Page 1

Service Manual

VM100 & VM101

Video Measurment Set

070-9288-02

This document supports firmware version 1.64

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the product’s

warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s warranty period; you may purchase up to three

years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit documentation,

recall assurance, and reminder notification of scheduled calibration. Coverage begins upon registration; you may purchase

up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your T ektronix representative and provide the information

below . Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City , State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Manual Conventions xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification T ables 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T erms Used in Specifications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Conditions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standards and Certification 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Characteristics 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Port 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Buttons and LCD Display 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menus 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Connectors 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On Procedure 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Conventions 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Level Description 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Restore 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sync Stripper 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gain, DC Offset, and Filtering 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase Lock Loop 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog-to-Digital Converter 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Signal Processor 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition Control 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Processor and Memory 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Interface (RS232) 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Display 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed Circuit Description 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 Service Manual

i

Page 6

Table of Contents

Performance Verification

General Information 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Requirements 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Record 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedure 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Restore 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sync Stripper 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gain, DC Offset, and Filtering 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase Lock Loop 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D Converter 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Signal Processor (DSP) 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition Control 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Processor and Memory 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Interface (RS232) 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Display 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Interval 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Setup 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Video Measurement Set 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Identification T est 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Phase Test 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Gain Test 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sync Amplitude T est 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Burst Amplitude T est 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bar Amplitude T est 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T K-factor Test 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chrominance-to-Luminance Delay T est 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chrominance-to-Luminance Gain T est 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Luminance Nonlinearity T est 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Group Delay T est 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Response T est 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedures

ii

General Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Interval 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personnel 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warmup Period 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required T est Equipment 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interrupting the Adjustments 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing the Adjustments 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 Service Manual

Page 7

Maintenance

Table of Contents

Preventing ESD 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Disposal 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Care 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning Procedures 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement Procedures 6–7. . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Procedures 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T op Cover 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Board 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Board 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lithium Battery 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T esting the Lithium Battery 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Limits 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the main board (A2) 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Examples of Analog Signal Measurements 6–21. . . . . . . . . . . . . . . . . . . . . . . . .

Phase Lock and DSP Diagnostic LEDs and Key Signals 6–25. . . . . . . . . . . . . . .

ACQ:SHOW Command 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the VM140 or VM141 System 6–30. . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packaging 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Standard Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Parts Ordering Information 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Electrical Parts List 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

Symbols 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Values 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graphic Items and Special Symbols Used in This Manual 9–2. . . . . . . . . . . . . . . . .

Component Locator Diagrams 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Mechanical Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 2–1: Front panel 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: LCD display characteristics 2–3. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: The Meas, Mem, and Print menus 2–4. . . . . . . . . . . . . . . . . .

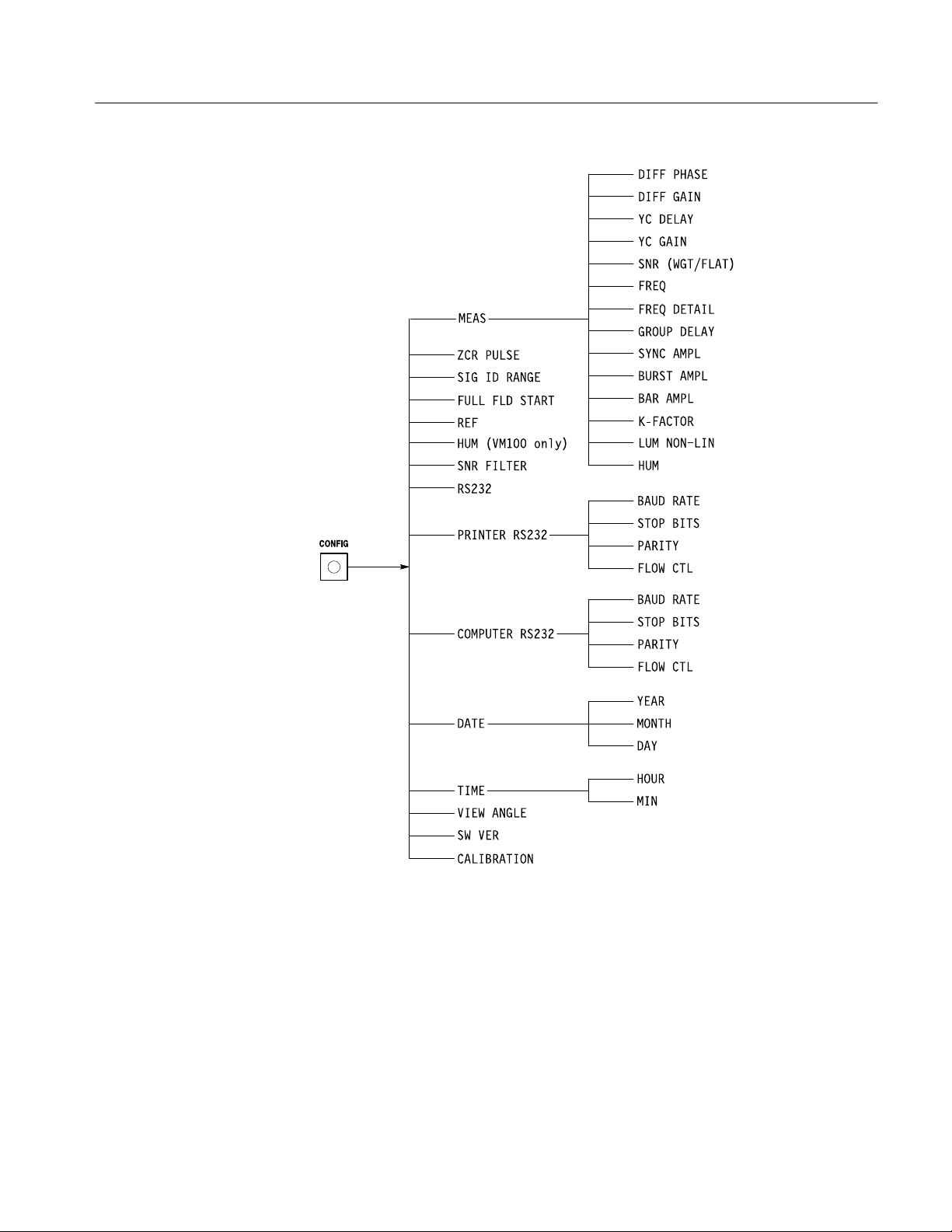

Figure 2–4: The CONFIG menu 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

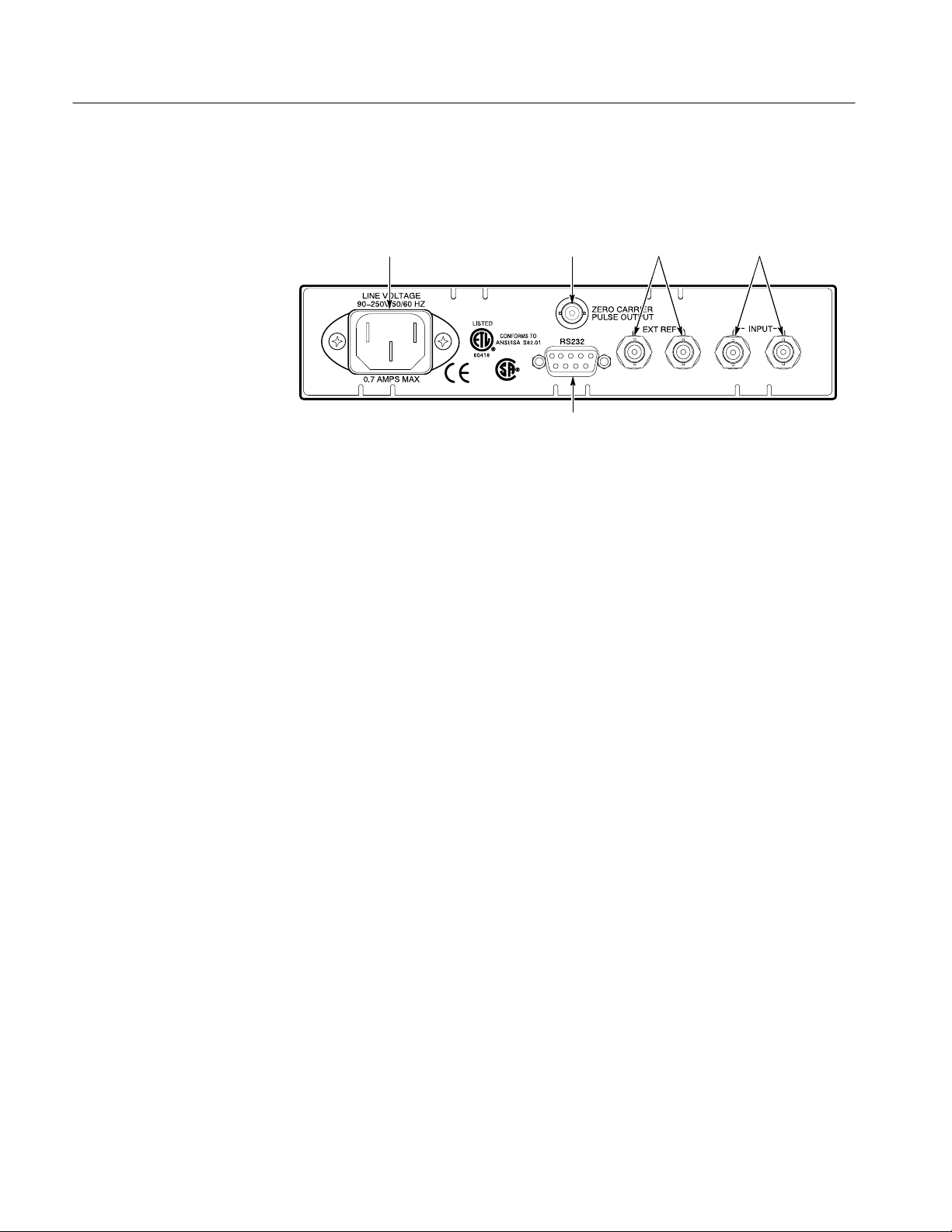

Figure 2–5: Rear panel connectors 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Simplified view of Gain, DC Offset, and Filtering block 3–5

Figure 3–2: Acquisition and DSP system 3–8. . . . . . . . . . . . . . . . . . . . . . .

Figure 3–3: Host processor and memory system 3–10. . . . . . . . . . . . . . . . .

Figure 4–1: Initial setup for the PV procedure 4–4. . . . . . . . . . . . . . . . . . .

Figure 5–1: Equipment setup for the adjustment procedure 5–4. . . . . . .

Figure 6–1: Top cover replacement 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Front panel assembly replacement 6–9. . . . . . . . . . . . . . . . . .

Figure 6–3: Front panel board replacement 6–10. . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Main board removal 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Front panel assembly removal 6–12. . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Power supply board replacement 6–13. . . . . . . . . . . . . . . . . . .

Figure 6–7: LCD board replacement 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–8: Lithium battery replacement 6–16. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Power supply test points and limits 6–19. . . . . . . . . . . . . . . . . .

Figure 6–10: Location of diagnostic LEDs 6–21. . . . . . . . . . . . . . . . . . . . . .

Figure 6–11: Setup for measuring analog signals 6–22. . . . . . . . . . . . . . . . .

Figure 6–12: Waveform at A2TP9 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–13: Waveform at A2TP10 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–14: VIDEO waveform at A2TP31 6–24. . . . . . . . . . . . . . . . . . . . .

Figure 6–15: COMP_SYNC waveform at A2TP15 6–24. . . . . . . . . . . . . . .

Figure 6–16: FIELD waveform at A2TP16 6–25. . . . . . . . . . . . . . . . . . . . . .

Figure 6–17: 8FSC_IN waveform at A2U116 pin 7 6–26. . . . . . . . . . . . . . .

Figure 6–18: HPULSE waveform at A2TP18 6–27. . . . . . . . . . . . . . . . . . . .

Figure 6–19: DSP_RCK waveform at A2U48 pin 1 6–27. . . . . . . . . . . . . . .

Figure 6–20: Example of the ACQ:SHOW command PC display 6–28. .

Figure 6–21: Setup for using the ACQ:SHOW command 6–29. . . . . . . . .

Figure 9–1: Interconnect diagram 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

VM100 & VM101 Service Manual

Page 9

Table of Contents

Figure 9–2: Block diagram 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–3: A2 Main board view A (671-3250-00/01/02/03) 9–5. . . . . . . .

Figure 9–4: A2 Main board view B (671-3250-00/01/02/03) 9–6. . . . . . . .

Figure 9–5: A2 Main board view C (671-3250-00/01/02/03) 9–7. . . . . . . .

Figure 9–6: A2 Main board component locator

(671-3250-00/01/02/03) 9–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–7: A2 Main board view A (671-3751-00) 9–9. . . . . . . . . . . . . . . .

Figure 9–8: A2 Main board view B (671-3751-00) 9–10. . . . . . . . . . . . . . . .

Figure 9–9: A2 Main board section C (671-3751-00) 9–11. . . . . . . . . . . . . .

Figure 9–10: A2 Main board component locator (671-3751-00) 9–12. . . . .

Figure 9–11: A1 Front Panel board 9–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: Exploded view 10–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 Service Manual

v

Page 10

Table of Contents

List of Tables

Table 1–1: Input signal requirements–VIDEO INPUT 1–3. . . . . . . . . . .

Table 1–2: Input signal requirements–EXT REF 1–3. . . . . . . . . . . . . . . .

Table 1–3: Measurement accuracy 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Output 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: AC power source 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Environmental characteristics 1–5. . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Certifications and compliances 1–6. . . . . . . . . . . . . . . . . . . . . .

Table 1–8: Physical characteristics 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–9: Remote control port 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Configuration parameters 2–7. . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Print parameters 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Computer interface parameters 2–13. . . . . . . . . . . . . . . . . . . . .

Table 2–4: Date parameters 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: Time parameters 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Power-on diagnostics 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–1: Test Equipment 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: Adjustments after repair 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Required test equipment 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–3: Adjustment steps 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Relative susceptibility to static discharge damage 6–2. . . . . .

Table 6–2: External inspection check list 6–4. . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: Internal inspection check list 6–4. . . . . . . . . . . . . . . . . . . . . . .

Table 6–4: Tools required for module replacement 6–8. . . . . . . . . . . . . . .

Table 6–5: Power-on diagnostics 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–6: Control mode communications parameters 6–31. . . . . . . . . . .

Table 7–1: Power cord identification 7–2. . . . . . . . . . . . . . . . . . . . . . . . . .

vi

VM100 & VM101 Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

If this equipment is used in any manner not specified, including failure to follow

any rating or direction for use, the protection provided by the equipment may be

impaired.

Injury Precautions

Product Damage

Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply potential

to any terminal, including the common terminal, that varies from ground by

more than the maximum rating for that terminal.

Ground the Product

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

. This product is grounded through the grounding conductor

Provide Proper Ventilation. To prevent product overheating, provide proper

ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Symbols and Terms

VM100 & VM101 Service Manual

T erms in this Manual. These terms may appear in this manual:

vii

Page 12

General Safety Summary

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to Manual

Double

Insulated

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

viii

VM100 & VM101 Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

VM100 & VM101 Service Manual

ix

Page 14

Service Safety Summary

x

VM100 & VM101 Service Manual

Page 15

Preface

Use this manual to service the video measurement set to the module or component level. Contact your local Tektronix service center or sales engineer for more

information on repair and adjustment services.

Related Manuals

The VM100 & VM101 Video Measurement Sets User Manual (Tektronix part

number 070-9522-XX) describes how to use the video measurement set.

Service Manual Conventions

In this manual, the term “module” refers to any field-replaceable component,

assembly, or part of the video measurement set.

Strategy for Servicing

To prevent personal injury or instrument damage:

H This product should be serviced only by a qualified service person

H Read the General and Service Safety Summaries at the front of this manual,

as well as Operating Information beginning on page 2–1

H Follow all warnings, cautions, and notes in this manual

Adjustment Interval

Generally, you should perform the Adjustment Procedures once a year. In

addition, perform the procedures after module replacement.

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well equipped to service the video

measurement set. Tektronix technicians train on Tektronix products and have

access to the latest information on product improvements and new options.

VM100 & VM101 Service Manual

xi

Page 16

Preface

Warranty Repair Service

At-Depot Repair or

Calibration Service

Module Exchange

Contacting Tektronix

Tektronix warrants this product for one year from date of purchase. The warranty

appears behind the title page in this manual. Tektronix technicians provide

warranty service at most Tektronix service locations worldwide. The Tektronix

product catalog lists all service locations worldwide.

The following services can be purchased to meet to your repair/calibration needs.

H A single repair and/or adjustment

H Calibrations using equipment and procedures that meet the traceability

standards specific to the local area

H Annual maintenance agreements that provide for either calibration and

repair, or calibration only.

Reduce down time for repair by exchanging modules for remanufactured ones.

Tektronix ships an updated and tested exchange module from the Beaverton,

Oregon service center, typically within 24 hours. Each module comes with a

90-day service warranty.

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

xii

VM100 & VM101 Service Manual

Page 17

Specifications

Product Description

This chapter provides a complete description of the specifications. Product

Description is a general description of the instrument. The Specification Tables,

which begin on page 1–2, contain the complete specifications.

The Tektronix VM100 and VM101 Video Measurement Sets are automatic video

measurement instruments. The VM100 measures NTSC signals and the VM101

measures PAL signals.

The video measurement sets use existing or inserted test signals and take

measurements consistent with regulatory specifications.

The video measurement sets display measurement results on a LCD screen. You

can also display measurement results on a serial printer or remote PC using the

RS-232 port. The video measurement sets perform the following measurements

(on-screen labels are shown in parentheses):

Differential Phase (DIFF PHASE)

Differential Gain (DIFF GAIN)

Chrominance-to-Luminance Delay (YC DELAY)

Chrominance-to-Luminance Gain (YC GAIN)

Signal-to-Noise Ratio (SNR WGT/FLAT)

Frequency Response (FREQ FCC or AVG)

Frequency Response Detail (FREQ FLAG, FREQ #1 through FREQ #6) or

(FRQmax and FRQmin)

Group Delay (GRPDLYmax and GRPDLYmin)

Sync Amplitude (SYNC AMPL)

Burst Amplitude (BURST AMPL)

Bar Amplitude (BAR AMPL)

2T K-Factor (2T K-FACTOR)

Luminance Nonlinearity (LUM NON-LIN)

Hum (HUM P-P, 50/60 Hz, and 100/120 Hz)

VM100 & VM101 Service Manual

1–1

Page 18

Specifications

Specification Tables

This section provides a complete description of the video measurement set

specifications. Refer to the Performance Conditions for a description of the

required temperature range and other pertinent operating conditions.

Terms Used in

Specifications

Performance Conditions

Characteristic. A characteristic refers to a property of the product.

Performance Requirement [REQ]. Performance Requirements define

characteristics that are essential to the intended application of the product,

usually in limit form.

Reference Information [RI]. Reference Information explains the performance

requirements or stipulates conditions under which the performance requirements

are effective. Reference information is not considered to be a statement of

guaranteed performance.

Specification. A specification is a document or a section of a document that lists

and describes characteristics and performance requirements of a product.

Typical. Typical refers to instrument performance that can be expected but is not

guaranteed.

The performance requirements listed in the Electrical Specifications apply over

an ambient temperature range of 0° C to +50° C. The rated accuracies are valid

over the entire 0° C to 50° C range and become “typical” for temperatures from

–10° C to 0° C. Test equipment used to verify performance requirements must be

calibrated and working within the specified limits.

All specifications (with the exception of Signal-to-Noise Ratio Measurement

Accuracy) apply for Signal-To-Noise Ratio ≥ 52 dB (weighted). Averaging

(AVG) is enabled for all specifications.

1–2

VM100 & VM101 Service Manual

Page 19

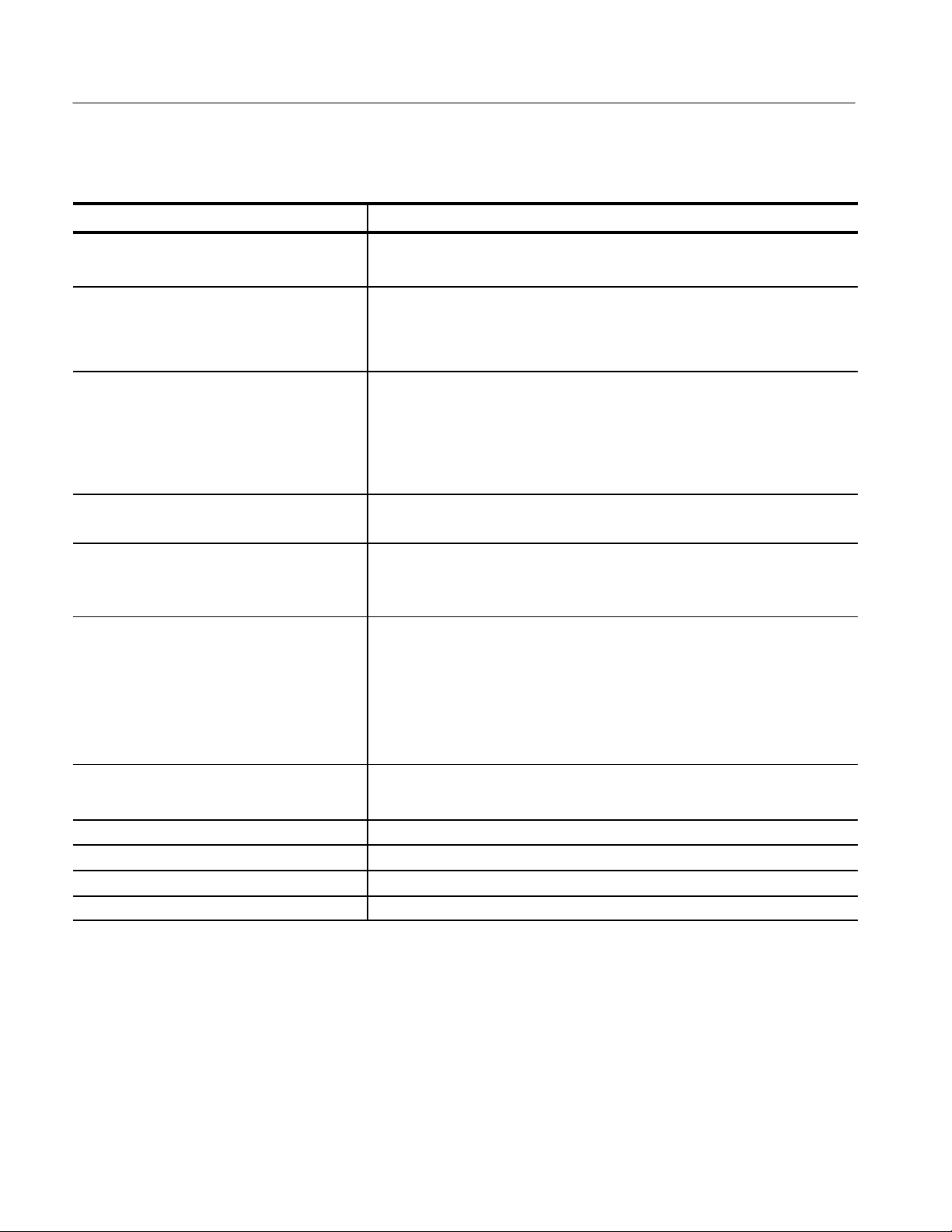

Electrical Specifications

T able 1–1: Input signal requirements–VIDEO INPUT

Category Description

Maximum Operating Voltage REQ: –1.8 V to +2.2 V

Absolute Maximum Input Voltage REQ: –8.5 V to +8.5 V

Minimum Operating Voltage REQ: 1 Vp-p video signal

RI: Typically operates with a 1 Vp-p input, +1 dB or –6 dB

DC Input Impedance REQ: ≥20 KW

RI: DC coupling

Return Loss REQ: >40 dB to 6 MHz

RI: DC coupling

Specifications

T able 1–2: Input signal requirements–EXT REF

Category Description

Absolute Maximum Input Voltage REQ: –8.5 V to +8.5 V

Minimum Operating Voltage REQ: 1 Vp-p video signal

RI: Typically operates with a 1 Vp-p input, +1 dB or –6 dB

DC Input Impedance REQ: ≥20 KW

Return Loss REQ: >40 dB to 6 MHz

Video INPUT / EXT REF

Loop-through Isolation RI: >70 dB (typical)

Crosstalk REQ: >70 dB to 6 MHz

T able 1–3: Measurement accuracy

Category

Differential Phase REQ: <1.0 °

Differential Gain REQ: <2.0 %

1

Description

RI: Typically <0.5° from 20° C to 30° C with test signal generator source

RI: Typically <1 % from 20° C to 30° C for nominal 300 mV chrominance

amplitude

1

All tests are performed with AVG enabled. Processing time for each measurement is a function of the signal-to-noise

ratio.

VM100 & VM101 Service Manual

1–3

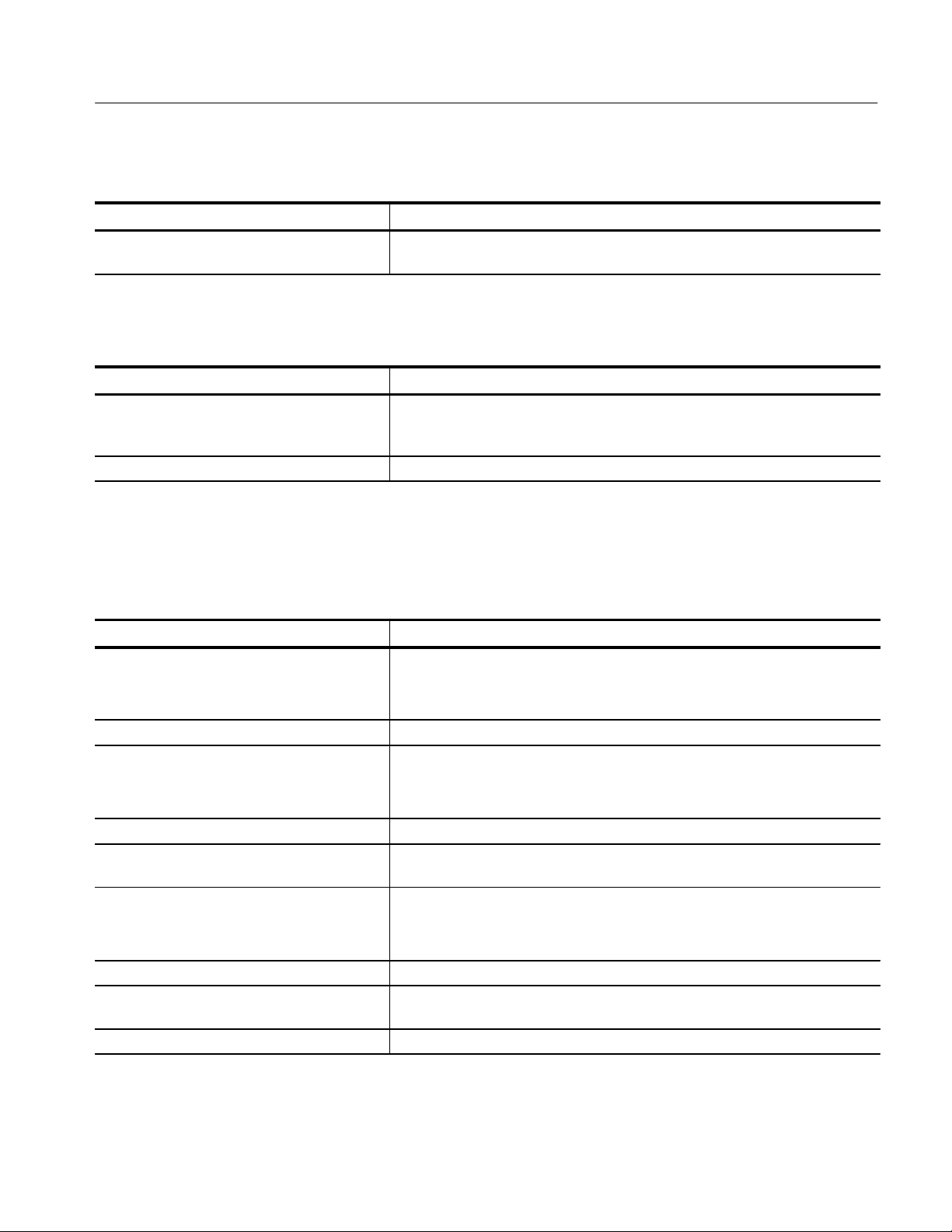

Page 20

Specifications

T able 1–3: Measurement accuracy (cont.)

Category

1

Description

Chrominance-to-Luminance Gain REQ: <2 %

RI: Typically <1 % from 20° C to 30° C with test signal generator source

Chrominance-to-Luminance Delay REQ: <20 ns

REQ: <10 ns from 20° C to 30° C with test signal generator source.

RI: Typically <5 ns from 20° C to 30° C with test signal generator source

Frequency Response REQ: <0.2 dB

RI: Typically <0.1 dB (1 %) from 20° C to 30° C with test signal generator

source

RI: VM100: 50 kHz to 4.2 MHz

VM101: 50 kHz to 5.8 MHz

2T K-Factor REQ: 2 %

RI: Typically <0.5 % from 20° C to 30° C with test signal generator source

2

Hum

REQ: ±1.0% for hum ≤4.0%

±2.0% for hum >4.0% and <15.0%

RI: Typically ±0.5% for hum ≤4.0%

Signal-to-Noise Ratio

(Weighted or Flat)

REQ: ±1 dB, 28 dB to <45 dB

±2 dB, 45 dB to <60 dB

±3 dB, 60 dB to 67 dB (WGT)

RI: VM100: Noise is weighted with EIA RS-250-B 5 MHz weighted noise

filter (T ektronix part number 015-0215-00 equivalent)

VM101: Noise is weighted with CCIR 567 weighted noise filter

Group Delay REQ: <20 ns

RI: 50 kHz to 4.8 MHz, within the bandwidth of the signal under test

Sync Amplitude

2

REQ: <1.0%

Burst Amplitude REQ: <1.0%

Bar Amplitude REQ: <1.0%

Luminance Nonlinearity REQ: <1.0%

1

All tests are performed with AVG enabled. Processing time for each measurement is a function of the signal-to-noise ratio.

2

The hum and sync amplitude measurements are inaccurate in the presence of Sound In Sync (SIS) signals.

1–4

VM100 & VM101 Service Manual

Page 21

Specifications

T able 1–4: Output

Category Description

Zero Carrier Reference Pulse Output RI: Can drive demodulator ZCRP trigger of TTL type (Tektronix TDM5,

DS1200, 1450) or 1.5 V

, 75 W type (Tektronix 1340, 1350)

p-p

T able 1–5: AC power source

Category Description

Mains Voltage Range REQ: 90-250 VAC

50/60 Hz

0.7 A

Power Consumption REQ: 30 W maximum

Environmental Characteristics

T able 1–6: Environmental characteristics

Category

Altitude

(see page 1–6 for safety-related information)

Humidity REQ: To 95% relative humidity at or below +50° C

Operating Temperature REQ: 0° C to + 50° C (32° F to 122° F)

Package Drop REQ: Meets Tektronix 062-2858-00, Rev. B

Random Vibration

(Operating and Non-Operating)

Shock (Operating) REQ: Meets Tektronix Class III (062-2858-00, Rev. B)

Storage Temperature REQ: –40° C to + 75° C (–40° F to +167° F)

Loose Load Vibration

(Repetitive Shock)

Vehicle Vibration REQ: Meets Tektronix 062-2858-00, Rev. B

Description

REQ: Operating: to 15,000 f (4572 m)

Non-operating: to 50,000 f (15,240 m)

RI: Maximum operating temperature decreases 1° C per 1000 f (305 m)

RI: Electrical specifications are guaranteed when the instrument is

operated in this temperature range

REQ: Meets Tektronix Class III (062-2858-00, Rev. B)

RI: Three drops on each face of 50 g, 11 ms duration, half-sine pulse

shape for a total of 18 drops

REQ: Meets Tektronix 062-2858-00, Rev. B (page 51, section 17.7.4)

VM100 & VM101 Service Manual

1–5

Page 22

Specifications

ertifications

Safety Standards and Certification

T able 1–7: Certifications and compliances

Category Description

Altitude

(Maximum Operating)

See page 1–5 for additional information

C

US Nationally Recognized Testing

Laboratory Listing

Canadian

Certification

European Union Compliance Low Voltage Directive 73/23/EEC, Amended by 93/68/EEC

Additional

Compliance

EC Declaration of

Conformity

Operating: to 6,500 f (2000 m)

ANSI/ISA S82

Safety Standard for Electrical and Electronic Test, Measuring, Controlling, and

Related Equipment

CAN/CSA C22.2 No.1010.1

Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use

UL31 11-1

Standard for Electrical Measuring and Test Equipment

IEC 1010-1

Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility and Low

Voltage Directive 73/23/ECC for Product Safety. Compliance was demonstrated to

the following specifications as listed in the Official Journal of the European

Communities:

EMC Directive 89/336/EEC:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted

Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast T ransient/Burst

Immunity

3

Low Voltage Directive 73/23/EEC:

EN 61010-1 Safety requirements for electrical

equipment for measurement, control,

and laboratory use

3

Using high quality shielded cables.

Equipment Type Test and Measuring

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B,

Class A Limits

1–6

VM100 & VM101 Service Manual

Page 23

T able 1–7: Certifications and compliances (cont.)

erial Port

Category Description

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1); rated for indoor use only

Safety Class Class I (as defined in IEC 1010-1, Annex H)

T emperature (Operating) +5° C to +50° C (+41° F to 122° F)

Physical Characteristics

T able 1–8: Physical characteristics

Category Description

Dimensions Height: 1.71 in (4.34 cm) Nominal

Width: 8.1 in (20.6 cm) Nominal

Depth: 17.2 in (43.7 cm) Nominal

Stand-Alone Instrument Weight 4.00 lbs (1.81 kg) Nominal

Packaged Weight (for domestic shipment) 7.12 lbs (3.23 kg) Nominal

Specifications

Remote Control Port

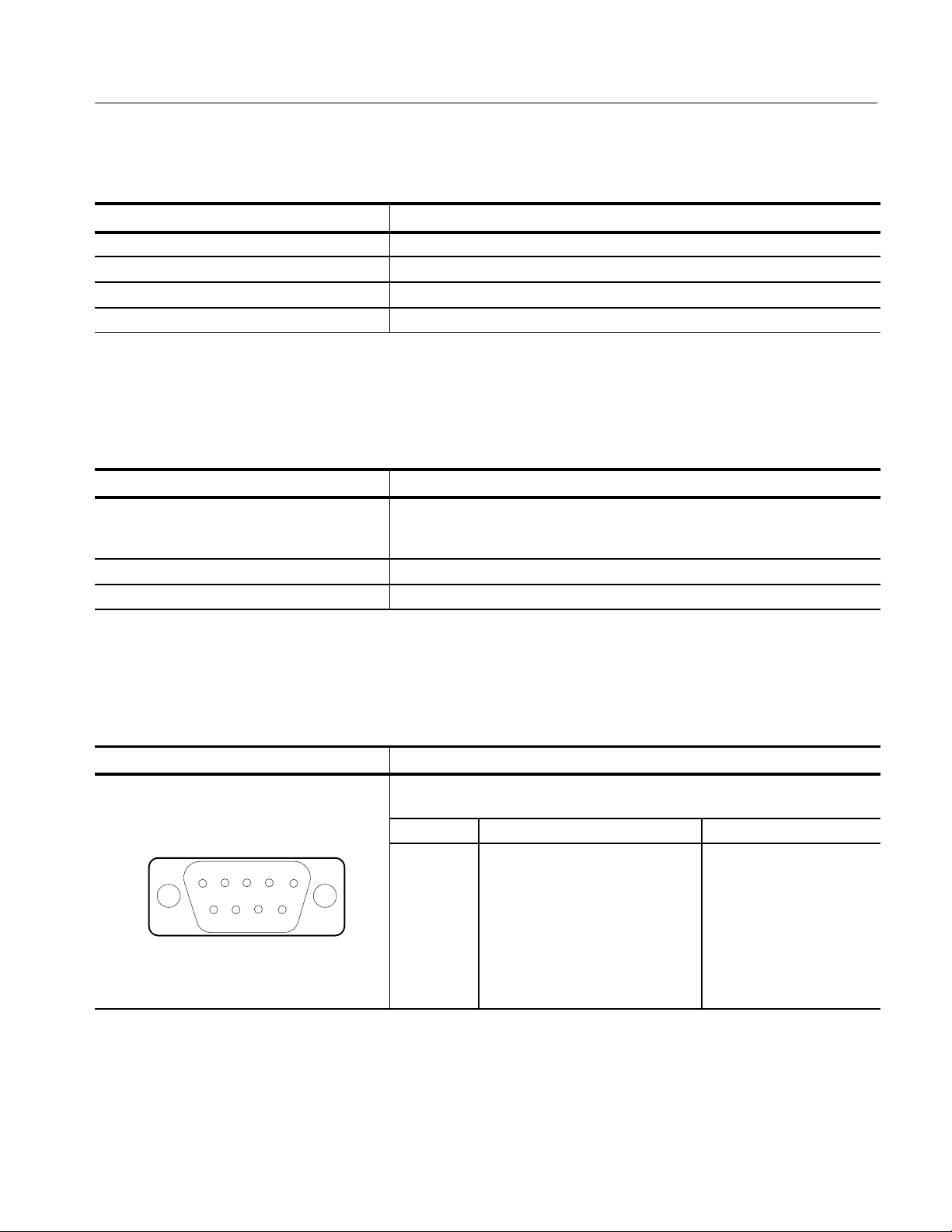

T able 1–9: Remote control port

Category Description

RS232 S

12345

6789

Connector: Nine-pin DCE female

Baud Rate: 1200, 2400, 9600, or 19.2K

Pin Signal Name RS232-C Name

1

2

3

4

5

6

7

8

9

Not Used

TX (Transmit Data; Output)

RX (Receive Data; Input)

Not Used

GND (Signal Ground)

Not Used

RTS (Request to Send; Output)

CTS (Clear to Send; Input)

Not Used

BA

BB

AB

CA

CB

VM100 & VM101 Service Manual

1–7

Page 24

Specifications

1–8

VM100 & VM101 Service Manual

Page 25

Operating Information

This section describes how to operate the video measurement set. The operating

information is limited to the functions required to perform the procedures found

in this manual. More detailed operating instructions can be found in the VM100

& VM101 Video Measurement Sets User Manual (Tektronix part number

070-9522-XX).

The Operating Information is divided into the following sections:

H Installation describes the power source requirements and explains where to

find a list of the power cord options

H Operating Information on page 2–1 describes the front panel buttons and

LCD display, the menus, the rear panel connectors, the power on procedure,

and configuration instructions

Installation

Power Source

Requirements

Operating Information

The video measurement set operates over the range of 90 V

either 50 Hz or 60 Hz. The power source should never apply more than 250 V

between the supply conductors or between either supply conductor and ground.

WARNING. To avoid personal injury due to electrical shock, never operate the

video measurement set without the protective ground connection by way of the

grounding conductor in the power cord.

This section provides the information you will need to operate the video

measurement set when performing the procedures in this manual. It contains the

following information:

H Descriptions of the front panel buttons and the LCD display

H Descriptions of the menus

H Descriptions of the rear panel connectors

H Power on procedure

to 250 V

rms

rms

at

rms

H Configuration instructions for each operating mode

VM100 & VM101 Service Manual

2–1

Page 26

Operating Information

Front Panel Buttons and

LCD Display

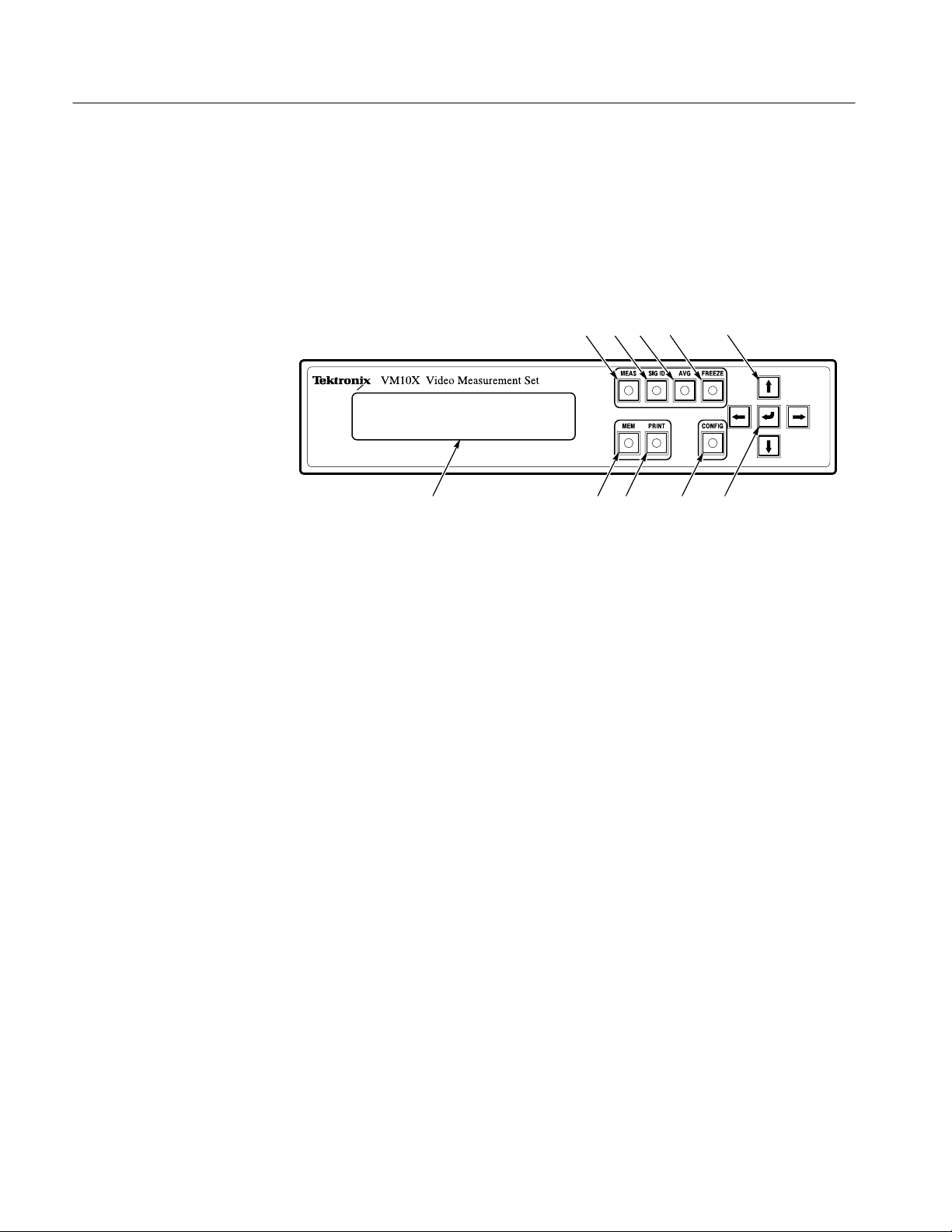

The front panel contains twelve buttons and an LCD display as shown in

Figure 2–1. There are seven function buttons, four arrow buttons, and the enter

button. A green LED indicator, located at the center of each function button,

lights to show when the associated function is turned on. The arrow buttons are

designated by directional arrows. A carriage return symbol (↵) identifies the

enter button.

1 2 4

10

3

9 8 7 6

5

Figure 2–1: Front panel

Five of the function buttons (MEAS, SIG ID, MEM, PRINT, and CONFIG) are

exclusive to each other. This means that only one of the functions can be active

at a time. When you press another of these buttons, the previous function

automatically turns off.

The following descriptions refer to Figure 2–1.

MEAS. Press the measure button to display the results of measurements the

1

video measurement set makes on the LCD display. Use the CONFIG menu to

turn measurements ON or OFF. Measurements must be ON to appear in the

MEAS list.

2

SIG ID. Press the signal identification button to display the name and location

of signals in the vertical interval and the source ID (when contained in the

signal).

3

AVG. Press this toggle switch to turn signal averaging on and off.

FREEZE. Press this toggle switch to turn the freeze feature on and off. When

4

FREEZE is turned on, all acquisition and measurement activity stops so that

you can view intermediate measurement and signal ID results.

5

Arrow Buttons. Press the up (↑) or down (↓) arrow buttons to scroll through

various LCD displays. Press the left (←) and right (→) arrow buttons to

change instrument parameters and to view measurement results on other

video lines.

2–2

VM100 & VM101 Service Manual

Page 27

Operating Information

6

Enter Button. Press the enter (↵) button to enter and exit the CONFIG

submenus and to control print and memory functions.

CONFIG. Press the configure button to access instrument configuration menus

7

and to view the instrument software version.

PRINT. Press the print button to print the current or saved measurement data or

8

to output results to a computer, using the RS-232 serial port. You must

configure the RS-232 port for printing and select the print parameters before

using the print function.

9

MEM. Press the memory button to save the current measurement and SIG ID

results in instrument memory and to access memory management selections

including ERASE, REPLACE, VIEW, and RENAME.

10

LCD Display . The LCD display shows measurement readouts and menu

selections. Figure 2–2 shows examples of the text and symbols you will see

on the LCD display. The symbols help you navigate quickly through the

menu system using the arrow buttons and the enter button. Dots (…)

following the menu name indicate that a menu has a submenu.

Shows submenu

Figure 2–2: LCD display characteristics

Arrow buttons

Enter button

VM100 & VM101 Service Manual

2–3

Page 28

Operating Information

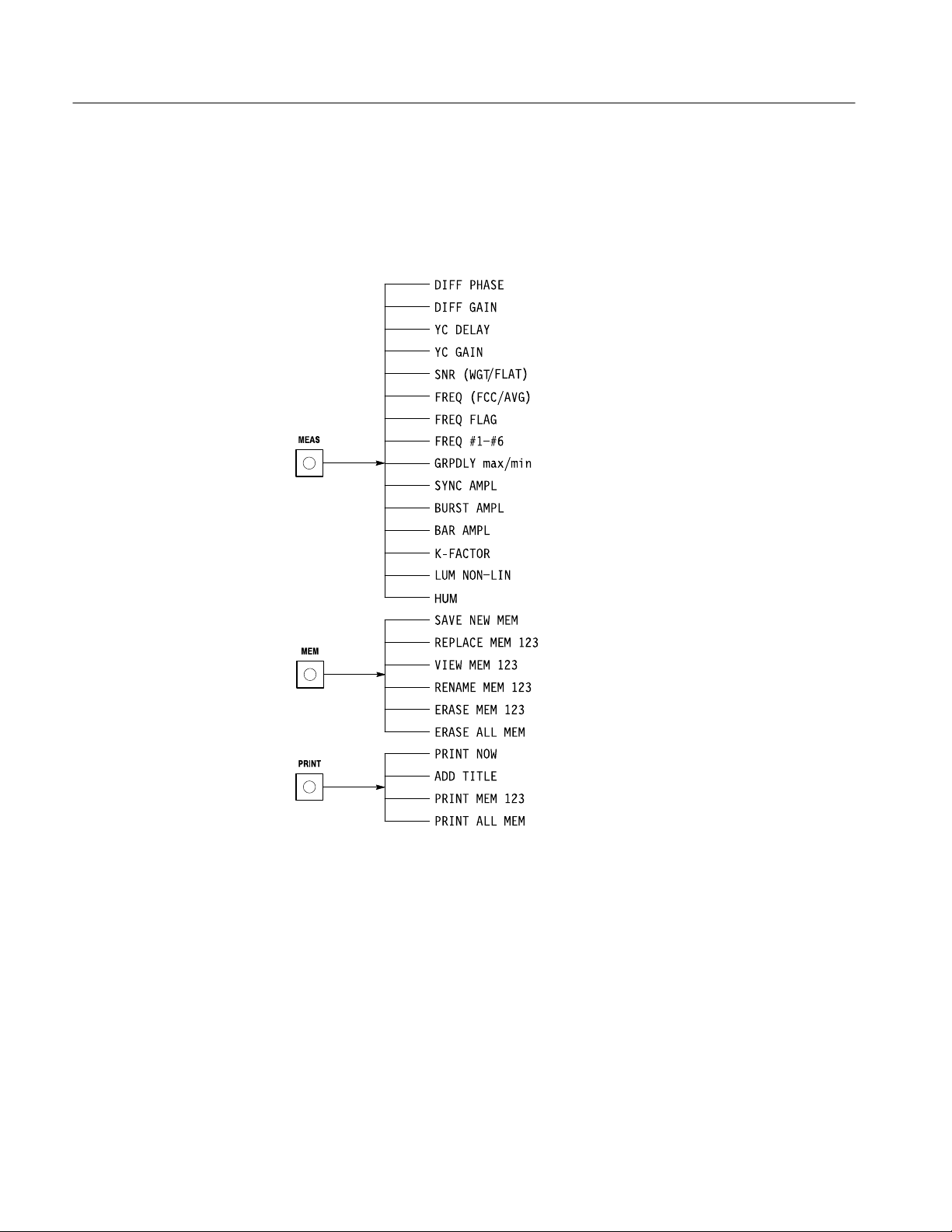

Menus

The MEAS, SIG ID, MEM, PRINT, and CONFIG buttons allow access to

additional selections or measurement results. Figures 2–3 and 2–4 show the

menu structure of the video measurement set. The SIG ID menu is not shown

because its contents depend upon the input signal characteristics.

2–4

Figure 2–3: The MEAS, MEM, and PRINT menus

VM100 & VM101 Service Manual

Page 29

Operating Information

Figure 2–4: The CONFIG menu

VM100 & VM101 Service Manual

2–5

Page 30

Operating Information

Rear Panel Connectors

There are seven connectors mounted on the video measurement set rear panel.

Refer to Figure 2–5 for descriptions.

1

2

3 4

5

Figure 2–5: Rear panel connectors

AC Power Connector. The AC power connector is a standard AC plug receptacle

1

for 120 or 240 V

power mains. The plug is compatible with each available

ac

power cord option.

2

ZERO CARRIER PULSE OUTPUT. The ZERO CARRIER PULSE OUTPUT

produces a reference pulse that triggers a demodulator. Signal amplitude is

1.5 V

when driving a 75 W load or TTL compatible when driving a high

p-p

impedance. This pulse is compatible with the trigger inputs on the following

Tektronix Demodulators: DS1200, TDM5, 1450, 1340, and 1350.

EXT REF. This high-impedance, loop-through input (two BNC connectors)

3

accepts external reference signals of composite video or black burst (1 V

Use this input if the video input has no sync information. The input is AC

coupled and compensated for 75 W. It is not internally terminated.

4

INPUT. This high-impedance, loop-through input (two BNC connectors)

accepts video input signals for the video measurement set. The input is AC

coupled and compensated for 75 W. It is not internally terminated.

5

RS232 Port. This nine-pin subminiature D-type female connector provides an

RS232 serial interface for printer and computer communication. The port also

provides the interface for waveform the monitor control function.

p-p

).

2–6

VM100 & VM101 Service Manual

Page 31

Operating Information

Power On Procedure

Configuration

To power on the video measurement set, connect it to the AC power source.

There is no power switch.

The power-on sequence completes in approximately 10 seconds. After power on

completes, check for the following conditions:

The LCD display shows the message No video present, or no lock possible

(if no signals are connected to the rear panel INPUT connector).

The MEAS button indicator lights.

NOTE. The AVG button indicator lights at power on if the AVG feature was in

use when AC power was last disconnected.

This section guides you through the configuration of each operating parameter.

(No configuration is necessary for basic operation.) Refer to Table 2–1 for an

overview of the parameters you can configure, the location of the configuration

instructions, and the factory default values.

If you need more detailed information about the instrument features, refer to the

VM100 & VM101 Video Measurement Sets User Manual (Tektronix part number

070-9522-XX).

NOTE. You cannot configure the hum frequency on the VM101.

The default value is 50 Hz.

T able 2–1: Configuration parameters

Parameter Page Number Factory Default Value

MEASURE 2–8 SNR is ON

All other measurements are OFF

ZCR PULSE 2–9 VM100: Line 10

VM101: Line 7

SIG ID RANGE 2–10 VITS

FULL FLD START 2–10 23

REF 2–11 Input

HUM (VM100 only) 2–11 60HZ

SNR FILTER 2–1 1 WEIGHTD

RS232 2–1 1 for printing

2–12 for computer

2–13 for waveform monitor operation

Computer

VM100 & VM101 Service Manual

2–7

Page 32

Operating Information

T able 2–1: Configuration parameters (cont.)

Parameter Factory Default V aluePage Number

PRINTER RS232

BAUD RATE

STOP BITS

PARITY

FLOW CTL

COMPUTER

RS232

BAUD RATE

STOP BITS

PARITY

FLOW CTL

1995 NOV 11 (Date)

YEAR

MONTH

DA Y

10:13:18AM (Time)

HOUR

MINUTE

VIEW ANGLE 2–15 80

SW VER 2–15 Current software version

CALIBRA TE 2–15 N/A

2–1 1

9600

1

NONE

NONE

2–12

9600

1

NONE

NONE

2–14 Today’s date

2–14 Current time

Use the following procedures to customize the operation of the video measurement set. Once you have configured the parameters, the video measurement set

powers on as you configured it. Refer to page 2–1 for detailed descriptions of

the front panel buttons or the LCD display.

NOTE. The video measurement set

uses the last setting that was saved for each

parameter if power is interrupted during configuration.

To exit the CONFIGURE menu at any time during these procedures, press the

MEAS, SIG ID, MEM, or PRINT buttons.

Configure the Measurements. The video measurement set

performs a group of

measurements when you press the MEAS button. The display update rate

depends upon the number of measurements made and the presence of valid input

signals. You can customize this feature for your application by selecting only the

measurements you need.

2–8

VM100 & VM101 Service Manual

Page 33

Operating Information

Perform the following steps to choose measurements that will be performed

when you press the MEAS button:

1. 2. 3. 4. 5.

Press the CONFIG

button.

Select

CONFIGURE

MEASURE

(default). Press the

↵ enter button.

Select the desired

measurement. See

list below.

Select ON or OFF.

Repeat steps 3 and

4 to configure

additional

measurements.

The following measurements are available:

Differential Phase (DIFF PHASE)

Differential Gain (DIFF GAIN)

Chrominance-Luminance Delay (YC DELAY)

Chrominance-Luminance Gain (YC GAIN)

Signal-to-Noise Ratio (SNR WGT/FLAT)

Frequency Response (FREQ FCC or AVG and FREQ DETAIL)

Group Delay (GRPDLYmax and GRPDLYmin)

Sync Amplitude (SYNC AMPL)

Burst Amplitude (BURST AMPL)

Press the MEAS

button to exit.

Configure the Zero Carrier Reference Pulse Trigger Output. The Zero Carrier

Reference Pulse Trigger Output synchronizes a demodulator when you take hum

measurements. You can configure the output to OFF or to any line from 10 – 20

(VM100) or 7 – 20 (VM101).

VM100 & VM101 Service Manual

Bar Amplitude (BAR AMPL)

2T K-Factor (2T K-FACTOR)

Luminance Nonlinearity (LUM NON-LIN)

Hum (HUM)

2–9

Page 34

Operating Information

Perform the following steps to configure the Zero Carrier Reference Pulse

Trigger Output:

1. 2. 3. 4.

Press the CONFIG

button.

Select CONFIGURE

ZCR PULSE.

Select OFF or a line

number.

Press the MEAS button

to exit.

Configure the Signal Identification Range. The SIG ID menu displays all of the

test signals that are present in the video signal applied to the INPUT connector.

You can configure the SIG ID range to match your system requirements (VITS

or FULL).

Perform the following steps to configure the SIG ID range:

1. 2. 3. 4.

Press the CONFIG

button.

Select SIG ID RANGE. Select VITS or FULL. Press the MEAS button

to exit.

NOTE. After you configure the signal identification range, the video measurement

set reacquires the signal.

2–10

Configure the Full Field Start Line. You can configure the video line used for full

field start (valid only when the SIG ID range is FULL). With this feature you can

view a specific video line within the active area.

Perform the following steps to configure the Full Field Start Line:

1. 2. 3.

Press the CONFIG

button.

Select FULL FLD

START.

Select 23 - 43 (VM100)

or 23 – 39 (VM101).

4.

Press the MEAS button

to exit.

NOTE. After you configure the full field start line, the video measurement set

reacquires the signal if FULL is selected.

VM100 & VM101 Service Manual

Page 35

Operating Information

Configure the Reference. You can configure the video measurement set to use

either an internally generated sync reference or a signal connected to the

EXT REF rear panel input. For example, use an external reference if the video

input has no sync information.

Perform the following steps to configure the Reference:

1. 2. 3.

Press the CONFIG

button.

Select CONFIGURE

REF.

Select INPUT or

EXTERNAL.

4.

Press the MEAS button

to exit.

Configure the Hum Measurement (VM100 Only). You can configure the hum

measurement to match your power line frequency (VM100 only). The video

measurement set configuration must match your power line frequency to produce

accurate hum measurement results.

Perform the following steps to configure the hum measurement:

1. 2. 3. 4.

Press the CONFIG

button.

Select HUM. Select 50HZ or 60HZ. Press the MEAS button

to exit.

Configure the Signal-to-Noise Ratio Filter. The video measurement set provides

weighted and flat filter selections for taking signal-to-noise measurements. You

can configure the filter type needed for your application.

Perform the following steps to configure the SNR filter:

Configure for Printing. The video measurement set can drive a printer, computer,

or waveform monitor using the RS232 serial port. To print the measurement

results, you must configure the RS232 serial port for printer operation and select

the parameters that match your printer.

VM100 & VM101 Service Manual

1. 2. 3. 4.

Press the CONFIG

button.

Select SNR FILTER. Select WEIGHTD or

FLAT.

Press the MEAS button

to exit.

2–11

Page 36

Operating Information

Perform the following steps to configure the RS232 serial port to drive a printer:

1. 2. 3. 4.

Press the CONFIG

button.

Select CONFIGURE

RS232=.

Select PRINTER. Press the MEAS button

to exit.

NOTE. If the serial port is not configured for printing, the print function is

disabled.

Refer to your printer manual to determine the settings for baud rate, stop bits,

parity, and flow control.

Perform the following steps to configure the print parameters:

1. 2. 3. 4. 5.

Press the CONFIG

button.

Select

CONFIGURE

PRINTER RS232.

Press the ↵ enter

button.

Choose the

appropriate setting

for the displayed

parameter. See

Table 2–2.

Select the next

parameter. See

Table 2–2. Repeat

steps 3 and 4 for all

parameters.

Press the MEAS

button to exit.

T able 2–2: Print parameters

2–12

Parameter Settings

BAUD RA TE 1200, 2400, 9600, 19.2K

STOP BITS 1 or 2

PARITY NONE, EVEN, ODD

FLOW CTL NONE, XON/XOFF, HARDWARE

Configure for Computer Communications. The video measurement set can drive a

computer, printer, or waveform monitor using the RS232 serial port. To send the

measurement results to a computer or to set up for remote operation, you must

configure the RS232 serial port for computer operation and select the parameters

that match your computer interface.

VM100 & VM101 Service Manual

Page 37

Operating Information

Perform the following steps to configure the RS232 port to drive a computer:

1. 2. 3.

Press the CONFIG

button.

Select CONFIGURE

RS232=.

Select COMPUTER. Press the MEAS button

4.

to exit.

NOTE. Refer to your computer manual to determine the settings for baud rate,

stop bits, parity, and flow control.

Perform the following steps to configure the computer interface parameters:

1. 2. 3. 4.

Press the CONFIG

button.

Select

CONFIGURE

COMPUTER

RS232. Press the ↵

enter button.

Choose the

appropriate setting

for the displayed

parameter. See

Table 2–3.

Select the next

parameter. See

Table 2–3. Repeat

steps 3 and 4 for all

parameters.

5.

Press the MEAS

button to exit.

NOTE. If COMPUTER was not selected at power on, you will experience a short

delay when scrolling through the CONFIGURE RS232 menu choices.

T able 2–3: Computer interface parameters

Configure for Waveform Monitor Control Function. The video measurement set can

drive a computer, printer, or 1740A-series waveform monitor using the RS232

serial port. The waveform monitor control function allows you to view the

waveform on a 1740A-series waveform monitor while the video measurement

set measures the signal parameters.

VM100 & VM101 Service Manual

Parameter Settings

BAUD RA TE 1200, 2400, 9600, 19.2K

STOP BITS 1 or 2

PARITY NONE, EVEN, ODD

FLOW CTL NONE, XON/XOFF, HARDWARE

2–13

Page 38

Operating Information

Perform the following steps to configure the RS232 port to drive a waveform

monitor:

1. 2. 3. 4.

Press the CONFIG

button.

Select CONFIGURE

RS232=.

Select CONTROL. Press the MEAS button

to exit.

Configure the Date. The video measurement set keeps track of the date. Perform

the following steps to change the date setting:

1. 2. 3. 4. 5.

Press the CONFIG

button.

Select

CONFIGURE

<DATE>. Press the

↵ enter button.

Choose the

appropriate setting

for the displayed

parameter. See

Table 2–4.

Select the next

parameter. See

Table 2–4. Repeat

steps 3 and 4 for all

parameters.

Press the MEAS

button to exit.

T able 2–4: Date parameters

Parameter Settings

YEAR 1990 through 2089

MONTH JAN through DEC

DA Y 1 through 31

2–14

Configure the Time. The video measurement set keeps track of the time. Perform

the following steps to change the time setting:

1. 2. 3. 4. 5.

Press the CONFIG

button.

Select

CONFIGURE

<TIME>. Press the

↵ enter button.

Choose the

appropriate setting

for the displayed

parameter. See

Table 2–5.

Select the next

parameter. See

Table 2–5. Repeat

steps 3 and 4 for all

parameters.

Press the MEAS

button to exit.

VM100 & VM101 Service Manual

Page 39

Operating Information

T able 2–5: Time parameters

Parameter Settings

HOUR 01AM to 12AM and 01PM to 12PM

MINUTE 00 to 59

Adjust the LCD View Angle. You can adjust the viewing angle of the LCD display

for the best readout with your lighting conditions. To change the viewing angle,

place the video measurement set in the lighting conditions where you will use it

and then perform the following steps:

1. 2. 3.

Press the CONFIG

button.

Select CONFIGURE

VIEW ANGLE.

Select 0 through 180 for

best LCD display.

4.

Press the MEAS button

to exit.

Display the Software Version Number. You can view the software version number

for the operating system installed in this video measurement set. Refer to this

number if you need to report a software problem or order a software upgrade.

The software version displayed here should correspond to the version number(s)

printed on the title page of this manual.

Perform the following steps to view the software version number:

1. 2. 3.

Press the CONFIG button. Select CONFIGURE SW VER. Press the MEAS button to exit.

Calibration. If you inadvertently enter the CALIBRATE menu, use the following

steps to exit the menu without changing internal video measurement set settings:

NOTE. Refer to the Adjustment Procedures section for test equipment require-

ments and detailed adjustment instructions.

VM100 & VM101 Service Manual

1. 2.

Select PRESS ↵ TO

ABORT CAL.

Press the ↵ enter button

to exit the menu.

2–15

Page 40

Operating Information

2–16

VM100 & VM101 Service Manual

Page 41

Theory of Operation

This section describes the electrical operation of the video measurement set

using the major circuit blocks or modules.

This section is divided into the following parts:

H Logic Conventions describes how logic functions are discussed and

represented in this manual.

H Block Level Description describes circuit operation to the functional block

level.

H Detailed Circuit Description on page 3–3 describes circuit operation to the

circuit and component level.

Logic Conventions

This manual refers to digital circuits with standard logic symbols and terms. All

logic functions use the positive-logic convention: the more positive of the two

logic levels is the high state, and the more negative level is the low state. The

specific voltages that constitute a high or low state may vary among the

electronic devices.

Block Level Description

DC Restore

Sync Stripper

A back slash prefixed to the signal name (/RESET) indicates active-low signals.

Signal names can be either active high, active low, or have both active-high and

active-low states.

Refer to Figure 9–2, the detailed block diagram found on page 9–4, when

reading the block-level description. The description explains the basic operation

of each circuit block. If you need more detailed information, refer to the Detailed

Circuit Description on page 3–3 and the component-level circuit diagrams

found in the Diagrams section.

The DC Restore circuit selects AC or DC input coupling and clamps the

backporch level of the video signal when AC coupling is active. To terminate the

INPUT the user must install a 75 W device to the unused INPUT connector.

The Sync Stripper consists of a reference select circuit and three sync separators.

The reference select circuit chooses either the INPUT video signal or an external

signal for the sync reference. The sync separator uses the selected sync reference

to generate composite, vertical, and horizontal sync signals.

VM100 & VM101 Service Manual

3–1

Page 42

Theory of Operation

Gain, DC Offset, and

Filtering

Phase Lock Loop

Analog-to-Digital

Converter

Digital Signal Processor

Acquisition Control

The Gain, DC Offset, and Filtering block provides signal processing to the input

video signal. The circuit selects one of three input filters, and also provides an

anti-aliasing filter to remove unwanted signal components from the A/D

Converter input. Under host processor control, the circuit provides fixed gain,

variable gain, and variable DC offset for the video signal.

The Phase Lock Loop synchronizes signals within the video measurement set to

a known reference. Either the video signal from the INPUT, or an external

reference applied to the EXT REF input, can be used. The Phase Lock Loop

locks to either the sync or burst signals.

The Analog-to-Digital (A/D) Converter converts the analog video signal into

10-bit digital words. The conversion rate is 8 times the subcarrier frequency.

The Digital Signal Processor (DSP) system is a coprocessor that makes rapid

calculations using the acquired data. Processed waveform data from the DSP is

available for use by the host processor.

The Acquisition Control stores data from the A/D Converter into waveform

memory. It also controls the real-time aspects of acquisition such as bus

arbitration phase lock operation, gain and DC offset settings.

Host Processor and

Memory

Remote Interface (RS232)

Front Panel

LCD Display

Power Supply

The host processor controls the main operating system functions including

acquisition, front panel control, and the LCD display. The operating system

stored in Flash EPROM can be upgraded through the RS232 port using an

external PC controller.

The Remote Interface (RS232) drives the rear-panel RS-232 connector for

remote operation.

The Front Panel contains a 13-switch keypad and 8 LED indicators. The host

processor reads the front panel registers to detect switch closures, and writes to

the registers to change the status of LED indicators.

The LCD Display provides displays of the measurement results, signal identification codes, and configuration parameters. The host processor provides signals

to control the display and set the LCD viewing angle.

The Power Supply provides +12 V, –12 V, and +5 V.

3–2

VM100 & VM101 Service Manual

Page 43

Detailed Circuit Description

This detailed circuit description explains the function of each major circuit.

Use this description to help you isolate faults when troubleshooting. As you read

the description, refer to the component-level circuit diagrams found in the

Diagrams section.

Theory of Operation

DC Restore

The DC Restore circuit (diagram

) consists of the Video Input and Input

1

Amplifier. These circuits combine to perform the following functions:

H Select AC or DC input coupling

H Clamp the backporch level of the video signal

Video Input. The video signal to be measured connects to loop-through INPUT

connectors at either J30 or J31. The unused connector must be terminated with

75 W. Transistors Q2 and Q3 establish the coupling mode. When the AC/DC

SEL line is high, C58 AC-couples the signal to amplifier U17. Acquisition

Control FPGA U99 (diagram

) controls the AC/DC SEL line. Switching

4

occurs to accommodate the requirements of signal measurement modes.

Input Amplifier. Input Amplifier U17 (diagram

) clamps the backporch level of

1

the video signal. Signal clamping determines the DC level measured at TP9.

When the amplifier is operating, the DC level at TP9 is equal to the video

backporch level at U17 pin-3, minus the voltage across sampling capacitor C13.

An operational amplifier within U17 performs the subtraction using R60 to feed

back the sample-and-hold output (buffered voltage on C13) to pin-1, the negative

input of the operational amplifier.

The CLAMP_PLS signal (from U31, diagram

backporch interval while U17 and C13 sample and hold the back porch level of

the incoming video. As a result, the backporch level of the clamped video is zero

volts. The OFFSET signal from U30C (diagram

negative input (pin 6) of the sample-and-hold amplifier to establish the DC level

of the clamped video.

When switch U18A is closed, the DC restore circuit is disabled. The

DCREST_ON signal from U99 (diagram

When the switch is closed, sampling capacitor C13 charges to the OFFSET

voltage. As a result only the OFFSET voltage is subtracted from the input video

signal, under normal conditions the sum of the backporch level and the OFFSET

voltage are subtracted.

VM100 & VM101 Service Manual

) goes low during the

2

) can then control the

4

) disables the DC Restore circuit.

4

3–3

Page 44

Theory of Operation

Sync Stripper

The Sync Stripper (diagrams

and 2) consists of a Reference Select circuit

1

and three Sync Separators. The Reference Select circuit chooses either the

internal video signal or an external signal for the sync reference. The Sync

Separators use the selected sync reference to generate composite, vertical, and

horizontal sync signals.

Reference Select. The selected sync reference signal controls video timing within

the video measurement set. Video switch U14 selects either the INT VIDEO

signal or an external signal connected to the EXT REF input. The INT/EXT

signal from U99 (diagram

) controls U14. When INT/EXT is high, the INT

4

VIDEO signal is selected.

Composite Sync Separator. The REF_VIDEO output from U16 drives pin-12 of

composite sync separator U6. From this input, U6 generates the COMP_SYNC

(horizontal and vertical composite synchronization) and BPSAMP (back porch

sample) signals at pin-24 and pin-28, respectively.

An AGC (automatic gain control) circuit within U6 compensates for low- or

high-gain input signals. Capacitor C55 samples and provides feedback of the

sync amplitude for the AGC circuit.

Vertical Sync Separator. Active filter U85A filters the COMP_SYNC signal, and

the combination of CR86, R172, and C213 provide envelope following. The

filter integrates the broad pulses of the vertical interval so that during the vertical

sync interval, the filter output goes lower than the output of the envelope

follower. For PAL signals, a low NTSC/PAL signal from U99 (diagram

)

4

increases the filter time constant by adding C24 to the filter.

Gain, DC Offset, and

3–4

Filtering

Comparator U85B compares the input and the output of the envelope follower.

Buffer U87A buffers the output and shifts the logic level for CMOS compatibility. The resulting FIELD signal (at TP16) reflects the vertical sync rate.

Horizontal Sync Separator. U31 (diagram

) uses the COMP_SYNC signal to

2

generate the horizontal sync (HSYNC) signal. HSYNC is output on pin 8.

Figure 3–1 shows a simplified diagram of the Gain, DC Offset, and Filtering

block. This block provides signal processing to the input video signal. It consists

of the the Filter Select and Analog Processing circuits, which perform the

following functions:

H Filter select

H Gain

H DC offset

H Anti-aliasing filter

VM100 & VM101 Service Manual

Page 45

Input amplifier Filter select Analog processing

Theory of Operation

Input

Flat

Lowpass

Chrom

Filter

switch

Filter 0

Filter 1

Filter 2

Figure 3–1: Simplified view of Gain, DC Offset, and Filtering block

Filter Select. Multiplexer U10 (diagram

to drive the A/D Converter: INT VIDEO (flat), CHROM (chrominance), and

LUM (lowpass). Control lines FILTER0, FILTER1, and FILTER2 from U99

(diagram

) select the filter.

4

The flat filter output signal (INT VIDEO) is taken directly from pin-14 of input

amplifier U17. Operational amplifiers U13 and U14 form a lowpass filter used to

generate the LUM signal for the hum measurement. Buffer U20 and its

surrounding components form a bandpass filter to generate the CHROM

(chrominance) signal.

Gain and

DC offset

Position

Vargain