Page 1

Instruction Manual

1720/1721

Vectorscope (S/N B060000 & Above)

070-5846-07

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright E Tektronix, Inc., 1986, 1990, 1993, 1995. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending.

Information in this publication supersedes that in all previously published material. Specifications and price change privileges reserved. The following are

registered trademarks: TEKTRONIX and TEK.

For product related information, phone: 800-TEKWIDE (800-835-9433), ext.

TV.

For further information, contact: Tektronix, Inc., Corporate Offices, P.O. Box

1000, Wilsonville, OR 97070--1000, U.S.A. Phone: (503) 627--7111; TLX:

192825; TWX: (910) 467--8708; Cable: TEKWSGT.

Page 3

WARRANTY

Tektronix warrants that this product, that it m anufactures and sells, will be free from defects in materials

and workmanshipfor a period of three (3) years from the date of shipment. Ifany such product proves defec-

tive during this warranty period, Tektronix, at its option, either will repair the defective produc t without

charge for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expi-

ration of the warranty period and make suitable arrangements for the performance of service. Customer

shall be responsible for packaging and shipping the defective product to the service center designated by

Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if

the shipment is to a location within t he country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products re-

turned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inade-

quate maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to

repair damage resulting from attempts by personnel other than Tektronix representative s to install, repair

or service the product; b) to repair damage resulting from improper use or connection to incompatible

equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or d) to

service a product that has been modified or integrate d with other products when the effect of such modifica-

tion or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU

OF ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS W ARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT

BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Table of Contents i.......................................................

General Safety Summary viii................................................

Preface x...............................................................

Section 1 Introduction and Specification 1--1....................................

Accessories 1--2............................................................

Standard Accessories 1--2.................................................

Optional Accessories 1 --2.................................................

Options 1--2...............................................................

CRT Options 1--2........................................................

Power Cord Options 1--2..................................................

Safety Information 1--3......................................................

Specifications 1--3..........................................................

Section 2 Operating Instructions 2--1...........................................

Front-Panel Controls and Indicators 2--1.........................................

INPUT 2--2............................................................

GAIN 2--2.............................................................

PHASE 2--3............................................................

DISPLAY 2--3..........................................................

MISCELLANEOUS 2--3..................................................

Rear-Panel Connectors 2--4...................................................

BNC Connectors 2--4....................................................

Subminiature D-Type Connectors 2--5.......................................

Power Input 2--6........................................................

Miscellaneous 2--6.......................................................

Using the 1720/1721 in Auxiliary Mode 2--6.....................................

INPUT Switching 2--7....................................................

REF Switching 2--7......................................................

LINE SELECT 2--7......................................................

STORE 2--7............................................................

RECALL 2-- 7..........................................................

Measurement Applications 2--14................................................

Color Measurements 2--14.................................................

Functional Use of the Vector Graticule 2--18......................................

Measurement of Color Bars 2--18............................................

Differential Gain and Phase Measurements 2--20...............................

X Y Measurements 2--22......................................................

Making Stereo Audio Phase Measurements 2--22...............................

Looking at Incidental Carrier Phase Modulation 2--23...........................

Service Safety Summary s--1.................................................

1720/1721

Section 3 Installation 3--1.....................................................

Packaging 3--1..........................................................

Electrical Installation 3--1....................................................

i

Page 6

Table of Contents

Section 4 Theory of Operation 4--1.............................................

Power Source 3--1.......................................................

Mains Frequency and Voltage Ranges 3--1....................................

Operating Options 3--1...................................................

X Y INPUT Connector 3--1...............................................

Auxiliary Connector 3--3..................................................

Mechanical Installation 3--4...................................................

Cabinetizing 3 --4........................................................

Securing the Instrument in its Cabinet 3--6...................................

Rack Mounting 3--7......................................................

Custom Installation 3--9..................................................

Overview 4--1..............................................................

Block Diagram 4--2.........................................................

Video Input 4--2.........................................................

Luminance Processing 4--2................................................

Microprocessor 4-- 2......................................................

Gain Cell 4-- 3..........................................................

Chrominance Processing 4--3..............................................

Demodulators 4--4.......................................................

Output Amplifiers 4 --4...................................................

CRT Blanking 4--4......................................................

Circuit Descriptions 4--5.....................................................

DIAGRAM 1 INPUT AND DEFLECTION AMPLIFIERS 4--5.......................

Video Input Amplifiers 4--5...............................................

Gain Cell 4-- 6..........................................................

DIAGRAM 2 SUBCARRIER REGENERATOR 4--6...............................

Reference Switch 4--7....................................................

Luminance and Chrominance Amplifiers 4--8.................................

Sync Separator 4--8......................................................

Bowes Oscillator 4--8....................................................

Back Porch Sample 4 --8..................................................

Loop Phase Detector and Amplifier 4--8.....................................

Quadrature Phase Detector and Amplifier 4--9.................................

Burst Clamp 4--9........................................................

Lock Detector and Bandwidth Switch 4--9....................................

Error Amplifier 4--9.....................................................

PAL Phasing 4--10........................................................

VCXO 4--10.............................................................

DIAGRAM 3 DEMODULATOR 4--11...........................................

V-Axis Switcher 4-- 11.....................................................

Chrominance Demodulators 4--12...........................................

Sync Tip Chrominance Clamp 4--12..........................................

Demodulator Output Filters and Amplifiers 4--12...............................

Vector Center Dot Position Clamp 4--12......................................

DIAGRAM 4 DEFLECTION AMPLIFIER 4--13...................................

XY Input Amps 4--14.....................................................

Deflection Amplifiers 4--14................................................

Center Dot Comparators 4--14..............................................

CRT Blanking 4--14......................................................

DIAGRAM 5 MICROPROCESSOR 4--15........................................

ii

1720/1721

Page 7

Microprocessor 4--15......................................................

DIAGRAM 6 CONTROL CIRCUIT 4--17........................................

Z-Axis Control 4--18......................................................

Trace Rotation 4--18......................................................

Graticule Illumination 4--18................................................

Post Regulators 4--18.....................................................

DIAGRAM 7 LOW VOLTAGE POWER SUPPLY 4--19.............................

Line Rectifier and Filter 4--19..............................................

Pulse Width Modulator 4--20...............................................

Output Filters 4--21.......................................................

Error Amplifier 4--21.....................................................

Feedback Transformer Driver and Peak Detector 4--21...........................

Output HV Shutdown 4--21.................................................

DIAGRAM 8 HIGH VOLT AGE POWER SUPPLY 4--22............................

HV Osc and Error Amp 4--22...............................................

Power Supply Outputs 4--23................................................

Focus Amplifier 4--23.....................................................

Grid Drive Circuit 4--23...................................................

Z-Axis Amplifier 4--23....................................................

Section 5 Checks and Adjustments 5--1.........................................

Recommended Equipment List 5--1.............................................

Electrical Instruments 5 --1................................................

Auxiliary Equipment 5 --3.....................................................

Performance Check Procedure Short-Form Reference 5--5...........................

Performance Check Procedure 5--6.............................................

Adjustment Procedure 5--17....................................................

Signal Connections 5--18..................................................

Adjustment Procedure Short-Form Reference 5--19.................................

Long-Form Adjustment Procedure 5--20..........................................

Table of Contents

1720/1721

Section 6 Maintenance 6--1....................................................

Preventive Maintenance 6--1..................................................

Cleaning 6--1...........................................................

V isual Inspection 6-- 2....................................................

Static-Sensitive Components 6--2...........................................

Performance Checks and Readjustments 6--3..................................

Troubleshooting 6--4........................................................

Foldout Pages 6--4.......................................................

Parts Lists 6-- 5..........................................................

Major Assembly Interconnection 6--5........................................

General Troubleshooting Techniques 6--6....................................

Specific Troubleshooting Procedures 6--8........................................

Power Supply 6--8.......................................................

Troubleshooting Procedure 6--8............................................

Introduction 6--8........................................................

Low Volts Supply 6--9....................................................

High Volts Supply 6--12...................................................

Serial Port and LED Driver Diagnostics 6--14..................................

Corrective Maintenance 6--15..................................................

Obtaining Replacement Parts 6--15..........................................

Mechanical Disassembly/Assembly 6--15.........................................

iii

Page 8

Table of Contents

Section 7 Options 7--1.........................................................

Bezel Removal 6--16......................................................

Graticule Light Removal and Replacement 6--17...............................

CRT Removal 6--18.......................................................

Replacement of the CRT 6--18..............................................

Removing the Rear Panel 6--19.............................................

Removing the Front Panel Circuit Board 6--19.................................

Removing the Main Board 6--20.............................................

Removing the Power Supply Board 6--22......................................

Repackaging 6--23...........................................................

Identification Tag 6--23....................................................

Repackaging for Shipment 6--23.............................................

Options 7--1...............................................................

CRT Options 7--1........................................................

Power Cord Options 7--1..................................................

Field Upgrade Kits 7--1......................................................

Cabinets 7--1...........................................................

Plain Cabinet (1700F00) 7--2..............................................

Carrying Case (1700F02) 7--2..............................................

Side-by-Side Rack Adapter (1700F05) 7--2...................................

DC Power Supply 7--2.......................................................

DC Power Supply Field Upgrade Kit (1700F10) 7--2...........................

Battery Pack (BP1) 7--2..................................................

Ordering 7--2..............................................................

Section 8 Replaceable Electrical Parts 8--1...................................

Parts Ordering Information 8--1................................................

Using the Replaceable Electrical Parts List 8--1...................................

Section 9 Diagrams/Circuit Board Illustrations 9--1.............................

Section 10 Replaceable Mechanical Parts 10--1...................................

iv

1720/1721

Page 9

List of Figures

Figure 2-1: Control and indicator locations. 2--1......................................

Figure 2-2: 1720/1721 rear panel. 2--5..............................................

Figure 2-3: Signal connection for the Operator’s Checkout Procedure. 2--9.................

Figure 2-4: 1720/1721 typical vector display. 2--10.....................................

Figure 2-5: Modulated staircase waveform shown on a 1721. 2--10........................

Figure 2-6: Color bar and modulated staircase signals both displayed on a 1721. 2--11.........

Figure 2-7: Connection for using black burst signal for External Reference. 2--12.............

Figure 2-8: 1720/1721 test circle display. 2 --12........................................

Figure 2-9: NTSC standard color phase Vector diagram. 2--15............................

Figure 2-10: PAL standard color phase Vector diagram. 2--15.............................

Figure 2-11: Partial 1720 graticule showing the 75% amplitude burst target. 2--16.............

Figure 2-12: Partial 1721 graticule showing the 75% amplitude burst target. 2--17.............

Figure 2-13: Fine detail of the 1720 graticule magenta target. 2--18........................

Figure 2-14: Fine detail of the 1721 graticule target. 2--19................................

Figure 2-15: Simulated 1720 graticule showing the relationship between amplitudes on the

I and Q modulation axes and the location of the color vector targets. 2--19.........

Figure 2-16: Simulation of a 1721 graticule showing the relationship between amplitudes

on the U and V axes and the locations of the color vector targets. 2--20...........

Figure 2-17: A simulation of a part of the 1720 graticule showing the differential phase and

gain measurement scales with approximately 10° differential Phase (dP). 2--21.....

Figure 2-18: Simulation of the 1721 Differential Gain and Phase graticule showing

approximately 10% differential Gain (dG). 2--22.............................

Table of Contents

1720/1721

Figure 3-1: Plug jumper locations.. 3--2.............................................

Figure 3-2: 1720/1721 REMOTE connector pins with their functions. 3--3.................

Figure 3-3: 1720/1721 AUXILIARY connector pins with their functions. 3--4...............

Figure 3-4: 1700F00 plain cabinet. 3--5.............................................

Figure 3-5: 1700F02 portable cabinet. 3--6...........................................

Figure 3-6: Cabinet securing screws. 3--7............................................

Figure 3-7: 1700F05 rack adapter. 3--7..............................................

Figure 3-8: 1700F05 rack adapter adjustment. 3--8.....................................

Figure 3-9: 1720/1721 and 1700F06 blank panel. 3--8..................................

Figure 3-10: Typical custom installation showing the console. 3--9........................

Figure 4-1: Simple block diagram of a 1720/1721 Vectorscope. 4--3.......................

v

Page 10

Table of Contents

Figure 4-2: Block diagram of the Phase Lock Loop 4--7................................

Figure 5-1: Rear view of Remote plug connections.. 5--4................................

Figure 5-2: Loop--through connection of black burst signal to both EXT REF and CH-B. 5--7..

Figure 5-3: Using the vector graticule --3 dB markings to measure bandwidth. 5--8...........

Figure 5-4: Signal connection for checking CH-A/CH-B phase matching. 5--10...............

Figure 5-5: Rear-panel XY INPUT connector showing inputs.. 5--14.......................

Figure 5-6: Audio frequency XY display. 5--15........................................

Figure 5-7: Adjustment and test point locations for 1720/1721 Vectorscope. 5--17.............

Figure 5-8: Starting connections for the adjustment procedure. 5--18.......................

Figure 5-9: Test points and adjustment locations for the ¦11.8V supplies. 5--21..............

Figure 6-1: Circuit board assembly locations 6--5.....................................

Figure 6-2: Multiple pin connectors used in the 1720/1721 Waveform Monitors 6--6..........

Figure 6-3: Screws that need to be removed to remove the bezel. 6--17......................

Figure 6-4: Screws that need to be removed to remove the rear panel 6--19..................

Figure 6-5: Screws that hold the Front Panel circuit board (A2) in place. 6--20...............

Figure 6-6: Screws holding the main circuit board (A3) in place. 6--21......................

Figure 6-7: Screws holding the Power Supply circuit board (A1) in place. 6--22..............

Figure 6-8: Repackaging 6--23.....................................................

vi

1720/1721

Page 11

List of Tables

Table 1--1: Signal Input 1--4..................................................

Table 1--2: Vector Mode 1--5..................................................

Table 1--3: XY Mode 1--7....................................................

Table 1--4: CRT Display 1--7..................................................

Table 1--5: Power Source 1--8.................................................

Table 1--6: Environmental Characteristics 1--8....................................

Table 1--7: Certification 1-- 9..................................................

Table 1--8: Physical Characteristics 1--9.........................................

Table 3--1: Internal Jumper Selection 3--2.......................................

Table 3--2: AUXILIARY Connector Pin Assignments 3--4..........................

Table 4--1: U613 Switching Control Outputs 4--16..................................

Table 5--1: Performance Check Procedure Short-Form Refe rence 5--5.................

Table 5--2: Adjustment Procedure Short-Form Reference 5--19........................

Table of Contents

Table 6--1: Static Susceptibility 6 --2............................................

Table 6--2: Power Supply Fault Symptoms 6--9...................................

Table 6--3: Low Volts Supply Voltages 6--9......................................

Table 6--4: Control Circuit Test Points 6--11......................................

Table 6--5: High Volts Supply Fault Symptoms 6--12................................

Table 6--6: High Voltage Oscillator Test Points 6--13................................

1720/1721

vii

Page 12

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

viii

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

1720/1721

Page 13

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

1720/1721

ix

Page 14

Preface

This manual documents the TEKTRONIX 1720/1721 Vectorscope. Information

that applies to all instruments in the series refers to the 1720/1721. Information

that applies to only specific instruments within the series refers to the model

numbers of those instruments (i.e., 1720, 1721).

The information in this manual is intended for instrument operators and service

technicians. Operators are assumed to be familiar with basic television terms and

measurements. Qualified service technicians are also assumed to be familiar with

television terms and measurements, and have moderate experience with analog

and logic circuits.

Section 1, Introduction and Specification, includes a general description of the

instrument followed by the Specifications. The Specifications include references

to the corresponding Performance check steps.

Section 2, Operating Instructions, familiarizes the user with the front-- and

rear-- panel controls, connectors, and indicators; includes an operator’s checkout

procedure; and includes other operator familiarization information.

Section 3, Installation, includes electrical and mechanical installation information. The electrical installation information includes adjustments and operational

changes available with the instrument. The mechanical installation information

includes rackmounting, custom installation, and portable use.

Section 4, Theory of Operation, provides an overall block diagram description

and detailed circuit descriptions. Read the block diagram description for an

overview of the instrument. The detailed circuit descriptions should be used

with the block diagram and schematic diagrams in the foldout pages for specific

information about individual circuits.

Section 5, Checks and Adjustments, includes the Performance Check

Procedure and the Adjustment Procedure. The Performance Check Procedure is

used to verify that the instrument’s performance is within its specifications, and

the Adjustment Procedure is used to adjust the instrument to meet its specifications. The procedures are preceded by a list of recommended test equipment.

Each procedure has a short form listing of the individual steps.

Section 6, Maintenance, includes preventive, troubleshooting, and corrective

information.

Section 7, Options, contains summaries of available instrument options.

Additional information concerning options is included in appropriate places

throughout the manual.

Section 8, Replaceable Electrical Parts, includes ordering information and part

numbers for all replaceable electrical parts.

x

Page 15

Preface

Section 9, Diagrams, contains servicing illustrations. These include adjustment

locations, circuit board part locations, a block diagram, schematic diagrams, and

waveforms. Parts locating tables are included that cross--reference the circuit

board illustrations and the schematic diagrams.

Section 10, Replaceable Mechanical Parts, includes ordering information and

part numbers for all replaceable mechanical parts. This parts list is referenced to

an exploded view mechanical drawing. Also included are lists of standard and

optional accessories.

xi

Page 16

Preface

xii

Page 17

Introduction and Specifications

Page 18

Page 19

Section 1 Introduction and Specifications

The TEKTRONIX 1720/1721 is an 8-1/2”--wide by 5-1/4”--high Vectorscope,

weighing 8-1/2 pounds. Both the 1720 (System M, NTSC) and the 1721

(System I, B, etc., PAL) versions can be powered from an ac source or, with the

addition of a field upgrade kit (1700F10), from 12 Vdc. The crt occupies

approximately two-thirds of the front-panel area, with the control panel taking up

the remainder of the space. Operation is controlled by a Microprocessor that

polls the front-panel switches. Front-panel switches are momentary-touch type

with lighted functional indicators. Some of the switches are also used to select

special functions, which are accessed by holding the switches in until the

Microprocessor recognizes the request.

The signal is displayed on a bright crt capable of displaying one line per frame.

It is of the mesh-type, for better geometry, and uses an internal graticule to

reduce parallax. Variable graticule scale illumination provides even lighting over

the usable graticule area without hot spots or voids, to improve measurement

accuracy and the quality of display pictures. Option 74 provides a P4 (white)

phosphor tube.

Composite video signals, for the Channel A and B Inputs and the External

Reference Signal Input, are brought in through high impedance bridging

loop-throughs, in order to protect the integrity of the signal paths. The input

switching allows for the display of Channel A, Channel B, or both inputs.

Synchronization can be either internal or external.

The 1720/1721 offers a choice of individual displays of vectors or XY or both.

The XY display, with accompanying graticule scale, allows this vectorscope to

be used for stereo audio monitoring. In addition to the usual color bar amplitude

and phase relationships, the vector display can also be used to make differential

gain and phase measurements. The 1721 has the +V display that is used to

check PAL system color encoders. Full 360° phase shift and a test circle are also

included in these vectorscopes.

Stereo audio input for XY display is balanced line through the rear-panel

REMOTE connector.

The 1720/1721, through the Auxiliary function, reacts to Store and Recall

commands from a companion 1730-Series Waveform Monitor, when the two are

interconnected. This provides for storing of up to four front-panel setups that

can be recalled when the Waveform Monitor Recall button is pressed, or a valid

1730-Series Remote ground closure occurs. The Auxiliary function can also take

advantage of the blanking strobe, from the waveform monitor, to unblank the

vectorscope crt for a line select display.

1720/1721

1- 1

Page 20

Introduction and Specifications

Accessories

Standard Accessories

The 1720/1721 is shipped with a set of accessories that are needed for its

installation or day-to-day operation. These are the “Standard Accessories.”

They are physically packaged in a small, cardboard carton within the packing

box.

In addition to the Standard Accessories, there are other accessory items that can

be purchased from Tektronix, Inc., which will either enhance operation or help to

customize the installation. The following list of accessories is divided into these

two categories. Part numbers for the standard accessories can be found at the

end of the Replaceable Mechanical Parts list.

1 1720/1721 Instruction Manual.

1 Power Cable Assembly.

Optional Accessories

Options

CRT Options

1 Spare Cartridge Fuse (3AG 2A, 250 V, Fast Blow).

3 Replacement Scale Illumination Bulbs (Tektronix P/N 150--0168--00 or

ANSI #73).

1 Auxiliary Control Cable, for use with a 1730-Series Waveform Monitor.

1700F00, Plain Cabinet (painted silver grey)

1700F02, Portable Cabinet (painted silver grey)

1700F05, Side-by-Side Rack Adapter

1700F06, Blank Half-Rack-Width Panel

Standard instruments are shipped with a P31 (green) phosphor crt installed.

Option 74 instruments are shipped with a P4 (white) phosphor crt installed.

Power Cord Options

1- 2

Any of the power cord options described in Section 7 can be ordered for the

1720/1721. If no power cord option is ordered, instruments are shipped with a

North American 125 V power cord and one replacement fuse.

1720/1721

Page 21

Safety Information

Specifications

Introduction and Specifications

1720/1721 instruments are intended to operate from an ac power source that will

not apply more than 250 V rms between the supply conductors or between either

supply conductor and ground. A protective ground connection by way of the

grounding conductor is essential for safe operation.

The 1720/1721 was tested for compliance in a cabinet. To ensure continued

compliance, the instrument will need to be enclosed in a cabinet that is equivalent to the Factory Upgrade Kits that are listed as Optional Accessories for the

1720/1721. Drawings of the available cabinets are contained in the Installation

Instructions (Section 3).

The Performance Requirements listed here apply over an ambient operating

temperature range of 0 to 50° C and are valid only when the instrument is

calibrated at 25°±5° C, following a minimum warm-up period of 20 minutes.

Procedure and the list of test equipment required to verify Performance

Requirements are located in Section 5.

1720/1721

1- 3

Page 22

Introduction and Specifications

Table 1- 1: Signal input

Characteristics Performance requirement Supplemental information

Step

number

Return loss (75Ω)

Video inputs (CH A, CH B)

EXT REF

Atleast40dBfrom50kHzto6MHz. Loop-through terminated in 75W. Input

in use or not in use, instrument power

on or off, all deflection factor settings.

Crosstalk between channels Greater than 70 dB of isolation be-

tween channels. Measured at F

SC

between Channel A, Channel B, and

EXT REF.

Loop-through isolation Greater than 70 dB of isolation be-

tween loop-throughs. Measured at F

between Channel A, Channel B, and

EXT REF.

Input requirements Stable display with composite video, or

black burst with 286 mV (300 mV PAL)

burst ±6dB.

DC input impedance (unterminated) Greater than 15 kΩ

EXT REF input Composite video (can be CW subcarr-

ier if two internal jumpers are moved).

Absolute maximum input voltage ±12 VDC plus peak AC

Maximum operating input voltage Peak AC + DC should be within

+8.0 V and --5.6 V for proper operation.

11

SC

3

Table 1- 2: Vector mode

Characteristic Performance requirement Supplemental information

Chrominance processing characteristics

Nominal subcarrier frequency (F

NTSC

PAL

)

sc

3.579545 MHz.

4.43361875 MHz.

Chrominance bandwidth

Upper --3 dB point

Lower --3 dB point

Fsc+500 kHz, ±100 kHz

F

--500 kHz, ±100 kHz

sc

Display

Vector phase accuracy

Vector gain accuracy

Quadrature phasing

±1.25 Measured with color bar signal

Typically, ±2.5%

Typically, ±0.5°

1- 4

Step

number

4

5

5

1720/1721

Page 23

Table 1- 2: Vector mode (cont.)

Characteristic

Introduction and Specifications

Step

Supplemental informationPerformance requirement

number

Subcarrier regenerator

NTSC pull --in range

PAL pull--in range

Pull--in time

Phase shift with subcarrier freqency change (NTSC)

Phase shift with subcarrier frequency change (PAL)

Phase shift with burst amplitude

change

Phase shift with input channel

change

Phase shift with VAR GAIN control

±50 Hz of F

±10 Hz of F

sc

sc

±2° from Fscto (Fsc+ 50 Hz) or Fscto

(F

-- 50 Hz)

sc

±2° from F

(F

-- 10 Hz)

sc

to (Fsc+ 10 Hz) or Fscto

sc

±2° from nominal burst amplitude to

±6dB.

±0.5°

±1° as gain varies from 3 dB to --6 dB.

Subcarrier regenerator freeruns in

absence of appropriate signal.

Reference can be burst of either

displayed signal or external reference

signal.

PAL units are tested to 10 Hz, but

typically lock to within 50 Hz.

Within 1 second, with subcarrier

frequency within 50 Hz (10 Hz for PAL)

od F

.

sc

With EXT REF selected.

6

6

6

6

7

7

Phase control range

Burst jitter

Display characteristics

Differential phase

Differential gain

Position control range, horizontal

Position control range, vertical

Clamp stability

Variable GAIN range

1720/1721

<0.5°

±1°

±1%

At least .25” (6 mm) from center.

At least .25” (6 mm) from center.

0.0156” (0.4 mm) or less.

+14 dB to --6 dB of 75% color bar

preset gain.

360° continuous rotation.

With 140 IRE (1 V PAL) composite

video input. INT or EXT referenced.

Measured with 140 IRE (1 V PAL)

linearity signal (5 step, 10 step, or

ramp) with 40 IRE (300 mV PAL) of

subcarrier.

Center spot movement with PHASE

control rotation.

+5 to --0.5 amplitude.

7

8

9

9

10

1- 5

Page 24

Introduction and Specifications

Table 1- 3: XY Mode

Characteristic Performance requirement Supplemental information

Input DC Coupled differential inputs through

rear-panel REMOTE connector.

Input amplitude 2to9V

Maximum input voltage ±15 V peak signal plus DC.

Frequency response

p--p

DC to greater than 500 kHz.

Adjustable full scale deflection 0 dBm

to +12 dBm for 600Ω system. Factory

set to 0 dBm. Specification verified

during calibration.

3 dB point.

Step

number

14

High gain mode

X and Y input phase matching Less than a trace width of separation

DC to greater than 100 kHz.

at 20 kHz.

3 dB point. Not a differential input,

minus inputs must be grounded.

Single ended. Phase matching may be

improved, above 20 kHz, by adjusting

C484.

Table 1- 4: CRT Display

Characteristic Performance requirement Supplemental information

CRT viewing area 80 X 100 mm.

Accelerating Potential 15.75 kV

Trace rotation range Greater than ±1° from horizontal. Total adjustment range i s typi cally 8°. 12

Graticule Internal vector, variable scale illumina-

tion.

14

13

Step

number

Table 1- 5: Power source

Characteristic Performance requirement Supplemental information

Mains voltage ranges 90 -- 250 V. Continuous range from 90 to 250 VAC. 2

Mains frequency range 48 -- 66 Hz.

Power consumption 0.7 A maximum, 0.35 A (21.4 Watts)

typical.

1- 6

Step

number

1720/1721

Page 25

Introduction and Specifications

Table 1- 6: Environmental Characteristics

Characteristic Supplemental information

Temperature

Non-operating

Operating

Altitude

Non-operating

Operating

Vibration -- operating 15 minutes each axis at 0.015 inch, frequency varied from

Shock -- non-operating 30 g’s, 1/2 sine, 11 ms duration, 3 shocks per surface (18 total).

Transportation Qualified under NTSC Test Procedure 1A, Category II (30--inch

Humidity Will operate at 95% relative humidity for up to five days. Do not

-- 5 5 t o + 7 5 °C

0to+50°C

To 50,000 feet

To 15,000 feet

10-55-10 Hz in 1-minute cycles wi th instrument secured to

vibration platform. Ten minutes each axis at any resonant point or

at 55 Hz if no resonant point is found.

drop).

operate with visible moisture on the circuit boards

Table 1- 7: Physical Characteristics

Characteristic Supplemental information

Dimensions

Height

Width

Length

Weight 8.5 lbs (3.8 kg).

5.25 inches (133.4 mm).

8.5 inches (215.9 mm)

10.125 inches (460.4 mm)

Table 1- 8: Certifications and Compliances

Category Standards or description

EC Declaration of Conformity -EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European Union:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

1720/1721

1- 7

Page 26

Introduction and Specifications

Table 1- 8: Certifications and Compliances (cont.)

Category Standards or description

Australia/New Zealand

Declaration of Conformity -- EMC

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

Installation (Overvoltage)

Category

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

EC Declaration of Conformity -Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA safety requirements for electrical and electronic measuring and

Additional Compliance IEC61010-1 Safety requirements for electrical equipment for measurement,

Installation (Overvoltage)

Category

Pollution Degree Pollution Degree 2 As defined in IEC 1010--1. Rated for indoor use only.

Safety Certification Compliance Temperature, operating: 0 to 50° C.

Altitude (maximum operating) 2,000 meters.

Equipment Type Test and measuring.

Safety Class Class I (as defined in IEC 1010--1, Annex H) -- grounded product.

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

AS/NZS 3548 Information Technology Equipment: 1995

Terminals on this product may have di ff erent installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appl iances, portable

tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product i s considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Compliance was demonstrated to the fol lowing specification as listed in the Official Journal of the

European Union:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1 Safety requirements for electrical equipment for measurement

control and laboratory use.

UL1244 Standard for electrical and electronic measuring and testing

equipment.

test equipment.

control, and laboratory use.

CAT II As defined in IEC 1010--1, Annex J.

1- 8

1720/1721

Page 27

Operating Instructions

Page 28

Page 29

Section 2 Operating Instructions

These instructions provide information about the front-panel controls, rear-panel

connectors, the Operator’s Familiarization/Checkout Procedures, and discussions

about vector and audio measurements using the 1720/1721.

Front-Panel Controls and Indicators

The front-panel controls and indicators consist of momentary contact push-button switches, variable controls, and backlit switch selections. See Figure 2-1 for

the control and indicator locations.

RO TATE

GAIN

CAL

1

MODE

VECT

XY

BOTH

VARIABLE BARS

4

6

FOCUS SCALE INTENS

8

9

AUXILIARY

2 3

ON

PAL

+V

ON

REF

INT

EXT

TEST

172X

PHASE

DISPLAY

POWER

VECTOR

SCOPE

INPUT

CH--A

CH--B

BOTH

GAIN

75%

100%

5

7

10

ON

13

14

15 16

Figure 2-1: Control and indicator locations.

1720/1721

= HOLD FOR FUNCTION

11

12

2- 1

Page 30

Operating Instructions

There are three push-button switches, located in the INPUT block, that have an

extra function. The extra function is accessed by holding the switch down for

approximately one second. The operating selection reverts to the top of the

listed functions when the push button is repushed to exit this extra function, with

the exception of TEST, which reverts to its original state when exiting.

INPUT

1. MODE

A momentary push-button switch that toggles between the vector and XY

displays. These two functions have back lighted nomenclature with rectangular

indicators.

Holding this button in switches the MODE to a display of both vector and XY

modes. In this mode both the VECT and XY nomenclature and rectangular

indicators light up to indicate that the 1720/1721 has been switched to this mode

of operation.

GAIN

2. REF

A momentary push-button switch that toggles between INT and EXT sync

references. These two functions have back lighted nomenclature with rectangular indicators.

Holding this button in switches the REF to an unlocked display of subcarrier and

enables the V-axis switcher, if a signal containing a subcarrier reference signal is

applied to the selected input. TEST nomenclature, framed by a blue box, lights

up when the 1720/1721 is switched to this mode.

3. CH--A CH--B

Momentary contact push-button switch that toggles the input between Channels

A and B. Back lighted nomenclature, with rectangular indicators, light to show

which is selected for display.

Holding this button in switches the INPUT to a display of both A and B Inputs.

This display requires an external sync reference. Both the CH-A and CH-B

indicators light when the 1720/1721 has been switched to this dual input mode.

4. VA R IA BL E

2- 2

A momentary contact push-button switch that toggles between VARIABLE gain

ON and off. The VARIABLE control adjusts amplifier input gain so that any

input signal between 0.5 V and 2.0 V peak-to-peak can be displayed. Control

has no detent, action is continuous. Back lighted nomenclature, with rectangular

indicators, lights up red to indicate that display gain is uncalibrated.

1720/1721

Page 31

PHASE

Operating Instructions

5. BARS

A momentary contact push-button switch that toggles between correct gain for

displaying 75% and 100% amplitude color bar signals, using a single set of

vector targets. Burst targets for both 75% and 100% amplitude color bars are on

the graticule. Back lighted nomenclature, with rectangular indicators, lights to

indicate that the 1720/1721 is set up to measure color bars.

6. PAL/+V (PAL Only)

A momentary contact push-button switch that selects either PAL (±V) or +V

only for the phase displays. +V overlays +V with --V on the +V Axis for

alternate line comparisons. Back lighted nomenclature, with rectangular

indicators, lights to indicate that either standard PAL or overlayed + and --V is

being displayed.

7. (control)

DISPLAY

MISCELLANEOUS

A continuously-variable control with 360° range to set the phase of the decoder

reference.

8. FOCUS

A 270° rotation potentiometer that is adjusted for display definition.

9. SCALE

A 270° rotation potentiometer that controls the level of graticule illumination.

INTENS

10.

A 270° rotation potentiometer that controls display brightness.

11. AUXILIARY

Toggles between AUXILIARY and independent operation. In the AUXILIARY

mode, a Line Strobe (to blank the 1720/1721 crt, for line selection) and data to

actuate the front-panel setup is accepted from a companion 1730-Series. Back

lighted nomenclature and a rectangular indicator both light to indicate that the

instrument is under AUXILIARY control.

1720/1721

2- 3

Page 32

Operating Instructions

12. POWER

Turns on and off external power to the 1720/1721. Contains a mechanical

indicator that indicates the status of the POWER switch, even when the mains

power is disconnected or shut down from another location.

13. ROTATE

A 270° rotation screwdriver adjustment that aligns the display with the graticule.

14. GAIN CAL

A 270° rotation screwdriver adjustment that sets the amplifier gains in the Vector

Mode.

15. VERT POS

A 270° screwdriver-adjustable, variable control that provides limited vertical

positioning of the display.

16. HORIZ POS

Rear-Panel Connectors

A 270° screwdriver-adjustable, variable control that provides limited horizontal

positioning of the display.

Signal input, power input, Auxiliary Control In, XY Input, and Demod Out are

all located on the 1720/1721 rear panel. Because of the similarity of the

1730-Series to the 1720/1721 rear panel, the word VECTORSCOPE appears at

the top of the panel. See Figure 2-2 for locations of rear-panel connectors.

2- 4

1720/1721

Page 33

Operating Instructions

1 23 4

VECTORSCOPE

PIX

MON

OUT

AUXILIARY CONTROL

IN

INPUT

CH--A

8

CH--B EXT REF

75 OHM LOOP --THROUGH

6

X Y INPUT

57

Figure 2-2: 1720/1721 rear panel.

1. AC POWER

A standard ac plug receptacle for the 120 or 220 V ac power mains. Plug is

compatible with any of the three power cord options available for the 1720/1721

Vectorscope.

2. DEMOD OUT

A75Ω output of the demodulated R-Y signal that can be fed into a companion

1730-Series to provide a horizontal sweep of demodulated video.

1720/1721

3. AUXILIARY

A 9-pin connector used to interface with the 1730-Series. Auxiliary control

consists of a signal line (Line Strobe) and a serial interface. The serial interface

allows the 1720/1721 to operate in conjunction with the 1730-Series Store/Recall

function.

4. XY INPUT

A 15-pin connector that is used for the differential input of a stereo audio signal

that is to be displayed in the XY mode. One set of inputs can be configured for

high gain single-ended input. Internal jumpers must be repositioned for this type

of input. See Section 3 (Installation) for more information.

2- 5

Page 34

Operating Instructions

5. EXT REF

A bridging loop-through input (compensated for 75Ω) for synchronizing signals.

As factory shipped, the input signal may be black burst or composite video.

Changing a pair of internal plug jumpers makes it possible to use CW Subcarrier

as an external reference; however, horizontal (line) sync must be present on the

CH-A INPUT for synchronization. External reference is selected by the

front-panel REF switch.

6. CH-B

A bridging loop-through input for composite video signal, compensated for 75Ω.

The input signal for display is selected by the front-panel INPUT switch.

7. CH-A

A bridging loop-through input for composite video signal, compensated for 75Ω.

The input signal for display is selected by the front-panel INPUT switch.

8. AC FUSE

A holder for an F-type cartridge fuse which is the instrument ac mains supply

fuse.

Using the 1720/1721 in AUXILIARY Mode

When the serial interface AUXILIARY cable (between the 1720/1721 and a

1730-Series) is connected, the 1720/1721 can be operated in the AUXILIARY

mode. The 1720/1721 AUXILIARY mode allows the Input and Reference

switching to follow the similar switches on the waveform monitor. For example,

when the 1730-Series INPUT switch is changed from A to B, the 1720/1721

INPUT switch will also change to B. Even though the vectorscope switching

(INPUT and REF) follows the waveform monitor, the vectorscope INPUT and

REF switches remain active so that they can be changed without changing the

waveform monitor switching. The following functions can be controlled by the

1730-Series in AUXILIARY mode:

INPUT switching

REFerence switching

LINE SELECT

2- 6

INPUT Switching

STORE and RECALL

INPUT switching allows the 1730-Series to select any of the three inputs (CH-A,

CH-B, or BOTH) when AUXILIARY is ON. Note that the 1720/1721 INPUT

1720/1721

Page 35

Operating Instructions

switch can be used independently, even though the instrument is in the AUXILIARY mode.

REF Switching

LINE SELECT

STORE

REF switching allows the 1730-Series to select either INT or EXT reference. It

will not switch to TEST when the 1730-Series is switched to CAL. Reference

will automatically be switched to EXT if the INPUT is switched to BOTH (from

either waveform monitor or vectorscope). If the 1720/1721 REF switch is in

TEST, the 1730-Series switching will not take it out of that mode.

The 1720/1721 normal operation is full field. When it is used in AUXILIARY,

the 1730-Series LINE SELECT switching controls the display on the vectorscope. It should be noted that the 1720/1721 has no line selection capability

when it is not connected to a 1730-Series Waveform Monitor.

The current state of the front panel can be stored, in AUXILIARY mode, by

executing the 1730-Series STORE command. When the 1730-Series STORE

button is pushed, the 1720/1721 front-panel indicators will blink to acknowledge

that the command was received. The current front-panel configuration will now

be stored in the 1720/1721 NOVRAM as soon as one of the 1730-Series

RECALL buttons is pushed.

NOTE. Use caution to retain desired 1730-Series stored configurations. Read the

STORE and RECALL SETUP instructions in Section 2 of the 1730-Series

Instruction manual before proceeding.

1720/1721

RECALL

Note that the indicators also blink when the 1720/1721 is not in AUXILIARY;

however, the front-panel configuration is not stored and the 1720/1721 front

panel will not change when that stored function (on the 1730-Series) is recalled.

When the 1720/1721 is in the AUXILIARY mode and contains stored front-panel configurations, it reacts to 1730-Series RECALLs. When one of these

RECALL buttons is pushed, the stored front-panel configurations of both

instruments will be recalled. All front-panel controls remain active during

AUXILIARY mode, and can be used to make changes in current front-panel

configurations.

During AUXILIARY operation, the 1720/1721 front-panel indicators continue to

accurately display its current status.

2- 7

Page 36

Operating Instructions

OPERATOR’S CHECKOUT PROCEDURE

The following procedure is provided as an aid in obtaining a display on the

1720/1721 Vectorscope, and may be used as a check of basic instrument

operation. Only instrument functions are checked in this procedure. All checks

can be made with a cabinet on and it is necessary to have all internal jumpers in

the factory-set position.

When a complete check of the instrument performance to specification is

desired, a qualified service technician should make the Performance Check in

Section 5 of this manual.

This procedure requires a source of composite video and composite sync signals.

A TEKTRONIX 1410 Series Television Test Signal Generator mainframe with

Sync, Color Bar, and Linearity modules was used in preparing this procedure.

1. Initial Setup

1720/1721 Vectorscope

MODE VECT

REF INT

INPUT CH A

VARIABLE off

BARS 75%

PAL/+V PAL (1721 only)

PHASE Will be set later

FOCUS Will be set later

SCALE Counterclockwise

INTENS Counterclockwise

POWER OFF

Connect the color bar signal to the CH-A INPUT and terminate the remaining

side of the loop-through input with a 75Ω termination. Connect the modulated

staircase signal to the CH-B INPUT, then loop through to the EXT REF and

terminate in 75Ω. See Figure 2-3.

Set up the signal sources for the following composite video signals:

2- 8

Full Field Color Bars

75% Ampl. 7.5% Setup ---- NTSC

1720/1721

Page 37

1410-- Series (rear)

Operating Instructions

75% Ampl. 0% Setup ---- PAL

Modulated Staircase

(Flat Field, 10 Step)

Black Burst Signal

(Sync and Burst only)

If the XY operation of the 1720/1721 is to be checked, an audio signal is

required. See the following:

Audio Signal: (About 2 V between 1 and 100 kHz.)

1720/1721 (rear)

Color bar signal

Mod staircase

Figure 2-3: Signal connection for the Operator’s Checkout Procedure.

2. Apply Power

Connect the instrument to a suitable ac power source and push the POWER

switch. Check that the indicator in the center of the switch is indicating that

POWER is ON.

NOTE. Do not set any of the front-panel screwdriver controls until after the

instrument warms up (at least 20 minutes).

Rotate the SCALE control clockwise and check that the graticule illuminates.

3. Obtain Display

Adjust the INTENS and FOCUS controls for the desired brightness and a

well-defined vector display. Use the PHASE control to place the vector tips and

burst(s) on their targets. See Figure 2-4.

75Ω Termination

1720/1721

2- 9

Page 38

Operating Instructions

d∅

10°

V

cy

50°

g

20%

dG

0°

YL

75% 100%

R

40°

30°

20°

10°

MG

Q

b

U

10°

10%

dG

yl

G

100%

75%

mg

CY

r

B

-- I

Figure 2-4: 1720/1721 typical vector display.

Adjust the SCALE illumination control for the desired brightness. Note that the

internal waveform graticule should be illuminated.

2- 10

1720/1721

Page 39

d∅

10°

Operating Instructions

V

cy

50°

g

20%

dG

0°

YL

75% 100%

R

40°

30°

20°

10°

MG

Q

b

U

10°

10%

dG

yl

G

100%

75%

mg

CY

r

B

-- I

Figure 2-5: Modulated staircase waveform shown on a 1721. A 1720 would have

what would appear to be an intensified burst.

1720/1721

2- 11

Page 40

Operating Instructions

4. Select Input

Select the Channel B input for a display of the modulated staircase signal. See

Figure 2-5.

Push in and hold the INPUT button until both the CH-A and CH-B indicators are

lit, and check for a display of both vectors and modulated staircase. See Figure

2-6.

V

cy

50°

R

40°

30°

20°

10°

MG

Q

b

U

d∅

10°

g

20%

dG

0°

YL

75% 100%

10°

10%

dG

yl

G

100%

75%

mg

CY

r

B

-- I

Figure 2-6: Color bar and modulated staircase signals both displayed on a 1721.

Briefly push the INPUT button and check that the CH-A indicator is the only

one lit and that only a vector display is present.

5. Select Reference

Connect the black burst signal to the EXT REF loop-through input and terminate

in 75Ω. See Figure 2-7.

2- 12

1720/1721

Page 41

1720/1721 (rear)

1410-- Series (rear)

Color bar signal

Black burst

Figure 2-7: Connection for using black burst signal for External Reference.

Push the REF button and check that the front-panel EXT indicator lights. Check

for a stable display of vectors (CH-A INPUT).

Operating Instructions

75Ω Termination

Push and hold the REF button until the front-panel TEST indicator lights.

Check for a test circle display. See Figure 2-8.

Leave the 1720/1721 REF in TEST.

1720/1721

2- 13

Page 42

Operating Instructions

d∅

10°

V

cy

50°

g

20%

dG

0°

YL

75% 100%

R

40°

30°

20°

10°

MG

Q

b

U

10°

10%

dG

yl

G

100%

75%

mg

CY

r

B

-- I

Figure 2-8: 1720/1721 test circle display.

6. Position Center Dot

Use a small screwdriver to adjust the vertical and horizontal positioning controls.

Check that there is sufficient range to move the dot through the geographic

center of the display (the graticule center target). It should be noted that the

amount of adjustment range varies from instrument to instrument.

Adjust the positioning controls to place the center dot at the exact center of the

graticule.

2- 14

7. Set Gain

With the test circle displayed, use a screwdriver to adjust the GAIN CAL fully

clockwise and check that the outer circle is outside of the outer (Red and Cyan)

graticule targets.

Set the GAIN CAL fully counterclockwise and check that the outer circle is

inside of the outer (Red or Cyan) graticule targets.

Set the GAIN CAL so that the outer circle passes through the outer (Red and

Cyan) graticule targets.

1720/1721

Page 43

Operating Instructions

8. Va ria ble

With the test circle displayed, push the VARIABLE push button and check that

the VARIABLE ON indicator lights.

Rotate the VARIABLE control fully clockwise and check that the display

increases in size.

Rotate the VARIABLE control fully counterclockwise and check that the outer

circle is inside the outer (Red and Cyan) targets.

Push the VARIABLE push button and check that the test circle is on the outer

targets and that the front-panel VARIABLE ON indicator is off.

9. Check the Rotation of the Display

Variations in the earth’s magnetic field may make adjustment of the ROTATE

control necessary at installation time or whenever the instrument is moved.

Connect the audio signal, through the XY INPUT connector on the rear panel, to

the +X input (pin 3). Set the 1720/1721 MODE to XY. Set up the audio signal

amplitude for a horizontal trace that is long enough to reach across the graticule

compass rose.

Check that the sweep is a straight line parallel to the horizontal axis. If not,

adjust the ROTATE adjustment until the sweep is parallel to the horizontal axis.

10. Check XY Mode

Connect the audio signal to both pins 3 and 7 of the rear-panel XY INPUT. Set

the 1720/1721 MODE to XY. Adjust the audio signal amplitude to place the

diagonal trace on the 45° graticule line. Adjust audio signal amplitude so that

the ends of the trace fall on the target (+) marks.

11. Check Dual Mode

Select INPUT A. With the color bar composite video signal connected to the

CH-A INPUT and the audio signal connected to the XY INPUT (pins 3 and 7)

push and hold the MODE push button until both VECT and XY are lit. Check

for a display of both vectors and the XY lissajous.

Measurement Applications

The 1720/1721 is unique in that it is a vectorscope capable of making both

chrominance and XY measurements. The information that follows is intended to

guide both new and experienced users through simple and complex measurement

techniques. The information is divided by major topics, which are then

subdivided into specific measurements.

1720/1721

2- 15

Page 44

Operating Instructions

Color Measurements

In color television, the visual sensation of color is described in terms of three

qualities: luminance, hue, and saturation.

Luminance. Luminance is brightness as perceived by the eye. As the eye is most

sensitive to green and least to blue light of equal energy, green is a bright color

and blue is a dark color as conveyed by the luminance signal to monochrome TV

receivers.

Chrominance. Chrominance is measured in terms of hue and amplitude. Hue is

the attribute of color perception that determines whether the color is red, blue,

green, etc. White, black, and gray are not considered hues. Hue is presented on

the vectorscope crt as a phase angle and not in terms of wavelength. For

example, red, having a wavelength of 610 millimicrons, is indicated as 104° on

the standard color phase vector diagram when the burst is at 180° for NTSC or

135° for PAL. The standard color phase vector diagram is shown in Figure 2-9

for NTSC and Figure 2-10 for PAL.

R-Y

RED

90°

104°

YELLOW

167°

123°

I

100

80

60

40

20

MAGENTA

61°

33°

Q

BURST

180°

GREEN

241°

CYAN

284°

--I

303°

B-Y

0°

BLUE

347°

Figure 2-9: NTSC standard color phase Vector diagram.

2- 16

1720/1721

Page 45

Operating Instructions

45°

45°

0.4

0.2

--0.2

--0.4

iV

CYAN

F

MAGENTA

a

0.2

-- a

CYAN

BLUE

BLUE

MAGENTA

F*

U

F=U+iV

F*=U--iV

RED

GREEN

YELLOW

--0.2

YELLOW

GREEN

RED

Figure 2-10: PAL standard color phase Vector diagram.

Saturation is the degree to which a color (or hue) is diluted by white light in

order to distinguish between vivid and weak shades of the same hue. For

example, vivid red is highly saturated and pastel red has little saturation.

Because saturation is a product of both luminance and chrominance amplitudes,

and a vectorscope can only measure chrominance amplitude, the radial distance

from the center to the end of the color vector is chrominance amplitude. If burst

vector amplitude corresponds to the 75% amplitude marking (see Figure 2-11 for

NTSC and Figure 2-12 for PAL), the colors represented by the vectors when they

are within the targets are of 75% amplitude.

1720/1721

If burst vector amplitude corresponds to the 100% marking and the chrominance

vectors are within the target, the color amplitude is 100%.

2- 17

Page 46

Operating Instructions

dᡢ

10°

0°

10°

20%

dG

10%

dG

YL

yl

75% 100%

WITH

SETUP

75%

100%

WITHOUT

SETUP

Figure 2-11: Partial 1720 graticule showing the 75% amplitude burst target, with and

without setup compensation.

Encoding. The hue and color amplitude information in the color television

system is carried on a single subcarrier frequency: 3.579545 MHz for NTSC and

4.43361875 MHz for PAL. These signals, in modulated subcarrier form, are

called chrominance. The hue information is carried by the subcarrier phase; the

color amplitude information is carried by means of amplitude modulation with

the subcarrier suppressed. A subcarrier which supplies phase information is

required for demodulation. No picture chrominance signals are present during

the horizontal blanking interval and a sample of the subcarrier, used by decoders

for a reference (called burst), is provided within this interval.

2- 18

dᡢ

10°

0°

10°

20%

dG

10%

dG

YL

75% 100%

75% AMPLITUDE

BURST TARGETS

yl

100%

75%

Figure 2-12: Partial 1721 graticule showing the 75% amplitude burst target.

1720/1721

Page 47

Operating Instructions

Decoding. To recover the hue information, phase demodulators are employed in

the vectorscope. The phase reference is the color subcarrier, which is regenerated by an oscillator in the instrument. The oscillator is locked in both phase and

frequency to the incoming color burst signal. The vectorscope displays the

relative phase and amplitude of the chrominance signal on polar coordinates. To

identify these coordinates, the vector graticule (see Figure 2-11 for NTSC and

Figure 2-12 for PAL) has points that correspond to the proper phase and

amplitude of the three primary colors and their complements, which are related

to the 180° burst vector for NTSC and the 135° burst vector for PAL. The

coordinates for the primary colors (red, blue, and green) and their complements

(cyan, yellow, and magenta), when the burst vector is at 225° for PAL, are

identified with lower case abbreviations.

Any errors in the color encoding, video tape recording, or transmission processes

which change these phase or amplitude relationships causes color errors on the

television receiver picture. The polar-coordinate-type of display, such as that

obtained on the 1720/1721, has proven to be the best method for portraying these

errors.

Functional Use of the Vector Graticule

Measurement of Color

Bars

The polar display permits measurements of hue in terms of the relative phase of

the chrominance signal with respect to the color burst. Relative amplitude of

chrominance to burst is expressed in terms of the displacement from center

(radial dimension of amplitude) towards the color point which corresponds to

75% (or 100%) amplitude for the color being measured.

On the 1720 graticule, each chrominance vector terminates in a system of

graticule targets in the form of two boxes (a small box inside a large box). See

Figure 2-13. The dimensions of the large boxes represent ±10° centeredonthe

exact chrominance phase, and ±20% of chrominance amplitude centered around

100% of standard amplitude. The dimensions of the smaller boxes represent

±2.5° and ±2.5 IRE.

1720/1721

2- 19

Page 48

Operating Instructions

MG

20%

60.68°

2.5°

2.5°

50.68°

20%

Q

b

U

50°

40°

30°

20°

10°

cy

2.5 IRE

10°

70.68°

10°

Figure 2-13: Fine detail of the 1720 graticule magenta target.

On the 1721 graticule, each chrominance vector related to the +V burst

terminates in targets that are in the shape of two boxes (a small box inside a large

box). See Figure 2-14. The large box represents ±10° centered on the exact

chrominance phase and ±20% of chrominance amplitude centered around 100%

standard amplitude. The dimensions of the inner target represent ±3° and ±5%

of chrominance amplitude; the vectors associated with the --V burst terminate in

the smaller targets.

2- 20

1720/1721

Page 49

Operating Instructions

MG

20%

60.65°

3°

3°

50.65°

20%

Q

b

U

50°

40°

30°

20°

10°

cy

10°

70.65°

5%

10°

Figure 2-14: Fine detail of the 1721 graticule target.

On the 1720, the small marks at intervals along the I and Q axes denote the

amplitudes of the chrominance components (see Figure 2-15). On the 1721, the

small marks at intervals along the U and V axes denote the amplitudes of the U

and V chrominance components (see Figure 2-16).

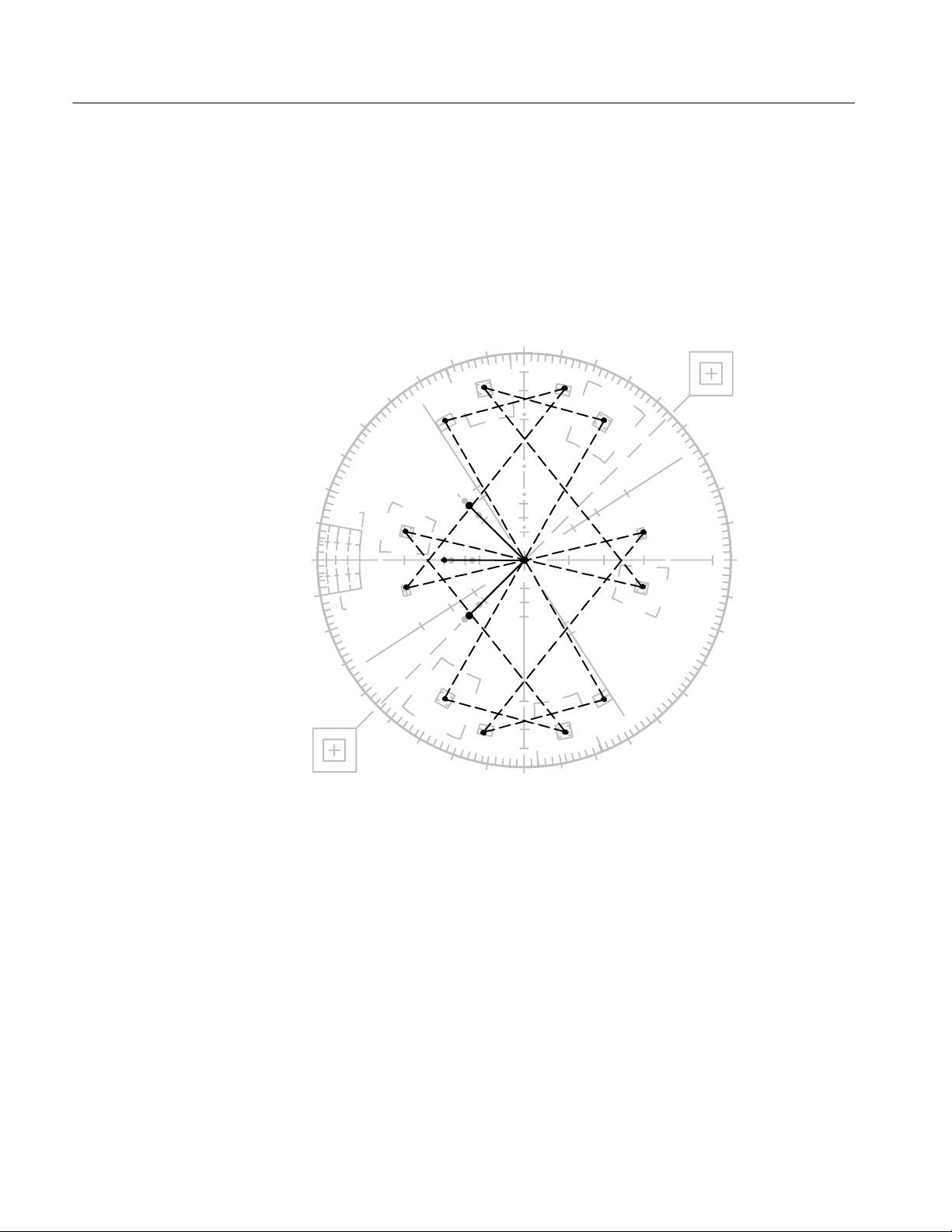

R--Y

+I

123°

I

90°

R

MG

+Q

33°

Q

BURST

180°

YL

B--Y

0°

B

-- Q

213°

G

CY

270°

-- I

303°

Figure 2-15: Simulated 1720 graticule showing the relationship between amplitudes

on the I and Q modulation axes and the location of the color vector targets.

1720/1721

2- 21

Page 50

Operating Instructions

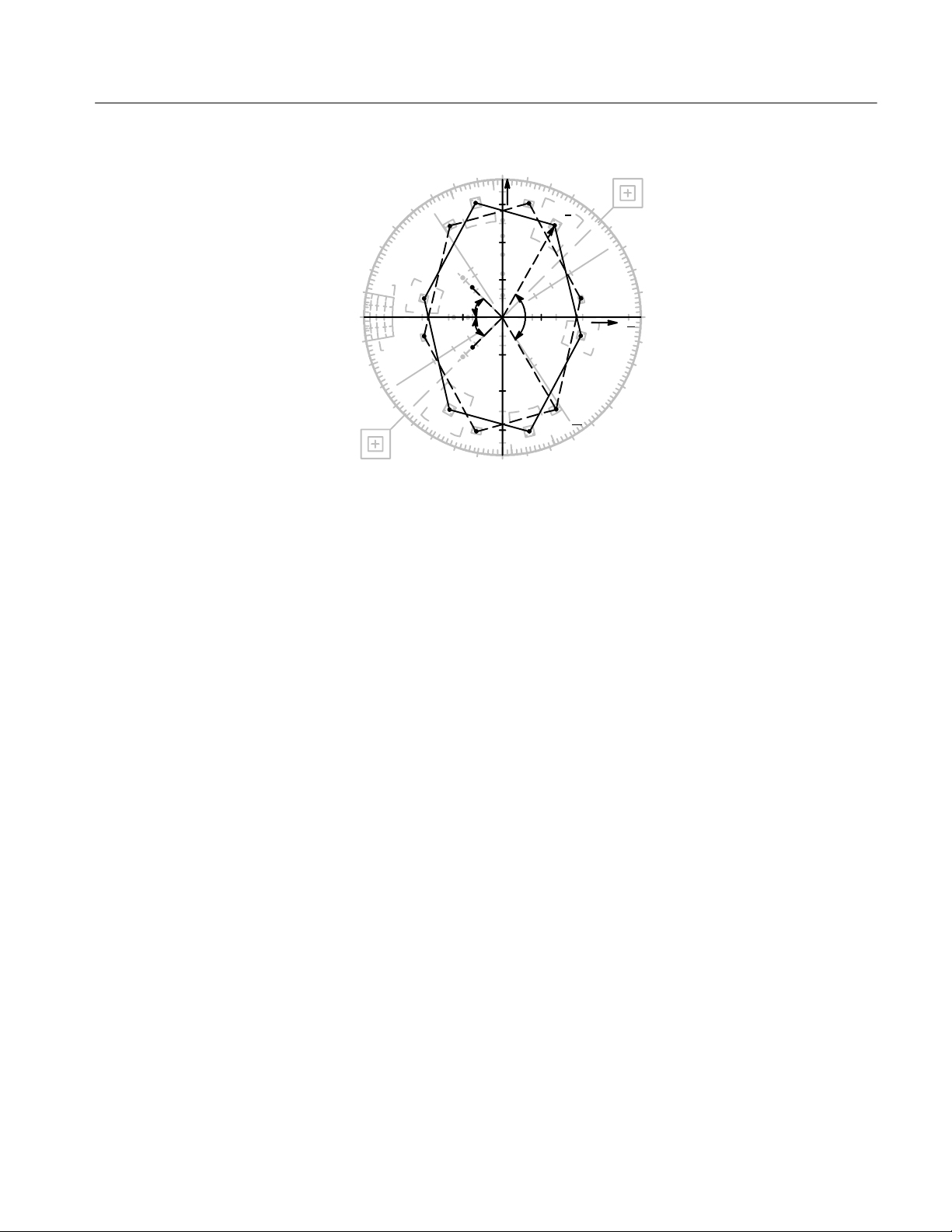

V

90°

+V BURST

135°

R

g

cy

MG

Q

mg

b

U

0°

B

180°

--V BURST

225°

YL

yl

G

r

CY

270°

Figure 2-16: Simulation of a 1721 graticule showing the relationship between

amplitudes on the U and V axes and the locations of the color vector targets.

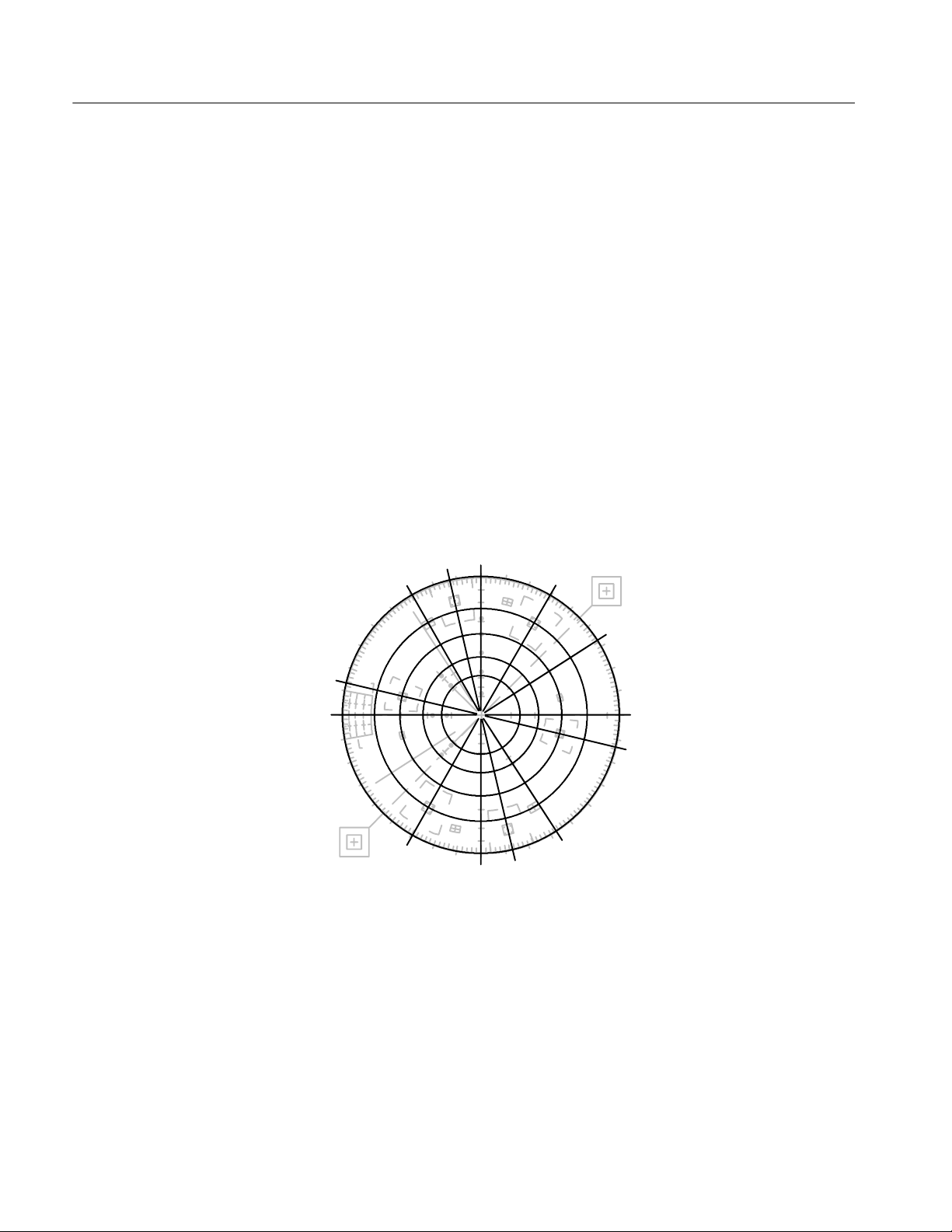

The horizontal and vertical axes of the vector graticule contain markings for

checking Vector Mode bandwidth. A subcarrier frequency sine wave whose

amplitude places it on the outer compass rose is used as a reference. When the

frequency is changed the diameter of the circle should reduce. At a point equal

to 70% of full amplitude (3 dB), there are gaps in the horizontal and vertical

axes. This calibration aid makes it possible to check the --3 dB points of the

demodulator output amplifiers.

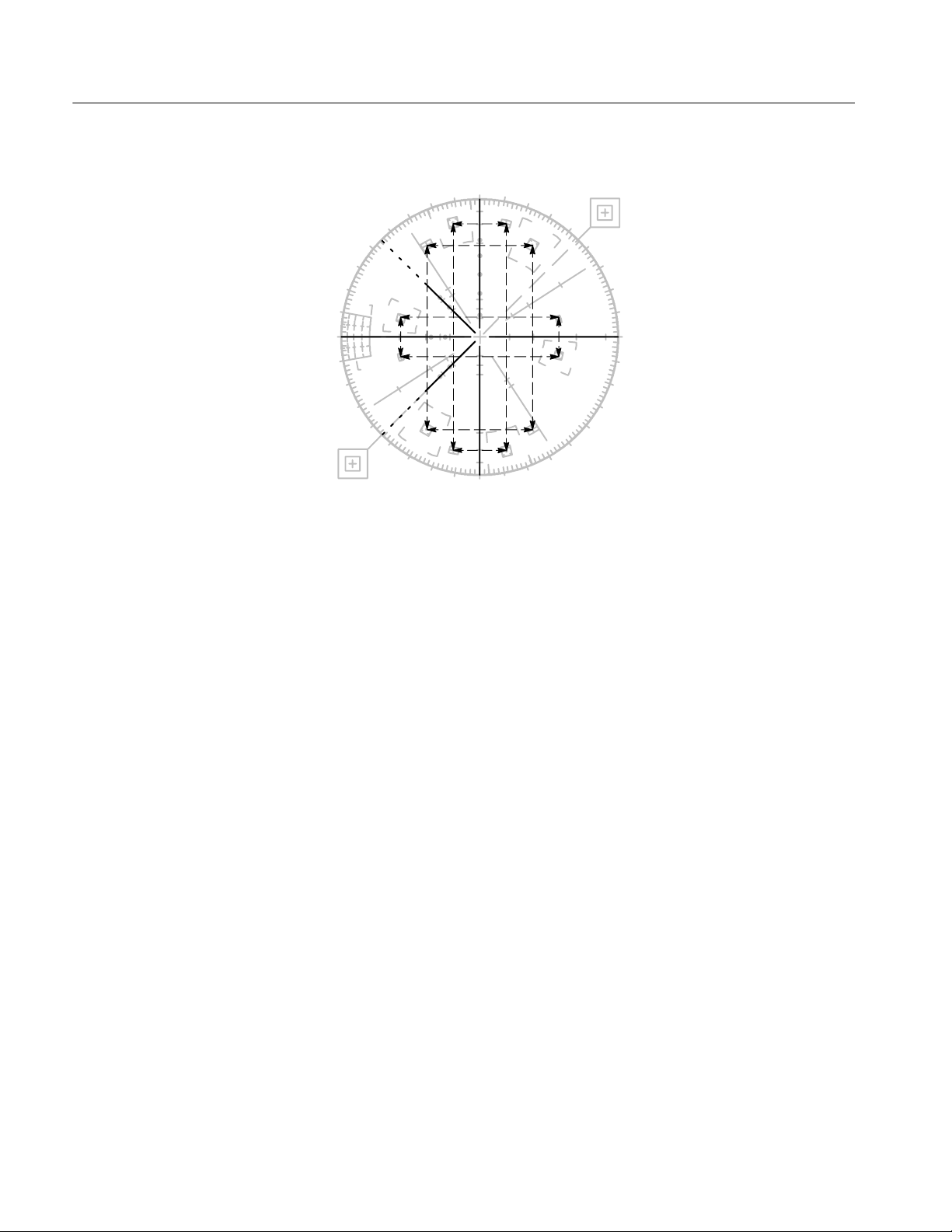

Differential Gain and

Phase Measurements

2- 22

The two major distortions that affect the signal are differential gain and

differential phase. They are chrominance non-linearities caused by luminance

amplitude variations. Both can be measured on the vectorscope. Differential

gain is a change in color subcarrier amplitude due to a change in the luminance

signal while the hue of the original signal is held constant. In the reproduced

picture, saturation will be distorted in the areas between the light and dark

portions of the scene. Differential phase is a phase change of the chrominance

signal, caused by a change in the luminance signal, while the original chrominance signal amplitude is held constant. In the reproduced picture, the hue will

vary with the scene brightness. Differential gain and differential phase may

occur separately or together.

1720/1721

Page 51

Operating Instructions