Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Tektronix

/

User Manual

VX1401

C

Size Mainframe

bus

Please check for change information

at the rear of this manual.

First

Edition:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Junc

1994

Page 3

Copyright O Tektronix, Inc.

1994.

A11 rights reserved.

Tektronix products are covered

that in all pre~iously published material. Specifications and price change privileges reserved.

,

,,

f

)I

by

US.

and foreign patents. issued and pending. Information in this publication supercedes

Printed in the U.S.A.

P.O.

Box

1000,

Tektronix, Inc.,

EKTRONIX and

Wilsonville,

TEK

are registered trademarks

OR

97070-1000

of

Tektron~x. Inc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

-

WARRANTY

1

.

I

c

Tektron~x warrants that thi\ product wlll be tree from detect\ in matellals and workman\h~p for 3 ~erlogt of thee,

(3)

year5 from the date ot sh~pment It any such product ploves defect~ve dur~ng th15 warranty

will

at ~ts optlon, e~ther

repalr the detectlbe product wlthout chalge tor part5 and labor, or w~ll prov~de

replacement In exchange to1 the detect~ve product

In order to obtain service under this warranty. Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

period.

,%

Tektron~x.

a

a

I/

,.

:

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

location within the country

in

which the Tektronix service center is located. Customer shall be responsible for

a

paying all shipping charges. duties. taxes. and any other charges for products returned to any other locations.

This warranty shall not apply to any defect. failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

to

resulting from attempts by personnel other than Tektronix representatives

install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment: or c) to service a

product that has been modified or integrated with other products when the effect of such modification or

integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF

ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF

SUCH DAMAGES.

J',

,

/

,

I),

,

{IF:

)I1

I''

>>iJ',;>i-i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Table

of Contents

Getting Started

.....................................................

Product Description

1 . 1

...............................................

System Configuration 1 . 1

Backplane

.........................................................

1- 2

......................................................

Compatibility 1 . 2

Installation

.............................................................

1

.

3

Operating Basics

FunctionalOverview

....................................................

2- 1

Power Budget

...........................................................

2- 1

Grounding

.............................................................

2- 1

................................................

5V Standby Power Supply 2 . 1

Fuses

..................................................................

2-

1

230VoltOperation

......................................................

2-2

Powercords

............................................................

2-2

Backplane

.............................................................

2-4

BackplaneJumpers

......................................................

2-4

Cooling

................................................................

2- 5

.....................................................

Syntax and Commands

3

.

1

..........................................................

Status and Events

3

.

1

...................................................................

Examples

5- 1

.................................................

Appendix A

.

Specifications

A . 1

.......................................

Appendix

B

.

Input/Output Connections

A

.

5

........................................

Appendix C

.

Power Budget Worksheet

A

.

7

Appendix

D

.

Servicing

.................................................

Adjusting Power Supply

A

.

9

............................................

.

Selecting Cooling Fan Speed A 11

...................................................

Cleaning Air Filters

A

.

11

.............................................

Assembly And Disassembly

A

.

12

...............................

.

Appendix E (Option 1 M)

MATE Applications A . 15

.............................................

Appendix F

.

Replaceable Parts

A

.

17

......................................................

Appendix

G

.

Options

A

.

19

..................................................................

Glossary

A

.

21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Operators Safety Summary

The general safety information in this summary is for both operating and servicing personnel.

Additional specific warnings and cautions are found throughout the manual where they apply,

and may not appear in this summary.

TERMS

In This Manual

WARNING

practices that could result in personal injury or

loss of life.

CAUTION

practices that could result in damage to the

module or other property.

Marked on the Module

DANGER

immediately accessible as one reads the

rnarking.

CAUTION

not immediately accessible as one reads the

marking, or a hazard to property, including the

module itself.

statements identify conditions or

statements identify conditions or

indicates a personal injury hazard

indicates a personal injury hazard

SYMBOLS

Power Source

This module is intended to operate in a

mainframe whose power source does

not apply more than

the supply conductors or between

either supply conductor and ground.

protective ground connection through

the grounding conductor in the power

cord(s) is essential for safe operation.

250V

Grounding the Module

This module is grounded through the

grounding conductor of the mainframe

power

shock, plug the mainframe power

cord(s) into a properly wired receptacle

before connecting to the module

connectors.

connection through the mainframe is

essential for safe operation.

Danger Arising from Loss

Upon loss of the protective-ground

connection, all accessible conductive

parts can render an electric shock.

cord(s). To avoid electrical

A

protective ground

of

rms between

A

Ground

In This Manual

This symbol indicates where

applicable cautionary or other

information is to be found.

0

Marked on the Module

!

This symbol indicates where

special explanatory information is

included in the manual. There is

no caution or danger associated

with the information.

DANGER

Protective ground (earth) terminal.

-

69

ATTENTION

manual.

0

Refer to manual before using.

High Voltage.

-

Refer to the

Use the Proper Fuse

To avoid fire hazard, use only fuses

specified in the module parts list. A

replacement fuse must meet the type,

voltage rating,

specifications required for the fuse that

it replaces.

Do Not Operate

and

current rating

in

Explosive

Atmosphere

To avoid explosion, do not operate the

module in an explosive atmosphere.

Do Not Remove Covers or Panels

To avoid personal injury, the module

covers should be removed only by

qualified service personnel. Do not

operate the module without covers and

panels properly installed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Preface

Conventions

This is the user manual for the VX1401 Mainframe.

)

Jh

Please read and follow all instructions for installation and

configuration.

This manual assumes you are familiar with VXIbus instruments

and operation, and with the purpose and function of this

instrument. The

Operatrng

Basics

section presents an overview

of this instrument's operation.

The names of all switches, controls, and indicators appear in

this manual exactly as they appear on the instrument.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

Product Description

Getting Started

System

Configuration

The Tektronix/CDS Instrument on a Card (IAC) System is an easy-to-use

integrated modular system for implementing automatic testing, data acquisition

and control, and remote-monitoring instrumentation systems. Based on IAC

technology, the system permits the compact, inexpensive "test station in a box"

approach to ATE, instead of bulky, expensive, "rack and stack" stations.

Versatile and rugged, the

advantages in space, cost, and performance.

One of the primary building blocks for this system is a Tektronix/CDS VXIbus

mainframe for C size and smaller modules. Tektronix/CDS offers two versions

of a C size mainframe with 13 slots capacity. (A five-slot C size mainframe, the

VX1405, is also available.) The two 13-slot mainframes, the VX1400 and

VX1401, provide alternatives not only in cost, power, and weight, but also in

dynamic current and noise performance.

The

VX1400 Mainframe provides slightly more useable power (702 Watts vs. 570

Watts). At lower cost and weight, though, the VX1401 Mainframe is the

preferred model in most other respects. By making more efficient use of

available power, the VX1401 provides substantially better dynamic current

capacity and low noise levels over a wider range of instrument loading than the

VX1400. The lower power capacity also permits extending the operating

temperature range to -10" to 55" C (from 0" to 50" C).

The VX1400 or VX1401 Mainframe is designed to hold up to 12 instrument

modules plus a Resource

VX4521 Advanced Slot 0 Device/Resource Manager Module, for use in IEEE-488

applications with an external system controller. Alternately, the mainframe can

use an embedded PC-AT-386 compatible system controller/slot 0 unit, such as

Tektronix/CDS VX4544. The VX4544, with a hard drive, floppy drive, and

the

a full-size expansion slot, occupies three instrument slots, leaving ten slots for

instrument modules.

Tektronix/CDS IAC system provides significant

Manager/Slot 0 module, such as the Tektronix/CDS

The

VX1401 is delivered complete with backplane, power supplies, all chassis

hardware, and a decorative front

hardware so that it may be mounted in a standard 19 inch NEMA equipment

rack. Sufficient room (3 inches) is provided between the front panel and the

metal front panel of the IAC modules to conceal cables being routed to the

(Unit Under Test) or other instruments. Cables are normally routed from

connectors located on the module front panels through an integral cable tray to

the rear of the chassis. In addition, vertical cabling between instruments in

VX1401 Mainframes is provided by cabling openings at the top and bottom of

the chassis in front of the instrument front panels. (Note that the unit may be

operated without the decorative panel installed. The thermal integrity of the

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ane el.

The unit also includes rack mounting

UUT

Page 11

VX1401 will not be affected if filler panels are properly installed in empty

slots.)

The

integrated unit controlled by a user-defined system controller, which may be an

external device or an internal embedded computer. All

IAC Modules are fully compatible with the VX1401.

series modules may also be utilized by using a 73A-853 Adapter Module.

Backplane

The VX1401 eight-layer monolithic backplane supports all of the VXIbus system

architecture features designed to facilitate system performance, including fast

bus arbitration, asynchronous bus structure, powerful capabilities for handling

interrupts, and non-multiplexed paths for address and data. All of the

specifications for signal timing, noise, crosstalk, termination, driving, and

loading fully comply with the VXIbus Standard. The VXIbus signal lines

specified for P2

incorporated into the backplane.

Compatibility

The required VMEbus terminations are also included as part of the backplane.

In addition, the VMEbus Specification requires that certain signals (IACK*,

BGINX*, BGOUTX*) be daisy-chained along the backplane. The provisions for

meeting this requirement are accessible through the front of the

Mainframe.

Section

VX1401 Mainframe with its installed plug-in IAC modules operates as an

(MODID, CLK 10, LBUS, SUMBUS, TRIG lines, etc.) are

1

TektronixICDS Series

In addition, CDS 53/63

VX1401

The VX1401 Mainframe supports all of the VXIbus requirements for a C size

mainframe. All VXIbus defined voltages are supplied

and -24 Volt power supplies are mounted in the VX1401). The VX1401 is switch

selectable for either 115 or 230 Volts AC at frequencies ranging from 45

Hz.

440

Cooling is supplied by four internally-mounted fans, one of which is dedicated

to cooling the power supplies. This results in a cooling capacity of an average of

35 Watts per slot for typical VXIbus IAC modules (455 Watts for a fully loaded

system), based on a maximum temperature rise of 10" C in the card cage and an

ambient temperature range of -10" to +55" C. The VX1401 will operate in

environmental conditions from -10" to +55" C, and in relative humidity ranging

from 09'0 to +95%. Its rugged 0.125 inch thick aluminum skin permits operation

in physically demanding applications.

Tektronix/CDS offers a variety of instrument and interface cards compatible

with the VX1401, which are designed to accomplish a wide range of test and

measurement functions. The current copy of the

and Ordering Guide gives detailed specifications and functional descriptions of

available IAC modules.

(+5, -5.2, -2, +12, -12, +24,

Hz

Tektronix/CDS Information

to

-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

Section

1

Installation

To mount a mainframe in a standard 19 inch rack, refer to the diagrams and the

steps below. To remove a mainframe, reverse these steps. The tools required are

a #2 Phillips-head screwdriver, a flat blade screwdriver, and a 3/8 in. wrench.

1.

The VX1401 Mainframe is shipped with the mainframe chassis slides

attached when ordered as part of a configured system. Remove the

cabinet slide sections, the mounting brackets, and the separately-bagged

hardware (nuts, bolts, and washers) from the shipping container. Save the

shipping container for future use. Any hardware remaining after

installation may be used as spares.

2.

Referring to Figure

1,

attach the front and rear mounting brackets to the

cabinet slide section. The rear brackets are longer than the front brackets.

Leave the hardware loose. If more than one mainframe is to be installed,

determine the position of all mainframes before installing the first one.

NOTE:

The mounting holes on the rails of a standard

19

inch rack are in an asymmetric pattern. Use the

correct mounting pattern for the main frame to be

installed.

Be sure that the TOP and TWO BOTTOM slots on the mounting bracket are

aligned with a tapped

#lo-32

hole on the rack rail. The second slot will

partially cover the hole beneath it. If the slots are not properly aligned,

installation of more than one mainframe will not be possible.

3.

Adjust the length of the combined mounting brackets and cabinet slide

section. Position the rear mounting brackets at the back of the cabinet.

Position the front mounting brackets against the rear side of the cabinet

front mounting rails, approximately in line with the front of the cabinet

slide section. Tighten the hardware once the brackets are adjusted.

4.

There should be a distance of 1.985 in. from the bottom of the mainframe

to the centerline of the bottom slot of the mounting bracket. Mount the

cabinet slide section to the cabinet as shown. Be sure that the cabinet slide

sections on both sides are mounted at the same height.

To make any necessary vertical adjustments, loosen the

#lo-32 screws that

secure the rack slide mounting brackets to the rack mounting rails. Move

the mainframe into position and tighten the screws. The vertical

adjustment range is approximately 0.06 inches.

5.

Check all of the hardware to see that it is tight and secure.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Section

I

WARNING

I

)

Inserting the

requires

card cage chassis slide wheel bearings into the

cabinet slide section, and one to lift the

mainframe. Because of the size and weight of the

frame, in jury may result if one person tries lo

main

install it alone.

6.

Fully extend the sliding section of one of the cabinet slides until it locks

into place. Repeat this procedure with the other cabinet slide.

7.

Lift the VX1401 Mainframe by its handles, and insert both attached

chassis slide sections into the sliding sections of the two cabinet slides.

Make sure that the chassis slide wheel bearings are engaged and are riding

freely.

8.

Completely insert the VX1401 Mainframe into the rack by depressing both

chassis member latches from their locked position, and pushing the

mainframe until its rack ears are flush against the cabinet mounting rails.

Additional mainframes can now be installed, if desired.

To install another mainframe above or below the first one, find the next set of

properly aligned mounting holes in the rack rails, and install the mounting

brackets of the mainframe rack slide assemblies as described above. If

necessary, adjust the height of either or both mainframes for proper vertical

clearance between them.

VX1401

two

people: one to help lift and guide the

Main frame into the cabinet

Repeat as needed to install all remaining mainframes.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Section

1

,-

CARD

CAGE

Fi~ure

---------------

I:

Cabinet Mounting

'

CABINET

NK)UNT

FRONT

MTG

RAIL

I

NG

BRACKET

OR

REAR

REF

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Section

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Functional Overview

Modules installed in the VX1400 are programmed by ASCII characters issued

from the system controller to the modules

and the VXIbus mainframe backplane. Refer to the manual for the VXIbus

device that will be the commander for details on the operation of that device.

Power Budget

The VX1401 has two power supplies located at the rear of the mainframe. At an

ambient temperature over +55"C, the power supplies are rated at 500 W. At

ambient temperatures of less than +55"C, the supplies are rated at 570

VX1401 Mainframe is designed to dissipate an average of

10°C temperature rise within the card cage. The Power Budget Worksheet in

Appendix A should be filled out before applying power to the card cage for the

first time to ensure that individual power supply voltages will not be exceeded.

Grounding

Operating

via

the module's VXIbus commander

35

W

Basics

per slot with

W.

The

a

A terminal block, providing access to chassis ground and power-supply ground,

is located at the rear of the card cage. Terminal

supply ground and Terminal

The system is shipped with a shorting bar between Terminals 1 and

connecting the two grounds together. The shorting bar may be removed to float

the power supplies.

At frequencies over

and agency safety approvals no longer apply. Never operate

the

5V

Standby Power Supply

The terminal block, located at the rear of the VX1401 Mainframe, has a screw

terminal labeled +5V

supply to the VX1401 Mainframe. The total current on the 5V standby input

may not exceed 0.5 amps.

Fuses

VX1401

1,

labeled PSGND, is power

2,

labeled ACGND, is chassis (water-pipe) ground.

63

Hz,

leakage current becomes signi ficanr

without the safety ground properly connected.

SBY

that can be used to connect a 5V standby power

2,

Each power supply has a fuse. For 115 V operation, fuse F1, located toward the

F2,

side of the mainframe, should be a 7A fuse.

mainframe, should be a 5A fuse.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

located toward the center of the

Page 17

230

Volt Operation

opera tin^

For

230

V

operation, fuse F1 should be a

The unit is shipped with the appropriate fuses for the country it is being

shipped to.

The VX1401 is shipped from the factory with the ac input voltage set for the

appropriate ac voltage of the country it is being shipped to. If the unit's

operating voltage must be changed for any reason, the

rear panel of the unit must be changed. To change the operating voltage, use a

slotted screwdriver to move the switch to the desired position

For continued protection against fire, replace the fuse with the specified values

230V

when changing to

Unplug the unit from the electrical outlet before

moving the switch, or the unit will be damaged.

operations.

Basics

3A

fuse, and

F2

should be a

AC

Select switch on the

(I

15

V

or

2.5A

230

fuse.

V).

Since all of the cooling fans are operated on

the unit are required.

Power Cords

24V

dc, no other modifications to

I

WARNING

The card cage operates from a single-phase power source, using

a detachable three-wire power cord with a two-pole, threeterminal grounding type plug. The voltage to ground (earth) from

either pole of the power source must not exceed

Before you connect the mainframe to the power source, be sure

that the AC Select switch on the rear fan plate is set to match

the power source, and

(two-pole, three-terminal, GROUNDING type).

All accessible conductive parts of

connected through the grounding connector of the power cord to

the grounding contact of the power plug. Therefore, the power

plug must be inserted into a mating receptacle with a grounding

Do

contact.

interruption in the grounding connection can create an electric

shock hazard.

not defeat the grounding connection. Any

that the power cords have suitable plugs

the card cage are directly

1

250

volts.

Card cages are shipped with the required power cords (as ordered by the

customer). Information on the available power cords is shown in the following

table. Contact your Tektronix representative or local Tektronix Field Office for

additional power-cord information.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Operating Basics

POWER CORD AND

I

PLUG LINE REFERENCE OPTION

CONFIGURATION USAGE VOLTAGE STANDARDS NUMBER

North ANSI C73.1 1

American 120V NENA 5-1 5-P Standard

120/15A

Universal

Euro 240V CEE

24OVl (7),ll.lV.Vll A1

10-1 6A

UK BS 1363

240V 240V IEC 83 A2

13A

Australian

24OVl 240V AS C112 A3

10A

PLUG

INFORMA TION

North

American 240V ANSI C73.20

240V/ NEMA 6-1 5-P A4

15A IEC 83

Switzerland

220Vl 220V SEV A5

6A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Operating Basics

Backplane

The backplane is a circuit board with two 96-pin DIN gas-tight connectors (PI,

P2) for each slot. Connector PI is located on top of the backplane, and

connector

P2

is located on the bottom of the backplane.

The backplane is fully VXIbus-compatible. The specifications for timing, noise,

crosstalk, termination, driving, and loading all comply with the VXIbus

Specification.

Refer to Appendix B for signal names. For details on the

definition of these signals, refer to the

IEEE

1014-1987 Specification for the

VMEbus signals and to the VXIbus Specification for definition of the VXIbus

signals.

The backplane contains circuitry on each end

of

the board which provides the

required signal-line-termination networks as described in IEEE 10 14-1 987. The

VXIbus signals requiring termination are also terminated by circuitry on the

backplane.

A Power Monitor circuit is included which meets the specifications in IEEE-

1019-1987. The reset time on power-up is about 250 msecs. The delay from

ACFAIL* to reset on power failure is approximately 8 msecs.

The backplane also contains the VXIbus-required MODID termination resistor,

differential

ECL

active clock drivers, and bus termination and protection.

A ground surface is provided around each connector to allow modules with a

totally enclosed shield to make contact with the backplane ground. The VXIbus

recommended clearance is provided.

-

Backplane Jumpers

The P1 bus on the backplane includes five daisy-chained signals for bus

arbitration and interrupt handling, as described in IEEE 1014-1987. If an empty

slot appears between used slots in the chassis, these daisy-chained signals must

be jumpered across the empty slot in order to allow the signals to propagate

down the backplane.

Thirty molded jumpers (CDS Part

#45OO

1

-

1020 1, packaged separately) are

supplied with the mainframe for jumpering backplane signals.

Individual molded jumpers can be placed on the backplane's jumper pins

between each BGIN to BGOUT signal (four jumpers), and between the IACKIN

to IACKOUT signal (one jumper). These jumper pins are accessible through the

front of the VX1401 Mainframe. The five sets of pins for a slot are to the

left

of the PI connector for that slot.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Operating Basics

Sinnal

BGOIN (B4)

(B5)

BGl

IN

(B6)

(B7)

BG2IN

(B8)

Jum~er

to Signal

BGOOUT

BG

1 OUT

Cooling

Cooling for the VX1401 Mainframe is provided by three 24V dc fans located at

the rear of the chassis just above the power supply. The air intake for the

blowers is through louvers located on the sides of the card cage. The exhaust is

through the three fans on the back panel of the card cage.

A

fourth fan is

located on the right side of the card cage and provides air to the power supplies.

The fan speed will increase as the air temperature in the card cage increases.

NOTE:

In some operating environments it may be necessary to have the

VX140l's cooling fans running at full speed all the time. Refer

to the Coolinn Fan S~eed Selection section in the Service

Manual for instructions on how to set the fans to full speed.

The air going across the IAC modules is filtered by a large rectangular internal

filter in a tray below the bottom of the IAC modules and above the cable tray.

A

filter for the power supply fan is mounted externally on the side of the card

cage. The filters should be cleaned regularly, with a schedule appropriate to the

operating environment. See the Cleaning Air Filters section in the Service

Manual.

The cooling design of the VX1401 Mainframe relies on the

front panels of the individual modules in the card cage to

completely enclose the front opening of the card cage. If any

slot in the card cage is not occupied by a module with a front

panel, a blank front panel must be installed for that slot.

Tektronix/CDS provides the required number of blank panels

for each card cage shipped, based on the number of cards

ordered. The plexiglas front panel is cosmetic, and is not

required for proper cooling.

The VX1401 Mainframe delivers cooling capacity evenly across all thirteen slots.

The graph shown in Figure 4 is accurate for any position in the card cage.

To determine if a VXIbus device will operate in the VX1401 Mainframe, the

system integrator must obtain the cooling requirement of the module to be used.

Take the published pressure drop in inches of water and check the cooling

capacity at that pressure drop.

If

the VX1401 can deliver an equal or greater

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Operating

Basics

cooling capacity than the module requires, the module may be used in the

VX1401 Mainframe.

Example:

The

VX4520 Module requires 1.6 l/sec at a pressure drop of 0.02

in.

H,O

to

achieve a temperature rise of less than 10"

C

over ambient temperature.

Looking at the graph, the VX1401 delivers about 6.5 l/sec at that pressure. The

VX4520 will operate in the VX1401 Mainframe.

M l N IMUM A l

RFLOW

AVA l LABLE

PER

SL07

2

4

6

A

l

RFLOW

(L I TERSI SEC)

Figure

4:

Cooling

Graph

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

The

VX1401

Syntax and Commands

-

Mainframe does not require programming.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

Svntax and Commands

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

Status and Events

Refer to the Operating Manuals for the installed modules to determine their

status and events.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

Status and Events

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Examples

The

VX1401

does not require programming.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

Examples

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Appendix

A

Specifications

Card Positions:

Installation:

AC Input Voltage:

AC Input Frequency:

AC Input Current:

.-

Inrush, Cold Start:

Maximum

Power Available:

Total of 13 positions. The left-most position is dedicated to the

VXIbus Slot 0 device. The remaining 12 positions are available

for instrument modules.

The mainframe is supplied with rack-mounting hardware and

chassis slides. Using the supplied hardware, the mainframe

may be mounted in a standard 19-in. NEMA equipment rack

(EIA RS

90 V to 132 V ac or 180 V to 250

rear panel. The unit is shipped set for 115

230 V (Europe).

45 to 63

Hz.

significant and agency safety approvals no longer apply. Never

operate the

connected.

10 Amperes at 115 V ac.

70 Amperes, maximum for

570 Watts -10" to 55"

3

10, ANSI C83.9-1972).

Hz.

The VX1401 will perform at frequencies up to 440

At frequencies over

VX1401 without the safety ground properly

C.

V

ac. Switch selectable on

63

Hz,

leakage current becomes

6

Amperes at 230 V ac.

Ih

cycle.

V

(U.S and Japan) or

DC

Voltage Capacity:

Voltage Regulation:

+5.0 V dc 55 Amperes

-5.2 V dc 10 Amperes

-2.0 V dc 2.5 Amperes

+24 V dc 6 Amperes

-24 V dc

+12 V dc 5 Ampere

-12 V dc

6

Amperes

1

Ampere

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Appendix

A

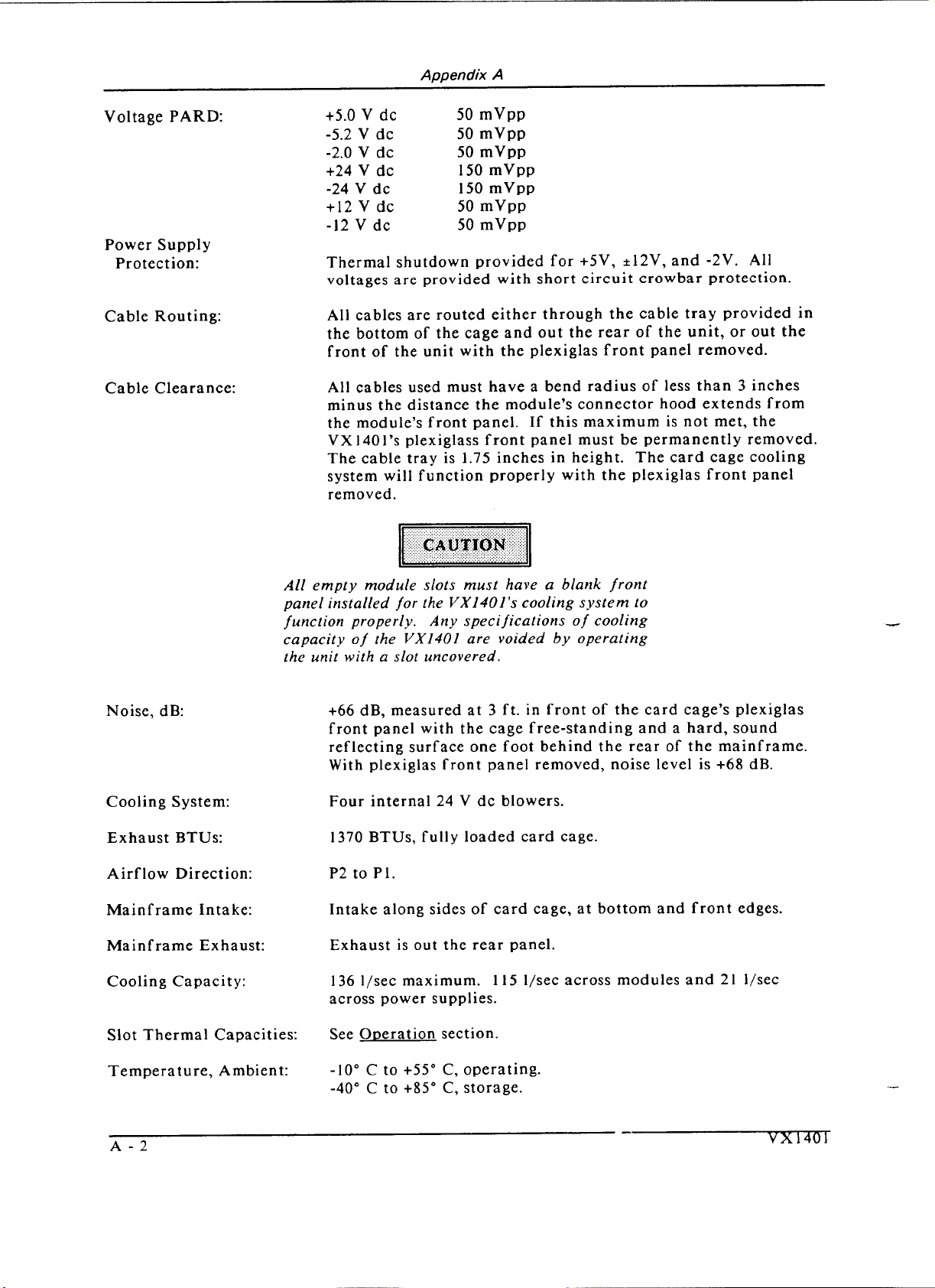

Voltage PARD:

Power Supply

Protection:

Cable Routing:

Cable Clearance:

Noise, dB:

Cooling System:

Exhaust BTUs:

Airflow Direction:

Mainframe Intake:

Mainframe Exhaust:

Cooling Capacity:

+5.0

V

dc 50 mVpp

-5.2 V dc 50 mVpp

-2.0 V dc 50 mVpp

+24 V dc 150 mVpp

-24 V dc 150 mVpp

+12 V dc 50 mVpp

-12

V dc 50 mVpp

Thermal shutdown provided for +5V, *12V, and -2V. All

voltages are provided with short circuit crowbar protection.

All cables are routed either through the cable tray provided in

the bottom of the cage and out the rear of the unit, or out the

front of the unit with the plexiglas front panel removed.

All cables used must have a bend radius of less than

3

inches

minus the distance the module's connector hood extends from

the module's front panel. If this maximum is not met, the

VX140l's plexiglass front panel must be permanently removed.

The cable tray is 1.75 inches in height. The card cage cooling

system will function properly with the plexiglas front panel

removed.

All empty module slots must have a blank front

panel installed for the VX1401's cooling system to

function properly. Any specifications of cooling

capacity of the

VX1401 are voided by operating

the unit with a slot uncovered.

+66

dB, measured at 3 ft. in front of the card cage's plexiglas

front panel with the cage free-standing and a hard, sound

reflecting surface one foot behind the rear of the mainframe.

With plexiglas front panel removed, noise level is

+68

dB.

Four internal 24 V dc blowers.

1370 BTUs, fully loaded card cage.

Intake along sides of card cage, at bottom and front edges.

Exhaust is out the rear panel.

136

l/sec maximum. 1 15 I/sec across modules and 21 I/sec

across power supplies.

Slot Thermal Capacities:

See O~eration section.

Temperature, Ambient:

-10"

C

to +55" C, operating.

-40"

C

to +85"

C,

storage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Appendix A

In a rack system, the ambient air temperature in the rack must

not exceed +55"

C.

Humidity:

Dimensions:

Weight: 25.5 kg. (56 lb).

Weight, Shipping: 30 kg. (66 lb).

(empty)

Equipment Supplied:

Safety Approvals:

Less than

Less than 75% R.H. non-condensing, +31°C to +40°C.

Less than 45% R.H. non-condensing, +41°C to +55"C.

431.8 mm wide (482.63 mm with rack-mounting ears), 355.6 mm

high, 622.3 mm deep (not including handles).

1

-

1

-

-

1

UL

CSA Certified: File number LR97263- 1.

Modules installed in the

at a minimum of 94V-1.

95% R.H. non-condensing, -10°C to +30°C.

(1

7 in x 14 in x 24.5 in).

VX1401 Mainframe.

Operating Manual (Part # 00000-31401).

Service Manual (Part # 00000-41401).

Listed: File number E137225.

VX1401 must use circuit boards rated

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

Appendix A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Pin

No.

InputIOutput Connections

P1 CONNECTOR PINOUTS

Row A Row B

Appendix

C

Row

B

DO0

1

DO

DO2

DO3

DO4

DO5

DO6

DO7

GND

SYSCLK

GND

1

DS

DSO

WRITE

GND

DTACK

GND

AS

GND

IACK

IACKIN

IACKOUT

AM4

A07

A06

A05

A04

A03

A02

A0 1

-12v

+5v

BBSY

BCLR

ACFAIL

BGOIN

BGOOUT

BGlIN

BGlOUT

BG2IN

BG20UT

BG31N

BG30UT

BRO

1

BR

BR2

BR3

AM0

AM1

AM2

AM3

GND

SERCLK

SERDAT

GND

IRQ7

IRQ6

IRQ5

IRQ4

IRQ3

IRQ2

IRQ l

+5V STBY

+5v

DO8

DO9

D 10

Dl 1

Dl2

Dl3

D 14

Dl5

GND

SYSFAIL

BERR

SYSRST

LWORD

AM5

A23

A22

A2 1

A20

A 19

A 18

A 17

16

A

A15

A 14

A13

A12

All

A10

A09

A08

+

12v

+5v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

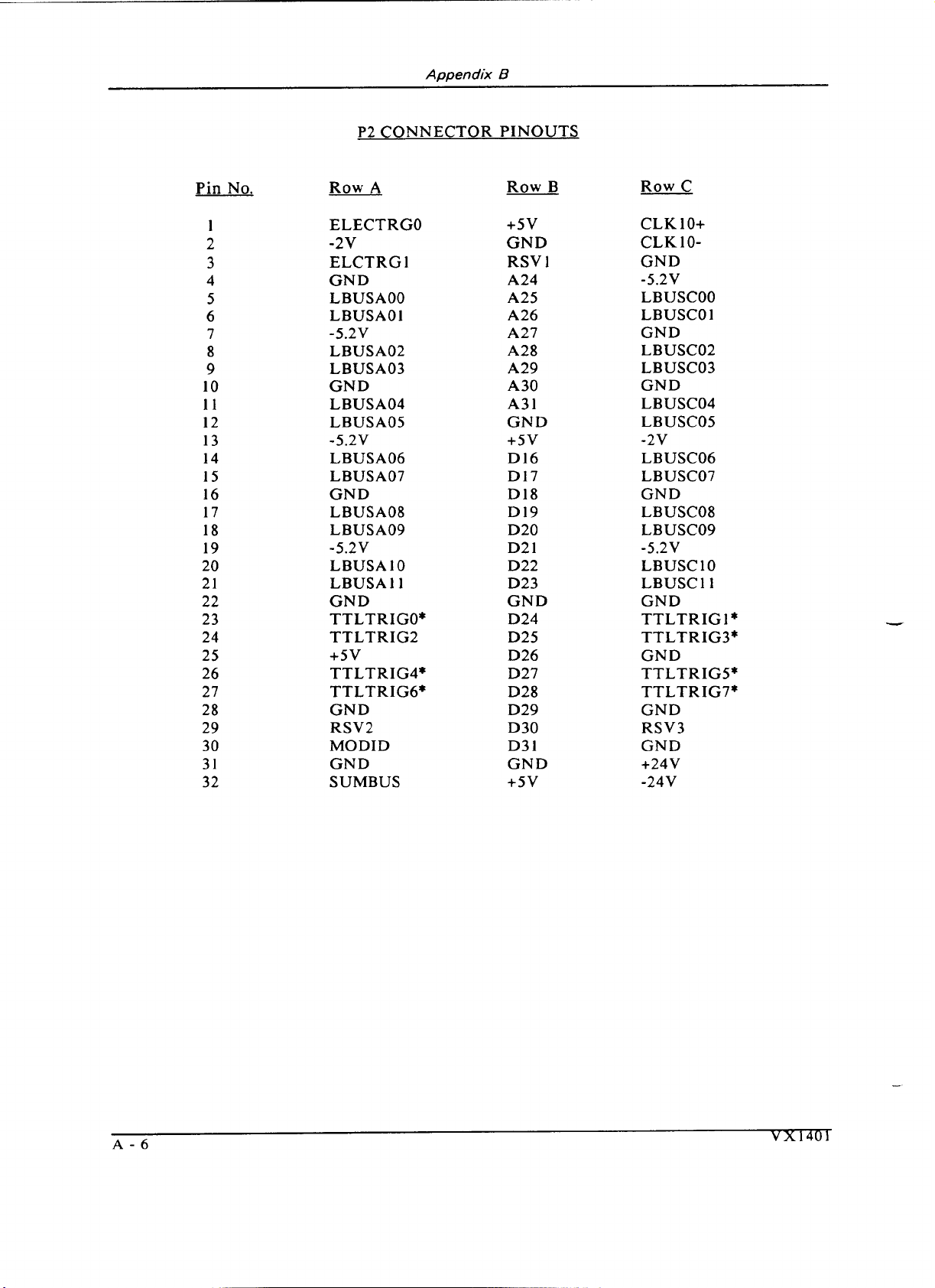

P2 CONNECTOR PINOUTS

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

1

2 2

23

2 4

25

26

27

28

2 9

30

3

1

32

Row

A

Row B

ELECTRGO

-2v

ELCTRGl

GND

LBUSAOO

LBUSAOl

-5.2V

LBUSA02

LBUSA03

GND

LBUSA04

LBUSAO5

-5.2V

LBUSA06

LBUSA07

GND

LBUSA08

LBUSA09

-5.2V

LBUSAIO

LBUSA 1 1

GND

TTLTRIGO*

TTLTRIG2

+5v

TTLTRIG4*

TTLTRIG6*

GND

RSV2

MODID

GND

SUMBUS

+5v

GND

RSV

1

A24

A25

A26

A27

A28

A29

A30

A3 1

GND

+5v

Dl6

D 17

D

18

D

19

D20

D2 1

D22

D23

GND

D24

D25

D26

D27

D28

D29

D30

D3 1

GND

+5v

Row

C

CLK 10+

CLK

10-

GND

-5.2V

LBUSCOO

LBUSCO

1

GND

LBUSC02

LBUSC03

GND

LBUSC04

LBUSCO5

-2v

LBUSC06

LBUSC07

GND

LBUSCO8

LBUSC09

-5.2V

LBUSC10

LBUSC11

GND

TTLTRIGI*

TTLTRIG3*

GND

TTLTRIGS*

TTLTRIG7*

GND

r5v3

GND

+24V

-24V

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

Appendix

Power Budget Worksheet

The system integrator must use the power budget worksheet to determine the

operating parameters

it.

of

the card cage and any instrument modules installed in

C

Slot

POWER

Card No. +5V -5V +12V +24V -12V -24V

No.

(WATTS

)

-2V

I

watts's10t

(40 max)

User

TOTAL

570

total

--

rnax

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

max max max max

max

1

570max

Page 35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Appendix

Servicing

I

WARNING

C

These servicing instructions are for use by quali jied personnel

only. To reduce the risk of electric shock, do not perform any

servicing other than that contained in the operating instructions

unless you are qualified to do so.

D

Adjusting

Power

If the power supplies need to be adjusted, refer to the drawing below and the

VX1401

procedure:

1.

2.

3. Place the chassis back upright and remove the fan plate (RP

4.

5.

Supply

Exploded Mechanical Assembly drawing and use the following

Remove the top and bottom covers as described in the

Disassembly

Remove the three screws (PSE

(PSI) to the chassis. These screws are on the bottom of the chassis, and are

easily accessed by tipping the chassis on its left side (as viewed from the

front).

on by nine screws (CCE 126-134). The fan plate will swing to the left.

Remove the five screws holding the baffle plate (BP2) on the power

supplies.

The

5V

to the right. The adjustment pots for both power supplies are now

accessible. Refer to the drawings below for their locations.

section.

4,

5,

and

6)

holding the

power supply may be lifted over the lip of the chassis and swung

NOTE.

Assembly and

5V

power supply

1). It is held

There must be at least a

supply. The backplane draws about

an additional load of at least

This can usually be met by a slot

other module.

Re-assemble the unit by reversing the above steps.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5.5

amp load on the

1.25

4.25

amps is needed.

0

module and one

+5V

amps, so

Page 37

Appendix

D

The adjustment for each supply voltage is independent, and may be adjusted

without affecting the other supplies.

The -12V supply has no adjustment. The

VXI

Specification and factory adjustments for each supply are as shown:

Power

VXI

Spec. Factory Adjustment

supply Min. Max. Min. Max.

+5 +4.875 +5.250 +5.100 +5.200

*

The -12V supply has no adjustment.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Appendix

D

Selecting Cooling

In some operating environments, it may be necessary to have the VX140l's

cooling fans running at full speed all the time. The VX1401 has a two-position

Fan Speed slide switch inside the mainframe. The switch is located in the power

supply bay, on the right side (referenced from the front of the mainframe)

above the power supply cooling fan. The fans are set to variable speed when the

slide switch is in the UP position, and to full speed when the switch is in the

Cleaning

DOWN

Unplug the VX1401 from the electrical outlet before setting the Fan Speed

switch.

Air Filters

Removal

The main filter can be removed from either the front or side of the mainframe.

To remove the filter from the front, a

are required.

position.

1.

Fan

Speed

#2

Phillips and a flat blade screwdriver

Remove any modules or blank filler panels covering slot

6.

Remove the small slotted screw that holds the rail's center support

2.

standoff in place. Be sure to keep the small lock washer from under

the screw.

Remove the

3.

the mainframe. The filter can now be slid out the front of the

mainframe.

To remove the filter from the side:

Remove the two slotted screws in the filter support bracket located

1.

on the left side of the mainframe (referenced from the front).

Remove the bracket for the filter support.

2.

and can be removed from the slot on the left side of the mainframe.

Be careful not to over-tighten the two slotted screws when reinstalling the bracket.

To remove the filter of the power supply's fan, use a flat bladed screwdriver

and snap the plastic grill out of the filter housing.

Cleaning

Clean both filters with mild soap and water.

re-installing them and using the mainframe.

6-32

flat screw that holds the standoff from underneath

The filter will drop down

Bc

sure the filters are dry before

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

Appendix

D

Assembly

And

Disassembly

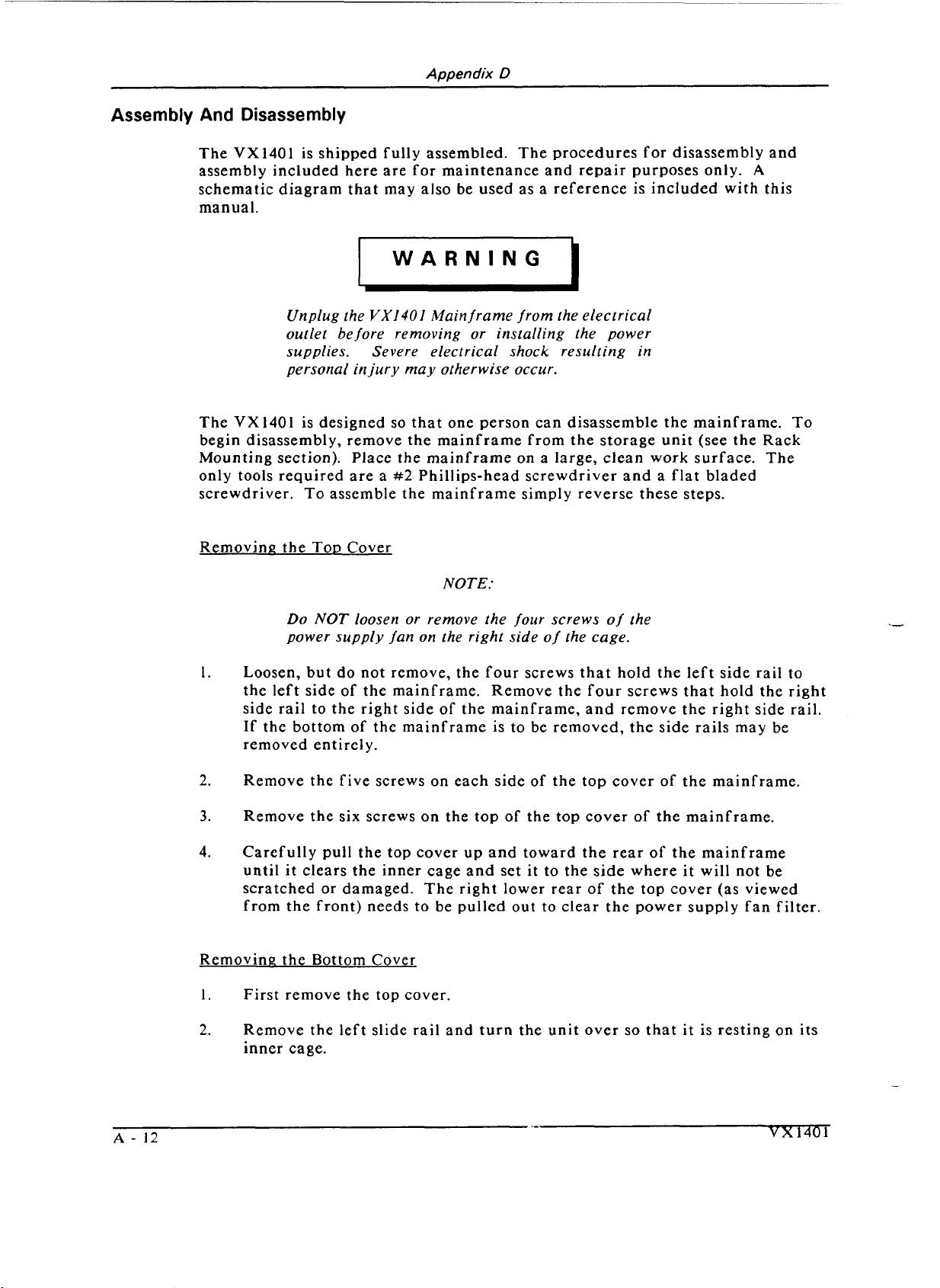

The VX1401 is shipped fully assembled.

assembly included here are for maintenance and repair purposes only.

schematic diagram that may also be used as a reference is included with this

manual.

I

WARNING

The procedures for disassembly and

A

I

Unplug the

ourlet before removing or installing the power

supplies. Severe electrical shock resulting in

personal injury may otherwise occur.

The VX1401 is designed so that one person can disassemble the mainframe. To

begin disassembly, remove the mainframe from the storage unit (see the Rack

Mounting section).

only tools required are a

screwdriver. To assemble the mainframe simply reverse these steps.

Removing the

Top Cover

VX1401

Place the mainframe on a large, clean work surface. The

Main frame from the electrical

#2

Phillips-head screwdriver and a flat bladed

NOTE:

Do NOT loosen or remove the four screws of the

power supply fan on the right side of the cage.

Loosen, but do not remove, the four screws that hold the left side rail to

the left side of the mainframe.

side rail to the right side of the mainframe, and remove the right side rail.

If the bottom of the mainframe is to be removed, the side rails may be

removed entirely.

Remove the five screws on each side of the top cover of the mainframe.

Remove the six screws on the top of the top cover of the mainframe.

Carefully pull the top cover up and toward the rear of the mainframe

until it clears the inner cage and set it to the side where it will not be

scratched or damaged. The right lower rear of the top cover (as viewed

from the front) needs to be pulled out to clear the power supply fan filter.

Removina the Bottom Cover

First remove the top cover.

1.

Remove the four screws that hold the right

Remove the left slide rail and turn the unit over so that it is resting on its

2.

inner cage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

Appendix

Remove the four screws on each side of the bottom cover of the

3.

D

mainframe.

Remove the one screw on the bottom of the mainframe.

4.

Carefully pull the bottom cover up and toward the rear of the mainframe

5.

until it clears the inner cage, and set it to the side, where it will not be

scratched or damaged.

At this point, the mainframe is disassembled enough to accomplish any

maintenance required.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Appendix

D

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

Appendix

E

(Option

1

M)

MATE

Applications

Option 1M: MATE Compatible Mainframe

If the

VX1401

Mainframe is ordered with Option lM, MATE Compatible, the

card cage is delivered with the following modifications:

Aluminum Rack Slides that meet or exceed the MATE guidelines.

MATE Butch Plate with provisions for mounting the

IEEE-488

connector

and the

DFI

BNC

connector.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

Appendix

E

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

Appendix

F

Replaceable

Q~Y.

per

Descri~tion Part Number Chassis

Top Cover

Bottom Cover

Line Fuse (5A)

Line Fuse (7A)

(1

Internal Line Fuse

Rack Ear (right)

Rack

Ear

(left)

Front Handle

Rear Handle

Rear Fan

Side Fan

Chassis Air Filter

Side Fan Filter

5A)

Parts

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

Appendix

F

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

Appendix

G

Options

The following options are available for the VX1401:

Plugs

Option A1 220V Euro plug

Option A2 240V

UK

plug

Option A3 240V Aust. plug

Option

A4

240V N. Amer. plug

Option A5 220V Swiss plug

Mainframes are shipped with the required power cords as ordered

by

the

customer. The available power cords are shown in

Power

Cords.

Option

01

Delete

Rack

Slide, Add Trim: removes the standard rack slides and replaces

them with Trim Plates, one on each side of the mainframe. A VX1401 Option 01

is not intended to be mounted in a standard NEMA rack.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

Appendix

G

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

Glossary

The terms in this glossary are defined as used in the VXIbus System. Although

some of these terms may have different meanings in other systems, it is

important to use these definitions in VXIbus applications.

Terms which apply

only to a particular instrument module are noted. Not all terms appear in every

manual.

Term Definition

Accessed

Indicator

ACFAIL*

A-Size Card

Asynchronous

Communication

Backplane

B-Size Card

Bus Arbitration

Bus Timer

Client

An amber LED indicator that lights when the module identity

is selected by the Resource Manager module, and flashes during

any 1/0 operation for the module.

A VMEbus backplane line that is asserted under these

conditions:

1) by the card cage Power Supply when a power

failure has occurred (either ac line source or power supply

malfunction), or

2)

by the front panel ON/STANDBY switch

when switched to STANDBY.

A

VXIbus instrument module that is 100.0 by 160 mm by 20.32

mm

(3.9

by 6.3 in by 0.8 in), the same size as a VMEbus single-

height short module.

Communications that occur outside the normal "command-

response" cycle. Such communications have higher priority

than synchronous communication.

The printed circuit board that is mounted in a VXIbus card

cage to provide the interface between VXIbus modules and

between those modules and the external system.

A VXIbus instrument module that is 233.4 by 160 mm by 20.32

mm (9.2 by 6.3 in by 0.8 in), the same size as a VMEbus double-

height short module.

In the VMEbus interface, a system for resolving contention for

service among VMEbus Master devices on the VMEbus.

A functional module that measures the duration of each data

transfer on the Data Transfer Bus (DTB) and terminates the

DTB cycle if the duration is excessive.

Without the termination

capability of this module, a Bus Master attempt to transfer data

to or from a non-existent Slave location could result in an

infinitely long wait for the Slave response.

In shared memory protocol (SMP), that half of an SMP channel

that does not control the shared memory buffers.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

CLKlO

CLK 100

Glossarv

A

10-MHz, *lo0 ppm, individually buffered (to each module

ECL

slot), differential

system clock that is sourced from Slot 0

and distributed to Slots 1-12 on P2. It is distributed to each

module slot as a single source, single destination signal with a

8

matched delay of under

A

100-MHz, i100 ppm, individually buffered (to each module

slot), differential

ECL

and distributed to Slots 1-12 on P3.

ns.

system clock that is sourced from Slot 0

It is distributed to each

module slot in synchronous with CLKlO as a single source,

single destination signal with a maximum system timing skew

8

of 2 ns, and a maximum total delay of

ns.

Commander

Command

Communication

Registers

Configuration

Registers

In the VXIbus interface, a device that controls another device

(a

servant). A commander may be a servant of another

commander.

A directive to a device. There are three types of commands:

In Word Serial Protocol, a 16-bit imperative to a servant from

its commander.

In Shared Memory Protocol, a 16-bit imperative from a client to

a server, or vice versa.

In a Message, an ASCII-coded, multi-byte directive to any

receiving device.

In word serial protocol, a set of device registers that are

accessible to the commander of the device. Such registers are

used for inter-device communications, and are required on all

VXIbus message-based devices.

A set of registers that allow the system to identify a (module)

device type, model, manufacturer, address space, and memory

requirements. In order to support automatic system and

memory configuration, the VXIbus standard specifies that all

VXIbus devices have a set of such registers, all accessible from

PI on the VMEbus.

--C

C-Size Card

A VXIbus instrument module that is 340.0 by 233.4 mm by

30.48 mm (13.4 by 9.2 in by 1.2 in).

Custom Device

A

special-purpose VXIbus device that has configuration

registers so as to be identified by the system and to allow for

definition of future device types to support further levels of

compatibility.

Data Transfer

Bus

One of four buses on the VMEbus backplane. The

Data

Transfer Bus allows Bus Masters to direct the transfer of

binary data between Masters and Slaves.

DC

SUPPLIES

A

Indicator

red LED indicator that illuminates when a

DC

power fault is

detected on the backplane.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

Device Specific

Protocol

Glossary

A

protocol for communication with a device that is not defined

in the VXIbus specification.

D-Size Card

DTB

DTB Arbiter

A VXIbus instrument module that is 340.0 by 366.7 mm by

(1

30.48 mm

3.4 x 14.4 in x 1.2 in).

See Data Transfer Bus.

A

functional module that accepts bus requests from Requester

modules and grants control of the DTB to one Requester at a

time.

DUT

ECLTRG

Device Under Test.

Six single-ended ECL trigger lines (two on

that function as inter-module timing resources, and that are

bussed across the VXIbus subsystem backplane. Any module,

including the Slot 0 module, may drive and receive information

from these lines. These lines have an impedance of 50 ohms;

the asserted state is logical High.

Embedded

Address

An address in a communications protocol in which the

destination of the message is included in the message.

ESTST

Extended

STart/STop protocol; used to synchronize VXIbus

modules.

Extended

Self Test

Any self test or diagnostic power-up routine that executes after

the initial kernel self test program.

External System

Controller

The host computer or other external controller that exerts

overall control over VXIbus operations.

FAILED

Indicator

A red LED indicator that lights when a device on the

has detected an internal fault. This might result in the

assertion of the SYSFAIL* line.

IACK Daisy Chain

Driver The circuit that drives the

daisy chain line that runs continuously through all installed

modules or through jumpers across the backplane.

P2

and four on

VXIbus

VMEbus Interrupt Acknowledge

P3)

ID-ROM

An NVRAM storage area that provides for non-volatile storage

of diagnostic data.

Instrument

Module

A plug-in printed circuit board, with associated components

and shields, that may be installed in a VXIbus card cage. An

instrument module may contain more than one device. Also,

one device may require more than one instrument module.

Interface

Device A VXIbus device that provides one or more interfaces to

external equipment.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 51

Interrupt

Handler

Glossary

A functional module that detects interrupt requests generated

by Interrupters and responds to those requests by requesting

status and identity information.

Interrupter

IRQ

Local Bus

Local Controller The instrument module that performs system control and

Local Processor The processor on an instrument module.

Logical Address The smallest functional unit recognized by a

Mainframe

Memory Device

A device capable of asserting VMEbus interrupts and

performing the interrupt acknowledge sequence.

The Interrupt

line that is asserted by an Interrupter to signify to the

controller that a device on the bus requires service by the

controller.

A

daisy-chained bus that connects adjacent VXIbus slots.

external interface functions for the instrument modules in a

VXIbus card cage or several card cages. See Resource Manager.

is often used to identify a particular module.

Card Cage For example, the Tektronix VX1401 Card Cage, an

A

storage element (such as bubble memory, RAM, and ROM)

that has configuration registers and memory attributes (such as

type and access time).

ReQuest signal, which is the VMEbus interrupt

VXlbus system. It

13

operable housing that includes

instrument module slots.

C-size VXIbus

-

Message

Message Based

Device

MODID Lines

Physical

Address

Power Monitor

A

series of data bytes that are treated as a single

communication, with a well defined terminator and message

body.

A

VXIbus device that supports VXI configuration and

communication registers. Such devices support the word serial

protocol, and possibly other message-based protocols.

Module/system identity lines.

The address assigned to a backplane slot during an access.

A

device that monitors backplane power and reports fault

conditions.

The top-most backplane connector for a given module slot in a

vertical card cage such as the Tektronix VX1400. The left-most

backplane connector for a given slot in a horizontal card cage.

a

The bottom backplane connector for

vertical C-size card cage such as the VX1400; or the middle

given module slot in a

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

Glossary

backplane connector for a given module slot in a vertical D-size

VX

card cage such as the

1500.

The bottom backplane connector for a given module slot in a

vertical D-size card cage such as the Tektronix VX1500.

Query

READY

Indicator

Register Based

Device

Requester

Resource

Manager

Self

Calibration

A form of command that allows for inquiry to obtain status or

data.

LED

A green

indicator that lights when the power-up

diagnostic routines have been completed successfully. An

internal failure or failure of +5-volt power will extinguish this

indicator.

A VXIbus device that supports VXI register maps, but not high

level VXIbus communication protocols; includes devices that

are register-based servant elements.

A functional module that resides on the same module as a

Master or Interrupt Handler and requests use of the DTB

whenever its Master or Interrupt Handler requires it.

A VXIbus device that provides configuration management

services such as address map configuration, determining system

hierarchy, allocating shared system resources, performing

system self test diagnostics, and initializing system

commanders.

A

routine that verifies the basic calibration of the instrument

module circuits, and adjusts this calibration to compensate for

short- and long-term variables.

Self Test

Servant

Server

Shared Memory

Protocol

0

Slot

Controller

0 Module

Slot

SMP

A set of routines that determine if the instrument module

circuits will perform according to a given set of standards.

A

self test routine is performed upon power-up.

A VXIbus message-based device that is controlled by a

commander.

A shared memory device that controls the shared memory

buffers used in a given Shared Memory Protocol channel.

A communications protocol that uses a block of memory that is

accessible to both client and server. The memory block

operates as a message buffer for communications.

0

See Slot

A

VXIbus device that provides the minimum VXIbus slot

services to slots 1 through

Module. Also see Resource Manager.

12

(CLKIO

and the module identity

0

lines), but that may provide other services such as CLK100,

SYNC100, STARBUS, and trigger control.

See Shared Memory Protocol.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 53

STARX

Glossary

(2)

Two

bi-directional,

50

ohm, differential

ECL

lines that

provide for inter-module asynchronous communication. These

pairs of timed and matched delay lines connect slot 0 and each

1

of slots

through 12 in a card cage. The delay between slots is

less than 5 nanoseconds, and the lines are well matched for

timing skew.

STARY

Two (2) bi-directional, 50 ohm, differential ECL lines that

provide for inter-module asynchronous communication. These

0

pairs of timed and matched delay lines connect slot

of slots

1

through

12

in a card cage. The delay between slots is

and each

less than 5 nanoseconds, and the lines are well matched for

timing skew.

STST

SYNC100

STart/STop protocol; used to synchronize modules.

A

Slot 0 signal that is used to synchronize multiple devices with

respect to a given rising edge of CLK100. These signals are

individually buffered and matched to less than 2ns of skew.

Synchronous

Communications A communications system that follows the "command-response"

cycle model. In this model, a device issues a command to

another device; the second device executes the command; then

returns a response. Synchronous commands are executed in the

order received.

SYSFAIL*

A

signal line on the VMEbus that is used to indicate a failure

by a device. The device that fails asserts this line.

System Clock

Driver

A

functional module that provides a 16-MHz timing signal on

the Utility Bus.

System

Hierarchy

The tree structure of the

commander/servant relationships of

all devices in the system at a given time. In the VXIbus

A

structure, each servant has a commander.

commander may

also have a commander.

Test Monitor

Test Program

Test System

TTLTRG

VXIbus

Subsystem

An executive routine that is responsible for executing the self

tests, storing any errors in the ID-ROM, and reporting such

errors to the Resource Manager.

A program, executed on the system controller, that controls the

execution of tests within the test system.

A

collection of hardware and software modules that operate in

concert to test a target DUT.

Open collector TTL lines used for inter-module timing and

communication.

One card cage with modules installed. The installed modules

a

include one module that performs slot

0 functions and

given

complement of instrument modules. The subsystem may also

include a Resource Manager.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 54

Glossary

Word Serial

Protocol

A

VXIbus word oriented, bi-directional, serial protocol for

communications between message-based devices (that is, devices

that include communication registers in addition to

configuration registers).

Word Serial

Communications Inter-device communications using the Word Serial Protocol.

WSP See Word Serial Protocol.

10-MHz Clock

A

10 MHz, i100 ppm timing reference. Also see CLK 10.

100-MHz Clock

A

100 MHz, *lo0 ppm clock synchronized with CLKIO. Also

see CLK

100.

488-TO-VXIbus

Interface

A message based device that provides for communication

between the

IEEE-488

bus and VXIbus instrument modules.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 55

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 56

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 57

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 58

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Loading...

Loading...