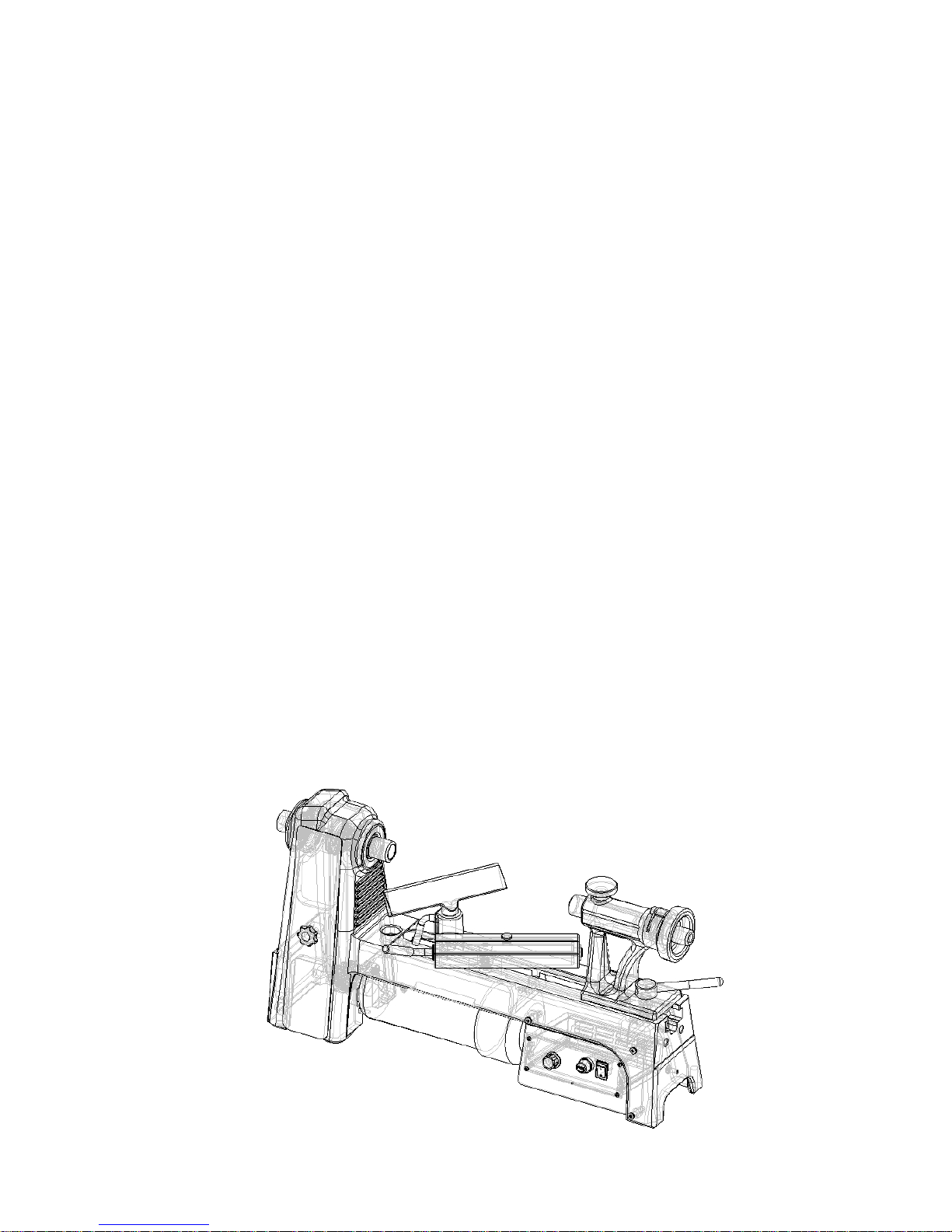

Nova

Mercury

TM

Woodlathe

Part No. 100-0109-002 Updated 14 October 2003

O PERATING M ANUAL

Nova Mercury Lathe Features at a glance

Add on Bed System

A lathe that meets your woodturning needs, your workshop space, or your pocket! Each segment is 12” in length. This

feature appeals for many different reasons:

As a compact lathe (standard configuration) it is great for small turning workshop spaces or as a portable unit.

As an extended bed lathe for those wanting to do longer spindles. One additional segment increases the between center

capacity to 23”(580mm). Two additional segments would give a 35” (890mm) capacity.

Outboard Turning

The Mercury is a mini lathe ideal for all inboard work up to 8” (200mm) diameter but you can stretch this capacity outboard.

The physical capacity of the outboard rest is about 14” but we recommend that you turn bowls up to 10” (250mm) diameter.

This gives it a capability in the ‘midi’ lathe range. You could occasionally do slightly larger bowls but would need to pay close

attention to correct cutting techniques.

Speed Range

The Nova Mercury lathe has a 3 step variable electronic speed range, one of the very best available for mini lathe work. Low

range: slower speeds from around 200rpm up to 1750 rpm for larger spindle and bowl work. Medium range: up to 3670rpm

for smaller items (eg pen work). Fast range: up to 5350rpm required for all miniature turning work. Most other mini lathes do

not have this fast speed range for true miniature work.

Electronic variable speed allows you to dial in the correct speed for the job and the conditions and not be limited to fixed

speed steps.

Solid Construction

Well proven design, the Nova Mercury is made from Cast Iron components for strength and rigidity. The headstock and bed

is a one piece casting for maximum rigidity – no fastenings or joins to rattle or cause vibration, as with many other mini

designs.

2

Welcome

Thank you for choosing our Nova Mercury Mini Lathe and welcome to the

Teknatool Product family. Your choice shows you want the best for your woodturning

and recognise the superior and unique benefits the Nova Mercury offers.

We strive to achieve the best value for your purchase - providing quality where it

counts, innovative features and a wide variety of accessories (some unique to

Teknatool). In addition - comprehensive, ongoing support: latest manual editions

downloadable from our website, free newsletters to keep you updated and woodturning

projects specially designed for your lathe and accessories.

In addition, especially for Mercury owners (many of whom are beginner turners) we

are going to build some special support features into our website.

Please send in your warranty registration to us (also can be sent to us via our

website) and feel free to contact us about any aspect of our products or service - we

regard our customers as our best development and improvement team - we'd love to

hear from you!

Once again, welcome to our 'Teknatool Family'. We hope you enjoy our products

and they enhance the creative pleasure you get from your woodturning!

Best Regards

Brian Latimer

Marketing Director

Teknatool International Ltd

8

3

Contact Teknatool

℡Phone: (+64) 9 837 6900

¬Fax: (+64) 9 837 6901

Email: service@teknatool.com

Website: www.teknatool.com

}Teknatool International Ltd

P.O.Box 180034 Luckens Point

Henderson, Auckland 1008

New Zealand

United States

Teknatool International

Free Phone: 1-866-748-3025

Free Fax: 1-866-748-4193

Email: service@teknatool.com

Website: www.teknatool.com

Woodcraft Supply Corp

Technical Service: 1-800-535-4486

Orders: 1-800-225-1153

Website:

www.woodcraft.com

Contact them for a copy of their catalogue, or for a list of

their stores throughout the USA.

Australia

Teknatool International

Free Phone: 1-800-140-761

Free Fax: 1-800-140-755

Email: service@teknatool.com

Website: www.teknatool.com

Contact us for a free catalogue and a list of stores

throughout Australia.

Canada

KMS Tools and Equipment Ltd

Phone: (+1) 604-522-5599

Free Phone: 1-800-567-8979

Fax: (+1) 604-522-0638

Email:

kmstools@kmstools.com

Website:

www.kmstools.com

United Kingdom

Robert Sorby

Phone: (+44) 114 225 0700

Fax: (+44) 114 225 0710

Email:

sales@robert-sorby.co.uk

Website:

www.robert-sorby.co.uk

France

Philbois Machines & Outils Pour Le Bois

Phone: (+33) 4-94-68- 82-32

Fax: (+33) 4-94-68-81-89

Email:

philbois@wanadoo.fr

Iceland

Gylfi Sigurlinnason

Phone: (+354) 555-1212

Fax: (+354) 555-2652

Email:

haki@centrum.is

Norway

WWW.Verktoy A/S

Phone: (+47) 51-88-68-00

Fax: (+47) 51-88-68-10

Email:

woodturning@ogreid.no

Website:

www.verktoyas.no

Japan

Ikeda Inc

Phone: (+81) 555-726-860

Fax: (+81) 555-726-865

Email:

fine@ikedatools.co.jp

South Africa

The Hardware Centre

Phone: (27) 011 791 0844

Fax: (27) 011 791 0850

This is the list of Countries/Resellers that currently stock

and sell the Nova Mercury Woodlathe. In addition,

Teknatool sells a more limited range into many other

countries. Contact us for details, or see our website.

4

Table of Contents

General Safety Rules .............................................................................................................. 6

Nova Mercury Woodlathe Specifications ................................................................................ 1

Setting Up Your Workshop.................................................................................................... 10

Workshop Requirements ................................................................................................... 10

Lathe Stand Recommendations ........................................................................................ 10

Assembling the Nova Mercury .............................................................................................. 11

Nova Mercury Components After Unpacking........................................................................ 11

Installing Handle .................................................................................................................... 12

Adding an Extension Bed .................................................................................................. 12

Mounting the Lathe to a Support Surface.......................................................................... 13

The Nova Mercury DC Variable Speed Motor....................................................................... 15

Belt and Variable Speed Range ........................................................................................ 15

Changing Belt Positions..................................................................................................... 16

Maintenance of the Motor .................................................................................................. 22

Using the Nova Mercury........................................................................................................ 14

Headstock .......................................................................................................................... 17

Toolrest .............................................................................................................................. 18

Tailstock............................................................................................................................. 19

Improving the Performance of your Lathe ......................................................................... 20

Learning Turning................................................................................................................ 20

Maintaining the Nova Mercury............................................................................................... 21

General Maintenance ........................................................................................................ 21

Lubrication Locations............................................................................................................. 21

Cleaning the Toolslide ....................................................................................................... 22

Cleaning the Tailstock ....................................................................................................... 22

Troubleshooting Guide .......................................................................................................... 23

Nova Mercury Woodlathe Exploded View............................................................................. 25

Nova Mercury Woodlathe Parts List...................................................................................... 26

Accessories ........................................................................................................................... 26

Teknatool Five Year Limited Warranty .................................................................................. 27

© Copyright 2000, 2001, 2002, 2003 by Teknatool International; All Rights Reserved. Nova Mercury

is a trademark of Teknatool International Ltd.

The information and specifications contained herein are subject to change. Teknatool is not

responsible for errors or omissions herein or for incidental damages in connection with the furnishing

or use of this information.

8

5

GENERAL SAFETY RULES

!

Warning! Failure to follow these rules may result in serious personal injury.

1. FOR YOUR OWN SAFETY, READ THE

MANUAL BEFORE OPERATING THE TOOL.

Learn the machine’s application and limitations

plus the specific hazards peculiar to it.

2. ALWAYS USE A FULL FACE SHIELD-

Strongly recommended (must comply with

ANSI STANDARD Z87.1 -USA) Everyday eyeglasses usually are only impact resistant and

safety glasses only protect eyes. A full face

shield fill protect the eyes and face. Also use

face or dust mask if cutting operation is dusty

3. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets or other jewelry which may get

caught in moving parts. Non slip footwear is

recommended. Wear protective hair covering

to contain long hair.

4. USE EAR PROTECTORS. Use ear muffs for

extended period of operation. Use muffs rated

to 103 DBA LEQ (8 hour).

5. DON’T USE IN DANGEROUS

ENVIRONMENT. Don’t use power tools in

damp or wet locations, or expose them to rain.

Keep work area well lighted.

6. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents. Build up of

sawdust is a fire hazard.

7. KEEP CHILDREN AND VISITORS AWAY. All

children and visitors should be kept a safe

distance from work area.

8. MAKE WORKSHOP CHILDPROOF with locks,

master switches, or by removing starter keys.

9. GROUND ALL TOOLS. This tool is equipped

with a three prong plug, it should be plugged

into a three hole electrical receptacle. If an

adapter is used to accommodate a two-prong

receptacle, the adapter lug must be attached to

a known ground. Never remove the third prong.

10. MAKE SURE TOOL IS DISCONNECTED

FROM POWER SUPPLY while the motor is

being mounted, connected, or reconnected.

11. DISCONNECT TOOLS before servicing and

when changing accessories such as blades,

bits cutters, etc.

12. AVOID ACCIDENTAL STARTING. Make sure

switch is in the Off position before plugging in

power cord.

13. NEVER LEAVE MACHINE RUNNING

UNATTENDED. Do not leave tool unless it is

turned off and has come to a complete stop.

14. KEEP GUARDS IN PLACE and in working order.

15. USE RIGHT TOOL. Do not use a tool or

attachment to do a job for which it was not

designed.

16. USE RECOMMENDED ACCESSORIES. The use

of improper accessories may cause hazards.

17. DON’T FORCE TOOL. It will do the job better and

be safer at the rate for which it was designed.

18. MAINTAIN TOOLS IN TOP CONDITION. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating

and changing accessories.

19. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

accidentally contacted.

20. REMOVE ADJUSTING KEYS AND WRENCHES.

Form a habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

21. DON’T OVERREACH. Keep proper footing and

balance at all times.

22. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade

or cutter only.

23. ATTENTION TO WORK. Concentrate on your

work. If you become tired or frustrated, leave it for

awhile and rest.

24. SECURE WORK. Use clamps or a vice to hold

work when practical. It’s safer than using your

hand and frees both hands to operate tool.

25. CHECK DAMAGED PARTS. Before further use of

the tool, any part that is damaged should be

carefully checked to ensure that it will operate

properly and perform its intended function. Check

for alignment of moving parts, binding of moving

parts, mounting, and any other conditions that may

affect its operation. Any damaged part should be

properly repaired or replaced.

26. DRUGS, ALCOHOL, MEDICATION. Do not

operate tool while under the influence of drugs,

alcohol, or any medication.

27. DUST WARNING. The dust generated by certain

woods and wood products can be injurious to your

health. Always operate machinery in well

ventilated areas and provide for proper dust

removal. Use wood dust collection systems

whenever possible.

Primary Caution:

Extreme care must be taken when handling the spindle threads. These are sharp and should not

be used to lift the lathe or to stop or manually rotate the spindle.

6

ADDITIONAL SAFETY RULES FOR WOODLATHES

!

Warning! Failure to follow these rules may result in serious personal

injury.

1. DO NOT MODIFY OR USE LATHE FOR USES

OTHER THAN FOR WHICH IT WAS

DESIGNED.

2. SEEK INSTRUCTION. If you are not thoroughly

familiar with the operation of woodlathes, obtain

advice from your supervisor, instructor, or other

qualified person. Instruction from a qualified

person is strongly recommended.

3. DO NOT OPERATE LATHE until it is completely

assembled and installed.

4. FOLLOW ELECTRICAL CODES. Make sure

wiring codes and recommended electrical

connections are followed and that the machine is

properly grounded.

5. KEEP WORK AREA CLEAN. Do not turn the

lathe On before clearing the lathe of all objects

(tools, scraps of wood, etc.). Keep the nearby

area and floor clear of debris.

6. CHECK SET-UP with power Off. Examine the

set-up carefully and rotate the work piece by

hand to check clearance before turning on

power.

7. DO NOT MAKE ADJUSTMENTS when the lathe

or work piece is turning. Make all adjustments

with power Off.

8. TIGHTEN ALL CLAMP HANDLES on the

headstock, tailstock, and toolrest before

operating lathe.

9. EXAMINE WORK PIECE and glue joints before

turning to make sure it has no defects that would

cause it to break when turning.

10. USE LOWEST SPEED when turning a new or

unbalanced work piece.

11. TURN AT RECOMMENDED SPEED. Always

operate the lathe at the recommended speeds.

Consult this manual for suggested speeds.

12. ADJUST TOOLREST close to the work piece.

Before turning, revolve the stock by hand to

make sure it clears the rest. At intervals, stop

the lathe and readjust the toolrest.

13. KEEP TOOL ON TOOLREST. The lathe tool or

chisel should be on the toolrest before the lathe

is turned On. Tools should remain on the

toolrest whenever the tool is engaged in contact

with the work piece.

14. REMOVE TOOLREST when sanding or

polishing so fingers do not get pinched.

15. DIRECTION OF FEED. Feed work into blade or

cutter only against

the direction of rotation of

workpiece.

16. USE CORRECT LATHE TOOLS. Do not use

spindle turning chisels for faceplace mounted

work, and vice versa. Spindle turning tools used

for faceplate turning may grab the work piece

and pull the chisel from your control.

17. WHEN ROUGHING STOCK do not jam the

lathe tool or chisel into work piece or take too big

a cut.

18. DO NOT POUND WORK PIECE into headstock

drive (spur) center when turning between

centers. Pound the drive center into the work

piece with a soft mallet before installing it

between centers in the lathe.

19. DO NOT USE TAILSTOCK to drive work piece

into the drive (spur) center when turning

between centers. Secure work between centers

with light pressure from the tailstock quill action.

20. FASTEN STOCK SECURELY BETWEEN

CENTERS. Make sure the tailstock is locked

before turning on the power.

21. NEVER LOOSEN TAILSTOCK spindle or

tailstock while work piece is turning.

22. CORECTLY USE FACEPLATE. When faceplate

turning, make sure work piece is securely

fastened to the faceplate and that appropriate

size faceplate is used to support the work piece.

Any screw fasteners must not interfere with the

turning tool at the finished dimension of the work

piece. Rough-cut the work piece as close as

possible to finished shape before installing on

faceplate.

23. DO NOT OPERATE LATHE IF DAMAGED OR

FAULTY. If any part of your lathe is missing,

damaged or broken, in any way, or any electrical

component fails, shut off the lathe and

disconnect the lathe from the power supply.

Replace missing, damaged, or failed parts

before resuming operation.

24. ADDITIONAL SAFETY INFORMATION

regarding the safe and proper operation of this

product is available from the National Safety

Council, 444 N. Michigan Avenue, Chicago,

IL 60611 in the Accident Prevention Manual of

Industrial Operations and also in the Safety Data

Sheets provided by the NSC. Also refer to the

American National Standards Institute ANSI 01.1

Safety Requirements for Woodworking Machines

and the U.S Department of Labor OSHA

1910.213 Regulation.

Important Note:

For Schools and Industrial applications the Nova Mercury Lathe will require the use of a NO VOLT

RELEASE. For these applications the lathe may also fall under additional regulations.

8

7

Nova Mercury Woodlathe Specifications

Toolrest:

Weight: 59lbs (24.58Kgs) Packaged.

Length: 6" (150mm)

Overall dimensions:

Shaft Diameter: 5/8" (15mm)

Length: 20.5" approx. (525mm)

Motor:

Includes projection of outboard spindle.

1/2 HP (Average Output) DC

(Permanent Magnet Type) Variable

Speed Drive.

Height: 11.5" approx. (285mm)

Top of headstock from bench.

Speeds:

Swing over bed: 8" (200mm)

Low Speed Pulley: 140rpm - 1750rpm

Distance Between Centers: 11" (280mm)*

(Left position pulley looking at spindle from

operator side)

(*Can be increased with 12” (300mm) extension beds)

Swing Outboard: 14" (355mm)*

Middle Speed Pulley: 320rpm - 3670rpm

(*Normal operational capacity is around 10” /250mm)

High Speed Pulley: 470rpm - 5350rpm

Headstock:

Standard Equipment:

Spindle Thread: 1" 8TPI RH.

Live (Revolving Center) 2MT

Headstock Bore: No.2 Morse Taper (2MT)

Spur Center 2MT

Outboard Spindle Thread: 1" 8TPI LH

2 1/2" (60mm) Faceplate

Through Bore: 3/8" (10mm)

6" (150mm) Toolrest

Traverse Hole through Spindle: 3/8"

(10mm)

Optional Accessories:

Mercury Bed Extension

(Accepts up to 3/8" steel rod to act as

spindle lock)

Mercury Outrigger

(work weight limits. 4-5lbs)(1.8-2.3kgs)

Tailstock:

Nova Chuck System

Tailstock Bore: 2MT

Nova Compac Chuck

Quill Travel: 2.5" (63mm)

Hole Through Tailstock: 3/8" (10mm)

8

9

Setting Up Your Workshop

Workshop Requirements

Consideration Recommendation

Lathe

Location

Locate the Nova Mercury close to a power source in an area with

good lighting. Allow for outrigger room should this accessory be

purchased. If you are using it in a workshop other machines in your

shop should not interfere with the operation of the lathe.

Lighting Your room or workshop should have adequate lighting. The work

area of the lathe should be well lit; there should not be shadows

cast on your work. If possible, locate near a window. A movable

spotlight may be helpful.

Electrical The Nova Mercury requires the appropriate outlet nearby to power

the motor. Wiring and outlets should adhere to local electrical

codes. If in doubt, seek advice from an electrician. Minimize use of

extension cords.

Ventilation Your room or workshop should be adequately ventilated. The

degree of ventilation will vary based on the size of the room and the

amount of work done. The Nova Mercury lathe does not normally

create a big dust problem however the use of dust collectors and

filters will minimize risks to your health.

Lathe Stand Recommendations

A sturdy and rigid stand is desirable so that the Nova Mercury Woodlathe can deliver

optimum performance. The larger the size of your turnings, the greater the importance of the

lathe stand design. However for many smaller projects simply mounting the mercury on a

bench top or table will suffice. For security it should be clamped in place.

Consideration Recommendation

Lathe Height

from floor

The height of the stand should locate the centerline of the lathe

spindle at the elbow height of the turner.

Stand Top The stand top should be flat so the lathe does not twist when it

is bolted down. Check for any gaps between lathe feet and

stand top before bolting down. Shim and prepare stand as

necessary.

Ideally the lathe should be mounted on spacer blocks to provide

extra clearance for motor and shavings.

Stand Weight The stand should have enough weight and mass so it doesn't

move when turning large work pieces, and so that the stand

can absorb vibrations.

Stand Legs The stand should sit level on the floor and not rock.

10

Assembling the Nova Mercury

1. Unpack the lathe and components from the shipping package.

2. Clean any parts coated with rust preventative with a cloth moistened with a petroleumbased solvent or cleanser, such as Kerosene. Coat the lathe bed with paste wax or use

a silicon spray.

Caution: Extreme care must be taken when handling the spindle threads. These are sharp

and should not be used to lift the lathe or to stop or manually rotate the spindle.

Nova Mercury Components after Unpacking

(The Bench fastening kit is not illustrated)

3. Insert the toolrest into the toolslide and fasten up with the toolrest lock arm.

4. Assemble the Tailstock handle.

8

11

Assembling the Tailstock

Handle

Screw the handle into the locking

stud clockwise until it is tight.

Installing Handle

Adding an Extension Bed

Each cast iron extension bed adds 300

mm (12 in.) to the lathe's capacity to turn

between centers.

1. Clean the joining ends of both bed

sections with a petroleum-based

solvent. Make sure there are no

dents or burrs on either mating

surface. Remove burrs and high

spots with a smooth file.

2. Bring the 2 mating faces together

and fit the 2 M10 cap screws, doing

them up "finger tight".

!

Warning!

Do not use a metal hammer to pound on the extension bed. This

may damage the bed, affect accuracy and tailstock action, and may

prevent you from adding another extension bed.

3. Bring the Tailstock along until it is on top of the join area where the bed extension face

meets the lathe bed face. The bed extension may need to be manipulated up-and-down

and sideways in order for the Tailstock to fit.

4. Clamp the Tailstock down in its current position.

5. Do the M10 cap screws up tight.

6. Check that the tailstock moves freely over the mating joint and also over the full length of

the add-on extension. If there is ridge between the two mating surfaces then repeat

steps 1-5 again or failing that use a smooth file to file the surfaces flush.

12

Mounting the Lathe to a Support Surface

1. Place the lathe on the stand or bench

top (as illustrated). Locate the front

edge of the lathe approximately

25 mm (1 in.) from the front of the

stand/bench top. Locate the left edge

of the lathe approximately 10mm

(3/8") in from the edge of the

stand/bench top. This provides a

comfortable reach when turning and

allows the optional outrigger unit to be

easily installed.

2. It will be useful to include spacer

blocks under the headstock and

tailstock end of the lathe. This will

create a gap under the motor so wood

shavings, chips and dust can be

removed. The alternative is that the 4

Rubber & Steel washers that are

supplied with the Bench fastening kit

be used with the Steel washer on top

of each Rubber washer. This will also

work as a vibration dampener.

3. If necessary, mark the four hole

locations (as illustrated) and drill

12mm (1/2-inch) holes.

4. Place a spirit level along the top of the

lathe bed. Any movement of the

bubble as the lathe is secured,

indicates a twist on the bed. For the

lathe to operate correctly the bed must

not twist; if necessary, use shims between the bed and stand top.

5. To bolt the lathe to the bench Teknatool have available as

6. accessories M10x20 Hex bolts-for bolting down to a thin sheetmetal bench or M10x70

Hex bolts or bolting down on a heavy wooden bench up to 2" thickness. The bolts are

supplied in kit form with four of each length bolt. Disregard the bolts not required.

The lathe must be mounted 1 to 1 1/2" on packers or the 4 x Rubber & Steel spacer washers

to avoid wood shavings from entering the motor housing.

Packers

8

13

Connecting the Mercury to Power Source

The electric motor, switch, cord and controllers are supplied with the Mercury lathe. The plug

must be plugged into a matching outlet that is properly installed and grounded in accordance

with local electrical codes.

The power cord should be 3-wire, having a grounding conductor and a grounding pin.

!

Warning!

Improper connection of the motor can result in a risk of electrical

shock.

If it is necessary to use an extension cord, the cord should be grounded. Use the correct wire

size for the extension cord, for a given cord length, to avoid power loss and over-heating.

L IMPORTANT: For best protection of the Lathe use a surge protected plug

outlet rated to at least 15 amps.

Ground Fault Interrupters (GFI's) or Residual Current Detectors (RCD's) are helpful

and are a recommended protection device for any powertool. They can be used in

conjunction with a DVR lathe without any problems.

14

Using the Nova Mercury Lathe

The Variable Speed DC Motor

!

The DC motor contains brushes that contact the commutator. It is very

important to allow between 30 to 45 minutes of 'run-in' time of these brushes before

any turning or significant load is applied. This should be done in the higher rpm range.

A clicking or swishing noise in the motor is normal which will reduce as the brushes

wear in. During normal operation 5 minutes of warm up may also be required on cold

mornings.

The motor is one of the most important elements in the lathe. The Mercury lathe uses a high

quality and powerful DC (direct current) motor to provide the best turning characteristics. It

has been wired in such a way that allows the lathe spindle to rotate in a counter-clockwise

direction (when facing the spindle).

We use a permanent magnet DC motor (PMDC) which produces the most torque for

conventional motors.

The motor is nominally rated at 1/2 Hp (180watts) but can produce a higher output than this.

Belt and Variable Speed Range

Coupled with the high torque DC motor we also use a 3-step pulley to provide optimum power bands. The

label on the controller displays the ranges as 1, 2 and 3. With the unit facing the operator, Band 1 is the left

most drive-belt position for the slower turning. Band 2 is in the middle and Band 3 on the right.

Optimal Speeds on Each Band

Speed

Band

Type of Work

RPM

Range

1

Slower Speed Range:

Larger faceplate & spindle work

140-1750

2

Medium Speed Range:

Small faceplate work (up to 5") & smaller diameter

spindle work

320-3670

3

Fast Speed Range:

Small turning & miniature turning work

470-5350

Total Speed Ranges Available

Belt

Step

1 2 3

RPM

Slow Medium Fast

140 320 470

200 510 760

510 1170 1780

810 1780 2770

1110 2400 3650

1430 3000 4600

1640 3570 5000

1750 3670 5350

The speed ranges are achieved with a variable speed controller. A microprocessor chip in conjunction with

other electronic components allows the input power to be manipulated. In return smooth variable DC power

c

be delivered from the controller to the motor.

!

This is a Y type appliance where all electrical workings and attachments are NOT to

be altered, replaced or worked on. Any work in this area is to be done by TEKNATOOL

International Only. Please contact Teknatool International should any damage to the

electrical workings occur.

8

15

Changing Speeds

1. When starting set the knob to about ¼ of the speed range and slowly bring the speed to

the desired revolutions.

2. Starting the motor at the lowest possible setting may cause it to fail due to loading.

However the lowest setting can be achieved by reducing the revolutions once the motor

is in motion.

3. Rapidly turning the knob from low up to high speed is not recommended.

Changing Belt Positions

1. To change the belt position,

ensure the machine is switched

off.

2. Unlock belt guard by

loosening knob. Rotate the

guard so that it is sitting

horizontal to bed (see picture).

3. Loosen the Motor mount

locknut by hand or using a

½”AF spanner.

4. Lift the Motor slightly to get

the belt off the pulley. The

motor adjustment range is

approximately 20mm (3/4").

5. Fit the belt to the desired

step.

6. Tension the belt by pressing down on the motor with the hand. Pressing down with 2 fingers

or the thumb will be adequate pressure. Slightly tighter pressure may be required for larger work.

Caution: Too much pressure on the motor will damage the motor bearings or break the motor

shaft.

7. When the correct tension has been made, while holding the motor at the correct tension,

tighten the motor mount locknut by hand and then using a ½”AF spanner.

Caution: Don't use too much tension on nut - It needs to be tightened only a little more than

finger tight with a ½”AF spanner. (AF: across flats)

8. Swing belt guard to close position and re-lock knob.

16

Headstock

The headstock houses the motor pulley, headstock pulley, bearings, a belt and the spindle.

The headstock spindle accepts centers and accessories with no. 2 Morse taper (#2 MT), plus

threaded faceplates and chucks. The thread size is

1" 8 TPI RH and 1"8 TPI LH.

Mounting a faceplate or chuck

1. Use the locking bar to hold the

headstock spindle in position.

2. Screw the faceplate or chuck onto

the spindle threads. A spindle washer

in-between may be used to make

removal easier. As you tighten the

faceplate or chuck body more force will

need to be applied on the locking bar

to hold the spindle stationery.

!

Warning!

The faceplate or chuck body

must contact the shoulder on

the spindle bearing.

3. Remove the spindle locking bar

before turning on the lathe.

4. Similarly use the bar to dismount.

Using a spur center

1. Mount the spur center to the work

piece as shown and then insert the

spur center and work piece into the

headstock spindle.

!

Warning!

Do not pound work piece into

headstock drive center when

turning between centers or you

may damage the headstock.

2. To remove the center, insert a 10

mm (3/8-inch) diameter wooden dowel

or steel rod through the headstock

spindle hole. While holding the center

so it doesn’t fall, tap it out.

For hardwoods drill centres and

saw diagonals for

spur drive center

8

17

Toolrest

1. To move the toolslide along the bed,

loosen the Camshaft Handle, move the

slide to the desired position, and

tighten the handle.

2. To adjust the toolrest, loosen the

Toolrest Lock Arm, position the

toolrest, and tighten the Lock Arm.

3. Adjust the toolrest close to the work

piece. Exact positioning may be varied

to suit the turner. Before turning,

revolve the stock by hand to make sure

it clears the rest. At intervals, stop the

lathe and readjust the toolrest.

!

Warning!

Lathe tools and chisels should

remain on the toolrest

whenever the tool is in contact

with the work piece.

Remove the toolrest when

sanding or polishing so fingers

do not get pinched.

18

Tailstock

!

Warning!

Never loosen the tailstock quill or

tailstock while the work piece is

turning.

1. To move the tailstock along the bed,

loosen the Tailstock Lock Arm, slide the

tailstock to the desired position, and tighten

the Lock Arm.

2. To move the tailstock quill in or out,

loosen the Quill Lock Knob and turn the

Handwheel. Lock the quill in place with the

Quill Lock Knob.

3. The tailstock quill accepts centers and

accessories with no. 2 Morse taper (#2

MT). To install a taper use a quick, firm

action by hand. Do not pound the taper in.

4. To remove a taper, insert the knock out

bar through the tailstock quill hole. While

holding the taper so it doesn’t fall, tap it

out.

5. The tailstock quill is hollow, allowing you

to bore holes through turnings if a hollow

center is used.

Adjusting the Tailstock for Turning Between Centers

1. Mount the spur center to the work piece and insert the spur center into the headstock

spindle, as previously described under "Using a Spur Center".

!

Warning!

Do not use the tailstock quill action to drive the work piece into the

spur center. This can create an unsafe and loose work piece.

2. Mount the live center into the tailstock quill using a quick, firm action by hand.

3. While holding the work piece, slide the tailstock to meet it and lock the tailstock in place.

Turn the Handwheel to apply light holding pressure to the work piece; it should turn

easily by hand, yet not be loose. Tighten the Quill Lock.

8

19

Improving the Performance of your Lathe

To get the best performance out of your lathe it is good woodturning practice to keep all chisels

and tools sharp. This can be achieved by regularly grinding the cutting edges on a grinder with

the aid of a sharpening guide. Keeping the edges sharp significantly reduces the loading on the

motor allowing for better output. Consequently turning conditions are improved and cleaner

finishes are obtainable.

For improved turning it is desirable to have wood removed in shavings as opposed to chips. The

position of your tool to the work-piece is very important in achieving this.

It is advisable to have an angle between the tool tip and the work-piece. The angle allows

shavings of wood to be 'scooped' off in strips. It must also be noted that the type of wood and

grain will affect the removal of wood from your work-piece.

To gain maximum torque from the motor it is advised that the belt is run on the smallest motor

pulley diameter i.e. closest to the Outrigger. Use the middle step for other general work.

Learning Turning

The last section outlined some simple guidelines and recommendations to get you started.

However the art and technique of turning is a subject beyond the scope of this operating

manual. It is recommended that you receive hands-on instruction on lathe turning and/or

refer to books and videos on the subject. For reference, some woodturning books are:

Woodturning A Foundation Course

by Keith Rowley

Turning Wood With Richard Raffan

by Richard Raffan

Creative Woodturning

by Dale Nish

The Fundamentals of Woodturning

by Mike Darlow

Woodcraft in the USA offer woodturning instruction courses. For more information visit

Woodcrafts website at www.woodcraft.com

20

Maintaining the Nova Mercury

General Maintenance

Interval Maintenance

After each use Clean the work area and lathe. Vacuum scraps and dust from the

inside the headstock, between the lathe bed rails, and under the

toolslide and tailstock.

Monthly Wax exposed cast iron parts with a good quality paste wax or

silicone spray, especially the bed rails. Buff out the wax thoroughly.

Check tightness of nuts and bolts; especially the grub screw (set

screw) on the motor pulley and the lathe mounting bolts.

Lubricate, with one or two drops of light-weight oil, the tailstock quill

threads, index pin shaft, and the toolslide camshaft (remove plastic

plug) and toolslide camshaft bores.

6 Months Grease tailstock quill threads. Turn the handwheel so the quill

threads are exposed, apply grease to the threads, crank the

handwheel back and forth to work in the grease, wipe off any

excess.

Lubricate the tailstock slot with one or two drops of light-weight oil.

Lubrication Locations

8

21

Cleaning the Toolslide

If the toolslide becomes hard to move and

adjust, cleaning and lubricating are required.

1. To make the toolslide slide more freely

along the bed, make sure the bed rails are

clean. Apply some paste wax to the rails.

2. If the toolslide is hard to move towards or

away from you, remove the toolslide from

the lathe bed. Clean the toolslide

camshaft (round eccentric rod) with a

petroleum-based solvent. Lubricate the

rod with a light-weight oil or a silicone

spray.

3. Slide the base back onto the lathe bed.

Cleaning the Tailstock

If the tailstock quill becomes hard to use or

the Handwheel is hard to turn, cleaning and

lubricating are required.

1. Remove the 6mm grub screw from the

tailstock. If necessary, turn the

Handwheel (to 12 o'clock) to expose

the set screw. You will see a hole in

the face of the handwheel that gives

access for an Allen key/wrench. A

3mm A/F (across flats) Allen key is

required (not supplied).

2. Using a screwdriver, remove the

keeper plate from the tailstock body.

3. Remove the quill and Handwheel from

the tailstock body.

4. Wipe clean all parts including the

inside of the tailstock.

5. Lubricate the quill and tailstock slot

with a light-weight oil and apply a small

amount of grease to the quill threads.

6. Reassemble.

Maintenance of the Motor

Keep the motor free of saw dust and wood chips especially around the fan housing.

Periodically check for any abnormal noise or excessive heat.

The Brushes should be checked every five years and replaced when brush length is less than

6mm (1/4").

For motor or electronic problems the machine should be taken to the nearest service center. See

the contact details at the front of this catalogue. In USA contact Woodcraft 1-800-535-4486.

22

Troubleshooting Guide

Problem Possible Cause and Solution

Excessive vibration. Out of balance, or large work piece. Reduce lathe speed to the lowest

speed possible and turn the work piece to a true circle.

Work piece is not held in the center. Check work piece mounting and

correct.

Work piece is not secure or held tight enough. Check work piece

mounting and correct.

Lathe incorrectly bolted to stand or bench. Refer to this manual for

lathe stand recommendations.

Stand or bench not well constructed too light, or standing incorrectly on

the floor. Make sure the stand is solidly constructed.

Over tensioning of belt is a primary cause of vibration. The drive belt is

running badly, over tensioned, or damaged. Apply a spray-on belt

dressing on the belt grooves, readjust belt tension, or replace the belt.

Motor pulley is not in correct alignment with the headstock pulley.

Loosen the motor pulley grub screw and align the pulleys. Ensure motor

pully grub screws are tight once in position.

Headstock pulley or motor pulley is loose. Check that the pulley set

screws are tight.

The headstock guard is loose or rattling. Check that the belt guard

knob is tight.

Ensure motor adjustment locknut and M5 nyloc nut are tight.

Motor vibrates. Many single-phase motors produce minor noise or

vibrations; these usually cannot be altered. Sometimes new brushes

take time to wear in and a reduction in noise can be noticed after a few

hours of running.

Faceplate or chuck

running out of true.

Dirt build-up on the rear of the faceplates or chuck. Clean off all build

up and dirt. Faceplates and chucks must mount securely against the

inner bearing ring surface of the spindle.

Turning tools not

sliding smoothly

across Toolrest.

Damaged surface on toolrest face caused by sharp edged tools. File

the toolrest using a fine smooth file and polish with extra fine

sandpaper. Also remove the sharp edges from the corners of turning

tools.

Spur drive center or

live center not holding

into the spindle taper

or quill taper when

turning.

Small end of Morse taper is damaged due to dropping or hitting. File or

polish away any damage. Check that inside of tapers have not been

scored.

Grease or oil inside of Morse tapers. Wipe clean the inside of the

tapers.

Insufficient pressure when installing the center. Use a quick, firm action

by hand to install a taper. Do not knock in using any solid object.

8

23

Troubleshooting Guide

Problem Possible Cause and Solution

Tailstock and

headstock center not

lining up correctly.

Bed incorrectly bolted to stand causing twist. Ensure stand and lathe

are correctly installed.

Tailstock base is not flush with bed. Check for debris on both surfaces

Motor doesn't run. Check for severed electrical cords. Remove plug from power outlet

socket. Check an appliance that you know works in the power outlet

socket. If it fails then check fuse in switch board corresponding to that

socket. If socket is operating then the control unit of the Mercury Lathe

may have blown. Contact your nearest service centre for replacement.

Tailstock handwheel

hard to turn or will not

turn.

Quill lock is locked; unlock the quill lock. If necessary, lightly tap a

block of wood against the handwheel handle; tap the handle in a

clockwise direction as viewed from the tailstock end.

Build up of dust and wood resin on the quill or inside of the handwheel

thread. Remove, clean, and lubricate the quill and tailstock as

described under "Cleaning the Tailstock".

The quill has been retracted too far and is locked against the

handwheel.

Tailstock quill

hard to move.

Quill lock is locked; unlock the quill lock.

The quill is damaged; turn the handle to expose the quill and check for

marks along the quill, especially on the edges of the slotted keyway

Remove the high spots with a smooth file and test the quill travel.

Replace the quill if necessary.

Tailstock not sliding

smoothly on bed ways.

Dirty bed ways and underside of tailstock body. Clean bed ways and

underside of tailstock body with a petroleum-based solvent.

Tailstock binds. The inside of the bed has a high spot. File the area with a smooth flat

file until the tailstock moves freely.

The tailstock adjustment plate has a rough spot or a burr. Remove the

tailstock and file the plate with a smooth flat file.

Tailstock jumps where

bed sections join.

The machined flat surfaces are not flush. File the area with a smooth

flat file until the tailstock moves freely.

For other technical issues contact your local service centre or e-mail us at

service@teknatool.com

. In the USA contact Woodcraft technical at tech@woodcraft.com or

phone 1800-535-4486

24

Nova Mercury Woodlathe Exploded View

See parts list on page 25

8

25

Nova Mercury Woodlathe Parts List

ITEM

NO.

QTY PART

NO.

DESCRIPTION SUPPLIED ITEM

NO.

QTY PART NO. DESCRIPTION SUPPLIED

1 1 37000 Headstock Yes 31 1 37070

37091

PCB Control Board

500W 115V

PCB Control Board

500W 230V

Yes

2 1 37003 Spindle 1"8 TPI RH Yes 32 1 37075 Control box cover Yes

3 3 IC55 Circlip Internal 55mm Yes 33 1 37079 Rocker On/off switch Yes

4 1 6006LLB Bearing-front Yes 34 1 37036 Knob variable speed

control

Yes

1 6006ZZ Bearing-back Yes 35 1 37086 Fuse Holder Yes

5 1 37001 Tailstock Yes 36

6 1 37007 Quill Tailstock Yes 37 1 37016 Belt Guard/Door Yes

7 1 37004 Handwheel Tailstock Yes 38 1 24055 M5 x 10 Knob Yes

8 1 37008 Knob - Quil Lock Yes 48 1 483J3 Belt Yes

9 1 24040 Keeper Plate - Tailstock Yes 49 1 EC30 External Circlip Yes

10 1 37005 Lockstud - Tailstock Yes 56 1 NN05 M5 nyloc nut Yes

11 1 37006 Lock Plate - Tailstock Yes 57 1 MP0525 M5x25 Earth screw Yes

12 1 28034 Lock Arm - Tailstock Yes 58 3 STPB8X11/4 Gauge 8x1 1/4" self

tapping screw

Yes

13

14

NOT ILLUSTRATED

15 1 37002 Toolslide Yes

16 1 37009 Camshaft Yes

1 38009 Fuse 250V 8amp 1 1/4"x1/4"

(old) or 37095 Fuse 250V 8amp

5x20mm (new)

Yes

17 1 37010 Sleeve-Camshaft Yes 1 37020 Knockout bar/spindle

locking bar

Yes

18 1 37011 Camnut Yes 1 2MTLC Morse Taper Live

Centre

Yes

19 1 37006 Lockplate Yes 1 2MTSPUR #2 Morse Taper Spur Yes

20 1 K0816 M8x16 CSk screw-cam nut Yes 1 SFP60T Faceplate 60mm 1" 8

RH/LH UNC

Yes

21 1 37015 Lock Arm - Toolrest Yes 1 MP05010 Screw M5 x 10 - Earth Yes

22 1 SLP10 M10 Starlock Yes 1 37070-P Power lead

23 1 HP-10 Hole plug 10 mm Yes 4 STPB4X3/4 Gauge4x3/4" self

tapping screw

Yes

24 3 G0606 Grubscrew M6 x 6 Yes

25 1 37081 Toolrest casting Yes

SUBASSEMBLIES

26 1 37069

37092

Motor 1/2 HP DC 115V

Motor 1/2 HP DC 230V

Yes 1 37040 Tailstock sub assembly

27 1 37017 Motor Pulley Yes 1 37066 Toolslide sub assembly

28 1 37021 Locknut Yes 1 38031 1/2 HP 115V Motor &

Controller sub assembly

29 2 FW6 M6 Flat Washer Yes

30 1 37074 Cover Control Box-Plastic Yes

26

Mercury Accessories

Add On Bed Extension # 38012

Extend the bed of your Nova Mercury Woodlathe

for greater capacity for turning between centers. Each bed

unit adds 300 (12 in)

SuperNova Chuck

A next-generation, self-centering chuck to securely hold

round and square work pieces for centerless turning. The

special Tuff Lock gearing delivers amazing holding power in

both the contraction and expansion mode. It has an openback for easy cleaning and can be tightened one-handed with

an articulated key. It includes a screw chuck. A wide variety

of optional jaws are available to hold almost any work piece.

Revolving Center System # NCLS or # NLCS1

A multi-function live center system to expand your options

when turning between centers. It includes quick-change

tapers: a hollow cup center point, threaded center, cone

center, and an extension center. Made with three bearings

and precision machined for a high quality finish.

Outrigger Unit #38011

Extend the bowl turning capacity of the Nova Mercury

Woodlathe to around 10” in diameter. This unit is made from

cast iron, is easy to position and control, and mounts to the

headstock end of the lathe.

Collet Quill

# NCQS (pre Dec 02) # 29013 (post Dec 02)

The Collet Quill is a handy drill holder that screws onto your

Mercury Tailstock Quill (and Headstock spindle for post Dec

02 Mercury lathes).

It has two advantages over normal drill chucks:

1. Virtually no overhang. MT Drill Chucks take up

considerable bed length, which restricts drilling

options.

2. Better support for Drilling Point. Drill length can

be shortened so only the optimum drill length is

used for the drilling job. Without the Morse taper,

the drill tip is centred more accurately with less

tendency to wander.

Revolving

Center

System

SuperNova

Chuck

For further details about Teknatool's lathe accessories please contact your local

retailer for more information, or contact us directly. Visit our website at

www.teknatool.com.

8

27

Teknatool Warranty

Teknatool Five Year Limited Warranty

This Teknatool product is backed by a FIVE YEAR warranty from the date of purchase. Teknatool International Ltd will repair or

replace, at its expense and option, this Teknatool product which in normal use has proven to be defective in workmanship or

material, provided that the customer returns the product prepaid to an authorized Teknatool service center with proof of purchase of

the product within TWO YEARS and provides Teknatool with reasonable opportunity to verify the alleged defect by inspection.

Furthermore, Teknatool International Ltd. extends this two year period for three additional years, excluding labor costs and drive

belts, provided the aforementioned conditions are met. Motors and electronic controls are not covered under this warranty; these are

warranted by their respective manufacturer.

Teknatool will not be responsible for any asserted defect which has resulted from normal wear, misuse, abuse, or repair or alteration

made by anyone other than an authorized service facility or representative. Under no circumstances will Teknatool International Ltd.

be liable for incidental, special, indirect, and consequential damages or expenses, including loss of profits or loss of operations. This

warranty is Teknatool International Ltd. sole warranty. There are no other warranties, whether written or verbal, whether expressed

or implied by law, trade, custom, or otherwise, whether of merchantability, fitness for purpose, or otherwise, except for remedies

available to customers under the Consumer Guarantees Act or other legislation.

OVERSEAS CUSTOMERS: Our Teknatool Distributors and agents will issue their own warranty to cover this product. Terms may vary

from those stated above; please check with your dealer.

L Note: Did you know you can register your warranty with Teknatool online? Visit our website on www.teknatool.com to

register your warranty faster today! Or you can fill out the card below, cut, fold, seal and post.

Teknatool Warranty Card

Return this card to validate your warranty, or register online

at www.teknatool.com.

To help us provide services and products that are better tailored to your

needs, please answer the following:

Name: ________________________________________

Address: ______________________________________

______________________________________________

______________________________________________

Email Address: _________________________________

Teknatool Product Model _________________________

Serial Number

(on headstock cover) ___________________

Date of Purchase _______________________________

Reseller _______________________________________

Would you like to be on our mailing list and receive

complimentary copies of our Teknatool Newsletter? (Personal

information is kept confidential.)

R Yes, by normal mail R Yes, by email R No

1. Where did you purchase the product? (check one)

R Local Woodturning Specialty R Manufacturer

R Local General Woodworking R Mailorder Catalog

R Other (specify) _____________________________________

2. Did you receive all information you required and expected?

R Yes R No

If no, explain: ________________________________________

3. What other products did you buy along with lathe purchase?

R Lathe Chuck R Finishes R Power Tools

R Lathe Chisels R Abrasives R Other Products

R Lathe Accessories (list) ______________________________

4. Why did you buy the Nova Lathe?

R Features R Quality R Warranty R Store Advice

R Price R NZ Made R Accessories R Product Support

R Recommended R Reputation of Brand

5. Rate your woodturning and woodworking experience:

R Beginner R Intermediate R Advanced

Comments _____________________________________________

L

Note: To locate your unique lathe serial number, locate the number stamped on the headstock guard sticker.

28

Steps to registering your Warranty by Mail:

1. Fill out the information on page 30, duplicate your serial number here for your future reference:

Serial Number:________________________

2. Cut along the dotted line as indicated by the scissors icon.

3. Take the cut out, and fold along dotted line as shown.

4. Seal edges with sellotape/glue/tape etc.

5. Affix appropriate Postage Stamps for postage to New Zealand and post.

6. Optional: List your return address details in the event of mishandled post.

Fold

Here

Fold

Here

Seal Alon

g

Ed

g

e

Affix

Postage

Return Address:

__________________________

__________________________

__________________________

__________________________

Post To: TEKNATOOL INTERNATIONAL

Warranty Registration

PO Box 180034 Luckens Point

Henderson

Auckland 1008

NEW ZEALAND

Seal Alon

g

Ed

g

e

8

29

Nova Mercury Woodlathe Manual

Publication Code: 100-0109-002

© Teknatool International 2000-2003

30

Loading...

Loading...