NOVA

Titan III Chuck

Publication 105-0717-006

Instruction Manual

Date: 28.July.2017

105-0717-006 2

NOVA Titan III Chuck Features:

Thank you for purchasing Teknatool Nova Titan 5inch Chuck. We are

confident that it will help in both enhancing as well as advancing your

woodturning. The Teknatool Nova Titan 5inch Chuck is a very versatile

unit, designed to offer a wide range of work holding modes. The Nova

Titan 5inch Chuck has a powerful grip while being quick and easy to

use.

It combines the best features of our Nova series chucks and similar

woodturning chucks (wide jaw movement, quick two way grip) with the

advantages of superior gripping power and a convenient one handed

operation. The Nova Titan also has some special safety features: a

travel stop on the jaws and a contracting scroll jaw action to centre

under power with no work mounted. This means that there is very little

chance of the jaws flying out of the chuck - a common hazard with

many chucks.

The Nova Titan, utilizing the two screw position, can take the existing

NOVA accessory jaws. This provides maximum interchange ability of

jaws between all NOVA chucks.

The Titan using the wide variety of accessory jaws can be used to

expand into recesses or contract around round/square wood spigots of

varying sizes and applications. The chuck can swap from the

expansion/dovetail mode to the spigot mode and back instantly, with

no adjustments or extra fittings being necessary. In either modes, any

spigot or recess size can be selected between the minimum and

maximum range of the jaws. With the add-on accessory jaws removed,

the jaw slides can be used to grip smaller spigots. The chuck also

utilises a powerful Woodworm screw for screw chuck work. (Included

with standard model only)

The Jaw accessories are included at the back of this manual. However

the range is steadily being expanded to include more options. Check

with your reseller or at www.teknatool.com for the latest accessories.

As a valued customer, we would be pleased to hear from you and how

you found your Nova Titan. Any comments on the chuck or accessory

ideas would be very welcome so that we can continue to offer what we

believe is the best woodturning chucking system available.

105-0717-006 3

Contact Teknatool

New Zealand and Rest of the World

Teknatool International Ltd

Phone: (+64) 9 477 5600

Fax: (+64) 9 477 5601

Email: service@teknatool.com

Website: www.teknatool.com

United States

Teknatool Service Center

Phone: 727-954-3433

Fax: 727-623-0902

Email: service@teknatool.com

Website: www.teknatool.com

Or you can contact the retailer where you purchased your NOVA Titan III Chuck, for

contact details, please see our website www.teknatool.com.

105-0717-006 4

Table of Contents:

GENERAL SAFETY RULES ................................................................. 5

ADDITIONAL SAFETY RULES: ............................................................ 7

Titan III Chuck Specifications ................................................................ 8

1 ¼”8TPI DIRECT THREADED MODEL ........................................... 8

M33 EUROLOCK DIRECT THREADED MODEL .............................. 8

Mounting the Titan III Chuck on a Lathe ............................................... 9

FITTING CHUCK TO LATHE ............................................................ 9

Using the Titan III Chuck ................................................................ ..... 10

Mounting Add-On Jaws ................................................................... 10

EXPANDING DOVETAIL OPERATION ........................................... 12

Forming a Recess ............................................................................... 13

SPIGOT OPERATION ..................................................................... 14

SPIGOT SIZE: ................................................................................. 15

FORMING SPIGOT: ........................................................................ 15

FREE END TURNING ..................................................................... 15

Maintaining the Titan III Chuck ............................................................ 16

General Maintenance ...................................................................... 16

Stop on JAW Travel......................................................................... 17

Insertion of jaw slides ...................................................................... 17

Troubleshooting Guide ........................................................................ 18

SKU 13061 EUROLOCK VERSION CHUCK ONLY ........................... 20

Installation Instructions: .................................................................. 20

NOVA Titan III Chuck Exploded View ................................................. 21

NOVA Titan III Chuck Parts List .......................................................... 22

Titan III Accessories ............................................................................ 23

Teknatool Warranty ............................................................................. 28

OVERSEAS CUSTOMERS: Our Teknatool Distributors and agents will

issue their own warranty to cover this product. Terms may vary from

those stated above; please check with your dealer. ............................ 28

© Copyright 2004-2017 by Teknatool International; All Rights Reserved.

Nova DVR is a trademark of Teknatool International Ltd.

The information and specifications contained herein are subject to change. Teknatool is not

responsible for errors or omissions herein or for incidental damages in connection with the

furnishing or use of this information.

105-0717-006 5

GENERAL SAFETY RULES

!

Warning! Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE MANUAL BEFORE

OPERATING THE TOOL. Learn the machine’s application,

limitations and the specific hazards particular to it.

2. ALWAYS USE A FULL FACE SHIELD. Strongly recommended.

(Must comply with ANSI STANDARD Z87.1 -USA) Everyday eyeglasses usually are only impact resistant and safety glasses only

protect eyes. A full face shield will protect the eyes and face. Also

use face or dust mask if cutting operation is dusty.

3. WEAR PROPER APPAREL. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get caught in

moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair.

4. USE EAR PROTECTORS. Use ear plugs or muffs for any period of

operation. Use muffs rated to 103 DBA LEQ (8 hour).

5. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lighted. The DVR Wood Lathe is intended for indoor use

only. Failure to do so may void the warranty.

6. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents. Build-up of sawdust is a fire hazard.

7. KEEP CHILDREN AND VISITORS AWAY. The Nova DVR is not

recommended for children or the infirm. Such personnel and

onlookers should be kept at a safe distance from the work area.

8. MAKE WORKSHOP CHILDPROOF. Utilize locks, master switches,

or by removing starter/lockout keys.

9. GROUND ALL TOOLS. If the tool is equipped with a three-prong

plug, it should be plugged into a three hole electrical receptacle. If an

adapter is used to accommodate a two-prong receptacle, the

adapter plug must be attached to a known ground. NEVER remove

the third or grounding prong.

10. DISCONNECT TOOLS. Ensure the plug is removed from the wall

socket before servicing and when changing accessories such as

blades, bits, cutters and fuses, etc.

11. AVOID ACCIDENTAL STARTING. Make sure switch is in the Off

position before plugging in power cord into the wall socket.

105-0717-006 6

12. NEVER LEAVE MACHINE RUNNING UNATTENDED. Do not

leave machine unless it is turned off and has come to a complete

stop.

13. KEEP GUARDS IN PLACE. Ensure guards are in working order.

14. USE CORRECT TOOLS. Do not use a tool or attachment to do a job

for which it was not designed.

15. DON’T FORCE THE TOOL. It will do the job better and be safer at the

rate/force for which it was designed.

16. MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp and clean

for the best and safest performance. Follow instructions for lubricating

and changing accessories.

17. NEVER STAND ON THE TOOL. Serious injury could occur if the tool

is tipped or if the cutting tool is accidentally contacted.

18. REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of

checking to see that keys and adjusting wrenches are removed from

tool before turning it on.

19. DON’T OVERREACH. Keep proper footing and balance at all times.

20. DIRECTION OF FEED. Feed work into the blade or cutter against the

direction of rotation.

21. ATTENTION TO WORK. Concentrate on your work. If you become

tired or frustrated, leave it for awhile and rest.

22. SECURE WORK. Use clamps or a vice to hold work when practical.

It’s safer than using your hand and frees both hands to operate tool.

23. CHECK DAMAGED PARTS. Before further use of the tool, any part

that is damaged should be carefully checked to ensure that it will

operate properly and perform its intended function. Check for

alignment of moving parts, binding of moving parts, mounting, and any

other conditions that may affect its operation. Any damaged part

should be properly repaired or replaced.

24. DRUGS, ALCOHOL OR MEDICATION. Do not operate machine while

under the influence of drugs, alcohol, or any medication.

25. DUST WARNING. The dust generated by certain woods and wood

products can be harmful to your health. Always use an approved dust

mask and operate machinery in well-ventilated areas. In addition,

provide a means for proper dust removal. Use wood dust collection

systems whenever possible.

105-0717-006 7

ADDITIONAL SAFETY RULES:

!

Warning! Failure to follow these rules may result in serious personal

injury.

1. SEEK INSTRUCTION. If you are not thoroughly familiar with the

operation of wood lathes, obtain advice from your supervisor, instructor,

or other qualified person. Instruction from a qualified person is strongly

recommended.

2. MAKE SURE WOOD is securely clamped in the chuck before turning it on

3. EXAMINE WORK PIECE and glue joints before turning to make sure it

has no defects that would cause it to break when turning.

4. CHECK SET-UP with power Off. Examine the set-up carefully and rotate

the work piece by hand to check clearance before turning on power.

5. ADJUST TOOL REST close to the work piece. Before turning, revolve

the stock by hand to make sure it clears the rest. At intervals, stop the

lathe and readjust the tool rest.

6. DO NOT MAKE ADJUSTMENTS when the lathe or work piece is turning.

Make all adjustments with power Off.

7. TIGHTEN ALL CLAMP HANDLES on the headstock, tailstock, and tool

rest before operating lathe.

8. USE LOWEST SPEED when turning a new or unbalanced work piece.

9. USE CORRECT SPEED for turning the wood blank as wood speed will

vary depending on diameter.

10. KEEP TOOL ON TOOL REST. Tools should remain on the tool rest

whenever the tool is engaged in contact with the work piece.

11. DO NOT ROTATE CHUCK under power without wood being gripped and

securely tightened in the chuck

12. USE CORRECT LATHE TOOLS. Do not use spindle turning chisels for

faceplate mounted work, and vice versa. Spindle turning tools used for

faceplate turning may grab the work piece and pull the chisel from your

control.

13. DO NOT POUND WORK PIECE into headstock drive (spur) center while

attached to the lathe when turning between centers. Pound the drive

center into the work piece with a soft mallet before installing it between

centers in the lathe.

14. DO NOT USE TAILSTOCK to drive work piece into the drive (spur) center

when turning between centers. Secure work between centers with light

pressure from the tailstock quill action.

15. FASTEN STOCK SECURELY BETWEEN CENTERS. Make sure the

tailstock is locked before turning on the power.

16. NEVER LOOSEN TAILSTOCK spindle or tailstock while work piece is

turning.

105-0717-006 8

Titan III Chuck Specifications

There are two models of the Nova Titan 5inch Chuck designed to meet

various woodturning requirements.

1 ¼”8TPI DIRECT THREADED MODEL

(SKU 13060)

Dedicated threaded chuck, 1 ¼”8 TPI. This cannot accept the

Standard NOVA Chuck Insert/Adaptors. This has a special PowerGrip

add on jaw set for heavy-duty spigot turning and heavy bowl work.

These jaws extend the tremendous gripping power and range of the

Nova Titan 5inch Chuck. Standard Model with PowerGrip Jaws

Accessory Kit: 1x M6 Grubscrew, 2 x Fibre washers, 1 x pinion handle,

8 x M6x10 Jaws screws, 1 x Woodworm screw, 1 x PowerGrip jaw set,

1 x M4 Allen key, 1 x M3 Allen key, Nova Titan III 5inch Chuck Manual.

M33 EUROLOCK DIRECT THREADED MODEL

(SKU 13061)

EUROLOCK Dedicated threaded chuck, M33 thread. This cannot

accept the Standard NOVA Chuck Insert/Adaptors. This has a special

PowerGrip add on jaw set for heavy-duty spigot turning and heavy

bowl work. These jaws extend the tremendous gripping power and

range of the Nova Titan 5inch Chuck. Standard Model with PowerGrip

Jaws Accessory Kit: 1x M6 Grubscrew, 2 x Fibre washers, 1 x pinion

handle, 8 x M6x10 Jaws screws, 1 x Woodworm screw, 1 x PowerGrip

jaw set, 1 x M4 Allen key, 1 x M3 Allen key, Nova Titan III 5inch Chuck

Manual.

105-0717-006 9

Mounting the Titan III Chuck on a Lathe

CORRECT MOUNTING OF CHUCK TO LATHE SPINDLE IS VERY

IMPORTANT TO ACHIEVE ACCURACY.

WE STRONGLY RECOMMEND THAT THE CHUCK IS NOT USED

ON LATHE SPINDLES UNDER 1in (25mm) diameter.

FITTING CHUCK TO LATHE

Correct fitting of chuck to lathe spindle is important to ensure accuracy.

The chuck body must contact an accurate shoulder on the lathe

spindle or bearings to ensure chuck will run true.

There can be a wide variety of lathe spindle thread and spigot

dimensions even within the same thread size. The internal thread size

is kept to standard tolerances.

CHECK THE FOLLOWING:

Although the Chuck may screw on part way it may not contact

properly with spindle spigot - a spacer may be necessary. This

would be the responsibility of the chuck user. Make sure the chuck is

screwed to lathe thread properly - a good check is to see whether it

screws home on the spindle same as any another lathe fixture such as

a faceplate. POOR FIT OF CHUCK TO LATHE SPINDLE CREATES

A SERIOUS HAZARD WHERE CHUCK COULD DISLODGE FROM

LATHE. DO NOT ATTEMPT TO USE CHUCK UNLESS THE CHUCK

IS CORRECTLY FITTED TO LATHE SPINDLE.

105-0717-006 10

Using the Titan III Chuck

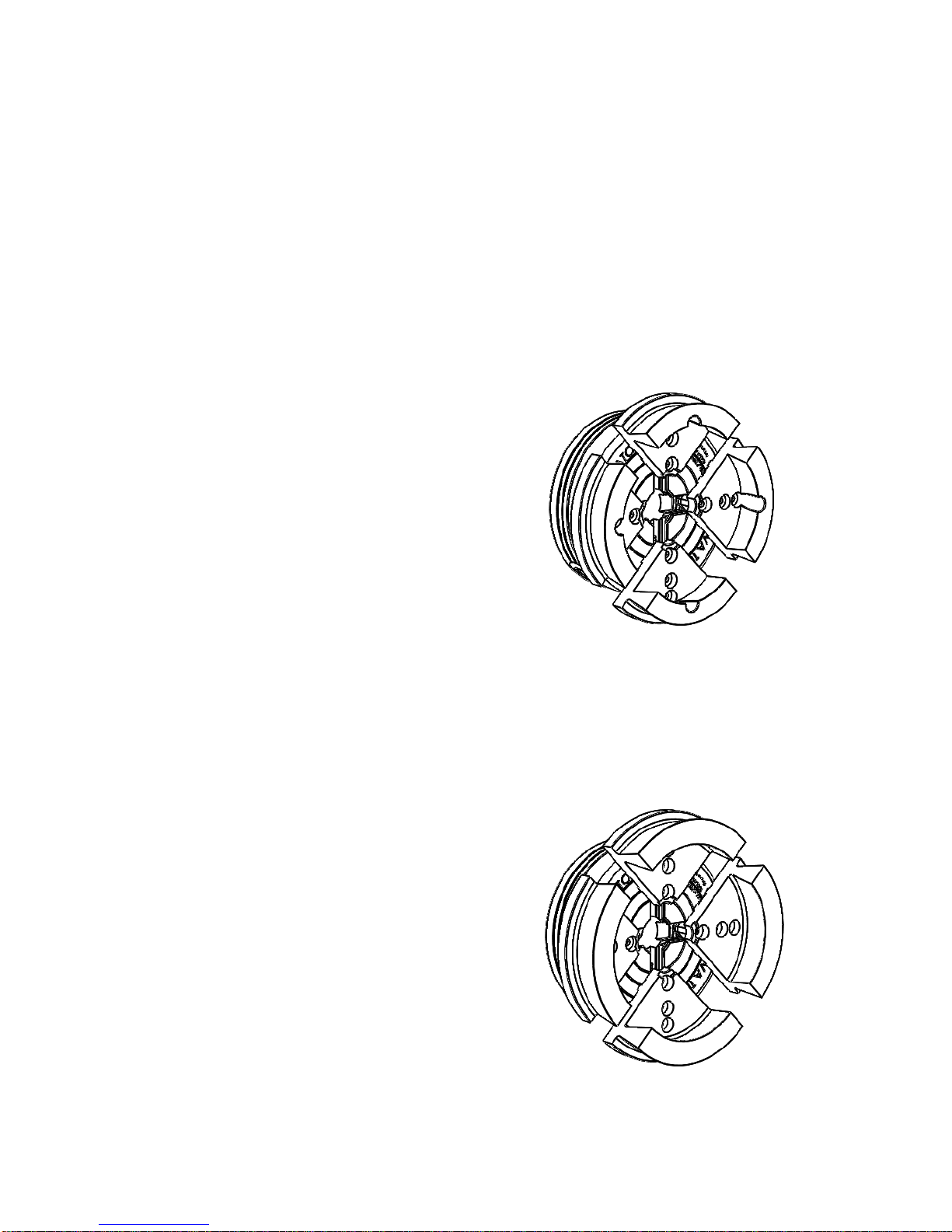

Mounting Add-On Jaws

MOUNTING ADD-ON JAWS

Your standard Nova Titan

5in chuck is provided with

PowerGrip add-on jaws.

They need to be located and

screwed on to the jaw slides

of the chuck. The same

procedure outlined below

must be followed for all

accessory jaws as well. IT IS

IMPORTANT TO LOCATE

JAWS PROPERLY IN THE

JAW SLIDES FOR THE

CHUCK TO FUNCTION

ACCURATELY.

Follow the method set out below

1. You will notice that the back of the jaws have a stepped location

ring. This location ring is designed to fit into the grooved section of

the jaw slide for precision location. Ensure that the slide and collet

back are clean and free from any burrs or damage that might affect

location. Place the jaw segment over the hole positions on the jaw.

Press the jaw segment firmly onto the jaw slide. For the first few

times you may need to GENTLY tap the jaws into the locator slot

with a block of wood.

2. The screws can now be screwed in, using the 4mm Allen Key

provided. Lightly grease or oil screws under each head and on the

threads before use to prevent the screws from seizing in the jaw.

Preferably use an anti-seize compound e.g. ROCOL J 166 AntiSeize Compound. Do all screws up finger tight and then back them

off one quarter to half a turn.

105-0717-006 11

3. Wind the mounted jaws into the centre of the chuck until they all

butt against the other. Now finally tighten screws, starting with

centre screws and then outside screws. Nip screws up firmly but

DO NOT OVER TIGHTEN.

4. Check there is no light between jaw slides and add on jaw

segments or that one or more segments is not higher or lower

than the rest. If this is the case repeat procedure above.

OPERATING MODES

SCREW CHUCK: This is a convenient mounting method. The

PowerGrip Woodworm screw is purpose-designed for screw chucking.

It is a cylindrical screw which maintains its full holding power along the

whole length, unlike normal tapered screws. The thin thread form is

specially designed to cause minimum damage to wood fibres. They

grip better than screws with thicker threads because there is a larger

volume of undamaged wood retained within the screw.The woodworm

screw is made complete with the boss section in one piece. The

woodworm screw is designed to be used with the powergrip jaws

remaining in place on the chuck. This facility is very convenient for

remounting work directly onto the jaws after the screw is removed. To

convert to this operation, place the boss section into the centre of the

chuck making sure flat shanks are aligned to the jaw slides and close

jaws around it. BEFORE FINAL TIGHTENING MAKE SURE THAT

THE FRONT OF THE BOSS SECTION OF THE SCREW IS SEATED

BEHIND AND AGAINST THE POWERGRIP JAWS. This will prevent

any tendency for the boss section to creep forward when the screw is

being used. The front face of the PowerGrip Jaws has been machined

to provide an accurate backing surface. This is quite an advantage,

providing a much tighter fit and better tolerance for irregular face stock.

This feature is also quite an advantage when using the screw to mount

a bowl for first stage bowl turning - forming the outside of the bowl

straight onto the jaws (the screw is first removed) after the recess has

been formed.

105-0717-006 12

SCREW DEPTH: The screw provides 19mm (3/4 inch) of thread

beyond the PowerGrip jaws. With all wood blocks over 150mm (6

inches) in diameter the full thread depth of 19mm should be used.

Irregular, rough tree blanks (e.g. small sections of tree limbs) not

exceeding the above sizes can be held quite firmly BUT caution must

be exercised. Check for adequate contact.

CAPACITY: DO NOT USE THE SCREW FOR VERY LARGE WOOD

BLANKS. Its use is intended for small bowl and screw chucking work.

The maximum capacity which should be mounted on the screw 250mm (10 inches) diameter x 100mm (4 inches). DO NOT EXCEED

600 RPM FOR THIS OPERATION. Use tailstock support.

PREPARATION: The 10.5mm thread requires a drilled hole about

8mm (5/16”) in diameter. The screw has considerable holding power

and it is sometimes difficult to unscrew, so wax or oil the thread before

mounting the wood. CARE: The threads are fine and can be damaged

by mishandling. DON’T hammer into wood! DO screw into a predrilled hole. Any nicks on the threads can be removed by carefully

filing.

EXPANDING DOVETAIL OPERATION

Expansion of the jaws into a recess. This function is for bowl and

platter turning where the projection (depth) of the wood blank is not too

great i.e. up to 150mm (6 inches). Characteristically these items have

a parallel wood grain. IT MUST NOT BE USED FOR ANY LONG

WORK (OVER 150MM) AS THERE WOULD BE GREAT DANGER OF

WOOD TEARING OUT AND DISLODGING FROM CHUCK.

Instructions below apply to the Powergrip jaws but the general

technique is the same with other accessory jaws. However, the

maximum size of wood blank that can be mounted, the maximum

turning speed and recess size varies with the different accessory jaws.

Consult specific instructions included for each jaw set.

This strong holding method, using the power grip jaws, bowls up to

400mm (16 inches) in diameter can be turned. DO NOT EXCEED

700RPM WITH THIS OPERATION. OUT OF BALANCE STOCK

MUST BE TURNED AT THE SLOWEST SPEED POSSIBLE.

105-0717-006 13

PowerGrip jaws: Any recess can be turned between 96mm (3.8”) and

120mm (4.7”) diameter. EUROPE/UK: Maximum recess size is 8mm

(0.30"). Choose the diameter that suits your bowl design. However, the

optimum turning recess diameter (on the outside) is 99mm (3 57/64”).

As the recess diameter is increased above 99mm, less jaw contact is

made. This needs to be kept in mind when considering the recess

depth and size of wood blank being mounted. Increase the recess

depth to maximum if a recess diameter in excess of 99mm is used.

The dovetail angle is 15 degrees.

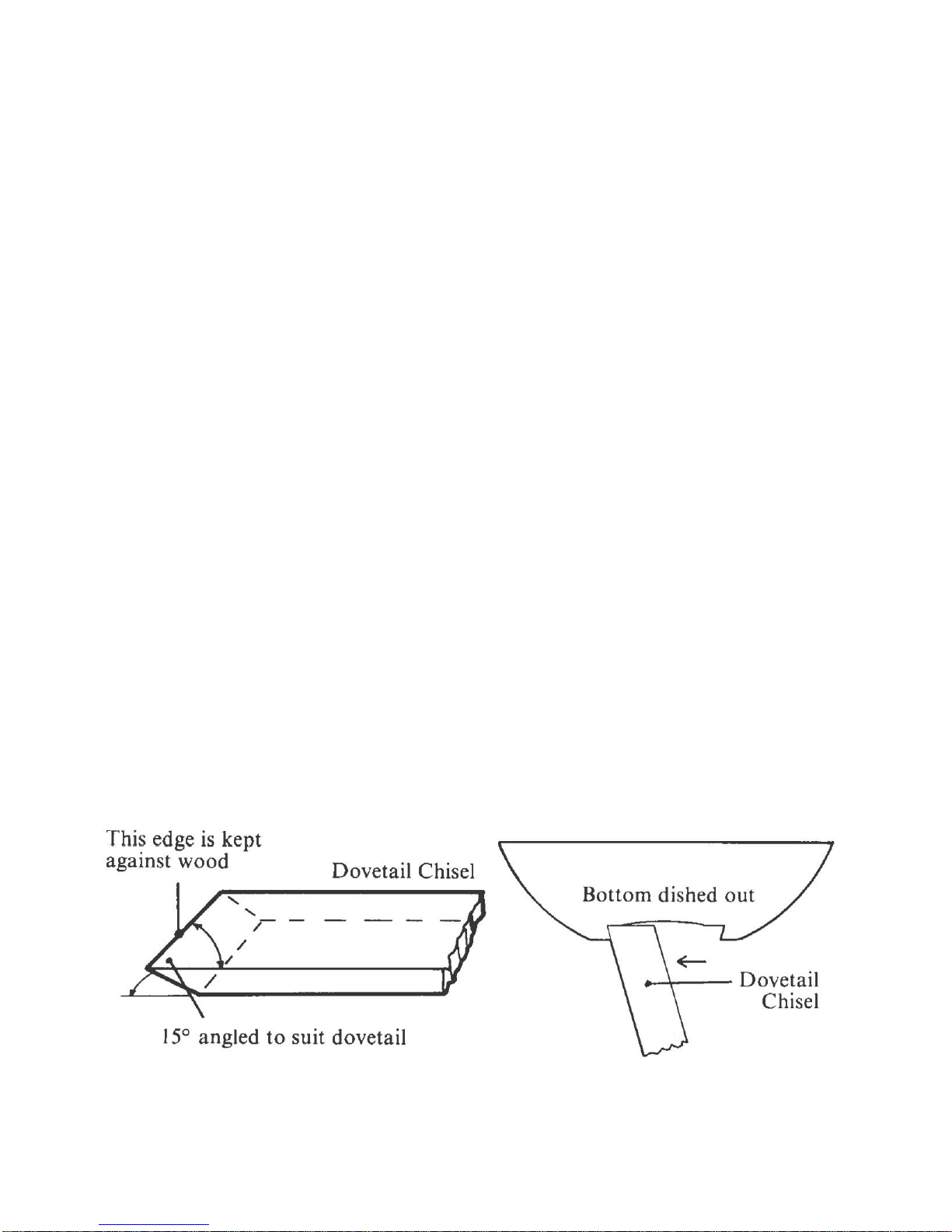

Forming a Recess

The jaw dovetail has been designed for use with a standard skew

scraper. This chisel will make a recess to the angle required. FOR

SAFETY REASONS WE STRONGLY ADVISE AGAINST USING ANY

OTHER TOOL. A profile of this chisel is shown below. It is best to

work with a tool, which is already ground, to the correct angle. All that

is necessary then is to keep the leading edge of the chisel flat on the

wood, moving forward and out to form the recess to the required

diameter and depth.

Mount bowl blank on screw as described in previous section. It may

be convenient to first mark out with a pencil, a circle on the bowl blank.

To mark out the recess diameter with pencil, hold pencil point to

desired radius, supported on the tool rest. Then revolve blank by hand

thus creating a pencilled circle. However, as specified above, any

recess diameter can be made between 96mm (3.8”) 120mm (4.7”) so

exact sizing of the recess is unnecessary.

Before scraping out the recess, slightly hollow out the centre of the

bowl blank with a bowl gouge or round nose scraper. The purpose is

105-0717-006 14

to relieve the centre so that when the recess is scraped out only half

the chisel edge needs to be used. We recommend this to reduce

tearing of the wood by scraping action; and to make the recess a little

more finished to give a better effect to the overall bowl. Extra

embellishments can also be made to the recess to enhance the bowl.

After the recess is finished and the outside of the bowl is turned to

shape, wind bowl back off screw. Bowl blank is now ready to be

reversed into the jaws. Expand the jaws into the recess. When the

jaws are expanded out into the recess, screw the wood blank gently

back and forth to make sure it is seated properly on the bottom face of

the jaws. WARNING: MAKE SURE THE JAWS ARE SEATED

PROPERLY IN THE RECESS AND THAT THE BOWL IS NOT

INCORRECTLY RIDING ON THE FLAT SHOULDER SECTION OF

THE JAWS BEHIND THE DOVETAIL. THIS COULD LEAD TO THE

BOWL DISLODGING FROM CHUCK. LOOSEN JAWS AND

REMOUNT CORRECTLY.

Now give a few gentle raps with the end of a chisel handle or wooden

mallet around centre of bowl. Use pinion handle to give an extra nip

up. Refer to chuck operation Page 4. Refer again to safety before

operation.

SPIGOT OPERATION

This is where the jaws contract around a wooden spigot for grip. This

function is mainly for box, goblet and vase turning, that is, end grain

items with a fair degree of overhang. This situation is one of the most

difficult to provide secure holding no matter what fixing method is used.

EXTREME CAUTION WITH THIS OPERATION MUST BE

EXERCISED. DO NOT EXCEED 700 RPM FOR THIS OPERATION. If

used properly the Nova Titan Chuck however, provides a very powerful

and secure grip in this mode. Instructions below apply to the Power

grip jaws but the general spigot technique is the same for other jaw

types. However, maximum turning speed and recess size varies with

different jaw types. Consult accessory jaw manual or instruction

sheets. With the power grip jaws a maximum size wood blank of

200mm (8 inches) diameter (NOT spigot size) by 310mm (12 inches)

length can be turned. Square timber of same length and between

60mm (2 23/64 inches) to 80mm (3 9/64inches) and grip of all four

105-0717-006 15

jaws into wood. MAKE SURE YOU HAVE AN ADEQUATE GRIP

BEFORE OPERATION by vigorously wrenching the limb mounted on

chuck. If any loosening occurs DO NOT PROCEED with operation.

Repeat tightening procedure and re-test grip.

SPIGOT SIZE:

PowerGrip jaws will grip a round spigot between 107mm (4.28 inches)

to 126mm (4.96 inches) approx. Square timber between 90mm (3.5

inches) to 110mm(4.33 inches) square approx. (Note: EUROPE/UK:

Maximum size is 6mm (1/4") less). Jaw slides only: With the add-on

jaws removed, the jaw slides will grip either round or square timber

down to 8mm (5/16inch). Length limits same for spigot work. Small

work not greater than this diameter can be turned at a speed NOT

EXCEEDING 1800 RPM. Larger work held in the jaw slides should not

exceed 700 RPM.

FORMING SPIGOT:

When selecting wood make sure it is sound without splits or weakness

- especially around the area where the spigot is to be formed.

REMEMBER WITH FREE END TURNING, THIS IS THE ONLY AREA

GRIP. IF ANY WEAKNESS IS FOUND, DO NOT PROCEED. Mount

wood between centres and turn the spigot area. Make the spigot as

parallel as possible to maximise the efficiency of the clamping action.

Only approximate sizing of the spigot is necessary, as the jaws will

accommodate a wide range of spigot diameters within the spigot limits

stated above.

FREE END TURNING

Turning where the work is not supported by the tailstock.

Check for adequate contact and grip of all four jaws into the wood

when using this operation. MAKE SURE YOU HAVE AN ADEQUATE

GRIP BEFORE OPERATION by vigorously wrenching the work piece

mounted in the chuck. If any loosening occurs DO NOT PROCEED

with this operation. Repeat tightening procedure and retest grip.

105-0717-006 16

Maintaining the Titan III Chuck

General Maintenance

CLEANING CHUCK: The Nova Titan Chuck is perfectly enclosed from

behind which makes the gearing mechanism maintenance free over a

long period of time. However, the chuck needs to be inspected

periodically for build up of wood dust in the jaw slide area on the front

side. Wood dust build up can make the jaws difficult to move. To clean

out the wood dust build up, the following method can be used. Remove

Jaw Slides. (First removing stop screw as explained in previous

section) then using a piece of wood (matchstick size) insert in the

bottom of scroll and rotate scroll ring. This will scrape out the

accumulated wood dust.

To disassemble chuck: Over a long period of usage there could be

some accumulation of very fine dust in the gearing area behind which

may require dismantling of chuck for a full clean. Following are steps

(Refer to exploded chuck diagram, Page 5) Using expanding pliers

remove the circlip securing the backing plate. This should give enough

access to clean the gears without further dismantling of the chuck. If

you want to dismantle further, follow these instructions. Remove the

two M6 fastening screws. Next hold the chuck with the jaw slide

surface facing up. Wiggle the pinions with the help of 8mm Hexagon

Wrench till the two dowel pins have fallen down. Next remove the

pinions. Remove the second circlip securing the scroll ring. The scroll

ring can be removed now. After you have cleaned the chuck assemble

the chuck back in the same order. Re-insert the jaw slides. Remember,

after you have re-assembled the gears, apply any general grease all

around the gear area!!

Remember to replace jaw travel stop screw!!

105-0717-006 17

Stop on JAW Travel

Stop screw is located at the end of the number 2 slideway, and number

4. The screw prevents jaw slides being unwound from the chuck. Do

not exert pressure against the screw with pinion action. If screw is

removed for disassembly it must be replaced before use. Refer

exploded view diagram on page 5 of the manual, and to drawing

accompanying insertion of jaw slides below.

Caution: Do not close jaw slides to a diameter less than 8mm (5/16”)

for work holding. Do not close jaw slides to fully closed position

because jaw slides could over travel on scroll and become

disengaged.

Insertion of jaw slides

Jaw slides are numbered 1 - 4 (numbering on end of slide). (Note:

Travel stop screws need to be removed. Refer to previous jaw slide

travel lock section). When the jaws are removed from the body they

need to be reset in sequence. To reset jaws in chuck body, rotate with

pinion gear until the lead of the scroll (like a thin wedge) appears in the

opening of the slide way # 2.

CAUTION: IT IS IMPORTANT TO ROTATE THE LEADING EDGE OF

THE SCROLL BACK SLIGHTLY TO CLEAR THE SLIDEWAY

BEFORE SLIDE CAN BE INSERTED. FAILURE TO ROTATE THE

SCROLL BACK COULD RESULT IN DAMAGE TO SCROLL.

Now insert No.2 slide into slideway and rotate scroll in a clockwise

direction (chuck facing you) until the lead of the scroll appears at the

next slideway. Now engage No.3 scroll in the same manner as No.2.

Proceed in the same way in a clock-wise sequence with No.4 and No.1

slides. Refer to the diagram.

105-0717-006 18

Troubleshooting Guide

Problem

Possible Cause and Solution

1. Chuck jams

when partially

threaded onto

spindle.

Check chuck body threads are free from damage.

Check spindle has engaged with chuck body

thread correctly. See 'Fitting to Chuck' Page 7.

Make sure the grub screw has not been

SCREWED IN.

2. Chuck body

appears not to

be true

Check insert is properly home in chuck body.

Check that the insert is correctly screwed onto

lathe spindle. Insert must back against accurate

face/register or bearing on lathe spindle. See Page

7.

3. Add on jaws

do not run true

Check jaws are mounted correctly on jaw slides.

For method see Page 9. For accuracy parameters

see Page 2. When the jaws are expanded beyond

a 50mm circle they will appear to be running out

but in fact are maintaining concentricity. Always

evaluate runout from turned wood clamped in jaws

4. Jaw Slides

closed to centre

and No. 1 slide

stays in centre

when jaws are

expanded again

Jaw Slide(s) have over travelled from scroll. It will

be necessary to tap back No 1 jaw slide until it has

re-engaged. See page 8 for 'insertion of jaw slide'.

5. Chuck very

stiff to operate or

jammed

Wood dust and shavings can clog the chuck in use.

The chuck should be cleaned. Follow instruction

Page 7

6. Jaw Slides

when Wound to

centre do not

meet

Slides have not engaged sequentially in clockwise

order with scroll - 1-2-3-4. Jaw Slides could have

been inserted out of order. Check insertion

procedure Page 8.

7. When chuck is

being removed

from spindle the

body unwinds

from insert

Either lock insert in body using grub screw and

fibre washer provided or use spanner on the insert

to wind chuck off lathe.

105-0717-006 19

8. Chuck jams on

lathe spindle

This is a common problem with fixtures on a lathe.

Use piece of wood & knock against base of pinion

gear in anticlockwise direction to jar loose from

spindle. To help prevent it try a plastic or fibre

washer between insert/chuck and spigot shoulder

of a spindle. Use of washer could affect accuracy.

9. Woodworm

screw creeps

forward or is not

seated properly

in chuck

Make sure woodworm screw boss is placed

correctly between jaw slides and behind jaws. See

Page 9

10. Wooden

spigot shifts

during turning

Check that the spigot area is made correctly for

jaws to grip. Check that the spigot is not oversize.

See spigot operation instruction Page 11. Use

careful chisel techniques that do not exert too

much pressure. Irregular rough wood blanks need

to be checked to see whether there is enough jaw

contact.

11. Wood blank

does not seat

properly in

internal dovetail

mounting

Check the angle of the dovetail recess made is the

same angle as the jaws. Make sure the bottom of

the recess is flat and square to face. See dovetail

operation Page 10. Check that the bowl is not

incorrectly riding on the flat shoulder of jaws behind

the dovetail.

105-0717-006 20

SKU 13061 EUROLOCK VERSION CHUCK ONLY

The Titan III EUROLOCK locking ring fixing system is a safety standard for European

lathes and chucks. The EUROLOCK chuck conforms to the European safety

standards for securing the chuck to the lathe by using the locking ring and is

compatible with both the new M33 Ring spindle and the M33 Standard spindle.

The Locking Ring supplied by the lathe maker

IMPORTANT! Release the Grub screw before removing the chuck.

Installation Instructions:

Step 1: Tighten the EU chuck to the spindle

on the lathe, make sure the rings on the

spindle and chuck have been clamped.

Step 2 & 3: Put the upper and lower part of

locking ring under the clamped rings as

shown.

Step 4: Using an 8mm Allen key, fasten the

two bolts on the locking ring.

105-0717-006 21

NOVA Titan III Chuck Exploded View

105-0717-006 22

NOVA Titan III Chuck Parts List

No.

Quantity

Description

Part Number

1 1 Allen Key 3mm

AK3.0

2 2 Fasten Screw

13004

3

2

Circlip

EC48

4

1

Cover

13003

5 1 Fibre Washer

5X1mm

NS1000

6 1 Grubscrew M6X6

A/h cup point

G0606

7 1 Scroll Ring

13035

8

1

Jawslide #1

1339011

1

Jawslide #2

1339012

1

Jawslide #3

1339013

1

Jawslide #4

1339014

9

1

Wrench Hex 8mm-T

Bar 150mm long

13006

10 2 Pinion gear

13036

11

4

Titan power grip jaw

13029

12

12

Head sunk screw

M6X10

CM5010181

13 1 Allen Key 4mm

AK4.0

14

1

Woodworm screw

10003

15 2 Position Screw

LSM4N

16

1

1 ¼” Chuck body

13038

1

M33 Eurolock

Chunk body

13039

105-0717-006 23

Titan III Accessories

OPTIONAL ACCESSORIES

The Nova Titan 5inch Chuck is one of the most versatile chucking

systems. It is fully compatible with the Nova and SuperNova Chucks

and shares the same extensive accessory range.

Optional accessories include over 18 different jaw sets and other items

to enable you to explore all areas of turning with your Nova Titan 5in

Chuck.

TITAN III 5.75” HD Deep Grip Jaw

Code:13040

Accessory Jaw for your Titan III chuck.

Special woodturning dovetail profile.

The Jaw Spigot length is

22mm/0.866Inchs

Contracting:87~116mm (3.5” ~ 4.5”)

Expanding: 119~153mm (4.5” ~ 6”)

*This jaw cannot be used on chucks other than NOVA Titan III

chuck

TITAN III 6.5” HD Deep Grip Jaw

Code:13041

Accessory Jaw for your Titan III chuck.

Special woodturning dovetail profile.

The Jaw Spigot length is

25mm/0.984Inchs

Contracting:99~133mm (3.9” ~ 5.2”)

Expanding: 136~170mm (5.3” ~ 6.6”)

*This jaw cannot be used on chucks other than NOVA Titan III

chuck

105-0717-006 24

COLE JAW SET

Code: JSCOLE

A versatile set designed

primarily for re-chucking of

bowls to remove chuck marks

or re-shape the bottoms of the

bowls that have already been

turned. Most other jaws etc can

be mounted on top of the Cole

Jaws for a combination jaw

facility.

POWERGRIP JAWS

Code: PJSN

These jaws have tremendous

holding power. Best used in

conjunction with the Nova Titan

5inch, as the extra gripping

power of the chuck enhances

the PowerGrip’s action. This jaw

is included with the standard

Nova Titan model. Able to hold

large work up to 750mm (29") in

diameter but has the added

advantage over the 130mm

jaws, of being able to hold long

spigots up to 19" long. Also has

a dovetail facility with up to

120mm (5”) recess.

105-0717-006 25

130mm JUMBO JAWS

Code: JS130N

The big brother to the 100mm

jaws. Designed to handle large

work up to 750mm (29") in

diameter. An ideal ‘companion’

jaw to the Nova Titan 5 inch as

the extra power of the Nova 5

inch matches the big capacity of

these jaws. No need to consider

larger chucks for those special

jobs - the Jumbo Jaws will

perform just as well. Has a

dovetail recess facility up to

149mm (5.86”).

100mm Jaw Set

Code: JS100N

Have an expanding dovetail

grip, strong reverse dovetail

grip for footed bowls. Made for

a larger range of work than

either the 50mm or Step jaws.

25mm Jaw Set

Code: JS25N

Designed for small bowl

(expanding dovetail mode) and

small spigot (contracting mode)

free end turning work below the

size that can be handled by the

standard 50mm jaws.

105-0717-006 26

Pin Jaw Set

Code: JSPIN

These special 25mm extended

jaws are designed to act like a

pin chuck - expanding into a

pre-bored hole. This is a useful

technique for free form edge

bowls. The real advantage

though is you don’t have to bore

an exact size as with pin jaws.

The longer jaws allow for a very

powerful spigot grip for smaller

work like lace bobbins etc. It

also has a small dovetail to

mount small bowls.

Step Jaw Set

Code: JS75N

Designed primarily to grip

footed bowls in the contracting

mode. Provides for optimum

grip of three different size foot

diameters. Also dovetail mode.

35mm Spigot Jaws

Code: JS-SP35

45mm Spigot Jaws

Code: JS-SP45

These two jaws provide a very

powerful contracting spigot grip

with the Titan Chuck. For long

unsupported spigot turning

applications.

105-0717-006 27

SPUR CENTRE

Code: NCSC

This is a rugged 4 pronged spur

drive with a 19mm square

shank, which fits snugly into the

Nova/SuperNova jaws. Creep

of the spur is prevented as the

shank is slotted to allow the

chuck jaws to close over it.

This spur is the answer for

turners who use their Nova

Titan almost all of the time but

want to be able to do those odd

spindle jobs without removing

the chuck from the lathe.

INSERT SPANNER

Code: 23014

Spanner to remove inserts off

lathe spindle or from chuck

body.

105-0717-006 28

Teknatool Warranty

Teknatool Two Year Limited Warranty

This Teknatool product is backed by a TWO YEAR warranty from the date of purchase. Teknatool

International Ltd will repair or replace, at its expense and option, this Teknatool product which in

normal use has proven to be defective in workmanship or material, provided that the customer returns

the product prepaid to an authorized Teknatool service center with proof of purchase of the product

within TWO YEARS and provides Teknatool with reasonable opportunity to verify the alleged defect

by inspection.

Teknatool will not be responsible for any asserted defect which has resulted from normal wear,

misuse, abuse, or repair or alteration made by anyone other than an authorized service facility or

representative. Under no circumstances will Teknatool International Ltd. be liable for incidental,

special, indirect, and consequential damages or expenses, including loss of profits or loss of

operations. This warranty is Teknatool International Ltd. sole warranty. There are no other

warranties, whether written or verbal, whether expressed or implied by law, trade, custom, or

otherwise, whether of merchantability, fitness for purpose, or otherwise, except for remedies available

to customers under the Consumer Guarantees Act or other legislation.

OVERSEAS CUSTOMERS: Our Teknatool Distributors and agents will issue their own warranty to

cover this product. Terms may vary from those stated above; please check with your dealer.

Note: Did you know you can register your warranty with Teknatool

online? Visit our website on www.teknatool.com to register your

warranty faster today!

105-0717-006 29

© Teknatool® International 2017

All Rights Reserved. Teknatool USA, Inc.

Register your warranty online

www.teknatool.com

Loading...

Loading...