Page 1

Service Manual

PQM300

Program QoS Monitor

071-0577-01

This document applies to firmware version 1.0

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077-0001

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Strategy xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service Offerings xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification T ables 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Conditions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Specifications 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Components 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Characteristics 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical (Physical) Characteristics 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certification and Compliances 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Shipping List 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Connections 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard and Mouse Connections 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input/Output Capabilities 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Inputs and Outputs 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Channels 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Monitor Connections 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Composite Decoder Connections 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Alarm Relay Board 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Time Operation 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Operation 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Time Power On 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Network Properties 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Networking the PQM300 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Web Browser Remote Control 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Remote Control 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Remote Control 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Remote Application Program 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incoming Inspection 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create an Emergency Repair Disk 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering Off the Program Monitor 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutting Down the PQM300 Application 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Program QoS Monitor Service Manual

i

Page 6

Table of Contents

Theory of Operation

Field Service 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Controls 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Icon T oolbar 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Security 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making Program Monitor Connections 2–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Composite Decoder 2–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Alarm Relay Board 2–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Control Option Front Panel Controls 2–33. . . . . . . . . . . . . . . . . . . . . . . . .

T ouch Screen Control Program 2–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ouch Screen Calibration 2–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Operation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Busses 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Controller 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCI Backplane 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Interface 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Pad 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Disk Drives 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floppy Disk Drive 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CD Drive 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Flat-Panel Display 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Picture Quality Monitor Functional Description 3–5. . . . . . . . . . . . . . . . .

Program Monitor Module Operation 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Digital I/O Block Description 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP Block Description 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCI Bus Interface 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot ROM 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Composite Decoder 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Generator 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sync Stripper 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D Converters 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoder 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FPGA 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Lock 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parallel to Serial Converter 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCI Interface 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Test Interval 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification Procedures 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

PQM300 Program QoS Monitor Service Manual

Page 7

Adjustment Procedures

Table of Contents

Program Monitor

Channel A Loop-Through

Amplitude 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shut Down the PQM300 Application 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Decoder Diagnostics 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoder 601 Out Amplitude 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Program Monitor Module 27 MHz Clock Frequency 4–14. . . . . . . . . . . . .

T est Equipment Setup 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Performance Verification 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Digital Video Check 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Composite Video Decoder Check 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Relay Board Check 4–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Monitor 27 MHz Oscillator Frequency Adjustment 5–1. . . . . . . . . . . . . . .

T est Equipment Setup 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Composite Decoder Board Adjustments 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Luma Gain 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Chroma Gain 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run the Decoder Diagnostic 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flat Panel T ouch Screen Calibration 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Preparation 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling Static-Sensitive Components 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior instrument 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact Disc Drive 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mouse 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interior 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In Case of Problems 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Problems 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Problems 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Isolation 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Program Monitor Module Diagnostics 6–8. . . . . . . . . . . . . . . . . . . . .

DMA T est Description 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T estdsp Commands 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Monitor Module Troubleshooting Checks 6–12. . . . . . . . . . . . . . . . . . .

Program Monitor Module LED Codes 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoder Board Error Messages 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoder Diagnostics 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decoder LED Indicators 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement Instructions 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Program QoS Monitor Service Manual

iii

Page 8

Table of Contents

Replaceable PQM300 Modules 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended T ools 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Bezel Trim Ring 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the PQM300 Cabinet 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the PQM300 Cabinet 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Bezel Trim Ring 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Application Modules 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a PQM300 Plug-In Module 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reinstalling a PQM300 Plug-In Module 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe Modules 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Interface Circuit Board Cover 6–23. . . . . . . . . . . . . . . . . . . . . . . .

Reinstalling the Front Panel Interface Circuit Board Cover 6–24. . . . . . . . . . . . .

Removing the Blank Key Pad Assembly 6–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Key Pad Assembly 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Flat Panel Display 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reinstalling the Flat Panel Display 6–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Key Pad Assembly 6–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Key Pad Assembly 6–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the CD and Floppy Disk Drive Assembly 6–29. . . . . . . . . . . . . . . . . .

Removing and Replacing the CDROM Drive 6–30. . . . . . . . . . . . . . . . . . . . . . .

Removing and Replacing the Floppy Disk Drive 6–31. . . . . . . . . . . . . . . . . . . . .

Reinstalling the CD and Floppy Disk Drive Assembly 6–31. . . . . . . . . . . . . . . .

Speaker Removal 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speaker Replacement 6–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and Replacing the Dual SCSI Hard Disk Drives 6–34. . . . . . . . . . . . .

Power Supply Removal and Replacement 6–35. . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Board Removal and Replacement 6–37. . . . . . . . . . . . . . . . . . . . . . . .

Controller I/O Board Removal and Replacement 6–39. . . . . . . . . . . . . . . . . . . . .

Interface Board Removal and Replacement 6–45. . . . . . . . . . . . . . . . . . . . . . . . .

Backplane Circuit Board Removal and Replacement 6–48. . . . . . . . . . . . . . . . . .

CPU Jumper Settings 6–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repacking for Shipment 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Obtaining Replacement Packaging 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options

Optional Configurations 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Power Cords 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts

Diagrams

iv

PQM300 Program QoS Monitor Service Manual

Page 9

Replaceable Mechanical Parts

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Servicing 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mfr. Code to Manufacturer Cross Index 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Appendix A: Software Repair A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If an Application Locks A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating and Using an Emergency Repair Disk A–1. . . . . . . . . . . . . . . . . . . . . . . . .

Create an Emergency Repair Disk A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Emergency Repair Disk A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reinstalling the PQM300 Program QoS Monitor Software A–4. . . . . . . . . . . . . . . .

Install the Windows NT Operating System A–4. . . . . . . . . . . . . . . . . . . . . . . . .

Install Windows NT Service Pack 4.0 A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install D Drive A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrade the Internet Explorer A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install JAVA Virtual Machine Upgrade A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Peer Web Services A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Custom Ethernet Driver A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Custom Display Driver A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Soft Shut Down Driver A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure for Auto Boot Up A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing and Using SNMP Services A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the AceComm NetPlus Manager A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Display Properties A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup for Flat Panel Display Boot Up A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COM Port Setting A–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the T ouch-Base SC3 Touch Screen Driver A–18. . . . . . . . . . . . . . . . . . . .

Install the Alarm Relay Board Driver A–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install PQM300 Application Files A–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assign a Community Name to the Program Monitor A–19. . . . . . . . . . . . . . . . . .

Table of Contents

PQM300 Program QoS Monitor Service Manual

v

Page 10

Table of Contents

List of Figures

Figure 2–1: Rear panel of the PQM300 program monitor with three

composite video channels and alarm relay option 2–3. . . . . . . . . . . . .

Figure 2–2: Keyboard and mouse connections on the front

side panel 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Program monitor connections for composite

decoder/program monitor pairs 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Program monitor module simplified block diagram 2–7. . . .

Figure 2–5: Composite decoder module simplified block diagram 2–7. .

Figure 2–6: On/Standby switch 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Host file for DNS name server 2–15. . . . . . . . . . . . . . . . . . . . . .

Figure 2–8: The Repair Disk dialog box 2–18. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–9: All data on the disk will be erased 2–18. . . . . . . . . . . . . . . . . . .

Figure 2–10: Toolbar shortcut icons 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–11: Configure menu selections 2–26. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–12: Change Access Control dialog 2–26. . . . . . . . . . . . . . . . . . . . .

Figure 2–13: Connection Configuration dialog box 2–27. . . . . . . . . . . . . . .

Figure 2–14: Alarm relay control connections 2–30. . . . . . . . . . . . . . . . . . .

Figure 2–15: Connection Configuration dialog box 2–31. . . . . . . . . . . . . . .

Figure 2–16: Relay Configuration dialog box 2–31. . . . . . . . . . . . . . . . . . . .

Figure 2–17: Relay board channel map 2–33. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–18: Local Control front-panel elements 2–33. . . . . . . . . . . . . . . .

Figure 3–1: Mainframe simplified block diagram 3–2. . . . . . . . . . . . . . . .

Figure 3–2: PQM300 Program QoS Monitor block diagram 3–5. . . . . . .

Figure 3–3: PQM300 Program QoS Monitor block diagram with

composite decoder modules 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–4: Program monitor module I/O section simplified

block diagram 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–5: Digital signal processor module DSP section simplified block

diagram 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–6: Decoder simplified block diagram 3–12. . . . . . . . . . . . . . . . . .

Figure 4–1: Connection for monitor module Main Out

loop-through check 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: CH 1 high amplitude 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: CH 1 low amplitude 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–4: CH 1 fall time 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

PQM300 Program QoS Monitor Service Manual

Page 11

Table of Contents

Figure 4–5: CH 1 rise time 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–6: Connections for the decoder 601 output check 4–12. . . . . . . .

Figure 4–7: Oscillator test point for frequency check 4–15. . . . . . . . . . . . .

Figure 4–8: Rear panel of PQM300 program monitor with composite

decoder modules installed 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–9: Program monitor serial digital video connections 4–17. . . . . .

Figure 4–10: Program monitor connections for composite

decoder/program monitor pairs 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–11: Relay board channel associations 4–31. . . . . . . . . . . . . . . . . .

Figure 5–1: 27 MHz clock test point for frequency adjustment 5–3. . . . .

Figure 5–2: Decoder board LED indicator locations 5–4. . . . . . . . . . . . . .

Figure 5–3: Decoder board adjustment locations 5–5. . . . . . . . . . . . . . . .

Figure 6–1: LED indicators on the DSP modules 6–12. . . . . . . . . . . . . . . . .

Figure 6–2: Decoder LED indicators 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Right side handle screws 6–19. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Rear panel feet removal 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Circuit board retaining plate 6–22. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Front panel circuit board cover removal 6–24. . . . . . . . . . . . .

Figure 6–7: Blank key pad assembly removal 6–25. . . . . . . . . . . . . . . . . . .

Figure 6–8: Flat panel display removal 6–27. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–9: Key pad assembly removal 6–28. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–10: Front panel interface circuit board connectors 6–29. . . . . . .

Figure 6–11: Chassis screw locations for CD drive 6–30. . . . . . . . . . . . . . .

Figure 6–12: Chassis screw locations for the floppy disk drive 6–31. . . . .

Figure 6–13: Floppy disk drive and CD audio connector installation 6–32

Figure 6–14: Speaker installation and fan locations 6–33. . . . . . . . . . . . . .

Figure 6–15: Power supply large and small screws locations 6–36. . . . . . .

Figure 6–16: Controller board orientation and screw locations 6–38. . . . .

Figure 6–17: SCSI ribbon cable connection location 6–40. . . . . . . . . . . . . .

Figure 6–18: Insert I/O board into slot 1 6–41. . . . . . . . . . . . . . . . . . . . . . .

Figure 6–19: Installing the I/O circuit board 6–42. . . . . . . . . . . . . . . . . . . .

Figure 6–20: I/O to controller board top interconnections 6–43. . . . . . . . .

Figure 6–21: I/O to controller board bottom interconnections 6–44. . . . . .

Figure 6–22: Top connection to controller board 6–44. . . . . . . . . . . . . . . . .

Figure 6–23: Location of J220 connections and wiring orientation 6–45. .

Figure 6–24: Front panel interface circuit board connectors 6–46. . . . . . .

Figure 6–25: Screw locations for the interface circuit board 6–47. . . . . . .

PQM300 Program QoS Monitor Service Manual

vii

Page 12

Table of Contents

Figure 6–26: Cut-away view showing wire routing of fan

and speaker wires 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–27: Backplane orientation and screw locations 6–49. . . . . . . . . .

Figure 6–28: CPU Jumper setting locations 6–51. . . . . . . . . . . . . . . . . . . . .

Figure 6–29: Placement of bottom spacer pad in inner shipping box 6–54

Figure 6–30: Repackaging the program monitor 6–55. . . . . . . . . . . . . . . . .

Figure 9–1: Simplified interconnection block diagram 9–2. . . . . . . . . . . .

Figure 10–1: Chassis parts 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Modules and mounting hardware 10–9. . . . . . . . . . . . . . . . . .

Figure 10–3: Front panel parts 10–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Interconnection cables 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–5: Cabinet parts and accessories 10–16. . . . . . . . . . . . . . . . . . . . .

Figure 10–6: PQM3FLC Local Control Option 10–19. . . . . . . . . . . . . . . . . .

List of Tables

Figure A–1: The Repair Disk dialog box A–3. . . . . . . . . . . . . . . . . . . . . . . .

Figure A–2: Repair disk preparation A–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure A–3: Hard drive partitions A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

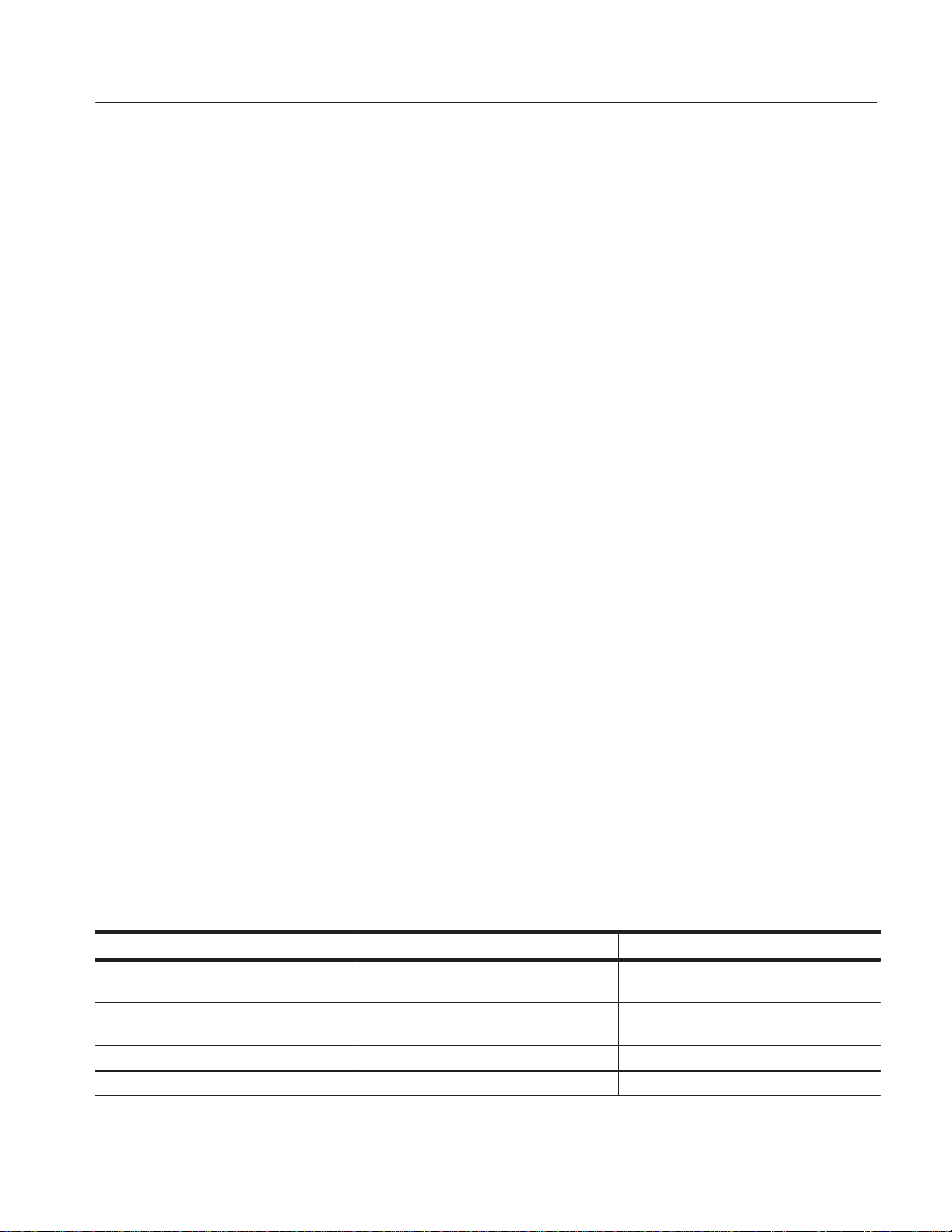

Table 1–1: Program monitor DSP board 1–3. . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: PQM3F01 NTSC/PAL composite decoder board 1–4. . . . . . .

Table 1–3: PQM3FRB, Option RB, alarm relay board 1–6. . . . . . . . . . .

Table 1–4: Alarm relay board connectors 1–6. . . . . . . . . . . . . . . . . . . . . .

Table 1–5: System components 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Rear panel interface 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Side panel interface characteristics 1–10. . . . . . . . . . . . . . . . . .

Table 1–8: AC power source characteristics 1–10. . . . . . . . . . . . . . . . . . . .

Table 1–9: Mechanical characteristics 1–10. . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Environmental characteristics 1–11. . . . . . . . . . . . . . . . . . . . .

Table 1–11: Electromagnetic Compatibility 1–12. . . . . . . . . . . . . . . . . . . . .

Table 2–1: Operating requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Alarm relay board connectors 2–8. . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Task shortcut icons 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Front panel-key controls 2–34. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: Touch screen techniques 2–35. . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

PQM300 Program QoS Monitor Service Manual

Page 13

Table of Contents

Table 4–1: Required equipment list 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: Test oscilloscope settings 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–3: Frequency counter setup 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–1: Required equipment list 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5–2: Frequency counter setup 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–1: Static susceptibility 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: T r oubleshooting 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–3: DMA Tests in the testdsp test suite 6–8. . . . . . . . . . . . . . . . . .

Table 6–4: Testdsp test suite 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–5: Testdsp options 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–6: Program Monitor LED codes 6–13. . . . . . . . . . . . . . . . . . . . . . .

Table 6–7: Decoder error messages 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–8: Decoder LED indicators 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–9: CPU Speed settings 6–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–10: Flat panel jumper settings 6–51. . . . . . . . . . . . . . . . . . . . . . . .

Table 6–11: Packaging material 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Optional accessories 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Power cord options 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PQM300 Program QoS Monitor Service Manual

ix

Page 14

Table of Contents

x

PQM300 Program QoS Monitor Service Manual

Page 15

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

PQM300 Program QoS Monitor Service Manual

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

xi

Page 16

General Safety Summary

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

xii

PQM300 Program QoS Monitor Service Manual

Page 17

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

PQM300 Program QoS Monitor Service Manual

xiii

Page 18

Service Safety Summary

xiv

PQM300 Program QoS Monitor Service Manual

Page 19

Preface

This manual contains the servicing information for the PQM300 Program QoS

Monitor. This instrument is composed of a mainframe chassis that contains the

CPU, the CPU I/O board, and PQM300 hardware PCI modules and supporting

circuitry. The CPU runs under the Window NT operating system running the

PQM300 application software.

The information included in this manual explains how to verify, service,

troubleshoot, and repair the system to the module level:

H Specifications describes functional characteristics and performance require-

ments for the PQM300 Program QoS Monitor.

H Operating Information tells you how to install and operate the instrument.

H Theory of Operation provides descriptions of the program monitor system

modules.

H Performance Verification describes how to verify the functional performance

of the PQM300 system.

H Adjustment Procedures gives the field adjustment procedures.

H Maintenance contains the following information:

H How to safely handle static sensitive modules and components

H How to remove and replace modules

H Diagnostic and Troubleshooting information and procedures

H Options provides a brief description of the available options for the program

monitor system.

H Replaceable Electrical Parts. See the Replaceable Mechanical Parts List.

H Diagrams provides a simplified interconnection block diagram.

H Replaceable Mechanical Parts List gives all module and mechanical parts

that comprise the program monitor system. Parts are identified on an indexed

illustration to make them easier to identify.

H Appendix A provides the procedure to follow in the event that the operating

system software needs to be repaired. Installing the application software and

loading the video test sequences are also explained.

PQM300 Program QoS Monitor Service Manual

xv

Page 20

Preface

Related Manuals

Manual Conventions

ThePQM300 Program QoS Monitor user documentation consists of the

following:

H The PQM300 Program QoS Monitor User Manual details how to operate

this picture quality monitoring system.

The following terms and conventions are used throughout this manual:

H The terms program monitor and PQM300 program monitor are used

interchangeably with the more formal term PQM300 Program QoS Monitor.

H The term mainframe refers to the computer platform that hosts the PQM300

Program QoS Monitor.

xvi

PQM300 Program QoS Monitor Service Manual

Page 21

Introduction

Before You Begin

This manual contains maintenance information for thePQM300 Program QoS

Monitor. Take a few minutes to read this short introduction before doing any

repair or service work on the instrument.

This manual is for servicing the PQM300 Program QoS Monitor. To prevent

injury to yourself or damage to the program monitor system, fulfill the following

requirements before you attempt service:

H Be sure you are a qualified service person.

H Read the Safety Summary found at the beginning of this manual.

H Read the following Service Strategy information.

When using this manual to service your program monitor system, be sure to heed

all warning, cautions, and notes.

Service Strategy

This manual contains the following maintenance and repair procedures:

H Periodic maintenance

H Performance verification

H Field adjustments

H Module removal and replacement

H Module-level fault diagnosis

Once you isolate a problem with a module, use the Replaceable Parts List in this

manual to determine the correct module part number to order from Tektronix.

PQM300 Program QoS Monitor Service Manual

xvii

Page 22

Introduction

Tektronix Service Offerings

Tektronix provides service to cover repair under warranty. Other services are

available that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians, trained on Tektronix products, are best

equipped to service your program monitor system. Tektronix technicians are

appraised of the latest information on improvements to the product as well as the

latest product options.

Warranty Repair Service

Repair Service

Self Service

Tektronix warrants this product for one year from the date of purchase. (The

warranty appears after the title page and copyright page in this manual.)

Tektronix technicians provide warranty service at most Tektronix service

locations worldwide. Your Tektronix product catalog lists all service locations

worldwide.

Tektronix offers single per-incident and annual maintenance agreements that

provide Depot Service repair of this product.

Of these services, the annual maintenance agreement offers a particularly

cost-effective approach to service for many owners of the PQM300 Program

QoS Monitor. Such agreements can be purchased to span several years.

Tektronix supports repair to the module level by offering a Module Exchange

program.

Module Exchange. This service reduces down time for repair by allowing you to

exchange most modules for remanufactured ones. Tektronix ships you an

updated and tested exchange module from the Beaverton, Oregon, service center.

Each module comes with a 90-day service warranty.

xviii

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the repair or adjustment services

previously described.

PQM300 Program QoS Monitor Service Manual

Page 23

Contacting Tektronix

Introduction

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

PQM300 Program QoS Monitor Service Manual

xix

Page 24

Introduction

xx

PQM300 Program QoS Monitor Service Manual

Page 25

Specifications

Page 26

Page 27

Specifications

Product Description

This section lists the electrical, physical, and environmental characteristics of the

PQM300 Program QoS Monitor.

NOTE. Version 2.0 of the PQM300 application software must be installed to

support the Alarm Relay board and the Local Control Flat Panel Display

options.

The program monitor is implemented on a platform that uses Microsoft’s

Windows NT operating system. Operating an a networked system, the PQM300

program monitor application is configured to begin automatically after the

power-on initialization and program loading are completed.

An optional SVGA monitor can be connected for a local display and the program

monitor can be controlled using a keyboard and a mouse.

The PQM300 program monitor provides program service quality assessments of

live Rec. 601 digital video signals. Quality of Service (QoS) monitoring

provides the following assessments and capabilities:

MPEG Defects

H Real-time MPEG defect (Discrete Cosine Transform based blockiness

artifacts) monitoring and reporting when a signal is present. The PDI level

(Picture Defect Indicator) provides immediate and continuous indication of

the video image quality.

H Fixed (manual) setting of blockiness period for a given pixel block size for

the MPEG defects measurement.

H Adaptive settings to automatically determine blockiness periods used for the

MPEG defects measurement.

H Period selection to monitor the detected blockiness period. This is a tool to

find the correct period for the fixed period setting and to monitor the

incoming video for blockiness period changes.

Frozen Frame, Repeated Frames, Loss of Service

H Video content constant (consecutive fields exactly identical)

PQM300 Program QoS Monitor Service Manual

1–1

Page 28

Specifications

H Repeated frame found in a moving sequence

H Absence of a serial digital video signal

H Absence of video content on the input

Uncorrelated Noise

H Indicates the amount of white Gaussian noise in the video signal (such as

that injected by analog video circuits)

Alarm Level Monitoring

H Individual alarm settings for all measurements (including blockiness period)

H Level thresholds for amplitude of error

H Time thresholds in number of fields for duration of error condition

H Percentage thresholds for an amount of error within a defined time threshold

Remote Control and Networking

H Web Browser control and monitoring of any program monitor accessible

over a TCP/IP network. Access is through the Netscape (4.5 or higher) or the

Internet Explorer (4.0 or higher) Web browser. An applet provides a remote

user interface to make all the configuration setups and display the measure-

ment results.

H SNMP agent (Simple Network Management Protocol) and MIB (manage-

ment information base) for integration into an existing SNMP infrastructure

to monitor picture quality from a central control point

H Multi-machine networking. A networked Windows NT PC or a PQM300

program monitor with local display, keyboard, and mouse, can be used to

control and monitor all PQM300 program monitors accessible over the

network.

NOTE. A locally attached SVGA monitor, mouse, and keyboard are used for the

initial set up of the PQM300 Program QoS Monitor.

Continuous Measurements

1–2

Measurements run continuously to monitor program quality in real-time. An

operator at a central control station can control the operation of the program

monitor installed in a system network.

PQM300 Program QoS Monitor Service Manual

Page 29

Specification Tables

Specifications

The tables list the specifications for the PQM300 Program QoS Monitor. All

specifications are guaranteed unless labeled typical. Typical specifications are

provided for your convenience but are not guaranteed. Specifications marked

with the n symbol are checked in the Performance Verification procedures

given in this manual.

The following definitions describe the information you will find in the specification tables.

H Specification. A document or a section of a document that lists and

describes characteristics and performance requirements of equipment and

certain programming material.

H Characteristic. A property of the product.

H Description. A statement that describes a characteristic usually in limit

form. This statement is considered to be binding on the company (seller),

and can be verified by performing the appropriate portion of the Performance

Verification Procedure, or by a separate and available procedure.

H Supplemental information. Statements that explain performance require-

ments or provide performance information. These are not considered to be

statements of guaranteed performance and are not ordinarily supported by a

performance check.

Performance Conditions

The Performance requirements are valid within the environmental limits if the

instrument was adjusted at 25_ C ± 5_ C and you allowed a minimum warm-up

time of 20 minutes.

Hardware Specifications

T able 1–1: Program monitor DSP board

Characteristic Description Supplemental information

Input Signal Format n Receives 270 MB/s serial digital signal Complies with ITU–R BT.601, BT.656, and

SMPTE 259M.

Channel 1: Main In and Main Out Active loop-through, BNC, 75 W termi-

nating

Channel 2: Ref In and Ref Out Active loop-through SMB, 75 W terminating

Channel 1 to Channel 2 Isolation 30 dB to 300 MHz

PQM300 Program QoS Monitor Service Manual

1–3

Page 30

Specifications

T able 1–1: Program monitor DSP board (Cont.)

Characteristic Supplemental informationDescription

Channel Synchronization The two inputs are asynchronous

Input Return Loss At least 15 dB (1 MHz to 270 MHz), with

power on.

Serial Receiver Equalization Range Proper operation with coaxial cable up to

14.5 dB loss at 135 MHz. Typical operation;

to 300 meters with Belden 8281 coaxial

cable.

Active loop-through output characteristics Meets SMPTE 259M levels and rise and

fall times. No reclocking is done on

loop-through output.

Loop Output Return Loss At least 15 dB (1 MHz to 270 MHz), with

power on.

Output Signal Format n 270 MB/s serial digital signal Complies with ITU–R BT.601, BT.656, and

SMPTE 259M. Exception: output frequency

accuracy only specified when not refer-

enced to an external input signal.

Output impedance 75 W

Return Loss At least 15 dB (1 - 270 MHz), with power

on.

Output level n 800 mV ± 50mV

Rise/Fall 0.3 ns to 1.2 ns, measured 20% to 80%

Jitter – Internal Reference Less than 0.2 UI, typically 0.3 ns peak-to-

peak.

Jitter – External Reference Depends on the reference input. Typically

peaking at 0.05 dB. Jitter attenuation 3 dB

point is typically at 650 kHz.

Frequency n 270 Mbits/s (27 MHz clock is checked)

Frequency accuracy ±1.5 ppm over temperature range plus

±1 ppm per year drift, when using the

internal oscillator.

Output connector BNC

DSP memory 256 MB fast SDRAM

T able 1–2: PQM3F01 NTSC/PAL composite decoder board

Characteristic Performance requirement Supplemental information

Input Channels

Video Format n NTSC, NTSC No Setup, PAL (B, D, G, H,

and I)

1–4

PQM300 Program QoS Monitor Service Manual

Page 31

Specifications

T able 1–2: PQM3F01 NTSC/PAL composite decoder board (Cont.)

Characteristic Supplemental informationPerformance requirement

Composite Input type Passive loop-through, 75 W, compensated,

BNC

Return loss 40 dB up to 6 MHz on composite video

Loop-through insertion loss 0.6 dB Max to 6 MHz for composite video

Input amplitude range +5%, –20% typical

Hum range 0.5 V peak-to-peak

Frequency range ± 20 ppm

Genlock jitter 0.5 degree on 0 dB signal, –20 dB hum,

–50 dB SNR

S-Video Input type Standard S-Video and connector. No

loop-through, terminated.

Return loss 25 dB typical

601 Out (serial digital video)

Connectors One BNC, one SMB. Identical signals on

both output connectors.

Format n 270 MB/s serial component only Complies with ITU-R BT.601, BT.656, and

SMPTE 259M.

Output level n 800 mV ± 80 mV

Rise/Fall n 0.4 ns to 1.2 ns, measured 20% to 80%

Jitter < 0.2 UI above 10 Hz

Output impedance 75 W, 15 dB return loss 5 to 270 MHz

Frequency 270 Mbit/s nominal, tracks input signal

Output mode 8 bit or 9 bit, not user selectable

Conversion Accuracy

Gain 1 ± 2% low frequency

Flatness 1% to 5 MHz for luma, relative to 500 kHz

Luma linearity 2%

Differential Gain 1%

Differential Phase 1 degree

Black Level Error 10 mV

PQM300 Program QoS Monitor Service Manual

1–5

Page 32

Specifications

T able 1–3: PQM3FRB, Option RB, alarm relay board

Characteristic Description

Relay contact rating 6 A at 15 V

Relay contact resistance 100 milliohms maximum

Relay life expectancy 10,000,000 actuations minimum

Alarm relay output Two 25-pin male D-sub connector to support alarm relay out.

Pin Assignment, see Table 1–4.

T able 1–4: Alarm relay board connectors

Relay number Relay contact pin out

Slot 8 Normally closed Common Normally open

1 16 3 15

2 5 17 4

3 19 6 18

4 8 20 7

5 22 9 21

6 14 23 10

7 1 24 11

8 2 25 12

Slot 9 Normally closed Common Normally open

9 16 3 15

10 5 17 4

11 19 6 18

12 8 20 7

13 22 9 21

14 14 23 10

15 1 24 11

16 2 25 12

1–6

PQM300 Program QoS Monitor Service Manual

Page 33

Specifications

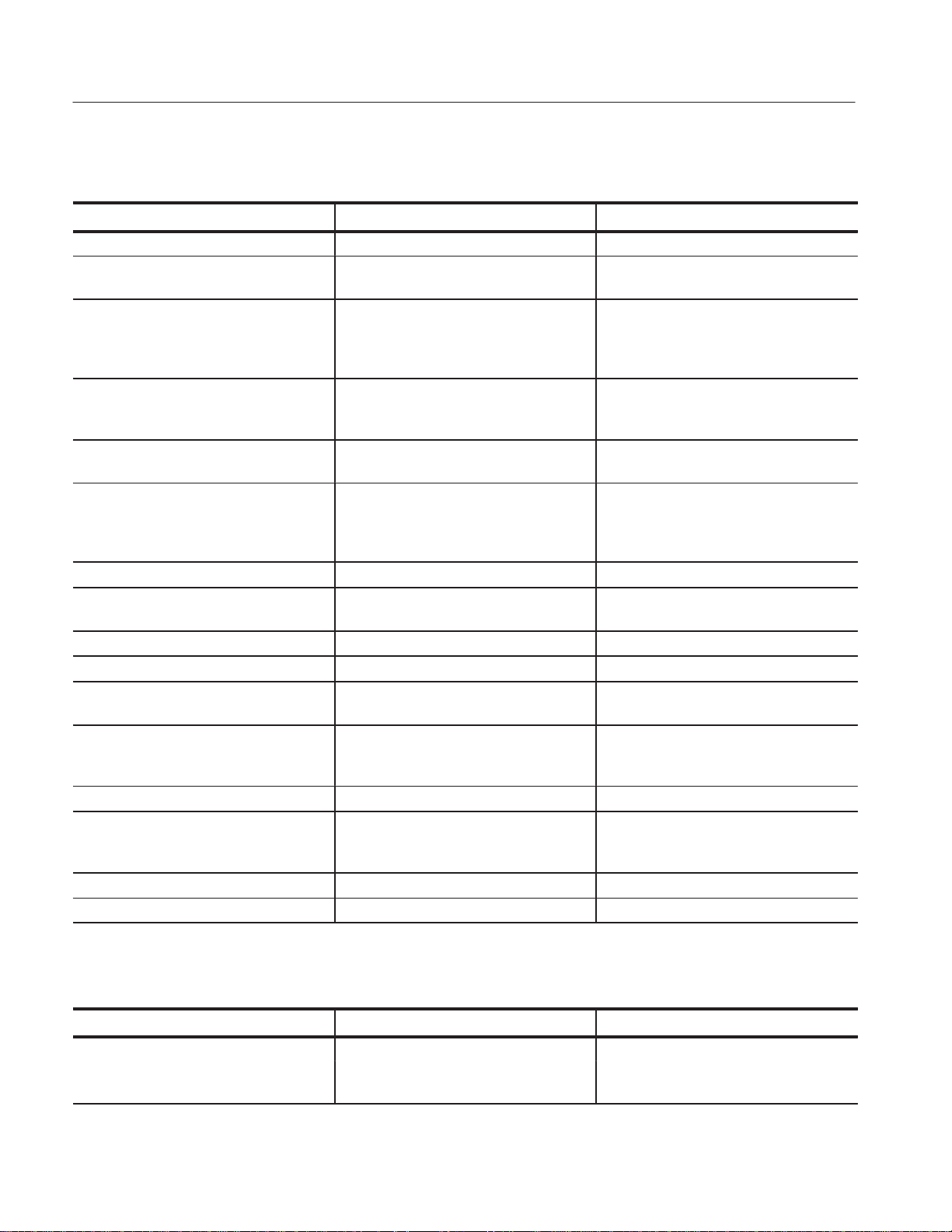

System Components

T able 1–5: System components

Characteristic Supplemental information

Mainframe T ektronix manufactured, common-platform mainframe

Form Factor Rack-mountable in standard 19-inch rack. SVGA monitor for local display and mouse

and keyboard for UI control are optional.

Processor Two 400 MHz Pentium II processors

System Memory 256 MB

Real Time Clock Real-time clock/calendar with a resolution of 1 second or less

Retention Time: Real-time clock, CMOS

setup, and PnP NVRAM

BIOS Phoenix BIOS, y2k compliant, field upgradable

Bus 32-bit PCI

Expansion Slots 8 PCI slots

Graphics 1024 × 768 SVGA resolution with 32 k colors minimum

Non-volatile Storage

Floppy Disk drive Standard 3.5 inch PC compatible floppy disk drive; 1.44 Mbyte high-density double

CD-ROM drive PC compatible half-height IDE CD–ROM drive, 8X

Hard Disk Drives Standard PC compatible Small Computer Systems Interface (SCSI) HDD. Two drives

Mainframe Interfaces One loop-through ethernet port

Projected battery life is typically 10 years

sided (2HD)

of 9.1 Gbyte capacity each. Captured video sequences and other user files are striped

on both hard drives.

One bi-directional RS-232/RS-422/RS-485 port

One parallel port (printer)

Two hot-pluggable keyboard ports (located on the rear panel and the left front side

panel). Use either connector to connect only one keyboard.

Two hot-pluggable mouse ports (located on the rear panel and the left front side panel).

Use either connector to connect only one mouse.

External Display

SVGA Monitor An SVGA monitor may be attached for external display of the user interface.

Digital Picture Monitor Output An ancillary display may be attached. The output protocol is ITU-R BT.601.

Front Panel Virtual front panel on external display monitor. Local user input is made using an

optional mouse and keyboard.

PQM300 Program QoS Monitor Service Manual

1–7

Page 34

Specifications

T able 1–5: System components (Cont.)

Characteristic Supplemental information

Internal Display (PQM3FLC local control

option)

Size

Resolution

Touch Panel

LCD, 6-bit, 250 NIT, CCFL backlight, 0. 264 MM pixel

10. 4 IN Diagonal

800 X 600 (SVGA)

Standard 10.4 in touch panel pointing device mounted on the surface of the TFT

display , connecting to the Front Panel Interface Board.

T able 1–6: Rear panel interface

Characteristic Description

Parallel interface port Port supports standard Centronics mode, Enhanced Parallel Port (EPP), or Microsoft

high-speed mode (ECP) and utilizes a 25-pin D-sub connector.

Compliant with IEEE P1284–C/D2 for bi-directional Parallel Peripheral Interface for

Personal Computers (draft) style 1284–C.

Pin assignments for compatible mode:

1. STROBE* 14. AUTOLF*

2. D0 15. ERR*

3. D1 16. INIT*

4. D2 17. SELECTIN*

5. D3 18. STROBE*

6. D4 19. GND

7. D5 20. GND

8. D6 21. GND

9. D7 22. GND

10. ACK* 23. GND

11. BUSY 24. GND

12. PaperEnd 25. GND

13. SELECT.

Serial interface port 9-pin male-D-sub connector to support RS232 serial port. Compliant to EIA/TIA 574

1–8

Pin Assignments (RS232):

1. DCD 6. DSR

2. RXD 7. RTS

3. TXD 8. CTS

4. DTR 9. RI

5. GND

PQM300 Program QoS Monitor Service Manual

Page 35

Specifications

T able 1–6: Rear panel interface (Cont.)

Characteristic Description

Serial interface port (cont.) Pin Assignments (RS485):

1. RXD– 6. CTS–

2. RXD+ 7. RTS+

3. TXD+ 8. CTS+

4. TXD– 9. RTS–

5. GND

SVGA Output Port 15-pin female high density-D-sub SVGA connector. Compliant with EIA RS 343A.

Selectable 640 X 480 (VGA), 800 X 600, and 1024 X 768 (SVGA).

Pin assignments:

1. Red 9. (key)

2. Green 10. GND

3. Blue 11. NC

4. NC 12. NC

5. GND 13. HSYNC

6. AGND 14. VSYNC

7. AGND 15. NC

8. AGND

USB Port Series A USB receptacle

Pin assignments:

1. Vbus 3. +Data

2. –Data 4. GND

Ethernet Port 10 Base-T/100 Base-T on PCI bus, RJ45 Connector, Plug & Plan compatible, Bus

master mode.

RJ45 Pin assignments:

1. TX+ 5. NC

2. TX– 6. RX–

3. RX+ 7. NC

4. NC 8. NC

PQM300 Program QoS Monitor Service Manual

1–9

Page 36

Specifications

T able 1–7: Side panel interface characteristics

Characteristic Description

Mouse Port PS2 compatible mouse port utilizing a mini-DIN connector.

Pin assignments:

1. data 4. +5V .

2. NC 5. clock

3. ground 6. NC

Keyboard Port PS2 compatible keyboard port utilizing a mini-DIN connector.

Pin assignments:

1. data 4. +5V .

2. NC 5. clock

3. ground 6. NC

USB Port Series A USB receptacle

Pin assignments:

1. Vbus 3. +Data

3. +data 4. GND

Power Characteristics

T able 1–8: AC power source characteristics

Characteristic Description

Source Voltage 100 VAC to 240 VAC " 10% (90 V AC to 264 VAC RMS), 47 Hz to 63 Hz, continuous

range CAT II

Fuse Rating 8 A Fast / 250 V

Maximum Power Consumption 330 Watts max, 145 Watts typical

Steady State Input Current 6 Amps max, 1.9 Amps RMS typical

Inrush Surge Current 36 Amps maximum

Power Factor Correction Yes

Mechanical (Physical) Characteristics

T able 1–9: Mechanical characteristics

Characteristic Description

Classification Transportable platform intended for either rackmount or bench/lab based applications.

Overall Dimensions

1–10

PQM300 Program QoS Monitor Service Manual

Page 37

Specifications

T able 1–9: Mechanical characteristics (Cont.)

Characteristic Description

Height 8.5 inches (w/o feet) (21.6 cm)

Width 17 inches (43.2 cm)

Depth 22 inches (55.9 cm)

Weight

PQM300 42 lb (19.1 kg)

Shipping Weight 64 lb (29.1 kg)

Construction Materials Chassis parts are constructed of aluminum alloy and aluminized steel; front panel and

trim pieces are constructed of plastic; circuit boards are constructed of glass and/or

ceramic-glass laminate

Environmental Characteristics

T able 1–10: Environmental characteristics

Characteristic Description

Cooling airflow Intake is from the front and sides of the instrument. Exhaust is to the bottom and rear of the

instrument.

Required Clearance 2 in. (50 mm) air space adjacent to the bottom of the instrument is required.

Use Rating Rated for indoor use only.

Atmospherics

Temperature:

Operating 5°C to 40°C (41°F to 104°F), 30°C (54°F)/hr max gradient, non-condensing (derated 1°C or

1.8 °F per 1,000 ft. or 305 m above 5,000 ft. or 1524 m altitude)

Non-operating –20°C to 60°C (–4°F to 140°F), 30°C (54°F)/hr max gradient (without disk media installed

in disk drives)

Humidity

Operating 20% to 80% relative humidity, non-condensing. Max wet bulb temperature: 29.4°C or 84.9°F

(derates relative humidity to X46% at 40°C or 104°F)

Non-operating 8% to 80% relative humidity, non-condensing. Max wet bulb temperature: 40°C or 104°F

(derates relative humidity to X54% at 50°C or 122°F)

Altitude

Operating Up to 10,000 ft. (3,040m), (derated 1°C or 1.8°F per 1,000 ft. [305 m] above 5,000 ft.

[1524 m] altitude).

Non-Operating 40,000 ft (12,190 m)

PQM300 Program QoS Monitor Service Manual

1–11

Page 38

Specifications

Certification and Compliances

T able 1–11: Electromagnetic Compatibility

Category Standards or description

EC Declaration of Conformity – EMC Compliance was demonstrated per EN55103–1/2 Product Family Standard for Audio, Video,

Audio-Video, and Entertainment Lighting Control Apparatus for Professional Use (Environment

Class E2; rack-mount application), using the following specifications:

Emissions:

EN 61000-3-2 Harmonic Currents, Conducted Emissions, AC Power Port

EN55103-1 Radiated Magnetic Field Emissions, Annex A, rack-mount,

Inrush Currents, Conducted Emissions, AC Power Port, Annex B

Signal and Control Ports, Conducted Emissions, Annex E

EN 55022 Class B, Radiated and Conducted Emissions.

Peak Inrush Currents

PQM300 main unit 36 A peak at 240 VAC/50 HZ, 15 A peak at 100 VAC/50 Hz

1

PQM300 Option 01 (Analog Composite Video Input) compliance to EN55022 Class B

Radiated emissions limits was demonstrated with S-Video cables (Tektronix part number

012-1554-00), each with two clamp-on EMI Suppression Ferrites (Tektronix part number

276-0344-00) attached on the cable at the end connected to the PQM300 Option 01

S-Video input connector.

2

Radiated emissions compliance with Option RB, the alarm relay boards, demonstrated

with Tektronix part number 174-3562-00 cables attached at the alarm I/O ports, and with

these cables twisted together.

Immunity:

1 2

1–12

IEC 61000-4-2 Electrostatic Discharge Immunity, Performance Criterion “B”

IEC 61000-4-3 RF Electromagnetic Field Immunity, Performance Criterion “A”

IEC 61000-4-4 Electrical Fast Transient/Burst Immunity, Performance Criterion “B”

IEC 61000-4-5 Electrical Slow Transient (Surge) Immunity, Performance Criterion “B”

IEC 61000-4-6 Conducted Radio Frequency Immunity, Performance Criterion “A”

IEC 61000-4-11 Voltage Short Interruption Immunity, AC Power Port, Performance

Criterion “C”

IEC 61000-4-11 Voltage Dips Immunity, AC Power Port, Performance Criterion “B” and “C”

EN55103–2 Radiated Magnetic Field Immunity, Annex A, Rack mount, Performance

Criterion “A”

PQM300 Program QoS Monitor Service Manual

Page 39

Specifications

T able 1–11: Electromagnetic Compatibility (Cont.)

Category Standards or description

Performance Criterion A: The apparatus will continue to operate as intended, in the presence of

the disturbing phenomena. The display will remain stable.

Performance Criterion B: The apparatus will continue to operate as intended after the disturbing

phenomena is removed. There will be no change of operating state or stored data.

Performance Criterion C: Normal function of apparatus is automatically restored when the

disturbing phenomena is removed or can be restored by operation of the controls. Apparatus

may self-reboot.

Australia Declaration of Conformity EMC Framework, with compliance demonstrated using the following standard:

AS/NZS 2064, Australian EMC Emissions Standard for Industrial, Scientific, and, Medical

Equipment.

USA, FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A

Limits.

T able 1–12: Environmental Limits and Use Classification for Safety Certification Compliance

Category Standards or description

Safety Certification Compliance

T emperature, operating +5_ C to +40_ C

Altitude (maximum operating) 2000 meters

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 61010-1, Annex H) - grounded product

Installation (Overvoltage)

Category

Pollution Degree Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Supply Voltage Range 100 VAC to 240 VAC "10%, 50/60 Hz, single phase

Fuse Rating Mains fuse is 8 A, 250 V, Fast; Not operator replaceable. Refer servicing to qualified service

Current Rating 6.0 Amps maximum

Relative Humidity

(maximum operating)

Pollution Degree Definition A measure of the contaminates that could occur in the environment around and within a

Overvoltage Category II (as defined in IEC 61010-1, Annex J)

personnel.

80 % for temperatures up to 31° C, decreasing linearly to 50 % at 40°C

product. Typically the internal environment inside a product is considered to be the same as the

external. Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products

in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

PQM300 Program QoS Monitor Service Manual

1–13

Page 40

Specifications

T able 1–12: Environmental Limits and Use Classification for Safety Certification Compliance (Cont.)

Category Standards or description

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Pollution Degree 3 Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is

protected from direct sunshine, rain, or direct wind.

European Union Compliance

Listing by a U.S. Nationally

Recognized T esting Laboratory

Canadian Certification CAN/CSA C22.2 No. 1010.1 Safety Requirements for Electrical Equipment for Measurement,

Additional Compliance UL3111-1 Standard for Electrical Measuring and Test Equipment.

Installation (Overvoltage) Category Terminals on this product may have different installation (overvoltage) category designations.

Laser Classification This product contains a CD ROM drive which utilizes a Class 1 laser and complies with

Compliance was demonstrated to the following specification as listed in the Official Journal of

the European Union:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A2 Safety Requirements for Electrical Equipment for Measurement

Control and Laboratory Use.

ANSI/ISA S82.01 Safety Standard for Electrical and Electronic Test, Measuring,

Controlling, and Related Equipment., 1994.

Control, and Laboratory Use.

IEC61010-1/A2 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use.

The installation categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CA T I Secondary (signal level) or battery operated circuits of electronic equipment.

EN60825–1:94, as well as with the U.S. FDA regulations. The drive is marked with the laser’s

classification and the date of manufacture, as well as the following information:

Complies with the DHHS rules 21 CFR Chapter 1, Subchapter J applicable at the date of

manufacture.

1–14

PQM300 Program QoS Monitor Service Manual

Page 41

Operating Information

Page 42

Page 43

Operating Information

This section provides basic information for installing and turning on the

PQM300 Program QoS Monitor. The operating menus are briefly described. For

a complete description of the operating menus see the PQM300 Program QoS

Monitor User Manual. You can also use the available online help to assist in

learning the purpose of the control selections in the configuration menus.

NOTE. Version 2.0 of the PQM300 application software must be installed to

support the Alarm Relay board and the Local Control flat panel display options.

Installation

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your instrument.

Check the Shipping List

Hardware Installation

Verify that you have received all of the parts of your program monitor. Use the

shipping lists that came with your instrument to compare against the actual

contents of your order. You should also do the following:

H Verify that you have the correct power cord for your geographical area.

H Verify that you have the PQM300 application software CD that contains a

backup copy of the installed software. Store the CD in a safe location where

you can easily retrieve the software for maintenance purposes.

H Verify that you have a boot disk in case you reformat the hard drive or

damage operating system files or drivers.

H Verify that you have a Windows NT software installation kit. This kit should

also be stored in a safe location. It will only be needed for maintenance

purposes.

H Verify that you have all the other standard and optional accessories that you

ordered.

This section deals with hardware installation. To reinstall software refer to

Appendix C: Software Installation in this manual.

The instrument comes standard with a rack-mount kit. For proper cooling, at

least two inches (5.1 cm) of clearance is recommended on the rear and sides of

PQM300 Program QoS Monitor Service Manual

2–1

Page 44

Operating Information

the mainframe. Use the instructions provided with the rack-mount kit to install

the rack-mount cradle in a standard rack and to install the PQM300 program

monitor in the cradle.

CAUTION. For rack mounting, the product must be installed in its specified rack

cradle. For proper cooling, the air temperature at all air intake vents (inside of

the rack) must not exceed 40

° C.

Before you can operate the product, you must connect the provided power cord.

Refer to Figure 2–1 and connect the power cord to the instrument. Refer to

Table 2–1 for the supply voltage rating and connect the other end of the power

cord to the proper source. Do not connect to any power sources other than those

for which the instrument is rated.

CAUTION. Keep the bottom of the instrument clear of obstructions to ensure

proper cooling.

Operating Requirements

Table 2–1 lists the operating requirements. Refer to Appendix A: Specifications

for a complete specification list.

T able 2–1: Operating requirements

Requirement Specification

Source voltage 100 VAC to 240 V AC " 10% (90 VAC to 264

VAC RMS), 47 Hz to 63 Hz

Steady State input current 6 A

Maximum power consumption 330 Watts max, 145 Watts typical

Temperature 5°C to 40°C (41°F to 104°F), 30°C (54°F)/hr

Humidity 20% to 80% relative humidity, non-condens-

Altitude (maximum operating) Up to 10,000 ft. (3,040m), (derated 1°C or

maximum, 1.25 A

RMS

max gradient, non-condensing (derated 1°C or

1.8 °F per 1,000 ft. or 305 m above 5,000 ft. or

1524 m altitude)

ing. Max wet bulb temperature: 29.4°C or

84.9°F (derates relative humidity to X46% at

40°C or 104°F).

1.8°F per 1,000 ft. [305 m] above 5,000 ft.

[1524 m] altitude).

RMS

typical

Interface Connections

2–2

The interface connectors on the rear and side of the program monitor, shown in

Figure 2–1 and Figure 2–2, provide the interconnection ports for peripheral

PQM300 Program QoS Monitor Service Manual

Page 45

Operating Information

devices and networking. Pin assignments for the rear panel and side panel

connectors are listed in Table 1–6 and Table 1–7 in Specifications.

Input 3Input 1 Input 2

12 5489367101112

Alarm relay

outputs

PrinterEthernetPower

Composite

program

decoder

RS-232

COM Port 2

Program

monitor

SVGA MouseKeyboardSCSI

Figure 2–1: Rear panel of the PQM300 program monitor with three composite video channels and alarm relay option

Keyboard and Mouse

Connections

Connect a keyboard and mouse either to the rear panel connectors as shown in

Figure 2–1 or to the left-hand side of the instrument as shown in Figure 2–2. Do

not connect to both. The keyboard and mouse can be plugged in and unplugged

while the program monitor is in operation.