xx

WFM5200 Series

Waveform Monitors

ZZZ

System Integration

Technical Reference

*P077054801*

077-0548-01

xx

WFM5200 Series

Waveform Monitors

ZZZ

System Integration

Technical Reference

Warning

The service instructions are f

To avoid personal injury, do not perform any servicing unless

you are qualified to do so. Refe

to performing service.

www.tektronix.com

077-0548-01

or use by qualified personnel only.

r to all safety summaries prior

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B ox 50 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

World wide , visit www.tektronix.com to find contacts in your area.

Table of Contents

General safety summary .............. ................................ ................................ ............. ii

Preface ............................................................................................................... v

Where to find more information............... ................................ ............................... v

Physical, e

Rack and custom installation ............................... ................................ ....................... 3

Instrument connectors.............................................................................................. 5

Video system installation ....... ................................ ................................ .................. 16

Power-on and power-off procedure.............................................................................. 20

Network operation......................................... .................................. ...................... 22

nvironmental, and power specifications...... ................................ ....................... 1

WFM5200 Series System Integrator i

General safety summary

General safet

To avoid fir

e or personal

injury

ysummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

Use proper

certified for the country of use.

Ground th

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To avo i d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

power cord. Use only the power cord specified for this product and

eproduct.This product is grounded through the grounding conductor

Power disconnect. The power cord disconnects the product from the power source.

Donotblockthepowercord;itmustremain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Use proper AC adapter. Use only the AC adapter specified for this product.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the manual's installation instructions for details

on installing the product so it has proper ventilation.

ii WFM5200 Series System Integrator

General safety summary

Terms in this manual

Symbols a nd terms on the

product

These terms may

appear in this manual:

WAR N ING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

dicates an injury hazard immediately accessible as you read

the marking.

WAR N IN G

indicates an injury hazard not immediately accessible as you

read the marking.

CAUTIO

N indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

WFM5200 Series System Integrator iii

General safety summary

iv WFM5200 Series System Integrator

Preface

Preface

Where t

This documen

systems for high definition multimedia interface (HDMI) formats and

high-definition (HD), standard-definition (SD), and 3 Gb/s SDI digital video

content where the Tektronix WFM5200 and WFM5250 Waveform Monitors

will be deployed.

This manual is divided into the following sections:

Physical, environmental, and power specifications (See page 1.)

Rack and custom installation (See page 3.)

Instrum

System installation (See page 16.)

Network operation (See page 22.)

o find more information

The following tables list the documentation that is available for the product and

shows where you can find it: in a printed manual, on the product documentation

OM, or on the Tektronix Web site.

CD-R

t provides information for system integrators who are designing

ent connectors (See page 5.)

Table i: Product documentation

Item Purpose Location

Installation and Safety Instructions Provides safety and compliance information along

with hardware installation instructions to present the

associated safety warnings. This manual is available in

English, Japanese, Russian, and Simplified Chinese.

User Manual

Online H elp

Specifications and Performance

Verification Technical Reference

Release Notes

Service Manual Provides information about adjustments, repair, and

Provides operation and application information.

In-depth instrument operation and UI help.

Specifications and procedures for checking instrument

performance.

Software release information about new features and

existing issues.

replaceable parts.

Printed m anual and also

available in electronic format

at www.tektronix.com/downloads

Product Documentation

CD and available at

www.tektronix.com/downloads

On the instrument

Product Documentation

CD and available at

www.tektronix.com/downloads

Available at

www.tektronix.com/downloads

Available at

www.tektronix.com/downloads

WFM5200 Series System Integrator v

Preface

Table ii: Relat

Item Purpose Location

Top 10 Application-Based Presets

Preventing Illegal Colors

(application note)

Understand

(poster)

A Guide to Standard and

High Defini

Measurements (primer)

Analog an

Monitoring (application note)

Audio Monitoring (application note)

ring Surround Sound Audio

Monito

(application note)

NTSC V

(primer)

PAL Systems Television

Measurements (primer)

ed reference documents

ing Colors and Gamut

tion Digital Video

d Digital Audio

ideo Measurements

Describes use

Describes ho

displays can be used to help prevent the undesired

impact of color gamut violations and to simplify the

assessment o

Provides a l

Arrowhead, and Lightning displays can be used to help

prevent the undesired impact of color gamut violations.

This book explains the basics of making standard and

high-defin

Describe

signals. Also discussed are specific differences in the

methods used to monitor analog audio versus digital

audio, a

analog audio to monitoring digital audio.

Describ

and explains the physical and electrical characteristics

and the specific strength and weaknesses of the

ent digital audio signal formats.

differ

Descri

audio and tells how to use the Surround Sound display

to visualize key audio-level and phase relationships

s audio format.

in thi

This b

measurements.

This book explains the basics of making PAL video

measurements.

ful presets and how to set them up.

w the Diamond, Arrowhead, and Lightning

f proper gamut compliance.

arge visual display of how the Diamond,

ition, digital-video measurements.

s how to monitor analog and digital audio

nd how to plan the transition from monitoring

es balanced and unbalanced audio signals,

bes the basics of 5.1-channel surround sound

ook explains the basics of making NTSC video

Product Documentation

CD and availab

www.tektronix.com/downloads

Product Docu

CD and available at

www.tektronix.com/downloads

Available at

www.tektro

Product Documentation

CD and available at

www.tektr

Availabl

www.tektronix.com/downloads

Availab

www.tektronix.com/downloads

Available at

www.te

Product Documentation

CD and

www.tektronix.com/downloads

uct Documentation

Prod

CD and available at

www.tektronix.com/downloads

le at

mentation

nix.com/downloads

onix.com/downloads

eat

le at

ktronix.com/downloads

available at

Table iii: Graphics and photos for system integrators

Item Purpose Location

Front and rear panel photos of the

WFM5200 and WFM5250

Front and rear panel line art

These photos might be useful if you need to present information

to your customer

This line art might be useful if you need to present information

to your customer

vi WFM5200 Series System Integrator

Product Documentation

CD

Product Documentation

CD and this manual

Physical, environmental, and power specifications

The physical, environmental, and power specifications apply to all instrument

models. Use this information to ensure proper ventilation and clearance when

installing a

Table 1: Physical specifications

Characteristic Description

Dimensions

Weight

Height

Width

Depth

Net

Shipping 12 lbs (5.4 kilograms ), approximate, excluding options and

Table 2: Power specifications

Characteristic Description

Power

Input Voltage

Input Power Frequency 50 or 60 Hz

Power Consumption, typical 50 to 110 VA at 110 or 240 VAC

n instrument into a rack.

5.25 in (133.4 millimeters)

8.5 in (215.9 millimeters)

4.75 in (120.7 millimeters)

3.3 lbs (1.5 kilograms)

accessories

100 to 240 VAC ± 10%

NOTE. More information about the power connector is available in this document.

e page 6, Power connector.) You can also read about the power-on and

(Se

power-off procedures. (See page 20.)

ble 3: Environmental specifications

Ta

Characteristic Description

emperature

T

Humidity

Altitude

Operating 0 °C to +40 °C

onoperating

N

Operating 20% to 80% relative humidity at up to +40 °C, noncondensing

Nonoperating

Operating 9,842 feet (3,000 meters )

Nonoperating

-20°Cto+60°C

Below 5% or above 90% relative humidity at up to +60 °C,

noncondensing

40,000 feet (12,192 meters)

WFM5200 Series System Integrator 1

Physical, environmental, and power specifications

Table 3: Environmental specifications (cont.)

Characteristic Description

Cooling

Base instrument (no optional sleeves) To allow for proper airflow, there must be at least 2 inches of

Portable cabinet

Rack cabinet

The variable fans provide forced air circulation. Do not block

ventilation openings.

clearance on both sides of the instrument, at least 2 inches

of clearance from the rear of the instrument, and at least a

1/2 inch of clearance from the top of the instrument.

Use only the Tektronix portable cabinet, WFMF02, to allow for

proper airflow with this instrument. W hen using the portable

cabinet, the same minimum clearances as the base instrument

apply.

Use only the WFMRACK-NN or WFMRACK-S2 rackmount

rack adapter for this instrument. To allow for proper airflow

when installing the rack adapter in a closed rack with solid

walls, there must be at least 2 inches of clearance from both

sides of the rack adapter frame to the rack side walls, at least 3

inches of clearance from the rear of the rack adapter frame to

the back wall of the rack, and at least a 1/2 inch of clearance

from the top of the rack adapter to another rack adapter or

installed instrument. The rack intake air to the side vents must

not exceed 40 °C.

2 WFM5200 Series System Integrator

Rack and custom installation

The instrument is shipped in a wrap-around chassis that covers the instrument

bottom and two sides. A cover is installed on the chassis, and the rear panel

is made up of t

You can operate the instrument in the instrument chassis (be sure the top cover is

on) or insta

adapter installation.) You can also install the instrument in a custom installation,

such as a console.

CAUTION. To prevent damage to the instrument and the cabinet, do not install the

instrument in any cabinet except the WFMRACK-NN, WFMRACK-S2, or other

rack approved by Tektronix for this instrument.

he module rear panels.

lled in an approved portable cabinet or rack adapter. (See page 4, Rack

Rack and custom installation

WFMRACK adapter

dimensions

The following two figures show the dimensions of the WFMRACK-NN and

WFMRACK-S2 rack adapter hardware.

Figure 1: WFMRACK rack adapter dimensions

WFM5200 Series System Integrator 3

Rack and custom installation

Custom installation

Rack adapter installation

Figure 2: WFMRACK rear-bracket guide dimensions

If you install the instrument in a custom application, such as a c onsole, b e sure to

provide adequate airflow. Follow these guidelines:

Do not block the ventilating holes.

Adhere to the clearance requirements. (See Table 3 on page 1.)

Install the rack adapter into the equipment rack before you install an instrument

into the adapter.

To install the instrument in a 19-inch equipment rack, you must use the

WFMRACK-NN or WFMRACK-S2 Rack Adapter kit. These rack adapters are

designed to house two half-rack instruments side-by-side in a rack. The -NN rack

can h ouse one full depth and one short depth instrument. The -S2 rack can house

two short depth instruments. For installation instructions, see the instruction

manual that is included in the kit.

4 WFM5200 Series System Integrator

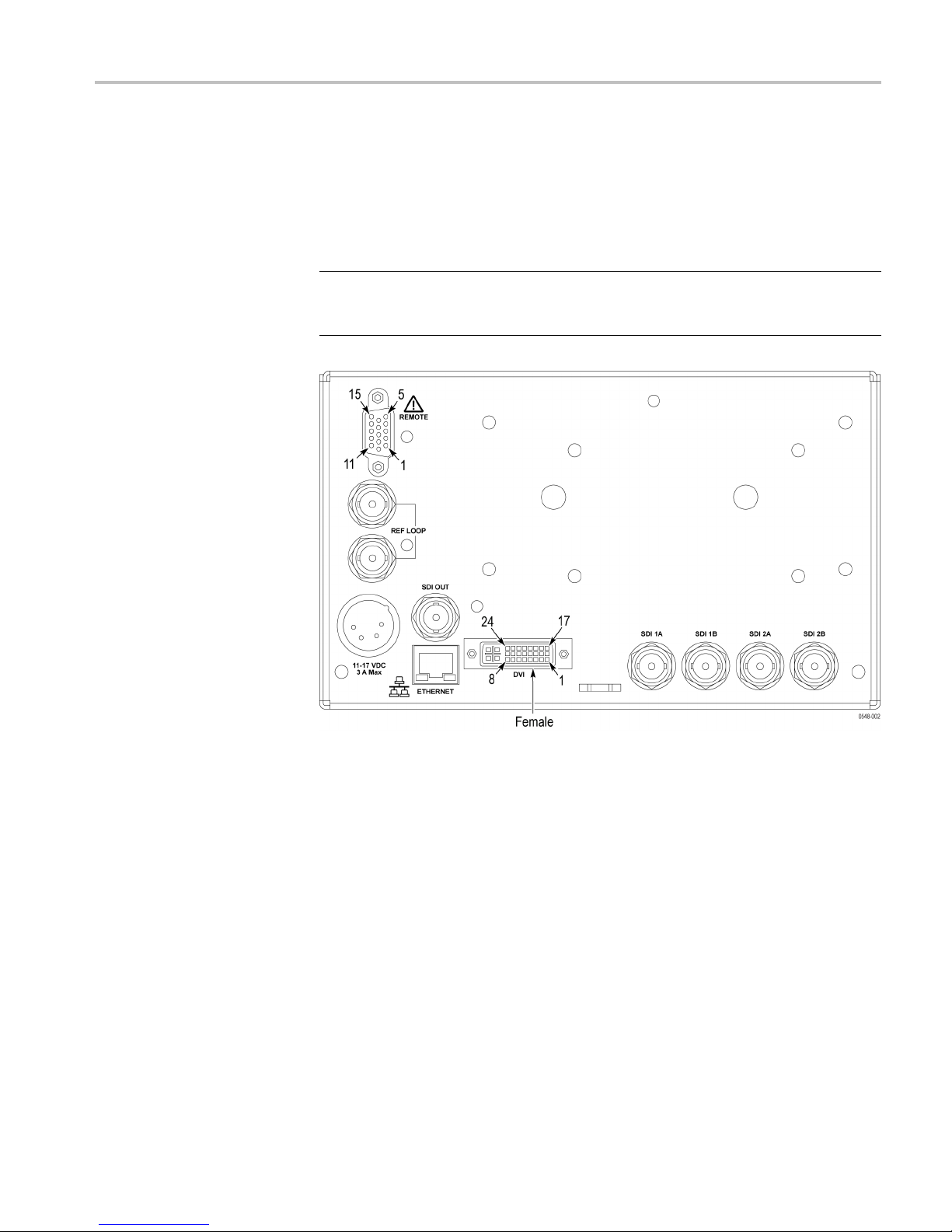

Instrument connectors

The WFM5200 and WFM5250 instruments have connectors on the front and rear

panels. The following pages describe the connector types, pin numbering, and

associated s

NOTE. More illustrations and photographs of these instruments are available in

JPEG format on the Tektronix Web site (www.tektronix.com/downloads) and on

the Product Documentation C D that was shipped with your instrument.

Instrument connectors

ignal requirements.

Figure 3: WFM5200 rear panel

WFM5200 Series System Integrator 5

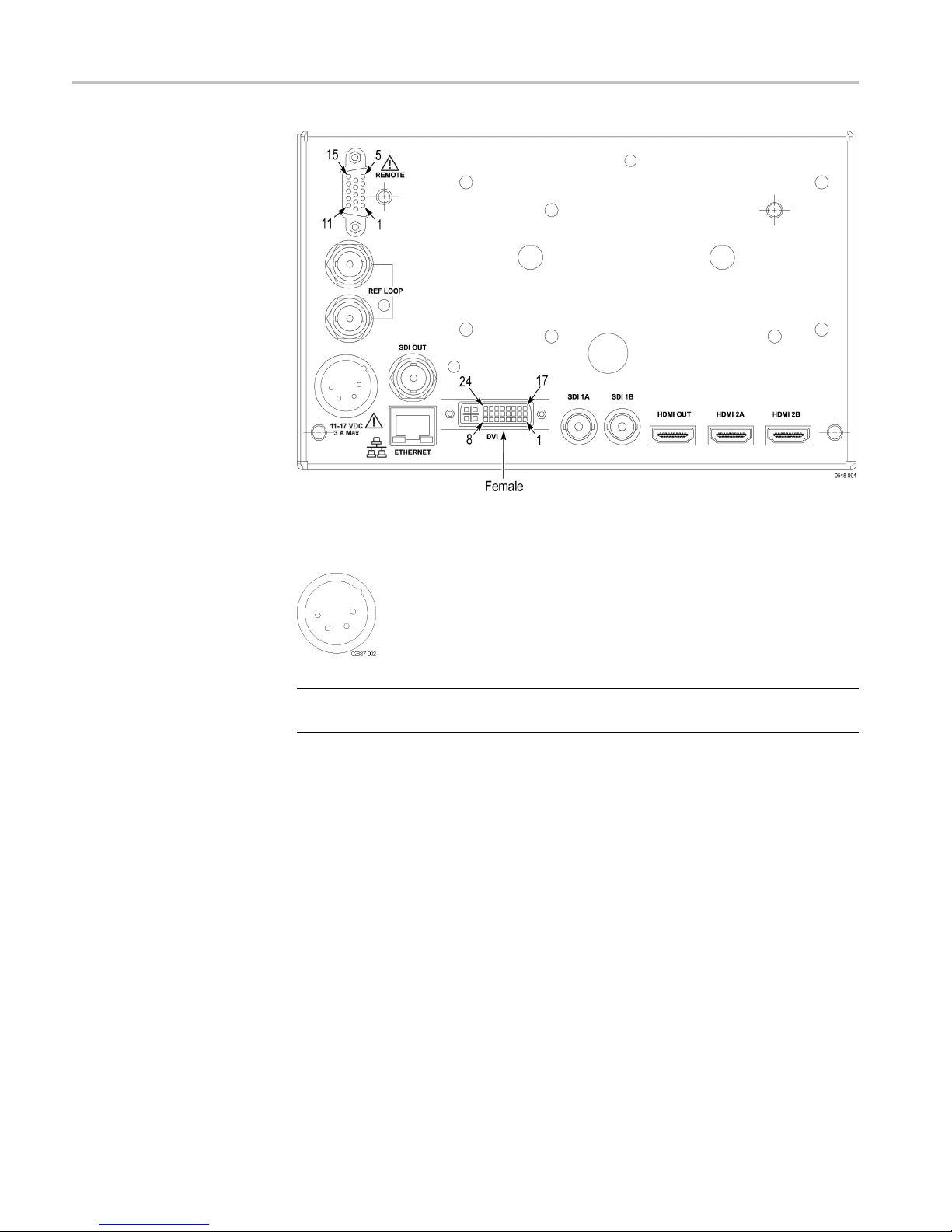

Instrument connectors

Figure 4: WFM5250 rear panel

Power connector

NOTE. If you ordered a power cord, it will come with a ferrite core. Install the

ferrite core as shown in the instructions with which it was shipped.

6 WFM5200 Series System Integrator

Instrument connectors

The instrument

operates from an external AC adapter and has the following power

requirements:

A single-phas

e power source with one current-carrying conductor at or near

earth-ground (the neutral conductor).

The power so

urce frequency must be 50 or 60 Hz, and a operating voltage

range must be from 100 to 240 VAC, continuous.

WAR N ING. To re d uc e r is k of fire and shock, make sure the mains supply voltage

fluctuations do not exceed 10% of the operating voltage range.

Systems with both current-carrying conductors live with respect to ground

(such as phase-to-phase in multiphase systems) are not recommended as

power sources.

NOTE. Only the line conductor is fused for over-current protection. The fuse is

al and not user replaceable. Do not attempt to replace the fuse. If you

intern

suspect the fuse has blown, return the unit to an authorized service center for

repair.

WFM5200 Series System Integrator 7

Instrument connectors

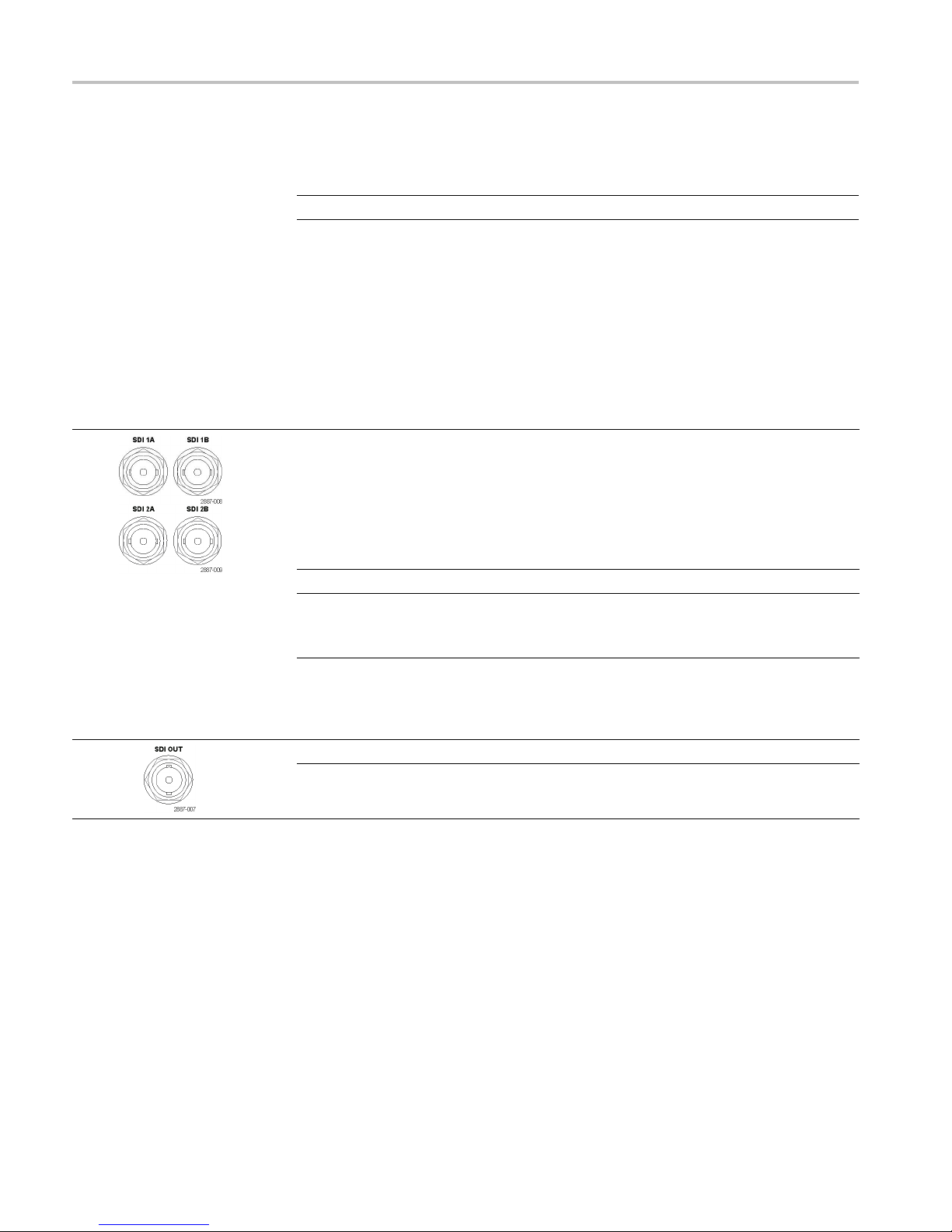

SDI video connectors

SDI inputs are s

elf-terminating inputs. Use the SDI 1A, 1B, 2A, and 2B inputs to

connect a serial digital video signal to the instrument.

NOTE. The SDI 2A and 2B connectors are only found on the WFM5200 model.

The SDI OUT can be selected to output either the looped-through input signal

or a test signal that contains configurable error brightups. This is done from the

Config > Outputs > SDI Output menu.

The following table lists the characteristics of the SDI video connectors.

Table 4: SDI video connector specifications

Connector Characteristic Description

NOTE. The SDI 2A and 2B

connectors are only found on

the WFM5200 model.

Input Type

Input Level

Cable Loss Accommodation: 270 Mb/s 0 to 30 dB attenuation at ½ of serial rate

Cable Loss Accommodation: 1.5 Gb/s,

3Gb/s

Output Type BNC, 75 Ω internally terminated

Output Level 800 mV ± 10% into 75 Ω load

BNC, 75 Ω internally terminated

WFM5250 only: 2 inputs, only one active at

a time except for Dual Link (2 inputs) or SIM

mode (Option SIM).

WFM5200 only: 4 inputs, only one active at

a time except in camera balance mode (2-4

inputs) or Dual Link (2 inputs).

800 mV ± 10%

Equivalent to approximately 300 m of

Belden 8281 at 270 Mb/s

0 to 20 dB attenuation at ½ of serial rate

Equivalent to approximately 80 m of

Belden 8281 at 1.485 Gb/s. Typical

performance to 110 m

MI video connectors

HD

(WFM5250 only)

HDMI inputs are self-terminating inputs. Use the HDMI 2A and 2B inputs to

route incoming HDMI signals into the rear-panel of the instrument. You cannot

monitor a 3D signal and an HDMI signal at the same time. You can only monitor

one at a time.

TheHDMIOUTcanbeusedtooutputanHDMIsignaltoanexternalHDMI

monitor. An HDCP compliant monitor is required in order to view an image for

HDCP compliant inputs, otherwise the screen may be blank. Also, the SDI output

will not be available when HDCP content is present on the HDMI input.

8 WFM5200 Series System Integrator

Instrument connectors

The following t

able lists the characteristics of the HDMI connectors.

NOTE. The HDMI 2A and 2B connectors are only found on the WFM5250 model.

Table 5: HDMI

Connector Characteristic Description

connector specifications

Input Type Type A conne

Format

Audio Uncompressed audio over HDMI is supported

HDCP HDCP version 1.4 is supported on both

Output T

Video

Audio

HDCP HDCP version 1.4 is supported on both

ype

2 inputs, only one active at a time

Supported formats include: 525i, 625i, 525p,

625p, 720p, 1080i, 1080p

(up to 8 channels)

inputs

BNC, 75 Ω

utput is always a loopout of the

Video o

currently selected HDMI input

Audio is passed from the HDMI input to the

output

s. If HDCP is present on the currently

input

selected input, it will be enabled on the

output.

ctor

internally terminated

Video external reference

connector

Use the REF LOOP connector to input a composite Black Burst signal or a

tri-level sync signal for use as a sync tim ing reference for the selected video

ut signal. The following table lists the signal characteristics of the external

inp

reference connectors.

Table 6: External reference connector specifications

Connector Characteristic Description

Input Type

Input Level -6 to +6 dB

Maximum Input Voltage Level

Maximum Absolute Input Voltage

BNC, passive loop-through, 75 Ω

ompensated

c

±5V,DC

±5V,DC

WFM5200 Series System Integrator 9

Instrument connectors

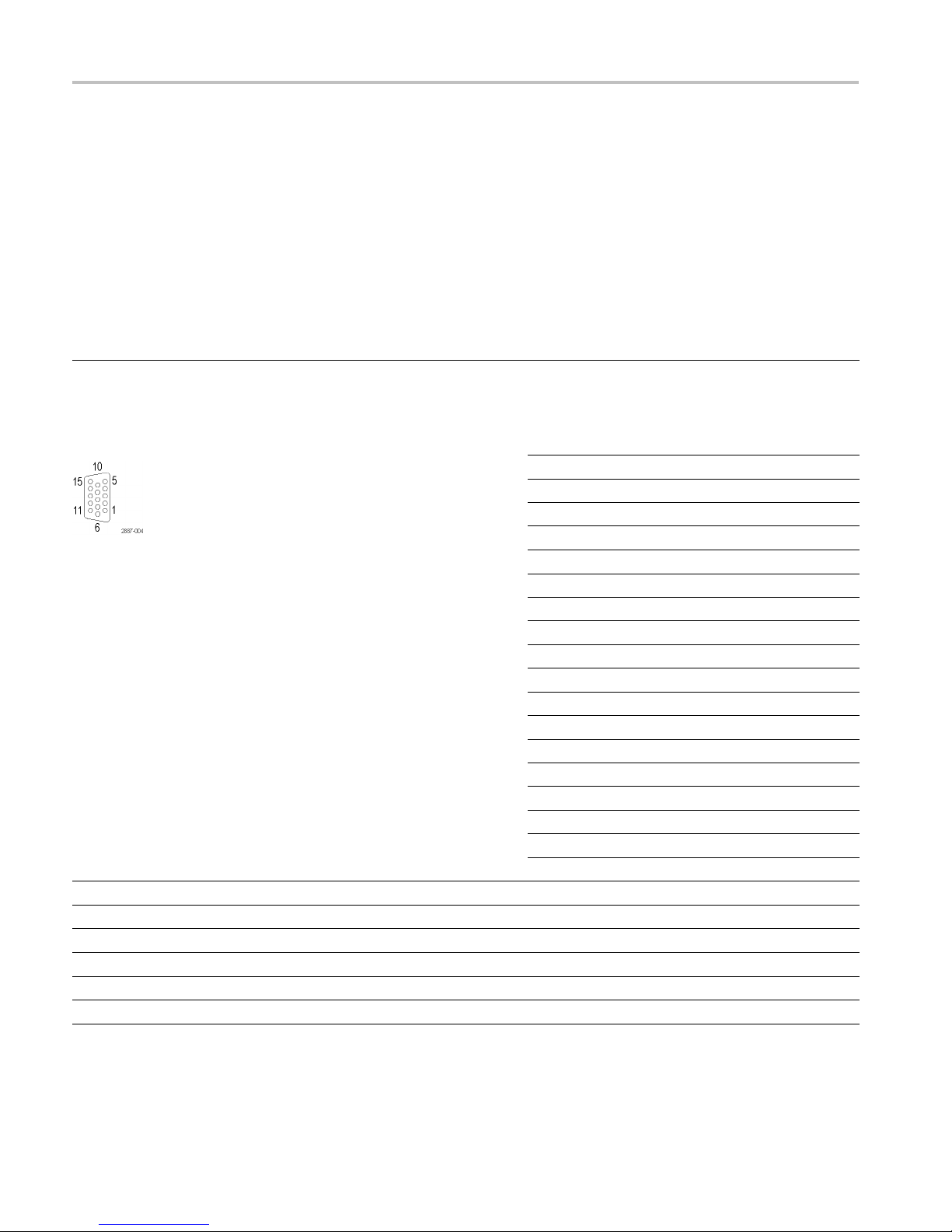

Remote connector

(WFM5200 only)

The REMOTE conn

contacts. It uses ground closures for remote control and sending indications to

ector is a 15-pin, female, D-type connector with socket

external equipment when alarms have occurred. The input of LTC is through the

REMOTE connector.

Use the Remote connector to input LTC time code signals, and to remotely select

one of the first four instrument presets in group “A” using ground closure. The

following table lists the signal characteristics of the Remote connector.

Table 7: WFM5200 remote connector pin assignments and preset functions

Characteristic Pin out Preset functions

Connector Pin Assignments

Characteristic

LTC Input Connector 15-pin DSUB, balanced, unterminated

LTC Input Signal Longitudinal Time Code per IEC Publication 461

LTC Signal Amplitude Range 0.2 V

Ground Closure Input Signal

Ground Closure Output Signal One open collector output

1GND(In)

2 Reserved (I/O)

3 Reserved (I/O)

4 Reserved (In)

5 Reserved (In)

6GND(In)

7 Time Code Positive (LTC In)

8 Time Code Negative (LTC In)

9 Ground Closure (Alarm Out)

10 Preset 1 (In)

11 Preset 2 (In)

12 Preset 3 (In)

13 Preset 4 (In)

14 Preset 5 (In)

15 Preset 6 (In)

Description

to 5.0 V

p-p

TTL thresholds, 5 V max input, -0.5 min input; pull low to assert

balanced differential or single-ended

p-p

Hex Binary

Pins 15,

14, 13,

12, 11,

10

F 111111

E XX1110 Preset 1 No action

D XX1101 Preset 2 No action

C

B XX1011 Preset 3

A XX1010 No action

9 XX1001 No action

8 XX1000 Preset 8

7

6 XX0110 Preset 6

5

4 XX0100 Preset 4

3 XX0011 Preset 3

2 XX0010 Preset 2

1 XX0001 Preset 1

0 XX0000 Unused

N/A

N/A

XX1100

XX0111 Preset 4 Preset 7

XX0101 Preset 5

10 1111 Preset 5

011111 P reset 6

Direct

mode

selection

none

Encoded

mode

selection

No action

SDI 1B/2B

SDI 1A/2A

N/A

N/A

10 WFM5200 Series System Integrator

Instrument connectors

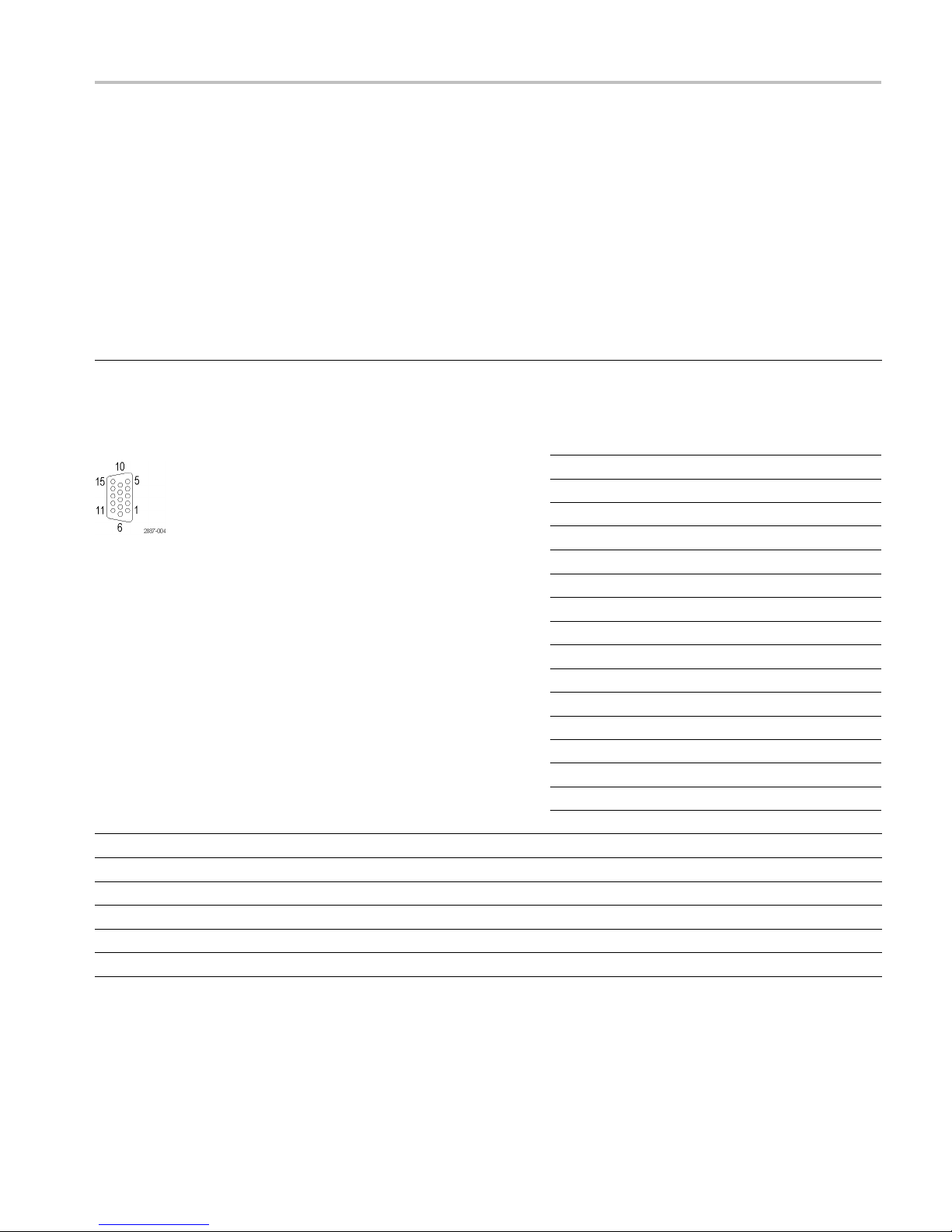

Remote connector

(WFM5250 only)

The REMOTE conn

contacts. It uses ground closures for remote control and sending indications to

ector is a 15-pin, female, D-type connector with socket

external equipment when alarms have occurred. The input of LTC is through the

REMOTE connector.

Use the Remote connector to input LTC time code signals, and to remotely select

one of the first four instrument presets in group “A” using ground closure. The

following table lists the signal characteristics of the Remote connector.

Table 8: WFM5250 remote connector pin assignments and preset functions

Characteristic Pin out Preset functions

Connector Pin Assignments

Characteristic

LTC Input Connector 15-pin DSUB, balanced, unterminated

LTC Input Signal Longitudinal Time Code per IEC Publication 461

LTC Signal Amplitude Range 0.2 V

Ground Closure Input Signal

Ground Closure Output Signal One open collector output

1GND(In)

2 Reserved (I/O)

3 Reserved (I/O)

4 Reserved (In)

5 Reserved (In)

6GND(In)

7 Time Code Positive (LTC In)

8 Time Code Negative (LTC In)

9 Ground Closure (A larm Out)

10 Preset 1 (In)

11 Preset 2 (In)

12 Preset 3 (In)

13 Preset 4 (In)

14 Preset 5 (In)

15 Preset 6 (In)

Description

to 5.0 V

p-p

TTL thresholds, 5 V max input, -0.5 min input; pull low to assert

balanced differential or single-ended

p-p

Hex Binary

Pins 15,

14, 13,

12, 11,

10

F 111111

E XX1110 Preset 1 HDMI B

D XX1101 Preset 2 HDMI A

C

B XX1011 Preset 3

A XX1010

9 XX1001

8 XX1000 Preset 8

7

6 XX0110 Preset 6

5

4 XX0100 Preset 4

3 XX0011 Preset 3

2 XX0010 Preset 2

1 XX0001 Preset 1

0 XX0000 Unused

XX1100

XX0111 Preset 4 Preset 7

XX0101 Preset 5

Direct

mode

selection

none

Encoded

mode

selection

No action

SDI B

SDI A

Channel B

Channel A

WFM5200 Series System Integrator 11

Instrument connectors

EXT DISPLAY connector

The EXT DISPLAY

connector is a female DVI-I connector with socket contacts.

This is the external display monitor output. The display resolution is 1024 x

768. The output supports DVI monitors directly and analog PC (RGB) monitors

with the use of a DVI-I to VGA adapter.

12 WFM5200 Series System Integrator

Instrument connectors

Table 9: EXT DIS

Connector Pin Description Pin Description

Characteristic

Output Connector DVI-I (integrated, digital and analog)

PLAY connector specifications

1

2

3

4

5

6

7

8 Analog vertical sync 20

9

10

11

12

C1

C2

C3

Description

TMDS Data 2–

Red – (Link 1)

TMDS Data 2+

Red + (Link 1)

TMDS Data 2/4 shield

TMDS Data 4–

Green – (Link 2)

TMDS Data 4+

Green + (Link 2)

DDC clock

DDC data

TMDS Data 1–

Green – (Link 1)

TMDS Data 1+

Green + (Link 1)

TMDS Data 1/3 shield

TMDS Data 3–

Blue – (Link 2)

Analog red

Analog green

Analog blue

13

14

15 + 5 V

16 Hot plug detect

17

18

19

21

22

23

24

C4

C5

TMDS Data 3+

Blue + (Link 2)

Ground

Power for monitor when in standby

TMDS Data 0–

Blue – (Link 1) and digital sync

TMDS Data 0+

Blue + (Link 1) and digital sync

TMDS data 0 /5 shield

TMDS Data 5–

Red – (Link 2)

TMDS Data 5+

Red + (Link 2)

TDMS clock shield

TDMS clock +

Digital clock + (Links 1 and 2)

TDMS clock –

Digital clock – (Links 1 and 2)

Analog horizontal sync

Analog ground

Return for R, G, B signals

WFM5200 Series System Integrator 13

Instrument connectors

Ethernet connector

Use the Etherne

t connector to connect the waveform monitor to your local

network. A network connection is required for remote control, software upgrades,

and enabling some instrument options.

The Ethernet connector includes built-in green and yellow LEDs to indicate signal

status as indicated below:

Lit green LED indicates connection is active

Lit yellow L

ED indicates a 100 MB transmission rate

Unlit yellow LED indicates a 10 MB transmission rate

The following table lists the signal characteristics of the Ethernet connector.

Table 10: Ethernet connector pin assignments

Connector Pin/LED Name Description

1 TX_D1+ Transceive Data+

2 TX_D1- Transceive Data-

3 RX_D2+ Receive Data+

4 Not used

Characteristic

Ethernet connector

5

6 RX_D2- Receive Data-

7

8 Not used

Description

RJ-45 LAN supporting 10/100/1000 B aseT; supports manual and DHCP address modes

Not used

Not used

14 WFM5200 Series System Integrator

Instrument connectors

Headphone jack

Use the headpho

ne jack, located on the front panel, to listen to the audio associated

with the selected video input signal. The following table describes the signal

characteristics of the headphone jack.

Table 11: Headphone jack specifications

Connector Characteristic Description

Output Type Standard 1/4-inch stereo phone jack,

capable of driving a 6.25 dBu sine wave into

32 Ω or 16 Ω

USB Connec

tor

Use the USB connector, located on the front panel, to save and restore instrument

presets and captured data using a USB memory drive. The following table

describes the signal characteristics of the USB connector.

Table 12

Connector Characteristic Description

: USB connector specifications

Type Host

Speed Compli

es with USB 1.1 and 2.0 Full Speed

Specification (12 Mb/s)

WFM5200 Series System Integrator 15

Video system installation

Video system installation

The instrument can operate almost anywhere in the distribution system.

NOTE. See the Specifications and Performance Verification manual on the

Product Doc

umentation CD for maximum-allowed cable lengths.

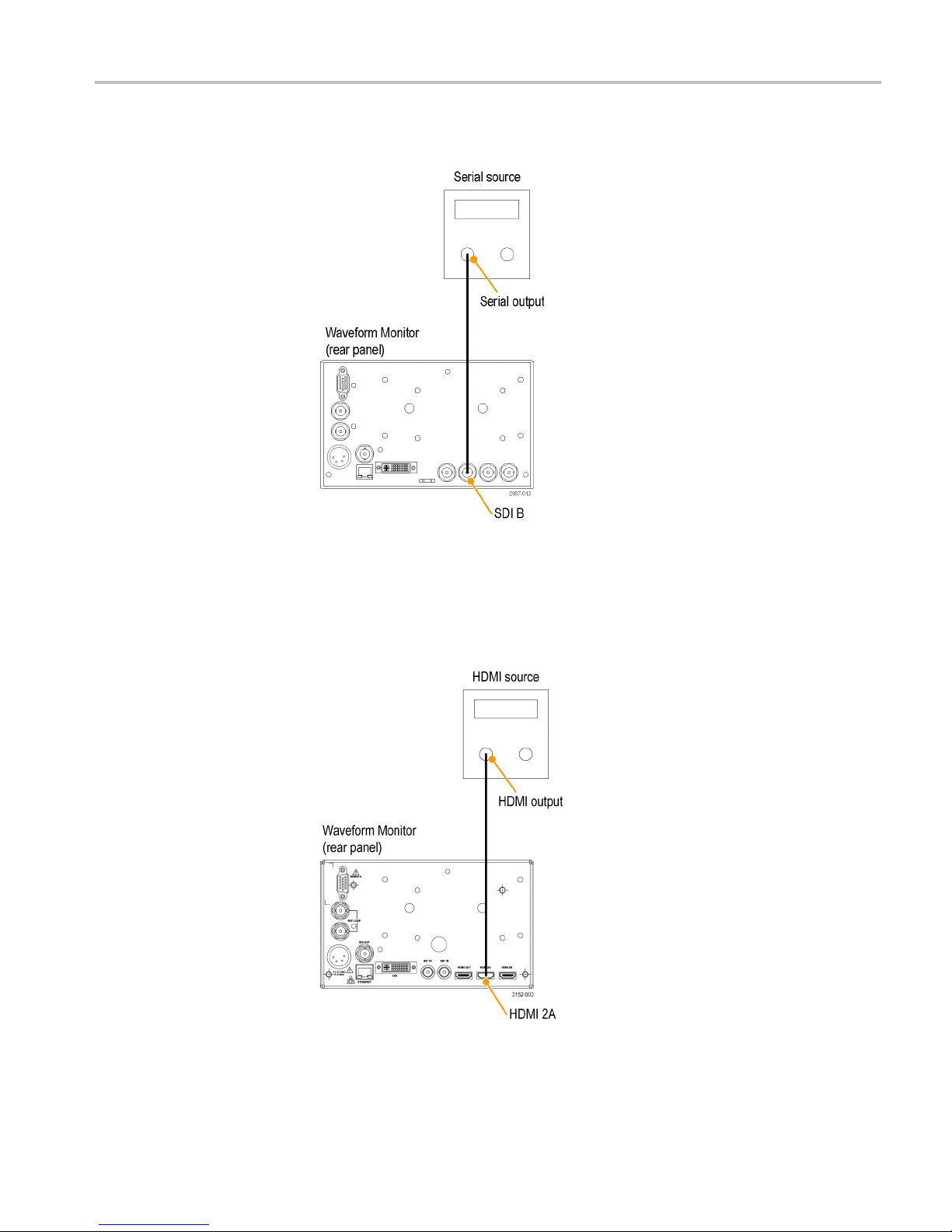

Install to monitor the

video bit st

ream of a serial

receiver

Route one or more incoming serial signals into the SDI inputs on the rear-panel

of the inst

Figure 5: Connecting SD, HD, or 3 Gb/s SDI signals to a WFM5200

rument.

NOTE. See the Specifications and Performance Verification manual on the

Product Documentation CD for maximum-allowed cable lengths.

16 WFM5200 Series System Integrator

Video system installation

Install to monitor the

embedded audio signal

in a serial digital video

stream

Route the incom

Figure 6: Connecting an SD, HD, or 3 Gb/s SDI signal with embedded audio

ing serial signal into one of the instrument SDI inputs.

Install to monitor the HDMI

content of a signal

You can route one incoming HDMI signal into one of the HDMI inputs on the

rear-panel of the instrument. You cannot monitor a 3D signal and an HDMI

signal. You can only monitor one at a time .

WFM5200 Series System Integrator 17

Video system installation

Install to output an HDMI

signal to an external

monitor

You c an output a

OUT connector.

NOTE. An HDCP compliant monitor is required in order to view an image for

HDCP compliant inputs, otherwise the screen may be blank. Also, the SDI output

will not be available when HDCP content is present on the HDMI input.

n HDMI signal to an external HDMI monitor using the HDMI

Install to monitor the

external referenc e signal

Route the incoming reference signal into one of the instrument REF inputs and

terminate the other connector with a 75 Ω terminator to ensure a closed loop.

Figure 7: Connecting an external reference signal

18 WFM5200 Series System Integrator

Video system installation

Line termination

Compatibility of BNC

center pins

You r ins tr um e n

t uses a passive loop-through reference input. Accordingly, the

loop-through input must be terminated externally. It is important that this external

termination meets accuracy and return loss requirements.

If the instrument is installed to monitor an operating link, the destination receiver

and the connecting cable serve as the termination. This monitoring connection

checks the performance of the entire path. The return loss of the instrument is

sufficiently high that, in most cases, the destina tion receiver sets the system return

loss.

In cases where the instrument is placed at the end of a link, a BNC termination

must be installed on one side of the loop-through reference connector. The

terminat

ion m ust be 75 Ω and DC coupled (good return loss extends to DC). An

appropriate termination for the EXT REF connector is Tektronix part number

011-0163-00, which is a 75 Ω, End-of-Line termination.

Most BNC

connectors for video equipment, whether 50 Ω or 75 Ω,usea50Ω

standard center pin. Some laboratory 75 Ω BNCconnectorsuseasmaller

diameter center pin. The BNC connectors on the instrument are designed to work

with the 50 Ω standard (large diameter) center pins.

Do not use connectors or terminators with the smaller center pins. They could

cause intermittent connections.

WFM5200 Series System Integrator 19

Power-on and power-off procedure

Power-on and p

AC power requirements

Power-

on

ower-off procedure

This instrum

conductor at or near earth ground. The line conductor is fused for over-current

protection. A protective ground connection through the grounding conductor in

the power cord is essential for safe operation.

The instrument operates from an external AC adapter with a line frequency of 50 or

60 Hz, over the range of 100-240 Volts, without the need for configuration, except

the power cord. The typical power draw is 27 Watts. Refer to the Specifications

and Performance Verification Technical Reference on the Product Documentation

CD for additional information on power and environmental requirements.

If you are using a battery as a power source, read the battery information provided

in Installation and Safety Instructions.

1. Connect the supplied power cord to the rear-panel power connector. If you are

using a battery, connect the battery as explained in the installation instructions

that come with the battery.

2. Press the power button on the instrument front-panel and the instrument will

turn on.

ent operates from a single-phase power sourc e with the neutral

Figure 8: WFM5200 front-panel

20 WFM5200 Series System Integrator

Power-on and power-off procedure

Power-off

Figure 9:

WFM5250 front-panel

NOTE. The power button on the front-panel does not disconnect mains power.

Only the power cord at the rear of the product can disconnect mains power.

Make sure that the power cord is accessible when the product is operating.

1. Press

the power button on the instrument front-panel to turn the instrument off.

2. To remove power completely, disconnect the power cord from the rear-panel

e instrument.

of th

WFM5200 Series System Integrator 21

Network operation

Network operation

This section provides the following information for operating the instrument on

alocalLANnetwork:

How to configure the instrument for operation on an IP network

How to configure the instrument to send and/or receive SNMP remote

commands

How to use a Web browser to start a remote application to enable control

of the instrument, or to download the Event and Diagnostic log files, or to

capture images of the instrument display

Ethernet

connection

Connect the instrument to your network using an Ethernet cable. You can connect

it directly to the instrument or through a HUB, as shown below.

Figure 10: Connecting to ethernet

22 WFM5200 Series System Integrator

Network operation

IP settings con figuration

To allow networ

k access to the instrument, you need to set the IP address.

Network addresses can b e assigned either automatically (DHCP) or manually. If

your network does not use DHCP, you will have to manually enter the address for

the instrument. To obtain a valid IP address, contact your LAN administrator.

Perform the following steps to configure the IP settings on the instrument:

1. Press the CONFIG button to display the Configuration menu.

2. Use the Gene

ral knob to navigate to Network Settings.

3. Press the right arrow key to select IP ConfigMode.

4. Press the SEL button to select between DHCP and Manual.

5. If you selected DHCP, you are finished.

6. If you selected Manual mode, you need to set the Subnet Mask and Gateway

Address parameters. Contact your LAN administrator for these values. (Be

sure to use compatible addresses between the PC and the instrument.)

7. Press the down arrow key to select IP Address.

8. Press the right arrow key. A dialog box will appear that allows you to enter

the IP address.

9. Repeat steps 7 and 8 for the Subnet Mask and the Gateway Address.

10. If desired, select Instrument Name and then press the right arrow button to

assign the instrument a network name.

11. Press the CONFIG button to close the configuration menu.

WFM5200 Series System Integrator 23

Network operation

SNMP remote control

configuration

SNMP remote con

trol is primarily intended for instrument access using automated

systems. If you intend to use SNMP commands to control the instrument, you

must first configure the SNMP settings on the waveform monitor.

NOTE. The SNMP commands are contained in a MIB (Management Information

Base). Refer to the WFM Series Waveform Monitors and WVR Series Waveform

Rasterizers Management Information Base Technical Reference (Tektronix

part number

077-0261-XX) for information about using the MIB to control the

waveform monitor.

The proce

dure to configure SNMP settings is similar to that previously described

for configuring the IP settings. Touch SNMP Setup in the Communication

submenu of the Main menu to configure the following SNMP parameters:

Remote SNMP Enable. Use this setting to configure the remote access to the

instrument via SNMP. You can select Off or On.

SNMP Traps. Use this setting to enable or disable the SNMP traps that are

sent from the instrument when error conditions are detected.

Trap Destination Address. Use these settings to enter up to four different

IP addresses to which SNMP traps will be sent when error conditions are

detected.

NOTE. A value of all zeroes for the IP address will disable that trap output.

Private Community String. Use this menu setting to enter the Private

Community string, which effectively is a password. Without this string,

SNMP commands cannot change values in the waveform monitor.

TE. Use the Private Community String to control the ability of SNMP

NO

commands to make changes to the waveform monitor. Use the Public Community

String to control the ability of SNMP commands to read information from the

waveform monitor.

Public Community String. This menu entry allows you to set the Public

Community string. This string is effectively a password. Without this s tring,

SNMP commands cannot read information from the instrument.

24 WFM5200 Series System Integrator

Network operation

Web browser operation

You can connect

to an instrument installed on an Ethernet IP network without

installing any software and using only a Web browser. Using the Web browser,

you can perform the following functions:

Start a remote application to enable control of the instrument

Download th

e Event and Diagnostic log files

Capture images of the instrument display

Perform the following steps to connect to the instrument using a Web browser:

1. Verify that the instrument has been configured for IP network operation and

note the IP address. (See page 23, IP settings configuration.)

2. Press the CONFIG button.

3. Use the General knob to navigate to Network Settings.

4. Press the right arrow key and then use the General knob to navigate to Web

Enable.

5. Press the SEL buttontoselectOn.

6. On you

r PC, start your Web browser and enter the network address of the

instrument into the URL entry box like this:

//123.123.123.123/

http:

NOTE. Many Web browsers do not correctly interpret IP addresses with leading

zeros. If the IP address shown in the Configuration menu contains leading zeros,

remove any leading zeros when you enter the address in the browser.

For example, the IP address 124.161.038.092 should be entered as follows:

124.161.38.92

7. The Web browser will display the remote interface for the instrument. To

make a selection, click the desired link.

WFM5200 Series System Integrator 25

Loading...

Loading...