Page 1

Instruction Manual

1705A

Spectrum Monitor (SN B040000 and Above)

070-8222-08

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - FAX 781.665.0780 - TestEquipmentDepot.com

Page 2

Table of Contents

General Safety Summary ix..............................................

Service Safety Summary xi..............................................

Preface xiii.............................................................

Contacting Tektronix xv

Introduction

Section 1 Introduction 1--1................................................

Typical Configurations 1--1...................................................

Options 1--2...............................................................

Accessories 1--2............................................................

Standard Accessories 1--2.................................................

Optional Accessories 1 --3.................................................

Safety Information 1--3......................................................

ELECTRICAL SPECIFICATION 1--4..........................................

APPLICA TIONS 1--9........................................................

Locating Satellites 1-- 9...................................................

Satellite Footprints 1--10...................................................

Using the 1705A for Satellite Communication 1--11................................

L--Band Input Signals 1--12....................................................

Zeroing in on a Satellite 1--13..................................................

Locating the Satellite 1--13.................................................

Identifying the Satellite 1--13...............................................

Finding The Correct Transponder 1--15.......................................

Optimize Signal Strength 1--15..............................................

Looking at Exciters with the 70 MHz Input 1--16...............................

Miscellaneous Uses for the 1705A 1--17..........................................

Operating Instructions

Section 2 Operating Instructions 2--1.......................................

Front-panel Controls and Indicators 2--1.........................................

FILTER 2--1............................................................

INPUT 2--1............................................................

SWEEP 2--2............................................................

DISPLAY 2--3..........................................................

POSITION 2--4.........................................................

POWER 2--4...........................................................

Rear--Panel Connectors 2--4...................................................

INPUTS 2--4...........................................................

POWER 2--5...........................................................

Powering--up 2--6...........................................................

Measurement Graticule 2--7...................................................

1705A Spectrum Monitor

i

Page 3

Table of Contents

Installation

Section 3 Installation 3--1.................................................

Vertical Scales 2--7......................................................

Horizontal Scales 2 --9....................................................

Center Frequency Readout 2--11................................................

Customizing Frequency Readout 2--14...........................................

Turning On or Off Readout 2--14............................................

Changing Readout Position 2--14............................................

Changing Readout Frequency 2--15..........................................

Test Mode 2--17..........................................................

Locating Ku--Band Satellites 2--17..............................................

Basic Operating Procedure 2--17............................................

Packaging 3--1..........................................................

Electrical Installation 3--1....................................................

Power Source 3--1.......................................................

Mains Frequency and Voltage Ranges 3--1....................................

+18 Volts For Block Down Converter 3--1....................................

Operating Options 3--2...................................................

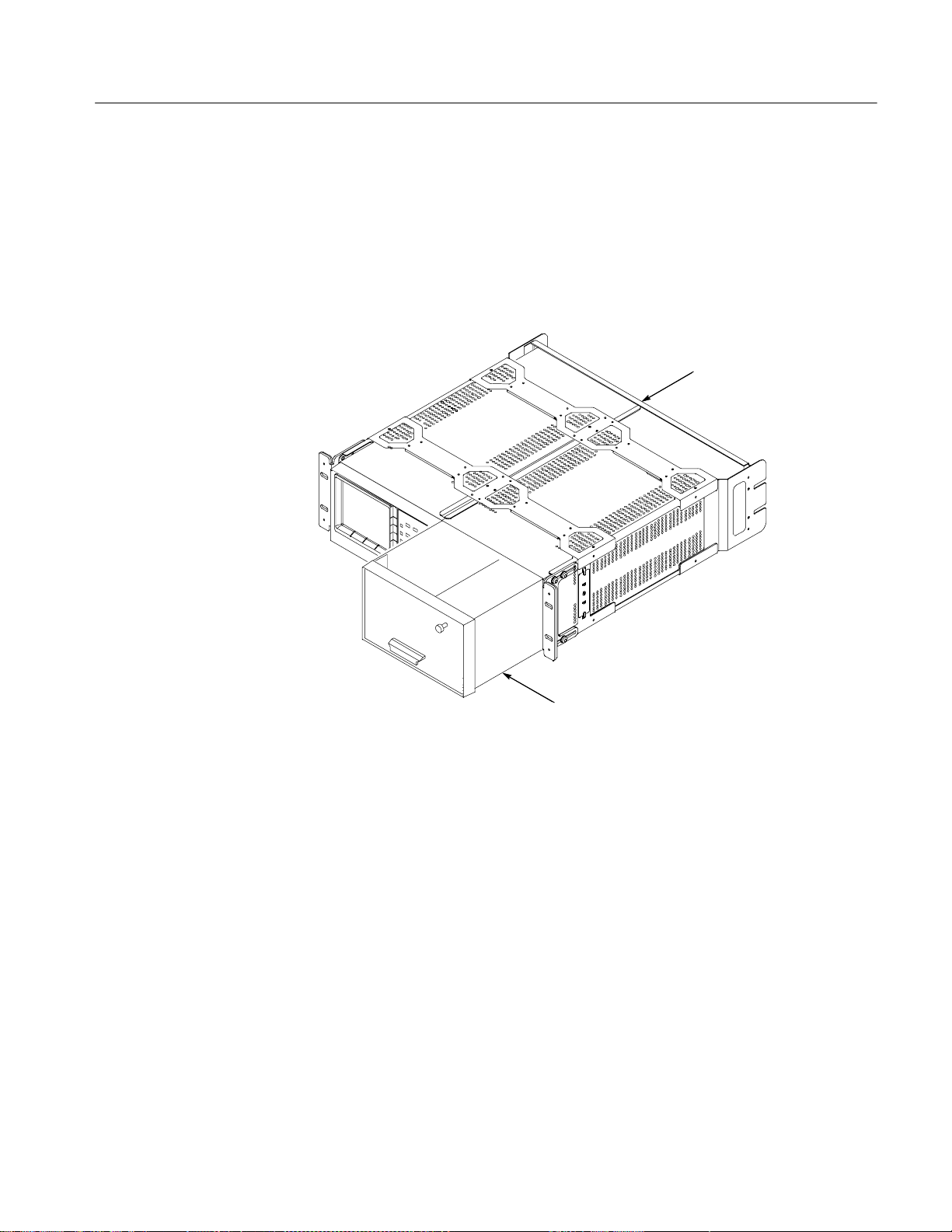

Mechanical Installation 3--2...................................................

Cabinet Options 3--2.....................................................

Cabinetizing 3--4........................................................

Rack Adapter 3--5.......................................................

Custom Installation 3--8..................................................

Theory of Operation

Section 4 Theory of Operation 4--1.........................................

Overview 4--1..............................................................

Block Diagram 4--1.........................................................

RF Input Circuits (Diagram 1) 4--1..........................................

IF Amplifier Circuits (Diagram 2) 4--2.......................................

Sweep Generator Circuits (Diagram 3) 4--2...................................

Deflection Amplifiers (Diagram 4) 4--3......................................

Microprocessor (Diagram 5) 4--3...........................................

Front Panel (Diagram 6) 4--3..............................................

Low Voltage Power Supply (Diagram 7) 4--3..................................

High Voltage (Diagram 8) 4--4.............................................

RF Input

L--Band Input 4--4.......................................................

70 MHz Input 4--4.......................................................

70 MHz Local Oscillator 4--5..............................................

IF Amplifier

2nd Local Oscillator 4--5..................................................

Input Filter, Mixer, and IF Amplifier 4--6.....................................

Resolution Filter and Log Detector 4--6......................................

Sweep Generator

Diagram 1 4--4..................................................

Diagram 2 4--5..................................................

Diagram 3 4--7..................................................

ii

1705A Spectrum Monitor

Page 4

Ramp Generator 4--7.....................................................

Gain Control (SPAN/DIV) 4--7.............................................

Sweep Shapers 4--7......................................................

Bright--Up Generator 4--8.................................................

Z--Axis Control 4--9.....................................................

Deflection Amplifiers

Diagram 4 4--9..................................................

Buffers 4--9............................................................

Vertical Deflection Amplifier 4 --10..........................................

Horizontal Deflection Amplifier 4--10........................................

Microprocessor

Diagram 5 4--11..................................................

Microprocessor 4--11......................................................

Readout 4--12...........................................................

Trace Rotate 4--12........................................................

Graticule Lights 4--12.....................................................

Front Panel

Diagram 6 4--12..................................................

Indicators, Controls, and Switches 4--12......................................

+18 Volt Supply 4--13.....................................................

Low Voltage Power Supply

Diagram 7 4--14..................................................

Line Rectifier and Filter 4--15..............................................

Pulse Width Modulator 4--15...............................................

Output Filters 4--16.......................................................

Error Amplifier 4--16.....................................................

Feedback Transformer Driver and Peak Detector 4--16...........................

Output Under-Voltage Shutdown 4--16........................................

High Voltage Power Supply

Diagram 8 4--17..................................................

HV Osc and Error Amp 4--17...............................................

Power Supply Outputs 4--18................................................

Focus Amplifier 4 --18.....................................................

Grid Drive Circuit 4--18...................................................

Z-Axis Amplifier 4--18....................................................

Table of Contents

Checks and Adjustments

Section 5 Checks And Adjustments 5--1.....................................

Recommended Equipment List 5--1.............................................

Electrical Instruments 5--1................................................

Auxiliary Equipment 5 --2.................................................

Performance Check 5--3......................................................

Short-Form Procedure 5--3................................................

Long Form Procedure 5--5................................................

Adjustment Procedure 5--17....................................................

1705A Spectrum Monitor

iii

Page 5

Table of Contents

Short--Form Procedure 5--17................................................

Long Form Procedure 5--18................................................

Maintenance 6- - 1..........................................

Section 6 Maintenance 6--1................................................

PREVENTIVE MAINTENANCE 6--1..........................................

Cleaning 6--1...........................................................

V isual Inspection 6--2....................................................

Static--Sensitive Components 6--2..........................................

Performance Checks and Readjustments 6--3..................................

TROUBLESHOOTING 6--3..................................................

Diagnostic Routines 6--4.....................................................

Memory Test 6--5.......................................................

DAC Test 6--7..........................................................

LED and Key Tests 6-- 8..................................................

Troubleshooting Aids 6--8....................................................

Foldout Pages 6--8.......................................................

Parts Lists 6--9..........................................................

Major Assembly Interconnection 6--10........................................

General Troubleshooting Techniques 6--10....................................

Power Supply Troubleshooting Procedure 6--12....................................

Introduction 6--12........................................................

Low Volts Supply 6--13....................................................

High Volts Supply 6--15...................................................

CORRECTIVE MAINTENANCE 6--18..........................................

Obtaining Replacement Parts 6--18..............................................

Test Selected Components 6--18.............................................

Mechanical Disassembly/Assembly 6--19.........................................

Bezel Removal 6-- 19......................................................

Graticule Light Removal and Replacement 6--20...............................

Removal of the CRT 6--21.................................................

Replacing the CRT 6--21...................................................

Removal of the Rear Panel 6--22............................................

Removal of Front--Panel Assembly 6--22......................................

Removing the L--Band Tuner 6--23..........................................

Removing the 70 MHz Tuner 6--24..........................................

Removal and Replacement of the Main Board 6--24.............................

Removal and Replacement of the Power Supply Board 6--25......................

Removing the LNB Power Supply Board 6--26.................................

REPACKAGING 6--27........................................................

Options

iv

Section 7 Options 7--1....................................................

Options 7--1...............................................................

Field Upgrade Kits 7--1......................................................

ORDERING 7--2...........................................................

1705A Spectrum Monitor

Page 6

Replaceable Electrical Parts

Section 8 Replaceable Electrical Parts 8--1...................................

Parts Ordering Information 8-- 1................................................

Using the Replaceable Electrical Parts List 8--1...................................

Cross Index--Mfr. Code Number to Manufacturer 8--1...........................

Abbreviations 8--1.......................................................

List of Assemblies 8--1...................................................

Column Descriptions 8--2.....................................................

Component No. (Column 1) 8--2.........................................

Tektronix Part No. (Column 2) 8--2.........................................

Serial/Assembly No. (Column 3 a nd 4) 8--2...................................

Name and Description (Column 5) 8--2......................................

Mfr. Code (Column 6) 8--2........................................

Mfr. Part No. (Column 7) 8--2..............................................

Diagrams/Circuit Board Illustrations

Replaceable Mechanical Parts

Table of Contents

Section 10 Replaceable Mechanical Parts 10--1................................

Parts Ordering Information 10--1................................................

Using the Replaceable Mechanical Parts List 10--1.................................

1705A Spectrum Monitor

v

Page 7

Table of Contents

List of Figures

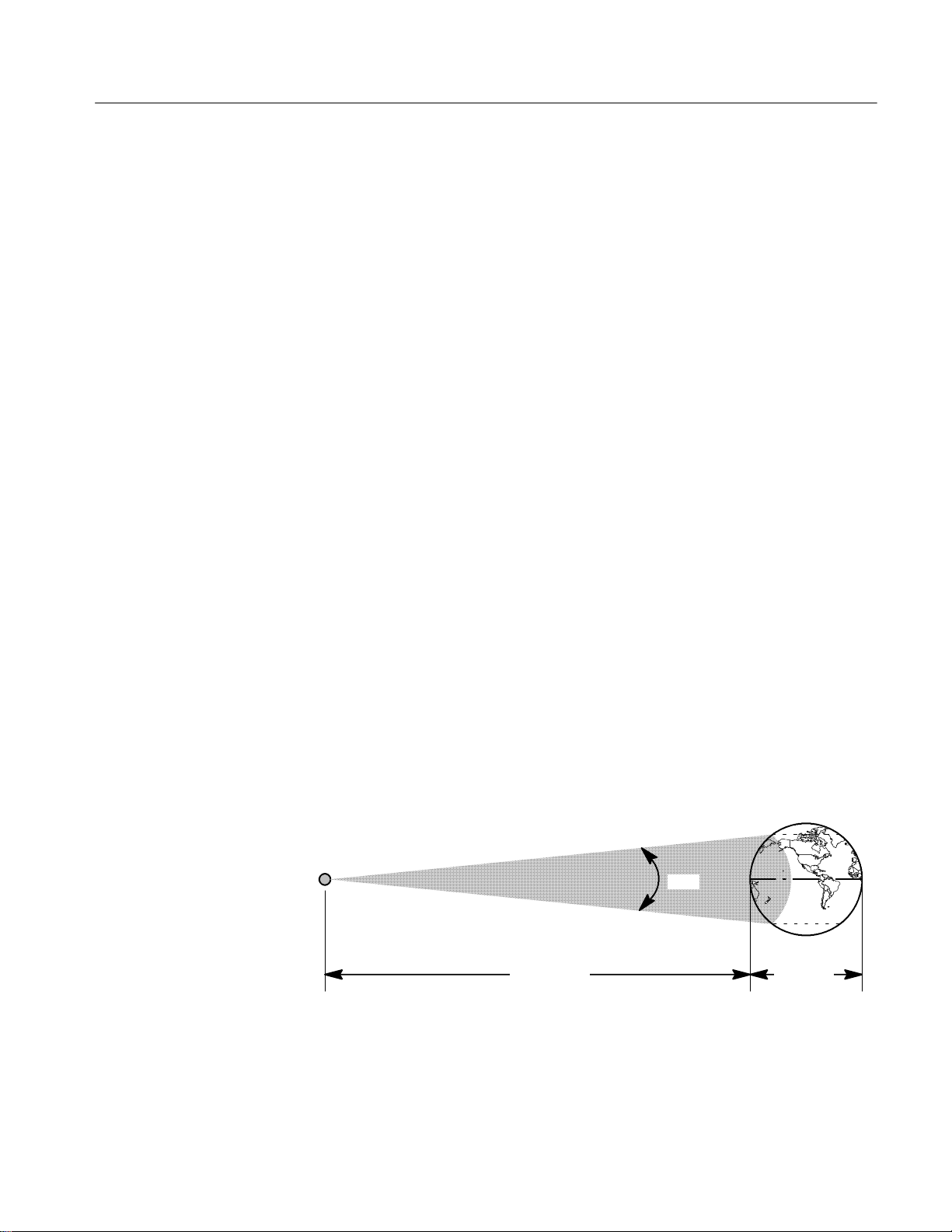

Figure 1-1: 1705A used to locate satellites and determine maximum signal level 1--2.........

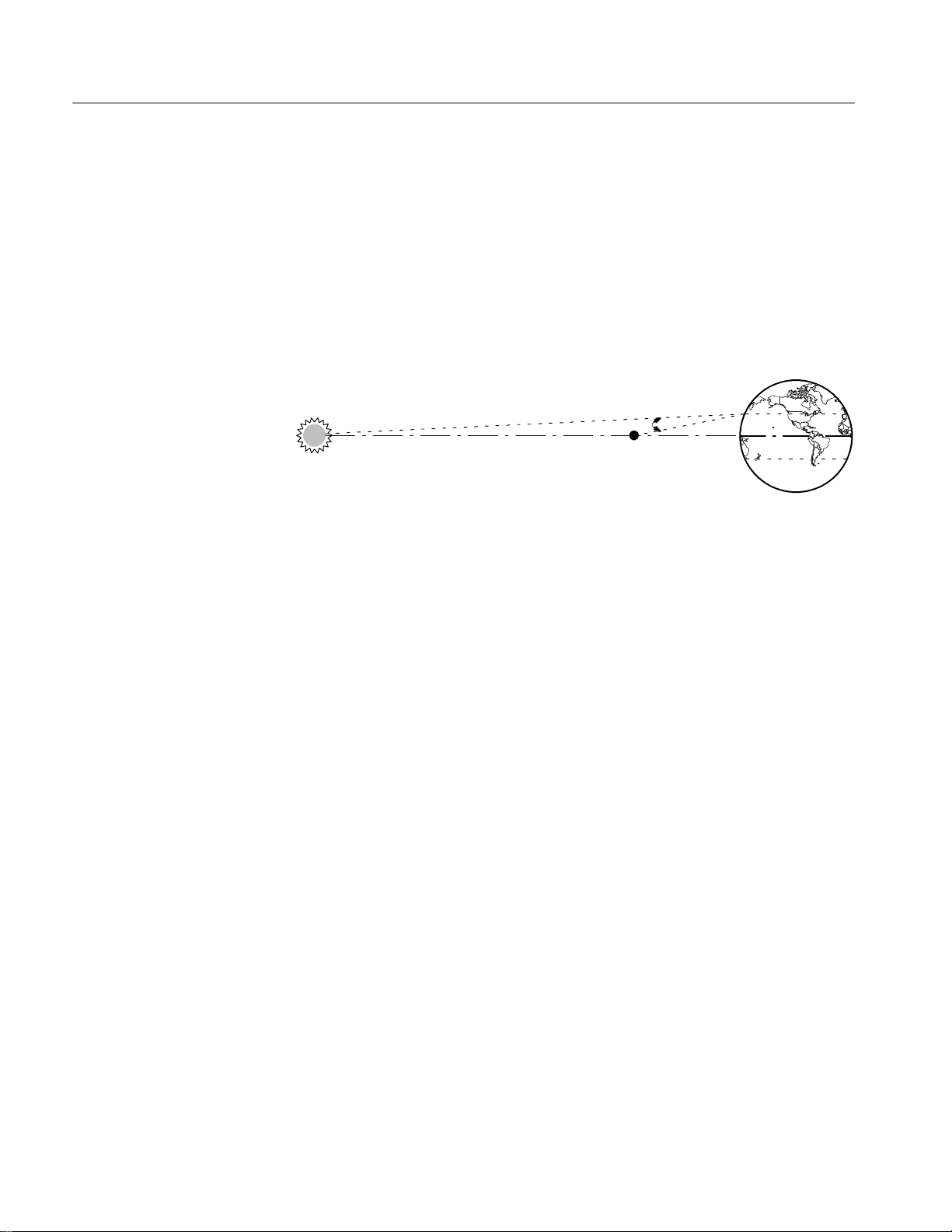

Figure 1-2: Relationship of a communications satellite to earth 1--9.......................

Figure 1-3: Angle A (the difference at a specific latitude between the angle to the sun

and the angle to a satellite) 1--10.........................................

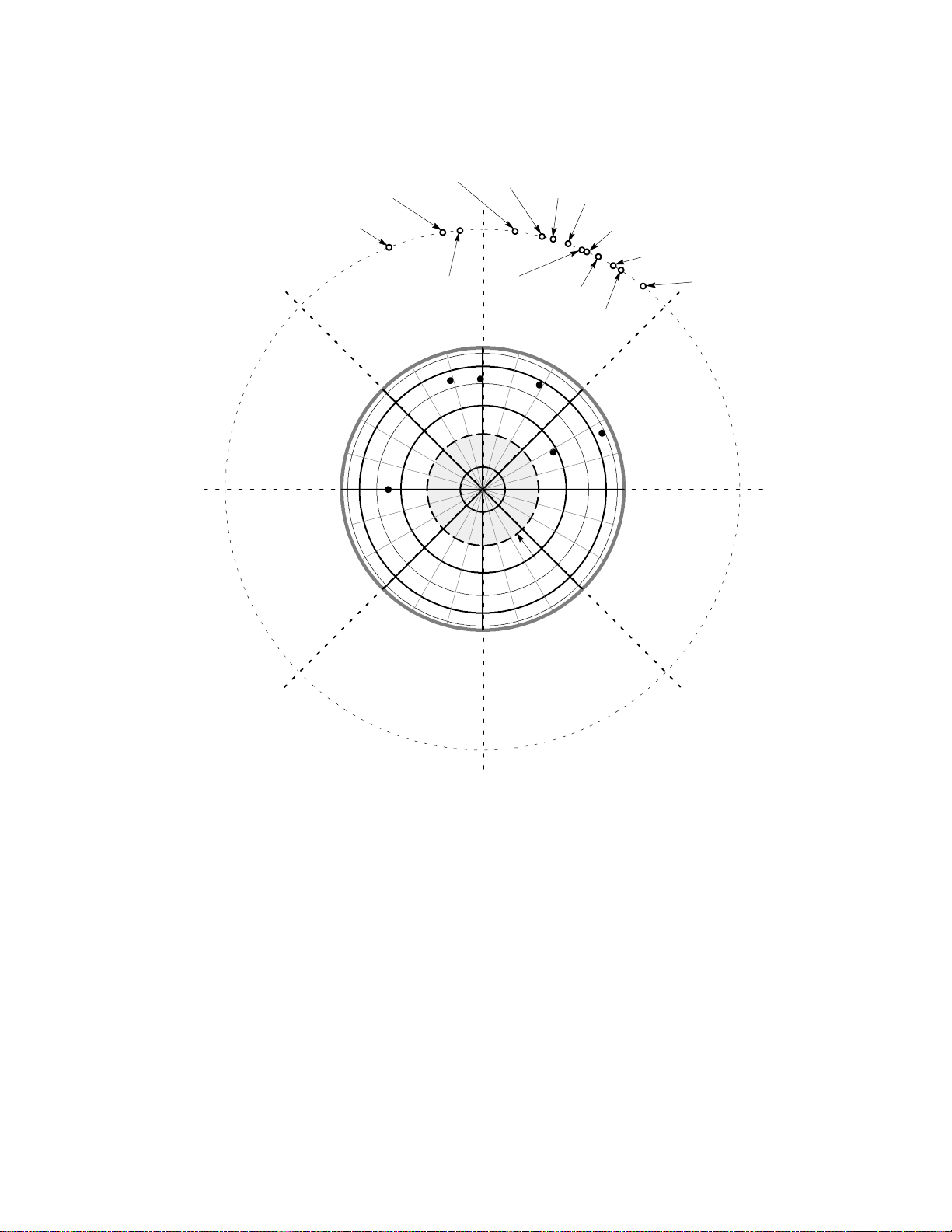

Figure 1-4: Sample longitudinal map of the Ku-Band satellites 1--11.......................

Figure 1-5: The western spot beam footprint for one Ku-Band satellite 1--12.................

Figure 1-6: A computer representation of the 1705A display showing the 12.198 GHz

horizontally polarized telemetry beacon on the SATCOM K2 satellite 1--14........

Figure 1-7: Transponder assignments for a typical Ku--Band, 16--transponder satellite

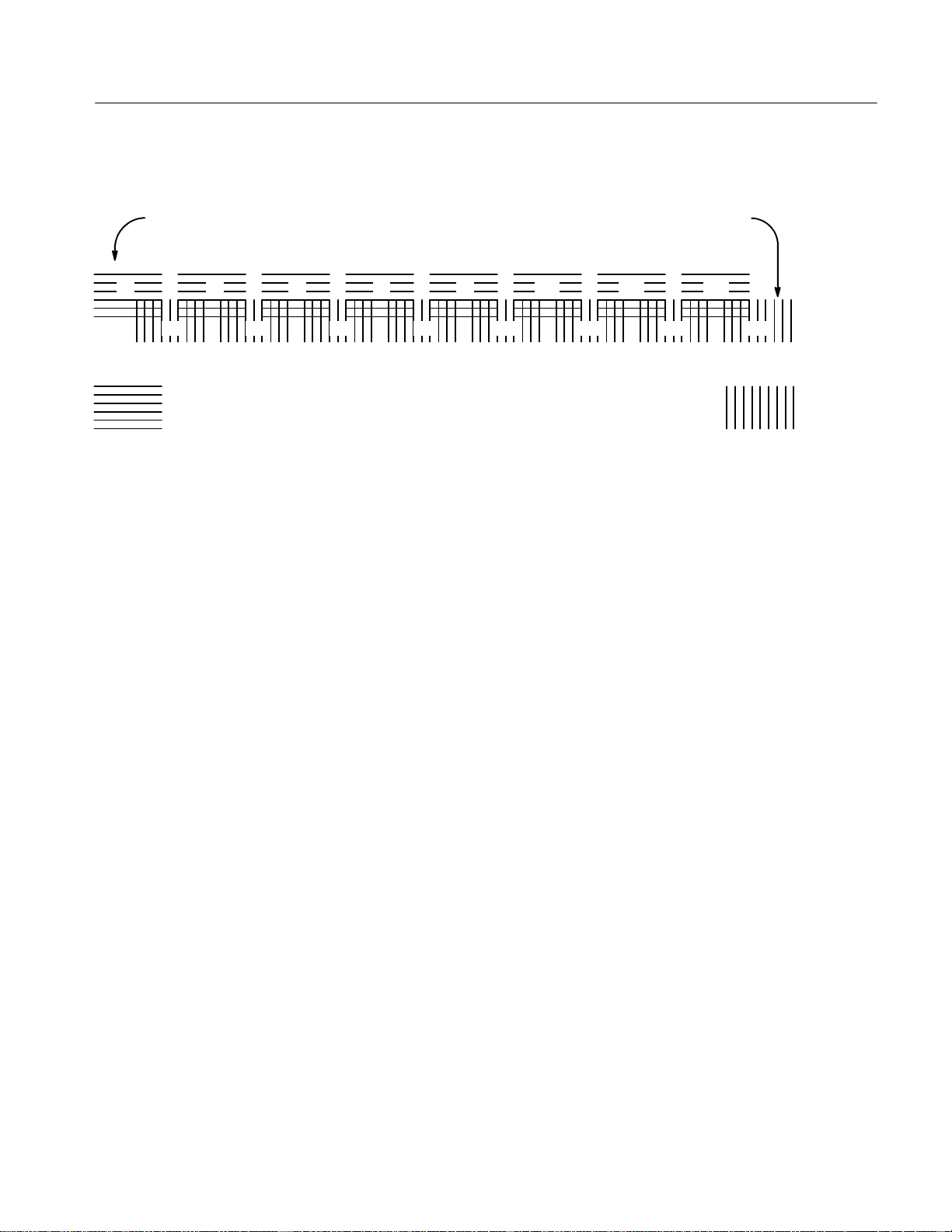

that employs alternate polarization 1--15....................................

Figure 1-8: Simulation of a 1705A FULL SPAN/DIV display 1--16.......................

Figure 1-9: Up link Video Exciter, Up converter, and High Power Amplifier (HPA) showing

how to hook up a 1705A Spectrum Monitor to look at the Video Exciter output 1--17

Figure 1-10: 1705A hooked up to look at either the output of the Video Exciter (70 MHz)

or the Receiver Input (L-Band) 1--18.......................................

Figure 2-1: 1705A front panel 2--2.................................................

Figure 2-2: 1705A rear panel controls and connectors 2--5..............................

Figure 2-3: 1705A display when powered up in L-BAND and FULL SPAN 2--6.............

Figure 2-4: 1705A graticule scale 2--7..............................................

Figure 2-5: Relationship of sweep to graticule showing minimum and maximum frequencies 2--10

Figure 2-6: Frequency relationship to horizontal graticule scale 2--11.......................

Figure 2-7: Center frequency cursor and readout for the L-Band with FULL SPAN/DIV 2--12...

Figure 2-8: 1705A CRT with the SCALE turned down 2--13.............................

Figure 2-9: The setting of the HORIZONTAL POSITION control can displace the location

of the displayed center frequency 2--13.....................................

Figure 2-10: Using the 1705A menus 2--15...........................................

Figure 2-11: An example of the readout displayed while satellite frequency is being set 2--16....

Figure 3-1: L-BAND INPUT connector and controls 3--2...............................

Figure 3-2: Dimensions of the 1700F00 plain cabinet 3--3...............................

Figure 3-3: 1700F02 portable cabinet dimensions 3--4..................................

Figure 3-4: Cabinet securing screws 3--5............................................

Figure 3-5: The WFM7F05 side-by-side rack adapter 3--5...............................

Figure 3-6: A WFM7F05 with a blank front panel (1700F06) 3--6........................

Figure 3-7: WFM7F05 rack mount cabinet with a 1700F06 utility drawer 3--7...............

vi

1705A Spectrum Monitor

Page 8

Table of Contents

Figure 3-8: Considerations for custom installation of an instrument 3--8....................

Figure 4-1: 1705A L--Band comb display showing the areas each of the six sweep shaper

variable resistors adjust 4--8.............................................

Figure 4-2: Output duty cycle of the pulse width modulator used in the +18 V Power Supply 4--13

Figure 4-3: Pinout of the CRT Socket 4--19...........................................

Figure 5-1: Initial equipment connections 5--6........................................

Figure 5-2: Check time mark graticule alignment 5--8..................................

Figure 5-3: Output of the SG503 connected directly to the 1705A 70 MHz INPUT 5--9.......

Figure 5-4: Equipment connections for L--Band checkout 5--12...........................

Figure 5-5: Aligning L--Band time markers with the graticule lines 5--13....................

Figure 5-6: Using the UHF Signal Generator to check L--Band Span/Division, Readout, Gain,

and Flatness 5--14.....................................................

Figure 5-7: Adjustment locations 5--19...............................................

Figure 5-8: DAC check waveforms used to check Focus, Astigmatism, Geometry, and setting

of the Trace Rotation 5--20..............................................

Figure 5-9: Location of the shorting strap used when adjusting sweep length 5--21............

Figure 6-1: Using the 1705A menus 6--4............................................

Figure 6-2: 1705A Test menu, displayed when Test is the Main menu selection 6--5..........

Figure 6-3: 1705A CRT display when the NOVRAM Test has been successfully completed 6--6

Figure 6-4: 1705A power up error message 6--7.......................................

Figure 6-5: DAC check waveform 6--8.............................................

Figure 6-6: Circuit board assembly locations 6--9.....................................

Figure 6-7: Multiple pin connectors used in the 1705A Spectrum Monitor 6--11..............

Figure 6-8: Bezel securing screws 6--20..............................................

Figure 6-9: Screws securing the rear panel 6--22.......................................

Figure 6-10: Screws securing the front panel board (A2) in place 6--23.....................

Figure 6-11: Screws holding the Main board (A3) and the Tuners (A5 and A6) in place 6--24....

Figure 6-12: Removing the Power Supply board 6--26...................................

Figure 6-13: Mounting screws for the LNB Power Supply circuit board, A4 6--26.............

Figure 6-14: Repackaging a 1705A instrument 6--27....................................

1705A Spectrum Monitor

vii

Page 9

Table of Contents

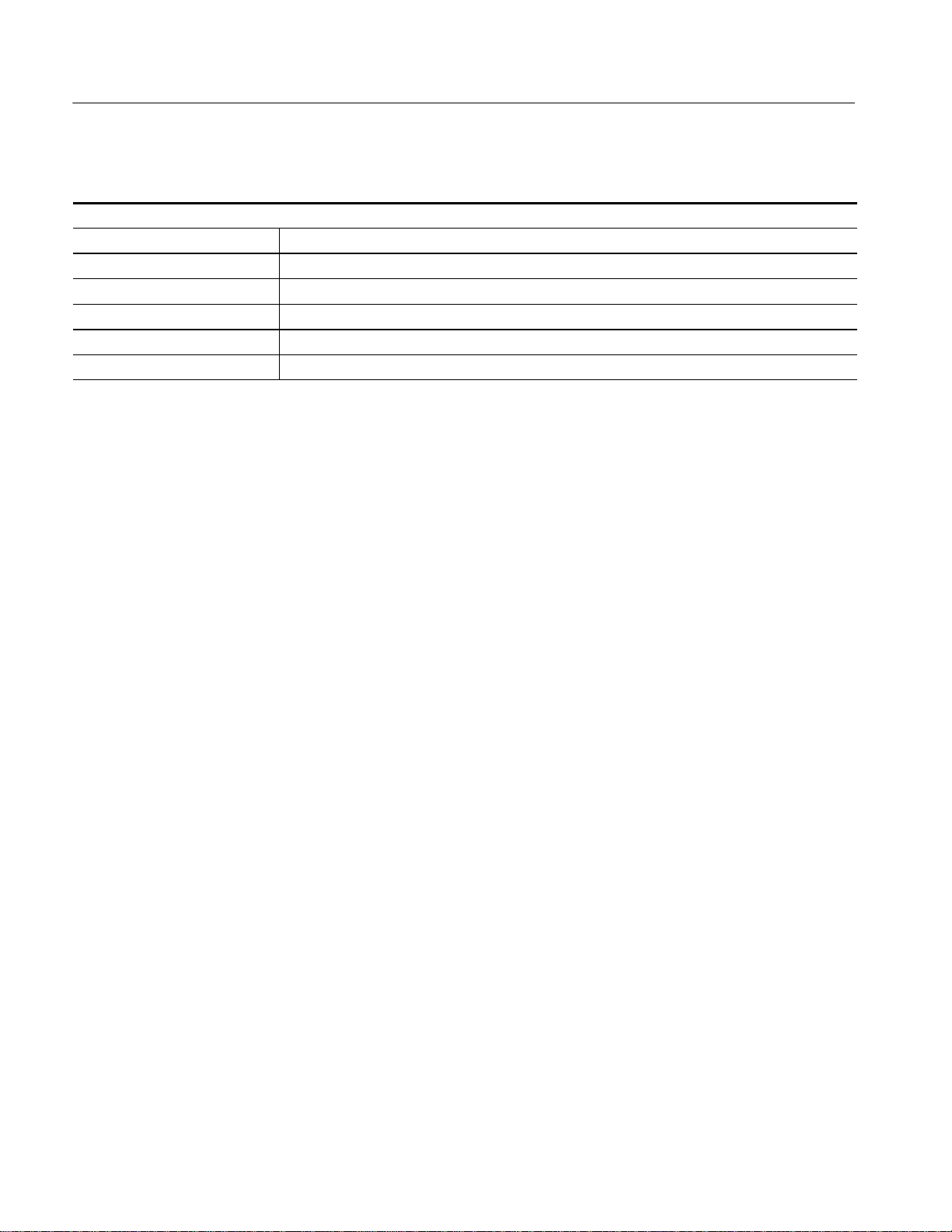

List of Tables

Table 1--1: Spectrum Display 1--4.................................................

Table 1--2: CRT Display 1--5.....................................................

Table 1--3: Power Source 1--5....................................................

Table 1--4: Environmental Characteristics 1--6.......................................

Table 1--5: Physical Characteristics 1--6............................................

Table 1--6: Certifications and Compliances 1--6......................................

Table 2--1: dB Reference 2--8.....................................................

Table 2--2: dBm to mv Conversion 2--9............................................

Table 2--3: Azimuth / Elevation Table for 21 CONUS Cities 2--18........................

Table 3--1: Internal Jumper Selection 3--2...........................................

Table 5--1: Preliminary Control Settings 5--6.........................................

Table 5--2: Preliminary Control Settings 5--18.........................................

Table 6--1: Static Susceptibility 6--2................................................

Table 6--2: Power Supply Fault Symptoms 6--12......................................

Table 6--3: Low Volts Supply Voltages 6--13.........................................

Table 6--4: Control Circuit Test Points 6--15..........................................

Table 6--5: High Volts Supply Fault Symptoms 6--16...................................

Table 6--6: High Voltage Oscillator Test Points 6--17...................................

Table 6--7: Test Selectable Components 6--19.........................................

Table 7--1: Power Cord Options 7--1...............................................

viii

1705A Spectrum Monitor

Page 10

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the ground lead of the probe to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

1705A Spectrum Monitor

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

ix

Page 11

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

x

1705A Spectrum Monitor

Page 12

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

1705A Spectrum Monitor

xi

Page 13

Service Safety Summary

xii

1705A Spectrum Monitor

Page 14

Preface

The information in this manual is intended for instrument operators and service

technicians. Operators are assumed to befamiliar with basic television terms and

measurements. Qualified service technicians are also assumed to be familiar with

television terms and measurements, and have moderate experience with analog

and logic circuits.

The manual is divided into two parts: Operator’s Information and Service

Information. The Operator’s Information is useful to both operators and service

technicians. The Service Information is intended only for qualified service

technicians.

Section 1, Introduction

Section 2, Operating

Instructions

Section 3, Installation

Section 4, Theory of

Operation

Section 5, Checks and

Adjustments

Section 1, Introduction, includes a general description of the instrument followed

by the Specifications. The Specifications include references to the corresponding Performance check steps.

Section 2, Operating Instructions, familiarizes the user with the front-- and

rear--panel controls, connectors, and indicators; includes an operator’s check-out

procedure; and includes other operator familiarization information.

Section 3, Installation, includes electrical and mechanical installation information. The electrical installation information includes adjustments and operational

changes available with the instrument. The mechanical installation information

includes rackmounting, custom installation, and portable use.

Section 4, Theory of Operation, provides an over-all block diagram description and

detailed circuit descriptions. Read the block diagram description for an overview of the

instrument. The detailed circuit descriptions should be used with the block diagram and

schematic diagrams in the foldout pages for specific information about individual

circuits.

Section 5, Checks and Adjustments, includes the Performance Check Procedure and the

Adjustment Procedure. The Performance Check Procedure is used to verify that the

instrument’s performance is within its specifications, and the Adjustment Procedure is

used to adjust the instrument to meet its specifications. The procedures are preceded by

a list of recommended test equipment. Each procedure has a short form listing of the

individual steps.

Section 6, Maintenance

1705A Spectrum Monitor

Section 6, Maintenance, includes preventive, troubleshooting, and corrective

information.

xiii

Page 15

Preface

Section 7, Options

Section 8, Replaceable

Electrical Parts

Section 9, Diagrams

Section 10, Replaceable

Mechanical Parts

Section 7, Options, documents instrument options. The information in this

section summarizes the options. Additional details are included in appro-priate

places throughout the manual.

Section 8, Replaceable Electrical Parts, includes order information and part

numbers for all replaceable electrical parts.

Section 9, Diagrams, contains servicing illustra-tions. These include adjustment

locations, circuit board part locations, a block diagram, and schematic diagrams.

Parts locating tables are included that cross--reference the circuit board illustrations to the schematic diagrams.

Section 10, Replaceable Mechanical Parts, includes ordering information and

part numbers for all replaceable mechanical parts. This parts list is referenced to

an exploded view mechanical drawing. Also included are lists of accessories and

optional accessories.

xiv

1705A Spectrum Monitor

Page 16

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

1705A Spectrum Monitor

xv

Page 17

Preface

xvi

1705A Spectrum Monitor

Page 18

Introduction

Page 19

Page 20

Section 1 Introduction

The TEKTRONIX 1705A Spectrum Monitor is an 8½” wide by 5¼” high

special purpose spectrum analyzer. It weighs approximately 8½ pounds and is

powered from an ac source. The crt occupies approximately two-thirds of the

front-panel area, with the control panel taking up the remainder of the space.

Operation is controlled by a microprocessor that polls the front-panel switches.

Front-panel switches are of the momentary touch type with lighted functional

indicators. In addition to polling the front panel, the microprocessor provides

the characters for an alphanumeric crt readout.

The signal is displayed on a bright crt. It is of the mesh type, for better

geometry, and uses an internal graticule to reduce parallax. Variable graticule

scale illumination provides even lighting over the usable graticule area to

improve measurement accuracy and the quality of display photographs.

The 1705A Spectrum Monitor is a swept front-end superheterodyne-type

spectrum analyzer with two inputs; L--Band to accommodate Low-Noise

Amplifier/Block Down Converter (LNB) outputs, and 70 MHz for use with

Video Exciters. The L--Band input (950 to 1800 MHz) is through an F-type

connector, while the 70 MHz input is through a standard bnc connector. The

L--BAND INPUT connector is the output for the selectable 18 V supply that is

the Block Down Converter auxiliary power.

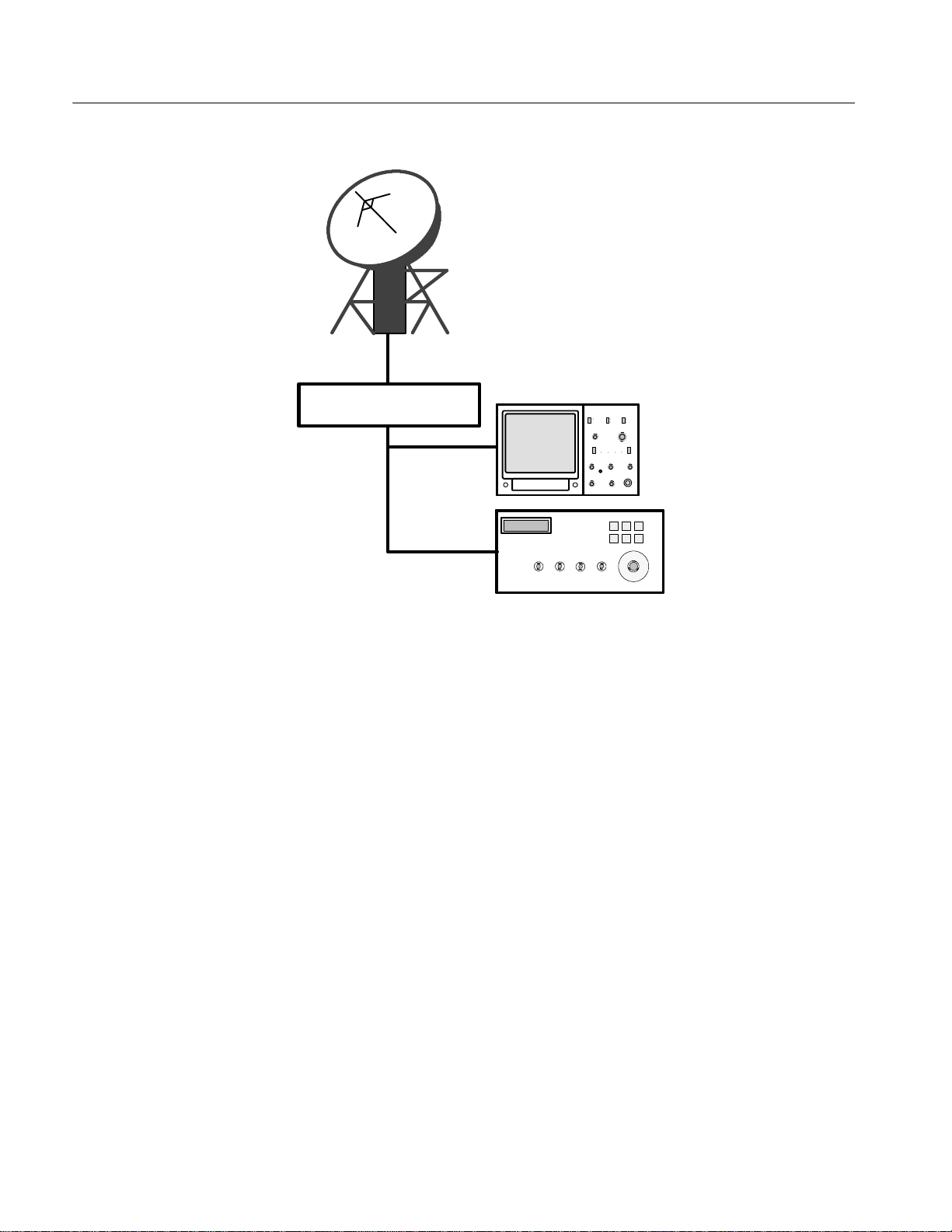

Typical Configurations

1705A Spectrum Monitor

The TEKTRONIX 1705A Spectrum Monitor is designed primarily for use in

locating satellites and monitoring their signals. It is designed so that it can be

rack mounted, in a dual-width rack adapter, along with a half-rack waveform

monitor, such as a TEKTRONIX 1740-Series Waveform/Vector Monitor.

However, it can be used as a portable instrument. It is intended to be connected

to the rf feed with a directional connector. See Figure 1-1. It is capable of

providing the dc power required to run an LNB. The auxiliary LNB power is

turned on or off by a rear-panel slide switch. An indicator on the rear panel

lights when the +18 V supply is operating normally.

1- 1

Page 21

Introduction

LOW-NOISE AMPLIFIER/

BLOCK DOWN CONVERTER

1705A

SPECTRUM MONITOR

Options

Accessories

Standard Accessories

RECEIVER

Figure 1-1: 1705A used to locate satellites and determine maximum signal level

The only options currently available for the 1705A Spectrum Monitor are the

power plug options described in Section 7 (Options). If no power cord options

are ordered, instruments are shipped with the North American 125 V power cord

and one replacement fuse.

1 Manual, Instruction

1 Adapter, F--type Male connector to BNC female connector

1 Power Cord, with the correct plug for the selected power plug option

1 Replacement Cartridge Fuse (correct rating for the power plug option)

1- 2

3 Replacement Scale Illumination Bulbs (Tektronix P/N 150-0168-00 or ANSI

#73)

1705A Spectrum Monitor

Page 22

Introduction

Optional Accessories

Safety Information

Camera, C9 (Option 20)

Viewing Hood (016-0475-00)

Front Panel Cover (200-3897-01)

1700F00, Plain Cabinet (painted silver grey)

1700F02, Portable Cabinet (painted silver grey with handle, feet, and front

cover)

1700F05, Side-by-Side Rack Adapter

1700F06, Blank Half-Rack Width Panel

1700F07, Utility Drawer

The 1705A Spectrum Monitor is intended to operate from an ac power source

that will not apply more than 250 V rms between the supply conductors or

between either supply conductor and ground. A protective ground connection,

by way of the grounding conductor, is essential for safe operation.

The instrument was tested for compliance in a cabinet. To ensure continued

compliance, the instrument will need to be enclosed in a cabinet that is equivalent to those listed as Optional Accessories for the 1705A. A drawing of the

1700F00 plain cabinet is contained in the Installation Instructions (Section 3).

1705A Spectrum Monitor

1- 3

Page 23

Introduction

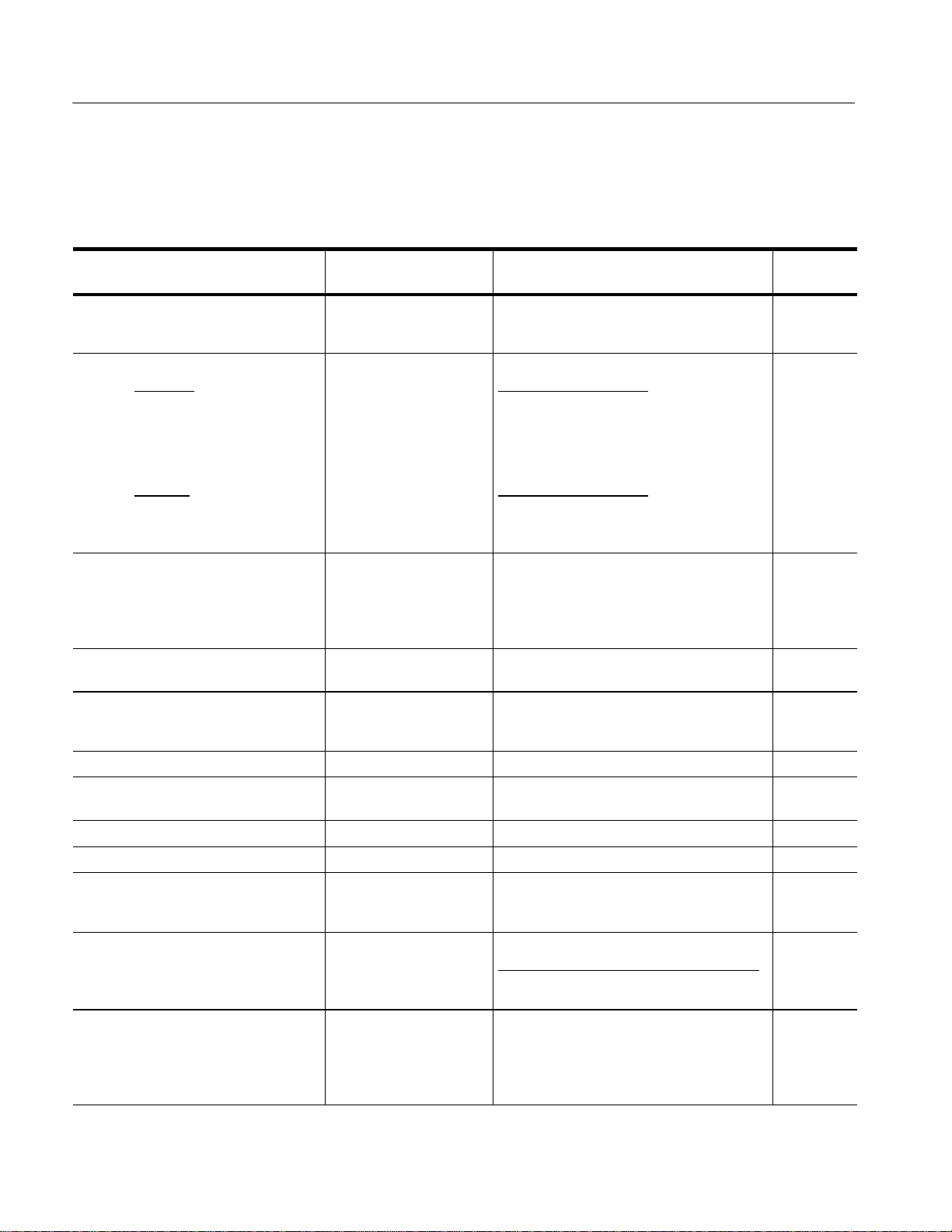

ELECTRICAL SPECIFICATION

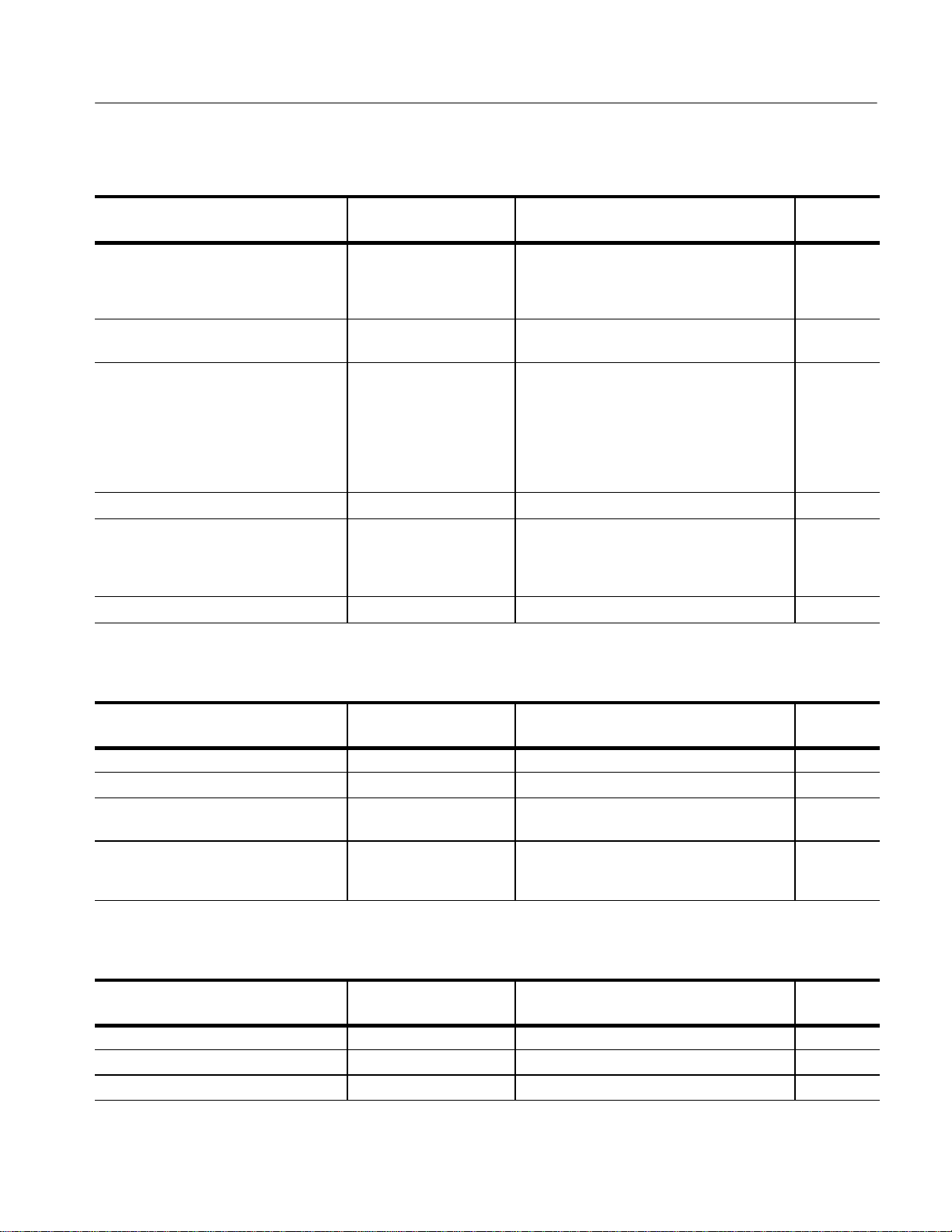

Table 1- 1: Spectrum Display

Performance

Characteristic

Frequency Range

L --- B a n d

70 MHz

Frequency Span

L --- B a n d

Full

10 MHz/Division

1 MHz/Division

100 kHz/Division

70

MHz

Full

1 MHz/Division

100 kHz/Division

Span/Div Accuracy Typically 0.5 minor Division.

Flatness L---Band ±5 dB.

Maximum Signal Input L --- B a n d : --- 3 0 d B m ,

Minimum Signal Input --- 8 0 d B m .

Relative Amplitude Accuracy L---Band (only)

Sweep Length

Sweep Speed Typically 20 --- 200 ms. 9

Positioning Range

Ver ti ca l

Horizontal

Displayed Frequencies in FULL

SPAN/DIV

L---BAND (900 --- 1900 MHz)

70 MHz (45 --- 100 MHz)

Frequency Readout Center Frequency shown by time

Requirements

950 to 1800 MHz

45 to 100 MHz

70 MHz ±2 dB.

75Ω.70MHz:

---20 dBm, 75Ω..

±3 dB/100 MHz.

+ and ---3 Divisions.

+ and ---2 Divisions.

Supplemental Information

F---type connector

Bnc connector

10 Horiz. Div. Equals:

1000 MHz

100 MHz

10 MHz

1MHz

10 Horiz. Div. Equals:

50 MHz

10 MHz

1MHz

Brightup offset by 1 Division in FULL

SPAN/DIV should still come on screen

in the next magnified position.

± from center (1400 MHz).

± from center (70 MHz).

Typically ±1 dB /100 MHz. 12

¶12 Divisions all SPANS/DIV settings.

Left Grat. Mid Grat. Right Grat.

Edge Line Edge

900 1400 1900

45 70 95

sharing graphic readout. Exact position on the trace of the center frequency shown by a caret in all spans except

FULL.

Check

Step

11

5

4, 5, 10, 11

11

12,

7

4

13

11

5

11

1- 4

1705A Spectrum Monitor

Page 24

Table 1- 1: Spectrum Display (Cont.)

Introduction

Performance

Characteristic

Frequency Bright Up

Marker Registration

Readout Accuracy L---Band ±20 MHz.

Resolution

6dBDown

300 kHz

10 kHz

Video Filter

Low Noise Amplifier/Block Down

Converter dc Supply (LNB Power)

2 dB Gain Accuracy

Requirements

70 MHz ±2 MHz

+18 Vdc ±5%. 250

mA max.

¶2 dB/Division.

Supplemental Information

Full Span has bright up and frequency

readout (without cursor). Bright-up

area will be on screen in at least the

next narrower span.

Typically ±10 MHz.

Typically ±1 MHz.

300 kHz ±1 Division at 100 kHz

Span/Div.

<2 minor Divisions at 100 kHz Span/

Div.

Reduces Video bandwidth to ¶10 kHz.

Output through L---BAND input

connector, switched on and off by

rear-panel slide switch. LED indicator

on rear panel.

<3 dB/Division at ---50 dBm. 14

5

11

5

6

6

8

3

Check

Step

Table 1- 2: CRT Display

Performance

Characteristic

Crt Viewing Area 80 X 100 mm.

Accelerating Potential 13.75 kV.

Trace Rotation Range Greater than ±1˚

Graticule Internal 8 X 10 Division spectrum

Requirements

from horizontal.

Supplemental Information

Total adjustment range is typically 8˚.

analyzer graticule with variable SCALE

illumination.

Table 1- 3: Power Source

Performance

Characteristic

Mains Voltage Range 90---250 V. Continuous range from 90 to 250 Vac. 2

Mains Frequency Range 48 Hz to 66 Hz.

Power Consumption 35 Wa tts (120 BTU/HR) maximum.

Requirements

Supplemental Information

Check

Step

Check

Step

1705A Spectrum Monitor

1- 5

Page 25

Introduction

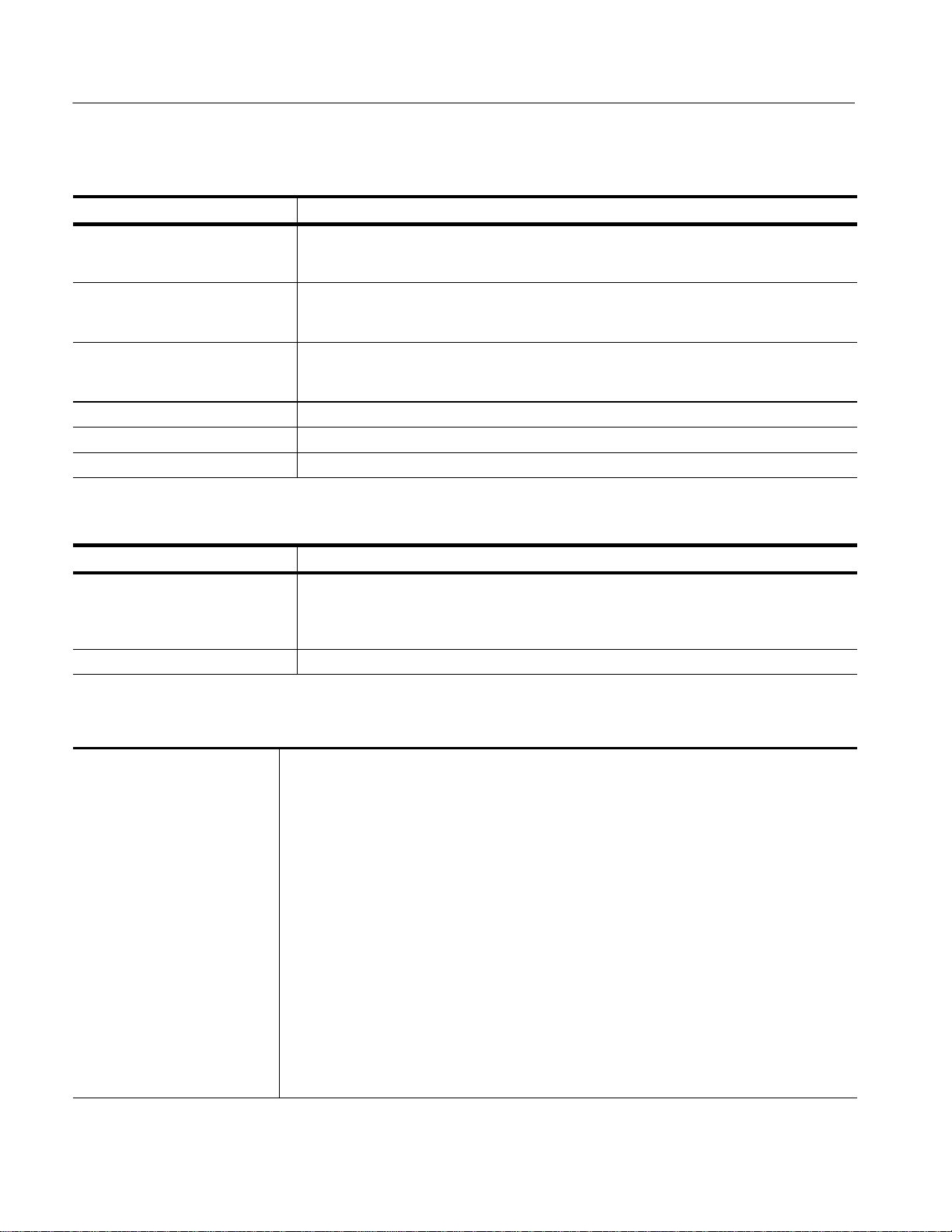

Table 1- 4: Environmental Characteristics

Characteristic Supplemental Information

Temperature

Non-Operating

Operating

Altitude

Non-Operating

Operating

Vibration --- Operating 15 minutes each axis at 0.015”, frequency varied from 10---55---10 Hz in 1-minute

Shock --- Non-Operating 30 g’s, ½ sine, 11 ms duration, 3 shocks per surface (18 total).

Transportation Qualified under NTSC Test Procedure 1A, Category II (30” drop).

Humidity Will operate at 95% relative humidity for up to five days.

--- 5 5 ˚Cto+75˚C.

0˚Cto+50˚C.

To 50,000 feet (15,000 meters).

To 15,000 feet (4,800 meters).

cycles with instrument secured to vibration platform. Ten minutes each axis at

any resonant point or at 55 Hz if no resonant point is found.

Table 1- 5: Physical Characteristics

Characteristic Supplemental Information

Dimensions

Height

Widt h

Length

Weight Approximately 8.5 lbs (approximately 3.8 kg).

5 1/4 inches (133.4 mm).

8 1/2 inches (215.9 mm).

18 1/8 inches (460.4 mm).

Table 1- 6: Certifications and Compliances

EC Declaration of Conformity -EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

High-quality shielded cables must be used to ensure compliance to the above listed standards.

This product complies when installed into any of the following Tektronix instrument enclosures:

1700F00 Standard Cabinet

1700F02 Portable Cabinet

1700F05 Rack Adapter

An increase of up to 20dB in the displayed noise floor may be observed if this instrument is

operated in electromagnetic fields of 3V/M or more, at frequencies of approximately 130, 250, 350,

or 490 MHz.

1- 6

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - FAX 781.665.0780 - TestEquipmentDepot.com

1705A Spectrum Monitor

Page 26

Introduction

Table 1- 6: Certifications and Compliances (cont.)

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits

Installation (Overvoltage)

Category

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Safety Standards

U.S. Nationally Recognized

Testing Laborat ory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA safety requirements for electrical and electronic measuring and

European Union Compliance Low Voltage Directive 73/23/EEC, amended by 93/69/EEC

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product i s considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products in

this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2

Pollution Degree 3

Pollution Degree 4

UL1244 Standard for electrical and electronic measuring and test equipment.

Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations where

neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution that generates persistent conductivity through conductive

dust, rain, or snow. Typical outdoor locations.

test equipment.

EN 61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

Additional Compliance IEC61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

1705A Spectrum Monitor

1- 7

Page 27

Introduction

Table 1- 6: Certifications and Compliances (cont.)

Safety Certification Compliance

Temperature, operating +5 to +40_ C

Altitude (maximum operating) 2000 meters

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010-1, Annex H) -- grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1). Note: Rated for indoor use only.

1- 8

1705A Spectrum Monitor

Page 28

APPLICATIONS

Introduction

The principal application for the TEKTRONIX 1705A Spectrum Monitor is to

provide a convenient method to locate and identify Ku-Band satellites, find the

correct transponder and check on its availability, and optimize antenna positioning and polarization. The remainder of this section provides basic satellite

communications application data. Specific operating instructions are located in

Section 2, Operating Instructions.

Locating Satellites

The communications satellites that the television industry is interested in lie in a

band directly over the earth’s equator, at a distance of approximately 35,900 km

(or about 3.7 times the earth’s diameter). Traveling at approximately

11,000 km/h the satellite completes one full orbit in 23 hours, 56 minutes,

4.9 seconds, which is referred to as a sidereal day. When a satellite completes

one orbit in a sidereal day it is geographically stationary (geostationary) to a

point on the earth’s surface. Without being geostationary, using a satellite would

be extremely complicated and the calculations required to determine when they

were in the usable window, and how long they would stay there would, in most

cases, require a computer.

At 35,900 km distance the earth subtends an angle of 18˚, which provides

coverage of approximately 40% of the earth’s surface. See Figure 1-2. Forty

percent (40%) of the earth’s surface corresponds to an area stretching from 70˚

North latitude to 70˚ South latitude. For rough assumptions, a satellite, in

geostationary orbit over the equator, could cover latitudes from the Arctic circle

(66˚ 30’ N) to the Antarctic circle (66˚ 30’ S). However it should be noted that

even though the satellite is capable of covering 40% of the earth’s surface the

actual coverage will be less in most cases because of the antenna design and

available transmitter power.

70° N

1705A Spectrum Monitor

18°

70° S

35,900 km

Figure 1-2: Relationship of a communications satellite to earth

Determining the exact angle from the horizon to a satellite (other than at the

equator) requires a knowledge of trigonometry, because of the relatively close

9,675 km

1- 9

Page 29

Introduction

orbit of the satellite. If the orbit of an equatorial orbiting satellite were roughly

equal to the distance from earth to the sun, ordinary latitude could be used to

determine the elevation of the antenna, which is, of necessity, very finely

focused. However since there is a disparity this angle is somewhat less than the

latitude for the earth station. See Figure 1-3. Simple logic readily points out

that as the latitude increases the angle from horizon to the satellite decreases. An

example of this would be that at 45˚ North or South latitude the angle above the

horizon is about 40˚ for a satellite at the earth station’s longitude. Figure 1-3

illustrates why it is not possible to pinpoint a satellite with ordinary navigation.

Satellite Footprints

SUN

A

SATELLITE

45° N

00°

(EQUATOR)

EARTH

Figure 1-3: Angle A (the difference at a specific latitude between the angle to the

sun and the angle to a satellite) is the reason ordinary navigation techniques

cannot be used to find a satellite

Figure 1-4 confirms that the angle from the prime meridian to a satellite will be

considerably different than the angle from a North American or European earth

station to the same satellite. It should also be noted that the elevation also

decreases for a satellite the further east or west from the earth station’s longitude.

Even though a satellite, in theory, can communicate with 40% of the earth’s

surface from its location, in most cases it will not. The antenna systems onboard

the satellites are usually designed to cover a specific area. These areas are

referred to as hemispheres, zones, and spots. A hemispherical beam is designed

to cover roughly 40% of the earth’s surface, for example, the western hemisphere. A zonal beam covers a specific area, for example, the Continental

United States, which is usually referred to as the CONUS beam. A spot beam is

exactly what it implies, concentrating on a smaller geographical area, such as the

western United States. With each of these beams there are areas where the signal

strength is greater. Figure 1-5 shows a propagation map for the western spot

beam for one Ku--Band satellite.

1- 10

1705A Spectrum Monitor

Page 30

SPACENET 2

45°W

69°

RCA K2

81°

SBS 3

RCA K1

85°

97°

GSTAR A2

103°

ANIK C2

112.5°

GSTAR A1

105°

MORELOS 2

116.5°

ANIK B

109°

SBS 5

122°

MORELOS 1

113.5°

SPACENET 1

135°W

120°

ASC 1

128°

Introduction

PRIME MERIDIAN

000°

NORTH

POLE

90°E

CHICAGO

LOS ANGELES

ARCTIC

CIRCLE

ANCHORAGE

HONOLULU

INTERNATIONAL DATELINE

135°E

180°

45°E

GREENWICH

ENGLAND

NEW YORK CITY

Figure 1-4: Sample longitudinal map of the Ku-Band satellites of most interest to

news vehicle earth stations on the North American continent and Hawaii

Using the 1705A for Satellite Communication

The 1705A has two separate inputs, one, the L--Band Input, is specifically

designed to work with LNB down converters, which have an output signal range

of 0.95 to 1.80 GHz. This provides a means of looking at the signals from either

Ku or C--Band satellites. The second input is identified as 70 MHz and accepts

signals from 45 to 100 MHz. This second input is primarily designed to work

with the IF frequency of an exciter, but can also be used to look at signals in the

low VHF television band and the FM broadcast band up to 100 MHz.

1705A Spectrum Monitor

1- 11

Page 31

Introduction

L- Band Input Signals

At the present time there are numerous satellites in geostationary orbit. The

transponders on each have specific assigned functions, which makes it essential

to accomplish at least four things before illuminating a particular transponder:

1. Locate a satellite.

2. Identify the satellite.

3. Find the transponder and check availability with the satellite operator.

4. Optimize signal strength and polarization.

Once a satellite is located and a particular transponder is identified, the 1705A

frequency readout can be set so that the entire range of transponder frequencies

can be read directly from the 1705A display. As it is shipped from the factory

the 1705A provides a readout in MHz for both bands. However, the 1705A has

several customizing routines that can be used to tailor displays for ease of

operation. In particular the Readout Mode routine provides for frequency offset,

so that the frequency displayed on the crt is the actual frequency of the transponder down link. The readout can be set to indicate any 1.10 GHz block within

the range of 0.9 GHz to 20 GHz.

VANCOUVER BC

SEATTLE

PORTLAND

SAN FRANCISCO

LOS ANGELES

SAN DIEGO

50dBw

47dBw

HELENA

BOISE

46dBw

44dBw

42dBw

Figure 1-5: The western spot beam footprint for one Ku-Band satellite

1- 12

1705A Spectrum Monitor

Page 32

Zeroing in on a Satellite

Introduction

In almost all cases a set procedure for Locating, Identifying, Finding (transponders), and Optimizing will be followed. The 1705A Spectrum Monitor is a tool

that greatly simplifies the individual steps so the correct satellite transponder can

be accessed in the minimum time.

Locating the Satellite

Identifying the Satellite

In most cases the elevation (angle above the horizon) and the true azimuth

(direction east or west to the satellite) of the antenna will be the same as it was

for the previous access of the same satellite. This angle can be found in one of

two ways, calculation or approximation from previous accesses; however, no

matter how the satellite is located the signal path will need to be optimized. In

most cases the approximate location of the satellite is known from previous

transactions and only identification of transponders and signal strength remain to

be dealt with.

Each of the satellites has one or more singular characteristics. In many cases the

singular characteristics can be easily identified on the spectrum monitor, which

can save valuable setup time. These characteristics can take the form of

telemetry beacons, transponder polarization schemes, or blocks of non-video

signals that stand out. And in a few cases, the easiest method of identification

may be the fact that the satellite is near another satellite that is readily identifiable.

T elemetry Beacons. Satellites have special tracking or telemetry beacons that

are easily recognizable on the spectrum monitor. Not only do these assist in

identifying the satellite, but they provide an accurate way to set the frequency

offset to correspond with actual satellite frequencies. Figure 1-6 shows a typical

Ku--Band satellite telemetry beacon. Note that the 1705A readout frequency can

be offset to read the down link frequency in GHz. S imilar beacons can be found

on some C--Band satellites also.

1705A Spectrum Monitor

1- 13

Page 33

Introduction

Tek

12.20 GHZ

+f

REF

--10

--20

--30

--40

--50

--60

--70

L

O

G

Figure 1-6: A computer representation of the 1705A display showing the 12.198 GHz

horizontally polarized telemetry beacon on the SATCOM K2 satellite (Span/Div set

to 100 kHz with a 10 kHz Resolution filter)

Transponder Polarization. Whether one or two polarizations are used can

often be an easy way to identify a satellite. For example, a satellite with

alternate polarization will have overlapping bandwidths, similar to those

depicted in Figure 1-7. In this example the center frequency of each transponder

down link is given. With the center frequency for each transponder known,

finding the correct transponder and determining its activity is easily accomplished with the 1705A Spectrum Monitor.

1- 14

1705A Spectrum Monitor

Page 34

TRANSPONDER

FREQUENCY AND NUMBER

DOWN LINK

FREQUENCY

11.729GHz 11.788GHz 11.847GHz 11.906GHz 11.965GHz 12.024GHz 12.083GHz 12.142GHz

1

3

5

7

9

11

TRANSPONDER

13

NUMBER

15

Introduction

2

11.7585GHz 11.8175GHz 11.8765GHz 11.9355GHz 11.9945GHz 12.0535GHz 12.1125GHz 12.1715GHz

HORIZONTAL

POLARIZATION

4

6

8

10

12

VERTICAL

POLARIZATION

14

16

Figure 1-7: Transponder assignments for a typical Ku-Band, 16-transponder satellite that employs alternate

polarization (Not all Ku-Band satellites conform to these frequencies and/or this polarization scheme)

Finding The Correct

Transponder

Once the satellite has been found it will be necessary to find the proper transponder and determine if it is available. With the 1705A frequency readout offset

correctly set up, it is possible to directly zero in on the correct transponder.

Figure 1-8 is a computer simulation of the 1705A Spectrum Monitor display in

FULL SPAN/DIVISION. Each division corresponds to 100 MHz. If the

satellite previously discussed is being looked at and the brightup is on the first

marker, then the first signal is transponder number 1 and the antenna feed horn is

horizontally polarized. Further, it is possible to determine that transponders 5, 7,

9, 13, and 15 are currently in use. Rotating the feed horn polarity 90˚ would

bring up a display of the vertically polarized transponder down links.

Optimize Signal Strength

1705A Spectrum Monitor

Once the correct satellite has been identified, minor adjustment to the antenna

position will optimize the link. The antenna azimuth and elevation can be fine

tuned for maximum signal strength and the opposite polarization carefully nulled

while observing the spectrum monitor crt screen.

1- 15

Page 35

Introduction

11. 7 3 GH Z

REF

Tek

--10

--20

--30

--40

--50

--60

13 5 7 9111315

--70

L

O

+f

G

Figure 1-8: Simulation of a 1705A FULL SPAN/DIV display showing six transponders

illuminated

Looking at Exciters with

the 70 MHz Input

The 70 MHz Input to the spectrum monitor is a bnc connector. It is designed for

use with the IF signal from an up link exciter. Most up link transmitters use an

exciter to drive an Upconverter and High Power Amplifier (HPA), and, in most

cases, the driving signal to the Upconverter is a 70 M Hz IF. If the exciter output

is at the up link frequency, a 70 MHz monitoring point is often provided.

Sometimes the coupling of the IF signal between the exciter and Upconverter is a

coaxial link that can be opened and a directional coupler installed for sampling

purposes. See Figure 1-9.

NOTE. The 70 MHz input is rated at --20 dBm maximum, external pads may be

required to meet this operating condition.

Once a directional coupler is installed a whole series of checks can be made,

including presence of the proper carriers and an indication of the modulation

level. More detail can be found in the Tektronix Television booklet “Television

Operational Measurements; Video and RF for NTSC Systems.”

1- 16

1705A Spectrum Monitor

Page 36

HPA

IN

UP CONVERTER

OUT

IN

Introduction

RF

OUT

1705A

SPECTRUM MONITOR

Figure 1-9: Up link Video Exciter, Up converter, and High Power Amplifier (HPA)

showing how to hook up a 1705A Spectrum Monitor to look at the Video Exciter

output

In addition to the other measurements that can be made a quick check of HPA,

antenna, and transponder (as a system) can be made by comparing the exciter

output (using the 70 MHz input) to the incoming signal from the down link

(using the L--Band Input) by simply switching between inputs. See Figure 1-10.

Miscellaneous Uses for the 1705A

The 1705A Spectrum Monitor 70 MHz band covers a frequency range from 45

to 100 MHz, at center screen. The low VHF television channels and major

portion of the FM broadcast band are within the frequency range of the 1705A.

If a spectrum monitoring application within this band of frequencies exists the

1705A can easily be used.

70 MHZ

INPUT

DIRECTIONAL

COUPLER

OUT

VIDEO

EXCITER

1705A Spectrum Monitor

1- 17

Page 37

Introduction

L-OUT

L-BAND

900--1450 MHZ

LNB

Ku-IN

1705A

SPECTRUM MONITOR

Ku-BAND

12 GHZ

HPA

IN

UP CONVERTER

OUT

IN

Ku-BAND

14 GHZ

RF

OUT

3dB

SPLITTER

70 MHZ

INPUT

RECEIVER

DIRECTIONAL

COUPLER

OUT

VIDEO

EXCITER

Figure 1-10: 1705A hooked up to look at either the output of the Video Exciter (70

MHz) or the Receiver Input (L-Band)

1- 18

1705A Spectrum Monitor

Page 38

Operating Instructions

Page 39

Page 40

Section 2 Operating Instructions

These instructions provide information about the front-panel controls and

indicators, rear-panel connectors and switch, powering-up, and the measurement

graticule and alphanumeric readout.

Front-panel Controls and Indicators

The front--panel controls and indicators consist of momentary contact push-button switches, with backlit switch selections, and variable controls. For frontpanel control and indicator locations, see Figure 2-1. There are also functions

that are accessed by holding the switch down for approximately 1 second. These

functions are identified by a blue box surrounding the front--panel label.

FILTER

1. VIDEO

INPUT

Turns on or off the Video Filter, which reduces the post detection bandwidth

(video), to reduce the high-frequency components for display noise

averaging. A front-panel LED indicator lights when the Video Filter is on.

Holding the Video switch activates the High Gain mode. An on-screen

readout indicates 2 dB/Div. To exit this mode, hold the switch again, and the

on-screen readout returns to 10 dB/Div. Gain selection will not affect the

momentary touch VIDEO On/Off selection.

2. RESOLUTION

Selects the 2

indicated by the front-panel indicator.

3. INPUT

L--BAND or 70 MHz —A push-button switch to select either the L--BAND

(900 to 2000 MHz) or the 70 MHz (45 to 100 MHz) input for display.

Indicator lights show which input is displayed.

nd

IF bandwidth. Toggles between 10 kHz and 300 kHz as

1705A Spectrum Monitor

2- 1

Page 41

Operating Instructions

Tek

+f

REF

--10

--20

--30

--40

--50

--60

--70

1

4

Tektronix

VIDEO

ON 300 KHz

SWEEP

SPEED

FOCUS SCALE INTENS

L

O

G

FILTER

100

KHz

TRACE

RO TATI ON

2

1705A

RESOLUTION

10 KHz

CENTER FREQUENCY

SPAN/DIV

MENU

1

10 FULL

MHz

MHz

DISPLAY

6

POSITION

HORIZONTA L VERTICAL

3

SPECTRUM

MONITOR

INPUT

LBAND

70 MHz

POWER

5

ON

= HOLD FOR FUNCTION

7

11

10

8

12

Figure 2-1: 1705A front panel; refer to text for descriptions of controls identified with circled numbers

SWEEP

4. SWEEP SPEED

A variable control that sets the sweep repetition rate, which is typically

between 20 and 200 ms.

5. CENTER FREQUENCY

A ten-turn variable control that determines the center frequency of the

displayed portion of the spectrum.

13

9

2- 2

1705A Spectrum Monitor

Page 42

Operating Instructions

6. SPAN/DIV

Two push-button switches (left and right) that select the calibrated span per

division. Each span is indicated by a front-panel LED.

FULL -- Provides a span of 50 MHz per division for the L--Band (900 -- 2000

MHz) input, and 5 MHz per division (45 to 100 MHz) for the 70 MHz input.

10 MHz -- Sets display span to 10 MHz per division. Displays a maximum

of 120 MHz for one full sweep (not available for the 70 MHz input). The

100 MHz portion of the sweep that is displayed is dependent on the setting

of the HORIZONTAL POSITION control.

1 MHz -- Sets display span to 1 MHz per division. Displays a maximum of

12 MHz for one full sweep. The 10 MHz portion of the sweep that is

displayed is dependent on the setting of the HORIZONTAL POSITION

control.

100 kHz -- Sets display span to 100 kHz per division. Displays a maximum

of 1.2 MHz for one full sweep. The 1 MHz portion of the sweep that is

displayed is dependent on the setting of the HORIZONTAL POSITION

control.

DISPLAY

MENU -- When both SPAN/DIV switches are pressed simultaneously, the

normal display is replaced by the Main menu. To exit the Main menu,

position the cursor by EXIT and press the INPUT switch. The M enu

functions are discussed in detail later in this section.

7. FOCUS

A variable control that adjusts the crt beam for optimum definition.

8. SCALE

A variable control that adjusts the level of graticule illumination.

9. INTENS

A variable control that adjusts the display brightness.

10. TRACE ROTATION

A screwdriver adjustment that aligns the crt trace with the crt graticule to

compensate for variations in the magnetic field surrounding the 1705A.

1705A Spectrum Monitor

2- 3

Page 43

Operating Instructions

POSITION

POWER

11. HORIZONTAL

A variable control that positions the trace horizontally (X axis).

12. VERTICAL

A variable control that positions the display vertically (Y axis).

13. POWER

Switches the instrument between a powered up state and standby. Portions

of the Power Supply circuit board have mains potential on them in either

state. A mechanical indicator in the center of the switch shows the status of

the POWER switch.

Rear - Panel Connectors

INPUTS

WARNING. Mains power is still applied to the 1705A Power Supply circuit board,

regardless of POWER switch state. To totally remove shock hazard, it is

necessary to unplug the instrument and wait for the capacitors to discharge.

Signal input and power input are located on the 1705A rear panel. See Figure 2-2 for the locations of the rear-panel connectors.

1. L--BAND

A75Ω input f-type connector used for the 900 -- 2000 MHz input of L--Band

rf, which is down converted by a Low-Noise Amplifier/Block Down

Converter (LNB) from the received satellite signal.

2. LNB POWER (Switch)

Switch to turn on or off the +18 V supply on the L--BAND INPUT connector. Supply is normally used to power a Low-Noise Amplifier/Block Down

Converter at the antenna.

2- 4

1705A Spectrum Monitor

Page 44

Operating Instructions

6

SPECTRUM MONITO R

WARNING

TO AVOID ELECTRI CAL SHOCK, THE POWER

CORD PROTECTI VE GROUNDI NG CONDUCTOR

MUST BE CO NNECTED TO EARTH GROUND.

0.7AMAX

50/60Hz

REPLACE FUSE ONLY WI TH

90-250V

250V 2A F TYPE

70 MHz

INPUT

!

5

4

3

333--3990 --01

DIE I N DIESEM GERATENTSTEHENDE

RONTGENSTRAHLUNG IST AUSREICHEND ABG ESCHIRMT

BESCHLEUNIGUNGSSPANNUNG KLEINER ALS

LNB POW-

ER

ON

L BAND

!

1

INPUT

LNB POW-

ER

ON

OFF

+18 VDC @ 2 50 mA

2

20kV

Figure 2-2: 1705A rear panel controls and connectors; refer to text for descriptions

of controls identified with circled numbers

3. LNB POWER (Indicator)

POWER

LED indicator that lights when the +18 V supply is turned on and operating

correctly. Indicator will not light if the +18 V supply is shorted.

4. 70 MHz

A75Ω input bnc-type connector used for the input of the 45 -- 100 MHz rf.

5. AC FUSE

Holder for the instrument’s mains fuse.

6. AC POWER

A standard ac plug receptacle for 120 or 220 Vac power mains.

1705A Spectrum Monitor

2- 5

Page 45

Operating Instructions

Powering- up

When the 1705A is first powered up, it should come up in a measurement mode.

Most commonly it will be configured as it was when it was last turned off. If

not, there are some very simple checks that should be made.

If the power switch is showing ON, but the graticule and front-panel indicators

do not come on, check for a mains power problem, such as a blown fuse or

interrupted power mains (unplugged or main breaker thrown). If these are right,

refer to a qualified service technician for troubleshooting.

If the Non-Volatile RAM (NVRAM) is defective, which disables the operation of

the Microprocessor, there is a crt readout. If the 1705A comes on with the

following message:

ERROR : CANNOT READ OR WRITE

TO 2444

PRESS [VIDEO] KEY TO EXIT

operation will be questionable and the 1705A should be thoroughly checked out

by a qualified service technician.

Normal start-up of the instrument should consist of a display of alphanumeric

frequency readout and a spectrum display similar to that in Figure 2-3.

Tek

1400 MHZ

REF

--10

--20

--30

--40

--50

--60

--70

L

O

G

Figure 2-3: 1705A display when powered up in L-BAND and FULL SPAN; CENTER

FREQUENCY set to approximately mid range

2- 6

1705A Spectrum Monitor

Page 46

Measurement Graticule

Operating Instructions

The 1705A is equipped with an internal graticule crt. The graticule has an 8 X

10 division scale that is lighted. Scale brilliance is controlled by the front-panel

SCALE control. Figure 2-4 shows the 1705A graticule. Refer to this figure and

subsequent figures when reading the following discussion of the graticule.

Vertical Scales

Tek

REF

--10

--20

--30

--40

--50

--60

--70

L

O

+f

G

Figure 2-4: 1705A graticule scale

The vertical scale is eight divisions in height. The center vertical scale is broken

into five equal minor divisions per major division. Note that the 0 dB reference

is at the top of the graticule and that 80 dB (maximum division) is at the bottom

of the graticule. There are two gain selections: normal gain (10 dB/div) and

high gain (2 dB/div). In normal gain mode, major divisions are 10 dB, which

makes each minor division 2 dB. When the GAIN front-panel push button is

held, high gain is selected, and major divisions are approximately 2 dB, which

makes minor divisions about 0.4 dB each.

1705A Spectrum Monitor

Since dB is a dimensionless ratio, and there are several scale variations, it is

essential that there be some discussion of the various scales. The unit of

measure described as dB (decibel) is 10 LOG P1/P2. If there is a specific scale

defined (m, k, w, p, etc.), there is a specific reference point established. The

1705A has input specifications in dBm, which means that they are referenced to

1 mW (milliwatt). Therefore, --30 dBm is 30 dB below 1 mW. Table 2--1 is a

handy reference table for dB and dBm. Table 2--2 provides a reference for

conversion from dBm to v.

2- 7

Page 47

Operating Instructions

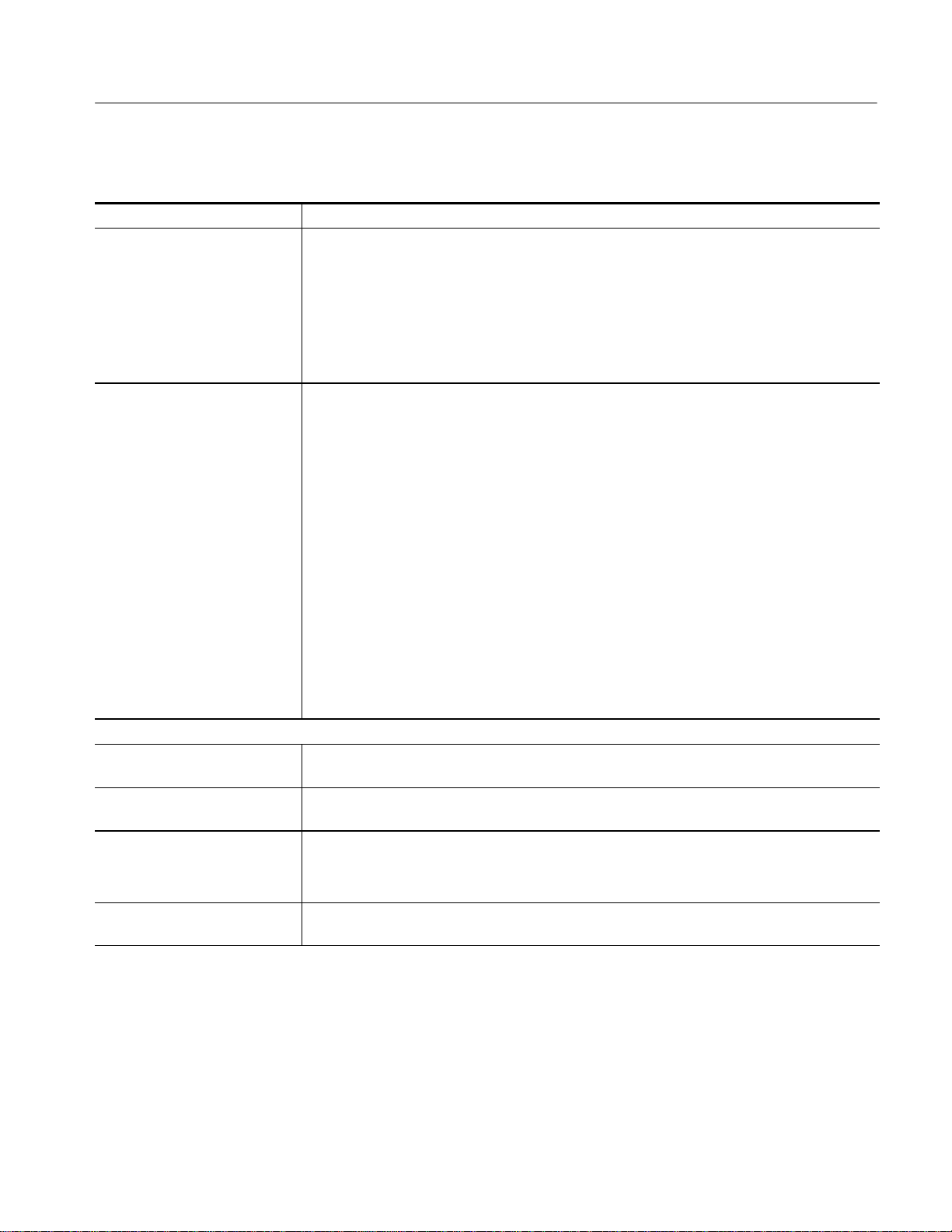

Table 2- 1: dB Reference

Reading in dB Voltage Ratio Power Ratio Reading in dB Voltage Ratio Power Ratio

0.0 1.000 1.000 25.0 17.783 316.228

0.1 1.012 1.023 26.0 19.953 398.107

0.2 1.023 1.047 27.0 22.387 501.187

0.3 1.035 1.072 28.0 25.119 630.957

0.4 1.047 1.096 29.0 28.184 794.328

0.5 1.059 1.122 30.0 31.623 1000.000

0.6 1.072 1.148 31.0 35.481 1258.925

0.7 1.084 1.175 32.0 39.811 1584.893

0.8 1.096 1.202 33.0 44.668 1995.262

0.9 1.109 1.230 34.0 50.119 2511.886

1.0 1.122 1.259 35.0 56.234 3162.278

1.5 1.189 1.413 36.0 63.096 3981.072

2.0 1.259 1.585 37.0 70.795 5011.872

2.5 1.334 1.778 38.0 79.443 6309.573

3.0 1.413 1.995 39.0 89.125 7943.282

4.0 1.585 2.512 40.0 100.000 10000.000

5.0 1.778 3.162 41.0 112.202 12589.254

6.0 1.995 3.981 42.0 125.893 15848.932

7.0 2.239 5.012 43.0 141.254 19952.623

8.0 2.512 6.310 44.0 158.489 25118.864

9.0 2.818 7.943 45.0 177.828 31622.777

10.0 3.162 10.000 46.0 199.526 39810.717

11.0 3.548 12.589 47.0 223.872 50118.723

12.0 3.981 15.849 48.0 251.189 63095.734

13.0 4.467 19.953 49.0 281.838 79432.023

14.0 5.012 25.119 50.0 316.228 100000.000

15.0 5.623 31.623 51.0 354.813 125892.541

16.0 6.310 39.811 52.0 398.107 158489.319

17.0 7.079 50.119 53.0 446.684 199526.231

18.0 7.943 63.096 54.0 501.187 251188.643

19.0 8.913 79.433 55.0 562.341 316227.766

20.0 10.000 100.000 56.0 630.957 398107.171

21.0 11.220 125.893 57.0 707.946 501187.234

22.0 12.589 158.489 58.0 794.328 630957.344

23.0 14.125 199.526 59.0 891.251 794328.235

24.0 15.849 251.189 60.0 1000.00 1000000.000

2- 8

1705A Spectrum Monitor

Page 48

Operating Instructions

Table 2- 2: dBm to

v Conversion

Reading in dBm v(75Ω) v(50Ω) Reading in dBm v(75Ω) v(50Ω)

--- 3 0 8660 7071 --- 1 0 5 1.540 1.257

--- 3 5 4870 3976 --- 1 1 0 0.866 0.707

--- 4 0 2739 2236 --- 1 1 5 0.487 0.398

--- 4 5 1540 1257 --- 1 2 0 0.274 0.224

--- 5 0 866 707 --- 1 2 5 0.154 0.126

--- 5 5 487 398 --- 1 3 0 0.087 0.071

--- 6 0 274 224 --- 1 3 5 0.049 0.040

--- 6 5 154 126 --- 1 4 0 0.027 0.022

--- 7 0 87 71 --- 1 4 5 0.015 0.013

--- 7 5 49 40 --- 1 5 0 0.009 0.007

--- 8 0 27 22 --- 1 5 5 0.005 0.004

--- 8 5 15 13 --- 1 6 0 0.003 0.002

--- 9 0 9 7 --- 1 6 5 0.002 0.001

--- 9 5 5 4 --- 1 7 0 0.001 0.001

--- 1 0 0 3 2 --- 1 7 5 0.000 0.000

Horizontal Scales

The horizontal graticule scales are divided into ten major divisions, which are

further divided into five minor divisions each. The horizontal scale corresponds

to frequency, with the lowest frequency to the left. Note the arrow in Figure 2-4

that signifies that the frequency ascends toward the right. Both the --60 and --80

dB lines are subdivided with minor division marks. Traditionally, many

spectrum analyzer measurements and specifications are between 6 and 60 dB.

The available sweep for the 1705A is 12 divisions long, which means that not all

of the frequencies that it is capable of displaying can be displayed simultaneously. Figure 2-5 compares the sweep length to the graticule. It shows the usable

areas of the sweep, as well as the minimum and maximum frequencies of the two

bands.

1705A Spectrum Monitor

2- 9

Page 49

Operating Instructions

MINIMUM

FREQUENCY

L-BAND = 900 MHz

70 MHz = 45 MHz

L-BAND = 2000 MHz

MID

FREQUENCY

SCALE = 10 DIVISIONS

SWEEP LENGTH = 12 DIVISIONS

MAXIMUM

FREQUENCY

70 MHz = 100 MHz

Figure 2-5: Relationship of sweep to graticule showing minimum and maximum

frequencies when CENTER FREQUENCY is set to mid band

Figure 2-6 shows frequencies associated with the graticule lines in FULL

SPAN/DIV when the CENTER FREQUENCY control is set to 1400 (for

L--Band) or 70 MHz (for the 70 MHz). Note also that the HORIZONTAL

POSITION control affects the frequency-to-graticule scale resolution. Determining where the HORIZONTAL POSITION control is set can easily be determined