Page 1

www.keithley.com

Series 2200

Multichannel Programmable DC Power Supplies

Specifications and Performance Verification

Technical Reference

2220S-905-01 Rev. B

/ Dec 2013

ECNEDIFNOCFOERUSAEMRETAERGA

Page 2

Page 3

Multichannel Programmable DC Power Supplies

Series 2200

Specifications and Performance Verification

Technical Reference

© 2013, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, Inc. is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, Inc. Other brand names are trademarks or registered trademarks of their respective

holders.

Document number: 2220S-905-01 Rev. B / Dec 2013

Page 4

Page 5

Safety precautions

The following safety precautions should be observed before using this product and an y associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all install a tion, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring inst ruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 6

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

If a

The

user documentation in all cases where the symbol is marked on the instrument.

The

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If yo u are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

symbol on an instrument means caution, risk of danger. The user must refer to the operating instructions located in the

symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

symbol indicates a connection terminal to the equipment frame.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do n ot app ly

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Safety precaution revision of January 2013.

ii 2220S-900-01 Rev. C/December 2013

Page 7

Table of Contents

Preface .............................................................................................................. iii

Welcome ........................... ................................ .................................. .......... iii

Products.............................. .................................. ................................ ........ iii

Extended Wa

Contact Information .......................................................................................... iv

Specifications .............................. ................................ .................................. ....... 1

Performance Verification ................. ................................ .................................. ...... 13

Test Record ................ ................................ .................................. .................. 15

Performance Verification Procedures ....................... ................................ ................ 23

rranty ......................... .................................. ................................ iv

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference i

Page 8

Table of Contents

List of Tables

Table 1: Series 2220 Dual Channel specifications.............................................................. 1

Table 2: Ser

Table 3: Series 2230 Triple Channel specifications for Channel 3........................... ................. 5

Table 4: Combined channel characteristics............................... ................................ ....... 7

Table 5: Series 2230 Triple Channel unit characteristics....................................................... 7

Table 6: Mains power characteristics ................. ................................ ........................... 8

Table 7: Common characteristics................................................................................. 8

Table 8: T

Table 9: Interfaces and output ports ......... ................................ ................................ ..... 9

Table 10: Mechanical characteristics............................................................................ 10

Table 11: Environment performance .... ................................ .................................. ...... 10

Table 12: Keypad special operations................ ................................ ............................ 10

Table 13: Safety characteristics.................................................................................. 11

Table

family .......................... ................................ .................................. .............. 12

Table 15: DC voltage accuracy with remote sense .................... ................................ ........ 16

Table 16: DC voltage accuracy without remote sense......................................................... 17

Table 17: DC voltage readback accuracy ....................................................................... 18

Table 18: DC voltage line regulation............................................................................ 19

le 19: DC voltage load regulation ......... .................................. ................................ 19

Tab

Table 20: DC current accuracy................................................................................... 20

Table 21: DC current readback accuracy ....................................................................... 21

Table 22: DC current line regulation ............................................................................ 22

Table 23: DC current load regulation ..... .................................. ................................ .... 22

Table 24: Voltage noise at 7 MHz ....... ................................ ................................ ........ 22

Table 25: Voltage noise at 20 MHz.............................. .................................. .............. 22

Table 26: Current noise at 20 MHz.......... ................................ ................................ .... 22

Table 27: Test equipment ........... ................................ ................................ .............. 24

ies 2230 Triple Channel specifications for Channels 1 and 2 .............. ..................... 3

erminal strip ................................ ................................ ............................. 9

14: Electromagnetic Compatibility (EMC) — Measurement, laboratory, and control product

ii Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 9

Preface

Welcome

Preface

Products

Thank you fo

Multichannel Programmable DC Power Supplies are flexible DC sources designed

to power a wide range of applications. The model 2230-30-1 and its variants

offer three power channels and the model 2220-30-1 and its variants provide two

channels. The output channels on both models are independent and isolated,

allowing you to power circuits with different references or polarities. Each

channel c

feature remote sense capability which can be used to reduce the effect of lead

resistance, delivering 0.03% basic voltage accuracy even when using long leads.

Basic current ac curacy is 0.1% for all channels and linear regulation delivers

low noise – less than 3 mVp-p. Flexible display modes make it easy to use the

two 30 V outputs in combination, and the USB interface makes it easy to build

PC-bas

model include a GPIB interface in combination with the USB interface.

compact power supplies cover a wide range of applications without

These

covering a lot of bench space. Versions of these power supplies are available for

use at 100 VAC nominal line voltage which is common in Japan. These versions

are indicated by the "J" suffix.

This manual contains information about the following products:

r using a Keithley Instruments product. The Series 2200

an be enabled or disabled as your application requires. All outputs

ed systems without converters or special cables. The G vers ions of each

Model Description

2220-30-1 Programmable Dual Channel DC Power Supply

2220G-30-1 Programmable Dual Channel DC Power Supply with GPIB Interface

2220J-30-1 Programmable Dual Channel DC Power Supply for Japan

2220GJ-30-1 Programmable Dual Channel DC Power Supply with GPIB Interface for Japan

2230-30-1 Programmable

2230G-30-1 Programmable Triple Channel DC Power Supply with GPIB Interface

2230J-30-1 Triple Channel Programmable DC Power Supply for Japan

2230GJ-30-1 Programmable Triple Channel DC Power Supply with GPIB Interface for Japan

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference iii

Triple Channel DC Power Supply

Page 10

Preface

Extended Warranty

Contact Information

Additional years of warranty coverage are available on many products. These

valuable contracts protect you from unbudgeted service expenses and provide

additional years of protection at a fraction of the price of a repair. Extended

warranties are available on new and existing products. Contact your local Keithley

Instrument

s representative for details.

If you have

following sources:

1. Keithley

2. Keithley web forum (http://forum.keithley.com)

3. Call Keithley Instruments corporate headquarters (toll-free inside the U.S. and

Canada only) at 1-888-KEITHLEY (1-888-534-8453), or from outside the

U.S. at

Instruments website (http://www.keithley.com).

any questions after reviewing this information, please use the

Instruments website (http://www.keithley.com)

+1-440-248-0400. For worldwide contact numbers, visit the Keithley

iv Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 11

Specifications

This section contains specifications for the Series 2200 Multichannel

Programmable DC Power Supplies. All specifications are guaranteed unless noted

as "typical.

not guaranteed. Specifications that are marked with the

in Performance Verification.

Table 1: Series 2220 Dual Channel specifications

Parameter Description

Channel 1 and 2,

nominal

Constant voltage

operation, nominal

Voltage range

This is the range

over which the

output voltage is

adjustable

Remote sense

voltage range

Voltage resolution,

nominal

age setting

Volt

accuracy with

remote sense

Voltage setting

accuracy without

remote sense

Current limit,

nominal

Voltage

temperature

coefficient, typical

Constant current

operation, nominal

Current range

This is the range

over which the

output current is

adjustable

Channels 1 and 2 are symmetrical and isolated. They are primarily targeted at powering analog circuits

operating around ground.

The unit may be set to a constant voltage over a range of currents

0to30V

The total voltage from the – terminal to the + terminal may not exceed the rated full scale (FS) voltage + 0.2 V,

allowing a minimum of 0.1 V/line for remote sense.

The maximum voltage difference between a terminal and its associated sense line may not exceed 1 V.

The available overhead above full scale voltage to support remote sense is limited to 0.1 V/line. However,

this widens as the output voltage decreases to the ultimate limit of 1 V/line. Thus, the maximum difference

specification controls operation except for the 2 V of output below full scale output.

1mV

±(0.03% of settling + 10 mV) at 25 °C ±5 °C with remote sense.

±(0.05% of settling + 10 mV) at 25 °C ±5 °C without remote sense.

Defined by the c onstant current setting. The changeover is automatic.

±(0.03% + 10 m V) per °C outside the 25 °C ±5 °C standard range

The unit may be set to a constant current over a range of voltages.

0Ato1.5A

" Typical specifications are provided for your convenience but are

symbol are checked

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 1

Page 12

Specifications

Table1:Series2220DualChannelspecifications (cont.)

Parameter Description

Current resolution,

nominal

Current set

ting

accuracy

Voltage li

mit,

nominal

Current

temperature

nt, typical

coefficie

Meter, nominal Internal readback capability. Voltage and current can be measured internally.

Current readback

ion, nominal

resolut

Current

readback accuracy

Current readback

temperature

coefficient, typical

Voltage

readback accuracy

Voltage readback

resolution, nominal

Voltage readback

temperature

ficient, typical

coef

Line regulation

– voltage

Line regulation

rent

–cur

Load regulation

– voltage

Load regulation

rrent

–cu

Voltage ripple,

20 MHz bandwidth

Voltage ripple,

Hz bandwidth

7M

Current ripple,

20 MHz bandwidth

Common Mode

Current Noise

1mA

±(0.1% + 5 mA) at 25 °C ±5 °C

0to30V

±(0.1% + 5 mA) per °C outside the 25 °C ±5 °C standard range

1mA

of reading + 5 mA) at 25 °C ±5 °C

±(0.1%

±(0.1% + 5 mA) per °C outside of the 25 °C ±5 °C standard range

±(0.03% of reading + 10 mV) at 25 °C ±5 °C standard range

1mV

±(0.03% of reading + 10 mV) per °C outside the 25 °C ±5 °C standard range

ge over the full rated line voltage range: ±(0.01% + 3 mV)

Chan

Change over full rated line voltage range: ±(0.1% + 3 mA)

nge from 0 to 100% of full scale current: ±(0.01% + 3 mV)

Cha

Change from 10 to 90% of full scale voltage: ±(0.01% + 3 mA)

<3mV

<1.

<1mV

<5mA

<1.5μA

and 20 mV

RMS

5mV

and 12 mV

RMS

and 3 mV

RMS

RMS

, 700 Hz bandwidth.

RMS

p-p

p-p

,typical

p-p

2 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 13

Table 1: Series 2220 Dual Channel specifications (cont.)

Parameter Description

Voltage transient

response settling

time, load change,

typical

Voltage transient

response settling

time, setting

change, rising,

typical

Voltage transient

response settling

time, setting

change, falling,

typical

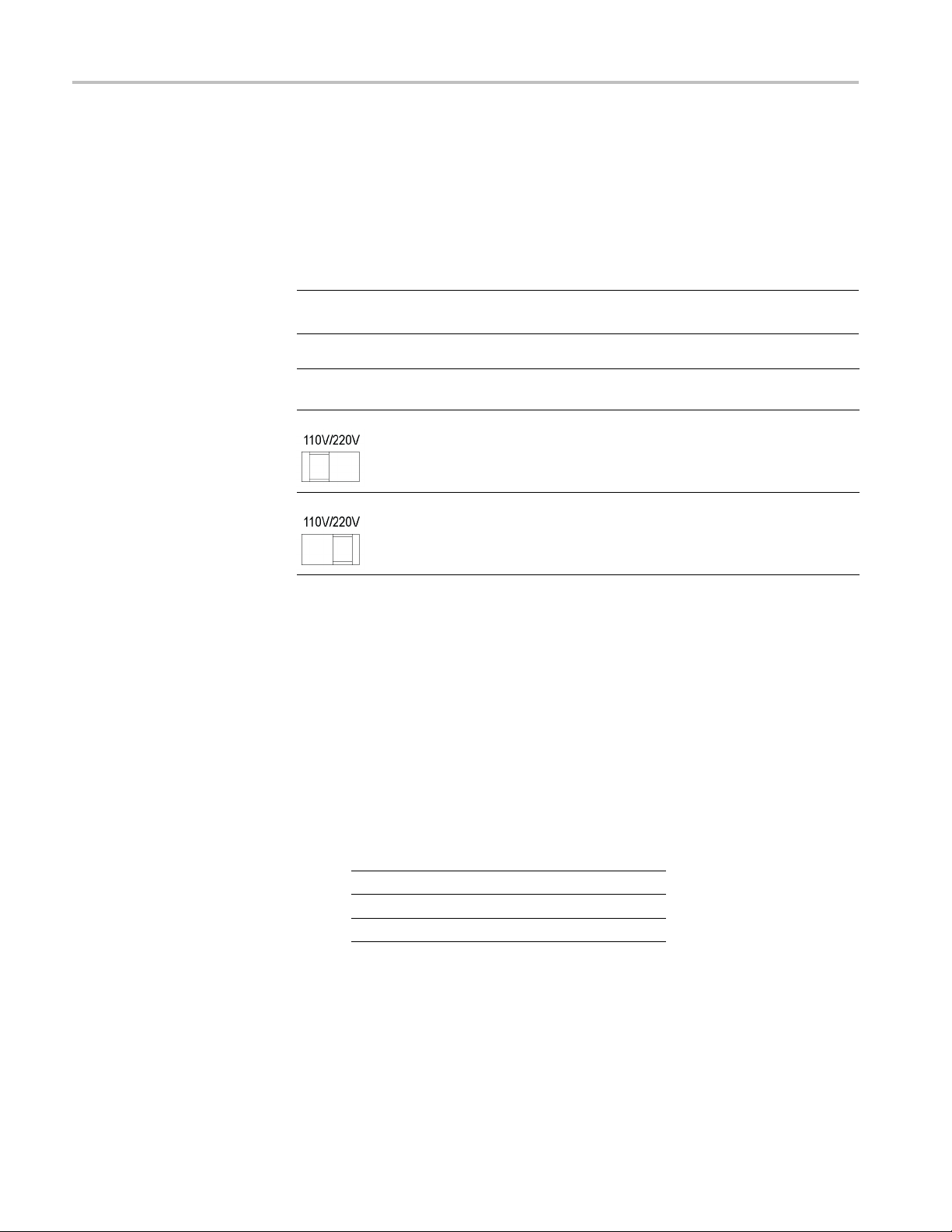

Unit SpecificMains

Requirements

<150 ms to within 75 mV following a change from 0.1 A to 1 A.

<150 ms from beginning of excursion to within 75 mV of terminal value following a change from 1 V to 11 V

intoa10Ω resistor.

<150 ms from beginning of excursion to within 75 mV of terminal value following a change from 11 V to

1Vintoa10Ω resistor.

2220-30-1 and 2220G-30–1

Line Selection

Switch

110V

220V

Voltage Frequency Fuse Rating Max VA +

110/115/120 50/60 Hz

220/230/240 50/60 Hz

Specifications

6.3A TH 250V 350

3.15A TH 250V 350

2220J-30-1 and 2220GJ-30–1

Voltage Frequency Fuse Rating Max VA +

50/60 Hz

50/60 Hz

6.3A TH 250V 350

3.15A TH 250V 350

Maximum Input VA,

typical

Line Selection

Switch

110V 100

220V 200

350 VA

Table2:Series2230TripleChannelspecifications for Channels 1 and 2

Parameter Description

Channel 1 and 2, nominal Channels 1 and 2 are symmetrical and isolated. They are primarily targeted at powering analog

circuits operating around ground.

Constant Voltage Operation,

nominal

Voltage Range

The unit may be set to be a constant voltage over a range of currents.

The output voltage may be adjusted from 0V to 30V.

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 3

Page 14

Specifications

Table2:Series2230TripleChannelspecifications for Channels 1 and 2 (cont.)

Parameter Description

Remote Sense Voltage Range The total voltage from - terminal to + terminal may not exceed the rated full scale voltage +0.2V,

allowing a minimum of 0.1V/line for remote sense.

The Maximum voltage difference between a terminal and its associated sense line m ay not

exceed 1V.

The available overhead above full scale voltage to support remote sense is limited to 0.1

V/line. However, this widens as the output voltage decreases to the ultimate l imit of 1 V/line.

Thus, the maximum difference specification controls operation except for the 2 V of output

below full scale output.

Voltage Resolution, nominal 1 mV

√ Voltage Setting Accuracy with

Remote Sense

√ VoltageSetting Accuracy without

Remote Sense

Current Limit, nominal Defined by Constant Current setting. Changeover is automatic.

Voltage Temperature Coefficient,

typical

Constant Current Operation,

nominal

Current Range The output voltage may be adjusted from 0 A to 1.5 A.

Current Resolution, nominal

√ Current Setting Accuracy

Voltage Limit, nominal 0 to 30 V.

Current Temperature Coefficient,

typical

Meter, nominal Internal readback capability. Voltage and current are measured internally.

Current Readback Resolution,

nominal

urrent Readback Accuracy

C

Current Readback Temperature

Coefficient, typical

Voltage Readback Accuracy

Voltage Readback Resolution,

nominal

Voltage Readback Temperature

Coefficient, typical

Line regulation – Voltage

Line regulation – Current

Load regulation – Voltage

+/-(0.03% of setting + 10 mV) at 25 °C ±5 °C with Remote Sense

+/-(0.05% of setting + 10 mV) at 25 °C ±5 °C without Remote Sense

+/-(0.03% of setting + 10 mV) per °C outside of the 25 °C ±5 °C standard range

The unit may be set to be a constant current over a range of voltages.

1mA

+/-(0.1% + 5 mA) at 25 °C ±5 °C.

+/-(0.1% + 5 mA) per °C outside of the 25 °C ±5 °C standard range

1mA

±(0.01% of reading + 5 mA) at 25 °C ±5 °C

±(0.01% + 5 mA) per °C outside the 25 °C ±5 °C standard range

±(0.03% of reading + 1 0 mV) at 25 °C ±5 °C

1mV

±(0.03% of reading + 10 mV) per °C outside the 25 °C ±5 °C standard range

Change over the full rated line voltage range: ±(0.01% + 3 mV)

Change over full rated line voltage range: ±(0.1% + 3 mA)

Change from 0 to 100% of full scale. Voltage: ±(0.01% + 3 mV)

4 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 15

Table 2: Series 2 230 Triple Channel specifications for Channels 1 and 2 (cont.)

Specifications

Load regulat

ion – Current

Change from 10 to 90% of full scale. Current: ±(0.01% + 3 mA)

While not readily testable, similar performance is expected over the 0% to 100% of full scale

range of the product.

Voltage Ripple, 20 MHz

bandwidth

h

<3mV

<1.5mV

Voltage Ripple, 7 MHz bandwidth < 1 mV

Current Ripple, 20 MHz

<5mA

and 20 mV

RMS

RMS

and3mV

RMS

RMS

and 12 mV

p-p

p-p

p-p

,typical

bandwidth

Common Mode Current Noise

Voltage Transient Response

<1.5μA

<150 ms to within 75 mV following a change from 0.1 A to 1 A.

. 700 Hz bandwidth.

RMS

Settling Time, Load Change,

typical

Voltage Transient Response

Settling Time, Setting Change,

<150 ms from beginning of excursion to within 75 mV of terminal value following a change

from1Vto11Vintoa10Ω resistor.

Rising, typical

Voltage Transient Response

Settling time, Setting Change,

<150 ms from beginning of excursion to within 75 mV of terminal value following a change

from11Vto1Vintoa10Ω resistor.

Falling, typical

Table 3: Series 2230 Triple Channel specifications for Channel 3

Parameter Description

Channel 3, nominal

Constant Voltage Operation,

nal

nomi

Voltage Range

ote Sense Voltage Range

Rem

ltage Resolution, nominal

Vo

Voltage Setting Accuracy with

√

Remote Sense

√ VoltageSetting Accuracy without

Remote Sense

Current Limit, nominal Defined by Constant Current setting. Chageover is automatic.

Voltage Temperature Coefficient,

typical

A third channel is provided. It is primarily targeted at logic power.

The unit may be set to be a constant voltage over a range of currents.

utput voltage may be adjusted from 0 V to 6 V.

The o

total voltage from - terminal to + terminal may not exceed the rated full scale voltage +0.2V,

The

allowing a minimum of 0.1V/line for remote sense.

The maximum voltage difference between a terminal and its associated sense line may not

eed 1V.

exc

The available overhead above full scale voltage to support remote sense is limited to 0.1

V/line. However, this widens as the output voltage decreases to the ultimate limit of 1 V/line.

us, the maximum difference specification controls operations except for the 2 V of output

Th

below full scale output.

V

1m

/-(0.03% of setting + 10 mV) at 25 °C ±5 °C with Remote Sense

+

+/-(0.05% of setting + 10 mV) at 25 °C ±5 °C without Remote Sense

+/-(0.03% of setting + 10 mV) per °C outside of the 25 °C ± 5 °C standard range

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 5

Page 16

Specifications

Table 3: Series 2230 Triple Channel specifications for Channel 3 (cont.)

Constant Current Operation,

The unit may be set to be a constant current over a range of voltages.

nominal

Current Range The output voltage m ay be adjusted from 0 A to 5 A.

Current Resolution, nominal

√ Current Setting Accuracy

1mA

+/-(0.1% + 5 mA) at 25 °C ±5 °C.

Voltage Limit, nominal 0 to 6 V.

Current Temperature Coefficient,

+/-(0.1% + 5 mA) per °C outside of the 25 °C ±5 °C standard range

typical

Meter, nominal Internal readback capability. Voltage and current can be measured internally. DVM connections

exist to allow measuring external voltages.

Current Readback Resolution,

1mA

nominal

Current Readback Accuracy

Current Readback Temperature

cient, typical

Coeffi

Voltage Readback Accuracy

Voltage Readback Resolution,

±(0.1% of reading + 5 mA) at 25 °C ±5 °C

±(0.1% +5mA) per °C outside of the 25 °C ± 5 °C standard range

3% of reading + 1 0 mV) at 25 °C ±5 °C

±(0.0

0.1 mV

nominal

Voltage Readback Temperature

±(0.03% of reading + 10 mV) per °C outside of the 25 °C ±5 °C standard range

Coefficient, typical

Line Regulation – Voltage

Line Regulation – Current

Load Regulation – Voltage

Load Regulation – Current

ge Ripple, 20 MHz

Volta

Bandwidthh

Voltage Ripple, 7 MHz

Change over the full rated line voltage range: ±(0.01% + 3 mV)

Change over full rated line voltage range: ±(0.1% + 3 mA)

Change from 0 to 100% of full scale. Voltage: ±(0.01% + 3 mV)

Change from 10 to 90% of full scale. C urrent: ±(0.01% + 3 mA)

<3mV

<1.5mV

<1mV

and 20 mV

RMS

RMS

and3mV

RMS

and 12 mV

p-p

.

p-p

p-p

,typical

bandwidth

nt Ripple, 20 MHz

Curre

Less than 6 mA

RMS

Bandwidth

μA

Common Mode Current Noise

age Transient Response

Volt

<1.5

<150 ms to within 75 mV following a change from 0.1 A to 1 A.

. 700 Hz bandwidth.

RMS

Settling Time, Load Change,

typical

Voltage Transient Response

Settling Time, Setting Change,

ing, typical

Ris

Voltage Transient Response

ttling Time, Setting Change,

Se

Falling, typical

<150 ms from beginning of excursion to within 75 mV of terminal value following a change

m0.4Vto4Vintoa4Ω resistor.

fro

50 ms from beginning of excursion to within 75 mV of terminal value following a change

<1

from0.4Vto4Vintoa4Ω resistor.

The specification does not include Command Decode Time.

6 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 17

Specifications

Table 4: Combin

Characteristic Description

Combined Channel

Characteristics, nominal

Series Combinations, nominal Deliver up to 60 V when CH1 and CH2 are wired in series. Voltage Readback is the combined

Available Series Configurations,

nominal

Series Co

Accuracy, typical

Series Combination Current

Accuracy, typical

Paralle

Available Parallel Configurations,

nominal

Parallel Combination Voltage

Accur

Para

Accuracy, typical

mbination Voltage

l Combination, nominal

acy (typical)

llel Combination Current

ed channel characteristics

The unit can be configured to provide functionality on Channel 1 and Channel 2 together.

voltage. Se

only. If the currents in the two channels are significantly different there is no indication of

CC/CV status for Channel 2.

Channels 1 and 2 are connected in series. Either channel 1 or channel 2 m ay be the most

positive s

±(0.10% o

±(0.1% + 5 mA) at 25 °C ±5 °C for Channel 1's current.

The current is only measured for Channel 1. The error is the same as for the Current

Measure

Deliver

combined current.

CH1 and CH2 are connected in parallel (+ to + and – to –)

±(0.05% of setting + 10 mV) at 25 °C ±5 °C

±(0.

ment Accuracy.

s up to 3 A when CH1 and CH2 are wired in parallel. The meter reads back the

2% +10 mA) at 25 °C ±5 °C

ttings changes are to the combined voltage. Current Readback is for Channel 1

ource.

f the setting + 50 mV) at 25 °C ±5 °C

Table 5: Series 2230 Triple Channel unit characteristics

Characteristic Description

Unit Characteristics, nominal Characteristics and specifications of features unique to this product, but unrelated to a

particular channel.

Unit SpecificMains

Requirements

Maximum Input VA, typical 450 VA

2230-30-1 and 2230G-30–1

Line Selection

Switch

110V

220V

2230J-30-1 and 2230GJ-30–1

Line Selection

Switch

110V 100

220V 200

Voltage Frequency Fuse Rating Max VA

110/115/120 50/60 Hz

220/230/240 50/60 Hz

Voltage Frequency Fuse Rating Max VA

50/60 Hz

50/60 Hz

6.3A TH 250V 450

3.15A TH 250V 450

6.3A TH 250V 450

3.15A TH 250V 450

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 7

Page 18

Specifications

Table 6: Mains p

ower characteristics

Characteristic Description

Source Voltage

The 2220-30-1, 2220G-30-1, 2230-30-1, and 2230G-30-1 each have two ranges, selectable

with a bottom panel switch. Each range is capable of ±10% excursions.

Marked Allowed nominal voltages

110

220

The 2220J-30-1, 2220G J-30-1, 2230J-30-1, and 2230GJ-30-1 each have two ranges,

selectable with a bottom panel switch. Each range is capable of ±10% excursions.

Marked Allowed nominal voltage

110

220

Source Frequency 50/60 Hz

Fuse Ra

ting, nominal

Model

2230, 2230G and 2220,

2220G

Table 7: Common characteristics

110/115/120 VAC

220/230/240 VAC

100 VAC

200 VAC

RMS

RMS

110 VAC setting 220 VAC setting

250V

6.3A T

159-0399-00

T 250V

3.15A

159-0493-00

RMS

RMS

Item Description

Setup Memory, nominal

30 setup memory locations

Output Timer, nominal The product includes a timer that can be used to disable the output after a predetermined

period of time.

Timer Set Time, nominal

The Timer may be set to any value between 1 and 999,999 seconds.

Timer Accuracy ±100 ppm

Software Voltage Limit, nominal The product offers the opportunity to change the maximum settable voltage on a temporary

basis. The MAX VOLT menu entry, when set below hardware maximum limit, disallows

adjusting the product to voltages in excess of the MAX VOLT limit.

Cleaning Requirements, nominal Inspect the power supply as often as operating conditions require. To clear the exterior

surface, perform the following steps:

1. Remove loose dust on the outside of the power supply with a lint free cloth. Use care to

avoid scratching the display.

2. Use a soft cloth dampened with water to clear the power supply. Use an aqueous solution of

75% isopropyl alcohol for more efficient cleaning.

Caution: To avoid damage to the surface of the power supply, do not use any abrasive or

chemical cleaning agents.

Caution: Avoid getting moisture inside the unit during external cleaning. Use only enough

cleaning solution to dampen the cloth or swab.

8 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 19

Specifications

Table 7: Common characteristics (cont.)

Item Description

Isolation Voltage, Output to

Chassis

Any output can be floated up to 240 V (DC + peak AC with AC limited to a maximum 3 V

maximum of 60 Hz) relative to the Earth Ground terminal. Note that remote sense terminals

should remain within 1 V of their respective outputs to avoid possible damage.

Isolation Voltage, Output to Output Any output can be floated up to 240 V (DC + pk AC with AC limited to a maximum of 3 V

and a maximum of 60 Hz) relative to any other output terminal. Remote sense terminals should

remain within 1 V of their respective outputs to avoid possible damage.

Table 8: Terminal strip

Item Description

The rear panel has a customer accessible terminal strip. This strip is comprised of a board-mounted section and a

technician-removeable section. The technician-removeable section offers the customer a safe set of screw terminals to connect

us instrument functions detailed below.

to vario

pk-pk

and

pk-pk

Table 9: Interfaces and output ports

Parameter

(instrument

model) Description

USB device,

nominal

(All models)

GPIB interface

(G models only)

Command

processing time,

typical

(All models)

USB 2.0 Full Speed device. 12 Mb/sec maximum.

IEEE-488.2 compliant

About 400 ms per command.

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 9

Page 20

Specifications

Table 10: Mecha

Parameter

Weight,

instrument,

nominal

Dimensions,

nominal

Cooling method,

nominal

Required cooling

clearance

Construction

materials, nominal

nical characteristics

9kg

(19.8 lbs)

Model

2230

Fan

Rear of instrument must be separated by at least 5 cm (2 in) from any airflow restrictions to assure adequate

cooling.

Bottom of instrument must have 1 cm (0.4 in) from any airflow restrictions. The protective boot maintains

the proper bottom clearance.

For rackm

instructions.

Chassis – Aluminum

Front Panel Plastics – PC/ABS blend

ount configuration, follow the clearance requirements provided with the rackmount installation

Table 11: Environment performance

Parameter All models

Temperature

Humidity

Altitude

Operating: +0 °C to +40 °C

Nonoperating: -20 °C to 70 °C

Operating:

5% to 95% relative humidity (% RH) at up to 40 °C, noncondensing

Nonoperating:

5% to 95% RH (relative humidity) at up to +40 °C,

5% to 60% RH above +40 °C up to +70 C, noncondensing

Operating: 100% capability up to 2,000 meters.

Nonoperating: Up to 4,000 meters

Dimensions (Width * Height * Depth

214 mm * 88 mm * 355 mm (8.45” * 3.47” * 13.9”)

Table 12: Keypad special operations

aracteristic

Ch

Display the heat sink temperature Enter + Esc + 1

Reset the unit to the factory default

ettings

s

scription

De

Enter+Esc+2

10 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 21

Specifications

Tabl e 13: Safet

y characteristics

Item Description

Safety Certifi

cations

U.S. National

UL61010-1–2004 Safety Requirements for Electrical Equipment for Measurement, Control,

and Laboratory Use

Canadian Certification

CAN/CSA C22

Measurement, Control, and Laboratory Use

European Union Compliance

Low Voltage Directive 2006/95/EC

EN61010-1

and Laboratory Use

Additional Compliance

IEC61010-1 2001 Safety Requirements for Electrical Equipment for Measurement, Control,

atory U se

ut can be floated up to 240 V (DC + peak AC with AC limited to a maximum 3V

Channel

Voltage

to Channel Isolation

and Labor

Any outp

maximum of 60 Hz) relative to any other channel terminal. Remote sense terminals should

remain within 1 V of their respective outputs to avoid possible damage.

Channel to Ground Isolation

e

Voltag

Any output can be floated up to 240 V (DC + peak AC with AC limited to a maximum 3V

m of 60 H z) relative to the Earth Ground terminal. Remote sense terminals should

maximu

remain within 1 V of their respective outputs to avoid possible damage.

ly Recognized Testing Laboratory (NRTL) Listing

.2 No. 61010-1-2004 Safety Requirements for E lectrical Equipment for

2001 Safety Requirements for Electrical Equipment for Measurement, Control,

pk-pk

pk-pk

and

and

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 11

Page 22

Specifications

Table 14: Elect

romagnetic Compatibility (EMC) — Measurement, laboratory, and control product family

Item Description

Regional Cert

ifications,

Classifications, and Standards List

European Uni

on

EC Council EMC Directive 2004/108/EC

Demonstrated using:

EN 61326-1:

Emissions

CISPR 11, Class A

Immunity

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-

IEC 61000-4-5

IEC 61000-4-6

IEC 61000

IEC 61000-4-11

EN 61000-3-2

EN 61000

1

Emissions that exceed the levels by this standard may occur when this equipment is

-3–3

connected to a test object.

Australia

2

EMC Fra

igh quality shielded cables to maintain compliance

.Useh

mework, demonstrated per Emission Standard CISPR11 in accordance w ith EN

61326-1

2006 Electrical Equipment for Measurement, Control, and Laboratory

4-4

-4-8

1

1,2

ity

Immun

Immunity, Electrostatic Discharge

, Enclosure Port

(ESD)

Immunity, Conducted Radio

Frequency

000-4-2

IEC 61

EN 61326-1, Performance Criterion “B”

IEC 61000-4-6

EN 61326-1, Performance Criterion “A”

12 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 23

Performance Verification

This section contains performance verification procedures for the specifications

marked with the

verification

These procedures cover all models of theSeries2200ProgrammableDCPower

Supplies. I

Print the test record on the following pages, and use it to record the performance

test resul

NOTE. Each individual performance test must be done for each channel. This

means two times for the 2220-30-1, 2220G-30-1, 2220J-30-1, and 2220GJ-30-1. It

means three times for the 2230-30-1, 2230G-30-1, 2230J-30-1, and 2230GJ-30-1.

NOTE. Completion of the performance verification procedure does not update the

stored time and date of the latest successful adjustment. The date and time are

updated only when the factory adjustment procedures are successfully completed.

procedures. (See Table 27 on page 24.)

gnore checks that do not apply to the specific model you are testing.

ts for your power supply.

symbol. Additional test equipment is required to complete the

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 13

Page 24

Performance Verification

The performanc

instrument. They do not adjust your instrument. If your instrument fails any of

the performance verification tests, you should contact Keithley service.

WARNING. Observe all safety precautions listed in this manual before using

this product and any associated instrumentation. Although some instruments

and accessories are used with nonhazardous voltages, there are situations

where hazar

qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Before using the product, carefully

read and follow all installation, operation, and maintenance information. Refer

to this manual for complete product specifications. Before performing any

maintenance, disconnect the line cord and all test cables. Operators of this

instrum

body must make sure that operators are prevented access and/or insulated from

every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit can operate at or

above 1000 volts, no conductive part of the circuit may be exposed.

WARNING. Do not loosen any screw on this product. There are no user

serviceable components inside.

ent must be protected from electric shock at all times. The responsible

everification procedures verify the performance of your

dous conditions may be present. This product is intended for use by

CAUTION. Use properly rated load wires. All load wires must be heavy enough not

to overheat when carrying the maximum short-circuit output current of the power

supply. If there is more than one load, then any pair of load wires must be capable

safely carrying the full-rated short-circuit output current of the power supply.

of

14 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 25

Performance Verification

Test Record

Model Serial Procedure performed by Date

Test Passed Failed

Self test

DC voltage accuracy with remote sense

DC voltage accuracy without remote sense

DC voltage readback accuracy

DC voltage line regulation

DC voltage load regulation

DC c urrent accuracy

DC current readback accuracy

DC current line regulation

DC current load regulation

Voltage noise at 7 MHz

Voltage noise at 20 MHz

Current noise at 20 MHz

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 15

Page 26

Performance Verification

Table 15: DC vol

Instrument te

voltage DUT voltage Test current Min Measured Max

Channel 1

0%

25%

50%

75%

100%

Channel 2

0%

25%

50%

75%

100%

Channel 3

0%

25%

50%

75%

100%

tage accuracy with remote sense

st

0.00000 V 0.5 A -0.01000 V

7.5000 V 0.5 A 7.48775 V

15.00000 V 0.5 A 14.98550 V

0.00000 V 2.5 A -0.01000 V

30.0000 V 0.5 A 29.98100 V

00 V

00 V

000 V

000 V

000 V

0000 V

50000 V

00000 V

V

0.5 A -0.0100

0.5 A 14.985

0.5 A 22.483

0.5 A 29.98

2.5 A -0.0

0.5

2.5

2.

2.

0.00000

7.5000 V 0.5 A 7.48775

15.000

22.500

30.00

0.00

1.5

3.0

4.

6.

A

A

5A

5A

1000 V

98550 V

14.

8910 V

2.9

48865 V

4.

98820 V

5.

0V

V

50 V

25 V

100 V

__________

__________

__________

_________

_________

_______

_______

______

_____

_____

____

___

___

__

_

___

___

____

_____

_____

______

_______

_______

________

_________

0.01000 V

7.51225 V

15.01450 V

_

_

0.01000 V

30.01900 V

0.01000

7.51225

15.014

22.516

30.01

0.01

15.

3.0

51135 V

4.

01180 V

6.

V

V

50 V

75 V

900 V

000 V

01450 V

1090 V

16 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 27

Performance Verification

Tabl e 16: DC vol

Instrument te

voltage DUT voltage Test current Min Measured Max

Channel 1

0%

25%

50%

75%

100%

Channel 2

0%

25%

50%

75%

100%

Channel 3

0%

25%

50%

75%

100%

tage accuracy without remote sense

st

0.00000 V 0.5 A -0.01000 V

7.50000 V 0.5 A 7.48625 V

15.00000 V 0.5 A 14.98250 V

22.50000 V 0.5 A 22.47875 V

30.00000 V 0.5 A 29.975000

00 V

00 V

000 V

000 V

0000 V

0000 V

50000 V

00000 V

V

0V

0.5 A -0.0100

0.5 A 7.48625

0.5 A 14.982

0.5 A 22.478

0.5 A 29.97

2.5 A -0.0

A

2.5

A

2.5

5A

2.

5A

2.

0.00000

7.50000

15.000

22.500

30.00

0.00

1.5

3.0

4.

6.

1000 V

8925 V

1.4

8850 V

2.9

48775 V

4.

98700 V

5.

0V

V

50 V

75 V

500 V

__________

__________

__________

_________

V

_________

_______

_______

______

_____

_____

____

___

___

________

__

_________

_

_

_

___

___

____

_____

_____

______

_______

_______

0.01000 V

7.51375 V

15.01750 V

22.52125 V

30.02500 V

0.01000

7.51375

15.017

22.521

30.02

0.01

1.5

3.0

51225 V

4.

01300 V

6.

V

V

50 V

25 V

500 V

000 V

1075 V

1150 V

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 17

Page 28

Performance Verification

Table 17: DC vol

Instrument

test voltage DUT voltage Test current

Channel 1

0%

25%

50%

75%

100%

Channel 2

0%

25%

50%

75%

100%

Channel 3

0%

25%

50%

75%

100%

tage readback accuracy

0.00000 V 0.5 A

7.50000 V 0.5 A

15.00000 V 0.5 A

22.50000 V 0.5 A

30.00000 V 0.5 A

00 V

00 V

000 V

000 V

0000 V

0000 V

50000 V

00000 V

V

V

0.5 A

0.5 A

0.5 A

0.5 A

0.5 A

2.5 A

2.5

2.5

5A

2.

5A

2.

A

A

0.00000

7.50000

15.000

22.500

30.00

0.00

1.5

3.0

4.

6.

Measured

voltage

________ ________ ________

________ ________ ________

________ ________ ________

________ ________ ________

________ ________ ________

_______

_______

______

_____

_____

____

___

___

__

_

_

_

__

___

___

____

_____

_____

______

_______

Vol tage

readout

_______

_______

______

___

_____

___

_____

____

____

_____

___

_____

___

______

__

_______

_

__

Absolute

difference

_

_

_______

_______

______

___

_____

___

_____

____

____

_____

___

_____

___

______

__

_______

_

__

Maximum

difference

0.01000 V

0.01225 V

0.01450 V

0.01675 V

0.01900 V

_

_

0.01000

0.01225

0.0145

0.0167

0.019

0.01

0.0

0.0

0.

0.

V

V

0V

5V

00 V

000 V

10375 V

10750 V

011125 V

01150 V

18 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 29

Performance Verification

Table 18: DC vol

Instrument Min line Max line Nom line Nom – Min Max – Nom Largest Max value

Channel 1

Channel 2

Channel 3

tage line regulation

_________ _________ _________ _________ _________ _________

_________ _________ _________ _________ _________ _________

_________ _________ _________ _________ _________ _________

0.0120000 V

0.0120000 V

0.0072000 V

Table 19: DC voltage load regulation

Instrument Min load Ref load Max load Ref – Min

Channel 1

Channel 2

Channel 3

_______ _______ _______ ________ ________ ________ _______

_______ _______ _______ ________ ________ ________ _______

_______ _______ _______ ________ ________ ________ _______

Max –

Ref

(Max–Ref)

/ 0.98 Largest

Max

value

0.0120000 V

0.0120000 V

0.0072000 V

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 19

Page 30

Performance Verification

Table 20: DC cur

Instrument test

current Test voltage DUT current Min Measured current Max

Channel 1

0%

25%

50%

75%

100%

Channel 2

0%

25%

50%

75%

100%

Channel 3

0%

25%

50%

5%

7

100%

rent accuracy

15 V 0.00000000 A -0.00500000 A

15 V 0.3750 A 0.36963 A

15 V 0.75000 A 0.74425 A

15 V 1.1250 A 1.11888 A

15 V 1.5000 A 1.49350 A

15 V 0.00000000 A -0.00500000 A

15 V 0.3750 A 0.36963 A

15 V 0.7500

15 V 1.1250 A 1.11888 A

15 V 1.5000 A 1.49350 A

3 V 0.00000000 A -0.00500000 A

3 V 1.25000000 A 1.24375000 A

3V 2.

3 V 3.75000000 A 3.74125000 A

3 V 5.00000 A 4.99000 A

0A

50000000 A

0.7442

49250000 A

2.

5A

__________

__________

__________

__________

__________

__________

__________

____

______

__________

__________

__________

__________

________

__

__________

__________

0.00500000 A

0.38037 A

0.75575 A

1.13113 A

1.50650 A

0.00500000 A

0.38037 A

5A

0.7557

1.13113 A

1.50650 A

0.00500000 A

1.25625000 A

50750000 A

2.

3.75875000 A

5.01000 A

20 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 31

Performance Verification

Tabl e 21: D C cur

Instrument te

current Test current

Channel 1

0%

25%

50%

75%

100%

Channel 2

0%

25%

50%

75%

100%

Channel 3

0%

25%

50%

75%

100%

rent readback accuracy

st

0A

0.375 A

0.75 A

1.125 A

1.5 A

0A

0.375 A

0.75 A

1.125 A

1.5 A

0A

5A

1.2

A

2.5

75 A

3.

5A

Measured

current Current readout

________ ________ ________

________ ________ ________

________ ________ ________

________ ________ ________

________ ________ ________

_______

_______

______

___

_____

___

_____

____

____

_____

___

_____

___

______

__

_______

_

__

_

_

_______

_______

______

_____

_____

____

___

___

__

_

_

_

__

___

___

____

_____

_____

______

_______

Absolute

difference

_______

_______

__

______

___

_____

___

_____

____

____

_____

___

_____

___

______

__

_______

_

Maximum

difference

0.00500000 A

0.0053750 A

0.00575000

0.0061250

0.0065000

_

_

0.00500

0.00537

0.0057

0.0061

0.006

0.00

0625000 A

0.0

0550000 A

0.0

00875000 A

0.

01000000 A

0.

A

0A

0A

000 A

50 A

5000 A

2500 A

50000 A

500000 A

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 21

Page 32

Performance Verification

Table 22: DC cur

rent line regulation

Test

Instrument

Channel 1

Channel 2

Channel 3

voltage Min line Max line Nom line

15 V

15 V

3V

______ ______ ______ ______ ______ ______

______ ______ ______ ______ ______ ______

______ ______ ______ ______ ______ ______

Table 23: DC current load regulation

Instrument

Channel 1

Channel 2

Channel 3

Meas @

min volts

_________ _________ _________ _________ _________ _________

_________ _________ _________ _________ _________ _________

_________ _________ _________ _________ _________ _________

Meas @

ref volts

Table 24: Voltage noise at 7 MHz

Voltage test

ment

Instru

el 1

Chann

el 2

Chann

nel 3

Chan

1

Load R must be rated at 100 W minimum.

load R

40 Ω

40 Ω

2.5 Ω

Nom –

Min

Max –

Nom Largest Max value

0.004500A

0.004500A

A

Meas @

maxvolts Ref-Min Max-Ref Largest

Maximum

difference

0.003120 A

0.003120 A

0.003400 A

1

rms

________

________

________

Measured

Maximum

rms

1mV

1mV

1mV

Measured

pk - pk

________

________

________

Maximum

pk - pk

3mV

3mV

3mV

Table 25: Voltage noise at 20 MHz

Voltage test

1

trument

Ins

nnel 1

Cha

annel 2

Ch

annel 3

Ch

1

Load R must be rated at 100 W minimum.

loa

40 Ω

40

5 Ω

2.

dR

Ω

Table 26: Current noise at 20 MHz

urrent test

C

Instrument

Channel 1 1 Ω

Channel 2 1 Ω

Channel 3 1 Ω

1

Load R must be rated at 100 W minimum.

load R

Measured

rms

________

________

________

1

Maximum

rms

3mV

3mV

3mV

easured

M

rms

________

________

________

Measured

pk

pk -

________

________

________

aximum

M

rms

3mVA

3mA

3mA

Maximum

pk

pk -

20 mV

20 mV

20 mV

22 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 33

Performance Verification

Performance V

erification Procedures

Performance Verification

Conditions

The following conditions must be met before performing these procedures:

1. The Device Under Test (DUT) and all test equipment must have been

operating continuously for 20 minutes in an environment that meets the

operating range specifications for temperature and humidity.

Test setup changes affecting the remote sense require an additional 20 minute

warm-up period.

2. The procedures are intended to be used in sequence. If it is necessary to

partially test the DUT using an individual test, a 20 minute warm-up period is

required

3. You must connect the DUT and the test equipment to the same AC power

circuit

you are unsure of the AC power circuit distribution. Connecting the DUT and

test instruments into separate AC power circuits can result in offset voltages

between the equipment, which can invalidate this performance verification

procedure.

4. The AC Power Source for the DUT must match the Voltage Selector switch

setting located on the bottom of the DUT.

for the individual test.

. Connect the DUT and test instruments into a common power strip if

Equipment Required

DUT voltage selector

switch AC source voltage

110 115 V 100 V

220 230

ese procedures use external equipment to directly check warranted

Th

characteristics. The following table lists the required equipment.

V

AC source voltage for

Japan products

V

200

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 23

Page 34

Performance Verification

Table 27: Test e

Item Minimum requi

1. Connectors Connectors fo

2. AC power source Variable AC output from 90 to 265 VA C with at least

3. Electronic load

4. DC voltmeter

5. High current hook up wire

urrent connections are

(High c

indicated with bold lines in the

setup illustrations)

quipment

rements

r hook up wire assemblies and test

resistors, item numbers 5, 6, 9, 10, and 11.

(Qty. 6) #10 fork lugs similar to Tyco part number

52951

(Qty, 14) Stackable, gold plated, banana plugs/jacks

similar to P

current connections, and connection to the load

resistors (items 10 and 11) used for noise testing.

(Qty. 4) Sheathed Banana Jacks similar to Pomona

model 4834

(item 9).

750 VA capacity

Variable DC Load capable of 6 ADC and 40 VDC B&K Precision 8510

Voltage measurement at 12 mV through 40 V to better

than 100 ppm accuracy with the ability to multiply the

result b

18 AWG (

To perform all tests, the following wire assemblies need

to be created:

#10 fork lug to #10 fork lug, Qty 2, (included in

Guild

omona model 4897-0. Used for lower

to put connectors on the Resistors

y a scalar.

minimum) hookup wire assemblies.

line 92301 if used)

Example

Kikusui PCR2000M

Keithley 2000 DMM

able Banana to #10 fork lug, Qty 2

Stack

able Banana to Bare Wire Qty 2.

Stack

Wire lengths are not critical.

6. Low c

(Low current connections are

indicated with light lines in the

setu

7. 50 mΩ precisionshunt resistor 0.050 Ω ±100 ppm at 25 W ±4 ppm/°C temperature

8. Current sense resistor cabling Kelvin 4 terminal measuring cables for shunt resistor to

urrent hook u p wire

p illustrations)

22 AWG (minimum) hookup wires

To perform all tests, the following wire assemblies need

created:

to be

ana plug to Banana plug, Qty 2

Ban

e Wire to stackable Banana, Qty 2

Bar

e Wire to Banana, Qty 2

Bar

Wire lengths are not critical.

coefficient

oltmeter

v

Guildline 9230A-50

Guildline 92301 cable set

24 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 35

Performance Verification

Table 27: Test equipment (cont.)

Item Minimum requirements Example

9. 50 mΩ resistor for Remote

Sense testing

(2 required)

Oneofthese50mΩ resistors

may be substituted with

item 7.

10. Load resistor for Voltage

Noise testing

Channel 1 12 Ω Vishay/Dale RH05012R00FE02

Channel 2 12 Ω Vishay/Dale RH05012R00FE02

Channel 3 ( 2230-30-1 and

2230J-30-1 only)

11. Load Resistor for Current

Noise testing

12. Oscilloscope 20 MHz bandwidth limited oscilloscope at 1 mV/division Tektronix DPO3012

13. Oscilloscope probe Low capacitance 1 MΩ/10 MΩ 1X/10X 6 MHz/200 MHz

14. Oscilloscope probe Low capacitance 10 MΩ 500 MHz probe

15. Coaxial cable 50 Ω BNC, male-to-male

16. BNC adapter BNC female to banana breakout

0.050 Ω,5W.

To perform the tests as illustrated, both leads of each

resistor require a Banana Jack connector (e.g. Pomona

model 4834).

Loading resistors for high current in voltage mode, and

high voltage in current mode

All resistors should be rated for at least 50 W. Ohms

tolerance within 5% . Resistor composition is not critical.

To perform the tests as illustrated, both leads of the load

resistor require a Banana plug/jack (or equivalent) to

connect to the power supply.

2.5 Ω Vishay/Dale RH0502R500FE02

1 Ω, 100 W, 5%

To perform the tests as illustrated, both leads of the load

resistor require a Banana plug/jack (or equivalent) to

connect to the power supply.

probe

OHMITE 15FR050E

Vishay/Dale HL10006Z1R000JJ

Tektronix P2220, 1X probe

Tektronix P6139A, 10X probe

Tektronix part number:

012-0482-00

Pomona Electronics 3073

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 25

Page 36

Performance Verification

Self Test

This procedure

its internal self tests. No test equipment or hookups are required.

1. Disconnect al

2. Power on the DUT. The front-panel display will light up briefly while the

DUT perform

up at once.

3. Review the d

strokes lost on any annunciator.

4. If the EEPROM is damaged or the latest operation data in the EEPROM is

missing, the display appears as follows:

uses internal routines to verify that the DUT functions and passes

l cables from the DUT outputs.

s its power-on self test. All the display annunciators will light

isplay with all the annunciators. Visually check if there are any

5. If the calibration data in the EEPROM is missing, the display appears as

follows:

6. If the latest operating state of the power supply in the EEPROM is missing,

the display appears as follows:

7. If there is no response when you power on the DUT, verify that there is AC

power to the power supply, verify the power-line voltage settings, and verify

hat the correct power-line fuse is installed. If you need more help, contact

t

Keithley.

8. Power off the DUT.

26 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 37

Performance Verification

Check DC Volta

ge

Accuracy with Remote

Sense

Equipment required

(Item 2) AC Power Source (Item 5) High current hook up wire (bold line

connections)

(Item 3) Electronic Load (Item 6) Low current hook up wire (fine line

)

50 Ω,5WResistor(Qty2)

(Item 4) DC V

oltmeter

connections

(Item 9) 0.0

For each of the channels sequentially.

1. Power off the DUT.

2. Remove the shorting clip from the Remote Sense connector on the rear panel

for the channel being tested. Be sure to retain the clip or clips for the channels

not bein

gtested.

Figure 1: Configuring the shorting clips on a Remote Sense connector to test

channel 1 on a 2230-30-1

Figure 2: Configuring the shorting clips on a Remote Sense connector to test

channel 2 on a 2230-30-1

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 27

Page 38

Performance Verification

Figure 3: Configuring the shorting clips on a Remote Sense connector to test

channel 3 on a 2230-30-1

3. Set up the equipment a s shown. (See Figure 4.)

NOTE. To assure accurate measurements, it is important that a significant amount

of current does not flow through the sense leads. For this reason, we recommend

that the wiring of the remote sense and the voltmeter be away from the high

t connections between the electronic load and the DUT.

curren

A solution is a pair fork lugs with all three wires crimped in. Another alternative

rk lug between the DUT and the load, and separate connections (probably

is a fo

also fork lugs) holding the wiring for one or both of the voltmeter and remote

sense. A third alternative is to stack banana jacks at the voltmeter, with the remote

sense toward the voltmeter, and the two high current connections on the outside.

28 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 39

Performance Verification

Figure 4: DC voltage accuracy with remote sense test setup. The channel 1 test

setup is shown.

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 29

Page 40

Performance Verification

4. Power on the DUT

NOTE. Ensure the warm-up criteria has been met as described in the Performance

Ver ification Conditions.

5. Set the voltmeter as follows:

a. Set to measu

b. Set to auto range.

c. Verify that the Math mx+b function is disabled (shift DCV), assuring that

volts are being read.

6. Set the electronic load as follows:

a. Set to Constant Current.

b. Set the to draw a constant current at the test current specified for the DUT

in the table for checking DC Voltage Accuracy With Remote Sense. (See

Table 15 on page 16.)

7. Set the channel under test (CUT) to the full scale (FS) output current.

8. Set the CUT to 0% of the FS output voltage (0 V).

.

re DC volts.

9. Turn the DUT output on.

10. Ente

11. Inc

12. Repeat steps 10 and 11 until you complete testing at 100% of the FS.

13. Power off the DUT.

14. Disconnect the hook up wires from the Remote Sense connector and reinstall

15. Power on the DUT.

This completes the check for one channel. If needed, return to step 1 to run

through the check for the next channel.

r the voltmeter reading into the table for checking DC voltage accuracy

with remote sense. (See Table 15 on page 16.)

rease the CUT output voltage by 25% of the FS output voltage.

the shorting clip on the channel you just tested.

30 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 41

Performance Verification

Check DC Volta

ge Setting

Accuracy Without Remote

Sense and Voltage

Readback Accu

racy

Equipment required

(Item 2) AC Power Source (Item 5) High current hook up wire (bold line

connections)

(Item 3) Electronic Load (Item 6) Low current hook up wire (fine line

)

(Item 4) DC V

connections

oltmeter

For each channel sequentially.

1. Set up the equipment as shown. (See Figure 5.)

NOTE. Ens

ure the warm-up criteria has been met as described in the Performance

Ver ification Conditions.

NOTE. To

assure accurate measurements, the voltmeter must connect as close as

possible to the front panel of the DUT. A solution is to use fork lugs between the

electronic load and the DUT, and banana plugs between the DUT and voltmeter.

An alternative solution is to use fork lugs for both connections at the DUT.

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 31

Page 42

Performance Verification

Figure 5: Voltage accuracy, regulation, and protection test setup. The channel

1 test setup is shown.

2. Set the voltmeter as follows:

a. Set to measure DC volts.

b. Set to auto range.

c. Verify that the Math mx+b function is disabled (shift DCV), assuring that

volts are being read.

3. Set the electronic load as follows:

a. Set to Constant Current.

b. Set to draw a constant current at the test current specified for the channel

under test (CUT) in the table for checking DC Voltage Accuracy without

Remote Sense. (See Table 16 on page 17.)

4. Set the CUT to the full scale (FS) output current.

5. Set the CUT to 0% of the FS output voltage (0 V).

6. Turn the DUT output on.

32 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 43

Performance Verification

7. Enter the voltm

without remote sense. (See Table 16 on page 17.)

8. Enter the volt

accuracy. (See Table 17 on page 18.)

9. Enter the CU

accuracy. (See Table 17 on page 18.)

10. Calculate t

enter the absolute value into the difference column of the table. (See Table 17

on page 18.)

11. Increase the CUT output voltage by 25% of the FS output voltage.

12. Repeat st

This completes the check for one channel. If needed, return to step 1 to run

through

the check for the next channel.

eter reading into the table for checking DC voltage accuracy

meter reading into the table for checking DC voltage readback

T Readback Voltage into the table for DC voltage readback

he difference of the two measurements taken in steps 8 and 9 and

eps 7 through 11 until you complete testing at 100% of FS.

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 33

Page 44

Performance Verification

Check DC Voltage Line

Regulation

This check proc

edure uses the same test setup as the previous procedure. (See

Figure 5.)

For each channel sequentially.

1. Change the AC

Power Source output to the minimum voltage specified in the

following table.

NOTE. Ensure the warm-up criteria has been met as described in the Performance

Ver ification Conditions.

DUT voltage selector

switch AC Power Source voltage Japan configured units

110 99 V 90

220 198 V 180

2. Set the voltmeter as follows:

a. Set to measure DC volts.

b. Set t

o auto range.

c. Verify that the Math mx+b function is disabled (shift DCV), assuring that

s are being read.

volt

3. Set the electronic load as follows:

a. Set to Constant Current.

b. Set to draw the specified test current.

Instrument Test current

Channel 1

Channel 2

Channel 3

0.5 A

0.5 A

2.5 A

4. Set the channel under test (CUT) to 100% of the full scale (FS) output current.

5. Set the CUT to 100% of the FS output voltage.

6. Turn the DUT output on.

34 Series 2200 Multichannel Programmable DC Power Supplies Technical Reference

Page 45

Performance Verification

7. Enter the voltm

Regulation under the min column for the CUT. (See Table 18 on page 19.)

eter reading into the table for checking DC Voltage Line

Series 2200 Multichannel Programmable DC Power Supplies Technical Reference 35

Page 46

Performance Verification

8. Change the AC Po

wer Source output to the maximum voltage specified in the

following table.

DUT voltage selector

switch AC Power Source voltage Japan configured units

110 132 V 110 V

220 264 V 220 V

9. Enter the voltmeter reading into table for checking DC Voltage Line

Regulation under the Max column for the CUT. (See Table 18 on page 19.)

10. Change the AC Power Source output to match the Voltage Selector switch

setting of the DUT.

DUT voltage selector

switch AC Power Source voltage Japan configured units

110 115 V 100 V

220 230 V 200 V

11. Enter the voltmeter reading into table for checking DC Voltage Line

Regulation under the Nom column for the CUT. (See Table 18 on page 19.)

12. Calculate the two values: Nom – Min and Max – Nom. Enter the values into

the appropriate columns. (See Table 18 on page 19.)

13. Enter the largest of the two values calculated in step 12 into the Largest

column. (See Table 18 on page 19.)

This completes the check for one channel. If needed, return to step 1 to run

through the check for the next channel.