Page 1

Service Manual

SDA601

Serial Digital Analyzer

070-8914-04

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its subsidiari es or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifica tions and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.c om to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Parts, modules and replacement products used by Tektronix for warranty work may be new or

reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL

NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY

OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii...................................

Service Safety Summary ix....................................

Introduction 1--1.....................................................

Reference Documentation 1--1..........................................

Performance Conditions 1--1...........................................

Specification Tables 1--2..............................................

Certifications and Compliances 1--4.....................................

Getting Started 2--1..................................................

Supplying Power 2--1.................................................

Connecting the SDA601 2--3...........................................

SERIAL INPUT 2--4..............................................

AUX Output 2--4.................................................

RS-232 Interface 2--4.............................................

Keypad and Display Conventions 2--8....................................

The On-Screen Display (OSD) 2--9......................................

Preliminary Settings 2--10..............................................

Set the Date and Time 2--10.........................................

Set the Battery Type 2--11...........................................

Enable (Disable) Auto Power Off 2--11................................

Disable (Enable) Timed LCD Backlight Turn Off 2--12....................

Performance Verification 2--12..........................................

Using Your SDA601 2--12..............................................

Analyzing a Signal 2--13............................................

Watching a Signal 2--15............................................

Alarms 2--19.....................................................

LCD Display Modes 2--20..........................................

AUX Output Modes 2--23...........................................

Saving and Recalling Presets 2--25....................................

Software Reset 2--26...............................................

Performance Verification

Required Test Equipment 3--1..........................................

Performance Verification Checklist 3--3..................................

Performance Verification Procedures 3--4.................................

Adjustment Procedures

Required Test Equipment 4--1..........................................

Adjustment Procedures 4--2............................................

SDA 601 Serial Digital Analyzer

Preparation 3--4..................................................

Procedures 3--6..................................................

i

Page 6

Table of Contents

Maintenance

Adjust SLM (Signal Level Meter) 4--2................................

Adjust the Deserializer VCO (“Serial Pot”) 4--4.........................

Set the Date and Time 4--7.........................................

Maintenance 5--1..............................................

Battery Hints 5--1....................................................

Preventive Maintenance 5--1...........................................

Cleaning 5--1....................................................

Static-Sensitive Components 5--2....................................

Troubleshooting Aids 5--3.............................................

Foldout Pages 5--3................................................

Diagrams 5--3...................................................

Circuit Board Illustrations 5--3......................................

Numbering 5--3..................................................

Self-Diagnostics 5--4..............................................

Corrective Maintenance 5--9...........................................

Obtaining Replacement Parts 5--9....................................

Torque Specification 5--9..........................................

Replacing Assemblies 5--10.........................................

Replaceable Electrical Parts

Replaceable Electrical Parts 6--1.................................

Parts Ordering Information 6--1.........................................

Using the Replaceable Electrical Parts List 6--1............................

Abbreviations 6--1................................................

List of Assemblies 6--2............................................

Column Descriptions 6--2..............................................

Replaceable Electrical Parts 6--4........................................

Diagrams

Diagrams and Circuit Board Illustrations 7--1.....................

Block Diagrams 7--1.................................................

Circuit Board Illustrations 7--3..........................................

Replaceable Mechanical Parts

Replaceable Mechanical Parts 8--1...............................

Parts Ordering Information 8--1.........................................

Using the Replaceable Mechanical Parts List 8--1...........................

Abbreviations 8--1................................................

Chassis Parts 8--2................................................

Column Descriptions 8--2..............................................

Replaceable Mechanical Parts 8--3.......................................

Index

ii

SDA 601 Serial Digital Analyzer

Page 7

List of Figures

Table of Contents

Figure 2--1: Opening the Battery Compartment 2--2.................

Figure 2--2: Connecting the SDA601 2--3..........................

Figure 2--3: Connecting to a DTE Device with a DB25 Serial Port 2--5..

Figure 2--4: Connecting to a DCE Device with a DB25 Serial Port 2--6.

Figure 2--5: A Printed Analysis Report 2--7........................

Figure 2--6: The Default “Watching” OSD 2--9.....................

Figure 2--7: The Initial SDA601 Utility Menu Display 2--10............

Figure 2--8: The Set Time Display 2--10............................

Figure 2--9: Front and side views 2--13.............................

Figure 2--10: The Analyze OSD 2--14..............................

Figure 2--11: The Initial SDA601 Utility Menu Display 2--16...........

Figure 2--12: The SDA601 “Watching” Display 2--17.................

Figure 2--13: Watch Errors Reported on the OSD 2--18...............

Figure 2--14: The Display Mode Selection Keys 2--21.................

Figure 2--15: The SDA601 Signal Level Display 2--21.................

Figure 2--16: The Cursor Data Display 2--22........................

Figure 2--17: The SDA601 Time Display 2--23.......................

Figure 2--18: The First Review Display 2--23........................

Figure 3--1: An Equipment Setup for Performance Verification 3--4...

Figure 3--2: AUX Output Containing the On-Screen Display (OSD) 3--5

Figure 3--3: The Initial SDA601 Utility Menu Display 3--6............

Figure 3--4: The TSG601 Display Indicating Normal CRCs 3--7.......

Figure 3--5: The Analyze OSD 3--8...............................

Figure 3--6: The TSG601 Display Indicating an Erroneous FFCRC 3--9

Figure 3--7: The TSG601 Display Indicating an Erroneous APCRC 3--9

Figure 3--8: The TSG601 Display Indicating a Zero APCRC 3--10......

Figure 3--9: The SDA601 Cursor Display 3--11......................

Figure 3--10: The First Watch Menu Display 3--12...................

Figure 3--11: The I/O Menu/Highlighting Item Display 3--12...........

Figure 3--12: Page Five of the Watching OSD 3--15...................

Figure 3--13: SDA601-to-PC Cable Connections 3--16................

Figure 3--14: Initial Return Loss Setup 3-- 17........................

Figure 4--1: A Setup for SLM Adjustment 4--2.....................

Figure 4--2: The First SLM Calibration Display 4--3.................

SDA 601 Serial Digital Analyzer

iii

Page 8

Table of Contents

Figure 4--3: A Setup for Adjusting the De-serializer VCO 4--5........

Figure 4--4: The “Adj Serial Pot” Menu Item 4--5...................

Figure 4--5: The VCO Lock Error Indicator 4--6....................

Figure 4--6: The “Set Time” Display 4--7..........................

Figure 5--1: Numeric SLM Data 5--7..............................

Figure 5--2: The SDA Number Keys 5--7...........................

Figure 5--3: Exploded View of the SDA601 5--10.....................

iv

SDA 601 Serial Digital Analyzer

Page 9

List of Tables

Table of Contents

Table 1--1: Serial Digital Video Input 1--2.........................

Table 1--2: Signal Level Meter 1--2...............................

Table 1--3: AUX Output 1--2.....................................

Table 1--4: Power Supply 1--2...................................

Table 1--5: Physical Characteristics 1--3...........................

Table 1--6: Environmental Characteristics 1--3.....................

Table 2--1: RS-232 Connector Pin Assignments 2--5.................

Table 3--1: Required Test Equipment 3--1.........................

Table 3--2: Initial Settings for the Video Measurement Set 3--5.......

Table 4--1: Required Test Equipment 4--1.........................

SDA 601 Serial Digital Analyzer

v

Page 10

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at all

times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

SDA 601 Serial Digital Analyzer

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Replace Batteries Properly. Replace batteries only with the specified type and

rating.

Recharge Batteries Properly. Recharge batteries for the recommended charge

cycle only.

Use Proper AC Adapter. Use only the AC adapter specified for this product.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Do Not Operate in Wet/Damp Conditions.

vii

Page 12

General Safety Summary

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Terms in this Manual

Symbols and Terms

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

viii

CAUTION

Refer to Manual

SDA 601 Serial Digital Analyzer

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

SDA 601 Serial Digital Analyzer

ix

Page 14

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Battery Recycling. This product may contain a Nickel Cadmium (NiCd)

rechargeable battery, which must be recycled or disposed of properly. Please

properly dispose of or recycle the battery according to local government

regulations.

Restriction of Hazardous

Substances

x

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

SDA 601 Serial Digital Analyzer

Page 15

Specifications

Page 16

Page 17

Specifications

Introduction

The material in this section is organized into two main groupings: the specification tables and the supporting figures. The specification tables include:

H General input and output signal characteristics and specifications

H Physical and environmental specifications

The supporting figures (waveform diagrams and related data) follow the

specification tables.

Reference Documentation

The following documents were used as references in the preparation of these

specifications:

Recommendations and Reports of the CCIR, 1978; Transmission of Sound

Broadcasting and Television Signals Over Long Distances (CMTT).

Performance Conditions

The Performance Requirements are valid if the instrument has been adjusted at

approximately 25° C, is being operated within environmental limits (see

Table 1--3), and has had a minimum warm-up of 20 minutes.

IEEE Standard Dictionary of Electrical Terms, Second Edition (1977)

IEEE Standard 100--1977.

IEC 60B (Secretariat) 170, “Helical-scan digital composite cassette recording

system using 19 mm magnetic tape (Format D--2) (NTSC, PAL, PAL-M).”

ANSI/ISA S82 — Safety Standard for Electrical and Electronic Test,

Measuring, controlling, and Related Equipment.

CAN/CSA C22.2 No. 1010.1-92 — Safety Requirements for Electrical

Equipment for Measurement, control, and Labratory Use.

IEC1010-1 — Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use (1990).

SDA 601 Serial Digital Analyzer 1--1

Page 18

Specifications

Specification Tables

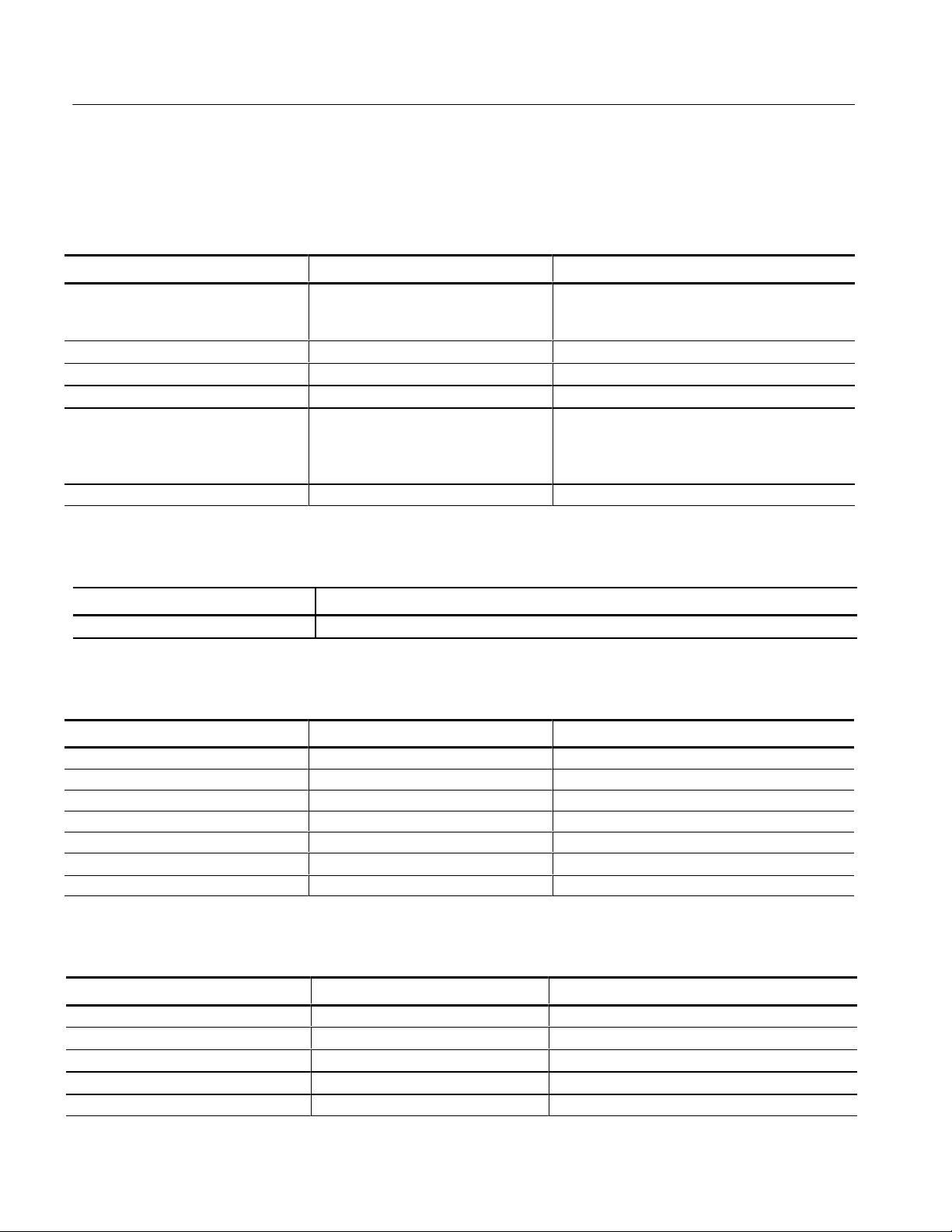

Table 1--1: Serial Digital Video Input

Characteristic Performance Requirements Supplemental Information

Format CCIR 601 Component 525/625, 10 bits data,

Scrambled NRZI; 270 Mb/s. Complies with SMPTE

259M and CCIR 656.

Input Impedance 75 Ω

Input Level 800 mV ± 80 mV (peak-to-peak) at signal source

Return Loss ≥ 15dB 1 MHz to 270 MHz

Serial Receiver Equalization Range Proper operation with 800 mV launch

amplitude and up to 15 dB loss at

135 MHz using coaxial cable with 1?

loss characteristics.

Error detection protocols supported EDH (RP-165), ØAPCRC

Nominally 150 m of Belden 8281 coaxial cable;

typically up to 200 m.

Ꭹ

f

Table 1--2: Signal Level Meter

Characteristic Information

Resolution 2 dB @ 135 MHz

Table 1--3: AUX Output

Characteristic Performance Requirements Supplemental Information

Output 5-bit output; monochrome signal

White Amplitude 700 mV ± 10% Terminated into 75 Ω

Sync Amplitude 300 mV ± 10% Terminated into 75 Ω

DC Offset ≤ 500 mV Terminated into 75 Ω

Quantization 22 mV

Impedance 75 Ω nominal

Return Loss ≥ 10 dB to 10 MHz

Table 1--4: Power Supply

Characteristic Performance Requirements Supplemental Information

DC Input Range 9to15Vdc ≥12 V required to charge optional battery pack

Supply Accuracy +5 V ±250 mV

Hum Typical: 25 mV

Noise ≤ 50 mV

Fuse 2 A slow blow, 32 V min

1--2 SDA 601 Serial Digital Analyzer

Page 19

Table 1--4: Power Supply (Cont.)

Power Limit

without adapter

with adapter

Power Consumption

Back light off

Back light on

Table 1--5: Physical Characteristics

Characteristic Information

Height 5.6 cm (2.2 in)

Width 9.1 cm (3.6 in)

Depth 19.1 cm (7.5 in)

Net Weight

SDA 601

SDA 601 with battery pack

Shipping Weight (with AC adapter) 1.50 kg (3.31 lb)

0.48 kg (1.06 lb)

0.68 kg (1.5 lb)

Specifications

Supplemental InformationPerformance RequirementsCharacteristic

6W

7W

Typical:

5.0 W

5.5 W

Table 1--6: Environmental Characteristics

Characteristic Information

Temperature

Operating

Storage

Altitude

Operating

Storage

Equipment Type Tes t

Equipment Class Class III (as defined in IEC 1010-1, Annex H)

Installation Category Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1)

Transportation Meets the requirements of NTSB Test Procedure 1A, category II (24 inch drop)

0° Cto+35° C (32° Fto+95° F)

-- 3 0 ° Cto+65° C(--22° F to +149° F)

to 15,000 feet (4572 m); IEC 1010-1 compliance to 2000 m

to 50,000 feet (15420 m)

Note: Rated for indoor use only.

SDA 601 Serial Digital Analyzer

1--3

Page 20

Specifications

Certifications and Compliances

EC Declaration of

Conformity -- EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 55103. Product family standard for audio, video, audio-visual and entertainment lighting control apparatus for professional use.

H Environment E2 — commercial and light industrial

H Part 1 Emission

H EN 55022. Class B radiated and conducted emissions

H EN 55103--1 Annex A. Radiated magnetic field emissions

H EN 55103--1 Annex B. Inrush current

H Part 2 Immunity

H IEC 61000--4--2. Electrostatic discharge immunity

H IEC 61000--4--3. RF electromagnetic field immunity

H IEC 61000--4--4. Electrical fast transient / burst immunity

Australia / New Zealand

Declaration of Conformity

-- E M C

EMC Compliance

H IEC 61000--4--5. Power line surge immunity

H IEC 61000--4--6. Conducted RF Immunity

H IEC 61000--4--11. Voltage dips and interruptions immunity

H EN 55103--2 Annex A. Radiated magnetic field immunity

EN 61000--3--2. AC power line harmonic emissions

Complies with EMC provision of Radiocommunications Act per these standard(s):

H AS/NZS 2064.1/2. Industrial, Scientific, and Medical Equipment: 1992

Meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility

when it is used with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

1--4

SDA 601 Serial Digital Analyzer

Page 21

Operating Information

Page 22

Page 23

Operating Information

This section duplicates material contained in the SDA601 user manual

(Tektronix p/n 070-8910-XX). The material is included here for your convenience. Please check the user manual whenever you need more information on

any topic.

Getting Started

Please note the following statements before using your SDA601.

CAUTION. Attempting to operate the SDA601 with an improper AC-to-DC adapter can result in damage to the instrument. To avoid damage, USE ONLY AN APPROPRIATE DC POWER SOURCE: Voltage must be 9 to 15 VDC; the

connector must have the NEGATIVE contact in the center; and open-circuit voltage of the power source must not exceed 18 VDC.

For best results, use the AC adapter that is supplied with the instrument. If the

supplied adapter is incorrect for the local AC power supply, contact your nearest

T ektronix representative.

Supplying Power

WARNING. Install or replace batteries only with the instrument switched OFF

and the AC adapter disconnected.

Replace the batteries only with standard AA batteries (1.2--1.5 V, nominal), or

with a Tektronix rechargeable battery pack (p/n 119-4488-00).

If you have any questions regarding the operation of this instrument, please

contact your nearest Tektronix representative or field office. In the United States

and Canada, you may also call the Tektronix information number, 1-800-TEKWIDE (1-800-835-9433), extension TV, between 8:00 am and 5:00 pm Pacific

time.

The SDA601 is DC powered. You may power it with the standard AC adapter,

the optional 9.6 V NiCad battery pack, eight standard AA batteries, or a “BP”

type external battery pack with the correct voltage and polarity. The external DC

power connector is on the left side of the instrument.

SDA 601 Serial Digital Analyzer 2- 1

Page 24

Operating Information

To install AA batteries or the battery pack, open the battery compartment of the

SDA601 by pressing down on the cover and sliding it in the direction of the

inscribed arrow, as shown in Figure 2--1. When the cover tabs line up with the

slots in the case, lift the cover away from the instrument. Install batteries in

alternating directions as indicated by the graphic molded into the “floor” of the

battery compartment. If using the optional battery pack, take the time to identify

both contacts and install the pack properly.

Figure 2- 1: Opening the Battery Compartment

When selecting a power source for your SDA601, please remember:

H Attempting to use an improper AC adapter can cause permanent damage to

the instrument. USE AN APPROPRIATE DC POWER SOURCE ONLY:

Voltage must be between 9 and 15 VDC; the center contact of the connector

must be NEGATIVE polarity; and open-circuit voltage must not exceed 18

VDC. For best results, use the adapter supplied with the instrument.

NOTE. Batteries must be installed to ensure uninterrupted operation when using

the wall adapter.

H There is no need to remove the optional NiCad battery pack for recharging.

The SDA601 will “trickle charge” the battery pack whenever the standard

AC adapter is attached and the instrument is switched off. It can take up to

16 hours to fully charge the battery pack. Note that charging w ill occur only

if the adapter supplies at least 12V; make sure that the adapter you use is

appropriate for the local AC supply.

H AA batteries are not included with the instrument; buy them locally.

Rechargeable AA batteries may be used, but they are NOT recharged

automatically. To recharge AA batteries, remove them from the instrument

and use an appropriate charger. For safety, read and follow the battery

charger instructions. Do NOT attempt to recharge standard alkaline batteries.

2- 2 SDA 601 Serial Digital Analyzer

Page 25

Operating Information

H After three minutes with no key press, the LCD back light will be dimmed to

save battery charge. (This may be disabled through the Utility/Diagnostics/

Power Manage menu; see page 2--12.)

H To guard against battery discharge if you forget to turn the SDA601 off,

enable Auto Power Off through the Utility/Diagnostics/Power Manage menu

(see page 2--11).

H The SDA601 can sense low battery voltage. It will warn you when the

charge is sufficient for approximately ten more minutes of operation. The

instrument will shut itself down when the battery voltage becomes too low

for reliable operation

The ON key toggles instrument power On and Off.

NOTE. If the instrument is operating with low batteries, it may turn itself off and

on. The batteries should be replaced or recharged depending on battery types.

Connecting the SDA601

Figure 2- 2: Connect ing the SDA601

Connect the instrument as shown in Figure 2--2. The OPTION connector is

reserved for later versions of the instrument. Note that the SDA601 has many

capabilities and features, and you may wish to gain familiarity with it by first

connecting it directly to a serial digital, component video signal generator such

as the Tektronix TSG601, an analog video monitor, and—if convenient—a

compact printer, such as the Seiko DPU 411 printer (Tektronix part number

119-4594-00), available from Tektronix distributors and through TekDirect.

SDA 601 Serial Digital Analyzer 2- 3

Page 26

Operating Information

SERIAL INPUT

AUX Output

Connect the instrument to your system through the SERIAL INPUT with 75Ω

coaxial cable.

NOTE. The SDA601 has internal, active termination. Any signal path that ends

with the instrument will be properly terminated only when the SDA601 is

switched on.

The AUX output signal may be thought of as “pseudo video.” It is derived from

the serial video input signal and converted to composite monochrome analog

video by an unfiltered 5-bit DAC. It is suitable for identifying the input and

displaying the cursor cross hairs, Highlighting, and the “OSD.” It:

H Lets you view the picture for convenient source identification.

H Can contain the On-screen Display (OSD; see page 2--9), which shows the

most recent Watch or Analyze results one page at a time—instead of one

item at a time as on the SDA601 display.

H With Pulse Cross enabled (see page 2--24), lets you “see” the contents of the

vertical and horizontal interval portions of the serial video signal.

RS-232 Interface

H Can include Cursor cross hairs for convenient positioning of the Cursors (see

page 2--22).

H When Highlighting (see page 2--24) is turned on, can help you locate and

identify errors in the picture, or the digital encoding of the signal.

By factory default, the AUX output is the Y (luminance) video component; you

may configure it, through the I/O menu, to be the R–Y or B–Y component

instead. (To access this setting, press

Connect an ASCII, serial printer to the RS-232 connector to create “hard copy”

analysis reports, or to log errors detected during a Watch session. You may also

capture the RS-232 output on a personal computer running a communications

application such as PROCOMMR or the Terminal accessory of MicrosoftR

WindowsT. With a printer or PC connected, you can choose—through the Alarm

menu—to have the SDA601 log every error as it occurs, or to print a Watch

report every ten seconds. This will permit unattended monitoring of your system.

See page 2--19 for more information.

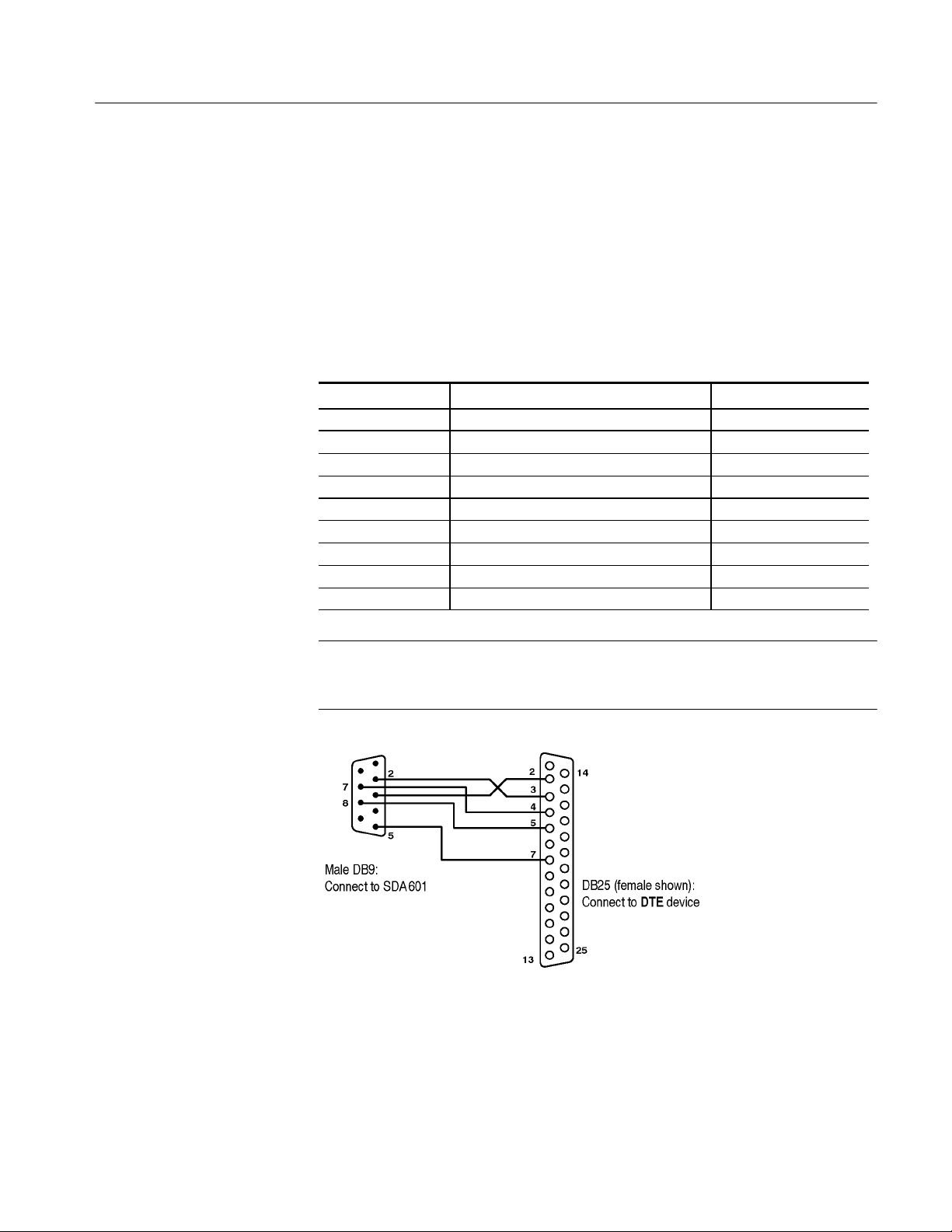

Connecting to the RS-232 Port. The SDA601 is an RS-232 DCE device. Table

2--1 lists the pin assignments of the connector. The connector pinout has been

chosen to interface directly with an IBM PC/AT 9-pin serial port using a

straight-through cable. Thus, when communicating with a DTE device that has a

male 9-pin (DB9) connector, use a cable that connects pins 2, 3, 5, 7, and 8

Shift, then Insert On/Off, then Y.)

2- 4 SDA 601 Serial Digital Analyzer

Page 27

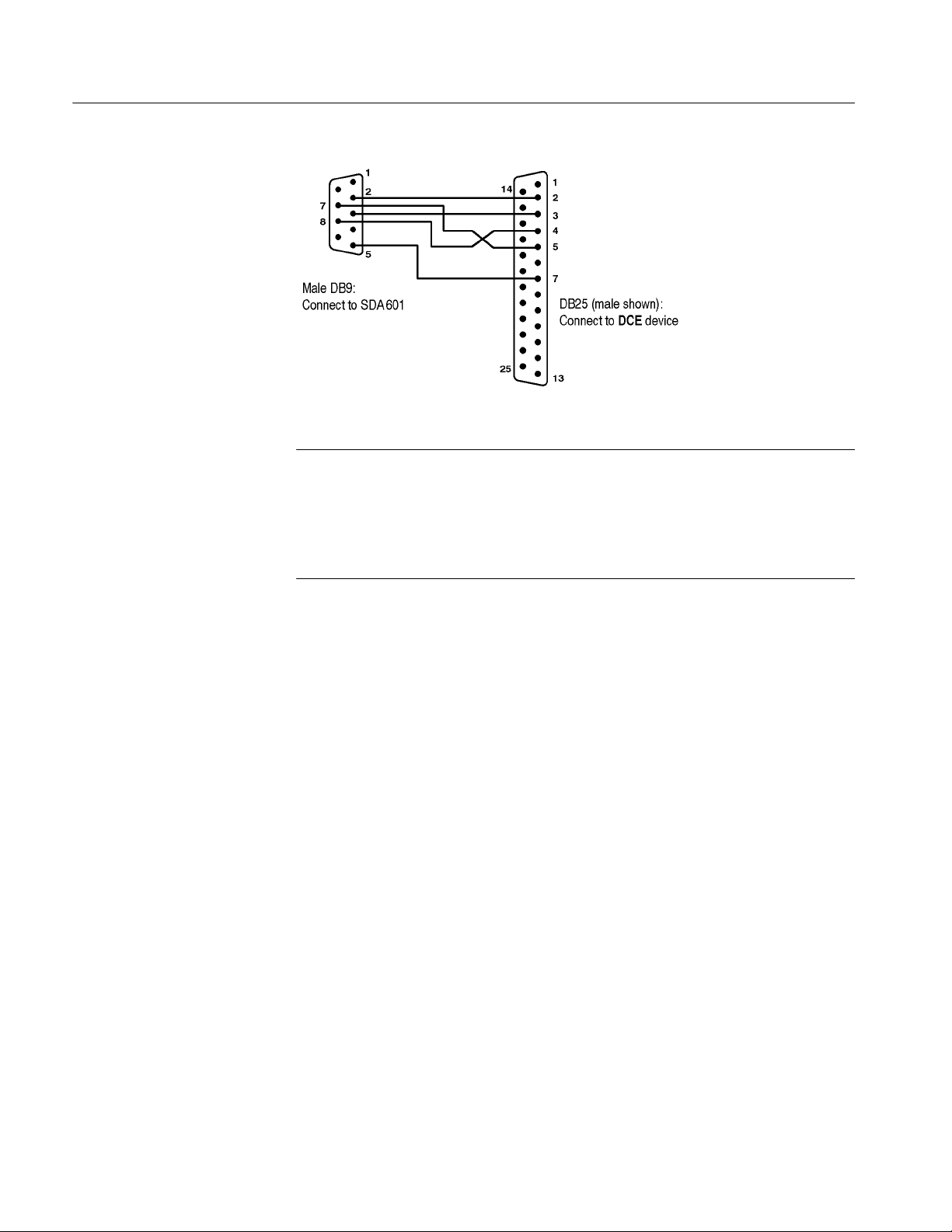

Operating Information

straight-through—a simple ribbon cable may be adequate. Use a null modem

cable (which swaps the lines between pins 2 and 3 and pins 7 and 8) to communicate with another DCE device. Figures 2--3 and 2--4 illustrate cable wiring for

communicating with a device that has a 25-pin serial connector.

Because of space limitations on the connector end of the SDA601, you may

have to insert a 9-pin adapter between the cable and the connector. If the cable

has a female end, use a male/male adapter such as ITT Cannon p/n 111805--1.

Table 2- 1: RS-232 Connector Pin Assignments

764 DB9 Pin Signal Name Signal Direction

1 Not connected —

2 RXD (Received Data) From SDA601

3 TXD (Transmitted Data) To SDA601

4 Not connected —

5 Signal Ground —

6 Not connected —

7 RTS (Request to Send) To SDA601

8 CTS (Clear to Send) From SDA601

9 Not connected —

NOTE. RS-232 signals are named from the perspective of the DTE device. Since

the SDA601 is a DCE device, pin 2 (“Received Data”) is an output from the

instrument; that is, the data is received by the connected DTE device.

Figure 2- 3: Connect ing to a DTE Device with a DB25 Serial Port

SDA 601 Serial Digital Analyzer 2- 5

Page 28

Operating Information

Figure 2- 4: Connect ing to a DCE Device with a DB25 Serial Port

NOTE. Most Personal Computers are DTE devices; however, printers may be

either DTE or DCE, and the type may not be obvious from the printer documentation or the gender of the RS-232 connector. If you have trouble outputting from

the SDA601, first verify that communication parameter and Baud rate settings

are correct, then try reversing the conductors at pins 2 and 3 and 7and 8 at the

cable end that is connected to the SDA.

RS-232/Printer Setups. Set the receiving device to 8 data bits, and one stop bit, if

possible.

The SDA601 supports both hardware (RTS/CTS) and software (Xon/Xoff)

handshaking; choose the appropriate handshaking protocol through the Utility/

Printer Setup submenu. Specify 60 lines per page (also in the Utility/Printer

Setup submenu) for most printers that use 8.5 x 11.0 inch paper.

Set the Baud rate and Parity—through the Utility/RS-232 Setup submenu—to

match the printer. When in doubt, set Parity to None.

Testing the Connection and Settings. To test your printer connection and settings,

perform a signal analysis by pressing

Analyze. Then, press Shift-Analyze.The

printer should respond by printing an analysis report that resembles the one

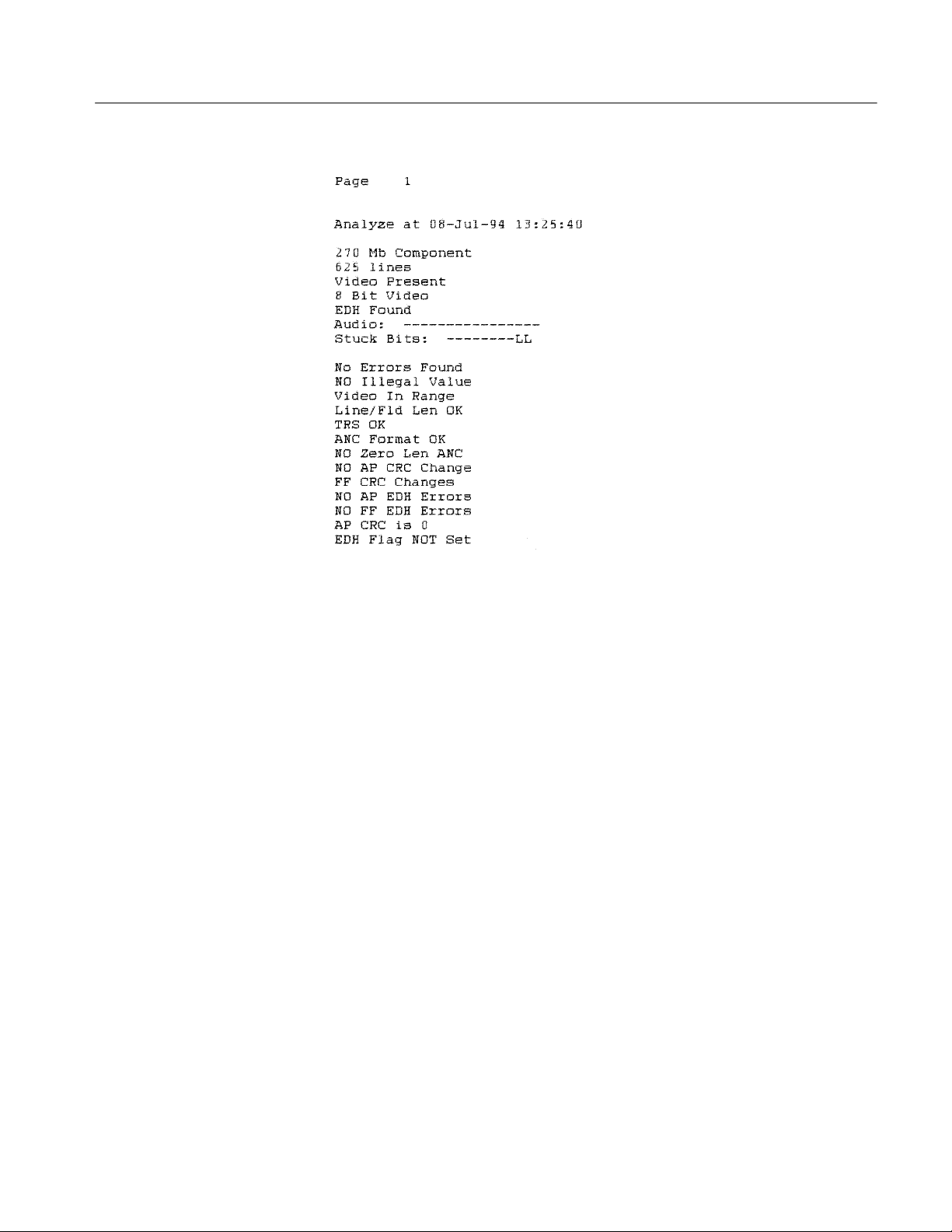

shown in Figure 2--5.

2- 6 SDA 601 Serial Digital Analyzer

Page 29

Operating Information

Figure 2- 5: A Printed Analysis Report

SDA 601 Serial Digital Analyzer 2- 7

Page 30

Operating Information

Keypad and Display Conventions

Please see the Instruction card (Tektronix part number 070-8912-00) supplied

with your SDA601 for a “tour” of the keypad and an explanation of the display

symbols. For your convenience, the following panels are taken from the card.

Additional key functions are:

SLM (A) — Invokes the SLM display mode. Press this key to su-

percede any other display mode and display the Signal Level Meter on the SDA601 LCD. See page 2--21.

Cursor (B) — Invokes the Cursor data display mode. Press this

key to supercede any other display mode and display the cursor

position (line and sample) on the SDA601 LCD. See page 2--21.

Pulse Cross (E) — Press repeatedly to cycle through the four AUX

output pulse cross modes: Normal, H (horizontal), V (vertical),

and Both (horizontal and vertical). See page 2--24.

2- 8 SDA 601 Serial Digital Analyzer

Page 31

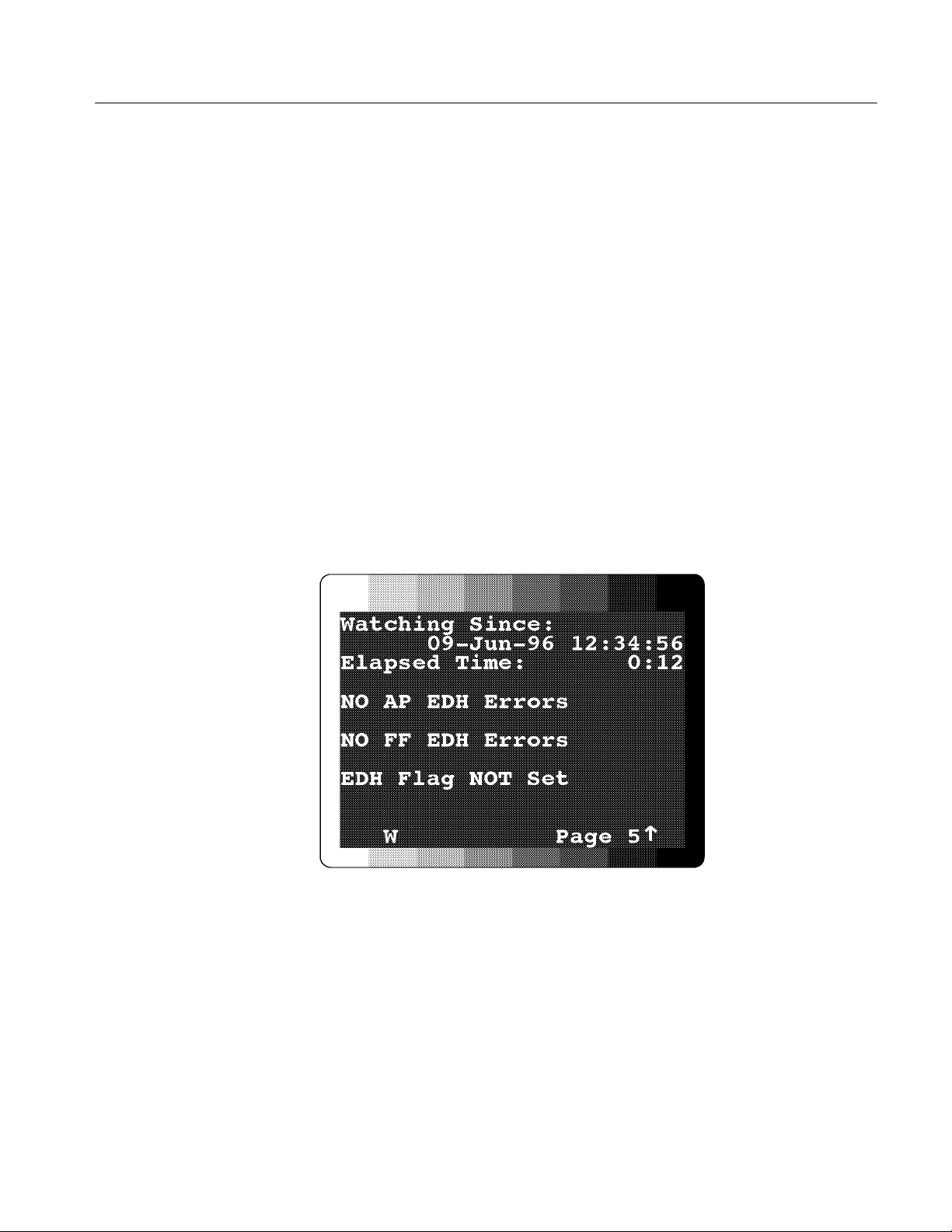

The On-Screen Display (OSD)

The OSD is a 12 line, 24 column display that can contain results from SDA601

Analyze and Watch sessions. It can be superimposed on the AUX output and

viewed on an attached video monitor. Toggle the OSD On/Off with the

On/Off key. The default OSD will resemble Figure 2--6 when the instrument is in

Watch mode. You can control several OSD characteristics (size, color, screen

position) through the Utility/OSD Setups submenu; see the User manual for

details.

Operating Information

Time (F) — Invokes the Time display mode. Press this key to su-

percede any other display mode and display the current date and

time on the SDA601 LCD. See page 2--23.

Review (G) — Invokes the Review display mode. Press this key to

supercede any other display mode and review the results of the

latest Analysis or Watch session on the SDA601 LCD. See page

2--23.

Insert

Figure 2- 6: The Default “Watching” OSD

The symbols on the bottom line of the OSD have the following meanings:

H The rotating line in the lower left indicates that Auto Power Off is enabled.

H The musical note symbol indicates that Alarms are toggled On with the

key or through the Alarm menu. This symbol can appear even when the

beeper and print errors items in the Alarm menu are set to Off.

H The “W” appears when the instrument is in Watch mode.

H The reversed “E” means that an error is detected.

SDA 601 Serial Digital Analyzer 2- 9

Alarm

Page 32

Operating Information

Preliminary Settings

H Similar reversed “S” and “SL” icons (not shown) will appear when SDA601

keypad is shifted and shift locked.

H The down-arrow in the lower right indicates that the B key may be used to

reveal another (higher-numbered) page. An up-arrow will appear in all other

pages to indicate that the

Y key may be used.

The Analyze OSD is similar; see Figure 2--10, on page 2--14.

Once the SDA601 is up and running, you should choose some settings

depending on how you’ll be using the instrument. These settings are made

through the Utility menu. Follow these directions to set the current date and

time, set the Battery Type, and enable Auto Power Down (if desired).

Set the Date and Time

1. To enter the SDA601 Utility menu, hold the Lock Out key down and press

the

ON button. Release the ON button, but continue to press the Lock Out key

until the display resembles Figure 2--7.

Figure 2- 7: The Initial SDA601 Utility Menu Display

2. Once in the Utility menu, use the

item, and press

Enter. The instrument display will change to resemble

Y and B keys to scroll to the Set Time

Figure 2--8.

Figure 2- 8: The Set Time Display

3. The underline cursor indicates the active character position. Move the cursor

with the

A and " keys. Enter the appropriate character from the SDA601

keypad. When the cursor is in positions that require numeric entry, the keys

will be automatically shifted. When you enter an appropriate character for

the field, the cursor will move one position to the right. The acceptable

2- 10 SDA 601 Serial Digital Analyzer

Page 33

Operating Information

month abbreviations are the first three characters of the English name: JAN;

FEB; MAR; APR; MAY; JUN; JUL; AUG; SEP; OCT; NOV; DEC.

Enter the time in 24 hour format; that is, if the present time is 4:15 pm, enter

16:15.

Set the Battery Type

4. When the correct date and time is shown on the display, press

Enter.Ifall

values are valid, the instrument will respond with the message “Time

Accepted.” If you have made an error and entered an invalid date or time, the

instrument will respond with an appropriate error message. If that happens,

correct the error and press enter.

5. Press any rectangular key to exit the Utility menu, or proceed to other

preliminary settings, as appropriate.

Confirm that the Battery Type setting is correct, and change it if necessary.

1. After setting the clock, press the

submenu item, and press

Enter.

B key once to scroll to the Diagnostics

2. In the Diagnostics submenu, scroll down to the Power Manage item with the

B key. Again, press Enter.

3. The top item in the Power Manage submenu is Battery Type. Toggle to the

selection that matches the type of battery you have installed in your

SDA601 by pressing either

A or ". The choices are “rechargeable” and

“disposable.” Select rechargeable when using NiCad AA cells or the optional

battery pack; choose disposable when you are using common Alkaline AA

batteries, which cannot be recharged. Press

Enter to confirm the choice.

4. When the correct battery type is indicated by an asterisk (*) on the lower

right of the LCD, continue to Auto Power Off, or press any rectangular key

to exit the Utility/Diagnostics/Power Manage submenu and return to normal

operation.

Enable (Disable) Auto

Power Off

“Auto Power Off” will switch the instrument off when ten minutes have passed

without a key press. Enable this feature when you are using battery power and

operating in an environment in which unplanned shutdown of the SDA601 is

permissible.

1. While still in the Utility/Diagnostics/Power Manage submenu, press the

key twice to scroll to the Auto Power Off item.

2. Disable/enable Auto Power Off by pressing either

A or ".PressEnter to

confirm the choice. Enabled Auto Power Down is indicated by a “rotating

line” symbol on the second line of the instrument display, and in the

lower-left corner of the OSD.

SDA 601 Serial Digital Analyzer 2- 11

B

Page 34

Operating Information

3. Use the

Disable (Enable) Timed LCD Backlight Turn Off

Another power saving feature of the SDA601 is timed turn-off of the LCD

backlight. It is enabled by default in a new or reset instrument. If you will always

operate with the AC adapter, you may wish to disable the feature. To toggle

backlight turn-off:

1. In the Utility/Diagnostics/Power Manage submenu, use the

2. Choose between “Timed Turn Off” and “On all the time” with either

3. As before, use the

Performance Verification

A performance verification procedure, which some users may require for

acceptance testing, is included in Section 3 of this manual.

Y and B keys to scroll to other “power manage” items, or press any

rectangular key to exit the menu and resume normal operation.

Y and B keys to

scroll to the LCD Backlight item.

A or ",

then press

Enter to confirm the choice.

Y and B keys to scroll to other “power manage” items, or

press any rectangular key to exit the menu and resume normal operation.

Using Your SDA601

NOTE. For more information on Serial Digital Video Systems, request Tektronix

publication 25W-7203-1 “A Guide to Digital Television System and Measurements” from your nearest Tektronix representative or field office.

See Figure 2--9 for a front and side view of the SDA601.

Here’s what you can do with your SDA601. Instructions for each function begin

on the indicated page.

H Analyze one second of the incoming signal and read the results on the

instrument display or an attached video monitor (page 2--13). You may also

print the results on an attached ASCII, serial printer (page 2--15).

H Watch the input signal, paying attention to selected signal characteristics, or

groups of characteristics (page 2--15). Errors are reported to the instrument

display panel and an attached video monitor. You may also log errors to an

attached printer (page 2--19).

H Set audible alarms to warn you of any errors encountered while the

instrument is “watching” the input signal (page 2--19).

2- 12 SDA 601 Serial Digital Analyzer

Page 35

Operating Information

H View decoded video on an analog picture monitor attached to the AUX

output (see page 2--4)

H Highlight, on the picture monitor, selected signal conditions or errors in the

context of the video signal. (page 2--24)

H Measure the approximate level of the digital input signal with the built-in

Signal Level Meter (SLM; page 2--21)

H Discover, with the help of video Cursors, the hex value of any sample in the

video frame (page 2--22).

H Shift the video frame horizontally and vertically with the Pulse Cross

feature to “see” the H and V intervals on the AUX picture monitor

(page 2--24).

Figure 2- 9: Fr ont and side views

Analyzing a Signal

SDA 601 Serial Digital Analyzer 2-13

Analyze Mode may be selected with the Analyze key at any time. In this mode,

the instrument attempts to lock onto the digital video signal and, if successful,

accumulates data from one second of the incoming signal. The instrument then

analyzes the status of the various signal characteristics and reports the results to

the Review List. The Review List may be viewed on the OSD (on an attached

Page 36

Operating Information

video monitor) as well as on the SDA601 LCD. The SDA601 up and down

arrow keys are used to scroll through the list of detected “conditions.”

The conditions detected and reported in an SDA601 analysis are:

Video format TRS (OK/incorrect)

Line standard (625 or 525) ANC Format (OK/incorrect)

Video present or missing Zero length ANC (yes/no)

Video resolution (8 or 10 bits) APCRC changes (yes/no)

EDH packet found/missing

FFCRC changes (yes/no)

Audio status (16 channels) APCRC errors (yes/no)

Stuck bits (if any) FFCRC errors (yes/no)

Illegal (digital word) values ØAPCRC (yes/no)

Video In/Out of range EDH flag set/not set

Line/field length (OK/incorrect)

Performing an Analysis. To analyze a signal, simply press

Analyze. The SDA601

will observe the incoming signal for one second, analyze the data, and write the

results to a “condition review list” and the OSD.

Reviewing the results on the OSD. There are three pages of results; use the

Y keys, as indicated by the arrow icons on the lower right of the OSD, to see all

B and

three pages.

Figure 2- 10: The Analyze OSD

Reviewing the results on the LCD. Use the B and Y keys to scroll through the

condition list on the instrument LCD. The display will “time out” after three

seconds of no key press and return to its pre-analysis state—Idle, or the data

enabled through the Display Select menu. Press Enter to return to the last-reviewed condition; press

B or Y to scroll down or up the list. You may also press

2- 14 SDA 601 Serial Digital Analyzer

Page 37

Operating Information

Review (G) to supercede all other LCD display modes and prevent “time out” of

the results display.

Printing an Analysis Report. With a printer connected to the RS-232 port and

properly configured (see the Reference section of the User manual), press

then

Analyze. A report, resembling the printout shown in Figure 2--5 (page 2--7),

Shift,

will be printed.

Audio and Stuck Bits Explained. Audio content and stuck bits are reported on the

LCD and Printer output in the same format as in the OSD, shown in Figure

2--10:

H The “Audio:” result line has room to display the status of all 16 audio

channels that can be embedded in digital video. The status of channels (#1

through #16, from left to right) are reported as “--” for no audio detected,

“A” for active audio, and “M” for mute (present, but silent).

H The “Stuck Bits:” line shows the status of the 10 bits of the video word (in

the active picture area), MSB to LSB left to right. If the signal contains any

stuck bits, they are indicated by an H (stuck high) or L (stuck low) in the

appropriate position. The two LSBs will be reported as L when an 8-bit

video signal is received. Other stuck bits may suggest either an incorrect

signal or faulty equipment.

Watching a Signal

Zero-length ANC. Is reported by the SDA601 when a Ø-value ANC “Data Count

word” is detected in the input data. The detection of zero-length ANC is

important because some digital video equipment can insert such an ANC into the

serial digital video data stream, even though it can cause difficulty in some

systems.

While Analyze takes a one-second “snapshot” of the input signal and reports the

status of a predefined list of characteristics, Watch mode permits continuous

observation of the signal characteristics—or “conditions”—of your choice. In

addition to reporting errors to the instrument display and the OSD, Watch mode

can also be configured to sound an audible (“beep” or “tick”) alarm to alert you

of any error, and log errors to a printer for later review.

The steps to monitoring a signal with the SDA601 are:

1. Select the conditions to be watched. This is done through the Watch menu,

which can be set—through the Utility menu—for selection of conditions on

a “Group” or “Item” basis. Group selection is the factory default.

In all, there are 20 Watch conditions. Eight conditions are always watched

and reported when “Watch Menu Type” is set to Group Select:

SDA 601 Serial Digital Analyzer 2-15

Page 38

Operating Information

Video format EDH packet found/missing

Line standard (625 or 525) Audio present/missing

Video present or missing Stuck bits (if any)

Bits in active picture (8 or 10) Other ANC (if any)

The twelve remaining conditions are organized into the four Watch groups:

Data Value Group: CRC Change Group:

Illegal (word) values

APCRC changes (yes/no)

Video In/Out of range FFCRC changes (yes/no)

Format Group: APCRC is/not Ø

Line/field length (OK/incorrect) EDH Group:

ANC Format (OK/incorrect) AP EDH errors (yes/no)

TRS (OK/incorrect) FF EDH errors (yes/no)

Zero length ANC (yes/no) EDH flag set/not set

When only the Data Value group is set to “Watch,” then, the SDA601 will

actually observe the status of ten conditions—the eight default conditions,

plus Illegal Values and Video In/Out of Range. If all four groups are selected,

all 20 conditions will be monitored.

Group selection can be inconvenient in some circumstances, however. An

example is observing a changing test signal that is being generated with

ØAPCRC. In this case, FFCRC changes are not an error, but a non-zero

APCRC is. Watching the CRC Change Group, then, could result in

inappropriate or misleading alarms.

To prevent this conflict, set the Watch Menu Type to “Item Select” through

the Utility menu and select the “AP CRC Not Ø” item through the Watch

Menu. To set the Watch Menu Type:

a. Hold the

menu. Release the

Lock Out key down and press the ON button to enter the Utility

ON button, but continue to press the Lock Out key until

the display resembles Figure 2--11.

Figure 2- 11: The Initial SDA601 Utility Menu Display

b. Go to the Watch Menu Type menu item by pressing the

B key three

times.

c. Press the

" key once to choose Item Select, then press ENTER to confirm

the choice.

d. Press

Watch to exit the Utility menu.

2- 16 SDA 601 Serial Digital Analyzer

Page 39

Operating Information

When Item Select is in effect, the list of “always-watched” conditions is

reduced to Video Format (270 Mb Component, for example) only. All other

items must be selected one-by-one through the Watch menu. The Watch

items, in the order they appear on the Watch menu, are:

Line Standard (report 525 or 625, or alarm on one or the other)

Video Missing

Active Picture Bits (8 or 10)

EDH Packet

Embedded Audio

Stuck Bits

Other ANC Data (not Audio or EDH)

Illegal Word Values

Over-range Video

Line/Field Length

TRS Errors

ANC Format Errors

Zero Length ANC

APCRC Changes

FFCRC Changes

APCRC not Ø (report, or alarm if not Ø)

AP EDH Errors

FF EDH Errors

EDH Flag Set

2. Set the appropriate alarms; see page 2--19.

3. Once all conditions have been selected and alarms configured, begin the

Watch session by pressing Watch. The message “Watch Started” will appear

briefly on the LCD. If none of the display options (Signal Level, Cursor

Data, or Current Time) have been turned on, the display will “time out” to

resemble Figure 2--12. If one or more of the LCD display modes (see page

2--20) has been activated, the display will revert to the display mode(s), and

the Watch session will continue in the background. In all cases, the results of

the session will be written to the OSD; press

Insert On/Off, if necessary.

Figure 2- 12: The SDA601 “Watching” Display

4. Review the condition list on the SDA601 LCD by pressing the

you reach the END OF LIST message. Use

Y to scroll back up the list as

B key until

desired. The LCD Watch review list will “time out” if more than 3.5 seconds

pass without a key press (press the

the display has timed out, press

Review key to prevent this time out). After

Enter to return to the last-displayed item;

SDA 601 Serial Digital Analyzer 2-17

Page 40

Operating Information

press

Y to move up the list and display the previous item; press B to display

the next item “down” the list.

5. If you have a video monitor connected to the AUX output, you may review

the condition list on the OSD. Toggle the OSD On with the

then page the OSD up and down with the

Y / B keys.

Insert On/Off key,

Pausing a Watch Session. A Watch session is temporarily suspended when you

invoke any other SDA601 menu (besides the Watch menu). Data collection

continues, but OSD and printer updates are suspended. When you exit the menu

by pressing a rectangular key, the OSD will update to include all events during

the time spent in the menu.

Stopping a Watch Session. The current Watch session will end when you press

Analyze or enter the Watch menu. After the analysis, or on leaving the Watch

menu, you may begin a new Watch session by pressing

Watch. Note that the

SDA601 will “forget” all data collected during a Watch session when the session

is concluded.

Restarting a Watch session. Pressing

Watch during a Watch session will restart the

Watch mode, resetting the elapsed time counter and the printer page count to

zero.

Figure 2- 13: Watch Errors Reported on the OSD

2- 18 SDA 601 Serial Digital Analyzer

Page 41

Operating Information

Interpreting Error Reports. The SDA601 reports errors in many Watch conditions

to the review list on an “errored seconds” basis, as shown in Figure 2--13. In this

illustration, one second of the Watched signal—approximately 25 seconds after

the Watch session was started—contained one or more changes in both the

FFCRC and the APCRC. In addition, more than 254 one-second periods of the

signal contained non-zero APCRCs (254 is the highest count possible in the

SDA601). The most-recent non-zero APCRC was detected in the last reported

one-second period, 7:12 into the Watch session.

The same reporting format is used on the SDA601 LCD.

Alarms

Alarms are enabled through the Alarm menu. When enabled, an alarm is

generated when one or more signal conditions or errors are detected by the

SDA601 in Watch mode. The SDA601 has two types of alarm:

H A “beeper” (audible) alarm that may be configured in one of three ways:

H Long Beep — Several seconds long, produced each time an alarm

condition is detected. In the case of frequently-recurring errors, the beep

will repeat continuously, if necessary; however, there may be fewer than

one alarm per error condition.

H Short Beep — One second duration; otherwise similar to the Long Beep.

H Beep “Tick” — A very short beep, almost a tick; useful when there are

many alarm conditions, when they occur in “bursts,” or for audible

feedback when performing equipment adjustments for proper operation.

H A Printer alarm, output on the RS-232 port. There are two ways to use the

printer during watch sessions:

H Log each error — or as many as the printer buffer allows. Intended for

extended monitoring of the signal when few, if any errors are expected.

You can leave the SDA601 (powered by the AC adapter) and a printer

unattended to log and help diagnose intermittent problems. This is the

same as the audible alarm in that, once configured, it can be controlled

with the

Alarm On/Off key.

H Print an error report every ten seconds — Strictly speaking, this option is

not an alarm because when it is selected, the instrument will print a

report every ten seconds of the Watch session whether an error has been

detected or not, and regardless of the Alarm On/Off state (set with the

key or through the menu). The print line will contain at least the time

and video format; errors, if any, that have occurred in the preceding

ten-second interval will also be printed.

Select alarm conditions or errors through the Watch menu (see “Watch Mode,”

above). Conditions that will always trigger an alarm if detected by the SDA601

in Watch mode are:

SDA 601 Serial Digital Analyzer 2-19

Page 42

Operating Information

No PLL Lock

Video Missing

“Other” ANC Data

Illegal Value

Video Over Range

Line/Field Len

EAV/SAV/TRS Error

ANC Format Error

Zero Length ANC

AP CRC change

FF CRC change

AP EDH error

FF EDH error

Flag Set

Conditions that will trigger an alarm only if they are configured to do so through

the Item W atch menu are:

Line Std Detect (if “Alarm if 525” or “Alarm if 625” is selected)

AP Bits (8/10) (if “Alrm if 8 bits” or “Alrm if 10 bits” is selected)

EDH packet miss (if “Alarm if Miss” is selected)

AP CRC Not Ø (if “Alarm Not Ø” is selected)

LCD Display Modes

Configure the beeper and printer alarms through the Alarm Menu. As you might

expect:

1. Enter the Alarm menu (press

Shift, then Alarm On/Off).

2. Scroll to the desired menu item with the B / Y keys.

3. Select the option with the

4. Confirm the option choice by pressing

A / " keys.

Enter.

5. Exit the Alarm menu by pressing any rectangular key.

Once the alarms are configured through the Alarm Menu, you may toggle all

alarms On/Off with the

Alarm On/Off key (which duplicates and overrides the

function of the “Alarm On/Off” item in the Alarm Menu). Note that turning the

alarms “On” with this key (or menu item) is equivalent to “arming” the alarms:

regardless of all other configuration options, the alarms will not “sound” unless

they are also turned On through the “Alarm On/Off” menu item or with the

key.

On/Off

Alarm

Three SDA601 LCD display modes—SLM (Signal Level Meter), Cursor, and

Time—may be invoked directly with the corresponding key (see Figure 2--14), or

through the

supercedes all other uses of the display. When selected through the

Display Select key/menu. When the mode is selected with its key, it

Display Select

menu, a mode will “time share” the display with any previously active mode(s).

2- 20 SDA 601 Serial Digital Analyzer

Page 43

Operating Information

A fourth display mode, Review, may be invoked with the

Review key only. The

four display modes are explained in the next few paragraphs.

Figure 2- 14: The Display Mode Selection Keys

SLM Display Mode. The SDA601 displays the relative level of the serial digital

input signal when you press the

through the

Display Select key/menu. The display will resemble Figure 2--15; note

SLM (A) key, or toggle “Disp Sig Level” On

that a longer “bar” indicates a weaker signal (often due to a longer cable).The

SDA601 SLM can help you identify points in your system where the digital

video signal may be marginal because of long cable runs or faulty equipment.

The signal level display will report an 800 mV

input signal as approximately

p-p

Ø dB (usually, only one segment will be “lighted,” if any).

Figure 2- 15: The SDA601 Signal Level Display

Selecting the Cursor, Time, or Review operating modes with the respective

keys—(

Signal Level display by pressing the front panel

Cursor (B), Time (F),orReview (G)—will turn the SLM Off. Reselect the

SLM (A) key, or—if you want two

or more modes to alternate on the display—toggle the SLM On through the

Display Select key/menu.

Cursor Display Mode. The SDA601 Cursor mode, selected by pressing the Cursor

(B)

key, makes it possible to locate a single word in the digital video frame and

discover the actual (hexadecimal) value of the selected word and the three words

SDA 601 Serial Digital Analyzer 2-21

Page 44

Operating Information

that follow. See Figure 2--16. The location of the selected word in the video

frame is also indicated by “cross hair” cursors in the AUX output; connect an

analog video monitor to see the cross hairs.

Figure 2- 16: The Cursor Data Display

The first line of the cursor data display contains the hexadecimal values of the

selected word and the three that follow it. Values typical for the SAV timing and

reference signal are shown in Figure 2--16. The video “type” of the selected word

is indicated by the sample ID:

B=C

color difference

B

Y = Cosited luminance

R=C

color difference

R

y (lowercase) = Isolated luminance

The second line contains the coordinates of the selected word. In the example,

the selected word is number 1712 of line 4 in field 1.

The cursor movement icon will be visible on the second line when the arrow

keys are “active” for cursor positioning. Normal cursor movement is one line up

or down for each

Engage shift lock (pressing

Y or B key press, and one word per press of the A or " key.

Shift twice) to accelerate horizontal movement to 20

words per key press, and increase vertical movement to 10 lines per key press.

Press Shift again to return to “fine” cursor control.

The cursor cross hairs are inserted in the AUX output whenever the

Cursor key is

pressed; they are not removed when Cursor mode is deactivated. You may

remove the cross hairs from the video display by setting Video Cursor, in the I/O

menu, to “No Display.”

The Cursor Data display may also be invoked through the Display Select menu, but

Cursor cross hairs must then be enabled separately, through the

To exit the Cursor Data display mode, press the

SLM (A), Time (F),orReview (G)

I/O menu.

key, or turn the display Off through the Display Select menu.

2- 22 SDA 601 Serial Digital Analyzer

Page 45

Operating Information

NOTE. To remove the cross hairs from AUX output—regardless of how you exit

Cursor Data display mode—you must also set the Video Cursor item in the

I/O

menu to “No Display.”

Figure 2- 17: The SDA601 Time Display

Time Display Mode. Press the Time (F) key to devote the SDA601 display to the

current date and time. If you wish to alternate the time display with previouslyselected SLM or Cursor data, toggle the “Disp Cur Time” item On through the

Display Select menu. The LCD will resemble Figure 2--17.

AUX Output Modes

Review Display Mode. Press the

Review (G) key to cancel the other display modes

(SLM, Cursor, and Time) and review the results of the ongoing Watch session—or the most recent Analysis—on the LCD. Once you have pressed

(G), the SDA601 display will resemble one of the two shown in Figure 2--18; use

the

B key to review the status of individual Analyze or Watch items.

Review

OR

Figure 2- 18: The First Review Display

Recall that the AUX output signal is “pseudo-video” that is decoded from the

digital input signal. It may be viewed on an analog video monitor. The AUX

output has three optional modes: the OSD (on-screen display), Pulse Cross, and

SDA 601 Serial Digital Analyzer 2-23

Page 46

Operating Information

Highlighting. See page 2--9 for an explanation of the OSD; Pulse Cross and

Highlighting are discussed in the following paragraphs.

Pulse Cross. Pulse Cross is an SDA601 AUX output mode that allows the user

to “see” the horizontal and/or vertical intervals, which are normally blanked in

video monitors. The original four-word timing reference signals (TRS, which

contain EAV and SAV) are replaced with legal video samples, and analog H and

V sync information is inserted in the original active picture region. There are

four pulse cross “states”:

Normal — blanked intervals, the instrument default

HCross — reveals the “horizontal interval” region of the signal

VCross — reveals the “vertical interval” region of the signal

Both — combines HCross and VCross

To select among the four pulse cross states, press the

Pulse Cross (E) key repeated-

ly until the desired state is visible on the video monitor.

To invoke pulse cross through the I/O menu:

1. Enter the I/O menu (press

2. Press the

3. With the

B key repeatedly to scroll down to the Pulse Cross menu item.

A / " keys, scroll to the desired pulse cross option.

Shift, then Insert On/Off).

4. Press Enter to select the new option.

5. Press any rectangular key to exit the I/O menu.

Highlighting. When the Highlighting option is selected, the SDA601 “flashes”

pixels in the AUX “video” output that correspond to certain Watch conditions.

With highlighting, you can visually monitor the occurrence, placement, and

prevalence of these signal conditions in the context of the video signal.

The following Watch conditions or errors can be highlighted on an attached

video monitor:

H ANC packet format error (e.g., checksum or parity errors)

H Zero-length ANC packets

H Other ANC data (data that is neither audio nor EDH format)

H Incorrect line/field length

H Incorrect TRS/EA V/SAV format

H Illegal data values

H Out of range video levels

2- 24 SDA 601 Serial Digital Analyzer

Page 47

Operating Information

To use Highlighting:

1. Configure the SDA601 to monitor one or more of the above items; see

“Watching a Signal” beginning on page 14.

Saving and Recalling

Presets

2. Enter the I/O menu (press

Shift, then Insert On/Off).

3. The first I/O menu item is Highlighting. Use the A or " key to select “On,

Dim Video” then press

Enter to confirm the choice.

Dim Video reduces the video signal by 50%, ensuring good contrast between

the video signal and highlighted pixels.

4. Exit the I/O menu by pressing any rectangular key.

5. If necessary, start or restart the Watch session by pressing

Watch.

6. The default OSD will obscure any highlighting in the portion of the picture

that it occupies. Therefore, if the OSD is on, toggle it off with the

Insert On/Off

key.

A convenient way to see the effects of Highlighting is to set either the Data

Value Group or the Video Over Range item to Watch, then input a Pluge signal.

The “sub-black” portion of active video will be highlighted.

Note that the ANC highlight conditions occur in the horizontal or vertical

interval. Use Pulse Cross to “see” those conditions.

The configuration of the SDA601 at any given time may be saved as a Preset for

later recall. Three different instrument configurations can be saved. Using

presets, you can easily change between completely different combinations of (for

instance) Watch conditions, alarm settings, LCD display options, and AUX

output options. To save a Preset:

1. Enter the Presets menu (press

2. Press

B once to reach the Save Preset item.

3. Choose a preset storage location (1, 2, or 3) with the

Shift, then Display Select).

A / " keys. Remember

that previous contents of the storage location will be overwritten in the next

step.

4. Press

Enter to save the current settings in the indicated location. “Working...

Done” will appear on the LCD during the save process.

5. Press any rectangular key to exit the Presets menu.

SDA 601 Serial Digital Analyzer 2-25

Page 48

Operating Information

To recall a previously saved Preset:

1. Enter the Presets menu.

Software Reset

2. Choose the Preset (1, 2, or 3) with the

A / " keys.

3. Press Enter to recall the saved configuration. “Working... Done” will appear

on the LCD. Some settings (I/O and Display settings, for example) will

change instantly; Watch and Alarm settings will be restored in the next

Watch session.

4. Press any rectangular key to exit the Presets menu.

NOTE. Recalling a preset will turn Watch mode off.

To reset the instrument NVRAM and restore the SDA601 to “factory” default

settings, select the Factory Reset item in the Utility/Diagnostics/NVRAM/TIC

Dgs submenu. See page 3--6 for instructions.

CAUTION. All user settings and presets will be lost.

2- 26 SDA 601 Serial Digital Analyzer

Page 49

Performance Verification

Page 50

Page 51

Performance Verification Procedures

The specifications for this instrument can be verified using the following

step-by-step procedure. Equipment that is called out in this procedure is assumed

to be operating correctly and within calibration.

Perform these verification procedures at regular intervals to ensure that instrument performance is within tolerance. The recommended frequency of performance verification is once every 2000 hours (approximately 12 months) of

operation.

A performance verification checklist begins on page 3--3.

Step-by-step performance verification procedures begin on page 3--4.

Required Test Equipment

The following list of equipment represents the minimum required for the

Performance Verification procedures. Alternate equipment must meet the

minimum specifications for the listed equipment. Use of inadequate equipment

may result in faulty measurements or calibration.

Table 3- 1: Required Test Equipment

Item Qty Information/Requirements Example

AC Adapter 1 Std. SDA601 accessory

Cable Simulator Able to simulate 25 and 150

meters of Belden 8281 coaxial cable.

Video Measurement Set 1 Monochrome Picture M onitor

Capability;

6.25% (or better) waveform

amplitude measurement accuracy.

75 Ω Coaxial Cables 3 Belden 8281 coax;

Male/Male BNC ends

75 Ω BNC Termination 1 0.025% precision Tektronix 011-0102-01

Faraday Cable Clone

Tektronix 1780R or

1781R

Tektronix 012-0159-00

SDA 601 Serial Digital Analyzer 3- 1

Page 52

Performance Verification Procedures

Table 3- 1: Required Test Equipment (Cont.)

Item ExampleInformation/RequirementsQty

Serial Digital Television

Signal Generator

1 Generates (per CCIR 601):

Equalizer SDI Checkfield

100% Color Bars

Limit Ramp

60% Sweep;

Erroneous FF CRC

Erroneous AP CRC

Zero-value (Ø) AP CRC

Tektronix

TSG 601 or TSG 422

Spectrum Analyzer 1 Freq. Range: 325 MHz

Sensitivity: up to 50 dB

Internal tracking generator

N-to-BNC adapter 2 Male N to female BNC Standard Tektronix 2712

High Frequency RF Bridge 1 ≥46 dB return loss sensitiv-

ity, 50 kHz to 325 MHz

75 Ω BNC adapter 1 Male-to-male Hewlett-Packard

Precision 50 Ω BNC cable 2 Tektronix

Tektronix 2712 Option 04

accessory; Tektronix

part number 103-0045-00

Wideband Engineering

part number A57TGACR

part number 1250-1288

part number 012-0482-00

3- 2 SDA 601 Serial Digital Analyzer

Page 53

Performance Verification Checklist

Use the following checklist if you are familiar with the operation of the SDA601

as well as digital video performance verification techniques. Step-by-step

instructions for all of the procedures begin on page 3--4.

1. Beeper and LCD display

2. OSD (on-screen display)

3. Keypad Test

4. AP CRC present, not 0

5. Erroneous FF CRC

6. Erroneous AP CRC

7. Ø AP CRC

8. Cursor and Data V alues

Performance Verification Procedures

9. Signal Level Meter Accuracy/Resolution

10. Current Time

11. Highlighting

12. Pulse Cross

13. Pixmon Y (white amplitude, sync amplitude, DC offset)

14. Pixmon R–Y Peak Amplitude

15. Pixmon B–Y Peak Amplitude

16. Serial Receiver Equalization

17. Print Report

18. Return Loss

SDA 601 Serial Digital Analyzer 3- 3

Page 54

Performance Verification Procedures

Performance Verification Procedures

Use the following step-by-step procedures to verify that the SDA601 meets

published specifications (see Section 1 of this manual). The order of these

procedures has been chosen to minimize changes in equipment setup. Performance parameters may be checked in any order.

Preparation

1. Connect the equipment as shown in Figure 3--1. Be sure all cable simulator

switches are in the “OUT” position.

Figure 3- 1: An Equipment Setup for Performance Verification

3- 4 SDA 601 Serial Digital Analyzer

Page 55

Performance Verification Procedures

2. Switch the equipment on and allow a 20-minute warm-up. Set the front panel

controls of the Tektronix 1780 (or 1781) as listed in Table 3--2.

Table 3- 2: Initial Settings for the Video Measurement Set

Control Setting

LEFT DISPLAY PIX

RIGHT DISPLAY WFM

INPUT CH A

REF INT

FILTER FLAT

WFM HORIZONTAL TWO, LINE

GAIN NORMAL

MAGNIFIER OFF

The picture on the Left Display of the Video Measurement Set should

resemble Figure 3--2. If the center portion of the display does not contain the

darker OSD (on-screen display) rectangle, press the SDA601

Insert On/OFF

button to toggle the OSD On.

Figure 3- 2: AUX Output Containing the On-Screen Display (OSD)

3. To enter the SDA601 Utility menu, hold the

the

ON button. Release the ON button, but continue to press the Lock Out key

Lock Out key down and press

until the display resembles Figure 3--3.

SDA 601 Serial Digital Analyzer 3- 5

Page 56

Performance Verification Procedures

Figure 3- 3: The Initial SDA601 Utility Menu Display

4. Reset the SDA601 software through the Utility:Diagnostics:NVRAM/TIC

Dgs:Factory Reset menu item. To do so:

Procedures

H Press

Y once to reach the “Diagnostics..” menu item, then press Enter to

“drop into” the Diagnostics submenu.

H Press

H Press

B three times to reach the “NVRAM/TIC Dgs..” menu item, then

press