Page 1

Service Manual Addendum

Phaser

™

340 and Phaser

Color Printer

™

350

This addendum contains information for servicing Phaser 340 Color Printers

printers serial-numbered BCxxxxx and up and Phaser 350 Color Printers.

July 1996

070-9100-85

Service Manual

1

Page 2

2

Phaser 340 overview

The Phaser 340 Color Printer is an Adobe PostScript Level 2 color, solid ink-jet

printer with Tektronix color matching extensions (TekColor 3.0). The Phaser 340

is marketed in two variations: The Phaser 340 and the Phaser 340 Plus (also

called Phaser 340 with Extended Features). Externally and mechanically, the

Phaser 340 and Phaser 340 Plus are identical. The startup page indicates

whether the printer is a “Plus” model. Additionally, the Macintosh printer

driver indicates if the printer is a “Plus” model.

Note

The Phaser 340 prints at an addressability of 300 dots per inch (dpi) and features

17 built-in fonts and 8 Mbytes of RAM, which can be upgraded to 12 Mbytes.

The Phaser 340 Plus prints at an addressability of 600 x 300 dots-per-inch or

300 x 300 dpi, features 69 built-in fonts, and comes with 24 Mbytes of RAM. The

Phaser 340 Plus is also capable of job pipelining; it can print one image and

process the data for the next image at the same time.

Both printers feature two available paper trays: A and A4, with an optional

500-sheet high-capacity Lower Paper Tray Assembly which gives the printer a

dual-tray capability. (The Lower Paper Tray Assembly is sometimes referred to

as the second feeder; it only supports paper printing.) The printers print images

on A- and A4-size paper and transparency film with 5 mm (0.2 in.) margins; the

bottom margin is 7 mm (0.3 in). Each can print up to a rate of four pages per

minute; although the Phaser 340 Plus has greater image processing capabilities

for faster image throughput. Both variations feature a SCSI port to support an

external SCSI disk for additional font storage and the Phaser CopyStation copier

option.

Unless otherwise noted, descriptions and servicing are identical for

the Phaser 340 and the Phaser 340 Plus.

Early in 1996, Tektronix introduced a significantly redesigned

Phaser 340 and Phaser 340 Plus, denoted by the serial numbers

xxxx, BDx xxxx, BEx xxxx, B6E xxxx and B6F xxxx . These

BCx

printers are often referred to as Version 2 printers. Theses printer

feature some new FRU components that are not compatible with older

printers. These printers also have an updated front panel menu

structure with new menu items.

A 68K processor oversees print engine operations; the printer’s PostScript image

processor is powered by a 32-MHz 29K RISC processor. The printer features an

integral bi-directional parallel port. A rear panel slot allows customers to install

one “smart card” Phaser Share Network Card. One version card provides an

RS-232C serial port and a LocalTalk port. A second, alternative card offers an

Ethernet port which includes support for EtherTalk, Novell NetWare and

TCP/IP. A third card provides a Token Ring interface supporting Novel

NetWare, TokenTalk, and TCP/IP. TCP/IP protocol support is standard in

printers serial-numbered BCxx

supported via a downloaded software key in earlier printers (Version 1 printers).

Phaser 340 and 350 Color Printers

xxx and up. TCP/IP protocol is optionally

Page 3

Phaser 350 overview

The Phaser 350 Color Printer is a significant improvement over the Phaser 340.

Foremost among the Phaser 350 Color Printer’s features is its 6 page-per-minute

FastColor print mode. The print mode is selectable through the front panel and

from printer drivers. Other features are: The ability to set the printer’s IP

address easily from the front panel, a multi-page print collation mode (hard disk

required), and PrintCheck which lets you preview the first print of a muliple

copy job before letting the printjob continue. The front panel features the printer

name and status information similar to the Phaser 550.

The Phaser 350 prints at an addressability of 300 dots per inch (dpi) and features

17 built-in fonts and 8 Mbytes of RAM, which can be upgraded to 24 Mbytes.

The Phaser 350 with the Extended Featues option prints at an addressability of

600 x 300 dots-per-inch (Enhanced) or 300 x 300 dpi (Standard), features

69 built-in fonts, and comes with 24 Mbytes of RAM. The Phaser 350 with

Extended Features is also capable of job pipelining; it can print one image and

process the data for the next image at the same time.

Version 3.0 Ethernet and TokenRing cards add support for Telnet and ftp, and

PhaserLink allows users to monitor and control the printer via an internet

browser.

Print engine exchange

In extreme situations it may be necessary for service personnel to exhange the

entire print engine, while transferring the main board which maintains

purchased options and network identity at the customer’s printer.

The two printer modules for this exchange program are:

650-3260-00 supports Phaser 340s serial-numbered B1xxxxx through

■

B9xxxxx, except B6Exxxx and B6Fxxxx.

650-3184-01 supports Phaser 340s serial-numbered BCxxxxx through

■

BExxxxx and B6Exxxx and B6Fxxxx. It also supports all Phaser 350s.

The 650-3260-00 engine is a 2:1 jet interlace chassis; the 650-3184-01 is a 4:1 jet

interlace chassis shipped with two front panel logos so the proper one can be

installed.

Service Manual

3

Page 4

4

B4 zz

B5 zz

B6 zz

B7 zz

B8 zz

B9 zz

BC zz

Serial numbering for Phaser 350

The serial number has the format of B YRxxxx where:

■

B = Beaverton

Y = Year (0-9)

■

■

R = Revision level (A thru Z, minus “I” and “O”)

xxxx = numerical values only (0-9)

■

This is the begining serial number for the Phaser 350:

B6A0100

■

Serial number history for Phaser 340

■

B = Beaverton

Y = Year (0 - 9)

■

■

M = Month (0 - 9, A, B, C)

D = Day (base 34)

■

■

R = Revision level (range 0 thru 9 and A thru Z; base 34)

xxxx = numerical values only (0 - 9)

■

■

zz = alphanumerial values (range 0 - 9 and A through Z; base 34)

These are previous printer serial number patterns in sequential order:

■

B15 First production output, serial number format B RYMDzz .

B25 V1.2 print engine firmware.

■

■

B35 V1.8 print engine firmware.

■

Serial number format change, serial number format B RzzDMY .

■

■

■

■

■

■

V1.22 print engine firmware.

V1.24 print engine firmware, field update is 650-3163-02.

Power supply 650-3365-01 or 650-3397-00 thermistor kit.

Redesigned cap/wipe/purge assembly 650-3258-01.

2-flag ink loader.

Version 2 chassis, Web support and NDS support on Netware, 4:1

jet interlace.

Phaser 340 and 350 Color Printers

Page 5

BD zz

BE zz

■

■

pick).

■

B6E Serial number format change; serial number format BY Rxxxx .

B6F New main board, 671-3760-80 is exchange part number.

■

De-skew hardware installed (only 14 printers shipped).

Same as BCzz (de-skew removed, too noisy during paper

Accessing the printer’s web page

For printers serial-numbered BCxxxxx and up and the Phaser 350. PhaserLink,

the Tektronix implementation of a World Wide Web server inside the printer,

allows a customer to communicate to the printer using a web browser. With

PhaserLink, a customer can view and set printer and networking parameters. A

homepage built into the printer links the printer to other homepages such as the

Tektronix World Wide Web home page.

To view the printer’s homepage, the printer must be connected to a network

supporting TCP/IP protocols and be assigned an IP address. Refer to the

PhaserShare Network Cards and Software User Manual .

PC-based diagnostics

The PC-based diagnostics allows you to interactively test and check the

operations and functionality of the printer. The diagnostics are provided on a

3-1/2 inch floppy diskette. All of the diagnostic tests are started from the PC.

Some of the tests are stored on-board the main board in ROM and are merely

started by the PC-based diagnostics; other tests are downloaded to the printer

from the PC. The test are functionally divided into two classes: 29K tests, which

execute test stored in the 29K processor’s ROM and the 68K tests which are

downloaded to the printer to test the 68K processor and the print engine.

The PC diagnostics were developed to run on a PC. The diagnostics are used

with an Apple® PowerBook® running PC emulation software as this is the

portable computer in use by Tektronix Field Service.

Note

Printers serial-numbered B0xxxxx to BB xxxxx use diagnostics

version 1.24. Printers serial-numbered BCxxxxx and up use

diagnostics version 2.40. Both diagnostics are available on the same

diskette. Printers B0xxxxx to BBxxxxx may receive a firmware

upgrade, upgrade kit Z340PL, revising the firmware to 2.40R. The

“R” is visible only on the ROM’s label, not on the printer’s startpage.

These printers require version 2.40R or 2.40RA diagnostics.

A future release of the diagnostics is planned that will automatically

select the correct version when the diagnostics are started.

Service Manual

5

Page 6

6

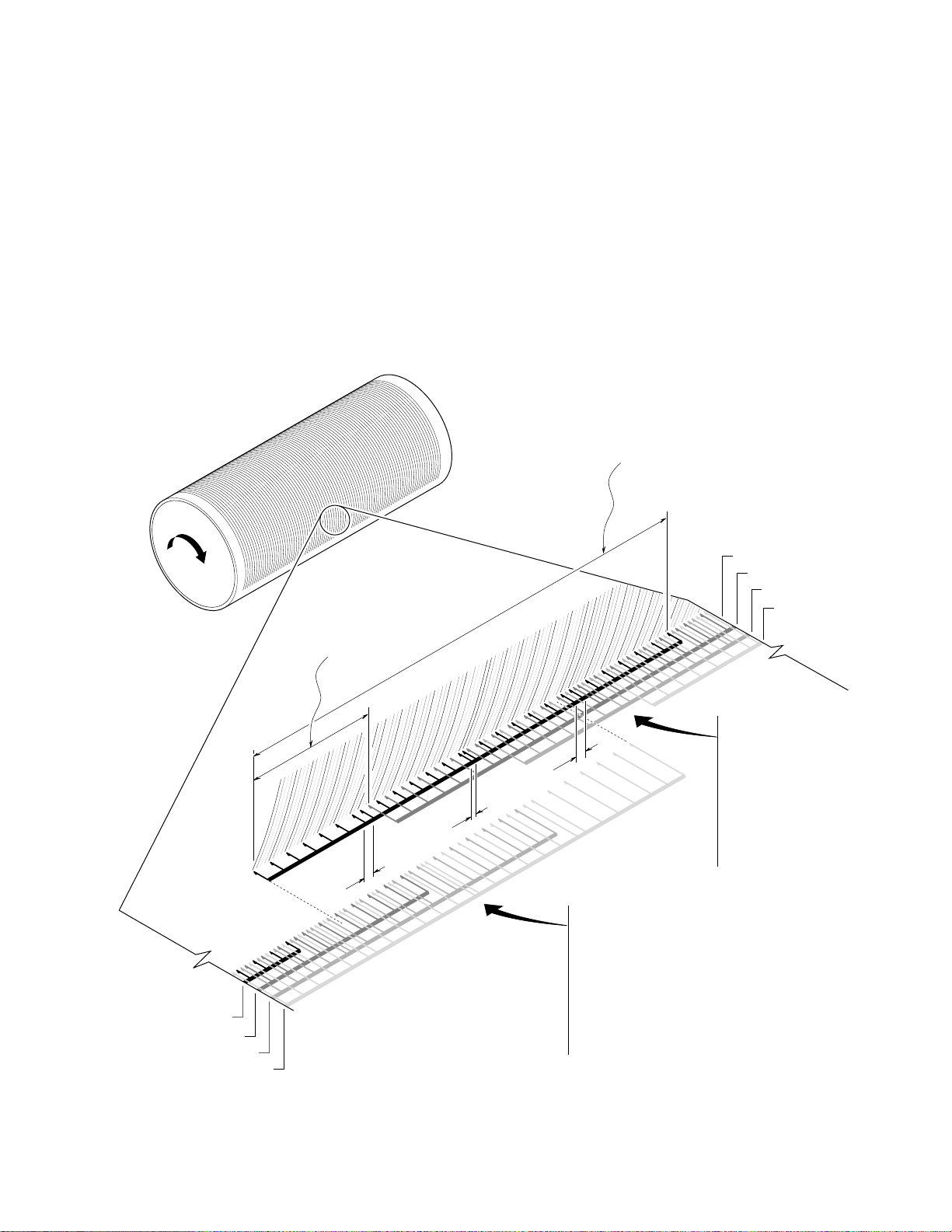

Jet interlacing

1.

2.

3.

4.

5.

6.

7.

Phaser 340 color printers serial numbered BC xxxxx and later and Phaser 350

printers use a different method of laying ink onto the drum; they perform a

“four-jet interlace.” As the drum reaches the correct speed of 176 rpm, the

ink-jets begin to fire to deposit the image on the oiled portion of the drum. As

the jets fire, the printhead slews in the x-axis to complete the image on the drum.

When the ink image is about 80% complete, the paper-pick cycle begins.

For 300 dpi printing, each jet lays down 28 pixel columns. Each jet lays down

one pixel column for each drum rotation (28 revolutions total). Each jet travels

horizontally the distance of 112 pixels to lay down its 28 pixel columns within

that 112 pixel-wide field. The 112 pixel-wide field of each jet overlaps the

112 pixel-wide field of six other jets; this is where interlacing occurs. To lay

down its 28 pixel columns, each jet follows this sequence:

Print 1st column, step four columns to the right, print 2nd column,

step four columns to the right. Repeat until 7 columns are laid down.

Step 2 additional columns to the right.

Print the 8th column, step 4 columns to the right, print 9th column,

step 4 columns to the right. Repeat until 7 columns are laid down

(total of 14 so far).

Step 1 additional column to the right.

Print the 15th column, step 4 columns to the right, print the 16th

column, step 4 columns to the right. Repeat until another 7 columns

are laid down (21 total so far).

Step 2 additional columns to the right.

Print the 22nd column, step 4 columns to the right, print the 23rd

column, step 4 columns to the right. Repeat until the last 7 columns

are laid down for a total of 28 pixel columns.

The intermediate 2-step, 1-step and 2-step movement between the 7th and 8th

pixel columns, the 14th and 15th columns, and the 21st and 22nd columns,

respectively, allow the 28 pixels columns of each jet to properly interlace with

the 28 pixel columns of the other jets it is combined with. A total of

2,432 columns, each 3,134 dots tall, are laid down.

The advantage of this print method is that variability between jets is “averaged

out” by being interlaced with three other jets. As shown in the illustration, of the

28 pixel columns printed by any single jet, only two of its pixel columns are

actually ever adjacent. Usually they are separated by three other pixel columns

produced by other jets, hence the name

spacing between jets and the 112 pixel-wide field that each jet travels, the pixel

columns of any one jet actually interlaces with the pixel columns of six other jets,

although no more than four at any one time.

four-jet interlace . Because of the 28 pixel

In reality, because of the fixed width of the printhead and inter-jet spacing, the

outermost jets cannot interlace completely with their adjacent jets. In this case,

the drum rotates for seven extra imaging rotations (14 if both end jets are

needed) for the printhead to reposition the end jets so they can fill-in the missing

pixel columns that cannot otherwise be interlaced.

Phaser 340 and 350 Color Printers

Page 7

7

For transparency printing, the image is printed in the same manner. However,

the image is printed, with smaller droplets, twice on the drum, the second image

positioned precisely over the first image before being transferred to the sheet of

transparency film; this increases image density.

For 600 x 300 dpi printing, each jet lays down 56 columns of ink drops spread

over a 224 pixel-wide field. The drum rotates 56 times to receive the pixel

columns. The same interlace method is used, except 14 pixel columns are

printed between the intermediate 2-step, 1-step and 2-step movements. A total

of 4,864 columns, each 3,134 dots tall, are laid down. The x-axis motor steps at

half the rate to double the resolution in the x-axis. Also, the printhead jets

output smaller, 600 dpi dots.

112 pixel-wide

field traveled by a jet

1 of 4

2 of 4

3 of 4

4 of 4

28 pixel

separation

between jets

2 Step

1 Step

2 Step

Output of four

side-by-side jets

1 of 4

2 of 4

3 of 4

4 of 4

Column of pixel dots

produced by four

adjacent jets are

interlaced together

for 300 dpi printing.

Each jet produces

28 pixel columns.

For 600 dpi printing,

each jet produces

56 pixel columns.

Columns of pixel

dots produced by

previous set of four

adjacent jets. Note

how the ending

columns of this set

interlace with

beginning columns

of the next set of

four jets.

9100-107

Service Manual

Page 8

8

Enabling TCP/IP with the authorization code

.

1.

2.

3.

1.

2.

3.

TCP/IP protocol support is standard in Phaser 340 printers serial-numbered

xxx and up and Phaser 350 printers. This feature depends upon the version

BCxx

of firmware on the PhaserShare card being 2.0 or higher. TCP/IP protocol is

optionally supported via a downloaded software key in earlier printers.

When the Phaser Share Ethernet card is installed, the EtherTalk and Novell

protocols are immediately active. For printer’s serial numbered B1xxxxx

through B9xxxxx, the Ethernet card’s TCP/IP protocol must be activated by a

downloadable authorization code, sometimes referred to as its software key.

The authorization code is printed on a certificate included with the printer (if the

option was factory-installed) or with the field upgrade kit. The

Manual and Phaser Share Network User Manual

authorization code and download it to the printer

two-step process: It consists of editng a file called “authorize.ps” that contains

the authorization code and then downloading the file to the printer using a file

downloading utility such as Font Downloader or LaserWriter Utility.

explain how to activate the

Downloading the code is a

Phaser Share User

Bypass mode

Bypass mode allows you to access the front panel menus (bypassing the engine

and PostScript initializing processes) without having to wait for the printhead to

warm up. This way, you can reset NVRAM or read fault codes immediately.

Meanwhile, the printer continues to warm-up and initialize “in the

background.” Even if the engine faults, bypass mode can be active.

Press and hold front panel buttons 1 and 2 (left two buttons). Turn on

the printer.

Wait for the message Entering Bypass Mode to be displayed

(about 40 seconds).

Release buttons 1 and 2. For the Phaser 350, do not press buttons 1

and 2 until the first “Warming Up” message is displayed, then quickly

press the buttons and hold for a few seconds until “Entering Bypass

Mode” is displayed.

Cool down mode

Phaser 340 printers serial-numbered BCxxxxx and up and Phaser 350 printers

have a menu item that accelerates the cooling of the printhead.

Enter the extended menu by pressing Menu and Exit .

Scroll to the Service Suppor t menu item and press Menu.

Scroll to the item Cool-down for Power Off and press OK .

The printer turn off all the engine heaters and runs the fans on high until the ink

in the printhead has solidified. Then the printer’s front panel informs you the

printer can be turned off.

Phaser 340 and 350 Color Printers

Page 9

Error codes and messages

Error codes indicate the following:

■

the failing system ( XX ,yyy.zz)

the failing subsystem (xx, YYY .zz)

■

■

the actual problem (xx,yyy.ZZ).

■ the print engine copy count (xx,yyy.zz:123) the error occurred on.

Codes from 24,000 through 24,999 are engine failures reported by the PostScript

controller. They are not stored in the fault history table of the NVRAM. They

are reported when the engine has been stuck in a state for 25 minutes.

Front panel and fault history log error codes and messages

Error code Meaning

4,000: PC (process control supervisor)....

4,001.40 (0x2401):

PC_DEV_FAULT_HEAD_READ

4,002.41 (0x2402):

PC_DEV_FAULT_HEAD_ZEROS

4,003.42 (0x2403):

PC_DEV_FAULT_HEAD_ONES

4,004.43 (0x2404):

PC_DEV_FAULT_HEAD_CHECK

SUM

4,005.44 (0x2405):

PC_DEV_FAULT_DM_

CAM_ERR

4,006.45 (0x2406):

PC_DEV_FAULT_300DPI_CAL

4,007.46 (0x2407):

PC_DEV_FAULT_600DPI_CAL:

4,008.47 (0x2408)

PC_DEV_FAULT_STUCK_DMC:

4,009.48 (0x2409)

PC_DEV_FAULT_DM_

CAM_BEGIN

Failure reading printhead NVRAM data: check the wiring to the

printhead, I

Printhead NVRAM data was all zeros: has this printhead been through

normalization? If so, check wiring to printhead.

Printhead NVRAM data was all ones: has this printhead been through

normalization? If so, check the wiring to the printhead.

Printhead NVRAM checksum failure: the data within the printhead

NVRAM has been corrupted. Check the the printhead ribbon cable and

associated connections.

Failure positioning drum maintenance cam during a drum maintenance

cycle: check drum maintenance cam solenoid, clutch, home sensor, and

related hardware.

Calibration failure: Target Volt-Sec Area of 300 dpi could not be

achieved. “Head Adjust” head drive voltage may be incorrectly set.

Possible hardware failure on printhead.

Calibration Failure: Target Volt-Sec Area of 600 dpi could not be

achieved. “Head Adjust” head drive voltage may be incorrectly set.

Possible hardware failure on printhead.

Failure to advance the drum maintenance tray sensor interrupt flag. It

has been in the new tray state for too long. Check the hardware.

At the start of a drum maintenance cycle, when the drum maintenance

cam position should have been at blade down, wick down, the drum

maintenance cam home sensor should have been TRUE and was

instead FALSE. Check the drum maintenance cam solenoid, clutch,

home sensor, and related hardware.

2

C bus and other hardware.

4,010.40 (0x240A)

PC_DEV_FAULT_DM_CAM_BU_

WU

During the drum maintenance cycle, when the drum maintenance cam

position should have been at blade up/wick up, the drum maintenance

cam home sensor should have been FALSE and was instead TRUE.

Check the drum maintenance cam solenoid, clutch, home sensor, and

related hardware.

Service Manual

9

Page 10

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

4,011.41 (0x240B)

PC_DEV_FAULT_DM_

CAM_BU_WD

4,012.42 (0x240C)

PC_DEV_FAULT_DM_

CAM_END

4,013.43 (0x240D)

PC_DEV_FAULT_GEAR_GRIND

4,015.45 (0x240F)

PC_DEV_FAULT_HEAD_

ADJUST_TIMEOUT

4,016.46 (0x2410)

PC_DEV_FAULT_HEAD_NV_

FORMAT

4,017.47 (0x2411)

PC_DEV_FAULT_AMBIENT_

TOO_COLD

During the drum maintenance cycle, when the drum maintenance cam

position should have been at blade up/wic k down, the drum maintenance

cam home sensor should have been FALSE and was instead TRUE.

Check the drum maintenance cam solenoid, clutch, home sensor, and

related hardware.

At the end of a drum maintenance cycle, when the drum maintenance

cam position should have been at blade down/wick down, the drum

maintenance cam home sensor should have been TRUE and was

instead FALSE. Check the drum maintenance cam solenoid, clutch,

home sensor, and related hardware.

During power-on initialization, the engine is unable to disengage the

process motor. Prior to declaring this fault, the engine has attempted to

move the process motor through enough revolutions to disengage the

head tilt mechanism, but the motor stalled. The X axis was then

displaced to the right 0.15 inches and the disengage was repeated, but

the motor stalled again. This fault is then declared. The head is unable

to move on its tilt axis, perhaps because it is colliding with something

(head restraint pin, cap, poorly installed ink loader, screwdriver.)

The engine spent too much time in printhead adjust state. The engine

declares a device fault and shuts down, rather than leave a hot heater

against a cold drum for an indefinite period

The printhead format number, stored in printhead NVRAM, is not

understood by this version of engine firmware.

Ambient temperature has fallen to less than 10

wrong with a heater.

o

C. Something may be

4,018.48 (0x2412)

PC_DEV_FAULT_LATE_CLEAN_

REQUEST

4,019.40 (0x2413) :

PC_DEV_FAULT_193DPI_CAL

5,000: Y axis (drum)

5,001.41 (0x2c01):

YA_HOME_FAIL

5,002.41 (0x2b02):

YA_STALL_FAIL

5,002.42 (0x2b03): YA_POS_FAIL Y-axis position failure, the drum is not where is should be, possibly

5,002.41 (0x2b02):

YA_STALL_FAIL

5,003.42 (0x2b03): YA_POS_FAIL Y axis position failure: the drum is not where it should be. Besides the

After the printer determined, at power up, that the printhead was warm

enough not to need cleaning, and while the printer was warming up the

printhead temperature dropped below the head-clean-needed threshold.

Something may be wrong with a heater.

Calibration Failure: Target Volt-Sec Area of Fast Color mode could not be

achieved. “Head Adjust” head drive voltage may be incorrectly set.

Possible hardware failure on printhead.

Drum home sensor failure: the drum turned one full revolution without

seeing the drum home sensor activate. Check the drum home sensor.

The Y-axis (drum) motor stalled, possibly because the drum position

sensor electronics have failed, or because the motor drive or drive belts

have failed, or because something is physically blocking the motion of

the drum.

because the drum position sensor electronics have failed, or because the

motor drive or drive belts have failed, or because something is physically

blocking the motion of the drum

The drum stalled: the drum stalled because the motor drive or drive

belts have f ailed, or because something is ph ysically b loc king the motion

of the drum.

possible mechanical problems, this can be caused by software latency

errors, if too many interrupts occur during drum positioning.

10

Phaser 340 and 350 Color Printers

Page 11

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

6,000: X axis

6,000.41 (0x3400):

XA_FAULT_MCURRENT

6,001.42 (0x3401):

XA_FAULT_NOHOME

6,002.43 (0x3402):

XA_FAULT_NGHOME

6,003.44 (0x3403):

XA_FAULT_LOST

7,000: Process motor

7,001.43 (0x3c01):

PM_FAULT_AUXILIARY_

MOTOR_ERROR

7,002.44 (0x3c02):

PM_FAULT_PROCESS_MOTOR_

STALL

7,003.45 (0x3c03):

PM_FAULT_ COMPOUND_

GEAR_SENSOR_BAD

7,004.46 (0x3c04):

PM_FAULT_DM_CAM_

SENSOR_BAD

X axis motor over/under current. Indicates that motor coil(s) are open, or

shorted, or the x-axis motor fuse has opened.

X-axis home position not found. Indicates that the x-axis home sensor

has failed, or something has prevented the printhead motion during a

home operation.

Unexpected x-axis home sensor activation. The sensor has failed, the

motor control is moving the printhead in the wrong direction, or the user

has engaged the printhead restraint mechanism.

A verify of the home calibration failed. After locating the home sensor

transition, the DMC computed x-axis position varied from the home value

by more than the acceptable tolerance.

The electronics report an error while operating the motor in the auxiliary

feeder (the optional lower tray)

The process motor stalled during operation. This has several possible

causes, depending on what the process motor was gear-connected to at

the time of failure.

No transitions are observed of the compound gear sensor when the

compound gear should be turning. Perhaps the sensor is bad, or the

process motor to compound gear linkage is broken.

No transitions are observed of the drum maintenance cam sensor. The

sensor may be bad or the drum maintenance cam may be jammed.

7,005.47:

PM_FAULT_PREHEAT_EXIT_

SENSOR_BAD ().

8,000: Cap drive and web sensors

8,001.44 (0x4401):

CAP_FAULT_HOME_

SENSOR

8,002.45 (0x4402):

CAP_FAULT_WEB_

SENSORS

8,003.46 (0x4403): CAP_FAULT_

OVERCURRENT

9,000: Ink loader: ink melters and printhead ink level sensors.

9,001.45 (0x4c01): IL_FAULT_C_

TWANGER

9,002.46 (0x4c02): IL_FAULT_M_

TWANGER

9,003.47 (0x4c03): IL_FAULT_Y_

TWANGER

9,004.48 (0x4c04): IL_FAULT_K_

TWANGER

The preheater exit sensor is not being detected, it is either unplugged or

defective.

An expected transition of the cap home sensor did not occur. The home

sensor may be faulty, or the cap motor may not be operating, or the cap

may be jammed and unable to move.

A fault is detected in the web sensors. Check the left and right

maintenance tray sensors and their wiring harness.

The cap/wipe/purge assembly stalled. (This f ault does not actually occur

because the mechanism is loose. When the assembly jams, the motor

skips over teeth.)

Malfunction of the ink level sensor in the cyan reservoir. Replace the

printhead.

Malfunction of the ink level sensor in the magenta reservoir . Replace the

printhead.

Malfunction of the ink level sensor in the yellow reservoir. Replace the

printhead.

Malfunction of the ink level sensor in the black reservoir. Replace the

printhead.

Service Manual

11

Page 12

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

9,005.40 (0x4c05):

IL_FAULT_C_JAM

9,006.41 (0x4c06):

IL_FAULT_M_JAM

9,007.42 (0x4c07):

IL_FAULT_Y_JAM

9,008.43 (0x4c08):

IL_FAULT_K_JAM

13,000:printhead thermals

13,001.40 (0x6c01):

TCH_JS_LEFT_OPEN

13,002.41 (0x6c02):

TCH_JS_LEFT_SHORT

13,003.42 (0x6c03):

TCH_JS_LEFT_HOT

13,004.43 (0x6c04):

TCH_JS_LEFT_SLOW

13,017.47 (0x6c11):

TCH_JS_RIGHT_OPEN

13,018.48 (0x6c12):

TCH_JS_RIGHT_SHORT

The cyan ink melt heater is on, but ink does not seem to be dripping.

Check that the ink stick is able to advance in the chute.

The magenta ink melt heater is on, but ink does not seem to be dripping.

Check that the ink stick is able to advance in the chute.

The yellow ink melt heater is on, but ink does not seem to be dripping.

Check that the ink stick is able to advance in the chute.

The black ink melt heater is on, but ink does not seem to be dripping.

Check that the ink stick is able to advance in the chute.

The thermistor in the left jetstack appears to be open. Replace the

printhead ribbon cable. Check connections. Peplace the printhead.

The thermistor in the left jetstack appears to be shorted. Replace the

printhead.

The left jetstack heater is running away. Unplug the printer NOW!

The left jetstack heater is not heating at all, or is not heating as quickly as

it should. Replace the printhead ribbon cable. Check connections.

Peplace the printhead.

The thermistor in the right jetstack appears to be open. Replace the

printhead ribbon cable. Check connections. Peplace the printhead.

The thermistor in the right jetstack appears to be shorted. Replace the

printhead.

13,019.40 (0x6c13):

TCH_JS_RIGHT_HOT

13,020.41 (0x6c14):

TCH_JS_RIGHT_SLOW

13,033.45 (0x6c21):

TCH_RESERVOIR_OPEN

13,034.46 (0x6c22):

TCH_RESERVOIR_SHORT

13,035.47 (0x6c23):

TCH_RESERVOIR_HOT

13,036.48 (0x6c24):

TCH_RESERVOIR_SLOW

14,000: Cap thermals

14,001.41 (0x7401):

TCC_THERMISTOR_OPEN

14,002.42 (0x7402):

TCC_THERMISTOR_SHORT

14,003.43 (0x7403):

TCC_THERMISTOR_HOT

14,004.44 (0x7404):

TCC_THERMISTOR_SLOW

The right jetstack heater is running away. Unplug the printer NOW!

The right jetstack heater is not heating at all, or is not heating as quickly

as it should. Replace the ribbon cab le. Check connections. Peplace the

printhead.

The thermistor in the reservoir appears to be open. Replace the

printhead ribbon cable. Check connections. Peplace the printhead.

The thermistor in the reservoir appears to be shorted. Replace the

printhead.

The reservoir heater is running away. Unplug the printer NOW!

The reservoir heater is not heating at all, or is not heating as quickly as it

should. Replace the ribbon cable. Check connections. Peplace the

printhead.

The cap/wipe/purge assembly thermistor appears to be open. Replace

the assembly.

The cap/wipe/purge assembly thermistor appears to be shorted.

Replace the assembly.

The cap/wipe/purge assembly heater is running away. Unplug the printer

NOW! Possible swapped sensor cable connectors on I/O #2.

The cap/wipe/purge assembly heater is not heating at all, or is not

heating as quickly as it should. Check for open connection or open

thermistor in power supply.

12

Phaser 340 and 350 Color Printers

Page 13

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

14,005.45:TCC_WRONG_

TYPE_CAP

15,000: Drum thermals

15,001.42 (0x7c01):

TCD_THERMISTOR_OPEN

15,002.43 (0x7c02):

TCD_THERMISTOR_SHORT

15,003.44 (0x7c03):

TCD_THERMISTOR_HOT

15,004.45 (0x7c04):

TCD_THERMISTOR_SLOW

16,000: Preheater thermals

16,001.43 (0x8401):

TCP_THERMISTOR_OPEN

16,002.44 (0x8402):

TCP_THERMISTOR_SHORT

16,003.45 (0x8403):

TCP_THERMISTOR_HOT

16,004.46 (0x8404):

TCP_THERMISTOR_SLOW

22,000: Media jams

The installed cap/wipe/purge assembly is the wrong type for this printer.

Verify and install the correct assembly or firmware for this printer.

The drum thermistor appears to be open. Replace the drum temperature

sensor.

The drum thermistor appears to be shorted. Replace the drum

temperature sensor.

The drum heater is running away. Unplug the printer NOW! Possible

swapped power cable with the preheater. Possible swapped sensor

cable at I/O #2.

The drum heater is not heating at all, or is not heating as quickly as it

should. Check for open connection or open thermistor in power supply.

The preheater thermistor appears to be open. Replace the paper

preheater.

The preheater thermistor appears to be shorted. Replace the paper

preheater.

The preheater heater is running away. Unplug the printer NOW!

Possible swapped power cable with the drum heater.

The preheater heater is not heating at all, or is not heating as quickly as

it should. Chec k for open connection or open thermistor in power supply.

22,000.37 Jam -- Media at standard tray, unexpected event standard tray ajar 1.

22,001.38 Jam -- Media at standard tray, unexpected event standard tray A4-size

22,002.30 Jam -- Media at standard tray, unexpected event standard tray not used.

22,003.31 Jam -- Media at standard tray, unexpected event standard tray ajar 2.

22,004.32 Jam -- Media at standard tray, unexpected event standard tray A-size

22,005.33 Jam -- Media at standard tray, unexpected event standard tray A4-size

22,006.34 Jam -- Media at standard tray, unexpected event standard tray A-size

22,007.35 Jam -- Media at standard tray, unexpected event standard tray not

22,008.36 Jam -- Media at standard tray, unexpected event paper pick sensor

22,009.37 Jam -- Media at standard tray, unexpected event paper pick sensor

22,010.38 Jam -- Media at standard tray, unexpected event paper A-width sensor

22,011.30 Jam -- Media at standard tray, unexpected event paper A-width sensor

transparency.

transparency.

paper.

paper.

present.

TRUE.

FALSE.

FALSE, A4-width sensor FALSE.

TRUE, A4-width sensor FALSE.

22,012.31 Jam -- Media at standard tray, unexpected event paper A-width sensor

FALSE, A4-width sensor TRUE.

Service Manual

13

Page 14

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,013.32 Jam -- Media at standard tray, unexpected event paper A-width sensor

22,014.33 Jam -- Media at standard tray, unexpected event paper preheat entry

22,015.34 Jam -- Media at standard tray, unexpected event paper preheat entry

22,016.35 Jam -- Media at standard tray, unexpected event paper preheat exit

22,017.36 Jam -- Media at standard tray, unexpected event paper preheat exit

22,018.37 Jam -- Media at standard tray, unexpected event paper exit sensor

22,019.38 Jam -- Media at standard tray, unexpected event paper exit sensor

22,020.30 Jam -- Media at standard tray, une xpected e vent paper hand-f eed sensor

22,021.31 Jam -- Media at standard tray, une xpected e vent paper hand-f eed sensor

22,022.32 Jam -- Media at standard tray, unexpected event auxiliary tray not

22,023.33 Jam -- Media at standard tray, unexpected event auxiliary tray A-size.

22,024.34 Jam -- Media at standard tray, unexpected event auxiliary tray A4-size.

TRUE, A4-width sensor TRUE.

sensor TRUE.

sensor FALSE.

sensor TRUE.

sensor FALSE.

TRUE.

FALSE.

TRUE.

F ALSE.

present.

22,032.33 Jam -- Media at auxiliary tray, unexpected event standard tray ajar 1.

22,033.34 Jam -- Media at auxiliary tray, unexpected event standard tray A4-size

22,034.35 Jam -- Media at auxiliary tray, unexpected event standard tray not used.

22,035.36 Jam -- Media at auxiliary tray, unexpected event standard tray ajar 2.

22,036.37 Jam -- Media at auxiliary tray, unexpected event standard tray A-size

22,037.38 Jam -- Media at auxiliary tray, unexpected event standard tray A4-size

22,038.30 Jam -- Media at auxiliary tray, unexpected event standard tray A-size

22,039.31 Jam -- Media at auxiliary tray, unexpected event standard tray not

22,040.32 Jam -- Media at auxiliary tray, unexpected event paper pick sensor

22,041.33 Jam -- Media at auxiliary tray, unexpected event paper pick sensor

22,042.34 Jam -- Media at auxiliary tray, unexpected event paper A-width sensor

22,043.35 Jam -- Media at auxiliary tray, unexpected event paper A-width sensor

transparency.

transparency.

paper.

paper

present.

TRUE.

FALSE.

FALSE, A4-width sensor FALSE.

TRUE,A4-width sensor FALSE

14

Phaser 340 and 350 Color Printers

Page 15

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,044.36 Jam -- Media at auxiliary tray, unexpected event paper A-width sensor

22,045.37 Jam -- Media at auxiliary tray, unexpected event paper A-width sensor

22,046.38 Jam -- Media at auxiliary tray, unexpected event paper preheat entry

22,047.30 Jam -- Media at auxiliary tray, unexpected event paper preheat entry

22,048.31 Jam -- Media at auxiliary tray, unexpected event paper preheat exit

22,049.32 Jam -- Media at auxiliary tray, unexpected event paper preheat exit

22,050.33 Jam -- Media at auxiliary tray, unexpected e vent paper exit sensor TRUE.

22,051.34 Jam -- Media at auxiliary tray, unexpected event paper exit sensor

22,052.35 Jam -- Media at auxiliary tray, unexpected e vent paper hand-feed sensor

22,053.36 Jam -- Media at auxiliary tray, unexpected e vent paper hand-feed sensor

22,054.37 Jam -- Media at auxiliary tray, unexpected event auxiliary tray not

22,055.38 Jam -- Media at auxiliary tray, unexpected event auxiliary tray A-size

FALSE, A4-width sensor TRUE

TRUE, A4-width sensor TRUE

sensor TRUE

sensor FALSE

sensor TRUE.

sensor FALSE.

FALSE.

TRUE.

F ALSE.

present.

22,056.30 Jam -- Media at auxiliary tray, unexpected event auxiliary tray A4-size.

22,064.38 Jam -- Media at front cover, unexpected event standard tray ajar 1.

22,065.30 Jam -- Media at front cover, unexpected event standard tray A4-size

22,066.31 Jam -- Media at front cover, unexpected event standard tray not used.

22,067.32 Jam -- Media at front cover, unexpected event standard tray ajar 2.

22,068.33 Jam -- Media at front cover, unexpected event standard tray A-size

22,069.34 Jam -- Media at front cover, unexpected event standard tray A4-size

22,070.35 Jam -- Media at front cover, unexpected event standard tray A-size

22,071.36 Jam -- Media at front cover, unexpected event standard tray not present

22,072.37 Jam -- Media at front cover, unexpected event paper pick sensor TRUE.

22,073.38 Jam -- Media at front cover, unexpected event paper pick sensor FALSE.

22,074.30 Jam -- Media at front cover, unexpected event paper A-width sensor

22,075.31 Jam -- Media at front cover, unexpected event paper A-width sensor

22,076.32 Jam -- Media at front cover, unexpected event paper A-width sensor

transparency.

transparency.

paper.

paper.

FALSE, A4-width sensor FALSE.

TRUE, A4-width sensor FALSE.

FALSE, A4-width sensor TRUE.

Service Manual

15

Page 16

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,077.33 Jam -- Media at front cover, unexpected event paper A-width sensor

22,078.34 Jam -- Media at front cover, unexpected event paper preheat entry

22,079.35 Jam -- Media at front cover, unexpected event paper preheat entry

22,080.36 Jam -- Media at front cover, unexpected event paper preheat exit sensor

22,081.37 Jam -- Media at front cover, unexpected event paper preheat exit sensor

22,082.38 Jam -- Media at front cover, unexpected event paper exit sensor TRUE.

22,083.30 Jam -- Media at front cover, unexpected event paper exit sensor FALSE.

22,084.31 Jam -- Media at front cover, unexpected event paper hand-feed sensor

22,085.32 Jam -- Media at front cover, unexpected event paper hand-feed sensor

22,086.33 Jam -- Media at front cover, unexpected event auxiliary tray not present.

22,087.34 Jam -- Media at front cover, unexpected event auxiliary tray A-size.

22,088.35 Jam -- Media at front cover, unexpected event auxiliary tray A4-size.

22,096.34 Jam -- Media at exit cover, unexpected event standard tray ajar 1.

TRUE, A4-width sensor TRUE.

sensor TRUE.

sensor FALSE.

TRUE.

FALSE.

TRUE.

FALSE.

22,097.35 Jam -- Media at exit cover, unexpected event standard tray A4-size

22,098.36 Jam -- Media at exit cover, unexpected event standard tray not used.

22,099.37, Jam -- Media at exit cover, unexpected event standard tray ajar 2.

22,100.38, Jam -- Media at exit cover, unexpected event standard tray A-size

22,101.30, Jam -- Media at exit cover, unexpected event standard tray A4-size

22,102.31, Jam -- Media at exit cover, unexpected event standard tray A-size paper.

22,103.32 Jam -- Media at exit cover, unexpected event standard tray not present.

22,104.33 Jam -- Media at exit cover, unexpected event paper pick sensor TRUE.

22,105.34 Jam -- Media at exit cover, unexpected event paper pick sensor FALSE.

22,106.35 Jam -- Media at exit cover, unexpected event paper A-width sensor

22,107.36 Jam -- Media at exit cover, unexpected event paper A-width sensor

22,108.37 Jam -- Media at exit cover, unexpected event paper A-width sensor

22,109.38 Jam -- Media at exit cover, unexpected event paper A-width sensor

transparency.

transparency.

paper.

FALSE, A4-width sensor FALSE.

TRUE, A4-width sensor FALSE.

FALSE, A4-width sensor TRUE.

TRUE, A4-width sensor TRUE.

16

22,110.30, Jam -- Media at exit cov er, unexpected ev ent paper preheat entry sensor

TRUE.

Phaser 340 and 350 Color Printers

Page 17

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,111.31 Jam -- Media at exit cov er, unexpected ev ent paper preheat entry sensor

22,112.32 Jam -- Media at exit cover, unexpected event paper preheat exit sensor

22,113.33 Jam -- Media at exit cover, unexpected event paper preheat exit sensor

22,114.34 Jam -- Media at exit cover, unexpected event paper exit sensor TRUE.

22,115.35 Jam -- Media at exit cover, unexpected event paper exit sensor FALSE.

22,116.36 Jam -- Media at exit cover, unexpected event paper hand-feed sensor

22,117.37 Jam -- Media at exit cover, unexpected event paper hand-feed sensor

22,118.38 Jam -- Media at exit cover, unexpected event auxiliary tray not present.

22,119.30 Jam -- Media at exit cover, unexpected event auxiliary tray A-size.

22,120.31 Jam -- Media at exit cover, unexpected event auxiliary tray A4-size.

22,128.30 Jam -- Media at exit tray, unexpected event standard tray ajar 1.

22,129.31 Jam -- Media at exit tray, unexpected event standard tray A4-size

22,130.32 Jam -- Media at exit tray, unexpected event standard tray not used.

22,131.33 Jam -- Media at exit tray, unexpected event standard tray ajar 2.

F ALSE.

TRUE.

FALSE.

TRUE.

FALSE.

transparency.

22,132.34 Jam -- Media at exit tray, unexpected event standard tray A-size

22,133.35 Jam -- Media at exit tray, unexpected event standard tray A4-size paper.

22,134.36 Jam -- Media at exit tray, unexpected event standard tray A-size paper.

22,135.37 Jam -- Media at exit tray, unexpected event standard tray not present.

22,136.38 Jam -- Media at exit tray, unexpected event paper pick sensor TRUE.

22,137.30 Jam -- Media at exit tray, unexpected event paper pick sensor FALSE.

22,138.31 Jam -- Media at exit tra y, unexpected e v ent paper A-width sensor FALSE,

22,139.32 Jam -- Media at exit tray, unexpected event paper A-width sensor TRUE,

22,140.33 Jam -- Media at exit tra y, unexpected e v ent paper A-width sensor FALSE,

22,141.34 Jam -- Media at exit tray, unexpected event paper A-width sensor TRUE,

22,142.35 Jam -- Media at exit tray, unexpected event paper preheat entry sensor

22,143.36 Jam -- Media at exit tray, unexpected event paper preheat entry sensor

22,144.37 Jam -- Media at exit tray, unexpected event paper preheat exit sensor

transparency.

A4-width sensor FALSE.

A4-width sensor FALSE.

A4-width sensor TRUE.

A4-width sensor TRUE.

TRUE.

FALSE.

TRUE.

Service Manual

17

Page 18

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,145.38 Jam -- Media at exit tray, unexpected event paper preheat exit sensor

22,146.30 Jam -- Media at exit tray, unexpected event paper exit sensor TRUE.

22,147.31 Jam -- Media at exit tray, unexpected event paper exit sensor FALSE.

22,148.32 Jam -- Media at exit tray, unexpected event paper hand-feed sensor

22,149.33 Jam -- Media at exit tray, unexpected event paper hand-feed sensor

22,150.34 Jam -- Media at exit tray, unexpected event auxiliary tray not present.

22,151.35 Jam -- Media at exit tray, unexpected event auxiliary tray A-size

22,152.36 Jam -- Media at exit tray, unexpected event auxiliary tray A4-size.

22,160.35 Jam -- Media at hand-feed, unexpected event standard tray ajar 1.

22,161.36 Jam -- Media at hand-feed, unexpected event standard tray A4-size

22,162.37 Jam -- Media at hand-feed, unexpected event standard tray not used.

22,163.38 Jam -- Media at hand-feed, unexpected event standard tray ajar 2.

22,164.30 Jam -- Media at hand-feed, unexpected event standard tray A-size

22,165.31 Jam -- Media at hand-feed, unexpected event standard tray A4-size

FALSE.

TRUE.

FALSE.

transparency.

transparency.

paper.

22,166.32 Jam -- Media at hand-feed, une xpected event standard tray A-size paper.

22,167.33 Jam -- Media at hand-feed, unexpected event standard tray not present.

22,168.34 Jam -- Media at hand-feed, unexpected event paper pick sensor TRUE.

22,169.35 Jam -- Media at hand-feed, unexpected event paper pick sensor FALSE.

22,170.36 Jam -- Media at hand-feed, unexpected event paper A-width sensor

22,171.37 Jam -- Media at hand-feed, unexpected event paper A-width sensor

22,172.38 Jam -- Media at hand-feed, unexpected event paper A-width sensor

22,173.30 Jam -- Media at hand-feed, unexpected event paper A-width sensor

22,174.31 Jam -- Media at hand-feed, unexpected event paper preheat entry

22,175.32 Jam -- Media at hand-feed, unexpected event paper preheat entry

22,176.33 Jam -- Media at hand-feed, unexpected event paper preheat exit sensor

22,177.34 Jam -- Media at hand-feed, unexpected event paper preheat exit sensor

22,178.35 Jam -- Media at hand-feed, unexpected event paper exit sensor TRUE.

FALSE, A4-width sensor FALSE.

TRUE, A4-width sensor FALSE.

FALSE, A4-width sensor TRUE.

TRUE, A4-width sensor TRUE.

sensor TRUE.

sensor FALSE.

TRUE.

FALSE.

18

Phaser 340 and 350 Color Printers

Page 19

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

22,179.36 Jam -- Media at hand-feed, unexpected event paper exit sensor FALSE.

22,180.37 Jam -- Media at hand-feed, unexpected event paper hand-feed sensor

22,181.38 Jam -- Media at hand-feed, unexpected event paper hand-feed sensor

22,182.30 Jam -- Media at hand-feed, unexpected event auxiliary tray not present.

22,183.31 Jam -- Media at hand-feed, unexpected event auxiliary tray A-size.

22,184.32 Jam -- Media at hand-feed, unexpected event auxiliary tray A4-size.

22,192.31 Jam -- Front access door open.

22,193.32 Jam -- Stripper access door open.

22,194.33 Jam -- Unexpected hand-feed interrupted operation.

22,195.34 Jam -- Y-axis motor (drum motor) stall.

22,196.35 Jam -- Media not present at preheat entry sensor for transfer start.

22,197.36 Jam -- Media trailing edge time-out at paper exit sensor.

22,198.37 Jam -- Media too short to fully transfer image.

22,199.38 Jam -- Media too long.

22,200.30 Jam -- Media leading edge time-out at paper exit sensor.

22,201.31 Jam -- A-width expected,A4-width seen at preheat entry media stage.

22,202.32 Jam -- A4-width expected, A-width seen at preheat entry media stage.

TRUE.

FALSE.

22,203.33 Jam -- Standard tray media leading edge time-out at paper pick sensor.

22,204.34 Jam -- Media leading edge time-out at A/A4 paper width sensors.

22,205.35 Jam -- Media leading edge time-out at preheat entry sensor.

22,206.36 Jam -- Media leading edge time-out at preheat exit sensor.

22,207.37 Jam -- Auxiliary tray media leading edge time-out at paper pick sensor.

22,208.38 Jam -- During hand-feed stage, media leading edge time-out at preheat

22,209.30 Jam -- A-width sensor TRUE, A4-width sensor FALSE at preheat entry

22,210.31 Jam -- A width sensor FALSE, A4 width sensor FALSE at preheat entry

22,211.32 Jam -- Media sensed at handfeed

22,212.33 Jam -- Media sensed at exit tray

22,213.34 Jam -- A width media sensed at preheat entry

22,214.35 Jam -- A-width sensor FALSE, A4-width sensor FALSE at preheat entry

22,224.36 Jam -- media location and cause unknown.

24,000 PostScript Errors

24,000.17 Engine reports power is off.

entry sensor.

stage.

stage

stage.

Service Manual

19

Page 20

Front panel and fault history log error codes and messages (cont'd.)

Error code Meaning

24,001.18 Engine reports it is running diagnostics.

24,002.10 Engine is stuck in the VxWorks shell.

24,003.11 Engine is stuck in mechanism initialization.

24,004.12

24,005.13 Engine is in state Ready but isn't permitting commands.

24,006.14 Engine is stuck, in STANDBY.

24,007.15 Engine is stuck while printing.

24,008.16 Engine is stuck while cleaning the drum.

24,009.17 Engine is stuck while purging the printhead.

24,010.18 Engine is stuck while wiping the printhead.

24,011.10 Engine is stuck while oiling the rollers.

24,012.11

24,013.12 Engine has a fault but won't indicate why. Possibly needs new drum

24,014.13 Engine is stuck while powering down.

unused

unused

maintenance tray or left maintenance tray sensor is defective or

disconnected.

24,015.14

24,016.15 Engine is stuck while oiling the drum.

24,017.16 Engine is stuck while turning the pick rollers.

24,018.17 Engine is stuck while warming up -- thermals won't stabilize.

24,019.18 Engine is stuck while warming up -- thermals are stable.

24,020.10 Engine is stuck while warming up -- it's too cold to warm up.

24,021.11 Engine is stuck while cooling down.

24,022.12 Engine is stuck while in cool state.

24,023.13 Engine is stuck while in printhead adjust state.

24.024.14 Engine is stuck while flushing the printhead.

unused

20

Phaser 340 and 350 Color Printers

Page 21

Menu map – Phaser 340 (Version 2)

Ready

Clean: media tray jams

Menu

Clean

Clean: light stripes

Clean: ink smears

Help pages

Menu map

Configuration page

Startup page

Demonstration pages

Page count

Page count: XXX Print quality: 300 dpi

TekColor: vivid color

TekColor: display

TekColor: SWOP

TekColor: euroscale

TekColor: commercial

TekColor: monochrome

TekColor: none

Print quality Printer defaultsTekColor: correction

Print quality: 600 x 300 dpi

Default tray

Default tray: upper

Default tray: lower

Default tray: auto

Startup page

Startup page: enabled

Startup page: disabled

Startup mode

Startup mode: enabled

Startup mode: disabled

Cleaning page source

Cleaning page source: upper

Main menu map (Phaser 340 printers serial-numbered BCxxxxx and up)

Cleaning page source: lowerl

Energy Star timeout

Timeout: XXX hrs.

Service Manual

21

Page 22

Option P3 installed Option P1 or P4 installed

Serial settings Network settings

Data rate

Data rate: XXXXX

Data bits

Data bit: 7

Data bit: 8

Stop bits

Stop bits: 1

Stop bits: 2

Parity

Parity: even

Parity: odd

Parity: mark

Parity: space

Parity: none

TCP/IP

TCP/IP: enabled

TCP/IP: disabled

EtherTalk

EtherTalk: enabled

EtherTalk: disabled

NetWare

NetWare: enabled

NetWare: disabled

HTTP

HTTP: enabled

HTTP: disabled

Service support

"menu"

Cooldown for Power Off

Head serial number

#: XXXXXXXX

Calibration date

Calibrated: XXXX

Engine FW version

FW version: XX.XX

Fault history

Purge Volume

****

Fault history 1

Fault history 5

Standard

Low

High

"menu & exit"

Engine copy count

Test prints

Service print 1

Service print 8

Head-To Drum Adjust

Reset printer

Reset NVRAM

Head adjust

Head adjust: XXX

Authorization code

Field 1: XX

Field 14: XX

Network settings

TCP/IP address

Language

Language: English

Language: Español

Language: Français

Language: Deutsch

Language: Italiano

Language: Japanese

**

***

***

Flow control

Flow control: XON/XOFF

Flow control: DTR

LocalTalk

LocalTalk: enabled

LocalTalk: disabled

Only appears when

*

option P3 Serial/LocalTalk

cord installed

A value controlling head

**

drive voltage. Standard

setting is 128.

Network card

***

Fault history 5 is the most

****

recent error.

Main menu map (Phaser 340 printers serial-numbered BCxxxxx and up - continued)

22

Phaser 340 and 350 Color Printers

Field 1: XXXX

Field 4: XXXX

Network mask

Field 1: XXXX

Field 4: XXXX

Broadcast mask

Field 1: XXXX

Field 4: XXXX

9100-120

Page 23

Menu map – Phaser 350

Ready

Clean: light stripes

Clean: media tray jams

Menu

Clean

Clean: ink smears

Help pages

Menu map

Configuration page

Startup page

Demonstration pages

RGB Color Sampler

CMYK Color Sampler

Page count

Page count: XXX Fast Color

TekColor: Vivid Color

TekColor: Display

TekColor: SWOP

TekColor: Euroscale

TekColor: Commercial

TekColor: Monochrome

TekColor: None

Print quality Printer defaultsTekColor Correction

Standard

Enhanced

Default tray

Default tray: upper

Default tray: lower

Default tray: auto

Startup page

Startup page: enabled

Startup page: disabled

SCSI Startup mode

SCSI Startup mode: enabled

SCSI Startup mode: disabled

Cleaning page source

Cleaning page source: upper

Cleaning page source: lowerl

Phaser 350 main menu map

Energy Star timeout

Timeout: XXX hrs.

Check Print

Check Print: Enabled

Check Print: Disabled

Check Print Timeout

Timeout: XXX mins

Collate Pages

Collate Pages: Enabled

Collate Pages: Disabled

Service Manual

23

Page 24

Option P3 installed Option P1 or P4 installed

Serial settings Network settings

Data rate

Data rate: XXXXX

Data bits

Data bit: 7

Data bit: 8

Stop bits

Stop bits: 1

Stop bits: 2

Parity

Parity: even

Parity: odd

Parity: mark

Parity: space

Parity: none

Flow control

Flow control: XON/XOFF

Flow control: DTR

LocalTalk

LocalTalk: enabled

TCP/IP

Enable Interface

TCP/IP Address

XXX.XXX.XXX.XXX

Increment Shift Set

Network Mask

XXX.XXX.XXX.XXX

Increment Shift Set

Gateway Mask

XXX.XXX.XXX.XXX

Increment Shift Set

Broadcast Mask

XXX.XXX.XXX.XXX

Increment Shift Set

EtherTalk

EtherTalk: enabled

EtherTalk: disabled

Netware

Novell: enabled

Novell: disabled

HTTP

HTTP: enabled

HTTP: disabled

Token Talk****

Token Talk: enabled

Token Talk: disabled

Service support

"menu"

Cooldown for Power Off

Head serial number

#: XXXXXXXX

Calibration date

Calibrated: XXXX

Head version

FW version: XX.XX

Engine FW version

FW version: XX.XX

Fault history

Fault history 1

Fault history 5

Purge Volume

if P3 option installed

*

if P4 option installed

****

Standard

Low

High

"menu & exit"

Engine copy count

Test prints

Service print 1

Service print 8

Head-To Drum Adjust

Reset printer

Reset NVRAM

Head adjust

Head adjust: XXX

Authorization code

Field 1: XX

Field 14: XX

Language

Language: English

Language: Español

Language: Français

Language: Deutsch

Language: Italiano

Language: Japanese

LocalTalk: disabled

Phaser 350 main menu map

24

Phaser 340 and 350 Color Printers

9100-121

Page 25

Phaser 340 Field Replaceable Units List

Phaser 340 FRU exterior parts list

Figure

A-1 parts

1 200-4223-02 1 Cover, Front Jam Access

2 200-4224-02 1 Cover, Stripper Access

3 200-4225-01 1 Cover , Top

4 200-4187-01 1 Cover Side, Right

5 200-4274-00 1 Cover Side, Left

6 200-4189-00 1 Cover, Back

7 367-0454-00 1 Handle, Release Lever

8 214-4639-00 2 Pivot Hinge, Front Cover

9 200-4220-00 1 Cap, Head Restraint

Part number Serial number

Effective Discontinued

334-8366-25 1 Logo Marker, Z340/Z340P

334-8366-29 1 Logo Marker, Z340J

Quantity Name and description

Service Manual

25

Page 26

3

2

5

7

8

1

8

9

6

4

9100-75

The Phaser 340 printer exterior FRUs

26

Phaser 340 and 350 Color Printers

Page 27

Phaser 340 FRU interior parts list

Figure

A-2 parts

1 386-6851-00 1 Finger, Stripper, Upper, Assembly

2 650-3426-00 1 Finger, Stripper, Lower, Kit

3 119-5237-00 1 Drum Temperature Sensor Assembly

4 650-3428-00 1 Drum/Transfix Assembly

5a, b 650-3299-00 1 Exit Roller and Lower Feed Roller

6 351-0959-00 1 Guide, Exit, Lower

7 650-3257-00 1 Front Panel Assembly

8a

8b

9 650-3153-00 1 Printhead and Install Kit

10 166-0704-00 1 Rigid Vacuum Tube

11 650-3362-03 1 Ink Loader

12 650-3461-00 1 Head Ribbon Cable and Clip

13 671-3038-06 1 Circuit Board, Power Control

14 162-0474-00 1 Tube

Part number Serial number

Effective Discontinued

650-3260-00

650-3184-01

650-3258-01

650-3185-00

B0

BC

B0

BC

xxxxx

xxxxx

xxxxx

xxxxx

BB

BB

xxxxx

xxxxx

Quantity Name and description

Print engine w/o Main Board and SIMMs

1 Cap/Wipe/Purge Assembly

Cap/Wipe/Purge Assembly, PTC-regulate

15 671-3331-50 1 Circuit Board, Interconnect

16 119-4894-00 1 Fan, Rear

17a

17b

17c

17d

17e

18a

18b

19a

19b

20a

20b

20c

20d

20e

21

21a

21b

22 650-3261-00 1 Motor, Stepper, Cap/Wipe/Purge

23 2 Belt, Cap/Wipe/Purge Drive - part of

671-3565-00

671-3641-00

671-3594-00

671-3809-00

671-3811-00

671-1561-01

671-3133-00

671-3037-80

671-3760-80

671-3468-02

671-3469-00

671-3470-02

386-6815-00

213-1090-00

650-3365-01

159-0047-00

159-0352-00

B0

B0

B0

BC

BC

B0

B6F

xxxxx

xxxxx

xxxxx

xxxxx

xxxxx

xxxxx

xxxx

BB

xxxxx

BB

xxxxx

BB

xxxxx

BExxxxx/B6Exxxx

1 Masked PS ROM SIMM, Z340

1 4 MByte RAM SIMM, Z340

1 Circuit Board, Main, Z340/Z340P

1

1

1

1

2

1

1

4

Masked PS ROM SIMM,Z340P

Masked PS ROM SIMM, Z340J “Kanji”

Masked PS ROM SIMM, Z340/Z340P

Masked PS ROM SIMM, Z340J “Kanji”

16 MByte RAM SIMM, Z340 Plus

Circuit Board, Main, Z340/Z340P

Network card, Ethernet, 4676FP1

Network card, LocalTalk/Serial, 4676FP3

Network card, TokenRing, 4676FP4

Blank cover plate (no card installed)

Blank cover plate thumbscrews

Power Supply

Fuse, 10A slow, F4

Fuse, 6.3A, DIN, F1, F2, F3, F5

Assembly, includes items 23 and 24

650-3268-00 belt kit

24 1 Drive Gear - part of 650-3296-00 kit

Service Manual

27

Page 28

Phaser 340 FRU interior parts list

Figure

A-2 parts

25 650-3266-00 1 Solenoid Valv e Assembly .

26 343-1580-00 1 Restraint, Printhead Shipping Assembly

27 174-3402-00 1 Cable, Power Supply

28 650-3363-00 1 Circuit Board, I/O 3

29 650-3262-00 1 Exit Gear Assembly

30 119-4893-00 1 Fan, Drum Cooling

31a

31b

32 119-4822-00 1 Sensor, Head Restraint

33 401-0732-00 1 Drum Ring Gear

34 650-3263-00 1 Y-Axis Pulley Assembly / with Belts

35 671-3192-52 1 Circuit Board, I/O 2

36 351-0972-00 1 Guide, Paper Tray, Right

37 214-4651-00 2 Drum Maintenance Tray Actuator,

38 351-0963-01 1 Guide, Nose, Right

39 351-0969-00 1 Guide, Pick Assembly

Part number Serial number

Effective Discontinued

650-3259-00

650-3186-00

B0

BC

xxxxx

xxxxx

BB

xxxxx

Quantity Name and description

1 X-Axis Drive Assembly

X-Axis Drive Assembly

Left/Right

40 351-0951-00 1 Guide, Paper Tray, Left

41 343-1566-00 1 Assembly, Spring/Retainer

42 351-0957-00 1 Guide, Nose, Left

43 351-0991-00 1 Guide Drawer Assembly, Right

44 351-0971-02 1 Guide Drawer Assembly, Left

45 401-0701-00 1 Roller, Pick Assembly

46 650-3163-02

671-3913-00

163-0646--00

650-3182-00

650-3183-00

47 386-6902-00 3 Tray Sense Buttons

48 671-3198-50 1 Paper Preheater Exit Sensor

49 119-4720-00 1 Paper Preheater Assembly with Upper

50 174-3398-00 1 Cable, I/O board 4 to I/O Board 3

51 174-3399-00 1 Cable, I/O Board 4 to Front Panel

52 650-3364-00 1 Drum Heater Assembly

53 147-0108-00 1 Process Motor

54 147-0109-01 1 Y-axis Drive Motor

xxxxx

B0

B0xxxxx BBxxxxx

B0xxxxx BBxxxxx

BC

xxxxx

BC

xxxxx

BB

xxxxx

1 Engine FW ROM, Z340, Z340P, V1.24

Engine FW ROM, Z340PL, V2.40RB

Engine FW ROM, Z340PL, V2.40RP

Engine FW ROM, Z340, “Base”, V2.40

Engine FW ROM, Z340P, “Plus”, V2.40P

Feed Roller

55 671-3191-53 1 Circuit Board, I/O 1

28

Phaser 340 and 350 Color Printers

Page 29

Phaser 340 FRU interior parts list

Figure

A-2 parts

56 202-0342-01 1 Accumulator

57 156-4001-00 1 NVRAM IC for Main Board

Part number Serial number

Effective Discontinued

650-3269-00 Hardware Kit

650-3267-00 Bushing Kit

650-3268-00 Belt Kit

650-3289-00 Flag Kit

650-3296-00 Gear Kit

Quantity Name and description

Belt, Paper Path Transport

Belt, Paper Transport

Belt, Drum Y-Axis

Belt, Motor Y-Axis

Belt, Cap/Wipe/Purge Drive, 2 per kit

Latch, Flag

Flag, Exit Sensor

Flag, Paper Out, Sense

Flag, Hand Feed

Flag, Paper-pick

Flag, Paper Tray Sense

Flag, Preheat Entrance

Flag, A

Flag, A-4

Flag, Exit Sensor

Flag, Advance Gear / Home

Pulley, Lower, Paper Transport

Gear, Compound, Paper Transport

Gear, Drum Maint Lower Idler

Gear, Paper Path Idler

Gear, Shaft, Eccentric

Gear, Compound, Shaft, Eccentric

Gear, #13

Gear, #14

Pulley, Gear, Compound

Pulley, Idler

Pulley, Left Drive

Roller, Maintenance Drive Belt

Assembly

Gear, Exit Roller

Gear, Exit, Drum Pulley

Gear, Exit, Idler

Gear, DM, First Stage

Gear, DM, Second Stage

Gear, DM, Third Stage

Gear, DM, Idle

650-3298-00 Spring Kit

Spring, Head Tilt

Spring, Exit Disengage

Spring, Belt Tensioner, Left

Spring, Paper Tray Flag

Spring, Drum Maintenance, Pivot

Spring, Actuator Return, Jam Access

Spring, Motor Mount, Right

650-3299-00 Shaft Roller Kit

Roller, Exit

Roller, Lower Transport

Cam, Drum Maintenance

Service Manual

29

Page 30

The Phaser 340 printer interior FRUs

58

19

16

15

13

12

11

18

17

46

56

57

14

10

20

21

27

25

24

23

22

26

33

9100-76

28

29

30

31

32

34

35

9

8

7

5a

6

4

3

2

1

41

37

55

54

53

52

51

50

48

49

40

36

47

39

43

44

38

42

45

5b

30

Phaser 340 and 350 Color Printers

Page 31

Phaser 340 FRU interior part list (left side)

Figure

A-3

parts

1 650-3430-00 1 Vacuum Pump Assembly

2 2 Belt, Cap/Wipe/Purge Drive, 2 Per - part of

3 650-3264-00 1 Position Sensing Assembly

4 1 Gear, Compound, Shaft, Eccentric - part of

5 119-4968-00 1 Transfix Gear Position Sensor

6 1 Belt, Paper Transport - part of 650-3268-00

7 401-0708-00 1 Clutch, Electric, Paper Transport

8 401-0706-01 1 Gear, Compound, Paper Path Assembly

9 401-0709-01 1 Clutch, Paper Pick

10 401-0710-00 1 Clutch, Drum Maintenance Cam Shaft

11 1 Belt, Paper Path Transport - part of

12a

12b

Part number Serial number

Effective Discontinued

401-0733-01

401-0751-00

B0

BC

xxxxx

xxxxx

BB

xxxxx

Quantity Name and description

650-3268-00 Belt Kit

650-3296-00 Kit

Belt Kit

650-3268-00 Belt Kit

1 Head Tilt Cam Gear

Service Manual

31

Page 32

12

2

3

1

10

11

4

5

8

6

7

9

The Phaser 340 printer interior FRUs (left side)

Phaser 340 supplies and accessories

Part number Serial number

Effective Discontinued

Supply 016-1341-00 Cleaning Kit

Supply 436-0293-01 1 Tray, Paper (A) Letter US, Standard

Quantity Name and description

9100-77

Supply 436-0292-01 1 Tray, Paper (A4) Metric, Standard

Supply 436-0288-00 1 Tray, Paper. (A) US letter, For LPTA

Supply 436-0289-00 1 Tray, Paper, (A4) Metric, For LPTA

Supply 436-0301-00 1 Tray, Transparency (A) US

Supply 436-0302-01 1 Tray, Transparency (A4) Metric

Supply 348-1373-00 1 Paper Separator Pad For Std Tray

Supply 436-0294-03 1 Cartridge, Drum Maintenance

Supply 436-0299-00 1 Tray, W aste Ink

32

Phaser 340 and 350 Color Printers

Page 33

Phaser 340 supplies and accessories (cont'd.)

Part number Serial number

Effective Discontinued

Supply 016-1307-00 Black Ink Stix (3 per box)

Supply 016-1308-00 Cyan Ink Stix (3 per box)

Supply 016-1309-00 Magenta Ink Stix (3 per box)

Supply 016-1310-00 Yellow Ink Stix (3 per box)

Supply 016-1359-00 Transparency Film, A-size, Std, 50 sheets

Supply 016-1360-00 Transparency Film, A4-size, Std, 50 sheets

Supply 016-1361-00 Transparency Film, A-size, Prem, 50 sheets

Supply 016-1362-00 Transparency Film, A4-size, Prem, 50 sheet

436-0277-00 1 Lower Tray Assembly w/ Letter Tray

436-0287-00 1 Lower Tray Assembly w/ A4 Tray

070-9100-01 Service Manual

070-9101-03 P340 Users Manual, English

070-9101-12 P340 Users Manual, French

070-9101-22 P340 Users Manual, Italian

070-9101-32 P340 Users Manual, German

070-9101-42 P340 Users Manual, Spanish

Quantity Name and description

070-9538-01 PhaserShare Networking and Printer

063-2278-01 SW Drivers and Utilities Diskettes

063-2491-01 SW Drivers and Utilities CD

065-0550-00 Carton Kit, Shipping

013-0299-00 1 Parallel adapter, Centronics 36 Pin to

012-1468-00 1 Cable, Parallel IEEE-1284-C to DB25M

012-1465-00 1 Cable, SCSI-2 to 50 Pin SCSI

012-1313-00 1 Cable, Serial, DB9F to DB25M

012-1312-00 1 Cable, Serial, DB25F to DB25M

Service 174-3493-00 1 Cable, Serial Adapter, Diags, Level Shifter

Service 063-2295-06 Service PC-based Diagnostics SW

Service 012-1498-00 Cable, Mac, Serial DIN8 to DB25M

Service 650-3300-00 Tool Kit - which includes the following:

Service 003-1489-00 1 Tool, Alignment, Encoder disk

Service 003-1499-00 1 Tool, Gap, Head to Drum

Service 003-1500-00 1 Tool, Belt Tensioner, Y-Axis

Management SW Manual

IEEE-1284-C “mini”

Diskette, V1, V2 and V3

Service 003-1503-00 1 Hot Head Handler

Service Manual

33

Page 34

Phaser 340 supplies and accessories (cont'd.)

Part number Serial number

Effective Discontinued

Service 003-1504-00 1 Hot Head Plug Assembly

Service 003-0827-00 1 Screwdriver, torque

Service 006-7824-01 Pack of 10 Alcohol Wipes

Service 161-0066-00 Power cord, Std., USA, Canada, 115V,

Service 161-0066-09 Power cord, Option A1, Universal

Service 161-0066-10 Power cord, Option A2, United Kingdom,

Service 161-0066-11 Power cord, Option A3, Australia, 240V

Service 161-0154-00 Power cord, Option A5, Switzerland, 220V

Kit Z340LTA Lower Tray Assembly w /A-size Tray

Kit Z340LTA,

Kit 4685F16 16 Mbyte RAM SIMM

Kit Z340ROM B0xxxxx BB

Svc Kit 650-3163-02 B0xxxxx B5

Svc Kit 650-3397-00 B0xxxxx B6

Kit Z340PL, Opt 01 B0xxxxx BB

Opt 01

xxxxx

xxxxx

xxxxx

xxxxx

Quantity Name and description

European, 220V

240V

Lower Tray Assembly w/ A4-size Tray

Upgrade to Z340 Plus, requires 4685F16

Version 1.24 Print Engine Firmware

Power Supply Thermistor Replacement Kit

PS SIMM v2.26; PE ROM v2.40RP.

Upgrades Z340 Plus to PhaserLink.

Requires V2,0 or 3.0 network card for

PhaserlInk features

Kit Z340PL, Opt 02 B0xxxxx BB

Kit Z350UP1 Firmware kit, V3.0 for Ethernet card

Kit Z350UP4 firmware kit, V3.0 for TokenRing card

Kit Z340FX, Opt 01 B0xxxxx BB

Kit Z340FX, Opt 02 BCxxxxx B6F

Kit Z340UP BCxxxxx B6F

xxxxx

xxxxx

xxxx

xxxx

PS SIMM v2.26; PE ROM v2.40RP.

Upgrades Z340 “Base” to PhaserLink.

Requires V2,0 or 3.0 network card for

PhaserlInk features

PS SIMM v2.26; PE ROM v2.40RP and 16

Mbyte RAM SIMM. Upgrades Version 1

Z340 “Base” to “Plus”.

PS SIMM v2.26; PE ROM v2.40P and 16

Mbyte RAM SIMM. Upgrades Version 2

Z340 “Base” to “Plus”.

Upgrades a Z 340 Plus (Extended Featues)

to a Z350 with Extended Features. Not

compatiable with B0xxxxxthrough

BBxxxxx. Not compatible to “Base” model.

34

Phaser 340 and 350 Color Printers

Page 35

Phaser 350 Field Replaceable Units List

Phaser 350 FRU exterior parts list

Figure

A-1 parts

1 200-4223-02 1 Cover, Front Jam Access

2 200-4224-02 1 Cover, Stripper Access

3 200-4225-01 1 Cover , Top

4 200-4187-01 1 Cover Side, Right

5 200-4274-00 1 Cover Side, Left

6 200-4189-00 1 Cover, Back

7 367-0454-00 1 Handle, Release Lever

8 214-4639-00 2 Pivot Hinge, Front Cover

9 200-4220-00 1 Cap, Head Restraint

Part number Serial number

Effective Discontinued

334-8356-34 Logo Marker, Z350

Quantity Name and description

Service Manual

35

Page 36

3

2

5

7

8

1

8

9

6

4

9100-75

The Phaser 350 printer exterior FRUs

36

Phaser 340 and 350 Color Printers

Page 37

Phaser 350 FRU interior parts list

Figure

A-2 parts

1 386-6851-00 1 Finger, Stripper, Upper, Assembly

2 650-3426-00 1 Finger, Stripper, Lower, Kit

3 119-5237-00 1 Drum Temperature Sensor Assembly

4 650-3428-00 1 Drum/Transfix Assembly

5a, b 650-3299-00 1 Exit Roller and Lower Feed Roller

6 351-0959-00 1 Guide, Exit, Lower

7 650-3257-00 1 Front Panel Assembly

8 650-3185-00 1 Cap/Wipe/Purge Assembly, PTC-regulate

9 650-3153-00 1 Printhead and Install Kit

10 166-0704-00 1 Rigid Vacuum Tube

11 650-3362-03 1 Ink Loader

12 650-3461-00 1 Head Ribbon Cable and Clip

13 671-3038-06 1 Circuit Board, Power Control

14 162-0474-00 1 Tube

15 671-3331-50 1 Circuit Board, Interconnect

Part number Serial number

Effective Discontinued

650-3184-01 Print engine w/o Main Board and SIMMs

Quantity Name and description

16 119-4894-00 1 Fan, Rear

17 671-3940-00

18 671-3133-00 1 16 MByte RAM SIMM

19 671-3760-80

20a

20b

20c

20d

20e

21

21a

21b

22 650-3261-00 1 Motor, Stepper, Cap/Wipe/Purge Assembly,

23 2 Belt, Cap/Wipe/Purge Drive - part of

24 1 Drive Gear - part of 650-3296-00 kit

25 650-3266-00 1 Solenoid Valv e Assembly .

26 343-1580-00 1 Restraint, Printhead Shipping Assembly

671-3688-01

671-3897-80

671-3468-03

671-3469-00

671-3470-03

386-6815-00

213-1090-00

650-3365-01

159-0047-00

159-0352-00

1 PS ROM SIMM, Z350 (masked)

1 Circuit Board, Main, P350

1

1

1

1

2

1

1

4

PS ROM SIMM, Z350J “Kanji” (masked)

Circuit board, Main, P350 Kanji

(no FW installed on these boards)

Network card, Ethernet, 4676FP1

Network card, LocalTalk/Serial, 4676FP3

Network card, TokenRing, 4676FP4

Blank cover plate (no card installed)

Blank cover plate thumbscrews

Power Supply

Fuse, 10A slow, F4

Fuse, 6.3A, DIN, F1, F2, F3, F5

includes items 23 and 24

650-3268-00 belt kit

27 174-3402-00 1 Cable, Power Supply

Service Manual

37

Page 38

Phaser 350 FRU interior parts list

Figure

A-2 parts

28 650-3363-00 1 Circuit Board, I/O 3

29 650-3262-00 1 Exit Gear Assembly

30 119-4893-00 1 Fan, Drum Cooling

31 650-3186-00 1 X-Axis Drive Assembly

32 119-4822-00 1 Sensor, Head Restraint

33 401-0732-00 1 Drum Ring Gear

34 650-3263-00 1 Y-Axis Pulley Assembly / with Belts

35 671-3192-52 1 Circuit Board, I/O 2

36 351-0972-00 1 Guide, Paper Tray, Right

37 214-4651-00 2 Drum Maintenance Tray Actuator, Left/Right

38 351-0963-01 1 Guide, Nose, Right

39 351-0969-00 1 Guide, Pick Assembly

40 351-0951-00 1 Guide, Paper Tray, Left

41 343-1566-00 1 Assembly, Spring/Retainer

42 351-0957-00 1 Guide, Nose, Left

43 351-0991-00 1 Guide Drawer Assembly, Right

Part number Serial number

Effective Discontinued

Quantity Name and description

44 351-0971-02 1 Guide Drawer Assembly, Left

45 401-0701-00 1 Roller, Pick Assembly

46 163-0821-00

163-0822-00

47 386-6902-00 3 Tray Sense Buttons

48 671-3198-50 1 Paper Preheater Exit Sensor

49 119-4720-00 1 Paper Preheater Assembly with Upper F eed

50 174-3398-00 1 Cable, I/O board 4 to I/O Board 3