Page 1

TECHNICAL MANUAL

OPERATOR, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS)

FOR

OSCILLOSCOPE, TEKTRONIX, MODEL 212

NSN 6625-01-061-5519

MULTIPLE LAUNCH ROCKET SYSTEM

TM 9-6625-646-14&P

DEPARTMENT OF THE ARMY

JUNE 1984

Page 2

TM 9-6625-646-14&P

WARNING

DANGEROUS VOLTAGE

is used in the operation of this equipment

DEATH ON CONTACT

may result if personnel fail to observe safety precautions

Never work on electronic equipm ent unless ther e is another per son near by who is familiar

with the operation and hazards of the equipment and who is com petent in administering

first aid. When the technician is aided by operators, he must warn them about dangerous

areas.

Whenever poss ible, the power supply to the equipment must be s hut off befor e beginning

work on the equipment. Tak e particular care to ground every capacitor likely to hold a

dangerous potential. When working inside the equipment, after the power has been

turned off, always ground every part before touching it.

Be careful not to contact high-voltage connections when installing or operating this

equipment.

Whenever the nature of the operation permits, keep one hand away from the equipment

to reduce the hazard of current flowing through vital organs of the body.

WARNING

Do not be misled by the term "low voltage." Potentials as low as 50 volts may

cause death under adverse conditions.

COMMON and probe ground straps are electr ically connected. Theref ore, an elevated

reference applied to any is present on each - as indicated by the yellow warning bands

under the probe retractable hook tips.

For Artificial Respiration, refer to FM 21-11.

EXTREMELY DANGEROUS POTENTIALS

greater than 500 volts exist in the following units:

1. CRT Power Supply

2. Horizontal Deflection System

3. Vertical Deflection System

a/(b blank)

Page 3

TM 9-6625-646-14&P

Copyright 1972 by Tektronix, Inc. All rights reserved. REPRODUCED BY PERMISSION OF TEKTRONIX, INC. Distribution is limited

to use in connection with the Multiple Launch Rocket System.

Technical Manual HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 9-6625-646-14&P Washington, D.C.,

8 June 1984

Operator’s, Organizational, Direct Support, and

General Support Maintenance Manual

(Including Repair Parts)

for

OSCILLOSCOPE, TEKTRONIX, MODEL 212

(NSN 6625-01-061-5519)

MULTIPLE LAUNCH ROCKET SYSTEM

REPORTING OF ERRORS

You can help improve this bulletin by calling attention to errors and by

recommending improvements and stating your reasons for the recommendations.

Your letter or DA Form 2028, Recommended Changes to Publications, s hould be

mailed directly to Commander, U.S. Army Missile Command, ATTN: DRSMISNPM, Redstone Arsenal, AL 35898. A reply will be furnished to you.

TABLE OF CONTENTS

Page

LIST OF ILLUSTRATIONS............................................................................................................................ iii

SECTION 0. GENERAL INFORMATION.......................................................................................... 0-1

Scope............................................................................................................................ 0-1

Indexes of publications................................................................................................. 0-1

SECTION 1. INTRODUCTION.......................................................................................................... 1-1

Option information........................................................................................................ 1-4

Accessories.................................................................................................................. 1-5

Manual change information.......................................................................................... 1-6

Calibration test equipment replacement....................................................................... 1-7

SECTION 2. FUNCTIONS OF CONTROLS AND CONNECTORS.................................................. 2-1

SECTION 3. PREVENTIVE MAINTENANCE.................................................................................... 3-1

Disassembly instructions.............................................................................................. 3-1

Cleaning........................................................................................................................ 3-1

Visual inspection........................................................................................................... 3-1

Semiconductor checks................................................................................................. 3-2

Recalibration................................................................................................................. 3-2

This manual is, in part, authenticated manufacturer’s commercial literature. A Maintenance Allocation Chart and Recommended Spare

Parts List has been added to supplement the commercial literature. The format of this manual has not been structured to consider

levels of maintenance.

i

Page 4

TM 9-6625-646-14&P

SECTION 4. CALIBRATION................................................................................................................ 4-1

Test equipment required................................................................................................. 4-1

Preliminary procedure..................................................................................................... 4-3

Preliminary control settings............................................................................................. 4-3

Procedure ....................................................................................................................... 4-4

SECTION 5. TROUBLESHOOTING AIDS.......................................................................................... 5-1

Component color-code ................................................................................................... 5-1

Semiconductor lead configurations ................................................................................ 5-2

Equipment recommended .............................................................................................. 5-2

SECTION 6. CIRCUIT DESCRIPTION................................................................................................ 6-1

Block............................................................................................................................... 6-1

Circuit operation.............................................................................................................. 6-1

SECTION 7. CORRECTIVE MAINTENANCE..................................................................................... 7-1

Obtaining replacement parts........................................................................................... 7-1

Component replacement ................................................................................................ 7-1

Instrument repackaging.................................................................................................. 7-4

SECTION 8. PARTS LIST, DIAGRAMS AND CIRCUIT BOARD ILLUSTRATIONS .......................... 8-1

Electrical parts list........................................................................................................... 8-2

Mechanical parts list....................................................................................................... 8-12

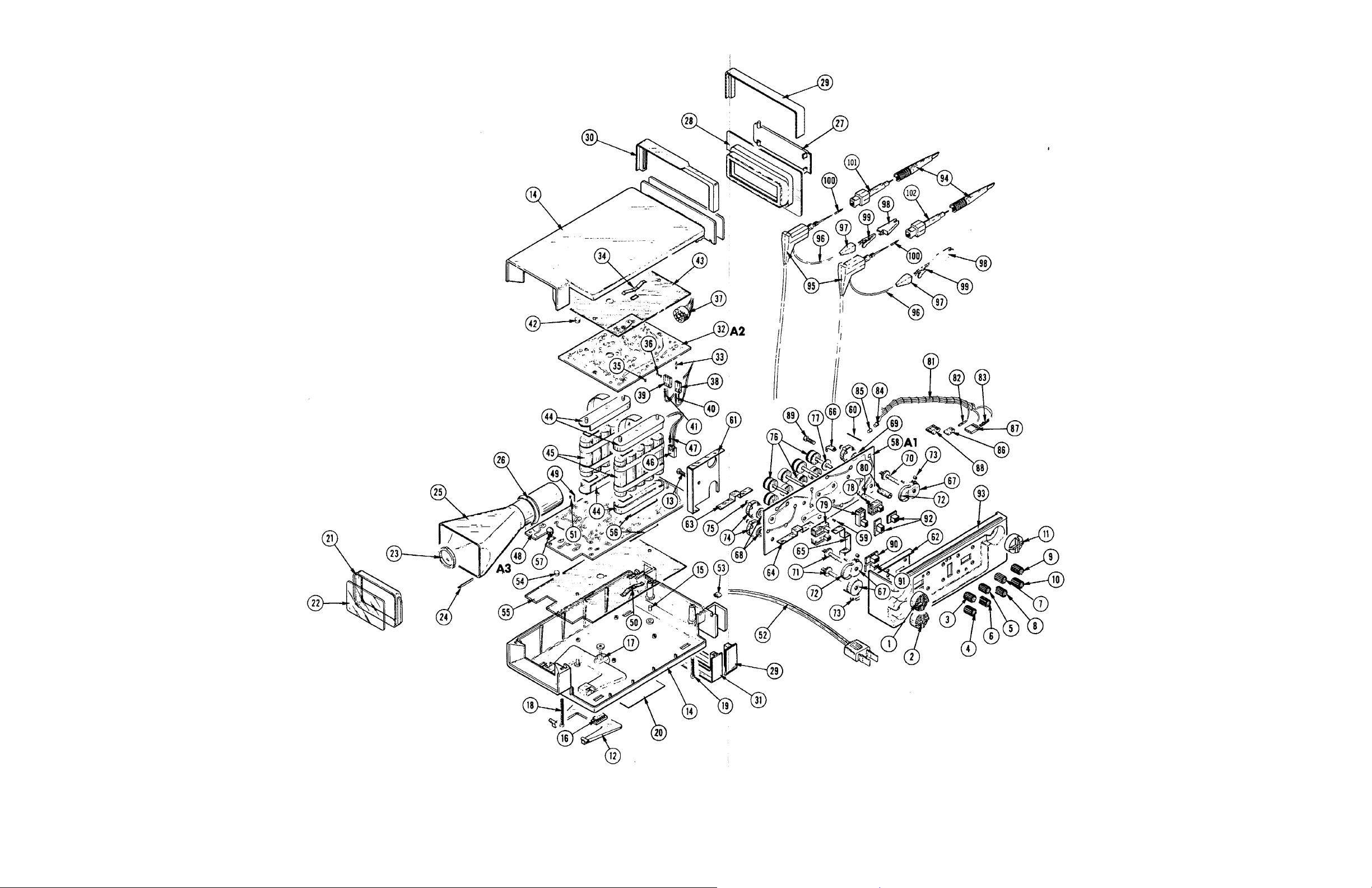

Exploded drawings.......................................................................................................... 8-17

Circuit board drawings and schematics.......................................................................... 8-19

APPENDIX A. REFERENCES ........................................................................................... A-1

B. MAINTENANCE ALLOCATION CHART (MAC)......................................... B-1

C. RECOMMENDED REPAIR PARTS LIST................................................... C-1

ii

Page 5

TM 9-6625-646-14&P

LIST OF ILLUSTRATIONS

Figure Title Page

1-1 212 Oscilloscope. 0-1

1-2 212 Oscilloscope Accessories. 1-5

2-1 Side Panel Controls and Connectors. 2-1

3-1 Location of Screws Securing Bottom Cover and Side Panel. 3-1

3-2 Location of Circuit Boards Within the 212. 3-2

4-1 Location of Power Supply Test Points and CRT Grid Bias

Adjustment. 4-4

4-2 Location of Trace Rotation Adjustment. 4-4

4-3 Location of Vertical Centering Adjustment and Test Point. 4-5

4-4 Location of Attenuator Compensation Capacitors. 4-7

4-5 Location of Horizontal Centering Adjustment and Test Point. 4-10

5-1 Color Code for Resistors, Ceramic Capacitors, and Dipped Tantalum

Electrolytic Capacitors. 5-1

5-2 Lead Configuration of Semiconductors Used in this Instrument. 5-2

6-1 Vertical Input Amplifiers Detailed Block Diagram. 6-2

6-2 Vertical and Horizontal Output Amplifiers Detailed Block Diagram. 6-3

6-3 Trigger/Sweep Generator Detailed Block Diagram. 6-4

6-4 Power Supply Detailed Block Diagram. 6-5

6-5 CRT Circuit Detailed Block Diagram. 6-6

7-1 Selecting C210 and C212 Capacitance Values for 48 to 52

Hz Operation. 7-2

7-2 Selecting C210 and C212 Capacitance Values for 58 to 62

Hz operation. 7-3

8-0 Mechanical Parts, Exploded View. 8-17

8-1 Block Diagram. 8-19

8-1A Al Input Circuit Board (Front). 8-21

8-1B Al Input Circuit Board (Near). 8-21

8-1C Waveform Conditions - Vertical Amplifier. 8-23

8-1D Vertical Amplifier Schematic Diagram. 8-23

8-1E Vertical Amplifier Schematic Diagram. 8-25

8-2 A2 Amplifier Circuit Board. 8-25

8-2A Waveform Conditions - Horizontal and Vertical Output Sweep

and Trigger. 8-27

8-2B Horizontal and Vertical Output Sweep and Trigger

Schematic Diagram. 8-27

8-3A A3 Power Supply Circuit Board, SN B040000-up. 8-29

8-3B A3 Power Supply Circuit Board, below SN B040000. 8-31

8-4 CRT Circuit Schematic Diagram. 8-33

8-5 Power Supply Schematic Diagram. 8-35

iii

Page 6

SECTION 0 GENERAL INFORMATION

TM 9-6625-646-14&P

O-1. Scope. This manual contains instructions for the

operator, organizational, direct support, and general

support maintenance of and calibration procedures for

Tektronix Oscilloscope, Model 212. Throughout this

manual, Tektronix Oscilloscope, Model 212 is referred

to as the 212.

O-2. Indexes of Publications.

Refer to the latest issue of DA Pam 310-4 to determine

whether there are new editions, changes, or additional

publications pertaining to Tektronix Oscillos cope, Model

212.

b. DA Pam 310- 7.

Pam 310-7 to determine whether there are modification

work orders (MWO’s) pertaining to Tektronix

Oscilloscope, Model 212.

O-3. Forms, Records, and Reports. Department of

Army forms and procedures used for equipment

maintenance and calibration are those prescr ibed by TM

38-750, The Army Maintenance Management System.

Accidents involving injury to personnel or damage to

materiel will be reported on DA Form 285, Accident

Report, in accordance with AR 385-40.

Refer to the latest issue of DA

a. DA Pam 310-4.

O-4. Reporting Equipment Improvement

Recommendations (EIR). If your 212 needs

improvement, let us know. Send us an EIR. You, the

user, are the only one who can tell us what you don’t like

about your equipment. Let us know why you don’t like

the design. Tell us why a procedure is hard to perform.

Put it on an SF 368 (Quality Deficiency Report). Mail it to

Commander, U.S. Army Missile Command, ATTN:

DRSMI-SNEM, Redstone Arsenal, AL 35898. We’ll send

you a reply.

O-5. Administrative Storage. To prepare the Tektronix

Oscilloscope, Model 212 for placement into and removal

from administrative storage, refer to Section 3, Chapter

4, AR 750-25-1, Maintenance of Equipment and

Supplies. Temporary storage should be acc omplished in

accordance with TB 750-25-1, Section 2, Maintenance

of Supplies and Equipment.

O-6. Destruction of Army Electronics Materiel.

Destruction of Tektronix Oscilloscope, Model 212 to

prevent enemy use shall be in accordance with TM 430002-26, Organizational Maintenance Manual,

Destruction of Equipment to Prevent Enemy Use for

Launcher, Rocket, Armored Vehicle Mounted: XM270,

Multiple Launch Rocket System.

0-1

Page 7

Figure 1-1. 212 Oscilloscope.

0-2

TM 9-6625-646-14&P

Page 8

SECTION 1

INTRODUCTION

TM 9-6625-646-14&P

The 212 Oscilloscope is a dual-channel portable

oscilloscope using all solid state and integrated circuitr y

(except the CRT). The s m all size of the 212 m ak es it an

extremely portable oscilloscope for on-location

maintenance in many fields of application.

The 500 kilohertz vertical system provides vertical

deflection factors from one millivolt (at a reduced

bandwidth) to 50 volts/division at the tip of either of the

two integral high-impedance probes. Both single-trace

and dualtrace modes of operation are offered. Singletrace displays are achieved by turning off either ver tical

channel with its position control. In the dual-trace mode,

the instrument automatically chops or alternates,

depending upon the sweep rate. The trigger circuits

provide stable triggering over the full bandwidth

capabilities of the vertical system.

The horizontal deflection system provides calibrated

sweep rates from 500 millisec onds to five m icrosec onds/

division. It also provides uncalibrated sweep rates, via a

variable sweep magnifier, to at least five times the

indicated sweep rate for a maximum of at least one

microsecond/ division. In addition, X-Y operation is

provided. Channel 1 supplies the horizontal (X)

deflection, with a range from less than one millivolt to 50

volts/division (at a reduced bandwidth of 50 kilohertz),

and Channel 2 the vertical (Y) deflection. The resultant

CRT display is presented on a 6 X 10 divis ion graticule

(each division equals 0.203 inch).

The 212 is operated either from AC line voltage or

from internal rechargeable batteries. The internal

batteries are recharged from the AC power line by the

integral battery charger.

This instrument will meet the following electrical

characteristics after complete instrument calibration.

These characteristics apply over an ambient temperature

of -15àC to +55àC (+5àF to +131àF), except as

otherwise indicated. W armup time for given accuracies

is five minutes.

VERTICAL DEFLECTION SYSTEM

Calibrated Range: One millivolt to 50 volt/division. 15

steps in 1-2-5 sequence.

Accuracy: Within 5% with VOLT S/DIV VAR control in

CAL position and gain correctly set at 5 mV/div.

Uncalibrated (variable) Range: Continuously variable

between calibrated settings. Extends maximum

deflection factor to at least 125 volts/division.

BANDWIDTH (with six-division reference):

10 mV/DIV to 50 V/DIV: DC to at least 500 kilohertz.

5 mV/DIV: DC to at least 400 kilohertz.

2 mV/DIV: DC to at least 200 kilohertz.

1 mV/DIV: DC to at least 100 kilohertz.

Lower Bandwidth Limit, AC (capacitively) Coupled:

about 2 hertz at all deflection factors.

INPUT RESISTANCE:

Approximately one megohm.

INPUT CAPACITANCE:

1 mV/DIV to 50 mV/DIV: Approximately 160

picofarads.

100 mV/DIV to 50 V/DIV: Approximately 140

picofarads.

MAXIMUM USABLE INPUT VOLTAGE:

50 V/DIV to .1 V/DIV: 600 volts (DC + peak AC). 600

volts peak-to-peak AC (five megahertz or less).

50 mV/DIV to 1 mV/DIV: 600 volts (DC + peak AC).

AC not over 2 kilohertz or risetime not less than 100

nanoseconds.

CHOPPED MODE:

From 500 ms/DIV to 2 ms/DIV of time base at

approximately 50 kilohertz.

ALTERNATE MODE:

From 1 ms/DIV to 5ps/DIV of time base.

INPUT IMPEDANCE MATCHING:

Matched to within approximately 10%.

DEFLECTION FACTOR:

1-1

Page 9

TM 9-6625-646-14&P

GAIN ACCURACY BETWEEN CHANNELS:

Within 5% with both VOLTS/DIV VAR controls in CAL

position and gain correctly set at 5 mV/DIV.

TRIGGERING

TRIGGER SENSITIVITY:

Internal: COMP: 0.2 division from DC to 500

kilohertz.

CH 2: 0.2 division from 2 hertz to 500 kilohertz.

External:

1.0 volt from DC to 500 kilohertz.

PRESET TRIGGER LEVEL:

Triggered at preset level on positive slope of

triggering signal. Sensitivity same as stated above.

DISPLAY JITTER:

0.5 microsecond or less at 500 kilohertz.

EXTERNAL TRIGGER:

Input Resistance: Approximately one megohm.

Input Capacitance: Approximately 30 picofarads.

Maximum Usable Input Voltage: 8 volts (DC + peak

AC) 16 volts peak-to-peak AC (one megahertz or less).

calibrated settings. Extends maxim um sweep rate to at

least 1.0 microsecond/division.

CH 1 HORIZONTAL INPUT:

Calibrated Deflection Factor: 1 millivolt to 50 volts/

division.

Variable: At least five times (using HORIZ MAG).

Accuracy: Within 10% (with HORIZ MAG control in

CAL position).

X-Y Phasing: Less than 3à at five kilohertz.

Maximum Input Voltage: 600 volts (DC + peak AC) ;

600 volts (peak-to-peak AC).

DISPLAY

GRATICULE:

Type: Internal black line, non-illuminated.

Area: Six divisions vertical by 10 divisions horizontal.

Each division equals 0.203 inch.

PHOSPHOR:

P31 Standard.

ISOLATION

HORIZONTAL DEFLECTION SYSTEM

SWEEP RATE:

Calibrated Range: 500 milliseconds to five

microseconds/ division. 16 steps in 1-2-5 sequence.

Accuracy (over center eight divisions): Within 5%

with HORIZ MAG control in CAL position and timing

correctly set at 1 ms/DIV (disregard f irs t 0.5 microsecond

of total sweep length).

Linearity (any two division portion within center eight

divisions): W ithin 5% (disregard f irst 10% of total sweep

length).

Variable Magnifier: Continuously variable between

PROBE COMMON TO 212 CASE EXTERIOR: (When

battery operated with AC power plug secured in the

insulated cover.) Maxim um s afe potential between pr obe

common (floating circuit ground) and 212 case exterior

not to exceed 500 V RMS sinusoidal, or 700 V (DC +

peak AC).

PROBE COMMON TO AC LINE: Maximum safe

potential between probe common (f loating c irc uit ground)

and the AC power line is not to exceed 250 V RMS

sinusoidal minus the AC power line RMS voltage. (i.e.,

when the AC power line RMS voltage is 117 V, the

maximum allowable potential on the probe common is

250 -117 = 133 V RMS.)

1-2

Page 10

AC OPERATION

CAUTION

Due to the capacitive line input

circuit, sudden voltage changes may

cause damaging input current

transients. Avoid operating this

instrument from squarewave inverter

supplies, or other sources that

produce large voltage transients.

LINE VOLTAGE RANGE: 110 to 126 volts, AC.

Batteries can not be charged during AC operation.

Instrument can be operated between 104 and 110 volts

with resulting slow discharge of internal batteries.

TM 9-6625-646-14&P

CHARGE OPERATING TEMPERATURE

TEMPERATURE 15°C +20°C to +30°C +55°C

(+5°F) (+68°F to +860F) (+131°F)

0°C (+32°F) 40% 60% 50%

+20àC to +30àC 65% 100% 85%

(+68° F to +86à F)

40°C (+104àF) 40% 65% 55%

GENERAL

ENVIRONMENT:

Temperature:

LINE FREQUENCY: 58 to 62 hertz.

NOTE

Refer to Option and Corrective

Maintenance information for other

line voltages and frequencies.

MAXIMUM POWER CONSUMPTION: Three watts or

less at 126 volts, 60 hertz.

INTERNAL BATTERY OPERATION

BATTERIES: 10 rechargeable A nickel-cadmium cells.

CHARGE TIME (from AC line): 16 hours f or full charge

(instrument off during charge cycle).

POWER (BAT TERY) INDICATOR: When ex tinguished,

indicates less than 10 minutes of sc ope operating life left

in the batteries.

BATTERY EXCESSIVE DISCHARGE PROTECTION:

Instrument operation automatically interrupted when

battery charge drops to 10 volts +0.5 volt.

TYPICAL OPERATING TIME (at maximum trace

intensity after full charge cycle at +20àC to +30àC):

Three to five hours. Longest operating tim e provided at

lower trace intensity.

Operating from Batteries , -15°C to +55 àC (+5àF to

+131àF).

Charging or operating from AC line, 0°C to +40°C

(+32°F to +104àF).

Storage, -40àC to +60°C (-40àF to +140à F).

Altitude:

Operating, to 25, 000 feet (maximum operating

temperature decreased by 10C per 1, 000 f eet above 15,

000 feet).

Non-operating, to 50, 000 feet.

Humidity (operating and non-operating): 5 cycles

(120 hours) to 95% relative humidity referenced to

MIL-E-16400F.

Shock (operating and non-operating): Tested with

two shocks at 150 g, one-half sine, two millisecond

duration each direction along three major axes.

WEIGHT (without accessories):

3.4 pounds (1.5 kilograms)

DIMENSIONS (measured at maximum points):

TYPICAL CHARGE CAPACITY (reference to charge/

discharge at +20àC to +30àC):

Height: 3.0 inches (7.6 centimeters).

Width: 5.25 inches (13.2 centimeters).

Depth: 8.9 inches (22.6 centimeters).

1-3

Page 11

TM 9-6625-646-14&P

OPTION INFORMATION

Your instrument may be equipped with one or more options. T his s ection desc ribes thos e options or dir ects the reader

to where the option is documented.

OPTION 1

Option 1 equips the 212 for operation from a 220 to 250 V ac 48 to 52 Hz power line source. O ption 1 parts values that

differ from the standard 212 are listed here. A power cord cable assembly, for adapting to appropriate power plugs, is

included with Option 1 instruments. Refer to the Corrective Maintenance and Diagrams sections of this manual for

additional information concerning Option 1.

ELECTRICAL PARTS LIST DIFFERENCES FOR OPTION 1

A3 670-2405-21* POWER SUPPLY Circuit Board Assembly (Option 1)

C204 283-0279-00 0.001 UF, 20%, 3 KV

C210 285-0932-00 1.0 UF, 10%, 400V

C212 285-0933-00 2.0 UF, 10%, 400V

C215 283-0279-00 0.001 UF, 20%, 3 KV

ADDITIONAL STANDARD ACCESSORIES FOR OPTION 1

161-0077-01 CABLE ASSEMBLY, POWER

(Adapts to users plug type)

*In some Option 1 instruments, the suffix number on the board may not be marked -21.

OPTION 2

Option 2 equips the 212 for operation from a 90 to 110 V ac 48 to 52 Hz power line source. Option 2 parts values that

differ from the standard 212 are listed here. Refer to the Corr ective Maintenance and Diagrams s ections of this manual

for additional information concerning Option 2.

ELECTRICAL PARTS LIST DIFFERENCES FOR OPTION 2

A3 670-2405-31 ** POWER SUPPLY Circuit Board Assembly (Option 2)

C210 285-0934-00 2.2 UF, 10%, 200V

C212 285-0935-00 4.4 UF, 10%, 200V

**ln some Option 2 instruments, the suffix number on the board may not be marked -31.

1-4

Page 12

TM 9-6625-646-14&P

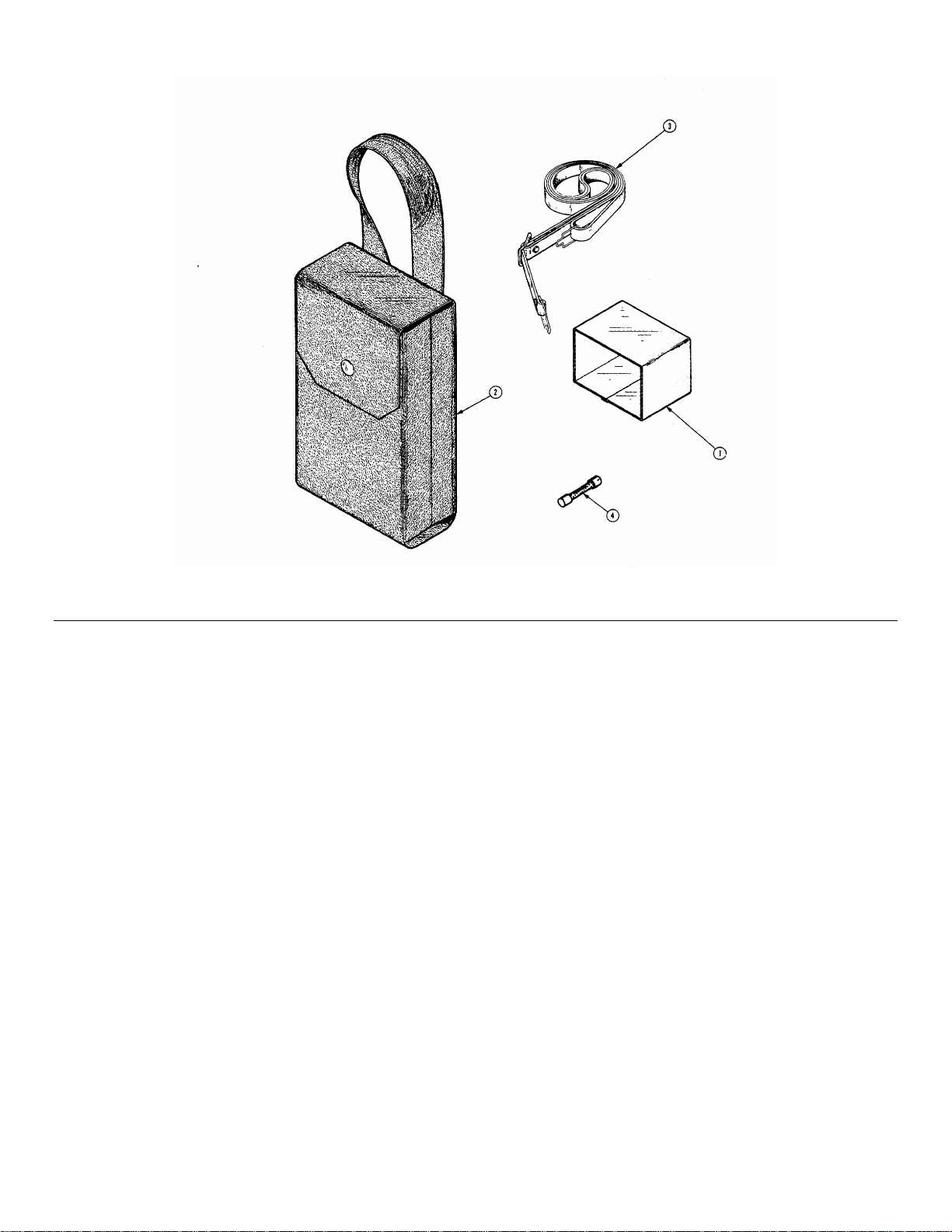

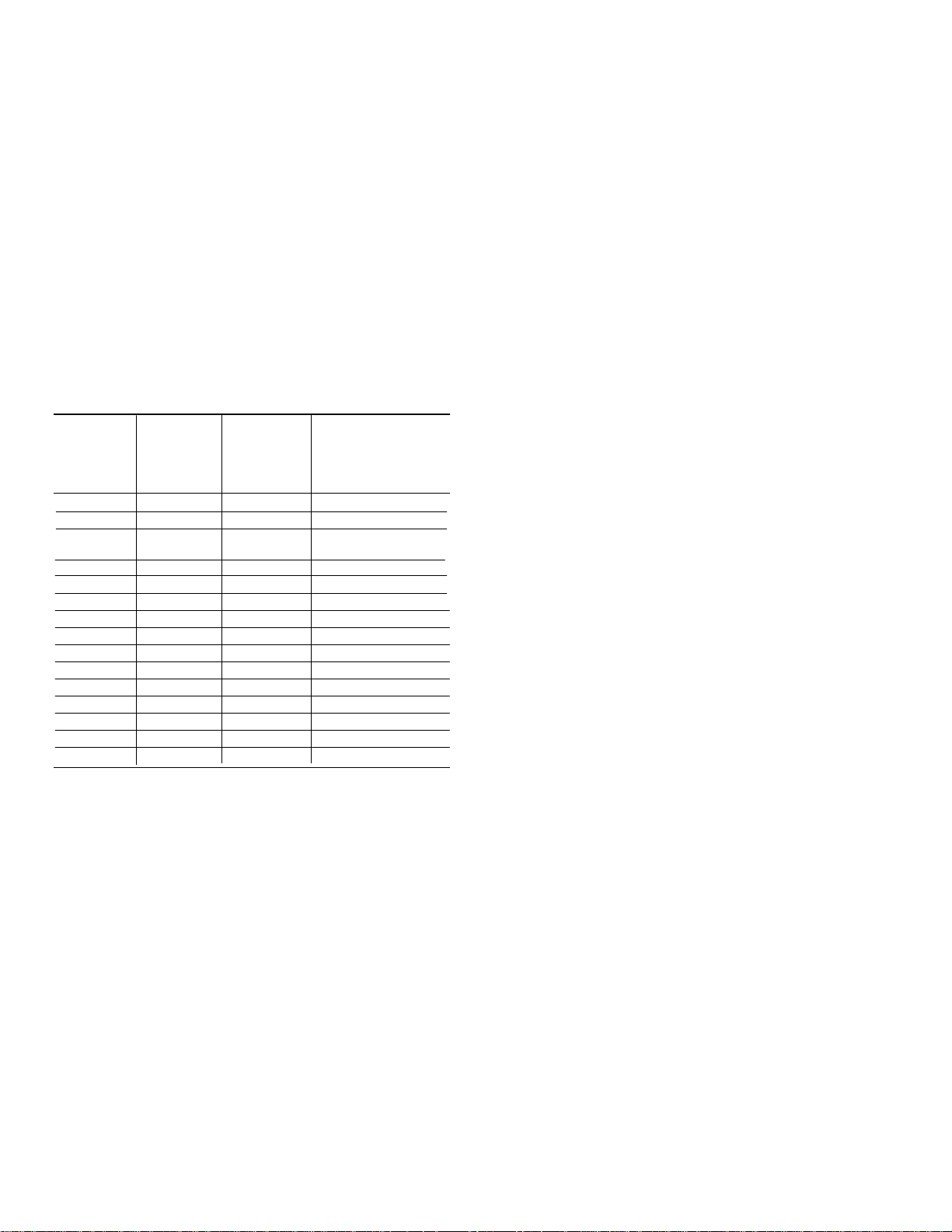

Fig. &

Index Tektronik Serial/Model No. Mfr

No. Part No. Eff Dscont Qty 1 2 3 4 5 Name & Description Code Mfr Part Number

-1 015-0199-01 1 VISOR, CRT: 80009 016-0199-01

-2 016-0512-00 1 CASE, CARRYING: 80009 016-0512-00

-3 346-0104-00 1 STRAP, CARRYING: 17516 4188-BA

-4 159-0121-00 2 FUSE, CARTRIDGE :DIN, 0.4A, 250V,5 SEC 75915 212.400

070-1375-00 1 MANUAL, TECH: OPERATORS 80009 070-1375-00

070-1376-00 1 MANUAL, TECH: INSTRUCTION 80009 070-1376-00

Figure 1-2. 212 Oscilloscope Accessories

1-5

Page 13

TM 9-6625-646-14&P

MANUAL CHANGE INFORMATION

At Tektronix, we continually strive to keep up with latest electronic developments by adding circuit and component

improvements to our instruments as soon as they are developed and tested.

Sometimes, due to printing and s hipping requirements, we can’t get these changes imm ediately into printed manuals.

Hence, your manual may contain new change information on following pages.

A single change may affect sever al sections. Since the change inform ation sheets are c arried in the manual until all

changes are permanently entered, some duplic ation may occur. If no such change pages appear following this page, your

manual is correct as printed.

SERVICE NOTE

Because of the universal parts procurement problem, some electrical parts in your instrument may be different

from those described in the Replaceable Electrical Parts List. The parts used will in no way alter or compromise

the performance or reliability of this instrument. They are installed when necessary to ensure prompt delivery to

the customer. Order replacement parts from the Replaceable Electrical Parts List.

1-6

Page 14

TM 9-6625-646-14&P

CALIBRATION TEST EQUIPMENT REPLACEMENT

Calibration Test Equipment Chart

This chart compares TM 500 produc t perform ance to that of older Tek tronix equipm ent. Only those characteris tics where

significant specification differences occur, are listed. In some cases the new instrument may not be a total functional

replacement. Additional support instrumentation may be needed or a change in calibration procedure may be necessary.

Comparison of Main Characteristics

DM 501 replaces 7D13

PG 501 replaces 107 PG 501 - Risetime less than 3.5 ns into 107 - Risetime less than 3.0 ns into

108 PG 501 - 5 V output pulse; 3.5 ns Risetime. 108 - 10 V output pulse; 1 ns Risetime.

111 PG 501 - Risetime less than 3.5 ns; 8 ns 111 - Risetime 0.5 ns; 30 to 250 ns

114 PG 501 + 5 V output. 114 - ±10 V output. Short proof output.

115 PG 501 - Does not have Paired, Burst, Gated, 115 - Paired, Burst, Gated, and Delayed

PG 502 replaces 107

108 PG 502 - 5 V output 108 - 10 V output.

111 PG 502 - Risetime less than 1 ns; 10 ns 111 - Risetime 0.5 ns; 30 to 250 ns

114 PG 502 -+5 V output 114 - 10 V output. Short proof output.

115 PG 502 - Does not have Paired, Burst, Gated, 115 - Paired, Burst, Gated, Delayed & Un-

2101 PG 502 - Does not have Paired or Delayed 2101 - Paired and Delayed pulse; 10 V

PG 506 replaces 106 PG 506 - Positive-going trigger output signal 106 - Positive and Negative-going trigger

067-0502-01 PG 506 - Does not have chopped feature. 0502-01 - Comparator output can be alter-

SG 503 replaces 190,

190A, 190B SG 503 - Amplitude range 5 mV to 5.5 V p-p. 190B - Amplitude range 40 mV to 10 V p-p.

191 SG 503 - Frequency range 250 kHz to 250 MHz. 191 - Frequency range 350 kHz to 100 MHz.

067-0532-01 SG 503 - Frequency range 250 kHz to 250 MHz. 0532-01 - Frequency range 65 MHz to 500

TG 501 replaces 180,

180A TG 501 - Marker outputs, 5 sec to 1 ns. 180A - Marker outputs, 5 sec to 1 us.

181 TG 501 - Marker outputs, 5 sec to 1 ns. Sine- 181 - Marker outputs, 1, 10, 100, 1000,

184 TG 501 - Marker outputs, 5 sec to 1 ns. Sine- 184 - Marker outputs, 5 sec to 2 ns. Sine-

2901 TG 501 - Marker outputs, 5 sec to 1 ns. Sine- 2901 - Marker outputs, 5 sec to 0.1 us.

50Ω.50Ω.

Pretrigger pulse delay. Pretrigger Pulse delay.

or Delayed pulse mode; +5 V dc pulse mode; +

Offset. Has +5 V output. Short-proof output.

Pretrigger pulse delay. Pretrigger pulse delay.

Delayed & Undelayed pulse mode; delayed pulse mode; +10 V output.

Has ±5 V output. Short-proof output.

pulse. Has ±5 V output. output.

at least 1 V; High Amplitude out- output signal, 50 ns and 1 V; High

put, 60 V. Amplitude output, 100 V.

nately chopped to a reference

voltage.

MHz.

Sinewave available at 5, 2, and 1 ns. Sinewave available at 20, 10,

Trigger output - slaved to marker and 2 ns. Trigger pulses 1, 10,

output from 5 sec through 100 ns. 100 Hz; 1, 10, and 100 kHz.

One time-mark can be generated at a Multiple time-marks can be

time. generated simultaneously.

wave available at 5, 2, and 1 ns. and 10, 000 us, plus 10 ns sinewave.

wave available at 5, 2, and 1 ns. wave available at 50, 20, 10, 5,

Trigger output - slaved to marker and 2 ns. Separate trigger pulses

output from 5 sec through 100 ns. of 1 and .1 sec; 10, 1, and .1 ms;

One time-mark can be generated at 10 and 1 /s. Marker amplifier proa time. vides positive or negative time

marks of 25 V min. Marker

intervals of 1 and .1 sec; 10, 1,

and .1 ms; 10 and 1 us.

wave available at 5, 2, and 1 ns. Sinewave available to 50, 10,

Trigger output - slaved to marker and 5 ns. Separate trigger

output from 5 sec through 100 ns pulses, from 5 sec to 0.1 us.

One time-mark can be generated at Multiple time-marks can be genea time. rated simultaneously.

10 V output.

NOTE: All TM 500 generator outputs are short-proof. All TM 500 plug-in instruments require TM 500-Series

Power Module.

1-7

Page 15

TM 9-6625-646-14&P

1-8

Page 16

SECTION 2

FUNCTIONS OF CONTROLS AND CONNECTORS

TM 9-6625-646-14&P

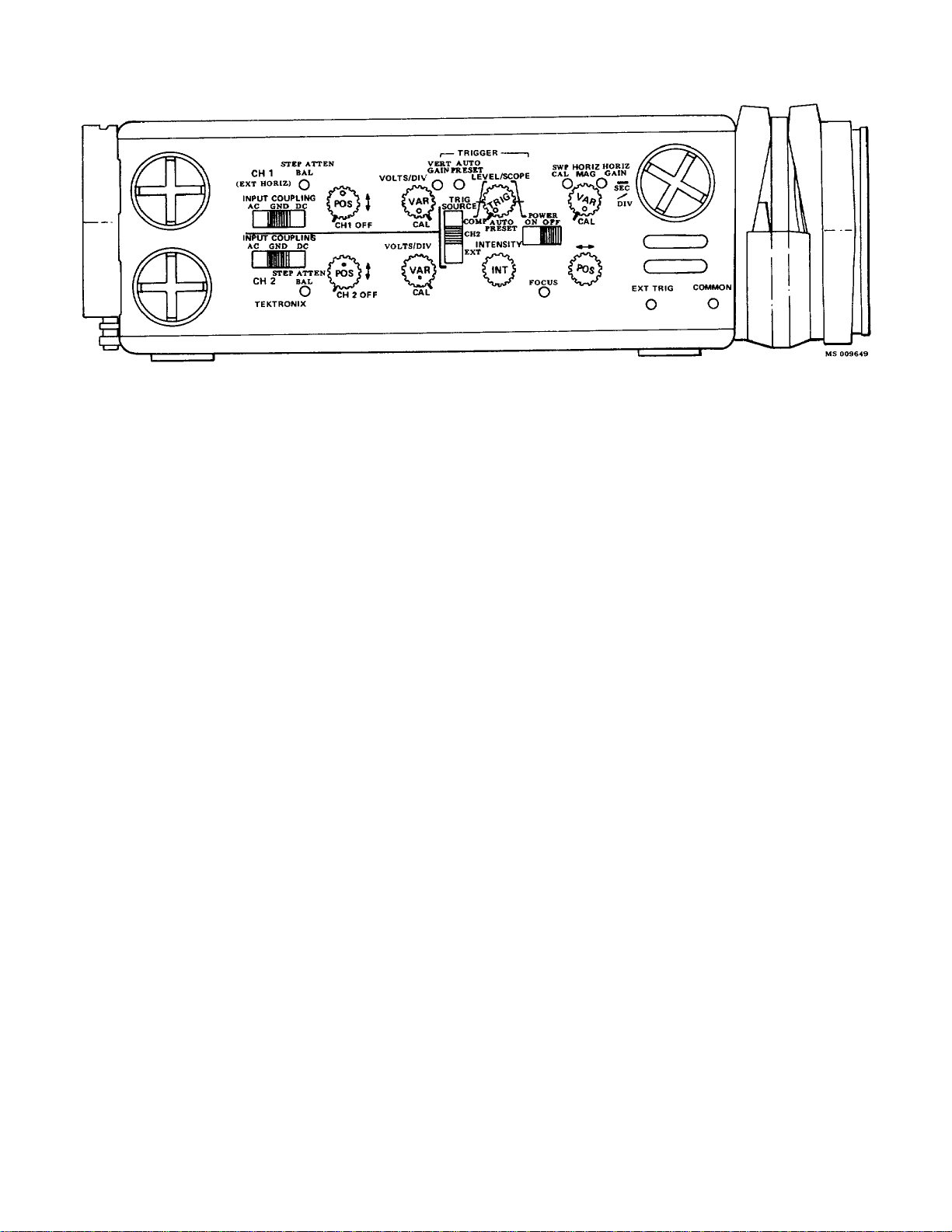

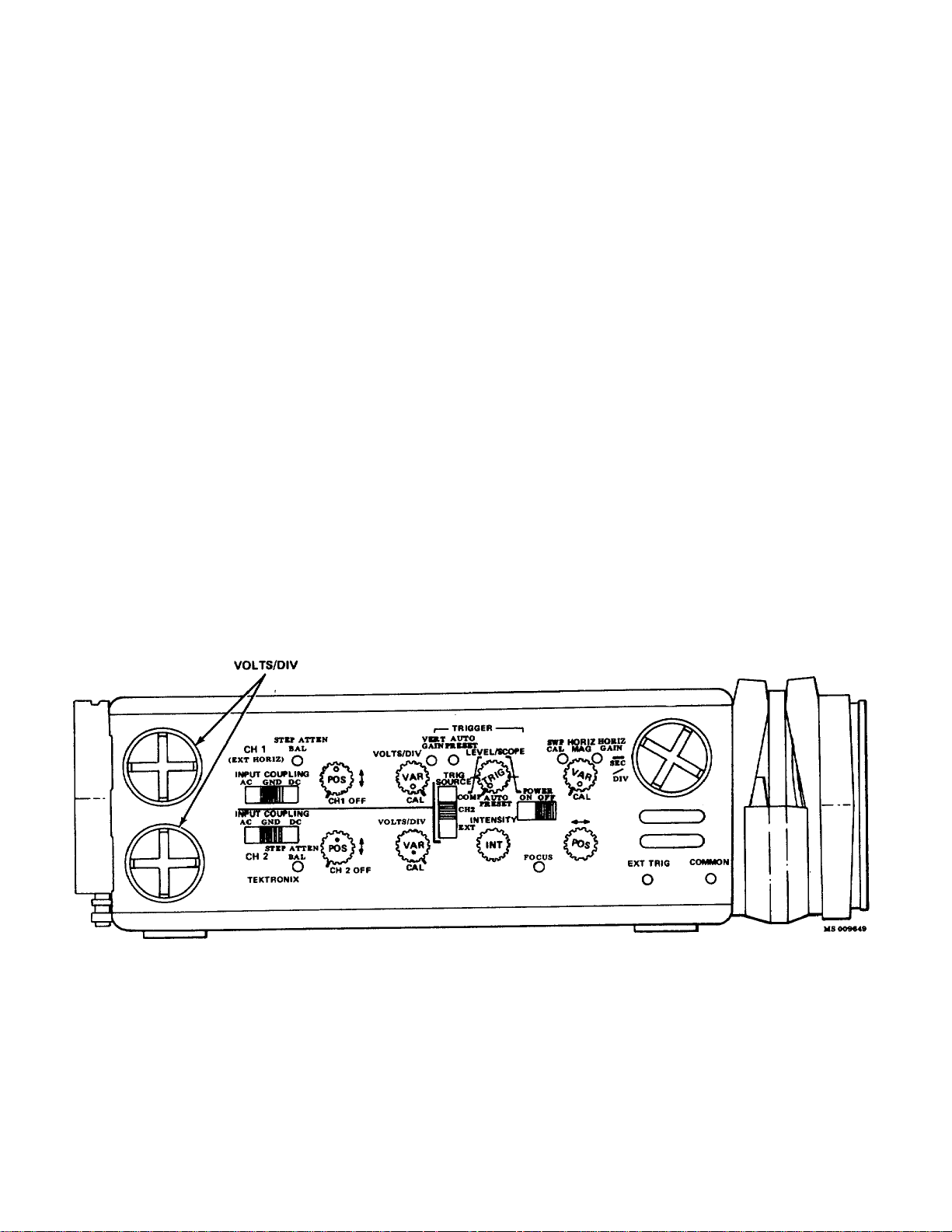

The controls and connectors neces sary for operation

of the 212 are located on the right side of the instrument.

(See Fig. 2-1.) The POWER (BATTERY) indicator is on

the front panel. A brief description of each contr ol and

connector is given here.

VOLTS/DIV-selects vertical deflection factor (vertical

VARiable control must be in CAL position for

indicated deflection.

INPUT COUPLING-selects the method used to couple

the channel input signal to the vertical amplifier

system.

AC-the DC component of input signal is blocked.

GND-vertical amplifier input circuit is grounded.

The applied input signal is connected to ground

through a one megohm resistor to provide a

precharge path for the AC input coupling

capacitor.

DC-all components of the input signal are

passed to the vertical amplifier system input.

STEP ATTEN BALance-a screwdriver adjustment to

balance the vertical amplifier system for minimum

trace shift when switching deflection factors.

Vertical POSition-controls the vertical position of the

appropriate trace. OFF detent turns the channel

off.

VOLTS/DIV VARiable-provides a continuously variable

deflection factor between the calibrated settings of

the VOLTS/DIV switch for the appropriate vertical

channel.

VERTical GAIN-screwdriver adjustment to set the gain of

the vertical amplifier system.

AUTO PRESET-screwdriver adjustment to set the AUTO

PRESET trigger point for automatic trigger

operation.

Trigger SOURCE-selects the source of the trigger signal.

COMP-the sweep is triggered from a sample of

the vertical deflection signal after the vertical

switching.

CH 2-the sweep is triggered from a sample of

the vertical deflection signal before the vertical

switching and only from CH 2.

EXT-the sweep is triggered from the signal

applied to the EXT TRIG banana jack.

Figure 2-1. Side Panel controls and connectors.

2-1

Page 17

LEVEL/SLOPE-selects the amplitude point and the s lope

of the trigger signal on which the sweep is triggered.

When the indicator dot is to the left of center, the

sweep is triggered on the positive-going slope of the

trigger signal; to the right of center, on the negative-

going slope. When the LEVEL/SLOPE control is set

to the AUTO PRESET detent, the sweep is

automatically triggered at a preset level on the

positive-going slope.

INTENSITY-controls brightness of CRT display.

TM 9-6625-646-14&P

Horizontal POSition-controls the horizontal position of the

trace.

SEC/DIV-selects horizontal sweep rate (HORIZ MAG

must be in CAL position for indic ated sweep rate) X-Y

position allows for X-Y operation; CH 2 supplies the

vertical deflection and CH 1 the horizontal deflection.

EXT TRIG-banana jack for input of an external trigger

signal.

SWP CAL-screwdriver adjustment to provide calibrated

sweep timing.

POWER-controls power to the instrument. Does not

interrupt charging current to the internal batteries

when the instrument is connected to an AC line

voltage.

FOCUS-screwdriver adjustm ent to obtain a well-defined

display.

HORIZontal MAGnifier-provides continuously variable

sweep magnification to a max imum of approxim ately

five times the sweep rate indicated by the SEC/DIV

switch.

HORIZontal GAIN-screwdriver adjustment to set the

basic gain of the horizontal amplifier system.

COMMON-banana jack to establish common ground

between the 212 and the external signal source or

equipment under test.

WARNING

COMMON and probe ground straps

are electrically connected. Therefore,

an elevated reference applied to any

is present on each - as indicated by

the yellow warning bands under the

probe retractable hook tips.

POWER ( BATTERY) Indicator-red light to indicate when

the instrument is on. When light extinguishes, less

than 10 minutes of operating life remain.

2-2

Page 18

SECTION 3

PREVENTIVE MAINTENANCE

Preventive maintenance, when performed on a

regular basis, can prevent instrument breakdown and

may improve the reliability of this instrument. The

severity of environment to which the 212 is subj ected will

determine the frequency of maintenance. A convenient

time to perform preventive maintenance is preceding

recalibration of the instrument.

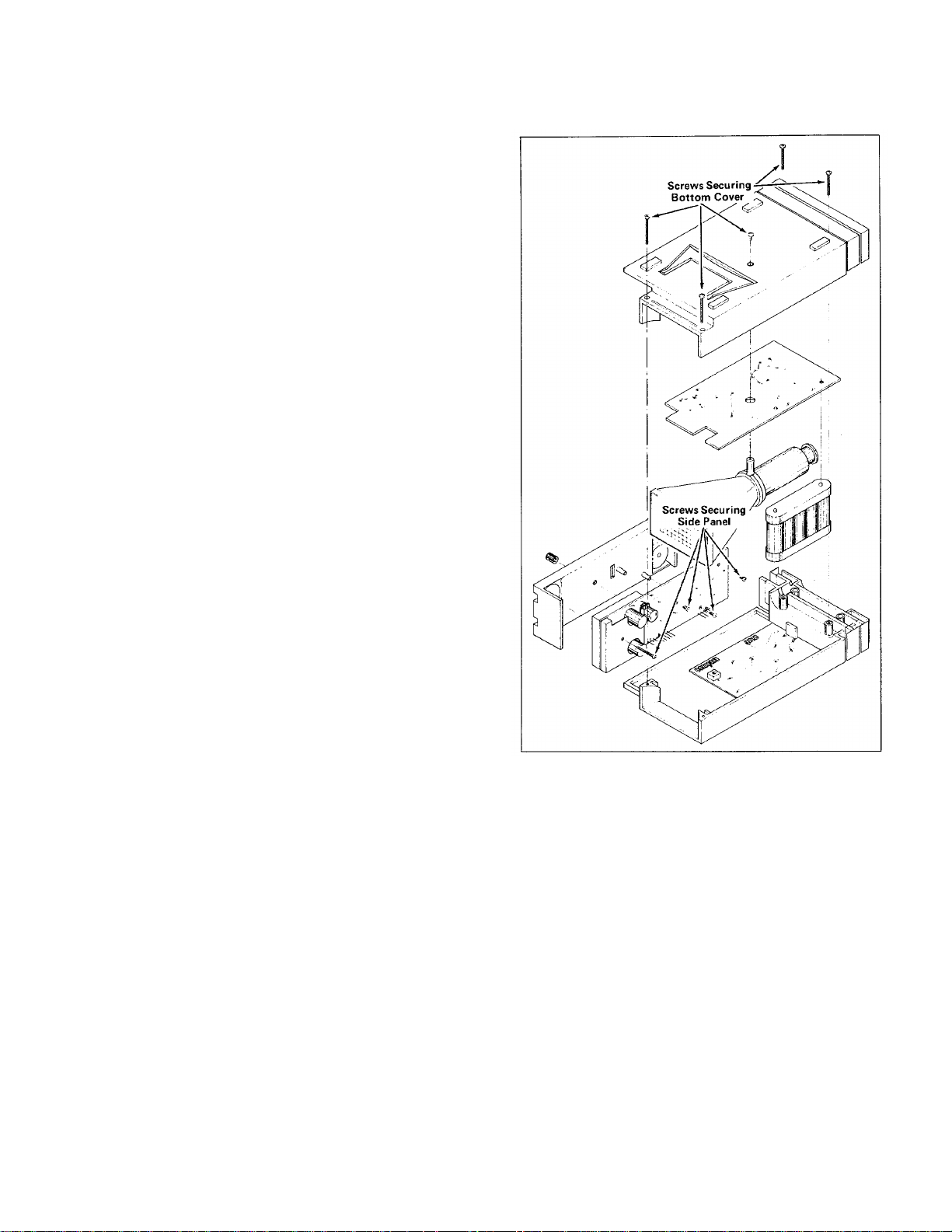

Disassembly

To gain access to the interior of the instrument,

unwind both the probe cords and the power cord from

the rear of the instrument. Remove the five screws in

the bottom cover of the instrument. See Fig. 3- 1. G ently

separate the bottom cover from the instrument and lay

aside. The Power Supply circuit board with the batteries

can be lifted up and pivoted out of the way. Most of the

internal workings of the instrument are now accessible.

If it is necessary to have access to the front of the

Input circuit board, remove the knobs from all of the

external control shafts. Remove the four screws

securing the side panel to the Input circuit board and

remove the instrument side panel.

TM 9-6625-646-14&P

Cleaning

The 212 should be cleaned as often as operating

conditions require. Accumulation of dir t in the inst rument

can cause component breakdown.

The high impact plastic covers provide protection

against dust in the interior of the instrument. Loos e dust

accumulated on these covers can be removed with a soft

cloth or small brush. The brush is also useful for

dislodging dirt on and around the side-panel controls.

Dirt which remains can be removed with a soft cloth

dampened in a mild detergent and water solution.

Abrasive cleaners should not be used.

It should be only occasionally necessary to c lean the

interior. The best way to clean the interior is to blow off

the accumulated dust with dry, low-velocity air. A

softbristle brush or a cotton-tipped applicator is useful for

cleaning in narrow spaces or for cleaning more delic ate

circuit components.

Figure 3-1. Location of screws securing bottom cover and

side panel.

CAUTION

Avoid the use of chemical cleaning

agents which might damage the

plastics used in this instrument.

Avoid chemicals which contain

hydrochloric acid, sodium hydroxide,

or sulfuric acid.

Visual Inspection

The 212 should be inspected occasionally for such

defects as broken connections, improperly seated

transistors, damaged circuit boards, and heat-damaged

parts.

3-1

Page 19

parts. The corrective procedure for most visible defects

is apparent; however, particular care must be taken if

heat-damaged components are found. Overheating

usually indicates other trouble in the instrument;

therefore, it is important that the cause of the

overheating be corrected to prevent recurrence of the

damage.

Semiconductor Checks

Periodically checking the semiconductors in the 212 is

not recommended. The best check of semiconductor

performance is actual operation in the instrument. If it is

desired to check the performance of a semiconductor

out of the instrument, a dynamic checker such as a

TEKTRONIX Type 576 Transistor Curve Tracer is

recommended. Lead configurations of the

semiconductors used in the 212 are shown in Fig. 5-2.

An extracting tool should be used to remove the 14-,

and 16-pin flat integrated circuits to prevent damage to

the pins. If an extracting tool is not available when

removing one of these integrated circuits, pull s lowly and

evenly on both ends of the device. Try to avoid having

one end of the integrated circuit disengage from the

socket before the other, as the pins may be damaged.

When replacing semiconductors, key the

semiconductor’s index with that of its soc ket. Failure to

do so can result in damaged components.

TM 9-6625-646-14&P

Recalibration

To assure accurate measurements, check the

calibration of this instrument after each 1000 hours of

operation or every six months if used infrequently. In

addition, replacement of components may necessitate

recalibration of the affected circuits. The calibration

procedure can also be helpful in localizing certain

troubles in the instrument. In some cases, minor

troubles may be revealed or corrected by recalibration.

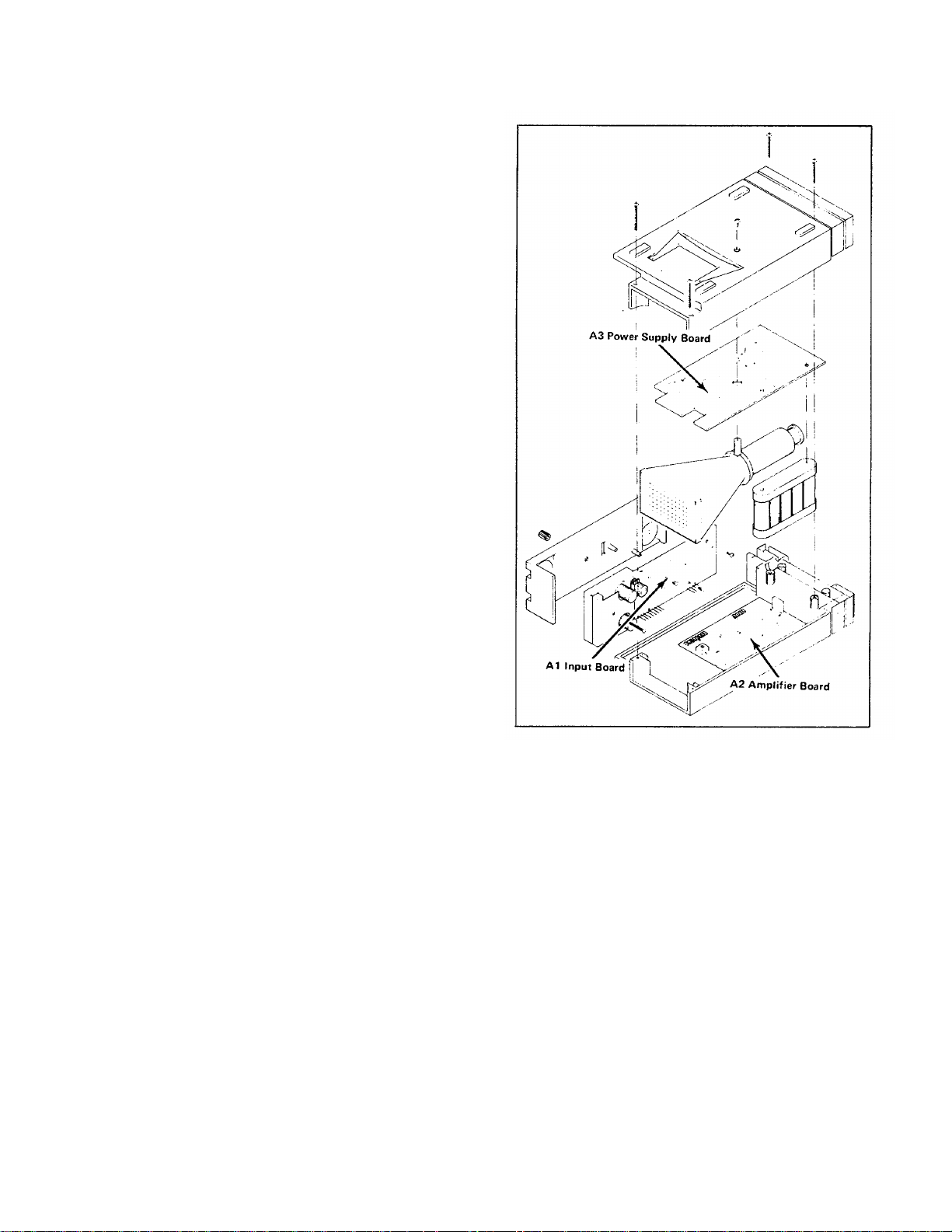

Figure 3-2. Location of circuit boards within the 212.

3-2

Page 20

SECTION 4

CALIBRATION

TM 9-6625-646-14&P

General

To assure instrument accuracy, check the calibration

of the 212 every 1000 hours of operation, or every six

months if used infrequently. Before complete calibr ation,

throughly clean and inspect this instrument as outlined in

the Preventive Maintenance section.

The following test equipment and accessories, or their

equivalent, are required for complete calibration of the

212. Given specifications for the test equipment are the

minimum necessary for acc urate calibration. Therefore,

the specifications of any test equipment must either meet

TEST EQUIPMENT REQUIRED

or exceed those listed below. All test equipment is

Tektronix, Inc., provides complete instrument repair

and recalibration at local Field Service Centers and the

Factory Service Center. Contact your local TEKTRONIX

Field Office or representative for further information.

assumed to be correctly calibrated and operating within

the listed specifications. Detailed operating instruc tions

for the test units are not given in this procedure. Refer to

the instruction manual for the test equipment if more

information is needed.

To aid in locating a step in this procedure, an index is

given prior to the complete procedure. Completion of

each step in the Calibration procedure ensur es that this

Special Calibration Fixtures

instrument meets the electrical specifications given in the

Introduction of this manual. Where possible, instrument

performance is checked before an adjustment is made.

For best overall instrument performance, make each

adjustment to the exact setting even if the CHECK- s tep

is within the allowable tolerances.

Special TEKTRONIX Calibration fixtures are used in

this procedure only where they facilitate instrument

calibration. These special calibration fixtures are

available from Tektronix, Inc. Order by part number

through your local TEKTRONIX Field Office or

representative.

TABLE 4-1.

TEST EQUIPMENT

Description Minimum Specifications Usage Example

1. Time-Mark Generator Marker outputs, 5 microseconds to 0.1 Horizontal timing check a. TEKTRONIX 2901

second; marker accuracy, within 0.1%. and adjustment. Time-Mark Generator.

b. TEKTRONIX 184

Time-Mark Generator.

2. Standard Amplitude Amplitude accuracy, 0.25%; signal Vertical and horizontal a. TEKTRONIX

Calibrator amplitude, 5 millivolts to 100 volts; amplifier gain checks and calibration fixture Part

output signal one-kilohertz square adjustments. Number 067-0502-01.

wave.

3. Square-Wave Frequency, one kilohertz; risetime, Vertical amplifier a. TEKTRONIX Type

Generator 100 nanoseconds or less; output compensation checks and 106 Square-Wave

amplitude, 0.4 volt to 40 volts. adjustments. Generator.

4. Low-Frequency Frequency, one kilohertz to 500 Vertical Amplifier a. General Radio

Constant-Amplitude kilohertz; output amplitude, at least bandwidth check. Trigger 1310-B Oscillator.

Signal Generator 200 millivolts. operation checks.

5. DC Voltmeter Range, zero to 1000 volts; accuracy, Power supply output level a. Triplett Model

within 3%; input impedance, checks. Vertical and 630-NA.

20, 000Ω/volt. horizontal centering

adjustment. CRT grid bias b. Simpson Model 262.

adjustment.

4-1

Page 21

TM 9-6625-646-14&P

TABLE 4-1 (cont)

Description Minimum Specifications Usage Example

6. Cable Impedance, 50 ohms; type, RG-58/U; External trigger operation a. TEKTRONIX Part

length, 42 inches; connectors, BNC. check. Horizontal gain Number 012-0057-01.

check and adjustment.

7. Adapter Connectors, BNC female and dual External trigger checks. a. TEKTRONIX Part

banana plug. Number 103-0090-00.

8. Adapter Connectors, GR874 and BNC female. Vertical Amplifier a. TEKTRONIX Part

compensation checks and Number 017-0063-00.

adjustment.

9. Termination Impedance, 50 ohms; accuracy, 2%; Vertical amplifier a. TEKTRONIX Part

connectors, BNC. compensation checks and Number 011-0049-01.

adjustment.

10. Attenuator Ratio, 10X; connectors, BNC; Vertical amplifier a. TEKTRONIX Part

impedance, 50 ohms. bandwidth check. Number 011-0059-01.

11. Adapter Connectors, probe tip to BNC. Used throughout a. TEKTRONIX Part

procedure for signal Number 013-0084-01.

interconnection.

12. T-Connector Connectors, BNC. External trigger operation a. TEKTRONIX Part

checks. Number 103-0030-00.

13. Screwdriver Three-inch shaft, 3/32 inch bit. Used throughout a. Xcelite R-3323.

Procedure to adjust

variable resistors.

14. Low-Capacitance 1 1/2-inch shaft. Used to adjust variable a. TEKTRONIX Part

Screwdriver capacitors. Number 003-0000-00.

INDEX TO CALIBRATION PROCEDURE

Power Supply and Display

1. Check Power Supply DC Levels

2. Adjust CRT Grid Bias (internal adjustment of

R273)

3. Adjust FOCUS (external side panel adjustment

of R398)

4. Adjust Trace Rotation (internal adjustment of

R141)

Vertical System Adjustment

5. Adjust Vertical DC Centering (internal

adjustment of R101)

6. Adjust CH 1 STEP ATTENuation BALance

(external

side panel adjustment of R415)

7. Adjust CH 2 STEP ATTENuation BALance

(external side panel adjustment of R315)

8. Adjust VERTical GAIN (external side panel

adjustment of R470)

9. Check CH 2 VARiable VOLTS/DIV Range

10. Check CH 2 VOLTS/DIV Accuracy VOLTS/DIV

Range

11. Check CH 1 VOLTS/DIV Accuracy and VARiable

12. Adjust CH 1 VOLTS/DIV Switch Compensation

(internal side panel adjustment of C407, C408, C409)

13. Adjust CH 2 VOLTS/DIV Switch Compensation

(internal side panel adjustment of C307, C308, C309

14. Check CH 2 Vertical Amplifier Bandwidth

4-2

Page 22

TM 9-6625-646-14&P

15. Check CH 1 Vertical Amplifier Bandwidth

Trigger Circuit Adjustment

16. Adjust AUTO PRESET (external side panel

adjustment of R375)

17. Check Trigger Circuit Operation

Horizontal System Adjustment

18. Adjust Hor izontal Centering (internal adjustm ent

of R366)

19. Adjust HORIZontal GAIN (external side panel

adjustment of R475)

20. Adjust SWEEP CALibration (external side panel

adjustment of R370)

21. Check HORIZ MAG Range

22. Check SEC/DIV Accuracy

PRELIMINARY PROCEDURE

NOTE

Titles for external controls of this

instrument are fully capitalized in this

procedure (e.g., INTEASITY). Internal

adjustments are initial capitalized

only (e.g., Grid Bias).

PRELIMINARY CONTROL SETTINGS

Preset the instrument controls to the settings given

below when starting a calibration procedure.

Channel 1 Controls

VOLTS/DIV 5 m

VOLTS/DIV VAR CAL

POS Midrange

INPUT COUPLING GND

Channel 2 Controls

VOLTS/DIV 5 m

VOLTS/DIV VAR CAL

POS OFF

INPUT COUPLING GND

This instrument should be adjusted at an ambient

temperature of +250C (+ 50C) for best overall accuracy.

1. Remove the instrument covers as described in

the Disassembly Instructions in the Preventive

Maintenance section.

2. Connect the instr ument to a 117 VAC 60 Hz line

source. If the batteries are not fully charged, leave the

212 connected to the line with the power switch turned

off for a period of approximately one hour before

continuing with calibration.

3. Set the instrument controls as given under

Preliminary Control Settings. Allow at least five minutes

of warmup before proceeding.

Trigger Controls

SOURCE COMP

LEVEL/SOURCE AUTO PRESET

Sweep Controls

SEC/DIV 1 m

HORIZ MAG CAL

POS Midrange

Display Controls

POWER ON

INTENSITY Fully Counterclockwise

4-3

Page 23

CALIBRATION PROCEDURE

POWER SUPPLY and DISPLAY

Equipment Required

1. DC Voltmeter 2. Three-inch Screwdriver

TM 9-6625-646-14&P

Control Setting

Preset instrument controls to the settings given under

Preliminary Control Settings.

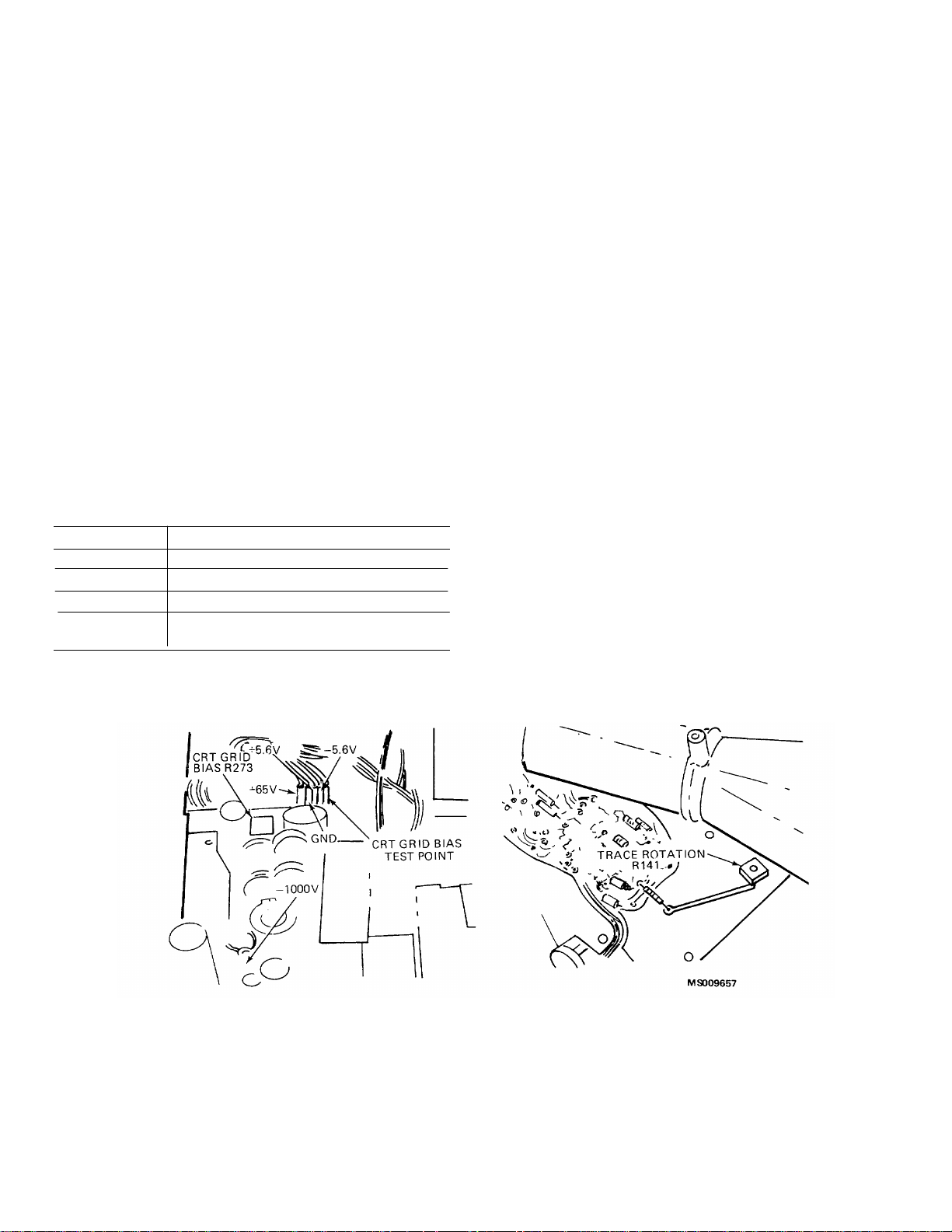

1. Check Power Supply DC Levels

NOTE

If the instrument has been operating

satisfactorily prior to recalibration,

proceed with step 2.

a.Using the DC voltmeter, measure the DC level of

the power supplies given in Table 4-2. Observe proper

meter polarity. See Fig. 4-1 for test point locations.

TABLE 4-2.

Power Supply Accuracy

Supply Measurement

-5.6 volt -5.6 volts ±0.4 volt

+5.6 volt +5.6 volts ±0.4 volt

+65 volt +65 volts ±4 volts

-1000 volt -960 volts ±40 volts

(due to meter loading)

2 of plug P3 (negative meter lead to pin 2) on the Power

Supply Board. See Fig. 4-1.

b.Turn the INTENSITY control fully clockwise.

c.CHECK-Meter reading of +1.9 volts.

d.ADJUST-CRT Grid Bias, R273 (s ee Fig. 4-1) for

a meter reading of +1.9 volts.

e.Disconnect all test equipment. Turn the

INTENSITY control fully counterclockwise.

3. Adjust FOCUS

a.Turn CH 2 POS midrange and CH 1 POS to the

OFF detent.

b.Set the SEC/DIV switch to X-Y and adjust the

INTENSITY control for a nominal display intensity.

c.ADJUST-FOCUS, R398 (located on the 212 side

panel) for a well-defined dot.

4. Adjust Trace Rotation

a.Set the SEC/DIV switch to 1 m.

b.CHECK-Free-running sweep is parallel with a

horizontal graticule line.

c.ADJUST-Trace Rotation, R141 (see Fig. 4-2) s o

the trace is parallel with the center horizontal graticule

line.

2. Adjust CRT Grid Bias

a.Connect the DC voltmeter between pin 5 and pin

Figure 4-1. Location of power supply test points and CRT

Grid Bias

adjustment.

Figure 4-2. Location of Trace Rotation adjustment.

4-4

Page 24

VERTICAL SYSTEM ADJUSTMENT

Equipment Requested

TM 9-6625-646-14&P

1.Standard Amplitude Calibrator

2.Square-Wave Generator

3.Low Frequency Constant Amplitude Signal

Generator

4.DC Voltmeter

5.GR-to-BNC Female Adapter

Control Settings

Preset instrument controls to the settings given under

Preliminary Control Settings, except as follows:

INTENSITY Visible Display

INPUT COUPLING DC

(both)

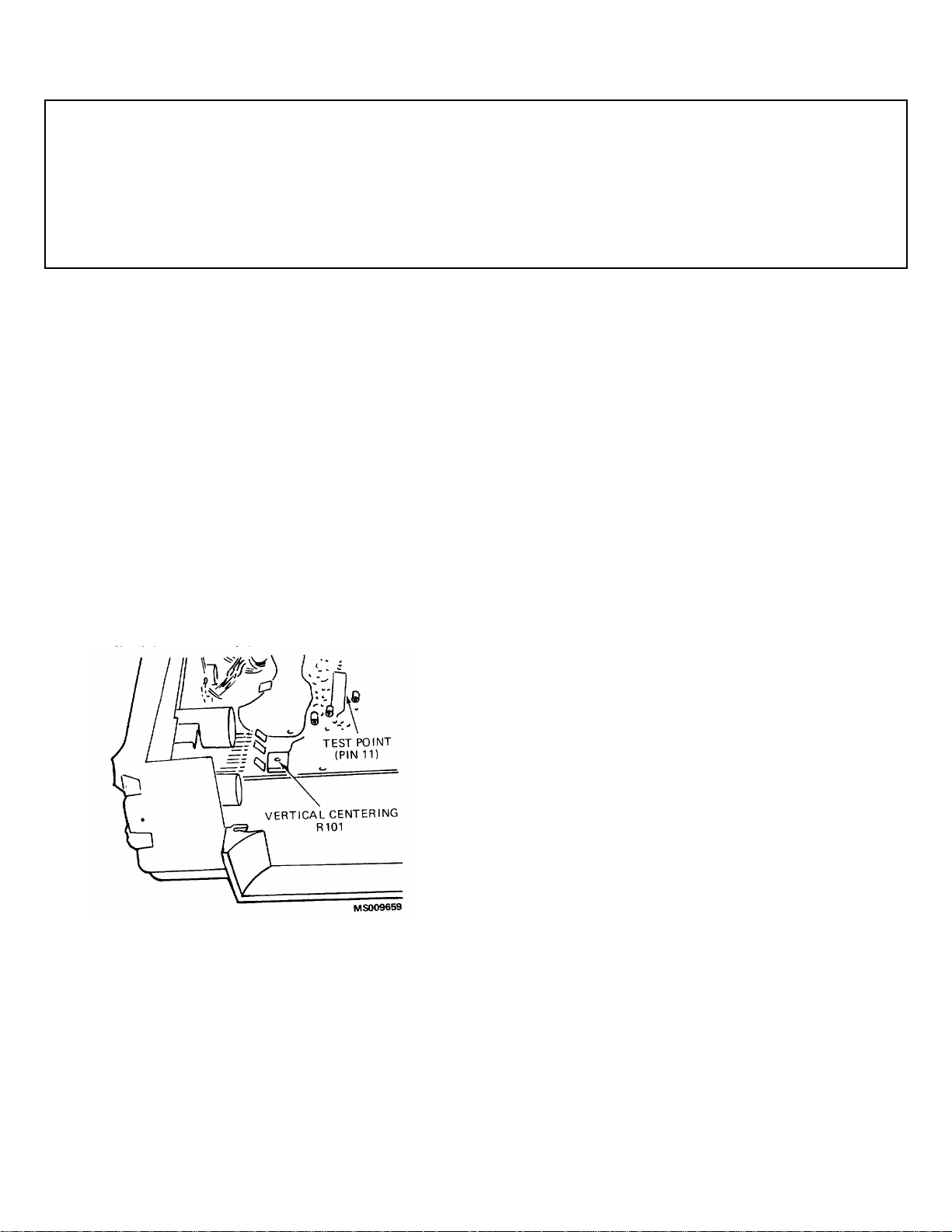

5. Adjust Vertical DC Centering

a.Connect the DC voltmeter between pin 11 of

U105 (positive meter lead to pin 11) and ground (see

Fig. 4-3).

b.Adjust CH 1 Vertical POS control for a 0 volt

meter reading.

c.CHECK-Trace should be within approximately

0.4 division of graticule center.

d.ADJUST-Vertical Centering, R101 (see Fig. 4-3)

to position the trace to the center horizontal graticule line.

e.Disconnect all test equipment.

6.Probe Tip-to-BNC Adapter

7.50-Ohm BNC Termination

8.10X 50-Ohm Attenuator

9.Three-inch Screwdriver

10.Low-Capacitance Screwdriver

6. Adjust CH 1 STEP ATTENuator BALance

a.Rotate the CH 1 VOLTS/D)V switch from 50 m

to 1 m.

b.CHECK-The CRT display for 0.1 division or less

of trace shift between adjacent switch positions when

rotating the VOLTS/DIV switch from 50 m to 1 m.

c.ADJUST-CH 1 STEP ATTEN BAL, R415

(located on the side panel) for minimum trace shift when

rotating the CH 1 VOLTS/DIV switch from 50 m to 1 m.

7. Adjust CH 2 STEP ATTENuator BALance

a.Turn the CH 1 POS control to the OFF detent

and the CH 2 POS control to midrange.

b.Rotate the CH 2 VOLTS/DIV switch from 50 m to

1 m.

c.CHECK-The CRT display for 0.1 division or less

of trace shift between adjacent switch positions when

rotating the VOLTS/DIV switch from 50 m to 1 m.

d.ADJUST-CH 2 STEP ATTEN BAL, R315

(located on the side panel) for minimum trace shift

rotating the CH 2 VOLTS/DIV switch from 50 m to 1 m.

Figure 4-3. Location of Vertical Centering adjustment and

test point.

8. Adjust VERTical GAIN

a.Set the CH 2 VOLTS/DIV switch to 5 m.

b.Connect the CH 2 probe tip to the output of the

Standard Amplitude Calibrator via a probe tip-to-BNC

adapter.

c.Set the Standard Amplitude Calibrator for a 20

millivolts output signal.

d.CHECK-The CRT display for four divisions of

deflection within 0.2 division.

e.ADJUST-VERT GAIN, R470 (located on the side

panel) for exactly four divisions of deflection.

4-5

Page 25

TM 9-6625-646-14&P

9. Check CH 2 VARiable VOLTS/DIV Range

a.Rotate the CH 2 VOLTS/DIV VAR control fully

clockwise.

b.CHECK-The CRT display for 1.6 divisions or

less of deflection. 1.6 divisions of deflection indicates a

VARiable VOLTS/DIV range of at least 2.5: 1.

c.Set the VARiable VOLTS/D IV control to CAL.

10. Check CH 2 VOLTS/DIV Accuracy

a.CHECK-Using the CH 2 VOLTS/DIV switch and

Standard Amplitude Calibrator settings given in Table 43, check that the deflection factor acc uracy for CH 2 is

within 5% at each position.

TABLE 4-3.

Vertical Deflection Accuracy

VOLTS/DIVStandard Vertical Maximum

Switch AmplitudeDeflection Error For

Setting Calibrator in Ù5% Accuracy

Output Divisions

1 m 5 millivolts 5 Ù0.25 division

2 m 10 millivolts 5

5 m 20 millivolts 4 Previously set in

10 m 50 millivolts 5

20 m 0.1 volt 5

50 m 0.2 volt 4

.1 0.5 volt 5

.2 1 volt 5

.5 2 volts 4

1 5 volts 5

2 10 volts 5

5 20 volts 4

10 50 volts 5

20 100 volts 5

50 100 volts 2

Ù0.25 division

step 8.

Ù0.25 division

Ù0.25 division

Ù0.2 division

Ù0.25 division

Ù0.25 division

Ù0.2 division

Ù0.25 division

Ù0.25 division

Ù0.2 division

Ù0.25 division

Ù0.25 division

Ù0.1 division

b.Disconnect the CH 2 probe tip from the Standard

Amplitude Calibrator.

a.Turn CH 2 POS to the OFF detent and the CH 1

POS to midrange.

b.Connect the CH 1 probe tip to the output of the

Standard Amplitude Calibrator via a probe tip-to-BNC

adapter.

c.CHECK-Using the CH 1 VOLTS/DIV switch and

Standard Amplitude Calibrator settings given in Table 43, that the deflection factor accuracy of CH 1 at each

position is within 5%.

d.Set the Standard Amplitude Calibrator for a 20

millivolts output signal.

e.Set the CH 1 VOLTS/DIV switch to 5 m.

f.Rotate the CH 1 VARiable VOLTS/DIV control

fully clockwise.

g.CHECK-The CRT display for 1.6 divisions or

less of deflection. 1.6 divisions of deflection indicates a

VARiable VOLTS/DIV range of at least 2.5: 1.

h.Set the VARiable VOLTS/DIV control to CAL.

12. Adjust CH 1 VOLTS/DIV Switch Compen-sation

a.Set the CH 1 VOLTS/DIV switch to 0.1 V.

b.Connect the CH 1 probe tip to the high amplitude

output of the Type 106 Square-Wave generator via a

GR-to-BNC female adapter, a 50-ohm BNC ter mination,

and a probe tip-to-BNC adapter.

c.Adjust the Square-Wave generator for a fourdivision display of a one kilohertz square wave.

d.Adjust the Triggering controls for a stable

display.

e.CHECK-The CRT display for flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

NOTE

If C307, C308, C309, C407, C408, or

C409 require adjustment, it will be

necessary to remove the instrument

side panel from the Input Board.

Refer to the Disassembly Instructions

for removal procedure.

11. Check CH 1 VOLTS/DIV Accuracy and VARiable

VOLTS/DIV Range

4-6

Page 26

f.ADJUST-C407 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration. (Use a low-capacitance screwdriver.)

g.Set the CH 1 VOLTS/DIV switch to 1 and adjust

the Square-Wave generator for a four-division display.

h.CHECK-The CRT display for flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

i.ADJUST-C408 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration.

j.Set the VOLTS/DIV switch to 10, remove the 50ohm BNC termination from the test s etup, and adjust the

Square-Wave generator for a four-division display.

k.CHECK-The CRT display for a flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

I.ADJUST-C409 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration.

m.Disconnect CH 1 probe tip from the test setup.

Figure 4-4. Location of attenuator compensation

capacitors.

TM 9-6625-646-14&P

13. Adjust CH 2 VOLTS/DIV Switch Compensation

a.Turn CH 1 POS control to the OFF detent and

turn CH 2 POS control to midrange.

b.Set the CH 2 VOLTS/DIV switch to 0.1 V/div.

c.Connect the CH 2 probe tip to the high amplitude

output of the Type 106 Square-Wave generator via a

GR-to-BNC female adapter, a 50-ohm BNC ter mination,

and a probe tip-to-BNC adapter.

d.Adjust the Square-Wave generator for a fourdivision display of a one-kilohertz square wave.

e.CHECK-The CRT display for flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

f.ADJUST-C307 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration.

g.Set the CH 2 VOLTS/DIV switch to 1 and adjust

the Square-Wave generator for a four-division display.

h.CHECK-The CRT display for a flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

i.ADJUST-C308 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration.

j.Set the CH 2 VOLTS/DIV switch to 10, remove

the 50-ohm BNC termination from the test setup, and

adjust the Square-Wave generator for a four-division

display.

k.CHECK-The CRT display for a flat-top waveform

with no more than +0.2 division, -0.1 division, or a total of

0.2 division of aberration.

I.ADJUST-C309 (see Fig. 4-4) for no more than

+0.2 division, -0.1 division, or a total of 0.2 division of

aberration.

m.Disconnect all test equipment, and re-install the

instrument side panel.

4-7

Page 27

14. Check CH 2 Vertical Amplifier Bandwidth

a. Set the CH 2 VOLTS/DIV switch to 1 m.

b. Connect the CH 2 probe tip to the output of the

Low Frequency Constant-Amplitude signal generator via

a 50-ohm BNC 10X attenuator and a probe tip-to-BNC

adapter.

c. Adjust the signal generator for a six-division

display for a one-kilohertz signal.

d. W ithout adjusting the output am plitude, increase

the output frequency until the display is reduced in

amplitude to 4.2 divisions.

e. CHECK-T he signal generator output must be at

least 100 kilohertz.

f. Set the VOLT S/DIV switch to 2m and adjust the

signal generator for a six-division display of a onekilohertz signal.

g. W ithout adjusting the output am plitude, increase

the output frequency until the display is reduced in

amplitude to 4.2 divisions.

h. CHECK-T he signal generator output must be at

least 200 kilohertz.

i. Set the VOLTS/DIV switch to 5m and adjust

the signal generator for a six-division display of a onekilohertz signal.

TM 9-6625-646-14&P

j. W ithout adjus ting the output amplitude, increase

the output frequency until the display is reduced in

amplitude to 4.2 divisions.

k. CHECK-The signal generator output frequency

must be at least 400 kilohertz.

I. Set the VOLTS/DIV switch to 10 m and adjust

the signal generator for a six-division display of a onekilohertz signal.

m. Without adjusting the output am plitude, increase

the output frequency until the display is reduced in

amplitude to 4.2 divisions.

n. CHECK-The signal generator output frequency

must be at least 500 kilohertz.

o. Remove CH 2 probe tip from the test setup.

15. Check CH 1 Vertical Amplifier Bandwidth

a. Connect CH 1 probe tip to the test setup.

b. Turn CH 2 POS to the OFF detent and CH 1

POS to midrange.

c. Set the CH 1 VOLTS/DIV switch to 1 m.

d. Repeat steps 14-c through 14-n.

4-8

Page 28

TRIGGER CIRCUIT ADJUSTMENT

Equipment Required

1. Low Frequency Signal Generator

2. 42-inch 50-Ohm BNC Cable

3. BNC-T Connector

Control Settings

Preset instrument controls to the settings given under

Preliminary Control Settings except as follows:

INTENSITY Visible Display

SEC/DIV .1 m

CH 1 INPUT COUPLING DC

CH 1 POS OFF

CH 2 POS Midrange

Trigger SOURCE CH 2

16. Adjust AUTO PRESET

a. Connect the CH 2 probe tip to the output of the

Low Frequency signal generator via a BNC-T connector

and a probe tip-to-BNC adapter.

b. Adjust the signal generator for a 0.2 division

display of a five-kilohertz signal.

c. CHECK-For a stable display.

d. ADJUST -AUTO PRESET, R375 (located on the

side panel) for a stable display.

17. Check Trigger Circuit Operation

TM 9-6625-646-14&P

4. BNC to Banana Plug Adapter

5. Three-inch Screwdriver

6. Probe tip-to-BNC Adapter

a. Set the CH 2 VOLTS/DIV switch to 1 V.

b. Adjust the signal generator for a one-division

display of a 500 kilohertz signal.

c. Set the CH 2 VOLTS/DIV switch to 5 V.

d. CHECK-A stable display can be obtained by

adjusting the LEVEL/SLOPE control to trigger on both

the positive-going and negative-going slopes of the

displayed waveform.

e. Return the LEVEL/SLOPE control to the AUTO

PRESET detent.

f. Set the Trigger SOURCE switch to COMP.

g. CHECK-A stable display can be obtained by

adjusting the LEVEL/SLOPE control to trigger on both

the positive-going and negative-going slopes of the

displayed waveform.

h. Set the Tr igger SOURCE switch to EXT and the

LEVEL/SLOPE control to the AUTO PRESET detent.

i. Connect the unused output of the BNC-T

connector to the 212 EXT T RIG input via a 42-inc h BNC

cable and a BNC-to-banana plug adapter.

j. CHECK-A stable display can be obtained by

adjusting the LEVEL/SLOPE control to trigger on both

the positive-going and negative-going slopes of the

displayed waveform.

4-9

Page 29

1.Standard Amplitude Calibrator

2.Time-Mark Generator

3.DC Voltmeter

4.42-inch 50-ohm BNC Cable

TM 9-6625-646-14&P

HORIZONTAL SYSTEM ADJUSTMENT

Equipment Required

5.BNC-to-Banana Plug Adapter

6.Probe Tip-to-BNC Adapter

7.Three-inch Screwdriver

Control Settings

Preset instrument controls to the settings given under

Preliminary Control Settings except as follows:

INTENSITY Visible Display

SEC/DIV X-Y

CH 2 POS Midrange

18. Adjust Horizontal Centering

a.Align dot to graticule center using HORIZ POS

and CH 2 VERT POS control.

b.Connect the DC voltmeter between pin 5 of

U105 (positive meter lead to pin 5) and ground. (See

Fig. 4-5 for test point and adjustment location.)

c.CHECK-For a reading of 0 volts, +0.2 volt.

d.ADJUST-Horizontal Centering, R366 for a meter

reading of 0 volts +0.1 V.

19. Adjust HORIZontal GAIN

a.Connect the CH 1 probe tip to the output of the

Standard Amplitude Calibrator via a probe tip-to-BNC

adapter.

b.Set the Standard Amplitude Calibrator for a 20

millivolts output.

c.Set CH 1 INPUT COUPLING switch to DC.

d.CHECK-The CRT display for two dots

separated horizontally by four divisions, +0.2 division.

e.ADJUST-Horiz Gain, R475 (located on the side

panel) for four divisions of deflection between dots.

f.Disconnect all test equipment.

20. Adjust SWEEP CALibration

a.Connect the CH 1 probe tip to the output of the

Time-Mark generator via a probe tip-to-BNC adapter.

b.Set the SEC/DIV switch to 1 m and the TimeMark generator for 1 millisecond markers.

c.Set CH 2 POS to the OFF detent.

d.Adjust the CH 1 VOLTS/DIV switch for a display

approximately three divisions in amplitude.

Figure 4-5. Location of Horizontal Centering adjustment

and test point.

4-10

Page 30

TM 9-6625-646-14&P

e. CHECK-T he CRT display for one time mark per

division. With the second time mark aligned with the

second vertical graticule line, the tenth tim e mark should

align with the tenth vertical graticule line within 0.4

division.

f. ADJUST-SWEEP CAL, R370 (located on the

side panel) for exactly eight divisions of deflection

between the second and tenth time marks.

21. Check Horizontal Magnification Range

a. Rotate the HOR IZ MAG control fully clockwise.

b. CHECK-The CRT display for at least five

divisions between adjacent time marks. Five-division

spacing indicates a HORIZ MAG control range of at least

5:1.

c. Return the HORIZ MAG control to the CAL

detent.

22. Check SEC/DIV Accuracy

a. CHECK-Apply the appropriate time marks and

check each position of the SEC/DIV switch for proper

timing over the center eight division portion of each

sweep, within 0.4 division.

4-11

Page 31

SECTION 5

TROUBLESHOOTING AIDS

TM 9-6625-646-14&P

TROUBLESHOOTING AIDS

Complete circuit diagrams are given in the rear of this

manual. The component number and electrical value of

each component in this instrument are shown on the

diagrams along with important voltages. The portions of

the circuit mounted on circuit boards are enclosed with

blue lines.

Figure 3-2 shows the location of the circuit boards

within the instrument along with the assembly (A)

numbers. The assembly numbers are also us ed on the

diagrams to aid in locating the boards. Pictures of the

circuit boards are shown in the Diagrams section, on the

back of the page opposite the circuit diagram, to aid

cross-referencing between the diagrams and the circuit

board pictures. Each electrical component on the boards

is identified by its circuit number as well as the

interconnecting wires and/or connectors.

Component Color Coding

The resistors used in this instrument are either

composition resistors or precision resistors. The

resistance values are color-coded on the components

with EIA color-code (some precision r esistors may have

the value printed on the body). The color-code is read

starting with the stripe nearest the end of the resistor.

Composition resistors have four stripes which c onsist of

two significant figures, a multiplier, and a tolerance value

(see Fig. 5-1). Precision resistors have five stripes

consisting of three significant figures, a multiplier, and a

tolerance value.

The capacitance values of common disc capacitors

and small tubular electrolytics are marked in mic rofarads

on the side of the component body. The molded

electrolytic capacitors ar e color-coded in picofarads (see

Fig. 5-1).

The cathode end of each glass-encased diode is

indicated by a stripe, a series of stripes, or a dot.

Figure 5-1. Color code for resistors, ceramic capacitors, and dipped tantalum electrolytic capacitors.

5-1

Page 32

Figure 5-2. Lead configuration of semiconductors used in this instrument.

TM 9-6625-646-14&P

Semiconductor Lead Configuration

Figure 5-2 shows the lead configurations of the

semiconductors used in this instrument.

Troubleshooting Equipment

The majority of troubleshooting to be done on the 212

can be accomplished with a 20, 000 ohms/volt VOM

such as a Triplett Model 630-NA or a Simpson Model

262. Use a dynamic transistor tester such as a

TEKTRONIX Type 576 Transistor-Curve Trac er to c heck

the semiconductor devices used in the 212. To check

waveform(s) in this instrument, use a test oscilloscope

with a DC to 500 kilohertz frequency response and one

millivolt to 50 volts/division deflection factor.

5-2

Page 33

SECTION 6

CIRCUIT DESCRIPTION

TM 9-6625-646-14&P

The following circuit description begins with a

discussion of the instrument using the block diagram

located in the Diagrams section at the rear of this

manual. Then each circuit is described in detail, using

detailed diagrams where necessary to show the

interconnections between the stages in each major

circuit and the relationship of the side-panel controls to

the individual stages. In addition to the block diagram,

complete schematics are given in the Diagrams section.

Block Diagram

Signals to be displayed on the CRT are applied to the

tips of the signal probes. The signals are then amplif ied

by the appropriate channel Input Amplifier circuit,

consisting of a two-section source-follower stage and two

feedback amplifiers. The Input Amplifier circuits also

contain the vertical deflection, position (with channel onOFF), input coupling, variable attenuation, and balance

controls.

The Trigger Generator circuit initiates the sweep

signal produced by the Sweep Generator. The input

signal to the Trigger Generator can be select ed internally

either from the capacitively coupled CH 2 Input Am plifier

signal, or from the direc tly coupled COMPosite signal of

the Feedback Amplifier. The Trigger Generator input

signal can also be selected from the external signal

applied to the EXT TRIG jack. The Trigger Generator

circuit contains coupling and sourc e controls in addition

to a combination level/slope control.

The Sweep Generator circuit produces a linear

sawtooth output signal when initiated by the Trigger

Generator circuit. The slope of the sawtooth signal is

controlled by the SEC/DIV switch. The Sweep Generator

circuit also produces an unblanking gate signal

coincident with the sawtooth waveform. This gate s ignal

unblanks the CRT to permit display presentation.

The output of U370 is amplified by the Horizontal

Amplifier circuit to produce the correct horizontal

deflection for the CRT for all positions of the SEC/DIV

switch. The Horizontal Amplifier contains a variable

magnifier to increase the sweep rate up to at least a

maximum of five times in any position of the SEC/DIV

switch.

The Power Supply and CRT circuits provide all the

voltages necessary for operation of this instrument.

Circuit Operation

In the following description of the electrical operation

and relationship of the circuits in the 212, circuitry

commonly used by TEKTRONIX is only briefly explained.

If more information is desired on the commonly used

circuits, refer to the following textbooks:

Phillip Cutler, "Semiconductor Circuit Analysis",

McGraw-Hill, New York, 1964.

Lloyd P. Hunter (Ed.), "Handbook of Semiconductor

Electronics", second edition, McGraw-Hill, New York,

1962.

Jacob Millman and Herbert Taub, "Pulse, Digital, and

Switching Waveforms", McGraw-Hill, New York, 1965.

6-1

Page 34

TM 9-6625-646-14&P

Vertical Input Amplifiers

Input signals for vertical deflection of the CRT of the

212 are applied to the tips of the attached probes. Each

Input Amplifier provides control of input coupling, variable

attenuation, vertical deflection factor, balance, and

vertical position (with channel on-OFF) for the

appropriate channel. Figure 6-1 shows a detailed block

diagram of the Vertical Input Amplifier circuit. A

schematic of this circuit is shown on diagram 1.

Input signals applied to the tips of the probes are

connected to the appropriate Attenuation Stage through

the INPUT COUPLING switches (S305 and S405) . The

deflection factor in each channel is determined by the

VOLTS/DIV switch (S310 or S410). In all positions of the

VOLTS/DIV switches below .1 V/DIV, the correct

deflection factor is achieved by changing the gain of

Feedback Amplifiers U320-A and U320-B. In switch

positions .1 V/DIV and up, precision attenuators are used

(in addition to changing the gain of U320-A and U320-B)

to achieve the correct deflection factors. When the

VOLTS/DIV VAR control is rotated, the signal is

attenuated across R320 or R420. This offers variable

(uncalibrated) deflection factors between the calibrated

settings of the VOLTS/DIV switch. The STEP ATTEN

BALance adjustments (R315 and R417) control the tr ace

shift when switching between deflection factors.

The 212 can be operated single trace by turning

either vertical POSition control to the OFF detent; this

disables that channel in the last feedback stage of the

Input Amplifier through the operation of the Vertical

Mode Multivibrator U440. The CH 2 trigger signal is

present regardless of the CH 2 POS control setting. In

the dual-trace mode, the instrument will automatically

chop or alternate, depending upon the sweep rate.

Figure 6-1. Vertical input amplifiers detailed block diagram.

6-2

Page 35

TM 9-6625-646-14&P

Vertical and Horizontal Output Amplifiers

The Vertical and Horizontal Output Amplifiers provide

the final amplification for the deflection signals. Figure 62 shows a detailed block diagram of these Output

Amplifiers. A schematic of these c ircuits is on diagram

2.

Both amplifiers contain the same basic circuitry. The

single-ended input signals are applied to paraphase

amplifiers, U105-A and U105-B, to convert the signal into

push-pull output signals. The Vertical Paraphase

Amplifier stage contains the VERT GAIN adjustment

(R470) that sets the over-all gain of the ver tical system,

and a Vertical Centering adjustment (R101) to set DC

centering. The Horizontal Paraphase Amplifier stage

contains the HORIZ GAIN adjustment (R475), the

HORIZ MAG control (R476), and the Horizontal POSition

control (R480). The output signals from the Paraphase

Amplifiers receive final amplification in the c ommon bas e

Output Amplifier stages.

Figure 6-2. Vertical and Horizontal output amplifiers detailed block diagram.

6-3

Page 36

TM 9-6625-646-14&P

Trigger/Sweep Generator

Integrated circuit U370 is a combination

Trigger/Sweep Generator. The Trigger portion derives

trigger signals internally, either from the capacitively

coupled CH 2 Vertical Input Amplifier, or from the direc tly

coupled COMPosite signal from the input of the Vertic al

Output Amplifier. The Trigger portion can also select

signals from an external signal applied to the EXT TRIG

banana jack. Controls are provided in this circuit to

select trigger level, slope, and source. Figure 6- 3 shows

a detailed block diagram of the Tr igger/Sweep G enerator

circuit. A schematic of this circuit is on diagram 2.

The Sweep Generator portion of U370 serves a

multiple purpose. In all positions of the SEC/DIV switch

except X-Y, the Sweep Generator is an integrator, which

generates a linear sawtooth voltage waveform. The

slope of the sawtooth voltage is controlled by the setting

of the SEC/DIV switch. U370 also produces an

unblanking gate signal coincident with the sawtooth

waveform. This gate signal is amplified by Unblanking

Amplifier Q134 and applied to the CRT to unblank the

CRT during sweep presentation. In addition, the Sweep

Generator supplies the clock pulses to the Vertical Mode

Multivibrator for alternate switching between channels.

In the X-Y position, the Sweep Generator section

becomes a feedback amplifier to amplify the signal

applied to the probe tip of CH 1.

Figure 6-3. Trigger/Sweep Generator detailed block diagram.

6-4

Page 37

TM 9-6625-646-14&P

Power Supply

The Power Supply provides the power necessary to

operate this instrument or, if the instrument is turned off,

to recharge the batteries. Figure 6-4 shows a detailed

block diagram of this circuit. A schematic of this circuit is

shown on diagram 4.

When the instrument is connected to a power line the

AC power is capacitively coupled to the Power Rectifier.

The rectified DC is used to either run the instrument or

recharge the internal batteries. The batteries act as a

large filter capacitor for the Input Rectifier in the AC line

mode of TM 9-6625-646-14&P operation. When the

instrument is not connected to a power line, operating

power is provided by the batteries. The POWER

(BATTERY) indicator, light emitting diode DS310, is

illuminated when the 212 is operating from line voltage or

adequately charged batteries. When about 10 minutes

of operating time remains, the battery charge drops to a

point where DS310 will extinguish. The Discharge

Protection circuit (0231, Q235) prevents the Converter

Multivibrator (Q242, Q249) from func tioning, and thereby

overdischarging the ’batteries, when the charge level of

the batteries falls below approximately 10 volts. The

Converter Multivibrator changes DC into AC, which is

applied across T250 and then rectified into the

appropriate DC voltages in the Rectifier circuit.

Figure 6-4. Power Supply detailed block diagram.

6-5

Page 38