Teledyne ACCQPrep HP125 Installation And Operation Manual

CCQPrep HP125

60-5233-812

Copyright © 2017 Teledyne Technologies Incorporated. All rights reserved.

Rev. C, January 2019

A

Installation and Operation Guide

ACCQPrep HP125 Installation and Operation Guide

WARNINGWARNING

WARNINGWARNING

WARNINGWARNING

CAUTION

WARNINGWARNING

Safety Warnings

ACCQPrep HP125 Installation and Operation Guide

Safety Warnings

Safety Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed in the following general

warnings:

Liquids associated with this instrument may be classified

as carcinogenic, biohazard, flammable, or radioactive.

Should these liquids be used, it is highly recommended that

this application be accomplished in an isolated

environment designed for these types of materials in

accordance with federal, state, and local regulatory laws,

and in compliance with your company’s chemical/hygiene

plan in the event of a spill.

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired.

If you are using flammable solvents or chemicals with this

system, vapor concentration levels may exceed the

maximum exposure levels as recommended by OSHA

Guide 1910.1000. To reduce those levels to a safe exposure,

Teledyne Isco recommends that you place the system in a

laboratory hood designed for the purpose of ventilation.

This hood should be constructed and operated in

accordance with federal state and local regulations. In the

event of a solvent or chemical spill, your organization

should have a plan to deal with these mishaps. In all cases,

use good laboratory practices and standard safety

procedures.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts.

These three levels are described in the sample alerts below.

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

3

ACCQPrep HP125 Installation and Operation Guide

DANGER

Safety Warnings

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

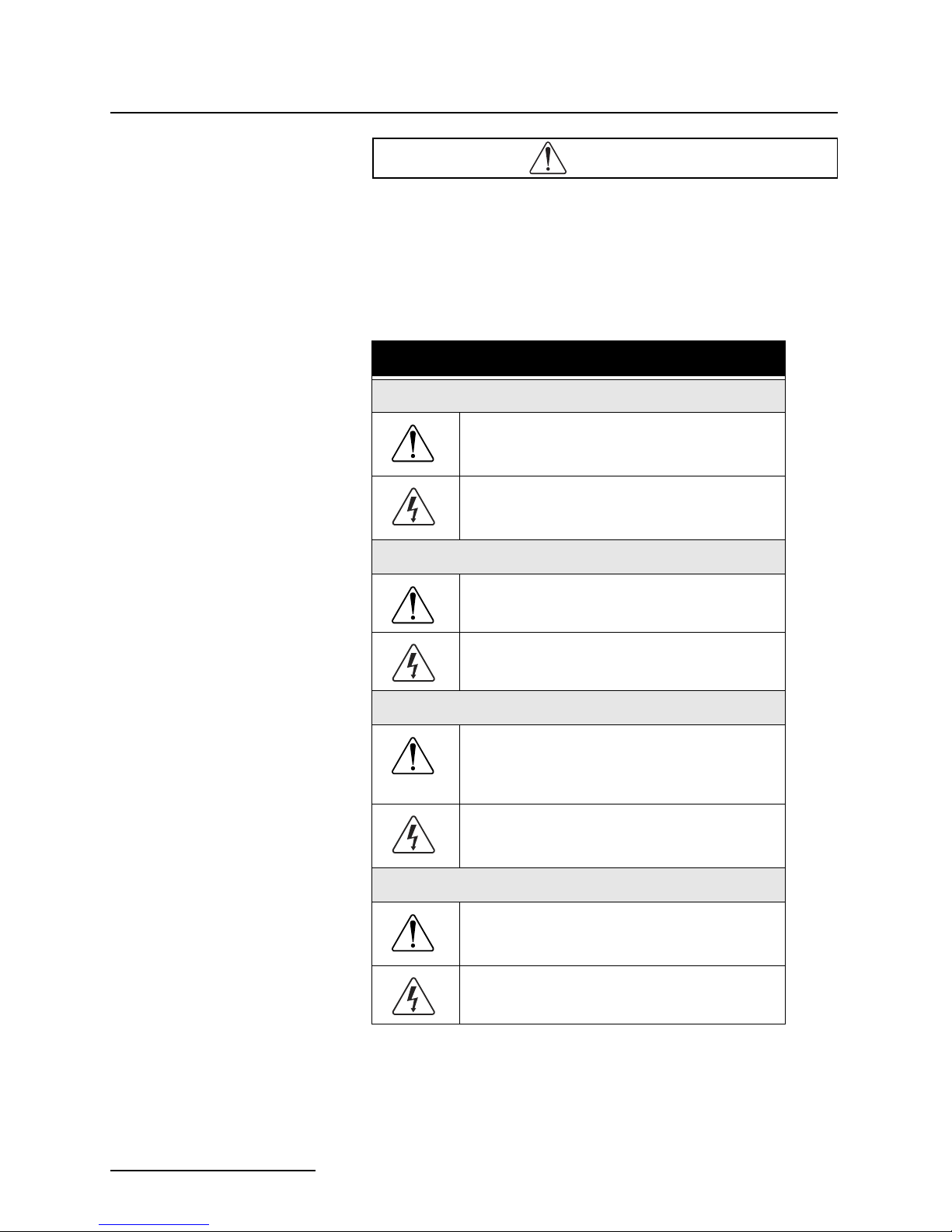

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained in the table below.

The exclamation point within the triangle is a

warning sign alerting you of important instructions

in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous

voltage” inside the product.

Hazard Symbols

Warnings and Cautions

Symboles de sécurité

Ce symbole signale l’existence d’instructions

importantes relatives au produit dans ce manuel.

Ce symbole signale la présence d’un danger

d’électocution.

Warnungen und Vorsichtshinweise

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf aufmerksam macht, daß

wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen,

das Sei vor “gefährlichen Spannungen” im

Inneren des Produkts warnt.

Advertencias y Precauciones

Esta señal le advierte sobre la importancia de las

instrucciones del manual que acompañan a este

producto.

Esta señal alerta sobre la presencia de alto

voltaje en el interior del producto.

4

ACCQPrep HP125 Installation and Operation Guide

Safety Warnings

For Additional

Information

Technical assistance for the Teledyne Isco ACCQPrep HP125 can

be obtained from:

Teledyne Isco

4700 Superior St.

Lincoln NE 68504

Phone: (800) 775-2965 or (402) 464-0231

Fax: (402) 465-3001

E-mail: IscoService@teledyne.com

5

ACCQPrep HP125 Installation and Operation Guide

Safety Warnings

6

ACCQPrep HP125

Table of Contents

Section 1 Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Operating Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 Multiple Control Possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 File Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Safety Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2 Installation

2.1 ACCQPrep Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Setting Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Solvent Line Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3 Fluid Line Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.4 ACCQPrep Equipped with Optional ELSD . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.5 Priming Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3 Installing the Manual Injection Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4 Installing the AutoSampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.1 Establishing the Fluid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.5 Column Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.5.1 Column mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.5.2 Column Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.5.3 Column Select Valve

(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6 Installation Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Section 3 Configuration

3.1 Configuration of the ACCQPrep. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 User Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Prep HPLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.1 Define a Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4.2 Delete a Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4.3 Creating Other Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.4 Creating Focused Gradients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Section 4 Operation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Method Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Starting a Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.1 Separation with an AutoInjector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.2 AutoInjection Operating Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.3 Separation using an AutoSampler Module . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3.4 Using the Queue Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

1

ACCQPrep HP125

Table of Contents

4.3.5 AutoSampler Injection Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.6 Fraction Collection with the AutoSampler . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.4 Operation Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Section 5 PeakTrak

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 PeakTrak Window Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Method File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.3 Run File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 PeakTrak Menu Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.3 MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.2.4 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2.5 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2.6 PeakTrak Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.7 Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.8 Column Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.2.9 Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.2.10 Set Data Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.2.11 MS Method Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.2.12 MS Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.2.13 Ionization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.2.14 Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.2.15 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.2.16 Set Administrator Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.3 Examples of PeakTrak actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.3.1 Editing a method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.3.2 Alternative Ways to Create Method Files . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.3.3 Defining a Gradient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.3.4 Real-time Gradient Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.3.5 Bypassing the Injection Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.3.6 Monitoring the Purity Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.3.7 Viewing runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.3.8 Manual Control of the ACCQPrep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Section 6 Maintenance

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.2 Collection Rack and Tray Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 System Standby and Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Tubing Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Flow Cell Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4.1 Post Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.4.2 Quick Cleaning when Recommended . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.4.3 Monthly Flow Cell Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5 ACCQPrep HP125 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.5.1 Injection Valve Rotor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.5.2 Pump Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.5.3 Seal Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.5.4 Check Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.6 AutoSampler Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.7 ELSD Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.7.1 Cleaning the ELSD Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.8 PurIon Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

2

ACCQPrep HP125

Table of Contents

6.8.1 ESI and APCI Removal from PurIon S and PurIon L . . . . . . . . . . . . . . . . 6-22

6.8.2 ESI and APCI Replacement PurIon S and PurIon L . . . . . . . . . . . . . . . . . 6-22

6.8.3 Cleaning the Ionization Source Capillary . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.8.4 Replacement of Ion Source Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.8.5 Overpressure Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.8.6 Check Valve Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.8.7 Replacing Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.8.8 PurIon Cone Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.8.9 Capillary Inlet Cone Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.8.10 Capillary Inlet Cone Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.8.11 Capillary Inlet Cone Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

6.8.12 PurIon Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Appendix A

A.1 Diagrams for the AutoSampler and ACCQPrep . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

3

ACCQPrep HP125

Table of Contents

4

ACCQPrep HP125

WARNING

Section 1 Introduction

1.1 Overview This Installation Guide provides:

• Safety information

• Unpacking instructions

• Installation instructions, including connections with

Windows and iOS operating systems

• Certification and warranty information

The Operating section will guide you on basic system operation.

1.2 Product Overview The Teledyne Isco ACCQPrep HP125 chromatography system

combines high resolution and productivity in a small footprint. It

features easy to use software, programmable gradients, UV

detection and peak collection, and automatic detection of collection tube racks. Its small size makes it a great personal

system and well-suited for operation within chemical hoods and

other limited indoor spaces. The extended pressure capability

supports operation of columns at high flow rates for maximum

throughput or added tolerance for high back pressures as

columns age.

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired; this may

increase your risk of injury.

The ACCQPrep HP125 is available in different configurations to

meet your needs. An optional Solvent Selector Valve Module supports up to three choices for solvent A and three different choices

for solvent B. Detection options include UV, UV/Vis, ELSD and a

mass spectrometer capable of detecting your compounds with up

to four individual mass signals including a range of masses.

Automation options include the AutoInjector for repeated injections of the same sample, an AutoSampler for single or repeated

injections of multiple samples, or a column select module supporting up to 4 Prep HPLC columns ranging from 4.6 mm up to

50 mm inner diameter (Larger columns may be used at less than

optimum flow rates).

1-1

ACCQPrep HP125

Section 1 Introduction

Figure 1-1 ACCQPrep HP125

ACCQPrep HP125 – This Prep HPLC system has flow rates

from 1-125 mL/min, with up to 6000 psi capability. A two component gradient can be formed from up to six solvents. The

system includes active solvent level sensing and detection of a

full waste container. The base system includes two fraction collection racks. With the optional AutoSampler up to four collection racks can be used. The RFID tagged racks can be replaced

while in operation with new racks for practically limitless

fraction collection.

ACCQPrep HP125 with optional ELSD – This system has

the same high performance features as the ACCQPrep HP125

system, but includes an internal evaporative light scattering

detector (ELSD). During operation, this detector can be combined with the UV (200–400 nm) or UV-vis (200–800 nm)

detection to isolate visible and UV absorbing compounds, as well

as compounds with little or no chromophores.

ACCQPrep HP125 with optional PurIon Mass

Spectrometer – This system has the same features as the

ACCQPrep HP125, but includes a mass spectrometer with a

detection range of 10 to 1200 Daltons (Da) (PurIon S) or 10-2000

Da (PurIon L systems). During purification, this system can be

combined with the UV (200 - 400 nm) or UV-V (200 - 800 nm)

detector to isolate visible and UV absorbing compounds, as well

as compounds with specific molecular weights or mass ranges.

1-2

ACCQPrep HP125

Note

Section 1 Introduction

1.3 Operating Overview The ACCQPrep HP125 system is equipped with a capacitive

touch screen display for local control.

The system also supports TCP/IP communication. This allows

direct control of the system by an external computer between

Ethernet ports of the ACCQPrep HP125 system and the computer.

TCP/IP communication also allows remote control of the system

via an established network. Remote controlling devices on the

network can be a Windows or Apple PC or Laptop, or an Apple

iSO mobile device (iPod Touch, iPhone, and iPad).

Teledyne Isco recommends that you obtain assistance from

your Information Technology department before attempting

direct or network connections. See Technical Note 28 Network-

ing Guidelines on the Isco website for more information.

1.3.1 Multiple Control

Possibilities

1.3.2 File Storage To support operation from a variety of direct and network con-

The system can be accessed from the built-in touch panel and up

to ten network devices. The touch panel shares control with all

connected devices. The system performs the most recent

command from any control input.

nections, the software and all files are stored in the ACCQPrep

HP125. This ensures that your compound purification methods

and run history files can be viewed from any connection.

Optionally, run files may be saved to a USB flash drive, a networked controlling computer, or a network drive.

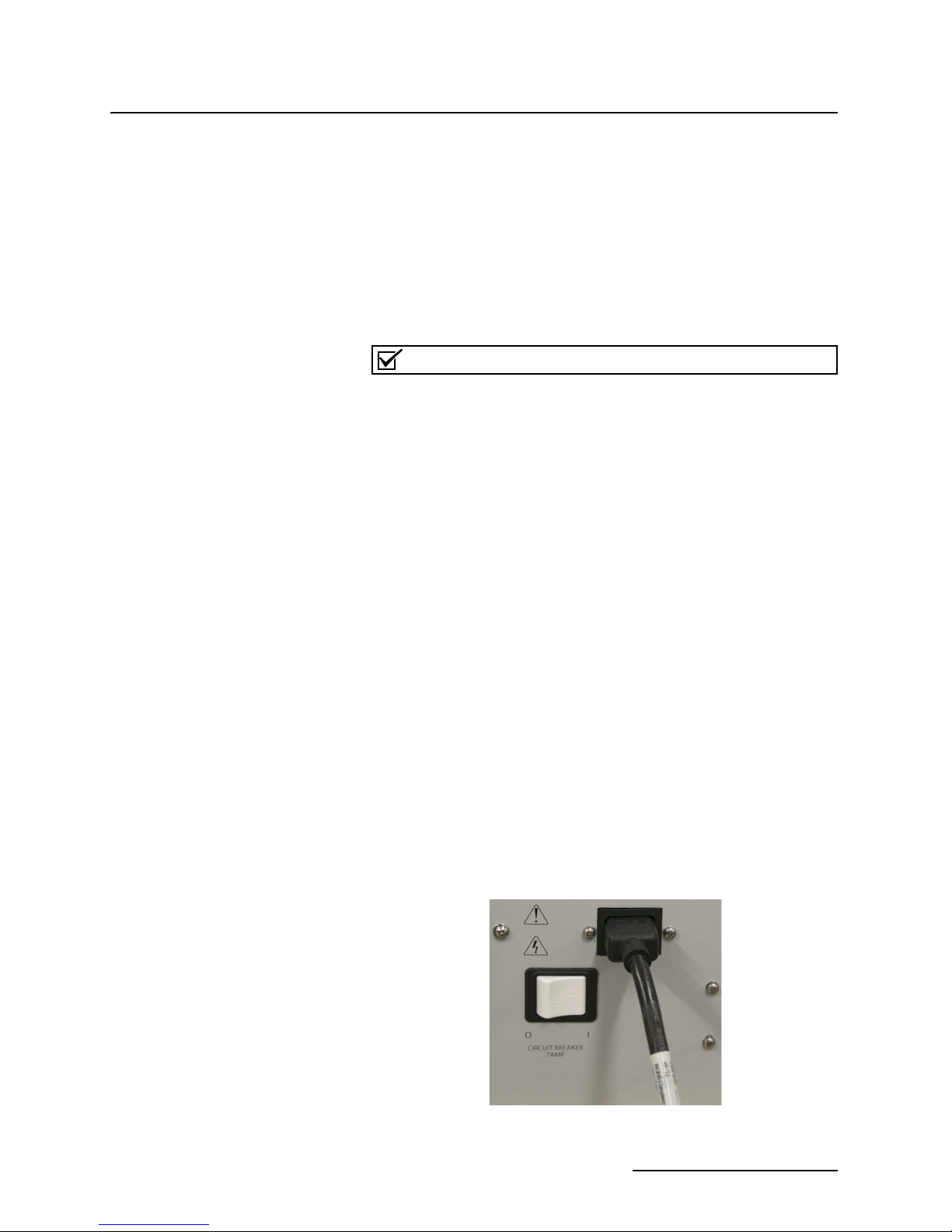

1.4 Safety Components The power cord is a safety disconnect for the ACCQPrep (Figure

1-2).

To remove power from the ACCQPrep remove the power cord by

pulling it straight out from the power inlet connector. The circuit

breaker is located adjacent to the power inlet connector. If an

internal circuit fault occurs, this breaker will trip. It can be reset

by pressing the end of the rocker labeled “1”. In addition,

switching the breaker manually to the “0” position will remove

power from the internal operating components.

Figure 1-2 Location of power cord for the ACCQPrep

1-3

ACCQPrep HP125

Section 1 Introduction

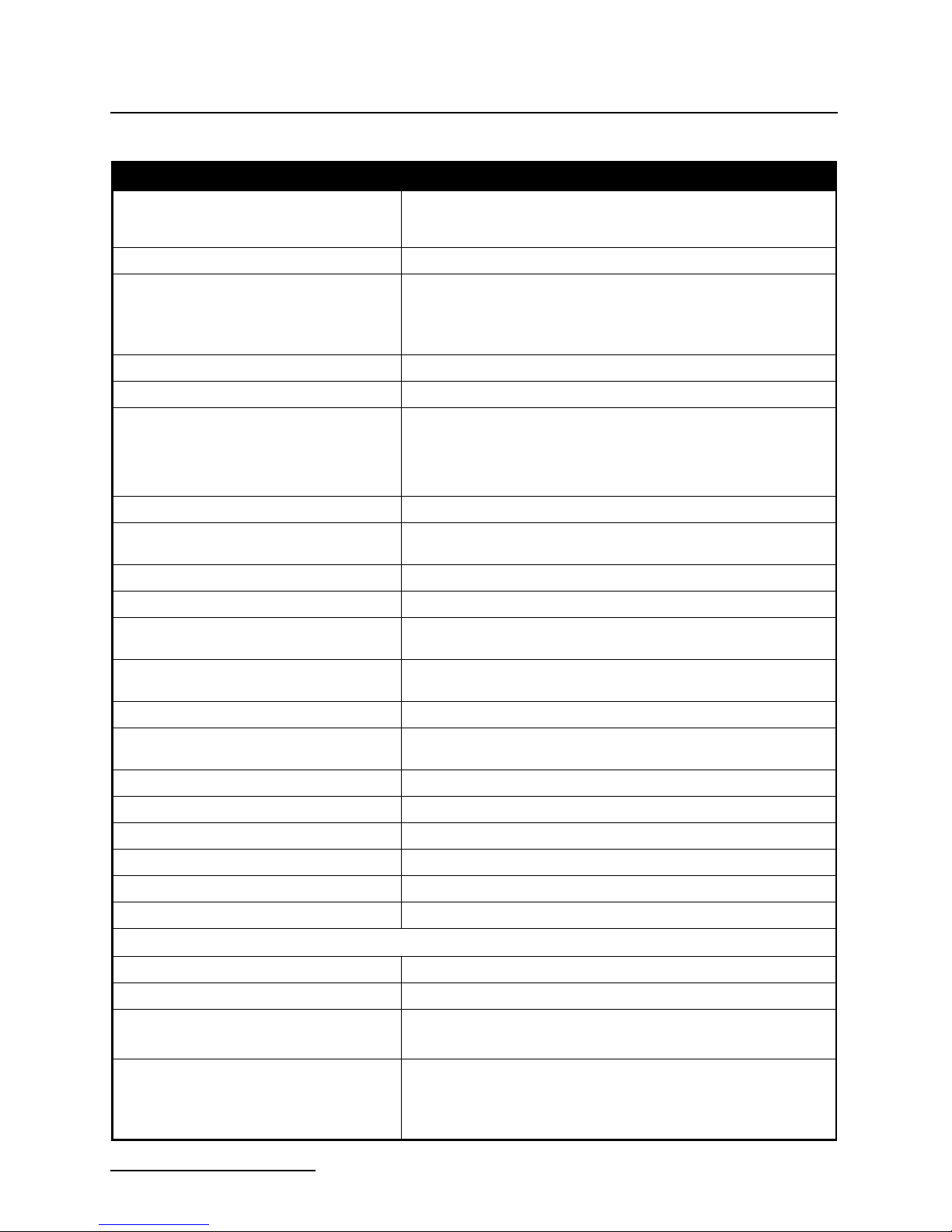

1.5 Specification

Table 1-1 ACCQPrep HP125

Dimensions of ACCQPrep

(Footprint without column or column cover

installed)

Dimensions of ACCQPrep AS 2x1 18.9 x 14.0 x 19.3 in (48.0 x 35.6 x 49.0 cm)

Weight

(Including AutoInjector, Column Selector

Valve Module, Solvent Selector Valve Module, and column cover)

Weight of ACCQPrep AS 2x1 27.3 lbs (12.4 kg)

User Interface 15" touchscreen

Power Input voltage range from 100 to 240 VAC,

Line Frequency 50/60 Hz

Ambient Temperature 20 to 40 °C (maximum temperature must be at least 15 °C below the

Humidity (when connected to power) 90% relative humidity maximum at 20 to 40 °C (non-condensing)

Flow Rate Range 1-125 mL/min, ELSD peak collection limited to 4-125 mL/min

Flow Rate Accuracy (tested with water at 6.9

bar or 100 psi)

Pressure Limit 414 bar (6000 psi) derated linearly from 6000 psi at 75 mL/min to

Pressure Accuracy 5% of full scale

27.5 x 14.0 x 20.0 in (69.9 x 35.6 x 50.8 cm)

93.2 lbs (42.3 kg)

106 lbs (48 kg) with optional Evaporative Light Scattering Detector

(ELSD)

300 VA maximum.

Line cord is the disconnect device. Power connection is via IEC

60320 C14 power inlet.

boiling point of the solvent)

± 2%

4000 psi at 125 mL/min

Gradient Formation Binary gradient 2 solvent inlets. Optional Solvent Selector Valve Mod-

Gradient Accuracy: ±1% of full scale

Peak Detection Modes Slope or threshold

Flow Cell Pathlength 0.3 mm, ±25% (Standard, other pathlengths available)

UV Detection Wavelength 200 to 400 nm, optional 200 to 800 nm UV-Vis

Wavelength Accuracy ±5 nm

Fraction Accuracy ±[2mL + (flow rate ÷ 60)]

ule expands to 3 solvents each for A & B

Optional ELSD

Gas Inlet Pressure 60 to 70 psig

Gas Consumption <2.5 SLPM

Spray Chamber Temperature Setting range: 10 to 60 °C

limited to minimum of 5 °C below ambient

Drift Tube Temperature Setting range: 30 to 90 °C

Must be 5 °C above spray chamber temperature Minimum temperature is 5 °C above ambient Maximum temperature is 60 °C above

ambient

1-4

ACCQPrep HP125

Section 1 Introduction

Table 1-1 ACCQPrep HP125

Electrical Safety per EN 61010-1

Pollution Degree 2

Installation Category II

Maximum Altitude 2000 meters

Note 1. All specifications are subject to change.

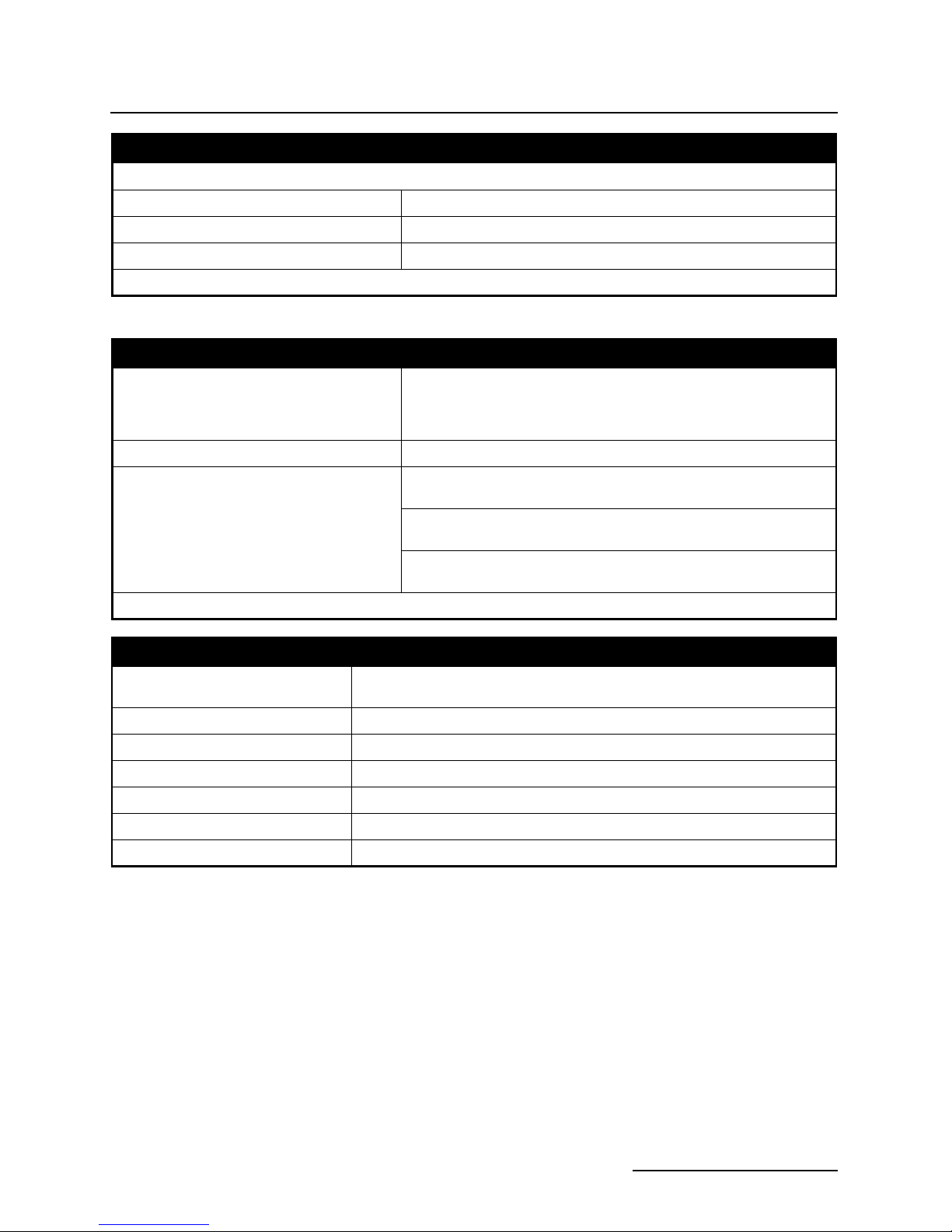

Table 1-2 ACCQPrep HP125 with PurIon System

Dimensions (H x W x D) ACCQPrep: 27.5 x 14.0 x 20.0 in (69.9 x 35.6 x 50.8 cm)

Mass Spectrometer 26 x 11 x 22 in (66 x 28 x 56 cm)

Roughing Pump 10 x 9 x 18 in (26 x 23 x 46 cm)

ELSD Detection Option that can be combined with either UV or UV-Vis

10 – 1200 Dalton for S model, 10-2000 for L model,

Mass Spectrometry Detection

1 Dalton Resolution

Electrospray Ionization (ESI) or optional Atmospheric Pressure

Chemical Ionization (APCI)

Simultaneous positive and negative ionization for both S and L

models.

Note 1. All specifications are subject to change.

Table 1-3 Component Materials List

Chromatographic Tubing 316 stainless steel tubing, PEEK, and

Fluoropolymer

Drain Tubing Vinyl with FEP liner

Chromatographic Valves PEEK, PPS, perfluorelastomer (FFKM)

Flowcell 303 SST, Type ES Quartz, SIMRIZ® SZ485

Chromatography Pump 316 Stainless Steel, UHMWPE, ETFE, ruby, sapphire, and zirconia

Pressure Transducer 316 and 17-4 PH stainless steels and perfluorelastomer (FFKM)

AutoSampler Wash Pharm-A-Line, polypropylene

®

1-5

ACCQPrep HP125

Section 1 Introduction

1-6

ACCQPrep HP125

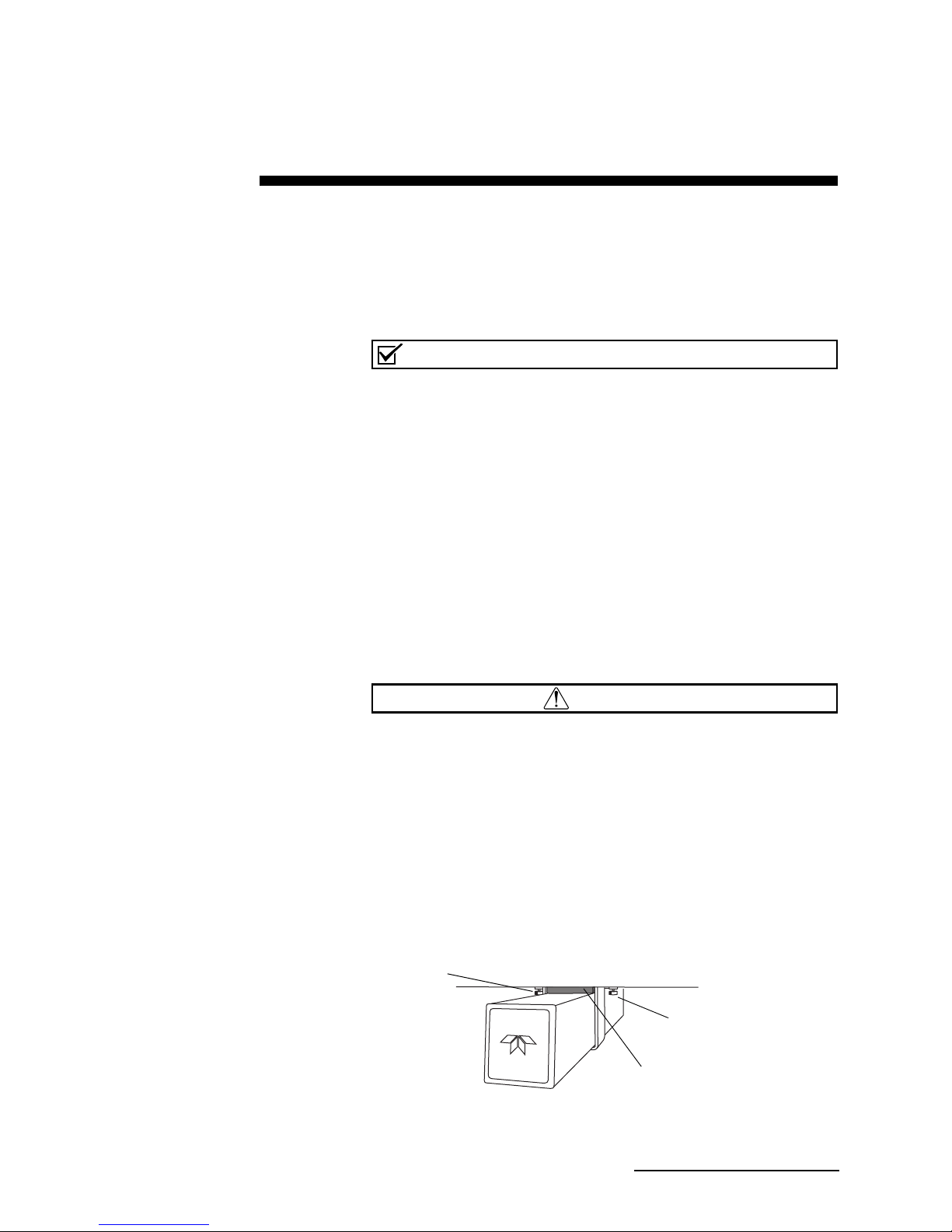

Note

CAUTION

Spacer

Thumbscrew

Thumbscrew

Section 2 Installation

2.1 ACCQPrep Installation The following section will cover the installation, connection of the

pump, and a review of the priming steps.

When the system ships, it will ship in two boxes to minimize the weight. One box will contain the unit and the

other box will have the pump and assorted accessories.

Tools Required • Hex wrench (included with the pump module)

1

•

/4” open end wrench

• Fitting wrench (allows more secure connection of ‘finger

tighten’ fittings) (Wrench is included in the ACCQPrep

accessory kit)

2.2 Setting Up the System The ACCQPrep chassis including AutoInjector, Solvent Selector

Valve Module, and Column Selector Valve Module, but without

the pump assembly, weighs up to approximately 64 pounds (29

kg). Handles are provided on each side of the instrument to facilitate lifting.

A two person lift is recommended to prevent injury.

The pump assembly weighs 25 pounds (11.5 kg) resulting in a

final weight of 93 pounds (42.3 kg) with the column cover

installed, but not including an optional AutoSampler.

The fraction collector arm is secured to prevent damage during

shipping. The arm securing bracket should be removed at this

time.

1. Loosen the bracket’s two thumbscrews along the sides of

the arm (Figure 2-1).

Figure 2-1 Remove arm stowing bracket and spacer

2-1

ACCQPrep HP125

Note

Note

Section 2 Installation

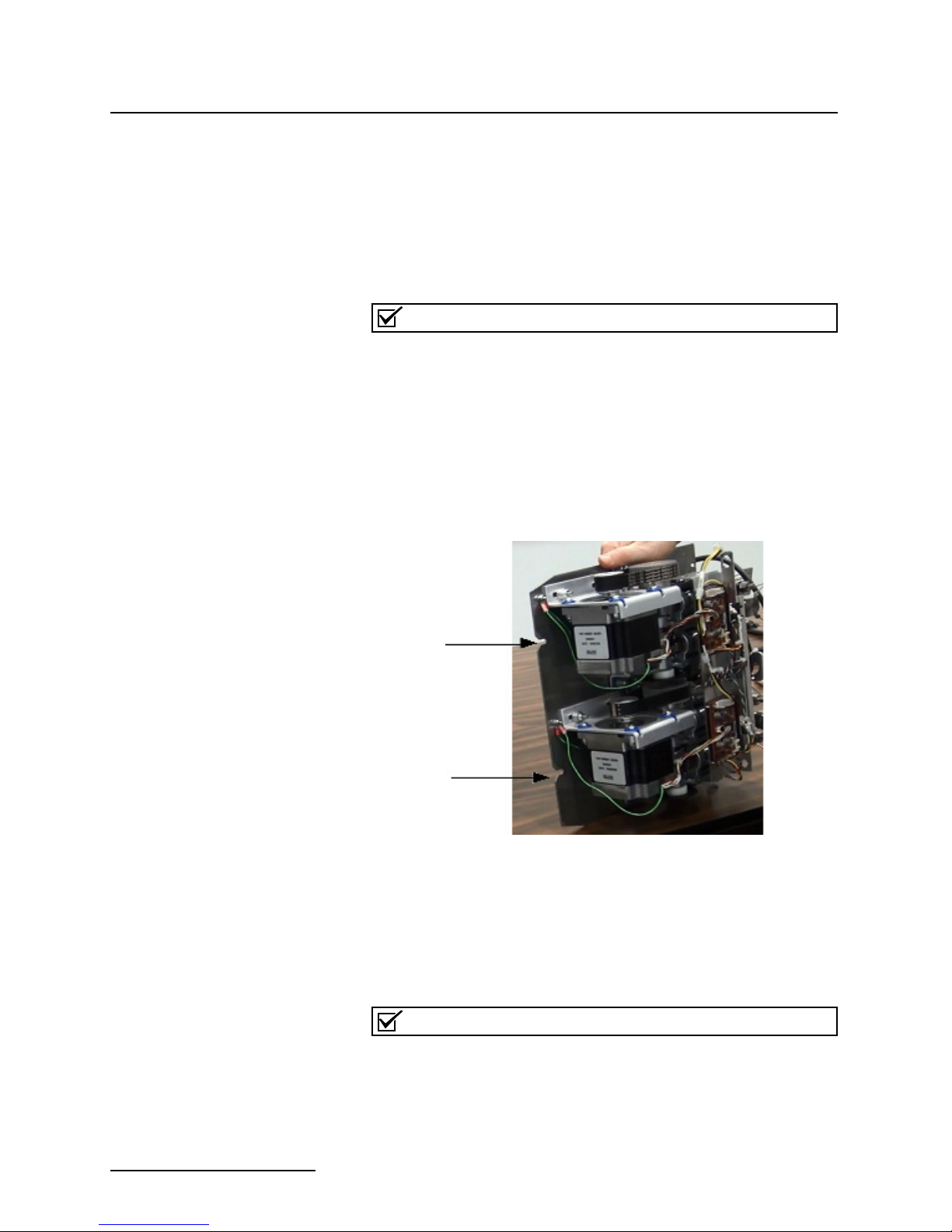

2.2.1

Pump Installation

2. Push the arm to the left or right to remove the spacer.

3. Store the bracket and spacer. These parts should be reinstalled if the system must be shipped again.

When you are ready to place the system, be sure it is situated in

such a way that the power cord is accessible to disconnect in case

of malfunction.

Be sure to move the two electrical connections and solvent

tubing out of the way before sliding the pump assembly

into the pump compartment.

To install the pump:

1. Remove the two pump retaining screws in the pump compartment.

2. Align the pump assembly horizontally with the two notches

facing the opening of the pump compartment (Figure 2-2).

Figure 2-2 Location of notches on the pump sled

2-2

3. Slide the pump assembly into the pump compartment. It

may require a little force since it is metal on metal sliding

together. If the force seems excessive, ensure there is nothing obstructing the pump assembly. Be sure to keep the

electrical connections and tubing out of the way so they do

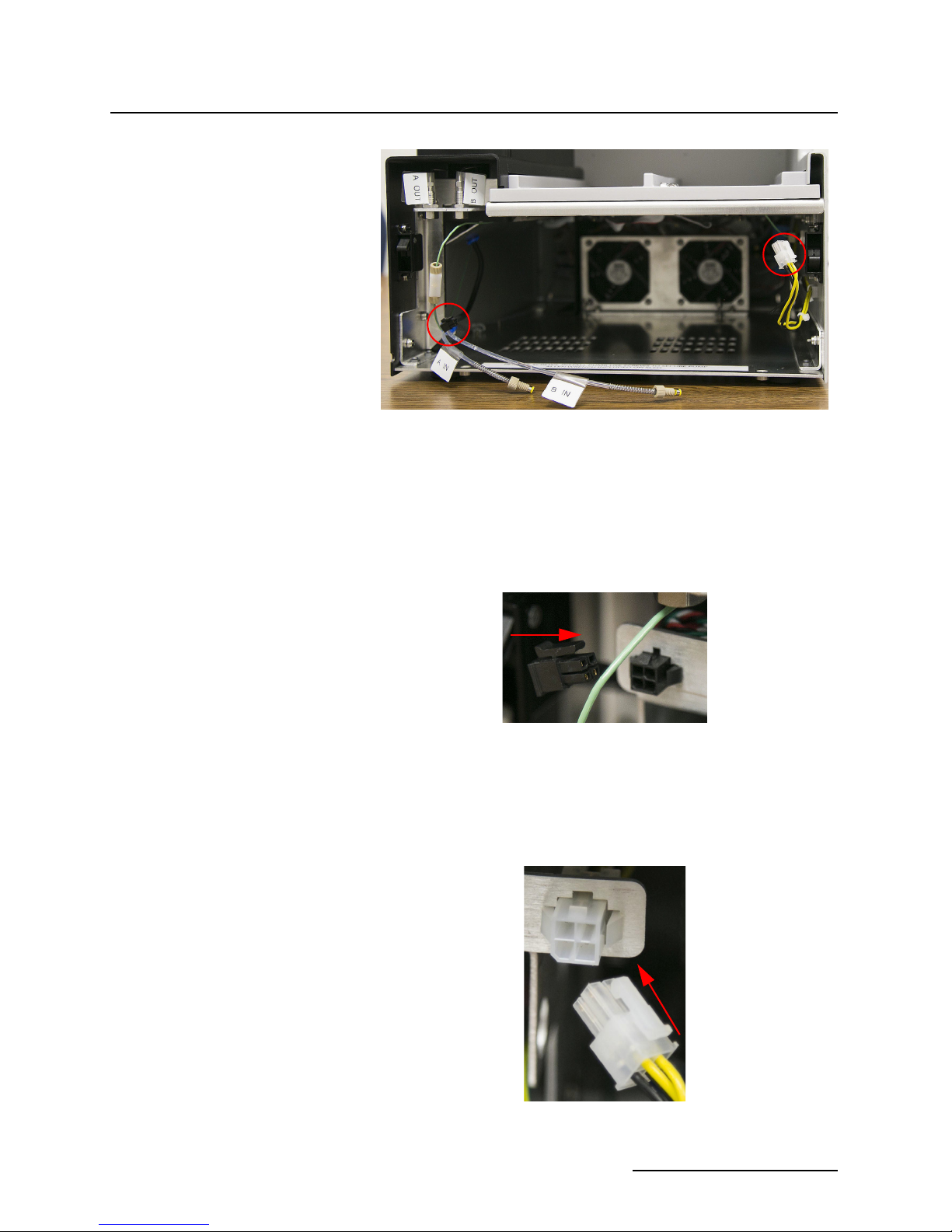

not get pushed inside of the compartment (Figure 2-3).

Be sure to observe the top of the pump assembly as it is being

inserted into the system. Make sure no wires from the case or

pump assembly are being snagging.

Figure 2-3 Pump compartment with electrical connection

shown

4. When the pump assembly is most of the way in the pump

compartment, connect the electrical connections on each

side of the pump. First, connect the black connection on the

left side. Ensure the tab on top of the connector is facing up

before pushing it into the mating connector (Figure 2-4).

ACCQPrep HP125

Section 2 Installation

Figure 2-4 Black connection with tab facing up

Then, connect the white connection on the right side. Ensure the

tab on top of the connector is facing up before pushing it into the

mating connector (Figure 2-5).

Figure 2-5 White connection with tab facing up

2-3

ACCQPrep HP125

Note

Bulk head unions

Te e Tee

Section 2 Installation

5. Once the electrical connections are complete, push the

pump assembly the rest of the way into the pump compartment until the holes in the front of the pump assembly are

aligned with the corresponding holes in the case bottom.

Hold downs at the back of the pump may cause extra

resistance for the last

6. To hold the pump in place, use the two hex screws,

removed previously, and the hex wrench to secure the

pump assembly (Figure 2-6).

Figure 2-6 Location of threaded holes, in the base of the

unit, and the hex wrench

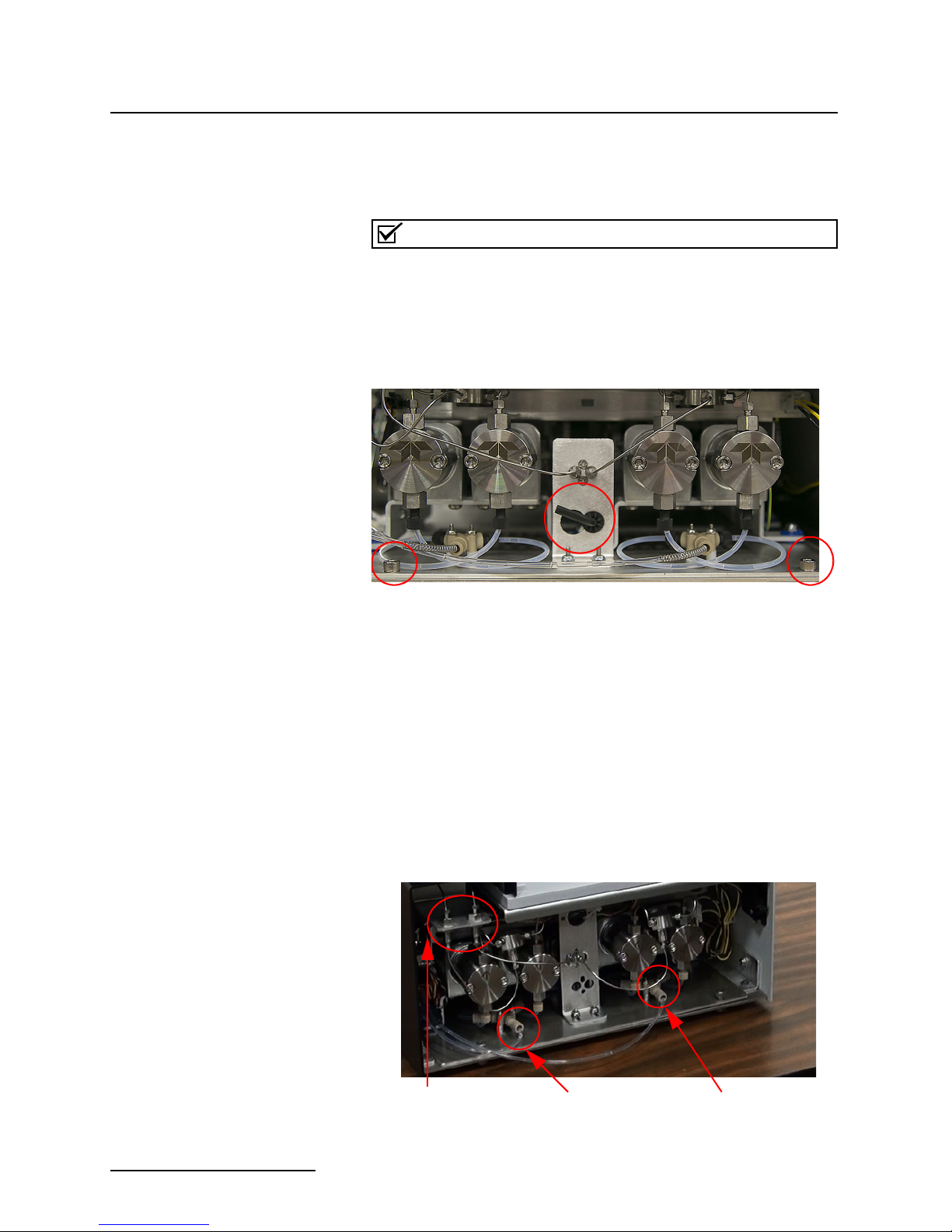

2.2.2 Solvent Line

Installation

1. The left two pump heads form the A solvent pump and the

outlets are connected to a tee. The outlet of this tee connects to the left bulkhead union. Tighten with the

end wrench.

2. The right two pump heads form the B solvent pump and

the outlets are connected to a tee. The outlet tee on this

side is connected to the pressure transducer in the middle

of the assembly. The remaining connector on the pressure

transducer must be connected to the right bulkhead union.

Tighten this fitting with the

2-7).

1

/2” of travel.

1

/4” open

1

/4” open end wrench (Figure

Figure 2-7 Line connections on the pumps

2-4

ACCQPrep HP125

Note

Section 2 Installation

3. Connect the shorter FEP inlet solvent line to the left side

pump’s PEEK tee. Slide the open side of the wrench

(included) over the tubing and FEP fitting and make small

turns as to not bend the tubing (Figure 2-8).

4. Connect the longer FEP inlet solvent line to the right side

pump’s PEEK tee. Slide the open side of the wrench

(included) over the tubing and FEP fitting and make small

turns as to not bend the tubing (Figure 2-8).

Figure 2-8 Wrench used to tighten the FEP inlet line

5. Once complete, install the faceplate onto the unit by snapping the side mounted connectors into place.

2.2.3 Fluid Line Installation

The solvent lines are installed at the factory and include labels

identifying the lines A1, A2, and A3 for the A solvents and line

B1, B2, and B3 for the B solvents when using the Solvent

Selector Valve Module.

1. Remove the two screws that secure the solvent lines for

shipment.

2. Place the solvent lines in the desired containers.

2-5

ACCQPrep HP125

Note

Section 2 Installation

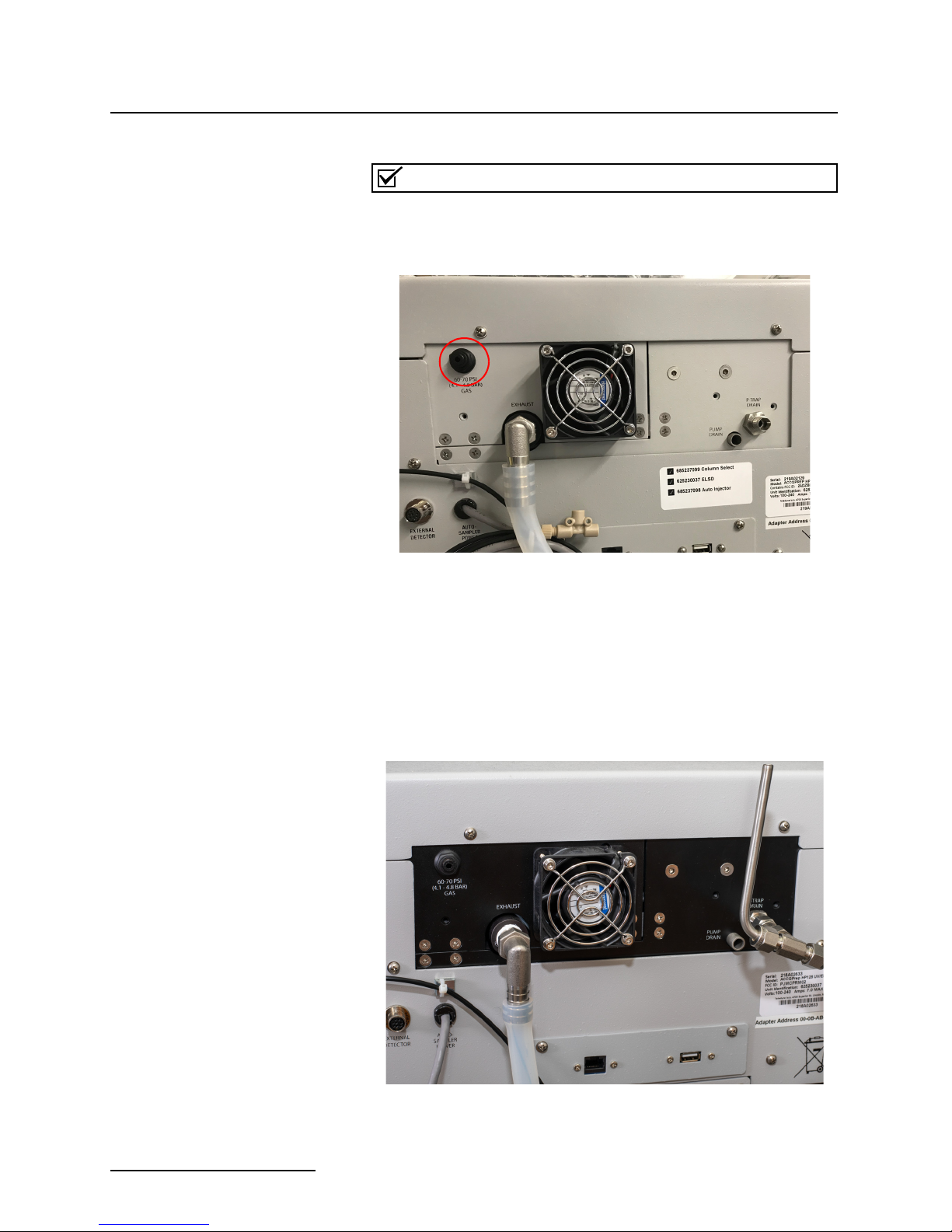

2.2.4 ACCQPrep Equipped

with Optional ELSD

Teledyne ISCO recommends >99% pure nitrogen from a

source that can deliver 2.5 SLPM at 60 to 70 psi.

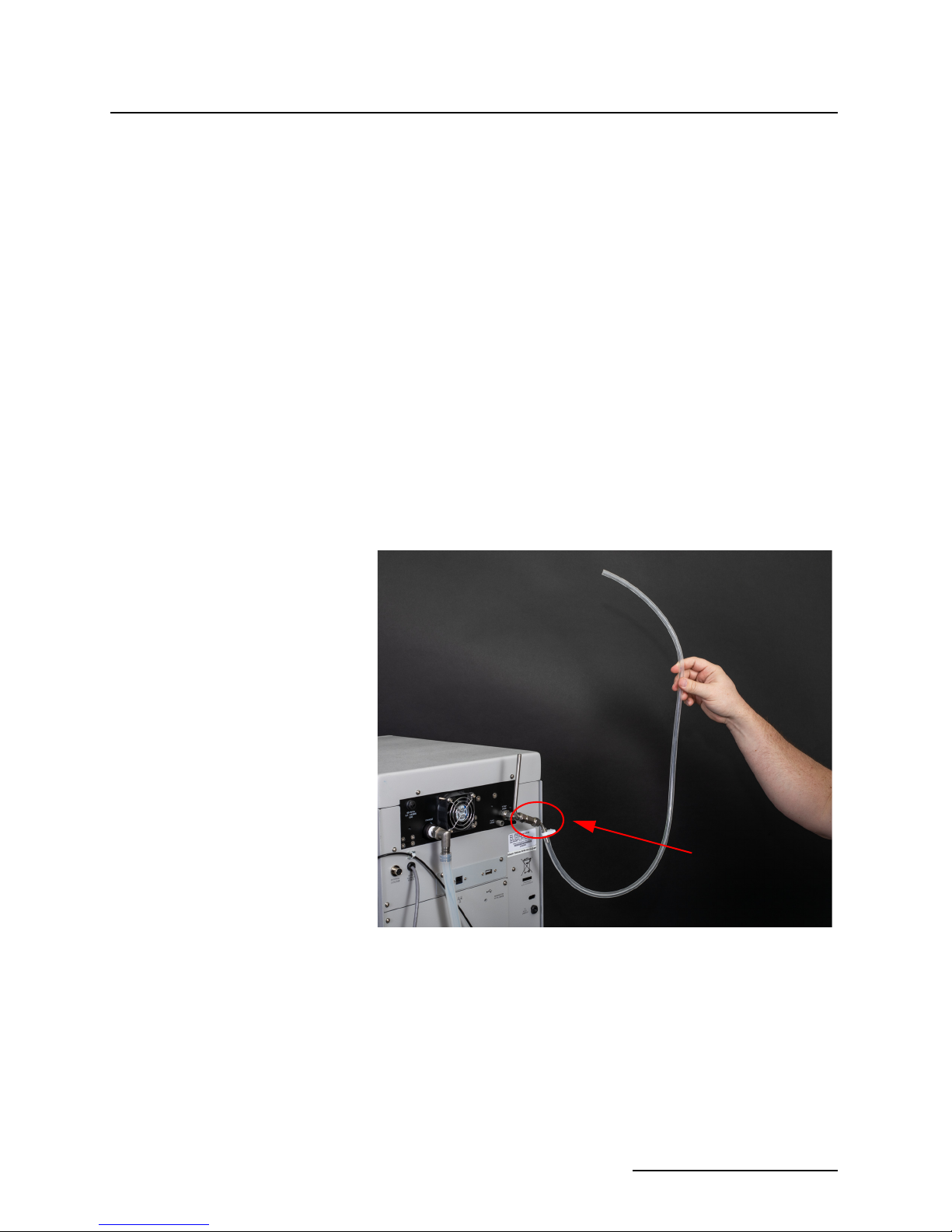

Figure 2-9 Location of ELSD gas port (Nitrogen input line

circled)

The ACCQPrep ELSD system has several additional connections.

1. Install the ELSD P-trap vent assembly found in the accessory package (PN 3-250004) by placing the short tube into

the port on the rear panel, orienting the vent as shown and

tightening the fitting nut finger tight plus a small amount

more with a wrench (Figure 2-10).

Figure 2-10 Back of ACCQprep with optional ELSD

2-6

ACCQPrep HP125

P-Trap drain vent

assembly drain line

Section 2 Installation

2. ELSD operation requires a carrier gas. To connect the carrier gas to the ACCQPrep:

• Locate the

1

/8 inch O.D. FEP tubing (PN:023-0503-02)

from the accessory package.

• Push one end of the tubing into the NITROGEN INLET

(Figure 2-9) port on the back of the system. The tubing

should be fully seated in the port.

• Cut the tubing to length and connect the other end to

the user-supplied carrier gas. An assortment of

1

/8 inch

adapters are supplied in the accessory kit to complete

the connection to your gas source.

3. The P-trap must be filled with fluid to prevent sample loss.

To accomplish this, raise the drain tubing attached to the

P-trap drain vent assembly above the instrument and

place 10 mL of liquid, such as isopropyl alcohol, into the

tube. Make sure the fluid level in the tubing doesn’t exceed

the level of the instrument case top. If the tubing is raised

too fast, fluid may flow out the top of the vent tube causing

a spill. Lift it high enough so the fluid enters the P-trap

drain (Figure 2-11).

Figure 2-11 Keep liquid level lower than the top of the

system

4. Route the end of the P-trap drain tube to a suitable waste

fluid collection container. Please be aware that as the tubing is lowered, several mL of isopropyl alcohol will run out

of the tubing. This is normal and means that the P-trap is

properly filled. Depending on your application, the P-trap

fluid may need periodic replenishment to ensure maximum

signal strength of the ELSD.

2-7

ACCQPrep HP125

Note

Note

CAUTION

Section 2 Installation

If accessible, the outlet end of the P-trap drain tube may be

used to refill the P-trap.

5. Route the attached tubing from the ELSD exhaust port

away from the system. This will prevent unnecessary solvent vapor alarms.

The ELSD exhaust will contain fine particles of compound. If

using outside of the hood, ensure that the exhaust port tubing

is routed to an exhaust handling system that meets your safety

and environmental requirements. Do not use tubing smaller

than the exhaust tube. If the exhaust is restricted, some of the

gas flow could be diverted out the P trap drain resulting in

reduced sensitivity and the need to route the P trap drain to an

exhaust. In normal operation, the exhaust gas is dry and does

not require a waste collection container.

Discontinue use of the ACCQPrep if liquid is present at the

Pump Drain. Contact Teledyne ISCO technical service for

assistance with correcting the leak.

2.2.5 Priming Steps The system will require priming with the desired solvents. To

prime the system:

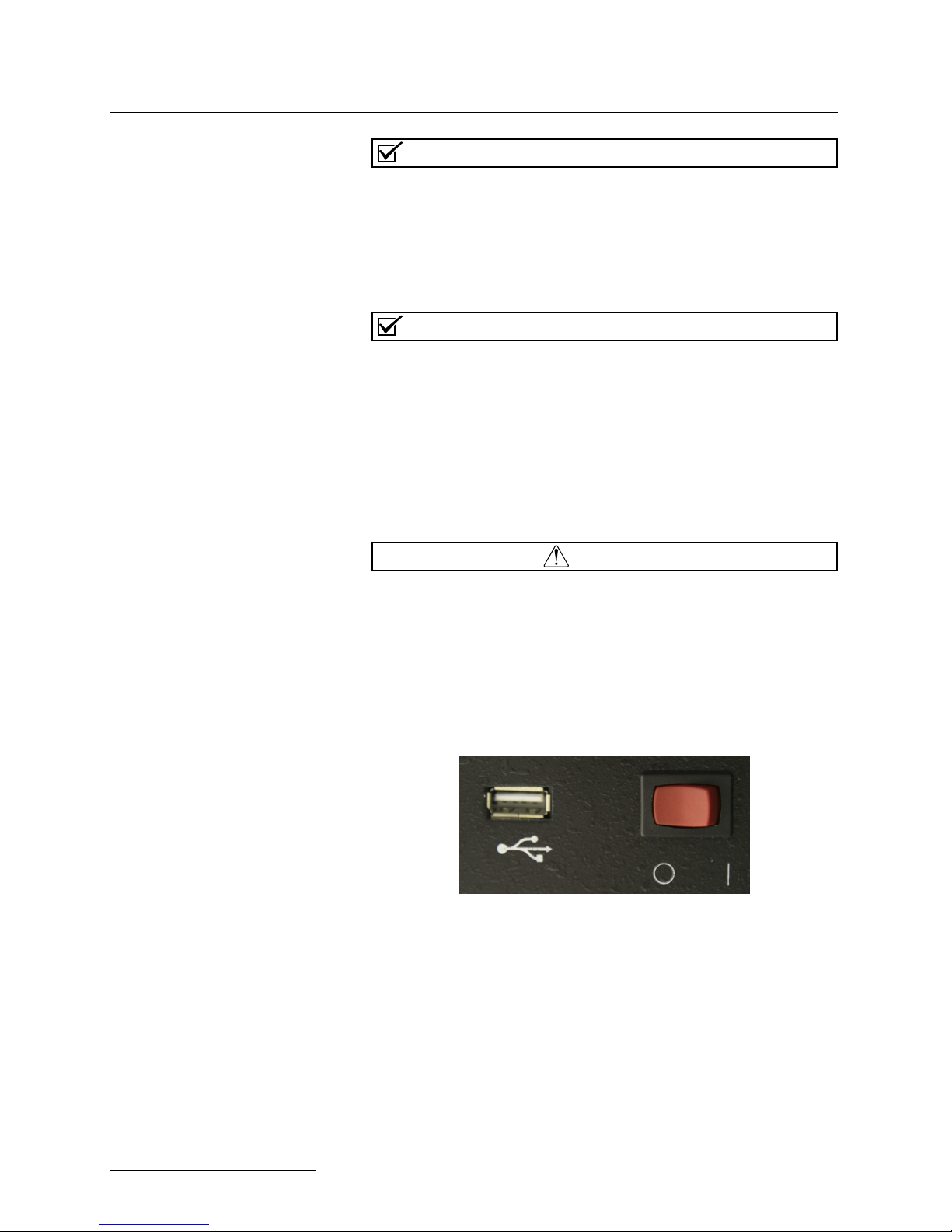

1. Press the red switch, next to the front USB port, to the O

position to boot up the system (Figure 2-12).

Figure 2-12 Front USB and On switch

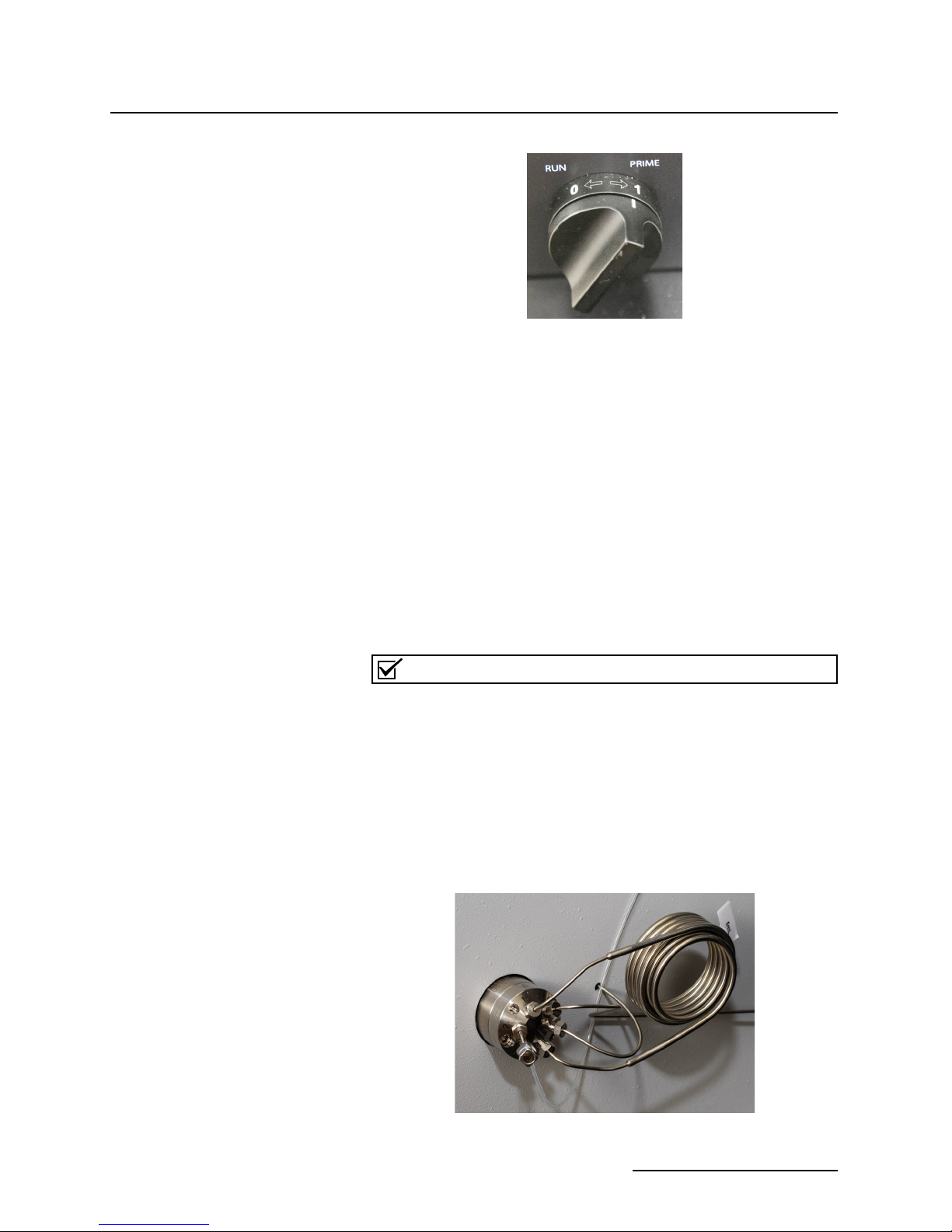

2. Turn the prime valve to the P

RIME position (Figure 2-13).

N

2-8

Figure 2-13 Turn the valve to the Prime position

Note

• If the solvent select option is not installed, the system

will immediately prime both solvent lines.

• If the solvent select option is installed, a dialog box

opens when the valve is switched to the P

The dialog box allows you to select which of the A

solvents and B solvents will be primed.

• If you have not already assigned names to the A and B

solvents, they can be named at this time using the drop

downs. If the name you want isn’t listed, it can be added

in the C

completed at a later time.

3. Once priming is complete, a new screen will appear directing you to turn the valve from the P

R

UN position.

ACCQPrep HP125

Section 2 Installation

RIME position.

ONFIGURATION screen. This action can be

RIME position to the

The system will prime both pumps simultaneously. There

is no method to prime A and B individually.

2.3 Installing the Manual

Injection Port

Manual sample injection can be performed with the system even

when equipped with an AutoInjector or AutoSampler.

If no AutoInjector or AutoSampler is installed, a luer injection

port (209900002) is included in the accessory package. To install,

place the fitting into the injection valve and tighten the nut

snugly (Figure 2-14).

Figure 2-14 ACCQPrep with Manual Injection Luer Port installed

2-9

ACCQPrep HP125

Section 2 Installation

Connect the included check valve(209016629) to the inject valve

waste line. Ensure that the arrow on the check valve points

toward the waste container. This check valve ensures sample

doesn’t run from the port when the injection syringe is removed.

If an AutoInjector or AutoSampler is installed and manual

injection is also desired, install the included check valve

(209016629) in the waste line from either the inject valve (if no

AutoInjector or AutoSampler is installed) or the waste line from

the sample load pump. Ensure that the arrow on the check valve

points toward the waste container. This check valve ensures

sample doesn’t run from the port when the injection syringe is

removed.

2.4 Installing the

AutoSampler

These instructions assume that the AutoSampler was purchased

with a new ACCQPrep. In that case, the AutoInjector portion of

the AutoSampler is already installed in the ACCQPrep. If not,

please refer to installation instructions included with the AutoInjector.

To install the AutoSampler:

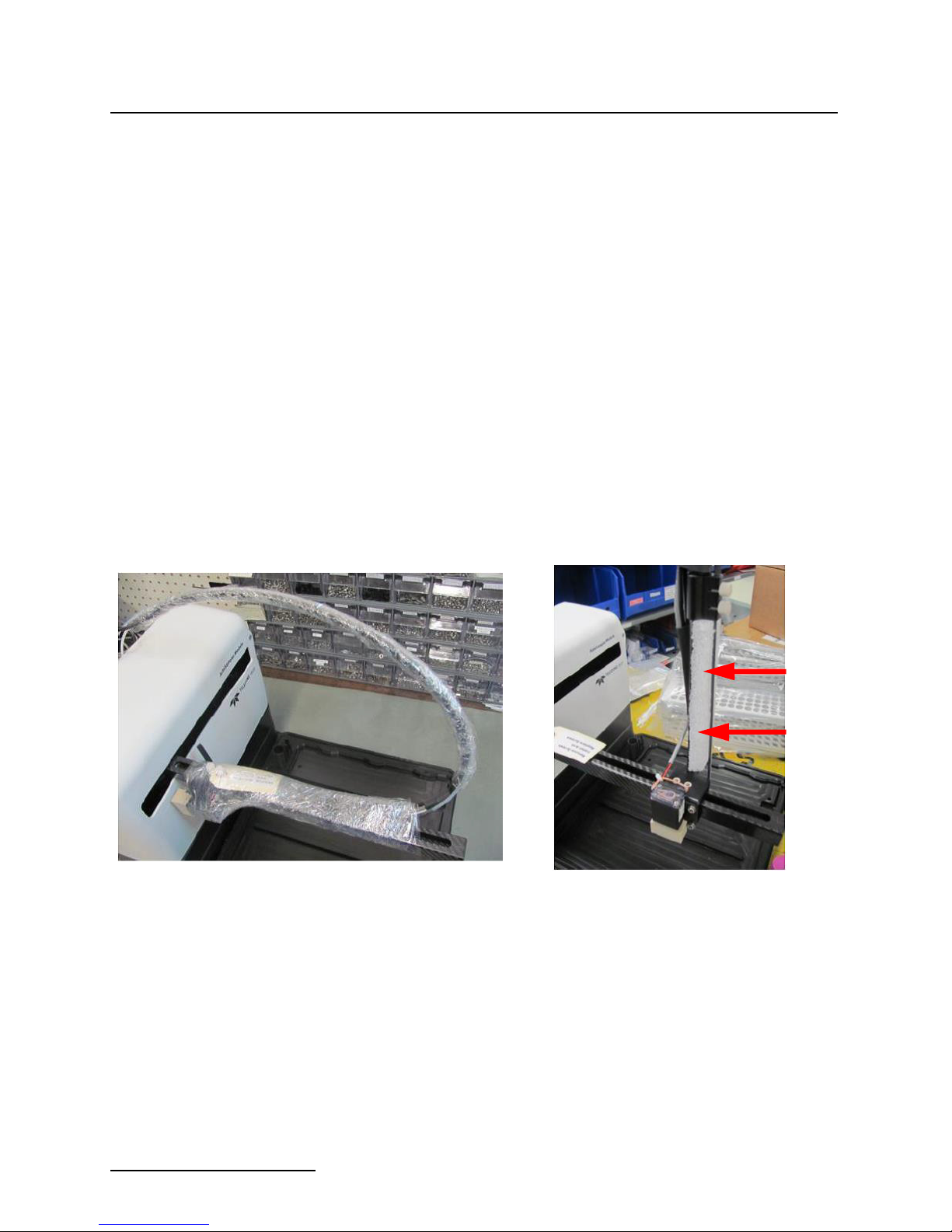

1. Carefully unpack the Z-Drive and remove the packing

materials from the Y-axis arm (Figure 2-15).

Figure 2-15AutoSampler Module and Z-Drive

2-10

2. Find the Y-axis carriage on the arm of the AutoSampler

Module. The Z-Drive will be attached to this carriage (Figure 2-16).

Figure 2-16 Z-Drive mounted on the Y-axis carriage

Note

3. Remove the two screws from the Y axis carriage. Slide the

Z-Drive onto the arm until the two holes align with the

matching holes in the Y-axis carriage.

4. Using the two plastic thumbscrews, secure the Z-Drive to

the carriage and finger tighten (Figure 2-17).

ACCQPrep HP125

Section 2 Installation

Figure 2-17 Z-Drive secured to the Y-axis carriage

5. Rotate the Z-Drive rotor back and forth to ensure that the

Z-Drive moved up and down freely (Figure 2-18).

If the rotor does not move freely, check that the other cables

are not interfering with the movement of the green probe cable.

2-11

ACCQPrep HP125

Wash station

Overflow drain

Waste line

Wash station

supply line

Section 2 Installation

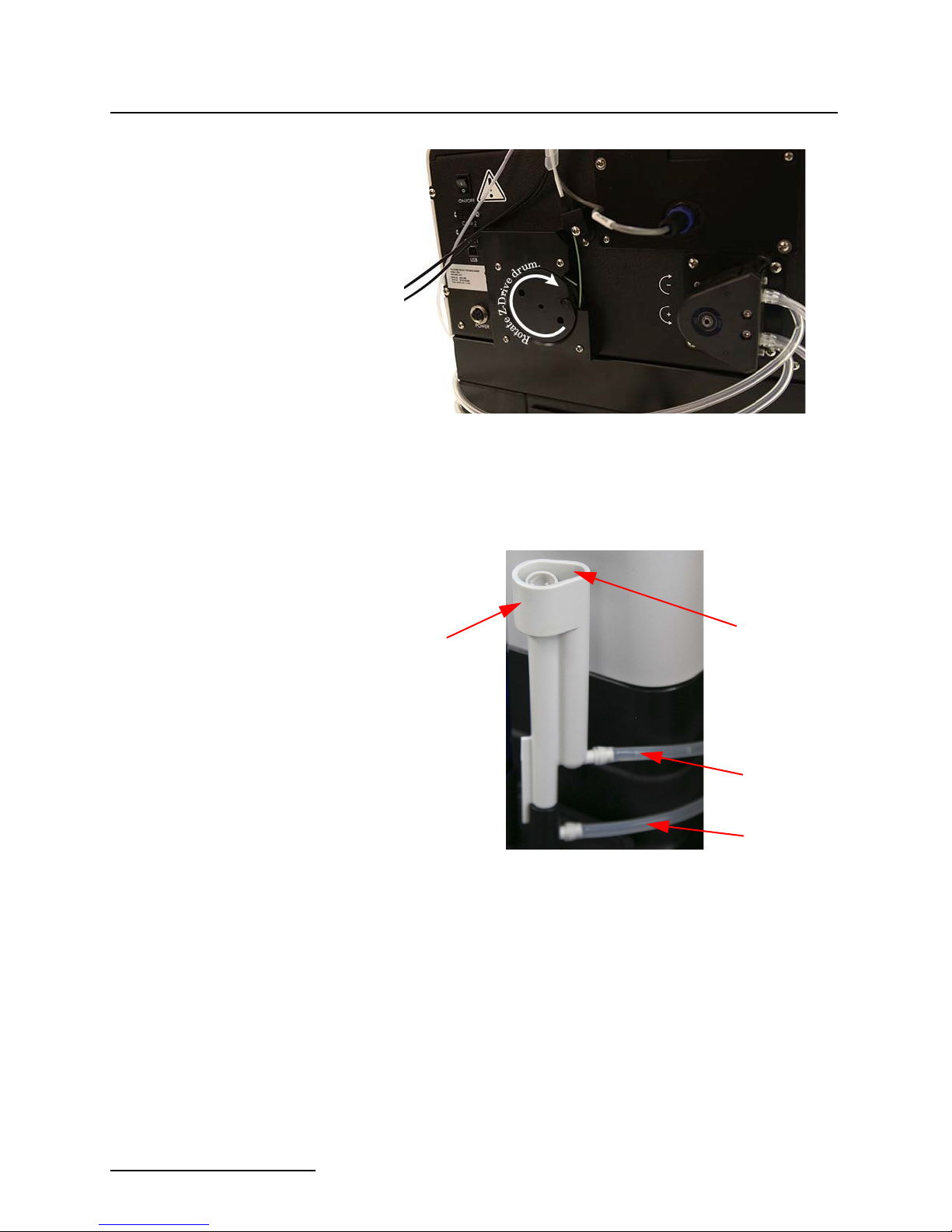

Figure 2-18 Z-Drive rotation

6. Mount the wash well by placing it into the receptacle

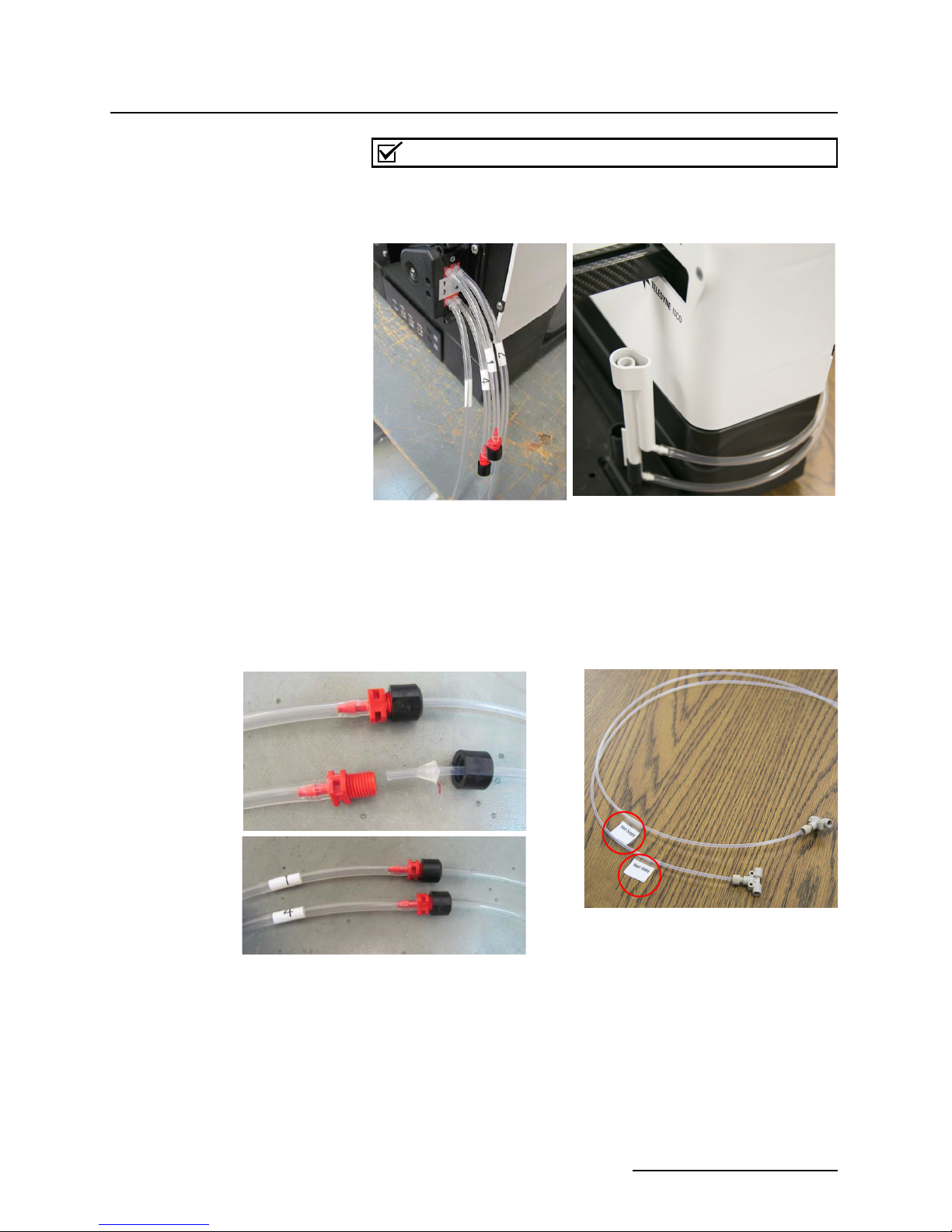

located on the right-rear portion of the AutoSampler Module bed (Figure 2-19).

Figure 2-19 AutoSampler Module wash well with tubing attached (top tube is waste to port #2 while

the bottom tube is supply port #3)

2-12

7. The wash well comes pre-plumbed to the peristaltic pump

ports. If disconnected in the future, it is important to connect the wash well waste tube (upper tube on wash well

labeled 2) to port “2” of the peristaltic pump and connect

the wash well supply tube (lower tube on wash well labeled

3) to port 3 of the peristaltic pump.

8. Connect the tube labeled “Wash Supply” to the tube

labeled “1” connected to port “1” of the peristaltic pump on

the back of the Autosampler Module. The free end of the

tubing can be placed in the wash solution container or tee’d

into a solvent supply line (Figure 2-20).

Note

The wash fluid peristaltic pump uses Pharm-A-Line tubing.

Please ensure the wash fluid is compatible with this tubing,

such as methanol.

Figure 2-20 AutoSampler Module peristaltic pump with tubing correctly attached

ACCQPrep HP125

Section 2 Installation

9. Connect the tube labeled “Wash Waste” to the tube labeled

“4” connected to port “4” of the peristaltic pump on the

back of the Autosampler Module. The free end of the tubing can be placed in the waste container or tee’d into an

existing waste line (Figure 2-21).

Figure 2-21 Wash and waste tubing connections and labels

2-13

ACCQPrep HP125

Do not

extend length.

See Step 11

for details.

Section 2 Installation

Auto Sampler Probe

Wash Pump

1 – Wash Inlet

2 – From Wash Station

3 – To Wash Station

4 – Waste

Column Valve

Optional

To Injection

Valve

Auto Injector

Optional

To bottom

column port

External

Detector

Sampler

Sampler

Power

Power

Auto

Auto

USBEthernet

USB

Check Valve

Sampler

Sampler

To

To

Auto

Auto

Waste

Wash Station

Fraction Collection

Solvent Level

Sensing

Solvent Lines

Sample

Not Used

Waste line

Wash station

supply

Needle Wash

Not Normally Used

Needle Wash

Inlet Line

Main

Main

Power

Power

Circuit Breaker

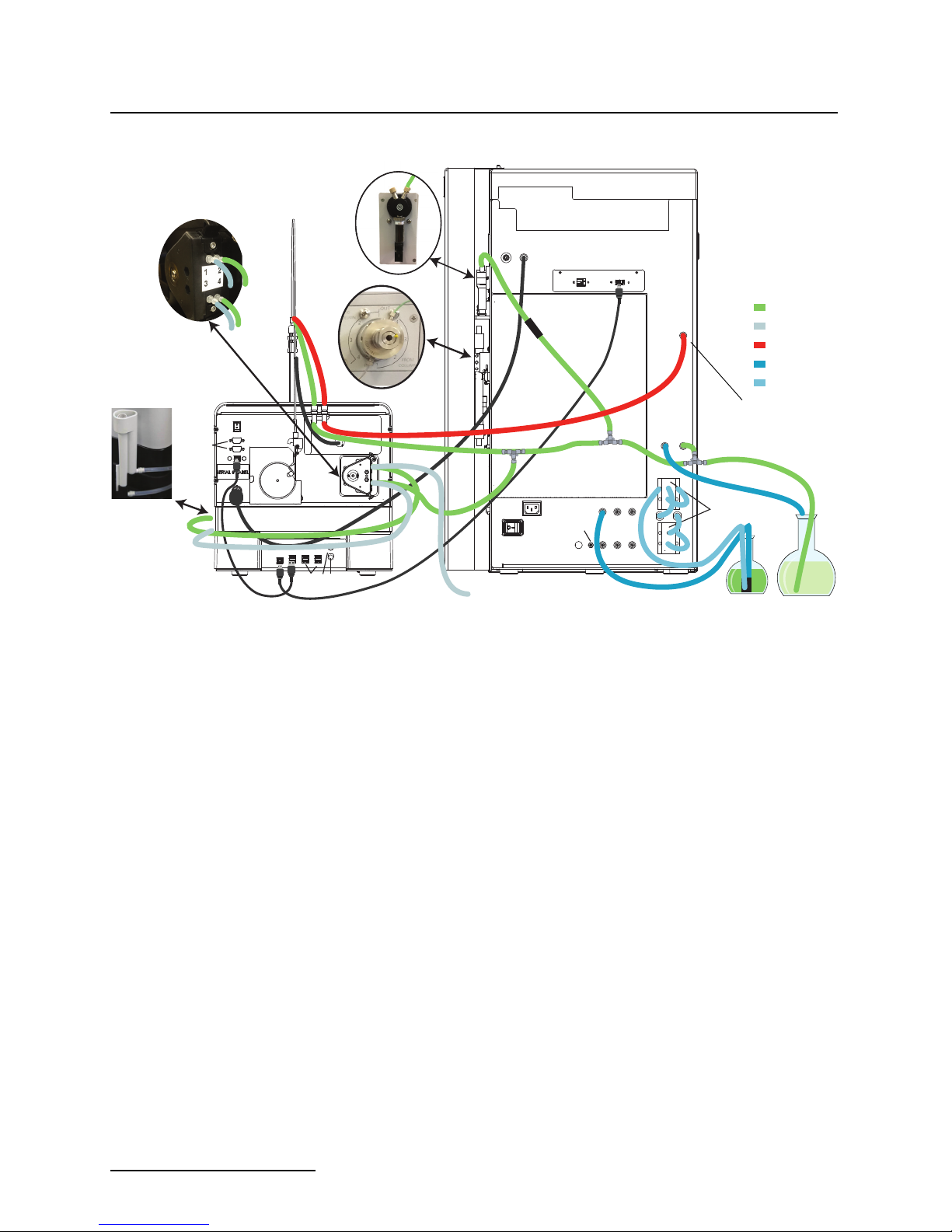

Figure 2-22 Tubing diagram of the AutoSampler connected

to the ACCQPrep (See Appendix A, Figure A-1

for a larger diagram)

10. Place the AutoSampler Module on the right side of the

ACCQPrep.

11. Connect the AutoSampler tubing labeled “To ACCQPrep”

to the connection on the ACCQPrep’s rear panel labeled “To

AutoSampler”. The length of this tubing is critical to control the delay volume for fraction collection on the AutoSampler. The overall length of the tubing to the diverter

valve should be 67” (170 cm).

12. Route the “To Waste” tubing to a suitable waste container

or tee to either the Wash Waste Line from the AutoSampler Module (from step 8 above or seen in Figure 2-22)

and/or the ACCQPrep waste line and injection valve waste

line with the supplied tee(s).

Optional

External Gas

Not Normally Used

Drain

Drain

A1 A2 A3

A1 A2 A3

Solvent Level Sensing

Solvent Level Sensing

B1 B2 B3

B1 B2 B3

Waste

Waste

Level

Level

Waste

Waste

Sense

Sense

Solvent Inlet

Solvent Inlet

J

A1

A1

A2

A2

A3

B

A

B

A

IN

IN

IN

IN

B3

B3

B1

B1

B2

B2

B4

B4

Repeat tubing for A1 Solvent as needed

Solvent inlet

valves

optional

If not used,

connect directly

to A and B

A1 Solvent

WASTE

2-14

Loading...

Loading...