Page 1

Service Manual

WFM 601A, WFM 601E, & WFM 601M

Serial Digital Component Waveform Monitor

070-9836-05

This document applies to firmware version 1.00

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of three (3) years from the date of shipment. If a product proves defective during this warranty period,

T ektronix, at its option, either will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY T O

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY . TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

Theory of Operation

General Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Power 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear-Panel Connectors 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Overview 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Menus 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Connectors 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram Descriptions 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 1, Input and Waveform Display 3–1. . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 2, Component 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 3, Microprocessor and Control 3–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supplies 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Equipment Required 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Data Report 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedure 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

Equipment Required 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Adjustment Software 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the TG2000/DVG1 Opt S1 Generator 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Adjustment Locations 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Illustrations 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TV Generator T est Signals 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Service Options 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 601A, WFM 601E, & WFM 601M Service Manual

i

Page 6

Table of Contents

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement Instructions 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

After Repair Adjustments 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Upgrade Software 6–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Diagrams and Circuit Board Illustrations 9–1. . . . . . . . . . . . . . . . . . . . . .

Symbols 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Values 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graphic Items and Special Symbols Used in This Manual 9–1. . . . . . . . . . . . . . . . .

Component Locator Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 7

List of Figures

Table of Contents

Figure 2–1: Dimensions of the 1700F00 cabinet 2–2. . . . . . . . . . . . . . . . . .

Figure 2–2: 1700F02 portable cabinet 2–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Rear view of the waveform monitor in a 1700F00

cabinet 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: The 1700F05 rack cabinet holds two instruments 2–5. . . . . .

Figure 2–5: 1700F05 cabinet showing utility drawer and blank panel 2–6

Figure 2–6: The WFM 601M waveform monitor front panel 2–9. . . . . . .

Figure 2–7: Elements of the waveform monitor menu controls 2–13. . . . .

Figure 2–8: Rear panel of the waveform monitor 2–14. . . . . . . . . . . . . . . .

Figure 2–9: Pin assignments for the RS-232 connector 2–15. . . . . . . . . . . .

Figure 2–10: Pin assignments for the REMOTE connector 2–16. . . . . . . .

Figure 3–1: Power supply block diagram 3–6. . . . . . . . . . . . . . . . . . . . . . .

Figure 4–1: Audio cable adapter 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Timing cursors 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: HF Bowtie magnified to measure null offset 4–18. . . . . . . . . .

Figure 4–4: Arrowhead gamut check 4–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–1: Jumper cable adapter 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–2: Minimum configurations for remote communications 5–4. .

Figure 5–3: Typical display of the adjustment procedures 5–7. . . . . . . . .

Figure 5–4: Location of circuit boards 5–15. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–5: A1 Power Supply board 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–6: A3 Main board 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–7: A5 Serial board 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–8: A7 Component board 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–9: Trace Rotation, Y Alignment, and Geometry – Horizontal

center marks 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–10: Post Readout, Offset, and Gain 5–18. . . . . . . . . . . . . . . . . . . .

Figure 5–11: Monitor Out YOffset 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–12: Gamut Limit – Strobe pulses 5–19. . . . . . . . . . . . . . . . . . . . . .

Figure 5–13: On-Screen Frequency Response 5–19. . . . . . . . . . . . . . . . . . .

Figure 5–14: Bowtie Timing 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–15: Electronic Graticule Adjustment 5–20. . . . . . . . . . . . . . . . . .

Figure 5–16: Diamond Eye Opening 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 601A, WFM 601E, & WFM 601M Service Manual

iii

Page 8

Table of Contents

Figure 5–17: Arrowhead PBPR – A7R827 adjustment 5–21. . . . . . . . . . . .

Figure 5–18: Arrowhead PBPR – A7R868 adjustment 5–21. . . . . . . . . . . .

Figure 5–19: Jitter Gain 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–20: Audio Graticule X and Y Offsets 5–23. . . . . . . . . . . . . . . . . . .

Figure 5–21: Digital Cursor – Correct waveform and Data Cursor

alignment 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–22: Digital Cursor – Alignment in DATA view 5–24. . . . . . . . . . .

Figure 5–23: 100% Color Bars signal 5–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–24: 100% Color Bars with Level Reference 5–25. . . . . . . . . . . . .

Figure 5–25: 2.5 MHz Bowtie signal 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–26: 5-step Staircase signal 5–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–27: Shallow Ramp signal 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–28: 100% Sweep signal 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–29: Multiburst signal 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Multiple pin connectors 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Removing large cable connectors 6–7. . . . . . . . . . . . . . . . . . .

Figure 6–3: Removing the case from the waveform monitor 6–7. . . . . . .

Figure 6–4: Removing the CRT bezel 6–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Removing the bezel knob panel from the bottom of the

waveform monitor 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Replacing graticule light bulbs using tweezers 6–10. . . . . . . .

Figure 6–7: Removing the CRT 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Routing for CRT wire harness 6–12. . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Removing the front-panel assembly 6–13. . . . . . . . . . . . . . . . .

Figure 6–10: Front-panel assembly 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–11: Removing the rear-panel input and BNC assembly 6–14. . . .

Figure 6–12: Connection locations on the A4 Input board 6–14. . . . . . . . .

Figure 6–13: Disassembling the BNC/Input assembly 6–15. . . . . . . . . . . . .

Figure 6–14: Components of the fan assembly 6–16. . . . . . . . . . . . . . . . . . .

Figure 6–15: Connections on the A3 Main Board 6–17. . . . . . . . . . . . . . . .

Figure 6–16: Removing the Power Supply board 6–18. . . . . . . . . . . . . . . . .

Figure 6–17: Location of connections on the Serial board 6–19. . . . . . . . .

Figure 6–18: Removing the A5 Serial board 6–20. . . . . . . . . . . . . . . . . . . . .

Figure 6–19: Removing the Component and DAC boards 6–21. . . . . . . . .

Figure 6–20: Separating the DAC and Component boards 6–22. . . . . . . .

Figure 6–21: Location of circuit board assemblies 6–25. . . . . . . . . . . . . . . .

Figure 6–22: Location of the line fuse on Power Supply board 6–26. . . . .

Figure 6–23: Configuration to troubleshoot the DAC board 6–33. . . . . . .

iv

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 9

Table of Contents

Figure 6–24: Configuration to troubleshoot the Component board 6–34. .

Figure 6–25: Configuration for RS-232 communications 6–38. . . . . . . . . .

Figure 6–26: Main board showing location of U13 6–39. . . . . . . . . . . . . . .

Figure 6–27: Repackaging a waveform monitor 6–48. . . . . . . . . . . . . . . . .

Figure 9–1: Main block diagram 1 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Component block diagram 2 9–4. . . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: Microprocessor and control block diagram 3 9–5. . . . . . . . .

Figure 9–4: A4 Input board and A4A1 BNC board 9–6. . . . . . . . . . . . . . .

Figure 9–5: A5 Serial board (front) 9–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–6: A5 Serial board (back) 9–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–7: A8 DAC board 9–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–8: A7 Component board 9–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–9: A3 Main board (front) 9–54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–10: A3 Main board (back) 9–57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–11: A2 Front Panel board 9–76. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–12: A1 Power Supply board 9–78. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: Front Panel exploded view 10–6. . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: DAC Bd, Component Bd, and CRT exploded view 10–8. . . .

Figure 10–3: Serial, Power, and Main boards exploded view 10–10. . . . . . .

Figure 10–4: Rear panel and Fan exploded view 10–12. . . . . . . . . . . . . . . . .

WFM 601A, WFM 601E, & WFM 601M Service Manual

v

Page 10

Table of Contents

vi

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 11

List of Tables

Table of Contents

Table 1–1: Electrical specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: CRT display 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: AC power source 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Environmental characteristics 1–11. . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Physical characteristics 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Safety standards 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Safety certification compliance 1–12. . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Certifications and compliances 1–13. . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Remote connector pin assignments and functions 2–16. . . . . .

Table 4–1: Audio values 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: List of special equipment and where it is used 5–5. . . . . . . . .

Table 5–2: Signals required for adjustment procedure 5–10. . . . . . . . . . .

Table 6–1: Static susceptibility 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: Circuit board functional names 6–25. . . . . . . . . . . . . . . . . . . . .

Table 6–3: Power supply fault symptoms 6–27. . . . . . . . . . . . . . . . . . . . . . .

Table 6–4: Low volts supply voltages 6–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Control circuit test points 6–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–6: Shut down logic levels 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–7: High volts supply fault symptoms 6–31. . . . . . . . . . . . . . . . . . .

Table 6–8: High-voltage oscillator test points 6–32. . . . . . . . . . . . . . . . . . .

Table 6–9: Adjustment required after repairing circuit boards 6–35. . . .

Table 6–10: Remote communication parameters 6–38. . . . . . . . . . . . . . . .

Table 6–11: Adjustment and verification required after an upgrade or

configuration 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8–1: List of circuit board assemblies 8–6. . . . . . . . . . . . . . . . . . . . .

Table 9–1: A4 Input board component locator 9–6. . . . . . . . . . . . . . . . . . .

Table 9–2: A4A1 BNC board component locator 9–6. . . . . . . . . . . . . . . . .

Table 9–3: WFM 601M A5 Serial board (front) component locator 9–8.

Table 9–4: WFM 601M A5 Serial board (back) component locator 9–10.

Table 9–5: WFM 601A A5 Serial board (front) component locator* 9–22.

WFM 601A, WFM 601E, & WFM 601M Service Manual

vii

Page 12

Table of Contents

Table 9–6: WFM 601A A5 Serial board (back) component locator* 9–22.

Table 9–7: WFM 601E A5 Serial board (front) component locator* 9–26.

Table 9–8: WFM 601E A5 Serial board (back) component locator* 9–27.

Table 9–9: A8 DAC board component locator 9–36. . . . . . . . . . . . . . . . . . .

Table 9–10: A7 Component board component locator 9–44. . . . . . . . . . . .

Table 9–11: A3 Main board (front) component locator 9–55. . . . . . . . . . . .

Table 9–12: A3 Main board (back) component locator 9–57. . . . . . . . . . . .

Table 9–13: A2 Front Panel board (front) component locator 9–76. . . . . .

Table 9–14: A2 Front Panel board (back) component locator 9–76. . . . . .

Table 9–15: A1 Power Supply board component locator 9–79. . . . . . . . . . .

viii

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

WFM 601A, WFM 601E, & WFM 601M Service Manual

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

ix

Page 14

General Safety Summary

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

x

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

WFM 601A, WFM 601E, & WFM 601M Service Manual

xi

Page 16

Service Safety Summary

xii

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 17

Preface

This manual provides servicing information for the WFM 601A, WFM 601E,

and WFM 601M Serial Digital Component Waveform Monitors. Procedures

described in this manual are designed for experienced service technicians. For

detailed operating information, refer to your waveform monitor User manual.

See section 7, Options, for the part number of the User manuals.

This manual supports both Module Level (for module exchange) and Component

Level service. Module Level service uses the block diagram and its descriptions

to isolate a problem to the circuits on a particular circuit board. To support

Component Level servicing there are schematic diagrams, circuit board

illustrations, and part location tables for each circuit board.

When preparing to service this instrument, remember that its circuit boards

contain surface mount components. Surface mount components require special

techniques and tools for removal and installation.

Most of the information and procedures in this manual are common across the

family of waveform monitors. However, each waveform monitor has several

unique features. When a procedure or a description is applies to a specific model,

it is indicated with the model number of the waveform monitor in parentheses.

About This Manual

This manual is composed of the following sections:

H Specifications provides a list of all instrument performance requirements,

operating environment requirements,and certifications.

H Operating Information provides an overview of the main instrument

features.

H Theory of Operation provides a block diagram description of the instrument

circuits.

H Performance Verification provides a manual procedure for verifying the

performance requirements in the Specifications section.

H Adjustment Procedures provides an automated procedure for adjusting the

waveform monitor following repair.

H Maintenance provides instructions for troubleshooting and replacing

instrument modules.

H Options provides a list of the available product options.

WFM 601A, WFM 601E, & WFM 601M Service Manual

xiii

Page 18

Preface

H Replaceable Electrical Parts provides a list of all electrical components used

in the instrument.

H Diagrams provides block diagrams, component locators, and schematics.

H Replaceable Mechanical Parts provides a list of all mechanical parts and

electrical modules not contained on a circuit board.

Tektronix Service

Offerings

Tektronix maintains a service organization that provides a number of services to

help you maintain the waveform monitor at its specified levels. These services

range from complete repair and adjustment, at a convenient location, to

supplying replacement parts. In addition, Tektronix provides training programs

for service technicians.

NOTE. When considering service offering, remember that Tektronix provides a

limited parts and service warranty for all its products. No customer repairs

should be attempted during the warranty period.

Service Training. Tektronix provides service training in a number of programs.

Classes are held at our Beaverton campus and at convenient locations by

arrangement. To learn more about service training programs, contact your local

Tektronix field office or representative. U.S. customers can call our service

organization directly using 1 (800) TEK WIDE [835-9433]; ask for “Service

Training.”

Field Service Centers. Tektronix maintains service centers worldwide. These

centers provide repair and calibration services for Tektronix instruments. They

can be contacted through your Tektronix field office or representative. In

addition, U.S. and Canadian customers can call 1 (800) TEK WIDE [835-9433]

for assistance in contacting their nearest service center.

xiv

Module Exchange. The Tektronix module exchange program provides a quick,

affordable way to return an instrument to operational status. You exchange a

defective module for a calibrated module at a cost well below the new module

price. Contact your Tektronix field office or representative for more information.

U.S. and Canadian customers can call 1 (800) TEK WIDE [835-9433].

NOTE. Circuit boards that are damaged due to mishandling or containing

modifications not originated by Tektronix are not acceptable for the exchange

program.

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 19

Preface

When exchanging a circuit board, it is essential that you have the following key

information ready to relay to our technician:

H Instrument type

H Serial number

H Installed options

H Assembly/circuit board number (AX)

H Nine-digit part number (671-XXXX-XX)

H Software version number installed on your waveform monitor

Factory Replacement Parts. Replacement parts are available through the local

Tektronix field office or representative. However, many common electronic parts

are available through local sources. Using a local source, where possible, will

eliminate shipping delays.

Changes to Tektronix instruments are sometimes made to accommodate

improved components and to improve circuit performance. Therefore, it is

important to include the following information when ordering parts:

H Part number

H Instrument type or number

H Serial number

H Modification or option number (if applicable)

If a part has been replaced with a new or improved part, the new part will be

shipped, if it is a direct replacement. If not directly replaceable the local

Tektronix field office or representative will contact the customer concerning any

changes. After any repair, circuit readjustment may be required.

WFM 601A, WFM 601E, & WFM 601M Service Manual

xv

Page 20

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: support@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

xvi

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 21

Page 22

Specifications

Product Description

This section provides a brief overview of the WFM 601A, WFM 601E, and

WFM 601M waveform monitor product features. The feature list is followed by

the product specifications.

The waveform monitors measure and display 4:2:2 component serial digital

signals. The waveform monitors display serial digital signals as the familiar

component signals and in a variety of standard measurement modes. You can use

the EDH (Error Detection and Handling) system and the suite of automated

checks of the serial digital format to verify data integrity.

Features

Most of the features listed in this section are common across all three waveform

monitors. Where a feature applies only to a specific model, the model is in

parentheses following the feature description. The waveform monitors offer the

following features:

H Two 270 Mbit serial component loop-through inputs

H Digital video standards SMPTE 259M, ITU-R BT.656, and ITU-R BT.601

H RGB and Y-P

H Eye Pattern display with Timing and Voltage Cursors (WFM 601E,

WFM 601M)

H Jitter demodulator with numeric jitter readout and video correlated jitter

waveform display (WFM 601M)

H Parade or Waveform display of Y, P

H RGB and composite Gamut checks with Diamond and Arrowhead displays

H Field, line, and word select with readout and bright up of selected lines on

Picture Monitor Out (Y or G Channel) (WFM 601E, WFM 601M)

H SMPTE RP-165 standard EDH indicator for presence

display format for 525 and 625 line signals

B-PR

, and PR component signals

B

H Digital Waveform and Data displays with Data-cursor correlation between

display modes (WFM 601M)

H Embedded Audio indentification

H Source-level meter and cable-length readout (WFM 601E, WFM 601M)

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–1

Page 23

Specifications

H Lightning and Vector displays

H Reclocked Serial Component Digital output following A/B switching

H Video Reference: Internal Serial Component signal (follows A/B switching)

or external composite

H Audio Lissajous display (WFM 601A)

Menus

Calibrator

Characteristics Tables

An expanded feature set is available through menus. You select menu items with

multi-use bezel buttons and knobs. When you select a menu item, such as

Voltage Cursors, on-screen labels show the current function of the bezel buttons

and knobs.

The waveform monitor provides an internal calibrator signal to set both vertical

and horizontal gain. The calibrator signal is a 700 mV, 100 kHz signal. Press the

CONFIG button and use the bezel knob to select the Calibrate menu. Press the

CAL SIG button to turn on the calibrator signal.

Table 1–1 lists the electrical specifications for the waveform monitors. Performance requirements are generally quantitative and can be tested by the Perfor-

mance Verification procedure this manual. Reference information describes

useful operating parameters that have typical values. These parameters are not

directly checked in the performance verification procedure. Table 1–8 lists the

EMC compliance specifications.

The Performance Requirements listed in the electrical specification portion of

these specifications apply over an ambient temperature range of 0° C to +40° C.

The rated accuracies are valid when the instrument is calibrated at an ambient

temperature range of +20° C to +30° C, after a warm-up time of 20 minutes.

1–2

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 24

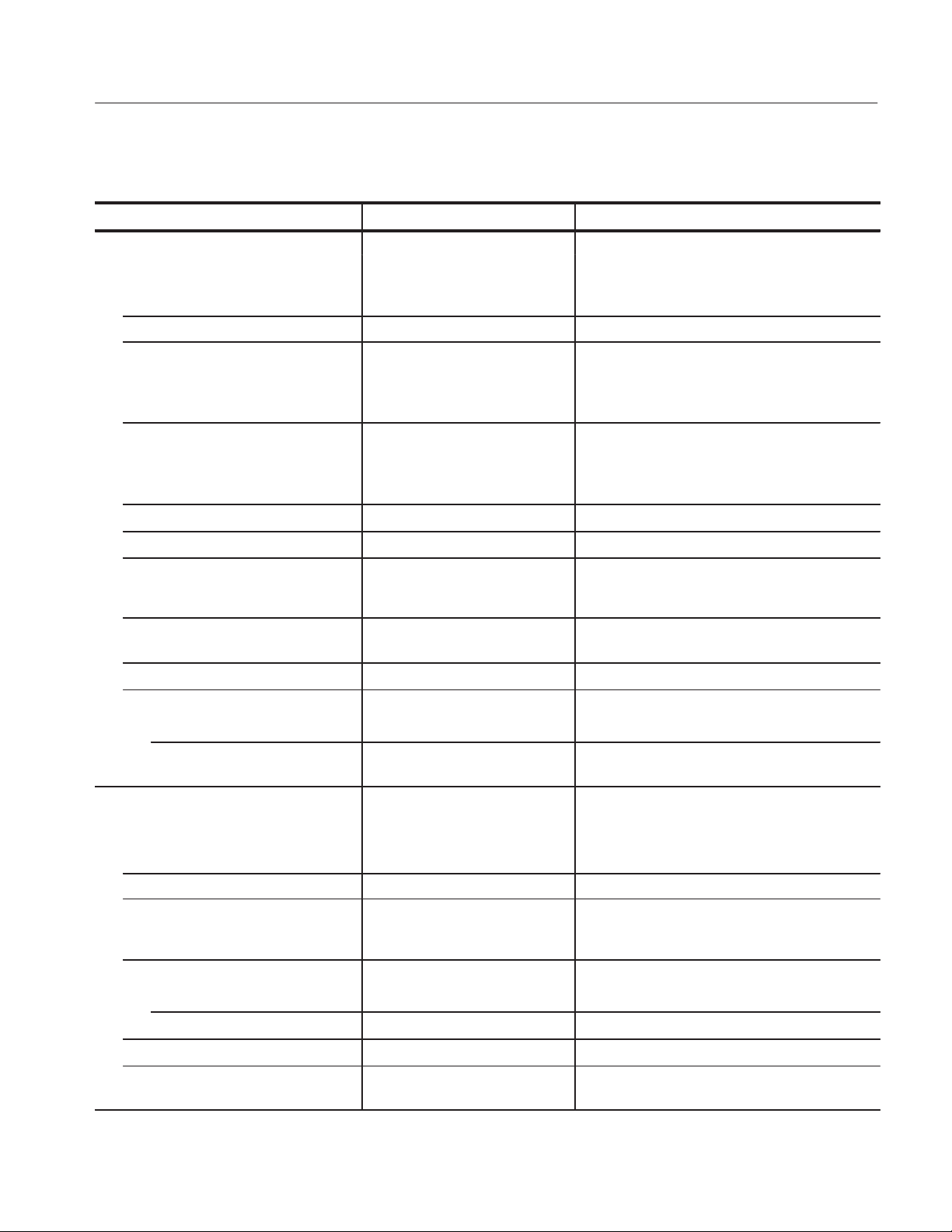

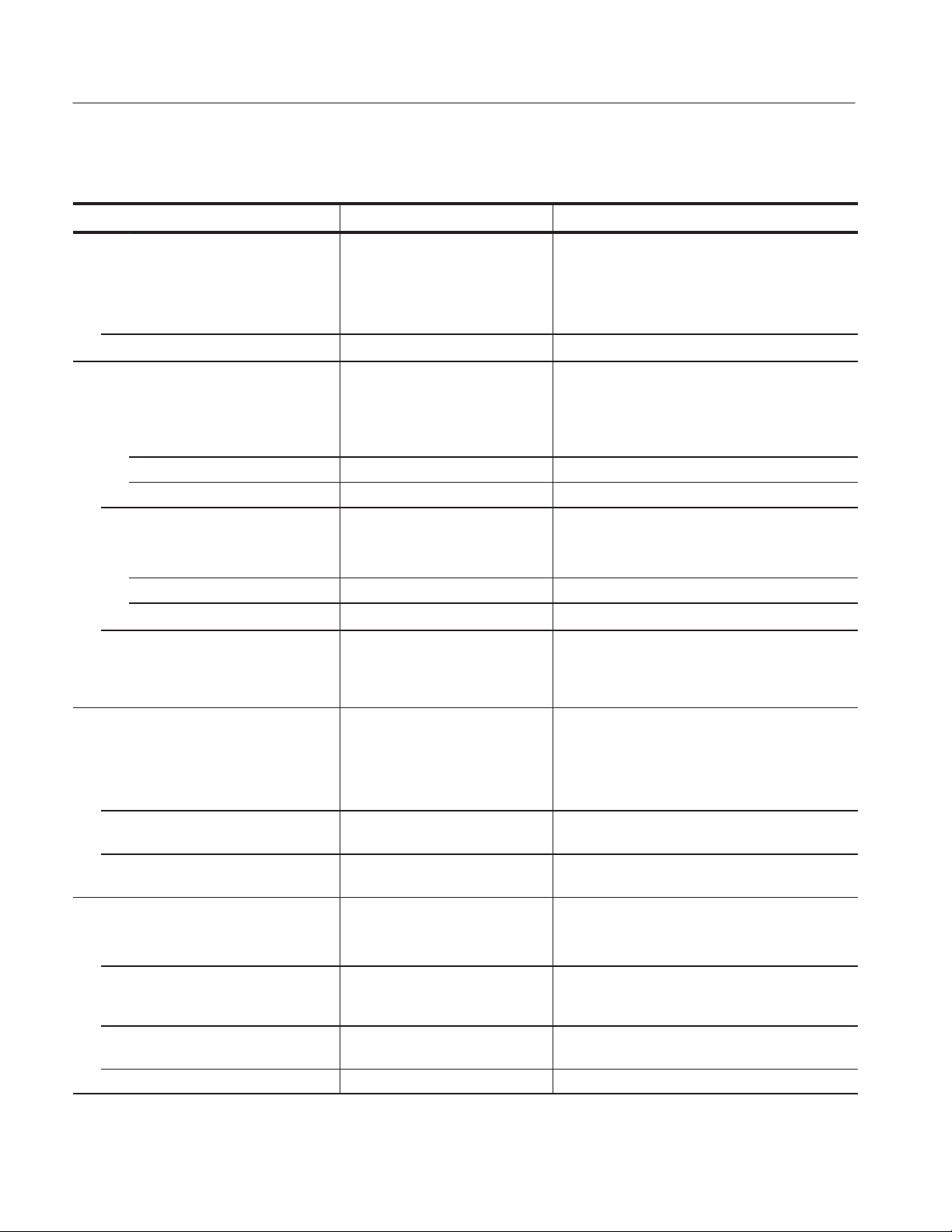

T able 1–1: Electrical specifications

Characteristic Performance requirement Reference information

Waveform V ertical Deflection

Deflection Factor For digital input: 700 mV digital

input = 700 mV $2% screen

display , any magnifier setting

Variable Gain Range 0.2X to 1.4X

Frequency Response Luminance channel (Y), to

5.0 MHz $2%;

Color difference channels (PB and

PR) to 2.5 MHz $2%

Transient Response

Field Rate Tilt

Line Rate Tilt

Offscreen Recovery 1% variation in baseline of a 5 MHz modulated

Voltage Cursor Accuracy

Differentiated Step Filter

Low Pass Filter

Gain

Response

Serial Digital Video Interface

(SER A and SER B inputs)

Format 270 Mbit/s component. Complies with SMPTE

Input Type Passive loop-through, 75 W compensated

Input Level

Return Loss

Power on

Power off

Insertion Loss

Transmission Bandwidth

$0.5% over 20–30° C, $1%

over rated temperature range

1 $ 1%

RGB on-screen accuracy $3%

Typically $1% to 5.75 MHz luminance (Y)

channel, and $1% to 2.75 MHz for the color

difference (PB and PR) channels

Preshoot v1%

Overshoot v1%

Ringing v1%

Pulse-to-bar ratio 0.99:1 to 1.01:1

v1%

v1%

pulse when positioned anywhere on screen.

X1, X5, or X10 with any variable gain setting

Amplitude of pulses v1% variation

v 3 dB attenuation at 1 MHz, w 40 dB

attenuation at 4 MHz

259M and CCIR 656

800 mV peak-to-peak $10%. Input voltages

outside this range might cause reduced receiver

performance.

w25 dB 1–270 MHz, channels on or off

w15 dB 1–270 MHz

v1%

50 kHz – 300 MHz $1.0 dB

–3 dB at not less than 500 MHz

Specifications

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–3

Page 25

Specifications

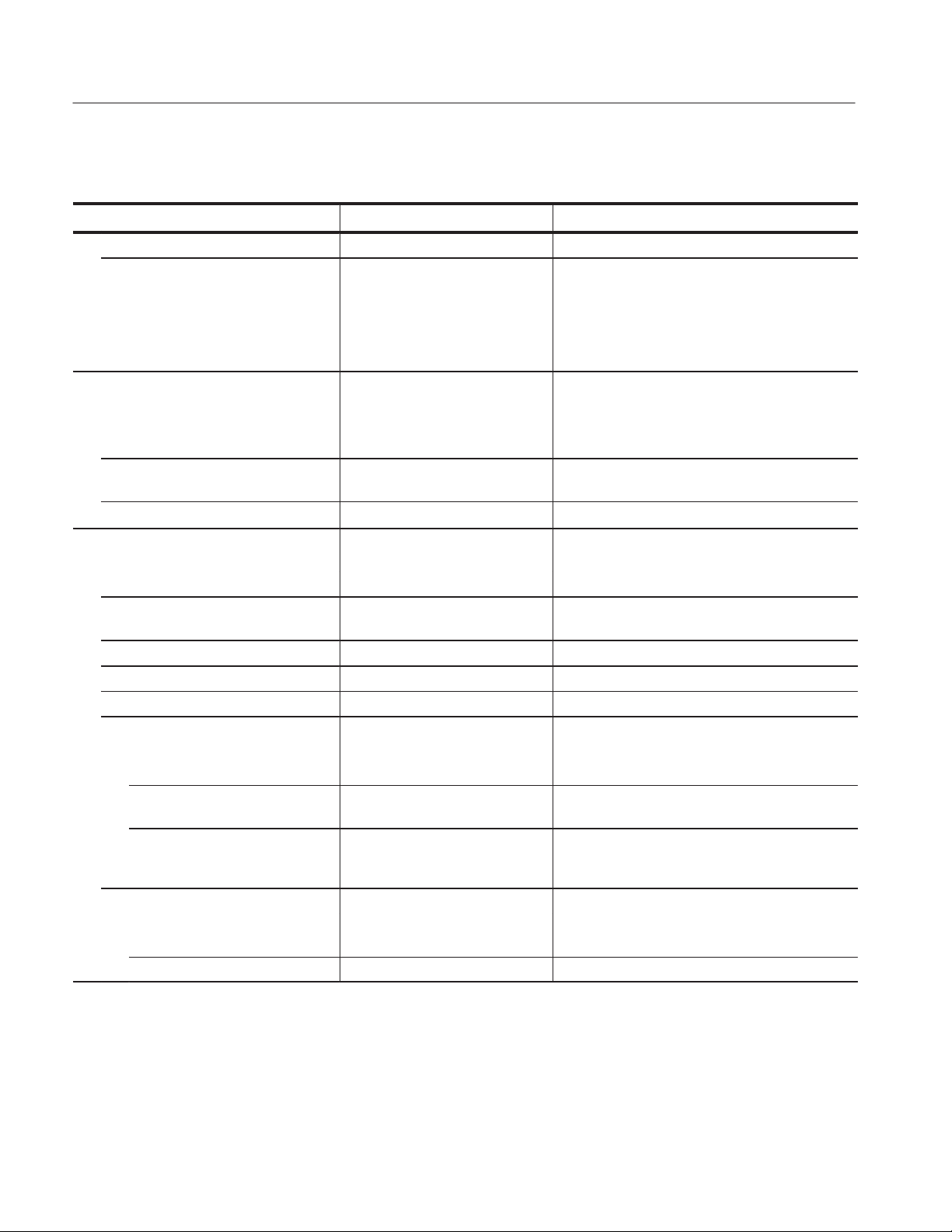

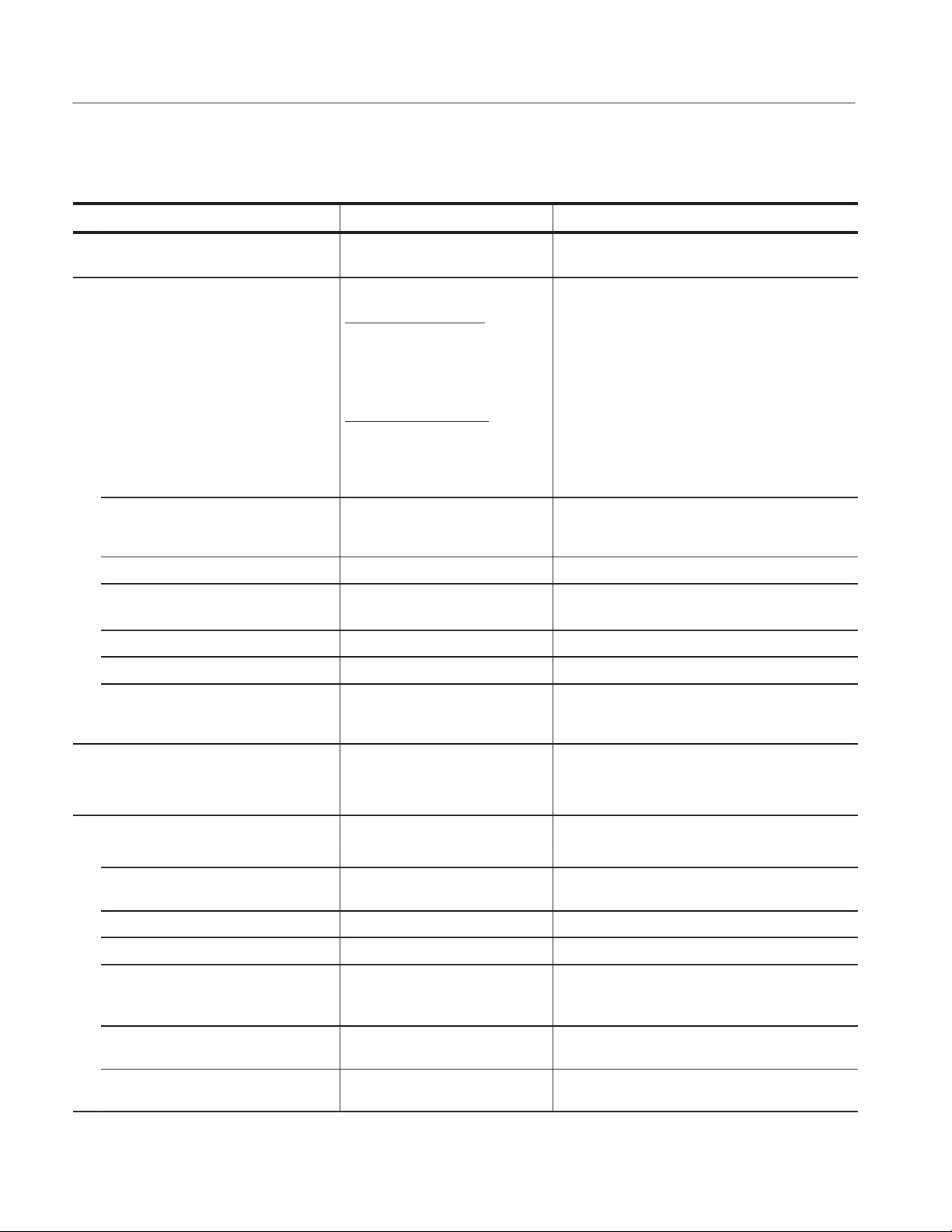

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Loop-through Input Isolation

Serial Receiver Equalization Range Proper operation with 19 dB loss

at 135 MHz using coaxial cable

having 1/√F loss characteristics.

800 mV launch amplitude and 200

meters (655 feet) of Belden 8281

coaxial cable

Serial Video Output (follows SER A/B

channel selection)

Format 270 Mbit/s component; complies with SMPTE

Output Level

Return Loss

Eye Pattern Display

(WFM 601E, WFM601M)

Type Equivalent time sampler

Bandwidth 50 kHz to 450 MHz: –3 dB to

Rise Time 500 ps (20-80%), 775 ps (10-90%)

Aberrations < 10%, 800 mV step

Time Base Jitter < 200 ps peak-to-peak

Jitter Attenuation

10 Hz Clock Bandwidth < 10% for frequencies > 20 Hz. –3 dB at

100 Hz Clock Bandwidth < 10% for frequencies > 300 Hz. –3 dB at

1 kHz Clock Bandwidth < 10% for frequencies > 3 kHz. –3 dB at

Display Modes

Overlay Overlays bits 0-9 of a serial word to form each Eye

10-Eye Parades bits 0-9 in a 10-Eye display

800 mV p-p 10% into 75 W load

+1 dB

50 dB to 300 MHz

259M and CCIR 656

Internal adjustment can change output to less than

600 mV and greater than 1000 mV

15 dB 1–270 MHz

Low frequency –3 dB point is 500 Hz

approximately 10 Hz

approximately 100 Hz

approximately 1 kHz

Up to 3 dB jitter gain from 2–4 kHz

opening

1–4

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 26

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Deflection Factor

Vertical

Horizontal

Overlay Mode

10-Eye Mode

Mag On

Jitter Display (WFM 601M)

Type Demodulated recovered clock

Digital Readout

Accuracy

Dynamic Range

Alignment Jitter 2.4 UI p-p

Timing Jitter 9.0 UI p-p

Resolution

Alignment Jitter 0.02 UI

Timing Jitter 0.1 UI

–3 dB Bandwidth

Alignment Jitter Bandwidth

selection

Timing JItter 10 Hz to 5 MHz

Jitter Waveform (WFM601M)

Accuracy

Dynamic Range 10 UI p-p

Deflection Factor

Horizontal Four modes available:

Vertical

X1

X5

X10

800 mV 5% with an 800 mV

p-p input

1 ns/div 3%

3 ns/div 3%

500 ps/div 3%

0.05 UI 10% of reading

10 Hz to 5 MHz

1 kHz to 5 MHz

10 kHz to 5 MHz

100 kHz to 5 MHz

10%

1 Line, 2 Line

1 Field, 2 Field

1 UI/div 5%

0.2 UI/div 10%

0.1 UI/div 20%

Specifications

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–5

Page 27

Specifications

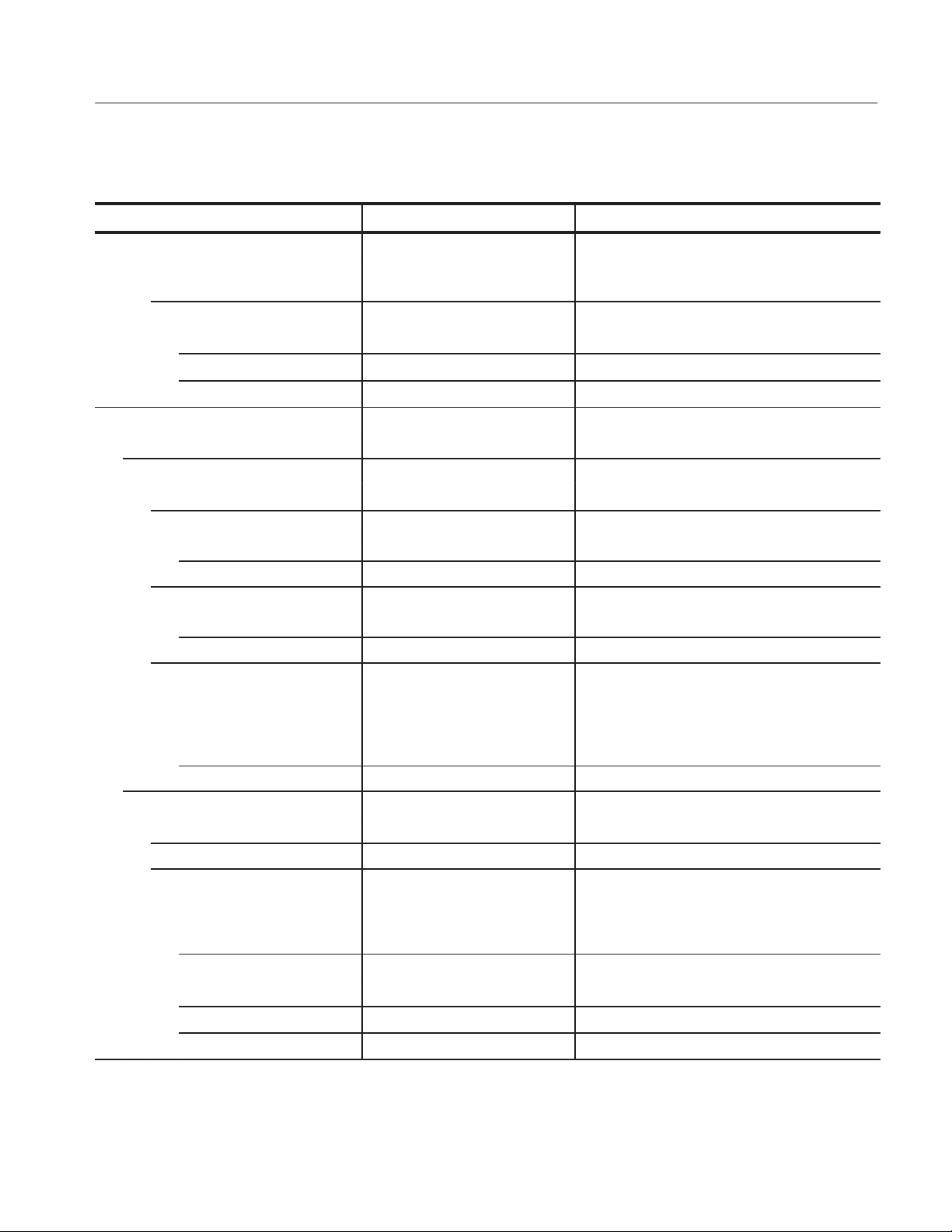

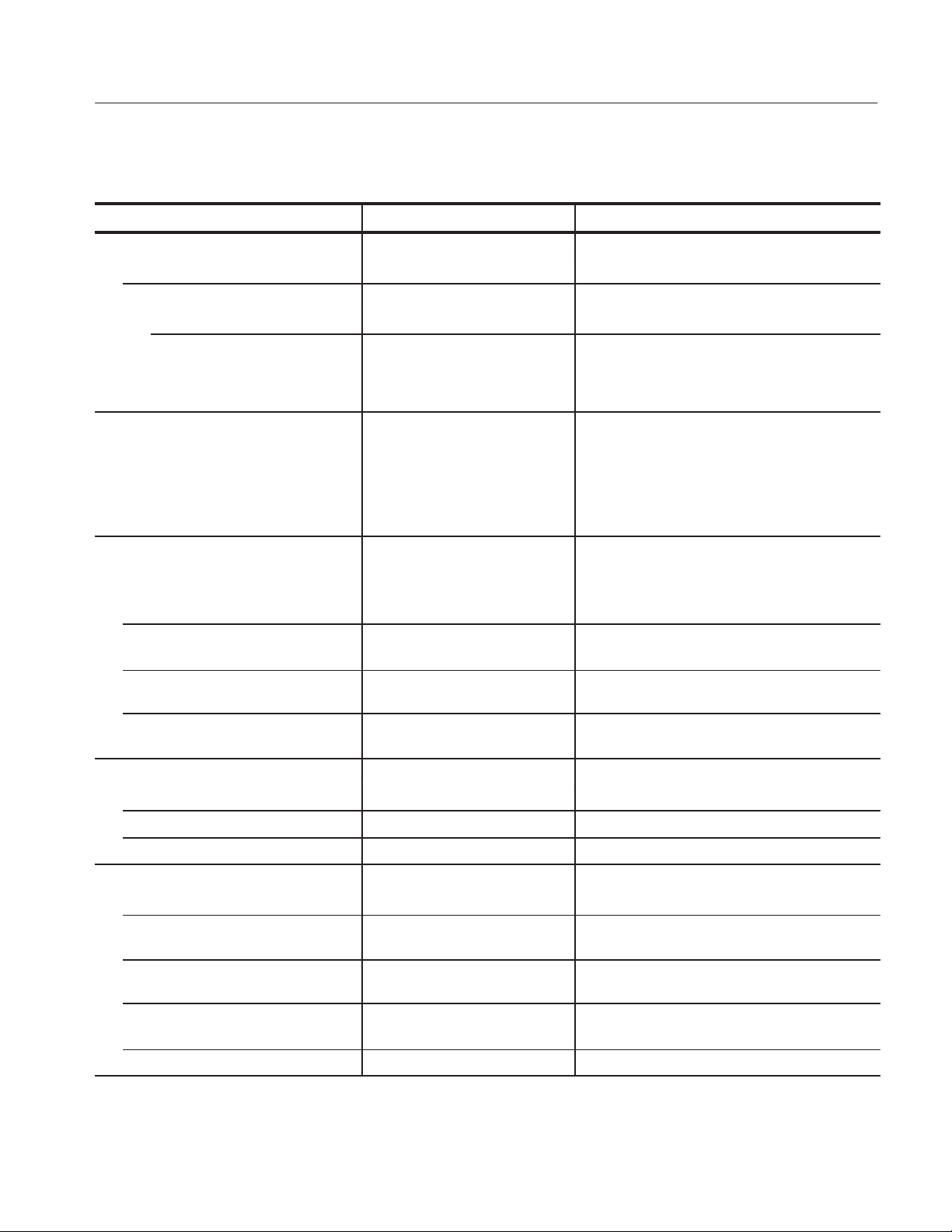

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

–3 dB Bandwidths

Bandwidth Selection 10 Hz to 5 MHz

1 kHz to 5 MHz

10 kHz to 5 MHz

100 kHz to 5 MHz

Jitter Output

Signal Level & Cable Length Detector

(WFM 601E, WFM601M)

Cable Length

Accuracy

Resolution 5 meters

Dynamic Range 0 to 400 meters (Belden 8281 cable)

Source Signal Level

Accuracy

Resolution 0.25 dB

Dynamic Range

Cable Types Supported cable types:

Video Error Detection

Type Active picture and full field with field rate

Reporting Means Front-panel ALARM indicator , rear-panel TTL line,

Error Statistics Asynchronous errored seconds. Active picture and

Diagnostics

Embedded Audio Identifies the presence of up to 16 channels of

Ancillary Data Identifies the presence of ancillary data (other than

Bit Activity Indicates if any of the 10 data bits are always high

Line Rate Indicates whether the signal is 525 or 625 line.

120 mV/UI 10% into 75 W load

10 meters 10% of reading (Belden 8281 cable)

0.5 dB for cable lengths from 0–100 meters

(Belden 8281)

3 dB

Belden 8281

Belden 1694A

Belden 1505A

resolution. Uses EDH (Error Detection and

Handling) system based on CRC check-word.

Complies with SMPTE RP165.

and CRT readout

full field statistics are separately compiled

AES/EBU digital audio

audio and EDH) and indicates if a checksum error

has occurred.

or low during the active picture for an entire field.

1–6

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 28

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Specifications

Format Errors

(WFM 601A, WFM601M)

Signal Lost Reports absence of the serial video signal.

Analog Audio Mode (WFM 601A)

Input DC coupled, differential input, 20 kW input

Full Scale Selection 0, 4, 8, and 12 dBu full scale, menu selectable

Full Scale Accuracy

Bandwidth

X and Y Input Phase Matching

Maximum Input Voltage ±8 V peak, measured to chassis ground

Digital Data Value Cursor and Listing

(WFM 601M)

Digital Waveform Non-interpolated waveform display . Cursor

Data Mode Displays interleaved data stream sequentially with

Video Mode Displays Y, Cb, Cr data streams separately.

Digital List Sequential list of sample values in table format.

External Reference

Input Analog composite video or black burst

Maximum Operating Input Voltage –1.8 V to +2.2 V, DC plus peak AC

Absolute Maximum Input Voltage –8.5 V to +8.5 V , DC plus peak AC

DC Input Impedance

$0.5 dB at 1 kHz

–3 dB w 500 kHz using a leveled

sine wave

v 1_, 20 Hz–20 kHz

Warns that a serial signal format error has

occurred for the following error types:

H SAV placed incorrectly relative to EA V.

H Line length error.

H Field length error.

H Reserved values used improperly.

H ANC data checksum error.

H ANC data parity error.

impedance

identifies selected sample value (hexadecimal,

decimal, binary). Cross-hair cursor inserted on

picture monitor output shows selected line and

sample. Vertical and horizontal shift of picture

monitor output when selecting blanking interval

line and sample values.

31 samples per screen width. Cursor identifies

selected sample value.

Channels are selected with VIDEO IN buttons.

Cursor identifies the selected sample value.

Cursor identifies selected sample. VIDEO mode

identifies samples as Y, Cb, Cr.

w 20 kW

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–7

Page 29

Specifications

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Return Loss

Waveform Horizontal Deflection

Sweep Internal Synchronization: Proper

horizontal and vertical synchronization with a component digital

signal conforming to CCIR Rec.

601/656 and SMPTE 125M.

External Synchronization: Proper

horizontal and vertical synchronization with a composite sync

signal of approximate line and field

rate.

Sweep Timing Accuracy

Sweep Linearity

Magnified Sweep Accuracy

Magnified Sweep Linearity

Timing Cursors

Horizontal Position Range Any portion of the synchronized

Calibrator

Waveform Square Wave

Component Vector Mode

Vertical Bandwidth

Horizontal to Vertical Bandwidth

Matching

Vertical Gain Accuracy

Horizontal Gain Accuracy

Display to Graticule Registration

Electronic Graticule Shape Minimal visible gaps or tails at corners of target

Vector Display PB is displayed on horizontal axis and PR is

1 Line: 5 ms/division $1%

2 Line: 10 ms/division $1%

$1%

1 Line: 0.2 ms/division $1%

2 Line: 1.0 ms/division $1%

$1%

Accuracy: $1% $0.5% over 20–30° C

sweep can be positioned on

screen in all sweep modes

Amplitude: 700 mV $1%

Frequency: 100 kHz $0.1%

v2° at 500 kHz and 2 MHz

$1%

$1%

v0.25 box with the color bar

black, display dot centered in

target

w40 dB to 6 MHz; typically w46 dB to 6 MHz,

w40 dB to 10 MHz

Sweep Length: [12 divisions

Sweep free runs without input

1 Field displays one full field, including field rate

sync. 2 Field displays two full fields and the field

rate sync between them.

Crystal-controlled 10 ms square wave

w1.0 MHz

boxes

displayed on vertical axis.

1–8

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 30

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Lightning and Diamond Mode

Vertical Gain Accuracy

Electronic Graticule Display

Diamond GBR Deflection axis indicated

Lightning Y is displayed vertically

RGB Gamut Error Indication

Detection Level Positive detection level = 735 mV

Arrowhead Mode (NTSC/PAL Composite

Limit Display Mode)

Signal to Graticule Registration Color bar black is positioned in the center of

Signal to Graticule Accuracy

(PAL values in parenthesis)

Composite Limit Cursor Accuracy

(PAL values in parenthesis)

Composite Limit Detection Level

Accuracy (P AL values in parenthesis)

Bowtie Mode

Common Mode Rejection Ratio

Accuracy

Interchannel Timing Match

Picture Monitor Outputs

Signal Format EBU/N10 or RGB, menu selectable

Active Video Accuracy

Black (Blanking) Output Level

(WFM 601M)

Frequency Response

(WFM 601M)

Non-Linearity (WFM 601M)

$2%

"7 mV (nominally 105% of legal

RGB)

Negative Detection level = –35 mV

"7 mV

"2 IRE, 100 IRE and 131 IRE

("2, 700 mV)

Detection level = 102% "3% of

cursor level

700 mV $1% peak-to-peak

(Y -PB-PR mode)

0 mV "35 mV

PB is displayed horizontally on top half of display.

PR is displayed horizontally on bottom half of

display .

7.5 IRE box within v.25 box width.

"2% at 100, 110, 120, 131 IRE (700 and 950 mV)

Detection level can be set to 100, 110, 120, or 131

IRE (700 or 950 mV PAL)

w34 dB at 2.5 MHz

$3%

$2.0 ns

Typically < "2% for RGB mode

Y to 5.75 MHz: $1%

PB and PR to 2.75 MHz: $1%

v0.5%

Specifications

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–9

Page 31

Specifications

T able 1–1: Electrical specifications (cont.)

Characteristic Reference informationPerformance requirement

Group Delay Error

(WFM 601M)

Interchannel Timing Match

(WFM 601M)

Sync Amplitude Accuracy

Sync to Video Timing

Return Loss

Y at 5.75 MHz: v10 ns

PB and PR at 2.75 MHz: v20 ns

Y -to-PB and Y-to-PR "5.0 ns

300 mV $10%

Analog sync is inserted on Y channel only (G

channel only in RGB mode)

525 line rate: 9.037 ms "0.050 ms

625 line rate: 9.777 ms "0.050 ms

50 kHz to 5 MHz: w40 dB

T able 1–2: CRT display

Characteristic Performance requirement Reference information

CRT Viewing Area 80 X 100 mm

Horizontal: 12.5 divisions

Vertical: 1.19 V

Accelerating Potential Nominally 13.75 kV

Trace Rotation Range

Graticule Internal with variable illumination

>$1° from horizontal Total adjustment range is typically w8°

T able 1–3: AC power source

Characteristic Description Reference information

Electrical Rating 90 – 250 V, 50/60 Hz, 1.5 A maximum ;

Continuous range from 90 to 250 VAC

Supply Type Single Phase

Supply Connection Detachable cord set

Power Consumption < 115 VA (75 watts)

Peak Inrush Current

Environment

1–10

WFM 601A, WFM 601E, & WFM 601M Service Manual

8.4A @ 90 VAC, 26A @ 250 VAC

E2

Page 32

T able 1–4: Environmental characteristics

Characteristic Standard Reference information

Specifications

Vibration Military Specification: Mil–T–28800D,

Paragraph 1.2.2, Class 3

Mechanical Shock Non-operating: 50 g 1/2 sine, 11 ms

duration, 3 shocks per surface (18 total)

Transportation Qualified under NST A Test Procedure

1A, Category II

Humidity Proper operation at 95% +0, –5%

Relative Humidity

T able 1–5: Physical characteristics

Characteristic Standard

Dimensions Height: 133.4 mm (5.25 in)

Width: 215.9 mm (8.5 in)

Depth: 460.4 mm (18.125 in)

Weight Net: 3.8 kg (8 lbs)

Shipping:7.2 kg (15.7 lbs) approximate

5 minutes at 5 – 15 Hz with 0.060 inch

displacement

5 minutes at 15 – 25 Hz with 0.040 inch

displacement

5 minutes at 25 – 55 Hz with 0.020 inch

displacement

24 inch drop

Do not operate with visible moisture on the

circuit boards.

T able 1–6: Safety standards

Characteristic Standard

U.S. Nationally Recognized Testing

Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1 - Safety Requirements for Electrical Equipment for

European Union Compliance Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC

Additional Compliance UL3111-1 - Standard for Electrical Measuring and Test Equipment

ANSI/ISA S82.01 - Safety Standard for Electrical and Electronic Test, Measuring,

Controlling, and Related Equipment, 1994

Measurement, Control, and Laboratory Use

EN61010-1 - Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use

IEC1010-1 - Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–11

Page 33

Specifications

T able 1–7: Safety certification compliance

Characteristic Standard

Temperature (operating) +5° to +40° C

Altitude (operating) 2000 meters

Relative Humidity (maximum operating) 80% for temperatures up to 31° C decreasing linearly to 50% at 40° C

Equipment Type Test and Measuring

Equipment Class Class I: Grounded product (as defined in IEC 1010-1, Annex H)

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J).

Note: Rated for indoor use only.

Category Examples of Products in this Category:

CA T III Distribution-level mains, fixed installation

CA T II Local-level mains, appliances, portable equipment

CA T I Signal levels in special equipment or parts of equipment,

telecommunications, electronics

Pollution Degree Pollution Degree 2: Do not operate in environments where conductive pollutants may

be present.

Note: Rated for indoor use only.

1–12

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 34

Specifications

T able 1–8: Certifications and compliances

Characteristic Standard

EC Declaration of Conformity Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility and Low Voltage

Directive 73/23/ECC for Product Safety. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EMC Directive 89/336/EEC

1,2

:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

Low Voltage Directive 73/23/EEC:

EN 61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use

1

Use high-quality shielded cables.

2

When installed in any of the following Tektronix instrument enclosures:

1700F00 (Tektronix part number 437–0100–04)

1700F02 (Tektronix part number 437–0018–07)

1700F05 (Tektronix part number 437–0095–04)

WFM 601A, WFM 601E, & WFM 601M Service Manual

1–13

Page 35

Specifications

1–14

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 36

Page 37

Installation

Hardware Installation

This section describes how to install and operate the WFM 601A, WFM 601E,

and WFM 601M Serial Digital Component Waveform Monitors. It also describes

how to remove the waveform monitors for servicing. Note that repackaging

information is located at the end of the Maintenance section.

This manual includes one 3.5-inch high-density floppy disk that contains service

software. This software is used for the adjustment procedure. Instructions for

using the disk are located in the Adjustment Procedure section of this manual.

Because operating environments vary, the waveform monitor is not shipped with

a cabinet unless one is ordered. All qualification testing for the waveform

monitor was performed in a 1700F00 cabinet. To guarantee compliance with

specifications, you should operate the waveform monitor in one of the cabinets

described here.

WARNING. When power is supplied to the rear panel, line voltage is still present

in the instrument, even if the Power switch LED is off.

Cabinets

WFM 601A, WFM 601E, & WFM 601M Service Manual

The cabinets offered for the waveform monitor provide EMI shielding, protect

against electrical shock, and protect against the accumulation of dust.

A rear panel fan supplies filtered, cooling air which exits through the cabinet

vent holes. Restricting the air flow through the vents or the rear fan can lead to an

excessive internal temperature. To ensure adequate ventilation, provide the

following clearance for the waveform monitor: three inches at the rear, two

inches on each side, and one inch each on the top and and the bottom.

NOTE. To meet EMI emission specifications, the waveform monitors must be

installed in a Tektronix 1700F00, 1700F02, or 1700F05 cabinet. The cabinet

front edges must securely contact the conductive front bezel on all four sides.

2–1

Page 38

Installation

The optional 1700F00 cabinet is the basic element for all of the cabinets. See

Figure 2–1. The 1700F02 portable cabinet is an enhanced version of the 1700F00

cabinet, as is the 1700F05 side-by-side rack mount cabinet. All cabinets are

available from your Tektronix representative.

21 cm

(8.25 in)

42.7 cm

(16.2 in)

13 cm

(5.1 in)

Figure 2–1: Dimensions of the 1700F00 cabinet

2–2

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 39

Installation

The portable cabinet, 1700F02, Figure 2–2, has a handle, four feet, and a flip-up

stand. The mounting hole sizes and spacing are different from those of the

1700F00.

21 cm

42.7 cm

(16.2 in)

(8.25 in)

13 cm

(5.1 in)

Figure 2–2: 1700F02 portable cabinet

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–3

Page 40

Installation

Installing the Waveform

Monitor in a Cabinet

Secure the waveform monitor in a cabinet using two 6-32 Pozidriver screws.

Figure 2–3 shows the location of these screws on the rear panel.

CAUTION. Do not carry a waveform monitor in a cabinet without installing the

rear panel mounting screws. Without the mounting screws, there is nothing to

keep the waveform monitor in its cabinet.

Cabinet securing

screws

Figure 2–3: Rear view of the waveform monitor in a 1700F00 cabinet

2–4

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 41

Installation

Rack Adapter

The optional 1700F05 side-by-side rack adapter, shown in Figure 2–4, consists of

two attached cabinets. Use it to mount the waveform monitor and another

half-rack width instrument, such as an analog component monitor, in a standard

19-inch rack.

You can adjust the rack adapter so that the waveform monitor is aligned with

other equipment in the rack. See Figure 2–4.

48.2 cm

(19 in)

13.2 cm

(5.3 in)

Mounting

holes

Mounting

holes

43.9 cm

(17.3 in)

Figure 2–4: The 1700F05 rack cabinet holds two instruments

WFM 601A, WFM 601E, & WFM 601M Service Manual

Front panel

alignment holes

2–5

Page 42

Installation

If you are using only one side of the rack adapter, insert a blank panel (1700F06)

or an accessory drawer (1700F07) in the unused section to improve airflow and

appearance. Figure 2–5 shows the blank panel and drawer.

1700F05

Repackaging for

Shipment

1700F07

1700F06

Figure 2–5: 1700F05 cabinet showing utility drawer and blank panel

To ship the waveform monitor to a Tektronix Service Center for service, use the

following instructions:

1. Attach a tag to the waveform monitor showing the name of the owner, the

complete address, the phone number, the instrument serial number and a

description of the required service.

2. Repackage the instrument in the original packaging materials. If the original

packaging materials are not available, use the following instructions:

a. Obtain a carton of corrugated cardboard with inside dimensions at least

six inches greater than the dimensions of the instrument. Use a shipping

carton that has a test strength of at least 275 pounds.

b. Surround the instrument with a protective, anti-static bag. For instru-

ments that are not in a cabinet, wrap a piece of cardboard around the

bagged instrument to protect the internal components.

2–6

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 43

Connecting Power

Installation

c. Pack dunnage or urethane foam between the instrument and the carton. If

using Styrofoam kernels, overfill the box and compress when closing the

lid. You need three inches of tightly packed cushioning on all sides of the

instrument.

3. Seal the carton with shipping tape or industrial staples.

The waveform monitor operates from a single-phase power source with the

neutral conductor at or near earth ground. The line conductor is fused for

over-current protection. A protective ground connection through the grounding

conductor in the power cord is essential for safe operation.

WARNING. When power is supplied to the rear panel, line voltage is still present

in the waveform monitor, even if the POWER switch LED is

off.

AC Power Requirements

Rear-Panel Connectors

The waveform monitor operates from an AC line frequency of 50 or 60 Hz, over

the range of 90–250 Volts, without requiring further configuration, except for the

power cord. Refer to page 7–1 for the power cord options. The typical power

draw is 75 W. Refer to the Specifications section for additional information on

power and environmental requirements.

For information on the rear panel connectors, refer to page 2–13.

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–7

Page 44

Installation

2–8

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 45

Operating Information

This section provides a brief description of the waveform monitors front- and

rear-panel features and connections. For detailed operating information, refer to

the User manual for the specific model.

Front Panel Overview

Figure 2–6 shows the front panel of the WFM 601M waveform monitor. The

front panels for the WFM 601A and WFM 601E waveform monitors are similar.

A brief discussion of each front-panel feature follows the illustration. Features

that are unique to one or two waveform monitor(s) are indicated in the discussions. For detailed information about the operation of the waveform monitor,

refer to the Reference section in the user manuals.

Figure 2–6: The WFM 601M waveform monitor front panel

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–9

Page 46

Operating Information

Bezel Knobs

Bezel Buttons

DISPLAY Buttons

The center three knobs located below the CRT have multiple functions. Your

selection of DISPLAY or MENU functions or items from on-screen menus

determine the current function of each knob. A label adjacent to the knob

indicates its current function. The outside knobs are permanently assigned to

control vertical and horizontal trace position.

The five bezel buttons along the right side of the CRT have multiple functions.

Your selection of DISPLAY modes, MENU functions, or on-screen items from

the displayed menus determine the current function of each button. A label

adjacent to each button indicates its current selection. The buttons either step

through a list of two or more items or turn a function on or off.

Six buttons in the DISPLAY area control the type of display. Most buttons

represent two related types of displays. Press a button to select one of its two

displays. Press the button again to select the other. When you select a display

type, the indicator LED beside it lights up.

EYE. Displays the serial input signal as an Eye pattern display. You can choose

standard or equalized Eye displays (WFM 601E, WFM 601M).

JITTER. Displays the peak-to-peak jitter measurement over a specified bandwidth. The display includes the demodulated jitter waveform for measurement

(WFM 601M).

VECTOR. Displays the component signals as either conventional Vector or

Lightning mode. Vector mode plots the chrominance signals, P

and Pr, against

b

each other to show their phase and amplitude relationships. The Lightning mode

shows amplitude and timing relationships between the luminance and chrominance signals. The top of the display plots Y against P

against P

.

r

while the bottom plots Y

b

GAMUT. Displays the video signal in Diamond or Arrowhead gamut displays.

Diamond mode evaluates RGB signals for gamut limit violations. Arrowhead

display plots Y versus chrominance magnitude to show adherence to composite

gamut limits. A gamut error message appears at the lower-left when an RGB or

Composite gamut error is detected. Turn this alarm on or off in the CONFIG

menu.

WAVEFORM. Displays the video signal as voltage versus time. Any or all of the

three channels can be displayed from a single video line.

2–10

PARADE. Displays up to three channels of the video signal in succession.

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 47

Operating Information

MULTIPLE. Allows two display modes to be active at the same time. The

Waveform or Parade can be displayed with either Vector, Lightning, or Diamond.

PICTURE. Displays the video signal source. When Line Select is on, the selected

line is highlighted to identify where it is in the video picture.

BOWTIE. Displays a bowtie test signal to determine timing differences between

the three component signals, Y, P

, and Pr. The external video source must

b

generate a Bowtie test signal.

DGTL WFM. Displays the digital word values as a waveform. The data values are

not interpolated to generate the waveform (WFM 601M).

DGTL LIST. Displays the sequential data values in a list. Data may be in linear

data sequence or as groups of four values as they appear in the multiplexed data

stream: C

, Y, CR, Y’ (WFM 601M).

B

VIDEO IN

SWEEP

ANALOG AUDIO. Displays the stereo analog audio input as a Lissajous pattern.

The size of the opening in the pattern is relative to the phase error between the X

and Y audio channels. (WFM 601A)

Turns on or off CH 1 (Y/R), CH 2 (P

/G), and CH 3 (PR/B) and selects the

B

SERIAL A or B digital signal input. At least one input and one channel are

always on.

Selects the waveform monitor sweep rate (LINE/FIELD) and horizontal

magnification (MAG). This area includes two buttons:

LINE / FIELD. Toggles through four sweep rates: 1-Line (5 ms/div), 2-Line

(10 ms/division), 1-Field, and 2-Field. Selections are limited in some display

modes.

MAG. Provides horizontal magnification of waveform signals. Use the Horizontal

Position bezel knob to move left or right on through the waveform.

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–11

Page 48

Operating Information

SERIAL

REF (Reference)

MENU

POWER

Displays a status screen providing EDH error statistics, including ANC data

errors and line/field length errors. In addition, the WFM 601E and WFM 601M

waveform monitors provide screens that report format errors, signal strength, and

cable length information. This area includes two indicators:

EDH DET. Lights up when the serial digital signal has the SMPTE RP165

specified Error Detection and Handling (EDH) signal.

ALARM. Lights up when a serial video data or format error occurs, or when the

serial signal is lost.

Selects either internal serial digital or external composite video input for the

instrument synchronization reference.

Provides access to configuration and measurement functions that affect the

DISPLAY mode. Press a MENU button to display that menu and enable the

associated functions. Press the button again to exit the menu and disable the

function.

Puts the waveform monitor into the standby or operational state.

CLEAR MENU

Using the Menus

Turns off the MENU function readouts without affecting the menu settings. Also,

provides access to alternative displays in some display modes.

The waveform monitors have a set of front-panel selectable MENU buttons that

call up CRT readout menus. These menus operate in conjunction with the five

bezel buttons along the side of the CRT and the three knobs directly beneath it.

See Figure 2–7.

Enabled menu selections are surrounded by a rectangle to indicate that they are

active.

Pressing the CLEAR MENU button turns off the menu readout while leaving the

functions associated with the current Display mode.

Pressing a MENU button when its menu is displayed turns off both the menu

readout and, in most cases, disables the function. By selecting Line Select,

Cursor, Filter, or Gain, the last settings are returned. For example, if X5 was

active when you last used the Gain menu, returning to the Gain menu restores X5

gain.

2–12

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 49

Display menus

with their

optional selections

Operating Information

Bezel buttons

Menu selection buttons

Rear Panel Connectors

Power Connector

Bezel knobs

Menu clear

Figure 2–7: Elements of the waveform monitor menu controls

Figure 2–8 shows the rear panel of the waveform monitor. A brief discussion of

each connector follows the illustration. Again, features unique to a specific

waveform monitor are indicated in the text.

The waveform monitor is designed to operate from a single-phase power source

with the neutral conductor at or near earth ground. Only the line conductor is

fused for over-current protection. A protective ground connection through the

grounding conductor in the power cord is essential for safe operation.

WARNING. Dangerous potentials are present on the Power circuit board. To avoid

electric shock, do not connect power to the waveform monitor if it is not enclosed

in a prescribed cabinet.

The waveform monitors operate from an AC line frequency of 50 and 60 Hz,

over the range of 90–250 VAC, without the need for configuration. Refer to the

Specifications section of this manual for additional information on power and

environmental requirements.

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–13

Page 50

Operating Information

Power connector

Figure 2–8: Rear panel of the waveform monitor

Loop-Through Inputs

There are three passive loop-through inputs located on the rear panel. All are

compensated for 75 W impedance and require proper termination at one end of

the loop-through connector or at the receiver in a monitored system.

SER A and SER B. Provides for connection of two 270 Mb serial component data

signals. These inputs have minimal impact on the monitored serial data path.

EXT REF. Provides for connection of an external synchronization signal such as

black burst or composite video.

Coaxial Outputs

Five rear panel connections drive signals into a 75 W environment.

MON OUT (Y/G, P

drive a component picture monitor. You can set the output format to YP

GBR. Invalid input signals cause a blinking highlight of the monitor display at

the line where the error occurs. This gamut error highlight or “bright-up” signal

is present on the Y (or G) output and is controlled in the CONFIG menu.

/B, PR/R). Provides three 75 W component signal outputs to

B

BPR

or

2–14

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 51

Operating Information

SERIAL OUT. Provides a reclocked version of the selected signal input (SER A or

SER B).

JITTER OUT. Provides a 75 W output signal from the jitter demodulator for the

WFM 601M waveform monitor. The Jitter high-pass filter (JITTER HPF)

selection does not affect this signal. You can view the jitter waveform on the

waveform monitor using the JITTER display mode. This output is disabled on

the WFM 601A and WFM 601E waveform monitors.

RS-232 Connector

Remote Connector

The RS-232 connector is a 9-pin D-type connector that provides a remote

verification interface. Figure 2–9 shows the pin assignments and the communication parameters for the RS-232 interface. The Remote Command set is defined in

Appendix C: Remote Commands of the User Manuals.

Communication parameters

Baud: 9600

Data bits: 8

Stop bits: 1

Parity: None

Flow control: Xon/Xoff

Pin

Number

1

2

3

4

5

6

7

8

9

Data Connection

DCD (Received line signal detector)

RXD (Received data)

TXD (Transmitted data)

DTR (DTE readly)

Signal ground

DCR (DCE readly)

RTS (Request to send)

CTS (Clear to send)

Not connected

Figure 2–9: Pin assignments for the RS-232 connector

The rear-panel REMOTE connector is a 25-pin, D-type connector that allows

low-level remote control. Use the RS-232 interface for control using SCPI

commands sent from a PC controller.

The 25-pin remote connector provides remote control of presets and monitoring

of line select and video alarm events. Eight of the Presets (stored front-panel

settings) can be stored or recalled remotely.

STORE. When pin 25 is grounded along with one of the preset pins, the current

front-panel settings are stored at the selected Preset location.

Line Select Strobe. Pin 15 outputs an active-low TTL pulse during selected lines

when in Line Select modes. Use this signal as a trigger for a logic analyzer or

oscilloscope.

WFM 601A, WFM 601E, & WFM 601M Service Manual

2–15

Page 52

Operating Information

Serial Video Alarm. Pin 16 outputs an active-low TTL level whenever the

front-panel ALARM light is illuminated.

Remote Connector Pin Assignments. Pin assignments for the REMOTE connector

are shown in Figure 2–10 and described in Table 2–1. You enable functions by

ground closures (TTL lows) on specified pins. Functions preceded by a forward

slash (/) indicate an active low state.

113

25

14

Figure 2–10: Pin assignments for the REMOTE connector

T able 2–1: Remote connector pin assignments and functions

Pin number

1 Not Used No connection allowed

2 Ground TTL ground

3 Not Used No connection allowed

4 Not Used No connection allowed

5 Ground TTL ground

6 Not Used No connection allowed

7 Ground TTL ground

8 +Y Audio Input Not used in the WFM 601E or the WFM 601M

9 –Y Audio Input Not used in the WFM 601E or the WFM 601M

10 +X Audio Input Not used in the WFM 601E or the WFM 601M

Function Signal requirement Miscellaneous information

11 –X Audio Input Not used in the WFM 601E or the WFM 601M

12 +Time Code Input Not used in the WFM601E or the WFM601M

13 –Time Code Input Not used in the WFM601E or the WFM 601M

14 Ground TTL ground

15 /Line Strobe In Line Select Modes,

true (low) during selected video

lines (TTL low)

2–16

WFM 601A, WFM 601E, & WFM 601M Service Manual

Page 53

T able 2–1: Remote connector pin assignments and functions (cont.)

Operating Information

Pin number

16 Serial Video Alarm True low . Low pulse when an

error occurs in the serial digital

input signal

17 Preset 1 Ground (TTL low) Recalls the stored Preset from this location, or

18 Preset 2 Ground (TTL low) Recalls the stored Preset from this location, or

19 Preset 3 Ground (TTL low) Recalls the stored Preset from this location, or

20 Preset 4 Ground (TTL low) Recalls the stored Preset from this location, or

21 Preset 5 Ground (TTL low) Recalls the stored Preset from this location, or

Miscellaneous informationSignal requirementFunction

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

22 Preset 6 Ground (TTL low) Recalls the stored Preset from this location, or

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.

23 Preset 7 Ground (TTL low) Recalls the stored Preset from this location, or

selects the Preset 1 memory location to store the

current front-panel settings. See the pin 25

description.