Page 1

KPC-TM

and

KPC488.2TM

Trigger MasterTM

Interfaces

Page 2

Page 3

User Guide

for the for the

KPGTM and KPC488.2TM KPGTM and KPC488.2TM

Trigger Master”” Trigger Master””

--

Interfaces Interfaces

Copvrishfl Kdtbley Data Acquisilicm 1993

KEITHLEY DATA ACQUlSlTiON - Keithley MetraSyWAsyst

440 Myles Slandiih Blvd., Taunton, MA 02780

RwisionA-FebntaylSS8

ParI Number: 24461

TEL 508/880-3000, FAX 508/880.0179

-3-

Page 4

Warranty Information

All products manufactured by KeithIey Data Acquisition are warrantedagsinst defective materials and

workmanship foraperiodofone year from thedateof delivery to theoriginalpurchaser. Any product

that is found to be defective within the warranty period will, at the option of the manufacmrer, be

repaired or replaced. This warnutty does not apply M products damaged by improper use,

Warning

Keithley Data Acquisition assumes no liability for damages consequent

lo the use of tkii product. This product is not designed with

components of a level of reliability suitable for use io life support or

critical applications.

Information furnished by Keithley Data Acquisition is believed to beaccurateandreliable. However,

Keithley Data Acquisition assumes no responsibility for the use of such information nor for any

infringements of patents or other rights of third parties that may result from its use. No license is

granted by implication or otherwise under any patent rights of Keithley Data Acquisition.

Copyright

All tights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form by any means, electronic, mechanical, photoreproductive, recording, or

otherwise without the express prior written permission of Keithley Data Acquisition.

Note:

Keitkley MetraBy@‘, Trigger Mast@‘, and Trigger-LiokTM are trademarks of Keithley Data

Acquisition.

BASKI?’ is a trademark of Dsrtmouth College.

IBM@’ and Micro Channel Architecture’” are registered trademarks of International Business

Machines Corporation.

PC, XT, AT, and PSh sre trademarks of International Business Machines Corporation.

MicrosofttR’ is a registered trademark of Microsoft Corporation.

Turbo C’“’ and TurboPascal’*’ sre registered trademarks of Borland IntemationaI.

-4-

Page 5

CHAPTER 1 - INTRODUCTION

Contents

1.1

1.2

1.3

1.4

CHAPTER 2 - INSTALLING Trigger

2.1

2.2

2.3

2.4

2.5 Installing Trigger Master

2.6 Running PLAYDOS.EXE or PLAYWIN.EXE

General Description

Distribution Software

Specifications

Trigger-Link

Master

Introduction

Inspecting the Boards

Setting Up the KPC-TM Board

Setting Up the KPC488.2TM Board

CHAPTER 3 - USING THE Trigger Master DRIVER

3.1

3.2

3.3

3.4

3.5

Introduction

Using the Driver

Using the Driver with BASICA

Accessing the Driver from C

Accessing the Driver from QuickBASIC and VisualBASIC

QuickBASIC

VisualBASIC

Accessing the Driver from TurboPascal

STCINIT

Calling STCINIT from BASICA

Calling STCINIT from C

Calling STCINIT from QuickBASIC and VisualBASIC

Calling STCINIT from TurboPascal and TurboPascal for Windows

STCSET

Calling STCSET from BASICA

Calling STCSETfmm C

Calling STCSET from QuickBASiC and VisualBASIC

Calling STCSET from TurboPascal and TurboPascal for Windows

STCCMD

Command Syntax

General Information

Line Numbers

Extensions

Integer Arguments

Time Scales

l-l

1-4

I-4

1-5

2-1

2-1

2-2

2-3

2-4

2-4

3-1

3-I

3-1

3-2

3-2

3-2

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-6

3-6

3-6

3-7

3-7

3-7

3-8

3-8

3-Q

3-9

3-Q

3-10

Page 6

Contents

3.6

Sending Commands in the Programming Languages

Calling STCCMD from BASICA

Calling STCCMD from C

Calling STCCMD from QuickBASIC and VisualBASIC

Calling STCCMD from TurboPascal and

TurboPascal for Windows

The Command Set

ARM

BEGIN

CONT

DO

END

FLAG

HALT

LOOP

TRIG

WAIT

X

STCSTAT

Request Syntax

General

Extensions

Making Requests in Programming Languages

Calling STCSTAT from BASICA

Calling STCSTAT from C

Calling STCSTAT from QuickBASIC and VisualBASIC

Calling STCSTAT from TurboPascal and

TurboPascal for Windows

Values Returned by STCSTAT

Interpreting Values in BASICA

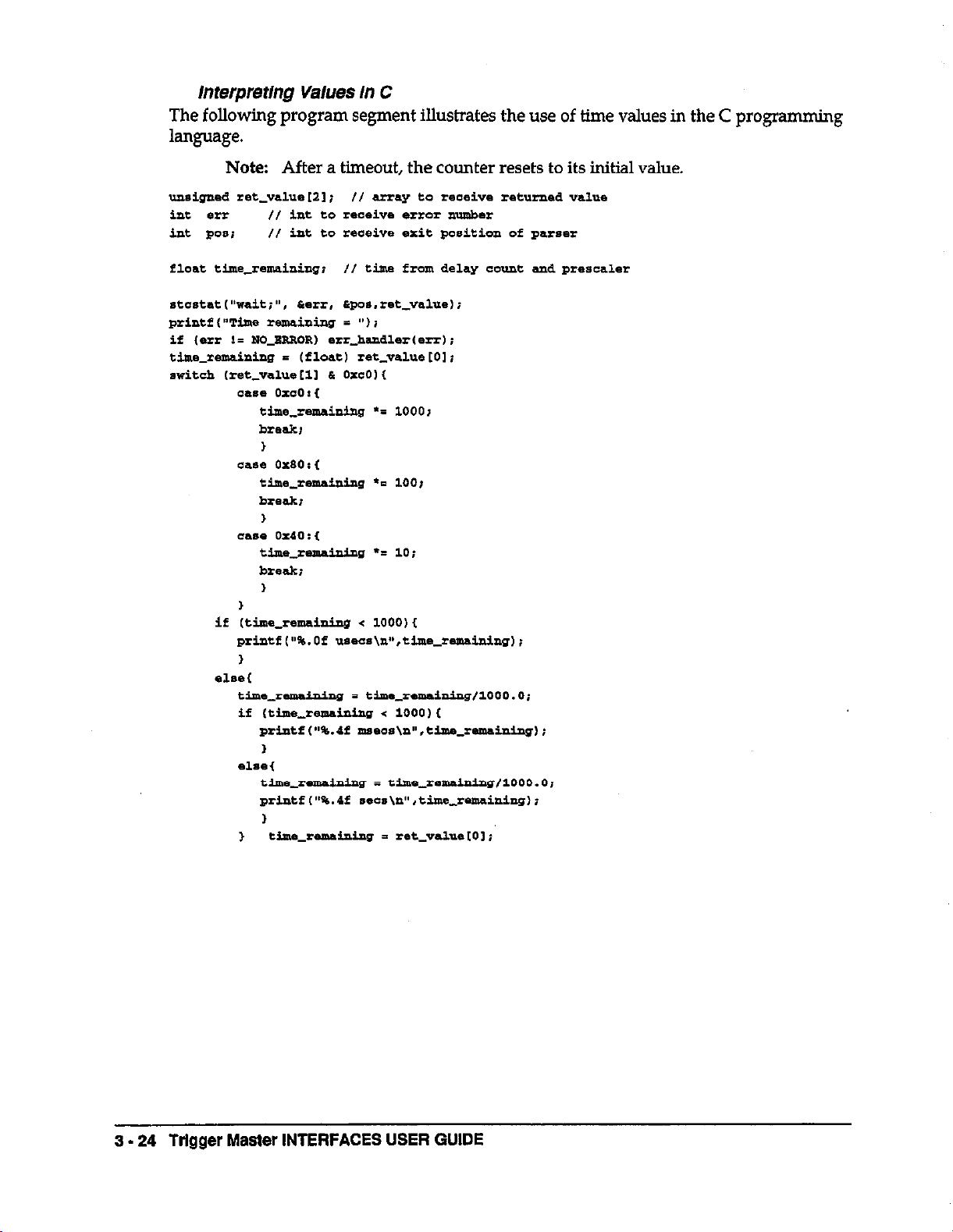

Interpreting Values in C

Interpreting Values in QuickBASIC and VisualBASIC

Interpreting Values in TurboPascal and

TurboPascal for Windows

The Request Set

ARM

CONT

FLAG

LOOP

STATUS

TRIG

WAIT

3-l 1

3-11

3-l 1

3-12

3-12

3-13

3-13

3-14

3-14

3-15

3-15

3-15

3-l 6

3-16

3-16

3-17

3-17

3-18

3-19

3-19

3-19

3-19

3-20

3-20

3-20

3-21

3-21

3-22

3-24

3-25

3-26

3-27

3-27

3-27

3-28

3-28

3-29

3-30

3-31

-6-

Page 7

3.7

3.8

CHAPTER 4 - PROGRAMMING EXAMPLES

STCLOAD

Calling STCLOAD from BASICA

Calling STCLOAD from C

Calling STCLOAD from QuickBASIC and VisualBASIC

Calling STCLOAD from TurboPascal and

TurboPascal for Window

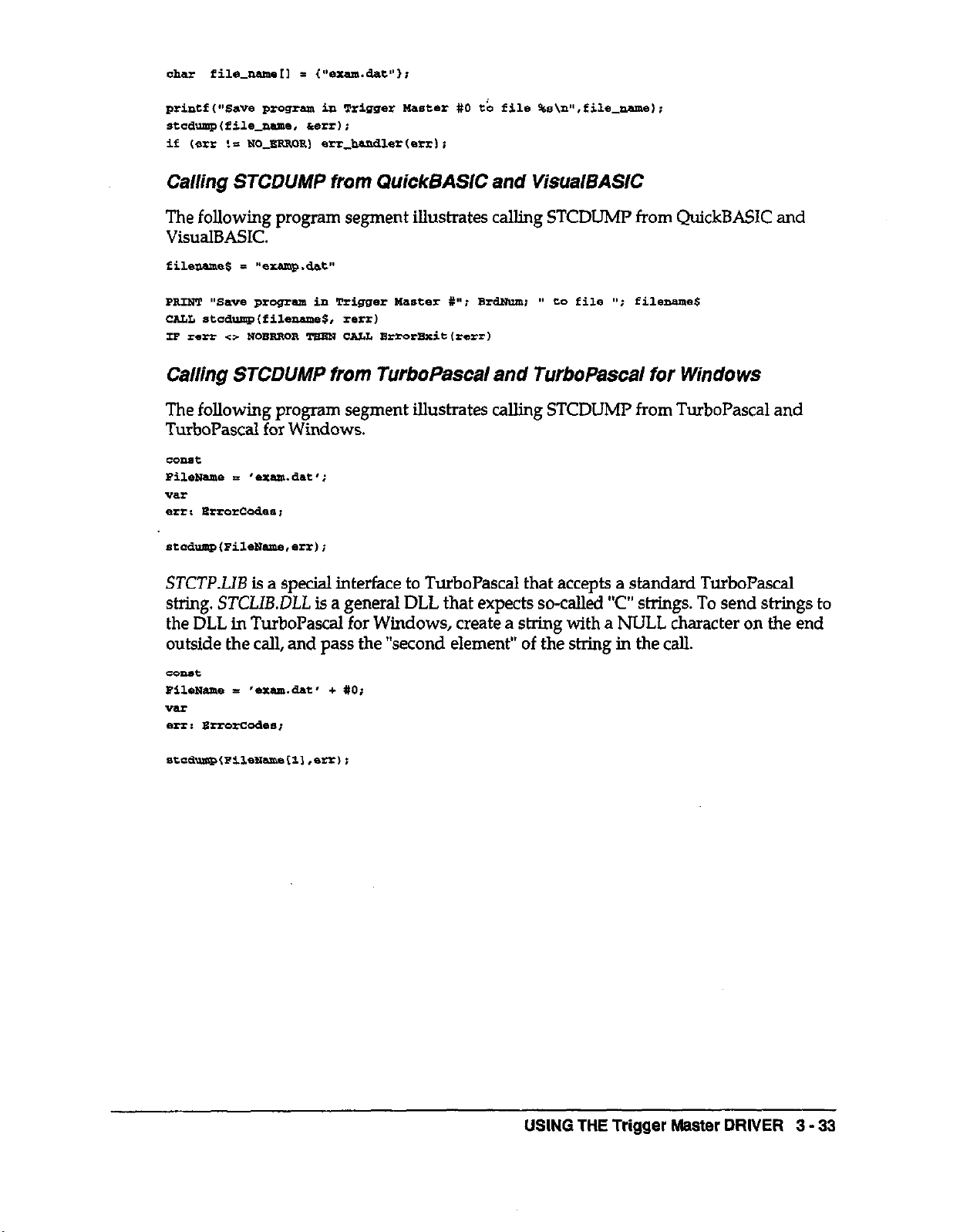

STCDUMP

Calling STCDUMP from BASICA

Calling STCDUMP from C

Calling STCDUMP from QuickBASIC and VisualBASIC

Calling STCDUMP from TurboPascal and

TurboPascal for Window

3-31

3-31 3-31

3-32

3-32

3-32

3-32

3-33

3-33

3-33

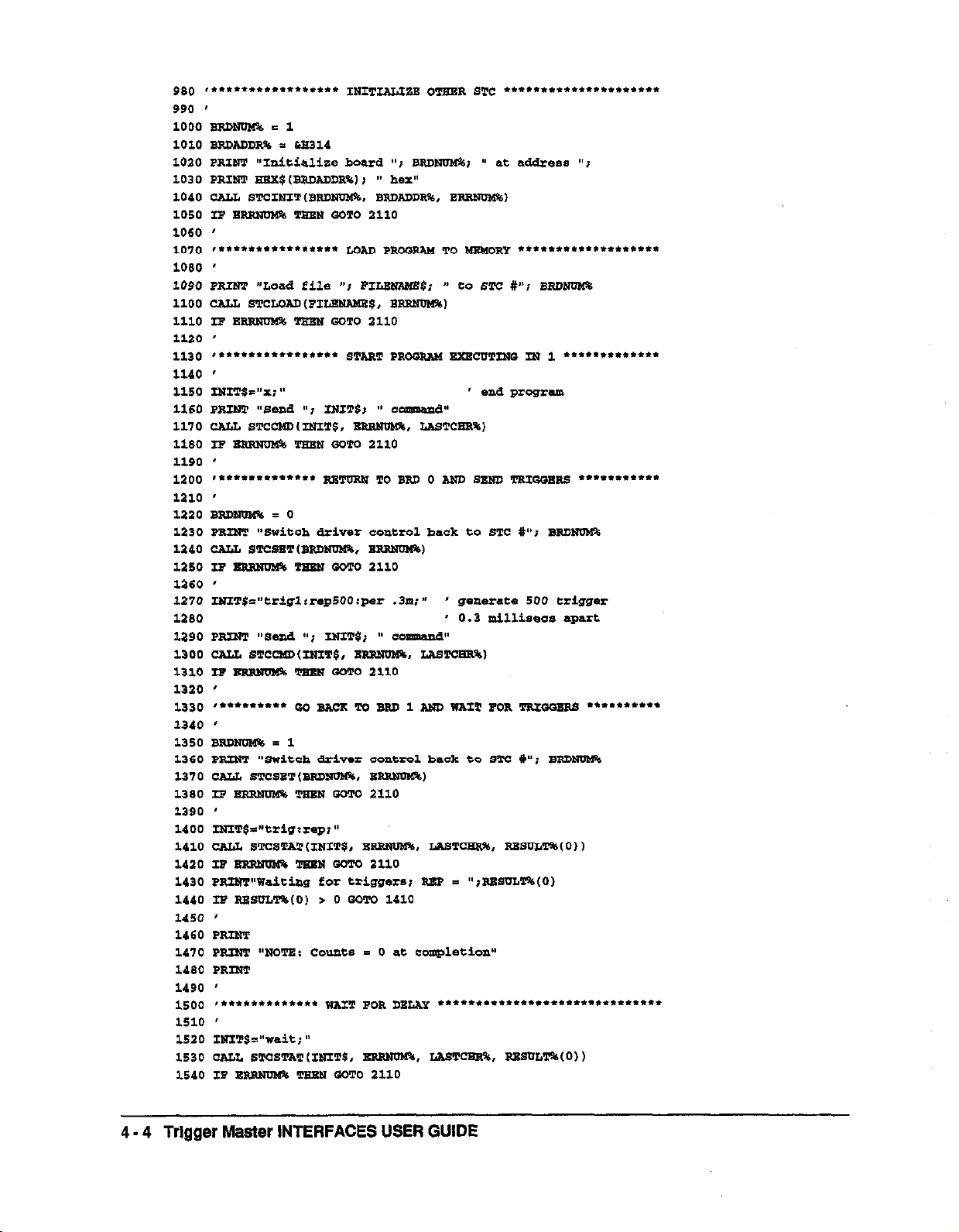

4.1

4.2 BASICA Language Example

4.3 C Language Example

4.4 QuickBASIC Example

4.5

CHAPTER 5 - CREATING PROGRAMS FOR Trigger Master MEMORY

5.1

CHAPTER 6 - CREATING A BACKGROUND DATA ACQUlSllION SYSTEM

FORDOS

6.1

6.2

6.3

6.4

6.5

Introduction

TurboPascal Example

Introduction 5-1

Introduction

The TSR Structure 6-2

NOKPC488 and MISSINGGPIBDEV 6-3

STCRUN

WAITONSTC and JMPWAITSTC 6-5

WAITONGPIB and WAITONAUX 6-5

STCFLAG 6-5

STCLOG 6-6

STCEXIT 6-6

A TSR Log 6-7

A TSR Example 6-8

Creating a TSR for C

4-1

4-2

4-7

4-11

4-15

6-1

6-4

6-11

- 7.

Page 8

Contents

APPENDIXES

Appendix A - Trigger Master ERROR MESSAGES

Appendix 6 - COMMAND QUICK START

B.l

8.2

8.3

0.4

8.5

B.6

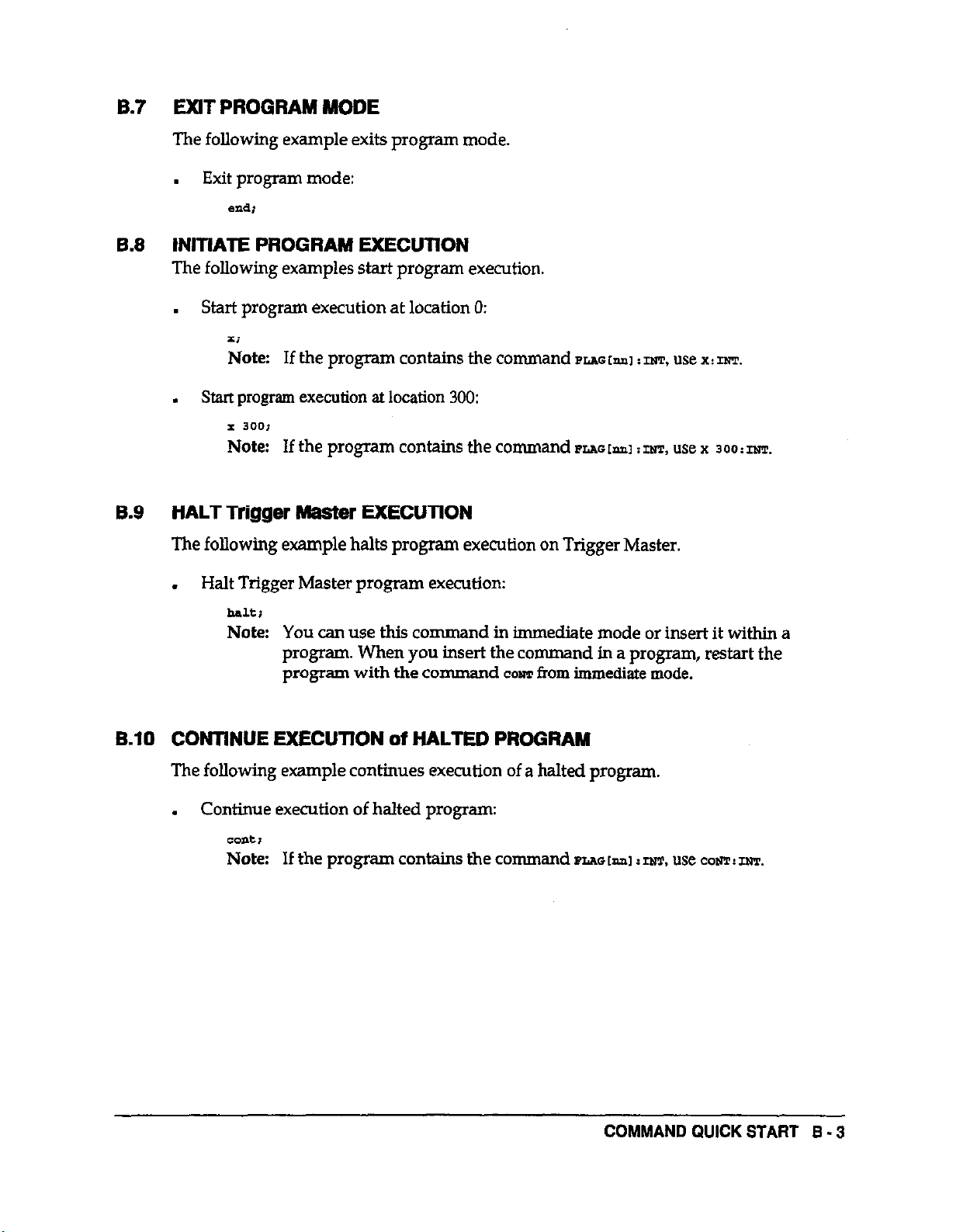

B.7

8.6

B.9

B.10

Appendix C -

C.1

c.2

c.3

c.4

C.5

C.6

c.7

Generate Trigger Outputs

Waft For Trigger Inputs

Enter Program Mode

Set Up and Terminate Program Loop (Program Mode Only)

Generate a Wait (Program Mode Only)

Track Program Execution and Generate interrupts

Exit Program Mode

lnftiate Program Execution

Halt Trigger Master Execution

Continue Execution of Halted Program

REQUEST QUICK START

Check Remaining Trigger Inputs Established by

ARM Command

Check Remaining Trigger Outputs Established by TRIG Command

Check the Actual State of the Trigger Lines

Check Time Remaining Before Next Trigger

Check Program Progress

Check Remaining Loop Count

Check Remaining Delay Time

B-1

B-l

B-2

B-2

0-2

B-2

B-3

B-3

B-3

B-3

C-l

C-l

C-l

C-l

c-2

c-2

c-2

-.s-

Page 9

1.1 GENERAL DESCRIPTION

Trigger Masterm is a system trigger controller for instruments and data acquisition

boards with external triggering. Trigger Master supports a variety of trigger functions

occurring in data acquisition systems. Trigger Master monitors trigger inputs, creates

delays, and generates trigger outputs.

An outstanding feature of Trigger Master is its ability to run programs from its own

memory and to generate interrupts at appropriate steps of program execution. This

allows Trigger Master, with

autonomous data acquisition system in your personal computer (PC) while you use

your PC for other purposes,

Trigger Master is implemented on two boards:

some

Chapter 1

INTRODUCTION

adjunct data acquisition hardware, to operate as an

. The KPC-TM board provides Trigger Master as a stand-alone plug-in board for the

PCru/XTn’/ATn”’ computer.

. The KPC488.2TM board combines Trigger Master with the high performance

KPC488.2AT GPIB interface to provide a standard interface with GPIB instruments.

Note: This manual describes Trigger Master. For information on the IEEE-488

functions, refer to the manual IEEE 488 Interface Boards which accompanies the

KPC488.2TM board.

Figure l-1 is a block diagram of Trigger Master.

Physically, Trigger Master is equipped with an 8-pin MicroDIN connector which has 6

trigger lines and 2 ground lines. In addition to Trigger-Linkn’ introduced later in this

chapter, the MicroDIN can connect directly to standard BNC connectors using the 8502

Trigger-Link Adapter.

Chapter 2 describes configuring and installtng the boards.

Trigger Master employs proprietary chips containing state machines that run from an 8-

MHz clock. This allows Trigger Master to respond to a change of trigger inputs by

generating a trigger output within 1.25 us. The state machine coordinates all functions

including the interfaces to Trigger-Link and the PC bus.

A PC program controls Trigger Master using 11 SCPI-like commands which a driver

transforms to microcode instructions, sending them to Trigger Master. Trigger Master

supports three modes of operation:

INTRODUCTION l-1

Page 10

Figure

.

l-1

Trigger Master Block Diagram

One mode of operation, Immediate Mode, allows some commands to be executed

immediately by Trigger Master.

. The second mode of operation, Progrum Mode, allows Trigger Master to store

commands in a 1-Kbyte program RAM as they are received for later execution.

Storing the program into RAM provides extremely powerful performance, since the

state machine can perform two level looping (one nested loop); for repeated

operations, the state machine uses available counters. This mode allows you to start

program storage and execution at any memory location, therefore allowing several

small programs to be resident in memory and allowing you to start them as

required.

. The third mode of operation, Run Mode, occurs while the Trigger Master executes a

program.

A user can generate trigger programs using any of the following methods:

Pass command strings from the user program to the Trigger Master driver.

.

. Write trigger programs using an ASCII-output word processor and then compile the

programs with STCCOMP.EXE.

Program interactively using PLAYWIN.EXE and PLAYDOSEXE, running,

.

respectively, from the Windows and DOS environments.

Any word processor that provides ASCII output allows you to write Trigger Master

programs, store them in ASCII, and then “compile” the output using the STCCOMP.EXE

program. Chapter 6 describes this procedure. The resulting “object” file is then easily

loaded into Trigger Master program memory and executed.

1 - 2 Trigger Master INTERFACES USER GUIDE

Page 11

The Trigger Master driver supports up to four boards simultaneously. The driver

accepts the following commands:

ARM

Set trigger input condition and wait for trigger

BEGIN Enter program mode

CONT Restart a halted program at the next step

DO Mark the start of a program sequence that is to be performed as a loop

END

Mark the end of a program mode sequence with a HALT and return to

immediate mode

FLAG Write a value to a diagnostic flag register (to trace program execution)

HALT Halt Trigger Master operation

LOOP Mark the end of a program loop

TRIG Generate triggers

WALT Cause a program to execute a time delay

X Begin program execution

The program STCRUNCOBJ, described in Chapter 6, builds terminate-and-stay-resident

programs (TsRs) for programs written in C. These programs are driven by interrupts

generated by

the

Trigger Master; the programs can run in the background in a DOS

environment while you run other programs from DOS.

Chapter 3 describes the PLAYDOSEXE and PLAYWIN.EXE programs which allow you

to become familiar with the commands and requests, test your hardware without doing

any programming, and generate Trigger Master programs for future execution.

PLAYDOSEXE

runs in the DOS environment, while

PLAYWINEXE executes from

Windows. Refer to Appendix B for a quick start on the commands and Chapter 3 for a

detailed description of the commands.

In addition to sending commands to Trigger Master you can also request information

from Trigger Master. Trigger Master supports the following requests:

ARM

CONT

FLAG

LOOP

Return information about the trigger detect circuitry

Return the current Trigger Master program position

Read the value from the diagnostic flag register

Return the execution status of a Trigger Master program loop

STATUS Return the value from the Trigger Master status register

TRIG

WAIT

Return information about the trigger output circuitry

Return the remaining delay time

Refer to Appendix C for a quick start on the requests and see Chapter 3 for a detailed

description of the requests. Chapter 4 provides programming examples of the

commands and requests in the supported languages.

INTRODUCTION l-3

Page 12

1.2 DISTRIBUTION SOFIWARE

This manual refers to Trigger Master software as the Di.dribution Software. The

Distribution Software contains utility files and driver files. Chapter 3 discusses these

1.3 SPEClFlCATlONS

Channels:

Basic Functions:

Micro Sequencer:

Modes:

Looping:

Loop Repeat:

Trigger Repeat:

Sequencer RAM:

Time Base Drift:

Trigger Input Pulse Width:

Trigger Output Pulse Width:

Detection Latency:

Async Trigger Latency:

Programmable Delay:

Trigger Connector:

Modes:

Power Consumption:

6 Input/Output

Trigger Detection

Trigger Generation

Delay Generation

PC Interrupts

Program, Immediate, or Run

2 Levels

1 - 4096

l-4096

1024 bytes

100 ppm max

4OOnsmin

5us

900 ns max

2.2 us max (trigger in to trigger out)

Range Resolution

1 us to 65.536 ms

10 us to 655.36 ms

100 us to 6.5546 set

1 ms to 65.536 set

1 us

1ous

100 us

1 ms

&pin microDIN

Sync, semi-sync (Trigger-Link), async

KPC-TM:

KPC488.2T2TM:

450 mA @5V max

1650 mA @5V max

Environmental:

Operating Temperature:

Storage Temperature:

Humidity:

oto+70c

-25 to +85 C

0 to 95%, non-condensing

Dimensions:

KPC-TM:

KPC488.2TM:

4.25 in H x 5.0 in. W (half-slot)

4.25 in. H x 13.25 in. W (ii.ilI slot)

Software:

Call Driver Languages:

Trigger Master DLL:

1 - 4 Trlgger Master INTERFACES USER GUIDE

BASICTM, QuickBASIC, C, Turbol’ascalsr’,

VisualBASIC for DOS.

Operation with Windows 3.x languages. Includes

VisualBASIC, Borland C++, C for Windows, and

TurboPascal.

Page 13

1.4

Trigger-Link

Trigger Master supports Trigger-Liim,

accuracy, and throughput to test and instrumentation systems. This section introduces

the features of Trigger-Link

You can easily change the trigger paths between instruments using Trigger-Link with

GPIB commands. The precise trigger signals on Trigger-Link enhance the accuracy and

throughput of the system. Even systems which contain lnsbuments without Trlgger-

Link can benefit by using the 8502 Trigger-Link Adapter. The 8502 Trigger-Link Adapter

is the interface to Trigger-Link for conventional BNC trigger connections. Figure l-2

illustrates various Trigger-Link configurations.

Mechanically, Trigger-Link consists of a cable with six signal paths and two grounds

which can be permanently daisy-chained between a group of instruments. The signal

paths convey trigger signals between instruments. With GPIB commands, instruments

can be configured to use one or more of the signal paths in a variety of modes. Thus the

trigger configuration of a group of instruments can be easily altered by software to suit

the requirements of a particular test.

ElectricalIy, Trigger-Link provides paths for trigger pulses between instruments, thus

eliminating the late&es involved with coordinating trigger functions with the GPIB

interface. This greatly increases system throughput and measurement preciseness for all

instrument systems. Instruments, which completely embrace the Trigger-Link standard,

employ a fast-track link between the trigger input and function execution and between

function conclusion and acknowledge output. Today, many instruments service the

trigger/acknowledge connectors periodically using a microprocessor that performs

other functions. However, this procedure results in unknown and variable timing

latencles as well as slower response.

which brings a new dimension of flexibility,

Trigger-Link supports three trigger modes:

SYNC MODE A source sends a trigger pulse or sequence of pulses to synchronize

the activities of one or more receivers. There is no acknowledgement

from the receiver(s) that they have received a pulse and are

responding properly to the trigger(s).

ASYNC MODE

The conventional two-wire handshake protocol where triggers are

sent on one line and the receiver acknowledges on a second line.

Conceivably, multiple instruments could share a common trigger

source, but each instrument would require a separate

acknowledgement line.

SEMI-SYNC

An innovative extension of the async mode which allows a single

trigger source and multiple receivers to carry out a handshake on a

single line. The trigger source will pulse the trigger line to an active

state for about 5 us. Upon receipt of the bigger all receivers wlIl hold

the trigger line in the active state before the trigger source goes

inactive. Each individual receiver will continue to hold the line active

until that receiver is ready to acknowledge it has completed its task.

When the line goes inactive the trigger source will know that all

receivers have completed their tasks.

INTRODUCTION ‘I - 5

Page 14

Figure l-2

I- 6 Trigger Master INTERFACES USER GUIDE

Trigger-Link Configuration Examples

Page 15

Chapter 2

INSTALLING Trigger Master

2.1

INTFlODUCTlON

The installation of Trigger Master includes the following:

. inspecting the KPC-TM and KPC488.2TM boards.

. setting jumpers and switches on

. inserting the two boards into your PC.

attaching all cables to the boards.

.

. running the PLAYDOS.EXE and PLAYWINEXE programs to exercise and verify

proper operation of the boards.

2.2 INSPECTING THE BOARDS

Remove each board from their protective packaging by grasping the metal rear panel

and removing the board from the anti-static bubble package.

Note: You

should handle the boards only by their edges. A static electric

discharge can damage

the

KPC-TM and KPC488.2TM boards.

the

integrated circuits on the boards.

INSTALLING Trigger Master 2 - 1

Page 16

2.3 SETTING UP THE KPC-TM BOARD

The KPC-TM board is a stand-alone system trigger controller which requires four byte-

wide I/O addresses. The board contains a switch to set up the base address in

increments of four bytes. This switch decodes address lines A9 to A2. The KPC-TM

board ships with a default setting of 3lO(hexadecimal) as

position OFF corresponds to a logical 1 and the position ON to a logical 0. Table 2-1 lists

the base addresses with the appropriate switch settings for each address.

shown in

Figure 2-l. The

Figure 2-l

You can configure

changing the jumper

KPC-TM Card Jumper and Switch Locations.

the

KPC-TM board to generate interrupts

on

jumper block J2. Trigger Master ships with the interrupts

on levels 2

through 7 by

disabled as shown in Figure 2-1.

Note: The KPC-TM Base Address switch settings are position values only. Refer to

Table 2-1 for the corresponding Address Line values.

Address

Decimal Hexadecimal

512

256

128

64

32

16

a a

4

200

100

80

40

20

10

4

&&e

9

a

7

6 4

5

4 6

3

2

Switch

m

1

2

3

5

7

a

Table 2-l

2 - 2 Trigger Master INTERFACES USER GUIDE

Base Address Switch Setdngs

Page 17

2.4

SElllNG UP THE KPC488.2Thl BOARD

The KPC488.2TM board implements the trigger master control function and GPIB

control function on the same board. Both the trigger master and GPIEi functions can

generate interrupts. This manual describes the settings for the interrupt Jumpers and the

switch and jumper settings for the GPIB function. Refer to the accompanying user

manual, IEEE 488 Interface Boards, for further information. Figure 2-2 shows the locations

of the jumpers and switches on the KPC488.2Th4 card.

2-2 KPC-488.2TIM Card Jumper and Switch Locations

To prevent the same level from being used by both functions, use the interrupt three-

row jumper blocks to select the interrupt.

Use Jumper blocks J5 and J3, shown in Figures

3-2 and 3-3, to set the interrupts levels for the

GPIB and Trigger Master. The top and middle

rows of the jumper blocks set the GPIB

interrupt level, and the bottom and middle

rows set the Trigger Master level.

. Placing a lumper vertically on the upper

and middle rows enables an interrupt level

for the GPIB. Placing a jumper vertically

the middle and bottom rows enables an

interrupt level for Trigger Master.

. Placing the GPIB jumper horizontally on

the upper row disables the GPIB interrupt and placing the trigger master jumper

horizontally on the bottom row disables the bigger master interrupt.

Figure 2-3 illustrates enabling interrupt level 12 for the GPIB and enabling interrupt

level 15 for Trigger Master (note that level 13 is unavailable on the PC/AT bus).

on

F

3gurfs

r

%ampfe

29 Jumper Blocks J5 and J

INSTALLING Trigger Master

2 - 3

Page 18

Trigger Master requires four byte-wide addresses; use switch SW3 to set the base

address in increments of 4. The switch decodes address lines A9 through A2. The

position OFF corresponds to a logical 1 and the position ON to a logical 0. The boards

ship with a default setting of 3lO(hexadecimal) as shown in Figure 2-2.

2.5 INSTALLING Trigger Master

Follow this procedure to install Trigger Master into your PC.

1. Turn the PC power switch to OFF. Unplug the power cord and disconnect all cables

from the rear of the system unit.

2. Remove the cover mounting screws from the rear of the system unit.

3. Slide the system unit cover forward. When the cover can go no further, tilt it up and

remove it from the base.

Note:

Install the KPC488.2TM board into a 16-bit slot; the KPC-TM board can

use an S-bit slot.

4. Remove the rear panel cover screw from one of the computers add-on slots.

5.

Press the board firmly into the main board expansion slot.

6. Seat Trigger Master cable in the Micro-DIN connector and align the board before

tightening the rear panel mounting screw.

7. Secure the board with the rear panel mounting screw.

8. Align the rear cover, sliding it back into place. Reinstall the mounting screws.

9.

Turn on the PC.

10. Make a backup of all application diskettes before copying the applications to your

PC’s hard disk.

11. Run the PLAYDOSEXE and PLAYWIN.EXE programs to exercise the boards.

Since the Trigger Master cable should seat completely in the MICRO DIN connector, you

may want to insert the cable and test the alignment of the card before tightening the

screw holding the bracket.

2.6 RUNNING PLAYDOSEXE or PLAYYVINEXE

Check the hardware and exercise Trigger Master after installation by running either the

PLAYDOSEXE or PLAYWIN.EXE program. PLAYDOSEXE runs from the DOS

environment and PLAYWIN.EXE executes in the Windows environment.

PLAYDOSEXE and PLAYWIN.EXE provide a menu interface to the standard Trigger

Master driver calls without requiring the use of a programming language. You can also

use these programs to create and document Trigger Master programs.

2

- 4 Trigger Master INTERFACES USER GUIDE

Page 19

The driver supports the following calls, which are described in detail in Chapter 3:

STCCMD Sends Trigger Master commands to the active Trigger Master

either for immediate execution or storage in Trigger Master

program memory.

STCDUMP Saves the contents of the active Trigger Master program memory

to a binary file.

STCINIT Checks for the presence of a Trigger Master. If Trigger Master is

found, it is initialized and made active. The driver can

simultaneously control up to four boards in the same computer.

STCLOAD Loads the contents of a binary file into Trigger Master program

memory.

STCSET

Selects a different Trigger Master to become active (this Trigger

Master must have been initialized).

STCSTAT Requests status information from the active Trigger Master.

The PLAYDOSEXE and PLAYWIN.EXE programs operate by listing these calls in a

main menu. When you select a call from the main menu, a form appropriate to that call

appears. Windows or buttons are provided, where necessary, for entering data or

making selections specific to that call. After l3ling in any blanks on the form, press the

button for the call to start execution. Any error messages retumed

from

the driver are

displayed.

Each form contains a “Help” button that provides assistance on that form. Context-

sensitive help is also available. To enable context-sensitive help, you must first include

the files PLAYWIN.HLP or PLAYDOSHLP in the same directory as the executible files

PLAYWIN.EXE or PLAYDOSEXE. Access help by pressing cFl> in PLAYWIN.EXE or

Shift+<Flz from PLAYDOSEXE.

If you select the STCCMD co mmand

from the main menu, a new menu appears listing

all the possible commands you may include with STCCMD. When you select a

command, another form appears that is specific to the that command. When you push

the STCCMD button, a window displays the comman

d string sent to the driver. The

“Man” selection is an option that allows you to manually.enter your own command

string (the string can contain multiple commands). If an error occurs during execution of

the STCCMD command, the driver displays an error message and places the value “**”

into your command string at the point the driver detected the error.

The “Man” form has a button that enables the “Paste” option. With this option

commands sent without errors from other command forms will also appear in

on,

the

“Man”

form command window. This procedure allows you to document a Trigger Master

program as you create it. You can save the contents Trigger Master memory with the

STCDUMP command. Since the STCDUMP co

mmand creates a non-readable

binary file,

you can use the “paste” provision to save the contents of the command window to obtain

a file of the command sequence used to generate the program.

When you execute the STCSTAT command, the command normally returns the status

only once. When you make a status request from PLAYWIN.EXE or PLAYDOSEXE, a

form is created which continually reads and displays the status. This procedure allows

you to follow the status changes as Trigger Master executes a program or command.

INSTALLING Trigger Master 2 - 5

Page 20

You can also watch the CONT STATUS request during program creation to determine

where the next program instruction will be loaded in memory.

The PLAYDOSEXE and PLAYWIN.EXE programs provide two methods of choosing a

different call or command and exiting a form:

Choose a new form without closing the current form. When you bring the current

.

form back up, the data you previously entered is still in the form. This procedure

simplifies the manual entry of commands, since you can recall the previous ten

commands by using the arrow keys at the side of the

entry

window. You can also

size and position forms to suit your needs.

. Click on the upper-lefthand button and choose the close option from the menu

displayed. When you next bring up the form, the data is reinitialized. To exit the

program, close the main menu (this automatically closes all forms).

2 - 6 Trlgger Master INTERFACES~USER GUIDE

Page 21

Chapter 3

USING THE Trigger Master DRIVER

3.1

INTRODUCTION

The Trigger Master driver supports the following languages: BASICA, Microsofto’

QuickBASIC, VisualBASIC (for DOS and Windows), Microsof@ C, C++, and C for

Windows, and Borlando’ TurboPascal and TurboPascal for Windows.

. For Windows applications, a Trigger Master DLL is placed in your Windows

directory.

. For DOS environment applications in QuickBASIC, VisualBASIC, C, and

TurboPascal, a Trigger Master file is linked with the application program.

.

For BASICA, a Trigger Master binary file is loaded with the program.

For maximum efficiency with all languages, the application program makes a direct call

to the appropriate driver code using the following calls-z

STCINIT

STCSET

STCCMD Sends co mmands to Trigger Master.

Checks for and initializes a Trigger Master at a specified board

address and then sets the driver to control that board. The driver

can simultaneously control up to four boards.

Switches Trigger Master control to a different board. The board

must have been initialized.

STCSTAT

STCLOAD Loads a binary flle into Trigger Master program memory.

STCDUMP Saves Trigger Master program memory to a binary file.

Requests status from Trigger Master.

3.2 USING THE DRIVER

The following sections describe “instalhng” the driver in each of the supported

languages.

Using the Driver with SASICA

Run the following code segment to load the driver In BASICA:

260 CLBhR , 52-1024

270 DBP sxo = 0

’ leave a045 for interface.

USING THE Trigger Master DRIVER 3 - 1

Page 22

Accessing the Driver from C

For Microsoft@’ C, compile your program and link the resulting object file with stcc.Zib

using a command such as the following:

You will need to include at least the function prototypes from stc.h in your program.

Note:

For C or C++ programs running under Windows, do

not link the

program to stcc.Zib. Instead, copy the file sfcIib.dll to your Windows

directory; the function prototypes in stcZib.dZl are identical to those in stc.h.

Accessing the Driver from QuickBASIC and VisualBASIC

QuickBASIC

Use one of the following methods when building an executable program from the DOS

prompt:

. If you use Version 4 or greater or Version 7 with near strings, link your program to

stcqb.lib.

. If you use Version 7 with far strings (compiled with /Fs), link your program to

stcqbzlib.

To run your program in the appropriate QuickBASIC environment, load the program

with one of the following files:

For Version 7, use the file stcqb7.qlb.

.

For Version 4.0 to version 7, use the file stcqb4.qlb.

.

In either case, you must include at least the function protocols from the file stcqb.bi in

your program.

3 - 2 Trigger Master INTERFACES USER GUIDE

Page 23

VisualBASIC

Place VisualBASIC function declarations in the Global section.

. For DOS applications:

To run a program from the environment, use the command VBDOS

/LSTCVED.QLB to load

VisualBASIC

with the Quick Library STCVBD.QLB.

Include function prototypes for the Trigger Master calls by incorporating the

Trigger Master include files with the statement ‘INCLUDE stcvbd.bi. The file

STCVBD.BI also includes error code definitions and an array to hold error

message strings. If you do not need to display error messages, delete the array;

otherwise, use the code in STCVBDLBAS to initialize the srray. You can build an

executable file

from

the environment or from the co mmand line. To build the file

from the command line, first compile each form or BASIC module of your project

using the command line compiler. Then, from the command line, link the

resulting object modules with the Trigger Master VisualBASIC for DOS library

STCVBDJJB to produce the executable file. The following command line

example illustrates the production of the file EXVBDMAK:

Be axvBD.Pm

BC sxvsD.aAs

LIta sxvm BxvBDI,,,STcvBP.LIB;

. For Windows applications:

Copy the file STCUB.DLL to your Widows directory. You will need to include function

prototypes for the Trigger Master calls in your global data The file STCVBWJXT

includes function declarations appropriate for the Global section of a VisualBASIC for

Windows application. This file also defines error codes and an error array. If you wish to

use the error array, you must include code from STCVBHXT in the load procedure of

your first form. The diffarence between the STCVBWXXT file and the DOS program file

STCVBDJXT is in the function declarations which are appropriate to STCLJB.DU.

Accessing the Driver from TurboPascal

Access the driver from a TurboPascal program (version 6) by including the following

statements in your program.

Far TurboPascal for Windows, copy the file STCLIB.DLL to your Windows directory

and include the folIowing statement in your program.

The include files contain function prototypes for the calls and define error codes. If you

want to display error messages, include an array for error strings. The file STCTPIPAS

contains code that you can add to your program to initialize the error array.

USING THE Trigger Master DRIVER 3 - 3

Page 24

3.3 STClNll

STCINIT checks for the presence of a board by writing to Trigger Master program

memory. STCINIT initially writes the value 0 and then increments this value through

255fdecimal). As the memory register is written, Trigger Master automatically

increments the on-board memory location so successive memory locations are loaded

with increasing values until reaching 255. At this point, STCINIT resets to 0 and repeats

the process until it writes to ail 1024 memory locations.

STCINIT then reads back the values. The process of reading the values automatically

increments the memory location.

cleared and STCINIT returns with no error.

If

the read

value

matches the write

value,

memory

is

If the board is present, it becomes “active” so that all subsequent cornman

ds or requests

to the driver will be sent to that board. Up to four boards can be initialized; as each

board is initialized, it becomes the “active” board. To reactivate an initialized board, use

the STCSET caIl.

Note:

Every time you run a program, you must initialize Trigger Master by

calling STCINIT before making any other calls. During initialization, only

Trigger Master program memory is deared; other registers may retain

values

from previous program execution.

STCINIT requires three arguments as follows:

STC~I'E~il9b,al%,i2%)

The variables definitions and ranges are as follows:

Variable Definition Ranae

il% (integer) Trigger Master reference number

al% Trigger Master board address

i2% (integer)

Indicates success of call

(refer to Appendix A for Trigger Master error messages.)

o-3

0-7FC

0 = suooessful

non0 = unsuccessful

Calling STCINIT from BASICA

Use the following BASICA code

segment

30fhex):

630 PRnm "mitialize board "2 m!mmm; *I It. address "i

610 PRINT Rsxs mmADDR%) t I' her"

650 ORLL STCIWITmsmmd%, RzamDDR%, -1

660 LF RMNON% THPN GOT0 2130

Note:

You must define ail arguments for the STCINIT call (BRDNUM%,

BRDADDR%, ERRNUM%) before making the call

3 - 4 Trigger Master INTERFACES USER GUIDE

to initialize a Trigger Master at address

Page 25

Calling STClNlT from C

Use the following code segment to initialize Trigger Master in C:

In C you can send values to the driver by placing them directly in the call. For example,

you could use the following code:

stchit(0,

0x300, ierr);

Since the driver returns err, you must have a predeflned variable to receive its value.

Calling STUN/T from QuickBASE and VisualBASIC

Use the following code to call STCINIT from QuickBASIC and VisuaIBASE

DIN .rerr As INTBOBR

DIM B.rcLNum As INmaR

DIMbdAddr AsIwmeER

s-=0

brdMdr ii &a310

PaIm "Ildtialie.3 board "IBrdaumi" at address "i

PRX”‘,’ BgX$tbrdiuWrl; ” hex”

In QuickBASIC and VisualBASIC, you can send values to the driver by placing them

directly in the call. For example, you could use the following code:

CALL s+cinie(o. LH310, *err1

Since the driver rehms

rerr, you must have a predeflned variable to receive its value.

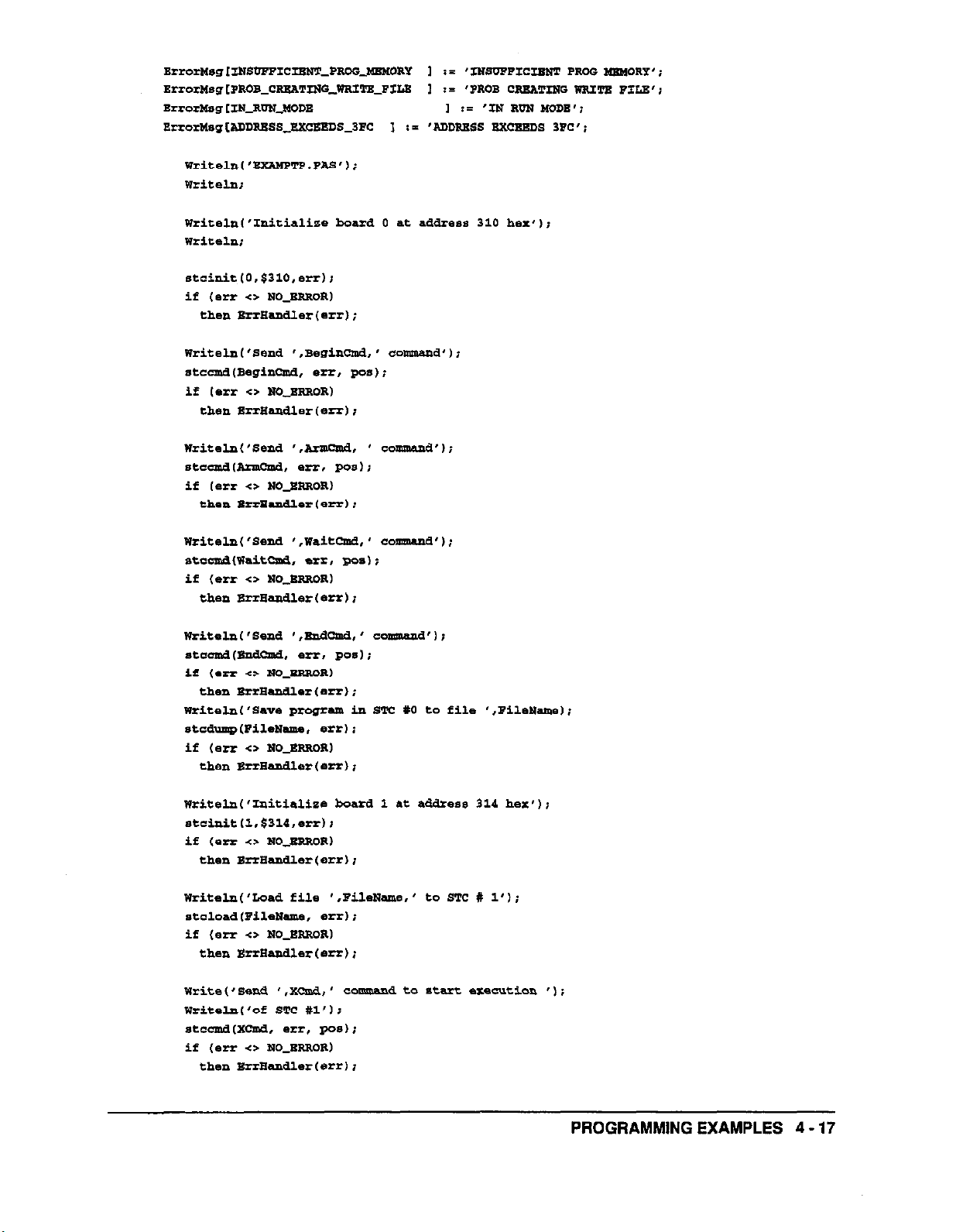

Calling STCINIT from TurboPascal and TurboPascal for Windows

The following code illustrates calling STCINIT from a TurboPascal or TurboPascal for

Windows program:

stcinir(1.$314,err~;

USING THE Trigger Master DRIVER 3 - 5

Page 26

3.4

STCSET

Use STCSET in multiboard systems to switch the driver from one board to another. The

boards must have been previously initialized with the STCINIT command (described in

the

previous section). STCSET accepts two arguments as follows:

The argument il% is an integer in the range of 0 through 3 that identifies the

board.

The argument i2.% is an integer that receives an error code. A value of 0 indicates

no error (refer to Appendix A for a list of error messages).

3.6 Trigger Master INTERFACES USER GUIDE

Page 27

Calling STCSET from QuickBASIC and VisualBASIC

The following code segment illustrates calling STCSET in QuickBasic and VisualBASIC.

BdM.UUEO

Calling STCSET from TurboPascal and TurboPascal for Windows

The following code illustrates calling STCSET from a TurboPascal or TurboPascal for

Windows program.

stcsetIl,*rr) i

3.5 STCCMD

STCCMD sends commands to a board. STCCh4D accepts three arguments as follows:

01 refers to a string that contains a command to be translated by the driver into

microcode. The translated microcode is then sent to Trigger Master either for execution

by the on-board state machine or for storage in the Trigger Master memory. The,driver

parses the command, checking for unknown commands, invalid syntax, or values out of

range.

ix% is an integer that receives an error code. The driver returns a value indicating the

sIatus of errors: a value of 0 indicates no errors; refer to Appendix A for a list of error

messages.

ia is an integer that receives the position of the last character the driver parsed. Since the

driver stops parsing the command line when it encounters an error, this value provides

assistance for ermr debugging.

Note: Trigger Master executes commands as they are parsed. IfTrigger Master

discovers an error in a multiple-command string, it executes the commands prior

to the error and then returns with an emlr code.

Refer to Appendix B for a quick introduction to the commands using examples. Run

PLAYDOS.EXB or PLAYWIN.EXB to experiment with the commands in a non-program

environment. See Appendix A for a description of the error messages.

USING THE Trigger Master DRIVER 3 - 7

Page 28

Command Syntax

This section describes the syntax for the string argument (cl) in the STCCMD call. The

STCCMD call supports the following commands: ARM, BEGIN, CONT, DO, END,

FLAG, HALT, LOOP, TRIG, WAIT, and X.

General Information

The following rules apply to ail STCCMD commands:

. Spell out the commands in their entirety (abbreviations are not supported).

.

Complete each command with a semicolon (;l.

. Use any combination of uppercase and lowercase letters wlthin strings (the driver is

insensitive to the case of characters).

. Do not use embedded spaces wlthin a command. For example, the command “be

gin;’ is illegal.

Some examples of legal and illegal strings are as follows:

IIlerral Legal

beg;

Begin;

begin b&N;

In the example “beg”, the driver returns the position 3 and the error 3 which correspond

to the “Incomplete Command” error. As soon as the driver encounters an error it returns

You can group multiple commands together using blank spaces (spaces, tabs, carriage

returns, and line feeds) to improve readability. The following examples are equivalent:

bWfi.Wd;

begin ;

begin:

end;

6JUd;

The driver executes multiple commands contained in a single string when it encounters

a semicolon.

In

the previous example, the driver executes the “begin” command when

the driver parses the “;11 following “begin”. As a result, the driver executes commands

one at a time. When the driver encounters an error, the previous commands have

already been executed.

3 - 8 Trigger Master INTERFACES USER GUIDE

Page 29

Line Numbers

The commands ARM and TRIG must be followed by one or more line numbers. The

line numbers indicate which of the six trigger lines are armed to look for trigger inputs

or will generate trigger outputs. When either command specifies multiple lines, the line

values must be separated by commas. The following examples illustrate legal and illegal

line values:

j&g@ gg&

trig 1, 5;

trig 1 5;

TRIG 6:

trig3,2,1;

Note: You may use the same number more than once in a command line. This

does not alter the operation and is not flagged as an error.

Extenslons

Certain commands accept extensions, which further define the command. You must

spell out the entire extension (abbreviations are not accepted) and each extension must

be preceded by a

colon.

The following example initiates Trigger Master program

execution with interrupts enabled:

For additional information on L, refer to the section “The Command Set”.

Commands can be followed by one or more integers. An integer cannot contain

embedded spaces, but the number may be separated from the command using one or

more spaces. The integers in the following example indicate the memory location where

program

storage

should start. The examples of legal and illegal command lines are:

&g& j&&

beginl23; begin 1 231

begin

133~

begin 123 ;

The driver checks the range of the number and returns an error if the value is out of

range.

USING THE Trigger Master DRIVER 3 - 9

Page 30

Time Scales

Two commands require time arguments: WAIT and TRIG. The WAIT command

generates time delays in a program running from Trigger Master memory (for further

information on both commands, refer to the section “The Command Set”). The WAIT

command syntax is:

%.a is a floating-point number that specifies a magnitude of time.

t indicates a time scale using one of the following three values:

sorS seconds

m or M milliseconds

n or U microseconds

The magnitude of limes (a.=) that can be used with the WAIT command range from 1

microsecond through 65.535 seconds. You can write time values using any choice of milts. For

example, the minimum and maximum times may be entered as any of the following values:

Minimum

lu

.OOl

m

0.000001 s

Maximum

65535000~

65535 m

65.535 s

The magnitude of the time between any leading and trallmg zeros must fit in a 16-bit

counter; therefore, the range is between 1 and 65535. This limits the so-called resolution

of the time scale (how fine a time increment you may specify). This allows the use of up

to five digits for 1 to 65535, but only four digits for 6554 to 9999. For example, the values

0.06553400 s and 0.06553500 s are legal, but the value 0.06553600 s is illegal. The driver

allows an increase of 0.00000100 s from the value 0.06553400 s to 0.06553500 s. If we

attempt to increment the same amount to get to 0.06553600 s, the driver returns the error

“TIME OVER RESOLUTION”. This requires a rounding up to the next higher value in

the digit to the left; in this example, the next larger value of time that can bespecified is

0.06554000 s. This value represents an increment of 0.00000500; the next incremental

value would be 0.00001000 (to 0.06555000 s).

3 - 10 Trigger Master INTERFACES USER GUIDE

Page 31

The time resolution depends on the time value as shown in the following table:

Delav Ranqe

0.000001 s to 0.065535 s 1 usec

0.065540 s to 0.65535 s

0.65540 s to 6.5535 s

6.5540 s to 65.635 s

Note:

If you attempt to enter the digits 65536, the driver returns the error “TIME

Resolution

10 usec

100 usec

1000 usec

OVER RBSOLUTION”. Unless your time scale is microseconds, you wlll

be over-range as well.

Sanding Commands in fbe Programmhg Languages

Commands are sent by calling STCCMD with the appropriate arguments. One of the

arguments is the string specifying the command. The general features of those strings

have been diicussed ln the previous section and the detailed use of each string will be

discussed in the following section. This

section shows the

use of the call in each of the

programming languages supported.

Calling STCCMD from BASICA

In BASICA, you must define all arguments before making the calI

Calling STCCMD from C

In C, you must declare unsigned variables to receive information from the driver.

However, the command string sent to the driver can be inserted directly in the call.

USING THE Trigger Master DRIVER

3 - 11

Page 32

Calling STCCMD from QuIckBASiC and VisualBASIC

In QuickBASIC and VisualBASIC you must declare integer variables to receive

information from the driver. However, the command string sent to the driver can be

inserted directly in the call.

begircme$ 5 “begin;” ’ begin pro*ram

DM rerr As Ib!mOBR

DIM POEa As *NmoaR

PRINT “Sand “i begincma$; ‘8 EOmfwad”

CALL

s+ccmd(beginamd$,

rerr, post)

IP r*rr <> WOWRROR 9!awN CALL Brrorzxit(rerr~

Calilng STCCMD from TurboPascal and TurboPascal for Wlndows

In TurboPascal and TurboPascal for Windows you must also declare unsigned variables

to receive information from the driver. However, the CO

mmand string sent to the driver

can be inserted directly in the call.

STCTPUB

string.

is a special interface to TurboPascal that accepts a standard TurboPascal

STCLIBDLL

is a general DLL that expects so-called “c” strings. To send strings to

the DLL in TurboPascal for Windows, create a string with a NULL character on the end

outside the call, and pass the “second element” of the string in the call.

3 - 12 Trigger Master INTSRFACES USER GUIDE

Page 33

The Command Set

The command set consists of ARM, BEGIN, CONT, DO, END, FLAG, HALT, LOOP,

TRIG, WAIT and X. The Trigger Master mode of operation determines how the

commands are operated on:

. In immediate mode, Trigger Master executes commands as they are received. The

commands BEGIN and CONT operate only in this mode.

. In program mode, the commands are stored in Trigger Master memory for future

execution. The commands DO, END, LOOP, and WAIT operate only in this mode.

. In run mode, Trigger Master is executing a program and will only recognize the

HALT command.

The remaining commands (ARM, FLAG, HALT, TRIG, and XI can be used in any mode

of operation.

The following sections discuss the commands in detail.

ARM

The Trigger Master trigger-detect logic latches trigger edges on the six trigger input lines

(the default is high-to-low transitions). The ARM command specifies a trigger input

transition pattern to be detected. When the ARM command executes in a Trigger Master

stored program, the program waits until the pattern is detected before proceeding to the

next program step. In immediate mode, you can loop using the TRIG request

(previously described) to detect the pattern.

The ARM command must be followed by one or more line numbers. If you enter

multiple line numbers, separate each number using commas. Specifying the same line

number more than once has no effect and is not flagged as an error. The following

example waits for high-to-low trigger transitions on lines 1 and 5.

-.si

You can specify the edge to latch by using a + (low-to-high) or - (high-to-low, the

default) behind the line number. The following example waits for a low-to-high

transition on line 1 and high-to-low transitions on lines 3 and 5.

ann I.+, a-, 5;

Note: Because of the latching

nature

of the detect circuit, the edges need not

occur simultaneously and the state of the trigger lines wlll generally

differ from the pattern specified in ARM when the trigger condition is

met.

In program mode, ARM supports the REP extension which allows you to wait for the

trigger pattern to be repeated from 1 to 4096 times before proceeding. The following

command line will wait for 23 repetitions of a trigger pattern of high-to-low transitions

on lines 1 and 4. Each time the pattern is detected, latches are automatically cleared and

rearmed.

USING THE Trigger Master DRIVER 3 - 13

Page 34

The general syntax for the ABM command is:

ARM flI+l-l 1....)[:Fsz nn1:

The variable r must be within the range 1 through 6 and the variable IYL must be in the range 1

through 4096.

BEGIN

Use BEGIN only in immediate mode to switch Trigger Master to program mode. The

BEGIN command optionally accepts a single argumenb the Trigger Master program

memory address where the program will start loading. This integer argument must be

in the range 0 through 1023 (the default starting address, with no argument, is 0). The

following example switches the driver to program mode and initializes the program

counter to 40.

begin 40;

The general syntax for the BEGIN command is:

The variable = must be in the range 0 through 1023.

Normally, you will start program loading and execution at address 0, but you may also have

multiple programs in memory (terminate each program with an

To

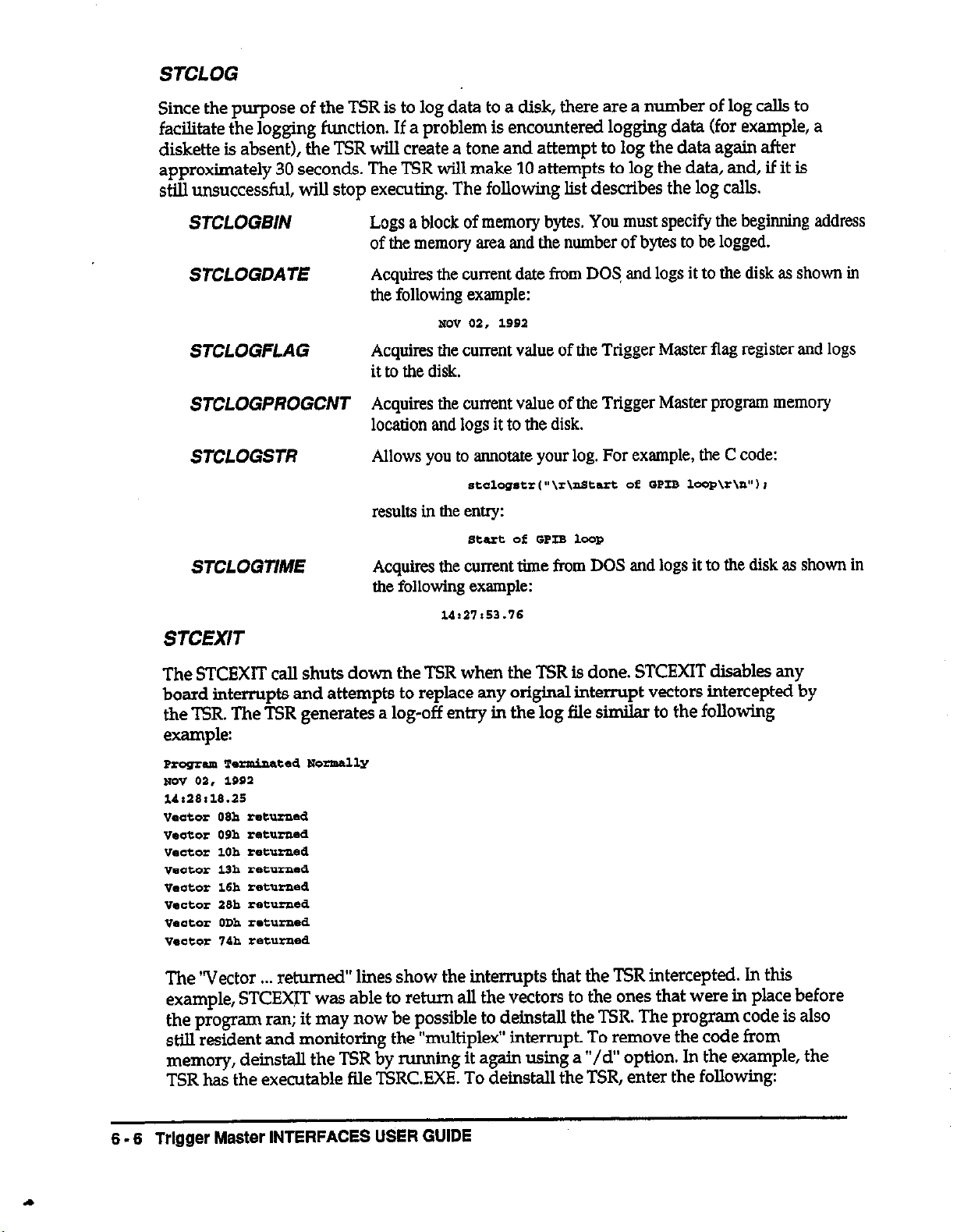

load or execute multiple programs, you must know the locations of the instructions.

Determine these locations either by building a program from

PLAYDOSJXE or by using the techniques described in Chapter 5, Creating

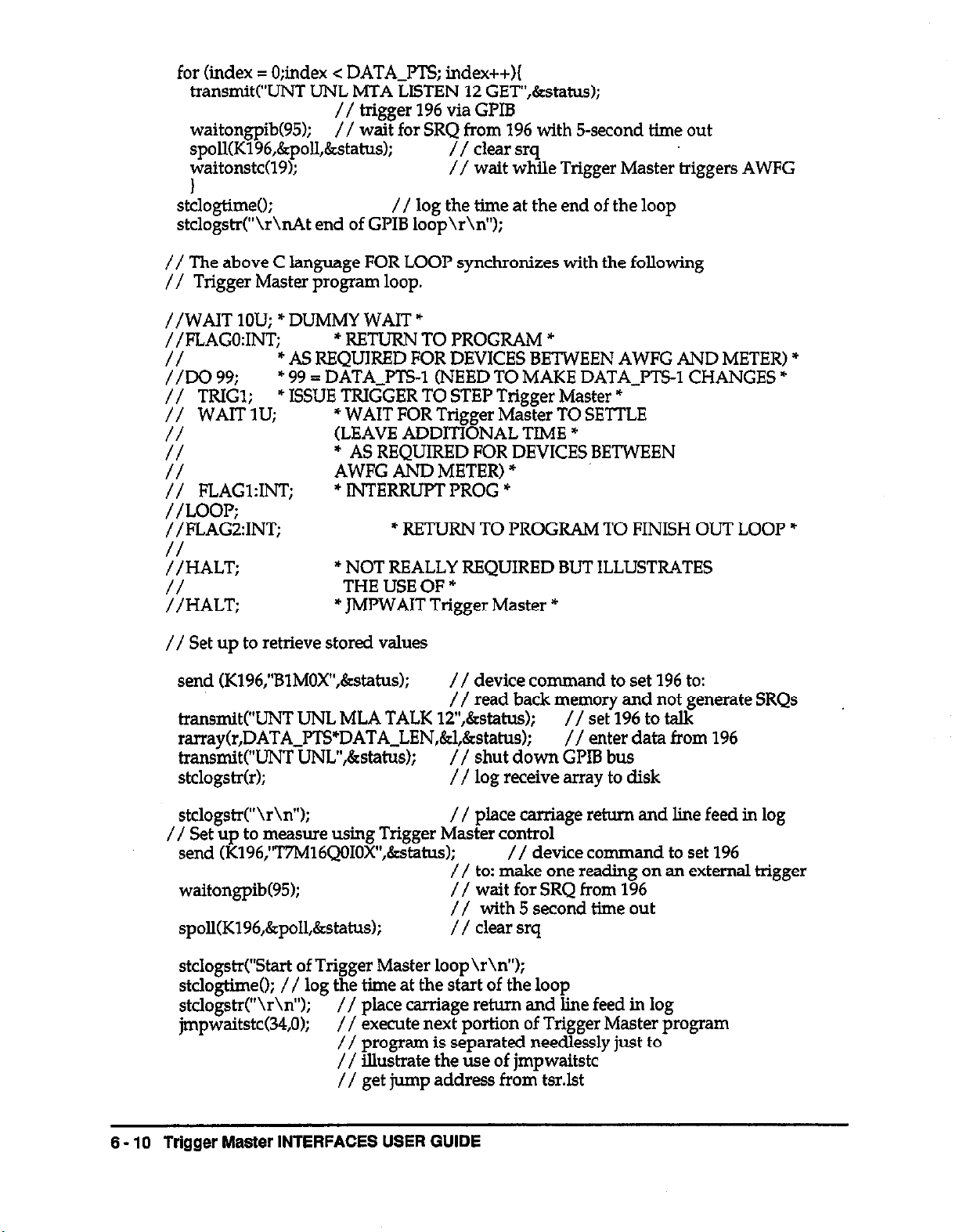

END

or HALT command).

PLAYWNEXE

or

Programs for

Trigger Master Memory.

CONT

Use CONT in immediate mode to restart a program that was stopped by a HALT

command

or FLAG[m]:INT

command within the program. You cannot reliably restart a

program that has been halted externally (from outside the program). If the program

contains additional FLAG[nn]:INT commands, use the CONT command with the INT

extension to clear the previous interrupt and arm Trigger Master to generate another

interrupt. The following example restarts a program without interrupts:

This example restarts a program executing out of Trigger Master memory. The general

syntax for the CONT command is:

ccmz Ir1NTl;

Note:

If you enable Trigger Master to generate interrupts, you must supply your own interrupt

service mutlnes.

3 - 14 Trigger Master INTERFACES USER GUIDE

Page 35

DO

Use DO in program mode to mark the start of a sequence of code which is to be

repeated. The DO command requires a single argument, which is an integer in the range

of 1 through 4096. The

argument

specifies the number of times the code sequence is to

repeat. The code sequence must be terminated by the LOOP command (described later

in this section). The driver allows two levels of loops; the driver will flag an error if you

attempt to start a third level. In the following example, first command1 executes, then

command2; this code sequence repeats 25 times:

de 25; cemmand1; c-i loop;

The general DO syntax is:

Do nni

nn is in the range 1 through 4096

END

Use END in program mode to insert a HALT (described later in this section) and return

Trigger Master to immediate mode. The driver wIII return an error if you attempt to end

a program that has DO commands which have not been resolved by a LOOP.

The general END syntax is:

FLAG

Use FLAG In program mode to insert FLAG

commands in a

program. As the program

executes, FLAG will write a byte to the flag register. The byte should be a value in the

range of 0 through 2.55 (0 is the default). You can then use the FLAG request to read the

flag register to determine which milestone your program

has

reached. If FLAG has the

INT extension in program mode, FLAG causes the Trigger Master program to generate

an interrupt and halt after wrltlng the flag. Use FLAG in immediate mode for test only;

this o~peratlon writes a byte ln the range of 0 through 255 (0 is the default) to the Trigger

Master flag register. For example, the following command writes 68 to the flag register:

The general syntax for the FLAG command is:

FLAG tno1 I:Qml:

The value nn is in the range of 0 through 255.

Use the extension :INT only in program mode.

Note:

If you enable Trigger Master to generate interrupts, you must supply your own

interrupt service routines.

USING THE Trigger Maeter DRIVER

3 - 15

Page 36

HALT

The HALT command stops Trigger Master activity, disables Trigger Master hardware

interrupts, and clears the hardware interrupt. When HALT executes during Trigger

Master program execution, you can use the CONT command to restart the program on

the next instruction. Use FLAG with the INT extension in a Trigger Master onboard

program to halt a program, write the flag register, and generate an interrupt.

The general syntax for the HALT command is:

LOOP

Use LOOP in program mode to terminate a loop Initiated with the DO command.

The general syntax for the LOOP command is:

Use TRIG to generate high-to-low trigger pulses (5 us active low). The TRIG command

accepts from 1 through 6 arguments with each argument specifying a line number.

Multiple line number arguments must be separated by commas. Repeating the same line

number more than

once has no effect

and does not flag an error. The following example

simultaneously generates 5-us pulses on lines 2 and 4.

You can generate a repetitive pulse train of 1 through 4096 pulses by using a REP

extension. If you use the REP extension, you must also use the PER extension with a

time; this time value specifies the REP period. The following TRIG example generates 72

~-US pulses on lines 2 and 3 with a repetition period of 16 milllseconds.

The maximum period you can specify is 65.535 seconds and the minimum period is 10

microseconds. Refer to the section Time Scales in this chapter for a complete discussion

on specifying times.

In program mode, you can use the SEMI extension alone, or in combination

with the

REP extension. The SEMI extension implements the semi-synchronous handshake. In

semi-synchronous handshake mode, Trigger Master initiates a 5-us active-low trigger

pulse on a line; handshaking devices then become active low within 5 us. To complete

the handshake, the devices release the line when they have completed their activity. The

handshake is complete when Trigger Master detects the low-to-high transition of the

line. In the semi-synchronous handshake mode, the TRIG command does not require the

PER extension.

The following example performs a semi-synchronous handshake on line 3.

trig S:sdr

Note: The SEMI extension is only valid in program mode.

The general syntax for the TRIG command is:

TRIO

Cl,...)

[ [rRBP pnt:PaR XT t,1mI,:SsbiI~Paa r‘r t>1 I [rsEMIl I;

The variables may contain the following values:

3 - 16 Trigger Master INTERFACES USER GUIDE

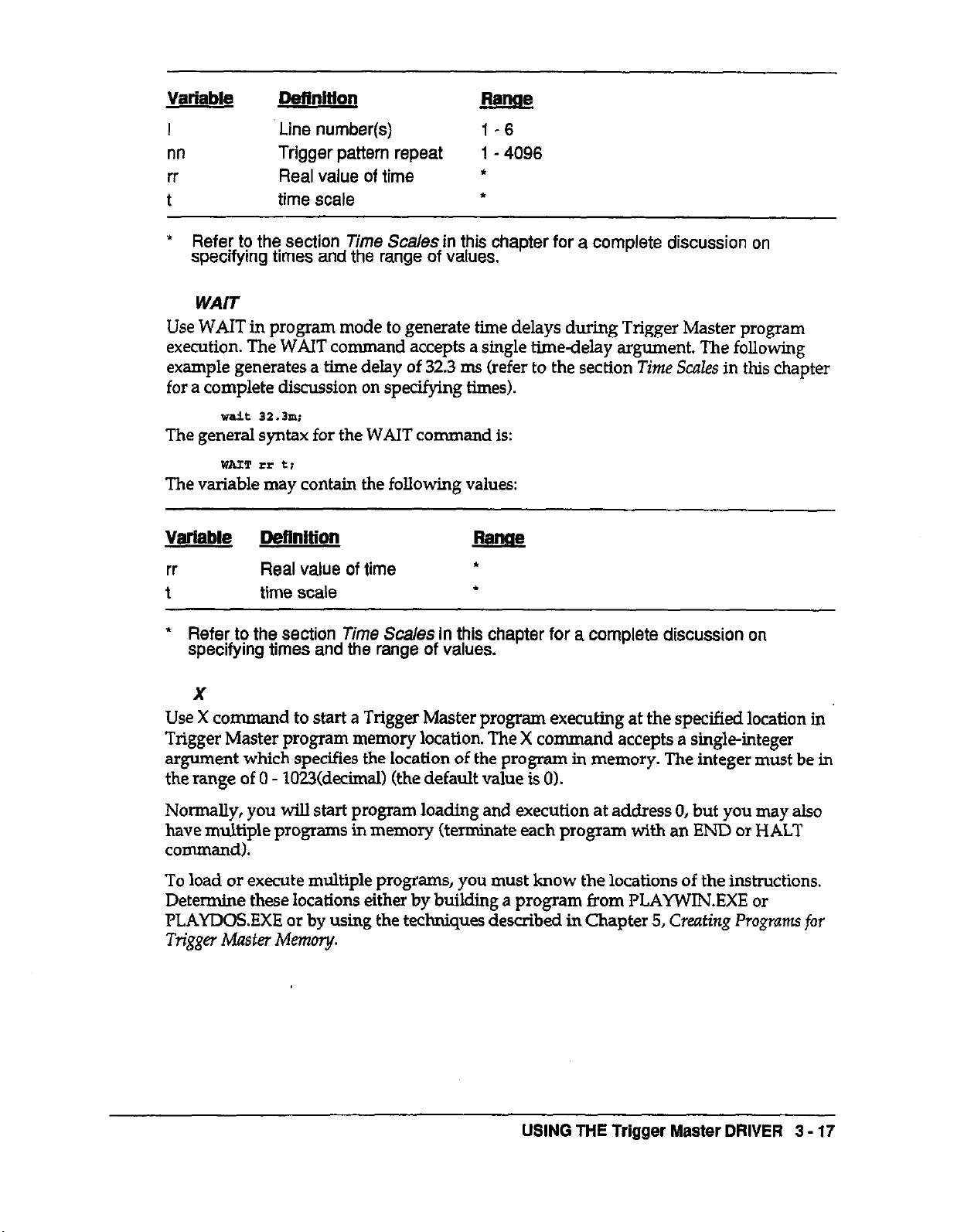

Page 37

Variable Definition

I

nn Trigger pattern repeat

rr Real value of time

t

Refer to the section Time S&es in this chapter for a complete discussion on

specifying times and the range of values.

Line number(s) l-6

time scale

I!@!x

1 - 4096

*

*

WAIT WAIT

Use WAIT in program mode to generate time delays during Trigger Master program Use WAIT in program mode to generate time delays during Trigger Master program

execution. The WAIT command accepts a single time-delay argument. The following execution. The WAIT command accepts a single time-delay argument. The following

example generates a time delay of 32.3 ms (refer to the section Time Scales in this chapter example generates a time delay of 32.3 ms (refer to the section Time Scales in this chapter

for a complete discussion on specifying times). for a complete discussion on specifying times).

wait 32.3m;

The general syntax for the WAIT command is:

mm ?x t;

The variable may contain the following values:

Variable Definition j?gJ@

rr Real value of time

t time scale

* Refer to the section

specifying times and the range of values.

X

Time

S&?/es in this chapter for a complete discussion on

*

*

Use X co mmand to start a Trigger Master program executing at the specified location in

Trigger Master program memory location. The X command accepts a single-integer

argument which specifies the

location

of the program in memory. The integer must be in

the range of 0 - 1023fdecimal) (the default value is 0).

Normally, you will start program loading and execution at address 0, but you may also

have multiple programs in memory (terminate each program with an END or HALT

command).

To load or execute multiple programs, you must know the locations of the instructions.

Determine these locations either by building a program from PLAYWIN.EXE or

PLAYDOSEXE or by using the techniques described in Chapter 5, Creating Programs for

Trigger Master Memory.

USING THE Trigger Master DRIVER

3 - 17

Page 38

Notes: If Trigger Master is operating in program mode, the driver inserts a

If your program contains a FLAG command with the INT extension, use the X command

with the INT extension to clear a previous interrupt and enable Trigger Master to

generate interrupts. The following example starts execution of a program at memory

location 178fdecimal):

x

178;

The general syntax for the X command is:

x Ino1 t:Iwr1r

The acceptable range for the variable nn is 0 through 1023fdecimal).

Note: If you enable Trigger Master to generate interrupts, you must supply your own

internrpt service routines.

3.6 STCSTAT

HALT at the current memory location. Trigger Master returns to

immediate mode prior to starting program execution.

In program mode, the driver returns an error if you attempt to end a

program containing DO commands that have not been resolved by a

LOOP command.

Use the STCSTAT command to return Trigger Master register values. STCSTAT accepts

four arguments in the following order:

Areument

1

2

Desaiution

A string specifying the Trigger Master register value to be returned.

An integer to receive the error code returned by the driver after

validating the request string.

3

An integer to receive the position of the last character parsed by the

driver. You can use this value to pinpoint problems lf the status

indicates an error.

4 An array of two integers to receive the data.

Appendix B provides a quick introduction to STCSTAT. The PLAYDOSEXE and

PLAYWIN.EXE programs allow you to experiment with requests in a non-programming

environment. Refer to Appendix A for a list of the possible error messages.

Note:

Once the Trigger Master driver has fllled

one

request, it immediately

returns. This is an opposite condition to commands, which perform

multiple requests before returning. Therefore, you should not place

multiple requests in the same string.

3 - 18 Trigger Master INTERFACES USER GUIDE

Page 39

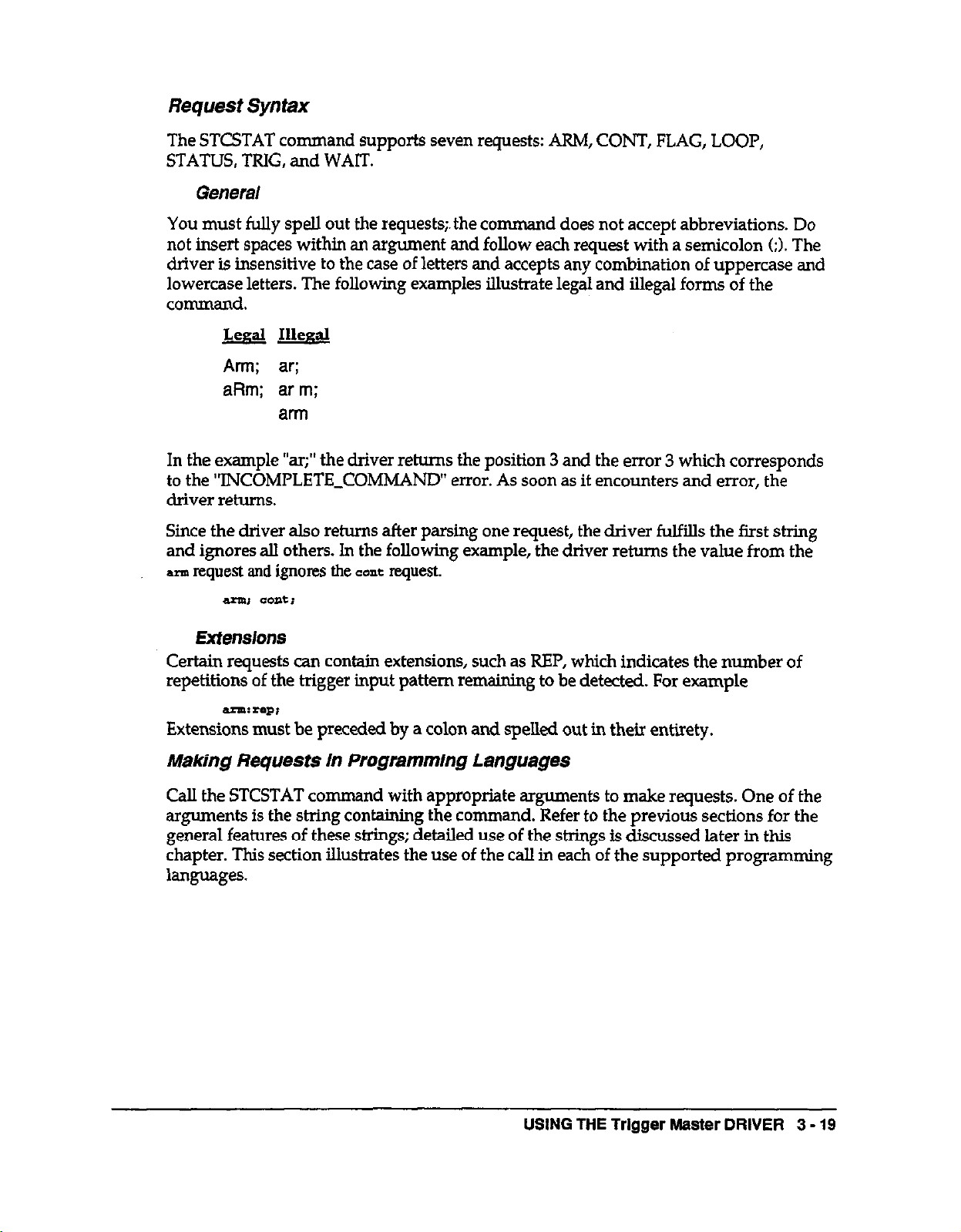

Request Syntax

The STCSTAT command supports seven requests: ARM, CONT, FLAG, LOOP,

STATUS, TRIG, and WAIT.

General

You must fully spell out the requests;. the comman

d does not accept abbreviations. Do

not insert spaces within an argument and follow each request with a semicolon (;). The

driver is insensitive to the case of letters and accepts any combination of uppercase and

lowercase letters. The following examples illustrate legal and illegal forms of the

command.

&al Illegal

Arm;

aRm; arm;

ar;

arm

In the example “ar;” the driver returns the position 3 and the error 3 which corresponds

to the ‘TNCOMPLETE-COMMAND” error. As soon as it encounters and error, the

driver returns.

Since the driver also returns after parsing one request, the driver fulfills the first string

and ignores all others. In the following example, the driver returns the value from the

-request and ignores the EO=~ request.

Extensions

Certain requests can contain extensions, such as REP, which indicates the number of

repetitions of the trigger input pattern remaining to be detected. For example

Extensions must be preceded by a colon and spelled out in their entirety.

Making Requests in Programming Languages

Call

the

STCSTAT command with appropriate arguments to

make

requests. One of the

arguments is the string containing the command. Refer to the previous sections for the

general features of these strings; detailed use of the strings is discussed later in this

chapter. This section illustrates the use of the call in each of the supported programming

languages.

USING THE Trigger Master DRIVER

3 - 19

Page 40

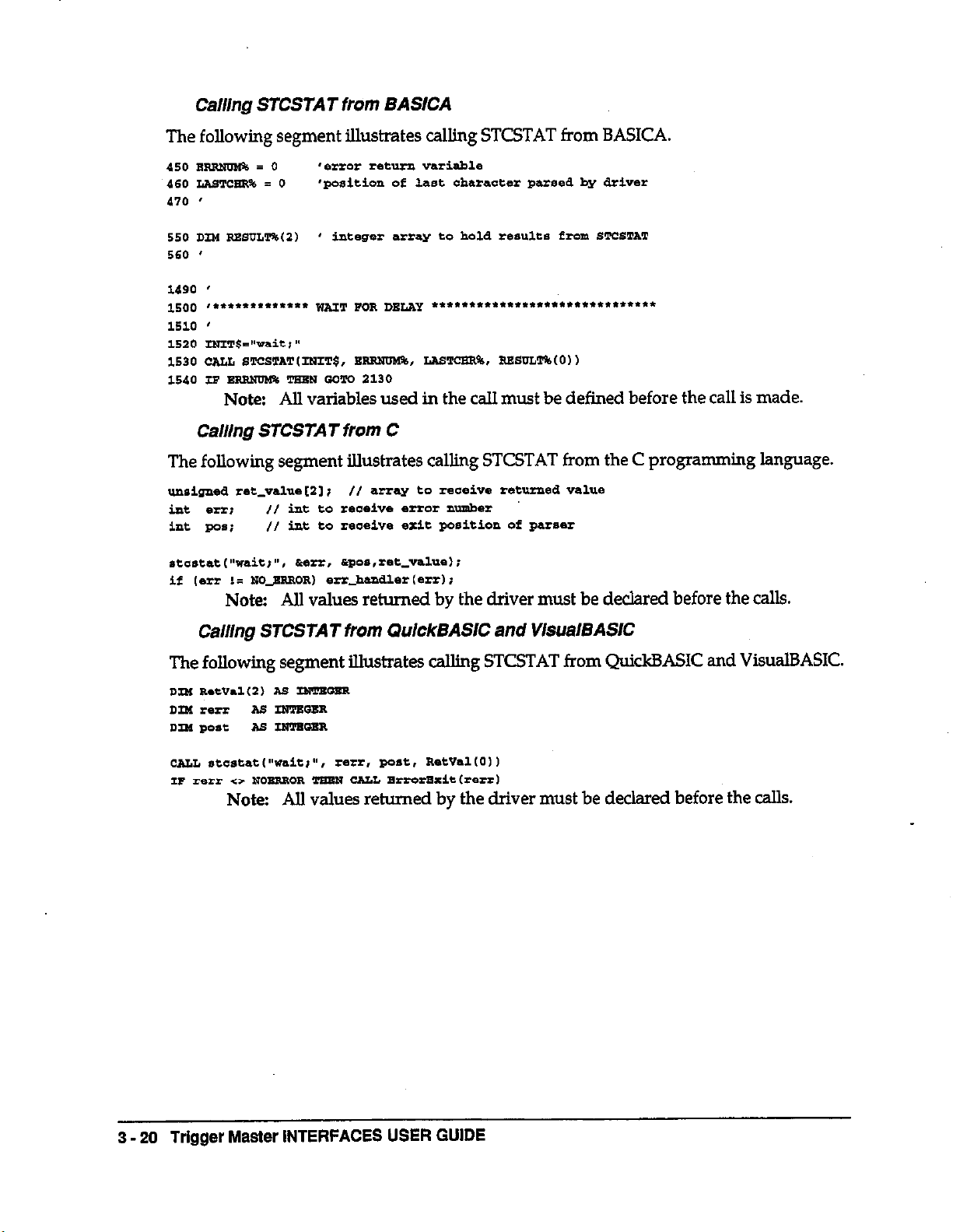

Calling STCSTAT from BASICA

The following segment illustrates calling STCSTAT from BASICA.

1490 '

1500 '*****f***=*** WAIT FOR DELAY

1510 ’

1510 INITS-Waiti”

1530 CALL slwmT’(INIT$, BRRMlld%, Las’EcHR%, iumJLT$(O))

1540 IF - TESN oow 2130

l tt.tt**f~**~~***~*~**~,~~**~*

Note: All variables used in the call must be defined before the call is made.

Calling STCSTAT from C

The following segment illustrates calling STCSTAT from the C programming language.

unsigned rat~“alue[2,> /I array to receive returnee value

int err; ,, ilIt to receive error nurber

int ws;

,/ int to reaeive exit pesition Of passer

sraseat(waiti”, &err, r*os,ree~“alue~;

if Ierr II tw~RRoR, erLhandle,r~err) ;

Note: AU values returned by the driver must be declared before the calls.

Calling STCSTAT from QuickBASIC

and VisualBASIC

The following segment W&rates calling STCSTAT from QuickBASIC and VisualBASIC.

DIM

Reval

As IuTmnR

DIM rerr As IwmOER

Dn4 pst As mTxt?ER

3 -

OPJJ, stCstat~“valti”, rerz1, past, astVal(Ol~

IF rer+ <> NOBBXOR mmi eALL ErrorEgxit kerr)

Note: All values returned by the driver must be declared before the calls.

20

Trigger Master INTERFACES USER GUIDE

Page 41

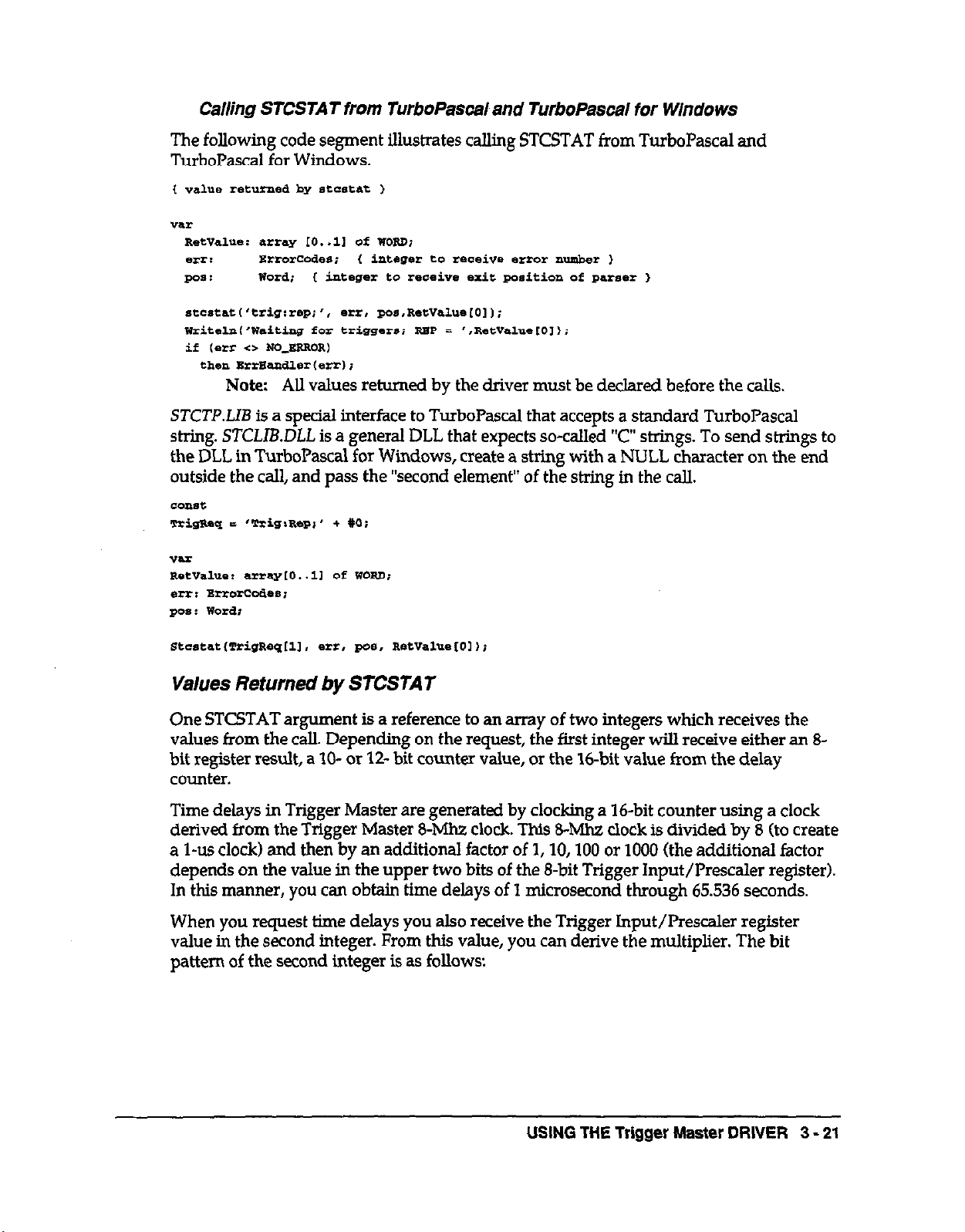

Calling STCSTAT from TurboPascal and TurboPascal for Windows

The following code segment U.&rates calling STCSTAT from TurboPascal and

TurboPascal for Windows.

R*t”a1Ye: array 10..11 ct WORD;

etlr: Errorcedes; C integer to receive error number )

pas: Word; t

stcrrtat('trig:rep;', er+, pas.Ret”01ue10,);

integer

to reaeiw exit **ition of p*rs*r I

w~ireln~‘waiting ioz triggers; RBP = ‘.Ret”alue~O,,;

if (err c> No_ERROR)

theri Earaadlerfen);

Note: All values returned by the driver must be declared before the calls.

STCTP.LIB is a special interface to TurboPascal

that

accepts a standard TurboPascal

string. STCLIB.DLL is a general DLL that expects so-called “c” strings. To send strings to

the DLL in TurboPascal for Windows, create a string with a NULL character on the end

outside the call, and pass the “second element” of the string in the call.

C-t

him-? =

‘TriS%R8Pi’ + Y0;

-?a?2

Retvalue: an~y~o..ll Of mm;

err: BrrOrccae*;

go*: wordt

Values Returned by STCSTAT

One STCSTAT argument is a reference to an array of two integers which receives the

values from the call. Depending on the request, the first integer will receive either an 8bit register result, a 10- or 12- bit counter value, or the %-bit value

from the

delay

counter.

Time delays in Trigger Master are generated by clocking a 16bit counter using a clock

derived from the Trigger Master 8-Mh7. clock. This 8-Mhz clock is divided by 8 (to create

a l-us clock) and then by an additional factor of 1, 10,100 or 1000 (the additional factor

depends on the value in the upper two bits of the 8-bit Trigger Input/Prescaler register).

In this manner, you can obtain time delays of 1 microsecond through 65.536 seconds.

When you request time delays you also receive the Trigger Input/Prescaler register

value in the second integer. From this value, you can derive the multiplier. The bit

pattern of the second integer is as follows:

USING THE

Trigger

Master DRIVER 3 - 21

Page 42

-3 *. .I

a m -0 , . 7 . I 1 3

2 , 0

0 0 0

0 0 0

0 OMIMOX

X X

X X X

Bits Ml and MO determine the time multiplier as follows:

m

0 0 1

0 1 10

1 0 100

1 I 1000

MO

Multiplier

When you request a time, you need only look at the second integer. The driver also uses

the second integer to return a code which is helpful in interpreting the result of the

operation. The following lists the various codes returned for different commands:

@&

FFFO

FFFl

FFF2

FFF3

FFF4

FFF5

FFOO

FFOl CONT;

FF02

FF03

Command

ARM;

ARM:POL;

FLAG;

STATUS:

TRIG:LATCH;

TRIG:IN

ARM:REP;

TRIG:REP;

LOOP;

LOOP:OUT;

3 - 22

Interpreting Values

In BASICA

BASICA handles S-bit values (integers) as signed values between -32768 and +32767

(Trigger Master returns integer values from unsigned 0 to 65535). Using the following

technique, you can interpret results as hexadecimal values or convert them to real values

(floating-point single precision).

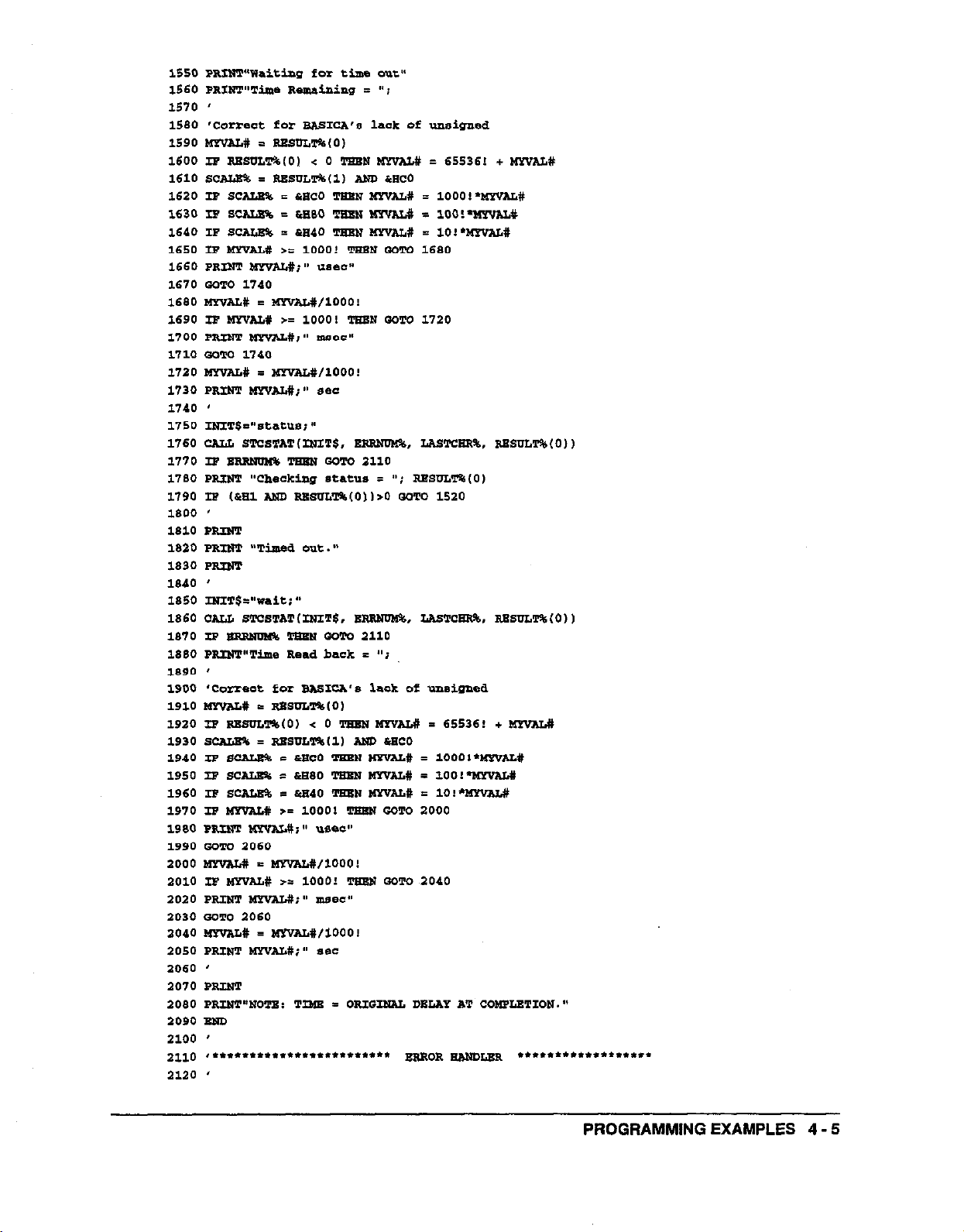

1580 ‘Consco for BASICA’S la& Of unsipnee

1590 l6YwJd4 = RBmm(o)

2.600 IF RBSULl%(O) < 0 Tam mAL.9 E 655361 + MYVALO

Note:

Trigger Master INTERFACES USER GUIDE

After a timeout occurs, the counter resets to its initial value.

Page 43

USING THE Trigger Master DRIVER 3 - 23

Page 44

3 - 24 Trigger Master INTERFACES USER GUIDE

Page 45

Interpreting Values In QuickBASE and VIsualBASIC

Quickl3ASIC and VisualBASIC handle 16-bit values (integers) as signed values in the

range from -32768 through +32767 (Trigger Master returns values in the range unsigned

0 - 65535). Use the following technique to interpret results as hexadecimal values or

convert them to real values.

Note: After a timeout, the counter resets to its initial value.

The

following code

segment intefprek a

time result returned by the STCSTAT in

QuickBAsIc.

USING THE Trigger Master DRIVER

3 - 25

Page 46

Interpreting Values in TurboPascal and TurboPascal for Windows

The following program segment illustrates the use of time values in TurboPascal and

TurboPascal for Windows.

Note: After a timeout, the counter resets to its initial value.

stcaratl’wait;‘. err, pos,Retvaluue[Ol);

lVrite('Tim* remaining = ‘I;

if (Llrr <> NO_ERRoR)

ehell BrrBa?dler,*rr,;

TimeRemaining := R.ewa1ue 1012

if (T5meRemaird.w < 1000)

ta.n writelalTiu,eRnmainining. ' usecso

else

begin

TheRemaining := TimeRelaa~gllooo.o;

if ~ThRsmaining < 1000~

riaerl WritelnmJrLetiini,' m-as')

else

begin

l5maRmining := zhRema~/looo.oi

writelnmmeRemainins,' se..');

endi

end;

Note: TurboPascal for Windows performs the WAIT command differently, but

processes the time in the same manner.

3 - 26

Trigger Master INTERFACES USER GUIDE

Page 47

The Request Set

The request set

consists

of the requests: ARM, CONT, FLAG, LOOP, STATUS, TRIG,

and WAIT. The following sections discuss the requests in detail.

ARM

ARM returns information about the trigger input circuitry. The ARM forms are:

ARM;

Returns the inverse of the Trigger Mask Register in the first element of the result

array and the value PPFO(bex) in the second element of the array. The contents of

the first element is in the following format:

A MASK bit value of 0 indicates that line is anned to receive a trigger.

ArlM:PoL;

Returns contents of the Trigger Polarity Register in the first element of the result

array and the value FFFl(hex) in the second element of the array. The contents of

the first element is in the following format:

A POL (polarity) bit value of 0 arms the driver for a high-to-low transition snd a

value of 1 arms the driver for a low-to-high transition.

?ma:RBp; Returns the

number

of trigger matches yet to be detected (Trigger Repeat

Counter) in tbe first integer of the result array and the value FFoo(hex) in the

second integer of the array.

CONT

The CONT request returns the

value

of the Microprogram Counter in the first integer of

the result array and the value FFOl(hex) in the second integer of the array. The

microprogram counter points to the next program step to execute. The syntax for the

CONT request is as follows:

This request is useful when loading multiple trigger programs. After loading the first

program, the cow request returns the address of the next available location witbin the sequence

RAM. This address would then be used as an argument in tbe next BEGIN command.

USING THE Trigger Master DRIVER

3 - 27

Page 48

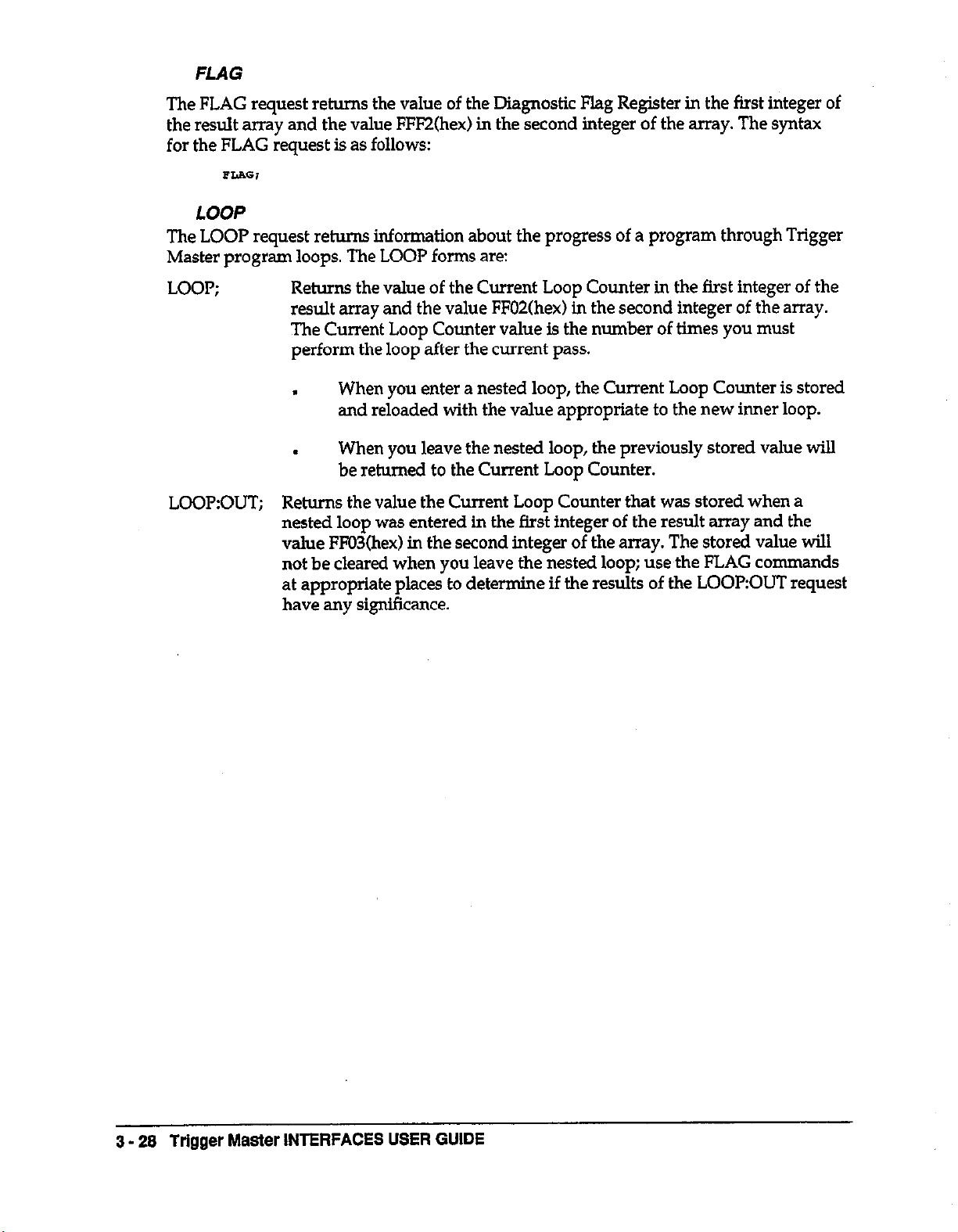

FLAG

The FLAG request returns the value of the Diagnostic Flag Register in the first integer of

the result array and the value FFl?Zfhex) in the second integer of the array. The syntax

for the FLAG request is as follows:

LOOP

The LOOP request returns information about the progress of a program through Trigger

Master program loops. The LOOP forms are:

LOOP;

LOOP:OUT;

Returns the value of the Current Loop Counter in the first integer of the

result array and the value FF02fhex) in the second integer of the array.

The Current Loop Counter value is the number of times you must

perform the loop after the current pass.

When you enter a nested loop, the Current Loop Counter is stored

.

and reloaded with the value appropriate to the new inner loop.

When you leave the nested loop, the previously stored value will

.

be returned to the Current Loop Counter.

Returns the value the Current Loop Counter that was stored when a

nested loop was entered in the fhst integer of the result array and the

value FFO3(hex) in the second integer of the array. The stored value will

not be cleared when you leave the nested loop; use the FLAG commands

at appropriate places to determine if the results of the LOOPOUT request

have any significance.

3 - 26 Trigger Master INTERFACES USER GUIDE

Page 49

STATUS

The STATUS request returns the value of

result array and the value FFFSfhex) in

the Status

the

second integer of the array. The contents of

the Status Register are in the following format:

The bits REG2, REGl, and REGO determine which data register is accessed.

A TRIG DET bit value of 0 indicates you have issued an ARM command and a

value of 1 means the conditions of your ARM command are met. (The TRIG DET

bit is valid only when Trigger Master is not executing a program.) During

program execution, this bit is also set, but the bit is automatically cleared on the

next microsequencer clock cycle (therefore, you may never see this bit set).

During program execution, use the ARM bit of the TRIG request to determine

this same

information.

An INT bit value of 1 indicates the board has generated an interrupt.

An INT-EN bit

value

of 1 indicates Trigger Master is set to generate interrupts.

Register in the first integer of

the

A RUN bit value of 1 indicates a program is executing.

The syntax for the STATUS request is as follows:

USING THE Trigger Master DRIVER

3 - 29

Page 50

TRIG

The TRIG request returns information about various registers. The TRIG forms take

several extensions as follows:

TRIG;

ARM TRIG

0 0

0 1

1 0

1 1

Returns the value of the Trigger Latch Register in the first integer of the result

array and the value FFF4(hex) in the second integer of the array. The format for

the Trigger Latch Register is:

The combined values of the TRIG bit

Definition

Inactive

Armed to Detect Trigger (program execution only)

Outputting Triggers

Semi-Sync Output (program execution only)

When executing a

conditions of your 1

SEMI trigger, the TRIG bit will also be set while awaiting the completion of

the handshake.

The CHG-CHl bit (channels 6-1 values indicate if trigger inputs have

been latched. In immediate mo d e, the channel bits remain set until

issue an ARM. command. When executing a program, the bits are

g tsz next mlcrosequencer clock, therefore you may never detect them

rogram, the ARM bit will be set while waiting for the

RM command to be met. If you had programmed a

and