Page 1

INSTALLATION INSTRUCTIONS

AND RECOMMENDATIONS FOR USE AND MAINTENANCE

INDUCTION HOBS

EINBAU-ANLEITUNG

UND EMPFEHLUNGEN FÜR GEBRAUCH UND INSTANDHALTUNG

INDUKTIONSKOCHFELD

INSTRUCTIONS POUR L’INSTALLATION

ET RECOMMANDATIONS D’UTILISATION ET D’ENTRETIEN

PLAQUES À INDUCTION

IR 631 - IT 631 - IR 641 - IT 641 - IRC 631

IR 630 - IT 630 - IR 831

Page 2

Introduction / Allgemeines / Présentation

GB

Notes about the cookware to be used with

your induction hob.

The size of the base of the cookware to be used

should be large enough to completely cover the

cooking zone drawn on the glass.

Depending on the type of cookware (material

and size), the induction zones may work with

smaller cookware.

Please remember that in order to work, the

induction elements need to be used with cookware that has a ferromagnetic base (material

attracted by a magnet).

Always use cookware with a flat, smooth base on the induction elements. Using

cookware with a deformed, concave or curved base can lead to overheating that can

damage the glass or the cookware.

Please take into account that the

cookware that you use can greatly affect the

how well the induction element works. You

may find cookware on the market that,

although marked as being suitable for induction hobs, does not work very well or is not

easily recognised by the induction element

due to the little amount or poor quality of the

ferromagnetic material that the cookware

has in its base.

DE

Hinweise zum Kochgeschirr

Der Boden des verwendeten Kochgeschirrs

sollte die gesamte Fläche der auf der

Glaskeramik gekennzeichneten Kochzone

bedecken.

Dennoch kann ebenso Kochgeschirr kleineren

Durchmessers verwendet werden, sofern

Material und Größe des Geschirrs eine

Magnetisierung erlauben.

Die Induktionszonen sind ausschließlich für

Kochgeschirr mit ferromagnetischem Boden

geeignet (magnetisierbares Material).

Der Boden des Kochgeschirrs sollte

glatt und vollkommen eben sein. Andernfalls

können Geschirr und Glaskeramik durch

Überhitzung beschädigt werden.

Induktionskochzonen hängt wesentlich von

der Art des verwendeten Kochgeschirrs ab.

Kochgeschirr für Induktionskochzonen wird

Die Leistung der

vom Hersteller entsprechend gekennzeichnet, jedoch ist dies keine Garantie dafür,

dass das Geschirr vom Kochfeld erkannt

wird oder dass die Leistung der Kochzonen

effektiv ausgenutzt werden kann.

Ausschlaggebend sind hier in jedem Fall

Qualität und Menge des im Boden des

Geschirrs verarbeiteten ferromagnetischen

Materials.

FR

Notes sur les récipients à utiliser sur votre

plan de travail à induction.

Le récipient à employer doit avoir un fond dont

la dimension de fond couvre complètement la

zone de cuisson qui figure sur la vitre.

Selon le type de récipient (matériel et dimension), les zones à induction peuvent fonctionner

avec des récipients plus petits.

Il convient de tenir compte que les plaques à

induction nécessitent pour fonctionner des récipients à fond ferromagnétique (matériau attiré

par un aimant).

Sur les plaques à induction, utilisez

toujours des récipients à fond plat et lisse.

L'emploi de récipients à fond déformé, concave ou ondulé provoque des surchauffes

qui peuvent endommager la vitre ou le propre récipient.

Il convient de tenir compte que le récipient que vous utilisez peut avoir une grande influence sur le rendement de toute plaque à induction. Il existe sur le marché des

récipients qui, malgré le fait d'être signalé

comme aptes pour l'induction, ont un rendement très faible ou des problèmes pour être

reconnus par la plaque à induction, en raison de la légère quantité ou qualité du matériel ferromagnétique qu'a le fond du récipient.

2

Page 3

1

2

1

2

3

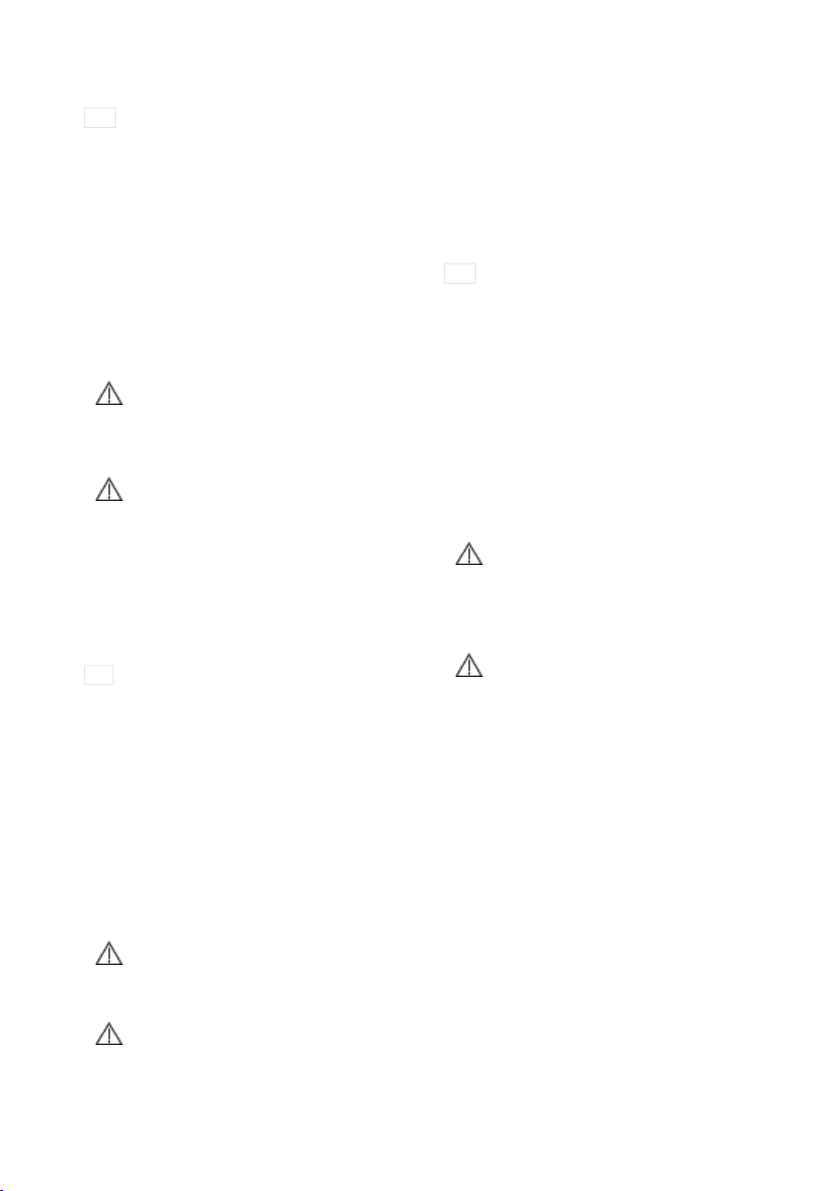

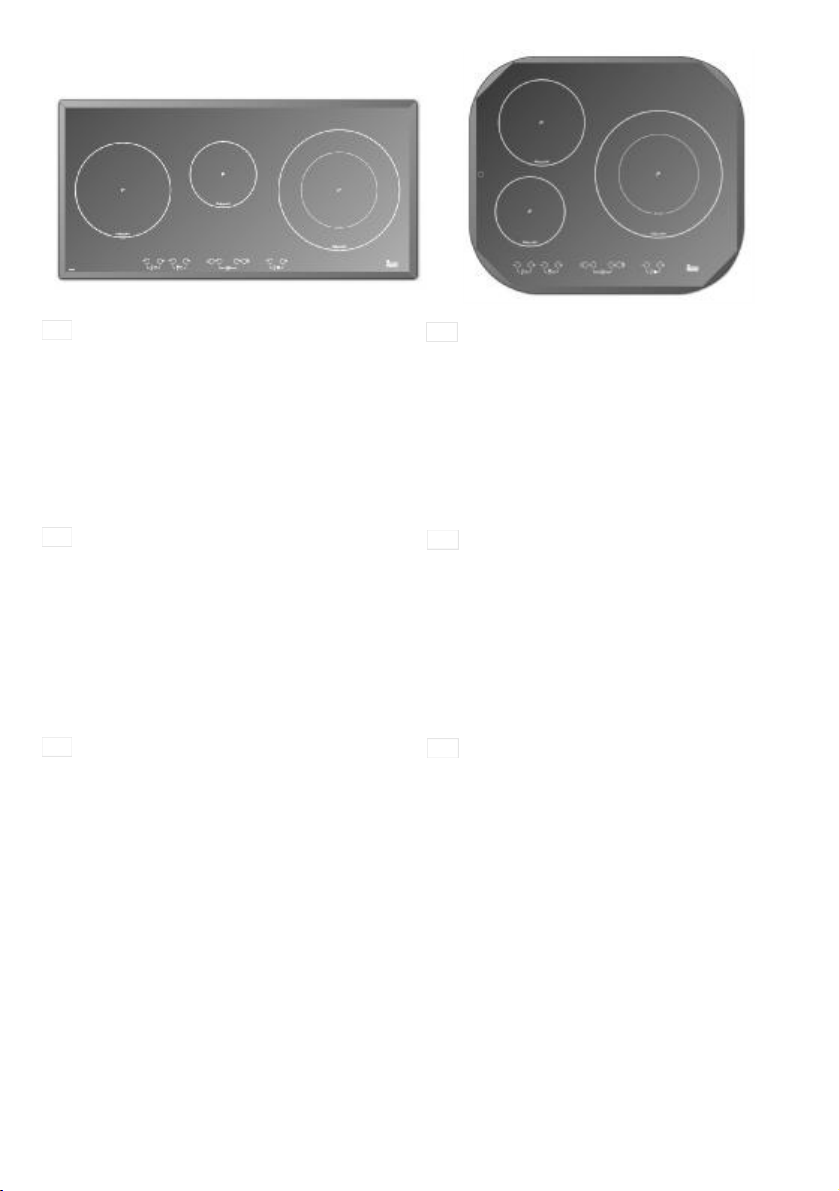

GB Model IR 641 / IT 641

1 2,100/3,000* W. induction hotplate.

2 1,600/2,300* W. induction hotplate.

3 1,100/1,800* W induction hotplate.

4 1,600/2,300* W. induction hotplate.

* Induction power with the Power function

enabled.

- Residual heat indicator (H)

- Maximum electric power: 6,400 W.

- Supply power: 230 Volts.

- Frequency: 50/60 Hertzs.

DE

Modell IR 641 / IT 641

1 Blitzkochzone 2.100/3.000* W.

2 Blitzkochzone 1.600/2.300* W.

3 Blitzkochzone 1.100/1.800* W

4 Blitzkochzone 1.600/2.300* W

* Induktionsleistung bei aktivierter

Power-Funktion

- Restwärmeanzeige (H)

- Maximale Leistung: 6.400 W

- Betriebsspannung: 230 V

- Frequenz: 50/60 Hz

Modèle IR 641 / IT 641

FR

1 Plaque radiante de 2.100/3.000* W.

2 Plaque radiante de 1.600/2.300* W.

3 Plaque radiante de 1.100/1.800* W

4 Plaque radiante de 1.600/2.300* W

* Puissance à induction avec la fonction

Power activée.

- Indicateur de chaleur résiduelle (H).

- Puissance maximum : 6.400 Watts.

- Tension d'alimentation : 230 Volts.

- Fréquence : 50/60 Hertz.

4

3

4

3

Page 4

1

1

2

3

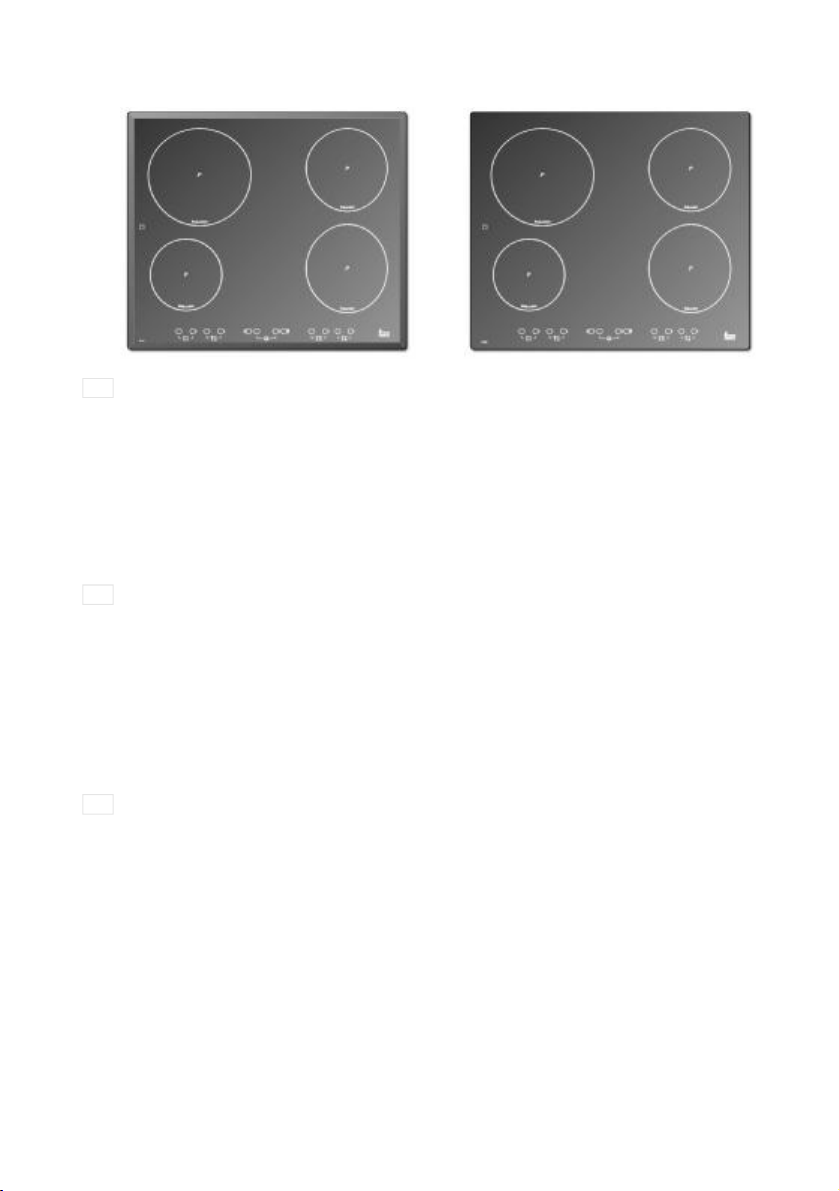

GB Model IR 631 /IT 631

1 2,100/3,000* W. induction hotplate.

2 1,500/1,800* and 2,400/3,200* W. dou-

ble induction hotplate.

3 1,100/1,800* W induction hotplate.

* Induction power with the Power function

enabled.

- Residual heat indicator (H)

- Maximum electric power: 6,400 W.

- Supply power: 230 Volts.

- Frequency: 50/60 Hertzs.

DE

Modell IR 631 / IT 631

1 Blitzkochzone 2.100/3.000* W.

2 Blitzkochzone 1.500/1.800* und

2.400/3.200* W.

3 Blitzkochzone 1.100/1.800* W

* Induktionsleistung bei aktivierter

Power-Funktion

- Restwärmeanzeige (H)

- Maximale Leistung: 6.400 W

- Betriebsspannung: 230 V

- Frequenz: 50/60 Hz

Modèle IR 631 / IT 631

FR

1 Plaque radiante de 2.100/3.000* W.

2 Plaque radiante de 1.500/1.800* et

2.400/3.200* W.

3 Plaque radiante de 1.100/1.800* W

* Puissance à induction avec la fonction

Power activée.

- Indicateur de chaleur résiduelle (H).

- Puissance maximum : 6.400 Watts.

- Tension d'alimentation : 230 Volts.

- Fréquence : 50/60 Hertz.

2

3

4

Page 5

1

1

2

3

GB

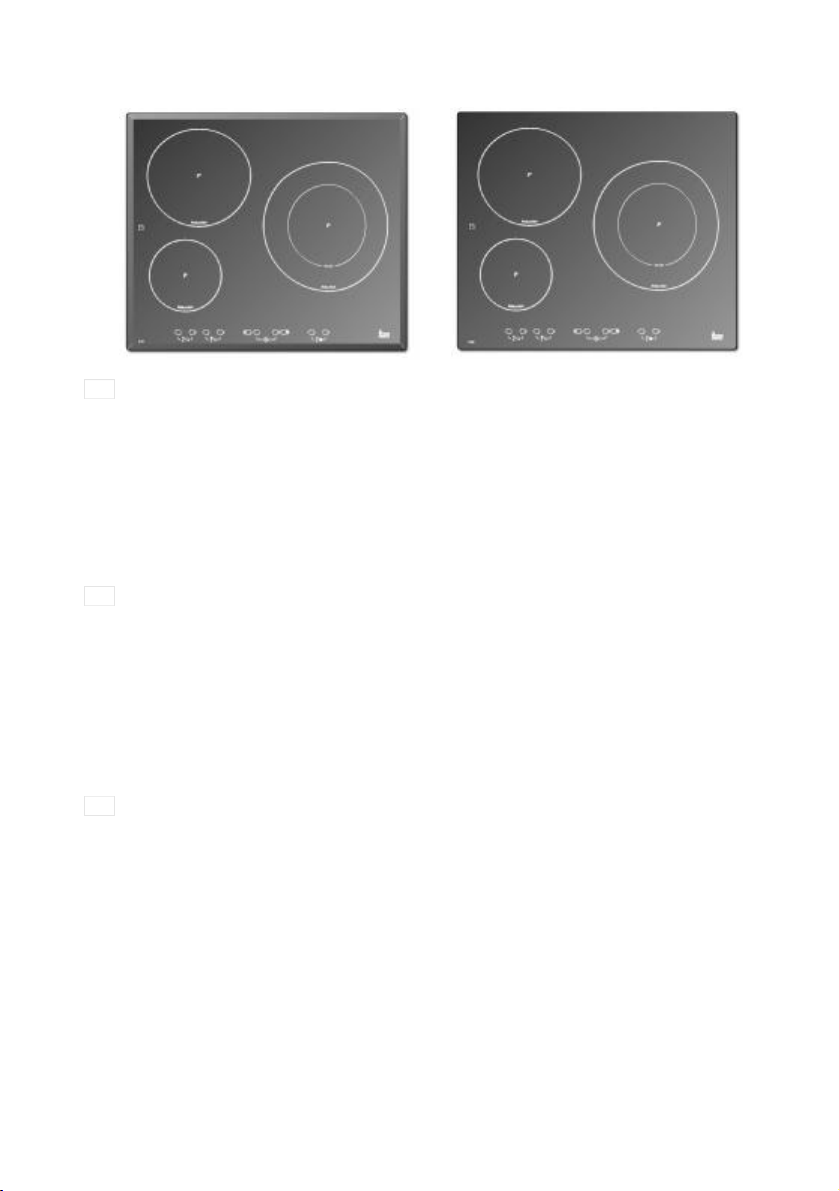

Models IR 630 / IT 630

1 1,600/2,300* W. induction hotplate.

2 1,500/1,800* and 2,400/3,200* W. double

induction hotplate.

3 1,100/1,800* W. induction hotplate.

* Induction power with the Power function enabled.

- Residual heat indicator (H)

- Maximum electric power: 6,100 W.

- Supply power: 230 Volts.

- Frequency: 50/60 Hertzs.

DE

Modell IR 630 / IT 630

1 Induktionskochzone mit 1.600/2.300* W.

2 Induktionskochzone mit 1.500/1.800* und

2.400/3.200* W.

3 Induktionskochzone mit 1.100/1.800* W.

* Induktionsleistung bei aktivierter PowerFunktion

- Restwärmeanzeige (H)

- Maximale Induktionsleistung: 6.100 W

- Betriebsspannung: 230 V

- Frequenz: 50/60 Hz

FR

Modèles IR 630 / IT 630

1 Plaque à induction de 1.600/2.300* W.

2 Plaque à induction de 1.500/1.800* et

2.400/3.200* W.

3 Plaque à induction de 1.100/1.800* W.

* Puissance à induction avec la fonction

Power activée.

- Indicateur de chaleur résiduelle. (H)

- Puissance maximum à induction: 6.100

Watts.

- Tension d'alimentation : 230 Volts.

- Fréquence : 50/60 Hertz.

2

3

7

Page 6

1

1

GB

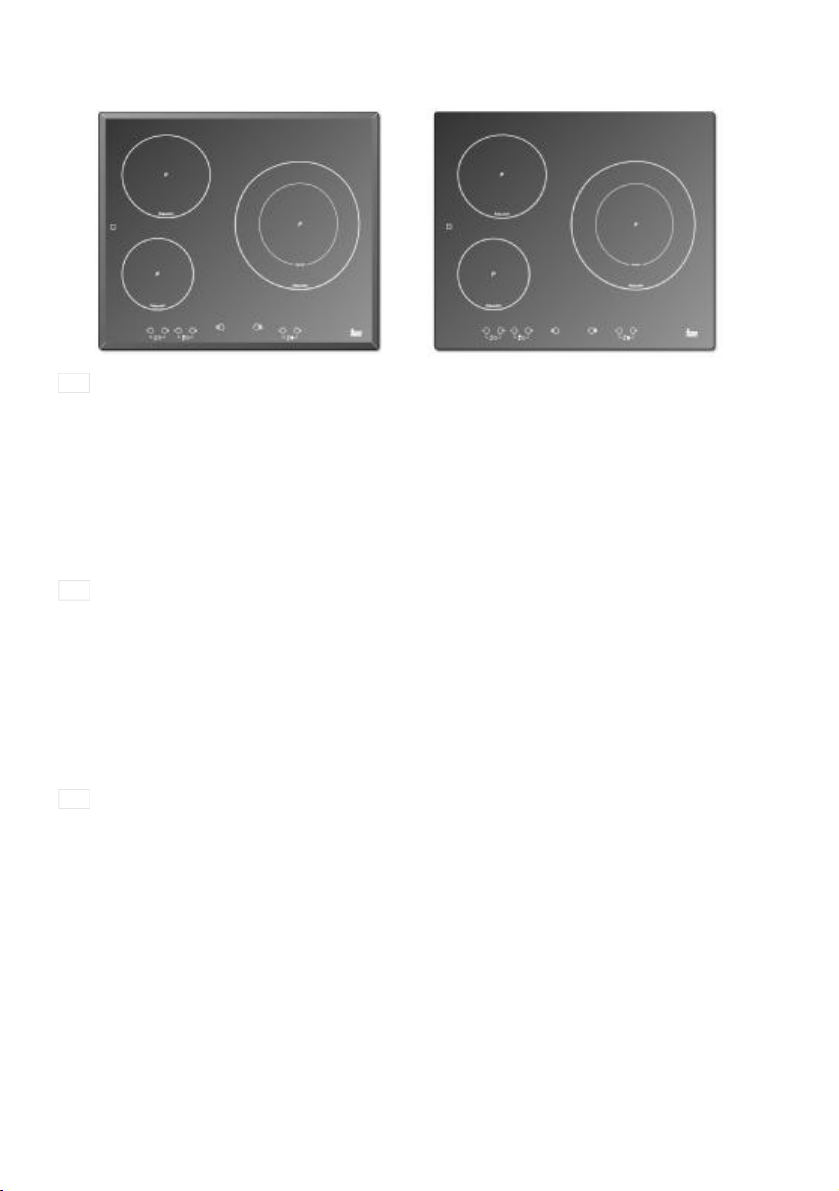

Modelo IR 831

1 2,100/3,000* W. induction hotplate.

2 1,100/1,800* W. induction hotplate.

3 1,500/1,800* and 2,400/3,200* W. double

induction hotplate.

* Induction power with the Power function

enabled.

- Residual heat indicator (H).

- Maximum electric power: 6,400 W.

- Supply power: 230 Volts.

- Frequency: 50/60 Hertzs.

DE

Modell IR 831

1 Induktionskochzone mit 2.100/3.000* W.

2 Induktionskochzone mit 1.100/1.800* W.

3 Induktionskochzone mit 1.500/1.800* und

2.400/3.200* W.

* Induktionsleistung bei aktivierter PowerFunktion

- Restwärmeanzeige (H)

- Maximale Induktionsleistung: 6.400 W

- Betriebsspannung: 230 V

- Frequenz: 50/60 Hz

Modèle IR 831

FR

1 Plaque à induction de 2.100/3.000* W.

2 Plaque à induction de 1.100/1.800* W.

3 Plaque à induction de 1.500/1.800* et

2.400/3.200* W.

* Puissance à induction avec la fonction

Power activée.

- Indicateur de chaleur résiduelle. (H)

- Puissance maximum à induction : 6.400

Watts.

- Tension d'alimentation : 230 Volts.

- Fréquence : 50/60 Hertz.

2

3

2

3

GB

Models IRC 631

1 1,600/2,300* W. induction hotplate.

2 1,500/1,800* and 2,400/3,200* W. double

induction hotplate.

3 1,100/1,800* W. induction hotplate.

* Induction power with the Power function enabled.

- Residual heat indicator (H)

- Maximum electric power: 6,100 W.

- Supply power: 230 Volts.

- Frequency: 50/60 Hertzs.

DE

Modell IRC 631

1 Induktionskochzone mit 1.600/2.300* W.

2 Induktionskochzone mit 1.500/1.800* und

2.400/3.200* W.

3 Induktionskochzone mit 1.100/1.800* W.

* Induktionsleistung bei aktivierter PowerFunktion

- Restwärmeanzeige (H)

- Maximale Induktionsleistung: 6.100 W

- Betriebsspannung: 230 V

- Frequenz: 50/60 Hz

FR

Modèles IRC 631

1 Plaque à induction de 1.600/2.300* W.

2 Plaque à induction de 1.500/1.800* et

2.400/3.200* W.

3 Plaque à induction de 1.100/1.800* W.

* Puissance à induction avec la fonction

Power activée.

- Indicateur de chaleur résiduelle. (H)

- Puissance maximum à induction: 6.100

Watts.

- Tension d'alimentation : 230 Volts.

- Fréquence : 50/60 Hertz.

6

Page 7

Guide to Using the Instructions Booklet

Dear customer,

We are delighted that you have put your

trust in us.

We are confident that the new hob that you

have purchased will fully satisfy your

needs.

This modern, functional and practical

model has been manufactured using topquality materials that have undergone

strict quality controls throughout the manufacturing process.

Before installing and using it, we would

ask that you read this Manual carefully and

follow the instructions closely, as this will

guarantee better results when using the

appliance.

Keep this Instruction Manual in a safe

place so that you can refer to it easily and

thus abide by the guarantee conditions.

In order to benefit from this Guarantee, it is

essential that you submit the purchase

receipt together with the Guarantee

Certificate.

You should keep the Guarantee

Certificate or, where relevant, the technical datasheet, together with the

Instruction Manual for the duration of

the useful life of the appliance. It has

important technical information about

the appliance.

Safety instructions

Before first use, you should carefully read

the installation and connection instructions.

These hob models may be installed in the

same kitchen furniture units as TEKA

brand ovens.

For your safety, installation should be

carried out by an authorised technician

and should comply with existing installation standards. Likewise, any internal work

on the hob should only be done by TEKA’s

technical staff, including the change of the

flexible supply cable of the appliance.

Please note:

When the hotplates are in operation or have recently been in operation,

some areas will be hot and can burn.

Children should be kept well away.

If the glass ceramic breaks or

cracks, the hob should immediately be

disconnected from the electric current

in order to avoid the risk of electric

shock.

Do not leave anything on the

hob’s cooking areas while it is not in

use. Avoid risk of fire.

Do not place metal objects, such

as knives, forks, spoons or lids on the

surface of the hob, as they may get very

hot.

7

Page 8

GB

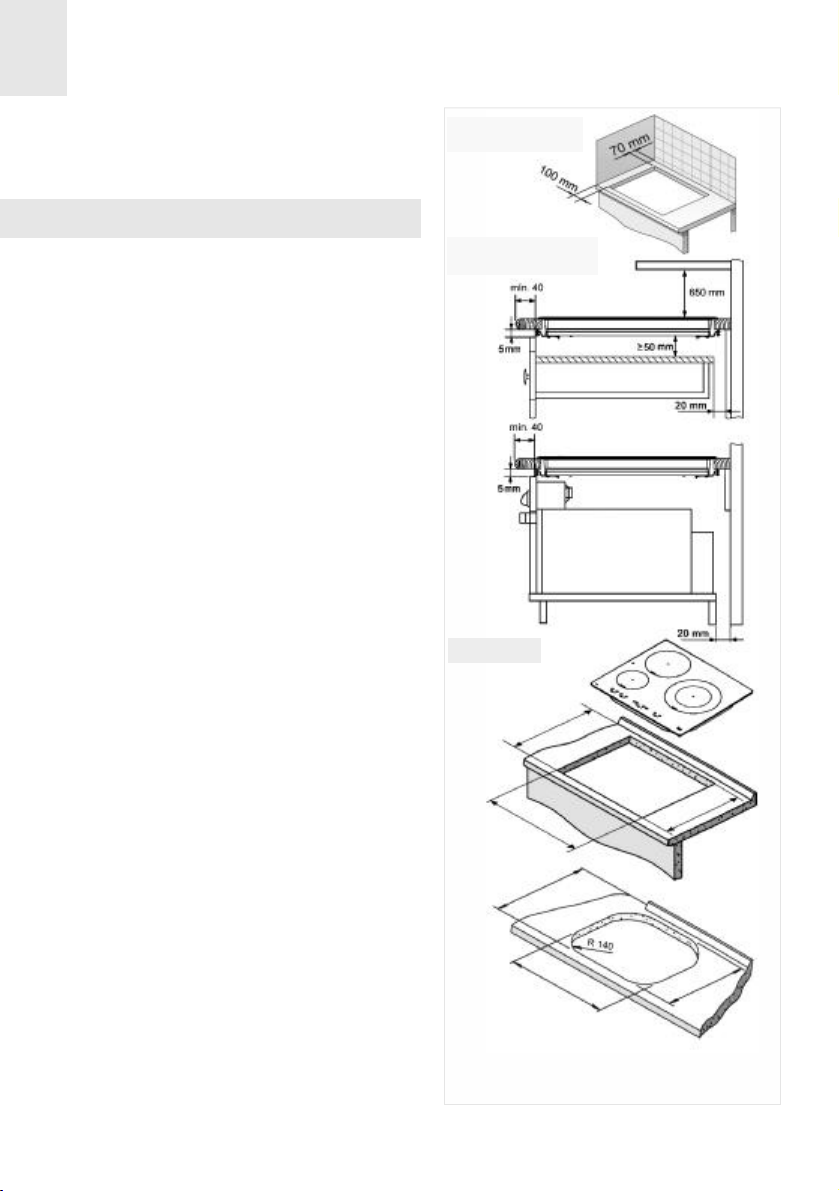

Installation

INSTALLATION AND SETUP SHOULD

BE CARRIED OUT BY AN AUTHORISED

TECHNICIAN IN LINE WITH CURRENT

INSTALLATION STANDARDS.

Positioning the hob

To install these models, an opening with

the dimensions shown in figure 1 will be

cut into the unit’s worktop.

The fastening system for the top is designed for furniture thicknesses of 20, 30 and

40 mm.

The minimum distance between the surface supporting the cooking pans and the

lower part of the kitchen unit or the hood

located above the hob should be 650 mm.

If the hood’s installation instructions

recommend that the gap is greater than

this, you should follow this advice.

The unit where the hob and oven will be

located will be suitably fixed.

INSTALLATION WITH CUTLERY DRAWER

Minimum distance

to wall

Minimum ventilation

distances

Fitting holes

fig. 1

DRAWER

OVEN

If you wish to install a tray drawer under

the top, place a cover or partitioning board

at least 5 cm deep from the top in order to

avoid any object placed on the drawer

obstructing the top ventilators. In this manner, we will also avoid any potential risk to

inflammable objects that may be stored in

the drawer.

INSTALLATION WITH FAN OVEN

UNDER THE HOB

The oven should be installed according to

the corresponding manual.

If a fan oven is being installed, please

remember that this hob has only been certified to work with TEKA brand ovens.

8

.

x

a

m

5

7

5

L

Model IRC 631:

.

x

a

m

5

7

5

L

The dimensions L and W are shown in the table

"Dimensions and characteristics" of the Technical

Information section.

W

W

Page 9

GB

Leave a space in the front of the cabinet so

that the hot air can ventilate properly. The

opening should be at least 5 mm high. The

longitude should be the width of the cabinet.

An opening of 20 mm should be made in

the back part of the cabinet in order to

allow cold air to enter (see figure 1).

Warnings:

To secure the hob to the cabinet, four brackets should be fastened to the existing holes

on the bottom part of the casing (two in the

front and two in the back). There are two

possibilities of where the brackets may be

placed, just as is shown in figure 2.

The model IR 831 includes ten brackets instead of four (three in the front, three in the

rear and two on each side).

When hobs are handled before

being installed, care should be taken in

case there is any protruding part or

sharp edge which could cause injury.

When installing units or appliances above the hob, the hob should be

protected by a board so that the glass

cannot be damaged by accidental

blows or heavy weights.

The glues used in manufacturing

the kitchen unit and in the adhesive on

the decorative laminate of the worktop

surface should be made to tolerate temperatures of up to 100ºC.

TEKA assumes no responsibility

for any malfunction or damage caused

by faulty installation.

PLEASE REMEMBER THAT THE GUARANTEE DOES NOT COVER THE

GLASS IF IT SUFFERS A VIOLENT

BLOW OR IF IT IS USED IMPROPERLY.

Fastering the hob

When the gap has been properly sized, the

sealing washer should be put on the lower

face of the glass. Silicone should not be

applied between the glass and the unit

worktop because if it becomes necessary to remove the hob from its position,

the glass could break when trying to

detach it.

Sealing washer

Sealing washer

fig. 2

Depending on the thickness of the cabinet, it

may be necessary to use the self tapping

screws that are provided as compliments for

securing; insert them in the circular holes of

the bracket. The thread of this hole will be

made when the screw is inserted inside of it.

The thread should be made before faste ning the bracket to the hob.

Connecting the electricity

The electric connection is made via an

omnipolar switch or plug where accessible,

which is suitable for the intensity to be tolerated and which has a minimum gap of 3

mm between its contacts, which will ensure

disconnection in case of emergency or

when cleaning the hob.

The connection should include correct earthing, in compliance with current norms.

If the flexible supply cable fitted to these

appliances ever needs to be changed, it

9

Page 10

GB

should be replaced by TEKA’s official service.

The input cable should not be in contact

either with the body of the hob or with the

body of the oven, if the oven is installed in

the same unit.

When using the hob for the first

time, please take care not to have

powerful halogen lights, like those of a

hood, shining over the sensor button

area of the hob. These lights may interfere with the starting of the system.

10

Page 11

GB

Technical Information

Technical details

Class 3 hob.

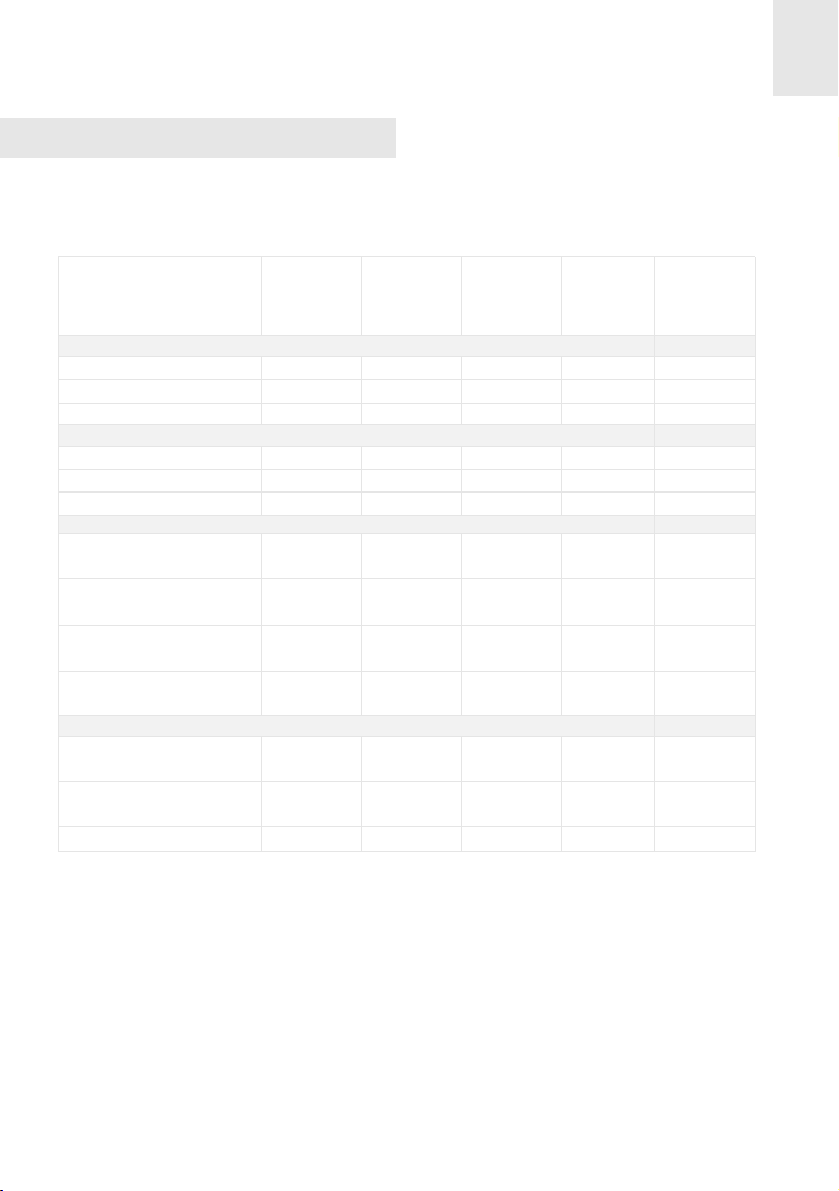

Dimensions and characteristics

Model

Hob dimensions

Height (mm)

Length (mm)

Width (mm)

Dimensions of the placement in the unit

Length (mm)

Width (mm)

Depth (mm)

Configuration

Induction hotplate

1,100 / 1,800*

Induction hotplate

1,600 /2,300* W

Inducción hotplate

2,100 / 3,000* W

Double induction hotplate

1,500/1,800* and 2,400/3,200* W

Electrics

Nominal Power

(W) for 230 V

Supply

voltage (V)

Frequency (Hz)

* Induction power with the Power function enabled.

(L)

(W)

W

IR 631

IT 631

60

600

510

560

490

55

1

1

1

6.400

50 / 60

IR 641

IT 641

60

600

510

560

490

55

6.400

230 V230 V

50 / 60

IR 630

IT 630

IRC 631

IR 831

GKI 630

60

600

510

560

490

55

1

2

1

1

60

590

510

570

490

55

1

1

65

800

400

780

380

61

1

1

1

1

6.100

230 V

50 / 60

1

6.100

230 V

50 / 60

1

6.400

230 V

50 / 60

11

Page 12

GB

Use and Maintenance

Before starting for the

first time

Before connecting the hob to the electrical

network, verify that the tension (voltage)

and the frequency of the hob correspond

to the voltage and frequency indicated on

the hob rating plate, which is located on

the underside of the hob and in the guarantee or, if applicable, on the technical

data sheet that should be kept with this

manual during the useful life of the apparatus.

The appliance is not designed to

be used by people (including children)

with reduced physical, mental or sensory abilities. It should also not be used

by people that do not have experience

handling the apparatus or who do not

have knowledge of the apparatus,

unless they are supervised by a person

who is in charge of their safety.

Children should not be allowed

to play with the apparatus.

The induction generator complies

with the European regulations in force.

We recommend, however, that people

using pacemaker heart devices or similar consult their doctor or, if in doubt,

refrain from using the induction areas.

Touch control user

instructions

CONTROL PANEL ELEMENTS(see fig. 3)

1

On/off sensor.

2

Hotplate indicators.

Power and/or residual heat indicators.

3

Reduce power sensor (less).

4

Increase power sensor (more).

5

Timer/Clock indicator.

6

Indicator of selected time (clock).

7

Locking sensor (for the rest of the sen-

8

sors, except on/off).

Indicator light of the induction element

9

with timer.

10

Pilot light for activated locking.

Time reduction sensor on clock (less).

11

Time increasing sensor on clock (more).

12

Countdown indicator (blinks each

13

second) .

N.B.: * Only visible when in operation.

The sensors marked on the control panel

are used for control purposes.

There is no need to exert pressure on the

glass - you enable the function you require simply by touching the sensor with your

finger.

Each action is confirmed by a beep.

12

fig. 3

Page 13

GB

SWITCHING THE APPLIANCE ON

SWITCHING THE HOTPLATES OFF

1 Touch the on sensor (1) for at least

one second. The Touch Control will activate, you will hear a beep and the indicators will turn on. If any of the cooking

areas is hot, the corresponding indicator

will alternate between showing a H and

a 0.

The following action must be carried out

within 10 seconds or the touch control will

automatically switch off.

When the touch control is activated, it can

be disconnected at any time by touching

the sensor (1), even if it has been

blocked (blocking function activated). The

sensor (1) always takes priority for disconnecting the touch control.

SWITCHING THE HOTPLATES ON

The hotplates will be found deactivated,

with their respective power indicators (3)

at 0, until a power level is selected. If all

the hotplates are set at 0, you have 10

seconds to activate any of them, otherwise

the touch control will automatically turn off.

Use the sensors and (4/5) to select

a power level. If you touch the sensor

(5), the plate will switch to level 1 and,

for each additional stroke, it will go up one

level until reaching the maximum value of

P. Using the sensor (4), you can redu-

ce the power level.

With the sensor (4), lower the power to

level 0.

The hotplate will automatically power off.

For a fast power up: no matter what the

power level, by simultaneously pressing

the sensors and (5/4), the plate will

immediately power off.

By powering off a hotplate, an H will be

shown on the power indicator, if the glass

surface is at a high temperature, indicating

that there a risk of burning. When the temperature has fallen, the indicator will power

off if the top is disconnected or, if it is turned on, it will indicate a 0.

POWERING OFF THE DEVICE

At any time, you can disconnect the top by

pressing the sensor (1). When doing

this, an acoustic signal is heard and the

power indicators (3) will turn off, except if

there is a residual H heat indicator active

due to the plate temperature.

Locking the sensors

Using the locking sensor (8), you can

block all the sensors on the touch control

panel. This will make it possible to avoid

undesired accidental operations occurring

or children being able to manipulate the

control.

For a fast powering up at maximum power:

with the plate at 0, touch the sensor (4)

once. The plate will directly activate at

level 9.

By continuing to press down on any of

these two sensors (4) or (5), they

will repeat the action every half a second,

without needing to press consecutively.

Bear in mind that with the touch control

powered up, the on/off sensor (1)

makes it possible to turn it off even if the

locking is activated (pilot 10 on). On the

other hand, if the touch control is turned

on, the locking function does not allow for

activating the on/off sensor (1). You

should first deactivate blocking.

13

Page 14

GB

To activate or deactivate the function,

simply keep pressing the sensor (8)

for about 1 second. When the function is

active, the pilot light (10) turns on.

Detecting pans

(induction hotplates)

The induction cooking plates incorporate a

container detector. This is to avoid the

plate operating without having a pan on

top or when the container is unsuitable,

e.g., if made of aluminium or another nonmetallic material.

The power indicator blinks if, with the plate

turned on, no container or an inappropriate container is detected.

If the containers are removed from the hotplate while operating, this will automatically cut off the power supply and the

power indicator will blinks. When putting

the container on the cooking hotplate

again, the power supply restarts at the

power level that was selected.

The time for detecting the container is 3

minutes. If three minutes go by without

having placed a container on the hotplate

or if an inappropriate container is placed

there, the cooking plate deactivates.

After use, always disconnect the

cooking plate. It is not sufficient to

remove the container. Otherwise, undesirable operation of the plate may occur

if another container were placed by

mistake during the container detection

period. Avoid possible accidents!

Power supplied according to

the power level selected

Bear in mind that induction areas adjust the

amount of power supplied according to the

size and type (material) of pan placed on

them. A smaller pan will receive less power

than a larger one. Thus, depending on the

pan being used, the power supplied may

vary from the values shown in Table 1.

Table 1

INDUCTION HOTPLATES

Power

selected

o

1

2

3

4

5

6

7

8

9

P

*The exact power will depend of the size and shape of the pan.

Ø 260 mm Hotplate

Inner area Both areas

54

72

120

180

276

450

600

840

1140

1440

1800

90

120

200

300

460

750

1000

1400

1900

2400

3200

14

Power in watts*

Ø 210 mm

Hotplate

70

110

150

240

500

600

850

1100

1550

2100

3000

Ø 180 mm

Hotplate

50

90

120

170

300

450

600

850

1150

1600

2300

Ø 145 mm

Hotplate

40

70

100

140

200

300

450

600

800

1100

1800

Page 15

GB

Power function

This function makes it possible to give a

plate "extra" power, higher than the nominal. This power level depends on the size

of the plate (see values indicated with * in

the Presentation section), reaching up to

3.200 W on the larger plates.

POWER FUNCTION CONNECTION

have its power limited to the remaining

power up to a total of 3,200 Watts. If the

power level on this plate is too high, the

touch control will automatically reduce it to

the maximum allowed (7).

Fondue function

This function is especially designed for

melting butter, cheese, chocolate, etc. It is

a lower power level than level 1.

1 Activate the plate corresponding to

power level 9.

2 From power level 9, press the sensor

and the symbol P will be displayed

on the indicator.

The Power function lasts for a maximum of

10 minutes. After this time, the power level

will automatically set to level 9.

POWER FUNCTION DISCONNECTION

The Power function can be disconnected

by pressing the sensor associated with

the hotplate in question.

The function can also be disconnected

automatically if the temperature in the cooking area is very high.

Bear in mind that the 3 and 4 model of plates have 2 independent power generators

of 3,200 W each, which respectively control the plates on the left and on the right.

For this reason, the Power function cannot

be activated at the same time in two plates

on the same side. In other words, if this

function operates in a plate on the left, the

Power cannot be activated on the other

plate on the other side, but it can be activated on the other plate on the other side.

To access this function:

1 Activate the plate you wish to use at

power level 1.

2 Press the sensor (4) and the indica-

tor will show the symbol .

To deactivate the function, simply touch

the sensors (4) or (5) and the indicator will display, respectively, a lower

power level 0 or higher 1.

Safety disconnection

MAXIMUM FUNCTION TIME

In the event of forgetting to turn off the plate,

it will automatically power off after a given

time after the last time the plate was activated. (See Table 2).

Once this function has been activated in a

hotplate, the one on the same side will

15

Page 16

GB

Table 2

Power

selected

1

2

3

4

5

6

7

8

9

P

When the "safety disconnecting" has occurred, in the corresponding plate's power

indicator the residual heat H indicator will

be displayed, if the glass temperature is

high enough.

SAFETY WHEN SENSORS ARE COVERED

MAXIMUM

OPERATION TIME

(in hours)

8

8

5

4

4

3

3

2

2

1

10 minutes

Take into account that this safety

function is activated even though the

Touch Control is turned off!

Do not leave any objects down on

the Touch Control!

Clock

(except models …630)

The top is fitted with a clock that can be

used for two different functions: as a plate

timer or as a countdown chronometer.

The clock as a countdown timer

(except models …630)

With this function, you can set a time after

which a sound signal will be heard.

To activate this function, proceed as

follows:

1 With the Touch Control powered on and

no plate with the timer activated, touch

one of the sensors (11) or (12)

corresponding to the clock.

The Touch Control incorporates a function

that detects when any object (container,

cloth or certain liquids) are covering the

panel sensors for more than 10 seconds.

This is to avoid the object activating or

deactivating any of the plates without you

realizing.

When the Touch Control detects an object

covering the sensors, it starts to bleep until

the object covering the control panel is

removed. If the Touch Control was turned

on, it is automatically disconnected for

safety reasons.

If after a few minutes the object covering

the sensors is not removed, the bleeping

will stop.

16

2 Power on the indicator (7), displaying

00.

3 Touch the sensors (11) or (12)

again to set the required time. After a

few seconds, the decimal point on clock

will start to blink (13), indicating that the

countdown has begun.

Be careful not to touch different sensors

other than (11) or (12) since, by

doing so, a plate may cease timing instead

of programming the chronometer.

Once the countdown has reached zero, a

series of bleeps will be heard. These can

be cancelled by touching any of the sensors (11) or (12) associated with

Page 17

GB

the clock.

tor (7) will start to blink.

If, while the clock is working as a countdown chronometer, at some point the

induction plates are set at power level 0,

the touch control panel will turn off after a

few seconds, but the chronometer will continue working until it finishes the countdown or the countdown is cancelled.

To cancel the chronometer, simply set the

remaining time to 00.

Timer function

(except models …630)

This function will help you with cooking as

you will not have to be present during the

following: the timer plate(s) will automatically turn off at the end of the set time. The

device has an individual timer for each

plate. This allows it to time all the plates at

the same time, if required.

The function is controlled with the time

increase/decrease sensors and

(11/12) associated with the clock (7).

SINGLE plate timer

To activate the timer on one single plate,

proceed as follows:

1 With the plate powered on and the clock

turned off, touch one of the sensors

(11) or (12) corresponding to the

clock.

2 Turn on the indicator (7) displaying 00.

At the same time, a blinking will appear on the indicators for each of the plates that are powered on.

3 In the next 5 seconds, touch one of the

sensors (4) or (5) corresponding to the plate you wish to time. The

will be set on the indicator for this

plate and the digits on the clock indica-

4 You have a further 5 seconds to select

the time required, simply by touching the

sensors (11) or (12) on the

clock. After a few seconds, the digits on

clock indicator (7) will stop blinking and

the decimal point on the clock and the

timed plate will start to blink, indicating

that the countdown has started.

Once the required time has been set, be

careful not to activate any other sensor

since the device may interpret that you

wish to exit the timer function. While the

clock digits blink, you can alter their value

but do not touch different sensors other

than (11) or (12).

Once the countdown is complete, the

timed plate will power off and a series of

bleeps will be heard that can be cancelled

by touching any of the sensors (11) or

(12) associated with the clock.

Timing more than one plate / Altering

the programmed time

During a countdown, you can alter the

remaining time or time a new plate.

1 With the Touch Control powered on and

a plate timed, touch one of the sensors

(11) or (12) corresponding to the

clock.

2 The countdown will stop and the indica-

tor (7) displays 00. A blinking will display on the indicators for each of the plates that are powered up.

3 At that point, you can time another plate

or alter the remaining time on a previously time set plate. To distinguish

them, take into account the decimal

point appearing on the bottom right

of the indicator (3), only on that/those

plate/s that are timed at that moment.

17

Page 18

GB

In the next 5 seconds, touch one of the

sensors (4) or (5) corresponding

to the plate that you wish to time or alter.

The will stop blinking in the indicator

for this plate and the digits on the indicator (7) of the clock will start to blink.

4 Touch the sensors (11) or (12)

again until the required time is set. After

a few seconds the decimal point in the

indicator (7) will start to blink, indicating

that the countdown has started.

minutes to cool the electronics if you

switch the cooker off when the fan is switched on.

Power surges

Touch controls can withstand a

certain degree of power surges in the

electricity supply. Abnormally high

power surges can cause the control

system to malfunction (as with any type

of electrical appliance).

If you wish to cancel a timing already set,

simply set the time desired in step 4 to 00 or,

directly, by turning off the plate in question.

When you have timed more than one

plate, by default, the indicator (7) of the

clock will display the shortest remaining

time. This time will correspond to the plate

whose indicator (3) displays the blinking

with the decimal point.

Remember that the decimal point in a

power indicator (3) shows you that this plate

is timed! If this decimal point is blinking and

it’s shown the , it means that the indicator

(7) of the clock is showing you, at that precise moment, the time remaining in the

countdown for that hotplate.

Please remember that if, during the

countdown, you turn off the touch panel

using the on/off sensor button (1),

the countdown will be cancelled!

Overheating safety feature

The induction areas are protected against

overheating that may cause damage to the

electronic system.

The internal fan is automatically enabled

and disabled, depending on the temperature of the electronic system. Therefore,

the fan may continue to work for a few

Suggestions and

recommendations

To ensure maximum performance from

your hob, follow these guidelines:

fig. 4

Right

* Use pans with a flat base, as the greater

the surface contact between the pan

and the glass, the greater will be the

heat transmission. We recommend the

use of heavy pans so that the base is

more difficult to dent. Figure 4 shows

how pans that are dented or concave

have a smaller contact surface.

* Make sure that the pans are well centred

on the outlines shown on the heating

area.

* Dry the pans’ bases before putting them

on the glass ceramic hob.

* Do not drag pans with corners or edges

that could damage the glass.

* The glass withstands some impacts from

large containers with no sharp edges.

Be careful with impacts from small and

sharp utensils.

Wrong

Wrong

18

Page 19

GB

* Avoid spilling sugar, or products contai-

ning sugar, on the glass, since these

may react with the hot glass and damage the surface.

Cleaning and care

To maintain the glass ceramic hob in good

condition, it should be cleaned with suitable products. The glass ceramic hob

should be cleaned after each use, when it

is lukewarm or cool. This will make cleaning easier as it will avoid any build-up of

dirt from repeated use.

Never use aggressive cleaning products or

products that can scratch the surfaces

(see the table that shows various common

products that may be used). Steam-based

appliances should not be used to clean the

hob.

LOOKING AFTER THE GLASS

The degree of soiling should be taken into

account when cleaning, and the items and

products used should vary according to

this.

Light soiling

Light, non-sticky, soiling can be cleaned

with a damp cloth and a soft detergent or

warm, soapy water.

Heavy soiling

Serious dirt and grease should be cleaned

using an agent specially made for glass

ceramic (for example, Vitroclen). Please

follow the manufacturer’s instructions.

Sticky stains that have been burned in can

be removed by using a scraper with a

razor blade.

Rainbow colouring: Caused by pans that

have dry bits of grease on their base or

when grease gets between the glass and

the pan while cooking. Can be removed

from the surface of the glass using a nickel

scourer with water or with a special glass

ceramic cleaner (for example, Vitroclen).

Plastic objects, sugar, or food with a high

sugar content that are melted onto the hob

should be removed immediately while hot,

using a scraper.

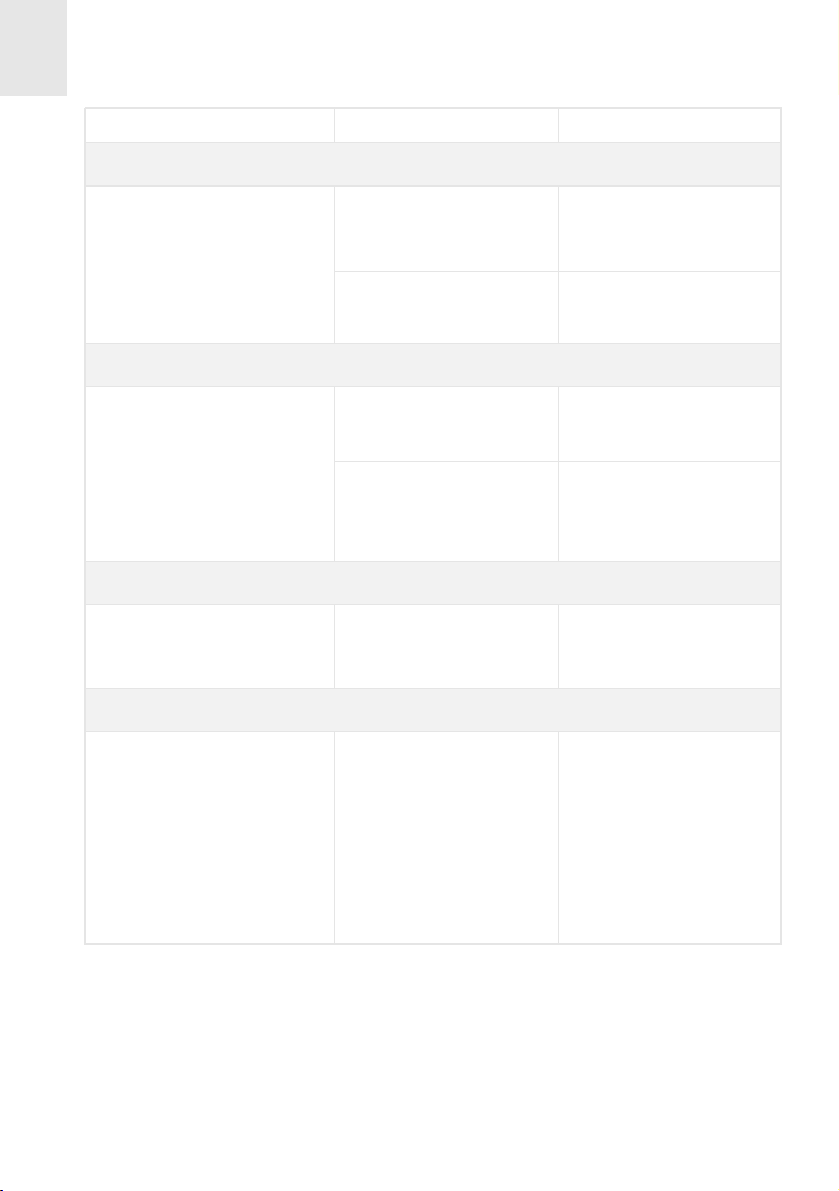

RECOMMENDED CLEANING PRODUCTS

Product

Soft and liquid detergents

Aggressive or powder detergents

Special glass ceramic cleaning agents (e.g. Vitroclen)

Grease-removing sprays (ovens, etc.)

Soft cloths

Kitchen towels

Kitchen cloths

Nickel scourers (never use dry)

Steel scourers

Hard synthetic scourers (green)

Soft synthetic scourers (blue)

Glass scrapers

Liquid polish for domestic appliances and/or glass

Should it be used to clean...

...the glass? ...the surround?

YES YES

NO NO

YES YES

NO NO

YES YES

YES YES

YES YES

YES NO

NO NO

NO NO

YES YES

YES NO

YES YES

19

Page 20

GB

When the glass’s colour changes.

This does not affect its effectiveness or

stability, and is generally caused by inadequate cleaning or by poor-quality pans.

Metallic sheens are caused by metal pans

sliding over the glass. They can be removed by thorough cleaning with a special,

glass ceramic cleaning agent (for example, Vitroclen), although it may be that the

cleaning needs to be repeated more than

once.

Worn trim is the result of using abrasive

cleaning products or pans with uneven

bases which wear down the serigraphy.

Use blades that are in perfect conditions, and change the blade as soon

as it shows any sign of wear.

When you finish using the scraper, fold it away and cover it well up.

(See fig. 6)

fig. 6

Protected blade Unprotected blade

Using the scraper

Please note:

Take great care when using the

glass scraper. The blade can cause

injury!

If you do not use the scraper properly, the blade could break and pieces

may get stuck between the decorative

side-piece and the glass. If this happens, do not try to remove the pieces

with your hand - use pliers or a sharppointed knife. (See fig. 5)

fig. 5

Only use the blade on the glass

ceramic surface - avoid the body of the

scraper coming into contact with the

glass, since this could scratch the

glass ceramic.

Pans may stick to the glass if

something has melted between them.

Do not attempt to unstick the pan when

it is cold - you could break the glass

ceramic.

TEKA INDUSTRIAL S.A. reserves the

right to alter its manuals in any way it

deems necessary or useful while not altering their basic characteristics.

The symbol on the product or on its

packaging indicates that this product

may not be treated as household waste.

Instead it shall be handed over to the

applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of correctly, you will help prevent potential negative consequences

for the environment and human health,

which could otherwise be caused by

inappropriate waste handling of this

product, please contact your local city

office, your household waste disposal

service or the shop where you purchased the product.

20

Page 21

GB

If something doesn’t work

Before calling the Technical Service, please

make the following checks:

Fault Possible cause Possible solution

The induction zones are not heating up

The pan is unsuitable (it

does not have a ferromag-

netic base or it is too

small).

When you start using the induction zones, you hear a buzzing sound

The pan is light or made

up of more than one part.

The buzzing comes from

energy being transmitted

directly to the base of the

The touch control does not come on

The sound of a fan can be heard while cooking, and it continues when

the cooker has been turned off.

induction zones to cool

pan.

The lock is enabled

There is a fan in the

the electronics.

Check that the pan base

reacts to a magnet, or use a

This buzzing is not a fault. If,

however, you wish to avoid it,

lower the power level slightly

or use a pan that has a hea-

vier base, and/or that is made

The fan only comes on when

cally, whether or not the hob

larger pan.

of a single part

Disable the lock.

the electronics heat up -

when the temperature goes

down it goes off automati-

is on.

When frying or making a stew, the energy in the induction zones seems

to decrease (“the hotplate gets less hot”)

If the temperature of the

glass or of the electrics

gets too high while coo-

king, a self-protection

system is triggered that

adjusts the power of the

hotplates so that the temperature does not get any

A plate powers off and message C is displayed on the indicators

Excess temperature in the

electronics or on the glass.

higher.

Overheating problems while

cooking only occur under

conditions of extreme use

(cooking for a long time at full

power) or when the hob has

been wrongly installed.

Check that the hob has been

installed as described in the

instruction manual.

Wait some time to allow the

electronics to cool down or

remove the container to

allow the glass to cool.

21

Page 22

GB

Fault Possible cause Possible solution

The hob suddenly starts to bleep

There is a cloth, container

or liquid on the Touch

Control.

The timer was activated

and the preset time has

finished.

The hob (or any of the hotplates) powers off during cooking

There is a container, cloth

or liquid covering the Touch

One or several of the hot-

A timed hotplate failed to power off at the end of the set time

The hotplate had not been

After a power outage (or the first time the hob is connected), the

control panel remains blocked

affecting the control panel.

Control.

plates has overheated.

set correctly.

There is a powerful light

Remove any object covering

the Touch Control and/or

clean any liquid that might

have been spilt on it.

Touch the clock sensor to

deactivate the bleep.

Remove any object that

might be covering the

Touch Control.

Allow the overheated hot-

plates to cool down for a

few minutes before powe-

ring them up again.

Make sure that the time

was set following the ins-

tructions manual.

Don't apply powerful lights

(for example, halogen spo-

tlights) over the control

panel when connecting the

hob to the electrical

current. A very powerful

light may cause the sensor

buttons not to calibrate

correctly after a power

outage.

22

Loading...

Loading...