Page 1

xx

TDS5000B Series

ZZZ

Digital Phosphor Oscilloscope

Read This First

www.tektronix.com

P061433105*

*

061-4331-05

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, visi t www.tektronix.com to find contacts in your area.

Page 3

Table of Contents

General Safety Summary .......................................................................................... 1

Compliance Information........................................................................................... 2

EMC Compliance................................... ................................ ........................... 2

Safety Comp

Environmental Considerations .......... ................................ .................................. ... 6

Preface ............................................................................................................... 7

Quick Start User Manual Information............. ................................ ............................... 8

Getting Started .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ..... . ... 8

Operating Requirements ... ................................ ................................ ................... 8

Powerin

Powering Off the Instrument ............ ................................ ................................ .... 10

Removing the Power ......................................................................................... 11

Using Your Instrument ......................... ................................ .............................. 11

Standard Accessories......................................................................................... 11

Service Manual Information...................................................................................... 12

ons............................... .................................. ................................ ........ 12

Opti

Side and Rear Panels ........... ................................ ................................ .............. 12

Cleaning ....................................................................................................... 14

PC Interface Board and Motherboard Cable Connections ............................................... 15

039-0185-xx Service Information......................................... ................................ .. 17

Replaceable Parts ............................................................................................. 28

ecification and Performance Verification .................................................................... 31

Sp

liance............................................................................................. 4

g On the Instrument................................................................................. 10

TDS5000B Read This First i

Page 4

Table of Contents

ii TDS5000B Read This First

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

To Avoid Fire or Personal

Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe a ll ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Connect the probe reference lead to earth ground only.

Do Not Operate Without Covers. Do not operate this product with covers or

panels removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect that there is damage to

this product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Terms in this Manual

TDS5000B Read This First 1

These terms may appear in this manual:

WAR NI NG . Warning statements identify conditions or practices that could result

in injury or loss of life.

Page 6

Compliance Information

CAUTION. Caution statements identify conditions or practices that could result in

damage to this

product or other property.

Symbols and Terms on the

Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

Compliance Information

This section lists the EMC (electromagnetic compliance), safety, and

environmental standards with which the instrument complies. This EMC section

replaces the Certifications and Compliances section in Table 1–11, of the

TDS5000B Series Technical Reference manual (071-1420-xx).

EMC Compliance

EC Declaration of

Conformity – EMC

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Com

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment

for measurement, control, and laboratory use.

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient/burst immunity

IEC 61000-4-5:2001. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

munities:

1234

5

5

6

2 TDS5000B Read This First

Page 7

Compliance Information

EN 61000-3-2:2

006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact.

Tektronix UK, Ltd.

West ern Pe n

insula

West ern Road

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a

test object.

3

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

4

Instrument rebooting may be experienced where the EUT takes longer than 10 seconds to recover from IEC

61000-4-11 transient immunity test.

5

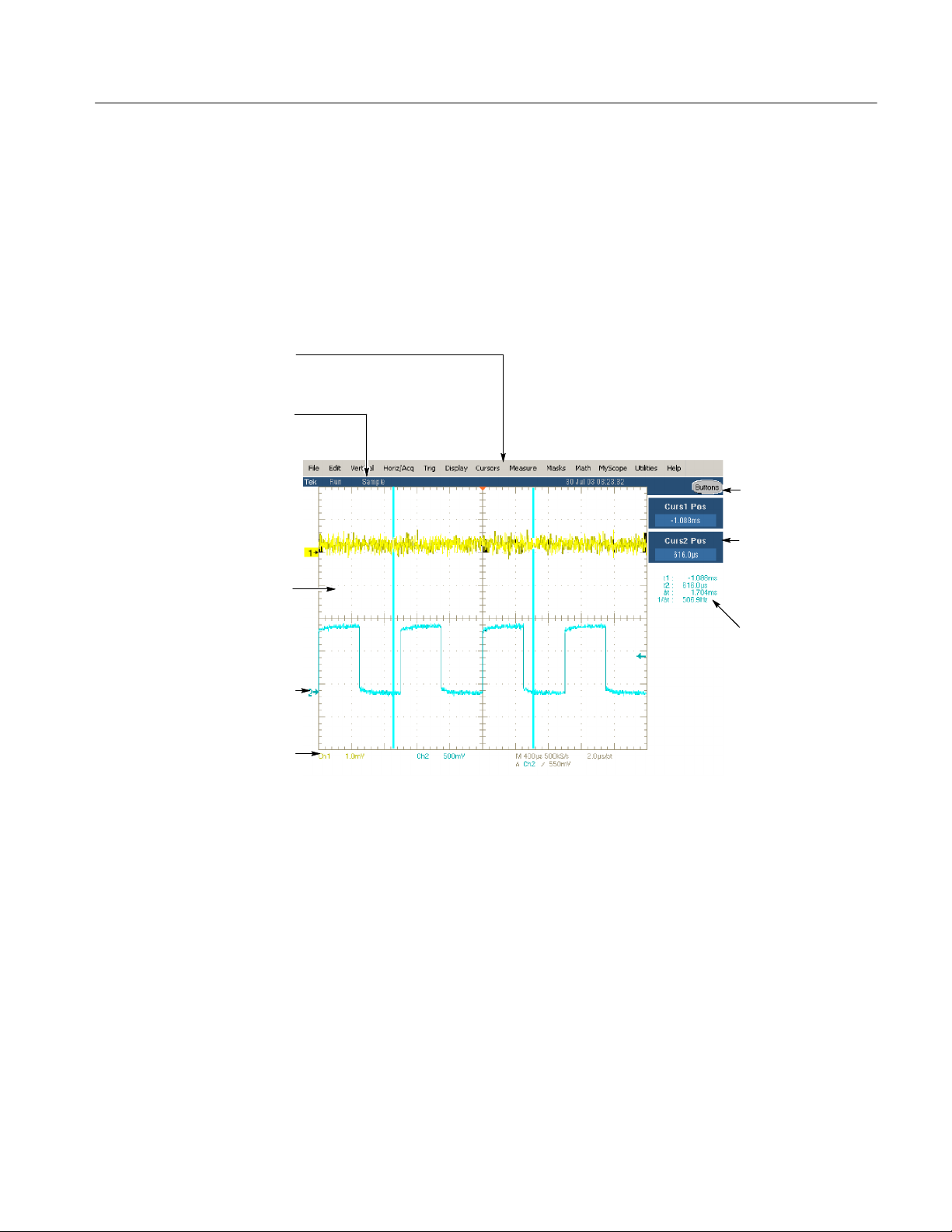

Under these conditions, the specifications are amended as follows: 1 mV/division to 1 V/division: < 0.2 division

waveform displacement or < 0.4 division increase in peak -to peak noise for (IEC 61000-4-3 and IEC 61000-4-6

tests)

6

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test

levels (IEC 61000-4-11).

Australia / New Zealand

Declaration of

Conform

ity–EMC

Complies with the EMC provision of the Radiocommunications Act per the

following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in

accordance with EN 61326-1:2006 and EN 61326-2-1:2006.

TDS5000B Read This First 3

Page 8

Compliance Information

Safety Compli

ance

EC Declaration of

Conformity – Low Voltage

U.S. Natio

nally Recognized

Testing Laboratory Listing

Canadian Certification

Additional Compliances

Equipment Type

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for

measurement control and laboratory use.

UL 61010B-1. Standard for electrical measuring and test equipment.

CAN/CSA-C22.2 No. 61010.1-97. Safety requirements for electrical

equipment for measurement, control, and laboratory use. Part 1.

IEC 61010-1: 2001. Safety requirements for electrical equipment for

measurement, control, and laboratory use.

nd measuring equipment.

Test a

Safety Class

Pollution Degree

Description

Pollution Degree

Class 1 – grounded product.

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

expected. This location is a typical office/home environment. Temporary

be

condensation occurs only when the product is out of service.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

4 TDS5000B Read This First

Page 9

Compliance Information

Installation (Overvoltage)

Category Descriptions

Overvoltage Category

Terminals on th

designations. The installation categories are:

Measurement C

low-voltage installation.

Measuremen

installation.

Measuremen

connected to the low-voltage installation.

Measureme

directly connected to MAINS.

Overvoltage Category II (as defined in IEC 61010-1)

is product may have different installation (overvoltage) category

ategory IV. For measurements performed at the source of

t Category III. For measurements performed in the building

t Category II. For m easurements performed on circuits directly

nt Category I. For measurements performed on circuits not

TDS5000B Read This First 5

Page 10

Compliance Information

Environmenta

Product End-of-Life

l Considerations

This section provides information about the environmental impact of the product.

Observe the following guidelines when recycling an instrument or component:

Handling

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to

end of life. In order to avoid release of such substances into the environment and

to reduce the use of natural resources, w e encourage you to recycle this product

in an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

Mercur

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the U nited States, refer to the E-cycling

Central Web page (www.eiae.org) for disposal or recycling information.

yNotification. This product uses an LCD backlight lamp that contains

the environment or human health if improperly handled at the product’s

This sym

Union requirements according to Directives 2002/96/EC and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries. For

informa

Tektronix Web site (www.tektronix.com).

bol indicates that this product complies with the applicable European

tion about recycling options, check the Support/Service section of the

Restriction of Hazardous

Substances

Perchlorate Materials. This product contains one or more type CR lithium

eries. According to the state of California, CR lithium batteries are

batt

classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

is product has been classified as Monitoring and Control equipment, and is

Th

outside the scope of the 2002/95/EC RoHS Directive.

6 TDS5000B Read This First

Page 11

Preface

Preface

The followin

and the TDS5000B Series Service manual.

g information affects the TDS5000B Series Quick Start User manual

TDS5000B Read This First 7

Page 12

Quick Start User Manual Information

Quick Start Us

er Manual Information

Getting Started

Use the foll

instrument quick start user manual documentation.

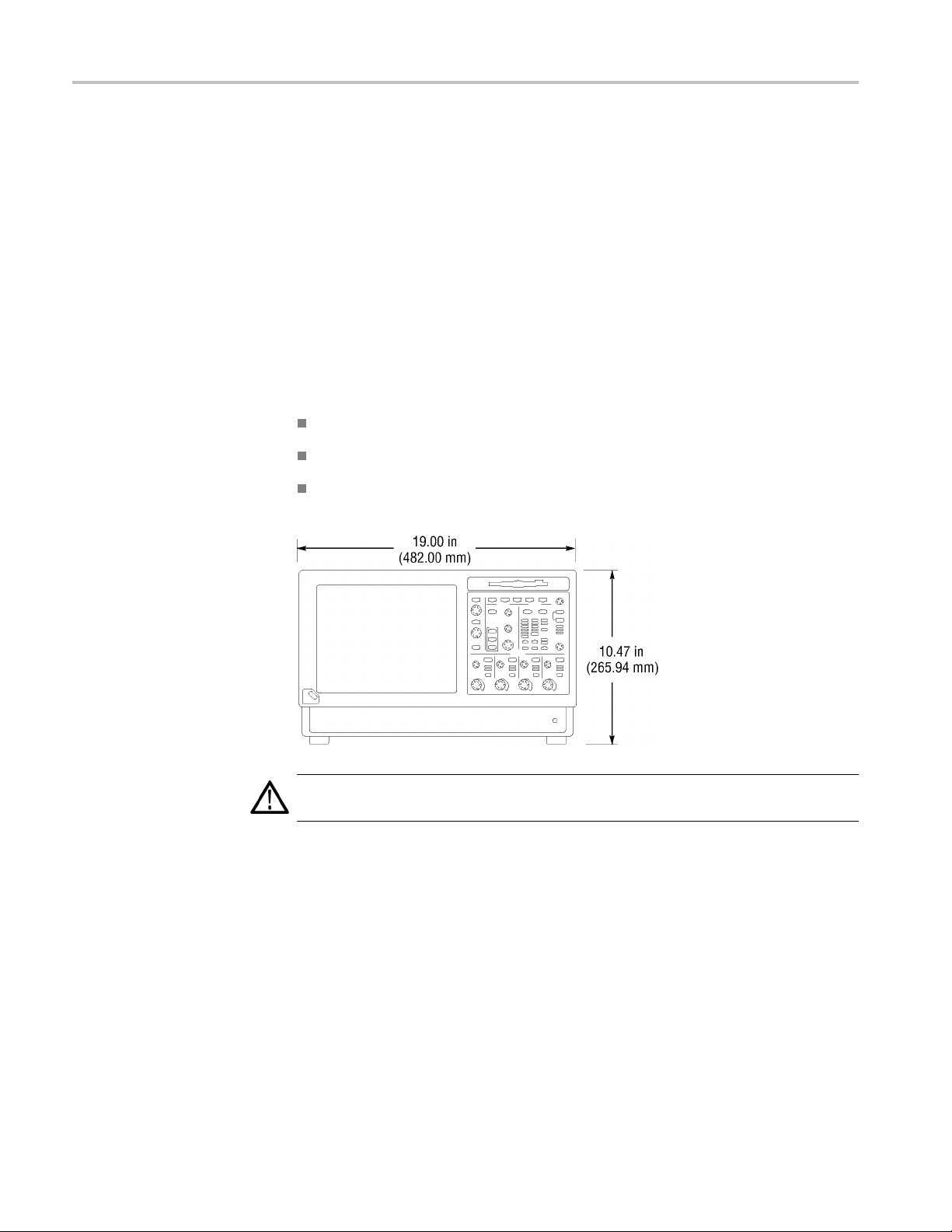

Operating Requirements

Place the bottom fee t of the instrument on a cart or bench and observe the

following clearance requirements:

owing information to replace or clarify information contained in your

Top, Rear, Front, and Right Side: 0 in (0 mm)

Left Sid

Bottom: 0.75 in (19 mm) minimum or 0 in (0 mm) standing on feet, flip

stand d

e: 3 in (76 mm)

own

TION. To ensure proper cooling, keep the bottom and sides of the instrument

CAU

clear of obstructions.

8 TDS5000B Read This First

Page 13

Quick Start User Manual Information

Environmental

Characteristic Description

Humidity, ope

Altitude, operating

Temperature, ambient operating

Maximum voltage

1MΩ input impedance 150 VRMS CAT I, and ≤400 peak

50 Ω input impedance <1 Vrms for settings below 100 mV/div

Requirements

rating

20% to 80% relative humidity with a maximum

wet bulb temperature of +29 °C (+84.2 °F) at

or below +45 °

Upper limit derated to 30% relative humidity

at +45 °C (+113 °F)

9,842 ft. (3,000 m)

+5 °C to +45 °C (+41 °F to +113 °F)

For steady-state sinusoidal waveforms,

derate at 2

9VRMSat≥3MHz

<5 Vrms for 100 mV/div settings and above

C (+113 °F) noncondensing.

0 dB/decade above 200 kHz to

TDS5000B Read This First 9

Page 14

Quick Start User Manual Information

Powering On th

e Instrument

Power Supply Requirements

Source volta

100-240 V

115 V

RMS

WARNING. To avoid fire or shock hazard that could result in injury or loss of life,

observe al

further ratings information before making connections to the product.

ge and frequency

±10%, 47-63 Hz, or

RMS

±10%, 360-440 Hz

Power consum

<220 watts

ption

l ratings and markings on the product. Consult the product manual for

Powering Off the Instrument

10 TDS5000B Read This First

Page 15

Removing the Power

Using Your Instrument

Quick Start User Manual Information

Documentation for your instrument is found by selecting Help >

Document

ation....

Standard Accessories

Before using your instrument, read the following information in the quick start

user man

The standard accessories list in the TDS5000B Series Quick Start User manual

(071-1355-XX) has been upgraded to include the following discs:

ual:

Safety Summary

Creating an Emergency Startup Disk

Getting Acquainted with Your Instrument

TDS5000B Series Operating System Restore disc (SN B040000 and above)

063-4160-xx.

TDS5000B Series Operating System Restore disc (SN B030000 to B039999)

063-3985-xx.

TDS5000B Series Operating System Restore disc (SN B020000 to SN

B029999) 063-3759-xx

TDS5000B Series Operating System Restore disc (SN B010100 to SN

B019999) 063-3693-xx

NOTE. Only serial numbers below B060100 include a fl oppy disc.

TDS5000B Read This First 11

Page 16

Service Manual Information

Service Manua

Options

Side and R

ear Panels

l Information

Use the follo

your TDS5000B Series Digital Phosphor Oscilloscopes (071-1362-XX) service

manual. This service manual is on the Tektronix Web site.

The TDS5054B and TDS5104B instruments have been upgraded to include the

following options: Option 18 (Touch Screen) and Option 3M (16 M points record

length).

The following side-panel illustrations (in the Theory of Operation section) have

been upgraded to include the latest component locations and are for reference

only. U

(071-1355-XX) to connect your instrument.

wing information to replace or clarify information contained in

se the instructions in the TDS5000B Series Quick Start User manual

12 TDS5000B Read This First

Page 17

Service Manual Information

TDS5000B Read This First 13

Page 18

Service Manual Information

Cleaning

Exterior Cleaning

Use these procedures to clean your oscilloscope. If additional cleaning is required

have your oscilloscope serviced by qualified service personnel.

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle

brush. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl alcohol

solution. Use a swab to clean narrow spaces around controls and connectors.

Do not use abrasive compounds on any part of the chassis that may damage the

sis.

chas

Clean the On/Standby switch using a dampened cleaning towel. Do not spray or

the switch directly.

wet

CAUTION. Do not use chemical cleaning agents that might damage the plastics

used in this oscilloscope. Use only deionized water when cleaning the front-panel

buttons. Use a 75% isopropyl alcohol solution as a cleaner and rinse with

deionized water. Before using any other type of cleaner, contact your Tektronix

Service Center or representative.

Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available from

Kimberly-Clark Corporation).

14 TDS5000B Read This First

Page 19

Service Manual Information

PC Interface B

oard and Motherboard Cable Connections

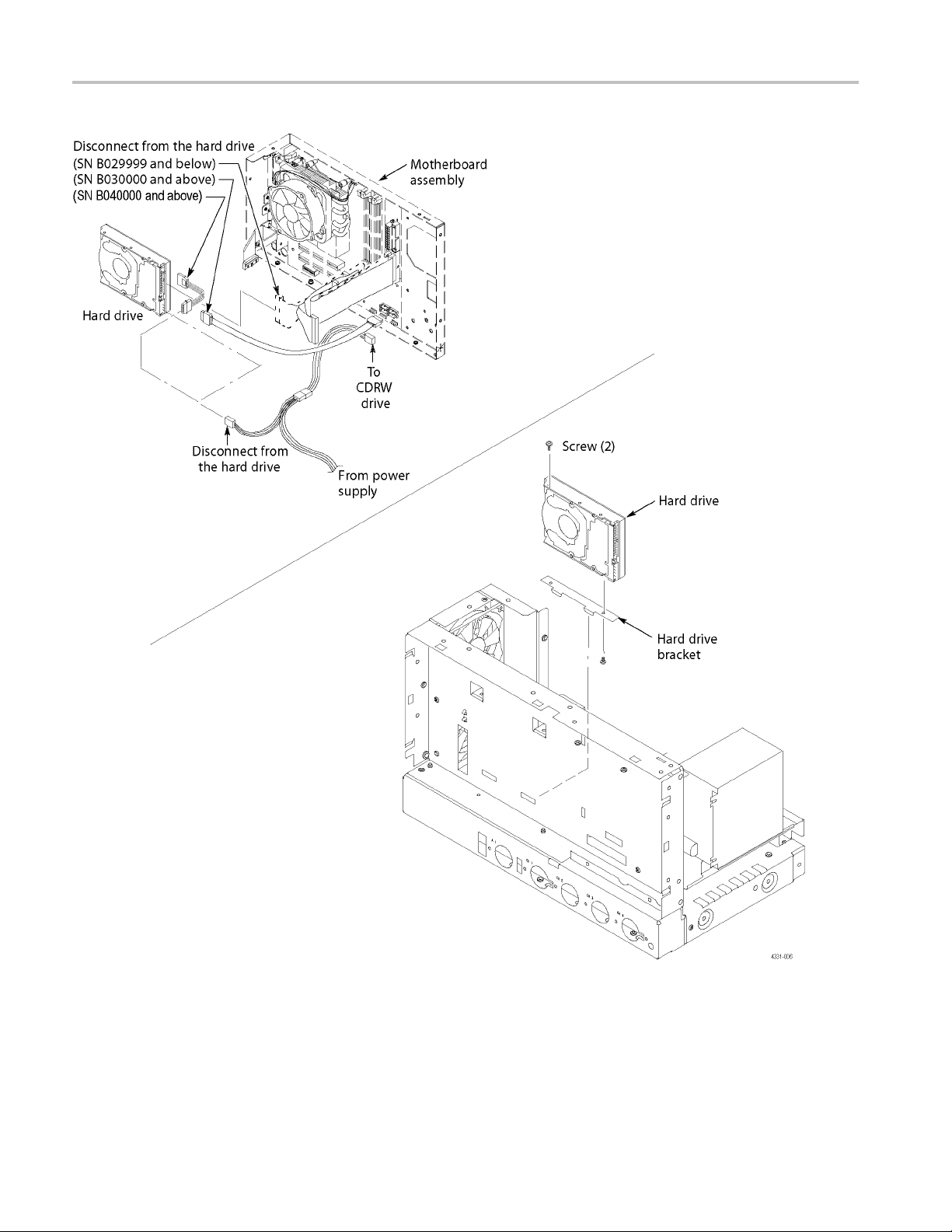

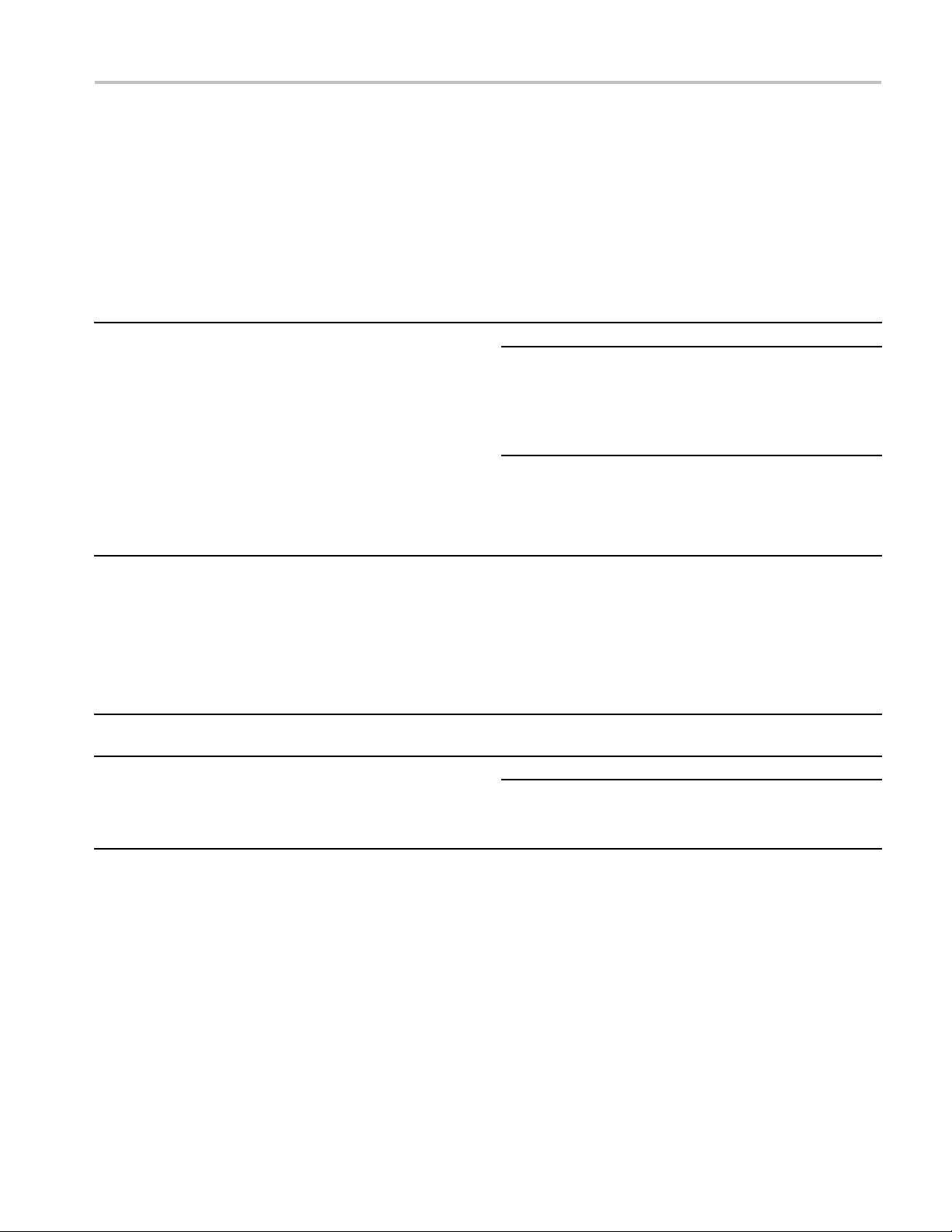

Replace Figures 6-17 and 6–18 in the Removal and Installation Procedures).

Figure 6-17: PC Interface board and motherboard cable connections

TDS5000B Read This First 15

Page 20

Service Manual Information

Figure 6-18: Desktop hard drive removal

16 TDS5000B Read This First

Page 21

Service Manual Information

039-0185-xx S

ervice Information

Use the following information when servicing instruments with serial numbers

B040000 and above or instruments using the 039-0185-xx Mother board. This

information

Table 1: 039-0185-xx μATX POST codes

Item no. Module

1

2 Memory Presence

3 Early Memory

4 Extend Memory DRAM

Turn Off Chipset and

CPU test

Initialization

select

is only for qualified service personnel.

Displayed POST

code Description

C0

C1

C2 OEM Specific-Board Initialization

C3

OEM Specific-Cache control cache

Processor Status (1FLAGS) Verification

Tests the following proce ssor status flags: Carry, zero, sign,

overflow.

The BIOS sets each flag and verifies.

The flags are set, then turns each flag off and verifies if it is off.

Read/Write/Verify all the CPU r egisters except SS, SP, and BP

with data pattern FF and 00.

RAM must be periodically refreshed to keep the memory from

decaying. This function ensures that the memory refresh

function is working properly.

First block memory detect

OEM Specific-Test to size on-board memory

Early chip set initialization

Memory presence test

OEM c hip set routines

Clear low 64K of memory

Test first 64K memory

OEM Specific-Turn on extended memory

Initialization

Cyrix CPU initialization

Cache initialization

TDS5000B Read This First 17

Page 22

Service Manual Information

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

5

6

7

8

9

10 Unclaimed NMI B1

11

12

Special Display

Handling

Early Shadow C5 OEM specific-Early shadow enable for fast boot

Cache presence test C6

CMOS Check CF CMOS checkup

Spurious

Program Chip Set

Setup Pages

Force load Default to

chipset

Reserved 2

Early Super IO Init

Reserved 4

Blank video

Reserved 6

Init KBC

KB test 8 Test the keyboard

Reserved 9

Mouse Init A Initialize the mouse

Onboard Audio init

Reserved

Reserved D

CheckSum Check

Reserved F

Auto detect E EPROM

Reserved 11

CMOS Check

Reserved 13

Chipset Default load

Reserved 15

Clock Init

Reserved 17

Identify the CPU

code Description

C4 OEM Specific-Display/Video Switch

B0

BF

E1–EF E1- Page 1, E2 - Page 2, and so on

1

3

5

7

B

C

E

10

12

14

16 Init onboard clock generator

18

Handling so that the Switch Handling display switch errors

never occur

External cache size detection

If interrupt occurs in protected mode.

If unmasked NMI occurs, display

Press F1 to disable NMI, F2 reboot.

To program chipset from defaults values

Chipset defaults program

Early Initialize of the super IO

Reset the Video controller

Keyboard controller init

Initialize the onboard audio controller if it exits

Check the integrity of the ROM, BIOS, and message

Check the Flash type and copy flash

write/erase routines to 0F000h segments

Check CMOS circuitry and reset CMOS

Program the chipset registers with CMOS values

Check the CPU ID and init L1/L2 cache

18 TDS5000B Read This First

Page 23

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

12

Reserved 19

Reserved 1A

Setup Interrupt Vector

Table

Reserved

Early PM Init 1D

Reserved 1E

Re-initial KB 1F Re-init KB

Reserved 20

HPM init 21

Reserved 22

Test CMOS Interface

and Battery Status

Reserved 24

Reserved 25

Reserved 26

KBC final Init

Reserved 28

Initialize Video Inter face

Reserved 2A

Reserved 2B

Reserved

Video memory test 2D Test video memory, write sign-on message to screen.

Reserved 2E

Reserved 2F

Reserved 30

Reserved 31

Reserved 32

PS2 Mouse setup

Reserved 34

Test DMA Controller 0

Reserved 36

Test DMA Controller 1

code Description

1B

1C

23

27

29

2C

33

35 Test DMA channel 0

37 Test DMA channel 1

Service Manual Information

Initialize first 120 interrupt vectors with SPURIOUS_INT_HDLR

and

initialize INT 00h-1Fh according to INT_TBL

First step initialize if single CPU onboard

If support HPM, HPM get initialized here

Verifies CMOS is working correctly and detects bad battery.

If failed, load CMOS defaults and load into chipset

Final Initial KBC and setup BIOS data area

Read CMOS location 14h to find out type of video in use.

Detect and Initialize Video Adapter.

Setup shadow RAM - Enable shadow according to Setup.

Setup shadow RAM - Enable shadow according to Setup.

Setup PS2 Mouse and reset KB

TDS5000B Read This First 19

Page 24

Service Manual Information

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

12

Reserved 38

Test DMA Page

Registers

Reserved 3A

Reserved 3B

Test Timer Counter 2 3C Test 8254 Timer 0 Counter 2.

Reserved 3D

Test 8259-1 Mask Bits 3E

Reserved 3F

Test 8259-2 Mask Bits 40

Reserved 41

Reserved 42

Test Stuck 8259’s

Interrupt Bits

Test 8259 Interrupt

Functionality

Reserved 44

Reserved 45

Reserved 46

Set EISA Mode

Reserved 48

Size Base and Extended

Memory

Reserved 4A

Reserved 4B

Reserved

Reserved 4D

Test Base and Extended

Memory

code Description

39 Test DMA Page Registers.

43

47

49

4C

4E

Verify 8259 Channel 1 masked interrupts by alternately turning

off and on the interrupt lines.

Verify 8259 Channel 2 masked interrupts by alternately turning

off and on the interrupt lines.

Turn off interrupts then verify no interrupt mask register is on.

Force an interrupt and verify the interrupt occurred.

If EISA non-volatile memory checksum is good, execute EISA

initialization.

If not, execute ISA tests an clear EISA mode flag.

Size base memory from 256 K to 640 K and extended memory

above 1 MB.

Test base memory from 256K to 640K and extended memory

above 1 MB using various patterns.

NOTE. This test is skipped in EISA mode and can be skipped

with ESC key in ISA mode.

Reserved 4F

USB init

Reserved 51

50

Initialize USB controller

20 TDS5000B Read This First

Page 25

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

12

Memory Test 52

Reserved 53

Reserved 54

CPU display

Reserved 56

PnP Init

Reserved 58

Setup Virus Protect

Reserved 5A

Awdflash Load

Reserved

Onboard I/O Init

Reserved 5E

Reserved 5F

Setup enable

Reserved 61

Reserved 62

Initialize & Install Mouse

Reserved 64

PS2 Mouse special

Reserved 66

ACPI init

Reserved 68

Setup Cache Controller

Reserved 6A

Setup Entering

Reserved

Initialize Floppy Drive &

Controller

Reserved 6E

FDD install 6F

Reserved 70

code Description

55

57

59

5B

5C

5D

60

63

65

67

69 Initialize cache controller

6B

6C

6D

Service Manual Information

Test all memory of memory above 1 MB using Virtual 8086

mode, page mode, and clear the memory

Detect CPU speed and display

CPU vendor specific version string and turn on all necessary

CPU features

Display PnP logo and PnP early init

Setup virus protect according to Setup

If required, will auto load Awdflash.exe in POST

Initializing onboard super IO

Display setup message and enable setup functions

Detect if mouse is present

initialize mouse

install interrupt vectors

Special treatment to PS2 Mouse port

ACPI s ub-system initializing

Enter setup check and auto-configuration check up

Initialize floppy disk drive controller and any drives.

Install FDD and setup BIOS data area parameters

TDS5000B Read This First 21

Page 26

Service Manual Information

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

12

Reserved 71

Reserved 72

Initialize Hard Drive &

Controller

Reserved 74

Install HDD

Reserved 76

Detect & Initializ e

Serial/Parallel

Reserved 78

Reserved 79

Detect & Initialize Math

Coprocessor

Reserved 7B

HDD Check for Write

protection

Reserved 7D

Reserved 7E

POST error check

Reserved 80

Reserved 81

Security Check

Write CMOS

Pre-boot Enable 84 Enable parity checker

Initialize Option ROMs

code Description

73 Initialize hard drive controller and any drives.

75

77

7A Initialize math coprocessor

7C

7F

82

83

85

IDE device detection and install

Initialize any serial and parallel ports (also game port)

HDD check out

Check POST error and display them and ask for user

intervention

Ask password security (optional)

Write all CMOS values back to RAM and clear screen

Enable NMI, enable cache before boot.

Initialize any option ROMs present from C8000h to EFFFFh.

NOTE. When FSCAN option is enabled, ROMs initialize from

C8000h to F7FFFh.

Reserved 86

Reserved 87

Reserved 88

Reserved 89

Reserved 8A

Reserved 8B

Reserved

8C

22 TDS5000B Read This First

Page 27

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

12

Quick POST Codes

13

Reserved 8D

Reserved 8E

Reserved 8F

Reserved 90

Reserved 91

Reserved 92

Boot Medium detection 93 Read and store boot partition head and

Final Init 94

Special KBC patch

Boot Attempt 96

Boot FF

Init onboard device 65

Early System setup

KBC and CMOS Init

Video Init 68

8259 Init 69

code Description

95

66

67

Service Manual Information

Final init for last micro details before boot

Set system speed for boot Setup NumLock status according to

Setup

Set low stack Boot via INT 19h.

Early Initialized the super IO

Reset Video controller

Keyboard controller init

Test the Keyboard

Initialized the mouse

Onboard audio controller initialize if exist

Check the integrity of the ROM, BIOS, and message

Check Flash type and copy flash write/erase routines to

0F000h segments

Check CMOS Circuitry and reset CMOS Program the chipset

registers with CMOS values Init onboard clock generator

Check the CPU ID and init L1/L2 cache

Initialize first 120 interrupt vectors with SPURIOUS_INT_HDLR

and initialize INT 00h-1Fh according to INT_TBL First step

initialize if single CPU onboard.

Re-init KB If support HPM, HPM get initialized here

Verifies CMOS is working correctly

detects bad battery

If failed, load CMOS defaults and load into chipset

Final Initial KBC and setup BIOS data area.

Read CMOS location 14h to find out type of video in use.

Detect and Initialize Video Adapter.

Test video memory, write sign-on message to screen.

Setup shadow RAM - Enable shadow according to Setup.

Init 8259 channel 1 and mask IRQ 9

TDS5000B Read This First 23

Page 28

Service Manual Information

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

13

Memory test 6A

CPU Detect and IO init

Reserved

Reserved 6D

Reserved 6E

Reserved 6F

Setup Init

Setup Cache C ontroller

Install FDD 72

Install HDD 73 Initialize hard drive controller and any drives

Detect & Initialize Math

Coprocessor

HDD Check for Write

protection

Reserved 76

Display POST error

CMOS and Option ROM

Init

code Description

6B

6C

70

71 Initialize cache controller

74 Initialize math coprocessor

75

77

78

Quick M emory Test

Detect CPU speed and display CPU vendor specific version

string and turn on all necessary CPU features

Display PnP logo and PnP early init

Setup virus protect according to Setup.

If required, will auto load Awdflash.exe in POST

Initializing onboard super IO

Display setup message and enable setup functions

Detect if mouse is present, initialize mouse, install interrupt

vectors

Special treatment to PS2 Mouse port

ACPI sub-system initializing

Enter setup check and auto-configuration check up

Initialize floppy disk drive controller and any drives

Install FDD and setup BIOS data area parameters

IDE device detection and install Initialize any serial and parallel

ports (also game port)

HDD check out

Check POST error and display them and ask for user

intervention

Ask password security (optional)

Write all CMOS values back to RAM and clear screen

Enable parity checker

Enable NMI

Enable cache before boot.

24 TDS5000B Read This First

Page 29

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

13

Reserved 79

Reserved 7A

Reserved 7B

Reserved

Boot Medium detection 7D Read and store boot partition head and cylinders values in

Final Init 7E

Special KBC patch

Boot Attempt 80

Boot FF

S4 POST Codes

14

Early Chipset Init

Cmos Check

Chipset default Prog 5C Program the chipset registers with CMO S values. Init onboard

Identify the CPU

Setup Interrupt Vector

Table

Test CMOS Interface

and Battery status

KBC final Init

Initialize Video Inter face

code Description

7C

7F

5A

5B

5D

5E

5F

60

61

Service Manual Information

Initialize any option ROMs present from C8000h to EFFFFh

NOTE. When FSCAN option is enabled, ROMs initialize from

C8000h to F7FFFh.

RAM

Final init for last micro details before boot

Set system speed for boot Setup NumLock status according to

Setup

Set low stack Boot via INT 19h

Early Initialized the super IO

Reset Video controller

Keyboard controller init

Test the Keyboard

Initialized the mouse

Check CMOS Circuitry and reset CMOS

clock generator

Check the CPU ID and init L1/L2 cache

Initialize first 120 interrupt vectors with SPURIOUS_INT_HDLR

and INT 00h-1Fh according to INT_TBL

First step initialize if single CPU Onboard

Re-init KB

If support HPM, HPM get initialized here.

Verifies CMOS is working correctly

detects bad battery. If failed, load CMOS defaults and load

into chipset

Final Initial KBC and setup BIOS data area

Read CMOS location 14h to find out type of video in use

Detect and Initialize Video Adapter

TDS5000B Read This First 25

Page 30

Service Manual Information

Table 1: 039-0185-xx μATX POST codes, (cont.)

Displayed POST

Item no. Module

14

BootBlock POST Codes

15

Video memory test 62 Test video memory, write sign-on message to screen

Setup PS2 mouse and

test DM A

Test 8259 64

Init Boot Device 65

Install Boot Devices 66

Cache Init

PM init 68 PM initialization

PM final Init and issue

SMI

Full on FF

Base memory test 1

KB init

Install interrupt vectors 12

Init Video 0D Video initializing

Init FDD 41

Boot FF Load boot sector

code Description

63

67

69

5

Setup shadow RAM - Enable shadow according to Setup

Setup PS2 Mouse and reset KB Test DMA channel 0

Test 8259 channel 1 and mask IRQ 9

Detect if mouse is present, initialize mouse, install interrupt

vectors

Special treatment to PS2 Mouse port ACPI sub-system

initializing Initialize cache controller

Enter setup check and auto-configuration check up

Initialize floppy disk drive controller and any drives

Install FDD and setup BIOS data area

Parameters Initialize hard drive

Cache init and USB init

Final init Before resume

Clear base memory area (0000:0000–9000:ffffh)

Initialized KBC

Install int. vector (0-77) and initialized 00-1fh to their proper

place

Scan floppy and media capacity for onboard super IO

26 TDS5000B Read This First

Page 31

Service Manual Information

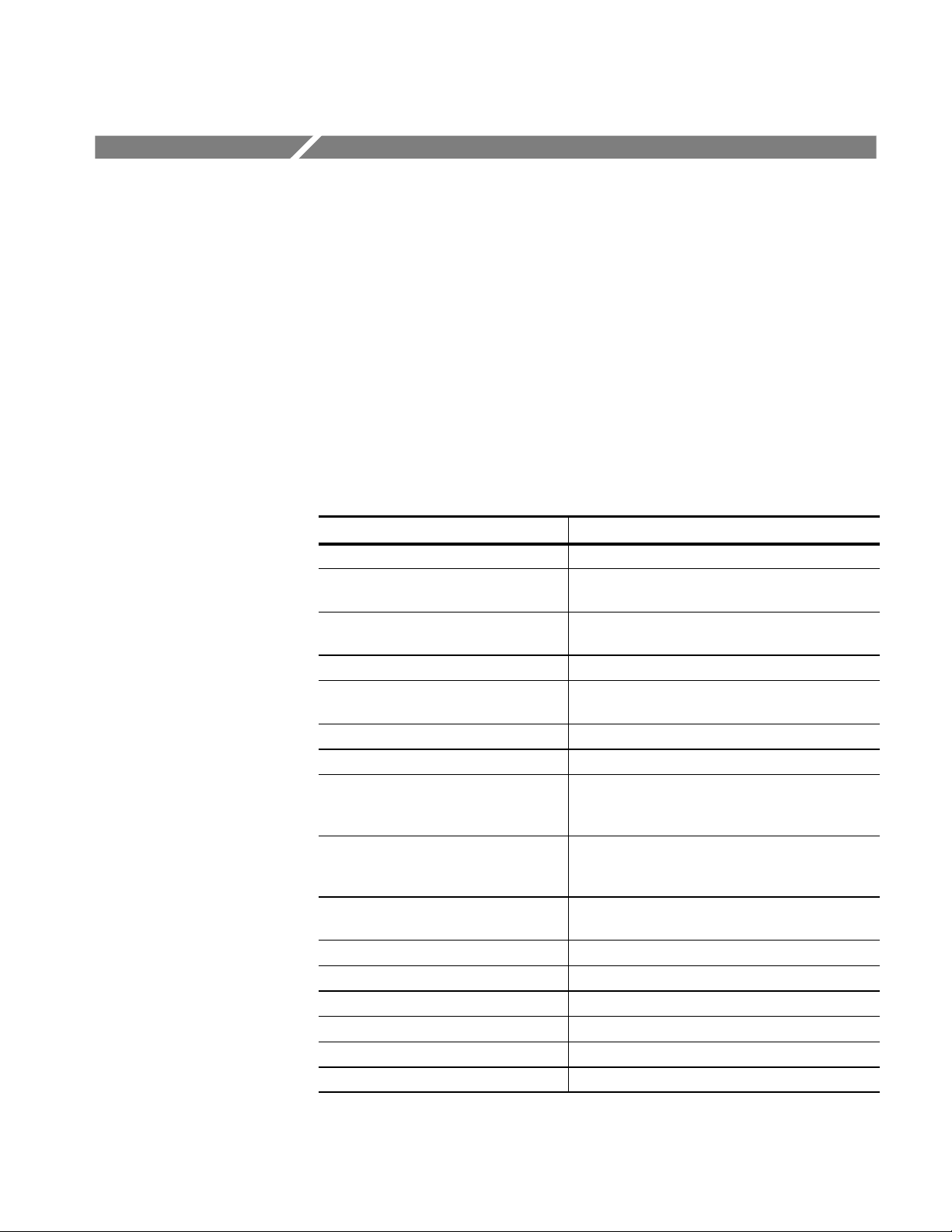

Table 2: 039-01

Item

no. Beep code Error message Description

1 1 long, 2 short Video adapter

2 R epeating

3 1 long, 3 short No video card or bad video RAM Reseat or replace the video card.

4

5

85-xx μATX beep codes

endless loop

High frequency

beeps whil

running

Repeating

High/Low

e

error

Memory error

Overheated CPU Check the CPU fan for proper operation and

CPU Either the CPU is not seated properly or it is

Bad video adap

video adapter. Ensure that the monitor cable

is connected properly.

Check for improperly seated or missing

memory.

check the c

damaged. The problem can also be due to

excess he

settings for proper fan speed.

ter or a bad connection to the

ase for proper air flow.

at. C heck the CPU fan or BIOS

TDS5000B Read This First 27

Page 32

Service Manual Information

Replaceable Parts

External parts

Use the following information to replace or clarify parts list information in the

service manual.

Fig. &

index

number

10-1-(not

shown)

Inner Pane

Fig. &

index

number

10-2-10

es

Modul

Fig. &

index

number

10-3-5

Tektronix

part

number

101-0158-xx B030000 1

Serial no.

effective

Serial no.

discont’d Qty Name & description

ls

Tektronix

part

number

441-2226-xx B010100 B019999 1

441-2376-xx B020000 B029999 1

441-2491-xx B030000 B039999 1

441-2557-xx B040000 1

Tektronix

part

number

039-0154-xx B010100 B019999 1

039-0159-xx B020000 B029999 1

039-0173-xx B030000 B039999 1

039-0185-xx B040000 1

Serial no.

effective

lno.

Seria

effective

Serial no.

discont’d Qty Name & description

l no.

Seria

discont’d Qty Name & description

TRIM RING; FR110,PC/ABS

CHASSIS ASSY;FOR ASHLAND MOTHER BOARD,0.050 AL

W/BRACKETS & HARDWARE

CHASSIS ASSY;FOR LACROSSE MOTHER BOARD,0.050 AL

W/BRACKETS & HARDWARE

CHASSIS ASSY;FOR TAPPEN MOTHER BOARD,0.050 AL

W/BRACKETS & HARDWARE

CHASSIS ASSY;FOR ADVANTECH MOTHER BOARD,0.050 AL

W/BRACKETS & HARDWARE

MOTHER BOARD ASSY;PENTIUM 4/CELERON BD, UATX,ASHLAND

2.1,W/O PROCESSOR,D845GVAD2L

MOTHER BOARD ASSY;PENTIUM 4/CELERON BD, UATX,LA

CROSSE,W/O PROCESSOR,BLKD865GLCLK INTEL P/N,SAFETY

CONTROLLED

MOTHER BOARD ASSY;PENTIUM 4, UATX,TAPPEN

BD,GIG E, PROCESSOR LGA775,DDR2 667MHZ,TOTAL 4

GIG,BLKD945GTPLKR,SAFETY CONTROLLED

MOTHER BOARD ASSY;ADVANTECH MICROATX, LGA 775

CORE 2 DUO, DDR2, PCI-E X1, SINGLE GBE LAN; ADVANTECH

AIMB-562VG-00A1E WITH ADD2 DISABLE AND BIOS 562X126N.BIN

SAFETY CONTROLLED

28 TDS5000B Read This First

Page 33

External parts

Service Manual Information

Fig. &

index

number

10-4-1

4b 174-5639-xx B040000+ 1

-5

Tektronix

part

number

119-7524-xx 1

119-6833-xx B010100 B060099 1

Serial no.

effective

Serial no.

discont’d Qty Name & description

DISK DRIVE,HARD; 160GB, 3.5 INCH, 7200 RPM, SATA II 3.0 GB/S

INTERFACE;,SAFETY CONTROLLED

CABLE ASSY MOLEX TO SATA POWER ADAPTER

DISK DRIVE; USB FLOPPY,3.5 INCH;1.44MB,0.5 INCH,TWO

SIDED,DOUBLE DENSITY,SAFETY CONTROLLED

Table 10–4 Drives

TDS5000B Read This First 29

Page 34

Service Manual Information

Accessories

Fig. &

index

number

10-6-

Tektronix

part

number

063-3693-xx B010100 B019999 1

063-3759-xx B020000 B029999 1

063-3985-xx B030000 B039999 1

020-2969-xx B040000 1

Serial no.

effective

Serial no.

discont’d Qty Name & description

TDS5000B SERIES OPERATING SYSTEM RESTORE CD

TDS5000B SERIES OPERATING SYSTEM RESTORE CD

TDS5000B SERIES OPERATING SYSTEM RESTORE CD

TDS5000B SERIES OPERATING SYSTEM RESTORE CD KIT

30 TDS5000B Read This First

Page 35

Specification and Performance Verification

Specification

and Performance Verification

Check the TDS

Performance Verification (071-1420-XX) manual on the Tektronix Web site for

the latest updates and a complete list of instrument specifications. The Web

site address is located on the copyright page at the front of this Read This First

document.

5000B Series Digital Phosphor Oscilloscopes Specifications and

TDS5000B Read This First 31

Page 36

Service Manual

TDS5000B Series

Digital Phosphor Oscilloscopes

071-1362-02

Revision A

This document applies to firmware version 1.00

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 37

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by na tional copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in al l previously published material. Specifications and price change privi leges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 38

Warranty 2

Tektronix warrant s that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment . If any such product proves defective during this warranty period, Tektronix, at i ts

option, either will repair the defective product without cha rge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to l ike new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packagi ng and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shippi ng charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or c onnection to incompatible equipment; c) to repair any

damage or ma lfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or int egrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 39

Page 40

Table of Contents

Specifications

Operating Information

General Safety Summary vii...................................

Service Safety Summary ix....................................

Environmental Considerations xi...............................

Preface xiii...................................................

Manual Structure xiii................................................

Manual Conventions xiii..............................................

Related Documentation xiv...........................................

Installation 2--1.....................................................

Before You Start 2--1.............................................

Environmental Considerations 2--1..................................

Connect the Peri pherals 2--2........................................

Power On the Instrument 2--4.......................................

Powering Off the Oscilloscope 2--4..................................

Create an E mergency Startup Disk 2--4...............................

Software Installation 2--5..........................................

Operating Information 2--6............................................

Back Up User Files 2--6...........................................

User Interface Map 2--7...........................................

Front Panel I/O Map 2--8..........................................

Rear Panel I/O Map 2--8...........................................

Front Panel Controls Map 2--9......................................

Instrument Diagnostics 2--10........................................

Signal Path Compensat ion 2--10.....................................

Using the Online Help 2--11.........................................

Theory of Operation

TDS5000B Series Service Manual

Logic Conventions 3--1...............................................

Module Overviews 3--1...............................................

i

Page 41

Table of Contents

Performance Verification

Calibration Procedure

Overview of the Procedure 5--3.........................................

Instrumentation Setup 5--3.............................................

Calibration Program Installation and Execution 5--5........................

Calibration Program Operation 5--5.....................................

Commands 5--7...............................................

Calibration Command Group 5--7.......................................

Diagnostics Command Group 5--19......................................

Sample Calibration Program 5--37................................

Overview 5--37.......................................................

Listing 5--38.........................................................

General 3--1....................................................

Input Signal Path 3--1.............................................

Display Panel 3--1................................................

Front Panel 3--2..................................................

Side Panels 3--3..................................................

Power Supply 3--3................................................

Fans 3--3.......................................................

Printer 3--3.....................................................

Calibration Interval 5--1...........................................

Calibration Environment 5--1.......................................

Calibration Dependencies 5--1......................................

Calibration After Repair 5--1.......................................

Required Equipment 5--2..........................................

Maintenance

Preventing ESD 6-- 1.................................................

Inspection and Cle aning 6--2...........................................

General Care 6--2................................................

Interior Cleaning 6--2.............................................

Exterior Cleaning 6--2............................................

Removal and Installation Procedures 6--7.........................

Preparation 6--7.....................................................

Procedures for External Modules 6--9....................................

Procedures for Modules 6--21...........................................

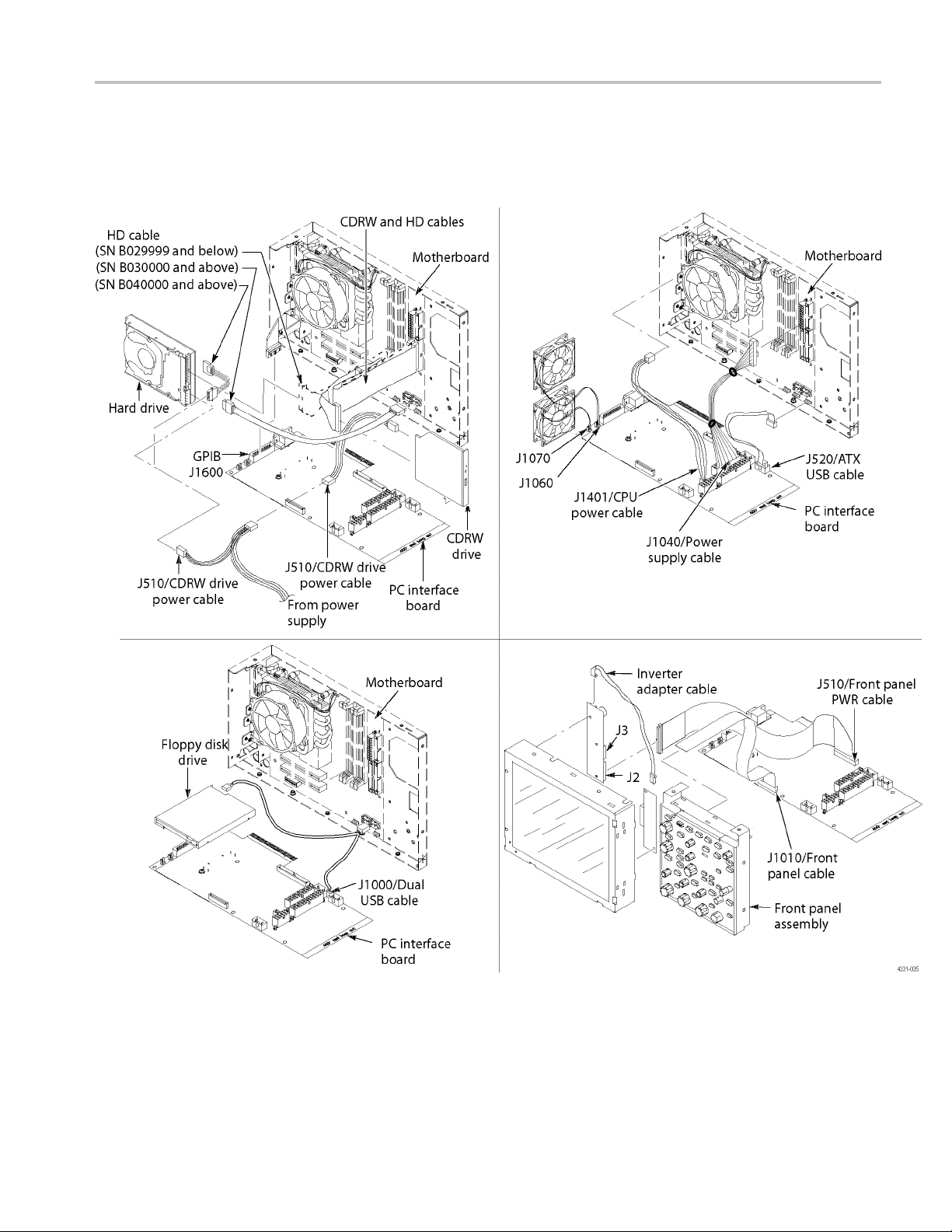

PC Interface Board and Motherboard Cable Connections 6--32.................

Troubleshooting 6--51...........................................

Service Level 6--51...................................................

Check for Common Problems 6--51......................................

Equipment Required 6--53..............................................

Fault Isolation Procedure 6--53..........................................

PC Interface and PC Motherboard Diagnostics 6-- 58.........................

Firmware Updates 6--61................................................

After Repair 6--61....................................................

BIOS Error Messages 6--62.............................................

BIOS Beep Codes 6--64................................................

PC Interface LEDs 6--65...............................................

ii

TDS5000B Series Service Manual

Page 42

Troubleshooting Using Reset Circuits 6--65................................

Installing the PC Motherboard Serial Number 6--69..........................

Update/Restore the PC Motherboard CMOS 6--69...........................

Installing an Authorization Key 6 --70.....................................

Hard Disk Drive Maintenance 6--70......................................

Repackaging Instructions 6--71...................................

Packaging 6--71......................................................

Shipping to the Service Center 6--71......................................

Options and Accessories

Options 7--1........................................................

Accessories 7--3.....................................................

Electrical Parts List

Diagrams

Symbols 9--1.......................................................

Mechanical Parts List

Table of Contents

Parts Ordering Information 10--1.........................................

Using the Replaceable Mechanical Parts List 10-- 1..........................

TDS5000B Series Service Manual

iii

Page 43

Table of Contents

List of Figures

Figure 2--1: Locations of peripheral connectors on the side panel 2--3..

Figure 2--2: On/Standby switch location 2--4.......................

Figure 2--3: User interface 2--7...................................

Figure 2--4: Locations of input/output connectors on the front panel 2--8

Figure 2--5: Locations of connectors on the rear panel 2--8...........

Figure 2--6: Front panel controls 2--9.............................

Figure 5--1: Calibration setup 5--3................................

Figure 6--1: Knob removal 6--10..................................

Figure 6--2: Trim removal 6--13...................................

Figure 6--3: Bottom cover removal 6--14............................

Figure 6--4: Right-side cover removal (SN B030000 an d above) 6--16....

Figure 6--5: Right-side cover removal (SN B029999 an d below) 6--16....

Figure 6--6: Printer frame removal 6--18...........................

Figure 6--7: Internal modules 6--19................................

Figure 6--8: Front panel assembly removal 6--22.....................

Figure 6--9: J1 flex cable connector removal 6--23....................

Figure 6--10: Front panel board and keyboard removal 6--24..........

Figure 6--11: Display removal 6-- 26................................

Figure 6--12: Touch panel and Display assembly removal 6--27.........

Figure 6--13: Display adapter board removal 6--28...................

Figure 6--14: Power flex circuit removal 6--29.......................

Figure 6--15: Flopp y disk drive assembly removal 6--30...............

Figure 6--16: Flopp y disk drive removal 6--31.......................

Figure 6--17: PC Interface board and motherboard cable

connections 6--32............................................

Figure 6--18: Desktop hard drive removal 6--34......................

Figure 6--19: Removing the CDRW drive from the bracket 6--36.......

Figure 6--20: CDRW drive assembly removal 6--37...................

Figure 6--21: Fan fastener removal 6--39...........................

Figure 6--22: Disconnecting the fan cables 6--40.....................

Figure 6--23: Power supply removal 6--41...........................

Figure 6--24: Motherboard removal 6--44...........................

Figure 6--25: Heatsink fan and microprocessor removal 6--45.........

Figure 6--26: PC interface board removal 6--47......................

iv

TDS5000B Series Service Manual

Page 44

Table of Contents

Figure 6--27: Acquisition circuit board removal 6--49.................

Figure 6--28: Primary troubleshooting tree 6--54.....................

Figure 6--29: Location of jumpers and reset button 6--55..............

Figure 6--30: The PCI busses (SN B030000 and above) 6--65...........

Figure 6--31: The PCI busses (SN B029999 and below) 6--65...........

Figure 6--32: Location of jumpers and reset button 6--66..............

Figure 6--33: PCI and AGP video connectors 6--68...................

Figure 9--1: TDS5000B series block diagram 9--2...................

Figure 10--1: External parts 10--4.................................

Figure 10--2: Inn er panels 10--6...................................

Figure 10--3: Modules 10--9......................................

Figure 10--4: Drives 10--11........................................

Figure 10--5: Acquisition assembly 10--12............................

Figure 10--6: Accessories 10--13....................................

TDS5000B Series Service Manual

v

Page 45

Table of Contents

List of Tables

Table 2--1: Additional accessory connection information 2--2.........

Table 5-- 1: Calibration required for module replaced 5--1...........

Table 5-- 2: Required equipment and materials 5--2.................

Table 5--3: GPIB devices required by test program 5--5.............

T able 5--4: CALibrate commands 5--7............................

Table 5-- 5: DIAgnostic Commands 5--19............................

T able 6--1: External inspection check list 6--3......................

T able 6--2: Internal inspection check list 6--4......................

Table 6--3: Tools required for module removal 6--8.................

Table 6--4: Failure symptoms and possible causes 6--51...............

Table 6-- 5: Power supply voltages 6--56............................

Table 6--6: Acquisition board voltages 6--56........................

Table 6--7: Power-on diagnostic tests 6--58.........................

Table 6-- 8: Action required for module replaced 6--61................

Table 6--9: BIOS Error messages 6--62............................

Table 6--10: Beep codes (SNB030000 and above) 6--64................

Table 6--11: B eep codes (SN B010100 to B029999) 6--64..............

Table 7--1: Instrument options 7--1...............................

Table 7-- 2: Instrument upgrades 7 --2.............................

T able 7--3: Standard accessories 7--3.............................

Table 7--4: Optional accessories 7--4..............................

vi

TDS5000B Series Service Manual

Page 46

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at all

times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

TDS5000B Series Service Manual

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmospher e.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

vii

Page 47

General Safety Summary

Terms in this Manual

Symbols and Terms

on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

viii

TDS5000B Series Service Manual

Page 48

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TDS5000B Series Service Manual

ix

Page 49

Service Safety Summary

x

TDS5000B Series Service Manual

Page 50

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

TDS5000B Series Service Manual

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

xi

Page 51

Environmental Considerations

xii

TDS5000B Series Service Manual

Page 52

Preface

Manual Structure

Manual Conventions

This manual contains service information for TDS5000B Series Digital

Phosphor Oscilloscopes. Read this preface to learn how this manual is structured, the conventions it uses, and where to find additional supplemental

information related to servicing this product.

You should also read the General and Service safety summaries before servicing

the product.

This manual is divided into chapters, which are made up of related subordinate

topics. These topics can be cross referenced as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

Modules

Replaceable Parts

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

Throughout this manual, any replaceable component, assembly, or part is

referred to by the term module. A module is composed of electrical and

mechanical assemblies, circuit cards, interconnecting cables, and user-accessible

controls.

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly, such as the hard disk drive, or a

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list of Chapter 10.

Symbols and terms related to safety appear in the Service Safety Summary found

at the beginning of this manual.

TDS5000B Series Service Manual

xiii

Page 53

Preface

Related Documentation

TDS5000B Series Digital Phosphor Oscilloscopes ship with the following

additional manuals and CD-ROMs:

H TDS5000B S eries Digital Phosphor Oscilloscopes Quick Start User Manual

H Getting Started with OpenChoice Solutions Manual with CD

H TDS5000B S eries Product Software CD. Includes: application, online help,

TDS5000B Series Programmer Online Guide (GPIB online help and PDF),

Performance Verification PDF, release notes, VISA information.

H TDS5000B S eries Elo Touchscreen Switcher Software CD. Refer to the

instructions in the CD booklet that came with the Touch Screen Switcher

Tool CD.

H TDS5000B S eries Operating System Restore CD

H Optional Applications Software for Windows-Based Oscilloscopes

xiv

TDS5000B Series Service Manual

Page 54

Specifications

Page 55

Page 56

Specifications

The specifications for this instrument are now available on the TDS5000B Series

Product Software CD-ROM that shipped with your product.

Look for the TDS5000B Series Digital Phosphor Oscilloscopes Specifications

and Performance Verification Technical Reference PDF, available on this disk.

TDS5000B Series Service Manual

1- 1

Page 57

Specifications

1- 2

TDS5000B Series Service Manual

Page 58

Operating Information

Page 59

Page 60

Operating Information

This chapter covers installation information and basic operation instructions.

Installation

The basic operating software is already installed on the hard disk. Refer to

Software Installation on page 2--5 for instructions on reinstalling the software.

NOTE. To avoid rebuilding your hard disk, be sure to create an emergency

startup disk. You will need this disk if you ever have to reinstall the Windows

operating system. Refer to Create an Emergency Startup Disk on page 2--4.

Before You Start

Environmental

Considerations

Verify that all parts and accessories for the oscilloscope are available. Use the

graphical packing list that came with the oscilloscope to determine the necessary

parts and accessories. Y ou should also verify that the following items are

available:

H The correct power cords

H The product-software CD set that includes installation copies of the software

installed on the oscilloscope

H All the accessories necessary to operate the oscilloscope

The oscilloscope is designed to operate on a bench or on a cart in the normal

position (on the bottom feet). For proper cooling, at least three inches (7.62 cm)

of clearance is required on the left side of the oscilloscope. If you operate the

oscilloscope while it is resting on the rear feet, make sure that you properly route

any cables coming out of the rear of the oscilloscope to avoid damaging them.

CAUTION. To prevent overheating the oscilloscope, keep the bottom and sides of

the oscilloscope clear of obstructions to ensure proper cooling.

TDS5000B Series Service Manual

2- 1

Page 61

Operating Information

NOTE. The Power Source and Environmental specifications tables list the

operating requirements for the oscilloscope. Power source, temperature,

humidity, and altitude are listed.

These tables are part of the TDS5000B Series Digital Phosphor Oscilloscopes

Specifications and Performance Verification Technical Reference PDF, available

on the TDS5000B Series Product Software CD-ROM (Tektronix part number

063-3692-xx).

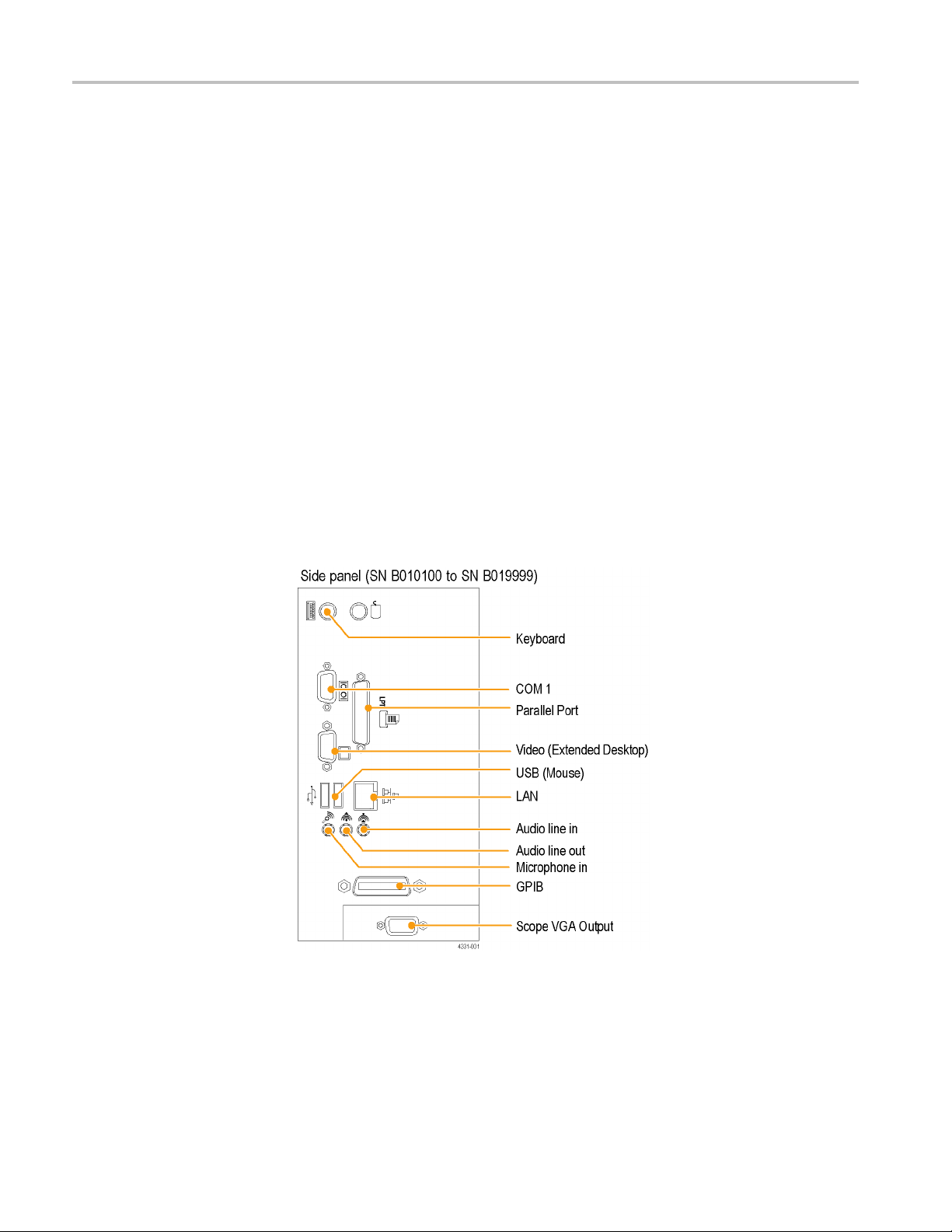

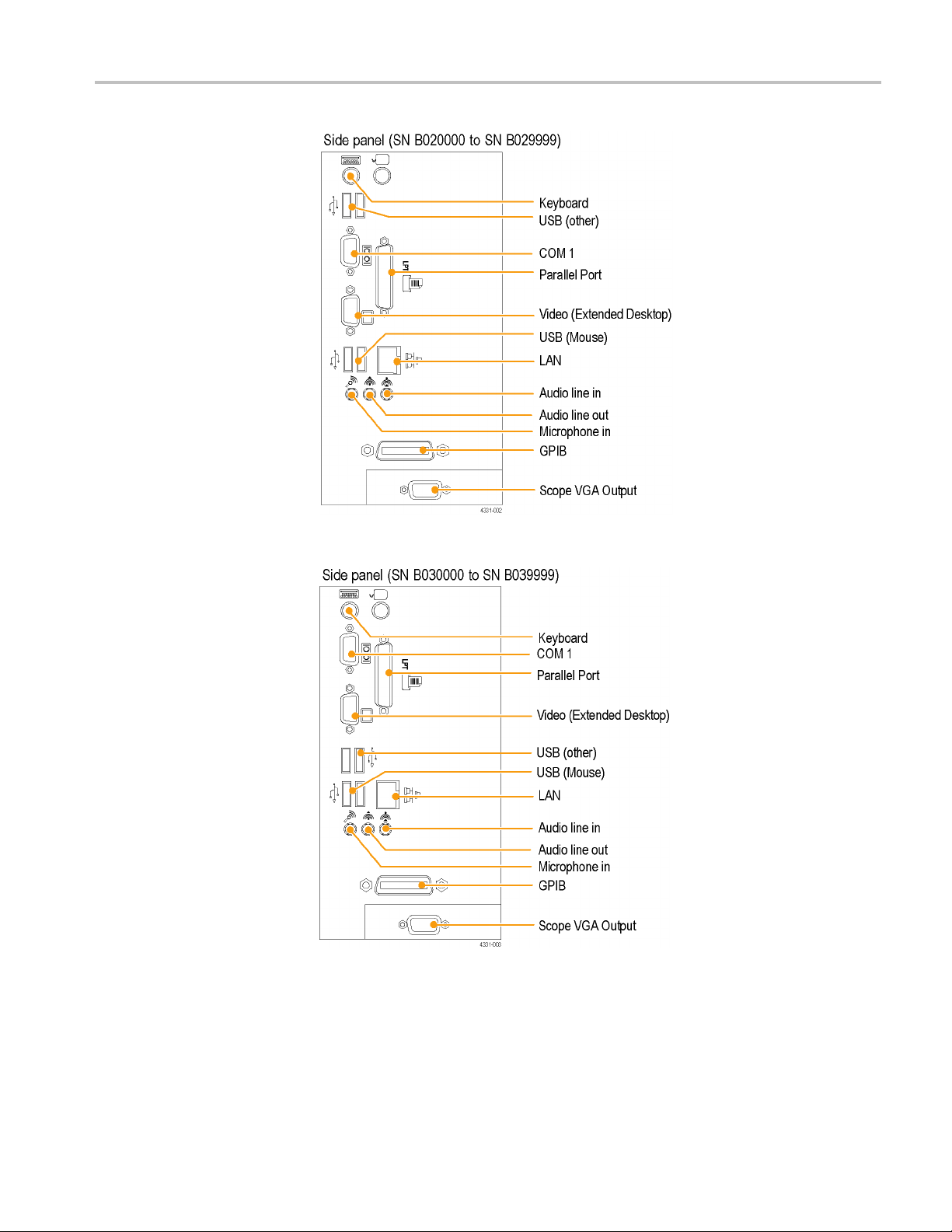

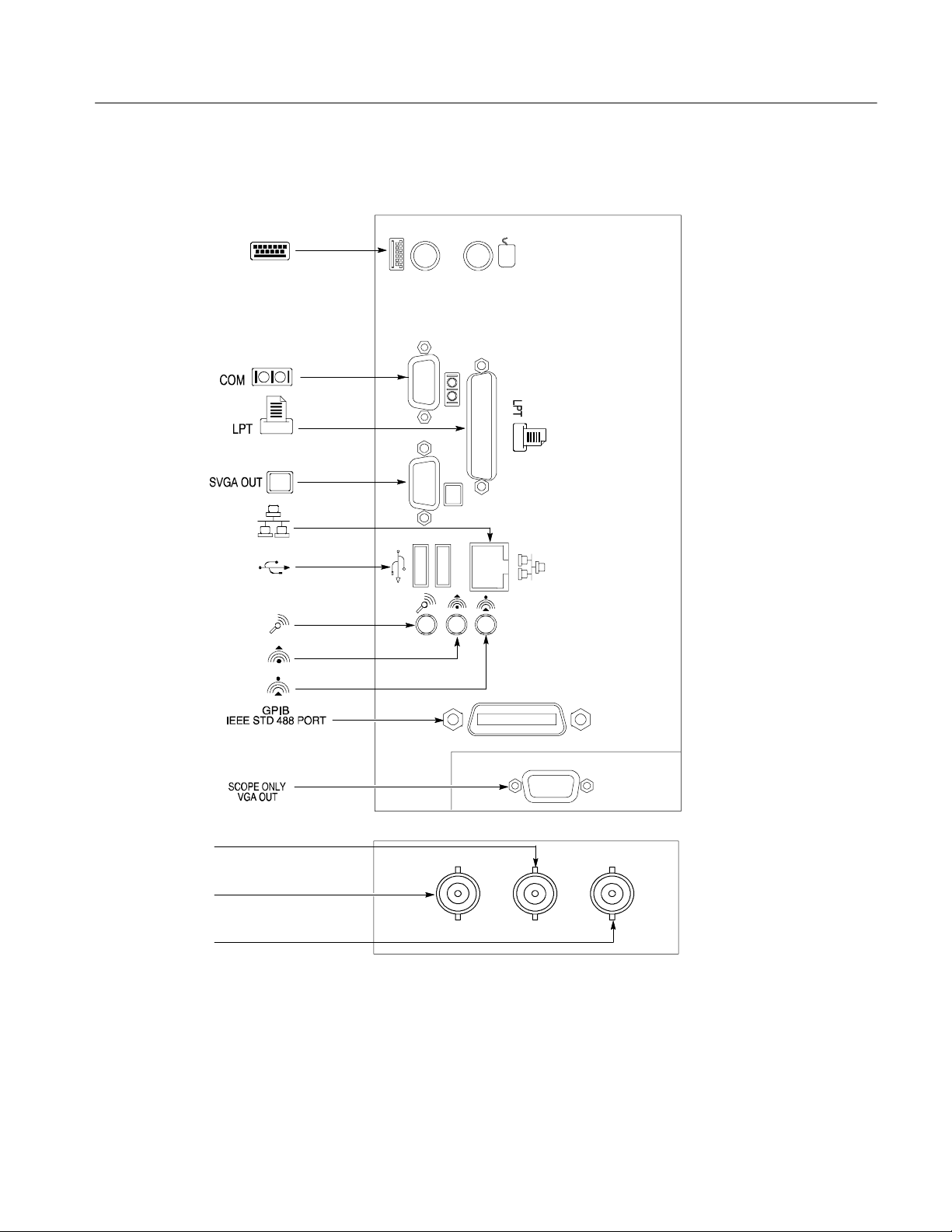

Connect the Peripherals

The peripheral connections are the same as those you would make on a personal

computer. The connection points are shown in Figure 2--1 on page 2--3. See

Table 2--1 for additional connection information.

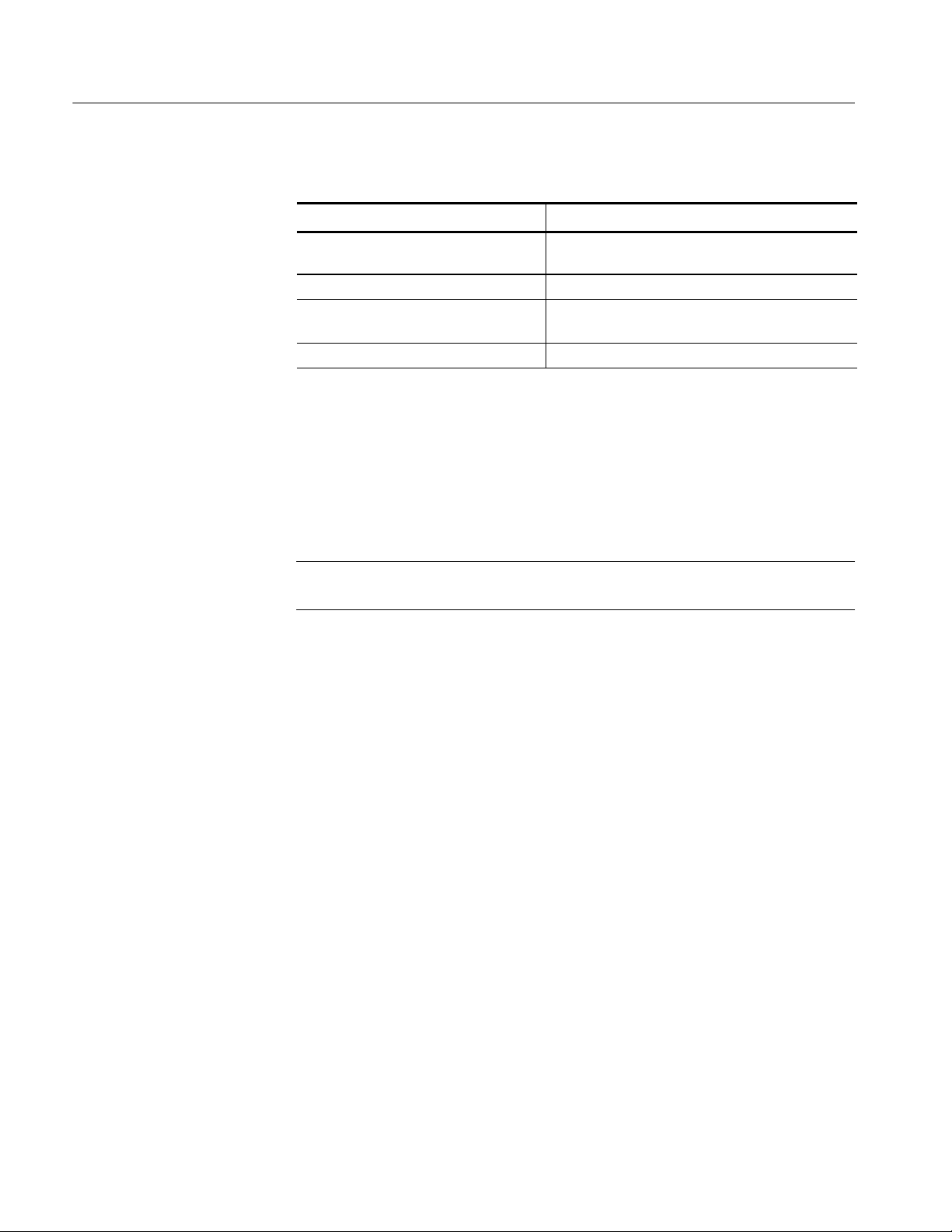

Table 2-1: Additional accessory connection information

Item Description

Monitor If you use a non-standard monitor, you may need to change the

the display settings to achieve the proper resolution for your

monitor.

External Printer Connect the printer to the EPP (enhanced parallel port)

connector directly. If your printer has a DB-25 connector, use

the adapter cable that came with your printer to connect t o the

EPP connector. For information on printer usage, see Printing

Waveforms in your user oscilloscope manual.

Rackmount Refer to the TDS5000B Rackmount Installation Instructions for

information on installing the rackmount kit.

Other Refer to the Application release notes on your product CD set

for possible additional accessory installation information not

covered in this manual.

2- 2

NOTE. We recommend that you plug USB devices dir ectly into the USB connectors on the oscilloscope chassis for improved reliability rather than connecting

the devices serially in a chain. If your mouse locks up, disconnect and reconnect

the USB connector to restore normal operation. If the oscilloscope front panel

and/or touch screen do not respond, press the On/Standby switch for at least

5 seconds to cycle power.

WARNING. To prevent injury to yourself or the oscilloscope, power off the

oscilloscope. before installing accessories (such as the mouse and keyboard) to

connectors. See Powering Off the Oscilloscope on page 2--4.

TDS5000B Series Service Manual

Page 62

Operating Information

Description

Keyboard

COM 1

Parallel Port

Video (Extended

Desktop)

LAN

USB (Mouse)

Microphone in

LocationsIcon/Label

Side panel

Audio line out

Audio line in

GPIB

Scope VGA Output

Rear panel

Trigger signal

output (AUX OUT)

Timebase reference

input (EXT REF)

CH 3 signal output

(SIGNAL OUT)

Figure 2-1: Locations of peripheral connectors on the side panel

TDS5000B Series Service Manual

2- 3

Page 63

Operating Information

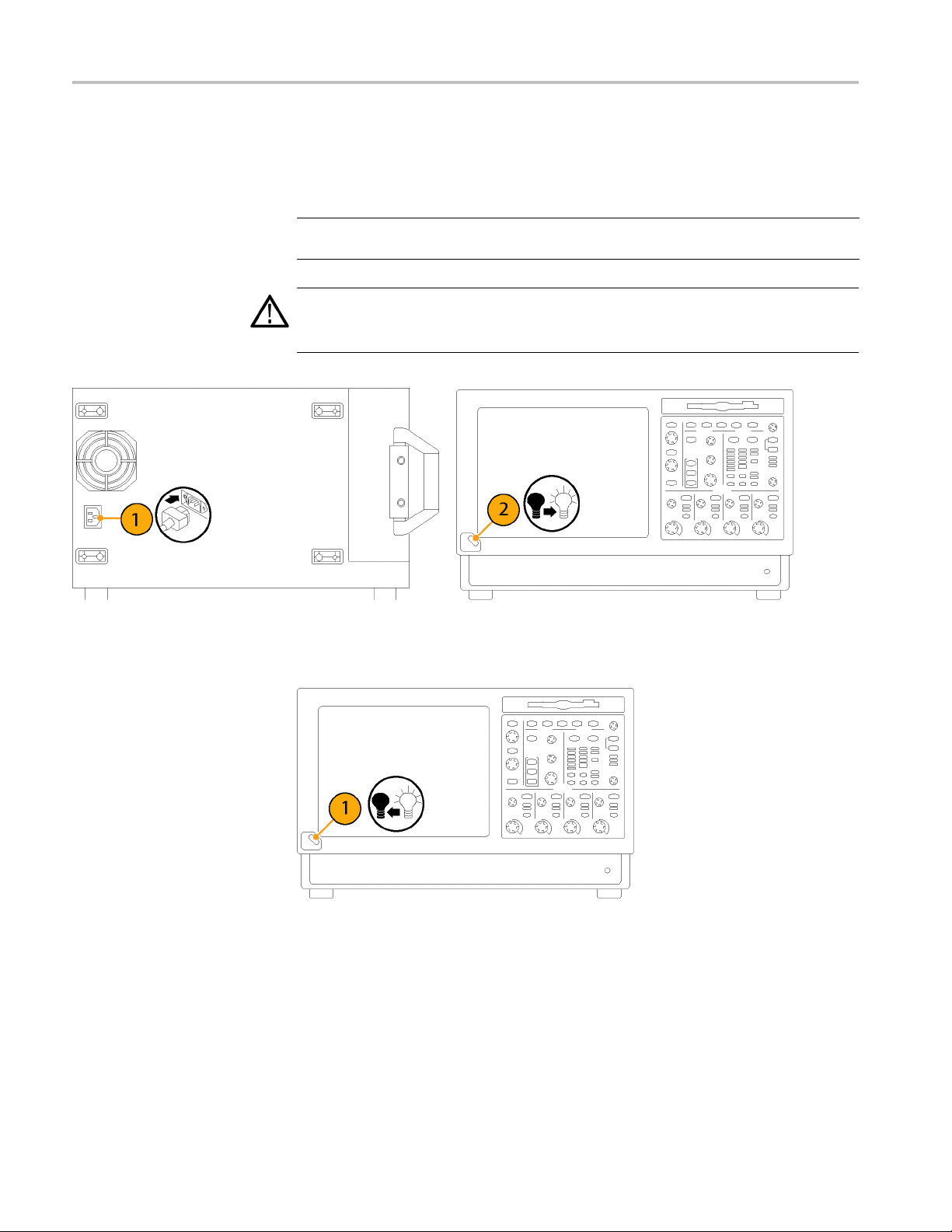

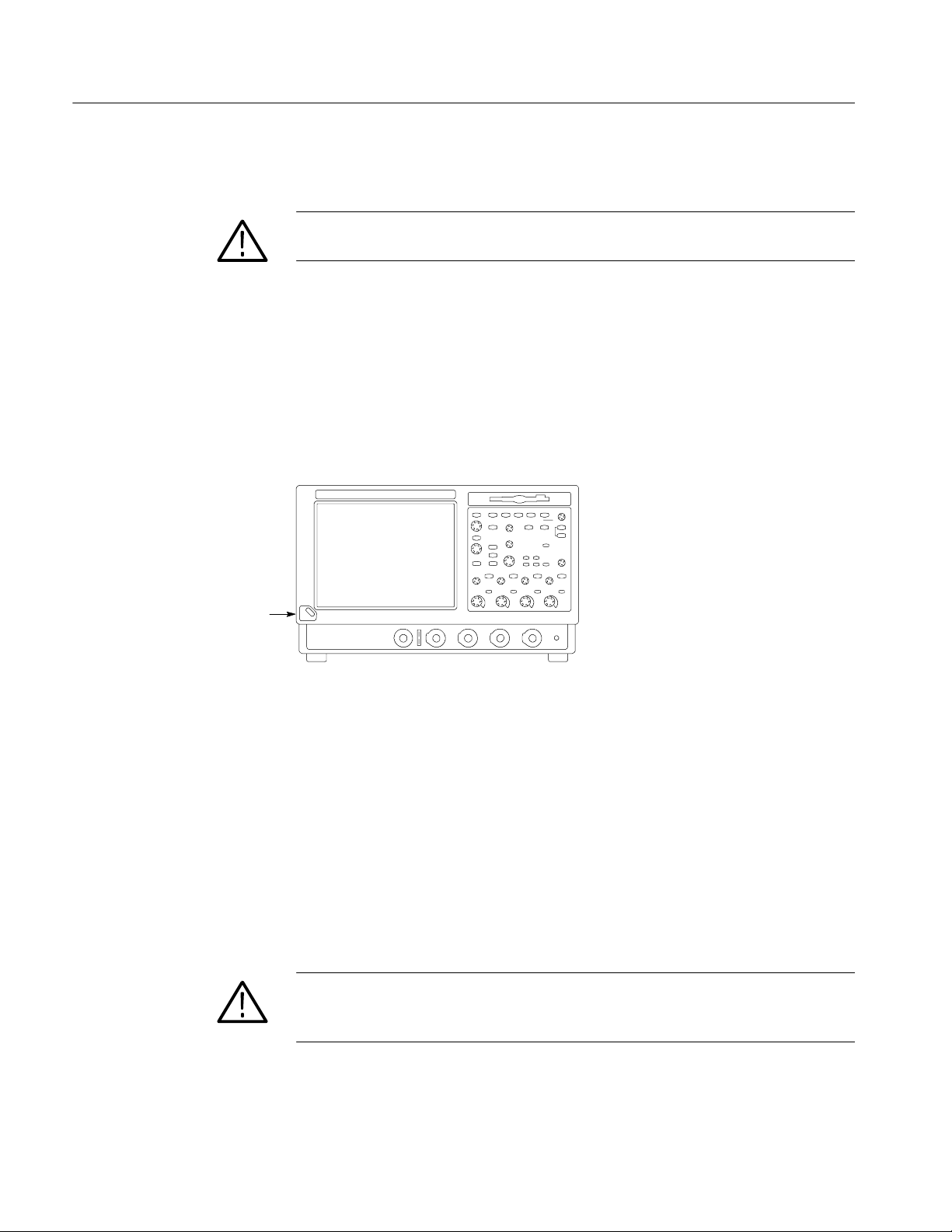

Power On the Instrument

Switch

Follow these steps to power on the instrument.

CAUTION. To prevent damage to the oscilloscope, connect the keyboard, mouse,

and other accessories before applying power to the product.

1. Connect the power cord.

2. If you have an external monitor, connect the power cord and power on the

monitor.

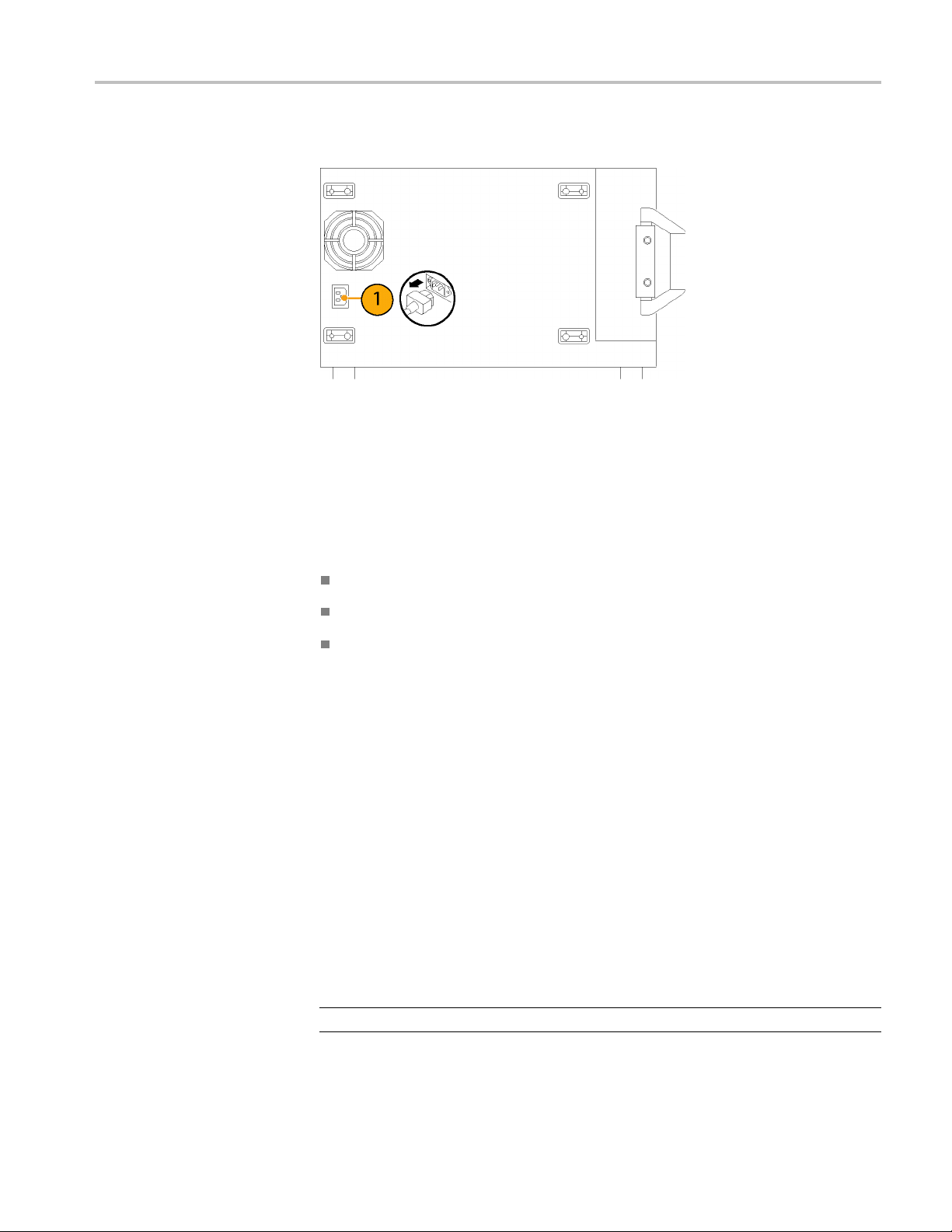

3. Press the On/Standby switch to power on the instrument (see Figure 2--2 for

the switch location).

4. Wait for the boot routine and low-level self test to complete.

Powering Off the

Oscilloscope

Create an Emergency

Startup Disk

Figure 2-2: On/Standby switch location

The oscilloscope has a built-in soft power-off function that safely powers off the

oscilloscope when you press the On/Standby switch.

To completely remove power to the instrument, press the On/Standby switch,

and then remove the power cord from the rear panel.

Now that you have completed the basic installation process, you should create an

emergency startup disk that you can use to restart your instrument in case of a

major hardware or software failure. You should create this disk, and then store it

in a safe place.

CAUTION. To prevent rebuilding the entir e instrument hard disk, create an

emergency startup disk and store it in a safe place. This disk may allow you to

recover your Windows installation.

The emergency startup disk contains basic files to restart your instrument. It also

contains files to check and format the hard disk.

2- 4

TDS5000B Series Service Manual

Page 64

Operating Information

Follow these steps to create the emergency startup disk:

1. Minimize the oscilloscope application: select Minimize from the File menu.

2. Select the Windows Start button, point to Programs >Accessories > System

Tools > Backup.

3. Select Emergency Repair Disk.

4. Insert a floppy disk into the disk drive and follow the on-screen instructions

to create the startup disk.

Software Installation

This section describes how to install the system software found on the productsoftware CD that accompanies this product. The instrument ships with the

product software installed, so only perform these procedures if reinstallation

becomes necessary.

Software Release Notes. Read the software release notes README.TXT ASCII

file on the product-software CD before performing installation procedures. This

file contains additional installation and operation information that supercedes

other product documentation.

To view the README.TXT file, open the Notepad Windows accessory and open

the file on the product-software CD. After installation, you can also read the

copy from a directory on the product:

C:\Program Files\Tektronix\TekScope\readme.txt

Operating System Restoration. Use the procedure that accompanies your

Operating System Restore CD should reinstalling system software become

necessary.

The compact disc contains the files necessary to restore the Windows operating

system and necessary drivers for the oscilloscope.

TDS5000B Series Service Manual

The Windows operating system and drivers are factory installed on the

oscilloscope hard disk. The compact disc serves as a backup in the event that you

have to rebuild the hard drive. You must restore the Windows operating system

before you can install the oscilloscope firmware and other product software.

Application Installation. Use the procedures that accompany your Product

Software CD should reinstalling the oscilloscope application software become

necessary.

The compact disc contains the files necessary to restore the oscilloscope

application and other software for the oscilloscope.

2- 5

Page 65

Operating Information

Operating Information

Software Lock for Upgrades. You can use the LockUpgrades utility to prevent

users from installing unauthorized firmware upgrades on the instrument. This

utility requires that a user enter a password before an upgrade can be installed.

To use the utility, run the LockUpgrades.exe file, and follow the on-screen

instructions. The LockUpgrades.exe file is in the following directory:

C:\Program Files\Tektronix\TekScope

NOTE. Using the Operating System Restore CD to reinstall the operating system

resets the LockUpgrades utility to the default setting and allows firmware

upgrades without password protection.

This section covers basic operation information so that you can operate and

prepare to service the instrument.

Back Up User Files

You should always back up your user files on a regular basis. Use the Microsoft

Backup tool to back up files stored on the hard disk. The Backup tool is located

in the System Tools folder in the Accessories folder.

1. Minimize the oscilloscope application by selecting Minimize from the File

menu.

2. Select the Windows Start button, point to Programs, Accessories, System

Tools, and then click Backup.

3. Use the Microsoft Backup tool to select your backup media and to select the