Page 1

Service Manual

WFM 1125

Digital Television Waveform Monitor

Option 0A/0B/0C/0D

071-0455-04

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright E Sony/Tektronix Corporation. All rights reserved.

Copyright E T ektronix, Inc.. All rights reserved

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in Japan

Sony/T ektronix Corporation, P.O. Box 5209, Tokyo Int’l, Tokyo 100–31 Japan

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 6

Page 7

Table of Contents

Specifications

Operating Information

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Characteristics 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and EMI 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Use 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplying Operating Power 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying and Interrupting Power 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installed Options 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Menus 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bezel Menu 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Menu 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAG/CAL Menu 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232C Connector 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Connector 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Theory of Operation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A15 Relay & Sync board 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A10 Input board 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A20 Main board 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A40 CPU board 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A30 Front Panel board 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A60 DC-DC board 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A5 DISPLAY board 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 1125 Option 0A/0B/0C/0D Service Manual

i

Page 8

Table of Contents

Performance Verification

Performance Verification 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Running the Performance Tests 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipments 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance T ests 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure

Adjustment Procedures 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements for Performance 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Adjustment 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Adjustment 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Adjustment 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Maintenance Procedures 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Updates 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floppy disks 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update Procedure 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Electrical Parts List

Diagrams

Mechanical Parts List

ii

Options and Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 0A Description 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 0B Description 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 0C Description 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 9

List of Figures

Table of Contents

Figure 2–1: Dimensions of the 1700F00 plain cabinet 2–4. . . . . . . . . . . . .

Figure 2–2: 1700F02 portable cabinet 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Rear view of the waveform monitor in a 1700F02

cabinet 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: The 1700F05 rack cabinet holds two instruments 2–7. . . . . .

Figure 2–5: 1700F05 cabinet showing utility drawer and blank panel 2–8

Figure 2–6: Elements of the WFM 1125 menu controls 2–13. . . . . . . . . . . .

Figure 2–7: DIAG/CAL menu structure 2–15. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: Pin assignments for the RS-232C connector 2–17. . . . . . . . . .

Figure A–1: Pin assignments for the REMOTE connector 2–19. . . . . . . . .

Figure 4–1: Ground closer with 15-pin D-type connector 4–3. . . . . . . . . .

Figure 4–2: Performance test initial hookup 4–6. . . . . . . . . . . . . . . . . . . .

Figure 4–3: Analog output test initial hookup 4–13. . . . . . . . . . . . . . . . . . .

Figure 4–4: Audio output test initial hookup 4–16. . . . . . . . . . . . . . . . . . . .

Figure 4–5: External reference test initial hookup 4–18. . . . . . . . . . . . . . . .

Figure 4–6: External reference test initial hookup 4–20. . . . . . . . . . . . . . . .

Figure 4–7: Monitor output test initial hookup 4–24. . . . . . . . . . . . . . . . . .

Figure 5–1: Rear view of the waveform monitor in a enclosure 5–2. . . . .

Figure 5–2: A5 display board view from top of the waveform

monitor 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–3: A5 display board view from top of the waveform

monitor (J310171 and above) 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–4: A10 input board view 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–5: A40 CPU board view and test points 5–11. . . . . . . . . . . . . . . . .

Figure 5–6: Power supply module view and VR501 5–12. . . . . . . . . . . . . .

Figure 6–1: RS-232C cable with 9-pin, D-type connectors 6–9. . . . . . . . .

Figure 6–2: A60 DC-DC board (view from top) 6–24. . . . . . . . . . . . . . . . . .

Figure 6–3: A20 Main board (view from top) 6–27. . . . . . . . . . . . . . . . . . . .

Figure 6–4: J100 and J110 connector pin configurations 6–29. . . . . . . . . .

Figure 9–1: Interconnections 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Block diagram 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: A20 Main board block diagram 9–4. . . . . . . . . . . . . . . . . . . . .

Figure 10–1: WFM 1125 Digital Television Waveform Monitor

exploded view 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WFM 1125 Option 0A/0B/0C/0D Service Manual

iii

Page 10

Table of Contents

List of Tables

Table 1–1: Vertical deflection system 1–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Horizontal deflection system 1–4. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Serial digital video interface 1–7. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Analog Output 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Stripped AES/EBU digital audio output 1 1–7. . . . . . . . . . . .

Table 1–6: External reference input 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Format display 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Field rate display 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–9: RBG transcoder 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Component vector mode 1–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–11: Lightning and diamond mode 1–10. . . . . . . . . . . . . . . . . . . . . .

Table 1–12: Bowtie mode 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–13: Status display mode 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–14: Save and display mode 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–15: Warning display 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–16: Calculation dynamic range 1–12. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–17: Setup memory 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–18: CRT display 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–19: AC power source 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–20: Installation requirements 1–13. . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–21: Environmental characteristics 1–14. . . . . . . . . . . . . . . . . . . . .

Table 1–22: Physical characteristics 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–23: Certifications and compliances2 1–15. . . . . . . . . . . . . . . . . . .

Table 2–1: Power-cord conductor identification 2–9. . . . . . . . . . . . . . . . .

Table 2–2: Effects of corrupted data 2–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Remote connector pin assignments and functions 2–19. . . . . .

Table 4–1: Required equipment 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: Required equipment 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Relative susceptibility to static-discharge damage 6–3. . . . . .

Table 6–2: External inspection check list 6–4. . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: Internal Inspection check list 6–5. . . . . . . . . . . . . . . . . . . . . . .

Table 6–4: Required equipment 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Floppy disk’s file list 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Standard accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Optional accessories 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

WFM 1125 Option 0A/0B/0C/0D Service Manual

v

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

vi

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

XĆRadiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

WFM 1125 Option 0A/0B/0C/0D Service Manual

vii

Page 14

Service Safety Summary

viii

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 15

Preface

Document Structure

This document supports serial number J310000 and above.

This preface contains information needed to properly use this document to

service the WFM 1125 Digital Television Waveform Monitor Option

0A/0B/0C/0D, as well as general information critical to safe and effective

servicing of this waveform monitor. This manual applies to any instrument with

serial number J310101 and above.

This document is divided into sections, such as Specification and Theory of

Operation. Further, it is divided into subsections, such as Product Description

and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures. Be

sure to read these introductions because they provide information needed to do

the service correctly and efficiently. The following is a brief description of each

document section.

H Specification contains a product description of the WFM 1125 Digital

Television Waveform Monitor Option 0A/0B/0C/0D and tables of the

characteristics and descriptions that apply to it.

H Operating Information includes general information and operating instruc-

tions at the level needed to safely power on and service this waveform

monitor. A statement of the service strategy that this document supports, and

instructions for shipment of the waveform monitor are found in this section.

H Theory of Operation contains circuit descriptions that support general service

and fault isolation down to the module level.

H Performance Verification contains a collection of procedures for confirming

that these waveform monitor function properly and meet warranted limits.

H Adjustment Procedures contains a collection of procedures for adjusting

these waveform monitor to meet warranted limits.

H Maintenance contains information and procedures for doing preventive and

corrective maintenance of these waveform monitor. Instructions for cleaning,

for firmware updates, and for fault isolation to a module are found here.

H Options contains information on servicing any of the factory-installed

options that may be present in your waveform monitor.

WFM 1125 Option 0A/0B/0C/0D Service Manual

ix

Page 16

Preface

Document Conventions

H Electrical Parts List contains a statement referring you to Mechanical

Replaceable Parts, where both electrical and mechanical modules are listed.

H Diagrams contains a block diagram and an interconnection diagram useful

for isolating failed modules.

H Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers, as well as the exploded view.

This document uses certain conventions which you should become familiar with

before doing service.

Modules

Symbols

Related Manual

Safety

Throughout this manual, any replaceable component, assembly, or part of these

waveform monitor is referred to generically as a module. In general, a module is

an assembly, like a circuit board, rather than a component, like a resistor or an

integrated circuit. Sometimes a single component is a module; for example, each

chassis part of the waveform monitor is a module.

Symbols and terms related to safety appear in the Safety Summary found at the

beginning of this document.

Besides the symbols related to safety, this document uses the following symbols:

STOP. The stop labels information which must be read in order to correctly do

service and to avoid incorrectly using or applying service procedures.

The WFM 1125 Digital Television Waveform Monitor Option 0A/0B/0C/0D

come with the following manual:

WFM 1125 Option 0A/0B/0C User Manual (Tektronix part number

071-0260-XX) contains information for operation the WFM 1125 Digital

Television Waveform Monitor Option 0A/0B/0C/0D.

x

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 17

Introduction

Service Strategy

STOP. Throughout this document, any field-replaceable component, assembly, or

part of this waveform monitor is referred to generically as a module.

This document contains all the information needed for periodic maintenance of

the WFM 1125 Digital Television Waveform Monitor Option 0A/0B/0C/0D.

(Examples of such information are procedures for checking performance and for

readjustment.) Further, it contains all information for corrective maintenance

down to the module level. This means that the procedures, diagrams, and other

troubleshooting aids help isolate failures to a specific module, rather than to

components of that module. Once a failure is isolated, replace the module with a

fresh unit obtained from the factory.

All modules are listed in Mechanical Parts List. To isolate a failure to a module,

use the fault isolation procedures found in Section 6, Maintenance.

Service Offerings

Warranty Repair Service

Repair or Calibration

Service

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians, trained on Tektronix products, are best

equipped to service your WFM 1125 Digital Television Waveform Monitor

Option 0A/0B/0C/0D. Tektronix technicians are appraised of the latest information on improvements to the product as well as the latest new options to the

product.

Tektronix warrants this product for one year from date of purchase. Tektronix

technicians provide warranty service at most Tektronix service locations

worldwide. Your Tektronix product catalog lists all service locations worldwide.

The following services may be purchased to tailor repair and/or calibration of

your WFM 1125 Digital Television Waveform Monitor Option 0A/0B/0C/0D to

fit your requirements.

AtĆDepot Service. Tektronix offers several standard-priced adjustment (calibration) and repair services:

WFM 1125 Option 0A/0B/0C/0D Service Manual

xi

Page 18

Introduction

H A single repair and/or adjustment.

H Calibrations using equipment and procedures that meet the traceability

standards specific to the local area.

H Annual maintenance agreements that provide for either calibration and repair

or calibration only of the waveform monitor.

Of these services, the annual maintenance agreement offers a particularly

cost-effective approach to service for many owners of the WFM 1125 Digital

Television Waveform Monitor Option 0A/0B/0C/0D. Such agreements can be

purchased to span several years.

OnĆSite Service. The annual maintenance agreement can be purchased with

on-site service, with repair and calibration done at your facility. This service

reduces the time your waveform monitor is out of service when calibration or

repair is required.

Self Service

Tektronix supports repair to the module level by providing Module Exchange and

Module Repair and Return.

Module Exchange. This service reduces down time for repair by allowing you to

exchange most modules for remanufactured ones. Tektronix ships you an updated

and tested exchange module from the Beaverton, Oregon service center, typically

within 24 hours. Each module comes with a 90-day service warranty.

Module Repair and Return. This service returns to you within 10 days the same

module that you shipped to Tektronix. The module shipped is repaired, tested,

and returned to you from the Beaverton, Oregon service center. It is not updated

to match current modules of the same type. Again, each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services just

described.

xii

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 19

Before You Begin

Introduction

This document is for servicing the WFM 1125 Digital Television Waveform

Monitor Option 0A/0B/0C/0D. To prevent injury to yourself or damage to the

waveform monitor, do the following tasks before you attempt service:

H Be sure you are a qualified service person.

H Read the Safety Summary found at the beginning of this document.

H Read Service Strategy in this section and Supplying Operating Power in

section 2.

When using this document for servicing, be sure to heed all warnings, cautions,

and notes.

WFM 1125 Option 0A/0B/0C/0D Service Manual

xiii

Page 20

Introduction

xiv

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 21

Specifications

Page 22

Page 23

Product Description

The WFM 1125 Digital Television Waveform Monitor Option 0A/0B/0C/0D

Option 0A/0B/0C/0D measures and displays HDTV serial digital signals. The

waveform monitor is a fully digital waveform monitor with a variety of standard

measurement modes displayed on an internal VGA display. An external VGA

display output is also provided. The digital architecture of the waveform monitor

allows you to save the displayed waveform to an internal memory. In order to

properly display intermittent events that may be missed in a single-line select

mode, the waveform monitor has a persistence display feature combining

information from many TV lines, much like an analog waveform monitor.

Refer to Specifications, for details of the waveform monitor performance.

Features

The waveform monitor offers the following features:

H Supports the following system formats:

H Option 0A: 1035/60i, 1035/59.94i, 1080/60i, and 1080/59.94i

H Option 0B: 720/60p and 720/59.94p

H Option 0C: 1035/60i, 1035/59.94i, 1080/60i, 1080/59.94i, 720/60p, and

720/59.94p

H Option 0D: 1035/60i, 1035/59.94i, 1080/60i, 1080/59.94i, 1080/50i,

720/60p, 720/59.94p, 1080/30sF, 1080/29.97sF, 1080/25sF, 1080/24sF,

1080/23.98sF, 1080/24p, and 1080/23.98p

H Digital component video signal displays, parade and vector modes

H Save and Display feature that saves and recalls the currently displayed signal

H CRC error detection

H Gamut error detection

H Infinite mode in persistence display that retains the image of transient signals

H Overlay and Parade displays

H Diamond, Lightning, and Bowtie displays

H Four graticules for waveform display

H Serial digital monitor output and CRC error monitor output

H Analog external reference input with passive loop through, bi-level or

tri-level sync

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-1

Page 24

Product Description

H AES/EBU digital audio output (except for 720/60p, 720/59.94p, 1080/24p,

and 1080/23.98p)

H Y, P

input

, Pr picture monitor analog output from selected serial digital signal

b

1-2

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 25

Specifications

Tables 1–1 through 1–20 list the electrical specifications for the WFM 1125

Digital Television Waveform Monitor Option 0A/0B/0C/0D Option

0A/0B/0C/0D. Performance requirements are generally quantitative and can be

tested by qualified service personnel. Reference information describes useful

operating parameters and typical characteristics and performance.

The performance requirements listed in the electrical specification portion of

these specifications apply over an ambient temperature range of 0° C to +40° C.

The rated accuracies are valid when the instrument is calibrated at an ambient

temperature range of +20° C to +30° C, after a warm-up time of 20 minutes.

Electrical Specifications

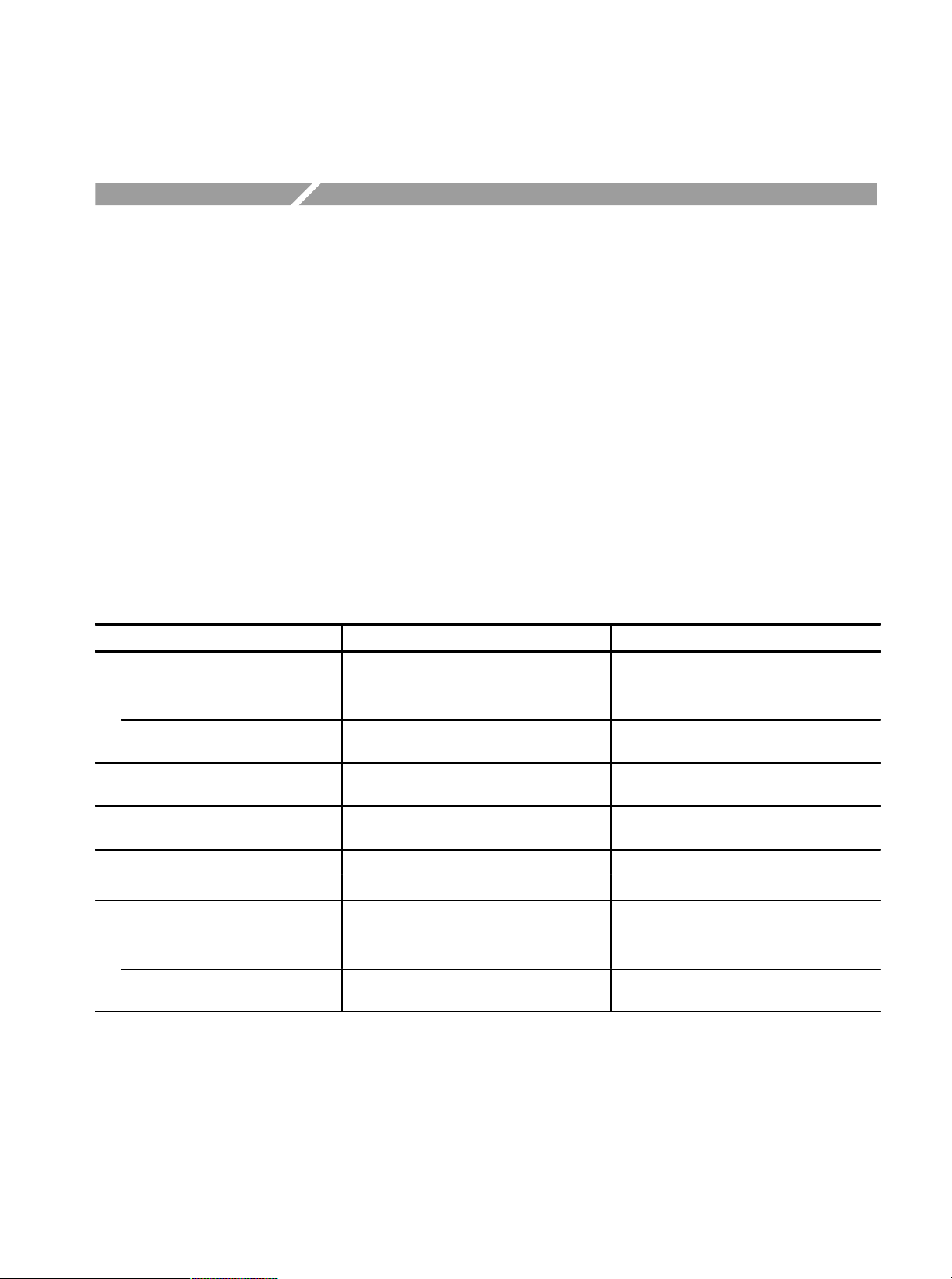

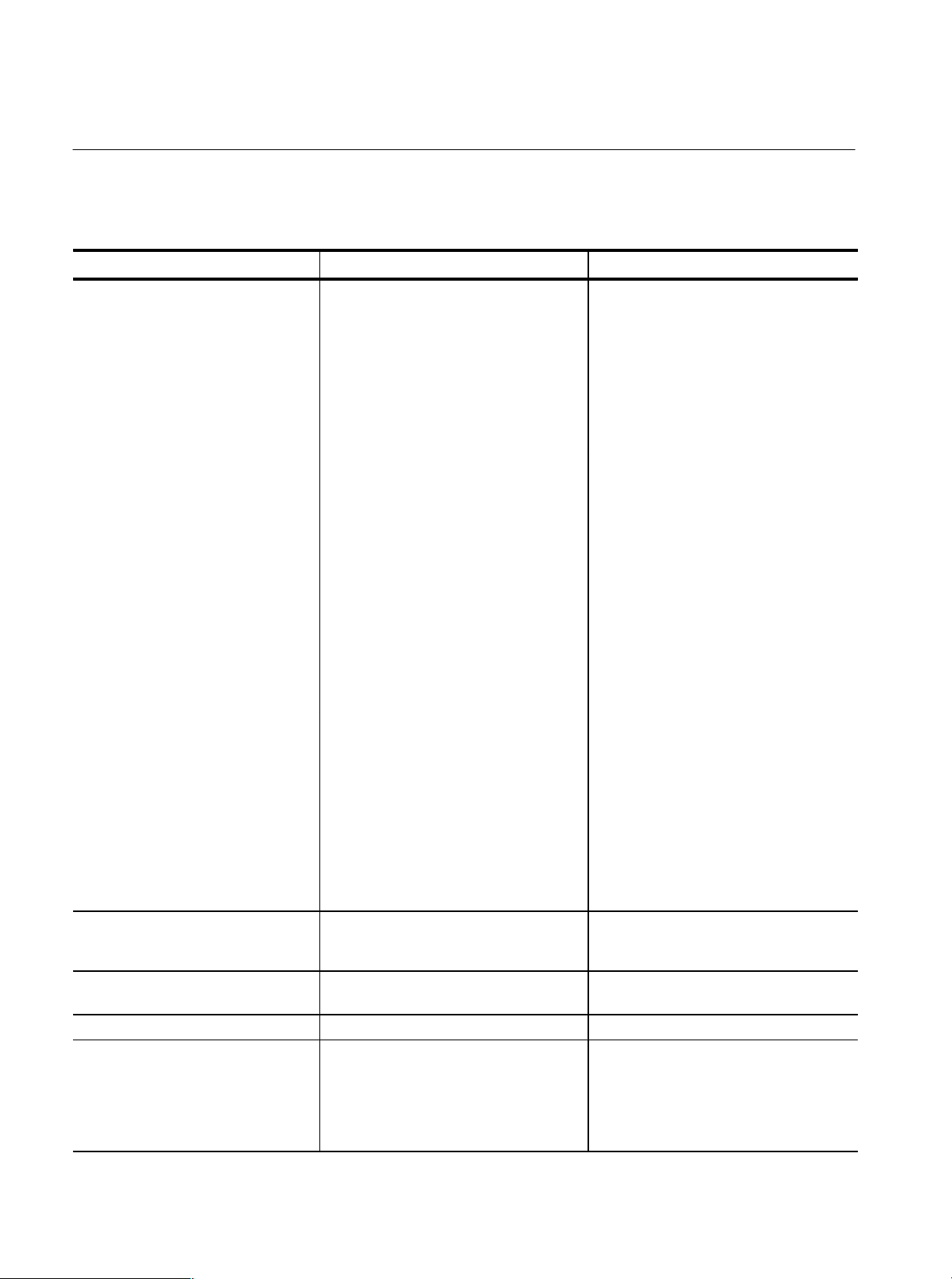

Table 1-1: Vertical deflection system

Characteristic Performance requirements Reference information

Frequency Response

Luminance Channel (Y) 50 kHz to 30 MHz: ≤±0.5 % of the frequency

response at 50 kHz.

Chrominance Channel (Pb,P

Low Pass Filter ≤ -10 dB at 15 MHz. The response at 15 kHz does not vary more

Gain Frequency response and gain accuracy are

Offset Range ±350 mV for CH 2 and 3 to CH 1

Cursor Error ≤ 0.25 % of full scale

Scale

mV Resolution of 40 pixel/100 mV (div), Standard

% Resolution of 28 pixel/10 % (div), Standard

) 50 kHz to 15 MHz: ≤±0.7 % of the frequency

r

response at 50 kHz.

37.125 MHz: ≤-12 dB

18.5625 MHz: ≤-12 dB

than 0.5 % between FLAT and LPF.

maintained in X5 and X10.

Resolution of 60 pixel/100 mV (div), Full

Resolution of 42 pixel/10 % (div), Full

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-3

Page 26

Specifications

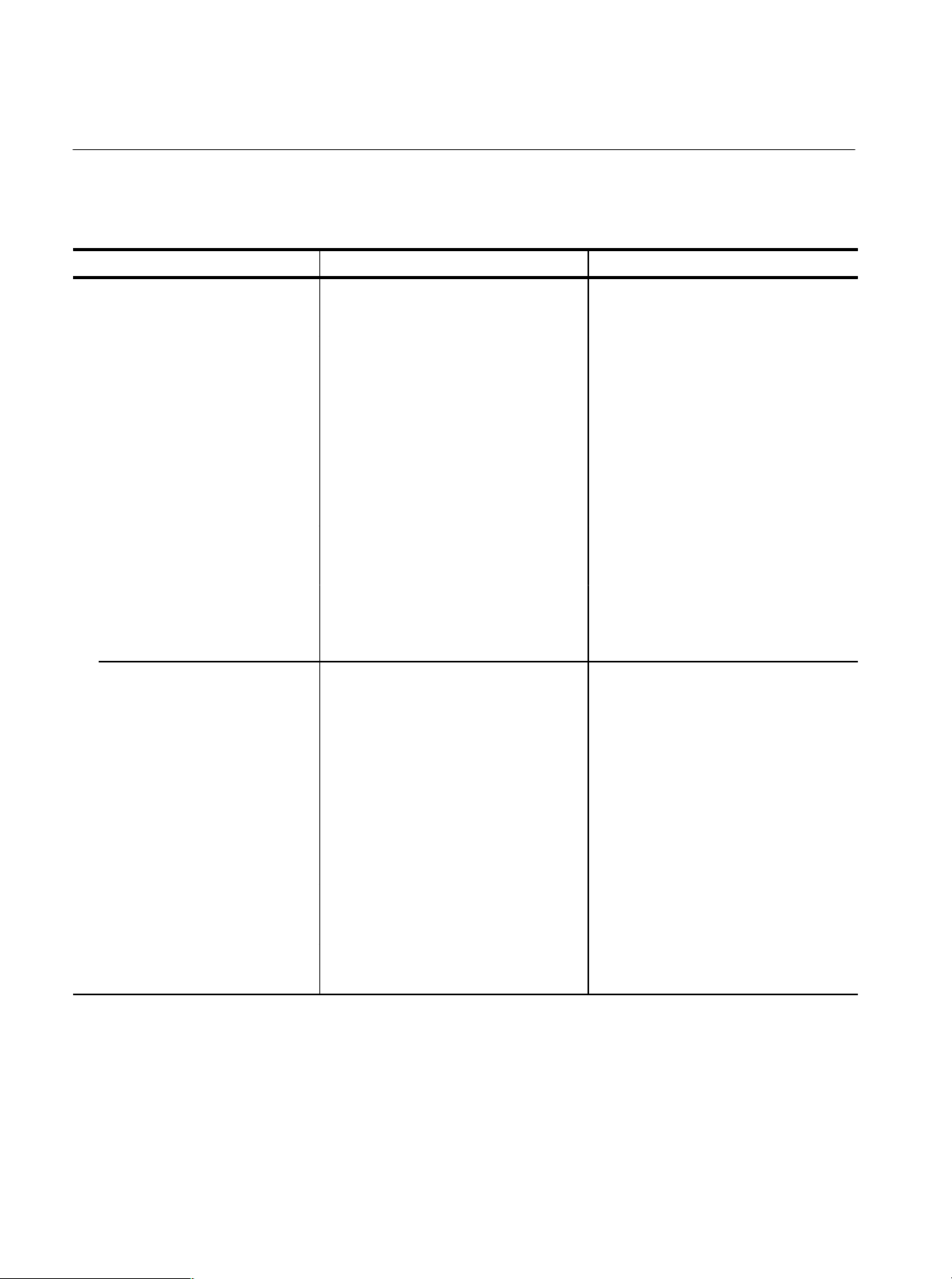

Table 1-2: Horizontal deflection system

Characteristic Performance requirements Reference information

Sweep RateĂ When there is no signal input, the message

No Signal" appears and no waveform is

displayed.

Option 0A or 240M/274M format

mode of Option 0C

1 Line

2 Lines

3 Lines

Overlay

1 Field Equal to the field rate of applied video sync.

2 Field Equal to the frame rate of applied video sync.

3 Field Equal to the field rate of applied video sync.

Option 0B or 296M format mode of

Option 0C

1 Line

2 Lines

3 Lines

Overlay

1 Field Equal to the field rate of applied video sync.

3 Field Equal to the field rate of applied video sync.

2.5 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/4 line rate of applied video sync.

5.0 ms/div, 0.2 ms/div (MAG ON)

Refreshed 1/8 line rate of applied video sync.

7.5 ms/div

Refreshed 1/13 line rate of applied video

sync.

2.5 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/13 line rate of applied video

sync.

2.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/5.17 line rate of applied video

sync.

4.0 ms/div, 0.2 ms/div (MAG ON)

Refreshed 1/11 line rate of applied video

sync.

6.0 ms/div

Refreshed 1/17 line rate of applied video

sync.

2.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/17 line rate of applied video

sync.

1-4

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 27

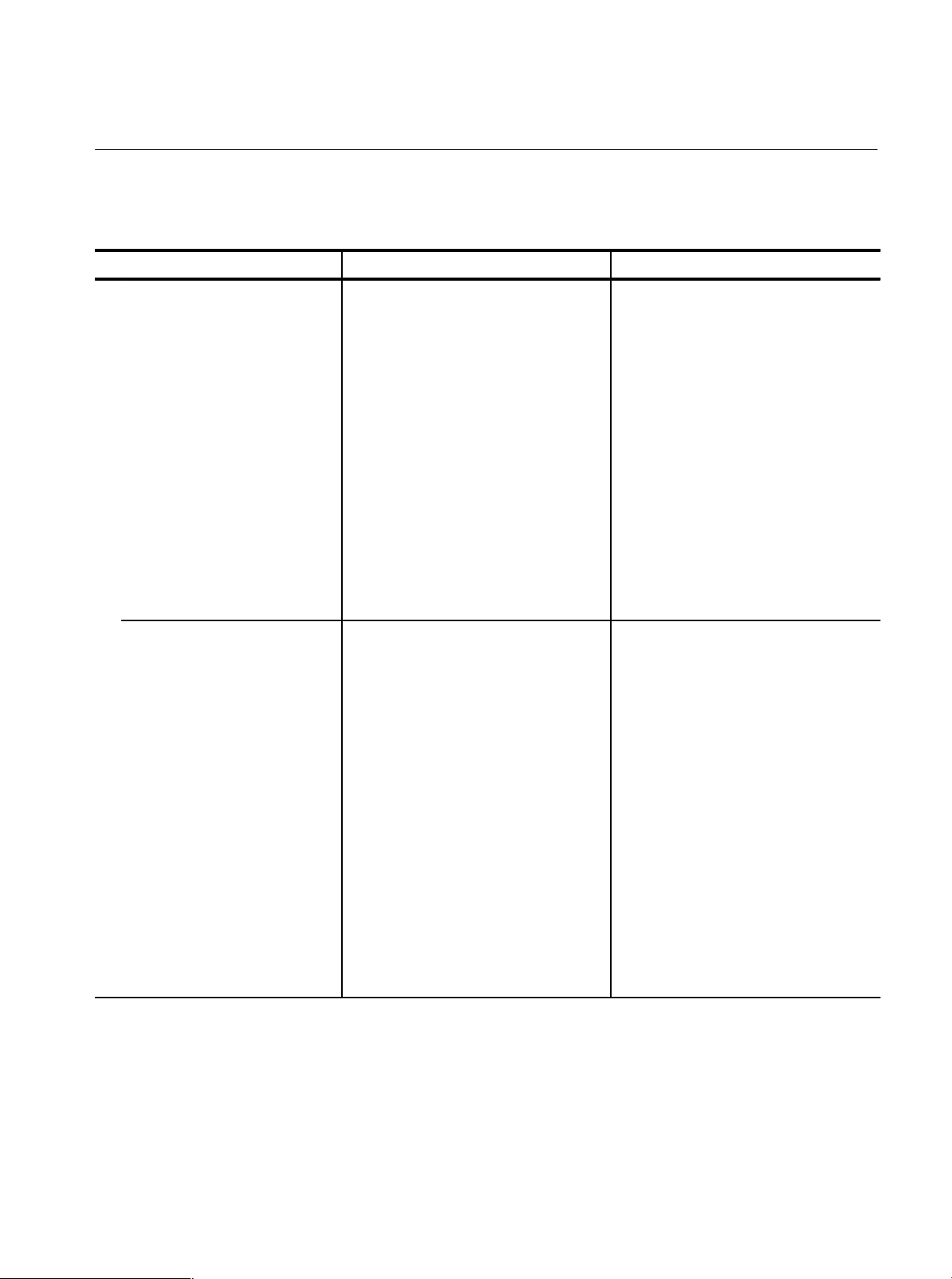

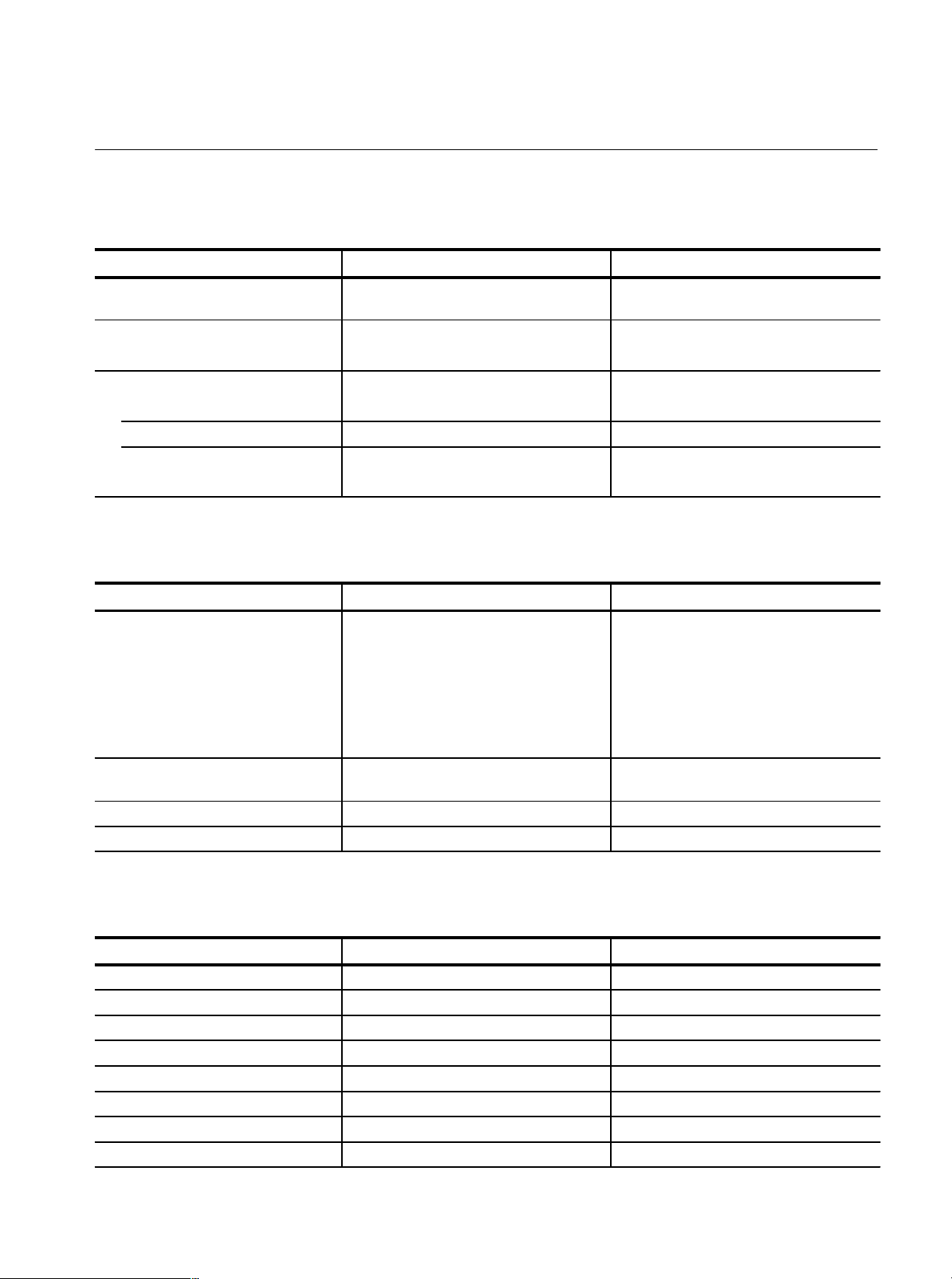

Table 1-2: Horizontal deflection system (Cont.)

Characteristic Reference informationPerformance requirements

Option 0D (Interlace mode)

1 Line

2 Lines

3 Lines

Overlay

1 Field Equal to the field rate of applied video sync.

2 Field Equal to the field rate of applied video sync.

3 Field Equal to the field rate of applied video sync.

Option 0D (Segment Frame mode)

1 Line

2 Lines

3 Lines

Overlay

1 Field Equal to the field rate of applied video sync.

2 Field Equal to the field rate of applied video sync.

3 Field Equal to the field rate of applied video sync.

Specifications

3.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/4 line rate of applied video sync.

6.0 ms/div, 0.4 ms/div (MAG ON) : 1035/60i,

1035/59.94i, 1080/60i, 1080/59.94i

6.0 ms/div, 1.0 ms/div (MAG ON) : 1125/50i

Refreshed 1/8 line rate of applied video sync.

9.0 ms/div

Refreshed 1/13 line rate of applied video

sync.

3.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/13 line rate of applied video

sync.

3.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/4 line rate of applied video sync.

6.0 ms/div, 0.4 ms/div (MAG ON) : 1080/30sF,

1080/29.97sF

6.0 ms/div, 1.0 ms/div (MAG ON) : 1080/25sF

6.0 ms/div, 1.2 ms/div (MAG ON) : 1080/24sF,

1080/23.98sF

Refreshed 1/8 line rate of applied video sync.

9.0 ms/div

Refreshed 1/13 line rate of applied video

sync.

3.0 ms/div, 0.1 ms/div (MAG ON)

Refreshed 1/13 line rate of applied video

sync.

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-5

Page 28

Specifications

Table 1-2: Horizontal deflection system (Cont.)

Characteristic Reference informationPerformance requirements

Option 0D (Progressive mode)

1 Line

2 Lines

3 Lines

Overlay

1 Field Equal to the field rate of applied video sync.

3 Field Equal to the field rate of applied video sync.

Horizontal Position Any positions of the synchronized video

Line Selection Displays selected line in 1 LINE.

Cursor Error ≤ 0.25 % of full scale

Scale Resolution 45 pixel/div (Option 0A)

2.0 ms/div, 0.1 ms/div (MAG ON) : 720/60p,

720/59.94p

3.0 ms/div, 0.1 ms/div (MAG ON) : 1080/24p,

1080/23.98p

Refreshed 1/17 line rate of applied video

sync : 720/60p, 720/59.94p

Refreshed 1/4 line rate of applied video sync

: 1080/24p, 1080/23.98p

4.0 ms/div, 0.5 ms/div (MAG ON) : 720/60p,

720/59.94p

6.0 ms/div, 1.2 ms/div (MAG ON) : 1080/24p,

1080/23.98p

Refreshed 1/11 line rate of applied video sync

: 720/60p, 720/59.94p

Refreshed 1/8 line rate of applied video sync

: 1080/24p, 1080/23.98p

6.0 ms/div : 720/60p, 720/59.94p

9.0 ms/div : 1080/24p, 1080/23.98p

Refreshed 1/17 line rate of applied video

sync : 720/60p, 720/59.94p

Refreshed 1/13 line rate of applied video

sync : 1080/24p, 1080/23.98p

2.0 ms/div, 0.1 ms/div (MAG ON) : 720/60p,

720/59.94p

3.0 ms/div, 0.1 ms/div (MAG ON) : 1080/24p,

1080/23.98p

Refreshed 1/17 line rate of applied video

sync : 720/60p, 720/59.94p

Refreshed 1/13 line rate of applied video

sync : 1080/24p, 1080/23.98p

signal in all sweep modes except for Save

and Display mode and Parade display mode.

Display selected line first in 2 LINE.

48.566 pixel/div (Option 0B, Option 0D)

1-6

For Option 0C, either of these resolutions is

appllied depending on the mode selected in

the FORMAT menu.

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 29

Specifications

Table 1-3: Serial digital video interface

Characteristic Performance requirements Reference information

Format 1.4835 to 1.485 Gbps, complying with

BTAĆS004A, SMAPTE 292M.

Serial Input

Impedance

Monitor Output

Level 800 mVpĆp ±10 %. 800 mVpĆp ±10 %

Impedance

Return Loss

75 W Unbalanced

75 W Unbalanced

y 15 dB at 5 MHz to 742.5 MHz

y 10 dB at 742.5 MHz to 1.5 GHz

Table 1-4: Analog Output

Characteristic Performance requirements Reference information

Format SMPTE 240M, SMPTE 274M, or SMPTE

296M (Option 0D)

SMPTE 240M or SMPTE 274M (Option 0A or

240M/274M format mode of Option 0C)

SMPTE 296M (Option 0B or 296M format

mode of Option 0C)

DAC Resolution Luminance Channel (Y) : 9 bit

Chrominance Channel (P

Impedance

Sync triĆlevel sync on Y channel

Table 1-5: Stripped AES/EBU digital audio output

Characteristic Performance requirements Reference information

Format ANSI S4.40

Impedance

Return Loss u25 dB at 0.1 MHz to 6 MHz

Amplitude 1.0 V ± 10 %

DC Offset 0.0 V ± 50 mV

Rise/Fall Time 30 ns to 44 ns

Sampling Rate 48 kHz (locked to video signal)

Phase Lock Time t15 s

1

75 W Unbalanced

75 W Unbalanced

b,Pr

) : 10 bit

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-7

Page 30

Specifications

Table 1-5: Stripped AES/EBU digital audio output

Characteristic Reference informationPerformance requirements

Output Channel CH A:1/2, 3/4, 5/6, 7/8

Output Control If the Audio Data Packet does not exist in the

1

Available only for Option 0A, 240M/274M fomat mode of Option 0C, or Interlace and Segment Frame modes of Option 0D.

1 (Cont.)

CH B:1/2, 3/4, 5/6, 7/8

The same channel is not selected on CHA

and CHB at the same time.

serial signal, the corresponding output is

disabled.

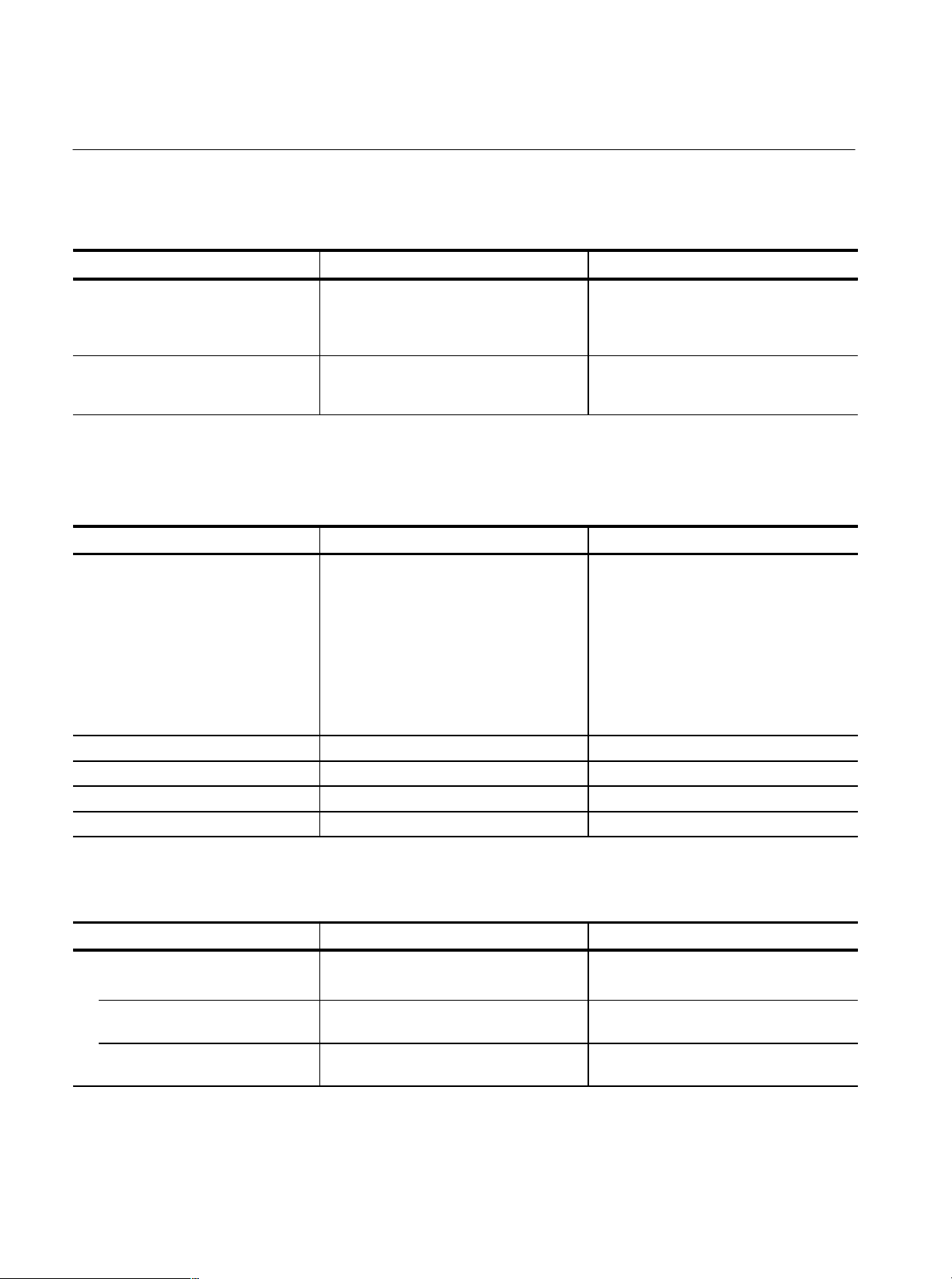

Table 1-6: External reference input

Characteristic Performance requirements Reference information

Sync Format RSĆ170A, PAL (2ĆLEVEL mode of Option 0D)

SMPTE 240M, SMPTE 274M, SMPTE 296M

(3ĆLEVEL mode of Option 0D)

SMPTE 240M, SMPTE 274M (Option 0A or

240M/274M format mode of Option 0C)

SMPTE 296M (Option 0B or 296M format

mode of Option 0C)

DC Input Impedance

Return Loss u30 dB to 30 MHz

Display Resolution 2 clockĂ]27 nsĂ

Uncertain Time Width t5ns

u15 kW

Unterminated

Table 1-7: Format display

Characteristic Performance requirements Reference information

Display Contents

240M When 240M in the COLOR menu is selected.

274M When 274M in the COLOR menu is selected

or 1080/24p format signal is inputted.

296M When 720/60p or 720/59.94p fomat signal is

inputted.

1-8

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 31

Table 1-8: Field rate display

Characteristic Performance requirements Reference information

Target Signal Selected Reference Signal

Display Contents Internal Detected Field Rate

60.00 Hz 59.97 Hz to 60.03 Hz

59.94 Hz 59.91 Hz to 59.97 Hz

??.?? Hz u60.03 Hz or t59.91 Hz

(Display Missing Reference")

Display Contents (Interlace mode of

Option 0D)

60i 59.97 Hz to 60.03 Hz

59.94i 59.91 Hz to 59.97 Hz

50i 48.024 Hz to 59.91 Hz

??.?? Unknown field late (Display Missing

Display Contents (Segment Frame mode

of Option 0D)

30sF 95.97 Hz to 60.03 Hz

29.97sF 59.91 Hz to 59.97 Hz

25sF 48.024 Hz to 59.92 Hz

24sF 47.976 Hz to 48.024 Hz

23.98sF 47.928 Hz to 47.976 Hz

??.?? Unknown field late

Display Contents (Progressive mode of

Option 0D)

60p 59.97 Hz to 60.03 Hz

59.94p 59.91 Hz to 59.97 Hz

24p 23.988 Hz to 24.012 Hz

23.98p 23.98 Hz to 23.988 Hz

??.?? Unknown field late

Internal Detected Field Rate

Reference")

Internal Detected Field Rate

(Display Missing Reference")

Internal Detected Field Rate

(Display Missing Reference")

Specifications

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-9

Page 32

Specifications

Table 1-9: RBG transcoder

Characteristic Performance requirements Reference information

Matrix coefficient

SMPTE240M

Gi =Yi - 0.2266 Pbi - 0.4766 Pri

SMPTE274M,ĂSMPTE296M

Bi =Yi + 1.826 P

Ri =Yi + 1.576 P

Gi =Yi - 0.1870 Pbi- 0.4678 Pri

Bi =Yi + 1.8558 P

Ri =Yi + 1.575 P

i

b

i

r

i

b

i

r

Table 1-10: Component vector mode

Characteristic Performance requirements Reference information

Frequency Response u 14 MHz

Vertical Gain Error t 0.25 %

Horizontal Gain Error t 0.25 %

Magnification X5 and X10

Display Pb: Horizontal

: Vertical

P

r

Table 1-11: Lightning and diamond mode

Characteristic Performance requirements Reference information

Vertical Gain Error t 0.25 %

Horizontal Gain Error t 0.25 %

Electronic Graticule Display

Lightning Y is displayed vertically.

Pbis displayed horizontally on top half of

display.

Pris displayed horizontally on bottom half of

display.

Diamond GBR Deflection axis indicated

1-10

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 33

Table 1-12: Bowtie mode

Characteristic Performance requirements Reference information

Common Mode Rejection Ratio uĂ44 dBĂto 15 MHz

Amplitude Error t 0.25 %

Internal Timing Match Zero error (coĆsited data)

Table 1-13: Status display mode

Characteristic Performance requirements Reference information

Display Capability 4000 words

Format HEX and DEC

Table 1-14: Save and display mode

Specifications

Characteristic Performance requirements Reference information

Delay Time (from time of button pushed) t 3 frames

Length of Reference Memories 1 frame

Table 1-15: Warning display

Characteristic Performance requirements Reference information

CRC Error LED LED lights for 0.5 seconds at error detected.

CRC Error Count CRC error count, elapsed time in this mode,

and the time of latest error detected are

displayed.

Resolution 10 ms

GAMUT Error LED lights for 10 milliseconds at error

detected. Error check timing is made at the

same time as the waveform is displayed.

Warning is derived from input data.

Error Detection Level

Positive

Negative

735 mV ±7 mV (105 % of legal RGB, Nom),

-35 mV ±7mV.

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-11

Page 34

Specifications

Table 1-16: Calculation dynamic range

Characteristic Performance requirements Reference information

Resolution Mode With 10ĆbitĆcalculation:

Y, R, G, B: -50 to 760 mV,

P

: -390 to +390 mV.

b/Pr

Waveform may have some distortion when

input data in analog level goes out of above

ranges.

D Range Mode With 9ĆbitĆcalculation:

Y, R, G, B: -450 to +1170 mV,

P

: -790 to +790 mV.

b/Pr

Waveform may have some distortion when

input data in analog level goes out of the

above ranges.

Table 1-17: Setup memory

Characteristic Performance requirements Reference information

Number of memory setups 4 setups (Option 0A/0B/0C)

100 setups (Option 0D)

Save and Recall This function is performed from front panel

menu and remote connector (ground closure)

for the memory location number 1 to 4. For

the other memory location number, it is

controlled through the RSĆ232C connector.

Table 1-18: CRT display

Characteristic Performance requirements Reference information

CRT Viewing Area 71 (V) X 95 (H) mm

Resolution Horizontal: 640 pixels

Vertical: 480 pixels

Table 1-19: AC power source

Characteristic Performance requirements Reference information

Range 90 - 240 VAC, 48 to 63 Hz

Power Consumption 90 W, 100 VA

Maximum Current 1.0 A

1-12

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 35

Specifications

Table 1-19: AC power source (Cont.)

Characteristic Reference informationPerformance requirements

Peak Inrush Current 10 A

Supply Connection Detachable cord set

2 Per EN 55103Ć1 Annex B

2

Table 1-20: Installation requirements

Characteristic Performance requirements Reference information

Heat Dissipation

Maximum Power 90 W max, 1.0 A rms at 50 Hz

Maximum Dissipation Voltage 90 V with 5 % clipping

Surge Current 40 A peak for equal to or less than 5 line

cycles, after the instrument has been turned

off for at least 30 seconds.

Clearance

Top and Bottom 2.5 cm

Side 5cm

Rear 15 cm

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-13

Page 36

Specifications

Environmental Characteristics

Table 1-21: Environmental characteristics

Characteristic Standard and reference information

Temperature

Operating 0° to +40° C

NonĆoperating -20°to +60° C

Altitude

Operating 4,500 m

Maximum operating temperature decreases 1°C each 300 m above 1,500 km.

NonĆoperating 15,000 m

Relative humidity

Operating 20 % to 80 % (No condensation)

NonĆoperating 5 % to 90 % (No condensation)

Vibration

Operating 10 minutes at 5 - 500 Hz with 0.32 g rms

NonĆoperating 10 minutes at 5 - 500 Hz with 2.46 g rms

Mechanical shock

NonĆoperating 294 m/s2(30 g) 1/2 sine, 11 ms duration, 3 shocks per surface (18 total)

Equipment Type Test and Measuring

Equipment Class Class I: Grounded product (as defined in IEC 1010Ć1, Annex H)

Installation Category Category II (as defined in IEC 1010Ć1, Annex J).

Note: Rated for indoor use only.

Category Examples of Products in this Category:

CAT III DistributionĆlevel mains, fixed installation

CAT II LocalĆlevel mains, appliances, portable equipment

CAT I Signal levels in special equipment or parts of equipment, telecommunications,

electronics

Pollution Degree Pollution Degree 2: Do not operate in environments where conductive pollutants may be

present.

1-14

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 37

Physical Characteristics

Table 1-22: Physical characteristics

Characteristics Descriptions

Dimensions

Height 133 mm

Width 216 mm

Depth 432 mm

Weight

Net Approximately 6.0 kg

Shipping Approximately 8.3 kg

Specifications

Safety and EMI

Table 1-23: Certifications and compliances3

Category Standards or description

EC Declaration of Conformity EMC

Australia/New Zealand

Declaration of Conformity - EMC

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European Union:

EN 55103Ć1: 1996 Emissions

EN 55022 Class B Radiated and Conducted Emissions

EN 61000Ć3Ć2 AC Power Line Harmonic Current Emissions

EN 61000Ć3Ć3 Line Voltage Alteration and Flicker

EN 55103Ć1 Annex A Magnetic Field Emissions

EN 55103Ć1 Annex B Power Line Inrush Current

EN 55103Ć2: 1996 Immunity

IEC 61000Ć4Ć2 Electrostatic Discharge Immunity

IEC 61000Ć4Ć3 RF Electromagnetic Field Amplitude Immunity

IEC 61000Ć4Ć4 Electrical Fast Transient/Burst Immunity

IEC 61000Ć4Ć5 AC Mains Surge Immunity

IEC 61000Ć4Ć6 Conducted RF Immunity

IEC 61000Ć4Ć8 Power Frequency Electromagnetic Field Immunity

IEC 61000Ć4Ć11 Mains Voltage Dip & Interruption Immunity

EN 55103Ć2 Annex A Magnetic Field Immunity

Environmental Class E2

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2Industrial, Scientific, and Medical Equipment: 1992

WFM 1125 Option 0A/0B/0C/0D Service Manual

1-15

Page 38

Specifications

Table 1-23: Certifications and compliances

Category Standards or description

EC Declaration of Conformity Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1

Additional Compliance IEC61010Ć1 Safety requirements for electrical equipment for measurement, control,

Installation (Overvoltage)

Category

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Safety Certification Compliance

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010Ć1, Annex H) - grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010Ć1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010Ć1). Note: Rated for indoor use only.

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Union:

Low Voltage Directive 73/23/EEC, amended by 93/69/EEC

EN 61010Ć1:1993 Safety requirements for electrical equipment for measurement control and

UL3111Ć1 Standard for electrical measuring and test equipment.

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III DistributionĆlevel mains (usually permanently connected). Equipment at this level is

CAT II LocalĆlevel mains (wall sockets). Equipment at this level includes appliances, portable

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

3

(Cont.)

laboratory use.

Safety requirements for electrical equipment for measurement, control, and

laboratory use.

and laboratory use.

typically in a fixed industrial location.

tools, and similar products. Equipment is usually cordĆconnected.

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

3 For EMC compliance and safety, use only high quality, shielded cables and operate the instrument in one of the following

Tektronix instrument enclosures:

1700F00 (Tektronix part number 437-0100-04)

1700F02 (Tektronix part number 437-0018-07)

1700F05 (Tektronix part number 437-0095-04)

1-16

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 39

Operating Information

Page 40

Page 41

Operating Information

This section is divided into the following three subsections:

H Preparation for Use. Describes the installation, environmental requirements,

information of how to power on or off, etc.

H Using the Menu. Describes the general menu operating information and

DIAG/CAL menu structure.

H Remote Control. Describes the remote interfaces for servicing.

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-1

Page 42

Preparation for Use

2-2

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 43

Preparation for Use

This subsection presents information you need to set up your WFM 1125 Digital

Television Waveform Monitor Option 0A/0B/0C/0D. This subsection contains

the following information:

H Installation.

H Operating Environment.

H Applying and Interrupting Power.

H Repacking.

Installation

This section provides instructions for installing the waveform monitor into a

standard rack or one of the optional cases. At installation time, save the shipping

carton and packing materials (including the anti-static bag) in case you need to

ship the instrument.

Included Accessories

Hardware Installation

The waveform monitor is shipped with several accessory items which may be

required for normal use. For more information on accessories, refer to page 7–1.

Because operating environments vary, the waveform monitor is not shipped with

a cabinet unless you have ordered one. All qualification testing for the waveform

monitor was performed in a 1700F00 cabinet. To guarantee compliance with

specifications, you should operate the waveform monitor in one of the cabinets

described here.

Cabinet Options. The cabinets offered for the waveform monitor provide EMI

shielding, protect against electrical shock, and protect against the accumulation

of dust. Figure 2–1 shows the plain cabinet, option 1700F00. A rear panel fan

supplies filtered, cooling air which exits through the cabinet vent holes.

Restricting the air flow through the vents or the rear fan can lead to an excessive

internal temperature.

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-3

Page 44

Preparation for Use

21.0 cm

(8.25 in)

42.7 cm

(16.2 in)

13.0 cm

(5.1 in)

Figure 2-1: Dimensions of the 1700F00 plain cabinet

WARNING. To meet EMI emission and safety specifications, the waveform

monitor must be installed in a Tektronix 1700F00, 1700F02, or 1700F05

enclosure. The enclosure front edges must securely contact the conductive front

bezel on all four sides.

The optional 1700F00 cabinet is the basic element for all of the cabinets. The

1700F02 portable carrying case is an enhanced version of the 1700F00 cabinet,

as is the 1700F05 side-by-side rack mount assembly. All cabinets are available

from your Tektronix representative.

The portable cabinet, 1700F02, is shown in Figure 2–2. The 1700F02 has a

handle, four feet, and a flip-up stand. The mounting hole sizes and spacing are

different from those of the 1700F00.

2-4

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 45

42.7 cm

(16.2 in)

Preparation for Use

21 cm

(8.25 in)

13 cm

(5.1 in)

Figure 2-2: 1700F02 portable cabinet

Cabinet Installation. Secure the waveform monitor in a cabinet using two Trox

T-15 screws. Figure 2–3 shows the location of these screws on the rear panel.

CAUTION. Do not carry the waveform monitor in a cabinet without installing the

rear panel mounting screws. Without the mounting screws, there is nothing to

keep the waveform monitor in its cabinet.

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-5

Page 46

Preparation for Use

Cabinet securing screws

Figure 2-3: Rear view of the waveform monitor in a 1700F02 cabinet

Rack Adapter Installation. The optional 1700F05 side-by-side rack adapter, shown

in Figure 2–4, consists of two attached cabinets. Use it to mount the waveform

monitor and another half-rack width instrument, such as an analog component

monitor, in a standard 19-inch rack.

2-6

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 47

Preparation for Use

You can adjust the rack adapter so that the waveform monitor is aligned with

other equipment in the rack. See Figure 2–4.

48.2 cm

(19 in)

13.2 cm

(5.3 in)

Mounting

holes

Mounting

holes

43.9 cm

(17.3 in)

Figure 2-4: The 1700F05 rack cabinet holds two instruments

Front panel

alignment holes

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-7

Page 48

Preparation for Use

If you are using only one side of the rack adapter, insert a blank panel (1700F06)

or an accessory drawer (1700F07) in the unused section to improve airflow and

appearance. Figure 2–5 shows the blank panel and drawer.

1700F05

sideĆbyĆside

rack adapter

1700F07

utility drawer

1700F06

blank panel

Figure 2-5: 1700F05 cabinet showing utility drawer and blank panel

2-8

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 49

Supplying Operating Power

NOTE. Read all information and heed all warnings in this subsection before

connecting the waveform monitor to a power source.

WARNING. AC POWER SOURCE AND CONNECTION. The waveform monitor

operates from a single-phase power source. It has a three-wir e power cord and

two-pole, three-terminal grounding type plug. The voltage to ground (earth) from

either pole of the power source must not exceed the maximum rated operating

voltage, 240 volts.

Before making connection to the power source, be sure the waveform monitor

has a suitable two-pole, three-terminal grounding-type plug.

GROUNDING. This instrument is safety Class 1 equipment (IEC designation).

All accessible conductive parts are directly connected through the grounding

conductor of the power cord to the grounded (earthing) contact of the power

plug.

Preparation for Use

Power Cord Information

WARNING. The power input plug must be inserted only in a mating receptacle

with a grounding contact where earth ground has been verified by a qualified

service person. Do not defeat the grounding connection. Any interruption of the

grounding connection can create an electric shock hazard.

For electric shock protection, the grounding connection must be made before

making connection to the instrument’s input or output terminals.

A power cord with the appropriate plug is supplied with each waveform monitor.

Table 2–1 gives the color-coding of the conductors in the power cord.

Table 2-1: PowerĆcord conductor identification

Conductor Color Alternate color

Ungrounded (Line) Brown Black

Grounded (Neutral) Light Blue White

Grounded (Earthing) Green/Yellow Green

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-9

Page 50

Preparation for Use

Operating Voltage

Memory Backup Power

Operating Environment

Operating Temperature

This waveform monitor operates with any line voltage from 90 to 240 VAC

with any line frequency from 48 to 63 Hz. No fuse is provided with this

waveform monitor.

The CPU module with on-board battery allows the WFM 1125 Digital Television

Waveform Monitor Option 0A/0B/0C/0D to retain some types of data upon loss

of the AC power source. The stored adjustment constants, saved front-panel

settings, current front-panel settings (instrument status), and waveforms saved in

memory are retained.

The on-board battery of the CPU module has a shelf life of about five years.

Partial or total loss of stored settings upon power on may indicate that the battery

needs to be replaced.

The following environmental requirements ensure proper operation and long

instrument life.

Operate the waveform monitor where the ambient air temperature is from 0_ C

to +40_ C. Store the waveform monitor in ambient temperatures from –20_ C to

+60_ C. After storage at temperatures outside the operating limits, allow the

chassis to stabilize at a safe operating temperature before applying power.

RMS

Ventilation Requirements

The waveform monitor is cooled by air drawn in and exhausted through its

cabinet side panels by an internal fan. To ensure proper cooling, allow at least

two inches (5 cm) clearance on both sides, one inch (2.5 cm) on the bottom and

top, and six inches (15 cm) on the rear. (The feet on the bottom provide the

required clearance when set on a flat surface.)

2-10

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 51

Applying and Interrupting Power

Consider the following information when you power on or power off the

instrument, or when power is interrupted due to an external power failure.

Preparation for Use

Power On

CRT Blinking

Power Off

At power on, the waveform monitor does not run the self check.

The waveform monitor has the internal diagnostic routines to allow you to

isolate faulty modules. If needed, run the internal diagnostics manually.

Refer to Section 6, Maintenance, for information on diagnostics and fault

isolation.

CAUTION. If the CRT blinks, turn off the power. Internal components could be

damaged.

The CRT blinks if the fan on the rear panel stops working. If the CRT blinks,

turn off the power switch and contact Tektronix for servicing.

CAUTION. DO NOT power off the waveform monitor when doing any of the

adjustments described in Section 5, Adjustment Procedures. To do so might

result in the loss of internally stored adjustment constants.

In general, do not power off the instrument when doing operations. Wait for the

instrument to finish the operation when doing adjustments, or saving setups.

Improper power off or unexpected loss of power to the waveform monitor may

result in the following corruptions of nonvolatile RAM (NVRAM). The following

table describes the messages displayed when power is restored after an

abnormal power off.

Table 2-2: Effects of corrupted data

Corrupted data type Results

Saved Setups Setup Lost

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-11

Page 52

Preparation for Use

Repackaging Instructions

Use a corrugated cardboard shipping carton having a test strength of at least

275 pounds and with an inside dimension at least six inches greater than the

instrument dimensions.

If the instrument is being shipped to a Tektronix Service Center, enclose the

following information: the owner’s address, name and phone number of a contact

person, type and serial number of the instrument, reason for returning, and a

complete description of the service required.

Seal the shipping carton with an industrial stapler or strapping tape.

Mark the address of the Tektronix Service Center and also your own return

address on the shipping carton in two prominent locations.

Installed Options

All options and optional accessories are listed and described in Section 7,

Options. For further information and prices of instrument options, contact your

Tektronix Field Office.

2-12

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 53

Using the Menus

You can set most functions with either context sensitive bezel button menus or

general configuration menus. The following subsections outline and describe

how to make selections from these menus. Figure 2–6 shows the buttons and

knob used for menu selection.

INTEN/MENU button

SELECT button and knob

Bezel Menu

Configure Menu

Display menus with

their optional selections

Figure 2-6: Elements of the WFMĂ1125 menu controls

This menu directly relates to display mode settings. When you change the display

mode by pressing any of the front panel function buttons, the menu item

associated with it appears at the right side of the display.

To select a bezel menu item, press the bezel button associated with the displayed

menu item.

This menu consists of general configuration menu items and operating modes

which are changed infrequently . If you press and hold the front panel INTEN/

MENU button, the menu items are listed on the display.

Bezel buttons

STANDBY button

If you turn the SELECT knob when the menu items are on display, the highlighted box moves across the menu. Press the SELECT button to select the

desired parameter item; it is highlighted to indicate that it takes effect.

For menu items which affect the whole hardware setting, a bezel menu item

prompts you to confirm your selection. Select OK or CANCEL.

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-13

Page 54

Using the Menu

DIAG/CAL Menu

To quit the menu mode, press the INTEN/MENU button again.

For example, turn the GAMUT on by stepping through the menus as follows:

1. Press and hold the INTEN/MENU button to display the Configure menu.

2. Turn the SELECT knob until GAMUT highlights.

3. Push the SELECT button to ON.

4. Push the INTEN/MENU button again to turn off the menu readout without

losing your selections.

For additional information on this menu, refer to the WFM1125 Option 0A/0B/0C

User Manual.

There are following three ways to enter into the DIAG/CAL mode:

H Turn on the Power switch on the rear panel while holding down the

STANDBY button on the front panel.

H Press the INTEN/MENU button while holding down the 5-th bezel button,

and then press the EXECUTE bezel button when the DIAG/CAL menu

appears.

H Turn on the Power switch on the rear panel when the firmwares have not

been downloaded yet to the internal modules.

NOTE. If you enter into the DIAG/CAL mode through the first or third ways, the

waveform monitor is not configured correctly. So, the I/O test in the MEMORY

test will report a FAIL even if the H/W is correct.

When you enter into the DIAG/CAL mode, the DIAG/CAL menu appears at the

far right of the screen (VGA monitor).

2-14

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 55

DIAG / CAL

Using the Menu

EXECUTE

INTEN/MENU

button to exit

DIAG / CAL

DIAG

DISPLAY

KEY/KNOB

LED

VERSION

STANDBY

button to exit

GRADIATION

STANDBY button

DISPLAY

GRID

CIRCLE

WHITE

DIAG

MEMORY

PLD

X/Y RAM

HK102/FIFO

ALL

Figure 2-7: DIAG/CAL menu structure

To select DIAG/CAL menu item, press the corresponding bezel button, and press

the STANDBY button to go back to the previous menu. When you select a menu

item to run the diagnostic or calibration routine, the menu disappears and

corresponding screes appears. Press the STANDBY button to exit that screen and

to restore the menu.

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-15

Page 56

Using the Menu

2-16

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 57

Remote Operation

The waveform monitor has two multi-pin connectors on the rear panel that

provide different types of remote control. The RS-232C port provides for a status

data output and factory servicing. The REMOTE connector provides a way to

load or save presets.

RS-232C Connector

The RS-232C connector is a 9-pin D-type connector that provides a status data

output and a remote verification interface. Figure 2–8 shows the pin assignments

and the communication parameters for the RS-232C interface.

54321

9876

Communication parameters

Baud: 9600 pbs (Power cycle always

reset to 9600 pbs.

From 300 to 115200 bps can

be set

while communicating.)

Data bits: 8 (unselectable)

Stop bits: 1 (unselectable)

Parity: None (unselectable)

Flow control: Hard flagging (unselectable)

Figure 2-8: Pin assignments for the RSĆ232C connector

Pin

Number

1

2

3

4

5

6

7

8

9

Data Connection

DCD (Received line signal detector)

RXD (Received data)

TXD (Transmitted data)

DTR (DTE ready)

Signal ground

DCR (DCE ready)

RTS (Request to send)

CTS (Clear to send)

Not connected

Required

n

n

n

n

n

WFM 1125 Option 0A/0B/0C/0D Service Manual

2-17

Page 58

Remote Operation

RSĆ232C Remote

Command

The following remote command can be sent through the RS-232C connector:

DUMP

When this command is received on STATUS mode, the waveform monitor

outputs the selected one line data from EAV. If this command is received on any

other mode, the waveform monitor returns an error message. The data output

format is CSV.

The following is an output example:

Line_number=0041

SMPL,Y, Pb, Pr

1920,03ff,03ff,

1921,0000,,0000

1922,0000,0000,

.

.

SAVE #

This command stores the current instrument settings in the memory location

specified #.

RECALL #

Remote Connector

This command recalls the instrument settings from the memory location

specified #.

The rear-panel REMOTE connector is a 15-pin, D-type female connector that

allows low-level remote control.

All the active control lines go to low level by grounding or TTL low level input.

Low means the function that can be effective when that pin is grounded or

becomes TTL low level (0 to +0.8 V), and High means the function can be

effective when that pin is opened or becomes TTL high level (2 to 5 V).

Pin assignments for the REMOTE connector are shown in Figure 2–9 and

described in Table 2–3. You enable functions by ground closures (TTL lows) on

specified pins. Functions with “overbars

” indicate an active low state.

2-18

WFM 1125 Option 0A/0B/0C/0D Service Manual

Page 59

Remote Operation

8

15 9

1

Figure 2-9: Pin assignments for the REMOTE connector

Table 2-3: Remote connector pin assignments and functions

Pin number Function Information

1 Line, Field Option 0A, 240M/274M format mode of Option 0C, or Interlace mode of Option 0D.

Field is set to ON and line is set to OFF when TTL signal level goes from High to

Low.

Field is set to OFF and line is set to ON when TTL signal level goes from Low to

High.

Option 0B, 296M format mode of Option 0C, or Progressive mode of Option 0D.

Field is set to ON and line is set to OFF when TTL signal level goes from High to

Low (1 Line Display).

Going from High to Low is ignored (2 Line Display).

Field is set to OFF and line is set to ON when TTL signal level goes from Low to

High.

2 RGB RGB transcoder becomes available when TTL level goes from High to Low.

RBG transcoder becomes disabled when TTL level goes from Low to High.

3 ONE, TWO Option 0A, 240M/274M format mode of Option 0C, or Interlace mode of Option 0D.