Page 1

177 STANDARD

TEST FIXTURE

SERVICE

Page 2

WARNING

COMMITTED

m EXCELLENCE

THE

ARE FOR USE BY QUALI

TO

PERFORM ANY SERVI

CONTAINED

UNLESS YOU

FOLLOWING SERVICING INSTRUCTIONS

AVOID PERSONAL INJURY, DO

CI

IN OPERATING INSTRUCTIONS

ARE QUALI

PLEASE CHECK FOR CHANGE INFORMATION

AT

FI

ED

PERSONNEL ONLY.

NOT

NG OTHER

FI

ED

THAN

TO DO

THAT

SO.

THE REAR OF THIS MANUAL.

Tektronix,

P.O.

Beaverton,

070-1472-00

Product Group 48

Box

Inc.

500

Oregon

97077

177 STANDARD

TEST FIXTURE

SERVICE

INSTRUCTION

Serial

Number

MANUAL

_____

First Printing JUL 1973

Revised JUN 1983

_

Page 3

Copyright ®

Contents of this

form without the written permission of Tektronix,

1973

Tektronix,

publication may not

Inc.

All

rights reserved.

be

reproduced

Inc.

in

any

Products of Tektronix,

by U.S.

TEKTRONIX,

registered trademarks of Tektronix,

is

Printed

are reserved.

Each

or stamped

deSignates the country of manufacture.

of the

unique to

United States have six unique digits. The country of

manufacture

and

foreign patents and/or pending patents.

TEK,

a registered trademark of Tektronix

in

U.S.A. Specification

INSTRUMENT SERIAL NUMBERS

instrument has a serial number

on

serial number are assigned sequentially and are

each

is

identified

Inc.

and

its subsidiaries are covered

SCOPE-MOBILE,

and

the chassis. The first number or letter

instrument. Those manufactured

as

follows:

and

Inc.

U.K.

price change privileges

on

~

TELEQUIPMENT

Limited.

a

pa~el

insert, tag,

The

last five digits

in

are

the

BOOOOOO

100000

200000

300000

700000

Tektronix, Inc., Beaverton, Oregon, USA

Tektronix Guernsey, Ltd.,

Tektronix United Kingdom, Ltd., London

Sony/Tektronix, Japan

Tektronix

The

Holland,

Netherlands

NV,

Channel Islands

Heerenveen,

Page 4

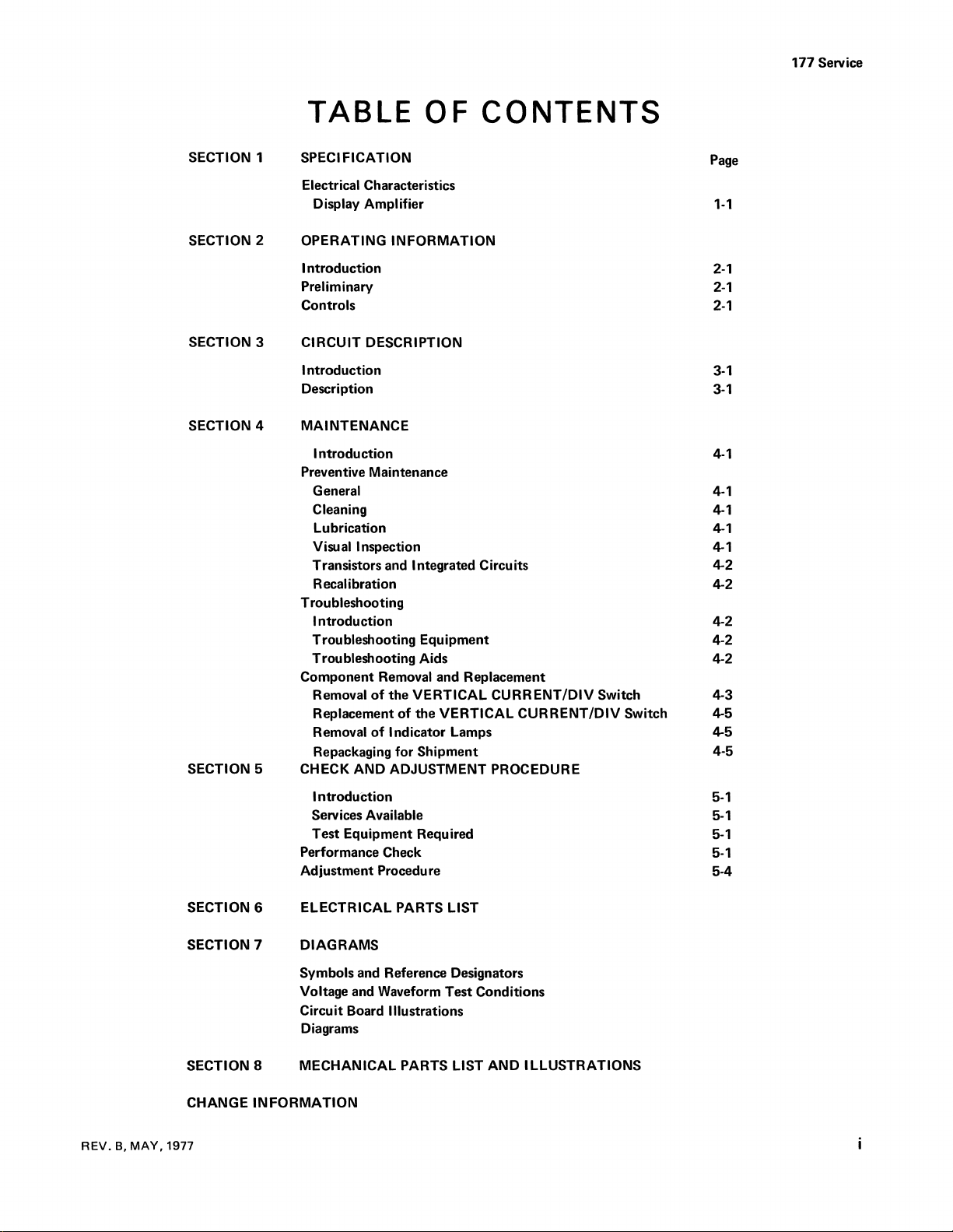

177 Service

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

TABLE

SPECI

FICATION

Electrical Characteristics

Display

OPERATING

Introduction

Preliminary

Controls

CIRCUIT DESCRIPTION

Introduction

Description

MAINTENANCE

Introduction

Preventive Maintenance

General

Cleaning

Lubrication

Visual Inspection

Transistors

Recalibration 4-2

Troubleshooting

Introduction

Troubleshooting Equipment 4-2

Troubleshooting Aids 4-2

Component Removal and Replacement

Removal

Replacement

Removal

Repackaging

CHECK

Amplifier

of

of

AND

OF

INFORMATION

and

Integrated Circuits 4-2

the

VERTICAL

of

the

I ndicator Lamps

for

Shipment

ADJUSTMENT PROCEDURE

CONTENTS

CURRENT!DIV

VERTICAL

CURRENT!DIV

Switch 4-3

Switch 4-5

Page

1-1

2-1

2-1

2-1

3-1

3-1

4-1

4-1

4-1

4-1

4-1

4-2

4-5

4-5

REV.

B.

MAY. 1977

SECTION 6

SECTION 7

SECTION 8

CHANGE

INFORMATION

Introduction

Services Available

Test Equipment Required

Performance Check

Adjustment Procedure

ELECTRICAL

DIAGRAMS

Symbols and Reference Designators

Voltage and Waveform Test Conditions

Circuit Board

Diagrams

MECHANICAL

PARTS LIST

Illustrations

PARTS LIST

AND

ILLUSTRATIONS

5-1

5-1

5-1

5-1

5-4

Page 5

177

Standard

Tes

t

Fixture.

177 Service

®

Page 6

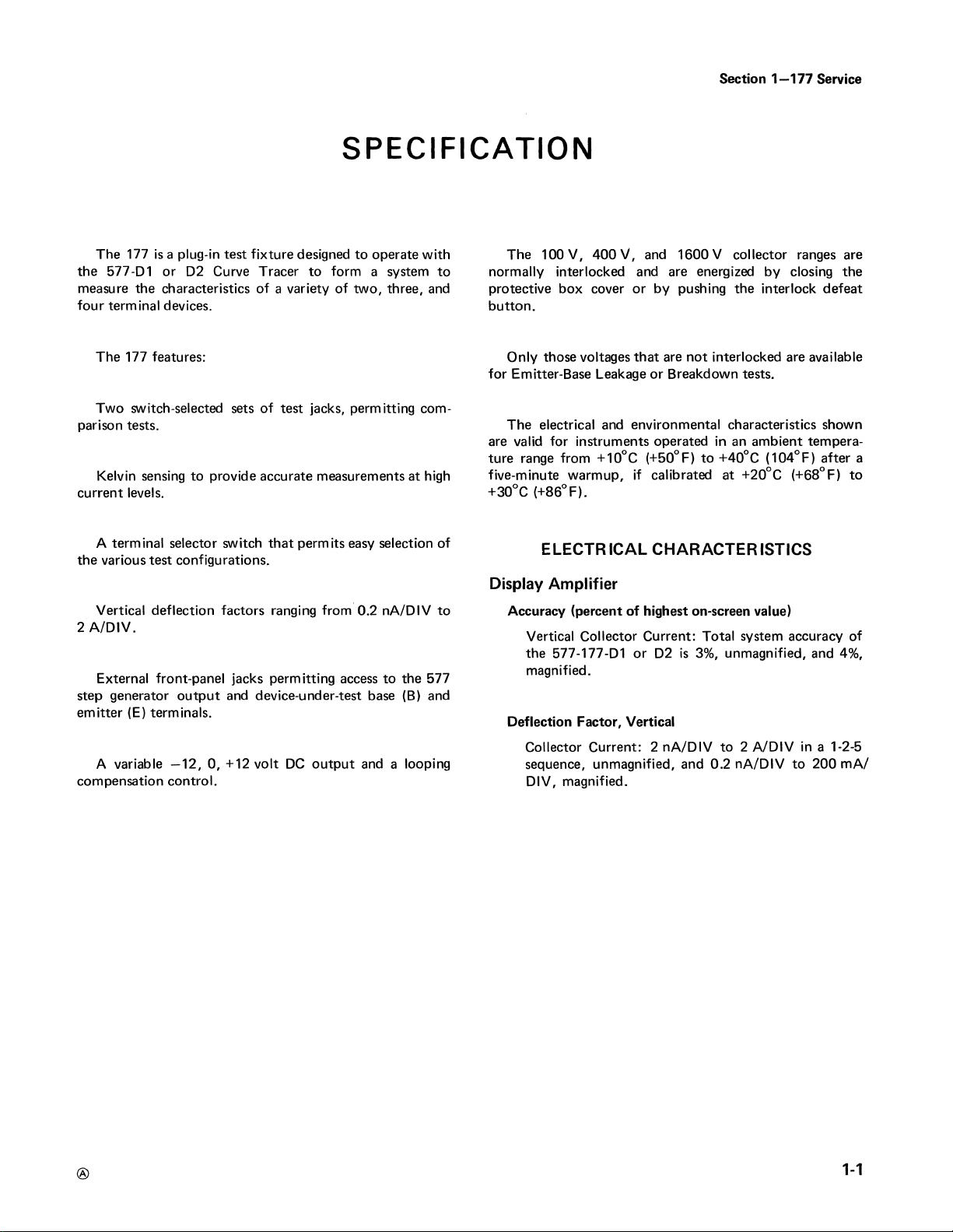

SPECIFICATION

The

177

is

a plug-in test fixture designed

the

577

-D

1 or

D2

Curve Tracer

measure the characteristics of a variety of two, three, and

four term ina

The

I devices.

177 features:

to

operate with

to

form a system

to

Section

The 100 V,

normally interlocked and are energized by closing

protective box cover

button.

Only those voltages

for Emitter-Base Leakage

400

V, and 1600 V collector ranges are

or

by pushing the interlock

that

are

not

interlocked are available

or

Breakdown tests.

1-177

Service

the

defeat

Two switch-selected sets

parison tests.

to

Kelvin sensing

current

the various

2 A/DIV.

step generator

emitter

compensation control.

levels.

A term inal selector switch

test

Vertical deflection factors ranging from

External front-panel jacks permitting access

(E) terminals.

A variable

provide accurate measurements at high

configurations.

output

-12,

0,

of

test jacks, perm itting com-

that

perm its easy selection of

and device-under-test base

+12 volt

DC

output

0.2 nA/DIV

to

the 577

(B)

and

and a looping

to

The

electrical and environmental characteristics shown

are valid for instruments operated

ture

range from +1O°C (+50°F)

five-minute warmup,

+30°C (+86°F).

E

lECTR

Display

Amplifier

Accuracy (percent of highest on-screen value)

Vertical Collector Current: Total system accuracy of

the

577-177-D1

magnified.

Deflection Factor, Vertical

Collector Current: 2

sequence, unmagnified, and

DIV, magnified.

if

calibrated

ICAl

CHARACTER ISTICS

or

D2

nA/DIV

in

an ambient tempera-

to

+40°C (104°F) after a

at

+20°C (+68°F)

is

3%, unmagnified, and 4%,

to

2 AlDIV

0.2 nA/DIV

in

to

a 1-2-5

200

mAl

to

®

1-1

Page 7

Page 8

Section

2-177

Service

OPERATING

Introduction

The

177 Test Fixture operates with a Tektronix 577

the

D1

or

D2

Curve Tracer and

of

1 or

of

the

front·panel controls of

D2

This section

description

577 -177

operating procedure.

-D

the

Operators Manual for a complete

Display

manual gives a brief functional

Preliminary

For initial preparation, refer

tions

section of

The

Operators Manual contains operating instructions,

well

as

general and specific application information.

the

577-177-D1 or D2 Operators Manual.

Unit

the

to

the

Operating Instruc-

as a system.

177. See

INFORMATION

BASE GROUNDED MODE (Base terminal

polarity

Disconnects

generator

minal

INPUT Connector.

Applies step generator

terminal.

to

the

to

that

output

the

base term

the

are

the

as

step generator

is

switched as follows):

EM

ITTER TERM

OPEN (OR EXT)

STEP GEN

EMITTER-BASE BREAKDOWN

Grounds

sweep voltage

voltage

ranges

is

is

inverted, and

the

emitter

and connects

front-panel EXT BASE OR

inal

emitter terminal. Only

not

interlocked are available.

the

em itter term inal

term inal from

the

output

and applies

to

emitter ter-

the

the

the

grounded,

the

step

EM

IT

em itter

collector

collector·

Controls

This

is

a brief description of

front-panel controls. More detailed information is given

the

Operators Manual.

EMITTER GROUNDED MODE

grounded; Base terminal

BASE TERM

STEP GEN

Applies step generator

tions

of

OPEN (OR EXT)

Disconnects

generator

the

front-panel EXT

Connector.

SHORT

Disconnects

generator

the

output

output

is

switched as follows):

test

fixture.

the

base terminal from

and connects base terminal

the

base terminal from

and grounds

the

functions of

(Emitter terminal

output

BASE

to

the

OR

the

base term inal.

base connec·

the

EM

IT

INPUT

the

the

in

is

step

to

step

STEP GEN OUTPUT Connector

Provides

EXT

Provides

depending

GROUND

Provides for external ground connection.

LEFT-RIGHT Switch

Three position

either

center position disconnects all terminals

term ina

together and are connected

generator, or

position of

Test Adapter

Two sets

for testing various sem icond uctor devices.

external access

BASE

OR

external access

on

the

left

Is.

The

the

of

to

the

step generator

EM

IT

IN

Connector

to

the

base or em itter

the

position of

toggle switch for applying

or

right set of terminal connectors.

em itter term inals are always connected

to

the

Terminal Selector switch.

Terminal Jacks

five recessed jacks accepting various adapters

the

Terminal Selector switch.

to

either ground,

collector sweep depending

test

except

output.

term

signals

the

emitter

to

the

on

ina

The

step

the

Is,

to

®

2-1

Page 9

Page 10

Section

3-171

Service

CIRCUIT

DESCRIPTION

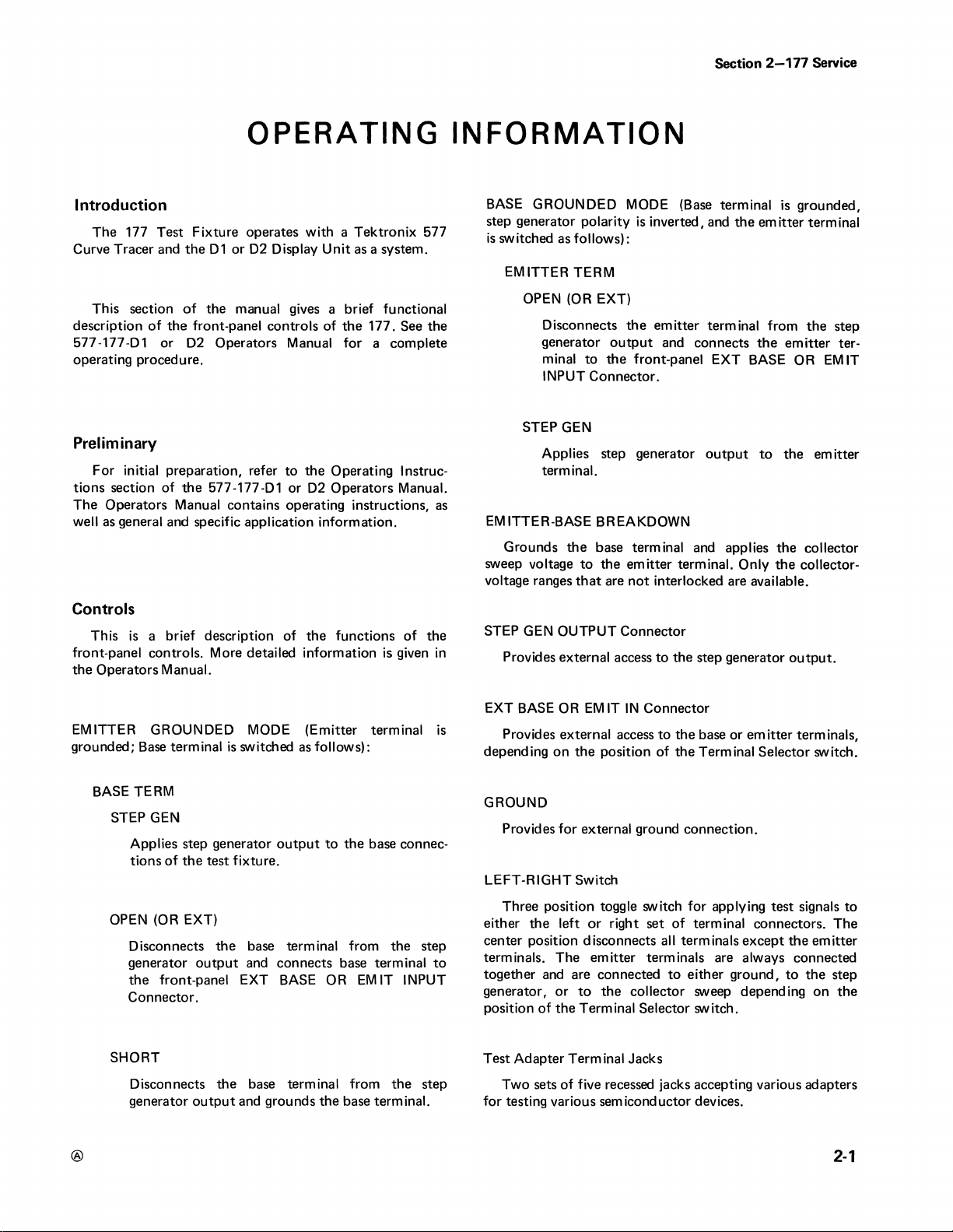

Introduction

This section of the manual contains a description of the

circuitry

schematic diagrams, with

values, are shown on

manual.

in

the 177 Standard Test Fixture. Complete

component

the

pullout pages at

numbers and parts

the

rear

of

this

Description

The

Standard

plifier (variable gain)

current-sensing resistor.

The

entire vertical preamplifier, including its power

supply, floats with respect

The

vertical preamplifier consists

followers,

fier, U616, and an inverting feedback amplifier, U6240626-0628,

switching.

577 vertical amplifier.

Current

connected between

under test.

Test

Fixture contains

that

to

0604A

The

and

B;

a non-inverting feedback ampli-

which provides

inverting amplifier

sensing resistors, R

the

collector supply and

the

vertical pream-

measures voltage across a

ground. See Fig. 3-1.

of

two FET source

the

1-2-5 current per division

output

630

connects

through R636, are

the

to

device

the

for

the

stray capacitance across

tors, keeping

of

the

U616

R618-R619. This divider

horizontal

VERTICAL CURRENT/DIV switch

2 mA/DIV). This voltage

same

test. This method permits monitoring

without

resistor.

On the high-current ranges

horizontal

sense terminal of

sensing. If Kelvin sensing

between

attenuator

U616

U624-0626-0628.

feedback resistance

(gain of

R627

the

time

constant

stray capacitance and R630 through R636.

output

attenuator

as

the

drawing

attenuator

C and C SENSE terminals connects

to

output

5L

in

parallel with R629 (gain

is

connected

in

to

voltage on

the C term

R627 and R628

the

current

is

connected directly

the

device under

ina

is

connected

The

input

is

composed of three resistors, R627

the

current sensing resis-

sim ilar

to

output

the

the

collector of

through

is

Is.

is

low-current ranges

horizontal

(5

mA/DIV

test

not

used,

to

the

resistance

in

parallel (gain of

of

1).

to

the

time

constant

a 10: 1 divider,

connected

(2

attenuator

the

the

collector voltage

the

current-sensing

to

to

to

the

inverting amplifier,

is

R621 and

to

of

nA/DIV

is

device under

2 A/DIV)

the

collector

permit Kelvin

22.Q

resistor

the

horizontal

2.5L

and

the

the

to

the

the

the

0604A

the

puts are fed

R612

(Gain Adj) make up

for

source-follower

C632, LOOPING COMPENSATION (front-panel

troll.

the

capacitance.

C630 and R660 through R665 (ganged with

current-sensing resistors, R630 through R636), compensate

REV.

and B (source followers) are connected across

current-sensing resistors, and

differentially

is

the

input

slightly more than 10,

losses.

compensates for stray capacitance

test

adapter, as well as some

B,

MAR.

1975

to U 616,

resistor for U616; R616 and R615

the

feedback resistor.

the

source-follower out-

the

X 1 0 ampl ifier.

to

compensate for

at

of

the

0604B

device-under-test

The

gain

the

gate and

is

FET

con-

the

set

The inverting

to

pin

21

P129.

prevent signal load

0-15-volt

the

resistors.

ranges of

and 1600

placed over

is

permits these three ranges

0626-0628

All

power

junction

When using

depressed. When

amplifier,

of

J110,

to

provide low-output impedance

ing

by

is

supplied by

supplies. 0 (test fixture common)

of

the

collector supply and

the

177

the

MAX

PEAK VOLTS switch

V)

are

not

enabled unless

the

test

adapter

the

U624-0626-0628,

the

vertical amplifier via pin 4

the

Test

cover

to

chopper

Fixture

or

be

the

the

interlock

is

closed,

enabled.

circu it.

floating 0+15 and

is

the

current

in

the

577,

(100V,

the

protective cover

S626

is

connected

connected

sensing

the

highest

400

defeat

button

is

closed and

of

to

to

V,

is

3-1

Page 11

::II

m

<

.tIl

s::

»

::0

VERTICAL

CURRENTI

DIV

DEVICE C

(")

~'

;:+'

COLLECTOR SUPPL Y

FROM 577

____________

Jll0

C630

,

,

,

I

r---

I

I

I

,

,

,

,

I

I

I

I

L_

R636

THROUGH

R613

R630

J¥+15

R612

.6'-15

R615

and

GAIN

.Il'+15

.6'-15

R616

R618

i":-C------------------------------~H~I~G;H~C~U~R~R;E~N~T--------------~04~>-------

r--

.l...

T B I

L__

DEVICE UNDER TEST I

(5mAto2A)

1___

24

-----

R619

R621

CURRENT

LOW

A

""iiii---------------------------'

J¥+15

.6'-15

R629

-.,

X5

I

R6Z8

______

R627

.6'+15

,

X2.5

r-

..J

I

Xl

~--~~----~--------------:2~1~1~~t.~VE:ri~:~T~~~~AL

U624,0626

0628

,d-15

L---------------:.6'~=~V~E:R:T~~IC~A~L~S~I~G~N~A~L~C-O~M-M--O-N----~2~2~.~~~~

(2

nA

- 2 rnA)

______________________________________________

I

I

I

~,>---,,--..,

I

i SUPPLY

~

I

;>--Jr--f-_-.J

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

,

I

I

I

I

I

I

I

I

I

I

I

I

I

~A~1'~

I~

Jll0

I

F~~~~~G

AMPLIFIER

• .6'

TO

HORIZONTAL

ATTENUATOR

o

~

...

ii'

...

0'

;:,

I

...

"-I

"-I

~

<

~'

Page 12

5628,

the

177

interlock_

the

safety-interlock

front

panel) may be pressed

defeat

switch (red

to

defeat

button

the

safety

on

Circuit

WARNING

Oescription-177

I

Service

The

using

option

100

V and

the

protective cover

in

the

177 (see Fig. 3-2

400

V supplies may be enabled

or

the

defeat

for

details).

switch

by

without

a wiring

To

the

between

To

the

between

enable

Interlock

point

enable

Interlock

point B and

This modification

supply can

likely lethal.

ING note should

the

the

+l00·volt

Defeat

A and

+400-volt

Defeat

switch,

point

switch.

point

supply

supply

is

not

be

lethal and the

If

this modification

be

permanently attached to the

without

remove link A

X.

without

remove link B and

X.

using

using

recommended. The 100 V

400

V supply

is

made a WARN-

is

very

177.

the

protective

and

connect a wire

the

protective

connect

box

or

box

of

a wire

®

Fig.

3-2.

100 V and

400 V Interlock

Defeat

bypass

option.

3-3

Page 13

Page 14

MAINTENANCE

Section

4-177

Service

I ntrod uction

This section of

in

preventive and corrective maintenance, with

troubleshooting.

PREVENTIVE

the

manual contains information for use

MAINTENANCE

General

Preventive

spection, lubrication,

ed

on

a regular basis improves

severity

determ ines

of

the

the

maintenance

etc.

environment

frequency

consists

Preventive

instrument

in

wh ich

of

maintenance.

of

cleaning, visual

maintenance

the

instrument

Cleaning

The

177

Test

Fixture

operating cond itions require. Accumulation

instrument

breakdown,

Exterior. Loose

instrument can

paint brush.

dislodging loose

controls. Dirt

dampened

cleaners should

Interior. Dust

removed occasionally

high-humidity environments.

using

a mild

applicator

can cause leakage currents and

especially

dust

be

removed

The

paint

dust

that

remains can

in

a mild

be

avoided.

in

the

dry,

low·velocity air. Remove any remaining

detergent

is

and

useful for cleaning circuit boards.

should

in a hum

accumulated

with a soft

brush

on and around

be

detergent

to

and

interior

prevent

Blowout

water

be

cleaned as

id

atmosphere.

on

the

cloth or a small

is

particularly useful for

removed with a

water

solution. Abrasive

of

the

instrument

electrical

accumulated

solution. A

some

perform-

reliability.

often

of

dirt

component

outside

the

front-panel

soft

should

conduction

dirt

cotton-tipped

aids

The

is

used

in

of

cloth

dust

with

to

in-

as

the

the

be

in

Lubrication

The reliability of

other

moving parts can be maintained if

properly lubricated.

switch contacts. Lubricate switch

grease (such

as

potentiometers,

Use

Tektronix

a cleaning·type

detents

Part No.

006-0219·00).

rotary switches, and

they

lubricant

on

with heavier

NOTE

bushings and potentiometers that

Shaft

are

not

should be lubricated with a lubricant (such

Tektronix Part No. 006-2574-00) that will

the electrical characteristics.

lubrication

kit

(Tektronix Part

Do

not

No.

not

over-lubricate. A

003-0342-01)

available.

Visual Inspection

The

177

Test

Fixture

for such

tions, improperly seated transistors, damaged circuit

and

obvious. However, particular care

damaged

cates

important

prevent recurrence

defects

heat

damaged parts.

The

corrective

components

other

trouble

that

as

the

should

broken

procedure

are

found.

in

the

cause

of

the

damage.

be

inspected occasionally

connections,

for

Overheating usually indi-

instrument.

of

overheating

loose pin connec-

most

visible

must

be

It

be

defects

taken

is,

therefore,

corrected

NOTE

Connecting the device under test to the test fixture in

a manner that causes current flow

sensing resistors

Fig.

4-1

and the Kelvin Sensing Check in the Trouble-

can

burn

out

in

the Kelvin

these resistors. See

shooting section.

are

rotary

sealed

as

affect

is

boards

if

heat

kept

is

to

Avoid the use

damage the plastics used

of

chemical cleaning agents that might

in

the instrument.

Do

use chemicals that contain benzene, toluene, xylene,

acetone, or similar solvents.

REV B

JUL

1979

not

The

current sensing resistors (R630 through R636)

can be damaged

disabling circuit

if

the vertical current over-range

in

the

577

is

not

functioning

properly. Check the over-range circuit after

ment

of

a current-sense resistor.

replace-

4-1

Page 15

Maintenance-177

Service

Troubleshooting Equipment

The

the

following

177:

equipment

is

useful for troubleshooting

Fig. 4-1 .

Location

of

Kelvin

sense

resistors.

Transistors and Integrated Circuits

Periodic checks of individual transistors and integrated

circuits are

operation

Sub·standard performance

performance check

in

not

the

recommended.

equipment

or

calibration procedure.

The

as reflected

is

normally detected during a

best check

by

performance.

Recalibration

To

ensure accurate measurements, check

calibration after each

operation,

or

if

the

year . Replacement

bration of

the

instructions are given

Adjustment

procedure can

section.

also be helpful

1000 hours (approximately) of

instrument

of

components

affected circuits. Complete calibration

in

The

Performance Check/Adjustment

is

used infrequently, every

may necessitate recali-

the

in

locating troubles.

the

instrument

Performance Check/

is

their

1. Semiconductor Tester.

transistors, diodes, and FETs used

helpful. A curve tracer, such as

577 gives

checking circuit

2.

the

most complete information.

DC

Voltmeter and

voltages and an

resistances and diodes are required.

20,000

for circuit

ohms/volt

load

ing

VOM

when

Some

means of testing

in

the

Tektronix

Ohmmeter.

ohmmeter

For

can be used

if

measuring voltage

the

A voltmeter for

most applications a

allowances are made

at

ance points.

3. Test

10

MHz

vertical deflection factor

be used

Oscilloscope. An oscilloscope with a

frequency response and 10 mV/Div

is

suggested. A 10X probe shou

to

reduce circuit loading.

Troubleshooting Aids

Diagrams. Circuit diagrams are given on

the

Diagrams section .

trical value

of

the

to

identify

of

each

Diagrams section for definition of

components

Switch Wafer

the

shown on

each wafer

the

code

of

end

front

or

diagram s are coded

in

the

is

the

wafer number counting from

the

switch.

rear

of

The

component

component

are shown. See

.

Identification. Rotary switch wafers

to

switch assembly.

The

letters F and R indicate

the

wafer performs

The

For example, a wafer designated 2R indicates

the

second wafer.

Circuit Description.

describes each circuit.

tion of

diagram

the

theory of circuit operation illustrated by a block

of

each section of circuitry. Following

Diagram description

that

contains unique or complex circuitry.

The

Circuit Description, Section 3,

The

section contains a brief descrip-

is

a detailed description of each circuit

foldout

number

the

ind icate the position

number portion

the

switching function.

the

instrument

575,

576

, or

for checking

high imped-

DC

to

10 V/

Div

pages in

and elec-

the

first page

symbols used

the

mounting

whether

the

the

the

rear of

Block

is

to

Id

of

of

TROUBLESHOOTING

Introduction

The

following information

troubleshooting

sections

information

of

this manual should

to

the

177. I nformation contained

aid

in

locating circuit defects (see

is

provided

be

used with

Operating and Circuit Description sections).

4-2

to

the

facilitate

in

other

following

the

Transistor and

The

lead configurations

177 Test Fixture are shown with

on

the

schematic diagram

Voltages and Waveforms.

forms are shown

Integrated Circuit Lead Configuration.

of

the

transistors and ICs in

the

in

blue

foldout

I

mportant

on

the

circuit board

aprons.

voltages and wave-

diagrams. Portions

photos

of

the

the

circuits mounted on circuit boards are enclosed by blue

lines

or

boxes.

®

Page 16

Maintenance-177 Service

Capacitor Identification. Capacitor values of disc

capacitors are marked on the capacitor body and electrolytic

capacitor values are either marked on the capacitor body or

are

color coded

Diode

enclosed diode

a dot. For diodes using a series of

Fig.4-2.

(see

Fig_

4-2).

Color Code. The cathode end of each

is

indicated by a stripe, a series

of

stripes, the color code

""'--VELLOW

5

47 x 10

6

=

4.7

capacitor

pF

",F

color

code.

Example

INDICATES

OR

4.7 x 10-

of

Electrolytic

glass-

stripes, or

1472-5

identifies either

the

Tektronix part number or the JEDEC

number. This code follows the standard color code except

that

a pink first band indicates a Tektronix part number,

i.e.,

pink-brown-gray-green

indicates Tektronix Part

Number 152-0185-00.

Circuit Boards. A photograph of each circuit board, with

circuit components identified,

the

schematic diagram relating most directly

board. Some board photos may be placed on

the

preceding circuit diagram. Each circuit board photo

sectioned by a grid system

is

included on

to

facilitate rapid location of

the

apron of

to

the circuit

the

back of

components by component number.

COMPONENT REMOVAL

of

the

Removal

VERTICAL

AND

REPLACEMENT

CURRENT/DIV

Switch

1. Remove the right-end (viewed from the front) panel

of

the

177.

Remove

the

left-end panel). Note

facilitate re-assembly. Machine screws hold

cover and self-thread

Fig. 4-3 for location of screws.

the

bottom-cover screws (including one from

the

two types

of

screws used,

the

ing

screws hold the end panels. See

to

bottom

is

SELF

THREADING

Fig. 4-3. Location

of

cover screws.

MACHINE

SCREWS

SELF

THREADING

1472-6

REV. B,

MAR.

1975

4-3

Page 17

Maintenance-177

2.

Turn the CURRENT/DIV switch

the

two

hex socket-head set screws

4-4). Loosen the set screw and turn

Fig.

DIV

knob

to

Note

the

screw and remove the knob and

through

the

make

position

front

Service

the

panel.

other

set screw accessible.

of

the

knob skirt. Loosen the set

WARNING

to

expose one of

(A

in

the

diagram,

the

CURRENT/

insulating bushing assembly

WARNING

Do

not

replace the insulating bushing with

un-insulated bushing,

as

high

as

1900 volts. Since

including entire switch assemblies,

place components and parts with the correct parts.

as

the switch shaft is elevated to

many

I

of

the components,

are

elevated,

an

re-

Replace

shown

isolates

which the

in

this coupling with only the part number

the Mechanical Parts List. This coupling

the

knob set screw from

voltage may be as high as 1600 volts.

the

switch,

o

o

hex socket-head screws.

Pull knob and bushing assembly

away from switch.

nut

Remove hex

from view

in

and one hidden

this drawing.

o

4-4

Pull the

Unsolder

wafers.

"';.'"

all

to

.he

leads

re.J

at

the

switch

__

....6

Fig.4-4.

Removal

of

VERTICAL

CURRENT/DIV

Switch.

®

Page 18

Maintenance-177 Service

Using a 12-point box-end wrench,

loosen the

switch

remov ing the hex nuts).

Refer

removed)

two

hex nuts

to

the

circuit

to

Fig.4-5

to

faciliate switch replacement.

(8

board (hold the screw head, C,

(drawing

in the diagram)

of

or

open-end wrench,

the

leads

that

that

hold

while

must

the

be

Removal

Knob

shown in Fig. 4-3.

These

sleeve.

with

the

Unsolder the

Red

mounted

pushing the assembly

from

Repackaging

If the Tektronix instrument is

Tektronix Service Center for service or repair, attach a tag

showing: owner (with address) and the name

individual

complete

service required.

of

Indicator Lamps

Sirt

Lamps. Remove the

lamp assemblies (gray plastic)

To

remove the lamp assembly,

needle-nose pliers

sleeve.

leads

Dangerous Voltage Lamp. This lamp assembly

in

a rubber grommet

the rear

while

for

at

your firm

instrument serial nuinber and a description

and

and

remove the lamp assembly.

out

pull ing

Shipment

that

right

end

from

snap

into

grasp

pull

the assembly away

and

may be removed

through the

from

the

can be contacted. Include

front

front).

to

be shipped to a

the 177

the plastic

the assembly

from

by

panel (push

of

an

of

the

as

is

Fig. 4-5.

replace

circu

Replacement

location

the

Unsolder the leads

it

board.

of

VERTICAL

of

the

leads

that

CURRENT/OIV

must

and

pull the switch away

VERTICAL

Switch

Place the switch mounting screws

holes

and

mounting

the more

the

a

flat

to

screwd river, tu rn the screw clockw

start the

loosen the

allow the

screw-head.

nuts on the opposite side

accessible switch-assembly screw. Partially tighten

next

nut.

Attach a piece

object (stick, screwdriver blade, etc.).

the tape

nut

nut

screw

Tighten the

Complete tightening

place the lock washer

of

tape having adhesive on

and

place the

on the screw.

on the opposite

to

turn.

nut

If

with

a wrench while holding the

both

of

the board

nut

the screw cannot be turned,

side

nuts, making

be

removed

switch.

to

remove

from

and

the

CURRENT/DIV

into

the

circuit

board

and

hex

nut

on

both

sides,

to

Attach

over the screw. With a

ise

just

of

the board enough

sure

are

tight.

the

far enough

that

both

nut

to

to

Save and re-use the package

was shipped.

available, repackage the instrument as follows:

Surround the instrument with

protect the finish

corrugated cardboard

having inside dimensions

than the instrument dimensions. Cushion the instrument

tightly packing three inches

by

foam between carton and instrument, on

carton with shipping tape

The carton test strength

pounds.

If the original packaging

of

the instrument. Obtain a carton

of

in

which your instrument

is

unfit for use

polyethylene sheeting

the correct carton strength and

of

no

less than six inches more

of

dunnage

or

industrial stapler.

for

your instrument is 200

or

urethane

all sides. Seal

or

not

to

of

Resolder all

REV JAN 1983

leads

into

their

respective switch terminals.

4-5

Page 19

Page 20

Section

5-177

Service

CHECK

Introduction

This

section

adjustment

check

specifications.

circuitry

Adjustment

made,

components

For

the

instrument

proced ures.

the

instrument

to

within

or

after

may

initial inspection, using

of

the

manual

The

Check

operation

The

Adjustment

the

design capabilities.

is

generally required

a long

time

interval

affect

instrument

side covers

in

AND

contains

procedure

against

procedure

in

accuracy.

the

check

place.

ADJUSTMENT

separate check and

is

provided

the

instrument

returns

after

a repair

which normal aging

proced~re,

has

to

the

been

of

leave

Set

the

Resistance

Q

1

10 Q

100

Q

1kQ

10

kQ

100

kQ

1MQ

10 MQ

controls

PROCEDURE

Watts Accuracy

10

5

1/2

1/4

1/4

1/8

1/8

1/8

PERFORMANCE CHECK

as follows:

1/4%

Services Available

Tektronix,

calibration service

offices.

representative

Inc., provides

Contact

for

complete

at

local field service

your

local

further

information.

Tektronix

Test Equipment Required

The

following

calibration

for

equipment

operating

bridge.

impedance,

1000;

These resistors are available from

(Tektronix

resistors are included

177

Part

1.

Digital

2.

Capacitor.

tolerance,

3.

Shunt

4.

Extender

without

Number

within

Accuracy,

test

equipment,

of

the

177

Standard

is

assumed

the

Voltmeter

500

MQ.

Capacitance,

±20%.

resistors. Range 1 Q

Part Number

Cable, (to

removing

067-0721-00.

to

be

listed specifications.

(4·1/2

0.01%; voltage range,

See

footnote

067-0691-00).

in

this kit.

permit

the

577

0.01

instrument

or

equivalent,

Test

correctly

digits)

to

making

bottom

or a DC

1, Table 5-1.

pF;

working

10 MQ.

Tektronix,

Two

adjustment

panel)

repair and

centers

and field

Field Office

is

required

Fixture.

calibrated and

±5

volts;

See

the

Inc.,

200

Tektronix

All

voltage

voltage,

table.

as a kit

Q,

to

or

test

input

1%

the

577-01

MAX PEAK VOLTS

SERIES

COLLECTOR SUPPLY

V AR IABLE COL-

HORIZ

NUMBER

All Dark

Horizontal POSITION

Vertical POSITION

RESISTORS

POLARITY

LECTOR

STEP FAMILY

X10

VOL

OF

Gray

VERT

%

TS/DIV

STEPS

Buttons

MAG

or

02

6.5

.12

+DC

o

200

V,

cou nterclockw i se

and Knobs in,

SINGLE

out

Centered

Centered

COLLECTOR

except:

177

VERTICAL

RENT/DIV

Terminal

LEFT-RIGHT

CU

R-

Selector

.2A

EMITTER

BASE

TERM,

Off

1. Check Vertical Preamplifier Balance

a. Vertically and

graticule

center.

horizontally

position

GROUNDED,

STEP

GEN

the

spot

to

REV.

B, SEPT.

1974

5-1

Page 21

Performance Check-177 Service

b. Switch the

throughout its

c.

CHECK-There

division of vertical movement while switching the VERTICAL

CURRENT/DIV through its range. (It may first

to

adjust R610 as in Step 1

range.

VERTICAL

should be not more than 0.5 major

CURRENT/DIV switch

be

necessary

of

177 adjustment procedure.)

2. Check Vertical Preamplifier Common-Mode

Rejection

a.

Set the controls

VERTICAL

RENT/DIV

COLLECTOR SUPPLY

POLARITY

Vertical POSITION

Horizontal POSITION

LEFT-RIGHT

b. Connect a patch cord between the

terminal

the plug in the bottom

1/4-inch ring terminal at one

as

connection

the

(front

E-Z

HOOK TIP

to

TP630.

CUR·

panel)

as

follows:

10nA

AC

centered

centered

Off

and

TP630. To

panel

of

end

of

C630. A hook

1,

provides a convenient

117

GROUND

reach

TP630, remove

the 117. TP630

tip,

means

is

such

of

3.

Check Vertical Current Per Division

a.

Push

Xl0

VERT MAG in. Reset the VERTICAL

CURRENT/DIV

VARIABLE COLLECTOR %

COLLECTOR SUPPLY CIRCUIT BREAKER

b.

Remove the C to E patch cord.

c.

Reset the controls as follows:

STEP/OFFSET AMPL

OFFSET MULT

STEP

SINGLE

OFFSET

ZERO

AID

VERTICAL CURRENT/DIV

LEFT-RIGHT

d.

a

Connect the DVM between E

set

of

terminals. Connect a

in Table 5-1,

terminals, right

to 2A, switch LEFT-RIGHT

FAMILY

10

second

column) between the

side.

to

100,

.1V/Step

0.000

press

out

in

2 nA

Off

and

Mil,

1/4%, resistor

to

RIGHT, turn

and

wait for the

to

open.

B on the right-side

(as

shown

117

Band

C

c.

Connect a patch cord between the

terminals, right

d.

Switch the LEFT-RIGHT switch

e.

Reset

f.

CHECK-Vertical deflection should

major divisions.

g.

Return the

the LEFT-RIGHT switch

h. Disconnect the ground

patch cord between C

side.

the

VARIABLE

VARIABLE

COLLECTOR %

COLLECTOR %

to

Off.

lead

and

E term inals.

WARNING

117 C and

to

RIGHT.

to

be

less

from TP630.

I

100.

than four

to

O.

Switch

Leave

the

E

e.

Switch the LEFT-RIGHT switch

DVM reading.

f.

Vertically position the spot

NOTE

The DISPLA Y

be

in the

FIL

TER NORM button

out

position to reduce the display noise

high sensitivities.

g.

With the OFFSET

bottom graticule line.

CHECK-The

h.

the DVM reading

shown in Table 5-1, columns 3

i. Switch the

STEP/OFFSET AMPL

MUL

difference

is

step

e,

VERTICAL

to

the next settings

to

RIGHT. Note the

to

the eighth graticule line.

may

T,

position the spot

in

DVM reading, relative

should

and

be

within

4.

CURRENT/DIV

in

the table.

have to

at

to

the

the limits

and

to

Replace the plug in the

bottom

panel

avoid contact with potentially lethal voltage.

5-2

of

the 177 to

j.

Press

reading.

the OFFSET ZERO button in

and

note the DVM

REV JAN 1983

Page 22

Performance

Check-177

Service

k.

Position the spot to the eighth graticule line.

I.

Release

OFFSET

the OFFSET ZERO button. With the

MUTL,

position the spot

to

line.

m.

be

within

CHECK-The

the limits shown in Table 5-1.

difference in the DVM reading should

n. Repeat the above procedure

VERTICAL

CURRENT/DIV

steps,

resistance specified in the table.

VERTICAL

CURRENT/

DIV

2 nA

5 nA

10

nA

20 nA

TABLE

STEP/ Resistor

OFFSET

AMPL

.1

V

.2V

.5V

V

1

5-1

(1/4%)

CoB

10 MQ

the bottom graticule

for

each

of

the

using

the value

of

Difference

in

DVM

Within

Reading ±3%,

B-E

±1nA

0.3200 V 0.0296 V

0.8000 V 0.0400 V

0.8800 V 0.0375 V

1.760 V

0.0638 V

VERTICAL

CURRENT/

DIV

.1

).LA

.2).LA

.5).LA

1

).LA

2).LA

5).LA

10).LA 10).LA

20).LA

50).LA 50).LA

.1

mA

.2

mA

.5

mA

1

mA

2mA

5

mA

10

mA

20mA

50

mA

.1

A

.2A

the

Pull

steps.

Xl0

TABLE

5-2

STEP/ Resistor in

OFFSET

AMPL

.1

).LA

.2

).LA

(1/4%)

CoB CoB

1

MQI

.5).LA

l).LA 100

kQ

I

2).LA

5).LA

10

kQ

20).LA

1

.1

.2

mA

mA

kQ

.5mA

1

mA

100 Q

2

mA

5mA

10

10mA

Q

20mA

50mA

.1

A

lQ3

.2A

VERT

MAG

and

proceed

Difference

DVM

Within

Reading ±3%,

±1nA

0.800 V 0.024 V

1.600 V 0.048 V

4.000 V 0.120 V

0.800 V 0.024 V

1.600 V 0.048 V

4.000 V 0.120 V

0.800 V 0.024 V

1.600 V 0.048 V

4.000 V 0.120 V

0.800 V 0.024 V

1.600 V 0.048 V

4.000 V 0.120 V

0.800 V

0.024 V

1.600 V 0.048 V

4.000 V 0.120 V

0.800 V 0.024 V

1.600 V

4.000 V

0.800 V

1.600 V

as

0.048 V

0.120 V

0.024 V

0.048 V

in the previous

50

nA

o. Switch the

2V

LEFT-RIGHT

4.400 V 0.1430 V

switch

to

Off.

p. Reconnect the DVM between Band C (or C SENSE).

q.

Proceed

as

in

steps

3 e through 3 h,

using

5-2.

r. Switch the

s.

Disconnect the DVM

llf

a DVM having an

the

formula:

where

V2 is

tile

100

meter

the

the

table.

Mil.

Rm

is

resistor in

less

than

LEFT-RIGHT

input

impedance

meter

reading,

input

impedance,

Do

not

switch

and

resistor.

of

V 1

is

and

use

a DVM having an

500

the

Rs

to

Off.

Mil

or

less is used, use

reading in

is

the

current

input

Table

impedance

Table

5-2,

sensing

50

.1

.2

t.

mAl

A

A

Push

50mA

.1

A

.2A

to

reset the COLLECTOR SUPPLY

10 Q

BREAKER.

u.

If

DISPLAY

FILTER

in.

4. Check Kelvin Sensing

a.

Set the controls

MAX

PEAK VOLTS

SERIES RESISTORS

Xl0

HORIZ MAG

HORIZ

VOL

Vertical POSITION

Xl0

VERT

VERTICAL

RENT/DIV

LEFT-RIGHT

TS/DIV

MAG

CUR-

as

follows:

1

1

was

Q3

Q3

4.000 V

0.800 V

1.600 V

used,

push

25

1.9

pull

5

mV,

COLLECTOR

centered

in

lA

Off

CIRCUIT

NORM

±4%

0.160V

0.032 V

0.064 V

button

2Magnification

the

.5A,

1A,

REV JAN 1983

and

occurs

2A

only

in

ranges in

the

the

577.

177.

These

measurements

check

3Measure

of

lead

and

near

contact

the

body

of

resistance.

low

value

resistors

to

reduce

the

effects

5-3

Page 23

Performance Check/

Adjustment-177

Service

b.

Place

an

013-0111-00 Diode Adapter in the

terminals, right side.

Place

a short, clean, piece

of

14

gauge

solid copper wire (preferrably tinned) in the adapter.

c.

Switch the

d.

Increase the

display eight divisions

e.

Horizontally position the bottom

LEFT-RIGHT

VARIABLE

of

vertical deflection.

switch

to

RIGHT.

COLLECTOR % control to

of

the trace

graticule center line.

f.

CHECK-The

horizontally, in either direction, not more than

top

of

the display should be displaced

15'mV

(three major divisions) from the graticule center line.

Fig.

5-1

for

an

example

l R

of

a typical display.

177

to

See

b. Increase

VARIABLE

eight-division vertical display.

c.

Horizontally position the

graticule center.

d.

CHECK-The

from

graticule center

If

this requirement cannot

incorrect adjustment

top

of

not

more than ±7

of

Vertical GAIN

ADJUSTMENT PROCEDURE

Initial Control Settings

MAX

PEAK VOLTS

SERIES RESISTORS

VARIABLE

LECTOR

HORIZ

Horizontal POSITION

HORIZ

X10

Vertical

X10VERT

VERTICAL

RENT/DIV

LEFT-RIGHT

COL-

%

VOL

TS/DIV

MAG

POSITION

MAG

CUR-

COLLECTOR %

bottom

to

of

the trace

produce

an

to

the display should be displaced

mV

(1.4 divisions).

be

met, the

and

cause

could

CM

R R controls.

be

6.5

.12

o

200

V,

COLLECTOR

centered

in

centered

in

.1

A

Off

Fig. 5-1.

damaged Kelvin

Typical

display

g.

If

the above requirement

sensing

for

Kelvin

resistors.

sensing check.

is

not met, the

See

NOTE under Visual I nspection heading

5. Check Error Due

to

CMRR and Gain Misadjust-

ment

a.

Set the controls

VARIABLE

LECTOR

MAX

PEAK VOLTS

SERIES RESISTORS

Horizontal POSITION

VERTICAL

RENT/DIV

COL-

%

CU

R-

as

follows:

o

6.5

120

centered

.5mA

1472-9

cause

may

be

Maintenance section

and

Fig. 4-1.

1.

ADJUST Vertical Preamplifier Balance

a.

Place

the curve tracer on its right

b.

ADJUST

-R610,

Atten Bal,

movement while switching the

DIV

from

.1

through the

A/DIV

access

through 50

hole in the bottom cover, shown in

side.

for

VERTICAL

nA/DIV

Fig. 5-2).

2. Adjust Vertical Preamplifier Gain

a.

Reset

the controls

MAX

PEAK VOLTS

SERIES RESISTORS

COLLECTOR

POLARITY

STEP/OFFSET AMPL

STEP

FAMILY

SINGLE

STEP/OFFSET

NORM

OFFSET

ZERO

AID

VERTICAL

CU

RENT/DIV

LEFT-RIGHT

as

SUPPLY

POLARITY

R-

follows:

400

8M

+

.05 VOLTS/Steps

press

in

out

in

50 nA

Off

no vertical spot

CURRENT/

(adjust R610

5-4

REV.

B,

MAR.

1975

Page 24

Adjustment-177

Service

TP630

Fig_ 5-2.

ATTEN

(Test

C630

Location

R610

Point)

of

controls,

BAL---..o

i

/

-

177

WARNING

-I

bottom

t @

panel.

I

R617

CMR J

~

/

R615

VERT

GAIN

1472

-10

J

Fig_

switch.

5-3.

Location

of

white

-green

wire

on

MAX

PEAK

VOLTS

Lethal voltages

may

be present on the

MAX

VOL TS switch and Collector Sweep circuit board in

the

577

any

time the

control

the

in the 100

177

is

not

only

at

when the

V,

400

Interlock Defeat

b_ Connect the

panel

to

the

wh ite-green

PEAK

between the B

MAX

the

of

connector P129

board (measure

on

VOLTS

PEAK

c. Patch the B terminal

LEFT-RIGHT

d. Set the

+0.400

e. Move the

the

MAX

VOLTS

volt,

PEAK

switch

term

switch

OFFSET

±0.4 mV.

DVM

(see

the

VARIABLE

0_ Lethal voltages

MAX

V,

or

1600 V positions, with the

button

pressed in.

GROUND

inal and the

switch_

lead

Fig. 5-4) on

voltage between the white-green

VOLTS

terminal

wire

on

(See

Fig_

to

the C terminal,

to

RIGHT

MUL T to

from

switch

COLLECTOR %

may

be

PEAK

VOL

on

the

rear wafer

5-3) . Connect

wh

ite-green w ire

_

produce a

B terminal

the

Collector

and

P129-4j.

present in

TS switch

the 177

on

right

DVM

to

terminal 4

PEAK

is

front

the

MAX

the

DVM

on

side. Set

reading

Supply

the

of

wire

Fig. 5-

4.

g. Remove

to

the

white

Location

the

-green wire.

of

P129,

DVM

Terminal 4.

and

the

patch cord

from

GROUND

f.

cover,

REV

ADJUST

for a DVM

APR

1982

-R615,

reading

Vert

gain, through

of

4.000

volts,

±20

the

mV.

bottom

h. Remove

the

patch cord

from C to

B.

5-5

Page 25

Adjustment-177

Service

3. Adjust Common-Mode Rejection

a.

Set the controls

MAX

PEAK

SERIES RESISTORS

VARIABLE

LECTOR

COLLECTOR SUPPLY

POLARITY

Xl0VERT

VERTICAL

RENT/DIV

LEFT-RIGHT

b.

Place

C terminal, right side.

c.

Connect a cord from front-panel GROUND

TP630.

cover

of

end

of

provides a convenient

d.

Switch LEFT-RIGHT

e.

ADJUST

panel

for

MAG

a patch cord from the front-panel G ROUND

To

reach

the 177. TP630

C630. A hook

minimum vertical deflection.

as

follows:

VOLTS

6.5

.12

COL-

%

CUR-

100

AC

pulled

10

nA

Off

TP630, remove the plug in the

is

a 1/4-inch ring term inal

tip,

such

as

the E-Z

means

of

connection

to

RIGHT.

-R617,

CM

R,

through the 177 bottom

HOOK

to

TP630.

to

to

bottom

at

one

TIP 1,

f.

INTERACTION-If

and

2.

g.

Set the

the patch cords

the 177 Test Fixture.

VARIABLE

and

R617

is

adjusted, repeat steps 1

COLLECTOR %

replace the plug in the

WARNING

I

to 0 and

bottom

Always replace the plug in TP630 access hole to avoid

contact with potentially lethal voltages.

4. Adjust C630

a.

Set the controls

X10

HORIZ

HORIZ

VERTICAL

LEFT-RIGHT

b. ADJUST

(keep the loop

SATION control while

TRACE

switch the

mine whether the trace

lines.

VOL

RENT/DIV

ROTATION control

VERTICAL

MAG

TS/DIV

CUR-

-C630

closed

as

follows:

pull

5

mV,

COLLECTOR

2

nA

Off

for

no

trace

tilt

with

the loop

with

the LOOPING COMPEN-

adjusting C630).

is

set

CURRENT/DIV

is

parallel to the horizontal graticule

Be

properly.

to

2 A and deter-

sure

If

remove

panel

closed

that the

in

doubt,

of

5-6

®

Page 26

REPLACEABLE

Section

6-177

Service

Replacement

or

representative.

Changes

components

improvements

ordering

type

Tektronix,

number.

parts,

or

number, serial

If

a part

Inc. Field

Change

ELECTRICAL

PARTS

PARTS ORDERING INFORMATION

parts are available

to

Tektronix

as

they

developed in

to

include

you

have ordered has been replaced

information,

become

number,

Office

instruments

the

or

if any,

from

or

th rough

are sometimes made

available, and to give you

our

engineering

following

and

modification

representative

is

located at the rear

department. It

information

will

contact

in

number

with

your

your

a new

you

of

SPECIAL NOTES AND SYMBOLS

XOOO

OOX

Part first added at this serial

Part removed after this serial

local

Tektronix,

to

accommodate

the

benefit

is

therefore

order: Part

if applicable.

or

improved

concerning

this manual.

number

number

Inc. Field

of

the

important,

number,

part,

any

change

Office

improved

latest

circuit

when

instrument

your

in

local

part

ITEM NAME

In the Parts List, an Item Name is separated from the

of

space

Because

further

utilized

limitations,

Item Name

where possible.

identification,

an Item

Name

the U.S. Federal

may sometimes

ABBREVIATIONS

ACTR

ASSY ASSEMBLY

CAP

CER

CKT

COMP

CONN

ELCTLT

ELEC

INCAND

LED

NONWIR

ACTUATOR

CAPACITOR

CERAMIC

CIRCUIT

COMPOSITION

CONNECTOR

ELECTROL

ELECTRICAL

INCANDESCENT

LIGHT

NON

YTIC

EMITT~NG

WIREWOUND

DIODE

description

appear

Cataloging

PLSTC

QTZ

RECP

RES

RF

SEL

SEMICOND

SENS SENSITIVE

VAR

WW

XFMR

XTAL

Handbook

by a colon

as

incomplete.

PLASTIC

QUARTZ

RECEPTACLE

RESISTOR

RADIO

FREQUENCY

SELECTED

SEMICONDUCTOR

VARIABLE

WIREWOUND

TRANSFORMER

CRYSTAL

(:).

For

H6-1 can be

REV

C,

FEB

1980

6-1

Page 27

Replaceable Electrical

Parts-177

Service

Mfr. Code

01121

01295

03508

04713

08806

24546

32997

52769

55292

56289

71313

71450

72136

72982

75042

76854

80009

81073

91637

CROSS

Manufacturer

ALLEN-BRADLEY COMPANY

TEXAS INSTRUMENTS, INC., SEMICONDUCTOR

GROUP

GENERAL ELECTRIC COMPANY, SEMI-CONDUCTOR

PRODUCTS

MOTOROLA, INC., SEMICONDUCTOR PROD. DIV. 5005 E MCDOWELL RD,PO BOX 20923

GENERAL ELECTRIC CO., MINIATURE

LAMP PRODUCTS DEPARTMENT NELA

CORNING GLASS WORKS, ELECTRONIC

COMPONENTS DIVISION 550

BOURNS, INC., TRIM POT PRODUCTS DIV.

SPRAGUE GOODMAN

LEDCO DIV., WILBRECHT ELECTRONICS, INC.

SPRAGUE ELECTRIC

CARDWELL CONDENSER CORP.

CTS CORP.

ELECTRO MOTIVE CORPORATION, SUB

INTERNATIONAL ELECTRONICS CORPORATION

ERIE TECHNOLOGICAL PRODUCTS, INC.

TRW ELECTRONIC COMPONENTS, IRC FIXED

RESISTORS, PHILADELPHIA DIVISION

OAK INDUSTRIES, INC., SWITCH DIV.

TEKTRONIX, INC.

GRAYHILL, INC.

DALE ELECTRONICS, INC.

DEPARTMENT ELECTRONICS

ELEC., INC.

CO.

INDEX-MFR.

OF

CODE NUMBER TO MANUFACTURER

Address

1201

2ND STREET SOUTH

POBOX

EXPRESSWAY

1200 COLUMBIA

134 FULTON

240 EAST

87

80

905

LAUTER

644

401

S.

POBOX

561

P.

5012,13500 N CENTRAL

PARK

PARK

HIGH

STREET

AVE.

AVENUE

PLATO

AVE,

500

BLVD.

HIGHWAY

POBOX

ST.

AVE.,

MARSHALL ST.

E.

MONTAUK

N.

WEST BLVD

W.

12TH ST.

N.

BROAD

MAIN ST.

HILLGROVE

O.

BOX 609

7600

PO

BOX 373

City, State, Zip

MILWAUKEE,

DALLAS,

SYRACUSE,

PHOENIX,

CLEVELAND,

BRADFORD,

RIVERSIDE, CA 92507

GARDEN CITY

PAUL,

ST.

NORTH ADAMS,

LINDENHURST,

ELKHART,

FLORENCE,

ERIE,

PHILADELPHIA,

CRYSTAL

BEAVERTON,

LA GRANGE, IL 60525

COLUMBUS,

WI

TX

75222

NY

AZ 85036

OH

PA

MN

IN

46514

SC

PA

16512

LAKE, IL 60014

OR

NE

53204

13201

44112

16701

PARK,

55107

MA 01247

NY

29501

PA

19108

97077

68601

NY 11040

11757

6-2

REV JAN 1983

Page 28

Replaceable Electrical

Parts-177

Service

Tektronix Serial/Model No.

Ckt

No. Part

Al

Al

A2 670-2505-00

C600

C601

C602

C629

C630

C630 281-0118-00 B054650

C632 281-0197-01

CR601 152-0324-01

CR602 152-0324-01 SEMICOND DEVICE:SILlCON,50V,50PA

CR611 152-0324-01

CR614 152-0324-01

CR651 152-0141-02 SEMICOND DEVICE:SILlCON,30V,150MA

CR652

DS650 150-0133-00

DS651

OS652 150-0048-00

0604A,B

0626

Q628 151-0188-00

R601

R602 304-0391-00

R604

No.

670-2504-00

670-2504-01 B030600

283-0128-00

290-0525-00

290-0525-00

283-0087 -00

281-0162-00

152-0141-02 SEMICOND DEVICE:SILlCON,30V,150MA

1 50-0048-00

151-1049-00 TRANSISTOR:SILlCON,JFE,N -CHANNEL,DUAL 80009 151-1049-00

151-0190-01 TRANSISTOR:SILlCON,NPN 80009

303-0222-00

31

5-051

Elf

B010l00

B010l00

B010l00

0-00

Dscont Name & Description

B030599 CKT BOARD ASSY:PREAMPLIFIER 80009

B054649

B039999

CKT BOARD ASSY:PREAMPLIFIER 80009 670-2504-01

CKT BOARD ASSY:INTERFACE 80009 670-2505-00

CAP.,FXD,CER DI:l00PF,5%,500V

CAP.,FXD,ELCTLT:4.7UF,20%,50V 56289 196D475X0050KAl

CAP.,FXD,ELCTLT:4.7UF,20%,50V 56289 196D475X0050KA 1

CAP.,FXD,CER DI:300PF,10%,1000V

CAP.,VAR,MICA D:8-60PF,500V

CAP.,VAR,MICA D:8-90PF,175V

CAP.,VAR,AIR 01:7.9-41

SEMICOND DEVICE:SILlCON,50V,50PA

SEMICOND DEVICE:SILlCON,50V,50PA

SEMICOND DEVICE:SILlCON,50V,50PA

LAMP,CARTRIDGE:14V,80MA,RED DOME LENS

LAMP,INCAND:5V,60MA

LAMP,INCAND:5V,60MA 08806

TRANSISTOR:SILlCON,PNP 04713 SPS6868K

RES.,FXD,CMPSN:2.2K

RES.,FXD,CMPSN:390

RES.,FXD,CMPSN:51 OHM,5%,0.25W 01121 CB5105

PF,

10%, 1800V 71313 148-0081-011

OHM,5%,lW

OHM,10%,lW

Mfr

Code

72982 871-536T2Hl

56289 403637

72136 T50417 -9

52769 GSM231

AT

20V,GE 03508 DE103

AT

20V,GE 03508

AT

20V,GE

AT

20V,GE 03508 DE103

03508

01295

01295

55292 70106-02

08806 683

01121

01121

Mfr Part Number

670-2504-00

01

J

DE103

DE103

1 N4152R

1 N4152R

683

151-0190-01

GB2225

GB3911

R606 321-0306-00

R610

R611

R612

R613 321-0385-00

R614 321-0481-00

R615 311-1302-00 RES.,VAR,NONWIR:l00K OHM,30%,0.25W

R616 321-0481-00

R617 311-1302-00

R617 311-1235-00 B030600

R618 321-0637-00 RES.,FXD,FILM:9.9K OHM,0.5%,0.125W 24546 NC55C9901D

R619 321-0197-02 RES.,FXD,FILM:l.l K OHM,0.5%,0.125W 91637

R621

R622 315-0152-00

R623

R624

R625

R626

R627

R628 321-0289-01 RES.,FXD,FILM: 10K OHM,0.5%,0.125W 91637 MFF1816Gl

R629

R630 307 -0358-00

R631

R632

311-

11

20-00 RES.,VAR,NONWIR: 1 00 OHM,30%,0.25W 71450 201-YA5531

321-0306-00

321-0385-00

B010l00

321-0222-07 RES.,FXD,FILM:2K OHM,O.l %,0.125W 91637 M FF1816C20000B

315-0153-00

315-0361-00 B030600

315-0361-00 B030600

315-0153-00

321-0289-01 RES.,FXD,FILM:l0K OHM,0.5%,0.125W 91637 MFF1816Gl

321-0929-07

308-0696-00

323-0729-01

B030600

B030600

8030599 RES.,VAR,NONWIR:l00K OHM,30%,0.25W 71450 201-YA5549

RES.,FXD,FILM:15K OHM,1%,0.125W

RES.,FXD,FILM:

RES.,FXD,FILM:

RES.,FXD,FILM:l00K

RES.,FXD,FILM:l

RES.,FXD,FILM:1M OHM,1%,0.125W

RES.,VAR,NONWIR:l00K OHM,20%,0.50W

RES.,FXD,CMPSN:l.5K OHM,5%,0.25W 01121

RES.,FXD,CMPSN:15K OHM,5%,0.25W 01121 CB1535

RES.,FXD,CMPSN:360 OHM,5%,0.25W

RES.,FXD,CMPSN:360 OHM,5%,0.25W 01121

RES.,FXD,CMPSN:15K OHM,5%,0.25W 01121 CB1535

RES.,FXD,FILM:2.5K OHM,O.l 0%,0.125W

RES.,FXD,FILM:

RES.,FXD,WW:90 OHM,0.5%,3W

RES.,FXD,FILM:900 OHM,0.5%,0.50W 75042

15K OHM,1%,0.125W 91637 MFF1816G15001 F

lOOK

OHM,l

%,0.125W 91637 MFF1816Gl0002F

OHM,l

M

1 0 OHM,O.l W

%,0.125W 91637 MFF1816Gl0002F

OHM,l

%,0.125W

91637 MFF1816G15001 F

24546

71450

24546

32997

01121 CB3615

91637 MFF1816C25000B

80009 307 -0358-00

91637 RS2B-B90ROOD

NA4Dl004F

201-YA5549

NA4Dl004F

T04-1

3386F-

MFF1816Dl1000D

CB1525

CB3615

CECTO-9000D

04

0001

0001

0

0

REV JAN 1983

6-:

Page 29

Replaceable Electrical

Parts-177

Service

Ckt No.

R633

R634

R635

R636 323-0799-01

R640

R641

R643

R645 301-0220-00

R646

R647

R648

R649

R650 311-1368-00

R651

R651

R651

R651

R651

R651

R659

R660

R661

R662

R663

R664

R665

S626

S626

S628

Part No.

323-0730-01 RES.,FXD,FILM:9K OHM,O.5%,O.50W 75042

323-0798-01 RES.,FXD,FILM:90K OHM,O.5%,O.50W

323-0611-01 RES.,FXD,FILM:900K OHM,O.5%,O.50W

301-0332-00

301-0220-00 RES.,FXD,CMPSN:220HM,5%,O.50W

301-0220-00

315-0472-00

301-0220-00

301-0220-00 RES.,FXD,CMPSN:220HM,5%,O.50W

315-0472-00

315-0103-00 RES.,FXD,CMPSN:l0K OHM,5%,O.25W

315-0822-00

301-0226-00

321-0097 -00

323-0729-01

323-0730-01

323-0798-01

323-0611-01

323-0799-01

260-0247 -00

Tektronix Serial/Model No. Mfr

Eft Dscont

& Description

Name

RES.,FXD,FILM:9M OHM,O.5%,O.50W 91637 HFF129G90003D

RES.,FXD,CMPSN:3.3K OHM,5%,O.50W

RES.,FXD,CMPSN:220HM,5%,O.50W

RES.,FXD,CMPSN:22 OHM,5%,O.50W

RES.,FXD,CMPSN:4.7K OHM,5%,O.25W

RES.,FXD,CMPSN:220HM,5%,O.50W

RES.,FXD,CMPSN:4.7K OHM,5%,O.25W

RES.,VAR,NONWIR:5K

(USED

IN

B010107,

B010ll~

B010126, BOl 0127 AND BOl 0128 ONLY)

RES.,FXD,CMPSN:8.2K OHM,5%,O.25W

RES.,FXD,CMPSN:22M OHM,5%,0.50W

RES.,FXD,FILM:l00 OHM,l%,0.125W

RES.,FXD,FILM:900 OHM,O.5%,0.50W 75042

RES.,FXD,FILM:9K OHM,0.5%,0.50W

RES.,FXD,FILM:90K OHM,0.5%,0.50W

RES.,FXD,FILM:900K OHM,O.5%,0.50W

RES.,FXD,FILM:9M OHM,0.5%,0.50W

(SEE

ASSEMBLY,

SWITCH,PUSH:SPST,lA,115VAC

SIN'S

B010l09,

B010117, B010119,

MECHANICAL PARTS LIST

FIGURE 1-47 THROUGH 1-52.)

OHM,20%,lW

B010l02,

B010ll0,

B010l03,

B010lll,

B01012~

FOR

B010l04,

B010112

B010121

REPLACEMENT

Code Mfr

91637 MFF1226G90001D

91637 MFF1226G90002D

01121

01121

01121

01121

01121

01121

01121

01121

01121

01121

01121

01121

91637

75042

91637 MFF1226G90001 D

91637

91637 HFF129G90003D

81073 30YY1009

Part Number

CECTO-9001

EB3325

EB2205

EB2205

EB2205

CB4725

EB2205

EB2205

CB4725

73A 1 G040L502M

CB1035

CB8225

EB2265

MFF1816Gl00ROF

CECTO-9000D

CECTO-9001

FF1226G90002D

M

D

D

S630

S640

S650 260-1491-00

U616

U624

260-1459-00

260-1458-00

156-0200-00

156-0200-00

SWITCH,ROTARY:VERTICAL SENSITIVITY

SWITCH,ROTARY:UNCTION

SWITCH,LEVER:4PDT,CENTER OFF

MICROCIRCUIT,LI:OPERATIONAL AMPLIFIER

MICROCIRCUIT,LI:OPERATIONAL AMPLIFIER

SELECTOR

76854

76854 5-28495-211

80009 260-1491-00

04713

04713

5-33152-826

MC1456Pl

MC1456Pl

6-4

REV JAN 1983

Page 30

Section 7

-171

Service

DIAGRAMS

AND

Symbols and Reference Designators

Electrical

Symbols

Logic

a

nd

The

compo

used

symbology

may

differ

following

nents shown

on

the

diagrams are

is

based

from

the

special symbols are

on

on

MI L-STD-806B in

manufacturer's data.

the

diagrams are in

Capacitors

Resistors = Ohms

based

used

on

10

= Values one

on

USA

the

diagrams:

CIRCUIT

the

following

or

Values

less

than one are

(n)

Standard

terms

External

External

Clockwise

Refer

Refer

Y32

of

positive logic.

Screwdriver a

control

control

to

diagram

to

waveform

BOARD

units

unless

greater are in picofarads

in

.2-1967.

Logic symbols

djustment

or

connector

rotation

number

number

ILLUSTRATIONS

noted

microfarads (I1F).

.

.

in

direction

indicated in

indicated in hexagon.

otherwise:

(pF).

depict

of

arrow.

diamond.

the

logic

funct

ion

performed

Voltages

cause

Typical

VARIABLE

COLLECTOR

SERIES RESISTORS

MAX

STEP/

HORIZ

All

All

INTENSITY

FOCUS

BRIGHTNESS

STORE

Terminal

VERTICAL

and waveforms (shown in blue)

of

differing

DC voltage measurements were obtained using

COLLECTOR

PEAK

VOLTS

OFF

AMPL

VOL

TS/DIV

Dark

Gray

STEP

FAMILY

Light

Gray

button

Selector

CURRENT/DIV

component

SUPPLY

Buttons

Buttons

POLARITY

and Knobs

VOLTAGE

tolerances

%

in

AND

in

or

internal

except:

WAVEFORM TEST CONDITIONS

577-177-01

the diagrams are

calibration_

the

571-D1

or

not

absolute and

following

or

D2

02

may

settings:

o

AC

.12

6.5

1

VOLT

100

V,

COLLECTOR

SINGLE

out