Page 1

PASTRY SHOWCASE

Page 1

E

INSTRUCTION MANUAL

Page 2

LIST

1 GUIDE TO THE MANUAL Page 3

2 TECHNICAL

3 DISPLAY CASE MARKING DATA Page 5

3.1 DISPLAY CASE IDENTIFICATION Page 5

3.1.1 DISPLAY CASE NAMEPLATE Page 5

3.1.2 CE MARKING Page 5

3.1.3 NAMEPLATE OF THE MAIN COMPONENTS Page 5

4 HOW TO USE AND PRESERVE THE INSTRUCTIONS MANUAL Page 5

4.1 INTENDED USER OF THE INSTRUCTIONS MANUAL Page 5

4.2 OBJECTIVES OF THE INFORMATION IN THE MANUAL Page 5

4.3 LIMITATIONS ON USE OF THE MANUAL Page 5

4.4 HOW TO PRESERVE THE MANUAL Page 5

5 HANDLING AND INSTALLING THE DISPLAY CASE Page 6

5.1 RECEIVING THE DISPLAY CASE Page 6

5.2 UNLOADING OPERATIONS Page 6

5.3 CHECKING THE SUPPL Y Page 6

5.4 UNPACKING Page 6

5.5 PERSONNEL REQUIREMENTS Page 6

5.6 HANDING THE DISPLAY CASE Page 6

6 ENVISIONED USE Page 7

6.1 OBJECTIVE OF THE PASTRY DISPLAY CASE Page 7

6.2 AREAL NAME Page 7

6.3 USE OF THE DISPLAY CASE Page 7

6.4 SAFETY REGULATIONS DURING USE Page 7

7 TECHNICAL DESCRIPTION OF THE DISPLAY CASE Page 8

7.1 GENERAL INFORMATION Page 8

8 INSTALLATION Page 9

8.1 GENERAL INFORMATION Page 9

8.2 POSITIONING Page 9

9

9.1 GENERAL

9.1.1 INITIAL STARTUP OF THE DISPLAY CASE Page 10

9.2 POSITIONING THE TUBS Page 10

9.3 USING THE SWITCHBOARD Page 10

10 MAINTENANCE Page 1

10.1 GENERAL

10.2 CLASSIFICA

10.3 REQUIREMENTS FOR MAINTENANCE PERSONNEL Page 11

10.4 CLOTHING Page 11

10.5 CLEANING THE GLASS STRUCTURE Page 11

10.6 CLEANING THE PLASTIC AND PAINTED PARTS Page 12

10.7 CLEANING THE DISPLAY SECTION Page 12

10.8 CLEANING THE CONDENSER Page 12

11 TROUBLESHOOTING Page 13

12 DISMANTLI

12.1 GENERAL INFORMATION Page 13

12.1.1 DISMANTLING FOR DEMOLITION Page 13

12.1.2 DISMANTLING FOR TRANSFER Page 13

13 CIRCUIT Page 14

INSTRUCTIONS FOR USE Page 10

DATA Page 4

INFORMATION Page 10

INFORMATION Page 11

TION OF INTERVENTIONS Page 11

NG Page 13

1

Page 15 14 ANNOTATIONS

Page 2

Page 3

y

1

GUIDE TO THE MANUAL

This manual has been drawn up by the manufacturer and is an integral part

of the machine supply. The information it contains is for non qualified (inexpert)

and qualified personnel.

This manual defines the purpose for which the machi ne was built and it

contains all necessary information to ensure its proper installation and safe

correct operation.

Other technical information that is not included in this manual is an integr al

part of the technical file prepared by TEFCOLD A/S and is available at its

facilities.

Be sure to consult this manual before proceeding with

installation, use and an

Constant observance of the regulations it contains will guarante e perso nnel

and machine safety, low-cost operation and a longer operating lift.

The careful analysis done by TEFCOLD A/S has made it possible to

eliminate most risks. However, be sure to follow all the instructions g iven in this

manual. Always refer to the manual before carrying out any operation. Safeguard

this manual and make sure it is al ways available next to the machine or in th e

nearby vicinity.

other work on the machine.

Before conducting any type of operation, disconnect the

machine from the electrical mains.

The diagrams and drawings are furnished by way of ex amp le. I n purs u an c e

to its policy of constant development and u pdating. Th e manufacturer m ay make

any changes without giving advance notice.

This manual must be kept for the entire life of the m achine. If it is lost or

destroyed, a copy can be requested from the m anufacturer. Be sure to indicate

the data listed on the nameplate (the price will be established by the

manufacture).

TEFCOLD A/S welcomes any comments from clients concerning

improvements to be made on the machine and will assess their implementation.

This document is the exclusive prop erty of TEFCOLD A/S and cannot be

divulged to third parties, either in whole or in part, without the written

authorization of TEFCOLD A/S

TEFCOLD A/S reserves all legal rights.

All the measurements listed in this manual are expressed in mm.

Page 3

Page 4

2

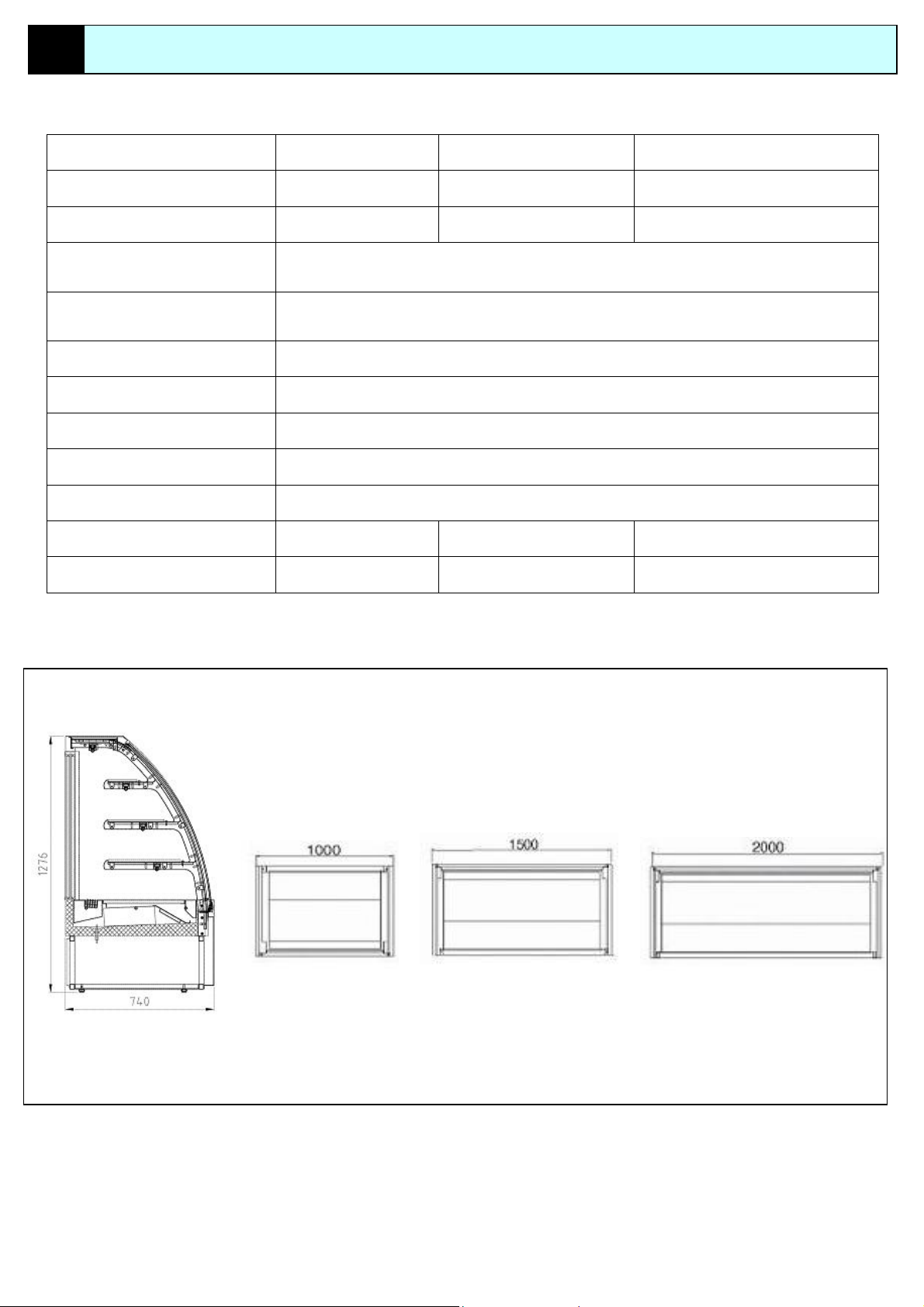

TECHNICAL DATA

MODEL

External dimensions (L*D*H) 1000*740*1276 1500*740*1276 2000*740*1276

Net Weight (Kg) 200 250 300

Interior temperature (℃) +2/+6℃

OTHELLO 100 OTHELLO 150 OTHELLO 200

Clmatic class (RH%)

Refrigerant R134a

Refrigeration Ventilate

Defrosting Stop compressor

Shelves Qty 3

Voltage 220-240V/50HZ/1PH

Input power 596 680 770

Energy consumption 9.9 11.3 12.8

30℃/60%

Dimension

OTHELLO

SECTION DRAWING

OTHELLO 100 OTHELLO 150 OTHELLO 200

Page 4

Page 5

3

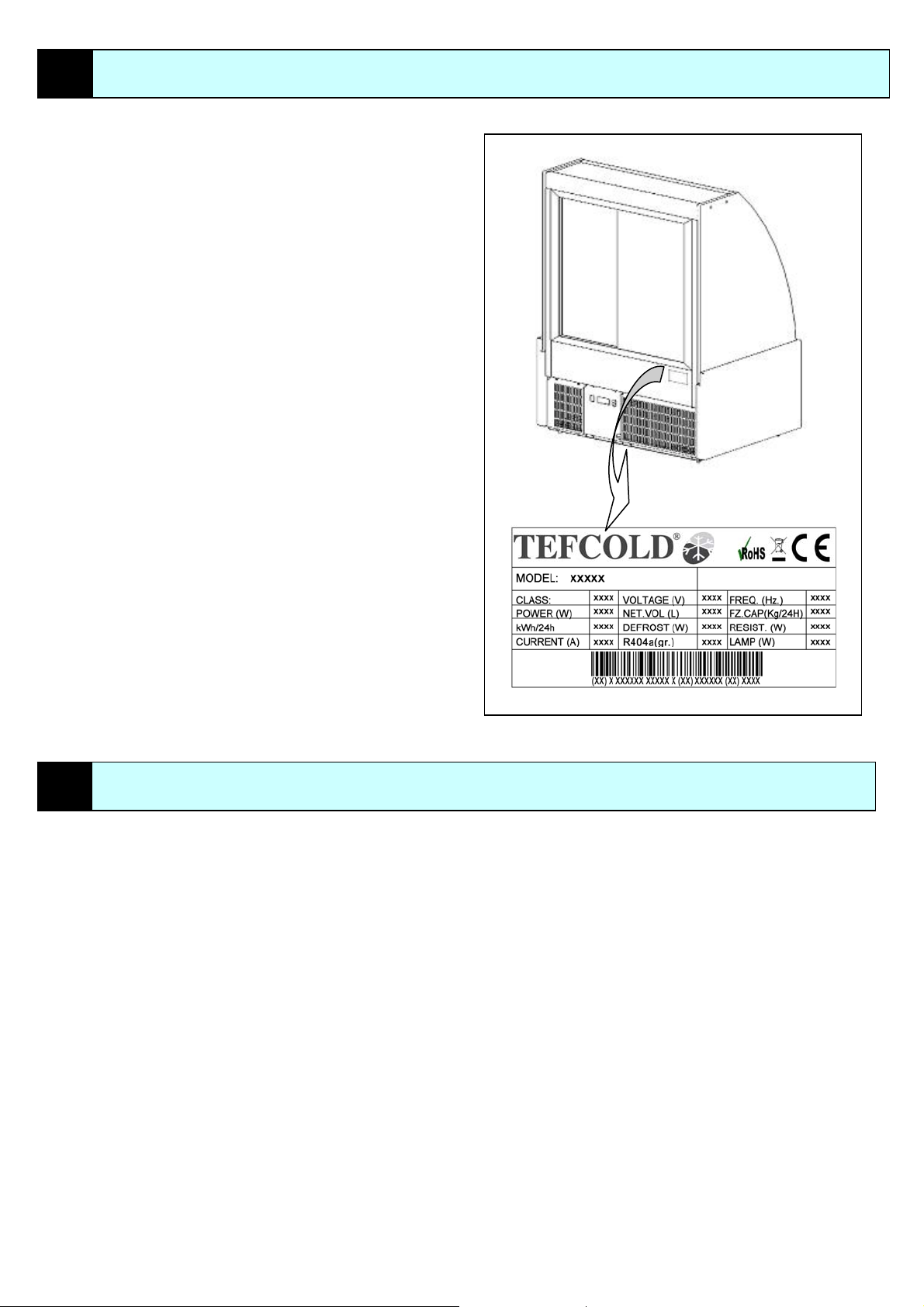

DISPLAY CASE MARKING DATA

3.1 DISPLAY CASE IDENTIFICATION

Before the display case is packaged, a nameplate is mounted on it,

identifying each case that is manufactured by its model and series.

Check to be sure that the instructions manual corres ponds to the display

case to which it is referring.

If any

information or technical assistance is required, in addition to the

model and machine type, you must also indicate its serial number etc.

3.1.1 DISPLAY CASE NAMEPLATE

The display case nameplate is locat ed on the rear part (operat or side)(Fig

1). The nameplate lists the information that identifies the machine, including

its model and serial number.

3.1.2 CE MARKING

The CE mark is applied directly to the nameplate on the display case.

3.1.3 NAMEPLATE OF THE MAIN COMPONENTS

The nameplates of all the components that w ere not manufactured direc tly

by TEFCOLD A/S (e.g. compressor, fans etc.) are mounted on the

components themselves in the position in which th ey were original placed

by the respective manufacturers.

4

HOW TO USE AND PRESERVE THE INSTRUCTIONS MANUAL

This chapter offers some indications on using the i nstruction manual and

on its use limitation.

4.1 INTENDED USER OF THE INSTRUCTIONS MANUAL

This instructions manual is intended for the following personnel.

Shipping, loading and unloading staff

Operators

Installers

Maintenance personnel

4.2 OBJECTIVES OF THE INFORMATION IN THE MANUAL

The purpose of this manual is to indicate how t he machine s hould be us ed

based on its design. It will also indicate its technical features, offering

instructions on how to move, install regulate and use it.

It will also guide you in maintenance work and facilitate spare parts orders.

Fig.1

4.3 LIMITATIONS ON USE OF THE MANUAL

It is important to remember that the instructions manual reflects the

techniques current at the time the machine was purchased, thus, the

manufacturer has the right to update the manual and the equipment without

updating the manual or any prior production, wi th the exception of unus ual

case.

4.4 HOW TO PRESERVE THE MANUAL

We would like to remind the user that the manual must be pres erved with

care to ensure it will last as lon g as the machine. Therefore, it is supplie d in

a special case that can protect it from wear and tear over years.

In addition, two copies of the section c onc erni ng “display case handing” are

furnished so that the shipper and th e personnel responsible for unloading

the machine can consult this section without referring to the main text.

If the manual gets lost or destroyed, a c opy can be requested through the

firm’s area representative or directly from the manufacturer. Be sure to

specify the type, serial number and year the display case was

manufactured.

Page 5

Page 6

5

HANDLING AND INSTALLING THE DISPLAY CASE

5.1 RECEIVING THE DISPLAY CASE

The display case has packaging around it to protect it during shipment a nd/or

storage, the body and the glass are packed separately.

Comprised of:

A wooden pallet

Two wooden boxes

Figure 2 show the standard packing.

There is a table (Fig.3) on the packing and its purpose is to give detailed

product information.

Dimensions: length width height

Hoisting hook-up points.

IMPORTANT: Remember that since cardboard packing is used, it is

subject to the action of atmospheric (rain, snow).

Therefore, the display cases must be stored in a dry indoor area.

HOIST

WITH FORK LIFT STORAGE

DIME

NSIONZ

Proc

MODEL L W H

OTHELLO 100 1035 775 1500

OTHELLO 150 1535 775 1500

OTHELLO 200 2035 775 1500

eed as follows for the unloading, transport and unpacking operations.

Page 6

Temporary or extended storage must be

done in indoor areas protected from

atmospheric agents.

Th

e display cases must be handled with

care.

Fig.3

5.2 UNLOADING OPERATIONS

The orientation of the packed display cas e mus t c omply with the indications

listed on the pictograms and the writing on the outside package.

Conduct the unloading operations using su itable hoisting equ ipment

(the capacity must be adequate for the we ight of the packed display case),

hoisting it as shown in Fig4.

5.3 CHECKING THE SUPPLY

Before taking delivery from the shipper, check the conditions of the

packi g. If it shows obvious damage on t he outside, the display case co uld

n

be damaged. In this case, unpack the display case in the shipper’s

presence. Any damage caused by i ncorrec t han dling and stora ge is not the

manufacturer’s responsibility.

CASE

IN THIS

A) Contact your area representative.

B) Draw up

C) Send a copy of the report to The manufacturer or area representative

a written report

5.4 UNPACKING

All the unpacked materials can be recycled in order to dispose of

according local legislation. Be sure to destroy plastic components to

prevent any hazards (suffocation) to children.

5.5 PERSONNEL REQUIREMENTS

We recommend that the operations to m ove the display case be handled

by personnel accustomed to using hoisting equipment, in full compliance

with the safety standards in force.

5.6 HANDING THE DISPLAY CASE

The display case can be lifted with a fork-lift truc k or with any other suit abl e

means with a minimum capacity of twice the weight of the display case

(see the specific nameplate). Operators running the hoisting equipment

must remain at an adequate distance from the hoisted part and must

ensure that no people or property is exposed t o danger if the display ca se

should drop. Movements must be slow and continu ous to prevent the case

from tipping over, etc.

The chapter offers various general information on the purposes of the

display case, describing its main functions and use limitations.

Damages caused by handling errors are not covered

by the WARRANTY

Page 7

6

ENVISIONED USE

6.1 OBJECTIVE OF THE PASTRY DISPLAY CASE

The ENERGY line of display cases has been designed to

ain the temperature of the pastry and not to lower it.

maint

T

herefore, the food can be put in the case only if it is

already cooled and has thus reached its preservation

temperature..

6.2 AREAL NAME

No other special technical knowledge is required to use the

cases.

display

Attentive reading of this manual is sufficient.

6.3 USE OF THE DISPLAY CASE

The room or area in which the display case is to be installed

must have the

--Indoors

following characteristics:

RIGH

T SIDE

CUS

--Minimum temperature of -18℃

--Maximum temperature of +30℃

--Relativ

6.4 SAFETY

To ensure accident prevention, y

the follo

and turn

The latter operation must be carried out exclusively by

authorized personnel trained on how to use the display case.

When this manual discusses switches and other components,

it indicates if they are to the right or left of the display case.

In most situation, the terms “left” and “right” refer to the

position of the operator standing in front of the work surface

and facing forward

e humidity (RH) +60%

PRECAUTIONS DURING USE

ou must read and observe

wing precautions before installing the display case

ing it on.

--Never allow anyone to use the display cause without proper

instruction.

--Careful

case.

--F

--Make sure that each

installed correctly.

ly read the instructions manual before using the display

ailure to observe use regulations can cause accidents

TOMER SIDE

piece of equipment or accessory is

OPERATOR SIDE

LEFT SID

Fig.5

E

Page 7

Page 8

7

TECHNICAL DESCRIPTION OF THE DISPLAY CASE

7.1 GENERAL INFORMATION

This chapter offers a technical description of the display case and its

operation. It supplies all the inf orma tion deemed useful for the operator an d

maintenance personnel so they can gai n a better understanding of correc t

operation to enable more rapid identification of any fault or malfunctions.

Display section

The display section is the area in the display case that holds

the bubs of food. The model and name for the display case is

different, but their function is same.

Glass stru

The glass structure is composed of two glass side panels

and a front window that makes it possible to

--guar

--protect the contents of the display section from foreign

matter

All the glass can be dismounted simply by removing the

screws and the connection bar. We recommend performing

these operations with the maximum care, observing the

indication listed in the maintenance chapter.

.

Motor compartment

The motor compartment is located in the lower section of the

showcase and all the components required for machine

operation are positioned together in a unit referred to the

condenser unit.

--The main components of the condenser unit are:

--Compressor

--Condenser

--Fan

--Condensation evaporation tub

--Solenoid valve

--Filter

--Other refrigeration components

The muter compartment is protected by a iron bracket.

Compressor split and rear grate that are bolted on to ensure

maximum safety. In particular during normal operation no one

is able to access it an come into contact with live or moving

elements .Only qualified technicians are allowed to access it.

Observing safety and maintenance regulations..

cture

antee the food clean

.

Page 8

Control panel

The control panel is the element th at manages the operation of the display

case.

This management (temperature control and maintenance, defrosting) is

entrusted to a command switchboa rd. In any event, the operator can utilize

this component to change the temperature inside the display section.

Verify that when the display case is installed, the general switch is it.

When the main switch is on, this guarante es the operation of the oil-heating

resistor inside the compressor (this is independent of the start-up of the

display case).

2

1

3

1. THERMOSTAT

2. MAIN SWITCH

3. LIGHT SWITCH

Fig.6

Page 9

r

8

INSTALLATION

8.1 GENERAL INFORMATION

This chapter offers all the technical information needed for installment

operations, in accordance with the regulations in force. The ins tallation a nd

test of proper display case operation must be carried out by qualified

personnel in full respect of the regulations in force and of the attached

assembly instructions. In the event of installat ions that do not comply with

the recommended installation, TEFCOLD A/S declines any responsibility

for personal injuries and/or property damage.

8.2 POSITIONING

The position of the display case is a very important factor that can

compromise proper machine operation. Correct pos itioning influences the

life of the display case and its c omponents. Above all, however, it affects

system operating expenses.

We advise you to carefully follow the instructions below (Fig.7 8 ).

Our technical servicing office can give you any additional clarificatio ns that

may be needed.

NEVER PERFORM

ANY OPERATIONS THAT ARE NOT CLEAR

Using a water level, verify that th

If necessary, use wooden shims to compensate for any defects in the

flooring.

e display case is perfectly flat.

Fig.7

NEVER place the display case near:

Doors

Windows

Sources of heat (e.g. radiators, heaters, etc.)

1) Do not place the power cable in a transit area. We also recomme nd

protecting the cable with trucking anchored to the floor.

2) NEVER touch the power plug if your hands are wet.

3) Verify that the power mains network is earthed in accordance with

the regulations in force.

4) NEVER insert any adapters or multiple o n the supply plug used to

connect the display case.

5) NEVER use extensions to connect the display case to the mains.

6) Verify that the mains voltage complies with the data listed on the

nameplate of the machine (maximum allowable variation ±6%.

TEFCOLD A/S declines any responsibility for personal injuries o

property damage caused by incorrect installation.

Fig.8

Page 9

Page 10

9

INSTRUCTIONS FOR USE

9.1 GENERAL INFORMATION The control switchboard is supplie d with a standard setting es tablished by

This chapter offers instructions for correct use ice cream display case.

9.1.1 INITIAL STARTUP OF THE DISPLAY CASE

Before starting up the display case, make sure there are no remaining

piec

es of the packaging inside the display section and then clean the

display case thoroughly.

9.2 POSITIONING THE TUBS

Placement of the tubs inside the display sec tion is an easy operat ion tha t is

also very important for the operation of the display case and proper ice

cream conservation. There is a sticker inside the d isplay section indicating

the loading limit of the display case. This reference allows you to get

maximum performance from the display case and optimum product

conservation.

er superpose the ice cream tubs.

Nev

IMPORTANT: NEVER exceed the loading limits; this will damage both the

product and the display case.

9.3 USING THE SWITHBOARD

The control panel contains all the instruments that make it possible to

manage the display case, as indicated in (Fig .9).

the manufacturer. However, the operator can intervene on the switchboard

to vary the temperature inside the display sec tion and to per form additio nal

defrosting.

in display panel

1)ma

press down “SET” buzzer, the display panel will allow 10 sec onds

After

operating time.

2)Digit

al display

h:procedure setting mode or main control panel setting mode

DP1 flas

Fig.9

Page 10

Page 11

10

MAINTENANCE

10.1 GENERAL INFORMATION 10.4 CLOTHING

This chapter offers all the technical information required to conduct regular

and extraordinary maintenance in compliance with the regulations in force.

BEFORE STARTING ANY MAINTENANCE WORK OR OPERATOR

CHECKS, YOU MUST :

Verify that the display case is turned off and that it is disconnected

from the power mains. Lis

Set up a sign indicating the work that is being done.

If necessary, procure adequate lifting equipment. IMPORTANT TOOLS FOR MAINTENANCE PERSONNEL

Verify that the operations to be done will not injure personnel or

damage nearby machinery.

display case has not been used for a long time (winter season), we

If the

are commend the following procedures before turning it on again.

Thoroughly clean the display section

Thoroughly clean the condenser

Thoroughly clean the glass structure

Thoroughly clean the external structure

Check the Ventilator fans to be sure they are not clogged.

IMPORTANT: Incorrect or poor maintenance can make the display case

hazardous to the operator and the personnel working near it.

10.2 CLASSIFICATION OF INTERVENTIONS

Maintenance work falls into two categories:

Normal maintenance: defined as work done to maintain normal

operating conditions for the display case, i.e. without requiring the

replacement of any parts.

This includes:

ntenance during the first ten hours of operation.

- Mai

eekly maintenance work.

- W

- Mont

- Work done every six months.

- Work done annually.

Extraordinary maintenance; defined as work comprising:

- W

- Work to be done at long intervals, i.e. work corresponding to the e nd

A

TTENTION

All the operations preceded by the symbol ” “ must be performed by a

specialized technician.

hly maintenance work.

ork required due to malfunction;

of the work of a main part and requiring the interru ption of display

case operation.

10.3 REQUIREMENTS FOR MAINTENANCE PERSONNEL

Maintenance of these machines must be c onducted SOLELY by qualified

personnel specializing in working with refrigerating systems.

The must know and understand the written instructions, laws and

regulations.

The instructions drawn up by TEFCOLD A/S include the man ual and the

signs on the machine and control parts. The laws and regulations i n force

in the country where the machine is bein g used may entail greater safety

provisions or identify further risks with respect to the ones listed in the

manual.

They must have had actua l training on the operations to be performed.

Maintenance workers must have re ad the instructions in this manual and

be familiar with all the commands s o that they can work in full co mpliance

of the safety regulations currently in force.

They must not be drug or alcohol abusers.

The use of these substances impairs ready reflexes and coordination.

A technician who uses prescription drugs must obtain medical advice on his

ability to conduct certain types of activities.

Page 11

Before starting any work operation, maintenance workers mist wear

suitable clothing that respects the indications envisioned by current

regulations. All the instruments that are used must be in perfec t condition

and be type tested. The maintenance worker must ALWAYS check the

supplied devices and replace them if they are damaged or are not

compliant.

ted below is a table with the devices the TEFCOLD A/S recommends.

WEAR PROTECTIVE GLOVES

WEAR GOGGLES (DURING WELDING WORK)

WEAR SAFETY

WEAR WORK OVERALLS WITHOUT ANY

LOOSE ENDS

SHOES

10.5 CLEANING THE GLASS STRUCTURE

Maintenance of the glass structure is very simple but i t must also be done

c

arefully due to the type of elements it comprises. It must be cleaned

weekly using warm water and Marseilles soap.

NEVER use inf

NEVER spray water to clean the display case.

o clean the display section, you ne e d to remove all the ice cream tubs and

T

place them in the refrigerator.

lammable or abrasive products.

Page 12

10

MAINTENANCE

10.6 CLEANING THE PLASTIC AND PAINTED PARTS

Learn these parts with warm water and neutral Mars eilles soap. Dry well

with a soft cloth (the display case must be turned off and disconnected from

the power mains).

A

TTENTION

NEVER use inf

NEVER spray water to clean the display case

10.7 CLEANING THE DISPLAY SECTION

To clean the display section, you need to remove all the cake and place

them in the refrigerator. At this point, you can clean this section.

Use only warm water and neutral Marseilles soap. Dry well with a soft c loth

(the display case must be turned off and disconnected from the power

mains).

TTENTION

A

NEVER use inf

NEVER spray water to clean the display case

lammable or abrasive products.

lammable or abrasive products.

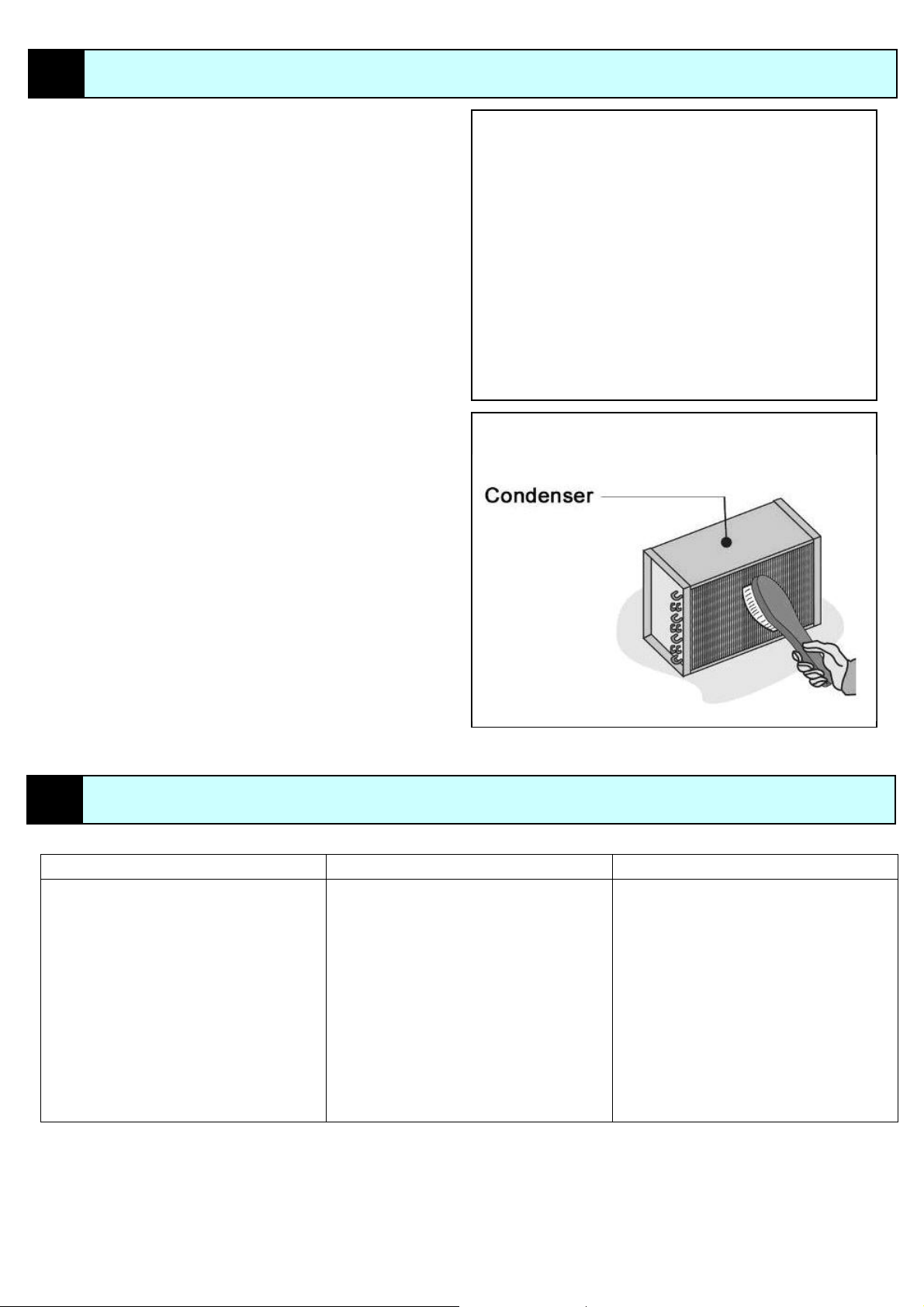

10.8 CLEANING THE CONDENSER

Maintenance work falls into two categories:

The condenser must be cleaned every 30 days max imum and this inv olves

removing the dust that collects in the fins.

IMPORTANT: Disconnect the display case from the power mains and

follow the instructions listed in the “General Information” section of this

chapter.

ing must be done gently without bendi ng or bre aking t he fi ns, us in g a

Clean

stiff brush.

IMPORTANT: Do not use fluids to clean the condenser.

T

o access the condenser, remove the front grate (Fig.10), removing the

screws that fasten it to the structure.

11

TROUBLE SHOOTING

No supply voltage. No supply voltage. Check the supply cable.

Main switch OFF. Main switch OFF. Verify that the main switch is section ON.

Plug not connected. Plug not connected. Check the position of the plug.

Switc

hboard not set correctly. Switchboard not set correctly. Set proper temperature.

Product exceeds loading limits. Product exceeds loading limits. Remove excess product.

Product put in when too hot or moist. Product put in when too hot or moist. Check product.

Electrical system fault. Electrical system fault. (*)Contact a qualified technician or TEFCOLD A/S.

(*)Contact a qualified technician or TEFCOLD A/S.

Refrigerating system fault. Refrigerating system fault.

Use

Floor uns

Sc

table. Floor unstable. Remove any external objects in contact with the

t with external objects. Contact with external objects.

rews loose (e.g. glass structure of grids).

Important

If these solutions are not successful, please contact TEFCOL D A/S’s Technical Servicing Department.

The operator must never intervene if intervention by qualified personnel is specified (*)

FAULT CAUSE SOLUTIONS

shims to stabilize the display case.

display case. Contac

Screws loose (e.g. glass structure of grids).

Chec

k screw tightness.

Fig.10

Page 12

Page 13

12

DISMANTLING

12.1 GENERAL INFORMATION 12.1.2 DISMANTLING FOR TRANSFER

This chapter offers all the technical informatio n required to dismantle the

display case in compliance with the regulations currently in force.

12.1.1 DISMANTLING FOR DEMOLITION

All of

If th

e display case is going to be scrapped, this creates two separate

problems:

Dis

The first one is administrative: The competent public offices must be

notified that the machine is being s crapped so that the document ation they

have on file about the machine can be canceled.

Perfec

display case comes with a set of legal documents, such as the manual,

The

the nameplate and the various authorizations that must be examined once

the decision is made to demolish the machine.

The second one involves physically display of the display case; to do

this, it is essential to contact specialized disposal companies or the

manufacturer.

eeding with demolition of the display case is absolutely forbidden

Proc

unless these indications have been observed.

If the display case needs to be dis mounted in order to move it to an other

area, proceed as follows:

Before s

tarting to disassemble the machine, you are required to shut off the

electrical supply.

this must be done by setting up special sig ns to i ndic ate what you ar e

doing.

assembly must be carried out by quali fied personnel or directly by the

manufacturer, being sure to separate and identify (mark) all the

components.

t organization during disassembly guarantees perfect and safe

reassembly.

e material must be kept in a dry area that is protected against weather.

All th

remounting the machine, check the material thoroughly for any

Before

damage.

Page 13

Page 14

13

OASI CIRCUIT CAPTION

CIRCUIT

Page 14

Page 15

14

ANNOTATIONS

Copy to be sent to the manufacturer – TEFCOLD A/S

CLIENT: TEL:

A

DDRESS: ZIP CODE:

C

ITY: PROVINCE:

Retailer’s stamps:

Delivery date:

Display case model:

Following installation of the display case, the client hereby declares that the work was carried out correctly and in compliance with the present i nstructions

manual. He further declares that he has seen its perfect operation and is aware of the instr uctions for correc t use and proper operation and m aintenance of the

display case.

CLIENT signature:

CORRECT INSTALLATION FORM

Installer’s stamps:

First name:

Last n

ame:

Address:

C

ity: Tel:

Delivery document:

S

erial number: Year:

Signature of the RETAILER/ INSTALLER:

*This declaration is not valid unless filled out completely and signed.

Zip code:

Page 15

Page 16

Since TEFC

OLD A/S is constantly working on the improvement the production, models, shapes, materials and colors

shown in this manual, could be modified as notice.

Page 16

Loading...

Loading...