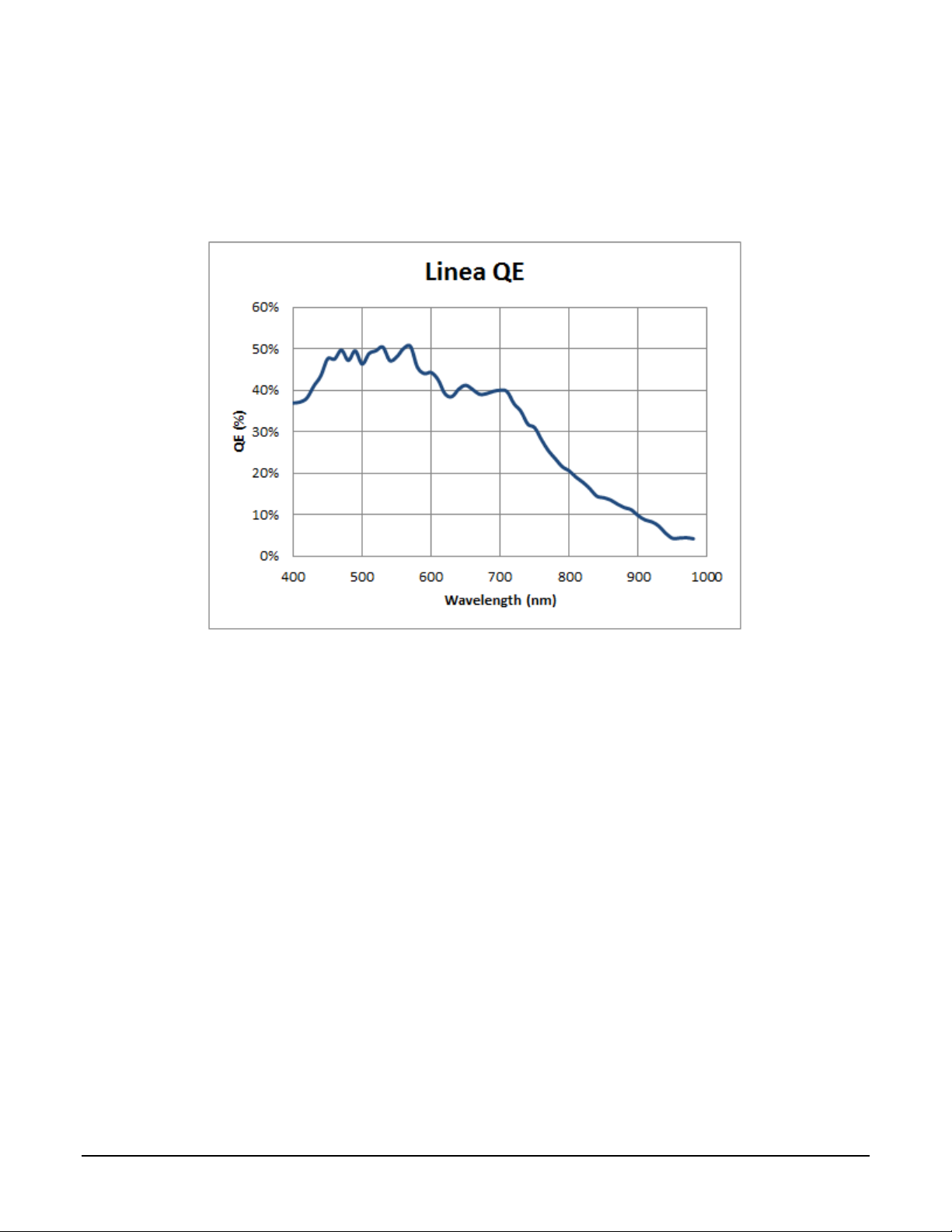

Effective Quantum Efficiency:

The quantum efficiency graph describes the fraction of photons at each wavelength that contribute

charge to the pixel.

Linea CL Series Camera Linea™ CL Series Overview • 11

Linea CL Camera Setup

System Precautions and Cleaning

Precautions

Read these precautions and this manual before using the camera.

Do not open the housing of the camera. The warrant y is voided if the housing is

opened.

• Confirm that the camera’s packaging is undamaged before opening it. If the packaging is

damaged please contact the related logistics pers onnel.

• Keep the camera’s front plate temperature in a range of 0 °C to 65 °C during operation.

• Do not operate the camera in the vicinity of strong electromagnetic fields. In addition, avoid

electrostatic charging, violent vibration, and excess moisture.

• Though this camera supports hot plugging, it is recommended that you power down and

disconnect power to the camera before you add or replace system components.

Cleaning the Device

To clean the device, avoid electrostatic charging by using a dry, clean absorbent cotton cloth

dampened with a small quantity of pure alcohol. Do not use methylated alcohol.

To clean the surface of the camera housing, use a soft, dry cloth. To remove severe stains use a

soft cloth dampened with a small quantity of neutral detergent and then wipe dry. Do not use

volatile solvents such as benzene and thinners, as they can damage the surface finish.

Electrostatic Discharge and the CMOS Sensor

Image sensors and the camera bodies housing are susce ptible to damage from electrostatic

discharge (ESD). Electrostatic charge introduced to the sensor window surface can induce charge

buildup on the underside of the window. If this occurs , the charge normally dissipates within 24

hours and the sensor returns to normal operation.

Recommended System Requirements

To achieve best system performance, the following minimum requirements are recommended:

• High bandwidth frame grabber. For example, Teledyne DALSA Xtium-CL series frame

grabbers: http://www.teledynedalsa.com/imaging/products/fg/#digital-cameralink

• Operating systems: Refer to frame grabber documentation for supported platforms.

.

12 • Linea CL Camera Setup Linea CL Series Camera

Camera Link frame grabber up to receive the standard 8-bit full mode.

computer chassis, before handling the camera hardware..

increased emission or decreased immunity and performance of the camera.

Setup Steps: Overview

Take the following steps in order to setup and run your camera system. They are described briefly

below and in more detail in the sections that follow.

1. Install and Configure Frame Grabber and Software

2. Connect Camera Link and Power Cables

3. Establish communication with the camera

Step 1: Install and Configure Frame Grabber and Software

Teledyne DALSA recommends its Xtium-CL series frame grabbers or equivalent. Follow the

manufacturer’s installation instructio ns.

For additional information on configuring fra me grabbers, see Appendix D: Camera, Frame Grabber

Communication.

Note: By default, Camera Link mode is set to the standard 8-bit full mode which

allows operation of up to 80 kHz (2k, 4k, 8k) or 48 kHz (16K) line rate. Set your

A GenICam™ compliant XML device description file is embedded within the camera firmware

allowing GenICam™ compliant application to know the camera’s capabilities immediately after

connection.

Installing Sapera LT gives you access to the CamExpert GUI, a GenICam™ compliant application.

Sapera LT is available free of charge for download from the Teledyne Dalsa

website.

Step 2: Connect Camera Link and Power Cables

The camera uses two Camera Link SDR26 cables transmitting the Camera Link Base, Medium, or

Full configuration.

• Connect the Camera Link cables from the camera to the frame grabber installed on the

computer.

• Connect a power cable from the camera to a power supply that can provide a constant

voltage from +5 VDC to +24 VDC (2k and 4k) or +12 VDC to +24VDC (8k and 16k).

WARNING! Grounding I nstr uctions

Static electricity can damage electronic components. It’s critical that you discharge

any static electrical charge by touching a grounded surface, such as the metal

Note: the use of cables types and lengths other than those spe cified may result in

For more information on Camera Link connector specifications, see Appendix E: Camera Link

Connector Info rma tion.

Linea CL Series Camera Linea CL Camera Setup • 13

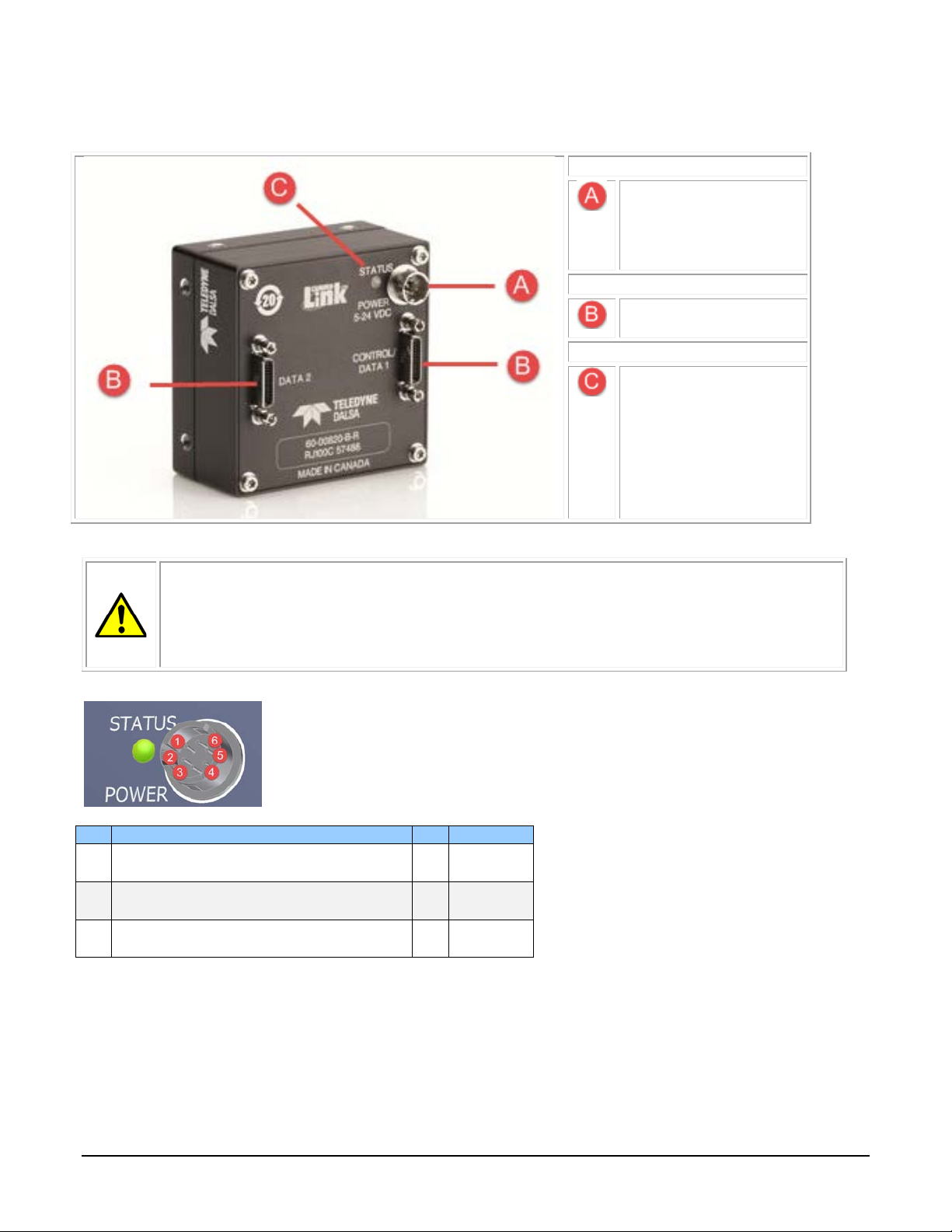

The following figure of the Linea CL back end shows connector and LED locations. See the

Power

Hirose 6-pin

(8k and 16k)

Control & Data

Camera Link 26-pin

SDR26 connectors

Status

Diagnostic LED

Pin

Description

Pin

Description

+12 V to +24 V DC (8K and 16K)

+12 V to +24 V DC (8K and 16K)

+12 V to +24 V DC (8K and 16K)

Mechanical Specifications section for details on the connectors and camera mounting dimensions.

• +5V to +24V DC

(2k and 4k)

• +12V to +24V DC

Power Connector

WARNING! Grounding I nstr uctions

It is extremely important that you apply the appropriate voltages to your camera.

Incorrect voltages may damage the camera. Input voltage re quirements: +5 VDC to

+24 VDC (2k and 4k models), 1 Amp. +12 VDC to +24 VDC (8K and 16K models),

2 Amp. Before connecting power to the camera, test all pow er supplies.

Hirose 6-pin Circular Male (Mating Part: HIROSE HR10A-7P-6S)

1 +5 V to +24 V DC (2K and 4K)

2 +5 V to +24 V DC (2K and 4K)

3 +5 V to +24 V DC (2K and 4K)

4 GND

5 GND

6 GND

14 • Linea CL Camera Setup Linea CL Series Camera

Use high-quality supplies in order to minimize noise.

LED is off

No power or hardware malfunction

Blinking Green

Powering up or ca lib r a ting

Green

Ready

Error. Check the built-in self test (BiST) register for the s p ec ific error

The camera meets all performance specifications using standard switching power supplies,

although well-regulated linear supplies provide optimum performance.

WARNING: When setting up the camera’s power supplies follow these guidelines:

• Apply the appropriate voltages.

• Protect the camera with a 1 amp slow-blow fuse between the power supply

and the camera.

• Do not use the shield on a multi-conductor ca ble fo r ground.

• Keep leads as short as possible in order to reduce voltage drop.

•

Note: If your power supply does not meet these requirements, then the camera

performance specifications are not guaranteed.

Power over Camera Link

The Linea 2k and 4k Camera Link cameras are Power over Camera Link (PoCL) compatible*, but

are not compliant with the full PoCL specification as their operation is dependent on the frame

grabber used. These cameras exceed the 4 W PoCL power specification, but some frame grabbers,

such as the Xtium frame grabber from Teledyne Dalsa, are able to supply sufficient power for the

camera’s operation.

PoCL can be enabled from within CamExpert. Be sure to connect the power supply to the Xtium

frame gabber in the PC.

PoCL power can only be supplied through the Data 1 (base) camera link port.

* The 8K and 16K models do not support PoCL.

Camera Status LED

The Linea CL has one multicolor LED to provide a simple visible indication of camera state. The

table below summarizes the operating states of the camera and the corresponding LED states.

When more than one condit io n is active, the LED indicates the condition with the highest priority.

LED State Definition

Red

Linea CL Series Camera Linea CL Camera Setup • 15

Step 3: Estab lish Commun ication with the Camera

Commands.

The camera is designed to power up with a GenICam-compliant interfa ce. CamExpert

provides an easy-to-use GUI that can be used to set up and operate the camera.

The camera also comes with Teledyne DALSA’s three letter command (TLC) interface

option, which can be accessed using a suitable terminal program such as

HyperTerminal™. If you want to use the TLC interface, refer to Appendix B: ASCII

To establish communication with the camera:

1. Power on the camera

2. Connect to the frame grabber

3. Connect to the camera

Power on the camera

Turn on the camera’s power supply. You may have to wait while the camera readies itself for

operation. The camera must boot fully before it will be recognized by the camera interface

application (for example, CamExpert) — the LED displays steady green once the camera is ready.

Connect to the frame grabber

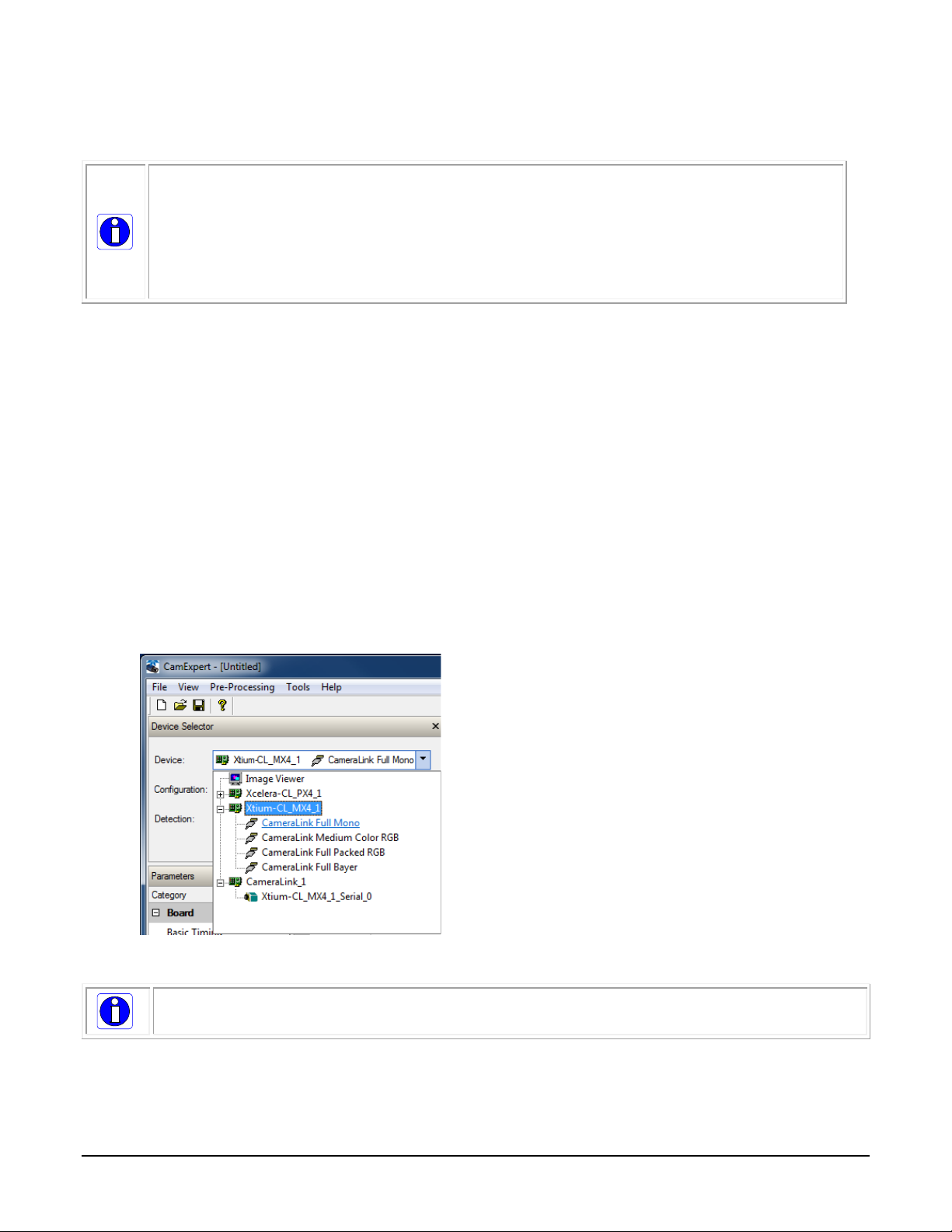

1. Start Sapera CamExpert (or equivalent Camera Link compliant application) by double

clicking the desktop icon created during the software installation.

2. CamExpert will search for installed Sapera devices. In the Devices list area on the left side,

the connected frame grabber will be shown.

3. Select the frame grabber device by clicking on the name.

Note: The first time you set up the camera you will need to establish a communication

link between the camera and frame grabber.

16 • Linea CL Camera Setup Linea CL Series Camera

Connect to the camera

1. Start a new Sapera CamExpert application (or equivalent Camera Link compliant interface)

by double clicking the desktop icon created during the software installation.

2. In CamExpert, for Teledyne DALSA frame grabbers, the camera appears below the Board

category.

Check LED Status

If the camera is operating correctly at this point, the diagnostic LED is steady green.

Software Interface

All the camera features can be controlled through the CamExpert interface. For example, under the

Camera Control menu in the camera window you can cont rol the line rate and exposure times.

Operate the Camera

At this point you will be ready to start operating the camera to acquire images, set camera

functions, and save settings.

Linea CL Series Camera Linea CL Camera Setup • 17

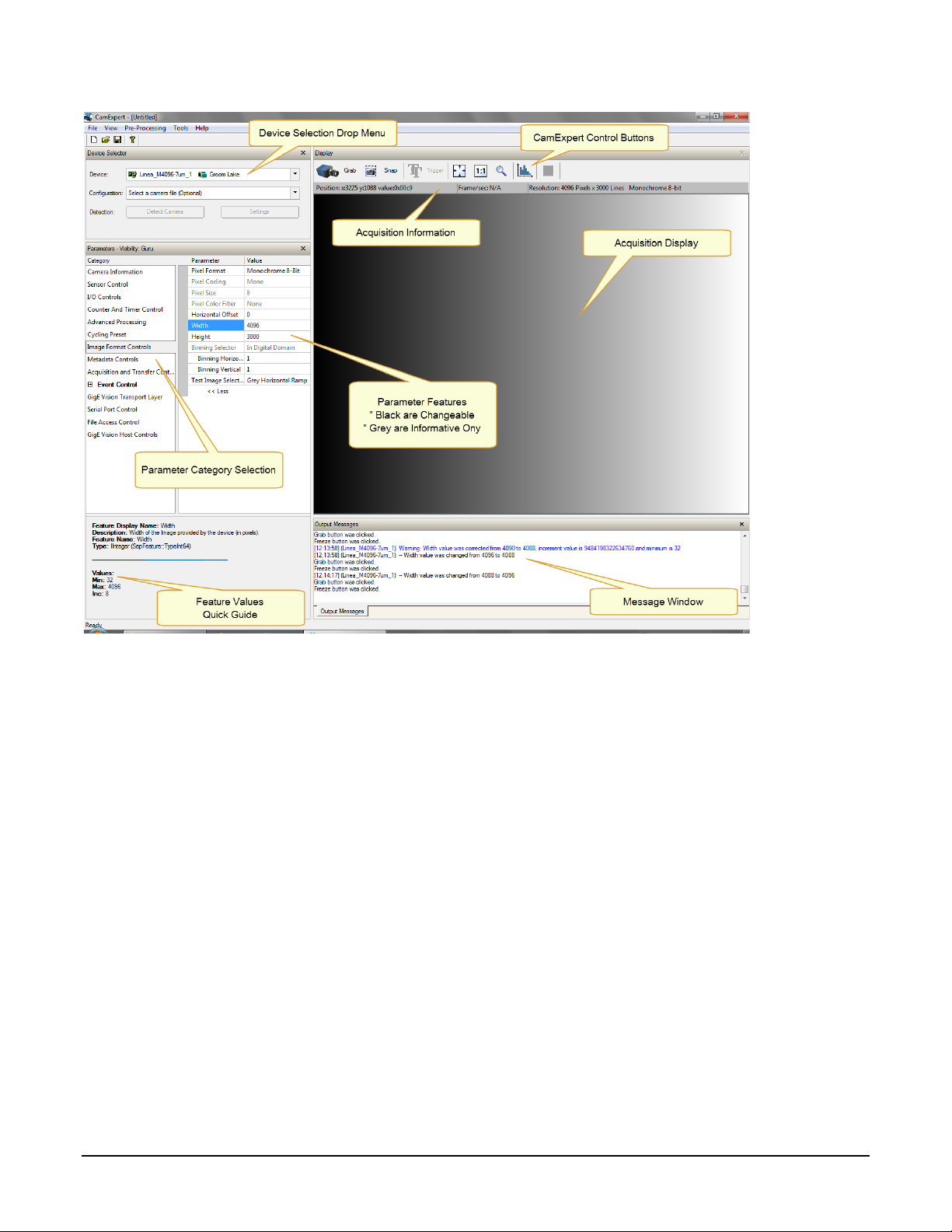

Using CamExpert with Linea CL Cameras

The Sapera CamExpert tool is the interfacing tool for GenCP compliant Camera Link cameras, and

is supported by the Sapera library and hardware. When used with a Linea CL camera, CamExpert

allows a user to test most of the operating modes. Additionally CamExpert saves the Linea CL user

settings configuration to the c amera or saves multiple configura tions as individual camera

parameter files on the host system (*.ccf).

An important component of CamEx pert is its liv e acquisition display win dow which allows

immed iate verification of timin g or contro l parameters w ithout the need to run a separate

acquisition program.

Click on any parameter and a short description is displayed below the Category pane. The same

conte xt sensitive help is available by clicking on the button then click on a camera

configuration parameter. Click on the button to open the help file for more descriptive

information on CamExpert.

Note: The examples shown may not entirely reflect the features an d pa ra m eter s a vailable from

the camera model and camera mode used in your applica tion.

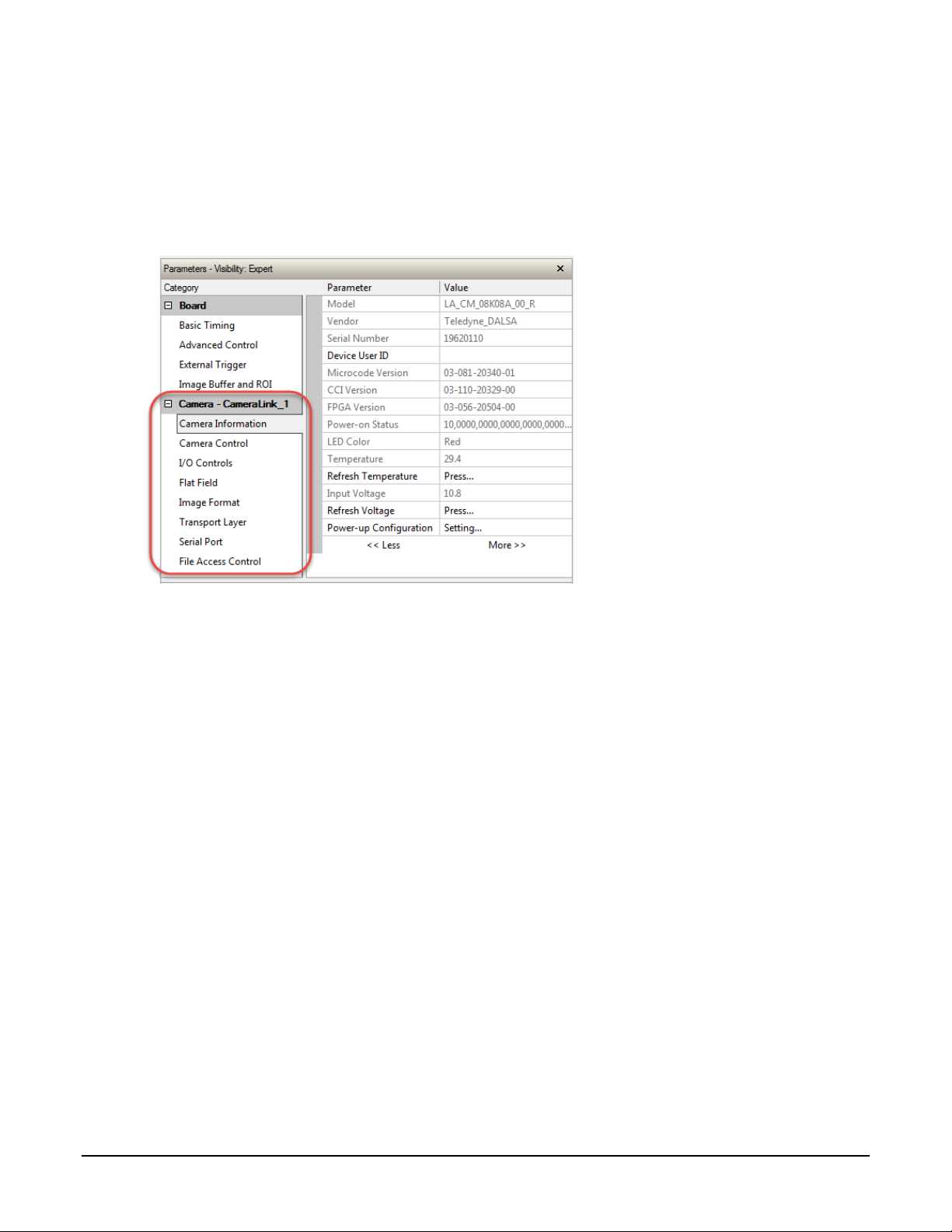

CamExpert Panes

The various areas of the CamExpert tool are described in the figure below. Device Categories and

Parameter features are displayed as per the device’s XML description file. The number of

parameters shown is dependent on the View mode selected (Beginner, Expert, Guru – see

description below).

18 • Using CamExpert with Linea CL Cameras Linea CL Series Camera

• Device Selector pane: View and select from any installed Sapera acquisition device. After a

device is selected, CamExpert will only present parameters applicable to that device. Optionally

select a camera file included with the Sapera installation or saved by the user.

• Parameters pane: Allows viewing or changing all acquisition parameters supported by the

acquisition device. CamExpert displays parameters only if those parameters are supported by

the installed device. This avoids confusion by eliminating parameter choices when they do not

apply to the hardware in use.

• Display pane: Provides a live or single frame acquisition display. Frame buffer parameters are

shown in an information b ar above the image window.

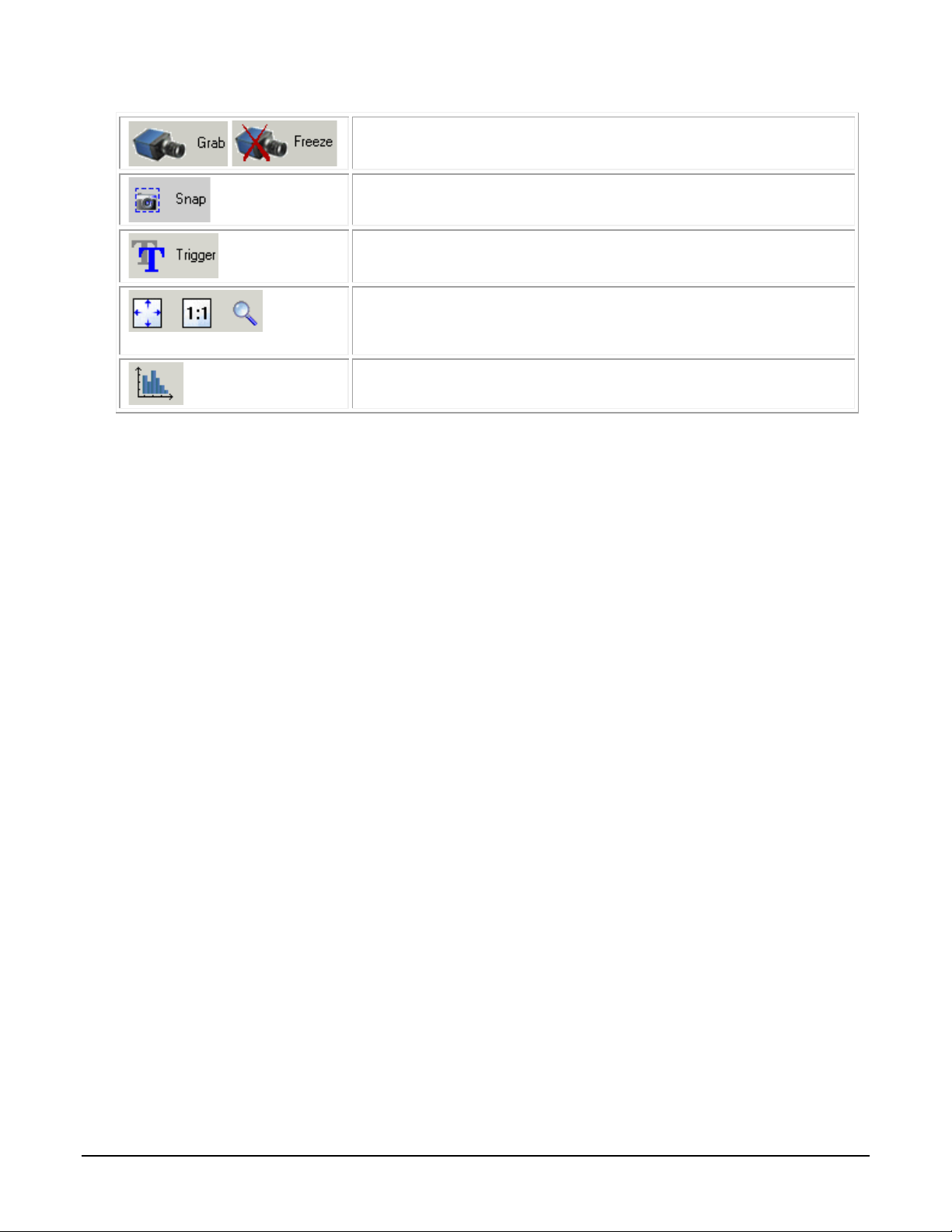

• Control Butto ns: The Display pane includes CamExpert control buttons. These are:

Linea CL Series Camera Using CamExpert with Linea CL Cameras • 19

Acquisition control button:

Click once to start live grab, click again to stop.

Single frame grab:

Click to acquire one frame from device.

Software trigger button:

With the I/O control parameters set to Trigger Enable d / Softwa r e Tr igg e r

type, click to send a single software trigger comm and .

CamExpert display contro l s:

(these do not modify the frame buffer data)

Stretch (or shrink) image to fit, set image display to original size, or zoom

the image to any size and ratio. This does not affect the acquisition.

Histogram / Profile tool:

Select to view a histogram or line/column prof i le dur ing liv e acq uis ition.

• Output pane: Displays messages from CamExpert.

CamExpert View Parameters O p tion

All camera features have a Visibility attribute which defines its requirement or complexity. The

states vary from Beginner (features required for basic operation of the device) to Guru (optional

features required only for complex operations).

CamExpert presents camera features based on their visibility attribute. CamExpert provides quick

Visibility level selection via controls below each Category Parameter list [ << Less More >> ]. The

user can also choose the Visibility level from the View ∙ Parameters Options menu.

Creating a Camera Configuration File in the Host

• When using the Teledyne DALSA Sapera SDK – the CCF is created automatically via a save.

• When using a 3

automatic. Simply follow the 3

• If the SDK is based on GenAPI 2.3 or lower, the user must call the command

DeviceFeaturePersistenceStart before using the SDK Save Came ra method and the command

DeviceFeaturePersistenceEnd at the end of the save function.

rd

party SDK application, if that SDK supports GenAPI 2.4, then the process is

rd

party Save Camera method as instructed.

20 • Using CamExpert with Linea CL Cameras Linea CL Series Camera

Camera Operation

The following sections describe typical operations performed with the camera. The descriptions rely

on the feature-based Camera Link GenCP protocol, using the Sapera CamExpert application. If you

are using a different application, the display configuration will differ but the category, parameter

(feature) names and possible values remain the same. References to related ASCII commands are

provided.

Factory Settings

The camera has been calibrated and configured at the factory to be ready for operation when first

powered up. The camera ships and powers up for the first time with the following factory settings:

• Camera Link Full, 8 bit pixels

• Internal trigger, line rate 10 kHz

• Internal exposure control, exposure time 50 µs

• 1x horizontal an d ver tical binning

• Offset 0, Gain 1x (lowest value)

• Flat field calibration is not active as this feature is dependent on your light source and lens.

Linea CL Series Camera Camera Operation • 21

Typical Setup and Evaluation

Optical Configuration

Typically, the first thing you want to do is to evaluate the camera’s image quality under operating

conditions similar to those that you are likely to use in your application. To do this, take the

following steps:

• The illumination, lens magnification, and focus should be set up as per you applicat ion .

• Getting the magnification right is best accomplished by setting the object-to-sensor

distance. Use the formula lens focal length x (2 + 1/magnification + magnification) to

calculate this distance. Magnificat ion equ als the sensor pixel size (7.04 µm or 3.52 µm ) /

(your object pixel size in µm).

• The approximate position of the sensor is at the first groove on the side of the camera case

from the front face of the camera.

Camera Timing & Control

It is easiest and quickest to evaluate the camera using the internal timing setups for line rate and

exposure time. The camera starts up in the default configuration of camera link full, 10 kHz line

rate and 50 µsec exposure time.

• If this line rate is too slow fo r your application, you will get a compressed image in the scan

direction. To increase the line rate, use the Internal Line Rate parameter in the Camera

Control category.

• Adjust the exposure time; refer to the Exposure Controls section.

• Set your camera direction: refer to the Pixel Readout Direction (Mirroring Mode) section.

Acquiring an Image

You can now begin imaging . Unless you have an application employing lots of light, the image is

likely to be too dark.

• Use the system gain to adjust the camera output to achieve the desired response. The

system gain range is from 1x to 10x. Refer to the Gain and Black Level (Offset) section.

• Once you have a suitable response, you can now focus the lens.

• The image may be darker at the edges due to lens vignetting, but this will be improved once

the camera is calibrated.

• Calibration is performed using a white reference where your object is normally located.

Refer to the Calibrating the Camera section. When calibrated, you should see an image from

the camera that is flat field corrected with the lens at the target level you set.

You are now ready to evaluate the image quality of the Linea camera under your operating

conditions.

22 • Camera Operation Linea CL Series Camera

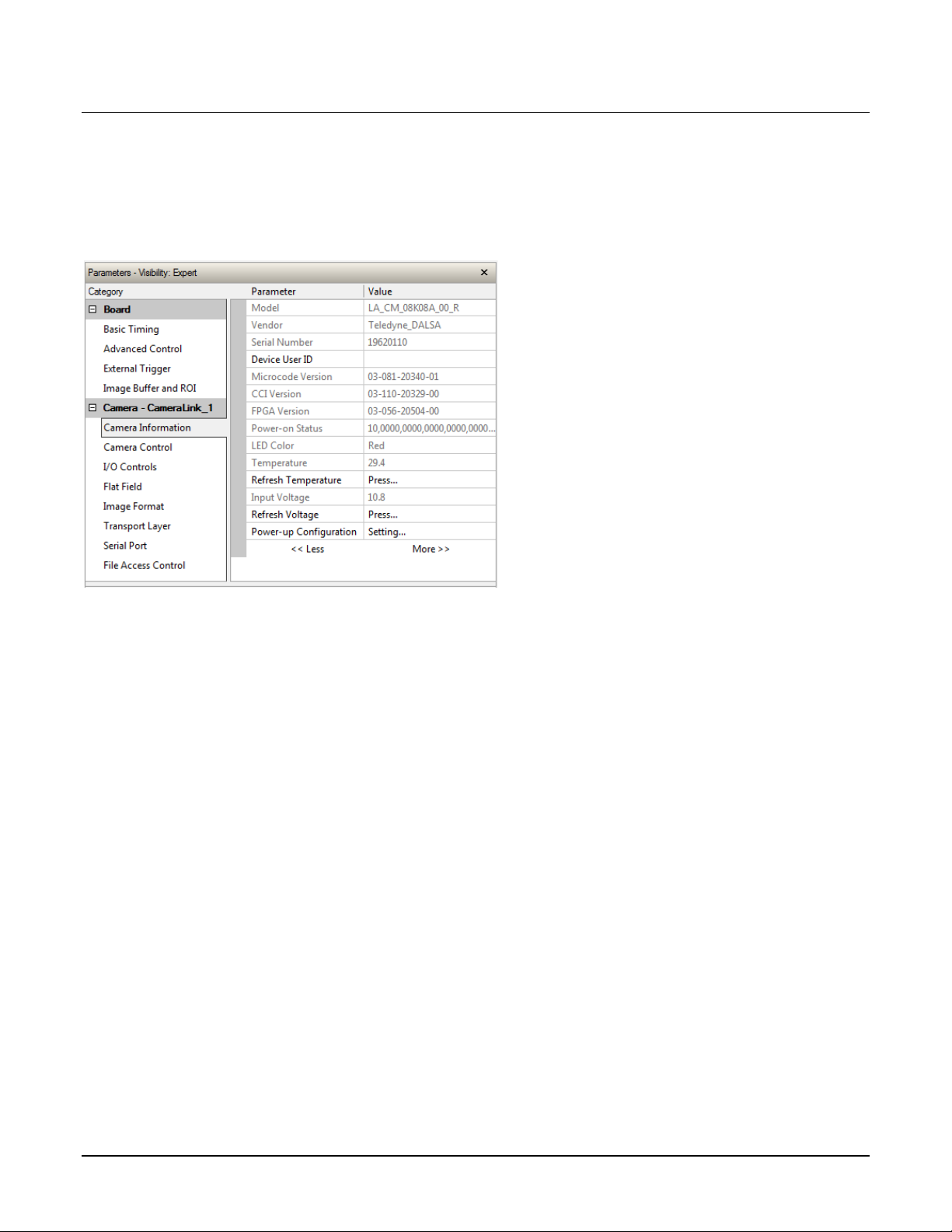

Check Camera and Sensor Information

Camera and sensor information can be retrieved via a controlling application—for example, the

CamExpert GUI shown in the following examples. Parameters such as camera model, firmware

version, sensor characteristics, and so forth, are read to uniquely identify the connected device.

The Camera Information category groups these parameters.

Verify Temperature and Voltage

To determine the voltage and temperature at the camera, use the Refresh Voltage and Refresh

Temperature features.

The temperature returned is the internal temperature in degrees Celsius. For proper operation this

value should not exceed 80 °C. If the camera exceeds the designated temperature it will stop

imaging and the LED will turn red. After you have diagnosed and remedied the issue use the

Restart Camera function.

The parameters used to select, load and save user sets are grouped together under the Camera

Information category. There are 8 user sets available and one factory set.

Linea CL Series Camera Camera Operation • 23

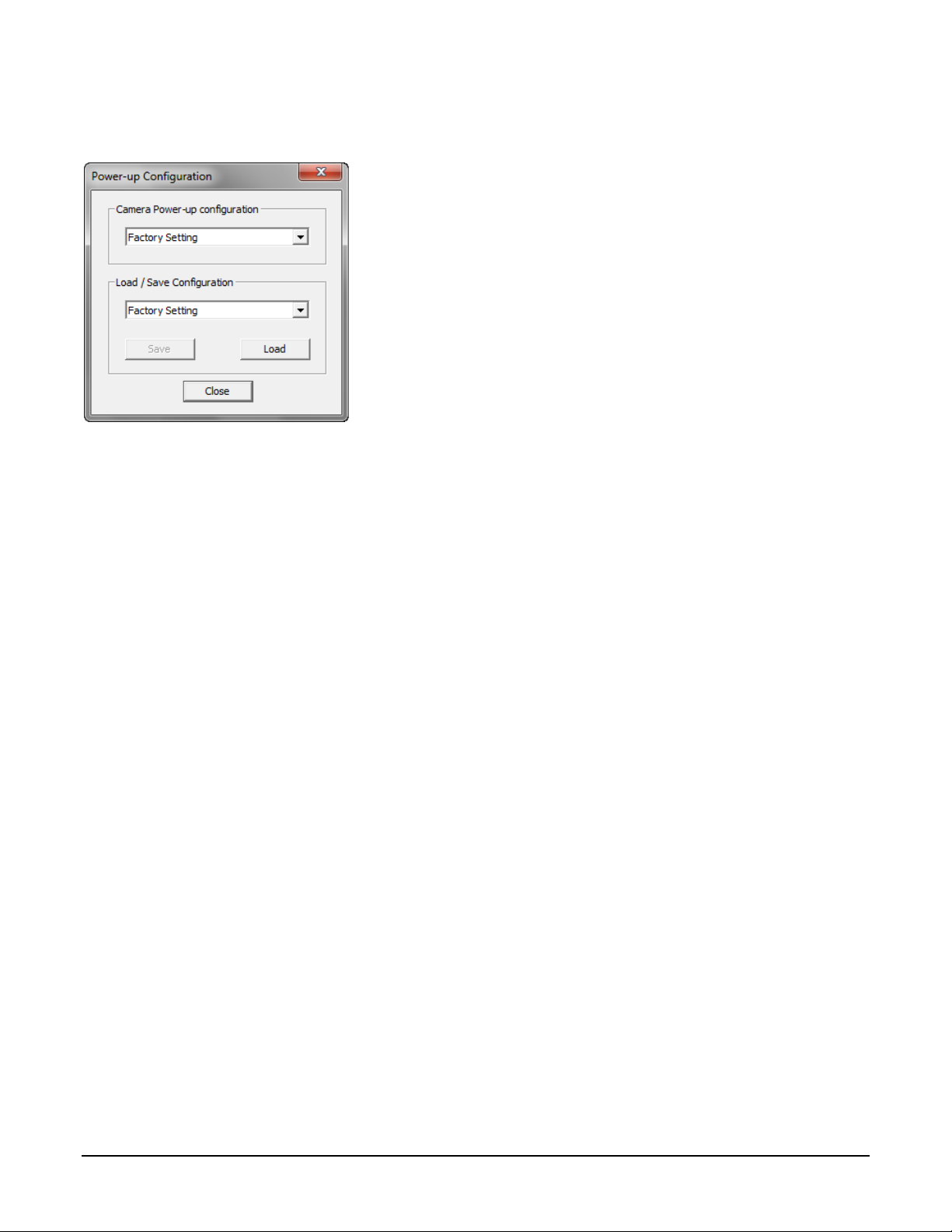

Camera Config uration Selection Dialog

CamExpert provides a dialog box which combines the features to select the camera power up state

and for the user to save or load a camera state from Linea CL memory.

Camera Power-up Configuration

Either the Factory or one of the User Settings can be used as the default setting and is the set

loaded when the camera is reset of powered up.

The first drop list selects the camera configuration state to load on power-up (see feature

UserSetDefaultSelector). The user chooses from one factory data set or one of 8 possible user

saved states.

User Set Configuration Mana g em en t

The user setting is the saved set of camera configurations that you can customize, resave, and

restore. By default the user settings are shipped with the same settings as the factory set.

The second drop list allows the user to change the camera configuration anytime after a power-up

(see feature UserSetSelector). To reset the camera to the factory configuration, select Factory

Setting and click Load. To save a current camera configuration, select from User Set 1 through

User Set 8, and click Save. Select a saved user set and click Load to restore a saved configuration.

Active Settings for Current Operation

The active setting for the current operation is the set of configurations that are active while the

camera is currently running, including all unsaved changes you have made to the settings before

saving them.

These active settings are stored in the camera’s volatile memory and will be lost and cannot be

restored if the camera resets, is powered down, or loses power.

To save these settings for reuse the next time you power up or reset the camera, or to protect

against losing them in the case of power loss, you must save the current settings. Once saved, the

current settings become the selected User Set.

24 • Camera Operation Linea CL Series Camera

Related ASCII Commands

usd

user set default

usl

user set load

uss

user set save

measurement can be used to set the applied voltage to the camera.

User Setting

The command User Set Save saves the current settings to non-volatile memory as a Use r Set.

The camera automatically restores the last saved user settings when it powers up.

To restore the last saved user settings, select the User Set parameter you want to restore and

then select the User Set Load parameter.

Factory Settings

The factory setting is the camera settings that were shipped with the camera and which loaded

during the camera’s first power-up. To load or restore the original factory settings, at any time,

select the Factory Setting parameter and then select the User Set Load parameter.

Note: By default, the user settings are set to the factory settings.

section).

Note: The voltage displayed is the camera’s input voltage. The voltage measurement

feature of the camera provides results within 1% of the actual voltage. The

Linea CL Series Camera Camera Operation • 25

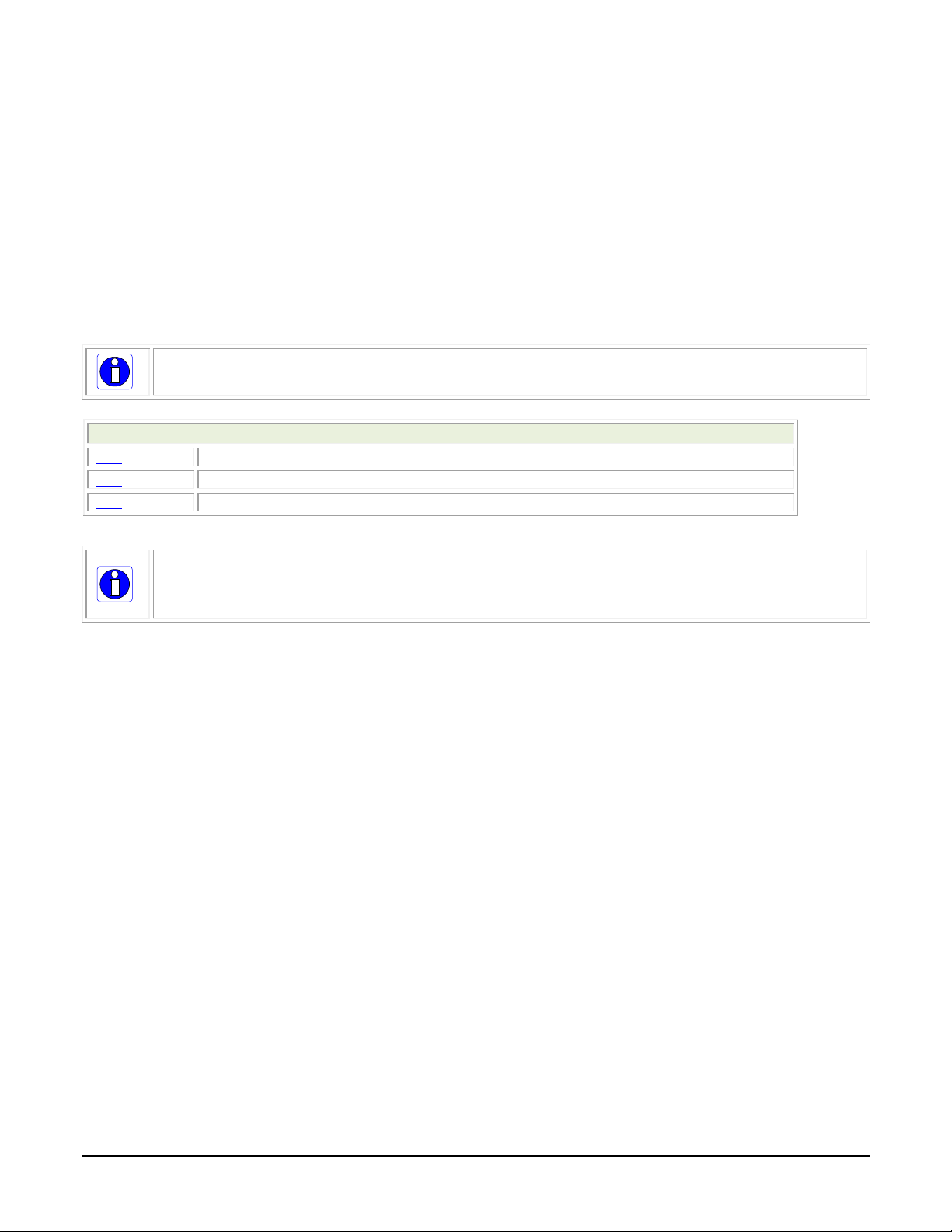

Set Baud Rate

Serial Port

Parameter

Description

achieve these baud rates.

Related ASCII Commands

sbr

set baud rate

The baud rate sets the speed (in bits per second—bps) of the serial communication port and is

available as part of the Serial Port category.

Baud Rate Sets the baud rate used by the camera’ s s er ia l port. Possible values

are:

• 9600 (factory default)

• 19200

• 57600

• 115200

• 230400*

• 460800*

Note: During connection, by default, CamExpert automa tic ally sets the

camera to maximum allowable baud.

*A Teledyne DALSA PX4 or equivalent frame gra bber is r equired to

Data Size 8 (read-only)

Parity None (read-only)

Number of Stop Bits 1 (read-only)

26 • Camera Operation Linea CL Series Camera

Name

Taps

Bits Per Pixel

Cables

Base

2

8, 12

1

Medium

4

8, 12

2

Full 8 8

2

Deca*

10 8 2

Camera Model

Available Camera Link Speeds

2K, 4K, and 8K

77 MHz

50 MHz

16K

85 MHz

62 MHz

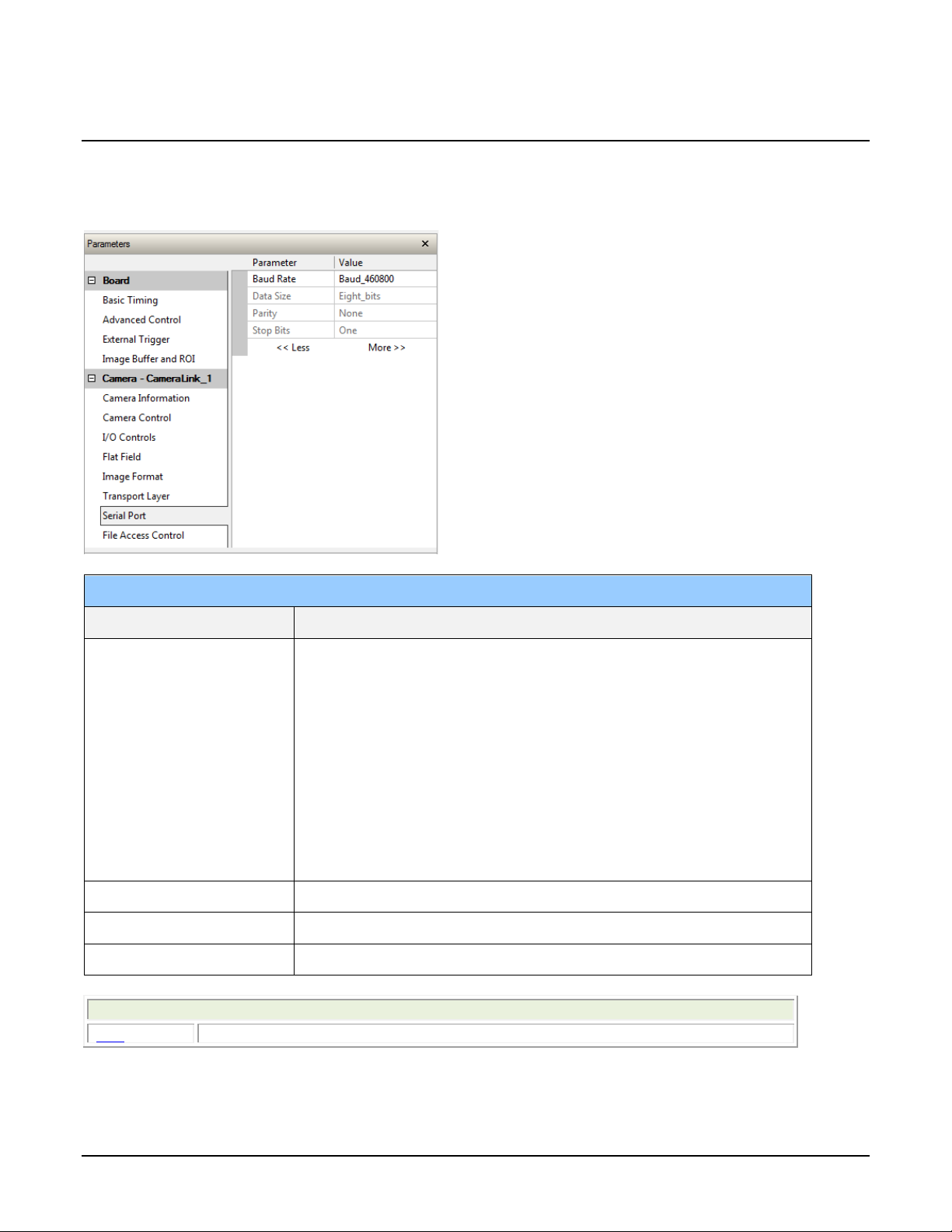

Related ASCII Commands

clm

camera link mode

spf

set pixel format

Camera Link Configuration

The following Camera Link configurations are available:

*8k and 16k models only

Available Camera Link speeds are model dependent:

The Camera Link Configuration feature is available in the camera’s Transport Layer category:

Linea CL Series Camera Camera Operation • 27

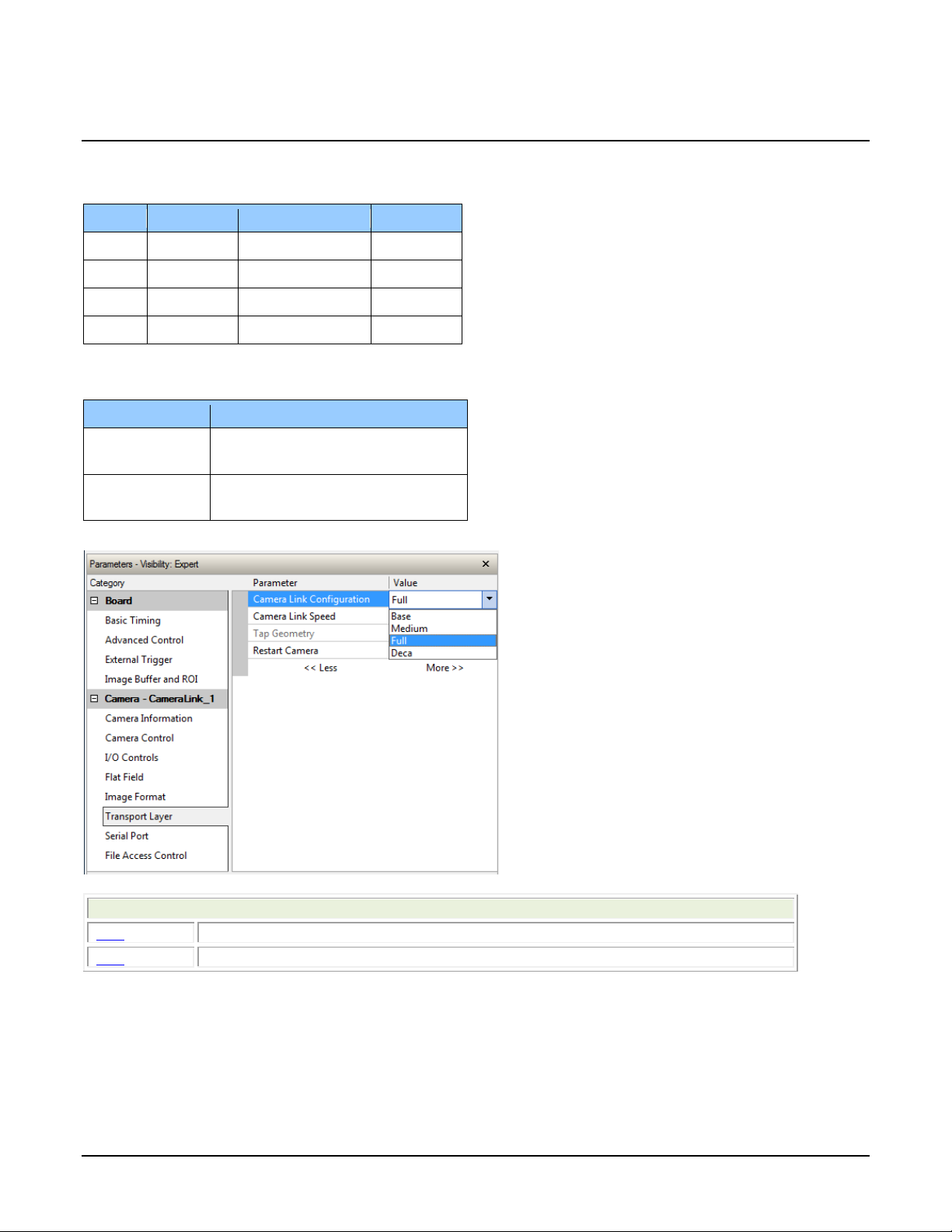

Pixel Format

Parameter

Description

Pixel Format

Sets the sensor pixel format. Possible values are:

configurations.

Related ASCII Commands

spf

set pixel format

Parameter

Description

Use the Pixel Format feature, found in the Image Format category, to select the format of the

pixel to use during image acquisition as either Mono 8 or Mono 12 bit depth.

Image Format

• Mono 8*

• Mono 12

*Only available format for Full Camera Link

Internal Test Image Generator

The Linea CL camera includes a number of internal test patterns which easily confirm camera cable

connections or dr iver installations, without the need for a camera lens or proper lighting. The

patterns are subject t o Linea CL processing such as Binning functions.

Use CamExpert to easily enable and select any test pattern from the drop menu while the camera

is not in acquisition mode. Select live grab to see the pa ttern output.

The Test Pattern feature is available in the Image Format category:

Image Format

Test Pattern Enable camera sensor test pattern. Possible values are:

28 • Camera Operation Linea CL Series Camera

Off

Ramp

Alternating

Fixed Pattern

Fixed Value

Fixed Value

32(2)

Related ASCII Commands

svm

set video mode

Important Note: to ensure best res ults , the conditions under which you calibrate the

operating conditions as possible.

1381(86)

Image is from the camera sensor.

Image is filled horizontally w ith an image that goes from th e

darkest possible value to the brigh te s t.

Alternating values. For 12-bit outpu t, pixel values alternate

between 1381 (0x565) and 2746 (0x ABA). For 8-bit outpu t,

pixel values alternate between 86 (0x56) and 172 (0xA C).

8 pixel cycling pattern. For 12-b it output, the patter n is

0x120|0x020|0x130|0x 030|0x140|0x040|0x15 0| 0x050. For

8-bit output, the patte r n is

0x12|0x02|0x13|0x03|0x14|0x04|0x15|0x05.

Fixed Grey Value. For 12-b it output: pixel valu e = 1381

(0x565). For 8-bit output: pixel value = 86 (0x56).

Fixed Grey Value. For 12-bit ou tput: pixel value = 32 (0x20) .

For 8-bit output: pixel value = 2 (0x2).

Calibrating the Camera

camera (for example, temperature and illuminat ion) should be as close to the actual

The goal of c alibration is for the camera to produce a uniform output image at a desired level while

imaging a uniform white object under conditions equal to the optical se tup for the user’s

application. Flat field coefficients consist of an offset and gain for each pixel. These are the first

user corrections applied to the image. The flat fie ld coefficients are saved and loaded with the user

set.

• Configure the camera to the required exsync and exposure timing, plus adjust the light level

for normal operation.

• Set the system gain to a value that best suits the application.

• The lens should be at the required magnification and aperture and be focused.

• As the white reference is located at the object plane, any markings or contaminants on its

surface (that is, dust, scratches, smudges) will end up in the calibration profile of the

camera. To avoid this, use a clean white plastic or ceramic material rather than trying to

rely on a paper reference. (Ideally, the white object will be moving during the calibration

process, as the averaging process of the camera will diminish the effects of any small

variation in the white reference.)

• Adjust the system gain until the peak intensity is at the desired DN level and then calibrate

the fixed pattern noise (FPN). Use a lens cap to ensure that no light reaches the sensor.

• Once complete, remove the lens cap and perform a photo response non-uniformity (PRNU)

calibration using the desired target value (in DN). You want all the pixels t o match. This

target value should be higher than the peak values you saw w hile first setting up the

camera.

Linea CL Series Camera Camera Operation • 29

• After several seconds the PRNU calibration will end and the correction coefficients will be

enabled. The system gain remains as first set.

• The coefficients and gain parameters, timing and control configuration ca n be stored in any

one of eight user sets and automatically retrieved at power-up or by user selection.

CamExpert has a default timeout of 20 seconds per command, which is too

short for the FFC calibration to run fully. You can change the default timeout by

setting a command line argument in the short-cut:

• Right-click on the short-cut in the start menu and select Properties.

• In the Target field, add the switch –timeout 60 (See below)

This increases the command timeout to 60 seconds.

Note that you must include a chara cter space between the clo sing

quotation mark in the target and the hyphen before the timeout value.

• Repeat for desktop short-cut

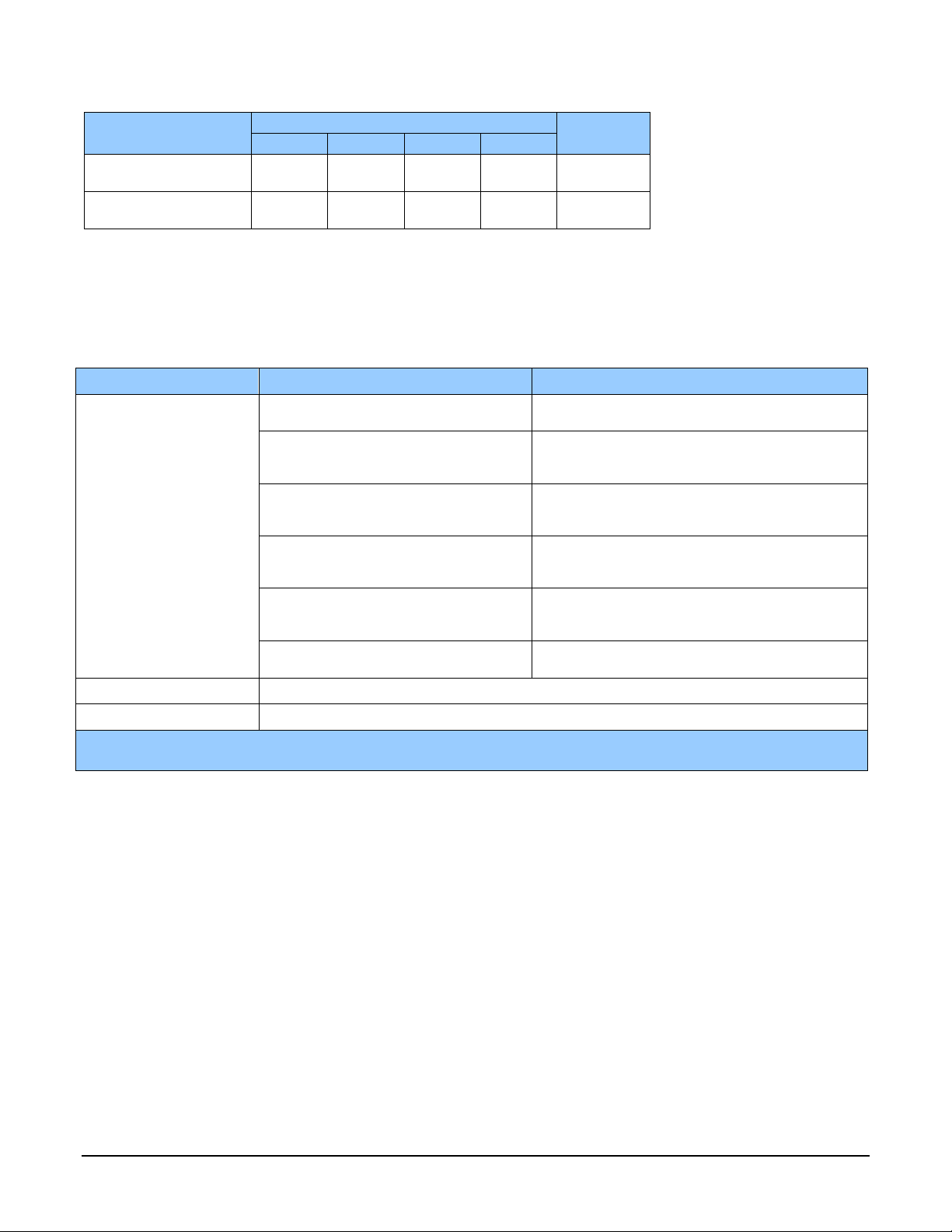

Flat Field Parameters

This Flat Field category contains a number of features that are used to correct image distortion due

to lens vignetting and uneven illumination.

30 • Camera Operation Linea CL Series Camera

Flat Field

to 0 and gains to 1x).

preferable to us e the “Basic” algorithm if possible.

12 bit: 0 to 4095 DN

Possible values: 2048 or 4096

calibrate different regions sequentially.

Default value is 0 DN for each pixel

Default 1x

Parameter

Mode Off – Flat field correction coeffic ients are not applied.

Calibration Algor ithm Basic – Direct calculation of coefficien ts based on curren t a verage line

Calibration Target After calibration all pixels will be scaled to outpu t this level

Calibration Sample Size Number of lines to a verage when calibrating.

ROI Offset X Together with “ROI Width”, specifies the range of pixels to be calibrated.

Description

On – Flat field correction coefficien ts are applied.

Initialize – Sending this value will r es e t a ll current coef ficients (offsets

values and target.

Low Pass Filter – A low pass filter is first ap plied to the curre nt

average line values before calculating the coefficients. Use this

algorithm if the calibration tar g et is not uniform white or it is not

possible to defocus the image. Bec a use of the low pass f ilter this

algorithm is not ab le to correct pixel-to-pixel variations and so it is

Range depends on pixel format:

• 8 bit: 0 to 255 DN

•

Pixel coefficien ts outside this ra nge are not changed . It is possible to

ROI Width Width of ROI, in pixels.

Calibration FPN Save average line (of “Calibration Sample Size” row s). This is the first

user correction applied – it is subtracted from each line.

This feature may not be of use to many users as the camera already

subtracts true “dark current” , but it may be useful for some to provide a

per pixel offset correction.

• Range 0 to 511 DN, 12 bit

•

Calibration PRNU Use “Correction Algorithm” to ca lc ulate the per pixel gain to achieve the

specified target outpu t.

• Range 0 to 15.9998x

•

Linea CL Series Camera Camera Operation • 31

Trigger Modes

I/O Controls

Parameter

Description

signal is the Camera L ink control line CC1 .

Related ASCII Commands

sem

set exposure mode

The camera’s image exposures are initiated by a trigger event. The trigger event is either a

programmable internal signal used in free running mode, an external input used for synchronizing

exposures to external triggers, or a programmed function call message by the controlling

computer. These triggering modes are described below.

The Trigger Mode feature is available in the camera’s I/O Controls category:

Trigger Mode

• Off: Internal trigger (trigger disabled): The camera freerunning mode has a programmable internal timer for line rate

and a programmable exposure period.

• On: External trigger (trigger enabled): Exposures are

controlled by an external trigger signal. The external trigger

32 • Camera Operation Linea CL Series Camera

Description

Line Rate

Exposure Time

Trigger Source

Exposure

programmable

Exposure

programmable

Exposure

Exposure Controls

Exposure control is defined as the start of exposure a nd ex posure duration. Exposure control

modes define the method and timing of controlling the sensor integration period. The integration

period is the amount of time the sensor is exposed to incoming light before the video line data is

transmitted to the controlling computer .

The camera can grab images in one of three ways, as described in the following table.

Internal Programmable

External Programmable

External Trigger Width

Internal, programmable Internal

Controlled by EXSYNC pulse Internal

Controlled by EXSYNC pulse External (EXSYNC) External

Internal

External

You determine the three imaging modes using a combination of the Exposure Time Source

parameters (including I/O parameters), Exposure Time and Internal Line Rate parameters.

• The feature Exposure Time Source selects the controlling method for the exposure.

• The start of exposure can be driven by an internal timer signal, an external trigger signal, or a

software function call.

• For External Trigger signals, the relationship between an external line trigger and the exposure

period is only applicable while the external line trigger does not exceed the maximum allowable

line rate.

• If the external line rate exceeds the maximum line rate allowed for a mode, the camera will

continue to output data at its maximum line rate. Though no image artifacts associated with

over-speed will occur, you may notice that under over-speed conditions the image will appear

compressed and the apparent distance travelled will be reduced.

The relevant exposure control features are grouped in the Camera Control category:

Linea CL Series Camera Camera Operation • 33

Camera Control

Parameter

Description

running): that is, the line trigger is disa bled (Trigger Mode off).

Width

the exposure duration.

be set to Timed.

Related ASCII Commands

ssf

set sensor framerate

sem

set exposure mode

set

set exposure time

Programmable Exposure

1

Programmable Exposure

1

Programmable Line Time

> 1

µ

s

Programmable Exposure

1

Sensor Readout

2

Sensor Readout

2

Sensor Readout

2

LVAL delay

3

LVAL

Internal Line

Rate

Camera line rate in a range from 300 Hz up to 80 kHz (2k, 4k, 8k) or 48 kHz

(16k).

This feature is only available when the camera is in Internal Mode (free

Exposure Time

Source

Set the operation mode for the c a m er a ’ s exposure. Trigger Wid th is only

available when Trigger Mo de is enabled.

Trigger

Uses the width of the current line trigger signal pulse to control

Timed The exposure duration time is set using the Exposur e Tim e

feature and th e exposure starts with the Line Start even t.

Exposure Time Sets the exposure time (in microseconds). Exposure Time Source feature must

Internal Programmable Exposure

The Linea CL in the Internal Programmable Exposure mode is the default free- running mode with

the external trigger off and internal exposure control. This mode is not synchronized to an external

signal. Line rate is the dominant factor when adjusting the line rate or exposure time. When setting

the line rate, exposure time will decrease, if necessary, to accommodate the new line rate. When

adjusting the exposure time the range is limited by the line rate. has the following features:

• The Trigger Source feature (see I/O Control category) selects an internal signal as trigger.

• Programmable internal trigger, where the maximum line rate limit is related to the Exposure

Time feature.

• Exposure duration is user programmable (exposure maximum is dependent on the line rate).

Minimum exposure (in µs) is model dependent.

1. Exposure time > 4µs (2K, 4K, 8K) or 2µs (16K)

2. Sensor readout time = 12.5µs (2K, 4K, 8K) or 20.8µs (16K)

3. LVAL delay = ~14.5µs (2K, 4K), 26µs (8K) or 41µs (16K)

34 • Camera Operation Linea CL Series Camera

Programmable Exposure

1

Programmable Exposure

1

Line Time

>

1

µ

s

Programmable Exposure

1

Sensor Readout

2

Sensor Readout

2

Sensor Readout

2

LVAL delay

3

LVAL

CC

1

To calculate the maximum line rate:

Maximum line rate =

(𝑒𝑥𝑝𝑜𝑠𝑢𝑟𝑒 𝑡𝑖𝑚𝑒+𝑙𝑜𝑤 𝑡𝑖𝑚𝑒∗)

1

*Exposure time must be greater than 4 µs, and low time greater than 1 µs (2K, 4K and 8K models)

or greater than 2 µs (16K model)

GenICam parameters to set:

• I / O Controls > Trigger Mode > Off

• Camera Control > Internal Line Rate > user value

• Camera Control > Exposure Time > user value

External Programmable Exposure

The External Programmable Exposure mode is similar to Internal Programmable except for the

exposure start being an external user input.

• The TriggerSource feature (see I/O Control category) selects an external signal line as trigger.

• Line rates and exposure limits are as defined for Internal Programmable Exposure.

• The falling edge of the EXSYNC (CC1) signal triggers the start of the internal exposure.

1. Exposure time > 4µs (2K, 4K, 8K) or 2µs (16K)

2. Sensor readout time = 12.5µs (2K, 4K, 8K) or 20.8µs (16K)

3. LVAL delay = ~14.5µs (2K, 4K), 26µs (8K) or 41µs (16K)

GenICam parameters to set:

• I / O Controls > Trigger Mode > On

• Camera Control > Exposure Time Source > Timed

• Camera Control > Exposure Time > user value

Linea CL Series Camera Camera Operation • 35

External Trigger Width Exposure

Exposure =

X

1

Line Time

>

1

µ

s

Sensor Readout

1

LVAL delay

2

LVAL

CC

1

X

1

X

2

X

3

Exposure

=

X

2

Sensor Readout

1

Exposure

=

X

3

Sensor Readout

1

the case when running internal exposure control.

An alternative external trigger mode allows the external signal width to control the exposure

duration. Line readout time remains similar to programmable exposure modes.

• EXSYNC (CC1) sets both the line period and the exposure time.

• The EXSYNC high duration sets the exposure time and the falling edge triggers the s ta rt of

exposure.

1. Sensor readout time = 12.5µs (2K, 4K, 8K) or 20.8µs (16K)

2. LVAL delay = ~14.5µs (2K, 4K), 26µs (8K) or 41µs (16K)

Note:

Maximum line rate =

(𝑒𝑥𝑝𝑜𝑠𝑢𝑟𝑒 𝑡𝑖𝑚𝑒+𝑙𝑜𝑤 𝑡𝑖𝑚𝑒∗)

1

*Exposure time must be greater than 4 µs, and low time greater than 1 µs (2K, 4K and 8K models)

or greater than 2 µs (16K model)

Warning! When running external line rate and external exposure time, the line rate

must not exceed 1 / (exposure time + low time). Under these conditions the

exposure time will become indeterminate and result in image artifacts. This is not

GenICam parameters to set:

• I / O Controls > Trigger Mode > On

• Camera Control > Exposure Time Source > Trigger Width

36 • Camera Operation Linea CL Series Camera

Camera Control

Single value added to each pix el. Apply a digital addition after an FPN correction: ± 1/ 8

12-bit mode

available range is -512 to +511.

8-bit mode

available range is -32 to +31.

Floating point dig ital multiplier applied to each pix e l. Set the gain as a n a m p lification

factor applied t o the video signal across all pixels: 1x to 1 0x.

Related ASCII Commands

ssb

set sensor blacklevel

ssg

set sensor gain

Gain and Black Level (Offset)

The gain and black level controls can make small compensations to the a cquisition in situations

where lighting varies and the lens iris can not be eas ily adjusted. Optima l gain and black level

adjustments maximizes t he Linea CL dynamic range for individual imaging situations.

Use the Offset and Gain features to maximize the use of the output dynamic range (especial ly

when pixel format is less than 12 bits). Typical use is to subtract minimum pixel value expected

and then adjust the gain to up the maximum pixel value to approach full scale.

Features and limitations are described be low.

• Black Level offset is expressed as a digital number providing a +/- offset from the factory

setting. The factory setting optimized the black level offset for maximum dynamic range und er

controlled ideal dark conditions.

• Digital Gain is expressed as a multiplication factor. Note that increasing digital gain does not

increase the low level resolution and increases the sensor noise proportionately.

The parameters that control gain and black level are grouped together in the Camera Control

category.

Offset

Gain

of available range. Positive values may be used to measure dark noise.

Depending on the the pixel for ma t, different offset ranges a r e a vailable:

Linea CL Series Camera Camera Operation • 37

Binning

Binning is the combining of two or more image sensor pixels to form a new combined pixel. A

binned image using the same exposure settings as a non-binned image will show an improved

signal-to-noise ratio, reduced scanning times (due to lower spatial resolution) and save as a

smaller image file size compared with a non-binned image, at the expense of lower image

resolution.

In 2 x 2 binning, 4 physical pixe ls on the sensor are combined into one image pixel. This operating

mode is ideal for applications that require faster acquisition and processing times and require

greater signal collection.

For this camera, the default binning value is 1 x 1,

The Binning Vertical and Binning Horizontal features in the Image Format category

represents the number of horizontal pixels that will be combined (added) together.

38 • Camera Operation Linea CL Series Camera

Image Format

must be combined (added) together: 2.

that must be combined (added) together.

Related ASCII Commands

sbh

set binning horizontal

Image Format

Parameter

Description

Line Mirroring

Off: All pixels are read out from left to right.

On: All pixels are read out from right to left.

Related ASCII Commands

smm

set mirroring mode

Parameter

Binning Vertic a l This feature represents the number of vertical photo-sensitive cells tha t

Binning Horizontal This feature represents the number of horizon tal photo-sensitive cells

Description

Pixel Readout Direction (Mirroring Mode)

The Line Mirroring feature, in the Image Format category, sets the tap readout from left to right or

from right to left. This feature is especially useful if you want to mount the camera “upside down.”

Linea CL Series Camera Camera Operation • 39

Area of Interest (AOI) Setup

Full Image Width

AOI 1

AOI

2

AOI 3

AOI

4

AOI

2 Offset

AOI

3 Offset

AOI 4 Offset

AOI

1

AOI 2

AOI 3

AOI

4

Resulting Output Image Width

The Area of Interest (AOI) feature can be used to reduce the amount of image-data output from

the camera. Use this feature when there are areas in the image that contain unneeded information.

An example where you would use this feature is in an application that is inspecting several

separated lanes of objects with one camera and the image between the lanes can be ignored.

The AOI feature allows from one to four specific areas of the pixel line to be specified where image

data will be output. Since the AOI feature reduces the amount of data output, this has the

additional benefit of allowing the cameras to operate at higher EXSYNC rates when using base or

medium camera link modes.

For example, in the 4K camera model, if the total number of pixels for the specified AOI`s is less

than 1 K when using base Camera Link mode at 77 MHz, the maximum EXSYNC rate can be 80

kHz; versus 56 kHz if all 4K pixels were output.

Note: The setup of AOI is alw a ys with respect to th e sensor. Therefore, if you are using the

mirroring mode with AOI , be awa r e that pixel one will be on the right side of the displayed image.

The AOI commands are grouped in the Image Format category.

To set up an AOI for the camera:

• The AOI mode must first be in the off position.

• Use the AOI Count to select the total number of AOIs desired to a max of 4.

• To set up each AOI individually use the AOI Selector to point to the AOI to be set up.

• AOI Offset X is used indicate the starting pixel of the AOI.

• AOI Width is used to indicate the width of the AOI.

40 • Camera Operation Linea CL Series Camera

Linea CL Series Camera Camera Operation • 41

To initiate operation of the AOI once setup:

Related ASCII Commands

sac

set AOI count

sad

set AOI selector, offset and width

sam

set AOI selector, offset and width

• The AOI mode must be changed to Active.

• Be sure to set the frame grabber image width to the sum of all AOI w idths set up in the

camera.

42 • Camera Operation Linea CL Series Camera

Saving and Restoring Camera Settings

The parameters used to select, load and save user sets are grouped together under the Camera

Information category. There are 8 user sets available and one factory set.

Camera Config uration Selection Dialog

CamExpert provides a dialog box which combines the features to select the camera power up state

and for the user to save or load a camera state from Linea CL memory.

Camera Power-up Configuration

Either the Factory or one of the User Settings can be used as the def a ult setting and is the set

loaded when the camera is reset of powered up.

The first drop list selects the camera configuration state to load on power-up (see feature

UserSetDefaultSelector). The user chooses from one factory data set or one of 8 possible user

saved states.

User Set Configuration Mana g em en t

The user setting is the saved set of camera configurations that you can customize, resave, and

restore. By default the user settings are shipped with the same settings as the factory set.

The second drop list allows the user to change the camera configuration anytime after a power-up

(see feature UserSetSelector). To reset the camera to the factory configuration, select Factory

Setting and click Load. To save a current camera configuration, select from User Set 1 through

User Set 8, and click Save. Select a saved user set and click Load to restore a saved configuration.

Active Settings for Current Operation

The active setting for the current operation is the set of configurations that are active while the

camera is currently running, including all unsaved changes you have made to the settings before

saving them.

These active settings are stored in the camera’s volatile memory and will be lost and cannot be

restored if the camera resets, is powered down, or loses power.

To save these settings for reuse the next time you power up or reset the camera, or to protect

against losin g them in the case of power loss, you must save the current settings. Once saved, the

current settings become the selected User Set.

Linea CL Series Camera Camera Operation • 43

User Setting

Related ASCII Commands

usd

user set default

usl

user set load

uss

user set save

The command User Set Save saves the current settings to non-volatile memory as a Use r Set.

The camera automatically restores the last saved user settings when it powers up.

To restore the last saved user settings, select the User Set parameter you want to restore and

then select the User Set Load parameter.

Factory Settings

The factory setting is the camera settings that were shipped with the camera and which loaded

during the camera’s first power-up. To load or restore the original factory settings, at any time,

select the Factory Setting parameter and then select the User Set Load parameter.

Note: By default, the user settings are set to the factory settings.

44 • Camera Operation Linea CL Series Camera

Type

File

Device Firmware

Microcode

XML

XML

Miscellaneous

FPGA Code

CCI

Warning! The camera firmware file versions must all be compatible or the

questions before proceeding.

Camera Firmware Updates

The user can upload new firmware using the File Access Control features via Sapera CamExpert.

To update the camera firmware several files must be updated. Files include the following:

camera risks becoming inoperable. Only after all required files are uploaded to

the camera can the camera be reset to activate the new firmware.

Before updating any firmware files verify that the file versions are correct. If

in doubt, contact your Teledyne DALSA representa tive if you have any

Download a List of Camera Parameters

For diagnostic purposes you may want to download a list of all the parameters and values

associated with the camera. To do this use the File Access Control

• Select “Miscellaneous” file type

• In the “File selector” drop down box select “CameraData” .

• Click “Download”.

• Save the text file and send the file to Teledyne DALSA customer support if required.

features via Sapera CamExpert:

Linea CL Series Camera Camera Operation • 45

File Access via the CamExpert Tool

• In the File Access Category, click on the “Setting…” button to open the File Access Control

dialog.

• From the file type drop menu, select the file type that will be uploaded to the Linea CL. This

CamExpert tool allows quick firmware changes or updates.

• From the File Selector drop menu, select the Linea CL memory location for the uploaded data.

This menu presents only the applicable data locations for the selected file type.

• Click the Browse button to open a typical Windows Explorer window.

• Select the specific file from the system drive or from a network location.

• Click the Upload button to execute the file transfer to the Linea CL.

• Note that firmware changes require a device reset command from the Transport Layer Controls.

46 • Camera Operation Linea CL Series Camera

Transport Layer

Parameter

Description

Restart Camera

Resets the camera and puts in the default settings, including a

9600 baud rate.

Related ASCII Commands

rc

reset camera

Resetting the Camer a

The Restart Camera feature, part of the Transport Layer category, resets the camera. The camera

resets with the default settings, including a bau d rate of 9600.

If camera detection is enabled, Teledyne DALSA frame grabber serial port settings are by default

configured to auto-detect and maximize the baud rate . To verify the setting, use the Sapera

Configuration utility, or in CamExpert use the Tools > Camera Detection > Settings menu

command to open the Communication Settings dialog.

Linea CL Series Camera Camera Operation • 47

Technical Specifications

Mechanical Specifications

2K and 4K Camera s

48 • Technical Specifications Linea CL Series Camera

8K and 16K Cameras

Linea CL Series Camera Technical Specifications • 49

Additional Notes on Linea CL Identification and Mechanical

Identification Label

Linea CL cameras have an identification label applie d to the back side, with the following information:

• Model Part number

• Serial number

• 2D Barcode

• CE and FCC logo

• “Made in Canada” Statement

EMC Declarations of Conformity

50 • Technical Specifications Linea CL Series Camera

Linea CL Series Camera Technical Specifications • 51

52 • Technical Specifications Linea CL Series Camera

Additional Reference Information

Optical Considerations

This section provides an overview to illumination, light sources, filters, lens modeling, and lens

magnification. Ea ch of these components contribute to the successful design of an imaging

solution.

Illumination

The amount and wavelengths of light required to capture useful images depend on the particular

application. Factors include the nature, speed, and spectral characteristics of objects being imaged,

exposure times, light source characteristics, environmental and acquisition system specifics, and