Page 1

INSTRUCTION MAdUAL

Models 1792,6422

Isolated BCD Outputs

Keithley instruments, Inc.

28775 Aurora Road/Cleveland, Ohio 44139/(216) 248-0400

Page 2

WARRANTY

Keithley Instruments, inc. warrants this product to be free from defects

in material and workmanship for a period of 1 year from date of shipment. During the warranty period, we will, at our option, either repair

or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will be

given prompt assistance and return instructions. Send the instrument,

transportation prepaid, to the indicated service facility. Repairs will be

made and the instrument returned, transportation prepaid. Repaired

products are warranted for the balance of the original warranty period,

or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from unauthorized

modification or misuse of any product or part. This warranty also does

not apply to fuses, batteries, or damage from battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, in-

cluding any implied warranty of merchantability or fitness for a particular use. Keithley Instruments, Inc. shall not be liable for any indirect,

special or consequential damages.

STATEMENT OF CALIBRATION

This instrument has been inspected and tested in accordance with

specifications published by Keithley Instruments, Inc.

The accuracy and calibration of this instrument are traceable to the

National Bureau of Standards through equipment which is calibrated at

planned intervals by comparison to certified standards maintained in

the Laboratories of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC.

INSTRUMENT DIVISION / 28775 Aurora Road / Cleveland, Ohio 44139 / U.S.A. / (216) 248-0400 / Telex: 98-5469

WEST GERMANY: Keithley Instruments GmbH / Heiglhofstr. 5 / 8000 Munchen 70 / (089) 710020 / Telex: 52-l 2160

GREAT BRITAIN: Keithley Instruments, Ltd. I 1, Boulton Road I Reading, Berkshire RG 2 ONL / (0734) 86-12-87/88 /Telex: 84-7047

FRANCE: Keithley Instruments SARL / 2, Bis Rue Leon Blum / B.P. 60 / 91121 Palaiseau Cedex / (6) 011-51-55 I Telex: 600-933

NETHERLANDS: Keithley Instruments BV / Arkelsedijk 4 / Postbus 559 / 4200 AN Gorinchem I (0) 1830-25577 / Telex: 24-684

SWITZERLAND: Keithley Instruments SA I Kriesbachstr. 4 / 8600 Dubendorf I 01/821-94-44 / Telex: 57-536

AUSTRIA: Keithley Instruments Ges.m.b.H. / Doblinger Haupstr. 32 / 1190 Wien / 314 289 / Telex: 13-4500

Page 3

MODELS 1792, 6422

I SOLATED BCD OUTPUTS

Copyright 1979, Keithley Instruments, Inc.

Third Printing, May 1981, Cleveland, Ohio

Document No. 30155, Rev. B

U.S.A.

Page 4

TABLE OF CONTENTS

SECTION TITLE

1.

l-l.

l-3. COHPATIBILITY. ..................... l-l

l-5. WARRANTY INFORMATION .................. l-l

l-7. CHANGE NOTICES ..................... l-l

l-9.

l-11. SPECIFICATIONS ..................... l-l

2. INITAL PREPARATION ...................... 2-l

2-l. INTRODUCTION ...................... 2-l

2-3.

2.5.

2-7. MODEL 1792 INSTALLATION. ................ 2-3

2-9. Fidel 1792 Output Connections. ............ 2-3

2-11. IIODEL 6422 INSTALLATION. ................

3.

3-l.

3-3.

3-9. CIRCUIT DESCRIPTION. .................. 3-3

3-11.

3-14

3-16.

3-18.

3-20.

3-22. DC-to-DC Converter .................. 3-5

3-24 TEST POINT DATA. .................... 3-5

3-26.

4.

4-l. GENERAL. ........................ 4-l

4-3.

4-5.

4-7.

GENERAL INFORMATION ................... l-l

INTRODUCTION ...................... l-l

SAFETY SYMBOLS ..................... l-l

UNPACKING AND INSPECTION ................ 2-l

PREPARATION FOR USE. .................. 2-l

GPERATION ....................... .3-l

INTRODUCTION ...................... 3-l

OVERALL OPERATION. ...................

Control Circuitry. ..................

Switching Circuitry. ................. 3-4

Isolator Network ................... 3-4

Busy/Hold Circuit. .................. 3-4

Output Registers And Buffers ............. 3-5

SPECIAL HANDLING OF STATIC SENSITIVE DEVICES ......

REPLACEMENTPARTS ...................

ORDERING INFORMATION ..................

SCHEMATIC. ....................... 4-l

COM’ONENT LAYOUT ....................

PAGE

2-4

3-l

3-3

3-6

4-l

4-l

4-l

FIGURE

2-l

2-2

3-1

3-2

3-3

3-4

I LLUSTRATI GNS

TITLE PAGE

Installation of Model 1792 ............... 2-2

Installation of Model 6422 ............... 2-5

Model 1792/6422 Block Diagram. ............... 3-l

Timing Diagram ..................... 3-2

Ring Counter and Gating. ................ 3-3

Busy/Hold Circuit. ................... 3-4

Page 5

UODELS 1792, 6422

GENERAL INFORMATION

SECTION 1 GENERAL lNFGRMATI(%

l-l. I NTRODUCT I ON.

l-2.

output options that convert displayed meter readings

to electrically isolated, latched, and buffered peral lel 8CD outputs.

printers or other external data hand1 ing equipment.

Logic

Output data includes sign and overrange signals. In

addition,

meter is updating data.

signal is normally used to initiate a print or load

operation at the listening device. An input control

I ine (HOLD) al lows the listening device to inhibit

the update of output data. When this line is high,

the data update rate is the same as the meter

conversion rate,

Operating characteristics for the Models

1792 are given in their respective Specification

Tables (Table l-l and l-2).

either factory or field installed.

installation procedures are provided in this manual,

because of the different mounting and output cabling

provisions of the options.

l-3. CGf+‘ATIBILITY.

l-4.

are

I nstr unents:

The Models 1792 and 6422 are isolated BCD

These can be appl ied to I ine

levels are TTL/DTL and CMOS compatible.

a BUSY control I i ne indicates that the

The trailing edge of this

typically 2.5 readings/second.

6422 and

Both options can be

Separate

The Model s 1792 and 6422 interface options

compatible with the following Keithley

Model 6422

Model 642 Electrometer Serial Nunber 53402A and

above.

Mode I 1792

Model 179 DMFl Serial Nunber 20000 and above.

Model 179-20A DMFl all Serial Numbers.

Model 177 DMM Serial Nunber 14500 and above.

Model 480 Picoammeter Serial Nunber 12000 and

above. Note:

same as Model 480 display.

First 3-l/2 digits at BCD auf-put

WARRANlY INFGRMATIOIJ.

l-5.

l-6.

cover of this Instruction Manual. If there is a

need to exercise the warranty, contact the Keithley

Representative in your area to determine the proper

action to be taken.

cilities in the United Kingdom and West Germany, as

well as in the

front cover of this Manual for addresses.

l-7.

l-8.

occur after printing of the Instruction Manual will

be explained on a Change Notice sheet attached to

the inside back cover.

l-9. SAFETY SYMOBCLS

l-10.

fol lows:

equipment.

these precautions are ignored.

1-11. SPECIFICATIONS.

l-12.

and 6422 are given

respectively.

The Warranty is given on the inside front

Keithley maintains service fa-

United States. Check the inside

CHANGE NOTICES.

Improvements or changes to the equipment which

Safety symobls used in thls manual are as

IM3oRTANT

The ! n symbol can be found in various places in

this manual. Careful ly read the associated CAUTION statements with regard to proper use and

handling of the equipment. Damage to the equip-

ment may occur if these precautions are ignored.

This

t

this manual.

the equipment which are potential shock hazards.

Careful ly read the associated WARNING statements

with regard to proper use and hand1 Ing of the

symbol can be found In various places in

This symbol indicates those areas on

Serious personal injury may result if

Detailed specifications for the Model 1792

In Tables l-l and 1-2,

l-l

Page 6

GENERAL INFORMATION

MODELS 1792, 6422

SPECIFICATIONS

TABLE I-1

SPECIFICATIONS, MODEL 1792 ISOLATED BCD OUTPUT

OUTPUTS : 4-l/2 digit parallel BCD, polarity,

overrange bit, busy.

BUSY:

OUTPUT UPDATE RATE:

CONTROL : E inhibits subsequent output updates

LOGIC LEVELS: TTL/DTL and CMOS compatible.

ISOLATION:

ENVIRONMENT: Operate 0 to 55”C, 0 to 805 RH.

OUTPUT CONNECTOR:

INSTALLATION: Field installable, mounts within

Low during output update (5Oms max).

Same as meter conversion rate

(2.5 reading/second typical).

when low.

Output High = 4.5V minimum while

sourcing lOOkA.

Low =

0.5V maximum while

sinking 3.2mA.

Control High = open or 4V minimum.

Low =

All outputs and controls isolated from

meter up to 1400V peak, 105V*Hz.

(lOlO, ,ll40pf typ1

Storage’ -25 to 7O’C.

26 pin card edge, mates with

CS294-1 (3M 3462 or equivalent)

and powered from Keithley meter.

Adds 0.2kg (0.51 bs).

Precludes Mode I 1788 battery pack

installation.

.5V maximum while

sinking 1mA.

TABLE l-2

SPECIFICATIONS, MODEL 6422 ISOLATED BCD OUTPUT

OUTPUT:

BUSY: Low during output update (50111s max).

OUTPUT UPDATE RATE:

CONTROL : HOLD inhibits subsequent output updates

LOGIC LEVELS:

I SOLAT I ON :

ENVIRONMENT:

OUTPUT CONNECTOR: 26 pin ribbon cable, unterminated.

INSTALLATION:

powered from Keithley meter. Adds 0.4kg (1.0 Lbs).

Precludes Model 6428 battery adapter

installation.

4-l/2 digit parallel BCD, polarity,

overrange bit, busy.

Same as meter conversion

rate (2.5 reading/second

typical).

when low.

TTL/DTL and CF%X compatible.

Output High = 4.5V minimum while

sourcing lOOpA.

Low = 0.5 maxlmum while

sinking 1 mA

Control High = open or 4V minimum.

Low = .5V maximum while

sinking 3.2mA

All outputs and controls isolated from

meter up to 30V peak, 105VoHz.

(lolon II ,4OPf tYP)

Operate 20°C to 30°C

Storage -25°C to +55’C.

Field installable, mounts within and

ASSESSORIES AVAILABLE: Model 1796 - 10’ ou-t-

put mating cable, one end unter-

minated.

Model 1797 - 10’ intercon-

nect cable to 750/7502 printer.

l-2

Page 7

MODELS 1792. 6422

INITIAL PREPARATION

SECTION 2. INITIAL PREPARATION.

2-l. INTRCOUCTION.

This section provides information for r(ncomlng

2-2.

inspection and preparation for use of your Model

1792/6422 BCD output option.

UNPACKING AND INSPECTION.

2-3.

2-4. The Model 1792/6422 was careful ly inspected,

both mechanically and electrically before shipment.

pack all items from the Sh i ppingcontainer and

check for any obvious damage which may have occured during transit.

shipping agent. Retain and use the original

packaging materials if reshipment is required.

The following items (Keithley Part No. in parentheses) are shipped with al I orders of your

option:

Model 1792

Model 6422

Upon receiving your BCD output option, un-

Report any damages to the

a - PC-498 and shield Assembly

1) PC-488 Assembly (29961D)

2) Shield Assembly (30108C)

Replacement Top Cover (30136C)

b.

c. A copy of this Instruction Manual (30155)

d. - Separate Optional Cable (Model 1796 or

1797), as ordered.

a. Assembled PC Board (299610) with modif ied PC-

498 (301658).

Shield (301328).

b.

-

5 Output Cable assembly with back panel and

strain rel iefs.

I) Cable assembly (302348-l)

2) Back panel (301318).

3) Two strain reliefs (27686A).

d

-. Mounting Hardware

I) Eight Standoffs (ST-94).

2) Eight 6-32 X 5/16” screws.

8. - A copy of this Instruction Manual (30155).

2-5. PREPARATION FOR USE.

2-6. The

for installation.

are provided.

instrument using

procedure.

1792/6422

FUNCTION

Common

Common

HOLD ( Input)

BUSY

Dl-B (2)

Dl-A (1)

Dl-0 (8)

01-C (4)

02-B (2)

02-A (1)

02-D (8)

02-C (4)

03-B (2)

D3-A (1)

D3-D (8)

D3-C (4)

04-B (2)

04-A (1)

04-D (8)

D4-C (4)

Common

05

Overrange

Sign

Common

Common

*Part of 6422 cable assembly or optional Model 1796

cable assembly.

Models 1792 and 6422

Separate installation procedures

Install the Model 1792/6422 in your

the

appl icable

TABLE 2-l

MODEL 1792/6422 Output Connections

P40 1 cs-294- 1 CABLE*

PIN NO.

1 1 1 BRN

2 2 2 RED

3 3 3 ORN

4 4 4 YEL

5 5 5 GRN

6 6 6 BLUE

7 7 7 VI0

8 8 8 GRAY

9 9 9 WHT

10 10 10 BLK

11 11 11 BRN

12 12 12 RED

13 13 13 ORN

’

14 14 14 YEL

15 15 15 GRN

16 16 16 BLUE

17 17 17 VI0

18 18 18 GRAY

19 19 19 WHT

20 20 20 BLK

21 21 21 BRN

22 22 22 RED

23 23 23 ORN

24 24 24 YEL

25 25 25 GRN

26 26 26 BLUE

PIN NO

are

WI RE NO. b COLOR

shipped ready

installation

2-l

Page 8

\NITIAL PREPARATION

MODELS 1792, 6422

CARD-EDGE .

CONNECTOR

I I

PIN 2 (TOP)

PIN 1 (UNDERNEATH)

-

,-Model 1792

;+ \P1?08

\GROUNF CLIP :

1

2-2

PL

ASTIC SPACER

(4 PLACES)

FIGURE 2-l.

1792-0023-A

Installation of Model 1792.

Page 9

MODELS 1792, 6422

INITIAL PREPARATION

2-7. MODEL 1792 INSTALLATION

The Model 1792 is installed internally in the

2-8.

Model 177, 179, 179-20A, or 480 and is powered by

the instrument% line operated power supply. Instal-

lation of the Model 1792 precludes use of the Model

1788 Battery Pack.

the Model 1792 as fol lows:

‘t

Disconnect the line cord before removing the

case cover.

a. Turn off power and disconnect line cord.

Turn the DMM bottom side up and loosen the

b.

-

four screws in the bottom cover.

c. Hold the top and bottom covers together to pre-

-

vent their separation and turn the DMM over to the

normal position.

Lift off the top cover and the calibration

d.

-

shield if installed.

Pack is installed,

the plug on the main printed circuit board and

remove the Model 1788. The four plastic spacers

must remain in place on the upright studs project-

ing through the main printed circuit board.

Do not

This shield must be installed during caii-

brat ion,

for your instrument.

as described in the Instruction Manual

Refer to Figure 2-1 and install

WARN I NC

If the Model 1788 Battery

disconnect its connector from

NOTE

discard the calibration

shield.

Install the Model 1792 in the instrument so that

9

it rests on the plastic spacers.

must make contact with the upper side of the shield

on the Model 1792.

h

Install the top cover that was shipped with

-0

the Model 1792. Th is cover has a s lot to

accommodate the card edge

mm

i1rL.c ~

Save all removed parts for reinstallation In

AL-

the event that the 1792 is to be removed at a

I ater date.

Model 1792 Output Connections.

2-9.

2-10.

connector (P401) to provide all input and output

connections to external equipment. This connector

mates with a Keithley CS-294-1 flat-ribbon connector

(3M 3462 or equivalent), which is not supplied.

The output connector pins are identified in Table

2-l.

Two optional cable accessories are available for interfacing the Model 1792 with external equipment.

The Model 1796 is a 10 foot (3 meter) flat ribbon

cable with 26 wires and an output mating connector

(CS-294-l) on one end.

unterminated so that a connector can be installed

that is compatible with the equipment to be

interfaced.

is the same as that given in Table 2-l for the Model

1792 output connector.

with the brown wire to pin 1, the red wire to pin 2,

and so on.

The Model 1792 uses a 26 pin card-edge

Pin identification for the Model 1796

connector of the Model

The other end is left

The wires are color coded

The ground clip

e. - If the Model 1788 was removed, set the LINE/

BAT switch on the main printed circuitboard to the

LINE position.

Connect P1008 to its mating recepticle on the

f

-*

printed circuit board (J1002 on the Model 480

and J1008 on the Models 177, 179 and 179-20A).

The Model 1797 is a 10 foot -(3 meter) cable that

provides the connections to interface the Model 1792

with the Keithley 750/7502 Line Printer.

is plug-to-plug compatible with both the Model 1792

and Hodel 750/7502 for easy installation. Table 2-2

identifies the cable connector pins and wires.

This cable

2-3

Page 10

INlTlhL PREPARATION MODELS 1792, 6422

Connect P1008 to 51013 on the mother board.

2-11. MODEL 6422 INSTALLATION

2-12.

Model 642 and is powered by the Model 642 line operated power supply. Installation of the Model 6422

precludes the use of the Model 6428 Battery Adapter

option. Refer to Figure 2-2 and instal I the Model

6422 as follows:

The Model 6422 is installed internally in the

WARNING

t

Disconnect the line cord before removing

the case cover.

8.

After making the connection, place the printed

circuit board outside of the Model 642 so that

there is no strain on the cable and the board will

be out of the way during installation of the

shield and spacers in the following steps.

Place the shield on the spacers and attach

f.

with the four screws, as shown.

cuit board will not fit properly unless the

shield is installed with the nut plates on the

bottom side and with the hole pattern positioned

as i I I ustrated.

The printed cir-

a. Turn off power and disconnect the I ine cord.

Remove the four attaching screws and remove

b.

-

the top cover.

c. Remove the two attaching screws from the plate

-

(or Model 6428) on the rear panel of the main-

frame. If the

it as foi lows:

I) Disconnect the connector from the plug

on the mother board.

2) Remove the attaching screw and spacer, and

remove the Model 6428 through the opening in

the rear panel.

Remove the front four attaching screws from

d.

the mother board and replace them with the metal

spacers, as shown in Figure 2-2.

may fit snugly and require use of a wrench to install them.

tighten them too tight.

Model 6428 is installed, remove

These spacers

Take care not to cross thread or

Install the four spacers into the shield.

I-.

Place the printed

h.

spacers (component side down) and attach it with

four screws.

Connect the output cable to the card-edge con-

i

-*

nectar and attach the assembly to the rear panel

of the mainframe with the two screws removed in

step c above.

Reinstall the case top cover.

L*

Connect the Model 6422 to your equipment by

k.

installing an appropriate connector on the un-

terminated end of the cable.

for the Cable assembly connector is the same as

that given in Table 2-l for the Model 1792/6422

output connector.

the brown wire to Pin 1, the red wire to pin 2,

and so on.

Save all removed parts for reinstal iation in

L-

the event that the Model 6422 is to be removed at

a later date.

The wires are color coded with

circuit board on the

Pin identification

2-4

Page 11

MODELS 1792, 6422

INITIAL PREPARATION

MOD I F I ED PC-498

(30165B)

STANDOFF (8)

FIGURE 2-2.

MAINFRAME

6422-0032-B

ASSEMBLY

Installation of Model 6422

2-5

Page 12

INITIAL PREPARATION

MODELS 1792. 6422

TABLE 2-2

Model 1797 Cable Connections

1792

FUNCTION

Common

Common

HOLD (Input)

BUSY 4

Dl-B (2)

Dl-A (1) 6

Dl-D (8) 7

Dl-C (4) 8

D2-B (2) 9

D2-A (1) 10

02-D (8)

D2-C (4) 12

D3-B (2) 13

03-A (1) 14

D3-D (8)

D3-C (4) 16

D4-B (2) 17

D4-A (1)

D4-D (8)

04-C (4)

Common 21

05 22

OVERRANGE

SIGN 24

Common

Common 26

cs-294- 1

PIN NO.

11

15

18

19

20

23

25

CABLE

WIRE NO.

AND COLOR

1

2

3

5

1 BRN

2 RED

3 ORN

4 YEL

5 GRN 2

6 BLUE

7 VI0

8 GRAY

9 WHT

10 BLK

11 BRN

12 RED

13 ORN

14 YEL

15 GRN 41

16 BLUE

17 VI0

18 GRAY

19 WHT

20 BLK 8

21 BRN 43,44,45

22 RED

23 ORN

24 YEL

25 GRN 12

26 BLUE

CS-27 1

PIN NO.

9

14

15

13

18

37

19

22

5

23

6

39

38

40

24

7

25

42

11

10

28,29

750/75op

FUNCTION

8-l gnd.

Common

HOLD (Output)

EXTERNAL PRiNT

3-2

3-l

3-8

3-4

4-2

4-l

4-8

4-4

5-2

5-l

5-8

5-4

6-2

6-l

6-8

6-4

7-2,7-4,7-8 gnd.

7-l

10-l

8-4

10-4 gnd.

10-8, I O-2 gnd.

2-6

O=On Scale

l=Overrai+

*Pr i nter Format

10 9 8 7 6 5 4 3 2 1 Column

L

SIGN

(+implied)

Page 13

MODELS 1792, 6422

OPERATION

SECTION 3. OPERATION.

3-1. INTRODUCTION.

3-2.

to provide overall operation, circuit descriptions,

This section describes operation of the Model

1792/6422.

apply to both models.

test point data and special handling requirements

for static sensitive devices.

OVERALL OPERATION.

3-3.

3-4. Figure 3-l shows the Model 1792/6422 in block

diagram form.

verting multiplexed BCO input data into synchronous

serial data.

an opto-electric coupler network and loaded into a

twenty bit shift register.

and appears at the output in parallel BCD format.

The STROBE and CLOCK lines come from the meter

3-5.

motherboard and provide timing for the 1792/6422.

The control

counter. The divider is phase-locked to the STROBE

Except where noted, the descr lptions

The information is arranged

The 1792/6422 operates by first con-

Serial data is then transmitted across

Data is then buffered

consists of a divider and a ring

pulse and divides the lOOkliz CLOCK by ten to produce the 1OkHz SYNC train. The ring counter output

drives the switching to convert the multiplexed BCD

digit data into a serial one bit format. The digit

five (D5) line is decoded to serialize the SIGN and

OVERRANGE I ines.

3-6.

couplers and buffers. The SYNC and DATA pul ses

are transmitted with the opto-couplers normally off

to conserve power.

3-7.

BUSY/HOLD network which controls the output shift

reg i ster. This network consists of a flip-flop, one

shot, and gating.

data update. However,

data wiil be ioaded, and the output wiii not change.

With the HOLD line high, data is updated at the

meter

second.

The isolating network consists of two opto-

The SYNC train after transmission goes into a

The BUSY output goes low during

if the HOLD I ine is low, no

conversion rate,

typically 2.5 readings/

Figure 3-l.

OUTPUT COMMON

Model 1792/6422 Block Diagram

3-l

Page 14

OPERAT I ON

STROBE

SYNC

GNO +-

I

I

I

I

t5v

2mSEC

MODELS 1792, 6422

I

I

I

I

4

39DmSEC

L

mu uuuu uuuu luuu

50

USE&+-

BUSY -

HOLD

sl-

-4

FLAG

SYNC

SHIFT

CLOCK

I”

II

I

I

II DATA I

I

L

I

I

7

I

’

d +t--20DnSEC iii hi. ~ ~

4

11 1 I I ’ 1 I I I 1

II I I I 1 I I I I I

1

I-*-- *--- .--- *--- au--

I

II

I

I

I

I’

//

7 y uSEC

+--2p SEC MIN.

-

1 1 1 I I I

’ I I

100

II

I 1 I I I I

I

I I

I I

r ZC

4

I

c- +5v

l

~380 mSEC

DON’T CARE

-!

= 20 mSEC COMMON

uuuu urn

I

I

I

I

I

I

3

I

I

I

I ~

I

I

I

I

I

I

f

I

I

I

I

3-2

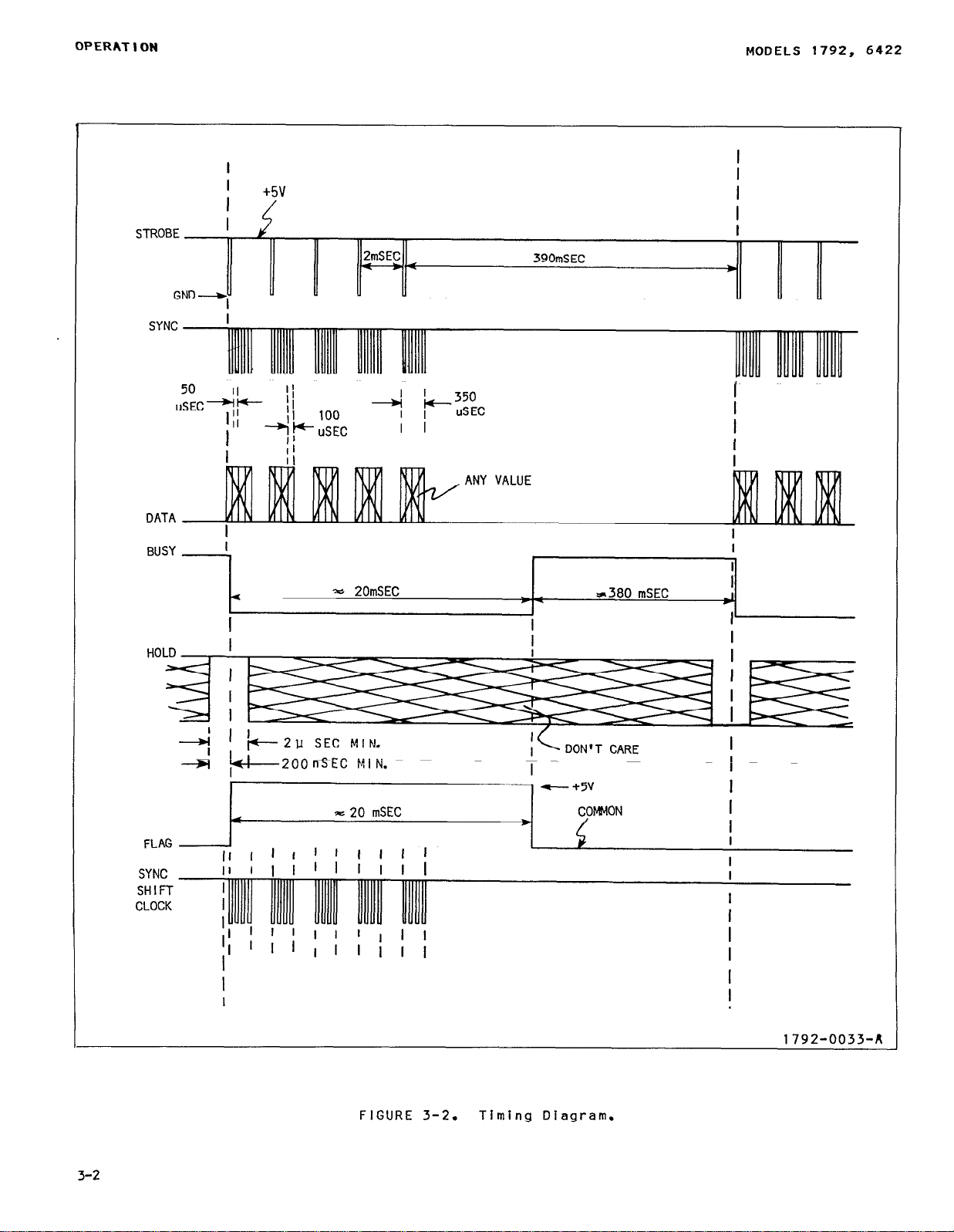

FIGURE 3-2.

1792-0033-A

Timing Diagram.

Page 15

MODELS 1792, 6422

OPERATION

3-a.

(+5V for the Model 1792 and t6V for the Model

6422).

provided by a DC-to-DC converter running at lOOkliz.

3-9.

3-10.

of the major circuit blocks described in Overall

Operation of the Model 1792/6422. The descriptions

are referenced to the Model 1792/6422 (schematic

299650,

schematics are also provided.

the Model 1792/6422 Waveform Diagram (Figure 3-2).

3-11.

3-12.

counter (U414) and a ring

gating.

produce 1OkHz optional transmission of the DATA and

SYNC tral ns across the opto-electric couplers.

STROBE pulses phase-lock the counter by presetting

Input power is furnished by the host meter

The power for the isolated (output) side is

CIRCUIT DESCRIPTIONS.

This section provides detailed descriptions

Page 4-4).

Control Circuitry.

The control

U414 divides the 1OOkHz CLOCK by ten to

Where necessary, simi pl if led

Timing is shown in

consists of a divide-by-ten

counter (U41lA) with

The

it to 2 on each pulse.

long term operation.

3-13.

and gating Is given in Figure 3-3.

pulse enables the transfer of one digit (four bits)

one bit at a time. There are five STROBE pul ses in

each complete data transfer.

STROBE pulse sets the latch comprised of U415A and

U415B, enabl ing U415D to gate the 1OkHz SYNC pulses

to the opto-electric coupler and to the CLOCK input

of U411A.

4

output lines Ql through Q4 to drive the quad switch

and serialize the digit data.

latch when the Ql through Q4 I ines are clocked to

al I zeros,

STROBE pulse. Since the latch is not reset until

U411A is clocked to al I zeros, a pulse of c- 500

nanoseconds is produced on the SYNC I ine after each

4 SYNC pul ses, but this is too fast to be acknow-

ledged by the opto electric couplers.

A simpl i fled schematic of the ring counter

U41lA gates a elll in sequence on its

and it remains in reset unti I the next

Th 1 s ensures synchronous

Each STROBE

In operation, the

U415C resets the

STROBE

HIGH l/2 CLOCK PULSE

AFTER 94 GOES HIGH.

FIGURE 3-3.

Ring Counter and Gating.

To U41lB

TO QUAD SWITCH

(U4 13)

1792-0036-A

3-3

Page 16

OPERAT \ ON MODELS 1792, 6422

3-14.

3-15.

provided by U413 and U416A.

4: 1 multi plexer.

nected through to the DATA opt-o-electric coupler

when its respective control I ine is driven high by

the ring counter (U4llAI.

dual 2:’ multiplexer, switching is controlled by the

digit 5 (D5) line.

significant digit and is transmitted first.

it is always a nOw or a lllw, bits 2, 3 and 4 are not

needed and can be used to transfer other information.

When the D5 line is high, the overrange and sign

status is sent on bits 4 and 3, respectively.

Conversely,

digits 4 through 1 are sent.

3-16.

3-17.

optically coupled isolators, two transistors and

their associated biasing resistors.

Switching Circuitry.

Switching to serialize the input BCD data is

U413 is connected as a

One of its input lines is con-

U4 16A is connected as a

The fifth digit is the most

Since

when the 05 line is low, 88 and 84 for

Isolator Network.

The isolator network is comprised of two

The isolators

provide 101oD isolation and are normally off to

conserve power. The transistors invert the pulses

and serve both as wave shapers and low impedance

buffers into the high impedance CMOS circuits.

3-18. Busy/Hold Circuit.

3-19.

cuit is given in Figure 3-4. The BUSY I ine always

goes low during a potential data transfer.

BUSY goes low, the f I ip-flop Is clocked and the HOLD

I ine checked to see

desired. If the HOLD line is high, the FLAG is set,

enabl ing U409D to gate the SYNC pul se train.

BUSY line

mi I I iseconds.

resets the fl ip-f lop and no data transfer can occur

until it goes low again. This will occur when the

one-shotmultivibrator

pulse of the next SYNC train.

A simpl ifled schematic of the BUSY/HOLD cir-

if a new data transfer is

remains

When the BUSY I ine returns high, it

for

low

is triggered by the first-

approximately 20

When

The

HOLD

BUSY

*U404 and U408 PROVIDE -400 NANOSECOND

DELAY TO ENSURE THAT FF RESET LINE IS LOW

BEFORE CLOCKING.

FIGIURE 3-4.

Busy/Hold Circuit.

SYNC CLOCK I NG TO

OUTPUT SHIFT REGISTERS.

1792-0035-A

3-4

Page 17

MODELS 1792, 6422

OPERATION

3-20. Output Registers And Buffers.

3-21. Five 4-stage serial-input/paral lel-ouiput

registers are connected together to form the twenty

bit output shift register. Serial input data is ap-

plied to the lrD1t input of U407A. Data is set up on

the fal I ing edges of the SYNC pulses and latched on

the rising edges. Data is shifted into the outpuf

register in a seq uBnce that can be determined by

reading the output line identification from top to

bottom on Schematic 29965D, page 4-4.

transfer is complete, the display information is

available at the oufput card-edge connector in a

buffered parallel BCD format.

3-22. DC-to-DC Converter.

3-23.

applied to switching transistor 0403. 0 i ode CR402

The 1OOkHz clock is buffered by U410 and

After data

TABLE 3-l.

Test Point Data

shunts one half cycle of buffer drive and provides

optimal switching of 0403 to prodllce maximum voltage

in the secondary of the transformer.

I imits the base current to 0403.

across transformer T401 and half- wave rectified by

CR401. Capacitor C401 and voltage regulator VR401

provide a stable positive five volt supply to the

isolated circuits.

3-24. TEST POI NT DATA.

3-25. The Model 1792/6422 has ten test points that

can be used for trocbl eshoot I ng or confidence test-

ing. Test point signals are described in Table 3-l.

The test points are accessible by removing the

instrument top cover as described in the applicable

instal lation procedure (i.e, Para. 2-l for Model

1792 or Para. 2-11 for Model 6422).

R411 I imits

Power is pul sed

Test

Point

TP’

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

Signal

1OkHz. Clock, SVpp, 50% duty cycle

SYNC (See Timing Diagram Figure 3-l).

Digital non-isolated common, OV reference

for TPl and TP5.

Non-isolated positive supply from meter

(6V f 5% Model 6422 and 5V f 5% for Model

1792).

DATA (See Timing Diagram Figure 3-l).

Complement of TP2.

Isolated DATA, same as TP5.

Isolated t5V f 0.25V.

SYNC SHIFT CLOCK-If HOLD is high,

same as TP2.

See Timing Diagram Figure 3-l.

If HOLD is low, +5V (high).

Reference

TP3

TP3

TP3

TP3

TPlO

TP’O

TP’O

TP’O

Isolated common, OV reference for TP6 thru

TP9.

3-5

Page 18

OPERAT I ON

MODELS 1792, 6422

3-26.

SENSITIVE DEVICES.

3-27. CMCS devices are designed to function at

very high impedance levels for low power consump-

t ion. For this reason, a normal static charge build

up on your person or clothing can be sufficient to

destroy these devices.

static sensitive devices In your Model

and provide instructions on how to avoid damaging

them when they must be removed/replaced.

SPECIAL HANDLING OF STATIC

The fol lowing steps I is-t the

1792/6422,

a. Static sensitive devices:

Keithley

Part Number

IC-107

IC-136

IC-102

IC-106

IC-105

IC-221

IC-145

I c-222

The above integrated circuits should be

b.

handled and transported only In protective con-

ta i ners. Typically they wil I be received in metal

tubes or static protective foam. Keep the devices

Reference

Designation

U401-U404 ,U408

u405-u407 ,u411

u409, u415

u410

U412

u413

u414

U416

in their original containers until ready for use.

Remove the devices from their protective con-

C.

talners only at a properly grounded work bench or

table, and only after grounding yourself by using

a wrist strap.

Handle the devices only by the body.

d.

touch the pins.

NOTE

P1008 is shipped with a piece of conductive

foam covering the pins to prevent static

damage.

placed If you disconnect P1008 to remove

your BCD option from its host instrunent.

e. Any printed circuit board into which a device

-

I s to be inserted must al so be grounded to the

bench or table.

f. - Use only anti-static type solder suckers.

Use only grounded tip soldering irons.

3-0

After soldering the device into the board,

h.

-

or properly Inserting it into the mating recep-

tacle, the device is adequately protected and

normal hand1 ing can be resuned.

This conductive foam should be re

Do not

3-6

Page 19

MODELS 1792, 6422

SECTION 4 REPLACEMENT PARTS

4-l. GENERAL.

This section contains information for order-

4-2.

ing replacement parts.

(Table 4-2, Page4-2) is arranged in alphabetical

order of the Circuit Designations of the components.

A Cross-Reference List of Manufacturers, containing

their addresses,

DRDERING INFORMATION.

4-3.

4-4.

concerning replacement parts, contact your Keithley

representative or the Factory. See the inside front

cover for addresses.

following information.

To place an order,

is given in Table 4-l.

The Replaceable Parts List

or to obtain information

When ordering, include the

REPLACEMENT PARTS

TABLE 4-l.

Cross-Reference of Manufacturers~

MFG.

CODE NAME AND ADDRESS

CLB

F-l

ITT

K-l Keithley Instruments, Inc.

Centralab Division

Milwaukee, WI 53201

FaIrchild Inst. Corp.

Mountain View, CA 94043 07263

Components

Lawrence, MA 15238

Cleveland, Ohio 44139

FED.

SUPPLY

CCQE

71590

88164

a. Equipment Model Number.

Part Description.

b.

-

c. Circuit Designation (if applicable).

Keithley Part Number.

d.

-

SCHEMATIC

4-5.

Model 1792/6422 BCD Option:

4-6.

Schematic No. 29965D page 4 - 4.

COFPDNENT LAYOUT.

4-7.

Physical location of the components is shown

4-8.

in Component Layout No. 29961D, Pageq-5.

MEP Mepco, Inc.

Morrlstcwn, NJ 07960

NAT

NCI

RCA RCA Corporation

T-l Texas I nstruments, Inc.

Nationa! Semi Corp.

Santa Clara, CA 95051

Nationa I Components, Inc.

West Pal m Beach, FL

Morrestown, NJ 08050

Dallas, TX 75231

8003 1

27014

02734

01295

4-l

Page 20

REPLACEMENT PARTS

MODELS 1792, 6422

TABLE 4-2

REPLACEABLE PARTS LIST

Circuit

3es ig.

/

4T40 I

/

4T402

I

2401

I

c402

I

C403

I

D404

I

CR401

I

CR402

I

P1008

I

PI008

I

Q401

I

Q402

I

Q403

I

R40l

I

R402

I

R403

I

R404

I

R405

I

R406

I

R407

I

R408

I

R409

I

R410

I

R4 11

I

R412

I

R413

Location Mfr. Mfr. Keithley

Description

IC, Optical Iy-Coupled Isolator D-4 F-4 F-l

IC, Optically-Coupled Isolator D-2 F-4 F-l FCD 820

Cap, 4.7uF, 2OV, ETT

Cap, 0.3311F, 2OV, ETT E-5

Cap, O.luF, 16V, CerD

Cap, 0.3311F, 2OV, ETT

Diode, Si I icon, 75mA, 75V

Diode, Si I icon, 75mA, 75V B-2 D-5 T-l lN914 RF-28

Cable Assembly (1792)

Cable Assembly (6422)

Transistor NPN Silicon D-4 E-4 T-l 2N3904 TG47

Transistor, NPN, Silicon

Transistor, NPN, Silicon C-l D-5 T-l 2N3904 TG-47

lOKD,t5%, 1/4W, CarbF E-6 D-3

lOOKR,*5%, 1/4W, CarbF E-5

lOKD,i5%, 1/4W, CarbF

lOKD,k5%, l/4W, CarbF

lOOKl2,*5%, 1/4W, CarbF

lOOKG,k5%, 1/4W, CarbF

39OO,i5%, 1/4W, CarbF

3908,*5%, 1/4W, CarbF

lOOKJ2,*5%, 1/4W, CarbF

lOKn,f5%, 1/4W, CarbF

lKn,tS%, 1/4W, CarbF

lOOKD,k5%, 1/4W, CarbF

lOOKn,k5%, 1/4W, CarbF

Sch. Pcb.

E-l D-4

F-4 ITT

B-l

A-4

E-l D-4 T-l lN914

A-2 H-5 K-l --- 27961A-l

A-2 H-5 K-l --- 2796 l A-2

D-2

E-3 E-4

E-2

D-4

D-2

D-4 F-4 MEP CR25* R-76-390

D-3

D-5

C-l D-5

B-l

D-4

D-3

D-5

F-5

F-4 T-l

F-4

F-4 MEP CR25”

E-4 MEP

F-4 MEP CR25”

F-4 MEP CR25” R-76-390

F-4 MEP CR25” R-76- 1OOK

D-5

E-4 MEP CR25” R-76-100K

F-4 MEP CR25* R-76- 1OOK

Code Des lg. Part No.

FCD 820 I C-82

I C-82

NCI KNS475A020K c-179-4.7

TAPA.33KZO

CLB UK16-104 C-238-. I

ITT

MEP CR25” R-76- 10K

MEP

MEP

MEP CR25” R-76- IOK

MEP CR25” R-76- 1K

TAPA .33K20 C-204-.33

2N3904 TG47

CR2 5”

CR25” R-76- 1OK

CR25”

C-204- .33

RF-28

R-76- 1 OOK

R-76-10K

R-76- 1OOK

R-76- IOOK

4-2

T401

u401

U402

u403

u404

u405

*Manufacturers Des ignat ion includes Part Descr Ipt ion; e.g., CR25,

Transformer, Power

IC, CMOS, Hex Buffer

IC, CMOS, Hex Buffer F-2,3 E-3

IC, CMOS, Hex Buffer

IC, CMOS, Hex Buffer F-5,D-5

IC, CMOS, Duel 4-Stage Static Shift

Reg i ster.

D-l

F-l ,E6

F-4

F-1,2

D-4 K-l --- TR- 170

D-3

E-3

F-3

D-4 RCA CD4015AE IC-136

RCA CD4050AE 10107

RCA CD4050AE IC-107

RCA CD4050AE

RCA CD4050AE IC-107

lOKP,*5%, 1/4W, CarbF for R40l.

IC-107

Page 21

MODELS 1792, 6422

REPLACEMENT PARTS

TABLE 4-2 (CONT.1

REPLACEAEILE PARTS t fSf

Circuit

Desig.

U406

u407

U408

u409

u410

u411

U412

u413

u414

u415

U416

VR401

DescrIptiOn

IC, CMDS, Dual 4-Stage Static Shift

Reg i ster. F-3,4

IC, CMOS, Dual 4-Stage Static Shift

Register.

IC, CMOS, Hex Buffer

IC, CMOS, Quad 2-Input NAND Gate

IC, CMOS, Hex lnverter

IC, CMOS, Dual 4-Stage Static Shift

Reg i ster.

IC, CMOS, Dual 4-Input NOR Gate

IC, CMOS, Quad Analog/Digital Switch

IC, CMOS, Presettable Divide-by-N

Counter.

IC, CMOS, Quad 2-Input NAND Gate

IC, CMOS, Quad 2 Channel Data Selector B-5

IC, 3-Terminal,

t5V Regu I ator f 5% E-l

scfa.

D-5,F-4

E-2,4,5,

DE-4,5

ABCD-1,2,3,5 D-5

CD-3

B-4,A-5 E-5 RCA

C-5

B-2 D-5

BC-3,4 E-5

LocatIon

Mfr.

Pcb. Coda

E-4 RCA

E-4 RCA

F-4 RCA

F-4 RCA

RCA

E-5 RCA

F-5 NAT

RCA

RCA

E-5 NAT

D-4 NAT

Mfr.

Desig.

CD4015AE

CD4015AE

CD4050AE

CD401 1AE

CD4049AE

CD40 15AE

CD4002AE

CD40 16CN

CD4018AE

CD401 IAE

CD45 19BCN

LM78L05ACZ

Keith1.y

Part No.

IC-136

10136

IC-107

10102

IC-106

10136

10105

10221

10145

10102

I c-222

I C-223

4-3

Page 22

Sxa (u -

-- ----.

il.l.m’

.

8

Z’

1 I

-

4-4

Page 23

P

VI

Page 24

SERVICE FORM

Model No.

Name

Company

Address

City

Serial No. P.O. No.

State

Date

Phone

Zip

List all control settings and describe problem.

(Attach additional sheets as necessary. 1

Show a block diagram of your measurement system including all instruments connected (whether power

is turned on or not). Also describe signal source.

Where is the measurement being performed? (factory, controlled laboratory, out-of-doors, etc.)

What power line voltage is used? Variation?

Frequency? Ambient Temperature?

Variation?

OF. Rel. Humidity? Other?

OF.

Any additional information. (If special modifications have been made by the user, please describe below.)

*Be sure to include your name and phone number on this service form.

Page 25

KEITHLEY INSTRUMENTS, INC.

INSTRUMENT DIVISION I 28775 Aurora Road / Cleveland, Ohio 44139 / U.S.A. / (216) 248-0400 / Telex: 98-5469

WEST GERMANY: Keithley Instruments GmbH / Heiglhofstr. 5 / 8000 Munchen 70 / (089) 710020 / Telex: 52-12160

GREAT BRITAIN: Keithley instruments, Ltd. / 1, Boulton Road / Reading, Berkshire RG 2 ONL / (0734) 86-l 2-87/88 /Telex: 84-7047

FRANCE: Keithley Instruments SARL / 2, Bis Rue Leon Blum / B.P. 60 / 91 121 Palaiseau Cedex / (6) 01 1-51-55 I Telex: 600-933

NETHERLANDS: Keithley Instruments BV I Arkelsedijk 4 I Postbus 559 / 4200 AN Gorinchem I (0) 1830-25577 I Telex: 24-684

SWITZERLAND: Keithley instruments SA / Kriesbachstr. 4 / 8600 Dubendorf / 01/821-94-44 / Telex: 57-536

AUSTRIA: Keithley Instruments Ges.m.b.H. / Db’blinger Haupstr. 32 I 1190 Wien / 314 289 / Telex: 13-4500

Loading...

Loading...