Service Manual

TDS6000B & TDS6000C Series

Digital Storage Oscilloscope

071-1798-00

This document applies to firmware version 4.00

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifica tions and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and techni cal support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of t he defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is locat ed. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for produc ts returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Operating Information

Theory of Operation

Figures iii...................................................

Tables iv...................................................

General Safety Summary v...................................

Service Safety Summary vii....................................

Environmental Considerations ix...............................

Preface xi...................................................

Manual Conventions xi..............................................

Installation and Operating Information 1--1...............................

Module Overviews 2--1...............................................

General 2--1....................................................

Input Signal Path 2--1.............................................

Display Panel 2--1................................................

Front Panel 2--2..................................................

Rear Panel 2--2..................................................

Low Voltage Power Supply 2--2.....................................

Fans 2--3.......................................................

Block diagram 2--3..................................................

Adjustment Procedure

Maintenance

Preventing ESD 4--1.................................................

Inspection and Cleaning 4--2...........................................

General Care 4--2................................................

Flat Panel Display Cleaning 4--2....................................

Interior Cleaning 4--3.............................................

Exterior Cleaning 4--3............................................

Inspection 4--3..................................................

Removal and Installation Procedures 4--7.........................

Preparation 4--7.....................................................

Trim, Cabinet, and Module Removal 4--9.................................

TDS6000B & TDS6000C Series Service Manual

i

Table of Contents

Removal Procedures 4--13..............................................

Acquisition Module 4--13...........................................

MicroATX Module 4--13...........................................

Bridge Module 4--14...............................................

PowerPC (PPC) Module 4--14.......................................

CD--ROM Drive 4--15.............................................

Display 4--15.....................................................

Side Fans 4--15...................................................

Internal Fans 4--15................................................

Front Panel 4--16..................................................

USB Module 4--16................................................

Hard Disk Drive 4--16.............................................

Troubleshooting 4--17...........................................

Service Level 4--17...................................................

Check for Common Problems 4--17......................................

Equipment Required 4--19..............................................

Fault Isolation Procedure 4--19..........................................

Checking the Power Supply Voltages 4--21.............................

If the Oscilloscope Will Not Boot 4--24................................

Booting Into Windows 4--24.........................................

If the Oscilloscope Application Does Not Work 4--24....................

PPC and MicroATX PC Diagnostics 4--25.................................

Power--on diagnostics 4--25.........................................

Checkit Utilities 4--27..............................................

Diagnostics 4--28.................................................

Software Updates 4--28................................................

After Repair 4--29....................................................

BIOS Error Messages 4--29.............................................

BIOS Beep Codes 4--31................................................

DIP Switch Controls 4 --31..............................................

Diagnostic LED 4--32.................................................

Troubleshooting Using Reset Circuits 4--34................................

Update/Restore the MicroATX Board CMOS 4--36..........................

Installing an Authorization Key 4--37.....................................

Repackaging Instructions 4--39...................................

Packaging 4--39......................................................

Shipping to the Service Center 4--39......................................

Mechanical Parts List

ii

Parts Ordering Information 5--1.........................................

Module Servicing 5--1............................................

Using the Replaceable Parts List 5--2....................................

Abbreviations 5--2...............................................

Mfr. Code to Manufacturer Cross Index 5--2...........................

TDS6000B & TDS6000C Series Service Manual

List of Figures

Table of Contents

Figure 2--1: TDS6000B and TDS6000C series block diagram 2--3......

Figure 4--1: Locator for trim and cabinet removal 4--11...............

Figure 4--2: Locator for internal modules 4--12......................

Figure 4--3: Primary troubleshooting tree 4--20......................

Figure 4--4: Low voltage power supply LED locations 4--21...........

Figure 4--5: Location of power--on and overcurrent LEDs 4--22........

Figure 4--6: Connectors J1, J2, and J3 4--23........................

Figure 4--7: The three PCI busses 4--34............................

Figure 4--8: PCI and MicroATX video connectors 4--35...............

Figure 4--9: Switch, jumper, and reset button locations 4--36...........

Figure 5--1: External parts 5--7..................................

Figure 5--2: Front panel and drives 5--10...........................

Figure 5--3: Front panel and drives (cont.) 5--12.....................

Figure 5--4: Power supply 5 --14...................................

Figure 5--5: ATX module detail 5--16..............................

Figure 5--6: Accessories 5--17.....................................

TDS6000B & TDS6000C Series Service Manual

iii

Table of Contents

List of Tables

T able 4--1: External inspection check list 4--3......................

Table 4--2: Tools required for module removal 4--8.................

Table 4--3: Column legend for Table 4--5 4--9......................

Table 4--4: Accessing modules 4--9...............................

Table 4--5: Failure symptoms and possible causes 4--17...............

Table 4--6: LVPS LED descriptions 4--21...........................

Table 4--7: Power supply voltages 4--23............................

Table 4--8: Power--on diagnostic tests 4--25.........................

Table 4--9: Action required for module replacement 4--29.............

Table 4--10: BIOS error messages 4--30............................

T able 4--11: Beep codes 4--31.....................................

Table 4--12: DIP switch functions 4--32.............................

Table 4--13: Diagnostic LED 4--33.................................

iv

TDS6000B & TDS6000C Series Service Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

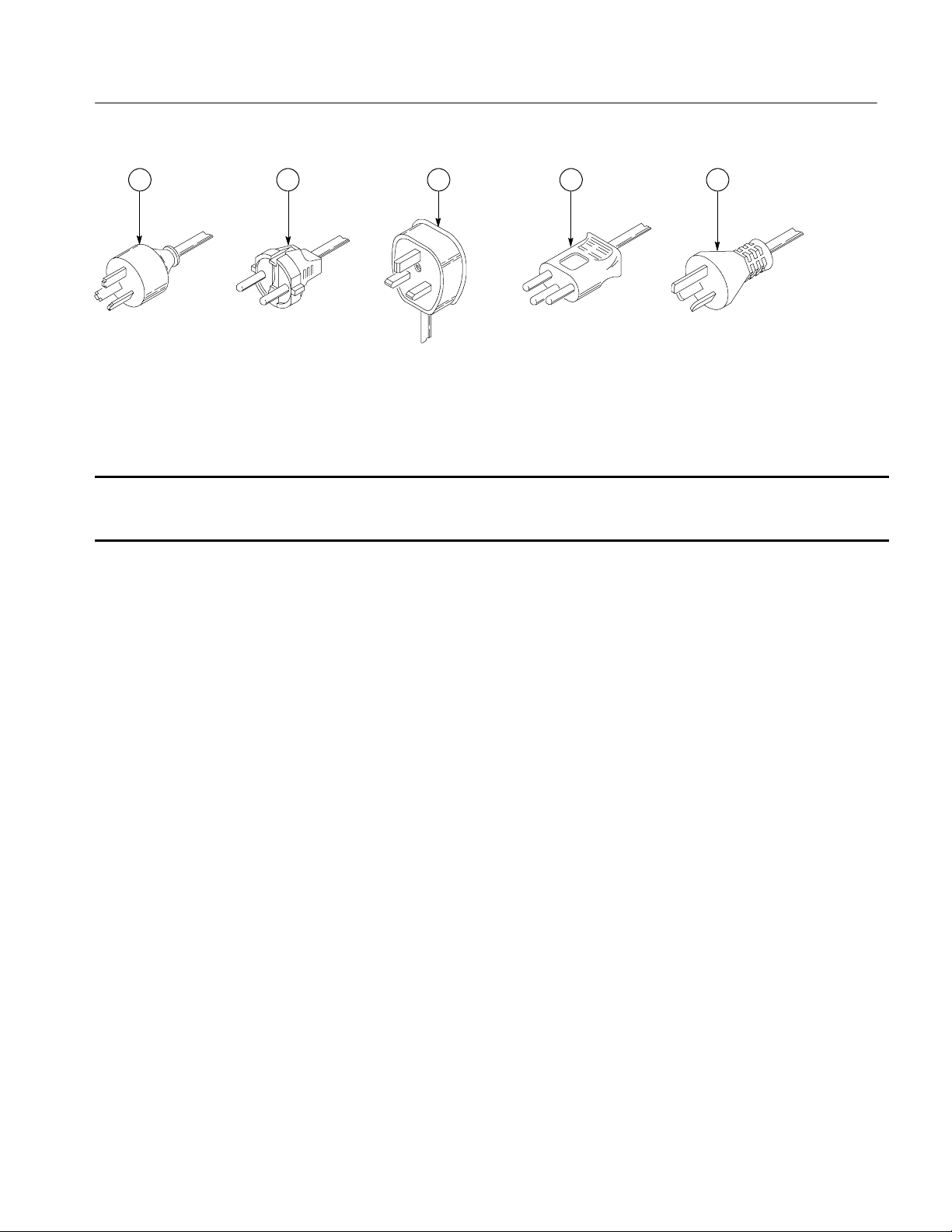

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV

circuits.

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at all

times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

TDS6000B & TDS6000C Series Service Manual

v

General Safety Summary

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Terms in this Manual

Symbols and Terms

on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

vi

Protective Ground

(Earth) Terminal

TDS6000B & TDS6000C Series Service Manual

Earth Terminal

Standby

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TDS6000B & TDS6000C Series Service Manual

vii

Service Safety Summary

viii

TDS6000B & TDS6000C Series Service Manual

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

TDS6000B & TDS6000C Series Service Manual

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

ix

Environmental Considerations

x

TDS6000B & TDS6000C Series Service Manual

Preface

Manual Conventions

This is the service manual for the TDS6000B & TDS6000C Digital Storage

Oscilloscope products. Read this preface to learn how this manual is structured,

what conventions it uses, and where you can find other information related to

servicing this product. Read the safety summaries preceding this preface for

safety and other important background information needed before using this

manual to service this product.

This manual uses certain conventions that you should become familiar with

before attempting service.

Replaceable Parts

Safety

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part or module. In

general, a replaceable part is any circuit board or assembly, such as the hard disk

drive, or a mechanical part, such as the I/O port connectors, that is listed in the

replaceable parts list.

Symbols and terms related to safety appear in the Service Safety Summary found

at the beginning of this manual.

TDS6000B & TDS6000C Series Service Manual

xi

Preface

xii

TDS6000B & TDS6000C Series Service Manual

Operating Information

Operating Information

For information on installing and operating your TDS6000B or TDS6000C

Series Digital Storage Oscilloscope, refer to the TDS6000B & TDS6000C Series

Digital Storage Oscilloscopes Quick Start User Manual. This manual is

available on the Web at www.tektronix.com.

TDS6000B & TDS6000C Series Service Manual

1- 1

Operating Information

1- 2

TDS6000B & TDS6000C Series Service Manual

Theory of Operation

Theory of Operation

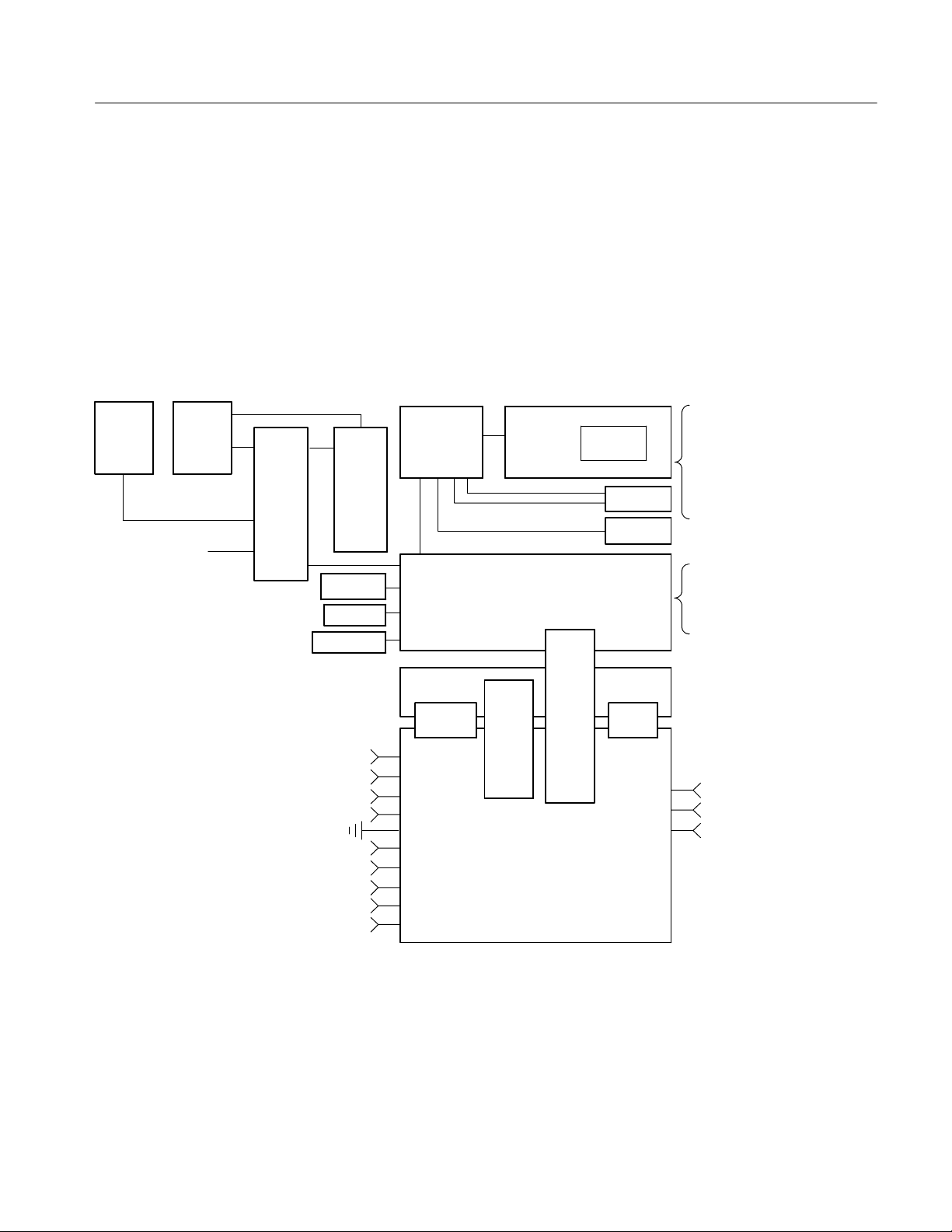

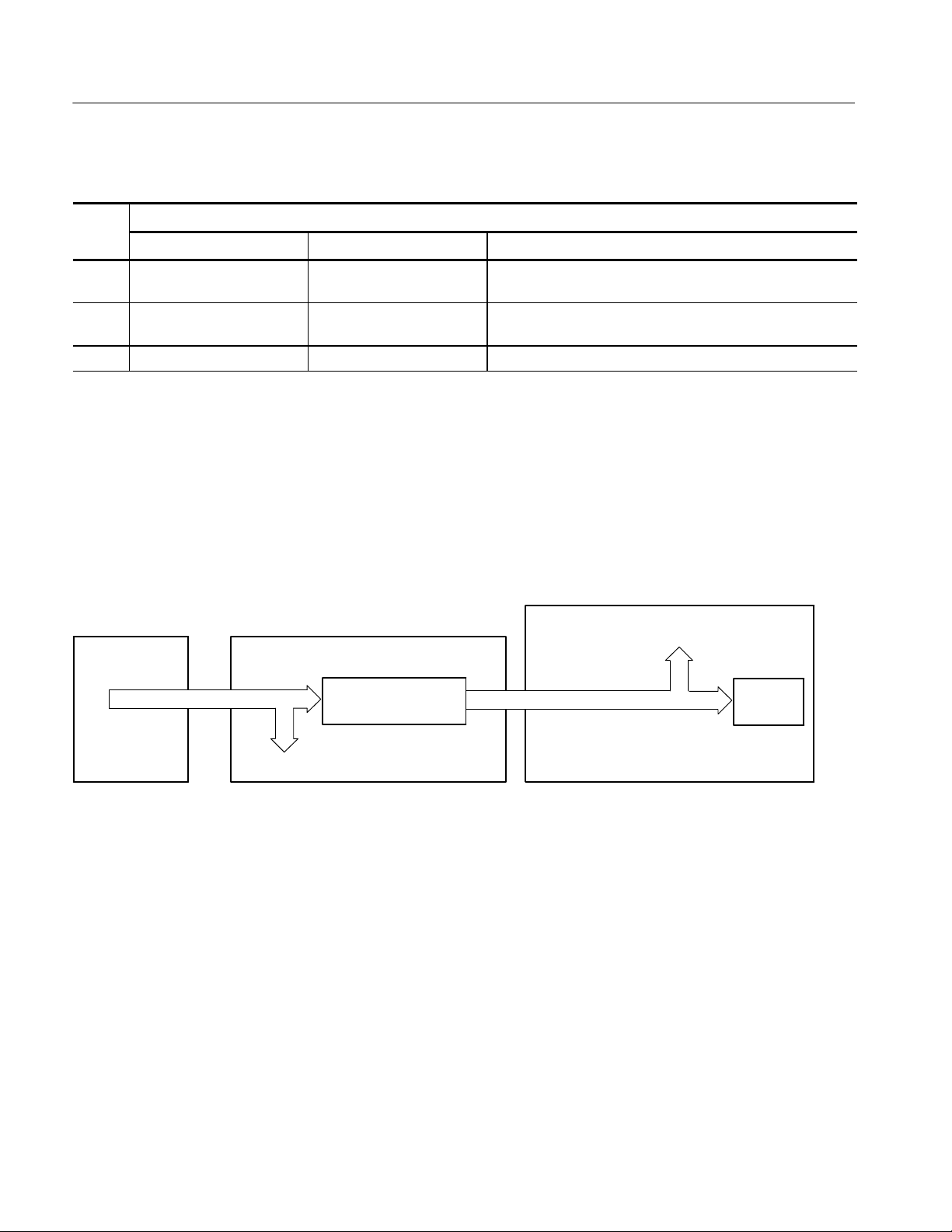

This section describes the electrical operation of the oscilloscope. Figure 2--1 on

page 2--3 shows the module interconnections.

Module Overviews

Module overviews describe the basic operation of each functional circuit block

asshowninFigure2--1onpage2--3.

General

Input Signal Path

A dual-processor system controls the oscilloscope. The oscilloscope features an

XGA resolution flat-panel display, a transparent touch screen, and a front-panel

with direct access to commonly used oscilloscope functions. You can also use

the oscilloscope with a mouse pointing device or keyboard.

A signal enters the oscilloscope through a direct coaxial connection to the input

connector, or a probe connected to the front panel.

Acquisition Board. The acquisition board conditions the input signals, samples

them, converts them to digital signals, and controls the acquisition process under

direction of the processor system. The acquisition system includes the multisource trigger, acquisition timebase, and acquisition mode generation and control

circuitry. The acquisition board is located in the bottom compartment of the

oscilloscope. Four vertical channels are accommodated. All channels feature a

TekConnectr interface for additional front-end signal conditioning functions.

Processor System. The processor system contains two processor boards with

microprocessors that control the entire oscilloscope.

Display Panel

TDS6000B & TDS6000C Series Service Manual

Waveforms and menus are displayed on a 10.4 inch, color, active-matrix LCD

display with touch panel.

Display System. Text and waveforms are processed by different parts of the

display circuitry. The display system (display adapter board and inverter board)

sends the text and waveform information to the display panel.

Touch Panel. The display board sends information from the touch panel to the

processor. Any changes in settings are reported to the processor system.

2- 1

Theory of Operation

Front Panel

The MicroATX board reads the front-panel switches and encoders. Any changes

in their settings are reported to the processor system. The MicroATX board also

turns the LEDs on and off.

Menu Switches. Front-panel menu switches are also read by the MicroATX board.

The touch screen processor sends any changes in menu selections to the

MicroATX processor system. The ON/STBY switch passes through the display

adapter board to the MicroATX board. The MicroATX board creates the signal

sent to the power supply to toggle power.

PowerPC Board. The PowerPC (PPC) board provides fast access to the Acquisition board and the display system. The MicroATX board reads the front-panel

switches and encoders and implements any changes requested by their settings.

The PPC board provides a GPIB interface through a rear panel connector.

MicroATX Board. The MicroATX board provides standard Windows functionality

and I/O port interfaces to the rear panel.

Micro ATX Bridge Board. Both processor systems, CDROM-RW drive, and hard

disk drive are connected together by, and communicate through, the bridge

board.

Rear Panel

Low Voltage Power Supply

The hard disk drive and CDROM-drive provide access to stored waveform data

and software to customize your oscilloscope with your measurement needs. The

GPIB allows for external control of the oscilloscope.

You can make hardcopies via the USB and parallel ports.

The MicroATX board has four USB ports and one serial port on the rear panel.

The MicroATX board also provides a front panel USB port. The MicroATX has

one serial port, which is routed to the rear panel. A microphone input and

earphone output exist on the MicroATX rear panel. Ethernet connector is RJ-45.

Keyboard and mouse are both PS/2.

The low voltage power supply is a switching power converter with active power

factor control. It supplies power to all of the circuitry in the oscilloscope.

The ON/STBY switch, located on the front panel, also controls all of the power

to the oscilloscope except for part of the circuitry in the standby power supply.

The power supply sends a power fail (~PF) warning to the processor and

acquisition systems if the power is going down.

Power is distributed throughout the oscilloscope through the front and rear power

distribution bus boards.

2- 2

TDS6000B & TDS6000C Series Service Manual

Theory of Operation

Block Diagram

Touch

panel

ON/STANDBY

Display

panel

Fans

Display

adapter

board

Two fan assemblies (six on the Side Fan Assembly and four on the Internal Fan

Assembly) provide forced air cooling for the oscilloscope. The fans are

controlled by the PPC.

This section contains the block diagram of the TDS6000B and TDS6000C

Digital Storage Oscilloscopes and modules, showing the major circuit blocks or

modules. The block diagram is shown in Figure 2--1, below.

SVGA

USB

Sound

Serial

Parallel

Ethernet

Mouse

Keyboard

GPIB

SCOPE

XGA OUT

Inverter

board

Front panel

Side fans

Internal fans

Bridge

MicroATX board

board

Power PC Processor board

Processor

CD ROM

Hard drive

LVPS board

AUX bus PA bus

Ch1

Ch2

Ch3

Ch4

AUX TRIG OUT

DC PROBE CAL

RECOVERED DATA

RECOVERED CLOCK

FAST EDGE

Figure 2- 1: TDS6000B and TDS6000C series block diagram

Power

bus

(front)

Power

bus

(rear)

REF

AUX IN

AUX IN

Acquisition

board

TDS6000B & TDS6000C Series Service Manual

2- 3

Theory of Operation

2- 4

TDS6000B & TDS6000C Series Service Manual

Adjustment Procedures

Adjustment Procedures

There are no user adjustment procedures for the TDS6000B and TDS6000C

Digital Storage Oscilloscopes. Adjustment of these instruments must be

performed by a Tektronix Service Center.

TDS6000B & TDS6000C Series Service Manual

3- 1

Adjustment Procedures

3- 2

TDS6000B & TDS6000C Series Service Manual

Maintenance

Maintenance

This section contains the information needed to do periodic and corrective

maintenance on the oscilloscope. The following subsections are included:

H Preventing ESD — General information on preventing damage by electros-

tatic discharge.

H Inspection and Cleaning — Information and procedures for inspecting the

oscilloscope and cleaning its external and internal modules.

H Removal and Installation Procedures — Procedures for the removal of

defective modules and replacement of new or repaired modules. Also

included is a procedure for disassembly of the oscilloscope for cleaning.

H Troubleshooting — Information for isolating failed modules. Included are

instructions for operating the oscilloscope diagnostic routines and troubleshooting trees. Most of the trees make use of the internal diagnostic routines

to speed fault isolation to a module.

H Repackaging Instructions — Information on returning an oscilloscope for

service.

Preventing ESD

Before servicing this product, read the safety summary and Introduction at the

front of the manual and the ESD information below.

CAUTION. Static discharge can damage any semiconductor component in this

oscilloscope.

When performing any service which requires internal access to the oscilloscope,

adhere to the following precautions to avoid damaging internal modules and their

components due to electrostatic discharge (ESD).

1. Minimize handling of static-sensitive circuit boards and components.

2. Transport and store static-sensitive modules in their static protected

containers or on a metal rail. Label any package that contains static-sensitive

boards.

3. Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these modules. Do service of static-sensitive

modules only at a static-free work station.

TDS6000B & TDS6000C Series Service Manual

4- 1

Maintenance

4. Nothing capable of generating or holding a static charge should be allowed

5. Handle circuit boards by the edges when possible.

6. Do not slide the circuit boards over any surface.

7. Avoid handling circuit boards in areas that have a floor or work-surface

Inspection and Cleaning

Inspection and Cleaning describes how to inspect for dirt and damage. It also

describes how to clean the exterior and interior of the oscilloscope. Inspection

and cleaning are done as preventive maintenance. Preventive maintenance, when

done regularly, may prevent oscilloscope malfunction and enhance its reliability.

Preventive maintenance consists of visually inspecting and cleaning the

oscilloscope and using general care when operating it.

on the work station surface.

covering capable of generating a static charge.

General Care

Flat Panel Display

Cleaning

How often to do maintenance depends on the severity of the environment in

which the oscilloscope is used. A proper time to perform preventive maintenance

is just before oscilloscope adjustment.

The cabinet helps keep dust out of the oscilloscope and should normally be in

place when operating the oscilloscope.

The display is a soft plastic display and must be treated with care during

cleaning.

CAUTION. Improper cleaning agents or methods can damage the flat panel

display.

Avoid using abrasive cleaners or commercial glass cleaners to clean the display

surface.

Avoid spraying liquids directly on the display surface.

Avoid scrubbing the display with excessive force.

Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available from

Kimberly-Clark Corporation).

4- 2

TDS6000B & TDS6000C Series Service Manual

Maintenance

Interior Cleaning

Exterior Cleaning

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a

soft-bristle, non-static-producing brush for cleaning around components. If you

must use a liquid for minor interior cleaning, use a 75% isopropyl alcohol

solution and rinse with deionized water.

WARNING. Before performing any procedure that follows, power down the

instrument and disconnect it from line voltage.

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a softbristle brush. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl

alcohol solution. Use a swab to clean narrow spaces around controls and

connectors. Do not use abrasive compounds on any part of the chassis that may

damage the chassis.

Clean the On/Standby switch using a dampened cleaning towel. Do not spray or

wet the switch directly.

CAUTION. Avoid the use of chemical cleaning agents which might damage the

plastics used in this oscilloscope. Use only deionized water when cleaning the

menu buttons or front-panel buttons. Use a 75% isopropyl alcohol solution as a

cleaner and rinse with deionized water. Before using any other type of cleaner,

consult your Tektr onix Service Center or representative.

Lubrication. There is no periodic lubrication required for this oscilloscope.

Inspection

Inspection — Exterior. Inspect the outside of the oscilloscope for damage, wear,

and missing parts, using Table 4--1 as a guide. Immediately repair defects that

could cause personal injury or lead to further damage to the oscilloscope.

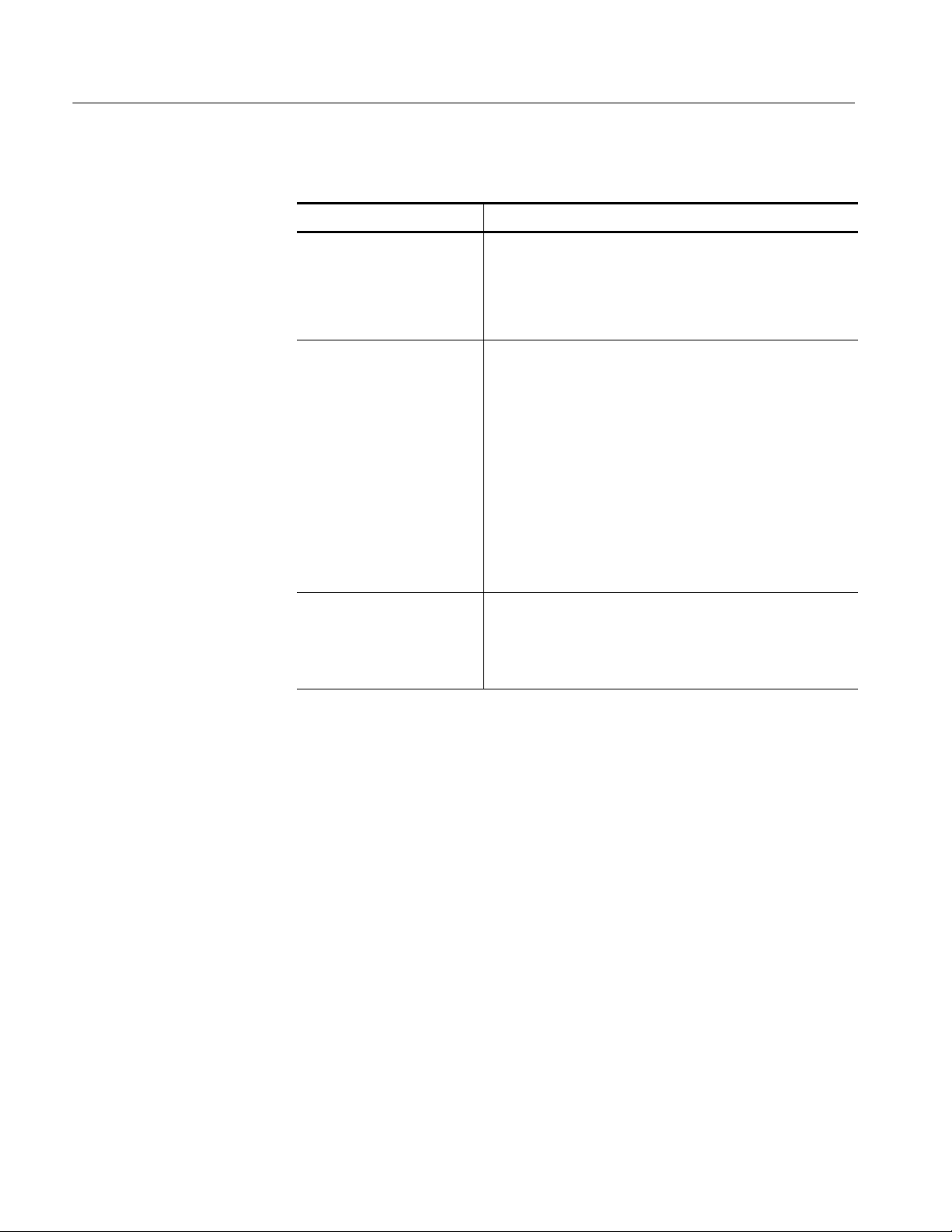

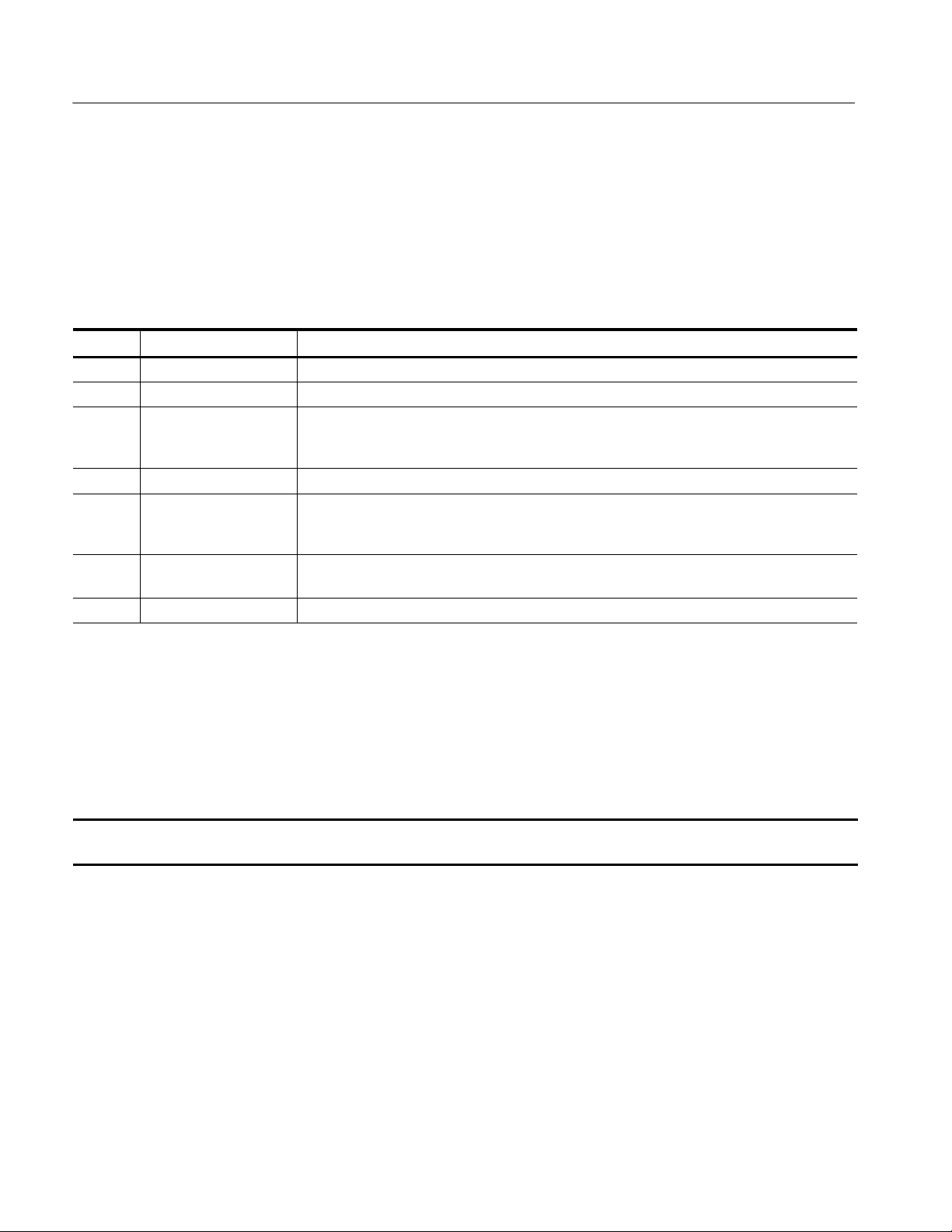

Table 4- 1: External inspection check list

Item Inspect for Repair action

Cabinet, front panel,

and cover

Front-panel knobs Missing, damaged, or loose

Connectors Broken shells, cracked insulation,

TDS6000B & TDS6000C Series Service Manual

Cracks, scratches, deformations,

damaged hardware

knobs

and deformed contacts. Dirt in

connectors

Repair or replace defective

module

Repair or replace missing or

defective knobs

Repair or replace defective

modules. Clear or wash out dirt

4- 3

Maintenance

Table 4- 1: External inspection check list (Cont.)

Item Repair actionInspect for

Carrying handle, and

cabinet feet

Correct operation Repair or replace defective

module

Accessories Missing items or parts of items,

bent pins, broken or frayed

cables, and damaged connectors

Repair or replace damaged or

missing items, frayed cables, and

defective modules

If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using excess

force or you may damage the plastic display surface.

CAUTION. To prevent getting moisture inside the oscilloscope during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Inspection — Interior. To access the inside of the oscilloscope for inspection and

cleaning, refer to the Removal and Installation Procedures in this section.

Inspect the internal portions of the oscilloscope for damage and wear. Defects

found should be repaired immediately.

If any circuit board is replaced, check Table 4--9in the Troubleshooting portion of

this Section to see if it is necessary to adjust the oscilloscope.

4- 4

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the oscilloscope.

Cleaning Procedure — Interior. To clean the oscilloscope interior, do the following

steps:

1. Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2. Remove any remaining dust with a lint-free cloth dampened in isopropyl

alcohol (75% solution) and rinse with warm deionized water. (A cottontipped applicator is useful for cleaning in narrow spaces and on circuit

boards.)

STOP. If, after doing steps 1 and 2, a module is clean upon inspection, skip the

remaining steps.

TDS6000B & TDS6000C Series Service Manual

Maintenance

3. If steps 1 and 2 do not remove all the dust or dirt, the oscilloscope may be

spray washed using a solution of 75% isopropyl alcohol by doing steps 4

through 8.

4. Gain access to the parts to be cleaned by removing easily accessible shields

and panels (see Removal and Installation Procedures).

5. Spray wash dirty parts with the isopropyl alcohol and wait 60 seconds for the

majority of the alcohol to evaporate.

6. Use hot (120_ F to 140_ F) deionized water to thoroughly rinse them.

7. Dry all parts with low-pressure, deionized air.

8. Dry all components and assemblies in an oven or drying compartment using

low-temperature (125_ F to 150_ F) circulating air.

TDS6000B & TDS6000C Series Service Manual

4- 5

Maintenance

4- 6

TDS6000B & TDS6000C Series Service Manual

Removal and Installation Procedures

This subsection contains procedures for removal and installation of all mechanical and electrical modules.

Preparation

WARNING. Before doing this or any other procedure in this manual, read the

Safety Summary found at the beginning of this manual. Also, to prevent possible

injury to service personnel or damage to the oscilloscope components, read

Installation in the TDS6000B & TDS6000C Series Digital Storage Oscilloscopes

Quick Start User Manual, available on the Web at www.tektronix.com, and

Preventing ESD in this section.

This subsection contains the following items:

H This preparatory information that you need to properly do the procedures

that follow.

H List of tools required to remove all modules.

H Procedures for removal and reinstallation of the electrical and mechanical

modules.

WARNING. Before doing any procedure in this subsection, disconnect the power

cord from the line voltage source. Failure to do so could cause serious injury or

death.

NOTE.ReadEquipment Required for a list of the tools needed to remove and

install modules in this oscilloscope. See Table 4--2, on page 4--8.

Read the cleaning procedure before disassembling the oscilloscope for cleaning.

Equipment Required. Most modules in the TDS6000B & TDS6000C Digital

Storage Oscilloscopes can be removed with a screwdriver handle mounted with a

size T-15, TorxR screwdriver tip. Other tools needed for complete disassembly

are listed in Table 4--2, on page 4--8.

TDS6000B & TDS6000C Series Service Manual

4- 7

Removal and Installation Procedures

Table 4- 2: Tools required for module removal

Item

no.

Name Description

General tool

number

1 Screwdriver handle Accepts Torx-driver bits 620-440

2 T-10 Torx tip Used for removing the electrical or

640-235

optical module chassis. Torx-driver

bit for T-10 size screw heads

3 T-15 Torx tip Used for removing most oscilloscope

640-247

screws. Torx-driver bit for T-15 size

screw heads

4

5 #0 phillips screwdriver Screwdriver for removing small

1

/8inch flat-bladed screw-

driver

Screwdriver for unlocking cable

connectors

Standard tool

Standard tool

phillips screws, CD & hard drive

6 Angle-Tip Tweezers Used to remove front panel knobs Standard tool

7

8

3

/

inch open-end wrench

16

3

/

inch nutdriver

or

16

9

/

inch open-end wrench

32

9

/32inch nutdriver

or

Used to remove the rear panel nut

posts

Used to remove the rear panel nut

posts

Standard tool

Standard tool

9 MA-800G Soldering Aid Used to remove the front panel trim Standard tool

4- 8

TDS6000B & TDS6000C Series Service Manual

Removal and Installation Procedures

Trim, Cabinet, and Module Removal

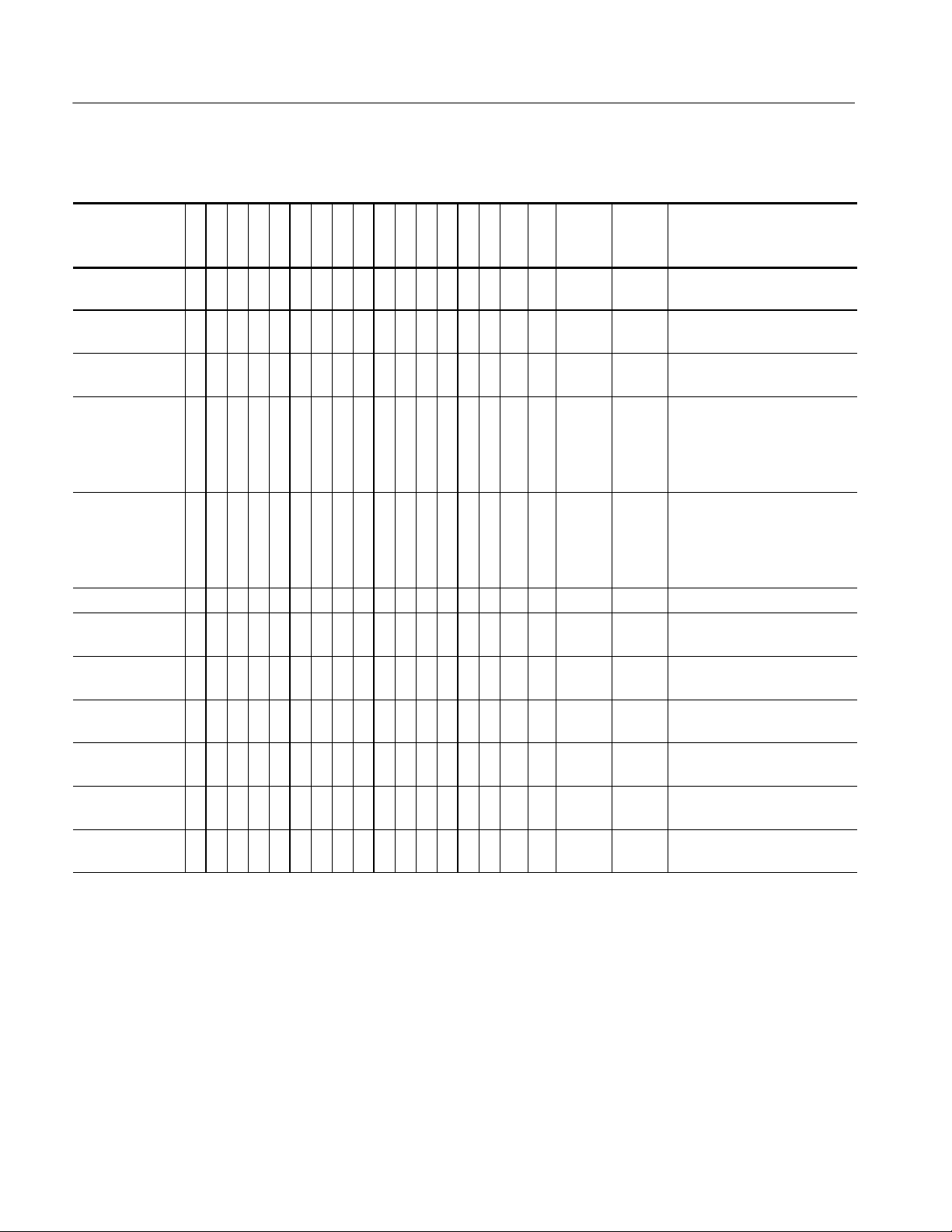

Table 4- 3: Column legend for Table 4 - 5

A -- Front cover (if installed) H -- Front panel assembly O -- Bridge board

B -- Front panel trim I -- 12V Aux distribution board P -- # of T15 Torx tip screws to remove

C -- Pouch (if installed) J -- Distribution board, front Q -- Number of connectors to unplug

D -- Cabinet, bottom K -- Distribution board, rear R -- Page reference

E -- Cabinet, top L -- PA Bus board assembly S -- Figure number reference

F -- Cover, LH side/top M -- MicroATX

G -- Cover, RH side, bottom N -- Connector bracket, CD--ROM drive

Table 4- 4: Accessing modules

A B C D E F G H I J K L M N O P Q R S

Assembly to

replace

Comment(s) / additional

assemblies to remove

Acquisition 5--15 5--4 Acquisition bd. is not field

serviceable. Contact service

depot.

MicroATX n n n n n n 11 1 5--15 5--4 Unfasten CD--ROM mounting

bracket to enable rotation of

MicroATX.

Bridge n n n n n n n n 10 5--15 5--4 Remove 10 T15 screws secur-

ing Power PC processor.

Remove 2 hex--head jack

screws securing Bridge connector to rear of unit.

SlidePPCforwardtoclear

Bridge connector.

Lift Bridge from slot on PPC.

CD-ROM drive n 2 5--13 5--3 Remove CD--ROM bezel.

Pull out CD--ROM drive.

CD--ROM drive

connector

Power PC (PCC)

processor

Display n n n n n 4 2 5--11 5--2

Display adapter 3 4 5--11 5--2 Remove display assy.

Display touch-screen

Distribution

board -- 12V AUX

n n n n n n 1 2 5--13 5--3 Remove CD--ROM drive.

Remove CD--ROM connector.

n n n n n n n n n 10 2 5--13

5--15

2 5--11 5--2 Remove display assy.

n n n n n 5--13 5--3

5--3

5--4

Remove MicroATX board, hard

drive, CDROM--RW, Bridge

board

Remove display adaptor

Remove touch--screen.

TDS6000B & TDS6000C Series Service Manual

4- 9

Removal and Installation Procedures

Table 4- 4: Accessing modules (Cont.)

Assembly to

replace

SRQPONMLKJIHGFEDCBA

Comment(s) / additional

assemblies to remove

Distribution

board -- front

Distribution

board -- rear

Distribution

board -- PA bus

Fans, side n n n n n 2 2 5--13 5--3 Unplug 2 fan connectors.

Fans, internal n n n n n 2 2 5--13 5--3 Unplug 2 fan connectors.

Front panel n n n n 4 1 5--11 5--2

Front panel interface

Front panel keypad

Hard disk drive

(HDD)

Hard disk drive

connector

Low voltage power supply (LVPS)

USB port (front

panel)

n n n n n 5--13 5--3

n n n n n 2 5--13 5--3

n n n n n 5--13 5--3

Unsnap 2 cable clamps.

Remove 2 screws from top of

fan assembly.

Lift fan assembly out.

Remove 2 screws from RH

side of fan assembly.

Slide fan assembly out to

right.

n 8 5--11 5--2 Remove front panel knobs

n 5--11 5--2 Remove front panel knobs,

front panel interface

2 5--13 5--3 Loosen 2 thumbscrews.

Pull out HDD.

n n n 1 2 5--13 5--3 Remove HDD.

Remove HDD connector.

n n n n n n n n n 5 2 5--15 5--4 Remove all four

distribution boards.

n n n 1 1 5--11 5--2

4- 10

TDS6000B & TDS6000C Series Service Manual

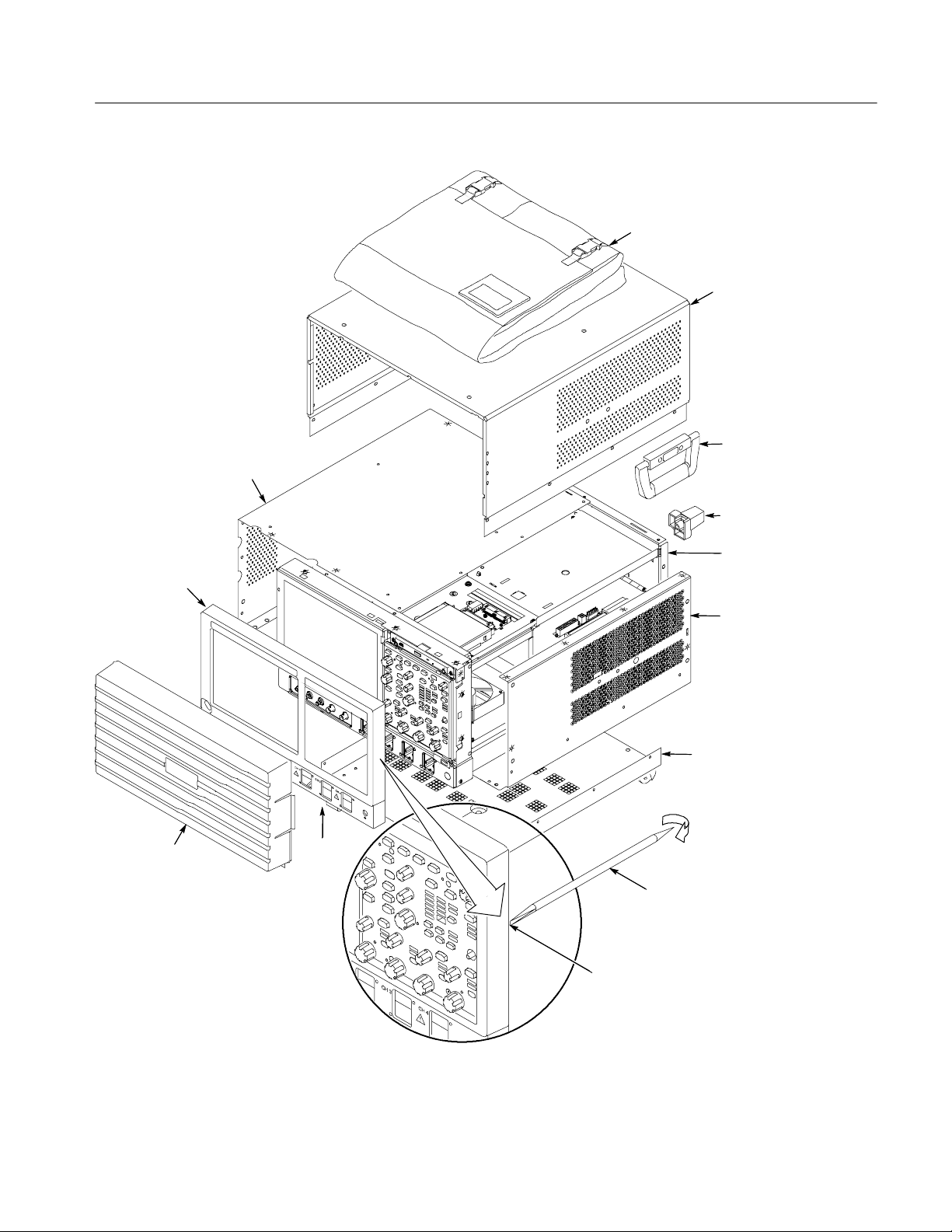

Left side / top

cover

Removal and Installation Procedures

Pouch

Top

cabinet

Carrying

handle

Rear foot

Front

panel trim

Front panel

cover

Chassis

Right side /

bottom cover

Bottom

cabinet

Acquisition

trim

Soldering aid

To remove the trim ring, slide the flat

end of a soldering aid into the side

slot on the trim ring. Press in, lift up

to hook it underneath, then pry out.

Figure 4- 1: Locator for tr im and cabinet removal

TDS6000B & TDS6000C Series Service Manual

4- 11

Removal and Installation Procedures

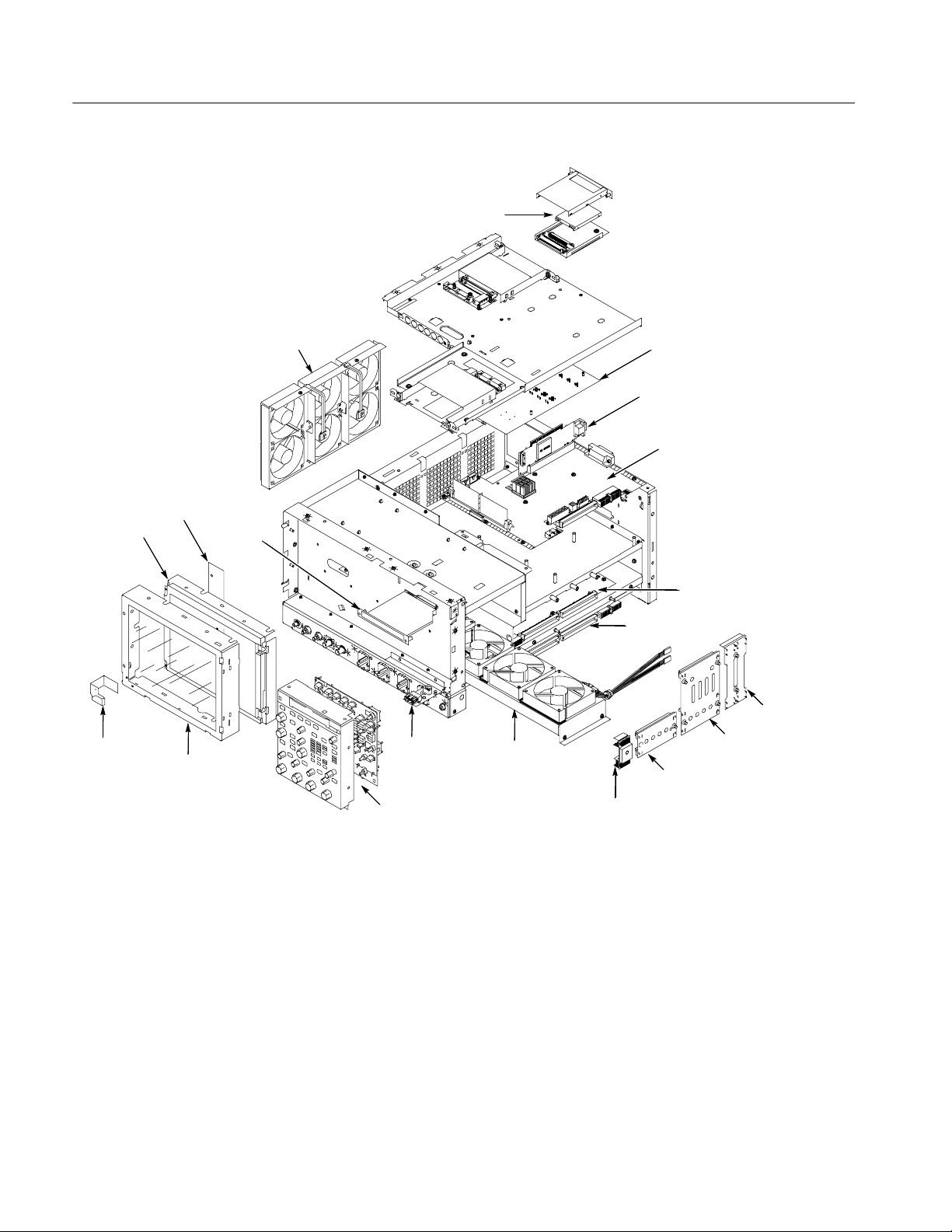

Side fan

assembly

Display

adapter

Display

assembly

board

CD--ROM

drive

Hard disk drive (HDD)

MicroATX board

Bridge board

Power PC (PPC)

processor

Low-voltage

power supply

assembly

Acquisition

board

Power

flex circuit

Touch--

screen

assembly

Figure 4- 2: Locator for internal modules

USB

adapter

Front panel

assembly

Internal fan

assembly

12V AUX

distribution

board

Front

distribution

board

PA bus

board

Rear

distribution

board

4- 12

TDS6000B & TDS6000C Series Service Manual

Removal Procedures

Removal and Installation Procedures

NOTE. Unless directed otherwise, installation is the reverse of the removal

procedure.

These procedures assume you have access to the module you are removing.

Refer to Table 4--4, page 4--9, to determine which trim and/or modules to

remove to gain access, and to direct you to the appropriate exploded drawing.

Figures 4--1 and 4--2, pages 4--11 and 4--12, are also provided as a quick

reference for trim and module locations.

CAUTION. When removing or installing the keypad, make sure you do not touch

the switch contacts with your fingers. The oils in your fingers will degrade or

damage the switch contacts. To help prevent damage to the keypad use cotton

gloves when removing or installing the keyboard pad.

Acquisition Module

MicroATX module

CAUTION. To avoid damage to the front panel Standby/On switch assembly, do

not set the Display module assembly on a work surface. Sliding the oscilloscope

over the edge of the work surface could break off the On/Standby switch

assembly.

The Acquisition module is not field serviceable. Contact the Tektronix service

depot for assistance.

Follow these steps to remove the MicroATX module.

1. Remove the four securing screws from the rear-panel and the three screws

from the side of the MicroATX module.

2. Disconnect the 12V Power Supply cable from J510 on the Power PC (PPC )

module.

3. Disconnect the Power Supply cable from J410 on the PPC module.

4. Gently lift up on the MicroΑΤΧ chassis until the Bridge module disconnects

from the MicroATX module PCI connector.

5. Raise the MicroATX chassis on its hinge, unsnap the prop, and insert the

prop into the retaining slot in the Main chassis side bar.

6. Disconnect the MicroATX cable from J9G1 on the MicroATX module.

TDS6000B & TDS6000C Series Service Manual

4- 13

Removal and Installation Procedures

7. Disconnect the Drive Power cable from J180 on the PPC module.

8. Disconnect the USB cable from J9F2 on the MicroATX module.

9. Raise the MicroATX chassis and snap the prop back into place.

10. Move the MicroATX chassis toward the back of the instrument, to disengage

the hinge, and lift it away from the Main chassis.

Bridge Module

Power PC (PPC)

Follow these steps to remove the Bridge module.

1. Raise the MicroATX module, as described in the previous step.

2. Remove the 10 screws securing the PPC module to the Main chassis.

3. Remove the two jack screws securing the XGA OUT connector to the rear

panel.

4. Remove the two jack screws securing the GPIB connector to the rear panel.

5. Slide the PPC module slightly toward the front of the oscilloscope, until the

XGA OUT connector is clear.

6. Unplug the Bridge module from J870 on the PPC module and lift it out.

Follow these steps to remove the Power PC (PPC) module.

1. Raise the MicroATX module, as described previously.

2. Disconnect and remove the Rear Power Distribution module.

3. Disconnect and remove the PA Bus module.

4. Disconnect the Wide Display cable from J290 on the PPC module.

4- 14

5. Disconnect the Narrow Display cable from J205 on the PPC module.

6. Disconnect the Fan Extender cables from J291 and J390 on the PPC module.

7. Remove the 10 screws securing the PPC module to the Main chassis.

8. Remove the two jack screws securing the XGA OUT connector to the rear

panel.

9. Remove the two jack screws securing the GPIB connector to the rear panel.

10. Slide the PPC module slightly toward the front of the oscilloscope, until the

XGA OUT connector is clear, then lift the PPC and Bridge modules out as a

unit.

TDS6000B & TDS6000C Series Service Manual

Removal and Installation Procedures

CD- ROM Drive

Display

Follow these steps to remove the CD--ROM drive.

1. Remove the two screws securing the CD--ROM bezel, and remove the bezel.

2. Pull the CD--ROM drive out from the Main chassis.

3. Remove the four screws securing the CD--ROM drive and Adapter board to

the CD--ROM drive bracket.

4. Separate the CD--ROM drive and the Adapter board.

Follow these steps to remove the Display module.

1. Remove the four screws securing the display to the Main chassis; two on the

top and two on the left side.

2. Gently remove the Display module from the Main chassis.

3. Disconnect the smaller Display cable from J3 on the Display Adapter board.

4. Disconnect the larger Display cable from J2 on the Display Adapter board.

CAUTION. Be careful when removing and reinstalling the Display module cables.

If the connectors have bent pins or are installed incorrectly the Display may be

destroyed.

Side Fans

Internal Fans

Follow these steps to remove the side fan assembly.

1. Disconnect the fan cables from the fan cable extenders.

2. Unsnap the cable clamps controlling the fan cables.

3. Remove the two screws securing the fan assembly to the Main chassis.

4. Lift the fan assembly up off the tabs on the Main chassis.

Follow these steps to remove the Internal Fan assembly.

1. Remove the two screws securing the internal fan assembly to the Main

chassis.

2. Slide the fan assembly out of the Main chassis.

3. Disconnect the two fan cables.

TDS6000B & TDS6000C Series Service Manual

4- 15

Removal and Installation Procedures

Front Panel

USB Module

Hard Disk Drive

Follow these steps to remove the Front Panel.

1. Remove the six screws that secure the Front Panel to the Main chassis; two

on the top, two on the right side, and two on the bottom.

2. Pull the Front Panel away from the Main chassis.

3. Disconnect the Front Panel cable from P1 on the Front Panel module.

Follow these steps to remove the USB module.

1. Disconnect the USB cable from J1 on the USB module.

2. Remove the one screw securing the USB module to the Main chassis.

3. Lift the USB module from its guide post.

Follow these steps to remove the hard disk drive.

1. Loosen the thumbscrews securing the hard drive to the rear panel.

2. Grasp the hard disk drive assembly by the thumb screws and pull until the

handle is exposed. Grasp the handle and pull the hard drive assembly straight

out of the instrument.

3. Pry the detents retaining the top cover apart, and remove the top cover.

4. Remove the four screws securing the hard drive to the bottom cover.

5. Separate the hard disk drive from the HDD Adapter board.

To replace the hard drive.

1. Connect the hard drive to the HDD Adapter board.

2. Attach the hard drive to the bottom cover with the four screws removed

above.

3. Snap the top cover onto the bottom cover.

4. Leaving the cover/handle extended, push the hard drive assembly into place

until it stops, ensuring that it is straight. Push the hard drive assembly firmly

to ensure that the connector is seated properly.

5. Slide the cover/handle in until it stops. It will be alsmost flush with the back

panel.

6. Finger tighten the two thumb screws to ensure that the removeable hard

drive is properly seated.

4- 16

TDS6000B & TDS6000C Series Service Manual

Troubleshooting

Service Level

WARNING. Before performing this or any other procedure in this manual, read

the General Safety Summary and Service Safety Summary found at the

beginning of this manual.

T o prevent possible injury to service personnel or damage to electrical components, please read Preventing ESD on page 4--1.

This section contains information and procedures designed to help you isolate

faults to a module.

This section assumes that service personnel have the prerequisite skills required

to work on this oscilloscope, including PC troubleshooting and Windows

operating system skills. Details of PC and Windows operation and service are

not in this manual.

For assistance, contact your local Tektronix Service Center.

This subsection contains information and procedures designed to help you isolate

faulty modules in the oscilloscope. If a module needs to be replaced, follow the

Removal and Installation Procedures located in this section.

Check for Common Problems

Use Table 4--5 to quickly isolate possible failures. The table lists problems and

possible causes. The list is not exhaustive, but it may help you eliminate a

problem that is quick to fix, such as a blown fuse or loose cable.

Table 4- 5: Failure symptoms and possible causes

Symptom Possible cause(s)

Oscilloscope will not power on H Power cord not plugged in

Front panel light comes on

(oscilloscope powers on), but

one or more fans will not

operate

H Faulty power supply

H Faulty fan cable

H Defective fan assembly

H Faulty power supply

TDS6000B & TDS6000C Series Service Manual

4- 17

Troubleshooting

Table 4- 5: Failure symptoms and possible causes (Cont.)

Symptom Possible cause(s)

PPC appears “dead”; power

light comes on, but monitor

screen(s) is (are) blank,

oscilloscope emits no beeps

H SO DIMMs incorrectly installed or missing. Missing DIMMs

will cause a POST fault and MicroATX will beep

H Defective Power PC (PPC) board

H Hold down on-standby button on the PPC, if system boots,

replace the power supply

Hard disk drive related

symptoms

CD-ROM related symptoms H Defective CD-ROM

H Improperly seated hard disk drive assembly

H Defective hard disk drive

H Incorrect hard disk type selected in the BIOS setup

H Replaceable hard disk drive not installed

H Power supply failure

H Corrupted BIOS module f irmware, reinstall firmware

H Hard disk drive not configured as bootable (slave) master

hard disk drive

H Loose cable

H Faulty bridge board

H Faulty PPC board

H Defective CD-ROM drive cable

H Defective CD-ROM board

H Incorrect CD-ROM configuration in the BIOS setup

4- 18

TDS6000B & TDS6000C Series Service Manual

Troubleshooting

Table 4- 5: Failure symptoms and possible causes (Cont.)

Symptom Possible cause(s)

Flat panel display blank H Display selection jum per set incorrectly on front panel

board (there are no jumpers on the board when the

oscilloscope is shipped from the factory; this i s the correct

default setting)

H Video adapter set to Integrated (connect monitor to

MicroATX VIDEO port, enter BIOS, set Video Adapter =

PCI)

H BIOS setting not Advance > Video Configuration > Primary

Video Adapter = PCI

H Defective cable from front panel board to display adapter

board

H Defective cable from inverter board to display adapter

board

H Defective cable from inverter board to backlighting display

lamp

H Defective backlighting display lamp

H Faulty display

H Faulty controller board

H Faulty inverter board

H Faulty display adapter board

BIOS error messages H Refer to the BIOS error m essage tabl es starti ng on

Equipment Required

You will need a digital voltmeter to check power supply voltages, as described

on page 4--22.

Testing might also be required to correct some faults. Under those circumstances,

you will need the test equipment listed in the TDS6000B & TDS6000C

Specifications and Performance Verification Technical Reference, available on

the documentation CD--ROM supplied with your instrument, or on the Web at

www.tektronix.com.

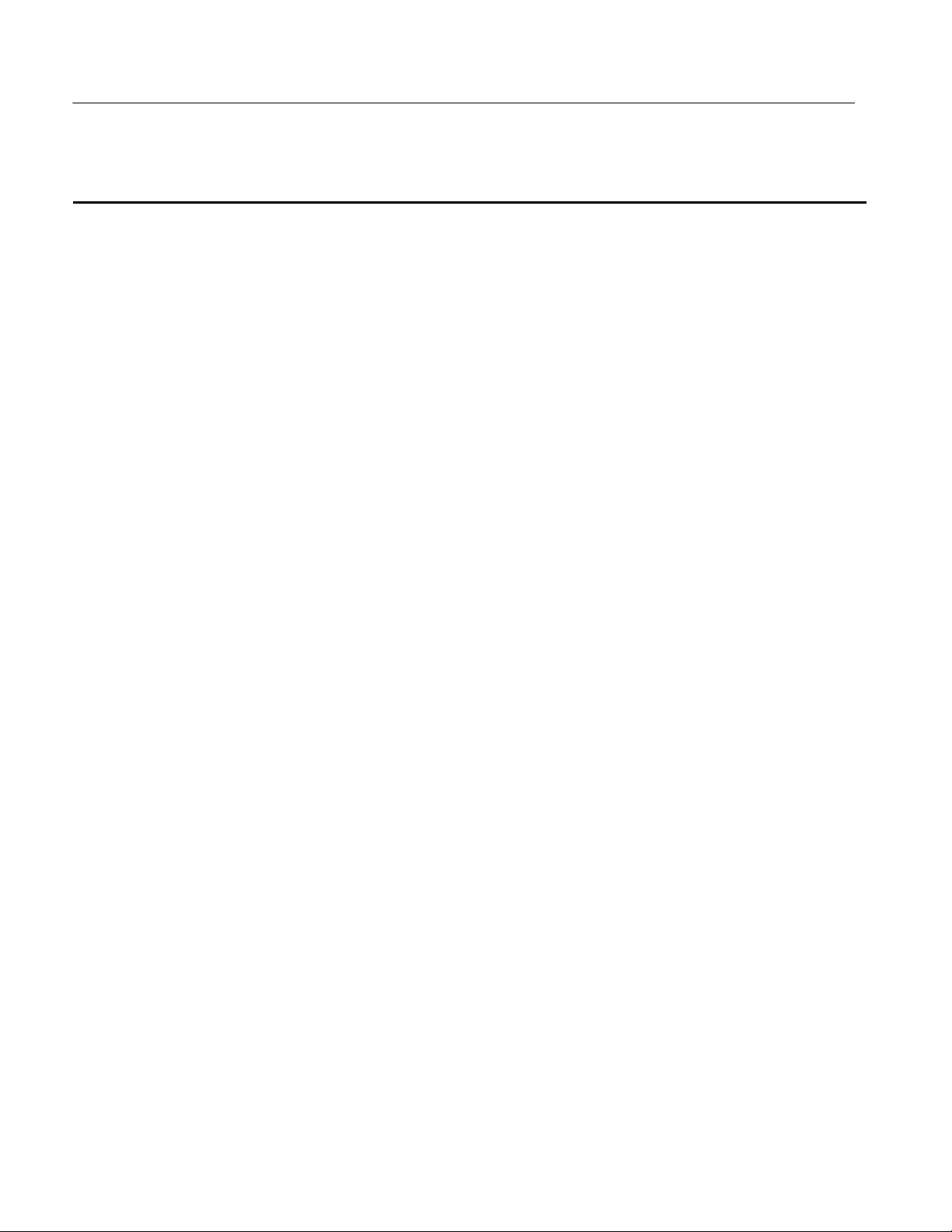

Fault Isolation Procedure

Follow the primary troubleshooting tree in Figure 4--3 for fault isolation. This

tree calls for you to run the diagnostics programs, and check for BIOS errors.

page 4--30

TDS6000B & TDS6000C Series Service Manual

4- 19

Troubleshooting

Start

Turn on power

Oscilloscope

powers on

(fans run)?

Yes

Oscilloscope appears

“dead” (dead screen)?

No

Flat-panel

display OK?

Yes

External

monitor

blank, if

present?

No

Possible cause:

1 Oscilloscope power

cord is not plugged in

No

2DoChecking Power

Yes

Beeps

Supply Voltages on

page 4--21

No

Install XGA

No

monitor to

XGA port

XGA OK.

No

Bad PPC, DA, bridge, or

inverter board. Loose

connections

Bad MicroATX, PPC, or bridge board

Yes

Possible cause:

1 Monitor cable defective or not

connected to oscilloscope

2 External monitor controls

turned down

3 Defective monitor

Possible cause:

1 SO DIMMs incorrectly

Yes

Yes

installed or missing

2 Defective controller

board

3 Check beep codes on

page 4--31

Move monitor

to VIDEO

BIOS setting, bad

PPC or bridge

XGA OK.

port.

board

Yes

No

Windows

Boots?

No

Yes

Run CheckIt Utilities

(see CheckIt Utilities

on page 4--27)

Passes all

tests?

No

Yes

Run oscilloscope diagnostics (see

page 4--28 for instructions)

Passes all

tests?

No

Yes

If the oscilloscope Application is not

already running, start it from the

Start menu.

Oscilloscope

Application

starts?

No

Yes

Done

1 See If the Oscilloscope

Will Not Boot on

page 4--24.

2 See Booting Into

Windows on page 4--24.

3 Boot to Safe Mode and

restore the registry.

4 Consult the

troubleshooting section

of your Microsoft

Windows manual

5 See Troubleshooting

Using Reset Circuits on

page 4--34.

Note: It is normal for

CheckIt Utilities to report

an audio failure.

Repair/replace failed part

identified by CheckIt

Utilities

1

Acquisition board

defective

Reinstall oscilloscope

software (see user

manual)

Do If the Oscilloscope

Application Does Not

Work on page 4--24

BIOS error

message?

Yes

See BIOS error

code, Table 4--10

on page 4--30

No

Figure 4- 3: Primary troubleshooting tree

4- 20

1

If only error is error code 512, run SPC after

warmup and then re--run diagnostics.

TDS6000B & TDS6000C Series Service Manual

Troubleshooting

Checking the Power

Supply Voltages

First, make a visual check. As viewed from the right side of the oscilloscope,

there are 11 LEDs on the power supply, which can be seen through the side panel

(see Figure 4--4). DS10 and DS11 are the Global Power indicators, DS3 is the

Standby indicator. When mains power is applied DS10 and DS11 will be on

(green). When the oscilloscope is in standby mode, DS3 will be on (red). When

the oscilloscope is switched to Operate mode, the red standby light will go off

and the remaining LEDs should turn on (green). If DS3 (red) comes on while the

oscilloscope is on, it indicates an overcurrent condition. Table 4--6 shows what is

indicated by the other LEDs.

DS7 DS6 DS1 DS8 DS9 DS4 DS2 DS5

Figure 4- 4: Low voltage power supply LED locations

Table 4- 6: LVPS LED descriptions

LED Voltage LED Indicates

DS1 -- 5 V Good to ACQ board

DS2 +3.3 V Good to PPC, ATX, and ACQ boards

DS4 +5 V Good to PPC, ATX, and ACQ boards

TDS6000B & TDS6000C Series Service Manual

DS10 DS11 DS3

4- 21

Troubleshooting

Table 4- 6: LVPS LED descriptions (Cont.)

LED LED IndicatesVoltage

DS5 +12 V Good to PPC and ATX boards

DS6 +12 V Aux 1 Good to ACQ bd. regulators

DS7 +12 V Aux 2 Good to ACQ bd. regulators

DS8 +15 V Good to ACQ board

DS9 -- 1 5 V Good to ACQ board

1

Becomes +2.6 V Demux supply.

1

1

4- 22

Low voltage power supply LEDs are near the

center of the power supply. A glow from them

is visible while looking through the side of the

Oscilloscope

Figure 4- 5: Location of power-on and over current LEDs

To check the power supply voltages, power on the oscilloscope and connect the

reference lead of a digital voltmeter to chassis ground.

Attach a 0.025 inch square pin to the probe tip of the other lead and insert it into

a pin on one of the connectors. The pins that should be carrying voltages are

listed in Table 4--7. The location of the J1 and J2 connectors is shown in

Figure 4--6 on page 4--23.

Measure the power supply voltages with the voltmeter and compare each reading

to the values listed in the tables. If the voltages are within about 5% of the

nominal voltages, your power supply is functional.

TDS6000B & TDS6000C Series Service Manual

Table 4- 7: Power supply voltages

Auxiliary power

distribution

board (P3) and

Power supply

(J3)

Voltage

Front power distribution board

(P2) and Power

supply (J2)

Voltage

Troubleshooting

Rear power distribution board

(P1) and Power

supply (J1)

Voltage

Pins A/B/C1, 2, 3,

9, 10, 11

+12 V Pins A/B/C1, 2, 3,

4, 7, 8, 11, 12, 13,

+5 V Pins A/B/C9, 10,11+12 V

14

Pins D1. 11 +6 V Pins A/B/C16, 17,

18, 21, 22, 23, 26,

-- 5 V Pins A/B/C14, 15,

16, 19, 20, 21, 22

27, 28, 29

PinsD2,3,9,10 +12 V Pins A31, 32 +15 V Pins A/B/C25, 26,

27, 30, 31, 32

Pins E1, 11 +3 V Pins C31, 32 -- 1 5 V

PinsE2,3,9,10 +12 V

J1 and P1

+3 V

+5 V

Figure 4- 6: Connectors J1, J2, and J3

TDS6000B & TDS6000C Series Service Manual

J2 and P2

PA bus

circuit board

Rear distribution

board

Front distribution

board

12VAUX

distribution board

4- 23

Troubleshooting

If the Oscilloscope Will

Not Boot

Booting Into Windows

If there is a display on the XGA port, but not on the LCD, the oscilloscope may

be in safe mode. Reboot the oscilloscope to clear this condition. If this does not

fix the problem, then replace the display assembly (LCD, lamps, and cable).

At boot time, and while using an external monitor connected to the MicroATX

external video port, press F2 to enter the BIOS setup. The Advanced Video

Configuration menu lets you select PCI (LCD) or Integrated (the MicroATX

VIDEO port on the rear panel). The lower XGA port on the rear panel is the PCI

video port (driven by the same video controller as the LCD).

If the oscilloscope will not boot, run the CMOS restore utility (see Update/Restore the MicroATX Board CMOS on page 4--36).

If booting starts, finds the hard disk, but hangs displaying the Windows splash

screen:

1. Select the Integrated video port using the setup menu.

2. Disable the busses and disconnect the PPC board by installing J114 and J115

(see Figure 4--9, page 4--36).

3. If the system boots (It will only boot to Windows, the oscilloscope application will not run) to the external MicroATX video port, replace the PPC

bridge board.

If the Oscilloscope

Application Does Not

Work

If the oscilloscope boots into Windows, but the oscilloscope application does not

work (the initial splash screen is displayed), check the following:

1. The application software.

2. The Acquisition board.

3. The PPC board.

4. Did someone exit the application using the Task Manager and then try to

reenter the application without rebooting?

5. Check the desktop properties (right click on the desktop and select Properties). On the Settings tab, 16 bit is required. Video merge will not work with

other settings. If you change the setting, reboot.

6. On the Settings tab of the desktop properties, select Advanced and then the

Performance tab. Hardware Acceleration must be set to Full for video merge

to work. If you change the setting, reboot.

4- 24

TDS6000B & TDS6000C Series Service Manual

PPC and MicroATX PC Diagnostics

y

The primary diagnostics for the oscilloscope are the power-on diagnostics, the

CheckIt Utilities diagnostics, and the oscilloscope diagnostics. Procedures for

running these diagnostics are described next.

Troubleshooting

Power-on Diagnostics

The power-on diagnostics check the basic functionality of the oscilloscope at

every power on. If any failures occur at power on, the screen displays the

calibration and diagnostics property page. Table 4--8 lists a subset of the power

on tests. Use the results of the tests to help you isolate problems to system

modules.

The power on tests ensure that hardware is installed and can be accessed by the

software. The tests provide limited diagnostic information, but do not provide

any performance information. The oscilloscope diagnostics provide more

extensive tests than the power-on diagnostics.

The power on tests check the generic hardware including the keyboard, mouse,

memory, CPU, and associated peripherals. The interrupt lines and trigger lines

are also checked.

If there are no failures, you can view the results of the tests in the Instrument

Diagnostics page under the Utilities menu.

Table 4- 8: Power-on diagnostic tests

Component Group&test Error Codes Power on Extended

Mainframe VTC Reset Test n

VTC Walk1 Test n

ADG Register Test n

ADG VXI Addr Test n

ADG VXI Data Test n

System Interrupt Lines n n

Trigger Lines n n

Processor Memory 111 DRAMWalk1

112 DRAMCell

113 DRAMMarch

114 NVRAM

n

PCI Bus 121 Scan Test n

TDS6000B & TDS6000C Series Service Manual

4- 25

Troubleshooting

Table 4- 8: Power-on diagnostic tests (Cont.)

Component ExtendedPower onError CodesGroup&test

RegAccess Ch1 Serial 211 AtoD

212 DAC

213 Preamp

Ch2 Serial 221 AtoD

222 DAC

223 Preamp

Ch3 Serial 231 AtoD

232 DAC

233 Preamp

Ch4 Serial 241 AtoD

242 DAC

243 Preamp

Direct R/W 251 Demux

252 DSY

253 SBTL

254 SGTL

IIC 261 AckIdle

262 Pogo_U1

263 U1350

Relays 271 Interrupt

272 Overloads

273 ShiftLoop

Serial 281 PA_unique

282 PLL

283 TH_IDs

284 TH_unique

285 Trigger DAC

286 U1500

287 U2000

n

n

n

n

n

n

n

n

4- 26

TDS6000B & TDS6000C Series Service Manual

Table 4- 8: Power-on diagnostic tests (Cont.)

Component ExtendedPower onError CodesGroup&test

Troubleshooting

Acquisition DemuxMem 311 MemData

312 MemAddr

313 DMA Read

314 DMA Write

315 FIR

Demux 321 RunAB

322 AcqDone

323 Xfer

324 ICD Bus

325 Intrlv

326 XYtest

327 FIR

Vertical 331 ADC Connects n

Interrupt 341 Bit Tests n

HF Step 351 PhaseCal n n

PLL 361 Clock Freq n

Acq Modes 371 HiRes

372 Peak Detect

373 SubSample

Memory 381 DataFormat

382 MemSpeed

Trigger Inputs 411LineStarted

412 CH1 started

413 CH2 started

414 CH3 started

415 CH4 started

416 Events

417 Comm

n

n

n

n

n

Internals 421 BTrig

Nibble 471 Bus n

Misc Cal Integrity 511 Factory Cal

GPIB 521 Interface n

CheckIt Utilities

If the oscilloscope passes all the BIOS tests and Windows boots, the primary tree

calls for you to run CheckIt Utilities diagnostics software. CheckIt Utilities is a

comprehensive diagnostic software application to check and verify the operation

of the PC hardware in the oscilloscope.

TDS6000B & TDS6000C Series Service Manual

n

422 BTrigEvents

423 TimeInterp

424 Holdoff

425 TrigInfo

n

512 SPC (run SPC)

4- 27

Troubleshooting

CheckIt Utilities. To run the CheckIt Utilities, you must have either a working

keyboard, a pointing device (mouse), and WindowsXP must be running. Before

starting the utilities install a test floppy disk in the floppy disk drive and a test

CD in the CD-ROM drive. Refer to the CheckIt Utilities online help for

additional information on running the utilities. Repair or replace any failed

component identified by the CheckIt Utilities.

Oscilloscope Diagnostics. If the oscilloscope passes all the CheckIt Utilities tests,

the primary tree calls for you to run the oscilloscope extended diagnostics. The

oscilloscope Diagnostics are a comprehensive software test that checks the

functionality of the oscilloscope. If the oscilloscope Diagnostics test fails, the

oscilloscope is defective.

Diagnostics

Software Updates

The oscilloscope has two levels of internal diagnostics that focus on verifying,

adjusting, and if need be, isolating faulty modules.

Both levels of internal diagnostics report any defective modules. If a defective

module is found, replace the module.

The two levels of diagnostics are the short confidence set and the extended set

that tests the oscilloscope circuitry in depth and takes more time. At power on,

the oscilloscope automatically executes the short set. The extended set is

optional and is executed by using the following procedure:

Prerequisites: Power on the oscilloscope and allow a 20 minute warm-up before

doing this procedure.

1. Turn off all other applications.

2. From the menu bar, touch Utilities and then select Instrument Diagnostics.

Software updates are easy to do. Simply install the firmware CD in your

oscilloscope and follow the displayed instructions or the instructions that

accompany the CD.

4- 28

Firmware updates are available for download at no charge from the Tektronix

web site. To find available software updates for your oscilloscope, go to

www.tektronix.com/software and enter your oscilloscope’s model number as

keyword. Updates are also available on CD. If you want to order a software

update on CD, contact your Tektronix service center.

TDS6000B & TDS6000C Series Service Manual

After Repair

Troubleshooting

After removal and replacement of a module due to electrical failure, you must

perform the adjustment or software update as indicated in Table 4--9.

Table 4- 9: Action required for m odule replaced

Adjustment

Module replaced

Front panel assembly No None

Acquisition board Yes

PPC Processor board No

MicroATX processor assembly

Same version

Updated

Display panel or display system No None

Power supply Yes None

Interconnect boards No None

Fans No None

Hard drive

New

Spare

1

Adjustment must be performed by Tektronix.

2

Replacement of this board must be performed by Tektronix.

3

Run SPC after the oscilloscope warms up.

required

No

No

No

No

1

2

3

Software update required

None

Installation by Tektronix is

required

None

Windows,

oscilloscope application

Windows,

oscilloscope application,

optional software applications,

run SPC after warmup

Run SPC after warmup

BIOS Error Messages

When the MicroATX board powers-on, the BIOS runs power-on-self-tests

(POST) to check the board. The BIOS writes error codes to location 80h and

tries to write the codes to the display. If the error is fatal, then the POST code

indicates the last successful checkpoint reached. Table 4--10 lists the error

messages displayed by the BIOS.

Once the display is enabled, errors are written to the display as text messages.

These messages are always displayed unless the board is configured for silent

boot or headless (no keyboard, mouse, or display) operation.

TDS6000B & TDS6000C Series Service Manual

4- 29

Troubleshooting

Table 4- 10: BIOS Error messages

Error message Description

GA20 Error Error when switching to protected mode during the memory test.

Pri Master HDD Error, Pri Slave HDD Error

Sec Master HDD Error, Sec Slave HDD Error

Pri Master Drive -- ATAPI Incompatible

PRI Slave Drive -- ATAPI Incompatible

Sec Master Drive -- ATAPI Incompatible

Sec Slave Drive -- ATAPI Incompatible

A: Drive Error No response from drive.

Cache Memory Bad Memory may be bad.

CMOS Battery Low Replace battery.

CMOS Display Type Wrong Check Setup to make sure type is correct.

CMOS Checksup Bad Run Setup to reset values.

CMOS Settings Wrong Settings corrupted or the battery has failed.

CMOS Date/Time Not Set Run Setup to correct values.

DMA Error Error during read/write test of controller.

FDC Failure Error while trying to access controller.

HDC Failure Error while trying to access controller.

CheckingNVRAM.... NVRAM is being checked.

Update OK! Invalid NVRAM has been updated.

Updated Failed Unable to update invalid NVRAM.

Keyboard Error Make sure keyboard is connected properly.

KB/Interface Error Keyboard test failed.

Memory Size Decreased If no memory was removed, the memory may be bad.

Memory Size Increased If no memory was added, system may have a problem.

Memory Size Changed If no memory was added or removed, the memory may be bad.

No Boot Device Available Boot device not found.

Off Board Parity Error Parity error occurred on an off-board card.

On Board Parity Error Parity error occurred in on-board memory.

Parity Error Error occurred in on-board memory at an unknown address.

NVRAM/CMOS/PASSWORD cleared by Jumper Turn off power and remove the jumper.

<CTRL_N> Pressed CMOS is ignored and NVRAM is cleared. Enter Setup.

Could not read sector.

Drive not an ATAPI device. Run Setup, and maker sure device is

set up correctly.

4- 30

TDS6000B & TDS6000C Series Service Manual

BIOS Beep Codes

Troubleshooting

When the MicroATX board powers-on a number of the BIOS checkpoints

generate an audible ‘beep’ code on failure using the standard PC speaker (also

routed through the board audio system). The beep codes are listed in Table 4--11.

Codes are also written to I/O port 80h and the video adapters. External ROM

modules may issue a series of tones on error detection.

The BIOS generates one short beep if the power up self tests complete without

error.

If your instrument does not contain a speaker, attach a speaker to the displayadapter board square pins to hear the codes.

Table 4- 11: Beep codes

Beep code Error message

1 Refresh failure

DIP Switch Controls

2 Cannot reset parity

3 Memory failure, first 64 KB

4 Timer failure

5 Not used

6 Cannot toggle 8042 GateA20

7 Exception interrupt error

8 Display memory R/W error

9 Not used

10 CMOS Shutdown register test error

11 Invalid BIOS

1 long, 1 short Video configuration failure, or external ROM module checksum error

DIP switches (see Figure 4--9 on page 4--36) are used to direct program flow

during power on self test (POST) of the power PC (PPC). A switch set to ON is

closed and presents a low state (0 V) to the switch buffer. This is the default

switch position. A switch set to OFF is open and presents a high state (3.3 V) to

the switch buffer. This is the ‘set’ position. Table 4--12 describes the switch

functions.

TDS6000B & TDS6000C Series Service Manual

4- 31

Troubleshooting

Table 4- 12: DIP switch functions

Test option

Switch

1 1 Meg RAM test 32 Meg RAM test POST cannot determine how much

2 Enable phase 2 POST Disable phase 2 POST Use to disable phase 2 of POST.

3 Do not loop on phase 2 POST Loop on entire phase 2 POST This switch is checked at every loop

4 Allow debug output Suppress debug output Used by the console. Checked at every

5 Loop on failing test Continue past failing test If a test fails (except DRAM march test)

6 Stop on failing test Continue past failing test If set and a test fails, the program

7 Do not cycle application diagnostics Application diagnostic cycle If set, the power-on diagnostics cycle,

Default

Set Description

DRAM is installed in the board.

iteration, so it is possible to break out

of this loop by moving switch 3 to the

default position. You cannot loop on a

single passing test.

write operation.

and switch 6 is set, this switch is

checked. You can break out of the loop

by moving switch 5 to the set position,

removing the fault, or by setting switch

6 to the default position.

checks switch 5. If not set, the program

will stop on a failure by branching to a

loop. To exit the loop, reset the power

PC.

which prevents completion of the boot

sequence.

8 Do not force power-up diagnostics Forces power-up diagnostics At power-on this switch is checked, and

if set, power-up diagnostics will run.

Diagnostic LED

Table 4--13 lists the actions performed at power-up of the power pc (PPC) and

the associated display on the diagnostic LED. See Figure 4--9 on page 4--36 for

the location of the Diagnostic LED (DS320). Until the MPC106 is initialized the

LED is not active. RESET forces the display to 8. H, L, P, and a blinking -indicate where the program is in the power-up sequence. As tests occur, the

associated number is displayed on the LED. A failing test displays a decimal

point and the test number.

4- 32