Page 1

xx

WFM720UP, WFM820UP, and WFM830UP Upgrades

for the WFM7200, WFM8200, and WFM8300

ZZZ

Waveform Monitors

Instructions

Warning

The servicing instructions ar

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do s

prior to performing service.

e for use by qualified personnel

o. Refer to all safety summaries

www.tektronix.com

P075100103*

*

075-1001-03

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B ox 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

World wide, vis i t www.tektronix.com to find contacts in your area.

Page 3

Ta ble of Contents

General Safety Summary .......................................................................................... 1

Kit Description................... ................................ ................................ ................... 3

Products.... ................................ .................................. ................................ ... 5

Required To

Kit Parts Lists ......................... ................................ .................................. ....... 6

Upgrade Installation................................... ................................ ............................. 9

Verify the Currently Installed Options...................................... ................................. 9

How to Prevent Electrostatic Discharge.................................................................... 10

Install the Software Upgrade ................................................................................ 11

Install

Install the Option Software Key............................................................................. 28

Verify the Upgrade .............. .................................. ................................ ................ 29

Quick Verification ............................................................................................ 29

Detailed Verification.......................................................................................... 29

ols ................................................................................................. 5

the Option Hardware ............... ................................ ................................ .. 15

WFM720UP, WFM820UP, and WFM830UP Upgrades i

Page 4

Table of Contents

ii WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

To Avoid Fire or Personal

Injury

Use Prope

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground

of the power cord. To a void electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avo i d fire or shock hazard, observe all ratings

and

information before making connections to the product.

Do n

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at

all times.

Do Not Operate Without Covers. Do not operate this product with covers or

panels removed.

rPowerCord. Use only the power cord specified for this product and

the Product. This product is grounded through the grounding conductor

markings on the product. Consult the product manual for further ratings

ot apply a potential to any terminal, including the common terminal, that

Do Not Operate With Suspected Failures. If you suspect that there is damage to

this product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

WFM720UP, WFM820UP, and WFM830UP Upgrades 1

Page 6

General Safety Summary

TermsinthisManual

Symbols and Terms on the

Product

Do Not Operate i

Do Not O perate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Prop

details on installing the product so it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

. Caution statements identify conditions or practices that could result in

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n Wet/Damp Conditions.

er Ventilation. Refer to the manual's installation instructions for

Warning statements identify conditions or practices that could result

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

2 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 7

Kit Description

Kit Description

This document provides instructions for installing the video and audio upgrades

listed below into an existing Tektronix WFM7200, WFM8200, or WFM8300

waveform mon

Table 1 : Supported upgrades

Video

Upgrades WFM820UP WFM830UP WFM720UP Description

Option 2SDI Adds a second SDI input module, adding 2 additional SDI

Option 3G Adds support for 3G-SDI signal formats.

Option CPS Adds support for Composite Analog Video Monitoring;

Option 3

Option

Optio

D

S3D

nGEN

itor.

inputs that support 3G-SDI, HD-SDI, and SD-SDI. (Option

3G is required for 3G-SDI support).

2 composite Analog inputs; passive loop-through. This

option no

Adds Ste

(including Simultaneous Input Monitoring (SIM) of dual

SDI inputs and synchronized left eye and right eye signals

monito

Adds St

(including Simultaneous Input Monitoring (SIM) of dual

SDI inputs and synchronized left eye and right eye signals

monit

Adds c

SD/HD SDI. O ption 3G required for 3G-SDI support.

t compatible with Option 2SDI.

reoscopic 3-D Video Monitoring Capabilities

ring (SyncVu™)).

ereoscopic 3-D Video Monitoring Capabilities

oring (SyncVu™)).

olor bar and pathological signal generator for

WFM720UP, WFM820UP, and WFM830UP Upgrades 3

Page 8

Kit Description

Table 1: Supported upgrades, (cont.)

Video

Upgrades WFM820UP WFM830UP WFM720UP Description

Option AVD Add support for out-of-service audio/video delay

measurement; requires Option AD or DPE.

Option SIM Adds simultaneous monitoring of 2 H D/SD-SDI inputs

or one HD/SD-SDI input and one CPS input; Option 3G

required for 3G-SDI formats support.

Audio

Upgrades WFM820UP WFM830UP WFM720UP Description

Option AD Adds Analog Audio Monitoring (2 sets of 6 channel

Analog Audio inputs and 8 channels of Analog Audio

outputs); 16 channels Embedded and AES/EBU Digital

Audio support (8 channels at a time).

Option DPE Adds Option AD capabilities (Analog and Digital Audio,

Embedded or External AES), plus support for decoding

and monitoring Dolby E, Dolby D, and Dolby Digital Plus

Audio. (Audio cable available separately).

Option DDP Adds support for decoding and monitoring Dolby Digital

Plus Audio.

This upgrade is only available for instruments that

currently support decoding and monitoring Dolby E and

Dolby D.

Analysis

Upgrades WFM820UP WFM830UP WFM720UP Description

Option EYE

Option PHY Adds Physical Layer Measurement Package (includes

Option PHY3 Adds Physical Layer Measurement Package (includes

Option PROD Adds Advanced Gamut Monitoring Package (Spearhead

Option DAT Adds data analysis capabilities. Allows for logic-level v iew

Adds Eye Pattern Display and Jitter Measurement

Package (includes 3G-SDI, HD-SDI, and SD-SDI

Eye pattern and Jitter waveform displays; automated

measurements of Eye pattern paramenters,Jitter, and

cable parameters; color bar and pathological signal

generation); Option 3G required for 3G-SDI support.

3G-SDI, HD-SDI, and SD-SDI Eye pattern and jitter

waveform displays; automated measurements of Eye

pattern parameters, jitter, and cable parameters; color bar

and pathological signal generation); Option 3G required

for 3G-SDI support.

3G-SDI, HD-SDI, and SD-SDI Eye pattern and jitter

waveform displays; automated measurements of Eye

pattern parameters, jitter, and cable parameters; Option

3G required for 3G-SDI support.

Display and Luma Qualified Vector Display).

of video and embedded audio data stream and ANC data

extraction.

4 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 9

Products

Kit Description

The following Tektronix products are supported by this kit:

WFM7200 All instruments

Required Tools

WFM8200 All i

nstruments

WFM8300 All instruments

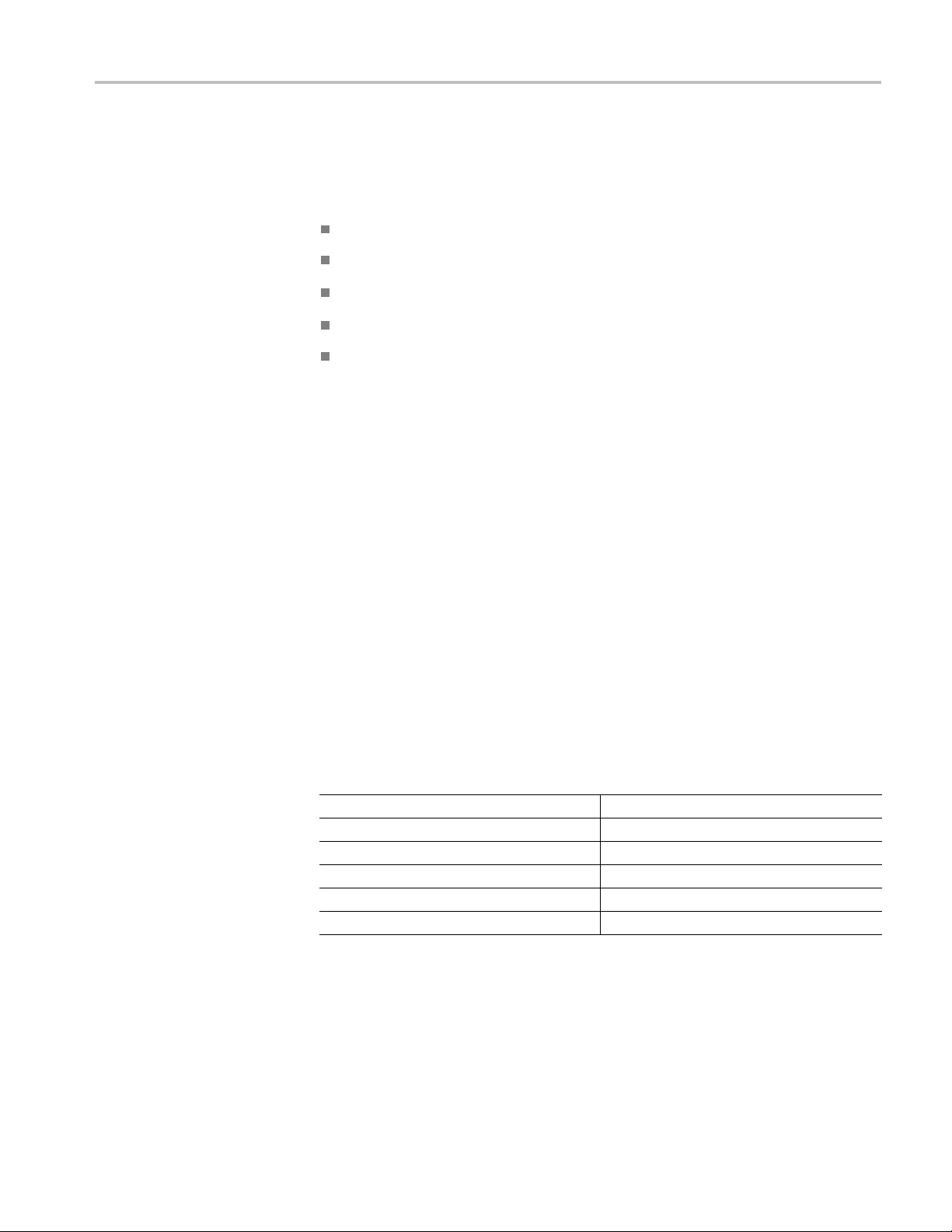

The following table lists the tools required to install the upgrade.

Table 2: Required tools

Name Description

TORX screwdriver handle (Hardware options

only)

T-10 and T-15 TORX tips (Hardware options

only)

h nut driver (Hardware options only)

1/4 inc

nch socket (Hardware options only)

9/16 i

ard PC

Stand

Anti-static wrist strap (Hardware options

only)

For WFM8000 Series upgrades, WFM8200

WFM8300 Specifications and

and

Performance Verification manual and all

test equipment listed within to perform the

ification checks

ver

For W FM7200 upgrades, WFM7200

ecifications and Performance Verification

Sp

manual and all test equipment listed within to

perform the verification checks

Accepts TORX-driver bits

TORX-driver bit for T-10 and T-15 screw

heads

rd tool

Standa

ocket to fit over BNC connector

Deep s

Running Windows 98, Windows NT 4.0,

ws ME, Windows 2000, or Windows

Windo

XP

Tektronix part number 077-0259-XX

Available for download from the Tektronix

site at www.tektronix.com/manuals

Web

Tektronix part number 077-0669-XX

ailable for download from the Tektronix

Av

Web s ite at www.tektronix.com/manuals

WFM720UP, WFM820UP, and WFM830UP Upgrades 5

Page 10

Kit Description

Kit Parts Lists

The following tables list the parts supplied with each upgrade kit. Before you

start the upgrade, verify that you received all of the parts for the upgrade kit you

ordered.

WFM820UP 2SDI

WFM830UP 2SDI

WFM720UP 2SDI

WFM820UP CPS

WFM830UP CPS

WFM720UP CPS

Table 3: Opt

Quantity Part number Description

1EA

1 EA 075-1001-XX

1 EA 870-0196-XX

1 EA 333-459

4 EA 220-04

4 EA 210-1039-XX

ion 2SDI parts list

——

3-XX

97-XX

ENVELOPE, IMPORTANT DOCUMENTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP, AND

WFM830UP

CIRCUIT B

WFM8200/WFM8300, ROHS COMPLIANT

REAR PANEL, SAFETY CONTROLLED, STD (SDI)

NUT, PLAIN, HEX; .5-28 X .562 HEX, BRS, NI

(NICKEL) PLATED

WASHER, LOCK; 0.521 ID, INT, 0.025 THK, STEEL,

ZINC F

UPGRADES

RD ASSY; SDI, TESTED,

INISH

NOTE. Once the hardware is installed, you must download the software to

activate Option 2SDI. Go to www.tektronix.com/downloads. (See page 11, Install

the Software Upgrade.)

Table 4: Option CPS parts list

Quantity Part number Description

1EA

1 EA 075-1001-XX

EA

1

——

72-0258-XX

8

ENVELOPE, IMPORTANT DOCUMENTS; CONTAINS

FTWARE OPTION KEY

SO

NSTRUCTIONS; WFM720UP, WFM820UP, AND

I

WFM830UP UPGRADES

CIRCUIT BD SUBASSY; ANALOG COMPOSITE

WFM820UP EYE

Table 5: Option EYE parts list

Quantity Part number Description

1EA

1 EA 075-1001-XX

1 EA 872-0189-XX

——

ENVELOPE, IMPORTANT DOCUMENTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP, AND

WFM830UP UPGRADES

CIRCUIT BOARD SUBASSY; 3G-EYE

6 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 11

Kit Description

WFM830UP PHY

WFM720UP PHY3

WFM820UP 3G

WFM830UP 3G

WFM720UP 3G

WFM820UP PROD

WFM830UP PROD

WFM720UP PROD

WFM820UP DDP

WFM830UP DDP

WFM720UP DAT

WFM720UP SIM

WFM720UP AVD

WFM720UP GEN

WFM820UP GEN

WFM820UP 3D

WFM720UP S3D

Table 6: Option

Quantity Part number Description

1EA

1 EA 075-1001-XX

1 EA 872-0189-XX

These are S

PHY and PHY3 parts list

——

ENVELOPE, IMPORTANT DOCUME NTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP, AND

WFM830UP UP

CIRCUIT BOA

W only upgrades. No hardware is needed for these upgrades.

Table 7: SW option upgrades parts list

Quantity Part number Description

1EA

1 EA 075-1001-XX

——

ENVELOPE, IMPORTANT DOCUME NTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP, AND

WFM830UP UPGRADES

GRADES

RD SUBASSY; 3G-EYE

WFM820

UP AD

WFM830UP AD

WFM720UP AD

Table 8: Option AD parts list

Quantity Part number Description

1EA

1 EA 075-1001-XX

1 EA 672-6478-XX

1 EA 131-7430-XX

1 EA 200-4804-XX

——

ENVELOPE, IMPORTANT DOCUME NTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP, AND

WFM830UP UPGRADES

CIRCUIT BD SUBASSY; DIGITAL AND ANALOG

AUDIO

CONN,DSUB; SLDR CUP,MALE,STR,62 POS,0.100

CTR,30 GOLD

COVER; SHIELD,ELEC CONN,37 POS DSUB,ZINC

WFM720UP, WFM820UP, and WFM830UP Upgrades 7

Page 12

Kit Description

WFM820UP DPE

WFM830UP DPE

WFM720UP DPE

Table 9: Option

Quantity Part number Description

1EA

1 EA 075-1001-XX

1 EA 672-6478-XX

1 EA 131-7430-XX

1 EA 200-4804-

1 EA 119-7167

DPE parts list

——

XX

-XX

ENVELOPE, IMPORTANT DOCUMENTS; CONTAINS

SOFTWARE OPTION KEY

INSTRUCTIONS; WFM720UP, WFM820UP AND

WFM830UP UP

CIRCUIT BD S

CONN,DSUB

CTR,30 GOLD

COVER; SHIELD,ELEC CONN,37 POS DSUB,ZINC

CIRCUIT BD ASSY; CAT552 DOLBY E/DIGITAL

DECODER M OD U LE; 72 PIN SIMM; SAFETY

CONTROL

GRADES

UB ASSY

; SLDR CUP,MALE,STR,62 POS,0.100

LED

8 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 13

Upgrade Installation

This section provides instructions for the following:

Verifying the currently installed options

Preventing electrostatic discharge

Installing the software upgrade

Upgrade Installation

Installing

Installing the software option key

thehardwareupgrade

Verify the Currently Installed Options

The software option key supplied in this kit is based on the serial number you

supplie

option key should enable the new option(s) you ordered, and also preserve your

previously purchased options.

Before you install the upgrade, perform the following steps to verify which

options are currently installed in your instrument. After you install the upgrade,

you will verify that the new options are installed and that any previously installed

options are still enabled.

1. Power on the instrument you are upgrading.

2. Press the CONFIG button on the front panel.

3. Navigate to Utilities > View Instrument Options.

4. Mak

d when you ordered the upgrade for the instrument. The new software

e a list of the installed options.

List installed options

WFM720UP, WFM820UP, and WFM830UP Upgrades 9

Page 14

Upgrade Installation

How to Prevent Electrostatic Discharge

When you perform any service that requires internal access to the instrument,

adhere to the following precautions to avoid damage due to electrostatic discharge

(ESD):

1. Minimize handling of static-sensitive circuit boards and components.

2. Transport and store static-sensitive boards or modules in static protected

containers.

3. Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these modules.

4. Service static-sensitive modules only at a static-free work station.

5. Do not allow anything capable o f generating or holding a static charge on

the work surface.

6. Handle circuit boards by the edges or hold onto grounded shields when

possible.

7. Do not slide circuit boards over any surface.

10 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 15

Upgrade Installation

Install the So

Before You Begin

ftware Upgrade

CAUTION. To prevent upgrade failure, your instrument must have the latest

version of software installed before you install the hardware upgrade and before

you install the software option key.

You do not need to perform the software upgrade if your instrument has the latest

version o f software installed. Perform the following steps to determine if the

software on your instrument needs to be upgraded:

1. Power on the instrument.

2. Verify the current software version installed on the instrument:

a. Press the CONFIG button on the front panel.

b. Navigat

c. In the Hardware and Software Versions display window, note the software

Instrument Software version number

etoUtilities > View HW/SW Version.

n number of the instrument.

versio

3. Verify the latest version of software at the Tektronix Web site:

a. Use the Web browser on a PC to navigate to the following Tektronix

Web site:

http://www.tektronix.com/downloads

b. On the Downloads Finder Web page, search by model number (such

as WFM8300) and filter by software and software type to locate the

software-upgrade package for the instrument.

c. Note the latest version number of the software-upgrade package(s).

Web site S oftware version number

4. If the latest software version at the Web site is newer than the version on your

instrument, you need to upgrade the software.

5. Download the latest version to your PC.

6. After the software package is downloaded, click on the self-extracting archive

to extract the following files into the directory of your choice: transfer.exe

and firmware.pkg. There may also be a readme.txt file.

WFM720UP, WFM820UP, and WFM830UP Upgrades 11

Page 16

Upgrade Installation

USB Software Installation

To perform the u

pgrade, you can use either the USB Software Installation

procedure or the Network Software Installation procedure. The time required to

complete the upgrade is about 25 minutes.

CAUTION. Once the instrument has started to e rase internal flash, DO NOT

remove power from the instrument. If you do so, the instrument flash will be

corrupted. The instrument will have to be sent to a Tektronix factory service

center to ha

ve the system software restored.

NOTE. If power to the instrument is lost before it begins erasing the internal flash,

you can re

start the software upgrade after the instrument reboots.

Use the following steps to upgrade the instrument software using a USB memory

device.

1. Insert the USB memory device into a USB port (of the PC containing the

software).

latest

2. On the PC, navigate to the USB device.

3. On the USB device, create a directory named:

WfmUpgrd

4. Open the WfmUpgrd directory and copy the firmware.pkg file (from the

extracted archive) to the USB device.

You should have a directory path

WfmUpgrd\firmware.pkg.

5. Safely remove the USB device from the PC and insert it into the USB port

on the front panel of the instrument.

6. Power on the instrument.

ress the CONFIG front panel button.

7.P

8. Navigate to Utilities > System Upgrade > Upgrade Options > USB

pgrade.

U

NOTE. If the instrument displays a message indicating that a USB device

containing firmware was not detected, make sure you have the correct directory

path on the USB device. Also, press the MAIN front panel button to check that

the USB device is properly mounted.

12 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 17

Upgrade Installation

Network Software

Installat

ion

9. Press the SEL fr

window.

10. Select Contin

to start the software upgrade.

During the u

upgrade status. Do not remove the USB device until the upgrade is complete.

Use the following steps to upgrade the instrument software using a network

connectio

1. Connect the instrument and PC to your local Ethernet network.

2. Power on the instrument.

3. Assign t

NOTE. The data-transfer utility requires that the instrument be assigned a valid

IP address. To allow network access to the instrument, the instrument must be

assigned a valid IP address for your network. Network addresses can be assigned

either manually or automatically using DHCP. If your network does not use

DHCP, you will have to manually enter the address for the instrument. To get a

IP address, contact your local LAN administrator.

valid

pgrade process, the instrument displays messages indicating the

n.

he instrument an IP address:

ont panel button. This displays the System Software Upgrade

ue from the System Software Upgrade window and press SEL

Alternatively, if you connect the PC directly to the instrument using an Ethernet

e, you can assign the instrument any IP address that is compatible with the

cabl

IP address of the PC.

ess the CONFIG button on the front panel.

a. Pr

b. Navigate to Network Settings > IP ConfigMode.

c. Select either Manual or DHCP as directed by your LAN administrator.

Select Manual if you are using an Ethernet cable to connect the PC

irectly to the instrument.

d

d. If you selected Manual mode, enter the IP address, subnet mask, and

gateway address as d irected by your LAN administrator. You need to

enter only an IP address if you are using an Ethernet cable to connect

the PC directly to the instrument.

NOTE. If you selected DHCP mode, the network automatically assigns the

instrument an IP address.

e. Press the CONFIG button on the front panel to close the menus.

WFM720UP, WFM820UP, and WFM830UP Upgrades 13

Page 18

Upgrade Installation

4. Prepare the ins

a. Press the CONFIG front panel button.

b. Navigate to Utilities > System Upgrade > Upgrade Options > Network

Upgrade.

c. Press the SEL front panel button. Note the IP address of the instrument

displayed in the System Software Upgrade window.

5. Perform the software upgrade:

a. On the PC, double-click the transfer.exe file to launch the transfer

program.

b. Type the IP address or DNS name of the instrument you are upgrading,

andthenpressEnter. This starts the software upgrade process.

CAUTION. To prevent upgrade failure, do not close the transfer.exe window

he transfer utility asks for another IP address.

until t

When the software upgrade completes, the instrument may reboot.

c. The tr

When the software upgrade completes, the instrument will reboot.

trument for the software upgrade:

ansfer utility displays done when the software upgrade completes.

Figure 1: Sample of transfer.exe window after the upgrade is complete

6. If the instrument did not reboot at the completion of the software upgrade,

remove and then reapply power to the instrument to cause it to reboot.

14 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 19

Upgrade Installation

Install the Op

tion Hardware

WAR N ING. Before installing any hardware option, disconnect the power cord

from the line voltage source. Failure to do so could cause serious injury or death.

CAUTION. To prevent upgrade failure, your instrument must have the latest

version of software installed before you install the hardware upgrade. (See

page 11, Install the Software Upgrade.)

The procedures in this section are for upgrades that require the installation of

hardware modules. For software-only upgrades, you do not need to remove the

instrument cover since these upgrades are enabled by the new software key you

received with this kit.

NOTE. I

you only need to install the option software key. (See page 28, Install the Option

Software Key.)

The hardware installation procedure consists of the following steps:

f you are only installing software-only upgrades (Option 3G or PROD),

ving the instrument cover and the module guide brackets

Remo

Installing the new hardware

Reinstalling the module guide brackets and the instrument cover

WFM720UP, WFM820UP, and WFM830UP Upgrades 15

Page 20

Upgrade Installation

Locations of the Optional

Hardware Modules

The modules for

locations. (See Figure 2.)

Figure 2: Rear panel showing the locations of the optional modules

the hardware options can be installed only in the specific

Remove the Instrument

Cover and Module Guide

Brackets

If you are installing an upgrade option that includes hardware installation, perform

the following steps to remove the instrument cover and module guide brackets.

WARNING. Disconnect the power source from the instrument before beginning

this or any procedure requiring you to remove the cover from the instrument

is. Fan blades and other components inside the instrument could cause

chass

serious injury if power is on while the instrument chassis is open.

1. Remo

2. If necessary, remove the instrument from the portable cabinet or rack adapter

3. Place the instrument on a static-safe work surface. Be sure to follow safe

4.R

ve power from the instrument.

eve.

sle

ndling procedures to avoid electrostatic damage to the instrument or

ha

module.(Seepage10,How to Prevent Electrostatic Discharge.)

emove the screws from the chassis cover. (See Figure 3.) Save the screws

for reinstallation.

16 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 21

Upgrade Installation

Figure 3: Removing the chassis cover

5. Slide the chassis cover toward the back of the instrument, and then lift and

remove the chassis cover from the instrument.

6. Remove the module guide brackets. (See Figure 4.) Note that the brackets are

keyed to the fit on the chassis in only one direction.

Figure 4: Removing the module guide brackets (option boards shown)

WFM720UP, WFM820UP, and WFM830UP Upgrades 17

Page 22

Upgrade Installation

Hardware Installation

WFM82UP EYE

WFM83UP PHY

WFM72UP PHY3

For O ption EYE a

steps to install the option m odule into the instrument. Read the entire installation

procedure before installing the module.

NOTE. Option EYE and Option PHY and PHY3 each occupy the same

compartment in the instrument. If your instrument already contains a module

in Slot 1, it must be removed.

If removing an option module is necessary, you c an reinstall the removed option

module if you require its functionality.

1. Remove th

screws for reinstallation.

2. Remove t

and lifting the module straight up and out of the box.

NOTE. If you have difficulty removing or installing a module or rear panel

because of a lack of clearance with an adjacent rear panel, loosen the screws on

the adjacent panel to allow more room for moving the desired module or rear

panel while you are performing this procedure.

nd Option PHY or PHY3 upgrades, perform the following

e three screws from the SDI rear panel. (See Figure 5.) Save the

he SDI module by disconnecting the connectors from the main board

Figure 5: Removing the Option EYE/PHY/PHY3 and CPS rear panel screws

18 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 23

Upgrade Installation

3. Install the new

fully inserting the two connectors on the module into J16 and J24 on the Main

Interface board. The recessed flange on the left side of the module rear panel

slides behind the adjacent rear panel. (See Figure 6.)

Option EYE or PHY or PHY3 module into the instrument,

Figure 6: Installing the Option EYE or PHY or PHY3 board

WFM720UP, WFM820UP, and WFM830UP Upgrades 19

Page 24

Upgrade Installation

Hardware Installation

WFM82UP 2SDI

WFM83UP

2SDI

WFM72UP 2SDI

4. Perform the fol

install. Otherwise, proceed to installing the next module.

a. Install the th

Figure 5.) Tighten the three screws and any adjacent rear panel screws

you loosened to 8 in/lbs.

b. Reinstall the instrument module support brackets and cover by performing

the removal procedure in reverse order. (See page 16, Remove the

Instrument Cover and Module Guide Brackets.)

c. Install the option software key. (See page 28, Install the Option Software

Key.)

For Option 2SDI upgrades, perform the following steps to install the Option

2SDI module into the instrument. Read the entire installation procedure before

installing the module.

NOTE. Option CPS and Option 2SDI boards occupy the same location in the

instrument. If your instrument already c ontains an Option CPS board, it must

be rem

functionality.

oved. You can reinstall the removed option module if you require its

lowing steps if you do not have any other hardware modules to

ree screws into the Option EYE/PHY/PHY3 rear p anel. (See

20 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 25

Upgrade Installation

1. Remove the four

remove the panel. Save the screws for reinstallation.

NOTE. If you have difficulty removing or installing a module or rear panel

because of a lack of clearance with an adjacent rear panel, loosen the screws on

the adjacent panel to allow more room for moving the desired module or rear

panel while you are performing this procedure.

screws from the Slot 2 rear panel. (See Figure 7.) Then

Figure 7: Removing the Slot 2 rear-panel screws

2. Install the Option 2SDI module supplied with this kit into the instrument,

fully inserting the connectors on the module into J17 and J20 on the Main

rface board. The recessed flange on the left side of the module rear panel

Inte

slides behind the adjacent rear panel.

3. Perf

NOTE. Once the hardware is installed, you must download the software to

activate Option 2SDI. Go to www.tektronix.com/downloads. (See page 11, Install

the Software Upgrade.)

orm the following steps if you do not have any other hardware modules to

install. Otherwise, proceed to installing the next module.

a. Ins

b. Re

c. Install the option software key. (See page 28, Install the Option Software

tall the four screws into the Option 2SDI rear panel. Tighten the four

screws and any adjacent rear panel screws you loosened to 8 in/lbs.

install the instrument module support brackets and cover by performing

the removal procedure in reverse order. (See page 16, Remove the

Instrument Cover and Module Guide Brackets.)

Key.)

WFM720UP, WFM820UP, and WFM830UP Upgrades 21

Page 26

Upgrade Installation

Hardware Installation

WFM82UP CPS

WFM83UP CPS

WFM72UP CPS

For Option CPS u

CPS module into the instrument. Read the entire installation procedure before

installing the module.

1. Remove the four screws from the Slot 2 rear panel. (See Figure 7.) Then

remove the panel. Save the screws for reinstallation.

NOTE. If you have difficulty removing or installing a module or rear panel

because of a lack of clearance with an adjacent rear panel, loosen the screws on

the adjacent panel to allow more room for moving the desired module or rear

panel whil

e you are performing this procedure.

pgrades, perform the following steps to install the Option

Figure 8: Removing the Slot 2 rear-panel screws

2. Install the Option CPS module supplied with this kit into the instrument, fully

rting the connector on the module into J20 on the Main Interface board.

inse

The recessed flange on the left side of the module rear panel slides behind

the adjacent rear panel.

3. Perform the following steps if you do not have any other hardware modules to

install. Otherwise, proceed to installing the next module.

a. Install the four screws into the Option CPS rear panel. Tighten the four

screws and any adjacent rear panel screws you loosened to 8 in/lbs.

b. Reinstall the instrument module support brackets and cover by performing

the removal procedure in reverse order. (See page 16, Remove the

Instrument Cover and Module Guide Brackets.)

c. Install the option software key. (See page 28, Install the Option Software

Key.)

22 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 27

Upgrade Installation

Hardware Installation

WFM82UP AD

WFM83UP AD

WFM72UP AD

For the Option A

audio module into the instrument. Read the entire installation procedure before

installing the module.

1. Remove the four screws from the audio rear panel. Save the screws for

reinstallation. (See Figure 9.)

2. Remove the audio rear panel.

NOTE. If you have difficulty removing or installing a module or rear panel

because of a lack of clearance with an adjacent rear panel, loosen the screws on

the adjacent panel to allow more room for moving the desired module or rear

panel while you are performing this procedure.

D audio upgrade, perform the following steps to install the

Figure 9: Removing the audio rear panel screws

3. On the new audio module, carefully squeeze the two circuit boards together

near the inter-board connector and verify that the connector is fully seated.

eFigure10.)

(Se

4. Install the new audio module into the instrument, fully inserting the module

nnector into J4 on the Main Interface board. The recessed flange on the left

co

side of the module rear panel slides behind the adjacent rear panel.

WFM720UP, WFM820UP, and WFM830UP Upgrades 23

Page 28

Upgrade Installation

Figure 10: Checking the inter-board connection

NOTE. Use the supplied 62-pin DSUB connector to attach analog-audio signals

to the instrument. Solder wires to the connector as needed to accommodate the

desired audio inputs and outputs. Refer to the Safety and Installation Instructions

for the c

onnector pin assignments.

Audio signals can be connected as either balanced or unbalanced. Be sure to use

asuita

cable is Belden 8451, which is a shielded twisted pair cable.

Alter

012-1688-00), which provides a two meter cable with XLR connectors for all

twelve inputs and eight outputs.

5. Perform the following steps if you do not have any other hardware modules to

ble cable when you are wiring balanced audio. An example of a suitable

natively, you can purchase an audio breakout cable (Tektronix part number

install. Otherwise, proceed to installing the next module.

a. Install the four screws into the audio rear panel. Tighten the four screws

and any adjacent rear panel screws you loosened to 8 in/lbs.

b. Reinstall the instrument module support brackets and cover by performing

the removal procedure in reverse order. (See page 16, Remove the

Instrument Cover and Module Guide Brackets.)

c. Install the option software key. (See page 28, Install the Option Software

Key.)

24 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 29

Upgrade Installation

Hardware Installation

WFM82UP DPE

WFM83UP DPE

WFM72UP DPE

For the Option D

audio module into the instrument. Read the entire installation procedure before

installing the module.

1. Remove the four screws from the audio-options rear panel. (See Figure 11.)

Save the screws for reinstallation.

2. Remove the audio-options rear panel.

NOTE. If you have difficulty removing or installing a module or rear panel

because of a lack of clearance with an adjacent rear panel, loosen the screws on

the adjacent panel to allow more room for moving the desired module or rear

panel while you are performing this procedure.

PE audio upgrade, perform the following steps to install the

Figure 11: Removing the a udio rear panel screws

WFM720UP, WFM820UP, and WFM830UP Upgrades 25

Page 30

Upgrade Installation

3. On the new audio

near the inter-board connector and verify that the connector is fully seated.

(See Figure 10.)

Figure 12: Checking the inter-board connection

4. Install the Dolby E module supplied in this kit into J631 of the audio module.

Fully insert the connector on the Dolby E module into the socket on the audio

module, and then rotate the Dolby E module in towards the audio module

until the Dolby E module latches into position. (See Figure 13.)

module, carefully squeeze the two circuit boards together

Figure 13: Installing the Dolby E module

26 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 31

Upgrade Installation

5. Install the new

connector into J4 on the Main Interface board. The recessed flange on the left

side of the module rear panel slides behind the adjacent rear panel.

NOTE. Use the supplied 62-pin DSUB connector to attach analog-audio signals

to the instrument. Solder wires to the connector as needed to accommodate the

desired audio inputs and outputs. Refer to the Quick Start User Manual for the

connector p

Audio signals can be connected as either balanced or unbalanced. Be sure to use

a suitable

cable is Belden 8451, which is a shielded twisted pair cable.

Alternat

012-1688-00), which provides a two meter cable with XLR connectors for all

twelve inputs and eight outputs.

6. Perform the following steps if you do not have any other hardware modules to

install. Otherwise, proceed to installing the next module.

a. Install the four screws into the audio rear panel. Tighten the four screws

in assignments.

cable when you are wiring balanced audio. An example of a suitable

ively, you can purchase an audio breakout cable (Tektronix part number

and any adjacent rear panel screws you loosened to 8 in/lbs.

audio module into the instrument, fully inserting the module

b. Reinstall the instrument module support brackets and cover by performing

the removal procedure in reverse order. (See page 16, Remove the

Instrument Cover and Module Guide Brackets.)

c. Install the option software key. (See page 28, Install the Option Software

Key.)

WFM720UP, WFM820UP, and WFM830UP Upgrades 27

Page 32

Upgrade Installation

Install the Op

tion Software Key

Read the entire procedure before installing the software option key.

CAUTION. To prevent upgrade failure, your instrument must have the latest

version of s

installing the option key. (See page 11, Install the Software Upgrade.)

1. Verify tha

2. Verify the IP address of the instrument:

a. Press the CONFIG button on the front panel.

b. Navigate to Utilities > Communications > Network Setup.

c. Note the IP address of the instrument.

d. If the instrument does not have an IP address set, ask your network

administrator for a valid IP address. Refer to the online help or the User

manual on how to set the instrument IP address.

3. Verify that you have access to a PC with a Web browser application that is

connected to a network with access to the instrument.

oftware installed before installing the hardware upgrade a nd before

t the instrument is powered on and connected to your local network.

4. Perform the following steps to enter the software option key:

a. On the PC, open your Web browser application.

b. In t

c. Click the Instrument Options linktoopentheActive WFM8200/8300

d. In the Key field, enter the 20-character option key string (with or without

e. Click the Submit button to enable the software option. The instrument

NOTE. If you purchased multiple options, the software option key supplied with

this kit activates all of the options you purchased.

he address bar of the Web browser, enter the IP address of

the instrument you are upgrading. This opens the Tektronix

WFM8200/WFM8300 Remote Interface screen.

Options screen.

dashes). The new option key is supplied in the Important Documents

envelope.

enables the option and adds the installed option to the list of currently

installed options shown at the top of the screen.

28 WFM720UP, WFM820UP, and WFM830UP Upgrades

Page 33

Verify the Upgrade

Verify the Upg

Quick Verification

rade

Perform the

installed and the instrument is functioning correctly:

1. Power on the

2. Verify the installed options by performing the following steps:

a. Press the CONFIG button on the front panel.

b. Navigate to Utilities > View Instrument Options to display the installed

c. Verify that the options installed prior to this upgrade are still enabled, and

NOTE. If the option(s) you just installed are not listed or if your previously

led options are not listed, contact Tektronix for assistance.

instal

3. Verify that the instrument passes the advanced diagnostic tests by performing

the f

following procedure to verify that the new option(s) have been

instrument.

options.

that the new option(s) you installed are enabled.

ollowing steps:

Detailed Verification

a. In the Config menu, navigate to Utilities > Run Diagnostics.

b. Press the SEL button.

c. Press the right arrow key to highlght the box next to Run Advanced

Diagnostics. This box is located at the bottom of the display screen.

d. Verify that for each diagnostic test the result reads Pass.

e. When the test is complete, press the right arrow key to highlight the box

next to Exit to exit the diagnostics display.

f. If you want to view the diagnostics test results again, select View

Diagnostic Log from the Utilities menu.

NOTE. If a diagnostic test fails, contact Tektronix for assistance.

If you want to perform additional verification of the installed options, perform

the Incoming Inspection Tests found in the Specifications and Performance

Ver ification manual using the specified test equipment.

WFM720UP, WFM820UP, and WFM830UP Upgrades 29

Loading...

Loading...