User Manual

VM100 & VM101

Video Measurement Sets

070-9522-05

This document supports firmware version 2.17

and above.

Copyright E Tektronix, Inc. All rights reserved. Printed in U.S.A.

Tektronix products are covered by U.S. and foreign patents, issued and

pending.

Information in this publication supersedes that in all previously published

material. Specifications and price change privileges reserved. The following

are registered trademarks: TEKTRONIX and TEK.

For product related information, phone: 800-TEKWIDE (800-835-9433),

ext. TV.

For further information, contact: Tektronix, Inc., Corporate Offices, P.O. Box

1000, Wilsonville, OR 97070–1000, U.S.A. Phone: (503) 627–7111; TLX:

192825; TWX: (910) 467–8708; Cable: TEKWSGT.

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects

in materials and workmanship for a period of one (1) year from the date of shipment. If a

product proves defective during this warranty period, Tektronix, at its option, either will

repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty , Customer must notify T ektronix of the defect

before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR

HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Service Assurance

If you have not already purchased Service Assurance for this product, you may

do so at any time during the product’ s warranty period. Service Assurance

provides Repair Protection and Calibration Services to meet your needs.

Repair Protection extends priority repair services beyond the product’s

warranty period; you may purchase up to three years of Repair Protection.

Calibration Services provide annual calibration of your product, standards

compliance and required audit documentation, recall assurance, and reminder

notification of scheduled calibration. Coverage begins upon registration; you

may purchase up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase

authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your Tektronix

representative and provide the information below. Service Assurance may not

be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City, State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Table of Contents

General Safety Summary x. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Overview xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Documentation Set xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Installation 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rackmounting 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source Requirements 1–6. . . . . . . . . . . . . . . . . . . . . . . .

Power On Procedure 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Time Operation 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Measurements 1–9. . . . . . . . . . . . . . . . . . . . . . . .

Configure the Zero Carrier Reference Pulse Trigger Output 1–10

Configure the Signal Identification Range 1–11. . . . . . . . . . . . .

Configure the Full Field Start Line 1–11. . . . . . . . . . . . . . . . . . .

Configure the Reference 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Hum Measurement (VM100 Only) 1–12. . . . . . . .

Configure the Signal-to-Noise Ratio Filter 1–13. . . . . . . . . . . . .

Configure the Luminance Nonlinearity Mode 1–13. . . . . . . . . . .

Configure the Limit Table Selection 1–13. . . . . . . . . . . . . . . . . .

Configure for Printing 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for Computer Communications 1–15. . . . . . . . . . . . .

Configure for Waveform Monitor Control Function 1–17. . . . . .

Configure the Date 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Time 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust the LCD View Angle 1–19. . . . . . . . . . . . . . . . . . . . . . . .

Display the Software Version Number 1–19. . . . . . . . . . . . . . . .

Calibration 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 User Manual

i

Table of Contents

Operating Basics

Functional Overview 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Buttons and LCD Display 2–2. . . . . . . . . . . . . .

Menus 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Connectors 2–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Tutorial 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Setup 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Configuration 2–11. . . . . . . . . . . . . . . . . . . . . . . .

Signal Identification 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Measurements 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Freezing the Measurement Activity 2–14. . . . . . . . . . . . . . . .

Storing Measurement Results 2–15. . . . . . . . . . . . . . . . . . . .

Printing Measurement and Signal Identification Results 2–17

Using Limits 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference

General Feature Reference 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Averaging 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freezing the Measurement Activity 3–3. . . . . . . . . . . . . . . . . . .

Using Signal Identification 3–3. . . . . . . . . . . . . . . . . . . . . . . . .

Using Memory Functions 3–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Measurement Results 3–11. . . . . . . . . . . . . . . . . . . . . . .

Using the Waveform Monitor Control Function 3–14. . . . . . . . .

Using the Zero Carrier Reference Pulse Output 3–16. . . . . . . . .

Taking NTSC Measurements (VM100) 3–17. . . . . . . . . . . . . . . . .

Measuring Differential Phase 3–20. . . . . . . . . . . . . . . . . . . . . . . .

Measuring Differential Gain 3–22. . . . . . . . . . . . . . . . . . . . . . . .

Measuring YC Delay 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring YC Gain 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Signal-to-Noise Ratio 3–27. . . . . . . . . . . . . . . . . . . .

Measuring Frequency Response (FCC) 3–29. . . . . . . . . . . . . . . .

Measuring Frequency Response Detail 3–32. . . . . . . . . . . . . . . .

Measuring Group Delay 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Sync Amplitude 3–35. . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Burst Amplitude 3–36. . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Bar Amplitude 3–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring 2T K-Factor 3–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Luminance Nonlinearity 3–39. . . . . . . . . . . . . . . . . .

Measuring Hum 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

VM100 & VM101 User Manual

Table of Contents

Taking PAL Measurements (VM101) 3–43. . . . . . . . . . . . . . . . . .

Measuring Differential Phase 3–46. . . . . . . . . . . . . . . . . . . . . . . .

Measuring Differential Gain 3–48. . . . . . . . . . . . . . . . . . . . . . . .

Measuring YC Delay 3–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring YC Gain 3–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Signal-to-Noise Ratio 3–52. . . . . . . . . . . . . . . . . . . .

Measuring Frequency Response (AVG) 3–54. . . . . . . . . . . . . . .

Measuring Frequency Response Detail 3–56. . . . . . . . . . . . . . . .

Measuring Group Delay 3–58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Sync Amplitude 3–59. . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Burst Amplitude 3–60. . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Bar Amplitude 3–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring 2T K-Factor 3–62. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Luminance Nonlinearity 3–63. . . . . . . . . . . . . . . . . .

Measuring Hum 3–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Appendix A: Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Terms Used in Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . .

Performance Conditions A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics A–5. . . . . . . . . . . . . . . . . . . . . . .

Safety Standards and Certification A–6. . . . . . . . . . . . . . . . . . . .

Physical Characteristics A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Port A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Remote Control B–1. . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Interface B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCPI B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Applications B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands and Queries B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Syntax B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Commands B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Commands B–11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Header B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Terminator and Message Separator B–9. . . . . . . . .

Command Characters B–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviating Commands B–10. . . . . . . . . . . . . . . . . . . . . . . .

Combining Commands B–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Commands B–12. . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 User Manual

iii

Table of Contents

Command List B–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Performance Verification C–1. . . . . . . . . . . . . . . . .

General Information C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Requirements C–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Record C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedure C–6. . . . . . . . . . . . . . . . . .

Appendix D: Error Messages D–1. . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Commands B–12. . . . . . . . . . . . . . . . . . . . . . . .

Memory Commands B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Change Commands B–15. . . . . . . . . . . . . . . . . . . . . . .

Configuration Commands B–17. . . . . . . . . . . . . . . . . . . . . . .

Report Measurements Commands B–23. . . . . . . . . . . . . . . . .

Help Commands B–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary

Index

iv

VM100 & VM101 User Manual

List of Figures

Figure 2–1: Front panel 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: LCD display characteristics 2–4. . . . . . . . . . . . .

Figure 2–3: The Meas, Mem, and Print menus 2–5. . . . . . . .

Figure 2–4: The CONFIG menu 2–6. . . . . . . . . . . . . . . . . . . .

Figure 2–5: Rear panel connectors 2–7. . . . . . . . . . . . . . . . .

Figure 2–6: Equipment setup for the tutorial 2–10. . . . . . . . .

Figure 2–7: Example of the initial SIG ID display 2–12. . . . .

Figure 2–8: Example of a SIG ID display with source

ID code 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Figure 2–9: Example of differential phase measurement

results 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–10: Measurements saved to memory 2–15. . . . . . . .

Figure 2–11: Renaming a memory location 2–16. . . . . . . . . . .

Figure 2–12: Date and time stamp display 2–17. . . . . . . . . . .

Figure 2–13: Adding a title 2–18. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–14: Typical high-limit error display 2–19. . . . . . . . .

Figure 2–15: Limit Violation 2–20. . . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Example of a SIG ID display with source

ID code 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: Example of display after saving to memory 3–6

Figure 3–3: Renaming a memory location 3–7. . . . . . . . . . .

Figure 3–4: Date and time stamp display 3–8. . . . . . . . . . . .

Figure 3–5: Connecting to a printer 3–11. . . . . . . . . . . . . . . . .

Figure 3–6: Adding a title 3–12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–7: Cable pinout for waveform monitor control

function 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–8: Example of differential phase measurement

results 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VM100 & VM101 User Manual

v

Table of Contents

Figure 3–9: Differential phase measurement screen 3–21. . .

Figure 3–10: Differential gain measur ement screen 3–23. . . .

Figure 3–11: Chrominance-to-luminance delay

measurement screen 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–12: Chrominance-to-luminance gain

measurement screen 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–13: Signal-to-noise ratio measurement scr een 3–28

Figure 3–14: Frequency response measurement screen 3–30.

Figure 3–15: Frequency flag measurement results 3–32. . . . .

Figure 3–16: Frequency detail screen showing first

packet 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–17: Measurement scr een showing maximum

packet amplitude 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–18: Group delay measur ement screen 3–34. . . . . . .

Figure 3–19: Sync amplitude measurement scr een 3–35. . . .

Figure 3–20: Burst amplitude measurement scr een 3–36. . . .

Figure 3–21: Bar amplitude measurement scr een 3–37. . . . .

Figure 3–22: 2T K-factor measur ement screen 3–38. . . . . . . .

Figure 3–23: Luminance nonlinearity measurement

screen 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–24: Hum measurement scr een with ZCR pulse 3–41

Figure 3–25: Hum measurement scr een with no

ZCR pulse 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–26: Example of differential phase

measurement results 3–43. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–27: Differential phase measur ement screen 3–47. .

Figure 3–28: Differential gain measur ement screen 3–49. . . .

Figure 3–29: Chrominance-to-luminance delay

measurement screen 3–50. . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Figure 3–30: Chrominance-to-luminance gain

measurement screen 3–51. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–31: Signal-to-noise ratio measurement scr een 3–53

VM100 & VM101 User Manual

Table of Contents

Figure 3–32: Frequency response measurement screen 3–55.

Figure 3–33: Frequency flag measurement screen 3–56. . . . .

Figure 3–34: Frequency detail screen showing first

packet 3–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–35: Measurement scr een showing maximum

packet amplitude 3–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–36: Group delay measur ement screen 3–58. . . . . . .

Figure 3–37: Sync amplitude measurement scr een 3–59. . . .

Figure 3–38: Burst amplitude measurement scr een 3–60. . . .

Figure 3–39: Bar amplitude measurement scr een 3–61. . . . .

Figure 3–40: 2T K-factor measur ement screen 3–62. . . . . . . .

Figure 3–41: Luminance nonlinearity measurement

screen 3–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–42: Hum measurement scr een with ZCR pulse 3–65

Figure 3–43: Hum measurement scr een with no

ZCR pulse 3–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–1: Rear panel RS-232 serial port (female) B–2. . .

Figure B–2: Remote control wiring, VM10X to nine-pin

PC connector B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–3: Remote control wiring, VM10X to 25-pin

PC connector B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–4: Remote control wiring, VM10X to 25-pin

modem connector B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B–5: Examples of remote operation B–5. . . . . . . . . . .

Figure B–6: Tree hierarchy B–7. . . . . . . . . . . . . . . . . . . . . . . .

Figure B–7: Command header B–7. . . . . . . . . . . . . . . . . . . . .

Figure B–8: Command header with parameter B–8. . . . . . .

Figure C–1: Initial setup for the PV Procedure C–6. . . . . . .

VM100 & VM101 User Manual

vii

Table of Contents

List of Tables

Table 1–1: Power cord identification 1–3. . . . . . . . . . . . . . .

Table 1–2: Configuration parameters 1–7. . . . . . . . . . . . . . .

Table 1–3: Print parameters 1–15. . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Computer interface parameters 1–16. . . . . . . . . .

Table 2–1: Equipment for tutorial 2–9. . . . . . . . . . . . . . . . .

Table 3–1: Additional signals identified by SIG ID

mode 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Control function communications

parameters 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: VITS signals used for NTSC measurements 3–19

Table 3–4: Packet frequencies for measuring frequency

response 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Test signals used for PAL measurements 3–45. .

Table A–1: Input signal requirements–VIDEO INPUT A–2

Table A–2: Input signal requirements–EXT REF A–2. . . . .

Table A–3: Measurement accuracy A–3. . . . . . . . . . . . . . . . .

Table A–4: Output A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–5: AC power source A–5. . . . . . . . . . . . . . . . . . . . .

Table A–6: Environmental characteristics A–5. . . . . . . . . .

Table A–7: Certifications and compliances A–6. . . . . . . . . .

Table A–8: Physical characteristics A–8. . . . . . . . . . . . . . . .

Table A–9: Remote control port A–8. . . . . . . . . . . . . . . . . . .

Table B–1: RS-232 pin connections B–2. . . . . . . . . . . . . . . . .

Table B–2: Parameter types for syntax descriptions B–8. . .

viii

Table B–3: Front panel commands B–12. . . . . . . . . . . . . . . . .

Table B–4: Measurement commands B–13. . . . . . . . . . . . . . .

Table B–5: Memory commands B–14. . . . . . . . . . . . . . . . . . . .

Table B–6: Signal change commands B–15. . . . . . . . . . . . . . .

VM100 & VM101 User Manual

Table of Contents

Table B–7: Configuration commands B–17. . . . . . . . . . . . . . .

Table B–8: Report measurements commands B–23. . . . . . . .

Table B–9: Help commands B–23. . . . . . . . . . . . . . . . . . . . . . .

Table B–10: CONfig:LINe subcommands B–34. . . . . . . . . . .

Table B–11: CONfig:LINe available lines B–35. . . . . . . . . . .

Table B–12: CONfig:MEAs subcommands B–37. . . . . . . . . .

Table B–13: NEXTmeas subcommands B–76. . . . . . . . . . . . .

Table B–14: PREVmeas subcommands B–78. . . . . . . . . . . . .

Table B–15: REP subcommands B–83. . . . . . . . . . . . . . . . . . .

Table C–1: Test equipment C–3. . . . . . . . . . . . . . . . . . . . . . . .

Table D–1: Error messages for manual operation D–1. . . . .

Table D–2: Error messages for remote operation D–1. . . . .

VM100 & VM101 User Manual

ix

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

If this equipment is used in any manner not specified, including

failure to follow any rating or direction for use, the protection

provided by the equipment may be impaired.

Injury Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord

specified for this product.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply

potential to any terminal, including the common terminal, that varies

from ground by more than the maximum rating for that terminal.

Ground the Product. This product is grounded through the grounding

conductor of the power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making

connections to the input or output terminals of the product, ensure

that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard,

do not operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and

rating specified for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not

operate this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire

hazard, do not operate this product in an explosive atmosphere.

Product Damage Precautions

Use Proper Power Source. Do not operate this product from a power

source that applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide

proper ventilation.

x

VM100 & VM101 User Manual

General Safety Summary

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. These symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

Double

Insulated

Certifications and Compliances

Refer to the specifications section for a listing of certifications and

compliances that apply to this product.

VM100 & VM101 User Manual

xi

General Safety Summary

xii

VM100 & VM101 User Manual

Preface

This is the user manual for the video measurement set. It contains

information about the NTSC (VM100

of the instrument. When operating instructions are different for

NTSC and PAL, you will receive complete instructions for each

version.

Manual Overview

You will find the following topics covered in this manual:

H Getting Started explains how to set up the video measurement set

for first-time operation. The section also provides a list of the

accessories and options you can purchase.

H Operating Basics explains the operation of each control,

indicator, and connector on the front and rear panels. The tutorial

helps first-time operators use many of the instrument features.

) and PAL (VM101) versions

H Reference provides a more detailed explanation of instrument

features and explains how to use each of the built-in signal

measurements.

H Appendix A: Specifications lists all instrument specifications and

certifications.

H Appendix B: Remote Control explains how to operate the video

measurement set using the RS-232 remote interface.

H Appendix C: Performance Verification explains how to verify the

video measurement set performance.

H Appendix D: Error Messages lists the error messages you might

receive when operating the video measurement set and gives the

actions you must take in response to each message.

VM100 & VM101 User Manual

xiii

Preface

Documentation Set

The VM100 and VM101 Video Measurement Sets are supported

by two manuals:

H The VM100 & VM101 Video Measurement Sets User Manual

(Tektronix part number 070-9522-XX) is included with each

instrument

H The VM100 & VM101 Video Measurement Sets Service Manual

(Tektronix part number 070-9288-XX) is an optional accessory

that you can purchase from Tektronix

xiv

VM100 & VM101 User Manual

Getting Started

Getting Started

This section provides the information you need to use the video

measurement set for the first time. Refer to the following sections to

prepare the instrument for operation:

H Product Description on page 1–1 describes the instrument

features

H Options on page 1–3 provides a list of the available options

H Accessories on page 1–4 describes the accessories that are

available for use with the video measurement set

H Mechanical Installation on page 1–4 describes different ways

for you to rackmount the video measurement set

H Electrical Installation on page 1–6 explains how to power on

the video measurement set

H First T ime Operation on page 1–7 explains how to configure the

video measurement set features for your application

Product Description

The Tektronix VM100 and VM101 Video Measurement Sets are

low-cost, automatic video measurement instruments. The VM100

measures NTSC signals and the VM101 measures PAL signals.

The video measurement sets are easy to operate. They use existing or

inserted test signals and take measurements consistent with

regulatory specifications. The video measurement sets allow you to

perform measurements that are useful for ensuring the quality of

your video signals.

The video measurement sets display measurement results on an

easy-to-read alphanumeric LCD screen with backlight. You can also

display measurement results on a serial printer or remote PC using

the RS-232 serial port.

VM100 & VM101 User Manual

1–1

Getting Started

The video measurement sets perform the following measurements

(on-screen labels are shown in parentheses):

H Differential Phase (DIFF PHASE)

H Differential Gain (DIFF GAIN)

H Chrominance-to-Luminance Delay (YC DELAY)

H Chrominance-to-Luminance Gain (YC GAIN)

H Signal-to-Noise Ratio (SNR WGT/FLAT)

H Frequency Response (FREQ FCC or AVG)

H Frequency Response Detail (FREQ FLAG, FREQ #1 through

H Group Delay (GRPDLYmax and GRPDLYmin)

FREQ #6) or (FRQmax and FRQmin)

H Sync Amplitude (SYNC AMPL)

H Burst Amplitude (BURST AMPL)

H Bar Amplitude (BAR AMPL)

H 2T K-Factor (2T K-FACTOR)

H Luminance Nonlinearity (LUM NON-LIN)

H Hum (HUM P-P, 50/60 Hz, and 100/120 Hz)

1–2

VM100 & VM101 User Manual

Options

You can purchase the video measurement set with one of the power

cord options shown in Table 1–1.

Table 1–1: Power cord identification

Getting Started

Plug Configuration

Normal Usage Option Number

North America

115 V

Europe

230 V

United Kingdom

230 V

Australia

230 V

Standard

A1

A2

A3

VM100 & VM101 User Manual

1–3

Getting Started

Accessories

When unpacking the video measurement set for the first time, check

inside the shipping carton for the following standard accessories:

H VM100 & VM101 Video Measurement Sets User Manual

(Tektronix part number 070-9522-XX)

H Power cable assembly, standard USA, 125 V (Tektronix part

number 161-0216-00)

H Replacement cushioning pads, six each (Tektronix part number

348-0844-00)

You can order optional accessories with the video measurement set

or purchase them through a Tektronix field office or distributor. The

following optional accessories are available:

H VM100 & VM101 Video Measurement Sets Service Manual

(Tektronix part number 070-9288-XX)

H RS-232 Cable, DCE to DTE

(Tektronix part number 174-1809-00)

H TVGF15 Mounting Kit

For use with a 1740A-series waveform monitor)

Mechanical Installation

The video measurement set requires no assembly. Please read the

following sections before installing the video measurement set into a

console or equipment rack.

NOTE. All qualification testing was performed with the factoryshipped cabinet installed. To guarantee compliance with specifications, operate the instrument only in the original cabinet.

1–4

VM100 & VM101 User Manual

Getting Started

Custom Installation

CAUTION. To avoid damage to the video measurement set, be sure to

attach it to a shelf that is strong enough to hold its weight

(4 lbs/1.81 kg).

For applications that require installation into consoles, the video

measurement set can be mounted with the front molding flush or

protruding from the console. Always allow approximately 3 inches

(7.6 cm) of rear panel clearance for cable and power cord

connections.

Rackmounting

The video measurement set is one-half-rack wide and one rack unit

high. It requires approximately 3 inches (7.6 cm) of rear panel

clearance for power cord and cable connections and 20 inches

(50.8 cm) in front of the rack for installation and removal.

You can order the following rackmounting kits from Tektronix:

H TVGF13 adapter (mounts two half-rack width instruments

side-by-side in a standard 19-inch rack)

H TVGF14 adapter (allows you to mount two half-rack width

instruments in a standard half-rack application)

NOTE. The video measurement set fits only in the lower portion of the

TVGF14 adapter.

VM100 & VM101 User Manual

1–5

Getting Started

Electrical Installation

This section explains how to connect the video measurement set to

an AC power source and how to recognize when the power on

sequence is complete. If you want to connect a printer, personal

computer (PC), or waveform monitor to the RS-232 serial port, refer

to page 1–14 and Appendix B: Remote Control for more information.

Power Source Requirements

WARNING. To avoid personal injury due to electrical shock, never

operate the video measurement set without the protective ground

connection by way of the grounding conductor in the power cord.

The video measurement set operates over the range of 90 V

250 V

apply more than 250 V

at either 50 Hz or 60 Hz. The power source should never

RMS

between the supply conductors or

RMS

rms

to

between either supply conductor and ground.

Power On Procedure

To power on the video measurement set, connect it to the AC power

source. There is no power switch.

The power on sequence completes in approximately 10 seconds.

After power on completes, check for the following conditions:

H The LCD display shows the message “No video present, or no

lock possible” (if no signals are connected to the rear panel

INPUT connector).

H The MEAS button indicator lights.

NOTE. The AVG button indicator lights at power on if the A VG

feature was in use when AC power was last disconnected.

1–6

VM100 & VM101 User Manual

First Time Operation

This section guides you through the configuration of each operating

parameter. (No configuration is necessary for basic operation.) Refer

to Table 1–2 for an overview of the parameters you can configure,

the location of the configuration instructions, and the factory default

values.

You can configure most parameters using a computer. Refer to

Appendix B: Remote Control for a listing of the remote commands.

T able 1–2: Configuration parameters

Getting Started

Parameter

MEASURE 1–9 SNR is ON; all other mea-

ZCR PULSE 1–10 VM100: Line 10

SIG ID RANGE 1–11 VITS

FULL FLD START 1–11 23

REF 1–12 INPUT

HUM (VM100 ONLY) 1–12 60HZ

SNR FILTER 1–13 WEIGHTD

LUM NON LIN 1–13 NORMAL

LIMITS 1–13 OFF

RS232 1–14 for printing

Page Number Factory Default Value

surements are OFF

VM101: Line 7

COMPUTER

1–15 for computer

1–17 for waveform

monitor operation

PRINTER RS232

BAUD RATE

STOP BITS

PARITY

FLOW CTL

VM100 & VM101 User Manual

1–14

9600

1

NONE

NONE

1–7

Getting Started

T able 1–2: Configuration parameters (cont.)

Parameter Factory Default ValuePage Number

COMPUTER RS232

BAUD RATE

STOP BITS

PARITY

FLOW CTL

REMOTE ADDR

1995 NOV 11 (Date)

YEAR

MONTH

DAY

10:13:18AM (Time)

HOUR

MINUTE

VIEW ANGLE 1–19 80

SW VER 1–19 Current software version

CALIBRATE 1–20 N/A

1–15

9600

1

NONE

NONE

0

1–18 Today’s date

1–18 Current time

1–8

Use the following procedures to customize the operation of your

video measurement set. Once you have configured the parameters,

the video measurement set powers on as you configured it. Refer to

Operating Basics if you need a detailed description of the front panel

buttons or the LCD display.

NOTE. The video measurement set uses the last setting that was saved

for each parameter if power is interrupted during configuration.

To exit the CONFIGURE menu at any time during these procedures,

press the MEAS, SIG ID, MEM, or PRINT buttons.

VM100 & VM101 User Manual

Getting Started

1.

NOTE. If the front panel has been locked with the REMLock remote

command, it can be unlocked by holding down the CONFIG button

and pressing the FREEZE button.

Configure the Measurements

The video measurement set performs a group of measurements when

you press the MEAS button. The display update rate depends upon

the number of measurements made and the presence of valid input

signals. You can customize this feature for your application by

selecting only the measurements you need.

NOTE. No new measurements are performed while the FREEZE or

CONFIG lights ar e on. The REPort and MEMory:SAVe commands

use the results that were present when either button was pressed.

The CONFIG button provides access to the instrument configuration.

Perform the following steps to choose measurements that will be

performed when you press the MEAS button or use the CONfig:MEAs:<subcommand> remote command on page B–37:

2. 3. 4. 5.

Press the

CONFIG

button.

Select

(default).

Press the ↵

enter button.

Select the

desired

measurement.

See list below.

Select or

. Repeat

steps 3 and 4

to configure

additional

measurements.

Press the

MEAS button

to exit.

VM100 & VM101 User Manual

1–9

Getting Started

The following measurements are available:

H Differential Phase (DIFF PHASE)

H Differential Gain (DIFF GAIN)

H Chrominance-Luminance Delay (YC DELAY)

H Chrominance-Luminance Gain (YC GAIN)

H Signal-to-Noise Ratio (SNR WGT/FLAT)

H Frequency Response (FREQ FCC or AVG and FREQ DETAIL)

H Group Delay (GRPDLYmax and GRPDLYmin)

H Sync Amplitude (SYNC AMPL)

H Burst Amplitude (BURST AMPL)

H Bar Amplitude (BAR AMPL)

H 2T K-Factor (2T K-FACTOR)

H Luminance Nonlinearity (LUM NON-LIN)

H Hum (HUM)

Configure the Zero Carrier Reference Pulse T rigger Output

The Zero Carrier Reference Pulse Trigger Output synchronizes a

demodulator when you take hum measurements. You can configure

the output to OFF or to any line from 10 – 20 (VM100) or 7 – 20

(VM101). See page 3–16 for information about using the Zero

Carrier Reference Pulse Trigger Output.

Perform the following steps to configure the Zero Carrier Reference

Pulse Trigger Output or use the CONfig:ZCRp remote command on

page B–45:

1. 2. 3. 4.

1–10

Press the CONFIG

button.

Select

.

Select or Line

10 – 20 (VM100)

or Line 7 – 20

(VM101).

Press the MEAS

button to exit.

VM100 & VM101 User Manual

Getting Started

Configure the Signal Identification Range

The SIG ID menu displays all of the test signals that are present in

the video signal applied to the INPUT connector . You can configure

the SIG ID range to match your system requirements (VITS, FULL,

or MAN). See page 3–3 for more information about SIG ID range

selection.

Perform the following steps to configure the SIG ID range or use the

CONfig:SIGnalid:RANge remote command on page B–42:

1. 2. 3. 4.

Press the CONFIG

button.

Select SIG ID

RANGE.

Select VITS,

FULL, or MAN.

Press the MEAS

button to exit.

NOTE. After you configure the signal identification range, the video

measur ement set reacquires the signal.

Configure the Full Field Start Line

You can configure the video line used for full field start (valid only

when the SIG ID range is FULL). With this feature you can view a

specific video line within the active area. See page 3–3 for more

information about SIG ID range selection.

Perform the following steps to configure the Full Field Start Line or

use the CONfig:SIGnalid:FULlfldstart remote command on

page B–40:

1. 2. 3.

Press the CONFIG

button.

Select FULL FLD

START.

VM100 & VM101 User Manual

Select 23 - 94

(VM100) or

23 – 39 (VM101).

4.

Press the MEAS

button to exit.

1–1 1

Getting Started

NOTE. After you configure the full field start line, the video

measur ement set reacquires the signal.

Configure the Reference

You can configure the video measurement set to use either an

internally generated sync reference or a signal connected to the

EXT REF rear panel input. For example, use an external reference if

the video input has no sync information.

Perform the following steps to configure the reference or use the

CONfig:REFerence remote command on page B–39:

1. 2. 3.

Press the CONFIG

button.

Select

CONFIGURE REF.

Select INPUT or

EXTERNAL.

4.

Press the MEAS

button to exit.

Configure the Hum Measurement (VM100 Only)

You can configure the hum measurement to match your power line

frequency (VM100 only). The video measurement set configuration

must match your power line frequency to produce accurate hum

measurement results.

Perform the following steps to configure the hum measurement or

use the CONfig:HUM remote command on page B–28:

1. 2. 3. 4.

1–12

Press the CONFIG

button.

Select HUM. Select 50HZ or

60HZ.

VM100 & VM101 User Manual

Press the MEAS

button to exit.

Getting Started

Configure the Signal-to-Noise Ratio Filter

The video measurement set provides weighted and flat filter

selections for taking signal-to-noise (SNR) measurements. You can

configure the filter type needed for your application.

Perform the following steps to configure the SNR filter or use the

CONfig:FILter remote command on page B–27:

1. 2. 3. 4.

Press the CONFIG

button.

Select

.

Select

or .

Press the MEAS

button to exit.

Configure the Luminance Nonlinearity Mode

The video measurement set provides normal and differentiated step

(diffstep) modes for taking the luminance nonlinearity (LUM

NON–LIN) measurements. You can configure the mode needed for

your application.

Perform the following steps to configure the luminance nonlinearity

mode or use the CONfig:LUM remote command on page B–36.

1. 2. 3. 4.

Press the CONFIG

button.

Select

.

Select or

.

Press the MEAS

button to exit.

Configure the Limit Table Selection

The video measurement set can compare each measurement to high

and low stored values. You can enable limit checking and select from

one of four tables of stored values. Use the RS-232 serial port to

change the limits from the factory default settings.

VM100 & VM101 User Manual

1–13

Getting Started

Perform the following steps to configure the limit table selection

1. 2. 3. 4.

Press the CONFIG

button.

Select LIMITS. Select OFF or

Table 1 to 4.

Press the MEAS

button to exit.

You can also use the remote command CONfig:LIMit described on

page B–30.

Configure for Printing

The video measurement set can drive a printer, computer, or

waveform monitor using the RS-232 serial port. To print the

measurement results, you need to configure the RS-232 serial port

for printer operation and then select the parameters that match your

printer.

Perform the following steps to configure the RS-232 serial port to

drive a printer:

1. 2. 3. 4.

1–14

Press the CONFIG

button.

Select

CONFIGURE

RS232.

Select PRINTER. Press the MEAS

button to exit.

NOTE. Refer to your printer manual to determine the settings for

baud rate, stop bits, parity , and flow control.

If the RS-232 serial port is not configured for printing, the PRINT

button does not respond when you press it.

VM100 & VM101 User Manual

Getting Started

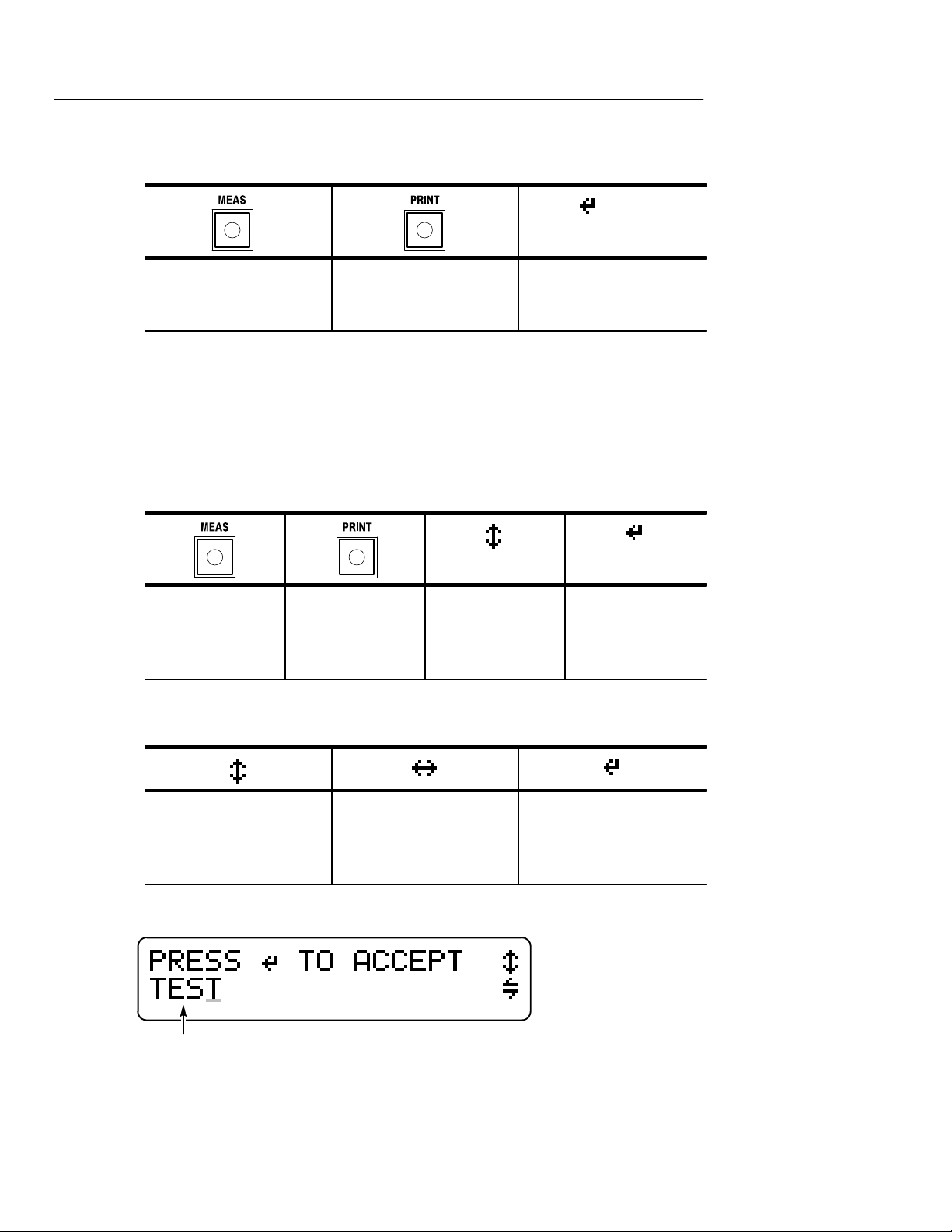

Perform the following steps to configure the print parameters:

1. 2. 3. 4.

Press the CONFIG

button.

Select

CONFIGURE

PRINTER RS232.

Press the ↵ enter

button.

Select the desired

parameters. See

Table 1–3.

Press the MEAS

button to exit.

Table 1–3: Print parameters

Parameter

BAUD RATE 300, 600, 1200, 2400, 4800, 9600,

STOP BITS 1 or 2

PARITY NONE, EVEN, ODD

FLOW CTL NONE, XON/XOFF, HARDWARE

Choices

19.2K

Configure for Computer Communications

The video measurement set can drive a computer, printer, or

waveform monitor using the RS-232 serial port. To send the

measurement results to a computer or to set up for remote operation,

you need to configure the RS-232 serial port for computer operation

and then select the parameters that match your computer interface.

Perform the following steps to configure the RS-232 serial port to

drive a computer:

VM100 & VM101 User Manual

1–15

Getting Started

1. 2. 3.

Press the CONFIG

button.

Select

CONFIGURE

RS232.

Select COMPUTER. Press the MEAS

4.

button to exit.

NOTE. Refer to your computer manual to determine the settings for

baud rate, stop bits, parity , and flow control.

Perform the following steps to configure the computer interface

parameters:

1. 2. 3.

Press the CONFIG

button.

Select

CONFIGURE

COMPUTER

RS232. Press the

↵ enter button.

Select the desired

parameters. See

Table 1–4.

4.

Press the MEAS

button to exit.

1–16

NOTE. If COMPUTER was not selected at power on, you will experience

a short delay when scrolling through the CONFIGURE RS232 menu

choices.

T able 1–4: Computer interface parameters

Parameter

Choices

BAUD RATE 300, 600, 1200, 2400, 4800, 9600, 19.2K

STOP BITS 1 or 2

PARITY NONE, EVEN, ODD

VM100 & VM101 User Manual

Getting Started

T able 1–4: Computer interface parameters (Cont.)

Parameter Choices

FLOW CTL NONE, XON/XOFF, HARDWARE, RCDS

1

REMOTE ADDR

1

0-126

Configure for Waveform Monitor Control Function

The video measurement set can drive a computer, printer, or

1740A-series waveform monitor using the RS-232 serial port. The

waveform monitor control function allows you to simultaneously

view the waveform on a 1740A-series waveform monitor while the

video measurement set measures the signal parameters. See

page 3–14 for more detailed information about the waveform

monitor control function.

Perform the following steps to configure the RS-232 serial port to

drive a waveform monitor:

1. 2. 3. 4.

Press the CONFIG

button.

Select

CONFIGURE

RS232.

Select CONTROL. Press the MEAS

button to exit.

1

Do not use the RCDS or REMOTE ADDR parameters. They support a

custom application.

VM100 & VM101 User Manual

1–17

Getting Started

Configure the Date

The video measurement set keeps track of the date. Perform the

following steps to change the date setting or use the CONfig:DATe

remote command on page B–26:

1. 2. 3. 4.

Press the CONFIG

button.

Select

CONFIGURE

<DATE>. Press

the ↵ enter button.

Select the YEAR,

MONTH, and DAY.

See list below.

Press the MEAS

button to exit.

The following date parameters are available:

H YEAR: 00 to 99 selects 1990 through 2089

H MONTH: JAN through DEC

H DAY: 1 through 31

Configure the Time

The video measurement set keeps track of the time. Perform the

following steps to change the time setting or use the CONfig:TIMe

remote command on page B–44:

1. 2. 3. 4.

1–18

Press the CONFIG

button.

Select

CONFIGURE

<TIME>. Press

the ↵ enter button.

Select the HOUR

and MINUTE. See

list below.

The following time parameters are available:

H HOUR: 01AM to 12AM and 01PM to 12PM

H MINUTE: 00 to 59

VM100 & VM101 User Manual

Press the MEAS

button to exit.

Getting Started

Adjust the LCD View Angle

You can adjust the viewing angle of the LCD display for the best

readout with your lighting conditions. To change the viewing angle,

place the video measurement set in the lighting conditions where you

will use it and then perform the following steps or use the CONfig:LCDangle remote command on page B–29:

1. 2. 3.

Press the CONFIG

button.

Select

CONFIGURE

VIEW ANGLE.

Select 0 through

180 for best LCD

display.

4.

Press the MEAS

button to exit.

Display the Software V ersion Number

You can view the software version number for the operating system

installed in this video measurement set. Refer to this number if you

need to report a software problem or order a software upgrade. The

software version displayed here should correspond to the version

number(s) printed on the title page of this manual.

Perform the following steps to view the software version number or

use the CONfig:SWVersion? remote query on page B–43:

1. 2. 3.

Press the CONFIG

button.

VM100 & VM101 User Manual

Select CONFIGURE

SW VER.

Press the MEAS button to

exit.

1–19

Getting Started

Calibration

CAUTION. To ensure that the video measur ement set meets all

performance requirements, only qualified service personnel should

perform the adjustments.

Refer to the VM100 & VM101 Video Measurement Sets Service

Manual for test equipment requirements and detailed adjustment

instructions.

If you inadvertently enter the CALIBRATION menu, use the

following steps to exit the menu without changing internal video

measurement set settings:

1. 2.

Select ↵

.

Press the ↵ enter button

to exit the menu.

1–20

VM100 & VM101 User Manual

Operating Basics

Operating Basics

This section provides the information you need to use each control,

indicator, and connector on the front and rear panels. It is divided

into the following sections:

H The Functional Overview explains how to read the LCD display.

You will also find functional descriptions of each front panel

button and rear panel connector and a graphical view of the

menus.

H The Tutorial on page 2–9 guides you through basic instrument

operation and measurement procedures.

Functional Overview

This section contains basic operating instructions for the front panel

buttons and LCD display, the menus, and rear panel connectors.

Refer to the following pages for the information you need:

H Front panel buttons and LCD display (see page 2–2)

H Menus (see page 2–4)

H Rear panel connectors (see page 2–7)

VM100 & VM101 User Manual

2–1

Operating Basics

Front Panel Buttons and LCD Display

The front panel contains twelve buttons and an LCD display as

shown in Figure 2–1. There are seven function buttons, four arrow

buttons, and the enter button. A green LED indicator, located at the

center of each function button, lights to show when the associated

function is turned on. The arrow buttons are designated by

directional arrows. A carriage return symbol (↵) identifies the enter

button.

10

Figure 2–1: Front panel

Five of the function buttons (MEAS, SIG ID, MEM, PRINT, and

CONFIG) are exclusive to each other . This means that only one of

the functions can be active at a time. When you press another of

these buttons the previous function automatically turns off.

1 2 4

9 8 7 6

3

5

2–2

NOTE. If the front panel has been locked with the REMLock remote

command, it can be unlocked by holding down the CONFIG button

and pressing the FREEZE button.

The following descriptions refer to Figure 2–1.

1. MEAS. Press the measure button to display the results of

measurements the video measurement set performs on the LCD

display. Use the CONFIG menu to turn measurements ON or

OFF. Measurements must be ON to appear in the MEAS list.

VM100 & VM101 User Manual

Operating Basics

2. SIG ID. Press the signal identification button to display the name

and location of signals used for measurement when the SIG ID

range is set to VITS or FULL, and the source ID (when contained

in the signal).

3. AVG. Press this toggle switch to turn signal averaging on and off.

4. FREEZE. Press this toggle switch to turn the freeze feature on and

off. When FREEZE is turned on, all acquisition and measurement

activity stops so that you can view intermediate measurement and

signal ID results.

To disable the front panel lock feature, hold down the CONFIG

button and press FREEZE.

NOTE. No new measurements are performed while FREEZE is on.

The report and memory save commands return the result that was

present when FREEze was pressed.

5. Arrow Buttons. Press the up (↑) or down (↓) arrow buttons to

scroll through various LCD displays. Press the left (←) and right

(→) arrow buttons to change instrument parameters and to view

measurement results on other video lines.

6. Enter Button. Press the enter (↵) button to enter and exit the

CONFIG submenus and to control print and memory functions.

7. CONFIG. Press the configure button to access instrument

configuration menus and to view the instrument software version.

To disable the front panel lock feature, hold down the CONFIG

button and press FREEZE.

NOTE. No new measurements are performed while CONFIG is on.

The report and memory save commands return the result that was

present when CONFIG was pressed.

8. PRINT. Press the print button to print the current or saved

measurement data or to output results to a computer, using the

RS-232 serial port. You must configure the RS-232 serial port for

VM100 & VM101 User Manual

2–3

Operating Basics

printing and select the print parameters before using the print

function.

9. MEM. Press the memory button to save the current measurement

and SIG ID results in instrument memory and to access memory

management selections including ERASE, REPLACE, VIEW,

and RENAME.

10.LCD Display. The LCD display shows measurement readouts and

menu selections. Figure 2–2 shows examples of the text and

symbols you will see on the LCD display. The symbols help you

navigate quickly through the menu system using the arrow

buttons and the enter button. Dots (…) following the menu name

indicate that a menu has a submenu.

Arrow buttons

Enter button

Shows submenu

Figure 2–2: LCD display characteristics

Menus

The MEAS, SIG ID, MEM, PRINT, and CONFIG buttons allow

access to additional selections or measurement results. Figures 2–3

and 2–4 show the menu structure of the video measurement set. The

SIG ID menu is not shown because its contents depend upon the

input signal characteristics.

2–4

VM100 & VM101 User Manual

Operating Basics

Figure 2–3: The MEAS, MEM, and PRINT menus

VM100 & VM101 User Manual

2–5

Operating Basics

2–6

Figure 2–4: The CONFIG menu

VM100 & VM101 User Manual

Operating Basics

Rear Panel Connectors

There are seven connectors mounted on the video measurement set

rear panel. Refer to Figure 2–5 for descriptions.

1

Figure 2–5: Rear panel connectors

1. AC Power Connector. The AC power connector is a standard AC

plug receptacle for 120 or 240 VAC power mains. The plug is

compatible with each available power cord option.

2. ZERO CARRIER PULSE OUTPUT. The ZERO CARRIER PULSE

OUTPUT produces a reference pulse that triggers a demodulator .

Signal amplitude is 1.5 V

TTL compatible when driving a high impedance. This pulse is

compatible with the trigger inputs on the following Tektronix

Demodulators: DS1200, TDM5, 1450, 1340, and 1350.

2

5

when driving a 75 W load or

p-p

3 4

3. EXT REF. This high-impedance, loop-through input (two BNC

connectors) accepts external reference signals of composite video

or black burst (1 V

sync information. The input is AC coupled and compensated for

75 W. It is not internally terminated.

4. INPUT. This high-impedance, loop-through input (two BNC

connectors) accepts video input signals for the video measurement set. The input is AC coupled and compensated for 75 W. It

is not internally terminated.

VM100 & VM101 User Manual

). Use this input if the video input has no

p-p

2–7

Operating Basics

5. RS232 Port. This nine-pin subminiature D-type female connector

provides an RS-232 serial interface for printer and computer

communication. The port also provides the interface for the

waveform monitor control function. See Appendix B: Remote

Control for pin assignments and a listing of remote commands.

2–8

VM100 & VM101 User Manual

Tutorial

Operating Basics

The following tutorial shows how to use most of the video

measurement set features. See the Reference section, which begins

on page 3–1, for more detailed information on interpreting specific

measurements.

During the tutorial you will perform the following tasks:

H Configure the instrument

H Perform signal identification

H T ake signal measurements

H Use freeze mode

H Save measurement results

H Print measurement and signal identification results (optional)

The required equipment to perform the tutorial includes a signal

source such as a live video feed or the output of an NTSC or PAL TV

signal generator with inserted VITS. If you want to print the

measurement results, you will also need an ASCII printer with cable.

Table 2–1 shows the equipment needed to complete the tutorial.

Table 2–1: Equipment for tutorial

Item Description

Test Signal Generator Produces NTSC and PAL

Cable, Precision 75 W

Coaxial

Termination, 75 W 75 W, male BNC connector

Serial ASCII Printer with

Cable (optional)

Minimum Requirements Example

signals

75 W, 42 in, male-to-male

BNC connectors

Nine-pin subminiature D-type

male connector

Tektronix TSG95

Tektronix part number

012–0074–00

Tektronix part number

011–0102–01

General purpose printer

with serial port

VM100 & VM101 User Manual

2–9

Operating Basics

Initial Setup

1. Connect the test equipment as shown in Figure 2–6.

TV signal generator

Printer (optional)

VM10X(rear)

RS-232 cable

BNC cable

Figure 2–6: Equipment setup for the tutorial

2. Power on the video measurement set as follows:

a. Connect the video measurement set to the AC power

source.

b. Wait until you can read the LCD display (approximately

10 seconds).

3. Power on the TV signal generator and printer (if connected).

4. On the video measurement set, press the AVG button to turn

averaging on (LED lights).

NOTE. You will normally operate the video measurement set with

averaging turned on.

75 W

2–10

VM100 & VM101 User Manual

Operating Basics

Instrument Configuration

NOTE. If the video measurement set displays the message No video

present, or no lock possible, check the connection and quality

of the video signal before proceeding.

The video measurement set is ready to begin taking measurements

immediately after power on. For the purpose of this tutorial you must

change or verify some instrument parameters before proceeding:

1. Turn on all measurements within the CONFIGURE MEASURE…

menu as follows:

a. Press the CONFIG button.

NOTE. No new measurements are performed while CONFIG is on.

The REPort and MEMory:SAVe commands use the results that wer e

present when CONFIG was pressed.

b. Press the ↵ enter button to enter the CONFIG--MEAS

submenu.

c. Use the ← or → arrow button to select DIFF PHASE = On.

d. Use the ↓ arrow button to select DIFF GAIN.

e. Use the ← or → arrow button to select DIFF GAIN = On.

f. Repeat steps d and e for each measurement within the list.

See page 1–9 for a complete list of the measurements.

2. If you want to print the measurement results, configure the

RS-232 serial port for your printer. See page 1–14 for detailed

instructions.

NOTE. Be sure to match the video measurement set printer parameters to your printer. Refer to the manual for your printer for the

correct settings. Refer to Appendix B: Remote Control for a detailed

description of the RS-232 serial port pinout.

VM100 & VM101 User Manual

2–1 1

Operating Basics

Signal Identification

The SIG ID menu, used when the SIG ID range is set to VITS or

FULL, displays the name of the video signal that appears on a

specific line. Perform the following procedure to identify the signals

on each line of your test signal:

1. Press the SIG ID button. Check the display for the field 1:line 9

signal identification for VM100. For the VM101, if the SIG ID

range is VITS check for field1:line 5; if the SIG ID range is

FULL, check for field 1:line 23 (Figure 2–7).

Figure 2–7: Example of the initial SIG ID display

2. Use the ↓ or ↑ arrow buttons to scroll through the vertical

interval test signals.

Each time you press the arrow button the display shows the name

and location of the next VITS. The decoded source ID code, if

present, appears on the right side of the bottom readout line

(Figure 2–8).

Source

ID code

Figure 2–8: Example of a SIG ID display with source ID code

2–12

VM100 & VM101 User Manual

Operating Basics

Signal Measurements

The MEAS button displays the results of signal measurements.

Perform the following procedure to use the MEAS feature:

1. If the LED in the AVG button is not lit, press the AVG button.

Measurements are normally made with averaging turned on.

2. Press the MEAS button.

Measurement mode is now active (the LED in the MEAS button

lights). SIG ID mode turns off automatically when you turn on

measurement mode. The display shows the results of the first

available measurement (Figure 2–9).

Figure 2–9: Example of differential phase measurement results

3. Use the ↓ or ↑ arrow buttons to scroll through the measurement

screens.

While in the measurement mode the video measurement set takes

measurements continuously. You will only see the results of

measurements that are turned on. (You turned them all on at the

beginning of this tutorial).

In general, the top line of the display contains the measurement

type on the left and the measured value on the right. The bottom

line contains the location and name of the signal that was used to

take the measurement. The video measurement set automatically

finds the best available signal to use for taking each measurement. For more detailed information about specific measurements, see the Reference section.

4. Use the ← or → arrow buttons to view the measurement results

for each field, line, and signal on which the measurement is

made.

VM100 & VM101 User Manual

2–13

Operating Basics

In MANUAL SIGNAL IDENTIFICATION mode, you can

change signals for measurement quickly by turning FREEZE on

and holding the ← or → arrow button down; releasing the arrow

button will cause the new signal to be identified. Remember to

turn FREEZE off to resume measurement.

Each time you select a new signal, the video measurement set

first updates the field, line, and signal readouts at the bottom of

the display. After the field, line, and signal readouts update, you

must wait a few seconds for the new measurement results to

appear on the display. If only one signal is available the

measurement results do not change when you press the ← or →

arrow buttons.

NOTE. If you select a new signal for the DIFF PHASE and YC GAIN

measur ements, the new signal is automatically used for the

DIFF GAIN and YC DELAY measurements, respectively. The video

measur ement set performs all other measurements independently.

Freezing the Measurement Activity

The freeze feature stops all acquisition and measurement activity.

You can then view the intermediate results of your measurement.

1. If the LED in the MEAS button is not lit, press the MEAS button

to turn on the measurement mode.

2. Repetitively press the ↓ or ↑ arrow button until the signal-to-

noise ratio (SNR) results are displayed. Notice how the

measurement results change over time.

3. Press the FREEZE button to turn on the freeze feature. The

measurements results do not change any more.

NOTE. No new measurements are performed while FREEZE is on.

The REPort and MEMory:SAVe commands use the results that wer e

present when FREEZE was pressed.

2–14

VM100 & VM101 User Manual

Operating Basics

4. Press the FREEZE button to turn off the freeze feature.

Storing Measurement Results

The memory function allows you to store measurement and signal

identification results. During the following procedure you save

measurement results to memory, rename the memory location, view

the saved results, and erase the results from memory.

NOTE. When you press the MEM button, the measurement mode

automatically turns off.

1. Press the MEM button.

2. Press the ↵ enter button to save the latest measurement results

into a new memory location (Figure 2–10).

If the save is successful, the next screen allows you to rename the

saved memory. If you receive a message that indicates you are

not able to save the results, refer to page 3–9 for instructions to

clear the memory before proceeding.

Figure 2–10: Measurements saved to memory

NOTE. You do not need to change the name of the memory location.

To accept the default name (such as UNNAMED–06), simply press

the enter button to accept the default name.

You cannot use the same name for more than one memory location.

3. To rename the memory location, press the ↵ enter button.

VM100 & VM101 User Manual

2–15

Operating Basics

NOTE. When renaming a memory location, you cannot use the name

UNNAMED–XX where “XX” is any combination of characters.

4. Use the ↓ or ↑ arrow buttons to select the first character of the

new name (Figure 2–11).

Name of memory location

Figure 2–11: Renaming a memory location

5. Press the → arrow button to move the cursor to the right, then use

the ↓ or ↑ arrow buttons to select the next character .

6. Repeat step 5 until the new name is complete (you can enter up to

ten characters).

7. Press the ↵ enter button to accept the new name.

8. To view the stored measurement results, press the ↑ arrow button

to display the message PRESS ↵ TO VIEW MEMORY.

9. Repetitively press the ← or → arrow button to select the memory

location you named in step 7.

10.Press the ↵ enter button to view the selected memory.

The first display contains the date and time stamp for the

measurement results (Figure 2–12).

2–16

VM100 & VM101 User Manual

Operating Basics

Figure 2–12: Date and time stamp display

11. Use the ↓ arrow button to scroll through the measurement results

and the signal identification screens.

12.To exit view mode, press the ↵ enter button or the MEM button.

13.Press the ↑ arrow button to display the message ↵

.

14.Use the ← or → arrow button to select the memory location you

named in step 7.

15.Press the ↵ enter button to erase the selected memory.

16.Repeat steps 8 and 9 to verify the memory location has been

erased.

Printing Measurement and Signal Identification Results

You can send the measurement and signal identification results from

the video measurement set directly to a printer . Use the following

procedure to print your test results with a title:

NOTE. Be sure that you have configured the RS-232 serial port for

your printer. See page 1–14 for detailed instructions.

If the RS-232 serial port is not configured for a printer, the PRINT

button is inactive.

1. If you have not already done so, connect the video measurement

set to the printer.

2. Press the MEAS button to turn on the measurement mode.

3. On the video measurement set, press the PRINT button.

VM100 & VM101 User Manual

2–17

Operating Basics

The following message appears on the display: ↵

.

NOTE. You can print the measurement results without a title. To do

so, press the ↵ enter button now.

4. To add a title to your printout, press the ↓ arrow button until the

message ↵ is displayed.

5. To add the title press the ↵ enter button.

6. Use the ↓ or ↑ arrow buttons to select the first character of the

new name.

7. Press the → arrow button to move the cursor to the right; use the

↓ or ↑ arrow buttons to select the next character (Figure 2–13).

Title

Figure 2–13: Adding a title

8. Repeat step 7 until the title is complete (you can enter up to ten

characters).

9. Press the ↵ enter button to accept the title.

10.Press the ↵ enter button to print the current measurement results

with your title.

The message appears after printing completes

successfully.

11. Press the ↵ enter button or the PRINT button to remove the

message.

2–18

VM100 & VM101 User Manual

Operating Basics

Using Limits

Use the limit check feature to verify if the measurement results are

within specified limits. Limit violations are shown on the LCD

display or returned from a query via the RS-232 remote control

interface. Limit checking can be enabled or disabled from either the

front panel controls or the remote control interface. If a limit table is

in effect when a measurement is stored, the contents of the limit

table will be saved with the signal and measurement data,

Limits are only checked at the time of display, the time of reporting,

or when the signal memory is recalled. During front-panel operation,

a limit is not checked unless the measurement is currently displayed.

During remote-control operation, a limit is not checked unless a

measurement or report command is issued while the violation is

occurring.

Four limit tables containing different values can be loaded into the

video measurement set through the remote control interface. The

limit tables can be selected from the front-panel configuration menu

or by using the remote control CONfigure:LIMit command.

NOTE. Limit values cannot be modified or inspected from the front

panel.

Exceeded limits are indicated on the LCD display by either an ↑ or ↓

arrow before the measurement value. See Figure 2–14.

Figure 2–14: T ypical high-limit error display

When measurements are reported remotely, exceeded limits are

indicated by a > or < symbol placed to the right of the measurement

value, followed by the limit value that was violated. The symbol

VM100 & VM101 User Manual

2–19

Operating Basics

indicates that the measurement value is either greater than or less

than the high or low limit value. See Figure 2–15.

Up arrow precedes measurement readout

+3.0

Signal value

0.0

Down arrow precedes measurement readout

Figure 2–15: Limit Violation

This completes the Tutorial.

HIGH LIMIT

No arrow

LOW LIMIT

2–20

VM100 & VM101 User Manual

Reference

General Feature Reference

The Reference section provides advanced information about the

video measurement set features. It is divided into the following

subsections:

H General Feature Refer ence explains how to use the basic

instrument features that are controlled from the front panel

H Taking NTSC Measurements on page 3–17 explains how to take

each of the built-in NTSC measurements using a VM100

H Taking PAL Measurements on page 3–43 explains how to take

each of the built-in PAL measurements using a VM101

Within the General Feature Reference section you will find detailed

information about features you access from the front panel, including

the following:

H Signal Averaging on page 3–2 explains how to use the averaging

function

H Freezing the Measurement Activity on page 3–3 provides

detailed information about the freeze feature

H Using Signal Identification on page 3–3 explains how to use the

SIG ID feature

H Using Memory Functions on page 3–6 explains how to use each

memory function

H Printing Measurement Results on page 3–11 explains how to print

test results, or upload them to a computer

H Using the Waveform Monitor Control Function on page 3–14

explains how to view the waveform on a monitor while the video

measurement set takes measurements

H Using the Zero Carrier Reference Pulse Output on page 3–16

explains how to use the Zero Carrier Reference Pulse Output

VM100 & VM101 User Manual

3–1

General Feature Reference

Signal Averaging

The AVG button is an on-off toggle switch that affects all of the

measurements. An LED indicator located at the center of the button

lights when averaging is ON. Use averaging to reduce the effect of

noise on your signal measurements.

How Averaging Works