Telecommunications Techniques Corporation T-Berd 211, T-Berd 209A User Manual

T-BERD 209A/211

T -CARRIER ANALYZER

REFERENCE MANU AL

JUNE 1994

50-10995-02

Rev. P

©1991 TELECOMMUNICATIONS TECHNIQUES CORPORATION®

20400 Observation Drive, Germantown, Maryland 20876

(800) 638-2049 • (301) 353-1550 (MD) • FAX (301) 353-0731

WWW Address: http://www.ttc.com

BRIDGTAP and MULTIPAT are trademarks of

Telecommunications Techniques Corporation (TTC),

A Dynatech Company.

SLC is a registered trademark of AT&T Technologies, Inc.

Specifications, terms, and conditions are subject to change without notice.

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION PAGE

GENERAL INFORMATION

1.1 INTRODUCTION........................................................................................1-1

1.2 INSTRUMENT OVERVIEW.......................................................................1-1

1.3 STANDARD FEATURES...........................................................................1-2

1.4 OPTIONS ....................................................................................................1-3

1.5 ACCESSORIES ..........................................................................................1-7

1.6 CABLES......................................................................................................1-8

1.7 ORDERING INFORMATION .....................................................................1-8

INSTRUMENT CHECKOUT AND SERVICE

2.1 UNPACKING AND INITIAL INSPECTION................................................2-1

2.2 EQUIPMENT INCLUDED ..........................................................................2-1

2.3 WARNINGS AND CAUTIONS...................................................................2-1

2.4 POWER REQUIREMENTS .......................................................................2-2

2.5 INSTRUMENT SELF-TEST/CHECKOUT.................................................2-3

2.6 IN CASE OF DIFFICULTY.........................................................................2-7

2.7 AC LINE FUSE REPLACEMENT..............................................................2-8

2.8 BATTERY CARE (T-BERD 209A ONLY) .................................................2-9

2.9 AUTO-CALIBRATION PROCEDURE .......................................................2-9

2.10 WARRANTY .............................................................................................2-10

2.11 EQUIPMENT RETURN INSTRUCTIONS...............................................2-11

INSTRUMENT DESCRIPTION

3.1 INTRODUCTION........................................................................................3-1

3.2 MAINFRAME — TEST SETUP .................................................................3-1

3.3 MAINFRAME — CIRCUIT CONNECTIONS ..........................................3-14

3.4 MAINFRAME — SIGNAL VERIFICATION .............................................3-17

3.5 MAINFRAME — STARTING TEST/COLLECTING RESULTS .............. 3-20

3.6 MAINFRAME — TROUBLESHOOTING CONTROLS ...........................3-25

3.7 MAINFRAME — PRINTER CONTROL...................................................3-29

G.821 PERFORMANCE ANALYSIS OPTION

3.8 G.821 OPTION — INTRODUCTION ......................................................3-33

3.9 G.821 OPTION — TEST SETUP ............................................................3-33

3.10 G.821 OPTION — STARTING TEST/COLLECTING RESULTS ..........3-33

3.11 G.821 OPTION — PRINTER CONTROL ...............................................3-34

iii

TABLE OF CONTENTS

SECTION PAGE

JITTER SPECTRAL ANALYSIS OPTION

3.12 JITTER SPECTRAL ANALYSIS OPTION — INTRODUCTION............3-35

3.13 JITTER SPECTRAL ANALYSIS OPTION — TEST SETUP .................3-35

3.14 JITTER SPECTRAL ANALYSIS OPTION — CIRCUIT

CONNECTIONS.......................................................................................3-36

3.15 JITTER SPECTRAL ANALYSIS OPTION — SIGNAL

VERIFICATION ........................................................................................3-36

3.16 JITTER SPECTRAL ANALYSIS OPTION — STARTING

TEST/COLLECTING RESULTS..............................................................3-36

3.17 JITTER SPECTRAL ANALYSIS OPTION — PRINTER CONTROL..... 3-37

ADVANCED BERT OPTION

3.18 ADVANCED BERT OPTION — INTRODUCTION.................................3-39

3.19 ADVANCED BERT OPTION — TEST SETUP....................................... 3-40

ENHANCED ESF OPTION

3.20 ENHANCED ESF OPTION — INTRODUCTION ...................................3-43

3.21 ENHANCED ESF OPTION — TEST SETUP .........................................3-43

3.22 ENHANCED ESF OPTION — STARTING TEST/COLLECTING

RESULTS .................................................................................................3-44

3.23 ENHANCED ESF OPTION — PRINTER CONTROL ............................3-48

TDR OPTION

3.24 TDR OPTION — INTRODUCTION .........................................................3-51

3.25 TDR OPTION — TEST SETUP...............................................................3-51

3.26 TDR OPTION — CIRCUIT CONNECTIONS..........................................3-54

3.27 TDR OPTION — STARTING TEST/COLLECTING RESULTS.............3-55

3.28 TDR OPTION — PRINTER CONTROL ..................................................3-57

FT1 OPTION

3.29 FT1 OPTION — INTRODUCTION ..........................................................3-59

3.30 FT1 OPTION — TEST SETUP................................................................3-59

3.31 FT1 OPTION — TROUBLESHOOTING CONTROLS ...........................3-61

LID OPTIONS

T-BERD T1 CHANNEL MONITOR OPTION

4.1 T1 CHANNEL MONITOR — FEATURES .................................................4-1

4.2 T1 CHANNEL MONITOR — CONNECTION TO T-BERD 209A/211 .....4-1

4.3 T1 CHANNEL MONITOR — TEST SETUP.............................................. 4-3

iv

TABLE OF CONTENTS

SECTION PAGE

T-BERD REPEATER POWER SUPPLY OPTION

4.4 REPEATER POWER SUPPLY — FEATURES........................................4-9

4.5 REPEATER POWER SUPPLY — WARNINGS AND CAUTIONS..........4-9

4.6 REPEATER POWER SUPPLY — T-BERD 209A/211 CONNECTION ..4-12

4.7 REPEATER POWER SUPPLY — T1 SPAN TESTING.........................4-13

4.8 REPEATER POWER SUPPLY — AC PO WER CONNECTION.............4-13

4.9 REPEATER POWER SUPPLY — CURRENT SETTING ......................4-13

4.10 REPEATER POWER SUPPLY — APPLYING POWER........................4-14

T-BERD DLC ANALYZER OPTION

4.11 DLC ANALYZER OPTION — FEATURES .............................................4-17

4.12 DLC ANALYZER OPTION — CONNECTING TO T-BERD 209A/211..4-19

4.13 DLC ANALYZER OPTION — TEST SETUP ..........................................4-19

4.14 DLC ANALYZER OPTION — CIRCUIT CONNECTIONS .....................4-29

4.15 DLC ANALYZER OPTION — SIGNAL VERIFICATION ........................4-32

4.16 DLC ANALYZER OPTION — STARTING TEST/COLLECTING

RESULTS ...............................................................................................4-36

4.17 DLC ANALYZER OPTION — TROUBLESHOOTING CONTROLS......4-41

4.18 DLC ANALYZER OPTION — PRINTER CONTROL .............................4-43

AUXILIARY FUNCTIONS

5.1 INTRODUCTION........................................................................................5-1

5.2 MAINFRAME — AUXILIARY FUNCTIONS..............................................5-1

5.3 DLC ANALYZER OPTION — AUXILIARY FUNCTIONS.......................5-37

TEST RESULTS

6.1 INTRODUCTION — TEST RESULTS ......................................................6-1

6.2 MAINFRAME — SUMMARY CATEGORY ...............................................6-1

6.3 MAINFRAME — LOGIC CATEGORY.......................................................6-3

6.4 MAINFRAME — BPV & FRAME CATEGORY .........................................6-5

6.5 MAINFRAME — SIGNAL CATEGORY.....................................................6-8

6.6 MAINFRAME — TIME CATEGORY .......................................................6-14

6.7 MAINFRAME — JITTER (T-BERD 211 ONLY) & WANDER

CATEGORY ...........................................................................................6-15

v

TABLE OF CONTENTS

SECTION PAGE

6.8 TEST RESULTS — DLC ANALYZER OPTION .....................................6-18

6.9 DLC ANALYZER OPTION — SUMMARY CATEGORY ........................6-18

6.10 DLC ANALYZER OPTION — DATALINK CATEGORY.........................6-21

6.11 DLC ANALYZER OPTION — CHANNEL CATEGORY .........................6-23

6.12 DLC ANALYZER OPTION — TIME CATEGORY ..................................6-26

PRINTER OPERATION

7.1 COMPATIBLE PRINTERS ........................................................................7-1

7.2 RS-232 PRINTER OPERATION ...............................................................7-1

7.3 CONNECTING THE PRINTER .................................................................7-2

7.4 GENERATING A PRINTOUT ....................................................................7-3

7.5 TYPES OF PRINTOUTS ...........................................................................7-4

REMOTE CONTROL OPERATION

8.1 INTRODUCTION........................................................................................8-1

8.2 REMOTE CONTROL SETUP....................................................................8-1

8.3 ERROR MESSAGES .................................................................................8-4

8.4 REMOTE CONTROL COMMAND FORMAT............................................8-5

SPECIFICATIONS

9.1 INTRODUCTION........................................................................................9-1

9.2 MAINFRAME — GENERAL SPECIFICATIONS ......................................9-1

9.3 MAINFRAME — INPUT SPECIFICATIONS.............................................9-2

9.4 MAINFRAME — OUTPUT SPECIFICATIONS.........................................9-3

9.5 MAINFRAME — ALARM CRITERIA.........................................................9-3

9.6 MAINFRAME — PATTERN SYNC DETECTION CRITERIA ..................9-4

9.7 MAINFRAME — LOOP CODES................................................................9-5

9.8 MAINFRAME — MEASUREMENTS.........................................................9-6

9.9 MAINFRAME — CONNECTORS..............................................................9-9

9.10 MAINFRAME — GROUNDING ...............................................................9-12

9.11 BATTERY OPTION SPECIFICATIONS (T-BERD 209A ONLY) ...........9-12

9.12 T-BERD T1 CHANNEL MONITOR OPTION SPECIFICATIONS ..........9-13

9.13 T-BERD REPEATER POWER SUPPLY OPTION

SPECIFICATIONS .................................................................................9-15

9.14 TIME DOMAIN REFLECTOMETER OPTION SPECIFICATIONS ........9-17

9.15 T-BERD DLC ANALYZER OPTION SPECIFICATIONS........................9-18

vi

TABLE OF CONTENTS

APPENDICES

A FACTORY DEFAULT SETTINGS............................................................ A-1

B OPERATING MESSAGES........................................................................ B-1

C STRESS PATTERNS................................................................................ C-1

D JITTER MASKS......................................................................................... D-1

E REMOTE CONTROL COMMANDS ......................................................... E-1

FIGURES PAGE

3-1 T-BERD 209A FRONT PANEL..................................................................3-2

3-2 T-BERD 211 FRONT PANEL....................................................................3-3

3-3 TEST SETUP CONTROLS AND INDICATORS .......................................3-4

3-4 FRONT-PANEL CONNECTIONS............................................................3-15

3-5 SIGNAL VERIFICATION INDICATORS .................................................3-17

3-6 STARTING TESTS AND COLLECTING RESULTS ..............................3-21

3-7 TROUBLESHOOTING CONTROLS .......................................................3-25

3-8 PRINTER CONTROLS ............................................................................3-29

3-9 SAMPLE JITTER VS FREQUENCY GRAPH ......................................... 3-37

3-10 TDR GRAPH PRINTOUT ........................................................................3-57

4-1 CONNECTING THE T-BERD T1 CHANNEL MONITOR

TO THE T-BERD 209A/211 ....................................................................4-2

4-2 T-BERD T1 CHANNEL MONITOR FRONT PANEL ................................4-4

4-3 T-BERD REPEATER POWER SUPPLY FRONT PANEL .....................4-10

4-4 T-BERD DLC ANALYZER OPTION FRONT PANEL .............................4-18

4-5 TEST SETUP CONTROLS AND INDICATORS .....................................4-19

4-6 T-BERD DLC ANALYZER CIRCUIT CONNECTIONS ..........................4-29

4-7 SIGNAL VERIFICATION CONTROLS AND INDICATORS...................4-33

4-8 CONTROLS TO START TESTS AND COLLECT RESULTS................4-36

4-9 SIGNALING INSERT CONTROLS AND INDICATORS.........................4-39

6-1 PULSE SHAPE AND PULSE MASK SPECIFICATIONS ......................6-11

6-2 TIMING SLIPS..........................................................................................6-12

6-3 TIMING SLIPS RESULTS DISPLAY.......................................................6-12

6-4 BAR GRAPH AND WHEEL VALUES .....................................................6-13

7-1 RESULTS PRINTOUT...............................................................................7-5

7-2 SIMULATED BRIDGE TAP RESULTS PRINTOUT.................................7-6

7-3 SIMULATED MULTIPATTERN RESULTS PRINTOUT...........................7-8

7-4 CONTROLS PRINTOUT............................................................................7-9

7-5 SAMPLE PULSE SHAPE PRINTOUT....................................................7-11

7-6 SAMPLE JITTER VS FREQUENCY GRAPH ......................................... 7-12

7-7 SINGLE TRACE TDR GRAPH................................................................ 7-13

7-8 DUAL TRACE TDR GRAPH ....................................................................7-14

vii

TABLE OF CONTENTS

TABLES PAGE

3-1 AUXILIARY FUNCTIONS........................................................................3-18

3-2 BRIDGTAP PATTERNS ..........................................................................3-11

3-3 MULTIPAT PATTERNS........................................................................... 3-12

3-4 SELECTABLE CABLE TYPES ................................................................3-53

4-1 CHANNEL TIMESLOT ASSIGNMENTS...................................................4-5

4-2 TYPICAL REPEATER VOLTAGE DROP ...............................................4-15

4-3 TYPICAL CABLE GAUGE VOLTAGE DROP.........................................4-15

4-4 MODE 1 SLC-96 DATALINK SOURCE TEST SIGNALS......................4-21

4-5 MODE 2 SLC-96 DATALINK TEST SIGNALS.......................................4-22

4-6 DS0 CHANNEL TEST SIGNALS ............................................................4-22

4-7 SLC-96 CHANNEL NUMBERING SCHEME..........................................4-27

4-8 D1D AND SLC FRAMED SIGNALING STATES....................................4-40

4-9 T1 ESF SIGNALING STATES .................................................................4-41

5-1 FRACTIONAL T1 BANDWIDTHS ...........................................................5-34

6-1 SPECTRAL ANALYSIS RESULTS.........................................................6-17

7-1 RS-232 PRINTER/CONTROLLER INTERFACE CONFIGURATIONS...7-1

8-1 T-BERD 209A/211 INTERFACE CAPABILITIES.....................................8-1

8-2 AUXILIARY FUNCTION PARAMETERS..................................................8-2

8-3 FRONT-PANEL SWITCH COMMANDS ...................................................8-6

8-4 AUXILIARY FUNCTION COMMANDS .....................................................8-7

8-5 REMOTE CONTROL-ONLY COMMANDS ...............................................8-9

8-6 BERD-BASIC COMMANDS ....................................................................8-10

8-7 TDR COMMANDS....................................................................................8-11

9-1 NETWORK INTERFACE PIN ASSIGNMENTS ......................................9-10

9-2 RS-232 PIN ASSIGNMENTS..................................................................9-11

9-3 T1 CHANNEL MONITOR OPTION RS-232 PIN ASSIGNMENTS........9-14

A-1 FACTORY DEFAULT SETTINGS............................................................ A-1

A-2 T-BERD DLC ANALYZER FACTORY DEFAULT SETTINGS................ A-4

viii

SECTION 1

GENERAL INFORMATION

GENERAL INFORMATION

1.1 INTRODUCTION

The purpose of this reference manual is to provide information about the physical features,

functional operation, and specifications of the Telecommunications Techniques Corporation

(TTC) T-BERD 209A and T-BERD 211 T-Carrier Analyzers.

This manual provides information on the following options that are available for the TBERD 209A and T-BERD 211.

• G.821 Performance Analysis Option (209A/211-1)

• Jitter Spectral Analysis Option (211-2)

• Rechargeable Lead-Acid Battery Option (209A-2)

• Advanced BERT Option (209A/211-3)

• Enhanced ESF Option (209A/211-4)

• Time Domain Reflectometer Option (209A/211-5)

• Fractional T1 Option (209A/211-6)

• T-BERD DLC Analyzer Option (209A/211-96)

• T-BERD T1 Channel Monitor Option (Model 40849)

• T-BERD Repeater Power Supply Option (Model 41084)

In addition to this manual, a T-BERD 209A/211 User’s Guide provides information on

setting up and operating the T-BERD 209A and T-BERD 211 in a number of in-service and outof-service applications.

1.2 INSTRUMENT OVERVIEW

The T-BERD 209A/211 is a portable and comprehensive test instrument for the installation and maintenance of T1 and T1C transmission systems. Designed primarily for central

office testing, the T-BERD 209A/211 can be used during circuit installation, acceptance testing

and troubleshooting. The T-BERD 209A/211 can receive and generate test patterns during outof-service circuit tests or can monitor T1 and T1C circuits without service interruption. The

T-BERD 209A/211 can emulate network devices, such as Network Interface Units (NIUs) or

Channel Service Units (CSUs). In addition, it can detect and isolate circuit problems in

customer premises and network equipment.

1-1

SECTION 1

GENERAL INFORMATION

1.3 STANDARD FEATURES

D4, ESF, and SLC™-96 framing patterns offer compatibility with a variety of framing

formats. An unframed mode is also available for applications where framing is not

required.

Summary test results category displays key non-zero and out-of-specification results,

eliminating the need to search through long lists of test results.

Automatic configure mode lets the T-BERD 209A/211 configure itself to the proper line

rate (T1 or T1C), framing, coding, and pattern. No set up is required when monitoring live

circuits.

Simultaneous logic error, bipolar violation, and frame error analysis is performed

along with associated error rate, errored second, and percent error-free second calculations.

Automated BRIDGTAP™ test allows the T-BERD 209A/211 to evaluate a T1 span for

bridge taps. The test automatically generates 21 test patterns which are monitored for

errors.

Automated MULTIPAT™ test generates five standard T1 test patterns with variable

duration that eliminates the need to perform individual tests with each pattern.

Signal analysis with simplex current, signal level, timing slip, and recovered clock

frequency measurements.

Slips and wander measurements identify wander impairments or the potential for frame

slips.

Pulse shape analysis allows you to measure the height, width, rise time, fall time,

overshoot and undershoot of a T1 pulse. Pulse shapes can also be measured for conformance to AT&T Compatibility Bulletin 119 or ANSI T1.403 Network Interface specifications.

Wideband and highband jitter (T-BERD 211only) is measured for current wideband and

highband peak-to-peak jitter and the maximum wideband and highband peak-to-peak jitter

since the start of the test. The results are presented in Unit Intervals (UIs).

Logic, BPV, and frame error insertion enables the T-BERD 209A/211 to simulate errors

as they occur. Errors may be inserted singly, in a burst, or at variable rates.

1-2

SECTION 1

GENERAL INFORMATION

RS-232 printer/remote control interface allows you to print graphic displays (e.g., pulse

shapes) and error analysis results, and to remotely control the T-BERD 209A/211.

Results history buffer stores up to six sets of your most recent test results that can be

viewed from the front panel.

1.4 OPTIONS

T-BERD 209A/211 mainframe options are discussed in detail in Section 3. T-BERD

209A/211 lid options are discussed in detail in Section 4.

G.821 Performance Analysis Option — Option 209A/211-1

CCITT Recommendation G.821 performance analysis evaluates the long-term perfor-

mance of your system.

Adds unavailable second, percent availability, degraded minute, percent degraded minute,

and severely errored second results to the LOGIC category.

Jitter Spectral Analysis Option — Option 211-2

(T-BERD 211 Only)

Analyzes timing jitter present on T1 networks.

Measures Jitter against five industry standards for jitter impairments or in UI.

Displays the relative amount of jitter as a percentage against a specification mask.

Rechargeable Lead-Acid Battery Option — Option 209A-2

(T-BERD 209A Only)

Provides battery backup when AC power is lost.

Provides continuous battery operation when AC power is not available.

Operates up to five hours on a single charge.

1-3

SECTION 1

GENERAL INFORMATION

Continuously charges when AC power is applied.

Turns off the display to conserve power when no switches are pressed for five minutes.

Advanced BERT Option — Option 209A/211-3

Adds a user programmable 1- to 2000-character hexadecimal test pattern that deter-

mines the circuit sensitivity to the pattern when transmitted.

Adds a minimum/maximum density stress pattern that can be used for framed or

unframed signal testing.

Adds test patterns that can stress test timing recovery circuits and span-line repeater

ALBO circuitry.

Provides intelligent repeater loop codes that enable the T-BERD 209A/211 to control

Teltrend, Wescom, Westell, XEL, or equivalent intelligent span equipment.

Provides command codes that enable the T-BERD 209A/211 to control Teltrend and

Westell T1 maintenance switches.

Enhanced ESF Option — Option 209A/211-4

Monitors and reports on the received ESF datalink ANSI T1.403 Performance Report

Message (PRM).

Analyzes and generates the PRM for the received T1 signal.

Adds a SMARTNIU mode that enables the T-BERD 209A/211 to query, retrieve, store,

and clear T1 circuit statistics obtained by a Westell NIU/Performance Monitor.

Time Domain Reflectometer Option — Option 209A/211-5

Uses TDR signal analysis to locate line impairments such as shorts, opens, splices, coils,

and bridge taps on copper wire pairs.

Displays faults and distances in plain English for shorts, opens, and bridge taps on the

front panel.

Provides printouts of test results, setup, and fault location trace using the TTC PR-

40A Thermal Printer.

1-4

SECTION 1

GENERAL INFORMATION

Enables fault identification and location on cable pairs of varying lengths (100 to 6500

feet).

Provides a TDR fault trace and distance graph that indicates all line impairments

detected on the cable pair in a normal or a magnified mode.

Enables printout or dual traces that compare the current trace to a reference trace.

Fractional T1 Option — Option 209A/211-6

Fractional T1 (FT1) modes provide contiguous and noncontiguous, 56xN and 64xN,

fractional T1 testing capabilities in D4, ESF, and ESFz framing formats.

Provides FT1 stress patterns that enable the T-BERD 209A/211 to test DDS and

fractional T1 circuits.

T-BERD DLC Analyzer Option — Option 209A/211-96 (Model 42170)

Provides drop and insert capability for DLC datalink and T1 channel information.

Displays DLC datalink alarm status on the front panel.

Generates DLC datalink alarms to test terminal alarm circuits.

Initiates and monitors automated maintenance test procedures.

Establishes far-end loopbacks over a given shelf or protection line. The selected shelf

is automatically switched to the protection line when placed in loopback.

Initiates a switch to protection line for a given shelf.

Generates on-hook, off-hook, and ringing conditions

using dedicated front-panel

switches.

Monitors A, B, C, and D channel signaling bits on all channels or timeslots simulta-

neously.

Monitors SLC-96 Mode 2 timeslot channel assignments from the front panel.

Provides VF outputs that enable DS0 channels or timeslots to be analyzed by an external

TIMS test set or listened to over the built-in speaker.

1-5

SECTION 1

GENERAL INFORMATION

Measures VF signal level and frequency for an individual DS0 channel or timeslot.

Inserts tones (404 Hz, 1004 Hz, and 2804 Hz) into an individual DS0 channel or timeslot.

Decodes DTMF dialing sequences and the dialed number of the received signal is

displayed.

Provides 2-wire VF input/output that enables two-way testing over a selected DS0

channel or timeslot.

T-BERD T1 Channel Monitor Option — Model 40849

Simultaneously displays all 24 signaling bits, which allows a quick look at the hook

switch and ringing status of a T1 channel or a view of the ongoing signaling of a T1 trunk.

Provides an LED bar graph display of the VF signal level from -54 dBm to +3 dBm in

3 dBm steps.

Drops and inserts the ESF or SLC-96 datalink for monitoring or testing with an external

test set.

Supplies a selected VF channel to an external VF test set via the VF OUT 600 OHMS

jack.

Establishes ISDN compatibility by dropping one of the 24 channels (64 kb/s).

T-BERD Repeater Power Supply Option — Model 41084

Provides power and a T1 signal interface, which enable testing and verification of newly

installed T-Carrier circuits before span power is applied at the central office.

Measures the voltage across the circuit to determine whether the applied voltage

correlates with the expected voltage dictated by the circuit design.

Measures span current to verify proper powering of span repeaters.

Uses a Loopback Connector to provide a hard loop at the central office, which allows

a single technician to sectionalize and isolate T1 span line faults.

1-6

SECTION 1

GENERAL INFORMATION

Complies with IEEE STD-743 and UL1459, Telephone Equipment, 1st and 2nd Editions,

as tested and listed by a National Recognized Testing Laboratory (NRTL).

1.5 ACCESSORIES

The following accessories aid in the installation, transport, and operation of the T-BERD

209A/211.

Part No. Description

10949 DC-to-AC inverter.

10958-01 19” rack mount with a 7” vertical space requirement.

10958-02 19” rack mount with a 9” vertical space requirement.

10959-01 23” rack mount with a 7” vertical space requirement.

10959-02 23” rack mount with a 9” vertical space requirement.

10966 Thermal printer paper (10 rolls).

40644-02 Soft carrying case.

41157 Repeater Extender.

PR-40A Thermal 40-column graphic printer with cable and carry-

ing case (AC or DC operation).

1-7

SECTION 1

GENERAL INFORMATION

1.6 CABLES

The following cables provide an interconnection between the T-BERD 209A/211, other

test sets, and the network.

Part No. Description

10199 15-pin D to 15-pin D (10’).

10420 310 plug to 310 plug (10’).

10558 310 plug to alligator clips (10’).

10559 310 plug to bantam plug (10’).

10598 WECO 310 plug to WECO 310 plug (4’).

10599 WECO 310 plug to bantam plug (4’).

10615 Bantam plug to bantam plug (10’).

10648 Bantam plug to alligator clips (10’).

10686 15-pin D to RJ45 (10’).

30697 WECO 310 plug to mini-test clips (6’).

1.7 ORDERING INFORMATION

Contact TTC Customer Service at (800) 638-2049 for information on ordering options or

accessories.

1-8

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

INSTRUMENT CHECKOUT AND SERVICE

2.1 UNPACKING AND INITIAL INSPECTION

The T-BERD 209A/211 shipping container should be inspected for damage when it is

received. If the shipping container or shipping material is damaged, it should be kept until the

contents of the shipment have been checked. If the contents are incomplete, notify TTC at (800)

638-2049. If the shipping container is damaged, notify the carrier as well as TTC, and keep the

shipping container and materials for the carrier’s inspection.

2.2 EQUIPMENT INCLUDED

• T-BERD 209A/211 T-Carrier Analyzer

• Power cord

• Reference Manual and User’s Guide

• Front cover or lid option

2.3 WARNINGS AND CAUTIONS

The following warnings list precautions that must be observed before and during all phases

of instrument operation. Failure to comply with these and other specific warnings contained

elsewhere in this manual may cause physical harm to the operator and/or damage to the

instrument. TTC assumes no liability due to the customer’s failure to comply with these

requirements.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis must be connected to an approved three-

contact electrical outlet or used with a three-contact adaptor with the grounding wire firmly

connected to an electrical ground at the power outlet.

2-1

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

KEEP AWAY FROM LIVE VOLTAGES

Do not remove the instrument from the chassis while the power is applied to the unit.

DO NOT OPERATE IN AN AMBIENT TEMPERATURE ABOVE 122 ° F (50 ° C)

Operating this unit in temperatures above 122° F (50° C) can cause damage to the unit.

2.4 POWER REQUIREMENTS

The T-BERD 209A/211 is configured with a 90 to 135 VAC single-phase 48 to 60 Hz

power supply. The AC Power switch, AC line fuse, and connector are located on the side of

the T-BERD 209A/211.

AC Power Connector — The AC power cord plugs into this three-prong receptacle

to provide line voltage to the instrument. The safety ground connection is wired directly

to the chassis.

AC Power Cord — This instrument is equipped with a three-conductor AC power cable.

The power cord must either be plugged into an approved three-contact electrical outlet or

used with a three-contact to two-contact adaptor with the grounding wire (green) firmly

connected to an electrical ground (safety ground) at the power outlet.

AC Line Fuse — The AC line fuse compartment is located between the AC power

connector and the AC Power switch. A 1A 250V Slo-Blo fuse (Littlefuse #218001 or

equivalent) provides overload protection for the T-BERD 209A/211 (in black holder). A

spare fuse is also located in the compartment (in white holder). Always use the correctly

rated fuse. Refer to Section 2.7 for instructions to replace a blown fuse.

AC Power Switch — The switch controls the AC power to the instrument. The switch

is labeled with a “1” for the ON position and a “0” for the OFF position. Always place the

switch in the OFF position before connecting power. When power is removed, the

front-panel configuration is retained in memory. Pressing the MODE switch when power

is applied displays the software and hardware revision levels. Pressing the RESTART

switch when power is applied defaults the instrument configuration to the factory defaults.

2-2

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

Low Battery LED (T-BERD 209A only) — When the optional lead-acid battery is

installed, the LED illuminates approximately 15 minutes before the battery is completely

drained of power. The history LED illuminates when the current LED is illuminated and

AC power is applied to the instrument.

Power Loss LED — Located on the front panel, the LED illuminates when the T-BERD

209A/211 regains power after a power loss. If a test is in progress at the time of a power

loss, the T-BERD 209A/211 is automatically restarted when power is regained. The LED

remains illuminated until either the HISTORY RESET switch is pressed or a major

switch change (e.g., MODE, PATTERN, etc.) has occurred. If a printer is connected, a

results printout is generated when power is restored.

2.5 INSTRUMENT SELF-TEST/CHECKOUT

1. Remove the front cover or lid option

Unsnap the metal latches on each side of the instrument. For the standard cover, turn

the cover upside down and pull the compartment panel out to access the AC line cord.

NOTE: Power on the T-BERD 209A/211 before connecting any of the lid options.

2. AC power cord

Insert the AC line cord into the AC receptacle on the T-BERD 209A/211 side panel

and plug the other end of the cord into a 115 VAC power source.

WARNING: Ground the instrument. To minimize shock hazard, the instru-

CAUTION: The T-BERD 209A/211 should be operated with a 1A, 250V, Slo-Blo

ment chassis must be connected to an electrical ground. The instrument is equipped with a three-conductor AC power cable. The power

cable must either be plugged into an approved three-contact electrical

outlet or used with a three-contact-to-two-contact adaptor with grounding wire (green) firmly connected to an electrical ground (safety

ground) at the power outlet.

fuse (Littlefuse #218001 or equivalent.) Always use correct fuse size.

2-3

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

3. AC Power switch

Press this switch to apply power to the T-BERD 209A/211. When the instrument is

powered up, an automatic self-test is initiated that:

• Momentarily illuminates all front-panel and switch LEDs.

• Checks the position of all switches. If a switch is stuck in an active position,

the switch is noted in the display.

• Checks the nonvolatile RAM (NOVRAM) and restores the front-panel switches

to the previous settings before the last power-down. If any changes are found,

the factory default settings are reloaded and the message RELOAD NOVRAM

is displayed.

• Checks the instrument RAM, EPROM, and microprocessor. If any error is

found, the messages BAD RAM, BAD ROM, or BAD PROCESSOR appears.

If one of these messages is displayed, contact the TTC Customer Service at

(800) 638-2049.

4. Press the MODE switch to select the AUX mode

5. Press the PATTERN switch to select AUX HALT/CONT

Set AUX HALT/CONT to HALT. Press the PATTERN switch to scroll through the

following auxiliary functions and set them as indicated:

• AUX PLS MASK — set to DSX (CB119)

• AUX ERR SEL — set to SINGLE ERROR

• AUX FRM ERROR — set to SINGLE ERROR

• AUX ER RATE — set to 1.0 E-6

6. MODE switch

Press this switch until the SELF TST operating mode appears in the MODE window.

7. Configure the T-BERD 209A/211

PATTERN

RECEIVE INPUT TERM.

TRANSMIT OUTPUT 0 dB(DSX).

8. Status and Alarm LEDs

These LEDs should illuminate: T1 Pulses, Pattern Sync, Frame Sync, and All Ones.

ALL ONES.

switches:

2-4

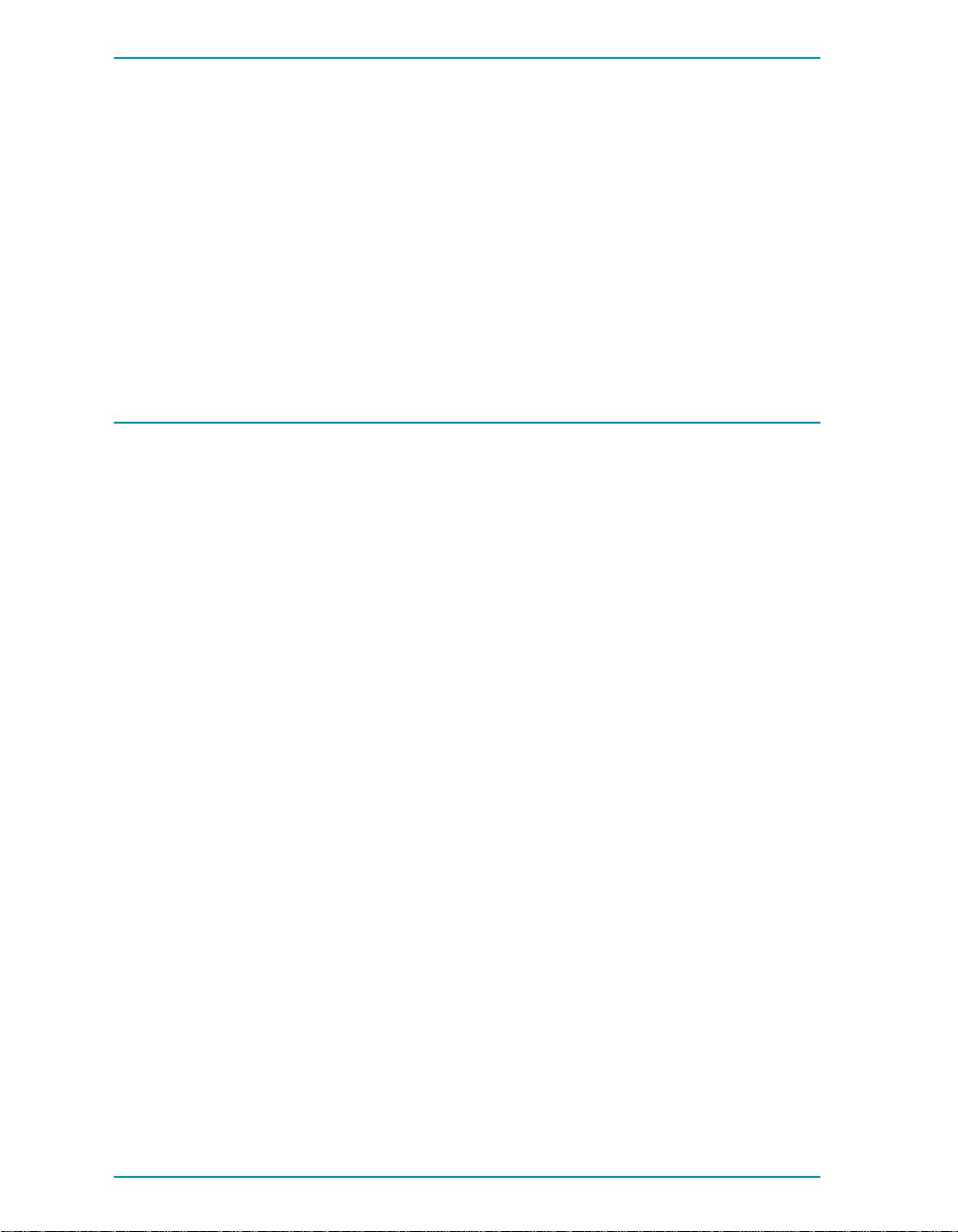

9. RESULTS I switches

Press the RESULTS I Category switch to select the SIGNAL category. Press the

RESULTS I Results switch to scroll through the results until the 41-RX LEVEL

test result appears. The value should be 0 dBdsx ±0.5 dB.

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

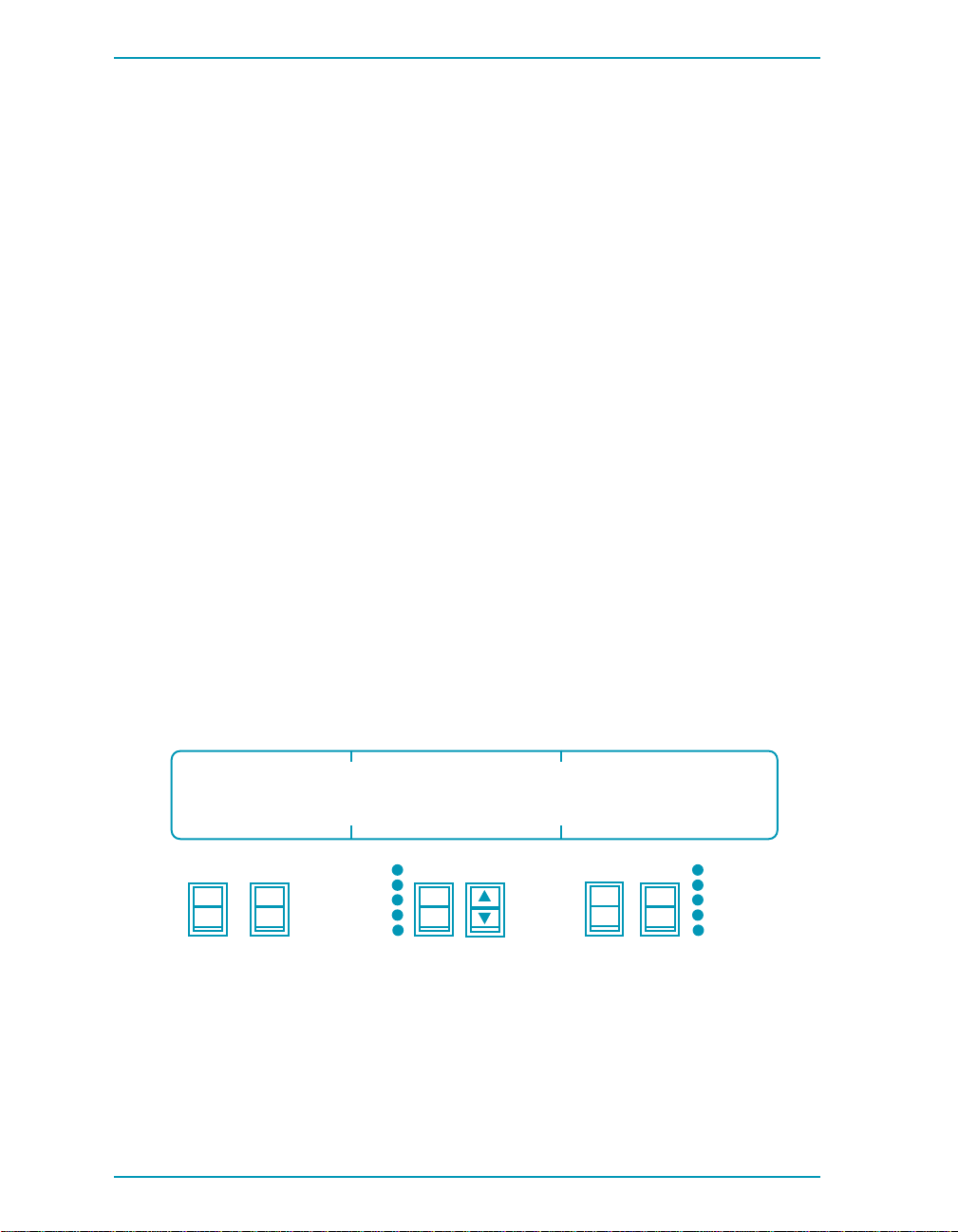

MODE

PATTERN

SELF TST 41-RX LEVEL

ALL ONES +0.0 dBdsx

MODE PATTERN RESULTS I

▲

▼

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

RESULTS II

▲

▼

10. Press the TRANSMIT OUTPUT switch to select -7.5 dB

Verify the 41-RX LEVEL result changes to -7.5 dBdsx ±1.5 dB.

11. Press the TRANSMIT OUTPUT switch to select -15 dB

Confirm that the 41-RX LEVEL result changes to -15 dBdsx ±2.0 dB.

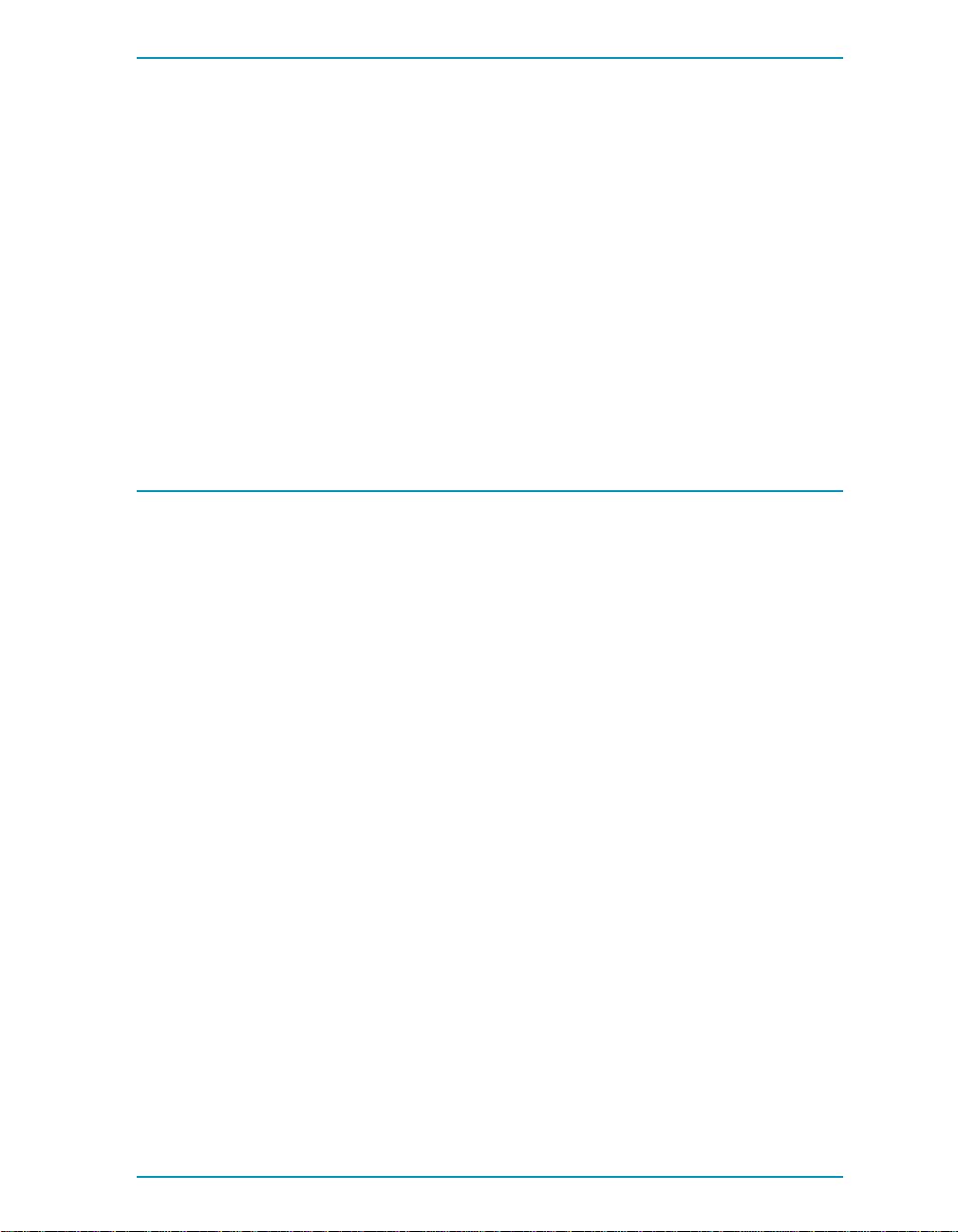

12. Press the RESULTS I Results switch to select 40-RX FREQ

Verify the value for this result is 1,544,000 Hz ±1 Hz.

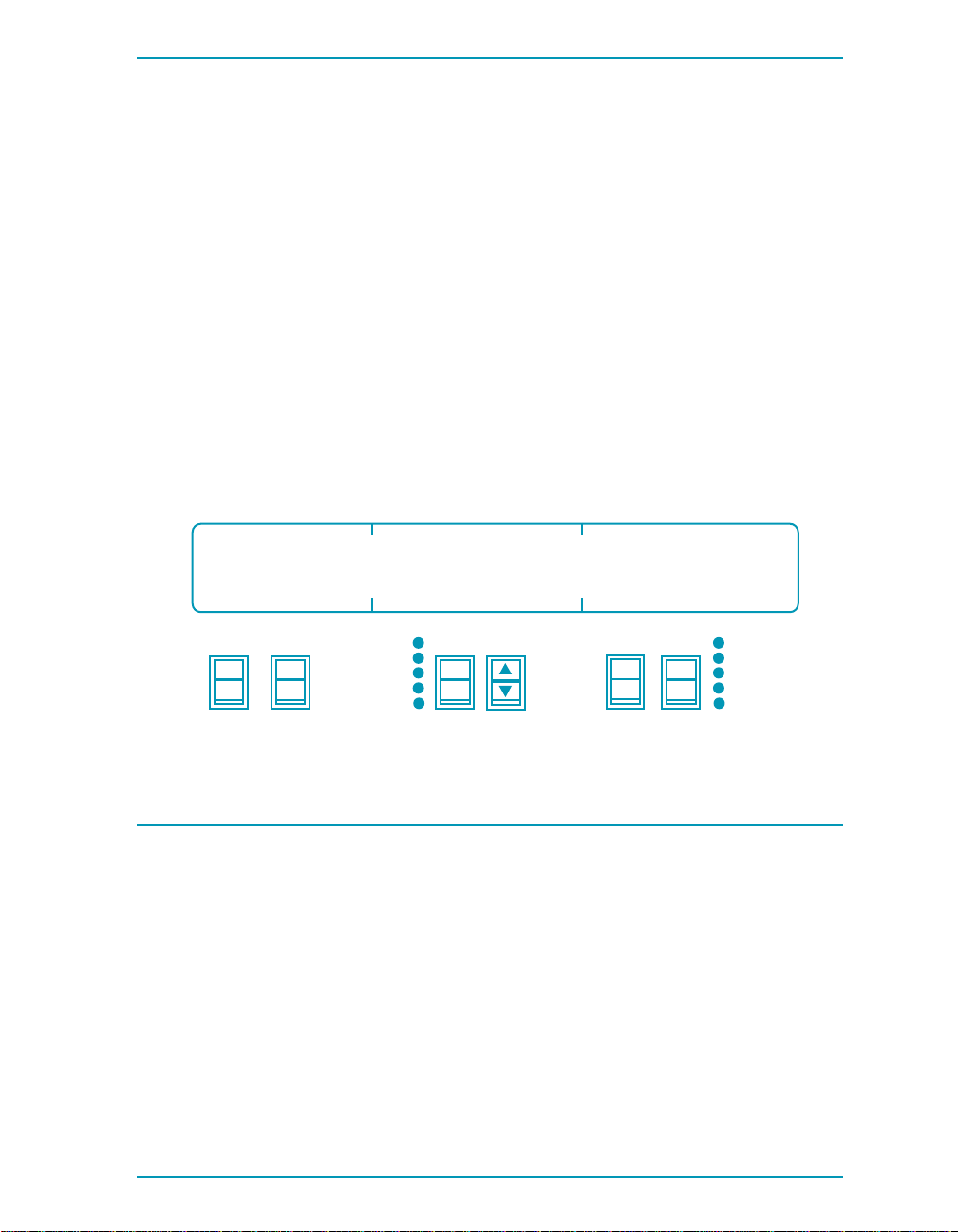

MODE

PATTERN

SELF TST 40-RX FREQ, Hz

ALL ONES 1,544,001

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

MODE PATTERN RESULTS I

▲

▼

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

RESULTS II

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

13. Press the RESTART switch

14. Press the RESULTS I Category switch to select the SUMMARY category

The message ALL RESULTS OK should appear in the RESULTS I window.

2-5

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

15. Press and release the FRAME ERROR INSERT switch several times

Verify the 30-FRM ERRORS test result appears in the display and increments by

one each time the switch is pressed.

16. Press and release the BPV ERROR INSERT switch several times

Verify the 25-VIOLATIONS test result appears in the display and increments by one

each time the switch is pressed.

17. Connect a cable between the TRANSMIT and RECEIVE jacks

Plug a bantam or WECO 310 patch cord into these connectors to loop the

TRANSMIT output to the RECEIVE input.

18. Configure the T-BERD 209A/211

MODE

TIC.

switches:

TIMING Select INT (internal timing).

19. Press and release the LOGIC ERROR INSERT switch several times

Verify the 00-BIT ERRORS test result appears in the display and increments by one

each time the switch is pressed.

20. Press the RESULTS I Category switch to select the SIGNAL category

Press the RESULTS I Results switch to scroll to the 40-RX FREQ test result.

Confirm that the received frequency is 3,152,000 Hz ±32 Hz.

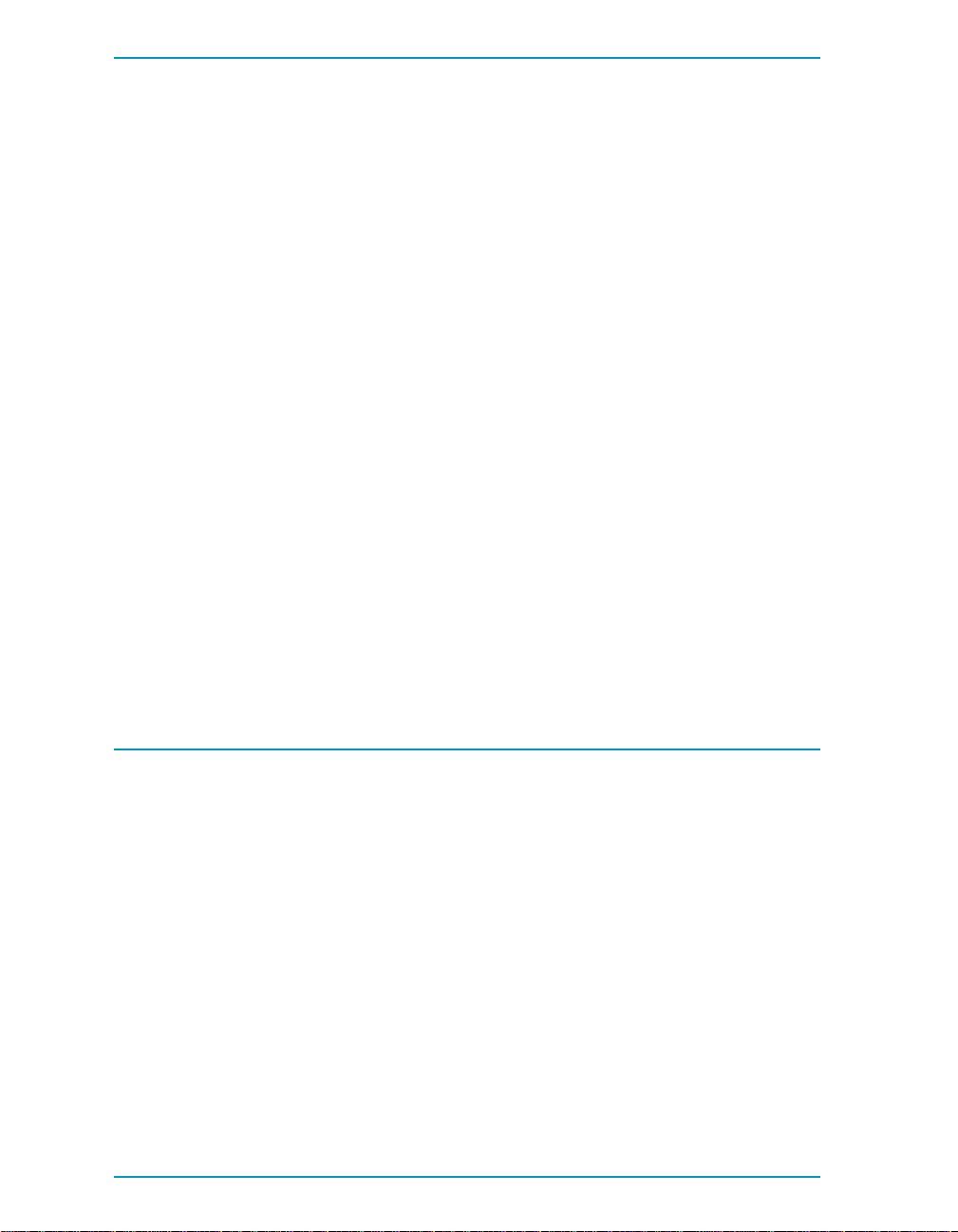

MODE

PATTERN

T1C 40-RX FREQ, Hz

ALL ONES 3,152,012

MODE PATTERN RESULTS I

▲

▼

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

RESULTS II

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

21. Press the RESTART switch

22. Press and hold the LOGIC ERROR INSERT switch

Press and hold this switch until the switch LED illuminates continuously.

2-6

INSTRUMENT CHECKOUT AND SERVICE

23. Press and hold the BPV ERROR INSERT switch

Press and hold this switch until the switch LED illuminates continuously.

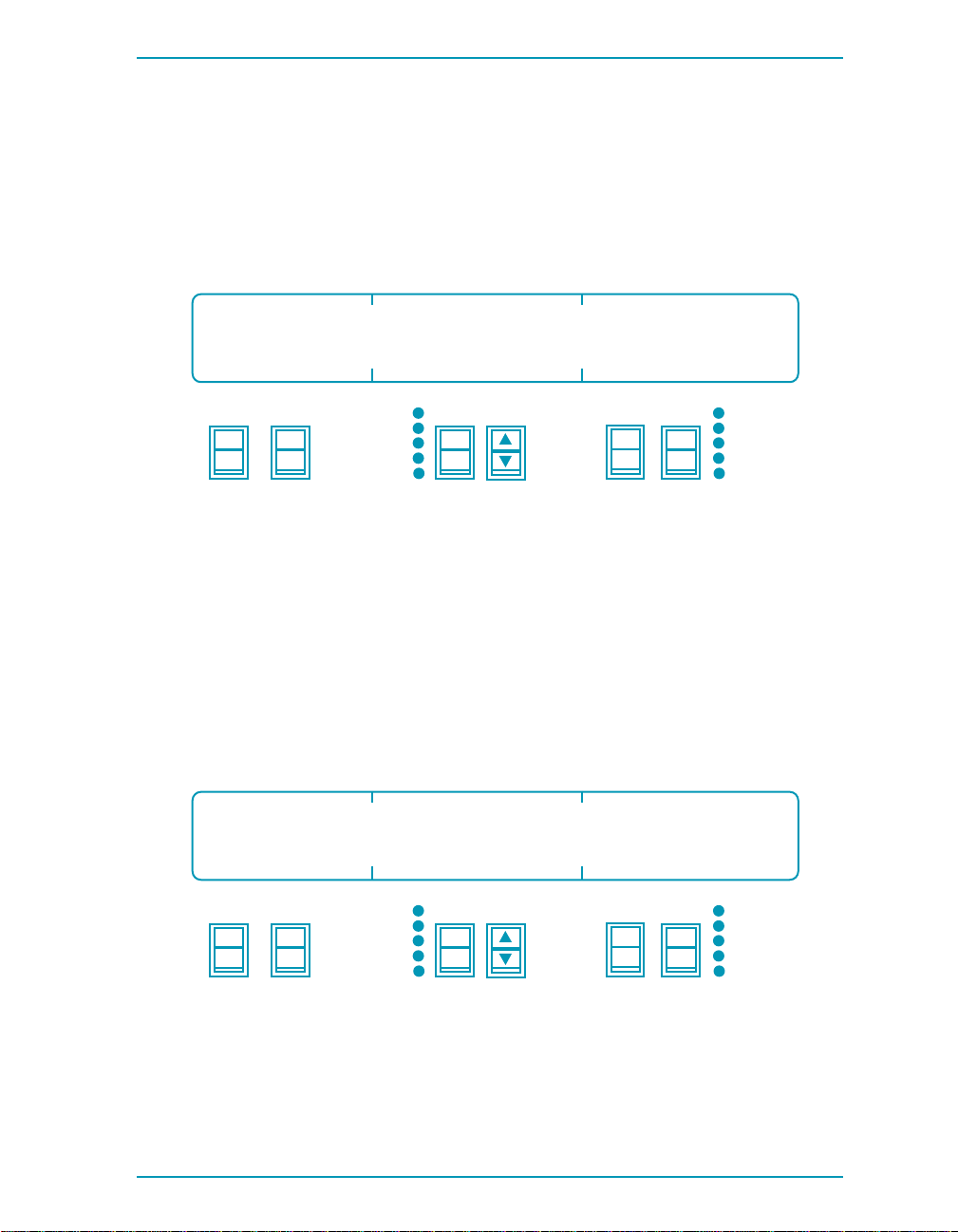

24. Display the 04-BIT ERR RT and 27-BPV RATE test results

Press the RESULTS I Category switch to select the LOGIC category. Press the

RESULTS I Results switch to scroll through the results until the 04-BIT ERR RT

test result appears.

Press the RESULTS II Category switch to select the BPV & FRAME category.

Press the RESULTS II Results switch to scroll through the results until the 27BPV RATE test result appears.

After 10 seconds, both of the displays should show values within the range 9.0 E-07

to 1.1 E-06.

SECTION 2

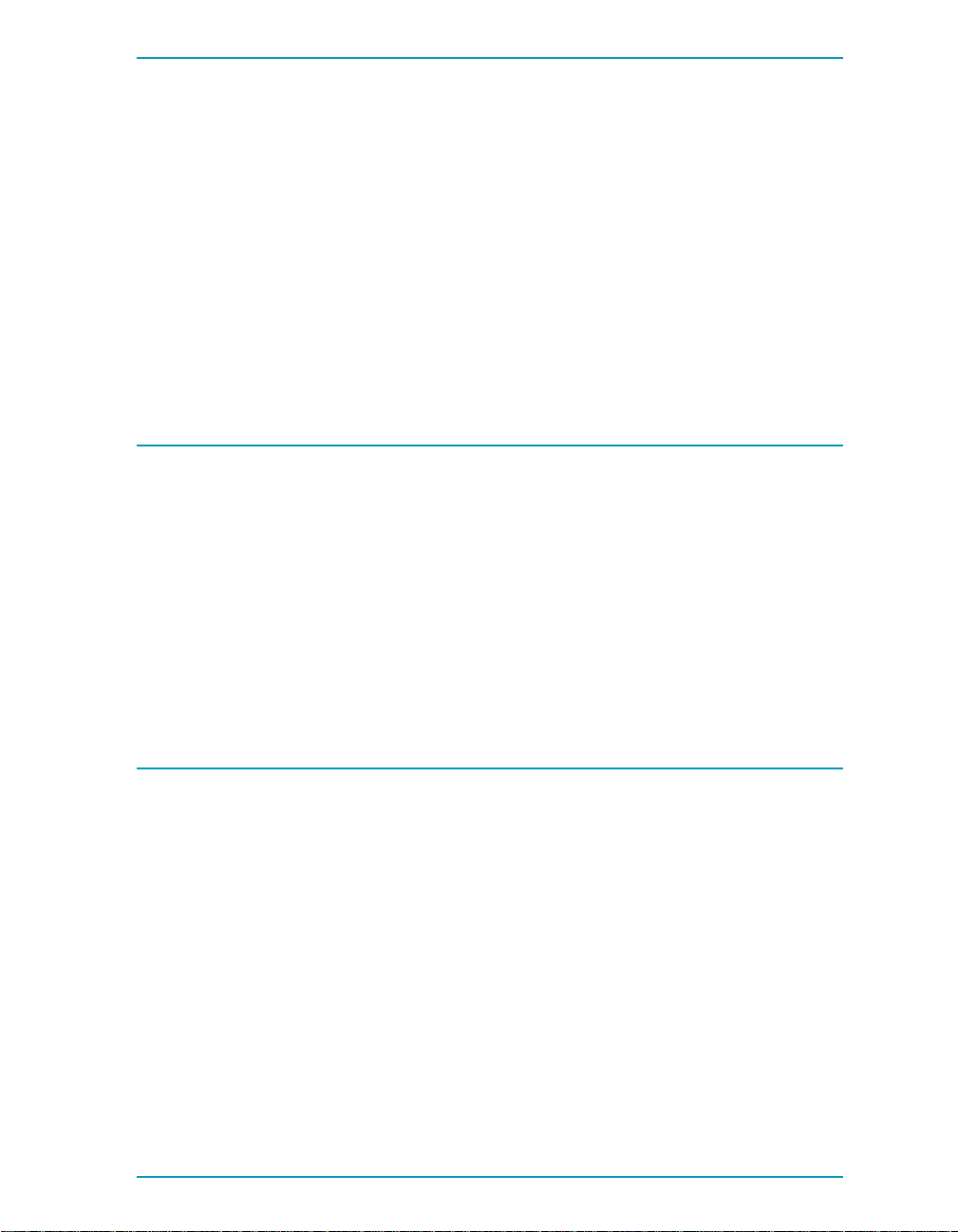

MODE

PATTERN

T1C 04-BIT ERR RT 27-BPV RATE

ALL ONES 1.0 E-06 1.0 E-06

MODE PATTERN RESULTS I

▲

▼

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

RESULTS II

▲

▼

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

2.6 IN CASE OF DIFFICULTY

If the T-BERD 209A/211 fails to operate and no front-panel indicators are illuminated:

• Check the AC power cord to ensure that it is securely connected to the T-BERD 209A/

211.

• Make sure that the power supply is uninterrupted by plugging another electrical

device into the electrical outlet used by the T-BERD 209A/211.

• Verify that a proper, working AC line fuse is installed.

• Verify that the T-BERD 209A/211 was powered on before the lid option was

connected.

2-7

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

If the T-BERD 209A/211 still fails to operate, contact TTC Customer Service at

(800) 638-2049.

In addition, contact TTC Customer Service if:

• The RELOAD NOVRAM message is displayed at each startup.

• The front-panel indicators illuminate, but the instrument does not operate properly.

Prior to calling, perform the Instrument Self-Test/Checkout procedure to localize the

problem.

To restore all switch settings to the factory defaults:

1. Power and RESTART switches

With the power off, press and hold the RESTART switch, then turn the power on.

2. RESTART switch

When the message CALIBRATING appears, release the RESTART switch. The

display and all the LEDs should illuminate, and the message RELOAD NOVRAM

should appear.

3. RESTART switch

Press the RESTART switch to take the T-BERD 209A/211 out of Self-Test mode.

2.7 AC LINE FUSE REPLACEMENT

The T-BERD 209A/211 AC line fuse is stored in the AC fuse receptacle located just

underneath the AC Power switch. If the fuse is open, it should be replaced with a 1A 250V,

Slo-Blo fuse (Littlefuse #218001 or equivalent). Always use the correctly rated fuse.

To replace the AC line fuse, perform the following:

1. AC Power switch receptacle

Locate the small tab to the plastic fuse cover just above the switch.

2. Open fuse cover

Using a small screwdriver or similar instrument, gently pry the fuse cover open. The

cover is hinged at the bottom.

2-8

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

3. Replace the fuse

Remove the opened fuse in the black holder and install a new fuse of the correct size.

There is a spare fuse in the white holder. When returning the fuse holder to the fuse

compartment, align the fuse holder arrow with the arrow on the inside of the

compartment cover.

4. Close fuse cover

Press down on the cover until it snaps shut. Watch that the cover opening does not

catch on the AC Power switch.

2.8 BATTERY CARE (T-BERD 209A ONLY)

When the lead-acid battery option is installed and the Low Battery LED illuminates, the

battery can continue to power the T-BERD 209A for another 15 minutes. The T-BERD 209A

can operate for approximately five hours on a fully charged battery. To fully recharge the

battery, connect the AC power to the T-BERD 209A for at least eight hours without turning the

instrument on. Whether the T-BERD 209A is on or not, the battery is always being charged.

The AUX PWR SAVE function can be used to prolong the battery charge by turning the

front-panel display off when the switches are not being used.

2.9 AUTO-CALIBRATION PROCEDURE

The T-BERD 209A/211 features an auto-calibration function that allows you to automati-

cally adjust receive level measurement, recovered clock extraction, T1/T1C detectors, and

simplex current measurements. Auto-calibration should be performed once a year to compensate for the normal aging of components.

You can perform auto-calibration by pressing the DISPLAY HOLD switch while turning

on the T-BERD 209A/211. Keep the DISPLAY HOLD switch pressed until the message

CALIBRATING appears in the display.

NOTE: Allow the unit to warm up at normal room temperature for approximately 30 minutes

before performing auto-calibration.

If an error occurs during auto-calibration, an error message appears in the display; contact

TTC Customer Service for assistance at (800) 638-2049.

2-9

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

2.10 WARRANTY

2.10.1 Warranty Policy

All equipment manufactured by TTC is warranted against defects in material and

workmanship. This warranty applies only to the original purchaser and is non-transferable

unless express written authorization of the warranty transfer is granted by TTC. No other

warranty is expressed or implied. TTC is not liable for consequential damages.

Liability under this warranty extends only to the replacement value of the equipment. The

warranty is void under the following conditions:

• Equipment has been altered or repaired without specific authorization from TTC.

• Equipment is installed or operated other than in accordance with instructions con-

tained in TTC literature and operating manuals.

2.10.2 In-Warranty Service

Equipment that requires in-warranty service must be returned to the factory with shipping

prepaid. The equipment should be packed and shipped in accordance with instructions in

Section 2.11. Before returning any equipment, the customer must obtain a Return Authorization (RA) number by contacting the TTC Repair Department at (800) 638-2049. The RA

number should then appear on all paperwork and be clearly marked on the outside of the

shipping container.

After the equipment is repaired by TTC, it will be tested to applicable specifications,

burned-in for at least 24 hours, retested, and returned to the customer with shipping prepaid.

A brief description of the work performed and the materials used will be provided on the

Equipment Repair Report furnished with the returned equipment.

2.10.3 Out-of-Warranty Service

The procedure for returning and repairing out-of-warranty equipment is the same as for

equipment still in warranty. However, there is a minimum charge applied to each request for

out-of-warranty service. The minimum charge guarantees the customer an estimate of the

repair costs and is used as credit against actual materials and labor costs should the equipment

be repaired. Contact the TTC Repair Department at (800) 638-2049 for specific information

on the minimum out-of-warranty repair charge.

2-10

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

The customer will be billed for parts plus standard labor rates in effect at the time of the

repair. The customer will also be required to furnish a purchase order number before repair

work can be started, and a hard copy of the purchase order must be received by TTC before the

repaired equipment is shipped to the customer. A description of the labor and materials used

will be provided in the Equipment Repair Report.

Once an out-of-warranty repair is made, the repaired part or component is warranted for

90 days. This warranty applies only to the part or component that was repaired; other parts or

components are not covered under the 90-day repair warranty.

2.11 EQUIPMENT RETURN INSTRUCTIONS

To all equipment returned for repair, attach a tag that includes the following information:

• Owner’s name and address.

• A list of the equipment being returned and the applicable serial number(s).

• A detailed description of the problem or service requested.

• The name and telephone number of the person to contact regarding questions about

the repair.

• The Return Authorization (RA) number.

NOTE: Leave all switches in the positions they were in when the problem occurred.

If possible, return the equipment using the original shipping container and material. If the

original container is not available, the unit should be carefully packed so that it will not be

damaged in transit; when needed, appropriate packing materials can be obtained by contacting

the TTC Repair Department. TTC is not liable for any damage that may occur during shipping.

The customer should clearly mark the TTC-issued RA number on the outside of the package

and ship it prepaid and insured to TTC.

2-11

SECTION 2

INSTRUMENT CHECKOUT AND SERVICE

2-12

SECTION 3

INSTRUMENT DESCRIPTION

INSTRUMENT DESCRIPTION

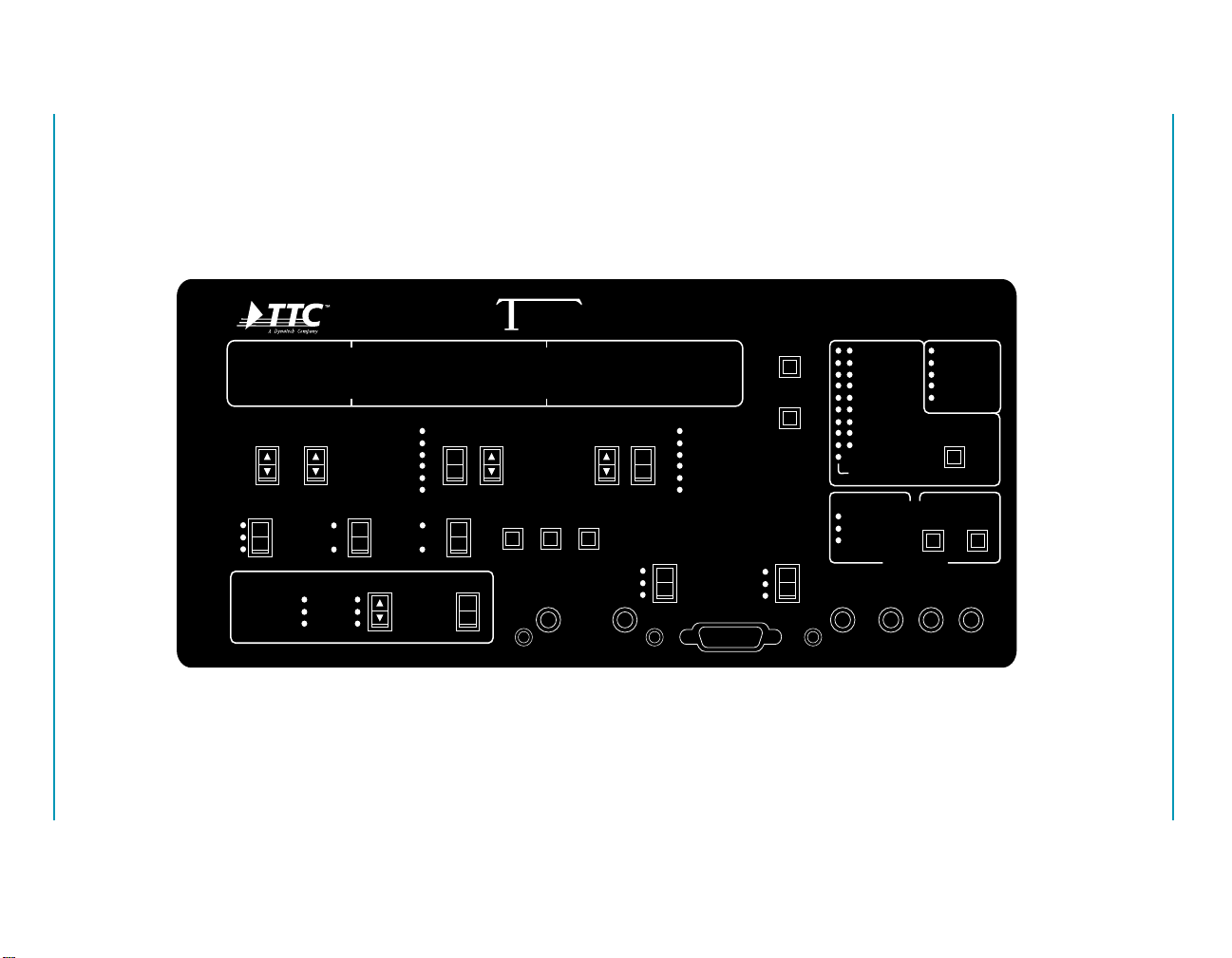

3.1 INTRODUCTION

This section can be used as a reference during testing and as a guide to understanding the

functions of the T-BERD 209A (see Figure 3-1) and T-BERD 211 (see Figure 3-2).

NOTE: Unless indicated, the capabilities of the mainframe T-BERD 209A/211 are applicable

to the options.

The switches, indicators, and connectors are presented in the following functional areas:

• Test Setup

• Circuit Connections

• Signal Verification

• Starting Test/Collecting Results

• Troubleshooting Controls

• Printer Controls

NOTE: Throughout this section, a circled number appears after each control name. These

numbers match the callouts in the figures. Use these numbers to locate switches,

indicators, and connectors on the front panel.

3.2 MAINFRAME — TEST SETUP

The following controls and indicators (see Figure 3-3) are described in the order that you

would normally use them to set up the T-BERD209A/211 to test a circuit from a DS1 access

point.

Help Card

The pull-out help card furnishes a quick reference to the following information:

• Available mode and pattern selections

• Auxiliary functions

• Available results, grouped by category and sorted by result number

• TDR Option setup parameters

3-1

3-2

209A

MODE

PATTERN

RECOVD

(LOOP)

SELF TST

25 - VIOLATIONS

T1-QRSS

2 HR

15 MIN

OFF

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

WANDER

AMI

B8ZS

MODE PATTERN

TIMING TEST CODE

EXT

INT

TIMED

CONT

PRINT EVENT PRINT

TEST END

ERROR

SEV ERR SEC

RESULTS

CONTROLS

RESULTS I

-BERD

T-CARRIER ANALYZER

ERROR INSERT

FRAME

T1 REF

(100Ω)

00-BIT ERRORS

RESULTS II

LOGIC

BPV

RECEIVE INPUT

BRIDGE

TERM

DSX-MON

RECEIVE TRANSMIT

0

SUMMARY

LOGIC

BPV & FRAME

SIGNAL

TIME

WANDER

TRANSMIT OUTPUT

0dB(DSX)

–7.5dB

–15dB

RESTART

DISPLAY

HOLD

SIGNAL LOSS

PATTERN LOSS

FRAME LOSS

ONES DENSITY

EXCESS ZEROS

YELLOW ALARM

ALL ONES

PULSE SHAPE

LOW BATTERY

POWER LOSS

HISTORY

RECEIVE

PRE-EXIST LOOP

LOOP UP

LOOP DOWN

LOOP CODES

T1 PULSES

T1C PULSES

PATTERN SYNC

FRAME SYNC

B8ZS

HISTORY

RESET

LOOP

UP

DSX OUTPUTS

SEND

LOOP

DOWN

SECTION 3

INSTRUMENT DESCRIPTION

Figure 3-1

T-BERD 209A Front Panel

Loading...

Loading...