Page 1

Installation and Service

Grass Valley Model 2200

Digital Video Switcher

Software Release 5.3

071-0157-00

Revised Printing: February, 1998

Page 2

Telephone Numbers

North America

(800) 547-8949

Fax: (530) 478-3181

Elsewhere

Distributor or sales office from

which equipment was purchased.

Web Addresses

Grass Valley Email Support

GVGSERVICE@tek.com

Grass Valley W eb Page

http://www.tek.com/Grass_V alley

Tektronix W eb Site

http://www.tek.com

Customer Support

Tektronix Grass Valley Products is committed to providing the most

responsive and professional product support available. We have a fully

staffed, highly trained support team ready to respond to anything from a

simple question to an emergency repair . Support is available via telephone

or email. For new and updated customer support documents, as well as

new product information, check the Tektronix web site and Grass Valley’s

web page.

Related Publications:

Manual Set TP0759-nn

User’s Guide TP0815-nn

Operation Reference TP0732 -nn

Postal Addresses

Mail

Tektronix Grass Valley Products

P.O. Box 1114

Grass Valley, CA 95945

Shipping

Tektronix Grass Valley Products

400 Providence Mine Rd.,

Nevada City, CA 95959

Copyright © Tektronix, Inc. All rights reserved. Printed in U.S.A.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specifications

and price change privileges reserved. TEKTRONIX, TEK, Grass Valley Group, Borderline,

E-MEM, TEN-X, Wavelink, and are registered trademarks, and Air Link, Auto Match,

Doubletake, E-Disk, Eagle V, Emphasys, EZ-Link, 409, Grass Valley, Horizon, Jogger, Kadenza, Kaleidoscope, K-Mask, Key-Layer, Key-Link, Krystal, MASTER System, Master 21,

MAX, Omni-Key, Performer, Programmed Motion, Silhouette, Softset, SqueezeBack,

Streamline, Super Edit, TEN-20, 20-TEN, Trace, TrailBlazer, VideoDesktop, Flex-Time, and

XEDL are trademarks of Tektronix, Inc. P.O. Box 1000 Wilsonville, OR 97070-1000 U.S.A.

The information in this manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Tektronix, Inc. Tektronix

assumes no responsibility or liability for any errors or inaccuracies that may appear in this

publication.

Tektronix, Inc., Video and Networking Division, P.O. Box 1114 Grass Valley, California

95945 U.S.A.

Page 3

Tektronix—Grass Valley Products

P.O. Box 1114

Grass Valley, CA 95945

916-478-3800

iii

Page 4

iv

Page 5

Contents

Important Safety Notices

Symbols and Their Meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Federal Communications Commission (FCC) Part 15 Information . . . . . . . . . . . . . . xiii

Power Cord Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

North American Power Supply Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

International Power Supply Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Section 1 — System Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Optional Features for Switcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Serial Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chroma Key Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Analog Output (Cell C15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Serial Output 1 (Cell C3) (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Serial Output 2 (Cell C11) (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Aux Output (Cell C16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Effects Send Matrix (Cell A11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Secondary Wipe Generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Dual Chromatte Advanced Chroma Keyer (Cells A3, A16, C8) . . . . . . . . . . . . . . . . . 1-7

BORDERLINE Key Edge Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Tally Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Look-Ahead Preview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Timed Aux Output (Cell B16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Extender Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Control Panel Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Switcher Frame Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Switcher Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

v

Page 6

Contents

Section 2 — Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Pre-installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Items Required but not Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Physical Specifications and Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Control Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Control Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Control Panel Rear Cable Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Inserting the Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Control Panel Redundant Power Supply Option Installation . . . . . . . . . . . . . . . . . . . 2-8

Switcher Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Switcher Frame Power Supply Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Switcher Frame Redundant Power Supply Installation . . . . . . . . . . . . . . . . . . . . . . . 2-16

Switcher Frame Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Installing and Removing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Mask Draw Tablet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Installing the Mask Draw Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Installing UD and KT Series Tablets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Installing SD Series Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Switcher Option Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Serial Digital Input Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Digital Output Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Serial Output 1 (Slot C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Serial Output 2 (Slot C11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Timed Aux Output (Slot C17) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Effects Send Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Chroma Keyer Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

BORDERLINE Key Edge Generator Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Secondary Wipe Pattern Generator Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Look Ahead Preview Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Timed Aux Output Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Framestore Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Remote Aux Panel Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Setting Rear Panel Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Tally Expansion Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Chassis Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Setting Tally Module Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Model 2200-2s Control Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Model 2200-2i Control Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Status Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Analog Reference Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Input Signal Connections (Video and Key) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Serial Digital Video Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Output Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Timed Aux Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Serial Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

vi

Page 7

Contents

Switcher Communications Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

DPM Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

The Video Connection (Aux Buses and Return Inputs) . . . . . . . . . . . . . . . . . . . 2-53

DPM Capabilities (Fixed and Pooled) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Control Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

Connecting to Kaleidoscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Connecting to a DPM–700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Video Production Editor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

GPI Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Remote Aux Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

Connector Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

JSO Cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

Power Supply Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

Remote Aux Panel Lens Chip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

Remote Aux Panel Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

Tally Expansion Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

Tally Output Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

Turning Tally Expansion Option On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Maintenance Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Connecting the Control Panel to Source Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

Switcher Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

Redundant Power Supply Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

System Timing (13.5 MHz, Serial I/O only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

Timing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

Switcher Delay = 70 µS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

Switcher Delay = 50 µS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

Switcher Delay for Between 50 µS and 90 µS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

Output Timing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

Section 3 — Functional Description

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Signal Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Input Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Output Voltages: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Switcher Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Serial Digital Input Module (064820) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Chroma Key Input Module (064817) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Serial Reentry Module (064822) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Serial (Digital) Output Modules (064821) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Analog Output Module (064819) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Timed Aux Output Module (064852) (Slot C16 and 17) . . . . . . . . . . . . . . . . . . . 3-10

vii

Page 8

Contents

Crosspoint Module (064800) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

M/E 1 Crosspoint Module (Slot A4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

M/E 2 Crosspoint Module (Slot A9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Keyer Carrier Module (064804) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Keyer Mezzanine (064826) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

M/E 1 Key 1 Keyer Carrier Module and Mezzanines (Slot A5) . . . . . . . . . . . . 3-16

M/E 1 Key 2 Keyer Carrier Module and Mezzanines (Slot A6) . . . . . . . . . . . . 3-16

M/E 2 Key 1 Keyer Carrier Module and Mezzanines (Slot A13) . . . . . . . . . . . 3-17

M/E 2 Key 2 Keyer Carrier Module and Mezzanines (Slot A14) . . . . . . . . . . . 3-17

BORDERLINE Mezzanine (067909) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

M/E 1 Key 1 Borderline (Slot A5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

M/E 1 Key 2 Borderline (Slot A6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

M/E 2 Key 1 Borderline (Slot A12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

M/E 2 Key 2 Borderline (Slot A14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Mixer Interface Module (064813) (Slot A8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Effects Send Module (064809) (Slot A11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Chroma Keyer Carrier Module (064807) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Chroma Key Mezzanine Module (064831) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

M/E 1 Chroma Keyer Module Set (Slot A3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

M/E 2 Chroma Keyer Module Set (Slot A16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Analog Chroma Key Input Module (064817) (Slot C8) . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Mix/Wipe Module (064803) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Wipe Mezzanine (064828) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Preview Mezzanine Module (064829) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

M/E 1 Mix/Wipe Module Set (Slot A7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

M/E 2 Mix/Wipe Module Set (Slot A12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Preview Module (064802) (Slot A15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Mask Mezzanine Board (064830) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Sync Generator Module (064801) (Slot A10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Frame Store (064814) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Overall System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Control Processor 1 Module (064805) (Slot A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Control Processor 2 Module (064806) (Slot A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Communications Processor 2: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

M/E 2 Processor Mezzanine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Communications I/O Module (064823) (Slot C10) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

GPI Module (064825) (Slot C4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Expanded Communications Carrier Module (064824) . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Serial Communications Mezzanine (068918) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Control Panel Modules Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Main Panel CPU Module (066262) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Upper Panel Microprocessor (PUP) Module (066271) . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Lower Panel Microprocessor (PUP) Module (066267) . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Display Module (066262) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Lower Left Switch Module (066263) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Lower Center Switch Module (066264) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Lower Right Switch Module (066265) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Upper Left Switch Module (066268) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Upper Center Switch Module (066269) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Upper Right Switch Module (066270) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Control Panel IO Module (066266) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Remote Aux Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Tally Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

viii

Page 9

Contents

Section 4 — Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Powering Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Removing Circuit Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Repairing Circuit Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Repairing Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Model 2200 Power Supply Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Frame Power Supply Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Frame Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Replacement of Individual Power Supply Assemblies . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Replacement of Multi-Output Power Supply Assembly . . . . . . . . . . . . . . . . . . 4-10

Removal of Pioneer Multi-Output Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Installation of Todd Multi-Output Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Mount Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Install Assembly in Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Replacement of +5 Volt Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Removal of Pioneer +5 Volt Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Installation of Todd +5 Volt Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Fan Jumper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Replacing Either Control Panel Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Control Panel Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Replacing Control Panel Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Pushbutton Lamp Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Switcher Frame Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Switcher Power Supply Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Switcher Frame Module Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Replacing Frame Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Draining the Control Processor RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Index

ix

Page 10

Contents

x

Page 11

Important Safeguards and Regulatory Notices

Information on the following pages provides important safety guidelines for both

Operator and Service Personnel. Specific warnings and cautions will be found

throughout the manual where they apply, but may not appear here. Please read

and follow the important safety information, noting especially those instructions

related to risk of fire, electric shock or injury to persons.

WARNING

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. T o reduce the risk

of electric shock, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so.

Symbols and Their Meaning

The lightning flash with arrowhead symbol, within an equilateral triangle, alerts

the user to the presence of “dangerous voltage” within the product’s enclosure that

may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the user to the presence

of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

The fuse symbol indicates that the fuse referenced in text must be replaced with

one having the ratings indicated.

This symbol represents an internal protective grounding terminal. Such a terminal

must be connected to earth ground prior to making any other connections to the

equipment.

This symbol represents an external protective grounding terminal. Such a terminal

may be connected to earth ground as a supplement to an internal grounding

terminal.

xi

Page 12

Safeguards and Notices

Warnings

CAUTION

This equipment contains static sensitive components. Use anti-static grounding

equipment whenever handling or servicing modules and components. When circuit

modules are removed from the frame, place them on a flat static controlled surface.

Failure to follow this precaution can result in component damage due to

electrostatic discharge.

■

Heed all warnings on the unit and in the operating instructions.

■

Do not use this product in or near water.

Disconnect ac power before installing any options.

■

■

The attachment plug receptacles in the vicinity of the equipment are all to be

of a grounding type, and the equipment grounding conductors serving these

are to be connected to earth ground at the service equipment.

Route power cords and other cables so that they are not likely to be damaged.

■

■

Disconnect power before cleaning. Do not use liquid or aerosol cleaners; use

only a damp cloth.

Dangerous voltages exist at several points in this product. To avoid personal

■

injury, refer all servicing to qualified personnel.

■

Do not wear hand jewelry or watches when troubleshooting high current

circuits, such as the power supplies.

■

During installation, do not use the door handles or front panels to lift the

equipment as they may open abruptly and injure you.

To avoid fire hazard, use only the specified correct type, voltage and current

■

rating as referenced in this service manual. Always refer fuse replacement to

qualified service personnel.

■

To avoid explosion, do not operate this product in an explosive atmosphere.

Have qualified personnel perform safety checks after any completed service.

■

■

Turn off power supplies and disconnect power cords before servicing the

control panel.

■

To reduce the risk of electric shock, ensure that the two power supply cords

are each plugged into a separate branch circuit.

If equipped with redundant power, this unit has two power cords. To reduce

■

the risk of electric shock disconnect both power supply cords before servicing.

■

High leakage current! Earth ground connection is essential before connecting

power supply.

xii

Page 13

Cautions

Safeguards and Notices

To prevent damage to equipment when replacing fuses, locate and correct the

■

trouble that caused the fuse to blow before applying power.

■

Verify that all power supply lights are off and that the power supply cords are

unplugged before removing power supply or servicing equipment.

Use only specified replacement parts.

■

■

Follow static precautions at all times when handling this equipment.

■

Leave the back of the frame clear for air exhaust cooling and to allow room for

cabling. Slots and openings in the cabinet are provided for ventilation. Do not

block them.

Front door is part of fire enclosure and should be kept closed during normal

■

operation.

Circuit boards in this product are densely populated with surface mount and

■

ASIC components. Special tools and techniques are required to safely and

effectively troubleshoot and repair modules that use SMT or ASIC

components. For this reason, service and repair of GVG products

incorporating surface mount technology are supported only on a module

exchange basis. Customers should not attempt to troubleshoot or repair

modules that contain SMT components. GVG assumes no liability for damage

caused by unauthorized repairs. This applies to both in- and out-of-warranty

products.EMC Regulatory Notices

Federal Communications Commission (FCC) Part 15 Information

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received including interference

that may cause undesireable operations.

xiii

Page 14

Safeguards and Notices

Power Cord Notices

North American Power Supply Cords

This equipment is supplied with a molded grounding plug (NEMA X-XXX) at one

end and a molded grounding receptacle (IEC 320-C13) at the other end.

Conductors are color coded white (neutral), black (line) and green or green/yellow

(ground).

Operation of this equipment at voltages exceeding 130 Vac will require power

supply cords which comply with NEMA configurations.

Black

Line

White

Neutral

International Power Supply Cord

This equipment is supplied with a molded grounding receptacle (IEC 320-C13) at

one end and stripped conductors (50/5 mm) at the other end. Conductors are CEE

color coded, light blue (neutral), brown (line) and green/yellow (ground). Other

IEC 320 C-13 type power supply cords can be used if they comply with the safety

regulations of the country in which they are installed.

Green or Green

with Yellow stripe

Brown

Blue

Green with

Yellow stripe

Ground

(Earth)

Line

Neutral

Ground

(Earth)

xiv

Page 15

1

Introduction

System Overview

This section presents a general description of the Grass Valley Group

Model 2200 Digital Production Switcher, its basic architecture, and a list of

video specifications.

System Description

The Model 2200 Production Switcher manipulates CCIR 601 4:2:2

component digital video and key signals. Outputs from the system are

serial digital. Analog component program and preview monitor outputs

are available.

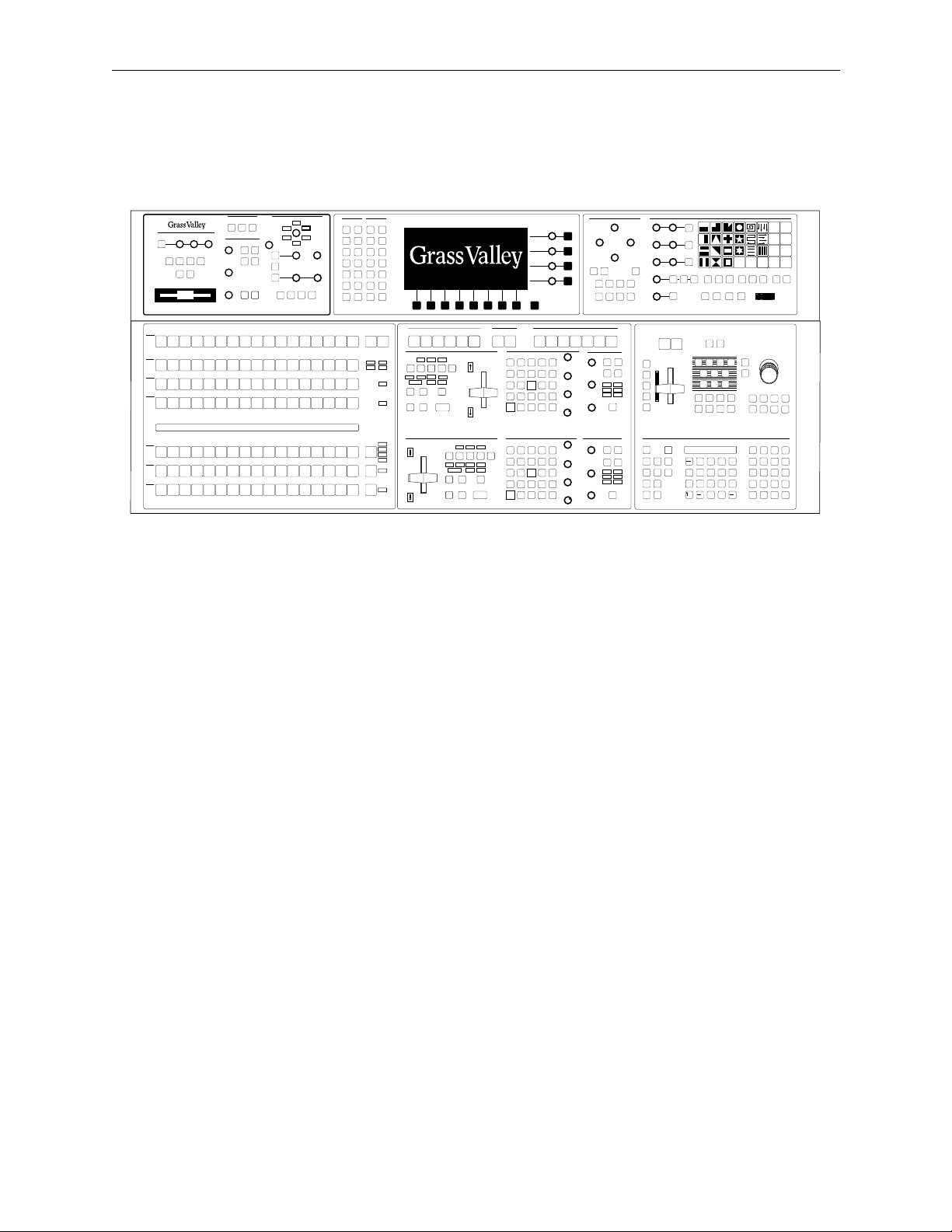

The Model 2200 control panel shown in

systems. Up to 32 video and key sources can be mapped to crosspoint

buttons and accessed directly from the control panel. In addition, the full

range of digital effects can be done directly form the same control panel.

Figure 1-1

provides two mix/effects

1-1

Page 16

Section 1 — System Overview

This manual covers the installation, functional description, maintenance,

and troubleshooting of the control panel and switcher electronics frame.

Chroma Keyer

Frame Store

Frame Store

Shadow

On

External Interface

Editor

GPI

Enable

Enable

Background

M/E 1

Vertical

Position

Position

Field 1

Grab

Freeze

Video

Key

Store

Store

Sec

Opacity Horizontal

Wash

Hue/

Field 2

Softness

Matte

Saturation/

Offset

Bk

Bkgd 1

Brightness

R

Periph

Enable

M/E 2

Sec

Wash

Matte 2 Flat

Bkgd 2

Shadow

On

Auto

Setup

Bkgd

Supr

M/E 1

Key 1

M

Y

B

G

C

Shadow

Opacity

Chroma Lum

M/E 1

M/E 2

Key 2

Key 1

Selectivity

M/E 2

Key 2

Effect Switcher

Picture

Effect

Config

Picture

Panel

Frame

Setup

Effect

Key/

Oper

Stencil

View

Input/

Run

Output

Control

Graphic

Path Aux

Display

Clear

Menu

Mixer

Config

Keyer

Status

E-MEM Key

Mask Matte

Bus

Disk Misc

Wipe Mask

M/E

Mode

Chroma

Key

Wipe

Frame

Frame

Store

Exit

Top/Gain

Left Right

Bottom/Clip

Force

Inhibit

Mask

Mask

Box

Pri

Wipe

M/E 1

M/E 1

Key 1

Key 2

Mask

Invert

Sec

Mask

Wipe

Bus

M/E 2

M/E 2

Key 1

Key 2

Symmetry

Opacity

Preset Size Aspect

Pattern Mix

Soft

Softness

Border

Width

Aspect

Rotate

Rotate

Reverse

Rotate

Normal

Mag

Speed

Pos

Rotation TypeRotate

Wipe Direction

Pattern

M/E 1

M/E 1

Sec

Pri

Mix

Delegate

RandomMenu Texture User

Flip

Split

Flop

Pattern Modifiers Positioner

M/E 2

M/E 2

Pri

Sec

H

Multi

V

Multi

Model

User 1

User 3

User 5 User 6

Wipe

Undo

Pos

Norm

2200

User 2

User 4

Learn

User

Wipe

Pos

Auto

Pvw

Aux

Key

A

B

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

1

1

1

1

Routr4Routr3Routr2Routr

1

Routr4Routr3Routr2Routr

1

Routr4Routr3Routr2Routr

1

Routr4Routr3Routr2Routr

1

Shift

Color

Routr3Routr

M/E 1

Bkgd

2

2

2

2

Pgm

Key 1

Routr3Routr

Color

Shift

Bkgd

Key 2

Shift

Color

Routr3Routr

Bkgd

Shift

Color

Routr3Routr

Bkgd

RTD1TK 1GF 2GF 1 GF 2

Key

A

B

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

VTR3VTR2VTR1Cam3Cam2Cam1Black DPM2DPM

1

1

1

1

1

1

Color

Routr4Routr3Routr2Routr

Routr3Routr

Shift

M/E 1

Bkgd

2

Color

Routr4Routr3Routr2Routr

Routr3Routr

Shift

M/E 1

Bkgd

2

Color

Routr4Routr3Routr2Routr

Routr3Routr

Shift

M/E 1

Bkgd

2

Figure 1-1. Model 2200 Control Panel

Modularity extends throughout the system, providing simple

configuration and expansion to meet your present and future needs. The

basic system consists of a switcher frame and a control panel. The switcher

frame and the control panel each have separate power supplies.

The switcher frame houses the serial and analog I/O modules, the signal

processing modules and the system controller.

M/E 2AM/E 2

Key

Priority

Bkgd

B

On

Layered

Mix

Cut

Key 1

Effect

Effect Effect

BkgdAKey

1

On On

Over

Wipe

Auto

Tran

Preview Only

M/E 2

Key 2

Key

2

On

Over

Preset

Black

60

Bus Delegate

Pvw

M/E 2

M/E 1

Pvw

Key

Priority

Pvw

Keyer

Normal Border

Key

Over

Video

Fill

Linear

Key

Key

On

Keyer

Normal Border

Key

Over

Video

Fill

Linear

Key

Key

On

Inhibit

Mask

Matte

Fill

Lum

Key

BkgdBBkgd

Inhibit

Mask

Matte

Fill

Lum

Key

BkgdBBkgd

Shadow

Force

Mask

Split

Key

Chroma

Key

A

Shadow

Force

Mask

Split

Key

Chroma

Key

A

Mask Aux1Aux2Aux

OutlineExtrude

Invert

Show

Key

Video

Auto

Key

Select

Key

Pri

Sec

Preset

Preset

Pattern

Pattern

Key

Key

2

1

OutlineExtrude

Invert

Show

Key

Video

Auto

Key

Select

Key

Sec

Pri

Preset

Preset

Pattern

Pattern

Key

Key

2

1

Borderline

Size/Position

Borderline

Opacity

Borderline

Size/Position

Borderline

Opacity

Aux

Aux

5

4

3

Matte

Pri

Sec

Stop

Wipe

Wipe

Next

Wash

Wash

Hue/

Softness

Saturation/

Offset

Gain

Brightness

Clip

Matte

Hue/

Softness

Saturation/

Offset

Gain

Brightness

Clip

KF

Matte 2

Flat

Hold

Matte

Input

Reverse

K1 Border

K1 Fill

K2 Border

K2 Fill

Rewind

Sec Wipe

Pri Wipe

Matte

Run

Select

Run Control

E-MEM

Auto

Pri

Sec

Wipe

Wipe

Recall

Wash

Wash

Chan 1

Enable

Matte 2

Flat

Matte

K1 Fill

K2 Fill

Pri Wipe

All

Chan 2

Misc

K1 Border

K2 Border

Bkgd

Global

Sec Wipe

Camera

Matte

Select

Enables Edit

Near

Side

Auto

Run

M/E 1

M/E 2

Far

Side

1345804-42224438

Lock

Learn

Seq

Effect

Dis

Bank

Freeze

Video

Source

Target

Locate

Size/

3D

Locate

Locate

Axis

Skew

Persp

XY

8

7

56

4

123

Undo

0

.

Freeze

Key

Camera

World

Axis

Lock

Rotate

Knob

Control

Spin

Aspect

Post

Xform

Center

Z

+/---

9

Bank

0

Bank

1

Trim

Tran

Rate

Enter

CameraGlobalChan 1

Chan 2

M/E 2

M/E 1

M/E 2

M/E 1

Pri

Pri

Sec

Sec

Clear

Const

Prev Next

Work

Dur

Buffer

Get

Cut

Go To

Go To

Time

KF

Put

Copy

Effect

DurKFDur

Time

Mark

Paste

Insert

Cursor

Cursor

Before

Insert

Mark

Modify

Mark

After

Block

Aux 1-4 Effects Send Only

M/E 1AM/E 1

Transition

Transition

B

Mix

Cut

Bkgd

On

Layered

Key 1

Effect

Effect Effect

Key

Bkgd

1

A

On

Wipe

Auto

Tran

M/E 1

Key 2

Key

2

On

On

Over

Over

Preset

Black

60

M/E 2

Pgm

Uncal

Uncal

Uncal

Uncal

Uncal

Key 1

Key 2

Uncal

Uncal

Uncal

1-2

Page 17

System Description

Power supplies for the system can be made fault tolerant with the optional

redundant supplies. See Section 2, Installation, for further information.

EFFECTS SEND

MATRIX

MIX EFFECTS

Video/Key

Signals In

PROCESSOR

Video/Key

Signals Out

MIX EFFECTS

PROCESSOR

CONTROL

PROCESSOR

Status

Terminal

SERIAL INPUT MODULES

SERIAL CROSSPOINT MATRIX

CONTROL

PANEL

LOGIC

CONTROL PANEL

POWER SUPPLY

Control Panel

Figure 1-2. Model 2200 Simplified Block Diagram

ANALOG AND SERIALOUTPUT MODULES

Switcher

Frame

Switcher Frame

Power Supply

1-3

Page 18

Section 1 — System Overview

Optional Features for Switcher

This section provides brief descriptions of options for the Model 2200

Digital Production Switcher.

Input Modules

The input format is component serial digital. Two Serial Digital Input

Modules are standard, this will provide 16 inputs. Up to two additional

Serial Digital Input Modules may be added for a total of 32 primary inputs.

Component Serial Digital Input Modules are installed in the rear bay of the

switcher frame. There is also a provision for installing one optional Analog

Chroma Key Input Module. This module provides two inputs for

component analog chroma keys. The following module types are available:

Serial Input Modules

Two modules standard, up to two additional modules optional. Eight

■

looping inputs on each module

Chroma Key Input Module

The Analog Input Module allows full bandwidth chroma keys. There is a

separate gain adjustment near each input BNC connector.

One module optional. provides two inputs–RGB, SIMPTE, EBU, Beta

■

or MII

1-4

Page 19

Output Modules

The switcher has two standard Serial Output Modules and can have one

optional Analog Preview Output, and one optional Aux Serial Output

Module. Each Serial Output Module option has eight different output

signals (two BNCs per output for a total of 16 BNCs on each module). The

Aux Output Module has eight outputs of which six are used. This provides

three independent output pairs (video/key) from aux buses 3A through

5B. The Analog Output Module has two component analog outputs, M/E 2

program and switched preview.

Analog Output (Cell C15)

■

M/E 2 Program Video

■

Switched Preview

Optional Features for Switcher

Serial Output 1 (Cell C3) (Standard)

■

Mask

■

Switched Preview

M/E 1 Preview

■

M/E 2 Preview

■

M/E 1 Program Video

■

■

M/E 1 Program Key

■

M/E 2 Program Video

■

M/E 2 Program Key

Serial Output 2 (Cell C11) (Standard)

■

M/E 1 Clean Feed

■

M/E 2 Clean Feed

Aux Bus 1A (Video)

■

Aux Bus 1B (Key)

■

Aux Bus 2A (Video)

■

Aux Bus 2B (Key)

■

■

Frame Store Video

■

Frame Store Key

1-5

Page 20

Section 1 — System Overview

Aux Output (Cell C16)

■

Aux Bus 3A (Video)

■

Aux Bus 3B (Key)

■

Aux Bus 4A (Video)

■

Aux Bus 4B (Key)

Aux Bus 5A (Video/Key)

■

Aux Bus 5B (Video/Key)

■

Effects Send Matrix (Cell A11)

The Effects Send Matrix option provides a method of integrating digital

effects devices into the switcher mix/effects system. Up to two send

channels can be used to route the A video, key 1, or key 2 from an M/E to

and from an external digital effects system.

This option comes in the form of an Effects Send Matrix Module which

installs in the front switcher frame bay.

Secondary Wipe Generators

An optional Secondary Wipe Generator for both Mix/Effects provides a

second wipe pattern for each of the M/E systems. With this option

installed, two independent wipe patterns are allowed within each M/E.

The output from the Secondary Wipe Generator can be mixed or non-

additively mixed with the output from the primary wipe generator to

create novel wipe patterns.

This option also allows the Preset wipe pattern to differ from the transition

wipe pattern. It can also be used as an additional mask source and a matte

generator modulator within each M/E.

The Secondary Wipe Generator Modules are sub-modules which mount

onto the Mix/Wipe Modules in each M/E.

1-6

Page 21

Optional Features for Switcher

Dual Chromatte Advanced Chroma Keyer (Cells A3, A16, C8)

Optional Chromatte™ Advanced Chroma Keyer Modules are available for

component chroma keying. Each module provides chroma keying for both

foreground keyers in an M/E. Dual Chromatte™ Chroma Keyer Modules

are installed in the front bay of the switcher frame. Any internal 4:2:2

component signal may be used to chroma key.

To use external analog component inputs for chroma keying, the optional

Dual Analog Component Chroma Key Input Modules must be installed.

The input module provides two analog component chroma key inputs

direct to both Chroma Keyer Modules. The input module is installed in the

rear bay of the switcher frame. This module provides the key only, the key

fill must come from the Serial Input Modules.

The following analog component formats are supported:

■

Betacam®

1

■

MII

SMPTE

■

EBU

■

BORDERLINE Key Edge Generation

BORDERLINE® Key Edge Generators are optional for each keyer in the

switcher. The BORDERLINE option is added by plugging a small sub-

module onto the Keyer module of an M/E. One sub-module can be

installed for each of the two keyers in each M/E.

Each BORDERLINE Key Edge Generator supports 1, 2, or 3 line wide

borders or outlines. Video fill is provided within the borders. Shadow and

extrude modes create 1 to 6 line wide edges, positioned either below left or

below right. Separate mattes are provided by the generators for edge and

fill. Key Edge opacity is adjustable.

Tally Output

The Tally Expansion Option provides 64 tally relay closures for on-air

source indicators. This option is a separate frame with the tally module and

support modules installed.

1. Betacam is the registered trademark of Sony Corporation.

1-7

Page 22

Section 1 — System Overview

Look-Ahead Preview

The Look-Ahead Preview option provides look-ahead preview processing

for the M/Es. This option is a mezzanine module which mounts on the

Mix/Wipe Module for that M/E. Without the Look-Ahead Preview

installed, only the switched preview is available for that M/E.

Timed Aux Output (Cell B16)

The Timed Aux Output Module provides three independent output pairs

(video/key) from aux buses 3A through 5B.

Extender Modules

A set of two Extender Modules is available.

Power Supplies

The switcher electronics frame and the control panel each have a single

standard power supply. The control panel power supply is located inside

the control panel tub. The switcher frames is powered by a power supply

that is mounted in the rack below the frame.

An optional redundant power supply assembly is available for the control

panel and the switcher frame.

Control Panel Power Supplies

Power is provided to the control panel by an assembly containing two

individual power supplies which is mounted inside the control panel tub.

The redundant power supply option provides a second, backup power

supply assembly. The optional assembly also mounts inside the panel.

1-8

Switcher Frame Power Supplies

Power for the switcher frame is provided by a single 19” rack mounted

assembly containing two individual power supplies. The assembly is rack

mounted directly below and wired directly to the switcher frame. When

the optional redundant supply is installed, it is rack mounted below the

standard supply and interconnected by a wiring harness. The frame power

supply assembly is air cooled by integral fans.

Page 23

Physical Description

Model 2200 Series electronic circuitry is contained on circuit modules in the

switcher frame, effects frame, and control panel.

In this manual and in other related documents, the circuit modules will be

referred to by the names and assembly numbers printed on them.

Control Panel

The control panel is the operator interface for the Model 2200 system and

provides all operator controls for the switcher and effects systems.

Through the control panel, the operator performs all actions via

mechanical buttons and controls, or through software controlled menus

and soft button adjustments. The control panel provides the data links to

both Frames.

Physical Description

Switcher Frame

The switcher frame is a large rack-mounted unit, see

all of the signal processing modules along with some control processor

modules.

The Head-of-State (HOS) processor and all M/E processors reside on two

Control Processor modules in Bay A (front bay) of the frame. Control

Processor 1 contains the HOS processor which supervises the state of the

switcher, handles communication with the control panel and controls the

video hardware. The M/E 1 processor also resides on this module.

The Control Processor 2 contains the circuitry for communication with the

editor, tally expansion and other remote control. The M/E 2 processor is on

this module.

Since each M/E has its own processor, failure of the HOS processor does

not shut down the entire switcher. Individual M/Es can continue to

operate independently, although in a degraded capacity (cuts, mixes and

fade- to-black continue to operate).

The control panel communicates with the switcher frame over two RS-422

data links, one per M/E. Both of the links is contained within a single cable

that may be up to 1000 feet long.

Figure 1-3

, that houses

1-9

Page 24

Section 1 — System Overview

Front Door

Impeller Fan —

Air flows up through the frame

Air

Outlets

(Both sides & rear)

Control and Signal

Processing Modules

Front Bay (A)

Air Filter

Figure 1-3. Signal Frame and Power Supply.

Input and Output Modules

and Options

Rear Bay (B)

Standard Power Supply

Assembly Slide Mounted directly

under the Signal Processing

1

0

1

0

Frame in the Equipment Rack

Optional Redundant Power Supply

Assembly Slide Mounted directly

under the Standard Power Supply

Assembly in the Equipment Rack

1-10

Page 25

System Specifications

Specifications for the Model 2200 System are listed on the following pages.

Refer to Section 2, Installation and Configuration, for information on the

mechanical characteristics of the system.

Specifications

1

are provided for the following:

System Specifications

Table 1-1

■

Table 1-2

■

Table 1-3

■

■

Table 1-4

■

Table 1-5

■

Table 1-6—Video System Characteristics (Analog and Digital)

■ Table 1-7—Environmental Characteristics

—Power Specifications

—Analog Input Video Characteristics

—Serial Digital Input Video Characteristics

—Analog Output Characteristics

—Serial Digital Output Characteristics

Table 1-1. Model 2200 Power Specifications.

Component Power Voltage Frequency

Control Panel 300 Watts 90–130 or 176–264 VAC – Autoranging 50-60 Hz – Nominal

Frame Power Supply 1600 Watts 176–264 VAC 50-60 Hz – Nominal

1. All specifications subject to change without notice.

1-11

Page 26

Section 1 — System Overview

Characteristic Requirement

Table 1-2. Analog Input Video Requirements.

Video Amplitude (Luminance channel) for

Chroma Key Inputs

Maximum luminance Excursion

Relative To Black level

(before clipping)

Video Amplitude For Color

Difference Chroma Key Inputs

(100% saturated bars)

Video Amplitude For RGB Chroma Key inputs 0.714mV with or without setup or

DC Offset Of Blanking Level

Common Mode Hum

Random Noise < –54 dB RMS relative to 1V p-p

Analog Reference Input Black (Burst is not required)

1

2

0.714 mV with/without setup or

0.700 mV without setup (with or without sync)

+108 IRE peak positive

– 6 IRE peak negative

Betacam ±467 mV

MII 60 Hz ±324 mV

MII 50 Hz ±350 mV

SMPTE ±350 mV

EBU ±350 mV

(Format for each input is individually

selectable)

700mV without setup (with or without sync)

Format for each input is individually selectable

±1 V olt DC

1.0 V p-p Max

Impedance (Chroma key and reference inputs) 75 Ω Terminating (Chroma Key/Analog Inputs)

Return Loss >40 dB to 5 MHz

Manual Timing steps 18 nS

Manual Timing range ±1 µS (Chroma Key inputs)

Common Mode Hum Attenuation >34 dB

1. Exclusive of Common Mode Hum

2. With DC Offset at 0.0 volts

75 Ω loop-through (Reference input)

1-12

Page 27

System Specifications

Table 1-3. Serial Digital Input Video Requirements.

Characteristic Requirement

Channel Coding Conforms to SMPTE RP–259M

Connector BNC

Input Impedance 75 Ω

Return Loss >15 dB 5 MHz to 270 MHz

Autotiming Range ±18 µS

Maximum Cable Length Equalized

(Belden 8281 type cable)

Number of Bits 8 or 10

225 meters (738 feet)

Table 1-4. Analog Output Specifications.

Characteristic Specifications

Output Amplitude 1.0 Volt p-p nominal

DC On Output Blanking Level <50 mV

Output Return Loss >34 dB to 5 MHz

Output Isolation >54 dB to 5 MHz

Output Y/C Timing error <10 nS

Number of Outputs 2 (RGB, SMPTE/EBU, MII or Betacam)

Table 1-5. Serial Digital Output Specifications.

Characteristic Specifications

Rise and Fall Times

(Between 20% and 80% amplitude points)

Channel Coding Conforms to SMPTE RP-259M

Aux Data Blanked

Between 400 pSec and 1.5 nSec

across 75 Ω termination

1-13

Page 28

Section 1 — System Overview

Characteristic Specifications

Connector BNC

Output Impedance 75 Ω

Return Loss >15 dB 5MHz to 270 MHz

Output Amplitude 800 mV p-p across 75 Ω ±10%

DC Offset on Output <50 mV across 75 Ω termination

Number of Bits 10 bits or 8 bits

Number of Outputs 2 (Timed Aux Output has 1)

Table 1-5. Serial Digital Output Specifications. - (continued)

Table 1-6. Video System Specifications (Analog or Digital).

Characteristic Specifications

Blanking Width 10.222 µS (525 line)

Number Of Quantization Bits 10 Minimum

Mix T r acking Error 0

Linearity During Mix Linearity Is Not Affected By Mix

Frequency Response During Mix Response Is Not Affected By Mix

Path Length 70 µS

Rounding Method (digital only) Adaptive Bit Reduction™ (Patent Pending)

10.666 µS (625 line)

Table 1-7. Environmental Specifications.

1-14

Characteristic Specifications

Operating Ambient Temperature Range 0° – 40° C (32° – 104° F)

Ambient Temperature for Specifications 20° – 30° C (68° – 86° F)

Relative Humidity (Operating) 95% Maximum (Non-Condensing)

Page 29

2

Introduction

Installation

This section describes the installation and setup of the Model 2200 Digital

Switcher. Installing the Model 2200 is done in the following order:

■ Unpacking

■ Installing the Control Panel

■ Installing the switcher frame in the rack

■ Option Installation

■ Cabling the equipment

■ Power connections

■ Configuring, testing and timing the installed system

Also included in this section are procedures to connect peripheral

equipment such as Grass Valley Editors, KALEIDOSCOPE, DPM-700,

Tally Control and GPI connections to the Model 2200.

2-1

Page 30

Section 2 — Installation

Unpacking

The Model 2200 is packaged in several boxes, which contain the following:

■ Switcher Frame

■ Control Panel

■ Cables and Power Cords

■ Power Supplies

■ Instruction Manuals

■ Options

Carefully check the contents of each box against the packing slip to ensure

that everything shipped to you was received. If any items are missing or

damaged, contact the shipping company or your supplier or sales

representative immediately.

Pre-installation Procedures

Before you install the Model 2200, there are certain considerations such as

tools required, physical specifications, safety and power requirements you

should be aware of. These considerations are covered in the following

sections.

Items Required but not Supplied

The following is a list of items required for installation:

■ Medium flat bladed screwdriver

■ Medium Phillips head screwdriver

■ #10, #15, & #20 Torx screwdrivers

■ 3/8” deep well socket

■ Torque Wrench (100 inch pound range)

■ 1/8” (3mm) drill

■ six #6 (M4) screws

2-2

Page 31

Pre-installation Procedures

Physical Specifications and Installation Requirements

Physical dimensions for the Model 2200, shown in Table 2-1, are provided

to assist you in the installation.

Table 2-1. Model 2200 Component Size Summary

Component Depth Width Height

2200 Control Panel 23.5 inches

(578 mm)

Switcher Frame 22.5 inches

(571.5 mm)

Power Supply 22.5 inches

(571.5 mm)

* Allow 14 rack units total under switcher frame if installing redundant Power Supply.

47.0 inches

(1.194 M)

Std (19 inches)

(483 mm)

Std (19 inches)

(483 mm)

13.8 inches

(350 mm)

26.25 inches

(666.7 mm)

12.25 inches

(311.1 mm)

Power Requirements

Power requirements for the Model 2200 control panel and switcher frame

are listed in Table 1-1 on page 1-11. The frame operates on 220 VAC only,

the control panel power supply is autoranging between 110 and 220 VAC.

Environmental Requirements

# of Rack

Units

n/a 150 lbs

15 175 lbs

7* 143 lbs

Weight

(67 kgs)

(78 kgs)

(65 kgs)

The Model 2200 has been designed to operate properly in environments

outlined in Table 1-7 on page 1-14.

Safety Requirements

The following precautions are provided to ensure that safety

considerations for both equipment and personnel are presented before

installation procedures are begun. To prevent injury or equipment

damage, read, understand, and follow all installation safety precautions.

any

2-3

Page 32

Section 2 — Installation

WARNING

Electrical potential is still applied to some internal components even when

the power switch/breaker is in the off position. To prevent electrical shock

when working on this equipment, disconnect the AC line cord from the AC

source before working on any internal components. A residual voltage may

be present immediately after unplugging the system due to large power

supply capacitors discharging. Wait thirty seconds to allow capacitors to

discharge before working on the system.

WARNING

The switcher frame weighs approximately 175lbs. (67 Kg.) when fully

configured. Provide appropriate equipment to support the frame during

installation.

Do not lift the control panel by the lid. The lid could open causing the unit to

fall creating a hazard to personnel and/or damage to the equipment.

WARNING

The Switcher Frame Power Supply assembly exhibits high leakage (fault)

currents due to the EMI suppression filter system. This power supply chassis

must be connected to earth ground via the ground wire provided in the AC

input cord. An additional ground lug is provided on the rear of the power

supply chassis for supplementary grounding purposes.

CAUTION

To avoid static damage to sensitive electronic devices, protect the Model 2200

Digital Switcher from static discharge. Avoid handling switcher modules in a high

static environment. Touch the switcher frame before you remove any modules.

This helps ensure that any potential difference between your body and the frame

is dissipated. If you handle the modules or make any repairs to them use a

grounding strap and grounded equipment.

2-4

Page 33

Installation

Control Panel Installation

Installation

The following procedures contain the instructions necessary to install the

control panel, switcher frame, and frame power supply. Procedures are

also included for optional circuit modules and cable installation. Before

proceeding, read and understand all precautions and notes.

This installation does not require countersunk or beveled edges. The tub

slips into the cutout from the top and is held in place by an overhanging lip

secured by six screws. To install the control panel in the console, proceed

with the following steps.

NOTE:

The control panel should be installed on as flat a surface as possible. It is

not recommended to have more than a 10 degree tilt, as this would add excessive

weight on the gas shocks supporting the control panel top.

Be sure to leave a minimum of 6.0” (153 mm) of clear space inside the console

behind the control panel for control, signal, and power cables and connectors.

Also, be sure to leave a minimum of 5.2” (152 mm) of clear space behind the

control panel so the lid can be fully opened, as shown in Figure 2-1.

23.5"

(597 mm)

1"

(25 mm)

2.2"

(56 mm)

(596 mm)

Figure 2-1. Model 2200 Control Panel Profile

23.5"

5.2"

(152 mm)

5.8"

(146 mm)

8.0"

(203 mm)

13.8"

(350 mm)

2-5

Page 34

Section 2 — Installation

Control Panel Cutout Dimensions

Using the dimensions shown in Figure 2-2, make cutouts in the console to

accommodate the control panel.

WARNING

Do not lift the control panel by the lid or the transition lever arms. Be careful

when opening or closing the panel lid. The gas shock supports may cause

the lid to open or close abruptly, causing possible injury or damage to the

equipment. Always lift the control panel by holding onto the tub.

Pilot Holes

Rear

21.8"

(554 mm)

0.2"

(5 mm)

1.8"

(46 mm)

22.16"

(563 mm)

21.2"

(538 mm)

Front

42.4"

(1077 mm)

46"

(1168 mm)

Figure 2-2. Model 2200 Control Panel Console Cutout Dimensions

Limits of

Cutout

Area

2-6

Page 35

Mounting

Surface

6.25"

(159 mm)

4.0"

(102 mm)

3.75"

(95 mm)

Installation

Control Panel Rear Cable Clearance

Using the dimensions shown in Figure 2-3, make cutouts in the rear of the

console platform.

Connectors and Ventilation.

Leave These Areas Clear.

5.3"

Vent

43.2" (1.097 M)

Cables

38.2" (970 mm)

24.4" (620 mm)

30.4" (772 mm)

47" (1.194 M)

REAR VIEW

Vent

Power

11.1"

(282 mm)

12.2"

(241 cm)

17.2" (436 mm)

(135 mm)

5.9"

(150 mm)

7.5"

(191 mm)

Figure 2-3. Required Cable Clearance

Inserting the Panel

1. Carefully place the control panel into the cutout in the console and

open the control panel.

2. Drill six pilot holes in the console through the holes in the control panel

flange using a 1/8” (3 mm) drill and secure the control panel to the

console with six #6 (M4) screws (not included) into these holes.

3. Do not connect power to the control panel until all cable connections

have been completed and verified.

2-7

Page 36

Section 2 — Installation

Control Panel Redundant Power Supply Option Installation

To install the control panel redundant power supply proceed as follows:

1. Open the control panel and turn the AC power switch(s) on the left

front of the enclosure to the OFF position. See Figure 2-4. At the rear of

the control panel, disconnect the power cord from the AC source.

Power Supply

(Standard)

Optional

Redundant

Power Switch

& Fuse

Power

ON/OFF

Switch

Fuse

Control Panel

Power Supply

Cover

Figure 2-4. Control Panel AC Power Switch Location.

2. Remove the enclosure covering the power supplies by removing the

screws securing it to the control panel tub.

NOTE:

Removing some control panel internal ribbon cables may make removing

the power supply enclosure easier.

Fan

Power Supply

(Redundant)

Control Panel

CPU Board

2-8

Page 37

Installation

Power

Supply

Access

Cover

(secured

by 6 screws)

Control Panel

I/O Board

(068949)

Power

ON/OFF

Switch

(Redundant)

(Redundant)

Fuse

EMI

Filter

Power

ON/OFF

Switch

Fuse

Standard

Supply

Figure 2-5. Removing Control Panel Power Standard Supply.

Fan

Redundant

Supply

Control Panel

CPU Board

3. Remove the ten screws securing the flat mounting plate supporting the

supply.

4. Attach the redundant power supply to the flat mounting plate.

5. Remove the U shaped plate which covers the redundant power supply

fuse, switch, and power connector holes.

6. Using the same screws, mount the power supply fuse, switch, and

power connector bracket.

7. Route the long cable behind the standard power supply and over the

standard AC filter.

8. Plug the short cable into the control panel I/O board.

9. Reattach the flat mounting plate, replace the power supply enclosure,

and reconnect any cables that were disconnected.

2-9

Page 38

Section 2 — Installation

Switcher Frame Installation

NOTE:

The switcher frame must be installed before either of the power supplies.

When planning your installation, ensure that the frame will be installed high

enough in the equipment rack to allow 7 rack units for the installation of the Frame

Primary Power Supply (and another 7 rack units for the optional redundant Power

Supply, if purchased) below it.

To allow the use of extender modules and access for other maintenance, sufficient

room should be allowed in front of the equipment rack (

≥

41 inches, 1.05 0 M.).

Sufficient room should also be allowed in the rear of the rack for access to cables and

the exhausting of cooling air.

The switcher frame mounts in a standard 19-inch (48.3 mm) wide

equipment rack. It is installed in the rack from the front and secured at the

front edges of the frame with screws (not provided by GVG). Its Power

Supply mounts below it in the rack on slide rails. The procedure for

installing the Power Supply follows the frame installation procedure.

To install the frame in the equipment rack, read the following precautions,

then refer to Figure 2-6 and complete the following steps:

WARNING

The Model 2200 switcher frame weighs appro ximately 175 lbs (67 Kg.) when

fully configured. Pr ovide appr opriate equipment to support the frame during

installation.

When the switcher frame and Po wer Supply are installed, the equipment rack

is top heavy and could topple. Ensure that the equipment rack is attached

solidly to the floor/building to prevent tipping when the frame and Power

Supply are installed.

When lifting the frame into place in the equipment rack, it is recommended

that a mechanical lifting device be used.

Ensure that the bottom plate of the frame is protected from damage while the

frame is being lifted into the equipment rack.

NOTE:

The switcher frame is shipped with a protective metal plate on the bottom.

Leave the plate in place to protect the power cables until the frame is mounted in

the rack.

2-10

Page 39

Installation

1. Ensure that all packing foam, strapping, and tape is removed from the

frame before installing the frame in the rack.

2. Carefully, with the aid of a mechanical lifting device, lift the frame and

place it in position in the equipment rack.

3. Align the frame so that its screw holes match up with those in the rack

and secure the 10 rack screws (not supplied) required by the rack

manufacturer.

4. Install all screws and tighten to the rack manufacturer’s specifications.

5. Remove the protective plate from the bottom of the switcher frame.

Switcher

Frame

Front

Note: Front Door Not

Shown For Clarity

Secure

Bolts

through

Frame

(5 each

side)

into

Rack

Install Standard Power

Supply Assembly and

Optional Redundant Power

Supply After Switcher is

Installed in Rack

(ensure shipping

plate has been removed

from bottom of Signal

Processor Frame)

1

0

1

0

Figure 2-6. Switcher Frame Installation

2-11

Page 40

Section 2 — Installation

Switcher Frame Power Supply Installation

The Primary Power Supply must be mounted immediately below the

switcher frame in the rack. If you are installing an optional Redundant

Power Supply, it must be located immediately below the Primary Power

Supply. Verify that you have allowed enough rack space (7 rack units per

Supply) before proceeding.

WARNING

T o reduce the risk of electric shoc k, do not perf orm an y servicing other than

that contained in the operating instructions unless you are qualified to do so.

To install the Switcher Frame Power Supply in the equipment rack, refer to

Figure 2-7 and proceed as follows: