Model 2182A

Nanovoltmeter

Quick Start Guide

Safety precautions

The following safety precautions should be observed before using this product and

any associated instrumentation. Although some instruments and accessories would

normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are

familiar with the safety precautions required to avoid possible injury. Read and follow

all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the

product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical

safety procedures and proper use of the instrument. They must be protected from

electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it

operating properly, for example, setting the line voltage or replacing consumable

materials. Maintenance procedures are described in the user documentation. The

procedures explicitly state if the operator may perform them. Otherwise, they should

be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and

repair products. Only properly trained service personnel may perform installation and

service procedures.

Keithley products are designed for use with electrical signals that are measurement,

control, and data I/O connections, with low transient overvoltages, and must not be

directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections

require protection for high transient overvoltages often associated with local AC mains

connections. Certain Keithley measuring instruments may be connected to mains.

These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument

labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be

present on cable connector jacks or test fixtures. The American National Standards

Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The

responsible body must ensure that operators are prevented access and/or insulated

from every connection point. In some cases, connections must be exposed to

potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is capable of operating

at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended

to be used with impedance-limited sources. NEVER connect switching cards directly

to AC mains. When connecting sources to switching cards, install protective devices

to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a

properly-grounded power receptacle. Inspect the connecting cables, test leads, and

jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as

rack mounting, a separate main input power disconnect device must be provided in

close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments

while power is applied to the circuit under test. ALWAYS remove power from the

entire test system and discharge any capacitors before connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes,

such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the

circuit under test or power line (earth) ground. Always make measurements with dry

hands while standing on a dry, insulated surface capable of withstanding the voltage

being measured.

When fuses are used in a product, replace with the same type and rating for

continued protection against fire hazard.

For safety, instruments and accessories must be used in accordance with the

operating instructions. If the instruments or accessories are used in a manner not

specified in the operating instructions, the protection provided by the equipment may

be impaired.

Do not exceed the maximum signal levels of the instruments and accessories.

Maximum signal levels are defined in the specifications and operating information and

shown on the instrument panels, test fixture panels, and switching cards.

Chassis connections must only be used as shield connections for measuring circuits,

NOT as protective earth (safety ground) connections.

If you are using a test fixture, keep the lid closed while power is applied to the device

under test. Safe operation requires the use of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire

recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer

to the operating instructions located in the user documentation in all cases where the

symbol is marked on the instrument.

The symbol on an instrument means warning, risk of electric shock. Use standard

safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal

contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display

lamp. Please note that the lamp must be properly disposed of according to federal,

state, and local laws.

The WARNING heading in the user documentation explains hazards that might result

in personal injury or death. Always read the associated information very carefully

before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains

hazards that could result in moderate or minor injury or damage the instrument.

Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains

circuits — including the power transformer, test leads, and input jacks — must be

purchased from Keithley. Standard fuses with applicable national safety approvals

may be used if the rating and type are the same. The detachable mains power cord

provided with the instrument may only be replaced with a similarly rated power cord.

Other components that are not safety-related may be purchased from other suppliers

as long as they are equivalent to the original component (note that selected parts

should be purchased only through Keithley to maintain accuracy and functionality of

the product). If you are unsure about the applicability of a replacement component,

call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are

designed to operate indoors only, in the following environment: Altitude at or below

2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree

1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild,

water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products

that consist of a circuit board with no case or chassis (e.g., a data acquisition board

for installation into a computer) should never require cleaning if handled according to

instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precautions as of June 2018.

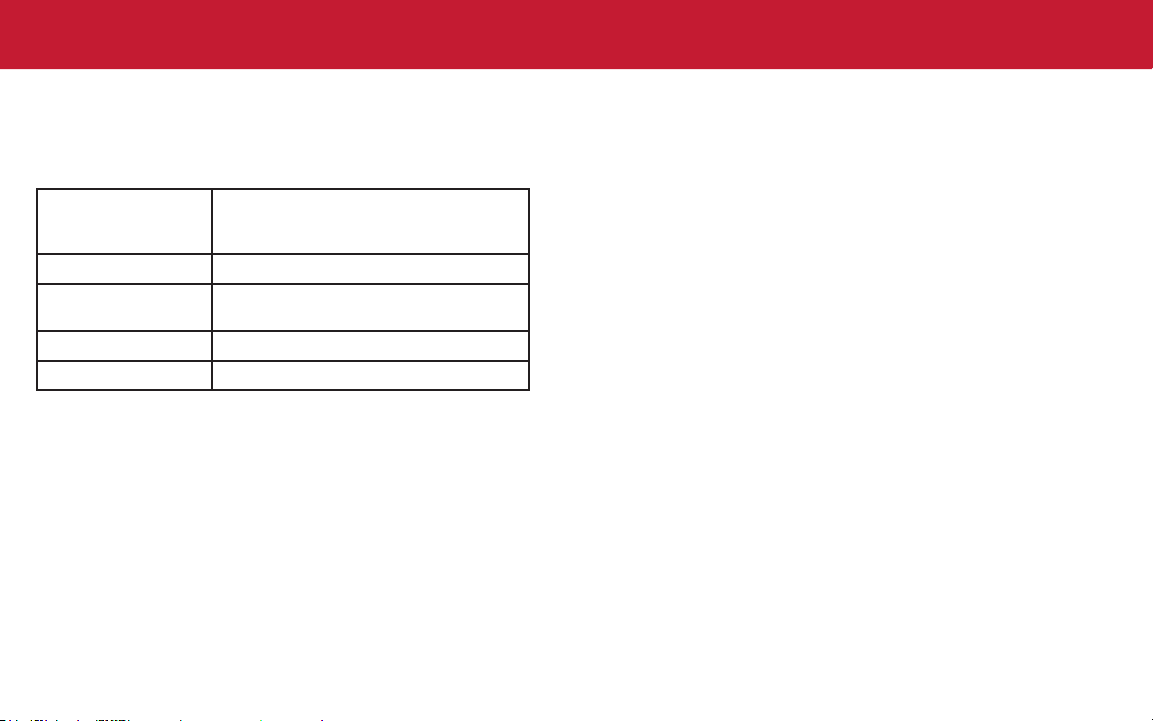

Safety

Power and environmental ratings

For indoor use only.

Power supply

Power consumption

Operating

environment

Storage temperature

Pollution degree

100 V ac /120 V ac / 220 V ac / 240 V ac

50 Hz, 60 Hz, and 400 Hz, automatically

sensed at power-up

22 VA

Specied for 0 °C to 50 °C; specied to 80%

relative humidity at 35 °C

−40 °C to 70 °C

1 or 2

Introduction

The two-channel Model 2182A Nanovoltmeter is optimized

for making stable, low noise voltage measurements and for

characterizing low resistance materials and devices reliably

and repeatably. It provides higher measurement speed and

signicantly better noise performance than alternative low

voltage measurement solutions.

The 2182A oers a simplied delta mode for making

resistance measurements when used in combination with a

reversing current source, such as the Model 6220 or 6221.

Complete documentation for the 2182A instrument is

available for download on the Keithley web page at

tek.com/en/products/keithley.

The 2182A documentation includes:

• Quick Start Guide: This document. It provides unpacking

instructions, describes basic connections, and reviews

basic operation information.

• User’s Manual: Includes installation, instrument

description, operation, and maintenance information.

• Service Manual: Provides performance

verication, calibration, routine maintenance, and

troubleshooting information.

• Information on accessories.

Measurement capabilities

• Two voltage measurement channels.

• Measure voltage from 1 nV to 100 V (channel 1);

10 nV to 12 V (channel 2).

• Temperature measurements

• Ratio, delta, mx + b, and percent math operations.

Introduction

Unpack and inspect the instrument

To unpack and inspect the instrument:

1. Inspect the box for damage.

2. Open the top of the box.

3. Remove the documentation and accessories.

4. Carefully lift the instrument out of the box.

5. Inspect the instrument for any obvious signs of

physical damage. Report any damage to the shipping

agent immediately.

6. There may be a protective lm over the display lens,

which can be removed.

You receive the 2182A with these accessories

and documents:

• Power line cord

• DeoxIT

®

Contact Cleaner

• Model 2107-4 Low-thermal Input Cable Assembly

• Model 2182-KIT Low-thermal Connector with Strain Relief

• Four copper alligator clips that attach to the copper lugs

of the cable assembly

• Software and documentation downloads information

• Safety precautions

• Model 2182A Nanovoltmeter Quick Start Guide

(this document)

Connect the instrument

Important test system safety information

This product is sold as a stand-alone instrument that may

become part of a system that could contain hazardous

voltages and energy sources. It is the responsibility of the

test system designer, integrator, installer, maintenance

personnel, and service personnel to make sure the system is

safe during use and is operating properly.

You must also realize that in many test systems a single

fault, such as a software error, may output hazardous signal

levels even when the system indicates that there is no

hazard present.

It is important that you consider the following factors in your

system design and use:

• The international safety standard IEC 61010-1 denes

voltages as hazardous if they exceed 30 V

42.4 V

locations. Keithley Instruments products are only rated for

dry locations.

• Read and comply with the specications of all instruments

in the system. The overall allowed signal levels may be

constrained by the lowest rated instrument in the system.

For example, if you are using a 500 V power supply with

a 300 V dc rated switch, the maximum allowed voltage in

the system is 300 V dc.

or 60 V dc for equipment rated for dry

PEAK

RMS

and

• Cover the device under test (DUT) to protect the operator

from ying debris in the event of a system or DUT failure.

• Make sure any test xture connected to the system

protects the operator from contact with hazardous

voltages, hot surfaces, and sharp objects. Use

shields, barriers, insulation, and safety interlocks to

accomplish this.

• Double-insulate all electrical connections that an operator

can touch. Double insulation ensures the operator is

still protected even if one insulation layer fails. Refer to

IEC 61010-1 for specic requirements.

• Make sure all connections are behind a locked cabinet

door or other barrier. This protects the system operator

from accidentally removing a connection by hand and

exposing hazardous voltages. Use high-reliability fail-safe

interlock switches to disconnect power sources when a

test xture cover is opened.

• Where possible, use automatic handlers so that operators

are not required to access the DUT or other potentially

hazardous areas.

• Provide training to all users of the system so that they

understand all potential hazards and know how to protect

themselves from injury.

• In many systems, during power up, the outputs may be in

an unknown state until they are properly initialized. Make

sure the design can tolerate this situation without causing

operator injury or hardware damage.

Unpack

NOTE

To keep users safe, always read and follow all safety warnings

WARNING

provided with each of the instruments in your system.

Install the instrument

Connect line power

The 2182A operates from a line voltage of 100 V ac,

120 V ac, 220 V ac, or 240 V ac at line frequencies of 45 Hz

to 66 Hz or 360 Hz to 440 Hz. It automatically senses line

frequency. Make sure the operating voltage in your area

is compatible.

You can use the 2182A on a bench or in a rack. See the

instructions that came with your rack-mount kit if you are

installing the 2182A in a rack.

To prevent damaging heat build-up and ensure specied

performance, make sure there is adequate ventilation and

airow around the instrument to ensure proper cooling. Do

not cover the ventilation holes on the top, sides, or bottom of

the instrument.

Position the instrument so that it is easy to reach any

disconnecting devices, such as the power cord and the

power switch.

The power cord supplied with the 2182A contains a

separate protective earth (safety ground) wire for use

with grounded outlets. When proper connections are

made, the instrument chassis is connected to power‑line

ground through the ground wire in the power cord. In

the event of a failure, not using a properly grounded

protective earth and grounded outlet may result in

personal injury or death due to electric shock.

Do not replace detachable mains supply cords with

inadequately rated cords. Failure to use properly rated

cords may result in personal injury or death due to

electric shock.

CAUTION

Operating the instrument on an incorrect line voltage

may cause damage to the instrument, possibly voiding

the warranty.

To connect line power:

1. Make sure the front-panel power switch is in the

o (O) position.

2. Connect the socket of the supplied power cord to the

power module on the rear panel.

3. Connect the plug of the power cord to a grounded

ac outlet.

Turn on the instrument

1. Disconnect any devices under test (DUTs) from

the 2182A.

2. Turn on the instrument by pressing the front-panel

POWER switch to the on (|) position.

You must turn on the 2182A and allow it to warm up for at

least 2½ hours to achieve rated accuracies.

Power‑up sequence

On power up, the 2182A performs self-tests and momentarily

lights all digit segments and annunciators. If a failure is

detected, the instrument momentarily displays an error

message and the ERR annunciator turns on.

When the instrument passes the self-tests, the rmware

revision levels are displayed. For example:

REV: A01 A02

Where A01 is the main board ROM revision and A02 is the

display board ROM revision.

After the power-up sequence, the instrument begins to

display readings.

Connect

Connections for testing

WARNING

CAUTION

To prevent electric shock, test connections must be

congured such that the user cannot come in contact

with test leads or any device under test (DUT) that is

in contact with the conductors. It is good practice to

disconnect DUTs from the instrument before powering

the instrument. Safe installation requires proper shields,

barriers, and grounding to prevent contact with test leads.

A hazardous voltage condition exists at or above 42 V

To prevent electric shock that could result in personal

injury or death, never make or break connections while

hazardous voltage is present.

PEAK

Exceeding the following limits may cause instrument

damage that will void the warranty.

Channel 1 HI and LO inputs have a maximum

measurement capability of 120 V

are protected to 150 V

to any terminal or 350 V

PEAK

. These inputs

PEAK

to chassis.

Channel 2 HI and LO inputs have a maximum

measurement capability of 12 V

protected to 150 V

protected to 70 V

.

protected to 350 V

PEAK

PEAK

PEAK

to any terminal. Channel 2 LO is

to Channel 1 LO. Both inputs are

to chassis.

. Channel 2 HI is

PEAK

PEAK

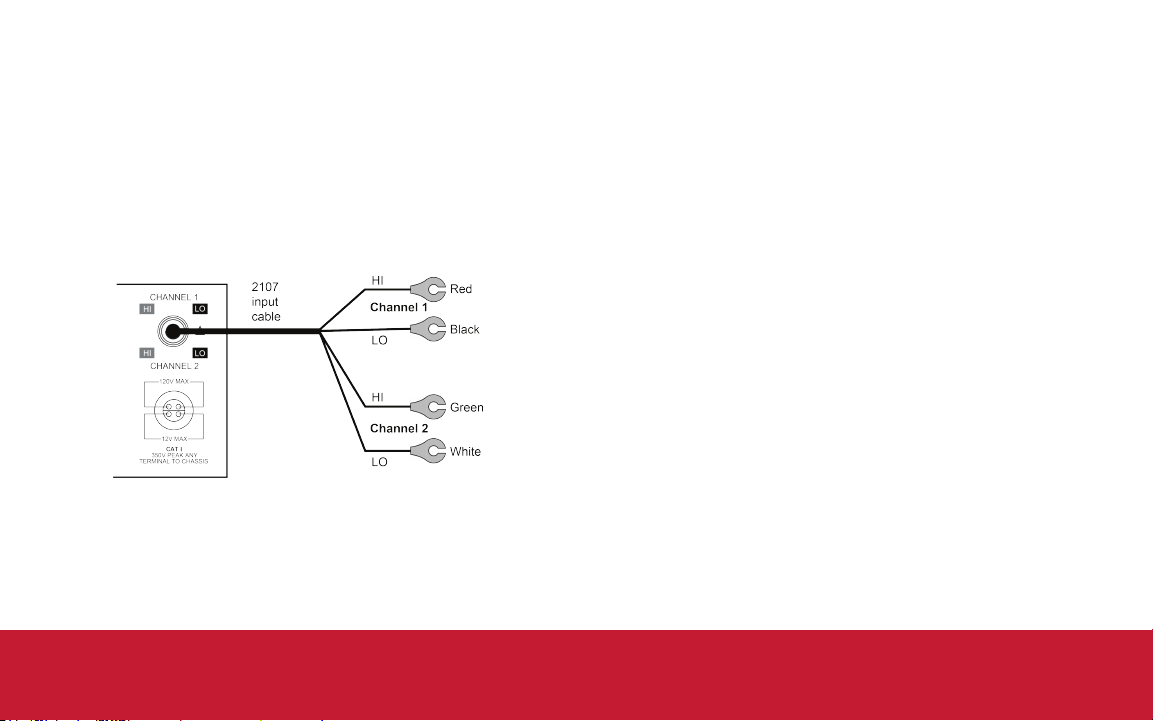

Model 2107 low‑thermal input cable

The 2107, shown in the following gure, is terminated with

a CHANNEL connector on one end and copper lugs on the

other end. The cable is shielded to chassis ground when

connected to the 2182A. You can use this cable to make

voltage measurements and temperature measurements that

use an external simulated reference junction.

To make voltage connections, clamp the cleaned copper

lugs of the cable to the cleaned copper connectors of the

test circuit. For the test circuit, use clean #10 copper bus

wire wherever possible. Clean copper-to-copper connections

minimize thermal electromagnetic elds (EMFs). EMFs can

corrupt a measurement.

Connect

Voltage measurement connections

You can perform single or dual channel voltage

measurements. The dual channel feature of the 2182A

allows you to make comparison measurements in a

test circuit.

The following gure shows typical connections to measure a

DUT using a single channel.

The following gure shows typical connections to make

comparison measurements of two devices in a test circuit.

For this measurement conguration, there is no voltage

dierential between the two measurement channels.

Channel 2 HI is connected directly to Channel 1 LO.

Temperature measurement connections

You can use Channel 1 of the 2182A to make temperature

measurements. The following gure shows connections

using the internal reference junction. The thermocouple wires

must be soldered directly to the CHANNEL connector.

The following gure shows temperature-only connections

using an ice bath as a simulated reference junction. The

connection points for the input cable and the thermocouple

wires are immersed in the ice bath.

Connect

Basic operation

Make a voltage measurement

Most front panel keys have two functions. The name on the

key indicates its primary function. The name in blue above a

key indicates its function when the SHIFT key is pressed.

For example, press DCV1 to select the Channel 1 voltage

measurement function. Press SHIFT then MX+B to choose

the mx + b function.

The following test veries basic operation of the 2182A. In

this test, you use the front-panel controls to make a voltage

measurement.

To measure voltage:

1. Make connections to the DUT as described in “Voltage

measurement connections.”

2. Press DCV1, which measures voltage on channel 1.

3. Press AUTO RANGE to enable automatic range setting.

4. Observe the voltage reading on the front panel.

Make a temperature measurement

NOTE

In this test, you use the front-panel controls to make a

temperature measurement.

To measure voltage:

1. Make connections to the DUT as described in

“Temperature measurement connections.”

2. Press SHIFT then TCOUP.

3. Select UNITS to set the temperature units (°C, °F, or K).

4. Select SENS and select TCOUPLE.

5. Select TYPE and select the thermocouple type that you

are using to measure temperature.

6. Select JUNC and select the type of reference

measurement:

• To reference measurements to the internal reference

junction: Select INTRNL.

• To reference measurements to an external simulated

reference: Select SIM. You are prompted to enter the

simulated reference temperature. Use the arrow keys

to display the value and press ENTER.

7. Select TEMP 1 to measure temperature on channel 1.

8. Observe the temperature reading on the front panel.

These steps conrm basic functionality of your instrument.

Test

Measurement considerations

FAQs

For sensitive measurements, follow these guidelines to

maximize measurement accuracy:

• Use only clean, copper-to-copper connections to minimize

thermal EMFs.

• Any solder connections should use silver solder to minimize

thermal EMFs.

• Clean all connector terminals of oxidation using a small

amount of DeoxIT.

• Use the relative oset (REL) to null out osets:

• Connect the circuit, but leave the source disconnected.

• Select DCV1 or DCV2 as appropriate.

• Press REL to null osets.

• Repeat for other channel if needed.

• Connect the source, and make the measurement.

• Keep the 2182A and test circuit away from electrical noise

sources, and shield if necessary.

Refer to the Model 2182A Nanovoltmeter User’s Guide for

additional information.

Where can I nd updated drivers or rmware?

For the latest drivers and additional support information, see

the Keithley Instruments support website.

To nd drivers that are available for your instrument:

1. Go to tek.com/en/support/product-support.

2. Enter 2182A and select GO.

3. Select Software.

Next steps

For more information, refer to the Keithley Instruments

website, tek.com/en/products/keithley.

You can nd support and additional information about

the instrument in the Model 2182A Nanovoltmeter User’s

Manual.

FAQs and next steps

Contact information: 1-800-833-9200

For additional contacts, see https://www.tek.com/en/contact-tek

Find more valuable resources at TEK.COM.

Copyright © 2022, Tektronix. All rights reserved.

Tektronix products are covered by U.S. and

foreign patents, issued and pending. Information

in this publication supersedes that in all previously

published material. Specification and price change

privileges reserved. TEKTRONIX and TEK are

registered trademarks of Tektronix, Inc. All other

trade names referenced are the service marks,

trademarks, or registered trademarks of their

respective companies.

2182A-903-01 Rev. B July 2022

*P2182A-903-01B*

Loading...

Loading...