Page 1

Service Manual

RTX100A

ISDB-T RF Signal Generator

071-1757-00

Revision A

Warnin g

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. L icensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Batteries are excluded from this warranty. Parts, modules and replacement products used by Tektronix

for warranty work may be new or reconditioned to like new performance. All replaced parts, modules and products become

the property of Tektronix.

In order to obt ain service under this warranty, Custom er must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, shipping charges prepaid, and

with a copy of customer proof of purchase. Tektronix shall pay for the return of the product to Customer if the shipment is

to a location within the country in which the Tektronix service center is located. Customer shall be responsible for paying

all shipping charges, duties, taxes, and any other charges for products returned to any other locations

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non--Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES

ٛF RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

Page 4

Page 5

Table of Contents

Specifications

General Safety Summary vii...................................

Service Safety Summary ix....................................

Environmental Considerations xi...............................

Preface xiii...................................................

Manual Structure xiii................................................

Manual Conventions xiv..............................................

Finding Other Information xiv.........................................

Introduction xv..............................................

Performance Check Interval xv........................................

Strategy for Servicing xv.............................................

Tektronix Service Offerings xvi........................................

Product Overview 1-1.........................................

Specifications 1-3.............................................

Performance Conditions 1-3...........................................

Functional Specifications 1-3..........................................

Electrical Specifications 1-4...........................................

Mechanical (Physical) Characteristics 1-11................................

Environmental Characteristics 1-11......................................

Certifications and Compliances 1-12.....................................

Theory of Operation

A12 Main Board 2-1.................................................

A20 PCI Backplane Board 2-3.........................................

A150 ISDB-T RF Output Board 2-4.....................................

A30 Front Panel Board 2-5............................................

A35 Power Switch Board 2-5..........................................

A40 AC Distributer Board 2-5.........................................

A50 Disk I/F board 2-5...............................................

Performance Verification

Equipment Required 3-2..............................................

RTX100A Test Record 3-3............................................

Procedures 3-4......................................................

Adjustment Procedures

Requirement for Adjustment 4-1.......................................

Equipment Required 4-1..............................................

Carrier Leakage Adjustment 4-2.......................................

RTX100A ISDB-T RF Signal Generator Service Manual

i

Page 6

Table of Contents

Maintenance

Related Maintenance Procedures 5-1....................................

Preparation 5-2.....................................................

Inspection and Cleaning 5-3...........................................

Removal and Installation Procedures 5-7.........................

Preparation 5-7.....................................................

Access Procedure 5-14................................................

Procedures for External Modules 5-15...................................

Procedure for Board Modules 5-21......................................

Procedure for Internal Modules 5-26.....................................

Setting the BIOS Configuration 5-35.............................

Procedure 5-35......................................................

Troubleshooting 5-37...........................................

Troubleshooting Trees 5-37............................................

Using the Recovery Discs 5-47...................................

Reinstalling Windows XP 5-47..........................................

Reinstalling the RTX100A Application 5-48...............................

Restoring the IEEE1394b Port Speed Setting 5-48..........................

Options

Diagrams

Replaceable Parts List

Options 6-1..................................................

Diagrams 7-1.................................................

Parts Ordering Information 8-1.........................................

Using the Replaceable Parts List 8-2....................................

ii

RTX100A ISDB-T RF Signal Generator Service Manual

Page 7

List of Figures

Table of Contents

Figure 1-1: Timing diagram of the SPI interface 1-10................

Figure 3-1: Equipment connection for checking the internal clock

output level 3-5............................................

Figure 3-2: Equipment connection for checking the internal clock

frequency 3-6.............................................

Figure 3-3: Equipment connection for checking the play

operation--SPI interface 3-7.................................

Figure 3-4: Equipment connections for checking the external

clock/reference and trigger inputs 3-11.........................

Figure 3-5: Equipment connection for checking the output

signal--ASI interface 3-14....................................

Figure 3-6: Equipment connections for checking the play

operation--ASI interface 3-16.................................

Figure 3-7: Equipment connection for checking the record

operation--ASI interface 3-17.................................

Figure 3-8: Equipment connection for checking the recorded

file--ASI interface 3-19.......................................

Figure 3-9: Fifth equipment connection for checking the

ASI interface 3-20..........................................

Figure 3-10: Equipment connection for checking the carrier

leakage 3-22...............................................

Figure 3-11: Equipment connection for checking the output level

and error 3-25.............................................

Figure 3-12: Equipment connection for checking the IEEE1394b

interface 3-27..............................................

Figure 4-1: Equipment connection for adjusting the carrier leakage 4-2

Figure 5-1: RTX100A orientation 5-10............................

Figure 5-2: External modules 5-11................................

Figure 5-3: Board modules 5-12..................................

Figure 5-4: Internal modules 5-13................................

Figure 5-5: Guide to removal procedures 5-14......................

Figure 5-6: Cabinet removal 5-16.................................

Figure 5-7: Right-side and left-side covers removal 5-17..............

Figure 5-8: Front-panel unit removal 5-18.........................

RTX100A ISDB-T RF Signal Generator Service Manual

iii

Page 8

Table of Contents

Figure 5-9: Disassembly of front-panel assembly 5-20................

Figure 5-10: A150 RF Output board, A12 Main board, CPU board,

and A20 PCI Backplane b oard removal 5-22....................

Figure 5-11: DVD drive removal 5-27.............................

Figure 5-12: Hard disk drive removal 5-28.........................

Figure 5-13: Internal and external fan removal 5-30.................

Figure 5-14: 12 V main power supply and A40 AC Distributer board

removal 5-32...............................................

Figure 5-15: RFI filter removal 5-33..............................

Figure 5-16: Troubleshooting procedure (1) 5-38....................

Figure 5-17: Troubleshooting procedure (2) 5-39....................

Figure 5-18: Troubleshooting procedure (3) 5-40....................

Figure 5-19: Troubleshooting procedure (4) 5-41....................

Figure 5-20: Troubleshooting procedure (5) 5-42....................

Figure 5-21: Troubleshooting procedure (6) 5-43....................

Figure 5-22: Troubleshooting procedure (7) 5-44....................

Figure 5-23: Troubleshooting procedure (8) 5-45....................

Figure 5-24: A20 PCI Backplane board view--back side 5-45..........

Figure 5-25: A20 PCI Backplane board view--right side 5-46..........

Figure 7-1: RTX100A block diagram 7--3.........................

Figure 7-2: RTX100A interconnect diagram 7--5....................

Figure 8-1: Cabinet and covers 8-5..............................

Figure 8-2: Internal modules (1) 8-7.............................

Figure 8-3: Internal modules (2) 8-9.............................

Figure 8-4: Front panel unit 8-11.................................

Figure 8-5: DVD drive unit 8-12..................................

Figure 8-6: Cables 8-14.........................................

iv

RTX100A ISDB-T RF Signal Generator Service Manual

Page 9

List of Tables

Table of Contents

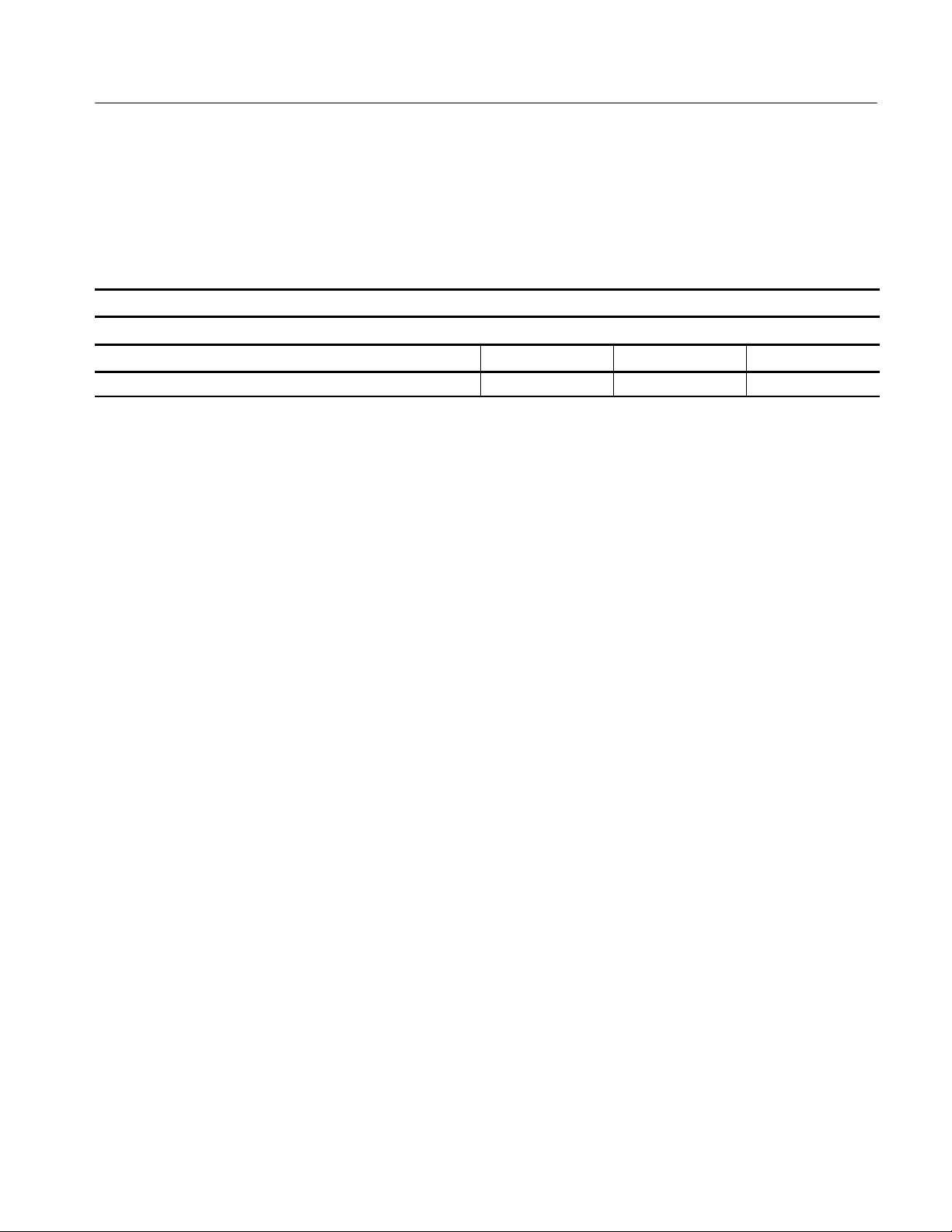

Table 1-1: Functional specifications 1-3..........................

Table 1-2: Mainframe 1-4......................................

Table 1-3: Mechanical characteristics 1-11.........................

Table 1-4: Environmental characteristics 1-11......................

Table 1-5: Certifications and compliances 1-12.....................

Table 3-1: Equipment required for performance verification 3-2.....

Table 3-2: RTX100A test record 3-3.............................

Table 3-3: Output channel and center frequency settings 3-23........

Table 4-1: Equipment required 4-1..............................

Table 4-2: Output channel and center frequency settings 4-3........

Table 5-1: External inspection check list 5-4......................

Table 5-2: Internal inspection check list 5-5.......................

Table 5-3: Summary of procedures 5-8..........................

Table 5-4: Tools required for module removal 5-9..................

RTX100A ISDB-T RF Signal Generator Service Manual

v

Page 10

Table of Contents

vi

RTX100A ISDB-T RF Signal Generator Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before m aking connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

No Power Switch. Power supply cord is considered the disconnecting device,

disconnect the main power by means of the power cord.

RTX100A ISDB-T RF Signal Generator Service Manual

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

viii

RTX100A ISDB-T RF Signal Generator Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

RTX100A ISDB-T RF Signal Generator Service Manual

ix

Page 14

Service Safety Summary

x

RTX100A ISDB-T RF Signal Generator Service Manual

Page 15

Environmental Considerations

This section provides i nformation about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Mercury Nortification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

RTX100A ISDB-T RF Signal Generator Service Manual

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

xi

Page 16

Environmental Considerations

xii

RTX100A ISDB-T RF Signal Generator Service Manual

Page 17

Preface

Manual Structure

This is the service manual for the RTX100A ISDB-T RF Signal Generator. This

manual contains information needed to service an RTX100A to the module level.

This manual is divided into sections, such as Specifications and Theory of

Operation. Furthermore, some sections are divided into subsections, such as

Product Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures.

Be sure to read these introductions because they provide information needed to

do the service correctly and efficiently. The following are brief descriptions of

each manual section.

H Specifications contains a description of the RTX100A and the characteristics

that apply to it.

H Theory of Operation contains circuit descriptions that support service to the

module level.

H Performance Verification contains procedures for confirming that an

RTX100A functions properly and meets warranted characteristics.

H Adjustment Procedures contains procedures for adjusting the RTX100A to

meet warranted characteristics.

H Maintenance contains information and procedures for performing preventive

and corrective maintenance of an RTX100A. These instructions include

cleaning, module removal and installation, and fault isolation to the module

level.

H Options contains descriptions of factory-installed options and field-upgrad-

able options.

H Diagrams contains block diagram and interconnection diagram.

H Replaceable Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

RTX100A ISDB-T RF Signal Generator Service Manual

xiii

Page 18

Preface

Manual Conventions

This manual uses certain conventions with which you should become familiar.

Some sections of the manual contain procedures for you to perform. To keep

those instructions clear and consistent, this manual uses the following

conventions:

H Names of front panel controls and menus appear in the same case (initial

capitals, all uppercase, and so forth) in the manual as is used on the

RTX100A front panel and menus.

H Instruction steps are numbered unless there is only one step.

H Bold text refers to specific interface elements that you are instructed to

select, click, or clear .

Example: To power on the RTX100A, press the ON/STBY switch.

H Italic text refers to document names or sections. Italics are also used in

NOTES, CAUTIONS, and WARNINGS.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the

RTX100A is referred to generically as a module. In general, a module is an

assembly (like a circuit board), rather than a component (like a resistor or an

integrated circuit). Sometimes a single component is a module. For example, the

chassis of the RTX100A is a module.

Symbols and terms related to safety appear in the General Safety Summary and

Service Safety Summary near the beginning of this manual.

Finding Other Information

Other documentation for the RTX100A includes:

H The RTX100A ISDB-T RF Signal Generator User Manual (Tektronix part

Example: The Diagrams section, beginning on page 7-1, includes a block

diagram and an interconnect diagram.

number 071-1755-XX) contains a tutorial to quickly describe how to operate

the RTX100A. It also includes an in-depth discussion on how to use the

RTX100A features.

xiv

RTX100A ISDB-T RF Signal Generator Service Manual

Page 19

Introduction

This manual contains information needed to properly s ervice the RTX100A

ISDB-T RF Signal Generator, as well as general information critical to safe and

effective servicing.

To prevent personal injury or damage to the RTX100A, consider the following

before attempting service:

H The procedures in this manual should be performed only by a qualified

service person.

H Read the General Safety Summary and the Service Safety Summary,

beginning on page vii.

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Performance Check Interval

Generally, the performance check described in Section 3, Performance Verification, should be done every 12 months. In addition, a performance check is

recommended after module replacement.

Strategy for Servicing

If the RTX100A does not meet performance criteria, repair is necessary.

This manual contains all the information needed for periodic maintenance of the

RTX100A.

This manual also contains all information for corrective maintenance down to the

module level. To isolate a failure to a module, use the fault isolation procedures

found in Troubleshooting, part of Section 5, Maintenance. To remove and

replace any failed module, follow the instructions in Removal and Installation

Procedures, also part of Section 5. After isolating a faulty module, replace it

with a fully-tested module obtained from the factory. Section 8, Replaceable

Parts List, contains part number and ordering information for all replaceable

modules.

RTX100A ISDB-T RF Signal Generator Service Manual

xv

Page 20

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well trained to service the RTX100A.

They have access to the latest information on improvements to the RTX100A as

well as the latest new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears after the title page in this manual. Tektronix technicians provide

warranty service at most Tektronix service locations. The Tektronix product

catalog lists all worldwide service locations or you can visit our website for

service information: www.tektronix.com.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for remanufactured ones. Each module comes with a

90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of these repair or adjustment services.

xvi

RTX100A ISDB-T RF Signal Generator Service Manual

Page 21

Specifications

Page 22

Page 23

Product Overview

The RTX100A ISDB--T RF Signal Generator converts a broadcast transport

stream into an RF signal and outputs it. In addition to the RF signal output

feature, the RTX100A records and plays MPEG--2 transport streams that are

compliant with ATSC, DVB, and ARIB standards.

The RTX100A provides the following features:

H RF modulated output of broadcast transport streams

H Direct RF output of ASI input signals

H Data rate: 200 Mbps maximum (RAM mode); 256 Kbps minimum

H Hierarchy display of stored or captured transport streams

H 188, 204, 208 bytes packet size, S --TMCC, M--TMCC, non transport stream,

H Real--time updating of stream parameters; continuity_counter, PCR/PTS/

UHF: 13 channel to 62 channel (473 MHz to 767 MHz)

and partial transport stream output formats

DTS, TOT/TDT/STT, NPT, and Reed Solomon (ISDB--T only)

H Continuous recording of captured streams

H PCR jitter insertion

H Triggered stream capture

H Full remote control using Ethernet interface

H Scheduler application for automated stream playout and record (Option SC

only)

H DVD ± RW drive

The RTX100 includes the ReMux application software that provides the

capability to create a t ransport stream of super frame structure defined in the

ISDB-S systems from an MPEG2 transport stream.

RTX100A ISDB-T RF Signal Generator Service Manual

1-1

Page 24

Product Overview

1-2

RTX100A ISDB-T RF Signal Generator Service Manual

Page 25

Specifications

Tables 1-1 through 1-4 list the functional, electrical, mechanical, and environmental characteristics of the RTX100A. Table 1-5 lists the national and

international standards t o which the RTX100A complies.

All listed specifications are guaranteed unless labeled with “typical”. Typical

specifications are provided for your convenience but are not guaranteed.

Performance Conditions

The electrical characteristics listed on t he following pages are valid under the

following conditions:

H The RTX100A must be in an environment where the temperature, altitude,

H The RTX100A must have a warm-up period of at least 20 minutes.

H The RTX100A must be operating at an ambient temperature between

humidity, and vibration conditions are within the operating limits described

in Table 1-4 on page 1-11.

+5 _Cto+40_C, unless otherwise noted.

Functional Specifications

Table 1-1: Functional specifications

Characteristics Description

System configuration

System OS Windows XP Professional

CPU 1.3 GHz

System memory 512 MB

Display 640 x 480 VGA resolution with 256 K colors

Storage device

Hard disk drive 160 GB

DVD ± RW drive Read and write: DVD+R, DVD+RW, DVD--R, DVD--RW, CD--R, and CD--RW

Read only: DVD--ROM and CD--ROM

Expansion slot 1-PCIslot

RTX100A ISDB-T RF Signal Generator Service Manual

1-3

Page 26

Specifications

Electrical Specifications

Table 1-2: Mainframe

Characteristics Description

Maximum output rate

Hard disk ≥120 Mbps

RAM ≥200 Mbps

Maximum record rate

Hard disk ≥120 Mbps (File size: < 4 GB, just after disk format operation)

≥90 Mbps (File size: 33 GB, just after disk format operation)

RAM ≥200 Mbps

Internal reference clock For Output_clock, PCR/PTS/DTS, packet operation timing, and TDT/STT time.

Frequency 27 MHz ± 1 ppm when manufactured.

Stability ± 0.5 ppm per year

± 1 ppm over temperature range

External reference/clock input

Connector type BNC

Input impedance, typical 50 Ω

Reference input

Frequency 8.129698 MHz, 10 MHz, and 27 MHz

Input level, typical Sine wave: 0 ± 6dBm

Square wave: 0.5 Vp-p to 3.0 Vp-p

Clock input

Frequency 160 kHz to 25 MHz (parallel clock)

1.28 MHz to 32 MHz (serial clock)

Input level, typical 0.5 V to 3.0 V

External trigger input/MISC output

Connector type BNC

Input impedance, typical 1kΩ

Threshold level Rising and falling edges are programmable.

High level >3.5 V (maximum input voltage: 7 V)

Low level <0.8 V

Output level

High level >2.2V(with50Ω termination)

Low level <0.8V(with50Ω termination)

Output impedance 50 Ω

1-4

RTX100A ISDB-T RF Signal Generator Service Manual

Page 27

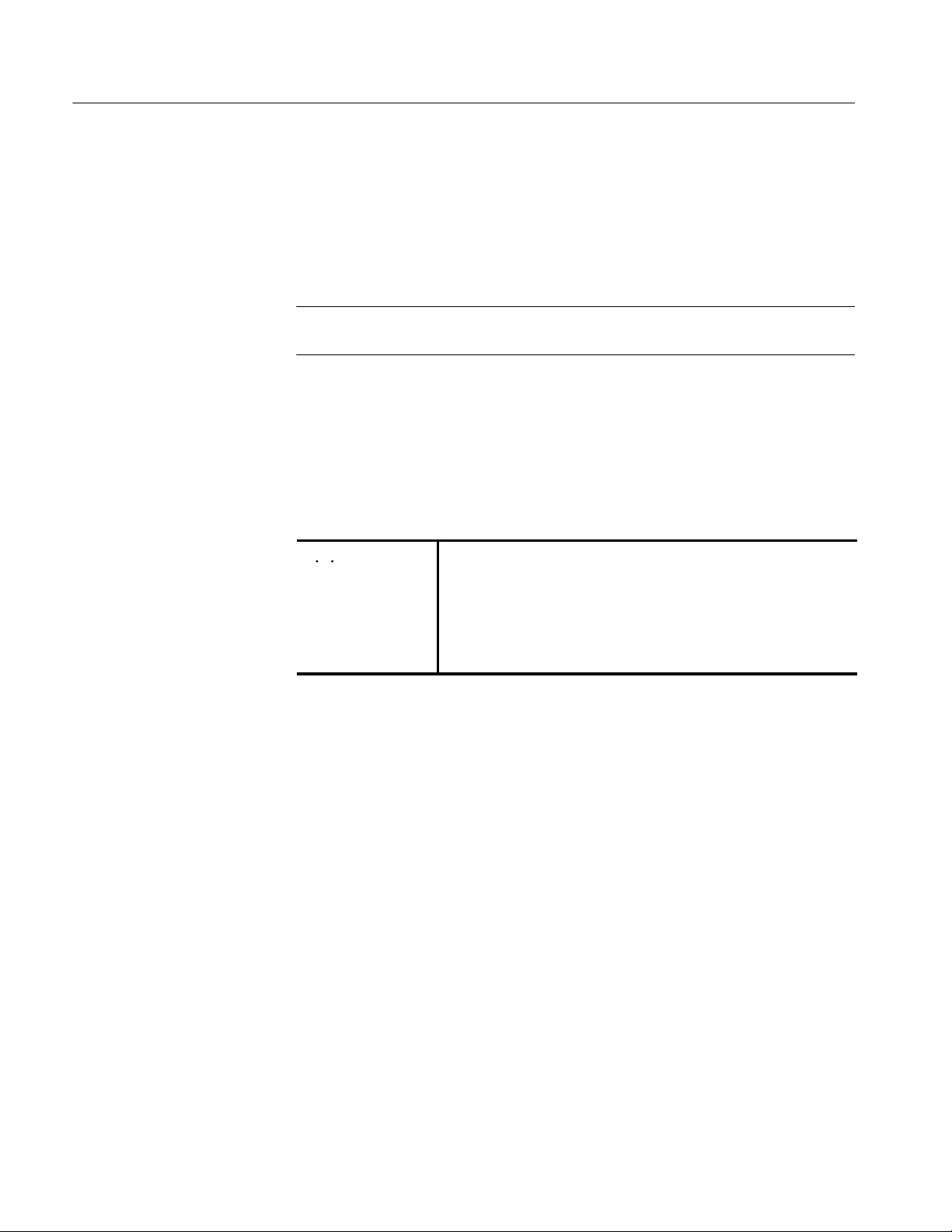

Table 1-2: Mainframe (Cont.)

Characteristics Description

PLL

Frequency 50 MHz to 100 MHz, locked to reference clock

Output clock 50 MHz maximum (serial clock)

26.75 MHz maximum (parallel clock)

Output rate 214 Mbps maximum

64 Kbps minimum

TS clock

TS clock = (X / (2 * Y * Z) ) * 27 MHz

Specifications

(Internal and external

reference, 27 MHz and 10 MHz)

(External parallel clock) TS clock = (X / (2 * Y * Z) ) * external parallel clock, 214 MHz maximum

(External serial clock) TS clock = (X / (2 * Y * Z) ) * external serial clock / 8,32 MHz maximum

P/N and Jitter (serial clock) < --104 dBc/Hz at 21.455707 MHz +20 kHz (RBW=300 Hz)

SPI interface

Connector type D-sub, 25 pin

Data rate 256 Kbps to 214 Mbps

Pin assignments 1 DCLK

Output

Output level, typical 330 mV to 550 mV (termination: internal 100 Ω, external 100 Ω), bus LVDS with 50 Ω

Offset 1.1 V to 1.5 V

15362 < X < 31248

1686 < Y < 3376

2 ≤ Z ≤ 65536

15632 < X < 31248

1 < Y < 16383

2 ≤ Z ≤ 65536

15632 < X < 31248

1 < Y < 16383

2 ≤ Z ≤ 65536

2GND

3to10 DATA7toDATA0

11 DVALID

12 PSYNC

13 Shield

14 DCLK

15 GND

16 to 23 DATA 7

24 DVALID

25 PSYNC

termination

to DATA 0

RTX100A ISDB-T RF Signal Generator Service Manual

1-5

Page 28

Specifications

Table 1-2: Mainframe (Cont.)

Characteristics Description

Output resistance, typical 100 Ω, between differential outputs (output off)

Data delay, typical ± 5 ns from the falling edge of DCLK (see Figure 1-1 on page 1-10)

Input

Input level, typical > +100 mV, < --100 mV, (RI+)--(RI--) with 100 Ω termination

Input resistance, typical 100 Ω (between differential inputs)

Clock pulse width, typical T/2 ± T/10, T=1/f (f=byte clock frequency) (see Figure 1-1 on page 1-10)

Data hold time, typical T/2 ± T/10, T=1/f (f=byte clock frequency, data are latched on DCLK rising edge)

(see Figure 1-1 on page 1-10)

ASI interface

Standard conformance EN 50083-9 Annex B

Connector type BNC

Impedance 75 Ω

Data rate 256 Kbps to 214 Mbps

Output

Number of outputs 1

Output voltage 800 mV ± 10%

Jitter ≤ 0.2 UI p--p

Rise/fall time ≤ 1.2 ns (20% to 80%)

Return loss < --17 dB (5 MHz to 270 MHz) into 75 Ω load

Input

Number of inputs 1

Input voltage, typical 200 mV to 800 mV

Return loss < --17 dB ( 5 MHz to 270 MHz) into 75 Ω load

Internal RF reference clock

Frequency 27 MHz ± 1 ppm when manufactured.

Stability ± 0.5 ppm per year

± 1 ppm over temperature range

External RF reference input

Connector type BNC

Input impedance, typical 50 Ω

Reference input

Frequency 10 MHz, 27 MHz

8.126948 MHz

Input level, typical 160 kHz to 26.75 MHz (parallel clock)

1.28 MHz to 32 MHz (serial clock)

1-6

RTX100A ISDB-T RF Signal Generator Service Manual

Page 29

Table 1-2: Mainframe (Cont.)

Characteristics Description

RF output

Connector type BNC

Output impedance, typical 75 Ω

Digital modulation

Standard ARIB B31 V1.1

Mode 1/2/3

Bandwidth 6MHz

Number of segments 13

Number of layers Maximum 3

Carrier modulation QPSK, 16 QAM, 64 QAM

NOTE: DPQSK is not supported. If DPQSK modulation is used in a broadcast transport stream,

the stream is modulated into QPSK. However, the signal output from the ASI connector is not

modulated into QPSK.

Inner coding Vitervi (1/2, 2/3, 3/4, 5/6, 7/8)

Outer coding Reed Solomon (204, 188)

Time interval 0,1, 2, 4, 8, 16

Guard interval 1/4, 1/8, 1/16, 1/32

UHF output

Frequency 470 to 770 MHz (channel plan steps)

Specifications

Channel Frequency Channel Frequency Channel Frequency

13 473.143 30 575.143 47 677.143

14 479.143 31 581.143 48 683.143

15 485.143 32 587.143 49 689.143

16 491.143 33 593.143 50 695.143

17 497.143 34 599.143 51 701.143

18 503.143 35 605.143 52 707.143

19 509.143 36 611.143 53 713.143

20 515.143 37 617.143 54 719.143

21 521.143 38 623.143 55 725.143

22 527.143 39 629.143 56 731.143

23 533.143 40 635.143 57 737.143

24 539.143 41 641.143 58 743.143

25 545.143 42 647.143 59 749.143

26 551.143 43 653.143 60 755.143

27 557.143 44 659.143 61 761.143

28 563.143 45 665.143 62 767.143

29 569.143 46 671.143

(Frequency: MHz)

RTX100A ISDB-T RF Signal Generator Service Manual

1-7

Page 30

Specifications

Table 1-2: Mainframe (Cont.)

Characteristics Description

Output amplitude Mode 1: --21 dBm to --29 dBm at 13 ch

Mode 2: --18 dBm to --26 dBm at 13 ch

Mode 3: --15 dBm to --23 dBm at 13 ch

Bit error rate, typical < 2.0 --E4 after Vitervi

VGA output

Connector type D-sub, 15 pin

Pin assignments 1RED 9 NC

2 GREEN 10 GND

3BLUE 11NC

4NC 12NC

5 GND 13 HSYNC

6 GND 14 VSYNC

7 GND 15 NC

8GND

Printer port Supports SPP (Standard Parallel Port), EPP (Enhanced Parallel Port ), and ECP (Extended

Capabilities Port) modes.

Connector type D-sub, 25 pin

Pin assignments 1 STROBE 14 AUTOLF

2D0 15ERR

3D1 16INIT

4 D2 17 SELECT

5D3 18GND

6D4 19GND

7D5 20GND

8D6 21GND

9D7 22GND

10 ACK 23 GND

11 BUSY 24 GND

12 Paper Empty 25 GND

13 SELECT

USB 2.0 interface

Number of connectors 2

Pin assignments 1VCC

2--DATA

3+DATA

4GND

LAN interface 10/100/1000 Base-T Ethernet interface

Connector type RJ45

Pin assignments 1 MDI_0+ 5 MDI_2--

2 MDI_0-- 6 MDI_1-3 MDI_1+ 7 MDI_3+

4 MDI_2+ 8 MDI_3--

1-8

RTX100A ISDB-T RF Signal Generator Service Manual

Page 31

Table 1-2: Mainframe (Cont.)

Characteristics Description

Serial interface (Com) RS-232C

Connector type D-sub, 9 pin

Pin assignments 1 DCD 6 DSR

2RX 7 RTS

3TX 8 CTS

4DTR 9 RI

5GND

IEEE1394B interface

Compliant IEEE1394B--2002

Pin assignments 1TPB-- 6 VG

2 TPB+ 7 NC

3TPA-- 8 VP

4TPA+ 9 TPB(R)

5TPA(R)

AC line power

Rating Voltage 100 VAC to 240 VAC, CAT II

Voltage Range 90 VAC to 250 VAC

Frequency Range 50 Hz to 60 Hz

Maximum power 180 VA

Maximum current 1.3 A

Main fuse data 5 A Time--delayed, 250 V (not operator replaceable)

2 A Time--delayed, 250 V (not operator replaceable)

Specifications

RTX100A ISDB-T RF Signal Generator Service Manual

1-9

Page 32

Specifications

DATA 0--7

DCLK

PSYNC

DVALID

DATA 0--7

DCLK*

DATA 0--7

188 bytes

5ns 5ns

Output data delay

T/2 T/10

T (1/f)

Transition period

T/2 T/10

Input clock pulse width

DCLK*

Input data hold time

Figure 1-1: Timing diagram of the SPI interface

1-10

RTX100A ISDB-T RF Signal Generator Service Manual

Page 33

Mechanical (Physical) Characteristics

Table 1-3: Mechanical characteristics

Characteristics Description

Net weight

Standard Approximately 6 kg

Dimensions

Height 132 mm (without feet)

Width 214 mm

Length 435 mm

Environmental Characteristics

Specifications

Table 1-4: Environmental characteristics

Characteristics Description

Temperature

Operating +5 _Cto+40_C

Non-operating -- 2 0 _Cto+60_C

Relative humidity

Operating 20% to 80% (No condensation)

Maximum wet-bulb temperature 29 _C

Non-operating 5% to 90% (No condensation)

Maximum wet-bulb temperature 29 _C

Altitude

Operating Up to 4.5 km (15,000 feet)

Maximum operating temperature decreases 1 _C each 300 m above 1.5 km

Non-operating Up to 15 km (50,000 feet)

Dynamics

Vibration

Operating 2.65 m/s2rms (0.27 Grms), 5 Hz to 500 Hz, 10 min, three axes

Non-operating 22.3 m/s2rms (2.28 Grms), 5 Hz to 500 Hz, 10 min, three axes

Shock

Non-operating 294 m/s2(30 G), half-sine, 11 ms duration

Installation requirements

Power dissipation 100 W maximum. Maximum line current is 1.3 A

rms

at 50 Hz

RTX100A ISDB-T RF Signal Generator Service Manual

1-11

Page 34

Specifications

Table 1-4: Environmental characteristics (Cont.)

Characteristics Description

Surge current ≦ 12 A peak for less than 5 line cycles at 25_C after product has been off for at least 30

seconds

Cooling clearance

Top clearance 5 cm

Side clearance 5cm

Rear clearance 5cm

Certifications and Compliances

Table 1-5: Certifications and compliances

Category Standards or description

EC Declaration of Conformity Meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EMC Directive 89/336/EEC:

EN 55011 EMC requirement for Class A electrical equipment for

measurement, control and laboratory use

EN 61000-3-2 AC Power Line Harmonic Emissions

IEC 61000-4-2 Electrostatic Discharge Immunity (Performance Criterion B)

IEC 61000-4-3 RF Electromagnetic Field Immunity (Performance Criterion A)

IEC 61000-4-4 Electrical Fast Transient / Burst Immunity (Performance Criterion B)

IEC 61000-4-5 Power Line Surge Immunity (Performance Criterion B)

IEC 61000-4-6 Conducted RF Immunity (Performance Criterion A)

IEC 61000-4-11 Voltage Dips and Interruptions Immunity (Performance Criterion B)

Low Voltage Directive 73/23/EEC: Amended by 93/68/EEC:

EN 61010-1: 2001 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use

Australia/New Zealand Declaration

of Conformity -- EMC

Complies with EMC provision of Radio Communications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

1-12

RTX100A ISDB-T RF Signal Generator Service Manual

Page 35

Specifications

Table 1-5: Certifications and compliances (Cont.)

Category Standards or description

Safety Complies with the following safety standards/regulations:

UL 61010-1 Standard for Electrical Measuring and Test Equipment.

CAN/CSA C22.2 No.61010-1-04 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use.

EN 61010-1:2001 Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use.

Installation (Overvoltage) Category Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances,

portable tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Overvoltage Category Overvoltage Category II (as defined in IEC 61010-1)

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products in this

category are generally encapsulated, hermetically sealed, or located in

clean rooms.

Pollution Degree 2

Pollution Degree 2

Pollution Degree

IEC Characteristics Equipment type:

Pullution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be expected.

This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations where

neither temperature nor humidity is controlled. The area is protected from

direct sunshine, rain, or direct wind.

Test and Measuring

Installation Category II (as defined in IEC 61010-1, Annex J)

Pollution Degree 2 (as defined in IEC 61010-1)

Safety Class 1 -- grounded product

RTX100A ISDB-T RF Signal Generator Service Manual

1-13

Page 36

Specifications

1-14

RTX100A ISDB-T RF Signal Generator Service Manual

Page 37

Theory of Operation

Page 38

Page 39

Theory of Operation

This section describes the basic operation of the major circuit blocks or modules

in the RTX100A. The Diagrams section, beginning on page 7-1, includes a block

diagram and an interconnect diagram.

A12 Main Board

The A12 Main board consists of the following blocks:

PCI Interface

Mega FIFO

TS Controller

The PCI interface consists of a PCI target and a PCI master. The PCI target has

three base address register areas. The PCI master has two DMA controllers used

to transfer data from the A12 Main board to the system memory or from the

system memory to the A12 Main board.

The Mega FIFO has 32 MB for playing and 32 MB forrecording a stream data. It

consists of two 256 megabit synchronous DRAM and FPGA. This FIFO is used

to compensate for non-realtime operation of Windows XP.

The TS controller consists of the following blocks:

TS Packet Type Controller. This controller sets a packet size of 188, 204, 208, and

Non TS (free length) as a TS packet type. For a Non TS format, the controller

also sets a packet length (16-255) and data length (16-255). The data length

shows an effective data length in one TS packet.

Data Valid Controller. This block generates a data valid signal that synchronizes

with the first byte of a TS packet when stream output is started.

Psync Controller. Psync is a signal to identify the sync byte in a transport stream.

When the controller is not in the Psync Regeneration mode, Psync is recognized

as the first byte of a transport stream. In this case, Psync is output in the constant

interval even when the sync byte is rewritten in the value except for 47h. For the

Super Frame mode, Psync is output only once in 384 packets.

Psync Regenerator. This block becomes active when the Psync Regeneration

mode is set. The block detects the sync byte (47h) in a data stream and regenerates a Psync signal. The psync generator supports 188, 204, 208 TS packets only.

RTX100A ISDB-T RF Signal Generator Service Manual

2-1

Page 40

Theory of Operation

PCR/DTS Updater. This block consists of a PCR counter and update logic. The

PCR counter is a complex counter, which consists of a 9-bit counter (range

0-299) and 33-bit counter. The counter counts the 27 MHz standard frequency.

The update logic replaces the PCR and PTS/DTS values in a transport stream

with the sum of the original value and the PCR counter value.

Receive Rate Counter. This 24-bit counter is used for receive-rate calculation on

recording process. When using a data valid signal (DVALID), the counter counts

byte data rate. When not using DVALID, the counter counts receive clock.

Transmit Byte Counter. This 32-bit counter counts transmitted bytes. This counter

can be read by the control software.

Interrupt Controller

TS Clock Generator

Reference Clocks

The interrupt controller sends the following interruption signals to the CPU: Play

FIFO empty, Record FIFO full, external trigger, 10 Hz, Playout DMA transfer

finished, and Record DMA transfer finished. These interruptions can be disabled

by the RTX100A application software. At power on, all interruptions are

disabled.

The TS clock generator consists of a VCO (Voltage Control Oscillator), phase

detector, frequency divider. The VCO is used for generating a TS clock, and it

covers frequencies of 400 MHz to 800 MHz. The frequency divider divides the

clock by 65536 to 1.

The reference clocks consist of 27 MHz TCXO and half-divided output of

54 MHz clock generator. These clocks are used to compare the frequency of the

TS Clock Generator.

2-2

RTX100A ISDB-T RF Signal Generator Service Manual

Page 41

A20 PCI Backplane Board

The A20 PCI Backplane board consists of the following connectors and

circuitries:

Theory of Operation

PCI and ISA Connectors

ATX Power Control Circuit

Interconnect Circuit

The J100, J110, and J120 connectors are PCI slots for 5 V. The J130 connector is

a P CI slot for 3.3 V and is reserved in the future. The J100 connector is the

system slot and is used to install the CPU board (single board computer: SBC).

The J110 and J120 connectors are used to install the A12 Main board and the

A150 ISDB-T RF Output board.

The PWR_Button line (Pins 9 and 10 of J310) of the SBC is connected to the

power switch on the A35 Power Switch board through the A30 Front Panel

board. When the power switch is pressed, the SBC causes the PSON# signal to

go low. When the PSON# signal becomes low, Q10 turns on and +12 V main

power is also on. When the power switch is pressed again, its status is sent to

BIOS and the PSON# signal turns high. This circuit includes a +12 V to +5 V

DC-DC converter, a +12 V to +3.3 V converter, and a + 12 V to --12 V converter.

There are four connectors in the interconnect circuit: J230, J240, J290, and J310.

J230 is used to connect the board to the LCD interface on the CPU board. J290

is used to connect the board to COM2 on the CPU board. J310 is used to connect

the board to the hard disk drive LED and reset/power button on the C PU board.

J240 is used to connect the board to the A30 Front Panel board. This circuit also

has an RS-232C level converter.

Fan Speed Control Circuit

IEEE1394b Interface

RTX100A ISDB-T RF Signal Generator Service Manual

U700 (PIC Micro) controls the internal fan revolution. It gets the temperature

data from the sensors (U720 and U730) through 12C BUS and controls the

supply voltage to the fan (7 V to 11.5 V).

The IEEE1394 interface consists of the 1394b link-layer device (U110), cable

transcriver/arbiter (U120), oscillator (Y100), serial EEPROM (U140), regulators

(U130 and U230), and IEEE1394b connector (J140).

2-3

Page 42

Theory of Operation

A150 ISDB -T RF Output Board

The A150 ASI ISDB-T RF Output board consists of the following blocks:

Local Bus Interface

ASI RX and ASI Decoder

ASI Encoder and ASI TX

PCI Interface FPGA

Channel Coding FPGA

OFDM Modulation FPGA

The local bus interface communicates with the A12 Main board. There are two

sets of 16-bit signal lines for Rx and Tx: 8-bit data lines for single-end connection, 4-bit control lines for single-end connection, and 4-bit control lines for

differential connection. These lines are connected to the A12 Main board in

one-on-one.

This block changes an ASI signal received from the ASI In connector into

parallel transport stream data.

This block changes parallel transport stream data into an ASI signal and output

the signal.

This block consists of an FPGA of ALTERA. It is the interface for PCI and

interchange of an incoming transport stream signal. It also generates an interrupt

signal when an IIP of a transport stream is decoded and Mode is changed.

This block performs coding of ISDB-T. It has four synchronous SRAMs as

buffers for interleaving.

This block performs OFDM modulation using IFFT.

Digital PLL FPGA

RF Carrier Synthesizer

Quadrature Modulator

2-4

RF DAC

This is a digitally controlled PLL, which synchronizes the reference clock

(VCXO) with an internal reference clock or an external clock. This block has a

feature to pass the U600 output to U1100.

This block converts OFDM modulated data to an analog signal. It has an oversampling circuit and digital filter for reducing spurious events. The block also

has two A/D converters for I and Q signals.

This block generates a carrier signal for the RF output. It directly generates a

career frequency of UHF.

This block performs I/Q modulation to a carrier signal from the A/D converter

output.

RTX100A ISDB-T RF Signal Generator Service Manual

Page 43

Theory of Operation

RF Matching Attenuator

A30 Front Panel Board

Front-panel Key Interface

and LED Control

LVDS Receiver for FPD

Link

Video Inverter Circuit

This block steps down an RF output level to the antenna input level of a receiver

and matches the impedance with 75 Ω.

The A30 Front Panel board consists of the front panel processor circuit, LVDS

receiver for FPD (flat panel display) link, video inverter circuit, rubber contact

switches, three connectors, and three LEDs.

The state of the front-panel keys are read by the one chip processor on the board

and any setting changes are reported to the SBC through COM2. The processor

also controls the LED on/off state.

The LVDS receiver converts the four L VDS data streams back into 28 parallel

bits of CMOS/TTL data (24 bits of RGB and 4 bits of Hsync, Vsync, DE, and

CNTL).

The video inverter circuit consists of an FPGA and SRAM. The circuit converts

the display data upside down because the LCD display is attached to the chassis

upside down.

A35 Power Switch Board

The A35 Power Switch board is connected to the A20 PCI Backplane board

through the A30 Front Panel board. There are two USB connectors on the board

that are directly connected to the USB2.0 interface connector on the CPU board.

The board also has the power supply module for the LCD back light.

A40 AC Distributer Board

The A40 AC Distributer board supplies s tandby power (5VSB) to the SBC and

the ATX power control circuit on the A20 Backplane board.

A50 Disk I/F board

The A50 disk I/F board connects the secondary IDE connector on the CPU board

with the DVD drive module.

RTX100A ISDB-T RF Signal Generator Service Manual

2-5

Page 44

Theory of Operation

2-6

RTX100A ISDB-T RF Signal Generator Service Manual

Page 45

Performance Verification

Page 46

Page 47

Performance Verification

This section provides procedures to verify the performance and functionality of

the RTX100A.

RTX100A ISDB-T RF Signal Generator Service Manual

3-1

Page 48

Performance Verification

Equipment Required

Table 3-1 lists the test equipment required to perform all of the performance

verification procedures. The table identifies examples of recommended

equipment and lists the required precision where applicable. If you substitute

other test equipment for the examples listed, the equipment must meet or exceed

the listed tolerances.

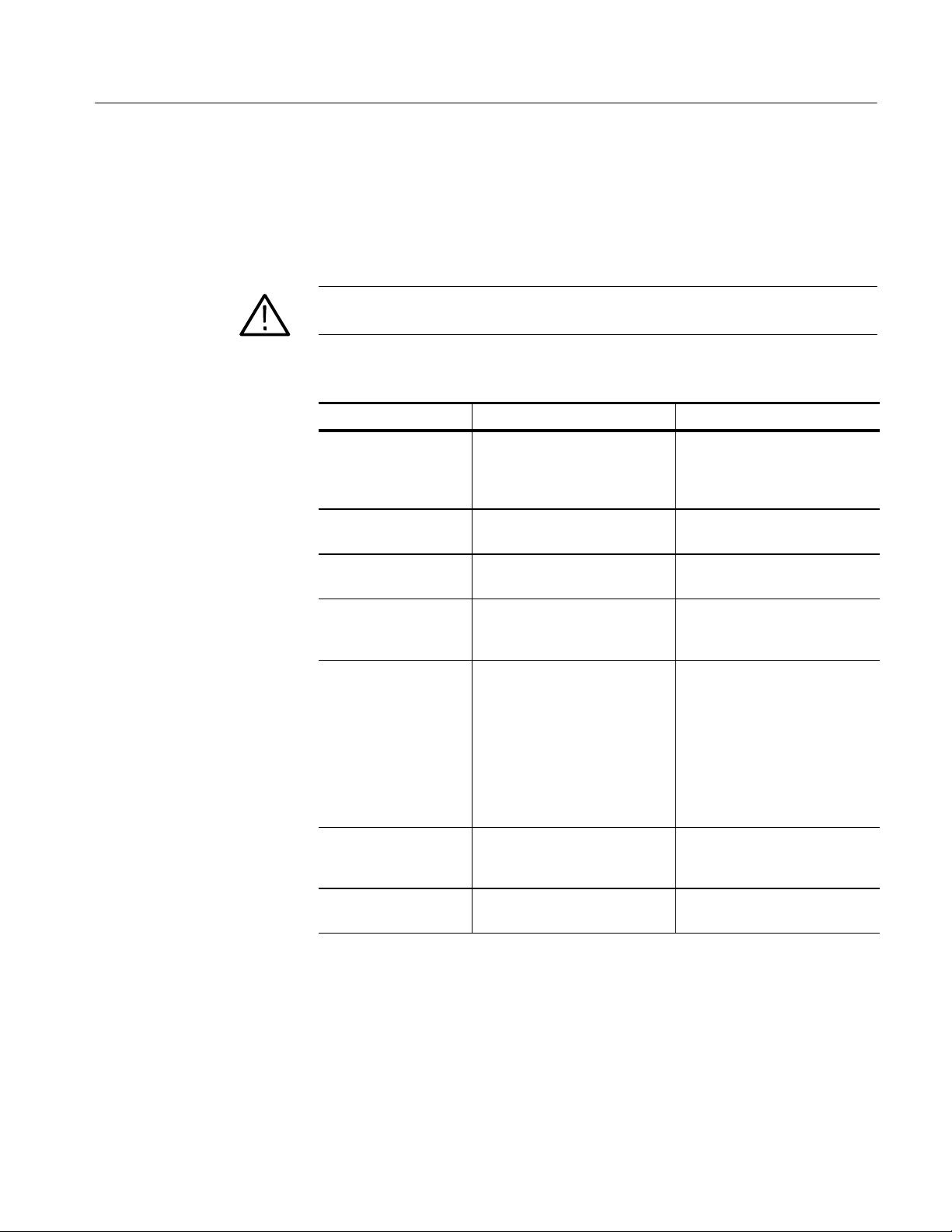

Table 3-1: Equipment required for performance verification

Item Qty. Minimum requirements Recommended equipment

Frequency counter 1 Frequency range: 0.1 Hz to 1.25 GHz

Precision: 8 digits or higher

MPEG analyzer 1 Tektronix MTS430 or MTS400

Function generator 1 Frequency: 40 M clock pattern

Amplitude: 3 V

Outputs: 2 channel

Oscilloscope 1 Bandwidth: 1 GHz or higher Tektronix TDS5104B

ISDB-T analyzer 1 Panasonic VP8480A

Spectrum analyzer 1 Resolution bandwidth: 10 Hz Agilent Technologies E4402B-COM

MPEG-2 measurement decoder 1 Rohde & Schwarz DVMD

Video monitor 1 SD--SDI video input Sony LMD-1420 and BKM-320D (SDI

Probe 1 Tektronix P5050

75 Ω signal adapter 1 Bandwidth: 1 GHz

Amplitude precision: --3 dB

50 Ω BNC cable 2 Length: 42 inches Tektronix part number 012-0057-01

50 Ω SMA cable 1 Candox Systems 5B--010--19--19--1000

75 Ω BNC cable 2 5C-2V, 1 m Canare DH5C01-S-SA

Parallel interface cable 1 25-pin, D-type Tektronix part number 012-A220-00

IEEE1394b cable 1 9pin--9pin

50 Ω N(Fe)-to-75 Ω N(Fe) adapter 1 Bandwidth: 2 GHz or higher Agilent Technologies 11852B

75 Ω BNC(Ma)-to-NC(Fe) adapter 1 Stack Electronics BA045

50 Ω N(Ma)-to-SMA(Fe) adapter 2 Stack Electronics BA057

IEEE1394b hard disk drive 1 Novac NV-HD352WB and

Agilent Technologies 53181A Option 015

Tektronix AFG3102

input adapter)

Tektronix AMT75

(supplied with the RTX100A)

hard disk drive (Tektronix part number

119-7146-00)

3-2

RTX100A ISDB-T RF Signal Generator Service Manual

Page 49

Performance Verification

RTX100A Test Record

Photocopy this page and use it to record the performance test result.

Table 3-2: RTX100A test record

Serial Number: Cal Date: Temperature: Humidity:

Performance Test Minimum

Internal Clock Frequency 26.999924 MHz MHz 27.000076 MHz

1

Test record limits are based on the SMPTE 310M frequency accuracy requirement.

1

Measured Maximum

1

RTX100A ISDB-T RF Signal Generator Service Manual

3-3

Page 50

Performance Verification

Procedures

The following conventions are used in the performance verification procedures:

H Each test lists the characteristic that is being tested and the equipment

required to perform the test.

H Each test contains complete setup i nstructions, which allows you to perform

each test individually or in order.

H The equipment connection illustrations are specific to the recommended

equipment (equipment nomenclature is labeled). If you are using substitute

equipment, the location of your signal connections may vary from those in

the illustrations.

NOTE. Before you begin the performance verification procedures, be sure that the

RTX100A is operating in an environment that is within the operating limits

described in Table 1-4 on page 1-11.

In addition, the RTX100A and the test equipment must be w armed up for at least

20 minutes to ensure accurate test results.

3-4

RTX100A ISDB-T RF Signal Generator Service Manual

Page 51

Performance Verification

q

p

Internal Clock Output

Level and Frequency

RTX100A rear panel

Accuracy

This test verifies the internal clock output level and frequency accuracy.

Equipment

required

Oscilloscope

Frequency counter

50 Ω BNC cable

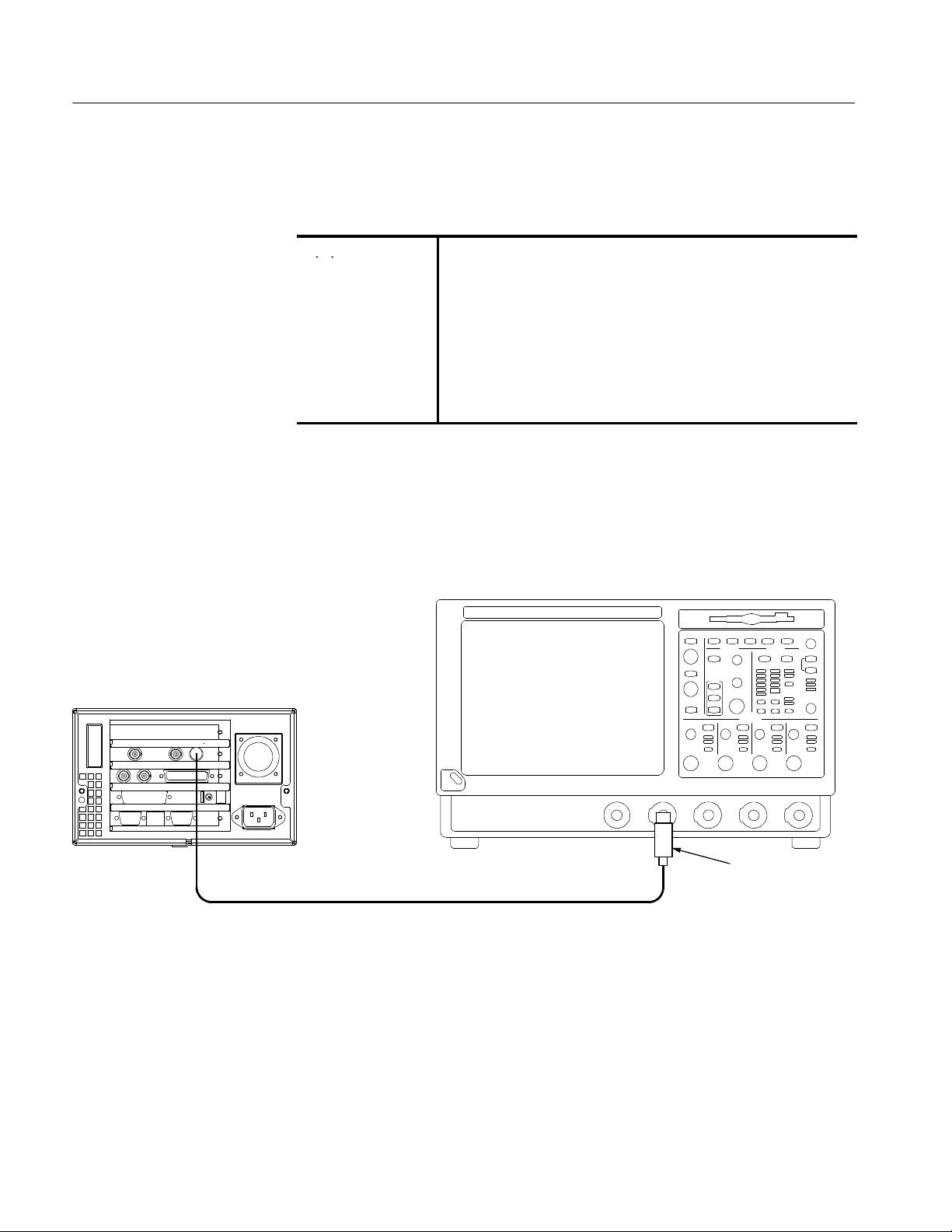

1. Use the 50 Ω BNC cable to connect the Trig In/Out connector on the

RTX100A to the oscilloscope CH1 input. See Figure 3-1.

Oscilloscope (TDS5104B)

50 Ω BNC cable

Figure 3-1: Equipment connection for checking the internal clock output level

2. Select Play > Others on the RTX100A to open the Others dialog box.

3. In the dialog box, select the Ext Trigger BNC button to open the Ext

Trigger BNC dialog box.

4. In the dialog box, set BNC IN/OUT to Output and BNC OUT Selection to

27MHz.

RTX100A ISDB-T RF Signal Generator Service Manual

3-5

Page 52

Performance Verification

5. Set the oscilloscope settings as indicated below:

Vertical scale 1 V/div (CH1)........

Input impedance 50 Ω.....

Horizontal scale 10 ns/div.....

Trigger position 50%......

Acquire mode Average 16.......

Trigger mode Auto........

Trigger level 1.20 V........

Trigger source CH1.......

Trigger slope Rising Edge........

Input coupling DC.......

Measure High Level, Low level............

6. Verify that the measured values are as follows:

High Level: > 2.2 V

Low Level: < 0.8 V

7. Disconnect the 50 Ω BNC cable from the oscilloscope CH1 input, and then

connect the BNC cable to the C H1 connector on the frequency counter. See

Figure 3-2.

RTX100A rear panel

Frequency counter (53181A Option 015)

50 Ω BNC cable

Figure 3-2: Equipment connection for checking the internal clock frequency

8. Set the frequency counter settings as indicated below:

MEASURE Frequency1.........

Gate Time: 0.20 s

CHANNEL1 Coupling: DC........

Impedance: 50

Trigger:AUTOTRIGON

9. Record the frequency counter reading in the test record. (See page 3-3.)

3-6

RTX100A ISDB-T RF Signal Generator Service Manual

Page 53

Performance Verification

q

p

10. In the Ext Trigger BNC dialog box, change BNC IN/OUT to Input.

11. Disconnect the BNC cable from the RTX100A and frequency counter.

SPI Interface

RTX100A rear panel

This test verifies that transport stream data is correctly played from and recorded

through the SPI In/Out connector on the RTX100A.

Equipment

required

MPEG analyzer

Parallel interface cable

test40.TRP file

Checking the Play Operation.

1. Use the parallel interface cable to connect the SPI In/Out connector on the

RTX100A to the DVB SPI In connector on the MPEG analyzer. See

Figure 3-3.

MPEG analyzer rear panel (MTS430)

Parallel interface cable

Figure 3-3: Equipment connection for checking the play operation- SPI interface

2. Start the MPEG Player application on the MPEG analyzer.

3. Set the application to the Record mode.

RTX100A ISDB-T RF Signal Generator Service Manual

3-7

Page 54

Performance Verification

4. Open the test40.TRP file on the RTX100A.

a. Select File > Open in the Play screen to open the Select File dialog box.

b. In the dialog box, select the test40.TRP file.

5. On the RTX100A, make the following settings:

Play menu

Data rate 214 Mbps....

Update Off......

Source RAM......

6. On the MPEG analyzer, make the following settings:

Record

Source SPI......

Target RAM, Size: 100 MB......

File

Save Mode Overwrite..

Save E:\MTXRTX_Test streams\Record_Files\........

SPI214Mbps

7. Press the PLAY button on the RTX100A to start playing the test40.TRP file.

8. Verify that the hierarchic view is displayed on the MPEG analyzer screen. In

addition, verify that the bit rate is 214 Mbps and the packet size is 188

bytes.

9. Click the Record button on the MPEG Player application to record the file.

10. After recording is completed, press the STOP button on the RTX100A.

Checking the Record Operation.

11. Change the interface cable connection from DVB/SPI In connector to

DVB/SPI Out connector on the MPEG analyzer.

12. Press the REC button on the RTX100A to display the Record screen.

13. On the RTX100A, make the following settings:

Record menu

Source SPI......

Target R AM......

Record Size 100 MB..

File menu

Save Mode Over Write..

Save D:\Record_Files\SPI214Mbps........

3-8

RTX100A ISDB-T RF Signal Generator Service Manual

Page 55

Performance Verification

14. Change the MPEG analyzer to the Play m ode.

15. Select File > Open on the MPEG analyzer to display the Open dialog box.

16. In the dialog box, navigate to the E:\MTXRTX_Test streams\

Record_Files, and then select the SPI214Mbps.trp file.

17. On the MPEG analyzer, make the following settings:

Play menu

Data Rate 214 Mbps...

Update Off......

Source RAM......

18. Click the PLAY button on the MPEG Analyzer to start playing the

SPI214Mbps.trp file.

19. Verify that the hierarchic view is displayed on the RTX100A screen. In

addition, verify that the bit rate display is 214 Mbps and the packet size

display is 188 bytes.

20. Press the REC button on the RTX100A to record the file.

21. After recording is completed, click the Stop button on the MPEG analyzer.

22. Exit the MPEG Player application on the MPEG analyzer.

Checking the Recorded File.

23. Change the interface cable connection from DVB/SPI Out connector to

DVB/SPI In connector on the MPEG analyzer.

24. Start the TS Compliance Analyzer on the MPEG analyzer.

25. In the Open Transport Stream dialog box, select Real-time Analysis,and

then make the following settings:

Interfaces DVB Parallel...........

Interface Settings Time Stamping....

26. Click the OK button.

27. Press the PLAY button on the RTX100A to display the Play screen.

28. Select File > Open to open the Select File dialog box.

29. In the dialog box, navigate to the D:\ Record_Files directory, and then select

the SPI214Mbps.trp file.

30. Select Play > Update > On on the RTX100A.

RTX100A ISDB-T RF Signal Generator Service Manual

3-9

Page 56

Performance Verification

q

p

31. Press the PLAY button on the RTX100A to start playing the

SPI214Mbps.trp file.

32. Verify that the hierarchic view is displayed on the screen and that no error

messages appear. In addition, verify that the bit rate is 40 Mbps and that the

transport stream packet size is 188 bytes.

NOTE. Ignore Program 3 and PID 120 (0x78) errors in the hierarchical view

because these are caused by the original test40.TRP file.

33. Press the STOP button on the RTX100A.

34. Close the TS Compliance Analyzer window.

External Clock/Reference

and External Trigger

Inputs

This test confirms that the external clock/reference input (Clock/Ref In) and

external trigger input (Trig In/Out) on the RTX100A are functioning correctly.

Equipment

required

MPEG analyzer

Function generator

Two 50 Ω BNC cables

Parallel interface cable

test64.TRP file

1. Usea50Ω BNC cable to connect the Clock/Ref In connector on the

RTX100A to the Ch1 connector on the function generator. See Figure 3-4.

2. Use the 50 Ω BNC cable to connect the Trig In/Out connector on the

RTX100A to the Ch2 connector on the function generator. See Figure 3-4.

3. Use the parallel interface cable to connect the SPI In/Out connector on the

RTX100A to the DVB/SPI In connector on the MPEG analyzer. See

Figure 3-4.

3-10

RTX100A ISDB-T RF Signal Generator Service Manual

Page 57

Performance Verification

A

Function generator (

50 Ω BNC cable

RTX100A rear panel

FG3102)

MPEG analyzer (MTS430)

50 Ω BNC cable

Parallel interface cable

Figure 3-4: Equipment connections for checking the external clock/reference and trigger inputs

4. Set the function generator settings as indicated below:

Ch 1 output

Function Square...........

Run Mode Continuous..........

Frequency 10 MHz..........

Output Amplitude 0.5 V....

Output Offset 2.0 V.......

Ch 2 output

Function Arb (Edit: Point Number: 100,...........

All Data: 16382)

Run Mode Continuous..........

Output Menu Load Impedance: 1 kΩ........

Output Amplitude 1.75 V....

Output Offset 0.875 V.......

5. Press the On button of the Ch1 output on the function generator.

6. Open the test64.TRP file on the RTX100A.

a. Select File > Open in the Play screen to open the Select File dialog box.

b. In the dialog box, select the test64.TRP file.

RTX100A ISDB-T RF Signal Generator Service Manual

3-11

Page 58

Performance Verification

7. Set Play > Update > On.

8. Select Play > Clock to open the Clock dialog box.

9. In the Clock dialog box, select ExtRef 10.

10. Press the PLAY button on the RTX100A to start playing the test64.TRP file.

11. Verify that PLL unlock error does not occur on the RTX100A.

12. Start the TS Compliance Analyzer on the MPEG analyzer.

13. In the Open Transport Stream dialog box, select Real-time Analysis,and

then make the following settings

Interfaces DVB Parallel...........

Interface Settings Time Stamping....

14. Click the OK button.

15. Verify that the hierarchic view is displayed on the MPEG analyzer screen

and that no error messages appear. In addition, verify that the bit rate is 64

Mbps and the packet size is 188 bytes.

NOTE. Ignore Program 3 and PID 120 (0x78) errors in the hierarchical view

because these are caused by the original test40.TRP file.

16. Change the clock source setting on the RTX100A and output frequency

setting on the function generator with the following and then repeat step 15.

Clock source setting (RTX100A) Output frequency setting (function generator)

ExtRef 27 27 MHz

Ext Ref 8.126984 MHz 8.126984 MHz

Ext P Clk 8MHz

17. Change the output frequency of the function generator to 32 MHz.

18. Select Play > Clock on the RTX100A to open the Clock dialog box.

19. In the dialog box, select Ext S Clk.

20. Repeat step 15 and verify that all items in the Priority 1 row are green.

NOTE. Ignore 2. 3.a PCR Repetition and 2.5 PTS errors in the Priority 2 row.

3-12

21. Press the STOP button on the RTX100A to stop the stream output.

RTX100A ISDB-T RF Signal Generator Service Manual

Page 59

Performance Verification

22. Select Play > Clock on the RTX100A to open the Clock dialog box.

23. In the dialog box, select Internal.

24. Press the On button of the Ch1 output on the function generator to stop the

signal output.

25. Press the On button of the Ch2 output on the function generator to start the

signal output.

26. Select Play > Others on the RTX100A to open the Others dialog box.

27. In the dialog box, set Ext Play Start to Rise.

28. Verify that the RTX100A starts playing when the Output menu is set to

Invert on the function generator.

29. Press the STOP button on the RTX100A to stop the stream output.

30. Press the On button of the Ch2 output on the function generator to stop the

signal output.

31. Return Ext Play Start to Off on the RTX100A.

32. Disconnect all cables from the RTX100A, function generator, and MPEG

analyzer.

RTX100A ISDB-T RF Signal Generator Service Manual

3-13

Page 60

Performance Verification

q

p

ASI Interface

This test verifies that transport stream data is correctly played from and is

recorded through the ASI interface on the RTX100A.

Equipment

required

MPEG analyzer

Oscilloscope

MPEG-2 measurement decoder

Video monitor

Two 75 Ω BNC cables

75 Ω signal adapter

test40.TRP file

Checking the Output Signal.

1. Use the 75 Ω BNC cable and the 75 Ω signal adapter to connect the ASI Out

connector on the RTX100A to the oscilloscope CH1 input. See Figure 3-5.

Oscilloscope (TDS5104B)

RTX100A rear panel

75 Ω BNC cable

Figure 3-5: Equipment connection for checking the output signal- ASI interface

75 Ω signal adapter

3-14

RTX100A ISDB-T RF Signal Generator Service Manual

Page 61

Performance Verification

2. Set the oscilloscope settings as indicated below:

Vertical scale 200 mV/div........

Input impedance 50 Ω.....

Horizontal scale 1.25 ns/div.....

Trigger position 50%......

Acquire mode Average 32.......

Trigger mode AUTO........

Trigger source CH1.......

Trigger level 0 V........

Trigger slope Rising Edge........

Input coupling DC.......

Measure Amplitude, Rise Time, Fall Time............

Gating Cursor Curs1 Pos1: --2.5 ns/Curs2: 2.75 ns.............

3. Open the test40.TRP file on the RTX100A.

a. Select File > Open in the Play screen to open the Select File dialog box.

b. In the dialog box, select the test40.TRP file.

4. Press the PLAY button to start playing the test40.TRP file.

5. Use the oscilloscope to measure that the amplitude, rise and fall times are as

follows:

Amplitude: 740 mV to 860 mV

Rise and fall time: ≤ 1.2 ns

RTX100A ISDB-T RF Signal Generator Service Manual

3-15

Page 62

Performance Verification

RTX100A rear panel

Checking the Play Operation.

6. Disconnect the BNC cable from the 75 Ω signal adapter on the oscilloscope,

and then connect the cable to the ASI/SMPTE In connector on the MPEG

analyzer. See Figure 3-6.

MPEG analyzer rear panel (MTS430)

75 Ω BNC cable

Figure 3-6: Equipment connections for checking the play operation- ASI interface

7. Start the MPEG Player application on the MPEG analyzer.

8. Set the application to the Record mode.

9. Set the MPEG analyzer settings as indicated below:

Record

Source SPI/ASI/310M......

Target RAM, Record Size: 100 MB......

SPI/ASI/310M

Input Port BNC...

BNC Port ASI...

File

Save Mode Over write..

Save E:\MTXRTX_Test streams\Record_Files\........

ASI214Mbps.trp

3-16

RTX100A ISDB-T RF Signal Generator Service Manual

Page 63

Performance Verification

10. On the RTX100A, make the following settings:

Play menu

Clock Data Rate: 214 Mbps.......

Update Off......

Source RAM......

11. Press the PLAY button on the RTX100A to start playing the test40.TRP.

12. Verify that the hierarchic view is displayed on the MPEG analyzer screen. In

addition, verify that the bit rate is 214 Mbps and the packet size is 188

bytes.

13. Click the Record button on the MPEG Player application to record the file.

14. After recording is completed, press the STOP button on the RTX100A.

15. Disconnect the 75 Ω BNC cable from the RTX100A and M PEG analyzer.

Checking the Record Operation.

16. Use the 75 Ω BNC cable to connect the ASI In connector on the RTX100A

to the ASI/SMPTE Out connector on the MPEG analyzer. See Figure 3-7.

MPEG analyzer rear panel (MTS430)

RTX100A rear panel

75 Ω BNC cable

Figure 3-7: Equipment connection for checking the record operation- ASI interface

RTX100A ISDB-T RF Signal Generator Service Manual

3-17

Page 64

Performance Verification

17. Press the REC button on the RTX100A to display the Record screen.

18. On the RTX100A, make the following settings:

Record menu

Source ASI.........

Record size 100 MB.....

Target RAM.........

File menu

Save Mode Over Write.....

Save D:\Record_Files\ASI214Mbps.trp...........

19. Set the MPEG analyzer to the Play mode.

20. Select File > Open on the MPEG analyzer to display the Open dialog box.

21. In the dialog box, navigate to the E:\MTXRTX_Test Streams\Record_Files directory, and then select the ASI214Mbps.trp file.

22. On the MPEG player, make the following settings:

Play

Clock Data Rate: 214 Mbps..........

Update Off.........

Source RAM.........

SPI/ASI/310M

BNC Port ASI......

Through Out Off....

23. Click the PLAY button on the MPEG analyzer to start playing the

ASI214Mbps.trp file.

24. Verify that the hierarchic view is displayed on the RTX100A screen. In

addition, verify that the bit rate is 214 Mbps and packet size is 188 bytes.

25. Press the REC button on the RTX100A to record the file.

26. After recording is completed, click the Stop button on the MPEG analyzer.

27. Exit the MPEG Player application on the MPEG analyzer.

28. Disconnect the 75 Ω BNC cable from the RTX100A and M PEG analyzer.

3-18

RTX100A ISDB-T RF Signal Generator Service Manual

Page 65

RTX100A rear panel

Performance Verification

Checking the Recorded File.

29. Use the 75 Ω BNC cable to connect the ASI Out connector on the RTX100A

to the ASI/SMPTE In connector on the MPEG analyzer. See Figure 3-8.

MPEG analyzer rear panel (MTS430)

75 Ω BNC cable

Figure 3-8: Equipment connection for checking the recorded file- ASI interface

30. Press the PLAY button on the RTX100A to display the Play screen.

31. Select Play > Update > On.

32. Open the ASI214Mbps file on the RTX100A.

a. Select File > Open to open the Select File dialog box.

b. In the dialog box, navigate to the D:\Record_Files directory, and then

select the ASI214Mbps.trp file.

33. Press the PLAY button to start playing the file.

34. Start the TS Compliance Analyzer on the MPEG analyzer.

35. In the Open Transport Stream dialog box, select Real-time Analysis,and

then make the following settings:

Interfaces ASI...........

Interface Settings Time Stamping....

36. Click the OK button.

37. Verify that the hierarchic view is displayed on the screen and that no error

messages appear. In addition, verify that the bit rate is 40 Mbps and that the

packet size is 188 bytes.

RTX100A ISDB-T RF Signal Generator Service Manual

3-19

Page 66

Performance Verification

NOTE. Ignore Program 3 and PID 120 (0x78) errors in the hierarchical view

because these are caused by the original test40.TRP file.

38. Press the STOP button on the RTX100A to stop the stream output.

39. Disconnect the 75 Ω BNC cable from the RTX100A and M PEG analyzer.

Checking a Moving Picture.

40. Usea75Ω BNC cable to connect the ASI Out connector on the RTX100A

to the TS ASI connector on the MPEG-2 measurement decoder. See

Figure 3-9.

41. Use the 75 Ω BNC cable to connect the SER75 Ω connector on the MPEG-2

measurement decoder to the SDI input on the video monitor. See Figure 3-9.