Page 1

TekExpress

®

HDM Advanced Analysis and Compliance Solution

Printable Application Help

*P077092604*

077-0926-04

Page 2

Page 3

TekExpress

®

HDM Advanced Analysis and Compliance Solution

Printable Application Help

www.tek.com

077-0926-04

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products

are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

Getting help and support

Technical support ........................................................................................................................... 1

Overview and key specifications

Overview and key specifications .................................................................................................... 3

Supported tests- HDM Source ........................................................................................................ 4

Supported tests- HDM Sink ............................................................................................................ 5

Supported resolutions- HDM Source ............................................................................................. 6

Supported resolutions- HDM Sink ................................................................................................. 6

Operating basics

Equipment connection setup (HDM Source) .................................................................................. 7

Equipment connection setup (HDM Sink for CTS 2.0) ............................................................... 16

Equipment connection setup (HDM Sink for CTS 1.4) ............................................................... 26

Application directories and usage ................................................................................................. 31

File name extensions .................................................................................................................... 32

Getting started

Installing the software .................................................................................................................. 33

Compatibility ........................................................................................................................... 33

Minimum system requirements ............................................................................................... 34

Windows 7 user accounts ........................................................................................................ 36

Install the software .................................................................................................................. 36

Activate the license ................................................................................................................. 38

View version and license information ..................................................................................... 39

Application basics

Run the application ....................................................................................................................... 41

Exit the application ....................................................................................................................... 41

Application controls and menus ................................................................................................... 42

Application controls ................................................................................................................ 42

Options menu .......................................................................................................................... 44

TekExpress HDM Advanced Analysis and Compliance Solution i

Page 6

Table of Contents

Setup panel ................................................................................................................................... 48

Setup panel overview .............................................................................................................. 48

Set DUT parameters ................................................................................................................ 48

Select tests ............................................................................................................................... 55

Set acquisition parameters (source only) ................................................................................. 58

Set test notification preferences .............................................................................................. 59

Configure test parameters ........................................................................................................ 59

Status panel overview ................................................................................................................... 64

Results panel ................................................................................................................................. 66

Results panel overview ............................................................................................................ 66

View test results ...................................................................................................................... 67

View test-related files .............................................................................................................. 68

Reports panel ................................................................................................................................ 69

Reports panel overview ........................................................................................................... 69

Select report options ................................................................................................................ 69

View a report ........................................................................................................................... 71

Report contents ........................................................................................................................ 72

TekExpress programmatic interface

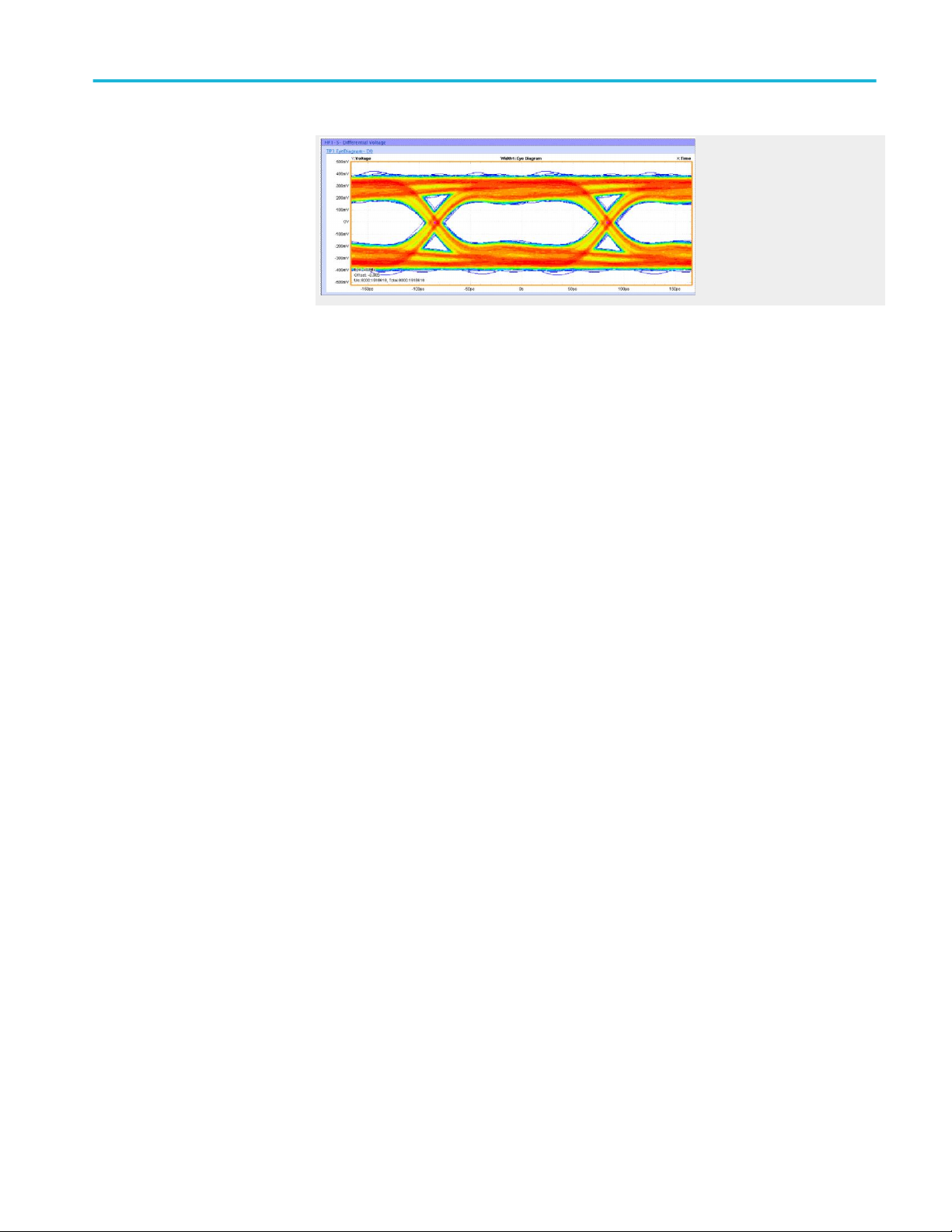

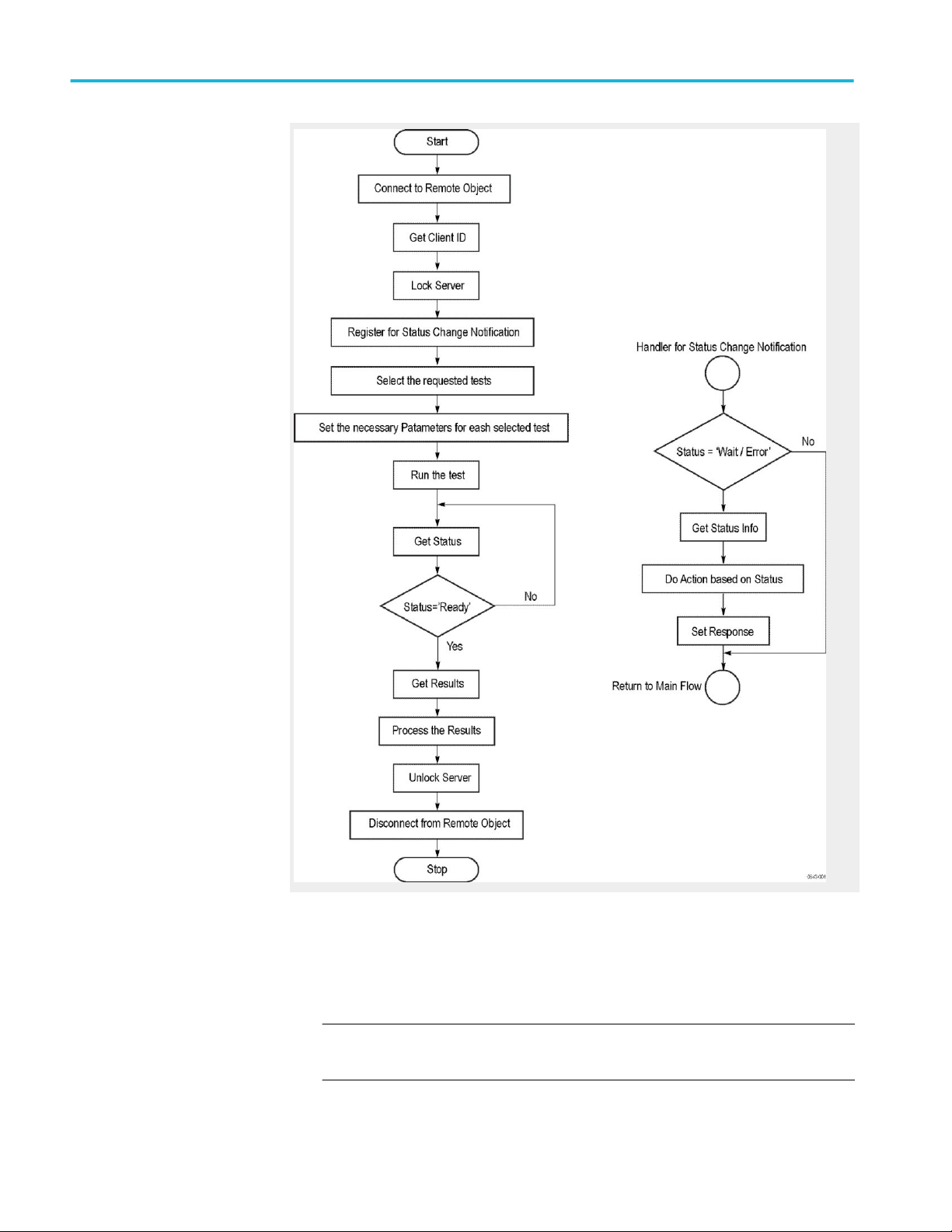

About the programmatic interface ................................................................................................ 75

To enable remote access ............................................................................................................... 76

Requirements for developing TekExpress client .......................................................................... 78

Remote proxy object ..................................................................................................................... 79

Client proxy object ....................................................................................................................... 80

Client programmatic interface overview ...................................................................................... 81

Program remote access code example .......................................................................................... 84

HDM application commands ........................................................................................................ 85

HDM application commands flow .......................................................................................... 85

Connect through an IP address ................................................................................................ 85

Lock the server ........................................................................................................................ 87

Disable the popups .................................................................................................................. 88

Set or get the DUT ID ............................................................................................................. 89

Set the configuration parameters for a suite or measurement ................................................. 91

Query the configuration parameters for a suite or measurement ............................................ 93

Select a test .............................................................................................................................. 95

Select a device ......................................................................................................................... 98

Select pattern(s) ....................................................................................................................... 99

Select a suite .......................................................................................................................... 101

Select a version ...................................................................................................................... 102

ii TekExpress HDM Advanced Analysis and Compliance Solution

Page 7

Run with set configurations or stop the run operation .......................................................... 103

Handle error codes ................................................................................................................. 104

Get or set the timeout value ................................................................................................... 105

Wait for the test to complete ................................................................................................. 106

After the test is complete ....................................................................................................... 110

Save recall or query a saved session ..................................................................................... 115

Unlock the server ................................................................................................................... 117

Disconnect from the server .................................................................................................... 118

Algorithms

About algorithms ........................................................................................................................ 119

HDM Source tests

HF1- 2 - Source TMDS electrical - 6G -TRISE, TFALL .......................................................... 121

HF1- 3 - Source TMDS Electrical - 6G - Inter-Pair Skew ......................................................... 124

HF1- 6 - Source TMDS Electrical - 6G - Clock Duty Cycle and Clock Rate ............................ 127

HF1- 7- Source TMDS Electrical - 6G - Clock jitter ................................................................. 130

HF1-1- Source TMDS Electrical - 6G -VL and VSwing ........................................................... 133

HF1- 8 - Source TMDS Electrical - 6G - Data Eye Diagram ..................................................... 137

HF1- 4 - Source TMDS Electrical - 6G - Intra-Pair Skew ......................................................... 144

HF1- 5 - Source TMDS Electrical - 6G - Differential Voltage .................................................. 147

Table of Contents

HDM Sink Electrical tests for CTS version 1.4

Test ID 8-5 TMDS Min-max differential swing tolerance ......................................................... 151

Test ID 8-6 TMDS Intra-pair skew test ...................................................................................... 154

Test ID 8-7 TMDS Jitter tolerance test ...................................................................................... 157

HDM - Sink Protocol tests for 1.4

Test ID 8-15 Character synchronization test .............................................................................. 161

Test ID 8-16 Acceptance of all valid packet types test .............................................................. 163

Test ID 8-19 Pixel encoding requirements test .......................................................................... 165

Test ID 8-20 Video format timing test ....................................................................................... 167

Test ID 8-21 Audio clock regeneration test ................................................................................ 169

Test ID 8-22 Audio sample packet jitter test .............................................................................. 171

Test ID 8-23 Audio formats test ................................................................................................. 173

Test ID 8-24 Interoperability with DVI test ............................................................................... 175

Test ID 8-25 Deep color test ....................................................................................................... 177

TekExpress HDM Advanced Analysis and Compliance Solution iii

Page 8

Table of Contents

Test ID 8-28 One bit audio test .................................................................................................. 179

Test ID 8-29 3D video format timing test .................................................................................. 181

Test ID 8-30 4Kx2K video format timing test ........................................................................... 183

Test ID 8-31 Extended colors and contents test ......................................................................... 185

HDM - Sink Electrical tests for CTS 2.0

HF2-1 Min-max Differential Swing Tolerance .......................................................................... 189

HF2-2 Intra-pair skew test .......................................................................................................... 199

HF2-3-Jitter Tolerance test ......................................................................................................... 208

HDM - Sink Protocol tests for CTS 2.0

HF2-6 Sink video timing - 6G - 2160p 24 bit color depth ......................................................... 219

HF2-7 Sink video timing - 6G - 2160p deep color ..................................................................... 224

HF2-8 Sink video timing - 6G - 2160p 3D ................................................................................. 230

HF2-23- Sink pixel decoding YCBCR 4:2:0 .............................................................................. 235

HF2-24 Sink pixel decoding YCBCR 4:2:0 deep color ............................................................. 240

HF2-25 Sink video timing - 21:9 (64:27) ................................................................................... 245

HF2-36 Sink video timing - 6G - non-2160p 24 bit color depth ................................................ 251

HF2-37 Sink video timing - 6G - non-2160p deep color ........................................................... 256

HF2-38 Sink video timing - 6G - non-2160p 3D ....................................................................... 263

Reference

Map the My TekExpress folder .................................................................................................. 269

iv TekExpress HDM Advanced Analysis and Compliance Solution

Page 9

Getting help and support

Technical support

Tektronix values your feedback on our products. To help us serve you better,

please send us your suggestions, ideas, or comments on your application or

oscilloscope. Contact Tektronix through mail, telephone, or the Web site,

www.tektronix.com.

When you contact Tektronix Technical Support, please include the following

information (be as specific as possible):

■

General Information

All instrument model numbers

■

Hardware options, if any

■

Probes used

■

Your name, company, mailing address, phone number, FAX number

■

Please indicate if you would like to be contacted by Tektronix about your

suggestion or comments.

Application Specific

Information

■

Software version number

■

Description of the problem such that technical support can duplicate the

problem

■

If possible, save the setup files for all the instruments used and the

application.

■

If possible, save the TekExpress setup files, log.xml, *.TekX (session files

and folders), and status messages text file.

■

If possible, save the waveform on which you are performing the

measurement as a .wfm file.

TekExpress HDM Advanced Analysis and Compliance Solution 1

Page 10

Getting help and support

2 TekExpress HDM Advanced Analysis and Compliance Solution

Page 11

Overview and key specifications

Overview and key specifications

The TekExpress HDM Advanced Analysis and Compliance Solution gives you

the tools to easily run high definition multimedia interface (HDMI) tests under

the HDMI Compliance test specifications 2.0. It provides a complete and reliable

solution for quick testing.

The application functionality is generally divided into three parts: the Source

Suite, the Sink Electrical Suite, and the Sink Protocol Suite. You can select which

suite and which version of the CTS you would like to use by clicking on the

Setup panel and clicking the DUT tab.

Supported Tests:

Supported Resolutions:

See also:

TekExpress HDM Source supports these automated Single ended and

Differential tests.

TekExpress HDM Sink supports these automated Sink tests.

HDM Source supports these resolutions.

HDM Sink supports these resolutions.

Equipment connection setup HDM Source

Equipment connection setup HDM Sink

Install the software

Application directories and usage

File name extensions

Instrument control settings

TekExpress HDM Advanced Analysis and Compliance Solution 3

Page 12

Overview and key specifications

Supported tests- HDM Source

TekExpress HDM Source supports automation of following differential and

single-ended tests:

Differential tests

■

HF1-2: Source TMDS Electrical – 6G – TRISE, TFALL

This test confirms that the rise times and fall times on the TMDS differential

signals fall within the limits of the specification.

■

HF1-3: Source TMDS Electrical – 6G – Inter-Pair Skew

This test confirms that the skew between two data lanes on the TMDS

differential signals fall within the limits of the specification.

■

HF1-5: Source TMDS Electrical – 6G – Differential Voltage

This test confirms that the voltage level of the TMDS differential signals

complies with the limits mentioned in specification.

■

HF1-6: Source TMDS Electrical – 6G – Clock Duty Cycle and Clock Rate

This test confirms that the duty cycle and clock rate of the TMDS differential

clock complies with the limits mentioned in specification.

■

HF1-7: Source TMDS Electrical – 6G – Clock Jitter

This test confirms that the clock jitter of the TMDS differential clock

complies with the limits mentioned in specification.

Single ended tests

■

HF1-8: Source TMDS Electrical – 6G – Data Eye diagram

This test confirms that the HDMI Data output has signal quality that meets

the eye opening required by the specification

■

HF1-1: Source TMDS Electrical – 6G – VL and VSwing

This test confirms that the low voltage level of the TMDS single ended

signals complies with the limits mentioned in specification.

■

HF1-4: Source TMDS Electrical – 6G – Intra-Pair Skew

This test confirms that the skew between the positive and negative lane of the

TMDS single ended signals complies with the limits mentioned in

specification.

4 TekExpress HDM Advanced Analysis and Compliance Solution

Page 13

Overview and key specifications

Supported tests- HDM Sink

TekExpress HDM Sink supports the following automated HDM Sink Electrical

and Sink Protocol tests.

These tests are supported for CTS Version 2.0:

HDM Sink Electrical tests

■

HF 2-1-Min/Max Differential Swing Tolerance

■

HF 2-2-Intra-Pair Skew

■

HF 2-3-Jitter Tolerance

HDM Sink Protocol tests

■

HF2-6 Sink Video Timing - 6G - 2160p 24 bit Color Depth

■

HF2-7 Sink Video Timing - 6G - 2160p Deep Color

■

HF2-8 Sink Video Timing - 6G - 2160p 3D

■

HF2-23 Sink Pixel Decoding YCBCR 4:2:0

■

HF2-24 Sink Pixel Decoding YCBCR 4:2:0 Deep Color

■

HF2-25 Sink Video Timing - 21:9

■

HF2-36 Sink Video Timing - 6G - Non-2160p 24 bit Color Depth

■

HF2-37 Sink Video Timing - 6G - Non-2160p Deep Color

■

HF2-38 Sink Video Timing - 6G - Non-2160p 3D

These tests are supported for CTS Version 1.4:

HDM Sink Electrical tests

■

Test ID 8-5: TMDS-Min/Max Differential Swing Tolerance

■

Test ID 8-6: TMDS-Intra-Pair Skew

■

Test ID8-7: TMDS-Jitter Tolerance

HDM Sink Protocol tests

■

Test ID 8-15: Character Synchronization

■

Test ID8 -16: Acceptance of All Valid Packet Types

■

Test ID 8-19: Pixel Encoding Requirements

■

Test ID 8-20: Video Format Timing

■

Test ID8-21: Audio Clock Regeneration

■

Test ID 8-22: Audio Sample Packet Jitter

■

Test ID 8-23: Audio Formats

■

Test ID 8-24: Interoperability with DVI

■

Test ID 8-25: Deep Color

■

Test ID 8-28: One Bit Audio

TekExpress HDM Advanced Analysis and Compliance Solution 5

Page 14

Overview and key specifications

■

Test ID 8-29: 3D Video Format Timing

■

Test ID 8-30: 4K 2K Video Format Timing

■

Test ID 8-31: Extended Colors and Contents

Supported resolutions- HDM Source

CTS 2.0: All of the TekExpress HDM tests can be performed for DUTs

operating in resolutions between 3.4 GHz to 6 GHz. Other resolutions that fall

within this range can be entered in the Low Resolution and High Resolution

fields on the DUT tab of the Setup panel.

When Low and High resolutions are the same, the software performs the test at

that one resolution.

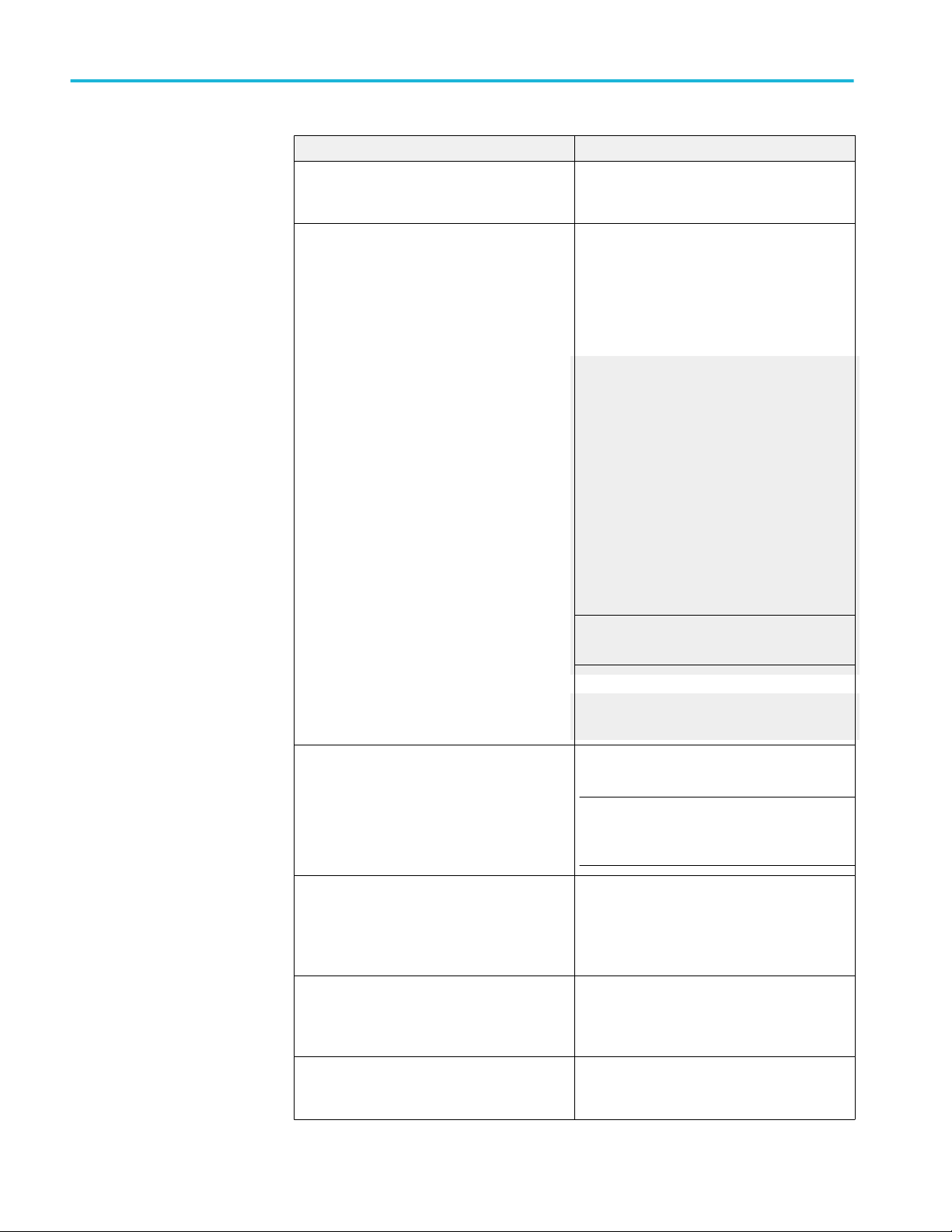

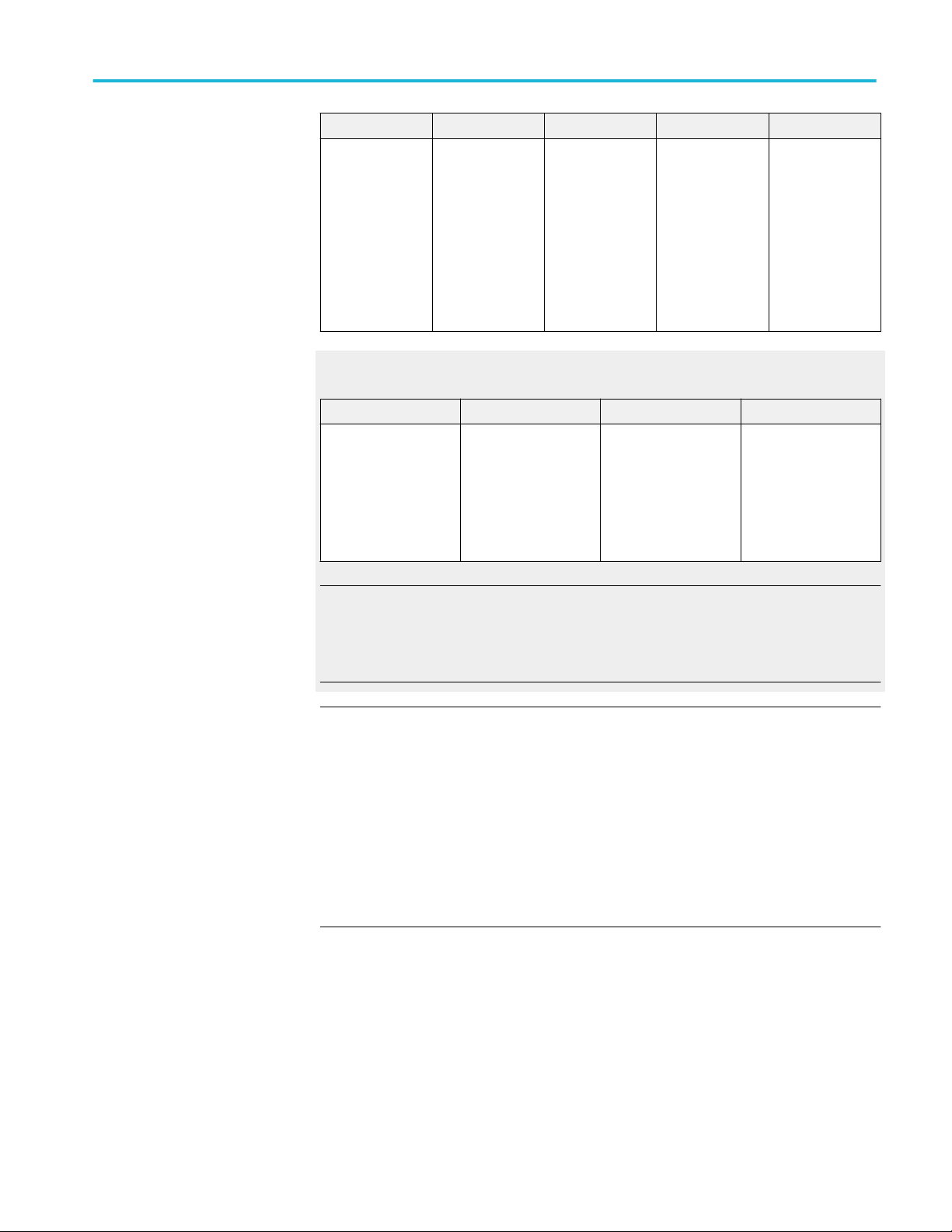

Table 1: Supported resolutions (Source)

DUT Configuration

Measurement name Highest supported TMDS

Character rate

HF 1-1: VL and V

HF 1-7: T

HF 1-3: Inter-Pair Skew Yes N/A

HF 1-3: Inter-Pair Skew Yes N/A

HF 1-5: Differential Voltage - -

Eye Width N/A Yes

Maximum Differential Voltage N/A Yes

Maximum Differential Voltage N/A Yes

HF 1-6: Clock Duty Cycle and

Clock rate

Maximum Duty Cycle Yes Yes

Minimum Duty Cycle Yes Yes

Clock Rate Yes Yes

HF 1-7- Clock Jitter Yes N/A

V

Swing

HF 1-8-Data Eye Diagram Yes N/A

RISE

SWING

and T

FALL

N/A Yes

Yes N/A

- -

Yes N/A

Lowest supported TMDS

Character rate

Supported resolutions- HDM Sink

CTS 2.0: All of the TekExpress HDM Sink tests can be performed at data rates

2.97 GHz, 3.71 GHz, 4.46 GHz and 5.94 GHz.

CTS 1.4: All of the TekExpress HDM Sink tests can be performed at data rates

27 MHz, 74.25 MHz, 148.5 MHz, 222.75 MHz and 297 MHz.

6 TekExpress HDM Advanced Analysis and Compliance Solution

Page 15

Operating basics

Equipment connection setup (HDM Source)

You need the following equipment to run HDM Source tests. (For details, see

Minimum system requirements):

■

A supported Tektronix oscilloscope

■

Four differential probes – P7313SMA, for single ended and differential tests

■

Four differential probes – P7720, for single ended and differential tests

■

Device under test (DUT)

■

TF-HDM-TPA-S fixture

■

A PWS4205, PWS2185, Keithley 24XX or 2220-30-1/ 2220J-30-1 Dual

Power Supply (if using external power supply option)

■

Any approved EDID analyzer

Connection diagrams and the tests they apply to are listed below.

Single-ended and differential tests

NOTE. In case of single stack 2 channel oscilloscopes, you need to make

appropriate channel configurations in TekExpress HDM software:

DPO75002SX, DPO75902SX, and DPO77002SX.

Table 2: Source differential tests

Test number and characteristic tested Setup diagram

HF1-2: Source TMDS Electrical – 6G – TRISE,

TFALL

HF1-3: Source TMDS Electrical – 6G – InterPair Skew

HF1-5: Source TMDS Electrical – 6G –

Differential Voltage

HF1-6: Source TMDS Electrical – 6G – Clock

Duty Cycle

HF1-7: Source TMDS Electrical – 6G – Clock

Jitter

Source differential diagram

Source differential diagram for SX series

oscilloscopes

Source differential diagram

Source differential diagram for SX series

oscilloscopes

Source differential diagram

Source differential diagram for SX series

oscilloscopes

Clock diagram

Clock diagram for SX series oscilloscopes

Clock diagram

Clock diagram for SX series oscilloscopes

TekExpress HDM Advanced Analysis and Compliance Solution 7

Page 16

Operating basics

Schematic for Source differential diagram

Schematic for Source differential diagram for SX series scopes

8 TekExpress HDM Advanced Analysis and Compliance Solution

Page 17

Operating basics

TekExpress HDM Advanced Analysis and Compliance Solution 9

Page 18

Operating basics

Table 3: Source single ended tests

Test number and characteristic tested Setup diagram

HF1-8: Source TMDS Electrical – 6G – Data

Eye Diagram

HF1-1: Source TMDS Electrical – 6G – VL and

VSwing

HF1-4: Source TMDS Electrical – 6G – IntraPair Skew

Source data eye diagram

Source data eye diagram

Source single ended diagram

Source single ended diagram

Source single ended diagram

Schematic for Source data eye diagram

NOTE. In case of single stack 2 channel oscilloscopes you have to make

appropriate channel configurations in TekExpress HDM software:

DPO72302SX, DPO73302SX, DPO75002SX, DPO75902SX, and DPO77002SX

10 TekExpress HDM Advanced Analysis and Compliance Solution

Page 19

Operating basics

Source data eye diagram for SX series oscilloscopes

TekExpress HDM Advanced Analysis and Compliance Solution 11

Page 20

Operating basics

Source single ended diagram

12 TekExpress HDM Advanced Analysis and Compliance Solution

Page 21

Operating basics

Source single ended diagram for SX series oscilloscopes

TekExpress HDM Advanced Analysis and Compliance Solution 13

Page 22

Operating basics

Schematic for Clock diagram

14 TekExpress HDM Advanced Analysis and Compliance Solution

Page 23

Schematic for Clock diagram for SX series oscilloscopes

Operating basics

TekExpress HDM Advanced Analysis and Compliance Solution 15

Page 24

Operating basics

See Also

Equipment connection setup (HDM Sink)

About algorithms

Equipment connection setup (HDM Sink for CTS 2.0)

You need the following equipment (for details, see Minimum system

requirements):

■

A supported Tektronix oscilloscope

■

Device under test (DUT)

■

Two TCA-SMA connectors

■

An AFG3102, AFG3102C, AFG3252, or an AFG3252C

■

Eight 12 GHz Bias T (mini circuit bias T model number zx85-12G-s+)

■

Two 120 psec Rise time filters (5115110-120)

■

A Power supply external (PWS4721, PWS4602, PWS4323, PWS4305, or

PWS4205)

■

Two AWG70002A instruments with option 01, 03 and 225, or two

AWG7122C instruments with option 1, 2/6, 8

■

TF-HDM-TPA-S

■

10 SMA cables (174-1428-00)

■

Four BNC to SMA converters

■

A BNC T connector

■

Four BNC cables of similar length

■

112 ps Delay Lines-Quantity 6#, Any recommended Delay

Line( SPECTRUM 8001-SM21-02)

■

0.15 Tbit skew- Quantity 6#, 5018CCSF from Carlisle Interconnect

Technologies

Connection diagrams and the tests they apply to are listed below.

NOTE. GPIB connection is supported only for AWG7122C. If using AWG7122C

and GPIB connections, three NI-GPIB cables are needed.

NOTE. In case of single stack 2 channel oscilloscopes you have to make

appropriate channel configurations in TekExpress HDM software:

DPO72302SX, DPO73302SX, DPO75002SX, DPO75902SX, and DPO77002SX.

16 TekExpress HDM Advanced Analysis and Compliance Solution

Page 25

Operating basics

Sink tests

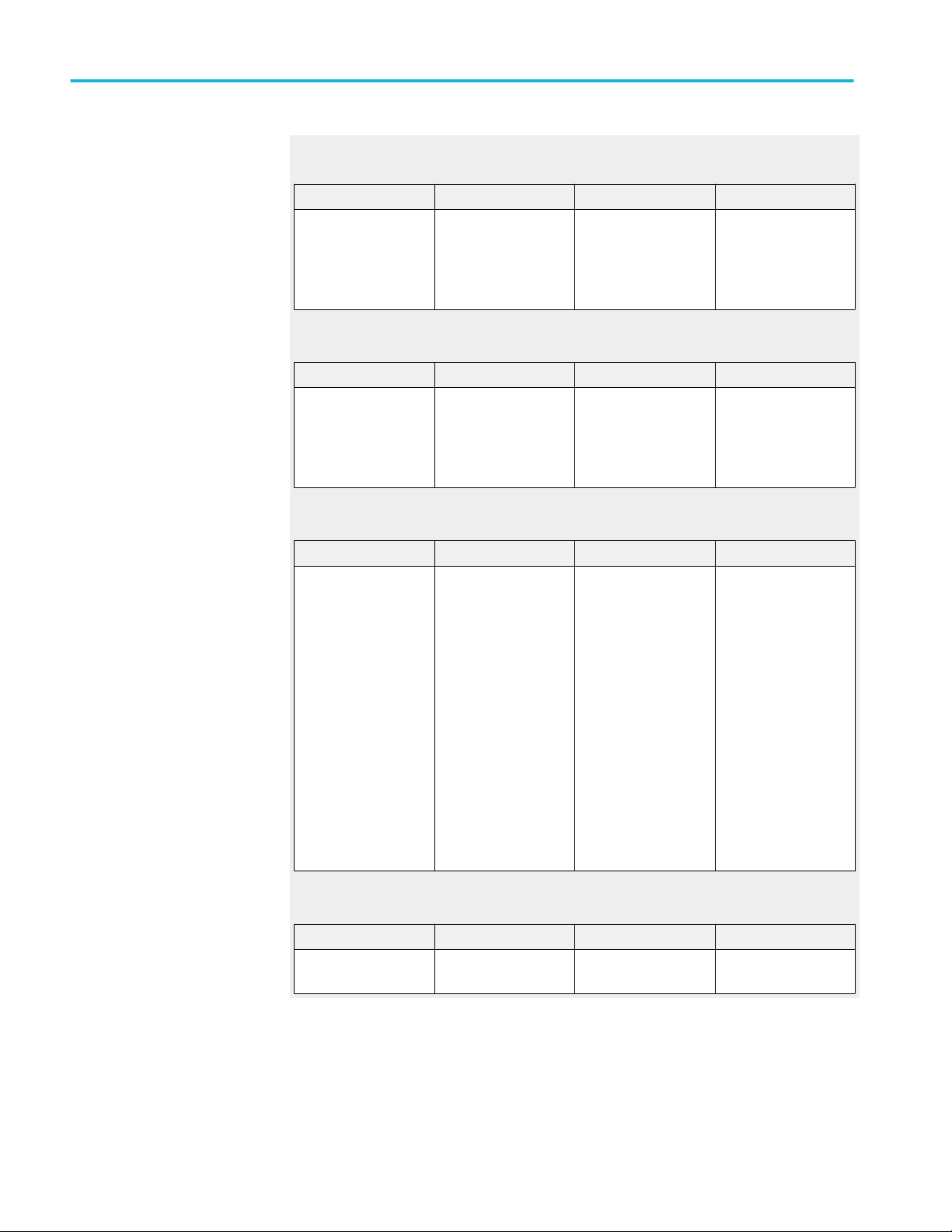

Table 4: Sink Electrical tests for 2.0

Test number and characteristic tested Setup diagram

*HF 2-1: Min/Max Differential Swing Tolerance Sink Electrical min diagram for AWG70002A

Sink Electrical max diagram for AWG70002A

Sink min/max diagram for AWG7122C

*HF 2-2: Intra-Pair Skew Sink Electrical intra-pair skew diagram for

AWG70002A

Sink intra-pair skew diagram for AWG7122C

*HF 2-3: Jitter Tolerance Sink Electrical jitter tolerance diagram for

AWG70002A

Sink jitter tolerance diagram for AWG7122C

Table 5: Sink Protocol tests for CTS 2.0

Test number and characteristic tested Setup diagram

HF2-6 Sink Video Timing - 6G - 2160p 24 bit

Color Depth

HF2-7 Sink Video Timing - 6G - 2160p Deep

Color

HF2-8 Sink Video Timing - 6G - 2160p 3D Sink Protocol diagram for AWG70002A

*HF2-23: Sink Pixel Decoding YCBCR 4:2:0 Sink Protocol diagram for AWG70002A

HF2-24 Sink Pixel Decoding YCBCR 4:2:0 Deep

Color

HF2-25 Sink Video Timing - 21:9 (64:27) Sink Protocol diagram for AWG70002A

HF2-36 Sink Video Timing - 6G - Non-2160p

24 bit Color Depth

HF2-37 Sink Video Timing - 6G - Non-2160p

Deep Color

HF2-38 Sink Video Timing - 6G - Non-2160p 3D Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG7122C

Sink Protocol diagram for AWG7122C

TekExpress HDM Advanced Analysis and Compliance Solution 17

Page 26

Operating basics

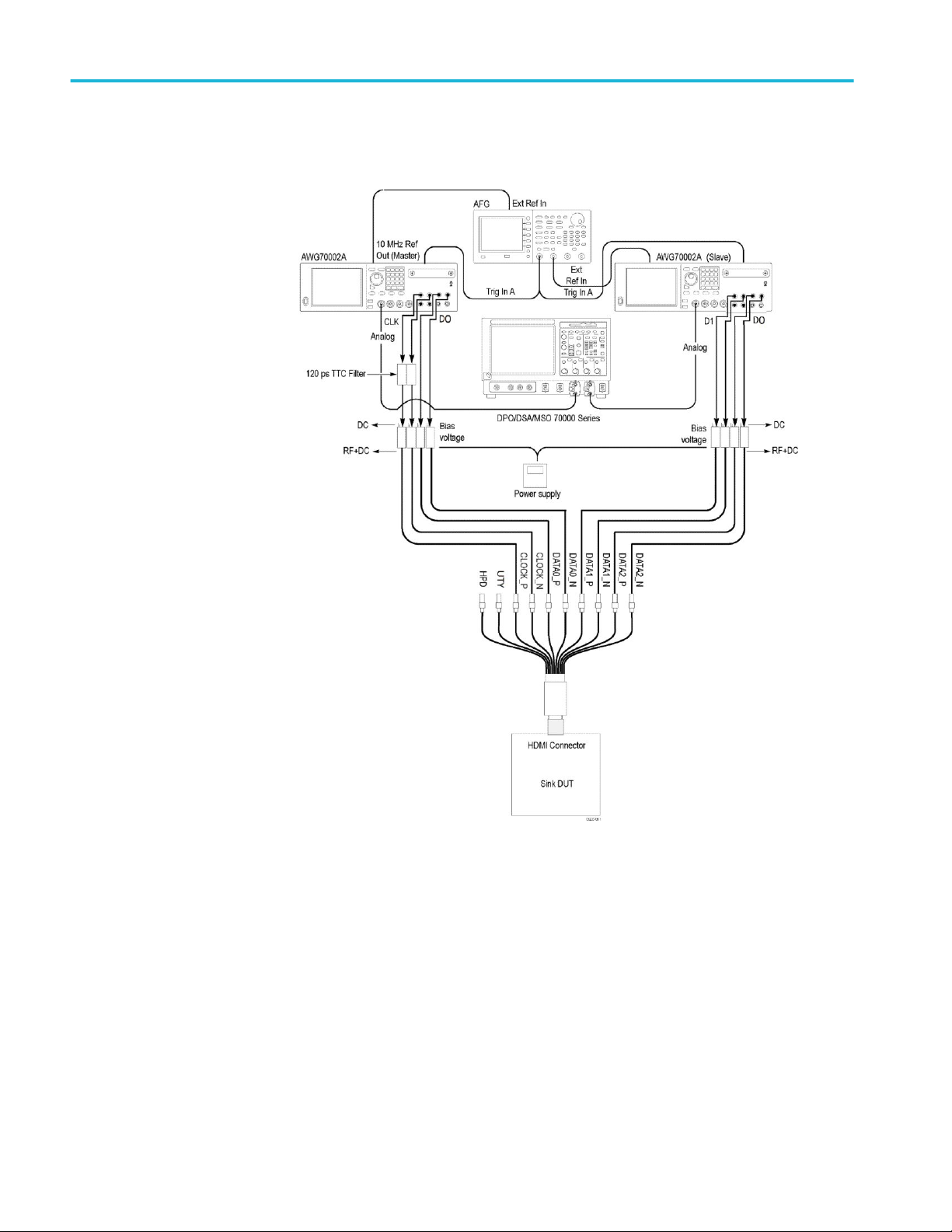

Schematic for Sink Protocol, Electrical (min, intra-pair skew, jitter

tolerance) tests for AWG70002A

18 TekExpress HDM Advanced Analysis and Compliance Solution

Page 27

Operating basics

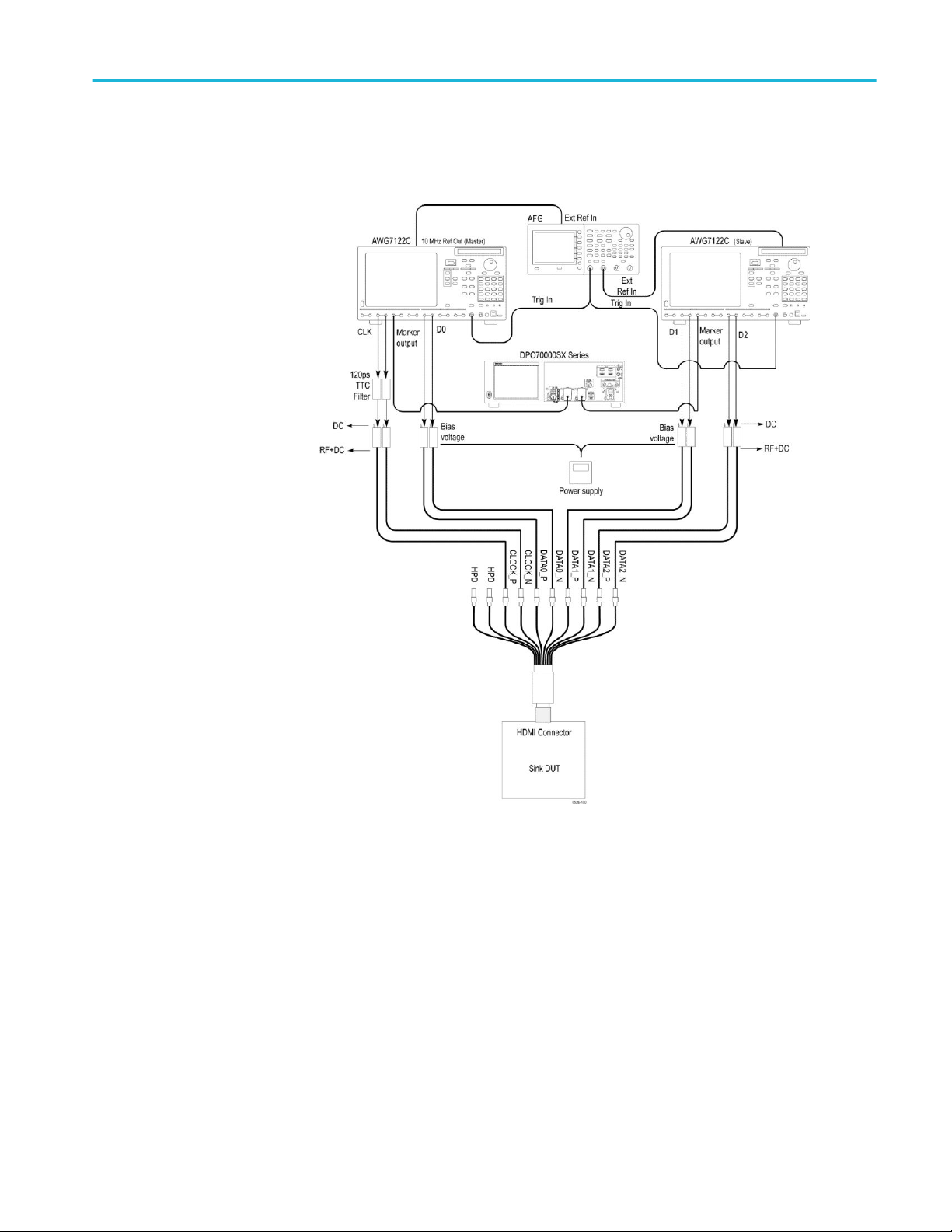

Schematic for Sink Protocol, Electrical (min, intra-pair skew, jitter

tolerance) tests for AWG70002A for SX series scopes

TekExpress HDM Advanced Analysis and Compliance Solution 19

Page 28

Operating basics

Schematic for Sink Electrical max test for AWG70002A

20 TekExpress HDM Advanced Analysis and Compliance Solution

Page 29

Operating basics

Schematic for Sink Electrical max test for AWG70002A for SX series scopes

NOTE. For AWG7122C, the connection remains the same as the nominal pattern.

TekExpress HDM Advanced Analysis and Compliance Solution 21

Page 30

Operating basics

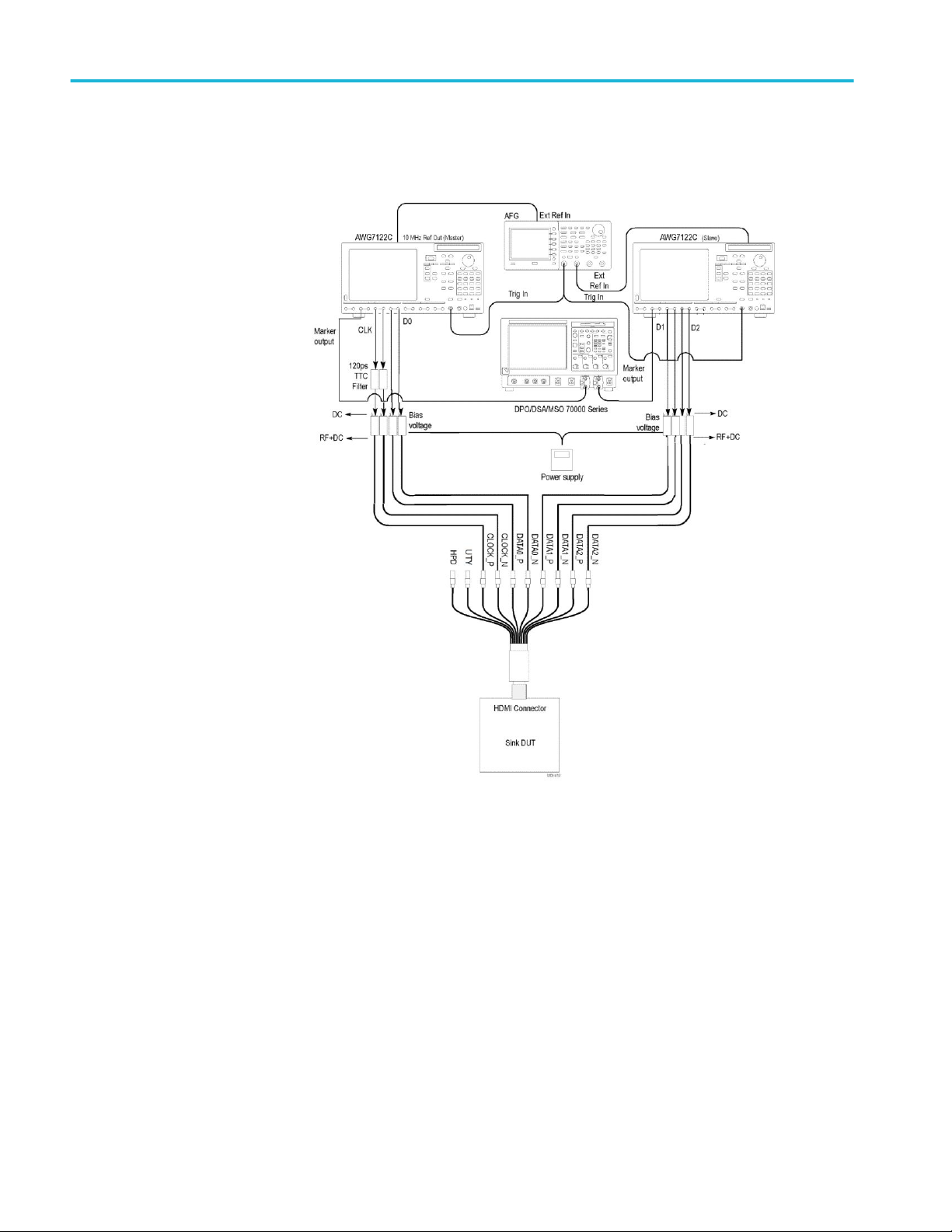

Schematic for Sink Electrical (jitter tolerance, intra-pair skew, and min/

max) tests for AWG7122C

22 TekExpress HDM Advanced Analysis and Compliance Solution

Page 31

Operating basics

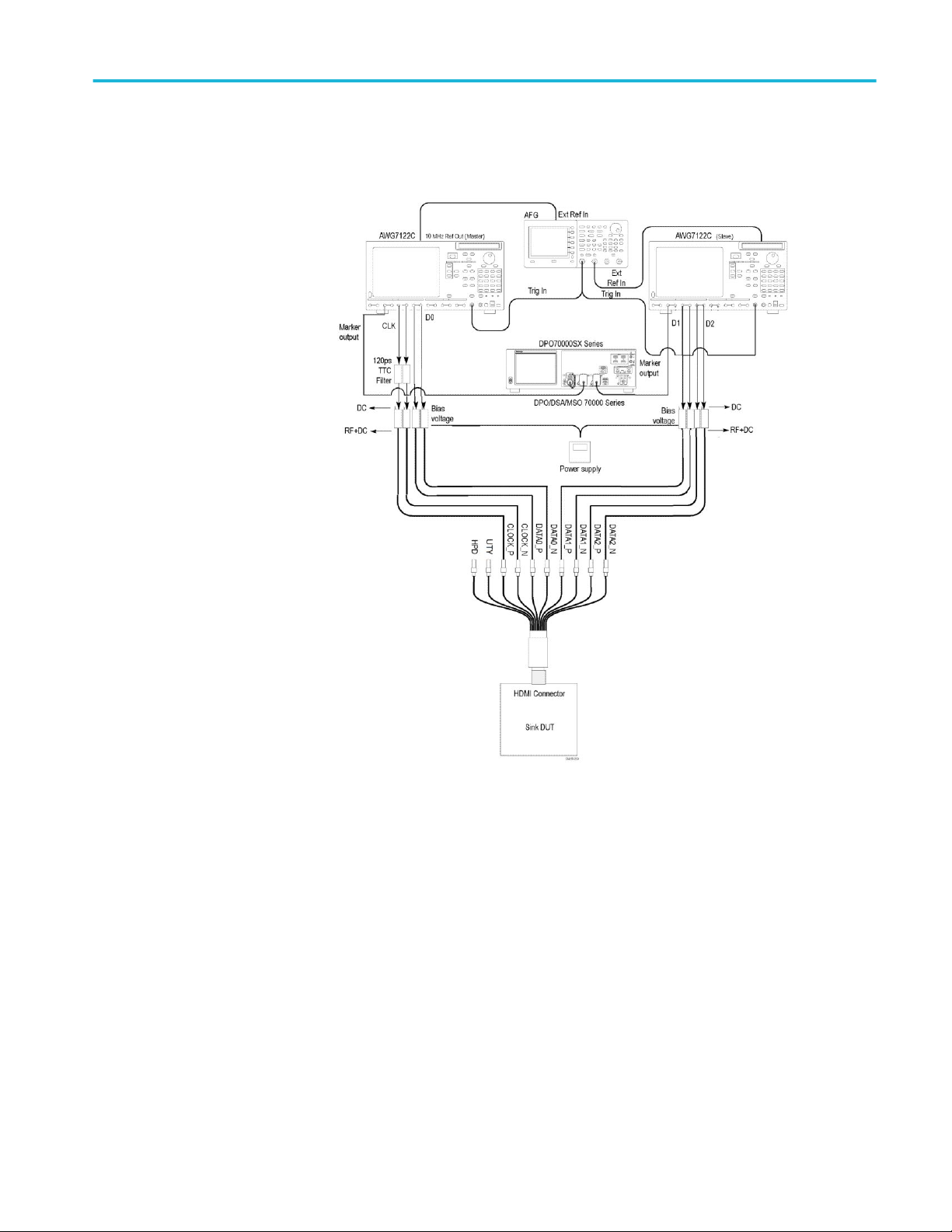

Schematic for Sink Electrical (jitter tolerance, intra-pair skew, and min/

max) tests for AWG7122C for SX series scopes

TekExpress HDM Advanced Analysis and Compliance Solution 23

Page 32

Operating basics

Schematic for Sink Protocol test for AWG7122C

24 TekExpress HDM Advanced Analysis and Compliance Solution

Page 33

Operating basics

Schematic for Sink Protocol test for AWG7122C for SX series scopes

TekExpress HDM Advanced Analysis and Compliance Solution 25

Page 34

Operating basics

Equipment connection setup (HDM Sink for CTS 1.4)

You need the following equipment (for details, see Minimum system

requirements):

■

A supported Tektronix oscilloscope

■

Device under test (DUT)

■

Two TCA-SMA connectors

■

An AFG3102,AFG3102C,AFG3252, or an AFG3252C

■

Eight 12 GHz Bias T (mini circuit bias T model number zx85-12G-s+)

■

Eight 6.4 GHz filter (5115110-120)

■

A Power supply external (PWS4721, PWS4602, PWS4323, PWS4305, or an

PWS4205)

■

Two AWG70002A instruments with option 01, 03 and 225, or two

AWG7122C instruments with option 1, 2/6, 8

NOTE. The AWG7122C should not be used for CTS 1.4.

Sink tests

■

TF-HDM-TPA-S

■

10 SMA cables (174-1428-00)

■

Four BNC to SMA converters

■

One BNC T connector

■

Three BNC cables

■

One BNC T connector

■

Four BNC cables of similar length

Connection diagrams and the tests they apply to are listed below.

NOTE. GPIB connection is supported only for AWG7122C. If using AWG7122C

and GPIB connections, three NI-GPIB cables are needed.

26 TekExpress HDM Advanced Analysis and Compliance Solution

Page 35

Operating basics

Table 6: Sink Electrical tests for 1.4

Test number and characteristic tested Setup diagram

Test ID 8-5: TMDS-Min/Max Differential Swing

Tolerance

Test ID 8-6: TMDS-Intra-Pair Skew Sink Intra pair skew diagram- single lane for

Test ID 8-7: TMDS-Jitter Tolerance Sink jitter tolerance diagram for AWG70002A

Sink electrical min diagram for AWG70002A

Sink Max diagram for AWG70002A

AWG70002A

Sink Intra pair skew diagram - all lanes for

AWG70002A

Schematic for Sink protocol, sink jitter tolerance, sink min test for AWG70002A

(CTS 1.4)

TekExpress HDM Advanced Analysis and Compliance Solution 27

Page 36

Operating basics

Schematic for Sink Intra pair skew for single lane test for AWG70002A

28 TekExpress HDM Advanced Analysis and Compliance Solution

Page 37

Operating basics

Schematic for Sink intra pair skew all lanes test for AWG70002A

TekExpress HDM Advanced Analysis and Compliance Solution 29

Page 38

Operating basics

Schematic for Sink Max for AWG70002A

Table 7: Sink Protocol tests for CTS 1.4

Test number and characteristic tested Setup diagram

Test ID 8-15: Character Synchronization Sink Protocol diagram for AWG70002A

Test ID 8-16: Acceptance of All Valid Packet

Types

Test ID 8-19: Pixel Encoding Requirements Sink Protocol diagram for AWG70002A

Test ID 8-20: Video Format Timing Sink Protocol diagram for AWG70002A

Test ID 8-21: Audio Clock Regeneration Sink Protocol diagram for AWG70002A

Test ID 8-22: Audio Sample Packet Jitter Sink Protocol diagram for AWG70002A

Sink Protocol diagram for AWG70002A

30 TekExpress HDM Advanced Analysis and Compliance Solution

Page 39

Operating basics

Test number and characteristic tested Setup diagram

Test ID 8-23: Audio Formats Sink Protocol diagram for AWG70002A

Test ID 8-24: Interoperability with DVI Sink Protocol diagram for AWG70002A

Test ID 8-25: Deep Color Sink Protocol diagram for AWG70002A

Test ID 8-28: One Bit Audio Sink Protocol diagram for AWG70002A

Test ID 8-29: 3D Video Format Timing Sink Protocol diagram for AWG70002A

Test ID 8-30: 4K 2K Video Format Timing Sink Protocol diagram for AWG70002A

Test ID 8-31: Extended Colors and Contents Sink Protocol diagram for AWG70002A

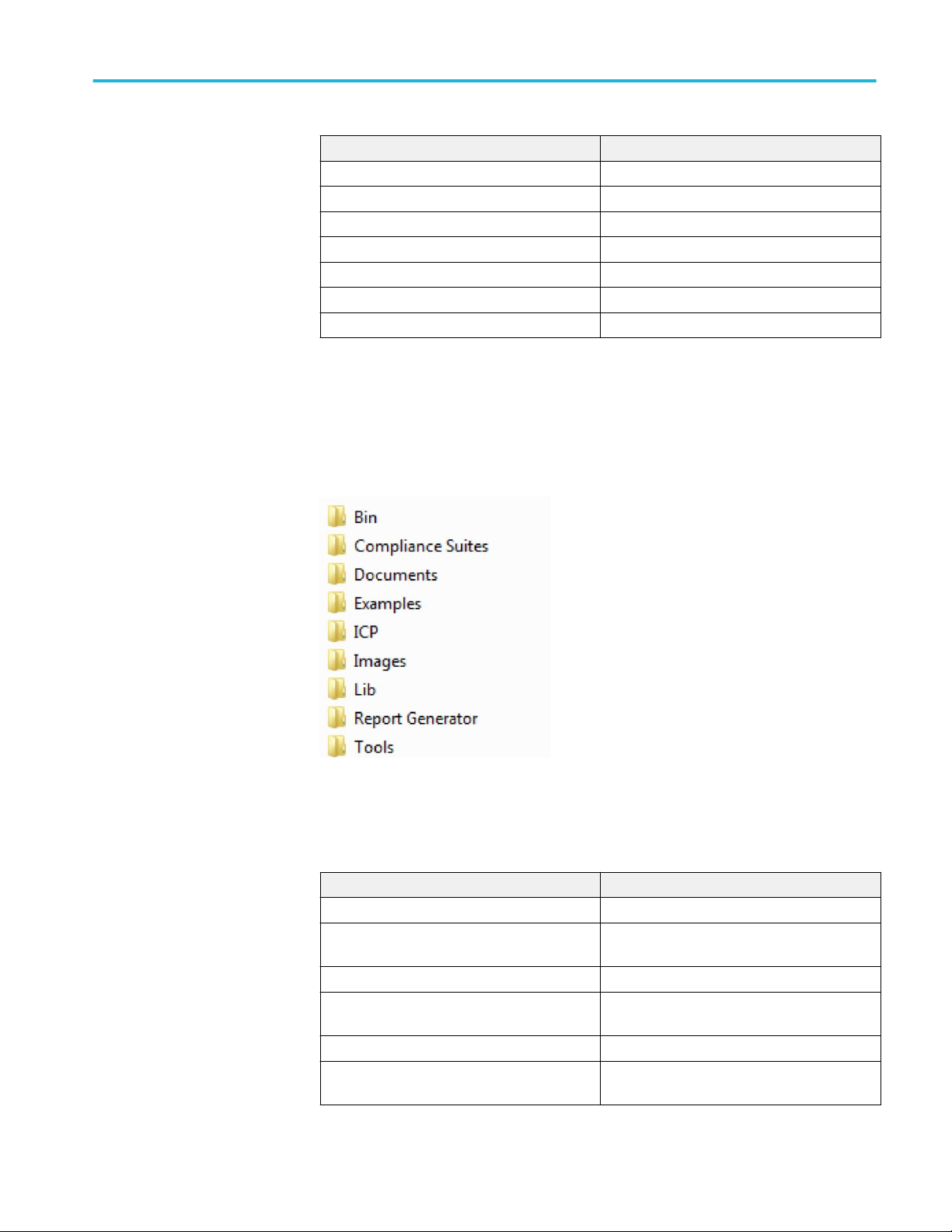

Application directories and usage

The application directory and associated files are organized as follows:

The following table lists the default directory names and their usage.

Table 8: Application directories and usage

Directory names Usage

InstallDir\TekExpress\TekExpress HDM Contains the application and associated files

TekExpress HDM\Bin Contains miscellaneous HDM application

libraries

TekExpress HDM\Compliance Suites Contains compliance-specific files and filter files

TekExpress HDM\Documents Contains the technical documentation for the

HDM application

TekExpress HDM\Examples Contains various support files

TekExpress HDM\ICP Contains instrument and HDM application-

specific interface libraries

TekExpress HDM Advanced Analysis and Compliance Solution 31

Page 40

Operating basics

Directory names Usage

TekExpress HDM\Lib Contains utility files specific to the HDM

application

TekExpress HDM\Report Generator Contains style sheets for report generation

TekExpress HDM\Tools Contains instrument and HDM application-

specific files

See Also

File name extensions

View test-related files

The TekExpress HDM software uses the following file name extensions:

File name extension Description

.TekX Session files are saved in this format but the extensions may not

be displayed

.py The test sequence file

.xml The encrypted XML file that contains the test-specific

configuration information

The log file extension is also xml

.wfm The test waveform file

.mht Test result reports are saved in this format by default. Test

reports can also be saved in MHTML or PDF formats.

.pdf Test report can also be saved in pdf format.

.flt Filter file used with transmitter tests

See Also

Application directories and usage

32 TekExpress HDM Advanced Analysis and Compliance Solution

Page 41

Getting started

Installing the software

Compatibility

The TekExpress HDM application runs on the following Tektronix oscilloscopes:

For CTS 2.0

■

DPO/DSA/MSO72004C, DPO/DSA/MSO71604C Digital Oscilloscopes with

Option DJA

■

DPO/DSA73304D and DPO/DSA72504D Digital Oscilloscopes with Option

DJA

■

DPO/MSO72304DX, DPO/MSO72504DX, DPO/MSO73304DX with

Option DJA

■

DPO75002SX, DPO75902SX, DPO77002SX, DPO72304SX, and

DPO73304SX with option DJA

NOTE. You can also use a 12.5 GHz bandwidth oscilloscope, but there may be a

10% variation in the measurement result.

For CTS 1.4

■

DPO/DSA/MSO72004C and/or DPO/DSA/MSO71604C Digital

Oscilloscopes

■

DPO/DSA73304D and DPO/DSA72504D Digital Oscilloscopes

■

DPO/MSO72304DX and/or DPO/MSO72504DX, DPO/MSO73304DX

■

Supports oscilloscopes > = 4 GHz

■

DPO75002SX, DPO75902SX, DPO77002SX, DPO72304SX, and

DPO73304SX with option DJA

See Also.

Minimum system requirements

TekExpress HDM Advanced Analysis and Compliance Solution 33

Page 42

Getting started

Minimum system

requirements

The following table shows the minimum system requirements for an oscilloscope

to run TekExpress.

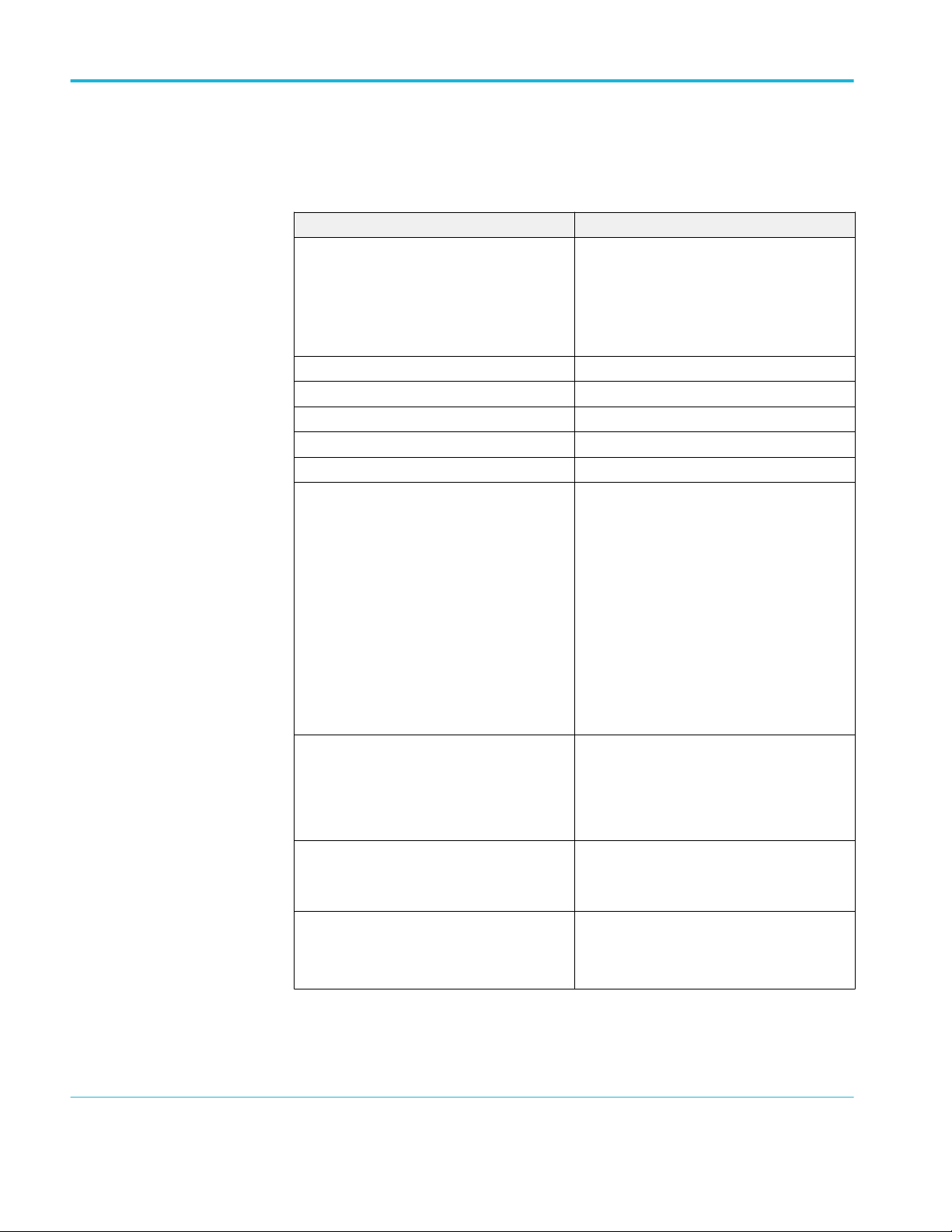

Table 9: System requirements

Component Description

Oscilloscope For CTS 2.0

BW ≥ 16 GHz, 16 M Record Length/Ch - Opt.

4M/2XL or more (for Eye Diagram and Jitter

tests), and 20XL for Inter Pair Skew tests.

For a list of compatible oscilloscopes, see

Compatibility.

Processor Same as the oscilloscope

Operating system Same as the oscilloscope

Memory Same as the oscilloscope

Hard disk Same as the oscilloscope

Display Same as the oscilloscope

Software

■

TekExpress HDM Advanced analysis and

Compliance software

■

DPOJET, Jitter and Eye Diagram Analysis

Tool Ver 6.2.1 and above

1

Probes

HDM sources

TDR tests

■

Microsoft Internet Explorer 6.0 SP1 or later

■

Microsoft Photo Editor 3.0 or equivalent

software for viewing image files

■

Adobe Reader 8.0 or equivalent software

for viewing portable document format (PDF)

files

■

Four differential probes – P7313SMA for

Single-Ended and Differential tests

■

Four differential probes - P7720 for SingleEnded and Differential tests

■

HDM Tx DUTs

■

HDM Ref waveforms

■

Oscilloscope – DSA8200 or equivalent with

80E03 and 80E04 modules and I-Connect

software

1

If TekExpress is running on an instrument having a video resolution lower than 800 x 600 (for example, a sampling oscilloscope), it is recommended

that you connect a secondary monitor, which must be enabled before launching the application.

34 TekExpress HDM Advanced Analysis and Compliance Solution

Page 43

Getting started

Component Description

HDM Generator for Sink

HDM fixtures For CTS 2.0 HDM fixture kits from Tektronix

HDM accessory kit ( to be used with AWG) TF-HDM-DS-Acc kit from Tektronix contains the

■

Two AWG70002A with option 01, 03 and

225 or two AWG7122C with option 1, 2/6,

8

■

One AFG3102/AFG3102C/AFG3252/

AFG3252C

■

TF-HDM-TPA-S

■

TF-HDMI-TPA-T (Termination fixture)

■

TF-HDM-TPA-STX

■

TF-HDMD-TPA-STX

following:

■

Eight Bias Tees from Mini-Circuits –

ZX85-12G-S+

Other devices

See Also.

■

For CTS 2.0: Two 120 ps TTC filters from

Picosecond Pulse Labs (5915-100-1200)

■

Microsoft compatible mouse or compatible

pointing device

■

Four USB ports (two USB ports minimum)

■

PCI-GPIB or equivalent interface for

instrument connectivity

■

10 SMA cables, 174-1428-xx

■

Four BNC cables

■

One BNC T connector

■

Four BNC-to-SMA adapter

■

External power supply PWS4721/

2

PWS4602/PWS4323/PWS4305/PWS4205

■

Any approved DDC Master

■

Any approved EDID analyzer

Compatibility

2

If TekExpress is installed on a Tektronix oscilloscope, the virtual GPIB port will be used by TekExpress for communicating with oscilloscope

applications. If external GPIB communication devices such as USB-GPIB-HS or equivalent are used for instrument connectivity, ensure that the Talker

Listener utility is enabled in the DPO/DSA oscilloscope's GPIB menu. For ease of use, connect to an external (secondary) monitor.

TekExpress HDM Advanced Analysis and Compliance Solution 35

Page 44

Getting started

Windows 7 user accounts

Windows 7 instruments need to have the User Account Control Settings set to

Never Notify. To set User Account Control Settings:

1. Go to Control Panel > User Accounts > Change User Account Control

settings.

2. Set it to Never Notify as shown in the image.

Install the software

The software can be installed on any compatible instrument running Windows 7.

1. Close all applications (including the TekScope application).

2. Go to the www.tek.com Web site and search for HDMI to locate the

installation file. Download the file HDM WebInstaller.exe.

3. Double-click the executable file to extract the installation files. After

extraction, the installer launches and displays the InstallShield Wizard.

4. The software automatically installs in the following location:

■

C:\Program Files\Tektronix\TekExpress\TekExpress HDM

5. The installer updates the TekScope Analyze menu to include TekExpress

HDM:

36 TekExpress HDM Advanced Analysis and Compliance Solution

Page 45

Getting started

See Also.

Minimum system requirements

Compatibility

TekExpress HDM Advanced Analysis and Compliance Solution 37

Page 46

Getting started

Activate the license

Activate the license using the option installation wizard on the oscilloscope.

Follow these steps to activate the TekExpress HDM license:

1. From the oscilloscope menu bar, click Utilities > Option Installation.

The TekScope Option Installation wizard opens.

2. Instructions for using the Options Installation window to activate licenses for

installed applications is provided in the oscilloscope online help. Press the F1

key on the oscilloscope keyboard to open the Option Installation help topic.

Follow the directions in the topic to activate the license.

See Also.

View version and license information

38 TekExpress HDM Advanced Analysis and Compliance Solution

Page 47

Getting started

View version and license

information

Use the following instructions to view application version information and

version information for the application modules such as the Programmatic

interface and the Programmatic interface client.

To view version information:

From the Options menu, select About TekExpress.

To view license information:

1. From the oscilloscope Help menu, select About TekScope.

The Options section in the dialog box displays a list of installed options,

including TekExpress HDM.

2. To view the Option key, look in the Option Installation Key section. When

finished, click OK to close the dialog box.

NOTE. For information regarding HDMXpress option, refer License section of

HDMXpress Online Help

See Also.

Activate the license

Options menu

TekExpress HDM Advanced Analysis and Compliance Solution 39

Page 48

Getting started

40 TekExpress HDM Advanced Analysis and Compliance Solution

Page 49

Application basics

Run the application

To run the HDM application, do either of the following:

■

■

When you open the application after installation, the application checks for a file

called Resources.xml located in the C:\Users\<username>\My Documents folder.

The Resources.xml file gets mapped to the X: drive when the application

launches. Session files are then stored inside the X:\HDM folder. The

Resources.xml file contains information about available network-connected

instruments. If this file is not found, the application runs an instrument discovery

program before launching HDM to locate available instruments.

If the application license was not installed using the TekScope menu Utilities >

Option Installation selection, you can open the application up to 10 times in

evaluation mode. Each time you open the application without supplying a valid

license key, one of the free trials is used.

Select Analyze > TekExpress HDM from the TekScope menu.

Double-click any saved HDMI session file.

Exit the application

Use the following method to exit the application:

1.

Click

2. Do one of the following:

■

If you have an unsaved session or test setup open, you are asked to save

it before exiting. To save it, click Yes. Otherwise click No. The

application closes.

■

A message box appears asking if you really want to exit TekExpress. To

exit, click Yes.

NOTE. Using other methods to exit the application results in abnormal

termination of the application.

on the application title bar.

TekExpress HDM Advanced Analysis and Compliance Solution 41

Page 50

Application basics

Application controls and menus

Application controls

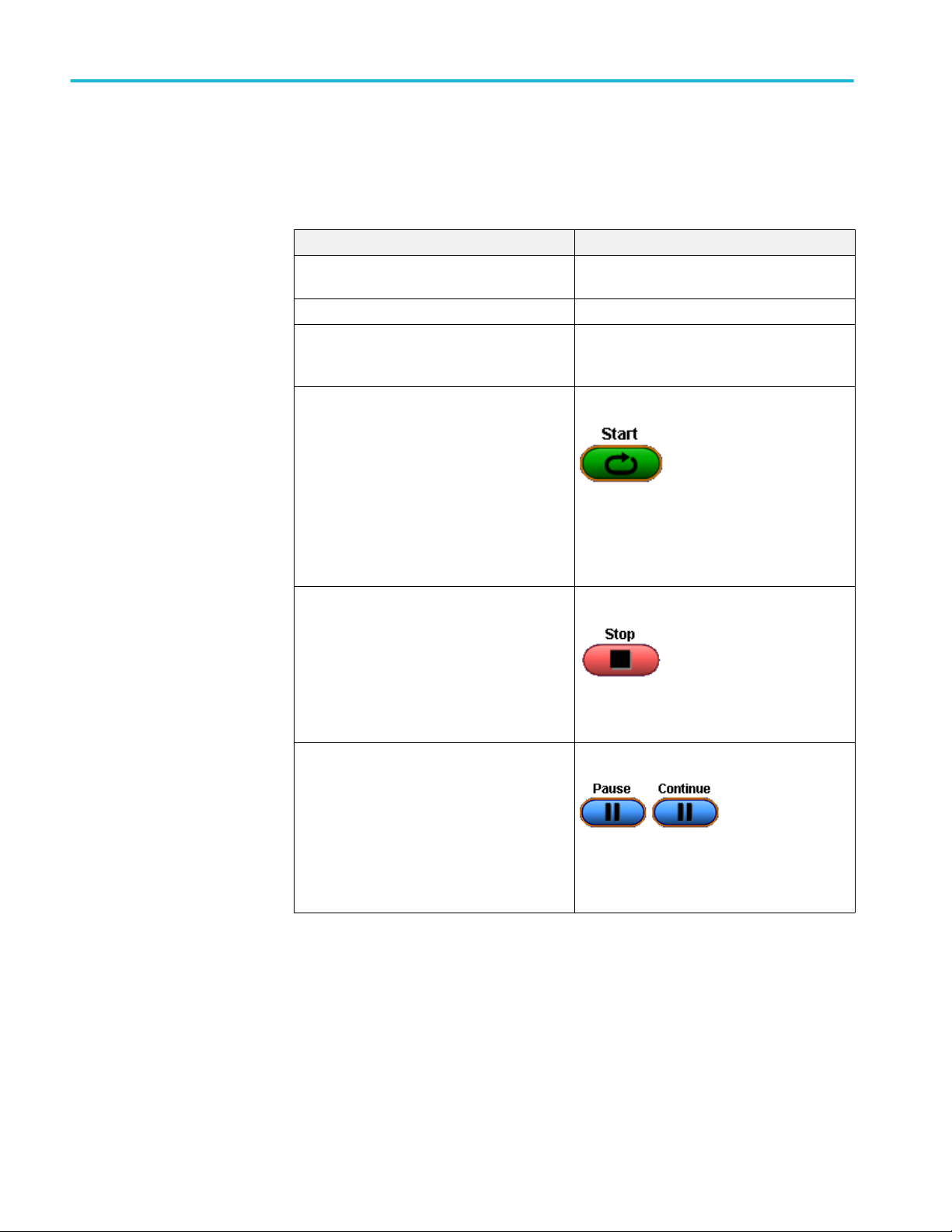

Table 10: Application control descriptions

Item Description

Options menu Opens the Options menu for access to global

controls

Panels Visual frames with sets of related options

Command buttons Buttons that initiate an immediate action such as

the Start, Stop, Pause, Continue, and Clear

command buttons

Start button

Starts continuous measurement acquisition and

analysis. If prior acquired measurements have

not been cleared, the new measurements are

added to the existing set.

Stop button

Pause \ Continue button

Stops (aborts) the current measurement

acquisition.

Use the Pause button to temporarily interrupt the

current acquisition. When a test is paused, the

button name changes to Continue.

42 TekExpress HDM Advanced Analysis and Compliance Solution

Page 51

Application basics

Item Description

Clear button

Clears all existing measurement results. Adding

or deleting a measurement, or changing a

configuration parameter of an existing

measurement, also clears measurements. This

prevents the accumulation of measurement

statistics or sets of statistics that are not

coherent. This button is available only on the

Results panel.

Clear Log

Save

Application window move icon

This button is available only on the Status panel.

This button is available only on the Status panel.

Place the cursor over the three-dot pattern in the

upper left corner of the application window.

When the cursor changes to a hand, drag the

window to the desired location.

TekExpress HDM Advanced Analysis and Compliance Solution 43

Page 52

Application basics

Options menu

Options menu overview. The Options menu is located in the upper right corner of

the application.

The Options menu has the following selections:

Options menu

Menu Function

Default Test Setup Opens an untitled test setup with defaults selected.

Open Test Setup Opens a saved test setup.

Save Test Setup Saves the current test setup selections.

Save Test Setup As Creates a new test setup based on an existing one.

Open Recent Displays a menu of recently opened test setups from which to

select.

Instrument control settings Shows the list of instruments connected to the test setup and

allows you to locate and refresh connections to connected

instruments.

Keep On Top Keeps the TekExpress HDM utility on top of other open windows

on the desktop.

Email settings dialog box Use to configure email options for test run and results

notifications.

Open Current Suite

RunSession

Help Displays TekExpress Help.

About TekExpress

Opens current Suite's run session. This option is selected in the

Options menu when you select Suite as Sink Electrical and Sink

Protocol in the DUT tab.

■

Displays application details such as software name, version

number, and copyright.

■

Provides access to software version and license information

for your HDM installation.

■

Provides a link to the Tektronix Web site.

44 TekExpress HDM Advanced Analysis and Compliance Solution

Page 53

Application basics

See also.

Application controls

Instrument control settings. Use the TekExpress Instrument Control Settings

dialog box to search for and list the connected resources (instruments) found on

specified connections (LAN, GPIB, USB, and so on) and each instruments

connection information. You access this dialog box from the Options menu.

Use the Instrument Control Settings feature to and view instrument connection

details. Connected instruments displayed here can be selected for use in the

Global Settings tab in the configuration section. See step 1 of Configure Tests for

details.

See also.

Options menu overview

TekExpress HDM Advanced Analysis and Compliance Solution 45

Page 54

Application basics

Email settings dialog box overview. Use the Email Settings dialog box to enable

TekExpress to send an email message when a test completes, produces an error,

or fails. Select the type of test run information to attach to the email (such as test

reports and test logs), the email message format, and the email message size

limit.

Open the Email Settings dialog box from the Options menu.

NOTE. Recipient email address, sender’s address, and SMTP Server are

mandatory fields.

See also.

Configure email settings

Options menu

Select test notification preferences

46 TekExpress HDM Advanced Analysis and Compliance Solution

Page 55

Application basics

Configure email settings. To be notified by email when a test completes, fails, or

produces an error, configure the email settings.

1. Select Options > Email Settings to open the Email settings dialog box.

2. (Required) For Recipient email Address(es), enter one or more email

addresses to which to send the test notification. To include multiple

addresses, separate the addresses with commas.

3. (Required) For Sender’s Address, enter the email address used by the

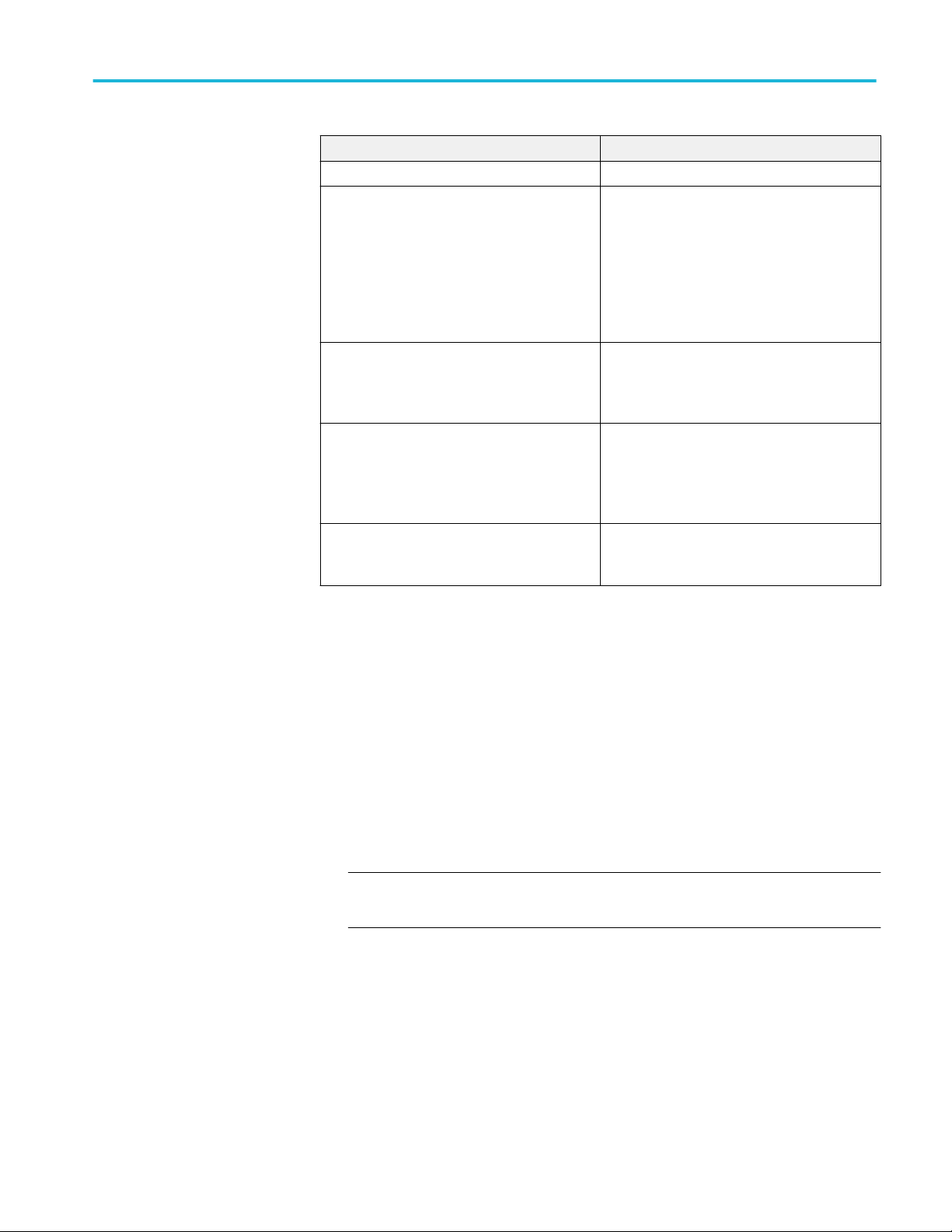

instrument. This address consists of the instrument name, followed by an

underscore, followed by the instrument serial number, the @ symbol and

then the email server used. For example:

DPO72004C_B130099@yourcompany.com.

4. (Required) In the Server Configuration section, type the SMTP Server

address of the Mail server configured at the client location, and the SMTP

Port number, in the corresponding fields.

If this server requires password authentication, enter a valid login name,

password, and host name in the corresponding fields.

NOTE. If any of the above required fields are left blank, the settings will not

be saved and email notifications will not be sent.

5. In the Email Attachments section, select from the following options:

■

Reports: Attach the test report to the notification email.

■

Status Log: Attach the test status log to the notification email. If you

select this option, then also select whether you want to receive the full

log or just the last 20 lines.

6. In the Email Configuration section:

■

Select the message file format to send: HTML (default) or plain text.

■

Enter a maximum file size for the email message (message plus

attachment files). Messages with attachments larger than this limit will be

truncated. The default is 5 MB.

■

Enter the number in the Number of Attempts to Send field, to limit the

number of attempts that the system makes to send a notification. The

default is 1. You can also specify a timeout period.

7. Select the Email Test Results When complete or on error check box. Use

this check box to quickly enable or disable email notifications.

8. To test your email settings, click Test Email.

9. To save your settings, click Apply.

10. Click Close when finished.

TekExpress HDM Advanced Analysis and Compliance Solution 47

Page 56

Application basics

Setup panel

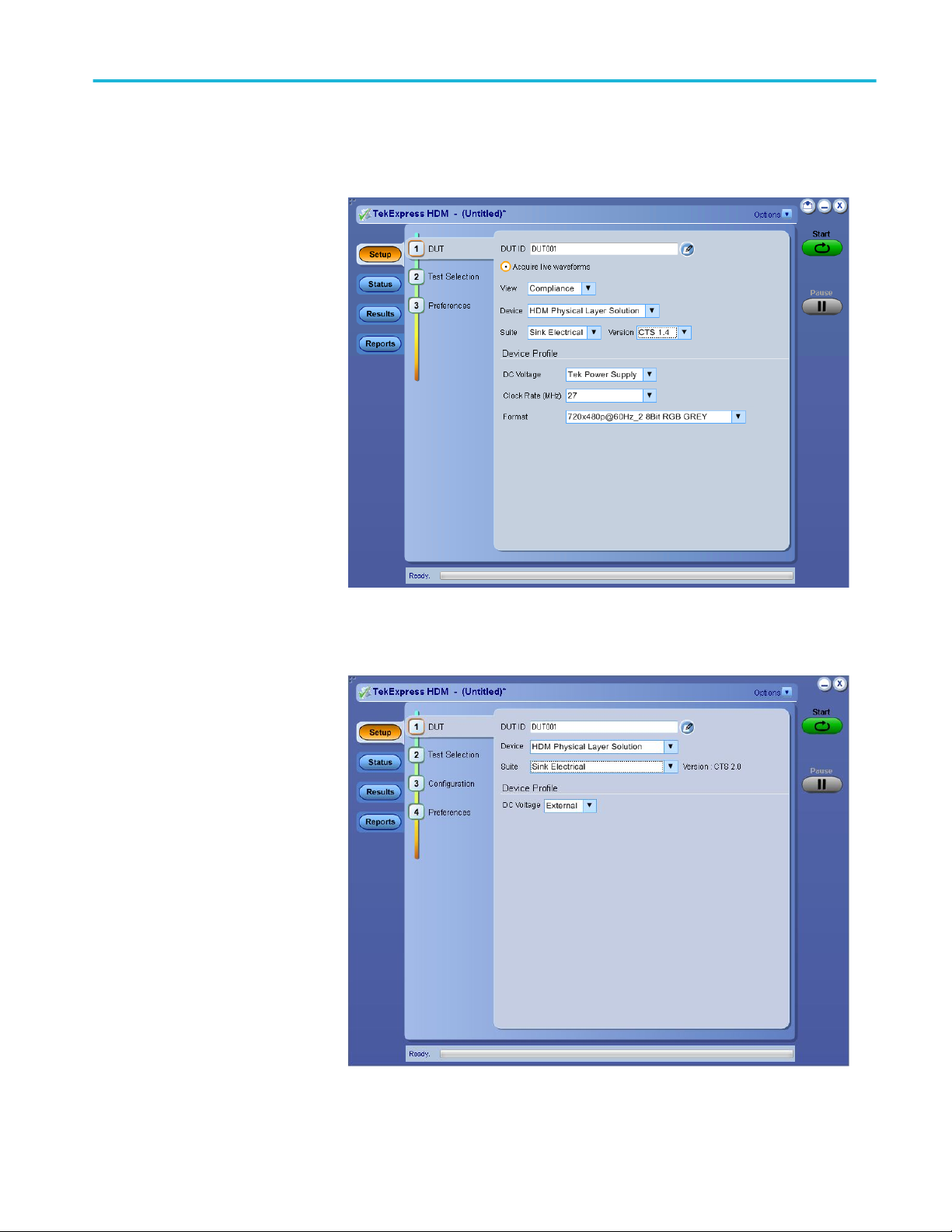

Setup panel overview

Source

The Setup panel contains sequentially ordered tabs that help guide you through a

typical test setup process.

Set the DUT parameters.

Select test(s).

Set lane acquisition source.

Configure the selected tests.

Select test notification preferences.

Items selected in a preceding Setup tab may change options available in the

following tabs. You can switch between the tabs in any order to modify your test

parameters.

Sink

The Setup panel contains sequentially ordered tabs that help guide you through a

typical test setup process.

Set the DUT parameters.

Select test(s).

Set DUT parameters

Configure the selected tests.

Select test notification preferences.

Items selected in a preceding Setup tab may change options available in the

following tabs. You can switch between the tabs in any order to modify your test

parameters.

Use the Setup panel DUT tab to select parameters for the device under test. The

settings are global and apply to all tests for the current session. DUT settings also

affect the list of available tests in the Test Selection tab.

Source

1. Source

Click Setup > DUT.

48 TekExpress HDM Advanced Analysis and Compliance Solution

Page 57

Application basics

Suite > Source

Table 11: DUT tab settings (Source)

Setting Description

Acquire live waveforms Acquire active signals from the oscilloscope for testing.

Use pre-recorded waveform

files

View Determines where to access the test configuration settings:

DC Voltage Internal\External Other\Tek Power Supply

Data Rates (Gbps) Highest: Select the Highest data rate to include in the tests.

TBit For High Data Rate (ps) Sets the TBit calculated for highest data rate

TBit For Low Data Rate (ps) Set the TBit calculated for lowest data rate

Probe Attenuation (X) Differential: 12.5/2.5

Recalc TBit Check or Uncheck Recalc TBit. TBit Should be calculated for

Run tests on a saved run session file. Select a run session file

from the list.

■

Compliance: View configuration settings by clicking

Setup > Test Selection > Configure

■

Advanced: Enables the Setup > Configuration tab in

which to view configuration settings.

Lowest: Select the Lowest data rate to include in the tests

Single-Ended: 12.5/2.5

at least once.

TekExpress HDM Advanced Analysis and Compliance Solution 49

Page 58

Application basics

Setting Description

Number of Lanes to Test Select the number of lanes to be tested: 1 Lane / 2 Lanes /

3 Lanes / 4 Lanes

Setup button Opens Test Lane Setup dialog box

50 TekExpress HDM Advanced Analysis and Compliance Solution

Page 59

Suite > Sink Electrical Sink Electrical for CTS 1.4

Application basics

Sink Electrical for CTS 2.0

TekExpress HDM Advanced Analysis and Compliance Solution 51

Page 60

Application basics

Table 12: DUT tab settings (Sink Electrical CTS 1.4 and 2.0)

Setting Description

For CTS 1.4: Clock Rate

(Gbps)

For CTS 2.0: Data Rate

(Gbps)

Format Select format from Device Profile

DC Voltage Select DC Voltage from the Device Profile

Select data rate or clock rate from Device Profile

52 TekExpress HDM Advanced Analysis and Compliance Solution

Page 61

Suite > Sink Protocol Sink Protocol for CTS 1.4

Application basics

Sink Protocol for CTS 2.0

TekExpress HDM Advanced Analysis and Compliance Solution 53

Page 62

Application basics

Table 13: DUT tab settings (Sink Protocol for CTS 1.4 and 2.0)

Setting Description

DC Voltage If Tek Power Supply is connected, select DC voltage as “Tek

Power Supply’ or “External”.

2. (Optional) Enter the ID for the device. The default value is DUT001. The

DUT ID parameter is added to reports.

3.

(Optional) To add comments to the test report, click the note pad icon ( ) to

the right of the DUT ID field. Enter comment text up to 256 characters. To

enable or disable displaying comments in the test report, see Select report

options.

4. Settings that do not apply to compliance testing cannot be changed and are

grayed out.

54 TekExpress HDM Advanced Analysis and Compliance Solution

Page 63

Application basics

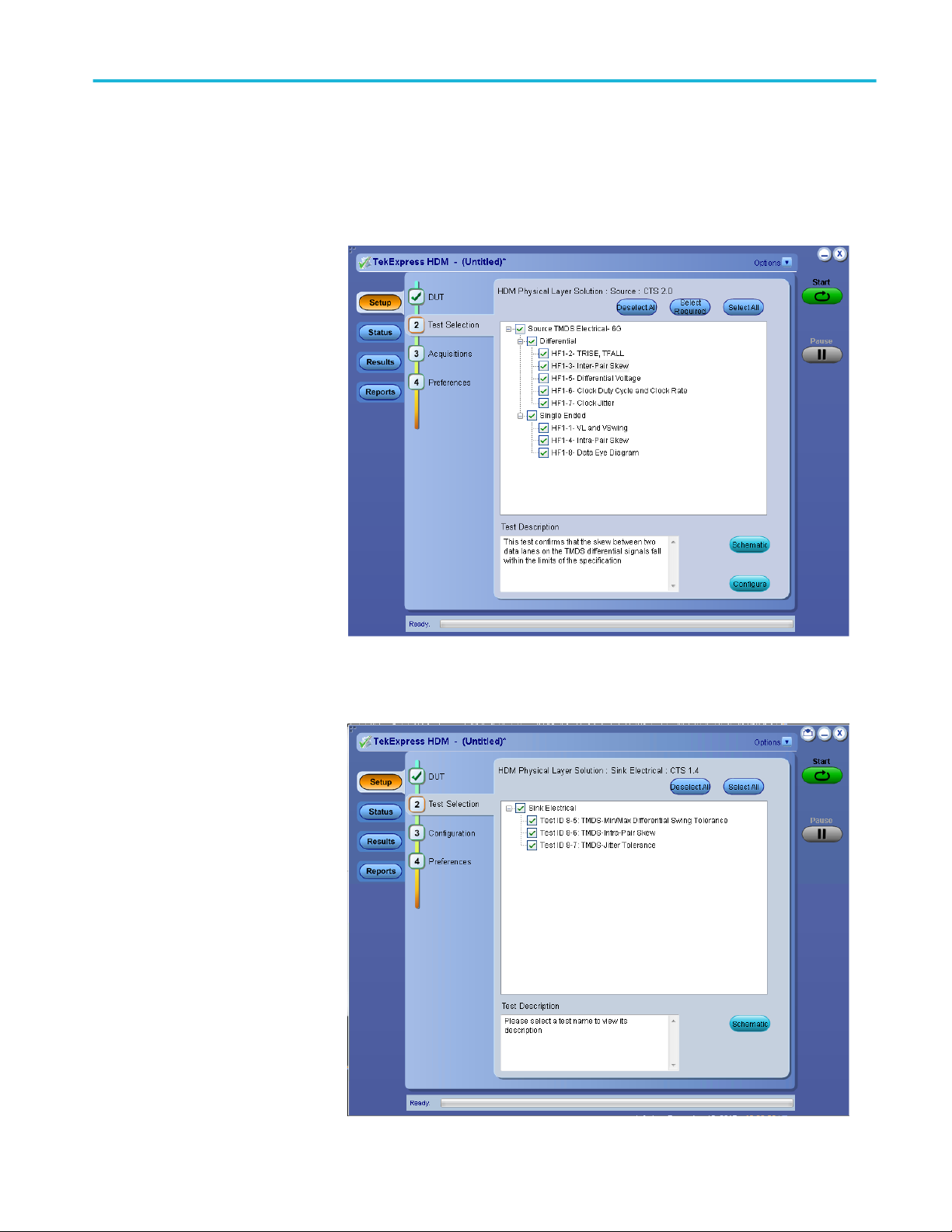

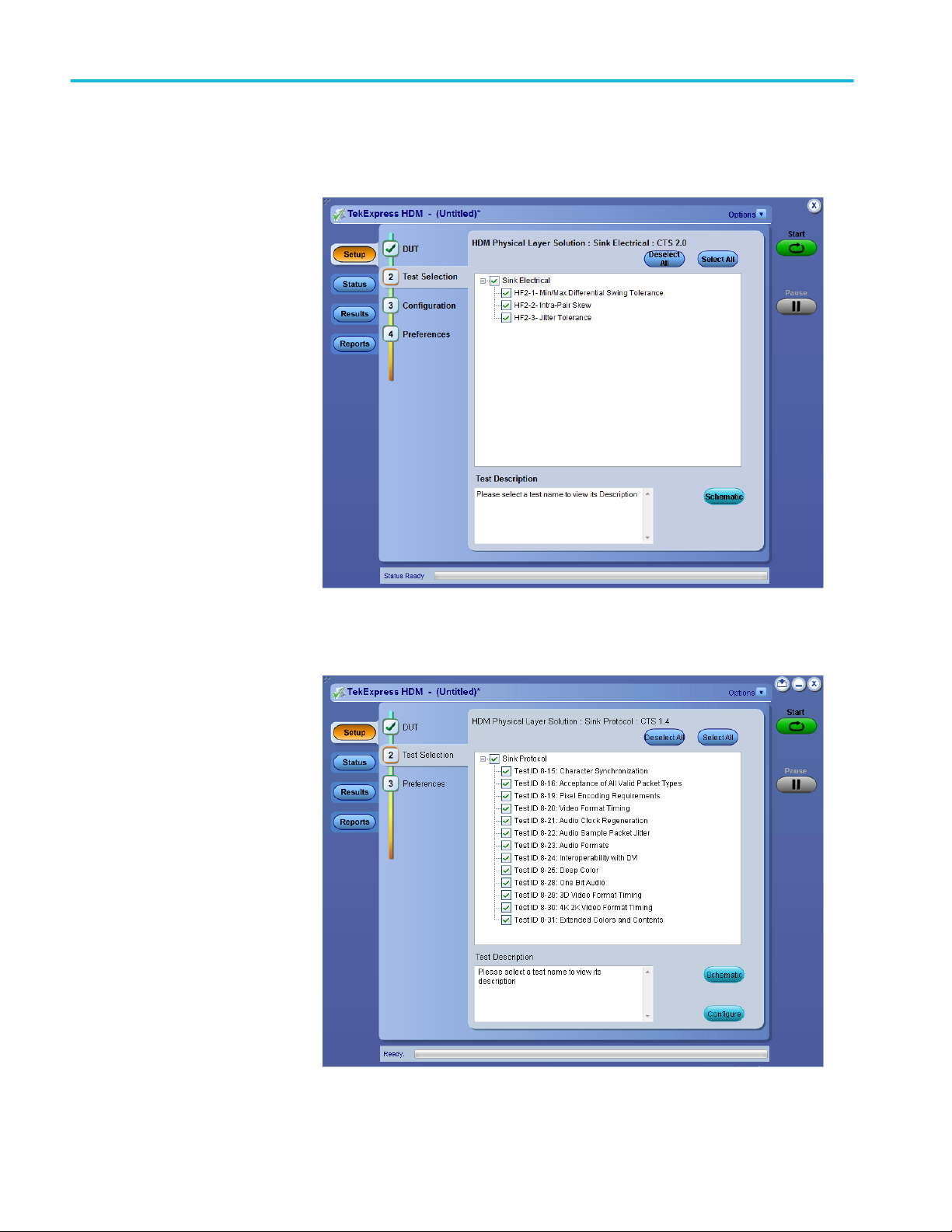

Select tests

Use the Test Selection tab to select the tests to run on the connected DUT.

1. Click Setup > Test Selection.

Source Electrical 2.0

Sink Electrical 1.4

TekExpress HDM Advanced Analysis and Compliance Solution 55

Page 64

Application basics

Sink Electrical for CTS 2.0

Sink Protocol 1.4

Sink Protocol 2.0

56 TekExpress HDM Advanced Analysis and Compliance Solution

Page 65

Application basics

2. Select the test(s) to run:

■

Click one or more check boxes adjacent to each test.

■

Click Deselect All to deselect all tests. All tests are selected by default.

■

Click Select All to select all tests.

3. Click Schematic to display a schematic diagram that shows the DUT test

setup. Use the diagram to verify the test setup before running the test.

TekExpress HDM Advanced Analysis and Compliance Solution 57

Page 66

Application basics

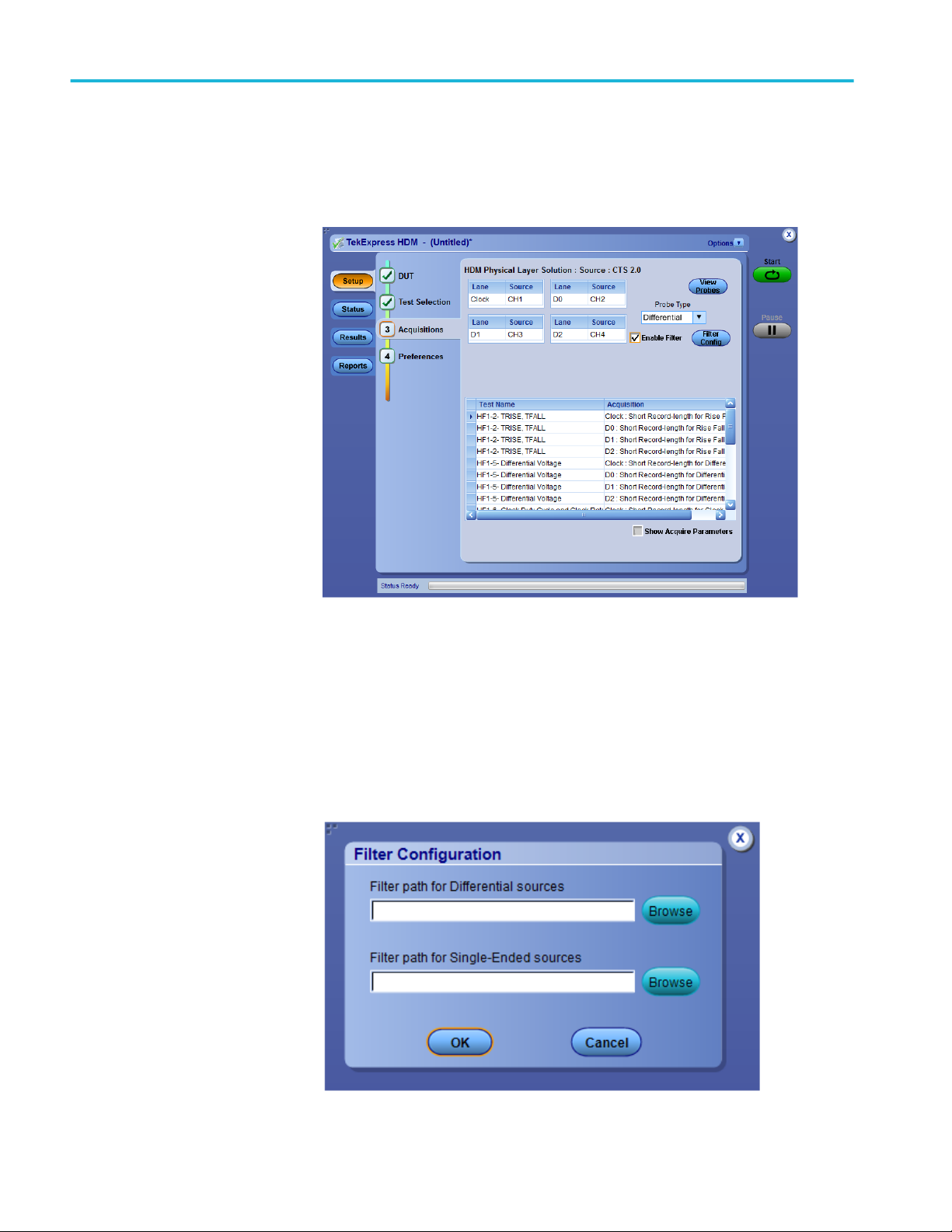

Set acquisition parameters

(source only)

Use the Acquisitions tab to set the signal source (channel) used to acquire data.

Acquisition options are available only when acquiring a live waveform.

1. Click Setup > Acquisitions.

2. Select Source field to select the oscilloscope channels to use for those lanes.

3. Select probe type from Probe Type field as Differential, Single-Ended, or

Eye-Diagram.

4. Check or uncheck the Enable Filter check box and configure the Filter

Configuration by clicking the Filter Config button and choose from the

displayed field.

58 TekExpress HDM Advanced Analysis and Compliance Solution

Page 67

Application basics

Set test notification

preferences

Configure test parameters

Use the Preferences tab to set the application to send an email when a test

measurement completes:

1. Click Setup > Preferences.

2. Select the Email Test Results when complete check box in the Email

Settings dialog box. Click Email Settings to configure the email settings.

See also.

Select report options

About configuring test parameters (source only). Use the configuration settings to

view the measurement parameters for selected tests. How the test configurations

are accessed depend on the View selected in the DUT tab.

NOTE. The View option is not applicable for Sink Electrical and Sink Protocol.

■

If you selected Compliance View in the DUT tab, then in the Test Selection

tab, select the desired test in the list and then click the Configure button.

■

If you selected Advanced View in the DUT tab, click the Configuration tab

in the Setup panel.

See also.

Configure tests parameters

Configure test parameters. The Configuration parameters let you set global and

individual test parameters. To return to test selection from the Configuration tab

or panel, click the Test Selection button.

NOTE. You cannot change test parameters that are grayed out.

Source and Sink.

1. Modify Global settings as desired:

■

To select the instruments for testing, click Global Settings. In the

Instruments Detected section, click in the shaded areas to activate the

drop-down lists and select an instrument. If you do not see the desired

instrument in the list, see Instrument control settings.

2. To modify any individual test measurement settings, click Measurements,

select the test in the tree view, and change the settings.

TekExpress HDM Advanced Analysis and Compliance Solution 59

Page 68

Application basics

Test parameters. Source - Global Settings

Sink Electrical - Global Settings

60 TekExpress HDM Advanced Analysis and Compliance Solution

Page 69

Source - Measurement

Application basics

Sink Electrical - Measurement

TekExpress HDM Advanced Analysis and Compliance Solution 61

Page 70

Application basics

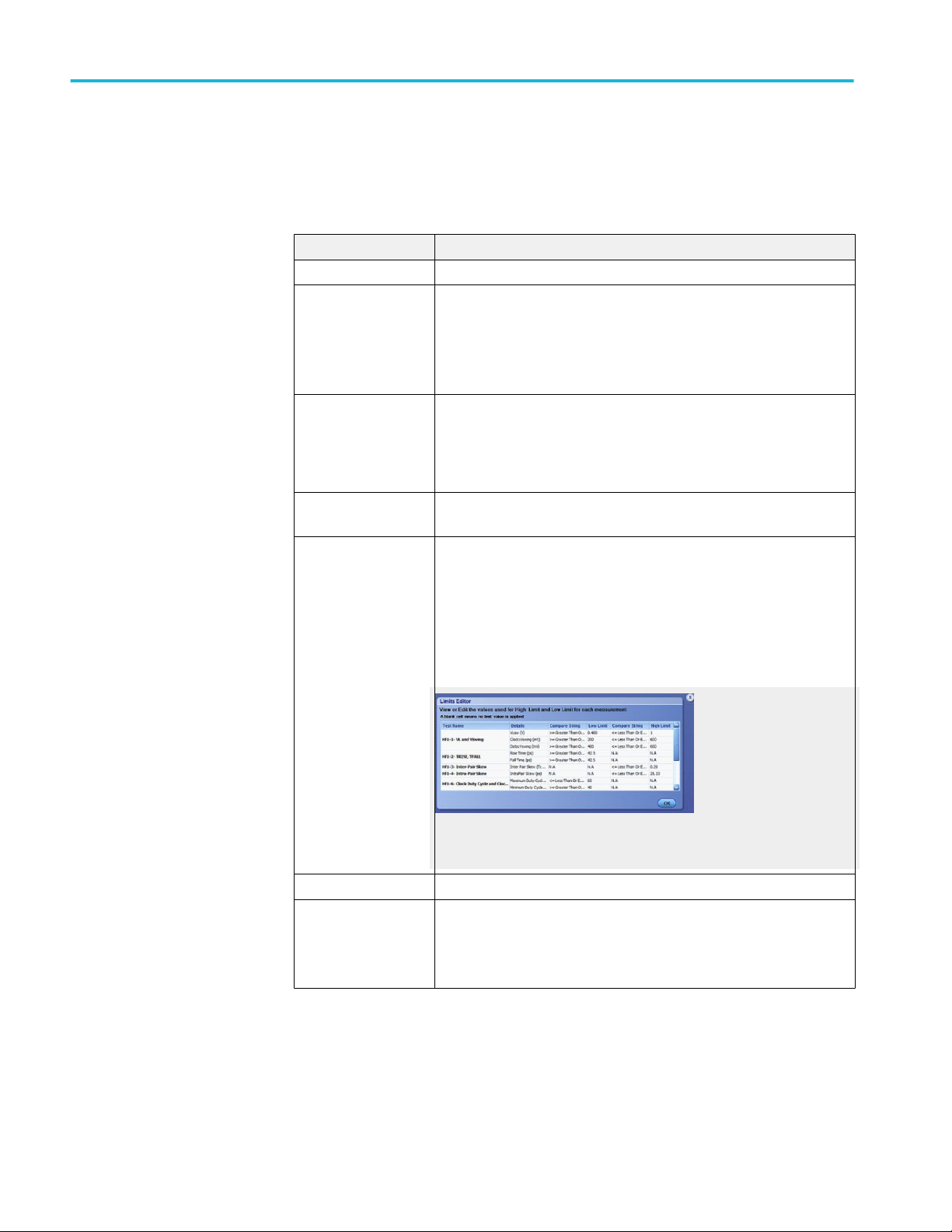

The following table lists common and specific test settings and parameters based

on the Suite selected in the DUT tab.

Table 14: Common and specific parameters and values

Parameter type Parameter

Common

Mode Determines whether test parameters are in compliance mode or can be

edited (User Defined Mode).

■

Compliance: Most test parameter values cannot be edited.

■

User Defined: Most test parameter values can be edited.

Global Settings These settings apply to all tests selected for the current session. You can

change only some of these settings.

■

Scope Settings: Specifies the instrument channel to use as the

source for the trigger. This can be changed.

Measurements These settings apply to the test selected in the tree view of the

configuration section.

Limits Editor (Source

only)

Shows the upper and lower limits for the applicable measurement using

different types of comparisons.

In Compliance Mode, you are able to view the measurement high and low

limits used for the test selected in the tree view of the Measurements tab.

When running tests in User Defined Mode, you can edit the limit settings

in the Limits Editor. When running tests in User Defined Mode, the cells

in the Limits Editor table are active for editing so you can change

parameters.

When running tests in User Defined Mode, the cells in the Limits Editor

table are active for editing so you can change parameters.

Specific to Source

Global Settings

■

Instruments Detected: Displays the list of instruments connected to

the scope.

■

DSP Filter (16GHz): DSP filter bandwidth is set to 16GHz by default.

62 TekExpress HDM Advanced Analysis and Compliance Solution

Page 71

Application basics

Parameter type Parameter

Measurements Scope Settings:

■

Sample Rate (GS/sec): Select the required sample rate from the

drop-down menu.

■

Record Length (M): Select the required record length from the dropdown menu.

Clock Setting:

■

PLL Mode: Configures the type of PLL.

■

Clock Recovery Method: Sets the method for recovering the clock.

■

Signal Type: Sets the type of signal for clock recovery.

■

Clock Edge: Sets the edges which are used for computation.

■

Loop Band Width (MHz): Sets the bandwidth of the PLL.

Specific to Sink

Electrical and Sink

Protocol

Global Settings Scope Connection:

■

Master AWG: Select the Master AWG address.

■

Slave AWG: Select the Slave AWG address.

NOTE. Applicable to Sink Electrical and Sink Protocol.

Measurements Pattern Settings:

■

Pattern Type:

■

Standard: Select to use the patterns embedded in the

application.

■

Custom: Select to use your own patterns.

■

Pattern Table button: Click to display and configure available list of

patterns.

NOTE. Applicable to Sink Electrical and Sink Protocol.

AWG Settings:

■

AWG Gain: Configure the gain.

■

Test Lane: Configure test lane for Sink Intrapair Skew Test.

■

Error Detector: Check if Error Detector is connected.

Power Supply:

■

Others: Used for further settings like frequency profile.

NOTE. Applicable only to Sink Electrical.

TekExpress HDM Advanced Analysis and Compliance Solution 63

Page 72

Application basics

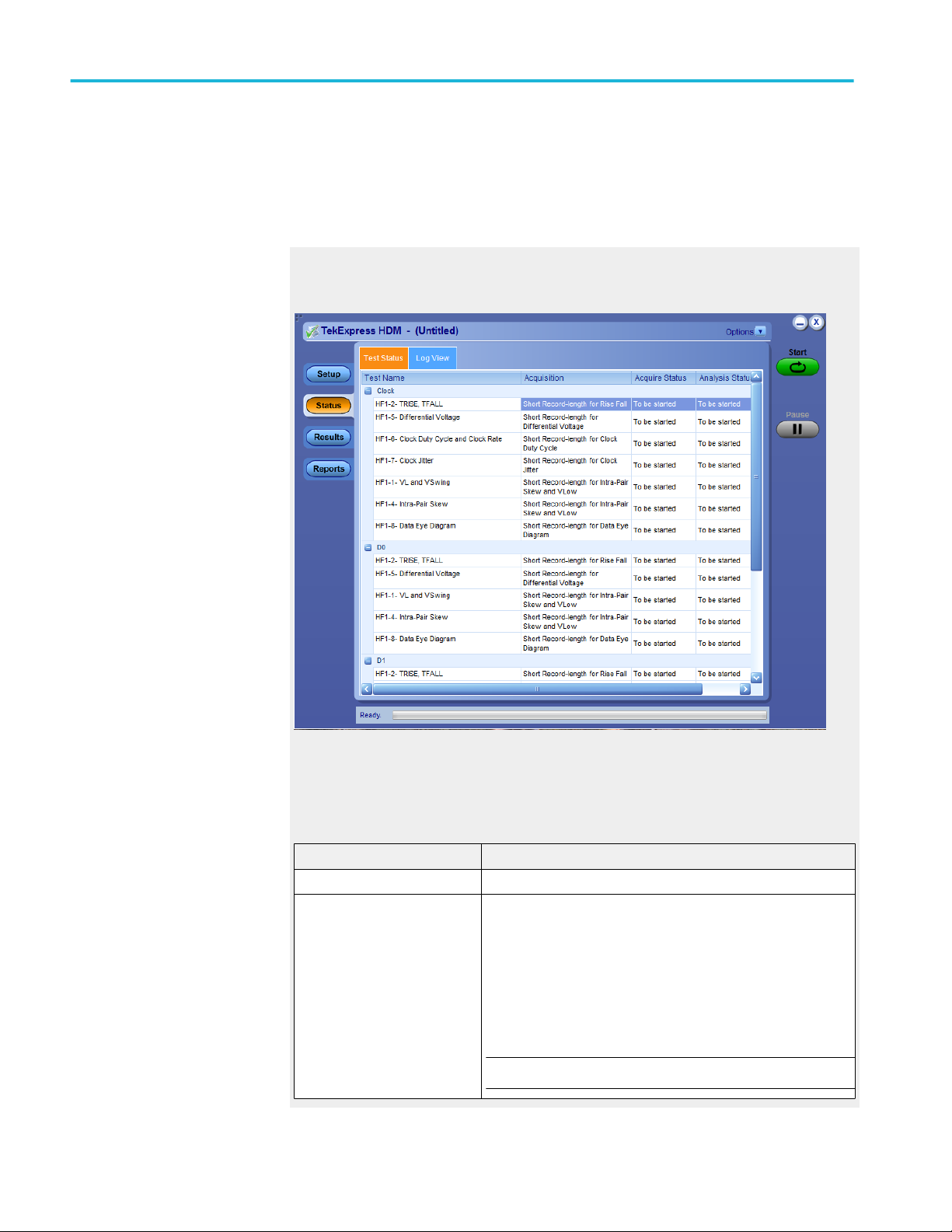

Status panel overview

The Status panel provides status on test acquisition and analysis (Test Status tab)

and a listing of test tasks performed (Log View tab). The application opens the

Test Status tab when you start a test run. You can select the Test Status or the

Log View tab to view these items while tests are running.

Test Status tab

The Test Status tab lists a high level status for each test.

Table 15: Test Status tab

Column Description

Test Name Name of the test

Acquire Status, Analysis Status Status of the signal acquisition or test analysis

■

To be started

■

In progress

■

Completed

■

Aborted

NOTE. Sink tests have a minimal set of status indicators.

64 TekExpress HDM Advanced Analysis and Compliance Solution

Page 73

Application basics

The Log View tab provides a list of the actions executed during the test. Use this

information to review or troubleshoot tests.

Log View tab

Table 16: Log View fields

Item Description

Message History Displays all run messages with timestamp

information

Auto Scroll Sets the program to automatically scroll down

the Message History window as information is

added to the log during the test.

Clear Log button Clears all messages in the Message History

window.

Save button Saves the log file as a text file for examination.

Displays a standard Save As File window and

saves the status messages in the file that you

specify.

TekExpress HDM Advanced Analysis and Compliance Solution 65

Page 74

Application basics

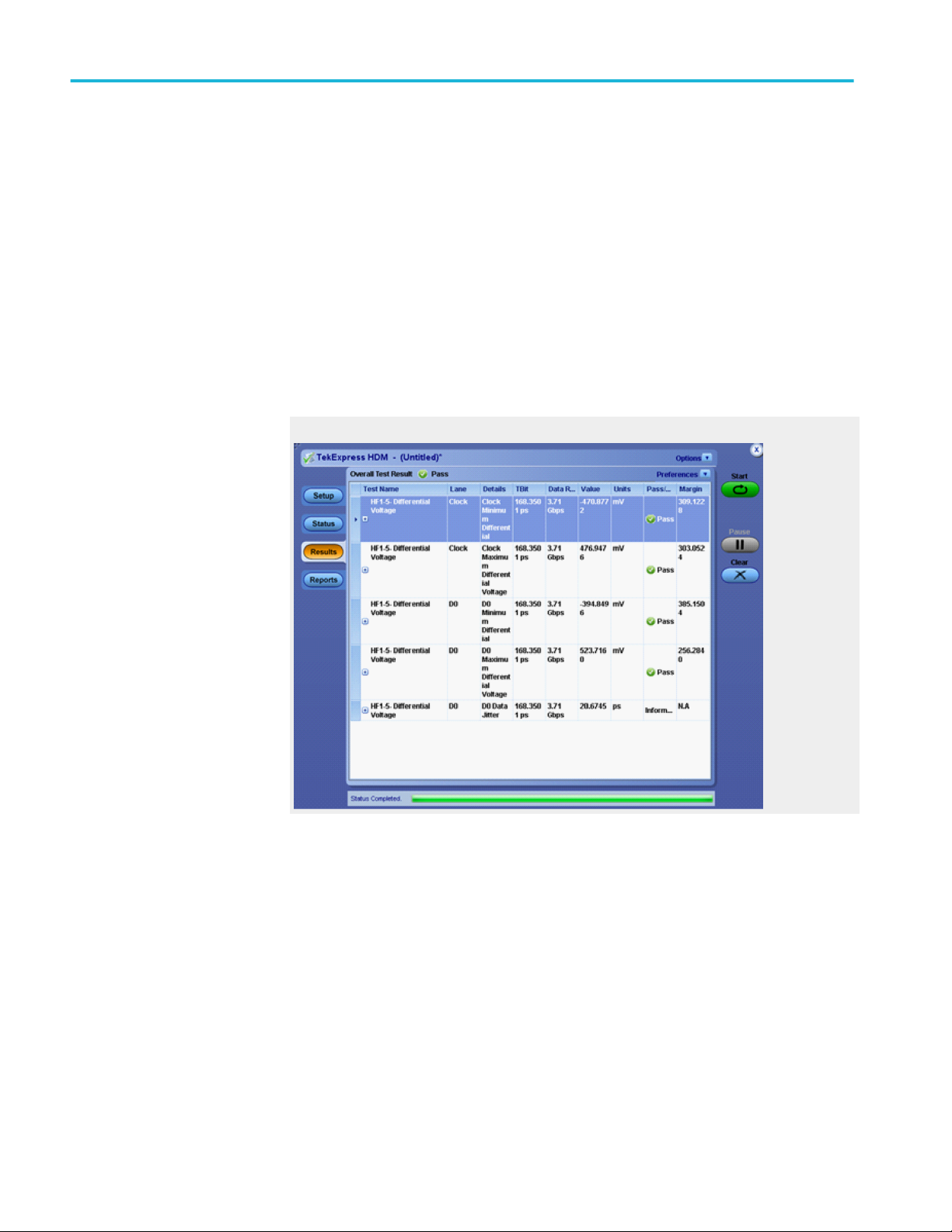

Results panel

Results panel overview

See also

View test results

When a test finishes, the application switches to the Results panel to display a

summary of test results. Set viewing preferences for this panel from the

Preferences menu in the upper right corner. Viewing preferences include showing

whether a test passed or failed, summary results or detailed results, and enabling

wordwrap. For information on using this panel, see View test results.

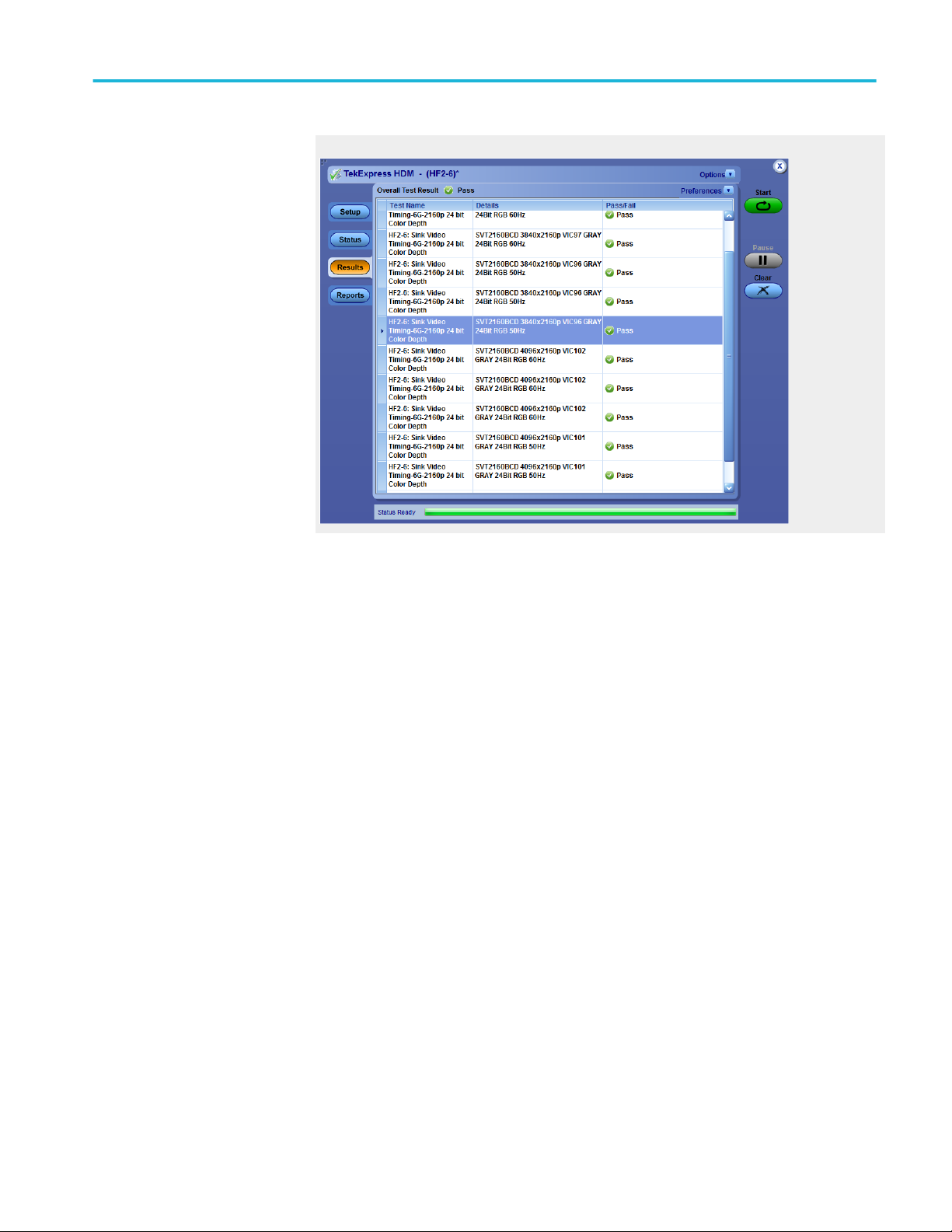

Results panel - Source results

66 TekExpress HDM Advanced Analysis and Compliance Solution

Page 75

Application basics

Results panel - Sink results for CTS 2.0

View test results

When a test finishes, the application switches to the Results panel, which displays

a summary of test results. The overall test result is displayed at the top left of the

Results table. If all of the tests for the session pass, the overall test result will be

Pass. If one or more tests fail, the overall test result will show Fail.

Each test result occupies a row in the Results table. By default, results are

displayed in summary format with the measurement details collapsed and with

the Pass/Fail column visible. Change the view in the following ways:

■

To expand all tests listed, select View Results Details from the Preferences

menu in the upper right corner.

■

To expand and collapse tests, click the plus and minus buttons.

■

To collapse all expanded tests, select Preferences > View Results

Summary.

■

To remove or restore the Pass/Fail column, select Preferences > Show Pass/

Fail.

■

To enable or disable the wordwrap feature, select Preferences > Enable

Wordwrap.

■

To expand the width of a column, place the cursor over the vertical line that

separates the column from the column to the right. When the cursor changes

to a double-ended arrow, hold down the mouse button and drag the column to

the desired width.

■

To sort the test information by column, click the column head. When sorted

in ascending order, a small up arrow is displayed. When sorted in descending

order, a small down arrow is displayed.

■

To clear all test results displayed, click Clear.

TekExpress HDM Advanced Analysis and Compliance Solution 67

Page 76

Application basics

See also.

View a report

View test-related files

Files related to tests are stored in the My TekExpress\HDM folder. In the HDM

folder, each test setup has a test setup file and a test setup folder, both with the

test setup name. The test setup file is preceded by the HDM icon and usually has

no visible file extension.

Inside the test setup folder is another folder named for the DUT ID used in the

test sessions. The default is DUT001.

Inside the DUT001 folder are the session folders and files. Each session has a

folder and file pair, both named for the test session using the naming convention

(date)_(time). Each session file is stored outside its matching session folder.

The first time you run a new, unsaved session, the session files are stored in the

Untitled Session folder located at ..\My TekExpress\HDM. When you name and

save the session, the files are placed in a folder with the name that you specify.

See also.

File name extensions

68 TekExpress HDM Advanced Analysis and Compliance Solution

Page 77

Application basics

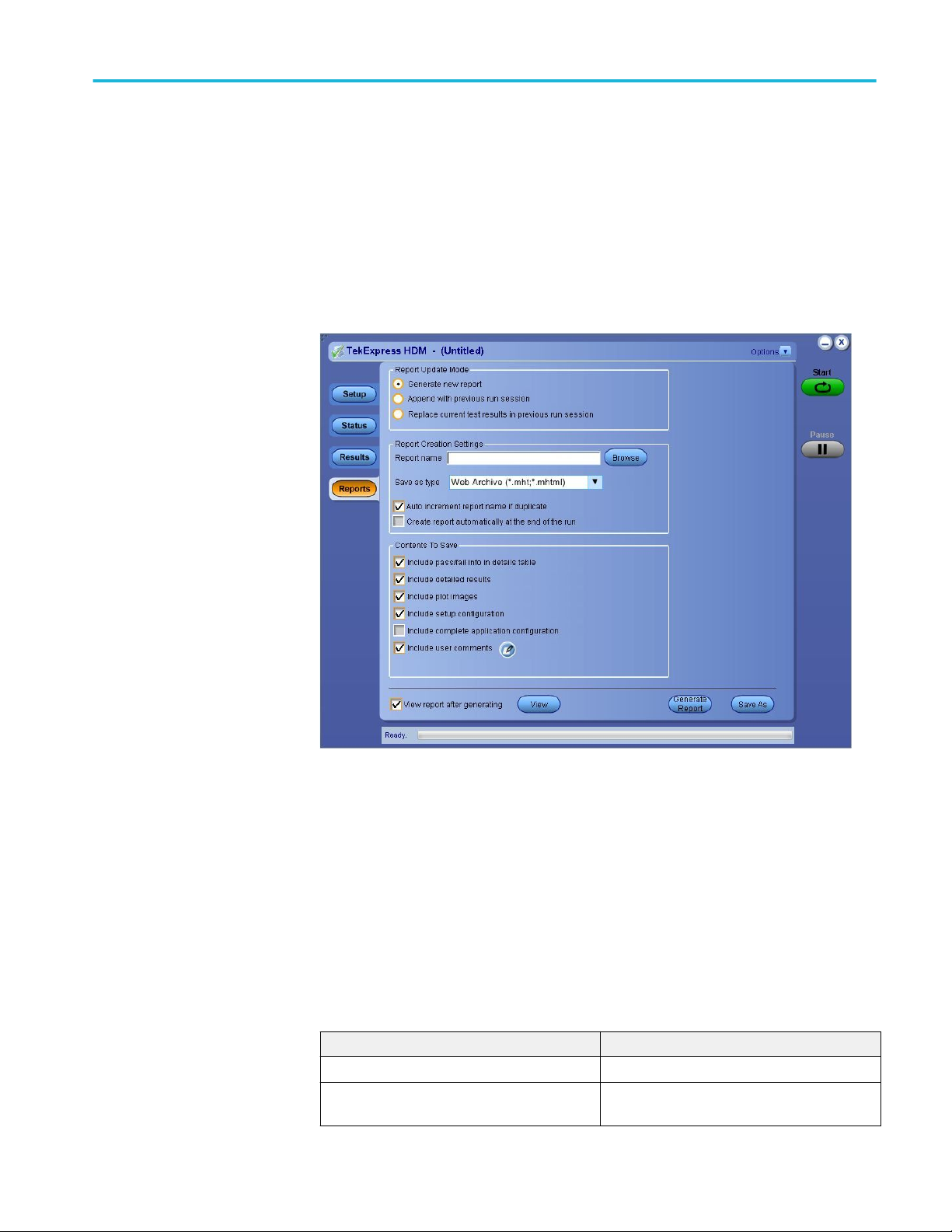

Reports panel

Reports panel overview

Use the Reports panel to open reports, name and save reports, select report

content to include, and select report viewing options.

For information on setting up reports, see Select report options. For information

on viewing reports, see View the report.

Select report options

TekExpress HDM Advanced Analysis and Compliance Solution 69

Use the Reports panel to select which test information to include in the report,

and the naming conventions to use for the report. For example, always give the

report a unique name or select to have the same name increment each time you

run a particular test. Generally, you would select report options before running a

test or when creating and saving test setups. Report settings are included in saved

test setups.

In the Reports panel, select from the following options:

Table 17: Report options

Setting Description

Generate new report Creates a new report.

Append with previous run session Appends the last run session and the previous

run session.

Page 78

Application basics

Setting Description

Replace current test results in previous run

session

Report name Displays the name and location from which to

Replaces the current test results in the previous

run session. Newly added tests results are

appended to the end of the report.

open a report. The default location is at X:\ HDM

\Reports. The report file in this folder gets

overwritten each time you run a test unless you

specify a unique name or select to auto

increment the report name.

To change the report name or location.

Do one of the following:

■

In the Report Name field, type over the

current folder path and name.

■

Click inside Report Name field and Click on

<image> or Double click inside the field to

launch Tek keyboard. Provide Report path

in the Tek keyboard and Click Enter key.

Be sure to include the entire folder path, the file

name, and the file type. For example: C:\Users

\UnserName\Documents\My TekExpress\HDM

\DUT001_Test_85.mht.

NOTE. You cannot change the file location using

the Browse button.

Open an existing report.

Click Browse, locate and select the report file

and then click View at the bottom of the panel.

Save as type Lists the available report formats for user to

generate. Supported formats are MHT and PDF.

NOTE. If you select a file type different from the

default, be sure to change the report file name

extension in the Report Name field to match.

Auto increment report name if duplicate Sets the application to automatically increment

the name of the report file if the application finds

a file with the same name as the one being

generated. For example: DUT001, DUT002,

DUT003. This option is enabled by default.

Include pass/fail results summary Sets the application to include the color block

labeled Test Result (indicating whether the test

passed or failed) in the report. For details, see

Report Contents in View a report.

Include detailed results Sets the application to include parameter limits,

execution time, and test-specific comments

generated during the test.

70 TekExpress HDM Advanced Analysis and Compliance Solution

Page 79

Setting Description

Include plot images Sets the application to include plotted diagrams.

Include setup configuration Sets the application to include information about

hardware and software used in the test in the

summary box at the top of the report.

Information includes: the oscilloscope model and

serial number, probe model and serial number,

the oscilloscope firmware version, SPC and

factory calibration status, and software versions

for applications used in the measurements.

Include Complete Application Configuration Sets the application to include a table listing

general, common, and acquired parameters

used in the test. This option is disabled by

default.