Page 1

Service Manual

WFM700 Series

Waveform Monitors

071-0915-04

This document applies to firmware version 1.3.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products re turned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or c onnection to incompatible equipment; c) to repair any

damage or malfunc tion caused by the use of non-Tektronix supplies; or d) to service a product that ha s been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENT AL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary vii...................................

Service Safety Summary ix....................................

Preface xi...................................................

Manual Content xi.................................................

Manual Conventions xi..............................................

Related User Documents xii..........................................

Related Reference Documents xiii......................................

Contacting Tektronix xiv.............................................

Theory of Operation

Operating Conditions 1--1.............................................

Overview 1--1.......................................................

Individual Module Descriptions 1--2.....................................

Diagrams 1--7.......................................................

Performance Verification

Prerequisites 2--1....................................................

Test Equipment Required 2--2..........................................

Performance Verification Conditions 2--4.................................

Self Tests 2--4.......................................................

Functional Tests 2--6.................................................

Performance Tests 2--9................................................

WFM700 Audio (Option DG) Performance Verification Procedure 2--50.........

WFM700/WFM7M Input Module Test Record 2--57.................

WFM700/WFM7A Input Module Test Record 2--63..................

WFM700/WFM7HD Input Module Test Record 2--67................

WFM700 Audio Module (Option DG) Test Record 2--71..............

Adjustment Procedures

Adjustments 3--1..............................................

Manual Adjustment Procedures 3--3.....................................

Instrument Driven Procedures 3--11......................................

WFM700 Series Waveform Monitors S ervice Manual

i

Page 6

Table of Contents

Maintenance

General Maintenance 4--1......................................

Firmware Upgrades 4--1..............................................

Preventing ESD 4--2.................................................

Inspection and Cleaning 4--3...........................................

Removal and Installation Procedures 4--7.........................

Cabinet 4--8........................................................

Chassis Cover 4--9...................................................

Plug-In Modules 4--11.................................................

Power Supply 4--18...................................................

Front End Assembly 4--19..............................................

Fans 4--22...........................................................

Fan Assembly 4--23...................................................

Main Circuit Board 4--25...............................................

Troubleshooting 4--27...........................................

Check for Problems 4--27..............................................

Diagnostics 4--30.....................................................

LED Fault Codes 4--32................................................

Troubleshooting Trees 4--33............................................

Repackaging Instructions 4--41...................................

Replaceable Parts

Replaceable Parts 5--1..........................................

Parts Ordering Information 5--1.........................................

Module Servicing 5--2................................................

Using the Replaceable Parts List 5--2....................................

ii

WFM700 Series Waveform Monitors S ervice Manual

Page 7

List of Figures

Table of Contents

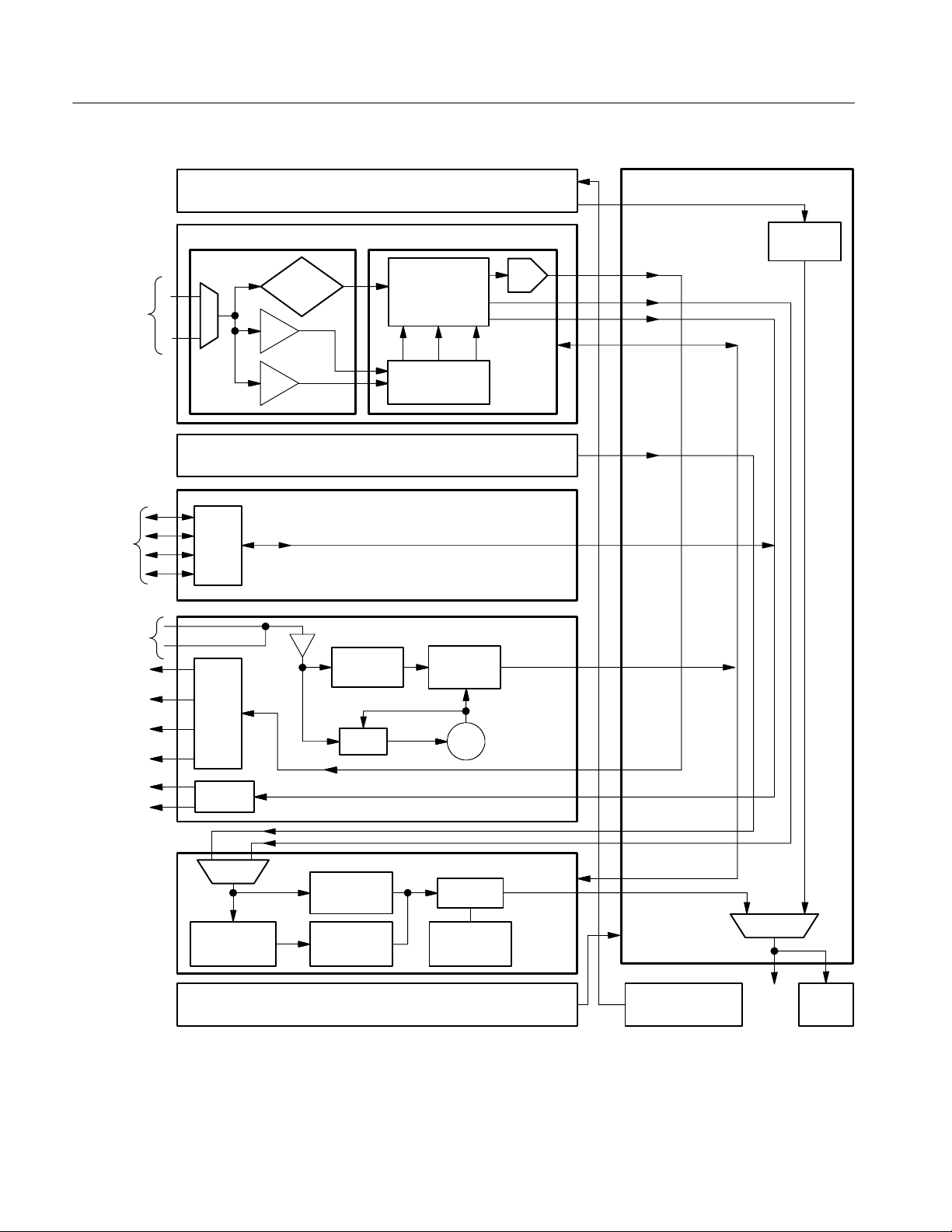

Figure 1--1: WFM700 signal flow block diagram 1--8................

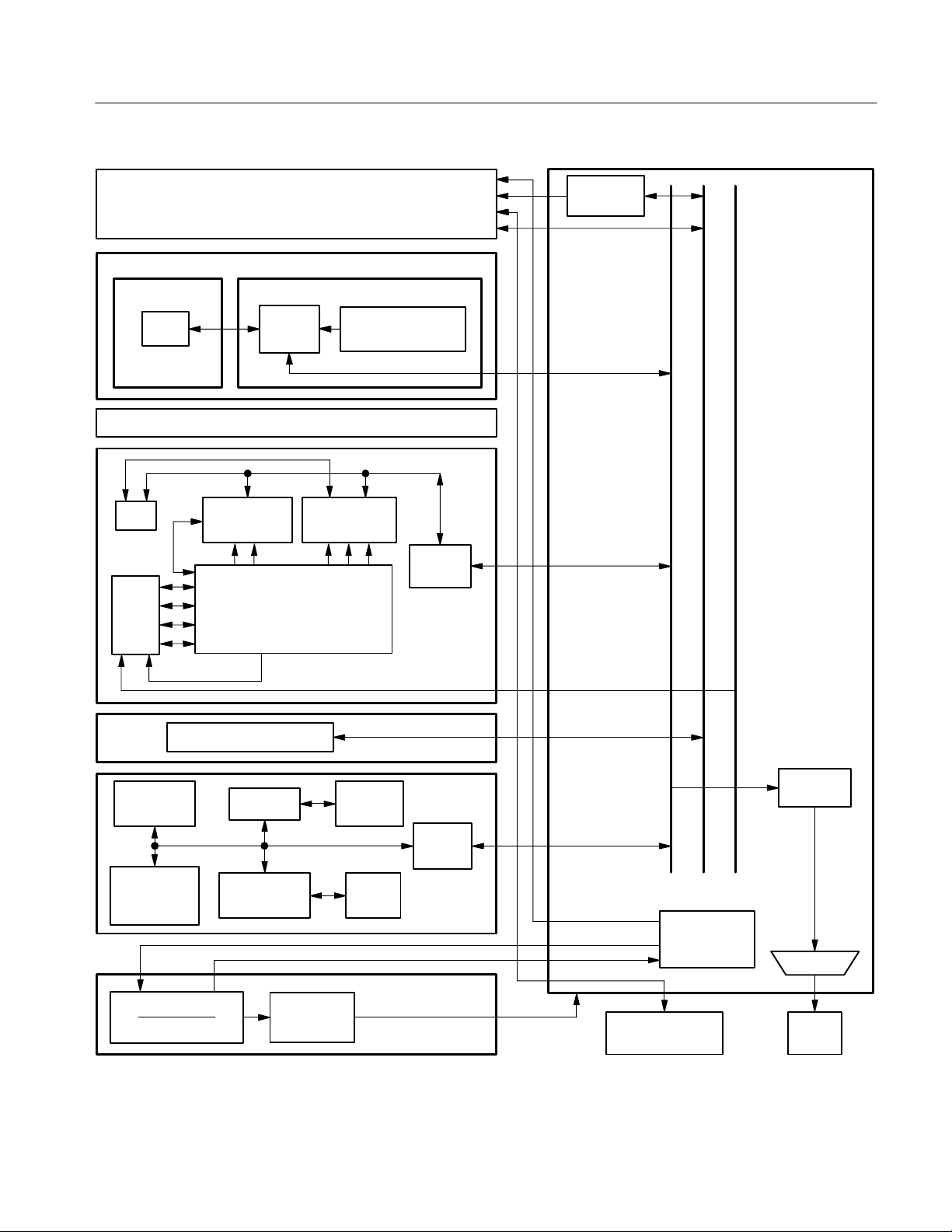

Figure 1--2: Control flow block diagram 1--9.......................

Figure 2--1: Signal data paths performance verification screen one 2--12.

Figure 2--2: Signal data p ath s performance verification screen two 2--12.

Figure 2--3: Serial video output level performance verification

screen 2--17................................................

Figure 2--4: SD PIX MON output level performance screen 2--18.......

Figure 2--5: HD pix G/Y video output level performance screen 2--20...

Figure 2--6: HD pix B/Pb and R/Pr video output level performance

screen 2--21................................................

Figure 2--7: SD pix video output level performance screen 2--22........

Figure 2--8: HD GBR frequency response performance screen 2--26.....

Figure 2--9: SD GBR frequency response performance screen 2--28.....

Figure 2--10: Eye vertical scale reference level screen 2--30............

Figure 2--11: Eye vertical scale performance screen 2--31..............

Figure2--12:Eyetimebasejitterperformancescreen 2--35............

Figure 2--13: Eye clock recovery bandwidth performance screen 2--37..

Figure 2--14: Eye clock recovery bandwidth performance screen 2--42..

Figure 2--15: Jitter gain check performance screen 2--45..............

Figure 2--16: Eye pattern display signal bandwidth performance

screen 2--47................................................

Figure 3--1: Adjustment locations on the video module 3--3...........

Figure 3--2: Serial out amplitude adjustment screen 3--5.............

Figure 3--3: SD PIX monitor adjustment screen 3--6.................

Figure 3--4: SD PIX G/Y output adjustment screen 3--8..............

Figure 3--5: SD PIX B/Pb and R/Pr output adjustment screen 3--8.....

Figure 3--6: HD PIX G/Y output adjustment screen 3--10.............

Figure 3--7: HD PIX B/Pb and PIX R/Pr output adjustment screen 3--10

Figure 3--8: Calibration routines menu 3--11........................

Figure 3--9: Eye vertical scale reference amplitude screen 3--13........

Figure 3--10: Eye vertical scale adjustment screen 3--14...............

Figure 3--11: SD Jitter gain adjustment screen 3--16..................

Figure 3--12: HD Jitter gain adjustment screen 3--18.................

WFM700 Series Waveform Monitors S ervice Manual

iii

Page 8

Table of Contents

Figure 3--13: Eye loop BW one UI adjustment screen 3--18............

Figure 3--14: Jitter HPF adjustment screen 3--23....................

Figure 4--1: Cabinet attaching screws 4--8.........................

Figure 4--2: WFM700 chassis cover, showing screws to loosen

and remove 4--10............................................

Figure 4--3: Plug-in module retaining screws 4--11...................

Figure 4--4: Grounding clip between two video modules 4--12..........

Figure 4--5: Removing a plug-in module 4--13.......................

Figure 4--6: WFM700 rear panel showing slot numbers 4--15..........

Figure 4--7: Inserting a module into the chassis 4-- 16.................

Figure 4--8: Installing the grounding clip between two video

modules 4--17...............................................

Figure 4--9: Front panel assembly 4--20............................

Figure 4--10: Keyboard access 4--21...............................

Figure 4--11: Fan assembly mounting 4--24.........................

Figure 4--12: Main circuit board securing screws 4--25................

Figure 4--13: Primary troubleshooting procedure 4--34...............

Figure 4--14: LED fault troubleshooting tree 1 4--35..................

Figure 4--15: LED fault troubleshooting tree 2 4--36..................

Figure 4--16: Blank screen troubleshooting tree 4--37.................

Figure 4--17: Front panel buttons and touch panel troubleshooting

tree 4--38..................................................

Figure 4--18: Diagnostics errors troubleshooting tree 4--39............

Figure 4--19: Audio (Option DG) diagnostics errors troubleshooting

tree 4--40..................................................

Figure 5--1: WFM700 replaceable circuit boards and cables 5--8......

Figure 5--2: WFM700 power supply assembly and rear panel

(B010999 and below) 5--10....................................

Figure 5--3: WFM700 replaceable chassis parts 5--13.................

Figure 5--4: WFM700 Audio board option DG 5--15..................

iv

WFM700 Series Waveform Monitors S ervice Manual

Page 9

List of Tables

Table of Contents

Table 2--1: T est equipment for performance verification 2--2.........

Table 3--1: Test equipment for adjustment procedures 3--2...........

Table 4--1: External inspection check list 4--4......................

Table 4--2: Internal inspection check list 4--5......................

Table 4--3: Tools required for module removal 4--7.................

Table 4--4: Failure symptoms and possible causes 4--27...............

Table 4--5: LED fault codes 4--32.................................

WFM700 Series Waveform Monitors S ervice Manual

v

Page 10

Table of Contents

vi

WFM700 Series Waveform Monitors S ervice Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. T o avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Replace Batteries Properly. Replace batteries only with the proper type and rating

specified.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

WFM700 Series Waveform Monitors S ervice Manual

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

viii

WFM700 Series Waveform Monitors S ervice Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

WFM700 Series Waveform Monitors S ervice Manual

ix

Page 14

Service Safety Summary

x

WFM700 Series Waveform Monitors S ervice Manual

Page 15

Preface

Manual Content

Manual Conventions

This is the service manual for the WFM700HD, WFM700A, and WFM700M

multi-format, multi-standard waveform monitors.

Read this preface to learn how this manual is structured, what conventions it

uses, and where you can find other i nformation related to servicing this product.

This manual contains only information related to servicing the WFM700

instrument. For information related to installing and operating the instrument or

for a list of instrument specifications, refer to the appropriate user document as

described in Related User Documents on the following page.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

Module

Plug-in Module

Replaceable Parts

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

The term module refers to a collection of items that are replaceable as a unit. A

module may contain electrical and mechanical assemblies, circuit boards, and

interconnecting cables.

The term Plug-in Module refers to the units that plug into the Main board.

This manual refers to any field-replaceable assembly or mechanical part by its

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly that is listed in t he Replaceable Parts section.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual.

Be sure to read both the General Safety Summary and Service Safety Summary

before performing any service to this instrument.

WFM700 Series Waveform Monitors S ervice Manual

xi

Page 16

Preface

Related User Documents

The following related English user documents are available if you need more

information about operating the instrument. These documents are located on the

WFM700 User Documentation CD-ROM or can be downloaded from the

Tektronix, Inc. Web site (www.tektronix.com).

H WFM700 User Manual. This document provides the basic information you

H WFM700 Series T echnical Reference (English). Contains the following

need to install and operate the instrument. Included is a listing of the options

and accesories available for the instrument.

technical information about the instrument:

H Electrical and physical specifications, including a list of certifications

and compliances

H Descriptions of each menu selection, the status displays, and the Option

DG audio displays

Non-English Language

Documents

H Instructions for operating the instrument using remote control, including

the ground closure, Web server , and SNMP interfaces

H Procedures for checking the basic functions of the instrument, for

upgrading the instrument firmware, and for performing the user-service

tasks such as cleaning and maintenance, cabinet and rack adapter

installation, and module installation or replacement

H WFM700 Release Notes. This document describes new features provided by

a firmware release and also describes problems or behaviors that you might

encounter while using the waveform monitor.

H WFM700 Series SNMP MIB Reference (English). Describes the syntax of the

variables and traps for remotely controlling the instrument over a network

using SNMP.

The following non-English language documents are available:

H WFM700 Series User Documentation Package (Japanese). Contains a

printed Japanese language user manual and the CD-ROM described on the

previous page.

H WFM700 Series User Documentation Package (Korean). Contains a

printed Korean language user manual and the CD-ROM described on the

previous page.

xii

WFM700 Series Waveform Monitors S ervice Manual

Page 17

Related Reference Documents

The following related reference documents are available at the Tektronix, Inc.

website (www.tektronix.com):

H Preventing Illegal Colors. This application note describes how the Diamond,

Arrowhead, and Lightning displays on the waveform monitor can be used to

help prevent the undesired impact of color gamut violations and to simplify

the assessment of proper gamut compliance.

H Understanding Colors and Gamut. This poster provides a large visual

display of how the Diamond, Arrowhead, and Lightning displays on the

waveform monitor can be used to help prevent the undesired impact of color

gamut violations.

H A Guide to Standard and High Definition Digital Measurements. This book

is a primer for understanding the basics for making standard and high-definition, digital-video measurements.

H Audio Monitoring. This application note describes balanced and unbalanced

audio signals, and explains the physical and electrical characteristics and the

specific strength and weaknesses of the different digital audio signal formats.

Preface

H Monitoring Surround Sound Audio. This application note describes the

basics of 5.1-channel surround sound audio and how to use the Surround

Sound display to visualize key audio-level and phase relationships in this

audio format.

WFM700 Series Waveform Monitors S ervice Manual

xiii

Page 18

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support www.tektronix.com/support

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific Standard Time

* This phone number is toll free in North America. After office hours, please leave a voice mail

message.

Outside North America, contact a Tektronix sales office or distributor; see the Tektronix Web

site for a list of offices.

xiv

WFM700 Series Waveform Monitors S ervice Manual

Page 19

Theory of Operation

Page 20

Page 21

Theory of Operation

This chapter contains a module-level description of the WFM700 instrument.

Two block diagrams are provided to aid the descriptions. Figure 1--1 on

page 1--8 shows the signal flow of the instrument and Figure 1-- 2 on page 1 --9

shows the control flow.

Operating Conditions

The electrical specifications of the instrument are listed in the WFM700 Series

Technical Reference document and apply over an ambient temperature range of

+0 _Cto+40_C. The rated accuracies are valid when the instrument is

calibrated in an ambient temperature range of +20 _Cto+30_C.

Overview

The WFM700 accepts either SD (Standard Definition) or HD (High Definition)

serial video data at the input connectors of an installed Input Module (in either

slots 1 or 2 of the WFM700 mainframe). The applied video signal i s sent to SD

and HD equalizers (to compensate for signal degradation due to cable loss) and

to the eye sampler. The compensated serial video signal is converted to parallel

video and a clock signal is recovered. The parallel signal is further processed to

extract the embedded audio signal, detect the video format, and generate an RGB

Analog video signal. The embedded audio is encoded into AES signals that are

sent to the optional Audio module by way of the audio bus.

The parallel video signal is sent to the Real-time Display module on a digital

bus, 10 bits for SD video and 20 bits for HD video. The RGB video is sent to the

Reference module on the analog bus for component video output at the P IX G/Y,

PIX B/Pb, and PIX R/Pr connectors and the VGA PIX MON connector.

The Real-Time Display module accepts the parallel video signal from the

selected Input Module. The video signal is processed to display the information

in various forms on the raster display. The output from the Real-Time Display

module is sent to the Main Interface board via LVDS pairs. There the video

signal is added with text and graticule information from the VGA controller. The

combined video signal is sent to the LCD and the EXT VGA output connector.

Timing is accomplished by using the clock and TRS (timing reference signal)

from the video input signal. A clock and and TRS (from an analog video signal)

can be input via the External Reference module using the AUX IN connector.

WFM700 Series Waveform Monitors S ervice Manual

1- 1

Page 22

Theory of Operation

Communication between modules and the CPU is accomplished via the Main

Interface board using two main control busses (PCI and Serial) and two RS232

connections. The Input Modules and Real-Time Display module use the PCI bus.

The Reference Module uses the Serial bus. The Front Panel uses RS232 to

communicate with the CPU which interprets the information and sends the

commands to the appropriate modules. The CPU also communicates with the

Environmental Controller (on the Main Interface board) via an RS232 connection.

Power for the WFM700 is provided by the power supply module. The power

supply module accepts line input voltages within the range of 100 VAC to

240 VAC. Anytime line input voltage is supplied to the power supply module, a

+5 V housekeeping supply is activated, providing power to the front panel

ON/STBY switch and to the Environmental Controller (EC) on the Main

Interface board. Pressing the ON/STBY button activates the main power supply

(within the Power Supply module), providing power to the entire instrument and

modules.

Once the power supply stabilizes, the CPU module polls all slots (via the PCI

bus and Serial Control bus) to determine the installed modules.

Individual Module Descriptions

The following descriptions provide more detail about the individual functions of

each instrument board or module.

Front Panel Processor

LCD and Backlight

The Front Panel Processor board sends all front panel actions (including the

touch screen) to the CP U board via the RS232 Bus.

The LCD panel displays the video output from the Main Interface board via the

VGA Mux. The Backlight board supplies the high voltage necessary to drive the

backlight for the LCD panel.

1- 2

WFM700 Series Waveform Monitors S ervice Manual

Page 23

Theory of Operation

Input Module

The Input module is comprised of two circuit boards, a Mezzanine board and an

Input board.

The Mezzanine board provides two terminating serial inputs, each supporting

either SD (SMPTE 259M) or HD (SMPTE 292M) SDI signals. A mux selects

between the two inputs and sends the signal to an eye pattern sampler block and

a serial receiver block (equalizing the signal). The eye pattern sampler block

implements a 3 GHz equivalent-time sampler to allow viewing the input eye

pattern. The equalized SD or HD signal and the eye pattern data samples are sent

to the Input board.

On the Input board, an SD or HD serial-to-parallel block provides clock recovery

and serial-to-parallel conversion of the selected input. An FPGA block multiplexes between the eye sampler output and serial receiver block output (depending on instrument mode), implements any needed waveform conditioning (such

as ancillary data extraction), and outputs the parallel signal (20 bits for HD

mode, 10 bits for SD mode) to the Real-Time Display (RTD) board. The FPGA

block also extracts up to eight channels of audio signal which is put on the audio

bus for future use.

A DAC block creates a picture monitor signal which is output through the VGA

PIX MON connector and the component video connectors (PIX G/Y, PIX B/Pb,

PIX R/Pr) on the Reference Module.

External Connectors

H INPUT A. Digital input for signal to be monitored. For WFM700HD, this

can only accept 1.485 Gb/s and 1.4835 Gb/s High Definition serial video.

For the WFM700A and WFM700M, this input can accept HD and 270 Mb/s

Standard Definition video. This is a 75 8 terminating input.

H INPUT B. Digital input for signal to be monitored. For WFM700HD, this

can only accept 1.485 Gb/s and 1.4835 Gb/s High Definition serial video.

For the WFM700A and WFM700M, this input can accept HD and 270 Mb/s

Standard Definition video. This is a 75 8 terminating input.

H SD PIX MON. This output is a copy of the PIX G/Y, B/Pb, R/Pr pix mon

output, but in reclocked SD serial digital format. It is operational only for

SD input formats.

H SERIAL OUT. Provides an equalized and buffered version of the selected

signal input (Video Input A or B).

H JITTER OUT. (WFM700M only) Provides a 75 8 output signal from the

jitter demodulator. This signal is only valid when the instrument is in Jitter

mode. Any signal present on this output at other times is not a calibrated

jitter signal.

WFM700 Series Waveform Monitors S ervice Manual

1- 3

Page 24

Theory of Operation

Reference Module

The External Reference module provides synchronization for the WFM700

instrument, allowing you to sync the display to an analog video input. The

Reference Module accepts PAL and NTSC signals with bi-level sync (SD) or

tri-level sync (HD) input, so that timing of the SDI input signals can be

compared to the analog sync reference. The External Reference module

automatically detects the input standard. The Reference Board timing signals are

available to both the Input Module and Real-Time-Display Module.

The sync signal from the External Reference module is embedded in a data

stream of 27 MHz (for SD video), and 74.25 MHz or 74.1758 MHz (for HD

video). This data stream is called the TR S signal, and contains H, V, and F

information. The External Reference module acts as a data hub or router for TRS

(timing reference signal) signals to and from the input modules (slots 0 or 1) and

the Real-Time Display module.

External Connectors

H REF IN LOOP-THROUGH. Compensated for 75 8 impedance; requires

proper termination at one end of the loop-through connector or at the

receiver in a monitored system. Provides for connection of an external

synchronization signal such as black burst or composite video.

H AUX IN. Future capability.

H VGA PIX MON. A copy of the PIX G/Y, B/Pb, R/Pr pix mon outputs. This

allows using an inexpensive VGA monitor for non-critical HD applications.

Most computer monitors will not lock to 50 Hz vertical rates or to Standard

Definition line rates, so this may not work in all applications.

H PIX G/Y, B /Pb, R/Pr. Provides three 75 8 component signal outputs to drive

a component picture monitor. You can set the output format to YPbPr or

RGB.

H AUX OUT 1 / AUX OUT 2. Future capability.

1- 4

WFM700 Series Waveform Monitors S ervice Manual

Page 25

Theory of Operation

Main Interface Board

The Main Interface board provides signal paths and communication paths

between all modules.

H PCI Bus and Serial Control Bus are used for control and data transfer. Both

go to all slots. The PCI Bus is typically used for modules requiring

high-speed performance and communication between modules without the

use of the CPU board. The Serial Control Bus is used for modules requiring

less control and speed.

H The Timing Bus is used to distribute the TRS signal to the Input Modules

and the RTD board.

H The Audio Bus routes the digital audio signal (extracted from the video

serial input) to the module slots for use by future modules.

H The Video Bus routes the parallel video signal (with clock and sync signals)

to the RTD slot from the two Input slots.

The Main Interface board provides power distribution, contains thermal sensors,

and contains the Environmental Controller (EC). The EC monitors the front

panel ON/STBY switch to control the main power supply (in the Power Supply

module) and monitors all low voltage power sensors for inaccurate voltage

levels.

The VGA Controller routes the video signal to both the LCD and the EXT VGA

output. This output can be used to drive an external monitor to produce the same

display as seen on the LCD.

External Connectors

H EXT VGA. Provides an exact copy of the LCD screen to drive an external

monitor.

WFM700 Series Waveform Monitors S ervice Manual

1- 5

Page 26

Theory of Operation

CPU Board

Real Time Display (RTD)

Board

The CPU board receives commands from the Front Panel (buttons, knobs, and

touch screen) via RS232 connections, then transmits instructions to the other

modules via the PCI bus and Serial bus. The CPU also defines the operation of

the video channels (but is not in the video signal path). All text and graticule

information for the LCD panel is generated by the CPU board and sent to the

LCD via the VGA Mux on the Main Interface board.

External Connectors

H REMOTE. 9 pin subminiature D-type connector used as a Ground Closure

interface for remote control.

H USB. This connector is not used and was removed for CPU board versions

671-4528-04 (SN B019999 and below) and 671-5751-03 (SN B024089 and

above).

H ETHERNET. (10/100 Base T). 10/100 Mbit/sec Ethernet interface. Used for

downloading firmware upgrades.

Real Time Display board receives the parallel digital video signal from the Input

module and processes the video data to display the information in various forms

on the raster display. The different forms of display consist of sweeps (overlay or

parade), x y (vectors, lighting, diamond, ect.), and picture monitor. The RTD

board handles either standard definition (SD) or high definition (HD) data. Only

one channel is processed at a time.

The RTD is divided into two logical sections. The first section, the DSP engine,

performs signal processing and routing operations to create standard waveform

monitor displays. The second section, the rasterizer engine, performs attack and

decay operations to simulate an analog CRT phosphor screen. The rasterizer also

has the ability to partition multiple displays into separate windows.

The RTD accepts a 10 or 20-bit data stream (SD or HD) from either of two input

slots. A polyphase interpolator increases the data rate and fills gaps in the data.

The higher data rate allows the rasterizer to plot more pixels per second to

improve the display quality. The Measurement Processing block produces

various waveform displays such as Parade, Vector, and Diamond and also

performs gain, offsetting, and filtering operations. It outputs pairs of numbers

used by the Rasterizer and its companion memory to build a display map.

Memory values are incremented or decremented depending on these number

pairs, varying pixel display brightness according to frequency of occurrence,

similar to a phosphor screen. A Picture Mode Processing block allows a raster

picture display of the input signal, suitably adjusted to the 640x480 VGA display

format. The Rasterizer output is applied to the color LCD display after it is

combined with any text and graticules from the VGA controller.

1- 6

WFM700 Series Waveform Monitors S ervice Manual

Page 27

Theory of Operation

Audio Module (Option DG)

The Audio board receives serial audio data in AES/EBU format from the

selected Input module, or from the AES I/O connectors if they are configured as

inputs. When configured as outputs, the AES I/O connectors supply AES/EBU

serial audio de-embedded from the selected video input. The selection of

extracted embedded audio groups takes place within the Input module.

AES/EBU signals from the selected source are processed to extract channel

status, validity, and parity bits. The audio data is examined for clip and mute

conditions, and word length (active bits) and peak values are determined. Audio

data is up-sampled to 192 kb/sec for further processing.

DSP processors compute audio level according to the configured level meter

ballistic. The CPU periodically polls the Audio Module to get the current audio

levels, and then draws the corresponding bars via the VGA controller. Other data

concerning audio (clip, mute, channel status etc) is communicated in a similar

fashion from the Audio Module to the CPU for display, data logging, or alarm

activation.

A DSP processor creates a Lissajous image that is periodically transferred

directly to the VGA controller via the PCI bus.

External Connectors

H AES 1-2 I/O / AES 3-4 I/O / AES 5-6 I/O / AES 7-8 I/O. Four AES/EBU

format, AES-3id compatible inputs or outputs. As outputs, they supply serial

audio de-embedded from the selected video input. As inputs, they can be

selected for complete processing and display in place of embedded audio.

Power Supply Module

Diagrams

The power supply module accepts line input voltages within the range of

100 VAC t o 240 VAC. Anytime line input voltage is supplied to the power

supply module, a +5 V housekeeping supply is activated, providing power to the

front panel ON/STBY switch and to the Environmental Controller (EC) on the

Main Interface board. The EC continuously polls the front panel ON/STBY

switch. Pressing the front panel ON/STBY button instructs the EC to activate a

relay in the power supply module, activating the Main Power supply. The Main

Power supply provides +5 V, +3.3 V, +12 V and --12 V to the circuits and other

modules via the Main Interface board. The EC monitors all power supply

voltages and shuts down the Main Power supply if a problem is detected.

Figure 1--1 on page 1-- 8 is a block diagram of the signal flow of the instrument.

Figure 1--2 on page 1--9 is a block diagram of the control flow.

WFM700 Series Waveform Monitors S ervice Manual

1- 7

Page 28

Theory of Operation

HD/SD

Serial In

AES

I/O

Ref In Loop

Through

VGA PIX Mon

PIX G/Y

PIX B/Pb

PIX R/Pr

A

B

Mezzanine

Board

I/O

Buffers

I/O

Buffers

Sampler

EQ

EQ

Eye

CPU

Board

SD

HD

Second

Input slot

Sync

Stripper

PLL Osc

FPGA for

Full-Speed Data

Massaging

HD SDClk

Serial to Parallel

Conversion

Generation

Input Module

Reference Module

TRS

DAC

HD/SD

Input

Board

Audio

Analog Bus

Main Interface Board

VGA

Controller

20 Bits at 75 MHz

plus clock and sync

Aux Out 1

Aux Out 2

Selector

Selector

Measurement

Processing

Picture Mode

Processing

Polyphase

Interpolator

Power Supply

Module

Figure 1- 1: WFM700 signal flow block diagram

1- 8

Audio Bus

RTD Module

Rasterizer

Fast Static

Memory

Timing Bus

Front panel controls

and touch screen

VGA MUX

output

WFM700 Series Waveform Monitors S ervice Manual

VGA

LCD

Panel

Page 29

Theory of Operation

CPU Board

Input Module

Mezzanine Board HD/SD Input Board

RAM

Control

I/O

Buffers

PLD

PCI

Interface

Second Input slot

DSP 0

Bars, Control

Hardware Processing

AES Receivers, Rate Converters,

FPGA

FPGA for Full-Speed

Data Massaging

Audio Module

DSP 1

Bars, Lissajous

PCI

Interface

Serial Bus

Multiplexer

Main Interface Board

PCI Bus

Audio Bus

Serial Control Bus

Control

TRS Generation and control

Measurement

Processing

Logic Devices

Polyphase

Interpolator

Housekeeping Supply

Power Relay

Rasterizer

Recursive and

Pix Processing

Main Power

Supply

Figure 1- 2: Control flow block diagram

Reference Module

Fast Static

Memory

SDRAM

Power Supply Module

RTD Module

PCI

Interface

RS232

On-Off

RS232

Front panel controls

and touch screen

Environmental

Controller “EC”

VGA

Controller

VGA MUX

LCD

Panel

WFM700 Series Waveform Monitors S ervice Manual

1- 9

Page 30

Theory of Operation

1- 10

WFM700 Series Waveform Monitors S ervice Manual

Page 31

Performance Verification

Page 32

Page 33

Performance Verification

This section contains three procedures to verify the operation of all models of the

WFM700 waveform monitor. This includes the Video modules (WFM7HD,

WFM7A, and WFM7M) and the Audio module (WFM7DG). Please disregard

checks that do not apply to the module type you are testing.

H Self Tests use the internal diagnostic routines to verify proper power-up,

modules recognized and operating, and signal paths. No external equipment

is required for these tests.

H Functional Tests verify that the waveform monitor and its installed modules

are operating correctly.

H Performance Tests verify that the waveform monitor and all its installed

modules meet the performance requirements listed in the Specifications

section of the WFM700 Series Technical Reference document. This section

also includes checks for operating parameters that are specified as typical but

are not guaranteed. Firmware version 1.3 or above is required to perform all

performance tests.

H Test Records are provided at the end of this chapter to record the results of

each performance test that checks a warranted characteristic.

Prerequisites

Before doing the performance verification procedures, note the following

prerequisites:

H Personnel — Users should be familiar with the operation of all test

equipment and the WFM700.

H Two V ideo Modules — The verification procedures must be performed on

both video modules if two are installed in the WFM700. Complete the entire

performance procedures on one video module at a time.

H Audio Module — The verification procedure for the Option DG Audio

module must be performed if the module is installed in the WFM700.

H Warm-up Period — Turn on the WFM700 and allow a 20-minute warm-up

period in an environment that meets the operating range specifications for

temperature and humidity. Verification of warranted characteristics done

before the operating temperature has stabilized might cause errors.

Also turn on other required test equipment and allow them to warm up for

their recommended time periods.

WFM700 Series Waveform Monitors S ervice Manual

2- 1

Page 34

Performance Verification

Test Equipment Required

Table 2--1 lists the test equipment required to perform all of the performance

verification procedures. Some equipment may not be necessary for your

waveform monitor. The procedures describe the input signal characteristics

necessary to perform the test. Where external test equipment is required, refer to

your test equipment’s user manual for instructions to obtain the correct signal.

Table 2- 1: Test equipment for performance verification

Test equipment Requirements Example

HD serial digital video

test signal generator

SD serial digital video

test signal generator

Analog video test signal generator

1080i 59.94 100% color bars

1080i 59.94 10-bit shallow ramp matrix

1080i 59.94 0% flat field

1080i 59.94 75% SMPTE color bars

1080i 59.94 100/0/100/0 color bars

1080i 59.94 100/0/75/0 color bars

1080i 50 100% color bars

1080i 60 100% color bars

720p 59.94 100% color bars

1080i 59.94 100% sweep 1 -- 30 MHz

1080i 59.94 100% flat field

1080i 59.94 20 -- 30 MHz multiburst

525-format 100% color bars

525-format 10-bit shallow ramp matrix

525-format 0% flat field

525-format 75% color bars

525-format 100% flat field

525 line 60% multiburst

PAL black

1080i 50 black

1080i 60 black

720p 59.94 black

Tektronix TG2000 with HDVG1

module

Tektronix TG2000 with DVG1

module

Tektronix TG2000 with AVG1

module

WFM700

Opt.

1

A HD M

D D D D

D D D

D D D

DG

RF generator 20 MHz to 2.5 GHz

<1 dB level flatness

10 Hz to 100 kHz phase modulation with < 3%

setting error

Sinewave generator Capable of 0.8 V

Digital audio generator/

analyzer

Test oscilloscope 2 GHz vertical bandwidth Tektronix TDS794 D D D D

35 kHz to 96 kHz sample rate range, jitter

measurement per AES--3 (1997)

at6MHzintoa508 load Rohde & Schwarz SMT03 Opt

p-p

2- 2

Rohde & Schwarz SMT03 Opt

SM--B2

50 8 N-to-BNC adapter

SM--B2

Rohde & Schwarz UPL06 Opt

B22, B29

D D D

WFM700 Series Waveform Monitors S ervice Manual

D

D

Page 35

Performance Verification

Table 2- 1: Test equipment for performance verification (cont.)

WFM700

1

Test equipment

RequirementsTest equipment

Requirements

Example

Example

VGA monitor with

cable

Autotransformer Output range 90 V to 264 V D D D

75 8 coaxial cables

(2 required)

General purpose digital video

Male-to-male BNC connectors

Belden 8281 D D D D

36 inches long

1

D D D

Opt.

DG

MHDA

75 8 coaxial cable

(1 required)

Low loss digital video

Male-to-male BNC connectors

Belden 1695A D D D

18 inches long

50 8 coaxial cables

(2 required)

Precision

Male-to-male BNC connectors

36 inches long

Tektronix part number

012-0482-00

D D D D

1.5% impedance and attenuation accuracy Tektronix AMT75 D D D

75 8-to-50 8 adapter

(for test oscilloscope

input)

Wideband

50 8-to-75 8 matching pad

90 meters and 325

meters of 75 8 cable

0to2.5GHz,

Rohde & Schwarz RAM D

N connectors,

75 8 N-to-BNC adapter

Low loss cable. Cable simulators can be used

Belden 8281 D D D

as substitutes as follows:

SD Cable Simulator Faraday SC75A800 B--G Cable

D D

Clone

HD Cable Simulator Faraday FFC Kit D D D

Return loss bridge 75 8 test port

50 8 input and output ports

Wide Band Engineering

A57TUC with male 75 8 BNC

D D D D

test port

Calculator Logarithmic function D D D D

1

You may need additional cables and adapters, depending on the actual test equipment you use.

WFM700 Series Waveform Monitors S ervice Manual

2- 3

Page 36

Performance Verification

Performance Verification Conditions

NOTE. Menu selections in the WFM700 Waveform Monitor differ between

firmware versions. The Performance Verification procedures assume you have

the latest firmware version installed in your instrument.

The following conditions must be met prior to doing these procedures:

1. The WFM700 Waveform Monitor must have been operating continuously

for twenty (20) minutes in an environment that meets the operating range

specifications for temperature and humidity.

2. Connect the WFM700 Waveform Monitor and the test equipment to the

same AC power circuit or to a common power strip if you are unsure of the

AC power circuit distribution.

Self Tests

This procedure uses i nternal routines to verify that the waveform monitor

functions and passes its internal self tests. No test equipment or hookups are

required.

1. Press the PRESET button.

2. Touch the -- m o r e -- soft key, then touch the Restore Factory soft key.

NOTE. Restoring factory settings overrides the current instrument state but does

not alter calibration or presets.

3. Press the CONFIG front panel button.

4. Touch System and then Diagnostics.

5. Touch Diagnostics, then View Diagnostic Log.

6. Touch **Erase** NVRAM Log to clear the log file.

7. Touch Back to Diags Menu.

8. Touch Run Full Powerup Diagnostics.

9. Touch Back to Diags Menu.

2- 4

10. Touch View Diagnostics Log.

11. CHECK the diagnostics log pages to verify that there are no red FAIL

messages.

WFM700 Series Waveform Monitors S ervice Manual

Page 37

Performance Verification

12. Touch **Erase** NVRAM Log to clear the log file.

13. Touch Back to Diags Menu.

14. Touch Run Internal Digital Path Diagnostics.

15. Read the screen text, and then touch Continue to acknowledge that a reboot

will be required. The diagnostic test will run.

16. CHECK for the following display properties:

a. Verify that four ramp patterns (bars) appear on the display as gray, blue,

green, and red.

b. Verify that each ramp pattern has brightness steps approximately every

1/16 inch.

c. Verify there are no color bands in the gray ramp display.

17. Press the flashing SELECT button to return to the diagnostics menu.

18. Touch View Diagnostics Log.

19. CHECK the diagnostics log pages to verify that there are no red FAIL

messages.

20. Touch **Erase** NVRAM Log to clear the log file.

STOP. Unless the WFM700 has the optional Audio module (Option DG), skip

down to step 28 to complete this procedure.

21. Touch Back to Diags Menu.

22. Touch Run Audio Path Diagnostics.

23. Read the screen text, and then touch Continue to acknowledge that a reboot

will be required. The diagnostic test will run.

24. Touch the Back to Diags Menu.

25. Touch View Diagnostics Log.

26. CHECK the diagnostics log pages to verify that there are no red FAIL

messages.

27. Touch **Erase** NVRAM Log to clear the log file.

28. Cycle the power to reboot the WFM700.

29. Press the PRESET button and touch the –more-- soft key.

30. Touch the Restore Factory soft key.

WFM700 Series Waveform Monitors S ervice Manual

2- 5

Page 38

Performance Verification

Functional Tests

These functional tests provide tests to check basic functionality of the inputs and

general operation prior to starting the Performance Tests. A more exhaustive

check of all functions and buttons is provided in the Technical Reference.

Preliminary Setup and

Test

The Preliminary Setup performs the following tasks:

H Sets the waveform monitor to a known state

H Provides instructions for test equipment setup used throughout the

Functional Tests

H Provides a preliminary check of the video input path and display

1. Press the PRESET button.

2. Touch the -- m o r e -- soft key, then touch the Restore Factory soft key.

Restoring factory settings overrides the current instrument state but does not

alter calibration or presets.

3. Connect a serial digital output from the HD video generator to INPUT A

using a 75 8 cable.

4. Set the HD video generator for a 1080i 59.94 100% color bars signal.

5. Connect a serial digital output from the SD video generator to INPUT B

using a 75 8 cable.

6. Set the SD video generator for a 525-format 100% color bars signal.

7. Press the INPUT button and touch the Input A soft key.

HD Input and Embedded

Audio Detection

2- 6

8. CHECK that an HD color bar signal is displayed.

9. Press the DISPLAY button. Adjust the Trace Settings, Graticule Settings,

and Readouts & Backlight settings for best viewing.

This procedure checks the input detection and audio disembedding data paths for

high definition video.

1. Press the WFM button.

2. Press the INPUT button and touch the Input A soft key.

3. Disable or disconnect the HD video generator signal to INPUT A.

4. CHECK that the red IInput UnlockedI message is displayed.

WFM700 Series Waveform Monitors S ervice Manual

Page 39

Performance Verification

5. Enable or reconnect the HD video generator signal to INPUT A.

6. CHECK that the red IInput UnlockedI message is gone.

7. Set the HD video generator for 2 groups of embedded audio, starting with

group 1.

8. Press the STATUS button.

9. Touch the Display soft key.

10. Touch the Session soft key and then touch the Done soft key.

11. Option DG only: Touch the Video Session soft key if necessary to select

Video Session.

12. CHECK that the embedded audio status reads as follows:

Embedded Audio: PPPP PPPP ---- ----

SD Input and Embedded

Audio Detection (WFM7A,

WFM7M only)

This procedure checks the input detection and audio disembedding data paths for

standard definition video.

1. Press the WFM button.

2. Press the INPUT button and touch the Input B soft key.

3. Disable or disconnect the SD video generator signal to INPUT B.

4. CHECK that the red IInput UnlockedI message is displayed.

5. Enable or reconnect the SD video generator signal to INPUT B.

6. CHECK that the red IInput UnlockedI message is gone.

7. Set the SD video generator for 2 groups of embedded audio, starting with

group 1.

8. Press the STATUS button.

9. Touch the Display soft key.

10. Touch the Session soft key and then touch the Done soft key.

11. Option DG only: Touch the Video Session soft key if necessary to select

Video Session.

12. CHECK that the embedded audio status reads as follows:

Embedded Audio: PPPP PPPP ---- ----

WFM700 Series Waveform Monitors S ervice Manual

2- 7

Page 40

Performance Verification

VGA Outputs

This procedure checks VGA PIX MON and EXT VGA outputs.

1. Connect a VGA monitor to the VGA PIX MON output.

2. Press the INPUT button and touch the Input A soft key.

3. Press the CONFIG button.

4. Touch the Video Inputs/Outputs soft key, then Next Menu.

5. Touch the Output Active for HD soft key.

6. Touch the RGB soft key.

7. CHECK that color bars are correctly displayed on the VGA monitor.

NOTE. Some VGA monitors do not synchronize correctly to color bars with

tri-level sync. If the picture is not locked, select a flat field signal from the

generator, then switch back to color bars.

8. Move the VGA monitor cable from the VGA PIX MON output to the EXT

VGA output.

9. CHECK that the external VGA display matches the display on the LCD.

10. Disconnect the test setup.

2- 8

WFM700 Series Waveform Monitors S ervice Manual

Page 41

Performance Tests

Performance Verification

The Performance Tests verify that the WFM700 waveform monitor (all models)

meets the warranted characteristics listed in the Specifications section of the

WFM700 Series T echnical Reference document. Characteristics with typical

specifications (not warranted) are also checked.

NOTE. WFM700 firmware version 1.3 or above is required to perform all tests in

this section. Verify the firmw are version and update if needed.

Power Source Ra nge

This test checks for stable operation over a varied AC input range.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the AC power cord from the WFM700 to the variable

autotransformer.

2. Power on both the autotransformer and the WFM700.

3. Connect the HD video generator to INPUT A using a 75 8 cable.

4. Set the HD video generator for a 1080i 59.94 100% Sweep1–30MHz

signal.

5. Press the INPUT button and select Input A.

6. Vary the autotransformer from 90 V to 264 V.

7. CHECK for a stable display and no error indications over the entire voltage

range.

8. Set autotransformer to 90 V.

9. Press the ON/STBY button to power off the WFM700.

10. Press the ON/STBY button to power on the WFM700.

11. CHECK that the WFM700 re-starts and after boot-up the HD color bar signal

is displayed.

12. Return the autotransformer setting to local nominal mains voltage.

WFM700 Series Waveform Monitors S ervice Manual

2- 9

Page 42

Performance Verification

Signal Data Paths

This test checks the digital data paths.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

The following characteristics are directly checked:

H Vertical Measurement Accuracy, YPbPr

H Vector Vertical Gain Accuracy

The following characteristics are indirectly checked:

H Frequency Response

H Sweep Accuracy and Linearity

H Vector Horizontal Gain Accuracy

H Vector Display to Graticule Registration

H Lightning and Diamond Vertical Gain Accuracy

H Arrowhead Signal to Graticule Registration

H Arrowhead Composite Limit Cursor Accuracy and Detection Level

Accuracy

1. Ensure that the Self Tests on page 2--4 have been performed and passed.

2. Connect the HD video generator to INPUT A using a 75 8 cable.

3. Press the INPUT button and select Input A.

4. Set the HD video generator for a 1080i 59.94 10-bit Shallow Ramp Matrix

signal.

5. Press the WFM button.

6. Touch Pr and Pb to turn off the color difference signals.

NOTE. The Y component must be on to allow both the Pr and Pb components to

be turned off.

2- 10

WFM700 Series Waveform Monitors S ervice Manual

Page 43

Performance Verification

7. CHECK that the steps in the displayed ramps are monotonic (all steps are in

the same direction) and approximately one pixel high. See Figure 2--1.

NOTE. If the steps are 4 pixels high, it may be that the input signal has only 8

bits of resolution.

8. Press the GAIN button.

9. Touch Gain: 10x.

10. CHECK that the steps in the ramps are 0.7 mV to 0.9 mV. (Use the voltage

cursors for this measurement.) See Figure 2--2.

11. Press the WFM button.

12. Touch Pb to turn on the Pb component.

13. Touch Y to turn off the Y component.

14. Press the GAIN button.

15. Touch Gain: 1x.

16. CHECK for step direction and height by repeating steps 7 through 10 above.

17. Press the WFM button.

18. Touch Y and Pr to turn these components back on. All components should

be on (Y, Pb, and Pr).

WFM700 Series Waveform Monitors S ervice Manual

2- 11

Page 44

Performance Verification

Cursors adjusted to

measure one step

Figure 2- 1: Signal data paths performance verification screen one

2- 12

Figure 2- 2: Signal data paths performance verification screen two

WFM700 Series Waveform Monitors S ervice Manual

Page 45

Performance Verification

Stop here for WFM7HD. The Signal Data Path procedure is now finished for the

WFM7HD Input Module. Continue with this check if testing a WFM7A or

WFM7M Input Module.

19. Connect the SD video generator to INPUT B using a 75 8 cable.

20. Set the SD video generator for a 525-format 10-bit shallow ramp matrix

signal.

21. Press the INPUT button and select Input B.

22. Press the WFM button.

23. Touch Pr and Pb to turn off the color difference signals.

NOTE. The Y component must be on to allow both the Pr and Pb components to

be turned off.

24. CHECK that the steps in the displayed ramps are monotonic (all steps are in

the same direction) and approximately one pixel high. See Figure 2--1.

NOTE. If the steps are 4 pixels high, it may be that the input signal has only 8

bits of resolution.

25. Press the GAIN button.

26. Touch Gain: 10x.

27. Press the CLR MENU button.

28. CHECK that the steps in the ramps are 0.7 mV to 0.9 mV. (Use the voltage

cursors for this measurement.)

29. Press the WFM button.

30. Touch Pr and Pb to turn these components back on. All components should

be on (Y, Pb, and Pr).

31. Press the GAIN button.

32. Touch Gain: 1x.

WFM700 Series Waveform Monitors S ervice Manual

2- 13

Page 46

Performance Verification

HD LCD Pixel Defects

(WFM7HD only)

This step checks for defective display pixels with a HD video signal.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the HD video generator to INPUT A using a 75 8 cable.

2. Set the HD video generator for a 1080i 59.94 100% flat field signal.

3. Press the INPUT button and select Input A.

4. Press the PICTURE button.

5. Count any pixels stuck low (not white).

6. Change the HD video generator signal to 0% flat field.

7. Count any pixels stuck high (not black).

8. CHECK the total number of pixels counted in steps 5 and 7 is less than six.

NOTE. If the bad pixel count exceeds six, perform the procedure again. If a pixel

fails for both black and white signals, count it only once.

SD LCD Pixel Defects

(WFM7A and WFM7M

only)

This step checks for defective display pixels with a SD video signal.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the SD video generator to INPUT B using a 75 8 cable.

2. Set the SD video generator for a 525--format 100% flat field signal.

3. Press the INPUT button and select Input B.

4. Press the PICTURE button.

5. Count any pixels stuck low (not white).

6. Change the SD video generator signal to 0% flat field.

7. Count any pixels stuck high (not black).

8. CHECK the total number of pixels counted in steps 5 and 7 is less than six.

NOTE. If the bad pixel count exceeds six, perform the procedure again. If a pixel

fails for both black and white signals, count it only once.

2- 14

WFM700 Series Waveform Monitors S ervice Manual

Page 47

Performance Verification

Error Detection Data

Paths

This test checks data paths and error detection.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

The following characteristics are directly and indirectly checked:

H Data Integrity

H RGB Gamut error Detection Level Limits

H RGB Gamut error Detection Level Accuracy

1. Connect the HD video generator to INPUT A using a 75 8 cable.

2. Set the HD video generator for a 1080i 59.94 0% flat field signal. Enable

Error Detection and Handling (EDH) if necessary.

3. Press the INPUT button and select Input A.

4. Press the STATUS button.

5. Touch the Display soft key.

6. Touch the Alarm Status soft key and then touch the Done soft key.

7. Touch the Serial Alarms soft key.

8. CHECK that the Embedded CRC status reads:

292M Y CRC error Status:OK

292M C CRC error Status:OK

9. Touch the General Alarms soft key.

10. CHECK that gamut errors read as follows:

RGB Gamut Error Status: OK

Composite Gamut Error Status: OK

11. Set the HD video generator for a 1080i 59.94 SMPTE color bars signal.

12. CHECK that gamut errors read as follows:

RGB Gamut Error Status: Alarm

Composite Gamut Error Status: OK

13. Set the HD video generator for a 1080i 59.94 100% color bars signal.

14. CHECK that gamut errors read as follows:

RGB Gamut Error Status: OK

Composite Gamut Error Status: Alarm

WFM700 Series Waveform Monitors S ervice Manual

2- 15

Page 48

Performance Verification

Serial Video Output

This test checks the serial video output signal into a 75 8 load.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the SD video generator to INPUT B using a 75 8 cable.

2. Set the SD video generator for a 525-format 100% color bars signal.

3. Connect the SERIAL OUT to the 75 8 input of the test oscilloscope using a

75 8 cable. Use a 75 8-to-50 8 adapter on the input of the test oscilloscope

if necessary.

4. Press the INPUT button and select Input B.

I

NOTE. If testing a WFM7HD, a display message will report

standard

I

. This will not affect the test.

unsupported

5. Measure the signal amplitude on the test oscilloscope and note this measurement. The following substeps will help obtain a measurable display on the

test oscilloscope.

a. Ensure that the termination is correct on the test oscilloscope.

b. Set the vertical scale to 200 mV/div, horizontal scale to 5 ns/div, and the

trigger position to 90%.

c. Set the display style to dots.

d. Set the trigger level to zero, and to neglect glitches of either polarity for

widths to 30 ns.

e. The oscilloscope display should show a few random transitions followed

by 30 ns with no transitions. This is followed by the triggering transition. See Figure 2--3.

f. When measuring, disregard signal noise. Measure the waveform

amplitude from the centers of the high and low levels in the region from

5 ns to 10 ns before the triggering transition.

g. Note the signal amplitude.

6. Calculate the percent amplitude error with the formula below using the

measured value from step 5.

Amplitude Error

Æ

Measured mV 800 mV

8

É

7. CHECK that the calculated error is between5%.

2- 16

WFM700 Series Waveform Monitors S ervice Manual

Page 49

Performance Verification

Measure amplitude before

triggering transition

Figure 2- 3: Ser ial video output level performance verification screen

SD PIX MON Output Level

This test checks the SD PIX MON output level into 75 8 load.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the SD video generator to INPUT B using a 75 8 cable.

2. Set the SD video generator for a 525-format 100% color bars signal.

3. Connect the SD PIX MON output to the 75 8 input of the test oscilloscope

using a 75 8 cable. Use a 75 8-to-50 8 adapter on the input of the test

oscilloscope if necessary .

4. Press the INPUT button and select Input B.

NOTE. A WFM7HD will report

I

unsupported standardI. This will not affect the

results of this check.

5. Measure the signal amplitude on the test oscilloscope. The following

substeps will help obtain a measurable display on the test oscilloscope. Note

this measurement.

a. Ensure that the termination is correct on the test oscilloscope. Use a

converter if necessary.

WFM700 Series Waveform Monitors S ervice Manual

2- 17

Page 50

Performance Verification

b. Set the vertical scale to 200 mV/div, horizontal scale to 5 ns/div, and the

trigger position to 90%.

c. Set the display style to dots.

d. Set the trigger level to zero, and to neglect glitches of either polarity for

widths to 30 ns.

e. The oscilloscope display should show a few random transitions followed

by 30 ns with no transitions. This is followed by the triggering transition. See Figure 2--4.

f. When measuring, disregard signal noise. Measure the waveform

amplitude from the centers of the high and low levels in the region from

5 ns to 10 ns before the triggering transition.

g. Note the measurement.

6. Calculate the percent amplitude error using the formula:

Æ

Percent Amplitude Error

Measured mV 800 mV

8

7. CHECK that the calculated error is within5%.

Measure amplitude before

triggering transition

É

2- 18

Figure 2- 4: SD PIX MON output level performance screen

WFM700 Series Waveform Monitors S ervice Manual

Page 51

Performance Verification

PIX Video Output Level

This step checks the active video and of black (blanking) levels.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the HD video generator to INPUT A using a 75 8 cable.

2. Press the INPUT button and select Input A.

3. Set the HD video generator for a 1080i 59.94 100% color bars signal.

4. Connect the PIX G/Y output to the 75 8 input of the test oscilloscope using

a758 cable. Use a 75 8-to-50 8 adapter on the input of the test oscillo-

scope if necessary.

5. Press the CONFIG button.

6. Touch the Video Inputs/Outputs soft key, then Next Menu.

7. Touch the Output Active for HD soft key, then YPbPr.

8. Press the CONFIG button twice to exit menu.

9. Set the test oscilloscope to view the first color bar. The following oscillo-

scope settings normally provide a usable display.

Vertical Scale 100 mV/div

Vertical Position –3.5 div

Horizontal Scale 1 us/div

Horizontal Trigger Position 50%

Trigger Slope Rising edge

Trigger Level 500 mV

10. Measure the amplitude between the black level and the first color bar and

note the measurement. See Figure 2--5.

11. Calculate the percent amplitude error using the formula:

Amplitude Error

Æ

Measured Amplitude mV 700 mV

7

É

12. CHECK that the calculated error is between 5%.

13. Measure the amplitude of the black level (the level preceding the first color

bar step) referenced to ground on the test oscilloscope. Note the measurement. See Figure 2--5.

14. CHECK that the black level is between 25 mV.

WFM700 Series Waveform Monitors S ervice Manual

2- 19

Page 52

Performance Verification

First color bar

Ground reference

Black level

Figure 2- 5: HD pix G/Y video output level performance screen

15. Move the cable from the PIX G/Y to the PIX B/Pb connector.

16. Set the test oscilloscope to view the signal. The following oscilloscope

settings normally provide a usable display.

Vertical Scale 100 mV/div

Horizontal Scale 10 us/div

Horizontal Trigger Position 10%

Trigger Slope Rising edge

Trigger Level 300 mV

17. Measure the peak-to-peak amplitude of the waveform displayed on the

oscilloscope. See Figure 2--6.

18. Calculate the percent amplitude error using the formula:

Amplitude Error

Æ

Measured Amplitude mV 700 mV

7

É

2- 20

19. CHECK that the calculated error is between 5%.

20. Measure the black level (the widest horizontal step) referenced to ground on

the test oscilloscope. Change test oscilloscope settings as needed to obtain

the best display. See Figure 2--6.

21. CHECK that the black level is between 25 mV.

WFM700 Series Waveform Monitors S ervice Manual

Page 53

Performance Verification

22. Move the cable from the PIX B/Pb to the PIX R/Pr connector.

23. Repeat steps 17 through 21.

Pk - Pk

level

Ground reference

Black

level

Figure 2- 6: HD pix B/Pb and R/Pr video output level performance screen

Stop here for WFM7HD. The PIX Video Output Level procedure is now finished

for the WFM7HD Input Module. Continue with this check if testing a WFM7A

or WFM7M Input Module.

24. Connect the SD video generator to INPUT B using a 75 8 cable.

25. Press the INPUT button and select Input B.

26. Set the SD video generator for a 525-format 100% color bars signal.

27. Connect the PIX G/Y output to the 75 8 input of the test oscilloscope using

a758 cable. Use a 75 8-to-50 8 adapter on the input of the test oscillo-

scope if necessary.

28. Press the CONFIG button.

29. Touch the Video Inputs/Outputs soft key, then Next Menu.

30. Touch the Output Active for SD soft key, then YPbPr.

31. Press the CONFIG button twice to exit the menu.

WFM700 Series Waveform Monitors S ervice Manual

2- 21

Page 54

Performance Verification

32. Set the test oscilloscope to view the first color bar. The following oscilloscope settings normally provide a usable display.

Vertical Scale 100 mV/div

Vertical Position –3.5 div

Horizontal Scale 5 us/div

Horizontal Trigger Position 50%

Trigger Slope Rising edge

Trigger Level 500 mV

33. Measure the amplitude between the black level and the first color bar and

note the measurement. See Figure 2--7.

34. Calculate the percent amplitude error using the formula:

Amplitude Error

Æ

Measured Amplitude mV 700 mV

7

É

35. CHECK that the calculated error is between 5%.

36. Measure the black level (the level preceding the first color bar step)

referenced to ground on the test oscilloscope. Change test oscilloscope

settings if needed. Note the measurement. See Figure 2--7.

37. CHECK that the black level is between 25 mV.

First color bar

2- 22

Ground reference

Black level

Figure 2- 7: SD pix video output level performance screen

WFM700 Series Waveform Monitors S ervice Manual

Page 55

Performance Verification

38. Move the cable from the PIX G/Y to the PIX B/Pb connector.

39. Set the test oscilloscope to view the signal. The following oscilloscope

settings normally provide a usable display.

Vertical Scale 100 mV/div

Horizontal Scale 10 us/div

Horizontal Trigger Position 10%

Trigger Slope Rising edge

Trigger Level 300 mV

40. Measure the peak-to-peak amplitude of the waveform displayed on the

oscilloscope. See Figure 2--6 on page 2--21.

41. Calculate the percent amplitude error using the formula:

External Reference

Amplitude Error

Æ

Measured Amplitude mV 700 mV

7

É

42. CHECK that the calculated error is between 5%.

43. Measure the black level (the widest horizontal step) referenced to ground on

the test oscilloscope. Change test oscilloscope settings as needed to obtain

the best display. See Figure 2--6.

44. CHECK that the black level is between 25 mV.

45. Move the cable from the PIX B/Pb to the PIX R/Pr connector.

46. Repeat steps 40 through 44.

47. Disconnect the cable from the PIX R/Pr connector.

This test checks for stable operation with external reference signals.

Performance Requirement. This test verifies performance characteristics and is

listed in the test record.

1. Connect the output from the analog video generator to one of the REF IN

connectors using a 75 8 cable.

2. Connect a 75 8 termination to the remaining REF IN connector.

3. Set the analog video generator for a PAL black signal.

4. Connect the output from the HD video generator to INPUT A using a 75 8

cable.

5. Set the HD video generator for a 1080i 50 100% color bars signal.

WFM700 Series Waveform Monitors S ervice Manual

2- 23

Page 56

Performance Verification

6. Press the DISPLAY button and touch the Thumbnail Picture soft key (to

turn off the thumbnail picture).

7. Press the WFM button.

8. Press the INPUT button and select Input A.

9. Touch the Reference: soft key so that Reference is set to External.

10. CHECK that the displayed waveform remains locked to the external

reference.

NOTE. The waveform is considered locked if the color bar steps are distinct and

I

the red