Series 2220

Multichannel Programmable

DC Power Supplies

User’s Manual

2220S-900-01 Rev. C / December 2013

www.keithley.com

*P2220S90001C*

2220S-900-01C

A Greater Measure of Condence

A Tektr onix Company

Series 2220

Multichannel Programmable DC Power Supplies

User's Manual

© 2013, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, Inc. is strictly prohibited.

®

TSP

, TSP-Link®, and TSP-Net® are trademarks of Keithley Instruments, Inc. All Keithley

Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Document number: 2220S-900-01 Rev. C / December 2013

Safety precautions

The following safety precautions should be observed before using this product and an y associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all install a tion, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring inst ruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

If a

The

user documentation in all cases where the symbol is marked on the instrument.

The

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If yo u are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

symbol on an instrument means caution, risk of danger. The user must refer to the operating instructions located in the

symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

symbol indicates a connection terminal to the equipment frame.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do n ot app ly

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Safety precaution revision of January 2013.

ii 2220S-900-01 Rev. C/December 2013

Table of Contents

Preface................................................................................................................................. ii

Welcome.......................................................................................................................... ii

Products ....... . . . . . . . ........ . . . . . . . . ........ . . . . . . . .......... . . . . . . . ....... . . . . . . . . ........ . . . . . . . . ........ . . . . . . . .......... . ... ii

Extended Warranty. . . . . . . . ......... . . . . . . . ........ . . . . . . . . .......... . . . . . . . ....... . . . . . . . . ......... . . . . . . . .......... . . . . . . . ...... iii

Contact Inf

CD-ROM Contents............................................................................................................... iii

Key Features .....................................................................................................................iv

Getting St

Standard Accessories.. . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . . ........ 1

Optional Accessories ...... . . . . . . . .......... . . . . . . . ........ . . . . . . . . .......... . . . . . . . ........ . . . . . . . . .......... . . . . . . . ........ . . . . 1

Available

Specifications..................................................................................................................... 4

Operating Requirements........ . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . 5

Front-pa

Rear-panel Features ......... . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ....... . . . . . . . . ........ . . . . . . . ........ . . . . . . . .. 10

Front-panel Operation. . . . ........ . . . . . . . . ......... . . . . . . . ........ . . . . . . . . ........ . . . . . . . . ......... . . . . . . . ........ . . . . . . . . ....... 12

Install

Cleaning ...... . . . . . . . . ........ . . . . . . . . ........ . . . . . . . . ......... . . . . . . . ........ . . . . . . . . .......... . . . . . . . ........ . . . . . . . ........... 16

Operating Basics ..................................................................................................................... 17

Basic S

Menu Operations................................................................................................................ 18

User Settings....................................................................................................................20

System

Configure The Instrument for Your Application . . . . . . ....... . . . . . . . . ........ . . . . . . . . ........ . . . . . . . . ......... . . . . . . . ........ . . . 23

Connect to a Device Under Test . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . . ........ . . . . . . 23

Index

ormation .............................................................................................................. iii

arted......................................................................................................................... 1

Services................................................................................................................ 2

nel Features............................................................................................................. 6

ing the System............................................................................................................ 14

ettings ................................................................................................................... 17

Information ............................................................................................................. 22

Table of Content

s

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual i

Preface

Preface

Welcome

Thank you for using a Keithley Instruments product. The Series 2200 Multichannel Programmable DC Power Supplies are

flexible DC sources designed to power a wide range of applicat ions. The model 2230-30-1 and its variants offer three

power channels and the model 2220-30-1 and its variants provide two channels. The output channels on both models are

independent and isolated, allowing you to power circuits with different references or polarities. Each channel can be enabled

or disabled as your application requires. All outputs feature remote sense capability which can be used to reduce the effect of

lead resistance, delivering 0.03% basic voltage accuracy even when using long leads. Basic current accuracy is 0.1% for all

channels and linear regulation delivers low noise – less than 3 mVp-p. Flexible display modes make it easy to use the two 30

V outputs in combination, and the USB interface makes it easy to build PC-based systems without converters or special

cables. The G versions of each model include a GPIB interface in combination with the USB interface.

These compact power supplies cover a wide range of applications without covering a lot of bench space. Versions of these

power supplies are available for use at 100 VAC nominal line voltage which is common in Japan. These v ersions are

indicated by the "J" suffix.

Products

This manual contains information about the following products:

Model Description

2220-30

2220G-30-1 Programmable Dual Channel DC Power Supply with GPIB Interface

2220J-

2220GJ-30-1 Programmable Dual Channel DC Power Supply with GPIB Interface for Japan

2230-

2230G-30-1 Programmable Triple Channel DC Power Supply with GPIB Interface

2230

2230GJ-30-1 Programmable Triple Channel DC Power Supply with GPIB Interface for Japan

-1

30-1

30-1

J-30-1

Programmable Dual Channel DC Power Supply

Programmable Dual Channel DC Power Supply for Japan

Triple Channel Programmable DC Power Supply

Triple Channel P rogrammable DC Power Supply for Japan

ii Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Extended Warranty

Additional years of warranty coverage are available on many products. These valuable contracts protect you from

unbudgeted service expenses and provide additional years of protection at a fraction of the price of a repair. Extended

warranties are available on new and existing products. Contact your local Keithley Instruments representative for details.

Contact Information

Preface

Ifyouhavean

1. Keithley In

2. Keithley we

3. Call Keithl

(1-888-534-8453), or from outside the U.S. at +1-440-248-0400. For worldwide contact numbers, visit the Keithley

Instruments website (http://www.keithley.com).

CD-ROM Co

A CD-ROM is shipped with each Series 2200 order. The Series 2200 Product Information CD-ROM contains:

User manual: Includes a description of connections, operation information, and maintenance information. Users looking

for basic operating information and an in-depth description of the way the instrument works (including troubleshooting

and optimization) should refer to this manual.

Quick Start Front Panel and Programm ing Operation Guide: Includes information about front panel operation and

corresponding SCPI command codes to perform essential functions.

Specifications and performance verification manual: Includes instrument specifi cations and procedures to verify that

instrument accuracy is within the limits stated in the instrument’s one-year accuracy specifications.

Programmer’s manual: Includes instrument programming information. Programmers looking for command references

should refer to this manual.

y questions after reviewing this information, please use the following sources:

struments website (http://www.keithley.com)

b forum (http://forum.keithley.com)

ey Instruments corporate headquarters (toll-free inside the U.S. and Canada only) at 1-888-KEITHLEY

ntents

PC Connectivity manual: Includes instructions for installing software, drivers, and files to use LabVIEW SignalExpress

Edition software to remotely acquire data and measurements from s upported instruments.

Drivers and release notes: IVI Instrument Driver, driver for National Instruments LabVIEW™, and related release

notes; SignalExpress Step and related release notes.

Keithley I/O layer and release notes.

Security and declassification instructions: Includes information about how to sanitize and secure the instrument for

customers with security concerns.

For the latest drivers and additional support information, see the Keithley Instruments website (http://www.keithley.com).

Series 2200 Multichannel Programmable D C Power Supplies User’s M anual iii

Preface

Key Features

The Series 2200 instruments offer:

Two 30 V at 1.5 A channels

6 V at 5 A, a third channel (2230 models only)

3-year factory warranty extendable to 5 years

Linear regulation

0.03% Basic voltage accuracy

0.1% Basic current accuracy

Less than 3 mVppripple and noise

Remote sense to compensate for lead resistance

30 user-defined setup memories

USB Device port on rear-panel for PC connectivity and remote programming; the G models include the GPIB interface

along with the USB interface

Works with National Instruments LabVIEW SignalExpress™ Tektronix Limited Edition Software which is available for

download at www.tektronix.com/downloads

iv Series 2200 Multichannel Programmable D C Power Supplies User’s Manual

Getting Started

Getting Start

ed

Standard Accessories

For the current list of standard and optional accessories, upgrades, and options available for your power supply, visit the

Keithley website, www.Keithley.com.

Table 1: Standard accessories

Accessory

Series 2200 Product Information CD-ROM. You can view a list of the contents of this CD. (See

page iii, CD-ROM Contents.)

Rear Panel Mating Connector with shorting clips for 2220-30-1 and 2230-30-1 CS-1655-15

Certificate of calibration

1

Power Cord

1

Models 2220J-30-1 and 2230J-30-1 come standard with a Japanese power cord. No other power cord options are available for these models.

One of the following:

North America (Option A0). The factory sets the 110V/220V selector switch

to 110 V.

Universal Euro (Option A1). The factory sets the 110V/220V selector switch

to 220 V.

United Kingdom (Option A2). The factory sets the 110V/220V selector switch

to 220 V.

Australia (Option A3). The factory sets the 110V/220V selector switch to 220 V.

Chile, Italy (Option A4). The factory sets the 110V/220V selector switch to 220 V.

Switzerland (O ption A5). The factory sets the 110V/220V selector switch to

220 V.

Denmark (Option A7). The factory sets the 110V/220V selector switch to 220 V.

Israel (Option A8). The factory sets the 110V/220V selector switch to 220 V.

Argentina (Option A9). The factory sets the 110V/220V selector switch to 220 V.

China (Option A10). The factory sets the 110V/220V selector switch to 220 V.

India (Option A11). The factory sets the 110V/220V selector switch to 220 V.

Keithley part

number

2220S-950-01

—

Optional Accessories

For the current list of standard and optional accessories, upgrades, and options available for your power supply, visit the

Keithley website, www.Keithley.com.

Table 2: Optional accessories

Keithley part

Accessory

Remote Sense Shorting Clip

Universal Fixed Mount Rack Kit 4299-7

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 1

number

344-0654-00

Getting Started

Table 2: Optional accessories (cont.)

Accessory

Fixed Mount Rack Kit RMU2U

RMU2U Rackmount Cosmetic Filler Panel

Series 2200 Multichannel Rear Panel Mating Connector CS-1655-15

USB Cable USB1-1

IEEE-488.2 Interface Board for the PCI Bus USB-1-1 USB Cable KPCI-488LPA

Double Shielded Premium IEEE-488 Interface Cables, 0.5m (1.6 ft)

Double Shielded Premium IEEE-488 Interface Cables, 1m (3.2 ft)

Double Shielded Premium IEEE-488 Interface Cables, 2m (6.5 ft)

Double Shielded Premium IEEE-488 Interface Cables, 3m (10 ft)

Double Shielded Premium IEEE-488 Interface Cables, 4m (13 ft)

Available Services

For the current list of available services and accessories, upgrades, and options for your instrument, visit the Keithley

ite, www.keithley.com.

webs

Keithley part

number

386-7598-xx

7007-05

7007-1

7007-2

7007-3

7007-4

Table 3: Available services

vice

Ser

year factory warranty extended to 1 additional year from date of

1shipment

calibrations within 3 years of service from date of shipment

3

thley part numbers

Kei

2220-30-1-EW

20G-30-1-EW

22

2230-30-1-EW

2230G-30-1-EW

20J-30-1-EW

22

2220GJ-30-1-EW

2230J-30-1-EW

230GJ-30-1-EW

2

/2220-30-1-3Y-STD

C

C/2220G-30-1-3Y-STD

C/2230-30-1-3Y-STD

C/2230G-30-1-3Y-STD

C/2220J-30-1-3Y-STD

C/2220GJ-30-1-3Y-STD

C/2230J-30-1-3Y-STD

C/2230GJ-30-1-3Y-STD

1

2 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Table 3: Available services (cont.)

Service Keithley part numb ers

3 (ANSI-Z540-1 compliant) calibrations within 3 years of service from

date of shipment

5 calibrations within 5 years of service from date of shipment C/2220-30-1-5Y-STD

5 (ANSI-Z540-1 compliant) calibrations within 5 years of service from

date of shipment

1

ct the part number that contains your instrument model. For example, you would select 2220-30-1-EW for a model 2220 instrument.

Sele

C/2220-30-1-3Y-DATA

C/2220G-30-1-3Y-DATA

C/2230-30-1-3Y-DATA

C/2230G-30-1-3Y-DATA

C/2220J-30-1-3Y-DATA

C/2220GJ-30-1-3Y-DATA

C/2230J-30-1-3Y-DATA

C/2230GJ-30-1-3Y-DATA

C/2220G-30-1-5Y-STD

C/2230-30-1-5Y-STD

C/2230G-30-1-5Y-STD

C/2220J-30-1-5Y-STD

C/2220GJ-30-1-5Y-STD

C/2230J-30-1-5Y-STD

C/2230GJ-30-1-5Y-STD

C/2220-30-1-5Y-DATA

C/2220G-30-1-5Y-DATA

C/2230-30-1-5Y-DATA

C/2230G-30-1-5Y-DATA

C/2220J-30-1-5Y-DATA

C/2220GJ-30-1-5Y-DATA

C/2230J-30-1-5Y-DATA

C/2230GJ-30-1-5Y-DATA

Getting Started

1

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 3

Getting Started

Specifications

For more specifications, refer to the Specifications and Performance Verification Technical Reference included on the

CD-ROM that was shipped with your instrument.

Table 4: Electrical ratings for the power connection, frequency 50/60 Hz

Model

2220-30-1

2220G-30–1

2220J-30-1

2220GJ-30–1

2230-30-1

2230G-30–1

2230J-30-1

2230GJ-30–1

Table 5: Environmental performance for all models

Parameter Description

Temperature

Humidity

Altitude

Line Selector

Switch Setting Voltage Range Fuse Rating Max Power

110 V / 220 V 110: 110/115/120

220: 220/230/240

110 V / 220 V

110 V / 220 V 110: 110/115/120

110 V / 220 V

Operating: +0 °C to +40 °C

Operating:

5% to 95% relative humidity (% RH) at up to 40 °C, non-condensing

Operating: 100% capability up to 2,000 meters

110: 100 V

220: 200 V

220: 220/230/240

110: 100 V

220: 200 V

For 110 V: 6.3 A TH, 250 V

For 220 V: 3.15 A TH, 250 V

For 110 V: 6.3 A TH, 250 V

For 220 V: 3.15 A TH, 250 V

For 110 V: 6.3 A TH, 250 V

For 220 V: 3.15 A TH, 250 V

For 110 V: 6.3 A TH, 250 V

For 220 V: 3.15 A TH, 250 V

350 VA

350 VA

450 VA

450 VA

Nominal Voltage Ratings

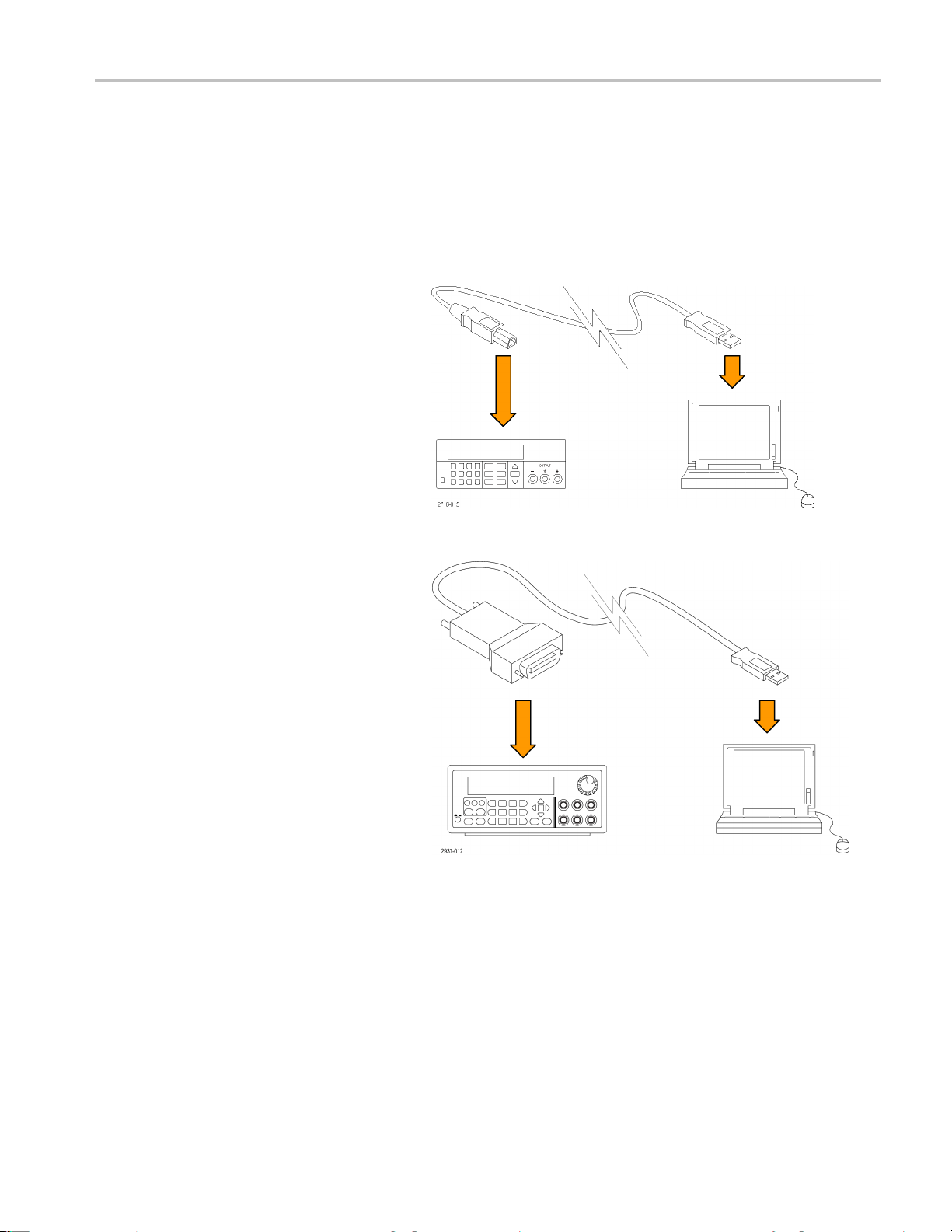

There are two ranges for all models, selectable by the line-voltage selector switch. C heck the voltage select switch on the

om of the power supply before turning it on:

bott

V setting, 110 / 115 / 120 VAC

110

V setting, 220 / 230 / 240 VAC

220

ctuations must not exceed 10% of the nominal rated voltage.

Flu

Float Voltage Rating

Float voltage rating: Any output can be floated up to 240 V (DC + pk AC with AC limited to a maximum of 3 V pk-pk and

maximum of 60 Hz) relative to any other output terminal. The remote sense terminals should remain within 1 V of their

respective outputs to avoid possible damage.

4 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Operating Requirements

1. Place the instrument on a bench or similar surface with the bottom of the instrument closest to the surface.

WARNING. Do not stand the instrument on its rear-panel. This position is unstable and the instrument might tip over and be

damaged or fall on s omeone and cause injury. To avoid damage to the instrument or bodily injury, only place the instrument

so that the bottom of the instrument is laid flat on a stable surface.

2. Before operating, ensure that the ambient temperature is between +0 °C and +40 °C (+32 °F to +104 °F).

WARNING. To ensure proper cooling, keep the front, sides, and rear of the instrument clear of obstructions.

WARNING. Observe all safety precautions listed in this manual before using this product and any associated instruments.

Although some instruments and accessories would be used with non-hazardous voltages, there are situations where

hazardous conditions may be present. This product is intended for use by qualified personnel who recognize shock hazards

and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation, operation, and

maintenance information carefully before using the product. Refer to this manual for complete product specifications. Before

performing any maintenance, disconnect the line cord and all test cables. Operators of this instrument must be protected

from electric shock at all times. The responsible body must ensure that operators are prevented access and/or insulated from

every connection point. In some cases, connections must be exposed to potential human contact. Product operators in these

circumstances must be trained to protect t hemselves from the risk of electric shock. If the circuit is capable of operating at or

above 1000 volts, no conductive part of the circuit may be exposed.

Getting Started

WARNING. Use properly rated load wires. All load wires must be heavy enough not to overheat when carrying the maximum

short-circuit output current of the power supply. If there is more than one load, then any pair of load wires must be capable

of safely carrying the full-rated short-circuit output current of the power supply.

WARNING. Do not loosen any screw on this product, except those in the rear connector, which are intended to retain

attached external wires to the connector. There are no user serviceable components inside.

WARNING. To reduce risk of fire and shock, ensure the mains supply voltage fluctuations do not exceed 10% of the

operating voltage range.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 5

Getting Started

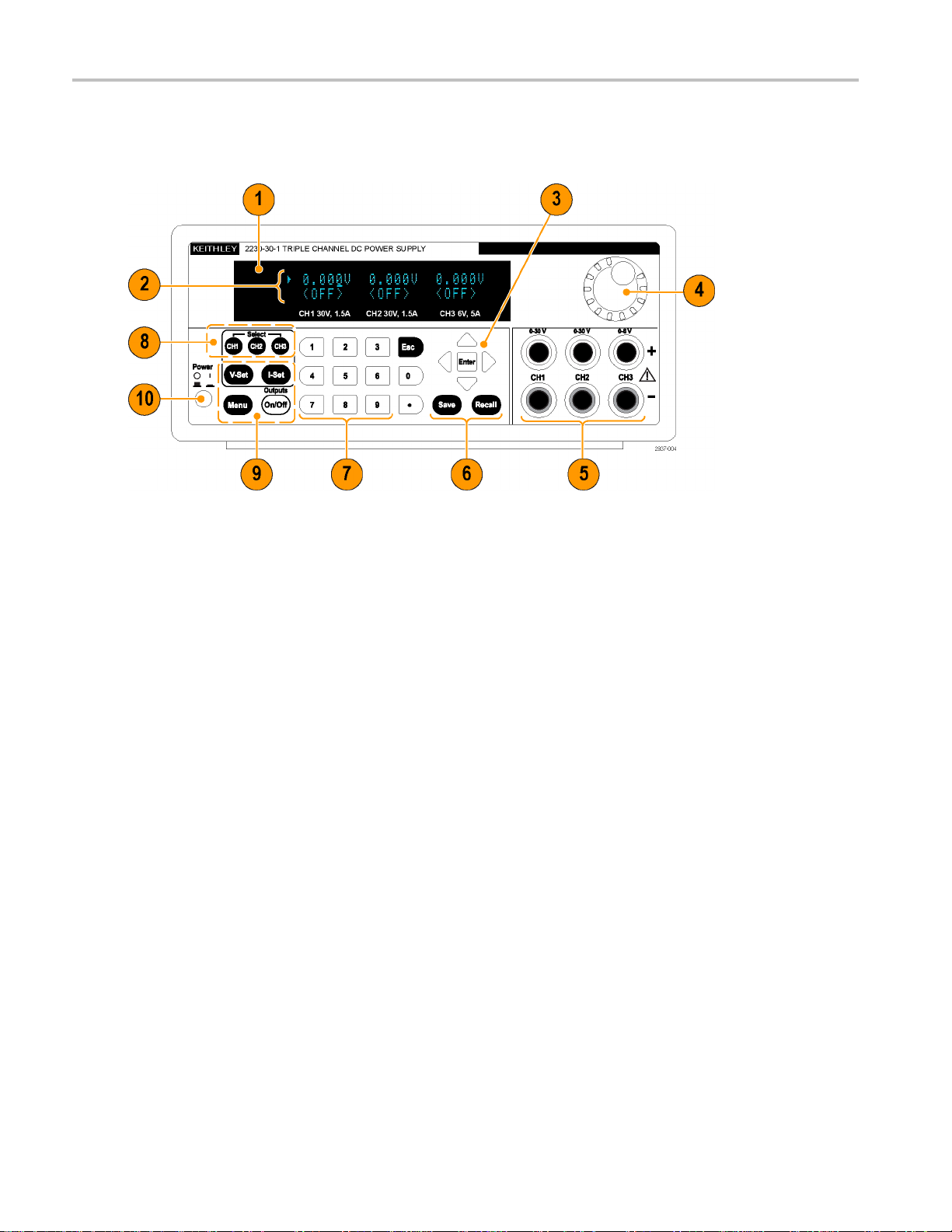

Front-panel Features

Controls and display elements are shown in the following illustrations and tables.

Figure 1: Front-panel for all versions of model 2230-30-1, which has three output channels.

1. Display

2. Top row: Voltage readings or settings for each channel.

Bottom row: Current readings or settings for each channel.

3. Up, down, right, and left arrow keys and Enter button

4. Multipurpose knob. Rotate to increase or decrease digits or to select menu items

5. Output connectors

6. Save and Recall function buttons

7. Number keys (0 to 9 and Esc) for direct numeric entry

8. Channel select buttons

9. V-Set, I-Set, Menu (Local), and Output On/Off function buttons

10. Power button

6 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

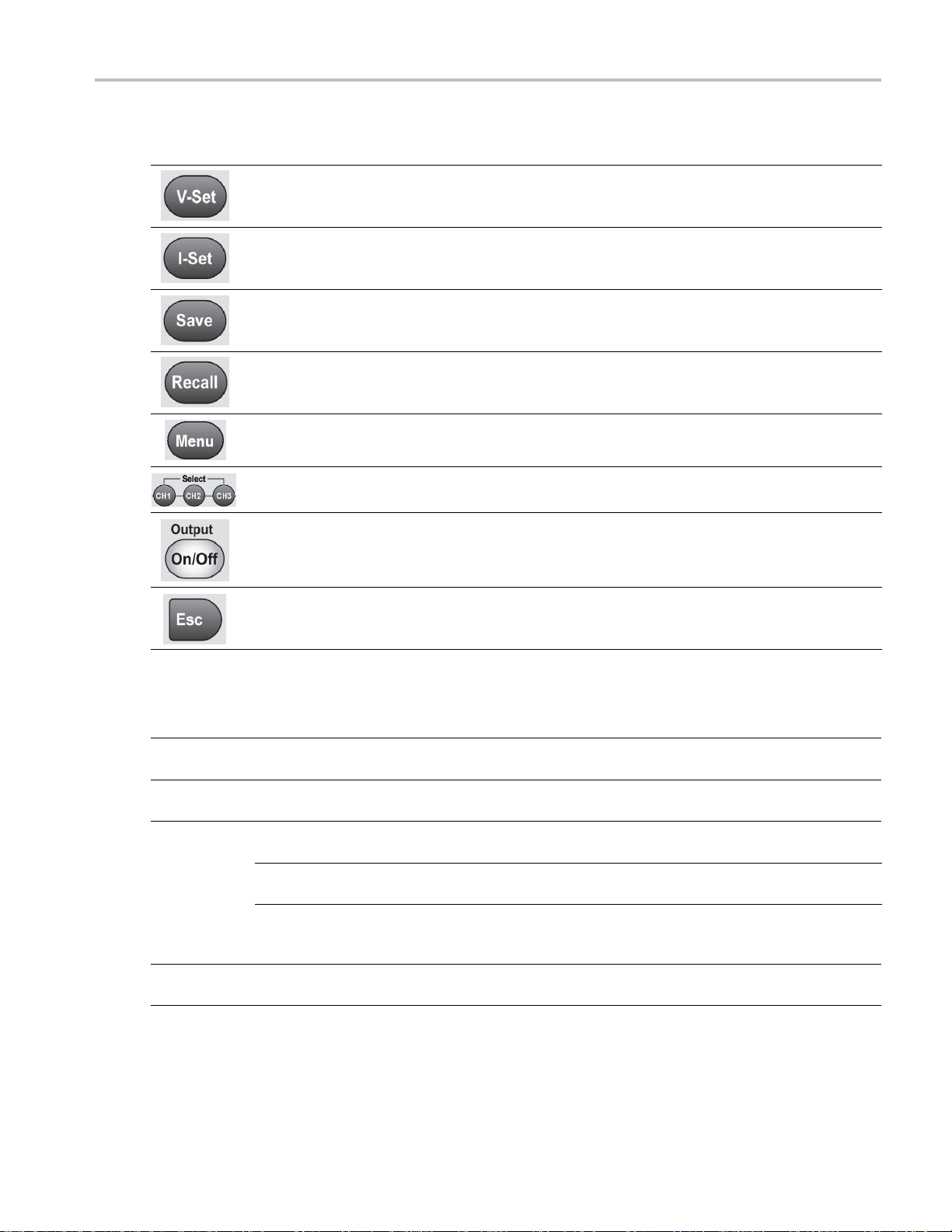

Function button descriptions

Button Description

Sets the voltage limit

Sets the current limit

Getting Started

Saves the pr

with the multipurpose knob, the up or down arrow keys, or the numeric keypad. The power supply

saves the settings after you push Enter.

Recalls a saved setting from a specified setup memory location (1 to 30). Select the memory location

with the mu

recalls the settings after you push Enter.

Used to acc

Enter to select the displayed menu item.

Selects the channel to be adjusted. The cursor indicates the currently selected channel.

Turns on or off all enabled output channels. The regulation mode, constant voltage (CV) or constant

current

Backs out of the selected function. If the instrument's focus is in a menu, pushing Esc will bac k up

one menu level.

esent settings to a specified setup memory location (1 to 30). Select the memory location

ltipurpose knob, the up or down arrow keys, or the numeric keypad. The power supply

ess the settings menu. Navigate the settings menu with the up and down keys. Push

(CC), is shown on the display when the output is turned on.

Menu descriptions

Primary

Menu

>Default Set Returns the instrument to the factory default setup values. This does not change the

>Enable

Channels

>Protection

Settings

>Track

CH1/CH2

Secondary

Menu Description

setup memory.

Enables or disables one or more output channels.

>Max Volt

Set

>Output

Timers

>Key Lock

Sets the maximum output voltage value to which you can set on a specified output

channel.

After you select “On”, you can set a time period after which a specified output channel

will turn off.

When activated, this feature locks the front-panel controls and prompts for a password

to enable settings changes. This feature does not lock the power switch or the output

on/off switch.

Maintains a constant ratio between Channel 1 and Channel 2. The ratio is the ratio

that is present when tracking is turned on.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 7

Getting Started

Menu descriptions (cont.)

Primary

Menu

> Combine

CH1+CH2

>User

Settings

>System Info

Secondary

Menu Description

Series V1+V2: By wiring Channel 1 and Channel 2 in series, you can output up to

60 V. When this setting is activated the meter will read the combined voltage across

Channel 1 and Channel 2.

Parallel I1+I2: By wiring Channel 1 and Channel 2 in parallel, you c an drive up to 3 A.

When this setting is activated the meter will read the combined current from Channel

1 and Channel 2.

>Output

Recall

>Save Last Recalls the operating parameters of the power supply after power up. It does this by

>Key Beep

>Knob Lock Locks the m ultipurpose knob.

>Communication Port

>Address

> Error Log Lists all errors that have occurred.

Firmware/SW version

>Cal Date Shows the date and time of the last calibration.

Sets the power output On/Off state after power up. “On” restores the state to that

which was in use before the power was last t urned off. “Off” disables this function and

configures the output channel to power up in the off state.

NOTE. Wait 3 seconds after changing the settings to allow the settings to be completely

stored before powering off the instrument

saving the last setting of operating parameters before you turn the instrument off and

then restoring the saved setting when you turn the instrument back on.

NOTE. Wait 3 seconds after changing the settings to allow the settings to be completely

stored before powering off the instrument.

Turns on or off a beeper sound when you push a button or press a key. “On” enables

the key sound. “Off” disables it.

For G versions only: Offers the option of selecting the GPIB interface or the USB

interface. USB is the default interface. When the GPIB interface is selected, an address

is displayed. The desired GPIB address can be entered using either the keypad, the

multipurpose knob, or the arrow keys.

Select a GPIB address. (This feature is not currently available.)

The Address selection is not available on the "G" versions.

Shows the versions of firmware installed on the instrument.

8 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Channel status messages

Symbol Description

OFF The power supp

CV Constant vol

CC Constant cur

tage mode

rent mode

Getting Started

ly output is off

Displayed e

Symbol Description

EEPROM Test Fail An EEPROM Error was detected during power-on self test. The instrument should be

User Data Lost

Channel Initialization

Failed

Calibration Data Lost A calibration data error was detected during power-on self test. Turn the instrument off and

Setup x Save Failure! Saving a s etup to memory x failed. The instrument should be returned to Keithley for service.

Invalid Operation A Save operation may have been attempted while the instrument was in tracking, series, or

Over Temperature... An internal over-temperature has been detected and the outputs have been turned off. Check

rror messages

returned to K eithley for service.

A user data error was detected during power-on self test. Turn the instrument off and then

turn it ba

returned to K eithley for service.

An output channel failure was detected during power-on self test. The instrument should

be returned to Keithley for service.

then tu

be returned to Keithley for service.

parallel mode. A tracking, parallel, or series setup cannot be saved in setup memory.

ARec

parallel mode. The recall function is disabled in these modes.

to make sure ambient temperature does not exceed the operating temperature specification

of t

down and press any button to clear the error. If the message occurs repeatedly, return the

instrument to Keithley for service.

ck on to clear the error. If the error occurs repeatedly, the instrument should be

rn it back on to clear the error. If the error occurs repeatedly, the instrument should

all operation may have been attempted while the instrument was in tracking, series, or

he instrument, and insure the fan has sufficient clearance. Allow the instrument to cool

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 9

Getting Started

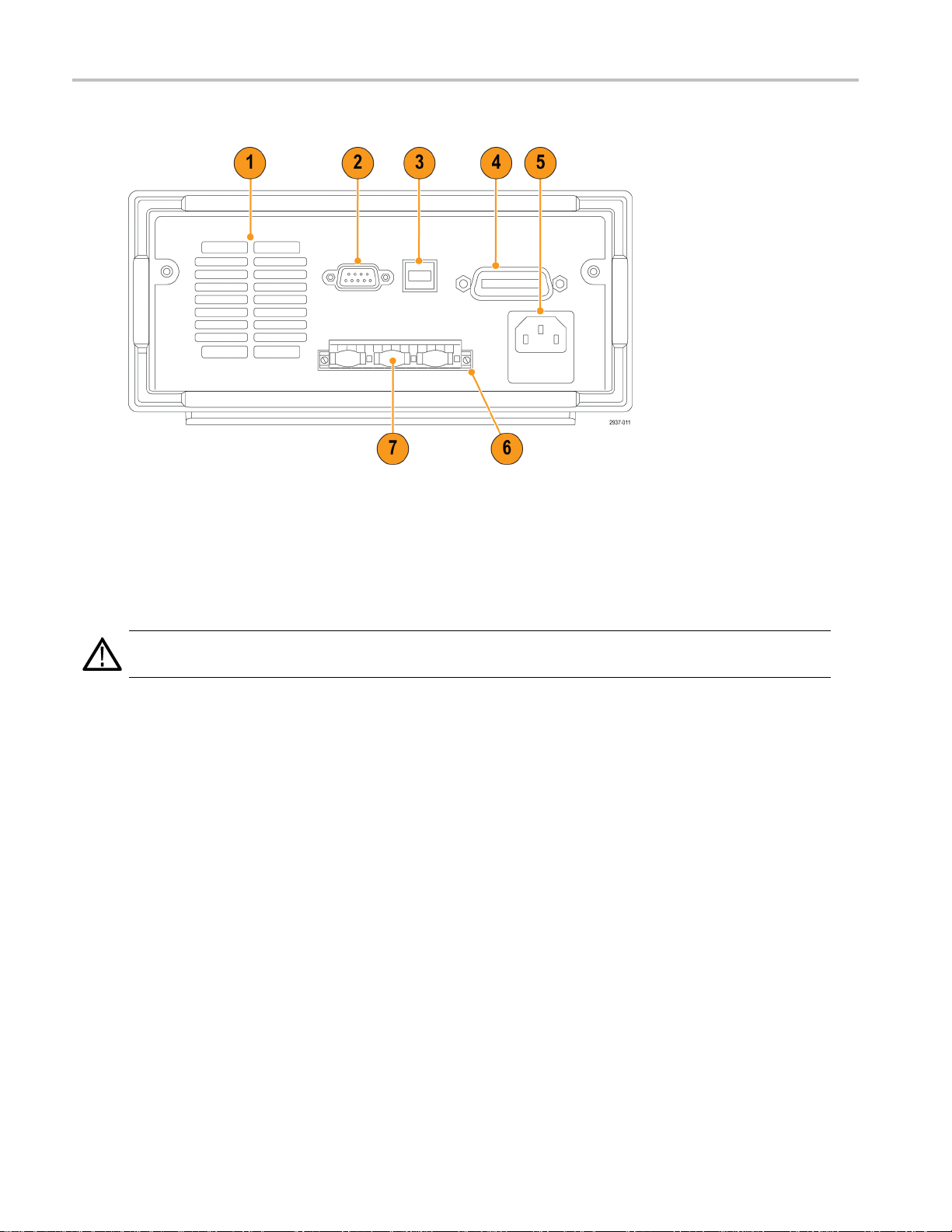

Rear-panel Features

Figure 2: Rear-panel of the 2230-30-1, 2230J-30-1, 2230G-30-1, and 2230GJ-30-1. Only the G versions have the

GPIB interface (item 4).

1. Cooling

2. Factory

CAUTION. Unauthorized use of the factory test port could damage this product.

3. USB Device por

4. GPIB interfac

5. 110 V/220 V po

6. 15-pin conne

Drive +, a Sense +, an Output Drive -, a Sense -, and an earth ground.

The Output Drive + terminals are equivalent to the front-panel output + connectors.

The Output Drive - terminals are equivalent to the front-panel output - connectors.

The Outp ut Sense + and - terminals are used for remote sensing.

The Earth Ground terminals are tied to each other, to the chassis of the instrument, and to the earth terminal on the

power cord.

7. Shorting clips (one per output channel). Use these for proper regulation when not using remote sense. The shorting clips

come insta

sense for one or more channels, remove the shorting clip for the corresponding channel(s).

vents.

test port.

t.

e (G models only).

wer connector.

ctor. Includes remote sense and earth ground connections. For each output channel, there is an Output

lled. They short the drive + to the sense + and the drive - to the sense - for each channel. To use remote

10 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

8. 110 V/220 V selector switch.

Getting Started

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 11

Getting Started

Front-panel Operation

Within a few seconds after powering on, the power supply shows the actual voltage for each channel on the top line of the

display and the actual current for each channel on the bottom line of the display.

You can enable or disable the output of the power supply from the front-panel by pushing the Output On/Off button. When

the output is off, the OFF message will appear on the display.

The display shows the present operating status of each channel with display messages. W hen a c hannel operates in constant

voltage mode, the CV indicator is d isplayed. When it operates in the constant current mode, the CC indicator is displayed.

NOTE. If the front-panel was locked with a password, enter the correct password after you push the function buttons (V-set,

I-set, Save, Recall,orMenu), then you can change the settings.

NOTE. To cancel a function operation (V-set, I-set, Save, Recall,orMenu), push the Esc button.

Initializing to the Default Setup

Use the d

1. Remove a

2. Turn on t

3. Push Men

4. Push En

5. Push th

The de

efault setup to get the power supply into a default initial state.

e down arrow button to select Yes.PushEnter to enable the default settings.

fault settings are:

tOn/Off= OFF

Outpu

= 1.000V for all channels

V-Set

= 0.1000A for all channels

I-Set

Lock = Off

Knob

olt Set = Off for all channels

Max V

ime Set = Off for all channels

Out T

put Recall = Off

Out

e Last = On

Sav

ll leads from the output connectors.

he power supply.

u. Default Set should appear on the display.

ter to bring up the default settings menu. No and Yes should appear on the display.

Beep = Off

Key

acking = Off

Tr

ries V1 + V2 = Off

Se

rallel I1 + I2 = Off

Pa

dress = 1

Ad

12 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Connect to an External Computer with USB

Getting Started

1. Load VISA on yo

download NI VISA from the National

Instruments website at www.NI.com.

NI VISA is requ

interface. It is recommended when using the

GPIB interface.

2. Connect the instrument to the computer

withaUSBca

then recognize the power supply as a

USB device. If National Instruments

SignalExp

will also give you the option of running

that program.

For more in

and running SignalExpress, see the

Connectivity Installation Manual on the

Document

shipped with your instrument. You can

also download a copy of this manual

from www.

3. G" versi

ons can connect to a computer

or a system using the GPIB interface.

Connect the GPIB interface using a

quipped with standard IEEE-488

cable e

connectors. The GPIB address is set as

described under the User Settings option

enu Descriptions section of this

in the M

manual.

ur computer. You can

ired when using the USB

ble. The computer will

ress is installed, the computer

formation on loading

ation Browser CD that was

Keithley.com/manuals.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 13

Getting Started

Installing the System

This section contains information on how to install your instrument. Before performing the procedures on the next several

pages to verify that the instrument is ready to use, do the following:

Unpack the instrument and check that you received all the items listed as standard accessories.

Check that you also received any other accessories that you ordered with your instrument.

Check the Keithley website (www.Keithley.com) for the most current information.

Powering the Instrument On and Off

To power on the instrument follow these steps:

1. Make all the connections.

2. Properly set the 110 V / 220 V selector switch on the bottom of the instrument.

3. Connect the power cord that was provided with the instrument to the power connector on the rear-panel. Connect the

power cord plug to a properly grounded electrical outlet.

4. Push the power button on the front-panel.

To power off the instrument, push the front-panel power button.

WARNING. To satisfy safety requirements, always use load wires heavy enough not to overheat when carrying the maximum

short-circuit output current of the power supply. If there is more than one load, then every pair of load wires must be capable

of safely carrying the full-rated current of the power supply.

What To Do If The Instrument Does Not Turn On

To solve problems you might encounter when turning on the instrument, follow these steps:

1. Verify that there is AC power to the power supply.

First, check that the AC power cord is firmly plugged into the power connector on the rear-panel of the power supply.

You should also make sure that the AC power source you plugged the power supply into is energized. Then, check

that the power supply is turned on.

2. Verify the power-line v oltage settings.

Check that the line voltage selector switch on the bottom of the instrument is set to the proper value for your country

(110 V

or 220 VAC). Change the voltage setting if it is not correct.

AC

14 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Getting Started

NOTE. Under certain circumstances, powering the instrument from a mains voltage for w hich it is not configured can

cause the mains

fuse to open.

3. Verify that th

If the fuse is damaged, replace the fuse for your power supply.

If you set the line selection to 110 V, use a 6.3 A, TH 250 V fuse.

If you set the line selection to 220 V, use a 3.15 A, TH 250 V fuse.

4. If you need more help, contact Keithley.

e c orrect power-line fuse is installed.

Check the Output

The following procedures check that the power supply develops its rated outputs and properly responds to operation

from the front-panel.

Voltage output check. To verify basic voltage functions without a load, follow these steps.

1. Remove all leads from the output connectors.

2. Turn on the power supply.

3. Push Menu. Default S et should appear on the display.

4. Push Enter to bring up the default settings menu. No and Yes should appear on the display.

5. Push the down arrow button to select Yes. Push Enter to enable the default settings.

6. Push the front-panel On/Off button to turn on the outputs. The OFF messages on the display should be replaced by

current readings and the CV indicators should turn on. The upper line of the display should show the actual output voltage.

7. Check that the front-panel voltmeter properly responds to the number keys. First, select a channel using one of the

channel select buttons.

Push V-set, use the number keys to set the voltage value to 0 and push Enter. Check if the displayed voltage value is

approximately 0 V and check if the displayed current value is approximately 0 A. You can confirm the 0 V setting with

a voltmeter.

8. Push V-set and use the numeric keys and Enter button to set the voltage value to the maximum allowable for your power

supply, as indicated on the unit's front-panel.

9. Check if the displayed voltage value is approximately the same value as the voltage setting.

10. Repeat steps 7 through 9 for each output channel.

Current output check. To verify the basic current functions with a short across the power supply output, follow these

steps:

1. Remove all leads from the output connectors.

2. Turn on the power supply.

3. Push Menu. Default S et should appear on the display.

4. Push Enter to bring up the default settings menu. No and Yes should appear on the display.

5. Push the down arrow button to select Yes. Push Enter to enable the default settings.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 15

Getting Started

6. Ensure that the output is disabled and the display OFF messages are shown for all channels. If needed, push the On/Off

button to ensur

e that the outputs are disabled and the OFF messages are displayed.

7. Use an insulat

Use a wire size

WARNING. To satisfy safety requirements, always use load wires heavy enough not to overheat when carrying the maximum

short-circuit output current of the power supply. If there is more than one load, then every pair of load wires must be capable

of safely car

8. Push the On/Off button to enable the outputs. The CC indicator should be on the channel with the shorted output.

9. Select a channel using one of the channel select buttons.

10. Push I-set and use the numeric keys and Enter button to set the current value to 0 A. Check if the displayed current

value is approximately 0 A.

11. Push I-set and use the numeric keys and Enter button to set the current value to the maximum allowable for the output

channel.

12. Turn all o

channels shows <OFF>.

13. Repeat steps 7 through 12 for each output channel.

14. Turn off the instrument and remove the short wire from the (+) and (-) output terminals.

ed test lead to connect a short across the (+) and (-) output terminals of the channel you will be testing.

sufficient to handle the maximum current. You should use at least a 22 gauge wire.

rying the full-rated current of the power supply.

Check if the displayed current value is approximately the same value as the maximum allowable.

utputs off by pressing the Output On/Off button. Note that the outputs are off when the display for all

Cleaning

Inspect the power supply as often as operating conditions require. To clean the exterior surface, perform the following steps:

1. Remove loose dust on the outside of the power supply with a lint-free cloth. Use care to avoid scratching the display.

2. Use a soft cloth dampened with water to clean the power supply. Use an aqueous solution of 75% isopropyl alcohol

CAUTION. To avoid damage to the surface of the power supply, do not use any abrasive or chemical cleaning agents.

CAUTION. Avoid getting moisture inside the unit during external cleaning. Use only enough cleaning solution to dampen

the cloth or swab.

for more efficient cleaning.

16 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Operating Basic

s

Operating Bas

Basic Settings

Set the Voltage Output or Voltage Limit for a Specific Channel

You may set the voltage limit from 0 V to the maximum voltage rating shown on the instrument nameplate. To set the

voltage limit, do the following:

1. The position of the cursor determines which channel will be adjusted. If the cursor is not located in the correct channel,

select the c

2. Push V-set

3. Use the num

keys or the multipurpose knob.

Set the Curren t Output or Current Limit for a Specific Channel

You may set the current limit from 0 A to the maximum current value of each model. The maximum current rating is shown on

the instrument name plate. To set the current limit, do the following:

1. The position of the cursor determines which channel will be adjusted. If the cursor is not located in the correct channel,

select the correct channel by pressing the appropriate channel Select button.

orrect channel by pressing the appropriate channel Select button.

.

eric keys and push Enter to set the voltage limit. You can also use the up, down, right and left arrow

ics

2. Push I-set.

3. Use the numeric keys and push Enter to set the current limit. You can also use the up, down, right and left arrow

keys or the multipurpose knob.

Save and Recall Setups

You can store up to 30 different setups in setup memory locations (1 to 30). Each setup includes the set voltage limits,

t current limits, and the protection menu settings for all channels. When shipped from the factory, setup memories 1

the se

through 30 are empty. Save and recall setups as follows:

Saving setups.

1. After you set up the power supply, (voltage and current limits and the protection menu settings), push the Save button.

2. Use the number keys or the arrow keys to select the setup memory (1 to 30) that you want to store the values in.

3. Push Enter to confirm the memory location.

Recalling setups.

1. Push Recall.

2. Use the number keys or the arrow keys to select the setup memory that you want to recall from.

3. Push Enter.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 17

Operating Basic

s

Menu Operations

Restore Default Setup

You can restore the factory default setting by doing the following:

1. Remove all leads from the output connectors.

2. Turn on the instrument.

3. Push Menu.

4. Push Enter to select Default Set.

5. Push the down arrow key to select Yes.

6. Push Enter.

Enable and Disable Output Channels

You can enable or disable each output channel using this menu setting. If a channel is disabled, it will remain off after the

Output On/Off button is turned on. The default setting is to have all channels enabled.

Protection Settings

The following protection settings allow you to set maximum voltage, use output timers, and lock the front-panel.

Set the maximum voltage. This control determines the maximum voltage that you can set using the V-set control. This

can help keep acciden

1. Push Menu.

2. Use the arrow keys to select Protection Settings.

3. Push Enter. Max Volt Set should appear on the display.

4. Push Enter. A list of Max V settings for each channel will appear.

5. Use the arrow keys to select the correct channel. Push Enter to select.

6. Use the numeric keys or the arrow keys or multipurpose knob to change the voltage value. The value must be less than

the maximum voltage output noted on the nameplate of the power supply.

7. Push Enter.

8. Push Esc to exit the menu system.

NOTE. The default maximum voltage is the full voltage range of the particular power supply being used.

tal over-voltage from being applied to sensitive loads. To set the maximum voltage, follow these steps:

Use output timers. Independent timers may be activated and set for each output channel. The timers start when the

Output On/Off button is turned on. When each active timer expires, its corresponding channel turns off.

Lock the front-panel. This function prevents any adjustments from being made to the instrument. Once the lock is

activated, a four-digit, user-specified password must be entered to change any instrument settings. Even after the front-panel

is locked, the Output On/Off control and power button continue to operate normally. Turning the power off deactivates

the lock and resets the password.

18 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Operating Basic

Use Tracking

When tracking is turned on, Channel 1 and Channel 2 respond together to any adjustments in voltage. A constant ratio will

be maintained between the voltage setting on the two channels. The ratio is determined by the voltage settings present

on Channel 1 and Channel 2 when tracking is turned on.

s

For example, if Channel 1 and Channel 2 are both set to 1 V when tracki

and any voltage change on Channel 1 will result in an identical change on Channel 2. If Channel 1 is set to 10 V and Channel

2 is set to 5 V when tracking is turned on, a two to one ratio will be maintained and any voltage change on Channel 1 will

result in a voltage change of half the size on Channel 2.

1. Push CH1, then V-Set, and then enter the desired voltage for Channel 1.

2. Push Enter.

3. Push CH2, then V-Set, and then enter a voltage in the desired ratio to Channel 1.

4. Push Enter.

5. Push Menu, use the down arrow key to navigate to Track CH1/CH2, and then push Enter.

6. Push the down arrow key to select Track On and then push Enter to turn on tracking.

7. Check that a T shows between the Channel 1 and Channel 2 voltage readings on the display. This indicates the

power supply is in the tracking mode.

NOTE. When the tracking mode is enabled, the output timer takes on the setting for Channel 1. The Channel 2 timer

setting is ignored.

ng is turned on, a one to one ratio will be maintained

Combine Channels

You can combine the meter readings of any channels. The following procedures show you how to do that for certain

applications, such as when outputs are wired in series or in parallel.

ries.

Combine metering of Channel 1 and Channel 2 when outputs are wired in se

outputs of Channel 1 and Channel 2 by doing the following:

NOTE. The wiring between the supplies drives the accuracy of measurements in this mode. Ensure that wire sizes are

sufficient, wires are short, and connections are tightened to maxim

1. Wire the outputs in series. (See page 24, Wiring in Series.)

2. Push Menu and use the up arrow key to navigate to Combine CH1+CH2.

3. Push Enter.

4. Use the down arrow key to navigate to V1+V2 Series and push Enter.

5. Check that the word Series appears on the display, replacing the Channel 2 voltage and current readings. This indicates

that the power supply is in the V1 + V2 Series state. The total output voltage is displayed on Channel 1.

6. Set the Channel 1 voltage to the desired voltage value (up to 60 V).

ize accuracy.

You can combine the

Combine m etering of Channel 1 and Channel 2 when outputs are wired in parallel. Youcancombinethe

outputs of Channel 1 and Channel 2 by doing the following:

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 19

Operating Basic

NOTE. All measurements are at the terminals. If the wires used to connect the channels together are too small, too long,

or improperly t

1. Wire the outputs in parallel. (See page 25, Wiring in Parallel.)

2. Push Menu and use the up arrow key to navigate to Combine CH1+CH2.

3. Push Enter.

4. Use the down arrow key to navigate to I1+I2 Parallel and push Enter.

5. Check that the word Para appears on the display, replacing the Channel 2 voltage and current readings. This indicates

that the power supply is in the I1 + I2 state. The total output current is displayed on Channel 1.

6. Set the Channel 1 current to the desired total current value (up to 3 A).

s

ightened, accuracy of measurements will be adversely affected.

User Setti

Recall the Power Supply ON/OFF Output State at Power On

This para

supply will restore the state of the output to that which was in use before the power was last turned off. If the output was

turned On when the power supply is turned off or loses power then the output will return to the On state when the power

supply i

to Off after the power supply is powered on.

To enable or disable this control,

1. Push Menu.

2. Use the up and down arrow keys to select >User Settings.

3. Push Enter.

4. Use the up and down arrow keys to select Output Recall.

5. Push Enter.

6. Use the up or down arrow keys to select On or Off.

7. Push Enter.

8. Push Esc to exit the menu system.

ngs

meter determines the On or Off output state after the power supply is powered on. If you select On, the power

s turned back on or power is restored. Off will disable this function and the output channel will always be set

NOTE. The default selection is set to Off.

Recall the Power Supply Operating Parameters at Power On

This parameter determines whether the power supply saves its most recent settings, such as voltage and current, and

restores these settings at power on. If you set this parameter to Off then the power supply returns to the default settings

at power on. If you select On, the power supply will restore the state to that which was in use before the power was

last turned off.

20 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Operating Basic

To enable or disable this control,

1. Push Menu.

2. Use the arrow keys to select >User Settings.

3. Push Enter.

4. Use the arrow keys to select Save Last.

5. Push Enter.

6. Use the arrow keys to select On or Off.

7. Push Enter.

8. Push Esc to exit the menu system.

NOTE. The default selection is set to On.

Set the Key Sound

This control can switch on or off the beeper that sounds when you push any button or press any key. To enable or disable

this feature,

s

1. Push Menu.

2. Use the arrow keys to select >User Settings.

3. Push Enter.

4. Use the arrow keys to select >Key Beep.

5. Push Enter.

6. Use the arrow keys to select On or Off.

7. Push Enter.

8. Push Esc to exit the menu system.

NOTE. The default selection is set to Off.

Lock the Multipurpose Knob

To lock the multipurpose knob so it cannot be used to change settings or to select menu items,

1. Push Menu.

2. Use the arrow keys to select >User Settings.

3. Push Enter.

4. Use the arrow keys to select Knob Lock.

5. Push Enter.

6. Use the arrow keys to select On or Off.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 21

Operating Basic

7. Push Enter.

8. Push Esc to exit the menu system.

s

System Inform

Check the Error Log

You c an v iew t

1. Push Menu.

2. Use the arro

3. Use the arr

errors that have occurred.

4. To exit the menu push Esc.

Check the Firmware Version o f the Instrument

This instrument includes two sets of firmware: Main and Auxiliary. To see the versions of installed firmware, do the following:

1. Push Menu.

2. Use the arrow keys or multipurpose knob and navigate to System Info and then push Enter.

3. Use the arrow keys or multipurpose knob and navigate to Main:. The numbers you see after Main: and Aux: are the

main firmware version and auxiliary firmware version, respectively.

4. To exit the menu push Esc.

ation

he error log by doing the following:

w keys or multipurpose knob and navigate to System Info and then push Enter.

ow keys or multipurpose knob and navigate to Error Log and then push Enter. You will see a list of any

Check the Calibration Date of the Instrument

nstrument stores the date that it was last calibrated. To see the calibration date, do the following:

This i

1. Push M

2. Use t

3. Use t

4. To exit the menu push Esc.

enu.

he arrow keys or multipurpose knob and navigate to System Info and then push Enter.

he arrow keys or multipurpose knob and navigate to the menu item below Main: . The date and time displayed are

the date and time of the last calibration performed on this instrument.

22 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Configure The Instrument for Your Application

The menu system includes settings, like Max Volt, that determine the maximum voltage output of the power supply and

settings, like Save Last and Output Recall, that determine how the instrument initializes itself at power-up.

This power supply features a constant voltage/constant current automatic crossover. This feature permits continuous

operation in the transition from constant-voltage mode to constant-current mode as the load changes. The intersection of

the constant-current and constant-voltage modes is called the crossover point.

For example, if the load is such that the power supply is operating in constant-voltage mode, the power supply provides

a regulated output voltage. As the load draws more current, the output voltage remains constant until the preset current

limit is reached. Then the crossover occurs. At that point, the output current becomes constant and the output voltage

drops in proportion to further load increases.

Crossover is indicated by the front-panel CC and CV messages. If the CV message appears, the instrument is operating in

constant-voltage mode. If the CC message appears, the instrument is operating in constant-current mode.

Crossover from the constant-current mode to the constant-voltage mode also occurs automatically in response to a

decrease in load current.

Connect to a Device Under Test

You can connect this instrument to a device that you w ant to test. In this section are procedures for configurations using local

and remote sense, and examples for parallel, serial, and bipolar wiring connections.

Operating Basic

s

NOTE. Wh

size sufficient to handle the maximum current.

WARNIN

short-circuit output current of the power supply. If there is more than one load, then any pair of load wires must be capable

of safely carrying the full-rated short-circuit output current of the power supply.

WARNI

short-circuit output current of the power supply. If there is more than one load, then every pair of load wires must be capable

of safely carrying the full-rated current of the power supply.

en connecting to a device under test, you should use at least a 22 gauge wire, which is the minimum wire

G. Use properly rated load wires. All load wires must be heavy enough not to overheat when carrying the maximum

NG. To satisfy safety requirements, always use load wires heavy enough not to overheat when carrying the maximum

Set Up to Use Local Sense

Configuring the power supply for local sense allows connection to the device under test with two lead wires, but does

not compensate for voltage drop in the leads.

1. On the rear-panel terminal strip, install wires or the supplied shorting clips between drive OUT + and SENSE +, and

between drive OUT - and SENSE -. When using the included shorting clips, they should be installed as shown

previously.(See page 10, Rear-panel Features.)

2. Connect to your device under test using two wires from the front-panel binding posts.

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 23

Operating Basic

Set Up to Use Remote Sense

Use remote sensing to regulate the output voltage at the device under test. This feature lets you compensate for the voltage

drop in the leads between the power supply front-end terminals and the device-under-test. To set the remote sensing mode:

1. Remove any jumpers or shorting clip on the rear-panel terminal strip connectors between drive OUT + and SENSE +

and between drive OUT – and SENSE –.

2. Connect a pair of sense leads from SENSE + and SENSE - to the device under test.

CAUTION. To assure system stability, use jacketed, twisted-pair cables between the remote sense terminals of the

instrument and the load.

3. Connect a pair of drive leads from the drive OUT + and drive OUT - to the device under test.

s

Load (Device Under Test)

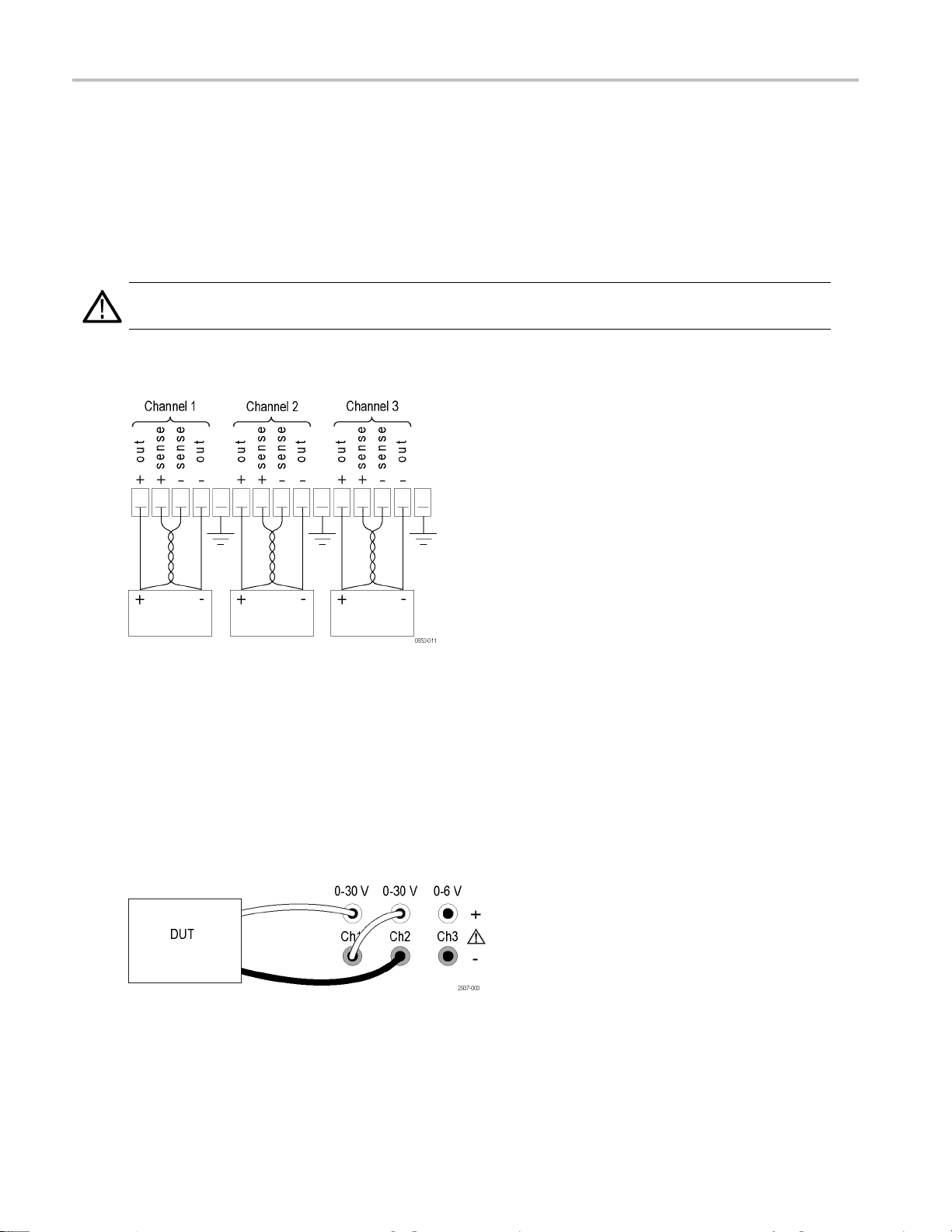

Wiring in Series

By wiring Channel 1 and Channel 2 in series, you can use your power supply to provide up to 60 V to a device under test.

The following figure shows how to wire the outputs for Series operation. (See Figure 3.)

Your instrument can also be configured to read the combined voltage from two channels. See Combine metering of Channel

1 and Channel 2 when outputs are wired in series to learn how to set the instrument to measure the combined

(See page 19.)

Figure 3: Series setup for model 2230-30-1 and device under test. Series setup for model 2220-30-1 is the same,

but Channel 2 is on the far right.

voltage.

24 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Operating Basic

Wiring in Parallel

By wiring Channel 1 and Channel 2 in parallel, you can use your power supply to provide up to 3 A to a device under test.

The following figure shows how to wire the outputs for Parallel operation. (See Figure 4.)

Your instrument can also be configured to read the combined current from two channels. See Combine metering of C hannel

1 and Channel 2 when outputs are wired in parallel to learn how to set the instrument to measure the combined current.

(See page 19.)

s

Figure 4: P

same, but Channel 2 is on the far rig ht.

arallel setup for model 2230-30-1 and device under test. Parallel setup for model 2220-30-1 is the

Wiring for Bipolar Applications

The outputs of your instrument can be wired as a bipolar source. When testing a system in which independent positive and

negative supplies are needed, the outputs should be wired as shown here. (See Figure 5.)

To make the positive and negative supplies track together, you can activate tracking. See Use Tracking to learn more about

ng and find out how to turn tracking on. (See page 19.)

tracki

Figure 5: Bipolar setup for model 2230-30-1 and device under test. Bipolar setup for model 2220-30-1 is the same,

hannel 2 is o n the far right.

but C

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 25

Operating Basic

s

26 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

Index

Index

Symbols and Numbers

110 V/220 V selector switch, 11

15-pin connector, 10

A

Accessorie

s

optional, 1

standard, 1, 2

B

Bipolar wi

Button

ring, 19

Channel select, 7

I-set, 7

Menu, 7

On/off, 7

Recall,

Save, 7

V-set, 7

7

C

l select button, 7

Channe

Channels

combining, 19

ning in parallel, 19

combi

combining in series, 19

Check

nt, 15

curre

no power, 14

voltage, 15

ectivity

Conn

USB, 12

Connector, 15–pin, 10

ectors, 6

Conn

Crossover, 23

Current

stant, 23

con

display, 6

limit adjustment, 17

D

splay, 6

Di

Upper messages, 9

E

Error message

F

Features, iv

Front-panel, 12

indicators

Function button

Channel select, 7

I-set, 7

Menu, 7

On/off, 7

Recall, 7

Save, 7

V-set, 7

I

tton, 7

I-set b u

Installation, 14

K

Key

6

arrow,

function, 6

number, 6

Save an

Key S ound, 21

Knob

Lock S

multipurpose, 6

d Recall, 6

et, 21

L

Local sense, 23

M

Volt Set, 18

Max

Menu button, 7

Messages, 9

or, 9

err

Multipurpose

knob, 6

ob lock, 21

Kn

s, 9

and buttons, 6

N

No power, 14

O

On/off button, 7

Operating requirements, 5

Operation

current limit adjustment, 17

recalling setups, 17

saving set

voltage limit adjustment, 1 7

Optional accessories, 1

Options, 1

Output

display, 6

Recall, 2

ups, 17

0

P

Parallel wiring, 19

Power

button,

off, 14

on, 14

socket

6

,10

R

Rear-panel, 10

Recall

n, 7

butto

output state at power on, 20

parameters at power on, 20

te sense, 10, 24

Remo

Requirements

operating, 5

S

e button, 7

Sav

Saving and recalling setups, 17

Series wiring, 19

ting

Set

current limit, 17

voltage limit, 17

ttings display, 6

Se

Shorting clip, 10

Specifications, 4

Series 2200 Multichannel Programmable D C Power Supplies User’s Manual 27

Index

Standard accessories, 1, 2

T

Troubleshoot

ing, 14

U

USB Device port, 10

V

V-set button, 7

Voltage

constant, 23

display, 6

limit adjustment, 17

setting maxim

um, 18

28 Series 2200 Multichannel Programmable DC Power Supplies User’s Manual

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc.

All other trademarks and trade names are the property of their respective companies.

Specifications are subject to change without notice.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY • www.keithley.com

Keithley Instruments, Inc.

A Greater Measure of Confidence

6/13

Loading...

Loading...