Page 1

OPERATING INSTRUCTIONS FOR

Model 3500 Series

Laser Gas Analysis System

P/N MXXXX

ECO:

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Copyright © 2005 Teledyne Analytical Instruments

Teledyne Analytical Instruments

Page 2

Model 3500

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at our

option, any material or construction in which defects become apparent within one year from

the date of shipment, except in cases where quotations or acknowledgements provide for a

shorter period. Components manufactured by others bear the warranty of their manufacturer.

This warranty does not cover defects caused by wear, accident, misuse, neglect or repairs

other than those performed by Teledyne or an authorized service center. We assume no

liability for direct or indirect damages of any kind and the purchaser by the acceptance of the

equipment will assume all liability for any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Laser Gas Analyzer

Specific Model Information

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Page 4

Model 3500

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

No

Symbol

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments iv

Page 5

Laser Gas Analyzer

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model 3500

Table of Contents

Peter.Adam@linde-gas.com

List of Figures ..............................................................................ix

List of Tables................................................................................xi

Introduction................................................................................... 1

1.1 Overview 1

1.2 Models Available in the 3500 Series 1

1.2.1 Available Options 1

1.2 Classification of LGA-2000 Laser Gas Analysis

Systems 2

1.2 Typical Applications 3

1.3 Features 4

1.4 System Components 4

Operational Theory.......................................................................7

2.1 Introduction 7

2.2 Principles of Operation 8

2.3 Software 10

Installation................................................................................... 11

3.1 Unpacking the Instrument 11

3.2 Installation Preparation 11

3.2.1 Installation and Adjustment Tools 11

3.2.2 Choosing Installation Spot 13

3.3 Analysis Section Installation 13

3.3.1 Welding Flanges 13

3.3.2 Installing Instrument Flanges 14

3.3.3 Checking Offset Using the Laser Pen and Target 15

3.3.3.1 Checking the Laser Pen for Alignment 15

3.3.3.2 Adjusting the Coaxial Offset of the Instrument

Flanges 16

Teledyne Analytical Instruments vi

Page 7

Laser Gas Analyzer

3.3.4 Installing the Transmitter Unit and the Receiver Unit 17

3.4 Central Processing Unit Installation 17

3.5 Purge System Installation 18

3.6 Electric Wiring and Connection 19

3.7 Optimize of the Optical Transmission Alignment 22

Operation .....................................................................................23

4.1 Front Panel 23

4.2 System Mode 24

4.2.1 Start-up Mode 24

4.2.2 Normal Mode 26

4.2.3 Error Mode 27

4.3 System Menu 27

4.3.1 MainMenu 28

4.3.2 Display 33

4.3.3 System 38

4.3.3.1 System Parameter Input Method 39

4.3.3.2 System sub menus 41

4.3.4 Cali. 46

4.3.4.1 Adjust Zero: 47

4.3.4.2 Cali. Co: 48

4.3.4.3 Backup 51

4.3.4.4 Restore 51

4.3.5 Com 51

4.3.6 Alarm 52

4.3.7 Additional Menus 57

4.3.7.1 Message Code: 57

4.3.7.2 Password Input: 58

4.3.7.3 Error Protection Menu: 58

Alarm Messages..........................................................................61

5.1 Relay Alarm 61

5.2 4-20mA Analog Output 61

5.3 LCD Alarm Message Display 62

Teledyne Analytical Instruments vii

Page 8

Model 3500

Maintenance and Calibration .....................................................67

6.1 Maintenance 67

6.1.1 Adjusting the Purge Gas Flow 67

6.1.2 Clean the Optical Parts 68

6.1.3 Optimize the Optical Transmission Alignment 70

6.2. Calibration 70

6.2.1 Calibration Procedure 72

6.2.2 Calibration Software 74

Extended Communication Functions........................................ 75

Appendix...................................................................................... 77

Specifications 77

Recommended Spare Parts List 79

Reference Drawings 79

Index............................................................................................. 81

Teledyne Analytical Instruments viii

Page 9

Laser Gas Analyzer

List of Figures and Screens

Figure 1-1 Control Section...............................................................5

Figure 1-2: Model 2500 Laser Gas Analysis System.......................6

Figure 2-1: System Diagram for the Model 3500 Series Analyzers.7

Figure 2.2 Schematic of “Single line” Spectroscopy........................9

Figure 3-1: General Layout of the Model 3500 Series Analyzer....12

Figure 3.2: Allowed offset for welded flanges................................14

Figure 3-3: Instrument Flange.......................................................15

Figure 3.4 Adjusting the Instrument Flanges with Laser Pen and

Target.....................................................................................16

Figure 3.5 Dimension of the Central Processing Unit (in mm).......17

Figure 3.6 Typical Purging System for the Model 3500.................19

Figure 3.7 Electric Connection Ports on the Central Processing

Unit for Non-fiber Optic Analysis Systems..............................20

Figure 3.8: Electric Connection Ports on the Central Processing

Unit for Analysis Systems Using Fiber Optic Pigtail ...............21

Figure 4-1: Model 3500 Series Front Panel...................................23

Figure 4.2 System Start-up Screen...............................................25

Figure 4.3 System Init Screen.......................................................25

Figure 4.5: System Menu Structure...............................................28

Figure 4-6: MainMenu—Graphic...................................................29

Figure 4.7 Numerical Value Mode of the MainMenu .....................30

Figure 4.8 Display menu................................................................33

Figure 4.9 Display Mode Options..................................................34

Figure 4.10 Unit Menu...................................................................34

Figure 4.11 Set Con. Unit menu....................................................35

Teledyne Analytical Instruments ix

Page 10

Model 3500

Figure 4.12 Pop-up Window for Language Selection....................36

Figure 4.13 TimeDate Menu..........................................................36

Figure 4.14 Admin. Menu.............................................................. 37

Figure 4.15 System main menu ....................................................38

Figure 4.16 Set Optical Path Length............................................. 40

Figure 4.22 Schematic showing purging gas channel...................45

Figure 4.35 Time sequence of the alarm relay automatic

restoration..............................................................................56

Figure 6.1 Schematic of the calibration setup ...............................70

Figure 6.2 Removing the Transmitter Receiver Units.................... 72

Figure 7.1 Schematic for Networked Multiple-point Remote

Measurement on Model 3500 Systems.................................. 75

Teledyne Analytical Instruments x

Page 11

Laser Gas Analyzer

List of Tables

Table 1-1 Instrument Designation for Selected Options..................2

Table 1-2: Typical Gas Analysis and Range....................................3

Table 3.1 Electric connections & definitions of Input, Output

Signals of Central Processing Unit.........................................21

Table 5.1 Relays and output status for Various Operation Modes 62

Table 5.2: LCD Display Alarm Messages......................................63

Teledyne Analytical Instruments xi

Page 12

Model 3500

DANGER

COMBUSTIBLE GAS USAGE

Depending on the selected options, some instruments may

be used in hazardous environments. This may involve the

measurement or monitoring of flammable or explosive

gases. It is the end user’s responsibility to ensure that all

safety related features of this instrument are properly

functioning and that the operator is fully trained in the

operation of the system as well as procedures for handling

the gases employed.

WARNING

Some instruments are approved as an intrinsically safe gas

analyzers for usage in a category (ia) Group IIC hazardous

area. This approval only to the equipment specified installed

in accordance with the information contained within this

manual. It is the customer's responsibility to ensure safety

especially when combustible gases are being analyzed since

the potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment is well understood by the user and that the

instrument as well as any approved support equipment is

properly installed. Misuse of this product in any manner,

tampering with its components, or unauthorized substitution

of any component may adversely affect the certification and

the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments xii

Page 13

Laser Gas Analyzer

DANGER

LASER RADIATION

This instrument produces laser radiation which can cause

damage to human tissue especially the eyes. Do not look at

the laser beam nor open any chamber or device without first

powering off the instrument.

WARNING: THE WAVELENGTH OF THE LASER BEAM INSIDE

THE MODEL 3500 SERIES OF ANALYZERS IS IN THE

RANGE OF 0.7 ~ 2µM. IT IS INFRARED AND

INVISIBLE. DO NOT LOOK DIRECTLY OR WITH

OPTICAL INSTRUMENT AT THE DIRECTION OF THE

LASER RADIATION

HAZARD

Teledyne Analytical Instruments xiii

Page 14

Model 3500

Teledyne Analytical Instruments xiv

Page 15

Laser Gas Analyzer Introduction

Introduction

1.1 Overview

The Model 3500 series Laser Gas Analysis System comprises a

range of instruments based on the features and configuration chosen at

the time of purchase. The system uses laser spectroscopy to accurately

measure and monitor the composition of a single or multiple gas species

in a gas mixture. It is especially useful for in-situ measurements and is

designed for online processes analysis. Options are available for

applications involving hazardous environments.

This manual describes the installation, calibration, operation, and

maintenance of the LGA system. The principles of instrument operation

are detailed in Section 2.

1.2 Models Available in the 3500 Series

The Model 3500 series of instruments are classified depending on

the options specified at the time of purchase. The specific model number

assigned is described below following a brief description of the available

options to choose from.

1.2.1 AVAILABLE OPTIONS

The standard Model 3500 LGA System is configured for single gas

species detection in a gas mixture using a flange mounted laser transmitter

and receiver for online in-situ measurements in non-hazardous environments.

The following list indicates available options for the Model 3500

series of analyzers (see also Table 1-1):

• Two gas detection in a gas mixture

• Fiber optic connection to remove sensitive laser and electronics

from monitoring environment

• Explosion-proof housing

• Intrinsically safe instrumentation

Teledyne Analytical Instruments 1

Page 16

Introduction Model 3500

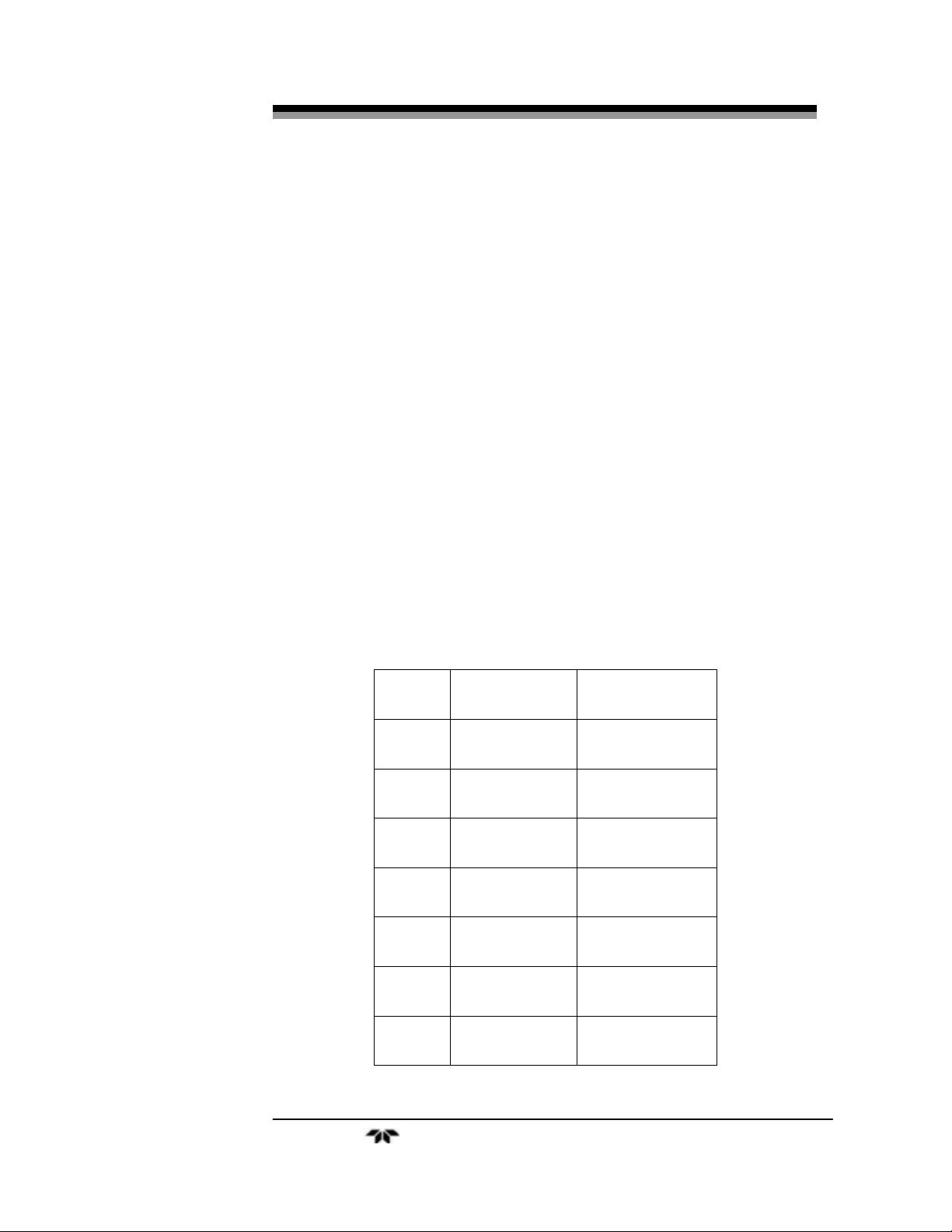

Table 1-1 Instrument Designation for Selected Options

3500C

3500P

3500CS

3500PS

3500-2C

3500-2P

3500-2CS

3500-2PS

3500F

3500I

3500FS

3500IS

3500-2F

3500-2I

3500-2FS

3500-2IS

Number

of Gas

Species

One Two

√

√

√

√

√ √

√ √

√

√

√

√

√

√

√ √

√ √

√

√

Detection Optical

Signal

Transmission

By-

In

Pass

Situ

√

√

√

√

√

√

√

√

√ √

√ √

√ √

√ √

Optical

Fiber

√

√

√

√

Non-

optical

Fiber

√ √

√

√ √

√

√ √

√

√ √

√

General

Purpose

√

√

√

√

Analysis Environment Model

Explosion-

proof

Positive

Pressure

√

√

√

√

Intrinsically

Safe

√

√

√

√

1.2 CLASSIFICATION OF LGA-2000 LASER GAS ANALYSIS SYSTEMS

The instruments in the Model 3500 range are named according to

the following rule:

Model 3500: Single gas analyzer

Model 3500-2: Two gas analyzer

Suffix C: Standard configuration without optical fiber

Suffix F Standard configuration with optical fiber

Suffix I: Intrinsically safe

Suffix P: Explosion-proof

Teledyne Analytical Instruments 2

Page 17

Laser Gas Analyzer Introduction

Suffix S: Bypass sampling mode

For example, the Model 3500C would indicate a standard (nonexplosion proof) single gas analyzer without an optical fiber capable of

in-situ analysis in non-hazardous environments. Similarly, the Model

3500F would indicate the same instrument but with an optical fiber

connection with the laser source located remotely from the monitoring

site.

1.2 Typical Applications

The Model 3500 Laser Gas Analysis System is a versatile tool for

online analysis and monitoring of a gas flow process. The Model 3500 is

suitable for a wide range of industrial applications including

petrochemical and steel industries where critical monitoring of process

gases is vital. Depending on the gas specie or species of interest, the

instrument is capable of measuring from the parts per million (ppm) to

100% range of concentration.

Table 1-1 shows typical gas species and their measurement range

for the Model 3500.

Table 1-2: Typical Gas Analysis and Range

Gases Threshold

O

HCL

HF

NH

CO

H2O

H2S

0.01%Vol. 0-2% Vol.,

2

0.1 ppm 0-15 ppm,

0.02 ppm 0-5 ppm,

0.2 ppm 0-20 ppm,

3

200 ppm 0-8000 ppm,

0.05 ppm 0-10 ppm, 0-

5 ppm 0-1000 ppm,

Measurement

Range

0-100% Vol.

0-8000 ppm

0-1000 ppm

0-10000 ppm

0-100% Vol.

70% Vol.

0-30% Vol.

Teledyne Analytical Instruments 3

Page 18

Introduction Model 3500

CH

HCN

CO

C2H

C2H

20 ppm 0-200 ppm,

4

0-10% Vol.

0.5 ppm 0-40 ppm,

0-10000ppm

1 ppm 0-100 ppm

2

(min)

0.2 ppm 0-20 ppm

2

(min)

2.0 ppm 0-200 ppm

4

(min)

1.3 Features

Compared to conventional gas analysis systems, the DLGA-3500

series have the following advantages:

• On-the-spot online measurement ability

• Options available for use in adverse environment conditions

• Quick response

• High measurement accuracy

• Minimal maintenance

• No replacement parts

• No cross interference from background gas species

• Enhanced accuracy over conventional IR and photonic

measurement systems

1.4 System Components

The Model 3500 consists of:

• Control unit

• Analysis section

• Purging system

Teledyne Analytical Instruments 4

Page 19

Laser Gas Analyzer Introduction

The central processing or control unit is a separate wall-mounted

enclosure located remotely from the process or point of analysis. It

houses the system electronics and includes the operator interface panel

on the front door. Figure 1 shows the Model 3500 control unit. A

separate enclosure is provided for the power supply

The operator interface consists of a panel of membrane switches for

controlling the operational mode of the instrument as well as entering

data. A large LCD display provides feedback to the user and indicates

the gas composition during analysis.

Figure 1-1 Control Section

The system is equipped with a separate power supply and output

control section which is also mounted remotely from the measurement

site. It houses power supplies and connectors for signal and relay output.

See Figure 1-2.

Teledyne Analytical Instruments 5

Page 20

Introduction Model 3500

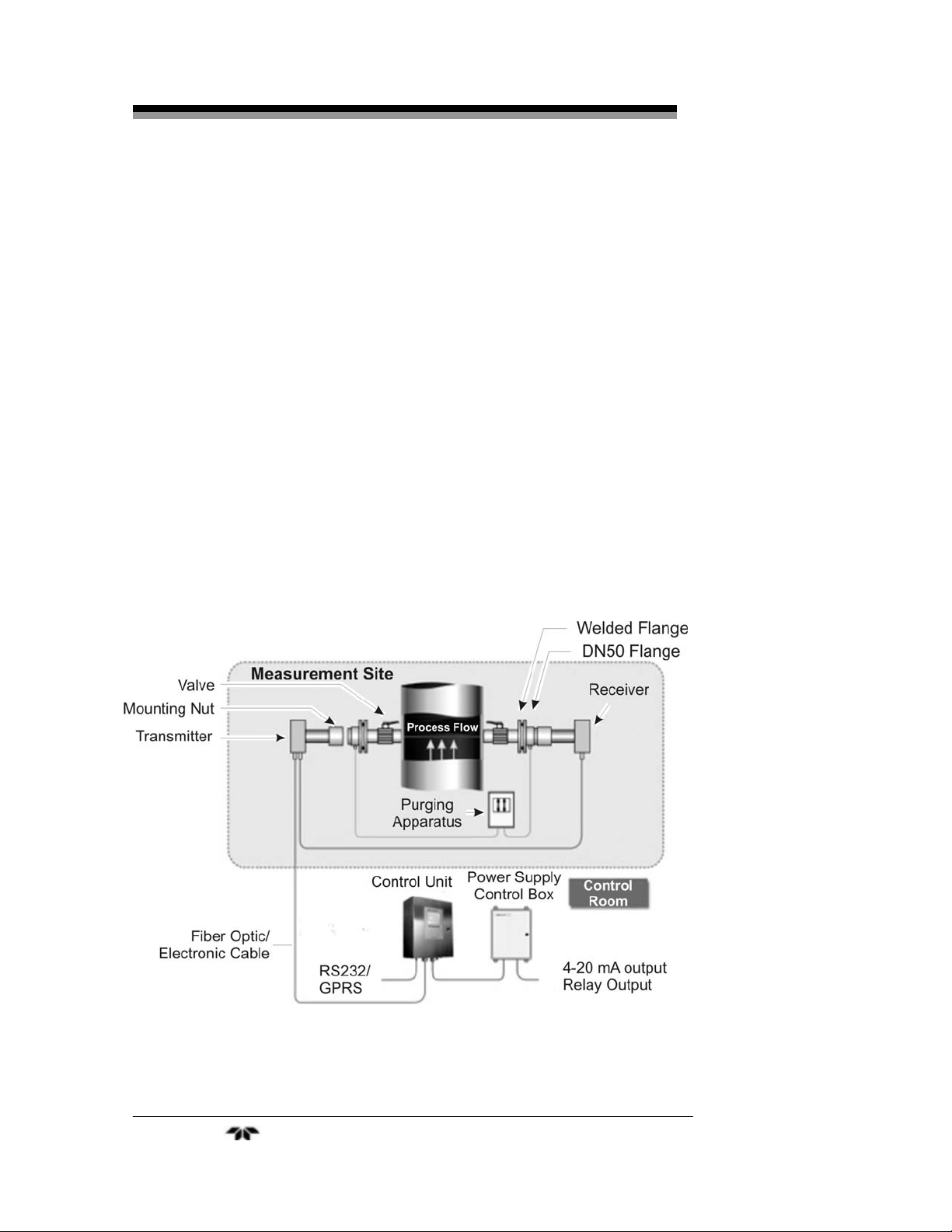

The analysis section is typically mounted at the point of

measurement and consists of the laser transmitter, receiver and flanges

for interfacing the unit with the process.

The transmitter unit and the receiver unit are mounted on flanges

which are welded onto the gas flow pipe. The transmitter is mounted

onto one flange with special adjustable fittings while the receiver is

mounted onto a similar flange diametrically opposed from the

transmitter. The transmitter unit launches a collimated laser beam into

the environment under test, and onto the sensor in the receiver unit. The

signal is sent to the central processing unit housed in the control unit.

An integral purging unit is incorporated to keep dust and gas

deposits from collecting on the analysis section windows thus

eliminating any interference or degradation of the laser induced signal.

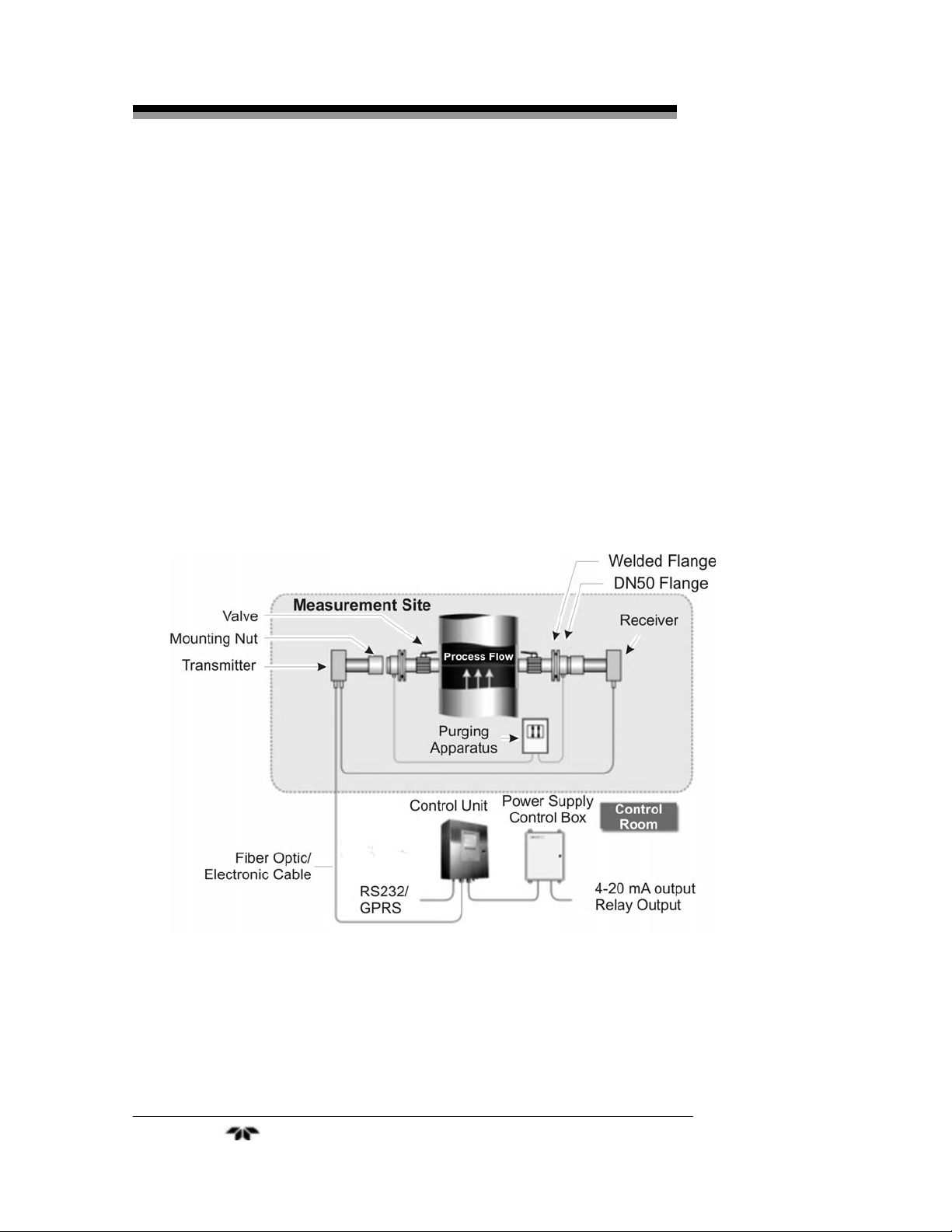

Figure 1-2 shows a typical Model 3500 Laser Gas Analysis System

with the control section remotely located from the analysis portion.

Figure 1-2: Model 2500 Laser Gas Analysis System

Teledyne Analytical Instruments 6

Page 21

Laser Gas Analyzer Operational Theory

Operational Theory

2.1 Introduction

The Model 3500 Laser Gas Analysis System is a high precision gas

concentration measurement and monitoring system capable of on-thespot online operation. It is comprised of three subsystems:

1. Central Processing Unit (Control Unit)

2. Analysis Section

3. Purge System

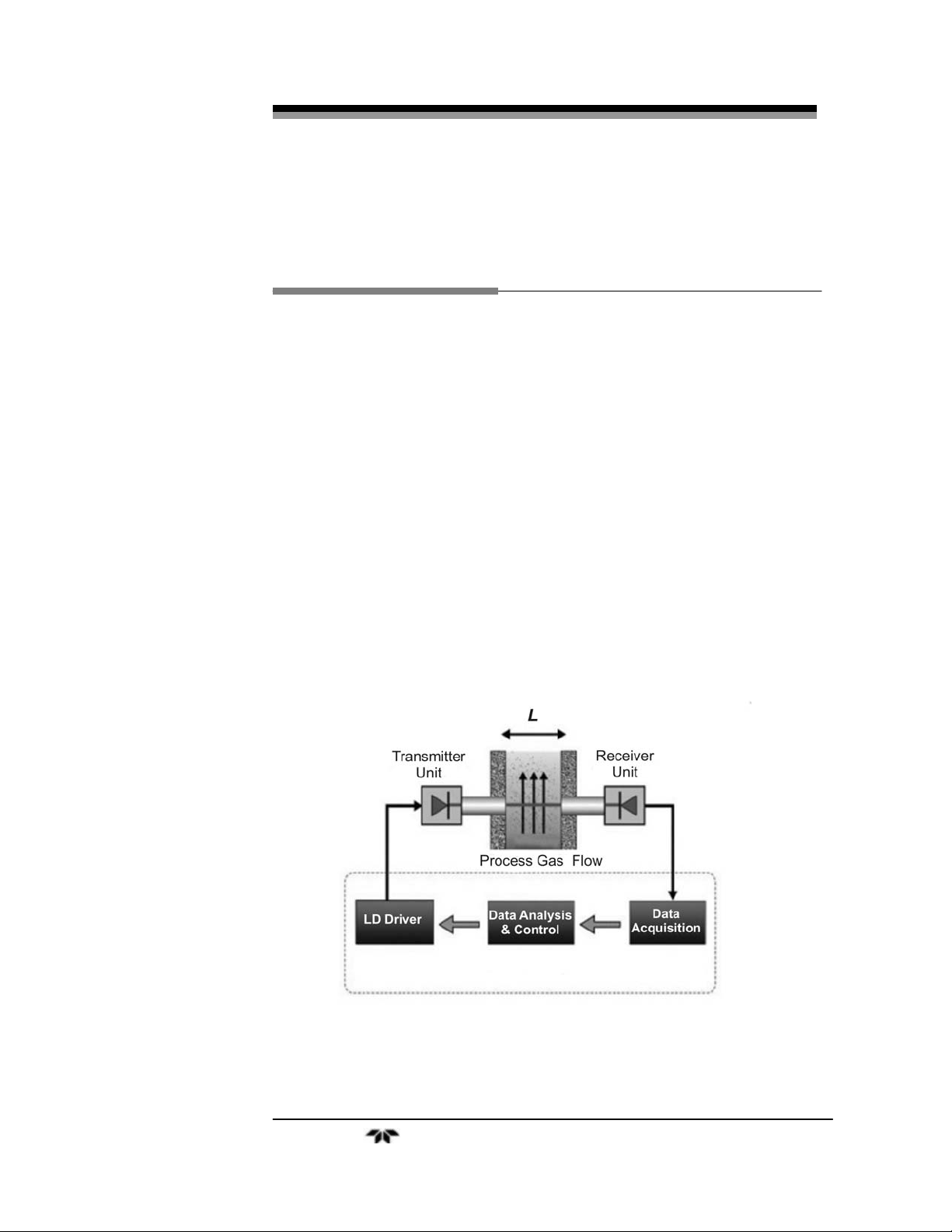

In the analysis section, the transmitter launches a laser beam across

the diameter of the industry pipe under test onto the receiver placed at

the other end. The resulting electrical signal is then sent to the central

processing unit and analyzed to yield the gas concentration and

displayed on the LCD screen. Signal and relay output is taken from the

power supply/control box. See Figure 2-1.

Figure 2-1: System Diagram for the Model 3500 Series Analyzers

Teledyne Analytical Instruments 7

Page 22

Operational Theory Model 3500

2.2 Principles of Operation

The Model 3500 Laser Gas Analysis System uses laser

spectroscopy to generate a signal based on the composition of a gas

mixture. While similar in nature to other photonic analyzers, the Model

3500 Laser Gas Analysis System offers many advantages over these

technologies.

Traditional online gas analyzers such as the Non-dispersive

Infrared (NDIR) Spectroscopy Online Gas Analyzer are subject to

interference from other constituents in the environment (including dust

and other gas species such as water vapor). This could be especially

severe when the measured gas is of low concentration. However, the

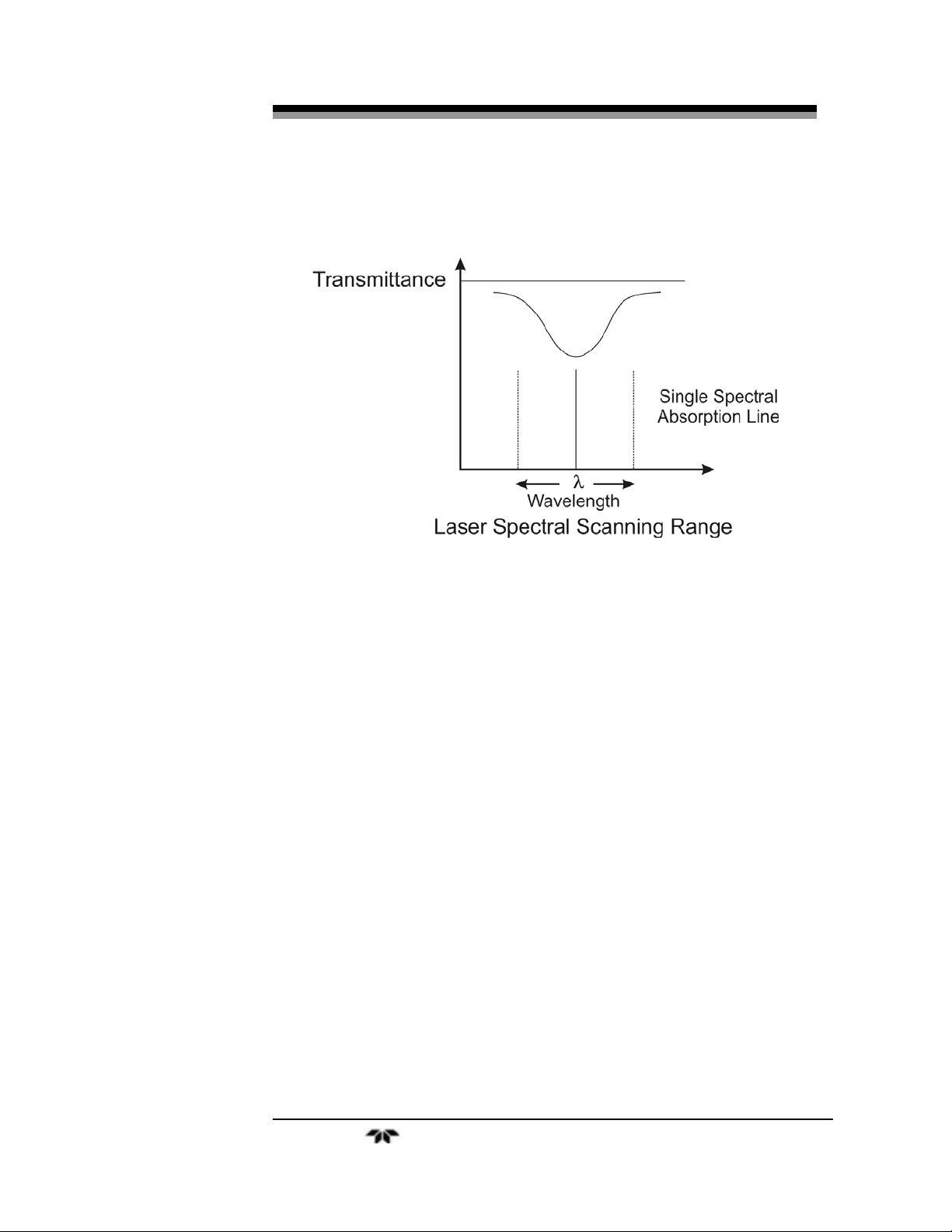

Model 3500 Laser Gas Analysis System series employ advanced Laser

Absorption Spectroscopy (DLAS) gas analysis and measurement

technology, i.e. “single-line” spectroscopic methods.

Conventional infrared spectroscopy uses light sources such as

lamps or LED’s that are normally non-laser and have very broad linewidths. The absorption spectrum obtained includes not only the spectral

lines from the gas under test, but also those from background gas species

which introduces cross interference. DLAS gas analyzers use diode

lasers that have line-widths of less than 0.0001nm, or only 1/106 of that

of the non-laser sources. By selecting a laser that will emit a specific

absorption line close to that of the gas under test and tuning its

wavelength through changing its temperature and driving current, an

absorption spectrum that only covers a single line of the gas under test

can be obtained and eliminates cross interference. See Figure 2-2.

The line-width of a diode laser is much narrower than that of the

gas molecule absorption spectrum. The Laser spectral line is depicted in

the figure as a light solid line.

The diode laser output from the transmitter goes through the

environment under test, gets absorbed by the target gas molecules, and

the resulted attenuated light is collected by the optical sensor in the

receiver unit. The attenuation is in proportion to the concentration of the

target gas. Varying the wavelength of the diode laser within the carefully

selected laser spectral scanning range (Figure 1.2), a gas absorption

spectral line without interference from the absorption spectra of

background dust and other gas species can be obtained for high

precision data analysis. This feature, no interference from background

dust and gases, enables the laser gas analysis systems to be applied on

the spot for online gas analysis. Conventional infrared spectroscopy, due

Teledyne Analytical Instruments 8

Page 23

Laser Gas Analyzer Operational Theory

to their vulnerability to interference from background gases and dust,

cannot or can hardly conduct on-the-spot measurement.

Figure 2.2 Schematic of “Single line” Spectroscopy.

The Model 3500 series of analyzers do not need complex gas

sampling and pretreatment. They have extremely quick response

because they skip the long gas sampling and transport process. As a

result, system maintenance is minimal since gas sampling and

pretreatment systems contribute to the majority of the maintenance

workload for conventional sampling gas analysis systems.

In conventional sampling gas analysis systems, it is the gas

concentration in the vicinity of the sampling tip that is sampled and

measured. Since gas concentration can have significant variance across

the section of gas flow pipe, inaccurate measurements result. No matter

how precise the subsequent data analysis is, the measurement results do

not accurately indicate the overall gas concentration in the gas flow pipe.

In contrast, the Model 3500 measures the average gas concentration

from the transmitter to the receiver. This represents the gas

concentration of the gas flow process much more accurately.

In addition, laser gas analysis systems have built-in temperature

and pressure auto-correction capability to enhance measurement

accuracy. These systems compensate for the temperature and pressure

Teledyne Analytical Instruments 9

Page 24

Operational Theory Model 3500

variance in the environment under test using a proprietary algorithm by

having input for temperature and pressure.

2.3 Software

An executable program is embedded program in the microprocessor

of the central process unit and is programmed to perform a multitude of

tasks including:

Signal processing

Data analysis

Managing system I/O including keyboard operations and display

Performs the system self-test

Calibration,

Alarm activation

In addition, the software establishes data communication with PC

through the RS232 serial communication port and GPRS modules. TAI

provides WINDOWS-based PC service program for all models in the

3500 series. Please refer to Appendix A for details.

Teledyne Analytical Instruments 10

Page 25

Laser Gas Analyzer Installation

Installation

Installation of the Model 3500 includes:

• Unpacking

• Mounting

• Flange connections

• Installing transmitter and receiver

• Electrical connections

• Optical transmission adjustments and fine tuning

3.1 Unpacking the Instrument

The unit is shipped with all the materials you need to install and

prepare the system for operation. Carefully unpack the analyzer and inspect

it for damage. Immediately report any damage to the shipping agent.

3.2 Installation Preparation

It is very important to prepare thoroughly before installing the

system. This includes having all the tools needed handy, choosing a

proper installation location, and correct welding of the flanges to the gas

flow pipe well. See section 3.3.1. Figure 3-1 shows the general layout of

the Model 3500 Laser Gas Analyzer.

3.2.1 Installation and Adjustment Tools

The following tools will be required for proper installation:

Wrenches M5 wrench—used to tighten the M5 bolts

connecting the instrument flange and

transmitter/receiver.

Two 12” adjustable wrenches—used to tighten

EMC and nut connector.

Teledyne Analytical Instruments 11

Page 26

Installation Model 3500

Two 8” adjustable wrenches—used to tighten

socket screws in purging system.

Socket screwdrivers M6 hexagonal socket screwdriver—used

to tighten M6 hexagonal socket bolt on the

receiver and transmitter box cover.

M5 hexagonal socket screwdriver—used to

tighten M5 hexagonal socket bolt on the receiver.

Screwdrivers 6mm slotted screwdriver—used to rotate the M8

fastening screws between the instrument and the

weld flanges, and the purging apparatus snap ring

screws.

3mm slotted screwdriver—used to connect

electric parts and components.

Digital multimeter.

Tubing cutter.

Tube bender for 6 and 12 mm tubing

Figure 3-1: General Layout of the Model 3500 Series Analyzer

Teledyne Analytical Instruments 12

Page 27

Laser Gas Analyzer Installation

3.2.2 Choosing Installation Spot

It is strongly recommended to install the system probes on a

straight section of the gas flow pipeline to ensure uniformity of the gas

flow. The length of straight pipe before the installation spot should be at

least twice (5 times, recommended) as much as the diameter of the pipe,

and half (twice, recommended) after the installation spot.

Note: The laser gas analysis system measures the average

concentration along the laser beam path (see Figure 1.2).

If there is no straight pipe section for mounting the flanges,

it may still be possible to get accurate measurements.

(Please contact our technical support center).

In addition, the installation spot should be chosen carefully

considering both safety and ergonomic factors. A platform should be

constructed when the chosen spot is not fully accommodating.

3.3 Analysis Section Installation

Installation of the analysis section involves:

• Welding flanges onto the process pipe

• Installing instrument flanges

• Checking the offset angle using the laser pen

• Adjusting the coaxial angle of the two instrument flanges,

• Installing the transmitter unit and the receiver unit.

3.3.1 Welding Flanges

The transmitter and receiver units of the analysis section are

mounted on DN50 flanges and mate to corresponding flanges which

must be welded onto the process pipe.

Note: The customer is responsible for correct welding of the

flanges onto the process pipe. The use of a competent

professional welder is required to ensure proper placement

of the flanges and provide a leak-free weldment.

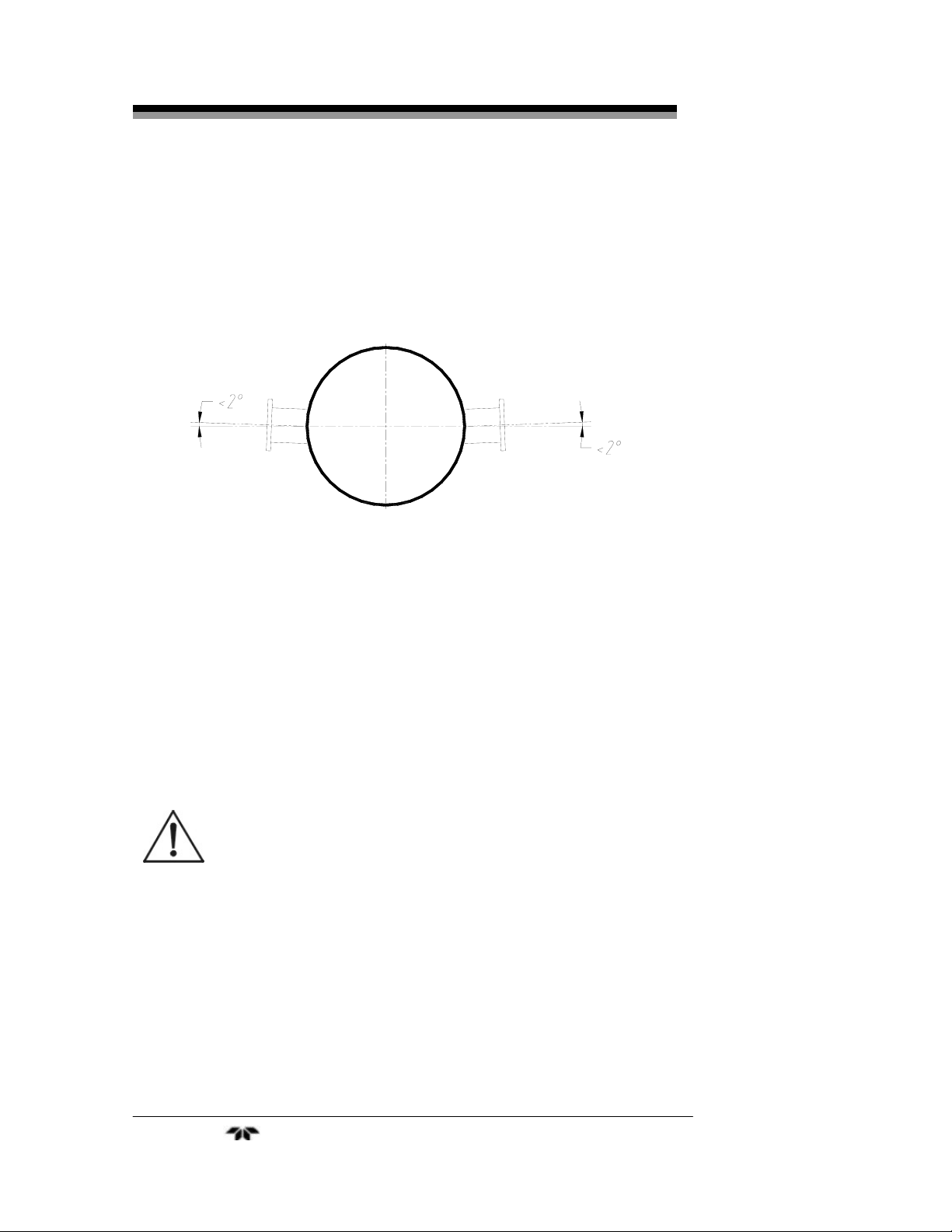

The precision adjustment between the welding flange and the

instrument flange with the supplied O-ring can fine tune the optical

transmission to a limited extent. This allows for the two welding flanges

Teledyne Analytical Instruments 13

Page 28

Installation Model 3500

to have a limited coaxial offset between them. When welding the two

welding flanges the offset angle between their axes must be held to less

than 4°. Typically, the two welded flanges are positioned horizontally on

the gas flow pipe well across the pipe diameter As Shown in Figure 3-2.

Figure 3.2: Allowed offset for welded flanges

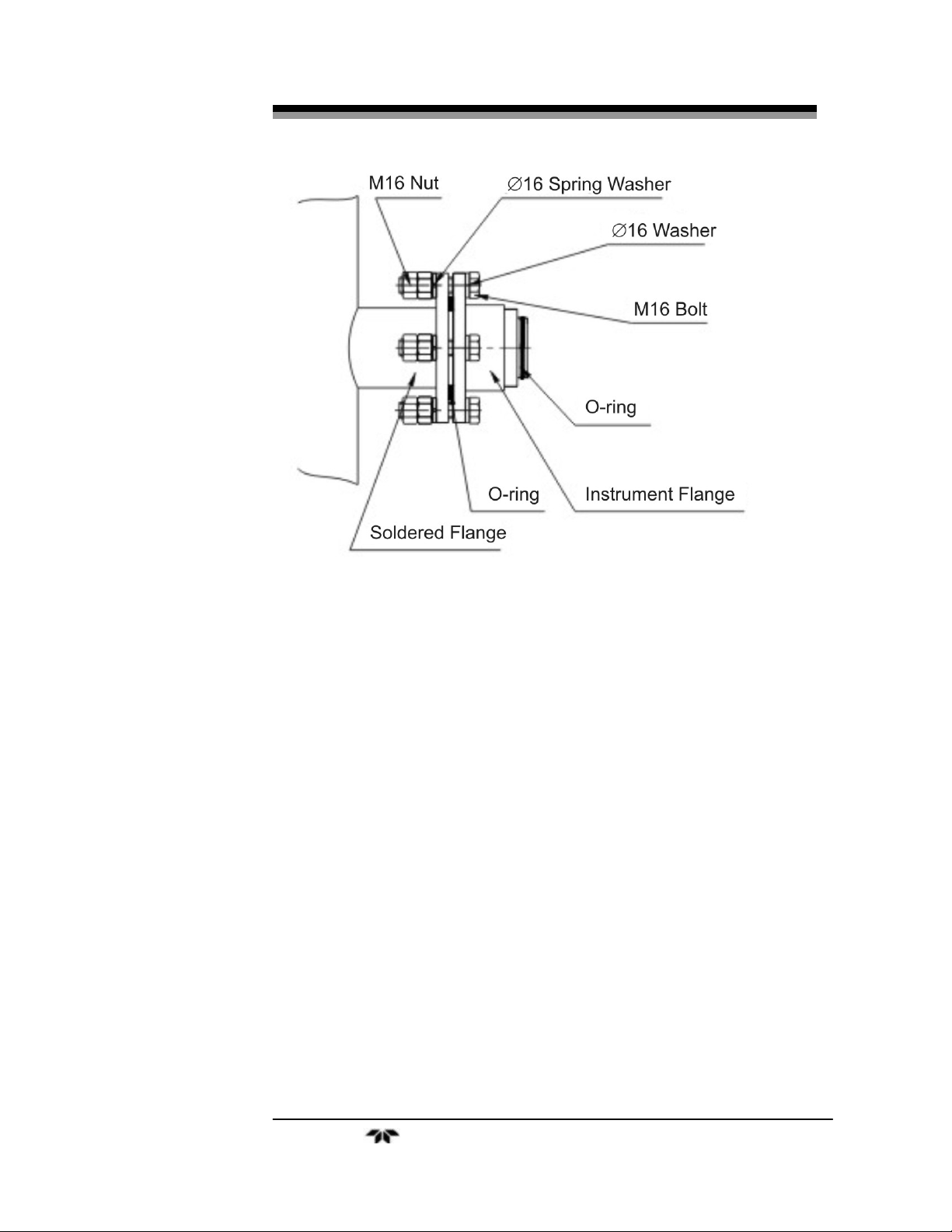

3.3.2 Installing Instrument Flanges

After welding the flanges, the Model 3500 probes can be installed.

Before installing, apply a lubricant to all the screw connections. To

make adjustments easier it is suggested that you use the adjusting aid

tools available from TAI (P/N XXXXX). These include a visible light

laser pen and a scaled target for alignment.

WARNING: POWER TO THE SYSTEM MUST BE OFF DURING

THE INSTALLATION OF THE TRANSMITTER AND

RECEIVER UNITS. DO NOT CONNECT OR SWITCH

ON THE POWER SUPPLY AT THIS STAGE. THE

LASER BEAM IS INVISIBLE AND CAN CAUSE EYE

DAMAGE.

Mount the two instrument flanges onto the welded welding flanges

with 8 M16 bolts (with spring washer and plain washer) and 2 O-rings.

Raise the instrument flanges to the same height as the welded flanges,

then tighten the 8 M16 bolts to about half tight to make sure that the Orings are sealing. Typically the distance between the instrument flange

and the welding flange is around 3mm. See Figure 3.3.

Teledyne Analytical Instruments 14

Page 29

Laser Gas Analyzer Installation

Figure 3-3: Instrument Flange

3.3.3 Checking Offset Using the Laser Pen and Target

The laser pen is an optical transmission adjustment aid tool

available through TAI. The part number is listed in the Spare Parts List

in the Appendix. The laser pen emits visible red light beam and is used

to adjust the coaxial offset of the two instrument flanges. This assumes

that the welded flanges were installed correctly and held to within 4

degrees total offset with respect to each other.

Prior to adjusting the instrument flanges the laser pen must first be

checked for alignment.

3.3.3.1 CHECKING THE LASER PEN FOR ALIGNMENT

To see if the laser pen is suitable for your installation, apply the

following test:

1. Mount the laser pen on one instrument flange and the scaled

target onto the other instrument flange. Tighten with mounting

nuts.

2. Turn on the laser pen and observe the light spot on the target.

Teledyne Analytical Instruments 15

Page 30

Installation Model 3500

3. Loosen the mounting nut, rotate the laser pen around and tighten

the mounting nut again. Record the new light spot.

The trace of light spot on the target forms a circle. If the diameter

is less than 1/600 of the distance between the laser pen and the scaled

target, then the coaxial degree of the pen is adequate. Otherwise, please

contact our technical support center. See Figure 3.4.

3.3.3.2 ADJUSTING THE COAXIAL OFFSET OF THE INSTRUMENT FLANGES

To adjust the coaxial offset of the two installed instrument flanges

use the following procedure:

a. Tighten the laser pen on one of the instrument flanges with a

mounting nut. Install the scaled target on the other instrument

flange. Turn on the laser pen and check whether the light spot

is on the center of the scaled target. If not, adjust (tighten or

loosen) the 4 M16 bolts on the instrument flange where the

laser pen is mounted until the light spot is at the center of the

target. See Figure 3.4.

Figure 3.4 Adjusting the Instrument Flanges with Laser Pen and

Target.

4. Switch the laser pen with the scaled target, and redo step 1.

5. Redo step 2 repeatedly until the light spot is always at the center

of the scaled target without any adjustment.

6. Keep the laser pen on, tighten the 4 fastening screws on the

instrument flange where the laser pen is mounted, and keep an

eye on the light spot on the scaled target. If it moves, repeat steps

1, 2, and 3 until the light spot does not move.

Teledyne Analytical Instruments 16

Page 31

Laser Gas Analyzer Installation

7. Repeat step 4 to tighten 4 fastening screws on the other

instrument flange.

3.3.4 Installing the Transmitter Unit and the Receiver Unit

Mount the transmitter unit on one of the instrument flanges as

shown in Figure 3.1. Tighten it with the mounting nut, then tighten the

fastening screw. Mount the receiver unit the same way.

3.4 Central Processing Unit Installation

The central processing unit is a wall-mountable enclosure that is

hung on the wall of the instrument control center or in an analysis room

in the field. There are four pothooks on the housing for this purpose.

Secure the unit case to the wall using 4 M6 screws. Refer to Figure 3.5

for the case dimensions. The central processing unit should be hung at a

proper height for comfortable operation.

Figure 3.5 Dimension of the Central Processing Unit (in mm).

To avoid turning on the power supply inadvertently and possibly

causing harm to operators in the field, the central processing unit is

Teledyne Analytical Instruments 17

Page 32

Installation Model 3500

designed without a power switch. A separate wall mountable enclosure

is supplied for housing the power supply and switches.

CAUTION: DO NOT DISCONNECT THE CABLE BETWEEN THE

CENTRAL PROCESSING UNIT, THE TRANSMITTER

UNIT AND THE RECEIVER UNIT WHEN THE POWER

SUPPLY IS ON. THIS COULD CAUSE DAMAGE TO

THE LASER.

3.5 Purge System Installation

If dust or other pollutant concentration is relatively high in the

environment under test, a purging system must be installed to protect the

optical devices in the transmitter and receiver units.

In a typical purging system, the purge gas is directed through the

inside of the instrument flange, the welding flange or a special purging

pipe, and into the gas flow pipe. The purging gas forms an air wall to

protect the optical devices. The purge flow required depends on the

process environment. Usually, a purge gas flow rate in the range of 5-50

L/min×2 is required.

Compressed air or nitrogen is the most frequently used purging gas

sources. A filter should be installed to remove dust, water and oil

droplets larger than 1 micron in size before entering the system to

prevent the purge gas from contaminating the optical devices,. TAI

provides a range of purge systems for various applications and most are

equipped with appropriate filters. Please contact technical support if

your application requires a purge system.

A typical purge system is shown in Figure 3.6. This unit uses

compressed air (or nitrogen) as the purge gas and includes a 1 micron

filter. Two needle valves and flowmeters are installed to monitor and

control the purge rate to the transmitter and receiver. The housing is

equipped with a window for visual access while the housing door is

sealed.

To install the purge unit, connect each gas outlet of the purge

system to a purge inlet on the instrument flanges. Connect the inlet to a

suitable purge gas supply. A regulator should be used to control the

pressure to the purge system. The gas pressure depends on the particular

purge system installed and will be noted on the unit.

Teledyne Analytical Instruments 18

Page 33

Laser Gas Analyzer Installation

Open the gas supply and set the regulator to the proper pressure.

Turn the needle valve on the flow meter to the maximum, and then

adjust the needle valve adjacent to the flow meter to get the required

flow rate.

CAUTION: THE PURGE FLOW SHOULD REMAIN ON AFTER

THE POWER TO THE UNIT HAS BEEN TURNED OFF.

THIS PREVENTS DUST AND OTHER POLLUTANTS

IN THE ENVIRONMENT UNDER TEST FROM

CONTAMINATING THE OPTICAL DEVICES IN THE

TRANSMITTER AND RECEIVER UNITS.

Figure 3.6 Typical Purging System for the Model 3500

3.6 Electric Wiring and Connection

Depending on the instrument configuration, the Model 3500 Laser

Gas Analysis System can be categorized as Non-fiber optic and Fiber

optic. Non-fiber optic models (C option) use diode lasers without a fiber

pigtail. In these models, the laser diode is located in the transmitter unit.

The fiber optic models (F option) use a fiber pigtail to transmit the laser

Teledyne Analytical Instruments 19

Page 34

Installation Model 3500

radiation to the process. In these models, the laser diode is located in the

central processing unit, and the laser output beam is sent to the

transmitter unit through optical fiber. The electrical connections are

slightly different between the two models as shown in Figures 3.7 and

3.8. These figures show the connection ports on the central processing

unit for non fiber optic unit (Figure 3-7) and the fiber optic unit (Figure

3-8). Both instruments use 250V/2A fuses.

The Model 3500 provides input, output, and communication ports

on the bottom of the central processing unit enclosure. The following

input/output/communication signals are supported:

Output: 3-channel relay alarm output

1 4-20mA gas concentration output

Input: 2 4-20mA pressure and temperature input

Comm: 1 channel RS232/GPRS port for communications

with PC.

The input and output signal lines are connected to the motherboard

inside the central processing unit via a connection socket. Table 3.1

shows the specific electric connection for different input and output

signals. Customers may choose to connect these signal lines according

to their needs.

1. Grounding pole

2. RS232 connection port

3. Cable port between the

central processing unit and

the probe

4. 4-20mA connection port

5. Relay connection port

6. Fuse socket

7. Power supply port

Figure 3.7 Electric Connection Ports on the Central Processing

Unit for Non-fiber Optic Analysis Systems.

Teledyne Analytical Instruments 20

Page 35

Laser Gas Analyzer Installation

1. Grounding pole

2. RS232 connection port

3. Cable port between central

processing unit and the

probe

4. 4-20mA connection port

5. Relay connection port

6. Fuse socket

Figure 3.8: Electric Connection Ports on the Central Processing

Unit for Analysis Systems Using Fiber Optic Pigtail

Table 3.1 Electric connections & definitions of Input, Output Signals of

Central Processing Unit

Socket No. On

Motherboard

31 5V Power Supply

32 DGND Power Supply Ground

33 RS232-RXD

34 RS232-GND

35 RS232-TXD

36 4-20mA Concentration Output (-)

37 4-20mA Concentration Output (+)

38 4-20mA Pressure Input (-)

39 4-20mA Pressure Input (+)

40 4-20mA Pressure Input24V Power Supply

41 4-20mA Temperature Input (-)

Name

42 4-20mA Temperature Input (+)

43 4-20mA Temperature Input 24V Power Supply

44 Warning Alarm Relay 1

Teledyne Analytical Instruments 21

Page 36

Installation Model 3500

45 Warning Alarm Relay 2

46 Error Alarm Relay 1

47 Error Alarm Relay 2

48 Concentration Alarm Relay 1

49 Concentration Alarm Relay 2

WARNING: TURN OFF THE POWER BEFORE ELECTRIC WIRING.

OTHERWISE THE SYSTEM WOULD BE DAMAGED.

3.7 Optimize of the Optical Transmission Alignment

At this point, the installation and initial adjustment of all

components have been completed and the instrument can be powered

up.

Turn on the power supply. The LCD screen displays the startup,

initializing, and self test screens successively. Images of these screens

can be found in the next section as Figures 4.2, 4.3, and 4.4 respectively.

If the self test is successful, the LCD screen will then display

measurement and status information. Note the transmittance value on

the status bar. If this value is greater than 80%, then the installation and

adjustment step is successful and the system can be placed in service.

Otherwise, follow the steps below to fine tune and optimize the optical

transmission between the transmitter unit and the receiver unit.

a. Open the receiver unit box cover.

b. Use a voltage meter to measure the voltage between 3(+) and

4(-) of the wiring extremity. When the optical transmission is

optimized, the voltage is about 4.2V.

c. Loosen the 4 fastening screws on the instrument flange

where the transmitter unit is mounted (see Figure 3.3). Adjust

the flange by either tightening or loosening the 4 M16 bolts

until the measured voltage stabilizes to its maximum value.

Tighten the four fastening screws.

d. Replace the box cover.

Teledyne Analytical Instruments 22

Page 37

Laser Gas Analyzer Operation

Operation

The executable embedded program in the MCU of the central

process unit performs signal processing and data analysis, manages

system I/Os including keyboard operations and LCD, and runs system

self-test, calibration, and alarm. Furthermore, it establishes data

communication with PC through RS232 serial communication port and

GPRS modules. FPI provides WINDOWS-based PC service program for

all models of LGA-2000 analysis systems. Please refer to Appendix A

for details.

4.1 Front Panel

The Model 3500 front panel consists of a LCD screen and a 16 key

membrane keyboard. The LCD screen displays system information as

described in the following sections. The membrane keyboard is used to

carry out all user operations such as setting alarm parameters, setting

environment temperature and pressure, setting the optical path length,

doing system calibration, etc. The front panel is showed in Figure 4.1.

Figure 4-1: Model 3500 Series Front Panel

Teledyne Analytical Instruments 23

Page 38

Operation Model 3500

There are 16 available keys on the membrane keyboard. They

include 2 function keys (SET and ESC), 2 direction keys for navigation

(<,>), 0-9 digit keys plus a decimal point for input, and a backspace key

(BKSP). They function as follows:

• “SET” is a function keystroke. Press it to enter sub menu or

confirm data input.

• “<” And “>” are direction keystrokes. They are used to move the

cursor.

• “ESC” is a function keystroke. Press it to exit the sub menu and

go back up the menu, or to cancel the input data.

• “0-9” are digit keystrokes. They are for number input.

• “.” is the decimal point.

• “BKSP” is the backspace keystroke. It is used to delete the last

input digit.

4.2 System Mode

During operation the Model 3500 Laser Analysis System can be in

three different modes.

• Start-up Mode

• Normal Mode

• Error Mode

4.2.1 Start-up Mode

When the power is turned on, the system will automatically invoke

the start-up mode. In this mode, the system initializes and performs the

self-test routine.

The first menu on LCD screen is the start-up menu and shows the

company logo and name, instrument model and name. See Figure 4.2.

Teledyne Analytical Instruments 24

Page 39

Laser Gas Analyzer Operation

Figure 4.2 System Start-up Screen

After two seconds, the system enters the initialization stage. The

process lasts 5 seconds. Figure 4.3 shows the system init menu on LCD

screen displaying “ System initializing…” status.

Figure 4.3 System Init Screen

After initialization, the system starts the self test routine to examine

whether the system function modules are working properly. Normally,

the process takes about 6 minutes. Figure 4.4 is the system self test

screen showing “System Selftesting…” status. If everything is OK,

Teledyne Analytical Instruments 25

Page 40

Operation Model 3500

system the self test ends and the system automatically enters normal

mode. In the normal mode, the LCD displays system information.

Figure 4.4: Self Testing Screen

4.2.2 Normal Mode

In the normal mode, the system performs gas concentration

measurement and monitoring. There are two different working states

within the normal mode:

Normal working status: In this state, the system is measuring

normally. The LCD shows the measured gas concentration value and

other system information; “Normal” is shown on the status bar. The

analog output port (4-20mA) sends out the corresponding measured

value.

Warning working status: When the system finds that the system

external input parameters (mainly the pressure and temperature of the

gas under test) are abnormal or the optical transmittance is too low, it

automatically switches to warning working status. In this status, the

front panel of the LCD shows the corresponding warning signal (Alarm

code on the status bar, and warning symbol

in MainMenu in

graphics mode). The system computes the gas concentration value using

default values for input parameters and sends out 4-20mA output

CAUTION: SCREEN DISPLAY OF THE MEASURED

CONCENTRATION MAY BE HIGHLY INACCURATE IN

THIS MODE.

Teledyne Analytical Instruments 26

Page 41

Laser Gas Analyzer Operation

4.2.3 Error Mode

When the analysis system detects any fatal error that may damage

the system permanently (for instance, when the temperature in the

central processing unit is too high or the temperature of the laser device

is abnormal), the system automatically switches from start-up mode or

normal mode to error mode. In this mode, the system will stop gas

concentration measurement and most system operations, and enter

protection status. The front panel on LCD shows the corresponding error

information (Alarm code in the status bar, and error symbol in

MainMenu in graphics mode). The output ports (4-20mA and relay) still

send out alarm information.

4.3 System Menu

The Model 3500 operation interface employs a user-friendly menu

structure. There are six main menus:

• MainMenu

• Display

• System

• Cali.

• Com.

• Alarm

The entire menu has a simple and clear structure as shown in Figure

4.5 and is easy to operate.

Teledyne Analytical Instruments 27

Page 42

Operation Model 3500

Figure 4.5: System Menu Structure

4.3.1 MainMenu

MainMenu is the menu displayed after the system finishes start-up,

initializing and selftesting, and enters normal working status. The

MainMenu has two display modes—graphics, and numeric. The two

modes are switched through the Display menu. The graphics mode is

shown in Figure 4.6.

Teledyne Analytical Instruments 28

Page 43

Laser Gas Analyzer Operation

a

b

c

d

Figure 4-6: MainMenu—Graphic

The meaning of each location on the menu is described below:

e

f

g

h

a. Menu name (the same for all the other menus)

b. The name of the gas under test

c. Bar that shows measured gas concentration value

d. The button pointing to sub menus. When the cursor is on the

button, it is highlighted. Press SET to enter the submenus.

(Functions the same for all the other menus).

e. Status bar that shows the current measured gas concentration

value and the working status of the system (If everything is

OK, it displays Normal; Otherwise, it gives the Alarm Code).

(Functions the same for all the other menus).

f. Average gas concentration value

g. Units for gas concentration

h. Upper limit of gas concentration alarm range. The lower limit

is shown on the left side. These two values can be reset from

the Alarm menu.

The numerical value mode is shown in Figure 4.7.

Teledyne Analytical Instruments 29

Page 44

Operation Model 3500

Figure 4.7 Numerical Value Mode of the MainMenu

The meaning of each item on the menu is listed below:

• Current concentration: the gas concentration value just measured

• Average concentration: gas concentration value after digital

filtering. It can alleviate the influence caused by the uncertainty

of gas flow.

• Standard dev: standard deviation of the measured gas

concentration.

• Gas temperature: the temperature of the gas under test.

• Gas pressure: the pressure of the gas under test.

• Ave. times: Number of times used in digital filtering.

• Trans: Transmittance of laser beam in the environment under

test. If the optical windows in the transmitter and the receiver are

contaminated by dust in the environment under test, or if the

optical path between the transmitter and the receiver deviates

from the optimal position, the transmittance decreases.

• Con. output--4mA: gas concentration value corresponding to

4mA of the 4-20mA gas concentration output.

Teledyne Analytical Instruments 30

Page 45

Laser Gas Analyzer Operation

τ

τ

• Con. output--20mA: gas concentration value corresponding to

20mA of the 4-20mA gas concentration output.

• System time: the time of system clock.

• System date: the date of system clock.

Note: The Model 3500 outputs average gas concentration at the

4-20mA gas concentration output port.

The computation method for average concentration and standard

deviation is described below:

Average Concentration

1

g

new

N

g

cur

1

⎛

⎜

⎝

⎞

g

−+=

1

⎟

N

⎠

old

Where:

g ——Average concentration value

new

g ——Current concentration value

cur

g —— the average concentration value before adding the

old

latest measurement

g

stored in the system memory

cur

N ——Ave. times

The method is in equivalent to having the current concentration

value pass through a low-pass filter with a cut-off frequency at

1

f

=

2

N

τπ

, where

measurement. Typically, the Model 3500 series instruments have

is the time the system needs to finish one

set

at ∼1 second at the factory. However, it can also be set at any value in

the range of 0.1~1 second upon customer request to suit particular

applications that require faster response time. Contact technical support

for more information.

Normally, every time the system finishes one measurement cycle,

the LCD display and output at the 4-20mA output port refreshes.

Standard Deviation

Teledyne Analytical Instruments 31

Page 46

Operation Model 3500

+++

In a sequence of the last k current concentration values:

CCCC ,,,.......

. The average value of the sequence is:

nnnkn

121 −−+−

=

C

...

CCC

nnkn

−+− 11

.

k

The standard deviation of current gas concentration is given by:

2

=

e

n

1

1

−+−

1

−

k

22

)()(...)(

−+−++−

CCCCCC

nnkn

.

The Model 3500 sets k to 20 by default. For a strictly random

concentration sequence, statistically, different k produces the same

standard deviation.

Note: The 4-20mA output port on the Model 3500 outputs the

average gas concentration value computed with the above

method, the standard deviation at the port is therefore

about

N1

of the value displayed on the LCD, where, N

is the average times set by the user.

In the MainMenu, there are 5 submenus: Display, System, Cali.,

Com. and Alarm. In the MainMenu, the system only reacts to “SET”,

“<” and “>”. All the other keystrokes are disabled.

Press “SET”—the system enters the submenu selected by the

cursor.

Press “<”—the cursor moves one position left. If the cursor is

already on the leftmost button, the cursor moves to

the rightmost button.

Press “>”—the cursor moves one position right. If the cursor is

already on the rightmost button, the cursor moves to

the leftmost button.

By operating the above keystrokes, you can enter the submenu of

MainMenu:

the

• Display: Press “SET”—the system enters the Display menu.

• System: Press “SET”—the system asks for Sys Pwd. If the

password is correct, the system enters the

Teledyne Analytical Instruments 32

System menu.

Page 47

Laser Gas Analyzer Operation

• Cali.: Press “SET”—the system asks for Cali Pwd. If the

password is correct, the system enters the

• Com.: Press “SET”—the system enters the Com. menu.

• Alarm: Press “SET”—the system enters the Alarm menu.

4.3.2 Display

Cali. menu.

In Display menu, there are five submenus, Mode, Unit, Language,

TimeDate and Admin. See Figure 4-8. Pressing “<”,”>” and “SET”,

users can select display mode, unit of parameters, language

(English/Chinese), set system clock time and date, and change

passwords. Press “ESC”, the system goes back to the

MainMenu.

Figure 4.8 Display menu

• Mode: Press “SET”, a small window popes up, asking the user to

choose between Numerical Value Mode and Graphics Mode.

The difference between the two display modes is described in

Section 4.3.1

MainMenu.

Teledyne Analytical Instruments 33

Page 48

Operation Model 3500

Figure 4.9 Display Mode Options

• Unit: Choose unit for different parameters. Press “SET” to enter

Unit submenu.

Figure 4.10 Unit Menu

Teledyne Analytical Instruments 34

Page 49

Laser Gas Analyzer Operation

Users can set the unit for concentration, length, temperature and

pressure by pressing “SET” in different cursor locations. For example,

press “SET” when the cursor is on

Con. Unit, the system enters the

following menu:

Figure 4.11 Set Con. Unit menu

The following units for concentration, length, temperature and

pressure are available:

• Con. Unit: ppm, %, g/m

3

, g/Nm3, mg/m3, mg/Nm3

• Len. Unit: m, cm, ft, inch

• Temp. Unit: °F, K, °C

• Pres. Unit: bar, Pa, mbar, psi, Mpa

Six units are provided in the

%, g/m

3

, g/Nm3, mg/m3, and mg/Nm3. Units in ppm and % are

commonly used for volume percentage concentration while g/m

3

mg/m

are mass volume ratio concentration units related to volume

percentage concentration through the ideal gas equation

Con. Unit menu to choose from: ppm,

3

and

. The units

g/Nm3 and mg/Nm3 are mass volume ratio concentration units (standard

state , pressure: 1.01325Bar, temperature: 273.1K).

Teledyne Analytical Instruments 35

Page 50

Operation Model 3500

• Language: Press “SET” to select between Chinese and English.

Figure 4.12 Pop-up Window for Language Selection

After the selection, all menus are in the language selected.

• TimeDate: Press “SET” to set system clock time and date.

Figure 4.13 TimeDate Menu

Teledyne Analytical Instruments 36

Page 51

Laser Gas Analyzer Operation

• Admin.: Press “SET”, the system asks for Pwd. If the Pwd is

entered correctly, the system enters the

Admin. menu. (Figure

4.14).

Figure 4.14 Admin. Menu

From the Admin screen you can change passwords and update the

system software. The selectable items are:

• Change Admin. Pwd: change the password to Admin. menu.

(Figure 4.14).

• Change Sys. Pwd: change the password to System menu (Figure

4.15).

• Change Cali. Pwd: change the password to Cali. menu (Figure

4.23).

• Update instrument software: press to enter software update

interface to upgrade system software.

To change the passwords of

System and Cali., you must enter the

Admin. Menu. The user who has the Admin. password has the highest

authority. With this privilege you can reset

System pwd and Cali. pwd

to ensure authorized system management.

Teledyne Analytical Instruments 37

Page 52

Operation Model 3500

The default Admin. Pwd is 2222. The default System. Pwd is

1111. The default

Cali. Pwd is 3333.

Additional information about software updates is available through

the technical support center.

4.3.3 System

System menu includes System main menu and System sub menu.

In the

MainMenu, move the cursor to System and press “SET”, the

system asks for password, if the password keyed in by the operator is

correct, the system enters the System main menu.

Note: In error mode, the system is in Error Protection Menu (see

Figure 4.39), and the System main menu is not accessible.

a

b

c

Figure 4.15 System main menu

The system main menu is shown in Figure 4.15. The data fields for

this menu are as follows:

d

• Path length: optical path length of the gas under test.

• Gas temperature: temperature of the gas under test.

• Gas pressure: pressure of the gas under test.

Teledyne Analytical Instruments 38

Page 53

Laser Gas Analyzer Operation

• Average times: number of times used to calculate average

concentration.

• Con. output--4mA: gas concentration value corresponding to

4mA of the 4-20mA gas concentration output.

• Con. output--20mA: gas concentration value corresponding to

20mA of the 4-20mA gas concentration output.

• Purge parameter: purging system parameters including the

length, temperature and density of the purging gas. Interaction

with the purge system is done through this menu.

• Transmission: Transmittance of laser beam in the environment

under test.

On this menu, the operator can move the cursor to a parameter

button, press “SET”, and a pop-up window occurs for the operator to

reset it (Figure 4.15). The items in the column refer to:

Item name

a.

Value

b.

Unit

c.

Way to set the item (key in manually or from a measurement).

d.

None will be shown here if it can only be keyed in.

4.3.3.1 SYSTEM PARAMETER INPUT METHOD

As an example, the following demonstrates the way to reset optical

path length.

Move the cursor to “Length” button and press “SET”. The Path

1.

length input window pops up.

Teledyne Analytical Instruments 39

Page 54

Operation Model 3500

Figure 4.16 Set Optical Path Length

2.

Key in the new optical path length value (Figure 4.17).

a

Figure 4.17 Input the New Optical Path Length Value

3.

Press “SET” to accept the new setting.

b

c

d

The call-outs on Figure 4.17 refer to:

Teledyne Analytical Instruments 40

Page 55

Laser Gas Analyzer Operation

a. Item name

b.

Unit of the item

Current value

c.

New data input. The underscore after the number shows where

d.

the next digit goes.

Note: After the system parameter input window pops up,

keystrokes “<” and “>” are disabled.

The “SET” key is used to accept the new setting and close the input

window. If no data is keyed in, and “SET” is pressed, the system

defaults to 0. If the data keyed in is out of range, an error alert is issued.

Use the “ESC” key to reject the new setting and close the input

window. The “ESC” key is used when you have input wrong data and do

not want the system to accept it.

The numerical keys “0-9” are used to enter data digits. The

underscore moves a position to the right with each input. Similarly, the

decimal point key “.” Is used to input the decimal point.

The Backspace key, “BKSP”, is used to delete the last data digit,

The underscore moves a position to the left with each deletion.

4.3.3.2 SYSTEM SUB MENUS

The sub menus of the System menu are:

• Path: —set optical path length value (0-12m), manual.

• Temp: — set temperature of the gas under test (200-3000) K,

manual or from a measurement. When choose Measure, the

system enters Measured Temperature Set menu.

• Pressure: —set pressure of the gas under test (0-20) bar, manual

or from a measurement. When choose Measure, the system

enters Measured Pressure Set menu.

• Av Times: —set number of times used to calculate average

concentration (0-90), manual.

• Out Set: —set the range of 4-20mA concentration output.

• Purge: —set parameters of the purging gas including purging gas

concentration, purging path and purging gas temperature.

Teledyne Analytical Instruments 41

Page 56

Operation Model 3500

• Apply: —after entering all the data, press this button to finish the

process.

Additional sub menus are located on the next screen. Move the

highlighted button to the ---- > symbol and press “Set”.

The additional system sub menus areas follows:

1. Measured Temperature Menu

Figure 4.18 Measured Temperature Menu

Items displayed on the Measured Temperature screen (Figure 4.18) are:

• Temp.input--4mA: The gas temperature input is taken from a

measurement. It is input to correspond with a 4-20mA output

signal. Temp.input--4mA is the gas temperature corresponding to

4mA.

• Temp.input--20mA: This is also taken from a measurement. It is

the gas temperature corresponding to 20mA.

The buttons on this menu refer to:

4mA: Set the corresponding gas temperature when the

temperature input signal is 4mA.

20mA: Set the corresponding gas temperature when the

temperature input signal is 20mA.

2. Measured Pressure Menu

Teledyne Analytical Instruments 42

Page 57

Laser Gas Analyzer Operation

Figure 4.19: Measured Pressure Menu

Items displayed on the Measured Pressure screen (Figure 4.19) are:

• Pres. input--4mA: The gas pressure input is taken from a

pressure measurement. It is input to correspond with a 4-20mA

output signal. Pres. input--4mA is the gas pressure corresponding

to 4mA.

• Pres. input--20mA: This is also taken from a measurement. It is

the gas pressure corresponding to 20mA.

The buttons on this menu refer to:

4mA: Set the corresponding gas pressure when the pressure

input signal is 4mA.

20mA: Set the corresponding gas pressure when the pressure

input signal is 20mA.

3. Concentration Output Menu

Items displayed on the Concentration Output screen (Figure 4.20)

are:

• Con. output--4mA: The measured gas concentration output is in

the form of 4-20mA. Con. output--4mA is the gas concentration

value corresponding to 4mA.

Teledyne Analytical Instruments 43

Page 58

Operation Model 3500

• Con. output--20mA: The measured gas concentration output is in

the form of 4-20mA. Con. output--20mA is the gas concentration

value corresponding to 20mA.

Figure 4.20 Concentration Output Menu

The buttons on this menu refer to:

4mA: Set the corresponding gas concentration (0-

99.9999)% when the gas concentration output signal

is 4mA.

20mA: Set he corresponding gas concentration (0-99.9999)%

when the gas concentration output signal is 20mA.

4. Purge Parameter Menu

On the Purge Parameter Menu (Figure 4.21), the selections are:

• Pur Len: Set the purging path length (Lf2+Lf1+Lb1+Lb2, Figure

4.22).

• Pur. Temp: Set the purging gas temperature.

• Pur. Con.: Set the concentration of gas under test in the purging

gas.

Teledyne Analytical Instruments 44

Page 59

Laser Gas Analyzer Operation

Figure 4.21 Purge Parameter Menu

Figure 4.22 Schematic showing purging gas channel

Note: The residual gas in LF3 and LB3 has been interpreted

during zeroing, and thus has no influence on the

Teledyne Analytical Instruments 45

Page 60

Operation Model 3500

measurement result.

4.3.4 Cali.

Cali. main menu is third from left on MainMenu. Pressing “SET”,

the system prompts for the password, if the password is entered

correctly, the system enters

Cali. main menu. (Figure 4.23)

Note: In error mode, the system is in Error Protection Menu (see

Figure 4.39), and the Cali. menu is not accessible.

Figure 4.23 Cali. Main Menu

From this menu, the operator can perform the following operations:

• Adjust zero point: Fill the calibration tube with standard gas

(such as high purity nitrogen) with 0% of the gas under test, and

zero calibrate.

• Calibrate coefficient: Fill the calibration tube with standard gas

(such as high purity Nitrogen) with known concentration of the

gas under test, and perform a span calibration operation.

Note: Perform the zero calibration before doing the span

calibration.

Teledyne Analytical Instruments 46

Page 61

Laser Gas Analyzer Operation

• Backup coefficient: Save current calibration coefficients as

backup. The operator can choose to backup any set of calibration

coefficients they are satisfied with. The Model 3500 has

calibration coefficients backed up before shipping.

• Restore coefficient: When the users are not happy with the

current calibration result, and are unable to get good calibration

results, they can restore the old more satisfying backup

calibration coefficients.

4.3.4.1 ADJUST ZERO:

Zero: Press “SET” when the cursor is on “Zero” button, the system

enters the Pre zeroing menu (Figure 4.24).

Figure 4.24 Pre zeroing sub menu

Choose “Accept” to accept the parameters, and the system starts

zeroing (Figure 4.25). The zeroing gauge bar shows the progress of the

process.

Teledyne Analytical Instruments 47

Page 62

Operation Model 3500

Figure 4.25 Zeroing menu

4.3.4.2 CALI. CO:

Figure 4.26 is the Cali.Co sub menu. On this menu, operators can

set calibration optical path length, temperature, pressure, concentration

parameters needed by the calibration system.

Figure 4.26 Calibration coefficient sub menu

Teledyne Analytical Instruments 48

Page 63

Laser Gas Analyzer Operation

The functions of the buttons on Cali.Co sub menu are:

• Cali.Len: Sets the optical path length of the calibration tube,

manual.

• Cali.Temp: Sets the temperature of the standard gas used for

calibration, manual or from a measurement. When “Measure” is

chosen, the system enters Measured Temperature Set menu.

• Cali.Pres: Sets the pressure of the standard gas used for

calibration, manual or from a measurement. When “Measure” is

chosen, the system enters Measured Pressure Set menu.

• Cali.Con: Enters the concentration value of the standard gas used

for calibration. This value is used to calculate calibration

coefficients.

• Pre.Cali: After inputting all the parameters above, press Pre.Cali

button to accept them, and the system enters the Calibration

Confirmation menu (Figure 4.27).

Note: The system accepts the above input parameters only after

Pre.Cali is pressed.

Figure 4.27 Calibration confirmation menu

Teledyne Analytical Instruments 49

Page 64

Operation Model 3500

The Calibration Confirmation menu (Figure 4.27) displays the

measured average gas concentration, standard deviation and the

concentration value of the standard gas (Calib. Concentration) which

were entered in the

Cali.Co sub menu (Figure 4.26).

Drift within a calibration interval is typically small in the Model

3500 series. If the measured average gas concentration differs

significantly from the entered Calib. Concentration, it is recommended

to choose “Cancel” to reject the calibration and check whether all

parameters on

Cali.Co sub menu (Figure 4.26) are correctly set. Check

also for leaks in the calibration system and whether the standard gas has

been in storage for too long a time..

Note also the standard deviation of the measured gas concentration.

If it is too large with respect to the measured gas concentration, i.e.

greater than 1%, the calibration inaccuracy would be high. Again, it is

recommended to choose “Cancel” to reject the calibration, and check

whether the gas concentration of the standard gas is too low. Make sure

you are using a standard with the recommended concentration value as

listed in the calibration parameter table that comes with the system.

If everything is OK, choose “Accept” to accept the calibration. The

system starts the calibration process and automatically displays the

calibration progression menu (Figure 4.28).

Figure 4.28 Calibration Progression

Teledyne Analytical Instruments 50

Page 65

Laser Gas Analyzer Operation

Note: The accuracy of the system depends on calibration. It is of

the utmost importance to perform a good, accurate

calibration. DO NOT accept any calibration that shows

abnormal behavior.

4.3.4.3 BACKUP

Backup saves the current calibration coefficients to memory. The

operator can choose to backup any set of calibration coefficients they are

satisfied with. The Model 3500 has calibration coefficients backed up

before shipping.

To backup the calibration parameters, move the cursor to the

“Backup” position and press “SET”.

4.3.4.4 RESTORE

If the current calibration parameters are found to be unsatisfactory,

you can restore previously stored backup calibration coefficients.