Page 1

AORM Software

Instruction Manual

Page 2

AORM Software Instruction Manual

© 2013 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials other than for internal sales and distribution purposes is strictly prohibited. However, clients are encouraged to distribute and duplicate Teledyne LeCroy documentation

for their own internal educational purposes.

AORM and Teledyne LeCroy are registered trademarks of Teledyne LeCroy, Inc. Windows is a registered trademark of

Microsoft Corporation. Other product or brand names are trademarks or requested trademarks of their respective holders. Information in this publication supersedes all earlier versions. Specifications are subject to change without notice.

923133 Rev A

June 2013

Page 3

AORM Software Package

WHAT CAN AORM DO?..................................................................................... 7

Histogramming...........................................................................................................................7

Trending..................................................................................................................................... 7

Model of Optical Recording Processing ....................................................................................7

Selecting Parameters ................................................................................................................7

SETUP AND MEASUREMENT DIALOG............................................................. 9

AORM Measurement Menus ................................................................................................... 11

Measurement Table................................................................................................................. 15

View Menu Selections ............................................................................................................. 16

Equalizer and PLL Dialog ........................................................................................................17

CREATING AND ANALYZING HISTOGRAMS................................................. 18

Selecting the Histogram Function............................................................................................18

Histogram Trace Setup Dialog ................................................................................................18

Setting Binning and Histogram Scale...................................................................................... 19

DISPLAYING TRENDS...................................................................................... 20

Trend Calculation.....................................................................................................................22

Parameter Buffer...............................................................................................................22

Parameter Events Capture ...............................................................................................22

Reading Trends.................................................................................................................22

MAKING OPTICAL DATA MEASUREMENTS.................................................. 24

View Modes .............................................................................................................................24

Configuration Options..............................................................................................................25

Configuration Menus ...............................................................................................................26

Setting Levels ..........................................................................................................................28

Setting nT ................................................................................................................................30

Maximizing Performance .........................................................................................................30

Pit or Space Identification........................................................................................................31

nT Pit/Space Categorization....................................................................................................33

BES BEGINNING EDGE SHIFT..................................................................... 34

923133 Rev A ISSUED: June 2013 1

Page 4

Description...............................................................................................................................34

Display Options........................................................................................................................36

BESS BEGINNING EDGE SHIFT SIGMA.....................................................37

Description...............................................................................................................................37

Display Options........................................................................................................................38

EES ENDING EDGE SHIFT............................................................................39

Description...............................................................................................................................39

Display Options........................................................................................................................41

EESS ENDING EDGE SHIFT SIGMA...........................................................42

Description...............................................................................................................................42

Display Options........................................................................................................................43

BEES BEGINNING ENDING EDGE SHIFT ...................................................44

Description...............................................................................................................................44

Display Options........................................................................................................................46

DP2C DELTA PIT TO CLOCK.......................................................................47

Description...............................................................................................................................47

Display Options........................................................................................................................49

DP2CS DELTA PIT TO CLOCK SIGMA......................................................50

Description...............................................................................................................................50

Display Options........................................................................................................................51

EDGSH EDGE SHIFT.....................................................................................52

Description...............................................................................................................................52

Display Options........................................................................................................................52

Example ............................................................................................................................ 53

More On Edge Shift .................................................................................................................54

PAA PIT AVERAGE AMPLITUDE..................................................................56

Description...............................................................................................................................56

Display Options........................................................................................................................56

Example ............................................................................................................................ 57

2 ISSUED: June 2013 923133 Rev A

Page 5

AORM Software Package

PASYM PIT ASYMMETRY............................................................................ 58

Description...............................................................................................................................58

Display Options........................................................................................................................58

Example ............................................................................................................................ 59

PBASE PIT BASE......................................................................................... 60

Description...............................................................................................................................60

Display Options........................................................................................................................60

Example ............................................................................................................................ 61

PMAX PIT MAXIMUM.................................................................................... 62

Description...............................................................................................................................62

Display Options........................................................................................................................62

Example:..................................................................................................................................63

PMIDL PIT MIDDLE LEVEL ........................................................................... 64

Description...............................................................................................................................64

Display Options........................................................................................................................64

Example ............................................................................................................................ 65

PMIN PIT MINIMUM...................................................................................... 66

Description...............................................................................................................................66

Display Options........................................................................................................................66

Example ............................................................................................................................ 67

PMODA PIT MODULATION AMPLITUDE..................................................... 68

Description...............................................................................................................................68

Display Options........................................................................................................................68

PNUM PIT NUMBER...................................................................................... 72

Description...............................................................................................................................72

Display Options........................................................................................................................72

Example ............................................................................................................................ 73

PRES PIT RESOLUTION .............................................................................. 74

Description...............................................................................................................................74

Display Options........................................................................................................................74

923133 Rev A ISSUED: June 2013 3

Page 6

Example ............................................................................................................................ 75

PTOP PIT TOP...............................................................................................77

Description...............................................................................................................................77

Display Options........................................................................................................................77

Example ............................................................................................................................ 78

PWID PIT WIDTH...........................................................................................79

Description...............................................................................................................................79

Display Options........................................................................................................................79

Example ............................................................................................................................ 80

Example 2: Histogramming ............................................................................................... 80

T@PIT TIME AT PIT........................................................................................84

Description...............................................................................................................................84

Example ............................................................................................................................ 84

TIMJ TIMING JITTER......................................................................................90

Description...............................................................................................................................90

Display Options........................................................................................................................90

Example ............................................................................................................................ 90

More About Timing Jitter .........................................................................................................92

SIGNALS, COUPLING, AND THRESHOLD SETTINGS ...................................94

Choice of Signals.....................................................................................................................94

Coupling...................................................................................................................................94

Threshold Selection.................................................................................................................94

USING PARAMETERS WITH TRENDS AND XY PLOTS .................................96

Example and Step-by-Step Instructions............................................................................96

IMPROVING HORIZONTAL MEASUREMENT ACCURACY............................. 99

BASE AND TOP CALCULATION DETAILS....................................................100

THEORY OF OPERATION...............................................................................103

Teledyne LeCroy DSO Process .............................................................................................103

Parameter Buffer ...................................................................................................................104

Parameter Events Capture ....................................................................................................104

4 ISSUED: June 2013 923133 Rev A

Page 7

AORM Software Package

Histogram Parameters........................................................................................................... 105

Zoom Traces and Segmented Waveforms............................................................................ 106

Histogram Peaks ...................................................................................................................106

Example ..........................................................................................................................106

Binning and Measurement Accuracy..................................................................................... 107

DVD PROCESSING MODEL........................................................................... 108

DVD RAM ..............................................................................................................................108

FILTERING ............................................................................................................................ 110

SLICER..................................................................................................................................110

APPENDIX A: NOTES ON ODATA MATH FUNCTION.................................. 112

Equalized ............................................................................................................................... 112

Operational Notes.................................................................................................................. 113

Leveled ..................................................................................................................................114

Extract Clk .............................................................................................................................114

How the Starting VCO Frequency and Phase are Determined.............................................120

923133 Rev A ISSUED: June 2013 5

Page 8

BLANK PAGE

6 ISSUED: June 2013 923133 Rev A

Page 9

AORM Software Package

WHAT CAN AORM DO?

The Advanced Optical Recording Measurement (AORM) package for Teledyne LeCroy digital

oscilloscopes provides a set of waveform measurements and mathematical functions for the

analysis of optical recording signals. Parameter measurements allow the categorizing and listing

of measurement values in a variety of ways. The math functions (Histogramming and Trending)

enable information to be revealed graphically.

The Advanced Optical Recording Measurement package provides parameter measurements for

evaluating jitter due to intersymbol interface and emulation of DVD’s equalizer, slicer, and PLL.

This functionality helps you to perform clock and jitter measurements, independent of a specific

Integrated Circuit, allowing you to concentrate on optical head or media performance only. To

support advanced optical recording drives that have constant angular velocity (CAV) or zone

constant linear velocity (ZCLV), parameter measurements support automatic determination of the

clock period.

Histogramming

Histograms can be created for any waveform parameter. They are displayed based on a set of

user settings such as bin width or number of parameter events to be used. Histogram parameters

are provided for measuring different histogram features such as standard deviation, number of

peaks, and most populated bin. Histograms are selected by defining a trace as a math function,

and selecting Histogram as the math function. As with other Zoom traces, histograms can be

positioned and expanded by using the front panel POSITION and ZOOM knobs.

Trending

The Trend function allows you to create a graph containing successive waveform parameter

measurement values. The trend function provides useful visual information on the variation of a

waveform parameter within a sector, or even over multiple sectors. The Trend functionality,

coupled with other scope features, enables you to graph certain parameters against one another.

Model of Optical Recording Processing

In many applications, it is important to make timing and jitter measurements directly from the RF

signal, independent of a specific DVD chip. The optical recording processing function in AORM

can perform this processing and can let you view the equalized data, sliced data, threshold,

and/or the recovered clock. You can control the cutoff frequency and boost of the equalizing filter,

the closed loop bandwidth of the 1

st

order integrating slicer, and the bandwidth of the phase-

locked loop (PLL).

Selecting Parameters

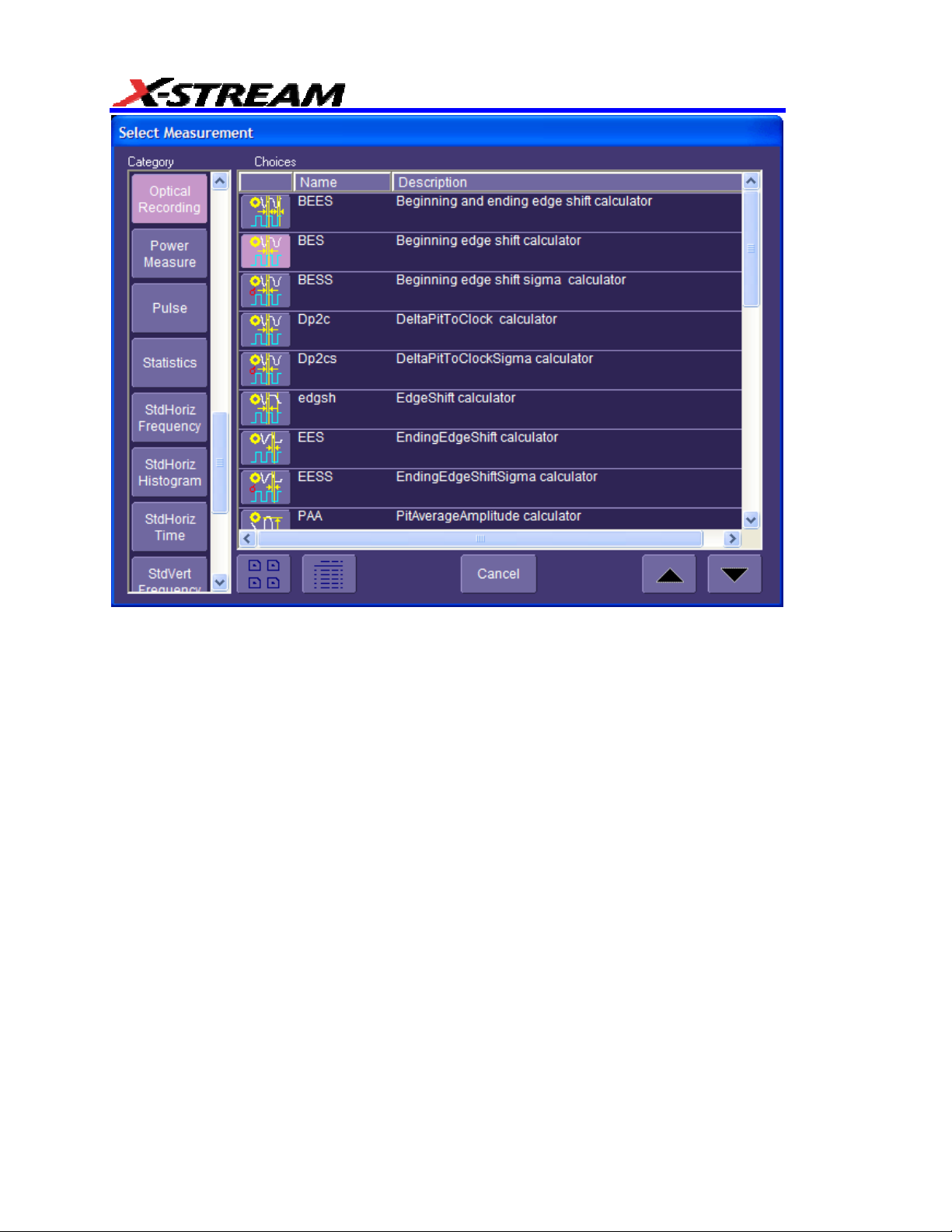

1. Select Measure from the menu bar,

2. Touch the Px tab for the desired parameter position (P1 to P8).

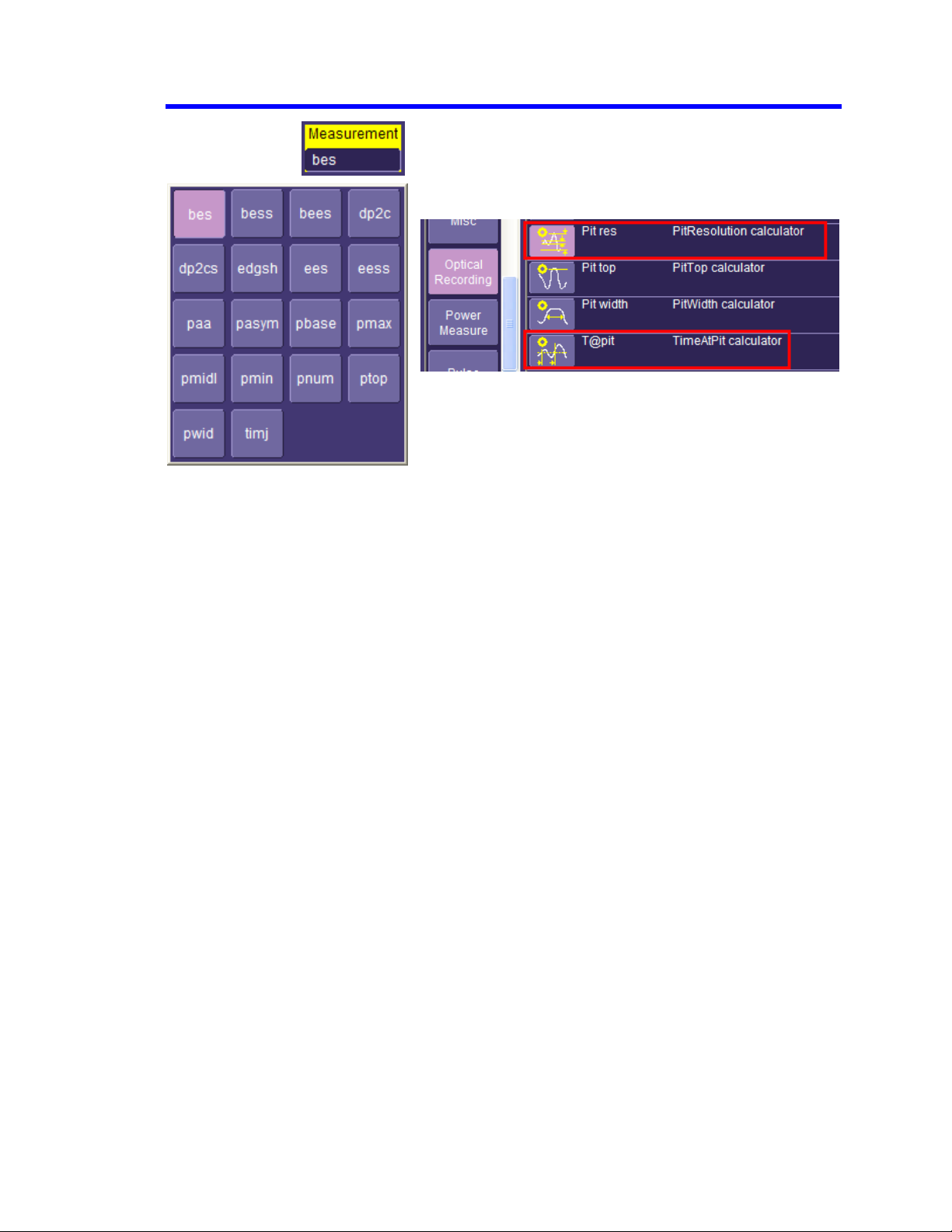

3. Touch inside the Measure field, then select the Optical Recording group of parameters:

923133 Rev A ISSUED: June 2013 7

Page 10

Paramete

cursors. The position of the cursors can be set by dragging, entering an exact value in the

Standard Cursors dialog, or by means of the Cursors front panel knobs. When you enable

tracking by checking the Track checkbox, you can move the parameter cursors across the

waveform so that measurement results can be taken on different sections of the waveform.

8 ISSUED: June 2013 923133 Rev A

rs allow measurements of the section of waveform lying between the parameter

Page 11

AORM Software Package

SETUP AND MEASUREMENT DIALOG

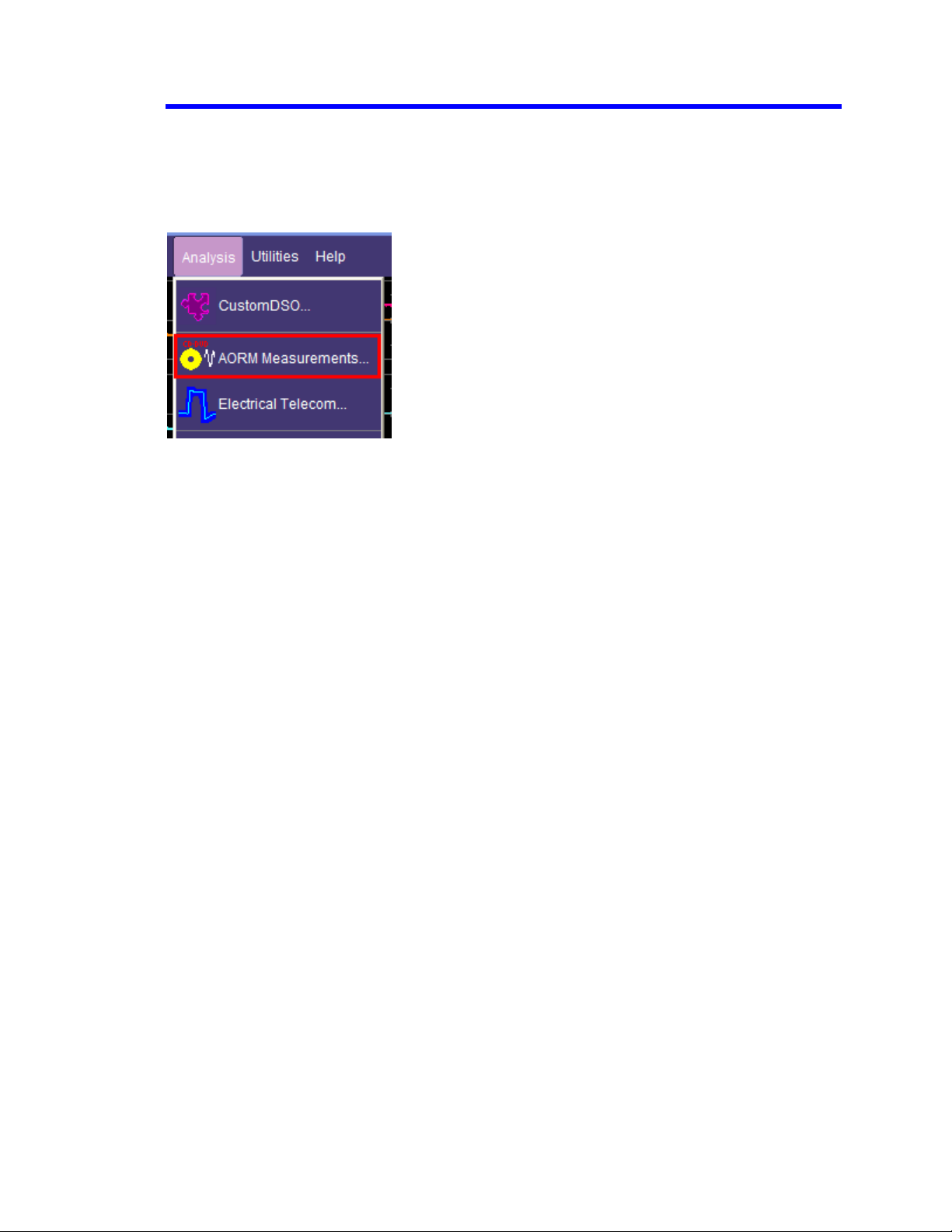

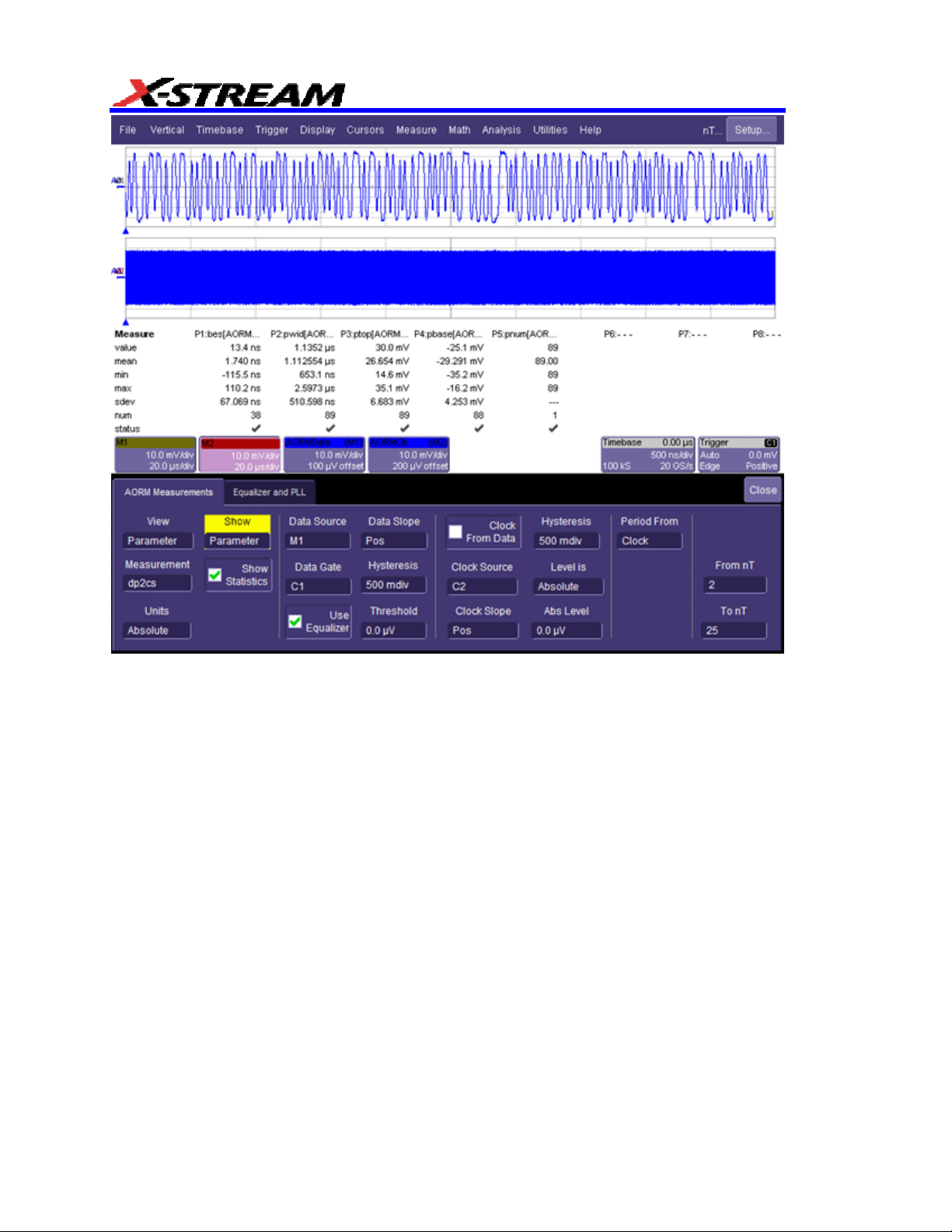

The “AORM Measurements” dialog is accessed from the menu bar’s Analysis menu. AORM is

supplied with X-Stream software version 4.2 and later. This highly interactive dialog allows you to

set up and configure the clock and data sources, select a measurement type, and analyze the

waveform, including statistics on parametric measurements:

923133 Rev A ISSUED: June 2013 9

Page 12

10 ISSUED: June 2013 923133 Rev A

Page 13

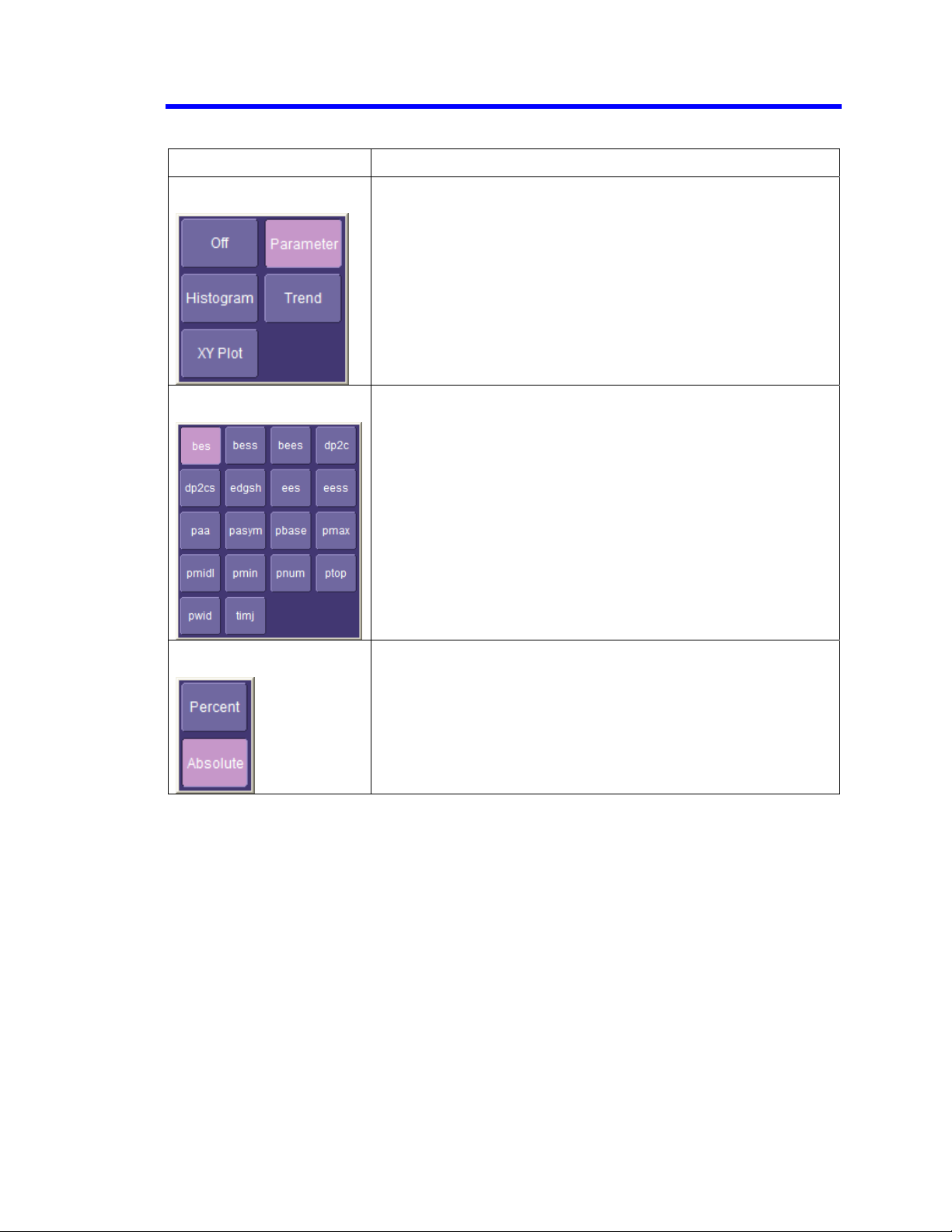

AORM Measurement Menus

Field Description

View

AORM Software Package

Measurement

Units

Allows you to

quickly select the most common views, with

graphing.

Selects the p

rimary measurement to be made. In the Parameter

view, the result for the selected measurement is displayed along

with other parameters.

The units u

sed for the horizontal parameter results. Absolute

refers to voltage or time units. Percent refers to results being

calculated as a percent of the clock period.

923133 Rev A ISSUED: June 2013 11

Page 14

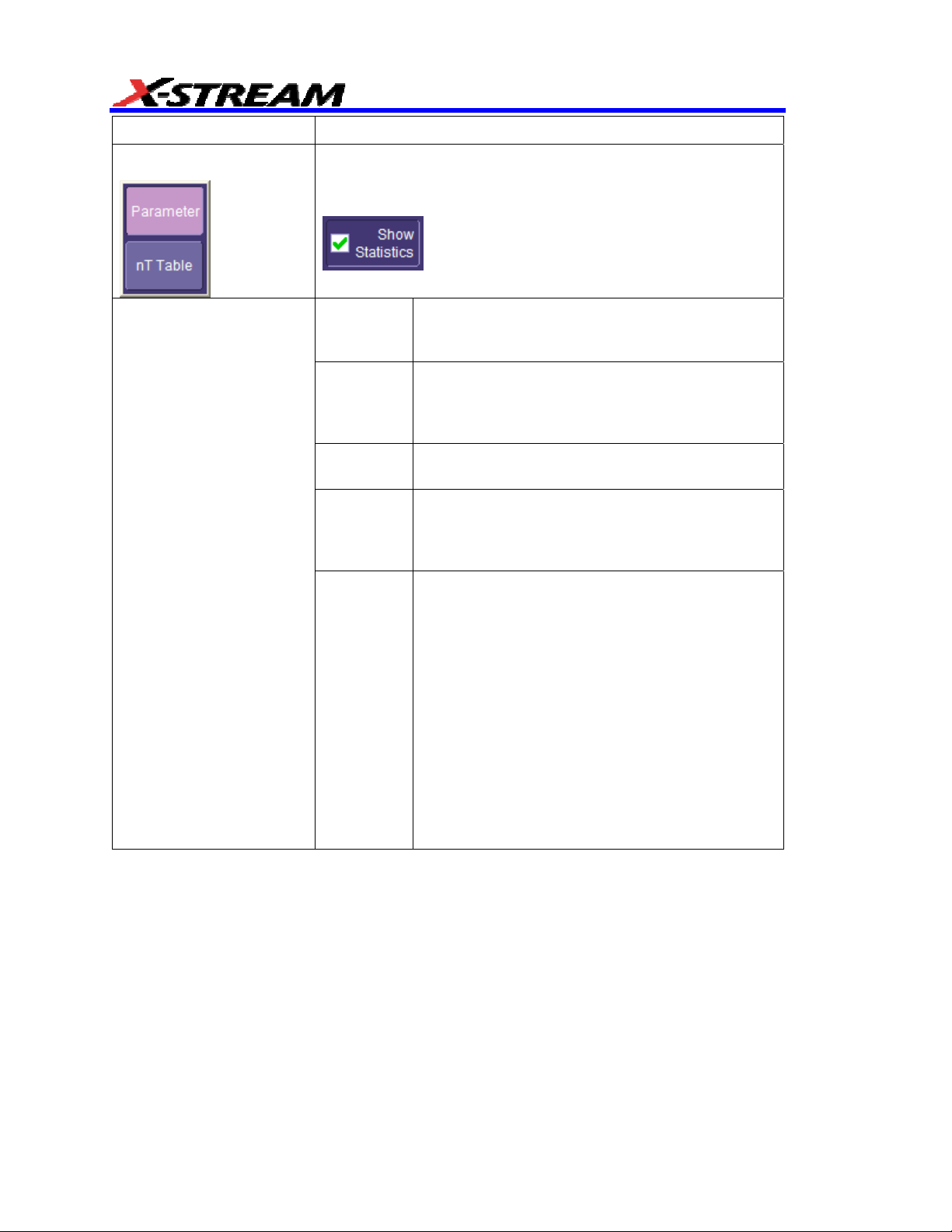

Field Description

Show

Data

Determine

s which table of values is displayed below the grid.

When Parameters is selected, a checkbox is displayed that

enables you to turn on or off the display of statistics values.

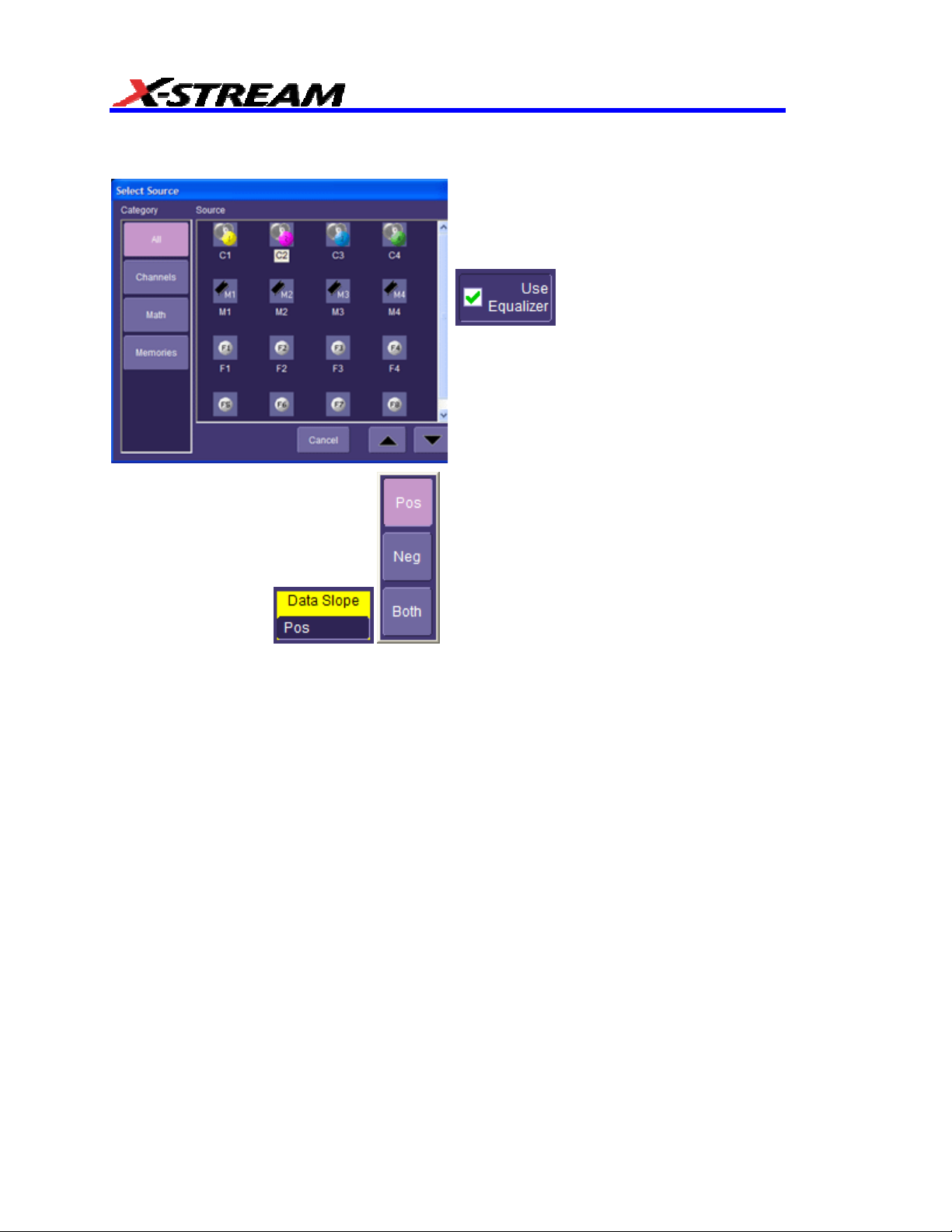

Source This can be a channel, math function, or memory

trace. A Use Equalizer checkbox is provided to

apply a filter to the data source.

Data Gate This can be a channel, math function, memory

trace, or other. It specifies the input that will be

used to determine where to perform measurements

on the input signal. The polarity is always high.

Use

This checkbox enables filtering of the data source.

Equalizer

Data Slope Polarity of the pits/spaces to use for the

measurement, when appropriate. Pos polarity

refers to pits, Neg polarity refers to spaces, Both

can be selected to use both pits and spaces.

Hysteresis The Hysteresis selection imposes a limit above and

below the Threshold, which precludes

measurements of noise or other perturbations

within this band. The width of the band is specified

in divisions.

Guidelines for Use

1. Hysteresi

noise spi

2. The larg

than the dista

s must be larger than the ma

ke you want to ignore.

est value of hysteresis usable

nce from the threshold to the closest

ximum

is less

extreme value of the waveform.

3. Unle

extreme level

ss you know the largest noise and closes

that will ever occur on any cycle,

leave some margin on both sides of the threshold.

12 ISSUED: June 2013 923133 Rev A

t

Page 15

AORM Software Package

Field Description

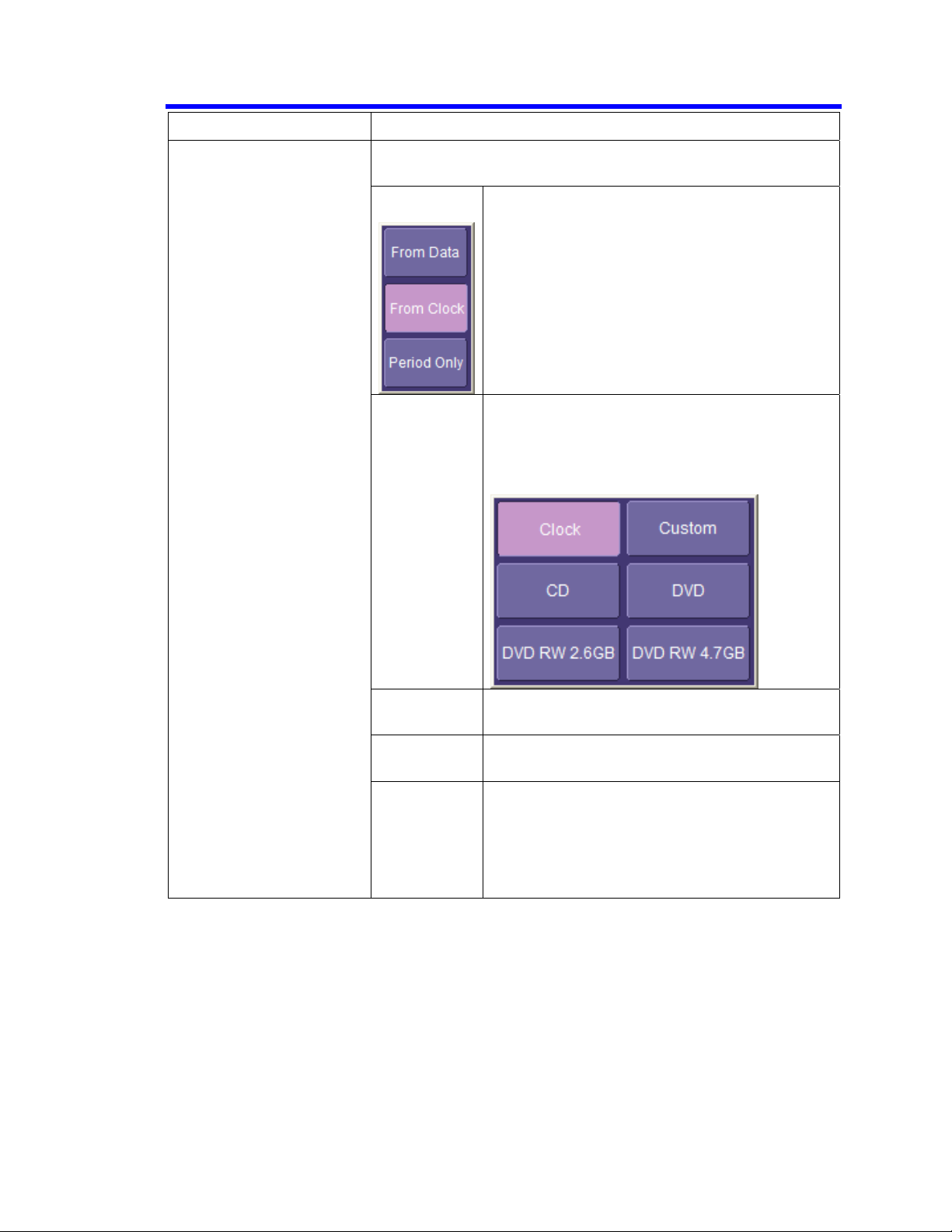

The clock need only be specified if the parameter requires a

clock for the calculation, or it is used as the source of the period.

Clock/Period By selecting From Data, you can have the clock

recovered from the data. In this case, all other

clock setup fields except Clock Slope are

unavailable.

When From Clock is selected, the period is

automatically measured from the clock provided.

The clock must then be configured.

When Period Only is selected,

Clock

Period

From

Indicates the period of the clock.

When a standard is selected, the period is set to

the value defined by the standard. You can also

set a xN multiplier (e.g., 10x).

Clock Source This can be a channel, math function, or memory

trace.

Clock Slope Choose Pos, Neg, or Near. “Near” means the

nearest clock edge to the data edge.

Hysteresis Size of the hysteresis band (in screen divisions)

with the level at the center of the band. Any

waveform being analyzed must pass beyond this

band before the next threshold crossing is

recognized. The Level may be set to Absolute or

Percent.

923133 Rev A ISSUED: June 2013 13

Page 16

Field Description

Subject nT

For BES, EES, BEES, BESS, and EESS, this specifies the pit of

interest. The results will be computed for each space/pit

(pit/space) pair using the subject pit and all the spaces within the

range specified.

Preceded by low nT

Preceded by high nT

From nT

To nT

Specifies the range of n indices that define the pits/spaces used

in the calculation. The range of n coupled with T are used to

categorize the pits/spaces based on their widths.

Specifies the range of n indices that define the pits/spaces used

in the calculation. The range of n coupled with T is used to

categorize the pits/spaces based on their widths.

14 ISSUED: June 2013 923133 Rev A

Page 17

AORM Software Package

Measurement Table

When the Parameter view is selected, up to 4 additional parameters, which are related to the selected

measurement, are displayed. The following table shows these additional parameters. For parameters

that can be shown in the XY display, it also shows the parameter that is used for the X axis.

Measurement Parameters XY

(setup for custom parameters) (x axis)

dp2c (s) t@pit,pwid,pnum t@pit

EDGESH t@pit,pwid,pnum t@pit

EES (s) pwid,ptop,pbase,pnum n/a

BES (s) pwid,ptop,pbase,pnum n/a

PAA pwid,ptop,pbase,pnum n/a

Pit width t@pit, ptop,pbase,pnum t@pit

timj t@pit, ptop,pbase,pnum t@pit

Pit base pwid,ptop,pbase,pnum pwid

Pit top pwid,ptop,pbase,pnum pwid

Pit minimum pwid,ptop,pbase,pnum pwid

Pit middle pwid,ptop,pbase,pnum pwid

Pit asym pwid,ptop,pbase,pnum n/a

Pit max pwid,ptop,pbase,pnum pwid

Pit num pwid,ptop,pbase n/a

923133 Rev A ISSUED: June 2013 15

Page 18

View Menu Selections

View Displays Additional Keys

Parameter

Histogram

Trend

XY Plot

The source traces will be displayed

along with the custom parameters

(see Measurement Table, next). If two

traces are to be displayed, dual grids

will be drawn.

When Histogram is selected, a

histogram of the selected parameter

is displayed in a second grid, and a

new tab, “AORM Histogram,”

appears.

When Trend is selected, a trend plot

of the selected parameter is displayed

in a second grid, and a new tab,

“AORM Trend,” appears.

Plots the trend of the selected

measurement vs. either the trend

t@pit or pwid, as appropriate; not

available for all measurements (see

Measurement Table, next, for details).

When XY Plot is selected, a trend

plot of the selected parameter is

displayed in a second grid, and a new

tab, “AORM Trend Y,” appears.

Statistics: toggles the parameter

statistics on/off.

Find Center And Width: determines

the best scaling for the histogram

based on up to the last 20,000

samples collected. This occurs

automatically if the Enable Auto Find

checkbox is checked.

Find Scale: determines the best

scaling for the trend (center and

height). This occurs automatically if

the Auto Find Scale checkbox is

checked.

Find Scale: determines the best

scaling for trends (center and height).

This occurs automatically if the Auto

Find Scale checkbox is checked.

16 ISSUED: June 2013 923133 Rev A

Page 19

Equalizer and PLL Dialog

Field Description

AORM Software Package

Track Clock

Filter Cutoff and Boost

Slicer Bandwidth

PLL Bandwidth

PLL Startup Period From

Check this checkbox to enable tracking.

An equalizer filter is applied prior to the measurements. You can

adjust the cutoff frequency and boost of the filter.

The data passes through a slicer to level the data (removes the

threshold due to low frequency effects). You can set the

bandwidth of the slicer.

If you checked the Clock From Data checkbox, a PLL is used to

recover the clock from the data waveform. In that case, the

bandwidth of the PLL can be adjusted.

Auto When Auto is selected, the startup frequency will be

determined by analyzing the peaks of the input signal.

User When User is selected, you can set the startup

frequency yourself. This is useful when the startup

frequency cannot be reliably determined from the input

signal.

923133 Rev A ISSUED: June 2013 17

Page 20

CREATING AND ANALYZING HISTOGRAMS

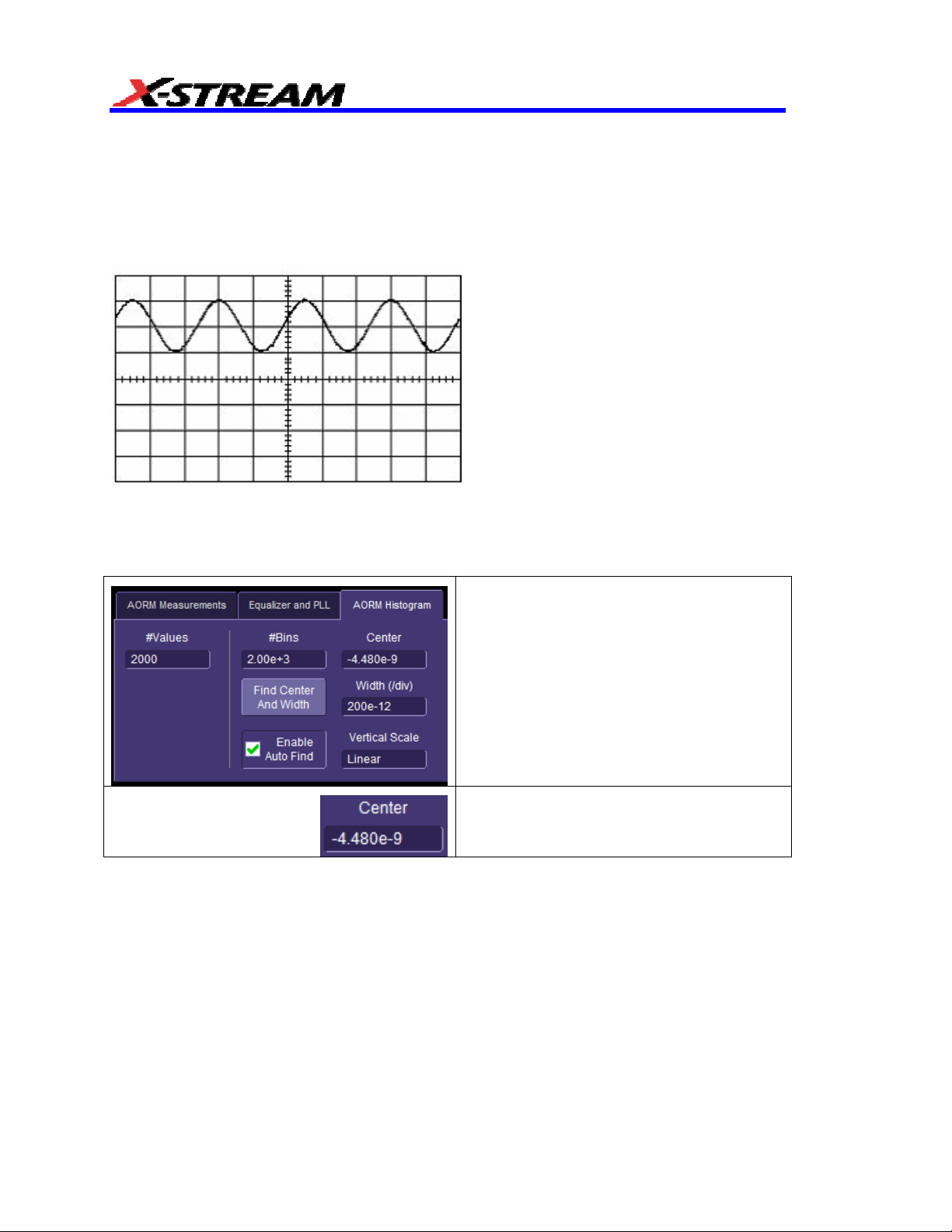

Selecting the Histogram Function

Histograms are created by graphing a series of waveform parameter measurements. The first

step is to define the waveform parameter to be histogrammed. The next figure shows a screen

display accompanying the selection of a frequency (freq) parameter measurement for a sine

wave on Channel 1.

Four

waveform cycles are shown, which will provide four freq parameter values for each

histogram on each sweep. With a freq parameter selected, a histogram based on it can be

specified.

Histogram Trace Setup Dialog

Each time a waveform parameter value is

calculated it can be placed in a histogram bin.

Enter the #Bins from 20 to 2000.

You can set from 20 to 2 billion parameter

value calculations for histogram display in the

#Values field.

18 ISSUED: June 2013 923133 Rev A

Page 21

AORM Software Package

The current horizontal per division setting for

the histogram. The unit type used is

determined by the waveform parameter type

that the histogram is based on.

The vertical scale.

• Linear make

linear. Th

desi

gnates a bin value of 0.

nts increase beyond th

cou

can be displayed on screen using the

curre

nt vertical scale, this

automatically increa

uence.

seq

s the vertical scale

e baseline of the histog

As the bin

at which

scale is

sed in a 1-2-

ram

5

• LinConstMax sets the vertical scalin

to a linear val

full vertical di

ue that uses clos

splay capability of

e to the

the

scope. The height of the histogram

will rem

ain al

most constant.

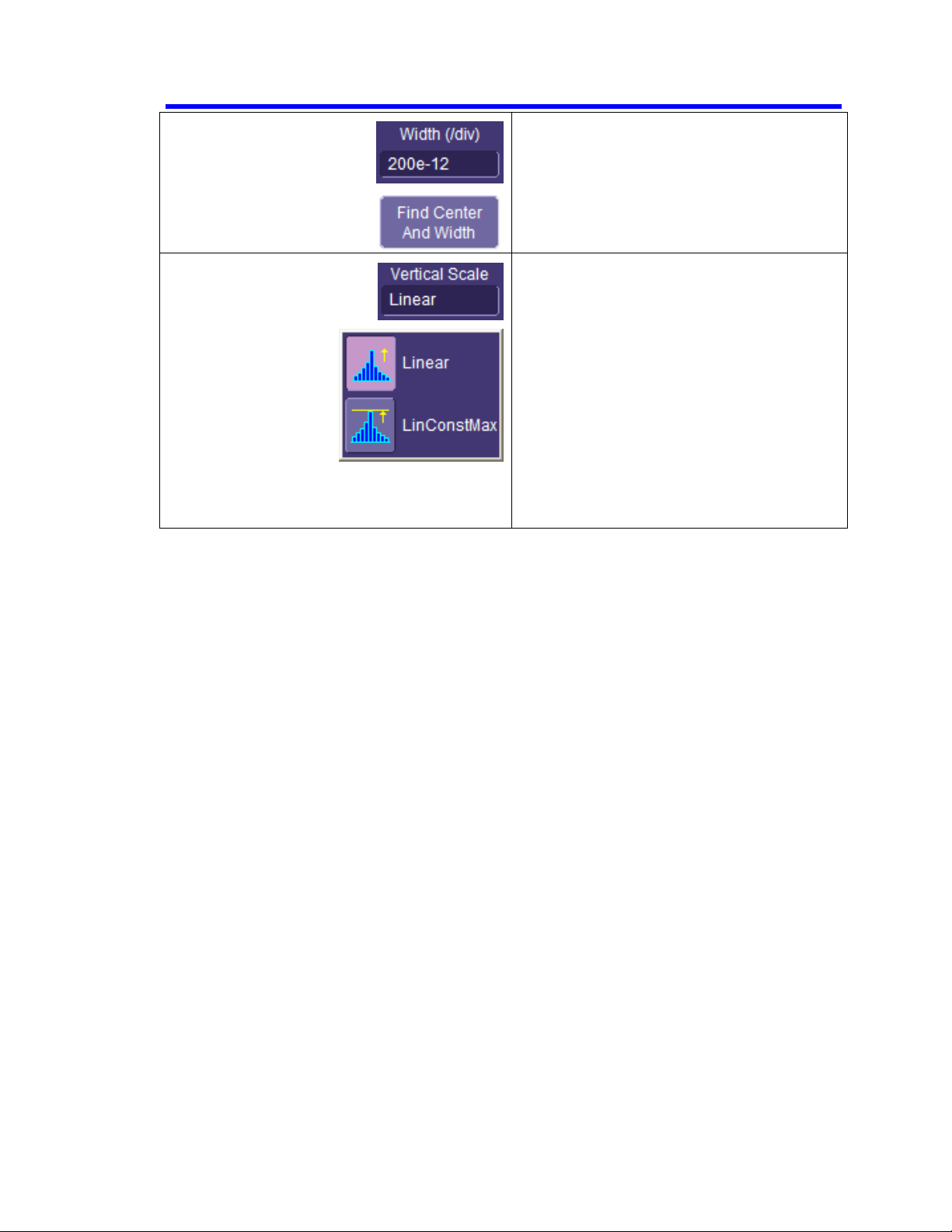

Setting Binning and Histogram Scale

For either the Linear or LinConstantMax vertical scale option, the scope automatically increases

the vertical scale setting as required, ensuring that the highest histogram bin does not exceed the

vertical screen display limit.

The Center and Width fields allow specification of the histogram center value and width per

division. The width per division multiplied by the number of horizontal display divisions (10)

determines the range of parameter values centered on the number in the Center field, used to

create the histogram.

g

923133 Rev A ISSUED: June 2013 19

Page 22

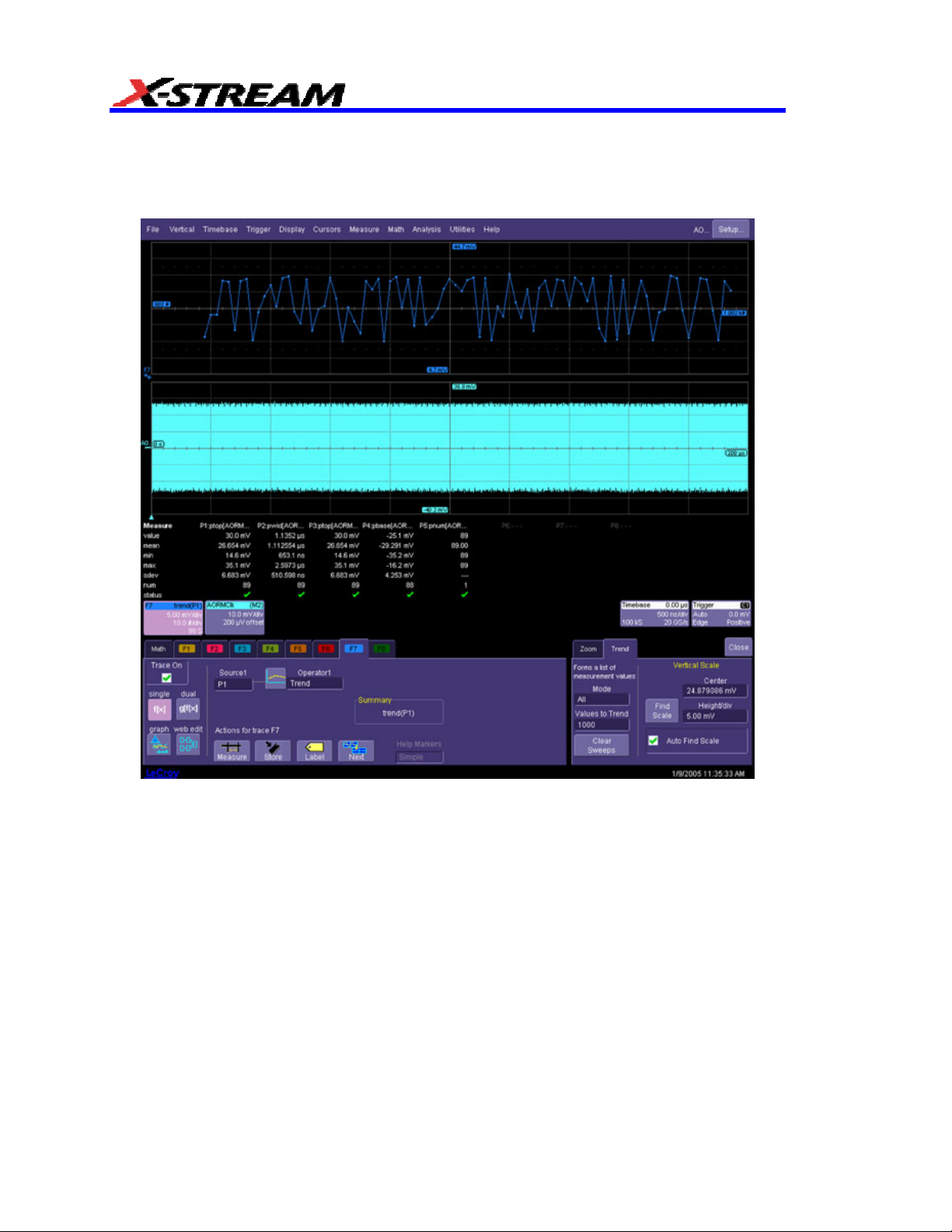

DISPLAYING TRENDS

The Trend function for processing waveforms creates a graph of successive waveform parameter

values. It provides useful visual information on waveform parameter variation. Used together with

other scope features, it allows you to graph certain parameters compared to others.

To Con

20 ISSUED: June 2013 923133 Rev A

figure a Trend:

From the menu bar select Math, then Math Setup… from the drop

1.

2. Touch

default).

3. Touch

an Fx tab that is not currently assigned a math function (i.e., Zoom function

inside the Source1 field and select a source waveform from the pop-up

-down menu.

by

menu.

Page 23

AORM Software Package

4. Touch inside the Operator1 field and select Trend

Opera

tor pop-up menu. The "Trend" setup dialog will appear at the right of the screen

5.

Decide whether all the parameter values, all per trace, or only the averag

para

meter calculations for each waveform acquisition should be placed in the tre

All -- every p

Av

erage -- trends only the average of all the values calculated on a given acquisition an

yields on

All per Trace -- for ea

cal

culations from the new data in the trend. Unless this is specifically required, All shou

ected.

be sel

arameter calculation on each waveform will be placed

e point in the trend per acqui

sition.

ch acquisition, clears the buffer and places all param

from the Select Math

:

e of all

nd.

in the trend.

d

eter

ld

6.

Choose the number of values to be placed in the generated trend.

If desired, you can also configure the center and heig

7.

the para

used to center the trend after it has been

Cen

asso

while u

Height/di

the para

923133 Rev A ISSUED: June 2013 21

meter being trended. However, this is not a requirement, and Find Scale can be

calculated.

ter is for selecting the mantissa, exponent, or number of digits resolution, us

ciated knob. The configuration is the value at the horizontal center line on th

nits are those of the parameter trende

d.

v selects the vertical value of each vertical screen division. Units ar

meter trend

ed.

ht of the trend in the base units of

ing the

e grid,

e those of

Page 24

Trend Calculation

Once the trend has been configured, parameter values will be calculated and trended on each

subsequent acquisition. Immediately following an acquisition, its trend values will be calculated.

The resulting trend is a waveform of data points that can be used the same way as any other

waveform. Parameters can be calculated on it, and it can be zoomed, serve as the x or y trace in

an XY plot, and can be used in cursor measurements.

The sequence for acquiring trend data is:

1. trigger

2. waveform acquisition

3. parameter calculations

4. trend update

5. trigger rearm

If the timebase is set in non-segmented mode, a single acquisition occurs prior to parameter

calculations. However, in segment mode, an acquisition for each segment occurs prior to

parameter calculations. If the source of trend data is a memory, storing new data to memory

effectively acts as a trigger and acquisition. Because updating the screen can take significant

processing time, it occurs only once a second, minimizing trigger dead time (under remote control

the display can be turned off to maximize measurement speed).

Parameter Buffer

The parameter buffer allows you to include up to one million values in the trend calculation.

Parameter Events Capture

The number of events captured per waveform acquisition or display sweep depends on the

parameter type. Acquisitions are initiated by the occurrence of a trigger event. Sweeps are

equivalent to the waveform captured and displayed on an input channel (1, 2, 3, or 4). For nonsegmented waveforms, an acquisition is identical to a sweep. Whereas for segmented

waveforms, an acquisition occurs for each segment, and a sweep is equivalent to acquisitions for

all segments. Only the section of a waveform between the parameter cursors is used in the

calculation of parameter values and corresponding trend events.

Reading Trends

A trend is like any other waveform: its horizontal axis is in units of events, with earlier events in

the leftmost part of the waveform and later events to the right. And its vertical axis is in the same

units as the trended parameter. When the trend is displayed, trace labels appear in their

customary place on the screen identifying the trace, the math function performed, and giving

horizontal and vertical information:

• # number of events per horizontal division

• Units per vertical division, in units of the parameter being measured

22 ISSUED: June 2013 923133 Rev A

Page 25

AORM Software Package

•

Vertical value at point in trend at cursor location when using cursors

•

Number of events in trend that are within unzoomed horizontal display range.

• Percentage of values lying beyond the unzoomed vertical range when not in cursor measurement

mode.

923133 Rev A ISSUED: June 2013 23

Page 26

MAKING OPTICAL DATA MEASUREMENTS

View Modes

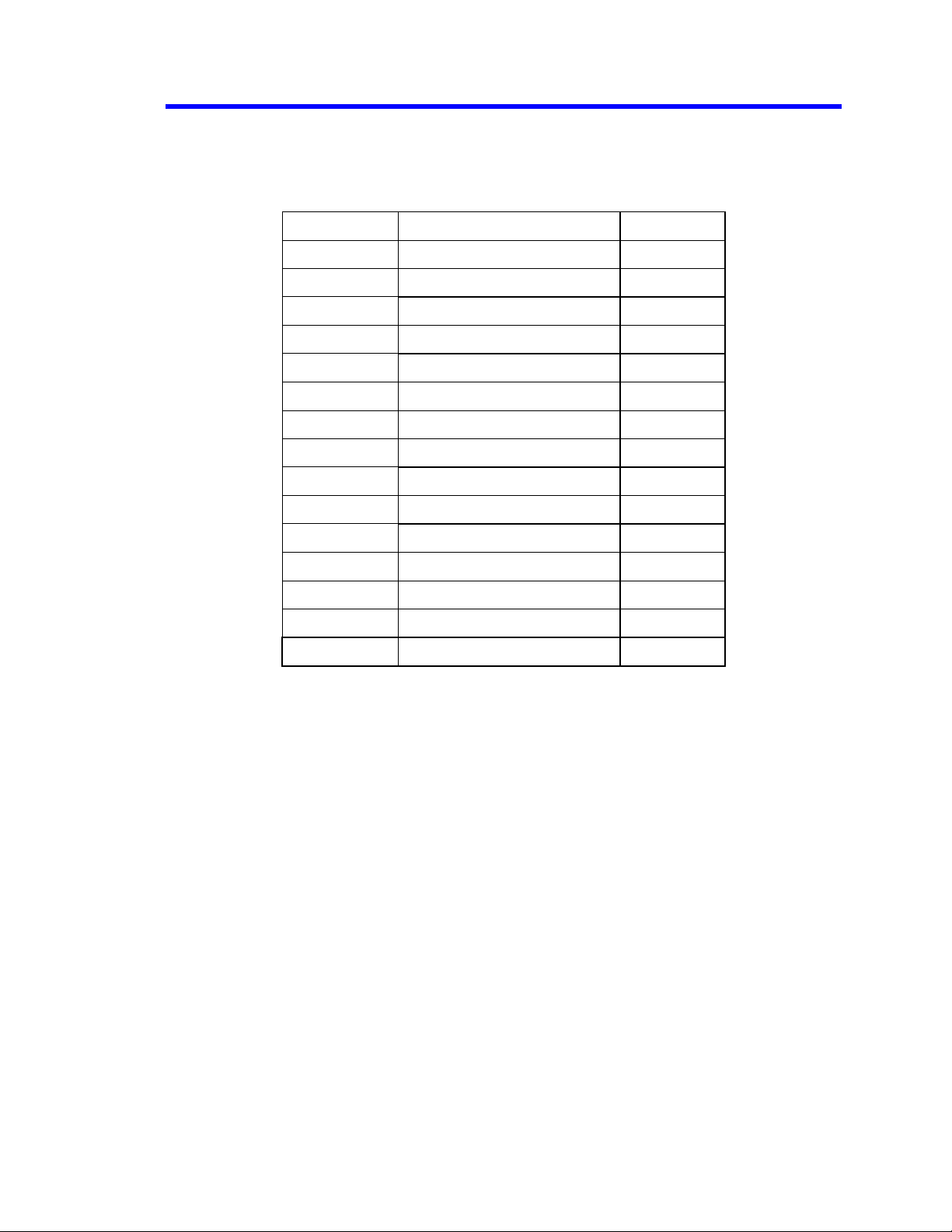

The two modes available for Optical Recording Measurements, “Custom” and “List by nT,” both

display measurements either as waveform parameters or as a list of values. This chapter further

describes these modes. The following table indicates which measurements can be made in each

mode.

Measurement Parameter nT Table

BEES x x

BES x x

BESS x x

Dp2c x x

Dp2cs x x

EES x x

EESS x x

EDGSH x x

PAA x x

Pit asym x

Pit base x x

Pit max x x

Pit middle x x

Pit minimum x x

Pit moda x

Pit number x x

Pit res x

Pit top x x

Pit width x x

T@pit x

Timj x x

24 ISSUED: June 2013 923133 Rev A

Page 27

AORM Software Package

Configuration Options

All configuration options are available for each parameter, except as noted in this table:

Range of nT

Subject nT

Parameter

Dp2c

Dp2cs

BEES

BES

BESS

EES

EESS

EDGSH

PAA

Pit asym

Pit base

Pit max

Pit middle

Pit minimum

Pit moda

Pit num

Pit res*

Pit top

Pit width

T@pit*

Timj x

x

x

x

x x

x x

x x

x x

x

x

x

x

x

x

x

x

x

x

x

x

x

* Available from Measure dialog

923133 Rev A ISSUED: June 2013 25

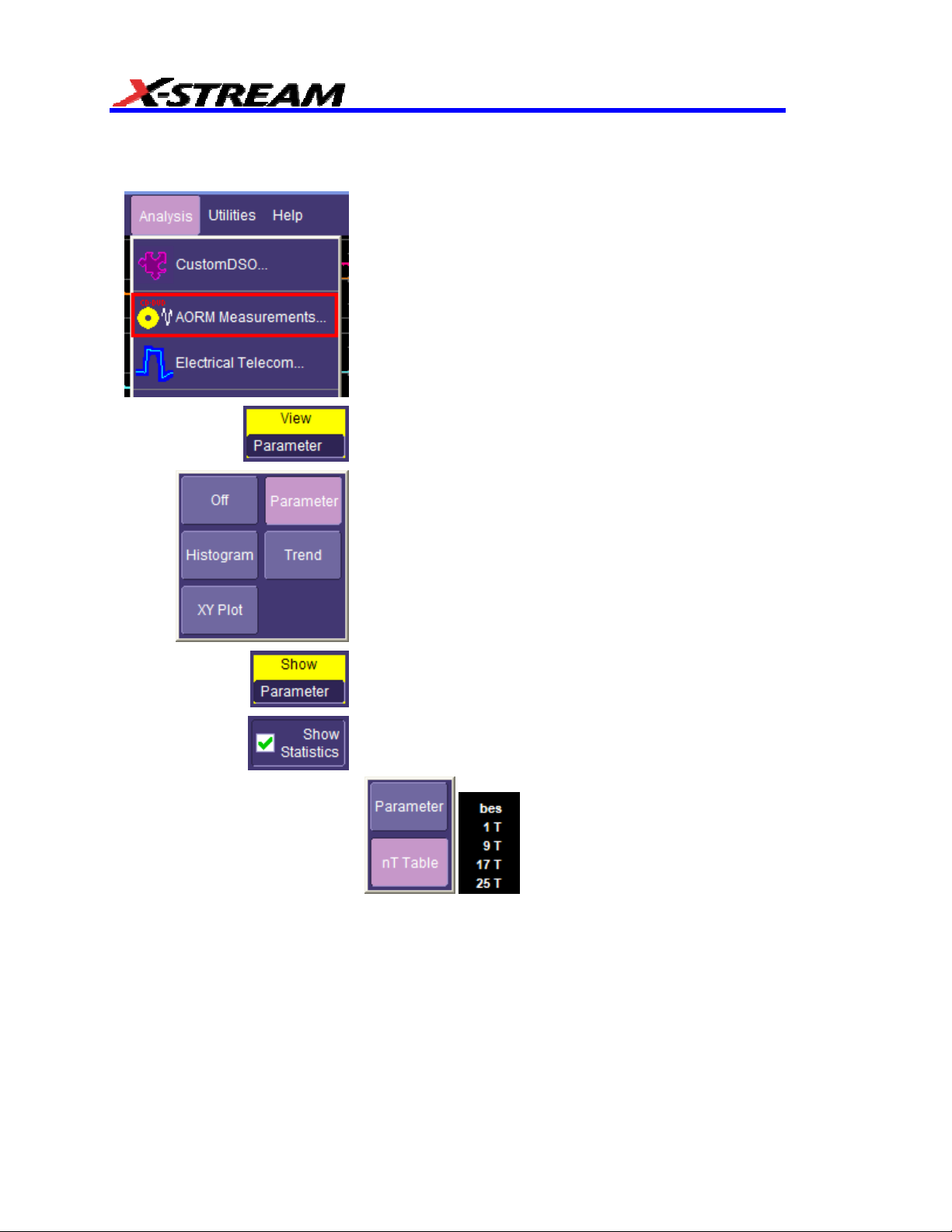

Page 28

Configuration Menus

The menus described on the following pages show how to configure any parameter.

Display the AORM dial

bar at the top of the screen and selecting AORM

Measurements… from the drop-down menu.

Touch insi

the pop-up menu.

de the View field and select a graph display from

og by touching Analysis in the menu

Touch insi

default group of parameters is automatically displayed when

Parameter is selected. In addition, if Show Statistics is

checked, standard statistics (mean, min, max, sdev, num)

are also displayed.

When nT Table is selected, a default list of nT is displayed:

26 ISSUED: June 2013 923133 Rev A

de the Show field and select a display mode. A

Page 29

AORM Software Package

Touch inside the Measurement field and select a

measurement from the pop-up menu. Besides the

parameters included in this menu, others are available from

the Select Measurement menu, accessible from the

Measure dialog:

923133 Rev A ISSUED: June 2013 27

Page 30

Setting Levels

To identify pits or spaces, thresholds and hysteresis are set.

Touch inside the Data Source field and select

a signal source.

Check Use Equalizer to apply a filter to the

Data Source.

To set up the

and PLL tab.

Touch insi

an edge from the pop-up menu.

equalizer, touch the Equalizer

de the Data Slope field and select

28 ISSUED: June 2013 923133 Rev A

Page 31

AORM Software Package

Touch inside the Data Gate field and select a

signal source. You can also select None. Data

Gate specifies the input that will be used to

determine where to perform measurements on

the input signal. If a Data Gate is selected, the

level is assumed to be high.

The Hysteresis selection imposes a limit

above and below the Threshold, which

precludes measurements of noise or other

perturbations within this band. The width of the

band is specified in divisions.

Select From Data from the Clock/Period menu

if you want to extract the clock from your input

waveform. In this case, all other clock setup

fields become unavailable except Clock Slope.

Choose Pos, Neg, or Near. “Near” means the

nearest clock edge to the data edge.

To keep noise out of parametric

measurements, set up a hysteresis band, in

divisions, about a level. The level can be set to

Absolute (volts) or Percent. In either case,

touch inside the Abs Level or Pct Level field

and enter a value, using the pop-up keypad.

923133 Rev A ISSUED: June 2013 29

Page 32

Select a clock period by having the period

calculated from the clock source, by choosing a

standard, or by manually setting a clock period.

If you choose a clock period from a standard,

you can also set a multiplier:

Setting nT

For BES, EES, BEES, BESS, and EESS, this

specifies the pit of interest. The results will be

computed for each space/pit (pit/space) pair

using the subject pit and all the spaces within

the range specified.

Specifies the range of n indices that define the

pits/spaces used in the calculation. The range

of n coupled with T are used to categorize the

pits/spaces based on their widths.

Maximizing Performance

A basic guideline that you should follow to maximize the performance of calculation in multiple

parameter configurations is that precisely the same Value for the clock period ‘T’, Threshold level,

and Hysteresis value should be used.

Following this guideline ensures that parameters can make use of results obtained in previous

parameter calculations. However, in most cases there is no need for different configurations of

the above three items in different parameter setups.

30 ISSUED: June 2013 923133 Rev A

Page 33

AORM Software Package

Pit or Space Identification

This is determined uniquely by the threshold, hysteresis, and edge polarity of threshold crossings.

A positive threshold crossing indicates the start of a positive polarity pit and the end of a negative

polarity space. A positive threshold crossing followed by a negative threshold crossing fully

delineates a pit. A negative crossing followed by a positive crossing fully delineates a space, as

illustrated in the following figure.

Voltage

Threshold

In order to prevent false pit and space identifications, hysteresis is provided. Hysteresis adds an

additional condition that must be met before a threshold crossing is recognized as a pit/space

edge. It requires that the waveform make an excursion of a certain distance from the threshold

before the next threshold crossing is recognized.

The next figure shows a threshold crossing that would result in incorrect pit identification without

hysteresis.

Space

False

Pit

Pit

Level

Threshold

923133 Rev A ISSUED: June 2013 31

Page 34

The hysteresis band shown in the next figure is centered on the user- selected voltage level

pit

threshold.

Pit meets condition of

crossing into Zone 3

End of space.

Space fully

identified

oltage

V

Threshold

Zone 3

Zone 2

Zone 1

Start of pit

Pit Width

End of pit. Start

of space Pit fully

First feature

will be a

identified

Space meets condition

of crossing into Zone 1

The hysteresis band divides the display into three zones. The ORM Package uses both the

voltage threshold and hysteresis settings to identify pits and spaces.

Criteria for identifying a “feature” (pit or space):

• The first feature identified after the left parameter cursor can be either a pit or space. If

the signal first enters Zone 1, the first feature identified (if additional constants are met)

will be a pit. If the signal first enters Zone 3, it will be a space.

• After first crossing into Zone 1 or Zone 3, the next time the signal crosses the voltage

threshold, it is recorded as the start time of a feature.

• If the first feature to be identified is a pit (signal entered Zone 1 first), after crossing the

voltage threshold the signal must cross into Zone 3 and then pass the voltage threshold

again to complete all conditions for identification as a pit. The first time that the signal

crosses the voltage threshold after entering Zone 3 is recorded as the end time of the pit

and the start time of the following space. The time between the start and end of the pit is

recorded as the pit width. If the first feature to be identified is a space, the signal first

entered Zone 3. The algorithm is used with directions reversed.

32 ISSUED: June 2013 923133 Rev A

Page 35

AORM Software Package

()(

⋅+<≤⋅

−

• For the entire signal, only a space can be identified after a pit, and only a pit can be

identified after a space.

• All subsequent features are identified by crossing into the appropriate zone after the end

of the previous feature. For a pit this is Zone 3, and for a space it is Zone 1. The end of

the previous feature is the beginning of the current feature being identified. The

subsequent first time the signal crosses the voltage threshold is recorded as the time of

the feature being identified. At this point, the feature has been fully identified.

nT Pit/Space Categorization

Because optical recording data is encoded using a pulse-width modulation mechanism, it is often

useful to perform signal analysis for selected pulse widths. Exploiting the fact that optical

recording data widths are ideally integral multiples of the data clock period ‘T’, the AORM

Package separates optical recording signal pits and spaces into groups whose widths fall into the

same integral multiple of clock periods. As a result, ORMs can be configured to provide values for

only pits or spaces, or both of these for a selected ‘nT’ value (‘nT’ denotes an integer multiple of

the clock period) or for a range of ‘nT’s.

The ideal clock period (T) is configured on the parameter nT setup.

Categorization of pits and spaces by nT based on width is done using the following equation:

)

TnwTn

5.05.0

th

When this condition is met, the pit or space of width w is said to belong to the n

index.

923133 Rev A ISSUED: June 2013 33

Page 36

BES BEGINNING EDGE SHIFT

Description

BES provides a measurement of the time between the beginning edge of the subject n in a specified

space/pit pair and the nearest specified clock edge. The measurement is calculated between the points

where the data and clock signals cross selected voltage thresholds. The clock period T can be entered by

the user, or measured from a user supplied clock signal, as described below.

The value calculated depends on the clock and data edges selected, as shown in the table below.

The data slope menu selects the polarity of the subject n pit/space. If Pos (positive) is selected,

the measurement is performed from the beginning edges of positive polarity pits and categorized

by the preceding space. If Neg (negative) is selected, the measurement is performed from the

beginning edges of negative polarity spaces and categorized by the preceding pit. If Both is

selected, the beginning edges of both pits and spaces are used in the calculation and categorized

by the preceding inverse polarity space/pit. The sizes of pits or spaces used in the measurement

are also determined by the range of ‘nT’ values chosen.

CLOCK

EDGE

time between beginning

edge of positive polarity

Positive

Negative

Near

The next figure shows the measurement of the beginning edge shift on a single subject 4T pit

preceded by a 3T space. In this example, the clock is specified as the positive edge. For each

space/pit combination, the beginning edge shift is calculated as the time difference between the

beginning pit edge and the clock edge. Additionally, the measurements will be sorted by the

space/pit pairs. For the positive polarity pit example shown in the figure after next, measurements t+ and tare for a single beginning edge shift measurement configured for positive edge, or negative edge. If nearest

is selected, the smaller of t- or t+ is used.

subject pit and nearest

positive clock edge

time between beginning

edge of positive polarity

subject pit and nearest

negative clock edge

time between beginning

edge of positive polarity

subject pit and nearest

clock edge

Pos Neg Both

DATA SLOPE

time between beginning

edge of negative polarity

subject space and

nearest positive clock

edge

time between beginning

edge of negative polarity

subject space and

nearest negative clock

edge

time between beginning

edge of negative polarity

subject space and

nearest clock edge

time between beginning

edge of subject pits and

spaces to nearest

positive clock edge

time between beginning

edge of subject pits and

spaces to nearest

negative clock edge

time between beginning

edge of subject pits and

spaces and nearest

clock edge

34 ISSUED: June 2013 923133 Rev A

Page 37

AORM Software Package

threshold

Data

3T

4T

beginning

edge shift

Beginning Edge Shift measurement of subject 4Tpit

Signal

Signal

Clock

Data Signal

Clock Signal

T

+

t

-

Zoom of Positive Polarity Pit Edge -- example measurement

923133 Rev A ISSUED: June 2013 35

Page 38

The measurement has configurable units. If absolute time is specified, the value is simply the time

∆

∆

=⋅⋅

+

−

indicated above. If percent is specified, the value of the measurement is the time normalized to the

clock period:

For all pits, a valid measurement will be obtained only when both pit/space edges can be determined,

bes

t

100%

T

100%

or t

(that is, there is a hysteresis-qualified threshold crossing beginning and ending the pit/space pair of

interest between the parameter cursors), and there is a clock edge of both polarities surrounding the

leading pit or space edge between the parameter cursors.

Display Options

ORM parameter calculations can be displayed, histogrammed, and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

All values of the time between beginning edge of the subject n pit

Parameter Statistics Off

Parameter Statistics On

nT Table

(space) and nearest clock edges for all subject pits (spaces)

preceded by the spaces (pits) within the selected ‘nT’ range for

the last acquisition.

Average, minimum, maximum, and sigma of the beginning edge

shift calculated for all identified pit/space pairs within the selected

‘nT’ range for all acquisitions since the last C

operation.

List of values of the average beginning edge shift for each ‘nT’

space (pit) within the selected range preceding the subject pit

(space) for the last acquisition.

T

LEAR SWEEPS

Histogram graph of the value of the beginning edge shift

Histogram Function

calculated for all pit/space pairs within the selected ‘nT’ range for

all acquisitions since the last C

LEAR SWEEPS operation.

Trend graph of the value of the beginning edge shift calculated for

Trend Function

all pit/space pairs within the selected ‘nT’ range for all acquisitions

since the last C

LEAR SWEEPS operation.

36 ISSUED: June 2013 923133 Rev A

Page 39

AORM Software Package

(

(

BESS

BESS

N

N

=⋅−

−

∑

∑

(

(

B

B

BES

BESN

N

==−

−

∑

∑

σ

B

BESS BEGINNING EDGE SHIFT SIGM A

Description

BESS provides a measurement of the mean, normalized standard deviation of the Beginning

Edge Shift measurements (see BES). When a single n is specified, or when you are in ‘nT Table’

Show mode, the value calculated for the n

standard deviation:

th

index is calculated using the following equation for

ESS

n

ESS

n

Beginning Edge Shift Sigma cannot be calculated for a given index n unless there are at least two

Beginning Edge Shift values calculated or that n index.

When Beginning Edge Shift is configured as a custom parameter with a range of n, the value

calculated is the standard deviation of the distribution that results by normalizing each independent

distribution categorized by the space (pit) nT preceding the subject pit (space). Distributions are

normalized by subtracting the mean of the distribution from all of the elements in the distribution. This

results in the following equation for overall Beginning Edge Shift Sigma resulting from the individually

categorized Beginning Edge Shift Sigma values:

overall

Note: The value calculated by BESS will generally not be the same as the sigma of the BES measurement displayed on

the parameter line when a range of n is used and statistics is on. This is because the two measurements are not the

same. The BESS measurement normalizes the results for each n by subtracting the mean BES from each BES in the n

distribution. This results in a superposition of mean-centered distributions, not a superposition of 0-centered distributions

contributing to BES measurements. BESS will always be less than or equal to the standard deviation of BES

measurements.

ES

)

n

2

)

2

n

1

n

n

n

2

nn

n

1

)

1

)

th

923133 Rev A ISSUED: June 2013 37

Page 40

Display Options

ORM parameter calculations can be displayed, histogrammed and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

Single value of the standard deviation of the mean normalized

Parameter Statistics Off

beginning edge shift values for pits/spaces of interest for last

acquisition.

Average, minimum, maximum, and sigma of the beginning edge

Parameter Statistics On

shift sigma value calculated per acquisition for all acquisitions

since the last C

LEAR SWEEPS operation.

List of values of the standard deviation of the beginning edge shift

nT Table

values for each ‘nT’ spaces (pit) within the selected range

preceding the subject pit (space) for the last acquisition.

Histogram of beginning edge shift sigma values calculated for

Histogram Function

each acquisition for all acquisitions since the last CLEAR SWEEPS

operation.

Trend of the beginning edge shift sigma values calculated for

Trend Function

each acquisition for all acquisitions since the last C

LEAR SWEEPS

operation.

38 ISSUED: June 2013 923133 Rev A

Page 41

AORM Software Package

EES ENDING EDGE SHIFT

Description

EES provides a measurement of the time between the ending edge of the subject n in a specified

space/pit pair and the nearest specified clock edge. The measurement is calculated between the

points where the data and clock signals cross selected voltage thresholds. The clock period T can

be entered by the user or measured from a user supplied clock signal, as described below.

The value calculated depends on the clock and data edges selected, as shown in the table below.

The Data Slope menu selects the polarity of the subject n pit/space. If Pos (positive) is selected,

the measurement is performed from the ending edges of positive polarity pits and categorized by

the following space. If Neg (negative) is selected, the measurement is performed from the ending

edges of negative polarity spaces and categorized by the following pit. If Both is selected, the

ending edges of both pits and spaces are used in the calculation and categorized by the following

inverse polarity space/pit. The sizes of pits or spaces used in the measurement are also

determined by the range of ‘nT’ values chosen.

CLOCK

EDGE

Positive

Negative

Near

The next figure demonstrates the measurement of the ending edge shift on a single subject 4T pit

followed by a 3T space. In this example, the clock is specified as the positive edge. For each pit/space

combination, the ending edge shift is calculated as the time difference between the ending pit edge and

the clock edge. Additionally, the measurements will be sorted by the pit/space pairs. For the positive

polarity pit example shown in the figure after next, the measurements t+, and t- are for a single ending edge

shift measurement configured for positive edge, or negative edge. If nearest is selected the smaller of t- or t+

is used.

time between ending

edge of positive polarity

subject pit and nearest

positive clock edge

time between ending

edge of positive polarity

subject pit and nearest

negative clock edge

time between ending

edge of positive polarity

subject pit and nearest

clock edge

Pos Neg

DATA SLOPE

time between ending

edge of negative

polarity subject space

and nearest positive

clock edge

time between ending

edge of negative

polarity subject space

and nearest negative

clock edge

time between ending

edge of negative

polarity subject space

and nearest clock edge

Both

time between ending

edge of subject pits and

spaces to nearest

positive clock edge

time between ending

edge of subject pits and

spaces to nearest

negative clock edge

time between ending

edge of subject pits and

spaces and nearest

clock edge

923133 Rev A ISSUED: June 2013 39

Page 42

threshold

Data

4T

3T

Signal

Clock

Signal

ending

edge shift

Ending Edge Shift measurement of subject 4T pit

Data Signal

Clock Signal

T

+

t

-

Zoom of Positive Polarity Pit Ending Edge -- example

40 ISSUED: June 2013 923133 Rev A

Page 43

AORM Software Package

∆

∆

=

⋅

⋅

+

−

The measurement has configurable units. If absolute time is specified, the value is simply the time as

indicated above. If percent is specified, the value of the measurement is the time normalized to the

clock period:

For all pits, a valid measurement will be obtained only when both pit/space edges can be determined

ees t

or t

(that is, there is a hysteresis-qualified threshold crossing beginning and ending the pit/space pair of

interest between the parameter cursors), and there is a clock edge of both polarities surrounding the

ending pit or space edge between the parameter cursors.

Display Options

ORM parameter calculations can be displayed, histogrammed, and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

All values of the average time between ending edge of the subject

Parameter Statistics Off

n pit (space) and nearest clock edges for all subject pits (spaces)

followed by the spaces (pits) within the selected ‘nT’ range for the

last acquisition.

100%

T

100%

T

Average, minimum, maximum, and sigma of the ending edge shift

Parameter Statistics On

calculated for all identified pits/spaces pairs within the selected

‘nT’ range for all acquisitions since the last C

LEAR SWEEPS

operation.

List of values of the average ending edge shift for each ‘nT’ space

nT Table

(pit) within the selected range following the subject pit (space) for

the last acquisition.

Histogram graph of the value of the ending edge shift calculated

Histogram Function

for all pit/space pairs within the selected ‘nT’ range for all

acquisitions since the last C

LEAR SWEEPS operation.

Trend graph of the value of the ending edge shift calculated for all

Trend Function

923133 Rev A ISSUED: June 2013 41

pit/space pairs within the selected ‘nT’ range for all acquisitions

since the last C

LEAR SWEEPS operation.

Page 44

EESS ENDING EDGE SHIFT SIGMA

(

(

EESS

EESS

EES

EES

N

N

−

−

∑

∑

σ

EES

(

(

E

E

N

N

⋅−−

∑

∑

Description

EESS provides a measurement of the mean, normalized standard deviation of the Ending Edge

Shift measurements (see EES). When a single n is specified, or when you are in ‘nT Table’ Show

mode, the value calculated for the n

deviation:

th

index is calculated using the following equation for standard

=

n

=

n

Ending Edge Shift Sigma cannot be calculated for a given index n unless there are at least two

Ending Edge Shift values calculated for that n index.

When Ending Edge Shift is configured as a custom parameter with a range of n, the value

calculated is the standard deviation of the distribution that results by normalizing each

independent distribution categorized by the space (pit) nT following the subject pit (space).

Distributions are normalized by subtracting the mean of the distribution from all of the elements in

the distribution. This results in the following equation for overall Ending Edge Shift Sigma

resulting from the individually categorized Ending Edge Shift Sigma values:

overall

=

ESS

Note: The value calculated by EESS will generally not be the same as the sigma of EES measurement when a range of

n is used and statistics are on. This is because the two measurements are not the same. The EESS measurement

normalizes the results for each n by subtracting the mean EES from each EES in the n

superposition of mean-centered distributions, not a superposition of 0-centered distributions contributing to EES

measurements. EESS will always be less than or equal to the standard deviation of EES measurements.

n

)

ESS

2

n

n

n

1

n

2

nn

n

1

)

1

2

)

)

th

distribution. This results in a

42 ISSUED: June 2013 923133 Rev A

Page 45

AORM Software Package

Display Options

ORM parameter calculations can be displayed, histogrammed and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

Single value of the standard deviation of the mean normalized

Parameter Statistics Off

Parameter Statistics On

nT Table

Histogram Function

Trend Function

ending edge shift values for pits/spaces of interest for last

acquisition.

average, minimum, maximum, and sigma of the ending edge shift

sigma value calculated per acquisition for all acquisitions since the

LEAR SWEEPS operation.

last C

List of values of the standard deviation of the ending edge shift

values for each ‘nT’ spaces (pit) within the selected range

following the subject pit (space) for the last acquisition.

Histogram of ending edge shift sigma values calculated for each

acquisition for all acquisitions since the last CLEAR SWEEPS

operation.

Trend of the ending edge shift sigma values calculated for each

acquisition for all acquisitions since the last CLEAR SWEEPS

operation.

923133 Rev A ISSUED: June 2013 43

Page 46

BEES BEGINNING ENDING EDGE SHIFT

Description

BEES provides a measurement of both the beginning and ending edge shift for a subject n pit

(space) preceded and followed by a specified space (pit). (See BES and EES.) The

measurement is calculated between the points where the data and clock signals cross selected

voltage thresholds. The clock period T can be entered by the user, or measured from a user

supplied clock signal, as described below.

The value calculated depends on the clock and data edges selected, as shown in the table below.

The Data Slope menu selects the polarity of the subject n pit/space. If Pos (positive) is selected,

the measurement is performed from the beginning and ending edges of positive polarity pits and

is preceded and followed by a space of the specified width. If Neg (negative) is selected, the

measurement is performed from the edges of negative polarity spaces and is preceded and

followed by a pit of the specified width.

CLOCK

EDGE

Positive

Negative

Near

DATA SLOPE

Pos Neg

times between edges of

positive polarity subject

pit and nearest positive

clock edge

times between edges of

positive polarity subject

pit and nearest

negative clock edge

times between edges of

positive polarity subject

pit and nearest clock

edge

times between edges of

negative polarity

subject space and

nearest positive clock

edge

times between edges of

negative polarity

subject space and

nearest negative clock

edge

times between edges of

negative polarity

subject space and

nearest clock edge

44 ISSUED: June 2013 923133 Rev A

Page 47

AORM Software Package

∆

∆

=⋅⋅

+

−

The next figure demonstrates the measurement of the beginning edge shift on a single subject 4T pit

preceded and followed by a 3T space. In this example, the clock is specified as the positive edge. The

beginning edge shift is calculated as the time difference between the beginning pit edge and the clock

edge while the ending edge shift is calculated as the time difference between the ending pit edge and

the clock edge.

threshold

Data

3T

4T

3T

Signal

Clock

Signal

beginning

edge shift

Beginning and Ending Edge Shift measurement of subject 4T pit

The measurement has configurable units. If absolute time is specified, the value is simply the

time, as indicated above. If percent is specified, the value of the measurement is the time

normalized to the clock period:

bees

ending

edge shift

100%

t

T

100%

or t

For all pits, a valid measurement will be obtained only when both edges of the leading and trailing

pits/spaces can be determined (that is, there is a hysteresis-qualified threshold crossing

beginning the start pit/space and ending the end pit/space of interest between the parameter

cursors), and there is a clock edge of both polarities surrounding the leading pit or space edge

between the parameter cursors.

T

923133 Rev A ISSUED: June 2013 45

Page 48

Display Options

ORM parameter calculations can be displayed, histogrammed, and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

Single value of the average time between the edges of the subject

Parameter Statistics Off

n pit (space) and nearest clock edges for all subject pits (spaces)

that are preceded and followed by the specified space (pits) for

the last acquisition.

Average, minimum, maximum, and sigma of the beginning and

Parameter Statistics On

ending edge shift calculated for all subject pits (spaces) that are

preceded and followed by the specified space (pits) for all

acquisitions since the last C

LEAR SWEEPS operation.

List of values of the beginning edge shift and the ending edge shift

nT Table

for all subject pits (spaces) that are preceded and followed by the

specified space (pits) for the last acquisition.

Histogram graph of the values of the beginning and ending edge

Histogram Function

shift calculated for all subject pits (spaces) that are preceded and

followed by the specified space (pits) for all acquisitions since the

LEAR SWEEPS operation.

last C

Trend graph of the value of the beginning and ending edge shift

Trend Function

calculated for all subject pits (spaces) that are preceded and

followed by the specified space (pits) for all acquisitions since the

LEAR SWEEPS operation.

last C

XY Plot

XY Plot displays the trend of one parameter vs. another.

46 ISSUED: June 2013 923133 Rev A

Page 49

AORM Software Package

DP2C DELTA PIT TO CLOCK

Description

Dp2c provides a measurement of the time between the leading edge of the pit (or spaces of

interest) and the nearest specified clock edge. The measurement is calculated between the

points where the data and clock signals cross selected voltage thresholds.

The value calculated depends on the clock and data edges selected, as shown in the table below.

If in the Data Slope menu Pos (positive) is selected, the measurement is performed from the

leading edges of positive polarity pits. If Neg (negative) is selected, the measurement is

performed from the leading edges of negative polarity spaces. And if Both is selected, the

leading edges of both pits and spaces are used in the calculation. The sizes of pits or spaces

used in the measurement are also determined by the range of ‘nT’ values chosen.

CLOCK

EDGE

time between leading

edge of positive polarity

positive

negative

near

For the positive polarity pit example shown as the zoom of the measurement (next two figures),

the measurements t+, t-, tn are for a single Delta Pit-to-Clock measurement configured for

positive edge, negative edge, or nearest edge, respectively.

pit and nearest positive

clock edge

time between leading

edge of positive polarity

pit and nearest

negative clock edge

time between leading

edge of positive polarity

pit and nearest clock

edge

Pos Neg

DATA SLOPE

time between leading

edge of negative

polarity space and

nearest positive clock

edge

time between leading

edge of negative

polarity space and

nearest negative clock

edge

time between leading

edge of negative

polarity space and

nearest clock edge

Both

time between leading

edge of pits and spaces

to nearest positive

clock edge

time between leading

edge of pits and spaces

to nearest negative

clock edge

time between leading

edge of pits and spaces

and nearest clock edge

923133 Rev A ISSUED: June 2013 47

Page 50

Delta Pit-to-Clock measurement

Data Signal

Clock Signal

Data Signal

Clock Signal

tn, t

+

Tn, T

+

t

-

T

-

Zoom of Positive Polarity Pit Edge - example measurement

48 ISSUED: June 2013 923133 Rev A

Page 51

AORM Software Package

The measurement has configurable units. If absolute time is specified, the value is simply the

time as indicated above. If percent is specified, the value of the measurement is the time

normalized to the local clock period. The local clock period is calculated as the time between the

two clock edges bracketing the clock edge used for the delta time measurement:

=⋅

∆∆

pc t

2

+

T

+

100%

100%

or t

−

T

−

⋅

∆

100%

⋅

∆

or t

Fo

r all pits, a valid measurement will be obtained only when both pit/space edges can be determined

(that is, there is a hysteresis qualified threshold crossing that begins and ends the pit/space of interest

between the parameter cursors), and when there is a clock edge of both polarities surrounding the

leading pit or space edge between the parameter cursors.

Display Options

ORM parameter calculations can be displayed, histogrammed and trended in a variety of ways.

DISPLAY TYPE VALUE DISPLAYED

All values of the average time between leading pit/space edges

Parameter Statistics Off

Parameter Statistics On

and nearest clock edges for all pits/spaces within the selected ‘nT’

range for the last acquisition.

Average, minimum, maximum, and sigma of the Delta Pit-to-Clock

calculated for all identified pits/spaces within the selected ‘nT’

range for all acquisitions since the last C

n

T

n

LEAR SWEEPS operation.

nT Table

Histogram Function

Trend Function

923133 Rev A ISSUED: June 2013 49

List of values of the average Delta Pit-to-Clock for each group of

pits/spaces of common ‘nT’ width for the last acquisition.

Histogram graph of the value of the Delta Pit-to-Clock calculated

for all pits/spaces within the selected ‘nT’ range for all acquisitions

since the last C

Trend graph of the value of the Delta Pit-to-Clock calculated for all

pit/space within the selected ‘nT’ range for all acquisitions since

the last C

LEAR SWEEPS operation.

LEAR SWEEPS operation.

Page 52

DP2CS DELTA PIT TO CLOCK SIGMA

(

(

Description

Dp2cs provides a measurement of the mean, normalized standard deviation of the Delta Pit-to-

Clock measurements (see Dp2c). When a single n is specified, or in ‘nT Table’ Show mode, the

value calculated for the n

Delt

a Pit-to-Clock Sigma cannot be calculated for a given index n unless there are at least two Delta

Pit-to-Clock values calculated for that n index.

When Delta Pit-to-Clock is configured as a custom parameter with a range of n, the value calculated is

the standard deviation of the distribution that results by normalizing each independent distribution

categorized by nT. Distributions are normalized by subtracting the mean of the distribution from all of

the elements in the distribution. This results in the following equation for overall Delta Pit-to-Clock

Sigma resulting from the individually categorized Delta Pit-to-Clock Sigma values:

th

index is calculated using the following equation for standard deviation:

PCS PC

∆∆

22

=

PCS

∆

2

σ

nn

∑

=

n

PC

∆

)

PC

∆

()

∑

2

2

−

n

N

n

N

1

−

2

2

n

n

PCS N

∆∆PCS

2

overall

Note: The value calculated by DP2CS will generally not be the same as the sigma of DP2C measurement displayed on

the parameter line when a range of n is used and statistics is on. This is because the two measurements are not the

same. DP2CS measurement normalizes the results for each n by subtracting the mean DP2C from each DP2C in the n