Page 1

Service Manual

WFM 90 and WFM 91

Handheld Waveform, Vector, Picture,

and Audio Monitor

070-8969-04

This document supports firmware version 1.00

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H A void delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 6

Page 7

Table of Contents

Specifications

Operating Information

Theory of Operation

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Strategy xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Offerings xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Summary Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedures 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Summary Adjustment 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Preparation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

After Repair Adjustments 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery-Fault Analysis 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-Voltage Power Supply 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 90 and WFM 91 Service Manual

i

Page 8

Table of Contents

Options

Replaceable Parts List

Diagrams

Fault Symptom T able 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Flowcharts 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Diagram 6–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

WFM 90 and WFM 91 Service Manual

Page 9

List of Figures

Table of Contents

Figure 2–1: Installing the viewing hood 2–2. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Installing the desk stand 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

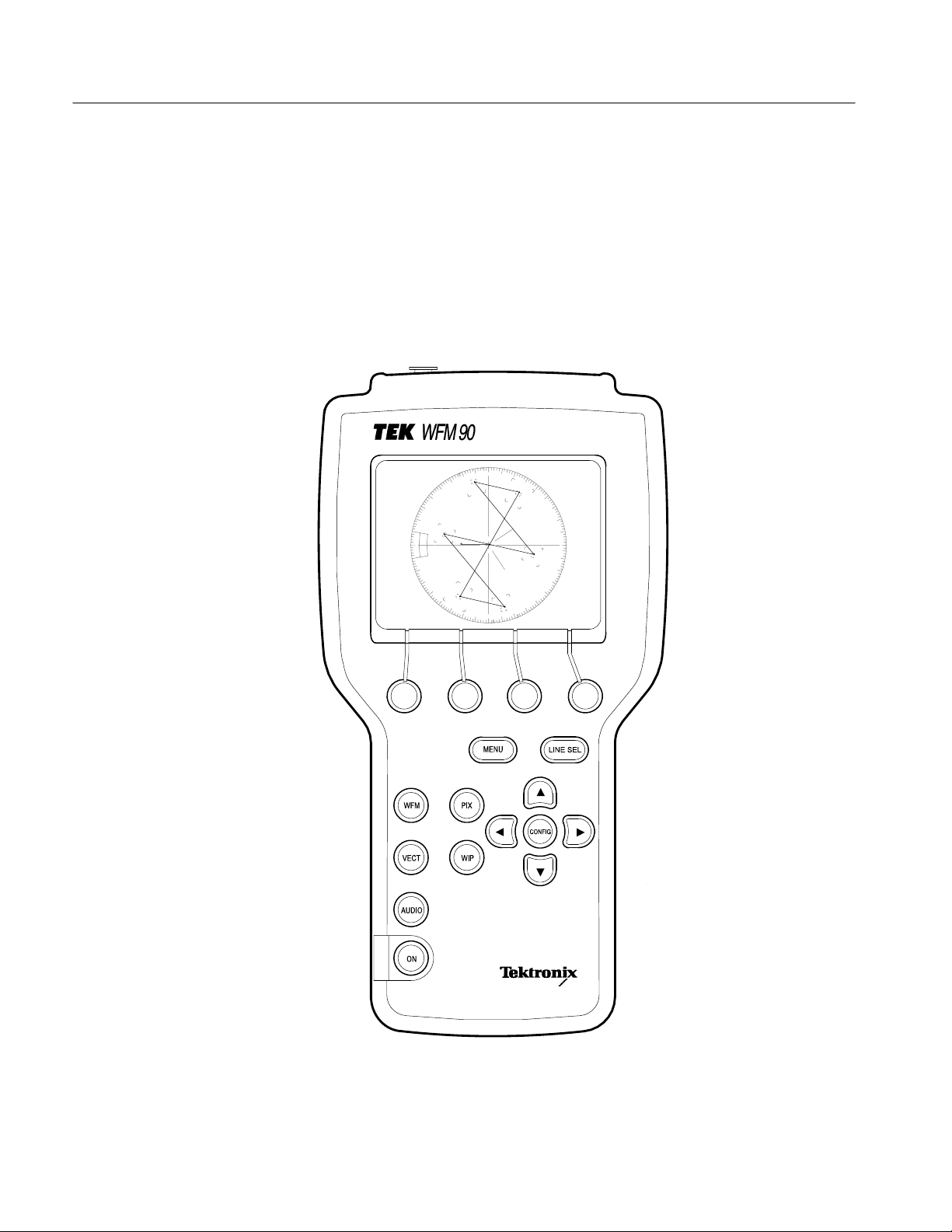

Figure 2–3: Instrument front panel 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

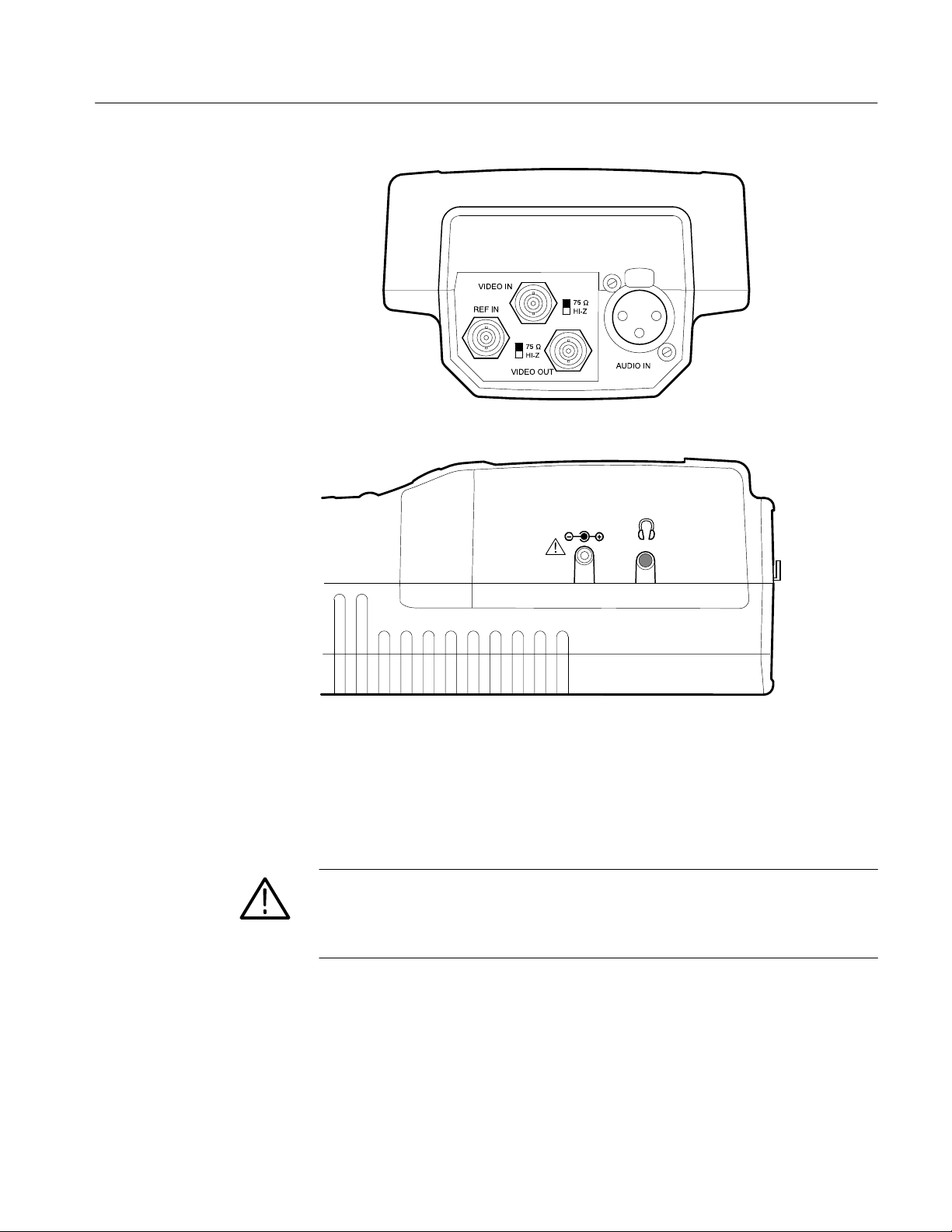

Figure 2–4: Instrument side panels 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: On-screen readout messages 2–9. . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Simplified block diagram 3–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: –3 dB marks on the vector graticule 4–12. . . . . . . . . . . . . . . . .

Figure 5–1: NTSC graticule showing the vector gain adjustment 5–9. . .

Figure 6–1: Removing the top cover 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Installing the LCD display cable 6–9. . . . . . . . . . . . . . . . . . . .

Figure 6–3: Installing the LCD display 6–11. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Installing the keypad 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Installing the Top board shield 6–15. . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Installing the Bottom board 6–17. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–7: Installing the battery cover 6–19. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Removal and replacement of the turnlock stud 6–20. . . . . . . .

Figure 6–9: Removing the NiCad battery pack 6–22. . . . . . . . . . . . . . . . . .

Figure 6–10: Installed polarity of alkaline batteries 6–23. . . . . . . . . . . . . .

Figure 6–11: Battery contact installation alignment 6–25. . . . . . . . . . . . . .

Figure 6–12: Battery power-wire and turnlock stud receptacle

installation 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–13: Battery orientation marker position 6–28. . . . . . . . . . . . . . . .

Figure 6–14: Installing the EMI suppressor 6–29. . . . . . . . . . . . . . . . . . . . .

Figure 6–15: Testing the battery charging circuit – WFM 90 SN B011362

and below; WFM 91 SN B010470 and below 6–32. . . . . . . . . . . . . . . . .

Figure 6–16: Testing the battery charging circuit – WFM 90 SN B011363

and above; WFM 91 SN B010471 and above 6–33. . . . . . . . . . . . . . . . .

Figure 6–17: Flowchart for no display 6–37. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–18: Flowchart for distorted waveform display 6–38. . . . . . . . . . .

Figure 6–19: Flowchart for no vector display 6–39. . . . . . . . . . . . . . . . . . . .

Figure 6–20: Flowchart for bad audio display 6–40. . . . . . . . . . . . . . . . . . .

Figure 6–21: Flowchart for no picture display 6–41. . . . . . . . . . . . . . . . . . .

Figure 6–22: Flowchart for bad graticules and menus 6–42. . . . . . . . . . . .

WFM 90 and WFM 91 Service Manual

iii

Page 10

Table of Contents

Figure 6–23: Flowchart for all white display 6–43. . . . . . . . . . . . . . . . . . . .

Figure 6–24: Flowchart for untriggered waveform display 6–44. . . . . . . .

Figure 6–25: Flowchart for unlocked vector display 6–45. . . . . . . . . . . . . .

Figure 6–26: Flowchart for vector display jitter 6–46. . . . . . . . . . . . . . . . .

Figure 6–27: Flowchart for distorted vectors 6–46. . . . . . . . . . . . . . . . . . . .

Figure 6–28: Flowchart for problems with the instrument controls 6–47.

Figure 6–29: Flowchart for bad menus in the picture display 6–48. . . . . .

Figure 6–30: Flowchart for dim or blotchy display 6–49. . . . . . . . . . . . . . .

Figure 6–31: Flowchart for bad displays except Picture mode 6–49. . . . . .

Figure 6–32: Circuit board connector and pin locations 6–50. . . . . . . . . . .

Figure 8–1: Exploded view 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–1: Interconnect diagram 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

WFM 90 and WFM 91 Service Manual

Page 11

List of Tables

Table of Contents

Table 1–1: Vertical deflection system 1–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: DC restoration 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Audio mode 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Horizontal deflection system 1–8. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Vector mode 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Synchronization 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Physical characteristics 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Environmental characteristics 1–10. . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Power source 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Safety/EMI 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Front panel and menu default settings 2–10. . . . . . . . . . . . . . .

Table 4–1: Summary verification procedure 4–1. . . . . . . . . . . . . . . . . . . .

Table 4–2: Equipment required for performance verification 4–2. . . . . .

Table 5–1: Summary adjustment 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Equipment required for performance verification 5–2. . . . . .

Table 6–1: Tools required for module removal 6–5. . . . . . . . . . . . . . . . . .

Table 6–2: Removal and replacement procedure list 6–6. . . . . . . . . . . . .

Table 6–3: Equipment required for troubleshooting 6–31. . . . . . . . . . . . .

Table 6–4: Low-voltage power supplies 6–35. . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Fault symptom table 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8–1: Replaceable parts list column descriptions 8–2. . . . . . . . . . . .

WFM 90 and WFM 91 Service Manual

v

Page 12

Table of Contents

vi

WFM 90 and WFM 91 Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

To avoid potential hazards, use this product only as specified.

To Avoid Fire or Shock Hazards:

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Use Proper AC Adapter. Use only the specified ac adapter provided with this

product to connect it to the mains supply.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Observe All Ratings. Observe and follow all ratings and markings on the product.

Consult the product manual(s) for further ratings information before making any

connections to the product.

This product is intended to be connected to electrical devices with their common

at ground potential. Do not connect to elevated or floating common voltages.

WFM 90 & WFM 91 Service Manual

vii

Page 14

General Safety Summary

Observe These Battery

Precautions

Battery Recycling

For information on replacing and recharging batteries specific to this product,

refer to the detailed instructions provided in this manual.

Replace Batteries Properly . Before replacing batteries, turn the instrument off

and disconnect the AC adapter.

Use only the size and type of batteries specified for this product. Be sure to

install the batteries in the proper polarity. Use care not to short battery terminals

together when replacing batteries.

When replacing alkaline batteries, all batteries should be replaced at the same

time.

Recharge Batteries Properly. Do not attempt to recharge alkaline batteries.

NiCad batteries are automatically recharged in this instrument.

Replace the NiCad battery pack if the batteries do not recharge within the

recommended time, or if the operating time from a full charge seems significantly shortened.

This product contains a Nickel Cadmium (NiCd) battery, which must be recycled

or disposed of properly. For the location of a local battery recycler in the U.S. or

Canada, please contact:

RBRC (800) BATTERY

Rechargeable Battery Recycling Corp. (800) 227-7379

P.O. Box 141870 www.rbrc.com

Gainesville, Florida 32614

viii

WFM 90 & WFM 91 Service Manual

Page 15

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

WFM 90 & WFM 91 Service Manual

ix

Page 16

General Safety Summary

x

WFM 90 & WFM 91 Service Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the power by means of

the ac adapter or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

WFM 90 & WFM 91 Service Manual

xi

Page 18

Service Safety Summary

xii

WFM 90 & WFM 91 Service Manual

Page 19

Preface

About This Manual

This manual provides instructions for servicing the WFM 90 and WFM 91

Handheld Waveform, Vector, Picture, and Audio Monitors. This manual

describes features and specifications that are common to all generator modules.

These include system configuration and the common control interface.

This manual is composed of the following sections:

H Specifications lists the electrical and environmental specifications and

provides a general product description.

H Operating Information describes installation and front panel operation of the

instrument.

H Theory of Operation contains a module-level description based on block

diagrams of the instrument circuitry.

H Performance Verification provides procedures for verifying instrument

performance.

Related Manuals

H Adjustment Procedures provides procedures for adjusting the instrument to

meet performance levels listed in Specifications.

H Maintenance contains instructions for cleaning the instrument, procedures

for removal and replacement of instrument modules, and troubleshooting

procedures.

H Options lists all of the options that you might find on your instrument.

H Replaceable Electrical Parts points you to Replaceable Mechanical Parts

for the list of replaceable electrical parts and assemblies.

H Diagrams contains the instrument interconnect diagram.

H Replaceable Mechanical Parts lists the part numbers of the replaceable

electrical and mechanical parts and assemblies.

The WFM 90 and WFM 91 Handheld Waveform, Vector, Picture, and Audio

Monitor User Manual (Tektronix part number 070-8968-XX) describes in detail

how to operate the instrument.

WFM 90 and WFM 91 Service Manual

xiii

Page 20

Preface

xiv

WFM 90 and WFM 91 Service Manual

Page 21

Introduction

Service Strategy

NOTE. Throughout this manual, any field-replaceable component, assembly, or

part of this oscilloscope is referred to generically as a module.

This manual contains all the information needed for periodic maintenance of the

WFM90 or WFM91 Handheld Waveform, Vector, Picture, and Audio Monitor.

(Examples of such information are procedures for checking performance and for

readjustment.) Further, it contains all information for corrective maintenance

down to the module level. The procedures, diagrams, and other troubleshooting

aids help isolate failures to a specific module, rather than to components of that

module. Once a failure is isolated, replace the module with a unit obtained from

Tektronix, Inc.

All modules are listed in Mechanical Parts List. To isolate a failure to a module,

use the troubleshooting procedures located in Maintenance. To remove and

replace any failed module, follow the removal and replacement instructions

located in Maintenance.

Service Offerings

Warranty Repair Service

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians, trained on Tektronix products, are best

equipped to service your instrument. Tektronix technicians are apprised of the

latest information on improvements to the product as well as the latest new

options to the product.

Tektronix warrants this product for one year from date of purchase. (The

warranty appears after the title page and copyright page in this manual.)

Tektronix technicians provide warranty service at most Tektronix service

locations worldwide. Your Tektronix product catalog lists all service locations

worldwide.

WFM 90 and WFM 91 Service Manual

xv

Page 22

Introduction

Repair or Calibration

Service

The following services may be purchased to tailor repair and/or calibration of

your WFM90 or WFM91 Handheld Waveform, Vector, Picture, and Audio

Monitor to fit your requirements:

Option M2. When you order option M2, you receive a five year warranty and

remedial service agreement.

Option M8. When you order option M8, you receive four free calibration and

performance tests.

At-Depot Service. Tektronix offers several standard-priced adjustment (calibration) and repair services:

H A single repair and/or adjustment.

H Calibrations using equipment and procedures that meet the traceability

standards specific to the local area.

H Annual maintenance agreements that provide for either calibration and repair

or calibration only of the instrument.

Of these services, the annual maintenance agreement offers a particularly

cost-effective approach to service for many owners of the WFM90 or WFM91

Handheld Waveform, Vector, Picture, and Audio Monitor. Such agreements can

be purchased to span several years.

Self Service

On-Site Service. The annual maintenance agreement can be purchased with

on-site service, with repair and calibration done at your facility. This service

reduces the time your instrument is out of service when calibration or repair is

required.

Service Training. Tektronix provides service training in a number of programs. In

addition to classes held at our Beaverton campus, special classes at convenient

locations can be arranged.

Tektronix supports repair to the module level by providing Module Exchange

and Module Repair and Return.

Module Exchange. This service reduces down time for repair by allowing you to

exchange most modules for remanufactured ones. Tektronix ships you an

updated and tested exchange module from the Beaverton, Oregon service center,

typically within 24 hours. Each module has a 90-day service warranty.

xvi

WFM 90 and WFM 91 Service Manual

Page 23

Before You Begin

Introduction

Module Repair and Return. This service returns to you within 10 days the same

module that you shipped to Tektronix. The module shipped is repaired, tested,

and returned to you from the Beaverton, Oregon service center. It is not updated

to match current modules of the same type. Again, each module has a 90-day

service warranty.

1-800-TEK-WIDE. For more information about any of the Tektronix service

offerings, US and Canadian customers can call our 24-hour service number at

1-800-TEK-WIDE. Service training questions may require specialists who are

only available between 8 am – 5 pm, Pacific time.

This manual is for servicing the WFM90 or WFM91 Handheld Waveform,

Vector, Picture, and Audio Monitor. To prevent injury to yourself or damage to

the instrument, do the following tasks before you attempt service:

H Be sure you are a qualified service person.

H Read the Safety Summary found at the beginning of this manual.

H Read Service Strategy in this section.

When using this manual for servicing, be sure to heed all warnings, cautions, and

notes.

WFM 90 and WFM 91 Service Manual

xvii

Page 24

Introduction

xviii

WFM 90 and WFM 91 Service Manual

Page 25

Specifications

Page 26

Page 27

Specifications

Product Description

This section includes the following information:

H Product description

H Characteristics tables

Refer to Performance Requirements on page 1–5 for the conditions over which

the characteristics listed in this section are valid.

The Tektronix WFM 90 or WFM 91 Handheld Waveform, Vector, Picture, and

Audio Monitor is a self-contained, rasterizing television monitor. The instrument

has a built-in LCD color display device and is powered by batteries or by an AC

adapter producing 12 VDC.

This product can be used in traditional in-house applications of television

production, post-production, and signal transmission. The portability of this

instrument allows it to be used in untraditional applications, such as field

production and system maintenance.

Key Features

The following is a list of the key features of this instrument:

H Rasterized waveforms and graticules shown on the built-in color, four-inch

diagonal, TFT LCD display with viewing angle adjustment

H Powered by batteries or an AC adapter

H Menu-assisted monitoring operation

H Video and audio signal input and output capability

H Waveform, Vector, Picture, Audio, and Waveform-in-Picture (WIP) display

modes

H Line Select mode for the selection of any single line of video for display

H Time-out mode to shut off power to the display backlight and/or the

instrument when the instrument is not in use

H Signal level alarm mode for the waveform and audio displays

H Preset menu to store or recall the front panel and menu setup

H Instrument readjustment is performed entirely from the front panel

WFM 90 and WFM 91 Service Manual

1–1

Page 28

Specifications

Description of Key

Features

The key features of this instrument are described below:

Rasterized Color LCD Display. This instrument uses a color, four-inch diagonal,

backlit, thin-film transistor (TFT) LCD raster display module. The proprietary

rasterizer displays analog waveforms or vectors simultaneously with the

appropriate measurement graticules. A viewing-angle control for the display

permits optimal signal viewing from different positions.

The LCD display retains an image if the instrument is left on in one display

mode for an extended period of time. This is typical for the LCD display device.

The retained image fades over time. The fading can be accelerated by leaving the

instrument turned off.

CAUTION. To prevent image retention in the LCD display, enable the backlight

time-out mode or turn the instrument off if the monitor will not be used for more

than two hours.

Battery or AC Adapter Operation. The instrument can be powered by six C-cell

batteries, alkaline or NiCad, or by an AC adapter wall unit with a negative center

lead producing 12 VDC. The rechargeable NiCad batteries are automatically

recharged when the 12 VDC adapter is plugged into the instrument (whether

instrument power is on or off). Alkaline batteries do not recharge. The message

Low Bat is displayed in the on-screen readout when the batteries get critically

low on power.

1–2

Menu-Assisted Monitoring Operation. The menus use a combination of on-screen

readout and multi-use buttons, in conjunction with the Arrow Buttons, to control

most of its monitoring functions. Enter the menus by pressing one of the Menu,

Config, or Line Sel buttons. Menus are exited by pressing the entry button for

the displayed menu, or by entering another menu.

Video and Audio Input/Output. The instrument displays signals from the one

channel of composite video input or from the one channel of audio input. An

external reference input allows the use of an external sync signal.

The video and external reference inputs each have a rear-panel switch providing

the choice of an internal 75 W signal termination or an unterminated high-impedance input. The audio input connector is a standard 3-pin XLR connector.

WFM 90 and WFM 91 Service Manual

Page 29

Specifications

The video output will drive a remote monitor or video switcher. The audio signal

is output through a mini-headphone stereo jack that outputs the mono input

signal to both stereo channels. The audio volume is fixed for each reference

level. The larger the displayed signal, the louder the volume.

Waveform Display Mode. The Waveform display mode provides a voltage-versustime display of the video signal with three standard sweep rates: 1H (5 ms/divi-

sion), 2H (10 ms/division), and 2F (two field). Each line-rate sweep can be

magnified X10 to the following sweep rates: 1H Mag (0.5 ms/division), and 2H

Mag (1 ms/division). The 2F sweep is magnified by approximately X20.

Vertical gain is fixed at X1 or X5, or is variable from 45% to 155% amplitude.

The gain setting tracks between the Waveform and Vector display modes. The

signal filters are Flat (no filter) and Luminance (low-pass filter). The Line Select

mode enables the selection of a single line of video for display.

Vector Display Mode. The Vector display mode presents an XY plot of the

demodulated chrominance phase and amplitude portion of the video signal. The

vector angle represents chrominance phase, and the distance from the center

represents chrominance amplitude. The vector display is useful when making

differential gain and phase measurements.

A full 360_ phase shifter and 75% and 100% color bar settings are provided.

Vector gain is fixed at X1 or X5, or is variable from 45% to 155% amplitude.

The gain setting tracks between the Waveform and Vector display modes. The

+V mode (PAL only) overlays the –V axis on the +V axis to check the PAL

system color encoders.

Picture Display Mode. The Picture display mode provides an unprocessed full

color display of the composite video signal. The NTSC Safe Action and Safe

Title areas, as well as the PAL Safe Area, can be highlighted. The vertical

interval portion of the signal can be viewed by vertically shifting the display.

Controls for adjusting the hue and color of the picture display are provided.

Audio Display Mode. The Audio display mode provides a voltage-versus-time

display of a single audio channel. The audio voltage is displayed on the vertical

scale with time on the horizontal scale at a two-field sweep rate.

Audio reference levels can be set to –10 dBu, 0 dBu, 4 dBu, or 8 dBu, with an

additional level available for microphone checks. The audio headroom reference

level can be set to –3 dB or +10 dB and is for audio signals below or above the

reference level, respectively.

WFM 90 and WFM 91 Service Manual

1–3

Page 30

Specifications

Waveform-in-Picture Display Mode. The Waveform-in-Picture (WIP) display

mode provides a 1/4-screen-sized window over the Picture display for any one of

the Waveform, Vector, or Audio displays. The WIP window can be positioned to

any one of the four corners of the display. The Arrow Buttons retain their default

function for the display mode in the WIP window.

Line Select Mode. The Line Select mode enables you to select any line of video

for viewing in either the Waveform or Vector display modes. The desired line

can be selected from either all video fields or from alternating fields. With

two-field sweep selected in the Waveform display mode, the selected line is

highlighted in the field display.

Time-out Mode. When the Time-out mode is enabled, power is turned off to the

display backlight and/or the instrument when the front panel has not been in use

for a menu-selected length of time.

Amplitude Alarm Mode. The Amplitude Alarm mode provides automatic signal

level checking in the Waveform and Audio display modes. In the Waveform

display mode, the portion of the waveform exceeding the 100 IRE (1.0 V PAL)

graticule line is highlighted. In the Audio display mode, the portion of the

waveform exceeding the selected reference level is highlighted.

More Information

Preset Menu. The Preset menu allows you to store the current instrument front

panel and menu settings for future use. In addition, there is a menu selection that

sets the front-panel and menu settings back to the factory-set defaults. Refer to

Default Settings on page 2–10 for a list of the default settings.

Instrument Readjustment. This instrument can be adjusted entirely from the front

panel after entering the Calibration menu. Instructions for adjusting the

instrument are located in the Adjustment Procedures section of this manual.

The location of some additional information is listed below:

H Refer to Battery Operation on page 2–3 for information on operating the

instrument with batteries

H Front panel operation is described in the Operating Information section

H Instrument options are listed in the Options section

H Standard and optional accessories are listed in the Replaceable Mechanical

Parts section

1–4

WFM 90 and WFM 91 Service Manual

Page 31

Characteristics Tables

Specifications

The characteristics tables use the following abbreviations:

Performance Requirement. All performance requirements in the characteristics

tables are identified with Req

in the Performance Verification section. Allow a warm-up time of 20 minutes

before performing the procedures.

Performance requirements in the electrical specifications are valid over an

ambient temperature range of +20° C to +30° C. The Performance Requirement

tolerances listed in the electrical specifications are doubled over the temperature

range of 0° C to +40° C, unless otherwise specified. Test equipment used to

verify performance requirements must be calibrated and working within the

limits specified in Equipment Required on page 4–2.

Reference Information. Information that amplifies a performance requirement or

is of special importance is indicated by REF. There is no need to check these

items to a specific tolerance.

and can be assured by performing the procedures

Safety Standards

The following safety standards apply to the WFM 90 or WFM 91 Handheld

Waveform, Vector, Picture, and Audio Monitor:

ANSI/ISA S82. Safety Standard for Electrical and Electronic Test, Measuring,

Controlling, and Related Equipment.

CAN/CSA C22.2 No. 1010.1-92. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use.

IEC1010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use (1990).

UL3111. Standard for Electrical Measuring and Test Equipment.

WFM 90 and WFM 91 Service Manual

1–5

Page 32

Specifications

T able 1–1: Vertical deflection system

Category Description

Frequency Response REF: Specifications apply for full screen height video input signal with Vari-

able Gain off.

REQ: Flat Filter 1 V Full Scale: 50 kHz to 6 MHz within 2% of response at 50 kHz.

REQ: Flat Filter X5 Gain: 50 kHz to 6 MHz within 5% of response at 50 kHz.

REF: Low Pass Filter: w40 dB attenuation at 3.58 MHz (NTSC) or

4.43 MHz (PAL).

REF: Response at 15 kHz does not vary between Flat and Lum (low pass)

filters by more than 1%.

Deflection Factor REQ: 1 V Full Scale: 1 V input displayed within 1% of 140 IRE.

REF: Flat filter selected.

REQ: X5 Gain: Gain accuracy within 5% with 1 V input signal.

REF: X5 Gain Registration: v1 major division of vertical shift from baseline

between unmagnified and magnified signal.

REQ: Variable Gain Range: Input signals between 0.8 V and 2 V can be adjusted

to 140 IRE (1.0 V) display. 160 mV to 400 mV for X5 Gain.

REQ: Position Range: 1 V signal can be positioned so that peak white and sync tip

can be placed at blanking level with the DC Restorer on, regardless of gain

setting.

Transient Response REF: Specifications apply for full screen height video input signal with Vari-

able Gain off, 1 V Full Scale or X5 Gain selected, and Flat filter selected.

REF: Pulse-to-Bar Ratio:

X1: 0.99:1 to 1.01:1.

X5: 0.98:1 to 1.02:1.

REF: Preshoot: v1%.

REF: Overshoot:

X1: v2%.

X5: v4%.

REF: Ringing:

X1: v2%.

X5: v4%.

REF: Field Rate Tilt: v1%.

REF: Line Rate Tilt: v1%.

REQ: Overscan: v2% variation in baseline of 100 IRE (700 mV) 12.5T (20T)

modulated pulse as it is positioned over the middle 80% of the screen.

Maximum Absolute Input Level REF: $5 VDC plus peak AC.

REF: Displays in excess of 200 IRE (1.428 V) may cause frequency re-

sponse aberrations.

1–6

WFM 90 and WFM 91 Service Manual

Page 33

T able 1–1: Vertical deflection system (Cont.)

Category Description

Specifications

DC Input Impedance

(Unterminated)

REQ: 15 kW.

REF: With input switch in the HIZ position.

Video Input Return Loss REF: 40 dB from 50 kHz to 6 MHz with 75 W termination on.

Video Out Return Loss (75W) REF: 30 dB from 50 kHz to 6 MHz.

Video Out Differential Gain (50% APL) REF: Within 1% with a 140 IRE (1.0 V PAL) unit display.

Video Out Differential Phase (50% APL) REF: Within 1° with a 140 IRE (1.0 V PAL) unit display.

T able 1–2: DC restoration

Category Description

DC Restorer Clamp Time REF: Back Porch.

Frequency Response at

60 Hz (50 Hz PAL)

REQ: Attenuation of 60 Hz (50 Hz PAL) on Input Signal:

Slow Mode: 20%.

Fast Mode: 90%.

REF: Blanking Level Shift with 10% to 90% APL Change:

APL changes from 50% to either 10% or 90% will cause blanking level

shift of 1 IRE unit (7.14 mV PAL) or less.

REF: Blanking Level Shift Due to Presence or Absence of Burst:

1 IRE unit (7.14 mV) or less shift from no color burst to presence of

color burst.

T able 1–3: Audio mode

Category Description

Reference Levels REQ: –10 dBu, 0 dBu, +4 dBu, +8 dBu.

REF: Nominal MIC Reference: –50 dBu.

Measurement Accuracy REQ: 0.5 dB at 1 kHz.

Frequency Response REQ: 0.5 dB from 50 Hz to 20 kHz.

Maximum Input Level Amplitude REF: +18 dBu.

DC Input Impedance REF: 15 kW.

Audio Output Connector REF: Mini stereo headphone jack.

Maximum Power Output REF: 250 mW.

WFM 90 and WFM 91 Service Manual

1–7

Page 34

Specifications

T able 1–4: Horizontal deflection system

Category Description

Sweep REQ: Sweep will occur in all horizontal mode settings with or without synchroniza-

tion.

REF: Sweep Length: Two Line and Two Field sweep length is nominally

12 divisions.

1LINE Sweep Repetition Rate REQ: Equal to line rate of applied video or external sync.

2LINE Sweep Repetition Rate REQ: Equal to half line rate of applied video or external sync.

2FLD Sweep Repetition Rate REF: Displays 2 full fields, including the field-rate sync between them.

2FLD Sweep Magnification REF: Approximately X20.

Sweep Magnifier Registration REF: Magnification occurs about the center of the screen.

Timing Accuracy REF: All timing and linearity specifications exclude the first and last major

divisions of the unmagnified display.

REQ: 10 ms/division (2LINE): Within 2%.

REQ: 5 ms/division (1LINE): Within 2%.

REQ: 1 ms/division (2LINE + MAG): Within 2%.

REQ: 0.5 ms/division (1LINE + MAG): Within 3%.

Integral Linearity REQ: Within 1%.

REF: Measured between the 10 ms and 110 ms points on the 10 ms/division

(2LINE) sweep.

Horizontal Position REF: Any portion of a synchronized video sweep can be positioned on

screen in all sweep modes.

T able 1–5: Vector mode

Category Description

Chrominance Processing Nominal Subcarrier

Frequency (F

SC

)

Chrominance Processing Chrominance

Bandwidth

Chrominance Processing +V Mode

(Applicable to PAL operation only)

Display Vector Phase Accuracy REF: 1.25°.

Display Vector Gain Stability REF: Typically 2.5%.

REF: NTSC: 3.579545 MHz.

PAL: 4.43361875 MHz.

REQ: Upper –3 dB Point: F

+500 kHz, 100 kHz.

SC

Lower –3 dB Point: FSC – 500 kHz, 100 kHz.

REF: +V-type display as selected by front-panel button. When pushed, the

V axis is inverted at a 1/2 line rate to produce a single vector display.

REF: Measured with color bar signal.

Display Quadrature Phasing REF: Typically 0.5°.

1–8

WFM 90 and WFM 91 Service Manual

Page 35

Specifications

T able 1–5: Vector mode (Cont.)

Category Description

Display Differential Phase REF: 1°.

REF: Measured with 140 IRE (1 V) linearity signal (5 step, 10 step, or Ramp)

with 40 IRE (300 mV) of subcarrier.

Display Differential Gain REF: 1%.

REF: Measured with 140 IRE (1 V) linearity signal (5 step, 10 step, or Ramp)

with 40 IRE (300 mV) of subcarrier.

Subcarrier Regenerator Pull-In Range REQ: NTSC: 50 Hz of FSC.

PAL: 10 Hz of F

REF: Subcarrier Regenerator free-runs in absence of appropriate signal.

Reference can be burst of either displayed signal or external reference

signal.

Subcarrier Regenerator Pull-In Time REF: Pull-In Time: Within 1 second, with subcarrier frequency within 50 Hz

(10 Hz for PAL) of FSC.

SC

.

Subcarrier Regenerator Phase Shift with

Subcarrier Frequency Change

Subcarrier Regenerator Phase Shift with Burst

Amplitude Change

Subcarrier Regenerator Phase Shift with Variable

REQ: NTSC: 2° from F

to (FSC + 50 Hz), or FSC to (FSC – 50 Hz).

SC

PAL: 2° from FSC to (FSC + 10 Hz), or FSC to (FSC – 10 Hz).

REQ: 2° from nominal burst amplitude to 6 dB.

REF: Internal or External burst reference.

REQ: 1° as gain is varied from +3 dB to –6 dB.

Gain Control

Subcarrier Regenerator Phase Control Range REF: 360° continuous rotation.

Subcarrier Regenerator Burst Jitter REF: 0.5° RMS or less.

REF: With 140 IRE (1 V) composite video input. INT or EXT referenced.

WFM 90 and WFM 91 Service Manual

1–9

Page 36

Specifications

T able 1–6: Synchronization

Category Description

Input Requirements REQ: Internal Reference: Composite video or black burst with sync amplitudes

40 IRE (300 mV PAL) 6 dB.

REQ: External Reference: Sync amplitude between 143 mV and 4 V will synchro-

nize sweeps.

External Reference Input REQ: DC Input Impedance (unterminated): 15 kW.

REF: Return Loss (75 W): 40 dB from 50 kHz to 6 MHz (with 75 W ter-

mination on, instrument power on).

REF: Absolute Maximum Input Voltage: 12 VDC plus peak AC.

T able 1–7: Physical characteristics

Category Description

Dimensions REF: Instrument:

5 inches (127 mm).

3.15 inches (80.0 mm).

9.6 inches (243.8 mm).

Shipping Box:

13.25 inches x 13.75 inches x 6 inches inside

14 inches x 14.25 inches x 6.25 inches outside

Weight REF: With batteries and pouch:

3 lbs, 9 oz.

Without batteries and pouch:

1 lb, 14 oz.

Shipping weight with packaging:

5 lbs, 14 oz.

T able 1–8: Environmental characteristics

Category Description

Operating Altitude REQ: To 15,000 feet (4572 meters).

REF: IEC 1010-1 compliance to 2000 meters.

Operating Temperature REQ: 0° to +50° C.

REF: IEC 1010-1 compliance to +40° C.

Equipment Type REQ: Measurement.

Installation Category REQ: Installation Category I (as defined in IEC 1010-1, Annex J).

REF: Rated for indoor use only.

Pollution Degree REQ: Pollution Degree 2 (as defined in IEC 1010-1).

1–10

WFM 90 and WFM 91 Service Manual

Page 37

Specifications

T able 1–8: Environmental characteristics (Cont.)

Category Description

Vibration — Operating REF: 15 minutes each axis at 0.015 inch, frequency varied from 10 Hz to

55 Hz to 10 Hz in 1-minute cycles with instrument secured to vibration

platform. Ten minutes each axis at any resonant point or at 55 Hz if no

resonant point is found.

Shock — Non-Operating REF: 100 g, 1/2 sine, 11 ms duration, 3 shocks per surface (18 total).

Transportation REF: Qualified under NTSC Test Procedure 1A, Category II (24-inch drop).

Humidity REF: Will operate at 95% relative humidity for up to five days. Meets the

five-day cycling humidity test as called out in Tektronix standard

062–2847–00.

T able 1–9: Power source

Category Description

Battery REF: 6 C-sized cell batteries, or Tektronix NiCad battery pack (Tektronix Part

Number. 146-0107-00).

Battery Charge Time REF: Fast Charge: 550 mA.

REF: Slow Charge: 150 mA.

Power Consumption REF: Picture Mode: 5.5 W

Waveform Mode: 7.2 W

Vector Mode: 7.2 W

Operating Time REF: Alkaline Batteries:

Picture Mode: 2.5 hours

Waveform Mode: 2 hours

Vector Mode: 2 hours

NiCad Batteries:

Picture Mode: 4 hours

Waveform Mode: 3 hours

Vector Mode: 3 hours

REF: Fully charged or new batteries.

External Power REQ: DC Source of 11 V to 18 V.

REF: Wall Unit Tektronix Part Numbers:

220 V European TUV 119–4540–00

240 V UK 119–4541–00

240 V Australia 119–4542–00

100 V Japan 119–4539–00

120 V North America 119–4538–00

WFM 90 and WFM 91 Service Manual

1–11

Page 38

Specifications

T able 1–10: Safety/EMI

Category Description

Certifications REQ: Designed to meet or exceed:

ANSI/ISA S82 – Safety Standard for Electrical and Electronic Test, Measuring, Controlling, and Related Equipment.

CAN/CSA C22.2 No. 1010.1-92 – Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use.

IEC1010-1 – Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use (1990).

UL31 11 – Standard for Electrical Measuring and Test Equipment.

EMI Compliance REQ: Designed to meet or exceed:

U.S.: FCC 47 CFR Part 15, Subpart B, Class A.

EC Declaration of Conformity Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

1–12

WFM 90 and WFM 91 Service Manual

Page 39

Operating Information

Page 40

Page 41

Operating Information

This section contains the following information:

H Mechanical and electrical installation instructions

H Operating instructions that relate to the service of this instrument

Installation

Before installing the WFM 90 or WFM 91 Handheld Waveform, Vector, Picture,

and Audio Monitor, refer to the Environmental Characteristic requirements,

located in Table 1–8 on page 1–10 of the Specifications section.

All qualification testing was performed with the factory shipped cabinet

installed. To guarantee compliance with specifications, only operate the

instrument in its cabinet.

Mechanical Installation

Follow these instructions when you are mechanically installing this instrument:

Unpacking. Save the shipping carton and packing materials (including antistatic

bag) in the event it becomes necessary to ship the instrument to a Tektronix

Service Center for service or repair. Refer to Repackaging Instructions on

page 6–4 for instructions on packaging the instrument for shipment.

Cabinet. The WFM 90 or WFM 91 Handheld Waveform, Vector, Picture, and

Audio Monitor is shipped installed in a cabinet. There are not any optional

cabinets available.

Viewing Hood. The optional viewing hood allows you to readily view the

instrument display in well-lighted situations. The hood is attached to the

instrument by first applying the supplied Velcro strips to the sides of the

instrument, and then pressing the flaps of the viewing hood onto the strips as

shown in Figure 2–1.

WFM 90 and WFM 91 Service Manual

2–1

Page 42

Operating Information

Figure 2–1: Installing the viewing hood

Desk Stand. The optional desk stand provides the user with a stable means to

hold the instrument upright on a flat surface. The prongs of the stand are inserted

into the holes in the back of the instrument as illustrated in Figure 2–2.

2–2

Figure 2–2: Installing the desk stand

WFM 90 and WFM 91 Service Manual

Page 43

Operating Information

Electrical Installation

Follow these instructions when physically installing this instrument:

Power Source. This instrument is designed to operate from either six C-cell

batteries, alkaline or rechargeable NiCad, or from an AC adapter wall unit

producing 12 VDC.

CAUTION. To avoid possible damage to the instrument circuitry when using a DC

power source other than the supplied AC adapter, ensure that the DC source is a

negative-ground +11 V to +18 V system with a negative center lead. The DC

source must provide 12 W of power.

Fuse. This instrument does not have an external power fuse. There are two fuses

located internally on the Bottom board. See page 6–34 of the Maintenance

section for instructions on how to check and replace the power supply fuses.

Battery Operation. The rechargeable NiCad batteries are automatically recharged

when the AC adapter is plugged into the instrument, whether the instrument

power is on or off. The battery charge time is approximately 6.5 hours when the

instrument is off and 20 hours when the instrument is on. The instrument shifts

into a safe trickle-charge mode, which can run indefinitely, when the NiCad

batteries are fully charged. See Table 1–9 on page 1–11 for information regarding

the length of time the instrument will operate on batteries.

The message Low Bat is displayed on screen when the remaining battery power

cannot guarantee reliable instrument operation. The length of time the instrument

will continue to operate after this message is displayed is dependent on the

current operating mode of the instrument and the type of batteries installed.

Use the rechargeable NiCad battery pack in full charge and discharge cycles to

optimize the battery life and capacity. Fully discharge the battery pack before

recharging, and then charge the battery pack until it is fully charged. A new

battery pack will take a few charge and discharge cycles to reach full capacity.

Refer to Batteries on page 6–21 for the instructions on how to install and remove

the batteries.

Operational Jumpers and Installed Options. This instrument does not have any

internal operational jumpers or installed options. All instrument configurations

are available through the on-screen menus.

Operating Environment. Refer to Table 1–8 on page 1–10 for the environmental

limits of this instrument.

WFM 90 and WFM 91 Service Manual

2–3

Page 44

Operating Information

Operating Information

This section will acquaint you with the basic principles of operating this

instrument so that you can service it. Detailed operating instructions are located

in the user manual.

Front Panel Controls

The instrument front panel is illustrated in Figure 2–3.

2–4

Figure 2–3: Instrument front panel

WFM 90 and WFM 91 Service Manual

Page 45

Operating Information

Power Switch. Press the ON button to toggle the instrument power on and off.

The current instrument keypad and menu selections are saved when the

instrument is turned off using this button.

NOTE. The instrument configuration is not saved if the power source is removed

before the instrument is turned off with this button.

Display Mode Selection. Use the following front-panel buttons to access the

different display modes:

H Press the WFM button to enter the Waveform display mode.

H Press the VECT button to enter the Vector display mode.

H Press the AUDIO button to enter the Audio display mode.

H Press the PIX button to enter the Picture display mode.

H Press the WIP button to enter the Waveform-in-Picture display mode. The

previously selected display mode, other than Picture, is shown in a

1/4-screen-sized window that overlays the Picture display.

Menu Control. Use the following front-panel buttons to enter the different menus:

H Press the MENU button to toggle the Operating menu on and off. The

Operating menu contains monitoring selections which are specifically related

to the currently selected display mode. Operating menu selections include

signal gain and filtering, audio reference levels, and safe action and title

outlines.

H Press the CONFIG button to toggle the Configuration menu on and off. The

Configuration menu contains selections which control overall instrument

monitoring operation. Configuration menu contents include signal and

display controls such as brightness and variable gain. Special modes for

monitoring signal amplitude and managing the battery power consumption

are enabled in this menu.

H Press the LINE SEL button to toggle the Line Select mode on and off and to

display the Line Select menu.

H The four unlabeled buttons directly below the display are referred to as the

Bezel Buttons. These buttons are used to make menu selections and are only

enabled while menus are displayed on screen.

WFM 90 and WFM 91 Service Manual

2–5

Page 46

Operating Information

Arrow Buttons. The function of the Arrow Buttons is dependent on the current

state of the instrument. For the Waveform and Audio display modes, they control

signal positioning. For the Vector display mode, they control vector phase, with

the

Y and B buttons providing fine adjustment, and the A and " buttons providing

coarse adjustment.

The Arrow Buttons retain their default function for the reduced display when the

Waveform-in-Picture display mode is selected. When the Configuration menu is

displayed, the Y and B buttons operate the menu category selection, while the A

and " buttons retain their default function for the current display mode.

Instrument Reset. Extraordinary conditions may cause the instrument controls to

become locked or to respond erratically. To reset the instrument, first press the

ON button to turn off the power, then press the ON button again while holding

down the WIP and LINE SEL buttons. The instrument should return to normal

operation with the keypad controls and menu selections assigned to the

factory-set defaults.

If this reset does not return the instrument to normal operation, refer to the

Troubleshooting Procedures section of this manual.

Side-panel Connectors

and Switches

The instrument side panels are illustrated in Figure 2–4.

Video Input and Output Connectors. The VIDEO IN and REF IN connectors are

passive BNC inputs, unterminated, and 75W-compensated for a video signal.

Each input has a rear-panel switch to provide an internal 75W signal termination.

The VIDEO OUT connector is a BNC used to output the instrument display to a

remote monitor or video switcher.

Audio Input and Output Connectors. The AUDIO IN connector is a standard

three-pin XLR connector for a single channel of audio input. The audio output

connector is a standard stereo mini headphone jack for the output of the audio

input signal. The mono input signal is heard on both stereo channels. The audio

volume is fixed for each reference level. The larger the displayed signal, the

louder the volume.

2–6

WFM 90 and WFM 91 Service Manual

Page 47

DC IN 11-18V

Operating Information

Figure 2–4: Instrument side panels

DC Input Power Connector. The DC IN power connector is a 2 mm plug which

accepts a 12 VDC power input, ranging from +11 V to +18 V, using a negative

center lead.

CAUTION. To avoid possible damage to the instrument circuitry when using a DC

power source other than the supplied AC adapter, ensure that the DC source is a

negative-ground +11 V to +18 V system with a negative center lead. The DC

source should be able to provide 12 W of power.

WFM 90 and WFM 91 Service Manual

2–7

Page 48

Operating Information

Special Operating Modes

The following special operating modes can be activated through the menus:

Amplitude Alarm Mode. The Amplitude Alarm mode provides a means to

automatically monitor the signal amplitude for the Waveform and Audio

displays. This mode is enabled through the Configuration menu.

For the Waveform display mode, the portion of the signal exceeding the 100 IRE

(1.0 V PAL) graticule line is highlighted. For the Audio display mode, the

portion of the signal exceeding the menu-selected reference level is highlighted.

The highlighted portion of the signal is also visible in the Waveform-in-Picture

(WIP) display mode.

Variable Gain Mode. The Variable Gain mode allows you to vary the signal gain

for the Waveform and Vector displays between 45% and 155%. This mode is

enabled through the Configuration menu.

The variable gain adjustment tracks between the Waveform and Vector display

modes and can be adjusted from the Waveform-in-Picture display mode. When

the Variable Gain mode is enabled, the message GAIN UNCAL is displayed in

the on-screen readout.

Time-out Mode. The Time-out mode allows you to automatically shut down the

backlight and/or the instrument after there has been no front-panel activity for a

menu-selected length of time. The Time-out mode enables you to reduce battery

power usage while the instrument is battery powered and also to extend the life

of the backlight bulb. This mode is enabled through the Configuration menu.

2–8

When the backlight times out, the LCD display goes blank and the instrument

appears to be off. The backlight is turned back on by pressing any front panel

button other than the ON button. The backlight shutdown is functional when the

instrument is either battery or DC powered.

When the instrument power times out, the ON button must be pressed to turn the

instrument back on. The instrument power shutdown is only functional when the

instrument is battery powered.

WFM 90 and WFM 91 Service Manual

Page 49

Operating Information

Calibration Mode. The Calibration mode allows you to adjust the instrument to

factory specifications, if necessary. The Calibration mode is entered by pressing

and holding the CONFIG button for a few seconds. The instrument adjustments

are performed entirely from the front panel with the use of specified input

signals. The instructions for readjusting the instrument to specifications are

located in the Adjustment Procedures section.

CAUTION. Do not attempt to adjust the instrument without using the instructions

listed in the Adjustment Procedures section, or your instrument may not meet the

published specifications.

On-screen Readout

This instrument uses on-screen messages to alert you to certain monitoring

conditions. Figure 2–5 shows the readout messages and their locations.

123

GAIN UNCAL 10uS/DIVEXT REF

MISSING SYNC

100

6

80

60

40

20

0

–20

–40

V1.1

LOW BAT

4

5

Figure 2–5: On-screen readout messages

Readout Description. Listed below are the corresponding descriptions of the

on-screen readout messages:

H The GAIN UNCAL message appears in the Waveform, Vector, and

Waveform-in-Picture display modes when the Variable Gain mode is

turned on.

H The EXT REF message appears in the Waveform and Vector display modes

when the video signal is locking to an external video reference signal.

H The sweep rate is only displayed in the Waveform display mode. There is no

sweep rate readout when 2 Field sweep is selected.

WFM 90 and WFM 91 Service Manual

2–9

Page 50

Operating Information

H The instrument software version number is displayed when the Configura-

tion menu is open with the DISPLAY category selected.

H The LOW BAT message is displayed when the instrument is battery operated

and the remaining battery power has reached a critically low level. The

remaining length of time that the instrument can be operated reliably is

dependent on the current operating mode.

H The MISSING SYNC message appears in all video display modes when the

signal reference has been lost.

Default Settings

You can reset the front panel and menu settings to the factory-specified default

settings through the Configuration menu. Monitoring adjustments such as signal

position, vector phase, and picture hue are also set. The factory settings are listed

Table 2–1.

T able 2–1: Front panel and menu default settings

Instrument Parameter Factory Default Setting

Display mode Waveform

Signal reference Internal

Filter Flat

DC restorer speed Slow

Gain X1

Variable gain Off

Sweep 2H (2 Line)

Mag Off

Bars 75%

Setup (WFM 90 only) Yes

Alt Phase (WFM 91 only) Off

2–10

Reference dBu 0 dBu

Headroom 3 dB

WIP location Bottom right

Alarms Off

Safe Action Off

Safe Title Off

Vertical shift Off

Backlight time-out Disabled

Instrument time-out Disabled

WFM 90 and WFM 91 Service Manual

Page 51

Theory of Operation

Page 52

Page 53

Theory of Operation

This section contains a module-level description of the instrument circuitry.

Block Diagram Description

The following description is based on the block diagram in Figure 3–1.

Input Board

Top Board

The signal input and output connectors are located on the Input board. There are

receivers for the three inputs, a switch for the video signal reference, and a

variable gain circuit for the audio input.

The video input signal has a DC voltage feedback clamp from the Bottom board.

The video output signal from the Bottom board is routed through the Input

board. The audio variable gain is controlled by the microprocessor serial bus,

which is routed to the Input board from the Top board through the Bottom board.

The Top board contains the microprocessor circuitry, the rasterizer and graphics

generator, the subcarrier oscillator, and the timing generator.

Microprocessor. The microprocessor takes input from the front-panel keypad to

control the operation of the instrument through the serial bus, parallel bus, and

dedicated control lines.

Rasterizer and Graphics. The rasterizer and graphics block produces all internally

generated video including waveforms, graticules, and menus. The rasterizer uses

the horizontal and vertical deflection signals to produce the waveforms. The

rasterizer uses the horizontal and vertical sync signals from the Bottom board to

lock to the incoming video signal.

The rasterizer needs a good analog timing voltage to run correctly. This timing

voltage is generated by a circuit loop between the Top and Bottom boards.

Problems with this circuit can be on either circuit board.

Bottom Board

WFM 90 and WFM 91 Service Manual

The Bottom board contains the power supply circuitry, the horizontal and

vertical deflection circuits, the NTSC or PAL decoder, the vectorscope and

burst-lock circuitry, the sync separator, and the audio amplifier for the headphone

output.

3–1

Page 54

Theory of Operation

Backlight Power Supply

Board

LCD Display and

Backlight

The Backlight Power Supply board uses the switched DC input voltage from the

batteries or external DC input to generate the voltage for the display backlight.

The backlight mounts into the display module.

The LCD Display module generates the display graphics using input signals

generated on the Top and Bottom boards. The power for the LCD Display

module comes from the Bottom board, while the power for the backlight comes

from the Backlight Power Supply board. The display backlight mounts into the

side of the LCD Display module.

3–2

WFM 90 and WFM 91 Service Manual

Page 55

Theory of Operation

Video

Out

Video

In

Ext

Ref

Audio

In

Headphone

DC In

11–18 VDC

Battery

Input Board

Fuse

Fuse

Var

Gain

Ref

Bottom Board P/O Top Board

Clamp

LPF

Vert

Defl

Horiz

Defl

Rasterizer

and

Graphics

Video

Out

Video In

Audio

Burst

Lock

RGB from

Rasterizer

and Graphics

Fsc

R–Y

Vectorscope

(Including Ø

shifter)

RGB

Front

Panel

Keys

Part of

mP

Instrument

Control

Power Supply

and Battery

NTSC (or PAL)

Decoder (Self

regenerator)

Control DAC

(16 analog

Outputs)

Charger

contained

subcarrier

16

Sync

Separator

±8 VDC

+5 VDC

Vector

±8 VDC

+5 VDC

Subcarrier

Oscillator

Timing

B–Y

Sweep

P/O Top Board

Part of

mP

Timing

Trig

DSync

RGB

Display

Brightness

and View

2

Adjust

RGB

LCD Display

and Backlight

Backlight

Power

Supply

Board

Sel Vid

Backlight

Brightness

Figure 3–1: Simplified block diagram

WFM 90 and WFM 91 Service Manual

3–3

Page 56

Theory of Operation

3–4

WFM 90 and WFM 91 Service Manual

Page 57

Performance Verification

Page 58

Page 59

Performance Verification

This section contains the following information:

H Summary verification procedure

H List of equipment required to perform the procedures

H Performance verification procedures

Summary Verification

The summary verification is listed in Table 4–1 and is intended for those who are

familiar with the complete performance verification procedures. Procedure titles

and page numbers provide a cross-reference to the performance verification

procedures on the following pages.

T able 4–1: Summary verification procedure

Procedure Procedure Requirement Page #

Preliminary setup Initial equipment connections and control settings. 4–5

Sync separation Signal synchronization will occur with input signals of composite video or

black burst, with sync amplitudes of 40 IRE (300 mV PAL) "6 dB for

internal reference, and sync amplitudes of between 143 mV and 4 V for

external reference.

Sweep timing and integral linearity Sweep Timing Accuracy: 5 ms/Div. (1 Line), 10 ms/Div. (2 Line), and

1.0 ms/Div . (2 Line + MAG), "2%. 0.2 ms/Div. (1 Line + MAG) "3%.

Integral Linearity: "1%.

Vertical gain and vertical magnifier registration 1 Volt Full Scale: 1 V input displayed within 1% of 140 IRE (1.00 V PAL).

X5 Gain: Gain accuracy within 5% with 1 V input signal. X5 Gain

Registration: v1 major division of vertical shift from baseline between

unmagnified and magnified signal.

Variable gain range and vertical position range Variable Gain Range: Input signals between 0.8 V and 2 V can be

adjusted to 140 IRE (1.0 V) display. 160 mV and 400 mV for X5 Gain.

Vertical Position Range: 1 V signal can be positioned so that peak white

and sync tip can be placed at blanking level, with the DC Restorer Clamp

on, regardless of gain setting.

Overscan v2% variation in baseline of 100 IRE (700 mV PAL) 12.5T (20T PAL)

modulated pulse as it is positioned over the middle 80% of the screen.

Input and DC restorer frequency response X1 Gain Response (Flat filter selected): 50 kHz to 6 MHz within 2% of

response at 50 kHz. X5 Gain Response (Flat filter selected): 50 kHz to 6

MHz within 5% of response at 50 kHz. Attenuation of 60 Hz (50 Hz PAL)

on Input Signal: SLOW mode: v20%. FAST mode: w90%.

4–5

4–6

4–7

4–7

4–8

4–9

WFM 90 and WFM 91 Service Manual

4–1

Page 60

Performance Verification

T able 4–1: Summary verification procedure (Cont.)

Procedure Page #Procedure Requirement

Vector phase stability Phase Shift with Subcarrier Frequency Change from FSC to FSC 50 Hz

10 Hz PAL): 2°. Phase Shift with Burst Amplitude Change from

(F

SC

Nominal to 6 dB: 2°. Phase Shift with V ariable Gain Control Varied

from +3 dB to –6 dB: 1°.

Chrominance bandwidth Chrominance Bandwidth: Upper –3 dB Point: FSC + 500 kHz, 100 kHz.

Lower –3 dB Point: F

Audio gain and frequency response Measurement Accuracy: 0.5 dB at 1 kHz. Frequency Response: 0.5 dB

from 50 Hz to 20 kHz.

– 500 kHz, 100 kHz.

SC

Equipment Required

Table 4–2 lists the required equipment and accessory items to perform the

performance verification procedures. Minimum equipment specifications are

followed by an example of equipment that meet these specifications.

An accuracy ratio of 4:1 or better for the warranted specifications will be

obtained using the equipment recommended in Table 4–2 with the following

exceptions:

H Audio Amplitude: 2.5:1

H Audio Flatness: 2.5:1

4–11

4–1 1

4–13

T able 4–2: Equipment required for performance verification

Equipment Description Minimum Requirements Equipment Example

Television test signal generator Color test signals for the television standard of

the monitor to be tested: color bar signal, pulse

and bar; with 2T pulse, 2T bar, and modulated

pulse, field square wave signal, and black burst

signal

Leveled sine wave generator Output Level Range: –11.55 dBm (200 mV) to

0.43 dBm (800 mV);

Frequency: 50 kHz to 10 MHz

Function generator Range: 0.1 to 5 Vpp when loaded by 75 W,

10 Vpp when unloaded;

Frequency: 50 kHz to 10 MHz.

Audio generator Amplitude Range: –10 dBu to 8 dBu;

Frequency: 1 kHz to 50 kHz

Voltmeter Range: 0 VDC to 100 VDC;

Accuracy: 0.1%

4–2

NTSC: Tektronix 14101 TV Test Signal Generator

with Option AA and Option AB (modified SPG2

and TSG7), TSG3, and TSG5

PAL: Tektronix 14111 TV Test Signal Generator

with Option AA and Option AB (modified SPG12

and TSG17), TSG13, and TSG15

Tektronix SG 5032 Leveled Sine Wave Generator

Tektronix FG 5032 Function Generator

Tektronix ASG 100 Audio Signal Generator

Tektronix DM 504A2 Digital Multimeter

WFM 90 and WFM 91 Service Manual

Page 61

T able 4–2: Equipment required for performance verification (Cont.)

Equipment Description Equipment ExampleMinimum Requirements

Performance Verification

Frequency counter Range: 10 Hz to 10 MHz;

Tektronix DC 503A2 Universal Counter

Accuracy: 0.001%

Video amplitude calibrator

(VAC)

Signal: Adjustable square wave 0.0 mVpp to

999.9 mVpp; Resolution: 0.1 mV; Accuracy:

Tektronix part number 067-0916-00

2

0.05%; Frequency: Approximately 270 Hz

Peak-to-peak detector Input Signal Range: 0.25 Vpp to 1.0 Vpp;

Flatness: 0.2% 50 kHz to 10 MHz;

Input Impedance: 75 W

Tektronix part number 015-0408-00 (includes

peak-to-peak detector head, Tektronix part

number 015-0413-00)

2