Page 1

Page 2

I

Table of Contents

Preface.............................................................................................................................0-1

Chapter 1 Safety Precautions........................................................................................1-1

1.1 Before Supplying Power to the Inverter ......................................................................1-1

1.2 Wiring..........................................................................................................................1-2

1.3 Before Operation ........................................................................................................1-3

1.4 Parameters Setting.....................................................................................................1-3

1.5 Operation....................................................................................................................1-4

1.6 Maintenance, Inspection and Replacement................................................................1-5

1.7 Disposal of the Inverter...............................................................................................1-5

Chapter 2 Model Description.........................................................................................2-1

2.1 Nameplate Data.........................................................................................................2-1

2.2 Inverter Models-Motor Power Rating .........................................................................2-1

Chapter 3 Environment and Installation.......................................................................3-1

3.1 Environment................................................................................................................3-1

3.2 Installation...................................................................................................................3-2

3.2.1 Installation Spaces ...........................................................................................3-2

3.2.2 External View………………………………………………………………………...3-3

3.2.2.1 External View (IP00/ IP20)...................................................................3-3

3.2.2.2 External View (IP55)............................................................................3-6

3.2.3 Warning Labels................................................................................................3-7

3.2.4 Removing the Front Cover and Keypad...........................................................3-8

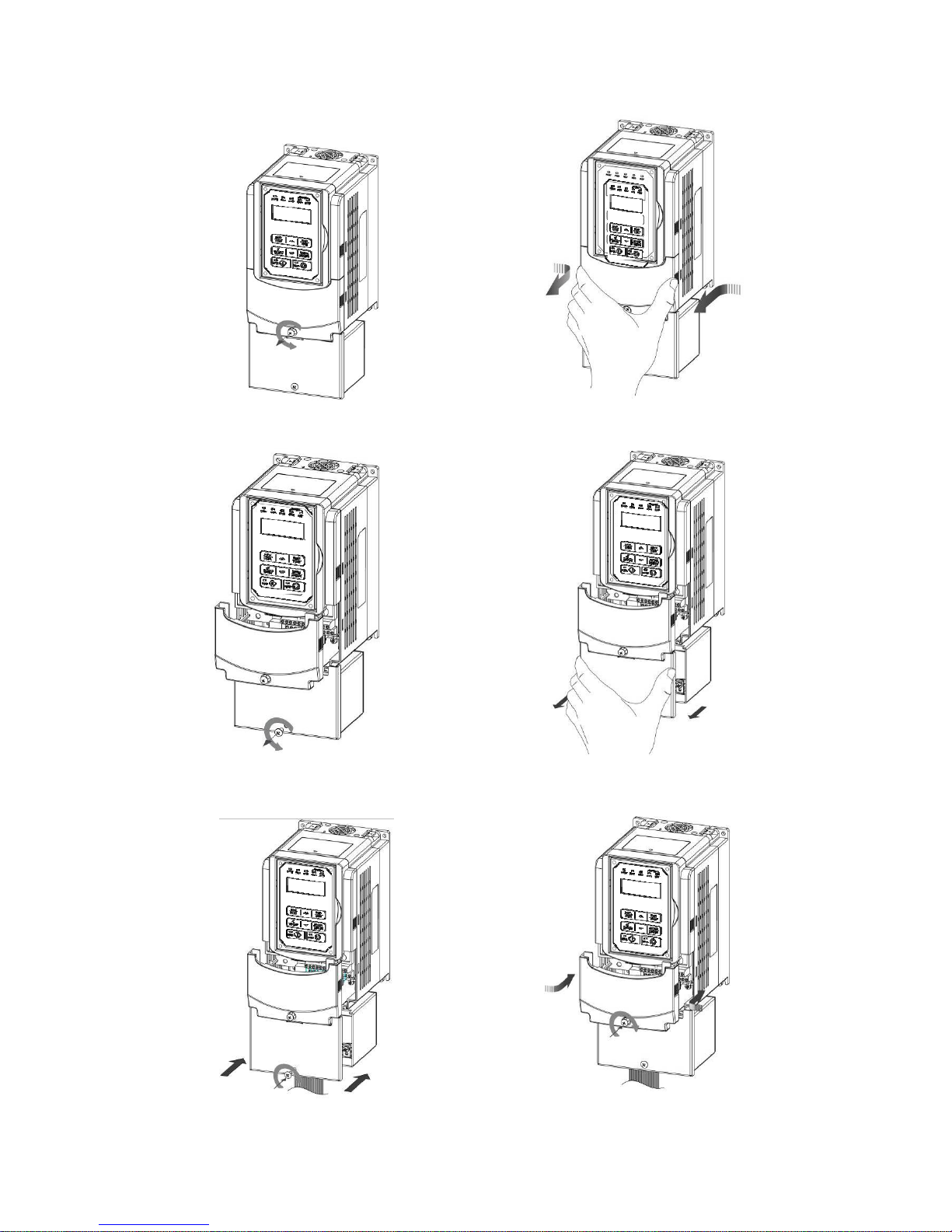

3.2.4.1 Standard Type (IP00/IP20) ............................................................3-9

3.2.4.2 Built-in Filter Type (IP20/IP00)........................................................3-15

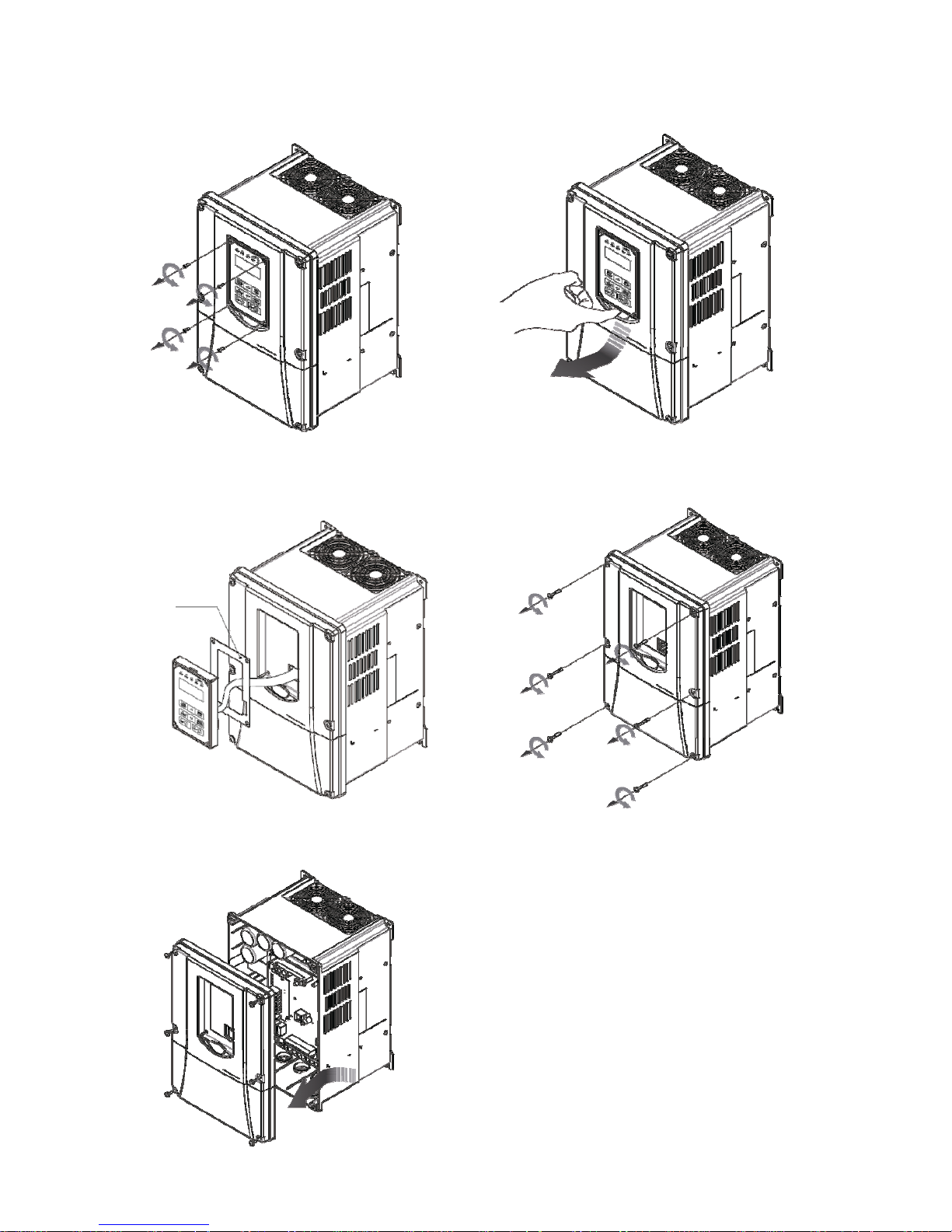

3.2.4.3 Built-in Filter Type (IP55)................................................................3-16

3.3 Inverter Wiring ..........................................................................................................3-18

3.3.1 Wire Gauges and Tightening Torque............................................................3-18

3.3.2 Wiring Peripheral Power Devices .................................................................3-19

3.3.3 General Wiring Diagram...............................................................................3-21

3.3.4 Single/ Multi- Pump Dedicated Wiring Diagram............................................3-22

3.3.5 Wiring for Control Circuit Terminals..............................................................3-25

3.3.6 Wiring for Main Circuit Terminals .................................................................3-28

3.3.7 Wiring Precautions .......................................................................................3-37

3.3.8 Input Power and Cable Length.....................................................................3-39

3.4 Inverter Specifications..............................................................................................3-40

3.5 Inverter Derating Based on Carrier Frequency .......................................................3-43

3.6 Inverter Derating Based on Temperature.................................................................3-47

3.7 Inverter Dimensions.................................................................................................3-48

3.7.1 Standard Type (IP00/IP20)...........................................................................3-48

3.7.2 Models with Built-in Filter (IP00/IP20)...........................................................3-56

3.7.3 Models with Built-in Filter (IP55) ..................................................................3-58

Chapter 4 Keypad and Programming Functions..........................................................4-1

4.1 LED Keypad................................................................................................................4-1

4.1.1 Keypad Display and Keys...............................................................................4-1

4.1.2 Seven Segment Display Description...............................................................4-3

4.1.3 LED Indicator Description...............................................................................4-5

4.1.4 Power-up Monitor ...........................................................................................4-7

Page 3

II

4.1.5 Modifying Parameters/ Set Frequency Reference..........................................4-8

4.1.6 Operation Control .........................................................................................4-10

4.2 LCD keypad..............................................................................................................4-11

4.2.1 Keypad Display and Keys............................................................................4-11

4.2.2 Keypad Menu Structure ..............................................................................4-13

4.3 Parameters...............……………………………………………………………………..4-17

4.4 Description of Parameters .......................................................................................4-62

4.5 Built-in PLC Function.............................................................................................4-253

4.5.1 Basic Command .........................................................................................4-253

4.5.2 Basic Command Function...........................................................................4-254

4.5.3 Application Functions..................................................................................4-255

4.6 Modbus Protocol Descriptions ..............................................................................4-262

4.6.1 Communication Connection and Data Frame.............................................4-262

4.6.2 Register and Data Format ..........................................................................4-266

4.7 BacNET Protocol Descriptions ..............................................................................4-285

4.7.1 BACnet Services.........................................................................................4-285

4.7.2 BACnet Protocol Structure..........................................................................4-286

4.7.3 BACnet Specifications................................................................................4-287

4.7.4 BACnet Object Properties...........................................................................4-288

4.8 MetaSys N2 Communication Protocol ..................................................................4-291

4.8.1 Introduction and Setting..............................................................................4-291

4.8.2 MetaSys N2 Specification...........................................................................4-291

4.8.3 Definition of MetaSys N2 Communication Protocol ....................................4-292

4.8.4 MetaSys N2 Communication Protocol in F510 Model.................................4-293

Chapter 5 Check Motor Rotation and Direction ...........................................................5-1

Chapter 6 Speed Reference Command Configuration ................................................6-1

6.1 Reference from Keypad .............................................................................................6-1

6.2 Reference from External Analog Signal (0-10V / 4-20mA) ........................................ 6-2

6.3 Reference from Serial Communication RS485 (00-05=3)...........................................6-4

6.4 Reference from two Analog Inputs .............................................................................6-6

6.5 Change Frequency Unit from Hz to rpm ....................................................................6-6

Chapter 7 Operation Method Configuration (Run / Stop)...........................................7-1

7.1 Run/Stop from the Keypad (00-02=0) – Default Setting .............................................7-1

7.2 Run/Stop from External Switch / Contact or Pushbutton (00-02=1)...........................7-2

7.3 Run/Stop from Serial Communication RS485 (00-02=3)............................................7-3

Chapter 8 Motor and Application Specific Settings.....................................................8-1

8.1 Set Motor Nameplate Data (02-01, 02-05)..................................................................8-1

8.2 Acceleration and Deceleration Time (00-14, 00-15) ..................................................8-2

8.3 Torque Compensation Gain (01-10) ...........................................................................8-3

8.4 Automatic Energy Savings Function (11-19)...............................................................8-4

8.5 Emergency Stop .........................................................................................................8-6

8.6 Direct / Unattended Startup .......................................................................................8-7

8.7 Analog Output Setup...................................................................................................8-8

Chapter 9 Using PID Control for Constant Flow / Pressure Applications..................9-1

9.1 What is PID Control? ..................................................................................................9-1

Page 4

III

9.2 Connect Transducer Feedback Signal (10-01)..........................................................9-3

9.3 Engineering Units .......................................................................................................9-4

9.4 Sleep / Wakeup Function ...........................................................................................9-5

Chapter 10 Troubleshooting and Fault Diagnostics..................................................10-1

10.1 General .................................................................................................................10-1

10.2 Fault Detection Function .......................................................................................10-1

10.3 Warning / Self-diagnosis Detection Function ........................................................10-5

10.4 Auto-tuning Error .................................................................................................10-12

10.5 PM Motor Auto-tuning Error.................................................................................10-13

Chapter 11 Inverter Peripheral devices and Options.................................................11-1

11.1 Braking Resistors and Braking Units ......................................................................11-1

11.2 AC Line Reactors....................................................................................................11-4

11.2.1 200V Class AC Reactor Dimensions..........................................................11-5

11.2.2 400V Class AC Reactor Dimensions..........................................................11-6

11.3 Input Noise Filters ..................................................................................................11-7

11.4 Input Current and Fuse Specifications ...................................................................11-9

11.5 Other options .......................................................................................................11-11

11.6 Communication options .......................................................................................11-16

11.7 Profibus Communication Option Card ..................................................................11-17

11.7.1 Introduction...............................................................................................11-17

11.7.2 Specification of JN5-CM-PBUS ................................................................11-17

11.7.3 Wiring Diagram of JN5-CM-PBUS............................................................11-18

11.7.4 Installation ................................................................................................11-18

11.7.5 Descriptions of Terminals, LEDs and DIP switch......................................11-21

11.7.6 Related Parameters for Communication...................................................11-22

11.7.7 Profibus I/O List........................................................................................11-22

11.7.8 Error Massage..........................................................................................11-26

11.7.9 GSD File...................................................................................................11-26

11.8 Protective Cover ...................................................................................................11-28

Appendix-A Instructions for UL....................................................................................A-1

Page 5

0-1

Preface

The F510 product is an inverter designed to control a three-phase induction motor. Please

read this manual carefully to ensure correct operation, safety and to become familiar with

the inverter functions.

The F510 inverter is an electrical / electronic product and must be installed and handled by

qualified service personnel.

Improper handling may result in incorrect operation, shorter life cycle, or failure of this

product as well as the motor.

All F510 documentation is subject to change without notice. Be sure to obtain the latest

editions for use or visit our website at http://globalsa.teco.com.tw.

Available Documentation:

1. F510 Start-up and Installation Manual

2. F510 Instruction Manual

Read this instruction manual thoroughly before proceeding with installation, connections

(wiring), operation, or maintenance and inspection.

Ensure you have sound knowledge of the inverter and familiarize yourself with all safety

information and precautions before proceeding to operate the inverter.

Please pay close attention to the safety precautions indicated by the warning and

caution symbol.

Warning

Failure to ignore the information indicated by the warning symbol

may result in death or serious injury.

Caution

Failure to ignore the information indicated by the caution symbol

may result in minor or moderate injury and/or substantial property

damage.

Page 6

1-1

Chapter 1 Safety Precautions

1.1 Before Supplying Power to the Inverter

Warning

¾ The main circuit must be correctly wired. For single phase supply use input terminals

(R/L1, T/L3) and for three phase supply use input terminals (R/L1, S/L2, T/L3).

Terminals U/T1, V/T2, W/T3 must only be used to connect the motor. Connecting the

input supply to any of the U/T1, V/T2 or W/T3 terminals will cause damage to the

inverter.

Caution

¾ To avoid the front cover from disengaging or other physical damage, do not carry the

inverter by its cover. Support the unit by its heat sink when transporting. Improper

handling can damage the inverter or injure personnel, and should be avoided.

¾ To avoid the risk of fire, do not install the inverter on or near flammable objects. Install

on nonflammable objects such as metal surfaces.

¾ If several inverters are placed inside the same control panel, provide adequate

ventilation to maintain the temperature below 40°C/104°F (50°C/122°F without a dust

cover) to avoid overheating or fire.

¾ When removing or installing the digital operator, turn off the power first, and then

follow the instructions in this manual to avoid operator error or loss of display caused

by faulty connections.

Warning

¾ This product is sold subject to IEC 61800-3. In a domestic environment this product

may cause radio interference in which case the user may need to apply corrective

measures.

¾ Over temperature protection function on motor is disabled.

Page 7

1-2

1.2 Wiring

Warning

¾ Always turn OFF the power supply before attempting inverter installation and wiring of

the user terminals.

¾ Wiring must be performed by a qualified personnel / certified electrician.

¾ Make sure the inverter is properly grounded. (200V Class: Grounding impedance shall

be less than 100Ω. 400V Class: Grounding impedance shall be less than 10Ω.) It is

required to disconnect the ground wire in the control board to avoid the sudden surge

causing damage on electronic parts if it is improperly grounded.

¾ Please check and test emergency stop circuits after wiring. (Installer is responsible for

the correct wiring.)

¾ Never touch any of the input or output power lines directly or allow any input or output

power lines to come in contact with the inverter case.

¾ Do not perform a dielectric voltage withstand test (megger) on the inverter or this will

result in inverter damage to the semiconductor components.

Caution

¾ The line voltage applied must comply with the inverter’s specified input voltage. (See

product nameplate section 2.1)

¾ Connect braking resistor and braking unit to the designated terminals. (See section

3.3.5)

¾ Do not connect a braking resistor directly to the DC terminals P(+) and N(-),otherwise

fire may result.

¾ Use wire gauge recommendations and torque specifications. (See Wire Gauge and

Torque Specification section 3.3.1)。

¾ Never connect input power to the inverter output terminals U/T1, V/T2, W/T3.

¾ Do not connect a contactor or switch in series with the inverter and the motor.

¾ Do not connect a power factor correction capacitor or surge suppressor to the inverter

output。

¾ Ensure the interference generated by the inverter and motor does not affect

peripheral devices.

Page 8

1-3

1.3 Before Operation

Warning

¾ Make sure the inverter capacity matches the parameters 13-00 before supplying

power.

¾ Reduce the carrier frequency (parameter 11-01) If the cable from the inverter to the

motor is over 80 ft (25m). A high-frequency current can be generated by stray

capacitance between the cables and result in an overcurrent trip of the inverter, an

increase in leakage current, or an inaccurate current readout.

¾ Be sure to install all covers before turning on power. Do not remove any of the covers

while power to the inverter is on, otherwise electric shock may occur.

¾ Do not operate switches with wet hands, otherwise electric shock may result.

¾ Do not touch inverter terminals when energized even if inverter has stopped,

otherwise electric shock may result.

1.4 Parameter Setting

Caution

¾ Do not connect a load to the motor while performing an auto-tune.

¾ Make sure the motor can freely run and there is sufficient space around the motor

when performing a rotational auto-tune.

Page 9

1-4

1.5 Operation

Warning

¾ Be sure to install all covers before turning on power. Do not remove any of the covers

while power to the inverter is on, otherwise electric shock may occur.

¾ Do not connect or disconnect the motor during operation. This will cause the inverter

to trip and may cause damage to the inverter.

¾ Operations may start suddenly if an alarm or fault is reset with a run command active.

Confirm that no run command is active upon resetting the alarm or fault, otherwise

accidents may occur.

¾ Do not operate switches with wet hands, otherwise electric shock may result.

¾ An external emergency stop switch is enabled when parameter 08-30 is set for the

run permissive function.

¾ It provides an independent external hardware emergency switch, which emergently

shuts down the inverter output in the case of danger.

¾ If automatic restart after power recovery (parameter 07-00) is enabled, the inverter will

start automatically after power is restored.

¾ Make sure it is safe to operate the inverter and motor before performing a rotational

auto-tune.

¾ Do not touch inverter terminals when energized even if inverter has stopped,

otherwise electric shock may result.

¾ Do not check signals on circuit boards while the inverter is running.

¾ After the power is turned off, the cooling fan may continue to run for some time.

Caution

¾ Do not touch heat-generating components such as heat sinks and braking resistors.

¾ Carefully check the performance of motor or machine before operating at high speed,

otherwise Injury may result.

¾ Note the parameter settings related to the braking unit when applicable.

¾ Do not use the inverter braking function for mechanical holding, otherwise injury may

result.

¾ Do not check signals on circuit boards while the inverter is running.

Page 10

1-5

1.6 Maintenance, Inspection and Replacement

Warning

¾ Wait a minimum of 5 minutes after power has been turned OFF before starting an

inspection. Also confirm that the charge light is OFF and that the DC bus voltage has

dropped below 25Vdc. Wait a minimum of 15 minutes while inverter is over 20HP.

¾ Never touch high voltage terminals in the inverter.

¾ Make sure power to the inverter is disconnected before disassembling the inverter.

¾ Only authorized personnel should perform maintenance, inspection, and replacement

operations. (Take off metal jewelry such as watches and rings and use insulated

tools.)

Caution

¾ The Inverter can be used in an environment with a temperature range from 14° -104°F

(-10-40°C) and relative humidity of 95% non-condensing.

¾ The inverter must be operated in a dust, gas, mist and moisture free environment.

1.7 Disposal of the Inverter

Caution

¾ Please dispose of this unit with care as an industrial waste and according to your

required local regulations.

¾ The capacitors of inverter main circuit and printed circuit board are considered as

hazardous waste and must not be burned.

¾ The Plastic enclosure and parts of the inverter such as the top cover board will

release harmful gases if burned.

Page 11

2-1

P/N BARCODE

S/N BARCODE

Chapter 2 Model Description

2.1 Nameplate Data

It is essential to verify the F510 inverter nameplate and make sure that the F510 inverter has the

correct rating so it can be used in your application with the proper sized AC motor.

Unpack the F510 inverter and check the following:

(1) The F510 inverter and quick setting guide are contained in the package.

(2) The F510 inverter has not been damaged during transportation there should be no dents or

parts missing.

(3) The F510 inverter is the type you ordered. You can check the type and specifications on the

main nameplate.

(4) Check that the input voltage range meets the input power requirements.

(5) Ensure that the motor HP matches the motor rating of the inverter.

2.2 Model Identification

F510InverterSeries

F510 - 4 010 - H 3 F

__

2:

4:

200V

400V

VoltageRating

005:

008:

150:

175:

215:

535:

800:

5HP

8HP

150HP

175HP

215HP

535HP

800HP

MotorRating

H:

C:

LEDOperator

LCDOperator

OperatorType

3: 3Ph

Input

Blank:

F:

NoRFI

RFIFiler

Noise Filter

ProtectionClass

Blank:

N4:

IP00/IP20

IP55

Inverter Model and Motor Rating

UL and CE Marks

Input Power Specifications

Output Power Specifications

Series No.

Page 12

2-2

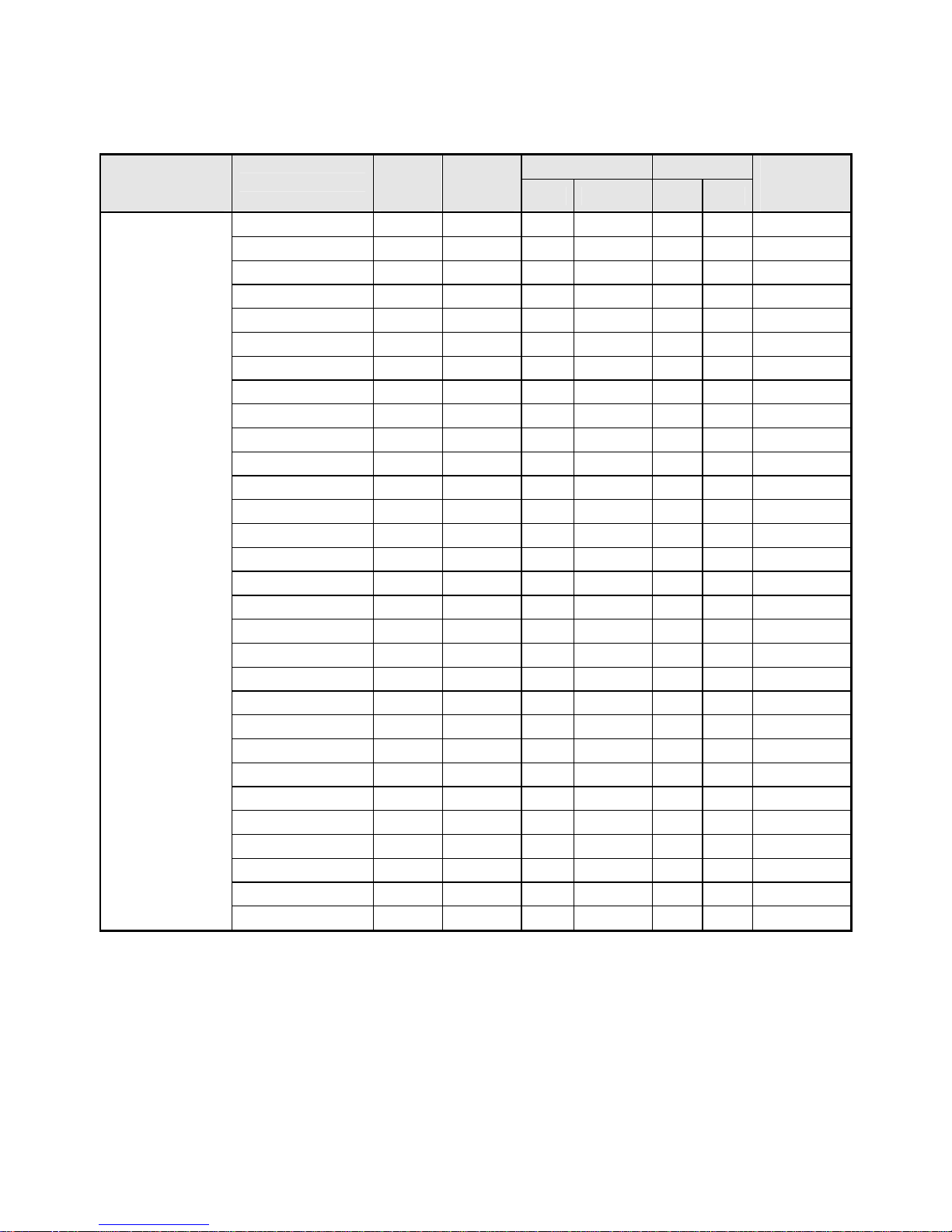

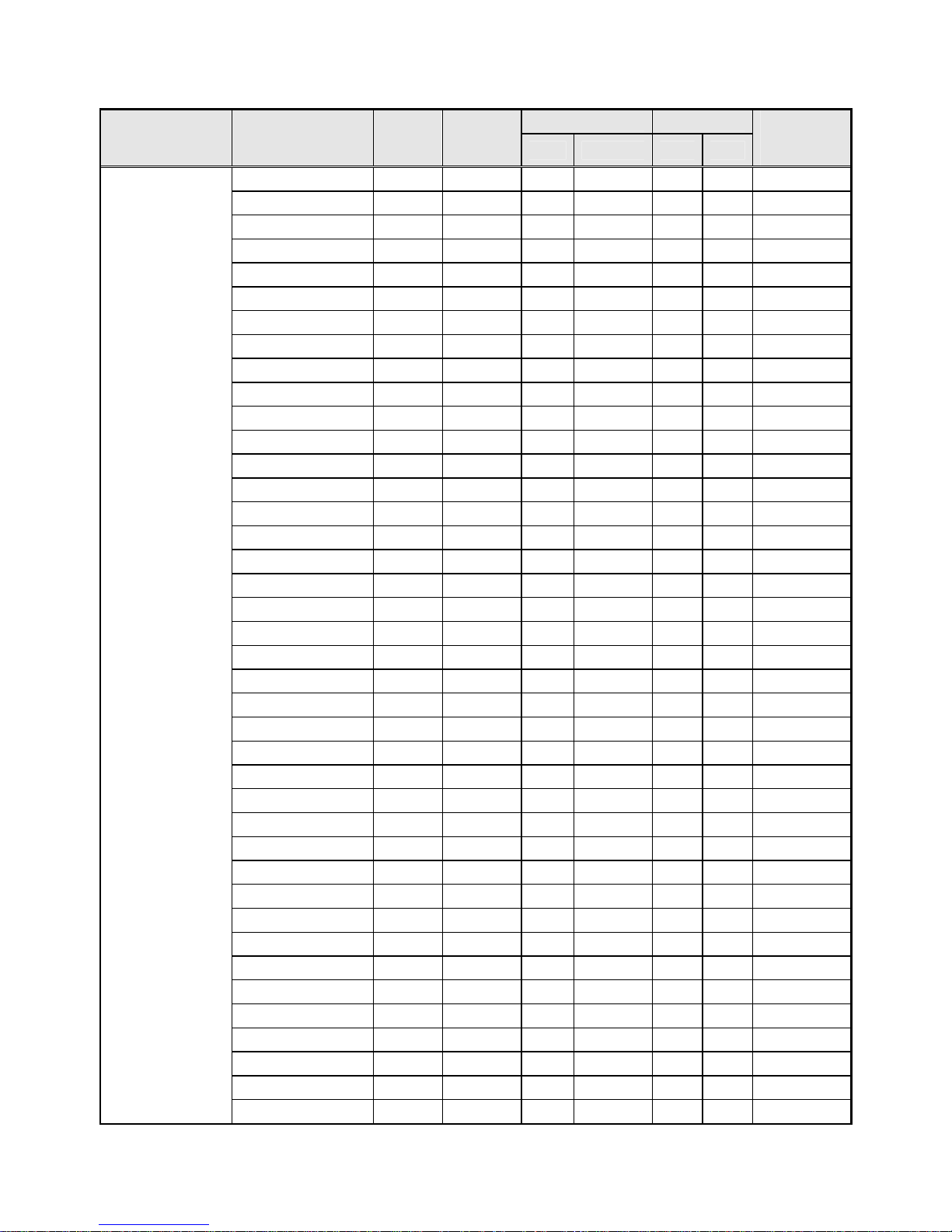

Inverter Models – Motor Power Rating:

200V Class

Filter Operator

Voltage (Vac)

&

Frequency (Hz)

F510 Model

Motor

Power

(Hp)

Applied

Motor

(kW)

with without LED LCD

Protection

Class

(IP55)

F510-2005-H3 5 3.7 ◎ ◎

F510-2005-C3 5 3.7

◎ ◎

F510-2008-H3 7.5 5.5

◎ ◎

F510-2008-C3 7.5 5.5

◎ ◎

F510-2010-H3 10 7.5

◎ ◎

F510-2010-C3 10 7.5

◎ ◎

F510-2015-H3 15 11

◎ ◎

F510-2015-C3 15 11

◎ ◎

F510-2020-H3 20 15

◎ ◎

F510-2020-C3 20 15

◎ ◎

F510-2025-H3 25 18.5

◎ ◎

F510-2025-C3 25 18.5

◎ ◎

F510-2030-H3 30 22

◎ ◎

F510-2030-C3 30 22

◎ ◎

F510-2040-H3 40 30

◎ ◎

F510-2040-C3 40 30

◎ ◎

F510-2050-H3 50 37

◎ ◎

F510-2050-C3 50 37

◎ ◎

F510-2060-H3 60 45

◎ ◎

F510-2060-C3 60 45

◎ ◎

F510-2075-H3 75 55

◎ ◎

F510-2075-C3 75 55

◎ ◎

F510-2100-H3 100 75

◎ ◎

F510-2100-C3 100 75

◎ ◎

F510-2125-H3 125 94

◎

◎

F510-2125-C3 125 94

◎

◎

F510-2150-H3 150 112

◎

◎

F510-2150-C3 150 112

◎

◎

F510-2175-H3 175 130

◎

◎

3ph

200~240V

+10%/-15%

50/60Hz

F510-2175-C3 175 130

◎

◎

Note:

z Short Circuit Rating: 200V Class: 5KA.

Page 13

2-3

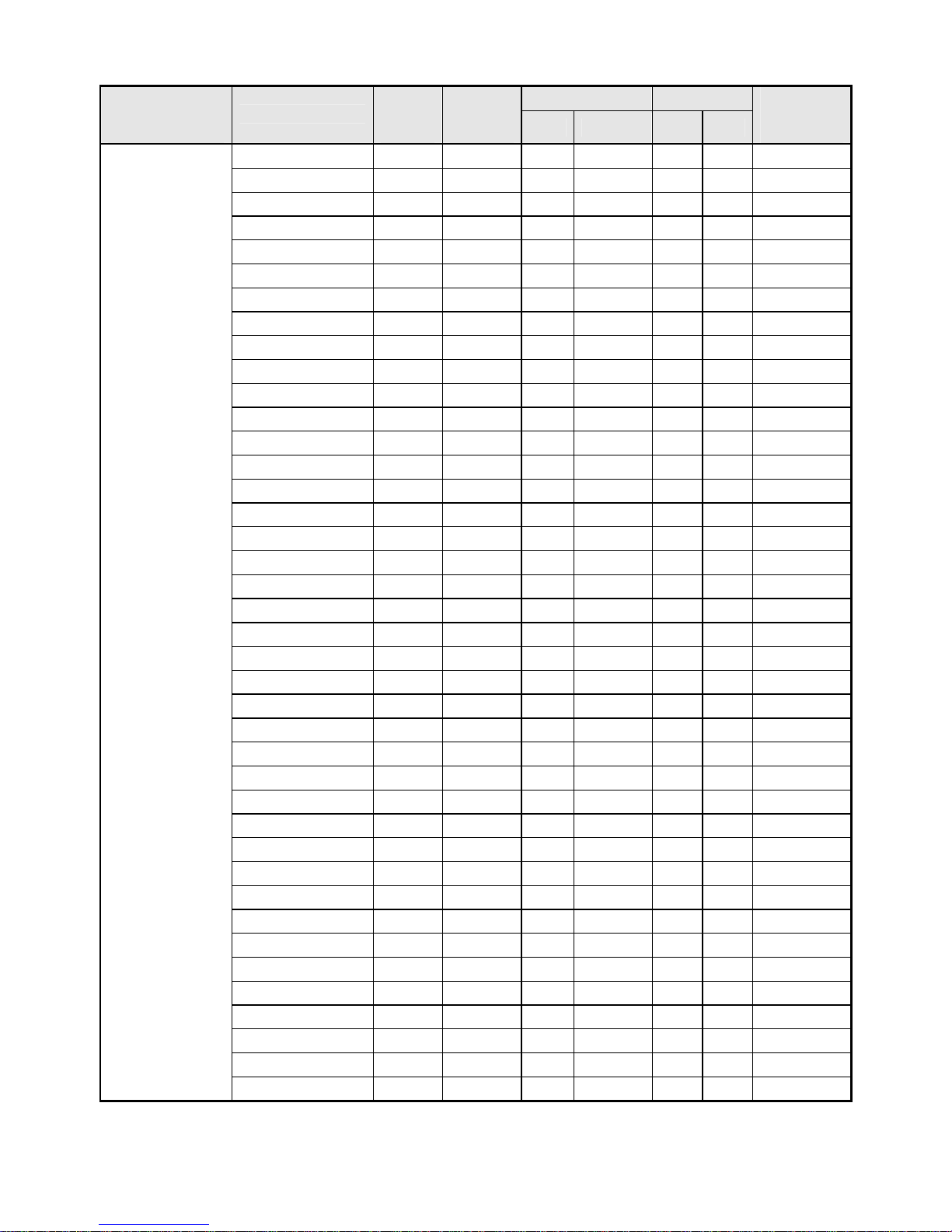

400V Class

Filter Operator

Voltage (Vac)

&

Frequency (Hz)

F510 Model

Motor

Power

(Hp)

Applied

Motor

(kW)

with without LED LCD

Protection

Class

(IP55)

F510-4005-H3 5 3.7 ◎ ◎

F510-4005-H3F 5 3.7

◎ ◎

F510-4005-C3 5 3.7

◎ ◎

F510-4005-C3F 5 3.7

◎ ◎

F510-4005-C3FN4 5 3.7

◎ ◎ ◎

F510-4008-H3 7.5 5.5

◎ ◎

F510-4008-H3F 7.5 5.5

◎ ◎

F510-4008-C3 7.5 5.5

◎ ◎

F510-4008-C3F 7.5 5.5

◎ ◎

F510-4008-C3FN4 7.5 5.5

◎ ◎ ◎

F510-4010-H3 10 7.5

◎ ◎

F510-4010-H3F 10 7.5

◎ ◎

F510-4010-C3 10 7.5

◎ ◎

F510-4010-C3F 10 7.5

◎ ◎

F510-4010-C3FN4 10 7.5

◎ ◎ ◎

F510-4015-H3 15 11

◎ ◎

F510-4015-H3F 15 11

◎ ◎

F510-4015-C3 15 11

◎ ◎

F510-4015-C3F 15 11

◎ ◎

F510-4015-C3FN4 15 11

◎ ◎ ◎

F510-4020-H3 20 15

◎ ◎

F510-4020-H3F 20 15

◎ ◎

F510-4020-C3 20 15

◎ ◎

F510-4020-C3F 20 15

◎ ◎

F510-4020-C3FN4 20 15

◎ ◎ ◎

F510-4025-H3 25 18.5

◎ ◎

F510-4025-H3F 25 18.5

◎ ◎

F510-4025-C3 25 18.5

◎ ◎

F510-4025-C3F 25 18.5

◎ ◎

F510-4025-C3FN4 25 18.5

◎ ◎ ◎

F510-4030-H3 30 22

◎ ◎

F510-4030-H3F 30 22

◎ ◎

F510-4030-C3 30 22

◎ ◎

F510-4030-C3F 30 22

◎ ◎

F510-4030-C3FN4 30 22

◎ ◎ ◎

F510-4040-H3 40 30

◎ ◎

F510-4040-H3F 40 30

◎ ◎

F510-4040-C3 40 30

◎ ◎

F510-4040-C3F 40 30

◎ ◎

3ph

380~480V

+10%/-15%

50/60Hz

F510-4040-C3FN4 40 30

◎ ◎ ◎

Page 14

2-4

Filter Operator

Voltage (Vac)

&

Frequency (Hz)

F510 Model

Motor

Power

(Hp)

Applied

Motor

(kW)

with without LED LCD

Protection

Class

(IP55)

F510-4050-H3 50 37 ◎ ◎

F510-4050-H3F 50 37

◎ ◎

F510-4050-C3 50 37

◎ ◎

F510-4050-C3F 50 37

◎ ◎

F510-4050-C3FN4 50 37

◎ ◎ ◎

F510-4060-H3 60 45

◎ ◎

F510-4060-H3F 60 45

◎ ◎

F510-4060-C3 60 45

◎ ◎

F510-4060-C3F 60 45

◎ ◎

F510-4060-C3FN4 60 45

◎ ◎ ◎

F510-4075-H3 75 55

◎ ◎

F510-4075-H3F 75 55

◎ ◎

F510-4075-C3 75 55

◎ ◎

F510-4075-C3F 75 55

◎ ◎

F510-4075-C3N4 75 55

◎ ◎

◎

F510-4100-H3 100 75

◎ ◎

F510-4100-C3 100 75

◎ ◎

F510-4100-C3N4 100 75

◎ ◎

◎

F510-4125-H3 125 94

◎ ◎

F510-4125-C3 125 94

◎ ◎

F510-4150-H3 150 112

◎ ◎

F510-4150-C3 150 112

◎ ◎

F510-4175-H3 175 130

◎ ◎

F510-4175-C3 175 130

◎ ◎

F510-4215-H3 215 160

◎ ◎

F510-4215-C3 215 160

◎ ◎

F510-4250-H3 250 185

◎ ◎

F510-4250-C3 250 185

◎ ◎

F510-4300-H3 300 220

◎ ◎

F510-4300-C3 300 220

◎ ◎

F510-4375-H3 375 280

◎ ◎

F510-4375-C3 375 280

◎ ◎

F510-4425-H3 425 317

◎ ◎

F510-4425-C3 425 317

◎ ◎

F510-4535-H3 535 400

◎ ◎

F510-4535-C3 535 400

◎ ◎

F510-4670-H3 670 500

◎ ◎

F510-4670-C3 670 500

◎ ◎

F510-4800-H3 800 600

◎ ◎

3ph

380~480V

+10%/-15%

50/60Hz

F510-4800-C3 800 600

◎ ◎

Note:

z Short Circuit Rating: 400V Class: 5KA.

Page 15

3-1

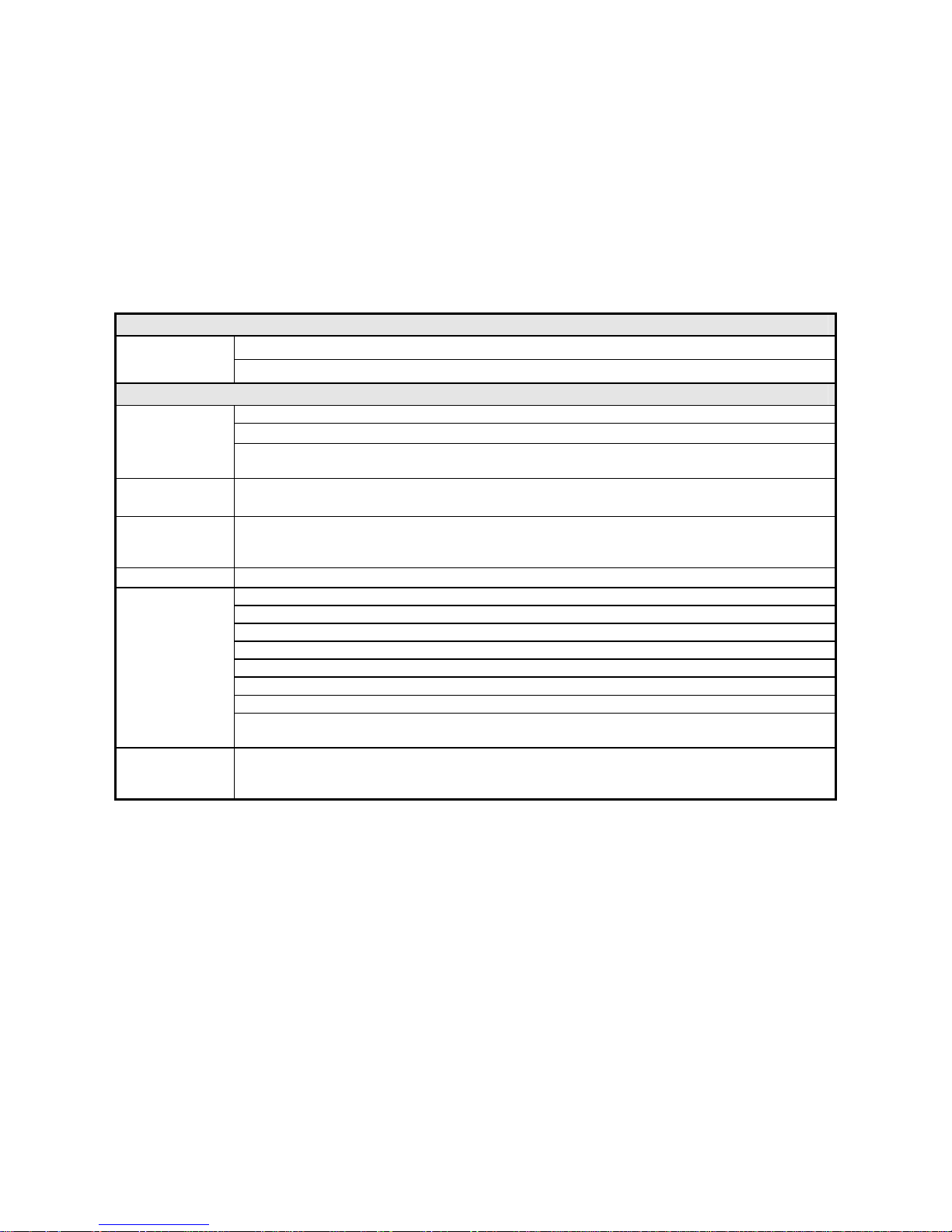

Chapter 3 Environment and Installation

3.1 Environment

The environment will directly affect the proper operation and the life span of the inverter. To

ensure that the inverter will give maximum service life, please comply with the following

environmental conditions:

Protection

IP20/ NEMA 1, IP00

Protection

Class

IP55/ NEMA 12

Ambient Environment

Ambient Temperature: -10°C - +40°C (14 -104 °F)

Without Cover: -10°C - +50°C (14-122 °F)

Operating

Temperature

If several inverters are placed in the same control panel, provide a heat removal means to

maintain ambient temperatures below 40°C

Storage

Temperature

-20°C - +70°C (-4 -158 °F)

Humidity

95% non-condensing

Relative humidity 5% to 95%, free of moisture.

(Follow IEC60068-2-78 standard)

Altitude

< 1000m (3,281 ft.)

Avoid direct sunlight.

Avoid exposure to rain or moisture.

Avoid oil mist and salinity.

Avoid corrosive liquid and gas.

Avoid dust, lint fibers, and small metal filings.

Avoid electromagnetic interference (soldering machines, power machines).

Keep away from radioactive and flammable materials.

Installation

Site

Avoid vibration (stamping, punching machines etc.).

Add a vibration-proof pad if the situation cannot be avoided.

Shock

Maximum acceleration: 1.2G (12m/s²), from 49.84 to 150 Hz

Displacement amplitude : 0.3mm (peak value), from 10 to 49.84 Hz

(Follow IEC60068-2-6 standard)

Page 16

3-2

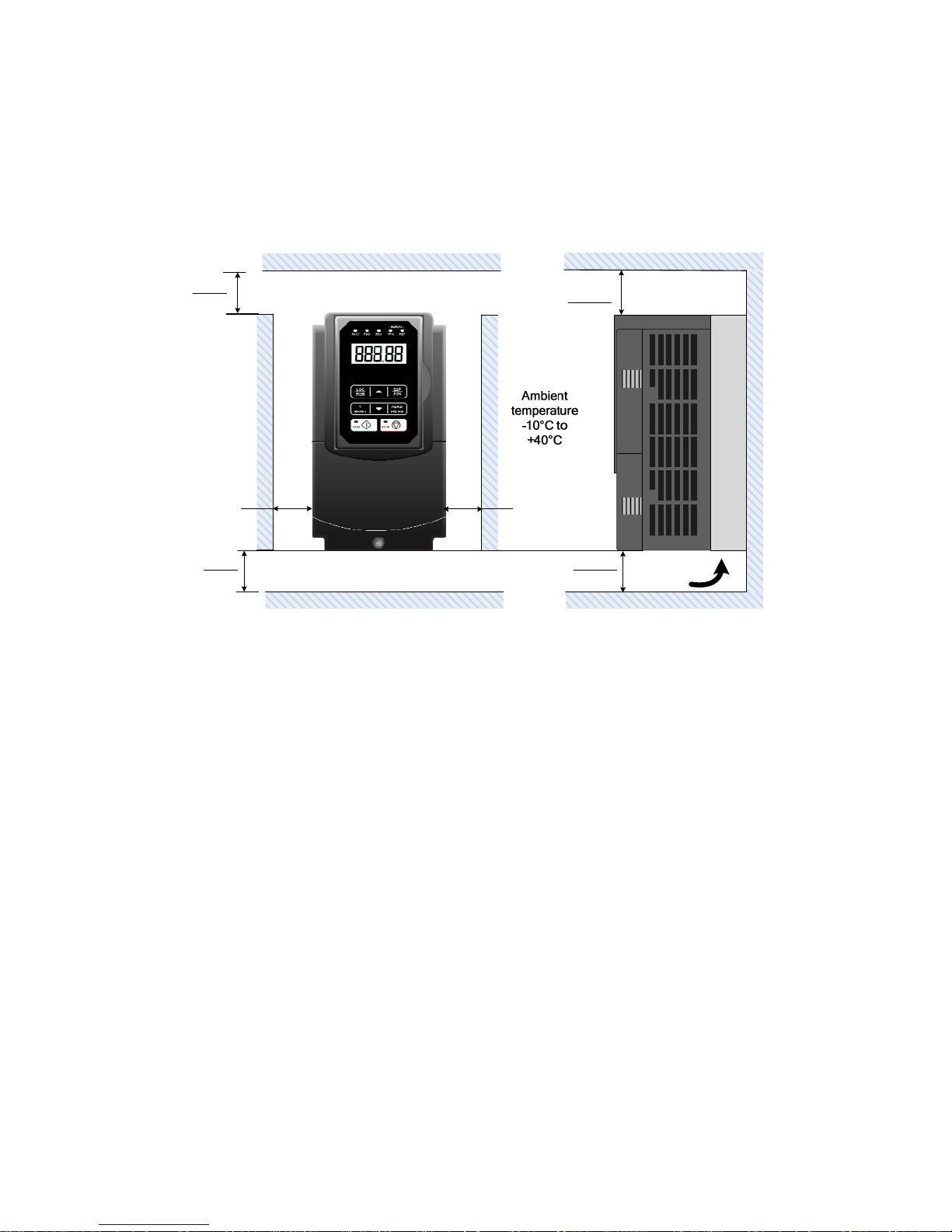

3.2 Installation

3.2.1 Installation Spaces

When installing the inverter, ensure that inverter is installed in upright position (vertical

direction) and there is adequate space around the unit to allow normal heat dissipation as per

the following Fig. 3.2.1

5.9in.

150mm

5.9in.

150mm

Air Flow

5.9in.

150mm

X

5.9in.

150mm

X

Fig 3.2.1: F510 Installation space

X = 1.18” (30mm) for inverter ratings up to 18.5kW

X = 1.96” (50mm) for inverter ratings 22kW or higher

Important Note: The inverter heatsink temperature can reach up to 90°C/ 194°F during

operation; make sure to use insulation material rated for this temperature.

Page 17

3-3

3.2.2 External View

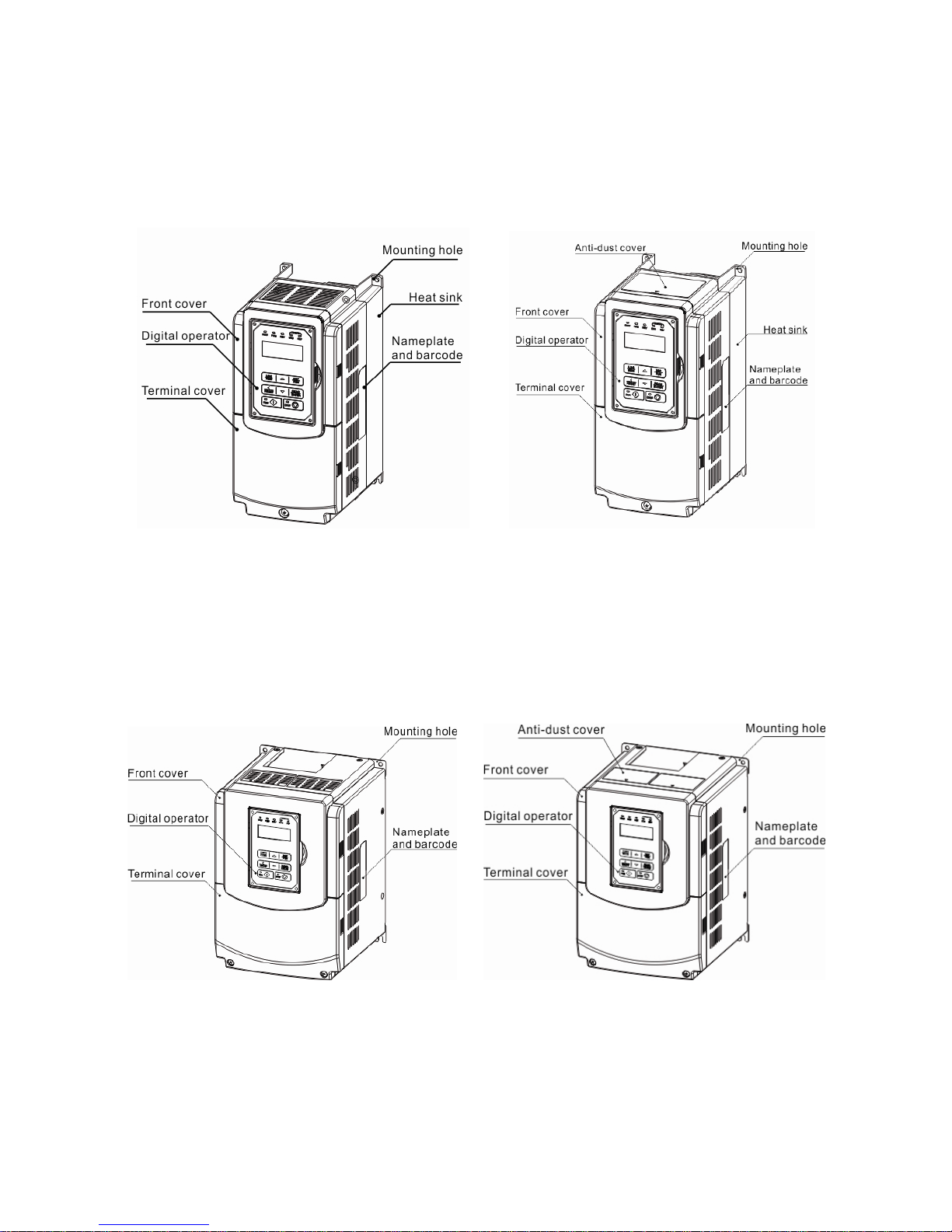

3.2.2.1 External View (IP00/ IP20)

(a) 200V 5-7.5HP/ 400V 5-10HP

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20, NEMA1)

(b) 200V 10-30HP/ 400V 15-40HP

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20, NEMA1)

Page 18

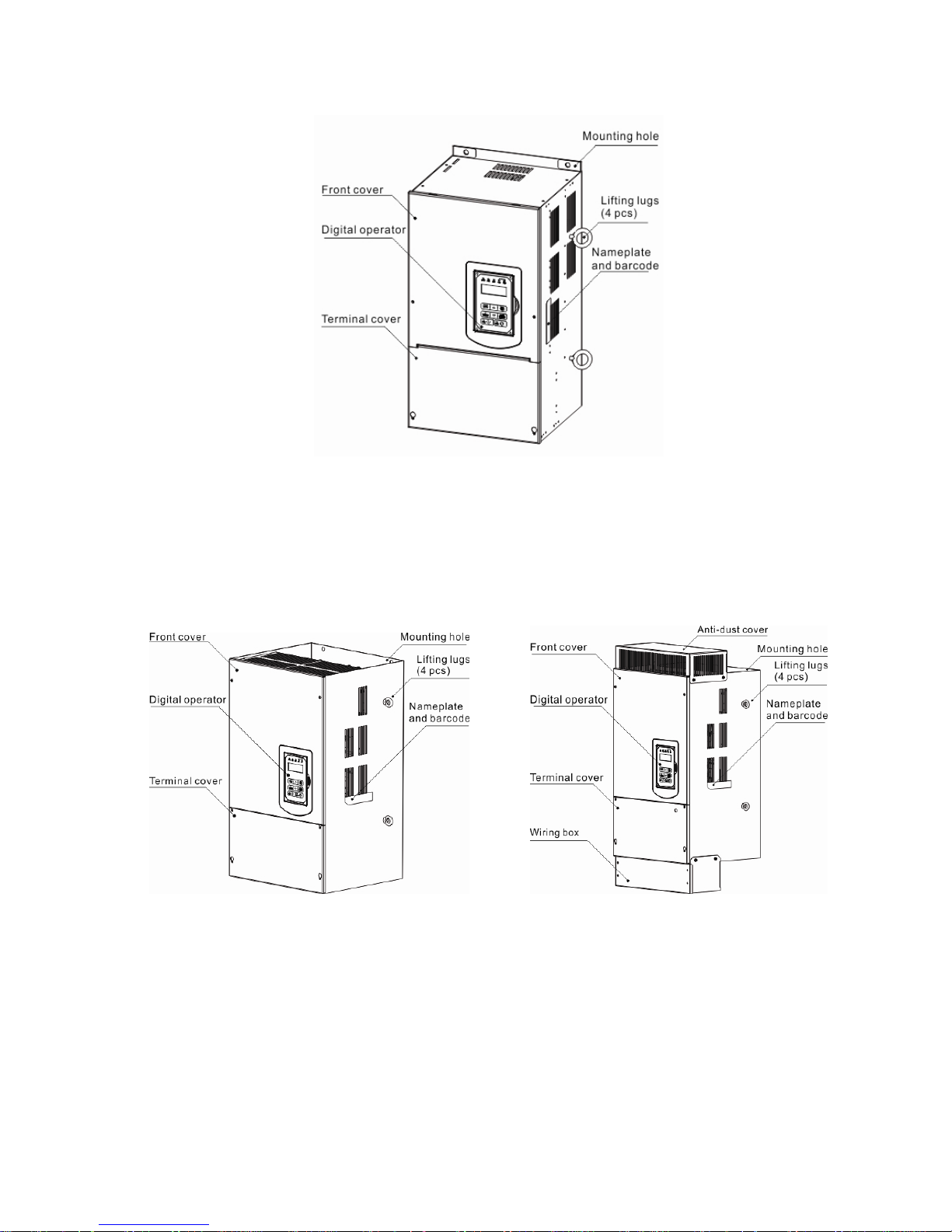

3-4

(c) 200V 40-50HP/ 400V 50-75HP

(Wall-mounted type, IEC IP20, NEMA1)

(d) 200V 60-125HP/ 400V 100-250HP

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20, NEMA1)

Page 19

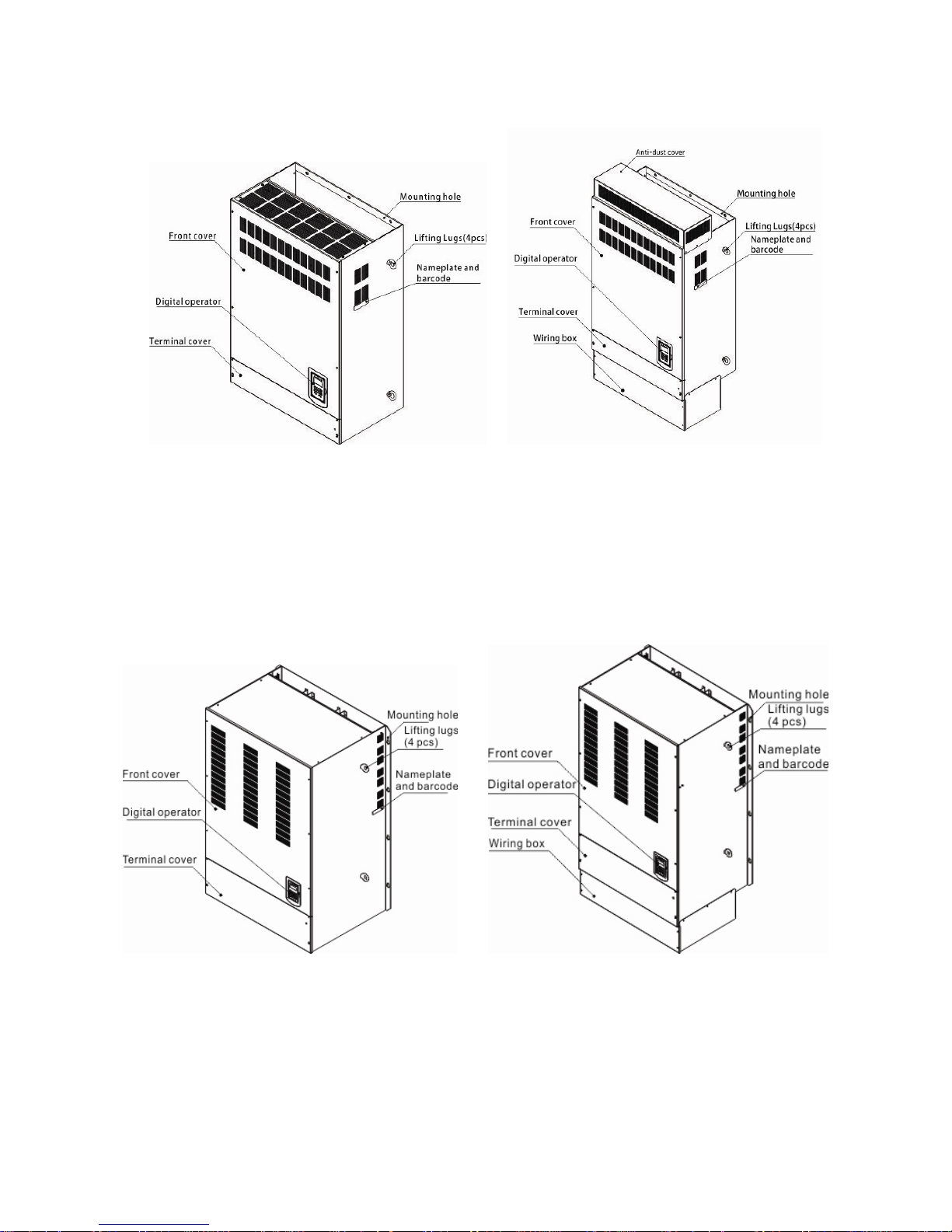

3-5

(e) 200V 150-175HP/ 400V 300-425HP

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20)

(f) 400V 535-800HP

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20)

Page 20

3-6

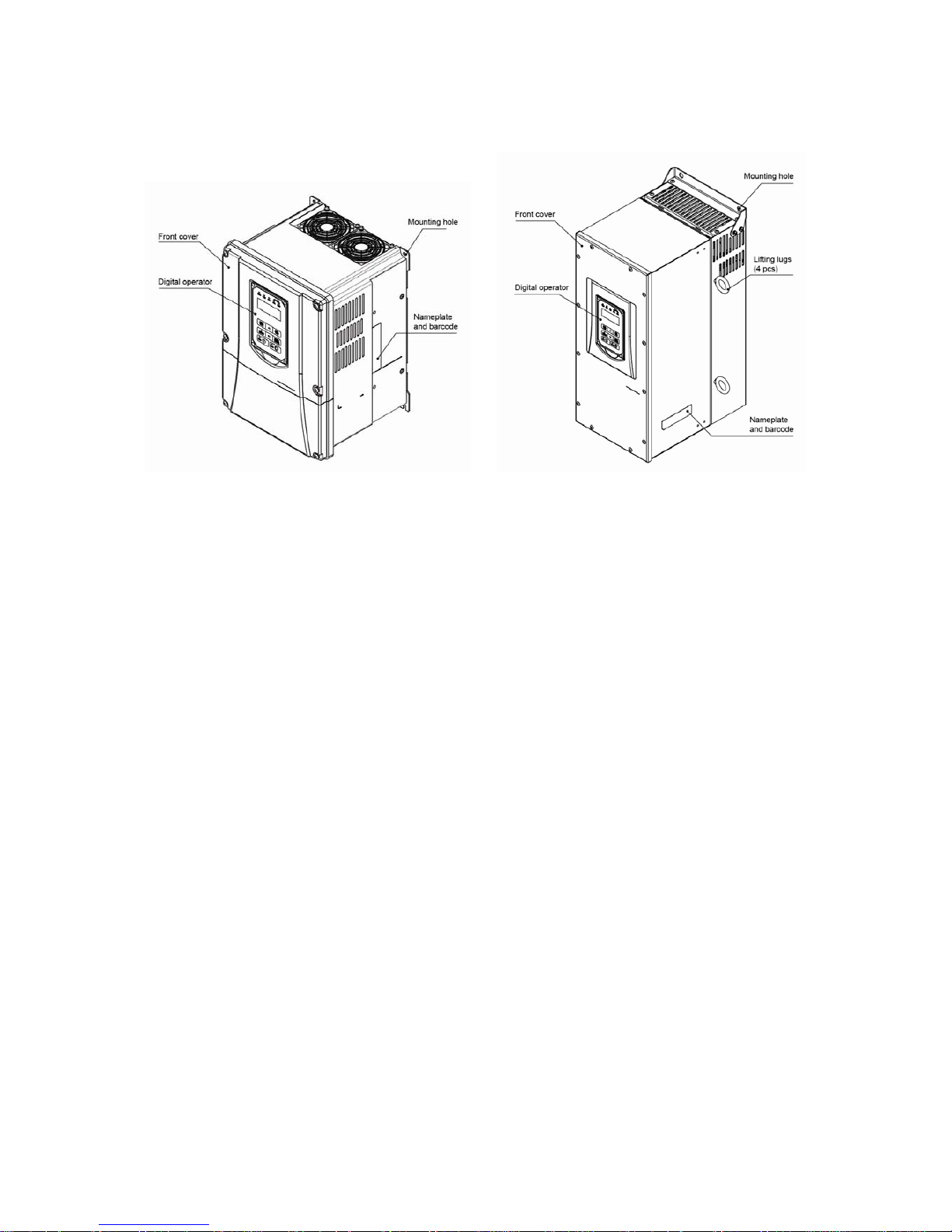

3.2.2.2 External View (IP55)

(a) 400V 5-25HP (b) 400V 30-100HP

(Wall-mounted type, IEC IP55) (Wall-mounted type, IEC IP55)

Page 21

3-7

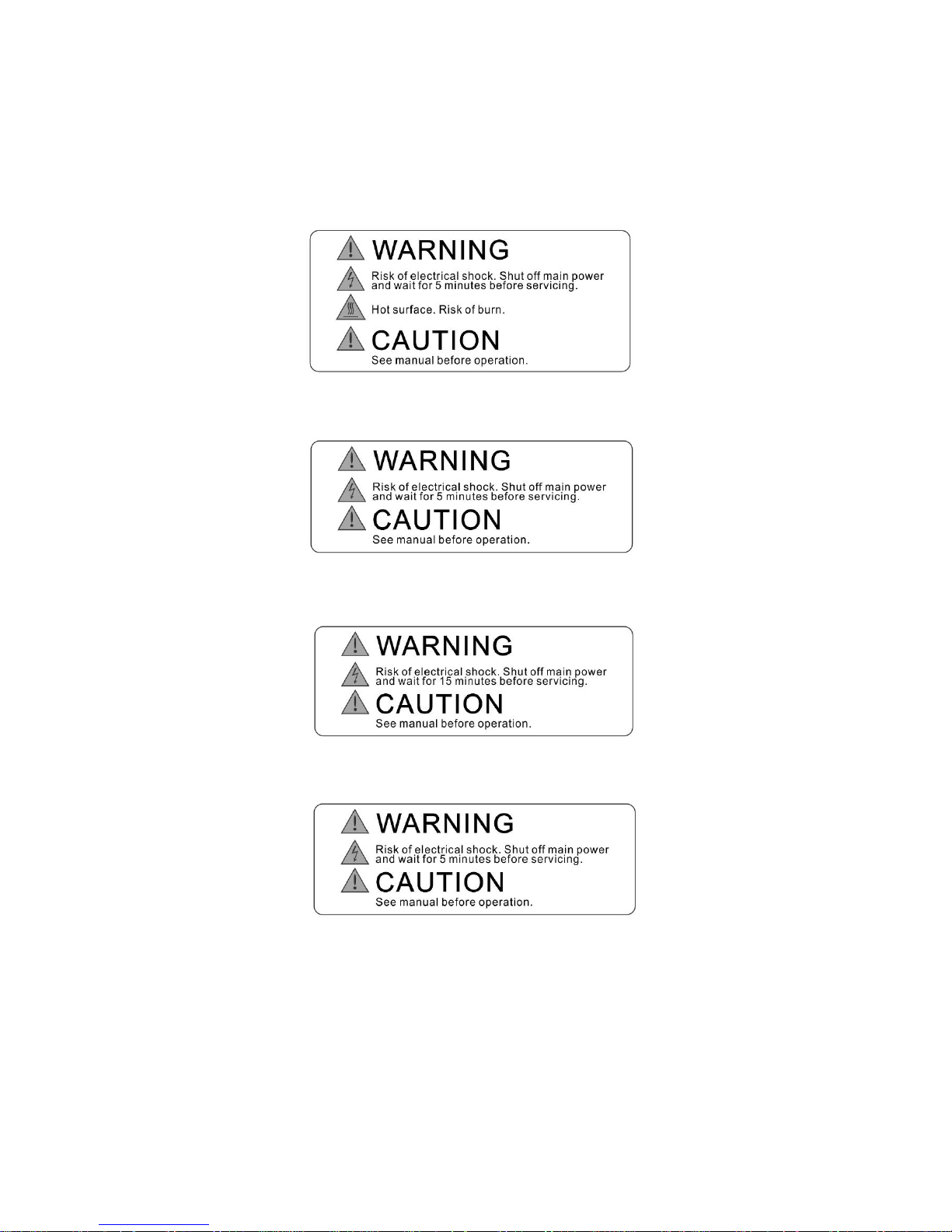

3.2.3 Warning Labels

Important:

Warning information located on the front cover must be read upon installation of

the inverter.

(a) 200V: 5-7.5HP/ 400V: 5-10HP (IP20)

(b) 200V: 10-15HP/ 400V: 15-20HP (IP20)

(c) 200V: 20-175HP/ 400V: 25-800HP(IP20)

(d) 400V:5-100HP (IP55)

Page 22

3-8

3.2.4 Removing the Front Cover and Keypad

Before making any wiring connections to the inverter, the front cover needs to be

removed.

IP00/ IP20 Type

Caution

• It is not required to remove the digital operator before making any wiring connections.

• Models 200V, 5 – 30 HP and 400V, 5 – 40 HP have a plastic cover. Loosen the screws

and remove the cover to gain access to the terminals and make wiring connections.

Place the plastic cover back and fasten screws when wiring connections have been

made.

• Models 200V, 40 - 175HP and 400V, 50 - 800HP have a metal cover. Loosen the

screws and remove the cover to gain access to the terminals and make wiring

connections. Place the metal cover back and fasten screws when wiring connections

have been made.

IP55 Type

Caution

• It is essential to remove the digital operator before making any wiring connections.

• Model 400V, 5 – 25 HP has a plastic cover. Loosen the screws and remove the cover to

gain access to the terminals and make wiring connections. Place the plastic cover back

and fasten screws when wiring connections have been made.

• Models 400V, 30 - 100HP has a metal cover. Loosen the screws and remove the cover

to gain access to the terminals and make wiring connections. Place the metal cover

back and fasten screws when wiring connections have been made.

Page 23

3-9

3.2.4.1 Standard Type (IP00/ IP20)

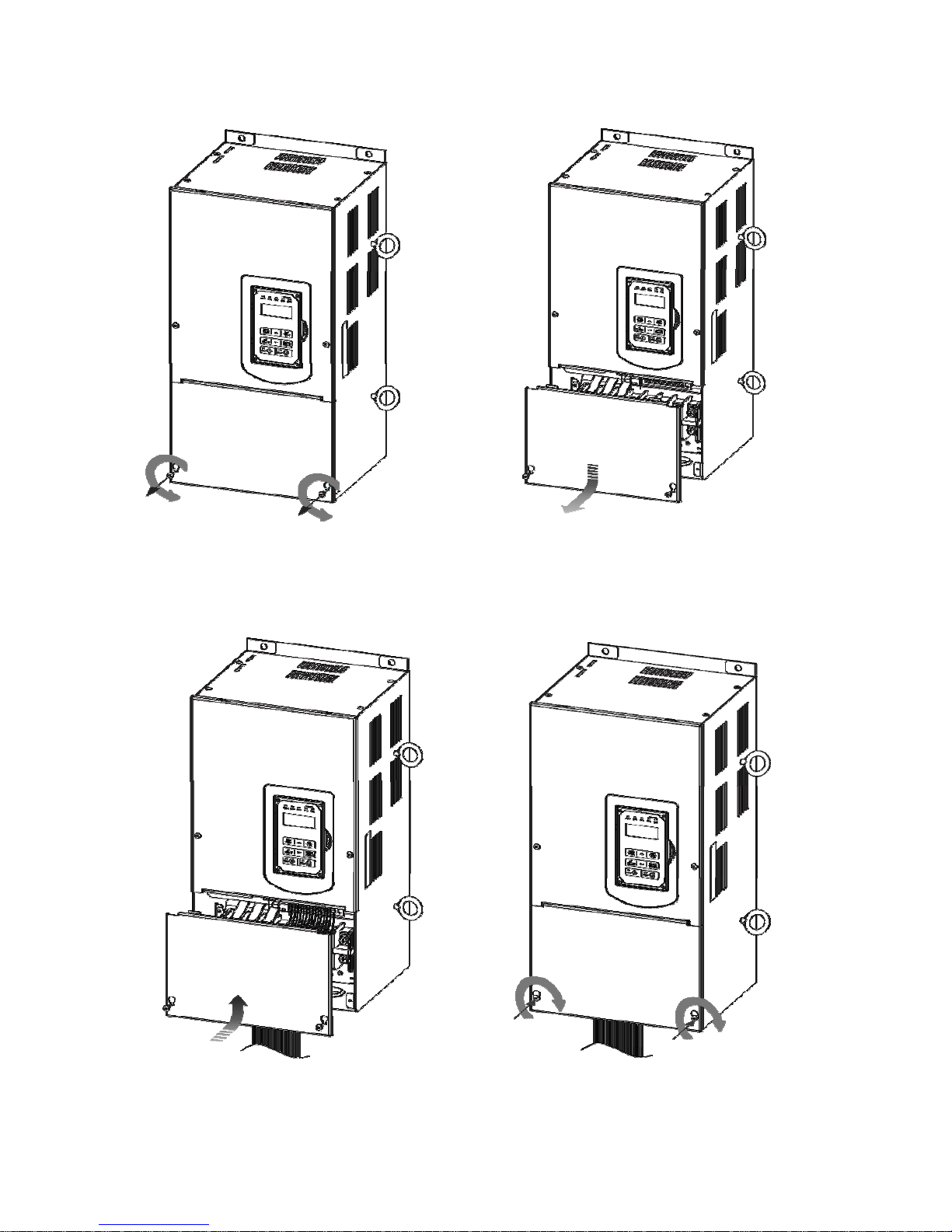

(a) 200V 5-7.5HP/ 400V 5-10HP

Step 1: Unscrew Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

Page 24

3-10

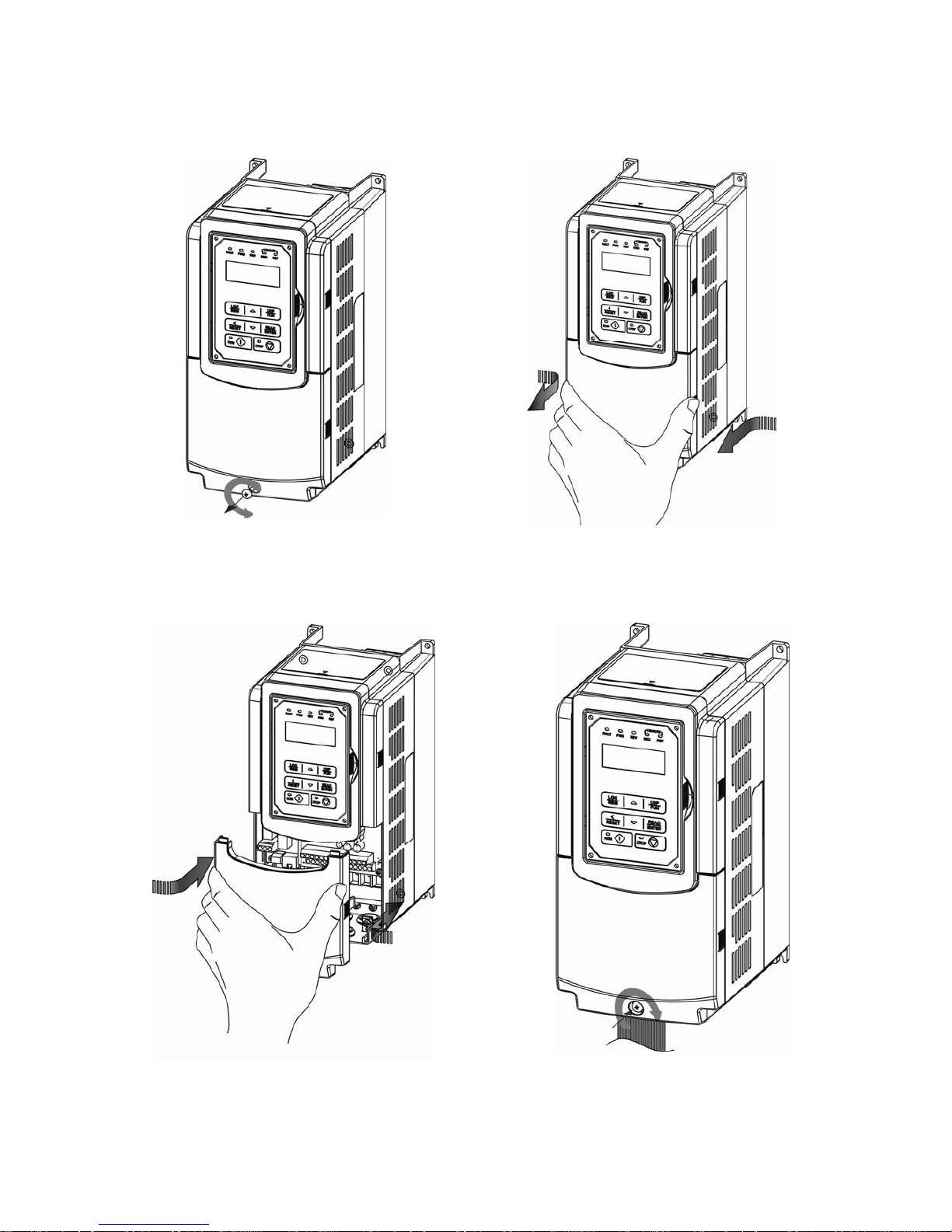

(b) 200V 10-30HP/ 400V 15-40HP

Step 1: Unscrew Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

Page 25

3-11

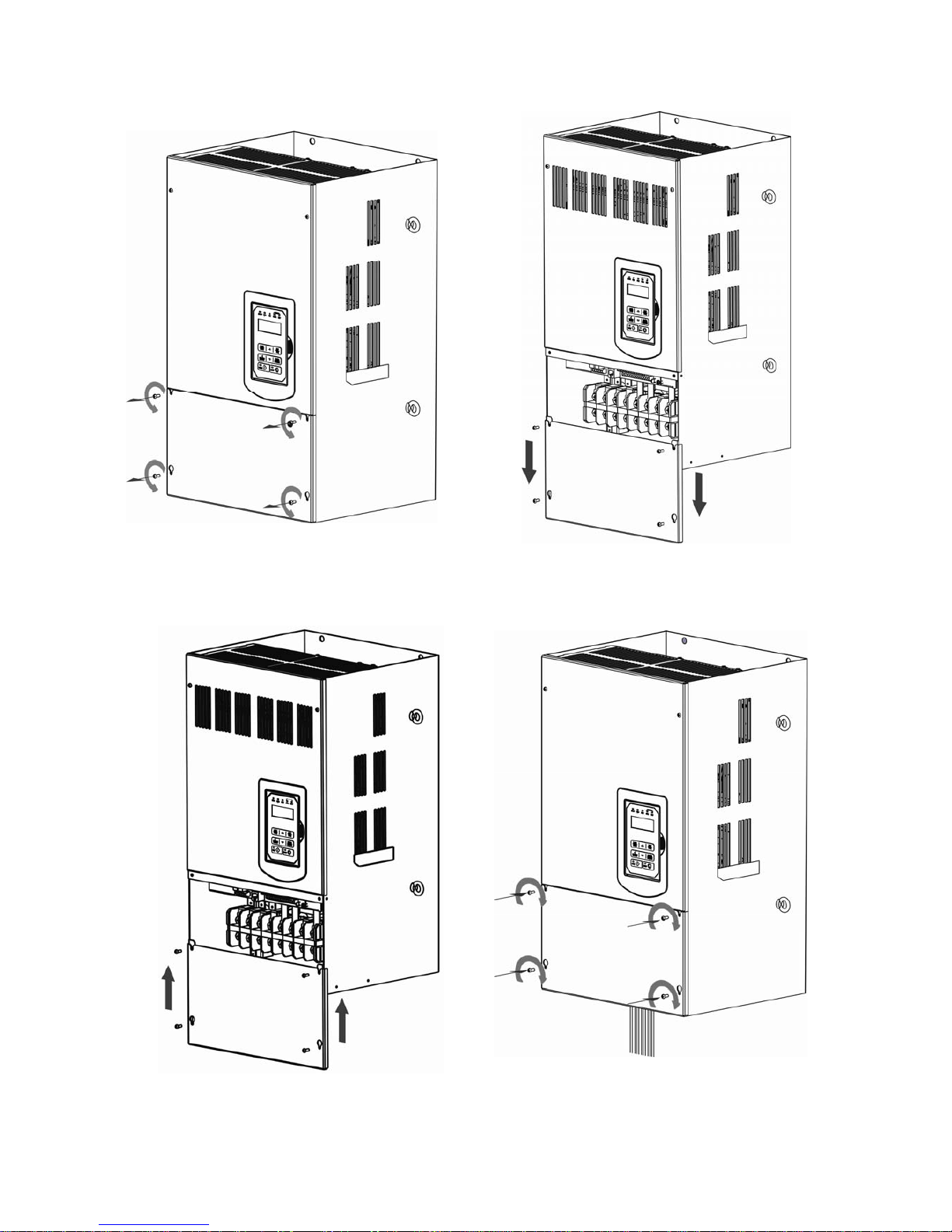

(c) 200V 40-50HP/ 400V 50-75HP

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

Page 26

3-12

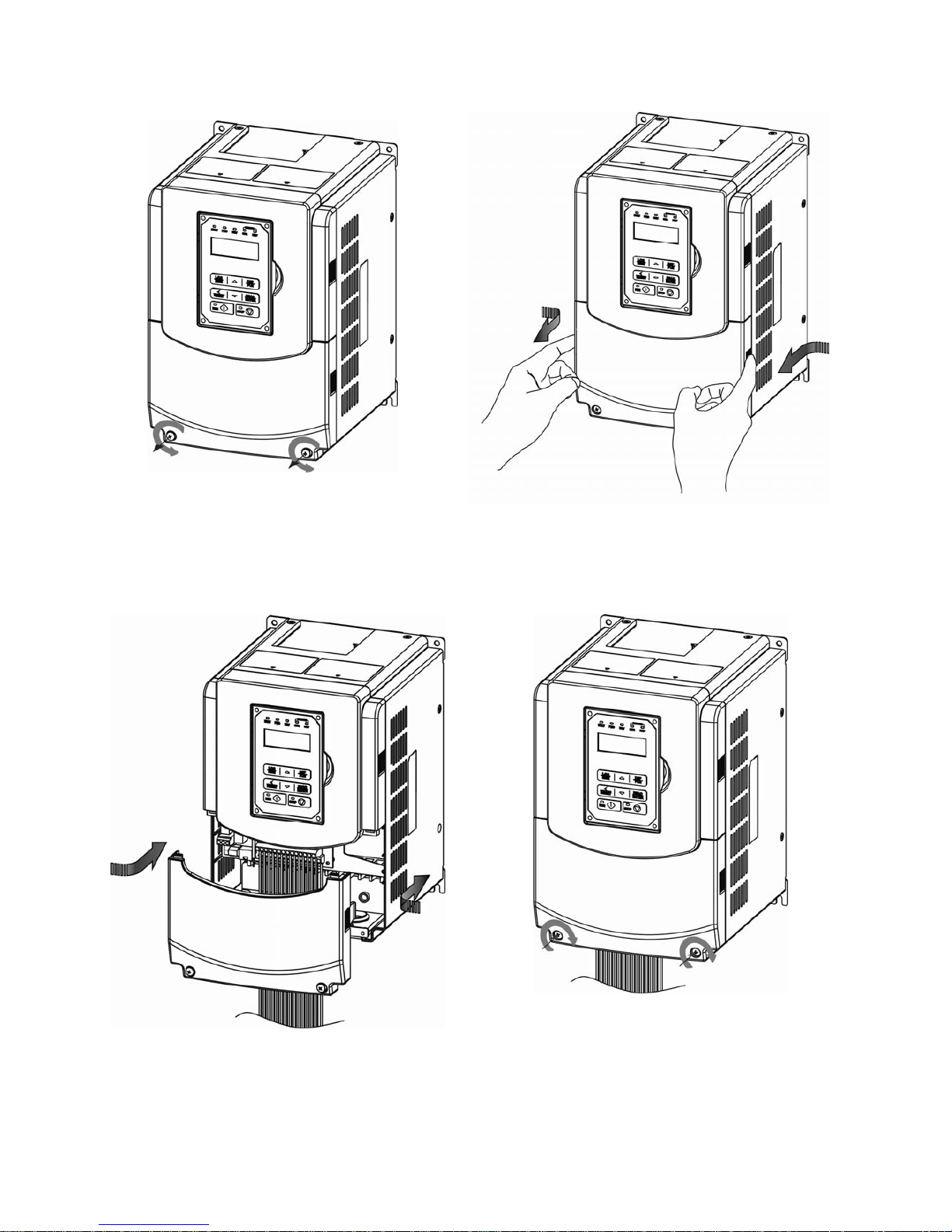

(d) 200V 60-125HP/ 400V 100-250HP

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

Page 27

3-13

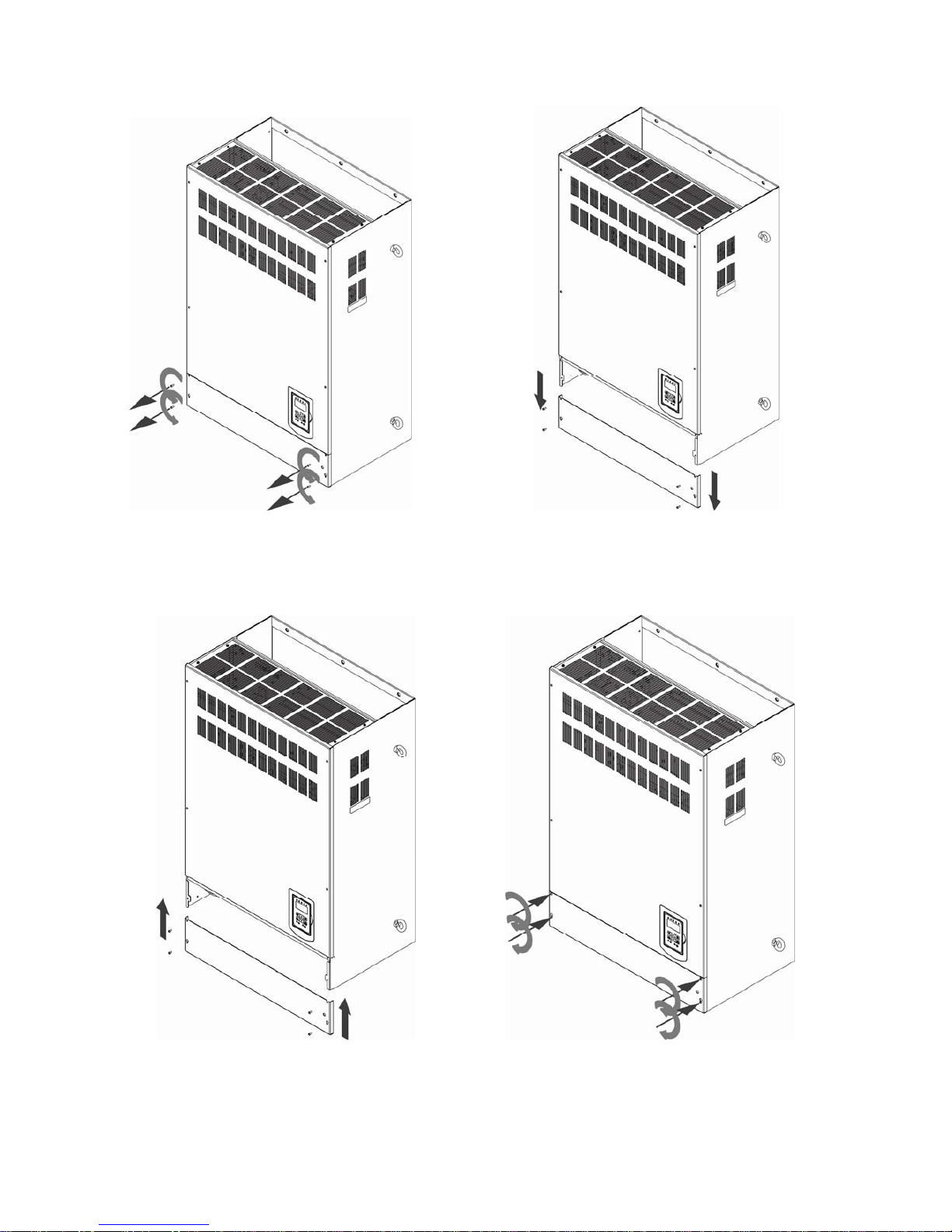

(e) 200V 150-175HP/ 400V 300-425HP

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover b Step 4: Fasten screw

Page 28

3-14

(f) 400V 535-800HP

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

Page 29

3-15

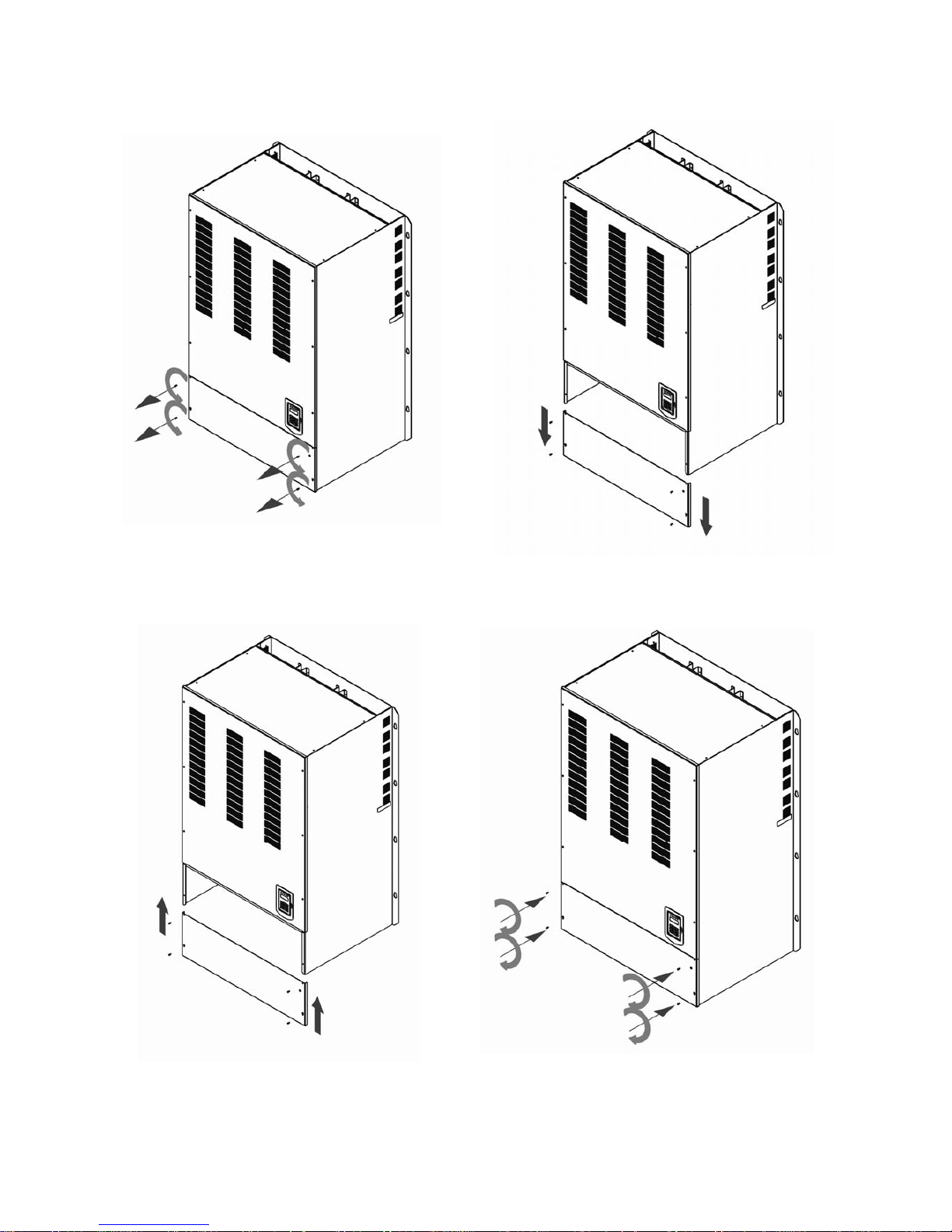

3.2.4.2 Built-in Filter Type (IP20/ IP00)

400V 5-75HP

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Unscrew filter section Step 4: Remove filter cover

Step 5: Make connections and place filter cover back Step 6: Fasten screw

Page 30

3-16

3.2.4.3 Built-in Filter Type (IP55)

(a) 400V 5-25HP

Step 1: Unscrew operator Step 2: Remove operator

Step 3: Pull out operator and remove power line Step 4: Unscrew cover

Step 5: Check the inside waterproof gasket is not pulled

away from cover while opening the cover

Waterproof gasket

Page 31

3-17

(b) 400V 30-100HP

Step 1: Unscrew operator Step 2: Remove operator

Step 3: Pull out operator and remove power line Step4: Unscrew cover and remove it

Waterproof gasket

Page 32

3-18

3.3 Inverter Wiring

3.3.1 Wire Gauges and Tightening Torque

To comply with UL standards, use UL approved copper wires (rated 75° C) and round crimp

terminals (UL Listed products) as shown in table below when connecting to the main circuit

terminals. Teco recommends using crimp terminals manufactured by NICHIFU Terminal Industry

Co., Ltd and the terminal crimping tool recommended by the manufacturer for crimping terminals

and the insulating sleeve.

Table 3.3.1.1 Wire gauges and tightening torque terminal screw size

Wire size

mm2 (AWG)

Terminal

Screw

size

Model of round

crimp terminal

Tightening torque

kgf.cm (in.lbs)

Model of

insulating

sleeve

Model of

crimp tool

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

0.75 (18)

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

1.25 (16)

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R2-3.5 8.2 to 10 (7.1 to 8.7) TIC 2 NH 1 / 9

M4 R2-4 12.2 to 14 (10.4 to 12.1) TIC 2 NH 1 / 9

M5 R2-5 22.1 to 24 (17.7 to 20.8) TIC 2 NH 1 / 9

2 (14)

M6 R2-6 25.5 to 30.0 (22.1 to 26.0) TIC 2 NH 1 / 9

M4 R5.5-4 12.2 to 14 (10.4 to 12.1) TIC 3.5/5.5 NH 1 / 9

M5 R5.5-5 20.4 to 24 (17.7 to 20.8) TIC 3.5/5.5 NH 1 / 9

M6 R5.5-6 25.5 to 30.0 (22.1 to 26.0) TIC 3.5/5.5 NH 1 / 9

3.5/5.5 (12/10)

M8 R5.5-8 61.2 to 66.0 (53.0 to 57.2) TIC 3.5/5.5 NH 1 / 9

M4 R8-4 12.2 to 14 (10.4 to 12.1) TIC 8 NOP 60

M5 R8-5 20.4 to 24 (17.7 to 20.8) TIC 8 NOP 60

M6 R8-6 25.5 to 30.0 (22.1 to 26.0) TIC 8 NOP 60

8 (8)

M8 R8-8 61.2 to 66.0 (53.0 to 57.2) TIC 8 NOP 60

M4 R14-4 12.2 to 14 (10.4 to 12.1) TIC 14 NH 1 / 9

M5 R14-5 20.4 to 24 (17.7 to 20.8) TIC 14 NH 1 / 9

M6 R14-6 25.5 to 30.0 (22.1 to 26.0) TIC 14 NH 1 / 9

14 (6)

M8 R14-8 61.2 to 66.0 (53.0 to 57.2) TIC 14 NH 1 / 9

M6 R22-6 25.5 to 30.0 (22.1 to 26.0) TIC 22 NOP 60/ 150H

22 (4)

M8 R22-8 61.2 to 66.0 (53.0 to 57.2) TIC 22 NOP 60/ 150H

M6 R38-6 25.5 to 30.0 (22.1 to 26.0) TIC 38 NOP 60/ 150H

30/38 (3 / 2)

M8 R38-8 61.2 to 66.0 (53.0 to 57.2) TIC 38 NOP 60/ 150H

M8 R60-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 60/ 150H

50/ 60 (1/ 1/ 0)

M10 R60-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M8 R70-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 150H

70 (2/0)

M10 R70-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M10 R80-10 102 to 120 (88.5 to 104) TIC 80 NOP 150H

80 (3/0)

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

M10 R100-10 102 to 120 (88.5 to 104) TIC 100 NOP 150H

M12 R100-12 143 to 157 (124 to 136) TIC 100 NOP 150H

100 (4/0)

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

Page 33

3-19

3.3.2 Wiring Peripheral Power Devices

Caution

z After power is shut off to the inverter, the capacitors will slowly discharge. Do NOT touch the

inverter circuitry or replace any components until the “CHARGE” indicator is off.

z Do NOT wire or connect/disconnect internal connectors of the inverter when the inverter is

powered up or when powered off and the “CHARGE”” indicator is on.

z Do NOT connect inverter output U, V and W to the supply power. This will result in damage to

the inverter.

z The inverter must be by properly grounded. Use terminal E to connect earth ground and

comply with local standards.

z It is required to disconnect the grounded wire in the control board when the inverter is not

grounded or floating ground power system.

z Do NOT perform a dielectric voltage withstand test (megger) on the inverter this will result in

inverter damage to the semiconductor components.

z Do NOT touch any of the components on the inverter control board to prevent damage to the

inverter by static electricity.

Caution

z Refer to the recommended wire size table for the appropriate wire to use. The voltage

between the power supply and the input of the inverter may not exceed 2%.

Phase-to-phase voltage drop (V) = 3 ×resistance of wire (Ω/km) × length of line m) × current×10-3.

(km=3280 x feet) / (m=3.28 x feet )

Reduce the carrier frequency (parameter 11-01) If the cable from the inverter to the motor is

greater than 25m (82ft). A high-frequency current can be generated by stray capacitance

between the cables and result in an overcurrent trip of the inverter, an increase in leakage

current, or an inaccurate current readout.

To protect peripheral equipment, install fast acting fuses on the input side of the inverter. Refer

to section 11.4 for additional information.

Page 34

3-20

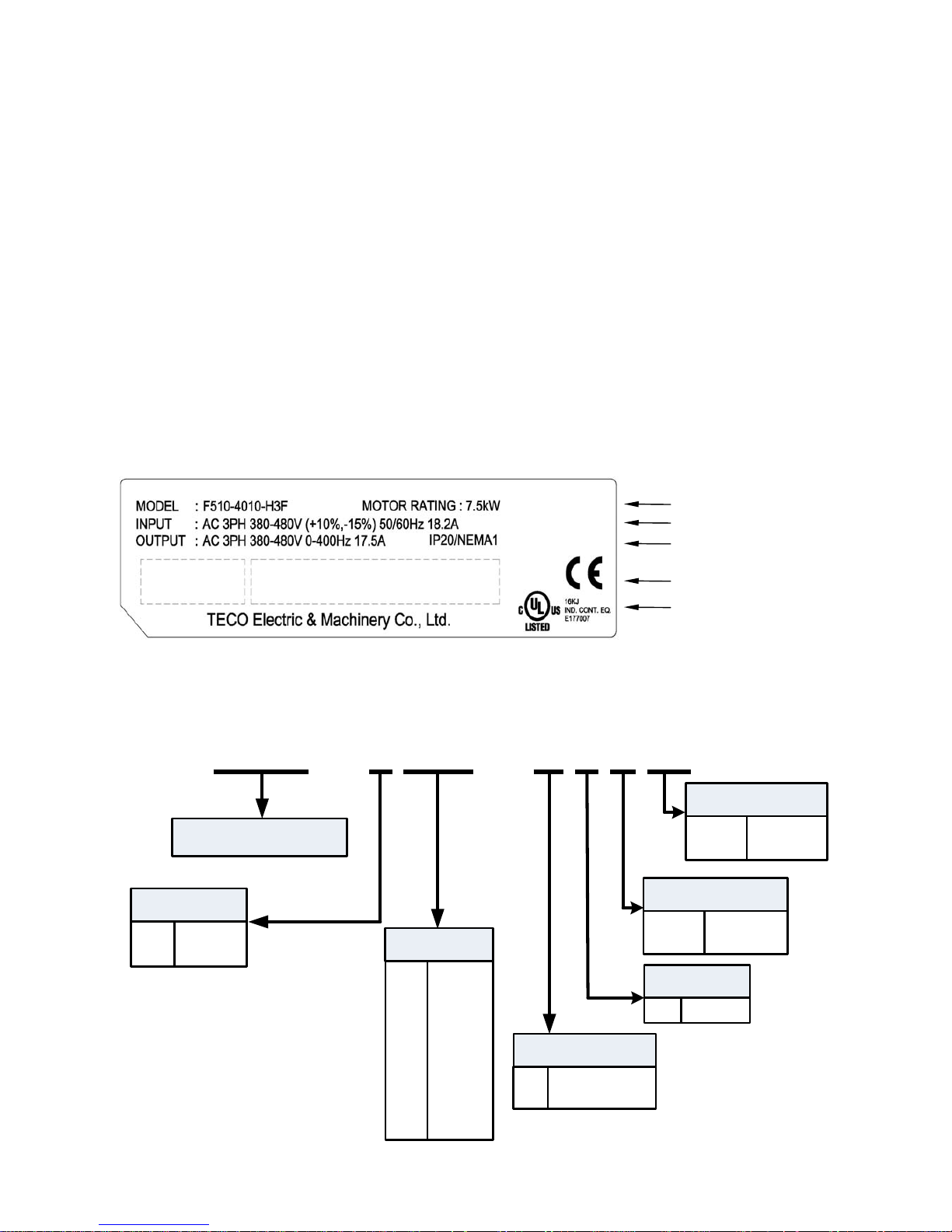

Power Supply

M

C

C

B

Molded

Circuit

Breaker

Magnetic

Contactor

AC

Reactor

Fast

Acting

Fuse

Input Noise

Filter

F510

Inverter

Ground

Induction

Motor

Ground

Output Noise

Filter

Power supply:

z

Make sure the correct voltage is applied to avoid damaging the

inverter.

Molded-case circuit breaker (MCCB) or fused disconnect:

z A molded-case circuit breaker or fused disconnect must be installed

between the AC source and the inverter that conforms to the rated

voltage and current of the inverter to control the power and protect

the inverter.

z

Do not use the circuit breaker as the run/stop switch for the

inverter.

Ground fault detector / breaker:

z

Install a ground fault breaker to prevent problems caused by

current leakage and to protect personnel. Select current range up to

200mA, and action time up to 0.1 second to prevent high frequency

failure.

Magnetic contactor:

z Normal operations do not need a magnetic contactor. When

performing functions such as external control and auto restart after

power failure, or when using a brake controller, install a magnetic

contactor.

z

Do not use the magnetic contactor as the run/stop switch for

the inverter.

AC line reactor for power quality:

z When inverters are supplied by a high capacity power source (>

600KVA), an AC reactor can be connected to improve the power

factor.

Install Fast Acting Fuse:

z To protect peripheral equipment, install fast acting fuses in

accordance with the specifications in section 11.4 for peripheral

devices.

Input Noise filter:

z A filter must be installed when there are inductive loads affecting the

inverter. The inverter meets EN55011 Class A, category C3 when

the TECO special filter is used. See section 11.3 for peripheral

devices.

Inverter:

z Output terminals T1, T2, and T3 are connected to U, V, and W

terminals of the motor. If the motor runs in reverse while the inverter

is set to run forward, swap any two terminals connections for T1, T2,

and T3.

z

To avoid damaging the inverter, do not connect the output

terminals T1, T2, and T3 to AC input power.

z Connect the ground terminal properly. (200V series: Rg <100Ω;

400V series: Rg <10Ω.)

Output Noise filter:

z An output noise filter may reduce system interference and induced

noise.

Motor:

z If the inverter drives multiple motors the output rated current of the

inverter must be greater than the total current of all the motors.

Page 35

3-21

3.3.3 General Wiring Diagram

The following is the standard wiring diagram for the F510 inverter (◎ indicates main circuit

terminals and ○ indicates control circuit terminals ). Locations and symbols of the wiring terminal

block might be different due to different models of F510. The description of control circuit terminals

and main circuit terminals can be referred to Table 3.3.5.1, 3.3.6.1 and 3.3.6.2

Page 36

3-22

3.3.4 Single/ Multi- Pump Dedicated Wiring Diagram

PUMP Wiring Diagram for Pressure Sensor of Voltage Type

Single Pump:

Multi-Pump:

S(+) S( - ) S1 S3 S5 AI2

E24VGS2S4S6F1F2POP I

24V +10V MTGNDGNDAI1

AO2 E

R1A R1B R1 C R2A R2C R3A R3C

AO1

S(+) S( - ) S1 S3 S5 AI2

E24VGS2S4S6F1F2POP I

24V +10V MTGNDGNDAI1

AO2 E

R1A R1B R1 C R2A R2C R3A R3C

AO1

F510 Single Pump Operation

Operation Switch

Pressure

Converter

TM2

SW2

SW3

NPN

J

P

1

J

P

2

V

I

S(+)

S(-) S1 S3 S5 AI2

E24VGS2S4S6 F1F2POP I

24V +10V MT GND GND

AI1

AO2 E

R1A R1B R1C R2A R2C R3A R3C

AO1

00-02 = 1 (Control Circuit Terminal); 00-05 = 5 (PID)

04-00 = 0 (0~10V); 10-00=0 (Target Source: Keypad)

10-01 = 2 (Feedback Source: AI2)

10-03 = XXX1b( PID is enabled)

23-00 = 1 (Pump); 23-01 = 0 (Single Pump)

-

+

Page 37

3-23

PUMP Wiring Diagram for Pressure Sensor of Current Type

Single Pump:

Multi-Pump:

Notes: 1. The position of dip switch requires being correct (SW2, SW3).

2. It is required to reconnect after setting Master/ Slave.

Page 38

3-24

3. 24VG and GND require short circuit.

4. When the communication modes is selected to be multiple pumps in parallel connection

(09-01=3), the baud rate settings (09-02) of Master and Slave are required to be consistent.

Refer to parameter 23-31 for the actions in parallel connection modes.

5. In the wiring of multi-pump current type pressure sensor, it is required to adjust Slave to

be 04-07(AI2 Gain) =252.0% and 04-08(AI1 Bias) =25.0%.

Page 39

3-25

3.3.5 Wiring for Control Circuit Terminals

Control circuit terminals identification

IP20 type

z 200V: 5HP~50HP,400V: 5HP~75HP

AI2S(+) S(-) S1 S3 S5 24V +10V MT GND GND AI1

AO1 AO2 E

R1A R1B R1C

E 24VG S2 S4 S6 F1 F2 PO P I

R2AR2CR3AR3C

z 200V: 60HP~125HP,400V: 100HP~800HP

S(+) S(-) S1 S3 S5 AI2

E 24VG S2 S4 S6 F1 F2 PO P I

24V +10V MT GND GND AI1

AO2 E

R1A R1B R1C R2A R2C R3A R3C

AO1

IP55 type

z 400V: 5HP~100HP

AI2S(+) S(-) S1 S3 S5 24V +10V MT GND GND AI1

AO1 AO2 E

R1A R1B R1C

E 24VG S2 S4 S6 F1 F2 PO P I

R2AR2CR3AR3C

Page 40

3-26

Table 3.3.5.1 Description of control circuit terminals

Type Terminal Terminal function Signal level/ information

S1

2-wire forward rotation/ stop command (default), multi-

function input terminals * 1

S2

2-wire reversal rotation/ stop command (default), multi-

function input terminals * 1

S3

Multi-speed/ position setting command 1 (default), multi-

function input terminals * 1

S4

Multi-speed/ position setting command 2 (default), multi-

function input terminals * 1

S5

Multi-speed/ position setting command 3 (default), multi-

function input terminal* 1

Digital

input

signal

S6 Fault reset (default), multi-function input terminal * 1

Signal Level 24 VDC

(opto-isolated)

Maximum current: 8mA

Maximum voltage: 30 Vdc

Input impedance: 4.22k

24V Digital signal SOURCE point (SW3 switched to SOURCE )

24V

Power

supply

24VG

Common terminal of Digital signals

Common point of digital signal SINK ( SW3 switched to

SINK )

±15%,

Max. output current: 250mA

(The sum of all loads

connected)

+10V Power for external speed potentiometer

±5%

(Max. current: 20mA )

MT Motor temperature detector of externally connecting PTC

1330 movement,

550 return

AI1 Multi-function analog input for speed reference (0-10V input)

From 0 to +10V

Input impedance: 20K

Resolution: 12bit

AI2

Multi-function analog input terminals *2, can use SW2 to

switch voltage or current input

(0~10V)/(4-20mA)

From 0 to +10V

Input impedance: 20K

From 4 to 20 mA

Input impedance: 250

Resolution: 12bit

GND Analog signal ground terminal

-

---

Analog

input

signal

E Shielding wire’s connecting terminal (Ground)

-

---

AO1

Multi-function analog output terminals *3 (0~10V/ 4-20mA

output)

AO2

Multi-function analog output terminals *3 (0~10V/ 4-20mA

output)

Analog

output

signal

GND Analog signals ground terminal

From 0 to 10V

Max. current: 2mA

From 4 to 20 mA

PO Pulse output, Band width 32KHz

Max. Frequency: 32KHz

Open Collector output

Load: 2.2 K

Pulse

output

signal

GND Analog signals ground terminal

-

---

PI Pulse command input, frequency width of 32KHz

L: from 0.0 to 0.5V

H: from 4.0 to 13.2V

Max. Frequency: 0 - 32KHz

Impedance: 3.89 K

Pulse

input

signal

GND Analog signals ground terminal

-

---

Page 41

3-27

Table 3.3.5.1 Description of control circuit terminals (Continued)

Type Terminal Terminal function Signal level/ information

R1AR1B-

R1C

Relay A contact (multi-function output terminal)

Relay B contact (multi-function output terminal)

Relay contact common terminal, please refer to

parameter group 03 in this manual for more functional

descriptions.

Rating:

250Vac: 10 mA ~ 1A

30Vdc: 10 mA ~ 1A

R2A-R2C With the same functions as R1A/R1B/R1C

Relay

output

R3A-R3C With the same functions as R1A/R1B/R1C

Rating:

250Vac: 10 mA ~ 1A

30Vdc: 10 mA ~ 1A

F1

On: normal operation.

Off: emergency stop.

(Jumper wired has to be removed to use external safety

function to stop.)

24Vdc, 8mA, pull-high

Safety

input

F2 Safety command common terminal 24V Ground

S (+)

RS-485

port

S (-)

RS485/MODBUS differential input and output

Grounding

E (G)

Grounding to earth

Shield the connecting terminal

----

Notes:

*1: Multi-function digital input can be referred to in this manual.

- Group 03: External Terminals Digital Input / Output Function Group.

*2: Multi-function analog input can be referred to in this manual.

- Group 04 - External Terminal Analog Signal Input (Output) Function Group.

*3: Multi-function analog output can be referred to in this manual.

- Group 04 - External Terminal Analog Signal Input (Output) Function Group.

Caution

Maximum output current capacity for terminal 10V is 20mA.

Multi-function analog output AO1 and AO2 are for use for an analog output meter. Do not

use these output for feedback control.

Control board’s 24V and 10V are to be used for internal control only. Do not use the

internal power-supply to power external devices.

Page 42

3-28

3.3.6 Wiring for Main Circuit Terminals

Table 3.3.6.1 Description of main circuit terminals (IP00/IP20 Type)

Terminal

200V:5~30HP

400V:5~40HP

200V: 40~175HP

400V: 50~800HP

R/L1

S/L2

T/L3

Input Power Supply

B1/P

B2

-

\

• B1/P-\:DC power supply

• B1/P-B2:external braking

resistor

⊕

-

• ⊕ -\:DC power supply

or connect braking module

U/T1

V/T2

W/T3

Inverter output

E

Ground terminal

Table 3.3.6.2 Description of main circuit terminals (IP55 Type)

400V

Terminal

5 - 100HP

R/L1,S/L2, T/L3 Input Power Supply

U/T1,V/T2, W/T3 Inverter output

B1, B2 Braking resistor connecting terminal

*1

♁1, ♁2 DC reactor connecting terminal

*2

B1, B2, \

DC power supply (DC+, DC-)

Braking module connecting terminal

( PE)

Ground terminal

*1. The model of 400V 25HP (18.5KW) or below is built-in braking transistor.

*2. Before connecting DC reactor, please remove short circuit between terminal ♁1 and ♁2.

Page 43

3-29

Main circuit terminals identification and screw size

IP20 Type

․200V: 5-7.5HP/ 400V: 5-10HP

Terminal screw size

T

M4 M4

․

200V: 10-15HP/ 400V: 15- 20HP

Terminal screw size

T

M4 M4

․200V: 20-30HP/ 400V: 25-40HP

Terminal screw size

T

M6 M6

․

200V: 40-50HP/ 400V: 50-75HP

Terminal screw size

T

M8 M8

T

T

T

T

Page 44

3-30

․200V: 60-75HP/ 400V: 100-125HP

Terminal screw size

Power supply

T

400V 100HP M8 M10

200V 60-75HP/

400V 125HP

M10 M10

․200V: 100-125HP/ 400V: 150-250HP

Terminal screw size

T

M10 M10

․200V: 150-175HP/ 400V: 300-425HP

Terminal screw size

T

M12 M10

․400V: 530-800HP

Terminal screw size

T

M10 M10

T

Page 45

3-31

IP55 Type

․400V: 5-7.5HP

Terminal screw size

T

M4 M4

․400V: 10-15HP

Terminal screw size

T

M4 M4

․400V: 20-25HP

Terminal screw size

T

M6 M6

․400V: 30-50HP

Terminal screw size

T1

M6 M6

Page 46

3-32

․400V: 60-75HP

Terminal screw size

T1

M8 M8

․

400V : 100HP

Terminal screw size

T1 T2

M8 M10 M8

Page 47

3-33

Input / Output Power Section Block Diagram

The following diagrams show the basic configuration of the power sections for the range of

horsepower and input voltages. This is shown for reference only and is not a detailed depiction.

IP00/IP20 Type

1. IP20 200V: 5~30HP 400V: 5~40HP

2. IP20 200V: 40~50HP 400V: 50~75HP

3. IP20 200V: 60~75HP 400V: 100~125HP 4. IP20 200V: 100~125HP

5. IP20 400V: 150~250HP

6. IP20 200V: 150~175HP

E

○

─

CONTROL

CIRCUITS

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

B1/P

SPS

B2

E

○

─

CONTROL

CIRCUITS

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

○

┼

SPS

E

N

P

DCL

SPS C/B

AC/DC

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

U/T1

V/T2

W

/T3

SPS

N

P

DCL

C/B

SPS

E

S/L2

T/L3

R/L1

E

N

P

DCL

SPS

C/B

AC/DC

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

E

N

P

DCL

SPS

C/B

AC/DC

W/T3

R/L1

T/L3

S/L2

U/T1

V/T2

Page 48

3-34

7. IP20 400V: 300~425HP

8. IP20 400V: 535~800HP

IP55 Type

1. IP55 400V: 5~15HP

2. IP55 400V: 20~25HP

3. IP55 400V: 30~100HP

E

○

─

C/B

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

B1

SPS

B2

○┼1

○

┼

2

DCL

Filter

E

○

─

C/B

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

B1

SPS

B2

○┼1

○

┼

2

DCL

Filter

E

○

─

C/B

R/L1

S/L2

T/L3

U/T1

V/T2

W

/T3

SPS

○┼1

○

┼

2

DCL

Filter

E

N

P

DCL

SPS

C/B

AC/DC

W/T3

R/L1

T/L3

S/L2

U/T1

V/T2

E

N

W/T3

R/L1

T/L3

S/L2

U/T1

V/T2

SPS

C/B

AC/DC

P

Page 49

3-35

Cooling Fan Supply Voltage Selection (400V class)

The inverter input voltage range of the F510 400V class models ranges from 380 to 460Vac. In

these models the cooling fan is directly powered from the power supply. Inverter models F510-

4125/ 4150/ 4175/ 4215/ 4250/ 4300/ 4375/ 4425/ 4535/ 4670/ 4800-H3 requires the user to select

the correct jumper position based on the inverter input voltage ("440V" is the default position for

these models). Please select the correct position according to the input voltage. If the voltage

setting is too low, the cooling fan will not provide adequate cooling for the inverter resulting in an

over-heat error. If the input voltage is greater than 460Vac, select the “460V” position.

(1) 400V: 150HP~250HP

(2) 400V:300HP~800HP

4KA69X613W01

DM1

25CN

36CN

32CN

31CN

33CN

34CN

35CN

FU1

220V

440V

S

R

TB3 1

+

220V

26CN

440V

TB4(220V)

380V1400/4151440V1460V

1

SA4(220V)

2

TB2

JP1 JP2 JP3 JP4

4KA69X571W01

4P108C0010103 VER.04

DM1 25CN

36CN

32CN

31CN

33CN

34CN

35CN

2

FU1

220V

440V

S

R

TB3

1

+

220V

26CN

440V

TB4(220V)

380V1400/4151440V1460V

1

SA4(220V)

JP1 JP2 JP3 JP4

Page 50

3-36

Power Input Wire Size, NFB and MCB Part Numbers

The following table shows the recommended wire size, molded case circuit breakers and magnetic

contactors for each of the F510 models. It depends on the application whether or not to install a

circuit breaker. The NFB must be installed between the input power supply and the inverter input

(R/L1, S/L2, T/L3).

Note: When using a ground protection, make sure the current setting is above 200mA and trip delay

time is 0.1 sec of higher.

Table 3.3.6.3 Wiring Instrument for 200V/400V class (IP00/IP20 type)

F510 Model Wire size (mm2)

Power

supply

Horse power

(HP)

Rated

KVA

Rated

current (A)

Main

circuit

*1

Grounding

E(G)

Control

line*2

NFB*3 MC*3

5HP 5.5 14.5

3.5~5.5 3.5~5.5 0.5~2

TO-50EC(30A) CU-16

7.5HP 8.0 22 5.5 5.5

0.5~2

TO-50EC(30A) CU-16

10HP 11.4 30 8

5.5~8 0.5~2

TO-100S(50A) CU-18

15HP 15 42 8

5.5~8 0.5~2

TO-100S(50A) CU-25

20HP 21 56 14 8

0.5~2

TO-100S(100A) CU-50

25HP 26 69 22 8

0.5~2

TO-100S(100A) CU-65

30HP 30 79 22 14

0.5~2

TO-225S(100A) CU-80

40HP 42 110 38 14

0.5~2

TO-225S(150A) CN-100

50HP 53 138 60 22

0.5~2

TO-225S(175A) CN-125

60HP 64 169 80 22

0.5~2

TO-225S(200A) CN-150

75HP 76 200 100 22

0.5~2

TO-225S(225A) CN-180

100HP 95 250 150 22

0.5~2

TO-400S(300A) CN-300

125HP 119 312 200 38

0.5~2

TO-400S(400A) CN-300

150HP 137 400 300 38

0.5~2

TO-600S(600A) S-K400

200V

3 Ø

175HP 172 450 250*2P 50

0.5~2

TO-800S(800A) S-K600

5HP 7.0 9.2

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-18

7.5HP 8.5 12.1

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-18

10HP 13.3 17.5

3~5.5 3.5~5.5 0.5~2

TO-50EC(20A) CU-18

15HP 18 23 5.5 5.5

0.5~2

TO-50EC(30A) CU-25

20HP 24 31 8 8

0.5~2

TO-100S(50A) CU-25

25HP 29 38 8 8

0.5~2

TO-100S(50A) CU-35

30HP 34 44 8 8

0.5~2

TO-100S(50A) CU-50

40HP 41 54 14 8

0.5~2

TO-100S(75A) CU-50

50HP 55 73 22 8

0.5~2

TO-100S(100A) CU-65

60HP 67 88 22 14

0.5~2

TO-100S(100A) CN-80

75HP 79 103 38 14

0.5~2

TO-225S(150A) CN-100

100HP 111 145 60 22

0.5~2

TO-225S(175A) CN-150

125HP 126 168 80 22

0.5~2

TO-225S(225A) CN-150

150HP 159 208 150 22

0.5~2

TO-400S(300A) CN-300

175HP 191 250 150 22

0.5~2

TO-400S(300A) CN-300

215HP 226 296 200 30

0.5~2

TO-400S(400A) CN-300

250HP 250 328 250 30

0.5~2

TO-400S(400A) S-K400

300HP 332 435 300 38

0.5~2

TO-600S(600A) S-K600

375HP 393 515 250*2P 50

0.5~2

TO-800S(800A) S-K600

425HP 457 585 250*2P 50

0.5~2

TE-1000(1000A) S-K600

535HP 526 700 300*2P 50

0.5~2

1000 800

670HP 640 875 300*2P 50

0.5~2

1200 1000

400V

3 Ø

800HP 732 960 300*2P 50

0.5~2

1200 1000

Page 51

3-37

*1. The main circuit terminals: R/L1, S/L2, T/L3 , U/T1, V/T2, W/T3, B1/P, B 2 , \, ⊕.

*2. Control line is the terminal wire on the control board.

*3. The NFB and MCB listed in the table are of TECO product numbers, products with same rated

specification of other brands may be used. To reduce electrical noise interference, ensure that a RC

surge absorber (R: 10/ 5W, C: 0.1f/1000VDC) is added to both sides of MCB coil.

Table 3.3.6.4 Wiring Instrument for 400V class (IP55 type)

F510 Model Wire size(mm2)

Power

supply

Horse

power

(HP)

Rated

KVA

Rated

current

(A)

Main

circuit

*1

Grounding

E(G)

Control

line*2

NFB*3 MC*3

5HP 7.0 9.2

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-18

7.5HP 8.5 12.1

2~5.5 3.5~5.5 0.5~2

TO-50EC(15A) CU-18

10HP 13.3 17.5

3~5.5 3.5~5.5 0.5~2

TO-50EC(20A) CU-18

15HP 18 23 5.5 5.5

0.5~2

TO-50EC(30A) CU-25

20HP 24 31 8 8

0.5~2

TO-100S(50A) CU-25

25HP 29 38 8 8

0.5~2

TO-100S(50A) CU-35

30HP 34 44 8 8

0.5~2

TO-100S(50A) CU-50

40HP 41 54 14 8

0.5~2

TO-100S(75A) CU-50

50HP 55 73 22 8

0.5~2

TO-100S(100A) CU-65

60HP 67 88 22 14

0.5~2

TO-100S(100A) CN-80

75HP 79 103 38 14

0.5~2

TO-225S(150A) CN-100

400V

3 Ø

100HP 111 145 60 22

0.5~2

TO-225S(175A) CN-150

*1. The main circuit terminals: R(L1), S(L2), T(L3), \, ♁1, ♁2, U(T1), V(T2), W(T3),B1, B2 (Polyethylene

power line of 600V is recommended to be used.)

*2. Control line is the terminal wire on the control board.

*3. The NFB and MCB listed in the table are of TECO product numbers, products with same rated

specification of other brands may be used. To reduce electrical noise interference, ensure that a RC

surge absorber (R: 10/ 5W, C: 0.1f/1000VDC) is added to both sides of MCB coil.

Page 52

3-38

3.3.7 Wiring Precautions

!

• Do NOT remove any protective covers or attempt any wiring while input power is

applied. Connect all wiring before applying input power. When making wiring

changes after power up, remove input power and wait a minimum of five

minutes after power has been turned off before starting. Also confirm that the

charge lamp is off and that DC voltage between terminals B1/P or (+) and (-)

does not exceed 25V, otherwise electric shock may result.

• Only authorized personnel should work on the equipment. (Take off metal

jewelry such as watches and rings and use insulated tools.), otherwise electric

shock or injury may result.

(A) Wiring for control circuit:

(1) Separate the wiring for control circuit terminals from main circuit wiring for terminals

(R/L1,

S/L2, T/L3, U/T1, V/T2, and W/T3).

(2) Separate the wiring for control circuit terminals (R1A, R1B, R1C / R2A, R2C /R3A, R3C)

from wiring for terminals S1~S6, A01, A02, GND, +10V-, AI1, AI2, and GND wiring.

(3) Use shielded twisted-pair cables (#24 - #14 AWG / 0.5 -2 mm

2

) shown in Fig. 3.3.7.1 for

control circuits to minimize noise problems. The maximum wiring distance should not

exceed 50m (165 ft).

Figure 3.3.7.1 Shielded Twisted-Pair

(B) Wiring for main circuit:

(1) The Input power supply voltage can be connected in any phase sequence to power input

terminals R/L1, S/L2, or T/L3 on the terminal block.

(2) DO NOT connect the AC input power source to the output terminals U/T1, V/T2 and. W/T3.

(3) Connect the output terminals U/T1, V/T2, W/T3 to motor lead wires U/T1, V/T2, and W/T3,

respectively.

(4) Check that the motor rotates forward with the forward run source. If it does not, swap any 2

of the output cables to change motor direction.

(5) DO NOT connect phase correcting capacitors or LC/RC noise filter to the output circuit.

Page 53

3-39

(C) Grounding:

(1) Connect the ground terminal (E) to ground having a resistance of less than 100.

(2) Do not share the ground wire with other devices, such as welding machines or power tools.

(3) Always use a ground wire that complies with the local codes and standards for electrical

equipment and minimize the length of ground wire.

(4) When using more than one inverter, be careful not to loop the ground wire, as shown below

in Fig. 3.3.7.2.

Figure 3.3.7.2 F510 Inverter Grounding

Page 54

3-40

3.3.8 Input Power and Cable Length

Cable size

The length of the cables between the input power source and /or the motor and inverter can

cause a significant phase to phase voltage reduction due to the voltage drop across the cables.

The wire size shown in Tables 3.3.6.3 & 3.3.6.4 is based on a maximum voltage drop of 2%. If this

value is exceeded, a wire size having larger diameter may be needed. To calculate phase tot

phase voltage drop, apply the following formula:

Phase-to-phase voltage drop (V) = 3 ×resistance of wire (Ω/km) × length of line m) × current×10-3.

(km=3280 x feet)

(m=3.28 x feet)

Cable length vs. Carrier frequency

The allowable setting of the PWM carrier frequency is also determined by motor cable length

and is specified in the following Table 3.3.8.1.

Table 3.3.8.1 Cable Length vs. Carrier Frequency

Cable length between

the inverter and

Motor in m (ft.).

< 30

(100)

30 – 50

(100 – 165)

50 – 100

(166 - 328)

>

100

(329)

Recommended carrier

frequency allowed

Parameter 11-01

16kHz

(max)

10 kHz

(max)

5 kHz

(max)

2 kHz

(max)

Installing an AC line reactor

If the inverter is connected to a large-capacity power source (600kVA or more), install an

optional AC reactor on the input side of the inverter. This also improves the power factor on the

power supply side.

Page 55

3-41

3.4 Inverter Specifications

Basic Specifications

(a) 200V class

(b) 400V class

Inverter capacity (HP)

425 535 670 800

Rated Output Capacity (KVA)

445 525 640 731

Rated Output Current (A)

585 700 875 960

Maximum Applicable Motor

*1

HP (KW)

425

(315)

535

(400)

670

(500)

800

(600)

Maximum Output Voltage (V)

3-phase 380V~480V

Output Rated

Maximum Output Frequency

(Hz)

Based on parameter setting 0.1~400.0 Hz

Rated Voltage, Frequency

3-phase 380V ~ 480V, 50/60Hz

Allowable Voltage Fluctuation

-15% ~ +10%

Power supply

Allowable Frequency

Fluctuation

±5%

*1: Take standard 4-pole induction motor as the base.

*2: F510 model is designed to be used in normal duty (ND), whose overload capability is 120% for 1 min.

Inverter capacity (HP)

5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 175

Rated Output Capacity (KVA)

5.5 8 11.4 15.2 21.3 26.2 30 41.9 52.5 64.3 76.2 95.2 118.8 152.4 171.4

Rated Output Current (A)

14.5 22 30 42 56 69 79 110 138 169 200 250 312 400 450

Maximum Applicable Motor *1HP

(KW)

5

(3.7)

7.5

(5.5)10(7.5)15(11)20(15)25(18.5)30(22)40(30)50(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

175

(130)

Maximum Output Voltage (V)

3-phase 200V~240V

Output Rated

Maximum Output Frequency (Hz)

Based on parameter setting 0.1~400.0 Hz

Rated Voltage, Frequency

3-phase 200V~240V, 50/60Hz

Allowable Voltage Fluctuation

-15% ~ +10%

Power supply

Allowable Frequency Fluctuation

±5%

Inverter capacity (HP)

5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 175 215 250 300 375

Rated Output Capacity

(KVA)

7.0

8.4

13.3 17.5 23.6 28.9 33.5 41.1 54.8 67 78.4 110

125

158 190 225 250 331 392

Rated Output Current (A)

9.2

12.1

17.5 23 31 38 44 54 73 88 103 145

168

208 250 296 328 435 515

Maximum Applicable

Motor *1HP (KW)

5

(3.7)

7.5

(5.5)

10

(7.5)

15

(11)

20

(15)

25

(18.5)

30

(22)

40

(30)

50

(37)

60

(45)

75

(55)

100

(75)

125

(90)

150

(110)

175

(132)

215

(160)

250

(185)

300

(220)

375

(280)

Maximum Output Voltage

(V)

3-phase 380V~480V

Output Rated

Maximum Output

Frequency (Hz)

Based on parameter setting 0.1~400.0 Hz

Rated Voltage, Frequency

3-phase 380V ~ 480V, 50/60Hz

Allowable Voltage

Fluctuation

-15% ~ +10%

Power supply

Allowable Frequency

Fluctuation

±5%

Page 56

3-42

*3: If it is greater than default carrier frequency, you need to adjust the load current based on the de-rating curve.

200V class

Carrier freq.

default setting

Carrier freq.

range

400V class

Carrier freq.

default setting

Carrier freq.

range

5~25HP 2KHz 2~16KHz 5~30HP 4KHz 2~16KHz

30HP 2KHz 2~12KHz 40HP 2KHz 2~16KHz

40~50HP 2KHz 2~12KHz (*4) 50~60HP 4KHz 2~12KHz (*4)

60~125HP 2KHz 2~10KHz (*4) 75~215HP 4KHz 2~10KHz (*4)

- - - 250HP 2KHz 2~8KHz

150~175HP 2KHz 2~5KHz 300~375HP 4KHz 2~5KHz

- - - 425HP 2KHz 2~5KHz

- - - 535~800HP 4KHz 2~5KHz

*4: If control mode is set to SLV mode and maximum frequency (01-02) is larger than 80 Hz, the carrier

frequency range is 2~8Hz.

The following table shows the maximum output frequency for each control mode.

Control

mode

Other settings

Maximum

output

frequency

V/F Unlimited 400Hz

200V 5~15HP, 400V 5~20HP 150Hz

200V 20~30HP, 400V 25HP 110Hz

400V 30~40HP 100Hz

200V 40~125HP, 400V 50~215HP,

carrier (11-01) is set as 8K or below 8K.

100Hz

200V 40~125HP, 400V 50~215HP,

carrier (11-01) is set as above 8K.

80Hz

SLV

200V 150~175HP, 400V 250~800HP 100Hz

PMSLV Unlimited 400Hz

Page 57

3-43

General Specifications

*1: Speed control accuracy will be different from the installation conditions and motor types.

*2: The factory default carrier frequency is different from models.

Operation Modes

LED keypad with seven-segment display *5 and LCD keypad (Optional HOA LCD keypad); all LCD keypad with

parameter copy function

Control Modes V/F, SLV, PMSLV with space vector PWM mode

Frequency Control Range

0.1Hz~400.0Hz

Frequency Accuracy

(Temperature change)

Digital references: ±0.01%(-10 to +40℃), Analog references: ±0.1% (25℃±10℃)

Speed Control Accuracy

±0.5% (Sensorless Vector Control Mode)

*1

Frequency Setting

Resolution

Digital references: 0.01Hz , Analog references: 0.06Hz/60Hz

Output Frequency

Resolution

0.01Hz

Inverter Overload 120%/1 min

Frequency Setting Signal

DC 0~+10V / 0~20mA or 4~20mA

Acceleration/ Deceleration

Time

0.0~6000.0 seconds ( separately set acceleration and deceleration time )

Voltage, Frequency

Characteristics

Custom V/F curve based on parameters

Braking Torque About 20%

Main Control Functions

Auto tuning, Soft-PWM, Over voltage protection, Dynamic braking, Speed search, Restart upon momentary power

loss, 2 sets of PID control, Slip Compensation, RS-485 communication standard, Simple PLC function, 2 sets of

analog outputs, Safety switch

Control Characteristics

Other Functions

Accumulated power-on/ run time, 4 sets of fault history records and latest fault record state, Energy-saving function

setting, Phase loss protection, Smart braking, DC braking, Dwell,S curve acceleration and deceleration, Up/Down

operation, Modbus, BACnet MS/TP and Metasys N2 communication protocol, Display of multi-engineering unit,

Local/ Remote switch, SINK/SOURCE input interface selection, User parameter settings

Stall Prevention

Current level can be setting (It can be set separately in acceleration or constant speed; it can be set with or without

protection in deceleration)

Instantaneous Over Current

(OC) and Output ShortCircuit (SC) Protection

Inverter stops when the output current exceeds 160% of the inverter rated current

Inverter Overload

Protection (OL2)

If inverter rated current 120%/1min is exceeded, inverter stops. The factory default carrier frequency is 2~4KHZ

*2

Motor Overload Protection

(OL1)

Electrical overload protection curve

Over voltage (OV)

Protection

If the main circuit DC voltage rises over 410V (200V class)/ 820V (400V class), the motor stops running.

Under voltage (UV)

Protection

If the main circuit DC voltage falls below 190V (200V class) /380V (400V class), the motor stops running.

Auto-Restart after

Momentary Power

Loss

Power loss exceeds 15ms.

Auto-restart function available after momentary power loss in 2 sec.

Overheat(OH) Protection Use temperature sensor for protection.

Ground Fault (GF)

Protection

Use current sensor for protection.

DC Bus Charge Indicator When main circuit DC voltage 50V≧ , the CHARGE LED turns on.

Protection Function

Output Phase Loss (OPL)

Protection

If the OPL is detected, the motor stops automatically.

Installation Location Indoor (protected from corrosive gases and dust)

Ambient Temperature

-10~+40℃(14℉~104℉) (IP20/NEMA1 or IP55/NEMA12), -10~+50℃(14℉~122℉) (IP00) without de-rating; with

de-rating, its maximum operation temperature is 60℃(140℉).

Storage Temperature

-20~+70℃(-4℉~+158℉)

Humidity

95%RH or less (no condensation)

Environment

Specifications

Altitude and Vibration Altitude of 1000m (3181ft) or below, below 5.9m/s2(0.6G)

Communication Function Built-in RS-485 as standard (Modbus protocol with RJ45/ BACnet/ Metasys N2)

PLC Function Built-in

EMI Protection

The built-in noise filter complies with EN61800-3 available for inverters 400V 75HP or below (IP20) / 400V 60HP or

below (IP55)

EMS Protection in compliance with EN61800-3

CE Declaration in compliance with EN61800-3 (CE & RE) and EN61800-5-1 (LVD, Low-Voltage Directive)

Safety

Certification

UL Certification UL508C

Accessories 1 to 8 Pump card, HOA LCD keypad, Profibus card

Page 58

3-44

3.5 Inverter Derating Based on Carrier Frequency

Note: Derating curve current of carrier frequency means inverter rated current.

(a) 200V Models

Model 2005 2008 2010

A 76% 83% 83%