Page 1

Portable Oxygen Analyzer

E

OPERATING & SERVICE INSTRUCTIONS FOR

AX300

PORTABLE OXYGEN ANALYZER

P/N M75389

Sep 18, 2009

CO 09-0159

TYPE B APPLIED PART:

Equipment provides a degree of protection against electric shock,

particularly regarding—

• Allowable Leakage Current

• Reliability of the protective earth connection (if present)

Teledyne Analytical Instruments i

Page 2

AX300

Copyright © 2009 Teledyne Analytical Instruments.

All Rights Reserved

No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any other language or computer language in whole or in

part, in any form or by any means, whether it be electronic, mechanical, optical, manual, or otherwise, without prior written consent of Teledyne Analytical Instruments,

16830 Chestnut Street, City of Industry, CA 91749-1580, USA.

Warranty

Teledyne warrants that the goods are free from defects of material and of construction

for a period of 2 years (or less, as the case may be, with consumables) from the date of

shipment from Teledyne. The liability of Teledyne, if any, shall be limited solely to the

replacement or repair of the goods, and shall not include shipping costs or other incidental damages as defined in Section 2-715 of the U.S. Uniform Commercial Code.

Teledyne cannot warrant any damage resulting from unauthorized repair, misuse, improper maintenance, negligence, or other events not caused by Teledyne or our goods.

CAUTION: FEDERAL LAW RESTRICTS THIS DEVICE TO SALE BY OR

ON THE ORDER OF A PHYSICIAN.

Teledyne Analytical Instruments ii

Page 3

Portable Oxygen Analyzer

About This Manual

This Manual describes the installation, configuration, operation and

maintenance instructions for Model AX300 portable oxygen analyzer.

This Manual contains Cautions, Warnings, and Notes to ensure safe

and efficient performance of the analyzer.

For convenience with operating and maintaining your analyzer, this

manual includes Specifications, Troubleshooting and Maintenance Spare

Parts sections.

How To Use This Manual

This manual is designed to walk you through the initial set-up of

the AX300 Portable Oxygen Analyzer. After you have used it to initially

commission your analyzer, it becomes a quick reference guide to help

you with specific questions or operating challenges.

Before operating the analyzer for the first time, you are advised to

read and familiarize yourself with the contents of this manual.

Teledyne Analytical Instruments iii

Page 4

AX300

Safety Messages

Your safety and the safety of others are very important. Please carefully read and understand the Caution, Warning and Notes found in several places in the manual.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE PUR-

POSES AND IN THE MANNER DESCRIBED IN THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER THAN

THAT FOR WHICH IT WAS INTENDED, UNPREDICTABLE

BEHAVIOR COULD RESULT POSSIBLY ACCOMPANIED

WITH HAZARDOUS CONSEQUENCES.

Teledyne Analytical Instruments iv

Page 5

Portable Oxygen Analyzer

Table of Contents

Safety Messages .......................................................................... iv

List of Figures .............................................................................. vii

List of Tables .............................................................................. viii

Introduction ................................................................................... 1

1.1 Features 2

1.2 Options 3

1.3 Applications 3

1.4 Operation Summary 3

Operating Instructions .................................................................. 6

2.1 Setup 6

2.1.1 Sensor Installation or Replacement 6

2.1.2 Mounting 8

2.1.2.1 V-Mount Adapter Installation 8

2.1.2.2 Universal Mounting Clamp Installation 9

2.1.3 Battery Installation 9

2.1.4 Calibration 10

2.1.5 Output 0-1 VDC or RS232 12

2.2 Operating Instructions 15

2.2.1 Procedure 15

2.3 Factors Affecting Sampling Accuracy 16

2.3.1 Humidity 16

2.3.2 Temperature 16

2.3.3 Pressure 16

2.3.4 Discrepancy in Readings 17

2.3.5 Anesthetic Gases 17

2.3.5.1 Gases That MAY INDUCE Reading Error 17

Teledyne Analytical Instruments v

Page 6

AX300

2.3.5.2 Care After Use in Nitrous Oxide 18

2.3.6 Cleaning 19

2.4 Dos and Don’ts 19

Service Instructions .................................................................... 21

3.1 General Service Information 21

3.2 Overall Maintenance 21

3.3 Battery Maintenance 21

3.4 Sensor Maintenance 22

3.5 Calibration 22

3.6 Factors Affecting Sampling Accuracy 22

3.7 Troubleshooting 22

3.8 Watchdog 25

3.9 Other Problems with the Analyzer 26

3.10 Return Authorization for Service 26

Appendix ...................................................................................... 28

A.1 Specifications 28

A.2 Spare Parts List 29

A.3 Optional Accessories 29

Teledyne Analytical Instruments vi

Page 7

Portable Oxygen Analyzer

List of Figures

Figure 1-1: AX300 Front View ......................................................... 1

Figure 2-1: Installing the R17MED Sensor ...................................... 7

Figure 2-2: Sensor Cable Connection to Analyzer ......................... 7

Figure 2-3: Mounting the Sensor in the Tee Adapter ....................... 8

Figure 2-4: V-Mount Adapter Installation ......................................... 8

Figure 2-5: Brass Insert for Universal Mounting Clamp ................... 9

Figure 2-6: Installing Batteries ....................................................... 10

Figure 2-7: Calibration Sequence .................................................. 11

Figure 2-8: 0-1 VDC or RS 232 Digital Output Port ....................... 13

Teledyne Analytical Instruments vii

Page 8

AX300

List of Tables

Table 2-1: Oxygen Reading Error in a Mixture of Anesthetic Gas . 17

Table 3-1 Troubleshooting ............................................................ 23

Table 3.2 Error Codes ................................................................... 25

Teledyne Analytical Instruments viii

Page 9

Portable Oxygen Analyzer Introduction

Introduction

The Teledyne Analytical Instruments AX300 Oxygen Analyzer, hereinafter referred to as AX300 or analyzer, is a portable analyzer designed to analyze oxygen concentration in medical gas mixtures. Oxygen analysis is linear across the single range of 0-100% using Teledyne’s class R17MED oxygen sensor.

Figure 1-1: AX300 Front View

The AX300’s liquid crystal display (LCD) consists of up to 3.5

characters plus a decimal point indicator capable of displaying up to

105%. An integral battery life indicator is displayed continuously on the

AX300.

The analyzer is powered by three AA alkaline batteries and is designed to operate for 2000 hours on a single set of batteries in a Nonalarm State.

A sensor failure alarm is incorporated which warns the user if the

sensor signal is lost or low. When this occurs, the √SENSOR display

Teledyne Analytical Instruments 1

Page 10

Introduction AX300

and a visual green light will flash, and the alarm buzzer will activate.

This alarm condition is also triggered when the oxygen concentration at

the point of analysis falls below 18% (Reference: ISO 7767 standard).

For safety reasons, the audible alarm cannot be silenced until the alarm

condition is resolved.

CAUTION: DURING NORMAL USE, ALARM CONDITIONS SHOULD

NOT BE OVERRIDDEN BY ACTIONS SUCH AS HOLDING

THE ALARM SILENCE KEY DEPRESSED OR REMOVING

THE BATTERIES. THE CAUSE FOR THE ALARM CONDITION SHOULD FIRST BE RESOLVED.

CAUTION: WHILE HOLDING DOWN THE ALARM SILENCE KEY MAY

MOMENTARILY SILENCE THE ALARM BUZZER, AUDIBLE

ALARM WILL RETURN UPON DISENGAGING THE ALARM

SILENCE KEY. HOLDING THE KEY FOR LONGER DURATIONS WILL INITIATE THE “STUCK KEY” ALARM, WHICH

CAN BE DEACTIVATED ONLY VIA REMOVING THE BATTERIES FROM THE ANALYZER. ANALYZER SHOULD BE

RECALIBRATED UP ON REPOWERING THE ANALYZER.

NOTE: THE ALARM SILENCE KEY DOES NOT PLAY ANY ROLE IN

THIS VERSION OF THE ANALYZER. IT IS DESIGNED IN

FOR ANY POSSIBLE FUTURE PRODUCT MODIFICATION.

1.1 Features

The following features are standard on the AX300:

Large easy to read 3½-digit LCD (see options)

Automatic LCD back lighting upon key press

Microprocessor controlled

Sensor fail/disconnect alarm indicator (audible and visual)

Non-adjustable concentration alarm below 18% O

2000 operating hours from 3 AA alkaline batteries

Battery status indicator

Stand for upright tabletop deployment

Optional hardware for pole clamping and V block support

Rugged high impact ABS plastic construction

2

Splash resistant case

Long life class R17MED sensor

Teledyne Analytical Instruments 2

Page 11

Portable Oxygen Analyzer Introduction

0-1 VDC digital output (optional RS-232)

FDA 510(k) market clearance

1.2 Options

The following options are available for the AX 300-I analyzer:

A-Option—2½-digit LCD instead of 3½-digit

Note: Contact the factory for modifying your analyzer for 2½-digit LCD. For

RS-232 reconfiguration, see Section 2.1.5.

B-Option—RS 232 digital output instead of 0-1VDC

Universal Pole Mounting Clamp (P/N CP 2345)

V-Mount Pole Clamp (P/N CP 2344)

V-Mount Wall Adapter P/N B 647)

0-1 VDC Interface Cable (P/NB-75554)

RS 232 Interface Cable (P/N B-75555)

1.3 Applications

The AX300 analyzer is intended for spot-checking the concentration of oxygen in gas mixtures used in applications such as Anesthesia

gas delivery and Respiratory care, and is intended for adult, pediatric

and neonatal populations.

1.4 Operation Summary

The AX300 analyzer uses Teledyne Analytical Instruments’ Patented R17MED oxygen sensor. The sensor output is used to determine

the oxygen gas concentration that is displayed on the LCD screen. The

concentration alarm of AX300 analyzer is non-defeatable and will alarm

when the oxygen concentration falls below the threshold of 18%. This

alarm is tied to sensor fail/disconnect alarm that will also warn the user

of a possible sensor problem when the oxygen concentration is less than

18%. When a fault is detected, the SENSOR indicator is displayed on

the LCD, and the audible and visual alarms are activated.

The Class R17MED oxygen sensor is a disposable sensor. The sensor has a cathode (sensing electrode), an anode (counter electrode), and

a compatible electrolyte, and is packaged in a small plastic sensor body.

Oxygen entering the sensor reacts with the anode and a proportional cur-

Teledyne Analytical Instruments 3

Page 12

Introduction AX300

rent is collected at the cathode, which is then converted into a digital

signal and displayed on the LCD screen on the analyzer.

Used with the R17MED sensor is a removable plastic diverter. This

diverter is used to facilitate the transport of gas mixtures through the

sensor. The diverter, packaged separately when shipped, is necessary

when the tee adapter is used to sample gas flowing through a tube.

The diverter is not necessary, and should not be used, when the

sensor is placed directly in a chamber or when the sensor is used in confined volume analysis such as incubators and inhalation tents.

CAUTION STATEMENTS:

THE R17MED SENSOR CONTAINS A CAUSTIC ELECTROLYTE AND LEAD. DO NOT TRY TO OPEN THE SENSOR

ASSEMBLY. CHECK THE SENSOR PERIODICALLY FOR

LEAKS. IF THE SENSOR IS LEAKING, REPLACE IT. DO

NOT TRY TO REPAIR IT. CONTACT YOUR DISTRIBUTOR

OR TELEDYNE FOR THE MATERIAL SAFETY DATA SHEET

RELATED TO HANDLING AND DISPOSAL OF THE SENSOR.

THE R17MED SENSOR CONTAINS A CAUSTIC ELECTROLYTE, AND IN THE EVENT OF A LEAK, THE ELECTROLYTE

MAY ATTACK CERTAIN MATERIALS IT IS EXPOSED TO,

SUCH AS ALUMINUM. USE PRECAUTION IN YOUR

CHOICE OF INTERFACE MATERIALS.

REMOVE AND SAVE THE DIVERTER WHEN THE SENSOR

IS USED IN CONFINED VOLUME APPLICATIONS.

THE AX300 OXYGEN ANALYZER, R17MED OXYGEN SENSOR AND ASSOCIATED HARDWARE ARE INTENDED FOR

USE AS SECONDARY DEVICES TO VERIFY THE CONCENTRATION OF OXYGEN IN GAS MIXTURES. DO NOT

USE THESE DEVICES AS PRIMARY LIFE-SUPPORT OR

PRIMARY MONITORING DEVICES.

THE INFORMATION OBTAINED FROM THE AX300

SHOULD NEVER BE USED TO ADJUST A LIFE-SUPPORT

SYSTEM. IT SHOULD ONLY BE USED AS AN INDICATION

THAT THE LIFE SUPPORT SYSTEM OR DEVICE IN THE

BREATHING SYSTEM THAT AX300 IS BEING USED WITH

MIGHT REQUIRE SERVICE AND/OR CALIBRATION.

Teledyne Analytical Instruments 4

Page 13

Portable Oxygen Analyzer Introduction

Left intentionally blank

Teledyne Analytical Instruments 5

Page 14

Operating Instructions AX300

Operating Instructions

Notes:

Upon receipt, INSPECT THE ENTIRE UNIT FOR ANY DAMAGE. Check the

unit and all included accessories for broken or loose parts. If damaged, DO NOT

USE. Notify the shipper, your distributor or Teledyne Analytical Instruments.

This equipment is internally powered using 3 AA batteries.

The LOCK/UNLOCK key helps prevent accidental change to the calibration set

point. At least two keys must be pressed in order to modify the critical calibra-

tion set point value.

If the keys are unlocked and no keys are pressed, the analyzer will revert to the

locked mode within nine seconds.

2.1 Setup

To use your AX300 analyzer, first install the batteries, then install the oxy-

gen sensor and then, calibrate the analyzer using the steps outlined in section

2.1.4.

2.1.1 Sensor Installation or Replacement

Note: Install the R17MED oxygen sensor before using the AX300 oxygen analyzer.

1. Remove the new sensor from its protective bag. Inspect the sensor for

damage or electrolyte leakage.

Warning: The sensor has a caustic electrolyte. Do not use a damaged or leaking

Warning: The sensor also contains lead. Leaking or exhausted sensors should be

Warning: The AX300 oxygen analyzer, R17MED oxygen sensor, and associated

sensor. Do not let the electrolyte come in contact with the skin. If it

does, flush affected area with water. Do not attempt to open or repair

the sensor.

handled and disposed of in accordance with local regulations.

hardware are non-sterile devices. Autoclaving or other chemical cleaning may damage the analyzer and the sensor.

Teledyne Analytical Instruments 6

Page 15

Portable Oxygen Analyzer Operating Instructions

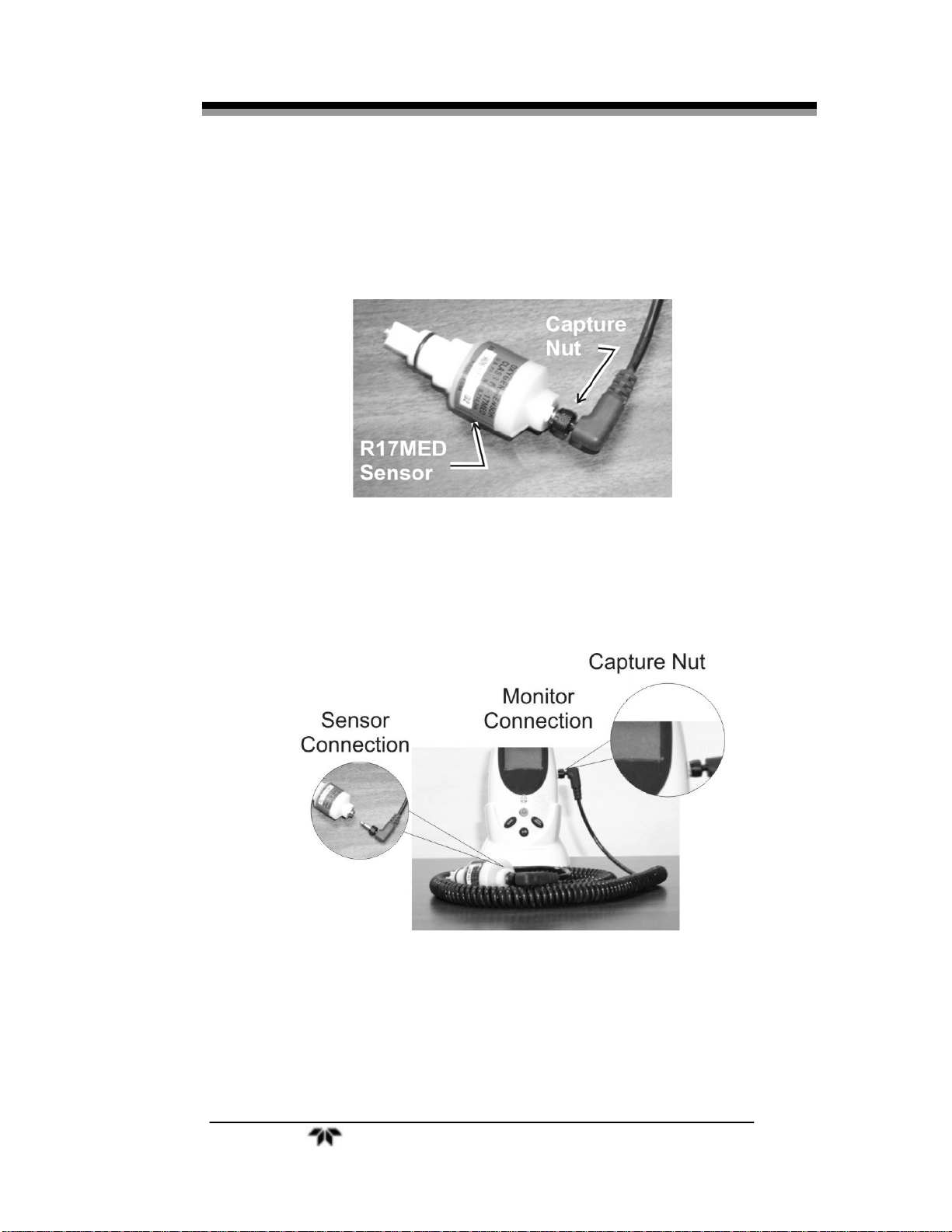

2. Plug one end of the coiled cable into the receptacle on the back of the

R17MED sensor and secure it in place with the capture nut located at the

base of the connector. See Figure 2-1.

Figure 2-1: Installing the R17MED Sensor

3. Plug the other end of the cable into the receptacle located on the side of the

unit and secure it using the capture nut. See Figure 2-2.

Figure 2-2: Sensor Cable Connection to Analyzer

Note: Cable shown is for illustration purposes only.

Note: Do not use the plastic flow diverter with the R17MED sensor when the sensor is

used for diffusion sampling (such as with oxygen tents, incubators, etc.). When

Teledyne Analytical Instruments 7

Page 16

Operating Instructions AX300

the sensor is used with a Tee Adapter, such as in a breathing system, the diver-

ter must be used as shown in Figure 2-3.

Figure 2-3: Mounting the Sensor in the Tee Adapter

2.1.2 Mounting

The AX300 can be mounted in several ways depending on the optional

equipment ordered at the time of purchase. See Section 1.3.

2.1.2.1 V-Mount Adapter Installation

The V-Mount Adapter consists of a matching plastic plate with integral V-

grooves that attach to the rear of the analyzer.

To install V-Mount Adapter, remove the battery compartment door by prying up the hinged latch at the bottom of the cover, then slide the adapter plate

into grooves provided in rear case. Replace the battery compartment door and

secure door latch. See Figure 2-4.

Note: Door latch fits tightly on the battery cover. Use a coin to gently pry up the latch.

Figure 2-4: V-Mount Adapter Installation

Teledyne Analytical Instruments 8

Page 17

Portable Oxygen Analyzer Operating Instructions

2.1.2.2 Universal Mounting Clamp Installation

The optional Universal Mounting Clamp comes with a 1/4-20 screw for securing the clamp to the rear of the analyzer. A threaded brass insert is installed on

the back of the analyzer for this purpose. See Figure 2-5.

Figure 2-5: Brass Insert for Universal Mounting Clamp

2.1.3 Battery Installation

Note: Three “AA” alkaline batteries must be installed in the unit before the analyzer

will operate. The unit must be recalibrated whenever new batteries are installed.

To install the batteries:

1. Turn the unit off (if it is on).

2. Hold the analyzer face down in the palm of your hand. Use a coin to

pry up the latch that secures the battery compartment door. Remove

the battery compartment door.

CAUTION: IMPROPER INSTALLATION OF THE BATTERIES MAY RESULT IN

DAMAGE TO THE UNIT AND BATTERIES.

Note: Use alkaline batteries only. Other battery types will produce erroneous battery

test readings.

3. Install 3 “AA” alkaline batteries into the holder as shown in Figure 2-

6. Each battery has its own slot. To insure proper polarity, place the

bottom (flat) or negative end of the battery in the end of the holder

marked “–”. Place the top (button) or positive end of the battery in the

end of the holder marked “+”. Do this for each battery.

Teledyne Analytical Instruments 9

Page 18

Operating Instructions AX300

Figure 2-6: Installing Batteries

4. Re-install the battery compartment door. When the unit is first turned

on, the screen will momentarily display all LCD segments. During

this period, diagnostic tests are being conducted to ensure that the

circuits are functioning correctly. The unit will activate the audible

and visual alarms for about 1 second. The LCD will flash

continuously indicating the unit is in the unlocked position ready for

calibration.

Note: When batteries are first installed or power is lost for any reason, the analyzer

defaults to the calibration mode. All keys except the CAL and ON/OFF (I/O)

keys will be inoperable until a successful calibration is achieved.

5. Note the battery display located below the oxygen readout display. It

continuously shows a bar graph of the remaining life to the batteries.

Using new batteries will illuminate all 5 segments from the left to the

right end of the bar. The bar graph indicator is continuously on when

the analyzer is powered on.

2.1.4 Calibration

The AX300 should be calibrated before each use and every 8 hours to main-

tain accuracy.

When batteries are removed for any reason or when new batteries are installed, the oxygen analyzer defaults to the calibration mode with the LCD display flashing 00.0. Only the CAL and ON/OFF (I/O) keys are functional at this

point.

Note: For first time and for routine maintenance calibrations, make sure that the sen-

sor and sensor cable are installed correctly before attempting to calibrate the

analyzer.

Teledyne Analytical Instruments 10

Page 19

Portable Oxygen Analyzer Operating Instructions

Figure 2-7: Calibration Sequence

To calibrate the analyzer (See Figure 2-7):

1. Turn the unit on by pressing the ON/OFF (I/O) key.

2. Check the battery status via the bar graph.

3. If the LCD is not flashing, press the LOCK/UNLOCK key to unlock

the keys. LCD will flash indicating that changes can be made to the

settings. If the batteries have just been installed the LCD will flash

00.0

4. As with most oxygen analyzers, the highest level of accuracy is

achieved when calibration is conducted using 100% oxygen. After installing the flow diverter as noted in Section 2.1.1, insert the sensor

into the plastic tee and connect to a supply of pure dry oxygen flowing at 1-2 liters per minute.

Note: An accessory calibration assembly (P/N C53790) is available from Teledyne for

use with the R17MED sensor

5. Wait about 20 seconds to ensure that the sample line is completely

purged with the calibration gas. Press the CAL key. The LCD will

count down from 9 to 0. The analyzer electronics will measure the

sensor output during this countdown to determine the gas concentra-

tion and selects the calibration range of either 100% or 20.9%. When

the calibration is complete, the LCD will display the gas value.

Note: At the end of the calibration countdown, the analyzer will display a solid number,

indicating acceptance of the calibration value. No further user action is required. If the LOCK/UNLOCK key is still pressed, the display will start blinking,

allowing the recalibration. If this LOCK/UNLOCK key-press is in error, either

Teledyne Analytical Instruments 11

Page 20

Operating Instructions AX300

press the key once more or allow the software to revert to the locked mode automatically, which will occur wi thin nine seconds of not pressing any function al

keys. Once the analyzer reaches the locked mode, press the LOCK/UNLOCK

key and press the CAL key to repeat calibration.

Note: The AX300 can only be calibrated using certified medical grade 100% oxygen or

ambient level air (20.9% Oxygen). Improper calibration or use of other gas concentrations will either activate the

assume that the gas delivered for calibration was 100% Oxygen. This latter behavior of the analyzer, which is common across other peer group analyzers,

would introduce significant error in analysis. Hence, use only certified medical

grade 100% Oxygen gas or ambient level air (20.9% Oxygen) to calibrate your

analyzer.

SENSOR indicator or render the analyzer to

6. Remove the sensor from the oxygen supply and confirm the LCD

reads less than 22% in room air. It is not necessary for it to read exactly 20.9%.

7. It is important to perform the calibration carefully and thoroughly, us-

ing calibration gases that are free from contaminates. The accuracy of

the analyzer is only as good as the accuracy of calibration gases used

and the accuracy of the procedure used to calibrate the analyzer.

Note: A single point air calibration is not recommended unless the sensor can be ex-

posed to a known source of fresh outdoor air. Hospital room air may often have

oxygen at above normal ambient levels of 20.9%, which will introduce errors in

the calibration. Air calibration should only be used for analyzing oxygen levels

between 21% and 40% and should never be used where a high degree of accuracy is needed.

Note: Never calibrate the unit in humidified gas, as water vapor makes the oxygen

concentration appear lower than it really is. See Section 2.3.1: Humidity.

8. The analyzer is now ready for use.

2.1.5 Output 0-1 VDC or RS232

The AX300 Portable Oxygen Analyzer comes with optional 0-1 VDC and

RS232 signal outputs for use with compatible external recording, indicating or

computing equipment.

An optional 0-1 VDC Interface Cable (P/N B-75554) is available from Teledyne for accessing the voltage output.

To connect the analyzer to an analog recording/indicating device:

1. Insert one end of the interface cable into the output port on the side of

the analyzer. See Figure 2-8.

2. Insert the other end into the analog recorder/indicator device

equipped to handle a 0-1 VDC signal.

Teledyne Analytical Instruments 12

Page 21

Portable Oxygen Analyzer Operating Instructions

When properly calibrated, the output signal generated by the analyzer is li-

near and proportional to the oxygen concentration.

If you requested Option-B (RS 232 digital output) at the time of purchase, a

digital RS 232 signal is output from the output port shown in Figure 2-8. Use the

optional RS 232 Interface Cable (P/N B-75555) available from Teledyne for

connection to a standard RS 232 port on a computer or other suitably equipped

digital device.

CAUTION: AX300 ANALYZER SHOULD ONLY BE CONNECTED TO AN

EN60601-1/IEC60606-1 APPROVED DEVICE.

Figure 2-8: 0-1 VDC or RS 232 Digital Output Port

RS232 signal output has been tested with Windows HyperTerminal. The setup

changes with different windows versions. If other software other than windows

HyperTerminal is used, consult with factory.

Windows 95 version

Baud: 2400

Data: 7

Parity: ODD

Stop bit: 1

Flow control: NONE

Teledyne Analytical Instruments 13

Page 22

Operating Instructions AX300

Windows 98, Windows 2000 and Window XP version:

Baud: 2400

Data: 8

Parity: ODD

Stop bit: 1

Flow control: NONE

Teledyne Analytical Instruments 14

Page 23

Portable Oxygen Analyzer Operating Instructions

2.2 Operating Instructions

2.2.1 Procedure

Note: Prior to every use, always test the batteries, check the sensor for any leaks or

damage, and check the analyzer calibration.

The AX300 analyzer can be used to measure a gas mixture for oxygen in

two basic modes:

In the inhalation side of breathing system upstream of any antibac-

terial filters, humidifiers and other such medicating devices

In confined volumes such as in incubators or tents

When analyzing for oxygen in breathing systems, the flow diverter must be

used. The diverter should be screwed onto the threaded front end of the

R17MED sensor. A tee adapter (plastic, P/N A268, or metal, P/N A283) should

be placed into the breathing loop, and the above sensor assembly plugged into

the tee adapter. See Figure 2-3.

CAUTION: CHECK THE BREATHING SYSTEM FOR LEAKS. BE CERTAIN THAT

THE SYSTEM DOWNSTREAM OF THE SENSOR DOES NOT PRODUCE ANY BACKPRESSURE OR RESTRICTION TO FLOW. ERRORS IN READINGS WILL RESULT IF THIS IS NOT FOLLOWED.

THE OXYGEN SENSOR IS A NON-STERILE DEVICE AND SHOULD

BE USED IN CONJUCTION WITH AN ANTI-BACTERIAL FILTER. ALWAYS INSTALL THE SENSOR ON THE INSPIRED LINE AHEAD OF

FILTERS, HUMIDIFIERS AND MEDICATING DEVICES. NEVER INSTALL THE SENSOR IN A LOCATION THAT WILL EXPOSE THE

SENSOR TO PATIENTS’ EXHALED BREATH OR SECRETIONS UNLESS YOU INTEND TO DISPOSE OF THE SENSOR AND FLOW

ADAPTER AFTER USE.

When analyzing for oxygen in confined volumes such as incubators, hoods,

etc., the flow diverter must be removed from the R17MED sensor so that it does

not interfere with the rapid exchange of gases to and from the sensing surface of

the sensor. Failure to remove the diverter in these applications may adversely

affect the response time of the sensor.

The R17MED sensor can be placed or hung inside incubators, tents, etc.

When it is necessary to thread the cable through a small hole in order to gain

access to the inside of a chamber, the cable should be disconnected at the sensor,

threaded through the hole, and reconnected inside the chamber.

Teledyne Analytical Instruments 15

Page 24

Operating Instructions AX300

2.3 Factors Affecting Sampling Accuracy

2.3.1 Humidity

Humidity does not directly affect the accuracy of the sensor's measurement.

However, when a nebulizer or other device is used to increase moisture levels in

gas mixtures, the moisture actually dilutes the mixture. This dilution effect decreases the oxygen concentration. Your portable oxygen analyzer accurately

measures the decreased oxygen concentration.

As with all diffusion based oxygen sensors, excessive condensation on the

sensing surface of the R17MED will block the diffusion of oxygen to the sensor,

rendering it inoperative. We recommend installing the sensor on the dry side of

the breathing system at all times.

2.3.2 Temperature

The R17MED oxygen sensor compensates for ambient temperature changes

in the range of 0–40°C (32–104°F). Since the thermistor that compensates for

these changes is located in the rear of the sensor assembly, it is important that

gas mixtures, flowing over the front of the sensor, be at room temperature, which

is assumed to the temperature around the rear of the sensor. Reading errors may

occur if gases at higher temperature from devices such as heated humidifier are

used to measure oxygen with R17MED oxygen sensor.

A small thermal tracking error may be encountered in applications where

the entire sensor assembly is placed in the gas mixture to be analyzed (such as in

the incubators). Holding the sensor in your hand for more than a few minutes can

also affect the temperature tracking which appears as a slow drift on the LCD.

No adjustments should be made during this period since this error will be eliminated when both the thermistor and sensing electrode have had sufficient time to

come to thermal equilibrium. This can take up to 2 hours.

2.3.3 Pressure

Virtually all gas sensors and analyzers measure the partial pressure of the

gas that they sample. The only time that these analyzers can accurately read percentages is when the total pressure does not vary over time between calibrations

and use. For this reason, it is important to calibrate the AX300 oxygen analyzer

(with R17MED oxygen sensor) at regular intervals. It is recommended that the

unit be calibrated prior to each use or every 8 hours. It is recommended that the

analyzer be calibrated at the same pressure as the gas it will be used to analyze.

If the gas being analyzed flows through some length of tubing, use similar tubing/apparatus and same pressure/flow rates when calibrating the analyzer.

Teledyne Analytical Instruments 16

Page 25

Portable Oxygen Analyzer Operating Instructions

When a ventilator is a part of the breathing system, the alternating “breathing” pressure cycles generated by the ventilator will be sensed as pressure pulses

by the sensor, and over time, such pulses manifest as pressure increases in the

fast-reacting sensors such as R17MED. This perceived pressure increase results

in correspondingly higher oxygen reading. While the concentration of oxygen is

not changing, it is the total pressure that is increasing producing a corresponding

increase in the partial pressure of oxygen.

2.3.4 Discrepancy in Readings

When a discrepancy in oxygen readings is detected, the oxygen analyzer’s

readings should be verified by checking the AX300 battery condition and calibration using 100% oxygen. If the analyzer can be calibrated, the unit can be assumed to be in good working order. If, after reinstalling the unit, the discrepancy

in oxygen readings persists, the problem is most likely elsewhere in the breathing

system. Resolve the cause(s) for the discrepancy before using the analyzer. The

troubleshooting section of this manual may provide additional assistance in locating the problem.

2.3.5 Anesthetic Gases

2.3.5.1 Gases That MAY INDUCE Reading Error

When using the R17MED sensor in the presence of anesthetic gases, the

oxygen reading may fall (see Table below). The magnitude of this error will depend upon the level of oxygen and the duration of exposure.

The anesthetic agents listed in the following table (Halothane, Enflurane,

Isoflurane, Sevoflurane, and Desflurane) were vaporized into a stream of 30%

oxygen / 70% nitrous oxide, and the resulting drops in oxygen level after an exposure of approximately two hours were noted.

Exposures in excess of two hours may produce slightly greater errors. The errors listed are typical for all oxygen sensors such as the R17MED. Exposing the

sensor to air or gases that do not contain anesthetic agents for a period of time

equal to or greater than the exposure interval will eliminate the reading error in

most cases.

Table 2-1: Oxygen Reading Error in a Mixture of Anesthetic Gas

Gas or Vapor Level

(Balance: Mixture of 30% O2 / 70% N2O, except where noted)

Gas or Vapor Test Level Oxygen Reading

Teledyne Analytical Instruments 17

Page 26

Operating Instructions AX300

Error

Helium 50%, balance O2 0%

Nitrous Oxide 80%, balance O2 0%

Carbon Dioxide 10%, balance O2 0%

Halothane 4% < 1.5% O2 *

Enflurane 5% < 1.5% O2 *

Isoflurane 5% < 1.5% O2 *

Sevoflurane 5% < 1.5% O2 *

Desflurane 15% < 1.5% O2 *

* Errors are approximate and may vary based on exposure times and concentra-

tions.

These performances meet or exceed the requirements of ISO 7767: 1997 (E).

CAUTION: THE AX300 SHOULD NOT BE USED IN THE PRESENCE OF FLAM-

MABLE ANESTHETICS SUCH AS DIETHYL ETHER OR CYCLOPROPANE.

CAUTION: THE ANALYZER, THE OXYGEN SENSOR AND ASSOCIATED

HARDWARE ARE NON-STERILE DEVICES. DO NOT AUTOCLAVE

THE ANALYZER OR SENSOR, AS THIS WILL DAMAGE THE

EQUIPMENT.

2.3.5.2 Care After Use in Nitrous Oxide

CAUTION: THE R17MED SENSOR SHOULD NOT BE LEFT IN NITROUS OXIDE

MIXTURES ANY LONGER THAN NECESSARY.

After exposure to nitrous oxide mixtures, the sensor should be left in 100%

oxygen overnight (e.g., left in a breathing system that has been flushed with pure

oxygen). If this is not practical, when using the tee, remove the plastic flow diverter and leave the sensor in room air. If the oxygen reading continues to drop

after each use in nitrous oxide, the sensor should be removed from service. If the

sensor can no longer be calibrated or if there is any sign of electrolyte leakage,

the sensor should be disposed of in accordance with local regulations and the

Material Safety Data Sheet (MSDS) available through Teledyne.

Teledyne Analytical Instruments 18

Page 27

Portable Oxygen Analyzer Operating Instructions

2.3.6 Cleaning

The AX300 and R17MED sensor are non-sterile devices.

The oxygen analyzer, oxygen sensor, and sensor interconnection cable may

be cleaned by wiping the surfaces with isopropyl alcohol or a mild cleaning solution.

When cleaning, do not allow liquids or moisture to enter the analyzer or

sensor internal cavities. Do not expose the electrical connections to the cleaning

solution. Do not immerse the analyzer, oxygen sensor or sensor interconnection

cable in water or any other liquid.

Do not expose the analyzer, oxygen sensor and interconnection cable to

steam, ethylene oxide, or radiation sterilization.

After cleaning, ensure that all surfaces are dry and the analyzer is properly

calibrated before using the analyzer.

2.4 Dos and Don’ts

– DO –

Read and understand the manual before using the analyzer

Calibrate every 8 hours or before every use.

Visually inspect the sensor for leakage before each use.

Calibrate using 100% oxygen and check in air.

Test batteries regularly and replace when battery indicator shows low

battery (no bars)

Keep the analyzer, sensor and connections dry, or on the dry side of

the breathing system.

Recalibrate after replacing the batteries.

Recalibrate after replacing the sensor.

Use only alkaline batteries.

Ensure that the R17MED sensor is properly connected to the analyz-

er.

Always use the plastic flow diverter when using the tee adapter.

Remove and save the plastic flow diverter when using the sensor in

non-flowing applications

Use only isopropyl alcohol or mild detergent, if cleaning is required,

Teledyne Analytical Instruments 19

Page 28

Operating Instructions AX300

– DON’T –

Use this analyzer if you suspect any malfunction.

Use the analyzer in the presence of flammable gases.

Use anything but alkaline batteries.

Autoclave or freeze the sensor or analyzer.

Open or try to repair a leaking or broken sensor.

Immerse the unit or sensor in any liquid.

Pass hot or cold gas mixtures over the sensor.

Expose the unit to devices that produce high levels of radio, short

wave, microwave, x-ray, or high frequency interference.

Use cleaning agents or liquids in the cable receptacles or around the

battery compartment.

Place the unit in a water vapor-saturated environment.

Expose the LCD to excessive sunlight.

Expose the unit to a condensing water environment such as a mist

tent.

Teledyne Analytical Instruments 20

Page 29

Portable Oxygen Analyzer Service Instructions

Service Instructions

3.1 General Service Information

Without access to special probes and test equipment, troubleshooting and repair

of the board or its components are not feasible. A factory replacement of the entire

PC board is recommended if necessary.

With the exception of replacing the sensor or batteries, there are no userserviceable components inside the unit. If a problem arises that cannot be corrected

by recalibration, changing the batteries or replacing the sensor as described in this

manual, the unit must be sent back to the factory for repair or replacement. See Section 3.10 for instructions on obtaining a Return Merchandise Authorization (RMA)

number before sending a unit back to Teledyne for repair.

3.2 Overall Maintenance

The AX300 analyzer requires very little maintenance, other than calibration,

checking the batteries and sensor. Occasional cleaning of the plastic surface can

be done with isopropyl alcohol. There are no user-serviceable components within

the analyzer.

3.3 Battery Maintenance

DO: Test batteries regularly. (Replace immediately when all battery

strength indicator bars are missing).

DO: Always use alkaline batteries.

DO: Recalibrate after replacing batteries.

The AX300 analyzer has a battery strength indicator that continuously displays the approximate amount of useful life remaining on the set of installed batteries. Excessive alarm activation will drain the batteries faster. The minimum

detectable change in battery voltage corresponds to an increment of about 50

hours, meaning that the battery voltage reading may not change for several hours

at a time.

If the analyzer is not used for a period of 30 days or more, the batteries

should be removed from the analyzer.

Teledyne Analytical Instruments 21

Page 30

Service Instructions AX300

3.4 Sensor Maintenance

DO check the sensor for damage or leaks before use.

DON’T immerse the R17MED sensor in liquid.

DON’T autoclave the R17MED sensor.

DON’T open or try to repair the sensor.

Before every use, the sensor, cable and connections should be checked.

Check the sensor for leaks and condensation. Check the cable for splitting or

cracked insulation. Make sure the connections are tight and dry.

In the event that the sensor has been damaged, consult the Material Safety

Data Sheet in the Appendix for handling guidelines.

3.5 Calibration

Incorrect readings can often be traced to improper calibration. The AX300

should be calibrated before each use and every 8 hours to maintain accuracy. It

must be calibrated whenever new sensor or batteries are installed. Calibration

using methods other than described in section 2.1.4 will lead to improper operation.

Whenever new batteries are installed or removed for any reason, the oxygen

analyzer defaults to the calibration mode with the LCD display flashing 00.0.

Only the CAL and ON/OFF (I/O) keys are functional at this point.

3.6 Factors Affecting Sampling Accuracy

Refer to Section 2.3 of this manual.

3.7 Troubleshooting

The AX300 oxygen analyzer provides a variety of built-in safety features that

prevent its use when a fault is detected. When a unit displays the message √ SENSOR

and sounds the audible and visual alarm continuously, it is an indication of a faulty

connection between the sensor and the unit or an expired or faulty sensor. It also indicates when oxygen concentrations are below 18%.

For assistance with troubleshooting, see Table 3-1.

Teledyne Analytical Instruments 22

Page 31

Portable Oxygen Analyzer Service Instructions

Table 3-1 Troubleshooting

Symptom Why What To Do

New sensor responds

slow or drifts.

Sensor will not read below 22 % after calibration

in 100% O2.

The sensor does not

react to changes in

oxygen concentration,

or the readings are unstable and drifting.

If the sensor is new

and was just removed

from its sealed bag it

may need to run for

several hours.

Calibration in 100%

was invalid or the

room air enriched with

excess oxygen.

Water may have condensed on the sensing surface.

Electrical interference

is disrupting the electronics

A) Wait 1–2 hours and recali-

brate.

A) Recalibrate using dry gas

B) Make sure that at least 6"

(30 cm.) of tubing is attached

to the exhaust side of the tee

adapter to prevent back filling. O2 flow rate should not

exceed 5 l/min.

C) Oxygen concentration at the

sensor is significantly higher

than 21%. Take the analyzer to a well-ventilated area

and check the reading

again.

D) Try calibrating with a known

good sensor, and if this fails,

contact customer support.

A) Remove the sensor from tee

adapter and unscrew the plastic flow diverter. Using absorbent tissue or cotton swab,

gently wipe off sensing surface inside threaded portion of

sensor assembly. Do not

damage the sensing surface,

and do not leave any tissue/swab residue on the

sensing membrane.

B) Relocate unit away from

sources of electrical noise

such as cauterizing equipment

and two-way radios.

The display is flashing

√ SENSOR

The unit has detected

a fault in the signal

from the sensor.

Sensor has expired.

The sensor has been

exposed to a gas containing less than 18%

A) Check sensor cable con-

nections to ensure they are

completely inserted into the

mating connector and the

capture nut is firmly in

place.

B) Expose the sensor in 100%

Teledyne Analytical Instruments 23

Page 32

Service Instructions AX300

Symptom Why What To Do

oxygen. O2 and check calibration.

C) The sensor output has fal-

len to a level where it is no

longer usable. Replace

sensor.

The oxygen reading

fluctuates or appears to

be incorrect.

The unit has stopped

working and the LCD is

displaying alphanumeric characters.

The sample pressure

may be changing.

The AX300 unit is

equipped with an electronic "watch dog,"

which analyzes the

circuitry within the unit

for potential faults and

renders the unit inoperable until the condition is corrected. (See

Watch dog section)

Several conditions can

activate the "watch

dog." Dropping the unit,

poor battery connections, and radio frequency interference are

the most common

causes. See the watch

dog section for additional information

A) During calibration, make

sure there is no restriction

on exhaust side of sensor. If

the reading changes with

flow, the sensor is pressurized or there may be a leak

in the system.

B) If a high degree of accuracy

is desired, or the concentration of O2 being analyzed is

in excess of 40%, calibration

with 100% is recommended.

C) If humidified gas is used to

ventilate the patient, water

vapor actually dilutes the

gas. See Section 2.3. .

D) If a blender is used, check

its calibration.

A) Disconnect the batteries and

inspect the contacts for corrosion. Reconnect the batteries. If the unit functions

properly, calibrate the unit

and reset the alarm values.

B) Try a new set of batteries.

C) Increase the distance be-

tween the unit and any

source of radio frequency interference. The sensor cable is a prime source of

pickup as it can act like an

antenna. Relocate the sensor cable and if possible

change its coiled length to

“de-tune” its antenna effect.

Placing the cable in a different position may also help.

No display A) Batteries expired.

B) Bad battery connec-

A) Check/replace batteries.

B) Check battery connections.

Teledyne Analytical Instruments 24

Page 33

Portable Oxygen Analyzer Service Instructions

Symptom Why What To Do

tion

C) Calibrate.

Note: In the event that none of these procedures produces desired results, remove the

batteries and return the unit to Teledyne for repair.

3.8 Watchdog

The AX300 is equipped with a watchdog circuit that continuously analyzes the

electronics for proper operation. If the watchdog detects a failure, one of the codes in

Table 3.3 will appear on the LCD.

The error codes can appear on the LCD when batteries are first installed,

during normal operation or if the unit is subjected to shock. In some cases, an

additional digit is used in the error code to supply additional information. For

example, the error code 6 and 7 are followed by another digit listed as (N) in Table 3.2. The error code 65 would indicate that a key is stuck and this key is the

Silence key.

In addition to supplying visual error codes, the audio device will beep a

number of times to indicate the general error in case the display is not functional.

Note: To reset the watchdog error code, remove one battery for 5 seconds and re-

place. If the error persists, contact your local representative or Teledyne fo r assistance.

Table 3.2 Error Codes

Error Code Audio Beeps Error

Indeterminate 2 The watchdog timer has timed out indicating

a serious software error

30 3 Analog output is different from the expected

value. May indicate a shorted or over-loaded

analog output or a failure of the analog to

digital converter or digital to analog converter circuit.

Teledyne Analytical Instruments 25

Page 34

Service Instructions AX300

50 5 The ADC circuit failed during POST.

6 (5) 6

(There is no

indication of

which key is

stuck)

7(2) 7

(There is no

indication of

the type of

DAC failure)

A stuck key has been detected. The second

digit example (5) on the display shows

which key is stuck:

1 - Batt

2 - Cal

5 - Silence

8 - Key Lock

A failure has occurred during the automatic

calibration of the digital to analog converter

(DAC) circuit. The second digit example (2)

shows the type of digital to analog failure.

0 - Measurement

1 - High Test

2 - Low Test

3 - Offset Cal

4 - Gain Cal

3.9 Other Problems with the Analyzer

Most other problems arise from either mechanical damage to the

analyzer or electronic component failure.

Repair or troubleshooting the PCB or individual components on the

board is not feasible. Under most circumstances, a replacement of the

entire PC Board is recommended. If the repair diagnosis indicates problem with the PCB, the analyzer must be returned to the factory for PCB

replacement.

3.10 Return Authorization for Service

For any service beyond sensor and battery replacement, the analyzer must be returned to the factory. A return merchandise authorization

(RMA) number must be obtained from Teledyne Analytical Instruments

prior to returning the analyzer for service. You can request a RMA

number via email by contacting us at:

Teledyne Analytical Instruments 26

Page 35

Portable Oxygen Analyzer Appendix

tetci_customerservice@teledyne.com

You can also contact us at the address below.

Customer Service Department

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580 USA

Phone (626) 934-1500, Fax (626) 961-2538

Or via the web at: www.teledyne-ai.com

Teledyne Analytical Instruments 27

Page 36

Appendix AX300

Appendix

A.1 Specifications

Range: 0-100% oxygen

Accuracy: +

Response Time: 90% in less than 6 seconds at 25 °C

Battery Life: Approximately 2000 hours of continuous

System Power: 3 AA alkaline batteries.

Sensor Type: Class R17MED

Alarm: Non-adjustable SENSOR alarm

Expected Life: 36 months in air at 25°C, Atmospheric

Dimensions: 2.5" W × 1.25" D × 4.5" H (66 mm x 33-

Sensor Cable: Retracted: 2 ft / Extended: 10 ft.

2% of full scale (at constant temperature

and pressure)

use in non-alarm condition

activates upon sensor problem or O

centration falls below 18%

Pressure and 50% Relative Humidity.

(~7.5 months under similar conditions

when continuously exposed to 100% oxy-

gen)

mm × 111.5 mm)

con-

2

Storage Temp. 10-30°C (continuous), 5-50°C (Intermit-

tent)

Operating Temp: 0-40°C

Teledyne Analytical Instruments 28

Page 37

Portable Oxygen Analyzer Appendix

A.2 Spare Parts List

QTY PART NO DESCRIPTION

1 C43690-R17MED Micro-Fuel Cell R17MED with

flow diverter P/N A50057

3 B99 “AA” size alkaline battery

1 C74721 Cable assembly

1 A268 Tee adapter (22 mm)

A.3 Optional Accessories

1 A50057 R17MED flow diverter

1 CP2345 Universal Pole Mounting Clamp

1 CP2344 “V” mount Pole Clamp

1 B647 “V” mount Wall Adapter

1 A51589 Sensor adapter cap, female (22 mm)

1 A51588 Sensor adapter cap, male (22 mm)

1 C53790 Calibration assembly

1 A284 Universal adapter set for pediatric

circuits (15mm)

1 A274 Tee adapter, autoclavable

1 A283 Tee adapter, metal

1 B75554 0-1 VDC Interface Cable

1 B75555 RS 232 Interface Cable

Schematics are available on request.

____________________

A minimum charge is applicable to spare parts orders.

Note: Orders for replacement parts should include the part number (if availa-

ble) and the model and serial number of the analyzer for which the

parts are intended.

Teledyne Analytical Instruments 29

Page 38

Appendix AX300

Orders should be sent to:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

Web: www.teledyne-ai.com

Or your local representative.

Teledyne Analytical Instruments 30

Loading...

Loading...