Technical Reference

TDS6000B & TDS6000C

Digital Storage Oscilloscopes

Specifications and Performance Verification

071-1659-03

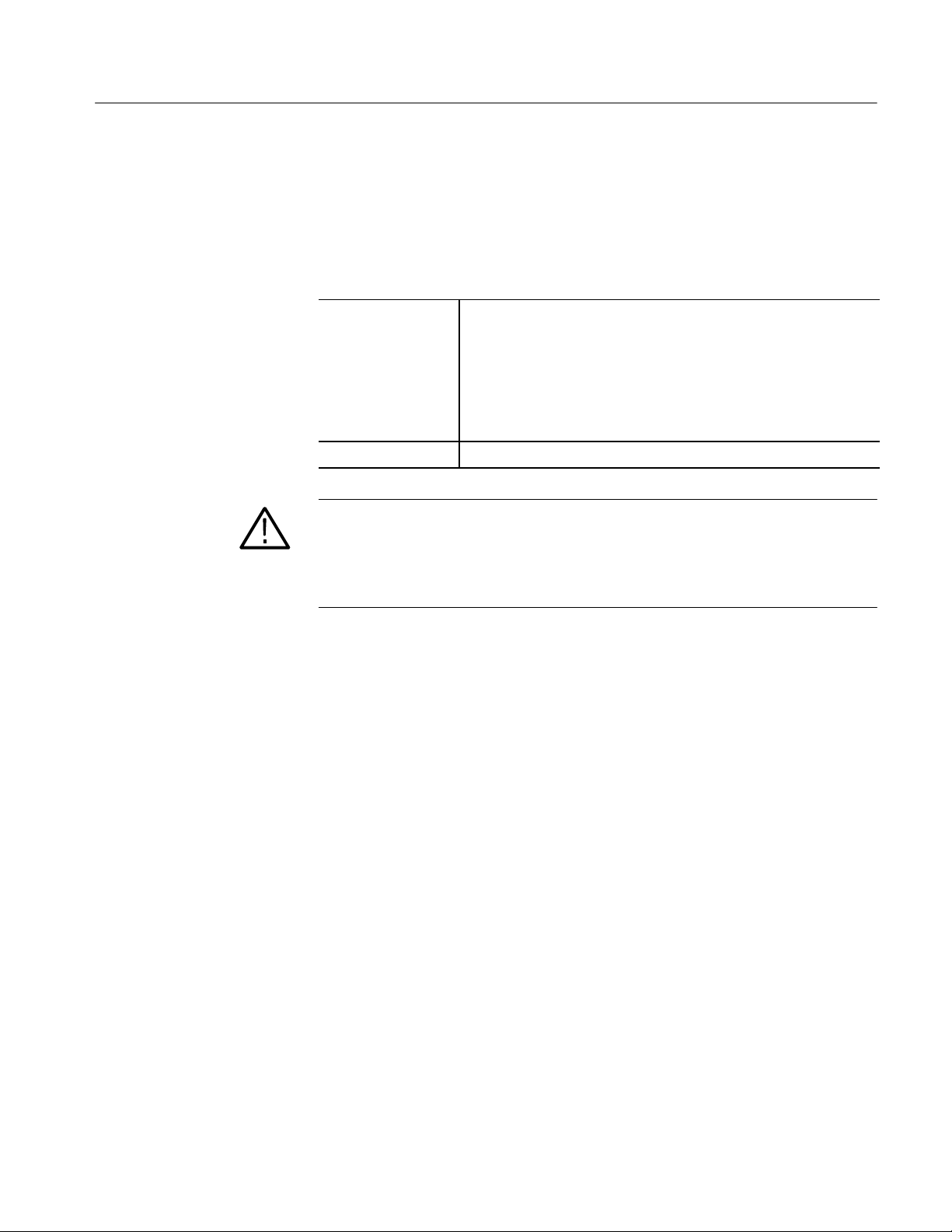

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P071165903*

071165903

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Table of Contents

Specifications 1--1.............................................

Product and Feature Description 1--1....................................

Acquisition Features 1--2..........................................

Signal Processing Features 1--2.....................................

Display Features 1--2.............................................

Measurement Features 1--3.........................................

Trigger Features 1--3..............................................

Convenience Features 1--3.........................................

Environmental and Compliance Specifications 1--4.........................

Certifications and Compliances 1--5.....................................

TDS6000B Series Specification Tables 1--7...............................

TDS6000C Series Specification Tables 1--22..............................

Performance Verification 2--1...................................

Conventions 2--2....................................................

Brief Procedures 3--1...........................................

Self Tests 3--1.......................................................

Functional Tests 3--2.................................................

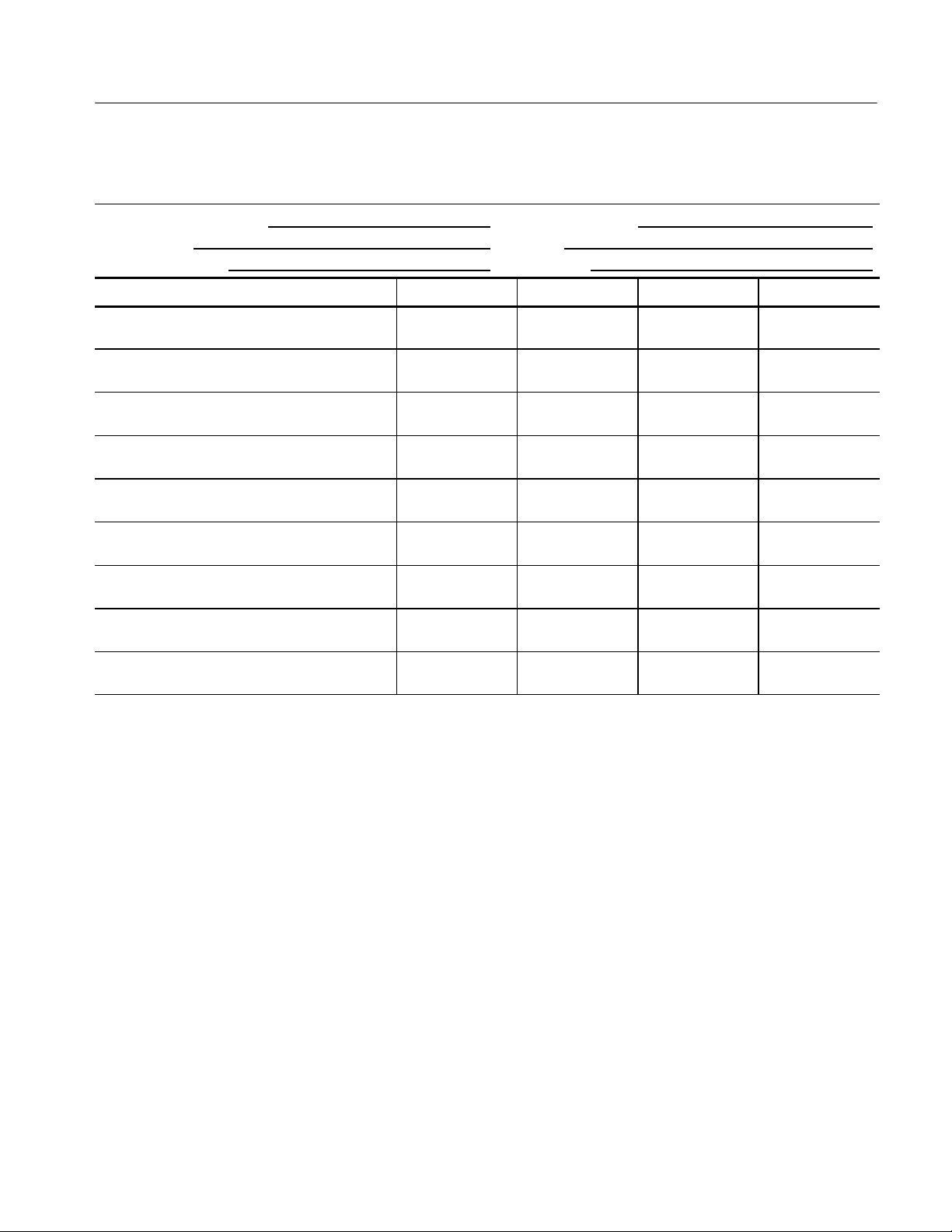

Check Vertical Operation 3--3......................................

Check Horizontal Operation 3--5....................................

Check Trigger Operation 3--7.......................................

Perform the Extended Diagnostics 3--9...................................

Performance Tests 4--1.........................................

Prerequisites 4--1....................................................

Equipment Required 4--2..............................................

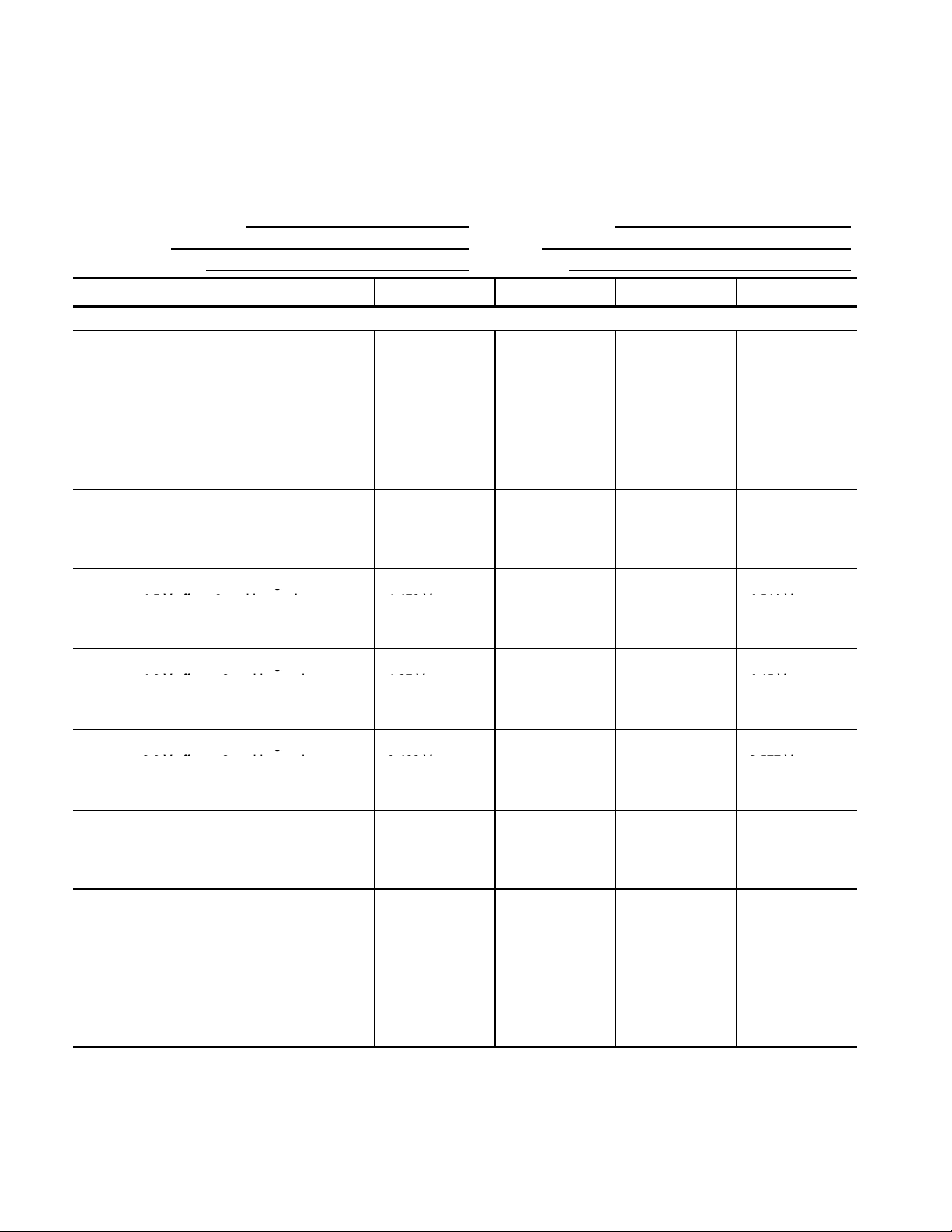

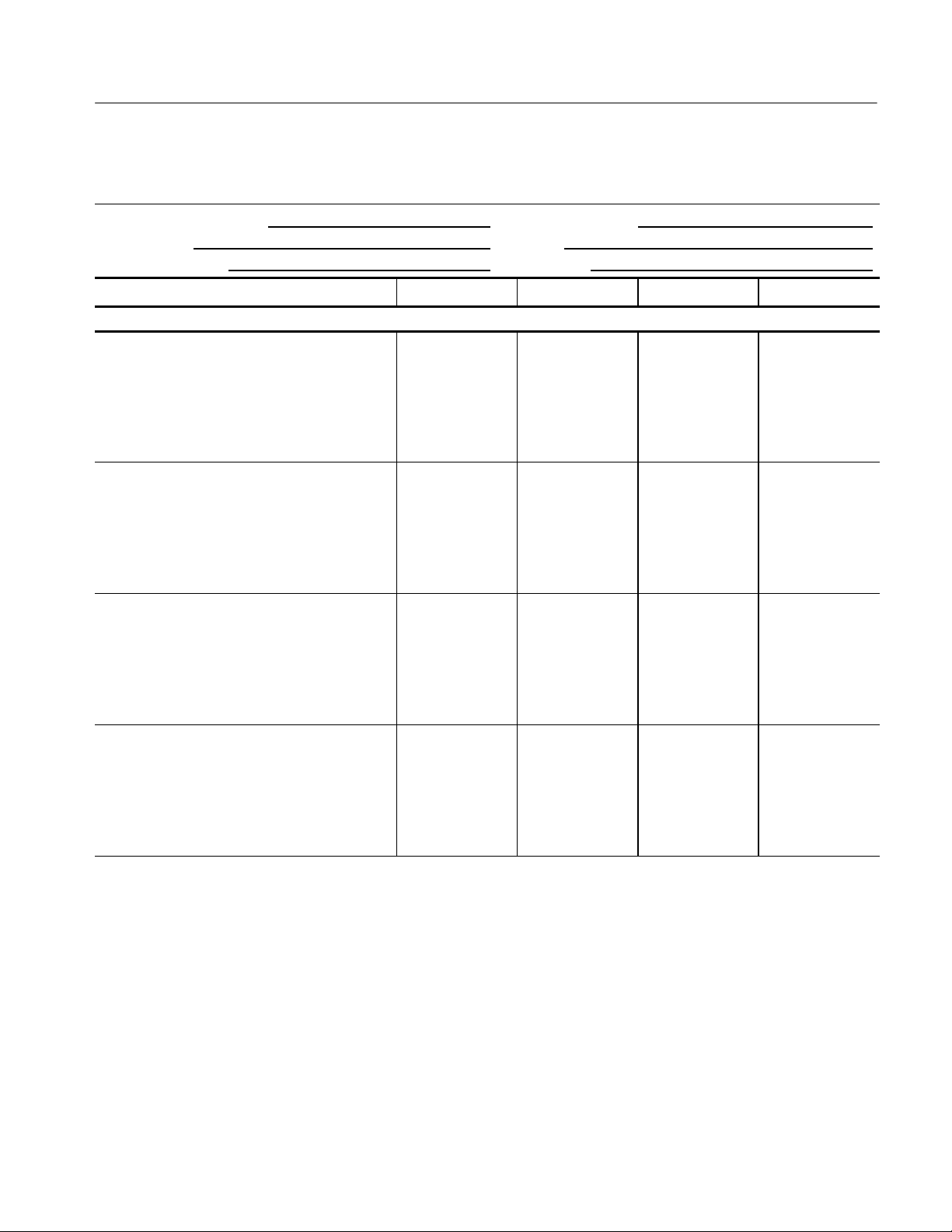

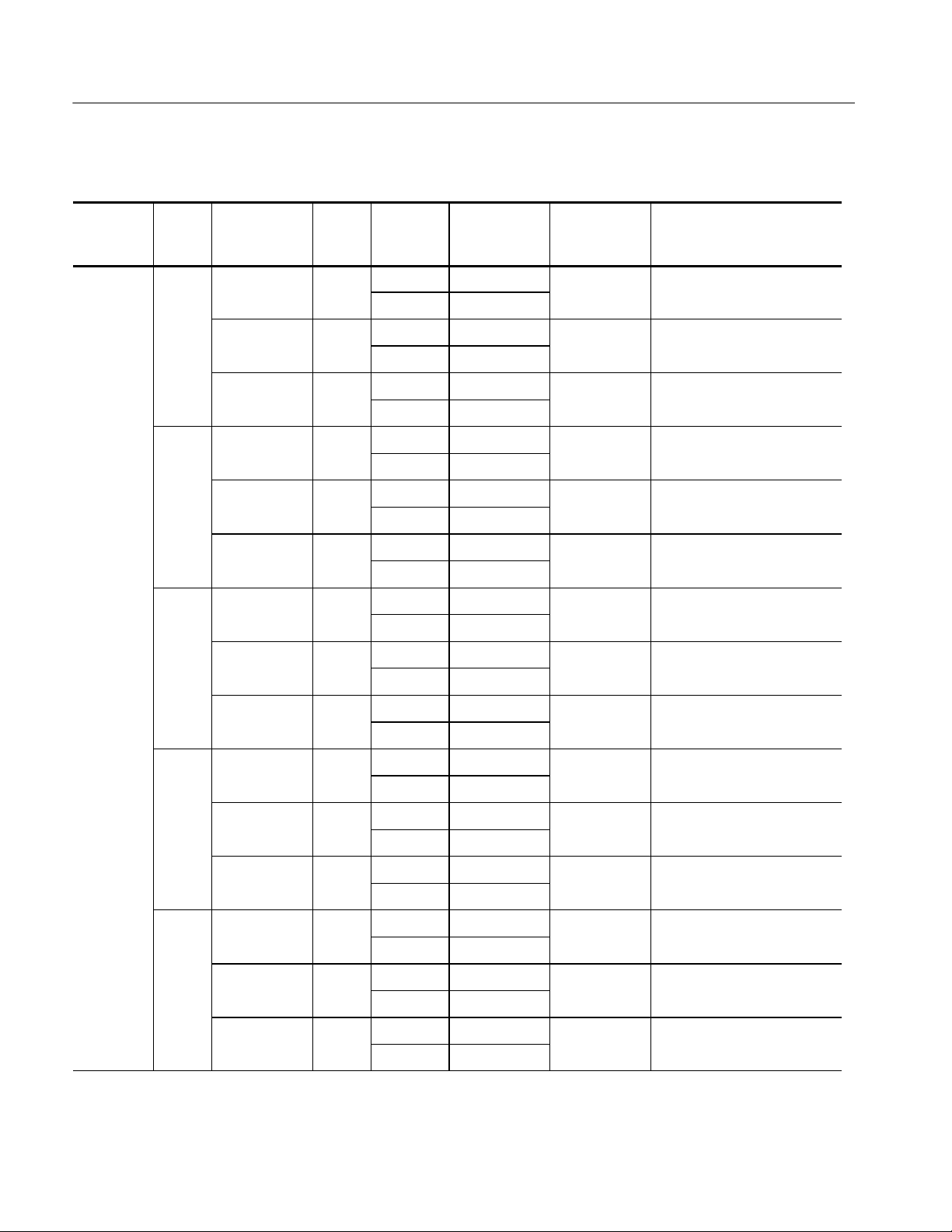

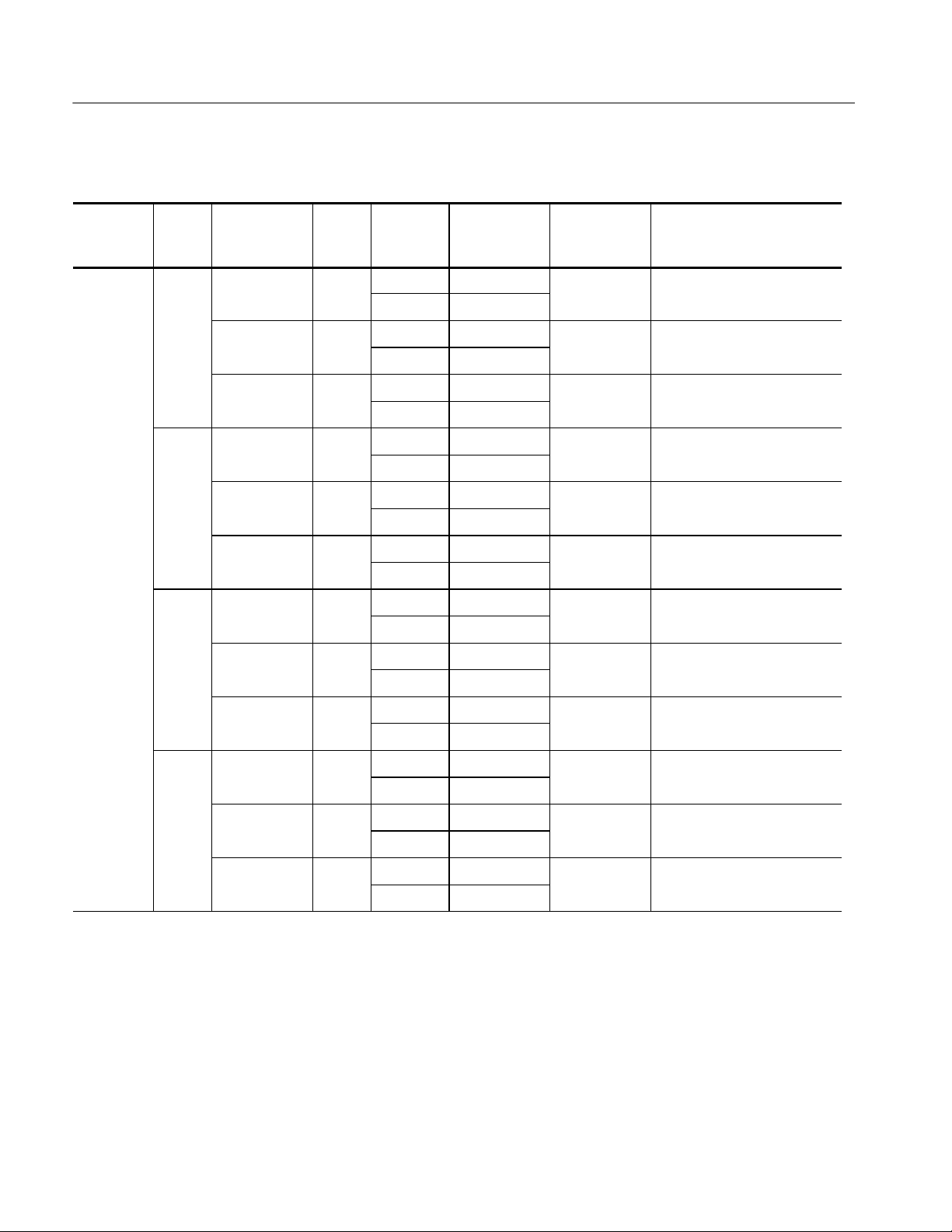

Test Record TDS6000B Series 4--4......................................

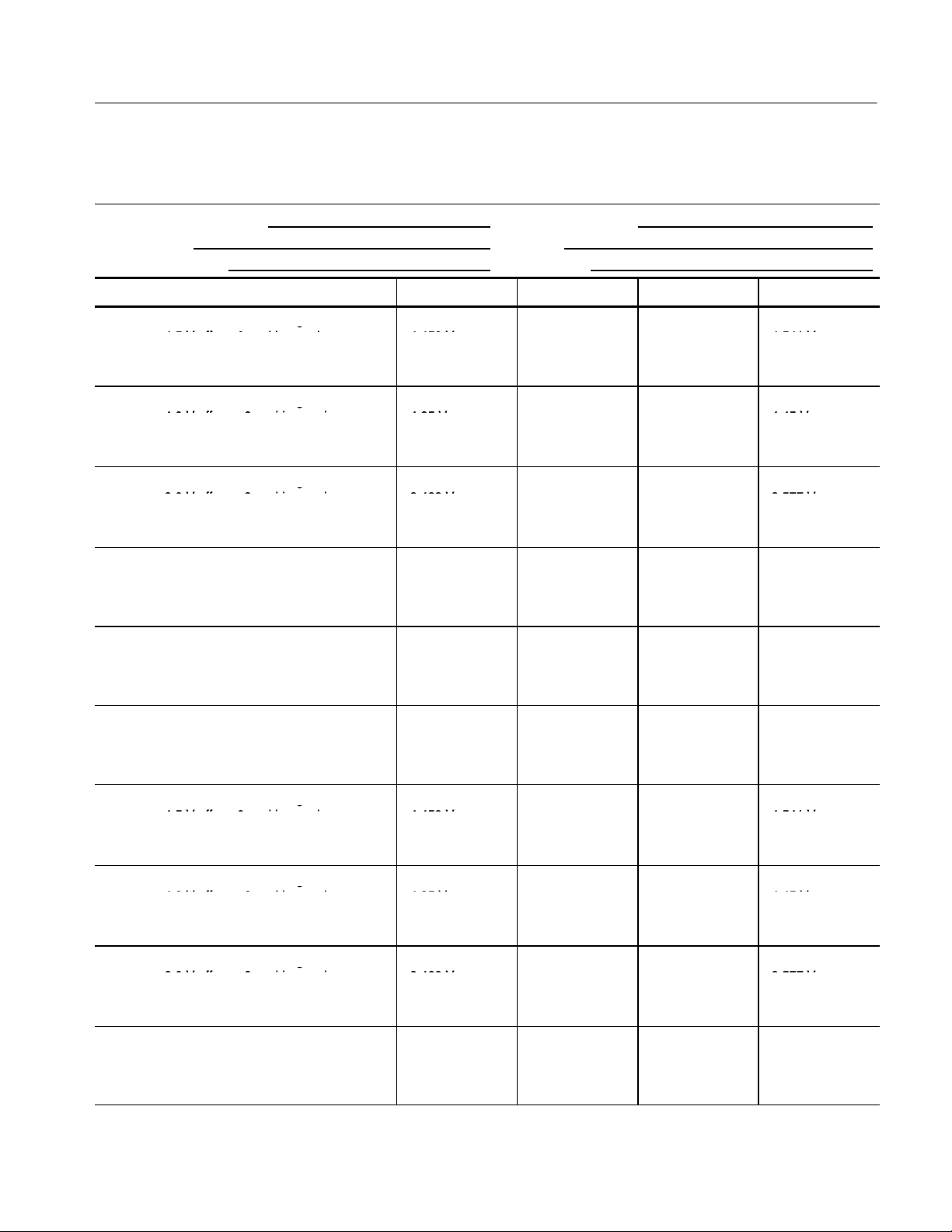

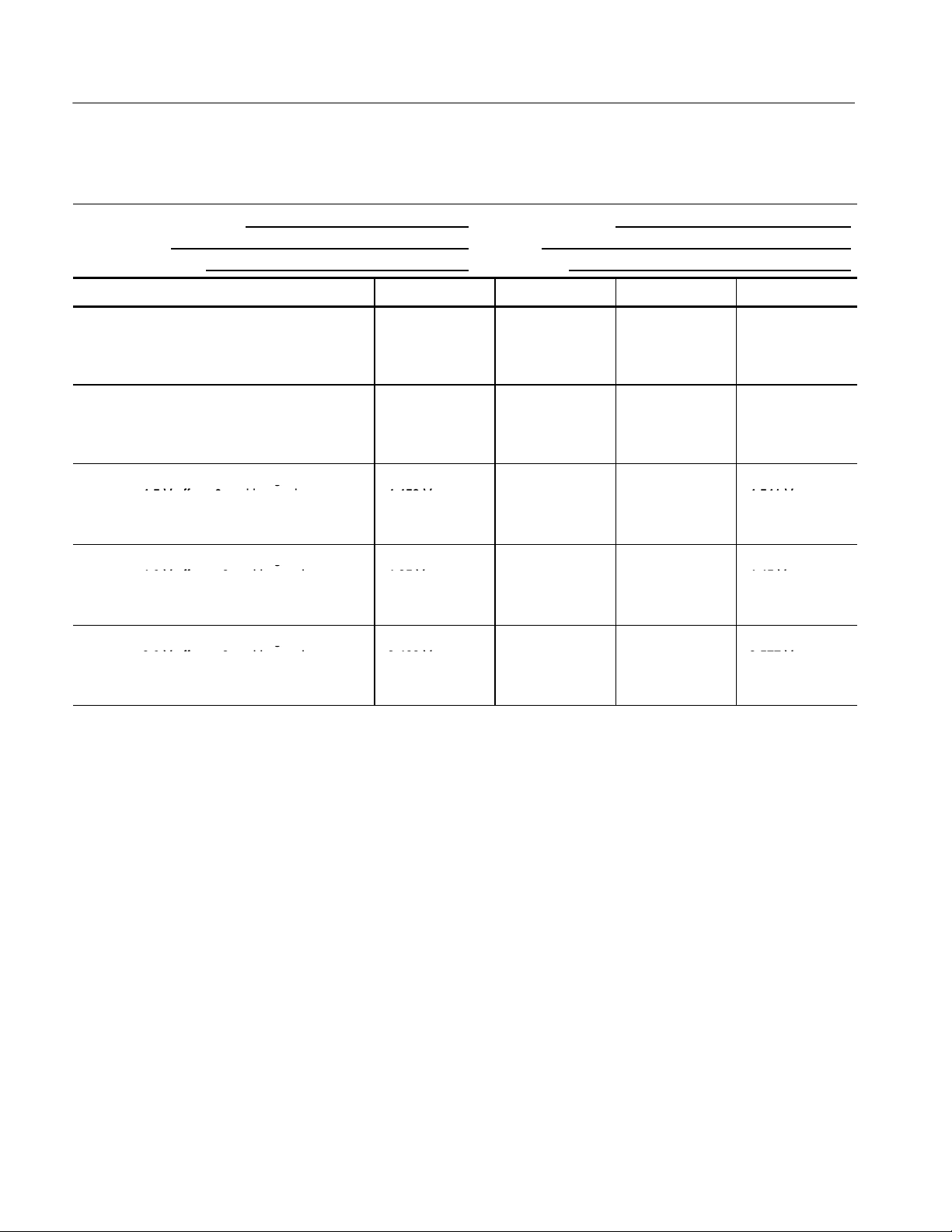

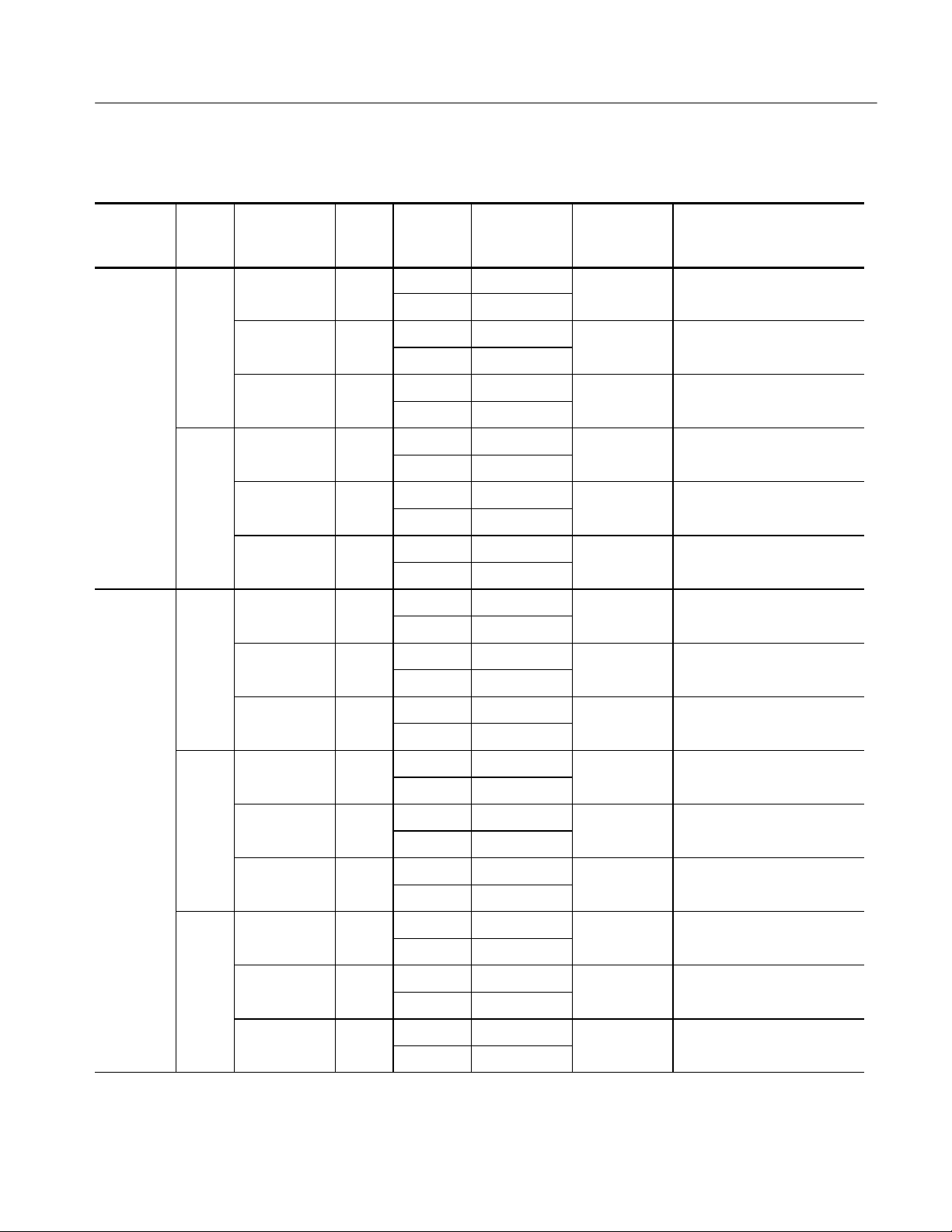

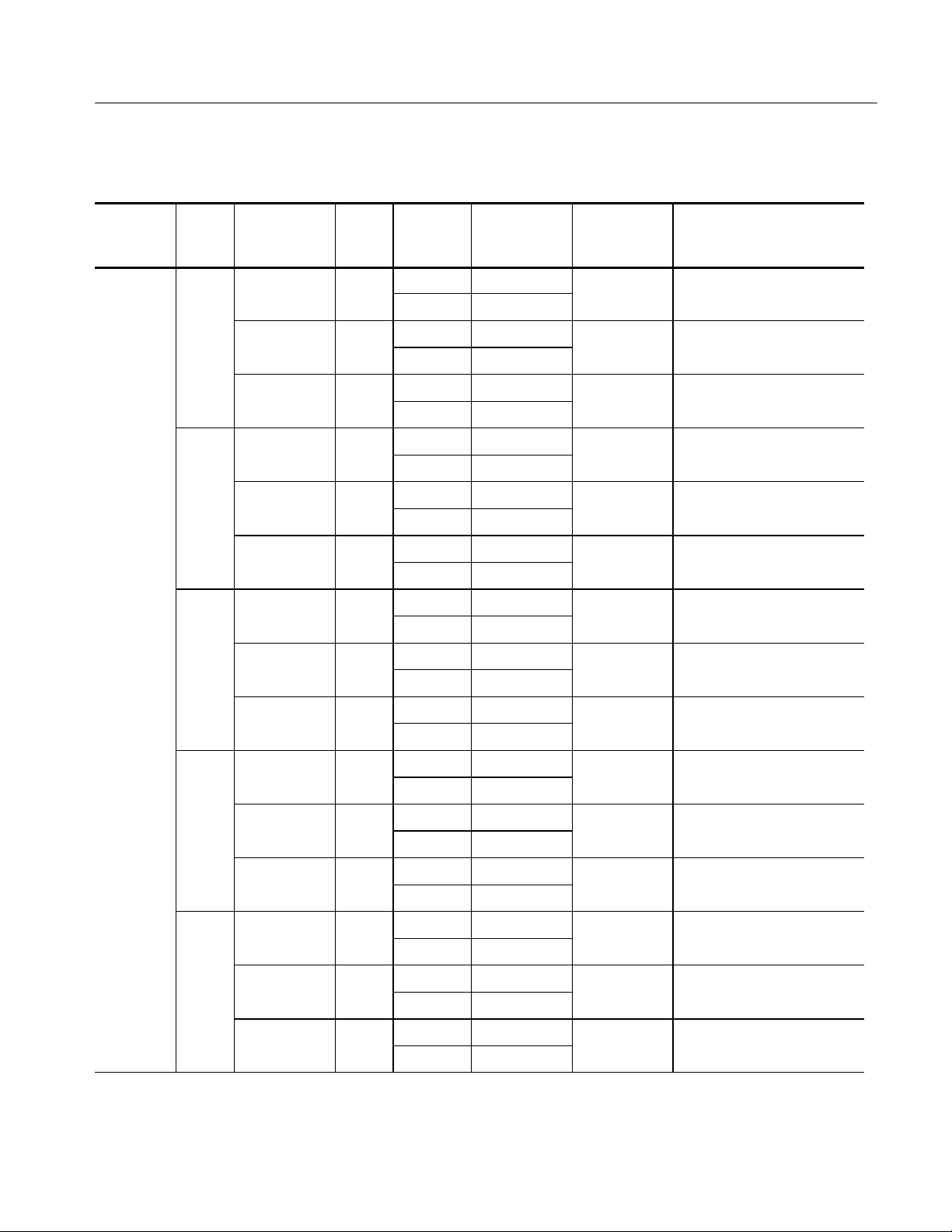

Test Record TDS6000C Series 4--16......................................

Signal Acquisition System Checks 4--29...................................

Check DC Voltage Measurement Accuracy 4--29........................

Check DC Gain Accuracy 4--34......................................

Check Offset Accuracy 4--50........................................

Check Maximum Input Voltage 4--54.................................

Check Analog Bandwidth 4--58......................................

Check Delay Between Channels TDS6000B Only 4--63...................

Check Channel Isolation (Crosstalk) TDS6000B Only 4--67...............

Check Input Impedance 4--72........................................

Time Base System Checks 4--73.........................................

Check Long-Term Sample Rate and Delay Time Accuracy and Reference 4--73

Check Delta Time Measurement Accuracy TDS6000B Series Only 4--76.....

Trigger System Checks 4--79............................................

Check Time Accuracy for Pulse, Glitch, Timeout, and Width Triggering 4--79.

Check Sensitivity, Edge Trigger, DC Coupled 4--82......................

Output Signal Checks 4--87.............................................

Check Outputs — CH 3 Signal Out and Aux Trigger Out 4--87.............

Fast Edge Output 4--90.............................................

Serial Trigger Checks (Option ST Only) 4--94..............................

TDS6000B & TDS6000C Series Specifications and Performance Verification

i

Table of Contents

List of Figures

Check Serial Trigger Baud Rate Limits and Word Recognizer Position

Accuracy 4--94............................................

Check Serial Trigger Clock Recovery Range 4--101.......................

Serial Trigger Checks (TDS6000C Only) 4--105.............................

Check Serial Trigger Baud Rate Limits 4--105...........................

Sine Wave Generator Leveling Procedure 4--108.............................

Figure 3--1: Universal test hookup for functional tests -- CH 1 shown 3--3

Figure 3--2: Channel button location 3--4..........................

Figure3--3:Setupfortimebasetest 3--6...........................

Figure 3--4: Setup for trigger test 3--8.............................

Figure 4--1: Initial test hookup 4--30...............................

Figure 4--2: Measurement of DC accuracy at maximum offset and

position 4--33...............................................

Figure 4--3: Initial test hookup 4--34...............................

Figure 4--4: Measurement of DC gain accuracy 4--49.................

Figure 4--5: Initial test hookup 4--51...............................

Figure 4--6: Measurement of offset accuracy 4--53....................

Figure 4--7: Initial test hookup 4--55...............................

Figure 4-- 8: Check maximum input voltage 4--57....................

Figure 4--9: Initial test hookup 4--59...............................

Figure 4--10: Measurement of analog bandwidth 4--62................

Figure 4--11: Initial test hookup 4--64..............................

Figure 4--12: Measurement of channel delay 4--66...................

Figure 4--13: Initial test hookup 4--68..............................

Figure 4--14: Initial test hookup 4--72..............................

Figure 4--15: Initial test hookup 4--73..............................

Figure 4--16: Initial test hookup 4--74..............................

Figure 4--17: Final test hookup 4--75...............................

Figure 4--18: Delta time accuracy test hookup for TDS6000B Series 4--77

Figure 4--19: Initial test hookup 4--80..............................

Figure 4--20: Measurement of time accuracy for pulse and glitch

triggering 4--81.............................................

Figure 4--21: Initial test hookup 4--83..............................

Figure 4--22: Measurement of trigger sensitivity -- 50 MHz results

shown 4--84................................................

Figure 4--23: Initial test hookup 4--88..............................

Figure 4--24: Measurement of trigger out limits 4--89.................

ii

TDS6000B & TDS6000C Series Specifications and Performance Verification

List of Tables

Table of Contents

Figure 4--25: Initial test hookup 4--90..............................

Figure 4--26: Measurement of probe compensator frequency 4--91......

Figure 4-- 27: Subsequent test hookup 4--92.........................

Figure 4--28: Measurement of probe compensator amplitude 4--93......

Figure 4--29: Initial test hookup 4--94..............................

Figure 4--30: Isolated 0 triggering 4--96............................

Figure 4--31: Isolated 1 triggering 4--98............................

Figure 4--32: N modulo 3 triggering 4--100...........................

Figure 4--33: Initial test hookup 4--101..............................

Figure 4--34: Clock recovery 4-- 104.................................

Figure 4--35: Initial test hookup 4--105..............................

Figure 4--36: Sine wave generator leveling equipment setup 4--108......

Figure 4-- 37: Equipment setup for maximum amplitude 4--110.........

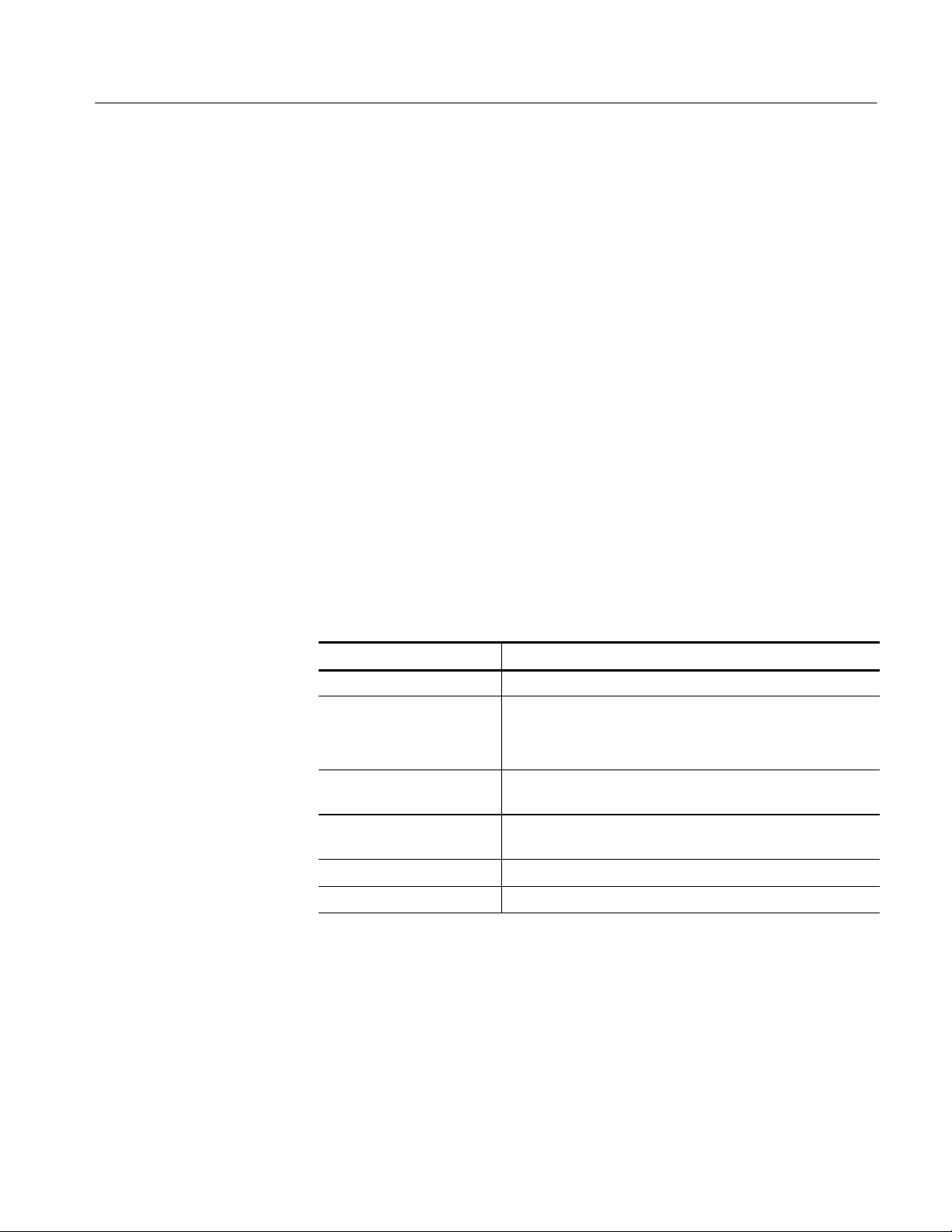

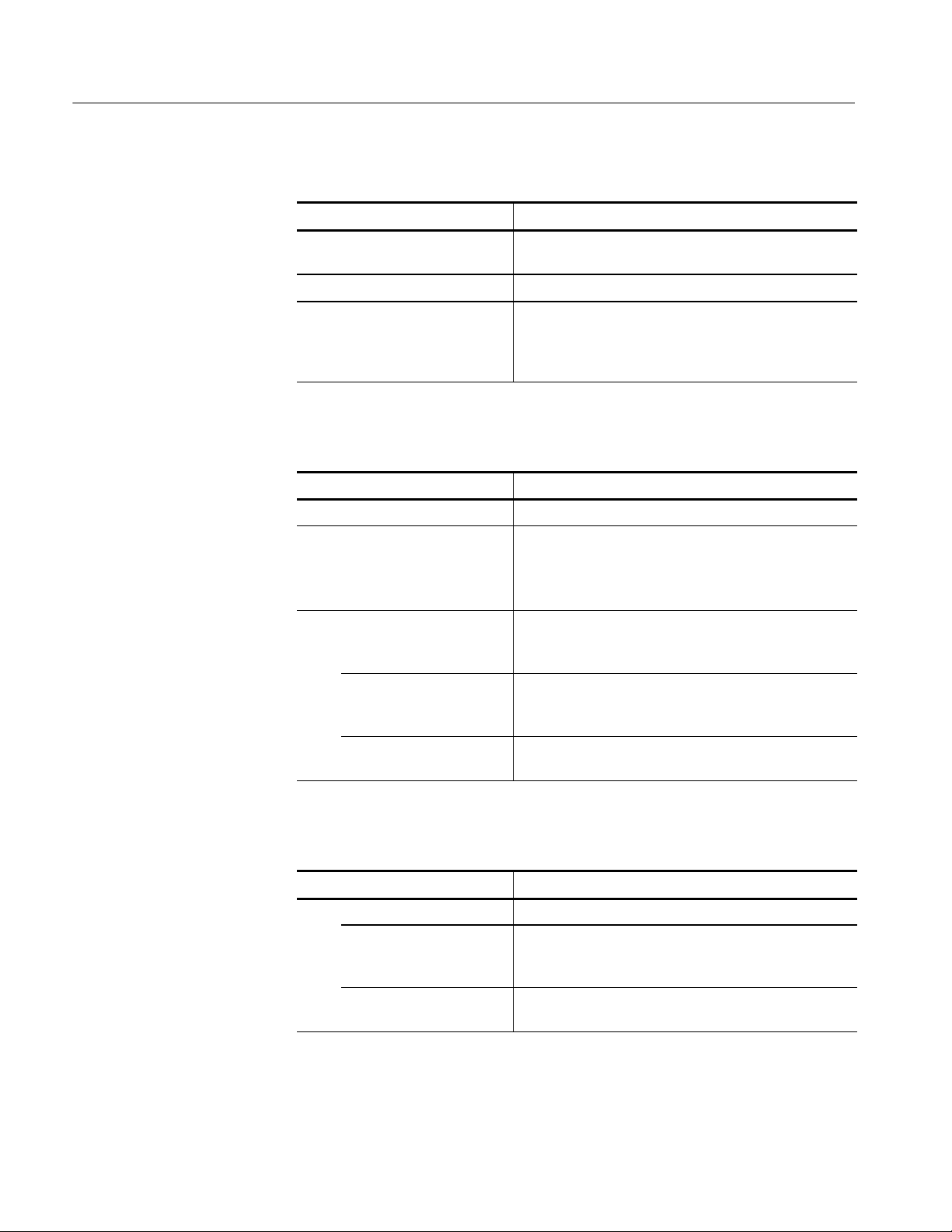

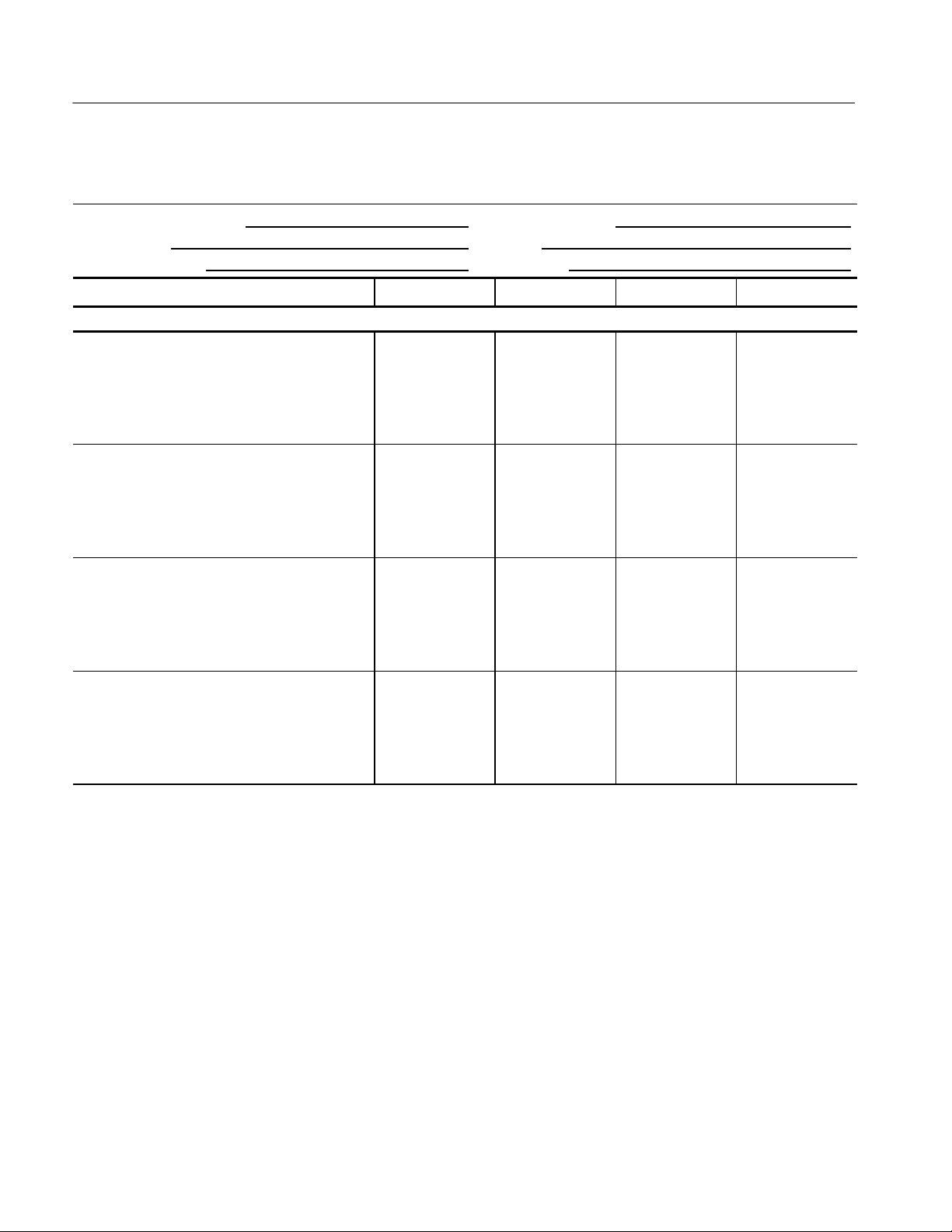

Table 1--1: TDS6000B & TDS6000C Series 1--1....................

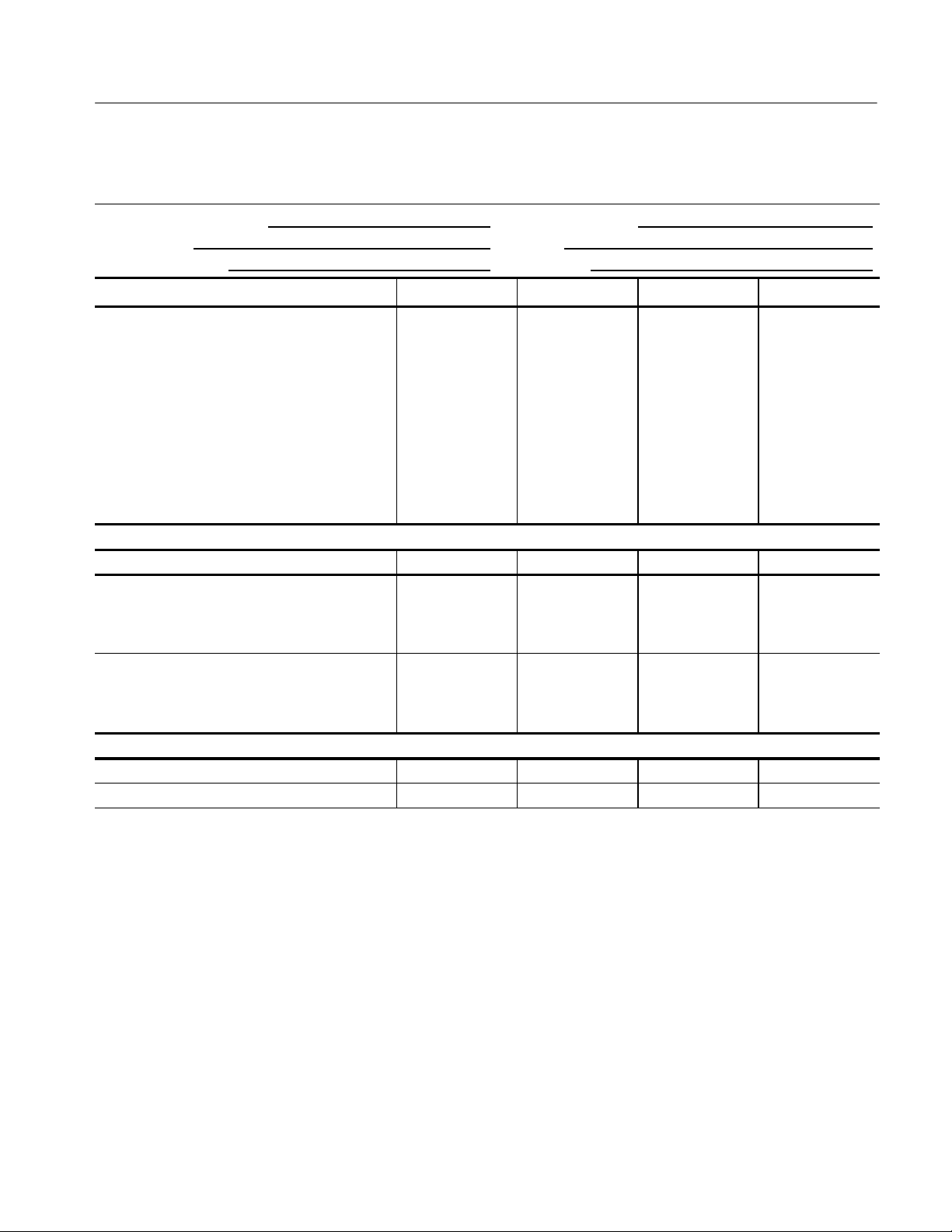

T able 1--2: Environmental specifications 1--4......................

Table 1--3: TDS6000B Series channel input and vertical

specifications 1--7..........................................

Table 1--4: TDS6000B Series horizontal and acquisition system

specifications 1--10..........................................

Table 1--5: TDS6000B Series trigger specifications 1--13..............

Table 1--6: TDS6000B Series serial trigger specifications (optional) 1--16

Table 1--7: TDS6000B Series display specifications 1--17.............

Table 1--8: TDS6000B Series input/output port specifications 1--17.....

Table 1--9: TDS6000B Series data storage specifications 1--20.........

Table 1--10: TDS6000B Series power source specifications 1--20.......

Table 1--11: TDS6000B Series mechanical specifications 1--20.........

Table 1--12: TDS6000C Series channel input and vertical

specifications 1--22..........................................

Table 1--13: TDS6000C Series horizontal and acquisition system

specifications 1--27..........................................

Table 1--14: TDS6000C Series trigger specifications 1--32.............

Table 1--15: TDS6000C Series serial trigger specifications

(Option ST) 1--35...........................................

Table 1--16: TDS6000C Series display specifications 1--37............

Table 1--17: TDS6000C Series input/output port specifications 1--37....

Table 1--18: TDS6000C Series data storage specifications 1--39........

TDS6000B & TDS6000C Series Specifications and Performance Verification

iii

Table of Contents

Table 1--19: TDS6000C Series power source specifications 1--39.......

Table 1--20: TDS6000C Series mechanical specifications 1--40.........

Table 3--1: Vertical settings 3--4.................................

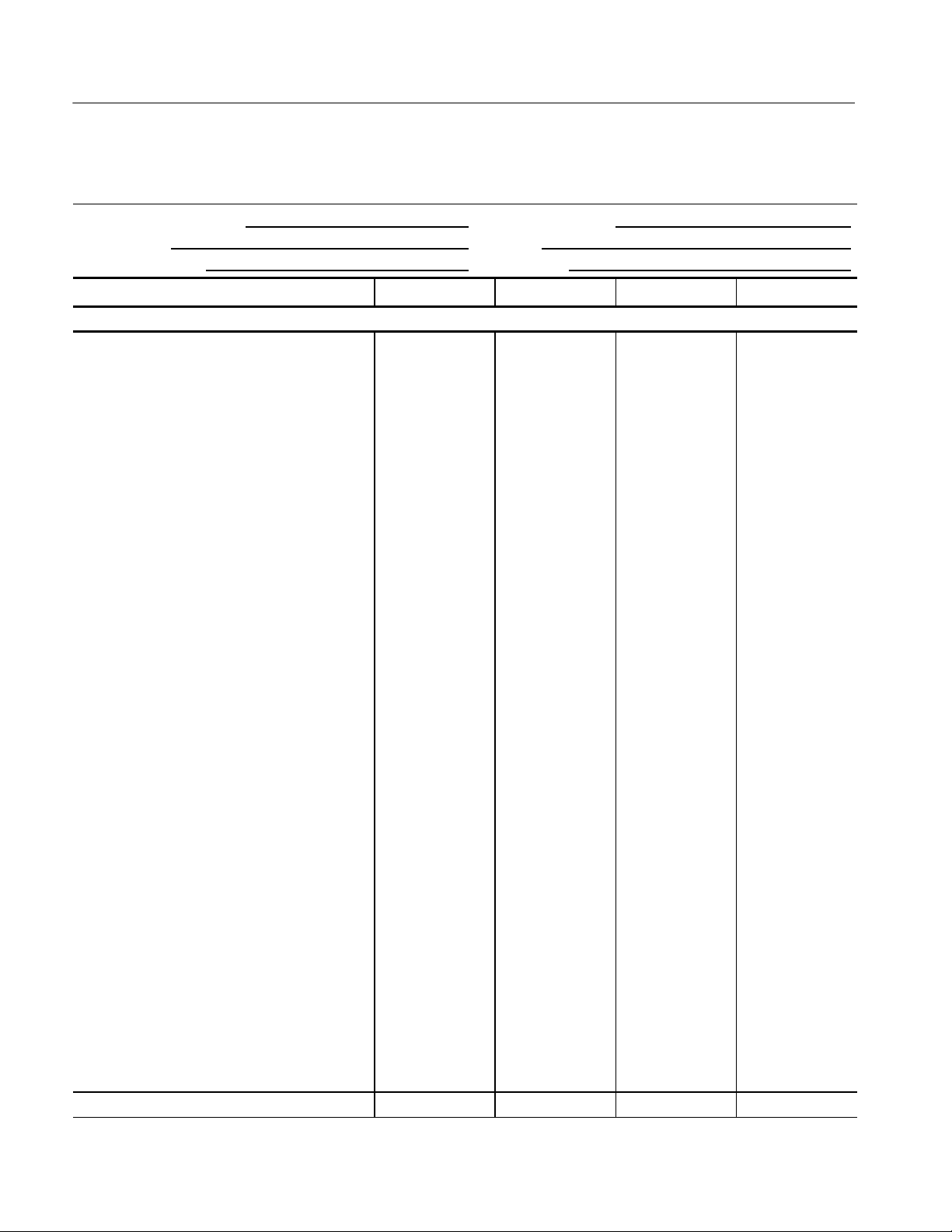

Table 4--1: Test equipment 4--2..................................

Table 4--2: DC Voltage measurement accuracy, TDS6000B Series 4--31..

Table 4--3: DC Voltage measurement accuracy, TDS6000C Series 4--31..

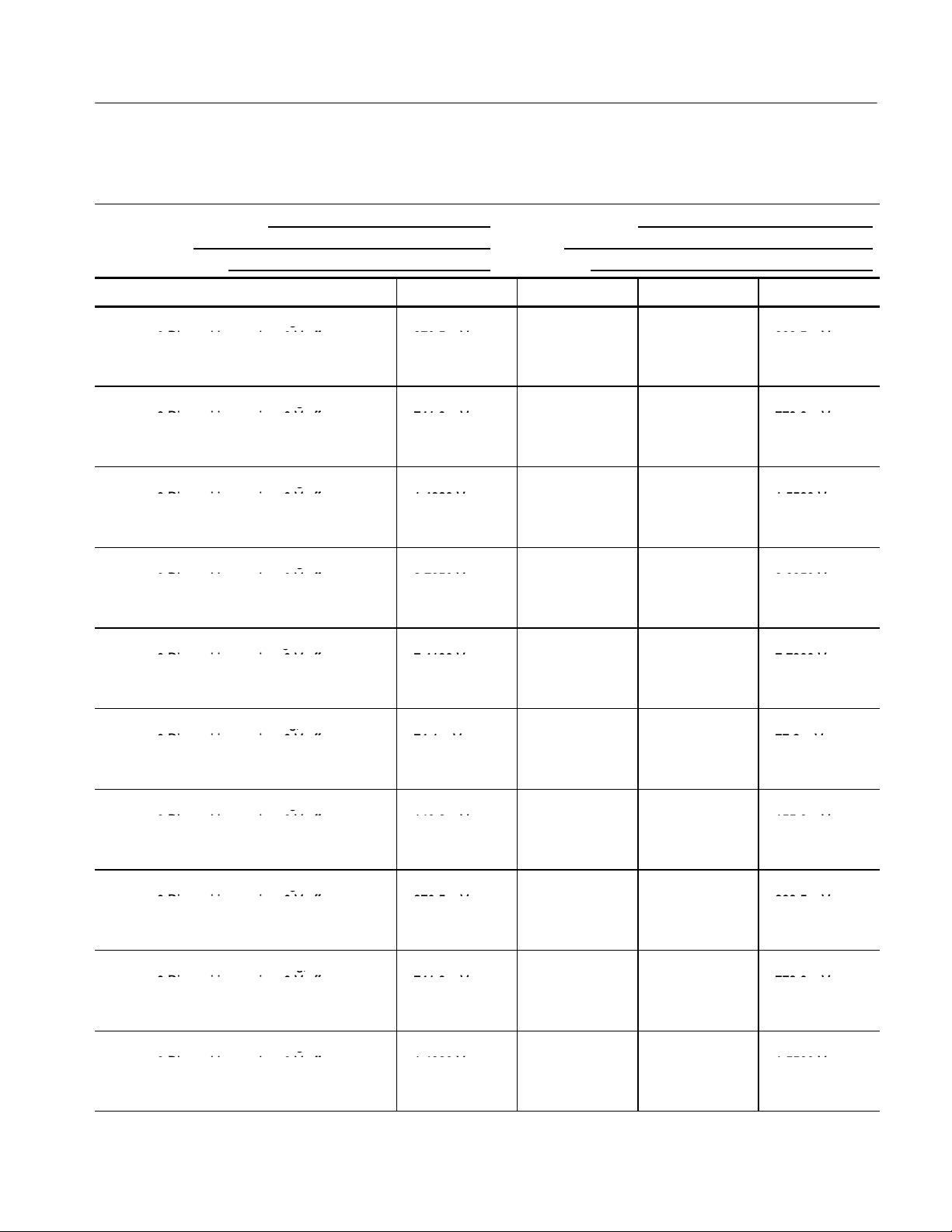

Table 4--4: Gain accuracy, TDS6000B Series 4--36...................

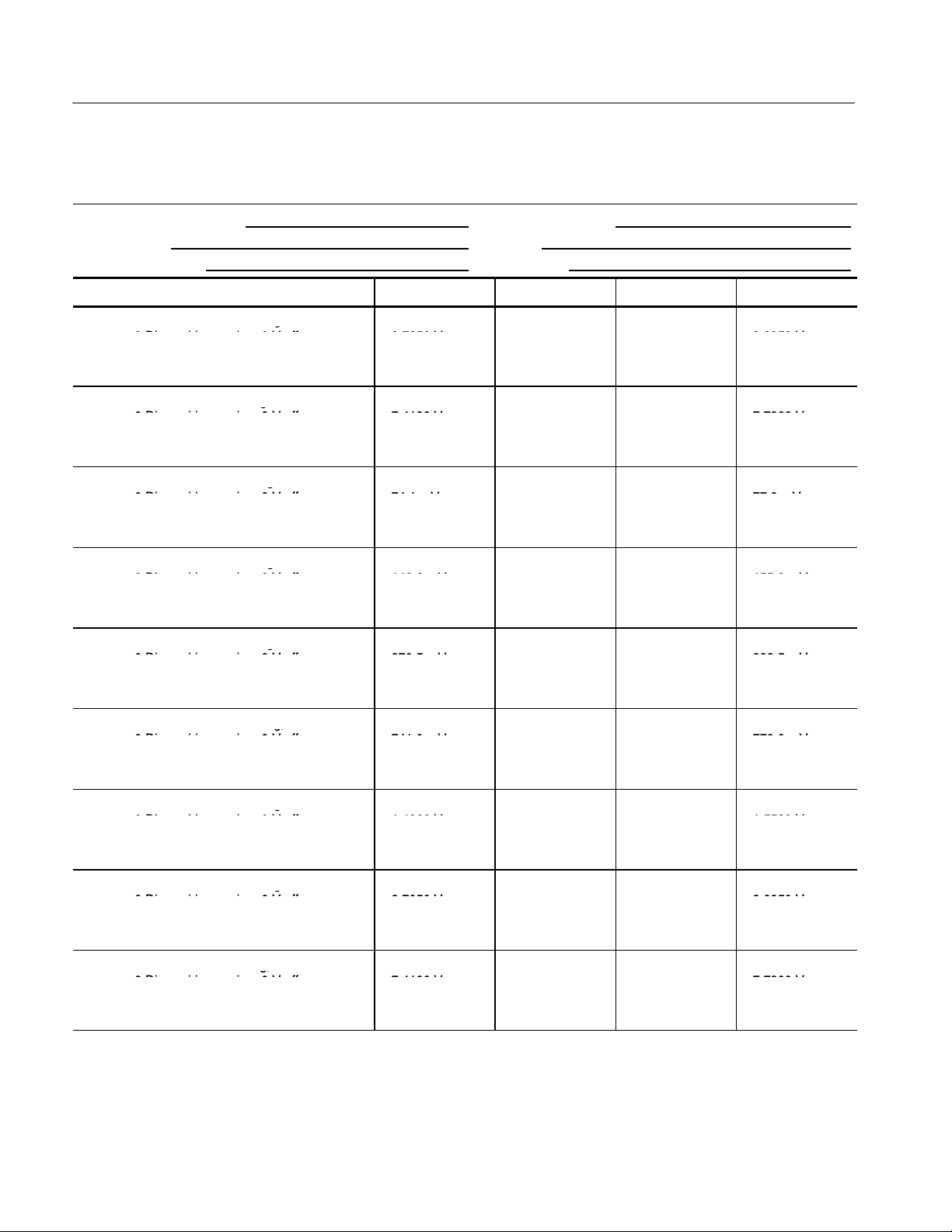

Table 4--4: Gain accuracy, TDS6000C Series 4--42...................

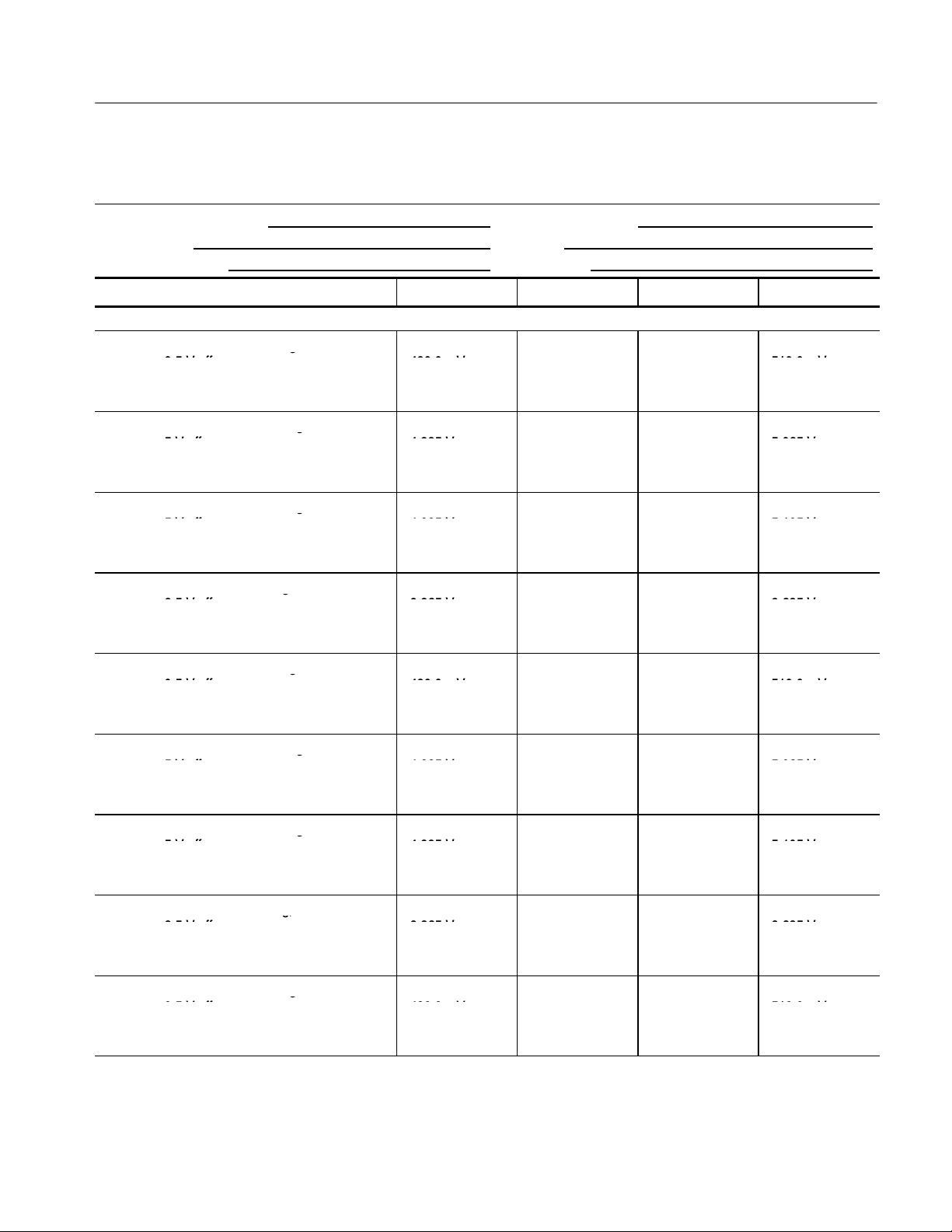

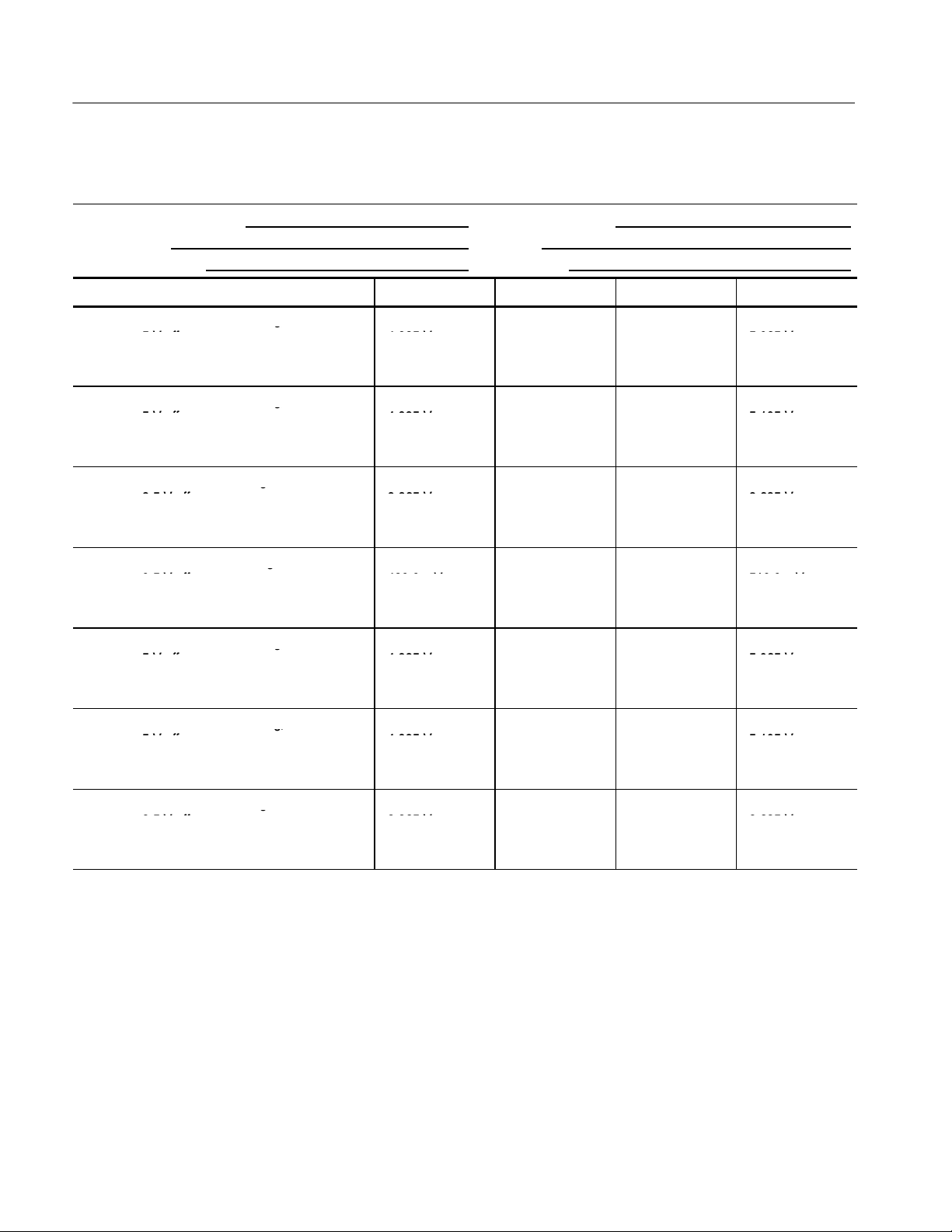

Table 4--6: Offset accuracy, TDS6604B & TDS6804B 4--52............

Table 4--7: Offset accuracy (full scale), TDS6124C & TDS6154C 4--52..

Table 4--8: Maximum input voltage limit 4--56......................

Table 4--9: Analog bandwidth, TDS6000B 4--60.....................

Table 4--10: Analog bandwidth, TDS6000C 4--60....................

Table 4--11: Delay between channels worksheet, TDS6000B only 4--67..

Table 4--12: Delta time measurement 4--78.........................

Table 4--13: Serial pattern data 4--95..............................

T able 4--14: Word recognizer data 4--97...........................

Table 4--15: Clock recovery input frequencies and baud rates 4--103....

Table 4--16: Generator serial streams 4--106.........................

Table 4--17: Serial pattern data 4--106..............................

iv

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

This chapter contains the specifications for the TDS6000B & TDS6000C Series

Oscilloscopes. All specifications are guaranteed unless labeled “typical.” Typical

specifications are provided for your convenience but are not guaranteed.

Specifications that are marked with the n symbol are checked in the Perfor-

mance Tests section. To make it easier to find the specifications for a particular

product, the specifications for the TDS6000B & TDS6000C Series are listed in

separate sections.

To meet specifications, the following conditions must be met:

H The oscilloscope must have been calibrated in an ambient temperature

between 20 °C and 30 °C(68°F and 86 °F).

H The oscilloscope must be operating within the environmental limits listed in

Table 1--2, page 1--4.

H The oscilloscope must be powered from a source that meets the specifica-

tions listed in Table 1--10, page 1--20.

H The oscilloscope must have been operating continuously for at least 20

minutes within the specified operating temperature range.

H You must perform the Signal Path Compensation procedure after the

20-minute warm-up period, and the ambient temperature must not change

more than 5 °C(9°F) without first repeating the procedure. See page 3--2 for

instructions to perform this procedure.

Product and Feature Description

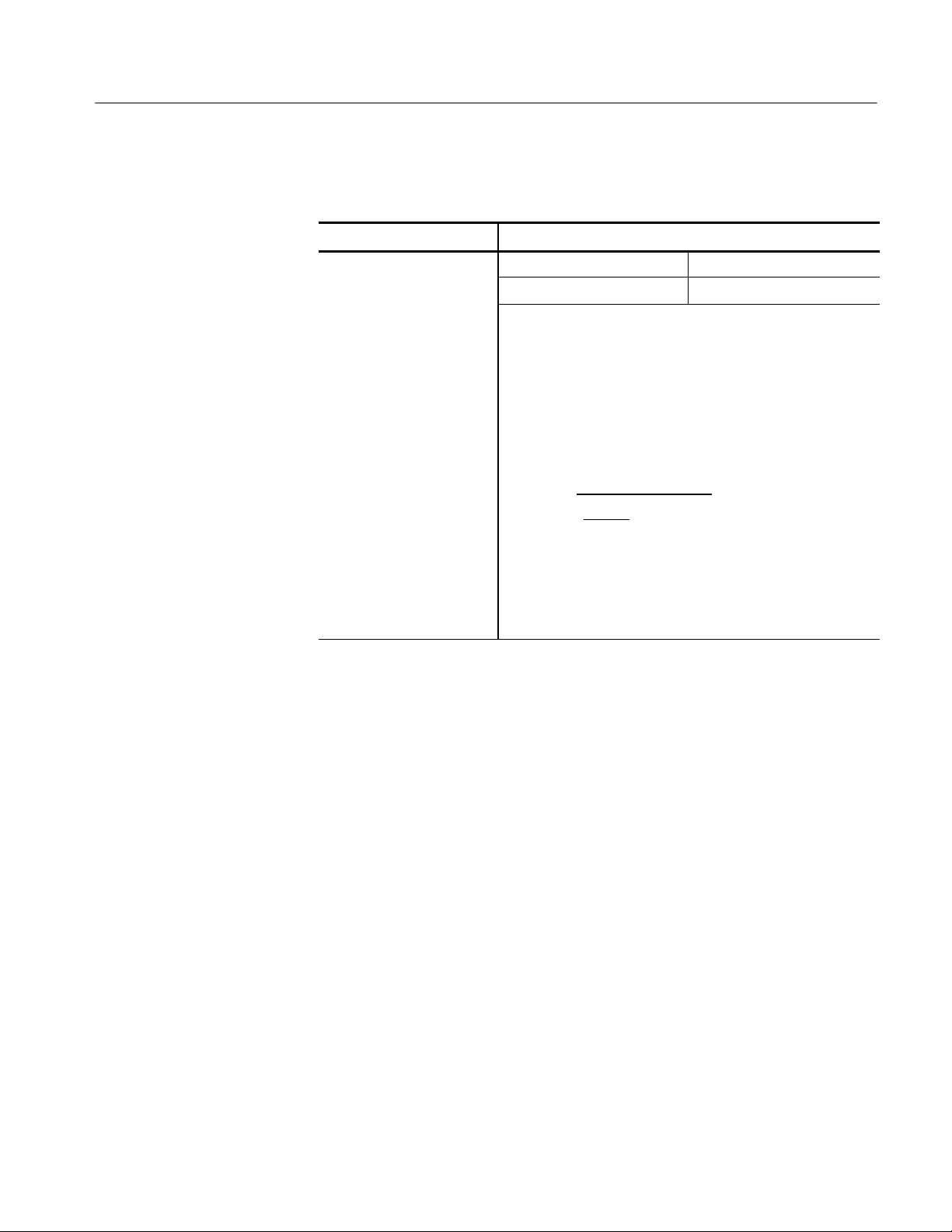

Your TDS6000B & TDS6000C Series is shown in Table 1--1.

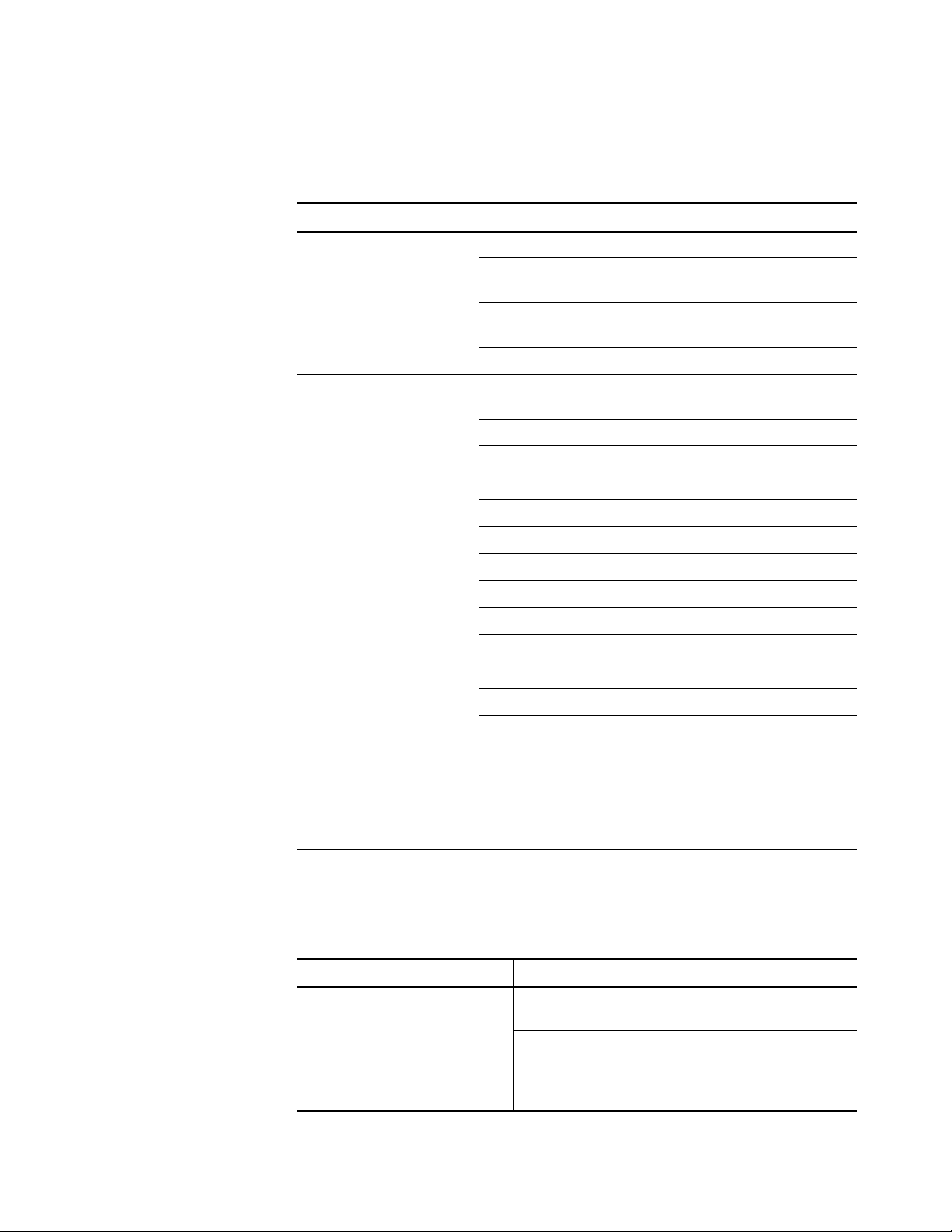

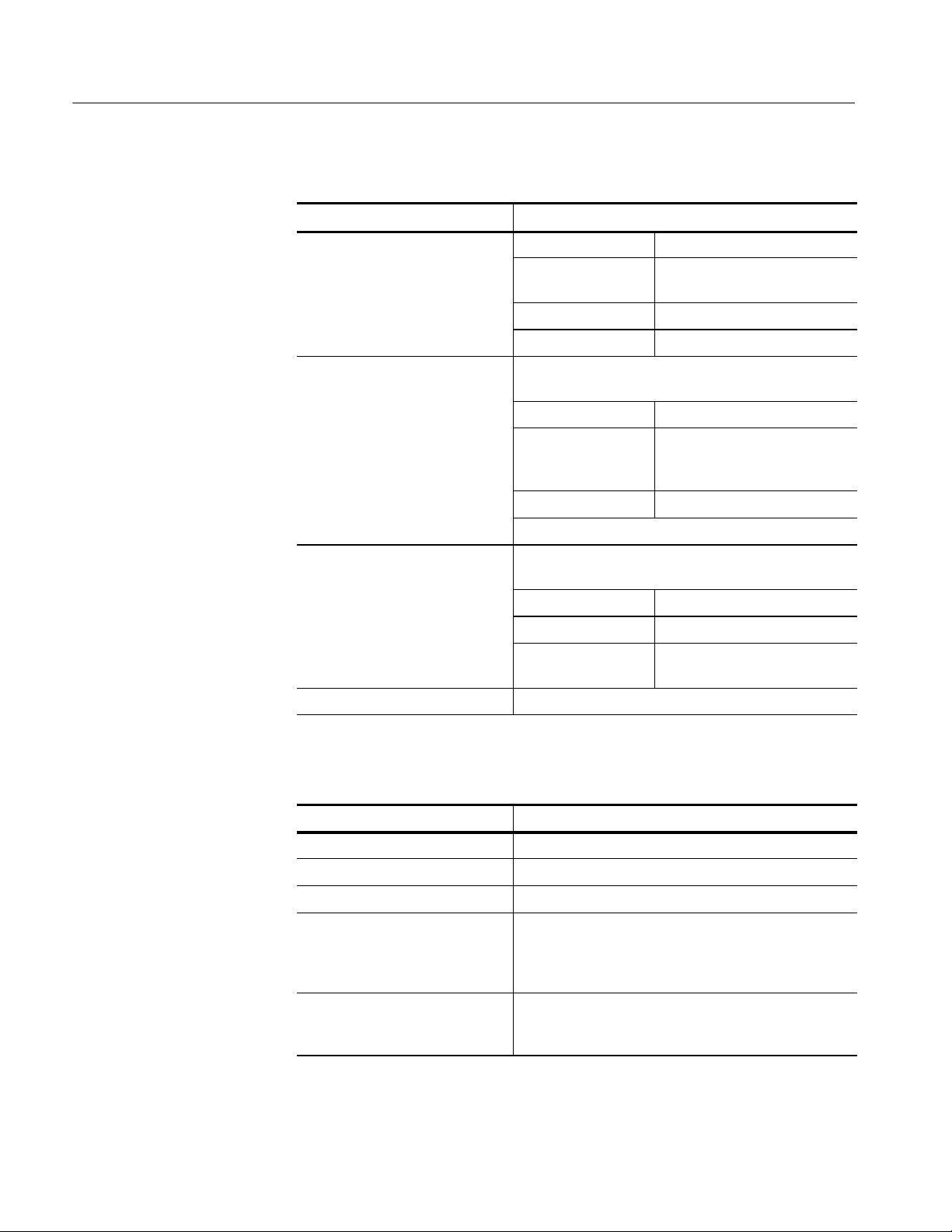

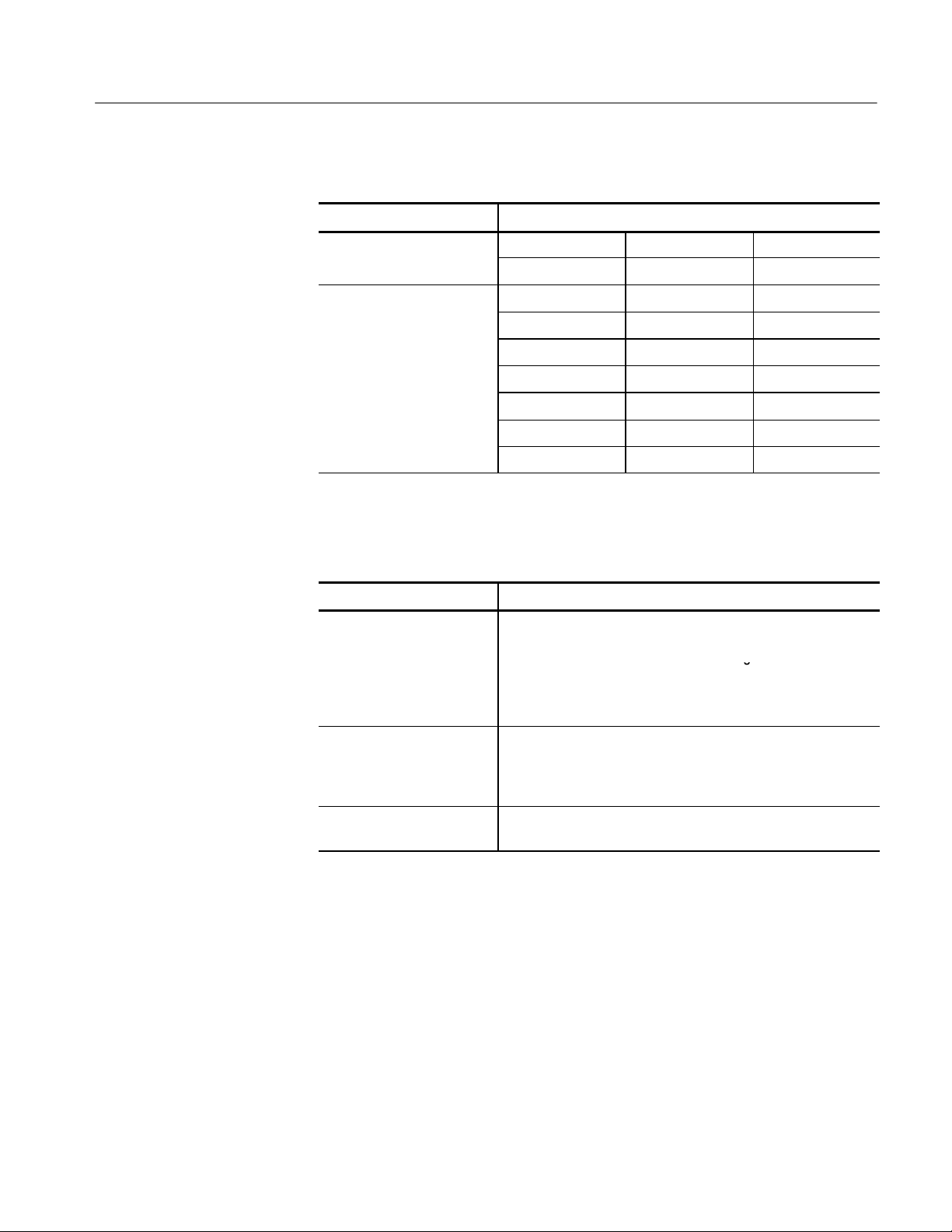

Table 1- 1: TDS6000B & TDS6000C Series

Model

TDS6604B 4 6GHz 20 GS/s

TDS6804B 4 8GHz 20 GS/s

TDS6124C 4 12 GHz 40 GS/s

TDS6154C 4 15 GHz 40 GS/s

1

40 GS/s on two channels, 20 GS/s on four channels

Number of

channels

Bandwidth

Maximum sample

rate (real time)

1

1

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 1

Specifications

Acquisition Features

Separate Digitizers. Ensure accurate timing measurements with separate digitizers

for each channel. Acquisition on multiple channels is always concurrent. The

digitizers can also be combined to yield a higher sample rate on two channels

(TDS6000C series only).

Long Record Lengths. Maximum record length up to 32,000,000 points simultaneously on all four channels (TDS6000C series only; requires Option 4M)or

64,000,000 points on two channels (both TDS6000B and TDS6000C series).

Peak Detect Acquisition Mode. See pulses as narrow as 50 ps even at the slower

time base settings. Captures narrow glitches at all real-time sampling rates.

Acquisition Control. Acquire continuously or set up to capture single shot

acquisitions. Enable or disable optional acquisition features such as equivalent

time.

Horizontal Delay. Use delay when you want to acquire a signal at a significant

time interval after the trigger point. Toggle delay on and off to quickly compare

the signal at two different points in time.

Signal Processing

Features

Display Features

Average, Envelope, and Hi Res Acquisition. Use Average acquisition mode to

remove uncorrelated noise from your signal. Use Envelope to capture and

display the maximum variation of the signal. Use Hi Res to increase vertical

resolution for lower bandwidth signals.

Waveform Math. Set up simple math waveforms using the basic arithmetic

functions or create more advanced math waveforms using the math expression

editor. W aveform expressions can even contain measurement results and other

math waveforms.

Spectral Analysis. Display spectral magnitude and phase waveforms based on

your time-domain acquisitions. Control the oscilloscope using the traditional

spectrum analyzer controls such as span and center frequency.

Color LCD Display. Identify and differentiate waveforms easily with color coding.

Waveforms, readouts, and inputs are color matched to increase productivity and

reduce operating errors.

MultiView Zoom. To take advantage of the full resolution of the instrument you

can zoom in on a waveform to see the fine details. Both vertical and horizontal

zoom functions are available. Zoomed waveforms can be aligned, locked, and

automatically scrolled.

1- 2

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Measurement Features

Trigger Features

Cursors. Use cursors to take simple voltage, time, and frequency measurements.

Automatic Measurements. Choose from a large palette of amplitude, time, and

histogram measurements. You can customize the measurements by changing

reference levels or by adding measurement gating.

Simple and Advanced Trigger Types. Choose simple edge trigger or choose from

eight advanced trigger types to help you capture a specific signal fault or event.

Dual Triggers. Use the A (main) trigger system alone or add the B trigger to

capture more complex events. You can use the A and B triggers together to set

up a delay-by-time or delay-by-events trigger condition.

Comm Triggers. Optional on TDS6000B & TDS6000C Series. Use comm

triggers to trigger on communication signals.

Serial Triggers. Optional on TDS6000B & TDS6000C Series. Use serial triggers

to trigger on serial pattern data.

Convenience Features

Recovered Clock and Data Triggers. Optional on TDS6000B & TDS6000C Series.

Use recovered clock and data internally to trigger your waveforms.

Autoset. Use Autoset to quickly set up the vertical, horizontal, and trigger

controls for a usable display.

Touch Screen Interface. You can operate all oscilloscope functions (except the

power switch) from the touch screen interface. If convenient, you can also install

a mouse and keyboard to use the interface.

Buttons or Menu Bar. You can choose a buttons (toolbar) operating mode,

optimized for using buttons with the touch screen, or a PC-style menu-bar

operating mode.

Open Desktop. The oscilloscope is built on a Microsoft Windows software

platform; the oscilloscope application program starts automatically when you

apply power to the instrument. You can minimize the oscilloscope application

and take full advantage of the built-in PC to run other applications. Move

waveform images and data into other applications by copying or pasting

information for short data records or exporting longer data records to a file.

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 3

Specifications

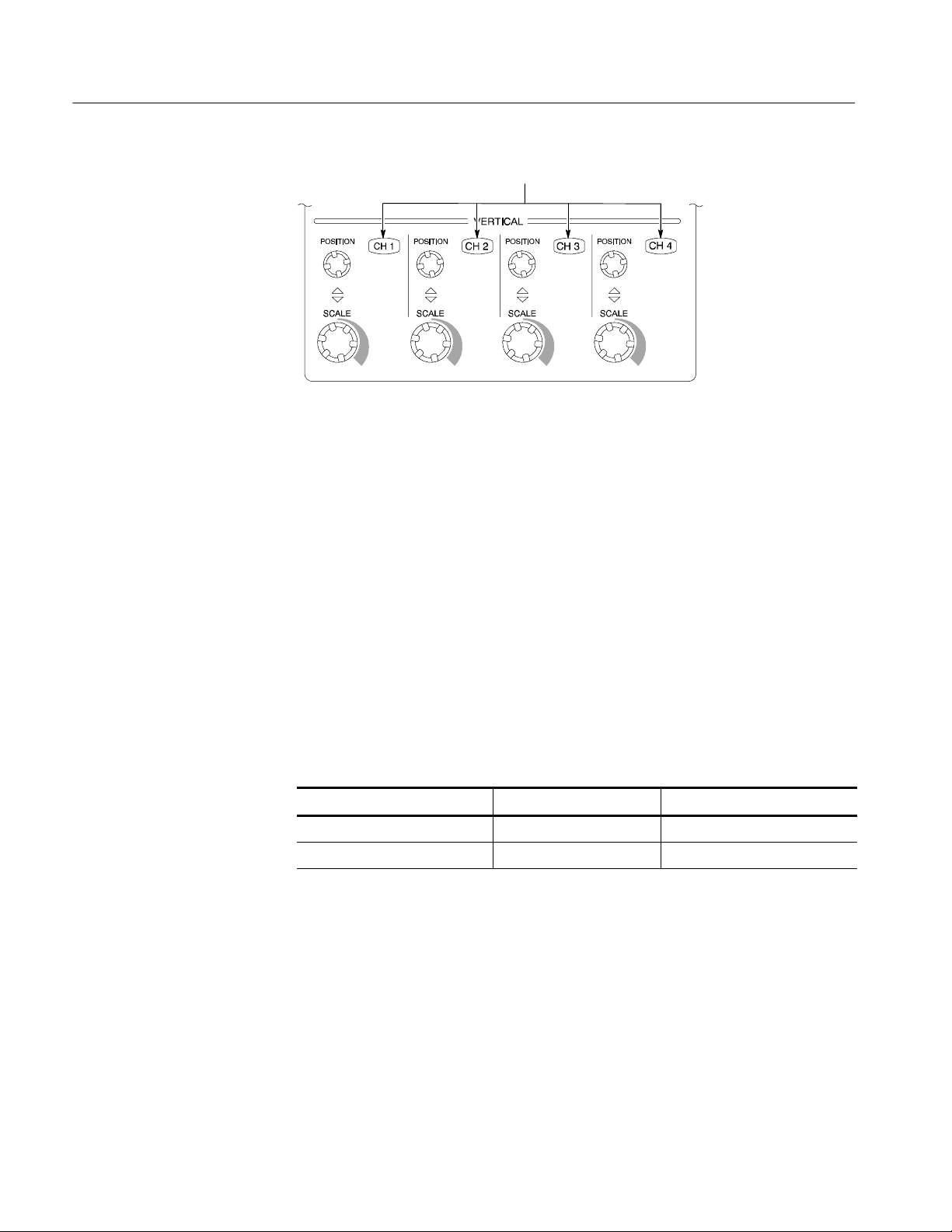

Dedicated Front Panel Controls. The front panel contains knobs and buttons to

provide immediate access to the most common oscilloscope controls. Separate

vertical controls are provided for each channel. The same functions are also

available through the screen interface.

Data Storage and I/O. The oscilloscope has a removeable hard disk drive and a

CD-RW drive, that can be used for storage and retrieval of data. The oscilloscope

has GPIB, USB, Centronics, and Ethernet ports for input and output to other

devices.

Online Help. The oscilloscope has a complete online help system that covers all

its features. The help system is context sensitive; help for the displayed control

window is automatically shown if you touch the help button. Graphical aids in

the help windows assist you in getting to the information you need. You can also

access the help topics through a table of contents or index.

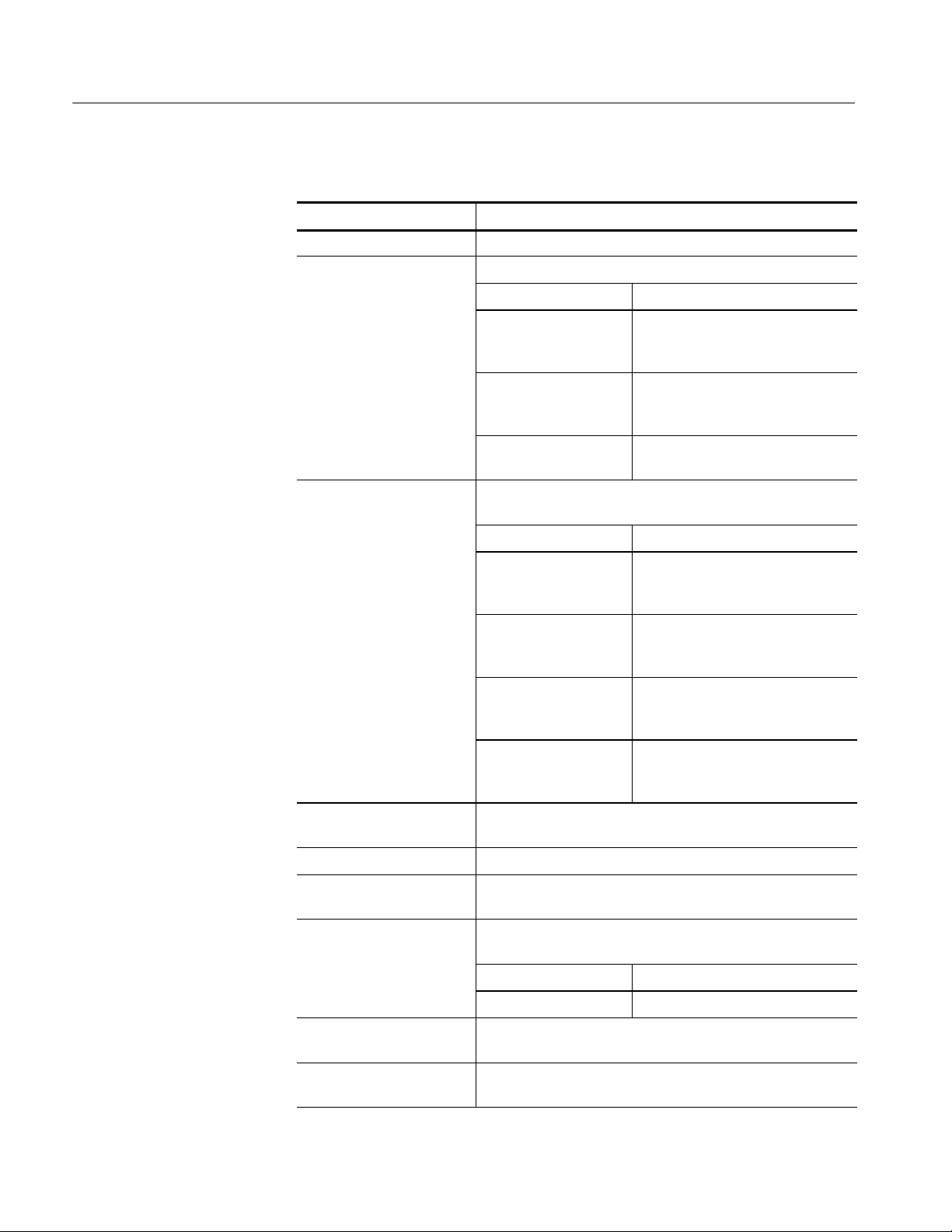

Environmental and Compliance Specifications

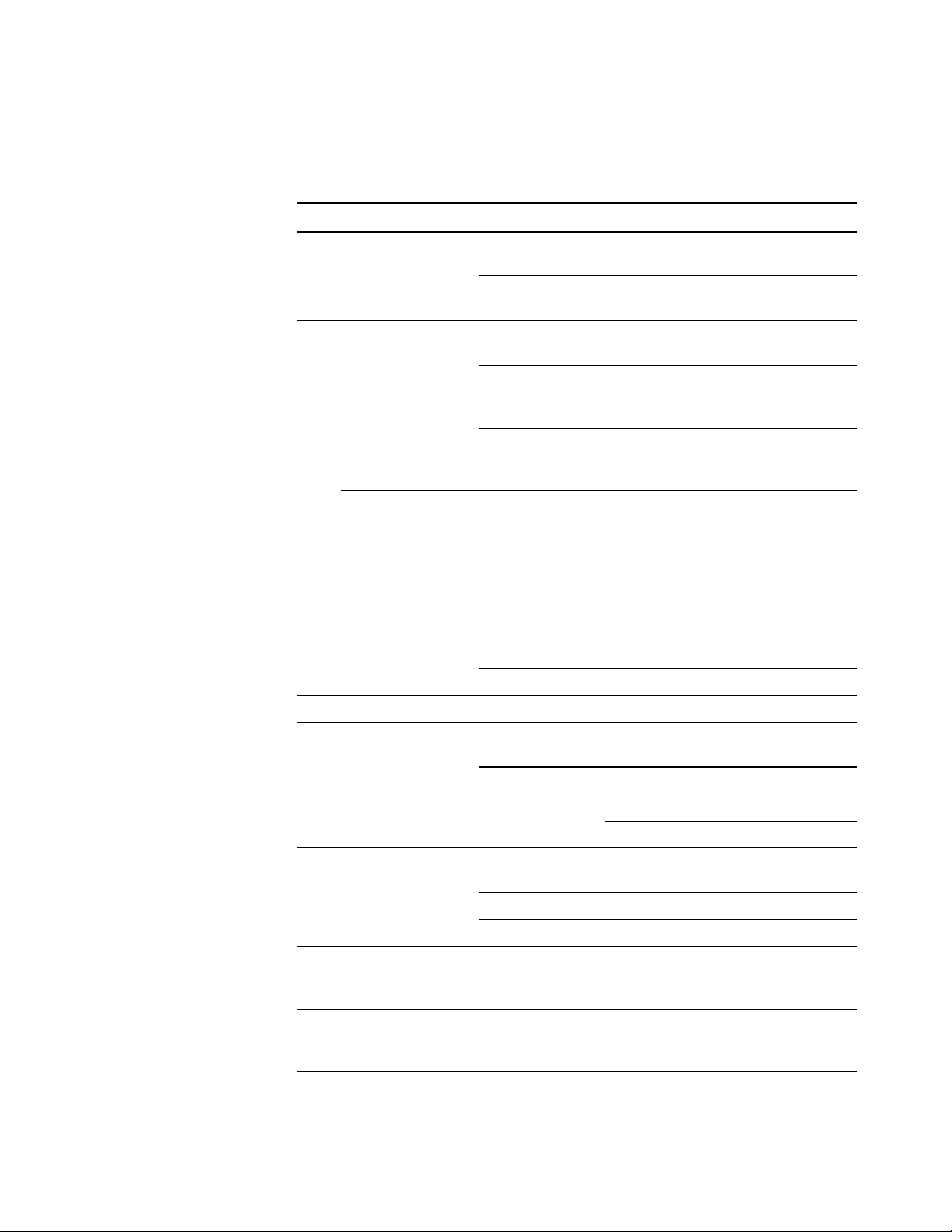

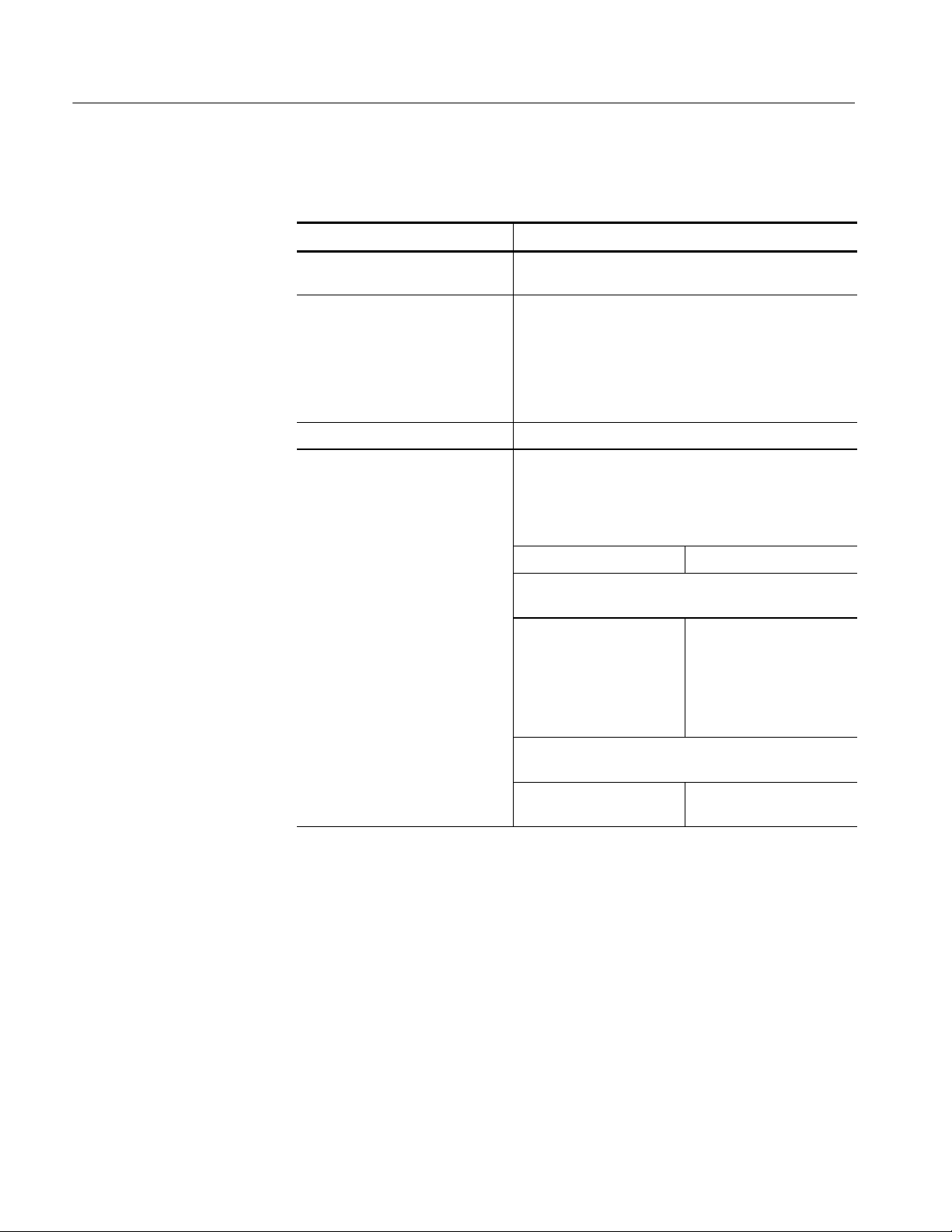

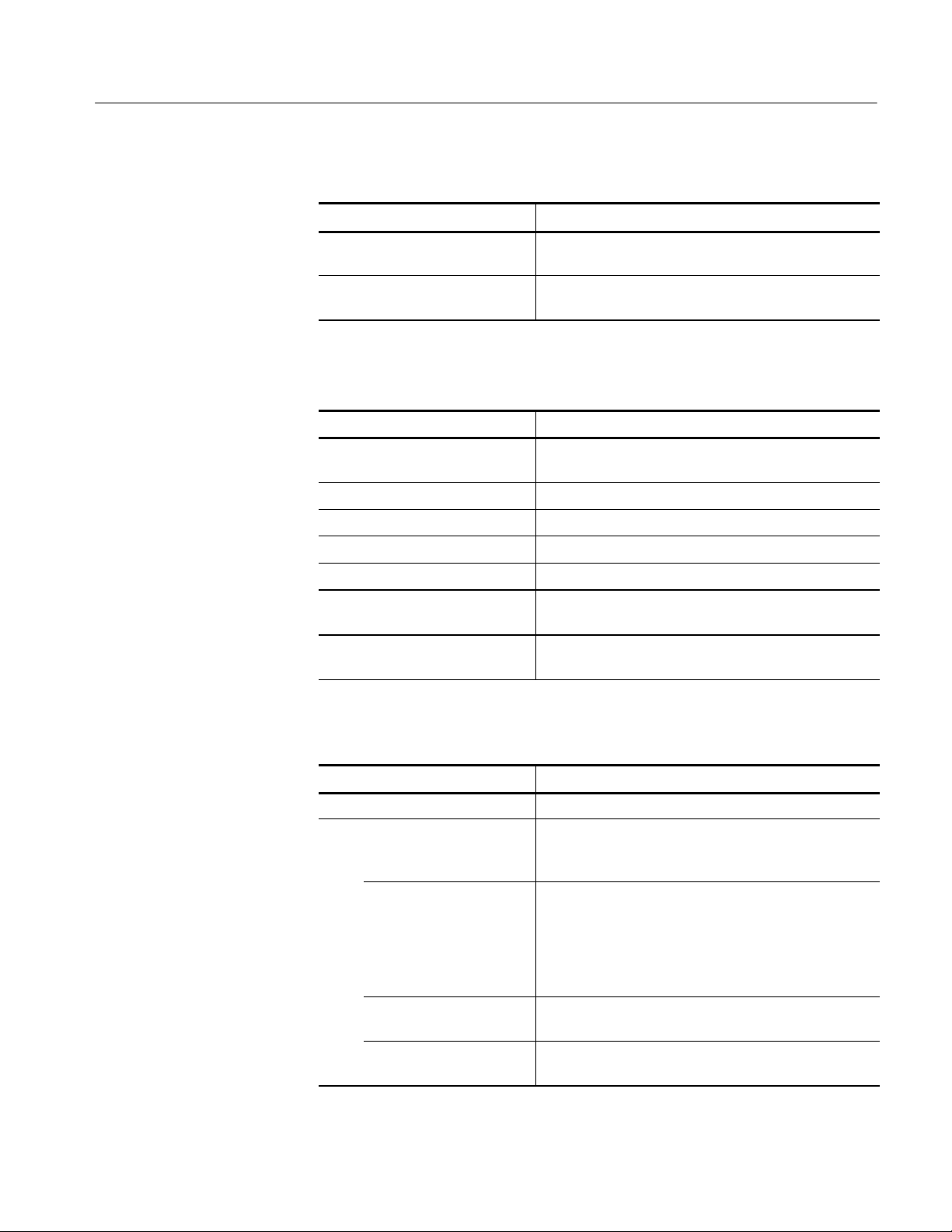

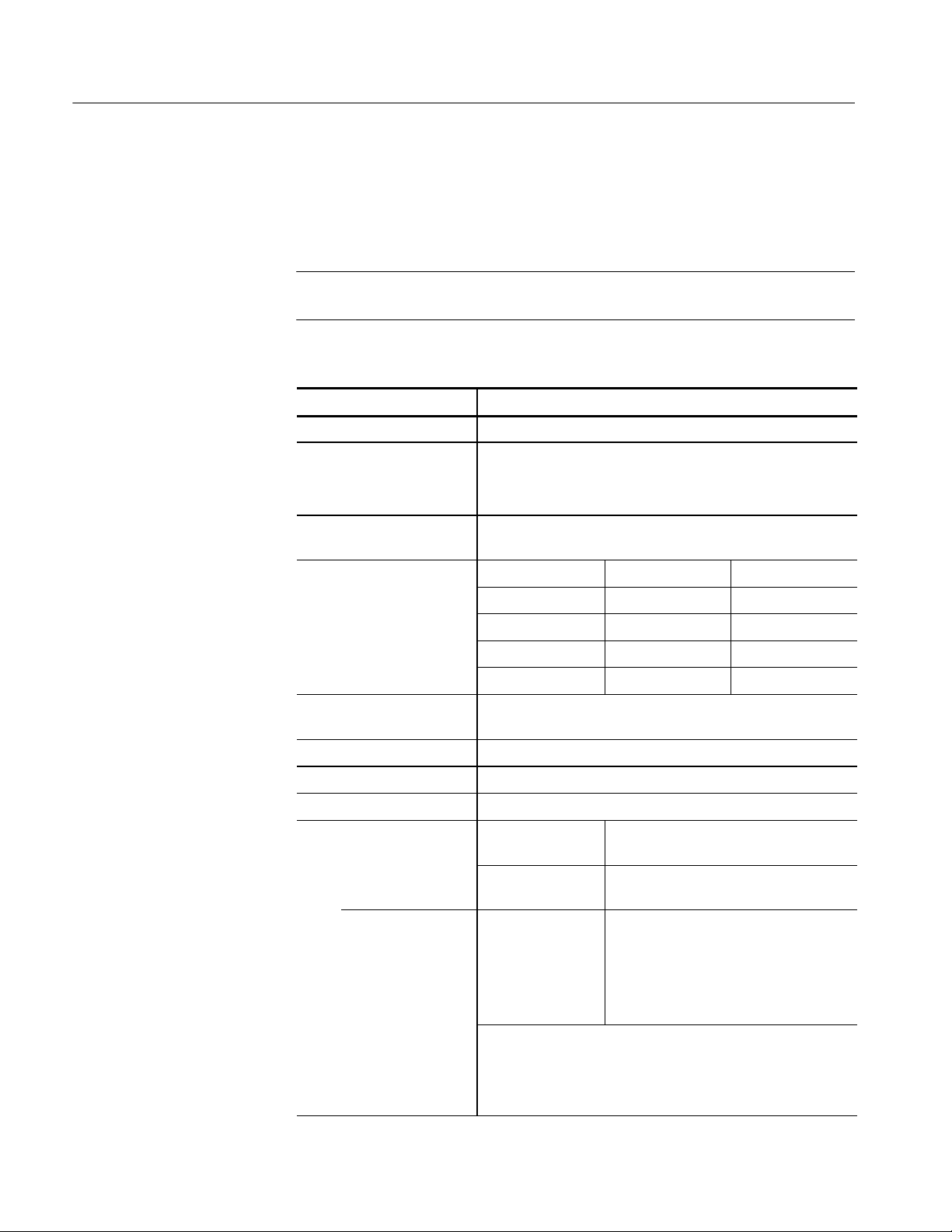

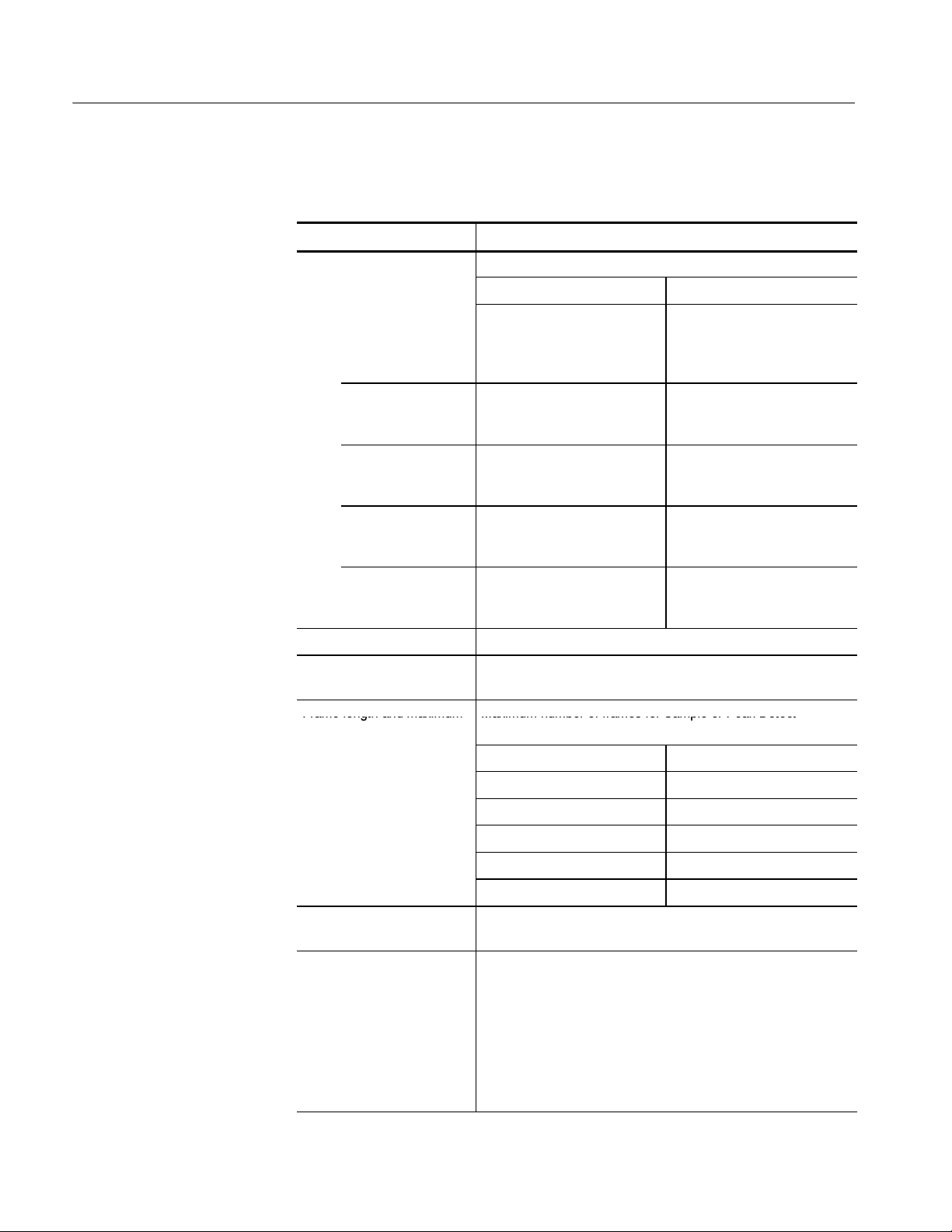

Table 1- 2: Environmental specifications

Characteristic Description

Temperature:

Operating: TDS6000B +5 °Cto+40°C(41°F to +104 °F), excluding media

Operating: TDS6000C +10 °Cto+45°C(50°Fto+113°F)

Nonoperating -- 2 2 °Cto+60°C(8°F to +140 °F)

Humidity, Operating 20% to 80% relative humidity with a maximum wet bulb

Nonoperating 5% to 90% relative humidity with a maximum wet bulb

Altitude, Operating 3,048 m (10,000 ft)

temperature of +29 °C(+84°F) at or below +50 °C

(+122 °F), noncondensing

Upper limit derated to 25% relative humidity at +50 °C

(+122 °F)

temperature of +29 °C(+84°F) at or below +60 °C

( +140 °F), noncondensing

Upper limit derated to 20% relative humidity at +60 °C

( +140 °F)

1- 4

Nonoperating 12,190 m (40,000 ft)

Random vibration, Operating 0.27 g

3 axes, 30 minutes total, with CD-RW installed

Nonoperating 2.28 g

30 minutes total, 3 axes

from 5 Hz to 500 Hz, 10 minutes on each axis,

RMS

from 5 Hz to 500 Hz, 10 minutes on each axis,

RMS

TDS6000B & TDS6000C Series Specifications and Performance Verification

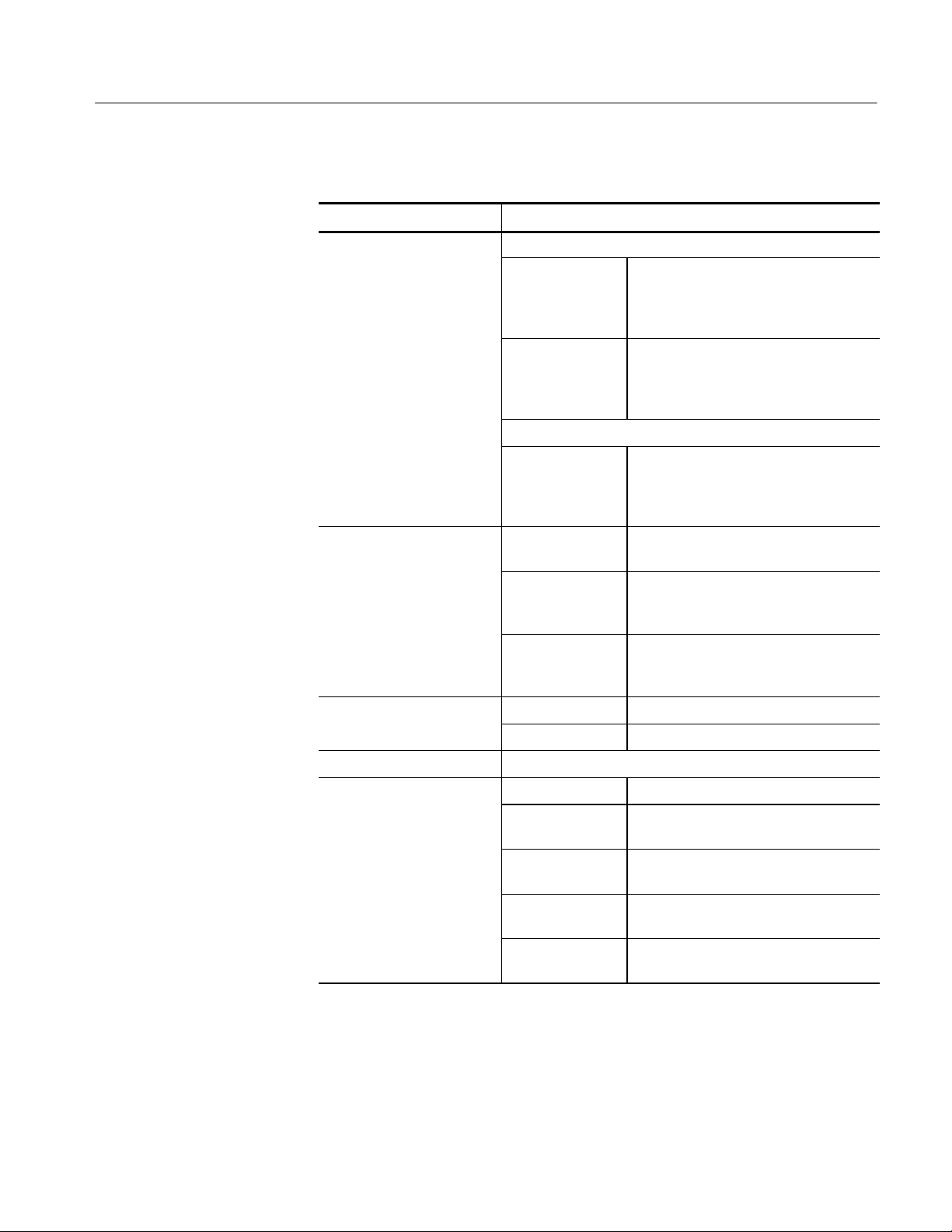

Certifications and Compliances

Specifications

EC Declaration of

Conformity - EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326. EMC requirements for Class A electrical equipment for measurement,

control, and laboratory use. Annex D.

123

H IEC 61000--4--2. Electrostatic discharge immunity

H IEC 61000--4--3. RF electromagnetic field immunity

H IEC 61000--4--4. Electrical fast transient / burst immunity

H IEC 61000--4--5. Power line surge immunity

H IEC 61000--4--6. Conducted RF Immunity

H IEC 61000--4--11. Voltage dips and interruptions immunity

EN 61000- 3- 2. AC power line harmonic emissions

EN 61000- 3- 3. Voltage changes, fluctuations, and flicker

1

Radiated emissions may exceed the levels specified in EN 61326 when this instrument is

connected to a test object.

Australia / New Zealand

Declaration of Conformity

-EMC

2

Performance criteria for when the oscilloscope is subjected to the continuously present

electromagnetic phenomenon:

10 mV/division to 1 V/division: .0.4 division waveform displacement or .0.8 division

increase in peak- to- peak noise

Performance criteria for when the oscilloscope is subjected to transient electromagnetic

phenomenon:

Temporary, self- recoverable degradation or loss of performance is allowed, but no change

of actual operating state or loss of stored data is allowed.

3

If interconnect cables are used, they must be low- EMI shielded cables such as the

following Tektronix part numbers or their equivalents: 012- 0991- 01, 012- 0991- 02 or

012- 0991- 03 GPIB Cable; 012- 1213- 00 (or CA part number 0294- 9) RS- 232 Cable;

012- 1214- 00 Centronics Cable; or LCOM part number CTL3VGAMM- 5 VGA Cable.

Complies with EMC provision of Radiocommunications Act per these standard(s):

H AS/NZS 2064.1/2. Industrial, Scientific, and Medical Equipment: 1992

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 5

Specifications

EC Declaration of

Conformity - Low Voltage

U.S. Nationally

Recognized Testing

Laboratory Listing

Canadian Certification

Additional Compliance

Equipment Type

Safety Class

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC.

H EN 61010-1:2001. Safety requirements for electrical equipment for

measurement control and laboratory use.

H UL 61010B--1:2004, 2nd Edition. Standard for electrical measuring and test

equipment.

H CAN/CSA C22.2 No. 61010--1--04. Safety requirements for electrical

equipment for measurement, control, and laboratory use. Part 1.

H IEC 61010--1:2001. Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Test and measuring equipment.

Class 1 -- grounded product

Pollution Degree

Descriptions

Pollution Degree

A measure of the contaminates that could occur in the environment around and

within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

H Pollution Degree 1. No pollution or only dry, nonconductive pollution

occurs. Products in this category are generally encapsulated, hermetically

sealed, or located in clean rooms.

H Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

H Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

H Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

1- 6

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Installation (Overvoltage)

Category Descriptions

Terminals on this product may have different installation (overvoltage) category

designations. The installation categories are:

H Measurement Category IV. For measurements performed at the source of

low-voltage installation.

H Measurement Category III. For measurements performed in the building

installation.

H Measurement Category II. For measurements performed on circuits directly

connected to the low-voltage installation.

H Measurement Category I. For measurements performed on circuits not

directly connected to MAINS.

Overvoltage Category

Overvoltage Category II (as defined in IEC 61010-1)

TDS6000B Series Specification Tables

The specifications for the TDS6000C Series oscilloscopes begin on page 1--22.

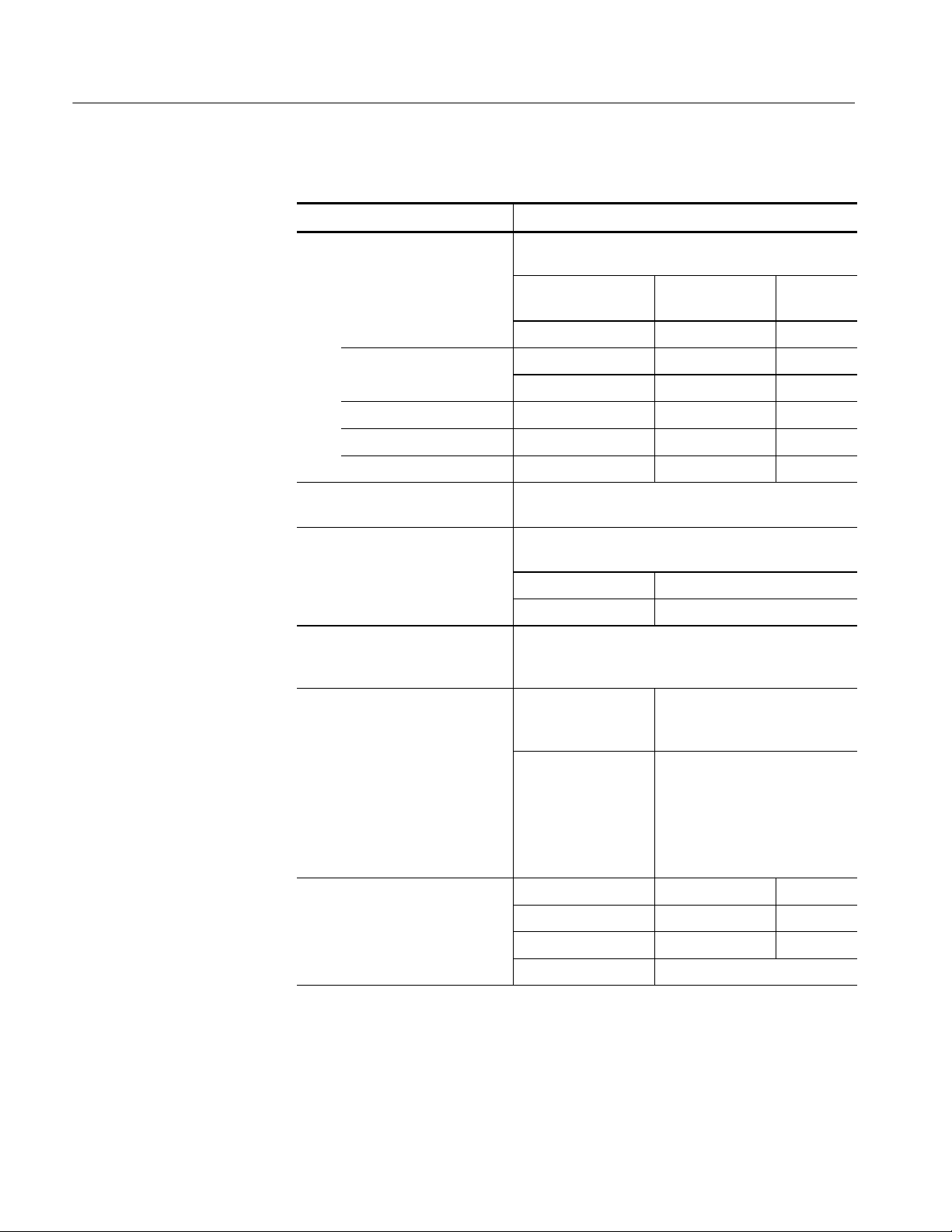

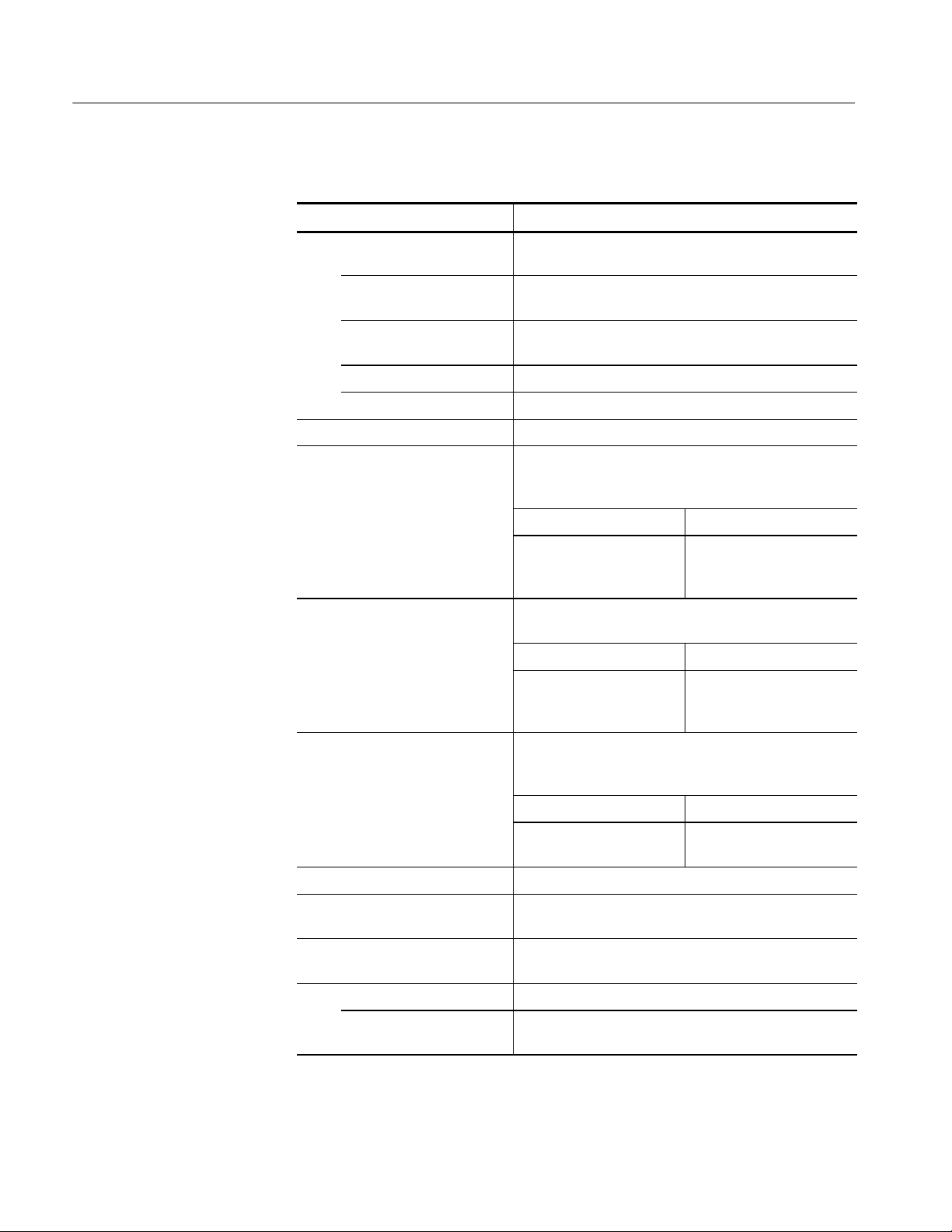

Table 1- 3: TDS6000B Series channel input and vertical specifications

Characteristic Description

Input channels Four

Input coupling DC 50 Ω and GND

Channel input is disconnected from input termination when

using GND coupling.

n Input impedance, DC

coupled

Maximum voltage at input <1 V

Number of digitized bits 8bits

Sensitivity range 10 mV/div to 1 V/division, in a 1-2-5 sequence

50 Ω ±2.5% at 25 _C(77_F), ±0.2% over 0 _Cto

40 _C(32_F to 104 _F)

for <100 mV settings

RMS

≤5V

for ≥100 mV settings

RMS

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 7

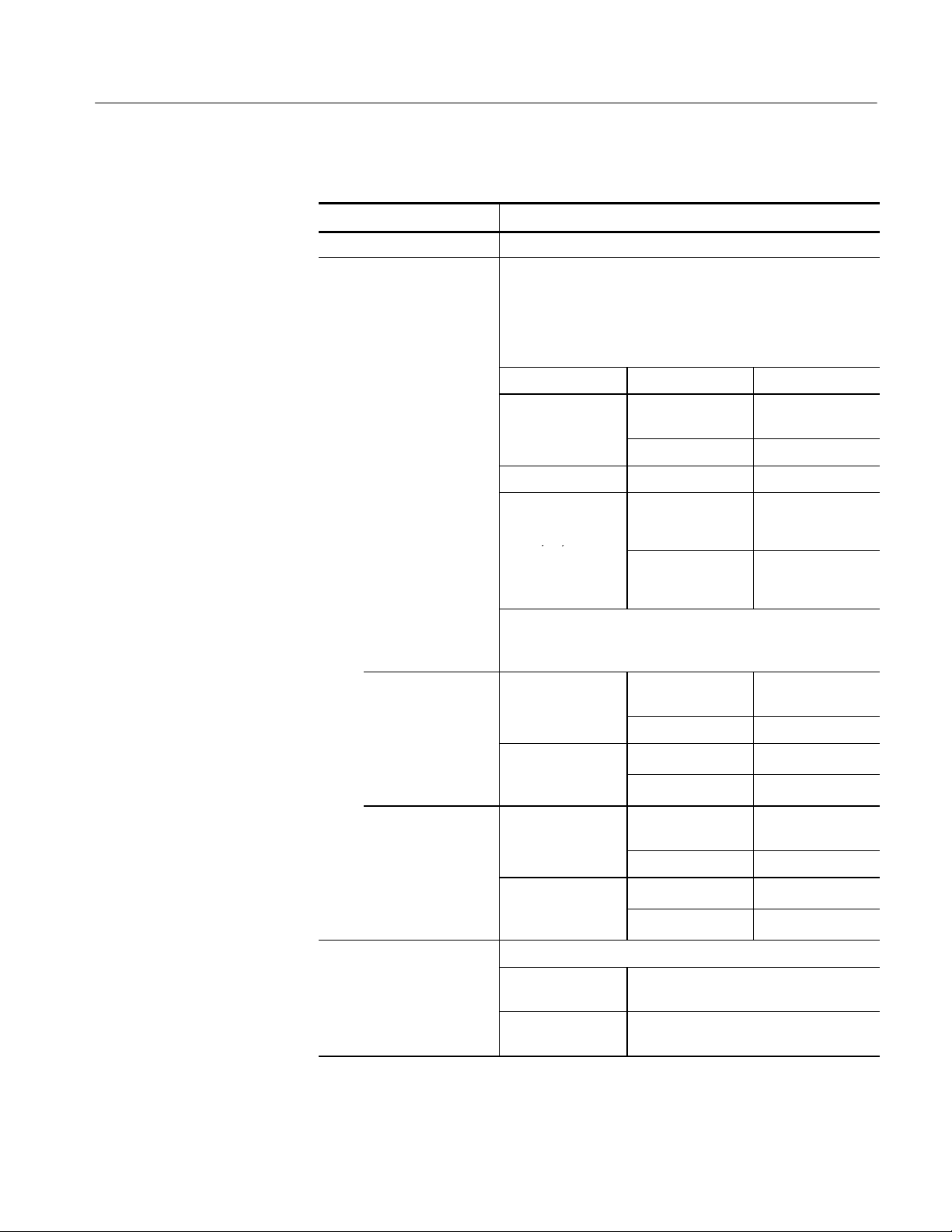

Specifications

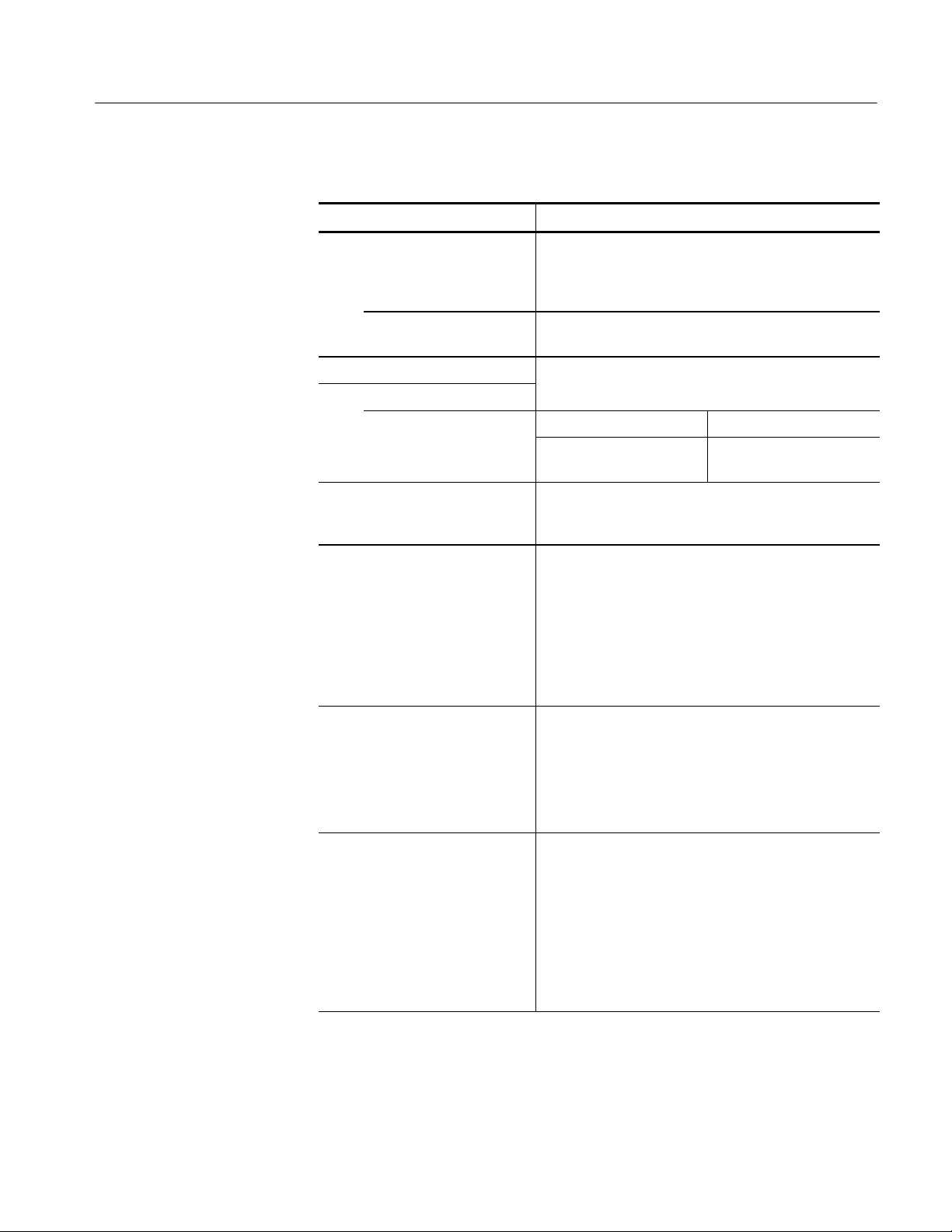

Table 1- 3: TDS6000B Series channel input and vertical specifications (Cont .)

Characteristic Description

n DC gain accuracy 10 mV/div to 99.5

mV/div

±(2.5% + | 2% × (net offset/1 V) | )

100 mV/div to 1

V/div

n DC voltage measurement

accuracy

Average acquisition

mode (≥16 averages)

Delta voltage be-

tween any two aver-

ages of ≥16 wave-

forms acquired under

the same setup and

ambient conditions

Nonlinearity, typical < 1 DL, differential; ≤ 2 DL integral, independent ly based

n Analog bandwidth DC 50 Ω coupling, with amplitude tolerance of --3dB operating

Measurement type DC accuracy (in volts)

10 mV/div to

99.5 mV/div

100 mV/div to

1V/div

10 mV/div to 99.5

mV/div

100 mV/div to

1V/div

where, net offset = offset -- ( position × volts/division)

temperatures of 15 °Cto40°C(59°F to 104 °F) inclusive.

±(2.5% + | 2% × (net offset/10 V) | )

±[(2.5% + | 2% × (net offset/1 V) | ) × |

reading -- net offset | + offset accuracy

+ 0.08 division × V/division]

±[(2.5% + | 2% × (net offset/10 V) | ) ×

| reading -- net offset | + offset accuracy

+ 0.08 division × V/division]

±((2.5% + | 2% × (net offset/1 V) | )×

| reading | + 0.16 division × V/division

setting)

±((2.5% + | 2% × (net offset/10 V) | ) ×

| reading | + 0.16 division × V/division

setting)

1- 8

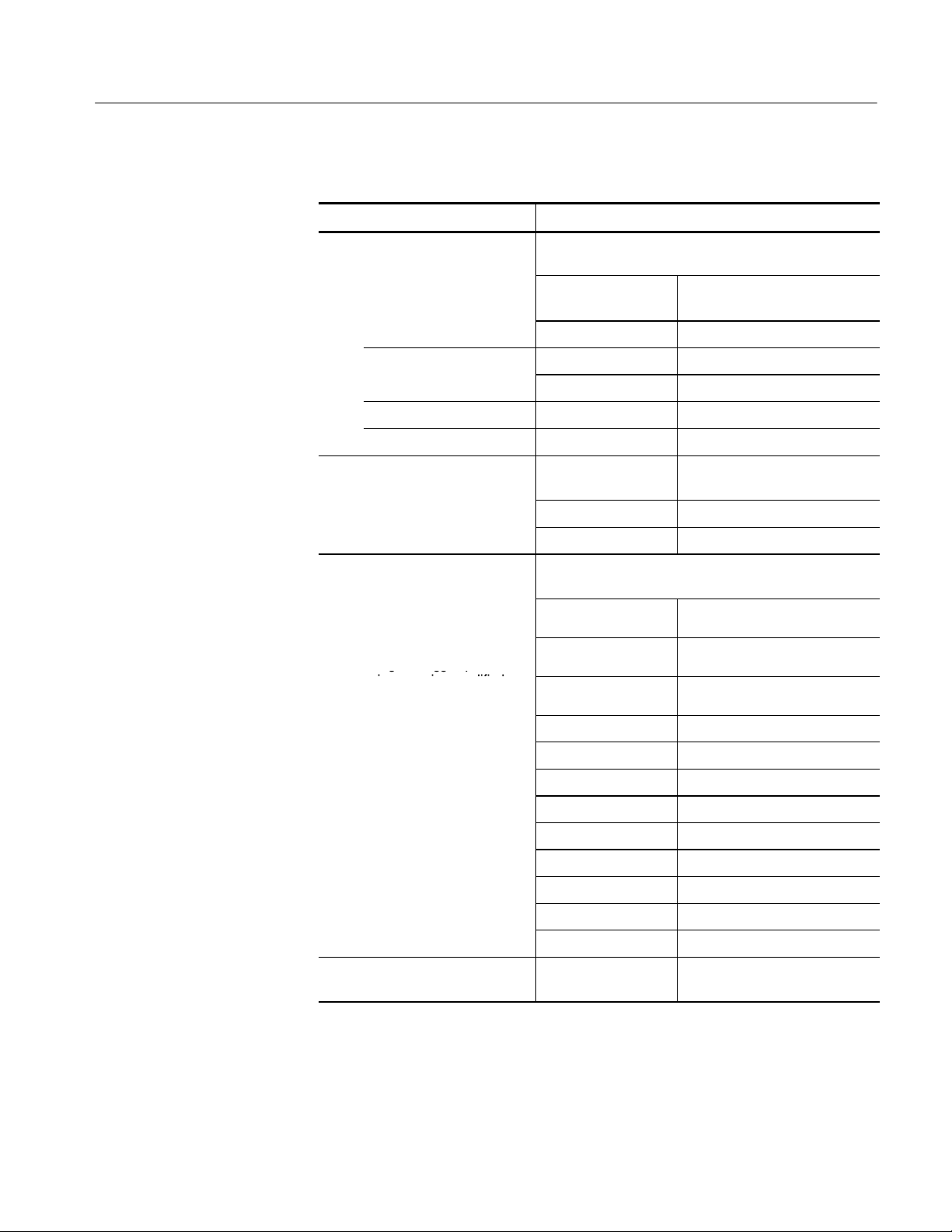

SCALE range Bandwidth

≥10 mV/div TDS6604B DC to ≥6GHz

TDS6804B DC to ≥7GHz

n Digitally enhanced bandwidth, DC coupled

Analog bandwidth with

P7380 or TCA-SMA adapter

for TDS6604B

Analog bandwidth with

P7380 or TCA-SMA adapter

for TDS6804B

DC 50 Ω coupling, with amplitude tolerance of --3dB operating

temperatures of 15 °Cto40°C(59°F to 104 °F).

SCALE range Bandwidth

≥10 mV/div TDS6804B DC to ≥8GHz

Full bandwidth, operating ambient 15 °Cto30°C(59°Fto

86 °F), derated by 20 MHz/ °C above 30 °C(86°F)

7 GHz, operating ambient 15 °Cto30°C(59°Fto86°F),

derated by 20 MHz/ °C above 30 °C(86°F)

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 3: TDS6000B Series channel input and vertical specifications (Cont .)

Characteristic Description

Rise time, typical No digital bandwidth enhancement

TDS6604B 10 -- 90% rise time is 70 ps vertical

sensitivities ≥ 10 mV/div

20 -- 80% rise time is 53 ps vertical

sensitivities ≥ 10 mV/div

TDS6804B 10 -- 90% rise time is 62 ps vertical

sensitivities ≥ 10 mV/div

20 -- 80% rise time is 43 ps vertical

sensitivities ≥ 10 mV/div

Digital bandwidth enhancement

TDS6804B 10 -- 90% rise time is 50 ps vertical

sensitivities ≥ 10 mV/div

20 -- 80% rise time is 35 ps vertical

sensitivities ≥ 10 mV/div

Step response settling errors,

typical

Pulse response, peak detect

or envelope mode

Position range ± 5 divisions

Offset range SCALE range Offset range

SCALE range and

step amplitude

10 mV/div to

99.5 mV/div,

with ≤ 1.5 V step

100 mV/div to

1V/div,

with ≤ 3Vstep

Sample rate setting Minimum pulse width

20 GS/s or less

10 mV/div to 50

mV/div

50.5 mV/div to

99.5 mV/div

100 mV/div to

500 mV/div

505 mV/div to

1V/div

Settling error at time after step

20 ns: ≤ 2%

1ms:≤ 0.1%

20 ns: ≤ 2%

1ms:≤ 0.2%

50 ps

±0.50 V

±0.25 V

±5V

±2.5 V

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 9

Specifications

Table 1- 3: TDS6000B Series channel input and vertical specifications (Cont .)

Characteristic Description

n Offset accuracy Volts/div setting Offset accuracy

10 mV/div to

99.5 V/div

100 mV/div to

1V/div

where, net offset = offset -- (position × volts/division)

Effective bits, typical Effective bits for 9 div peak--to--peak sine wave input sampled

at 50 mV/division and 20 GS/s.

Input frequency Effective bits

10 MHz 5.7 bits

1GHz 5.5 bits

1.5 GHz 5.4 bits

2GHz 5.2 bits

2.5 GHz 5.0 bits

3GHz 4.9 bits

4GHz 4.5 bits

5GHz 3.7 bits

6GHz 3.5 bits

6.5 GHz 3.0 bits

±(0.7% ×| net offset | + 1.5 mV + 0.1 div

× V/div setting)

±(0.8% ×| net offset | + 15 mV + 0.1 div

× V/div setting)

1- 10

7GHz 2.5 bits

n Delay between channels ≤30 ps between any two channels with the sam e scale and

coupling settings

n Channel-to-channel crosstalk

≥15:1 at rated bandwidth, and ≥80:1 at ≤1.5 GHz or the rated

bandwidth, whichever is less. Assumes two channels with the

same scale settings

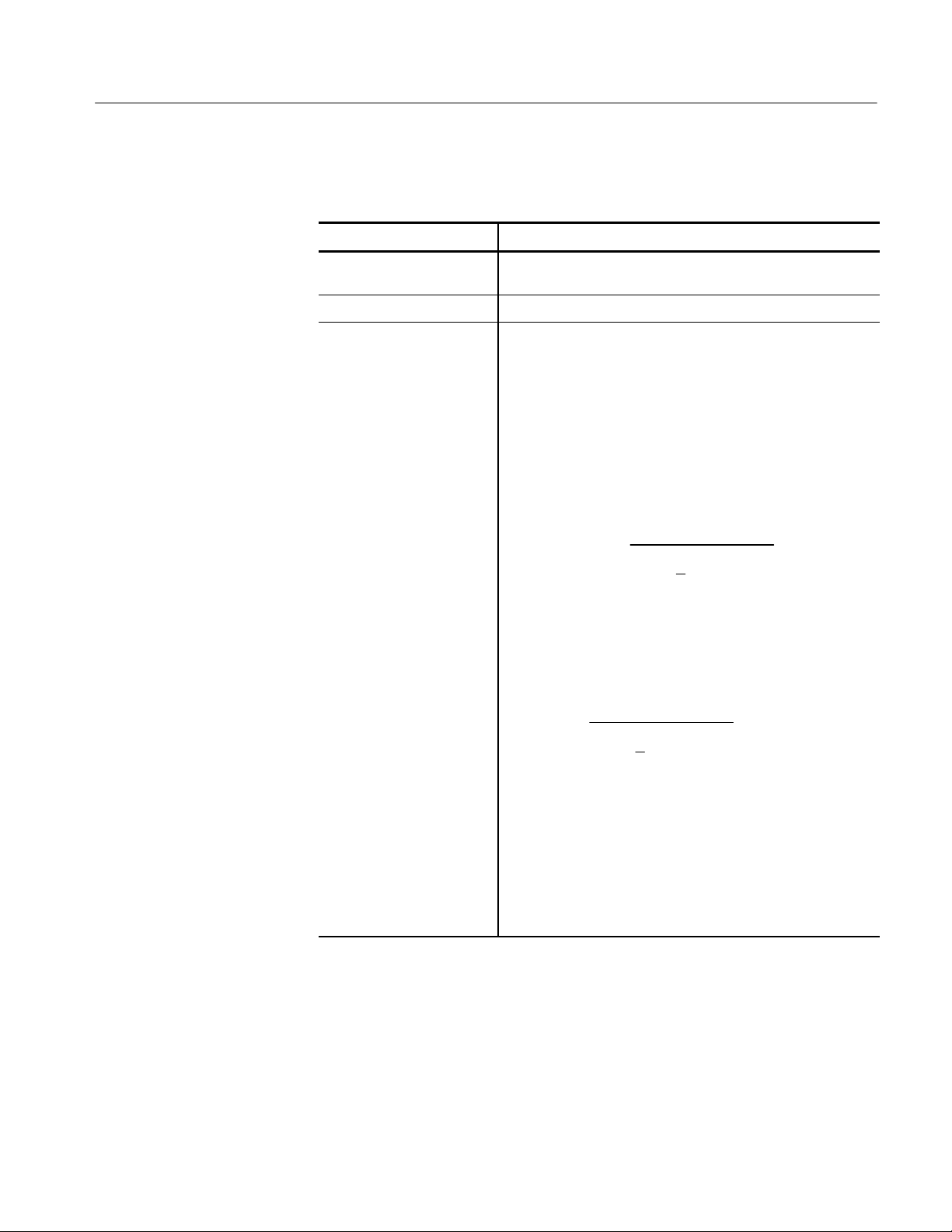

Table 1- 4: TDS6000B Series horizontal and acquisition system

specifications

Characteristic Description

Real-time sample rate range Number of channels

acquired

1, 2, 3, or 4 1.25 S/s to 500 MS/s in a

Sample rate range

1-2.5-5 sequence, followed

by 1.25 GS/s, 2.5 GS/s,

5G S/s, 10 GS/s, 20 GS/s

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Framelengthandmaximum

MaximumnumberofframesforSampleorPeakDetec

t

Table 1- 4: TDS6000B Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

Equivalent-time sample rate or

interpolated waveform rate range

Acquisition modes Sample, Peak Detect, Hi Res, Average, and Envelope

Record length Maximum record length supported by acquisition

Sample mode 1, 2, 3, or 4 32,000,000

10 GS/s, 12.5 GS/s, 20 GS/s, 25 GS/s, 40 GS/s,

50 GS/s, 62.5 GS/s, 80 GS/s, 100 GS/s, 125 GS/s,

160 GS/s, 200 GS/s, 250 GS/s, 312.5 GS/s, 320 GS/s,

400 GS/s, 500 GS/s, 625 GS/s, 800 GS/s, 1 TS/ s, 2 T S/s

hardware, at any sample rate

Channels Record length

Hi Res mode, ≤1.25 GS/s

sample rate

Seconds/division range 40 s/div to 25 ps/div

Maximum FastFrame update rate,

nominal

Frame length and maximum Maximum number of frames for Sample or Peak Detect

number of frames

1, 2, 3, or 4 2,000,000

310,000 frames per second

acquisition mode, depending on memory option installed

Frame length Maximum number of

frames

50 points Standard: 7008

Option 2M: 28552

Option 3M: 57280

Option 4M: 114736

250 points Standard: 4160

Option 2M: 16944

Option 3M: 33992

Option 4M: 68096

500 points Standard: 2752

Option 2M: 11232

Option 3M: 22536

Option 4M: 45152

2000 points Standard: 912

Option 2M: 3712

Option 3M: 7456

Option 4M: 14944

5000 points Standard: 384

Option 2M: 1584

Option 3M: 3184

Option 4M: 6384

n Internal time-base reference

frequency

TDS6000B & TDS6000C Series Specifications and Performance Verification

10 MHz ±2.5 ppm over any ≥100 ms interval.

Aging <1 ppm per year.

1- 11

Specifications

Table 1- 4: TDS6000B Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

n Long term sample rate and

delay time accuracy

Aperture uncertainty, typical Short term:

Time base delay time range ≤0nsto250s

±2.5 ppm over any ≥100 ms interval

≤1.5 ps RMS, records having duration ≤100 ms

≤800 fs RMS, records having duration ≤10 s

Long term:

≤15 parts-per-trillion RMS, records having duration

≤1 minute

n Delta time measurement accuracy

For a single channel, with signal amplitude >5 divisions,

reference level set at 50%, interpolation set to sin(x)/x,

volts/division set to ≥ 5 mV/div, with risetime >1.4 x T

and <4 x Tsor 150 ps (whichever is greater) and acquired

≥10 mV/Div, where T

Conditions Accuracy

Single shot signal, sample acquisition mode, Full

bandwidth

70 to 200 ps at 20 GS/s.

140 to 400 ps at 10 GS/s.

280 to 800 ps at 5 GS/s.

>100 averages, Full bandwidth selected (real or

equivalent time)

70 to 200 ps ± (4 ps + 2.5 ppm ×

is the sample period.

s

(0.06/sample rate +

2.5 ppm × | reading | ) RMS

± (0.3/sample rate +

2.5 ppm × | reading |) peak

| reading | )

s

1- 12

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 5: TDS6000B Series trigger specifications

Characteristic Description

Trigger jitter, typical 1.5 ps RMS for low frequency fast rise time signal.

n Edge Trigger Sensitivity, DC

coupled

Edge trigger sensitivity, typical All sources, for vertical scale settings ≥10 mV/div and

All sources, for vertical scale settings ≥10 mV/div and

≤1V/div

Trigger Source Sensitivity

Main trigger, Ch1 -Ch4

Delayed trigger, Ch1 -Ch4

Auxiliary input 200 mV from DC to 50 MHz,

≤1V/div

Trigger coupling Sensitivity

NOISE REJ 3x the DC-coupled limits for

AC Same as DC-coupled limits for

≤0.5 div DC to 50 MHz

≤1 div at 1.5 GHz

≤1.5 div at 3 GHz

≤2.5 div at 7 GHz (TDS6804B)

≤2.5 div at 6 GHz (TDS6604B)

≤0.5 div from DC to 50 MHz

≤1 div at 1.5 GHz

≤1.5 div at 3 GHz

≤2.5 div at 7 GHz (TDS6804B)

≤2.5 div at 6 GHz (TDS6604B)

increasing to 500 mV at 2 GHz

frequencies < 5 GHz

frequencies >100 Hz, attenuates

signals <100 Hz

HF REJ Same as DC coupled limits for

LF REJ Same as DC coupled limits for

Auxiliary trigger input resistance

and range, typical

Lowest frequency for Set Level to

50%, typical

Logic-type trigger sensitivity, typical Logic type triggers: 1.0 div, from DC to 1 GHz

50 Ω, ±5 V (DC + peak AC)

50 Hz

Runt type: 1.0 div

TDS6000B & TDS6000C Series Specifications and Performance Verification

frequencies <20 kHz, attenuates

signals >20 kHz

frequencies >200 kHz, attenuates signals <200 kHz

1- 13

Specifications

Table 1- 5: TDS6000B Series trigger specifications (Cont.)

Characteristic Description

Logic-qualified pulse-type trigger

minimum timing requirements

For vertical scale settings ≥10 mV/div and ≤1 V/div at the

TekConnect input.

Minimum logic qualifying event duration

Glitch type 100 ps 40 ps 60 ps

Runt type Runt width + 150 ps 160 ps --16 ps

Time-qualified runt type Runt width + 330 ps 160 ps 175 ps

Width type 190 ps 40 ps 175 ps

Transition type 330 ps 225 ps 175 ps

Window 190 ps --20 ps 0ps

Transition trigger, delta time

range

Events delay triggering, minimum

timing requirements, typical

Setup/Hold hold time violation

trigger, minimum clock pulse

widths, typical

1nsto1s

Minimum requirements for vertical settings from 10

mV/div to 1 V/div at the TekConnect input

Pulse width Time between channels

150 ps 1ns

For vertical settings from 10 mV/div to 1V/div at the

TekConnect input, the minimums are:

Minimum time from

active clock edge to

inactive edge

Set up time Hold time

Minimum time from inactive

clock edge to active edge

1- 14

Setup/Hold hold time violation

trigger, Setup/Hold time ranges

User’s hold time

+ 500 ps for hold

times ≥0.

User’s hold time

+ 1.5 ns for hold times

<0.

Setup time

Hold time -- 1 n s 102 ns

Setup + Hold time 500 ps

500 ps

Minimum Maximum

--100 ns 100 ns

TDS6000B & TDS6000C Series Specifications and Performance Verification

Table 1- 5: TDS6000B Series trigger specifications (Cont.)

ang

mumtimerangetowhich

ggg,p

Characteristic Description

Pulse-type trigger minimum timing

requirements

For vertical scale settings ≥10 mV/div and ≤1 V/div at the

TekConnect input

Specifications

Minimum pulse width

or transition time

Glitch type 170 ps 250 ps

Runt type 225 ps 250 ps

Time-qualified runt type 360 ps 450 ps

Width type 225 ps 250 ps

Transition type 225 ps 300 ps

n Timing accuracy for time-qualified triggers

Time range for time-qualified

triggers

The minimum to the maximum time r

the instrument can be set

for glitch trigger, pulse

trigger, or time-qualified

runt trigger.

etowhich

Time range Accuracy

360 ps to 1.5 s ± 10% of setting

1.51 sto1s ± 100 ns

500 ps to 1 s

Time range

500 ps to 950 ps 20 ps

1nsto10ns 200 ps

10.5nsto20ns 500 ps

Minimum rearm time

Time resolution

21 ns to 50 ns 1ns

52 ns to 100 ns 2ns

104 ns to 200 ns 4ns

210 ns to 500 ns 10 ns

520 ns to 2 s 20 ns

2.01 sto10ms 16 ns

10 ms to 100 ms 160 ns

100 ms to 1 s 2 s

Delayed Trigger time delay range Delay time = 5 ns to

250 s

TDS6000B & TDS6000C Series Specifications and Performance Verification

Event count = 1 to 10,000,000

1- 15

Specifications

Table 1- 5: TDS6000B Series trigger specifications (Cont.)

Characteristic Description

Trigger level or threshold range Trigger Source Sensitivity

Any channel ±12 divisions from center of

screen

Auxiliary trigger input ±5V

Line trigger ±0 V, not settable

Trigger level or threshold accuracy,

typical

Trigger position error, typical Edge trigger, DC coupling, for signals having a slew rate

Trigger holdoff range 250 ns to 12 s, maximum plus random holdoff

Edge trigger, DC coupling, for signals having rise and fall

times >1 ns

Trigger Source Accuracy

Any channel ± [(2% ×| setting -- net offset | )

+ (0.35 div × volts/div setting) +

offset accuracy]

Auxiliary Not specified

where, net offset = offset -- (position × volts/division)

at the trigger point of ≥ 0.5 division/ns

Acquisition mode Error

Sample, Average ± (1 waveform interval + 200 ps)

Peak Detect, Envelope

± (2 waveform interval + 200 ps)

Table 1- 6: TDS6000B Series serial trigger specifications (optional)

Characteristic Description

Serial trigger number of bits 64

1- 16

Serial trigger encoding types NRZ

n Serial trigger baud rate limits Up to 1.25 GBd

n Clock recovery frequency range 1.5 MBd to 3.125 GBd. Above 1250 MHz the clock is only

available internally as a trigger source. Below 1250 MHz

the clock is also available at the Recovered Clock output

along with regenerated data.

n Clock recovery jitter (RMS) <0.25% bit period + 7 ps RMS for PRBS data patterns.

<0.25% bit period + 6 ps RMS for repeating 0011 data

patterns.

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 6: TDS6000B Series serial trigger specifications (optional) (Cont.)

Characteristic Description

Clock recovery tracking/acquisition

range

± 5% of requested baud.

Minimum signal amplitude needed

for clock recovery, typical

1 division p-p up to 1.25 GBd

1.5 divisions p-p above 1.25 GBd

Table 1- 7: TDS6000B Series display specifications

Characteristic Description

Display type 210.4 mm (8.3 in) (W)× 157.8 mm (6.2 in) (H), 263 mm

(10.4 in) diagonal, liquid crystal active-matrix color display

Display resolution 1024 horizontal × 768 vertical pixels

Pixel pitch 0.2055 mm horizontal, 0.2055 mm vertical

Response time, typical 15 ms, white to black

Display refresh rate 59.94 frames per second

Viewing angle, typical Horizontal: 60 degrees left, 60 degrees right

Vertical: 45 degrees up, 60 degrees down

Displayed intensity levels Each RGB input is 6 bits, giving 64 intensity levels of

each color component

Table 1- 8: TDS6000B Series input/output port specifications

Characteristic Description

Rear-panel I/O ports Ports located on the rear panel

Video output port Upper video port, DB-15 female connector, connect a

second monitor to use dual-monitor display mode,

supports Basic requirements of PC99 specifications

Parallel port (IEEE 1284) DB-25 connector, supports the following modes:

S Standard (output only)

S Bidirectional (PS-2 compatible)

S Bidirectional enhanced parallel port (IEEE 1284

S Standard, mode 1 or mode 2, v 1.7)

S Bidirectional high-speed extended capabilities

Serial port DB-9 COM1 port, uses NS16C550-compatible UARTS,

transfer speeds up to 115.2 kb/s

Keyboard port PS-2 compatible, oscilloscope power must be off to make

connection

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 17

Specifications

Table 1- 8: TDS6000B Series input/output port specifications (Cont.)

Characteristic Description

Mouse port PS-2 compatible, oscilloscope power must be off to make

connection

LAN port RJ-45 connector, supports 10 base-T and 100 base-T and

gigabit ethernet

Audio ports Miniature phone jacks for stereo microphone input and

stereo line output

USB ports Four rear panel and one front panel USB 2.0 connectors

GPIB port IEEE 488.2 standard interface

XGA video port 15 pin D-subminiature connector on the rear panel

n DC Probe Cal Output Voltage,

Offset Voltage, and Frequency

Front-panel BNC connector for calibrating CD offset of

active probes. Signal is only present during the probe

calibration operation.

Output voltage Frequency

330 mV (from base to top)

1 kHz ± 5%

± 20% into a 50 Ω load

(Voh = 0 V, Vol = --330mV

Fast Edge Signal Output Voltage,

Offset Voltage, and Frequency

Front-panel SMA connector used as probe deskew signal

and as passive probe compensation signal

Output voltage Frequency

330 mV (from base to top)

1 kHz ± 5%

± 20% into a 50 Ω load

(Voh = 0 V, Vol = --330mV

n Auxiliary Output levels Front-panel BNC connector, provides a TTL-compatible

pulse (polarity selectable) for each A or B trigger

(selectable)

V

high V

out

≥2.5 V into open circuit,

≥1.0 V into 50 Ω load

low (true)

out

≤0.7 V with ≤4mAsink,

≤0.25 V into 50 Ω load

Auxiliary Output pulse width, typical Pulse width varies, 1 s minimum

n External Reference input

sensitivity

Vin ≥200 mV peak to peak for input frequencies between

9.8 MHz and 10.2 MHz

1- 18

External reference input frequency

range

Input voltage, maximum 7V

p-p

Input impedance 1.5 kΩ, Cin = 40 pF. Measure impedance at >100 kHz to

make the blocking capacitor invisible.

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 8: TDS6000B Series input/output port specifications (Cont.)

Characteristic Description

n External reference 9.8 MHz to 10.2 MHz. Run SPC whenever the external

reference is more than 2000 ppm different than the

internal reference or the reference at which SPC was last

run.

Input sensitivity ≥200 mV

for input frequencies between 9.8 MHz and

p-p

10.2 MHz

n Internal reference output

Frequency 10 MHz ±ኃ2.5 ppm over any ≥100 ms interval

Output voltage V

high V

out

≥2.5 V into open circuit

≥1.0 V into 50 Ω load

low (true)

out

≤0.7 V with ≤4mAsink

≤0.25 V into 50 Ω load

Serial data output baud rate range Fbd < 1250 MBd

Output swing of 1010 repeating pattern at this baud will

be at least 200 mV into 50 Ω.

Serial clock output frequency range Peak-to-peak output swing at 625 MHz is at least 200 mV

peak-to-peak into 50 Ω. Higher frequencies will be further

attenuated by approximately 6 dB per octave above

625 MHz (at 1250 MHz the amplitude will typically be

about 130 mV peak-to-peak into 50 Ω).

Either AC or DC coupled 50 Ω termination is allowed, but

with AC coupling the clock will provide 10% more

amplitude.

Serial data and clock output voltages, typical

Voh = --1.0 V, Vol = -- 1.7 V; assume load impedance

greater than 1 kΩ (50Ω source termination)

If a 50Ω or 75Ω load is used, either a DC blocking

capacitor must be put in series with the signal or the

termination must be referenced to approximately --1.3 V.

The signal amplitude will be correspondingly reduced.

Serial data output latency 15 ns (±4 ns) plus the following synchronous latency

depending on the data encoding:

35.5 clock cycles for NRZ, CMI, Manchester, and B-0-V

decoded data

36.5 clock cycles for NRZ1 decoded data

39.5 clock cycles for B3ZS decoded data

40.5 clock cycles for B4ZS decoded data

42.5 clock cycles for B6ZS decoded data

44.5 clock cycles for B8ZS decoded data

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 19

Specifications

Table 1- 9: TDS6000B Series data storage specifications

Characteristic Description

Nonvolatile memory retention time,

typical

CD-RW Front-panel CD-RW drive, read write

Hard disk Rear-panel, removeable hard disk drive (Front panel

≥5 years

location available via option FHD at time of order. Moves

CD-RW drive to rear. FHD not field retrofi table.) Capacity

will vary according to current market conditions.

Table 1- 10: TDS6000B Series power source specifications

Characteristic Description

Power consumption ≤500 Watts (650 VA)

Source voltage and frequency 100 to 240 V ±10%,50Hzto60Hz

115 V ±10%, 400 Hz

CAT II

Fuse rating Either one of the following sizes can be used, each size

requires a different fuse cap. Both fuses must be the

same type.

0.25 in x 1.25 in size UL198G and CSA C22.2, No. 59, fast acting: 8 A, 250 V

(Tektronix part number 159-0046-00, Bussman ABC-8,

Littelfuse 314008)

5 mm x 20 mm size IEC127, sheet 1, fast acting “F”, high breaking capacity:

6.3 A, 250 V (Bussman GDA 6.3, Littelfuse 21606.3)

Table 1- 11: TDS6000B Series mechanical specifications

Characteristic Description

Weight

Benchtop configuration 21 kg (47 lbs) without front cover, power cord, pouch

23 kg (50 lbs) with front cover, power cord, pouch

24 kg (53 lbs) packaged for shipment

Rackmount kit 22.4 kg (49 lbs) rackmounted instrument

5.6 kg (12.2 lbs) kit packaged for domestic shi pment

1- 20

TDS6000B & TDS6000C Series Specifications and Performance Verification

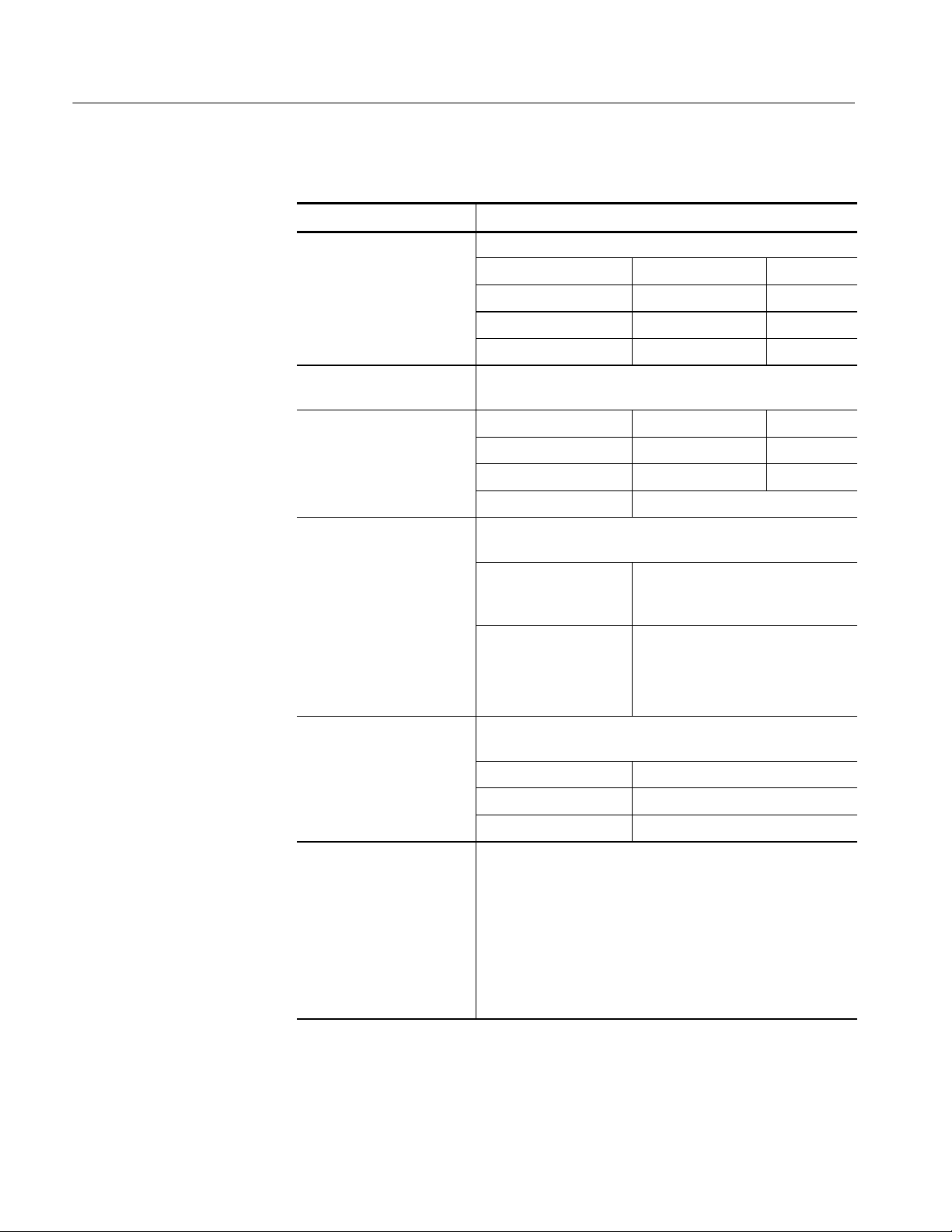

Table 1- 11: TDS6000B Series mechanical specifications (Cont.)

Characteristic Description

Dimensions

Benchtop configuration With front cover Without front cover

Specifications

278 mm (10.95 in) height,

456 mm (17.96 in) width

Rackmount configuration

(Option 1R)

Cooling Fan-forced air circulation with no air filter.

Required clearances To p 0mm(0in)

Construction material Chassis parts are constructed of aluminum alloy, front

With rack handles Without rack handles

267 mm (10.5 in) height

502 mm (19.75 in) width

642 mm (25.26 in) depth

Bottom 0 mm (0 in) when standing

Left side 76 mm (3 in)

Right side 76 mm (3 in)

Rear 0 mm (0 in) on rear feet

panel is constructed of plastic laminate, circuit boards are

constructed of glass laminate, outer shell is spray painted

finished.

277 mm (10.9 in) height,

456 mm (17.96 in) width

581 mm (22.85 in) depth

267 mm (10.5 in) height

482 mm (19 in) width

591 mm (23.26 in) depth

on feet, flip stands down

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 21

Specifications

A

ada

p

)

SMAadapter)

TDS6000C Series Specification Tables

The following tables contain the specifications for the TDS6000C Series

oscilloscopes.

NOTE. Some of the specifications use the V/FS (volts/full scale) notation. To

convert to the volts/division notation, divide the V/FS by 10.

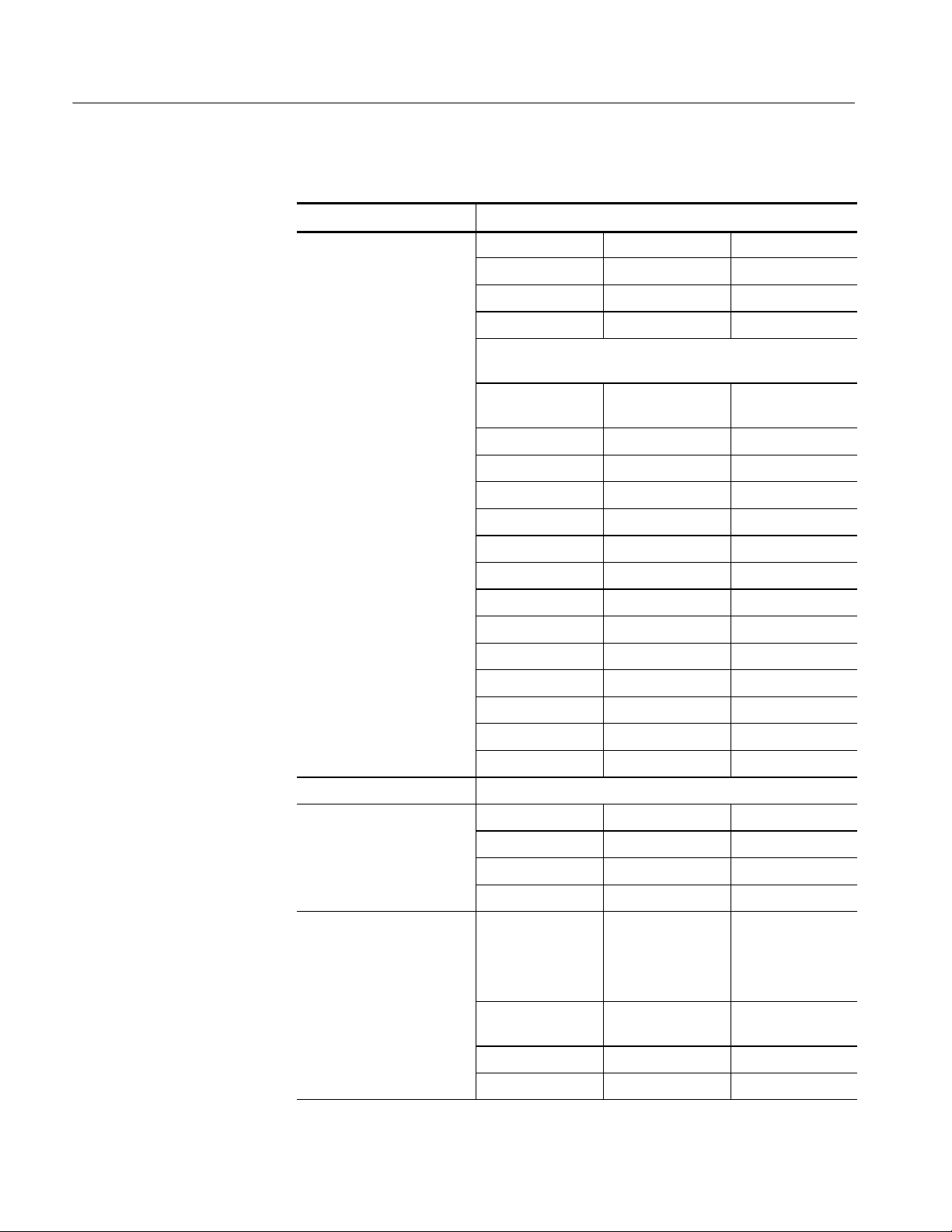

Table 1- 12: TDS6000C Series channel input and vertical specifications

Characteristic Description

Input channels Four

Input coupling DC 50 Ω and GND

Channel input is disconnected from input termination when

using GND coupling.

n Input impedance, DC

coupled

Input VSWR, typical

(Measured with TekConnect

SM

Maximum voltage at input <1 V

Number of digitized bits 8bits

Sensitivity range 50 mV/FS to 10 V/FS (below 100 mV/FS uses zoom)

n DC gain accuracy ±2%

n DC voltage measurement

accuracy

ter

Gain setting, ≥16

averages

Delta voltage between any two averages of ≥16 waveforms acquired under

the same setup and

ambient conditions

50 Ω ± 1.5% at 25 _C(77_F),

50 Ω ±2.0% 10 _Cto45_C(50_Fto113_F)

Input frequency VSWR <1 V/FS VSWR ≥1V/FS

<2.5 GHz 1.25 1.2

<6 GHz 1.5 1.2

<14 GHz 2.1 1.5

<15 GHz 2.5 1.5

for <1 V/FS settings

RMS

5.5 V

Measurement type DC accuracy (in volts)

100 mV/FS to

10 V/FS

100 mV/FS to

10 V/FS

for ≥1 V/FS settings

RMS

±[(2% × | reading -- net offset | + offset

accuracy + 0.008 × FS]

±[(2% × | reading | + 0.016 × FS]

Where, net offset = offset -- ( position × volts/division)

Net offset is defined as the vertical value of the center of the

digitizing range, usually in volts. With Zoom off, net offset is the

center of the waveform display.

1- 22

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

50/

,

Enh

anc

Enh

anc

Table 1- 12: TDS6000C Series channel input and vertical specifications (Cont .)

Characteristic Description

Nonlinearity, typical < 1 DL, differential; ≤ 2 DL integral, independently based

n Analog bandwidth DC 50 Ω coupling, with amplitude tolerance of --3dB operating

temperature of 25 °C(77°F) at all gain settings when

Bandwidth Enhancement is being used.

15 GHz bandwidth is achieved with Bandwidth Enhancement

and is available at 40 GS/s only.

SCALE range Model Bandwidth

Without Bandwidth

Enhancement

With Bandwidth

Enhancement

With P7313 probe,

typical

With P7380 probe,

typical

All TDS6124C DC to >12 GHz

TDS6154C DC to >12 GHz

SCALE range Model Bandwidth

10 mV/div,

20 mV/div,

50 mV/div,

100 mV/div,

200 mV/div,

500 mV/div

Tolerance of --3dB at 15 GHz guaranteed up to 30 _C(86_F),

above 30 _C(86_F) tolerance goes down by 0.08dB per

degree C.

Without Bandwidth

Enhancement,

-- 3 d B

With Bandwidth

ement,

-- 3 d B

Without Bandwidth

Enhancement,

-- 3 d B

TDS6124C DC to >12 GHz

TDS6154C DC to >15 GHz

TDS6124C DC to 11 GHz

TDS6154C DC to 11 GHz

TDS6124C DC to 11 GHz

TDS6154C DC to 12.5 GHz

TDS6124C DC to 8 GHz

TDS6154C DC to 8 GHz

With Bandwidth

ement,

-- 3 d B

Rise time, typical Without Bandwidth Enhancement

TDS6124C 10 to 90% rise time: 30 ps

TDS6154C 10 to 90% rise time: 30 ps

TDS6000B & TDS6000C Series Specifications and Performance Verification

TDS6124C DC to 8 GHz

TDS6154C DC to 8 GHz

20 to 80% rise time: 20 ps

20 to 80% rise time: 20 ps

1- 23

Specifications

Table 1- 12: TDS6000C Series Channel input and vertical specifications

Characteristic Description

With Bandwidth Enhancement

TDS6124C 10 to 90% rise time: 31 ps

20 to 80% rise time: 22 ps

TDS6154C 10 to 90% rise time: 25 ps

20 to 80% rise time: 18 ps

Step response settling errors Gain setting full

scale

TDS6124C and TDS6154C without Bandwidth Enhancement

100 mV to 10 V/div 100≤%FS,no

TDS6124C with Bandwidth Enhancement

100 mV to 10 V/div ≤100% FS, no

TDS6154C with Bandwidth Enhancement

100 mV to 10 V/div ≤100% FS, no

Pulse response, peak detect

or envelope mode

Position range ±0.5 full scale

Sample rate setting Minimum pulse width

All

±Step amplitude Settling error at

time after step

100 ps: < 10%

more than 50% FS

overdrive

more than 50% FS

overdrive

more than 50% FS

overdrive

25 ps

400 ps: < 5%

3 ns: < 2%

1 ms: < 0.1%

100 ps: < 8%

400 ps: < 1%

3 ns: < 0.1%

1 ms: < 0.1%

100 ps: < 8%

400 ps: < 1%

3 ns: < 0.1%

1 ms: < 0.1%

1- 24

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 12: TDS6000C Series Channel input and vertical specifications (Cont .)

Characteristic Description

Offset range Gain setting Net offset range

(includes position

range)

100 mV/FS ±0.50 V ±0.45 V

200 mV/FS ±0.50 V ±0.40 V

500 mV/FS ±0.50 V ±0.25 V

1V/FS ±5V ±4.5 V

2V/FS ±5V ±4.0 V

5V/FS ±5V ±2.5 V

10 V/FS ±5V 0

Formulas for offset range calculation, excluding position

±|0.5V -- (0.5 × FS)| 100 mV/FS to 995 mV/FS

Net offset range

(excludes position

range)

±|5V -- (0.5 × FS)| 1V/FSto10V/FS

n Offset accuracy Volts/div setting Offset accuracy

100 mV/FS to

995 mV/FS

1V/FSto

10 V/FS

Net offset = offset -- (position × volts/division)

Effective bits, typical Effective bits for 0.9 × FS p--p sine wave input sampled at

500 mV/FS and 40 GS/s (Bandwidth Enhancement ON).

Input frequency Effective bits

10 MHz 5.9 bits 5.7 bits

1GHz 5.5 bits 5.3 bits

2GHz 5.4 bits 5.2 bits

3GHz 5.2 bits 5.0 bits

4GHz 5.0 bits 4.8 bits

5GHz 4.9 bits 4.7 bits

6GHz 4.8 bits 4.6 bits

7GHz 4.7 bits 4.5 bits

±(0.35% ×| net offset | + 1.5 mV +

1% × FS)

±(0.35% ×| net offset | + 15 mV +

1% × FS)

Effective bits

TDS6124C

TDS6154C

8GHz 4.6 bits 4.4 bits

9GHz 4.5 bits 4.3 bits

10 GHz 4.5 bits 4.3 bits

11 GHz 4.4 bits 4.2 bits

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 25

Specifications

c

a

Bandwidt

h

Bandwidt

h

Bandwidt

h

Table 1- 12: TDS6000C Series Channel input and vertical specifications (Cont .)

Characteristic Description

12 GHz 4.4 bits 4.2 bits

13 GHz -- 4.1 bits

14 GHz -- 4.1 bits

15 GHz -- 4.1 bits

Effective bits for 0.9 × FS p--p sine wave input sampled at

500 mV/FS and 40 GS/s (Bandwidth Enhancement OFF).

Input frequency Effective bits

TDS6124C

10 MHz 5.7 bits 5.7 bits

1GHz 5.3 bits 5.3 bits

2GHz 5.2 bits 5.2 bits

3GHz 5.0 bits 5.0 bits

4GHz 4.8 bits 4.8 bits

5GHz 4.7 bits 4.7 bits

6GHz 4.6 bits 4.6 bits

7GHz 4.5 bits 4.5 bits

8GHz 4.4 bits 4.4 bits

9GHz 4.3 bits 4.3 bits

10 GHz 4.3 bits 4.3 bits

11 GHz 4.2 bits 4.2 bits

12 GHz 4.2 bits 4.2 bits

Delay between channels ≤20 ps between any two channels with the same gain settings

Channel-to-channel crosstalk, typi

l

Conditions (GHz) TDS6124C TDS6154C

<1 V/FS, 0 to 10

150:1 150:1

Effective bits

TDS6154C

≥1 V/FS, 10 to12 80:1 80:1

<1 V/FS, 12 to15 50:1 N/A

Noise, typical

Gain setting TDS6154C

Full Scale Volts/div

100 mV 5 mV,

10 mV

160 mV 16 mV 950 V 840 V 950 V

200 mV 20 mV 1.1 mV 940 V 1mV

1- 26

TDS6000B & TDS6000C Series Specifications and Performance Verification

Enhancement ON

690 V 570 V 670 V

TDS6124C

Enhancement ON

Both with

Enhancement OFF

Specifications

g

Table 1- 12: TDS6000C Series Channel input and vertical specifications (Cont .)

Characteristic Description

300 mV 30 mV 1.6 mV 1.45 mV 1.6 mV

400 mV 40 mV 2.1 mV 1.85 mV 2.1 mV

500 mV 50 mV 2.5 mV 2.3 mV 2.4 mV

800 mV 80 mV 4.4 mV 3.8 mV 4.1 mV

900 mV 90 mV 4.8 mV 4.3 mV 4.6 mV

1 V 100 mV 6.9 mV 5.7 mV 6.8 mV

2 V 200 mV 10.5 mV 9.5 mV 10 mV

5 V 500 mV 25 mV 23 mV 24 mV

10 V 1 V 56 mV 46 mV 50 mV

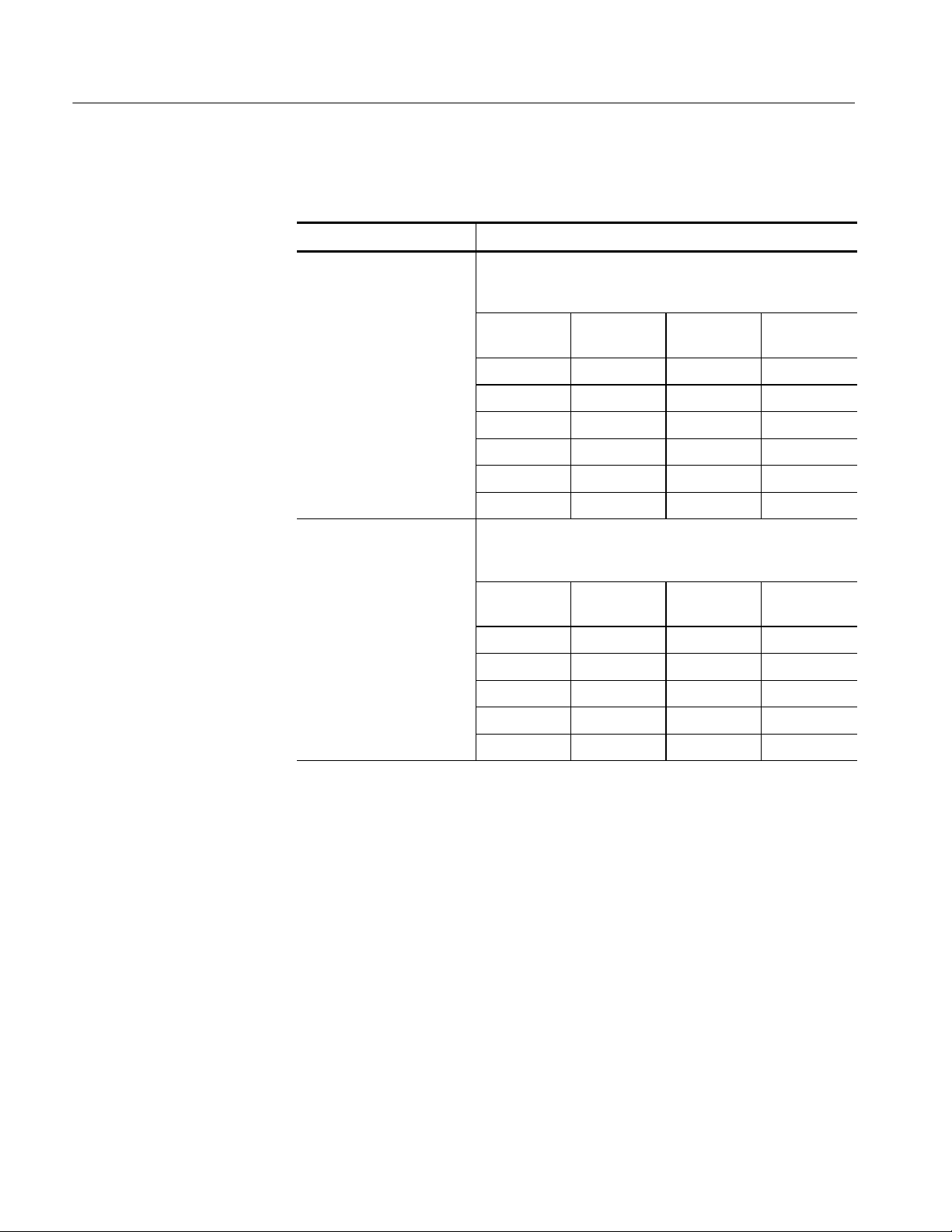

Table 1- 13: TDS6000C Series horizontal and acquisition system

specifications

Characteristic Description

Real-time sample rate range 1.25 S/s to 500 MS/s in a 1-2.5-5 sequence followed by

1.25 GS/s, 2.5 GS/s, 5 GS/s,10 GS/s, 20 GS/s, 40 GS/s with

either on channel turned on or the following t wo-channel

combinations: Ch1/Ch3, Ch1/Ch4, Ch2/Ch3, Ch2/Ch4. Other

two-channel combinations or more than two channels only go t o

20 GS/s.

Equivalent-time sample rate

or interpolated waveform

rate range

Acquisition modes Sample, Peak Detect, Hi Res, Average, Envelope, and

10 GS/s, 12.5 GS/s, 20 GS/s, 25 GS/s, 40 GS/s,

50 GS/s, 62.5 GS/s, 80 GS/s, 100 GS/s, 125 GS/s,

160 GS/s, 200 GS/s, 250 GS/s, 312.5 GS/s, 320 GS/s,

400 GS/s, 500 GS/s, 625 GS/s, 800 GS/s, 1 TS/ s, 2 T S/s

Waveform Database

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 27

Specifications

Framelengthandmaximum

MaximumnumberofframesforSampleorPeakDetec

t

Table 1- 13: TDS6000C Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

Record length Maximum record length supported by acquisition hardware:

Channels Record length

Sample mode

operating at

10 GS/s, 20 GS/s,

40 GS/s

Sample mode

operating at

≤5 GS/s

Sample mode

operating at

10 GS/s, 20 GS/s

Sample mode

operating at

≤5 GS/s

High Resolution

mode operating at

≤1.25 GS/s

Seconds/division range 40 s/div to 25 ps/div

Maximum FastFrame update

rate, nominal

Frame length and maximum Maximum number of frames for Sample or Peak Detect

number of frames

1or2

1or2 32 M

3or4 32 M

3or4 16 M

1, 2, 3, or 4 2M

310,000 frames per second

acquisition mode, depending on memory option installed

Frame length Maximum number of frames

64 M

50 points Option 4M: 114736

250 points Option 4M: 68096

500 points Option 4M: 45152

2000 points Option 4M: 14944

5000 points Option 4M: 6384

n Long term timebase and

delay time accuracy

Aperture uncertainty, typical Tot al:

1- 28

TDS6000B & TDS6000C Series Specifications and Performance Verification

±2 ppm initial accuracy. Aging <1 ppm per year from the date of

factory calibration.

<350 fs RMS, for record duration <10 s

<2.5 ps peak, for record duration <10 s

<2 ps + 15 parts/trillion, for record duration >20 s

Random Jitter only (excludes interleaving errors)

<300 fs RMS, for record duration <10 s

<2.5 ps peak, for record duration <10 s

<2 ps + 15 parts/trillion, for record duration >20 s

Table 1- 13: TDS6000C Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

Aperture uncertainty (long

tem), typical

Time base delay time range 5nsto250s

≤15 parts per trillion RMS, records having duration ≤1 minute

Specifications

Delta time measurement

accuracy, typical

Approximate formula to calculate delta-time measurement

accuracy (DTA) for a given instrument setting and input signal is

shown below (assumes insignificant signal content above

Nyquist):

A = input signal amplitude (volts)

t

= 10 to 90% measured rise time (seconds)

rm

N = input-referred noise ( volts RMS)

t

= short/medium term aperture uncertainty (seconds RMS)

j

TBA = time base accuracy (2 ppm)

duration = delta-time measurement (seconds)

assume edge shape that results from Guassian filter response.

2

N

DTA

Assumes insignificant error due to aliasing.

For time durations less than 100 ns, the rms ji tter i n DTA

measurements can be estimated as:

DTA

= 5 × 2 × Ꮑ

pk−pk

= 2 × Ꮑ

Ꭹ

rms

Ꭹ

Ꮑ

× t

rm

A

TBA × duration (seconds peak--to--peak)

× t

2

Ꮖ

+ t

rm

N

Ꮑ

A

2

Ꮖ

+ t

j

2

Ꮖ

(seconds rms)

j

Ꮖ

+

The term under the square-root sign is the stability, and is due to

TIE. The errors due to this term occur throughout a single-shot

measurement. The second term is due to both the absol ute

center-frequency accuracy and the center-frequency stability of

the timebase and varies between multiple single-shot

measurements over the observation interval (the amount of time

from the first single-shot measurement to the final single-shot

measurement). The observation interval may not exceed 1 year.

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 29

Specifications

Table 1- 13: TDS6000C Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

TDS6154C Bandwidth Enhancement ON, single shot, sample mode,

assume full-scale setting of 500 mV and signal amplitude of

350 mV

10--90%

Risetime (trm)

25 ps <100 ns 556 fs 2.98 ps

35 ps <100 ns 608 fs 3.24 ps

40 ps <100 ns 639 fs 3.39 ps

60 ps <100 ns 783 fs 4.11 ps

80 ps <100 ns 948 fs 4.94 ps

100 ps <100 ns 1.12 ps 5.82 ps

TDS6124C Bandwidth Enhancement ON, single shot, sample mode,

assume full--scale setting of 500 mV and signal amplitude of

350 mV

Duration DTA rms DTA pkpk

10--90%

Risetime (trm)

35 ps <100 ns 570 fs 3.05 ps

40 ps <100 ns 591 fs 3.16 ps

60 ps <100 ns 693 fs 3.66 ps

80 ps <100 ns 814 fs 4.27 ps

100 ps <100 ns 948 fs 4.94 ps

Duration DTA rms DTA pkpk

1- 30

TDS6000B & TDS6000C Series Specifications and Performance Verification

Table 1- 13: TDS6000C Series horizontal and acquisition system

specifications (Cont.)

Characteristic Description

Jitter noise floor, typical TDS6124C TDS6154C

420 fs 420 fs

Applies to time periods as long as 10 s

The formula to calculate jitter noise floor (JNF) for a given

instrument setting is given below:

FS = Full scale setting (volts)

A = signal amplitude as a fraction of full scale

trm = 10 to 90% displayed (or measured) rise time (seconds)

N = Input-referred noise (volts RMS)

= short term aperture uncertainty (seconds RMS)

tj

2

JNF =

Ꭹ

Ꮑ

FS × A

N

× trm

2

Ꮖ

+ t

(seconds rms)

j

Specifications

Numbers used for the above calculations:

TDS6124C: FS = 500 mv, A = 0.8, trm = 42 ps,

N=2.1mV,t

TDS6154C: FS = 500 mv, A = 0.8, trm = 30 ps,

N=2.6mV,t

= 350 fs

j

= 350 fs

j

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 31

Specifications

c

c

a

c

a

Table 1- 14: TDS6000C Series trigger specifications

Characteristic Description

Trigger jitter, typical 1 ps RMS for low frequency fast rise time signal.

Edge Trigger Sensitivity DC

oupled, typi

Edge trigger sensitivity,

typical

l

All sources, for vertical scale settings ≥10 mV/div and ≤1V/div.

Trigger Source

Main trigger, Ch1 thru

Ch4

Delayed trigger, Ch1 thru

Ch4

Auxiliary trigger 250 mV from DC to 50 MHz, increas-

All sources, for all vertical scale settings.

Trigger coupling Sensitivity

NOISE REJ 15%xFSfromDCto50MHz

AC Same as DC-coupled limits for

HF REJ Same as DC coupled limits for

Sensitivity

4%xFSfromDCto50MHz

10% x FS at 3 GHz

30% x FS at 9 GHz

4%xFSfromDCto50MHz

10% x FS at 3 GHz

30% x FS at 9 GHz

ing to 500 mV at 2 GHz

35% x FS at 3 GHz

50% x FS at 5 GHz

frequencies >100 Hz, attenuates

signals <100 Hz

frequencies <20 kHz, attenuates

signals >20 kHz

1- 32

LF REJ Same as DC coupled limits for

frequencies >200 kHz, attenuates

signals <200 kHz

Auxiliary trigger input resistance and range, typical

Auxiliary trigger level range ±4.5 V

Lowest frequency for Set

Level to 50%, typical

Events delay triggering,

minimum timing requirements, typi

Delayed trigger event counter range

n Delayed trigger time

delay range

l

50 Ω, ±5 V (DC + peak AC)

50 Hz

Minimum requirements for vertical settings from 10 mV/div to

1 V/div at the TekConnect input

Pulse width

100 ps 1.1 ns

1 to 10,000,000

3.2nsto3Ms

Time between channels

TDS6000B & TDS6000C Series Specifications and Performance Verification

Table 1- 14: TDS6000C Series trigger specifications (Cont.)

Characteristic Description

Trigger sensitivity, typical Specified at the TekConnect input:

Logic type triggers: 1.5 div, from DC to 1 GHz

(for 10 mV/div to 1 V/div vertical settings)

Runt type: 1.5 div

Width and glitch 1.5 div, from DC to 1 GHz

Specifications

n Minimum timing requirements

Width trigger 120 ps, 620 ps n/a n/a

Logic qualified width

trigger

Glitch trigger 70 ps, 215 ps n/a n/a

Logic qualified glitch

trigger

Runt trigger 130 ps, 280 ps n/a n/a

Time qualified runt

trigger

Logic qualified runt

trigger

Time and logic

qualified runt trigger

Window trigger 320 ps, 460 ps n/a n/a

Logic qualified

Window trigger

For vertical scale settings ≥10 mV/div and ≤1 V/div at the

TekConnect input.

Minimum pulse width,

Minimum rearm time

190 ps, 250 ps 40 ps 175 ps

100 ps, 250 ps 112 p s 36 ps

476 ps, 510 ps n/a n/a

210 ps, 250 ps 408 ps 105 ps

520 ps, 360 ps 160 ps 105 ps

190 ps, 460 ps 260 ps 105 ps

Setup time Hold time

Transition trigger 490 ps, 670 ps n/a n/a

Logic qualified transition trigger

Timeout trigger 550 ps, 300 ps +

Logic qualified Timeout trigger

420 ps, 670 ps 220 ps 92 ps

Maxim ignored pulse

width, Minimum rearm

time

pulse width

620 ps, 300 ps +

pulse width

TDS6000B & TDS6000C Series Specifications and Performance Verification

Setup time Hold time

n/a n/a

92 ps 0ps

1- 33

Specifications

c

a

g

ger,ty

pic

a

trigger,typical

c

a

300psonlyappliestotriggertypesthatcansupportapulsethi

s

Table 1- 14: TDS6000C Series trigger specifications (Cont.)

Characteristic Description

Minimum timing requirements, logi

tri

nd state type

l

Minimum duration of logic state: 100 ps (10 Gbps)

Trigger type Min pulse width Rearm time

Logic 80 ps 660 ps

State 168 ps 580 ps

Time qualified logic 130 ps 630 ps

Transition trigger, delta time

range

Setup/Hold violation trigger,

setupand hold ranges

Setup/Hold hold time violation trigger, minimum clock

pulse widths, typi

n Timing accuracy for

time-qualified triggers

l

1nsto1s

Feature Minimum Maximum

Setup time

Hold time -- 1 n s 102 ns

Setup + Hold time 500 ps

For vertical settings from 10 mV/div to 1V/div at the TekConnect

input, the minimums are:

Minimum time from active clock edge to inactive edge

User’s hold time +500 ps

for hold times ≥0.

User’s hold time +1.6 ns

for hold times <0.

Typical, for range of 1 ns to 1.8 ns.

Time range Accuracy

<500 ns ± (20% of setting + 0.5 ns)

520 ns to 1 s ± (0.01% of setting + 100 ns)

--100 ns 100 ns

Minimum time from inactive clock

edge to active edge

500 ps

Time range for time-qualified

triggers

Minimum to maximum time range to

which the instrument

canbesetforglitch

trigger, pulse trigger,

or time-qualified runt

trigger.

1- 34

TDS6000B & TDS6000C Series Specifications and Performance Verification

300 ps to 1 s

narrow. For example, time-qualified runt can only recognize

pulses down to 500 ps.

Table 1- 14: TDS6000C Series trigger specifications (Cont.)

Characteristic Description

Trigger level or threshold Trigger Source Sensitivity

range

Any channel

Auxiliary trigger input ±5V

Line trigger ±0 V, not settable

±0.6 × FS from center of screen

Specifications

Trigger level or threshold

accuracy, typical

Trigger position error, typical Edge trigger, DC coupl ing, for signal s having a slew rate at the

Trigger holdoff range 250 ns to 12 s plus random holdoff

Edge trigger, DC coupling, for signals having rise and fall times

>1 ns

Trigger Source Accuracy

Any channel ± [(2% ×| trigger level -- net offset | )

+ (3.5% × FS) + offset accuracy]

Auxiliary Not specified

where, net offset = offset -- (position × volts/division)

trigger point of ≥ 5% FS/ns

Acquisition mode Error

Sample, Average ± (1 waveform interval + 50 ps)

Peak Detect, Envelope ± (2 waveform interval + 50 ps)

Table 1- 15: TDS6000C Series serial trigger specifications (Option ST)

Characteristic Description

Serial trigger number of bits 64, ≤1.25 Gbd

40, >1.25 Gbd

Serial trigger, serial

decoding

nSerial trigger baud rate

limits

nClock recovery frequency

range

NRZ, ≤1.25 Gbd

8B10B, 1.25 Gbd to 3.125 GBd

Up to 3.125 Gbd

>1.25 Gbd requires 8B10B encoded data

1.5 MBd to 3.125 GBd. Above 1250 MHz t he clock is only

available internally as a trigger source. Below 1250 MHz t he

clock is also available at the Recovered Clock output along with

regenerated data.

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 35

Specifications

accuracy

Table 1- 15: TDS6000C Series serial trigger specifications (Option ST) (Cont.)

Characteristic Description

Clock recovery jitter (RMS),

typical

<0.25% bit period + 2 ps RMS for PRBS data patterns.

<0.25% bit period + 1.5 ps RMS for repeati ng 0011 data patterns.

Bit rate Pattern Jitter (RMS)

3.125 Gbd 00110011 2.8 ps

2.74 Gbd 00110011 2.9 ps

2.35 Gbd 00110011 3.1 ps

2.34 Gbd 00110011 3.1 ps

1.95 Gbd 00110011 3.3 ps

1.57 Gbd 00110011 3.6 ps

100 MBd 00110011 27 ps

10 MBd 00110011 252 ps

n Serial trigger, serial

word recognizer position

Clock recovery tracking/acquisition range

Minimum signal amplitude

needed for clock recovery,

typical

Edge trigger, DC coupling, for signals having a slew rate at the

trigger point of ≥ 5% FS/ns

Acquisition mode Error

Sample, Average ± (1 waveform interval + 50 ps)

Peak Detect, Envelope ± (2 waveform interval + 50 ps)

± 5% of requested baud.

1 division p-p up to 1.25 GBd

1.5 divisions p-p above 1.25 GBd

1- 36

TDS6000B & TDS6000C Series Specifications and Performance Verification

Specifications

Table 1- 16: TDS6000C Series display specifications

Characteristic Description

Display type 210.4 mm (8.3 in) (W)× 157.8 mm (6.2 in) (H), 263 mm (10.4 in)

diagonal, liquid crystal active-matrix color display

Display resolution 1024 horizontal × 768 vertical pixels

Pixel pitch 0.2055 mm horizontal, 0.2055 mm vertical

Response time, typical 15 ms, white to black

Display refresh rate 59.94 frames per second

Viewing angle, typical Horizontal: 60 degrees left, 60 degrees right

Vertical: 45 degrees up, 60 degrees down

Displayed intensity levels Each R-G-B input is 6 bits, giving 64 intensity levels of each color

component

Table 1- 17: TDS6000C Series input/output port specifications

Characteristic Description

Rear-panel I/O ports Ports located on the rear panel

Video output port Upper video port, DB-15 female connector, connect a

second monitor to use dual-monitor display mode,

supports Basic requirements of PC99 specifications

Parallel port (IEEE 1284) DB-25 connector, supports the following modes:

-standard (output only)

bidirectional (PS-2 compatible)

bidirectional enhanced parallel port (IEEE 1284

standard, mode 1 or mode 2, v 1.7)

-bidirectional high-speed extended capabilities

Serial port DB-9 COM1 port, uses NS16C550-compatible UARTS,

transfer speeds up to 115.2 kb/s

Keyboard port PS-2 compatible, power must be off to make connection

Mouse port PS-2 compatible, power must be off to make connection

LAN port RJ-45 connector, supports 10 base-T and 100 base-T and

gigabit ethernet

Audio ports Miniature phone jacks for stereo microphone input and

stereo line output

USB ports Two rear panel USB 2.0 connectors

GPIB port IEEE 488.2 standard interface

XGA video port 15 pin D-subminiature connector on the rear panel

TDS6000B & TDS6000C Series Specifications and Performance Verification

1- 37

Specifications

Table 1- 17: TDS6000C Series input/output port specifications (Cont.)

Characteristic Description

n DC Probe Cal Output Voltage,

Offset Voltage, and Frequency

Front-panel BNC connector for calibrating CD offset of