Page 1

GLOBAL WpI

ASHA, HIGH EFFICIENCY, MEDIUM VOLTAGE [P]

APPLICATIONS:

z Pumps z Fans & Blowers z Compressors

FEATURES:

z Output Range: 100 - 1000 HP

z Speed: 3600, 1800, 1200 & 900 RPM

z Enclosure: Weather Protected Type I (WPI)

z Voltage: 2300/4160V

z Three Phase, 60 Hz, 1.15 Service Factor (Continuous)

z Standard Features: 100 Ohm Platinum Stator RTD's (2 per Phase), Space Heaters (120V)

z Class F Insulation

z Class B Temperature Rise

z NEMA Design B Torques

z Oversized Main Conduit Box Rotatable in 90 Degree Increments. Fully Gasketed with NPT Threaded Entrance - F1 Mounted

z Designed for 40˚C Ambient Temperature

z Designed for 3300 ft. Elevation

z Rotation: Bi-Directional Except 2 Pole which is Counter-Clockwise (CCW) facing the Drive End

z Cast Iron Frame and End Brackets

z 1045 Carbon Steel Shaft

z Aluminum Die Cast Squirrel Cage Rotor Construction for F#449T and Below

z Squirrel Cage Copper or Copper Alloy Bar Rotor Construction for F#5000 and Above

z Paint System: Phenolic Rust Proof Base Plus Polyurethane Top Coat

z Paint Color: Dark Gray - Munsell 7.5B 3.5/0.5

z High Quality Ball (or Roller) Bearings Regreasable with Mobil Polyrex™ EM

z Insulated Non-Drive End Bearing on 2 Pole Motors; 600 HP and Larger

z Labyrinth Type Metal Flinger on Both Ends

z Cast Iron Inner and Outer Bearing Caps

z Grounding Terminal Inside Main Box and on Motor Foot

z Stainless Steel Nameplate

z Suitable for Inverter Use per NEMA MG-1 Part 31.4.4.2

z 6 Leads

z Motors are CSA Approved

(1)

(2)

(3)

(4,5)

Effective 07-08-18

Supercedes 03-24-17

EXTRAS/ OPTIONS:

Please refer to pages 147 - 154 for common modifications that can be performed.

Notes:

(1) Slower speeds available as Made to Order.

(2) Consult a Stock Product Application Specialist for suitability in higher ambient environments, and for variable and constant torque speed ranges.

(3) Consult a Stock Product Application Specialist for suitability at higher elevations.

(4) Motor service factor is 1.0 when operated on a VFD.

(5) Precautions should be taken to eliminate or reduce shaft currents that may be imposed on the motor by the VFD as stated per NEMA MG-1. Part 31.

An isolation transformer or other method of mitigating common mode voltages from motor terminals must be utilized. Please refer to page 209 to

check out our accompanying TEAMMaster™ starters.

Page 2

GLOBAL WpI

ASHA, HIGH EFFICIENCY, MEDIUM VOLTAGE [P]

Effective 07-08-18

Supercedes 03-24-17

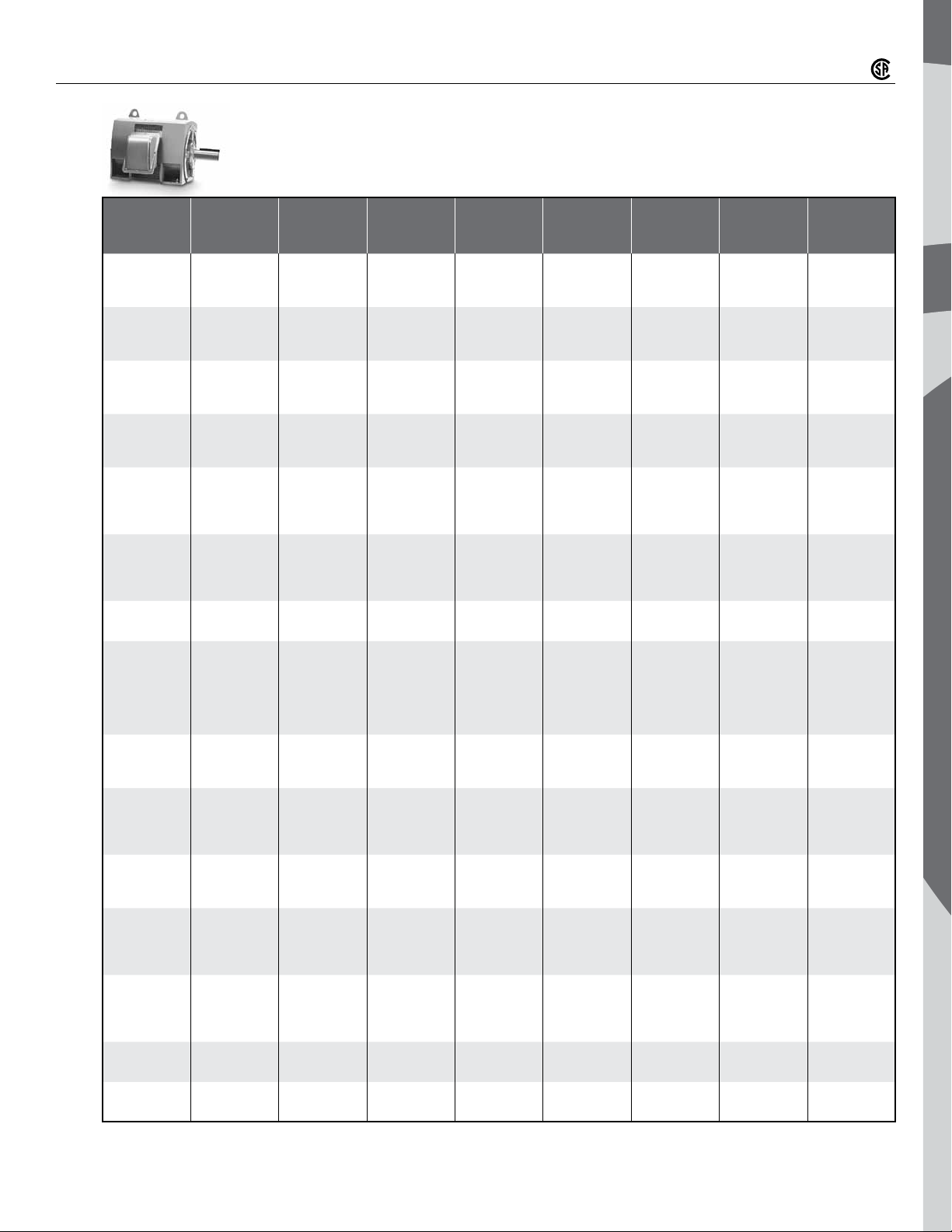

CATALOG NO. HP RPM FRAME FL EFF (%) FL PF (%)

P1002 100 3600 444TS 91.0 90.2 22.8 1,292

P1004 100 1800 444T 91.0 87.5 23.5 1,680

P1006 100 1200 445T 91.0 80.0 25.7 2,205

P1006R 100 1200 445T 91.0 80.0 25.7 2,205

P1252 125 3600 444TS 91.0 90.2 28.5 1,370

P1254 125 1800 444T 91.0 87.5 29.4 1,490

P1256 125 1200 447T 91.7 80.0 32.0 2,139

P1256R 125 1200 447T 91.7 80.0 32.0 2,139

P1502 150 3600 445TS 91.7 90.2 34.0 1,450

P1504 150 1800 445T 91.7 87.5 35.0 1,645

P1506 150 1200 449T 91.7 80.0 38.0 2,547

P1506R 150 1200 449T 91.7 80.0 38.0 2,547

P2002 200 3600 447TS 91.7 90.2 45.0 1,733

P2004 200 1800 447T 91.7 87.5 47.0 2,050

P2004R 200 1800 447T 91.7 87.5 47.0 2,050

P2006 200 1200 5007C 91.7 81.5 50.1 3,057

P2502 250 3600 449TS 92.4 91.0 56.0 2,095

P2504 250 1800 449T 92.4 87.5 58.0 2,668

P2506 250 1200 5007B 92.4 84.0 60.3 3,362

P2506R 250 1200 5007C 92.4 84.0 60.3 3,362

P2508 250 900 5009B 92.4 78.5 64.5 3,990

P3002 300 3600 449TS 93.0 91.0 66.0 2,280

P3004 300 1800 5007B 93.0 88.5 68.3 3,255

P3006 300 1200 5009B 93.0 84.0 71.9 3,945

P3006R 300 1200 5009C 93.0 84.0 71.9 3,945

P3008R 300 900 5808C 93.0 80.0 75.5 4,515

P3502 350 3600 5007A 93.0 90.2 78.1 2,991

P3504 350 1800 5007B 93.6 88.5 79.1 3,465

P3506R 350 1200 5009C 93.0 84.0 83.9 3,938

P4002 400 3600 5009A 93.6 90.5 88.4 3,485

P4004 400 1800 5009B 93.6 89.5 89.4 4,065

P4004R 400 1800 5009C 93.6 89.5 89.4 4,065

P4006 400 1200 5808B 93.6 85.5 93.6 5,055

P4006R 400 1200 5808C 93.6 85.5 93.6 5,055

P4008 400 900 5808B 93.0 81.5 98.8 5,250

P4008R 400 900 5808C 93.0 81.5 98.8 5,250

P4502 450 3600 5808A 93.6 91.0 98.9 5,145

P4504 450 1800 5808B 93.6 88.5 102.0 4,200

P4506 450 1200 5808B 93.6 85.5 105.0 5,640

P4506R 450 1200 5808C 93.6 85.5 105.0 5,640

P5002 500 3600 5808A 94.1 91.0 109.0 4,680

P5004 500 1800 5808B 94.1 89.5 111.0 5,115

P5006 500 1200 5808B 94.1 85.5 116.0 6,038

P5006R 500 1200 5808C 94.1 85.5 116.0 6,038

P5008 500 900 5810B 93.6 82.5 121 6,325

P6002 600 3600 5808A 94.5 91.3 130 5,135

P6004 600 1800 5808B 94.1 89.5 133 5,418

P6006R 600 1200 5810C 94.1 86.5 138 6,120

P6008 600 900 6806B 94.1 84.0 142 6,983

P7002 700 3600 5810A 94.5 91.7 151 5,410

P7004 700 1800 5808B 94.5 90.2 154 5,355

P7004R 700 1800 5808B 94.5 90.2 154 5,355

P7006R 700 1200 5810C 94.5 86.5 160 6,625

P7008 700 900 6808B 94.5 84.0 165 7,860

P8002 800 3600 5810A 95.0 91.7 172 5,475

P8004 800 1800 5810B 94.5 90.2 176 5,828

P8006 800 1200 6806B 94.5 86.5 183 7,770

P8006R 800 1200 6806C 94.5 86.5 183 7,770

P8008R 800 900 6808C 94.5 84.5 188 8,820

P9002 900 3600 5810A 95.0 91.7 193 5,685

P9004 900 1800 5810B 95.0 90.2 197 6,143

P9006 900 1200 6806B 95.0 86.5 205 8,190

P10002 1000 3600 5810A 95.0 90.2 214 5,950

P10004 1000 1800 6806B 95.0 90.2 219 7,750

P10006R 1000 1200 6808C 95.0 86.5 228 8,610

Notes:

(1) Data subject to change without notice.

(2) "R" at the end of the Catalog number means motor has Roller Bearing on the Drive End.

FL AMPS

(2300V)

APPROX.

SHIPPING

WT. (lbs.)

Loading...

Loading...