Page 1

553_D

tekmarNet® Thermostat 553

Installation & Operation Manual

Introduction

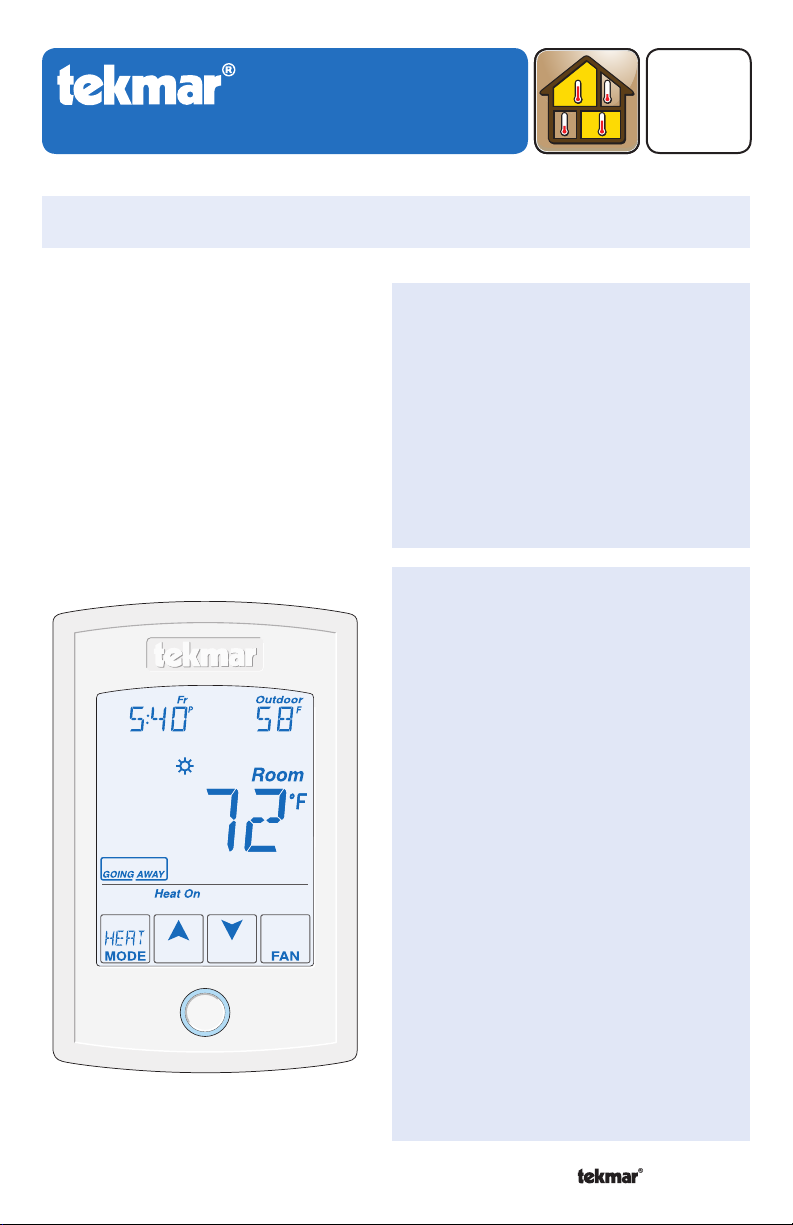

The tekmarNet® Thermostat 553

is a communicating touchscreen

thermostat designed to operate one

or two heating stages, one cooling

stage, a fan and relative humidity.

04/13

Zoning

Replaces: New

Energy Saving Features

Programmable Schedule

•

Zone Synchronization

•

Zone Post Purge

•

Warm Weather Shut Down

•

Cooling Interlock

•

Auto Heating Cycle

•

Temporary Hold

•

Away Scene Key

•

Additional Features

2 Auxiliary Sensor Inputs

•

tekmarNet® Communication

•

Compatible

Touchscreen Technology

•

Outdoor & Floor Temperature

•

Display

Backlight

•

Radiant Floor Heating & Cooling

•

Freeze Protection

•

Pump & Valve Exercising

•

Heat / Cool Priority

•

Air Group Master & Member

•

Network Schedule Master or

•

Member

Optimum Start

•

Scenes

•

Daylight Savings Time

•

Room Temperature Limiting

•

Relative Humidity Control

•

A Watts Water Technologies Company

1 of 48

© 2013

553_D - 04/13

Page 2

Table of Contents

Getting Started ...............................2

Installation ...........................................3

Caution ............................................3

Preparation .....................................3

Removing The Thermostat Base ....3

Mounting The Thermostat Base .....4

Thermostat Wiring ..........................4

Compatible Sensors .......................5

Testing the Thermostat Wiring ........5

Mounting the Thermostat ................6

Switch Settings ....................................7

User Interface ......................................8

Home Screen ..................................8

Symbols Description .......................8

Programmable Settings .......................9

Programming Menus ......................9

Set Temp Menu ........................10-13

Time Menu ....................................14

Schedule Menu ........................15-16

Display Menu ...........................16-17

Scenes Menu ................................17

Monitor Menu ...........................18-21

Toolbox Menu ..........................21-23

Setup Menu............................. 24-30

Sequence of Operation ......................31

Heat and Cool Applications ..........31

Heating Operation .........................31

Cooling Operation .........................33

Room Min and Max Limits ............33

Mode Operation ............................34

Pump and Valve Operation ...........34

Fan Operation ...............................35

Relative Humidity Operation .........35

Air Group Operation......................37

Time Clock ....................................37

Temperature Adjustment ..............38

Programmable Schedules ............39

Scenes (System Override) ............40

Secondary Temperature Display ..41

Access Levels ...............................42

tekmarNet

®

Address .....................42

Cleaning the Thermostat ..............42

Troubleshooting .................................43

Error Messages ...................... 43-47

Technical Data ..............................47

Limited Warranty and Product

Return Procedure .........................48

Getting Started

Congratulations on the purchase of your new tekmar® thermostat.

This manual will step through the complete installation, programming and sequence

of operation for this control. At the back, there are tips for control and system

troubleshooting.

A Watts Water Technologies Company

2 of 48

© 2013 553_D - 04/13

Page 3

------------------------------------------------------

--------------------------------------------------

Installation

-------------------------------------------------

Caution

Improper installation and operation of this control could result in damage to the equipment

and possibly even personal injury or death. It is your responsibility to ensure that this

control is safely installed according to all applicable codes and standards. This electronic

control is not intended for use as a primary limit control. Other controls that are intended

and certified as safety limits must be placed into the control circuit.

Preparation

Tools Required

tekmar or jeweller screwdriver

•

Phillips head screwdriver

•

Materials Required

18 AWG LVT Solid Wire (Low

•

Voltage Connections)

Installation Location

Choose the placement of the thermostats early in the construction process to enable

proper wiring during rough-in.

Consider the following:

Interior Wall.

•

Keep dry. Avoid potential leakage onto the control.

•

Relative Humidity less than 90%. Non-condensing environment.

•

No exposure to extreme temperatures beyond 32-122°F (0-50°C).

•

No draft, direct sun, or other cause for inaccurate temperature readings.

•

Away from equipment, appliances, or other sources of electrical interference.

•

Easy access for wiring, viewing, and adjusting the display screen.

•

Approximately 5 feet (1.5 m) off the finished floor.

•

The maximum length of wire is 500 feet (150 m).

•

Strip wire to 3/8” (10 mm) for all terminal connections.

•

Use standard 8 conductor, 18 AWG wire.

•

------------------------------------------------------

Wire Stripper•

--------------------------------------------------

-------------------------------------------------

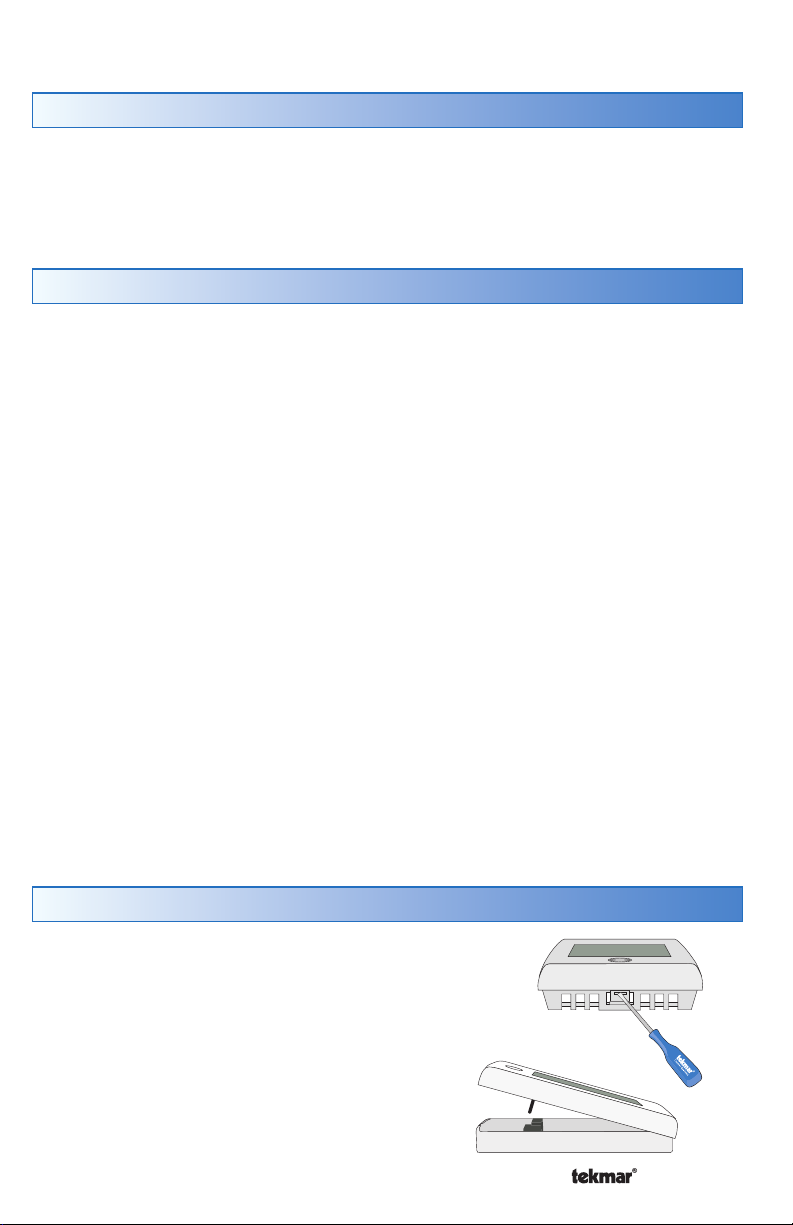

Removing The Thermostat Base

To remove the thermostat base:

Locate the tab on the bottom of the

•

thermostat.

Push the tab with either your thumb or with

•

a screwdriver.

Lift the thermostat front away from the

•

thermostat’s base.

A Watts Water Technologies Company

3 of 48

© 2013 553_D - 04/13

Page 4

Mounting The Thermostat Base

If a single gang box is used:

•

Feed the wiring through

the large hole of the

thermostat base.

Fasten the base of the

•

thermostat to the gang box.

Terminate wiring to the

•

wiring strip.

Push the thermostat front

•

onto the thermostat base.

If a gang box is not used:

Feed the wiring through the

•

large hole in the thermostat

base.

Mount the thermostat base

•

directly to the wall.

Use screws in the screw

•

holes to fasten the

thermostat to the wall. At

least one of the screws

should enter a wall stud or

similar rigid material.

Terminate wiring to the

•

wiring strip.

Push the thermostat front

•

onto the thermostat base.

Thermostat

Thermostat

Front

Front

Thermostat

Base

Thermostat

Base

3 1/4”

(83 mm)

Stud

Gang

Box

Stud

Wall

Thermostat Wiring

The thermostat can be wired in three different ways.

Stand Alone

stage heating relay (Rh - W1) can be wired directly to switching relays.

tekmarNet®4 - Allows the thermostat to be wired using 4 wires to a tN4 Wiring Center

or Zone Manager. The tN4 communication bus can also be daisy-chained to allow

multiple thermostats to be connected together without home running wires back to the

mechanical room.

tekmarNet

Wiring Center, House Control, or Zone Manager. This allows easy wiring for retrofit

applications.

Application specific wiring diagrams are provided in the 553_A brochure.

A Watts Water Technologies Company

- Similar to tekmarNet®4 wiring with tN4 wiring terminal not used. First

®

2 - Allows the thermostat to be wired point-to-point using 2 wires to a tN2

4 of 48

© 2013 553_D - 04/13

Page 5

------------------------------------------

--------------------------

--------------------------------------------

Compatible Sensors

The thermostat is compatible with Indoor Sensor type 076, 077, 084, Slab Sensor

type 072, 073, 079, Outdoor Sensor type 070, Universal Sensor 082 and Duct Sensor

type 083.

Testing the Thermostat Wiring

Testing tekmarNet®2 Wiring

Testing the Power

If the thermostat display turns on, this indicates that the thermostat is operating

correctly and there are no electrical issues. In the event that the display is off, or the

display is cycling on and off:

1. Remove the thermostat wiring cover.

2. Check to ensure that the tN2 wires on the thermostat are connected to a zone on a

House Control, Wiring Center, or Zone Manager.

3. Use an electrical meter to measure DC voltage between the tN2 terminals.

If the DC voltage is 0 V (dc) for at least 20 seconds, then there is an open or

•

------------------------------------------

short circuit in the tN2 wires.

If the DC voltage is 0 V (dc) for 10 seconds and then is 23 to 24 V (dc) for 5

•

seconds, this indicates the wiring is correct.

4. If the thermostat display is off, or is cycling on and off, move the thermostat to the

next available zone on the House Control, Wiring Center, or Zone Manager.

If the thermostat display remains permanently on, there may be a fault with the

•

previously tried zone on the House Control, Wiring Center, or Zone Manager.

If the thermostat display continues to be off, or is cycling on and off, there may

•

be a fault on the thermostat.

If a fault is suspected, contact your tekmar sales representative for assistance.

Testing tekmarNet®4 and Stand Alone Wiring

Testing the Power

1. Remove the front cover from the thermostat.

2. Use an electrical test meter to measure (ac) voltage between the R and C terminals.

The reading should be 24 V (ac) +/– 10%.

3. Install the front cover.

--------------------------

Testing the Relay Outputs

The thermostat includes a User Test to check if the thermostat’s relays are operating

and that the thermostat is wired correctly to the HVAC equipment. The User Test setting

can be located in the Toolbox menu. Either Heat or Cool test can be selected.

Cancel button - Exits the user test and returns the Toolbox menu.

Hold button - Pauses the user test step for up to 5 minutes.

Next Item button - Advances the user test to the next test step.

A Watts Water Technologies Company

--------------------------------------------

5 of 48

© 2013 553_D - 04/13

Page 6

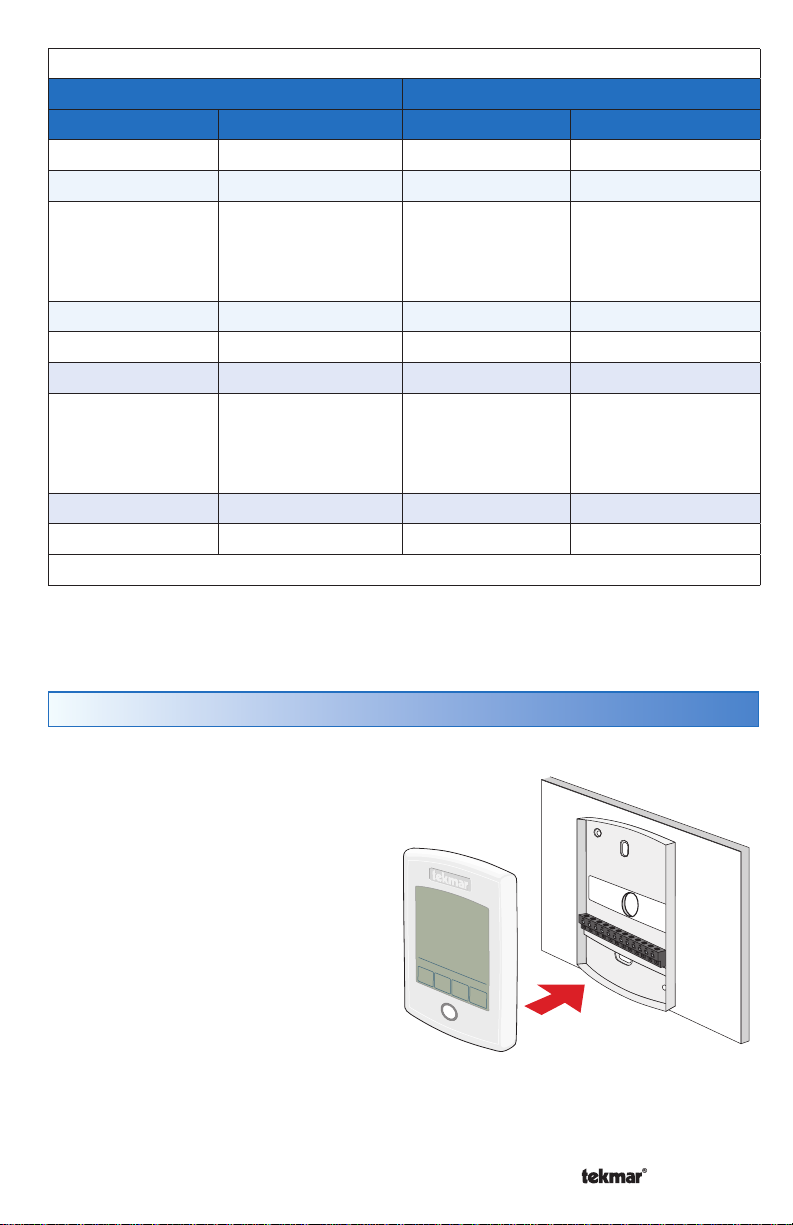

User Test Sequence

Heat Test Cool Test

Step Relay(s) Closed Step Relay(s) Closed

O RELAY ON Rc to G/O O RELAY OFF Rc to G/O

B RELAY OFF Rc to G/O B RELAY ON Rc to G/O

FAN ON Rc to G/O

(conventional)

Rc to ACC

(heat pump)

FAN ON Rc to G/O

(conventional)

Rc to ACC

(heat pump)

Y HEAT ON Rc to Y Y COOL ON Rc to Y

W2 HEAT ON Rc to ACC HUMIDIFY ON Rc to ACC

W HEAT Rh to W DEHUMIDIFY ON Rc to ACC

HUMIDIFY ON Rc to ACC

HRV ON Rc to ACC

(heat and cool)

Rc to Y

(two-stage heat)

DEHUMIDIFY ON Rc to ACC

HRV ON Rc to ACC

*availability of test step and additional relay closures based upon Setup menu settings.

Mounting the Thermostat

Push the thermostat front onto the

thermostat base. Installation is now

complete.

A Watts Water Technologies Company

Thermostat

6 of 48

Thermostat

Base

Front

Push

© 2013 553_D - 04/13

Page 7

Switch Settings

Switch

1

2

Back of

Thermostat

Position

ON

OFF

ON

OFF

/

Switch

Settings

Mmm YYYY

Lot # 12345

Lock

tekmarNet

ON

Thermostat 553

Two Stage Heat, One Stage Cool, Fan

2

1

www.tekmarcontrols.com

Power: tN2 or 24 V (ac) ±10% 1.8 VA

Relay: 24 V (ac) 2 A

Unlock

Unused

Designed and assembled in Canada

Meets Class B: ICES & FCC Part 15

Action

LOCK ACCESS LEVEL

Thermostat is locally locked and the access level cannot be changed.

Set to Lock when installation has been completed.

UNLOCK ACCESS LEVEL

Thermostat is unlocked and the access level may be changed. Go to

the Toolbox menu to change the access level. Set to Unlock during

the installation process.

Note: tekmarNet® system controls include a Global Lock that locks all

connected thermostats. Set the tekmarNet® system control to unlock

to allow access level adjustment on all connected thermostats.

Not used

Not used

A Watts Water Technologies Company

7 of 48

© 2013 553_D - 04/13

Page 8

User Interface

Home Screen

Adjust

the Time

Adjust the

Schedule

Away Key

Switch between

Auto, Heat,

Cool, Off &

Emergency Mode

Adjust the

Temperature

Symbols Description

HEAT ON

Heat is turned on.

COOL ON

Cooling is turned on.

FAN

The fan is turned on.

%RH

Humidifying

%RH

Dehumidifying

SUN

Operating at the occupied (day)

temperature.

MOON

Operating at the unoccupied

(night) temperature.

tekmarNet

Communication is present.

®

Home

Button

Display Humidity, Heat

Cool settings, Floor or

Outdoor temperature

Room

Temperature

Turn the Fan on

Return to the

‘Home’ Screen

from any menu

WARNING SYMBOL

Indicates an error is present.

ARROWS

Adjust the displayed setting.

SCENE AWAY

Operating at Away temperature.

TEMPORARY HOLD

Holds temperature for 3, 6, 9 or

12 hours.

WWSD

Warm Weather Shut Down.

COOL

Cooling system is on.

MIN or MAX

Reached the room min or max.

MIN FL or MAX FL

Reached the floor min or max.

A Watts Water Technologies Company

8 of 48

© 2013 553_D - 04/13

Page 9

Programmable Settings

-----------------------------------------

--------------------------------------------------------

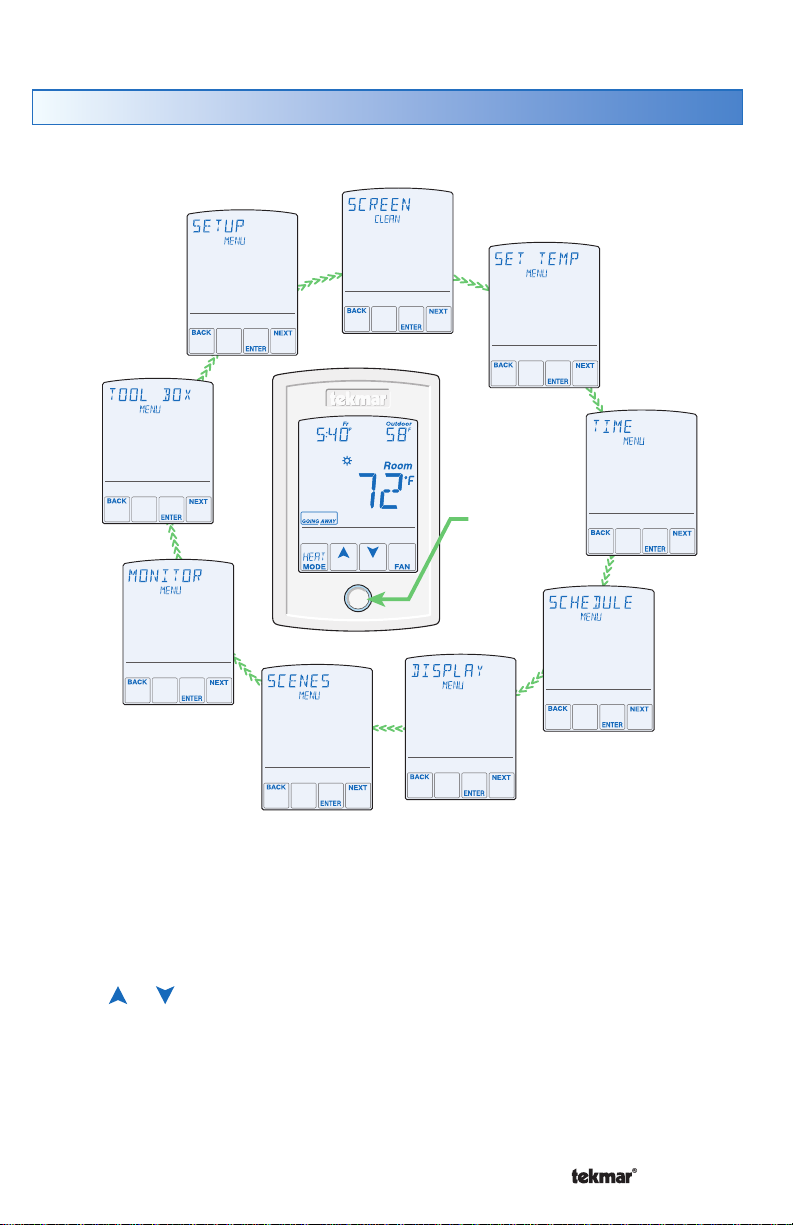

Programming Menus

Press and hold the Home button for 3 seconds to enter the programming menus. The

thermostat returns to the last programming menu previously used.

Press and

hold for 3

seconds to

access the

programming

menus.

Select a Programming Menu

Touch “NEXT” to advance (clockwise in above illustration) to the next menu.

•

Touch “BACK” to go backwards (counterclockwise in above illustration) through

•

-----------------------------------------

the menus.

Touch “ENTER” to enter a menu.

•

Setting Items

Touch or arrow to adjust the setting if required.

•

Touch “NEXT ITEM” to advance to the next item within the menu.

•

Touch “BACK ITEM” to go backwards to the previous item within the menu.

•

To return to the parent menu after changing a setting, press and release the

•

--------------------------------------------------------

Home button.

To return to the Home screen, press and release the Home button twice or wait

•

30 seconds to automatically return to the Home screen.

A Watts Water Technologies Company

9 of 48

© 2013 553_D - 04/13

Page 10

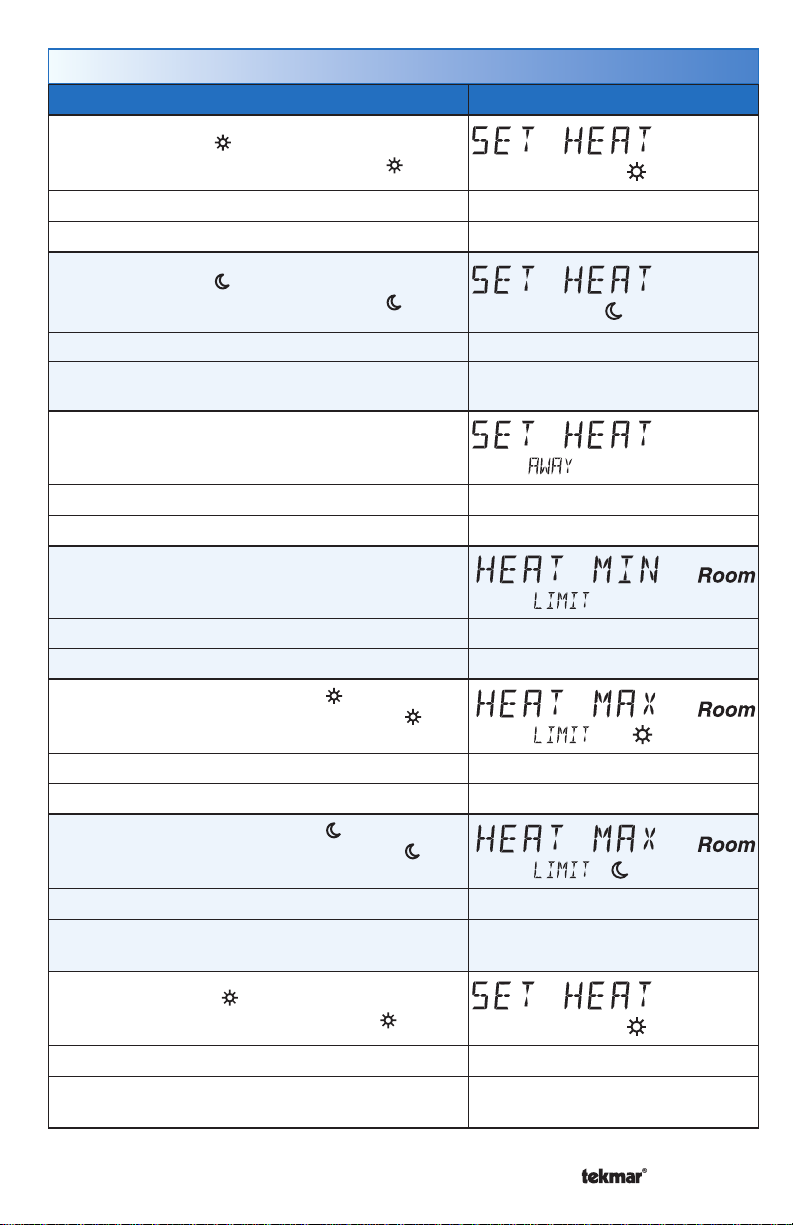

Set Temp Menu (1 of 4)

Setting Display

SET HEAT ROOM

Room

Set the room heating temperature for the event.

Access Level: Installer, User Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Always available. Default: 70°F (21.0°C)

SET HEAT ROOM

Room

Set the room heating temperature for the event.

Access Level: Installer, User Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Schedules are in use or Scenes are

set to All or Guest.

SET HEAT ROOM AWAY

Set the room heating temperature for the Away

Default: 65°F (18.5°C)

Room

scene.

Access Level: Installer, User Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Scenes is set to Away, All or Guest. Default: 62°F (16.5°C)

HEAT MINIMUM ROOM LIMIT

Set the minimum room heating limit.

Access Level: Installer Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Always available. Default: 40°F (4.5°C)

HEAT MAXIMUM ROOM LIMIT

Set the maximum room heating limit for the

event.

Access Level: Installer Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Always available. Default: 85°F (29.5°C)

HEAT MAXIMUM ROOM LIMIT

Set the maximum room heating limit for the

event.

Access Level: Installer

Conditions: Schedules are in use or Scenes are

set to All or Guest.

Range: 40 to 95°F (4.5 to 35.0°C)

Default: 85°F (29.5°C)

SET HEAT FLOOR

Set the floor heating temperature for the event.

Floor

Access Level: Installer, User Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Room Sensor set to OFF and Sensor

1 or Sensor 2 set to Floor.

A Watts Water Technologies Company

10 of 48

Default: 72°F (22.0°C)

© 2013 553_D - 04/13

Page 11

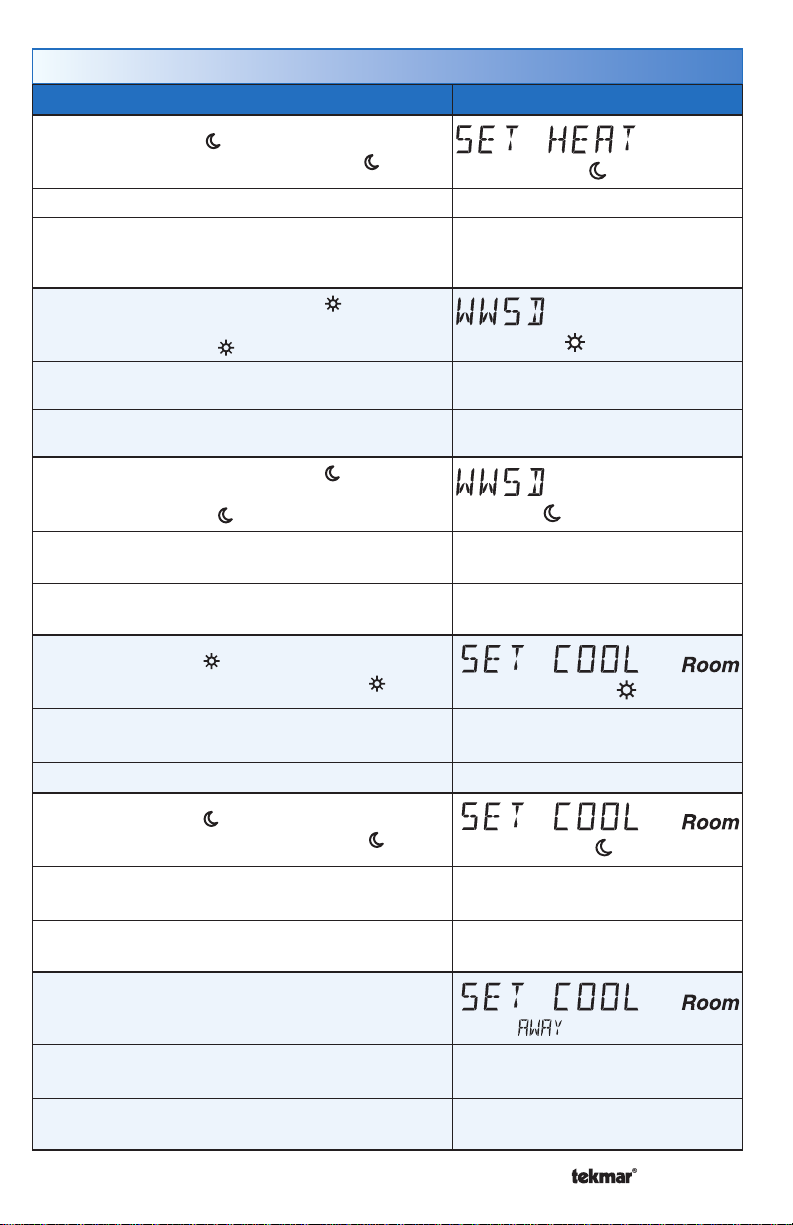

Set Temp Menu (2 of 4)

Setting Display

SET HEAT FLOOR

Set the floor heating temperature for the event.

Access Level: Installer, User Range: 40 to 95°F (4.5 to 35.0°C)

Conditions: Room Sensor set to OFF and Sensor

1 or Sensor 2 set to Floor and Schedules are in

Default: 65°F (18.5°C)

use or Scenes are set to All or Guest.

WARM WEATHER SHUT DOWN

Set the outdoor air temperature at which heating is

suspended during the event.

Access Level: Installer

Conditions: An outdoor sensor must be available.

Range: CTRL (control), 40 to

100°F (4.5 to 38.0°C), OFF

Default: CTRL (with tN System

Control or 70°F (21°C) (Standalone)

WARM WEATHER SHUT DOWN

Set the outdoor air temperature at which heating is

suspended during the event.

Access Level: Installer

Conditions: An outdoor sensor must be available and

Schedules are in use or Scenes is set to All or Guest.

Range: CTRL (control), 40 to

100°F (4.5 to 38.0°C), OFF

Default: CTRL (with tN System

Control or 60°F (15.5°C) (Standalone)

Floor

SET COOL ROOM

Set the room cooling temperature for the event.

Access Level: Installer, User

Range: 50 to 100°F

(10.0 to 38.0°C)

Conditions: Y RELAY is set to HP or AC. Default: 78°F (25.5°C)

SET COOL ROOM

Set the room cooling temperature for the event.

Access Level: Installer, User

Conditions: Y RELAY is set to HP or AC and

Schedules are in use or Scenes is set to All or Guest.

Range: 50 to 100°F

(10.0 to 38.0°C)

Default: 85°F (29.5°C)

SET COOL ROOM AWAY

Set the room cooling temperature during the Away

scene.

Access Level: Installer

Conditions: Y RELAY is set to HP or AC and

scenes is set to Away, All or Guest.

A Watts Water Technologies Company

11 of 4 8

Range: 50 to 100°F

(10.0 to 38.0°C)

Default: 85°F (29.5°C)

© 2013 553_D - 04/13

Page 12

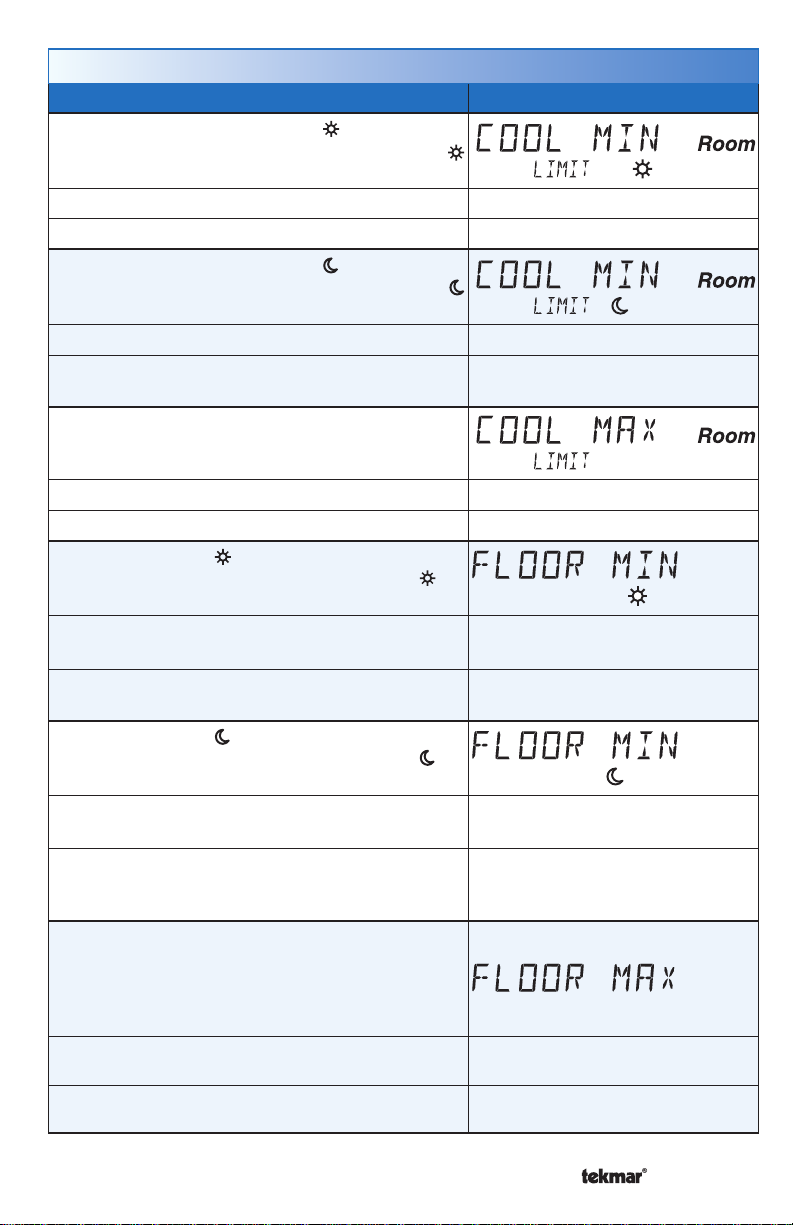

Set Temp Menu (3 of 4)

Setting Display

COOL MINIMUM ROOM LIMIT

Set the minimum room cooling limit while in the

event.

Access Level: Installer Range: 50 to 100°F (10.0 to 38.0°C)

Conditions: Y RELAY is set to HP or AC. Default: 50°F (10.0°C)

COOL MINIMUM ROOM LIMIT

Set the minimum room cooling limit while in the

event.

Access Level: Installer Range: 50 to 100°F (10.0 to 38.0°C)

Conditions: Y RELAY is set to HP or AC and

Schedules are in use or Scenes is set to All or Guest.

COOL MAXIMUM ROOM LIMIT

Set the maximum room cooling limit.

Access Level: Installer Range: 50 to 100°F (10.0 to 38.0°C)

Conditions: Y RELAY is set to HP or AC. Default: 100°F (38.0°C)

FLOOR MINIMUM

Set the floor heating temperature while in the

event.

Access Level: Installer

Conditions: Sensor 1 or 2 is set to Floor, and W

Terminal is set to HRF1, HRF2 or OTHR.

FLOOR MINIMUM

Set the floor heating temperature while in the

event.

Access Level: Installer

Conditions: Sensor 1 or 2 is set to Floor, and W

Terminal is set to HRF1, HRF2 or OTHR & Schedules

are in use or Scenes are set to All or Guest.

FLOOR MAXIMUM

Set the floor maximum temperature in order to

protect the floor covering.

Suggested settings: Tile = 90°F (32°C)

Hardwood Floor = 85°F (29°C)

Access Level: Installer

Conditions: Sensor 1 or 2 is set to Floor, & W

Terminal is set to HRF1, HRF2 or OTHR.

Default: 50°F (10.0°C)

Range: OFF, 40 to 122°F

(4.5 to 50.0°C)

Default: 72°F (22.0°C)

Range: OFF, 40 to 122°F

(4.5 to 50.0°C)

Default: OFF

Range: 40 to 122°F

(4.5 to 50.0°C), OFF

Default: 85°F (29.5°C)

A Watts Water Technologies Company

12 of 48

© 2013 553_D - 04/13

Page 13

Set Temp Menu (4 of 4)

Setting Display

TEMPORARY HOLD

Temperature adjustment in the home menu can result

in either permanent temperature setting change or

temporary temperature setting change that lasts 3, 6,

9, 12 hours or until the next scheduled event.

Access Level: Installer Range: OFF or ON

Conditions: None Default: OFF

FAN

Set the minimum percentage the fan should operate

while in the event. This provides ventilation for the

building. Each 10% is 6 minutes per hour.

Access Level: Installer, User Range: Auto, 10 to 90%, ON

Conditions: G/O RELAY set to FAN or ACC Relay set

to FAN. 10 to 90% available if Ventilation Mode is On.

FAN

Set the minimum percentage the fan should operate while

in the event or Away scene. This provides ventilation

for the building. Each 10% is 6 minutes per hour.

Access Level: Installer, User Range: Auto, 10 to 90%, ON

Conditions:

FAN, and

G/O RELAY set to FAN or ACC Relay set to

Schedules used or Scenes set to Guest or All.

10 to 90% available if Ventilation Mode is On.

Default: Auto

Default: Auto

HUMIDITY MINIMUM

Set the minimum humidity level during the event.

Access Level: Installer, User Range: OFF, 20 to 80%

Conditions: Humidify Mode set to HM1, 2, 3. Default: 40%

HUMIDITY MAXIMUM

Set the maximum humidity level during the event.

Access Level: Installer, User Range: 20 to 80%, OFF

Conditions: Dehumidify Mode set to DHM1, 2, 3. Default: 60%

HUMIDITY MAXIMUM AWAY

Set the maximum humidity level during Away scene.

Access Level: Installer, User Range: 20 to 80%, OFF

Conditions: Dehumidify Mode set to DHM1, 2, 3. Default: OFF

HUMIDITY

Select if the humidification or dehumidification system

should operate during the event or away scene.

Access Level: Installer, User Range: OFF or On

Conditions: Humidity Mode set to DHM1, 2, 3 or

Dehumidify Mode set to DHM1, 2, 3.

A Watts Water Technologies Company

13 of 48

Default: OFF

© 2013 553_D - 04/13

Page 14

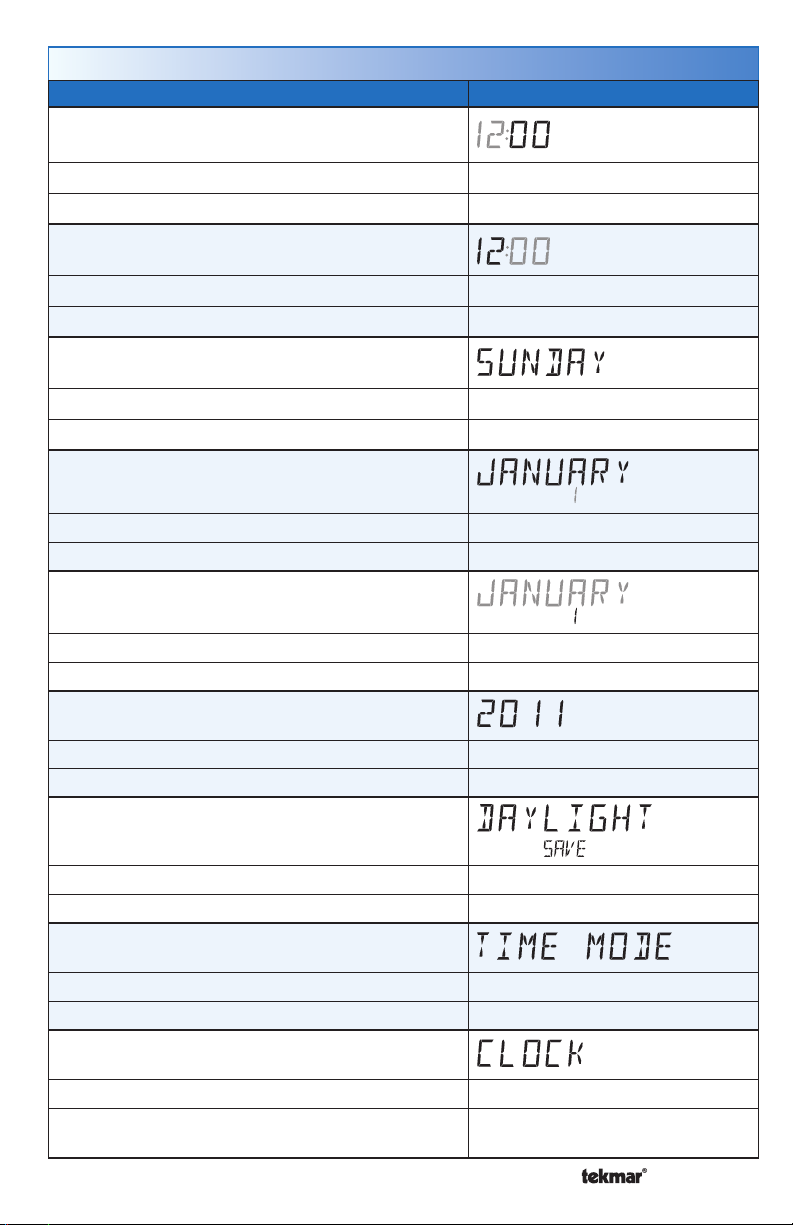

Time Menu (1 of 1)

Setting Display

MINUTES

Select the current time minutes.

Access Level: Installer, User Range: 00 to 59

Conditions: Always available. Default: 00

HOURS

Select the current time hours.

Access Level: Installer, User Range: 12 AM to 11 PM or 00 to 23

Conditions: Always available. Default: 12 AM

DAY OF WEEK

Select the current day of the week.

Access Level: Installer, User Range: Sunday to Saturday

Conditions: Always available. Default: Sunday

MONTH

Select the current month.

Access Level: Installer, User Range: JANUARY to DECEMBER

Conditions: Always available. Default: JANUARY

DAY OF MONTH

Select the day of the current month.

Access Level: Installer, User Range: 1 to 31

Conditions: Always available. Default: 1

YEAR

Select the current year.

Access Level: Installer, User Range: 2011 to 2255

Conditions: Always available. Default: 2011

DAYLIGHT SAVINGS TIME

Select if daylight savings time is observed.

Access Level: Installer, User Range: OFF or ON

Conditions: Always available. Default: ON

TIME MODE

Select either 12 or 24 hour time format.

Access Level: Installer, User Range: 12 or 24 hour

Conditions: Always available. Default: 12 hour

CLOCK

Select whether to show the time clock on the display.

Access Level: Installer, User Range: OFF or ON

Conditions: The time is always shown when a sched-

ule is used and the clock setting option is hidden.

A Watts Water Technologies Company

14 of 4 8

Default: OFF

© 2013 553_D - 04/13

Page 15

Schedule Menu (1 of 2)

The schedule menu can operate on a 24 hour or 7 day repeating schedule. When a

24 hour schedule is selected, “SuMoTuWeThFrSa” is shown on the top of the screen

to show that the event time applies to all days of the week. When a 7 day schedule

is selected, each individual day of the week is shown with the event time.

Setting Display

EVENT 1

The first programmable schedule time period of

the day. The

temperature settings are used

during this time period.

Access Level: Installer, User

Conditions: Schedule setting is set to Zone or

Master 1, 2, 3, 4 and Event/Day is set to 2 or 4.

EVENT 2

The second programmable schedule time period

of the day. The temperature settings are used

during this time period.

Access Level: Installer, User

Conditions: Schedule setting is set to Zone or

Master 1, 2, 3, 4 and Event/Day is set to 2 or 4.

EVENT 3

The third programmable schedule time period

of the day. The temperature settings are used

during this time period.

Access Level: Installer, User

Conditions: Schedule setting is set to Zone or

Master 1, 2, 3, 4 and Event/Day is set to 4.

EVENT 4

The fourth programmable schedule time period

of the day. The temperature settings are used

during this time period.

Access Level: Installer, User

Conditions: Schedule setting is set to Zone or

Master 1, 2, 3, 4 and Event/Day is set to 4.

SuMoTuWeThFrSa

Range: 12:00 AM to 11:50 PM, SKIP

or 00:00 to 23:50, SKIP

Default: 6:00 AM

SuMoTuWeThFrSa

Range: 12:00 AM to 11:50 PM, SKIP

or 00:00 to 23:50, SKIP

Default:

10:00 PM when Event/Day is 2

8:00 AM when Event/Day is 4

SuMoTuWeThFrSa

Range: 12:00 AM to 11:50 PM, SKIP

or 00:00 to 23:50, SKIP

Default: 6:00 PM

SuMoTuWeThFrSa

Range: 12:00 AM to 11:50 PM, SKIP

or 00:00 to 23:50, SKIP

Default: 10:00 PM

A Watts Water Technologies Company

15 of 48

© 2013 553_D - 04/13

Page 16

Schedule Menu (2 of 2)

Setting Display

SCHEDULE

Select if the thermostat should change the temperature

automatically using a programmable schedule.

OFF = Programmable schedule is not used.

Zone = Applies to this thermostat only.

Master 1, 2, 3, 4 = In charge of one of four available

network schedules.

Member 1, 2, 3, 4 = Follows selected network

schedule.

Access Level: Installer, User

Conditions: In a tekmarNet® system, settings adjustable

in Installer access level only.

EVENT PER DAY

Select the number of temperatures per day.

Access Level: Installer, User Range: 2 or 4

Conditions: Schedule setting is set to Zone or

Master 1, 2, 3, 4.

24 HOUR / 7 DAY

Access Level: Installer, User Range: 24 hour or 7 day

Conditions: Schedule setting is set to Zone or Master

1, 2, 3, 4.

OPTIMUM START

Select whether or not to use optimum start. The

thermostat learns the heat up and cool down rates

of the room and starts heating or cooling in advance

of Event 1 or Event 3.

Access Level: Installer, User Range: OFF or ON

Conditions: A schedule must be in use. Default: ON

Range: OFF, Zone, Master 1, 2, 3,

4, Member 1, 2, 3, 4

Default: OFF

Default: 2

Default: 24 hour

Display Menu (1 of 2)

Setting Display

UNITS

Select Fahrenheit or Celsius as the temperature

units.

Access Level: Installer, User Range: °F or °C

Conditions: Always available. Default: °F

A Watts Water Technologies Company

16 of 48

© 2013 553_D - 04/13

Page 17

Display Menu (2 of 2)

Setting Display

BACKLIGHT

Select how the display backlight operates.

ON = Always full brightness.

DIM = Dim when inactive, on when touched.

= Dim in , off in . On when touched.

DIM

= On in , off in . On when touched.

ON

OFF = Off when inactive, on when touched.

Access Level: Installer, User

Conditions: Always available.

Range: DIM, ON, DIM , ON , OFF

Default: DIM

SECONDARY ITEM

Determine the default item in the upper right hand

corner of the Home screen.

Range: NONE, OUT (outdoor),

Access Level: Installer, User

FLOR (floor), HUM (humidity),

TEMP (heat and cool temperature)

Conditions: Always available. Default: HUM (humidity)

Scenes Menu (1 of 1)

Setting Display

SCENES

Enable or disable the use of scenes (building overrides)

on this thermostat.

Access Level: Installer, User

Conditions: Settings ALL and GUEST only available

in Installer access level.

SCENE 4

Select how the thermostat should respond to scene 4.

Access Level: Installer

Conditions: Scenes is set to All. Default: SCHD (Schedule)

AWAY KEY

Enable or disable the away touch key on the home

screen.

Access Level: Installer, User Range: OFF or ON

Conditions: Scenes is set to ALL, AWAY, or GUEST. Default: OFF

LOCAL NETWORK GROUP

Select if scenes and time clock are shared when

connected to a tekmarNet

®

system.

OFF = Send and receive messages.

ON = Receive messages only.

Access Level: Installer Range: OFF or ON

Conditions: Always available. Default: OFF

Range: NONE, AWAY, ALL, GUEST

Default: NONE

Range: SCHD,

, , Away

A Watts Water Technologies Company

17 of 48

© 2013 553_D - 04/13

Page 18

Monitor Menu (1 of 4)

Setting Display

ROOM AVERAGE

Current room temperature. Displays the average if

there are multiple room sensors.

Access Level: Installer

Conditions: Sensor 1 or 2 is set to ROOM. Default: Not applicable.

FLOOR AVERAGE

Current floor temperature. Displays the average if

there are multiple floor sensors.

Access Level: Installer

Conditions: Sensor 1 or 2 is set to FLOR. Default: Not applicable.

AIR GROUP AVERAGE

Average room temperature of the thermostat and all

air group member thermostats.

Access Level: Installer

Conditions: Setup menu setting Air Group Master

must be set to 1 through 16.

W SUPPLY

First stage heating supply water temperature.

Access Level: Installer

Conditions: W TERM set to HRF1, HRF2, CONV

or COIL.

Range: -58 to 212°F

(-50.0 to 100.0°C)

Range: -58 to 212°F

(-50.0 to 100.0°C)

Range: -58 to 212°F

(-50.0 to 100.0°C)

Default: Not applicable.

Range: -22 to 266°F

(-30.0 to 130.0°C)

Default: Not applicable.

ROOM LOCAL

The built-in room sensor temperature measurement.

Access Level: Installer

Conditions: Setup menu setting Room Sensor is

set to ON.

SENSOR 1

The temperature measurement from the sensor 1

input wiring terminals.

Access Level: Installer

Conditions: Sensor 1 is set to ROOM, FLOR, COIL

or DUCT.

A Watts Water Technologies Company

18 of 48

Range: -58 to 212°F

(-50.0 to 100.0°C)

Default: Not applicable.

Range: -58 to 212°F

(-50.0 to 100.0°C)

Default: Not applicable.

© 2013 553_D - 04/13

Page 19

Monitor Menu (2 of 4)

Setting Display

SENSOR 2

The temperature measurement from the sensor 2

input wiring terminals.

Access Level: Installer

Conditions: Sensor 2 is set to ROOM, FLOR, or OUT. Default: Not applicable.

HUMIDITY LOCAL

The built-in relative humidity sensor measurement.

Access Level: Installer Range: 0 to 100%

Conditions: Humidity Sensor is set to On. Default: Not applicable.

OUTDOOR HIGH

The highest recorded outdoor air temperature

measurement. Touch the number and the ENTER

key to reset.

Access Level: Installer, User

Conditions: An outdoor temperature is available. Default: Not applicable.

OUTDOOR LOW

The lowest recorded outdoor air temperature

measurement. Touch the number and the ENTER

key to reset.

Access Level: Installer, User

Conditions: An outdoor temperature is available. Default: Not applicable.

ROOM HIGH

The highest recorded room temperature measurement.

Touch the number and the ENTER key to reset.

Access Level: Installer, User

Conditions: Room Sensor is set to ON or Sensor 1

or 2 is set to ROOM.

ROOM LOW

The lowest recorded room temperature measurement.

Touch the number and the ENTER key to reset.

Access Level: Installer, User

Conditions: Room Sensor is set to ON or Sensor 1

or 2 is set to ROOM.

Range: -58 to 212°F

(-50.0 to 100.0°C)

Range: -76 to 149°F

(-60.0 to 65.0°C)

Range: -76 to 149°F

(-60.0 to 65.0°C)

Range: -76 to 149°F

(-60.0 to 65.0°C)

Default: Not applicable.

Range: -76 to 149°F

(-60.0 to 65.0°C)

Default: Not applicable.

A Watts Water Technologies Company

19 of 48

© 2013 553_D - 04/13

Page 20

Monitor Menu (3 of 4)

Setting Display

FLOOR HIGH

The highest recorded floor temperature measurement.

Touch the number and the ENTER key to reset.

Access Level: Installer, User

Conditions: Sensor 1 or 2 is set to FLOR. Default: Not applicable.

FLOOR LOW

The lowest recorded floor temperature measurement.

Touch the number and the ENTER key to reset.

Access Level: Installer, User

Conditions: Sensor 1 or 2 is set to FLOR. Default: Not applicable.

FILTER HOURS

The total number of hours the fan has been operating

since the air filter was last replaced. Touch the number

and the ENTER key to reset and clear the Change

Filter warning message.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Always available. Default: 0000 hours

HEAT Y HOURS

The total number of hours the heat pump has been

in heating operation. Touch the number and the

ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Y RELAY is set to HP. Default: 0000 hours

HEAT W HOURS

The total number of hours the first stage heat W has

been operated for heating. Touch the number and

the ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: W TERM is set to HRF1, HRF2, CONV,

COIL, FURN , BKUP or OTHR.

HEAT W2 HOURS

The total number of hours the second stage heat

W2 has been operating. Touch the number and the

ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: ACC RELAY is set to W2. Default: 0000 hours

COOL Y HOURS

The total number of hours the air conditioner or

heat pump has been in cooling operation. Touch the

number and the ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Y RELAY is set to AC or HP. Default: 0000 hours

A Watts Water Technologies Company

20 of 48

Range: -76 to 149°F

(-60.0 to 65.0°C)

Range: -76 to 149°F

(-60.0 to 65.0°C)

Default: 0000 hours

© 2013 553_D - 04/13

Page 21

Monitor Menu (4 of 4)

Setting Display

COOL W HOURS

The total number of hours the W relay has been

operated for radiant floor cooling. Touch the number

and the ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Floor Cool is set to ON and W TERM is

set to HRF1 or HRF2.

FAN HOURS

The total number of hours the fan has been operated.

Touch the number and the ENTER key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: G/O RELAY is set to FAN or ACC Relay

is set to FAN.

HUMIDIFY HOURS

The total number of hours the humidifier has been

operated. Touch the number and the ENTER key

to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Humidify Mode is set to HM1, 2, 3. Default: 0000 hours

DEHUMIDIFY HOURS

The total number of hours the dehumidifier has

been operated. Touch the number and the ENTER

key to reset.

Access Level: Installer, User Range: 0000 to 9999 hours

Conditions: Dehumidify Mode is set to DHM1, 2, 3. Default: 0000 hours

Default: 0000 hours

Default: 0000 hours

Toolbox Menu (1 of 3)

Setting Display

ACCESS LEVEL

Selects the access level of the thermostat, which determines

which menus and items are available.

Access Level: Installer (INST), User, Limited (LTD), Secure

(SEC)

Conditions: Adjustable only when thermostat switch setting

set to UNLOCK OR tekmarNet® system control switch setting

set to UNLOCK.

A Watts Water Technologies Company

21 of 48

Range: INST, USER, LTD,

SEC

Default: INST

© 2013 553_D - 04/13

Page 22

Toolbox Menu (2 of 3)

Setting Display

STATUS INFO

Toggles between “Status Info” and the current status including

any overrides from the tekmarNet

System Normal = Thermostat operating normally.

Override W = The tekmarNet® system control is either

forcing the W relay on or off.

Cooling Floor = Floor cooling is in effect.

WWSD = Warm Weather Shut Down is in effect.

CWSD = Cold Weather Shut Down is in effect.

Air Group Master Cool = The air group master thermo-

stat is cooling.

Optimum Start Heat or Cool = Heating or cooling system

starts early in order to meet setpoint at Event 1 or 3.

Floor Max = The floor has reached its maximum tempera-

ture. Some under heating could occur.

Floor Min = The floor is operating at its minimum temperature. Some over heating could occur.

Baseload On = Baseload heating is on even though the

room temperature is satisfied. Reduces heat up time when

the sun sets in the evening.

Hydronic Heat Off = The air group master is in cooling

mode and air group member thermostats’ heating is shut off.

Interlock Wait = The thermostat is switching between heating

to cooling or from cooling to heating.

Priority Heat = Air group members are calling for heat. Cooling

is suspended.

Access Level: Installer, User Range: See Description

Conditions: Always available. Default: System Normal

ADDRESS

The tekmarNet® address of this thermostat. To manually set

the address, use the up or down arrow buttons.

Access Level: Installer

Conditions: tekmarNet®2 or 4 detected.

SOFTWARE AND TYPE VERSION

Displays the software version and the tekmar type number.

®

system control.

Range: AUTO, 01 to 24,

b:01 to b:24, 1:01 to 1:24,

2:01 to 2:24, 3:01 to 3:24

Default: AUTO

Access Level: Installer, User, Limited, Secure Range: 553

Conditions: Always available. Default: 553

A Watts Water Technologies Company

22 of 48

© 2013 553_D - 04/13

Page 23

Toolbox Menu (3 of 3)

Setting Display

DEVICE COUNT

Provides a count of all the tekmarNet® thermostats and

setpoint controls on the tekmarNet® system.

Access Level: Installer

®

Conditions: Must be connected to a tekmarNet

system.

USER TEST

Use the up or down arrow keys to select either the heat or

cool test sequence, then press the NEXT key to begin. Press

HOLD to pause at step for 5 minutes. Press NEXT to advance

to the next step.

Access Level: Installer

Conditions: Always available.

OFFSET ROOM

Manual offset correction of the room temperature.

Range: 1 to 24

Default: 1

Range: OFF, HEAT, COOL

Default: OFF

Access Level: Installer

Conditions: Always available.

Range: -5 to +5°F (-3.0 to

+3.0°C)

Default: 0°F (0.0°C)

OFFSET HUMIDITY

Manual offset correction of the room humidity.

Access Level: Installer

Conditions: Always available.

Range: -10 to +10%

Default: 0%

FILTER CHANGE HOURS

Select the amount of time the fan operates before the air filter

requires maintenance.

Access Level: Installer

Range: OFF, 200 to 2000

hours

Conditions: Always available. Default: OFF

LOAD FACTORY DEFAULTS

Touch Enter to load the factory defaults settings.

Access Level: Installer Range: None

Conditions: Always available.

Default: Keep existing

settings

ERROR HISTORY 1 THROUGH 5

Displays a history of the last 5 errors that have occurred on

the thermostat in the past 30 days. Touch Enter to manually

clear the error code.

Access Level: Installer

Conditions: An error must have occurred.

A Watts Water Technologies Company

23 of 48

Range: See

Troubleshooting section

Default: Not applicable

© 2013 553_D - 04/13

Page 24

Setup Menu (1 of 7)

Setting Display

SENSOR 1

Select the auxiliary sensor input 1 type.

Access Level: Installer

Conditions: Always available. Default: OFF

SENSOR 2

Select the auxiliary sensor input 2 type.

Access Level: Installer

Conditions: Always available. Default: OFF

ROOM SENSOR

Select whether the built-in room temperature sensor

is on or off.

Access Level: Installer Range: OFF or ON

Conditions: Only available when Sensor 1 or 2 is set

to ROOM or FLOR.

HUMIDITY SENSOR

Select whether the built-in humidity sensor is on

or off.

Access Level: Installer Range: OFF or On

Conditions: Always available.

Y RELAY

Select the cooling equipment the Y relay operates.

HP = Heat pump

AC = Air conditioner

HUM = Humidifier

Access Level: Installer Range: OFF, HP, AC, HUM

Conditions: Always available. Default: AC

W TERMINAL UNIT

Select the heating equipment the W relay operates.

HRF1 & 2 = High & low mass hydronic radiant floor

CONV = Baseboard convectors

COIL = Fan coil

FURN = Furnace

OTHR = Other than hydronic heating

Access Level: Installer

Conditions: HRF1, HRF2, CONV, COIL only available

when connected to a tekmarNet® System Control.

CONV, COIL, FURN are not available when Y

RELAY = HP.

Range: OFF, ROOM, FLOR (floor),

COIL, DUCT

Range: OFF, ROOM, FLOR (floor),

OUT (outdoor)

Default: ON

Default: On

Range: NONE, HRF1, HRF2,

CONV, COIL, FURN, OTHR

Default:

OTHR (standalone)

®

HRF1 (tekmarNet

System Control)

A Watts Water Technologies Company

24 of 48

© 2013 553_D - 04/13

Page 25

Setup Menu (2 of 7)

Setting Display

W PUMP

Select whether the primary or mix system pump on

a tekmarNet® system control should operate while

the first stage of heat W is operating.

Access Level: Installer Range: OFF or ON

Conditions: Only available when a tekmarNet® system

control is connected and W TERM is set to HRF1 or

HRF2 or connected to a tN2 Wiring Center.

W THERMAL MOTOR

Select whether the first stage of heat W operates a

thermally actuated zone valve (wax actuator). When

set to ON, there is a 3 minute delay before operating

the pump and any heat sources.

Access Level: Installer Range: OFF or ON

Conditions: Only available when a tekmarNet

®

system control is connected and W TERM is set to

HRF1 or HRF2 or connected to a tN2 Wiring Center.

ACCESSORY RELAY

Select the equipment the accessory relay operates.

W2 = Second stage heat

HUM = Humidifier

DHUM = Dehumidifier

HRV = HRV for dehumidification

FAN = Intermittent fan

Access Level: Installer

Conditions: Always available. Default: W2

W2 TERMINAL

Select the type of second stage W2 heating.

CONV = Baseboard convectors

COIL = Hydronic fan coil

FURN = Forced air furnace

OTHR = Non-hydronic heating that does not require

the fan to operate

Access Level: Installer Range: CONV, COIL, FURN, OTHR

Conditions: ACC RELAY is set to W2.

W2 SOURCE

Select the water temperature of the W2 heating.

Access Level: Installer Range: BOIL, TANK, MIX

Conditions: ACC RELAY is set to W2 and W2 TERMINAL

is set to CONV or COIL.

Default: ON

Default: OFF

Range: OFF, W2, HUM, DHUM,

HRV, FAN

Default: FURN (standalone)

COIL (tekmarNet

Default: BOIL

®

System Control)

A Watts Water Technologies Company

25 of 48

© 2013 553_D - 04/13

Page 26

Setup Menu (3 of 7)

Setting Display

W2 PUMP

Select whether the primary or mix system pump on

a tekmarNet® system control should operate while

W2 is operating.

Access Level: Installer Range: OFF or ON

Conditions: ACC RELAY is set to W2 and W2 TERMINAL

is set to CONV or COIL.

W2 THERMAL MOTOR

Select whether W2 operates a thermally actuated

zone valve (wax actuator). When set to ON, there

is a 3 minute delay before operating the pump and

any heat sources.

Access Level: Installer Range: OFF or ON

Conditions: ACC RELAY is set to W2 and W2 TERMINAL

is set to CONV or COIL.

W2 DELAY

The minimum amount of time that the W and/or heat

pump compressor must be operating before the W2

can turn on.

AUTO = Automatic PID staging

OVR = W2 only turns on when Mode is set to EMER.

Available only when Y Relay is set to HP.

Access Level: Installer Range: AUTO, 5 to 180 min, OVR

Conditions: ACC Relay is set to W2 and a heat pump

or first stage heat W is available.

W2 DIFFERENTIAL

Select the W2 differential turn on point from the

previous heat stages.

Access Level: Installer Range: 0.0 to 8.0°F (0.0 to 8.0°C)

Conditions: ACC Relay is set to W2 and a heat pump

or first stage heat W is available. W2 is set to COIL

or FURN.

LOCKOUT W2

The outdoor temperature above which the W2 heat is

disabled. When Mode is set to EMER (emergency),

the backup heat is allowed to turn on.

Access Level: Installer

Conditions: ACC Relay is set to W2 and a heat pump

or first stage heat W is available.

Default: ON

Default: OFF

Default: 60 minutes

Default: 1.0°F (1.0°C)

Range: 40 to 65°F, OFF

(4.5 to 18.5°C, OFF)

Default: 60°F (15.5°C)

A Watts Water Technologies Company

26 of 48

© 2013 553_D - 04/13

Page 27

Setup Menu (4 of 7)

Setting Display

Y MINIMUM OFF

Select the compressor minimum off time.

Access Level: Installer Range: 0:30 to 10:00 minutes

Conditions: Y RELAY is set to AC or HP. Default: 5:00 minutes

COOLING CWSD

Select the outdoor temperature below which the

cooling system is disabled.

Access Level: Installer

Conditions: Y RELAY is set to AC or HP and the

outdoor temperature is available.

INTERLOCK

Select the amount of time for the heat-cool interlock.

Applies only when Mode is set to Auto. Reduces

excessive heat-cool switchovers.

Access Level: Installer Range: 10 to 180 minutes

Conditions: Y RELAY is set to AC or HP. Default: 30 minutes

BALANCE POINT SCHEDULE

Select if the heat pump balance point should change

based upon a programmable schedule.

Access Level: Installer

Conditions: Y RELAY is set to HP and the outdoor

temperature is available.

Range: OFF, 35 to 75°F

(OFF, 1.5 to 24.0°C)

Default: 55°F (13.0°C)

Range: OFF, ZONE, MEMBER 1

to 4

Default: OFF

BALANCE POINT

Heat pump balance point during the time period.

Access Level: Installer

Conditions: Y RELAY is set to HP and the outdoor

temperature is available.

BALANCE POINT

Heat pump balance point during the time period.

Access Level: Installer

Conditions: Y RELAY set to HP, BALANCE POINT is set

to schedule and outdoor temperature is available.

A Watts Water Technologies Company

27 of 48

Range: OFF, 10 to 70°F

(OFF, -12.0 to 21.0°C)

Default: OFF

Range: OFF, 10 to 70°F (OFF,

-12.0 to 21.0°C)

Default: OFF

© 2013 553_D - 04/13

Page 28

Setup Menu (5 of 7)

Setting Display

W HEAT WWSD

Select the outdoor temperature above which the

radiant floor heating is shut off.

Access Level: Installer

Conditions: Two stage heating with the second stage

being a heat pump, fan coil or a furnace and the

outdoor temperature is available.

W CYCLES PER HOUR

Select the number of heating cycles per hour.

SYNC = 20 minute zone synchronization.

AUTO = Automatic cycles per hour to minimize

temperature swings.

Access Level: Installer Range: SYNC, AUTO, 2 to 12

Conditions: W TERMINAL is set to OTHR, W2 is

set to OTHR or the thermostat is not connected to a

tekmarNet® system control.

Y DURING W2

Select whether the heat pump compressor can

operate when W2 heat is on. When Mode is set to

EMER (emergency), the heat pump compressor Y

is always shut off.

Access Level: Installer Range: OFF or ON

Conditions: ACC RELAY is set to W2 and Y RELAY

is set to HP.

BASELOAD

Select the level of radiant floor baseload heating.

This warms the floor so that solar gain and / or air

heating systems do not cause cold floors.

Access Level: Installer Range: OFF, LOW, MED, HIGH

Conditions: Only available when a tekmarNet®

system control is connected and W TERM is set to

HRF1 or HRF2 and SENSOR 1 or 2 is not set to

FLOR (floor).

FLOOR COOL

Select whether or not the thermostat operates W for

radiant floor cooling.

Access Level: Installer Range: OFF or ON

Conditions: Setup menu setting W TERM is set to HRF1

or HRF2 and the thermostat must be connected to a

tekmarNet® heat pump or chiller system control.

Range: OFF, 32 to 80°F

(0 to 26.5°C, OFF)

Default: 60°F (15.5°C)

Default: SYNC

Default: OFF

Default: OFF

Default: OFF

A Watts Water Technologies Company

28 of 48

© 2013 553_D - 04/13

Page 29

Setup Menu (6 of 7)

Setting Display

AIR GROUP MASTER

Select if the thermostat is a master of an air group.

Access Level: Installer Range: NONE, 1 to 16

Conditions: The thermostat must be connected to

other thermostats using tekmarNet® and Y RELAY

is set to HP or AC.

AIR GROUP MEMBER

Select if the thermostat is a member of an air

group.

Access Level: Installer Range: NONE, 1 to 16

Conditions: The thermostat must be connected to

other thermostats using tekmarNet® and Y RELAY

is set to OFF or HUM.

PRIORITY

Select either heating or cooling priority.

Access Level: Installer Range: HEAT or COOL

Conditions: Air Group Master is set to 1 to 16. Default: COOL

G / O RELAY

Select the operation of the G / O relay.

Access Level: Installer

Default: NONE

Default: NONE

Range: FAN or OFF

(Y RELAY is set to AC or HUM)

O or B (Y RELAY is set to HP)

Default:

Conditions: Always available.

FAN (Y RELAY is set to AC)

O (Y RELAY is set to HP)

VENTILATION MODE

Select whether the fan provides ventilation.

Access Level: Installer Range: OFF or ON

Conditions: G/O RELAY is set to FAN or ACC RELAY

is set to FAN.

Default: OFF

HEAT PURGE

Select the fan coil or furnace heating purge based

upon either time or on duct air temperature.

Range: 0:00 to 3:00 minutes

Access Level: Installer

(no duct sensor) or

70 to 160°F, OFF (21.0 to 71.0°C,

OFF) (with duct sensor)

Conditions: W or W2 is set to COIL or FURN. Default: 0:30 min or 100°F (38.0°C)

A Watts Water Technologies Company

29 of 48

© 2013 553_D - 04/13

Page 30

Setup Menu (7 of 7)

Setting Display

COOL PURGE

Select the fan coil or furnace cooling purge based

upon either time or on duct air temperature.

Range: 0:00 to 3:00 minutes

Access Level: Installer

Conditions: W or W2 is set to COIL or FURN. Default: 0:00 min or 60°F (15.5°C)

FAN DELAY

Select the time delay to allow the fan coil or furnace

to warm up prior to activating the fan. This avoids

blowing cold air.

Access Level: Installer

Conditions: G/O RELAY is set to FAN, ACC RELAY

is set to FAN, Sensor 1 is not set to COIL and W1 or

W2 TERMINAL is set to COIL or FURN.

HEAT COIL MINIMUM

Select the minimum coil temperature before operating

the fan for heating.

Access Level: Installer

Conditions: Sensor 1 is set to COIL and W1 or W2

TERMINAL is set to COIL.

(no duct sensor) or

OFF, 40 to 70°F (OFF, 4.5 to

21.0°C) (duct sensor required)

Range: NONE, 0:10 to 6:00

minutes

Default: 0:30 minutes

Range: OFF, 70 to 180°F

(OFF, 21.0 to 82.0°C)

Default: 110°F (43.5°C)

HUMIDIFY MODE

Select the humidifier operation mode.

Access Level: Installer Range: OFF, HM1, HM2, HM3

Conditions: Humidity sensor is on and ACC RELAY

is set to HUM or Y RELAY is set to HUM.

HM3 is only available when a forced air heating

Default: OFF

terminal unit is selected.

DEHUMIDIFY MODE

Select the dehumidifier mode.

Access Level: Installer Range: OFF, DHM1, DHM2, DHM3

Conditions: DHM1 and DHM2 available when Humidity

sensor is on and ACC RELAY is set to DHUM.

DHM3 available when Humidity sensor is on and

Default: OFF

ACC RELAY is set to HRV.

A Watts Water Technologies Company

30 of 48

© 2013 553_D - 04/13

Page 31

Sequence of Operation

------------------------------------------------

--------------------------------------------------------

----------------------------------------------

Heat and Cool Applications

The 553 can operate in several different combinations of conventional and heat pump

applications. Supported conventional heating applications are:

Application RH% Options

1 Heat / 1 Cool / 1 Fan / Relative Humidity Humidification Modes 1, 2, 3

Dehumidification Modes 1, 2, 3

2 Heat / 1 Fan / Humidification Humidification Modes 1, 2, 3

Dehumidification not possible

2 Heat / 1 Cool / 1 Fan None

Supported heat pump applications are:

Application RH% Options

1 Radiant Floor Heat / 1 Heat Pump / 1 Fan None

1 Radiant Floor Heat / 1 Heat Pump / Relative Humidity Humidification Modes 1 or 3

Dehumidification Modes 1, 2, 3

1 Radiant Floor Heat / 1 Heat Pump / Backup Heat None

Heating Operation

Set Heat Temperature

When using only a room temperature sensor, the thermostat operates the heating

system to maintain the Set Heat Room temperature.

Floor Heating

When using both a room and a floor temperature sensor, the thermostat always maintains

the Floor Minimum temperature, even when the air temperature is satisfied. When the

air temperature is below the Set Heat Room temperature, the thermostat operates the

heating system to maintain the Set Heat Room temperature. The floor is never heated

above the Floor Maximum setting in order to protect the floor covering. Suggested

Floor Maximum settings are 90°F (32°C) for tile, stone, or concrete floors and 85°F

(29°C) for wood floors.

Radiant Floor Baseload

When the terminal unit is selected to be a Hydronic Radiant Floor (HRF1 or HRF2)

and no floor temperature sensor is installed, the thermostat has an option to provide

baseload heating. This allows the radiant floor to be heated even though the room air

temperature is satisfied. This is useful in areas where a radiant floor heating zone is

overlapped by an air heating system. The radiant floor heating is overwhelmed by the

quick heat up rate of the air heating system, resulting in a radiant floor heating zone

that rarely turns on. The radiant baseload option allows the radiant floor to counteract

the air heating system by heating the floor at a reduced output even when the room air

temperature is satisfied. This is also useful in areas that experience large solar gains

through windows. The radiant baseload is automatically shut off in the summer by the

warm weather shut down feature.

A Watts Water Technologies Company

--------------------------------------------------------

------------------------------------------------

----------------------------------------------

31 of 48

© 2013 553_D - 04/13

Section A

Section B

Page 32

Warm Weather Shut Down

--------------------------------------------

-------------------------------------------------------

----------------------------------------------------

--------------------------------------------------

--------------------------------------------

When the outdoor air temperature exceeds the Warm Weather Shut Down (WWSD)

setting on the tekmarNet® main control, the heating system is shut off.

A W HEAT WWSD setting is available to allow a forced air heating system to heat the

building while the radiant floor heat system is shut off during mild outdoor temperatures.

This is advantageous in the spring and fall when heating is required at night and cooling

is required during the day. As the outdoor temperature falls below the W HEAT WWSD

setting, the radiant floor becomes the primary heat source and the heat pump provides

supplemental heating.

Balance Point

-------------------------------------------------------

An air source heat pump’s Coefficient Of Performance (COP) decreases with colder

outdoor temperature. This affects the heating output capacity of the heat pump to

heat the building. When the COP is equal to 1, the heat pump no longer provides an

economic advantage over electric heating elements or other supplemental heating fuel.

The outdoor temperature at which this occurs is known as the balance point. When the

outdoor temperature falls below the balance point, the heat pump is shut off and the

backup supplemental heat source is operated to heat the building. The 553 has the

ability for the balance point setting change based upon a programmable schedule. This

is useful in cases where the electrical utility offers different energy pricing throughout

the day.

Freeze Protection

----------------------------------------------------

The thermostat operates the heat whenever the room or floor temperature falls below

40°F (4.5°C) even when the mode is set to off.

Two -Stage Heating

--------------------------------------------------

The 553 generally operates a radiant floor or baseboard as the first stage of heat and

a forced air heating system as the second stage. When an outdoor temperature sensor

is available, the 553 can change the order of the heat stages using the Radiant Floor

Warm Weather Shut Down or the Balance Point to operate the system as comfortably

and efficiently as possible. For additional control of the second stage operation, the

553 includes a time delay and a temperature differential setting. Both setting conditions

must be met before the second stage heat is allowed to turn on.

Warm Weather

Shut down

A Watts Water Technologies Company

Radiant Floor Warm

Weather Shut Down

W2

Lockout

32 of 48

Colder Outdoor

Temperature

Balance

Point

© 2013 553_D - 04/13

Page 33

-----------------------------------------------

------------------------------------------------

-------------------------------------

The first stage operates on a temperature differential of ±0.7°F (±0.4°C) centered

around the heating setpoint. The second stage heat turns on when the temperature

drops 0.7°F - W2 Differential setting below the heating setpoint. The second stage is

shut off once the temperature reaches the heating setpoint.

The second stage W2 is prevented from turning on until the first stage heat W or the

heat pump operates for the elapsed time set by the W2 Delay setting. Auto provides the

shortest wait time. A setting of OVR prevents the second stage from operating unless

the thermostat Mode is set to Emergency heat.

Cooling Operation

Set Cool Temperature

-----------------------------------------------

Section C

The thermostat operates an air conditioner or a heat pump to provide cooling. The “Cool

On” symbol is shown on the display when the thermostat is cooling.

Radiant Floor Cooling

------------------------------------------------

The thermostat has the option to support radiant floor cooling when connected

to a heat pump control using tekmarNet® communication. The terminal unit type

must be set to be HRF1 or HRF2, the floor cooling setting must be set to On and

the heating system must be in Warm Weather Shut Down (WWSD). When the heat

pump system control operates in cooling mode, all thermostats set for floor cooling

on the tekmarNet® bus all activate the first stage heating contact (W1) at the same

time to allow chilled water into the system. The thermostat continues to operate the

floor cooling until either the room temperature reaches the Set Heat temperature

plus 3°F (Set Heat+1.5°C) or reaches a minimum temperature of 74°F (23.5°C). If

only a floor sensor is installed, the floor cooling setpoint is 67°F (19.5°C).

Cooling Cold Weather Shut Down

-------------------------------------

When the outdoor air temperature falls below the Cooling Cold Weather Shut Down

(CWSD) setting on the thermostat, the cooling system is shut off.

No Cooling

Warmer Outdoor

Temperature

Section D

Cooling Cold

Weather Shutdown

Room Min and Max Limits

Warm Weather

Shut Down

Floor

Cooling

Heating and cooling minimum and maximum temperature settings are available in

the Set Temp menu. These allow the installer to select start and stop limits for the

temperature settings in both heating and cooling for the User and Limited access

levels. This is useful in commercial installations and child / guest bedrooms where

availability of the full temperature setting range may not be desirable.

A Watts Water Technologies Company

33 of 48

© 2013 553_D - 04/13

Page 34

----------------------------------------------------------

------------------------------------------------------------

---------------------------------------

---------------------------------------------------

Mode Operation

The thermostat includes a mode key. Available modes are:

Heat - Allows heating

•

Cool - Allows cooling

•

Auto - Automatically switches between heating and cooling as necessary. The

•

Section E

interlock time is applied when switching from heating to cooling or from cooling

to heating.

Emergency - Only available when operating a heat pump. When set to

•

Emergency the heat pump is locked out and the hydronic and backup heat are

operated.

Hydronic Pump and Valve Operation

Exercising

When connected to a tekmarNet® system control, the thermostat exercises the heat relay for

10 seconds every 3 days. Exercising helps prevent zone valves or zone pumps from failing

due to precipitate buildup. During exercising, the thermostat shows “TEST” on the display.

Flushing

The flushing feature is for open-loop systems that use a domestic hot water tank as a

heat source. Flushing ensures that fresh potable water is circulated through the system

once each day. If the thermostat is connected to a tekmarNet® system control with the

Flushing feature turned on, the thermostat display will display “FLUSHING” for the

duration of the flushing operation.

Hydronic System Supply Pump

When connected to a tekmarNet® system control, the thermostat’s W1 Pump setting

affects how the primary pump or mix pump on the system control operates. When

connected to the boiler bus, the boiler system or primary pump is operated. When

connected to the mix bus, the mix system pump is operated.

If the thermostat operates a motorized or thermal motor zone valve, the W1 Pump

setting should be set to On.

If the thermostat operates a thermal motor (wax actuator) zone valve, set the W1 Thermal

Motor setting to On. This provides a three minute delay to allow the zone valve to open

before the primary or mix pump is turned on.

In special applications with multiple zoning manifolds, the W1 Pump setting can be set

to Off. This allows a Zone Group Pump located on the Zone Manager, or Wiring Center

to operate the pump for the manifold.

DHW Tank Priority

When a tekmarNet® system control is heating an indirect Domestic Hot Water (DHW)

tank, the thermostat may shut off the heating zones to allow the DHW tank to recover

quickly. This is determined by the DHW priority of the tekmarNet

----------------------------------------------------------

------------------------------------------------------------

---------------------------------------

---------------------------------------------------

Section F

®

system control.

A Watts Water Technologies Company

34 of 48

© 2013 553_D - 04/13

Page 35

Fan Operation

------------------------------------------------------

------------------------------------------------------

The fan operates together with the air heating or cooling systems. The user can also

select to operate the fan manually by pressing the Fan button. This allows the user to

choose between Auto and On. “Auto” allows the fan to operate together with heating or

cooling but normally the fan is off. “On” forces the fan to operate continuously.

Section G

Ventilation Fan

In order to provide ventilation to the building, the fan can also operate for additional

time beyond what is required for the heating and cooling systems. Ventilation allows the

user to select the fan to operate for a minimum percentage out of each hour. Options

are 10 to 90%, in 10% (6 minutes per hour) increments, as well as Auto and On. This

is available when the Vent Mode setting in the Setup menu is set to On.

Once Ventilation is set to On, the Fan minimum run time percentage during the and

events can be set so that the fan can operate on a schedule and/or together with scenes.

Fan Post Purge

The fan relay includes a post purge feature that operates the fan after the heating or

cooling system has shut off. When a duct temperature sensor is installed the length

of post purge is based on the air duct temperature and the Heat Purge or Cool Purge

temperature settings. When there is no duct temperature sensor installed, the length

of post purge is based upon the Heat Purge and Cool Purge time settings.

Relative Humidity Operation

Relative Humidity (RH) is controlled by maintaining the Minimum Humidity using

humidification and by maintaining Maximum Humidity using dehumidification. The RH

is maintained within a 5% differential. The differential is applied above the minimum

setpoint, and applied below the maximum setpoint.

To avoid condensation on windows, the minimum relative humidity setting can be

changed according to the following outdoor temperatures.

------------------------------------------------------

------------------------------------------------------

Section H

Outdoor Temperature

Suggested RH Min

RH is affected by changes in the ambient air temperature. When using a programmable

schedule, the thermostat calculates the relative humidity setpoint with respect to the Set

Heat Room setting when in heat mode, the Set Cool Room when in cool mode,

and the average between Set Heat Room and Set Cool Room when in auto mode.

This may result in changes in displayed RH when the mode is changed.

When the mode is set to off, the humidification and dehumidification systems do not

operate.

A Watts Water Technologies Company

-10°F (-23°C) 0°F (-18°C) 10°F (-12°C) 20°F (-7°C) 30°F (-1°C)

20% 25% 30% 35% 35%

35 of 48

© 2013 553_D - 04/13

Page 36

The thermostat has three humidification modes.

---------------------------------------------

Mode Operation

HM1 Stand Alone Humidifier

Humidifier operates independently of the HVAC system.

Available in all modes except off.

HM2 Humidifier with Fan

Humidifier ducted together with HVAC system. The system fan is operated whenever the humidifier is operating. This is only available when

operating a conventional heating system with a fan.

Available in all modes except off.

HM3 Humidifier with Air Heating

Humidifier ducted together with HVAC system. The air system must be

heating (heat pump, furnace, electric or hydronic fan coil) in order to

allow the humidifier to operate.

Available when heating.

The thermostat has three dehumidification modes.

Mode Operation

DHM1 Stand Alone Dehumidifier

Dehumidifier operates independently of the HVAC system.

Available in all modes except off.

DHM2 Coil Dehumidification

A DX coil compressor is operated with the blower fan operating at its

dehumidification speed.

DHM3

HRV Dehumidification

(requires an outdoor temperature reading to be available)

The HRV is operated based upon indoor dew point and outdoor air temperature. The HRV operates when the indoor dew point is 5.5°F (3.0°C)

above the outdoor temperature. The HRV is shut off when the indoor dew

point falls to 2°F (1.0°C) above the outdoor temperature.

Available in all modes except off.

DX Coil Frost Protection

---------------------------------------------

When operating a coil dehumidification system (DHM2), frost protection of the DX coil

can be provided when an optional Duct Sensor 083 is installed. In the event that the

duct air temperature nears freezing, the thermostat removes the dehumidification signal

and the cooling compressor is allowed to operate together with the fan operating at full

speed to allow the DX coil to warm up.

A Watts Water Technologies Company

36 of 48

© 2013 553_D - 04/13

Page 37

Air Group Operation

Section I

In order to prevent heating and cooling at the same time, this thermostat can operate

together with other thermostats on a tekmarNet

®

system to form an air group. On older

model thermostats the air group functionality was previously described as a cool group.

In an air group, one thermostat is assigned as the air group master. The air group master

operates both the air heating and cooling equipment for the group. The 553 can be

set to be a master or a member of the air group. When operating as a air group, the

air temperature readings of all the air group member thermostats are communicated

to the air group master thermostat and an average temperature is determined. When

the air group master is in cooling operation, the air group member thermostats do not

operate the heating system for air heating.

When operating a heat pump, the 553 also has the ability to prevent air group member

thermostats from heating while the outdoor temperature is between the Warm Weather

Shut Down (WWSD) and the Radiant Floor WWSD (W Heat WWSD) setting. This allows

the air system heat pump, fan coil or furnace to heat the building during mild outdoor

weather and avoids heating up the radiant floor slab.

If the Set Heat Room temperature is adjusted while the air group is cooling, COOL is

flashed on the display to alert the user that the air group cooling system is presently

on and heating is not available. Once the cooling system shuts off, heating is available

if required.

Air Group

MemberMemberMaster

tekmarNet® Communication

Time Clock

Section J

The thermostat includes a time clock that is automatically visible in the Home

menu when a programmable schedule is used. If the schedule is not used, the

user has the option to select whether the time is shown in the Home menu.

During a loss of power, the thermostat continues to keep the correct time and

date for at least 4 hours. If the power is off for more than 4 hours, the user will

need to set the time.

The thermostat supports automatic update for daylight savings time. Simply set

Daylight Save to On together with the correct day, month, and year and the time

is automatically updated each spring and fall.

When connected to a tekmarNet

®

system, adjustment of the time on one thermostat

updates all connected thermostats. This option can be disabled by selecting the

Local Network Group setting to be On.

A Watts Water Technologies Company

37 of 48

© 2013 553_D - 04/13

Page 38

Temperature Adjustment

--------------------------------

-------------------------------

-----------------------------------------------------

Section K

Permanent Adjustment - No Schedule

When no programmable schedule is used, touch the up or down arrows to permanently

set the “Set Heat Room” or “Set Cool Room” temperature. This thermostat is capable

of controlling both air and floor temperature.

Permanent Adjustment - With Schedule

--------------------------------

-------------------------------

When a programmable schedule is used, there are two room heating temperatures

available, one for the

time period and another for the time period. When

touching the or arrows to change the temperature, only the temperature for

the current time period is changed.

1. To adjust the temperature for both time periods, press and hold the Home button

for 3 seconds to enter the programming menus.

2. Enter the “SET TEMP” menu to adjust the following settings:

Set Heat Room (air heating or air heating with floor sensor)

•

Set Heat Room (air heating or air heating with floor sensor)

•

Set Heat Room AWAY (air heating or air heating with floor sensor)

•

Floor Min (air heating with floor sensor)

•

Floor Min (air heating with floor sensor)

•

Set Cool Room (air cooling)

•

Set Cool Room (air cooling)

•

Set Cool Room AWAY (air cooling)

•