Page 1

I

!r

I

I

ffironlx

COMMITTED

TO EXCELLENCE

I

I

I

t

lo

I

I

I

THE

ARE

TO

PERFORM

CONTAINED

UNLESS

FOLLOWING

FOR

USE BY

AVOID

ANY

YOU

WARNING

SERVICING INSTRUCTIONS

QUALI

PERSONAL

SERVICING

IN

OPERATING

ARE

PLEASE

AT THE REAR OF THIS MANUAL.

FIED PERSONNEL

INJURY,

OTHER THAN

INSTRUCTIONS

QUALI

FIED TO

CHECK

DO

FOR

ONLY.

DO

SO.

NOT

THAT

CHANGE

INFORMATION

I

I

I

-o

I

I

Tektronix,

P.O.

Beaverton,

070-1483-00

Box

Inc.

500

Oregon

97077

INSTFTUCTION

Serial

Number

MANUAL

First

Printing

Revised APR

AUG

1981

1973

Page 2

Copyright

Contents of

any f orm

o

w

tn1.ltlhewritten

1973

lfektronix,

publication

this

Inc. All rights reserved.

not

may

perm

ssi,O.n= olrTgktranl

reproduced

be

x,.

in

,n,f-l

o:

I

I

I

I

I

Products

covered by U.S. and

patents.

TEKTRONIX,

registered

MENT is a registered trademark of

Lim ited,

Printed

privileges

Tektronix, lnc.

of

foreign

TEK,

SCOPE-MOBILE,

trademarks

in U.S.A. Specif

reserved.

are

of Tektronix,

ication and

its

and

patents

subsidiaries

and/or

and

Inc.

Tektronix U.K.

pending

@

TELEQUIP-

price

change

are

are

I

rl

I

I

I

I

I

I

I

or

Page 3

I

214 Service

!o

I

I

I

I

I

I

TABLE

SECTIO

SECTION 2 FUNCTIONS

N 1

INTRODUCTION

General Information

Specifications

Vertical

Triggering

Horizontal

Display

lsolation

AC

Operation

Internal

Environmental

Physical

Front Panel

Side

Deflection

Deflection

Battery Operation

OF

Panel

Controls

System

CONTROLS

Controls

OF

System

AND CONNECTORS

CONTENTS

Page

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-3

1-3

1-4

14

2-1

2-2

lo

I

I

I

I

I

I

SECTION 3 MAINTENANCE

Introduction

Preventive

General

Cleaning

Lubrication

Visual

CRT Care

Recalibration I nformation

Disassembly

Troubleshooting

Introduction

Troubleshooting

Trou

Corrective Maintenance

Obtaining Replacement Parts

Component Replacement

Recalibration

I nstrument

Mai

ntenance

lnspection

nstructions

I

bleshooting Equi

After Repair

Repackaging

Aids

pment

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-2

3-2

3-3

3-3

3-3

3-3

33

3-3

34

3-6

3-6

f.

I

REV APR 1981

Page 4

214

Service

SECTIO N

TABLE

4 CALIBRATION

General

Test

Equipment

Special Calibration

Preliminary

Preliminary

Power

Check

Adjust

Adjust FOCUS

Adjust

Adjust

Adjust

Adjust

Adjust

Vertical

Adjust

Adjust

Adjust

Adjust

Adjust

Check

Check Channel 2

Check

Check CH

Variable

Gheck Channel

Gheck Channel

Check

Trigger

Adjust

Gheck Trigger

Check

Horizontal

Adjust

Adjust

Adjust

Check Variable

Check

Procedure

Control

Supply

and

Power

Supply DC

CRT

Grid Bias

Trace Rotation

Storage Operating

Wall Band Level

Enhance

Hum Balance

System

Vertical

Channel

Channel

Vertical

Storage Vertical

Ghannel 2

lnput

Goupling

1 Volts/Division

Volts/Division

Vertical

Circuit

AUTO PRESET

Single

Sweep Operation

System

Horizontal

Horizontal

Calibration

Sweep

SEC/DlV

OF

Required

Level

DC

1

2

Gain

1 Volts/Div

2 Volts/Div

Amplifier

Circuit

Horizontal

Accuracy

CONTENTS

Fixtures

Settings

Display

Gentering

Attenuator

Step

Step Attenuator

Gain

Variable

Volts/Division

Switches

Bandwidth

Level

Operation

Centering

Gain

Levels

Level

Balance

Balance

Volt/Division

Accuracy

Accuracy

Range

Gompensation

Compensation

Magnifier

and

Range

Range

(cont)

Page

4-1

4-1

4-1

4-3

4-3

4-4

4-4

4-5

4-5

4-5

4-5

4-6

4-7

4-7

4-8

4-8

4-8

4-8

4-9

4-9

4-9

4-9

4-10

4-10

4-10

4-11

4-12

4-13

4-13

4-13

4-13

4-15

4-15

4-15

4-15

4-16

4-16

o:

I

I

I

I

I

I

ll

I

I

I

I

I

I

REV.

APR

1974

o:

@i

Page 5

214 Service

fr

I

I

I

I

I

I

TABLE

SECTION

SECTION

6 CIRCU IT

OF

5 TROUBLESHOOTING

Diagram Information

Gomponent Color Coding

Troubleshooting

DESCRIPTION

Block

Diagram Description

Circuit

Operation

Vertical I nput

Vertical

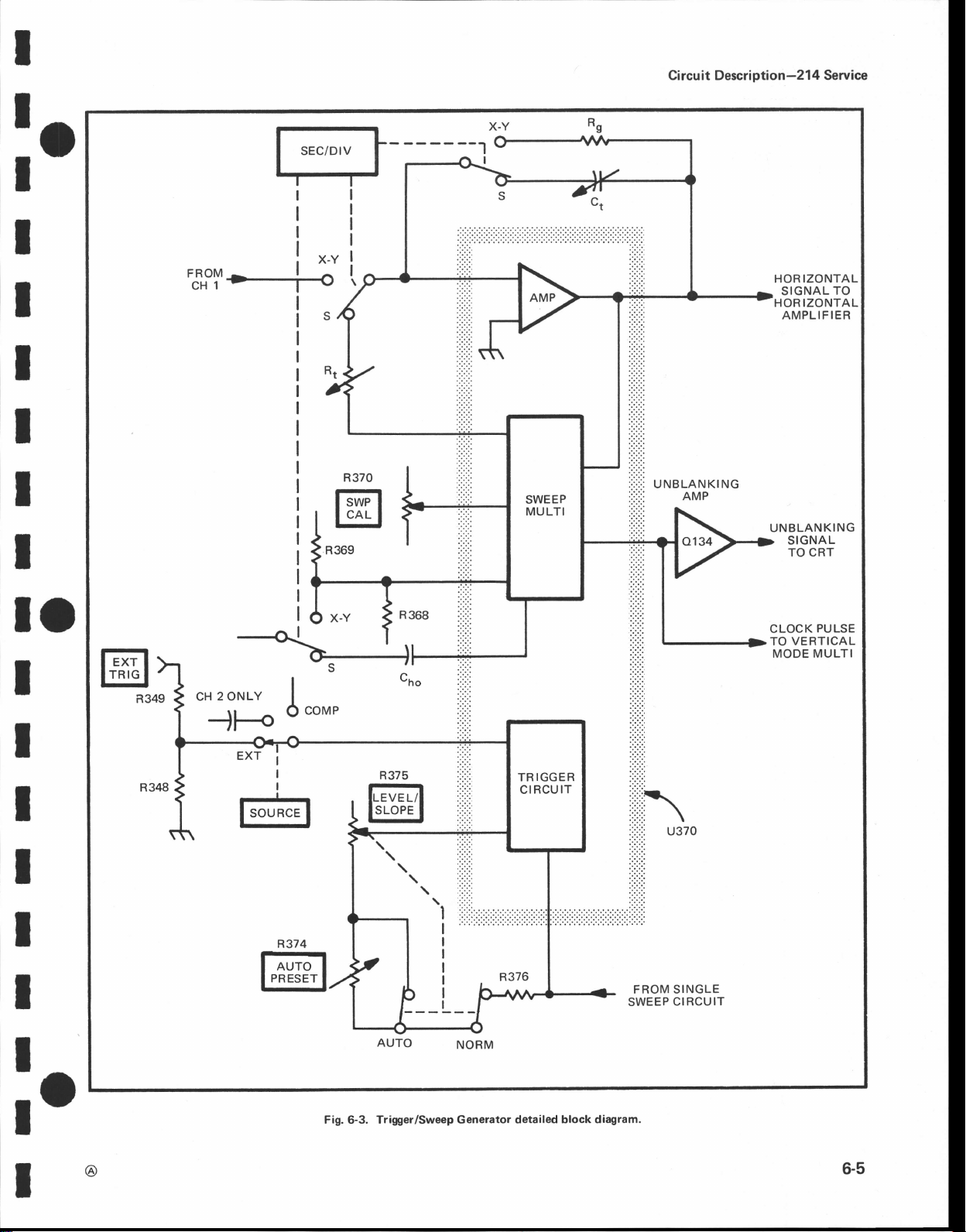

Trigger

Sweep Generator

Single Sweep

Storage

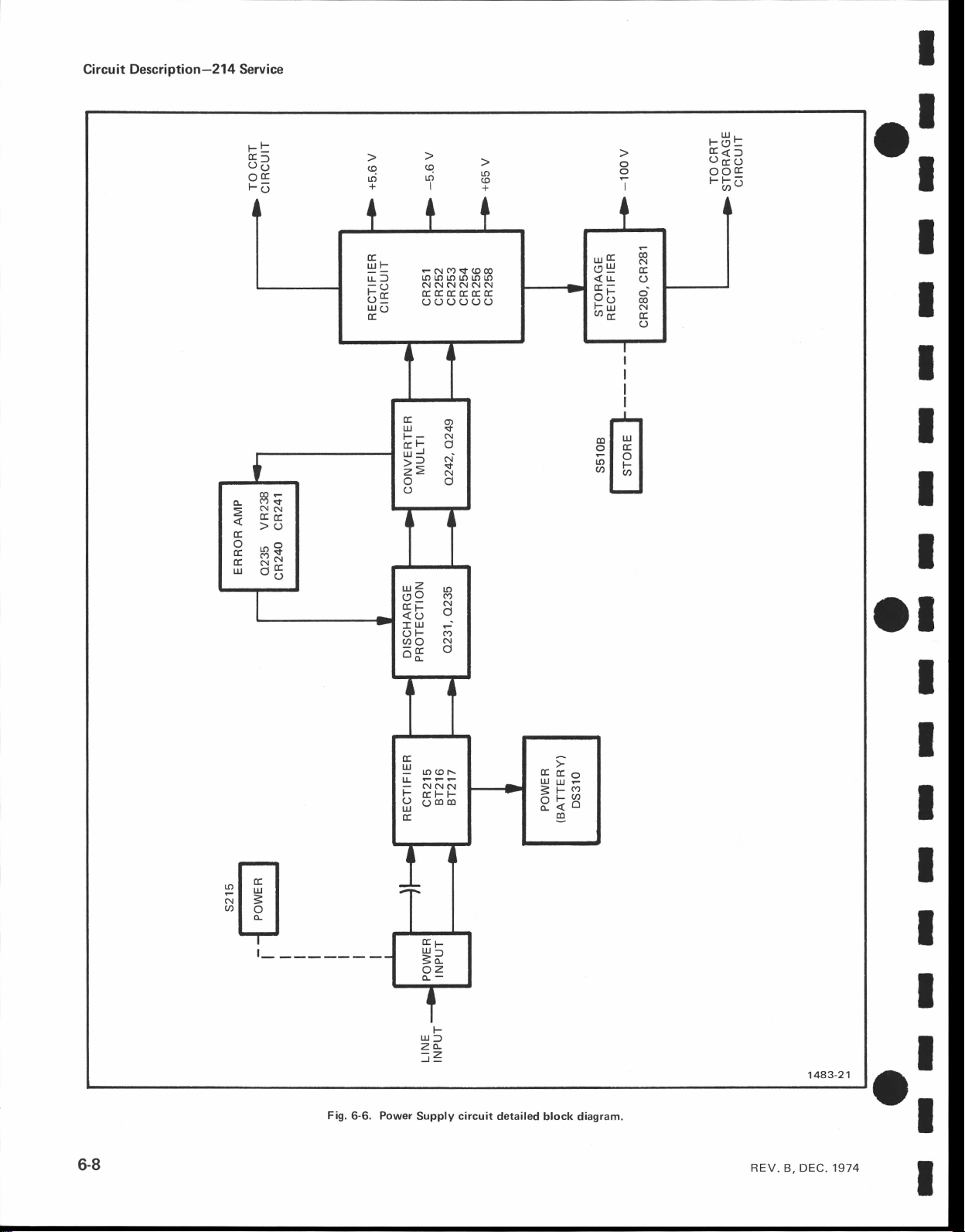

Power Supply

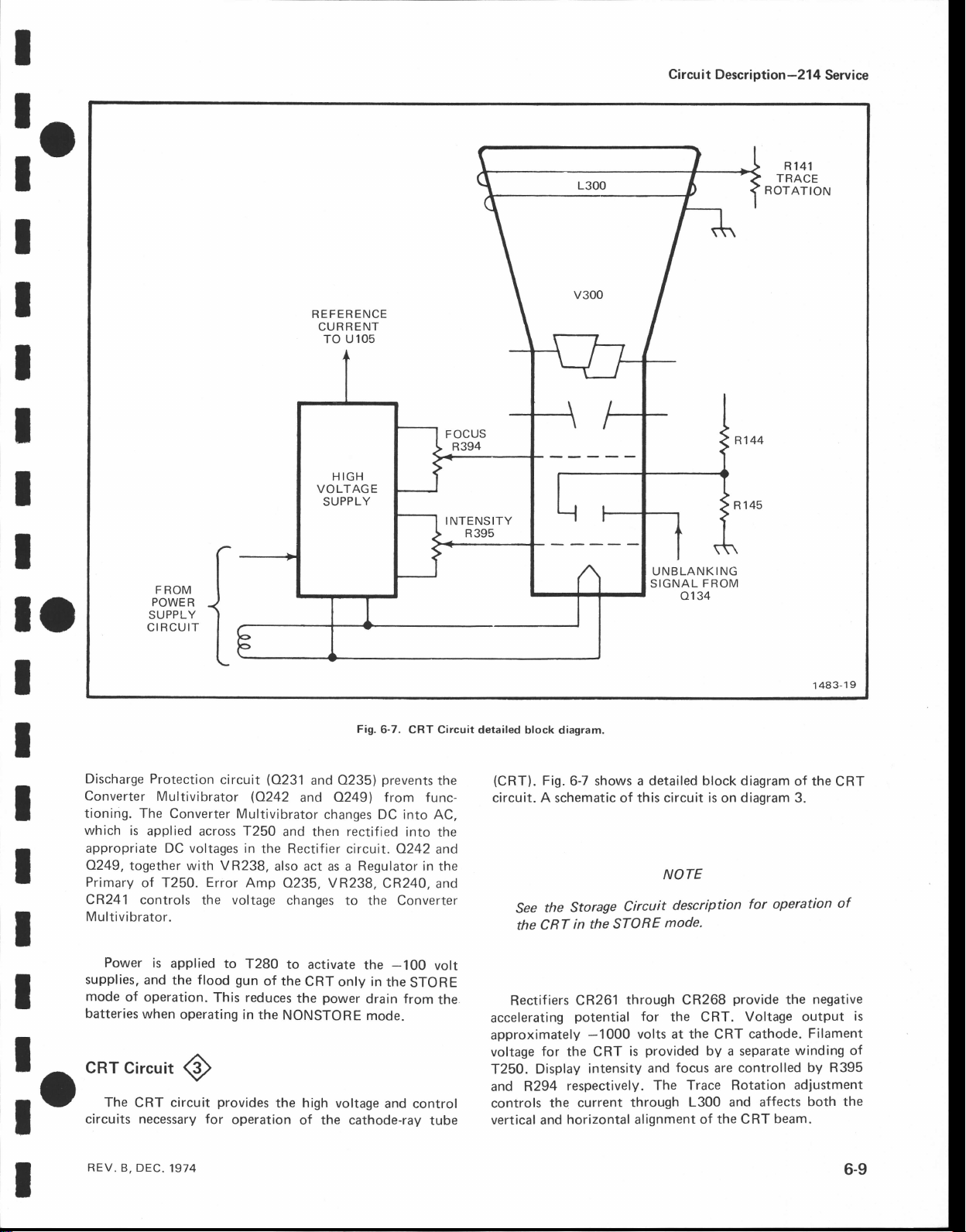

CRT Circuit

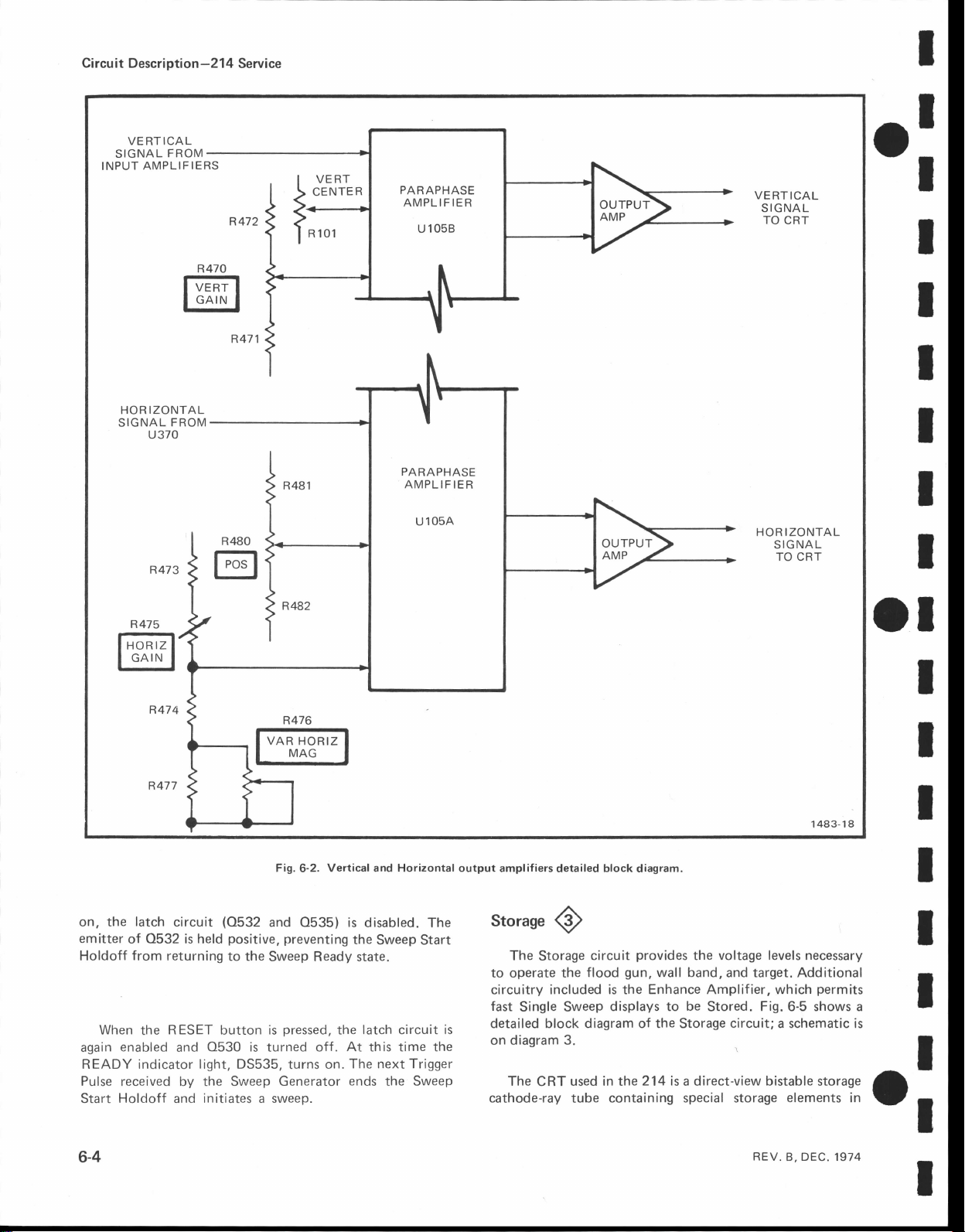

and Horizontal Output Amplifiers

Generator

CONTENTS

AIDS

Equ

ipment

Amplifiers

(cont)

Page

5-1

5-1

5-1

6-1

6-1

6-3

6-3

6-3

6-3

6-3

6-4

6-7

6-9

lo

I

I

I

I

I

I

SECTION

SECTION

OPTION INFORMATION

SECTION 9

SECTION 10 MECHANICAL

CHANGE

7 DELETED

(INFORMATION

8 ELECTRICAL

DIAGRAMS AND

INFORMATION

PARTS

INCORPORATED

NOW

LIST

CIRCUIT BOARD

PARTS LIST

IN

SECTION

ILLUSTRATIONS

3I

:o

t

I

REV.

c, ocr. re75

Page 6

o:

I

I

t

I

t

I

ot

I

I

I

I

I

I

Tektronix

21

4

Storage

Oscilloscope.

o:

Page 7

I

Section

1-214

Service

fo

t

GENERAL

I

I

I

I

I

I

f

-

I

O

I The horizontal

I

I

I

.

I

t

I

I

I

I

The

Tektronix 214

portable

weight

measurements.

tions where

tional

mechanically

and other

provides

reduced

of the integral

automatically

rate.

channel with its

iffi :xl,,.ff

of vertical frequency

s1,\reep

division.

magnifier,

sliveep

division.

Sweep

faster.

horizontal

from

reduced

vertical

instrument that

with

display storage

(NONSTORE)

constructed

extremes

dual-channel

The

vertical deflection

bandwidth)

Single-trace

,,

rates

from

Uncalibrated

are

rate for

Stored

mode)

X-Y

operation is

deflection

less

than

bandwidth

deflection

the ability

lt is designed for

high-impedance

chop or

operation

position

i::lil"J

available

a maximum

Automatic Enhance

at sl,eep rates

one millivolt

of the

INFORMATION

Storage

associated

DC-to-500

to 50

alternate,

?l:ffJ

response.

deflection

500 milliseconds

$,\reep rates,

to at least five

provided

of the

of 50

applied

Oscilloscope is

combines

to make

general-purpose

is desired,

operation.

to withstand

portability.

with

kilohertz

factors

volts/division

is achieved

control.

from

probes.

depending

Single

?1,H",.

system

of

least

at

of 0.1 millisecond/division

with

Channel

applied

kilohertz).

(X)

to

50 volts/division

(Y)

INTRODUCTION

a solid-state

small

size and light

precision

along with

The

the

one millivolt

at the tip

The

by

turning

Sweep operation

waveform

applicaconven-

instrument

shock,

vibration,

vertical

of either

214

will either

upon the

off either

system

(at

srueep

is

'j;'#,^'J?lf

ffi

provides

to five microseconds/

via

a variable

times

the indicated

one microsecond/

occurs

Channel

signal.

(in

1 supplying

with

signal,

2

,Ji:

calibrated

$/eep

the

Single

and

the

a range

(at

supplies the

a

instrument

This

teristics after complete instrument calibration.

acteristics apply over an ambient temperature

-15oC

the internal batteries, and OoC to

when operating from an AC line source, except

indicated. Warmup

is

+55oC

to

will meet

(+5"F

for

time

the

+131"F)

to

given

following

+40"C

accuracies is

SPECIFICATIONS

Vertical Deflection

a

DEFLECTION FACTOR:

Calibrated Range:

in

steps

CAL

division.

between

factor to

BANDWIDTH

About two hertz

a 1-2-5 sequence.

Accuracy:

position

Uncalibrated

calibrated settings. Extends maximum

least

at

mV/DlV

10

5 mV/DlV:

2

mV/DlV: DC to at least 200 kilohertz.

1 mV/DlV:

Lower Bandwidth Limit, AC

Within 5%

(using

DC to at least 400 kilohertz.

DC

System

millivolt

One

with

VAR VOLTS/DlV

gain

and

(variable)

125 volts/division.

to 50 V/DlV:

to at least

at all

correctly

Range:

sixdivision reference):

DC to at least

100

def lection factors.

to

kilohertz.

(capacitively)

electrical

when operating from

(+32"F

50 volts/division.

set at

Continuously

five

charac-

These char-

range of

+104"F)

to

as otherwise

five

minutes.

control in

millivolts/

variable

deflection

kilohertz.

500

Coupled:

15

I

f.

I

The cathode-ray tube

Storage tube

division equals

The

internal

recharged

charger

@

having

0.203 inch).

214 is

operated either

rechargeable

from

(with

the

the

(CRT)

a 6 X

batteries.

power

AC

instrument

is

a direct-view

10 division

from

AC line

The internal

line by

OFF).

graticule

voltage or

batteries

the integral

bistable

(each

from

are

battery

INPUT RESISTANCE:

INPUT CAPACITANCE:

1 mV/DlV to

farads.

100 mV/DlV

farads.

mV/DlV:

50

to 50

One

megohm, within 5%.

Approximately 160

V/DlV:

Approximately

140

pico-

pico-

1-1

Page 8

I ntroducti

on-21 4 Service

MAXIMUM

50

volts

50

not

AC

nanoseconds.

CHOPPED

rate at approximately

ALTERNATE MODE:

rate,

INPUT

1Oo/o.

GAIN

with

gain

USABLE

V/DlV

peak-to-peak

mV/DlV to 1 mV/DlV:

over

MODE: From 500

IMPEDANCE MATCHING: Matched to within

ACCURACY BETWEEN CHANNELS: Within 5%

both VAR VOLTS/DIV

correctly

V/DlV:

to 0.1

AC

nruo kiloherlz or

set at 5

Triggering

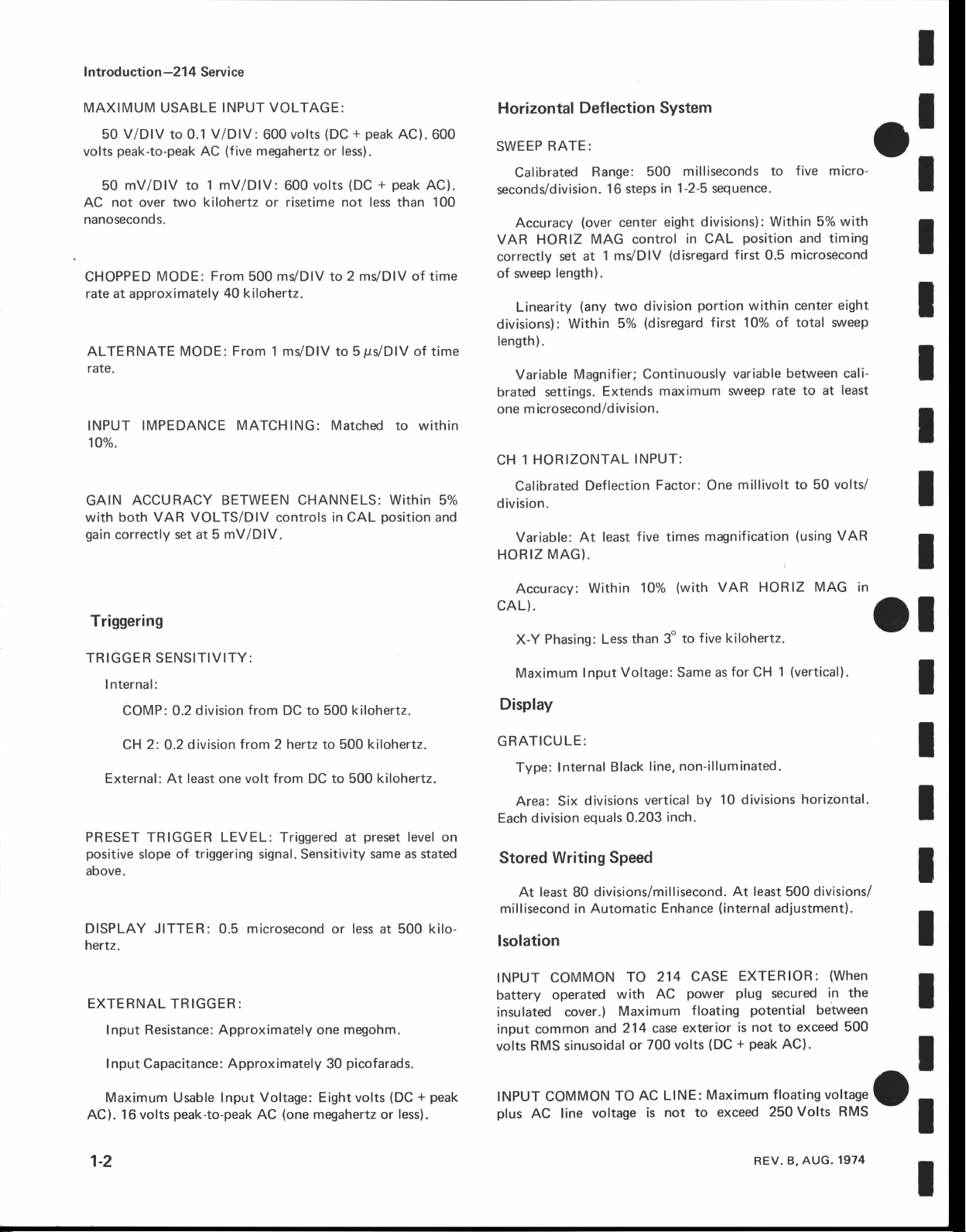

TRIGGER

I nternal:

SENSITIVITY:

COMP: 0.2

division

INPUT VOLTAGE:

(DC + peak

volts

600

(five

megahertz

mVDIV

40 kilohertz.

From 1 mVDIV

controls

mV/DlV.

from

or

volts

600

risetime

to

to 5

in CAL

DC to 500 kilohertz.

AC).

600

less).

(DC

+ peak

less

not

2 ms/DlV of time

pslDlV

AC).

than 100

of time

position

and

Horizontal

SWEEP

Calibrated

seconds/division.

Accuracy

VAR HORIZ

correctly

of wveep

Linearity

divisions):

length).

Variable

brated

m icrosecond/d

one

1

CH

Calibrated

division.

Variable:

HORIZ

Accuracy:

CAL).

X-Y

Maximum Input

Deflection

RATE:

Range:

16 steps

(over

MAG control

1 mVDIV

at

set

length).

(any

trruo

Within

Magnifier; Continuously

settings.

HORIZONTAL

MAG}

Phasing:

Extends

Deflection

least

At

Within

Less

Display

System

milliseconds

500

1-2-5 sequence.

in

divisions): Within

eight

center

in CAL

(disregard

division

(disregard

5%

ivision.

INPUT:

five

1O%o

than 3o

Voltage: Same

portion

maximum

Factor:

times

(with

five kilohertz.

to

five micro-

to

5%

position

first

within center

first

lOo/o

variable

svveep

millivolt

One

magnification

VAR HORIZ MAG in

for

as

CH

and timing

microsecond

0.5

of total srueep

between cali-

rate to at

to 50 volts/

(using

(vertical).

1

with

eight

least

VAR

o:

I

I

I

I

t

I

ol

t

2:

CH

External:

PRESET

positive

above.

DISPLAY

hertz.

EXTERNAL

AC). 16 volts

slope

lnput Resistance: Approximately one

nput

I

Maximum

division

0.2

least

At

TRIGGER

of triggering signal.

JITTER: 0.5

TRIGGER:

Capacitance:

Usable Input

peak-to-peak

from

2 hertz to 500

volt from

one

LEVEL:

Approximately

Triggered

microsecond

Voltage:

(one

AC

1-2

kilohertz.

to 500 kilohertz.

DC

preset

at

Sensitivity

Eight volts

megahertz or less).

same as stated

or less at 500 kilo-

megohm.

picofarads.

30

(DC + peak

level on

GRATICU

Type:

Area: Six

Each

Stored Writing

millisecond

LE:

Internal

division

At least 80

equals

in

Black

divisions

0.203

Speed

divisions/millisecond.

Automatic

lsolation

f NPUT COMMON

battery

insulated

input common

volts RMS sinusoidal

$i,'

operated

?ily

I.'

cover.)

TO

with AC

Maximum

214 case

and

?li,H

line,

vertical

inch.

Enhance

214 CASE

700 volts

or

:$

i:

non-illuminated.

10 divisions

by

At least 500 divisions/

(internal

power

f loating

exterior

(DC

adjustment).

EXTER

plug

secured

potential

is not

+ peak

IOR :

to exceed

AC).

=#ff:ä,"

Jläl;:?.:"$f,ffi

B,

REV.

horizontal.

(When

the

in

between

500

1974

AUG.

I

I

I

t

I

I

o

t

I

Page 9

I

I

: O

I

sinusoidal

AC) is not to exceed 350

AC

or L4

,

Operation

times the

line voltage

AC

volts

plus

(DC

+ peak

Internal

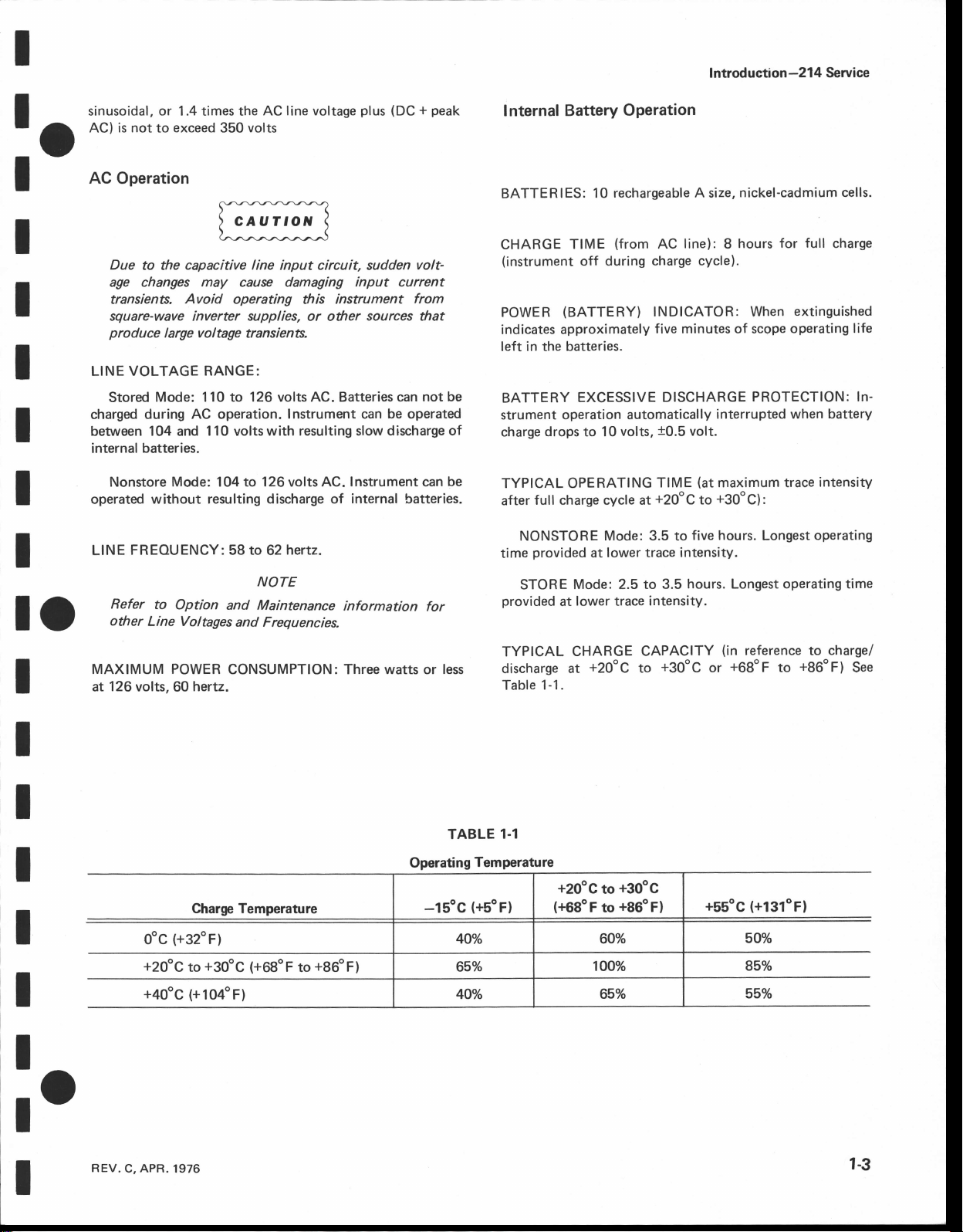

BATTERIES:

Battery

Operation

rechargeable A

10

I ntrod u cti on

nickel-cadmium

size,

-21

4 Service

cells.

I

I

t

I

I

I

lo

I

Due

to

capacitive

the

changes may

age

transients.

sguare-wave

produce

LINE VOLTAGE

Stored

charged

between 104 and 110 volts

internal

Nonstore Mode: 104 to 126 volts AC.

operatd without

NE FREOUENCY:58

Lf

Refer

other

MAXIMUM

at 126 volts,

Avoid

inverter supplies,

large voltage

RANGE:

Mode: 110 to 126 volts

during AC operation.

batteries.

to

Option

Line Voltages

POWER

hertz.

60

line

input circuit,

cauffi damaging

operating this instrument

transients.

Instrument can be operated

with resulting slow discharge

resulting discharge of

to

62hertz.

NOTE

and Maintenance

and Frequencies.

CONSUMPTION:

sudden

input current

or other

AC.

sources that

Batteries

Instrument can be

internal

information

Three watts or less

volt-

from

not be

can

batteries.

for

of

(from

CHARGE

(instrument

POWER

indicates

left

BATTERY

strument

charge

TYPICAL OPERATING

after

NONSTORE

time

STORE

provided

TYPICAL

discharge

Table

TIME

off during

(BATTERY)

approximately

in

batteries.

the

EXCESSIVE

operation automatically

drops to 10

full charge cycle at

provided

Mode: 2.5

at

CHARGE CAPACITY

at

1-1 .

volts,

Mode: 3.5 to

lower trace

at

lower

trace

+20oC

to 3.5

to

charge

INDICATOR:

five

intensity.

line):

AC

minutes of scope

DISCHARGE

+0.5

volt.

TIME

+20oC

five hours.

intensity.

hours.

+30"C

hours

8

cycle).

interrupted

(at

maximum trace

+30oC):

to

Longest

(in

*68oF

or

for full

When

PROTECTION: In-

Longest

operating time

reference

to

charge

extinguished

operating

when battery

intensity

operating

charge/

to

+86oF)

life

St.

t

I

t

I

I

I

lo

REV.

ooc

+20"c

+40oc

APR.

C,

Charge

(+32"F)

+sgog

to

(+104"F)

1976

Temperature

(+68oF

to

+86oF)

TABLE

Operating

_lsoc (+soF)

1-1

Temperature

4OYo 6OYo

65Vo

40o/o

+20"G

(+69"F

+30"c

to

+86oF)

to

100% 85Yo

650/o

+55oC

(+131oF)

SOYo

55Yo

1-3

Page 10

I

ntroducti on-214

Service

Environmental

Temperature:

Operating from

+131"F)

Operating

+104"F)

Non-Operating,

Altitude:

Operating, to 25,000 feet

perature

feetl.

Non-Operating,

from

decreased

Batteries,

AC

Line, 0"C to

-40"C

to

by loC

50,000

to

per

-15"C

+ggog

feet.

to

(-40"F

(maximum

1,000 feet

+55oC

+40oC

(+5oF

(+32oF

+140"F)

to

operating tem-

above 15,000

to

to

Humidity

l;,'r1rl''.ätJ:

Shock

shocks

each direction

Physical

WEIGHT

DIMENSIONS

Height;

Width: 5.25

Depth:

(operating

(operating

at 150

along

(without

inches

3.0

inches

9.5

and

relative

e'o/o

non-operating): Tested

and

g,

one-half sine,

major axes.

accessories): 3.5

(measured

inches

at maximum

(7.6

centimeters)

(13.2

(24.1

non-operating):

humiditv in

millisecond

two

pounds

points):

centimeters)

centimeters)

f ive

cycle,

rererence to

with

duration

(1.6

kilograms)

nruo

O

I

:

I

I

I

I

I

I

I

ol

I

I

I

I

I

I

14

t

ot

@

Page 11

I

Section

2-214

Service

:O

I

I

I

I

I

I

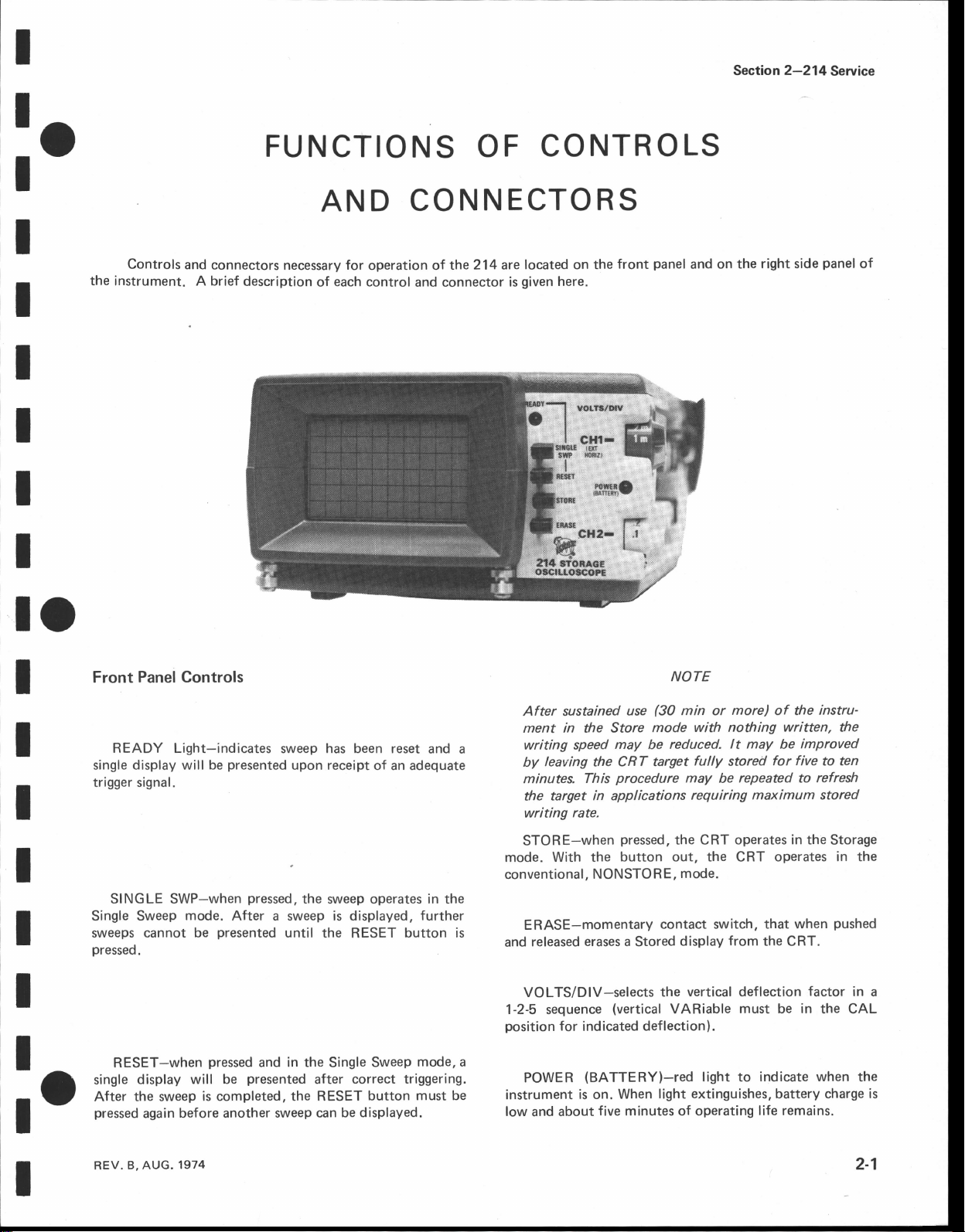

Controls

the instrument. A bri€f

and connectors

FUNCTIONS

AND

necessary for operation of the

description

of

each

CONNECTORS

control and connector is

OF

214 are located on the

CONTROLS

given

here.

front

panel

and on the

right side

pansl

of

lo

I

I

I

I

I

I

t

lo

Panel Controls

Front

READY

single

trigger

SINGLE SWP-when

Single

sweeps

pressed.

RESET-when

single

After

pressed

Light-indicates

display will be

signal.

Sweep

display will

the sweep

mode.

cannot be

before another

again

is completed, the RESET

presented

pressed,

After a

presented

pressed

and

presented

be

has been

sweep

upon receipt

the sweep operates in the

is displayed,

sweep

until

the RESET

in

the

Single

after

can be displayed.

sweep

reset

of an adequate

Sweep

correct triggering.

button

and a

further

button is

mode, a

must

be

After sustained

ment in the

writing speed

leaving

by

minutes.

target in

the

writing

STORE-when

mode. With

conventional,

ERASE-momentary

released

and

VOLTS/DlV-selects

1-2-5

sequence

position

instrument

low

for

POWER

and about

Store

may

the CRT

procedure

This

applications

rate.

the

NONSTORE,

erases

(vertical

indicated

(BATTERY)-red

When

is on.

five minutes of operating

NOTE

(30

use

pressed,

button out, the CRT operates

a

Stored

min or

mode

reduced.

be

target

may

the CRT operates in the

mode.

contact

display

the

VARiable

deflection).

light

more)

with nothing written, the

lt may be

fully

stored

repeated to

be

reguiring maximum stored

switch,

vertical deflection

light to indicate when the

extinguishes,

that

from

the

must

life remains.

instru'

of the

improved

for five

battery charge

CRT.

be

to

refredt

when

factor

in

the CAL

Storage

ten

in the

pushed

in

a

is

I

REV.

B, AUG.

1974

2-1

Page 12

Functions

Side

channel input

the

STEP ATTEN

the

deflection

Vertical POS-controls

appropriate trace. Detent turns the channel

VAR VOLTS/DlV-provides

deflection

VOLTS/DIV

the

PRESET trigger

of Controls

Panel

Controls

INPUT

frequency

The

large

AC

VERT

AUTO PREsET-screwdriver adiustment

TRIG

COUPLING-selects

signal to the

AC-DC

limit

GND-vertical

applied signal

resistor to

valve

input coupling capacitor.

DC-all

vertical system

entire

components of

vertical

amplifier

factors,

factor

switch.

GAIN-screwdriver

vertical system.

SOURCE-selects the source of the trigger

and

Connectory2l4

and Gonnectors

method

vertical

component

{-3

amplifier inpüt circuit is

BAL-screwdriver

for

between

point

for

input

of

point}

dB

is

connected to

provide a precharge

system.

minimum trace

AUTO

is

the input

vertical

the

a continuously

the calibrated settings of the

adjustment to set the

sl,\reep

used

amplifier

signal is blocked.

2hertz.

about

ground

signal are

adjustment to

shift when changing

operation.

Service

to couple the

system.

grounded.

through

path

passed

position

OFF.

to set the

Low

a

for

the

to

balance

of the

variable

gain

of

signal.

LEVEL/SLOPE-selects

the trigger

of

the indicator

triggered on

right of center,

the

LEVEL/SLOPE

detent, the srueep

on the

INTENs|TY-controls

SWP CAl-screwdriver

svveep timing.

POwER-controls

interrupt charging

instrument

FOCUS-screwdriver

display.

VAR HORIZ

sweep

the weep

HORIZ GA|N-screwdriver

gain

of the

Horizontal

trace.

signal on

dot

the

positive{oing

connected

is

magnification

indicated

rate

horizontal

POS-controls

which the sweep

is

to

positivegoing

on the

control is set to

is automatically

slope.

power

current

to an AC line

adiustment

MAc-provides

to a

system.

amplitude

the

left

the

brightness of

adiustment

to

maximum of

by the

or

slope of the trigger

negative€oing slope. When the

triggered at a

to

the

internal batteries when the

the

to

SEC/DIV

adiustment

horizontal

the

point

and slope

is

triggered.

center,

the

to

instrument. Does

voltage.

obtain

continuously

AUTO

the

CRT

provide

at least

sruitch.

to set the

position

the sweep is

preset

display.

calibrated

welldefined

a

five

When

signal; to

PRESET

level

not

variable

times

basic

of the

o:

I

I

I

I

I

I

^ I

I

U

t

I

I

I

I

COMP-sweep

the vertical signal after

of

2-sweep is

CH

of the CH

EXT-sweep is triggered from

applied

to

is triggered

triggered

2 vertical

EXT TRIG banana

the

2-2

from

a DC-coupled sample

the vertical switching.

from

an

AC-coupled sample

signal before the vertical

the DC-coupled

jack.

switching.

signal

SEC/Dlv-selects

the

detent

214

be in CAL

must

EXT TRIG-banana

between

under test.

ment

the

for

iack

and the

(VAR

rate

sweep

indicated

external signal

sweep

establish common

to

HORIZ

rate).

source or

MAG

ground

equip-

@

I

I

or

Page 13

I

_o

Section

3-214

Service

I

I

I

I

t

I

I

IO

I

I

I

I

I

Introduction

This

section

information

maintenance,

of the

use in

preventive

for

or

troubleshooting of

PREVENTIVE

General

Preventive

inspection, lubrication,

regular

ment

breakdown

instrument.

214

is

tenance.

maintenance

Avoid

might

Avoid

sodium hydroxide,

maintenance

preventive

basis,

The

subjected

A

convenient

preceding

is

the use

damage

chemicals

may improve

and

severity of environment

will determine the

CAUT'ON

of

chemical

plastics

the

which

or

Cleaning

The

214

conditions

can cause

The

dust in

lated

small brush.

and around

removed

and water

require.

component

high-impact

the

on these

with

solution.

should

interior

The

the exterior

a soft cloth

be

Accumulation

breakdown.

plastic

of

the

covers

can be removed

brush is

Abrasive

MAITUTEIUANGE

manual

MAINTENANCE

etc. When

maintenance

time to

recalibration

contain

sulfuric

cleaned

covers

instrument.

also useful

controls.

dampened

cleaners

contains maintenance

maintenance,

214.

the

consists

used

of cleaning, visual

performed

can

the

frequency of

perform preventive

of the

cleaning

in this instrument.

hydrochloric

acid.

as

often

of dirt in

provide

protection

Loose dust

with

for

dislodging

Dirt

that remains

in a mild

should not

sEcil0N

Lubrication

corrective

on a

prevent

reliability

to which

agents which

the instrument

a

instru-

of this

instrument.

acid,

as operating

against

accumu-

soft cloth

dirt

can

detergent

be used.

the

main-

or

on

be

require lubrication. No lubrication

the

reliability

sealed can

that does

Tektronix

Visual Inspection

defects as broken connections,

tors, damaged circuit

corrective

however,

components

trouble in the instrument; therefore,

the

damage.

CRT

following

this instrument:

intensity that is used,

rates, X-Y displays, or the

intensity

a

vertical

display area.

3

Generally,

contacts

The

overheating is important

Care

prolong

To

1.

Care

2. Avoid repeated use

particular

there are

rotary

or

potentiometers

of

be maintained by

not

affect

Part

No.

214

should

procedure

particular

found.

are

useful

the

precautions

must

be taken in the

permanently

may

display is being

position

occasionally to use other

006-2574-00).

be

boards,

for

care must be

Overheating usually indicates

should be

particularly

no components

should be used on

parts

of the

electrical

inspected

and heat

most visible

to

life

STORE

damage

of the same area

Stored

rotary

that are not

lubrication

characteristics

Do not over-lubricate.

occasionally for

improperly

damaged

defects is

taken

correcting

prevent

of the

Storage

observed

degree of writing-beam

when

mode.

the CRT screen.

repeatedly,

in the

with

recurrence

using slow sweep

214

that

switches. The

permanently

lubricant

a

(e.9.,

such

seated

transis-

parts.

The

apparent;

heatdamaged

if

other

the cause

of the

screen,

when

Too-high beam

the screen. lf

of

change the

portions

the

operating

of the

of

I

I

lo

I

Cleaning

sary.

The best

accumulated

brush

or a cotton-tipped

narrow

REV.

spaces

NOV.

C,

the interior

way to clean

dust

with

for

or

cleaning

1977

should

only

be

occasionally

the interior

dry, low-velocity

applicator

more

is

useful

delicate

is

blow

to

air.

A soft-bristle

for

eleaning

components.

neces-

off the

in

3.

Do not leave

no longer needed.

4.

Operate

required.

in

a Stored display

NONSTORE

the

on

the screen when

mode unless

it is

Storage

3-1

is

Page 14

Main ten

an ce

-21

4 Servi

ce

Recalibration

ensure accurate

To

instrument

this

of

To

probe

cases,

gain

wrap at

months

components

circuits.

localizing

in

minor

I nstructions

access

cords and

the

every six

ment of

affected

helpful

some

recalibration.

Disassembly

both

probe

I nformation

measurements.

each

after

if used

to

rear of the214.

infrequently.

necessitate

may

calibration

The

certain

troubles

may

the interior of

power

the

check the

1000 hours of

In addition,

recalibration

procedure

troubles

in

be revealed or

instrument,

the

from

cord

calibration

operation,

can also

instrument. In

the

corrected

instrument's

the

or

replace-

the

of

be

by

unwind

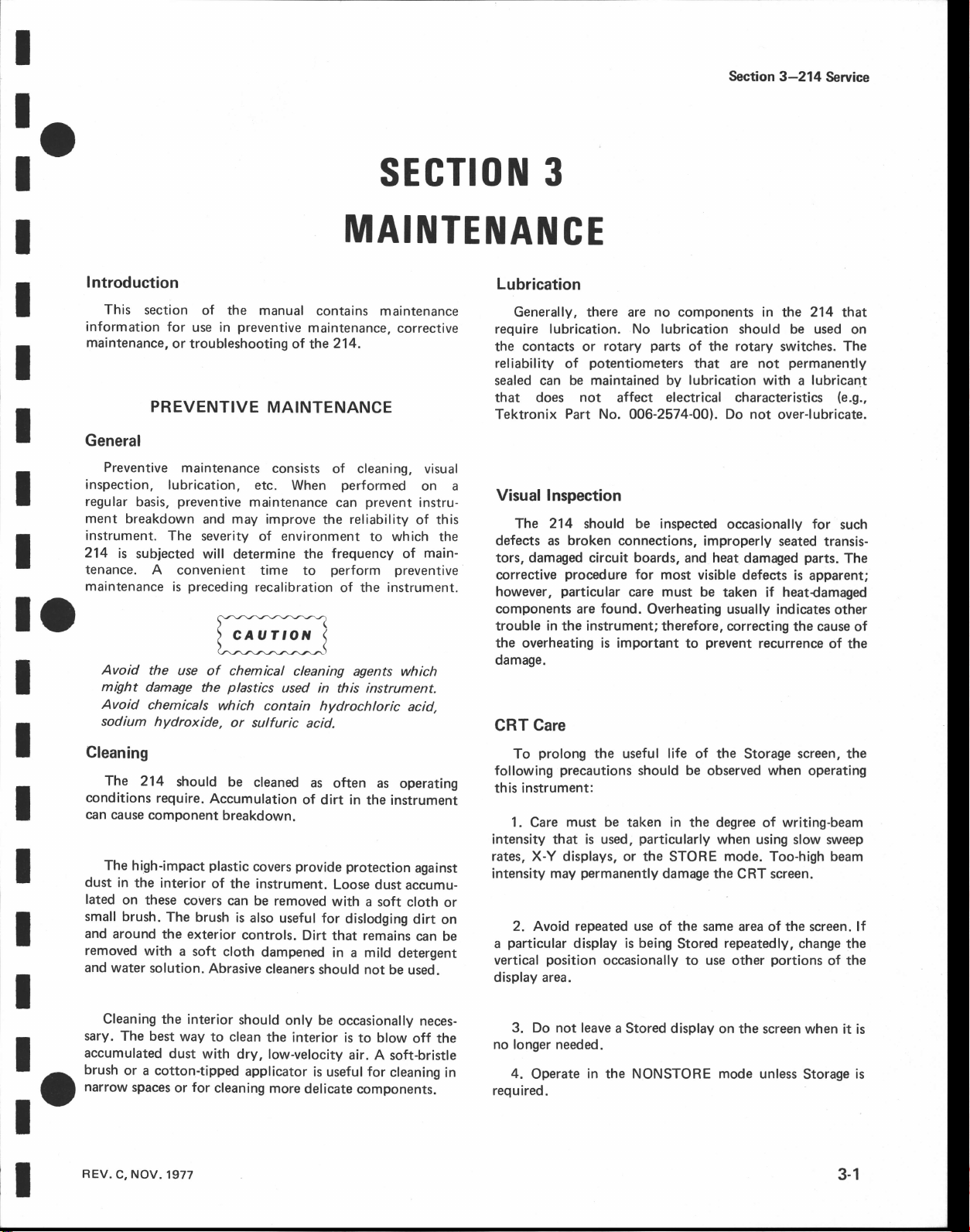

The arrows

direction

Fig. 3-1.

Remove

instrument.

instrument

the

circuit

pivoted

the

board,

out of

instrument

the

on

wrap

to

five screws

the

3-2. Separate

Fig.

See

lay it aside.

and

the

and

way.

the

now accessible

are

NOTE

probe

wrap

probes

the

in the

batteries,

Most of

proper

indicate

and

bottom

the

Power

The

can

internal

the

for maintenance.

the

power

cover of the

bottom

Supply

lifted

be

cord. See

cover

workings of

from

(A-3)

up an;d

o:

I

I

I

I

I

YELLOW GROUND

POSITIONED

HERE BEFORE

WRAP OF

THE

CLIP

PROBE

IS

FINAL

I

OI

I

I

I

I

I

I

I

3-2

Fig.3-1.

method

Proper

REV. APR 1974

for

wrapping

probes.

t

or

@i

Page 15

I

Maintenan

ce-214

Service

:o

t

I

I

I

I

I

I

lo

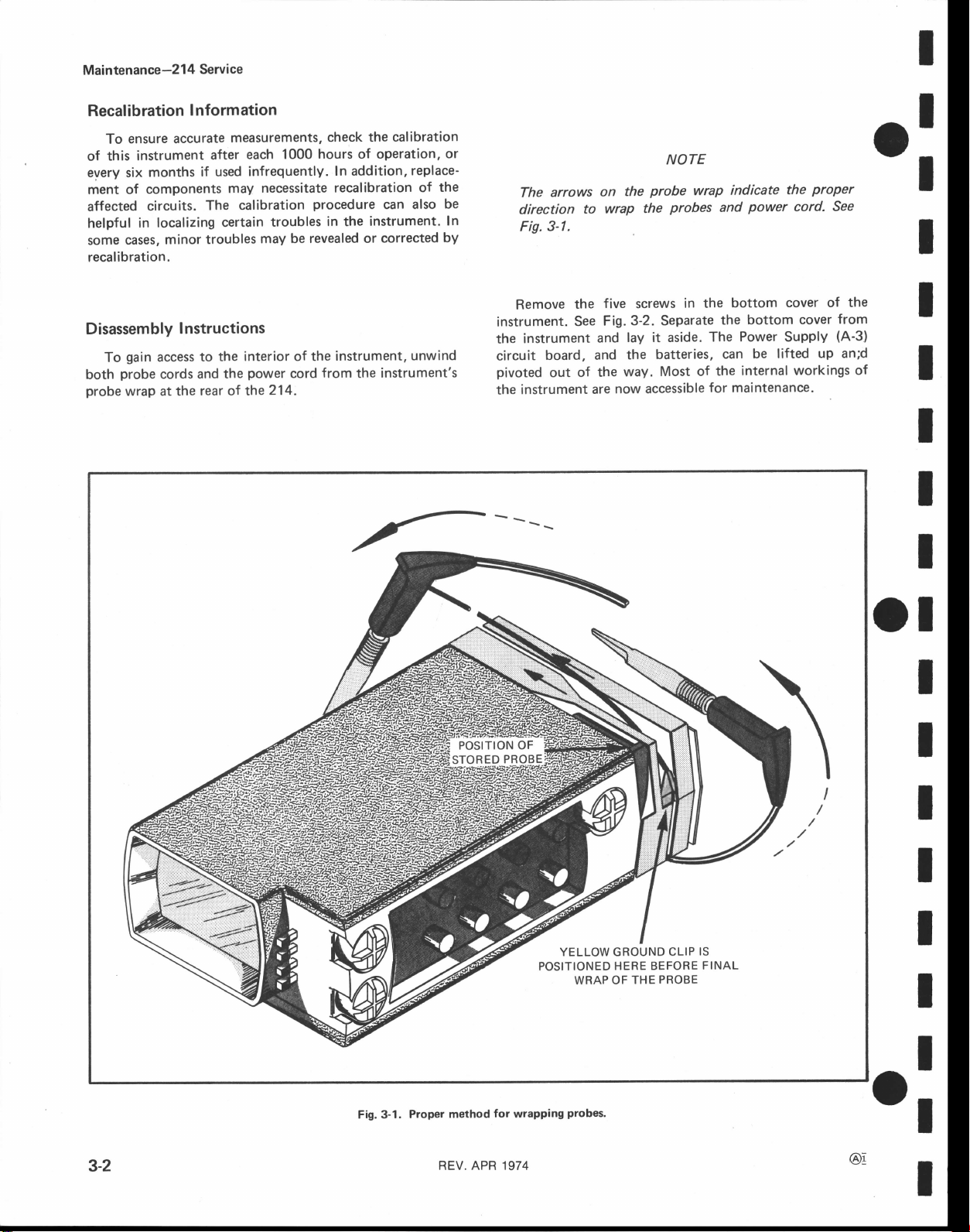

SCREWS

SECURING

SIDE

SCREWS SECURING

BOTTOM

PANEL

COVER

front

NOTE

panel

to

the lnput

pushbuttons

board

before

-

Secure the

and replace the

re-assem

Single Sweep board

bl ing th e instrum ent.

TROUBLESHOOTING

Introduction

following

The

troubleshooting

sectaons of

following information

component.

helpful

very

Description section

Troubleshooting

Diagrams. Complete

foldout

number

instrument are

the

designators

mentl. lmportant

on the

on

pages

and

Diagrams

diagrams.

circuit boards are

information is

214

the

manual

this

An

understanding of

in locating troubles. See

for more information.

Aids

in

the

electrical

shown on

section

identify components

to

used

voltages

The

provided

Information

should

to aid

Diagrams section. The component

value

portions

enclosed

.in

circuit diagrams are

of

the diagrams

for definition of the

waveforms

and

with blue

contained

be used along

locating the defective

the circuit operation is

each component

of

(see

the circuit

to

the

first

in this

are

lines.

facilitate

in

other

with

Circuit

given

in this

page

reference

instru-

shown

also

mounted

the

on

of

I

I

I

I

I

I

I

r

I

t

SCREWS SECURING

SINGLE SWEEP

Fig.

3-2.

Single

Single

the Power

removing

at a time,

(A-4)

panel

board to the

properly

Power

l^".*'J#:träJi:1":nJ:Hl

a

-

the Input circuit board and, with

the

Location

Sweep

For

calibration or troubleshooting

Sweep

the

board.

and the

connect the

Supply

lf access

panel,

front

BOARD

of

screws securing

(lnstrument

board.

(A-4)

circuit

Supply

(A-3)

panel pushbuttons

front

until they

Next, remove

two

screws

(A-1)

Input

circuit board.

front

to the

remove

bottom

shown

upside

board

should be

circuit board.

disconnect from

the

READY light

securing

circuit board.

Single

of the

the instrument

the

Sweep

Input

the READY

circuit board to

cover,

down.)

within

This

pulling

by

the

Single

(See

tA-l)circuit

[';:':ilJ';::lll

side

panel,

side

the 214, the

reconnected

is done by

them,

Single Sweep

from

the front

(A-4)

Sweep

Fig.3-2.)

panel.

board is

light

Then

out of

and

to

first

one

the

Troubleshooting

malority

The

214

can

be

such

262.

Type 577

conductor devices

in

thid

500 kilohertz

50 volt/division

Obtaining Replacement

Standard

replacements

local

many

obtained

them from Tektronix,

replacement

tolerance, rating, and description.

accomplished

Triplett Model

as a

dynamic

Use a

Transistor-Curve

instrument,

CORRECTIVE

Tektronix

of the

locally

Equipment

troubleshooting

of

with

630-NA

transistor

Tracer

used in the

use

a test oscilloscope

frequency

deflection

Parts.

for

the

Field

standard electronic

in

parts,

response and

factor.

MAINTENANCE

Parts

All electrical

214

can

Office or

less time

Inc.

Before

check the

a 20,000

tester such

214. To

be obtained

than

to be done on

ohms/volt

or a

Simpson

as a Tektronix

check the

to

check

with

millivolt

one

and mechanical

through

representative. However,

components can be

is required

purchasing

parts

or ordering

list for

the

VOM

Model

semi-

waveforms

a DC

to

to

part

your

to

order

value,

REV

DEC 1980

C

3-3

Page 16

-21

Maintenan ce

When

to remember that the

component

instrument. All

replacements unless it

component

performance.

4

Service

selecting

may

will not adversely

NOTE

replacement

physical

affect its

replacement

is known that a different

parts,

performance

parts

affect the instrument

is important

it

size and shape of a

in the

should be

direct

Ordering

Tektronix,

Instrument

1

.

2. lnstrument

3. A

description

circuit

number).

4. Tektronix

When ordering

Parts.

include

Inc.,

type.

serial

Part Number.

replacement

follovrüing information:

the

number.

(if

part

the

of

parts

electrical,

from

o:

include

I

Special

components,

214.

Tektronix, Inc.

ments,

cordance with our

parts

Tektronix,

local

Parts.

These

components are

or are

used

in this

Inc.

Tektronix

"o

some special

manufactured

Order all

Field

rrraro*

In

addition to the

components are

manufactured or selected by

meet

to

specifications. Most of the

instrument have

specific

special

Office or

/

SCREW

for Tektronix,

representative.

MOUNTED

standard

performance

been

parts

directly

ITTER

EM

electronic

used

in the

require-

Inc. in

mechanical

manufactured by

from

ac-

your

Disconnect

power

source

Component

Gircuit

given

beyond

on

in the

damaged

soldered

are

wired board.

WART'TG

instrument

the

before

Replacement

Board

Replacement.

repair, the

components

Mechanical

BASE2 Uilil

N.CHANNEL

from any

replacing

components.

lf a circuit

entire assembly

replaced.

be

can

Parts

List

ili-)

ffil

EMITTER

1

BASE

(}388

UNIJUNCTION

external

board

including all

Part

for

the completely

is

numbers

I

I

I

I

I

ol

t

I

coLLEcro-ffi

BASE

GATE

DRAIN

SOURCE

I

34

DUAL

EMrrrER

coLLEcro-,fi

SOURCE

DRA|N

GATE

Fig. 3-3. Lead

EMrrrER

eÄse

TRANSISTORS

14

14-PtN

INTEGRATED

configurations of semiconductors

coLLEcro-ffi

INDEX

C]RCUITS

EMrrrER

BASE

16-PtN

this instrument.

in

used

INDEX

,affi

1

ru-r^J-J

1483-04

or

1981

E DEC

REV

I

I

I

I

I

Page 17

I

Mai ntenan

e,e-21

4

Service

:o

I

I

I

I

I

I

I

I

o

I

I

I

Transistor Replacement. Transistors should

replaced unless actually

sockets during

original sockets.

may affect the

transistors

the instrument which

of

Replacement transistors

or a

type

configuration

Some

which do

tor is replaced by a

different

plastic

manufacturer's basing diagram

transistor sockets

basing used for metal-case transistors.

An extracting tool should be used

16'pin

pins.

one

both ends

disengage

be

semiconductor's index with

do

flat

lf an

these integrated

of

damaged.

will result

so

routine maintenance, return

Unnecessary

are replaced, check

direct

of the transistors used

case

not

agree

manufacturer

integrated circuits

extracting

of the device.

from

the socket before

When

in damaged components.

il: i:f,j#r

replacement

Power

ment from

necessary

C212 to maintain

and

Refer

three

quency

parts.

Supply

power

sources

change

to

Table

to

of the

3-1

more commonly used line voltage/line

combinations.

defective.

callbration

may

replacement.

transistors

with those shown

transistor

than the original,

in this

instrument

is not

tool

circuits,

Avoid

replacing

that

.'ilr"[+ *,Fj:r:'"l;#i#

Gapacitors. When

other

electrical

the

proper

for

the

correct

lf removed

replacement of transistors

this instrument.

of

the

operation

be affected.

strould be of

Fig. 3-3

in this instrument.

have lead conf

which is

for

correct

are

remove

to

prevent

to

available

pull

slowly

having

one

the

other,

semiconductors, key

the socket. Failure

of

operating

1 15

than

value

of

current leve.ls to the batteries.

values

of

not be

from,

them to

When

of that

the original

shows

here.

VAC

the

igurations

lf

a transis-

made by a

check the

basing.

for

wired

14-

the

damage

when removing

and evenly

end

as the

capacitors C210

capacitance

to the

of the

pins

the instru-

Hz, it is

60

their

their

part

lead

All

the

and

on

l.C.

may

the

to

for

fre-

Due

voltage changes

sients.

wave

large

Selection

frequency

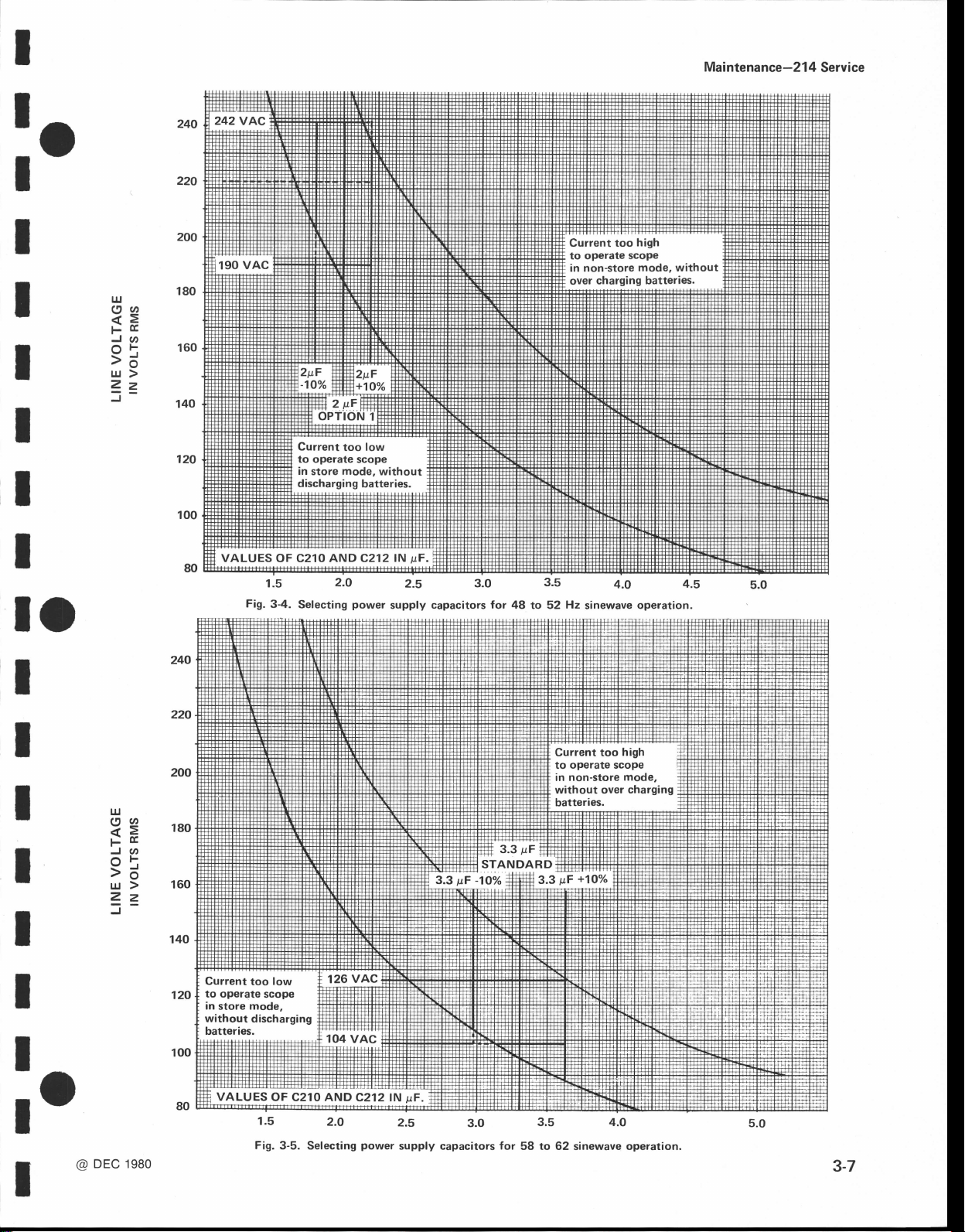

3-4 and

ated on a

minimum

to the

instrument.

the

values of C210 and

provides

selected

ratings should be at

applied

C2O4

nominal

from other

24OV 5O

with

Selectable

selected

than

change

The value of

330

1. Install a 27O

the capacitive

to

Avoid

operating

inverter supplies,

vol

tage transients.

capacitor

of

combinations

For example,

3-5.

Hz line,

60

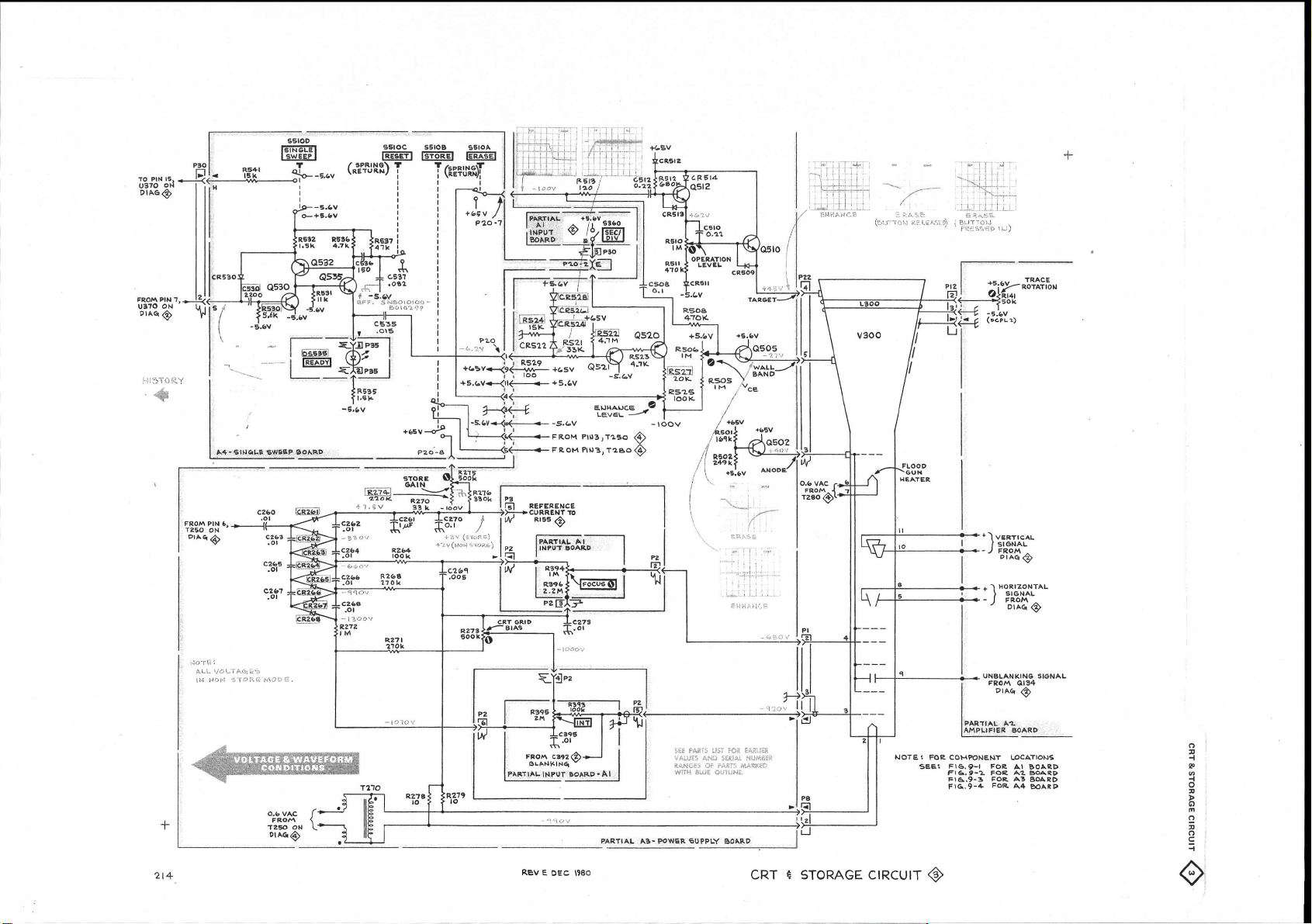

maximum

and

pF

3.3

.OO1

1.5

O

as

set SEC,/DIVto

(fully

capacitance

lt

Hz information.

50

from

a type suitable

voltage.

line

and C215

value only

1 15V

than

Hz operation, C2O4

gF

3kV capacitors.

Gomponents.

f

a switching

or

divisions

when

follows:

for each channel

changing

R388 is

clockwise).

also

when

power

may

cause

this

or other sources that

values

is illustrated by the

if

graph

the

line voltage limits, with

values,

provides

for

C212

least 1.414 times the

values

the

Hz or 1 15V 60

50

unblanked trace

sweep

selected

O resistor for R388, turn the

.5 s, and

line circuit, sudden

damaging current tran-

instrument

for

instrument is to be

the

in

for

information

other

These

for AC

must be changed

instrument

C215 should

and

Resistor R388

and

speeds

from

a

INTENSITYto

set

from

produce

line voltage/line

other

graphs

Fig.3'5 illustrates the

proper

operation

for

voltages. Fig. 3-4

line

capacitors should be

operation

minimum intensity

from 5 ms

range

and

value

is

to be operated

power

Hz

be

height of

27O,3OO, or

oI

square-

Figs.

in

oper-

respect

of

selecting

voltage

of the

from the

For

line.

replaced

value is

no more

ms.

2

to

214 on,

maximum

il

I

I

I

lo

I

Nominal Power

Voltage/Frequency

1 10 to 126 VAC

58 to 62

(Standard)

90 to 1

48

to

(Option

224 to 250

48

to 52

(Option

1981

F DEC

REV

TABLE 3.1

POWER SUPPLY CAPACITORS

Line

c210 - c212

+10%,2O0

pF,

3.3

Hz

10 VAC

Hz

52

2)

Hz

1)

VAC

VDC Tektronix

PN

285-0925-00

+1O%,200

4

ttF,

VDC Tektronix

PN

285-0935-00

+1oo/o,4OO

2

ttF,

VDC Tektronix

PN

285-0933-00

The

2.

the CH

set CH

horizontal

Check

3.

trace

lf each unblanked

4.

divisions, turn offthe214,

R388, recheck and

for

unblanked

high while

when

will show as

traces

1 dot

2 POS to

graticule

that

elftends

switching

the top

to

no more than

vertically

traces

maintaining

dots. Set CH

horizontal

place

the CH 2 dot to the

li ne.

1.5 divisions of unblanked

from each dot.

exceeds

trace

installthe next

repeat steps

are no more than

minimum

from 5 ms to

sweep

speed

POS

1

graticule

2through 4 until

1.5 divisions

intensity

place

to

line

bottom

1.5 vertical

larger

change

2 ms.

3-5

and

size

Page 18

Maintenan

ce-214 Service

Recalibration

After

any electrical component has been replaced, the

calibration

well

as

circuits.

calibration

work has been

I nstrument

lf

Tektronix

the

Service Center

(wittr

owner

firm

that

number

and

that

of

the calibration

as

Since the

the

of

Repackaging

for

address) and

can be

a description

After Repair

particular

power

instrument

entire

in the

done

instrument is

service

contacted,

supply.

or

the name

of the

circuit should be checked,

of other closely related

supply affects all circuits,

should be

be shipped

to

repair,

attach a tag

of an

complete

service required.

checked if

Tektronix

to a

showing:

individual

instrument serial

at

your

Save and

shipped.

available,

The carton test strength

re-use the

lf

the

repackage the

Surround

protect

corrugated

having inside dimensions

than

by tightly

foam between

carton

the

the instrument

with shipping

package

original

the instrument

finish

of the

cardboard of

packing

three inches

carton and

in which

packaging

instrument as

with

instrument.

the correct

of

dimensions.

instrument, on all sides.

or industrial stapler.

tape

your

for

your

is unfit

follows:

polyethylene

Obtain a

carton strength and

less

no

than

Cushion the instrument

dunnage

of

instrument is 200

instrument was

for

sheeting to

inches more

six

or

use or

carton of

urethane

Seal

pounds.

not

I

I

-

I

V

I

I

I

I

r

I

I

I

I

I

ol

I

I

I

I

I

I

3-6

REV E DEC

o:

1981

Page 19

I

:o

I

I

I

I

UJ

gs

Ftr

J tt,

ot

>ö

uJ>

Zz

180

160

:

in non-store

mode, without

Maintenan

ce-214 Service

I

I

I

lo

I

I

I

I

lrJ

s9

dz

ljE

!

JO

e5

-o

LU>

V=

J

120

100

180

Fig.

Current

to operate scope

in

discharging

1.5

3-4.

Selecting

store

too

mode,

2.O

power

low

without

batteries.

supply

2.s

capacitors for

3.0

3.5

48 to 52

Hz

Current

operate scope

to

in non-store

without over charging

batteries.

4.o

sinewave

high

too

mode,

4.s

operation.

I

I

I

lo

t

DEc 1e8o

@

140

Current

to

120

100

operate

an

store mode,

without discharging

batteries.

low

too

scope

1.5

Fig.

3-5. Selecting

2.O

2.5

power

supply capacitors

3.0

3.5 4.0

for

58 to 62 sinewave operation.

3-7

Page 20

o:

I

I

t

t

I

I

ol

I

I

I

I

I

I

o:

Page 21

I

:o

Section

4-214

Service

I

I

I

I

I

I

r

I

I

f

I

General

ensure

To

the 214 every

if

used

infrequently.

oughly

Preventive

recalibration

Service

or

ensures

ilff ff : il,,"#l,

O

before an adjustment

performance,

even

clean and inspect

Tektronix,

Center.

representatave

Completion

that

the

if

CHECK-

instrument

1000

hours

Before

Maintenance

Inc.,

at local Field

Contact

of

this instrument

lälJo,

make

section.

provides

for further

each

J

l,

each

step

CALIBRATION

accuracy,

of

this

complete

Service

your

step in

" iil

i,"''}I

is

adiustment

is

within the

check the

operation, or every

complete

instrument

local

information.

the

made. For best overall

calibration,

as outlined

instrument repair

Centers and the Factory

Tektronix

Calibration

meets

ll,?y;

the

Il

to

the exact setting

allowable tolerances.

calibration

six months

thor-

in

and

Field

Office

procedure

electrical

g-*

;J""[ä

of

the

TEST

following

The

equivalent,

214.

Given specifications

minimum necessary for

specifications of any test equipment

exceed

be

specifications.

units

instruction

mation

Special Calibration Fixtures

procedure

These special

Tektronix,

Tektronix Field

those

correctly calibrated

are

is needed.

Special

only where

EOUIPMENT

test

required for

are

listed below.

Detailed

given

not

manual for

Tektronix

calibration

Inc.

Order by

Office

REOUIRED

equipment

accurate

and operating

operating instructions for

in

the

Calibration

they

part

representative.

or

and accessories,

complete

for

the test

calibration.

All test

this

facilitate

equipment

procedure.

equapment

test

fixtures

fixtures

number

instrument

calibration

equipment

Therefore,

must

either meet

is

within

Refer to the

if more infor-

are used

are

available

through

or their

of the

are the

the

or

assumed to

listed

the

the test

in

this

calibration.

from

your

local

I

I

1.

DC Voltmeter

I

I

I

I

2.

Co nstant-Amplitude

Signal Generator

l;.1?lilll*of;'0".

lro

@

Description

Low-Frequency

Range, zero

accuracy,

impedance,

Frequency,

500

tude,

Ampf itude

signal

volts

signal,

wave.

within

kilohertz;

least 200 millivolts.

at

amplitude,

to 100 volts;

one-kilohertz

to 1000 volts;

3o/o; input

20,000 O/volt.

kilohertz

one

output

accuracy, O.25o/o;

five

to

ampli-

milli-

output

square

TABLE 4-1

Test Equipment

Power

checks, CRT Grid Bias,

age Level adiustments. Vertical

adjustments.

Storage Enhance

ment.

bandwidth

tion checks.

Vertical and

checks

Supply

horizontal

and

Vertical amplifier

and adjustments.

output

centering

Level adjust-

and trigger

horizontal

opera-

level

Stor-

gain

Example

Triplett

Simpson Model 262.

a. General

Tektronix

a..

Model

Radio 1310-B

Part

630-NA.

Oscillator.

No. 067-0502-01.

+1

Page 22

Caf i brati o n

-21

4

Service

Description

4.

Square-Wave

Generator

5.

Time-Mark Gen-

erator

6. Ramp Generator

7.

Attenuator Ratio,

8. Cable

9.

Adapter Connectors,

10. Adapter Co

Minimum

F requency,

risetime, 100

fess;

output

volt to 40 volts.

Marker outputs,

nd s

seco

marker

O.1o/o.

F requency, ät

microseconds;

tude, at

nal

triggering, both AUTO

and NORMAL.

impedance,

lmpedance, 50

RG-58/U;

connectors,

female.

n n ectors,

BNC.

Specifications

one kilohertz;

nanoseconds

amplitude, o.4

five

0.1 second;

to

accuracy,

least 100

output

least

10X; connectors, BNC;

volts;

six

O.

S0

O; type

length, 42

BNC.

GR874 and

probe

or

micro-

within

ampli-

exter-

inches;

BNC

tip-to-

TABLE

Vertical amplifier

tion checks and

Horizontal

adiustment.

Hum Balance

Storage

ment. Vertical

bandwidth check.

E

check.

Vertical amplifier

tion

Used

for

(contl

4-1

timing

Enhance

xternal

signal

trigger operation

checks and adjustments.

throughout

interconnection.

Usage

compensa-

adiustments.

checks and

adjustment.

Level

amplifier

comp€nsa-

procedure

adiust-

Example

Tektronix Type

a.

Generator.

a. Tektronix

Mark Generator.

b.

Tektronix

Generator.

a. Tektronix

Generator

Power Supply.

Tektronix

a.

a. Tektronix

Tektronix

a.

Tektronix

a.

Type

Type 183 Time-Mark

Type RG 501 Ramp

with Type TM

Part No.

Part No. 012{057-01.

Part

Part No. 013-008401

106

Square-Wave

2901 Time-

501

1-0059-02.

01

No.017-006300.

o:

I

I

I

I

I

I

ol

I

11 . Adapter Connectors,

banana

12. Termination lmpedance,

2o/oi

13. T-Connector Connectors,

14.

Screwdriver

1 5. Low-Capaci-

tance Screwdriver

Three-inch shaft;

bit.

plug.

connectors, BNC.

1

1/2-inch shaft.

+2

BNC

Cl;

50

BNC.

female-to-

accuracy,

3132 inch

External trigger

Vertical amplifier

tion checks

External trigger

throughout

Used

to

adjust

Used to adiust

citors.

checks.

and adjustments.

checks.

variable

resistors.

variable capa-

compensa-

procedure

a. Tektronix

a. Tektronix

Tektronix

a.

Xcelite

a.

a. Tektronix

R-3323

No. 103{090{0

Part

No.

Part

Part No.

Part No.003{000{)0

10049-01 .

01

103003000

REV

B APR

1980

I

I

I

I

I

o:

I

Page 23

I

Cal i brati o n-21 4 Service

I

-

I

I

I

I

I

I

I

I

O

-7

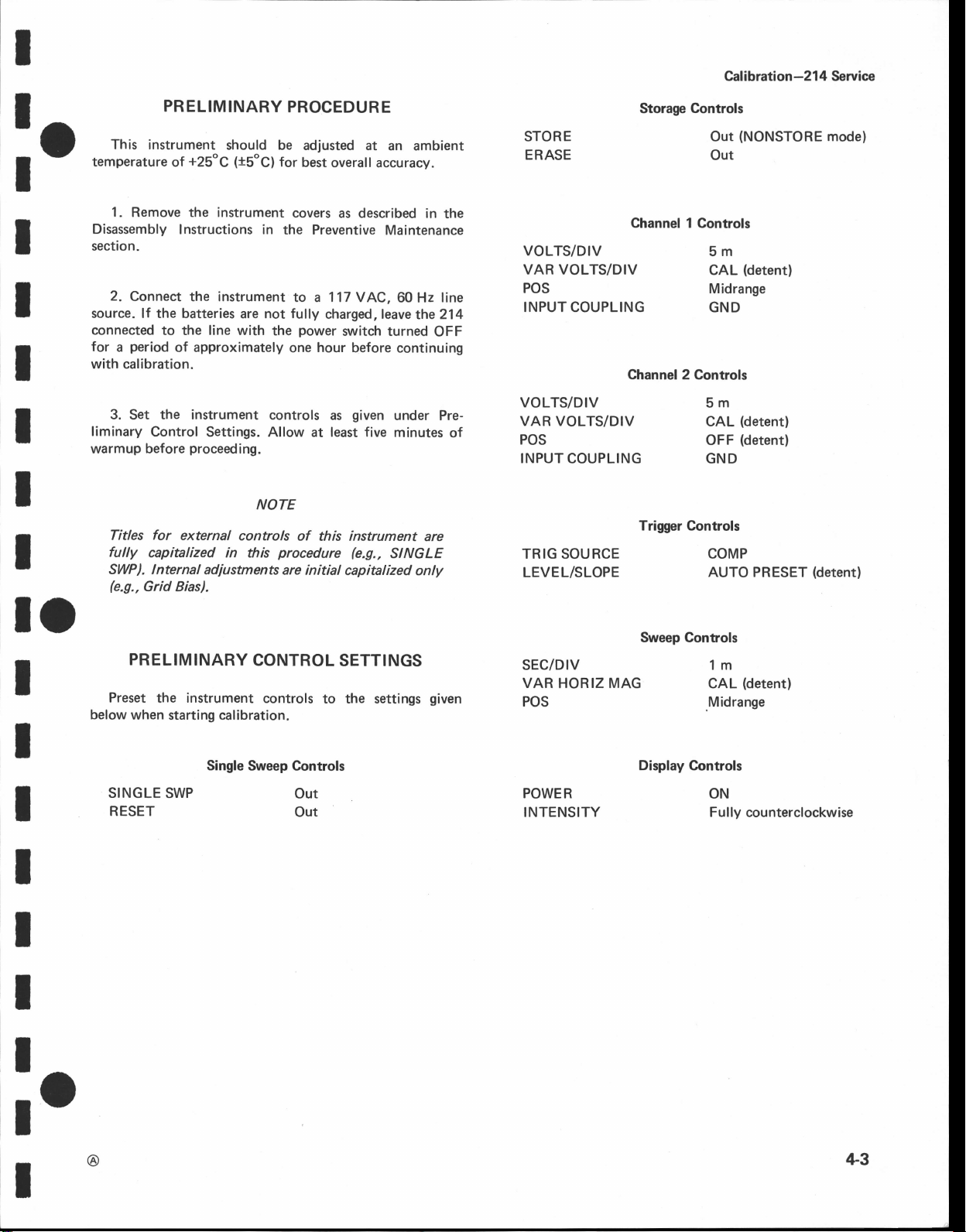

This instrument

temperature

1.

Remove

Disassembly

section.

2.

Connect

source. lf the batteries

connected

period

for

a

with calibration.

3.

Set

liminary

warmup before

Titles

fully

capitalized

SWP). lnternal

(e.9.,

Grid

PRELTMTNARv

should be

(ts"C)

+25"C

of

the

instrument

Instructions in

the instrument

are not

to the

the instrument

Control

for

line

with

of approximately

Settings. Allow at least

proceeding.

external controls

in this

adjustments

Bias).

pRocEDURE

for

the

fully

the

one hour before

controls

NOTE

procedure

are initial

adiusted at

best

overall accuracy.

covers as described

Preventive

to a 117 VAC,

charged,leave

power

as

of

this

an ambient

Maintenance

60 Hz

the214

switch

turned

continuing

given

under

five

minutes

instrument

(e.g.,

SINGLE

capitalized only

in the

line

OFF

Pre-

of

are

Storage Controls

STORE

ERASE

Channel

VOLTS/DIV

VAR

VOLTS/DIV

POS

INPUT COUPLING

Channel 2 Controls

VOLTS/DIV

VAR VOLTS/DIV

POS

INPUT COUPLING

Trigger Controls

TR IG

LEVEL/SLOPE

RCE COMP

SOU

Out

{NONSTORE

Out

1

Controls

5m

(detent)

CAL

Midrange

GND

5m

(detent)

CAL

(detent)

OFF

GND

AUTO PRESET

mode}

(detent)

lo

I

I

I

I

I

I

PRELIMINARY

Preset

below

when starting calibration.

SINGLE

RESET

instrument

the

SWP

Single

Sweep

CONTROL

controls

Gontrols

SETTINGS

to

Out

Out

the settings

given

SEC/DIV

VAR

HORIZ

POS

POWER

INTENSITY

Sweep Gontrols

MAG

Display Gontrols

1m

(detentl

CAL

Midrange

ON

ly

Ful

counterclockwise

!r

I

@

+3

Page 24

Calibratio n

-214

Service

Equipment Required

1.

2.

3. Low-Frequency Constant-Amplitude

erator

Control

Preset

Prel iminary

Check

1.

lf

prior

Generator

Ramp

Voltmeter

DC

(General

the instrument has

Radio

Settings

.instrument

Control

Power

to recalibration,

(TM

1310-8

controls

Settings.

Supply

proceed

501/RG

Oscillator)

the

to

DC Levels

NOTE

been

operating

with

501)

settings

step

POWER

ntisfactorily

2.

SUPPTY AND DISPLAY

Signal Gen-

given

under

4. Probe

5.

6. Three-inch Screwdriver

Supply

-5.6

+5.6

+65

-1000

b.

To measure the

tip-to-BNC

10X BNC Attenuator

Power

V

V

V

v

Adapter

TABLE

Supply

-5.6

+5.6

+65

-960

(due

-100

4.2

Accuracy

Measurement

10.4

volts

10.4

volts

t4

volts

to

V

supply:

volts

140

volts

meter loading)

volt

volt

volts

o:

I

T

I

I

I

I

ol

a.

Using

power

pofarity.

supplies

the DC Voltmeter,

given

in

See

Fig. 4-1

tor

Table

test

measure

4-2.

point

Fig. 4-1.

the DC level of the

(A)

proper

Location

Observe

locations.

meter

of

Grid Bias adjustment

1. Depress the

Measure

2.

-110

to

volts

3. Press the

(B)

and

the

volts

STORE

Power

STORE

-100V

(see

button

test

supply

button.

supply

4-21.

Fig.

points.

release

to

for

reading

a

it.

of

t

-95

I

I

I

I

I

o:

4-4

REV. B, AUG.

1974

Page 25

I

Caf i brati o n

-21

4

Service

:o

I

I

t

I

I

I

I

Fig.

*2.

Location of

-100

2. Adjust CRT Grid

a. Connect the

plug

of

Supply

P3

Board

DC

(negative

(A-3).

See

point.

tost

V

Bias

Voltmeter

meter lead

4-1.

Fig.

between

pin

to

2)

pin

on the Power

5

and

ptn

b. Position

line.

c.

CHECK-Free-running

horizontal

d. ADJUST-Trace Rotation adjustment, R141

Fig.

graticule

2

graticule

4-3)

to align the

line.

the

trace to

I ine.

the

sweep with the

center horizontal

$/\,eep is

parallel

center

graticule

with the

(see

horizontal

lo

r

I

I

I

I

I

I

I

I

I

b.

Turn the

c.

CHECK-Meter

d. ADJUST-CRT

rneter reading

e.

Disconnect

fully

trol

Adjust FOCUS

3.

Turn the

a.

POS control to the

b.

Set

INTENSITY

c. ADJUST-FOCUS, R398

panel)for

INTENSITY control fully

reading

Grid Bias adiustment, R273,

+1.9

of

counterclockwise.

the

control

welldefined dot.

a

volts.

meter leads.

POS

2

CH

OFF

SEC/DIV

for a nominal

clockwise.

+1.9

of

control to midrange and

detent,

switch to X-Y and

volts.

Turn the INTENSITY con-

display

(located

intensity.

on the

for

a

the

CH

adjust the

214

side

Fig.

4-3.

Location

5. Adiust Storage

a. Determine

(1)

vertically

graticule

(21

1

INTENSITY

(3)

tg. 4Al

F

(41

and

22

Power

(5)

button.

of Trace Rotation

Operating

upper writing

the

1 POS

Turn the

position

divisions.

Set

PREsET-Operating

f

ul

Connect

ground

Supply

Depress

CH

two traces within

the

the

SEC/DIV

fully

control

ly

counterclockwise.

the

{negative

(A-3)

the

clockwise.

DC Voltmeter

meter lead

board. See

SINGLE

switch

adjustment.

Level

limit

of the CRT.

control

to 5 m and turn

adjustment, R510

Level

between

Fig.4-4.

button and the STORE

SWP

midrange

to

the center

pin

ground)

to

4

of

on

and

four

the

{see

plug

the

4. Adjust Trace Rotation

- O

I

I

a. Set the

l@

SEC/DIV

switch to 1

m.

(6)

Press the

(7)

Press the RESET

ERASE

button.

button.

4-5

Page 26

Cal i bration-214 Service

I

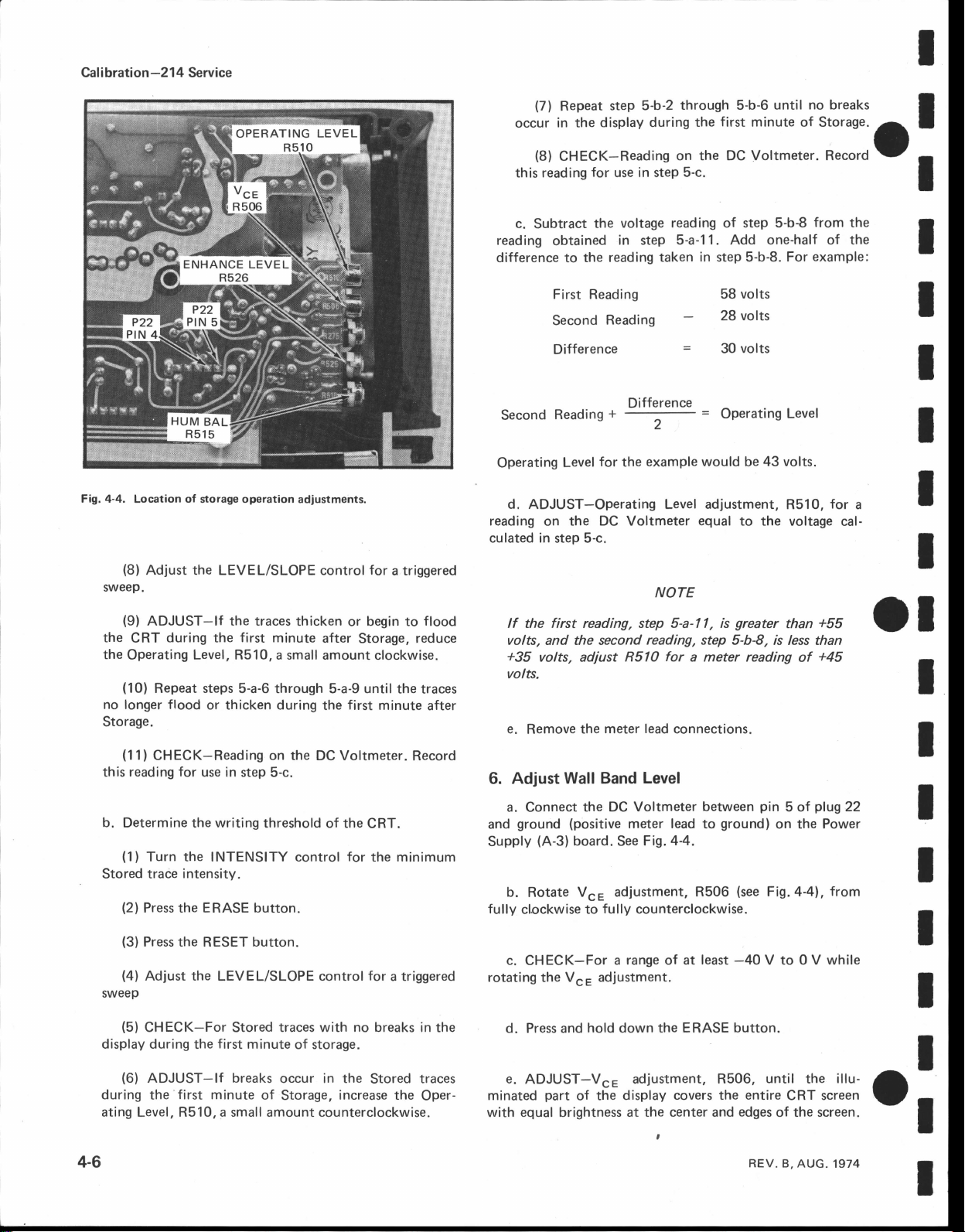

Fig.4-4.

sweep.

Location

(8)

Adjust the

of

storage operation

LEVEL/SLOPE control

adjustments.

for

a triggered

(71

Repeat

in the display

occur

(8)

CHECK-Reading

this reading

c.

Subtract

reading

difference to

Second

Operating

reading on the DC Voltmeter

culated in step

obtained

First Reading

Second

Difference

Reading*

d.

ADJUST-Operating Level adjustment, R510,

for

the

the

Level

5-c.

step 5-b-2

use in step

voltage reading of step 5-b€

in step

reading taken

Reading

Difference

T=

for

the

through

during

on the DC Voltmeter. Record

5-c.

5-a-1

example would be 43

NOTE

s-b-G

first

the

1.

Add one-half of the

in

step

volts

58

28 volts

volts

30

OperatingLevel

equal

to the voltage

until no breaks

minute of Storage.

from

the

volts.

example:

for

a

cal-

5-b-8. For

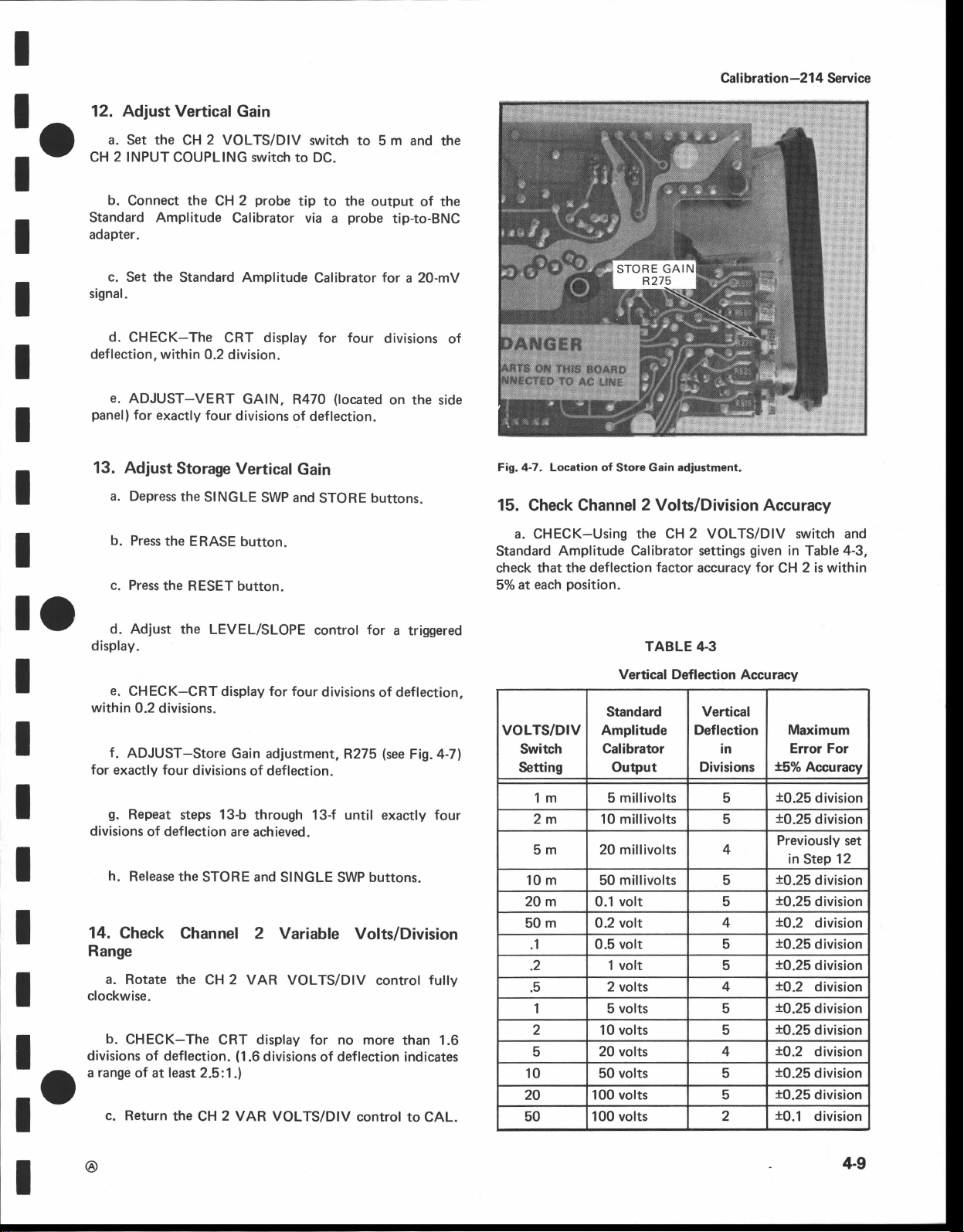

|!

^-.

I

I

I

I

I

I

I

I

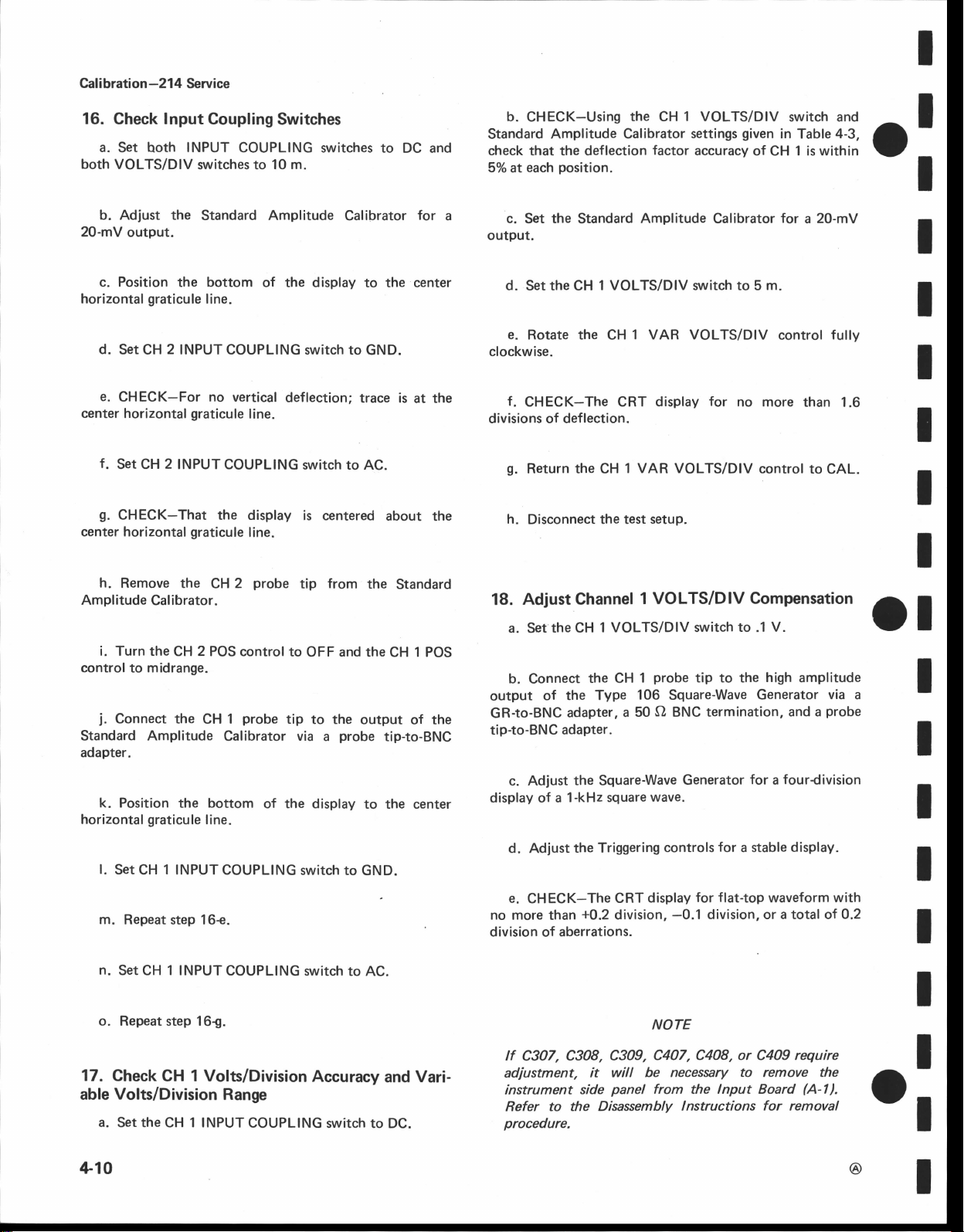

(9)

ADJUST-|f the traces

the

the

no longer

Storage.

this

b. Determine

Stored trace

sweep

display during

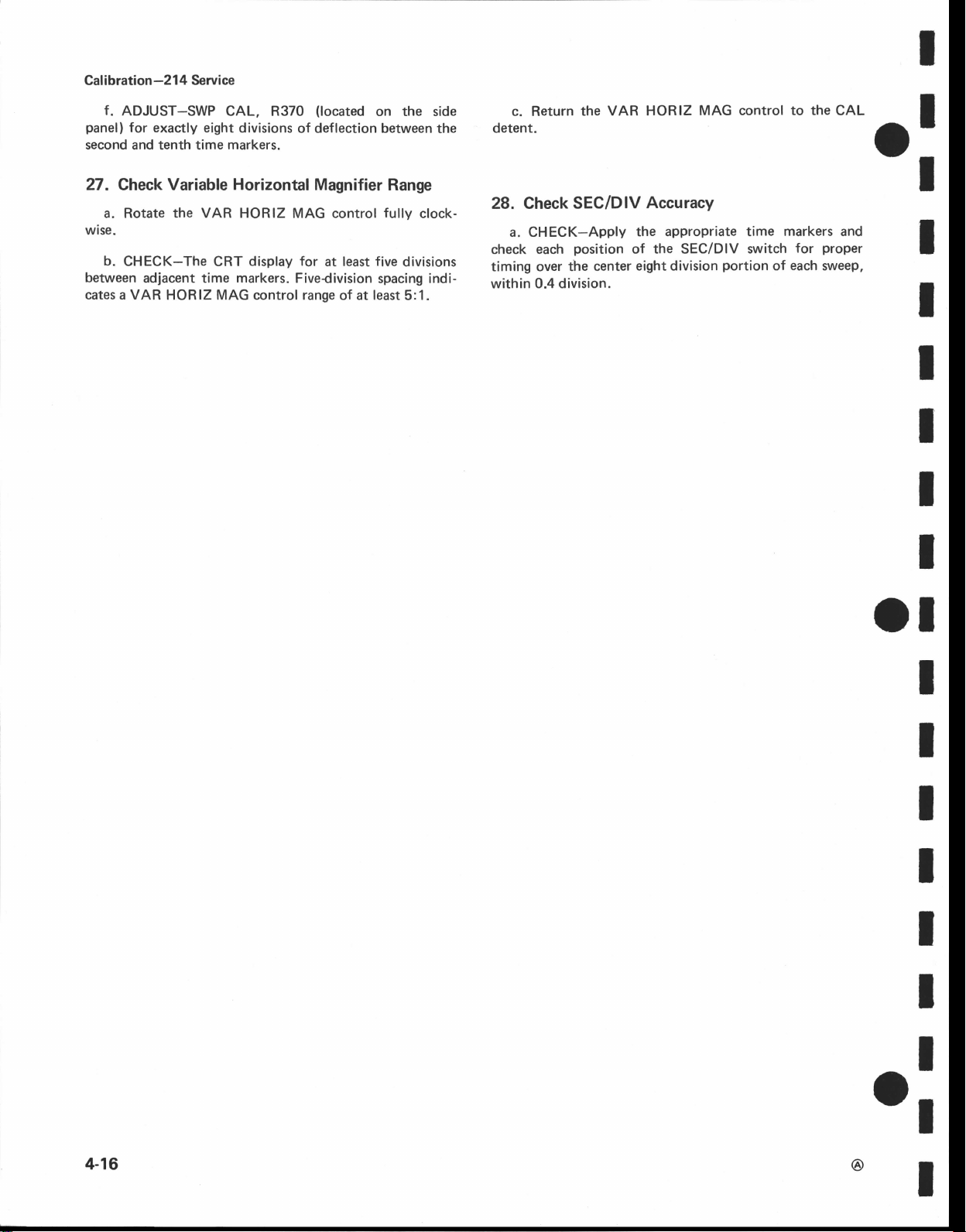

during the first minute

CRT

Operating

(101

(11)

reading for

(1)

Turn the

(2)

Press the ERASE button.

(3)

Press the

(4)

Adjust the

(5)

CHECK-For

Level, R510, a small amount

Repeat

CHECK-Reading

steps

flood

use in

the

intensity.

RESET

the

or

thicken

5-a-6 through

thicken during the

on

the DC

step 5-c.

writing

INTENSITY control

threshold

button.

LEVEL/SLOPE control

Stored

first

traces with no breaks

minute

of storage.

or

after

5-a-9

first

Voltmeter. Record

of the

for

reduce

the traces

minute

triggered

a