Page 1

Series 2200

Programmable DC Power Supplies

Reference Manual

2200S-901-01 Rev. D / May 2017

www.tek.com/keithley

*P2200S-901-01D*

2200S-901-01D

Page 2

Series 2200

Programmable DC Power Supplies

Reference Manual

© 2017, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments. Other brand names are trademarks or registered trademarks of their respective

holders.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: 2200S-901-01 Rev. D / May 2017

Page 3

Safety precaut ions

The following safety precautio ns should be obser v ed befor e usin g this product and any associated instrumentation . Alt ho ugh

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. M easurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley Instruments measuring instruments may be

connected to mains. These instruments will be marked as categor y II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circ uit may be ex posed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 4

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The

symbol on an instrument means caution, risk of danger. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The

If this

symbol indicates a connection terminal to the equipment frame.

symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h az ards that coul d dama ge the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — inc lud ing t he pow er

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. The detachable mains power cord provided with the

instrument may only be replaced with a similarly rated power cord. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

Unless otherwise noted in product-specific literature , Keithle y Instru ment s instr ume nts are desi gne d to operate indoors only, in

the following environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution

degree 1 or 2.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Safety precaution revision as of March 2016.

Page 5

Table of contents

Introduction ............................................................................................................... 1-1

Welcome .............................................................................................................................. 1-1

Extended warranty ............................................................................................................... 1-2

Contact information .............................................................................................................. 1-2

CD-ROM contents ................................................................................................................ 1-2

Key features ......................................................................................................................... 1-3

Standard accessories ........................................................................................................... 1-4

Optional accessories ............................................................................................................ 1-4

Services available ................................................................................................................ 1-4

Specifications ....................................................................................................................... 1-4

Electrical ratings for the power connection ................................................................................ 1-5

Environmental performance ...................................................................................................... 1-5

Nominal voltage ratings ............................................................................................................. 1-6

Float voltage rating .................................................................................................................... 1-6

General operation ..................................................................................................... 2-1

Operating requirements ....................................................................................................... 2-1

Installing the system ............................................................................................................. 2-3

Power the instrument on and off ............................................................................................... 2-3

Check the output ....................................................................................................................... 2-3

Operating basics .................................................................................................................. 2-5

Front panel at a glance ............................................................................................................. 2-5

Rear panel at a glance ............................................................................................................ 2-13

110 V/220 V selector switch .................................................................................................... 2-15

Front panel operation .............................................................................................................. 2-15

Rear panel operation ............................................................................................................... 2-26

Operation examples ........................................................................................................... 2-29

Saving setups example ........................................................................................................... 2-29

Timer example ........................................................................................................................ 2-30

List mode example .................................................................................................................. 2-30

Default setup ...................................................................................................................... 2-33

Clear and sanitize procedures ........................................................................................... 2-34

Terms ...................................................................................................................................... 2-34

Memory devices ...................................................................................................................... 2-35

Data export devices ................................................................................................................ 2-36

Remote operation ..................................................................................................... 3-1

Section overview .................................................................................................................. 3-1

Communication interf ac es.................................................................................................... 3-1

Using the USB ........................................................................................................................... 3-1

Using the GPIB ......................................................................................................................... 3-2

Command timing ....................................................................................................................... 3-2

Command syntax ................................................................................................................. 3-3

Page 6

Table of contents

Reference Manual

Series 2200 Programmable DC Power Supplies

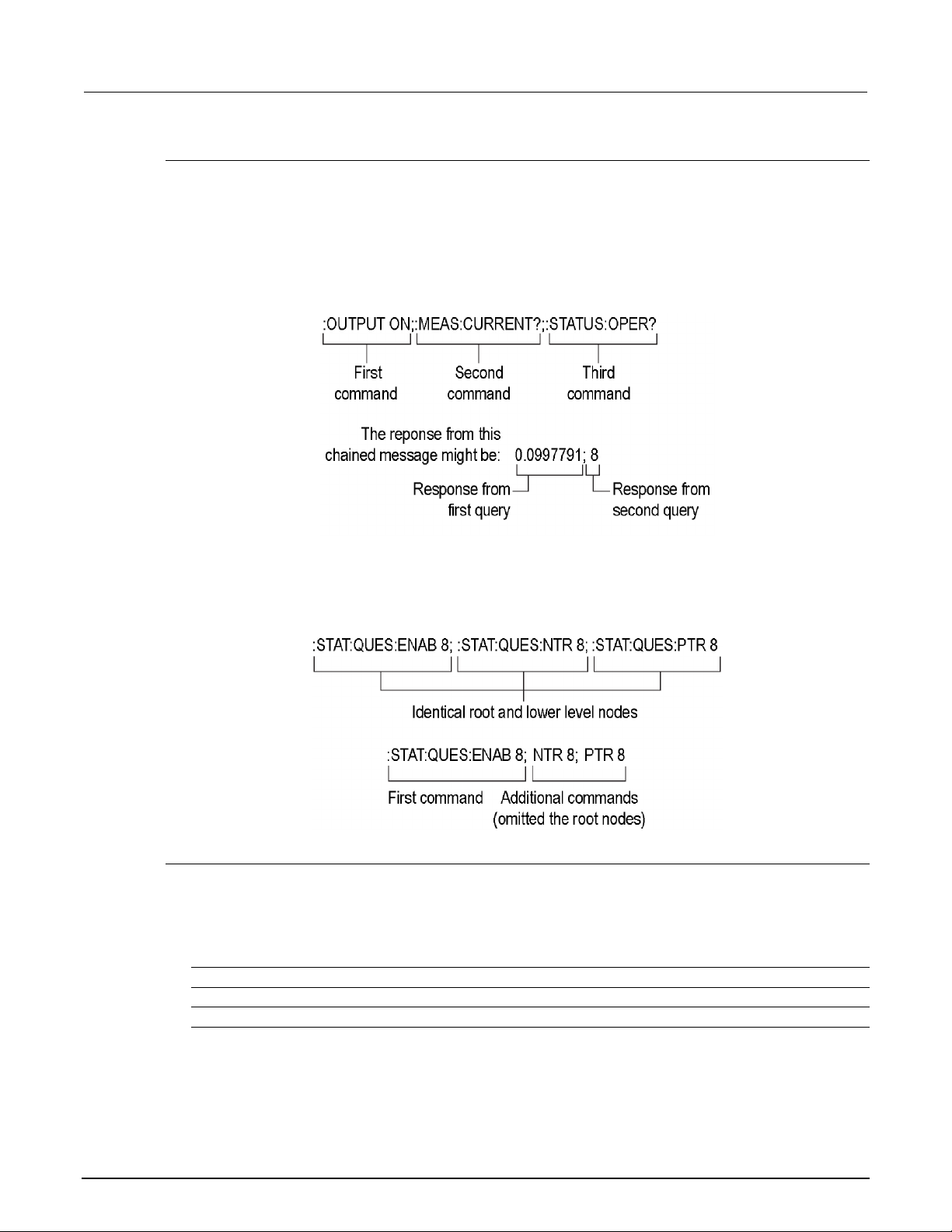

Command and query structure .................................................................................................. 3-4

Command entry ......................................................................................................................... 3-5

Command groups ................................................................................................................. 3-9

Command reference ................................................................................................. 4-1

Commands listed in alphabetical order ................................................................................ 4-2

*CLS (no query form) ........................................................................................................... 4-2

CONFigure:SOUNd[:STATe] ............................................................................................... 4-3

*ESE ..................................................................................................................................... 4-3

*ESR? (query only) .............................................................................................................. 4-4

FETCh:CURRent[:DC]? (query only) ................................................................................... 4-4

FETCh:VOLTage[:DC]? (query only) ................................................................................... 4-5

FETCh[:SCALar]:POWer? (query only) ............................................................................... 4-5

*IDN? (query only) ................................................................................................................ 4-6

MEASure:CURRent[:DC]? (query only) ............................................................................... 4-6

MEASure:VOLTage[:DC]? (query only) ............................................................................... 4-7

*OPC .................................................................................................................................... 4-7

*PSC..................................................................................................................................... 4-8

*RCL (no query form) ........................................................................................................... 4-9

*RST (no query form) ........................................................................................................... 4-9

*SAV (no query form) ......................................................................................................... 4-10

[SOURce:]CURRent[:LEVel] .............................................................................................. 4-10

[SOURce:]DIGital:DATA .................................................................................................... 4-11

[SOURce:]DIGital:FUNCtion .............................................................................................. 4-12

[SOURce:]FUNCtion:MODE .............................................................................................. 4-13

[SOURce:]LIST:COUNt ...................................................................................................... 4-13

[SOURce:]LIST:CURRent[:LEVel] ..................................................................................... 4-14

[SOURce:]LIST:MODE ....................................................................................................... 4-15

[SOURce:]LIST:RCL (no query form) ................................................................................ 4-15

[SOURce:]LIST:SAVe (no query form) .............................................................................. 4-16

[SOURce:]LIST:STEP ........................................................................................................ 4-16

[SOURce:]LIST:VOLTage[:LEVel] ..................................................................................... 4-17

[SOURce:]LIST:WIDth ....................................................................................................... 4-17

[SOURce:]OUTPut:DFI:SOURce ....................................................................................... 4-18

[SOURce:]OUTPut:PON[:STATe] ...................................................................................... 4-19

[SOURce:]OUTPut:PROTection:CLEar (no query form) ................................................... 4-19

[SOURce:]OUTPut:RI:MODE ............................................................................................ 4-20

Page 7

Series 2200

of contents

Programmable DC Power Supplies Reference M anual Table

[SOURce:]OUTPut[:STATe] ............................................................................................... 4-20

[SOURce:]OUTPut:TIMer:DELay ....................................................................................... 4-21

[SOURce:]OUTPut:TIMer[:STATe] .................................................................................... 4-22

[SOURce:]VOLTage[:LEVel] .............................................................................................. 4-23

[SOURce:]VOLTage:PROTection[:LEVel] ......................................................................... 4-24

[SOURce:]VOLTage:PROTection:STATe.......................................................................... 4-25

[SOURce:]VOLTage:RANGe ............................................................................................. 4-26

*SRE................................................................................................................................... 4-27

STATus:OPERation:CONDition? (query only) ................................................................... 4-27

STATus:OPERation:ENABle ............................................................................................. 4-28

STATus:OPERation[:EVENt]? (query only) ....................................................................... 4-29

STATus:QUEStionable:CONDition? (query only) .............................................................. 4-29

STATus:QUEStionable:ENABle ......................................................................................... 4-30

STATus:QUEStionable[:EVENt]? (query only) .................................................................. 4-31

STATus:QUEStionable:NTRansition ................................................................................. 4-32

STATus:QUEStionable:PTRansition .................................................................................. 4-33

*STB? (query only) ............................................................................................................. 4-34

SYSTem:ERRor? (query only) ........................................................................................... 4-34

SYSTem:KEY ..................................................................................................................... 4-35

SYSTem:LOCal (no query form) ........................................................................................ 4-36

SYSTem:POSetup ............................................................................................................. 4-36

SYSTem:REMote (no query form) ..................................................................................... 4-37

SYSTem:RWLock (no query form) .................................................................................... 4-37

SYSTem:VERSion? (query only) ....................................................................................... 4-37

*TRG (no query form) ......................................................................................................... 4-38

TRIGger[:IMMediate] (no query form) ................................................................................ 4-38

TRIGger:SOURce .............................................................................................................. 4-39

*TST? (query only) ............................................................................................................. 4-39

*WAI (no query form) ......................................................................................................... 4-40

Programming examples ..................................................................................................... 4-40

Example 1 ............................................................................................................................... 4-41

Example 2 ............................................................................................................................... 4-43

Example 3 ............................................................................................................................... 4-43

Example 4 ............................................................................................................................... 4-44

Troubleshooting guide ............................................................................................. 5-1

What to do if the power supply does not turn on ................................................................. 5-1

Page 8

Table of contents

Reference Manual

Series 2200 Programmable DC Power Supplies

Next Steps ................................................................................................................. 6-1

Additional Series 2200 information ...................................................................................... 6-1

Maintenance .............................................................................................................. A-1

Cleaning ............................................................................................................................... A-1

Performance verification and adjustments ............................................................. B-1

Performance verification ...................................................................................................... B-1

Test record ................................................................................................................................ B-2

DC voltage accuracy with remote sense ................................................................................... B-3

DC voltage accuracy without remote sense .............................................................................. B-4

DC voltage readback accuracy ................................................................................................. B-5

DC voltage line regulation ......................................................................................................... B-6

DC voltage load regulation ........................................................................................................ B-6

DC overvoltage detection .......................................................................................................... B-6

DC current accuracy ................................................................................................................. B-7

DC current readback accuracy .................................................................................................. B-8

DC current line regulation.......................................................................................................... B-9

DC current load regulation ........................................................................................................ B-9

Voltage noise at 7 MHz ........................................................................................................... B-10

Voltage noise at 20 MHz ......................................................................................................... B-10

Current noise at 20 MHz ......................................................................................................... B-10

Performance verification procedures ................................................................................. B-11

Performance verification conditions ........................................................................................ B-11

Equipment required ................................................................................................................. B-12

Test equipment ....................................................................................................................... B-13

Self test ................................................................................................................................... B-14

Check DC voltage accuracy with remote sense ...................................................................... B-15

Check DC voltage accuracy without remote sense and voltage readback accuracy ............... B-18

Check DC voltage line regulation ............................................................................................ B-20

Check DC voltage load regulation ........................................................................................... B-22

Check DC overvoltage detection ............................................................................................. B-24

Check DC current and DC current readback accuracy ........................................................... B-26

Check DC current line regulation ............................................................................................ B-28

Check DC current load regulation ........................................................................................... B-30

Check voltage noise (7 MHz) .................................................................................................. B-32

Check voltage noise (20 MHz) ................................................................................................ B-34

Check current noise ................................................................................................................ B-36

Adjustment procedures ...................................................................................................... B-38

Initialization ............................................................................................................................. B-38

Voltage adjustment ................................................................................................................. B-40

Current adjustment .................................................................................................................. B-44

Overvoltage protection (OVP) ................................................................................................. B-45

Status model ............................................................................................................. C-1

Status and events ................................................................................................................ C-1

Status reporting structure ..................................................................................................... C-1

Registers .............................................................................................................................. C-3

Status registers ......................................................................................................................... C-3

Enable registers ........................................................................................................................ C-7

Queues ..................................................................................................................................... C-9

Page 9

Series 2200

of contents

Programmable DC Power Supplies Reference M anual Table

Messages and codes ................................................................................................................ C-9

Display character codes ........................................................................................... D-1

ASCII code chart .................................................................................................................. D-2

Index ........................................................................................................................... I-1

Page 10

Specifications ........................................................................... 1-4

Welcome

Section 1

Introduction

In this section:

Welcome .................................................................................. 1-1

Extended warranty ................................................................... 1-2

Contact information .................................................................. 1-2

CD-ROM contents .................................................................... 1-2

Key features ............................................................................. 1-3

Standard accessories ............................................................... 1-3

Optional accessories ................................................................ 1-4

Services available .................................................................... 1-4

Thank you for choosing a Keithley Instruments product. The Series 2200 Programmable DC Power

Supplies provide a wide range of voltage outputs to address the testing and characterization of

components, circuits, modules, and complete devices whether you are in a research laboratory, in

design and development, or in production test. The Series 2200 consists of the following models with

output voltages from 20 V to 72 V that can deliver 86 W, 96 W, 100 W, and 150 W of power. In

addition, these power supplies can act as constant current sources as well as constant voltage

sources. The Series 2200 power supplies offer an excellent combination of performance, versatility,

and ease of use that allow you to obtain quality test data as quickly as possible. They perform as

effectively in automated test systems as they do in manual instrument configurations.

• 2200-20-5

• 2200-30-5

• 2200-32-3

• 2200-60-2

• 2200-72-1

• 2220-30-1

• 2220G-30-1

• 2220J-30-1

• 2220GJ-30-1

• 2230-30-1

• 2230G-30-1

• 2230J-30-1

• 2230GJ-30-1

Page 11

Section

Reference Manual

1: Introduction Series 2200 Programmable DC Power Supplies

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Contact information

If you have any questions after you revie w the infor mation in this documentation, please co ntac t your

local Keithley Instruments office, sales partner, or distributor. You can also call the corporate

headquarters of Keithley Instruments (toll-free inside the U.S. and Canada only) at 1-800-935-5595,

or from outside the U.S. at +1-440-248-0400. For worldwide contact numbers, visit the

Instruments website (http://www.tek.com/keithley).

CD-ROM contents

A CD-ROM is shipped with each Series 220 0 ord er .

Keithley

The Series 2200 Product Information CD-ROM contains:

• Reference Manual: Includes advanced operation topics and maintenance information. Programmers

looking for a command reference, and users looking for an in-depth description of the way the

instrument works (including troubleshooting and optimization), should refer to the Reference Manual.

• Drivers and release notes: IVI Instrument Driver, driver for National Instruments LabVIEW™, and

related release notes.

• Additional product information: The product specifications are also included on the CD-ROM.

For the latest drivers and additional support information, see the Keithley Instruments website

(http://www.tek.com/keithley).

1-2 2200S-901-01 Rev. D / May 2017

Page 12

Series 2200

Introduction

2200-20-5

Programmable DC power supply. 20 V, 5 A, 1 channel, USB, GPIB

2200-30-5

Programmable DC power supply. 30 V, 5 A, 1 channel, USB, GPIB

2200-72-1

Programmable DC power supply. 72 V, 1.2 A, 1 channel, USB, GPIB

2220-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB

2220J-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, for Japan

2220GJ-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, GPIB, for Japan

2230-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB

2230G-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, GPIB

includes a 6 V, 5 A channel for powering digital circuits

2230J-30-1

Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, for Japan

includes a 6 V, 5 A channel for powering digital circuits

Programmable DC Power Supplies Reference M anual Section 1:

Key features

The Series 2200 offers:

• Single-output, DC power

• Linear regulation

• 0.03 percent basic voltage accur acy

• 0.05 percent basic current acc uracy

• Less than 1 mV RMS ripple and noise

• 40 user-defined setup memories

• USB 2.0 device port on rear panel for PC connectivity and remote programming

• IEEE-488.2 General Purpose Interface Bus (GPIB) interface for PC connectivity and remote

Not every Model has a GPIB connection (see the next table).

programming

Model Description

2200-32-3 Programmable DC power supply. 32 V, 3 A, 1 channel, USB, GPIB

2200-60-2 Programmable DC power supply. 60 V, 2.5 A, 1 channel, USB, GPIB

2220G-30-1 Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, GPIB

2230GJ-30-1 Programmable DC power supply. 30 V, 1.5 A, 2 channel, USB, GPIB, for Japan

includes a 6 V, 5 A channel for powering digital circuits

includes a 6 V, 5 A channel for powering digital circuits

2200S-901-01 Rev. D / May 2017 1-3

Page 13

Section

Reference Manual

Rear panel mating connector

131984300

Documentation and Driver CD

2200S-950-01

Certification of calibration

N/A

IEEE-488.2 Interface Board for the PCI Bus

KPCI-488LPA

USB Cable Type A to B 1m (3.2 ft)

USB-B-1

USB Cable Type A to B 3m (10 ft)

USB-B-3

Fixed Rack Mount Kit

4299-7

Double Shielded Premium IEEE-488 Interface Cables, 0.5m (1.6 ft)

7007-05

Double Shielded Premium IEEE-488 Interface Cables, 1m (3.2 ft)

7007-1

Double Shielded Premium IEEE-488 Interface Cables, 2m (6.5 ft)

7007-2

Double Shielded Premium IEEE-488 Interface Cables, 3m (10 ft)

7007-3

Double Shielded Premium IEEE-488 Interface Cables, 4m (13 ft)

7007-4

1-year factory warranty extended to 3 years from date of shipment

2200-3Y-EW-STD

3 calibrations within 3 years of purchase

C/2200-3Y-STD

3 (ANSI-Z540-1 compliant) calibrations within 3 years of purchase

C/2200-3Y-DATA

1: Introduction Series 2200 Programmable DC Power Supplies

Standard accessories

Accessory Keithley part number

Optional accessories

Optional accessory Keithley part number

Services available

Services Keithley part number

Specifications

This topic provides information about:

• Electrical ratings for the power connection

• Environmental performance

• Nominal voltage ratings

• Float voltage rating

For additional specifications, refer to Series 2200 Programmable DC Power Supplies Specifications

(document number SPEC-2200S) on the Product Information CD-ROM that came with your Series

2200. For the latest version of the specifications, go to the Keithley Instruments website

http://www.tek.com/keithley.

1-4 2200S-901-01 Rev. D / May 2017

Page 14

Series 2200

Introduction

2200-20-5

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

350 VA

2200-30-5

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

For 220 V: 2.5 A TH, 250 V

2200-60-2

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

For 220 V: 2.5 A TH, 250 V

2220-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

For 220 V: 2.5 A TH, 250 V

2220J-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

For 220 V: 2.5 A TH, 250 V

2230-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

2230G-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

2230J-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

2230GJ-30-1

110 V / 220 V

50 / 60 Hz

For 110 V: 5 A TH, 250 V

For 220 V: 2.5 A TH, 250 V

500 VA

Temperature

Temperature Operating: +0 °C to +40 °C

Humidity

Operating:

Pollution degree 2, For indoor use only.

Altitude

Operating: 100 percent capability up to 2,000 meters.

Programmable DC Power Supplies Reference Manual Section 1:

Electrical ratings for t he pow er connec t ion

Model Line selector

Frequency Fuse rating Max power

switch setting

2200-32-3 110 V / 220 V 50 / 60 Hz For 110 V: 5 A TH, 250 V

2200-72-1 110 V / 220 V 50 / 60 Hz For 110 V: 5 A TH, 250 V

2220G-30-1 110 V / 220 V 50 / 60 Hz For 110 V: 5 A TH, 250 V

2220GJ-30-1 110 V / 220 V 50 / 60 Hz For 110 V: 5 A TH, 250 V

350 VA

350 VA

500 VA

500 VA

Environmental performance

Parameter

5 percent to 95 percent relative humidity ( percent RH) at up to 40 °C, noncondensing

2200S-901-01 Rev. D / May 2017 1-5

Page 15

Section

Reference Manual

1: Introduction Series 2200 Programmable DC Power Supplies

Nominal voltage ratings

There are two ranges for all models, selectable by the line-voltage selector switch. Check the voltage

select switch on the bottom of the power supply before turning it on:

• 110 V setting, 110 / 115 / 120 VAC

• 220 V setting, 220 / 230 / 240 VAC

Float voltage rating

Float voltage rating: up to 100 V (DC + peak AC) between earth ground and any output terminal.

Fluctuations must not exceed 10 percent of the nominal rated voltage.

1-6 2200S-901-01 Rev. D / May 2017

Page 16

Clear and sanitize procedures ................................................ 2-34

In this section:

Operating requirements ........................................................... 2-1

Installing the system ................................................................. 2-3

Operating basics ...................................................................... 2-5

Operation examples ............................................................... 2-29

Default setup .......................................................................... 2-33

Operating requirements

This section provides information about operating requirements for the Series 2200 instruments.

Section 2

General operat ion

Observe all safety precautions listed in Safety precautions (on page 1-1

the Series 2200 instruments and any associated instruments.

Read and follow all installation, operation, and maintenance information carefully before using the

Series 2200 instruments.

Refer to the following sources for complete product specifications:

) and in this topic before using

• Specifications (on page 1-4)

• Series 2200 Programmable DC Power Supplies Specifications (document number SPEC-2200S)

on the Product Information CD-ROM that came with your Series 2200. For the latest version of

the specifications, go to the Keithley Instruments website

1. Place the bottom of the instrument on a bench or similar surface. Do not stand the instrument on

it's rear panel. Refer to the following figure for an illustration of how to position the instrument.

Do not stand the instrument on its rear panel. This position is unstable and the instrument

might tip over and be damaged or fall on someone and cause injury. To avoid damage or

bodily injury, place the bottom of the instrument flat on a stable surface.

(http://www.tek.com/keithley).

Page 17

Section

Reference Manual

2: General operation Series 2200 Programmable DC Power Supplies

Figure 1: Place bottom of instrument on flat stable surface

2. Before operating, ensure that the ambient temperature is between +0 °C and +40 °C (+32 °F to

+104 °F).

To ensure proper cooling, keep the front, sides, and rear of the instrument clear of

obstructions.

Use properly rated load wires. All load wires must be heavy enough not to overheat when

carrying the maximum short-circuit output current of the power supply. If there is more than

one load, then any pair of load wires must be capable of safely carrying the full-rated shortcircuit output current of the power supply.

To reduce risk of fire and shock, ensure the mains supply voltage fluctuations do not exceed

10% of the operating voltage range.

Do not loosen any screw on this product, except those in the rear connector, which are intended to

retain attached external wires to the connector. There are no user serviceable components inside.

2-2 2200S-901-01 Rev. D / May 2017

Page 18

Series 2200

ion

Programmable DC Power Supplies Reference M anual Section 2: General operat

Installing the system

This section contains information on how to install your Model 2200 power supply.

• Unpack the instrument and check that you received all the items listed as standard accessories.

• Check that you also received any other accessories that you ordered with your instrument.

To verify that the power supply is ready to use, follow the procedures to:

• Power the instrument on and off (on page 2-3)

• Check the output (on page 2-3)

Power the instrument on and off

To power on the instrument follow these steps:

1. Make all the connections.

2. Properly set the 110 V / 220 V selector switch located on the bottom of the instrument.

Figure 2: Selector switch

3. Connect the power cord that was provided with the instrument to the power connector on the rear

panel. Connect the power cord plug to a properly grounded electrical outlet.

4. Press the power switch on the front panel.

To power off the instrument, press the power switch on the front panel.

To satisfy safety requirements, always use load wires heavy enough not to overheat when

carrying the maximum short-circuit output current of the power supply. If there is more than

one load, then every pair of load wires must be capable of safely carrying the full-rated

current of the power supply.

Check the output

The following procedures check that the power supply develops its rated outputs and properly

responds to operation from the front panel.

2200S-901-01 Rev. D / May 2017 2-3

Page 19

Section

Reference Manual

2: General operation Series 2200 Programmable DC Power Supplies

Voltage output check

To verify basic voltage functions without a load, follow these steps.

1. Remove all leads from the output connectors.

2. Turn on the power supply.

3. Press Shift and Menu (1). >Default Set shows on the display.

4. Press Enter to bring up the default settings options. No and Yes appear on the display.

5. Press the right arrow key to select Yes. Press Enter to enable the default settings.

6. Press the front-panel On/Off key to enable the output. The OFF message on the display turns off

and the CV message on the display turns on. The upper line of the display shows the actual

output voltage and current. The lower line shows the settings.

7. Check that the front-panel voltmeter properly responds to pressing keys on the numeric keypad.

Press V-set, use the numeric keypad to set the voltage value to 0 and press Enter. Check if the

displayed voltage value is approximately 0 V and check if the displayed current value is

approximately 0 A. You can confirm the 0 V setting with a voltmeter.

8. Press V-set and use the numeric keys and Enter to set the voltage value to the maximum

allowable for your power supply, as indicated on the instrument’s front panel.

9. Check if the displayed voltage value is approximately the same value as the voltage setting.

Current output check

To verify the basic current functions with a short across the power supply output, follow these steps:

1. Remove all leads from the output connectors.

2. Turn on the power supply.

3. Press Shift and Menu (1). >Default Set shows on the display.

4. Press Enter to bring up the default settings options. No and Yes appear on the display.

5. Press the right arrow key to select Yes. Press Enter to enable the default settings.

6. Ensure that the output is disabled and the display OFF message is turned on. If needed, press the

On/Off key to ensure that the output is disabled and the OFF message is turned on.

7. Use an insulated test lead to connect a short across the (+) and (-) output terminals.

Use a wire size sufficient to handle the maximum current. You should use at least a 22 gauge

wire.

To satisfy safety requirements, always use load wires heavy enough not to overheat when

carrying the maximum short-circuit output current of the power supply. If there is more than

one load, then every pair of load wires must be capable of safely carrying the full-rated

current of the power supply.

8. Press the On/Off key to enable the output. The CC message should be lit.

9. Press I-set and use the numeric keypad and Enter key to set the current value to 0 A. Check if

the displayed current value is approximately 0 A.

10. Press I-set and use the numeric keys and Enter to set the current value to the maximum

allowable for your current supply. Check if the displayed current value is approximately the same

value as the maximum allowable.

11. Turn off the power supply and remove the short wire from the (+) and (-) output terminals.

2-4 2200S-901-01 Rev. D / May 2017

Page 20

Series 2200

General operation

Programmable DC Power Supplies Reference M anual Section 2:

Operating basics

Front panel at a glance

The front panel of the Keithley Instruments Series 2200 contains the following items:

• Power switch

• Display

• Arrow keys

• The navigation wheel

• Output connectors

• Keys

• Number keys

You can use the keys, display, and the navigation wheel

to access, view, and edit the configuration

menu items and set values.

For additional information about the front panel, see the Front panel operation (on page 2-15

) section.

The front panel of the Series 2200 is shown in the following figure.

Figure 3: Front panel

2200S-901-01 Rev. D / May 2017 2-5

(1) Display

The display shows information.

(2) Information

During operation, the display provides information about the output (top row) and settings (bottom

row) for volts (left column) and current (right column). During configuration, the display shows the

configuration menus (bottom row).

Page 21

Section

ference Manual

2: General operation Series 2200 Programmable DC Power Supplies Re

(3) Arrow keys

(4) Navigation wheel

Up, down, right, and left arrow keys (▲ and ▼) and Enter key.

Rotate the navigation wheel to increase or decrease digits or to select menu items.

(5) Output connectors

Three banana jack output connectors provide high, low, and chassis ground connections.

(6) Save and recall keys

See Key descriptions (on page 2-7) for descriptions of these keys.

(7) Numeric keypad

The numeric keypad provides number keys (0 to 9 and Esc) for direct numeric entry.

(8) V-Set, I-Set, Shift, and Output On/Off keys

See Key descriptions (on page 2-7) for descriptions of these keys.

(9) Power switch

Press the power switch to turn the instrument on (|). Press it again to turn the instrument off (0).

2-6 2200S-901-01 Rev. D / May 2017

Page 22

Series 2200

General operation

V-set

Sets the voltage limit. See Setting the voltage limit (on page 2-17) for more

information.

I-set

Sets the current limit. See Setting the current limit (on page 2-17) for more information.

Save

Saves the present settings to a specified setup memory location (1 to 40). See Save

and recall setups (on page 2-18) for more information.

Recall

Recalls a saved setting from a specified setup memory location (1 to 40). See Save

and recall setups (on page 2-18) for more information.

Shift

following table for more information on Shift + numeric keypad descriptions.

Output

Turns on or off the output channel of the power supply. The regulation mode, constant

turned on.

Esc

will back up one menu level.

Shift

1

Brings up the configuration menus. Turn the navigation wheel or

Enter to select which menu to use.

Shift

2

Brings up the list selection. Turn the navigation wheel or press the up

or down arrow keys to scroll through the various lists you can run.

Shift

3

Generates a manual trigger event.

Shift

7

Returns control from remote operation to local front panel control. This

operation generates a return to local message.

Programmable DC Power Supplies Reference M anual Section 2:

Key descriptions

The keys provide front panel control and configuration. See Front panel at a glance (on page 2-5) for

an illustration of each key location. The following tables describe how to use each key.

Key descriptions

Keys Description

Used to access secondary functions of the numeric keys. For example, when the Shift

key is used with the 1 key, the combination displays the configuration menu. See the

On/Off

voltage (CV) or constant current (CC), is shown on the display when the output is

Backs out of the selected function. If the instrument’s focus is in a menu, pressing Esc

Shift + numeric keypad descriptions

Key Numeric

Description

keypad

press the up or down keys to scroll through the list of menus. Press

2200S-901-01 Rev. D / May 2017 2-7

Page 23

Section

Reference Manual

Display the instrument firmware version.

Shift + 8

Display the internal temperature of the instrument.

Shift + . (decimal point) + 1

Perform a factory reset. All setups and lists are erased.

Shift + . (decimal point) + 2

Unlock the keypad.

If the instrument's keypad and front panel controls

2200-20-5

4205

2200-30-5

4305

2200-32-3

4323

2200-60-2

4602

2200-70-1

4721

keypad.

2: General operation Series 2200 Programmable DC Power Supplies

Keypad special operations

See the following table for the Series 2200 keypad special operations.

Operation Key press

are locked, you will need a password to unlock

them. If you forget the password, enter the

appropriate default code for the model instrument

you are using:

Model Default code

Cycling the instrument power also unlocks the

2-8 2200S-901-01 Rev. D / May 2017

Page 24

Series 2200

General operation

>Default Set

No

Yes

more information.

>Protect

>Reset Protect

No

Yes

Reset Protect menu selections to the

factory default configuration.

>Max Volt Set

Off

off.

On

Max =

Set or edit maximum output voltage

more information.

>OVP Set

Off

Turn overvoltage protection (OVP)

off.

On

OVP =

page 2-19) for more information.

>Out Time Set

Off

Turn out time mode off.

On

Time =

Turn out time mode on and set or edit

setting a timer with Out Time Set.

>Key Lock

Password =

unlock

Indicates that no password is set to

Enter up to 4 digits to set a password.

Lck

Indicates that a password has been

set.

>Edit

>Recall 1-7

Empty

Recall or edit lists saved in up to 7

information.

Continuous

Repeat =

30) for a list example.

Step

Repeat =

Set instrument to step mode. If set,

Programmable DC Power Supplies Reference M anual Section 2:

Configuration menus description

Use the configuration menus to configure (setup) the instrument. Sometimes the configuration menus

are called the settings menus. See the following table for information on the primary menu selections,

secondary menu selections, options, and a brief description of each selection. The following table

indicates default settings in bold.

Primary

menu

Secondary menu First option Additional

option(s)

Allows you to ...

Return the instrument to the factory

default configuration. See Initializing

to the default setup (on page 2-17) for

Turn maximum output voltage setting

for the instrument. See Setting the

maximum voltage (on page 2-18) for

List

Turn overvoltage protection on and

set or edit the voltage threshold. See

Setting the overvoltage protection

(on

the time period. See T imer ex ampl e

(on page 2-30) for an example of

lock all front panel controls except

power switch and output on/off key.

locations. Empty indicates no saved

list. See

Define a list of voltage and

current steps (on page 2-24) for more

Set instrument to continuous mode. If

set, the instrument executes the

entire sequence of steps as soon as it

receives the next trigger signal.

Repeat allows you to set or edit

number of times to repeat the list.

List Steps allows you to indicate the

number of steps in the list.

See List mode example (on page

2-

2200S-901-01 Rev. D / May 2017 2-9

Page 25

Section

Reference Manual

the instrument will advance to each

number of steps in the list.

>User

>Reset User

No

Yes

Reset User menu selections to the

factory default configuratio n.

>Output Recall

Off

Turn output recall mode off.

On Set power output state to that which

information.

>Save Last

On

Save last operating parameters in

information.

Off

Turns save last mode off.

>Key Beep

Off

sound.

On

Turns on key press notification

page 2-21) for more information.

>Knob Lock

Off

Unlocks navigation wheel .

On

Locks navigation wheel . See Lock

for more information.

>System

>Reset System

No

Yes

factory default configuratio n.

>Port Mode

Trigger

Set port mode input to trigger. You

Source).

RI/Def

Set port mode input and output to

inhibit mode (RI mode).

Digital

alphabetical order (on page 4-2).

>Trig Source

Manual

Set rear panel port mode to manual

trigger.

External

trigger.

Bus

Set rear panel port mode to bus

trigger.

2: General operation Series 2200 Programmable DC Power Supplies

Primary

menu

Secondary menu First option Additional

option(s)

Allows you to ...

step only after it receives a trigger

signal.

Repeat allows you to set or edit

number of steps.

List Steps allows you to indicate the

was in use before power was last

turned off. See Recall the power

supply ON/OFF output state at power

on (on page 2-20) for more

use before turning instrument off.

Restores saved parameters when

instrument turned on. See

power supply operating parameters at

power on (on page 2-21) for more

Recall the

Turns off key press notification

sound. See Setting the key sound (on

the navigation wheel (on page 2-22)

Reset System menu selections to the

must also set the trigger source (Trig

RI/Def. You must also set the remote

Set port mode input and output to

digital. This setting is for

programmable interface comm ands

described in

Set rear panel port mode to external

Commands listed in

2-10 2200S-901-01 Rev. D / May 2017

Page 26

Series 2200

General operation

Immediate

Set rear panel port mode to

immediate trigger.

>RI Mode

Off

Turn remote inhibit (RI) mode off.

Latching

Set remote inhibit mode to latching.

0 V).

Live

Set remote inhibit mode to live. Live

RI input is high (5 V)

>DFI Source

Off

source mode off.

Ques

Set the DFI source to question

(Ques).

Oper

Set the DFI source to operation

(Oper).

ESB

Set the DFI source to error status

byte (ESB).

RQS

Set the DFI source to request service

(RQS.

>Communication

USBTMC

Set the communications mode to

USBTMC.

GPIB

Set the communications mode to

more information.

RS232

9600,8,N,1

modes.

Programmable DC Power Supplies Reference M anual Section 2:

Primary

menu

Secondary menu First option Additional

option(s)

Turn the discrete fault input (DFI)

Allows you to ...

Latching mode turns the output

channel off when the instrument

detects a high-to-low transition (5 V to

mode the output channel off when the

RI input is low (0 V) and on when the

Address=22

GPIB. Set or edit the GPIB primary

address. See

To change GPIB

address settings (on page 3-2) for

Set the communication mode to

RS232. Set or edit the RS232

address. USBTCM and GPIB are the

recommended communication

Upper display messages

The instrument shows messages on the upper row of the display to indicate output operating and

error conditions. See Configuring the instrument for your application (on page 2-16

information about these messages. See the following tables for the messages and a description of

what the messages indicate.

) for general

2200S-901-01 Rev. D / May 2017 2-11

Page 27

Section

Reference Manual

OFF

Power supply output is off.

CV

CC

Instrument is operation in constant current (CC) mode.

RI

Instrument output has been turned off by the remote inhibit (RI) input. See

[SOURce:]DIGital:FUNCtion (on page 4-12) for more information.

OVP

Instrument has sensed a voltage level above the threshold set for overvoltage control

more information.

RSV

Instrument has sensed a reverse remote sense polarity condition and turned the output

sense (on page 2-23) for more information.

OTP

Instrument has sensed an excessive internal temperature and turned off the output.

OVP

If overvoltage protection (OVP) is set, the instrument displays the OVP message to

protection (on page 2-19) for more information.

Lck

If the front-panel controls are locked, the instrument displays the Lck message. See

unlocking the front panel controls.

2: General operation Series 2200 Programmable DC Power Supplies

Operating conditions

Messages Description

Instrument is operating in constant voltage (CV) mode.

Error conditions

Messages Description

and turned off the output. See Setting the overvoltage protection (on page 2-19) for

off. Polarities of source and sense conne ctio ns must be the same. See Using remote

If the instrument displays the OTP message, the instrument should be shut down immediately. Do

not operate the instrument when temperatures are above the internal temperature trip level to avoid

damaging internal components.

Lower display messages

The instrument shows the following messages on the lower row of the display.

Message Description

Indicates that OVP is set. Flashes when OVP has tripped. See Setting the overvoltage

Configuration menus description (on page 2-9) for information on the >Protect >Key

Lock configuration. See Keypad special operations (on page 2-8) for information on

2-12 2200S-901-01 Rev. D / May 2017

Page 28

Series 2200

General operation

Programmable DC Power Supplies Reference M anual Section 2:

Rear panel at a glance

The rear panel of the Series 2200 contains the following items:

• Cooling vents

• Factory test port

• USB device port

• GPIB IEEE-488 port

• 110 V/220 V power connector

• 12-pin connector; includes remote sense

• Shorting clip. Use this for proper regulation when not using remote sense. This connector comes

installed. It shorts the + drive to the + sense and the - drive to the - sense. To use remote sense,

remove the clip.

Figure 4: Rear panel

The rear panel of the Series 2200 is shown in the following figure.

2200S-901-01 Rev. D / May 2017 2-13

(1) Cooling vents

Exhaust vent for the internal cooling fan. Keep the vent free of obstructions to prevent overheating.

Page 29

Section

Reference Manual

2: General operation Series 2200 Programmable DC Power Supplies

(2) Factory test port

Do not use the factory test port.

Unauthorized use of the factory test port could damage this product.

(3) USB device port

(4) General purpose interface bus (GPIB) connector

The USB 2.0 high-speed device port supports remote control and data transfer to a PC.

The GPIB supports remote control and data transfer to a PC.

(5) 110 V/220 V power connector

Using the supplied line cord, connect to a grounded AC power outlet.

(6) 12-pin connector

The 12-pin connector includes remote sense. The illustration of the 12-pin connector (see Rear panel

at a glance (on page 2-13).) shows the location of the following output and control connectors:

• Two "Output Drive + " connectors are equivalent to the front-panel output + connector

• Two "Output Drive - " connectors are equivalent to the front-panel output - connector

• Two connectors: "Output Sense + " and "Output Sense - " are used for remote sensing

• Two No Connect connectors on the rear panel terminal strip are unused

• Four connectors "Control In + ", Control In - ", "Control Out + ", and Control In - " on the rear panel

terminal strip are configured by the port mode controls. They support the trigger, RI/DFI, and digital I/O

functions. See >System in Configuration menus description (on page 2-9

the port mode controls.

) for more information about

(7) Shorting clip

Use the shorting clip for proper regulation when not using remote sense. This connector comes

installed. It shorts the + output drive to the + sense and the - output drive to the - sense for local

sensing at the output terminals. To use remote sense, remove the clip.

2-14 2200S-901-01 Rev. D / May 2017

Page 30

Series 2200

General operation

Programmable DC Power Supplies Reference M anual Section 2:

110 V/220 V selector switch

The 110 V/220 V selector switch is located on the bottom of the instrument as shown in the following

figure.

Figure 5: Selector switch

Front panel operation

Within a few seconds after turning on, the power supply displays the actual voltage and current output

value on the display’s top line and the voltage and current settings on the bottom line.

You can enable or disable the output of the power supply from the front panel by pressing the Output

On/Off key. When the output is off, the OFF message displays to the right of the current and voltage

values.

The display shows the present operating status of the power supply with display messages. When the

power supply operates in constant voltage mode, the CV message displays. When the power supply

operates in the constant current mode, the CC message displays.

If the front panel was locked with a password, enter the correct password after you press a key (Vset, I-set, Save, Recall, or Shift), then you can change the settings.

To cancel a function operation (V-set, I-set, Save, Recall, or Shift), press Esc.

2200S-901-01 Rev. D / May 2017 2-15

Page 31

Section

Reference Manual

2: General operation Series 2200 Programmable DC Power Supplies

Configuring the instrument for your application

The configuration menus (see Configuration menus description (on page 2-9)) include settings, like

OVP and Max Volt, that determine the maximum voltage output of the power supply. The menu

system also includes settings, like Save Last and Output Recall, that determine how the

instrument initializes itself when it is turned on.

This power supply features a constant voltage/constant current automatic crossover. This feature

permits continuous operation in the transition from constant-voltage mode to constant-current mode

as the load changes. The intersection of the constant-current and constant-voltage modes is called

the crossover point.

For example, if the load is such that the power supply is operating in constant-voltage mode, the

power supply provides a regulated output voltage. The output voltage remains constant as the load

increases until the preset current limit is reached. Then the crossover occurs. At that point, the output

current becomes constant and the output voltage drops in proportion to further load increases.

Crossover is indicated by the front panel CC and CV messages. If the CV message appears, the

instrument is operating in constant-voltage mode. If the CC message appears, the instrument is

operating in constant-current mode.

Crossover from the constant-current mode to the constant-voltage mode also occurs automatically in

response to a decrease in load. For example, suppose you are charging a 12 V battery. Initially, the

open circuit voltage of the power supply is preset for 13.8 V. A low-battery places a heavy load on the

power supply, and it operates in constant-current mode. You adjust the instrument to charge the

battery at the rate of 1 A. As the battery becomes charged and its voltage approaches 13.8 V, the

load decreases to the point where the battery no longer demands the full 1 A charging rate. The

power supply then crosses over to constant-voltage mode.

2-16 2200S-901-01 Rev. D / May 2017

Page 32

Series 2200

General operation

Output On/Off

OFF

V-Set

1.000 V

I-Set

0.1000 A

Max Volt Set

Off

OVP Set

Off

Out Time Set

Off

Key Lock

Off

Output Recall

Off

Save Last

On

Key Beep

Off

Knob Lock

Off

Port Mode

Trigger

Trig Source

Manual

RI Mode

Off

DFI Source

Off

Communication

RS232

Programmable DC Power Supplies Reference M anual Section 2:

Initializing to the default setup

Use the default setup to get the power supply into a default initial state:

1. Remove all leads from the output connectors.

2. Turn on the power supply.

3. Press Shift and Menu (1) to access the configuration menus. >Default Set shows on the

display.

4. Press Enter to bring up the default settings menu. No and Yes show on the display.

5. Press the right arrow key or navigation wheel

6. Press Enter to enable the default settings.

See the following table for the default settings.

Default setting

to select Yes.

2200S-901-01 Rev. D / May 2017 2-17

Setting the current limit

You may set the current limit from 0 A to the maximum current value of each model. The maximum

current rating is shown on the instrument name plate.

1. Press I-set.

2. Use the arrow keys, numeric keypad, or the navigation wheel

to enter the current limit.

3. Press Enter to set the current limit.

Setting the voltage limit

You may set the voltage limit from 0 V to the maximum voltage rating shown on the instrument name

plate.

1. Press V-set.

2. Use the arrow keys, numeric keypad, or the navigation wheel

3. Press Enter to set the voltage limit.

to enter the voltage limit.

Page 33

Section

Reference Manual

2: General operation Series 2200 Programmable DC Power Supplies

Save and recall setups

You can store up to 40 different setups in setup memory locations (1 to 40). Each setup includes the

set voltage limit, the set current limit, and the protection menu settings. When shipped from the

factory, setup memories 1 through 40 are empty. Save and recall setups as follows:

To save a setup:

1. After you set up the power supply, (voltage and current limits and the protection menu settings),

push the Save key.

2. Use the arrow keys, numeric keypad, or the navigation wheel

to select the setup memory (1 to

40) that you want to store the values in.

3. Press Enter to confirm the memory location.

To recall a setup:

1. Press Recall.

2. Use the arrow keys, numeric keypad, or the navigation wheel

to select the setup memory that

you want to recall from.

3. Press Enter.

Setting the maximum voltage

The Max Volt Set control determines the maximum voltage that you can set using t he V-set control.

This can help keep accidental over-voltage from being applied to sensitive loads. Set the maximum

voltage as follows:

To set the maximum voltage:

1. Press Shift and Menu (1) to access the configuration menus.

2. Use the arrow keys, numeric keypad, or the navigation wheel

3. Press Enter and turn the navigation wheel

one click clockwise. >Max Volt Set shows on the

display.

4. Press Enter. Off (default) shows on the display.

5. Use the arrow keys, numeric keypad, or the navigation wheel

6. Press Enter to turn on the maximum voltage feature.

7. Use the numeric keys, arrow keys, or navigation wheel

must be less than the maximum voltage output noted on the nameplate of the power supply.

8. Press Enter.

9. Press Esc to exit the menu system.

to select >Protect.

to select On.

to change the voltage value. The value

When you adjust the voltage value to the maximum voltage limit, the voltage setting flashes back at

you.

The default maximum voltage is the full voltage range of the particular power supply being used.

2-18 2200S-901-01 Rev. D / May 2017

Page 34

Series 2200

ral operation

Programmable DC Power Supplies Reference M anual Section 2: Gene

Setting the overvoltage protection

The OVP Set control turns overvoltage protection (OVP) on or off. If overvoltage protection is turned

on and the instrument senses a voltage level above the threshold set for over-voltage control, the

instrument will turn off the output and clamp the voltage on the output to below one volt.

To set the overvoltage protection:

1. Press Shift and Menu (1) to access the configuration menus.

2. Use the arrow keys, numeric keypad, or navigation wheel

3. Press Enter.

4. Use the up or down arrow keys to select >OVP Set.

5. Press Enter.

6. Select On.

7. Press Enter.

8. Enter the desired OVP value with the num er ic ke ypad, arrow k e ys, or navigat ion w hee l

9. Press Enter

The lower display shows OVP when the overvoltage protection feature is activated. The OVP

indicator will flash on and off when the overvoltage protection feature detects an overvoltage

condition.

to select >Protect.

.

The default value for the Max Volt Set parameter is On.

Resetting the power supply after an overvoltage trip

To reset the power supply after an overvoltage trip:

1. Determine and remove the source of the overvoltage. Overvoltage may be caused by setting the

voltage limit too high, external voltage sources, or equipment failure.

2. Press the Output On/Off key to clear the OVP status. This will put the power supply output in the

off state.