Page 1

User Manual

TDS 520 & 540

Digitizing Oscilloscopes

070-8317-01

This document supports Version 2 firmware.

Please check for change information at the rear

of this manual.

First Printing: March 1992

Last Revised: November 1992

Page 2

Copyright E Tektronix, Inc. 1991, 1992. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Microsoft is a registered trademark of Microsoft Corporation

IBM is a registered trademark of International Business Machines

GPIB-PCII and GPIB-PCIIA are registered trademarks of National Instruments Corporation

Epson is a registered trademark of Epson America, Inc.

Interleaf is a trademark of Interleaf, Inc.

PostScript is a registered trademark of Adobe Systems Incorporated

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of three (3) years from the date of shipment. If a product proves defective during this

warranty period, T ektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by T ektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the T ektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than T ektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

This apparatus has been designed and tested in accordance with IEC Publication 348, Safety Requirements for

Electronic Measuring Apparatus, and has been supplied in a safe condition. This manual contains some

information and warnings which have to be followed by the user to ensure safe operation and to retain the

apparatus in safe condition.

The apparatus has been designed for indoor use. It may occasionally be subjected to temperatures between +5_ C

and –10_ C without degradation of its safety.

Page 5

Welcome

This is the User Manual for the TDS 520 and TDS 540 Digitizing Oscilloscopes.

Related Manuals

If you are a new user, try the

operation of your digitizing oscilloscope.

Concepts

The

scope. These articles help you understand why your instrument works the

way it does.

Use the

for a complete list of tasks covered in that section.

Appendices

The

tion, and other useful information.

The following documents are related to the use or service of the digitizing

oscilloscope.

H

The

070-8318-03) describes using a computer to control the digitizing oscilloscope through the GPIB interface.

H

The

gives you a quick overview of how to operate your digitizing oscilloscope.

H

The

070-8582-00) describes use of the Advanced DSP Math option (for TDS

oscilloscopes equipped with that option only).

section covers basic principles of the operation of the oscillo-

In Detail

TDS Family Programmer Manual

TDS 520 & 540 Reference

TDS Family Option 2F Instruction Manual

section to learn how to perform specific tasks. See page 3-1

provide an option and accessories listing, product specifica-

Tutorial

section to become familiar with the

(Tektronix part number

(Tektronix part number 070-8316-01)

(Tektronix part number

TDS 520 & TDS 540 User Manual

H

H

H

TDS Family Option 13 Instruction Manual

The

070-8567-00) describes using the optional Centronicsr and RS-232

interfaces for obtaining hardcopy (for TDS oscilloscopes equipped with

that option only).

TDS 520

The

070-8603-00) tells how to verify the performance of the digitizing oscilloscope.

TDS 520 Service Manual

The

TDS 540 Service Manual

the

maintaining and servicing your digitizing oscilloscope to the module level.

&

TDS 540 Performance Verification

(Tektronix part number 070-8312-01) and

(070-8314-01) provide information for

(Tektronix part number

(Tektronix part number

i

Page 6

Conventions

In the

Tutorial

contain steps of instructions for you to perform. To keep those instructions

clear and consistent, this manual uses the following conventions:

H

Names of front panel controls and menu labels appear in boldface print.

H

Names also appear in the same case (initial capitals, all uppercase, etc.)

in the manual as is used on the oscilloscope front panel and menus. Front

panel names are all upper case letters, for example, VERTICAL MENU,

CH 1, etc.

H

Instruction steps are numbered. The number is omitted if there is only

one step.

H

When steps require that you make a sequence of selections using front

panel controls and menu buttons, an arrow ( ➞

between a front panel button and a menu, or between menus. Also,

whether a name is a main menu or side menu item is clearly indicated:

Press VERTICAL MENU ➞ Coupling (main) ➞ DC (side) ➞ Band-

width (main) ➞ 100 MHz (side).

Using the convention just described results in instructions that are graphically intuitive and simplifies procedures. For example, the instruction just

given replaces these five steps:

1. Press the front panel button VERTICAL MENU.

and

In Detail

sections, you will find various procedures which

) marks each transition

2. Press the main menu button Coupling.

3. Press the side-menu button DC.

4. Press the main menu button Bandwidth

5. Press the side menu button 100 MHz

H

Sometimes you may have to make a selection from a popup menu: Press

TRIGGER MENU ➞ Type (main) ➞ Edge (popup). In this example, you

repeatedly press the main menu button Type until Edge is highlighted in

the pop-up menu.

ii

Welcome

Page 7

T utorial

Contents

Product Description v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Up viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1: Displaying a Waveform 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 2: Multiple Waveforms 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3: Automated Measurements 1-12. . . . . . . . . . . . . . . . . . . . . . . .

Example 4: Saving Setups 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concepts

In Detail

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling and Positioning Waveforms 2-13. . . . . . . . . . . . . . . . . . . . . . . . . .

Measurements 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

At a Glance 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition Modes 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autoset 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cursor Measurements 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delayed Triggering 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Modes 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 520 & TDS 540 User Manual

Edge Triggering 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardcopy 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Help 3-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal Control 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limit Testing 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Triggering 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement System 3-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Accessories 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Cal 3-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Compensation 3-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Selection 3-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Triggering 3-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Communication 3-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving and Recalling Setups 3-110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving and Recalling Waveforms 3-112. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Channels 3-115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Path Compensation 3-117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Glossary & Index

Status 3-119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering 3-120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical Control 3-124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Math 3-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zoom 3-130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: Options and Accessories A-1. . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Specification A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Algorithms A-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: Packaging for Shipment A-39. . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E: Factory Initialization Settings A-41. . . . . . . . . . . . . . . . . . . .

Change Information

i

Contents

Page 9

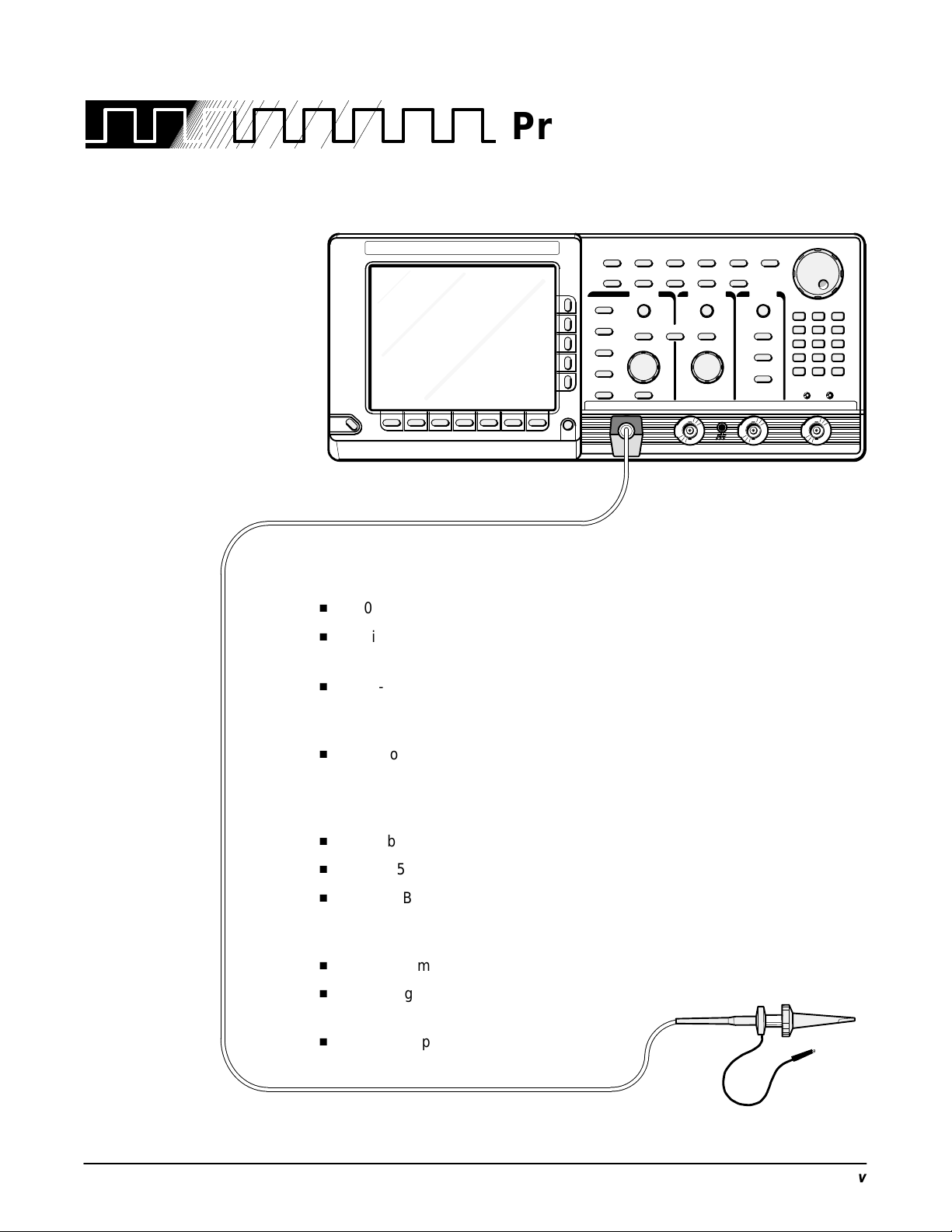

Product Description

Your Tektronix digitizing oscilloscope is a superb tool for acquiring, displaying,

and measuring waveforms. Its performance addresses the needs of both

benchtop lab and portable applications with the following features:

H

500 MHz maximum analog bandwidth.

H

1 Gigasample/second maximum digitizing rate (TDS 540);

500 Megasamples/second maximum digitizing rate (TDS 520).

H

Four-channel acquisition—the TDS 540 offers four full-featured channels;

the TDS 520 offers two full-featured channels and two channels with

limited vertical scale selections: 100 mV, 1 V, and 10 V.

H

Waveform Math—Invert a single waveform and add, subtract, and multiply

two waveforms. On instruments equipped with option 2F, integrate or

differentiate a single waveform or perform an FFT (fast fourier transform)

on a waveform to display its magnitude or phase versus its frequency.

H

Eight-bit digitizers.

H

Up to 15,000-point record length per channel (50,000-point optional).

H

Full GPIB software programmability. GPIB hardcopy output. On instruments equipped with option 13, hardcopy output using the RS-232 or

Centronics ports.

H

Complete measurement and documentation capability.

H

Intuitive graphic icon operation blended with the familiarity of traditional

horizontal and vertical knobs.

H

On-line help at the touch of a button.

TDS 520 & TDS 540 User Manual

v

Page 10

Safety

Please take a moment to review these safety precautions. They are provided

for your protection and to prevent damage to the digitizing oscilloscope. This

safety information applies to all operators and service personnel.

Symbols and Terms

These two terms appear in manuals:

H

statements identify conditions or practices that could result in

damage to the equipment or other property.

H

statements identify conditions or practices that could result in

personal injury or loss of life.

These two terms appear on equipment:

CAUTION

H

indicates a personal injury hazard not immediately accessible

as one reads the marking or a hazard to property including the equipment

itself.

H

DANGER

indicates a personal injury hazard immediately accessible as

one reads the marking.

This symbol appears in manuals:

vi

Static-Sensitive Devices

These symbols appear on equipment:

DANGER

High Voltage

Protective

ground (earth)

terminal

ATTENTION

Refer to

manual

Safety

Page 11

Safety

Specific Precautions

Observe all of these precautions to ensure your personal safety and to prevent damage to either the digitizing oscilloscope or equipment connected to it.

Power Source

The digitizing oscilloscope is intended to operate from a power source that will

not apply more than 250 V

either supply conductor and ground. A protective ground connection, through

the grounding conductor in the power cord, is essential for safe system

operation.

between the supply conductors or between

rms

Grounding the Digitizing Oscilloscope

The digitizing oscilloscope is grounded through the power cord. To avoid

electric shock, plug the power cord into a properly wired receptacle where

earth ground has been verified by a qualified service person. Do this before

making connections to the input or output terminals of the digitizing oscilloscope.

Without the protective ground connection, all parts of the digitizing oscilloscope are potential shock hazards. This includes knobs and controls that may

appear to be insulators.

Use the Proper Power Cord

Use only the power cord and connector specified for your product. Use only a

power cord that is in good condition.

Use the Proper Fuse

To avoid fire hazard, use only the fuse specified in the parts list for your

product, matched by type, voltage rating, and current rating.

Do Not Remove Covers or Panels

To avoid personal injury, do not operate the digitizing oscilloscope without the

panels or covers.

Electric Overload

Never apply a voltage to a connector on the digitizing oscilloscope that is

outside the voltage range specified for that connector.

Do Not Operate in Explosive Atmospheres

The digitizing oscilloscope provides no explosion protection from static discharges or arcing components. Do not operate the digitizing oscilloscope in

an atmosphere of explosive gases.

TDS 520 & TDS 540 User Manual

vii

Page 12

Start Up

Before you use the digitizing oscilloscope, ensure that it is properly installed

and powered on.

Operation

To properly install and power on the digitizing oscilloscope, do the following:

Installation

1. Be sure you have the appropriate operating environment. Specifications

for temperature, relative humidity, altitude, vibrations, and emissions are

included in

2. Leave space for cooling. Do this by verifying that the air intake and exhaust holes on the sides of the cabinet (where the fan operates) are free

of any airflow obstructions. Leave at least 2 inches (5.1 cm) free on each

side.

Appendix B: Specification

WARNING

To avoid electrical shock, be sure that the power cord is disconnected before checking the fuse.

3. Check the fuse to be sure it is the proper type and rating (Figure i). You

can use either of two fuses. Each fuse requires its own cap (see Table i).

The digitizing oscilloscope is shipped with the UL approved fuse installed.

at the rear of this manual.

viii

4. Check that you have the proper electrical connections. The digitizing

oscilloscope requires 90 to 250 VAC

63 Hz, and may require up to 300 W.

5. Connect the proper power cord from the rear-panel power connector

(Figure i) to the power system.

, continuous range, 47 Hz to

rms

Start Up

Page 13

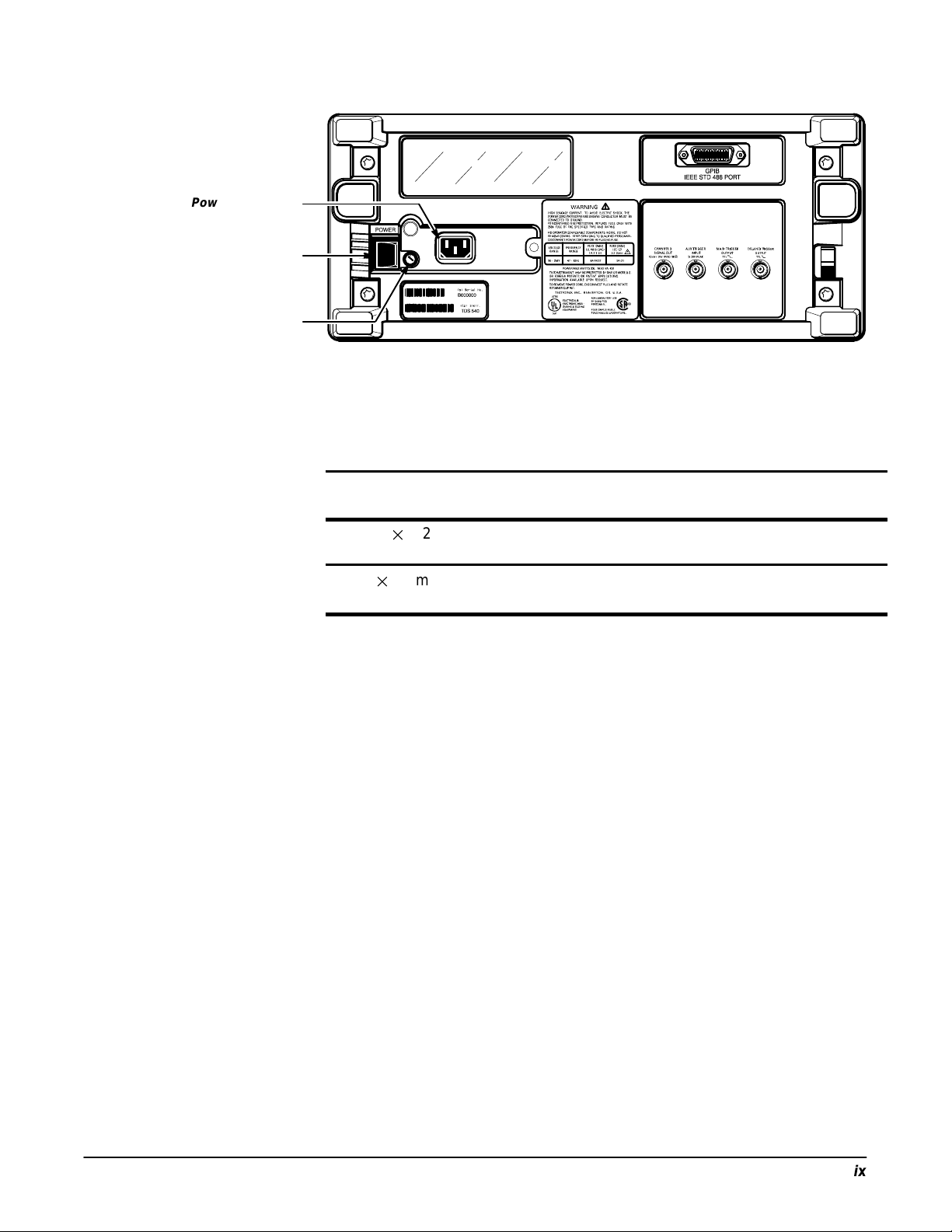

Power Connector

Principal Power Switch

Fuse

Start Up

Figure i: Rear Panel Controls Used in Start Up

Table i: Fuse and Fuse Cap Part Numbers

Fuse

.25 inch 1.25 inch (UL 198.6, 3AG):

Fuse Part

Number

Fuse Cap Part

Number

159–0013–00 200–2264–00

6 A FAST, 250 V.

5 mm 20 mm (IEC 127): 5 A (T),

159–0210–00 200–2265–00

250 V.

Power On

1. Check that the rear-panel principal power switch is on (Figure i). The

principal power switch controls all AC power to the instrument.

2. If the oscilloscope is not powered on (the screen is blank), push the

front-panel ON/STBY button to toggle it on (Figure ii).

The ON/STBY button controls power to most of the instrument circuits.

Power continues to go to certain parts even when this switch is set to

STBY.

Once the digitizing oscilloscope is installed, you can leave the principal

power switch on and use the ON/STBY button as the power switch.

TDS 520 & TDS 540 User Manual

ix

Page 14

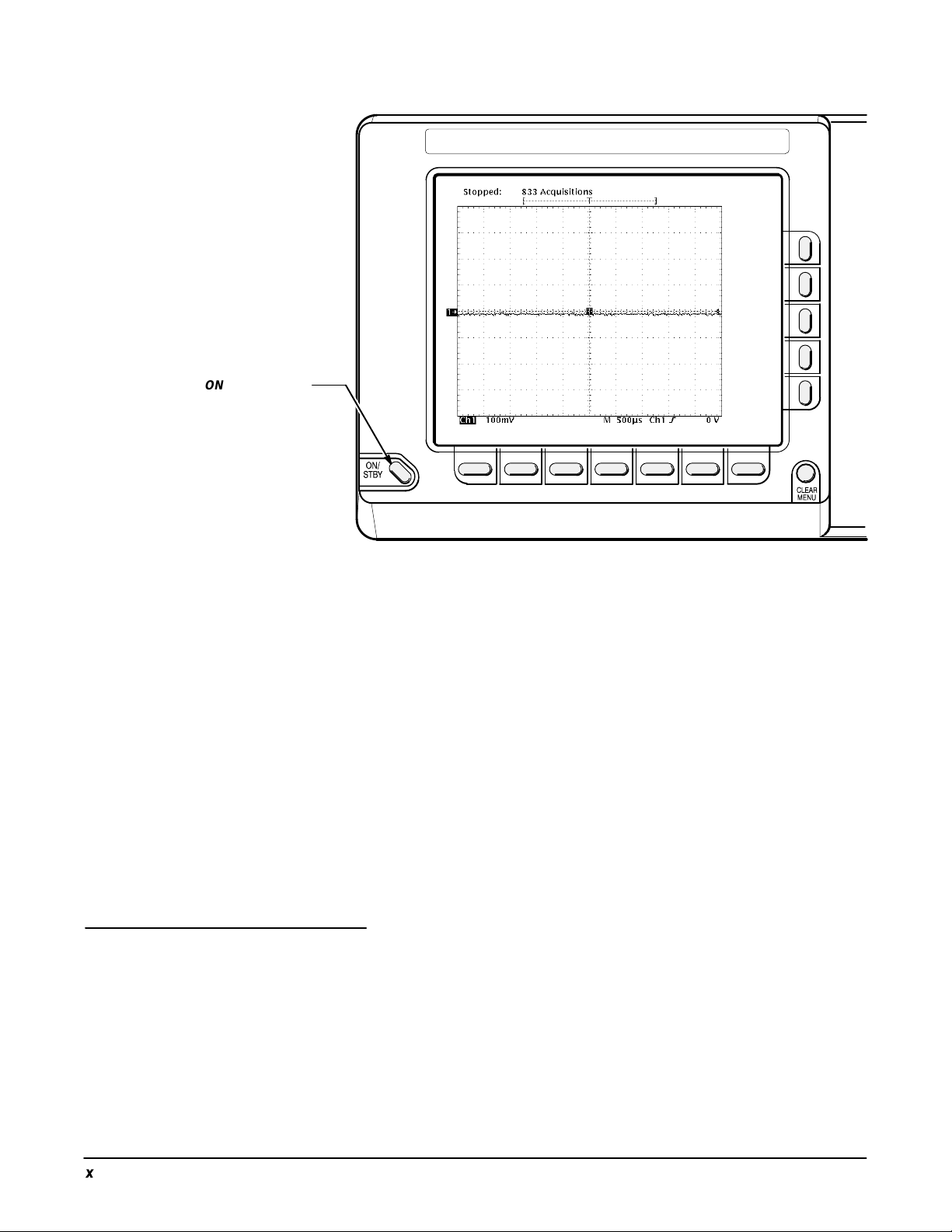

ON/STBY Button

Figure ii: ON/STBY Button

Self Test

The digitizing oscilloscope automatically performs power-on tests each time it

is turned on. It will come up with a display screen that states whether or not it

passed self test. (If the self test passed, the status display screen will be

removed after a few seconds.)

Check the self test results.

If the self test fails, call your local Tektronix Service Center. Depending on the

type of failure, you may still be able to use the oscilloscope before it is serviced.

Before You Begin

x

Power Off

Press the ON/STBY switch to turn off the oscilloscope.

Now that you have set up your oscilloscope for operation, you should know

about two features that help to ensure maximum accuracy for your most

critical measurements,

Signal Path Compensation (SPC)

the current ambient temperature, helping to ensure maximum possible accuracy for your most critical measurements. See

page 3-117 for a description of and operating information on this key feature.

Signal Path Compensation

lets you compensate your oscilloscope for

and

Probe Cal.

Signal Path Compensation

Start Up

on

Page 15

Start Up

Probe Cal

lets you compensate any channel of your oscilloscope for the effect

of the probe on gain accuracy and offset accuracy. Like SPC, Probe Cal helps

ensure maximum possible accuracy for your most critical measurements. See

Probe Cal

on page 3-84 for a description of and operating information on this

feature.

TDS 520 & TDS 540 User Manual

xi

Page 16

xii

Start Up

Page 17

Tutorial

Page 18

Page 19

Overview

This section contains four examples that show you how to operate the basic

functions of the digitizing oscilloscope. Use the

on page 3-2) to help you locate the correct knobs, buttons, and menus.

At a Glance

section (starting

Setting Up for the

Examples

Example 1

H

and adjust waveforms, and use the autoset function.

Example 2

H

Example 3

H

Example 4

H

setups.

Before you perform these examples, read

decide to skip this tutorial, use the

about the digitizing oscilloscope arrangement and specific functions.

All the examples use the same setup. Once you perform this setup, you do

not have to change the signal connections for any of the other examples.

Remove all probes and signal inputs from the input BNC connectors along the

lower right of the front panel. Then, using one of the probes supplied with the

digitizing oscilloscope, connect from the CH 1 connector to the PROBE

COMPENSATION connectors (Figure 1-1).

teaches you how to reset the digitizing oscilloscope, display

explains how to add, control, and delete multiple waveforms.

introduces you to the automated measurement system.

discusses saving and recalling the digitizing oscilloscope

Conventions

Concepts

and

on page ii. If you

In Detail

sections to learn

TDS 620 & 640 User Manual

Figure 1-1: Connecting a Probe for the Examples

1Ć1

Page 20

Example 1: Displaying a Waveform

In this first example you learn about resetting the digitizing oscilloscope,

displaying and adjusting a waveform, and using the autoset function.

Resetting the

Digitizing

Oscilloscope

SETUP Button

All examples in the tutorial begin by resetting the digitizing oscilloscope to a

known factory default state. Reset the oscilloscope when you begin a new

task and need to “start fresh” with known default settings.

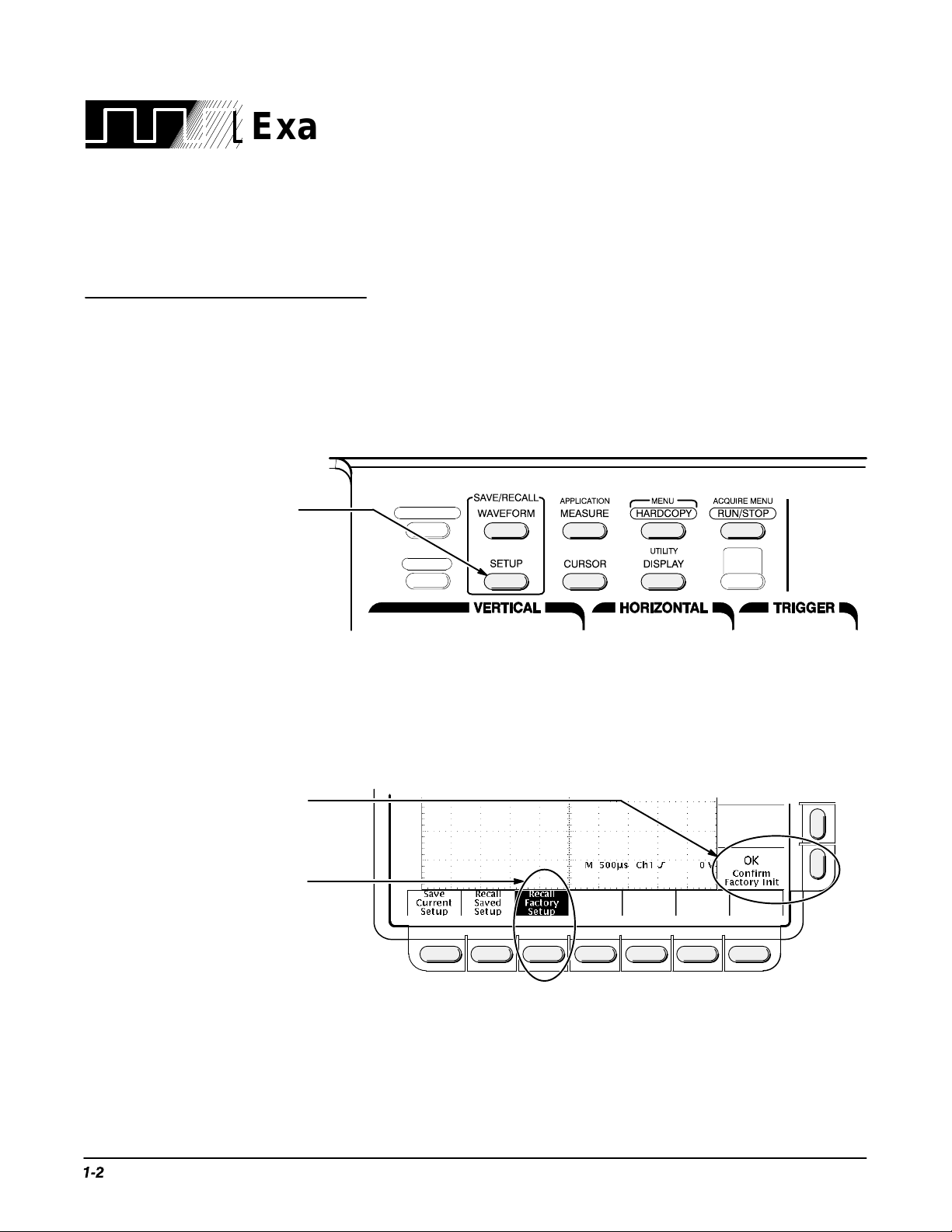

1. Press the save/recall SETUP button to display the Setup menu (Fig-

ure 1-2).

Figure 1-2: SETUP Button Location

The digitizing oscilloscope displays

screen. Figure 1-3 shows the Setup main menu.

main menus

along the bottom of the

1Ć2

OK Confirm Factory Init

Menu Item and Button

Recall Factory Setup

Menu Item and Button

Figure 1-3: The Displayed Setup Menu

Section Name (Nm:Sect)

Page 21

Example 1: Displaying a Waveform

2. Press the button directly below the Recall Factory Setup menu item.

The display shows

side menus

along the right side of the screen. The

buttons to select these side menu items are to the right of the side menu.

Because an accidental instrument reset could destroy a setup that took a

long time to create, the digitizing oscilloscope asks you to verify the

Recall Factory Setup selection (see Figure 1-3).

3. Press the button to the right of the OK Confirm Factory Init side menu

item.

NOTE

This manual uses the following notation to represent the sequence

of selections you made in steps 1, 2 and 3:

UP ➞ Recall Factory Setup (main) ➞ OK Confirm Factory Init

(side).

Note that a clock icon appears on screen. The oscilloscope displays this

icon when performing operations that take longer than several seconds.

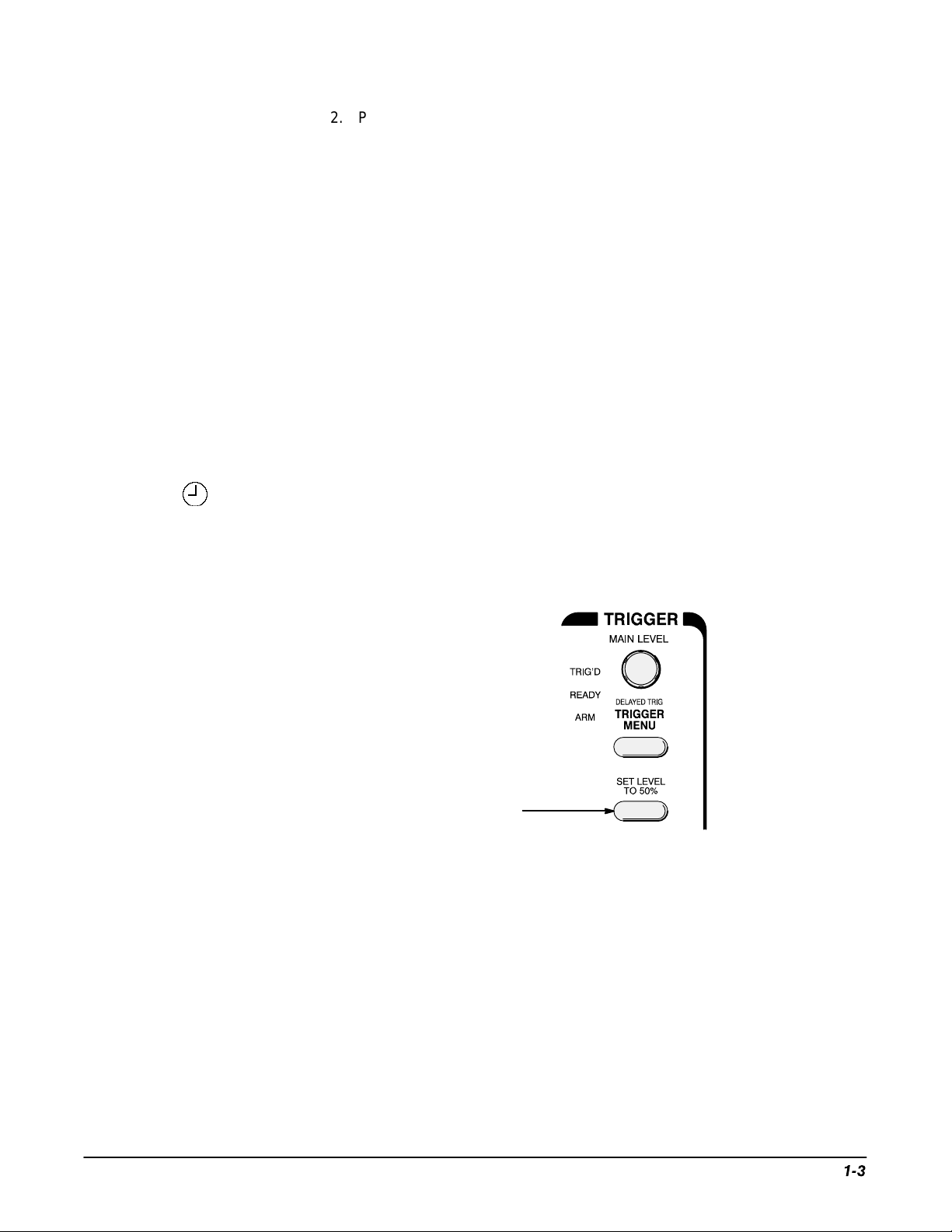

4. Press SET LEVEL TO 50% (see Figure 1-4) to be sure the oscilloscope

triggers on the input signal.

Press save/recall SET-

TDS 620 & 640 User Manual

SET LEVEL TO 50% Button

Figure 1-4: Trigger Controls

1Ć3

Page 22

Example 1: Displaying a Waveform

Display Elements

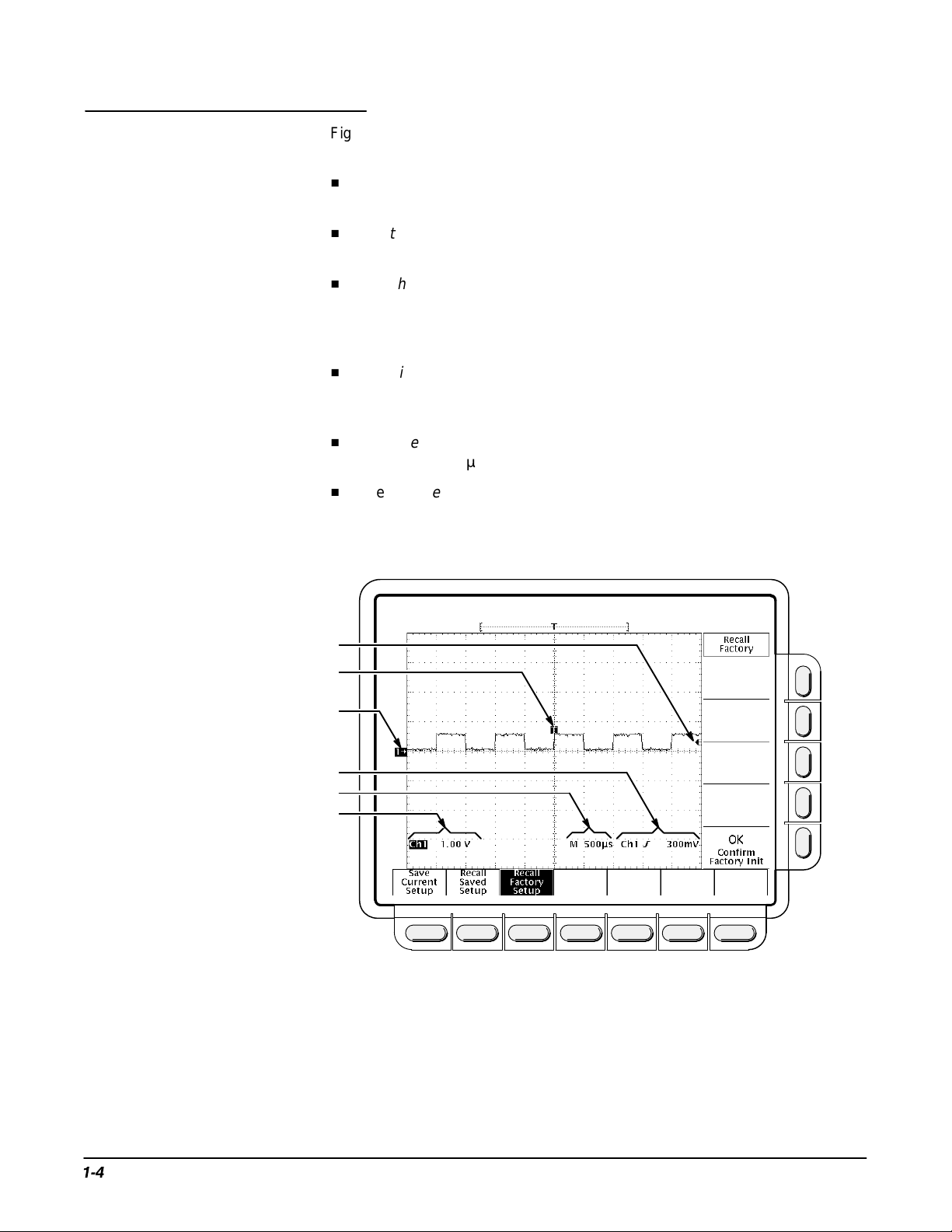

Figure 1-5 shows the display that results from the instrument reset. There are

several important points to observe:

H

trigger level bar

The

shows that the waveform is triggered at a level near

50% of its amplitude (from step 4).

H

trigger position indicator

The

shows that the trigger position of the wave-

form is located at the horizontal center of the graticule.

H

channel reference indicator

The

shows the vertical position of channel 1

with no input signal. This indicator points to the ground level for the

channel when its vertical offset is set to 0 V in the vertical menu; when

not

vertical offset is

H

trigger readout

The

set to 0 V, it points to the vertical offset level.

shows that the digitizing oscilloscope is triggering on

channel 1 (Ch1) on a rising edge, and that the trigger level is about

200-300 mV.

H

time base readout

The

shows that the main time base is set to a horizon-

tal scale of 500ms/div.

H

channel readout

The

indicates that channel 1 (Ch1) is displayed with DC

coupling. (In AC coupling, ~ appears after the volts/div readout.) The

digitizing oscilloscope always displays channel 1 at reset.

Trigger Level

Bar

Trigger Position

Indicator

Channel Reference

Indicator

Trigger Readout

Time Base Readout

Channel Readout

Running: 100kS/s Sample

Figure 1-5: The Display After Factory Initialization

Right now, the channel, time base, and trigger readouts appear in the graticule area because a menu is displayed. You can press the CLEAR MENU

button at any time to remove any menus and to move the readouts below the

graticule.

1Ć4

Section Name (Nm:Sect)

Page 23

Example 1: Displaying a Waveform

Adjusting the

Waveform Display

The display shows the probe compensation signal. It is a 1 kHz square wave

of approximately 0.5 V amplitude. You can adjust the size and placement of

the waveform using the front-panel knobs.

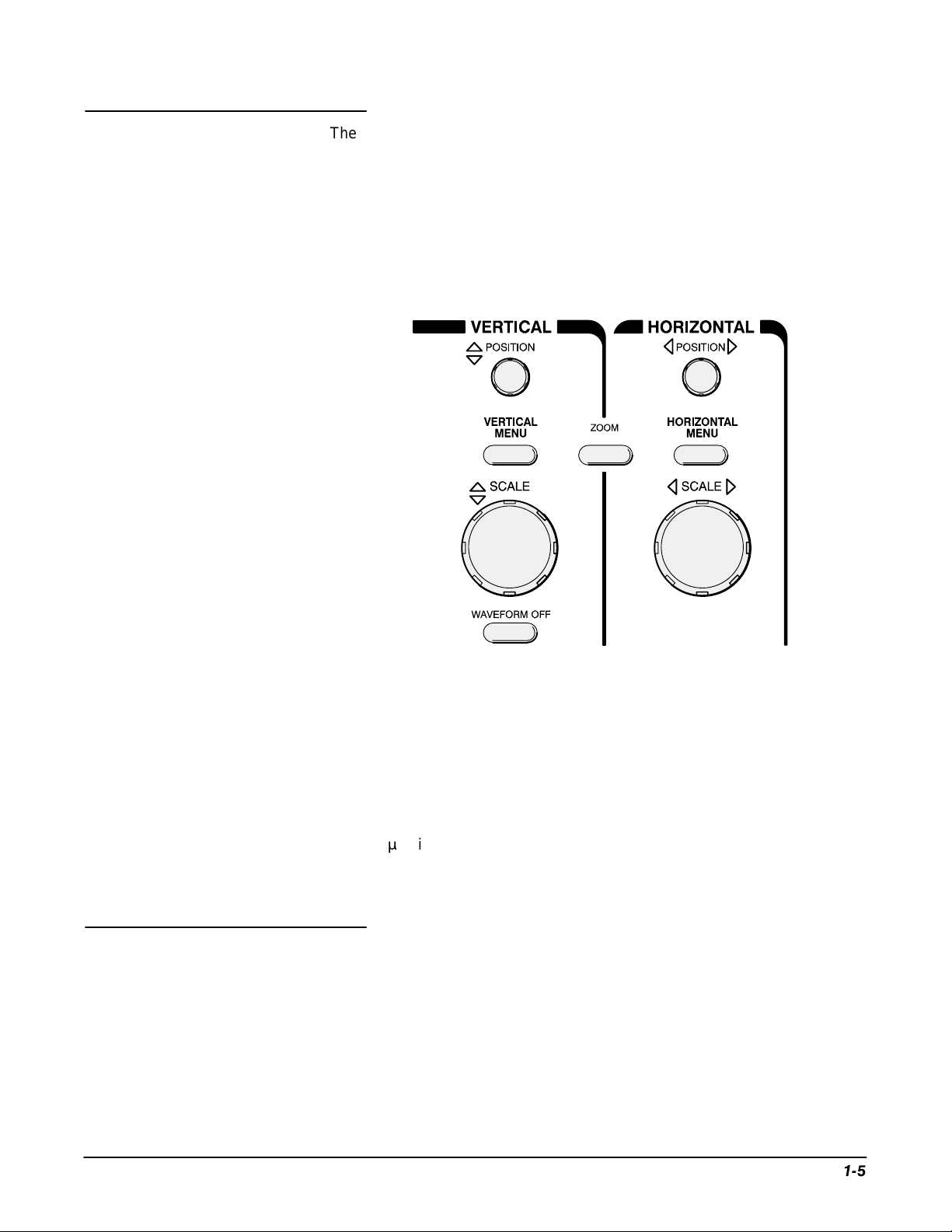

Figure 1-6 shows the main VERTICAL and HORIZONTAL sections of the

front panel. Each has SCALE and POSITION knobs.

1. Turn the vertical SCALE knob clockwise. Observe the change in the

displayed waveform and the channel readout at the bottom of the display.

Using Autoset

Figure 1-6: The VERTICAL and HORIZONT AL Controls

2. Turn the vertical POSITION knob first one direction, then the other.

Observe the change in the displayed waveform. Then return the waveform to the center of the graticule.

3. Turn the horizontal SCALE knob one click clockwise. Observe the time

base readout at the bottom of the display. The time base should be set to

200ms/div now, and you should see two complete waveform cycles on

the display.

When you first connect a signal to a channel and display it, the signal displayed may not be scaled and triggered correctly. Use the autoset function

and you should quickly get a meaningful display.

When you reset the digitizing oscilloscope, you see a clear, stable display of

the probe compensation waveform. That is because the probe compensation

signal happens to display well at the default settings of the digitizing oscilloscope.

TDS 620 & 640 User Manual

1Ć5

Page 24

Example 1: Displaying a Waveform

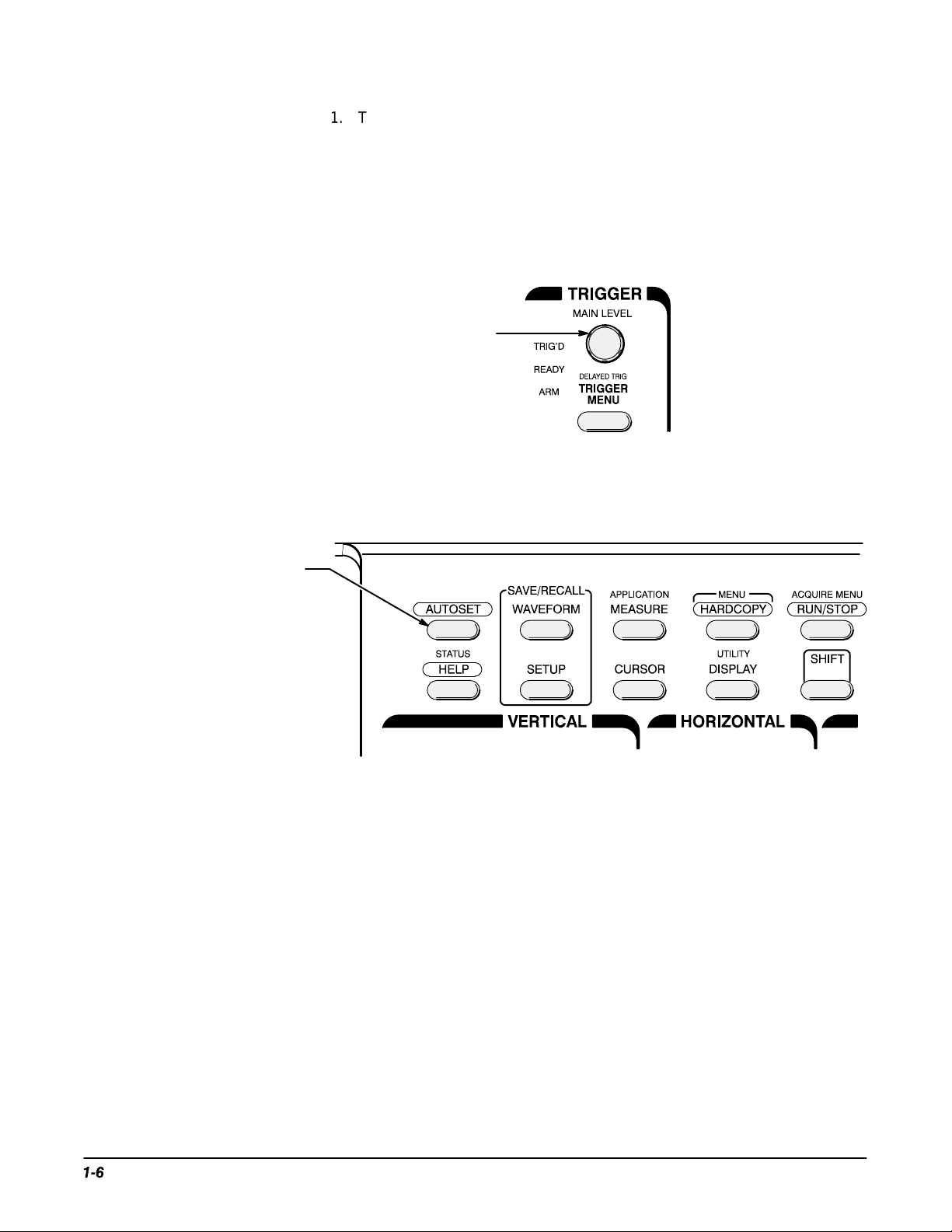

1. To create an unstable display, slowly turn the trigger MAIN LEVEL knob

(see Figure 1-7) first one direction, then the other. Observe what happens

when you move the trigger level above the highest part of the displayed

waveform. Leave the trigger level in that untriggered state.

2. Press AUTOSET (see Figure 1-8) and observe the stable waveform

display.

MAIN LEVEL Knob

Figure 1-7: TRIGGER Controls

AUTOSET Button

Figure 1-8: AUTOSET Button Location

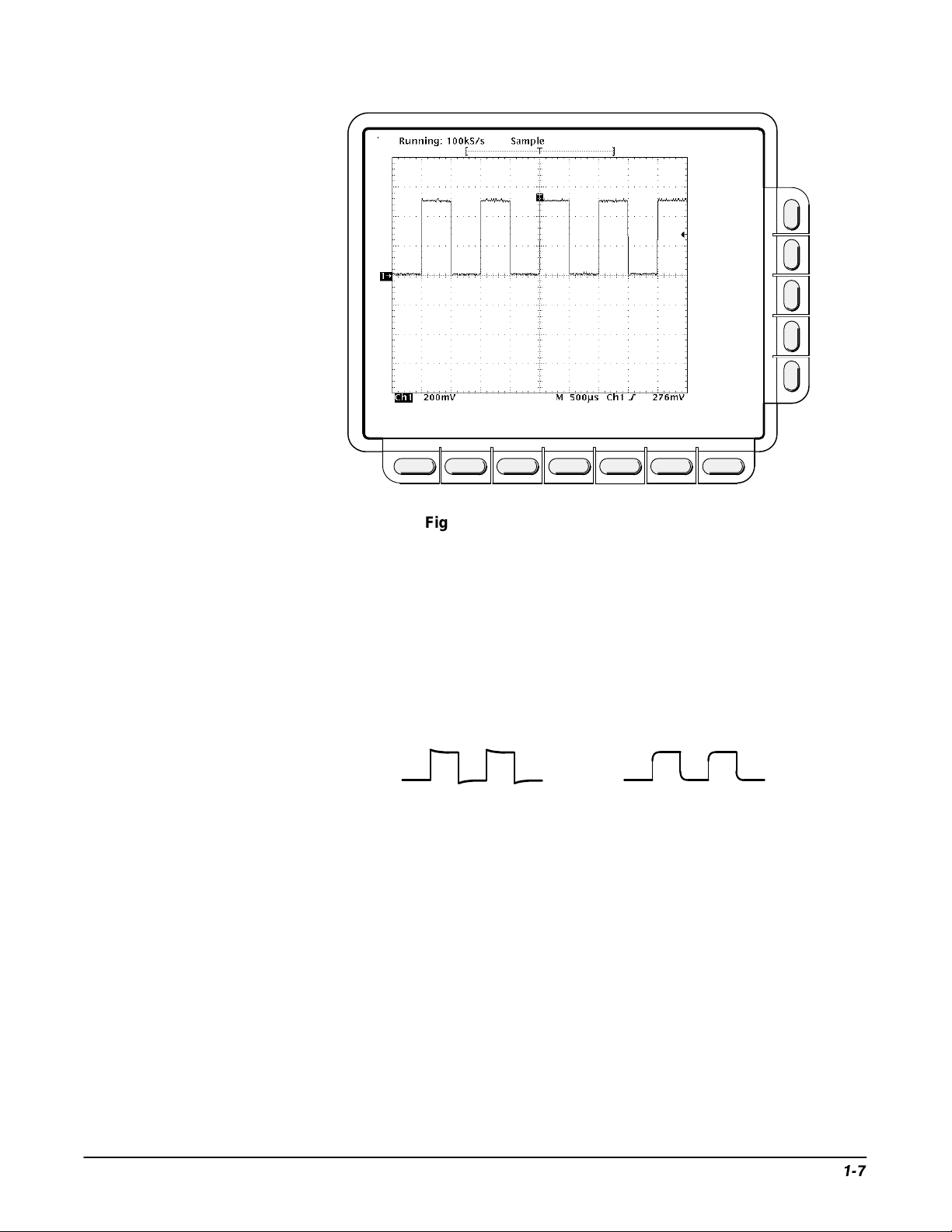

Figure 1-9 shows the display after pressing AUTOSET. If necessary, you can

adjust the waveform now by using the knobs discussed earlier in this example.

1Ć6

Section Name (Nm:Sect)

Page 25

Example 1: Displaying a Waveform

Figure 1-9: The Display After Pressing Autoset

NOTE

If the corners on your displayed signal look rounded or pointed (see

Figure 1-10), then you may need to compensate your probe. The

Probe Compensation

Figure 1-10: Display Signals Requiring Probe Compensation

section on page 3-90 explains how to do that.

TDS 620 & 640 User Manual

1Ć7

Page 26

Example 2: Multiple Waveforms

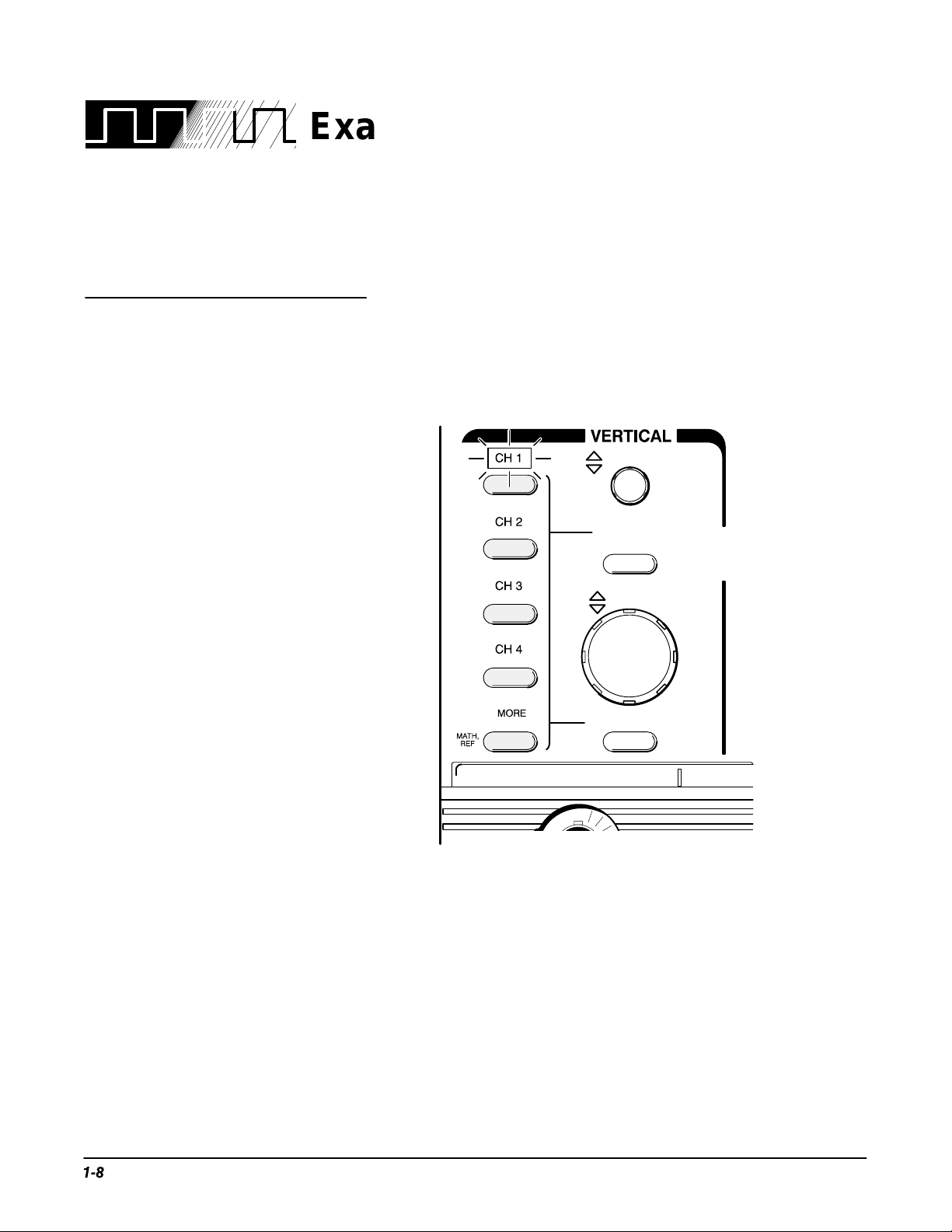

In this example you learn how to display and control more than one waveform

at a time.

Adding a Waveform

The VERTICAL section of the front panel contains the channel selection

buttons. On the TDS 640 Digitizing Oscilloscope, these are CH 1, CH 2,

CH 3, CH 4, and MORE (Figure 1-11); on the TDS 620, they are CH 1, CH 2,

AUX 1, AUX 2, and MORE.

1Ć8

Figure 1-11: The Channel Buttons and Lights (TDS 540 Shown)

Each of the channel (CH) buttons has a light above its label. Right now, the

CH 1 light is on. That light indicates that the vertical controls are set to adjust

channel 1.

The following steps adds a waveform to the display.

1. If you are not continuing from the previous example, follow the instructions on page 1-1 under the heading “Setting Up for the Examples.”

Section Name (Nm:Sect)

Page 27

Example 2: Multiple Waveforms

2. Press SETUP ➞ Recall Factory Setup (main) ➞ OK Confirm Factory

Init (side).

3. Press AUTOSET.

4. Press CH 2.

The display shows a second waveform, which represents the signal on

channel 2. Since there is nothing connected to the CH 2 input connector,

this waveform is a flat line.

There are several other important things to observe:

H

The channel readout on the display now shows the settings for both

Ch1 and Ch2.

H

There are two channel indicators at the left edge of the graticule.

Right now, they overlap.

H

The light next to the CH 2 button is now on, and the CH 1 light is off.

Because the knobs control only one channel at a time, the vertical

controls are now set to adjust channel 2.

H

The trigger readout still indicates that the trigger is detecting trigger

events on Ch1. The trigger source is not changed simply by adding a

channel. (You can change the trigger source by using the TRIGGER

MENU button to display the trigger menu.)

5. Turn the vertical POSITION knob clockwise to move the channel 2 wave-

form up on the graticule. You will notice that the channel reference indicator for channel 2 moves with the waveform.

6. Press VERTICAL MENU ➞ Coupling (main).

The VERTICAL MENU button displays a menu that gives you control

over many vertical channel parameters (Figure 1-12). Although there can

be more than one channel displayed, the vertical menu and buttons only

adjust the selected channel.

Each menu item in the Vertical menu displays a side menu. Right now,

the Coupling item in the main menu is highlighted, which means that the

side menu shows the coupling choices. At the top of the side menu, the

menu title shows the channel affected by the menu choices. That always

matches the lighted channel button.

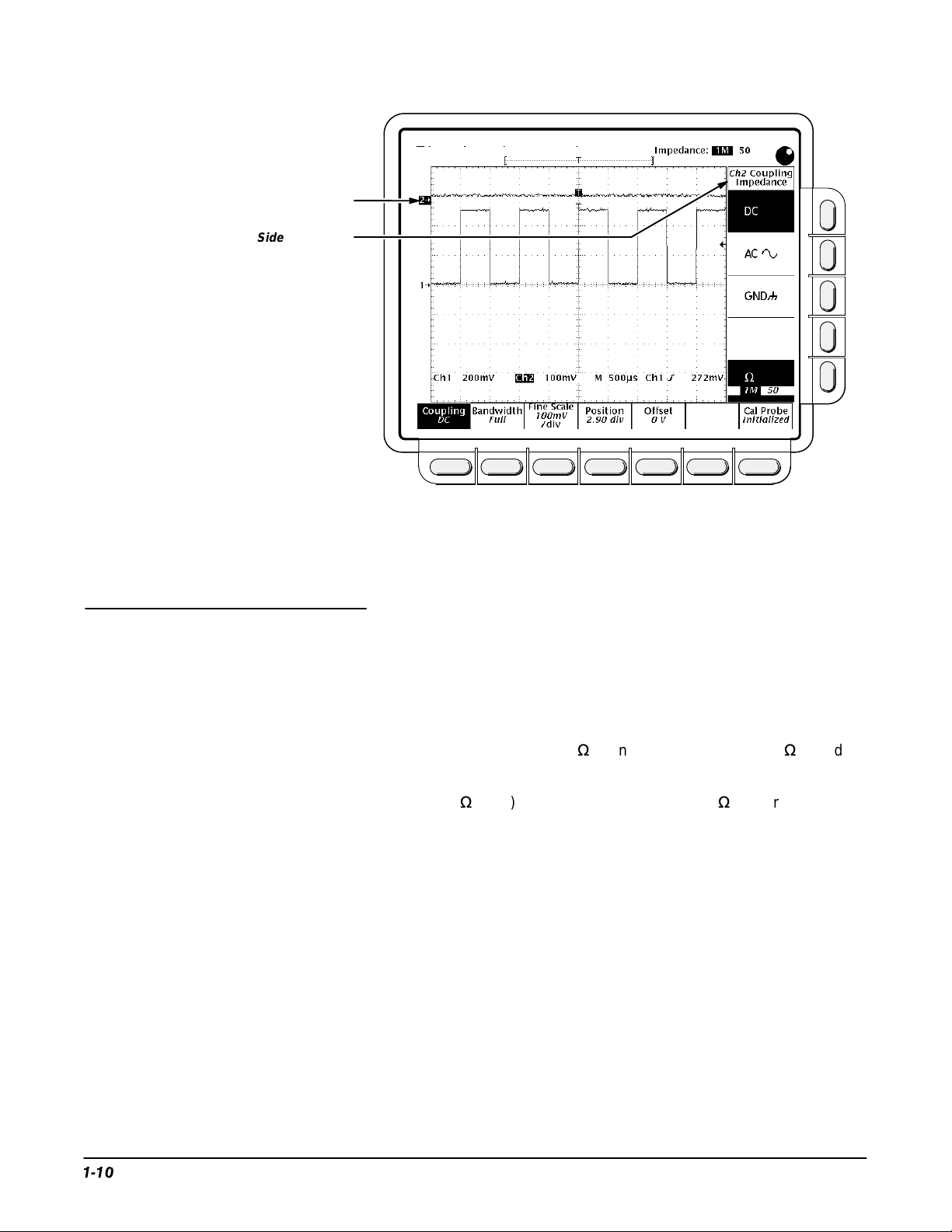

7. Press W (side) to toggle the selection to 50 W. That changes the input

coupling of channel 2 from 1 MW to 50 W. The channel readout for channel 2 (near the bottom of the graticule) now shows an W indicator.

TDS 620 & 640 User Manual

1Ć9

Page 28

Example 2: Multiple Waveforms

Ch2 Reference Indicator

Side Menu Title

Running: 100kS/s Sample

Changing Controls

to Another Channel

Figure 1-12: The Vertical Main Menu and Coupling Side Menu

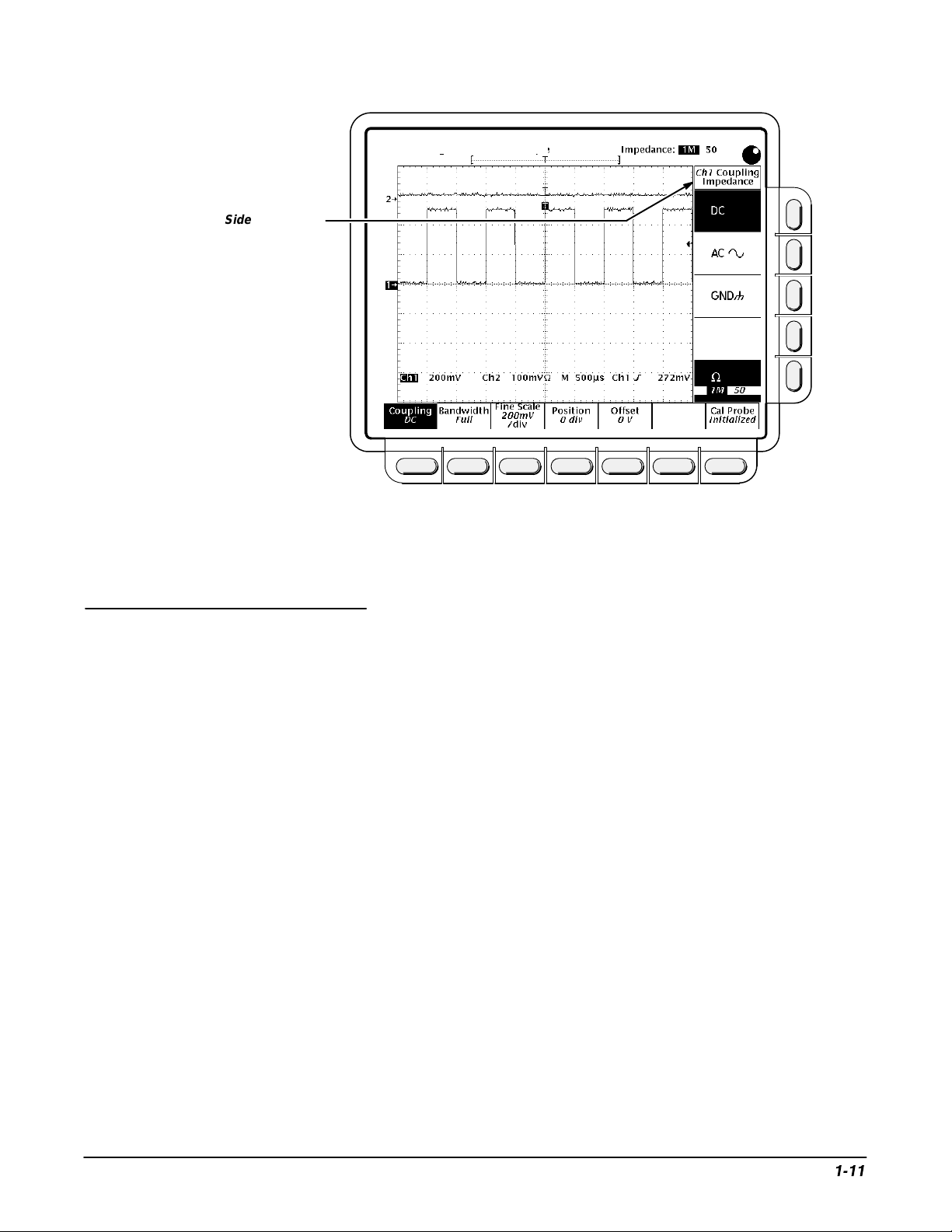

Pressing a channel (CH) button sets the vertical controls to that channel. It

also adds the channel to the display if that waveform is not already displayed.

1. Press CH 1.

Observe that now the side menu title shows Ch1 (Figure 1-13), and that

the light above CH 1 is lighted. The highlighted menu item in the side

menu has changed from the 50W channel 2 setting to the 1MW impedance setting of channel 1.

2. Press CH 2 ➞ W (side) to toggle the selection to 1MW. That returns the

coupling impedance of channel 2 to its initial state.

1Ć10

Section Name (Nm:Sect)

Page 29

Side Menu Title

Example 2: Multiple Waveforms

Running: 100kS/s Sample

Removing a

Waveform

Figure 1-13: The Menus After Changing Channels

Pressing the WAVEFORM OFF button removes the waveform for the current-

ly selected channel. If the waveform you want to remove is not already selected, select that channel using the channel (CH) button.

1. Press W AVEFORM OFF (under the vertical SCALE knob).

Since the CH 2 light was on when you pressed the WAVEFORM OFF

button, the channel 2 waveform was removed.

The channel (CH) lights now indicate channel 1. Channel 1 has become

the selected channel. When you remove the last waveform, all the CH

lights are turned off.

2. Press W AVEFORM OFF again to remove the channel 1 waveform.

TDS 620 & 640 User Manual

1Ć11

Page 30

Example 3: Automated Measurements

In this example you learn how to use the automated measurement system to

get numeric readouts of important waveform characteristics.

Displaying

Automated

Measurements

To use the automated measurement system, you must have a stable display

of your signal. Also, the waveform must have all the segments necessary for

the measurement you want. For example, a rise time measurement requires

at least one rising edge, and a frequency measurement needs at least one

complete cycle.

1. If you are not continuing from the previous example, follow the instructions on page 1-1 under the heading “Setting Up for the Examples.”

2. Press SETUP ➞ Recall Factory Setup (main) ➞ OK Confirm Factory

Init (side).

3. Press AUTOSET.

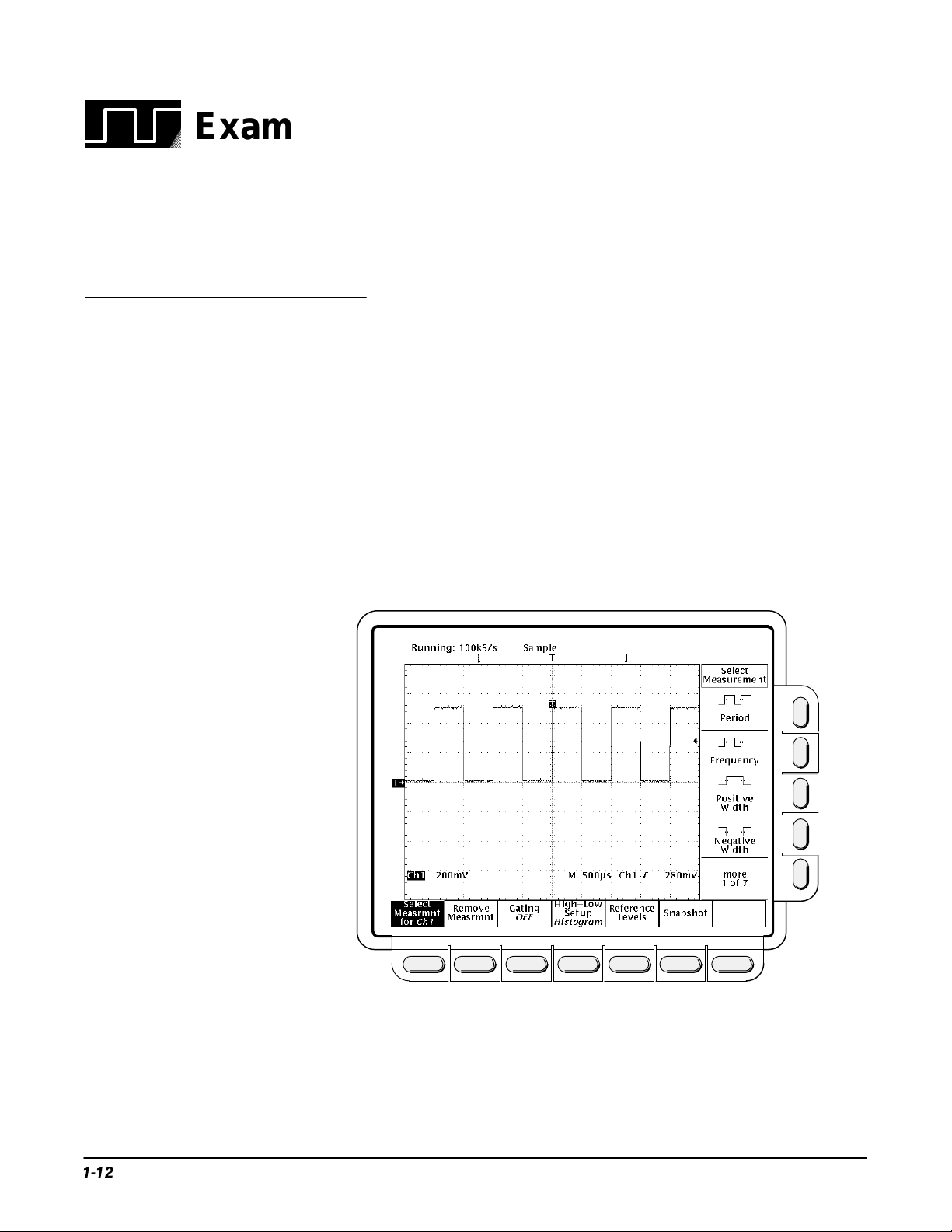

4. Press MEASURE to display the Measure main menu (see Figure 1-14).

1Ć12

Figure 1-14: Measure Main Menu and Select Measurement Side Menu

Section Name (Nm:Sect)

Page 31

Example 3: Automated Measurements

5. If it is not already selected, press Select Measrmnt (main). The readout

for that menu item indicates which channel the measurement will be

taken from. All automated measurements are made on the selected

channel.

The Select Measurement side menu lists some of the measurements that

can be taken on waveforms. There are many different measurements

available; up to four can be taken and displayed at any one time. Pressing the button next to the –more– menu item brings up the other measurement selections.

6. Press Frequency (side). If the Frequency menu item is not visible, press

–more– (side) repeatedly until the Frequency item appears. Then press

Frequency (side).

Observe that the frequency measurement appears within the right side of

the graticule area. The measurement readout includes the notation Ch1,

meaning that that measurement is taken on the channel 1 waveform. (To

take a measurement on another channel, select that channel, and then

select the measurement.)

7. Press Positive Width (side) ➞ –more– (side) ➞ Rise Time (side) ➞

Positive Duty Cycle (side).

All four measurements are displayed. Right now, they cover a part of the

graticule area, including the displayed waveforms.

8. To move the measurement readouts outside the graticule area, press

CLEAR MENU (see Figure 1-15).

TDS 620 & 640 User Manual

1Ć13

Page 32

Example 3: Automated Measurements

Running: 100kS/s Sample

Press here to

remove menus

from screen.

Removing

Measurement

Readouts

Changing the

Measurement

Reference Levels

Figure 1-15: Four Simultaneous Measurement Readouts

The Measure menu lets you remove measurements you no longer want

displayed. You can remove any one measurement, or you can remove them

all with a single menu item.

Press MEASURE ➞ Remove Measrmnt (main) ➞ Measurement 1, Mea-

surement 2, and Measurement 4 (side) to remove those measurements.

Leave the rise time measurement displayed.

By default, the measurement system will use the 10% and 90% levels of the

waveform for taking the rise time measurement. You can change these values

to other percentages or change them to absolute voltage levels.

To examine the current values, press Reference Levels (main) ➞ High Ref

(side).

The General Purpose Knob

1Ć14

The general purpose knob, the large knob with the indentation, is now set to

adjust the high reference level (Figure 1-16).

Section Name (Nm:Sect)

Page 33

General Purpose Knob

Setting and Readout

General Purpose

Knob Icon

Highlighted Menu Item with

Boxed Readout Value

Example 3: Automated Measurements

Figure 1-16: General Purpose Knob Indicators

There are several important things to observe on the screen:

H

The knob icon appears at the top of the screen. That indicates that the

general purpose knob has just been set to adjust a parameter.

H

The upper right corner of the screen shows the readout High Ref: 90%.

H

The High Ref side menu item is highlighted, and a box appears around

the 90% readout in the High Ref menu item. The box indicates that the

general purpose knob is currently set to adjust that parameter.

Turn the general purpose knob left and right, and then use it to adjust the high

level to 80%. That sets the high measurement reference to 80%.

Hint: To make large changes quickly with the general purpose knob, press the

SHIFT button before turning the knob. When the light above the SHIFT button

is lit and the display says

Coarse Knobs

in the upper-right corner, the gener-

al purpose knob speeds up significantly.

The Numeric Keypad

Any time the general purpose knob is set to adjust a numeric parameter, you

can enter the value as a number using the keypad instead of using the knob.

Always end the entry of a number by pressing the ENTER (

).

TDS 620 & 640 User Manual

The numeric keypad also provides multipliers for engineering exponents, such

as m for milli, M for mega, and m for micro. To enter these multiplier values,

press the SHIFT button, then press the multiplier.

1Ć15

Page 34

Example 3: Automated Measurements

1. Press Low Ref (side).

Displaying a

Snapshot of

Automated

Measurements

2. On the numeric keypad, press the 2, the 0, and the ENTER (

tons, which sets the low measurement reference to 20%. Observe that

the rise-time value has changed.

3. Press Remove Measrmnt (main) ➞ All Measurements (side). That

returns the display to its original state.

You have seen how to display up to four individual automated measurements

on screen. You can also pop up a display of almost all of the automated

measurements available in the Select Measrmnts side menus. This snapshot of measurements is taken on the waveform currently selected using the

channel selection buttons.

As when displaying individual measurements, you must have a stable display

of your signal, and that signal must have all the segments necessary for the

measurement you want.

1. Press Snapshot (main) to pop up a snapshot of all available single

waveform measurements. (See Figure 1-17).

) but-

1Ć16

Figure 1-17: Snapshot of Channel 1

The snapshot display includes the notation Ch 1, meaning that the measurements displayed are taken on the channel 1 waveform. You take a

snapshot of a waveform in another channel by first selecting that channel

using the channel selection buttons.

Section Name (Nm:Sect)

Page 35

Example 3: Automated Measurements

The snapshot measurements do not continuously update. Snapshot

executes a one-time capture of all measurements and does not update

those measurements unless it is performed again.

2. Press Again (side) to do another snapshot and update the snapshot

measurements.

3. Press Remove Measrmnt (main) to remove the snapshot display. (You

can also press CLEAR MENU, but a new snapshot will be executed the

next time you display the Measure menu.)

TDS 620 & 640 User Manual

1Ć17

Page 36

Example 4: Saving Setups

This example shows you how to save all the settings of the digitizing oscilloscope and how to recall the setup later to quickly re-establish the previously

saved state. The oscilloscope provides several storage locations where you

can save the setups.

Besides being able to save several complete setups, the digitizing oscilloscope remembers all the parameter settings when you power it off. That

feature lets you power on and continue where you left off without having to

reconstruct the state of the digitizing oscilloscope.

Saving a Setup

First, you need to create an instrument setup you want to save. The next

several steps establish a two-waveform display with a measurement on one

waveform. The setup created is complex enough that you might prefer not to

go through all these steps each time you want that display.

1. If you are not continuing from the previous example, follow the instructions on page 1-1 under the heading “Setting Up for the Examples.”

2. Press SETUP ➞ Recall Factory Setup (main) ➞ OK Confirm Factory

Init (side).

3. Press ➞ AUTOSET.

4. Press MEASURE ➞ Select Measrmnt (main) ➞ Frequency (side).

(Press the –more– side menu item if the Frequency selection does not

appear in the side menu.)

5. Press CH 2 ➞ CLEAR MENU.

6. Press SETUP ➞ Save Current Setup (main) to display the Setup main

menu (see Figure 1-18).

Note that the setup locations shown in the side menu are labeled

user

or

either

labeled

there. If you work in a laboratory environment where several people

share the digitizing oscilloscope, check with the other users before

you overwrite their setup. Setup locations labeled

factory setup stored as a default and can be used to store current

setups without disturbing previously stored setups.

factory.

user

, you will overwrite the user setup previously stored

If you save your current setup in a location

factory

have the

1Ć18

Section Name (Nm:Sect)

Page 37

Example 4: Saving Setups

Recalling a Setup

Figure 1-18: Save/Recall Setup Menu

7. Press one of the To Setup side menu buttons to store the current instru-

ment settings into that setup location. Remember which setup location

you selected for use later.

There are more setup locations than can be listed at one time in the side

menu. The –more– side menu item gives you access to all the setup

locations.

Once you have saved a particular setup, you can change the settings as

you wish, knowing that you can come back to that setup at any time.

8. Press MEASURE ➞ Positive Width (side) to add that measurement to

the display.

To recall the setup, Press SETUP ➞ Recall Saved Setup (main) ➞ Recall

Setup (side) for the setup location you used in the last exercise. The positive

width measurement is now removed from the display because you selected it

after you saved the setup.

This completes the tutorial. You can restore the default settings by pressing

SETUP ➞ Recall Factory Setup (main) ➞ OK Confirm Factory Init (side).

TDS 620 & 640 User Manual

1Ć19

Page 38

Example 4: Saving Setups

1Ć20

Section Name (Nm:Sect)

Page 39

Concepts

Page 40

Page 41

Overview

Understanding the basic concepts of your digitizing oscilloscope will help you

use it effectively. This section explains the following concepts:

H

The triggering system, which establishes conditions for acquiring signals. Properly set, triggers can convert displays from unstable jumbles or

blank screens into meaningful waveforms. See

H

The acquisition system, which converts analog data into digital form.

Acquisition

See

H

The waveform scaling and positioning system, which changes the

dimensions of the waveform display. Scaling waveforms involves increasing or decreasing their displayed size. Positioning means moving them

up, down, right, or left on the display. See

on page 2-13.

forms

H

The measurement system, which provides numeric information on the

displayed waveforms. You can use graticule, cursor and automated

measurements. See

on page 2-7.

Measurements

on page 2-17.

Triggering

Scaling and Positioning Wave-

on page 2-2.

At the end of each topic,

more information can be found.

To explore these topics in more depth and to read about topics not covered in

this section, see

In Detail.

For More Information

Page 3-1 lists the topics covered.

will point you to sources where

TDS 520 & TDS 540 User Manual

2Ć1

Page 42

Triggering

This section describes the edge trigger of the main trigger system and explores, in a general sense, the topic of triggering. This oscilloscope also has

logic and pulse triggers in the main trigger system and a delayed trigger

system. They are described in Section 3.

Triggers determine when the digitizing oscilloscope starts acquiring and

displaying a waveform. They help create meaningful waveforms from unstable jumbles or blank screens (see Figure 2-1).

Triggered Waveform Untriggered Waveforms

Trigger Sources

Figure 2-1: Triggered Versus Untriggered Displays

The trigger event establishes the time-zero point in the waveform record, and

all points in the record are located in time with respect to that point. The

digitizing oscilloscope continuously acquires and retains enough sample

points to fill the pretrigger portion of the waveform record (that part of the

waveform that is displayed

screen).

When a trigger event occurs, the digitizing oscilloscope starts acquiring

samples to build the posttriger portion the waveform record (displayed

or to the right of, the trigger event). Once a trigger is recognized, the digitizing

oscilloscope will not accept another trigger until the acquisition is complete.

The basic trigger is the edge trigger. An edge trigger event occurs when the

source

trigger

specified voltage

You can derive your trigger from various sources.

H

Input channels—the most commonly used trigger source is any one of

the four input channels. The channel you select as a trigger source will

function whether it is displayed or not.

(the signal that the trigger circuit monitors) passes through a

level

before,

in a specified direction (the trigger

or to the left of, the triggering event on

after,

slope

).

2Ć2

Concepts

Page 43

H

AC Line Voltage—this trigger source is useful when you are looking at

signals related to the power line frequency. Examples include devices

such as lighting equipment and power supplies. Because the digitizing

oscilloscope generates the trigger, you do not have to input a signal to

create it.

H

Auxiliary Trigger—this trigger source is useful in digital design and

repair. For example, you might want to trigger with an external clock or

with a signal from another part of the circuit. To use the auxiliary trigger,

connect the external triggering signal to the Auxiliary Trigger input connector on the oscilloscope rear panel (TDS 540 only).

Triggering

Types

Trigger Modes

The digitizing oscilloscope provides three types of triggers for the main trigger

system: edge, pulse, and logic. These triggers are described in individual

articles found in the section

H

Edge—the “basic” trigger. You can use it with both analog and digital test

circuits. An edge trigger event occurs when the trigger

the trigger circuit is monitoring) passes through a specified voltage

in the specified direction (the trigger

H

Pulse—special trigger primarily used on digital circuits. Three classes of

pulse triggers are

the main trigger only.

H

Logic—special trigger primarily used on digital logic circuits. You select

Boolean operators for the trigger sources. Triggering occurs when the

Boolean conditions are satisfied. There are two kinds of logic triggers,

state

and

pattern.

only.)

The trigger mode determines how the oscilloscope behaves in the absence of

a trigger event. The digitizing oscilloscope provides two different trigger

modes,

normal

and

automatic

In Detail.

width, runt,

(Logic triggers are available the main trigger system

.

A brief definition of each type follows:

source

slope

).

and

glitch

. Pulse triggering is available on

(the signal

level

TDS 520 & TDS 540 User Manual

H

Normal—this trigger mode lets the oscilloscope acquire a waveform only

when it is triggered. If no trigger occurs, the oscilloscope will not acquire a

waveform. (You can push FORCE TRIGGER to force the oscilloscope to

make a single acquisition.)

H

Automatic—this trigger mode (auto mode) lets the oscilloscope acquire a

waveform even if a trigger does not occur. Auto mode uses a timer that

starts after a trigger event occurs. If another trigger event is not detected

before the timer times out, the oscilloscope forces a trigger anyway. The

length of time it waits for a trigger event depends on the time base setting.

2Ć3

Page 44

Triggering

Be aware that auto mode, when forcing triggers in the absence of valid triggering events, does not sync the waveform on the display. In other words,

successive acquisitions will not be triggered at the same point on the waveform; therefore, the waveform will appear to roll across the screen. Of course,

if valid triggers occur the display will become stable on screen.

Since auto mode will force a trigger in the absence of one, it is useful in

observing signals where you are only concerned with monitoring amplitude

level. Although the unsynced waveform may “roll” across the display, it will not

disappear as it would in normal trigger mode. Monitoring of a power supply

output is an example of such an application.

Holdoff

Trigger Points

Trigger Level

When a trigger event is recognized, the oscilloscope disables the trigger

system until acquisition is complete. In addition, the trigger system remains

disabled during the holdoff period that follows each acquisition. You can set

holdoff time to help ensure a stable display.

For example, the trigger signal can be a complex waveform with many possible trigger points on it. Though the waveform is repetitive, a simple trigger

might get you a series of patterns on the screen instead of the same pattern

each time.

Digital pulse trains are good examples (see Figure 2-2). Each pulse looks like

any other, so many possible trigger points exist. Not all of these will result in

the same display. The holdoff period allows the digitizing oscilloscope to

trigger on the correct edge, resulting in a stable display.

Acquisition

Interval

Acquisition

Interval

2Ć4

Holdoff Holdoff

Triggers are Not Recognized During Holdoff Time

Holdoff

Figure 2-2: Trigger Holdoff Time Ensures Valid Triggering

Concepts

Page 45

Triggering

Holdoff is settable from 0% (minimum holdoff available) to 100% (maximum

available). To see how to set holdoff, see

minimum and maximum holdoff varies with the horizontal scale. See

Variable, Main Trigger

and maximum values.

on page A-23 of Appendix B for the typical minimum

Mode & Holdoff

on page 3-39. The

Holdoff,

Coupling

Trigger coupling determines what part of the signal is passed to the trigger

circuit. Available coupling types include AC, DC, Low Frequency Rejection,

High Frequency Rejection, and Noise Rejection:

DC coupling

H

AC and DC components to the trigger circuit.

AC coupling

H

(AC components above 10 Hz are passed if the source channel is in

1 MW coupling; above 200 kHz are passed in 50 W coupling.) It removes

the DC components from the trigger signal.

High frequency rejection

H

gering signal. That allows only the low frequency components to pass on

to the triggering system to start an acquisition. High frequency rejection

attenuates signals above 30 kHz.

Low frequency rejection

H

Low frequency rejection attenuates signals below 80 kHz.

Noise Rejection

H

amplitude for stable triggering, reducing the chance of falsely triggering

on noise.

passes all of the input signal. In other words, it passes both

passes only the alternating components of an input signal.

removes the high frequency portion of the trig-

does the opposite of high frequency rejection.

lowers trigger sensitivity. It requires additional signal

Trigger Position

TDS 520 & TDS 540 User Manual

The adjustable

trigger occurs. It lets you properly align and measure data within records. The

part of the record that occurs

part that occurs

To help you visualize the trigger position setting, the top part of the display

has an icon indicating where the trigger occurs in the waveform record.You

select in the Horizontal menu what percentage of the waveform record will

contain pretrigger information.

Many users find displaying pretrigger information a valuable troubleshooting

technique. For example, if you are trying to find the cause of an unwanted

glitch in your test circuit, it may prove valuable to trigger on the glitch and

make the pretrigger period large enough to capture data before the glitch. By

analyzing what happened before the glitch, you may uncover clues about the

source of it.

trigger position

after

the trigger is the posttrigger portion.

defines where on the waveform record the

before

the trigger is the pretrigger portion. The

2Ć5

Page 46

Triggering

Slope and Level

Trigger Level Can be

Adjusted Vertically

The slope control determines whether the oscilloscope finds the trigger point

on the rising or the falling edge of a signal (see Figure 2-3).

You set trigger slope by selecting Slope in the Main Trigger menu and then

selecting from the rising or falling slope icons in the side menu that appears.

The level control determines where on that edge the trigger point occurs (see

Figure 2-3).

Positive-Going Edge Negative-Going Edge

Trigger Slope Can be Positive or Negative

Figure 2-3: Slope and Level Controls Help Define the Trigger

Delayed Trigger

For More

Information

The digitizing oscilloscope lets you set the main trigger level with the trigger

MAIN LEVEL knob.

As mentioned earlier in this section there is also a delayed trigger system that

provides an edge trigger (no pulse or logic triggers). When using the delayed

time base, you can also delay the acquisition of a waveform for a user-specified time or a user-specified number of delayed trigger events (or both) after a

main trigger event.

Delayed Triggering

See

See

Edge Triggering

Horizontal Controls

See

Logic Triggering

See

Pulse Triggering

See

Triggering

See

, on page 3-120.

, on page 3-25.

, on page 3-36.

, on page 3-49.

, on page 3-58.

, on page 3-99.

2Ć6

Concepts

Page 47

Acquisition

Acquisition is the process of sampling the analog input signal, converting it

into digital data, and assembling it into waveform record. The oscilloscope

creates a digital representation of the input signal by sampling the voltage

level of the signal at regular time intervals (Figure 2-4).

Sampling and

Digitizing

+5.0 V

0 V 0 V 0 V 0 V

Input Signal Sampled

Points

–5.0 V

Digital

Values

+5.0 V

–5.0 V

Figure 2-4: Acquisition: Input Analog Signal, Sample, and Digitize

The sampled points are stored in memory along with corresponding timing

information. You can use this digital representation of the signal for display,

measurements, or further processing.

You specify how the digitizing oscilloscope acquires data points and assembles them into the waveform record.

The trigger point marks time zero in a waveform record. All record points

before the trigger event make up the pretrigger portion of the the waveform

record. Every record point after the trigger event is part of the posttrigger

portion. All timing measurements in the waveform record are made relative to

that trigger event.

TDS 520 & TDS 540 User Manual

Each time it takes a sample, the oscilloscope digitizer produces a numeric

representation of the signal. The number of samples may be larger than the

number of points in your waveform record. In fact, the oscilloscope may take

several samples for each record point (Figure 2-5).

Interval for One Waveform Record Point

Samples For a

Record Point

Figure 2-5: Several Points May be Acquired for Each Point Used

2Ć7

Page 48

Acquisition

The digitizer can use the extra samples to perform additional processing,

such as averaging or looking for minimum and maximum values.

The digitizing oscilloscope creates a waveform record containing a user-specified number of data points. Each record point represents a certain voltage

level that occurs a determined amount of time from the trigger event.

Record Length

The number of points that make up the waveform record is defined by the

record length. You can set the record length in the Horizontal menu. The

digitizing oscilloscope provides record lengths of 500, 1,000, 2,500, 5,000,

and 15,000 points.

You can order option 1M that provides a maximum record length of 50,000

points. That option is available only at the time of original purchase; it cannot

be installed later.

Sampling Methods

Sampling is the process of converting the analog input signal to digital data

for display and processing. The two general methods of sampling are

and

time

equivalent-time

.

real-

Real-Time Sampling—In real-time sampling, the oscilloscope digitizes all

the points it acquires after one trigger event (see Figure 2-6). Use real-time

sampling to capture single-shot or transient events.

Record Points

Sampling Rate

Figure 2-6: Real-Time Sampling

Two factors that affect real-time sampling on the digitizing oscilloscope are

interleaving

Interleaving

digitizing speeds by combining the efforts of several digitizers. For example, if

you want to digitize on all channels at one time (four on the TDS 540 and two

on the TDS 520), each of those channels can digitize at a maximum real-time

speed of 250 Megasamples/second (per channel).

If you use two channels, the TDS 540 oscilloscope can combine the efforts of

two digitizers to each channel and acquire at 500 Megasamples/second (per

channel).

and

interpolation

.

refers to the ability of the digitizing oscilloscope to attain higher

2Ć8

REV MAY 1992

Concepts

Page 49

Acquisition

If you focus on only one channel at the maximum possible real-time rate, the

TDS 520 oscilloscope can acquire at 500 Megasamples/second using both its

digitizers, while the TDS 540 oscilloscope can combine all four digitizers and

acquire at 1 Gigasample/second.

Depending on how many channels you are using and the speed of the time

base, at some point the digitizing oscilloscope

samples to create a waveform record. (See the discussion on page 2-10 for

more details about when that happens.) At that point, the digitizing oscilloscope will create the waveform record in one of two ways depending on

whether you have limited the oscilloscope to real-time sampling or enabled

equivalent-time sampling (you make that choice in the Acquisition menu).

If you have restricted it to real-time sampling, the digitizing oscilloscope uses

a process called interpolation to create the intervening points in the waveform

record. There are two options for interpolation: linear or sin(x)/x.

will not be able to get enough

Linear interpolation

by using a straight line fit. It assumes all the interpolated points fall in their

appropriate point in time on that straight line. Linear interpolation is useful for

many waveforms such as pulse trains.

Sin(x)/x interpolation

actual values acquired. It assumes all the interpolated points fall along that

curve. That is particularly useful when acquiring more rounded waveforms

such as sine waves. Actually, it is appropriate for general use, although it may

introduce some overshoot or undershoot in signals with fast rise times.

computes record points between actual acquired samples

computes record points using a curve fit between the

NOTE

When using either type of interpolation, you may wish to set the

display style so that the real samples are displayed intensified

relative to the interpolated samples. The instructions under

on page 3-31 explain how to turn on intensified samples.

Style

Display

Equivalent-Time Sampling—The digitizing oscilloscope only uses equiva-

lent-time sampling if you have enabled the equivalent-time option in the

Acquisition menu

which to create a waveform record.

and the oscilloscope is not able to get enough samples with

TDS 520 & TDS 540 User Manual

In equivalent-time (ET) sampling the oscilloscope acquires samples over

many repetitions of the event (Figure 2-7). It should only be used on repetitive

signals.

2Ć9

Page 50

Acquisition

Record Points

1st Acquisition Cycle

2nd Acquisition Cycle

3rd Acquisition Cycle

nth Acquisition Cycle

Figure 2-7: Equivalent-Time Sampling

The oscilloscope takes a few samples with each trigger event and eventually

constructs a waveform record using the samples from multiple acquisitions.

That feature lets you accurately acquire signals with frequencies much higher

than the digitizing oscilloscope real-time bandwidth.

Selecting Sampling

Mode

The digitizing oscilloscope uses a type of equivalent-time sampling called

random equivalent-time sampling

. Although the samples are taken sequentially in time, they are random with respect to the trigger. That is because the

oscilloscope sample clock runs asynchronously with respect to the input

signal and the signal trigger. The oscilloscope takes samples independent of

the trigger position and displays them based on the time difference between

the sample and the trigger.

The sampling speeds and the number of channels you choose affect the

mode the digitizing oscilloscope uses to sample waveforms. Basically, if the

time base is 200 ns or slower, the digitizing oscilloscope uses real-time sampling for creating waveform records.

When the time base is faster than 50 ns, the digitizing oscilloscope creates

waveform records using equivalent-time sampling or interpolation. For speeds

between 200 ns and 20 ns, the digitizing oscilloscope creates waveform

records differently depending on the number of input channels and type of

oscilloscope you are using (see Table 2-1).

2Ć10

Concepts

Page 51

Table 2-1: Sampling Mode Selection —

100 ns/Div to 50 ns/Div

Acquisition

Acquisition Modes

Instrument and

Number of Channels

TDS 540,

any 1 channel

TDS 540,

any 2 channels

TDS 540,

3 or more channels

TDS 520,

any 1 channel

TDS 520, any 2 channels

The digitizing oscilloscope supports five acquisition modes.

Sample

H

H

Peak Detect

H

Hi Res

100 ns/Div 50 ns/Div

Real-time Real-time

Real-time Equivalent-time or

interpolated real-time

Equivalent-time or

interpolated real-time

Real-time Equivalent-time or

Equivalent-time or

interpolated real-time

Equivalent-time or

interpolated real-time

interpolated real-time

Equivalent-time or

interpolated real-time

Bandwidth

Coupling

H

Envelope

H

Average

Sample acquisition mode, which acquires in real time, is the mode most

commonly used. You can read about Sample and the other acquisition modes

Acquisition Modes,

in

Bandwidth

and display accurately (that is, with less than 3 dB attenuation).

You can set different bandwidths with the digitizing oscilloscope. Lower band-

width settings let you eliminate the higher frequency components of a signal.

The TDS 500 offers Full (500 MHz), 100 MHz, and 20 MHz bandwidth settings.

You can couple your input signal to the digitizing oscilloscope three ways. You

can choose between AC, DC, or Ground (GND). You also can set the input

impedance.

H

H

refers to the range of frequencies that an oscilloscope can acquire

DC coupling shows both the AC and DC components of an input signal.

AC coupling shows only the alternating components of an input signal.

beginning on page 3-11.

TDS 520 & TDS 540 User Manual

2Ć11

Page 52

Acquisition

For More

Information

H

Ground (GND) coupling disconnects the input signal from the acquisition.

H

Input impedance lets you select either 1 MW or 50 W impedance.

NOTE

If you select 50 Wimpedance with AC coupling, the digitizing oscilloscope will not accurately display frequencies under 200 kHz.

See

Scaling and Positioning Waveforms

Acquisition Modes

See

, on page 3-11.

, on page 2-13.

2Ć12

Concepts

Page 53

Scaling and Positioning Waveforms

Record View

Channel Reference Icon

Scaling and positioning waveforms means increasing or decreasing their

displayed size and moving them up, down, right, and left on the display.

Two display icons, the channel reference indicator and the record view, help

you quickly see the position of the waveform in the display (see Figure 2-8).

The channel reference icon points to the ground of the waveform record when

offset is set to 0 V. This is the point about which the waveform contracts or

expands when the vertical scale is changed. The record view, at the top of the

display, indicates where the trigger occurs and what part of the waveform

record is displayed.

Original Position Positioned Vertically Positioned Horizontally

Original Scale Scaled Horizontally

Figure 2-8: Scaling and Positioning

Scaled

Vertically

TDS 520 & TDS 540 User Manual

2Ć13

Page 54

Scaling and Positioning Waveforms

Vertical System

You can adjust the vertical position of the selected waveform by moving it up

or down on the display. For example, when trying to compare multiple waveforms, you can put one above another and compare them, or you can overlay

the two waveforms on top of each other. To move the selected waveform turn

the vertical POSITION knob.

You can also alter the vertical scale. The digitizing oscilloscope shows the

scale (in volts per division) for each active channel toward the bottom left of

the display. As you turn the vertical SCALE knob clockwise, the value decreases resulting in higher resolution because you see a smaller part of the

waveform. As you turn it counter-clockwise the scale increases allowing you

to see more of the waveform but with lower resolution.

Besides using the position and scale knobs, you can set the vertical scale and

position with exact numbers. You do that with the Vertical menu Fine Scale

and Position selections and the general purpose knob and/or the keypad.

Offset

Vertical offset changes where the channel reference indicator is shown with

respect to the graticule. Offset adds a voltage to the reference indicator

without changing the scale. That feature allows you to move the waveform up

and down over a large area without decreasing the resolution.

Offset is useful in cases where a waveform has a DC bias. One example is

looking at a small ripple on a power supply output. You may be trying to look

at a 100 mV ripple on top of a 15 V supply. The range available with offset

can prove valuable as you try to move and scale the ripple to meet your

needs.

Horizontal System

2Ć14

Adjusting the horizontal position of waveforms moves them right or left on the

display. That is useful when the record length of the waveform is so large

(greater than 500 points) that the digitizing oscilloscope cannot display the

entire waveform record at one time. You can also adjust the scale of the

waveform. For example, you might want to see just one cycle of a waveform

to measure the overshoot on its rising edge.

You adjust the horizontal scale of the displayed waveform records using the

horizontal SCALE knob and the horizontal position using the horizontal

POSITION knob.

The digitizing oscilloscope shows the actual scale in the bottom right of the

display. The scale readout shows the time per division used. Since all live

waveforms use the same time base, the digitizing oscilloscope only displays

one value for all the active channels.

Concepts

Page 55

Actual High-Frequency Waveform

Apparent Low-Frequency

Waveform Due to Aliasing

Sampled Points

Scaling and Positioning Waveforms

Aliasing

When

aliasing

actual waveform being input or a waveform is not stable even though the light

next to TRIG’D is lit. Aliasing occurs because the oscilloscope cannot sample

the signal fast enough to construct an accurate waveform record (Figure 2-9).

happens, you see a waveform with a frequency lower than the

Figure 2-9: Aliasing

One simple way to check for aliasing is to slowly change the horizontal scale

(time per division setting). If the shape of the displayed waveform changes

drastically, you may have aliasing.

In order to represent a signal accurately and avoid aliasing, you must sample

the signal more than twice as fast as the highest frequency component. For

example, a signal with frequency components of 500 MHz would need to be

sampled at a rate faster than 1 Gigasamples/second.

There are various ways to prevent aliasing. Try adjusting the horizontal scale,

or simply press the AUTOSET button. You can also counteract some aliasing

by changing the acquisition mode in the Acquisition menu. For example, if

you are using the sample mode and suspect aliasing, you may want to

change to the peak detect mode. Since the peak detect mode searches for

samples with the highest and lowest values, it can detect faster signal components over time.

Delayed Time Base

You can set a main time base and a delayed time base. Each time base has

its own trigger. There are two types of delayed time base acquisitions, with

each based on its triggering relationship to the main time base. These are

delayed runs after main and delay triggerable (after time, events, or both)

acquisitions.

TDS 520 & TDS 540 User Manual

The delayed time base is useful in catching events that follow other events.

See

Triggering

on page 2-2 for more information on the delayed trigger.

2Ć15

Page 56

Scaling and Positioning Waveforms

Zoom

Autoset

You can use zoom to see more detail without changing the acquired signal.

When you press the ZOOM button, a portion of the waveform record can be

expanded or compressed on the display, but the record points stay the same.

Zoom is very useful when you wish to temporarily expand a waveform to

inspect small feature(s) on that waveform. For example, you might use zoom

to temporarily expand the front corner of a pulse to inspect its aberrations.

Use zoom to expand it horizontally and vertically. After you are finished, you

can return to your original horizontal scale setting by pressing one menu

button. (The zoom feature is also handy if you have acquired a waveform

while using the fastest time per division and want to further expand horizontally.)

Autoset lets you quickly obtain a stable waveform display. It automatically

adjusts a wide variety of settings including vertical and horizontal scaling.

Other settings affected include trigger coupling, type, position, slope, mode,

and display intensities.

does.

Autoset

on page 3-18 describes in detail what autoset

For More

Information

Autoset

See

Delayed Triggering

See

Horizontal Control

See

Vertical Control

See

Zoom

See

, on page 3-18.

, on page 3-130.

, on page 3-25.

, on page 3-49.

, on page 3-124.

2Ć16

Concepts

Page 57

Measurements

The digitizing oscilloscope not only displays graphs of voltage versus time, it

also can help you measure the displayed information (see Figure 2-10).

Measurement

Sources

Automated

Measurements

Ch 1

Frequency

100 MHz

Ch 1 Period

10 ns

Graticule

Cursors

Cursor

Readouts

Figure 2-10: Graticule, Cursor and Automated Measurements

The oscilloscope provides three measurement classes. They are: graticules,