Page 1

Tektronix TLA5201B Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/analyzers/tektronix-inc/tla5000b/TLA5201B

Page 2

xx

Tektronix Logic Analyzer Family

ZZZ

Quick Start User Manual

www.tektronix.com

077-1575-03

Page 3

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

MagniVu and TekLink are trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 4

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate m aintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. T EKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 5

Warranty 9(b)

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on the media will be

free from defects in materials and workmanship for a period of three (3) months from the date of shipment. If any such medium or

encoding proves defective during the warranty period, Tektronix will provide a replacement in exchange for the defective medium.

Except as to the media on which this software product is furnished, this software product is provided “as is” without warranty of any

kind, either express or implied. Tektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

period. If Tektronix is unable to provide a replacement that is free from defects in materials and workmanship within a reasonable

time thereafter, Customer may terminate the license for this software product and return this software product and any associated

materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND

CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FO R ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDO R HAS ADVANCE NOTICE OF THE

POSSIBILITY OF SUCH DAMAGES.

Page 6

Table of Contents

Preface................................................................................................................................. ii

Key Features

Documentation ...................................................................................................................iii

Version Differences ..............................................................................................................iii

Basic Setup

Installation Documentation.......................................................................................................1

Connecting to a Network. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . 1

Connectin

Connecting to Your Instrument . . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . . 2

Navigating the Logic Analyzer Windows .. ... .. . .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. 4

Basic Step

Data Window Overview .. . .. ... .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . 7

Getting Acquainted with Your Instrument .. .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . ..8

Set the De

Configure the Setup Window . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . 8

Define the Trigger Window .. ... ... .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... .. . .. . . 13

Define th

Acquire Data.....................................................................................................................19

Using the Tabbed Trigger Window .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . 20

ing Data........................................................................................................................ 21

Analyz

Zooming Data ................................................................................................................... 21

Measure Waveform Data using Cursors ....................................................................................... 22

Using t

View Acquired Data with MagniVu High-Resolution Timing . .. . .. . .. .. . .. . .. ... .. . .. . .. ... .. . .. . .. .. . .. . .. . .. .. . .. . .. . .. .. . .. . 25

Managing Data.. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ..... 27

g Setups................................................................................................................... 27

Savin

Loading Setups. . .. . .. ... ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. . .. . 28

iView Integrated Measurements .....................................................................................................29

ecting the Logic Analyzer and the Oscilloscope . .. . .. . .. . .. . .. .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. .. . . 29

Conn

Acquiring the iView Data........................................................................................................ 31

Aligning the Oscilloscope Data with the Logic Analzyer Data . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. .. . .. . .. . .. . .. .. 31

lication Examples................................................................................................................. 34

App

Triggering on a Glitch . . .. .. . .. . .. . .. .. . .. . .. . .. ... .. . .. . .. . .. .. . .. . .. . .. .. . .. . .. . .. ... .. . .. . .. . .. .. . .. . .. ... .. . .. . .. . .. ... .. . .. . 34

State Acquisition ................................................................................................................37

ggering on a Setup & H old Violation.. ... .. . .. . .. . .. . .. .. . .. . .. . .. ... ... .. . .. . .. . .. ... .. . .. . .. . .. . .. .. . .. . .. . .. ... ... .. . .. . .. 40

Tri

Specifications .........................................................................................................................42

Index

..................................................................................................................... ii

s........................................................................................................................... 1

g Probes to the System Under Test. . .. . .. ... ... ... ... .. . .. . .. . .. . .. . .. . .. . .. . .. . .. ... ... ... ... .. . .. . .. . .. . .. . .. . .. . . 1

s for Using a Logic Analyzer . ... ... .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. ... ... .. . .. . .. . .. . .. ... .. . .. . .. 6

fault System .......................................................................................................... 8

e Waveform Window . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . .. ... ... ... .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. .. 15

he Data Measurement Window ......................................................................................... 24

Table of Content

s

TLA Quick Start User Manual i

Page 7

Preface

Preface

This manual describes the basic operation and concepts of the Tektronix Logic Analyzer series instruments. The TLA5000B

Series Logic Analyzers are stand-alone products and the TLA7000 Series Logic Analyzers are configurable modular

products. The TLA7000 Series Logic Analyzers can be configured with a variety of logic analyzer modules and serial

analyzer modules. All logic analyzers have integrated operation capabilities with Tektronix oscilloscopes. This manual

supports the following instruments:

TLA5000B Series Logic Analyzers (TLA5201B, TLA5202B, TLA5203B, TLA5204B)

TLA7000 Series Mainframes (TLA7012, TLA7016) and their associated modules

Key Features

The Tektronix Logic Analyzers can help you verify and debug hardware designs, processor and bus designs, and embedded

software a

nd hardware integration. Key features include:

34/68/102

500 ps (2 G

125 ps (8 G

difficult problems

Up to 235 MHz state acquisition analysis of synchronous digital circuits, TLA5000B series

Up to 800 MHz state acquisition analysis of synchronous digital circuits, TLA7Axx series

Up to 1400 MHz state acquisition analysis of synchronous digital circuits, TLA7Bxx series

Simultaneous state, high-speed timing and analog analysis through the same logic analyzer probe to pin-point elusive

faults without double probing, TLA7ACx series, TLA7Bxx series, and Tektronix oscilloscopes

Glitch and setup/hold violation triggering finds and displays elusive hardware problems

Transitional storage extends the signal analysis capture time

Connectorless probing system with 0.5 pF total capacitive loading eliminates the need for on-board connectors,

minim

onix also offers the TLA7S08 and TLA7S16 serial analyzer modules for PCI Express validation of silicon, computer

Tekt r

systems, and embedded systems. Key features include:

8- and 16-channel serial analyzer modules with 32 M 8b/10b symbols memory depth per channel

2.5 Gb/s and 5 Gb/s acquisition speeds for PCI Express 1.0 and PCI Express 2.0

/136 channel logic analyzers

Hz) 256 Mb deep timing analysis

Hz) MagniVu high resolution timing acquisition simultaneous with deep timing or state acquisition to find

izes intrusion on circuits, and is ideal for differential signal applications

Support for x1, x2, x4, x8, and x16 PCI Express links

ii TLA Quick Start User Manual

Page 8

Documentation

The following table lists related documentation, available as printed documents or as PDF documents on the TLA

Documentation CD and on the Tektronix Web site (www.tektronix.com). Other documentation, such as online help, is

available on the instrument.

Related Documentation

Item Purpose Location

TLA Quick Start User Manuals

Preface

High-level operational overview

Online Help

Installation Quick Reference Cards High-level installation information

Installation Manuals

XYZs of Logic Analyzers

Declassification and Securities

instructions

Application notes

t Specifications & Performance

Produc

Verification Procedures

TPI.NET Documentation

upgrade kits

Field

In-depth operation and UI help

Detailed first-time installation

ion

informat

Logic analyzer basics

Data security concerns specific

to sanitizing or removing memory

from Tektronix products

devices

Collection of logic analyzer application

specific notes

TLA Pro

performance verification procedures

Detailed information for controlling the

logic analyzer using .NET

Upgrade information for your logic

analyzer

duct s pecifi cations and

Optional Service Manuals Self-service documentation for

Version Differences

Some of the illustrations in this document may have different icons than your instrument due to differences in software

versions. Refer to the online help for the menu features of your software version.

TLA Quick Start User Manual iii

modules and mainframes

Page 9

Preface

iv TLA Quick Start User Manual

Page 10

Basic Setups

Installation Documentation

For installation instructions and descriptions of controls and connectors on your instrument, refer to the installation reference

card or installation manual that came with the instrument. (See page iii, Documentation.)

Connecting to a Network

The user interface operates under the Microsoft Windows® operating system. Before you connect to a network, Microsoft

recommend

s the following to ensure your instrument is protected:

Basic Setups

Useaninte

Install op

Use up-to-

See the in

rnet firewall

erating system updates regularly

date antivirus software

stallation manual for detailed instructions on connecting to a network.

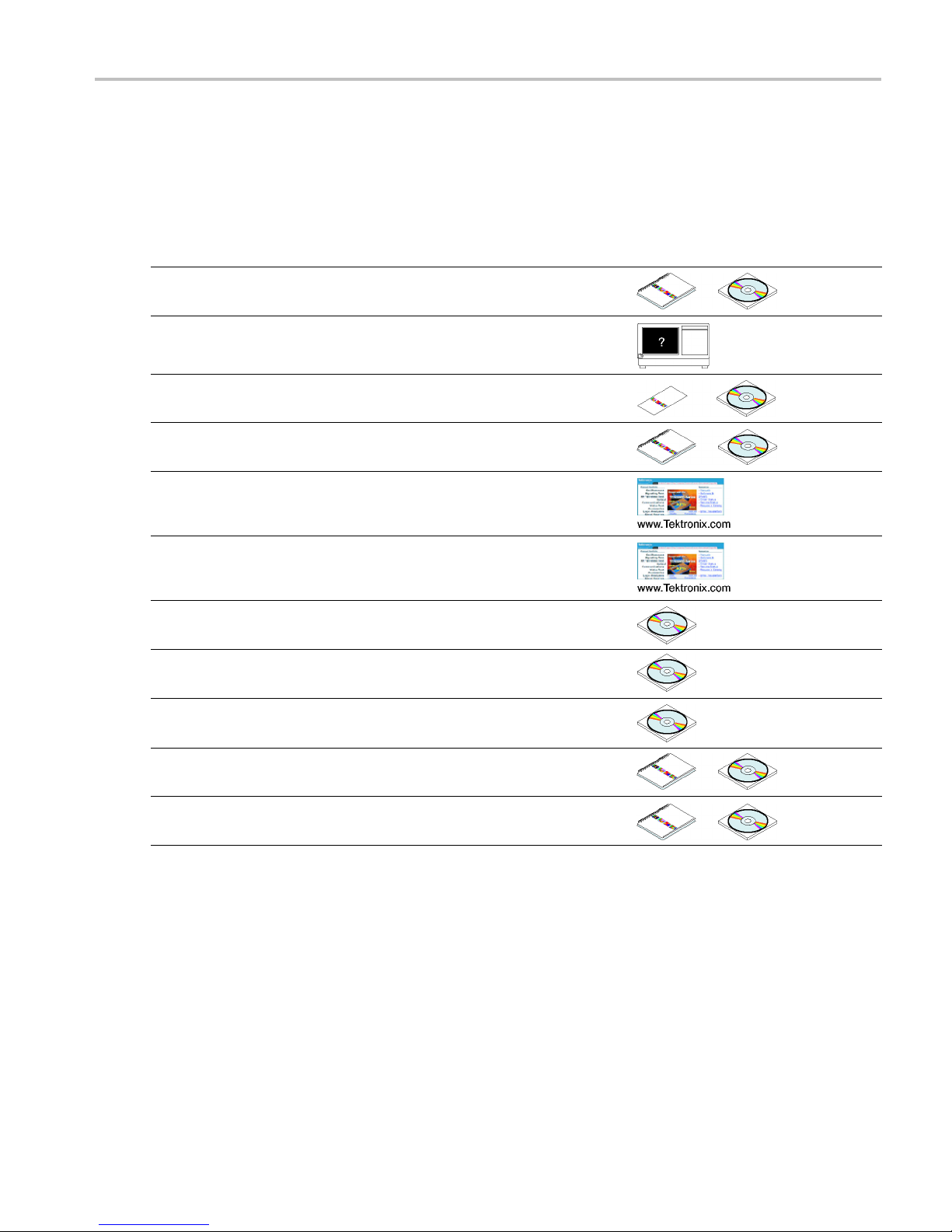

Connecting Probes to the System Under Test

The logic analyzer has different methods of

ing probes to the system under test.

connect

Refer to the illustration and connect your

probes to the system under test.

Square pin connectors. Use

l-purpose probes to connect to

genera

the system under test using square pin

connectors or square-pin adapters.

Connectorless compression

ctors. Use land pattern probes for

conne

applications that connect many channels

to connectorless compression contacts

e system under test.

on th

or connectors. Use Mictor

Mict

connector probes for applications

requiring many channels to be quickly

ected using Mictor connectors or

conn

Mictor adapters.

TLA Quick Start User Manual 1

Page 11

Basic Setups

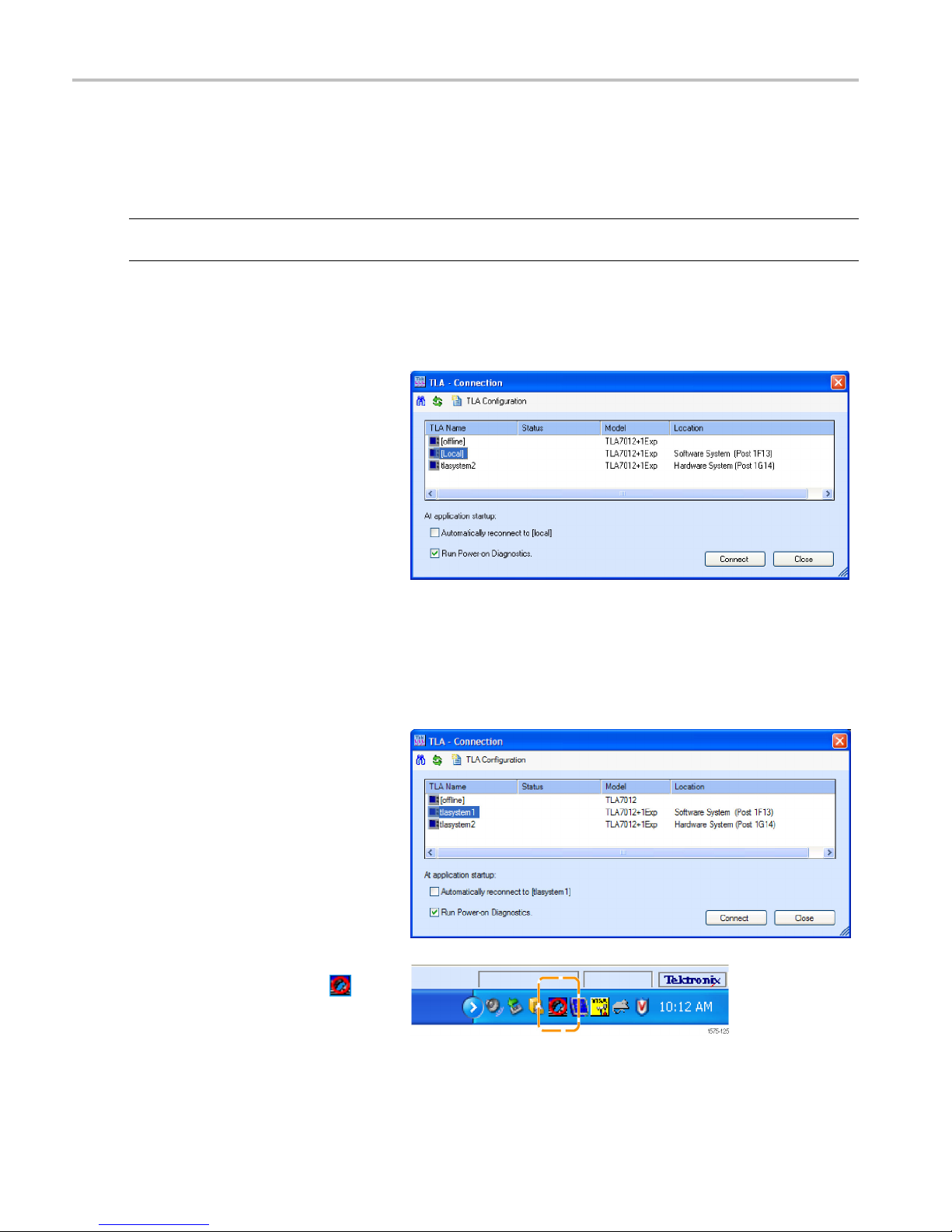

Connecting to Your Instrument

You can connect to your instrument as Remote Host, Remote Desktop, or Local.

To access the TLA Connection dialog box, start the TLA Application software on the instrument or on your PC.

NOTE. The TLA Connection dialog box appears when you start the instrument from a PC or when you restart the TLA

application without shutting down the instrument.

Local Connection

Choose a Local connection when you want to work directly on the instrument.

NOTE. Make sure that you s elect Local

instead of Offline when you want to connect

to your local instrument. Selecting Offline

does not connect you to an instrument.

Remote Host Connection

Connect as Remote Host when you want to run the application o n your PC to control the instrument remotely, and then

store the data locally on your PC.

NOTE. You must be connected to a LAN

to use R emote Host and the TLA Server

(TLA7012 and TLA5000B) must be running.

Refer to Controlling the Logic Analyzer

Remotely in the TLA7000 Series Logic

Analyzers Installation Manual for more

informationonconfiguring your instrument

for remote operation.

NOTE. To start the TLA Server on a

TLA7012 instrument, right-click the

Server) icon in the toolbar at the bottom right

side of the screen and select Start TLA

Server

(TLA

2 TLA Quick Start User Manual

Page 12

Basic Setups

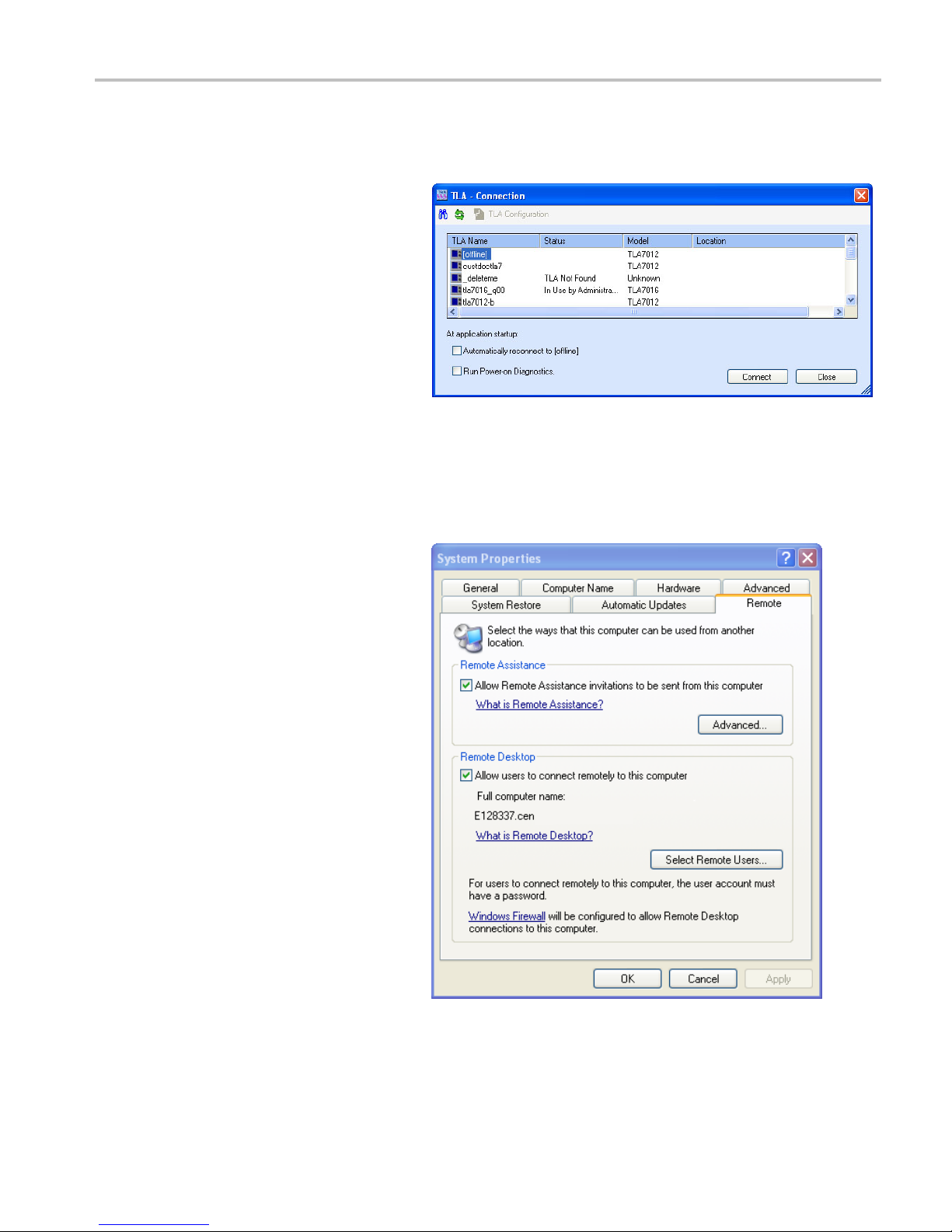

Offline

You can work offline, without connecting to an instrument, to modify setups or view data files that you previously saved.

Click the TLA Application on the desktop and

then select Offline.

Remote Desktop

Connect as Remote Desktop when you want to run the application on the instrument from your PC and store the data

on the instrument.

To enable the Remote Desktop, ensure that

the Micro

dialog box on the instrument is setup as

shown.

See the M

http://www.microsoft.com for more

information on working remotely.

soft Windows System Properties

icrosoft Web site

TLA Quick Start User Manual 3

Page 13

Basic Setups

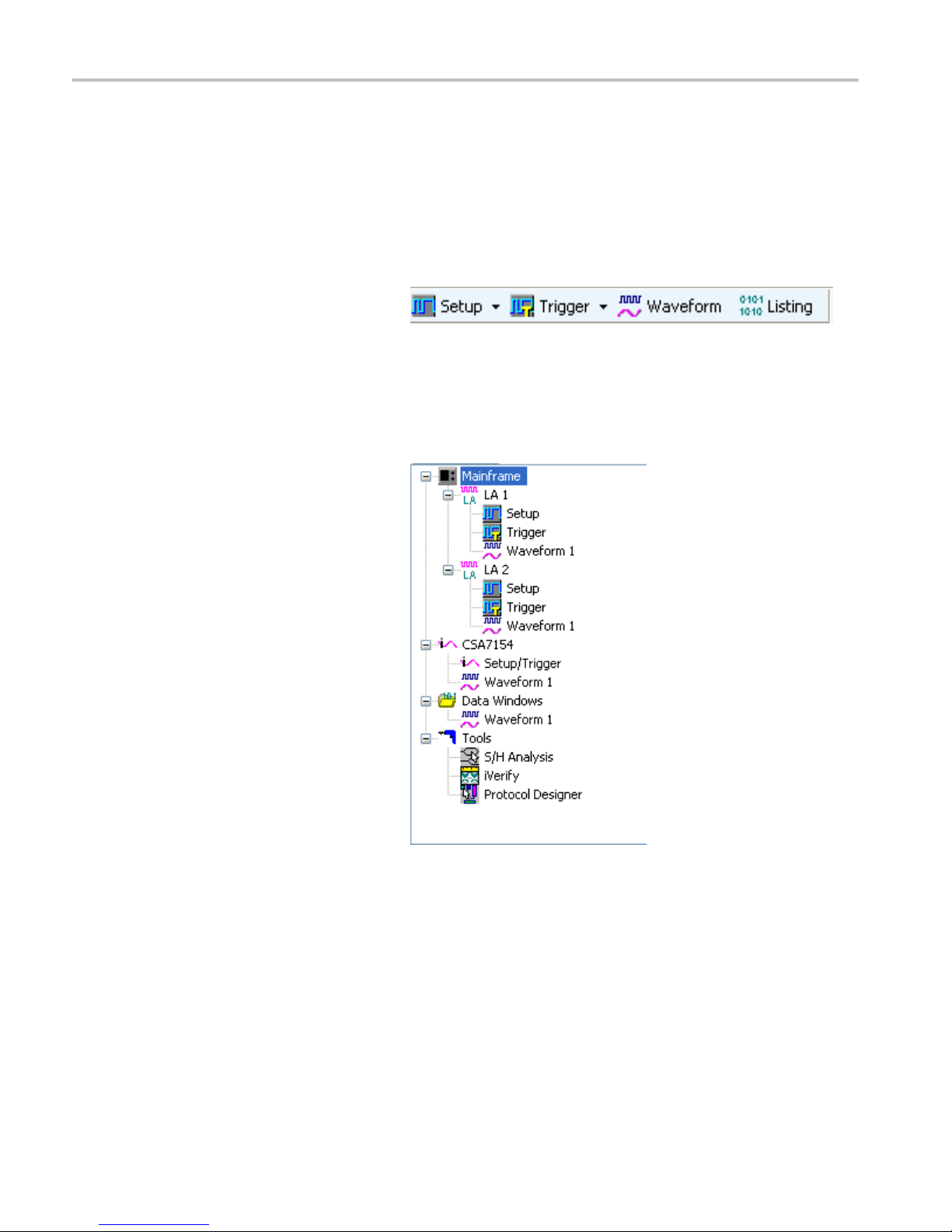

Navigating the L ogic Analyzer Windows

Tektronix provides several different ways of navigating the logic analyzer windows to accomplish your basic tasks. Choose

the one that works best for you.

Toolbar Buttons

Use the toolbar buttons to quickly navigate between key windows while making the best use of screen space.

Click one of

Setup window, Trigger window, Waveform

window, or Listing window.

Toolbar Bu

Use the TLA Explorer to quickly access key windows from a tree structure.

The TLA Explorer shows all of the modules in

the logic analyzer and their subcomponents.

the buttons to quickly access a

ttons

4 TLA Quick Start User Manual

Page 14

Basic Setups

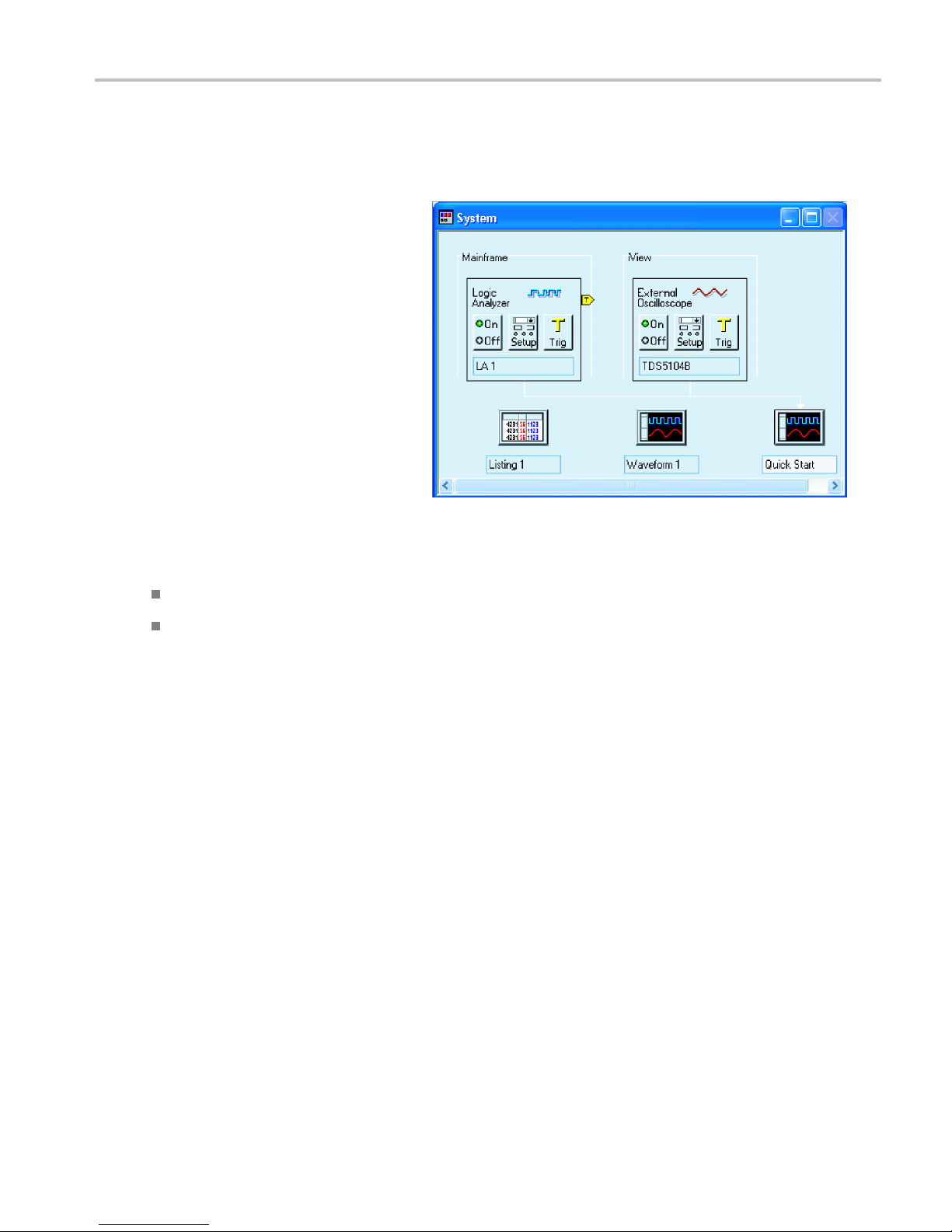

System Window

The System window shows a block diagram representation of the modules and data windows available with your logic

analyzer. Click an icon to open the related window.

Quick Tips

To open the System window, select System from the Window menu or press function key F9.

Use the front-panel buttons to navigate between windows on the TLA7012 Portable Mainframe.

TLA Quick Start User Manual 5

Page 15

Basic Setups

Basic Steps for Using a Logic Analyzer

The basic steps for using the logic analyzer are summarized below.

1. Use the Setup window to set up the logic analyzer signals, threshold voltages, clocking, and sampling, and samples per

signal

2. Specify triggering in the Trigger window.

3. Configure a Waveform window.

4. Acquire data.

5. Analyze the data in the Waveform or Listing window.

6 TLA Quick Start User Manual

Page 16

Data Window Overview

Use data windows to display and analyze data acquired by your instrument. The Waveform window is the default data

window. Create other data windows using the New Data Window wizard.

NOTE. To start the New Data Window

wizard click

Data Window from the Window menu.

in the toolbar or select New

Basic Setups

Waveform Wi

Use Waveform windows to display waveform data from the logic analyzer or from an external oscilloscope. Waveform

windows are best used for diagnosing timing problems, measuring hardware timing-related characteristics, and verifying

correct hardware operation by comparing recorded results against data sheet timing diagrams.

ndow

Listing Window

Use Listing windows to display acquired data in a state table display. Listing windows can be used for state machine debug

ions, tracing relative software execution, system optimization, and following data through a system design.

applicat

Histogram Window

Use Histogram windows to display acquired data as histograms. Histogram data is useful for evaluating the performance of

software, such as determining which routines or functions take most of the time perform ing certain tasks.

Source Window

Use Source windows with Listing windows to track the execution of source code in software applications.

h Window

Grap

Use Graph windows to display the results of acquired data in a graph or chart format.

Protocol Window

Protocol windows to display and analyze protocol data.

Use

TLA Quick Start User Manual 7

Page 17

Getting Acquain

ted with Your Instrument

Getting Acqua

The following sections show how to set up the logic analyze r and to do timing analysis using data from a simple D-type

flip-flop. Flip-flops serve as building blocks in digital systems. Although most flip-flops are buried inside complex ASICS and

other devices, they are useful for showing hardware debugging techniques using a logic analyzer. The examples in this

document use only a few channels to acquire data. However, you can use the same concepts with hundreds of channels.

inted with Your Instrument

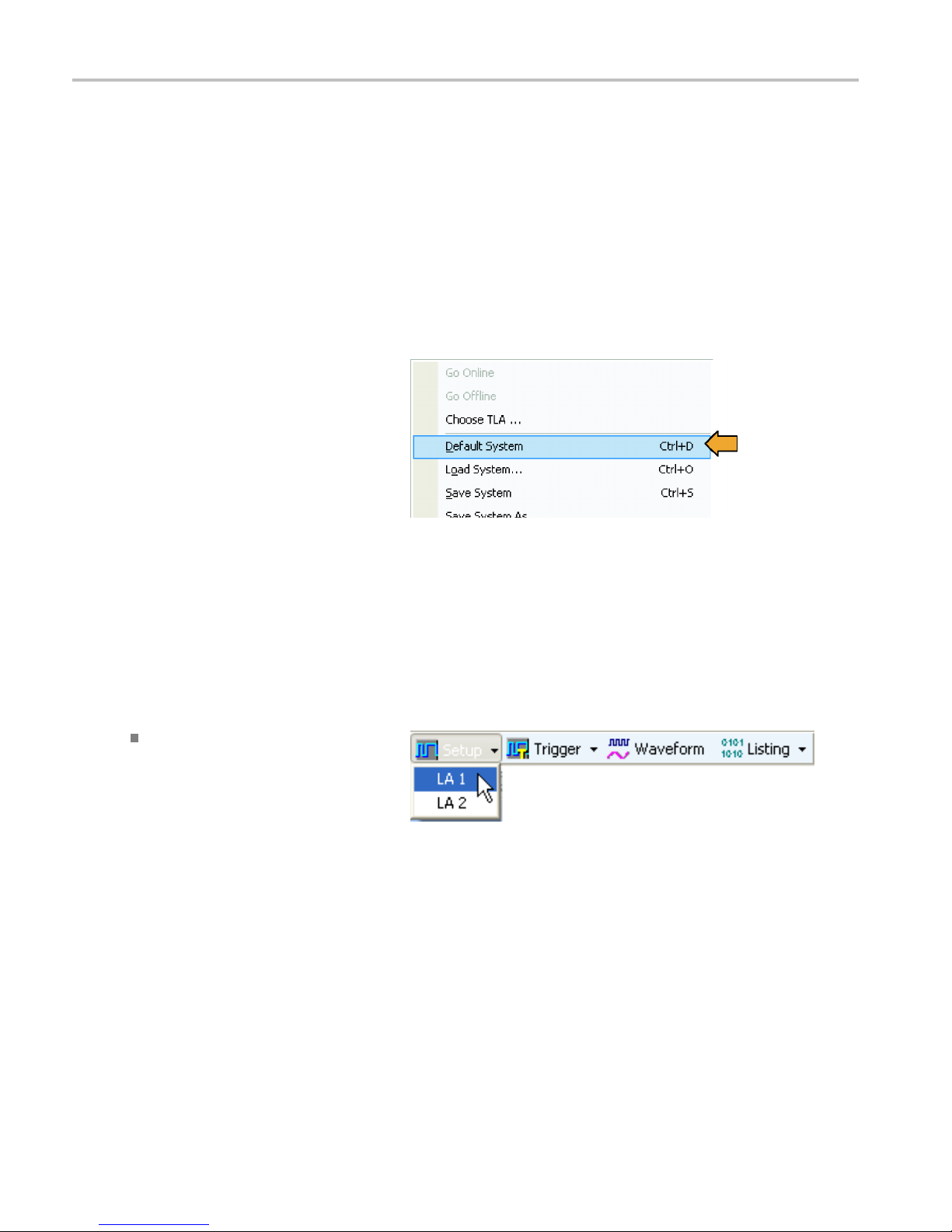

SettheDefaultSystem

Use the Default System setup to load the factory default settings.

1. Power on the instrument and wait for

the instru

tests.

2. Select Default System from the File

menu.

3. Click OK.

ment to complete the power-on

Configure the Setup Window

Use the following procedures to define data signals, to set the clocking, to set the probe threshold voltages, and to use

other features of the Setup window.

Open the Setup Window

Click the Setup button in the TLA toolbar

and to select the Setup window for your

instrument.

8 TLA Quick Start User Manual

Page 18

Getting Acquain

tedwithYourInstrument

Specify the Sampling Meth od

When you select asynchronous sampling, the logic analyzer selects when data is sampled (sample point). Asynchronous

sampling is also known as timing acquisition.

When you use synchronous sampling, the system-under-test specifies the sample point by an external clock. Synchronous

sampling is also known as state acquisition.

The following example uses asynchronous sampling.

1. Select Asynchronous.

2. Set sample period (or use default

setting).

3. Select the threshold voltage.

The threshold voltage is applied to all probe

channels. You can set threshold voltages for

individual channels in the bottom part of the

Setup window.

NOTE. If your logic analyzer has a support package installed, a custom clocking tab is available. The label on the tab is

the same as the support package.

TLA Quick Start User Manual 9

Page 19

Getting Acquain

Set the Storage O ptions

Use Storage to specify the length of each data acquisition and how to store the acquisition.

1. Select the number of samples to

store per signal. The selections vary

depending on your logic analyzer.

2. Select how to store the acquisition.

ted with Your Instrument

Select Samples to store samples

specified by the trigger actions.

Select 63-Sample Blocks to store

samples in bloc ks of 63 bits;

this is often recommended for

troubleshooting program flow.

Select Samples + Glitches to store

glitch data (Asynchronous sampling

only).

Select Samples + Violations (Setup

and hold violations) to store setup

and hold violations (Synchronous

and Custom sampling only).

10 TLA Quick Start User Manual

Page 20

Getting Acquain

Deskew the Probe Signals

When using Synchronous or Custom sampling, you might want to deskew the signals in your setup.

1. Set the deskew parameters.

2. Click Deskew to begin the deskew

process.

Create Groups

tedwithYourInstrument

Groups are

When you en

1. Enter a name for the group, for example,

2. Determine the probe section that you

logical collections of probe signals often related to busses on your system-under-test.

ter the Setup window the first time, an empty group card appears on the right side of the Setup window.

Address Bus.

want to use. For example, click A3 to

select the signals for section A3.

TLA Quick Start User Manual 11

Page 21

Getting Acquain

ted with Your Instrument

3. Drag selected s

ignals to the group card.

4. To create additional groups, click the

plus sign at the right edge of the Groups

column.

12 TLA Quick Start User Manual

Page 22

Getting Acquain

tedwithYourInstrument

Check Signal Activity

You can easily check for signal activity at the probe tips by looking at the Activity & Threshold indicators in the Setup

window. When there is signal activity, the indicators change from a 1 to a 0 with yellow in between. Each data and clock

signal has its own indicator.

Note the signals in the example:

The signal connected to A3(5) is low as

indicated by the zero (o).

The signal connected to A3(4) is high as

indicated by the one (1).

The signal connected to A3(3) is

transitioning as indicated in yellow..

NOTE. If the signals are inverted the zero

(O ) appears on top and the one (1) is on the

bottom.

If there is no probe activity, check for the following:

Check the probe connections.

Verify that the target system is powered on

Check the probe threshold voltages. (Click the Activity & Threshold indicators to open a dialog box to adjust the

threshold voltages.)

Define the Trigger Window

Use triggers to tell the logic analyzer when to acquire data and display the results in a data window.

1. Click t

he Trigger button in the TLA

toolbar and select the Trigger window for

your instrument.

TLA Quick Start User Manual 13

Page 23

Getting Acquain

ted with Your Instrument

2. In the Easy Trig

program from the list. For example,

select Trigger immediately to trigger

the instrumen

Use the area below the trigger program

list to enter more details for the trigger

programs, if

3. Click and dra

to the point in memory where you want

the instrument to trigger. The default

selection i

ger tab, select a trigger

t on any data.

needed.

gtheTrigger Pos indicator

s 50%.

Quick Tips

After you have acquired data, use the Ta bbed Trigger window to define simple trigger programs without having to close

the Waveform or Listing window.

Use EasyTrigger to define the trigger program for most applications; use PowerTrigger to customize the trigger program

for specific needs.

14 TLA Quick Start User Manual

Page 24

Define the Waveform Window

For most applications, y ou will define the data windows for your needs. For this example, you will use the Waveform window.

Open the Waveform Window

Click the Waveform button to open the

Waveform window.

Delete the Default Waveforms

1. Press the CTRL key and select each

waveform

name that you w ant to delete.

Getting Acquain

tedwithYourInstrument

TLA Quick Start User Manual 15

Page 25

Getting Acquain

ted with Your Instrument

2. Right-click an

Waveforms.

d select Delete

Quick Tip

Use the delete key on the keyboard to delete highlighted waveforms.

16 TLA Quick Start User Manual

Page 26

Getting Acquain

tedwithYourInstrument

Add Waveforms

Use the following steps to add the waveforms that you defined in the Setup window. (See page 11, Create Groups.)

1. Right-click in the waveform label area

and select Add Waveform.

2. Expand each group.

TLA Quick Start User Manual 17

Page 27

Getting Acquain

3. Press the Ctrl key while selecting each

signal that you want to add to the

Waveform wind

4. Click Add.

5. Click Close.

Quick Tip

Select By Name to add the probe signals to the Waveform window by their channel names. This is useful for groups

that hav

ted with Your Instrument

ow.

e only one channel.

18 TLA Quick Start User Manual

Page 28

Acquire Data

After you have defined all of the setups and connected the probes to the target system, you are ready to acquire data. You

can acquire a single sequence of data, or you can continuously acquire data.

Making a Single Acquisition

1. Click Run.

The Run button changes to Stop until the

instrument has met the trigger conditions

and has acquired the data. The button

changes back to Run after data has been

acquired.

2. If the instrument does not trigger, click

Status. Use the information in the dialog

box to see if the logic analyzer is waiting

for the trigger or if it has triggered and is

filling its acquisition memory.

When a trigger occurs, the instrument

displays the flip-flop Clock, Input, and

Output data in the Waveform window.

The trigger point is represented by the

red trigger marker (T).

Getting Acquain

tedwithYourInstrument

Quick Tip

To verify that the instrument is acquiring data during long periods of inactivity on the screen, check that the Tek icon in

the upper right corner of the screen is animated.

Making Repetitive Acquisitions

1. Click the Repetitive Run button to acquire

data repetitively. The icon changes from

an arrow to a loop.

2. Click Run. T he instrument will acquire

data until you click Stop or until you

click the Repetitive Run button again to

change back to single run mode.

TLA Quick Start User Manual 19

Page 29

Getting Acquain

ted with Your Instrument

Using the Tabbed Trigger Window

You can define a trigger program using the Tabbed Trigger window without closing the Waveform or Listing window. The

following example shows how to set up the instrument to trigger on a channel edge.

You can also use this procedure to quickly define other trigger programs. To acquire complex data, you can still use

the Power Trigger window.

1. Click Run.

Data must be present before you can use the

Tabbed Trigger window.

2. Click Trigger in the tabbed window.

3. Click and drag the Channel Edge icon

from the Tabbed Trigger window to the

waveform.

Output

The instrument will display the details of

the program in the Trigger Details area.

ails are s imilar to those in the

The det

Power Trigger window. You can edit any

of the details.

4. Click Run to acquire data and trigger

strument based on the new trigger

the in

program.

20 TLA Quick Start User Manual

Page 30

Analyzing Data

Your instrument has several tools for analyzing data, such as zooming data, measuring data, and viewing data with MagniVu

high-resolution timing. This section provides concepts and procedures for analyzing data in the Waveform window. Some of

these features also apply to the Listing window; refer to the online help for more details.

Zooming Data

To zoom data in the Waveform window:

1. Click and drag from left to right over the

area you want to zoom.

Analyzing Data

2. Click the Zoom In button a few times to

zoom the timing data samples.

Quick Tips

Click and drag from the right to the left to zoom to the previous selection.

Use the Zoom In and the Zoom Out buttons in the toolbar as an alternative method of zooming data.

Rearrange the toolbars, as needed, to access command buttons, if the command buttons appear off-screen.

TLA Quick Start User Manual 21

Page 31

Analyzing Data

Measure Waveform Data using Cursors

Use the Snap to Edge feature with cursors in the Waveform window to measure the time between waveforms.

1. Point the mouse at Cursor 1 over the

waveform that you want to measure.

2. Click and drag Cursor 1 toward a leading

or trailing edge of the waveform.

3. Release the mouse to snap the cursor to

the next waveform edge.

4. Repeat for Cursor 2.

22 TLA Quick Start User Manual

Page 32

5. If the Delta-time toolbar is turned off,

click

6. Read the time difference between the

two cursors.

.

Quick Tips

Analyzing Data

If the cursors do not appear in the Waveform window, use the right-click menu to move the cursors on screen (select

Move Cursor 1 Here ).

You can use the Snap to Edge feature with any of the user marks.

You can click to add multiple Delta-Time toolbars in the same Waveform window.

You can use the Delta-Time toolbar to measure time between any two marks. Select the marks from the drop-down

lists in the toolbar.

TLA Quick Start User Manual 23

Page 33

Analyzing Data

Using the Data Measurement Window

Use the Data Measurement window to quickly take measurements in the Waveform or Listing window.

1. Click Measurements.

2. Click and dr

Clock waveform, and release.

The selected measurement will be added

to the Data

bottom of the display.

3. Repeat for any other measurements.

4. Click the Statistics tabintheData

Measurement window to display the

results of the measurement along with

other statistics. Measurements are taken

on the existing data without having to

acquire new data.

ag the Period icon to the

Measurement window at the

24 TLA Quick Start User Manual

Page 34

Quick Tips

To take a measurement on new data, click Run.

To save the measurement data to a file, click the Export button in the Statistics tab of the Data Measurement window.

To select a measurement in the Waveform window, select the waveform label, right-click the waveform, select Add LA

Data Measurement, and then select a measurement from the list.

View Acquired Data with MagniVu High-Resolution Timing

Analyzing Data

MagniVu hig

details that you may not see using Deep timing. It is like having two logic analyzers in one. Using a single probe you can view

Deep timing data for long time spans and MagniVu high-resolution timing data for greater resolution at the area of interest.

The MagniVu high-resolution data is automatically acquired with each acquisition. However, the waveforms may not be

visible. T

1. Click below the waveform labels to

deselect all waveforms.

2. Click MagniVu to add the MagniVu data

to the Wav

The MagniVu timing waveforms are

added to the window in a different color.

h-resolution timing provides 125 ps sampling (500 ps sampling on TLA7N4 modules) on all waveforms to analyze

o add MagniVu timing waveforms:

eform window.

TLA Quick Start User Manual 25

Page 35

Analyzing Data

3. Click the Zoom Out button until you see

4. MoveCursor1toanareainthe

the entire MagniVu timing waveforms.

Note that the M

agniVu timing data is 16

K bits long as compared to the Deep

timing data. Deep timing lets you acquire

a large amoun

t of data; MagniVu timing

lets you focus on the details of the data.

Waveform window outside the range of

the MagniVu data.

26 TLA Quick Start User Manual

Page 36

5. Zoom on Cursor 1. The MagniVu button

indicates the MagniVu waveforms are

off screen.

Managing Data

6. Click the Magn

MagniVu data on-screen.

iVu button to center the

Quick Tip

Click the MagniVu button in the Listing or Waveform window to turn the MagniVu display on and off.

Managing Data

This section contains procedures for managing data, such as saving setups and loading saved setups.

Saving Setups

After defining your setup, you can save it for future use.

1. Select Save System As.

TLA Quick Start User Manual 27

Page 37

Managing Data

2. Select one of the following save options:

3. Enter a file name.

4. Click Save.

Quick Tips

Save all Acquired Data

Save only Unsuppressed Data

Don’t Save Acquired Data

Save often to avoid losing critical setups and data.

See the online help for details on saving setups.

Loading Setups

Use the following steps to load the setup that you saved under Getting Acquainted with Your Instrument. (See page 8.)

1. Select Load System.

28 TLA Quick Start User Manual

Page 38

2. Select the file name.

3. Click Open.

4. Click Yes when you are prompted to

confirm your actions.

iView Integrate

d Measurements

iView Inte

You can use the iView feature to connect an external Tektronix oscilloscope to the logic analyzer, acquire data from both

instruments, and display the results on the logic analyzer. This is useful for displaying the analog components of a signal in

the same data window as the digital components.

In the following examples the logic analyzer and the oscilloscope will acquire the same data. The logic analyzer captures

the digital components and the oscilloscope captures the analog components.

Use the following steps to set up the oscilloscope for these examples. Refer to the documentation that came with your

oscilloscope for operating instructions.

1. Connect the oscilloscope probe to the same signal source as the logic analyzer (for this example, connect to the

2. Power on the oscilloscope.

3. Press the Default Setup button on the oscilloscope, and then press the Autoset button. You should have a signal on

grated Measurements

Q output of the flip-flop).

the oscilloscope screen.

Connecting the Logic Analyzer and the Oscilloscope

After completing the oscilloscope and logic analyzer setups, use the iView wizard to connect the two instruments together.

TLA Quick Start User Manual 29

Page 39

iView Integrate

1. From the logic analyzer System

d Measurements

menu, select Add iView External

Oscilloscope

....

2. Follow the ins

of the iView wizard to do the following

steps:

Select the oscilloscope.

Connect the iView cable to the logic

analyzer.

Connect the

oscilloscope.

Verify the GPIB address of the

oscilloscope.

Identify where to display the

oscillosc

Specify t

Verify th

3. Click Fin

wizard.

tructions on each page

iView cable to the

ope data.

he triggering.

e connections and setups.

ish on the last page of the

Quick Tips

Start the iView wizard by clicking the iView icon in the Listing window or Waveform window. If you have a TLA7012

Portable Mainframe, start the iView wizard by pressing the front-panel iView button.

If the oscilloscope is properly connected to the logic analyzer when you start the iView wizard, the wizard will bypass

the connection instructions. Follow the on-screen instructions to finish the installation or to return to the start page of

the wizard.

The oscilloscope is added to the TLA

Explorer and to the System window.

30 TLA Quick Start User Manual

Page 40

Acquiring the iView Data

The next steps consist of acquiring the initial data, and then adjusting the data to properly view and analyze the data.

Acquire the Initial Data

1. Click M a gniView to turn on the MagniVu

waveforms.

2. Click iView to turn on the iView

waveforms.

If desired, delete any of the unused

oscilloscope waveforms.

3. Click Ru n to acquire and display

waveform data from both instruments.

Depending on the oscilloscope and your

Waveform window settings, you may

not see any waveform data from the

oscilloscope. If necessary, click the iView

button in the Waveform window to bring

the waveform on screen.

iView Integrate

d Measurements

Aligning the Oscilloscope Data with the Logic Analzyer Data

Complete the following steps to fine-tune the data alignment.

1. Zoom the display to measure the

time difference between the glitch in

the MagniVu waveform and in the

oscilloscope waveform:

2. Move Cursor 1 to the leading edge of the

glitch in the MagniVu waveform.

3. Click the oscilloscope waveform label

to allow you to read the voltage

measurements.

If the highlighted waveform is too bright,

click the area below the waveform labels

to turn the highlighting off (you may need

to resize the Waveform window to show

the label area with no labels).

4. Move Cursor 2 to the point on the

glitch where the waveform crosses the

threshold voltage as indicated by the

measurement readout.

5. Note the Delta Time value.

TLA Quick Start User Manual 31

Page 41

iView Integrate

6. Select Time Alignment . . . from the

d Measurements

Data menu.

7. Select the oscilloscope as the data

source.

8. Enter the offset value (Delta Time value)

into the Adjust time offset box.

9. Click OK.

32 TLA Quick Start User Manual

Page 42

iView Integrate

d Measurements

The oscillosco

with the logic analyzer data.

pe data is now time-aligned

Quick Tips

A positiv

analyzer data. A negative offset value will move the oscilloscope waveform to the left.

Click the iView button in the Waveform window or press iView button on the TLA7012 front panel to turn the iView

signals on and off.

e Adjust Time offset value will move the oscilloscope waveform in the display to the right with respect to the logic

TLA Quick Start User Manual 33

Page 43

Application Exa

mples

Application Examples

The examples in this section show how to use your instrument to do common logic analyzer tasks. These examples use the

basic setups with the flip-flop examples developed earlier in this document. (See page 8, Getting Acquainted with Your

Instrument.) Refer to the setups as needed to step through the application examples.

Triggering on a Glitch

Logic analyzers are useful for debugging elusive, intermittent problems, such as glitches. Use the following procedures to set

up the logic analyzer to trigger on a glitch.

Set up the G

1. Configure the Setup window and ensure

that Asynchronous is selected. (See

page 8, Confi

2. Open the

in the waveform label area, and select

Add Waveform . . ..

litch Trigger

gure the Setup Window.)

Waveform window, right-click

34 TLA Quick Start User Manual

Page 44

3. Select the groups (Clock, Input, and

Output for this example).

4. Click Add.

5. Click Close.

6. Click Run.

7. Click Trigger.

Application Exa

mples

TLA Quick Start User Manual 35

Page 45

Application Exa

8. Click and drag the Glitch icon from the

9. Select the groups that you want the logic

mples

Tabbed Trigger window to the Output

group wavefor

analyzer

m.

to trigger on. Clear any other

signals.

The signal where you dropped the G litch

icon is s

elected by default. You can

select the groups you want and avoid

triggering on signals that may contain

s that you do not care about.

glitche

10. Click R

11. Expand

un.

the Output group to see the

highlighted glitch on the Q waveform.

12. Click MagniVu.

The glitch data is highlighted in red

ry sample point for each signal

at eve

in the Deep timing waveforms. The

MagniVu timing waveforms show the

-resolution glitch data.

high

36 TLA Quick Start User Manual

Page 46

State Acquisition

You can use the logic analyzer for state data analysis; you can view the data in tabular form in the Listing window.

Define the Setup Window

State acquisition uses an external clock from the target system to tell the logic analyzer when to sample data.

1. Configure the signals in the Setup

window. (See page 8, Configure the Setup

Window.)

2. Select Synchronous.

3. Select the Single Clock source. For this

example, select CK0().

4. Select the rising edge of the clock.

5. Select Samples.

Application Exa

mples

Configure the Trigger

1. Define the setups for the Waveform

window. (See page 15, Define the

Waveform Window.)

You will use the Waveform window

setups to help define the trigger.

2. Click Trigger in the tabbed window.

3. Click and drag the Channel Edge icon

from the Tabbed Trigger window to the

Output waveform.

TLA Quick Start User Manual 37

Page 47

Application Exa

Acquire Data

1. Click Run.

mples

2. Zoom the data a

acquired data.

The LA1: Clock(0) waveform data

shows no changes because the data

is sampled on

Each tic mark of the S ample clock

waveform represents a clock edge.

The MagniVu high-resolution data

still displ

s necessary to view the

each rising clock edge.

ays timing data.

Configure the Listing Window

1. Click the

instrument in the TLA toolbar.

Listing window button for your

The listing window has no data in it. You

need to add the data columns to the

to see the data.

window

38 TLA Quick Start User Manual

Page 48

Application Exa

mples

2. Right-click in

the data area and select

Add Column.

3. Expand the

groups, press the Ctrl key

while selecting each column, and click

Add to add the columns to the Listing

window.

4. Click Clo

se.

5. Click and drag the Timestamp column to

the right of the last column. Timestamps

may be easier to read in this position.

Note the data in the Listing window.

The clock data appears as zeros

because the data is sampled on the

rising edge of the clock.

The Input and Output data appear as

ones and zeros.

The Timestamp column lists the time

between data samples.

The trigger point is halfway through the

data because the Trigger position was

set to 50%.

TLA Quick Start User Manual 39

Page 49

Application Exa

mples

Triggering on a Setup & Hold Violation

Use the Setup & Hold triggering to capture setup and hold violations. This example uses the same setups for the Setup

window as the previous example. (See page 37, State Acquisition.)

Define the Setup Window

1. Configure the signals in the Setup

window. (See page 8, Configure the

Setup Window.)

2. Select Synchronous.

3. Select the Single Clock source. For this

example, select CK0().

4. Select the rising edge of the clock.

5. Select Samples.

Configure the Trigger

1. Click Run.

2. Click Trigger.

3. Click and drag the Setup and Hold icon

from the Tabbed Trigger window to the

Input waveform.

40 TLA Quick Start User Manual

Page 50

4. Select the desired value for the Input

group/signal setup time.

5. Select the desired hold time.

Acquire and Measure the MagniVu High-Resolution Timing Data

1. Click Run.

Application Exa

mples

2. View the da

The instrument triggers on the rising

edge of the clock signal at the violation.

The setup a

highlighted in red for each setup and hold

violation on the Deep timing waveform.

Use the Ma

measure the actual details.

3. Zoom the data as necessary to see the

MagniVu waveforms.

4. Select System Trigger in the

Measure

5. Move Cu

transition.

6. Read the setup time from the D elta-Time

readout.

ta in the Waveform window.

nd hold violation area is

gniVutimingtoviewand

ment toolbar.

rsor 2 to the data input

TLA Quick Start User Manual 41

Page 51

Specifications

Specification

This section provides the warranted and mechanical specifications for the TLA5000B Series Logic Analyzers, TLA7000

Series Logic Analyzers, TLA7Bxx, TLA7ACx, and TLA7N4 Series Logic Analyzer. All specifications (marked with the.

symbol) are guaranteed and can be checked directly or indirectly at your nearest Tektronix location or by following the

procedures described in i ndividual service manuals or performance verification documents. Typical specifications are

provided for your convenience but are not guaranteed.

The performance limits in these specifications are valid under the following conditions:

The instrument must be in an environment with temperature, altitude, humidity, and vibration within the operating limits

described in these specifications.

Logic analyzer modules must be installed in a logic analyzer m ainframe.

The instrument must have had a warm-up period of at least 30 minutes.

The instrument must have been calibrated and adjusted at an ambient temperature between +20 °C and +30 °C.

Atmospheric characteristics

Characteristic Description

Temperature:

Operating and nonoperating

Relative Humidity:

Operating and nonoperating

Altitude:

Operating and nonoperating

1

TLA7Bxx and TLA7ACx series module operating temperature is +40 °C maximum.

2

TLA7012 operating temperature is 45 °C maximum due to the CD-RW DVD drive.

3

7Bxx series module relative humidity derates to approximately 57% at +40 °C.

TLA

4

TLA7Bxx and TLA7ACx series module operating humidity is 5% to 90% up to +30 °C, 75% from +30 to +40 °C, noncondensing. Maximum

wet-bulb temperature is +29.4 °C.

5

TLA7Bxx and TLA7ACx series module nonoperating humidity is 5% to 9 0% limited by a wet bulb temperature of +40 °C.

s

Operating (no media in floppy disk drive or DVD drive):

+5 °C to +50 °C, 15 °C/hr maximum gradient, noncondensing (derated 1 °C

per 305 m (1000 ft) above 1524 m (5000 ft) altitude)

12

Nonoperating (no media in floppy disk drive o r DVD drive):

–20 °C to +60 °C, 15 °C/hr maximum gradient, noncondensing

Operating (no media in floppy disk drive or DVD drive):

20% to 80% relative humidity, noncondensing. Maximum wet bulb temperature:

+29 °C (derates relative humidity to approximately 22% at +50 °C)

34

Nonoperating (no media in floppy disk drive o r DVD drive):

8% to 80% relative humidity, noncondensing. Maximum wet bulb temperature:

+29 °C (derates relative humidity to approximately 22% at +50 °C)

5

Operating:

To 3000 m (9843 ft), (derated 1 °C per 305 m (1000 ft) above 1524 m (5000 ft)

altitude

Nonoperating:

12190 m (40,000 ft)

42 TLA Quick Start User Manual

Page 52

Product Features

Specifications

Characteristi

CLK10 Frequency (mainframes)

TLA7012 mainframe slots

TLA7016 mainframe slots

MagniVu memory depth (samples per

channel)

c

Description

10 MHz ±100 PPM

4

13

2048 for TLA7N4 modules

16,000 for TLA7ACx modules and TLA5000B instruments

128,000 for TLA7Bxx modules

MagniVu sampling period

125 ps for TLA7ACx modules and TLA5000B instruments

500 ps for TLA7N4 modules

20 ps for TLA7Bxx modules

Data is asynchronously sampled and stored in a separate high-resolution memory.

The storage speed may be changed (by software) to 250 ps, 500 ps, or 1000 ps,

so that the MagniVu memory covers more time at a lower resolution.

Number of channels

TLA5201B 32 data and 2 clock

TLA5202B, TLA7AC2, TLA7BB2

TLA5203B

TLA5204B, TLA7N4

64 data and 4 clock

96 data, 4 clock, and 2 qualifier

128 data, 4 clock, and 4 qualifier

TLA7AC3, TLA7BB3 96 data and 6 clock/qualifier

TLA7AC4, TLA7BB4, TLA7BC4 128 data and 8 clock/qualifier

Acquisition memory depth

TLA5000B

TLA7ACx, TLA7Bxx

TLA7N4

2 M or optionally 8 M or 32 M samples (PowerFlex options)

64 M per channel, maximum

64 K or 256 K or 1 M or 4 M samples (PowerFlex options)

TLA Quick Start User Manual 43

Page 53

Specifications

Warranted Specifications

Characteristi

c

Description

Input parameters with probes

Threshold Accuracy

TLA5000B, TLA7N4 ±100 mV

TLA7ACx, TLA7Bxx ±(35 mV + 1% of the threshold voltage setting)

Channel-to-channel skew

TLA7N4

≤ 1.6 ns maximum (When merged, add 0.5 ns for the slave module.)

TLA5000B ≤ ±150 ps maximum

≤ 75 ps (Typical)

TLA7ACx

≤400 ps maximum

When merged, add the following for slave modules: 0.0 ns when data is acquired

on the slav

e modules through local clocks 125 ps when data is acquired on

the slave modules by the master modules’ clock and merge deskew has been

performed. 375 ps when data is acquired on the slave modules by the master

clock and merge deskew has NOT been performed.

ximum, module only (for P6800 and P6900 series probes, add ±60 ps)

TLA7Bxx

module’s

±40 ps ma

±20 ps (Typical), module only

Asynchr

onous sampling

Sampling period

1

test sampling rate for each logic analyzer goes to 50 ms in a 1–2–5

The fas

sequence

TLA7N4

4 ns, 250 MS, all channels

2 ns, 500 MS half channels

TLA7ACx, TLA5000B 2 ns, 500 MS, all channels

1000 MS, half channels

1ns,

500 ps 2000 MS, quarter channels

Bxx

TLA7

1.25 ns, 800 MS, all channels

625 ps, 1600 MS, all channels

ps, 3200 MS, half channels

313

157 ps, 6400 MS, quarter channels

Minimum recognizable word

(across all channels)

ynchronous sampling

S

2

Channel-to-channel skew + sample uncertainty

Example for a P6860 Probe and a 1.25 ns sample period: 160 ps + 1.25 ns =

45 ns

1.

Setup and hold window size (data and qualifiers)

TLA7N4

Maximum window size = Maximum channel-to-channel skew + (2 x sample

uncertainty) + 4 ns. Maximum setup time = User interface setup time + 0.8 ns.

Maximumholdtime=Userinterfaceholdtime+2ns

Maximum setup time for slave module of a merged pair = User interface setup

time + 0.8 ns

Maximum hold time for slave module of a merged pair = User interface hold time

+0.7ns

44 TLA Quick Start User Manual

Page 54

Warranted Specifications (cont.)

Characteristic Description

TLA5000B

TLA7ACx (single module) Maximum window size = Maximum channel-to-channel skew + (2 x sample

TLA7Bxx

Maximum s

ynchronous clock rate

TLA7N4

TLA5000

B

TLA7ACx 120 MHz in quarter-speed mode (8.3 ns minimum between active clock edges)

TLA7Bxx 750 MHz, one sample point per clock, all channels

Trigger System

Trigger State sequence rate

1

It is possible to use storage control and only store data when it has changed (transitional storage).

2

Applies to asynchronous sampling only. Setup and hold window specification applies to synchronous sampling only.

3

Software controls the selection between full-speed, half-speed, and quarter-speed modes.

4

This is a special mode and has some limitations such as the clocking state machine and trigger state machine only running at 500 MHz.

Maximum window size = Maximum channel-to-channel skew + (2 x sample

uncertainty) + system variation + 100 ps

uncertainty) + 100 ps Maximum setup time = User interface setup time + 75 ps

Maximum hold time = User interface hold time + 50 ps

220 ps maximum (180 ps Typical) single channel on single module

240 ps maximum (200 ps Typical) single channel on merged module

200 MHz i

n full-speed mode (5 ns minimum between active clock edges)

100 MHz in half-speed mode (10 ns minimum between active clock edges)

235 MHz in full speed mode (4.25 ns minimum between active clock edges)

235 MHz in half-speed mode (4.25 ns minimum between active clock edges)

450 MHz

800 MHz on half channels

in full-speed mode (2.2 ns minimum between active clock edges)

4

Software controls the selection between full-speed and half-speed modes.

750 MHz, four samples points per clock, half channels

MHz, one sample point per clock, all channels

1400

1400 MHz, two sample points per clock, half channels

Same rate as valid data samples received; 500 MHz maximum (TLA7Bxx,

800 MHz maximum)

Specifications

3

3

3

3

TLA Quick Start User Manual 45

Page 55

Specifications

Mechanical characteristics

Characteristi

c

Description

TLA5000B dimensions

Height

Width

Length

284.44 mm (11.200 in)

288.29 mm (11.350 in)

444.5 mm (17.500 in)

TLA7012 dimensions

Height (with feet) 29.46 cm (11.6 in)

Width

Depth

Height (

imensions

with feet)

TLA7016 d

Width

Depth

xx, TLA7ACx, and TLA7N4 dimensions

TLA7B

Height

Width

45.08 cm (17.75 in)

45.97 cm (18.1 in)

34.67 cm

42.42 c

67.31 c

262 mm

61 mm

(13.7 in)

m (16.7 in)

m (26.5 in)

(10.32 in)

(2.39 in) with merge connector in the recessed position

Width increases by 10.41 mm (0.41 in) with merge connector in the extended

position.

Length

373 mm (14.7 in)

Weight (TLA5000B and mainframes include empty accessory pouch, slot covers, and front cover)

TLA715

TLA721 and TLA7X M

TLA7012

TLA7016

TLA5201B

TLA5202B

TLA5203B

TLA5204B

13.9 kg (30 lbs 12 oz)

26.7 kg (58 lbs 11 oz), with benchtop controller

18.45 kg (40 lbs 12 oz)

24 kg (52 lbs 14 oz)

11.8kg(25lb15oz)

11.85kg(26lb2oz)

11. 9 kg (26 lb 4 oz)

12kg(26lb7oz)

TLA7AC2, TLA7BB2 2.282 kg (5 lb 0.5 oz)

TLA7AC3, TLA7BB3 2.381 kg (5 lb 4 oz)

TLA7AC4, TLA7BB4, TLA7BC4 2.438 kg (5 lb 6 oz)

TLA7N4

2.55 kg (5 lbs 10 oz)

46 TLA Quick Start User Manual

Page 56

Index

Index

A

Acquiring dat

iView, 31

Acquisition

state, 9

timing, 9

Activity indicators, 13

Adding an ex

Antivirus software, 1

a, 19

ternal oscilloscope, 29

B

Basic steps, 6

C

Clocking

Connecting, 2

Connection

Cursors

Custom sampling, 11

,9

See also Sampling

probes,

local, 2

Remote D

Remote Host, 2

measur

1

esktop, 3

ing data, 22

D

Data Measurement window, 24

indows, 7

Data w

Default system, 8

Delta-Time toolbar, 23

ew, 11

Desk

Documentation, iii

Drag and drop measurements, 24

E

y Trigger tab, 14

Eas

EasyTrigger, 14

External oscilloscope, 29

F

rewall, 1

Fi

G

Glitch data, 36

Glitch triggering, 34

Group card, 1

Groups

creating, 11

naming, 11

1

I

Instrument connection, 2

Instrument setups, 1

iView, 29

aligning data, 31

iView wizard, 29

L

window, 7

Listing

adding columns, 39

moving columns, 39

Loading

Local connection, 2

setups, 28

M

MagniVu button, 25

Vu timing, 25

Magni

viewing setup and hold

violations, 41

ring data, 22

Measu

Memory depth

setting, 10

N

ork, 1

Netw

New Data Window wizard, 7

O

offline, 3

fline operation, 3

Of

Opening

Setup window, 8

igger window, 13

Tr

Waveform window, 15

P

Power Trigger

PowerTrigger, 14

Probe

connections

threshold voltages, 9

Probe activity, 13

window, 20

,1

R

Related do

Remote Desktop, 3

Remote Host, 2

Repetitiv

Run button, 19

Run/Stop button, 19

cumentation, iii

e Run button, 19

S

g

Samplin

asynchronous, 9

Custom, 11

nous, 9

synchro

Saving setups, 27

Setup window

,11

deskew

group cards, 11

opening, 8

ng, 8

sampli

setting memory depth, 10

Signal Mapping area, 11

s

Setup

loading, 28

saving, 27

l Mapping area, 9, 11

Signa

Snap to Edge, 22

Specifications

spheric, 42

atmo

mechanical, 46

State acquisition, 9, 37

tus dialog box, 19

Sta

Storage options, 10

System Window, 5

T

bbed Trigger window, 14, 20, 36

Ta

Target system

connections, 1

TLA Quick Start User Manual 47

Page 57

Index

Threshold indicators, 13

Time offset, 33

Timing acquisition, 9

TLA Connection dialog box, 2

TLA Explorer,

Toolbar Buttons, 4

Trigger

defining, 13

Triggering

glitch, 34

setup and hol

4

d, 40

U

Using the logic analyzer, 6

W

Waveform window, 7

opening, 15

Waveforms

adding, 17

deleting, 15

Windows

Listing, 7, 38

Waveform, 7

opening, 15

Z

Zooming data

,21

48 TLA Quick Start User Manual

Loading...

Loading...