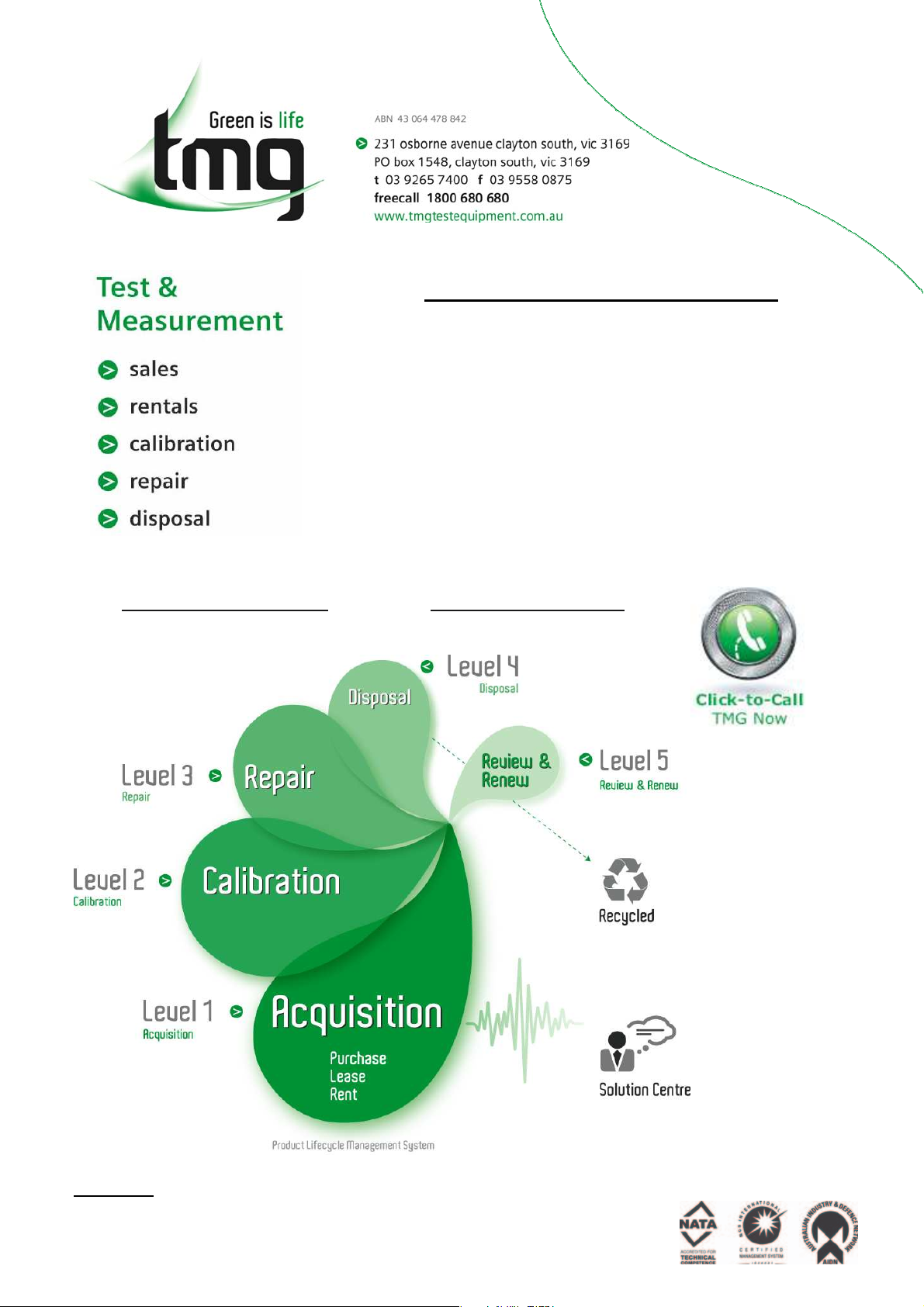

Page 1

Complimentary Reference Material

This PDF has been made available as a complimentary service for you to assist in

evaluating this model for your testing requirements.

TMG offers a wide range of test equipment solutions, from renting short to long

term, buying refurbished and purchasing new. Financing options, such as

Financial Rental, and Leasing are also available on application.

TMG will assist if you are unsure whether this model will suit your requirements.

Call TMG if you need to organise repair and/or calibrate your unit.

If you click on the “Click-to-Call” logo below, you can all us for FREE!

TMG Corporate Website TMG Products Website

Disclaimer:

All trademarks appearing within this PDF are trademarks of their respective owners.

Form 080/01

Page 2

User Manual

TDS5000 Series

Digital Phosphor Oscilloscopes

071-0876-02

This document applies to firmware version 1.00

and above.

www.tektronix.com

Page 3

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX, TEKPROBE, and TEK are registered trademarks of Tektronix, Inc.

Microsoft, Windows, and Windows ME are registered trademarks of Microsoft Corporation.

Page 4

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when t h e effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Page 6

Table of Contents

Getting Started

General Safety Summary xi...................................

Preface xiii...................................................

About This Manual xiii...............................................

Related Manuals and Online Documents xiv..............................

Contacting Tektronix xv.............................................

Product Description 1--1........................................

Models 1--1........................................................

Key Features 1--1....................................................

Product Software 1--2................................................

Firmware Upgrade 1--3...............................................

Probes Supported 1--4................................................

Installation 1--5...............................................

Unpacking 1--5......................................................

Checking the Environment Requirements 1--6.............................

Connecting Peripherals 1--6............................................

Powering On the Oscilloscope 1--8......................................

Shutting Down the Oscilloscope 1--9....................................

Creating an Emergency Startup Disk 1--9.................................

Backing Up User Files 1--10............................................

Installing Software 1--10...............................................

Connecting to a Network 1--12..........................................

Setting up a Dual Display 1--13..........................................

Adjusting Display Contrast 1--17........................................

Incoming Inspection 1--19.......................................

Assemble Equipment 1--19.............................................

Self Tests 1--20.......................................................

Functional Tests 1--21.................................................

Perform the Extended Diagnostics 1--30...................................

Accessories and Options 1--31....................................

Options 1--31........................................................

Accessories 1--33.....................................................

Operating Basics

TDS5000 Series User Manual

Operational Maps 2--1.........................................

Documentation Map 2--2.......................................

Front Panel I/O Map 2--3.......................................

Control Panel Map: Quick Access to Most Often Used Features 2--4...

User Interface Map -- Complete Control and Display 2--5............

Display Map -- Single Graticule 2--6..............................

Side and Rear Panel I/O & Connectors Map 2--7...................

Left Side 2--7.......................................................

i

Page 7

Table of Contents

Reference

Rear 2--7...........................................................

System Overview Maps 2--8.....................................

Functional Model Map 2--8............................................

Process Overview Map 2--10............................................

Overview 3--1.................................................

Acquiring Waveforms 3--3......................................

Signal Connection and Conditioning 3--4.................................

Connecting and Conditioning Your Signals 3--5........................

Setting Up Signal Input 3--8........................................

Autosetting the Oscilloscope 3--12....................................

Resetting the Oscilloscope 3--13.....................................

Input Conditioning Background 3--14.................................

Setting Acquisition Controls 3--21.......................................

Acquisition Modes 3--21............................................

Controlling Acquisitions 3--22.......................................

Roll Mode 3--22..................................................

Preventing Aliasing 3--23...........................................

Incompatible Modes 3--24..........................................

Setting Acquisition Modes 3--25.....................................

Starting and Stopping Acquisition 3--26...............................

Using Roll Mode 3--28.............................................

Acquisition Control Background 3--29....................................

Acquisition Hardware 3--30.........................................

Sampling Process 3-- 30.............................................

Sampling Modes 3--31.............................................

Waveform Record 3--31............................................

Real-time Sampling 3--32...........................................

Equivalent-time Sampling 3--33......................................

Interpolation 3--34................................................

Interleaving 3--35.................................................

Using Fast Acquisitions Mode 3--35......................................

Using Fast Acquisitions 3--36........................................

Turning Fast Acquisitions On and Off 3--39............................

Setting the Display Format 3--41.....................................

Using FastFrame 3--42.................................................

Using FastFrame Acquisitions 3--43..................................

To Set FastFrame Mode 3--44.......................................

Time Stamping Frames 3--45........................................

Triggering 3--49................................................

Triggering Concepts 3--50..............................................

Trigger Event 3--50................................................

Trigger Sources 3--50..............................................

Trigger Types 3--51................................................

Trigger Modes 3--51...............................................

Trigger Holdoff 3--52..............................................

Trigger Coupling 3--52.............................................

Horizontal Position 3--53...........................................

Slope and Level 3--53..............................................

Delayed Trigger System 3--53.......................................

ii

TDS5000 Series User Manual

Page 8

Table of Contents

Triggering from the Front Panel 3--54.....................................

Setting up Triggers 3--54...........................................

Checking Trigger Status 3--57.......................................

Additional Trigger Parameters 3--59......................................

Advanced Triggering 3--62.............................................

Triggering on a Glitch 3--68.........................................

Triggering on a Runt Pulse 3--70.....................................

Triggering on the Pulse Width 3--73..................................

Triggering on Transition Time 3--75..................................

Triggering on Pulse Timeout 3--77....................................

Triggering on a Pattern 3--79........................................

Triggering on Logic State 3--82......................................

Triggering on Setup/Hold Time Violations 3--84.........................

Triggering on Window Threshold Violations 3--87.......................

Triggering on a Video Signal 3--89...................................

Sequential Triggering 3--91.............................................

Using Sequential Triggering 3--91....................................

Triggering on a Sequence 3--95......................................

Displaying Waveforms 3--99......................................

Using the Waveform Display 3--100.......................................

Display Elements 3--100.............................................

Acquisition Preview 3--101..........................................

Display Methods 3--101.............................................

Displaying Waveforms in the Main Graticule 3--104......................

Customizing the Waveform Display 3--106.................................

Using Display Controls 3--106........................................

Using the Zoom Feature 3--110...........................................

Using Zoom with Waveforms 3--110...................................

Measuring Waveforms 3--115.....................................

Taking Automatic Measurements 3 --115....................................

Using Automatic Measurements 3--116.................................

Taking Automatic Measurements 3--119................................

Localizing a Measurement 3 -- 122.....................................

Taking Cursor Measurements 3--124.......................................

Cursor Types 3--124................................................

Using Cursors 3--125...............................................

Setting Cursor Sources 3--128........................................

Using Histograms (Optional) 3--130.......................................

Starting and Resetting Histogram Counting 3--132........................

Histogram Measurements 3--133......................................

Creating and Using Math Waveforms 3--135.........................

About Math Waveforms 3--136...........................................

Purpose 3--136....................................................

Standard Math versus Advanced Math 3--137............................

Other Uses for Math Waveforms 3--138.................................

Using Math 3--138.................................................

Creating a Math Waveform 3--144.....................................

Operations on Math Waveforms 3--147.....................................

Displaying and Measuring Math Waveforms 3--148.......................

Defining Spectral Math Waveforms 3--151..................................

TDS5000 Series User Manual

iii

Page 9

Table of Contents

Using Spectral Math Controls 3--152...................................

Recognizing Aliasing 3--172.........................................

Selecting a Predefined Spectral Math Function (Optional) 3--174............

Defining a Spectral Math Waveform 3--175.............................

Defining a Spectral Math Waveform (Optional) 3--176....................

Data Input/Output 3-- 183.........................................

Saving and Recalling Setups 3--183.......................................

Saving A Setup 3--185..............................................

Recalling a Setup 3--187.............................................

Saving and Recalling Waveforms 3--189...................................

Saving a Waveform 3--190...........................................

Recalling A Waveform 3--192........................................

Clearing References 3--194..........................................

Exporting and Copying Waveform Data 3--196..............................

Exporting Waveform Data 3--197.....................................

Using an Exported Waveform 3--200...................................

Copying Waveform Data 3--202.......................................

Printing Waveforms 3--205..............................................

Printing from the Front Panel 3--205...................................

Printing from the Menu Bar 3--205....................................

Setting Up the Page 3--205...........................................

Previewing the Page 3--205..........................................

Printing Banners 3--206.............................................

Using Print Screen 3 --207............................................

Using the Date/Time Stamp 3--207....................................

Remote Communication 3--207...........................................

GPIB 3--207......................................................

Other Communication 3--208.........................................

Accessing Online Help 3--209......................................

Using Online Help 3--209...............................................

Appendices

iv

Appendix A: Specifications A--1..................................

Product and Feature Description A--1....................................

Acquisition Features A--2..........................................

Signal Processing Features A--2.....................................

Display Features A--3.............................................

Measurement Features A-- 3.........................................

Trigger Features A--3..............................................

Convenience Features A--3.........................................

Specification Tables A--5..............................................

Appendix B: Automatic Measurements Supported B--1..............

Appendix C: Cleaning C--1......................................

Exterior Cleaning C--1............................................

Flat Panel Display Cleaning C--1....................................

Appendix D: Menu Bar Commands D-- 1..........................

File Commands D--1..................................................

Edit Commands D--2.................................................

Vertical Commands D--3..............................................

Horizontal and Acquisition Commands D--4...............................

TDS5000 Series User Manual

Page 10

Glossary

Index

Table of Contents

Trigger Commands D--5...............................................

Display Commands D--6...............................................

Cursors Commands D--7...............................................

Measure Commands D--7..............................................

Standard Math Commands D--8.........................................

Advanced Math Commands (Optional) D--9...............................

Utilities Commands D--10..............................................

Help Commands D--10.................................................

Appendix E: Optimizing Measurement Accuracy E--1...............

Compensating the Oscilloscope E--1.................................

Connecting Probes for Calibration E--3...............................

Calibrating Probes E-- 3............................................

Compensating Low Frequency Probes E--5............................

Deskewing Channels E--6.........................................

TDS5000 Series User Manual

v

Page 11

Table of Contents

List of Figures

Figure 1--1: Locations of connectors on side and rear panels 1--7......

Figure 1--2: On/Standby switch location 1--8.......................

Figure 1--3: Drag area for Windows task bar 1--16...................

Figure 1--4: Universal test hookup for functional tests,

CH 1 shown 1--22...........................................

Figure 1--5: Channel button location 1--22..........................

Figure 1--6: Location of vertical and horizontal scale readouts 1--23....

Figure 1--7: Setup for time base test 1--25...........................

Figure 1--8: Setup for trigger test 1--27.............................

Figure 1--9: Setup for the file system test 1--29.......................

Figure 3--1: Oscilloscope System Overview: Signal Acquisition 3--3....

Figure 3--2: Input and Acquisition Systems and Controls 3--4.........

Figure 3--3: Setting vertical range and position of input channels 3-- 16..

Figure 3--4: Varying offset moves the vertical acquisition window

on the waveform 3--17.......................................

Figure 3--5: Horizontal acquisition window definition 3--18...........

Figure 3--6: Common trigger, record length, and acquisition rate

for all channels 3--20........................................

Figure 3--7: Roll modes 3--23.....................................

Figure 3--8: Aliasing 3--24........................................

Figure 3--9: Digitizer configuration 3--30...........................

Figure 3--10: Digital acquisition — sampling and digitizing 3--30.......

Figure 3--11: The waveform record and its defining parameters

(horizontal delay on) 3--32....................................

Figure 3--12: Real-time sampling 3--32.............................

Figure 3--13: Equivalent-time sampling 3--33.......................

Figure 3--14: Normal DSO and Fast Acquisitions displays 3--36........

Figure 3--15: Normal DSO Acquisition and Display mode versus

Fast Acquisitions mode 3--38..................................

Figure 3--16: Fast Acquisitions XY display 3--41.....................

Figure 3--17: FastFrame 3--42....................................

Figure 3--18: FastFrame time stamp 3--48..........................

Figure 3--19: Oscilloscope System Overview: Triggering 3--49.........

Figure 3--20: Triggered versus untriggered displays 3--50.............

Figure 3--21: Holdoff adjustment can prevent unwanted triggers 3--52..

vi

TDS5000 Series User Manual

Page 12

Table of Contents

Figure 3--22: Slope and level controls help define the trigger 3--53......

Figure 3--23: Example advanced trigger readout 3--62................

Figure 3--24: Violation zones for Setup/Hold triggering 3--66..........

Figure 3--25: Triggering on a Setup/Hold time violation 3--86..........

Figure 3--26: Triggering with Horizontal Delay off 3--92..............

Figure 3--27: Triggering with Horizontal Delay on 3--93..............

Figure 3--28: Trigger and Horizontal Delay summary 3--94............

Figure 3--29: Oscilloscope System Overview: Customizable

Display 3--99...............................................

Figure 3--30: Display elements 3--100...............................

Figure 3--31: Horizontal position includes time to horizontal

reference point 3--103.........................................

Figure 3--32: Annotated display 3--115..............................

Figure 3--33: High/Low tracking methods 3--117......................

Figure 3--34: Reference level calculation methods 3--118...............

Figure 3--35: Components determining Time cursor

readout values 3--126.........................................

Figure 3--36: Horizontal histogram view and measurement data 3--131...

Figure 3--37: Math waveform created from source waveform 3--135......

Figure 3--38: Spectral analysis of an impulse 3--136...................

Figure 3--39: Functional transformation of an acquired waveform 3--136.

Figure 3--40: Derivative math waveform 3--141.......................

Figure 3--41: Peak-peak amplitude measurement of a derivative

waveform 3--142.............................................

Figure 3--42: Duration and resolution control effects 3--153.............

Figure 3--43: Definition of gate parameters 3--154.....................

Figure 3--44: Effects of frequency domain control adjustments 3--156....

Figure 3--45: Effects of adjusting the reference level 3--157.............

Figure 3--46: Effects of adjusting the reference level offset control 3--158.

Figure 3--47: Example of the effects of setting the phase

suppression threshold 3--159...................................

Figure 3--48: Windowing the time domain record 3--161...............

Figure 3--49: Example of scallop loss for a Hanning window

without zero fill 3--163........................................

Figure 3--50: Time and frequency graphs for the Gaussian

window 3--164...............................................

Figure 3--51: Time and frequency domain graphs for the

Rectangular window 3--165....................................

Figure 3--52: Time and frequency graphs of the Hamming

window 3--166...............................................

TDS5000 Series User Manual

vii

Page 13

Table of Contents

Figure 3--53: Time and frequency graphs for the Hanning

window 3--167...............................................

Figure 3--54: Time and frequency graphs for the Kaiser-Bessel

window 3--168...............................................

Figure 3--55: Time and frequency graphs of the Blackman-Harris

window 3--169...............................................

Figure 3--56: Time and frequency domain graphs for the Flattop2

window 3--170...............................................

Figure 3--57: Tek Exponential window in the time and the

frequency domains 3--171.....................................

Figure 3--58: How aliased frequencies appear in a spectral

waveform 3--173.............................................

Figure 3--59: Auto-increment file name feature 3--184.................

Figure 3--60: Print preview dialog box 3--206.........................

Figure B--1: Levels used to determine measurements B--3............

viii

TDS5000 Series User Manual

Page 14

List of Tables

Table of Contents

Table 1--1: Recommended probe cross reference 1-- 4................

Table 1--2: Additional accessory connection information 1--7.........

Table 1--3: Instrument options 1--31...............................

Table 1--4: Instrument upgrades 1--32.............................

Table 1--5: Standard accessories 1--33.............................

Table 1--6: Optional accessories 1--34..............................

Table 3--1: Additional resolution bits 3--21.........................

Table 3--2: Sampling mode selection 3--34..........................

Table 3--3: How interleaving affects sample rate 3--35................

Table 3--4: XY format pairs 3--42.................................

Table 3--5: Pattern and state logic 3--64...........................

Table 3--6: Defining and displaying waveforms 3--101.................

Table 3--7: Customizable display elements 3--106.....................

Table 3--8: Cursor types 3--124....................................

Table 3--9: Cursor units 3--126....................................

Table 3--10: Functions available in Standard Math and

Advanced Math 3--137........................................

Table 3--11: Math expressions and the math waveforms

produced 3--138.............................................

Table 3--12: Spectral analyzer controls 3--152........................

Table 3--13: Window characteristics 3--161..........................

TDS5000 Series User Manual

Table A--1: TDS5000 models A--1................................

Table A--2: Channel input and vertical specifications A-- 5...........

Table A--3: Horizontal and acquisition system specifications A--11.....

Table A--4: Trigger specifications A --13............................

Table A--5: Display specifications A--16............................

Table A--6: Input/output port specifications A--17...................

Table A--7: Data storage specifications A--18........................

Table A--8: Power source specifications A--19.......................

T able A--9: Mechanical specifications A--19.........................

Table A--10: Environmental specifications A--20.....................

Table A--11: Certifications and compliances A--21...................

Table B--1: Supported measurements and their definitions B --1.......

ix

Page 15

Table of Contents

Table D--1: File menu commands D--1............................

Table D--2: Edit menu commands D--2............................

Table D--3: Vertical menu commands D--3.........................

T able D--4: Horiz/Acq menu commands D--4.......................

Table D--5: Trig menu commands D--5............................

Table D--6: Display menu commands D--6.........................

Table D--7: Cursors menu commands D--7.........................

Table D--8: Measure menu commands D-- 7........................

Table D--9: Standard Math menu commands D--8..................

T able D--10: Advanced Math menu commands D--9.................

Table D--11: Utilities menu commands D--10........................

Table D--12: Help menu commands D--10..........................

x

TDS5000 Series User Manual

Page 16

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with metal covers or

panels removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

TDS5000 Series User Manual

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

xi

Page 17

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

xii

TDS5000 Series User Manual

Page 18

Preface

About This Manual

This is the user manual for the TDS5000 Series oscilloscope. It covers the

following information:

H Describes the capabilities of the oscilloscope and how to get started using the

instrument

H Explains how to operate the oscilloscope: how to control acquisition of,

processing of, and input/output of data and information

H Lists specifications and accessories of the oscilloscope

This manual is composed of the following chapters:

H Getting Started shows you how to configure and install your oscilloscope

and provides an incoming inspection procedure.

H Operating Basics uses maps to describe the various interfaces for controlling

the oscilloscope, including the front panel and the software user interface.

These maps provide overviews of the product and its functions from several

viewpoints.

H Reference comprises an encyclopedia of topics (see Overview on page 3--1)

that describe the oscilloscope interface and features, and gives background

and basic information on how to use them. (The online help onboard the

oscilloscope application describes the interface, features, and their usage;

detailed descriptions of all programming commands are found in the

TDS5000 Series Oscilloscope Online Programmer Guide.)

H Appendices provides additional information including instrument specifica-

tions, measurement and menu descriptions, cleaning information, and

calibration instructions.

TDS5000 Series User Manual

xiii

Page 19

Preface

Related Manuals and Online Documents

This manual is part of a document set of standard-accessory manuals and online

documentation; this manual mainly focuses on installation, background, and user

information needed to use the product features. See the following list for other

documents supporting oscilloscope operation and service. (Manual part numbers

are listed in Accessories & Options on page 1--31.)

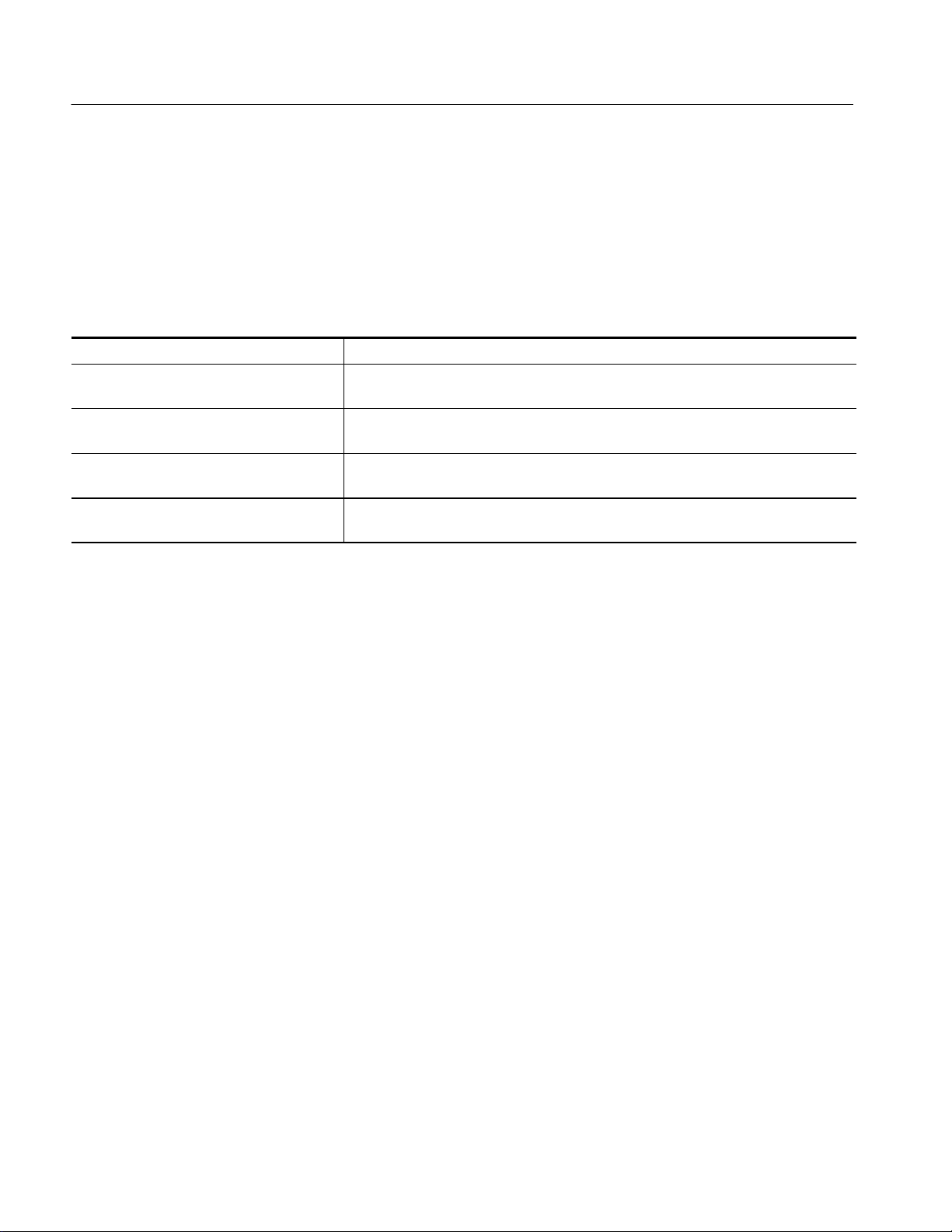

Manual name Description

TDS5000 Series Digital Phosphor Oscilloscopes Online Help

TDS5000 Series Digital Phosphor Oscilloscopes Reference Manual

TDS5000 Series OscilloscopeOnline

Programmer Guide

TDS5000 Series Digital Phosphor Oscilloscopes Service Manual

1 Located on the TDS5000 Series Product Software CD. See CD instructions for installation instructions.

An online help system, integrated with the User Interface application that ships with this

product. The help is preinstalled in the oscilloscope.

A quick reference to major features of the oscilloscope and how they operate.

A listingf the programming commands and other information related to controlling the

oscilloscope over GPIB

A description of how to service the oscilloscope to the module level. This optional

manual must be ordered separately.

1

.

For more information on how the product documentation relates to the

oscilloscope operating interfaces and features, see Documentation Map on

page 2--2.

xiv

TDS5000 Series User Manual

Page 20

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

TDS5000 Series User Manual

xv

Page 21

Preface

xvi

TDS5000 Series User Manual

Page 22

Product Description

This chapter describes the TDS5000 Series Digital Phosphor Oscilloscopes and

their options. Following this description are three sections:

H Installation shows you how to configure and install the oscilloscope, as well

as how to reinstall the system software included with the product.

H Incoming Inspection provides a procedure for verifying basic operation and

functionality.

H Accessories lists the standard and optional accessories for this product.

Models

This manual supports three very similar oscilloscopes:

H TDS5052 Digital Phosphor Oscilloscope

H TDS5054 Digital Phosphor Oscilloscope

H TDS5104 Digital Phosphor Oscilloscope

Key Features

This user manual applies to all of the above oscilloscopes: differences between

the oscilloscopes are noted when necessary.

TDS5000 Series oscilloscopes are high-performance solutions for verification,

debugging, and characterization of sophisticated electronic designs. The series

features exceptional signal acquisition performance, operational simplicity, and

open connectivity to the design environment. Classic analog-style controls, a

large display with an optional touch-sensitive screen, and graphical menus

provide intuitive control. Open access to the Windows operating system enables

unprecedented customization and extensibility. Key features include:

H Up to 1 GHz bandwidth and 5 GS/s real time sampling rate, depending on

the model

H Record lengths up to 8,000,000 samples, depending on memory option

H Fast acquisition at up to 100,000 acquisitions per second for analog

oscilloscope emulation and isolation of data-dependent failures during

conformance/performance testing

H 1.5% DC vertical gain accuracy

TDS5000 Series User Manual

1- 1

Page 23

Product Description

H Two or four input channels (each with 8-bit resolution), Channel 3 signal

output (depending on model), and auxiliary trigger input and output

H Sample, envelope, peak-detect, high-resolution, and average acquisition

modes

H Full programmability, with an extensive GPIB command set and a message-

based interface

H Extensive suite of advanced triggers including edge, logic, pulse, video, and

sequence at up to 1 GHz bandwidth

H Powerful built-in measurement capability, including optional histograms,

automatic measurements, and measurement statistics

H A large 10.4 inch (264.2 mm) color display that supports color grading of

waveform data to show sample density

H An intuitive graphical user interface (UI) with online help

H Internal disk storage

Product Software

H Wide array of probing solutions

H Optional integrated thermal printer

H Optional touch screen

H Optional CD-RW drive

The oscilloscope includes the following software:

H System Software. The product software runs on a specially configured

version of Windows 2000. Windows 2000 is preinstalled and enables you to

install other compatible applications. To reinstall Windows 2000, use the

Operating System Restore CD-ROM, a standard accessory with your

oscilloscope. Do not attempt to substitute any version of Windows that is not

specifically provided by Tektronix for use with your oscilloscope. (Note that

older versions of the instrument may use Windows ME; contact Tektronix

sales support for information about upgrading an older instrument to

Windows 2000.)

H TDS5000 Product Software. This preinstalled software is the oscilloscope

application and runs on Windows 2000. It provides the user interface (UI)

and all other oscilloscope control functions. You can minimize or even

exit/restart the oscilloscope application as your needs dictate. However, it is

recommended that you exit the oscilloscope application only when installing

new software.

1- 2

TDS5000 Series User Manual

Page 24

Product Description

H Support Software. The TDS5000 Series Product Software CD-ROM,

included with the oscilloscope, contains additional software and files that

may be useful to you.

H Readme file. This text file contains release notes and updates that are not

included in other product documentation.

H GPIB Programmer Online Help software. This software is available as

WinHelp or as a PDF file. It contains the information you need to

program the oscilloscope through its GPIB interface.

H Performance Verification Procedures. The product CD-ROM contains

instructions to perform a manual performance verification.

See the instructions for the TDS5000 Series Product Software CD-ROM for

information about installing the support software.

Occasionally new versions of software for your oscilloscope may become

available at our web site. See Contacting Tektronix on page xv in the Preface.

Firmware Upgrade

Tektronix may offer firmware upgrade kits for the oscilloscope. Contact your

Tektronix service representative for more information (see Contacting Tektronix

on page xv).

TDS5000 Series User Manual

1- 3

Page 25

Product Description

Probes Supported

Table 1--1 lists the recommended probes for each oscilloscope. Descriptions of

each probe follow the table.

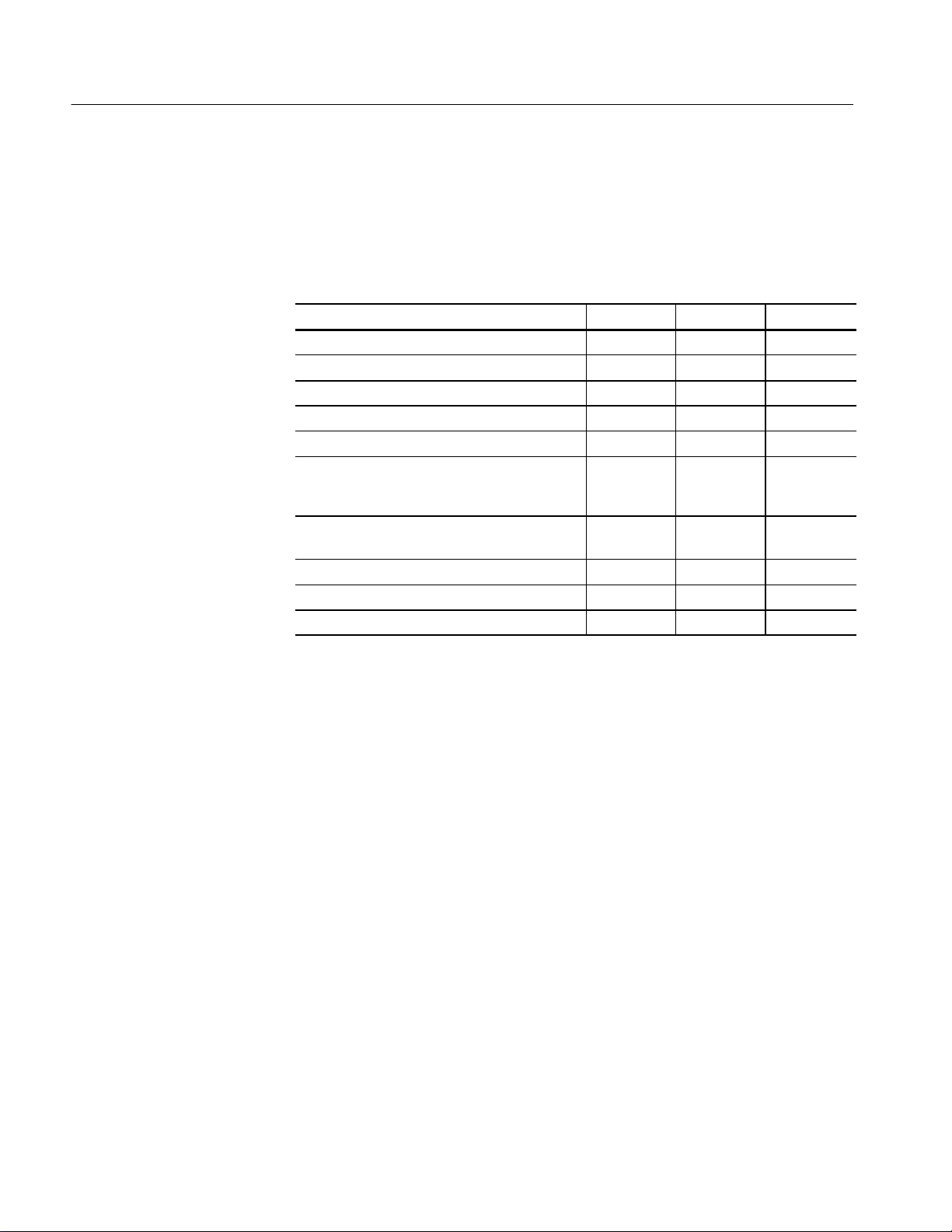

Table 1- 1: Recommended probe cross reference

Probe TDS5052 TDS5054 TDS5104

Passive, 10X P5050 P5050 P5050

Passive, 100X P5100 P5100 P5100

Passive, 1000K P6015A P6015A P6015A

Active CMOS/TTL P6243 P6243 P6245

All Technology P6245 P6245 P6245

Differential Digital P6246,

P6247,

P6248

High Voltage Differential P5205,

P5210

Current, AC Only CT-6 CT-6 CT-6

Current, AC/DC TCP202 TCP202 TCP202

Low Capacitance P6158 P6158 P6158

P6246,

P6247,

P6248

P5205,

P5210

P6246,

P6247,

P6248

P5205,

P5210

H P5050 10X, 500 MHz passive probe

H P5100 100X, 250 MHz passive high voltage probe

H P6015A 1000X, 100 MHz passive high voltage probe

H P6243 Active, high speed digital voltage probe, FET, DC to 1.0 GHz

H P6245 Active, high speed digital voltage probe, FET, DC to 1.5 GHz

H P6246 Active, high bandwidth differential probe, FET, DC to 400 MHz

H P6247 Active, high bandwidth differential probe, FET, DC to 1 GHz

H P6248 Active, high bandwidth differential probe, FET, DC to 1.7 GHz

H P5205 Active 100 MHz differential probe

H P5210 Active, 50 MHz differential probe

H TCP202 Current Probe, DC to 50 MHz, 15 A DC

H CT-6 Current probe, designed for temporary in-circuit installation, 250 kHz

to 2 GHz, 50 Ω input

H P6158 20X, 3 GHz low capacitance probe

1- 4

TDS5000 Series User Manual

Page 26

Installation

This section addresses oscilloscope installation:

H Unpacking on page 1--5

H Checking the Environment Requirements on page 1--6

H Connecting Peripherals on page 1--6

H Powering On the Oscilloscope on page 1--8

H Shutting Down the Oscilloscope on page 1--9

H Creating an Emergency Startup Disk on page 1--9

H Backing Up User Files on page 1--10

H Installing Software on page 1--10

H Connecting to a Network on page 1--12

H Setting Up a Dual Display on page 1--13

H Adjusting Display Contrast on page 1--17

Unpacking

CAUTION. Be sure to create your emergency startup disk as described on

page 1--9. You may need that disk if you ever need to reinstall Windows 2000 on

the oscilloscope hard drive.

The graphical packing list shows the standard accessories that you should find in

the shipping carton. The number of probes depends on the model you ordered.

You should verify that you have:

H The correct power cord for your geographical area.

H Four compact discs that include copies of the software installed on the

oscilloscope and additional support software that may be useful to you:

TDS5000 Series Operating System Restore (two CDs), TDS5000 Series

Product Software, and Optional Applications Software for Tektronix

Windows-Based TDS Instruments. Store the product software in a safe

location.

H All the standard and optional accessories that you ordered.

TDS5000 Series User Manual

1- 5

Page 27

Installation

Remember to fill out and send in the customer registration card. The registration

card is packaged with this manual.

Checking the Environment Requirements

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your oscilloscope.

Site Considerations

Operating Requirements

Connecting Peripherals

The oscilloscope is designed to operate on a bench or on a cart in the normal

position (on the bottom feet). For proper cooling, at least three inches (7.62 cm)

of clearance is required on the left side of the oscilloscope. The bottom and rear

require the clearance provided by the oscilloscope feet.

CAUTION. To ensure proper cooling, keep the bottom and left side of the

oscilloscope clear of obstructions.

The Specifications in Appendix A list the power source, temperature, humidity,

and altitude operating requirements for the oscilloscope.

The peripheral connections are the same as those on a personal computer. The

connection points are shown in Figure 1--1. See Table 1--2 on page 1--7 for

additional connection information.

NOTE. We recommend that you plug USB devices directly into the USB connectors on the oscilloscope chassis for improved reliability rather than connecting

the devices serially. If your USB mouse locks up, disconnect and reconnect the

USB connector to restore normal operation. If the oscilloscope front panel

and/or touch screen do not respond, press the On/Standby switch for at least 5

seconds to cycle power .

1- 6

TDS5000 Series User Manual

Page 28

Installation

CAUTION. To avoid product damage, shut down the oscilloscope and disconnect

the power cord from the power source before connecting any accessories. A USB

mouse, keyboard, or other USB device can be connected or disconnected with

the power on. See Shutting Down the Oscilloscope on page 1--9.

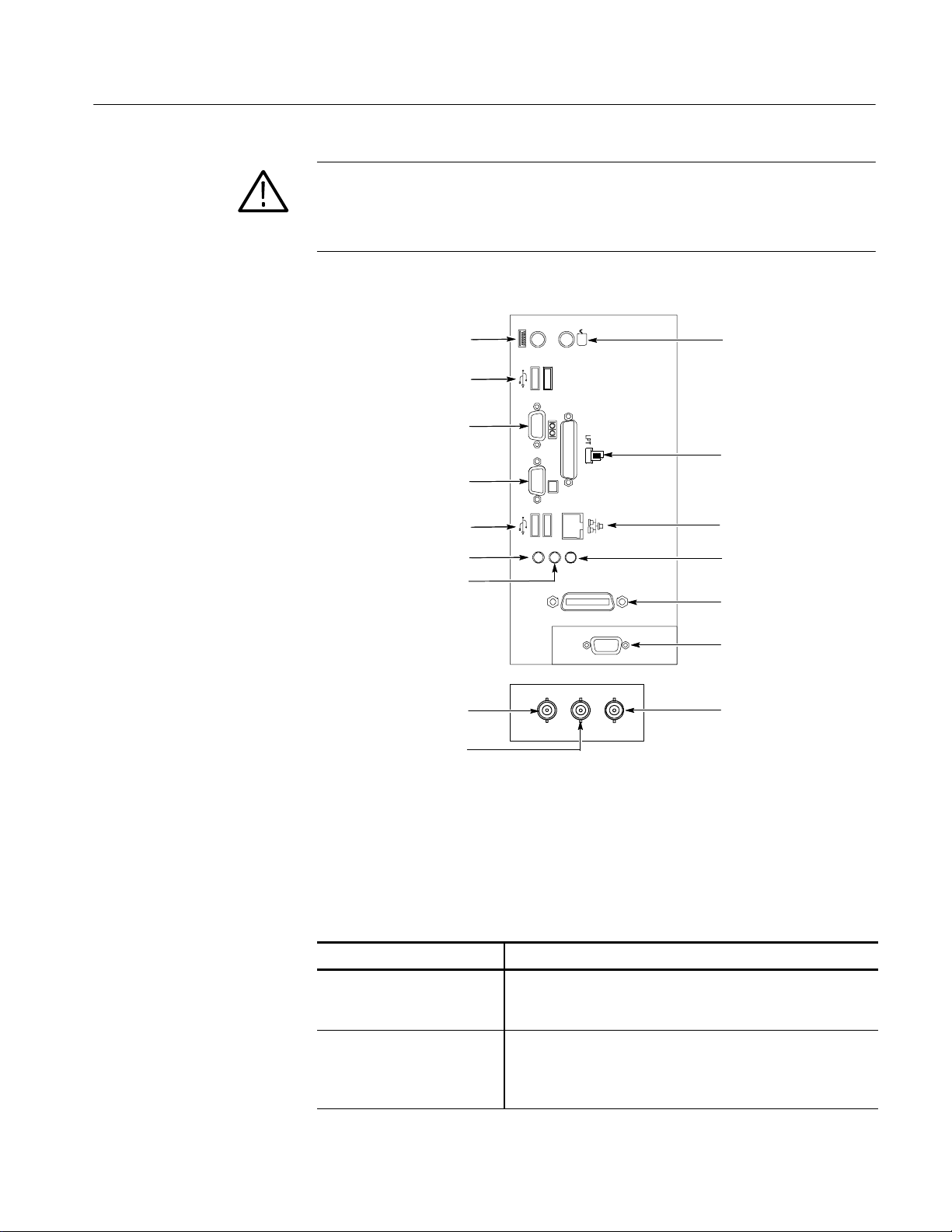

Keyboard

USB

PC SVGA Output

RS-232

USB*

Microphone in

Audio line out

Timebase reference input

(EXT REF)

Trigger signal output

(AUX OUT)

Mouse

Centronics Printer

Ethernet

Audio line in

GPIB

Scope VGA Output

CH 3 signal outpuT

(SIGNAL OUT)

Figure 1- 1: Locations of connectors on side and rear panels

TDS5000 Series User Manual

*These connectors are on later model insturments only.

Table 1- 2: Additional accessory connection information

Item Description

Monitor If you use a nonstandard monitor, you may need to change the

Windows 2000 display settings to achieve the proper resolution

for your monitor.

Printer Connect an external printer to the Centronics parallel port

connector directly. If your printer has a DB-25 connector, use

the adapter cable that came with your printer. For information

on printer usage, see Printing Waveforms on page 3--205.

1- 7

Page 29

Installation

Table 1- 2: Additional accessory connection information (Cont.)

Item Description

Rackmount For installation information, refer to the instructions that came

Other Refer to the Readme file on the TDS5000 Series Product

Powering On the Oscilloscope

Follow these steps to power on the oscilloscope for the first time.

CAUTION. To ensure proper operation, connect the keyboard, mouse, and other

accessories before applying power to the product the first time.

with your rackmount kit.

Software CD for possible additional accessory installation

information not covered in this manual.

On/Standby

Switch

1. Connect the one end of the oscilloscope power cord to the oscilloscope, and

the other end to a power source.

2. If you have connected an external monitor, connect the monitor power cord

to a power source and power on the monitor.

3. Push the On/Standby switch to power on the oscilloscope (see Figure 1--2 for

the switch location).

Figure 1- 2: On/Standby switch location

1- 8

TDS5000 Series User Manual

Page 30

Shutting Down the Oscilloscope

When you push the front-panel On/Standby switch, the oscilloscope starts a

shutdown process (including a Windows shutdown) to preserve settings and then

go into standby mode. Avoid disconnecting the power cord to shut down the

oscilloscope.

NOTE. If you remove power instead of using the On/Standby switch to shut down

the oscilloscope, the oscilloscope will be in the factory Default Setup when

powered up the next time.

It may be necessary to hold the On/Standby switch for up to 20 seconds for the

shutdown process to initiate.

To completely remove power to the oscilloscope, perform the shutdown process

just described and disconnect the power cord from the power source.

Installation

Creating an Emergency Startup Disk

Now that you have completed the basic installation process, you should create an

emergency startup disk that you can use to restart your oscilloscope in case of a

major hardware or software failure. Store this disk in a safe place.

CAUTION. Create this disk and store it in a safe place. It may allow you to

recover your Windows 2000 installation without rebuilding the entire

oscilloscope hard disk.

The emergency startup disk contains basic files to restart your oscilloscope. The

disk also contains files to check and format the hard disk.

Windows ME

Follow these steps to create the emergency startup disk for an instrument using

Windows ME:

1. Minimize the oscilloscope application by selecting Minimize in the File

menu.

2. Click the Windows Start button, point to Settings, and click Control Panel.

3. In the Control Panel window, double-click Add/Remove Programs.

TDS5000 Series User Manual

4. Click the Startup Disk tab.

5. Insert a floppy disk into the disk drive, and follow the on-screen instructions

to create the startup disk.

1- 9

Page 31

Installation

Windows 2000

Backing Up User Files

Follow these steps to create the emergency startup disk for an instrument using

Windows 2000:

1. Minimize the oscilloscope application by selecting Minimize in the File

menu.

2. From the Windows taskbar, select Start, Programs, Accessories, System

Tools, Backup.

3. In the Welcome display, click Emergency Repair Disk.

4. Insert a floppy disk into the disk drive, and follow the on-screen instructions

to create the startup disk.

Always back up your user files on a regular basis. Use the Windows Backup tool

to back up files stored on the hard disk. The BackUp tool is located in the

System Tools folder in the Accessories folder.

Use these steps to back up your files:

1. Exit the oscilloscope application by selecting the File menu Exit command.

Installing Software

Software Release Notes

2. Click the Windows Start button.

3. Select Programs, Accessories, System Tools, Backup.

4. Use the Backup Wizard to select the items you want to back up and the

destination. You can back up to the floppy drive, or to a third-party storage

device over one of the side-panel ports.

The oscilloscope system and application software is preinstalled at the factory. If

you have to reinstall the software for any reason, refer to the instructions that

accompany the CD-ROMs shipped with the oscilloscope.

Read the software release notes (README.TXT) on the product software

CD-ROM before performing installation procedures. This file contains additional

information that supercedes other product documentation.

To view README.TXT, start the Windows Notepad accessory and open the file

from the TDS5000 Series Product Software CD-ROM.

1- 10

TDS5000 Series User Manual

Page 32

Installation

Accessory Software

The TDS5000 Series Product Software CD-ROM contains accessory software

and files that you can install on the oscilloscope or another PC. Refer to the

instructions that accompany the CD-ROM for installation information.

TDS5000 Series Programmer Online Guide. The GPIB programmer information is

available as a separate WinHelp file that you can install and access from the Help

menu GPIB Online command. For your convenience, you can also install it on

the GPIB system controller PC.

From the system controller PC, you can copy and paste commands from the

online help file directly into your test programs. The programmer information

contains:

H GPIB configuration information for the oscilloscope

H Lists of the command groups and the commands they contain

H Detailed command descriptions including syntax and examples

H Status and error messages

H Programming examples

The programmer information is also available as a PDF file on the TDS5000

Series Product Software CD-ROM.

Optional Application Trial

Versions

Desktop Applications

Manual Performance Verification Procedure. This is a printable PDF file that

describes a manual method to verify the oscilloscope performance using generic

test equipment.

The Optional Applications Software for Tektronix Windows-Based TDS

Instruments CD-ROM contains trial versions of useful programs that you can

install and run five times per application. You can then purchase an upgrade from

Tektronix if you decide that you want to continue to use the application. Refer to

the instructions that accompany the CD-ROM for installation information.

You can install desktop application software on the oscilloscope. The oscilloscope has been tested with the following software products installed:

H Microsoft Office 98 (Word, Excel, PowerPoint, etc.)

H MathCad

H MATLAB

TDS5000 Series User Manual

1- 11

Page 33

Installation

Other software products may be compatible but have not been tested by

Tektronix. If the oscilloscope malfunctions after you install software, uninstall

the software and then reinstall the oscilloscope application to restore proper

operation.

Exiting the Oscilloscope Application. Before installing other desktop applications,

exit the oscilloscope application. To do this, select the File menu Exit command.

TDS5000 Options and

Upgrades

Some TDS5000 options and upgrades contain software that needs to be installed

and/or enabled. Follow the specific instructions that come with the option.

Tektronix provides a key that you must enter (one time) to enable all options or

upgrades that you have purchased. To enter the key, select the Option Installation

command from the Utility menu of the oscilloscope application, and follow the

on-screen instructions.

Connecting to a Network

You can connect the oscilloscope to a network to enable printing, file sharing,

internet access, and other communications functions. Before you make the

connection, do the following steps to enable network access to the oscilloscope:

1. Begin with the oscilloscope power off.

2. Attach a keyboard and mouse to the oscilloscope.

3. Power on the oscilloscope.

4. As the oscilloscope begins to boot, press the keyboard F2 key repeatedly

5. In the BIOS Setup Utility, use the keyboard right-arrow key to highlight the

until the message “Loading SETUP” appears.

Advanced menu at the top of the screen.

1- 12

6. Use the arrow down key to highlight Peripheral Configuration in the

Advanced screen, and then press Enter.

7. Use the arrow down key to highlight LAN Device in the Peripheral

Configuration screen, and then press Enter.

8. Use the arrow up or down key to highlight Enabled, and then press Enter.

9. Press the F10 key to save and exit. Confirm the Save of Configuration

changes when you are prompted on screen.

TDS5000 Series User Manual

Page 34

10. Use the Windows network setup utility to define the oscilloscope as a

NOTE. If you want to disable network access for the oscilloscope, perform the

above procedure, except substitute Disabled for the command listed in step 8.

The oscilloscope will boot faster with network access disabled.

Setting up a Dual Display

Dual display lets you view Windows and other applications on an external

monitor while running the oscilloscope. You can also drag up to five dockable

control windows from the TekScope application onto the display of the second

monitor. For example, this feature allows you to have the Horizontal/Acquisition, the Horizontal Zoom, and the Display Setup Control Windows (half screen)

open on the second monitor at the same time.

Installation

network client, and configure it for your network. You can find the network

setup utility in the Windows Start menu if you select Settings > Control

Panel and then double click Network. You should consult your network

administrator for specific instructions to make these settings.

Windows ME

TDS5000 Series User Manual

If your instrument is using Windows ME, use the following steps to set up the

oscilloscope for dual display operation:

1. Disconnect the oscilloscope power cord from the power source so that you

can connect an external monitor.

2. Connect a keyboard and mouse to the oscilloscope.

1- 13

Page 35

Installation

3. Connect an external monitor to the upper SVGA port on the side panel of the

oscilloscope.

4. Connect the oscilloscope power cord to the power source, and power on the

oscilloscope and the external monitor.

5. The oscilloscope should detect that the new monitor is connected. Follow the

instructions on the oscilloscope screen to install new drivers for the monitor.

6. Type Ctrl+M or select Minimize from the File menu to minimize the

oscilloscope application.

7. On the Windows desktop, right click the mouse and select Properties to

open the Display Properties dialog box.

8. Select the Settings tab and click the disabled monitor in the display box.

9. Click Yes when you are prompted to enable the new monitor.

10. Set the resolution that you want to use on the external monitor (16 bit or

better).

Windows 2000

11. Click on the external monitor in the display box, and drag the external

monitor to the correct orientation.

CAUTION. Do not change the resolution settings for the internal LCD monitor.

The internal resolution must be 640 x 480. The colors must be set to High Color

(16 bit). If you use other settings, the video port may not work properly.

12. Click OK to apply the settings.

13. Reboot your instrument. The new monitor will display additional desktop

area.

If your instrument is using Windows 2000, use the following steps to set up the

oscilloscope for dual display operation:

1. Disconnect the oscilloscope power cord from the power source so that you

can connect an external monitor.

2. Connect a keyboard and mouse to the oscilloscope.

3. Connect an external monitor to the upper SVGA port on the side panel of the

oscilloscope.

1- 14

4. Connect the oscilloscope power cord to the power source, and power on the

oscilloscope and the external monitor.

TDS5000 Series User Manual

Page 36

Installation

5. The oscilloscope should detect that the new monitor is connected. Follow the

instructions on the oscilloscope screen to install new drivers for the monitor.

6. Type Ctrl+M or select Minimize from the File menu to minimize the

oscilloscope application.

7. On the Windows desktop, right click the mouse, and select Properties to

open the Display Properties dialog box.

8. Select the Settings tab.

9. Right click on the disabled monitor in the display box, and select Attached.

(Monitor 2 is attached to the instrument display; Monitor 1 is the disabled

monitor.)

10. Set the resolution that you want to use on the external monitor (24 bit or

better).

11. Click on the external monitor in the display box, and drag the external

monitor to the correct orientation.

CAUTION. Do not change the resolution settings for the internal LCD monitor.

The internal resolution must be 640 x 480. The colors should be set to either

High Color (16 bit) or True Color (24 bit) with 24 bit color the preferred setting.

(The external monitor should be set equal or better). If you use other settings,

the video port may not work properly.

12. Select Apply.

13. Select Yes to restart your computer. The new monitor will display additional

desktop area.

TDS5000 Series User Manual

1- 15

Page 37

Installation

Using Dual Display

Figure 1- 3: Drag area for Windows task bar

To make the best use of the new display area, do these additional steps to move

the Windows controls to the external monitor:

1. Click (and hold) on the Windows task bar in the area shown in Figure 1--3,

and then drag it upwards and toward the external monitor. The task bar will

first go to the side of the internal monitor, then to the side of the external

monitor, and finally to the bottom of the external monitor.

2. Release the mouse when the task bar is where you want it to be.

3. Select all the Windows desktop icons on the internal monitor, and drag the

icons to a position on the external monitor.

Click here to drag task bar

Disabling an External

Monitor

4. If you use the oscilloscope online help system, you can drag the help

windows to the external monitor so that you can read them while you operate

the oscilloscope.

5. When you open any Windows application, drag the windows from the

application to the external monitor.

To disable the external monitor, do these steps:

1. Right click on the Windows desktop, and select Properties to open the

Display Properties dialog box.

2. Click the Settings tab in the Display Properties dialog box.

3. Right click the external monitor

4. Deselect Attached (or Enabled) in the pop-up menu. You can also deselect

Extend my Windows desktop onto this monitor at the bottom of the dialog

box on the external monitor.

1- 16

TDS5000 Series User Manual

Page 38

Adjusting Display Contrast

If you find that the oscilloscope screen is too bright or too dark, use these steps

to adjust the LCD display contrast to your preference. You need to have a mouse

attached to perform this procedure.

Installation

Windows ME

Windows 2000

If your instrument is using Windows ME, do the following steps:

1. Right click with the mouse on the Windows desktop.

2. Select Properties.

3. Select the Settings tab.

4. Click Advanced.

5. Select the Chips tab.

6. Click Gamma.

7. Adjust slider control for desired contrast.

8. Right click on the slider, and select Exit.

If your instrument is using Windows 2000, do the following steps:

1. Right click with the mouse on the Windows desktop.

2. Select Properties.

3. Select the Settings tab.

TDS5000 Series User Manual

4. Click Advanced.

5. Select the Color tab.

6. Adjust slider control for desired gamma setting.

7. Click Apply.

8. Click OK.

1- 17

Page 39

Installation

1- 18

TDS5000 Series User Manual

Page 40

Incoming Inspection

This section contains instructions for performing the incoming inspection

procedure. This procedure verifies that the oscilloscope is operating correctly

after shipment, but does not check product specifications. This procedure

contains the following parts:

H Self Tests on page 1--20 provides instructions for performing the internal

self tests.

H Functional Tests on page 1--21 measures the time- and amplitude-reference

signals at the PROBE COMPENSATION connector.

H Perform the Extended Diagnostics on page 1--30 provides instructions for

performing internal self calibration and the extended diagnostics.

If the oscilloscope fails any test within this section, it may need service. To

contact Tektronix for service, see Contacting Tektronix on page xv of Preface.

Make sure you have put the oscilloscope into service as detailed in Installation

starting on page 1--5. Then assemble the following test equipment before

proceeding with the tests.

Assemble Equipment

Self tests do not require any test equipment. The functional tests require:

H One passive 10X oscilloscope probe (P5050 or equivalent)

H One 1.44 MB, 3.5 inch, formatted floppy disk

TDS5000 Series User Manual

1- 19

Page 41

Incoming Inspection

Self Tests

This procedure uses internal routines to verify that the oscilloscope functions and

was adjusted properly. No test equipment or hookups are required.

Equipment

required

Prerequisites Power on the oscilloscope and allow a 20 minute warm-up.

1. Internal Diagnostics: Perform these substeps to verify internal diagnostics.

a. Display the system diagnostics menu:

H If the oscilloscope is in toolbar mode, click Menu (far right toolbar

button) to switch to menu bar mode.

H From the Utilities menu, select Instrument Diagnostics to open the

Instrument Diagnostics control window.

H Ensure that ALL is selected from each drop-down list.

b. Run the system diagnostics:

H Disconnect any input signals from all four channels.

H Click Run in the Instrument Diagnostics control window.

c. Wait: The internal diagnostics do an exhaustive verification of proper

oscilloscope function, taking five to fifteen minutes. When complete, the

resulting status appears in the diagnostics control window.

None

1- 20

d. Verify that no failures are found and reported: All tests should pass. If

any failures occur, record the failure information and contact your local

Tektronix service personnel for more information.

e. Run the signal path compensation routine:

H From the Utilities menu, select Instrument Calibration to open the

Instrument Calibration control window.

H Click Calibrate to start the routine.

f. Wait: Signal path compensation may take up to ten minutes to run.

g. Confirm signal path compensation returns passed status: Verify that the

word Pass appears in the Status text box.

2. Return: Click Close to exit the Instrument Calibration control window.

TDS5000 Series User Manual

Page 42

Functional Tests

Incoming Inspection

The purpose of these procedures is to confirm that the oscilloscope functions

properly. The following equipment is required:

H One passive 10X oscilloscope probe (P5050 or equivalent)

H A 3.5 inch, 1.44 MB, formatted floppy disk to check the file system

STOP. These procedures verify that the oscilloscope features operate. They do not

verify that they operate within limits. Therefore, when the instructions in these

functional tests call for you to verify that a signal appears on screen “that is

about five divisions in amplitude” or “has a period of about six horizontal

divisions,”and so on, do not interpret the quantities given as limits.

Do not make changes to the front-panel settings unless directed to by these

procedures. Each verification procedure requires you to set the oscilloscope to

certain default settings before verifying functions. If you make additional

changes to these settings you may obtain invalid results. In this case, redo the

procedure from step 1.

When you are instructed to push a front-panel button or screen button, the button

may already be selected (its label is lighted). If this is the case, it is not

necessary to push the button.

TDS5000 Series User Manual

1- 21

Page 43

Incoming Inspection

Equipment

required

Prerequisites None

One passive 10X oscilloscope probe (P5050 or equivalent)

1. Initialize the oscilloscope: Push the front-panel DEFAULT SETUP button.

2. Hook up the signal source: Connect the oscilloscope probe from the probe

compensation terminal to the channel input that you want to test (beginning

with CH 1) as shown in Figure 1--4.

TDS5000 oscilloscope

Connect probe from PROBE

COMP terminal to CH 1 input

Figure 1- 4: Universal test hookup for functional tests, CH 1 shown

3. Turn off all channels: If any of the front-panel channel buttons are lighted,

push those buttons to turn off the displayed channels. See Figure 1--5.

Channel buttons

Figure 1- 5: Channel button location

4. Select the channel to test: Push the channel button for the channel that you

are currently testing. The button lights, and the channel display appears on

the screen.

1- 22

TDS5000 Series User Manual

Page 44

Incoming Inspection

5. Set up the oscilloscope: Push the front-panel AUTOSET button. This sets

the horizontal and vertical scale for a usable display and sets the trigger

source to the channel you are testing.

6. Verify that the channel is operational: Confirm that the following statements

are true.

H The vertical scale readout (see Figure 1--6) for the channel under test

shows a setting of 500 mV, and a square-wave probe compensation

signal about 2 divisions in amplitude is on the screen.

TDS5000 Series User Manual

Vertical scale readout Horizontal scale readout

Figure 1- 6: Location of vertical and horizontal scale readouts

H The front-panel VERTICAL POSITION knob for the channel that you

are testing moves the signal up and down on the screen when rotated.

H Turning the VERTICAL SCALE knob counterclockwise for the channel

that you are testing decreases the amplitude of the waveform on the

screen. Turning the knob clockwise increases the amplitude. Returning

the knob to 500 mV returns the amplitude to about 2 divisions.

7. Verify that the channel acquires in all acquisition modes: From the

Horiz/Acq menu, select Horizontal/Acquisition Setup to open the

1- 23

Page 45

Incoming Inspection

Horizontal/Acquisition Setup control window. Click the Acquisition tab.

Click each of the five acquisition modes and confirm that the following

statements are true:

H Sample mode displays an actively acquiring waveform on the screen.

(Note that there is a small amount of noise present on the square wave).

H Peak Detect mode displays an actively acquiring waveform with the

high and low values (peaks) of consecutive sample intervals displayed.

Therefore, the noise seen in Sample mode is visible here as well.

H Hi Res mode displays an actively acquiring waveform with the noise

that was seen in Sample mode reduced.

H Average mode displays an actively acquiring waveform with the noise

reduced using a multiple acquisition averaging technique.

H Envelope mode displays an accumulation of multiple acquisitions using

Peak Detect mode.

8. Test all channels: Repeat steps 2 through 7 until all four input channels are

verified.

9. Remove the test hookup: Disconnect the oscilloscope probe from the channel

input and the probe compensation terminal.

1- 24

TDS5000 Series User Manual

Page 46

Time Base Test

Incoming Inspection

Equipment

required

Prerequisites None

One passive 10X oscilloscope probe (P5050 or equivalent)

1. Initialize the oscilloscope: Push the front-panel DEFAULT SETUP button.

2. Hook up the signal source: Connect the oscilloscope probe from the probe

compensation terminal to the CH 1 input as shown in Figure 1--7.

TDS5000 oscilloscope

Connect probe from PROBE

COMP terminal to CH 1 input

Figure 1- 7: Setup for time base test

3. Set up the oscilloscope: Push the front-panel AUTOSET button.

4. Set the time base: Use the front-panel HORIZONTAL SCALE knob to set

the horizontal scale to 200 s/div. The time-base readout is displayed at the

bottom of the graticule (see Figure 1--6).

5. Verify that the time base operates: Confirm the following statements:

H One period of the square-wave probe-compensation signal is about five

horizontal divisions on the screen for the 200 s/div horizontal scale

setting.

H Rotating the SCALE knob clockwise expands the waveform (more

horizontal divisions per waveform period), counterclockwise rotation

contracts it, and returning to 200 s/div returns the period to about five

divisions.

H The HORIZONTAL POSITION knob positions the signal left and right

on the screen when rotated.

TDS5000 Series User Manual

1- 25

Page 47

Incoming Inspection

6. Verify horizontal delay:

a. Center a rising edge on screen:

H Turn the HORIZONTAL POSITION knob so that the rising edge

where the waveform is triggered is lined up with the center

horizontal graticule.

H Change the HORIZONTAL SCALE to 20 s/div. The rising edge of

the waveform should remain near the center graticule, and the falling

edge should be off screen.

b. Turn on and set horizontal delay:

H From the Horiz/Acq menu, select Horizontal/Acquisition Setup to

open the Horizontal/Acquisition Setup control window.

H Click the Horizontal tab in the control window that displays.

H On the Horizontal tab, click Delay Mode to toggle delay mode On.

H Click on the Horiz Delay control text box to display the pop-up

keypad. Click the keypad icon to open the keypad. Use the keypad to

set the horizontal delay to 500 s, and click ENTER.

c. Verify the waveform: Verify that a falling edge of the waveform is within

a few divisions of the center graticule.

d. Adjust the horizontal delay: Rotate the upper multipurpose knob to

change the horizontal delay setting. Verify that the falling edge shifts

horizontally. Rotate the front-panel HORIZONTAL POSITION knob.

Verify that this knob has the same effect (it also adjusts delay, but only

when delay mode is on).

e. Verify the delay toggle function:

H Rotate the front-panel HORIZONTAL POSITION knob to center

the falling edge horizontally on the screen.

H Change the HORIZONTAL SCALE to 40 ns/div. The falling edge

of the waveform should remain near the center graticule. If not,

readjust the delay setting to center the falling edge.

H Push the front-panel DELAY button several times to toggle the

delay off and on and back off again. Verify that the display switches

quickly between two different points in time (the rising and falling

edges of the signal).

1- 26

7. Remove the test hookup: Disconnect the probe from the channel input and

the probe compensation terminal.

TDS5000 Series User Manual

Page 48

Trigger Test

Incoming Inspection

Equipment

required

Prerequisites None

One passive 10X oscilloscope probe (P5050 or equivalent)

1. Initialize the oscilloscope: Push the front-panel DEFAULT SETUP button.

2. Hook up the signal source: Connect the oscilloscope probe from the probe

compensation terminal to the CH 1 input as shown in Figure 1--8.

TDS5000 oscilloscope

Connect probe from PROBE

COMP terminal to CH 1 input

Figure 1- 8: Setup for trigger test

3. Set up the oscilloscope: Push the front-panel AUTOSET button.

4. Verify that the main trigger system operates: Confirm that the following

statements are true.

H The trigger level readout for the A (main) trigger system changes with

the front-panel TRIGGER LEVEL knob.

H The front-panel TRIGGER LEVEL knob can trigger and untrigger the

square-wave signal as you rotate it. (Leave the signal untriggered).

H Pushing the front-panel TRIGGER LEVEL knob sets the trigger level to

the 50% amplitude point of the signal and triggers the signal that you

just left untriggered. (Leave the signal triggered.)

TDS5000 Series User Manual

1- 27

Page 49

Incoming Inspection

5. Verify that the delayed trigger system operates:

Set up the delayed trigger:

a.

H From the Trig menu, select A--B Trigger Seq to open the Trigger

Setup control window. The window opens to the A→BSeqtab.

H Click Trig After Time under A Then B.