Page 1

xx

Tektronix PPG4001

ZZZ

PatternPro® Programmable Pattern Generator

User Manual

*P077108900*

077-1089-00

Page 2

Page 3

xx

Tektronix PPG4001

ZZZ

PatternPro® Programmable Pattern Generator

User Manual

www.tektronix.com

077-1089-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacem ent products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, w ith shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from imp roper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has b een modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED . TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODU CTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WIL L NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, IN CIDEN TAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF W HET HER TEKTRONIX OR THE VENDOR H AS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other th an Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

Important safety information ..................... ................................ ................................. v

General safety summary ...................................................................................... v

Service safety summary ................................ .................................. ................... vii

Terms in this manual ..................... .................................. ................................. vii

Symbols and terms on the product ......................................................................... viii

Preface .............................................................................................................. ix

Features ...... ................................ .................................. ................................ ix

Documentation ................................................................................................. x

Getting started.... . . . ..... . ..... . ..... . . ... . . . ..... . ..... . ..... . . ..... . ..... . ..... . . ... . . . ..... . ..... . .... . . .... . . ... 1

Installation............................... .................................. ................................ ..... 1

Controls and connectors ........................................................................................... 4

Functional verification ............................................................................................. 6

Instrument setup ............................................................................................... 6

Power on and verify instrument operation ... .................................. ............................. 6

Verify the eye diagram ............... .................................. .................................. ..... 8

Check other settings . . ..... . ..... . ..... . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . 9

Data and clock output instructions...... .................................. .................................. . 9

Input and output descriptions..................................................................................... 11

Overview ............ .................................. .................................. ...................... 11

Data outputs . .................................. ................................ ................................ 12

Graphical user interface (GUI) touch screen ......... .................................. ........................ 13

Jitter insertion (optional feature) ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... 15

Jitter sources. . ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ... . . . .... . . .... . ..... . ..... . ..... . ... 15

Specifications .. ................................ .................................. .................................. 17

Data outputs . .................................. ................................ ................................ 17

Clock outputs........................ .................................. ................................ ........ 17

Data patterns .................................................................................................. 18

Jitter insertion . . . .... . . .... . . .... . . .... . . .... . . ... . . . .... . . .... . . .... . . .... . . .... . . ... . . . .... . . .... . . .... . . .... 19

Trigger system ................................................................................................ 20

Clock inputs ................................................................................................... 20

Reference clock ............................................................................................... 21

Control interfaces ....................... .................................. .................................. .. 21

Physical characteristics................................... .................................. .................. 22

Remote programming....... .................................. ................................ .................... 23

USB interface ................................................................................................. 23

Command information ................. ................................ .................................. .... 23

Common commands............... .................................. .................................. ............ 24

Summary....................................................................................................... 24

Reference ...................................................................................................... 24

PPG4001 Pattern Generator User Manual i

Page 8

Table of Contents

Regular comman

Summary....................................................................................................... 25

Reference ................... .................................. ................................ ...................... 29

:DIGital:PATTern:LENGth .................................................................................. 29

:DIGital:PATTern:TYPE ............. .................................. .................................. .... 29

:DIGital:PATTern:PLENgth ............. .................................. .................................. 30

:DIGital:PATTern:DATA..................... .................................. .............................. 31

:DIGital:PATTern:HDATa ................................................................................... 32

:DIGital:PATTern:SERRor....................................... .................................. .......... 33

:DIGital:PATTern:ERATe.... .................................. ................................ .............. 33

:DIGital:PATTern:ERATe:STATe ........................................................................... 33

:DIGital:PATTern:BSHift .................................................................................... 34

:DIGital:SIGNal[:POS|:NEG]:CROSsover:[VALue]..................................................... 34

:MMEMory:STORe:PDATa................................................................................. 35

:MMEMory:STORe:STATe ................................................................................. 35

:MMEMory:LOAD:PDATa ................... ................................ .............................. 35

:MMEMory:LOAD:STATe .................................................................................. 36

:MMEMory:MOVE:PDATa ....................... .................................. ........................ 36

:MMEMory:MOVE:STATe.................................................................................. 36

:MMEMory:DELete:PDATa............... .................................. ................................ 37

:MMEMory:DELete:STATe ............... .................................. ................................ 37

:MMEMory:CATalog:PDATa? ............................ .................................. ................ 37

:MMEMory:CATalog:STATe?................... .................................. .......................... 38

:OUTPut0:SOURce........................................................................................... 38

:OUTPut0:DIVider ........................................................................................... 38

:OUTPut:POLarity.................................... .................................. ...................... 39

:OUTPut[:STATe]..................................... ................................ ........................ 39

:OUTPut:CLOCk:DIVider................................................................................... 39

:SENSe:ROSCillator:SOURce ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . 40

[:SOURce]:FREQuency[:CW|:FIXed] . .................................. .................................. 40

[:SOURce]:PM[:HF][:STATe]............................................................................... 40

[:SOURce]:PM[:HF]:INTernal1[:DEViation] ............................................................. 41

[:SOURce]:PM[:HF]:INTernal1:FREQuency ............................... .............................. 41

[:SOURce]:PM[:HF]:INTernal1:STATe.................................................................... 41

[:SOURce]:PM[:HF]:INTernal2[:DEViation] ............................................................. 42

[:SOURce]:PM[:HF]:INTernal2:STATe.................................................................... 42

[:SOURce]:PM[:HF]:INTernal4:CALibration............................. ................................ 42

[:SOURce]:PM[:HF]:INTernal4[:DEViation] ............................................................. 43

[:SOURce]:PM[:HF]:INTernal4:FILTer................................ .................................. .. 43

[:SOURce]:PM[:HF]:INTernal4:FREQuency ............................... .............................. 43

[:SOURce]:PM[:HF]:INTernal4:PLENgth......................................... ........................ 44

ds ...... .................................. ................................ ........................ 25

ii PPG4001 Pattern Generator User Manual

Page 9

Table of Contents

[:SOURce]:PM[

[:SOURce]:PM:LF[:INTernal3][:DEViation] ............................................................. 44

[:SOURce]:PM:LF[:INTernal3]:FREQuency ............................................................. 45

[:SOURce]:PM:LF[:INTernal3]:STATe .............. .................................. .................... 45

[:SOURce]:VOLTage[:POS|:NEG][:LEVel][:IMMediate]:[:AMPLitude] ..................... ........ 45

[:SOURce]:VOLTage[:POS|:NEG][:LEVel][:IMMediate]:OFFSet ... . . ..... . ..... . ... . . . .... . ..... . ... 46

[:SOURce]:

[:SOURce]:VOLTage[:LEVel][:IMMediate]:LINK..................................... .................. 46

:SYSTem:ERRor[:NEXT]?...... ................................ .................................. .......... 47

:TRIGger:SOURce ..................... .................................. .................................. .. 47

:TRIGger:LOCK.............................................................................................. 48

User service ........................................................................................................ 49

Service

General care ..... .................................. .................................. .......................... 49

Preventive maintenance.................. .................................. .................................. 50

Fuse replacement ................. .................................. ................................ .......... 51

Repack the instrument for shipment.............. ................................ .......................... 51

Compliance information .......................................................................................... 53

EMC c

Safety compliance ............................................................................................ 54

Environmental considerations ............................................................................... 56

Index

offerings.................. ................................ .................................. .......... 49

ompliance . ................................ .................................. .......................... 53

:HF]:INTernal4:STATe.......................... .................................. ........ 44

VOLTage[:POS|:NEG][:LEVel][:IMMediate]:TERMination.............................. 46

PPG4001 Pattern Generator User Manual iii

Page 10

Table of Contents

List of Figure

Figure 1: Front panel controls and connectors .................................................................. 4

Figure 2: Re

Figure 3: Verification setup........................................................................................ 6

Figure 4: Clock (top) and data (bottom) waveforms ........................................................... 8

Figure 5: Typical eye diagram example......................... .................................. ............... 9

Figure 6: Block diagram.............................. .................................. .......................... 12

Figure 7: GUI Main menu........................................................................................ 13

ar panel connectors .................................................................................. 5

List of Tables

Table i

Table 1: Power requirements...................................................................................... 2

Table 2: Maximum operating environmental considerations .................................................. 3

Table 3: Front panel controls and connectors ................................................................... 4

Table 4: Rear panel connectors ...... .................................. ................................ ........... 5

Table 5: GUI menu parameter locations .. ................................ .................................. .... 13

: PPG4001 Product options................................................................................ x

s

iv PPG4001 Pattern Generator User Manual

Page 11

Important safety information

This manual contains information and warnings that must be followed by the user

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page vii, Service safety summary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid inj

Carefully read all instructions. Retain these instructions for future reference.

ury and prevent damage to this product or any products connected to it.

oavoidfire or personal

T

injury

Comply wi

For correct and safe operation of the product, it is essential that you follow

general

in this manual.

The pro

Only qualified personnel who are aware of the hazards involved should remove

the co

Before use, always check the product with a known source to be sure it is

oper

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

When incorporating this equipment into a system, the s afety of that syste m is the

responsibility of the assembler of the system.

e proper power cord. Use only the power cord specified for this product and

Us

certified for the country of use.

th local and national sa fety codes.

ly accepted safety procedures in addition to the safety precautions specified

duct is designed to be used by trained personnel only.

ver for repair, maintenance, or adjustment.

ating correctly.

o not use the provided power cord for other products.

D

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

Do not disable the power cord grounding connection.

PPG4001 Pattern Generator User Manual v

Page 12

Important safety information

Power disconne

source. See instructions for the location. Do not position the equipment so that

it is difficult to operate the power cord; it must remain accessible to the user at

all times to allow for quick disconnection if needed.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

The measuring terminals on this product are not rated for connection to mains or

Category II, III, or IV circuits.

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

ct. The power cord disconnects the product from the power

Examine the exterior of the product before you use it. Look for c racks or missing

pieces.

Use only specified replacement parts.

Use proper fuse. Useonlythefusetypeandratingspecified for this product.

Wear eye protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

vi PPG4001 Pattern Generator User Manual

Page 13

Important safety information

Provideasafew

convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with

handles for lifting and carrying.

Servicesafetysummary

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

service procedures. Read this Service safety summary and the General safety

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or a djustm ents of this

product unless another person capable of rendering first aid and resuscitation is

present.

orking environment. Always place the product in a location

Terms in this manual

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

strength after performing a repair.

These terms may a ppear in this manual:

WAR NI NG . Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

PPG4001 Pattern Generator User Manual vii

Page 14

Important safety information

Symbols and te

rms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARN ING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

When this symbol is marked on the pr oduct, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

betakentoavoidthem.(Thissymbolmayalsobeusedtorefertheuserto

ratings in the manual.)

The follo

wing symbol(s) may appear on the product:

viii PPG4001 Pattern Generator User Manual

Page 15

Preface

Preface

Features

The Tektroni

control over operating parameters, including PRBS and user-defined patterns

and jitter insertion.

The operatio nal flexibility and pattern generation capability makes this unit

suitable for use in many different applications, including creating stressed serial

data patterns for receiver testing and characterization.

The Tektronix PPG4001 Pattern Generators provides serial data and clock outputs

with the following features:

4Gb/sto40Gb/soperation

Fully integrated benchtop instrument

Fixed data amplitude and offset

Fast rise/fall time

x PPG4001 PatternPro® Pattern Generator gives you extensive

500 mV single ended (1 V differential)

-500 mV to 0 V swing single-ended

8 ps 20/80% rise/fall time

User programmable data or built-in PRBS patterns

Adjustable internal clock source

Full-rate single-ended output

Half-rate differential output

10 kb/s resolution

Selectable prescaler output

External clock input

Trigger output

programmable as pattern trigger or clock/n

Jitter insertion (option):

High Frequency SJ/RJ/BUJ jitter insertion (Option HFJIT)

Low frequency jitter insertion (Option LFJIT)

External modulation input

PPG4001 Pattern Generator User Manual ix

Page 16

Preface

Documentation

Save up to twent

y-five user patterns in nonvolatile memory

Save up to twenty-five generator setups in nonvolatile memory

Touch screen graphical user interface & USB TMC interfaces

3RU height, full-rack design

Table i: PPG4001 Product options

Option Descriptio

HFJIT

LFJIT

High frequ

Low frequ

n

ency jitter insertion (SJ/RJ/BUJ)

ency jitter option

The following documentation is available:

PPG/PED Safety & Installation Manual, printed version shipped with the

product

This PPG4001 PatternPro Pattern Generator User Manual (PDF versions only,

downloadable from the Tektronix Web Site)

Product data sheets (PDF versions only, downloadable from the Tektronix

Web Site)

Declassification & Security instructions (PDF versions only, downloadable

from the Tektronix Web Site)

Check the Tektronix Web Site for a dditional product documentation at

www.Tektronix.com.

x PPG4001 Pattern Generator User Manual

Page 17

Getting started

Installation

The Tektronix PPG4001 Pattern Generator is carefully inspected e lectrically and

mechanically before shipment. After unpacking all items from the shipping

carton, che

during transit (there might be a protective film over the display, which can be

removed). Report damage to the shipping agent immediately. Save the original

packing carton for possible future shipment.

ck for any obvious signs of physical damage that may have occurred

Accessories

The following accessories a re included with your instrument:

Pattern

Power cord

Rack mount ears on the front of the instrument

PPG/PED Installation & Safety instructions

Accessoriesasordered

generator

PPG4001 Pattern Generator User Manual 1

Page 18

Getting s tarted

Power requirem

ents

CAUTION. Operating the instrument on an incorrect line voltage can cause

damage, possibly voiding the warranty. To avoid this, operate the instrument

with the correct line voltage.

The instrument operates from a single-phase line voltage listed in the following

table. Line voltage and line frequency are automatically sensed; there are no

switches to set. Check to ensure the operating voltage in your area is compatible.

Table 1: Power requirements

Item Description

Voltage 100 V to 240 V

Frequency 50 Hz to 60 Hz

Power 360 W, maximum

Power fuse

The pow

er cord supplied with the instrument contains a separate ground for use

T 2A 250V

with grounded outlets. When proper connections are made, the instrument chassis

is connected to power line ground through the ground wire in the power cord

providing protection against electric shock.

Ventilation

The unit has fans in the rear, as well as cooling vents on the bottom and side

panels to keep it from overheating.

CAUTION. Inadequate ventilation can damage the instrument; to avoid damaging

the instrument, observe the following precautions:

Do not block the c ooling vents.

Do not position any devices adjacent to the instrument that force air (heated or

unheated) into or onto the instrument surfaces or cooling vents. This additional

irflow could compromise performance.

a

When rack mounting the instrument, ensure there is adequate airflow around the

instrument rear, sides, and bottom to ensure proper cooling. Adequate airflow

enables air temperatures within approximately one inch of the instrument surfaces

to remain within specified limits under all operating conditions.

2 PPG4001 Pattern Generator User Manual

Page 19

Getting started

Environmental

considerations

The following t

able describes th e maximum operating environmental ratings for

your instrument.

Table 2: Maximum operating environmental considerations

Feature Description

Temperature

Humidity

Altitude

40 °C (104 °F)

80% for temperatures up to 31 °C (88 °F) decreasing linearly to 50%

at 40 °C (104 °F)

2000 m (6562 ft.)

PPG4001 Pattern Generator User Manual 3

Page 20

Controls and connectors

Controls and c

Figure

1: Front panel controls and connectors

onnectors

The followin

connectors.

NOTE. The exact location and spacing of the Data Out connectors may be

different depending on the output options ordered with the instrument.

g illustration and table describe the front panel controls and

Table 3: Front panel controls and connectors

Item Description

1

On/off switch Push this button to turn the instrument on and off. The green indicator inside the button lights

up when the instrument is on.

2 Display

3

Half-rate (/2)CLOCK Out

nectors

con

4

TA O UT connectors

DA

5

vided (/n) CLOCK OUT

Di

connector

6

FULL CLOCK OUT connector Single-ended full-rate clock output with 2.4 mm connector

7

Half-rate (/n) CLOCK IN

connector

8

Trigger Out SMA Differential Trigger Output. Levels swing from –500 mV to 0 V. Can be used single ended.

The display is a touch screen graphical user interface.

Differential half-rate clocks output with 2.4 mm connectors

Plus and minus Data outputs w ith 2.4 mm connectors

ngle-ended divided clock output with 2.92 mm connector. Binary divide ratios are selected

Si

through the user interface.

Half-rate clock input with a 2.4 mm connector, AC coupled. Used to supply an external half-rate

clock signal.

4 PPG4001 Pattern Generator User Manual

Page 21

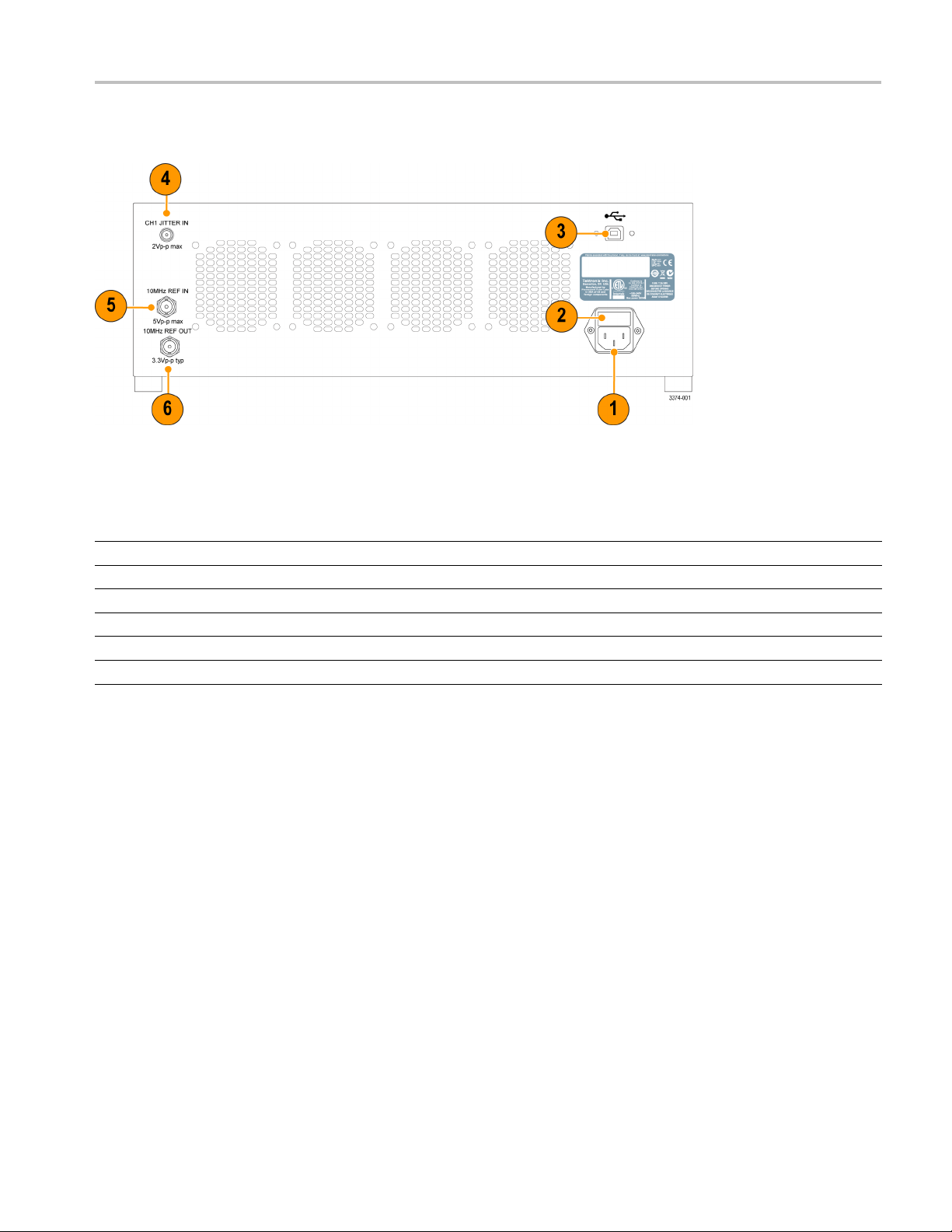

Controls an d connectors

The following i

Figure 2: Rear panel connectors

Table 4:

Item Descrip

1

2 F use holder

3

4JITTERIN

5

6

Rear panel connectors

AC line r

USB con

10 MHz REF IN

10 MH

eceptacle

nection

zREFOUT

Connect

Line fu

Connec

SMA in

BNC in

BNC o

llustration and table describe the rear panel connectors.

tion

the appropriate power cord here.

se, 5 X 20 mm, 2 A, 250 V, SLO BLO

t the USB cable here to control the instrument from an external computer.

put for external jitter insertion (Option HFJIT)

put for external frequency reference

utput for buffered version of the frequency reference (internal or external)

PPG4001 Pattern Generator User Manual 5

Page 22

Functional verification

Functional ve

Instrument setup

rification

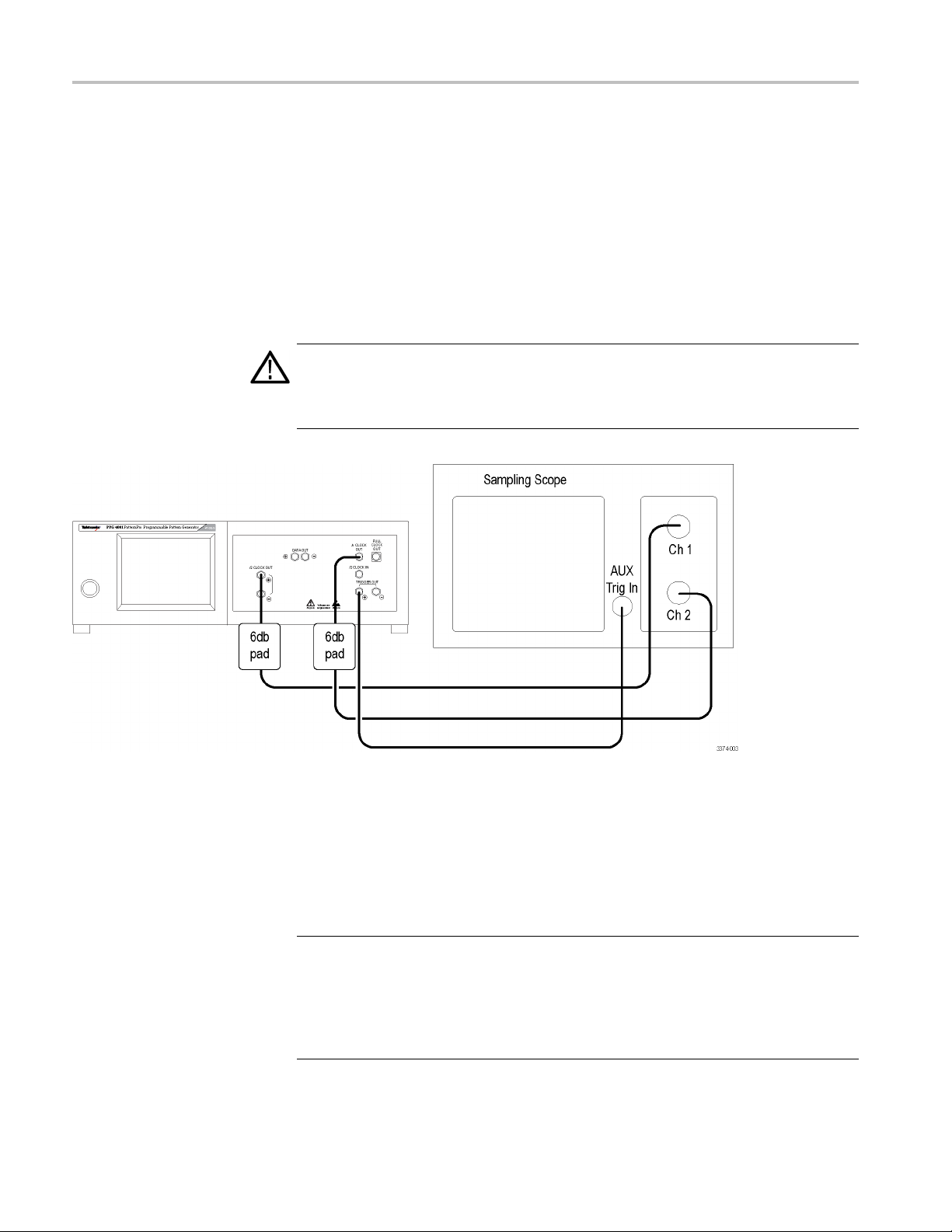

Atypicalse

following figure. The diagram uses only the + side of all differential connections,

the - side can be tested in the same manner. Use a Tektronix DSA8300 Digital

Serial Analyzer Sampling Oscilloscope or similar for functional verification.

CAUTION. Damage to the pattern generator and/or associated equipment can

occur if the input and output voltage ratings are exceeded. Check the input and

output vo

electrical attenuators where voltage ratings are commonly exc eeded.

tup for verifying the pattern generator operation is shown in the

ltage ratings for your equipment. The following illustration shows

Figure 3: Verification setup

Power on and verify instrument operation

The following steps assume the unit is connected as shown in the verification

setup.

NOTE. Note: The generator is internally tem perature compensated for timing and

output level continuously and automatically. Internal timing calibration will also

take place whenever the frequency is set (either manually or through remote

programming). Setting the frequency (or resetting the frequency to its current

value) is recommended after an initial 20-minute warm-up, or if a significant

change in ambient temperature has occurred during operation.

6 PPG4001 Pattern Generator User Manual

Page 23

Functional verification

1. Push front pane

The green light on the switch turns on.

The instrument goes through the start-up sequence.

TheMainmenudisplaysonthetouchscreen.

2. Select UTILITY by touching the on-screen button.

3. Select SAVE.

4. Select REC

5. Select BACK.

6. Select MAIN.

7. Turn OUTPUT ON.

8. Use the AUTO SCALE function on the sampling oscilloscope to identify and

display signals.

9. Adjust the sampling oscilloscope voltage, timing and display settings as

needed.

Channel 1 shows a square wave at the default clock rate.

l on/off switch.

ALL DEFAULTS (The instrument loads all the default settings.)

Channel 2 shows PRBS data with pattern trigger.

utput should be similar to the following figure (the displayed data

The o

pattern may differ).

PPG4001 Pattern Generator User Manual 7

Page 24

Functional verification

Verify the eye diagram

Figure 4: Clock (top) and data (bottom) waveforms

1. Select

2. Select TRIGGER.

3. Select TRIGGER TYPE = CLK/N.

4. Set NDIVISORto 64.

5. Turn off the display on the oscilloscope channel 1 (clock signal).

UTILITY.

8 PPG4001 Pattern Generator User Manual

Page 25

Functional verification

6. Adjust the samp

Output should be similar to the following figure.

ling oscilloscope amplitude, timing and display as needed.

Check

Data

Figure 5: Typical eye diagram example

other settings

Access the remaining menus to experiment with other settings.

and clock output instructions

Each side of the d ifferential signal has a typical voltage swing of from 0 V

to -500 mV.

Treat the outputs with care as they are static sensitive.

PPG4001 Pattern Generator User Manual 9

Page 26

Functional verification

For DC-co upled

Terminate the DUT or load w ith 50 to ground.

Terminate any unused output 50 to ground.

For AC-coupled use:

Provide a 50 to ground path prior to any DC block (a bias tee with

50 to ground. For example, use a bias tee, model number PSPL5542,

available from Tektronix.).

Terminate any unused output 50 to ground.

use:

10 PPG4001 Pattern Generator User Manual

Page 27

Input and output descriptions

Overview

RF connectors

Connector torque

specifications

Data out and /Data out

ut and /Trig out

Trig o

Data and Clock front panel RF connectors are 2.4 mm. All o ther front panel RF

connections are SMA.

Minimum:

Recommend

Maximum:

NOTE. Please note the s pecial termination instructions. (See page 9, Data and

clock ou

These a re the primary outputs from the unit. The outputs can be used single-ended

or differentially. Data pattern and timing can be controlled manually or remotely.

These differential outputs provide a timing reference for viewing the data signals.

The output amplitudes are fixed. Trigger options are PATTERN or CLOCK/N.

When using a pattern trigger, the trigger corresponds to the beginning of a pattern.

The pattern trigger mode can be used with user-defined or PRBS data. For the

CLOCK/N trigger mode, the clock frequency is reduced by a factor of N where

value N is required to be a multiple of 64.

the

ed:

tput instructions.)

2 i n-lbs (0.226 N-m)

7-10 in-lbs (0.791-1.130 N-m)

15 in-lb (1.695 N-m)

Full-clock out

/2 clock out

PPG4001 Pattern Generator User Manual 11

The clock output reflects the data rate; there is one full clock cycle per bit of

data. The clock output is AC coupled and the amplitude is fixed. The internal

ock actually operates over a range of 20 GHz to 40 GHz. When data rates

cl

<20 Gb/s are used, the internal clock will operate at a multiple of the data rate and

bit-stretching is used to produce data at the specified rate.

The /2 clock output reflects one half of the data rate; there is one full clock cycle

per two bits of data. The clock output is AC coupled and the amplitude is fixed.

The internal clock actually operates over a range of 20 GHz to 40 GHz. When

data rates <20 Gb/s are used, the internal clock will operate at a multiple of the

data rate and bit-stretching is used to produce data at the specified rate. The user

interface will indicate the /2 clock rate for this case. A built-in clock divider

can be used to divide the internal clock before it is sent to the /n clock output

(divisors of 1,2,4,8,16).

Page 28

Input and output descriptions

/2 Clk in

Functional block diagram

This is the inpu

a range of 10 GHz to 20 GHz.

The basic functional blocks are shown in the following figure.

t used to supply an e x ternal clock. Clock frequency is restricted to

Data ou

tputs

Output range

Figure 6: Block diagram

The instrument is designed to drive a 50 load. The voltage window is fixed over

a range from 0 V to -500 mV.

ING. To ensure proper operation, never load the output with less than 50 Ω.

WARN

12 PPG4001 Pattern Generator User Manual

Page 29

Graphical user interface (GUI) touch screen

Graphical use

r interface (GUI) touch screen

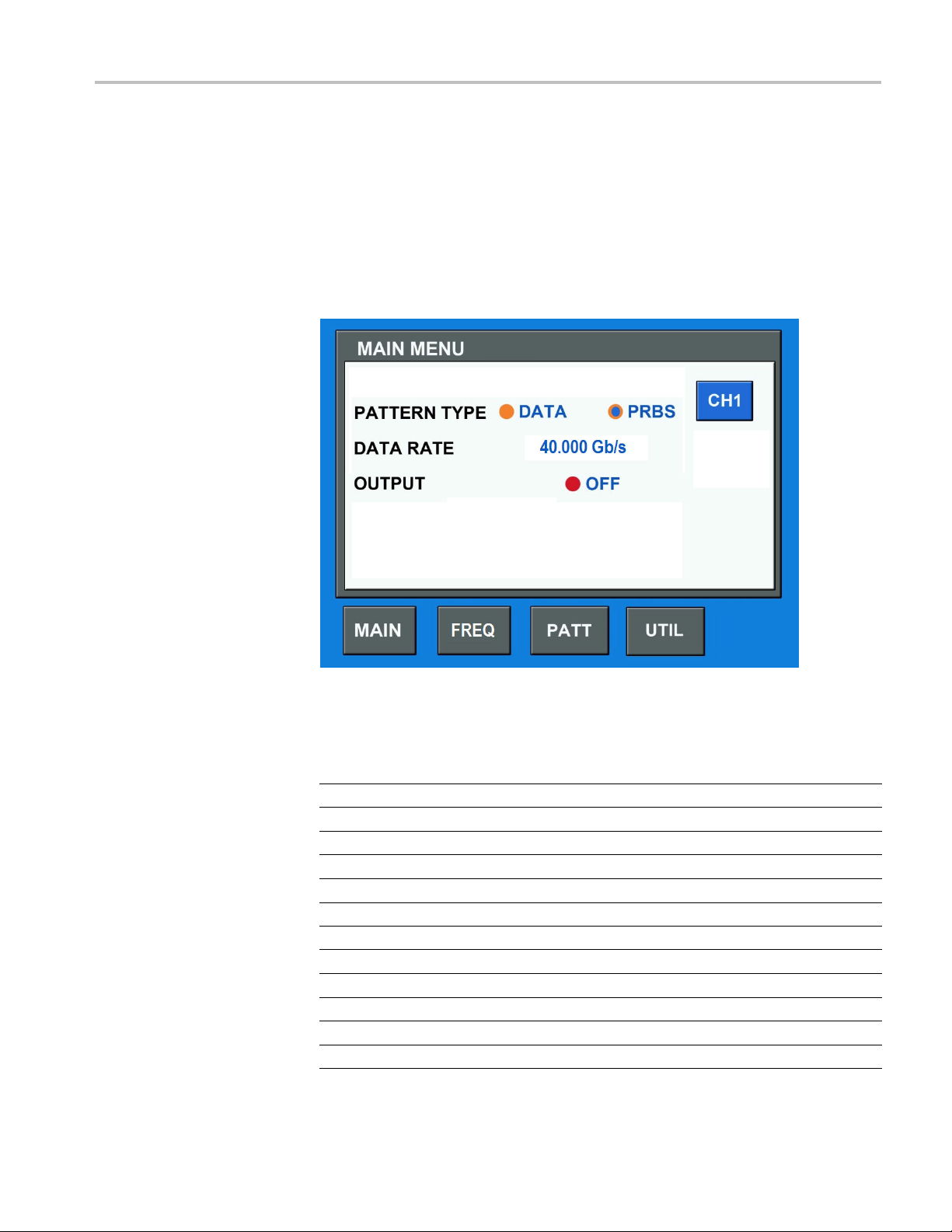

This unit is e

through this user interface. An example of the GUI is shown in the following

figure.

The following table gives a listing of where to find various parameters within

the menu structure.

quipped with touch screen controls. All manual settings are accessed

Figure 7: GUI Main menu

Table 5: GUI menu parameter locations

Parameter Found in menu(s)

10 MHz Ref (int / ext)

Data Rate

External Clock Enable TIMING [EXTFREQ]

Internal Clock Rate TIMING

Jitter Enable

Output Clock Rate TIMING

Pattern Length PATTERN

Pattern Type MAIN, PAT TER N

Pattern (user defined)

PRBS Length

Output ON / OFF MAIN, VOLTS

Recall Pattern

UTILITY

MAIN, TIMING

TIMING [JITTER]

PATT ER N [ DATA ]

PATT ER N

PATTERN [SAVE] [RECALL]

PPG4001 Pattern Generator User Manual 13

Page 30

Graphical user interface (GUI) touch screen

Table 5: GUI menu parameter locations (cont.)

Parameter Found in menu(s)

Recall Setup UTILITY [SAVE] [RECALL]

Save Pattern PATTERN [SAVE] [STORE]

Save Setup UTILITY [SAVE] [STORE]

Trigger Options UTILITY [TRIG GER]

14 PPG4001 Pattern Generator User Manual

Page 31

Jitter insertion (optional feature)

Jitter insert

ion (optional feature)

Jitter sources

Built-in high-frequency

sinusoidal modulation

source (Op

uncorrelated jitter (BUJ,

includedinOptionHFJIT)

Built-in random noise

modula

tion source (Option

tion HFJIT)

Built-in bounded

HFJIT)

The pattern g

page 19, Jitter insertion.)

Programmable frequency from 5 kHz to 100 MHz

Programma

Programmable amplitude up to 50 ps

Programmable modulation data rates from 100 Mb/s to 2.5 Gb/s

Full suite of program mable PRBS sequences

Low-pass filter values 25/50/100 MHz

Programmable amplitude up to 5 ps

enerator can be ordered with a built-in jitter insertion options. (See

ble amplitude up to 50 ps

P-P

P-P

RMS

Built-in low-frequency

sinusoidal modulation

source (Option LFJIT)

External modulation

ce

sour

External modulation input

(Jitter in)

SJ programmable frequency from 10 Hz to 10 MHz, from 5000 UI

0.5 UI

P-P

Amplitude up to 50 ps

5V

maximum input

P-P

Frequency range: DC to 100 MHz

Any waveform (or random)

Total jitter of the instrument (external plus built-in jitter) mu st not exceed the

above specifications for External modulation source.

from 5 kHz to 100 MHz

P-P

P-P

to

PPG4001 Pattern Generator User Manual 15

Page 32

Jitter insertion (optional feature)

16 PPG4001 Pattern Generator User Manual

Page 33

Specifications

Data outputs

Amplitude

Rise/fall time

Data output jitter

Connector type

DC coupled. Each side of the differential pair swings from -500 mV to 0 V.

Ground-referenced CML. Terminated 50 to ground.

Single-ended. 500 mV, typical

Differential. 1.0 V, typical

Scope bandwidth can impact the m ea sured signal rise time.

20 to 80%. 8ps,typical

10 to 90%. 12 ps, typical

Measured at 40 Gb/s with 211-1 PRBS

Total jitter (1E-12). 7ps

Random jitter. 200 fs, RMS, typical @ 40 Gb/s

2.4 mm

,typical

p-p

Output impedance

Clock outputs

Full rate clock output

Half-rate clock output

50 Ω. Single-ended

100 Ω. Differential

AC co upled, single-ended

Frequency. 20 GHz to 40 GHz

Amplitude. 500 mV

Connector type. 2.4 mm

AC coupled, differential

Amplitude. 500 mV

Connector type. 2.4 mm

,typical

p-p

,typical

p-p

PPG4001 Pattern Generator User Manual 17

Page 34

Specifications

/n clock o utput

Trigger output

Data patterns

Pattern type

Data rate

AC coupled, sin

gle ende d

Programmable divider. n = 2, 4, 8, 16

Amplitude. 500 mV

,typical

p-p

Connector type. 2.4 mm

Programmed as pattern trigger or clock/n (with n = multiples of 128)

Amplitude. -500 mV to 0 V, DC coupled

Connector type. SMA

Data (from memory) or PRBS

Programmable/adjustable

PRBS pattern lengths

Data pattern depth

Range. 4Gb/sto40Gb/s

Resolution. 10 kb/s

Accuracy. ±5 ppm

27-1 bits. Polynomial = X7+X6+1

9

2

-1 bits. Polynomial = X9+X5+1

11

2

-1 bits. Polynomial = X11+X9+1

15

2

-1 bits. Polynomial = X15+X14+1

23

2

-1 bits. Polynomial = X23+X18+1

31

2

-1 bits. Polynomial = X31+X28+1

Range. 2to4,194,304bits

Resolution. 1bit

18 PPG4001 Pattern Generator User Manual

Page 35

Specifications

Programmable error

Jitter insertion

High frequency jitter

insertion option

Built-in sine source

insertion

Error insertio

n can be enabled with either single bit error insertion or at a

programmable rate.

Single bit errors. Ye s

Programmable bit errors. 10

-3

to 10

-15

BER

Add-on option for the instrument. Sum of external, in ternal sine, interna

and BUJ. Exceeding the range can generate errors.

Total modulation range. 50 ps

p-p

Programmable from either the front panel touch screen or remote control.

Frequency range. 5kHzto100MHz

Amplitude range. 0to50ps

p-p

Accuracy. ±10%, typical

l noise,

Built-in random noise

source

Built-in BUJ source

External modulation input

Programmable from either the front panel touch screen or remote control.

Amplitude range. 0to5

RMS

Accuracy. ±10%, typical

Programmable from either the front panel touch screen or remote control.

Amplitude range. 0to50ps

p-p

Modulation data rates. 100Mb/sto2.5Gb/s

PRBS sequences. 7,9,11,15,23,31

Filter values. 25/50/100 MHz filters

DC coupled, 3 dB bandwidths

Frequency range. DC to 100 MH

Amplitude range. 0to50ps

Maximum input. 5V

p-p

z

p-p

PPG4001 Pattern Generator User Manual 19

Page 36

Specifications

Low frequency jitter

insertion (Option LFJIT)

Trigger system

Trigger wa veform

Add-on option

SJ modulation range curve points.

Parameter Value

10 Hz f

100 Hz f

1kHzf

mod

10 kHz f

100 kHz f

1MHzf

2MHzf

10 MHz f

mod

mod

mod

mod

mod

mod

mod

5000 UI

2000 UI

2000 UI

2000 UI

100 UI

10 UI

p-p

1UI

p-p

0.5 UI

p-p

p-p

p-p

p-p

p-p

p-p

Pattern mode. 1 pattern per trigger for pattern length = multiple of 128

128 patterns per trigger for other pattern lengths

Clock/n mode. 128 through (2

32

- 128), n= any multiple of 128 in that range

Output impedance

Connector type

Clock inputs

Frequency range

Input signal

High level

Low level

Duty cycle. 50%, for either Pattern or Clock/n

0V,typical

-500 mV, typical

50 , DC-coupled

SMA

10 GHz to 20 GHz, half rate

500 mV

, typical, AC coupled

p-p

Maximum input signal

800 mV

p-p

20 PPG4001 Pattern Generator User Manual

Page 37

Specifications

Input impedance

Reference clock

Input frequen

Maximum input signal

Input impedance

10 MHz reference

cy range

Input signal

Output signal

input/output

50 , AC-couple

100 MHz

1V

, typical, 50% duty square wave

p-p

5V

, ±10 V DC, Damage threshold

p-p

50 ,AC-cou

1.2 V

Yes, BNC connector

, typical, Square wave

p-p

d

pled

Control interfaces

Front pan

Computer programmable

el touchscreen

interface

Yes, edit all instrument settings

GUI

USB TMC, program all instrument settings

PPG4001 Pattern Generator User Manual 21

Page 38

Specifications

Physical characteristics

Front panel width (with

mounting tabs)

Height

Width

Depth (rack mount)

Weight

Operating temperature

48.3 cm (19.0 in)

13.3 cm (5.25 in)

45.1 cm (17.75 in)

35.1 cm (13

11.1 kg (24.5 lbs)

0°Cto40°C(32°Fto104°F)

.8 in)

22 PPG4001 Pattern Generator User Manual

Page 39

Remote programming

USB interface

All automated programming is accomplished through a USB TMC interface.

Command information

Sequential vs. overlapped

Long and s

Channel numbers

hort form

All commands are sequential commands. Sequential commands complete before

the next is executed. This means that completion of any command can be verified

by following it with any query. When the query response is received, the previous

command is certain to b e complete.

Commands have both a long and short form. In command descriptions, the long

form is the entire command while the short form is the part in capital letters.

Commands must be either the exact long form or the exact short form, other

combin

The PPG4001 pattern generator is currently available as a single-channel unit

(Channel 1) Commands for non-existent channels are not valid.

ations will create an error.

PPG4001 Pattern Generator User Manual 23

Page 40

Common commands

Common comman

Summary

Command Description

*IDN? Read Instrument's Identification string

*RST Reset instrument to default settings

Reference

*IDN?

Read the instrument’s identification string.

The returned s tring has the following format:

“Tektronix In c., Mod el code,SN,FWREV” Where:

ds

Model code = 12604

SN = serial number

FWREV

= firmware revision

*RST

Resets the instrument to default settings. This sets all parameters to their default

values, including output enable, pattern length, a nd pattern data.

24 PPG4001 Pattern Generator User Manual

Page 41

Regular commands

Summary

The following table provides a summary of the remote control commands.

Command Parameters Default Description

DIGITAL sub

:DIGital

:PAT Tern

:SIGNal [:POS|:NEG]:CROSsover

Memory subsystem

:STORe

system

:LENGth

:TYPE

:PLENgth <numeric>

:DATA <numeric>,

:HDATa <numer

or

:SERR

:ERATe <numeric> 1e-3 inserts error into the

:ERATe:STATe OFF | ON OFF

:BSHift

[:VALue] <numeric>

:PDATa <string>

:STATe

<numeric> 8

DATA | PR

<numer

<arbitrary block>

<numeric>,

<arbitrary block>

none

<numeric> 0

<string>

BS

ic>,

ic>,

set/query Pattern

Length

PRBS set/que

7

1000…

1000…

n/a

50% set/query crossing

n/a

n/a

ry Pattern type

ry PRBS length

set/que

ery Pattern Data

set/qu

set/query Pattern

Data in hexadecimal

cter format

chara

insert a single error

he data output

into t

output at the

data

specified rate

le error rate

enab

injection into the data

output

shift the pattern by the

ecified number of

sp

bits relative to nominal

position

oint

p

store pattern data in

system me mory

store instrument

settings in system

memory

Regular commands

(See page 29.)

(See pag

(See pag

(See pa

(See page 32.)

(See p

(See

(See page 33.)

(See page 34.)

(See page 34.)

(See page 35.)

(See page 35.)

e 29.)

e 30.)

ge 31.)

age 33.)

page 33.)

PPG4001 Pattern Generator User Manual 25

Page 42

Regular commands

Command Parameters Default Description

:LOAD

:PDATa <string>

:STATe

:MOVE

:PDATa <string>,

:STATe

:DELete

:PDATa <string>

:STATe

:CATalog

:PDATa

:STATe n/a n/a get list of instrument

put subsystem

Out

TPut0

:OU

OURce

:S

IVider

:D

:OUTPut

:POLarity NORMal |

[:STATe] OFF | ON OFF set/query data output

:OUTPut

:CLOCk:DIVider

<string>

<string>

<string>,

<string>

>

<string

n/a n/a get list of stored

Riodic |

PE

BITStream

umeric>

<n

INVerted

<numeric> varies programs the clock

n/a

n/a

n/a

n/a

n/a

n/a

TS

BI

8

12

NORM set/query data output

recall patter

from system memory

recall instr

settings from system

memory

rename existing

pattern data file in

system mem

rename existing

instrume

file in system memory

delete stored pattern

data file

memory

delete i

settings file in system

memory

patte

system memory

settings files in system

memo

se

event

set/query trigger

divider

polarity

enable/disable status

divider output for the

internal clock

nt settings

in system

nstrument

rn data files in

ry

t/query trigger out

n data

ument

ory

(See page 35.)

(See page 36.)

(See page 36.)

(See page

(See pag

(See page 37.)

(See page 37.)

(See page 38.)

ee page 38.)

(S

(See page 38.)

(See page 39.)

(See page 39.)

(See page 39.)

36.)

e 37.)

26 PPG4001 Pattern Generator User Manual

Page 43

Command Parameters Default Description

Sense subsystem

:SENSe:ROSCillator

:SOURce INTernal |

Source subsystem

[:SOURce]

:FREQuency[:CW|:FIXed]

PM [:HF]

:[:STATe] OFF | ON OFF set/query overall

al1[:DEViation]

:INTern

:INTernal1:FREQuency

rnal1:STATe

:INTe

:INTernal2[:DEViation] <numeric> 0 ps

Tern al2: STATe

:IN

:INTernal4:CALibration GAUSsian | CEI GAUS set/query BUJ

:INTernal4[:DEViation] <numeric> 0 ps

NTernal4:FILTer

I

:INTernal4:FREQuency

:INTernal4:PLENgth <numeric> 31

:INTernal4:STATe OFF | ON OFF set/query internal

EXTernal

<numeric>

<numeri

<numeric> 1 MHz

OFF | O

OFF

<

<numeric>

c>

N

|ON

numeric>

INT

30 G Hz set/query clock

0ps

OFF set/q

OFF set

00 MHz

1

2 GHz set/query internal HF

set/query 10 MHz

reference source

frequenc

jitter i

enable/disable status

set/query internal HF

sine jitter amplitude

set/query internal HF

sine j

HF sine jitter

enable/disable status

set/query internal

rand

random jitter

enable/disable status

am

s

BUJ jitter amplitude

set/query internal HF

BUJ generator filter

bandwidth

BUJ generator clock

frequency

set/query internal HF

BUJ generator PRBS

length

HF BUJ jitter

enable/disable status

y

nsertion

itter frequency

uery internal

om jitter amplitude

/query internal

plitude cal

et/query internal HF

Regular commands

(See page 40.)

(See page 40.)

(See page 40.)

(See page 41.)

(See page 41.)

age 41.)

(See p

(See page 42.)

epage42.)

(Se

(See page 42.)

Seepage43.)

(

(See page 44.)

(See page 44.)

(See page 44.)

(See page 45.)

PPG4001 Pattern Generator User Manual 27

Page 44

Regular commands

Command Parameters Default Description

:PM:LF

[:INTernal3][:DEViation] <numeric> 0 UI

[:INTernal3]:FREQuency

[:INTernal3]:STATe OFF | ON OFF set/query internal

:VOLTage#[:POS|:NEG][:LEVel][:IMMediate]

[:AMPLit

:OFFSet

:TERMination <numeric> 0 V

:VOLTage#[:LEVel][:IMMediate]

:LINK

System subsystem

:SYSTem:ERRor[:NEXT]?

Trigger subsystem

:TRIGger

:SOURce IMMediate |

:LOCK

ude]

<numeric> 10 kHz

<numeric

<numeric> 0 V

none

EXTernal

none

>

500 mV

OFF Enable/disable Linking (See page 46.)

n/a

IMM

n/a

set/query int

sine jitter amplitude

set/query internal LF

sine jitter frequency

LF sine jitt

enable/disable status

set/query data

amplitude

set/query data offset (See page 46.)

set/query data term (See page 46.)

query error queue

set/query clock source (See page 47.)

initiate lock to external

clock

ernal LF

er

(See page 44.)

(See page 45.)

(See page 45.)

(See page 45.)

(See page 47.)

(See page 48.)

28 PPG4001 Pattern Generator User Manual

Page 45

Reference

:DIGital:PATTern:LENGth

Reference

Form

Parameters Numeric

Value Coupling

Range Coupling

Default

Description

Example

Set & Query

None

None

8

Programs the Pattern Length. This value is only relevant if the pattern type is DATA.

The length can be any integer from 2 through 4,194,304.

Set pattern length to 56

:DIG:PATT:LENG 56

Query pattern length

:DIG:PATT:LENG?

:DIGital:PATTern:TYPE

Form

eters

Param

Value Coupling

Range Coupling

Default PRBS

cription

Des

Example

Set & Query

DATA | PRBS

None

None

grams the Pattern Type.

Pro

t the pattern type to PRBS

Se

:DIG:PATT:TYPE PRBS

Query pattern type

DIG:PATT:TYPE?

:

PPG4001 Pattern Generator User Manual 29

Page 46

Reference

:DIGital:PAT

Form

Parameters

Value Coupling

Range Coupling

Default

Description

Example

Tern:PLENgth

Set & Query

7|9|11|15|23|31

None

None

7

Programs the Pattern PRBS Length. PRBS Length is specified as 2

specified value. This value is only relevant if the pattern type is PRBS.

Set the PRBS length to (2

:DIG:PATT:PLEN 7

Query PRBS length

:DIG:PATT:PLEN?

N

-1, where N is the

7

-1)

30 PPG4001 Pattern Generator User Manual

Page 47

Reference

:DIGital:PAT

Form

Parameters <start address>,<bit count>,<data>

Value Coupling

Range Coupling

Default Default data is a 1 in position 1, all other bits are 0 .

Description

Example

Tern:DATA

Set & Query

<start address> is numeric, and is the bit number in pattern data memory of the first bit to write.

<bit count> is the number of bits to write into pattern data memory.

<data> is an arbitrary block of program data as defined in IEEE-488.2-1992, section 7.7.6.2. It

starts with a "#" character, followed by a single character representing the length of the length,

then 1 to 5 characters specifying the length as a decimal number, then the program data.

None

None

Programs the pattern data memory. Each byte of pattern data is a character (0 or 1)

representing one bit of pattern data. The start address can be any bit location, 1 – <max

address>. <max address> is > is 4,194,304. The bit count can be any number 1 – 1024. The

entire pattern data memory is accessible for reads or writes, even outside the range of the

current pattern length setting. The bit count parameter and the length of the data block must

match. (<start address> + <bit c ount>) must be ≤ (<max address> + 1).

:DIG:PATT:DATA 1,16,#216010000 01 01 01 001 0

This command does the following:

Starts loading the Ch 1 data into bit location 1.

Specifies that 16 bits of data will be loaded.

In the <data>:

#: signifies the beginning of the block

2: indicates that the length of the data length is two characters

16: indicates that data length is 16 bytes. (16 ASCII characters)

0100000101010010: is the character representation of the data

Thus, bits 1 through 16 in the channel 1 pattern data memory will be set to 0100000101010010.

:DIG:PATT:DATA? 1,8

This query reads 8 bits of pattern data starting from address 1. Given the above pattern data

memory contents, the response would be "#1801000001".

PPG4001 Pattern Generator User Manual 31

Page 48

Reference

:DIGital:PAT

Form

Parameters <start address>,<bit count>,<data>

Value Coupling

Range Coupling

Default Default data is a 1 in position 1, all other bits are 0.

Description

Example

Tern:HDATa

Set & Query

<start address> is numeric, and is the bit number in pattern data memory of the first bit to write.

<bit count> is the number of bits to write into pattern data memory.

<data> is an arbitrary block of program data as de fi ned in IEEE-488.2-1992, section 7.7.6.2. It

starts with a "#" character, followed by a single character representing the length of the length,

then 1 to 5 characters specifying the length as a decimal number, then the program data.

None

None

Programs the pattern data memory using hexadecimal character format. Each byte of pattern

data is a hexadecimal character (0-9, A-F or a-f) representing four bits of pattern data. The

start address can be any bit location, 1 – <max address>. <max address> is 4,194,304. The

bit count can be any number 1 – 4096. The entire pattern data memory is accessible for reads

or writes, even outside the range of the current pattern length setting.

The bit count parameter must be equal to 4 times the length of the data block or up to 3 bits

fewer. If it is fewer, then the extra bits in the last data byte are ignored. (<start address> +

<bit count>) must be ≤ (<max address> + 1).

:DIG:PATT:HDAT 1,16,#144152

This command does the following:

Starts loading the Ch 1 data into bit location 1.

Specifies that 16 bits of data will be loaded.

In the <data>:

#: signifies the beginning of the block

1: indicates that the length of the data length is one character

4: indicates that data length is 4 bytes. (4 A SCII characters)

4152: is the c haracter representation of the data

Thus, bits 1 through 16 in the channel 1 pattern data memory will be set to 0100000101010010.

:DIG:PATT:HDAT? 1,8

This query reads 8 bits of pattern data starting from address 1. Given the above pattern data

memory contents, the response would be "#1241".

Note that if the query requests a number of bits that is not a multiple of 4, s ome bits in the last

byte will not be meaningful, and will be 0.

32 PPG4001 Pattern Generator User Manual

Page 49

Reference

:DIGital:PAT

Form

Parameters None

Value Coupling

Range Coupling

Default n/a

Description

Example Insert one error into the data output.

Tern:SERRor

Set

None

None

Inserts a single error into the data output. Error insertion w orks for either data patterns or

PRBS patterns. If there is no pattern currently being output, for instance if the outputs are

disabled, the command has no effect.

:DIG:PATT:SERROR

:DIGital:PATTern:ERATe

Form

ters

Parame

oupling

Value C

Coupling

Range

lt

Defau

Description

ple

Exam

Set & Query

c

Numeri

None

None

1e-3

rt errors into the data output at the specified rate. Error rate insertion w orks for either data

Inse

patterns or PRBS patterns when error rate is enabled.

rt 2E-12 error rate into the data output.

Inse

:DIG:PATT:ERAT 2e-12

Gital:PATTern:ERATe:STATe

:DI

Form

Parameters

Value Coupling

Range Coupling

Default OFF

Description

Example Enable error insertion rate into the data output.

Set & Query

OFF | ON

None

None

Enables insertion of errors into the data output at a rate specified by the :DIGital:PATTern:ERATe

command.

:DIG:PATT:ERAT:STAT ON

PPG4001 Pattern Generator User Manual 33

Page 50

Reference

:DIGital:PAT

Form

Parameters Numeric

Value Coupling

Range Coupling

Default

Description

Example

Tern:BSHift

Set & Query

None

None

0

Shift the pattern by the specified number of bits relative to nominal position.

Insert bit shift of 10 into the data output.

:DIG:PATT:BSH 10

:DIGital:SIGNal[:POS|:NEG]:CROSsover:[VALue]

Form

Parameters

Value Coupling

Range Coupling

Default 50%

Description Programs the NRZ signal crossing point. Positive and negative outputs have independent

Example

Set & Query

Numeric [no units, value is in %]

None

None

crossing point adjustment, specified by [:POS | :NEG].

: to maintain normal complement behavior, if the POS output crossing point is set to

Note

50+X, then the NEG should be set to 50-X. For example, if the POS were set to 57%, the

NEG would be set to 43%.

Set negative output crossing point to 45 % .

IG:SIGN:NEG:CROS 45

:D

Query negative output crossing point?

:DIG:SIGN:NEG:CROS?

34 PPG4001 Pattern Generator User Manual

Page 51

Reference

:MMEMory:STO

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

Example

Re:PDATa

Set

String

None

None

Store the current pattern data into the system memory. The pattern length and all pattern data

up to the pattern length are stored. The filename can be up to 8 characters long and is not

case-sensitive. Filenames must consist of only alphanumeric characters.

Store the pattern data in system memory.

:MMEM:STOR:PDAT “PATT1011”

:MMEMory:STORe:STATe

Form

Parameters

Coupling

Value

Coupling

Range

ult

Defa

Description

Example

Set

String

None

None

N/A

Sto

stored except for pattern data, pattern length and output enable status. The filenamecanbeup

to 8 characters long and is not case-sensitive. Filenames must consist of only alphanumeric

cha

St

:MMEM:STOR:STAT “PARAM22”

re the instrument setting into the system memory. Every parameter of the instrument is

racters.

ore the parameters in system memory.

MMEMory:LOAD:PDATa

:

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

Example

Set

String

None

None

Recalls the pattern data from a saved file in system memory. The pattern length and all data up

to the pattern length are recalled. Pattern memory addresses above the pattern length are not

changed. The filename can be up to 8 characters long and is not case-sensitive. Filenames

must consist of only alphanumeric characters.

Recall the pattern data from file “PATT1011”.

MMEM:LOAD:PDAT “PATT1011”

PPG4001 Pattern Generator User Manual 35

Page 52

Reference

:MMEMory:LOA

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

Example

D:STATe

Set

String

None

None

Recalls the instrument setting from a saved file in system memory. Every parameter of the

instrument is recalled except for pattern data, pattern length and output enable status. The

filename can be up to 8 characters long and is not case-sensitive. Filenames must consist

of only alphanumeric characters.

Recall the instrument settings from file “PARAM22”.

:MMEM:LOAD:STAT “PARAM22”

:MMEMory:MOVE:PDATa

Form

ters

Parame

Value Coupling

Range Coupling

Default N/A

cription

Des

Example

Set

String

None

None

Rename the existing saved pattern data file in system memory. The filename can be up to

8 characters long and is not case-sensitive. Filenames must consist of only alphanumeric

cha

Re

:MMEM:MOVE:PDAT “PATT1011”, “PATT010 1”

racters.

name the pattern data file PATT1011 to PATT0101.

MMEMory:MOVE:STATe

:

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

Example

Set

String

None

None

Rename the existing saved instrument settings fi le in system memory. The filename can be up

to 8 characters long and is not case-sensitive. Filenames must consist of only alphanumeric

characters.

Rename the instrument settings filePARAM22toPARAM.

:MMEM:MOVE:STAT “PARAM22”, “PARAM”

36 PPG4001 Pattern Generator User Manual

Page 53

:MMEMory:DELete:PDATa

Reference

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

Example

Set

String

None

None

Deletes an existing saved pattern data file in system memory. The filename can be up to

8 characters long and is not case-sensitive. Filenames must consist of only alphanumeric

characters.

Delete the existing pattern data file PATT0101.

:MMEM:DEL:PDAT “PATT0101”

:MMEMory:DELete:STATe

Form

Parameters

Value Coupling

Range Coupling

Default N/A

Description

mple

Exa

Set

String

None

None

Deletes an existing saved instrument settings file in system memory. The filename can be up

to 8

characters.

Delete the existing instrument settings file PARAM.

:MMEM:DEL:STAT “PARAM”

characters long and is not case-sensitive. Filenames must consis t of only alphanumeric

:MMEMory:CATalog:PDATa?

Form

Parameters None

Value Coupling

Range Coupling

Default N/A

Description

Example

PPG4001 Pattern Generator User Manual 37

Query

None

None

Get the list of pattern data files s tored in system memory. All the filenames stored in the

system memory are returned as capital letters.

Get the list of pattern data filesstoredinsystemmemory.

:MMEM:CAT:PDAT?

Page 54

Reference

:MMEMory:CAT

Form

Parameters None

Value Coupling

Range Coupling

Default N/A

Description

Example

alog:STATe?

Query

None

None

Get the list of instrument settings filesstoredinsystemmemory.Allthefilenames stored in the

system memory are returned as capital letters.

Get the list of instrument settings filesstoredinsystemmemory.

:MMEM:CAT:STAT?

:OUTPut0:SOURce

Form

ters

Parame

Value Coupling

Range Coupling

Default

ription

Desc

ample

Ex

Set & Query

PERiodic | BITStream

None

None

PERio

Prog

Set the trigger out event to bit stream.

:OUTP0:SOUR BITSTREAM

dic

rams the trigger out event.

iodic means the trigger will output a signal whose frequency is the clock rate divided

PER

by N, where N is the trigger divider setting.

BITStream means trigger pulses will be aligned with the pattern length.

:OUTPut0:DIVider

Form

Parameters Numeric

Value Coupling

Range Coupling

Default

Description

Example

38 PPG4001 Pattern Generator User Manual

Set & Query

None

None

128

Programs the trigger divider. This is meaningful only if the trigger output event is set to

periodic.. For the PPG4001, valid values are multiples of 128.

Set the trigger divider to 128.

:OUTP0:DIV 128

Page 55

Reference

:OUTPut:POLa

Form

Parameters

Value Coupling

Range Coupling

Default NORMal

Description

Example

rity

Set & Query

NORMal | INVerted

None

None

Programs the polarity of the channel outputs.

Set for inverted output

:OUTPUT:POLARITY INV

:OUTPut[:STATe]

Form

ters

Parame

Value Coupling

Range Coupling

Default OFF

ription

Desc

Example Disable the output.

Set & Query

OFF | ON

None

None

Programs the enable/disable status of the channel outputs. If the unit has optional

pre-emphasis outputs, the state of the pre-emphasized output is set together with that of

standard output.

the

TP OFF

:OU

:OUTPut:CLOCk:DIVider

Form

Parameters

Value Coupling

Range Coupling

Default Varies with model & options. The minimum allowed value is either 1 or 2.

Description

Example

Set & Query

1|2|4|8|16

None

None

Programs the clock output divider. The input to this divider is internal clock, and the output from

the divider goes to the c lock output or to the divided clock output if the full rate & divided outputs

are separate. The max and min valid values depend on the instrument model and options.

Program clock divider for 8.

:OUTP:CLOC:DIV 8

PPG4001 Pattern Generator User Manual 39

Page 56

Reference

:SENSe:ROSCi

Form

Parameters

Value Coupling

Range Coupling

Default

Description

Example

llator:SOURce

Set & Query

INTernal | EXTernal

None

None

INT

Programs the 10 MHz reference source.

Set the 10 MHz reference source to use the internal reference.

:SENSE:ROSCILLATOR:SOURCE INT ERN AL

[:SOURce]:FREQuency[:CW|:FIXed]

Form

ters

Parame

oupling

Value C

Coupling

Range

lt

Defau

Description

mple

Exa

Set & Query

c[Hz]

Numeri

None

None

30e9

rams the internal clock frequency, and also selects the internal clock as clock source if

Prog

it is not already selected.

Set frequency to 28 G Hz.

:FREQ 28e9

[:SOURce]:PM[:HF][:STATe]

Form

Parameters

Value Coupling

Range Coupling

Default OFF

Description

Example Enable overall HF jitter insertion.

Set & Query

OFF | ON

None

None

Programs the overall channel jitter insertion enable/disable status. The HF sources are HF

sine, random, and external. If enabled, the external jitter source is enabled and the internal

sources are set according to their i ndividual controls.

:PM ON

40 PPG4001 Pattern Generator User Manual

Page 57

Reference

[:SOURce]:PM

Form

Parameters

Value Coupling

Range Coupling

Default

Description

Example

[:HF]:INTernal1[:DEViation]

Set & Query

Numeric [S]

None

None

0ps

Programs the peak-to-peak amplitude of the channel internal sine jitter source. Units are in

seconds.

Set the internal HF sine jitter source to 11 ps peak-to-peak.

:PM:INT1 11ps

[:SOURce]:PM[:HF]:INTernal1:FREQuency

Form

Parameters Numeric [Hz]

Value Coupling

Range Coupling

Default

ription

Desc

mple

Exa

Set & Query

None

None

1MHz

Programs the frequency of the channel internal HF sine jitter source. Units are Hz.

Set sinusoidal jitter frequency to 1.3 MHz.

:PM:INT1:FREQ 1.3MHz

[:SOURce]:PM[:HF]:INTernal1:STATe

Form

Parameters

Value Coupling

Range Coupling

Default OFF

Description

Example Enable the internal HF sine jitter source.

Set & Query

OFF | ON

None

None